Patents

Literature

62results about How to "Regulate fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonate material with excellent transparent light diffusion function and preparation method thereof

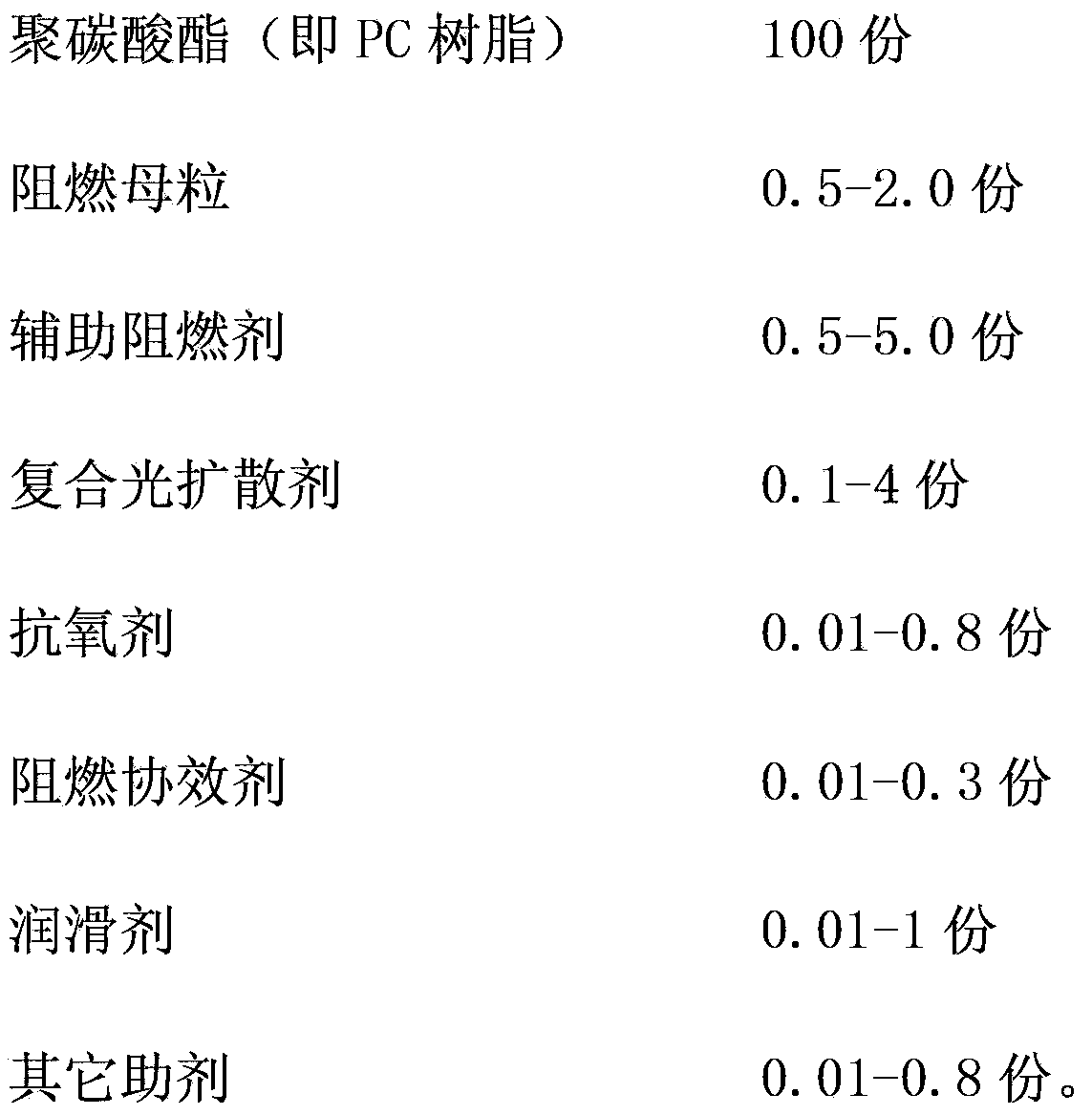

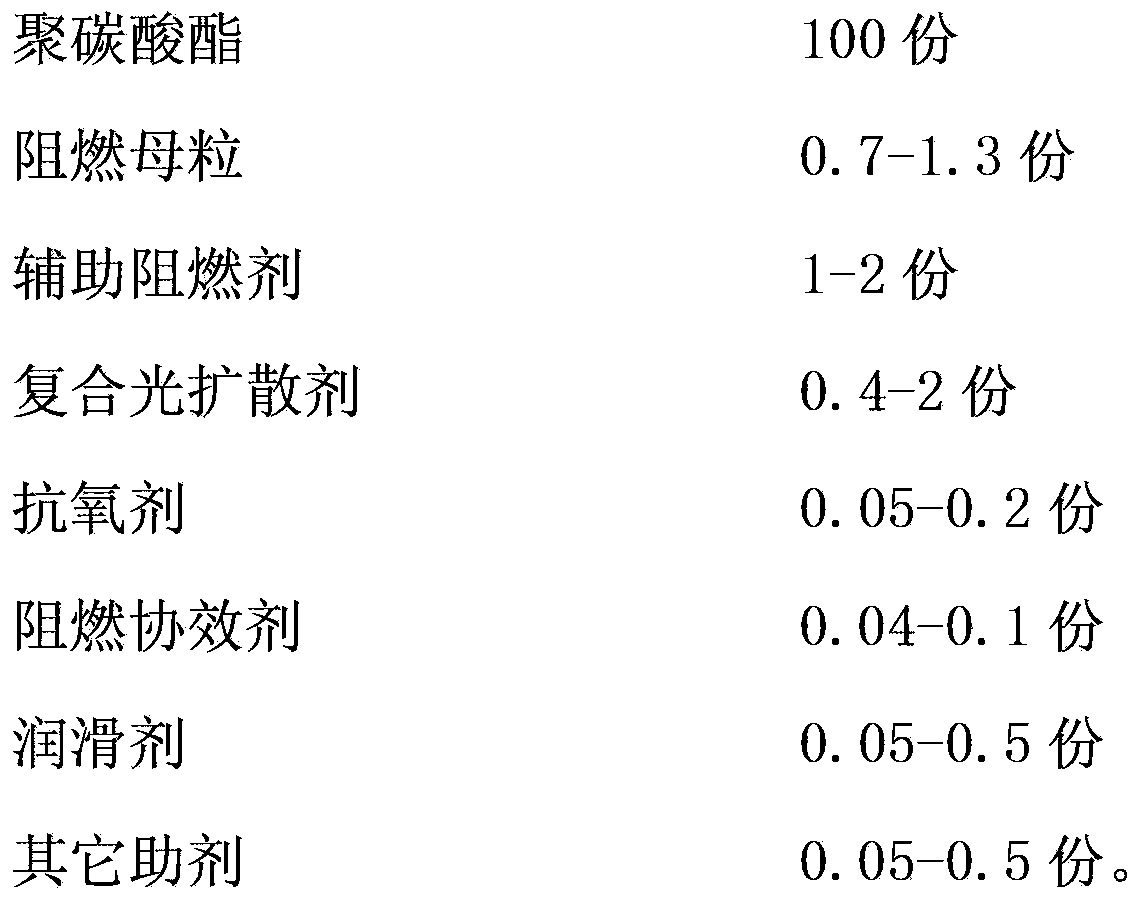

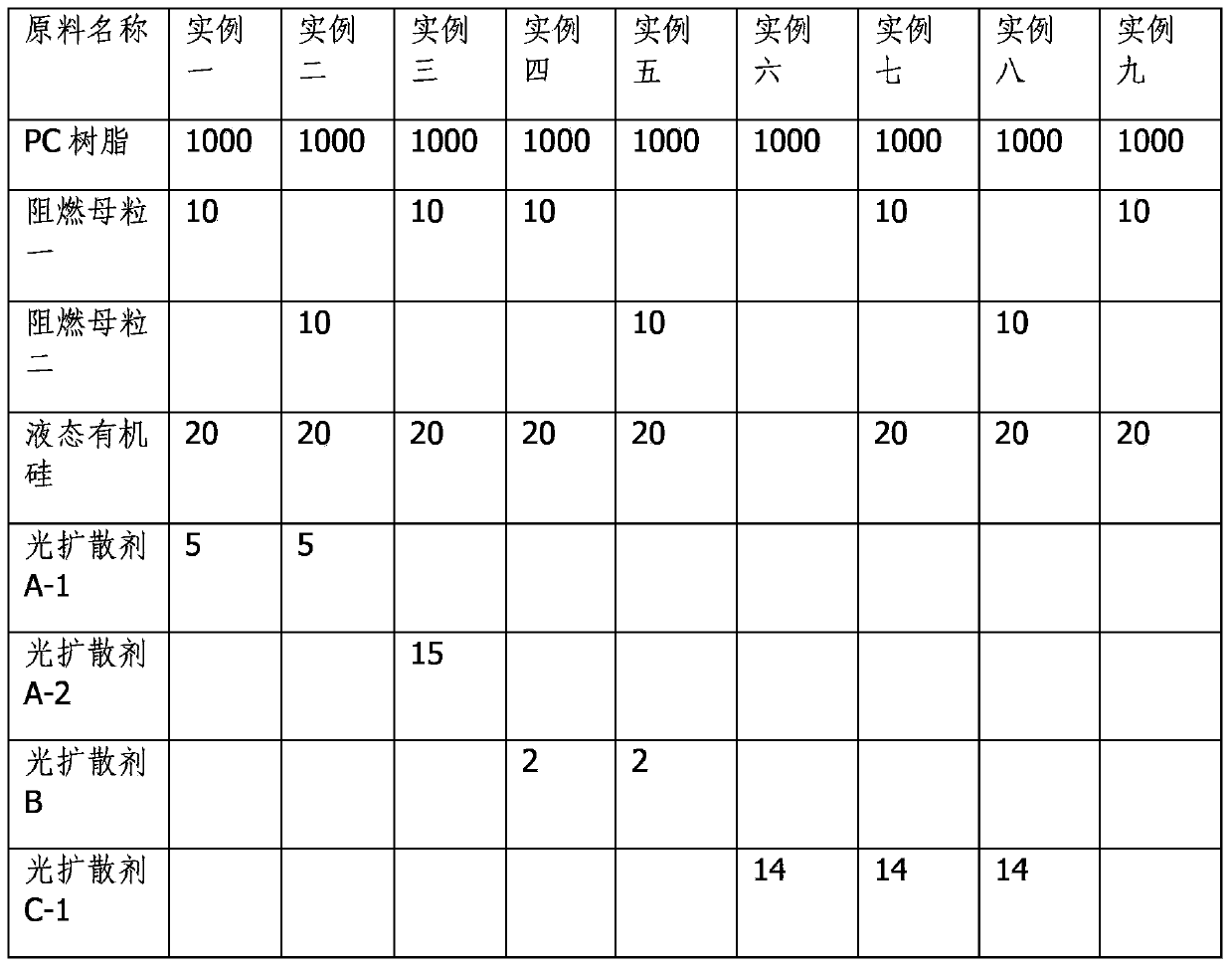

The invention discloses a PC (Polycarbonate) material with an excellent transparent light diffusion function and a preparation method thereof. The PC material is composed of polycarbonate, flame retardant masterbatch, an auxiliary flame retardant, a compound light diffuser, an antioxidant, a flame retardant synergist, a lubricant and other auxiliaries. The principle ingredient of the PC material is PC resin; the PC material is extruded by two steps, wherein the first step is to blend a sulfonate type major flame retardant and an organic silicon flame retardant with the PC resin by melting and granulate the mixture through extrusion by virtue of a twin-screw extruder so as to obtain the light diffusible flame retardant masterbatch, and the second step is to add the compound light diffuser, the flame retardant masterbatch, the antioxidant, the flame retardant synergist, the lubricant and other auxiliaries for further melting blending by taking PC as the major ingredient, and then extrude and granulate the mixture. The flame-retardant light diffusible PC material provided by the invention can be widely applied to an LED (Light-Emitting Diode) lamp, the backlight of a liquid crystal display, a transmission type screen, a decorative lighting billboard, an advertisement lamp box and the like in the lighting field.

