Patents

Literature

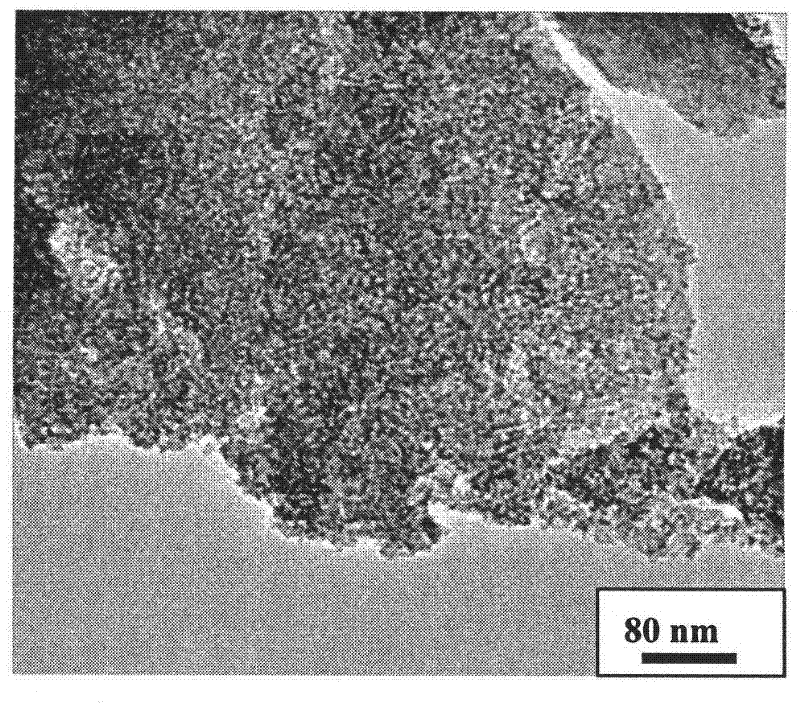

47 results about "Cobalt(II) nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt Nitrate is the Inorganic compound with the formula Co(NO₃)₂·xH₂O. It is cobalt(II) salt. The most common form is the hexahydrate Co(NO₃)₂·6H₂O, which is a red-brown deliquescent salt that is soluble in water and other polar solvents.

Preparation method of positive electrode material of lithium-sulfur battery, and lithium-sulfur battery

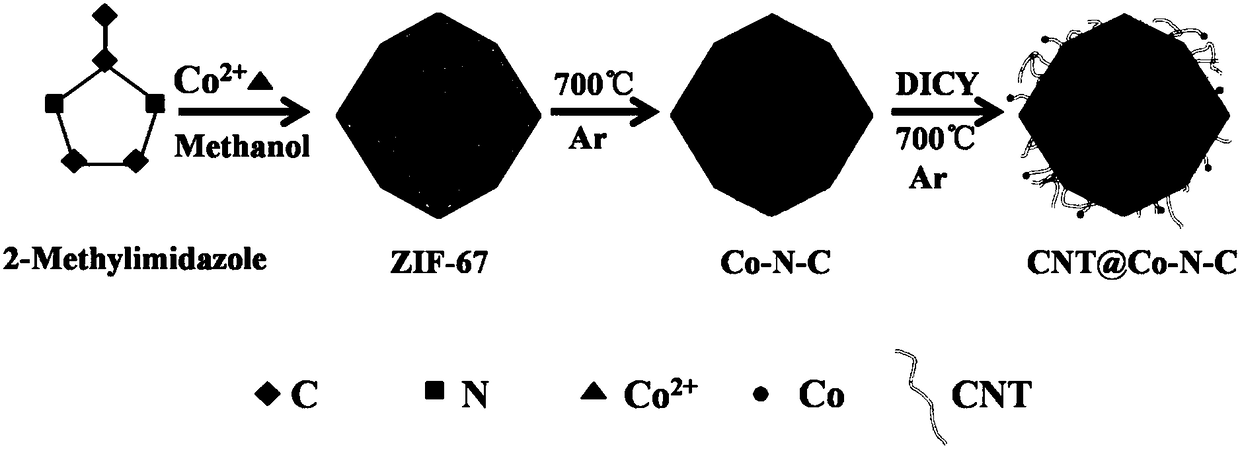

ActiveCN108598390AInhibition of the shuttle effectIncrease the areaMaterial nanotechnologyCell electrodesMetal-organic frameworkCarbonization

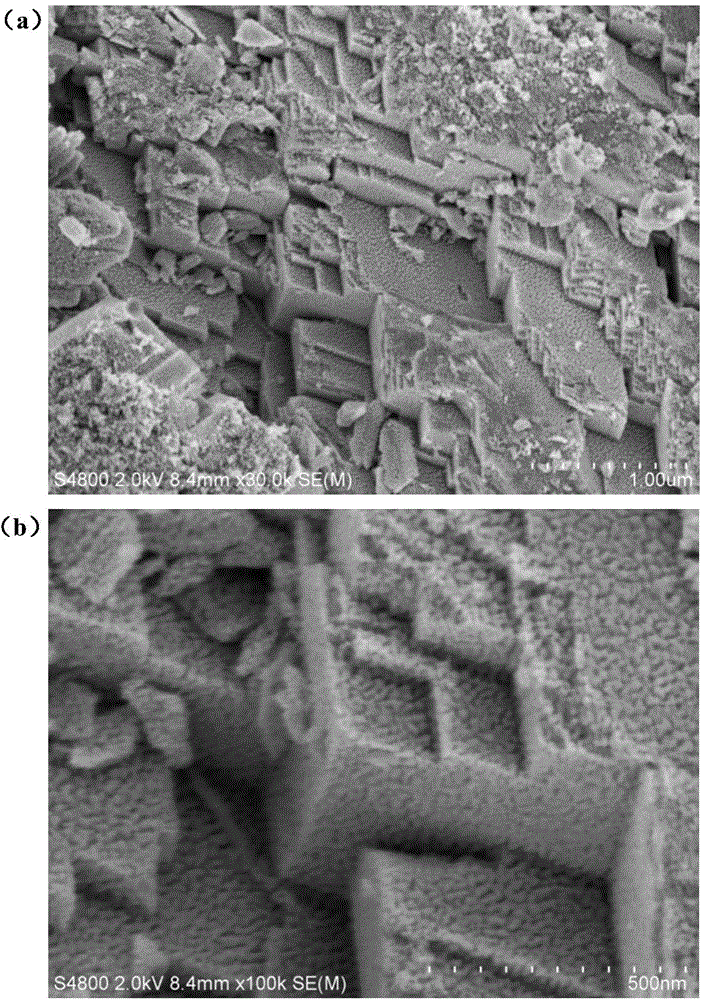

The invention relates to a preparation method of a positive electrode material of a lithium-sulfur battery. The preparation method comprises the following steps of enabling cobalt nitrate and 2-methylimidazole to be dissolved into a solvent and performing standing, centrifuging and drying to obtain ZIF-67; performing carbonization on ZIF-67 in inert atmosphere and performing cooling to the room temperature to obtain Co-N-C; and performing carbonization on Co-N-C and dicyandiamide in the inert atmosphere, and performing cooling to the room temperature to obtain CNT@ Co-N-C. The lithium-sulfur battery comprises the positive electrode material used for the lithium-sulfur battery. Beneficial effects are achieved as follows: compared with the single metal organic framework compound-based composite material, the specific surface area and the conductivity of the positive electrode material disclosed in the invention are enlarged and improved, and sulfur load can be realized more effectively;in addition, a shuttle effect of polysulfide in the battery reaction process can be suppressed more effectively; and a constant-current discharge test on the assembled battery proves that the electrochemical performance of the composite material with the carbon nanotubes in an in-situ growth manner is more excellent.

Owner:武汉新能源研究院有限公司

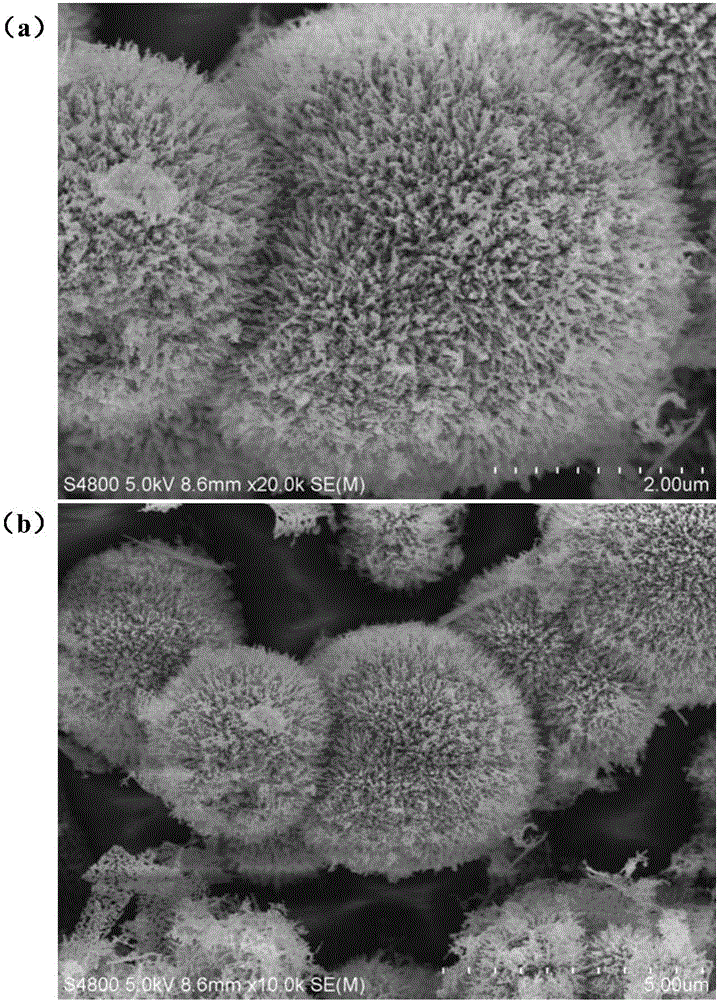

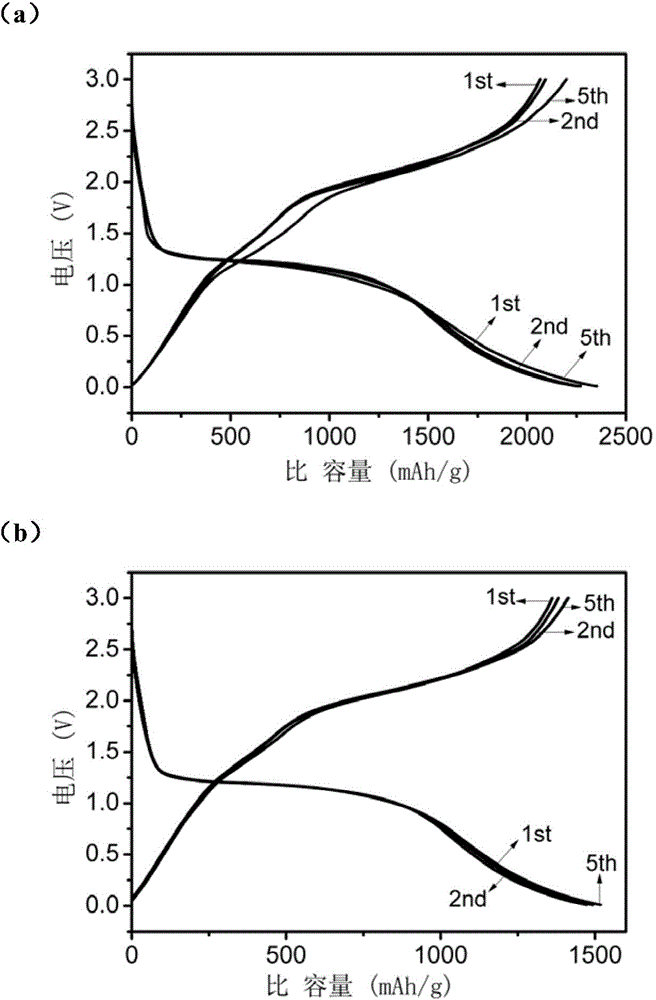

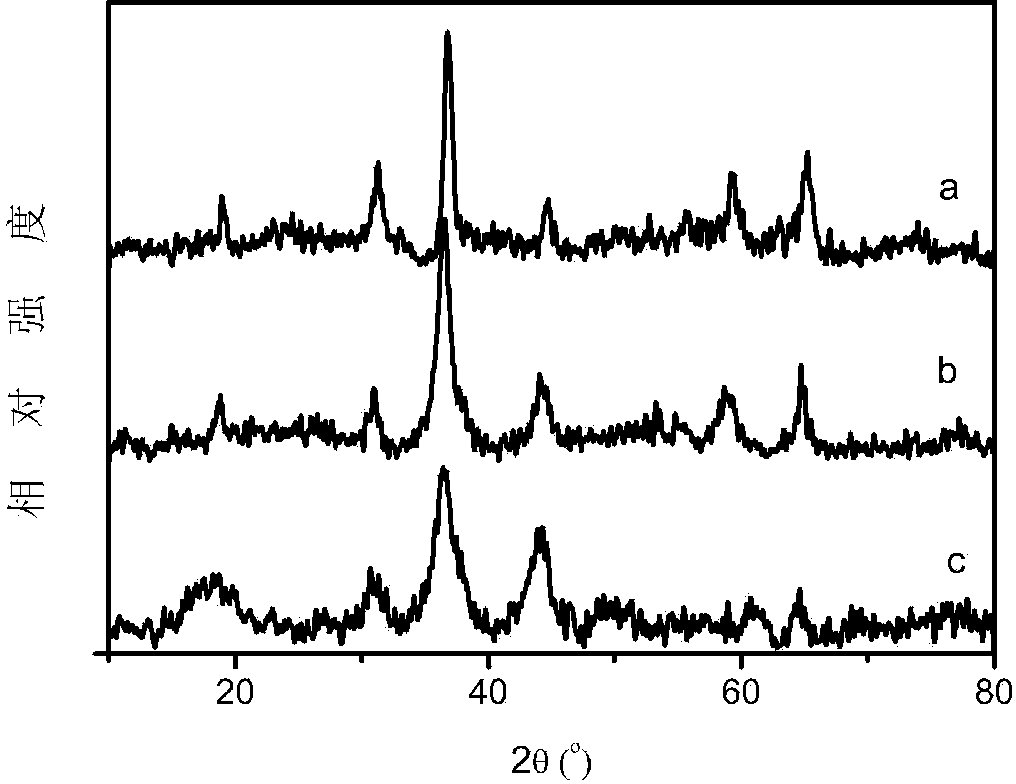

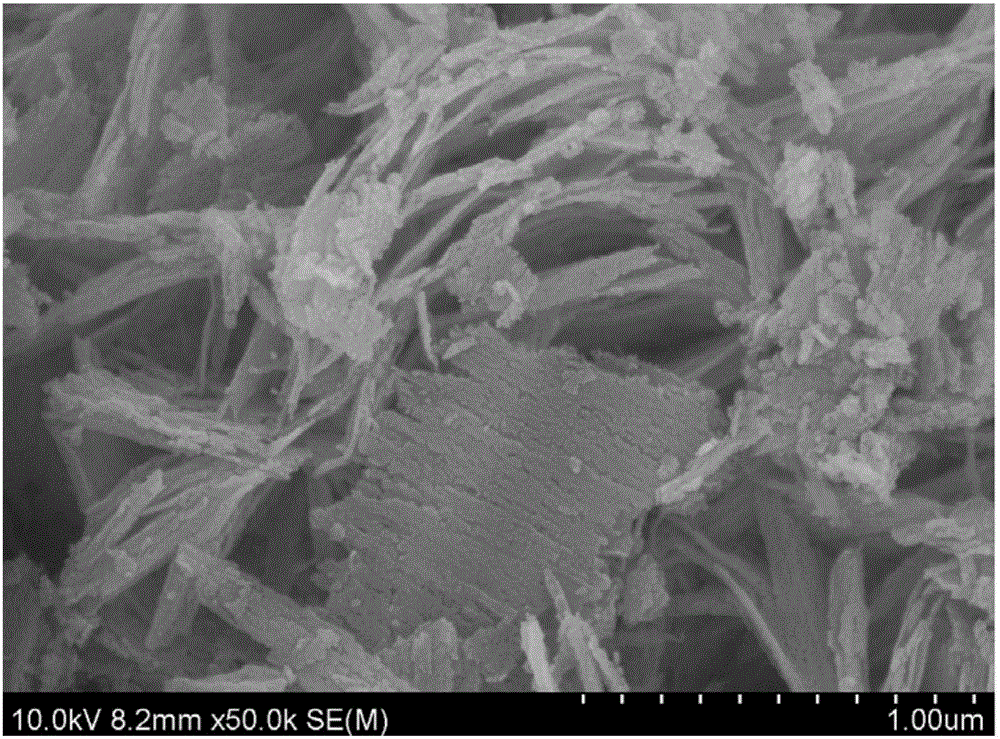

Nickel-cobalt oxide electrode material as well as preparation method and applications thereof

The invention discloses a nickel-cobalt oxide electrode material as well as a preparation method and applications thereof. The nickel-cobalt oxide electrode material is NiCo2O4 oxide prepared by adopting a hydrothermal method. The method concretely comprises the following steps: adding nickel nitrate (Ni(NO3)2.6H2O) and cobalt nitrate (Co(NO3)2.6H2O) into distilled water and fully mixing, adding urea and methanol to provide hydroxyl groups, and adding PVP as a complexing agent, and reacting in a reaction kettle to obtain NiCo2O4 oxide. Different material shapes can be obtained by adopting different reaction parameters, so that different lithium ion battery performances can be realized. The method has the advantages of being simple in technology, wide in the sources of raw materials, capable of performing large-scale production, and the like. The first discharge capacity of the lithium ion battery cathode material prepared from the material can achieve 2000mAh / g, the capacity has no obvious change after being circulated for 20 times, and the charging and discharging performances are excellent. By adopting the lithium ion battery prepared, the capacity is high, the cyclic performance is good and the lithium ion battery can be used for industrial production.

