Patents

Literature

182results about How to "Good environmental performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retail environment

InactiveUS20070069014A1Enhance retail sale artImprove the environmentVisual presentationMarketingEmbedded systemMicro environment

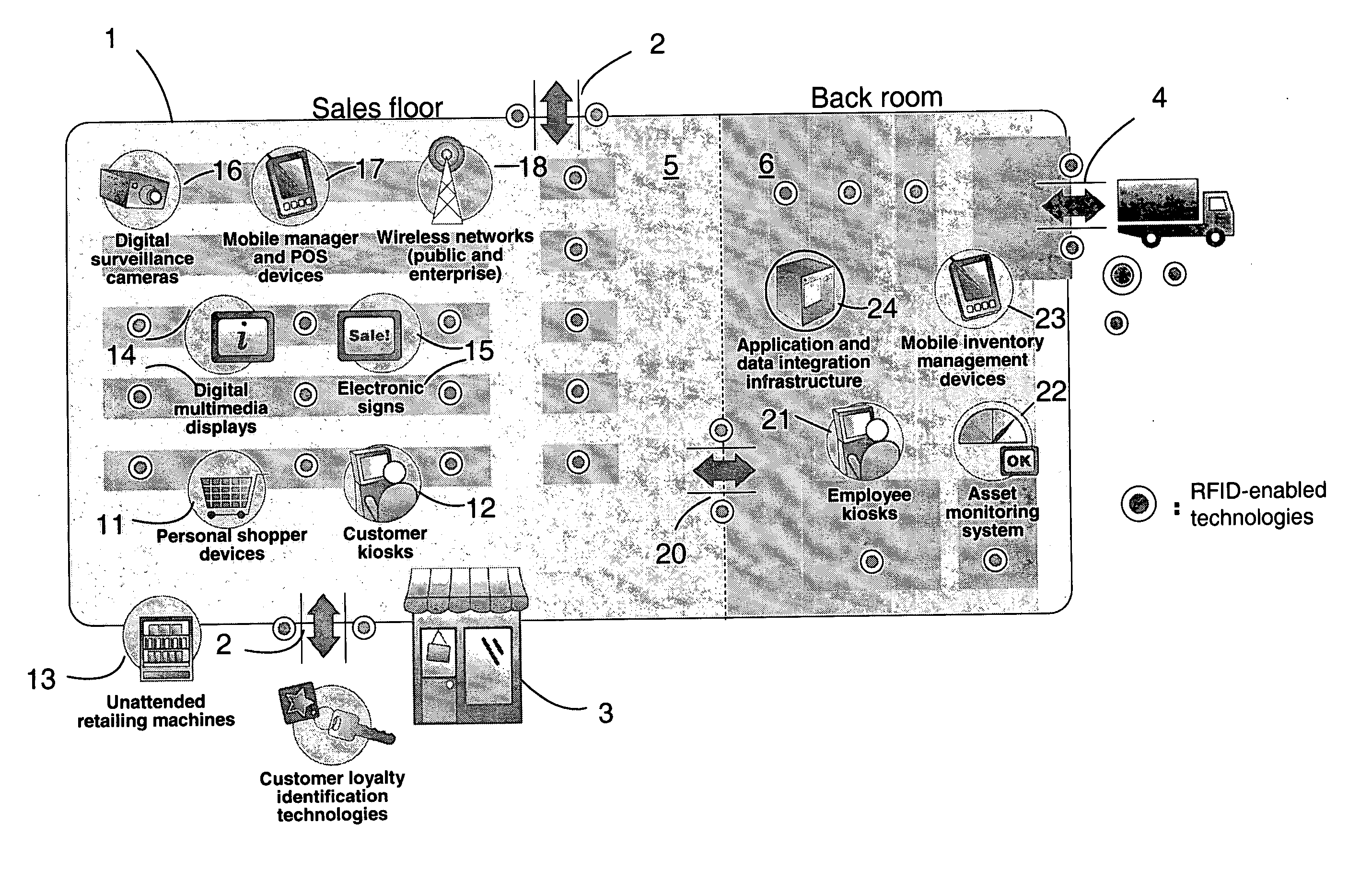

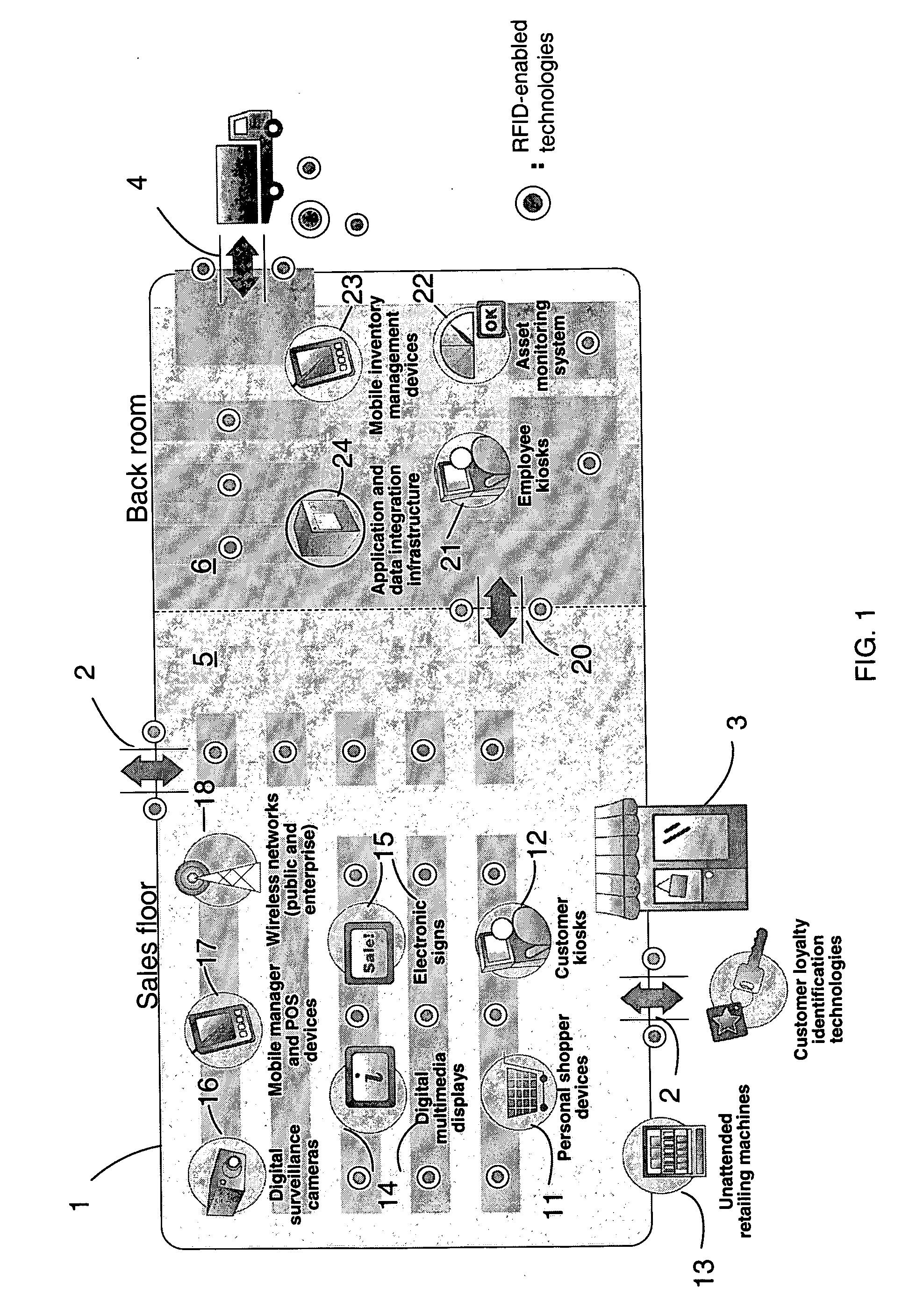

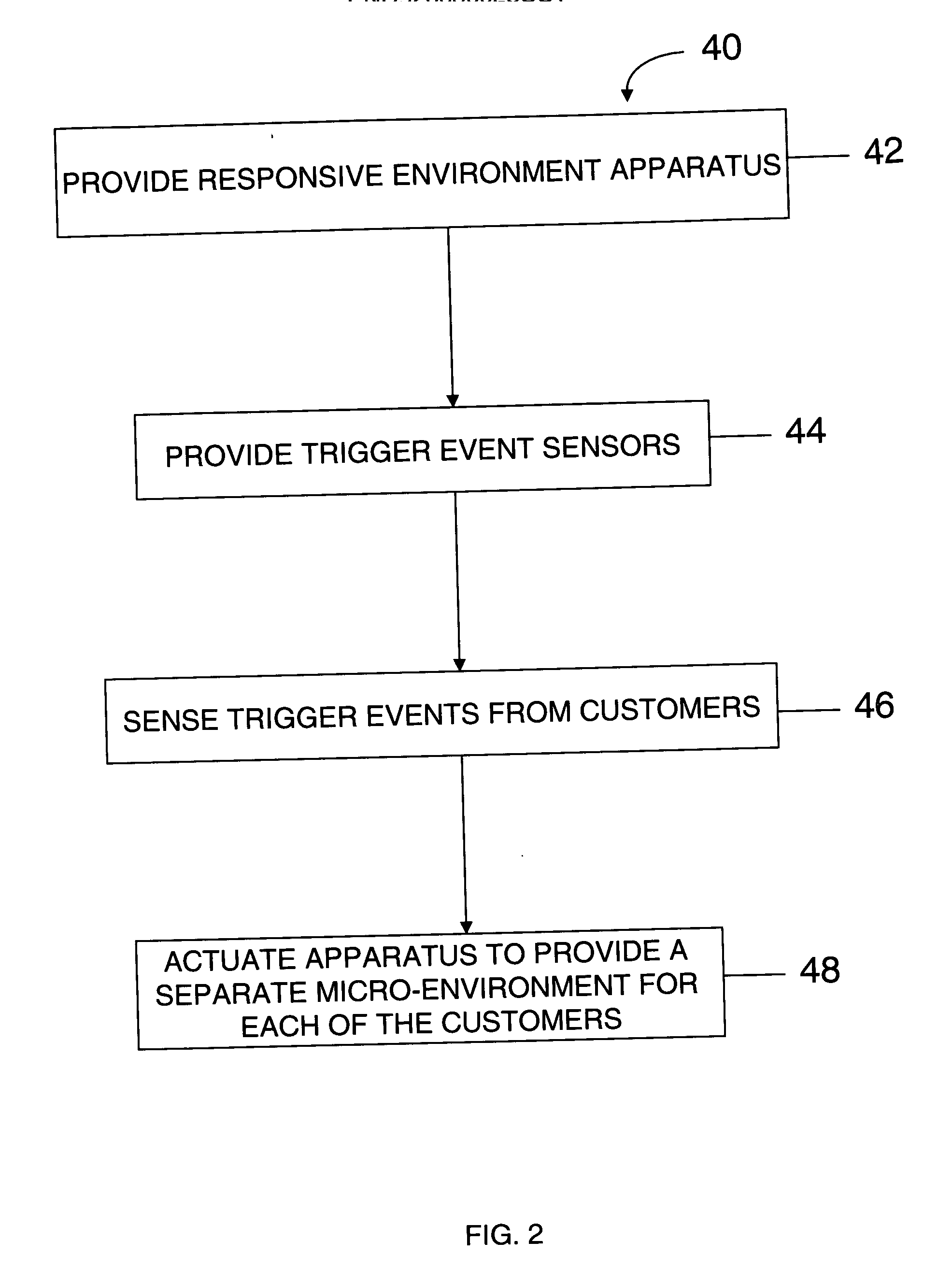

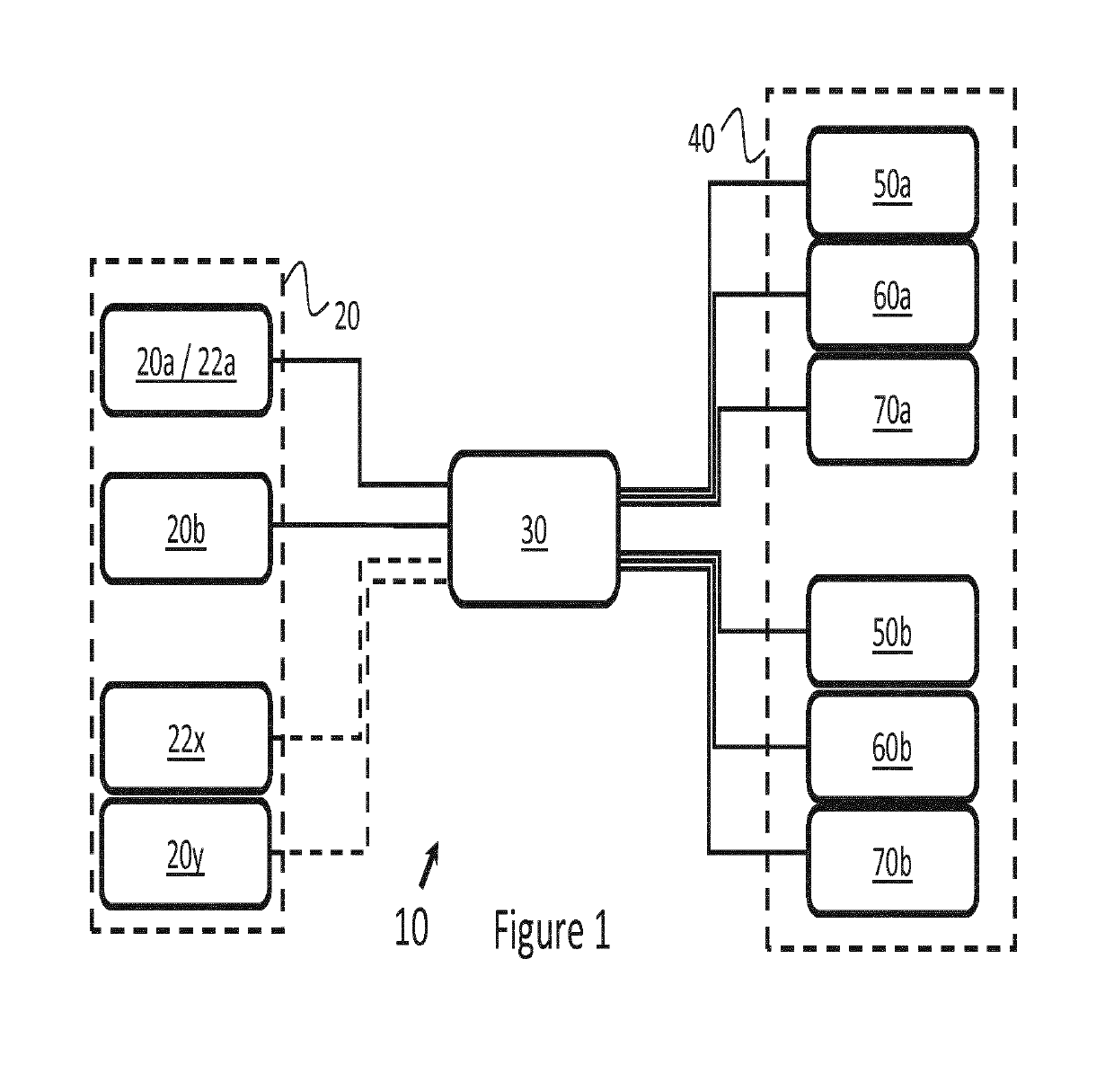

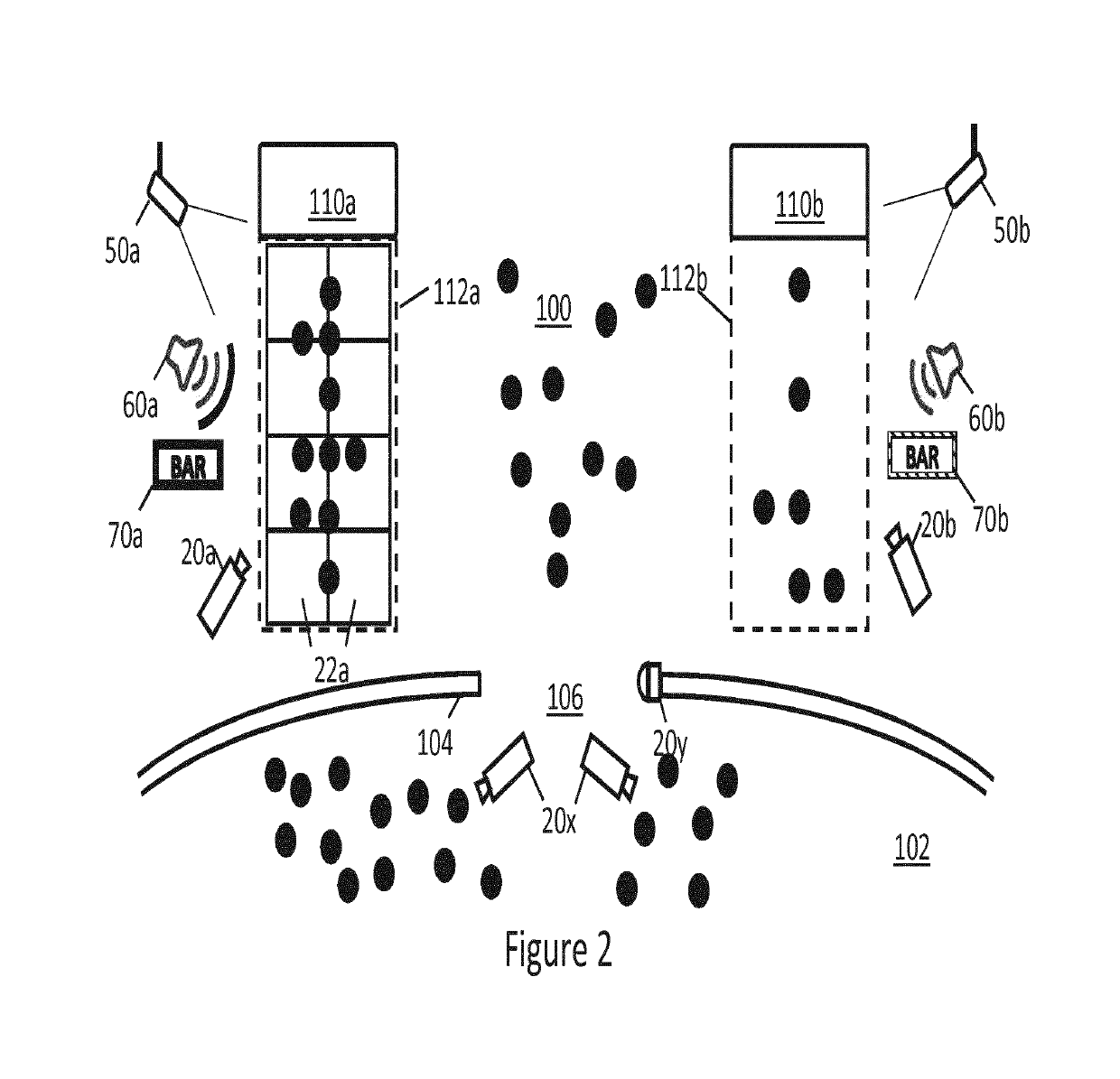

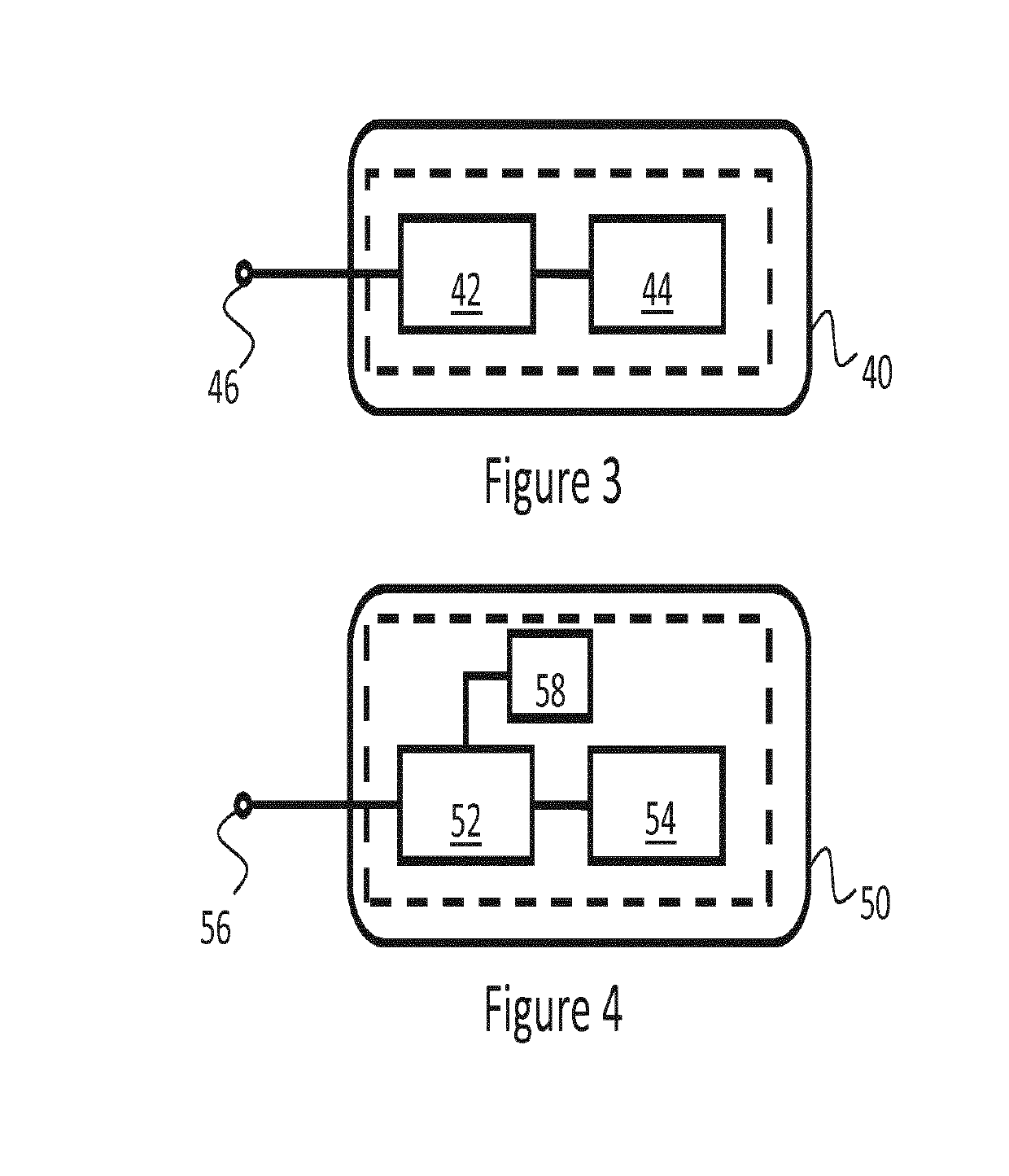

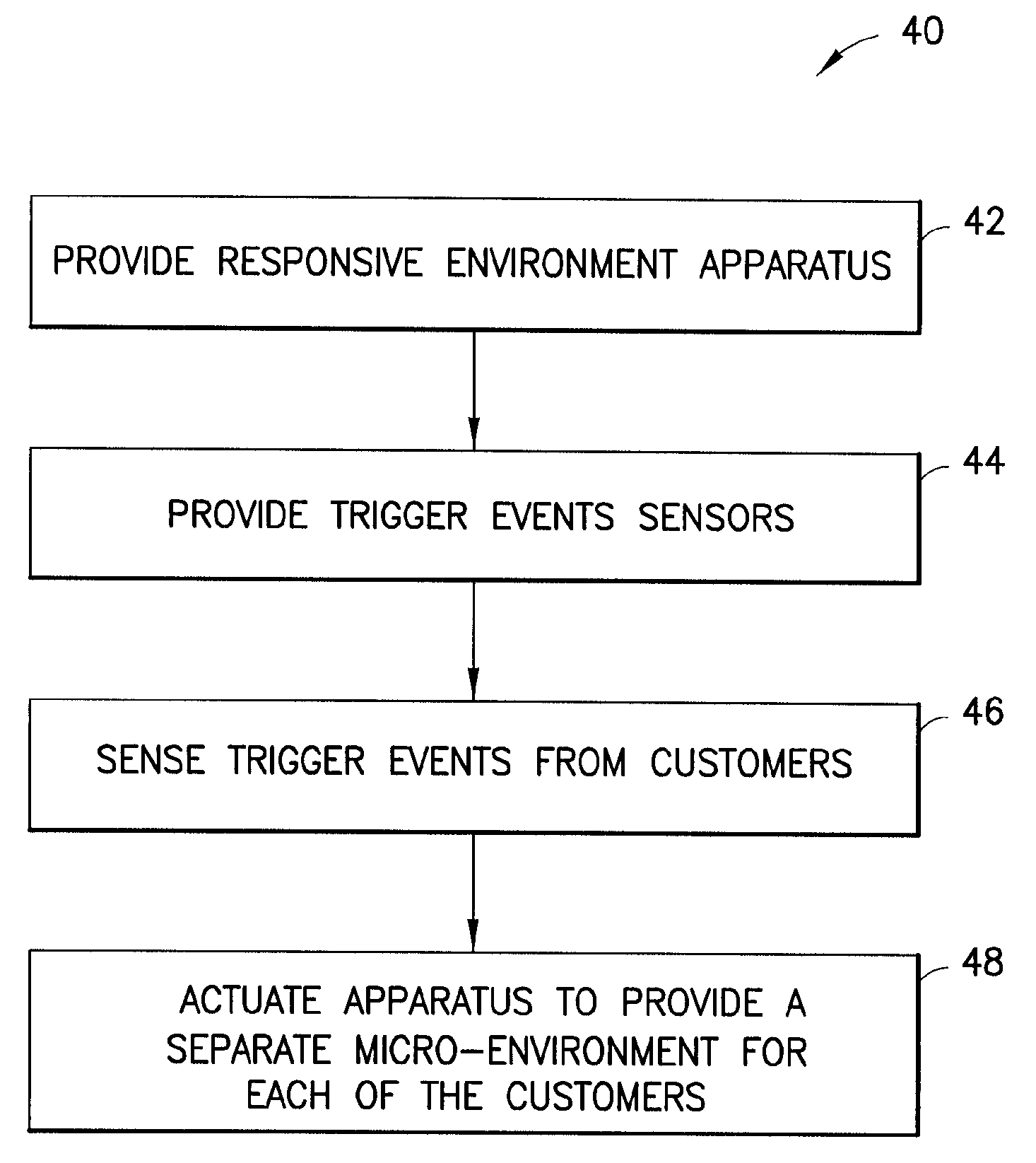

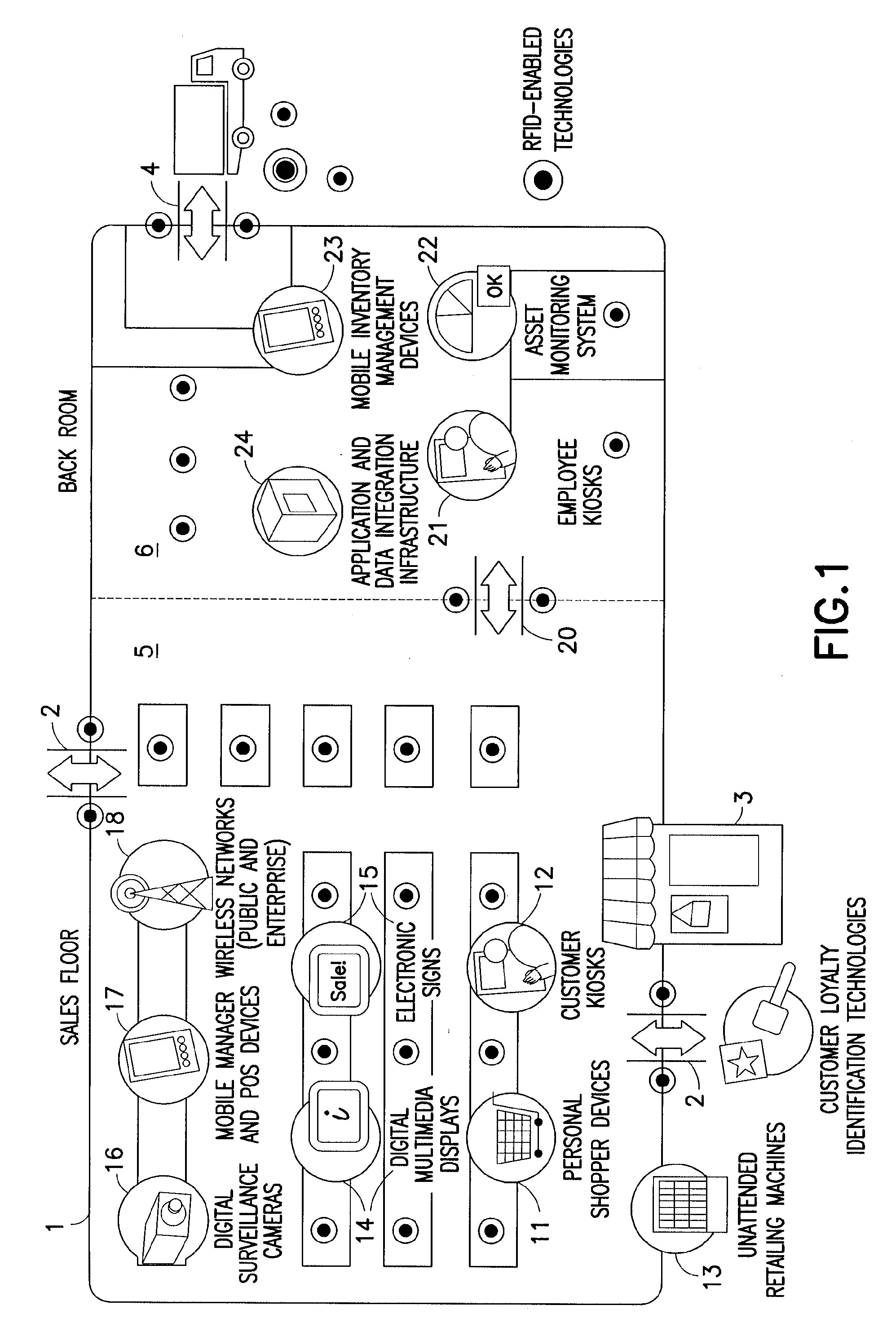

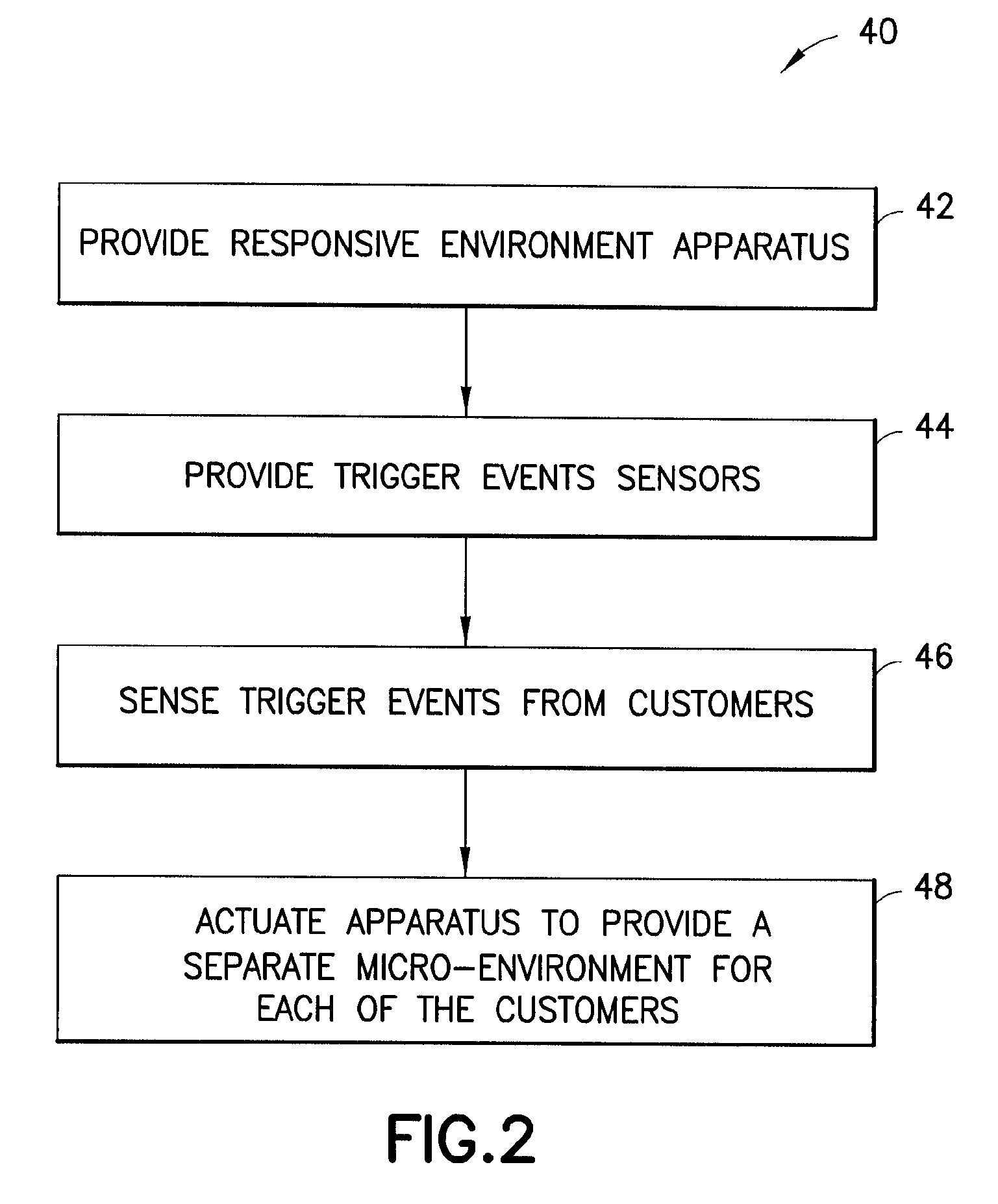

A retail store has responsive environment apparatus installed which is controlled by processing apparatus. Trigger event sensors coupled to the processing apparatus, are positioned throughout the store. When customers enter and move about the store, the processing apparatus senses various trigger events and in response thereto creates a micro-environment in the vicinity of each customer, catering to the characteristics of that customer. The micro-environment physically moves as the customer moves about the store. The micro-environment is dynamic in that it is engaged in a continual response loop based on the response trigger events of the customer throughout this interactive cycle with the micro-environment.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

Preparation method and construction process of waterborne marble-imitated multicolor paint

ActiveCN101693800AGood water and rub resistanceGood environmental performanceMulticolor effect coatingsChemistryDispersed media

The invention discloses a preparation method and the construction process of a waterborne marble-imitated multicolor paint, in particular to a compounding technology and the construction process of the water-in-water type multicolor external wall paint. The paint consists of a disperse phase and a disperse medium, wherein the waterborne multicolor dispersoid containing water-soluble colloid is taken as the disperse phase and the water is taken as the disperse medium, namely the multicolor dispersoid is uniformly dispersed in the water-dispersed medium containing the film-forming substance. The wall paint has excellent wall decoration and protection performance and high performance-to-price ratio; and as the coating is thin and light and has elasticity and stain resistance, the paint can be applicable to the high-rise external walls and the external heat-preservation coating decoration, thus solving the problem that the self-weight is large in the practical application process of the marbles, the wall bricks and the glass curtain walls. In the invention, the wall paint solves the construction localization that the special spraying gun is only used for the waterborne multicolor paint, the normal spraying gun for building can be used, therefore, the construction is convenient and is easy for operation, and the wall paint has wider application prospect.

