Patents

Literature

33results about How to "Good rewetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silk afterfinishing compound softening agent and preparation method

The invention relates to a silk afterfinishing compound softening agent and a preparation method. The softening agent is nontoxic, nonirritating, very low in yellowing possibility, good in re-wettability, biodegradable, and completely harmless to an environment. The method comprises the steps that required water temperature is selected between 0 DEG C and 100 DEG C according to used different quaternization raw materials; 1-30% of ester quaternary ammonium salt is added to water, and stirred; and then 1-30% of hydrophilic amino silicone oil is added and stirred uniformly after ester quaternary ammonium salt is completely dissolved or dispersed in the water and forms a uniform white viscous emulsion. The softening agent has the advantages that 1, the softening agent adopts raw animal or plant synthetic chemicals as main components of the softening agent, and is completely nontoxic, nonirritating, very low in yellowing possibility, and good in re-wettability, and 2, the softening agent is biodegradable and completely harmless to the environment, and is an ideal silk fabric afterfinishing softening agent.

Owner:ZHEJIANG HSDP SILK TECH

Denitration catalyst regeneration solution and preparation method thereof as well as catalyst regeneration method

ActiveCN103949291AGood water solubilityImprove catalytic performanceCatalyst regeneration/reactivationIonCopper nitrate

The invention discloses a denitration catalyst regeneration solution and a preparation method thereof as well as a catalyst regeneration method. The denitration catalyst regeneration solution comprises the following raw material ingredients in parts by weight: 4-6 parts of vanadyl oxalate, 0.08-0.10 part of cerium nitrate, 0.11-0.13 part of lanthanum nitrate, 0.05-0.07 part of copper nitrate, 0.4-0.6 part of silica sol ST-O and 95 parts of deionized water. The catalyst regeneration method comprises the following steps of firstly, evenly mixing vanadyl oxalate and the deionized water; then, feeding cerium nitrate, lanthanum nitrate and copper nitrate into mixed solution, and fully stirring until the mixture is completely dissolved; finally, feeding silica sol ST-O, and continuing to stir until homogeneous phase is obtained; and sequentially carrying out strong scavenging and ultrasonic cleaning on an inactivated denitration catalyst module, soaking the module in cleaning solution for 18-25 minutes, continuing soaking the module in the regeneration solution for 25-40 minutes, taking out the denitration catalyst module and drying. After the denitration catalyst regeneration solution and the catalyst regeneration method are adopted, the activity of the inactivated denitration catalyst can be efficiently recovered, and the temperature range of the catalyst activity is widened.

Owner:江苏万德环保科技有限公司

Hydrophilic fabric softener

The invention discloses a hydrophilic fabric softener, which is prepared from the following components by weight: 20-30 parts of hydrophilic amino silicone oil, 12-20 parts of dodecylbenzene sulfonic acid, 15-36 parts of fatty alcohol-polyoxyethylene ether, 14-25 parts of amino modified polysiloxane, 21-32 parts of sodium tripolyphosphate, 5-18 parts of hydroxy methyl cellulose, 3-9 parts of acrylamide, and 100-150 parts of water. By the way, the hydrophilic fabric softener provided by the invention has smooth handfeel and good filling power, provides fabrics with good re-wettability and antistatic properties, provides textile fiber with good lubricating properties, and improves the tear and friction properties.