Owner:WUHAN UNIV

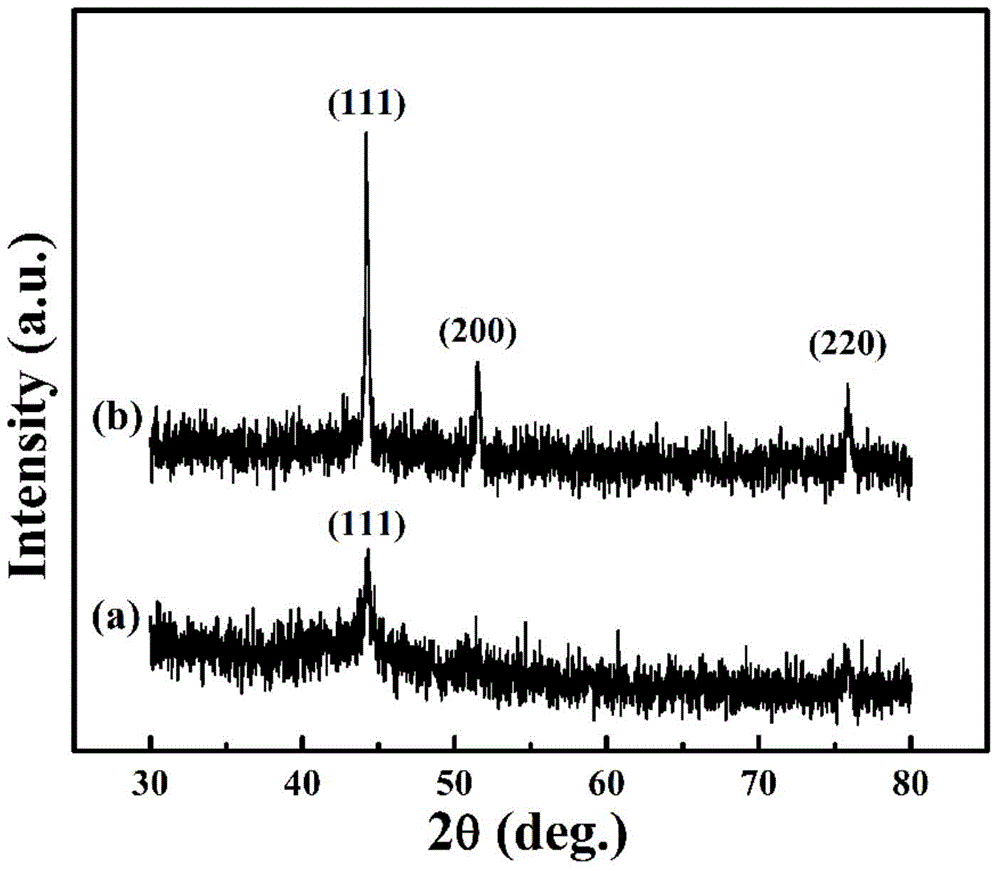

Preparing method of cobalt nanometer materials

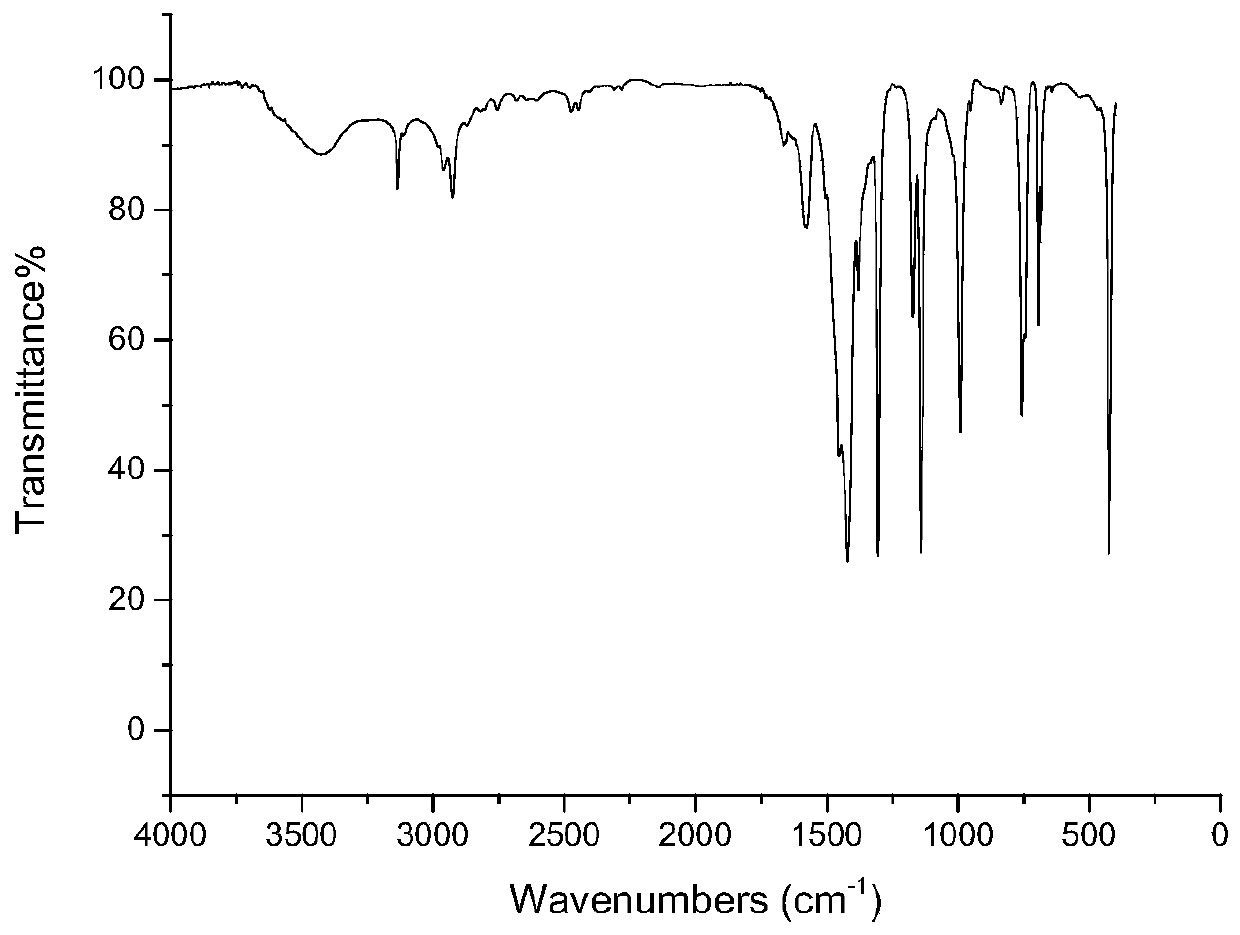

InactiveCN105328202AGuaranteed uniformityThe synthesis process is simpleNanotechnologyTube furnaceCobalt(II) nitrate

The invention discloses a preparing method of cobalt nanometer materials. The preparing method comprises the following steps that firstly, cobalt-nitrate hexahydrate, a complexing agent and a dispersing agent are sequentially added into 0.1 L of deionized water, magnetic stirring is carried out, and a mixed solution is obtained; secondly, the solution is placed in a drying box with the temperature of 150-200 DEG C to be dried till the loose porous state is achieved; and thirdly, a precursor is placed in a tubular furnace with the temperature of 300-500 DEG C to be roasted at the high temperature for 5-7 hours, and then the cobalt nanometer materials can be obtained. Cobalt nitrate containing six kinds of crystal water and several common carbohydrate are adopted as raw materials, the raw materials are cheap and easy to obtain, cost is low, and industrial production is greatly facilitated.

Owner:NANJING UNIV OF SCI & TECH

Fluid/slurry bed cobalt-alumina catalyst made by compounding and spray drying

ActiveUS20060035783A1High cobalt concentrationOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereRuthenium

A method for producing a cobalt on alumina catalyst is disclosed. The catalyst is prepared by thoroughly mixing cobalt nitrate into a peptized alumina slurry, and then spray-drying the slurry to form attrition resistant microspheres. The cobalt prepared by this invention is fully reducible. Optionally, metals such as ruthenium can be added to the cobalt / alumina catalyst by impregnation or methods known in the prior art.

Owner:CLARIANT INT LTD

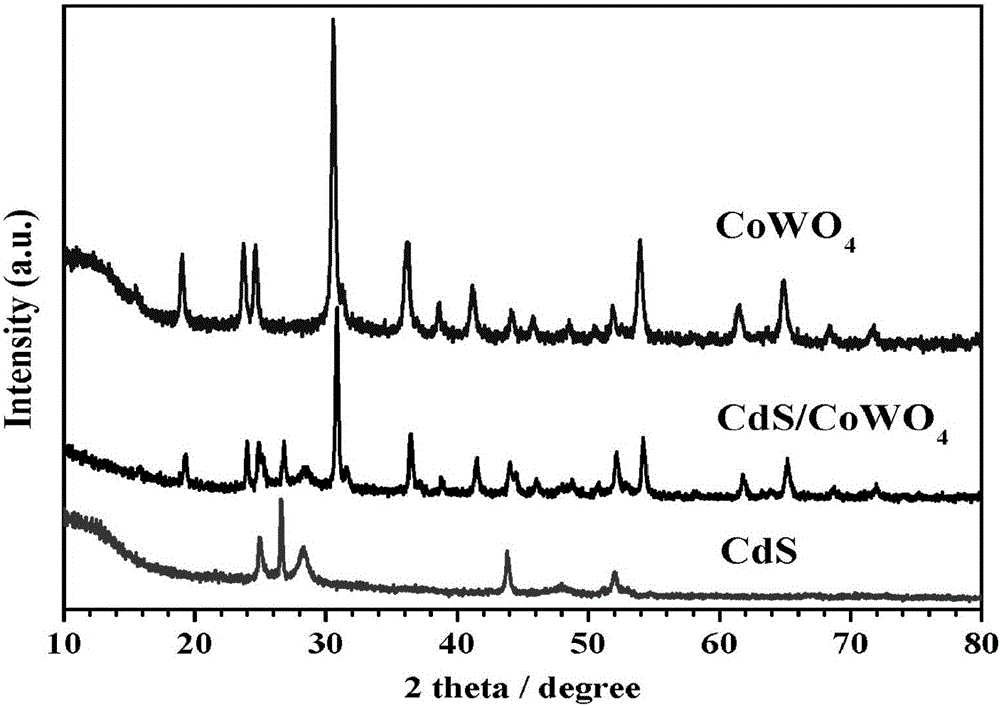

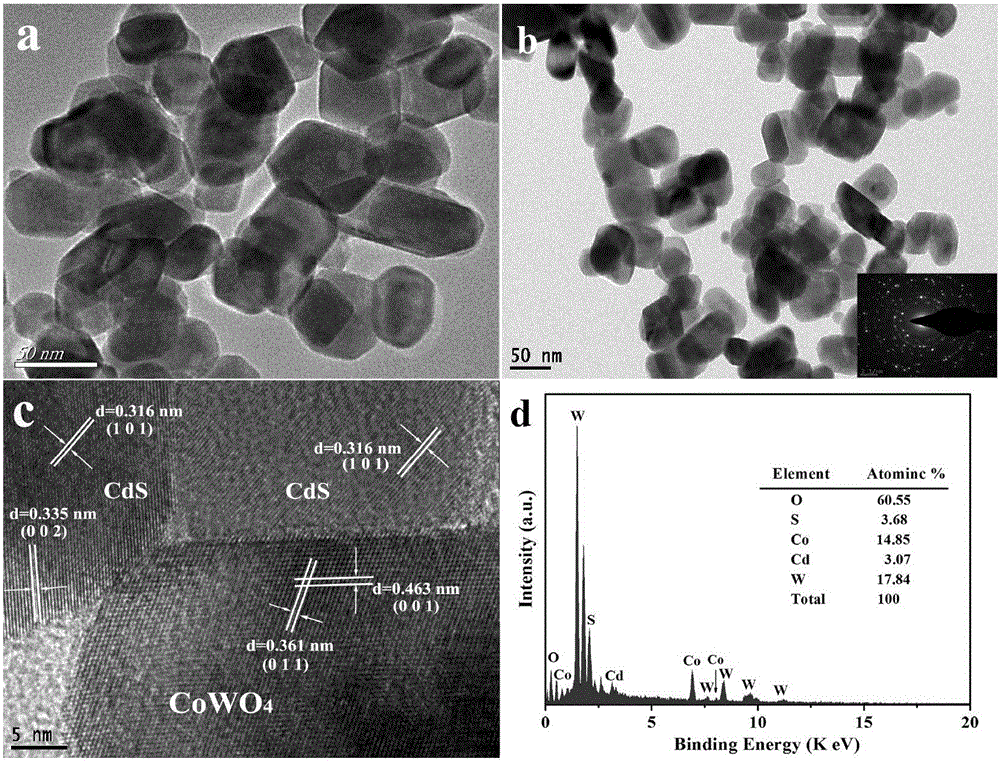

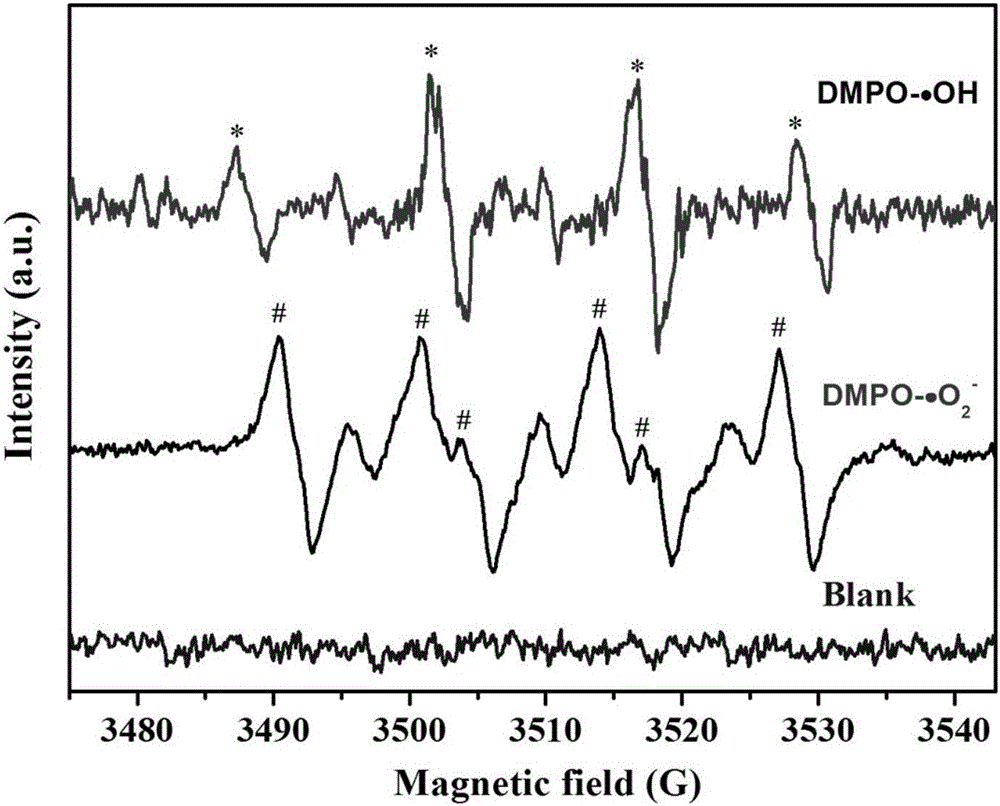

Method for preparing CdS/CoWO4 heterojunction composite photocatalyst

ActiveCN106076367AAssess photocatalytic activityMaterial nanotechnologyPhysical/chemical process catalystsHeterojunctionThiourea

The invention relates to transition metal tungstate, and concretely relates to a method for preparing a CdS / CoWO4 heterojunction composite photocatalyst by taking sodium hydroxide, sodium tungstate and cobalt nitrate as raw materials. The method comprises the following steps: taking a proper amount of sodium tungstate, adding the sodium tungstate in a cobaltous chloride-containing solution, adding a certain amount of sodium hydroxide while stirring, adjusting the pH value of the solution to 8, performing a hydrothermal reaction at the temperature of 180 DEG C for 12 hours, alternatively cleaning ethanol used for precipitation and deionized water for three times; performing ultrasonic disperse on CoWO4 in deionized water, adding equal amount of thiourea and cadmium acetate, continuously stirring the materials and uniformly mixing the materials, performing the hydrothermal reaction at the temperature of 180 DEG C for 24 hours, after the reaction is complete, filtering a precipitate, washing the precipitate, and drying the precipitate to obtain the CdS / CoWO4 heterojunction composite photocatalyst. The composite photocatalyst has good photocatalytic activity proved by methylene blue (MB) degradation experiment under visible light.

Owner:JIANGSU UNIV

Fluid/slurry bed cobalt-alumina catalyst made by compounding and spray drying

ActiveUS7560412B2Other chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereRuthenium

Owner:CLARIANT INT LTD

Preparation method for manganese-lithium phosphate and carbon nano tube nanocomposite

InactiveCN103515599AEvenly dispersedReduce manufacturing costMaterial nanotechnologyCell electrodesLithium hydroxideManganese

The invention relates to a preparation method for a manganese-lithium phosphate and carbon nano tube nanocomposite. The method comprises the following processes: dripping phosphoric acid into a lithium hydroxide solution to prepare lithium phosphate, then adding manganese salt and ferric salt into a lithium phosphate dispersing solution and stirring uniformly to obtain a precursor solution, conducting a heat seal reaction to obtain manganese-lithium phosphate or iron-doped manganese-lithium phosphate, adding the manganese-lithium phosphate or iron-doped manganese-lithium phosphate and cobalt nitrate into deionized water, mixing, then dripping a sodium hydroxide solution, and washing, filtering in a suction manner, grinding, calcinating, reducing and growing a precipitate to obtain the manganese-lithium phosphate and carbon nano tube nanocomposite or an iron-doped manganese-lithium phosphate and carbon nano tube nanocomposite. According to the nanocomposite prepared with the method, a carbon nano tube grows uniformly on the manganese-lithium phosphate, the degree of graphitization is high, the process is simple, the defect of low electronic conductivity of manganese-lithium phosphate or iron-doped manganese-lithium phosphate is overcome, the charge and discharge properties of the nanocomposite are improved, and the application prospect is broad.

