Preparation method of sheet spinel structure cobalt-manganese composite oxide

A spinel structure and composite oxide technology, which is applied in chemical instruments and methods, catalyst activation/preparation, combustion methods, etc., can solve the problems of undiscovered cobalt-manganese composite oxides with sheet shape, increased cost, and difficult large-scale Production and other issues, to achieve the effect of no washing, good reaction performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 4.656g cobalt nitrate hexahydrate and 2.860g manganese nitrate solution (mass fraction is 50%) and place in a 500mL beaker, add 200mL absolute ethanol, stir and dissolve to obtain solution A; weigh 3.620g oxalic acid dihydrate and place in 100mL In the beaker, add 50mL of absolute ethanol, stir and dissolve to obtain solution B; under stirring, drop solution B into solution A drop by drop, and continue stirring for 4-6h; The final precipitate obtained was dried in a blast oven at 70-80°C for 12 hours, and then dried; the dried solid was roasted in a muffle furnace at a temperature of 300°C for 4 hours, and a heating rate of 2°C / min, to obtain flaky cobalt-manganese composite oxides.

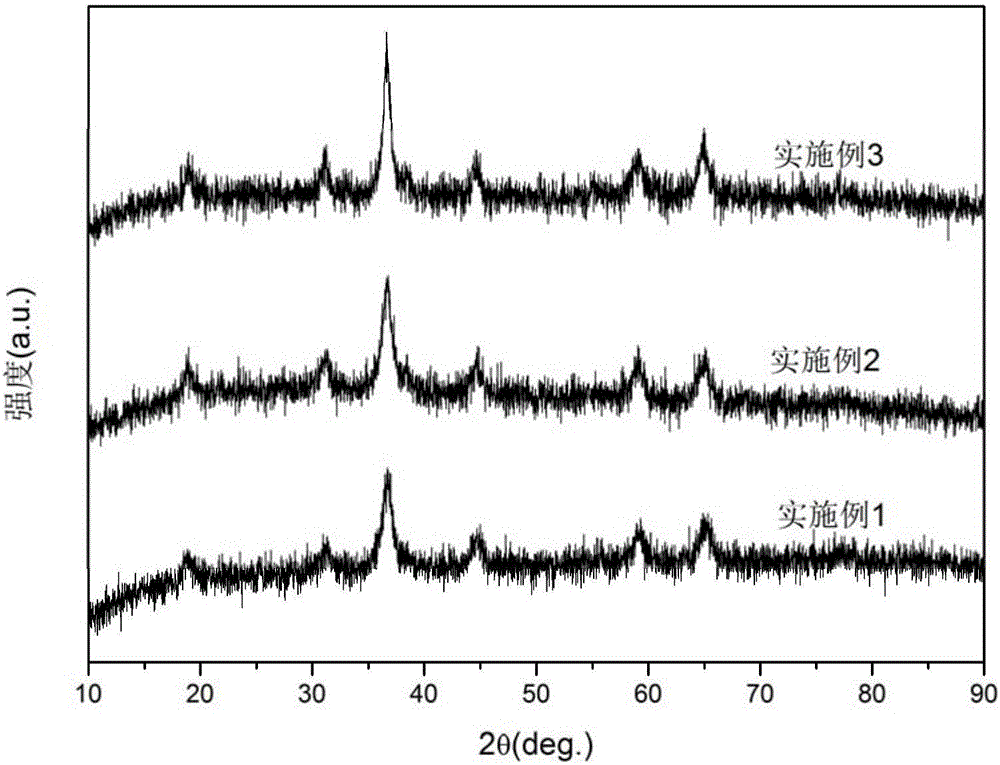

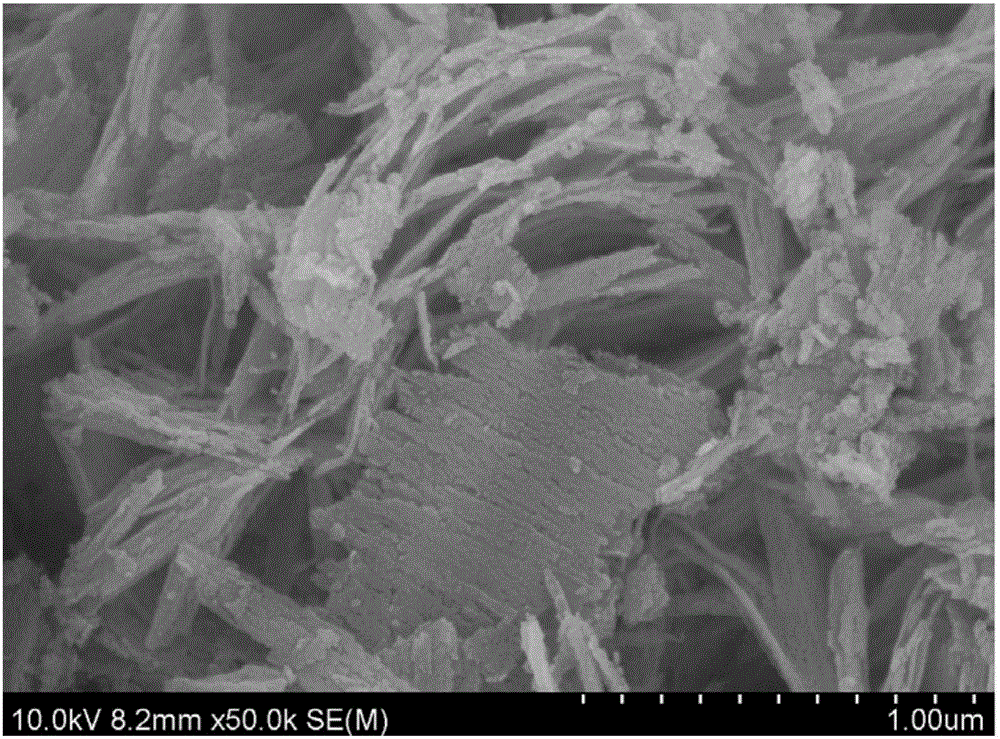

[0033] like figure 2 As shown in the SEM results, the thickness of the sheet is 0.03 μm. figure 1 The XRD pattern result of Example 1 shows that the oxide is a spinel structure.

Embodiment 2