Owner:NANTONG DONGFANG PLASTIC CO LTD

Rare-earth doped leadless and low-melting point sealing glass and its preparation method

InactiveCN101456674AMaintain the ability to formExpand the scope of glass formingRare earthCopper oxide

The invention relates to a method for preparing rare earth doped lead-free sealing glass with low melting point, which comprises the following steps: based on raw materials adopted by a Bi2O3-ZnO-B2O3 glass system, adding proper amount of rare earth oxide into the raw materials, and mixing, melting, annealing, grinding and sieving the mixture to obtain the rare earth doped lead-free sealing glass with the low melting point. The sealing glass comprises the following main components by weight portion: 65.22 to 85.22 portions of bismuth oxide, 4.63 to 11.78 portions of boric acid, 5.76 to 10.76 portions of zinc oxide, 0.80 to 2.80 portions of copper oxide, 0.42 to 2.42 portions of cobalt oxide, 3.32 to 8.47 portions of barium carbonate, 0.4 to 1.8 portions of aluminum oxide, and 0.1 to 6.0 portions of rare earth oxide. The method solves the problems that the sealing glass with the low melting point has low sealing temperature, high sealing strength, stable glass structure and the like under lead-free conditions, and has the advantages of simple process, practicability and reliability; and the prepared rare earth doped lead-free sealing glass with the low melting point is particularly suitable for sealing and closing of stainless steel materials, electrons and electric appliances.

Owner:WUHAN UNIV OF TECH

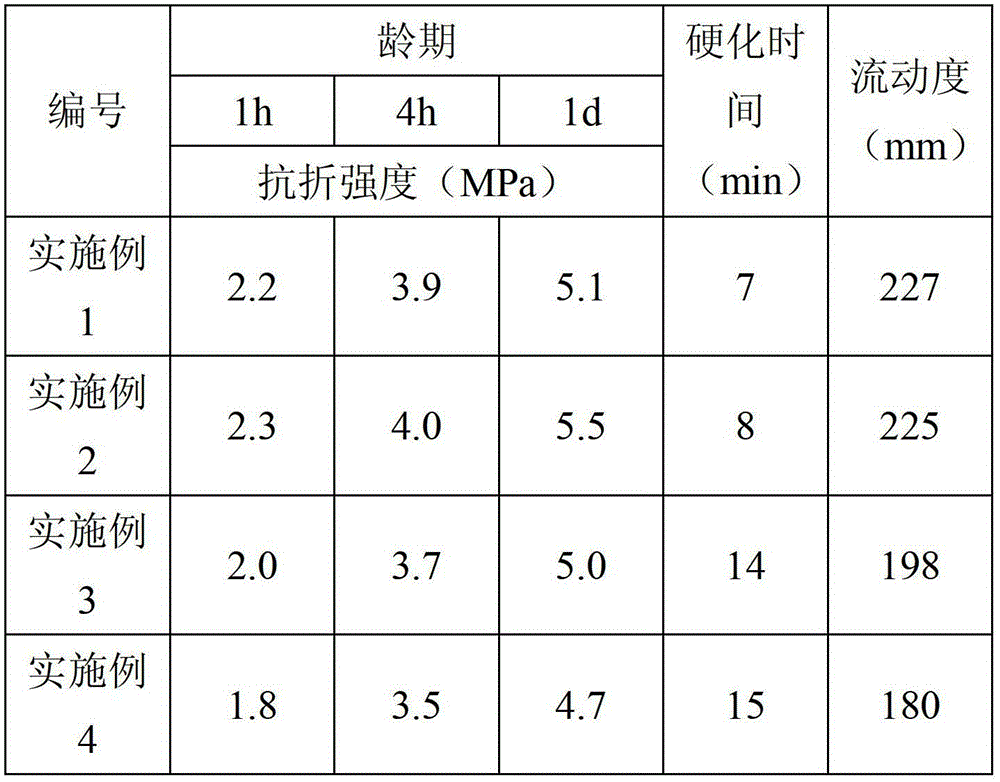

Multifunctional quick repair material for cement concrete pavements and preparation method thereof

