Patents

Literature

72results about How to "No need to wash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid phase chip for joint detection of multiple tumor markers and preparation method thereof

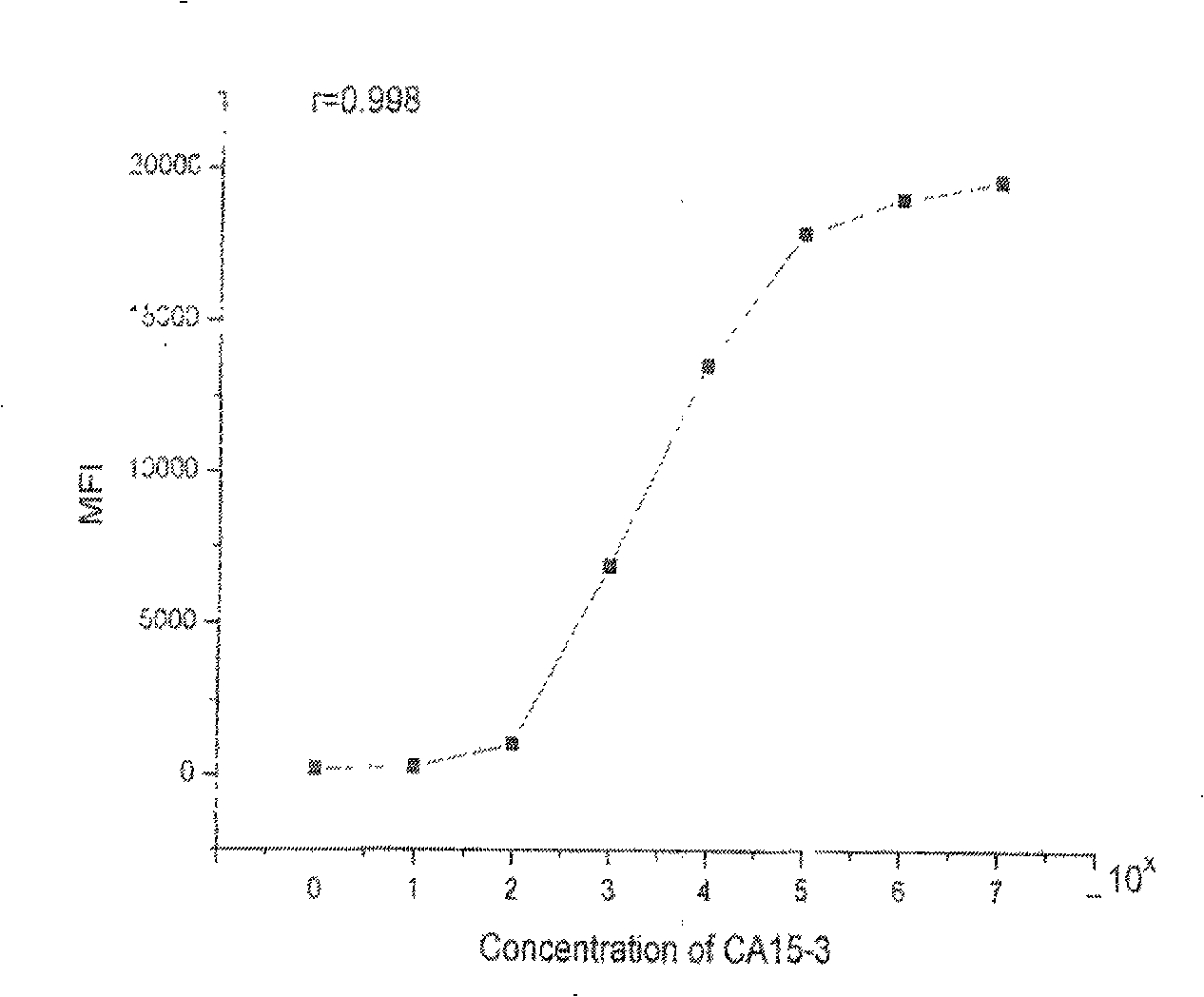

The invention relates to a liquid phase chip for joint detection of multiple tumor markers and a preparation method thereof. The liquid phase chip comprises micro-balloons of a coupled antibody (at least two of the followings: AFP, CEA, CA125, CA153, CA19-9, CA242, CA72-4, PSA, HGH, Beta-HCG), corresponding biotin-labeled detection antibodies, streptavidin phycoerythrin and vegetable hydrosol or polysaccharide hydrosol which has a solute content of 1-10 wt per thousand and does not contain protein. The preparation of the liquid phase chip comprises refining and purification of hydrosol, coupling between captured antibodies and micro-balloons, preparation of biotin-labeled antibodies, dispersing the coupled micro-balloons into the vegetable hydrosol or the polysaccharide hydrosol, and the like. The liquid phase chip has the advantages of stable performance, good micro-balloon dispersivity, long preservation time, fast and convenient use and operation, small amount of samples in use, high detection sensitivity, wide linear scope and low detection cost, can detect ten tumor markers at most at one time, and requires a cost which is a quarter of the total fee of conventional methods.

Owner:HENAN YUKANG BIOTECH

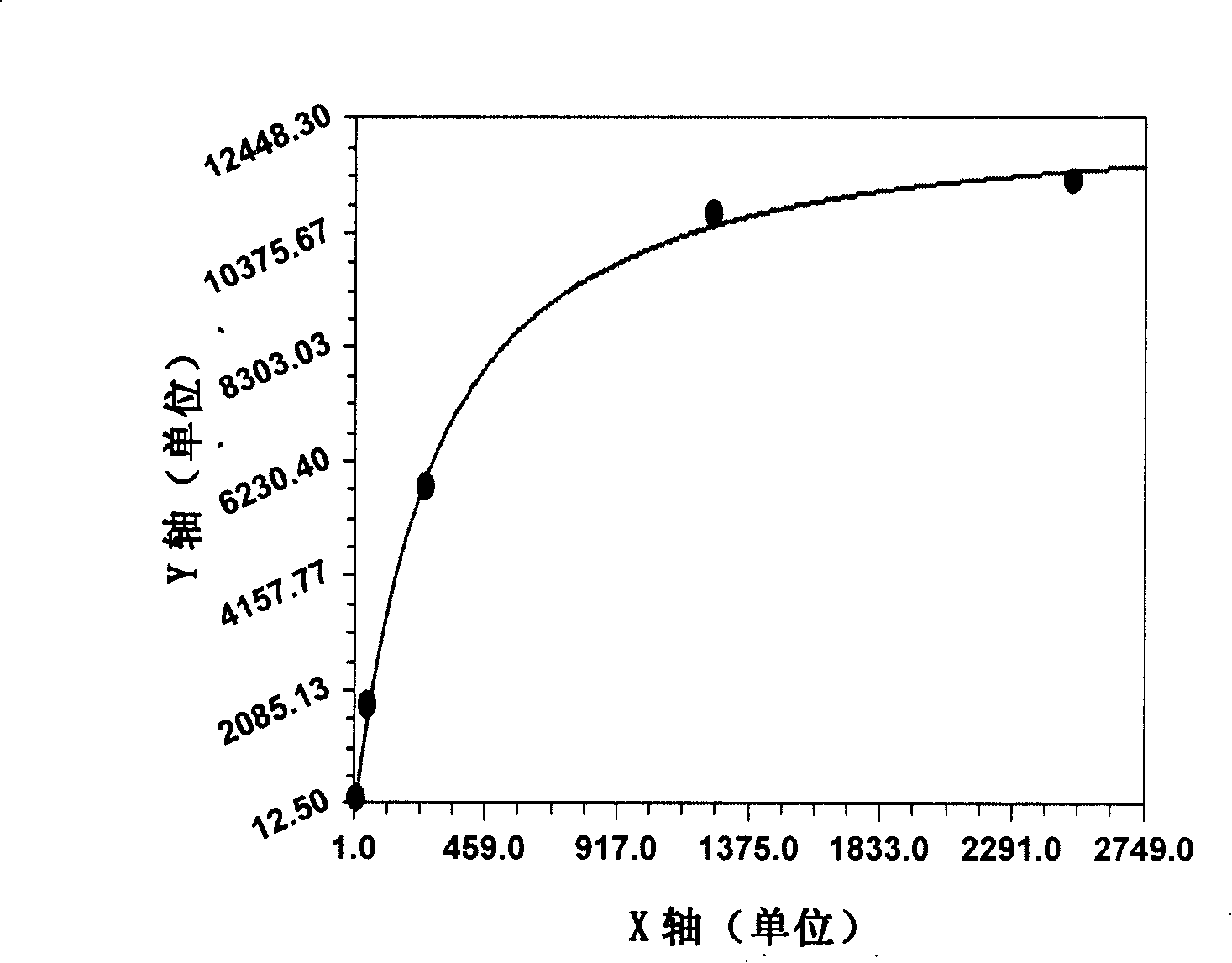

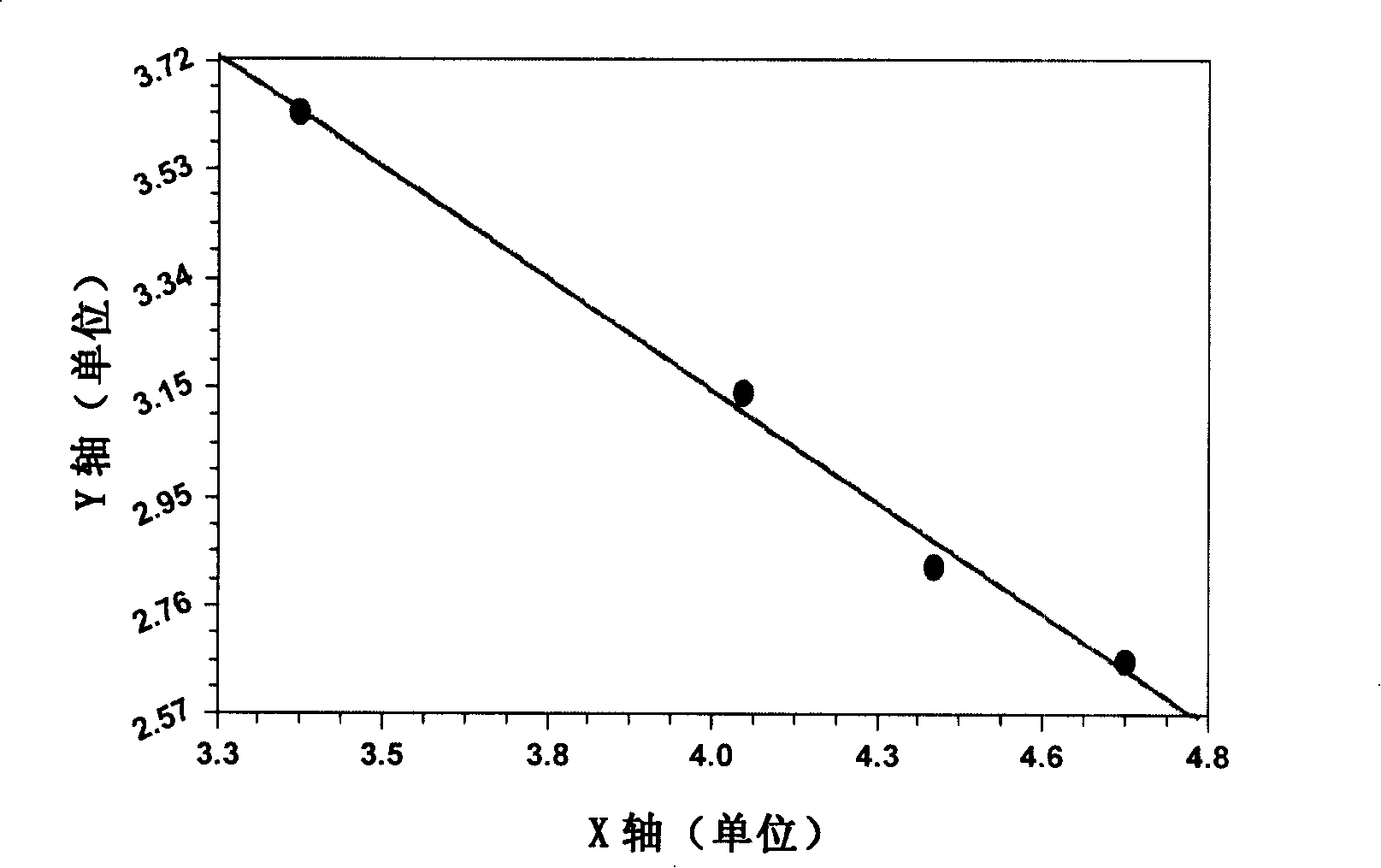

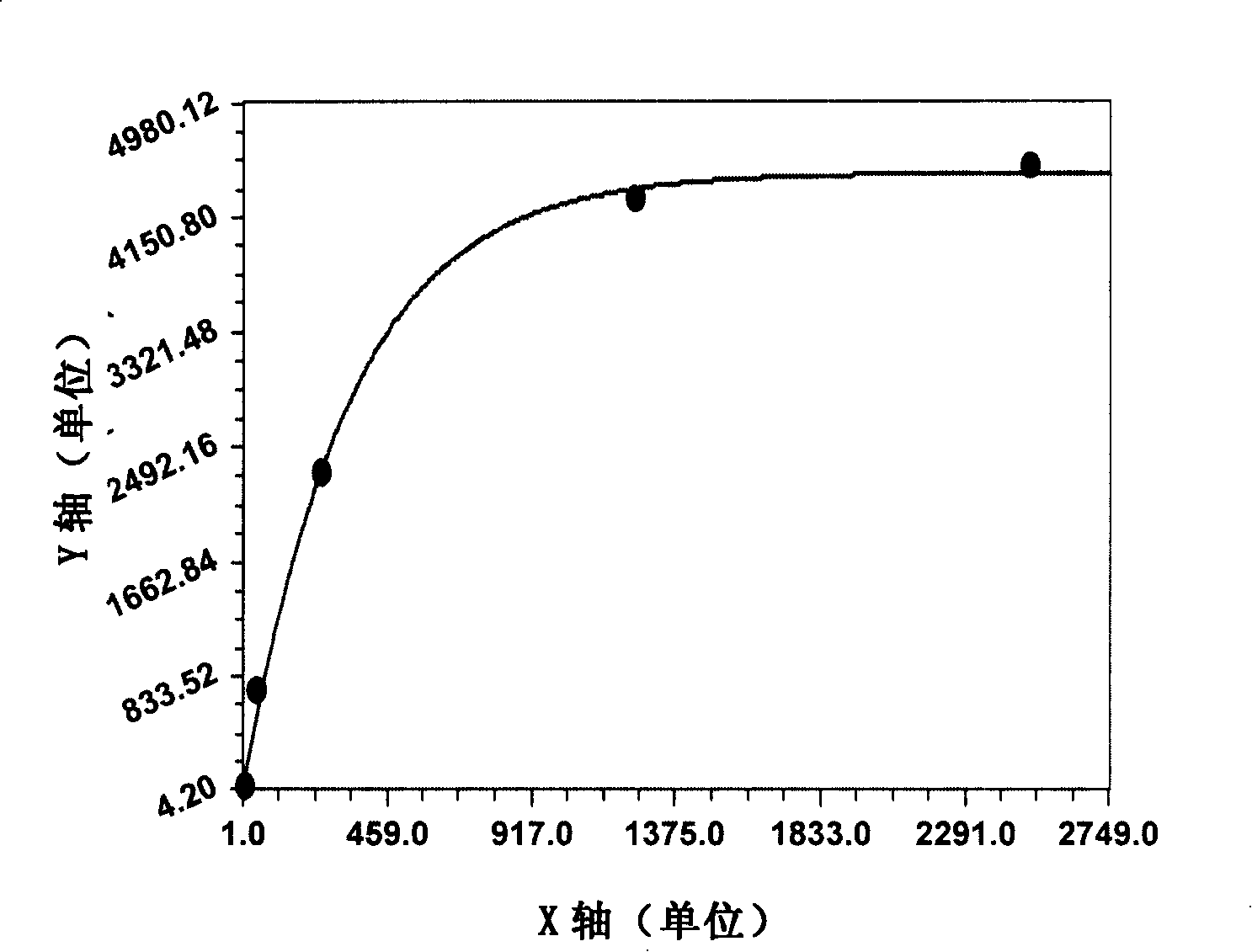

Method and reagent box for expanding immune detecting measurable range

The invention discloses a method and a corresponding kit to expand the detectable range of objects to be detected in immunity analysis.