Owner:TIANJIN UNIV

Preparation method for Cu-Co-S-MOF nanosheet and application thereof

ActiveCN110428976AImprove conductivityImprove redox performanceMaterial nanotechnologyHybrid capacitor electrodesCopper nitrateCobalt(II) nitrate

The invention relates to a preparation method for a Cu-Co-S-MOF nanosheet, which comprises the following steps: S1, cobalt nitrate hexahydrate is dissolved in deionized water to obtain a solution A, 2-methylimidazole is dissolved in deionized water to obtain a solution B, the solution A and the solution B are mixed, clean foamed nickel is then added for reaction, and foamed nickel with Co-MOF is obtained; S2, copper nitrate hexahydrate and the cobalt nitrate hexahydrate are dissolved in isopropanol, a mixed solution C is obtained after dissolution, and carbon disulfide and pentamethyldiethylenetriamine are added to the mixed solution C, and a mixed solution D is obtained; and S3, the foamed nickel with Co-MOF is added to the mixed solution D and is transferred to a reactor for a hydrothermal reaction, and after the reaction, the Cu-Co-S-MOF nanosheet is obtained. Compared with the prior art, the preparation method is environmentally-friendly, the preparation method is simple, large-scale production is facilitated, the obtained Cu-Co-S-MOF nanosheet can be applied to an electrode material, and excellent electrochemical performance can be obtained.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

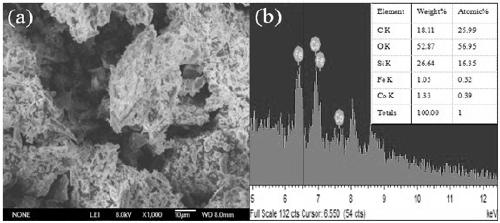

Cobalt-iron bimetal in-situ doped MCM-41 catalyst, and preparation method and application thereof

InactiveCN109999890ALarge specific surface areaRich in channelsWater/sewage treatment by irradiationMolecular sieve catalystsCobalt(II) nitrateDyeing wastewater

The invention relates to a cobalt-iron bimetal in-situ doped MCM-41 catalyst, a preparation method thereof, and an application of the catalyst in the degradation of dye wastewater. The preparation method comprises the following steps: an ethyl orthosilicate-ethanol mixed solution is added dropwise to an aqueous solution of cetyltrimethylammonium bromide and sodium hydroxide, the obtained solutionis continuously stirred to form a gel, an ethanol-water solution of cobalt nitrate and iron nitrate is added to the gel, the obtained mixture is crystallized in a reaction kettle, and the crystallizedmixture is filtered, washed, dried and calcined to obtain the MCM-41 molecular sieve catalyst with the framework doped with CoFe. The catalyst can be used to degrade methyl orange in the dye wastewater. The CoFe / MCM-41 catalyst has the advantages of simple preparation process, good structural stability, and uniform dispersion of metals in the molecular sieve framework, and can efficiently degradethe methyl orange by activating PMS or H2O2 under the action of microwave radiation.

Owner:QINGDAO UNIV OF SCI & TECH

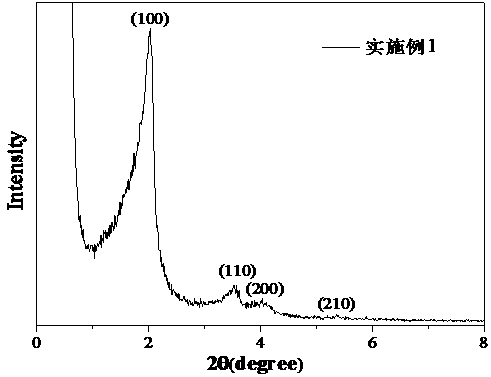

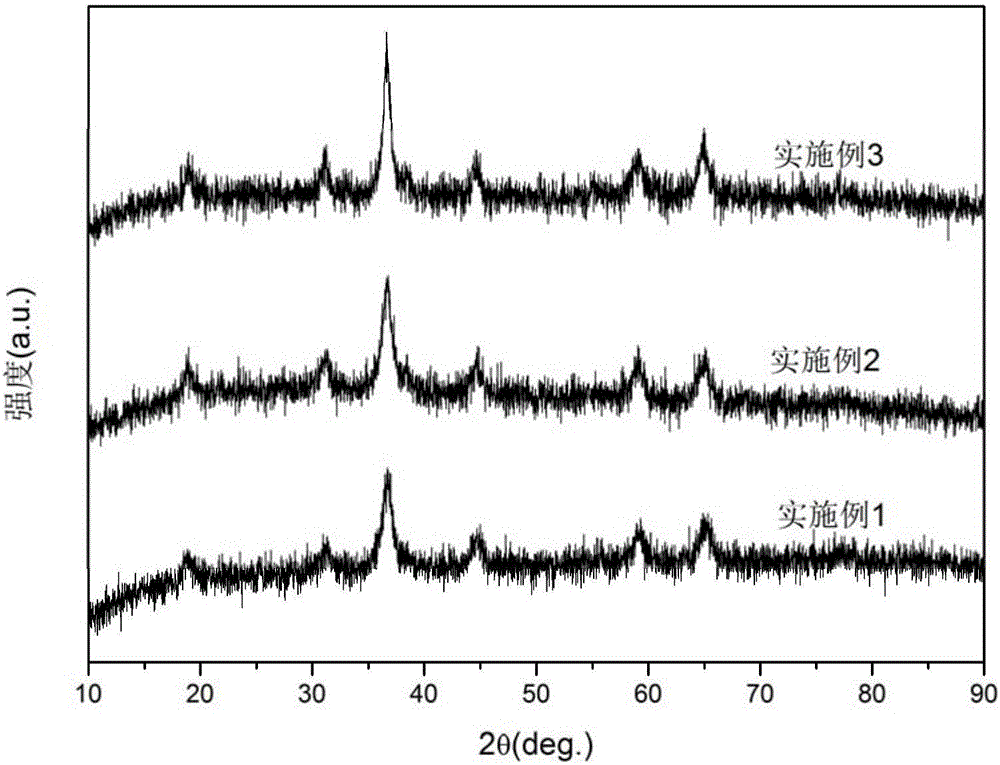

Z-Scheme composite system as well as preparation method and application of Z-Scheme composite system

ActiveCN107433203AMeets friendly requirementsSimple processPhysical/chemical process catalystsCooking & bakingTetracycline Hydrochloride

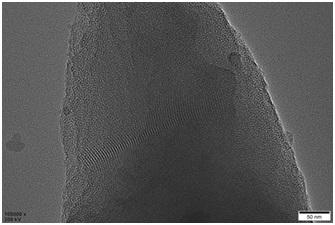

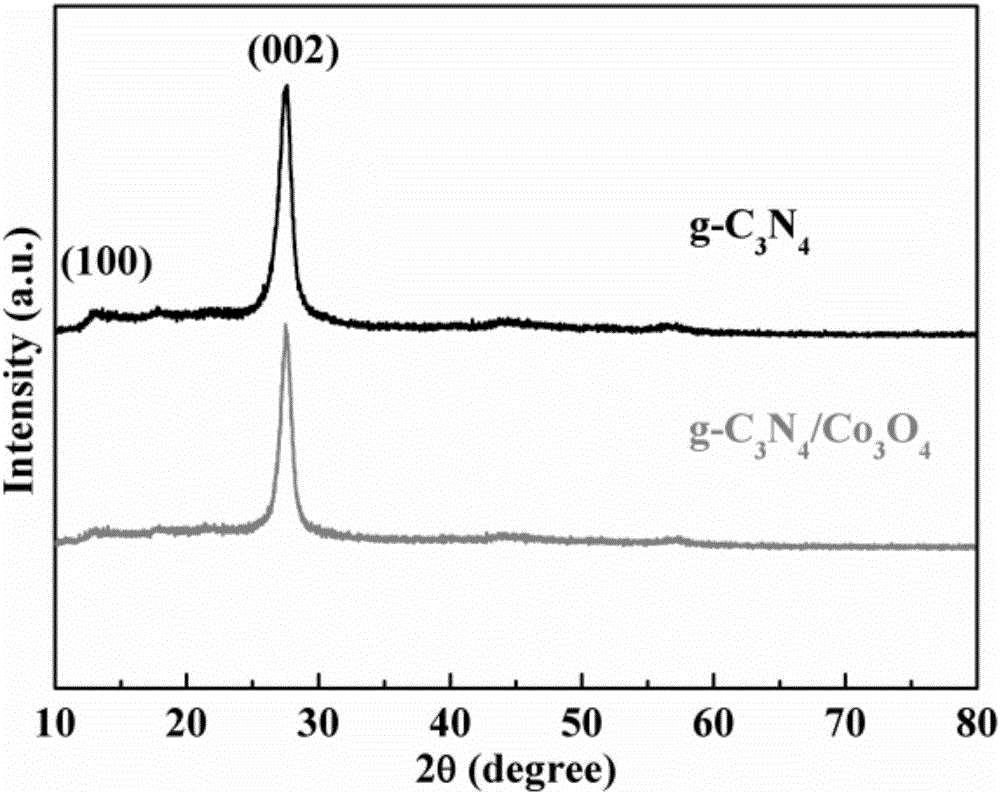

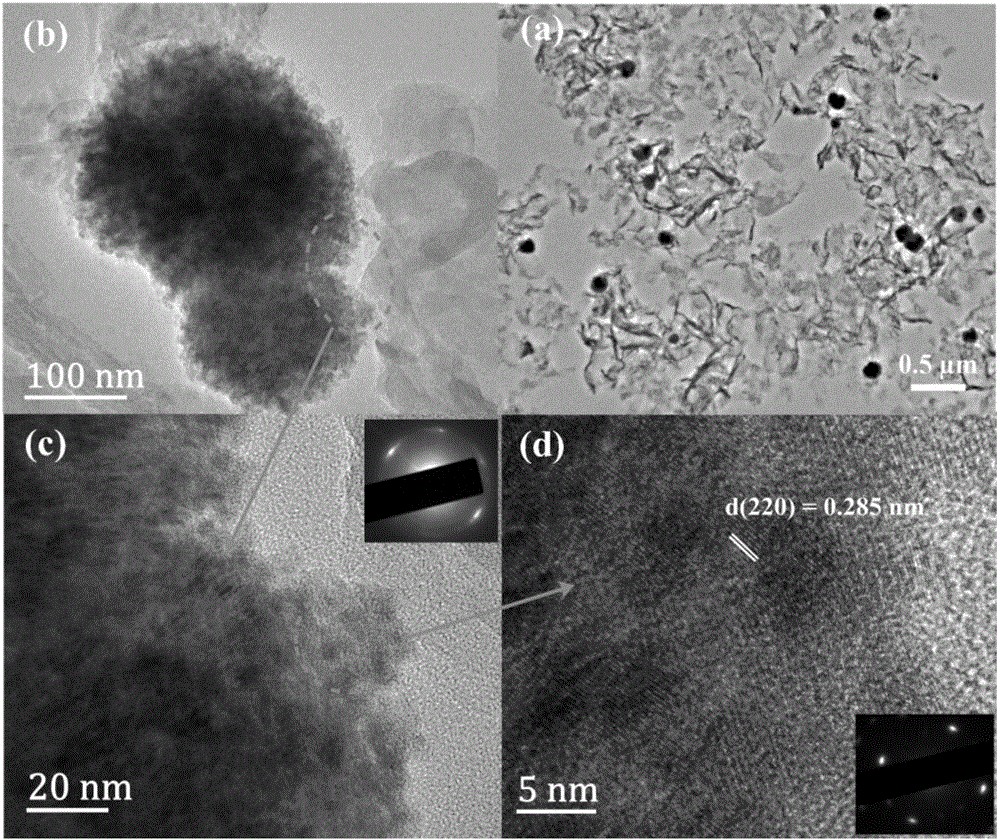

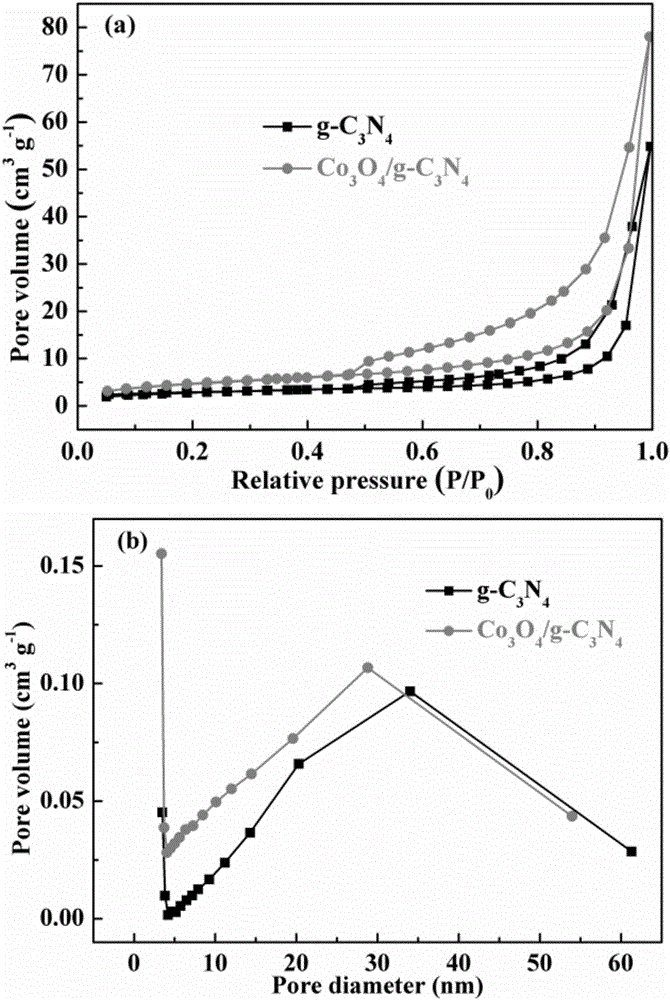

The invention belongs to the technical field of nanometer material synthesis and relates to a "Z-Scheme" Co3O4 / g-C3N4 composite system which is synthesized by one step by using a simple and rapid hydrothermal method and can be used for degrading tetracycline hydrochloride under visible light, wherein the surface of g-C3N4 is modified by a mesoporous Co3O4 nanosphere composed of monocrystal nanodots in the system. A sample is prepared by the steps: firstly, preparing g-C3N4 for later use; and then, controllably preparing the "Z-Scheme" Co3O4 / g-C3N4 composite system, accurately weighing a certain quantity of cobaltous nitrate hexahydrate and cetyltrimethyl ammonium bromide, dissolving cobaltous nitrate hexahydrate and cetyltrimethyl ammonium bromide into a mixed solution of deionized water and methanol, then, adding g-C3N4, carrying out magnetic stirring for 24h after carrying out ultrasonic dispersion for 30min, then, transferring a suspension liquid into a 50ml high-pressure reactor, carrying out reaction in a baking oven at 180 DEG C for 24h to obtain a dark yellow sediment, and then, carrying out centrifuging, cleaning and drying.