The invention relates to pavement repair, particularly a multifunctional quick repair material for cement concrete pavements, which is prepared by mixing the following raw materials in percentage by weight: 20-30% of magnesium oxide, 14-26% of ammonium monoacid phosphate, 9-14% of boric acid, 5-20% of aluminate cement, 2-10% of fly ash, 2-10% of rubber powder, 0.5-1.5% of polypropylene fiber, 0.5-1.5% of redispersible latex powder, silica sol and water; the silica sol accounts for 20-60% of the water. The preparation method of the multifunctional quick repair material for cement concrete pavements is implemented by proportionally mixing the raw materials. The material is convenient for construction, has enduring effect after curing, and has quick and enduring repair capacities for most damage forms of cement concrete pavements.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Rapid repair material based on building broken stones and preparation method thereof

The invention relates to building stone repairing. A rapid repair material based on building broken stones comprises a gelation mixture which quickly solidifies with water, wherein the gelation mixture comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. A preparation method of the materials comprises the following steps of: 1, preparing the magnesium phosphate cement; 2, mixing the magnesium phosphate cement, the sand and the silica sol so as to form the gelation mixture which comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. The gelation mixture can be quickly solidified with the water to repair the stones. In addition, the gelation mixture is gelatineous before being solidified and facilitates construction; after the solidification, the small solidification shrinkage rate and a durable effect are obtained; and the repair material has high hardness and good water resistance after the solidification.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

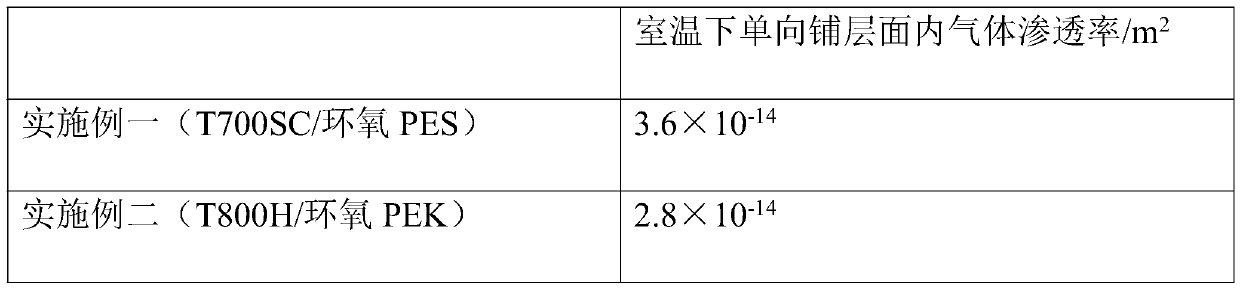

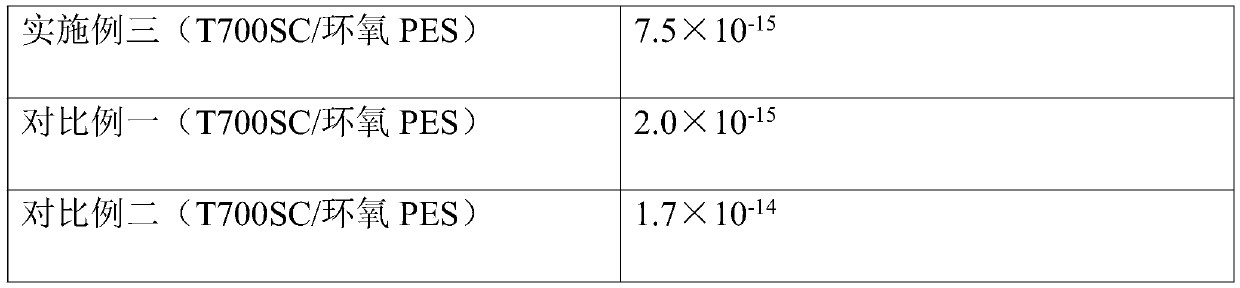

Preparation method of carbon fiber/toughened epoxy resin prepreg for vacuum bag forming process

The invention discloses a preparation method of a carbon fiber / toughened epoxy resin prepreg for a non-autoclave vacuum bag forming process. According to the method, the dissolution degree and the particle size of a curing agent and a toughening agent in epoxy resin are controlled by controlling a resin formula, the particle sizes of the curing agent and the toughening agent and process conditionsfor resin system configuration, and meanwhile, two modification effects are achieved: 1, the resin system is toughened; and 2, the requirements of a non-autoclave process on the viscosity of the resin in the prepreg and a room-temperature storage period are met. The prepared epoxy resin system is prepared into a rubber film, the carbon fiber / epoxy resin prepreg is further prepared by adopting a rubber film calendering method, and the semi-impregnated prepreg (unsaturated impregnated prepreg) is obtained by controlling the pressure and temperature during compounding of the rubber film and carbon fibers.