Owner:无锡市华誉日用品厂

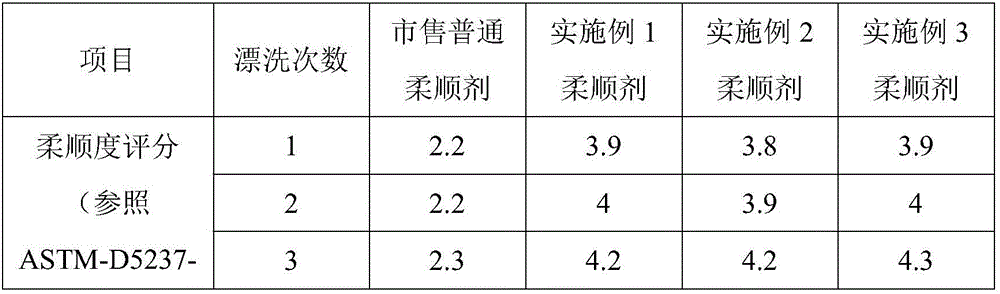

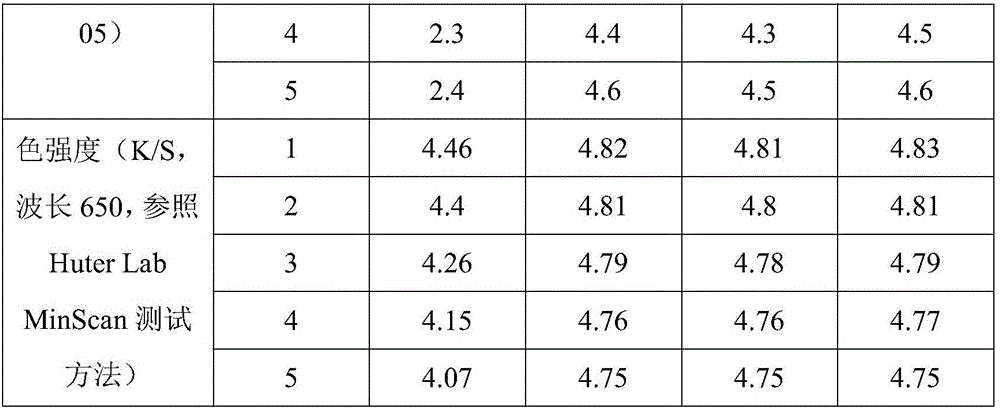

Fabric softener and production method thereof

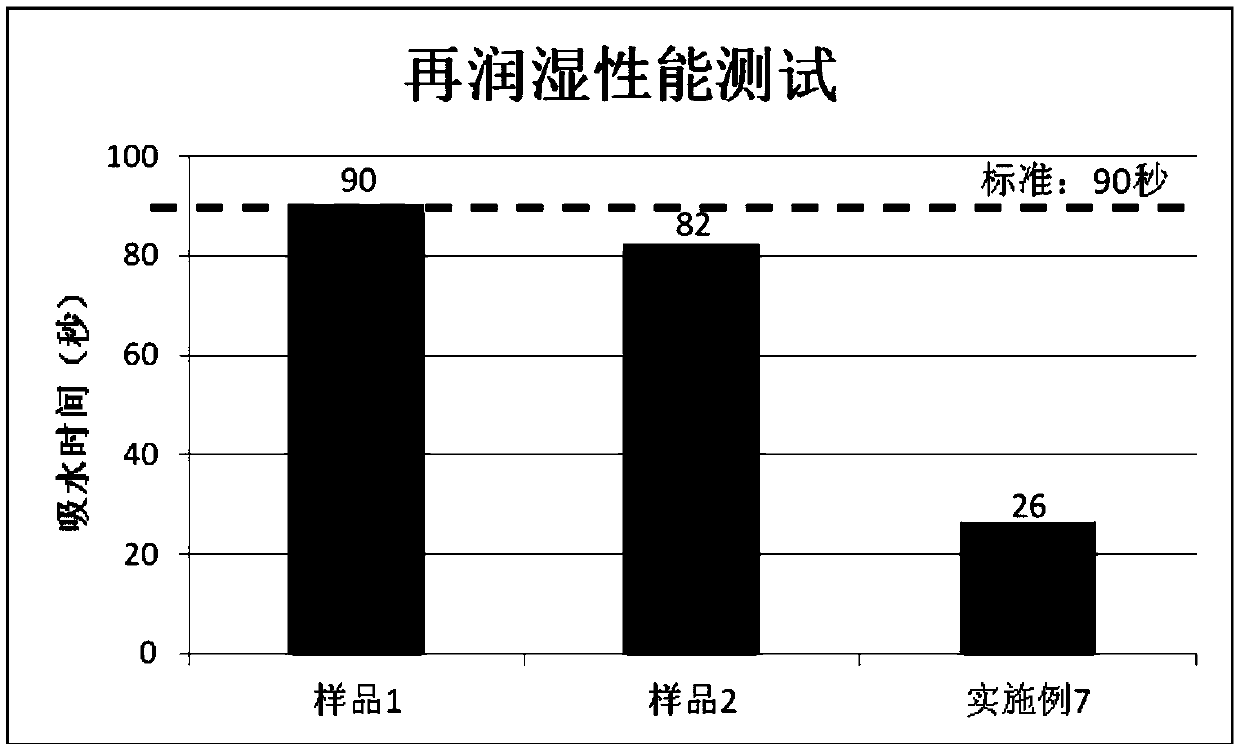

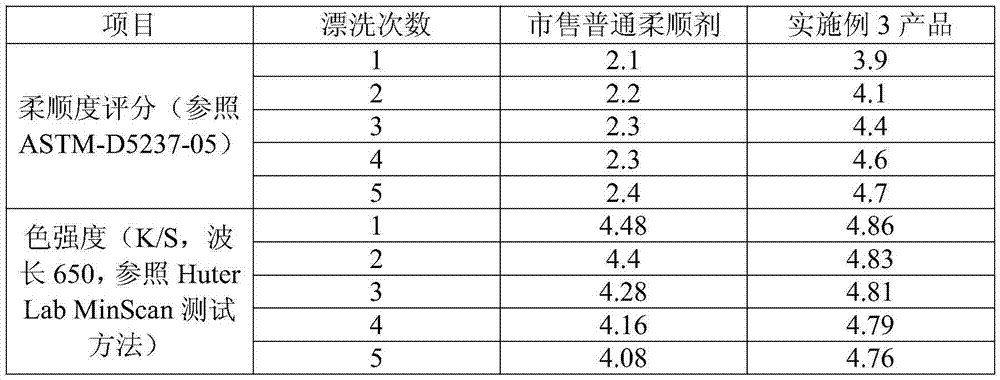

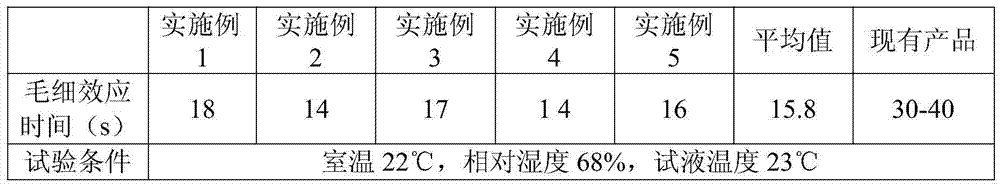

ActiveCN109097995AImprove flexibilityGood rewettingGrip property fibresSURFACTANT BLENDFabric softener

The invention provides stable fabric softener composition in a waterborne dispersion form. The composition is prepared from components as follows: (i) a cationic surfactant selected from triethanolamine ester based quaternary ammonium salt, amido amine based quaternary ammonium salt, imidazoline quaternary ammonium salt or a combination thereof; (ii) a nonionic surfactant selected from a polyalcohol type nonionic surfactant, wherein the weight ratio of the component (i) to the component (ii) is (15:1)-(5:1). The invention also relates to a preparation method and an application of the fabric softener composition.

Owner:SHANGHAI JAHWA UNITED

Environment-friendly steel pickling bath acid mist inhibitor

The invention discloses an environment-friendly steel pickling bath acid mist inhibitor which is prepared from the following raw materials in percentage by weight: 20-30% of glycerol monostearate, 20-30% of crop straw solid extract, 5-10% of glycerol, 2-4% of 4-sulfo-orthophthalic acid, 1-2% of heptadecylhydroxyethylcarboxymethyl imidazoline and the balance of water. Compared with the prior art, the inhibitor is especially suitable for a volatile acid pickling process, can obviously inhibit acid mist, and has corrosion resistance. The inhibitor has more obvious effect especially in a hydrochloric acid pickling process when the air humidity or acid concentration is high.

Owner:合肥华清高科表面技术股份有限公司

Marine organism antibacterial fabric softener

InactiveCN102493185AGuaranteed to be sterileGood killing effectBiochemical fibre treatmentBacteria removalPollution

The invention relates to marine organism antibacterial fabric softener, which is applicable to post-wash caring of various clothing and enables bacteria removal and softening to be simultaneously completed. After the marine organism antibacterial fabric softener is used, clothing is as bright as new, soft, smooth, neat and tight-fitting and has an antistatic effect. The marine organism antibacterial fabric softener added with marine organism antibacterial ingredients is nontoxic, non-irritant and capable of efficiently removing bacteria on the clothing, such as staphylococcus aureus, escherichia coli and candida albicans. The marine organism antibacterial fabric softener has the advantages that the softener is harmless to fabrics and highly stable, the softener made according to a phosphate-free aluminum-free neutral formula is environmentally pollution-free and harmless to skin, and the softener is simple in production process, low in cost and the like. The formula of the marine organism antibacterial fabric softener includes (by weight) 6.0-8.0% of marine organism prebiotics, 0.5-1.0% of bacitracin, 8.0-12.0% of palm anodic ester-based quaternary ammonium salt, and the balance of pure water.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

High-efficiency softening agent applied to laundry room

The invention relates to an agent applied to laundry rooms, and in particular relates to a high-efficiency softening agent applied to laundry rooms. The agent can be used for after-washing care after clothes are washed in laundry rooms. The agent has the beneficial effects that the alkali residue in the washing process is effectively neutralized, the washed fabrics are soft, fluffy, smooth, pressed and free of static electricity; the fabrics are good in anti-static property and rewettability, free of damage, yellowing and deformation and rapid and convenient to iron; the washing process in the laundry room is simplified; and the working efficiency of workers is improved. The agent has certain extermination function to bacteriums, is simple in production process and free of danger in the production process. According to the technical scheme of the invention, the agent comprises the following components in parts by weight percent: 15-23wt% of citric acid, 6-8wt% of ethylene diamine tetraacetic acid, 12.0-16.0wt% of palm cation ester group quaternary ammonium salt, an appropriate amount of essences and 100wt% of deionized water; the preparation method comprises the following steps of firstly, adding the needed deionized water into a reaction kettle, heating to 25-30 DEG C; secondly, adding ethylene diamine tetraacetic acid and citric acid according to proportion, and stirring for 5-8min; thirdly, adding the palm cation ester group quaternary ammonium salt according to proportion ratio, carrying out emulsification reaction, and stirring for 15-20min; and fourthly, cooling down and subpackaging.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Washing-free degerming wrinkle-eliminating fabric care agent

