Cobalt-nitrogen doped carbon composite material and preparation method thereof

A technology of nitrogen-doped carbon and composite materials, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems that hinder the commercialization of fuel cells, low platinum reserves, and gaps in platinum-based catalysts, and achieve ingenious experimental design and preparation The effect of environmental protection and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

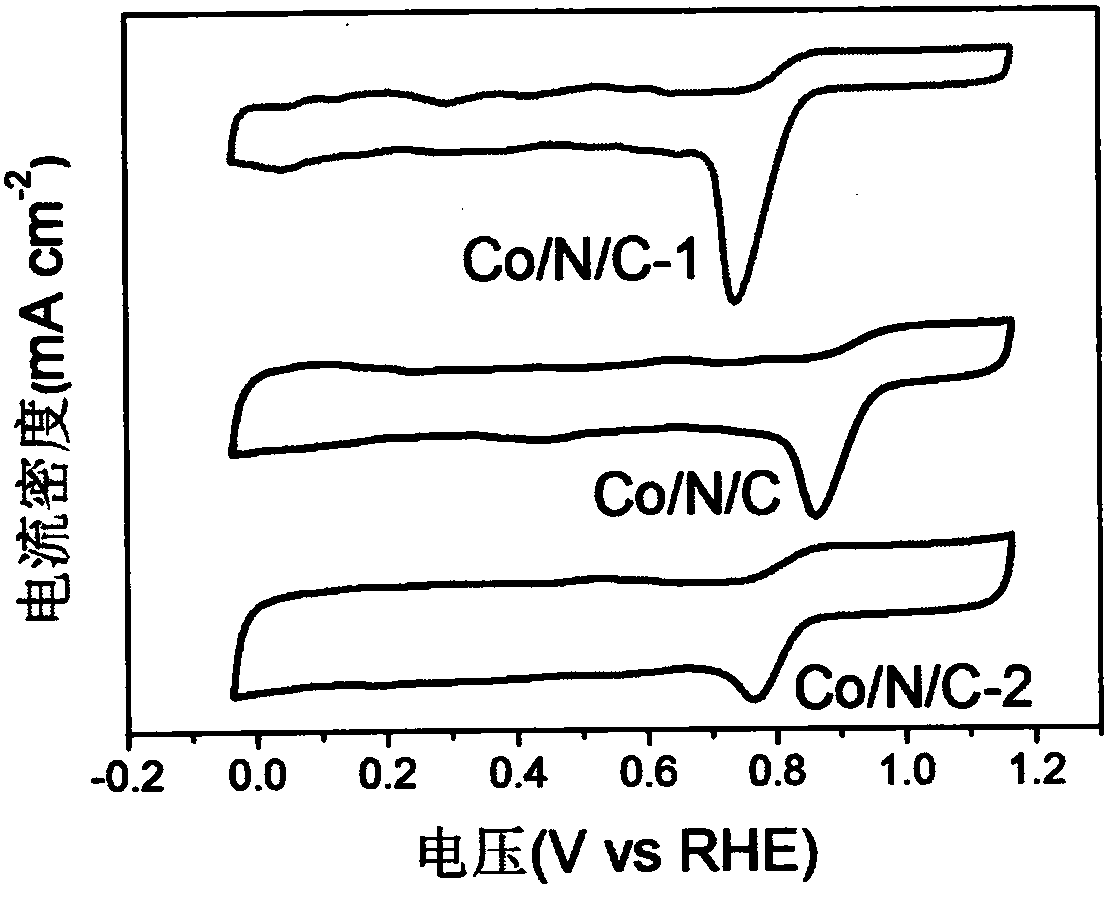

Embodiment 1

[0029] A preparation method of cobalt-nitrogen doped carbon composite material:

[0030] (1) Add cobalt nitrate, magnesium nitrate, aluminum nitrate, and urea mixed in a mass ratio of 0.4:2:1:30 to deionized water, and heat the solution to 100°C;

[0031] (2) Prepare a solution after washing the prepared layered double hydroxide;

[0032] (3) Adjust the pH value of the solution to weakly alkaline, and then add dopamine hydrochloride at a mass ratio of 1:1;

[0033] (4) After drying the sample, add melamine, the mass ratio of the sample to melamine is 1:10, and stir evenly;

[0034] (5) Heat the sample at 750℃ for 2h while stirring;

[0035] (6) Wash the sample thoroughly, vacuum and dry at 80°C, and the final composite material obtained is recorded as Co / N / C.

Embodiment 2

[0037] The difference from Example 1 is that the mass ratio of cobalt nitrate, magnesium nitrate, and aluminum nitrate is 0.2:2:1, and the final composite material obtained is denoted as Co / N / C-1.

Embodiment 3

[0039] The difference from Example 1 is that the mass ratio of cobalt nitrate, magnesium nitrate, and aluminum nitrate is 0.8:2:1, and the final composite material obtained is denoted as Co / N / C-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com