Owner:鳄鱼尼卡(上海)新材料有限公司

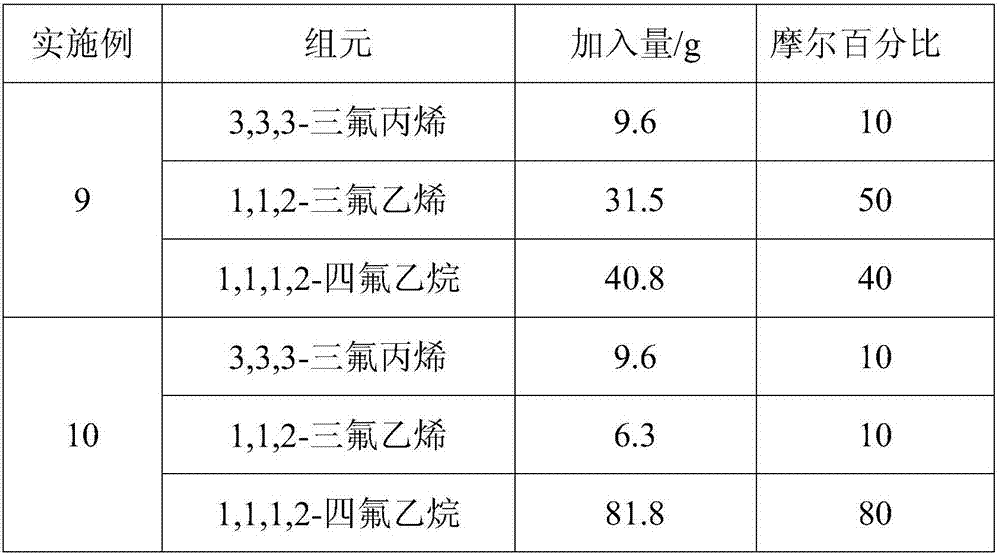

Environmentally-friendly mixed refrigerant for replacing HCFC-22

ActiveCN107987797AGood environmental performanceLow GWP valueHeat-exchange elementsChemistryEnvironmentally friendly

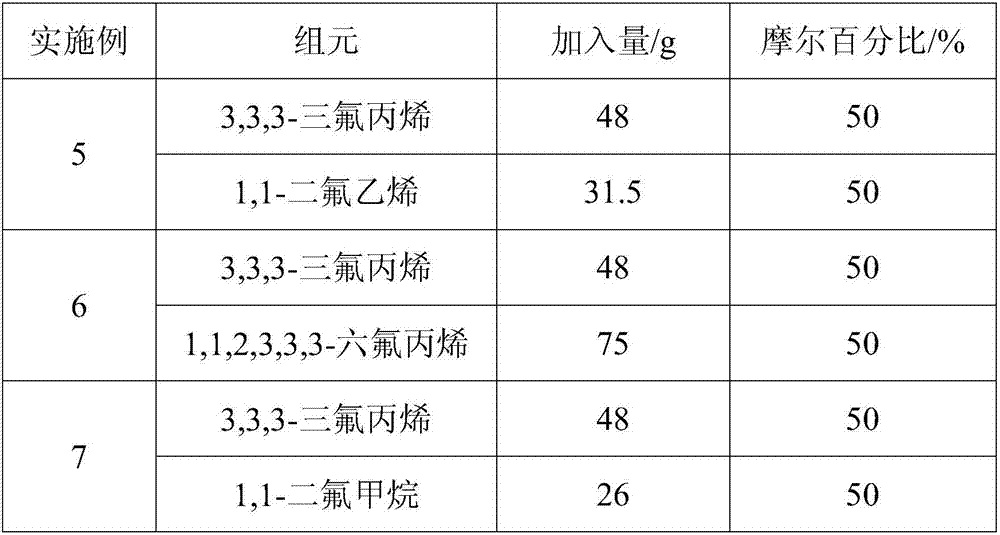

The invention provides an environmentally-friendly mixed refrigerant I. The environmentally-friendly mixed refrigerant I is characterized in that 1, 1, 2-trifluoroethylene, 1, 1-difluoroethylene, 1, 1, 2, 3, 3, 3-hexafluoropropylene, 1, 1-difluoromethane and other substances are added to trifluoropropene or tetrafluoropropene, thus the direct filling performance of the mixed refrigerant in an airconditioning system is improved. Additionally, the invention also provides an environmentally-friendly mixed refrigerant II. The environmentally-friendly mixed refrigerant II is characterized in that1, 1, 2, 2-tetrafluoroethane, 1, 1, 1, 2-tetrafluoroethane, 1, 1, 1, 2, 2-pentafluoroethane, 1, 1, 1, 2, 3, 3, 3-heptafluoropropane, trifluoroiodomethane, etc. are added in the abovementioned mixture,thus the flammability of the refrigerant is reduced. The invention also provides an environmentally-friendly mixed refrigerant III. The environmentally-friendly mixed refrigerant III is characterizedin that AlF3, FeF3, MgF2 and CuO nanoparticles are added in the abovementioned mixture, so that the intermiscibility of the refrigerant and mineral frozen engine oil can be improved.

Owner:XIAN MODERN CHEM RES INST

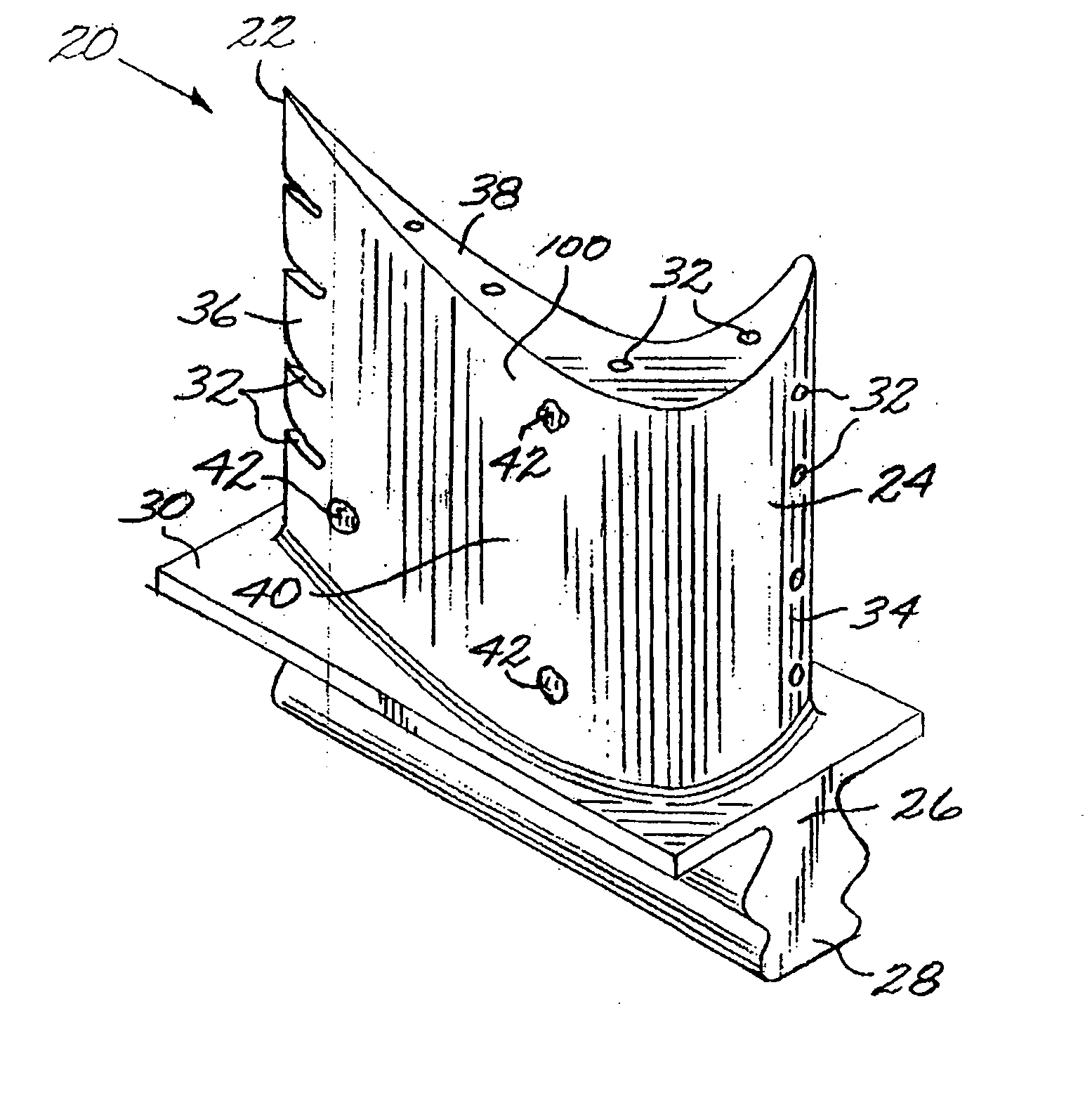

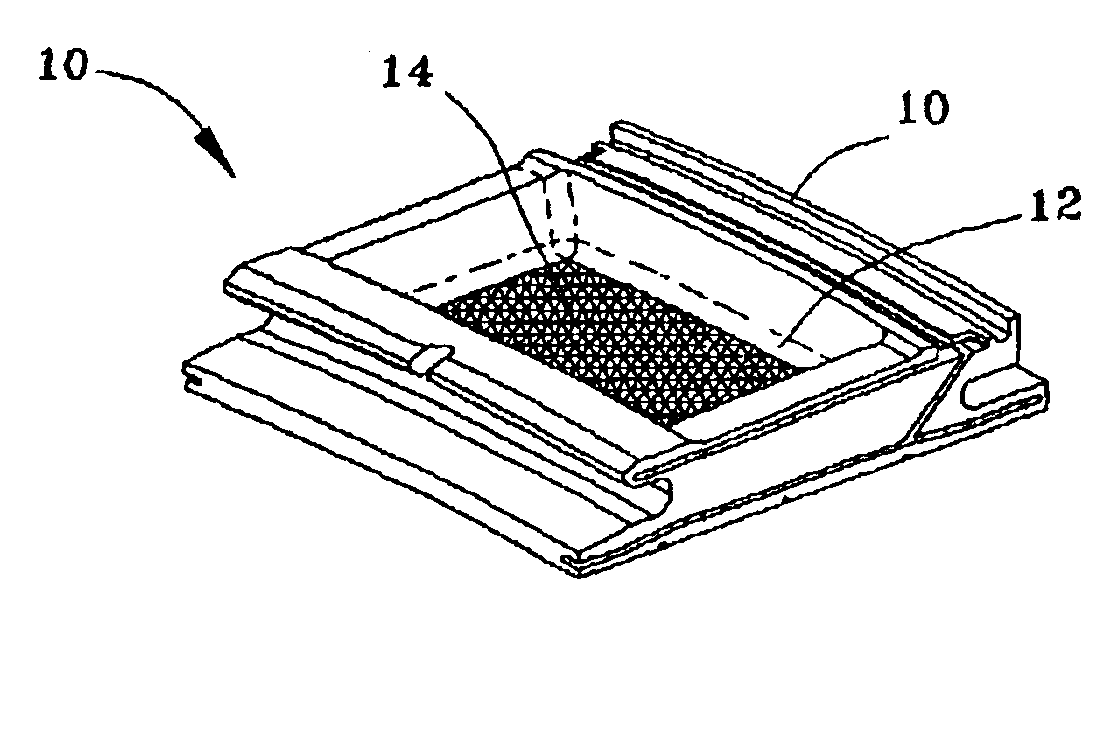

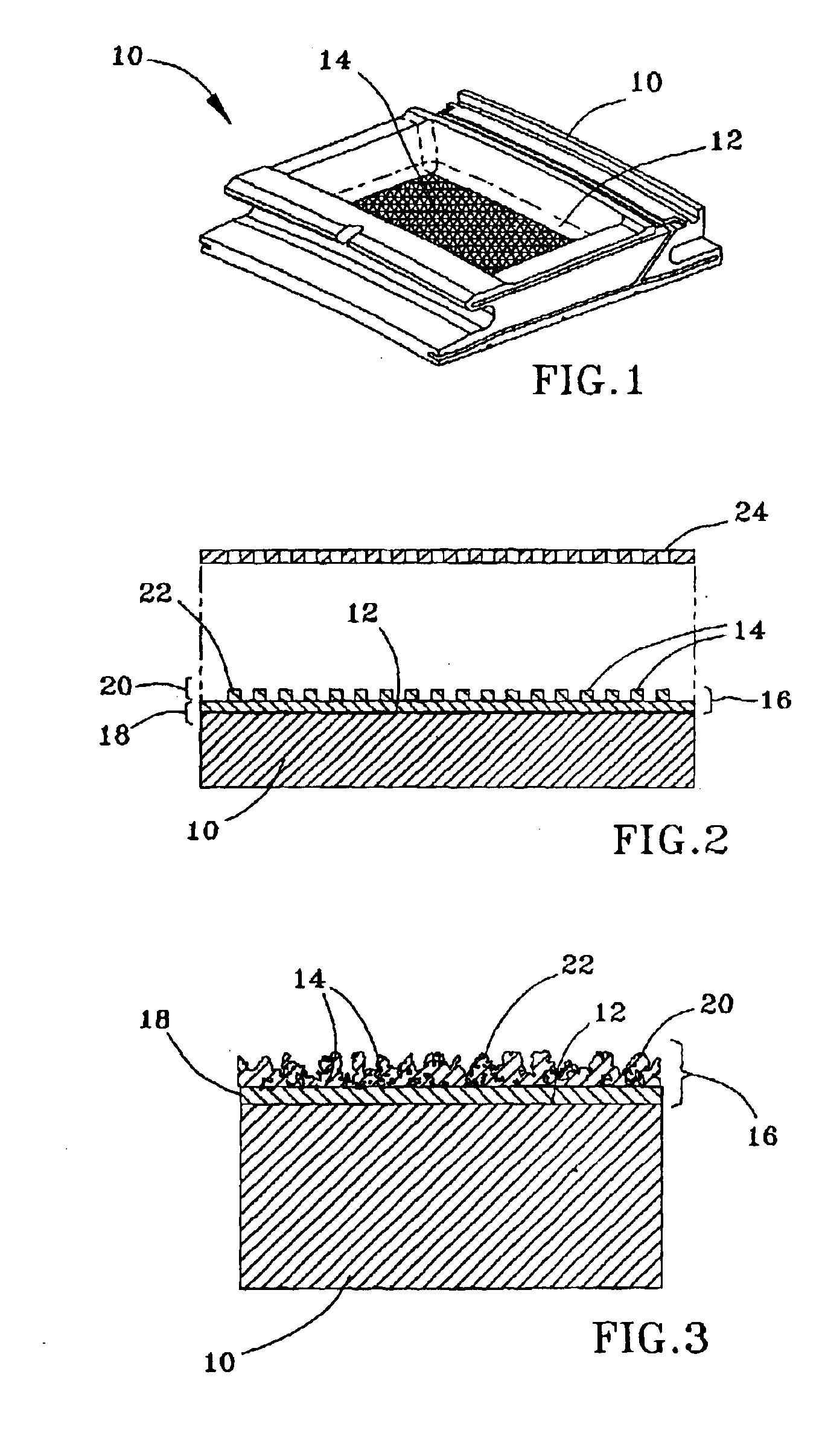

Coating and coating process incorporating raised surface features for an air-cooled surface

InactiveUS20050271514A1Improve heat transfer performanceImprove protectionMolten spray coatingEngine fuctionsMetallic coatingSubstrate surface

Owner:GENERAL ELECTRIC CO

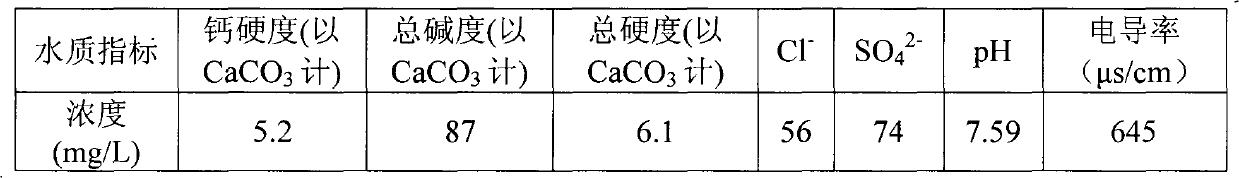

Composite water treatment agent of closed type circulating water system

InactiveCN102557276AEasily biodegradableGood environmental performanceScale removal and water softeningRare-earth elementSoftened water

The invention discloses a composite water treatment agent of a closed type circulating water system. The formula of the composite water treatment agent comprises carboxylic polymer, gluconate, molybdate, zinc salt, rare-earth element nitrate, azoles corrosion inhibitor and water. The composite water treatment agent of the closed type circulating water system has good corrosion and scale inhibition performance and environmental protection performance, is suitable for systems taking the softened water and tap water as make-up water, is phosphorus-free and nontoxic, is easy for biological degradation, and is also suitable for carbon steel and copper material systems.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH +1