Owner:BEIHANG UNIV

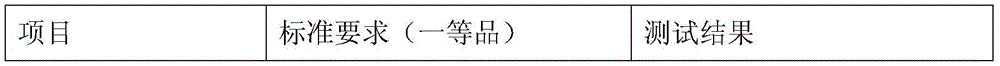

Nontoxic environmentally friendly water-based coating and a preparing method thereof

InactiveCN107353733AImprove the level ofGood compatibilityAntifouling/underwater paintsPaints with biocidesWater basedDispersed media

The invention discloses a non-toxic and environment-friendly water-based paint and a preparation method thereof, comprising the following components in parts by weight: 100-130 parts of water-soluble resin, 80-100 parts of filler, 1-5 parts of preservative, and film-forming aid 2 to 10 parts, 2 to 8 parts of dispersant, 20 to 60 parts of deionized water; the preparation method is as follows: S1: After stirring the water-soluble resin, preservative, dispersant and deionized water evenly, add filler, disperse at high speed, Obtain the mixture; S2: Add film-forming aids to the mixture, then perform high-speed dispersion, disperse evenly and sieve to obtain the finished product. The water-based paint provided by the invention can be firmly combined with the substrate, has high gloss, good leveling, stable paint performance, good durability, and high decorative performance. Deionized water is used as a dispersant, which is green, environmentally friendly and safe. low cost.