InactiveCN103866560AEasy to useNo need to washBiochemical fibre treatmentWrinkle skinAlkyl polyglycoside

The invention relates to a textile care agent for civil use, in particular to a washing-free degerming wrinkle-eliminating fabric care agent which is used for textile products like clothing and can be used directly without washing. The washing-free degerming wrinkle-eliminating fabric care agent has the following beneficial effects: (1) the agent is convenient to use and does not need washing; (2) softening and degerming are carried out synchronously, and a killing effect is exerted on common harmful microbes, especially pathogenic bacteria thereof; (4) after usage of the agent, clothes are soft, fluffy, smooth and fitting and have no static electrons; (5) no damage is posed to the fabric and the skin, and the agent has good stability; (6) the agent is composed of marine organisms and plant components and poses no pollution to the environment; (7) the fabric has good antistatic performance and rewettability, no damage, no yellowing and no deformation; and (8) a preparation process for the agent is simple and has low cost. A formula for the agent comprises (weight percent): 3.0 to 4.0 of alkyl polyglycoside, 0.5 to 1.0 of 6501 and 8.0 to 12.0 of a palm cationic ester quaternary ammonium salt, with the balance being purified water.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Novel silk softening agent and preparation method thereof

InactiveCN105442315APromote degradationEasy to prepareGrip property fibresAnimal fibresCarrageenanSilanes

The invention discloses a novel silk softening agent and a preparation method thereof, and belongs to the technical field of softening agent processing. The novel silk softening agent comprises the follow raw materials: ester group quaternary ammonium salt, silane modified polyurethane, polyether modified silane, sodium lignosulfonate, sodium alkyl benzene sulfonate, starch grafted sodium acrylate, sodium polyacrylate, sodium N-lauroyl glutamate, calcium lignin sulfonate, citronellal, malic acid, carrageenan, locust bean gum, triadimefon, and deionized water. The novel silk softening agent is prepared by steps of ester group quaternary ammonium salt dissolution, microwave reactions, antifoaming, and pH value adjustment. The provided novel silk has a strong biodegradable performance, and is green and environment-friendly. The preparation method is simple, convenient, and feasible. The preparation cost is low, and thus the popularization and application are easy to promote.