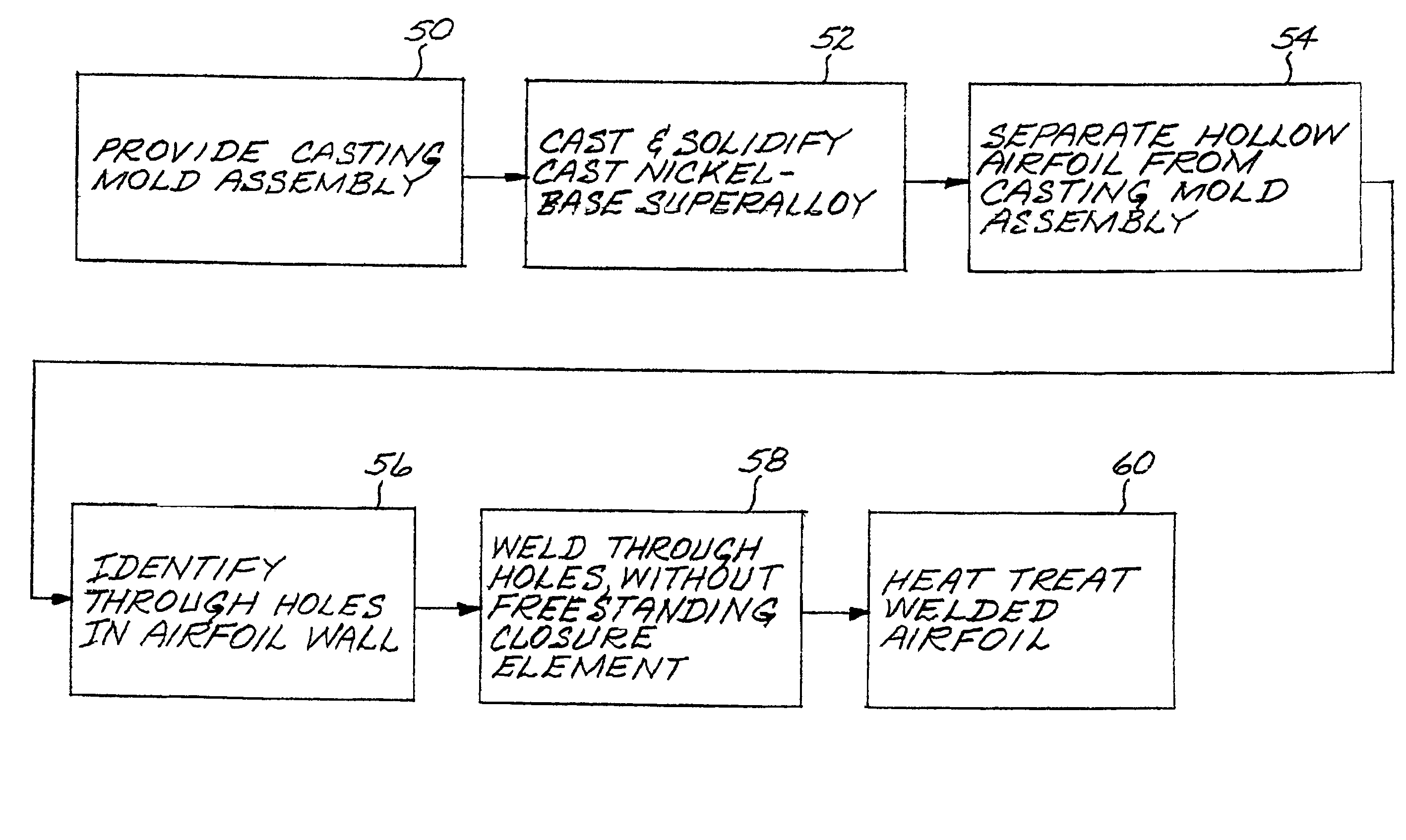

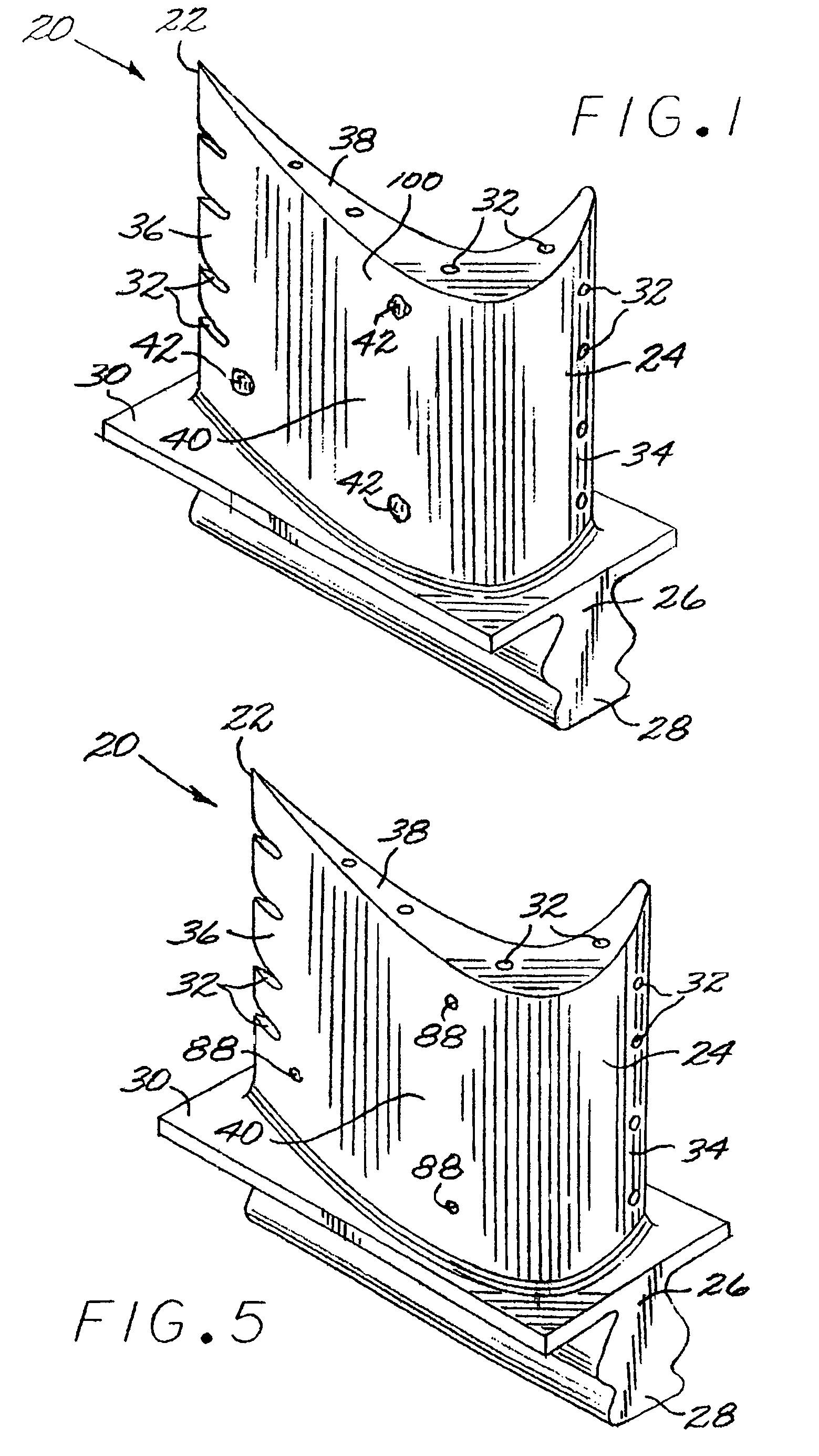

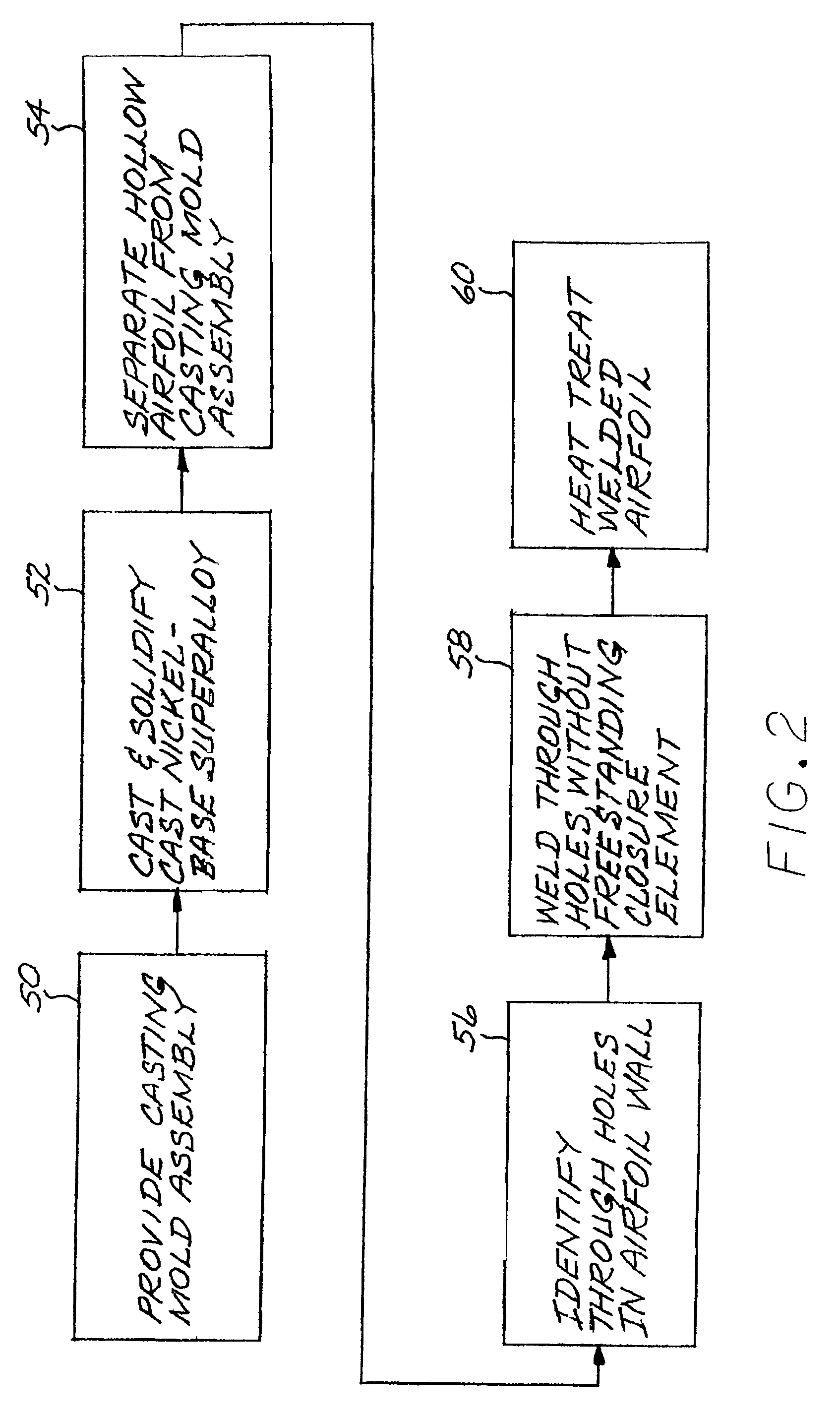

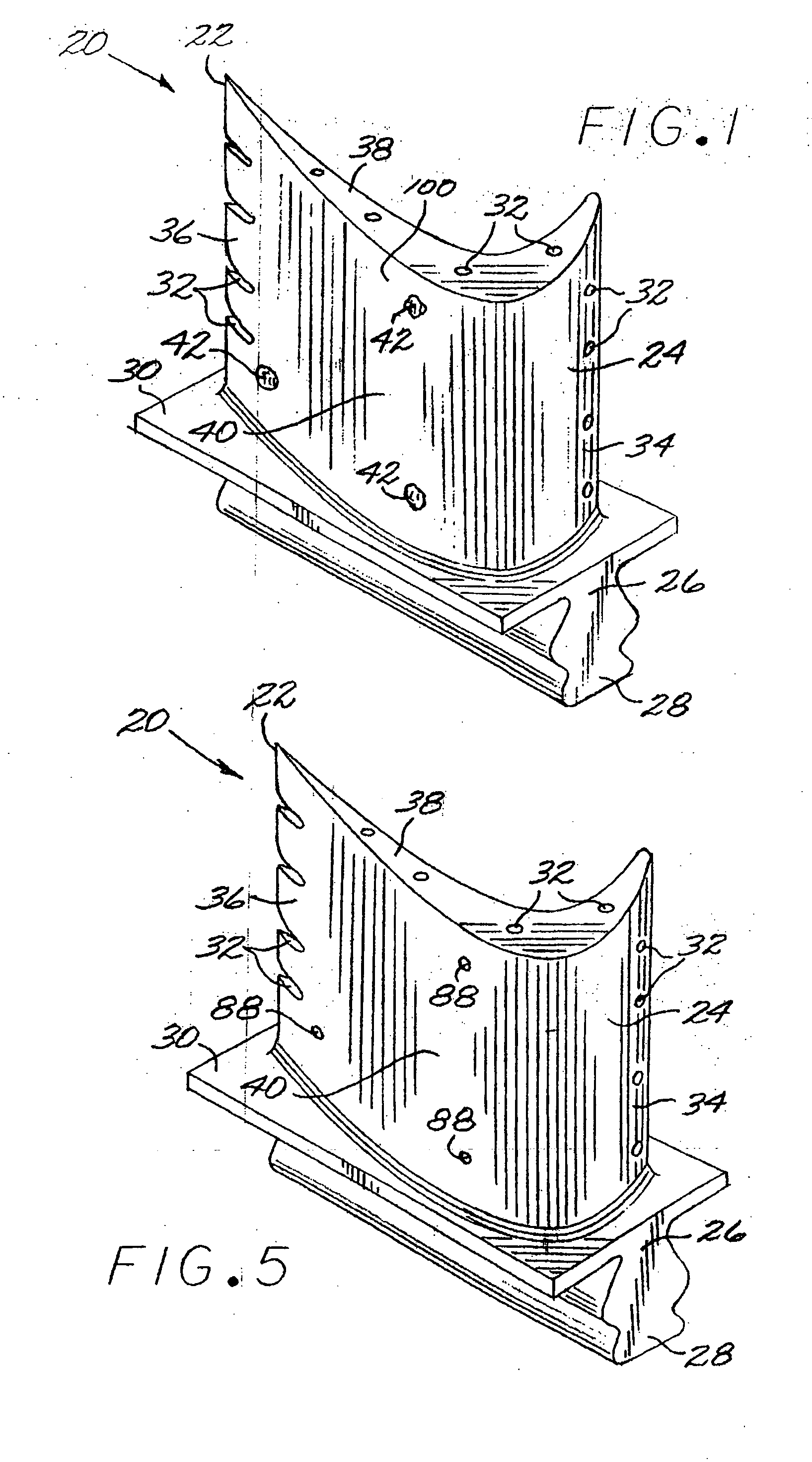

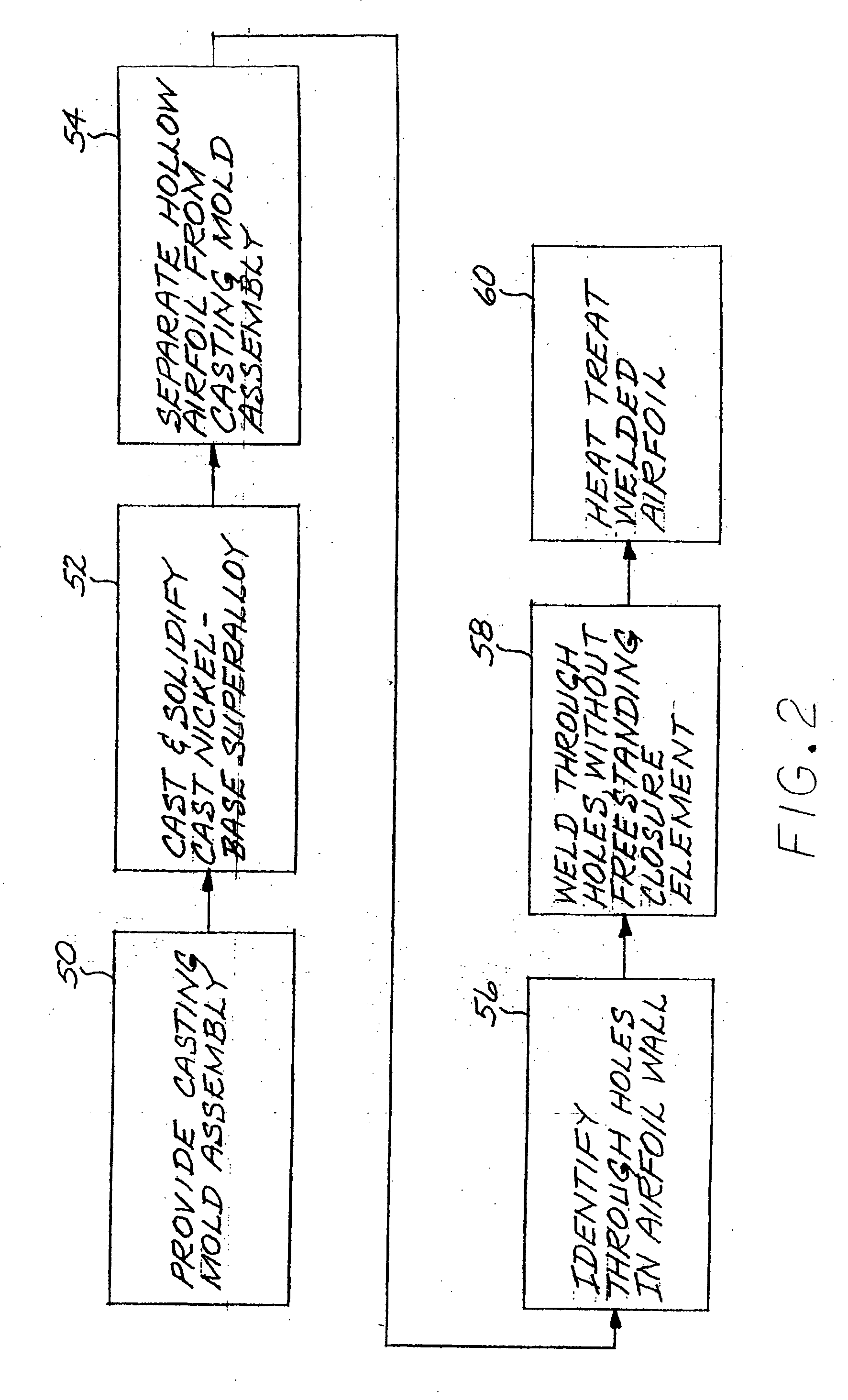

Weld closure of through-holes in a nickel-base superalloy hollow airfoil

InactiveUS7322396B2Small physical and mechanical propertiesImprove adhesionTurbinesBlade accessoriesCasting moldNickel based

A hollow airfoil is fabricated by providing a casting mold assembly including a casting mold, a casting core, and a standoff spacer that prevents the casting core from contacting the casting mold to define a casting space. A first nickel-base superalloy is cast into the casting space and solidified to form the hollow airfoil. The presence of a through-hole extending through a wall of the hollow airfoil is identified, and the through-hole is closed by welding using a second nickel-base superalloy, without using any freestanding closure element.