Owner:YANGTZE UNIVERSITY

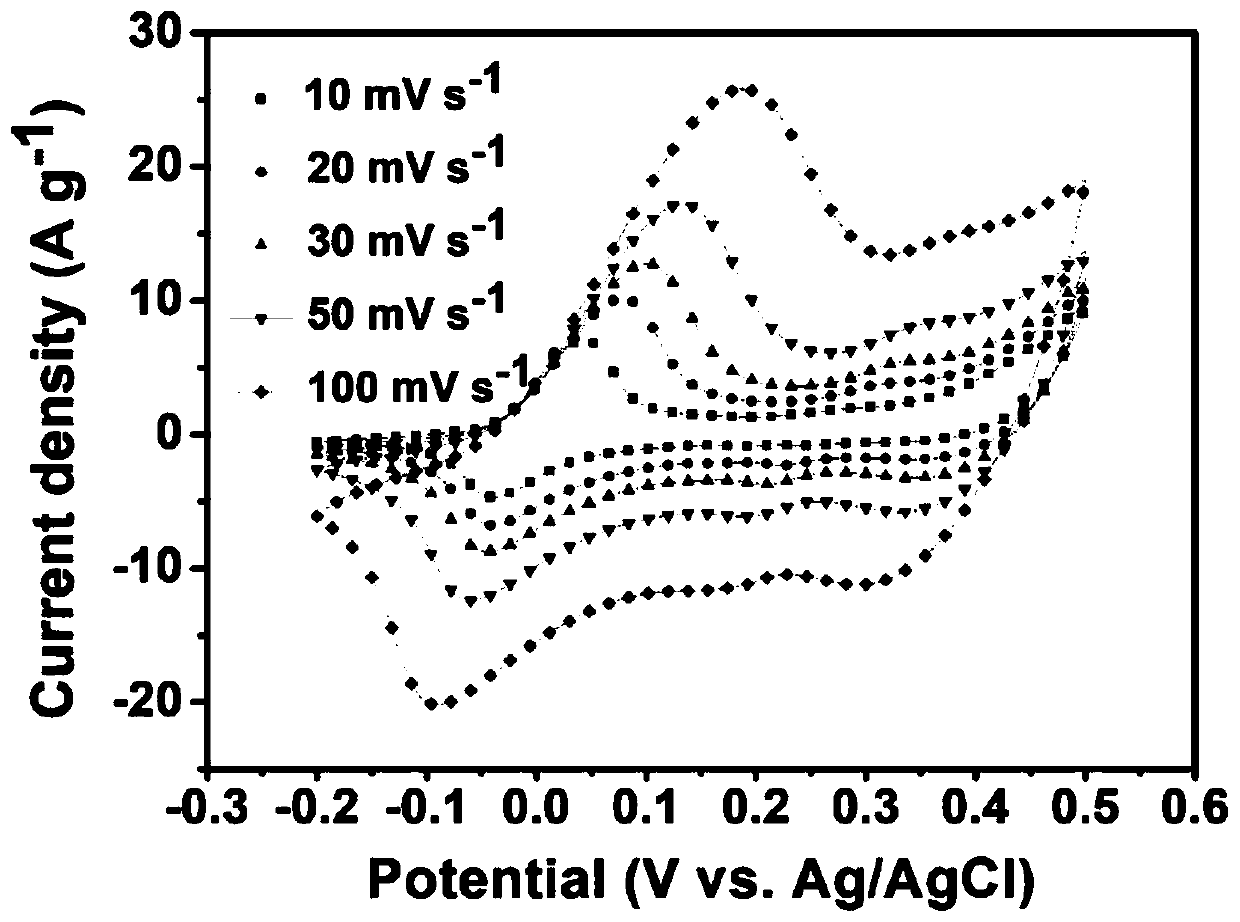

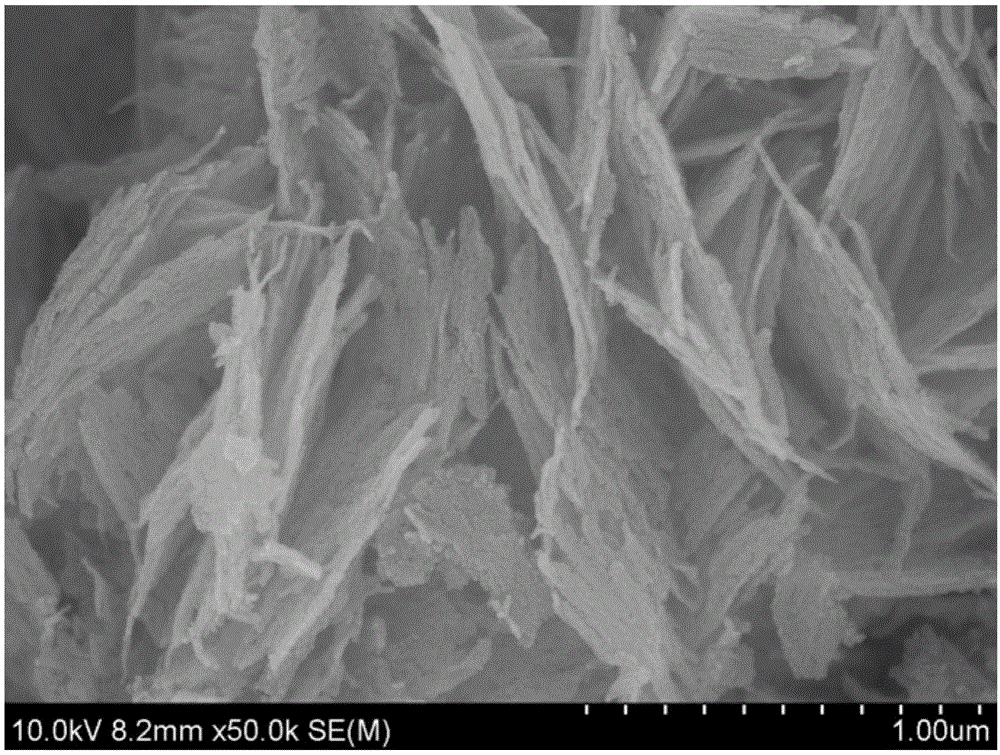

Active material used for capacitor electrode and preparation method of active material

ActiveCN103578772AIncrease contactEasy transferElectrolytic capacitorsCyclic processCobalt(II) nitrate

The invention provides an active material used for a capacitor electrode and a preparation method of the active material. The preparation method comprises the following steps: nickel nitrate hexahydrate and / or cobalt nitrate hexahydrate are adopted as raw materials to prepare a mixed solution of 1-methyl-2-pyrrolidone and water; backflow stirring and solvent thermal reaction are performed on the mixed solution so that a hydroxide precursor is obtained; thermal treatment is performed on the precursor so that a nickel oxide, a cobalt oxide or a nickel and cobalt oxide active material is obtained. The manufactured nickel and cobalt oxide material is multistage and porous so that contact of the material and an electrolyte and transmission of ions can be effectively enhanced. Besides, because of the multistage structure of the material, a problem of agglomeration in the cycle process of nano-materials can be prevented. Any surfactants or soft and rigid templates are not introduced to the preparation process of the material so that the whole preparation process is simplified.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

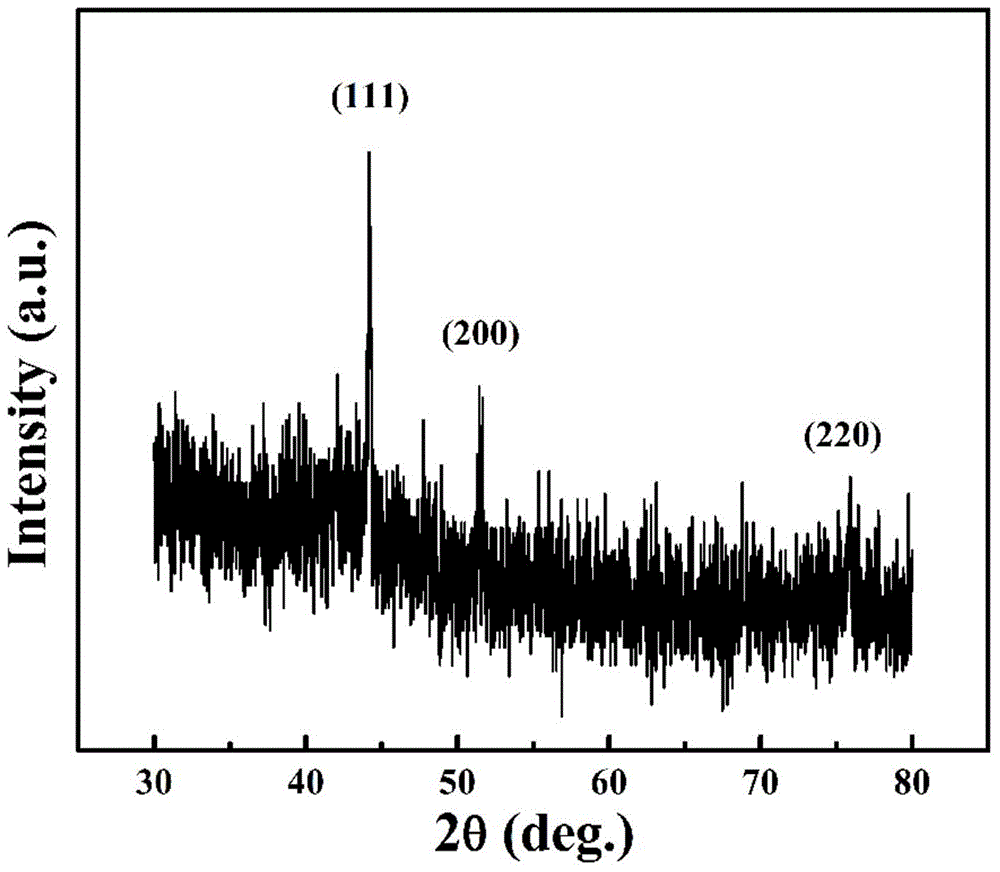

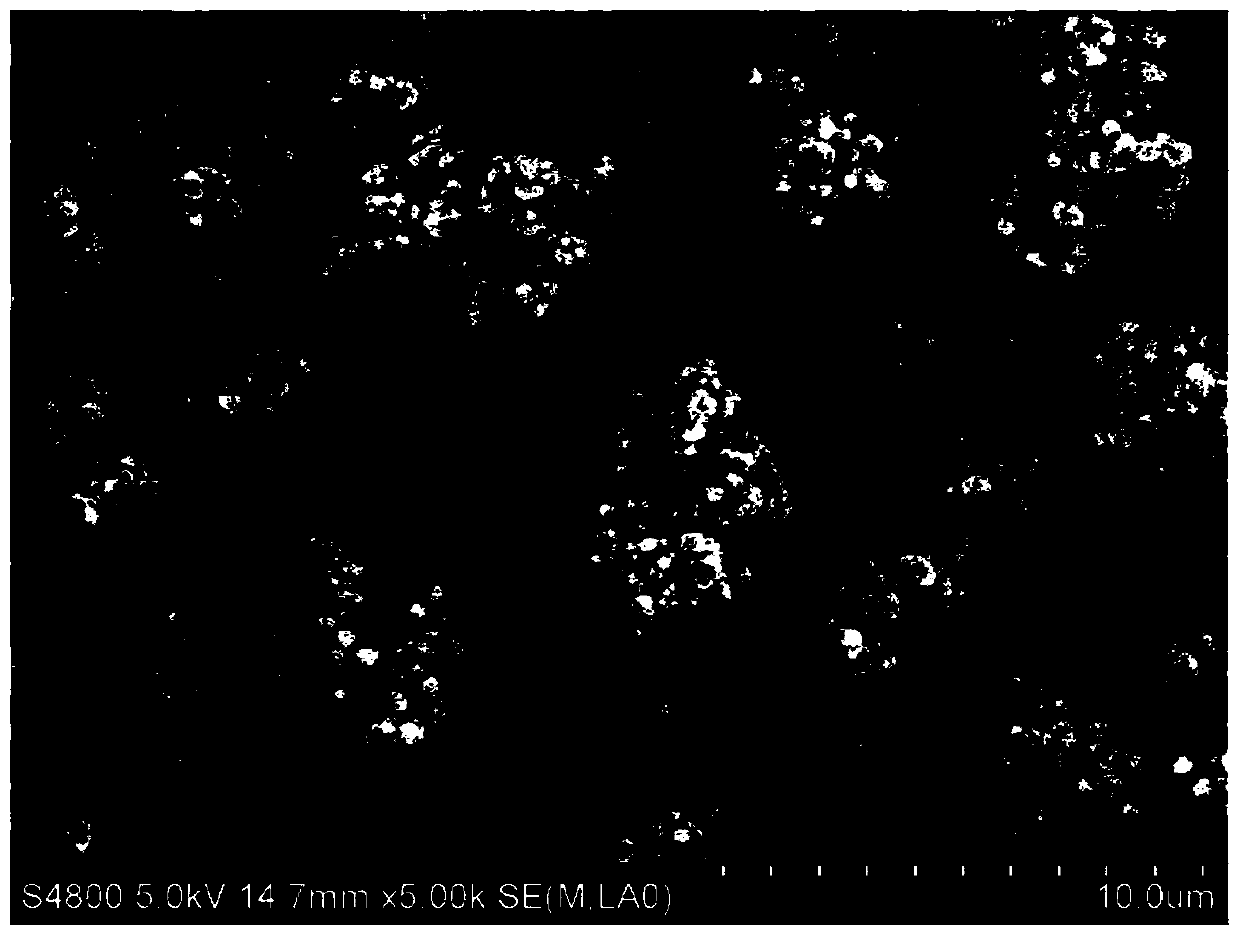

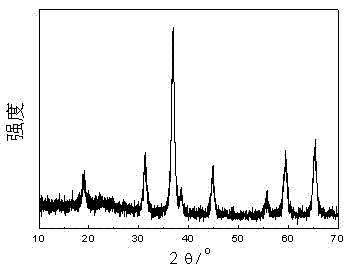

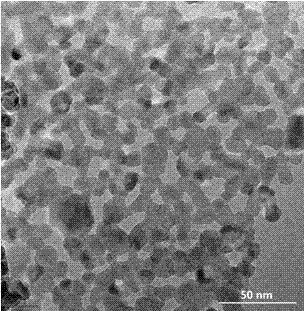

Preparation method for cobalt nanoparticles

InactiveCN102554256AGood dispersionLow production temperatureNanotechnologyCobalt(II) nitrateSolvent

The invention discloses a preparation method for cobalt nanoparticles. According to the preparation method, cobalt nitrate is used as a raw material, low molecular alkylol amine is used as a reducing agent, vinyl pyrrolidone is used as a surfactant and a stabilizer, and absolute ethyl alcohol, absolute methyl alcohol or absolute propyl alcohol is used as a solvent; and the preparation method comprises the following steps of: dissolving the materials respectively and mixing uniformly; reacting with stirring under the temperature condition of 60-80 DEG C until the color of reaction solution becomes stable dark yellow; naturally cooling to room temperature; and concentrating and drying to obtain spherical cobalt nanoparticles. The method provided by the invention has the advantages of low toxicity in production, low production temperature, simple production process, simple equipment and low production cost; and the obtained cobalt nanoparticles are spherical and have high dispersibility and average particle diameter of not greater than 10 nm.

Owner:NINGBO UNIV

Preparation method of sheet spinel structure cobalt-manganese composite oxide

InactiveCN106693985ASimple ingredientsLow costCatalyst activation/preparationIncinerator apparatusFiltrationCobalt(II) nitrate

The invention provides a preparation method of a sheet spinel structure cobalt-manganese composite oxide. The preparation method comprises the following steps: 1, weighing an aqueous solution of cobalt nitrate hexahydrate and manganous nitrate, dissolving in absolute ethyl alcohol, stirring and dissolving to obtain a solution A; additionally weighing excessive oxalic acid dihydrate, dissolving in the absolute ethyl alcohol, stirring and dissolving to obtain a solution B; 2, adding the solution B dropwise into the solution A while stirring, and continuing to stir to obtain a mixed solution; 3, after completing stirring, conducting suction filtration on the mixed solution, and drying a precipitate obtained through suction filtration in an air circulation oven; 4, roasting the dried solid in a muffle furnace to obtain the sheet spinel structure cobalt-manganese composite oxide. According to the preparation method, other metal cations except the necessary metal salts are not introduced, the preparation method has the advantages of cheap raw materials, simple operation, washing-free, even distribution of products, and high purity, and the obtained product shows very high activity on the complete oxidation reaction of benzene.

Owner:SHANGHAI JIAO TONG UNIV +1

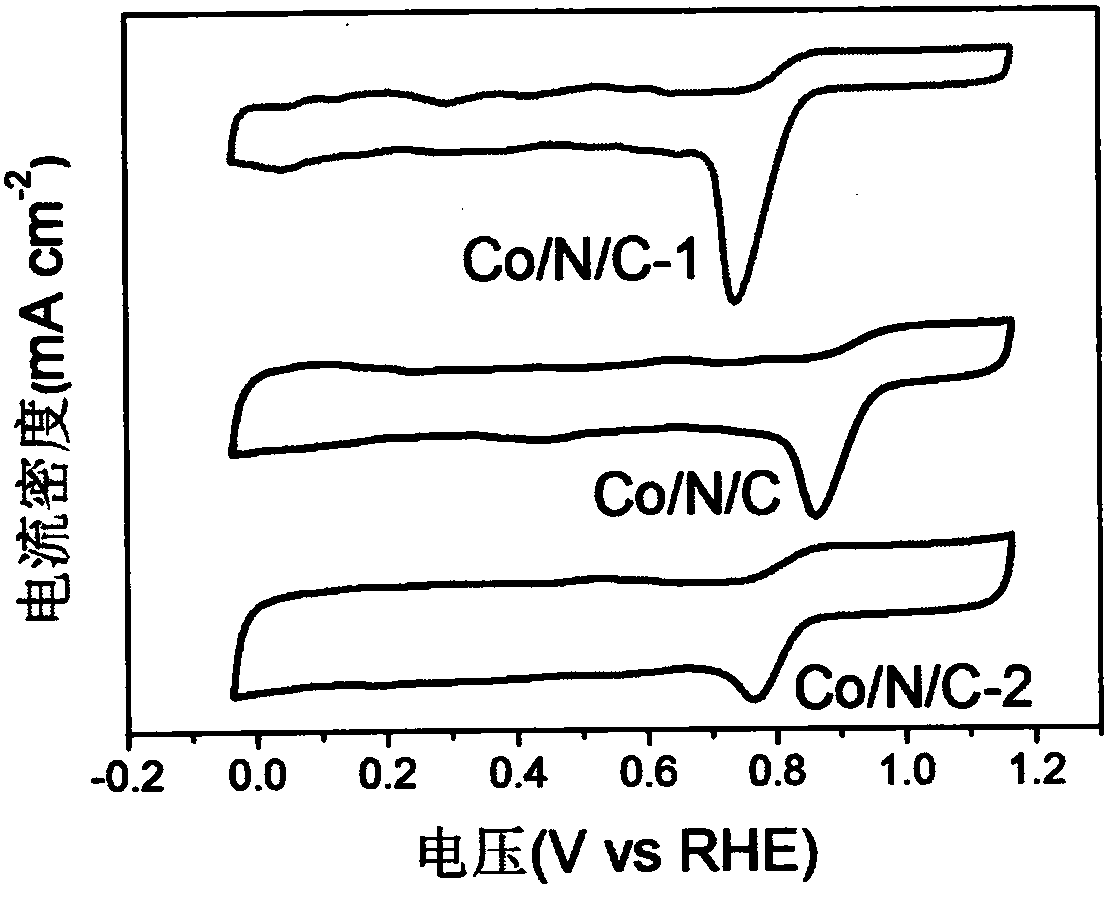

Cobalt-nitrogen doped carbon composite material and preparation method thereof

ActiveCN108565469AThe preparation process is environmentally friendlyEasy to operateCell electrodesCarbon compositesCobalt(II) nitrate

The invention discloses a cobalt-nitrogen doped carbon composite material and a preparation method thereof. The cobalt-nitrogen doped carbon composite material is prepared from cobalt nitrate, dopamine and melamine; the preparation method comprises the steps that cobalt nitrate, magnesium nitrate, aluminum nitrate and urea are added into deionized water, the solution is heated to 100 DEGC, and a layered double hydroxide is prepared; the layered double hydroxide is prepared into a solution after being washed; the ph value of the solution is regulated to be a slightly alkaline value, and dopamine hydrochloride is added; after a sample is dried and stirred with melamine to be uniform, and then thermal treatment is performed; a sample is sufficiently washed and dried. The prepared composite material is a high-performance oxygen reduction catalyst and has the good cyclic stability.