Owner:张莘蔓

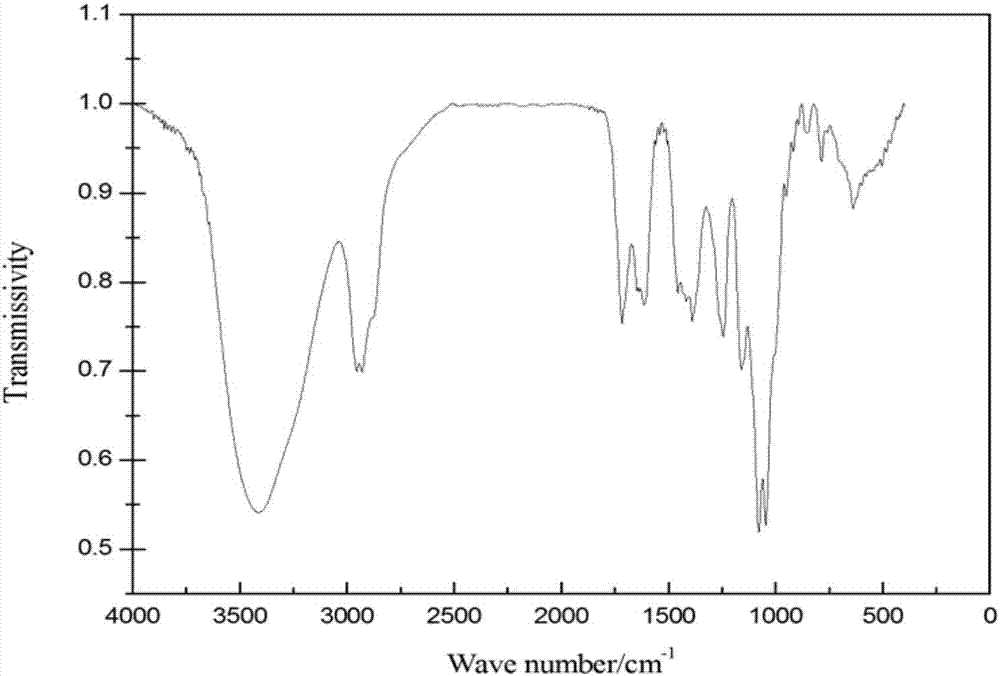

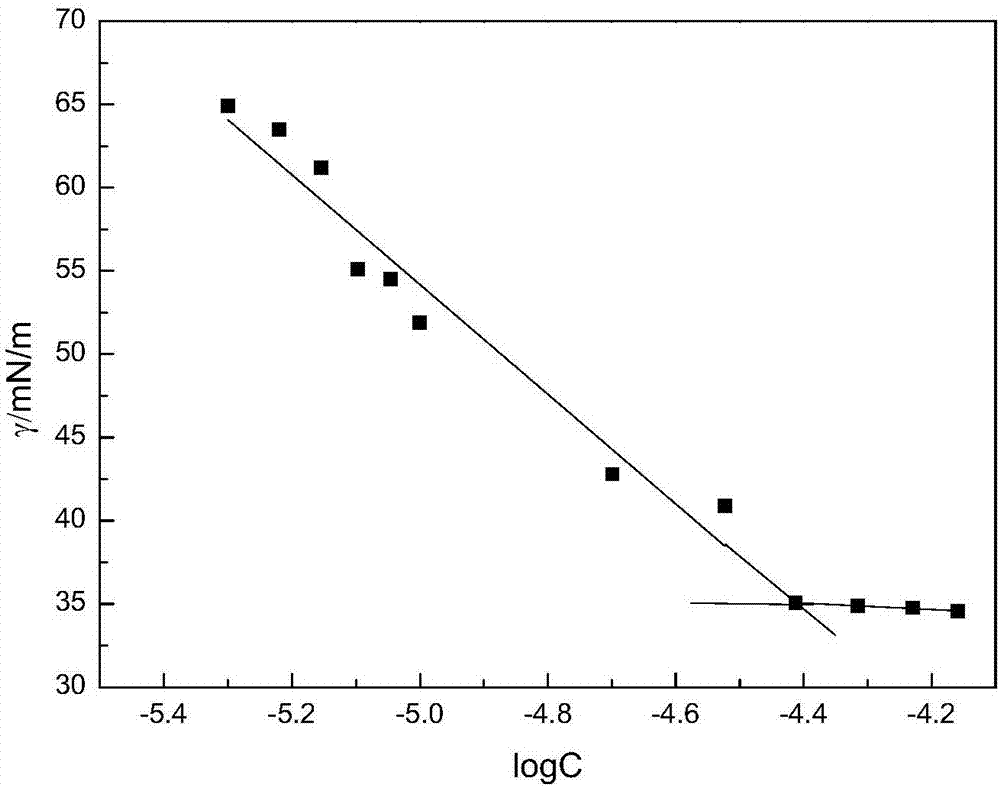

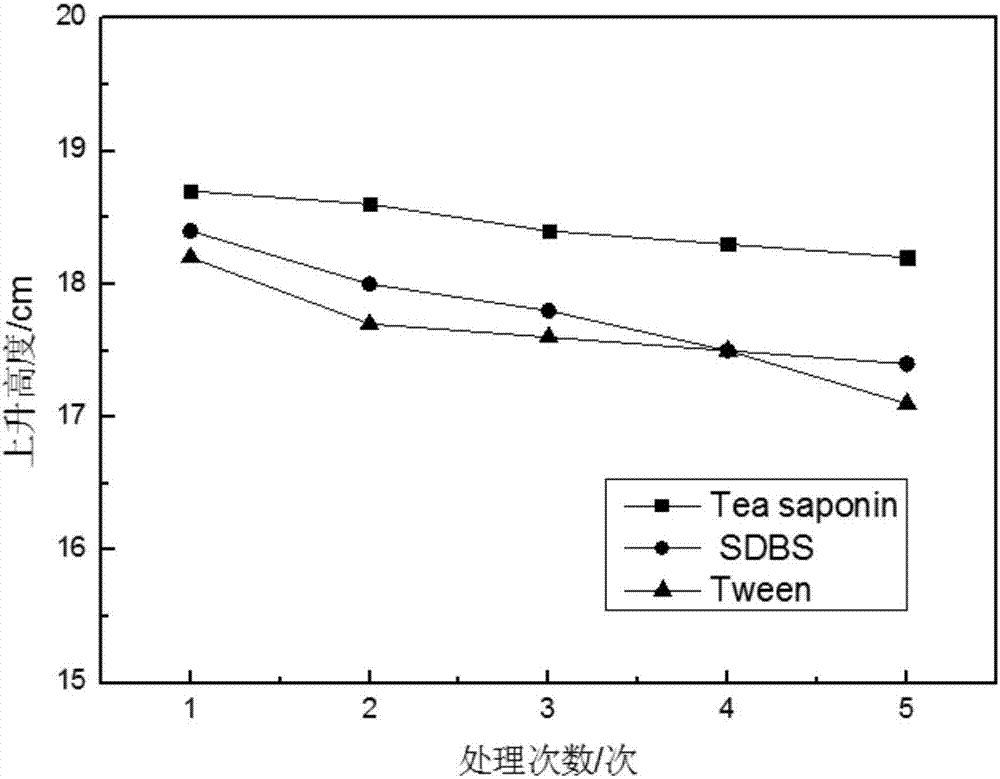

Tea seed saponin as well as preparation method and application thereof

InactiveCN107213844AReduce consumptionHigh selectivityTransportation and packagingMixingSolventTea leaf

The invention belongs to the field of plant extracting and specifically relates to tea seed saponin as well as a preparation method and application thereof. According to the tea seed saponin disclosed by the invention, tea seed cake which is hardly utilized is utilized as a raw material, and a microwave-assisted alkalescent ethanol method is utilized to extract the tea seed saponin and perform further flocculation and purification to obtain the pure tea seed saponin. A critical micelle concentration of the prepared pure tea seed saponin is 3.9*10<-5> mol / L, the surface tension of the prepared pure tea seed saponin is 34.8mN / m under the concentration, and the tea seed saponin has relatively good solubilization property, rewetting property and emulsifying property and good foaminess and foam stability. The preparation method has the advantages of small extracting solvent consumption, high efficiency, time saving, high selectivity and high yield and purity. In addition, according to the tea seed saponin disclosed by the invention, biological active ingredients in the tea seeds are fully utilized, comprehensive utilization and maximum benefit of tea seed resources are achieved, and environmental pollution is reduced.

Owner:GUANGZHOU UNIVERSITY

An environmentally friendly steel pickling acid mist inhibitor

Owner:合肥华清高科表面技术股份有限公司

Fabric softener

The invention discloses a fabric softener. The fabric softener comprises the following components in parts by mass: 3-15 parts of ester quaternary ammonium salt, 1-5 parts of water-soluble polyether silicone oil, 2-10 parts of amino silicone oil, 0.2-0.8 parts of EDC, 0.06 ~ 0.18 parts of N-hydroxy thiosuccinimide, and 70-80 parts of deionized water. The fabric softener of the invention can effectively reduce the color change when the amino silicone oil with a high ammonia value has the advantages of good softness and smoothness, and has no damage to the fabric after use, and increases the softness and the gas permeability of the fabric, after washing, the fabric has good rewetting property, antistatic performance, no yellowing, light fragrance, and long fragrance stay.

Owner:湖北健客日化有限公司

Denitrification catalyst regeneration liquid, preparation method of regeneration liquid, and catalyst regeneration method

ActiveCN103949291BRestore activityChange wetting angleCatalyst regeneration/reactivationOxalateCerium nitrate

The invention discloses a denitration catalyst regeneration solution and a preparation method thereof as well as a catalyst regeneration method. The denitration catalyst regeneration solution comprises the following raw material ingredients in parts by weight: 4-6 parts of vanadyl oxalate, 0.08-0.10 part of cerium nitrate, 0.11-0.13 part of lanthanum nitrate, 0.05-0.07 part of copper nitrate, 0.4-0.6 part of silica sol ST-O and 95 parts of deionized water. The catalyst regeneration method comprises the following steps of firstly, evenly mixing vanadyl oxalate and the deionized water; then, feeding cerium nitrate, lanthanum nitrate and copper nitrate into mixed solution, and fully stirring until the mixture is completely dissolved; finally, feeding silica sol ST-O, and continuing to stir until homogeneous phase is obtained; and sequentially carrying out strong scavenging and ultrasonic cleaning on an inactivated denitration catalyst module, soaking the module in cleaning solution for 18-25 minutes, continuing soaking the module in the regeneration solution for 25-40 minutes, taking out the denitration catalyst module and drying. After the denitration catalyst regeneration solution and the catalyst regeneration method are adopted, the activity of the inactivated denitration catalyst can be efficiently recovered, and the temperature range of the catalyst activity is widened.