Owner:GENERAL ELECTRIC CO

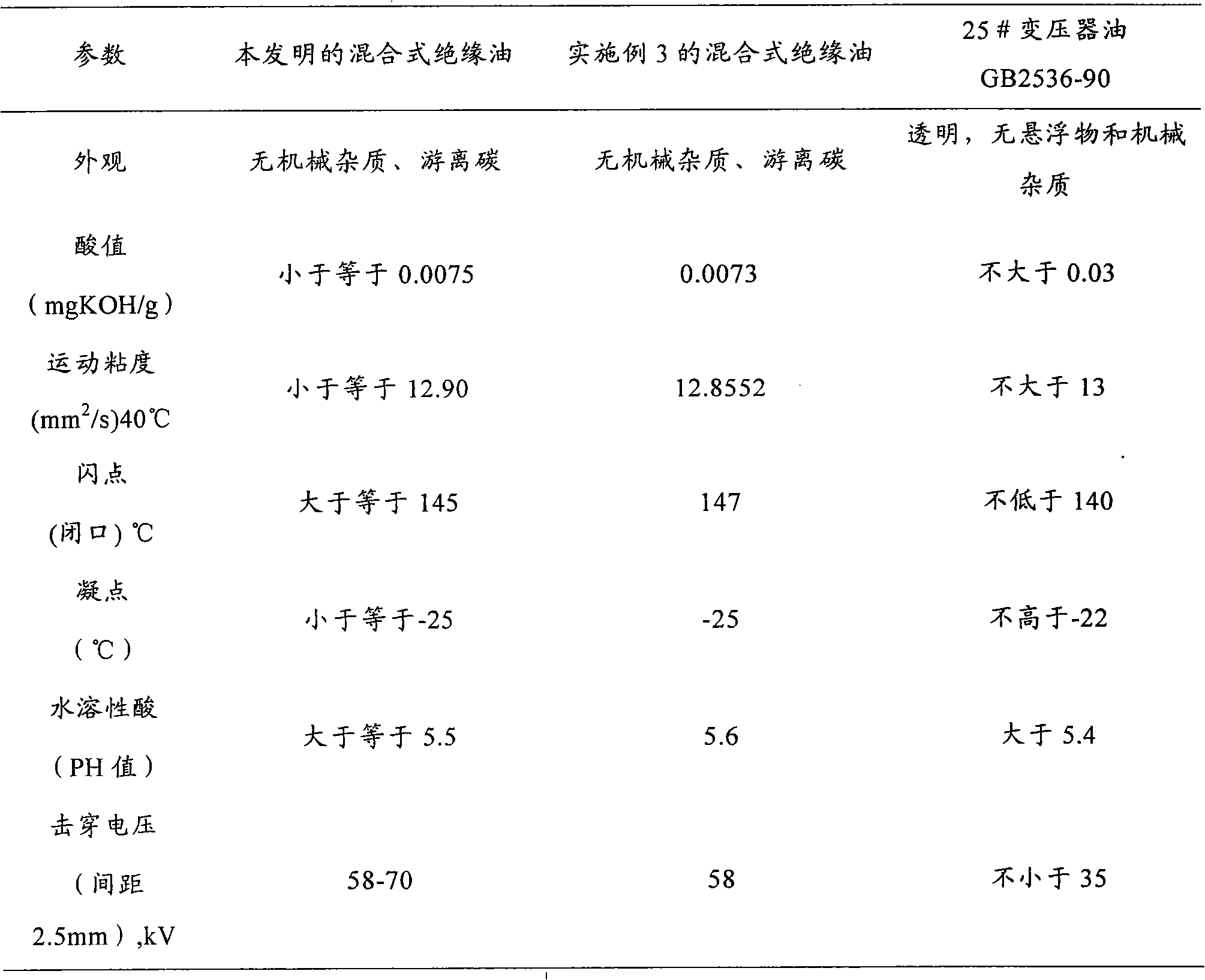

Mixed insulating oil and preparation method thereof

InactiveCN101619254AGood oxidation stabilityGood environmental performanceBase-materialsChemistryWater saturation

The invention provides mixed insulating oil which has high degree of water saturation and can effectively restrain the aging of insulating paper. The mixed insulating oil contains the following raw materials in percentage by weight: 15-25 percent of plant oil and 75-85 percent of mineral insulating oil. Compared with the prior transformer oil, the mixed insulating oil has better oxidation stability and environmental-friendly performance as well as higher breakdown voltage and can effectively restrain the aging of the insulating paper so as to prolong the service life of a transformer, reduce the equipment fault and improve the safety and the reliability of the operation of the transformer. In addition, the invention also provides a preparation method of the mixed insulating oil.

Owner:CHONGQING UNIV

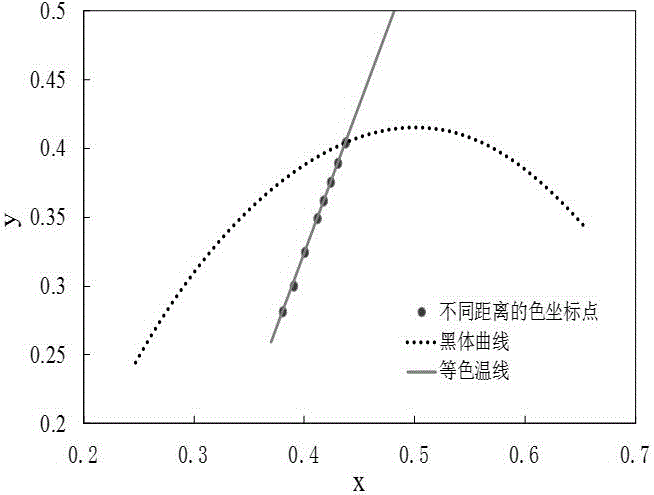

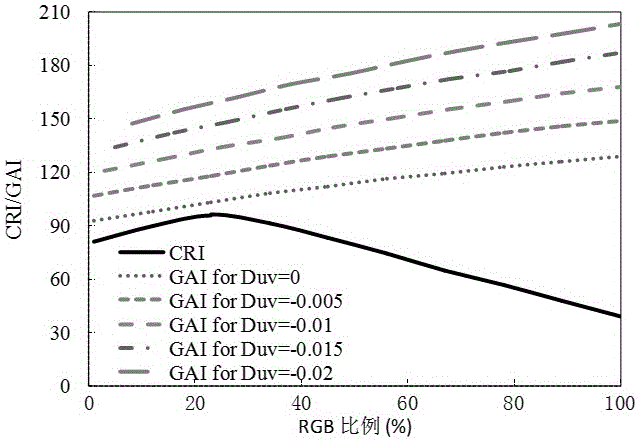

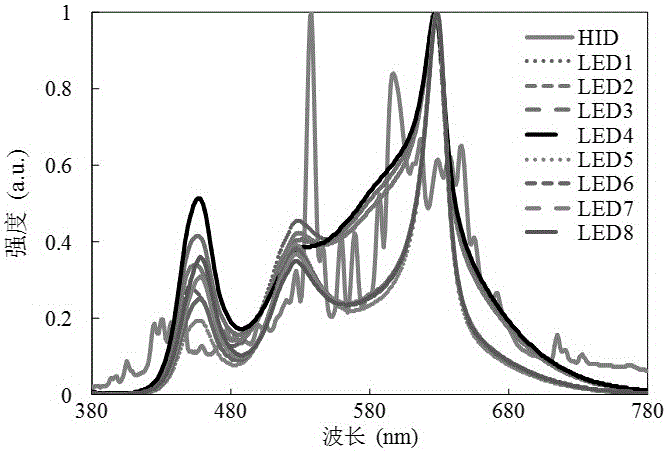

White light LED illuminating system with high light color quality and designing method thereof

InactiveCN105042365AImprove light and color qualityHigh white light preferencePoint-like light sourceElectric lightingGamutLighting system

The invention belongs to the technical field of semiconductor illumination, and particularly discloses a white light LED illuminating system with the high light color quality and a designing method thereof. As the distance Duv from color coordinate points in CIE 1931 color gamut space to a blackbody line is optimized, the LED color mixture illuminating system having the high white light preference degree at the required color temperature is obtained, the color quality of a white light source can be improved, and the lamplight environmental effect can be improved; meanwhile, the required CRI and the high GAI can be guaranteed. The color temperature adjustment range of the white light LED illuminating system is 2,000 K to 10,000K, and the distance Duv from the color coordinate points to the blackbody line is larger than or equal to -0.1 and smaller than or equal to 0. By means of the Duv-optimizing color mixture designing method, the LED illuminating system with the high white light preference degree is obtained, and the white light LED illuminating system and the designing method can be applied to illuminating places with the high light quality requirements.

Owner:FUDAN UNIV

Environmentally benign anti-icing or deicing fluids

InactiveUS7138071B2Not readily run off surfaceImprove abilitiesOther chemical processesOrganic acidOrganic compound

Deicing compositions comprised of hydroxyl-containing organic compounds and / or organic acid salts are disclosed.

Owner:MLI ASSOC

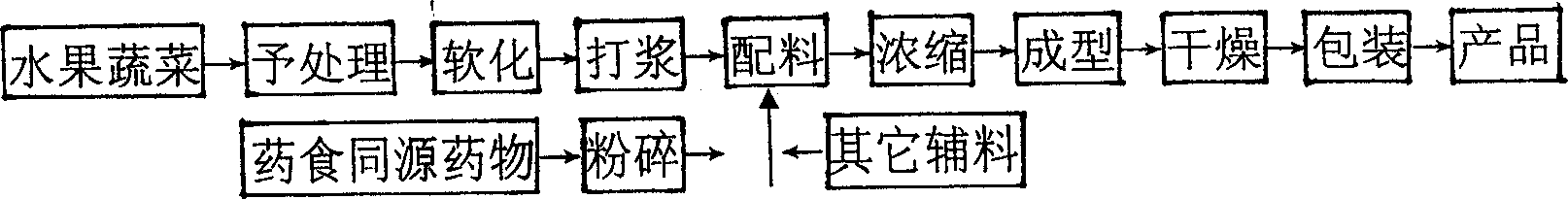

Health-care fruit and vegetable food with function of looseing bowel to relieve constipation and its prodn. method

InactiveCN1461606AImprove gastrointestinal functionInhibit or reduce damageFood preparationPre treatmentSugar

A health-care fruit-vegetable food for looseing bowel to relieve constipation is prepared from fruits (banana, apple, etc), vegitables (carrot, etc.) Chinese-medicinal materials (aloe, wolfberry fruit, etc), oligose, honey, white granular sugar, etc through pre-treating, softening, beating, sieving, pulverizing, proportional mixing, concentrating, shaping, drying and package.

Owner:韩文轩 +2

Weld closure of through-holes in a nickel-base superalloy hollow airfoil

InactiveUS20070084582A1Small mechanical propertiesSmall physical propertiesTurbinesBlade accessoriesCasting moldMaterials science

A hollow airfoil is fabricated by providing a casting mold assembly including a casting mold, a casting core, and a standoff spacer that prevents the casting core from contacting the casting mold to define a casting space. A first nickel-base superalloy is cast into the casting space and solidified to form the hollow airfoil. The presence of a through-hole extending through a wall of the hollow airfoil is identified, and the through-hole is closed by welding using a second nickel-base superalloy, without using any freestanding closure element.

Owner:GENERAL ELECTRIC CO

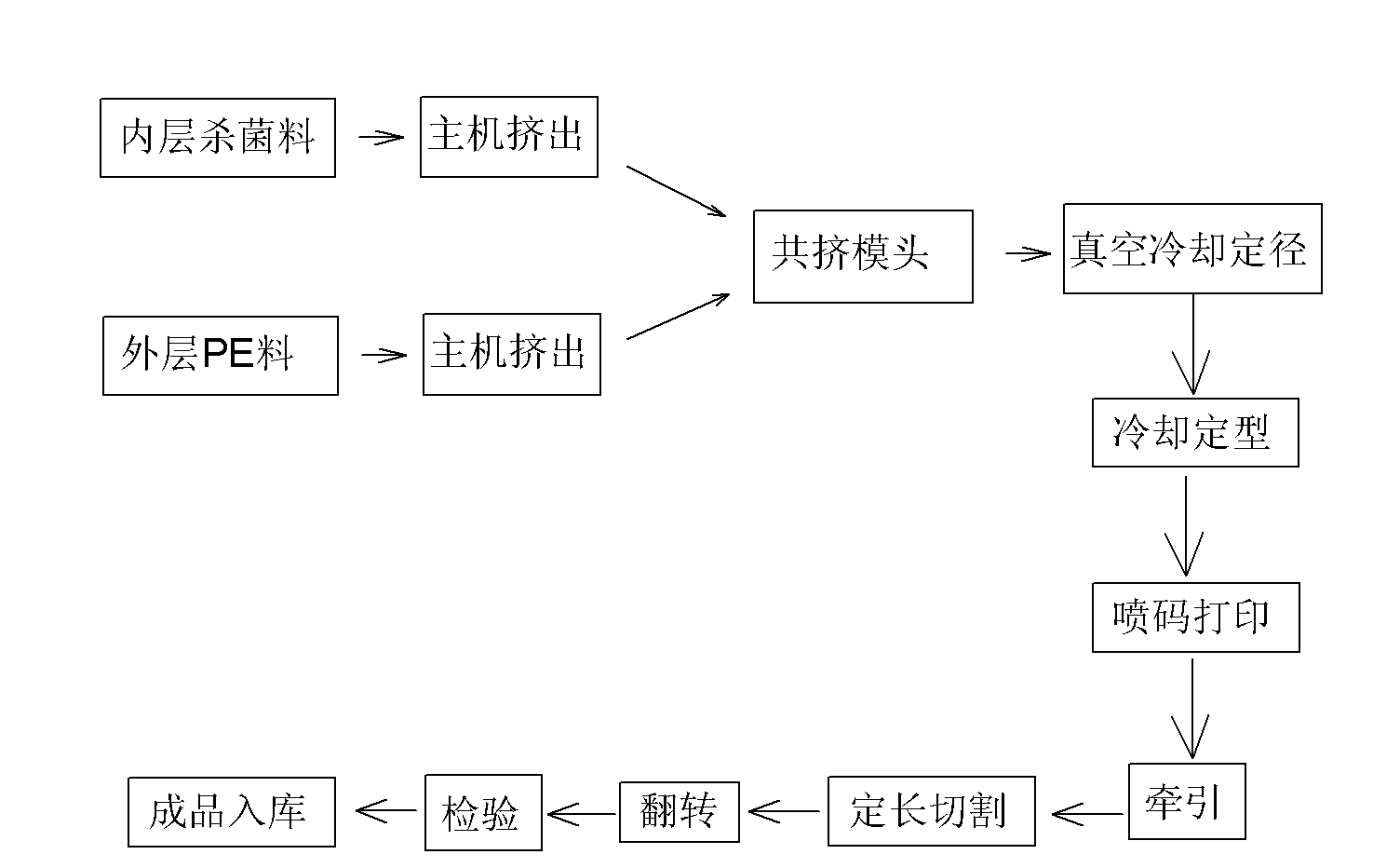

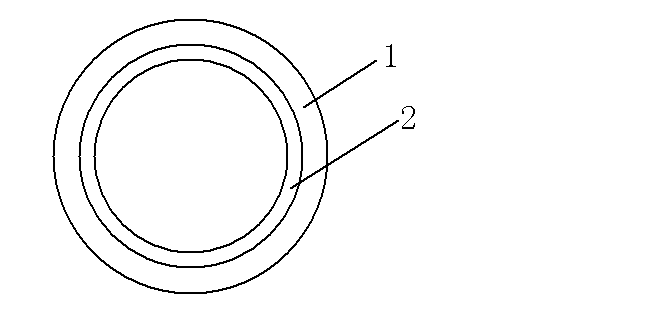

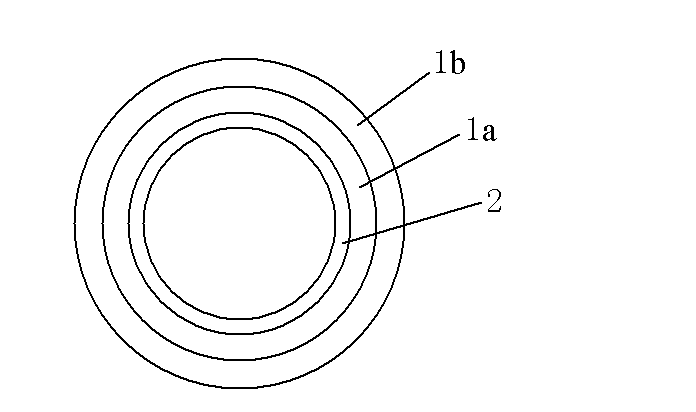

Method for producing temperature-resisting, anti-seismic and antibacterial compound polyethylene water supply pipe

The invention relates to a method for producing a temperature-resisting, anti-seismic and antibacterial compound polyethylene water supply pipe, which can be used for solving the problems of the prior art that the pipe shaping process is difficult, the service life is short, the anti-seismic property is poor, the pipe is easily damaged and the antibacterial property is inferior. The method comprises the following steps: respectively extruding and heating a polyolefin PE (polyethylene) outer layer and a polyolefin PERT (polyethylene raised temperature) inner layer, and then extruding a two-layer or multi-layer coextruded compound pipe from a same extruding port, wherein the compound pipe has tightly combined adjacent layers and at least contains the polyolefin PE outer layer and the polyolefin PERT inner layer; heating the polyolefin PE outer layer and the polyolefin PERT inner layer in sections in the cylinder area and a mold head area of an extruder; shaping the combined compound pipe in vacuum; placing the compound pipe in a water tank for cooling; printing the pipe; dragging the pipe; and cutting the pipe according to the fixed size. The compound polyethylene water supply pipe provided by the using the method has non toxic or side effect, is temperature-resisting and antibacterial, is strong in acclimation, has high cost performance, is simply processed, is conveniently, safely and reliably used, has strong strength and excellent toughness, is strong in anti-seismic property, is difficult to age, break and soak, and has low comprehensive cost.

Owner:康泰塑胶科技集团(郑州)有限公司

A crowd management system

ActiveUS20190104596A1Easy to adaptAvoid problemsElectrical apparatusElectric light circuit arrangementEnvironmental effectCrowds

A crowd management system for influencing a crowd of people to distribute itself between a first region and a second region, comprising: at least one presence sensor configured to sense occupancy information from the first region and the second region; and a controller configured to receive said occupancy information from the at least one presence sensor; and at least one environmental control element configured to control an environmental effect in both the first region and second region; wherein said controller is configured to compare the occupancy information relating to the first region and the second region and based thereon to control the environmental effect in both the first region and the second region via the at least one environmental control element, such that the environmental effect in one of the first region or the second region is relatively more attractive or repellent than the other, in order to thereby influence at least a portion of the crowd to distribute or redistribute itself between the first region and the second region.