Owner:DONGHUA UNIV

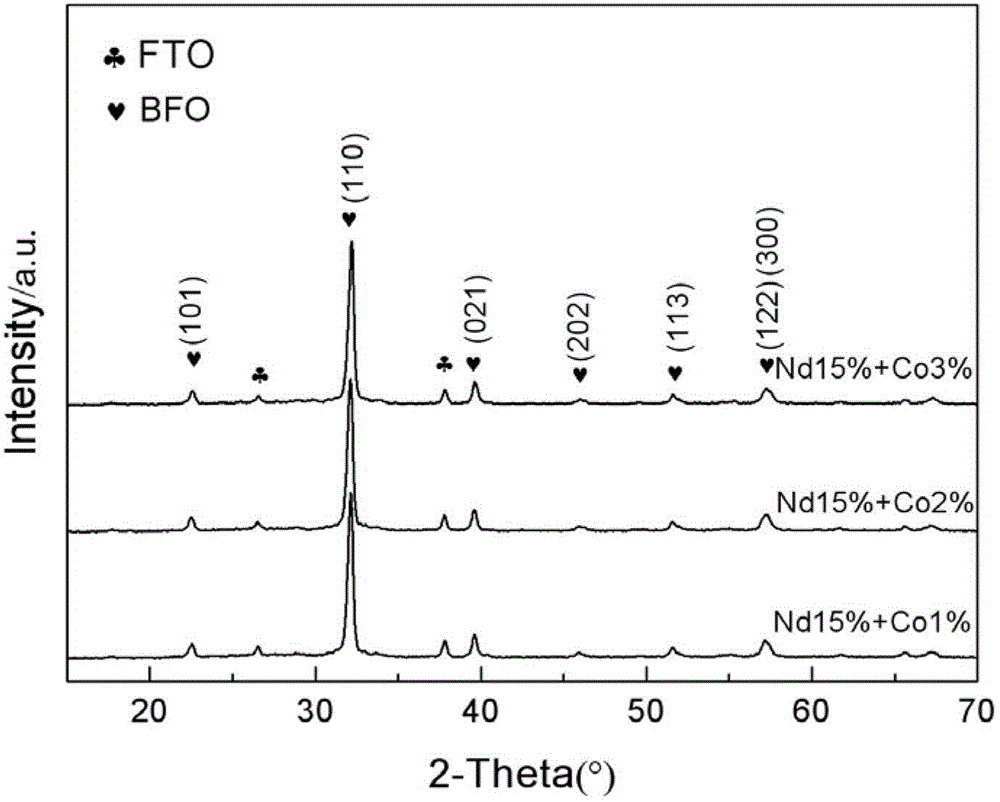

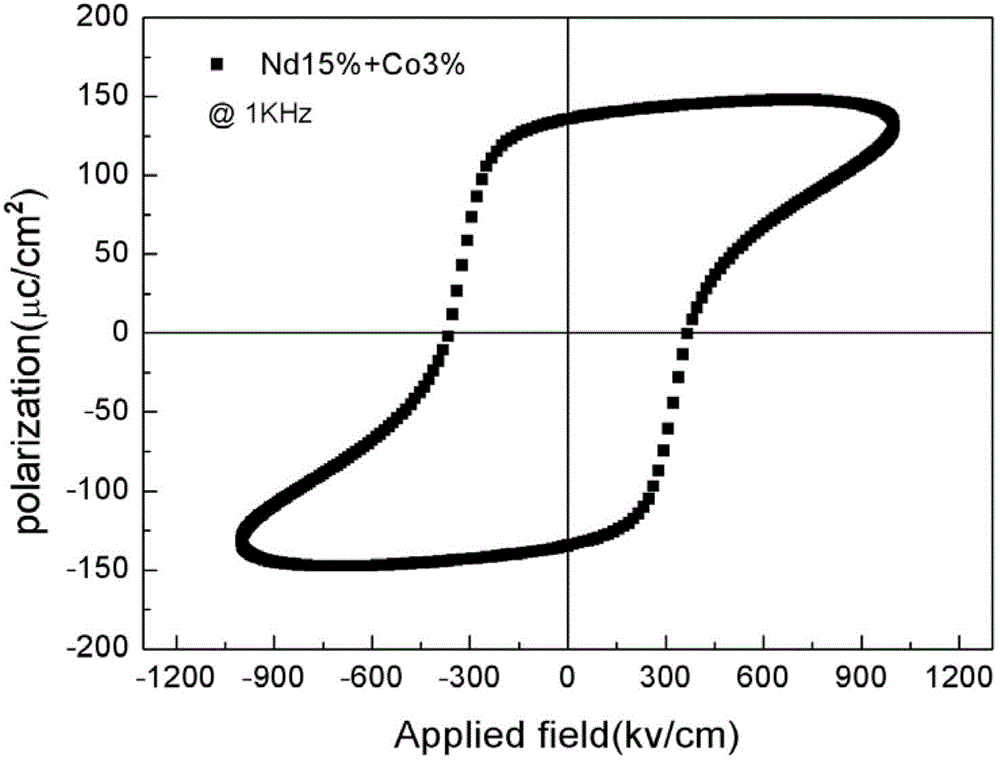

Method for preparing high-remanent-polarization BiFeO3 film with preferentially growing (110) crystal face by sol-gel process

ActiveCN103060887AImprove ferroelectric propertiesWell mixedFrom gel statePolycrystalline material growthAcetic anhydrideCobalt(II) nitrate

The invention provides a method for preparing a high-remanent-polarization BiFeO3 film with preferentially growing (110) crystal face by a sol-gel process, which comprises the following steps: dissolving bismuth nitrate, ferric nitrate, neodymium nitrate and cobalt nitrate used as raw materials in a mol ratio of 0.90:(1-x):0.15:x (x=0.01-0.03) in mixed ethylene glycol monomethyl ether and acetic anhydride (in a volume ratio of 3:1) to obtain a stable BiFeO3 precursor solution with the metal ion concentration of 0.3 mol / L, wherein bismuth ions are 5% excessive to compensate the volatilization in the film annealing process; and evenly coating the BiFeO3 precursor solution on an FTO (fluorine-doped tin oxide) substrate, drying to obtain a dry film, and carrying out layer-by-layer quick annealing at 550 DEG C to obtain the crystalline BiFeO3 film with expected thickness. The facility requests are simple, the experimental conditions can be easily achieved, and the BiFeO3 film with preferentially growing (110) crystal face, of which the remanent polarization is higher than 130 mu C / cm<2>, can be prepared by accurately controlling the solvent ratio of the precursor solution and the codoping of the A-B position.

Owner:SHAANXI UNIV OF SCI & TECH

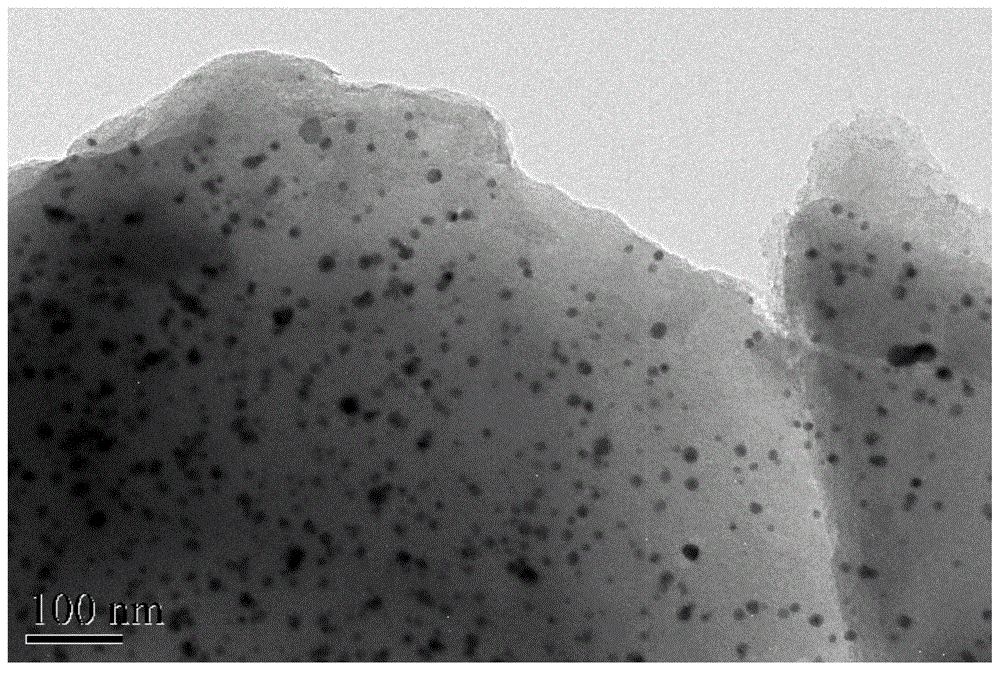

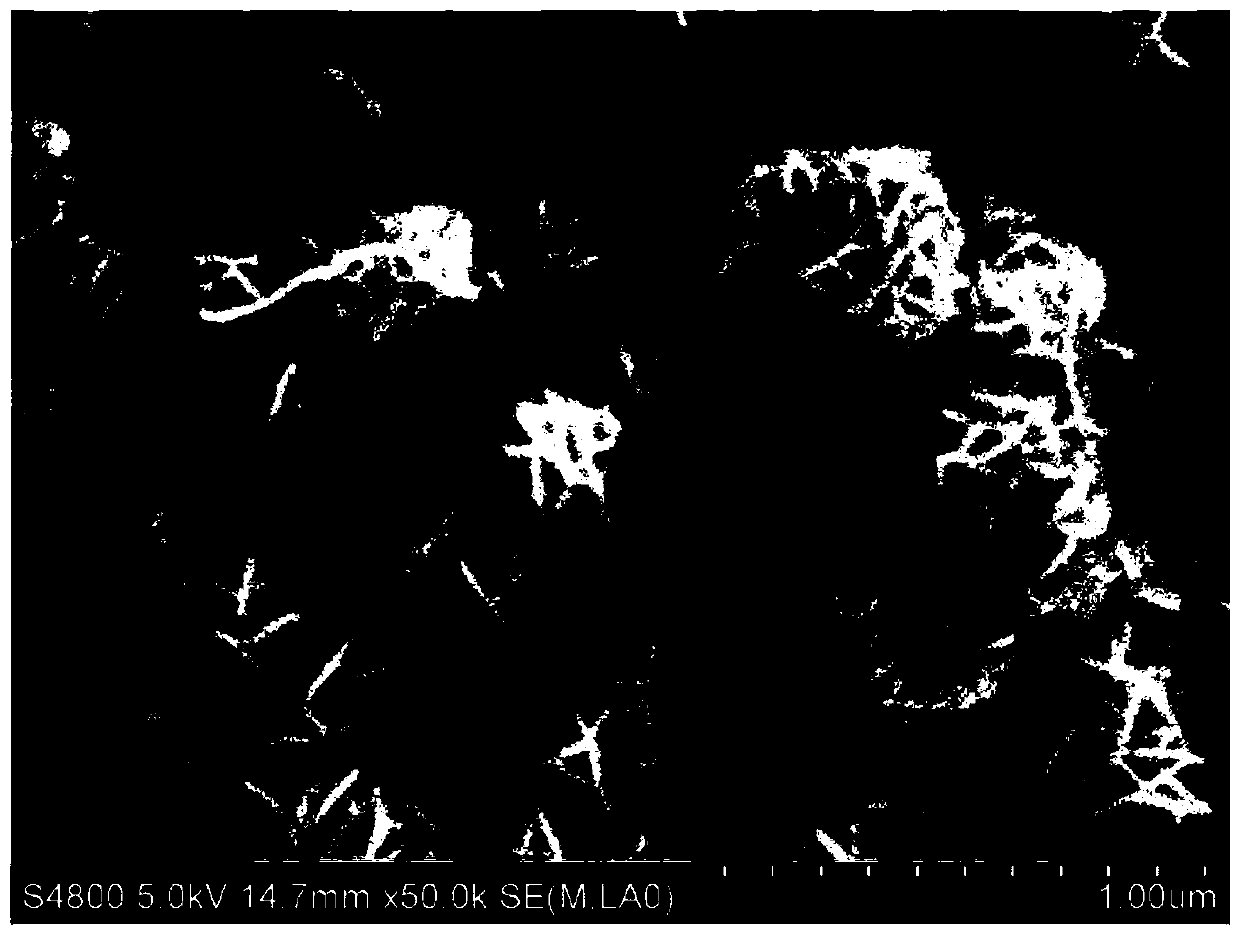

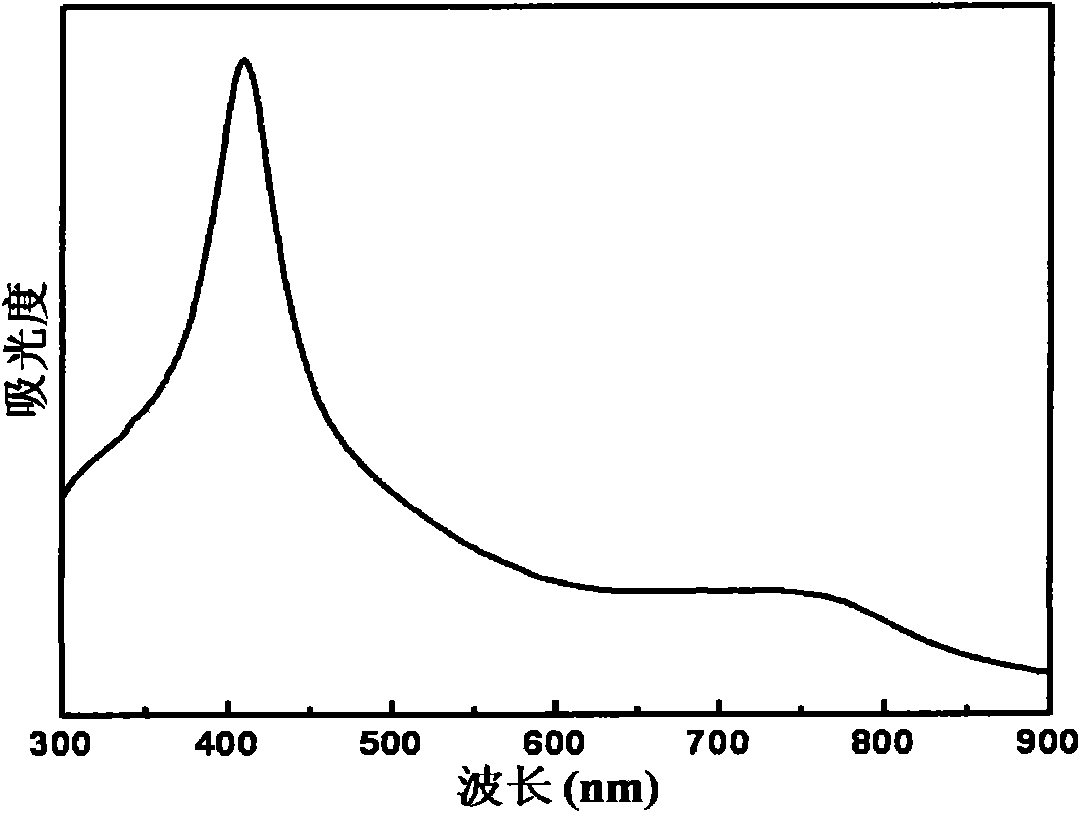

Silver nanoparticle-dispersed cobalt oxide functional thin film material and preparation method