Owner:SHANGHAI TELLGEN LIFE SCI CO LTD

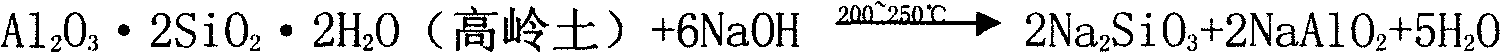

Production process of bamboo charcoal fiber

InactiveCN102051701AFunction increaseHygroscopicArtificial filaments from cellulose derivativesDry spinning methodsSpinningCellulose acetate

The invention relates to a production process of bamboo charcoal fiber, comprising the following steps: pulverizing bamboo charcoal powder until the particle size is below the micron order, dispersing evenly; preparing cellulose triacetate from refined cotton linters as a raw material, dissolving the cellulose triacetate in dichloromethane to form a 10-50wt% spinning solution, adding bamboo charcoal micro powder to the spinning solution, wherein the weight ratio of the bamboo charcoal micro powder to the cellulose triacetate is 1:(50-100), and preparing bamboo charcoal acetate fiber by a dry spinning method. The invention has high performances of both bamboo charcoal fiber and acetate fiber, the manufactured fabric has the functions of moisture absorption, permeability, antibiosis, bacteriostasis, deodorization, high adsorption, temperature and humidity adjustment, far infrared radiation, electromagnetic radiation prevention and the like, and the fabric is soft, delicate, nonirritating and hypo-allergenic to skin, washable, sunfast, heat resistant, easy to wash, vermin-proof and moisture-proof.

Owner:ZHEJIANG MINXIN ECO TECH

Quantitative kit for detecting dog IL-6 by adopting homogeneous chemiluminescent immunoassay and use method thereof

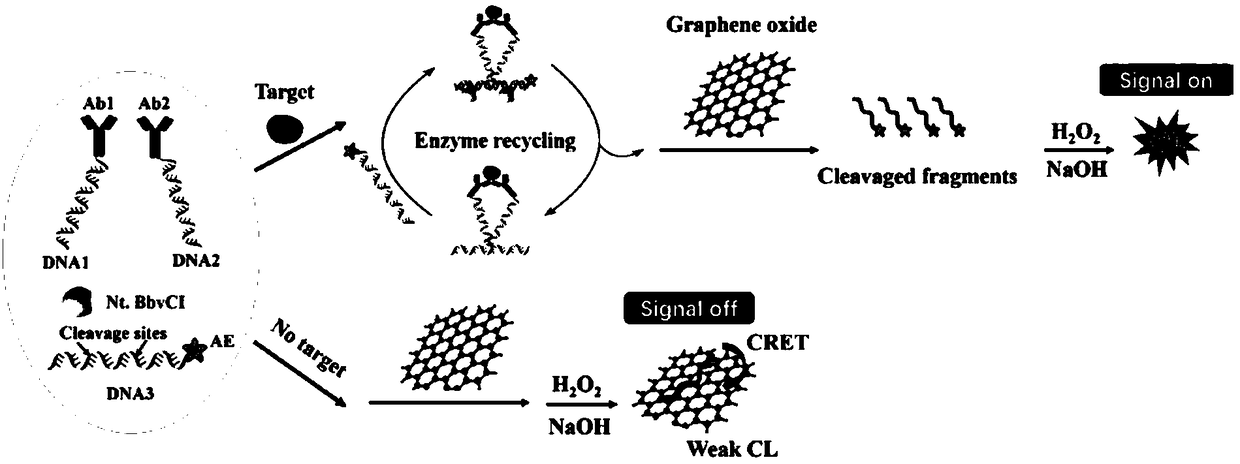

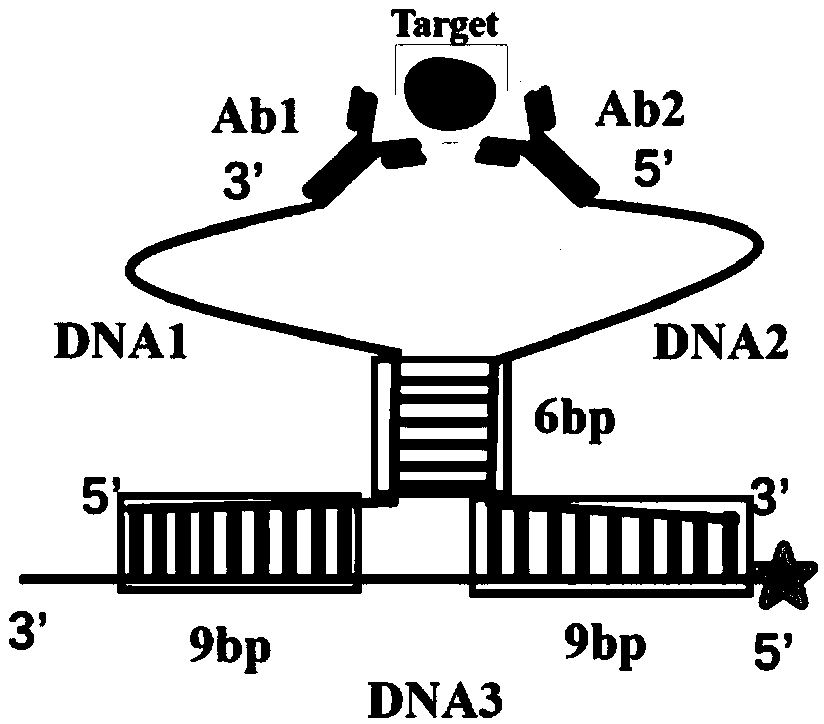

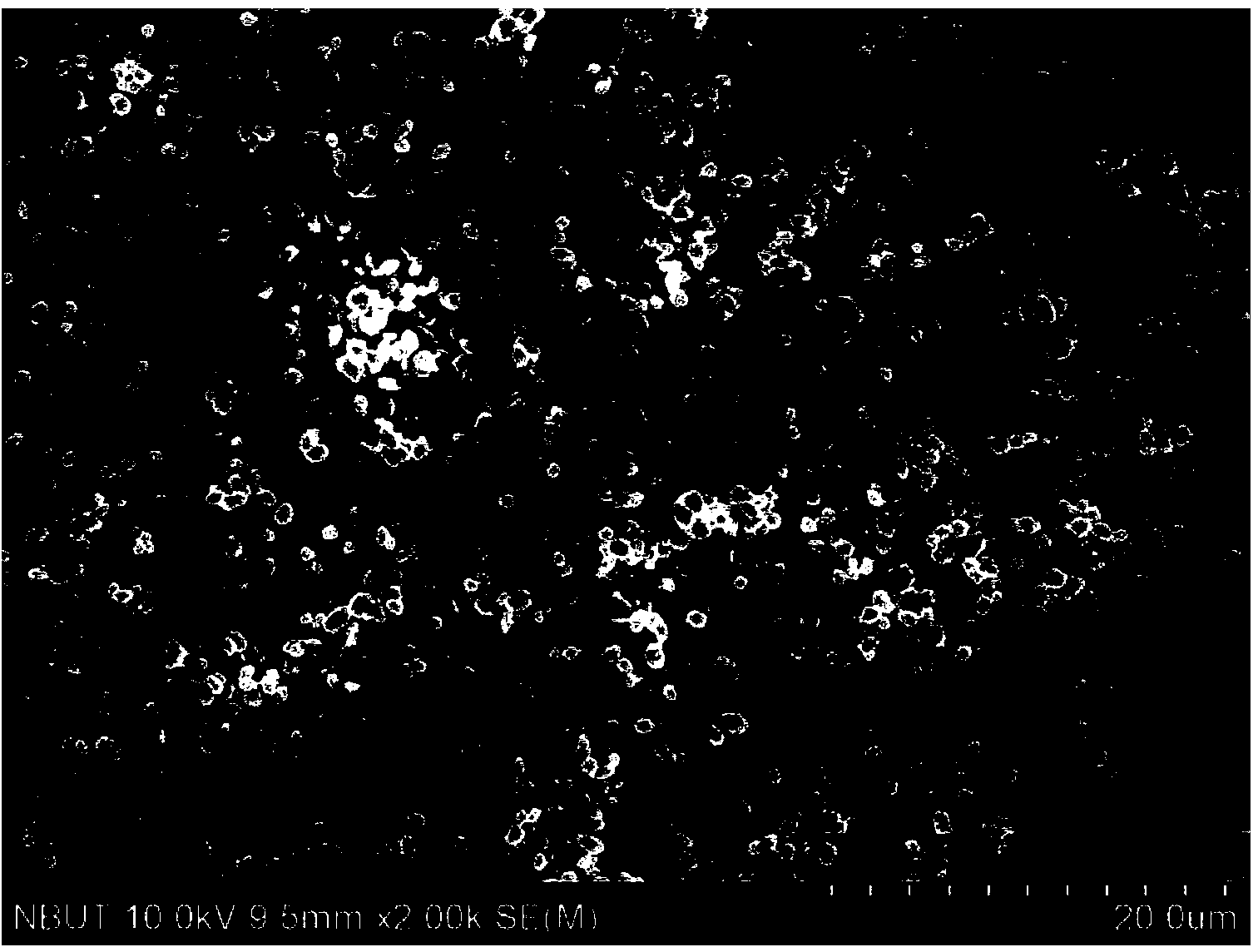

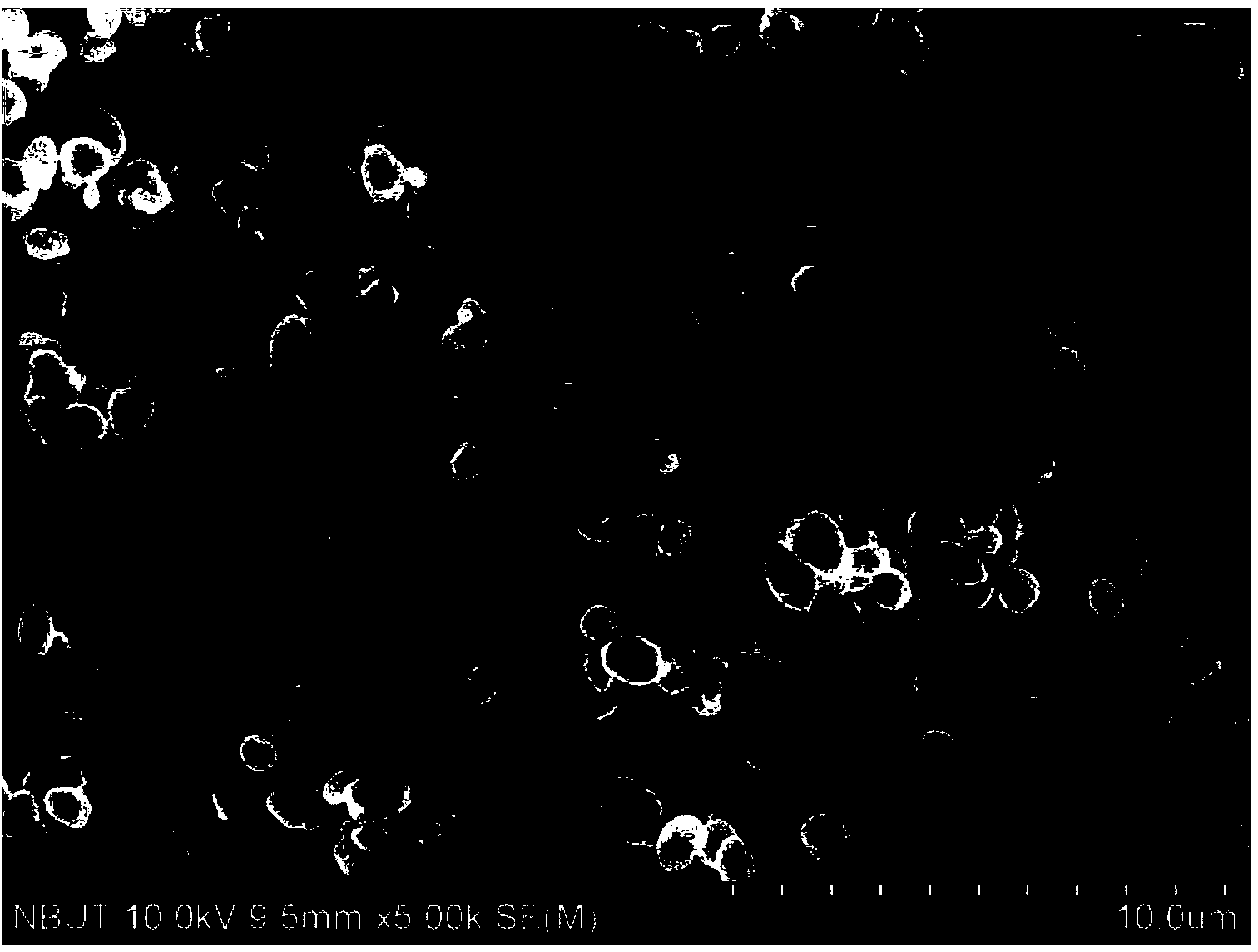

InactiveCN109030829AEasy to operateShort analysis timeChemiluminescene/bioluminescenceBiological testingEnzyme digestionChemiluminescent immunoassay

The invention relates to the chemiluminescent immunoassay, in particular to a quantitative kit for detecting dog IL-6 by adopting homogeneous chemiluminescent immunoassay and a use method thereof. A detection solution adopted by the kit contains DNA1-IL-6 antibody1 conjugate, DNA2-IL-6 antibody2 conjugate, DNA3 for marking acridinium ester (AE), restriction enzyme and graphene oxide; DNA1 and DNA2have six complementary bases, the DNA3 contains two enzyme digestion sites, and has nine bases to complementarily pair with the DNA1 and the DNA2; the DNA3 is adsorbed on the surface of the grapheneoxide through the Pai-Pai stacking effect, and the chemiluminiscence of the AE marked at the tail end is quenched due to the occurring of the CRET. The method is the homogeneous immunoassay method, the operation is simple, and the analysis time is greatly shortened, the measure of the single sample can be accomplished in 5-10min, by combining the ortho-bunting effect and a chemiluminescent molecular beacon, a switch of the graphene quenching mechanism is induced through immunoreaction, thereby releasing a chemiluminiscence signal without washing, separation and purification steps.