Owner:SIGNIFY HLDG BV

Retail Environment

ActiveUS20070295560A1Enhance the retail sales artsImprove the environmentHotelsAbsorbent padsBuilt environmentEmbedded system

A retail store has responsive environment apparatus installed which is controlled by processing apparatus. Trigger event sensors coupled to the processing apparatus, are positioned throughout the store. When customers enter and move about the store, the processing apparatus senses various trigger events and in response thereto creates a micro-environment in the vicinity of each customer, catering to the characteristics of that customer. The micro-environment physically moves as the customer moves about the store. The micro-environment is dynamic in that it is engaged in a continual response loop based on the response trigger events of the customer throughout this interactive cycle with the micro-environment.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

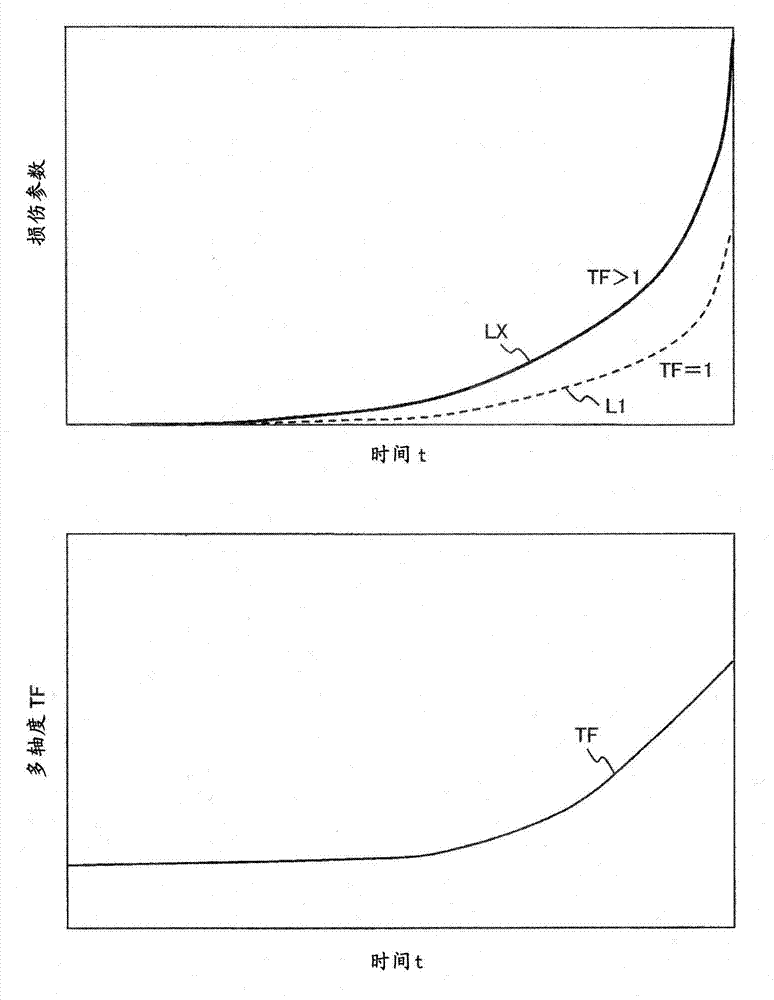

Method and system for evaluating creep damage of high temperature component

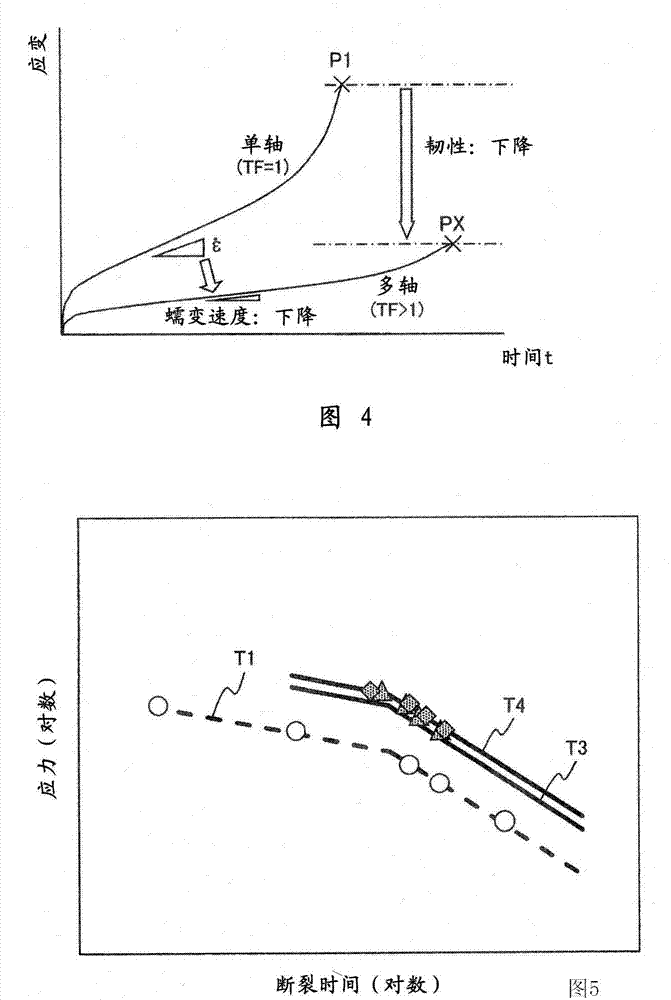

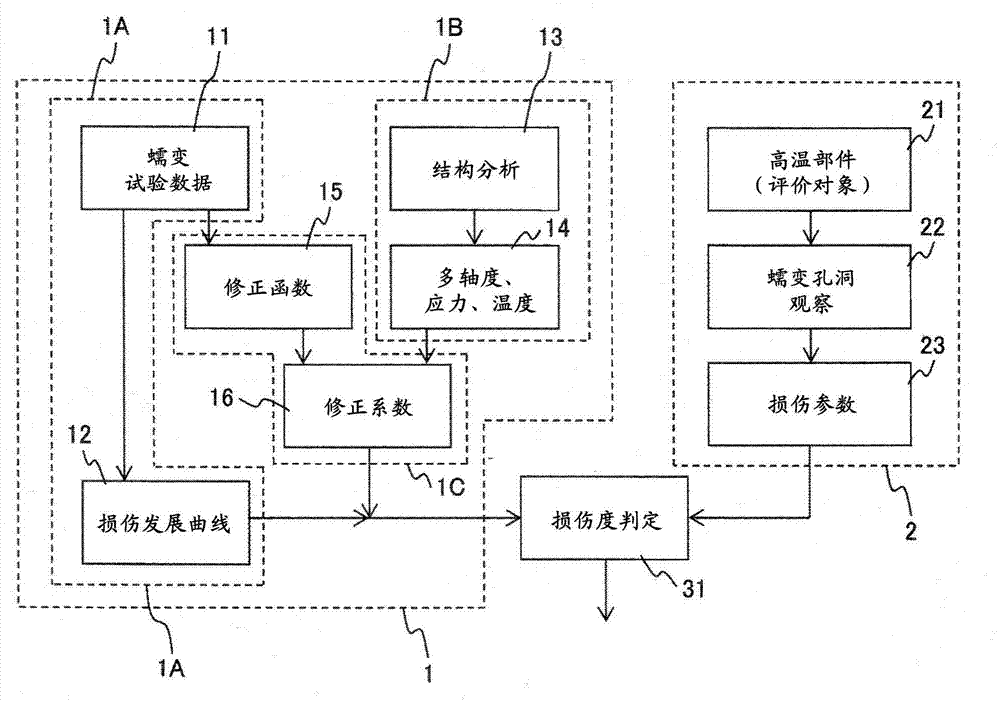

InactiveCN103712865AAvoid replacement optimizationReduce economic lossStructural/machines measurementMaterial flaws investigationTemporal changeAlloy

The invention provides a method and system for evaluating creep damage of a high temperature component. For components composed of heat-resisting steel and heat-resisting alloy, used at high temperature and damaged by creeping, the provided method for evaluating creep damage corresponds to stress multiaxiality and other stress states of components, so that the precision of residual service life evaluation and damage evaluation can be improved. The method for evaluating creep damage of a high temperature component for use under a high temperature environment is characterized in that temporal change in damage parameter of the high temperature component under a uniaxial condition and temporal change in multiaxiality of the high temperature component are obtained, and the temporal change in damage parameter is corrected by the temporal change in multiaxiality to assess the degree of creep damage of the high temperature component.

Owner:HITACHI LTD

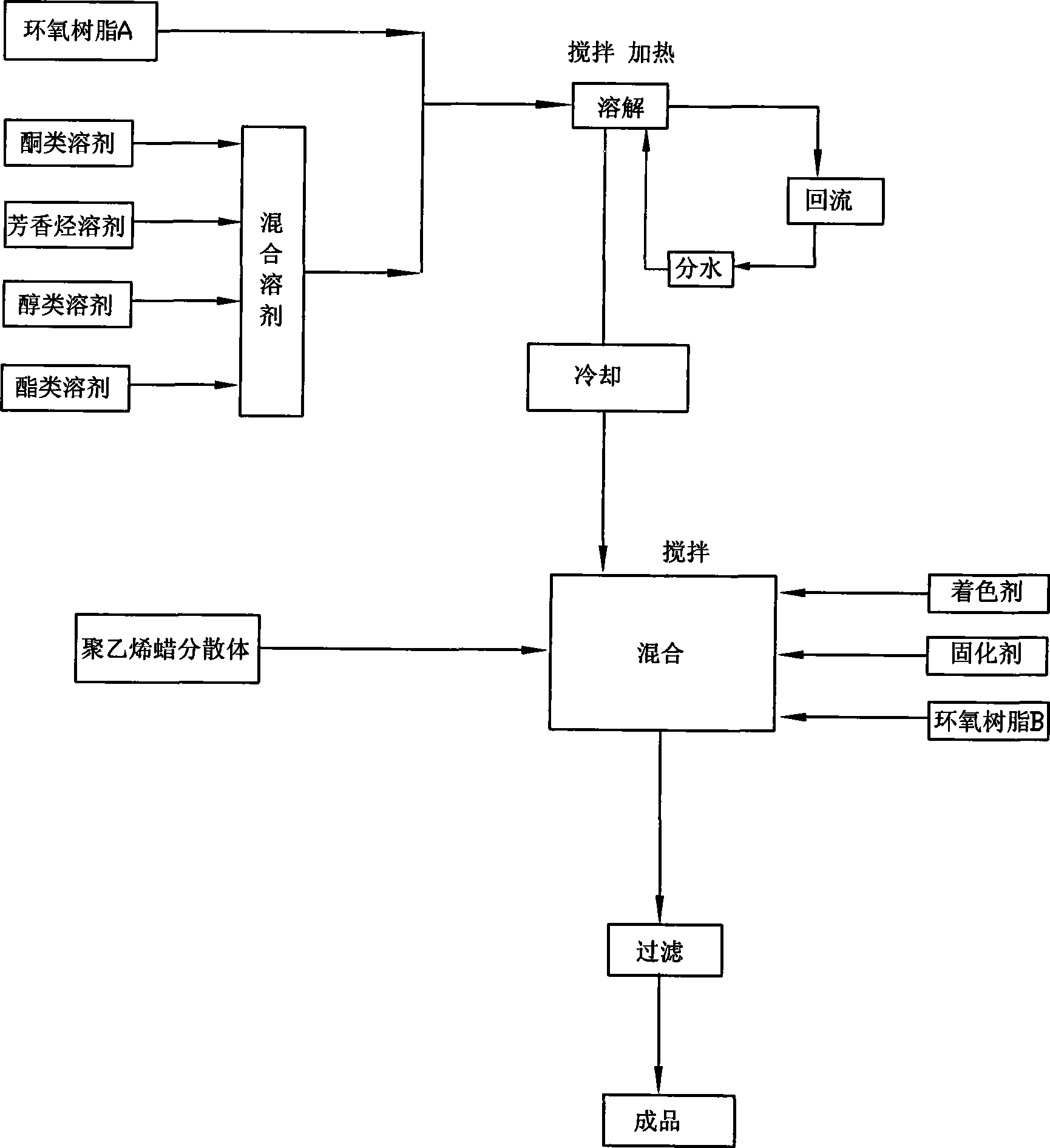

Adhesive for imperial crown cap polyolefin pad for beer or beverage and preparation thereof

InactiveCN101503606AGood environmental performanceSave resourcesNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventPolyolefin

The invention relates to the field of chemical engineering of adhesives, in particular to an adhesive for crown cap polyolefin gaskets for beer and beverage and a preparation method thereof. At present, crown cap gaskets for the national beer and beverage are mostly made of polyvinyl chloride (PVC) material, and compositions of the polyvinyl chloride material contain chemical substances which are harmful to human bodies. The adhesive for the crown cap polyolefin gaskets for the beer and beverage is prepared by compounding the following raw materials by weight portion: 18 to 43 portions of epoxy resin A, 3 to 11 portions of epoxy resin B, 43 to 57 portions of mixed solvent, 3 to 5 portions of polyethylene wax dispersion, 0.7 to 1.1 portions of colorant, and 4.9 to 10.3 portions of curing agent. The product has the advantages of no harm to human bodies, good hygienic property, firm adhesion and good sealing performance, realizes the successful substitution of new materials at the same time, and pushes the popularization and application of the crown cap polyolefin gaskets for the beer and beverage.

Owner:西安昌泰化工厂

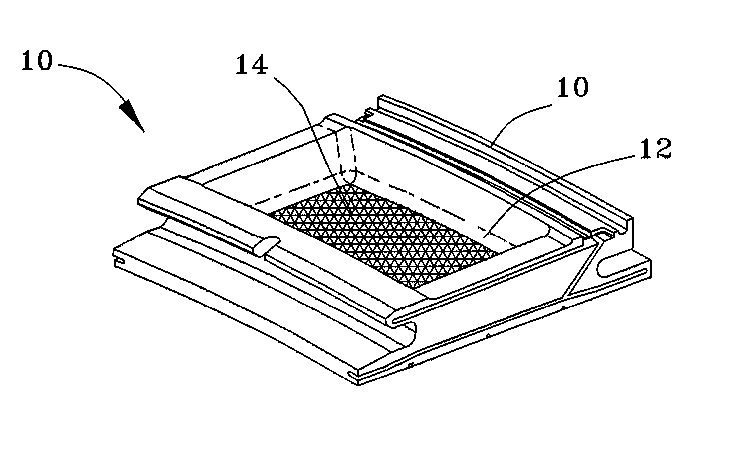

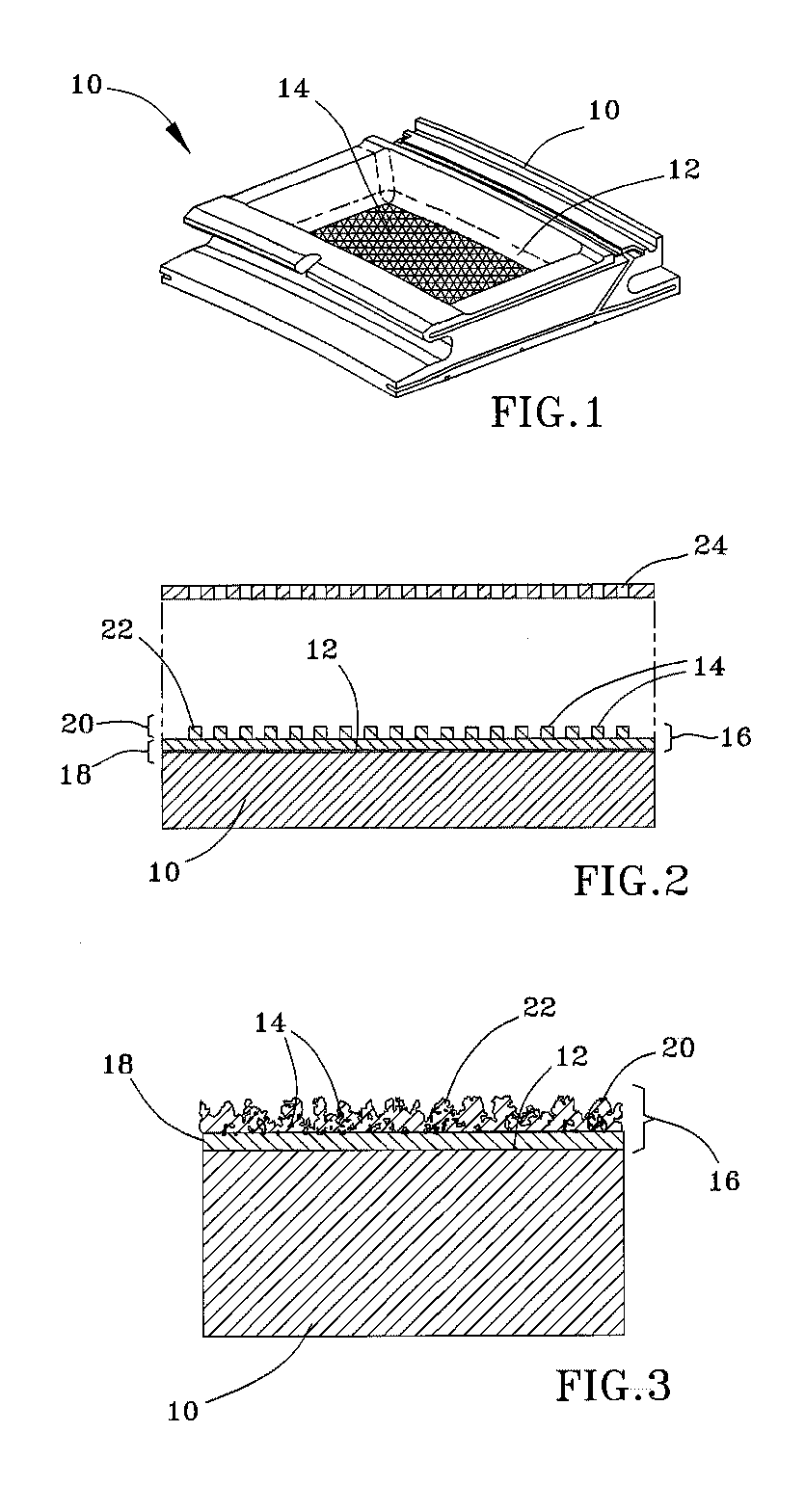

Coating and coating process incorporating raised surface features for an air-cooled surface

InactiveUS6924002B2Improve heat transfer performanceImprove protectionMolten spray coatingEngine fuctionsSubstrate surfaceAir cooling

A coating and coating process for incorporating surface features on an air-cooled substrate surface of a component for the purpose of promoting heat transfer from the component. The coating process generally comprises depositing a first metallic coating material on the surface of the component using a first set of coating conditions to form a first environmental coating layer, and then depositing a second metallic coating material using a second set of coating conditions that differ from the first set, such that an outer environmental coating layer is formed having raised surface features that cause the surface of the outer environmental coating layer to be rougher than the surface of the first environmental coating layer.

Owner:GENERAL ELECTRIC CO

Environmentally benign anti-icing or deicing fluids

InactiveUS20090314983A1Not readily run off surfaceImprove abilitiesOther chemical processesOrganic acidOrganic compound

Deicing compositions comprised of hydroxyl-containing organic compounds and / or organic acid salts are disclosed.

Owner:SAPIENZA RICHARD +2

Environmentally benign anti-icing or deicing fluids

InactiveUS20070012896A1Reduce shipping costsNot readily run off surfaceOther chemical processesOrganic acidOrganic compound

Owner:SAPIENZA RICHARD +2

Environmentally benign anti-icing or deicing fluids

InactiveUS20050179000A1Reduce shipping costsNot readily run off surfaceOther chemical processesOrganic acidSimple Organic Compounds

Deicing compositions comprised of hydroxyl-containing organic compounds and / or organic acid salts are disclosed.