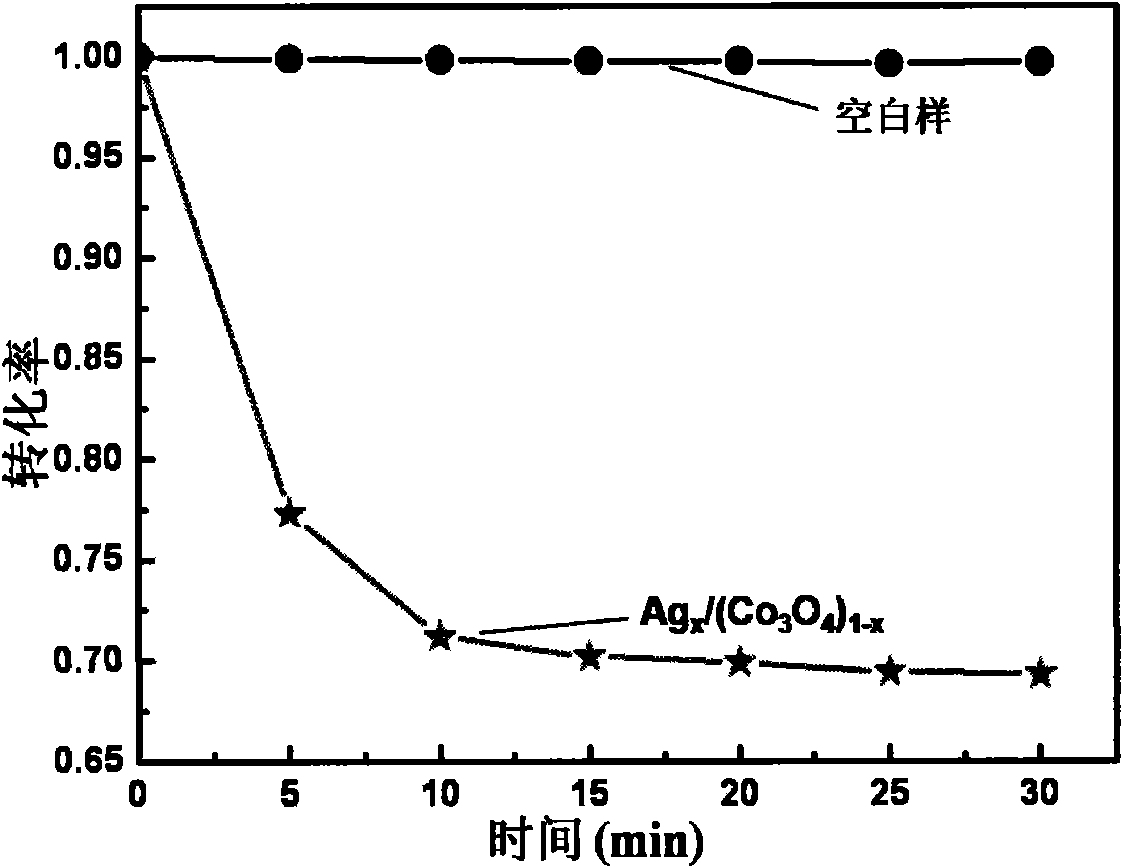

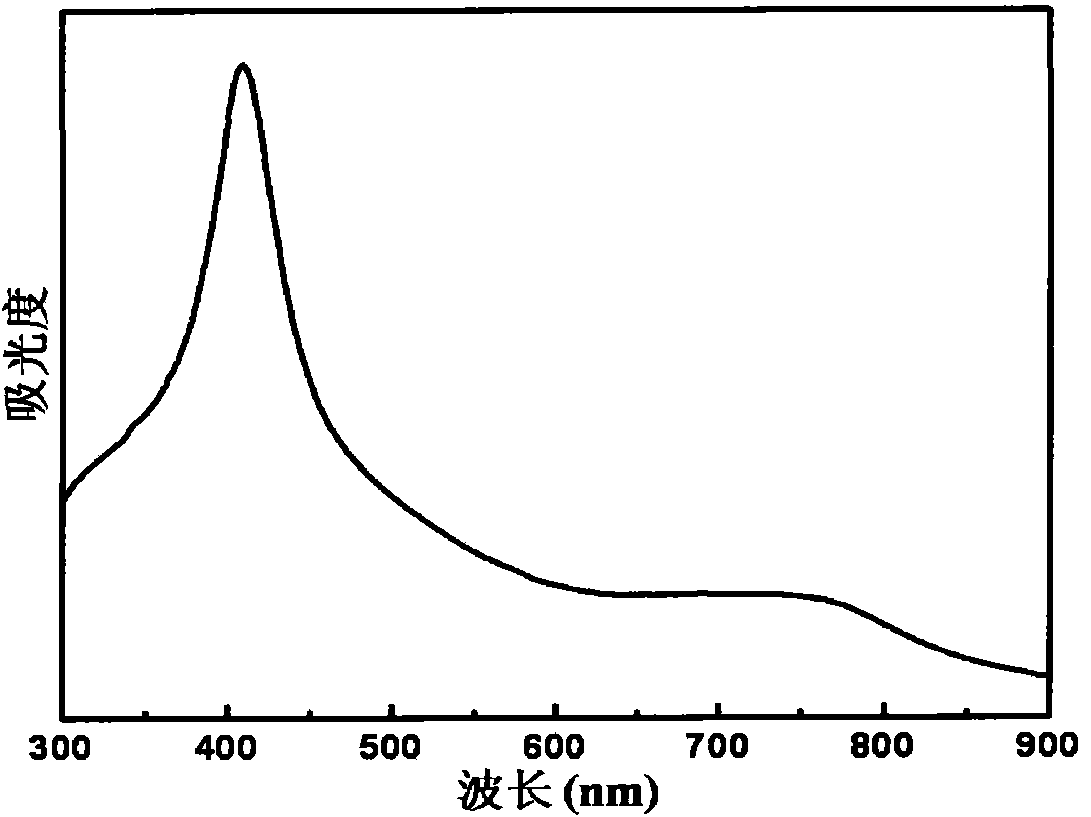

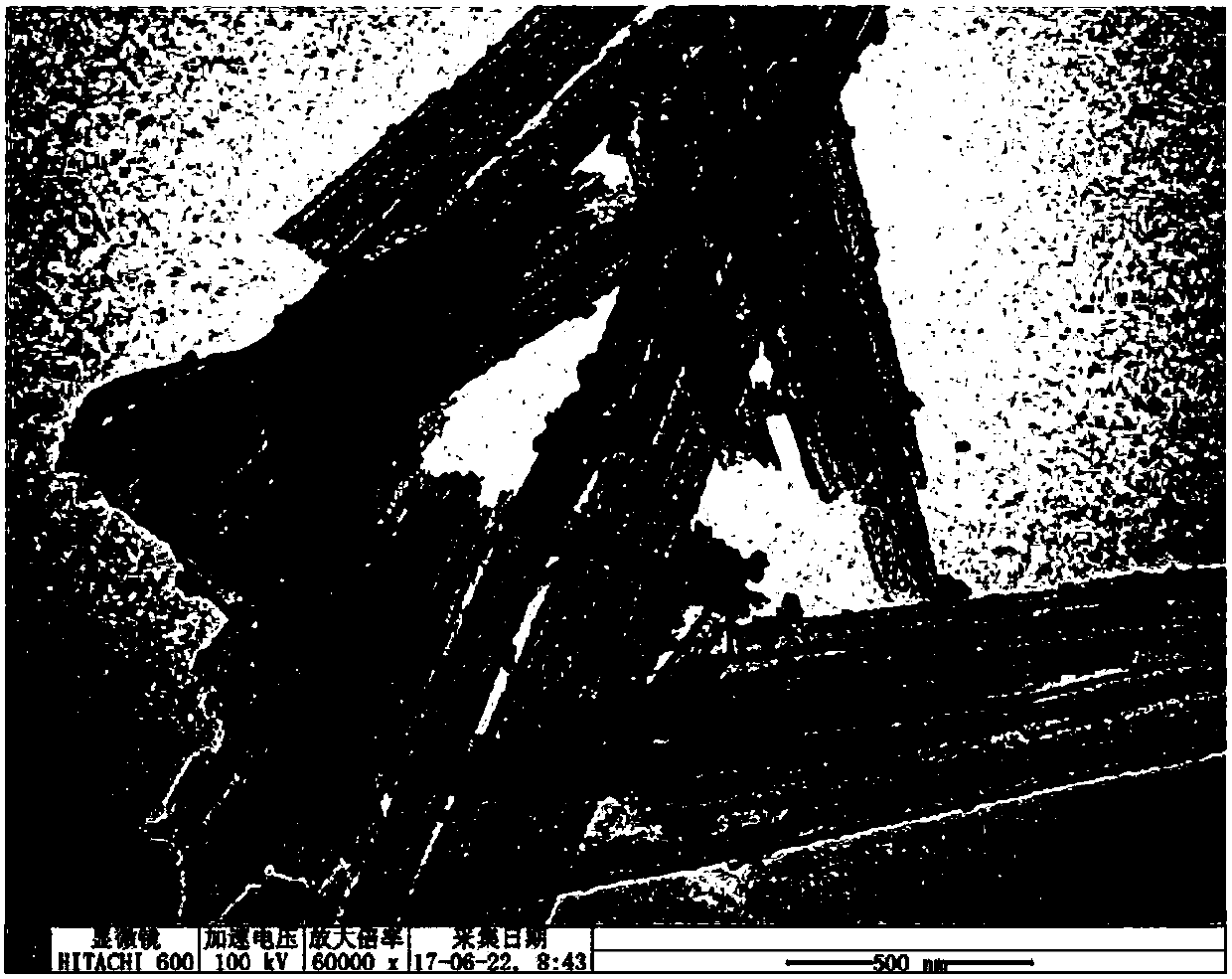

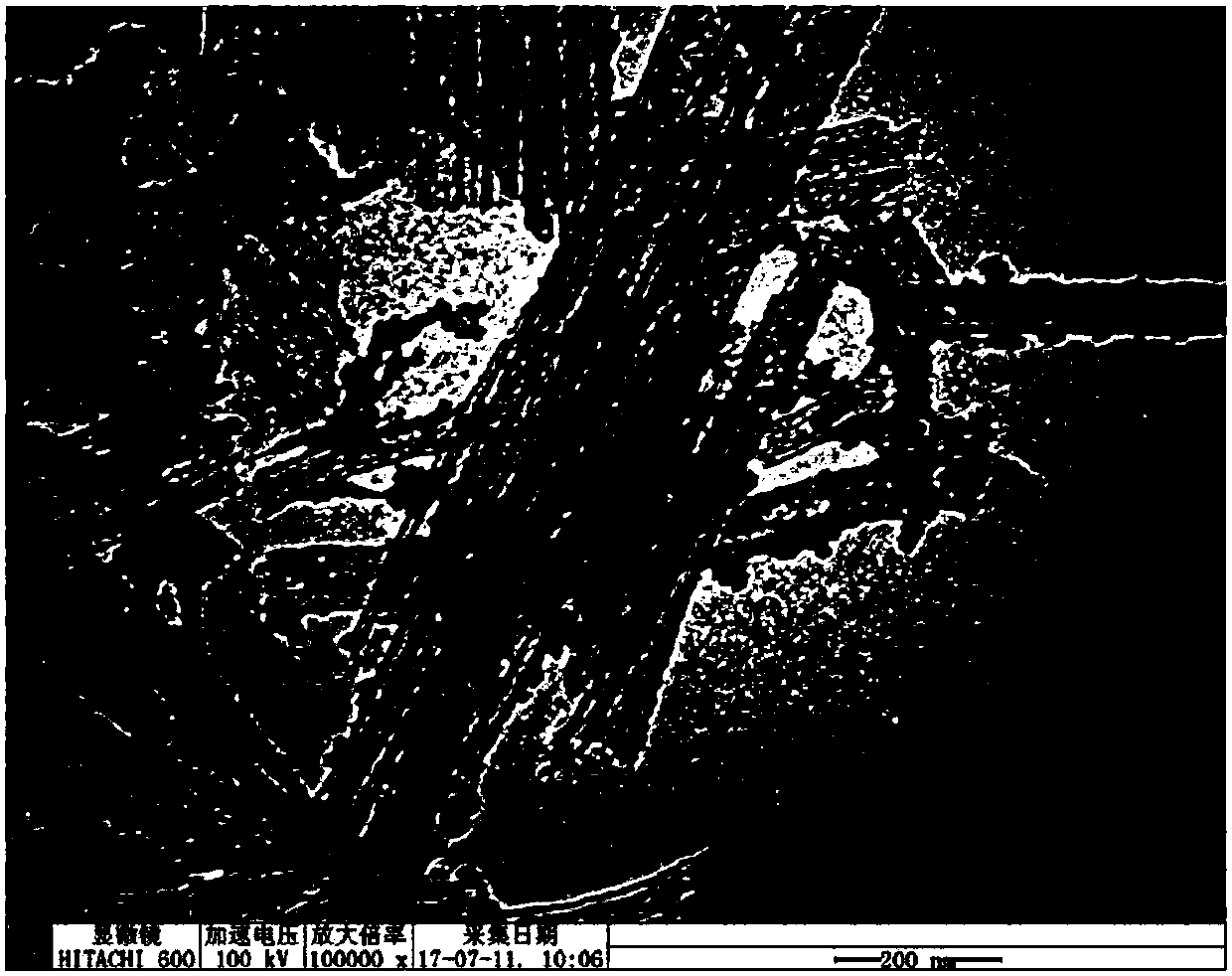

InactiveCN101773838APrecise control of stoichiometric ratioGood catalytic propertiesMetal/metal-oxides/metal-hydroxide catalystsComposite filmChemical solution

The invention relates to a silver nanoparticle-dispersed cobalt oxide functional thin film material and a preparation method, and belongs to the field of photocatalysis. The material is characterized in that the general formula of chemical compositions of the thin film material is Agx / (Co3O4) 1-x, wherein x indicates the mole fraction of constituent element of Ag, and x ranges from 0.01 to 0.85. In the process, cobalt nitrate and silver nitrate are used as raw materials, and ethylene glycol monomethyl ether is used as a solvent; a precursor solution with accurate stoichiometric proportion and uniform compositions is synthesized by chemical solution method, and film is coated on a glass substrate by a spin coater, and finally the Agx / (Co3O4) 1-x composite film is obtained by thermal decomposition and annealing. Silver nanoparticles are uniformly dispersed in a cobalt oxide matrix, and the diameter of the silver particle is 1- 500nm; and the film can observe the plasma resonance absorption peaks of metal particles at a wave band of 350-450nm, and the film has excellent photocatalytic properties under the irradiation of visible light.

Owner:UNIV OF SCI & TECH BEIJING

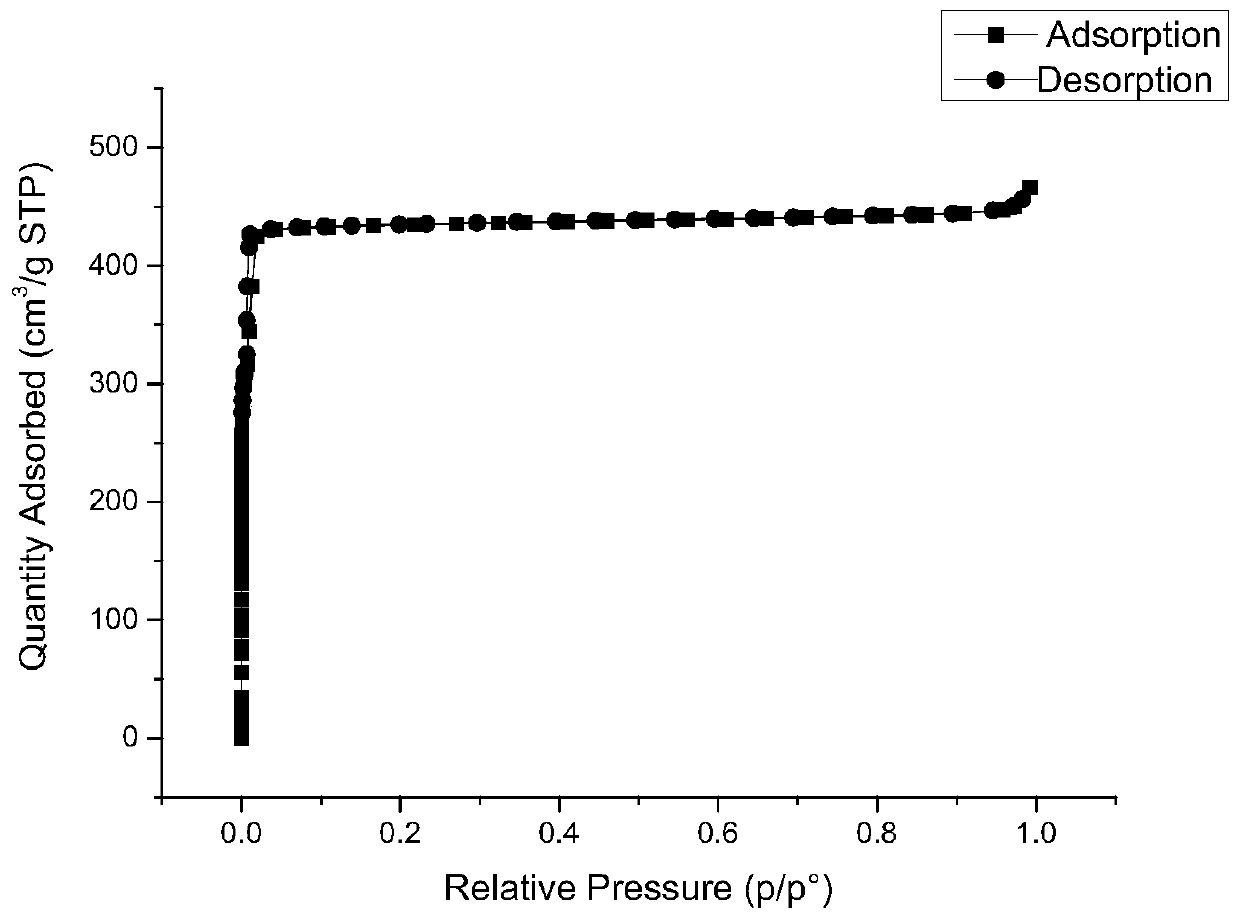

Preparation method of cobalt and nitrogen codoped carbon nanoparticle-carbon nanotube composite material

ActiveCN107899598ALarge specific surface areaRich mesostructureMaterial nanotechnologyCatalyst activation/preparationNanowireMass ratio

The invention relates to a preparation method of a cobalt and nitrogen codoped carbon nanoparticle-carbon nanotube composite material, and belongs to the technical field of preparation of nanocomposite materials. The problems of complex process, high cost, special expensive devices and adversity to large-scale production of existing preparation methods are solved. The preparation method of the cobalt and nitrogen codoped carbon nanoparticle-carbon nanotube composite material mainly adopts CdS nanowires, dopamine and cobalt nitrate as raw materials, the CdS nanowires are coated with the dopamine in the presence of cobalt nitrate, and the obtained sample undergoes high temperature calcination to obtain the composite material. The mass ratio of the CdS nanowires to the cobalt nitrate is controlled to adjust the morphology of the obtained material. The preparation method has the advantages of simple process and low cost. The composite material has a large specific surface area and rich meso-porous structures, so the material has an excellent oxygen reduction electrocatalysis performance, and has a wide application prospect in the fields of fuel cells, biological sensing, metal-air cells and supercapacitors.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-efficiency catalyst for Fenton reaction, and preparation method and application thereof

ActiveCN106914269ASimple preparation processHigh catalytic efficiencyPhysical/chemical process catalystsWater treatment compoundsCobalt(II) nitrateFenton reaction

The invention discloses a catalyst for the Fenton reaction. The catalyst is prepared from ferrous sulfate, copper sulfate and cobalt nitrate by dissolving ferrous sulfate, copper sulfate and cobalt nitrate in deionized water and then adjusting the pH value of the obtained aqueous solution of the metal salts to 3 to 4, wherein a mol ratio of ferrous sulfate to copper sulfate to cobalt nitrate is 1: 0.5: 1 to 1: 6: 1, and the ratio of the total amount of ferrous sulfate, copper sulfate and cobalt nitrate to the usage amount of deionized water is 0.8 to 1.5 mol: 1 L. The invention also discloses application of the catalyst for the Fenton reaction to treatment of electroplating wastewater containing organic matter complexes. The catalyst for the Fenton reaction is a composite catalyst containing ferrous iron, copper and cobalt and is simple to prepare; the catalyst can effectively eliminate organic matters in complexation states, and the removal rate of heavy metal complexes can reach 99% or above; and the catalyst allows nickel in effluent to reach the standard, enables the removal rate of COD to reach 85% or above and substantially reduces the COD value of the effluent.