Owner:南京浦光生物科技有限公司

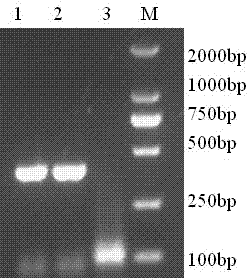

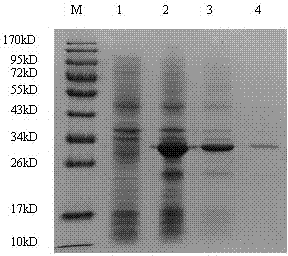

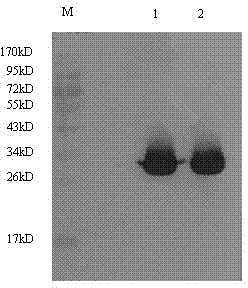

Battery-grade ferric phosphate and preparation method

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +1

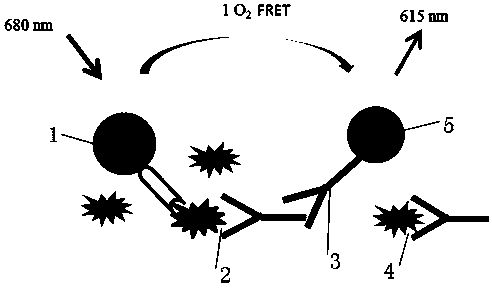

Porcine reproductive and respiratory syndrome virus antibody competitive AlphaLISA detection kit and detection method thereof

The invention discloses a porcine reproductive and respiratory syndrome virus (PRRSV) antibody competitive AlphaLISA detection kit and a detection method thereof. The PRRSV antibody competitive AlphaLISA detection kit comprises a donor bead, an acceptor bead, a PRRSV N protein monoclonal antibody and an N protein antibody having a His label. The competitive AlphaLISA detection method for detecting a PRRSV antibody is established by optimizing test reaction conditions comprising the donor bead, the acceptor bead, the monoclonal antibody, the antigen and serum is established in the invention. The PRRSV antibody detection kit has the advantages of good specificity, high sensitivity, less serum consumption, no washing, no hemolysis influence, low detection cost and short detection time.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Competitive Alpha LISA (linked immuno sorbent assay) detection kit for classical swine fever virus (CSFV) antibody and detection method thereof

InactiveCN103499693AStrong specificityHigh sensitivityBiological testingImmunoassaysAntigenSerum ige

The invention discloses a competitive Alpha LISA (linked immuno sorbent assay) detection kit for a classical swine fever virus (CSFV) antibody and a detection method thereof. The detection kit comprises donor microspheres, receptor microspheres, a swine fever virus E2 protein monoclonal antibody and an E2 protein antigen with a His label. A competitive Alpha LISA detection method for the CSFV antibody is created by optimizing test reaction conditions such as the donor microspheres, the receptor microspheres, the monoclonal antibody, the antigen and serum. The kit for detecting the CSFV antibody is good in specificity, high in sensitivity, low in usage amount of the serum, low in detection cost and short in detection time, does not need to be washed and can not be influenced by hemolysis.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

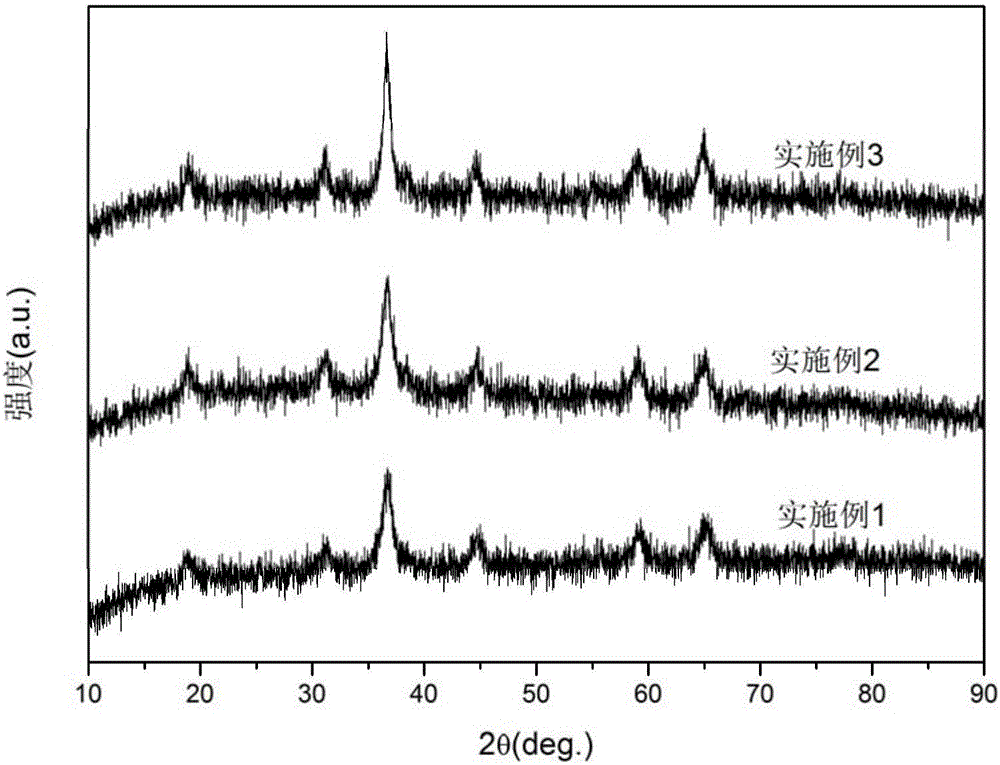

Method for rapidly synthesizing nanometer 3A molecular sieve

InactiveCN102627294AThe reaction procedure is simpleSimple processAluminosilicate zeolite type-AMolecular sievePotassium hydroxide

The invention discloses a method for rapidly synthesizing a nanometer 3A molecular sieve. The method is implemented in a way that aluminum hydroxide, sodium hydroxide, potassium hydroxide, potassium silicate and amorphous silicon dioxide are taken as raw materials for synthesizing the nanometer 3A molecular sieve. The method for synthesizing the nanometer 3A molecular sieve comprises the following steps of: dissolving an aluminum hydroxide solid into a mixed solution of sodium hydroxide, potassium hydroxide and potassium silicate; heating and crystalizing while stirring, wherein the alkalinity of the solution is gradually increased along with crystallization; adding aluminum hydroxide and amorphous silicon dioxide for reacting with an alkali; continually crystalizing a product; and filtering and drying a crystallization product to obtain a nanometer 3A molecular sieve product. The method has the characteristics that: (1) the reaction program and process flow are simple, and the synthesis time is short; (2) the raw material utilization ratio is high, and the prepared 3A molecular sieve has low pH value and is not required to be washed; and (3) the prepared nanometer 3A molecular sieve has the advantages of high product purity, large specific surface area, high selective adsorption performance and the like, and has low price.

Owner:ZHEJIANG NORMAL UNIVERSITY

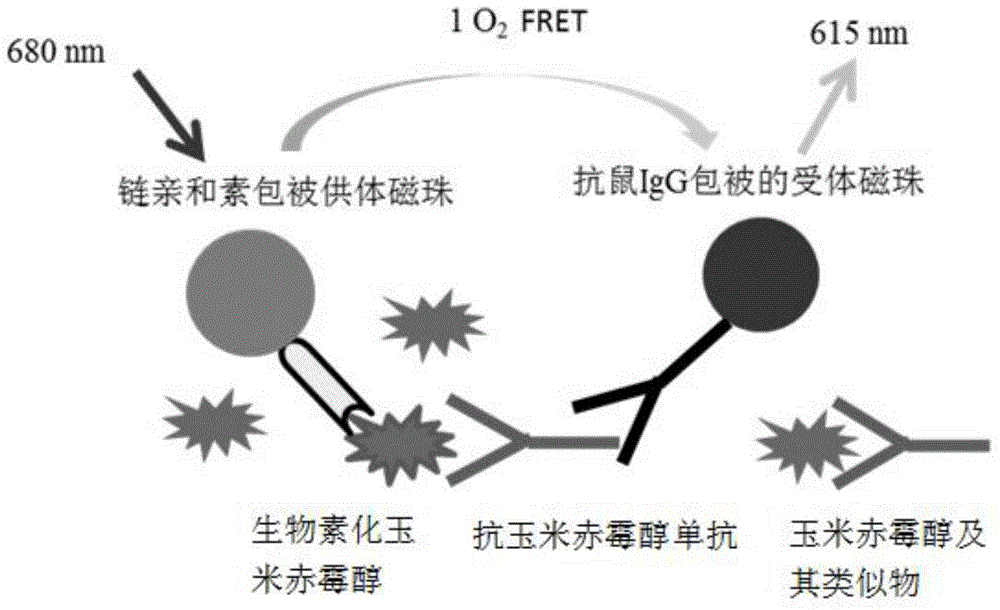

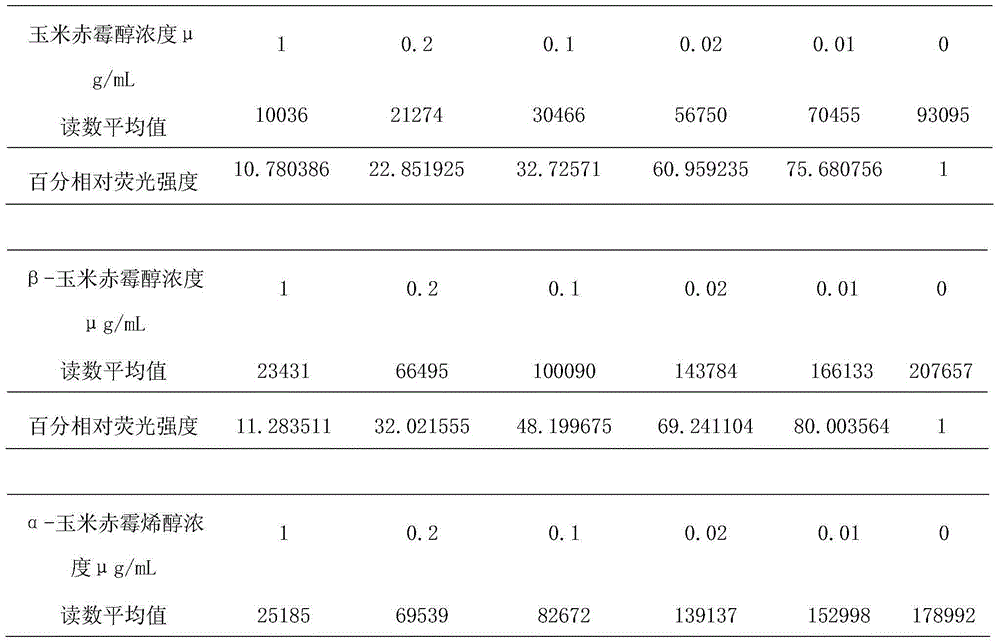

Alpha LISA detection kit for zeranol and analogue in meat product

InactiveCN104634977AReduce dosageHigh sensitivityBiological testingBiotinylationBiotin-streptavidin complex

The invention discloses an Alpha LISA detection method for zeranol and an analogue in a meat product and an Alpha LISA detection kit. The detection kit includes a zeranol standard substance, a beta-zeranol standard substance, an alpha-zearalanel standard substance, a beta-zearalanel standard substance, a zearalenone standard substance, a zearalenone standard substance, biotinylated zeranol, an monoclonal antibody resisting zeranol, an anti-mouse IgG coupled receptor magnetic bead, a streptavidin donor magnetic bead, a detection buffer solution, a white reaction plate, a sealing film and an operating manual. According to the detection method and the detection kit, the amount of samples is few, the sensitivity is high, no washing steps are needed and the detection period is short.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Antibacterial treatment process of curtain fabric material with functions of free washing and environmental protection

InactiveCN101575781AGood air permeabilityDry clothHeating/cooling textile fabricsLiquid/gas/vapor textile treatmentToxicityWoven fabric

The invention relates to an antibacterial treatment process of a curtain fabric material with functions of free washing and environmental protection, used for the antibacterial treatment of a non-woven fabric made from polypropylene fibers and used as the curtain fabric material with functions of free washing and environmental protection. The antibacterial treatment process comprises the following steps: immersing a non-woven fabric into a rolling groove of a rolling cart, which contains antibacterial agent solutions with the proportion of 1:20-100 and then rolling the non-woven fabric by rollers for padding treatment; sending the non-woven fabric after the padding treatment to a heat setting machine to carry out heat setting treatment within the temperature range of 60-130 DEG C, wherein the padding treatment and the heat setting treatment of the non-woven fabric are synchronously carried out continuously, and the movement speed of the non-woven fabric is 500-1500m / h. The curtain fabric material produced by the invention has the advantages of good air permeability, easy maintenance of dry curtain fabric surfaces, dirt resistance, free washing, no toxicity and irritative peculiar smell, easy recycling, environmental protection, good antibacterial property and low antibacterial treatment cost.