Owner:MLI ASSOC

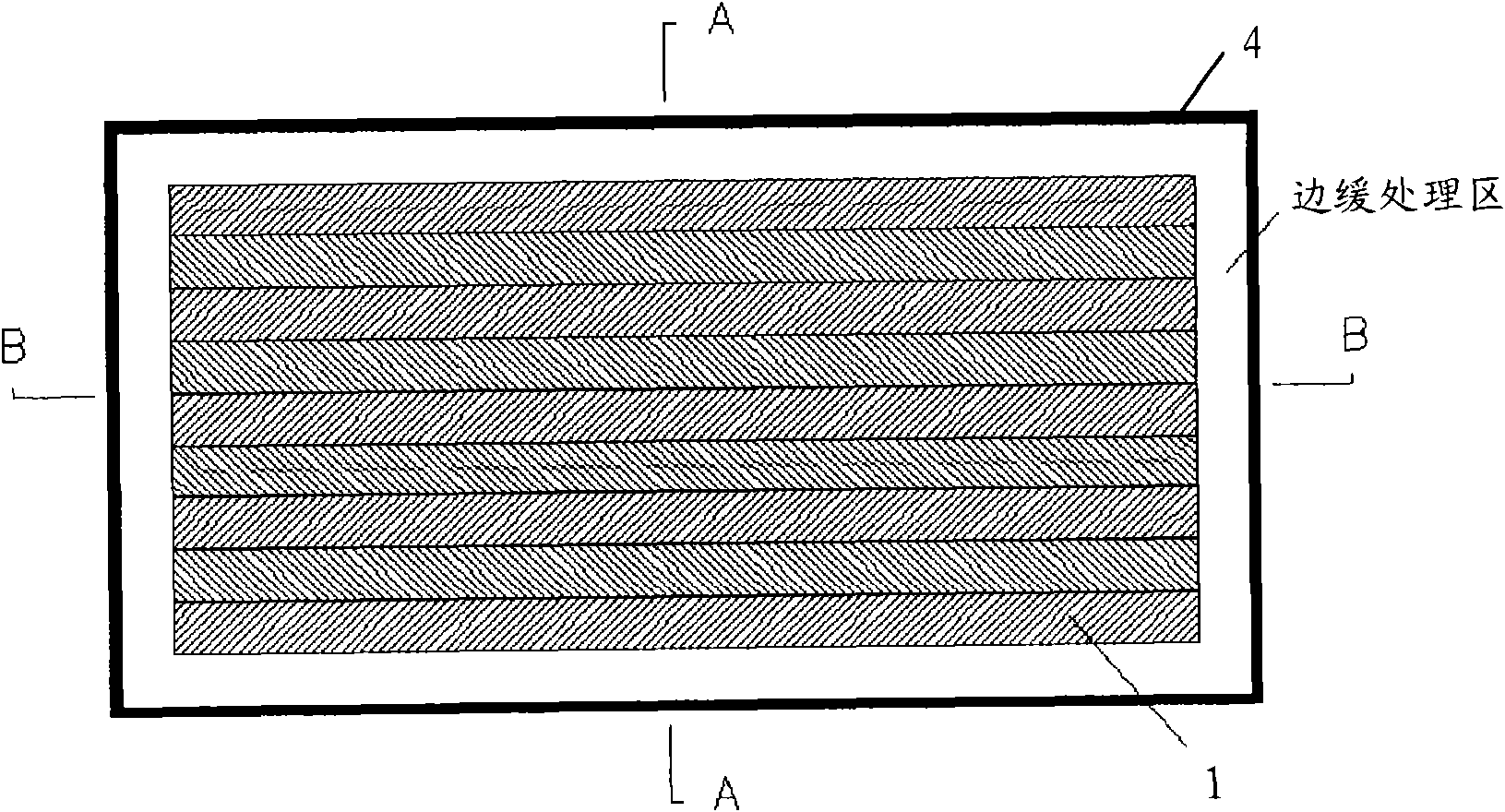

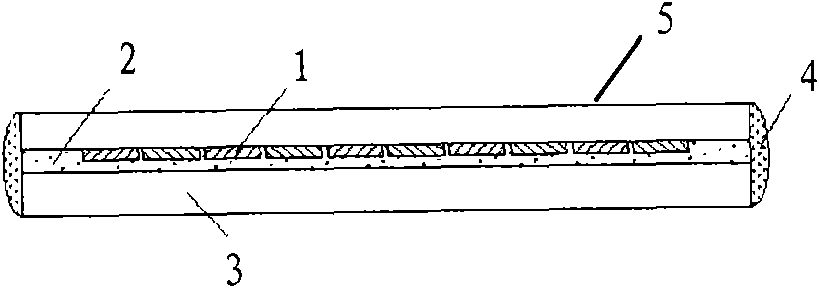

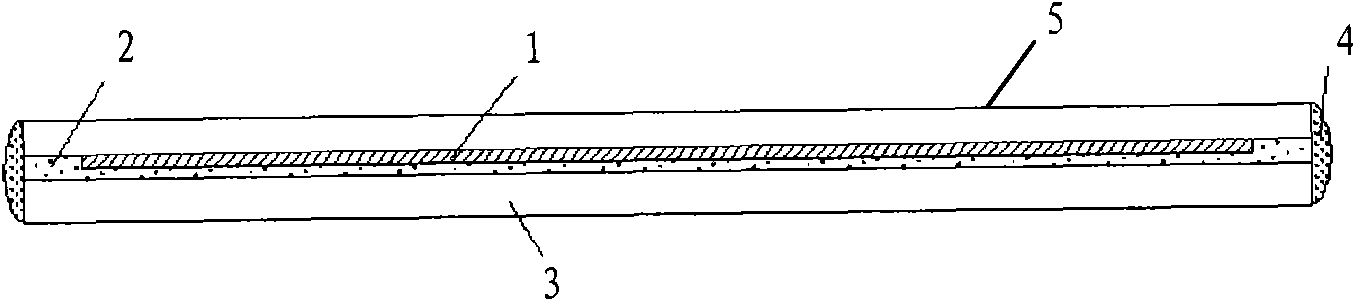

Thin film solar cell component and encapsulation method thereof

InactiveCN101621088AGood resistance to mechanical damageGood ability to adapt to the environmentFinal product manufactureSemiconductor devicesMoistureLight transmission

The invention provides a thin film solar cell component encapsulation mode, including cutting off films at all the edges of thin film solar cells, superimposing and bonding the thin film solar cell component (1) with a lower bottom surface (3) by binding agent (2) to form a component, and smearing an outdoor aging resistant waterproof glue layer (4) with appropriate thickness. The laminated structure not only causes the thin film solar cell to be effectively protected and have better pollution resistance, damp resistance and mechanical damage resistance performances but also ensures luminousness to be enough, so as to keep conversion efficiency of the cell; the outdoor aging resistant waterproof glue layer (4) is smeared at the edges, and the outdoor aging resistant waterproof glue layer not only can be used as a buffer layer to prevent the glass of the component from being broken by bump but also can prevent outside moisture and impurity from being directly contacted with the binding agent (2) on the section of the component, thus weatherability of the component is improved and the service life of the thin film solar cell is greatly prolonged.

Owner:GS SOLAR FU JIAN COMPANY

Environmentally benign anti-icing or deicing fluids

InactiveUS20090261290A1Not readily run off surfaceImprove abilitiesOther chemical processesIndirect heat exchangersOrganic acidOrganic compound

Deicing compositions comprised of hydroxyl-containing organic compounds and / or organic acid salts are disclosed.

Owner:MLI ASSOC

Particle material for producing beer and beverage crown cap polyolefin gasket and preparation method thereof

The invention relates to a particle material for producing a beer and beverage crown cap polyolefin gasket and a preparation method thereof. The material of the crown cap gasket for beer and beverage is mostly prepared from a polrvinyl chloride; and because the material of the crown cap gasket for beer and beverage contains a plasticizer, a stabilizer, vinyl chloride monomer residue in polrvinyl chloride and the like, the edible safety problem exists. The particle material is prepared by the following steps: mixing the following raw materials in parts by weight: 58.1-72.5 parts of low densitypolyethylene, 18.2-39.4 parts of thermoplastic elastomer, 2.5-8.5 parts of antioxidant master batch and 0-0.8 part of coloring master batch; and then extruding, granulating, water cooling, screening and drying; and finally cooling to form the particle material finished product. According to the invention, a safe material is adopted to replace an limited material, thus edible safety is ensured, and the particle material also has the advantage of good environmentally-friendly property and is beneficial to human body health, and food package amount is greatly reduced.

Owner:XIAN CHANGTAI PACKAGE MATERIALS

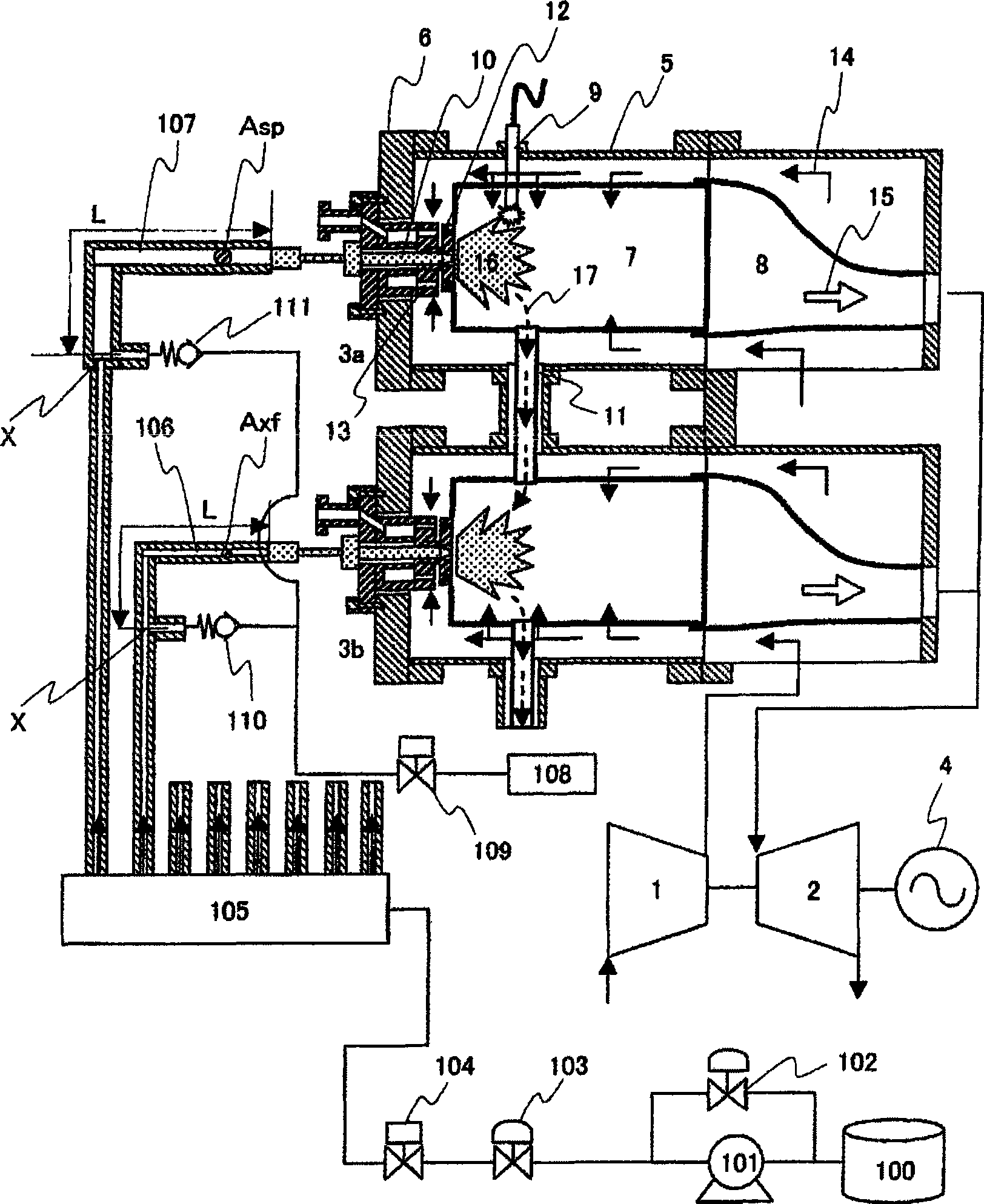

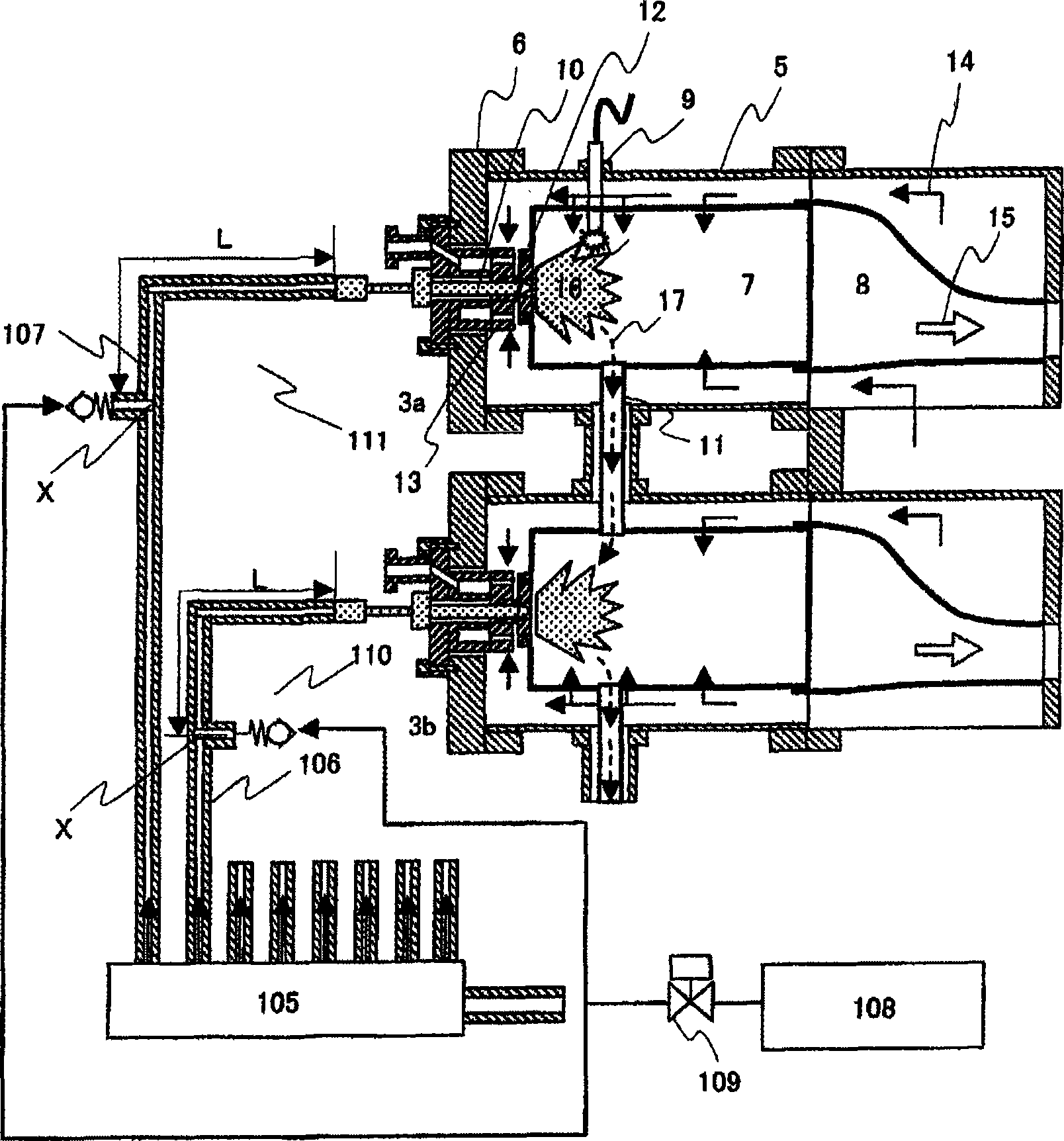

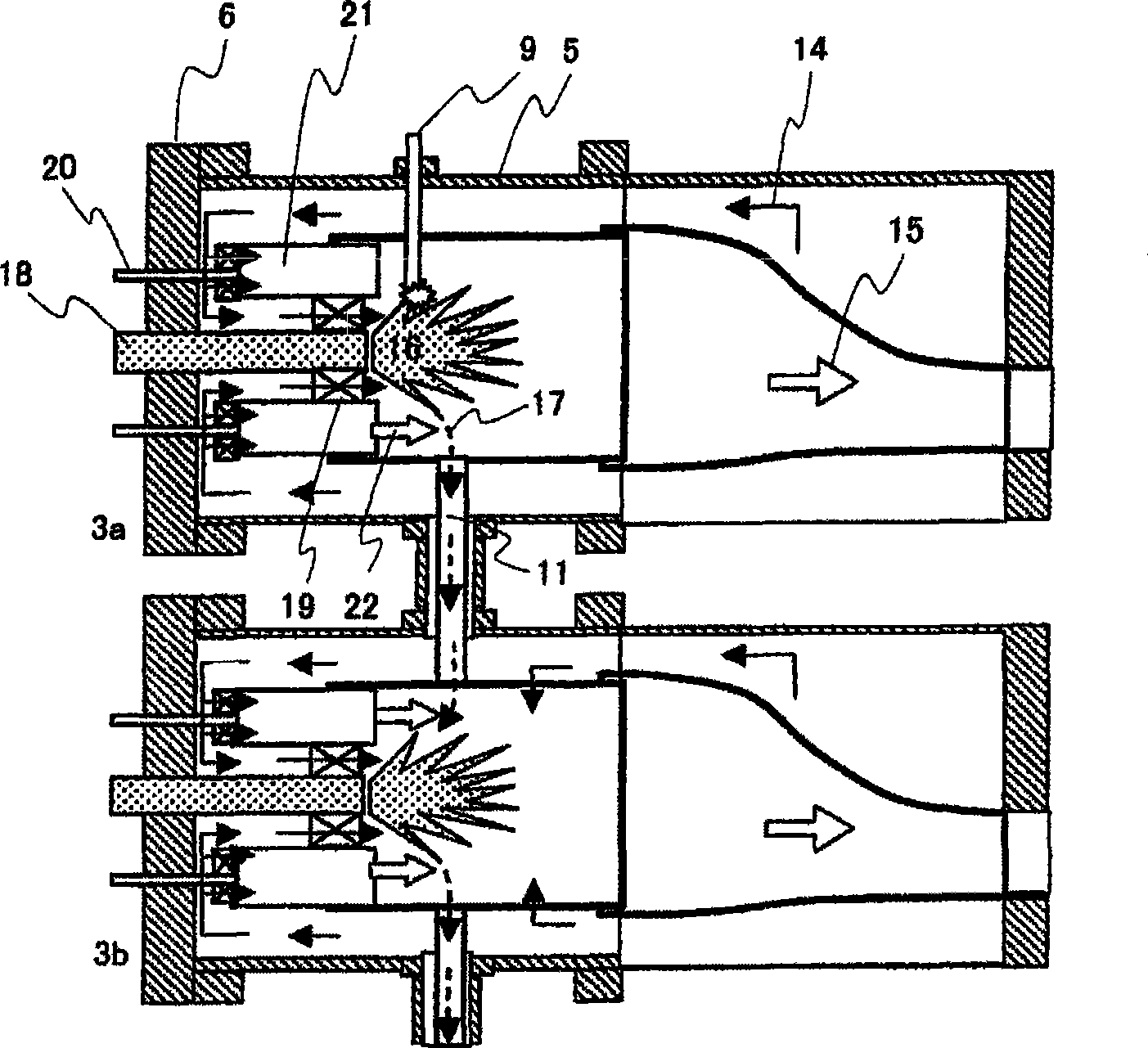

Combusting system, remodeling method for combusting system, and fuel injection method for combusting system

