Dental titanium alloy material

A titanium alloy and dental technology, applied in the field of dental titanium alloy materials, can solve the problems of low hardness and strength, high cost, poor wear resistance, etc., and achieve improved wear resistance, lower melting point and cost, and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

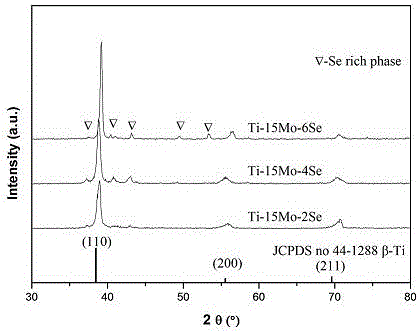

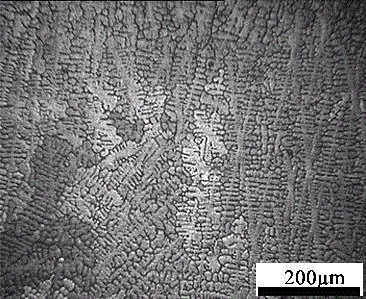

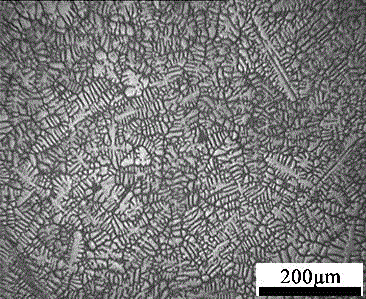

Image

Examples

Embodiment 1

[0017] 1. Ingredients

[0018] Molybdenum 150g

[0019] Selenium 20 grams

[0020] Ce 0.5 g

[0021] Sponge titanium balance

[0022] Total weight: 1000 grams

[0023] 2. Melting

[0024] First put titanium sponge, alloying elements and intermediate alloys into a vacuum non-consumable water-cooled copper crucible electric arc furnace, and evacuate the furnace to 1×10 -3 Pa, and then high-purity inert gas is introduced to repeatedly wash the furnace to eliminate the influence of the atmosphere during the alloy smelting process. Through the arc generated between the arc port on the anode of the copper crucible and the cathode of the tungsten tip, a huge amount of heat is released, and the alloy is melted rapidly to obtain an ingot. Finally, the ingot was turned over 5 times and remelted repeatedly to ensure the composition uniformity of the alloy.

[0025] 3. Main technical indicators of the titanium alloy prepared in this embodiment:

[0026] The hardness of the alloy: ...

Embodiment 2

[0028] 1. Ingredients

[0029] Molybdenum 150g

[0030] Selenium 40g

[0031] Lanthanum 1 g

[0032] Sponge titanium balance

[0033] Total weight: 1000 grams

[0034] 2, smelting method is the same as embodiment 1;

[0035] 3. Main technical indicators of the titanium alloy prepared in this embodiment:

[0036] The hardness of the alloy: HV=389, yield strength: 1344MPa, compressive strength: 1880MPa, density: 5.07g / cm 3 .

Embodiment 3

[0038] 1. Ingredients

[0039] Molybdenum 150g

[0040] Selenium 60g

[0041] Ce 1 g

[0042] Sponge titanium balance

[0043] Total weight: 1000 grams

[0044] 2, smelting method is the same as embodiment 1;

[0045] 3. Main technical indicators of the titanium alloy prepared in this embodiment:

[0046] The hardness of the alloy: HV=406, yield strength: 1315MPa, compressive strength: 1600MPa, density: 5.11g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gross weight | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com