Owner:WUJIANG CITY JIREH GREEN TECH

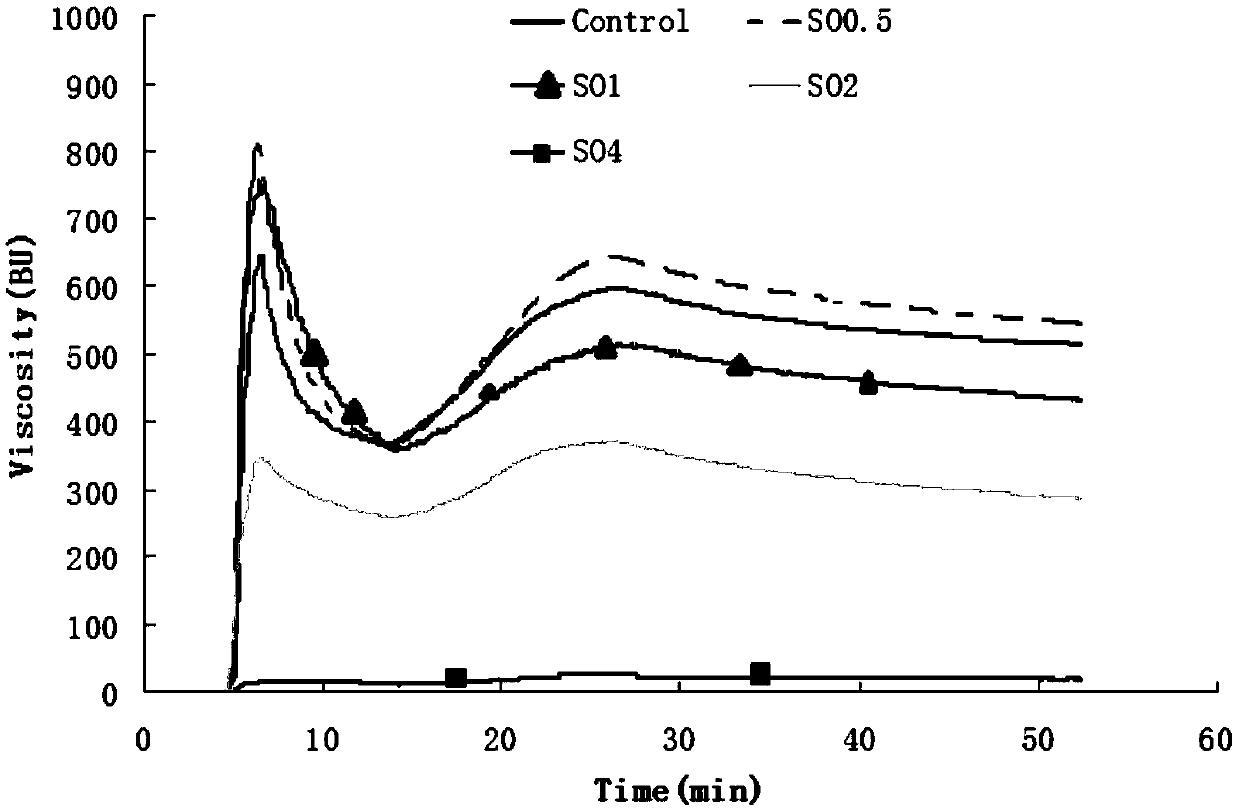

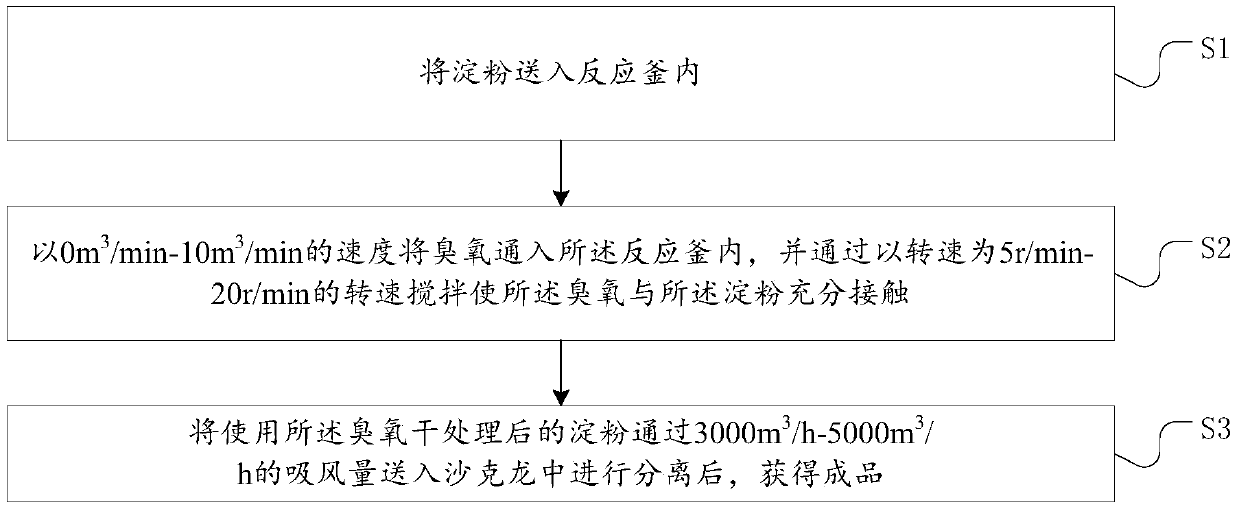

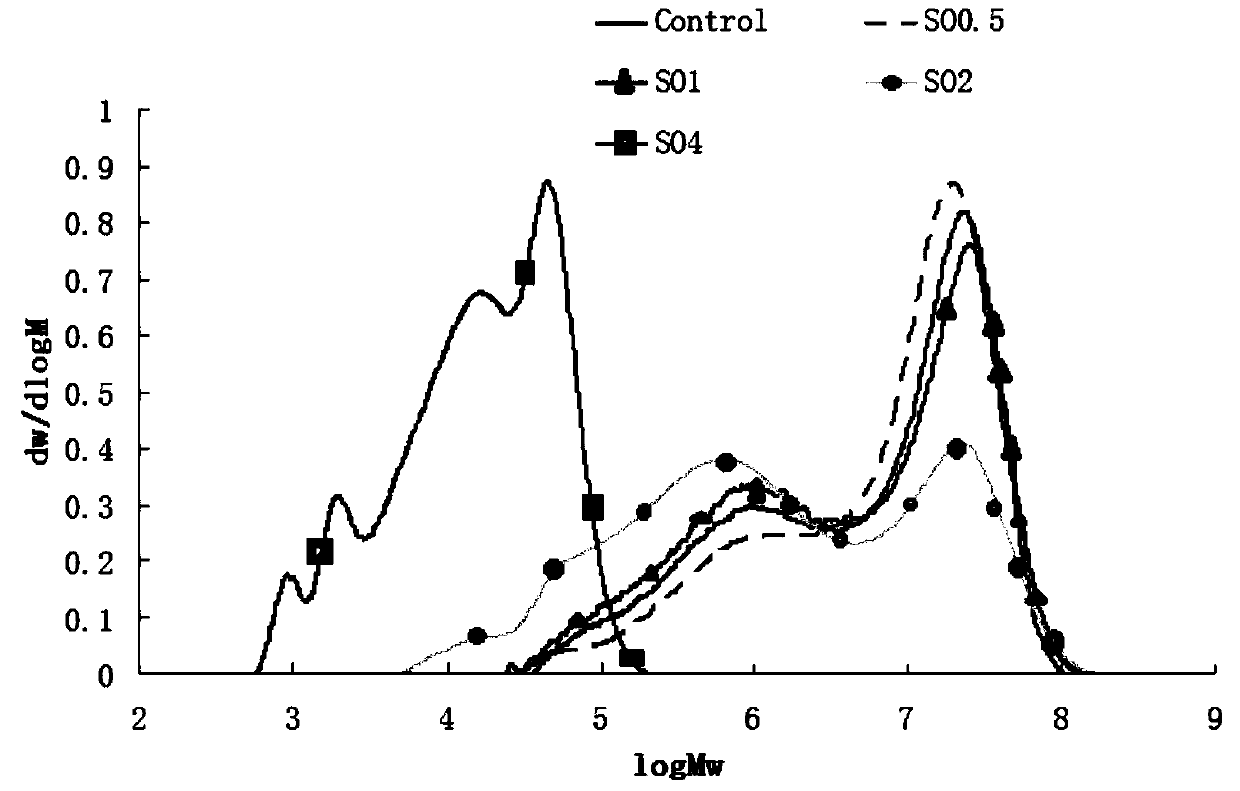

Method for reducing molecular weight of starch through dry method

The invention discloses a method for reducing the molecular weight of starch through a dry method. The method comprises the steps of firstly, feeding the starch into a reaction still, and inputting ozone into the reaction still to react with the starch; then, separating the starch which is subjected to dry treatment by using the ozone by feeding the starch into a cyclone dust remover, thus obtaining the starch of which the molecular weight is reduced. According to the method disclosed by the invention, high-quality modified starch which is higher in carboxyl group content, low in molecular weight and lower in characteristic viscosity value can be prepared; meanwhile, the whole reaction process of the method is kept in a dry treatment process, a product is green and healthy, no reagent residue exists, and the safety of the modified starch is ensured, so that the method can be widely applied to various modern industries such as papermaking, spinning and particularly food and medicine; meanwhile, an operation technology of the method is simple in operation, no sewage and wastewater are discharged, washing is not needed, and the productivity is up to 99 percent or more, so that the operation technology can replace a traditional wet technology to prepare LMW (Low Molecular Weight) oxidized starch, and an actual application significance is obtained.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Competitive Alpha LISA (linked immuno sorbent assay) detection kit for porcine circovirus (PCV) 2 antibody and detection method thereof

The invention discloses a competitive Alpha LISA (linked immuno sorbent assay) detection kit for a porcine circovirus (PCV) 2 antibody and a detection method thereof. The detection kit comprises donor microspheres, receptor microspheres, a PCV 2 Cap protein monoclonal antibody and a Cap protein antigen with a His label. A competitive Alpha LISA detection method for the PCV antibody is created by optimizing test reaction conditions such as the donor microspheres, the receptor microspheres, the monoclonal antibody, the antigen and serum. The kit for detecting the PCV antibody is good in specificity, high in sensitivity, low in usage amount of the serum, low in detection cost and short in detection time, does not need to be washed and can not be influenced by hemolysis.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

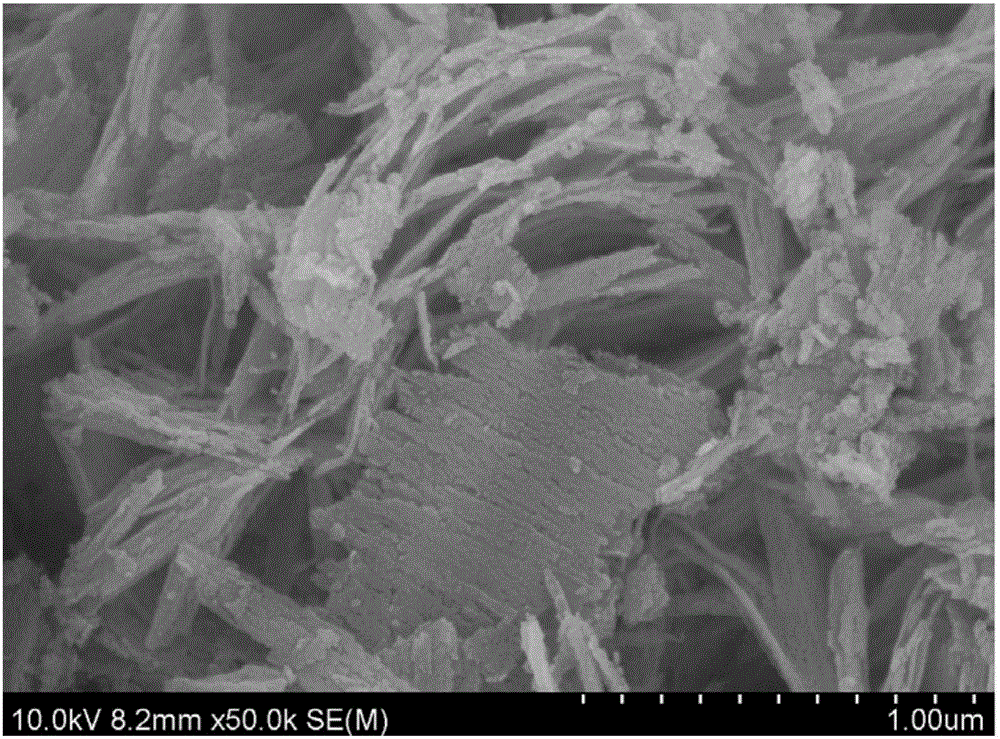

Preparation method of sheet spinel structure cobalt-manganese composite oxide

InactiveCN106693985ASimple ingredientsLow costCatalyst activation/preparationIncinerator apparatusFiltrationCobalt(II) nitrate

The invention provides a preparation method of a sheet spinel structure cobalt-manganese composite oxide. The preparation method comprises the following steps: 1, weighing an aqueous solution of cobalt nitrate hexahydrate and manganous nitrate, dissolving in absolute ethyl alcohol, stirring and dissolving to obtain a solution A; additionally weighing excessive oxalic acid dihydrate, dissolving in the absolute ethyl alcohol, stirring and dissolving to obtain a solution B; 2, adding the solution B dropwise into the solution A while stirring, and continuing to stir to obtain a mixed solution; 3, after completing stirring, conducting suction filtration on the mixed solution, and drying a precipitate obtained through suction filtration in an air circulation oven; 4, roasting the dried solid in a muffle furnace to obtain the sheet spinel structure cobalt-manganese composite oxide. According to the preparation method, other metal cations except the necessary metal salts are not introduced, the preparation method has the advantages of cheap raw materials, simple operation, washing-free, even distribution of products, and high purity, and the obtained product shows very high activity on the complete oxidation reaction of benzene.

Owner:SHANGHAI JIAO TONG UNIV +1

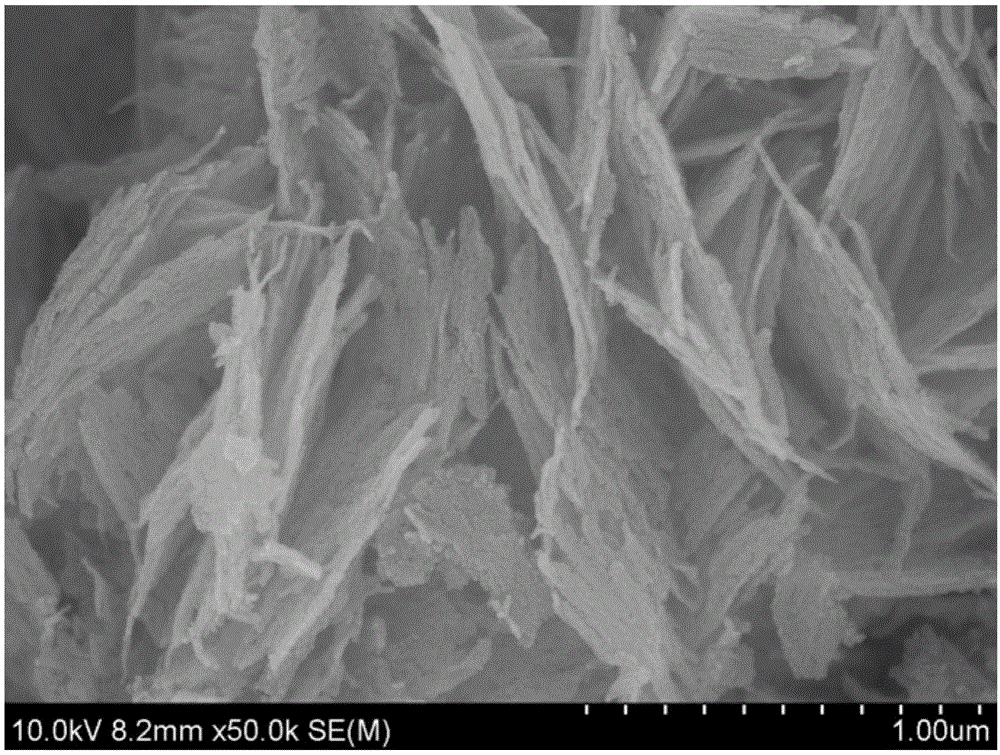

Preparation method of cuprous oxide nano material and hydrogen evolution performance of cuprous oxide nano material

InactiveCN108910933AThe synthesis process is simpleExcellent electrocatalytic hydrogen evolution performanceMaterial nanotechnologyCopper oxides/halidesHydrogenBasic copper carbonate

The invention discloses a preparation method of a cuprous oxide nano material and hydrogen evolution performance of the cuprous oxide nano material, and belongs to the technical field of nanometer materials. According to the preparation method, ethylene glycol and diethylene glycol are used as reducing agents, copper hydroxide and basic copper carbonate with specific morphology are used as coppersources, and the copper hydroxide and the basic copper carbonate copper are reduced to form cuprous oxide nano material with maintained morphology under the protection of inert gas through a gas phasereduction method. The reaction steps are simple and are environmentally friendly, the obtained product does not need to be washed, and a pure cuprous oxide product can be obtained. According to the preparation method provided by the invention, the simple and rapid method is adopted for synthesizing the cuprous oxide nano material with the maintained morphology, and the prepared cuprous oxide nanomaterial has the performance of electro-catalytic hydrogen evolution.

