Waterborne glass baking paint and preparation method thereof

A glass baking varnish, water-based technology, applied in the direction of coating, etc., can solve the problems of glossiness, poor weather resistance, poor wear resistance, short service life, etc., and achieve the effect of simple construction, improved service life and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

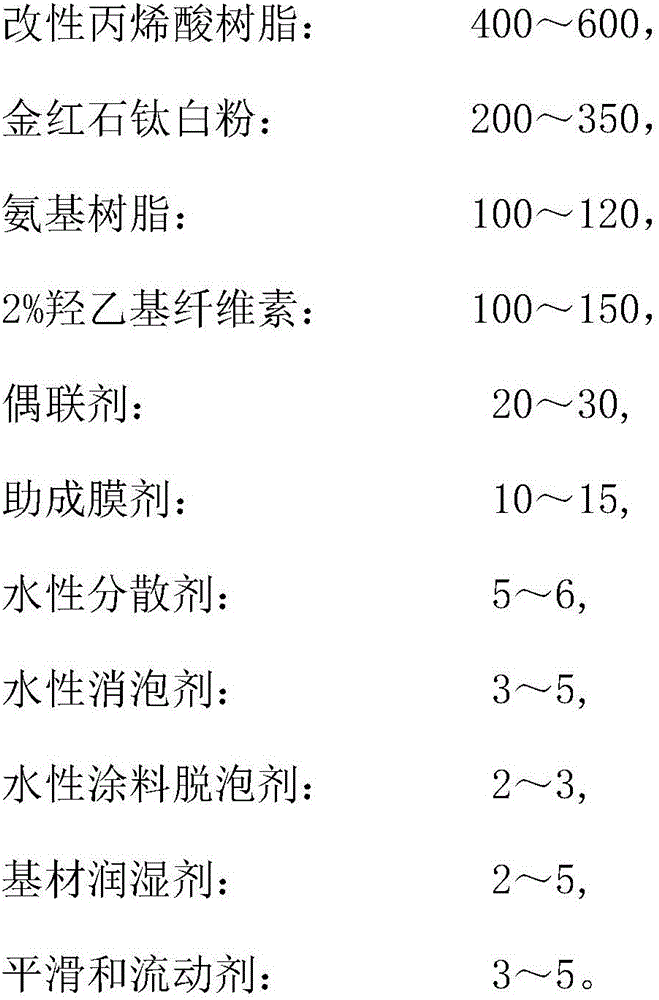

[0026] A kind of water-based glass baking varnish, is characterized in that: be made of the component of following weight ratio:

[0027]

[0028]

[0029] Above-mentioned water-based glass baking varnish is prepared by the following specific steps:

[0030] a. Put in 2% hydroxyethyl cellulose and water-based dispersant in turn, turn on the machine at 400-600 / min and stir for 5 minutes. ;

[0031] b. Add the water-based defoamer at the speed of 400-600 rpm, and stir the substrate wetting agent evenly for 5 minutes;

[0032] c. Then add rutile titanium dioxide and disperse at a high speed of 1000-1200 rpm for 15 minutes;

[0033] d, and then use a horizontal sand mill to sand, and the fineness is below 15 microns;

[0034] e. Then add water-based paint defoamer, smoothing and flow agent, coupling agent, and film-forming agent in order to disperse for 5 minutes at 600-800 rpm;

[0035] f. Finally, add modified acrylic resin and amino resin and stir at 500-700 rpm for 1...