Owner:NANJING YUANQUAN TECH CO LTD

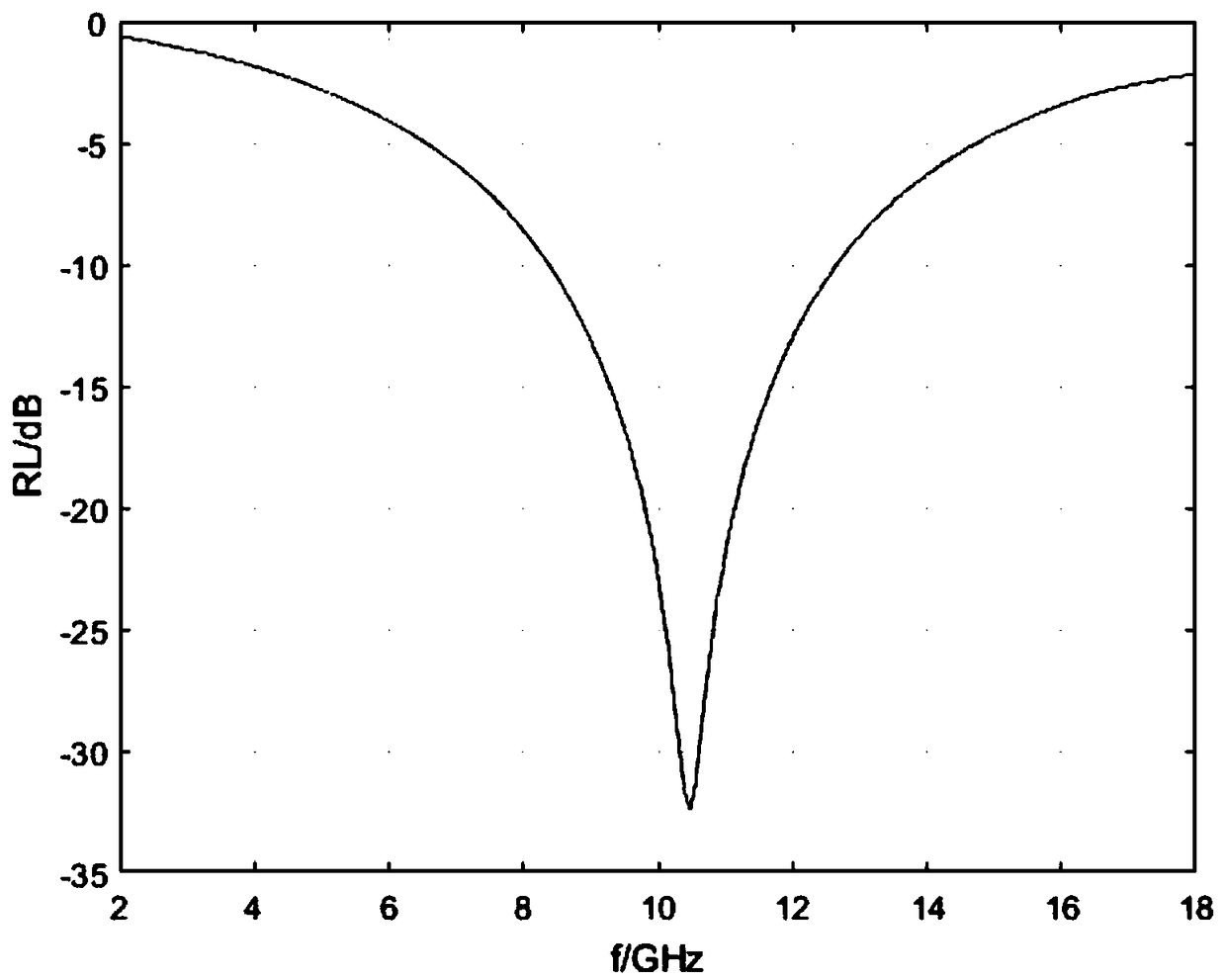

Cobalt-nickel/silica aerogel composite microwave absorb material and preparation method thereof

ActiveCN109257915ARich porous structureImprove absorbing performanceMagnetic/electric field screeningSupercritical dryingMicrowave

The invention discloses a cobalt-nickel / silica aerogel composite microwave absorbing material and a preparation method thereof. The microwave absorbing material comprises a silica aerogel and cobalt,nickel and a cobalt-nickel alloy magnetic metal grown in situ on the silica aerogel. The preparation method comprises the following steps: 1. Mixing cobalt nitrate, nickel nitrate, ethylene glycol, tetraethylorthosilicate and phosphoric acid; 2, cooling the mixed solution, adding isopropanol and deionized water, and continuously stirring; 3, putting the wet gel obtained in the step 2 into the isopropyl alcohol solution of nickel nitrate and cobalt nitrate for normal temperature aging; 4, supercritically dryingaged wet gel in the step 3; The microwave absorbing material has microwave absorbingproperties of magnetic metals of metals such as cobalt, nickel and their alloys. The preparation method can prepare a light microwave absorbing material with rich porous structure.

Owner:承德中宇众航新材料有限公司

Preparation method of high-compaction-density lithium nickel cobalt aluminum oxide ternary anode material

The invention relates to a preparation method of a lithium electrode anode material, and specifically discloses a preparation method of a high-compaction-density lithium nickel cobalt aluminum oxide ternary anode material. The preparation method comprises the following steps of a, preparing a cobalt nitrate solution, carrying out complexation by utilizing ammonium hydroxide, and numbering as a solution 1; preparing a NaOH solution, adding a NH3.H2O solution in the NaOH solution, and numbering as a solution 2; preparing a mixed solution of cobalt nitrate, nickel nitrate and aluminium nitrate, carrying out complexation by utilizing the ammonium hydroxide, and numbering as a solution 3; preparing a NaOH solution, adding a NH3.H2O solution, and numbering as a solution 4; b, mixing the solution 1 and the solution 2 to react to obtain a cobalt oxide precursor; c, enabling the cobalt oxide precursor and the solution 3 and the solution 4 to react to obtain a nickel cobalt aluminum hydroxide precursor; d, carrying out ball-milling mixing on the lithium carbonate and the nickel cobalt aluminum hydroxide precursor; e, sintering by utilizing a muffle furnace; and f, preparing the lithium nickel cobalt aluminum oxide anode ternary material. The preparation method provided by the invention has the advantages that the compaction density of the ternary material is improved, and the battery capacity and the circulating property of the material are both remarkably improved.

Owner:宁夏科捷锂电池股份有限公司

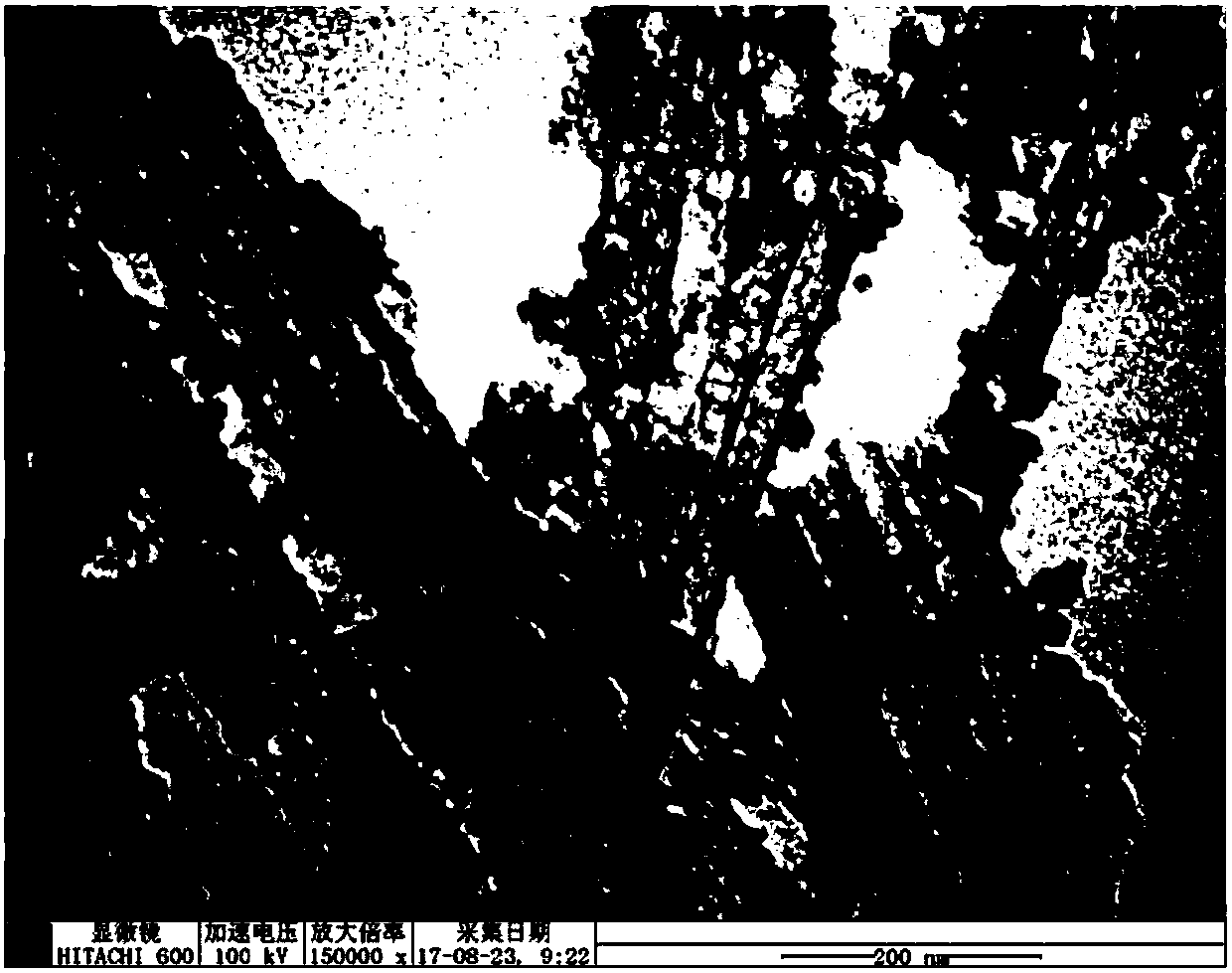

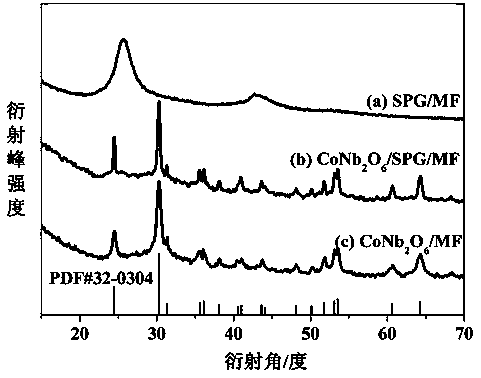

Flexible composite electrode material, a preparation method and an application thereof

ActiveCN109273280ALight in massIncrease elasticityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceDoped graphene

The invention belongs to the field of preparation of electrode materials for supercapacitors, in particular to flexible composite electrode material, a preparation method and an application thereof. The flexible composite electrode material of the invention is prepared by uniformly mixing graphene oxide, H2SO4 and phytic acid in aqueous solution, transferring the mixture to a hydrothermal kettle,and hydrothermally reacting to obtain thiophosphorus doped graphene; Mixing anhydrous niobium pentoxide and hydrofluoric acid, transferring to a reaction kettle, hydrothermally reacting, adding ammonium oxalate, sulphur phosphorus doped graphene and cobalt nitrate into the obtained reaction liquid B, placing the mixture into a melamine sponge, raising the temperature, adding methyl amine solution,and obtaining cobalt niobium precursor; CoNb2O6 / graphene / melamine sponge flexible composite electrode material was prepared by calcining melamine sponge under nitrogen atmosphere. The reaction condition of the invention is mild, easy to control and the process is simple; The prepared CoNb_2O_6 has good dispersibility, uniform and controllable size, and has high reversible specific capacitance when used as flexible electrode of supercapacitor, so it is expected to be industrially produced.

Owner:JIANGSU UNIV

Method for preparing cobalt carbonate-cobalt phosphate composite photocatalyst

InactiveCN107096555ASolubility product constant is smallImprove catalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationSodium phosphatesNanoparticle

The invention discloses a method for preparing a cobalt carbonate-cobalt phosphate composite photocatalyst. The method comprises the following specific steps: weighing 12mmol to 16mmol of cobalt nitrate, preparing a 12mmol / L cobalt nitrate solution, weighing 6.6mmol to 8mmol of sodium carbonate, and preparing a 16mmol / L sodium carbonate solution; mixing the two kinds of solutions at the revolution rate of 350rpm to 400rpm so as to form a colloidal substance, carrying out sustained stirring for 3 to 4 hours, and subjecting sodium carbonate and cobalt nitrate to a reaction during stirring, so as to produce cobalt carbonate colloid; putting the cobalt carbonate colloid in a semi-permeable membrane bag, washing with distilled water for 3 to 4 times so as to remove free ions, then, adding the cobalt carbonate colloid into 60mL to 80mL of 2mol / L to 4mol / L sodium phosphate solution, carrying out soaking for 2 to 4 days so as to form cobalt phosphate nanoparticles on surfaces of cobalt carbonate particles, carrying out solid-liquid separation, washing solids with deionized water for 2 to 3 times, and carrying out drying at the temperature of 75 DEG C to 105 DEG C, thereby preparing the cobalt carbonate-cobalt phosphate composite photocatalyst. According to the method, a catalyst is formed on the surface of cobalt carbonate, and the catalyst and a support are combined tightly.

Owner:CHANGZHOU UNIV

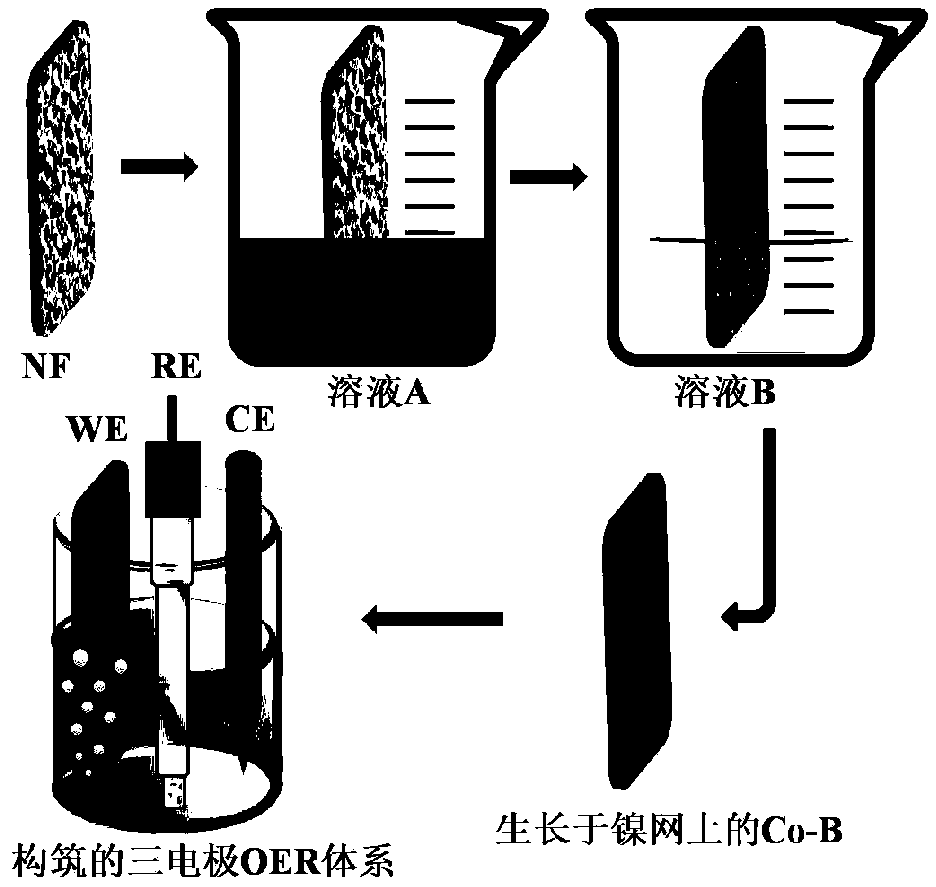

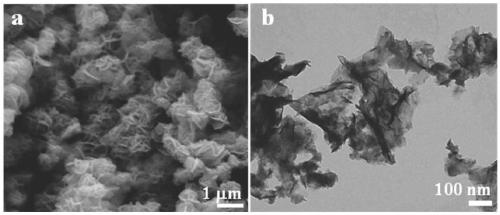

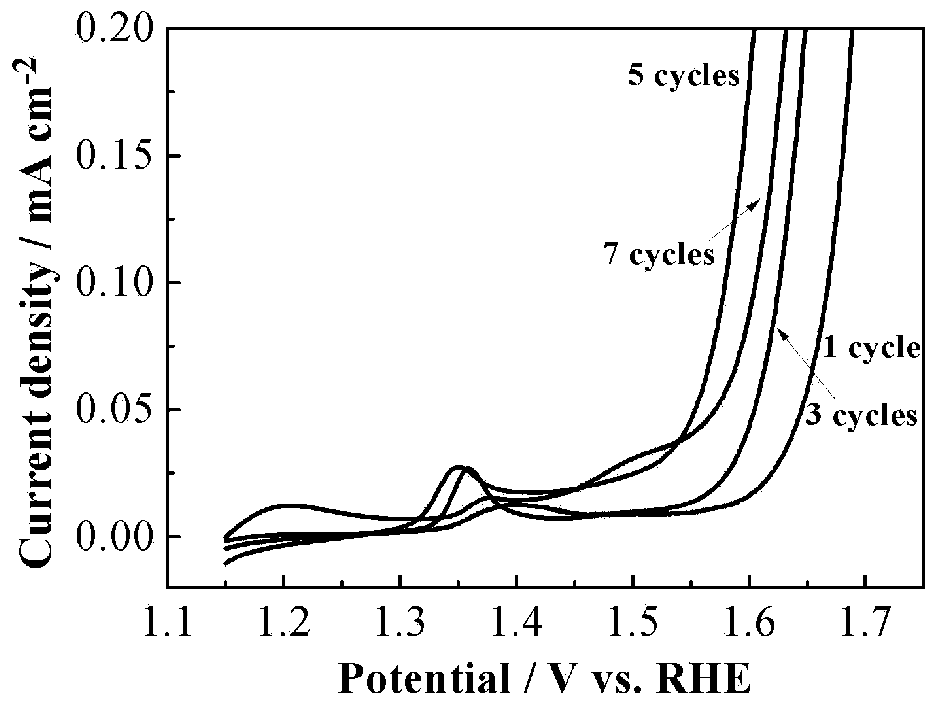

Preparation method of nickel boride base oxygen evolution catalyst

PendingCN109518217AImprove electrochemical stabilityImprove electrochemical activityElectrode shape/formsBorideAlcohol

