Composite water treatment agent of closed type circulating water system

A water treatment agent, closed-loop technology, used in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc. Among them, certain types of supplementary water, use restrictions and other issues can achieve the effect of good protection, good environmental performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

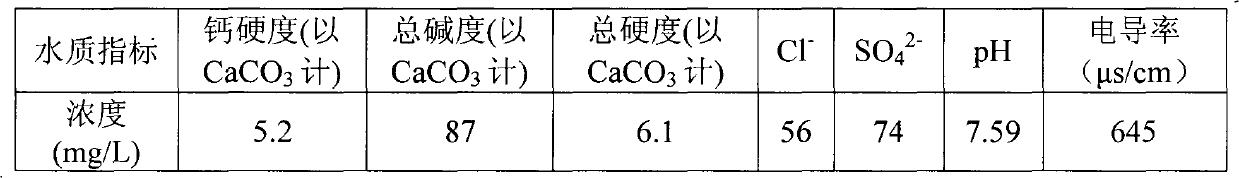

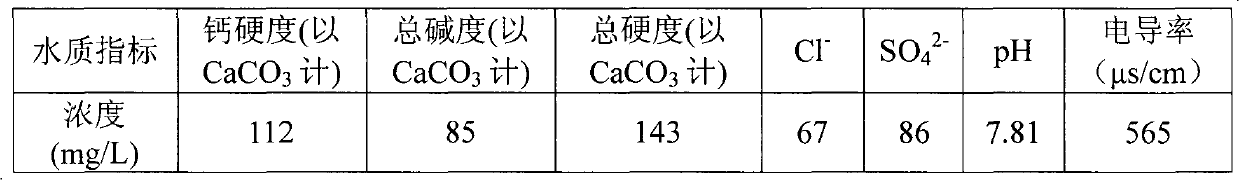

Embodiment 1

[0038] Closed circulation water system composite water treatment agent composition: polyaspartic acid 28%, sodium gluconate 11%, sodium molybdate 7%, zinc sulfate 5.5%, lanthanum nitrate 3.5%, benzotriazole 1.5%, de Ionized water 43.5%.

[0039] The dosage concentration of the compound water treatment agent in the closed circulation water system is 60mg / L.

[0040] According to the test results of water quality I, the corrosion rate of carbon steel coupons is 0.026mm / a, and the corrosion rate of copper coupons is 0.0015mm / a.

[0041] According to the water quality II test results, the corrosion rate of carbon steel coupons is 0.021mm / a, and the corrosion rate of copper coupons is 0.0013mm / a; the scale inhibition rate of calcium carbonate is 99.2%.

Embodiment 2

[0043] Closed circulation water system composite water treatment agent composition: polyaspartic acid 15%, acrylic acid / hydroxyethyl methacrylate / methyl acrylate copolymer 13%, calcium gluconate 15%, sodium molybdate 4%, zinc sulfate 3%, zinc chloride 2%, praseodymium nitrate 2%, benzotriazole 1%, deionized water 45%.

[0044] The concentration of compound water treatment agent in the closed circulation water system is 70mg / L.

[0045] According to the test results of water quality I, the corrosion rate of carbon steel coupons is 0.018mm / a, and the corrosion rate of copper coupons is 0.0011mm / a.

[0046] According to the water quality II test results, the corrosion rate of carbon steel coupons is 0.016mm / a, and the corrosion rate of copper coupons is 0.0009mm / a; the scale inhibition rate of calcium carbonate is 99.4%.

Embodiment 3

[0048] Closed circulation water system composite water treatment agent composition: polyepoxysuccinic acid 21.5%, sodium gluconate 15%, ammonium molybdate 7%, zinc chloride 5.5%, cerium nitrate 3.5%, methyl benzotriazole 2 %, deionized water 45.5%.

[0049] The concentration of compound water treatment agent in the closed circulation water system is 70mg / L.

[0050] According to the test results of water quality I, the corrosion rate of carbon steel coupons is 0.011mm / a, and the corrosion rate of copper coupons is 0.0008mm / a.

[0051] According to the water quality II test results, the corrosion rate of carbon steel coupons is 0.009mm / a, and the corrosion rate of copper coupons is 0.00082mm / a; the scale inhibition rate of calcium carbonate is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com