Owner:ANHUI NORMAL UNIV

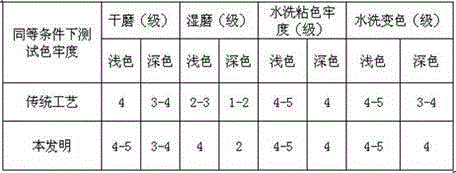

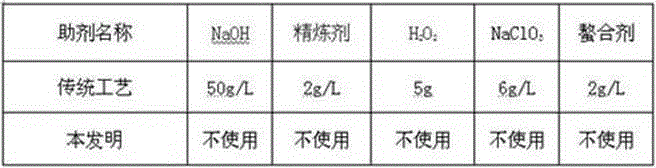

Pre-treatment process of textile fabric

ActiveCN105155282AImprove dyeing effectEfficient decompositionBiochemical fibre treatmentBleaching apparatusWastewaterBiological agent

The invention relates to a pre-treatment process of a textile fabric. The pre-treatment process comprises: a step of clear water boiling, a step of biological agent immersion, and a step of pre-treatment of dyeing in an overflow tank. The step of biological agent immersion comprises: adding a biological agent, citric acid, and glucose into the textile fabric; adjusting the pH value to 4.5-5.0; and immersing the textile fabric at a constant temperature in a range of 35-39 DEG C for 8-12 days, wherein the biological agent is a plant ferment consisting of brown sugar, fruits, and water. A preparation method of the plant ferment includes fermenting brown sugar, fruits, and water in the absence of light for 2.5-3.5 months in a sealed environment. Since the biological agent is added, pectin and lignin in linen fiber can be effectively decomposed. Compared with a traditional process, the pre-treatment process is saved in water, power, and gas. Discharge of waste water is greatly reduced due to no addition of a printing and dyeing auxiliary, thereby satisfying the requirement of environment protection and energy saving.

Owner:SHAOXING CITY KEQIAO DISTRICT DELONG CLOTH

Waterless wax fluid for cleaning vehicle

An anhydrous liquid wax for cleaning the surface of vehicle is prepared from hydrogen contained methyl silica oil, polyoxyvinyl nonylphenolether, amine lauryldimethyl oxide, and optional ethanediol, N-methyl-2-pyrrolidone and SiO2 through proportionally mixing, and mixing with water. Its advantages are no need of using water to flush vehicle in advance, and high detergency and protecting function.

Owner:徐铁生

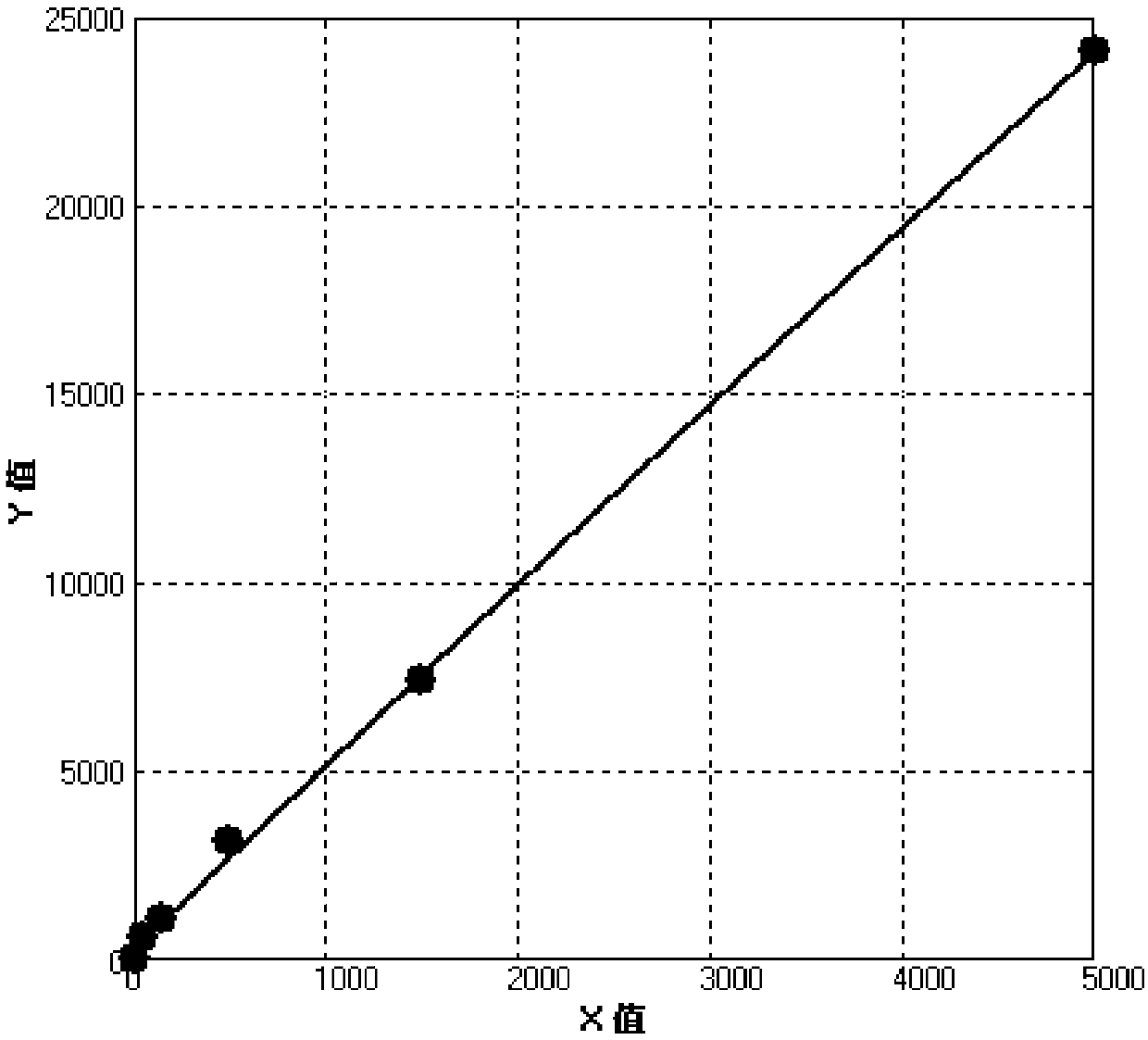

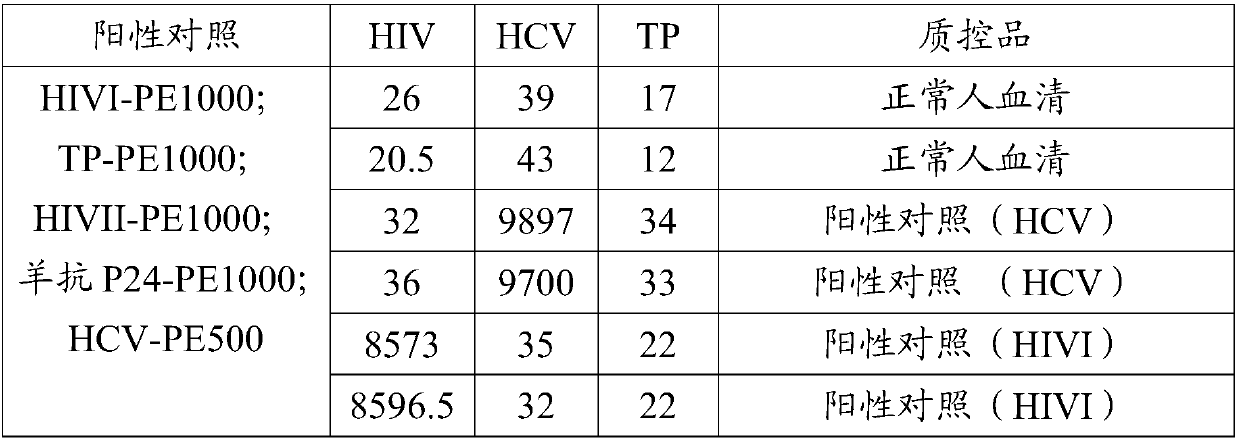

Reagent kit for screening infectious diseases and quantitating hepatitis B surface antigen and applications

PendingCN110275022AImprove throughputHigh speedBiological material analysisBiological testingAntigenTransmissible disease

The invention provides a reagent kit for screening infectious diseases and quantitating a hepatitis B surface antigen and applications. The technology of the invention has the advantages of free combination, high throughput, high speed, low cost, high accuracy, god repeatability, wide linear range, no need for washing and simple operation. The introduction of liquid chip technology and products in clinical diagnosis can greatly improve the detection efficiency and reduce the detection cost. On a platform of the invention, the detection of human sAg concentration with high throughput, high speed, low cost, high accuracy and god repeatability can be realized, and quantitative experiments of HIV, HCV and TP can be carried out. Compared with conventional immunoassay, the invention aims to provide the high-throughput, rapid and accurate technical platform and reagent kit which can detect a plurality of infectious disease antigens and antibodies at the same time.

Owner:北京协和洛克生物技术有限责任公司

Method and reagent box for expanding immune detecting measurable range

The invention discloses a method and a corresponding kit to expand the detectable range of objects to be detected in immunity analysis.