ActiveCN101446420AImprove reliabilityGood environmental performanceBurnersBurner safety arrangementsStart timeCombustor

Owner:MITSUBISHI POWER LTD

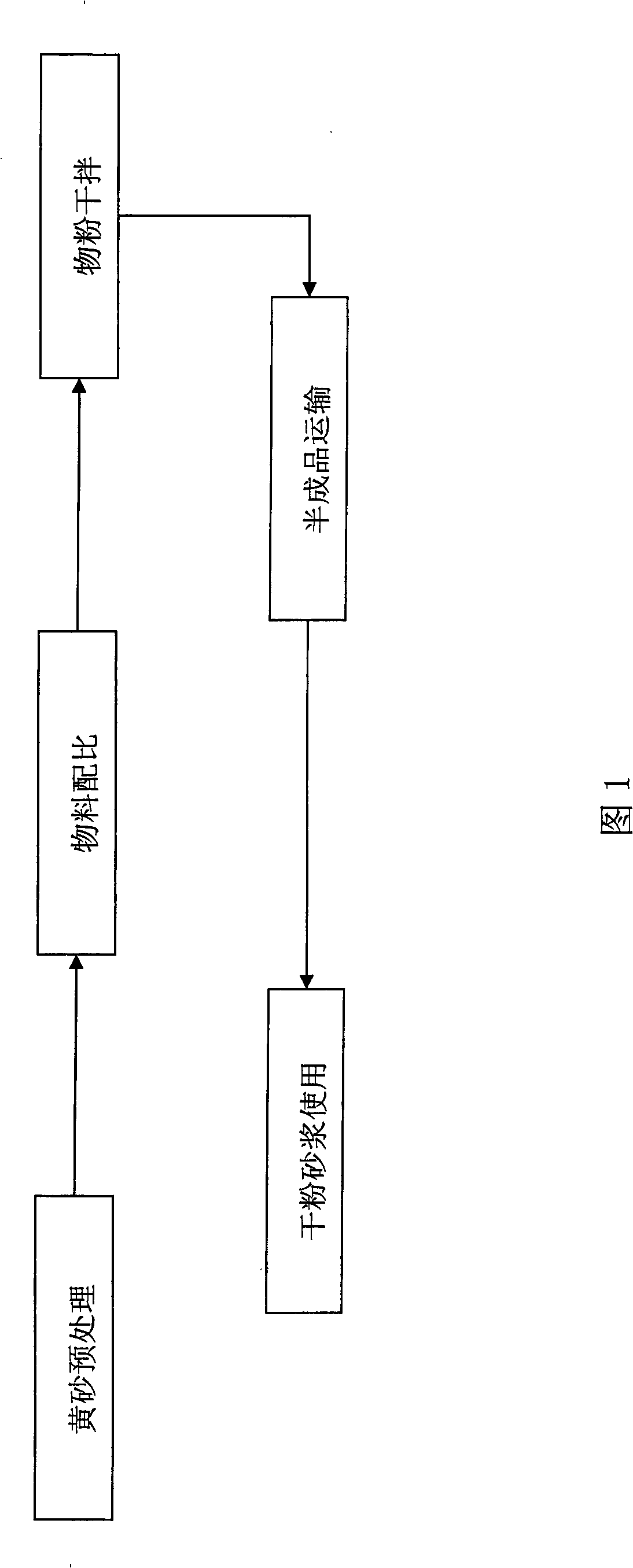

Dry powder mortar and method for preparing the same

InactiveCN101357839AAvoid substandard qualityKeep drySolid waste managementSodium BentoniteRoad surface

The invention relates to a dry powder mortar composition for construction, in particular to the high-strength construction dry powder mortar which can be widely used in building, plastering and road surface in the construction industry; the dry powder mortar comprises cement, yellow sand, fly ash and thickened powder, the dry powder mortar is characterized in that the weight percentages of the components are as follows: cement: 15 percent; yellow sand: 76 percent; fly ash: 6 percent; thickened powder: 2.9985 percent; and bentonite: 0.0015 percent; a preparation process includes the following steps: a. the pretreatment of the yellow sand is carried out; b. the material preparation is carried out; c. the mixing of the materials and the powder is carried out; d. and the sand powder is dry-mixed for use. The technical problems to be solved by the invention are as follows: the traditional mortar mixing is uneven, impurities are contained therein, the silt content is too high, the water-retaining function does not realize, the bleeding is severe and the separation phenomenon occurs, thereby causing unstable quality, great environmental pollution, great material waste, no mechanical construction, inconvenient transportation and high labor intensity.

Owner:常州市众华建材科技有限公司

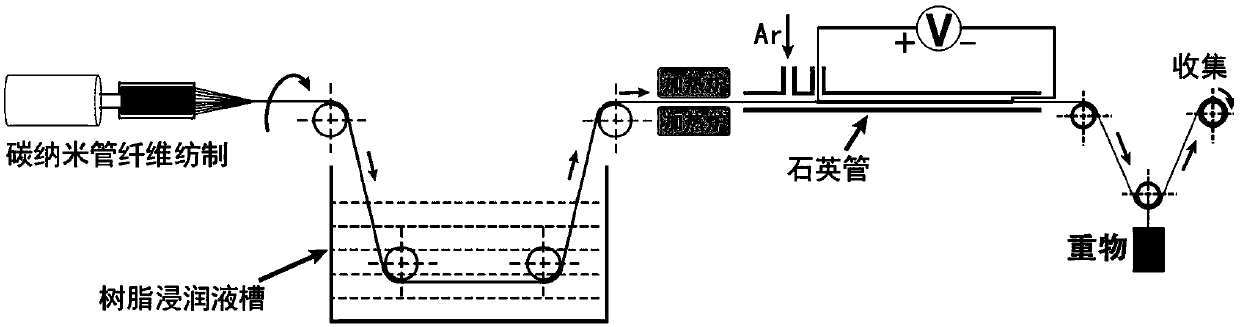

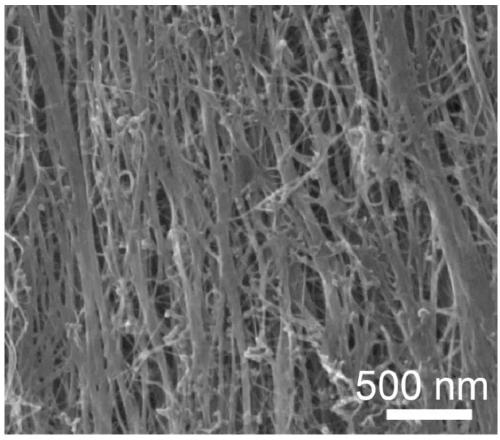

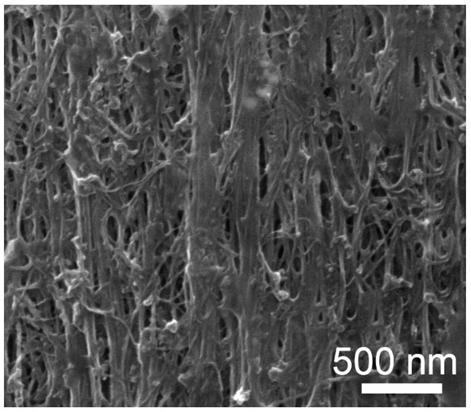

High-performance carbon nanotube/carbon composite fiber and rapid preparation method thereof

ActiveCN111101371AIncrease the force between the tubesHigh strengthCarbon fibresCarbon compositesCarbon nanotube

The invention discloses a high-performance carbon nanotube / carbon composite fiber and a rapid preparation method thereof. The preparation method comprises the following steps of during the carbon nanotube fiber spinning process and / or after the spinning is completed, fully infiltrating a precursor solution of a polymer with a high residual carbon rate and twisting the carbon nanotube fiber, and then removing a solvent on the surface of the carbon nanotube fiber; and applying a drafting force to the obtained carbon nanotube composite fiber, introducing current into the carbon nanotube compositefiber, so that a precursor of the polymer with the high residual carbon rate in the carbon nanotube composite fiber is crosslinked and cured, and then the formed polymer is carbonized to obtain the high-performance carbon nanotube / carbon composite fiber. The preparation method of the invention is fast and efficient, and the carbon nanotube / carbon composite fiber with high orientation and a compact structure can be prepared in only 10 seconds, which not only can greatly improve the mechanical property and the electrical property of the carbon nanotube fiber, but also enable the carbon nanotubefiber to have excellent resistance to extreme environment.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Woman hemostatic absorption plug

InactiveCN101628123AEffective hemostasisEffective antibacterial and antibacterialTamponsBandagesFiberBiocompatibility Testing

The invention discloses a woman hemostatic absorption plug which comprises a plug body. The woman hemostatic absorption plug is characterized in that the plug body consists of a plug core and an outer layer for packaging the plug core, the plug body is formed by rolling an activated carbon fiber felt textile, the outer layer is made of chitin-chitosan non-woven fabrics, and a lead-out line is fixed on the plug body. By using the adsorption and drainage actions of activated carbon fibers as well as the good biocompatibility, the haemostatic action, the antibacterial action, the bacteriostatic action and the healing promoting action of chitin-chitosan fibers, pathogens and bad secretions in a vagina are adsorbed and taken out of bodies, thereby achieving the purposes of disease cure and prevention. The woman hemostatic absorption plug is safe, nontoxic, harmless and non-irritant to human bodies.

Owner:YUNNAN SHUYUN TECH

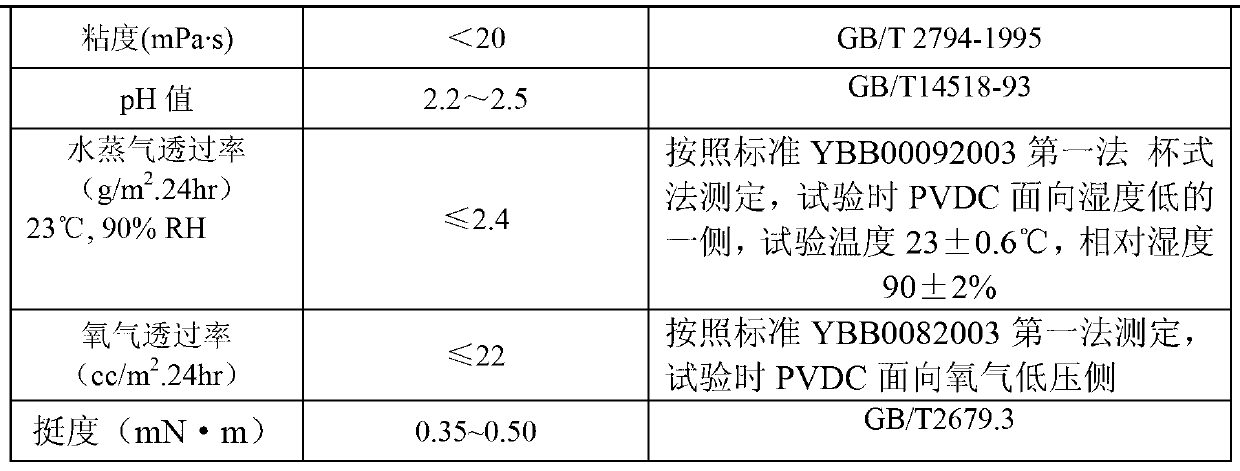

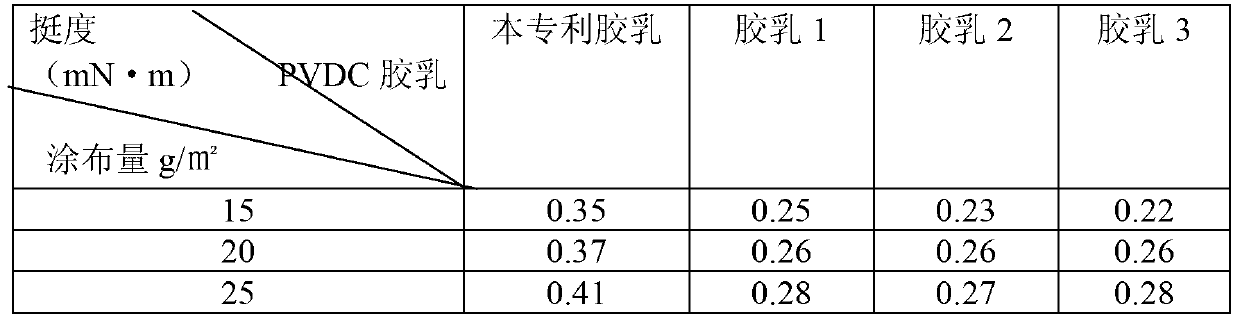

Special PVDC (Polyvinyl Dichloride) latex for lining paper and preparation method of special PVDC latex

ActiveCN103342771AGood stabilityGood environmental performanceCoatings with pigmentsCoatingsMethacrylamideSodium silicate

The invention relates to special PVDC (Polyvinyl Dichloride) latex for lining paper. The PVDC latex comprises the following raw materials: a mixed monomer, auxiliaries, an initiator, an emulsifying agent, a seed emulsifying agent and deionized water, wherein the auxiliaries include ammonium acetate, ferrous chloride and nano inorganic silicon. The inorganic silicon in the nano inorganic silicon is one or more of silicon dioxide, silicon disulfide, sodium silicate, potassium metasilicate, aluminum silicate, calcium silicate, silicic acid and silicon carbide. The invention also provides a preparation method of the special silicon disulfide for lining paper. The auxiliary, namely the nano inorganic silicon is added into the PVDC latex, so that the stiffness of a paper sheet is increased effectively; in addition, the mixed monomer containing vinylidene chloride, methacrylamide, acrylic ester and acrylic acid as well as the initiator, the emulsifying agent, the seed emulsifying agent and the auxiliaries are adopted, so that the PVDC latex is prepared; and the prepared PVDC latex has good stability and has the characteristics of environmental friendliness, good air and oxygen resistance and particularly high stiffness when used for packaging cigarettes after being coated on the lining paper.

Owner:HAINAN SHINER IND

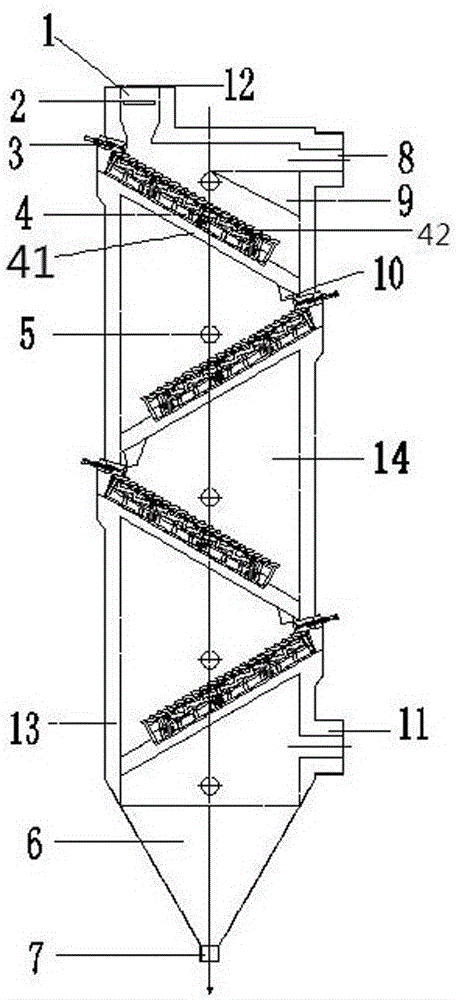

Closed-loop steel sintered red ore cooling device and process method thereof

ActiveCN106123609AIncrease productionGood qualityHandling discharged materialCooling methodsCold air

The invention discloses a closed-loop steel sintered red ore cooling device. The device comprises a device body, a heat exchange cavity arranged in the device body, a feeding inlet formed in the upper end of the device body, a uniform distributor arranged at the lower end of the feeding inlet, a discharging outlet formed in the lower end of the body, a uniform temperature device and at least one fire grate. The uniform temperature device is arranged on the device body and communicates with a cold air outlet. The at least one fire grate is movably installed in the heat exchange cavity. Each fire grate and the heat exchange cavity form an obliquely-downward angle, and the fire grates are parallel to each other. A pushing device is arranged at the front end of each fire grate. A hopper is arranged at the tail end of each fire grate. The device replaces a cooling section of an original sintering machine or a ring cooling machine. Compared with an original cooling mode, the device is high in yield, good in quality and low in energy consumption. Compared with the original cooling mode, the yield of a marching type sintering machine can be increased by 30%-40%, zone firing is increased by 5%-10%, and energy consumption only accounts for about 50% of the original cooling mode.

Owner:BEIJING RUIDA HONGXIN TECH CO LTD

Environment-friendly imitation ceramic tableware material and preparing method thereof

An environment-friendly imitation ceramic tableware material is prepared from polylactic acid, calcium phosphate biological ceramic, hemp cellulose and a processing and modifying assistant. The preparing method comprises the following steps of: drying polylactic acid, calcium phosphate biological ceramic and hemp cellulose respectively; premixing the polylactic acid, calcium phosphate biological ceramic powder, hemp cellulose and the processing and modifying assistant; and feeding the premixed material into a granulating machine for plasticizing and mixing, and carrying out extrusion and granulation to obtain the environment-friendly imitation ceramic tableware material. The environment-friendly imitation ceramic tableware material provided by the invention has the advantages that tripolycyanamide and formaldehyde are not contained, and the problems that the conventional imitation ceramic tableware has residual tripolycyanamide and formaldehyde monomer and the tableware releases toxicity when being heated in a microwave oven can be solved, so that the tableware is safe and reliable, and can be degraded or utilized by thermoplastic processing after being discarded; the calcium phosphate biological ceramic powder and the hemp cellulose are added to the material, so that the strength, toughness and heat-resistant quality of the polylastic acid material are improved. The environment-friendly imitation ceramic tableware material can replace the conventional tripolycyanamide imitation ceramic tableware material, is convenient in raw material source and simple to process, can be produced by the conventional plastic equipment, and is easy for industrial production and application of imitation ceramic tableware.

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com