Embodiment 2

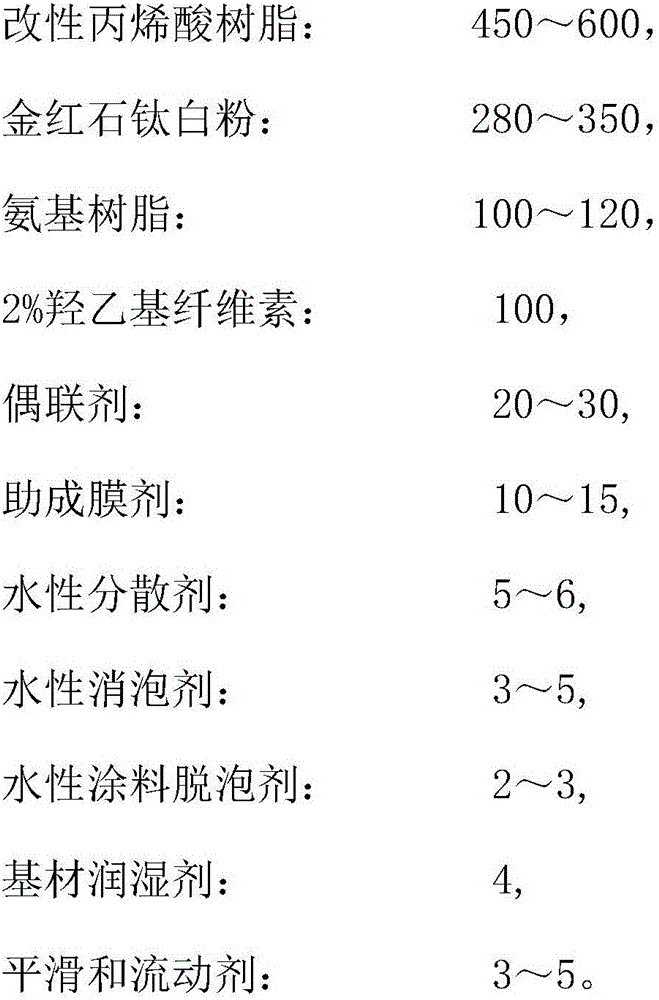

[0037] A kind of water-based glass baking varnish, is characterized in that: be made of the component of following weight ratio:

[0038]

[0039]

[0040] Above-mentioned water-based glass baking varnish is prepared by the following specific steps:

[0041] a. Put in 2% hydroxyethyl cellulose and water-based dispersant in turn, turn on the machine at 400-600 / min and stir for 5 minutes. ;

[0042] b. Add the water-based defoamer at the speed of 400-600 rpm, and stir the substrate wetting agent evenly for 5 minutes;

[0043] c. Then add rutile titanium dioxide and disperse at a high speed of 1000-1200 rpm for 15 minutes;

[0044] d, and then use a horizontal sand mill to sand, and the fineness is below 15 microns;

[0045] e. Then add water-based paint defoamer, smoothing and flow agent, coupling agent, and film-forming agent in order to disperse for 5 minutes at 600-800 rpm;

[0046] f. Finally, add modified acrylic resin and amino resin and stir at 500-700 rpm for 1...

Embodiment 3

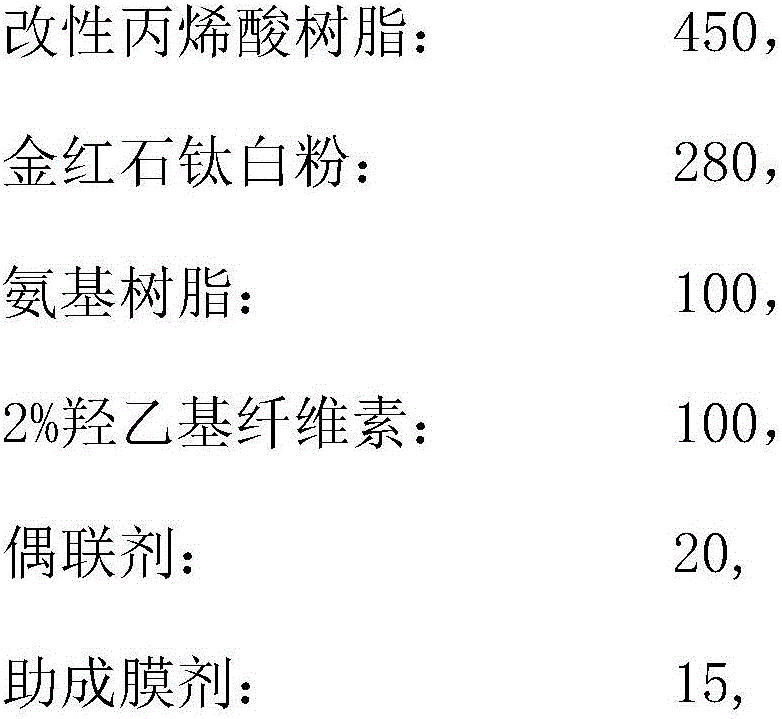

[0048] A kind of water-based glass baking varnish, is characterized in that: be made of the component of following weight ratio:

[0049]

[0050] Above-mentioned water-based glass baking varnish is prepared by the following specific steps:

[0051] a. Put in 2% hydroxyethyl cellulose and water-based dispersant in turn, turn on the machine at 400-600 / min and stir for 5 minutes. ;

[0052] b. Add the water-based defoamer at the speed of 400-600 rpm, and stir the substrate wetting agent evenly for 5 minutes;

[0053] c. Then add rutile titanium dioxide and disperse at a high speed of 1000-1200 rpm for 15 minutes;

[0054] d, and then use a horizontal sand mill to sand, and the fineness is below 15 microns;

[0055] e. Then add water-based paint defoamer, smoothing and flow agent, coupling agent, and film-forming agent in order to disperse for 5 minutes at 600-800 rpm;

[0056] f. Finally, add modified acrylic resin and amino resin and stir at 500-700 rpm for 10 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com