Owner:SHANGHAI TELLGEN LIFE SCI CO LTD

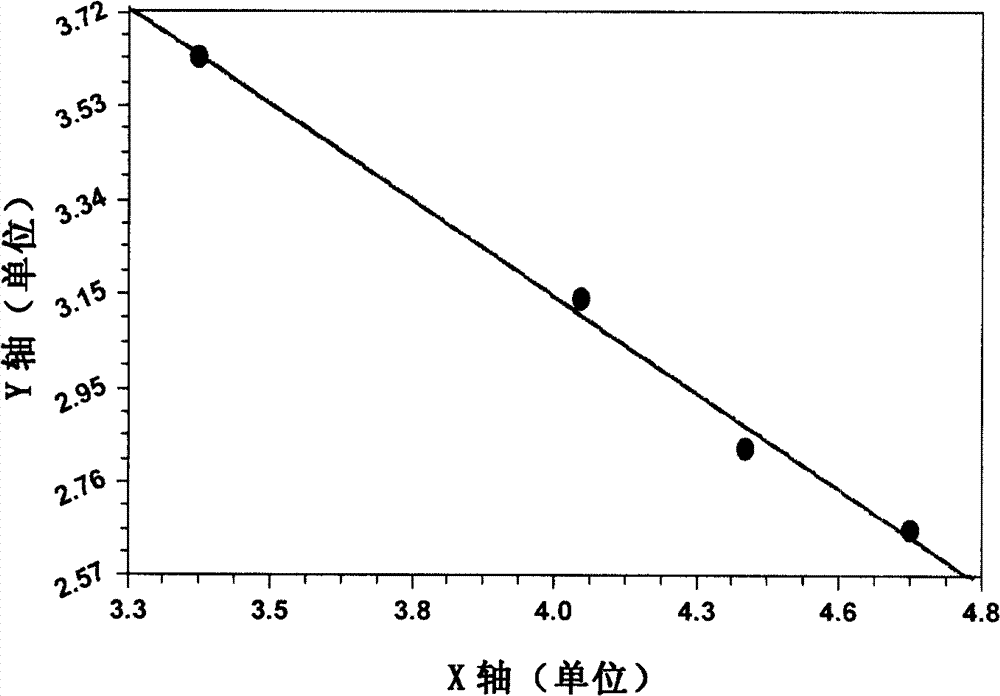

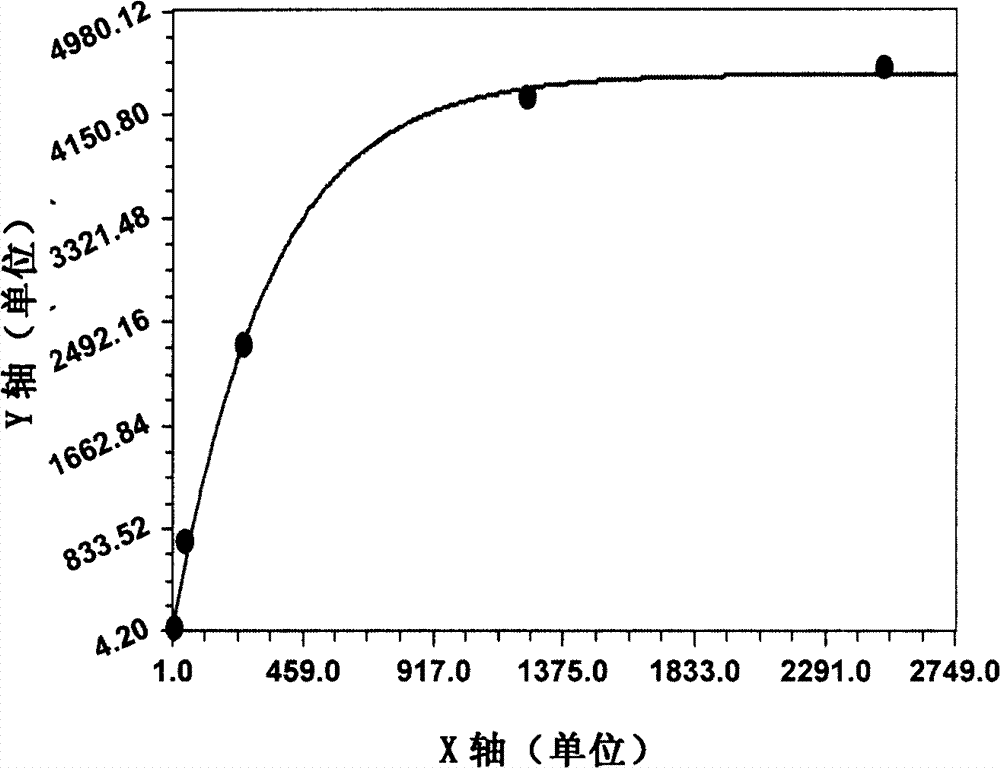

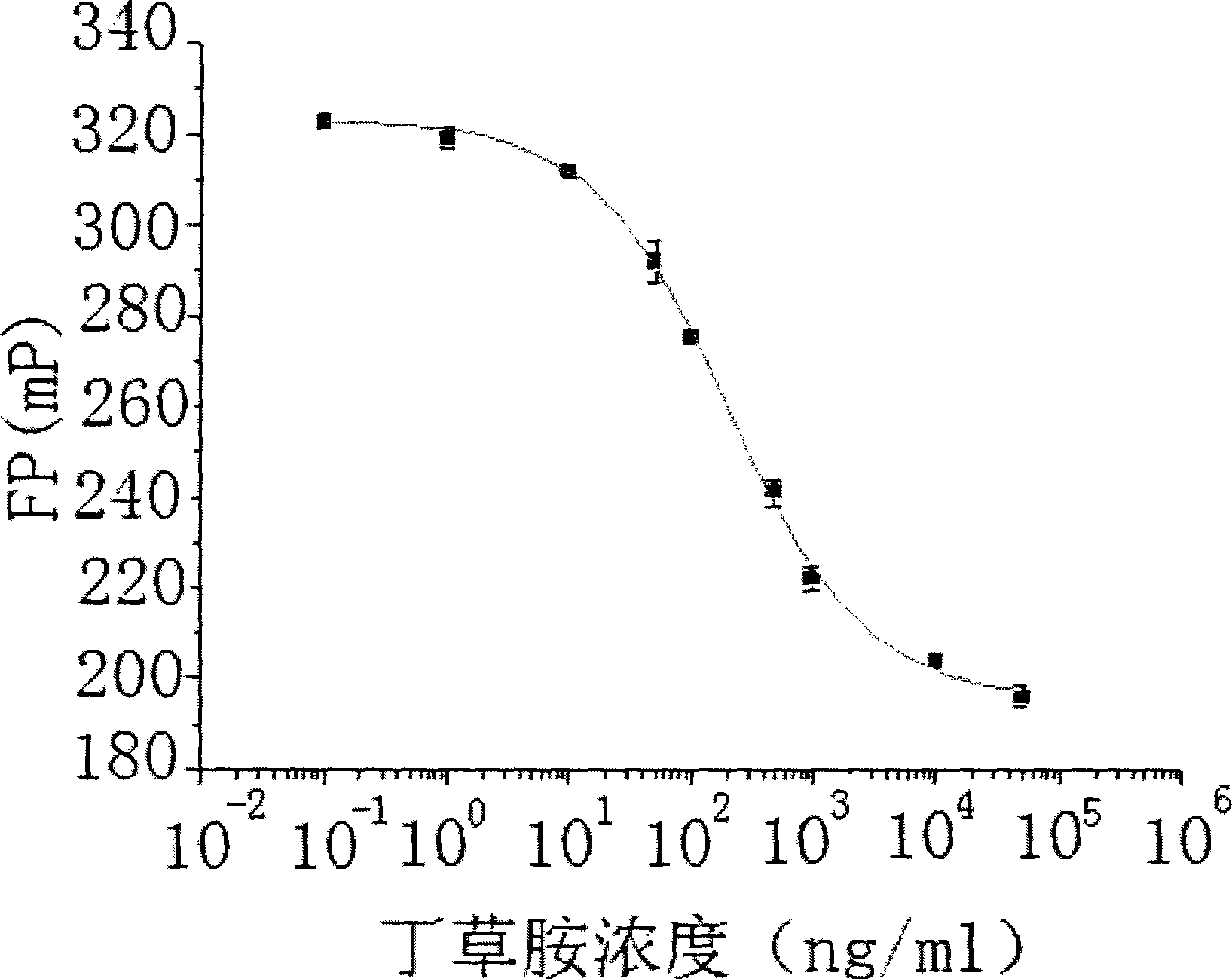

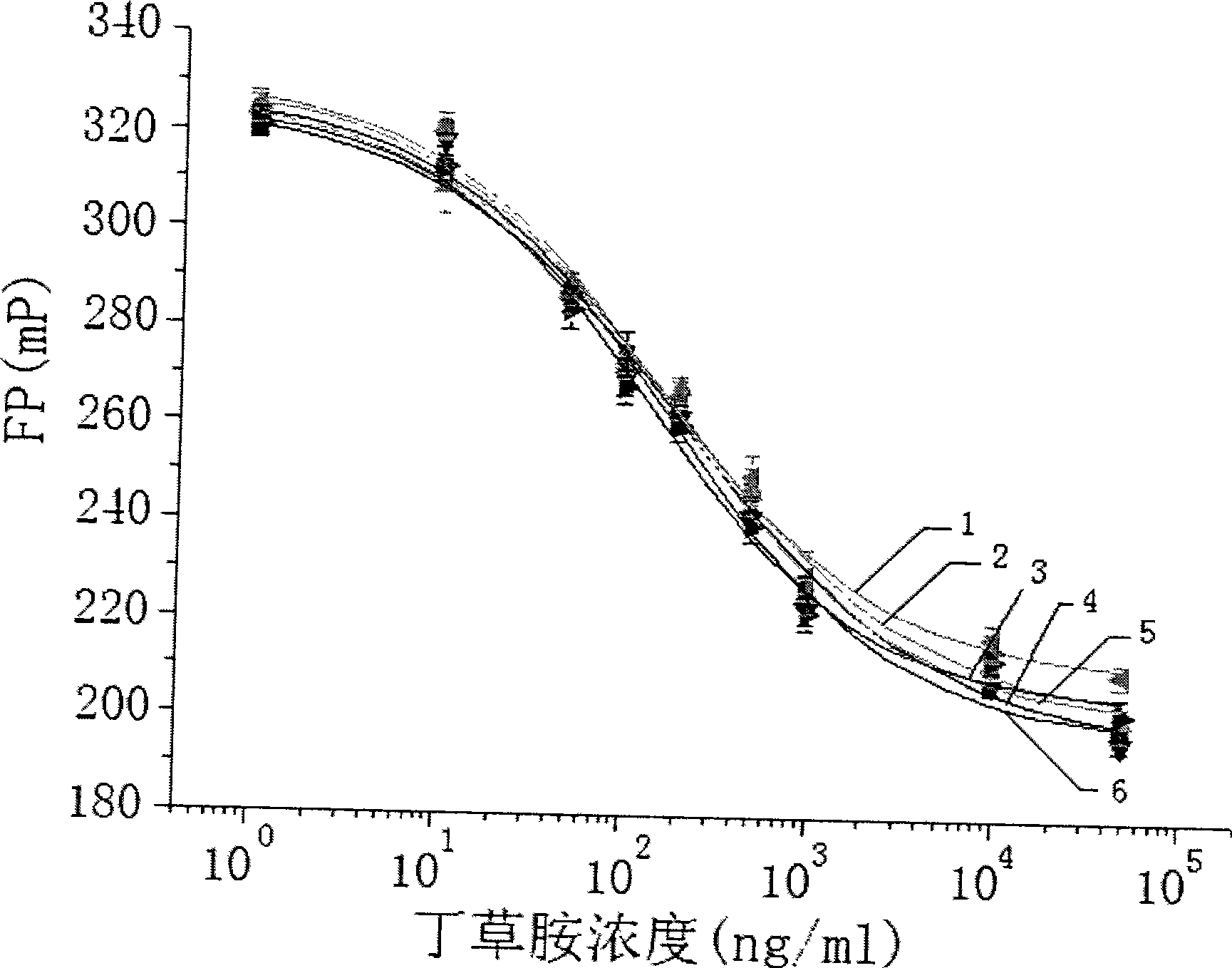

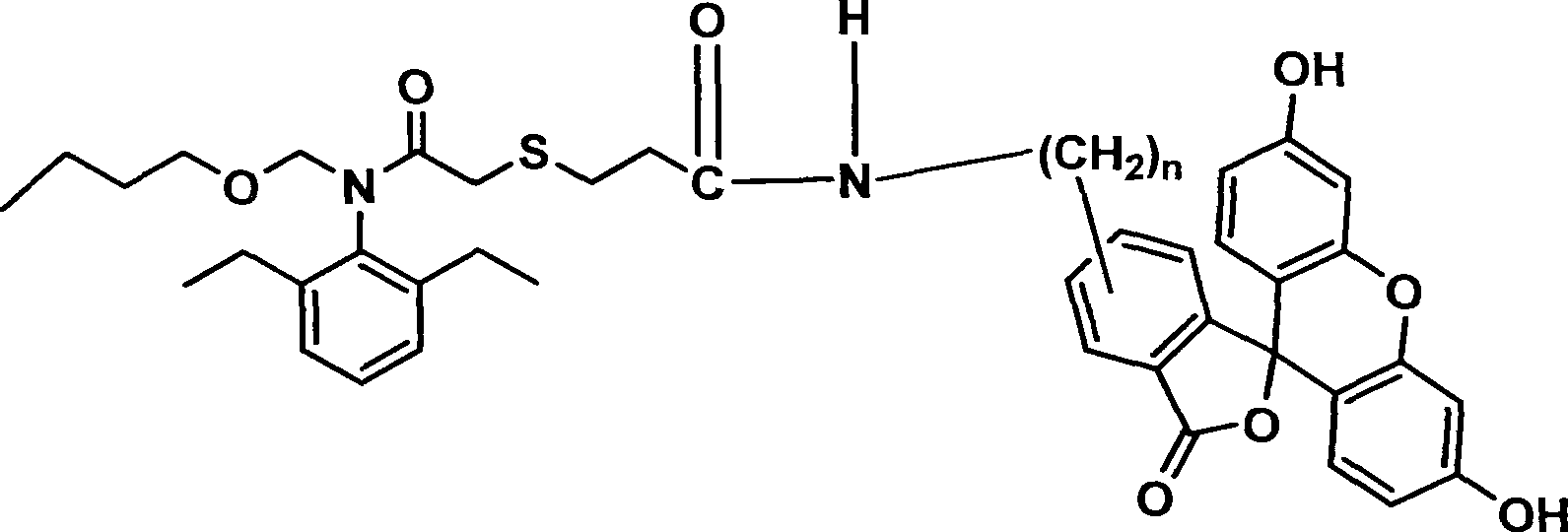

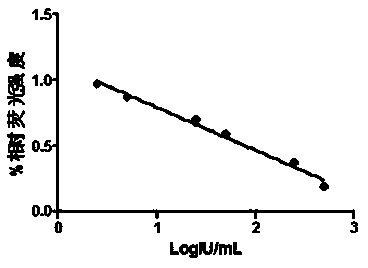

Butachlor polarized fluorescence immunity detection method

InactiveCN101368946AShort reaction timeNo need to washChemiluminescene/bioluminescenceBiological testingFluorescence immunoassayHigh flux

The invention discloses a butachlor polarization fluorescence immunoassay method, mainly comprising the following steps: mixing the sample to be analyzed with the fluorescent-labeled hapten, adding the butachlor antibodies, directly measuring the polarization fluorescence signals of the reaction system, and calculating the butachlor concentration in the sample to be analyzed according to the standard curve set up by the butachlor standard sample. The method can be operated at room temperature, and the entire reaction time is very short; the method can simultaneously detect a plurality of samples in one step, without washing; after being equipped with a mechanical hand, the invention can realize sample adding and automated reading, which is a high-flux automated immunoassay method.

Owner:SOUTH CHINA AGRI UNIV

Preparing method for 1,1,1,3,3-pentachloropropane

ActiveCN101260022AEasy to recycleNo need to washOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingAcetonitrileSolvent

The invention discloses a preparation method for 1, 1, 1, 3, 3-pentachloropropane, aiming to solve the problem that catalyst is difficult to recycle. The invention uses carbon tetrachloride and vinyl chloride as raw material and carries out telomerization to synthesize 1, 1, 1, 3, 3-pentachloropropane, wherein cocatalyst is organic amine; solvent is acetonitrile or tert-butyl alcohol; main catalyst is copper organic complex; the molecular general formula is R(OC6H3COO)Cu, and R in the formula is H, CH3, NH2 or COOH. The invention is mainly used for the preparation of 1, 1, 1, 3, 3-pentachloropropane.

Owner:XIAN MODERN CHEM RES INST +1

Kit for detecting procalcitonin with spatial proximity chemiluminescence method and a detection method of kit

InactiveCN109142335AEliminate glow interferenceFew componentsChemiluminescene/bioluminescenceBiological material analysisAntibodyAdjuvant

The invention relates to a kit for detecting procalcitonin with a spatial proximity chemiluminescence method and a detection method of the kit. The kit comprises an enzyme marker, a luminescent marker, an adjuvant, a trigger and a calibrator, wherein the calibrator contains calibration products of PCT antigens with different concentrations and a 0.1 M phosphate diluent; the enzyme marker containscomponents of a peroxidase labeled PCT detection antibody and a 0.05 M phosphate buffer; the luminescent marker contains components of a 9,10-dihydracridine labeled PCT capture antibody and 0.05 M Tris buffer; the adjuvant contains components of a luminescent adjuvant and a citrate buffer; the trigger is a 0.05 M Tris buffer. The detection method as a true homogeneous chemiluminescence technologydoes not need a carrier, coating and washing processes are omitted, and the kit comprises few components, has high sensitivity and good repeatability and is easy to operate.

Owner:无锡壹闪生物科技有限公司

AlphaLISA detection kit of penicillinase in milk product

InactiveCN103529181AReduce dosageHigh sensitivityTesting dairy productsBiotinylationBiotin-streptavidin complex

The invention provides an AlphaLISA detection kit of penicillinase in a milk product, and the AlphaLISA detection kit comprises a penicillinase standard product, biotin penicillinase, anti-penicillinase monoclonal antibody, an anti-mouse-IgG (immunoglobulin G) coated receptor magnetic bead, a streptavidin donor magnetic bead, a detection buffer solution, a white reaction plate, a sealing membrane and an operating specification. The anti-mouse-IgG coated receptor magnetic bead includes 100 mug / mL of a receptor magnetic bead, 0.05% of Proclin-300, and a phosphate buffer solution (PBS) with the PH of 7.4, and the streptavidin donor magnetic bead includes 100 mug / mL of a donor bead, 25mM of HEPES, 100mM of a NaCl solution and 0.05% of the Proclin-300. An AlphaLISA detection method of the penicillinase in the milk product is established by use of the AlphaLISA detection kit, and the method has the advantages of less sample use amount, high sensitivity, no washing, short detecting period, and the like.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Washing-free degerming wrinkle-eliminating fabric care agent

InactiveCN103866560AEasy to useNo need to washBiochemical fibre treatmentWrinkle skinAlkyl polyglycoside

The invention relates to a textile care agent for civil use, in particular to a washing-free degerming wrinkle-eliminating fabric care agent which is used for textile products like clothing and can be used directly without washing. The washing-free degerming wrinkle-eliminating fabric care agent has the following beneficial effects: (1) the agent is convenient to use and does not need washing; (2) softening and degerming are carried out synchronously, and a killing effect is exerted on common harmful microbes, especially pathogenic bacteria thereof; (4) after usage of the agent, clothes are soft, fluffy, smooth and fitting and have no static electrons; (5) no damage is posed to the fabric and the skin, and the agent has good stability; (6) the agent is composed of marine organisms and plant components and poses no pollution to the environment; (7) the fabric has good antistatic performance and rewettability, no damage, no yellowing and no deformation; and (8) a preparation process for the agent is simple and has low cost. A formula for the agent comprises (weight percent): 3.0 to 4.0 of alkyl polyglycoside, 0.5 to 1.0 of 6501 and 8.0 to 12.0 of a palm cationic ester quaternary ammonium salt, with the balance being purified water.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