[0035] Weigh 4.656g cobalt nitrate hexahydrate and 2.860g manganese nitrate solution (mass fraction is 50%) and place in a 500mL beaker, add 200mL absolute ethanol, stir and dissolve to obtain solution A; weigh 3.620g oxalic acid dihydrate and place in 100mL In the beaker, add 50mL of absolute ethanol, stir and dissolve to obtain solution B; under stirring, drop solution B into solution A drop by drop, and continue stirring for 4-6h; The obtained precipitate was dried in a blast oven at 70-80°C for 12 hours, and dried; the dried solid was roasted in a muffle furnace at a temperature of 400°C for 4 hours and a heating rate of 2°C / min, to obtain flaky cobalt-manganese composite oxides.

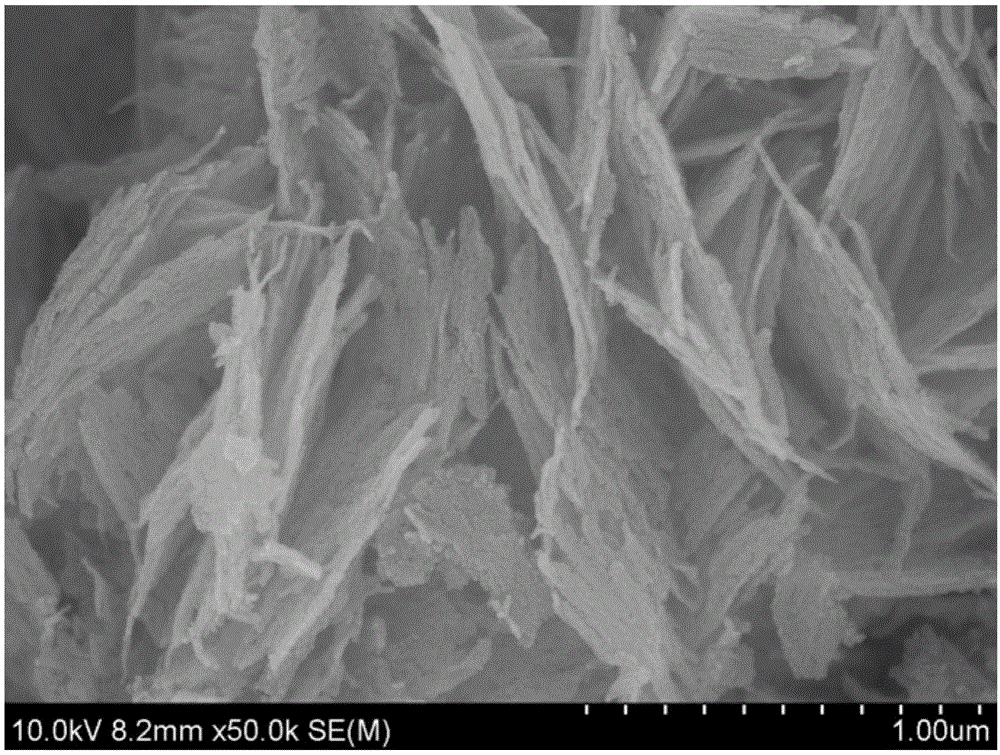

[0036] like image 3 As shown in the SEM results, the thickness of the sheet is 0.02 μm. figure 1 The XRD result of Example 2 shows that the oxide is a spinel structure.

Embodiment 3

[0038] Weigh 4.656g cobalt nitrate hexahydrate and 2.860g manganese nitrate solution (mass fraction is 50%) and place in a 500mL beaker, add 200mL absolute ethanol, stir and dissolve to obtain solution A; weigh 3.620g oxalic acid dihydrate and place in 100mL In the beaker, add 50mL of absolute ethanol, stir and dissolve to obtain solution B; under stirring, drop solution B into solution A drop by drop, and continue stirring for 4-6h; The final precipitate obtained was dried in a blast oven at 70-80°C for 12 hours, and dried; the dried solid was roasted in a muffle furnace at a temperature of 500°C for 4 hours and a heating rate of 2°C / min, the flaky cobalt-manganese composite oxide is obtained.

[0039] like Figure 4 As shown in the SEM results, the thickness of the sheet is 0.03 μm. figure 1The XRD result of Example 3 shows that the oxide is a spinel structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com