Owner:江苏万德环保科技有限公司

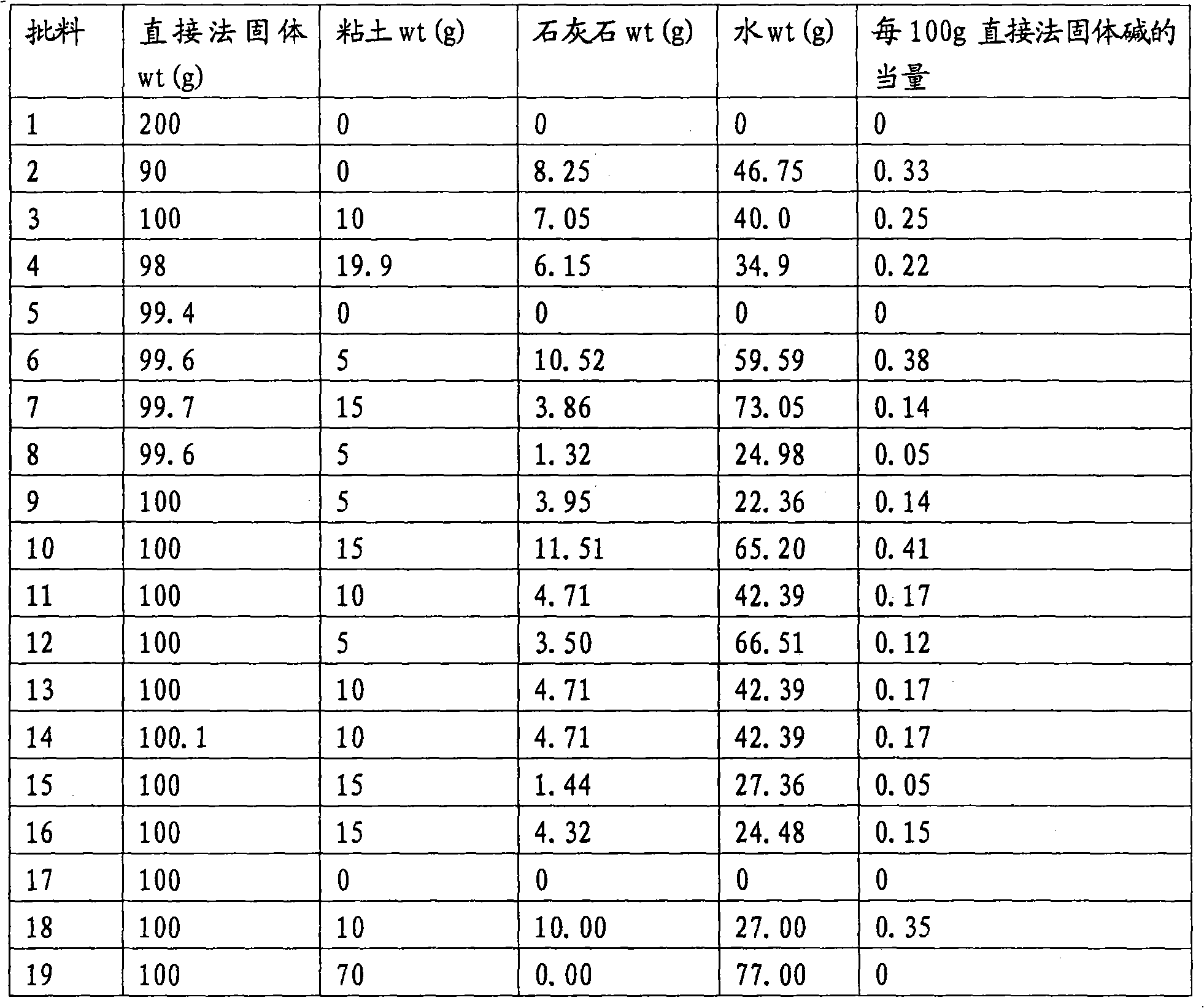

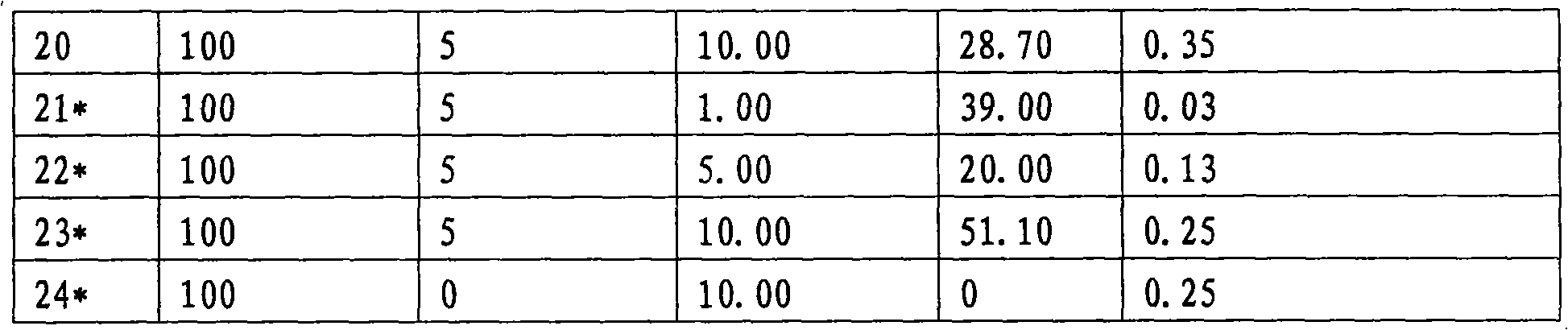

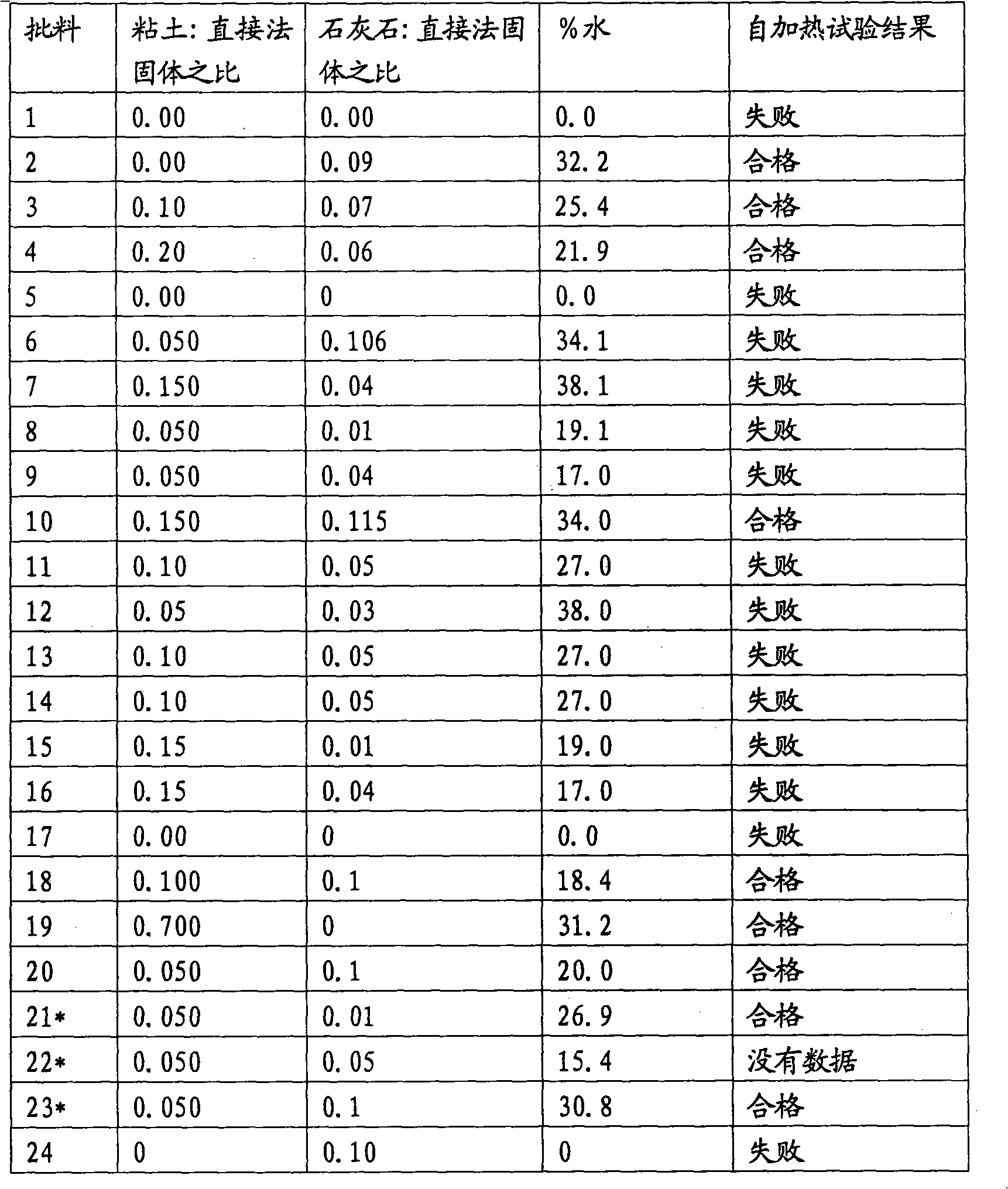

Solids passivation

InactiveCN101965235ALow costImprove other propertiesSolid waste disposalTransportation and packagingChemistryDirect process

Owner:DOW CORNING CORP

Silk softener

InactiveCN105951446AImprove the bactericidal effectGood rewettingBiochemical fibre treatmentGrip property fibresFlavouring agentPreservative

The invention discloses a silk softener which comprises the following raw materials in parts by weight: 80 to 100 parts of surfactant, 6 to 10 parts of antifoaming agent, 3 to 5 parts of foam stabilizer, 2 to 4 parts of penetrant, 2 to 3 parts of emulsifier, 1 to 2 parts of dispersing agent, 2 to 4 parts of cross-linking agent, 2 to 3 parts of modifier, 2 to 3 parts of thickener, 1 