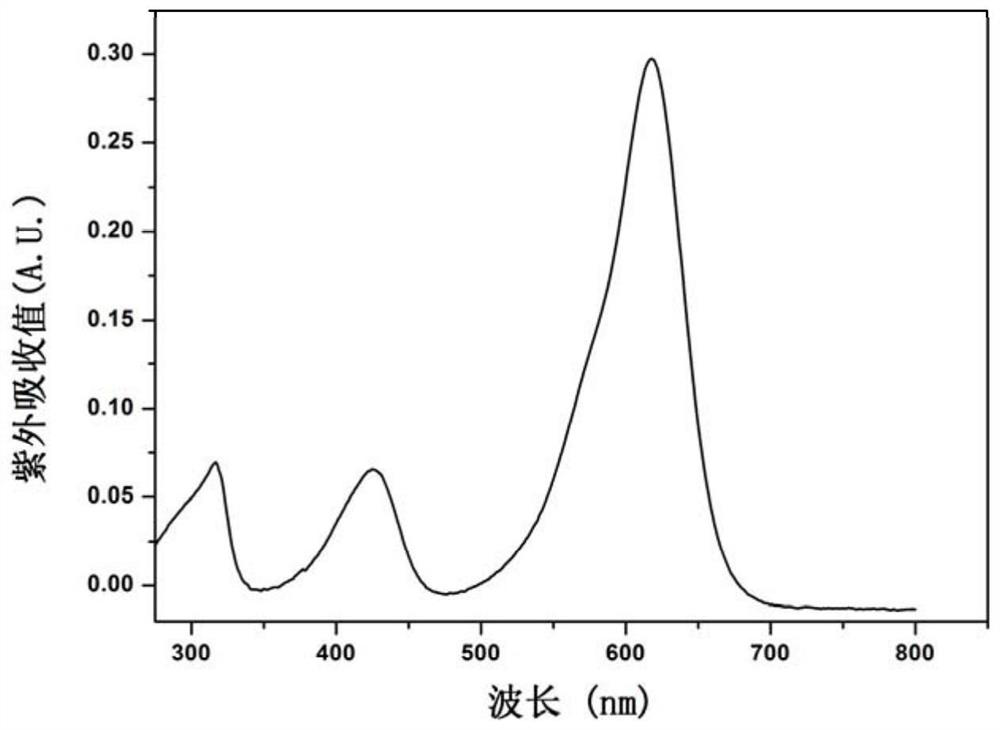

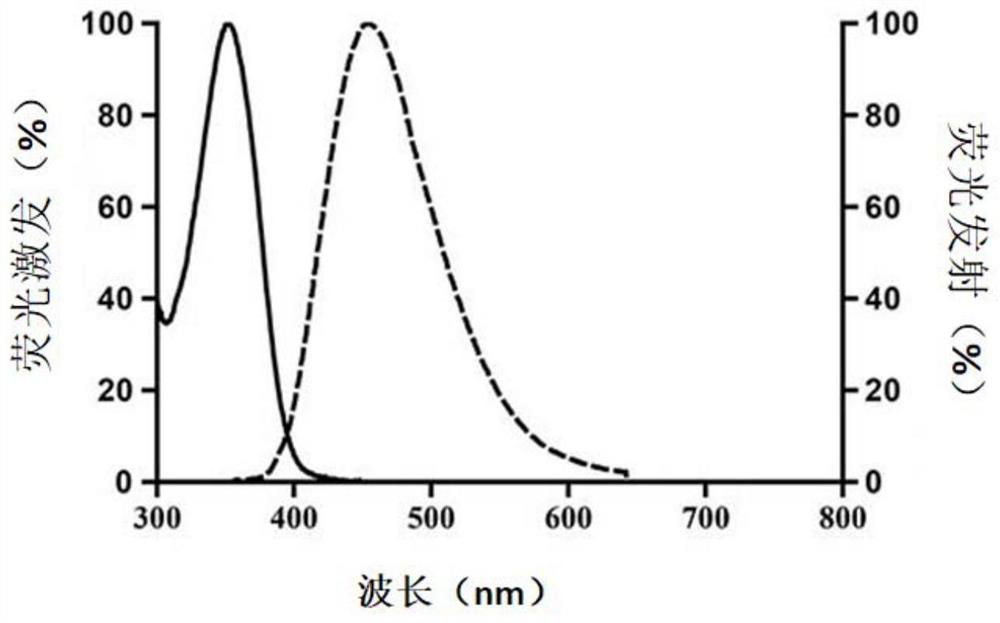

Cell nucleus fluorescent dye and dyeing method thereof

PendingCN114057604AIncrease varietyGood membrane permeabilityOrganic chemistryDiaryl/thriaryl methane dyesFluorescent stainingPhoto stability

The invention provides a cell nucleus fluorescent dye as well as a dyeing method and application thereof, and provides a novel fluorescent dye for cell nucleus dyeing. The cell nucleus fluorescent dye has good membrane permeability, high sensitivity, rapid nucleus dyeing efficiency, good light stability, good biocompatibility and longer-wavelength exciting light and emission light, and can be applied to fluorescent dyeing of cell nucleuses.

Owner:SHENZHEN INST OF ADVANCED TECH

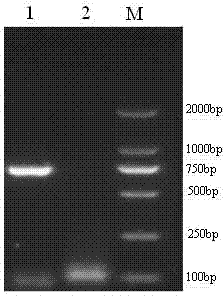

Method for synthesizing tetracyclo[7.3.1.02,7.17,11]tetradecane

ActiveCN101781160AHigh reaction yieldSimple processHydrocarbon by isomerisationAluminum trichlorideAluminium

The invention discloses a method for synthesizing tetracyclo[7.3.1.02,7.17,11]tetradecane and aims to solve the problems of a large amount of acidic wastewater, complex product separation and low yield of the prior art. In the method, tetracyclo[7.4.0.02,7.13,6]tetradecane serving as a raw material reacts in the presence of chloroaluminate ionic liquid at 50 to 130 DEG C for 1 to 8 hours; the product is cooled and stood for layering to obtain the tetracyclo[7.3.1.02,7.17,11]tetradecane, wherein the molar ratio of the chloroaluminate ionic liquid to the tetracyclo[7.4.0.02,7.13,6]tetradecane is 0,05-2:1; the chloroaluminate ionic liquid may be chloroalkylamine-aluminium choride, haloalkylimidazole-aluminium choride or haloalkylpyridine- aluminium choride; and the molar ratio of the aluminium choride to the haloalkylamine, haloalkylimidazole or the haloalkylpyridine is 0.5-1:1. The method is mainly used for synthesizing tetracyclo[7.3.1.02,7.17,11]tetradecane hydrocarbon fuel.