The invention provides a preparation method of a nickel boride base oxygen evolution catalyst. The method comprises the following steps that a nickel net used for an afflux base is soaked in diluted hydrochloric acid to remove an oxidation layer, then ultrasonically washed with ethyl alcohol and redistilled water in sequence, and dried on the vacuum condition for standby application; a cobalt nitrate water solution and a sodium hydroxide solution of sodium borohydride are prepared respectively, and dissolved oxygen in the cobalt nitrate water solution and the sodium hydroxide solution of the sodium borohydride are removed for standby application; the nickel net is sequentially soaked in the cobalt nitrate water solution and the sodium hydroxide solution of the sodium borohydride, one-timesoaking in the cobalt nitrate water solution and the sodium hydroxide solution of the sodium borohydride is taken as one circulation, the circulation is repeated for a plurality of times, and a cobaltboride nanometer layer is generated on the surface of the nickel net and dried to obtain the nickel boride base oxygen evolution catalyst. The preparation method has the following beneficial effectsthat in comparison with a conventional method of synthesizing boride powder firstly and then dripping and spraying the solution to the afflux base, higher electrochemical stability and activity are possessed.

Owner:UNIV OF JINAN

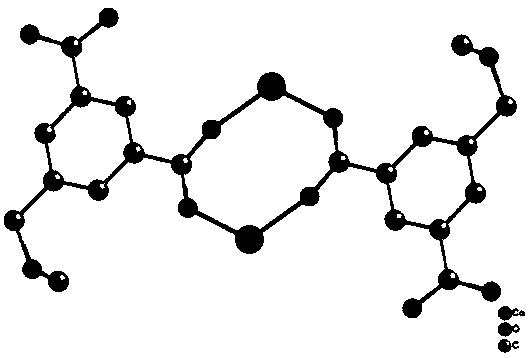

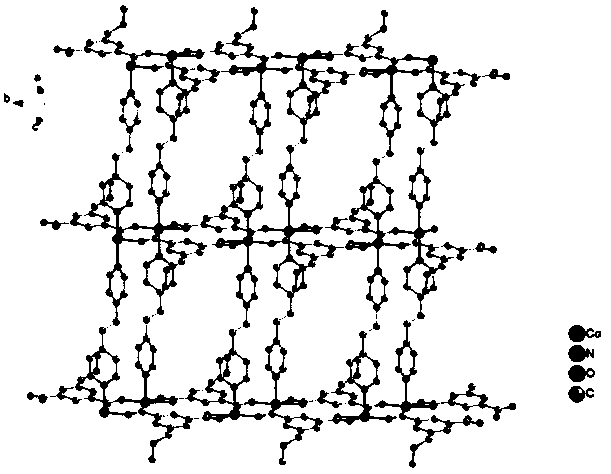

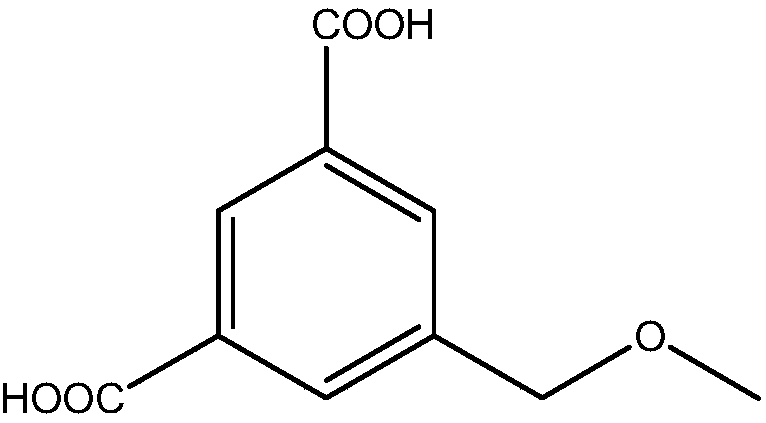

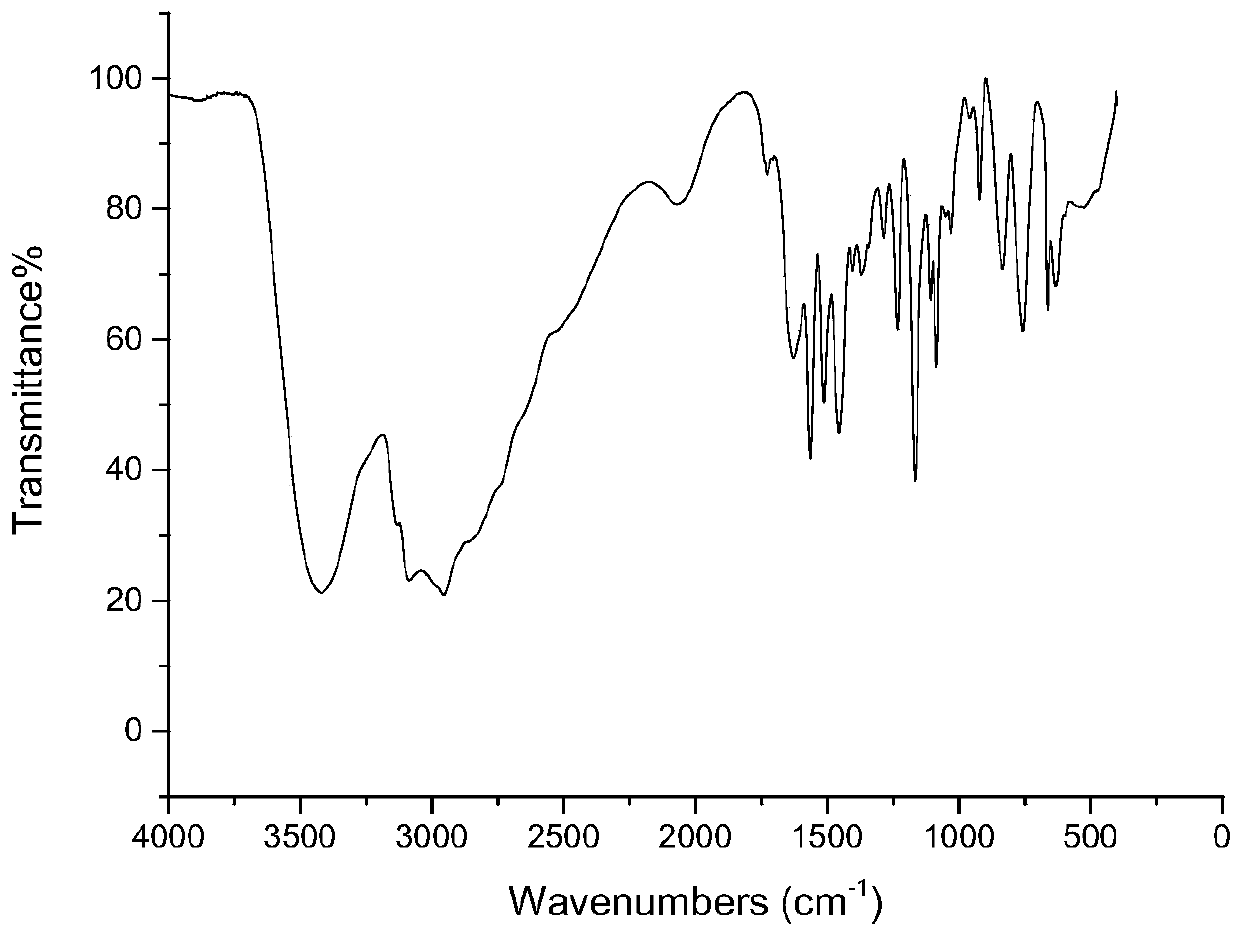

Double-core-cobalt bacteriostatic material and preparing method thereof

The invention discloses a double-core-cobalt bacteriostatic material and a preparing method thereof. The double-core-cobalt bacteriostatic material is a 5-methoxymethyl isophthalic acid cobalt coordination polymer, and the chemical formula of the basic structural unit is [CoL(bpa)], wherein L represents the complete proton-stripping state of 5-methoxymethyl isophthalic acid, and bpa represents 1,2-bis(4-pyridyl)ethane. According to the double-core-cobalt bacteriostatic material and the preparing method thereof, a hydrothermal reaction method is utilized, 5-methoxymethyl isophthalic acid and 1,2-bis(4-pyridyl)ethane serve as ligands and cobalt nitrate or cobalt acetate serves as a metal source, and 5-methoxymethyl isophthalic acid, 1,2-bis(4-pyridyl)ethane and cobalt nitrate or cobalt acetate are heated in water for 3 days at 130 DEG C to obtain the coordination polymer. The 5-methoxymethyl isophthalic acid cobalt coordination polymer has a double-core-cobalt structure; under the concentration of 2.5 g / L, the coordination polymer has the bacteriostatic annulus diameter of 17.00 mm on staphylococcus aureus, and has the bacteriostatic annulus diameter of 19.2 mm on escherichia coli, and can serve as the bacteriostatic material.

Owner:河南十月企业管理咨询有限公司

Metal-organic framework and ionic liquid composite material, preparation method thereof and application of composite material

ActiveCN109894086AHigh adsorption valueNo pollution in the processOther chemical processesDispersed particle separationViscous liquidMetal-organic framework

The invention relates to a metal-organic framework and ionic liquid composite material, a preparation method thereof and an application of the composite material. The method includes the steps: 1) ionic liquid preparation: dissolving 1, 2-dibromoethane and N-(3-aminopropyl) imidazole in acetone, performing stirring reaction for 18-24 hours at normal temperature to obtain dark brown viscous liquid,and centrifuging and washing mixture to obtain ionic liquid; 2) metal-organic framework and ionic liquid composite material preparation: dissolving ionic liquid in methyl alcohol, adding 2-methylimidazole, stirring mixture for 12 hours at the normal temperature to obtain ionic liquid solution, pouring the prepared ionic liquid solution into methanol solution of cobalt nitrate, stirring mixture for 10minutes, standing for 24 hours to obtain purple sediment, and centrifuging, washing and drying the purple sediment to obtain the metal-organic framework and ionic liquid composite material. The metal-organic framework and ionic liquid composite material has high adsorptive valued for carbon dioxide and is non-toxic, green and environmentally friendly.

Owner:WUHAN UNIV OF TECH

Method for preparing porous Co3O4 powder

InactiveCN103241781ASimple preparation processSuitable for large-scale industrial productionCobalt oxides/hydroxidesCrucibleCobalt(II) nitrate

The invention discloses a method for preparing porous Co3O4 powder. The method comprises the following steps of: completely dissolving and mixing cobalt nitrate and glycine in deionized water, then putting a crucible filled with the mixed solution in a muffle furnace to heat and decompose the mixed solution to obtain black fluffy foams; and carrying out thermal treatment on the black fluffy foams for 1.0-1.5 hours at 355-550 DEG C to obtain the porous Co3O4 powder. The method disclosed by the invention is simple in preparation process, free of any template or surfactant and suitable for large-scale preparation.

Owner:ZHEJIANG UNIV

Preparing method of counterpoison for protecting Co-Mo Co of anti-sulfur change catalyst

InactiveCN100430140CEnhanced anti-toxicityChange selectivityCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacSulfur

The present invention relates to preparation process of counterpoison for protecting Co-Mo catalyst for the sulfur resisting conversion of CO. The preparation process includes soaking the active carrier gamma-Al2O3 in the immersion liquid with ammonium molybdate in 7+ / -0.1 wt%, soluble cobalt salt in 1.2+ / -0.1 % accounting in CoO, redox matter in 1-15 wt%, and ammonia water in 1-5 wt%, and stoving after soaking. The counterpoison can protect the activity of Co-Mo catalyst for the sulfur resisting conversion of CO to ensure the normal operation of the catalyst.

Owner:湖北双雄催化剂有限公司

Nanometer copper-based catalyst and preparation method thereof

ActiveCN108970631AEasy to separateEnhance catalytic oxygen production activityPhysical/chemical process catalystsHexamethylenediamineCopper nitrate

The invention discloses a nanometer copper-based catalyst and a preparation method thereof, and belongs to the field of chemistry. Dimethylimidazole and cobalt nitrate hexahydrate are used as raw materials for mixed calcination; a porous hollow nanometer crystal lattice is formed; then, copper nitrate hexahydrate is added; copper ions are mixed into the crystal lattice; the ligand active bodies are formed; the catalysis oxygen generation activity is enhanced in light driving water oxidization; the oxidization efficiency is improved. Cyanoguanidine and ammonium metavanadate are used as raw materials; through calcination, catalyst precursors doped with graphite phase carbon nitride are obtained; the oleic acid loading catalysis quantity is improved; the consumption of catalysts is reduced. The ferric trichloride hexahydrate, anhydrous sodium acetate, 1,6-hexamethylenediamine and the like are used as raw materials for forming magnetic loading articles; the superparamagnetic property is realized; the catalyst can be recovered to be repeatedly utilized; the use efficiency of the catalyst is improved. The catalyst and the preparation method solve the problems of low catalysis activity and great addition quantity of the existing catalyst.

Owner:MAOMING KEDA CHEM

New method for preparing LaCoO3/SBA-16 and LaMnO3/SBA-16 catalyst

The invention discloses a new method for preparing LaCoO3 / SBA-16 and LaMnO3 / SBA-16 catalyst, comprising the following steps: comprising the following steps: preparing carbon-containing mesoporous SBA-16; dissolving lanthanum nitrate and cobalt nitrate into ethylene glycol; adding the mixed liquor of methyl alcohol and the ethylene glycol to obtain lanthanum cobaltate precursor solution; or addingthe methyl alcohol and deionized water to lanthanum nitrate solution, manganous nitrate solution and citric acid solution to obtain the lanthanum manganate precursor solution; dipping the carbon-containing mesoporous SBA-16 by utilizing the above precursor solution at the ultrasound wave; drying and heating to 700 DEG C at the speed of 1 DEG C / min in nitrogen; keeping for 4h; cooling to 50 DEG C;switching into the air; and heating to 750 DEG C at the speed of 1 DEG C / min and keeping for 4h to obtain the LaCoO3 / SBA-16 and LaMnO3 / SBA-16 catalyst with a mesoporous structure. The new method of the invention has active components, is in a highly dispersed state and in a porous structure, and has excellent catalytic performance.

Owner:BEIJING UNIV OF TECH

Preparation method for acid-alkali-resistant adherent enamel plate

The invention discloses a preparation method for an acid-alkali-resistant adherent enamel plate, and belongs to the technical field of decorative materials. According to the preparation method for theacid-alkali-resistant adherent enamel plate, quick lime and water react with each other to generate calcium hydroxide, the calcium hydroxide reacts with sulfate in blast furnace slag to generate dihydrate gypsum, high-density sintering of glaze is facilitated, and then the enamel plate surface has the high hardness and wear resistance; heavy metal ions in the glaze of the blast furnace slag mostly exists in the form of the sulfate, the heavy metal ions in the glaze can achieve complexing with triethanolamine, hydrogen ions are consumed under the acidic condition, and aluminum ions in the glaze and the heavy metal ions generate hydrated silicate on the surface under the alkaline condition; and cobalt nitrate and nickel nitrate are taken as an adherence promoter for the glaze, the cobalt nitrate and the nickel nitrate are molten and decomposed into cobalt oxide and nickel oxide at the low temperature in the firing process, therefore, the adherence of the glaze can be improved, the highacid and alkali resistance is achieved, and the wide application prospect is achieved.

Owner:毛军华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com