to 2 parts of preservative, 0.8 to 1.2 parts of flavouring agent and 700 to 1,000 parts of water. The silk softener disclosed by the invention is excellent in sterilization performance, and has a sterilizing rate of over 96% on staphylococcus aureus, escherichia coli and candida albicans; a preparation method of the silk softener is simple, convenient and feasible; the silk softener is low in preparation cost and is beneficial to popularization and application.

Owner:广西南宁马山东龙蚕业有限责任公司

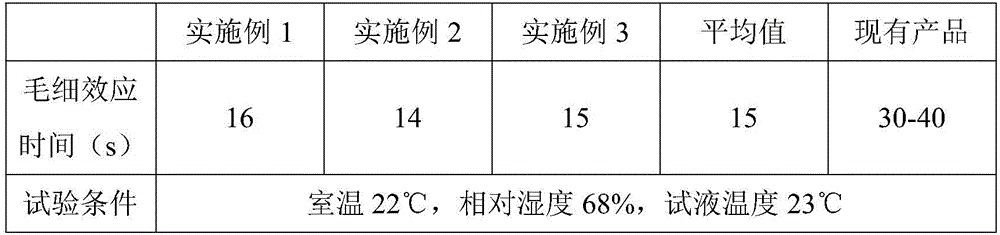

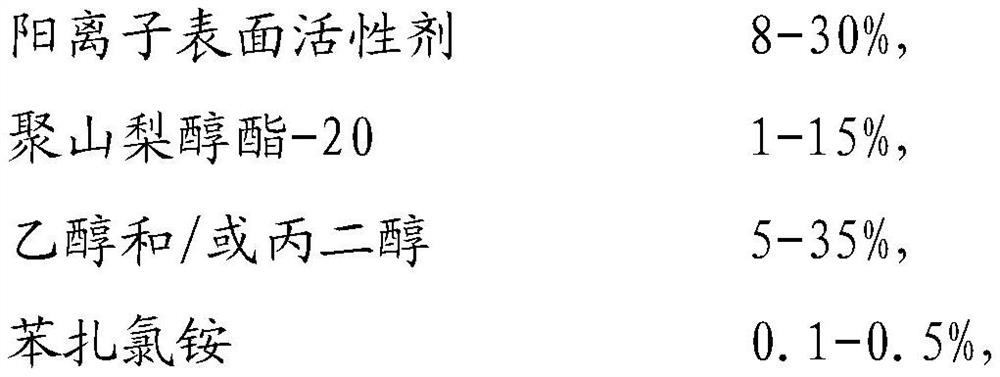

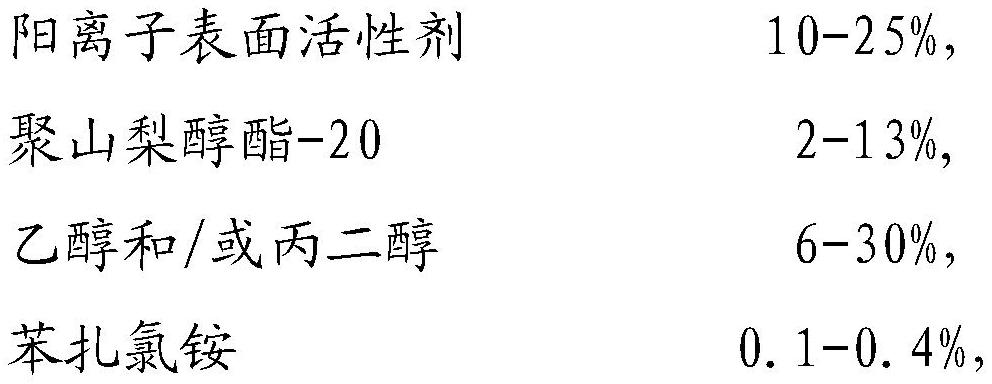

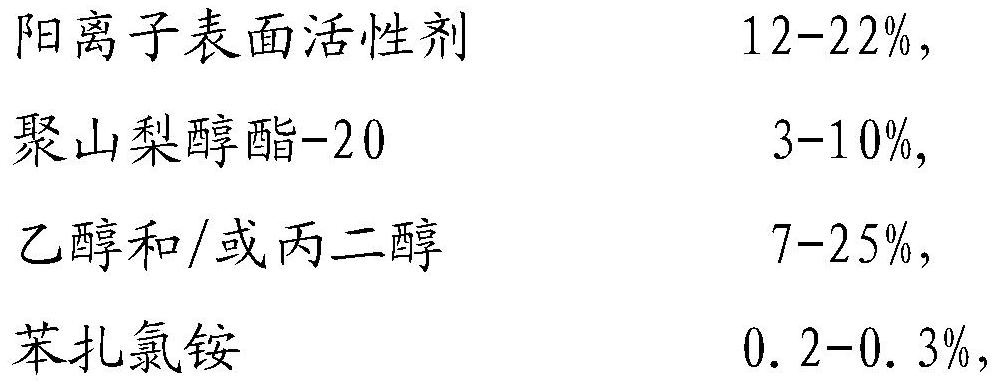

Transparent antibacterial softener and preparation method thereof

PendingCN114411420AImprove antibacterial propertiesGood rewettingBiocideBiochemical fibre treatmentActive agentChemical products