Owner:XIAN MODERN CHEM RES INST

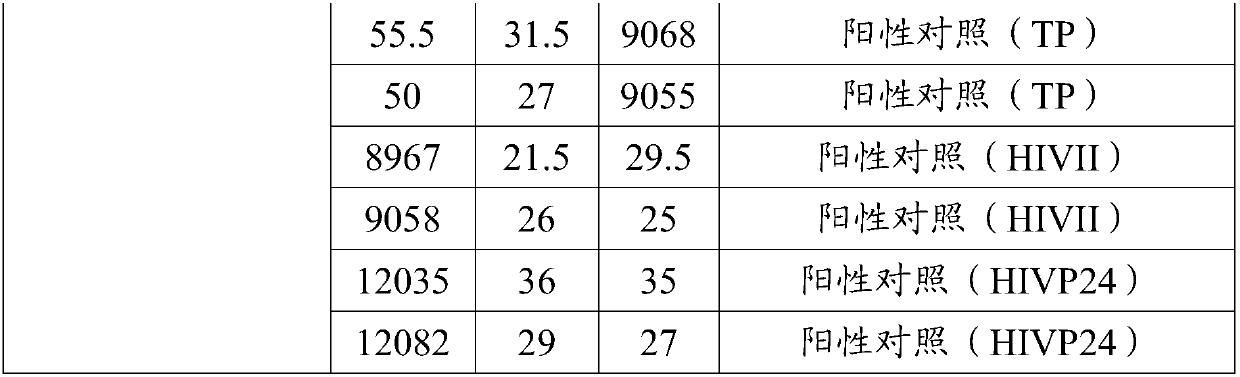

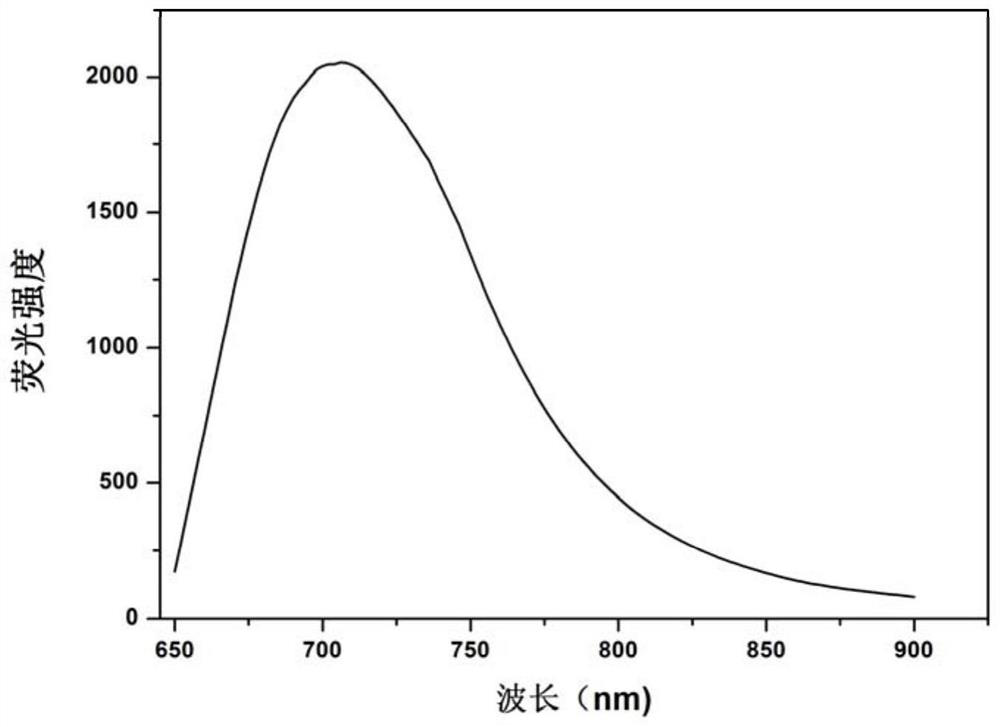

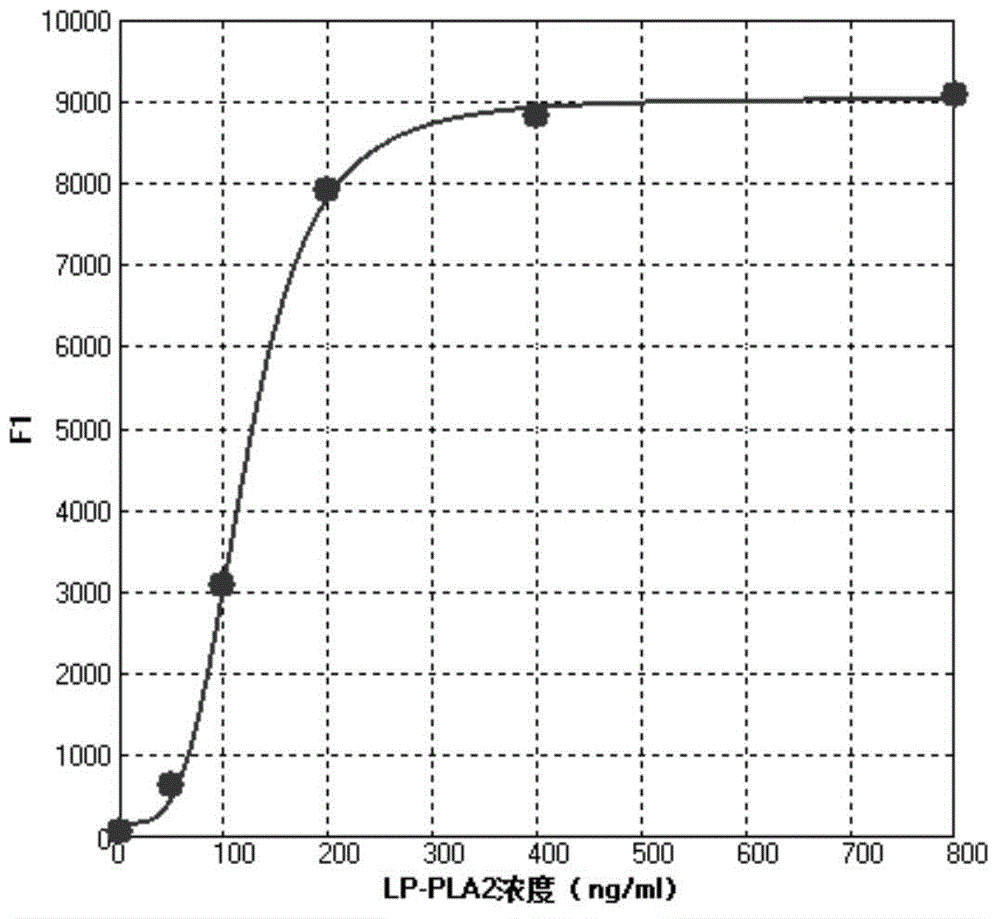

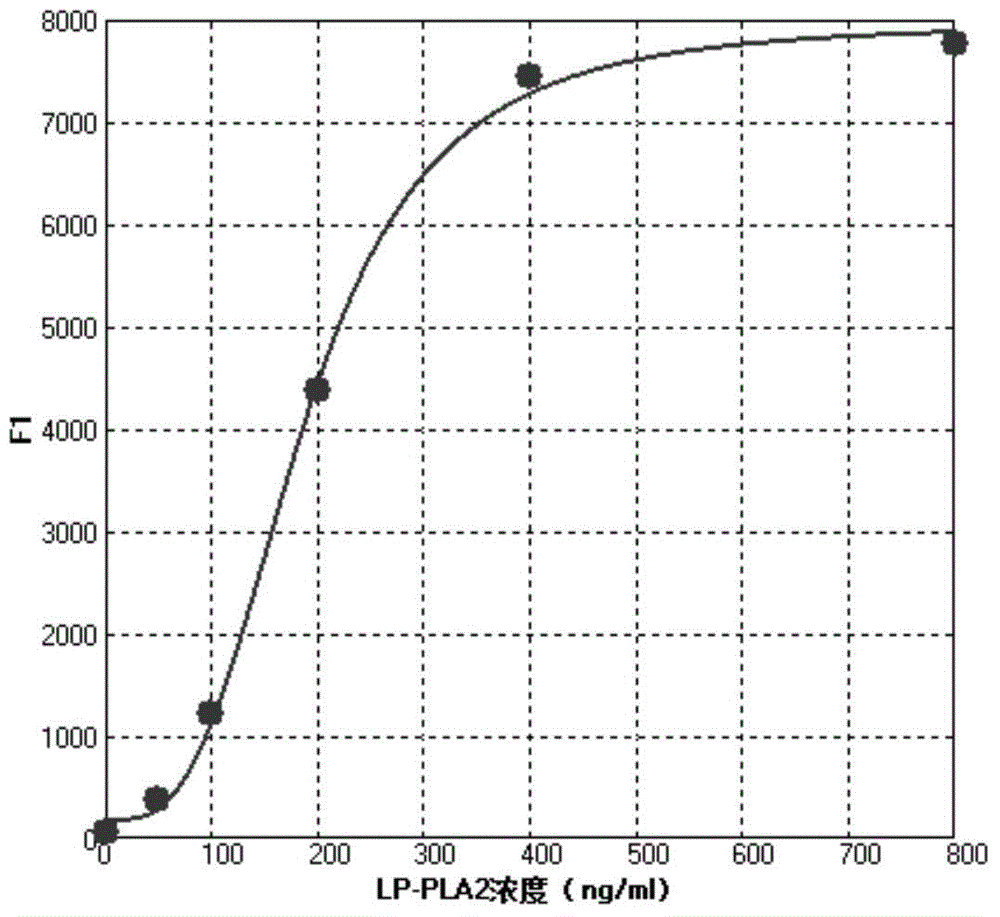

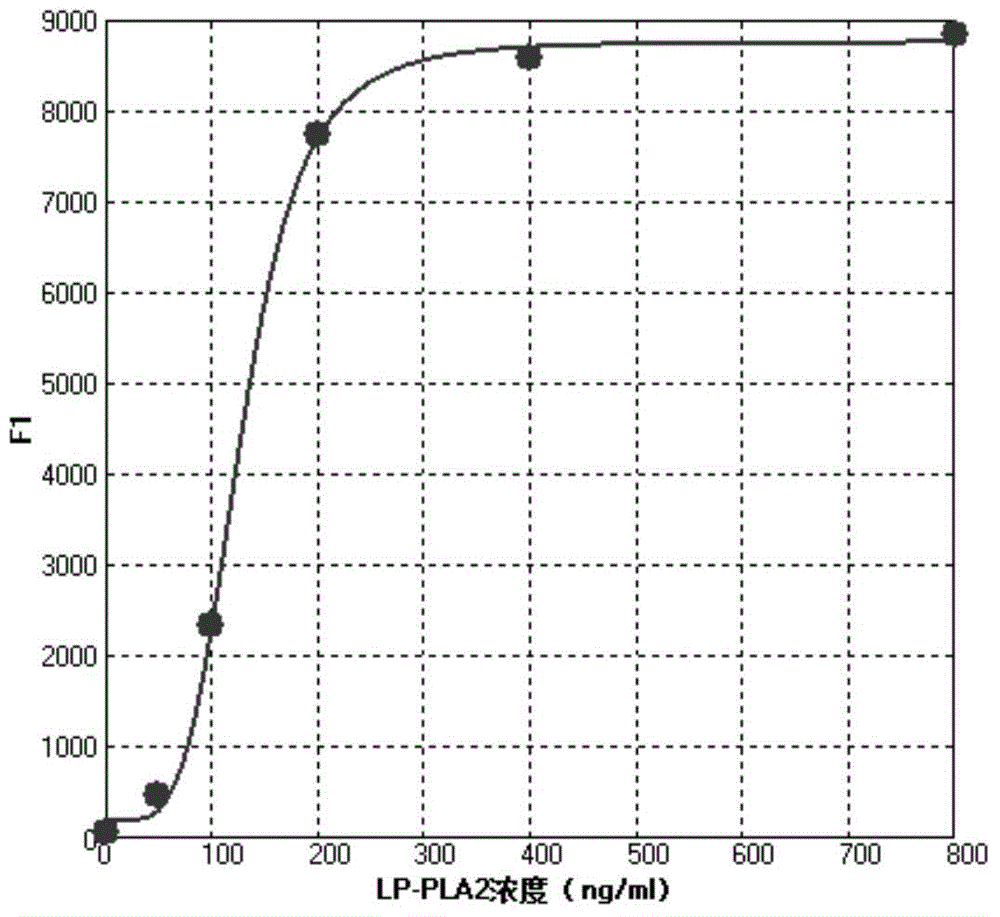

Liquid-chip kit for quantitatively detecting concentration of lipoprotein phospholipase A2 in sample and preparation method thereof

InactiveCN104820097AImprove throughputHigh speedDisease diagnosisBiotin-streptavidin complexPhosphate

The invention belongs to the technical field of in-vitro immunodetection and particularly relates to a kit for detecting the concentration of lipoprotein phospholipase A2 in a sample and a preparation method thereof. The kit comprises microspheres coated with lipoprotein phospholipase A2, a micropore reaction plate, a standard product and a quality control product of a concentration gradient of lipoprotein phospholipase A2, a biotin-marked lipoprotein phospholipase A2 antibody, streptavidin-marked phycoerythrin, and a phosphate buffer solution containing a protein protection agent. Detection instruments used for the detection is MAGPIX of Luminex and Luminex 200, 3D; on the platform, measurement for the concentration of lipoprotein phospholipase A2 of human plasma by high flux, high speed, low cost, high accuracy and good repeatability can be realized, and simultaneously, detection markers of different types can be freely combined and added, so that simultaneous detection of multiple markers is realized, the accuracy rate for diagnosis of cardiovascular diseases is increased and the kit has important application prospect.

Owner:北京协和洛克生物技术有限责任公司

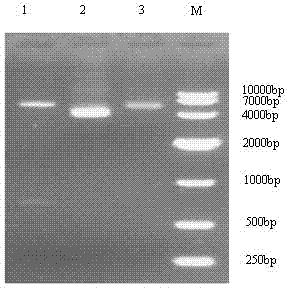

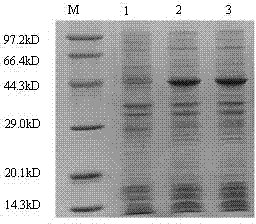

Use of 1-methyl-4-isopropyl-bicyclo[2, 2, 2] octane-2, 3-diacid anhydride

InactiveCN1629152ALow welding activityHigh soldering activity even at low temperatureOrganic chemistryWelding/cutting media/materialsHydrogen pressureCycloaddition

The invention relates to the novel use of welding agent which contains 2,2} octane-2,3-dianhydride as the main component, wherein a monoterpene derivative which includes acid anhydride functional group as the characteristic construction for welding agent, whose preparation comprises, using the Diels-Alder ring addition reaction product of alpha-terpinene and maleic anhydride as raw material, using 5% of Pd / C as catalyst, whose consumption is 1-10% of the raw material weight, the hydrogen pressure is 0.1-1.0Mpa, and the hydrogenation reaction is carried out at the condition of 20-35 deg. C, alcohols such as menthol or ethanol are used as solvent

Owner:HARBIN UNIV OF COMMERCE

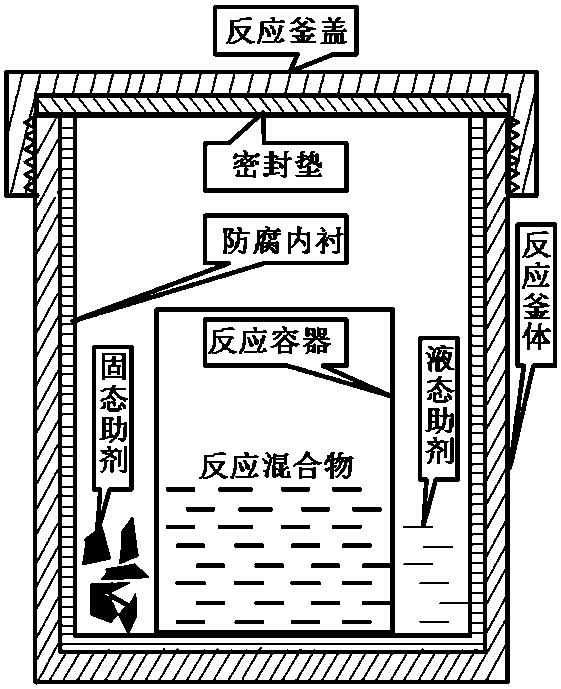

Method for assisted synthesis of porous composite material by using assistant transfer byproduct

InactiveCN110483557AFavorable for crystallization reactionHigh yieldGas treatmentOrganic compound preparationSolventReagent

The invention discloses a method for assisted synthesis of a porous composite material by using an assistant transfer byproduct. According to the method, an alkaline auxiliary agent is placed in a reaction device and is not in direct contact with reactants, and the amount-of-substance ratio of the auxiliary agent to by-product acid is controlled, so that the porous composite material is obtained through heating treatment in a sealed reaction kettle; and the grain size and distribution of the composite framework material are regulated and controlled; meanwhile, by-product acid in the mother liquor steam is in contact with an alkaline additive to form salt to be fixed, the salt is not returned to the mother liquor anymore; the salt can be used as a by-product for sale, while the mother liquor is directly used as a solvent to dissolve the next batch of reaction raw materials. The whole reaction process is easy to operate, low in operation cost, zero in three-waste emission, high in yieldand easy to realize large-scale production.

Owner:TAIYUAN UNIV OF TECH

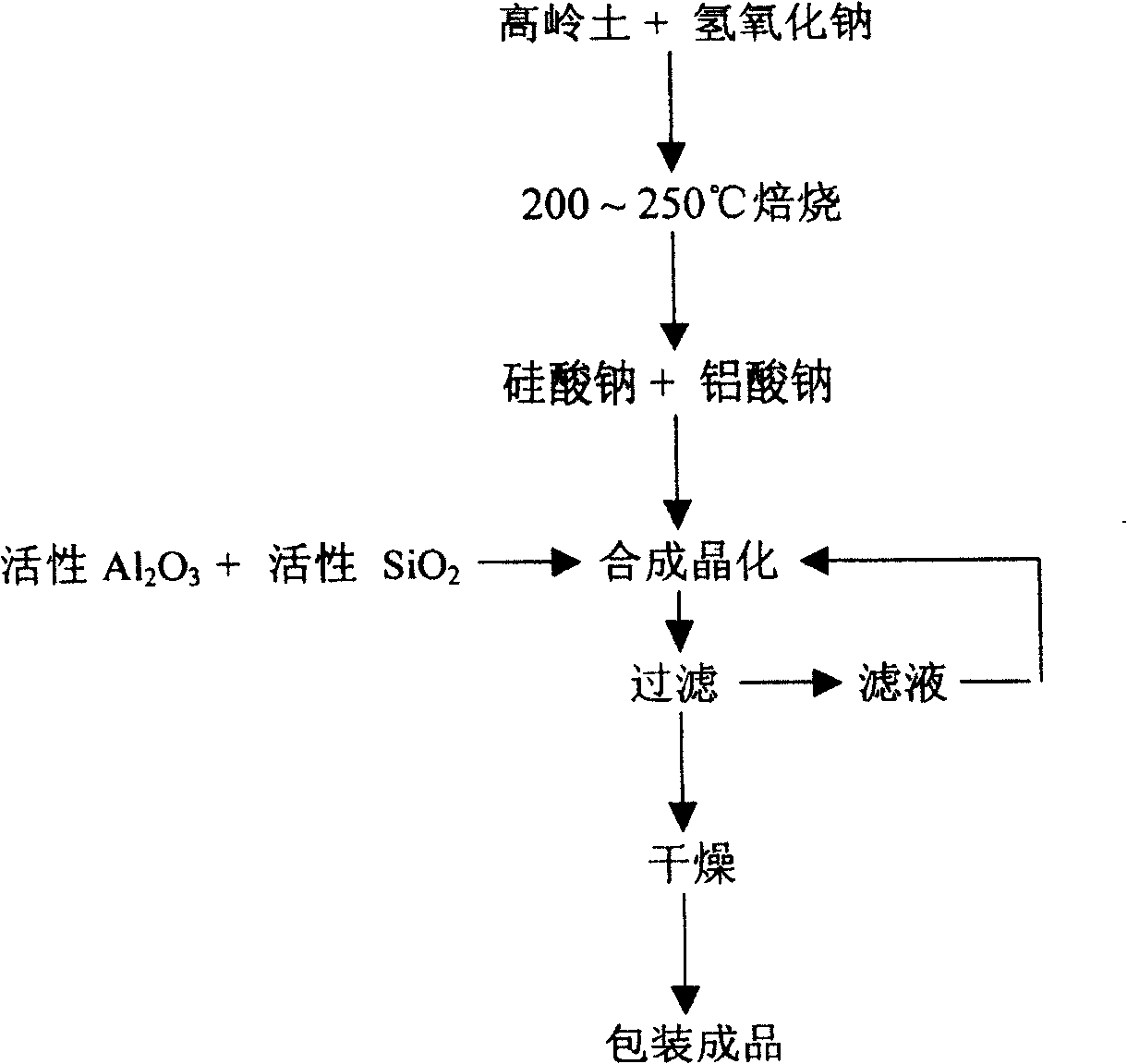

4A zeolite synthesized from kaolin by low-temperature alkali fusion method

InactiveCN100434364CLow reaction temperatureReduce energy consumptionAluminosilicate zeolite type-AChemical synthesisKaolin clay

This invention relates to a method for preparing 4A zeolite with kaoline as the raw material aiming at providing a preparation method for composite 4A zeolite with kaoline as the raw material against the shortcomings of the present chemosynthesis method, acidified bentonite method and a kaoline high temperature calcining method including the following steps: mixing uniformly kaolin and NaOH in a certain proportion and heating them for 1-3h, adding a certain volume of active Al2O3, active SiO2 and water in the activated product to be thermal-crystalized for 0.5-4h under 80-95deg.C then to filter the product and dry it to get the 4A zeolite product.

Owner:ZHEJIANG NORMAL UNIVERSITY

High-strength and high-perviousness filtering cloth material

The invention discloses a high-strength and high-perviousness filtering cloth material. The filtering cloth material is prepared from the following raw materials in parts by weight: polyethylene, polypropylene, polyvinylpyrrolidone, carbon nanotube, polyethylene glycol, carbon fiber, modified polyethylene acrylate, ionic modified clay, surface modifying agent, thermoplastic polyurethane, anti-ageing agent and lubricating agent. The high-strength and high-perviousness filtering cloth material disclosed by the invention has the beneficial effects that by scientific proportioning of all the materials and components, under the synergistic effect of all the components, the strength and the perviousness of the filtering cloth material are improved, so that the filtering cloth material can be applicable to the condition of rapid filtration and has a wide application range; meanwhile, by the comprehensive effect of the ionic modified clay, the surface properties of the polyethylene and the polypropylene are improved, and the filtering effect is improved; due to addition of the modified polyethylene acrylate and the thermoplastic polyurethane, the filtering effect of the filtering cloth material is further improved, and the filtering capability of the filtering cloth is improved, so that the high-strength and high-perviousness filtering cloth material has great promotion value.

Owner:ANHUI YUANYE FILTER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing tetracyclo[7.3.1.02,7.17,11]tetradecane Method for synthesizing tetracyclo[7.3.1.02,7.17,11]tetradecane](https://images-eureka.patsnap.com/patent_img/84b02786-5271-49c3-bb19-a0520ca259a5/GSA00000037239100011.PNG)

![Use of 1-methyl-4-isopropyl-bicyclo[2, 2, 2] octane-2, 3-diacid anhydride Use of 1-methyl-4-isopropyl-bicyclo[2, 2, 2] octane-2, 3-diacid anhydride](https://images-eureka.patsnap.com/patent_img/cc192d72-22bc-4af0-8612-d4c51114a8c5/A2004100439270002C1.PNG)

![Use of 1-methyl-4-isopropyl-bicyclo[2, 2, 2] octane-2, 3-diacid anhydride Use of 1-methyl-4-isopropyl-bicyclo[2, 2, 2] octane-2, 3-diacid anhydride](https://images-eureka.patsnap.com/patent_img/cc192d72-22bc-4af0-8612-d4c51114a8c5/A20041004392700041.PNG)