The invention discloses a transparent bacteriostatic softener and a preparation method thereof, and relates to the technical field of daily chemical products, the softener is prepared from the following components by mass: 8-30% of a cationic surfactant, 1-15% of polysorbate-201, 5-35% of ethanol and / or propylene glycol, 0.1-0.5% of benzalkonium chloride, and the balance of water; the cationic surface active agent is selected from imidazoline quaternary ammonium salt and hexadecyl trimethyl ammonium chloride, and the mass ratio of the imidazoline quaternary ammonium salt to the hexadecyl trimethyl ammonium chloride is 1: (0.2-3). According to the present invention, the cationic surface active agent and the nonionic surface active agent are matched, and the specific alcohol and the benzalkonium chloride are added so as to prepare the low-temperature stable antibacterial and rewetting agent, such that the low-temperature stable antibacterial and rewetting agent has effects of low temperature stability, excellent antibacterial property, good rewetting property and significant softening effect.

Owner:WALCH GUANGZHOU COMMODITY

a fabric softener

ActiveCN109082887BGood flexibilityImprove breathabilityGrip property fibresPolymer scienceSilicone oil

The invention discloses a fabric softener which comprises, by weight, 3-15 parts of esterquats, 1-5 parts of water-soluble polyether silicone oil, 2-10 parts of amino silicon oil, 0.2-0.8 part of EDC(dichloroethane), 0.02-0.1 part of NHS (N-hydroxysuccinimide) and 70-80 parts of deionized water. The fabric softener can effectively reduce the color change when giving full play to the advantages of good softness and smoothness of amino silicone with high ammonia value, no harm is caused to fabric after use of the fabric softener, and softness and air permeability of the fabric can be increased; the fabric is good in rewettability, antistatic, non-yellowing, elegant in fragrance and lasting in fragrance depositing after washing.

Owner:湖北健客日化有限公司

High-efficiency cleaning solution for vehicles

InactiveCN108085191AGood compatibilityGood decontamination effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium Hypophosphite MonohydrateSodium silicate

The invention provides a high-efficiency cleaning solution for vehicles. The cleaning solution is prepared from the following raw materials in percentage by weight: 1-3% of sodium hydroxide, 2-7% of trisodium phosphate, 0.6-1.3% of a DX penetrant, 0.8-2% of sodium hypophosphite, 1-3% of sodium silicate, 0.2-0.8% of methanol, 0.5-1.8% of TX-10, 0.3-1.5% of a high polymer composite synergistic activator and the balance of deionized water. The high-efficiency cleaning solution for vehicles, provided by the invention, solves the problem of lack of high-efficiency decontamination in the prior art and also can reduce environmental pollution.

Owner:车神宝汽车服务江苏有限公司

Fabric softener

ActiveCN108797129AGood flexibilityImprove breathabilityGrip property fibresWater solubleColor changes

The invention discloses a fabric softener. The fabric softener comprises, by mass, 3 to 15 parts of an esterquat, 1 to 5 parts of water soluble polyether silicone oil, 2 to 10 parts of amino silicon oil, 0.2 to 0.8 part of EDC, and 70 to 85 parts of deionized water. The fabric softener possesses the excellent flexibility and slippery of high amino value amino silicone oil, is capable of reducing color change effectively; no damage on fabric is caused; fabric flexibility, and permeability can be improved; after washing, fabric re-wetability is excellent, antistatic performance is achieved, yellowing is avoided, the fragrance is elegant and fresh, and lasts long.

Owner:湖北健客日化有限公司

Consumable material with uniform color distribution for 3D printing pen

InactiveCN108641489AEven color distributionFast curingAdditive manufacturing apparatusPencil leadsMaterials preparationOligomer

The invention discloses a consumable material with uniform color distribution for a 3D printing pen. The consumable material is composed of oligomers, a photoinitiator, an assistant initiating agent,a surface active agent, a suspending agent, photodiffusion power and color paste or toner. The raw materials comprise, by weight, 60%-88% of oligomers, 1%-12% of photoinitiator, 1%-6% of assistant initiating agent, 1%-6% of surface active agent, 1%-3% of antisticking agent, 0.1%-3% of suspending agent, 0.5%-2% of photodiffusion power and the balance color paste or toner. The cost of the nonsticking consumable material for the printing pen is 10% of the cost of the traditional consumable material, the solidifying temperature rise is required to be within 45 DEG C, the solidifying time is within8 s, overquick solidifying speed can easily cause uneven color distribution, and the suspending agent is added to avoid uneven color distribution in the material preparation and solidifying processesof the color paste or toner, so that color and the whole system are uniform, the suspending performance is added, the color paste or toner does not precipitate, the physico-chemical property of the whole system is same, and color distribution is uniform.

Owner:天长市天荣电子有限公司

a fabric softener

Owner:湖北健客日化有限公司

A low-temperature antifreeze fabric softener

ActiveCN109023933BGood flexibilityImprove breathabilityGrip property fibresPolymer scienceSilicone oil

The invention discloses a low temperature antifreeze fabric softener. The low-temperature antifreeze fabric softener comprises the following components in parts by mass: 3 to 15 parts of ester quaternary ammonium salt, 1 to 5 parts of water-soluble polyether silicone oil, 2 to 10 parts of amino silicone oil, 0 .2 to 0.8 parts of EDC, 0.02 to 0.1 parts of NHS, 2 to 5 parts of an antifreeze, and 75to 85 parts of deionized water. The fabric softener of the invention can effectively reduce the color change when the amino silicone oil with a high ammonia value has the advantages of good flexibility and slipperiness, after use, the fabric softener has no damage to the fabric, can increase the softness and breathability of the fabric, after washing, the fabric has good rewetting property, antistatic performance, no yellowing, light fragrance, and long fragrance stay, and maintains good fluidity under cold climate environment of -25 DEG C.

Owner:湖北健客日化有限公司

Softening agent containing sanguisorba officinalis l extract

InactiveCN106917280AImprove anti-static effectGood rewettingLight resistant fibresGrip property fibresIsoflavonesPollution

The invention relates to a softening agent containing a sanguisorba officinalis l extract, wherein the components comprise, by mass, 20-31% of cyclocarya paliurus, 3-6% of a sanguisorba officinalis l extract, 5-8% of soybean isoflavone, 13-18% of natural essence, 2-3.5% of an epimedium extract, 10-18% of trichlorohydroxydiphenyl ether, 3-6% of Brazil essential oil, and 40-55% of deionized water, the cyclocarya paliurus is chloropropyltrimethoxysilane, the natural essence is imidazoline natural essence, and the Brazil essential oil is calcium chloride. According to the present invention, the softening agent has advantages of good softening and fluffiness effect after disinfection and washing, low use concentration, no damage on fabrics, good stability, no damage on skin, low cost and no environment pollution, can strongly kill common harmful microorganisms, especially pathogenic bacteria, and can ensure that the fabric does not contain bacterial and has characteristics of good static electricity resistance, good re-mixing wetting property, no damage and no yellowing after the washing.

Owner:QINGDAO XINYIFA IND & TRADE

Softening agent containing forsythia suspensa extract

The invention relates to a softening agent containing a forsythia suspensa extract, wherein the components comprise, by mass, 20-31% of chlorohydrocarbyl functional group silane, 3-6% of a forsythia suspensa extract, 5-8% of tanshinone IIA, 11-15% of sulfuric acid methyl acetate, 2-3.5% of stearic acid, 10-15% of ethanol, 3-6% of plant essence, and 40-61% of deionized water, the chlorohydrocarbyl functional group silane is chloropropyltrimethoxysilane, the sulfuric acid methyl acetate is imidazoline sulfuric acid methyl acetate, and the plant essence is calcium chloride. According to the present invention, the softening agent has advantages of good softening and fluffiness effect after disinfection and washing, low use concentration, no damage on fabrics, good stability, no damage on skin, low cost and no environment pollution, can strongly kill common harmful microorganisms, especially pathogenic bacteria, and can ensure that the fabric does not contain bacterial and has characteristics of good static electricity resistance, good re-mixing wetting property, no damage and no yellowing after the washing.

Owner:QINGDAO XINYIFA IND & TRADE

Silk post-finishing compound softener and preparation method

Owner:ZHEJIANG HSDP SILK TECH

One-bath desizing and dyeing process for viscose leather base fabric

ActiveCN103669009BRewettingGood rewettingBiochemical fibre treatmentDyeing processWater bathsDesizing

Owner:福建福能南纺卫生材料有限公司

Softening agent containing black cohosh extract

InactiveCN106917274AImprove anti-static effectGood rewettingFibre treatmentHydroxytyrosolBlack Cohosh Extract

The invention relates to a softening agent containing a black cohosh extract, wherein the components comprise, by mass, 23-40% of a ziziphus jujuba mill.var.spinosa extract, 3-6% of a black cohosh extract, 5-8% of a plant extract, 11-15% of hydroxytyrosol, 2-3.5% of a hedera nepalensis extract, 10-15% of a ginkgo extract, 3-6% of myristic acid sodium sarcosinate, and 40-61% of deionized water, the ziziphus jujuba mill.var.spinosa extract is chloropropyltrimethoxysilane, the hydroxytyrosol is imidazoline hydroxytyrosol, and the myristic acid sodium sarcosinate is calcium chloride. According to the present invention, the softening agent has advantages of good softening and fluffiness effect after disinfection and washing, low use concentration, no damage on fabrics, good stability, no damage on skin, low cost and no environment pollution, can strongly kill common harmful microorganisms, especially pathogenic bacteria, and can ensure that the fabric does not contain bacterial and has characteristics of good static electricity resistance, good re-mixing wetting property, no damage and no yellowing after the washing.

Owner:QINGDAO XINYIFA IND & TRADE

Environmentally-friendly Setaria viridis softening agent preparation method

InactiveCN109267334AImprove use valueEasy to degradeGrip property fibresWater bathsThermal insulation

The invention provides an environmentally-friendly Setaria viridis softening agent preparation method, which comprises: washing Setaria viridis, drying, crushing, and screening; adding petroleum ether, and extracting; filtering, and distilling to remove the petroleum ether to obtain an extract A and filtering residue; adding the extract A to a NaOH solution in a dropwise manner, and carrying out areaction; cooling, adding hydrochloric acid in a dropwise manner, carrying out thermal insulation, carrying out standing layering, taking the upper layer liquid, washing, and carrying out rotary evaporation to obtain a component B; carrying out a stirring heating reaction on the component B, stannous oxide and oxalyl chloride; carrying out cooling pressure reducing thermal insulation, and coolingto obtain a component C; taking the filtering residue, adding an ethanol aqueous solution, and carrying out water bath heating reflux; filtering to obtain an extraction liquid, carrying out adsorption decoloration, and carrying out pressure reducing distillation to obtain a component D; and mixing and stirring the component C and the component D to obtain the product. According to the present invention, the prepared environmentally-friendly Setaria viridis softening agent has good softness to the cloth, does not irritate to the skin, and further has characteristics of soft hand feeling, strong smoothness, good wettability and good softening effect.

Owner:SUZHOU TIANAO SPECIAL EMBROIDERY CO LTD

Softening agent containing centella asiatica (l.) urban extract

InactiveCN106917288AImprove anti-static effectGood rewettingLight resistant fibresCentella asiatica extractSilanes

The composition and mass percentage of the softening agent containing centella asiatica extract of the present invention are 20%-31% of chlorocarbon group functional group silane, 3%-6% of centella asiatica extract, 5%-8% of lovage extract, 13%-18% of natural essence, 2%-3.5% of Kathon, 10%-18% of raspberry extract, 3%-6% of plant nourishing essential oil and 40%-55% of deionized water. The chlorohydrocarbyl functional group silane is chloropropyltrimethoxysilane. The natural essence is imidazoline natural essence. The plant nourishing essential oil is calcium chloride. The softener containing centella asiatica extract of the present invention has good soft and fluffy effect after disinfection and washing; low use concentration does not damage fabrics; good stability does not damage skin; low cost and price does not pollute the environment; it is harmful to common Microorganisms, especially pathogenic bacteria, have a strong killing effect. After washing, the fabric is guaranteed to be bacteria-free; the fabric has good antistatic and re-wetting properties, and there is no damage to yellowing.

Owner:QINGDAO XINYIFA IND & TRADE

Lilac-extract-containing softener

InactiveCN106894232AImprove anti-static effectGood rewettingBiochemical fibre treatmentGrip property fibresSilanesChloride

The components and mass percentages of the softener containing lilac flower extract of the present invention are 23%-40% of chlorohydrocarbon functional group silane, 3%-6% of lilac flower extract, 5%-8% of plant extract, methyl sulfate 11%-15% vinegar salt, 2%-3.5% sodium alginate, 10%-15% ginkgo extract, 3%-6% sodium myristate sarcosinate and 40%-61% deionized water. The chlorohydrocarbyl functional group silane is chloropropyltrimethoxysilane. Described methyl sulfate is imidazoline methyl sulfate. The sodium myristate is calcium chloride. The softener containing lilac flower extract of the present invention has good soft and fluffy effect after disinfection and washing; low use concentration does not damage fabrics; good stability does not damage skin; low cost and price does not pollute the environment; it is harmless to common harmful microorganisms In particular, the pathogenic bacteria have a strong killing effect, and the fabric is guaranteed to be free of bacteria after washing; the fabric has good antistatic and re-wetting properties, and there is no damage to yellowing.

Owner:QINGDAO XINYIFA IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com