Owner:天津市金三鑫水性涂料科技有限公司

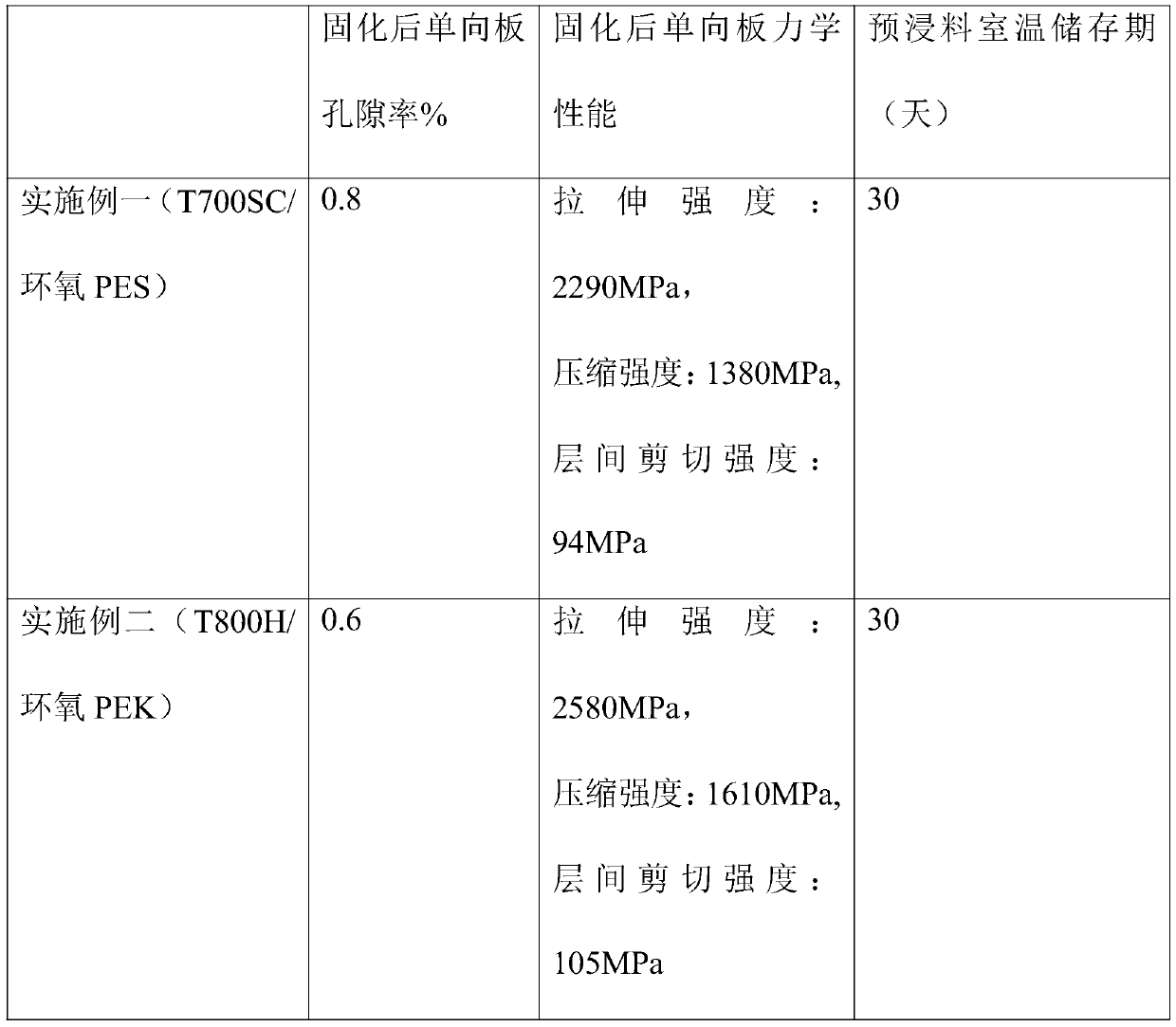

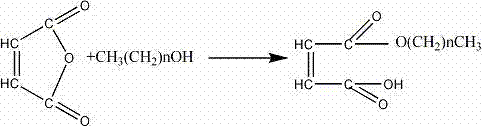

Leather comprehensive fat liquor and preparation method of the same

ActiveCN103088169AIncrease chain lengthGood flexibilityLeather impregnationOil and greaseEngineering

The invention discloses a leather comprehensive fat liquor and a preparation method of the same. Currently, the defects, such as high price, poor stability, layering propensity, high solvent dosage and pungent smell, are common issues for the leather comprehensive fat liquor. In the method, esterification and sulfitation products of high alcohol, modified soybean phospholipid, sulfonated plant oil, animal fat, mineral oil emulsifier and water are mixed evenly at 45-65 DEG C, the pH value is regulated to be 6-8, and the solid content is regulated to be 45-55%, thus, the leather comprehensive fat liquor is obtained. The product of the method is excellent in appearance liquidity, the leather fatted by the fat liquor is excellent in softness and fullness, and the surface of the fatted leather is smooth and moist.

Owner:传化智联股份有限公司 +2

Nanometer silver paste for terminal electrode of multi-layer ceramic capacitor and method for preparing same

InactiveCN101582328AEvenly dispersedImprove conductivityFixed capacitor terminalsNon-conductive material with dispersed conductive materialCeramic capacitorSurface-active agents

The invention belongs to the technical field of electronic and micro-electronic materials, and particularly relates to a nanometer silver paste for a terminal electrode of a multi-layer ceramic capacitor and a method for preparing the same. The nanometer silver paste is prepared from the following components by mass percentage: 45 and 80 percent of silver powder of which the grain diameter is between 10 and 100nm, 10 to 40 percent of organic carrier, 1 to 10 percent of boron aluminum titanium silicate glass powder, 1 to 9 percent of dispersant, 0.5 to 9 percent of defoamer and 0.5 to 8 percent of surface active agent, wherein the organic carrier is an ethyl acetate or ethyl acetate system of polyacrylic resin, and the molecular weight of the polyacrylic resin is between 10,000 and 15,000. In the process of producing and processing the paste, no hazard exists, which facilitates environmental protection; the boron aluminum titanium silicate glass powder and the ceramic substrate of the corresponding multi-layer ceramic capacitor are almost the same or similar in physical property, so that the boron aluminum titanium silicate glass powder and the ceramic substrate of the corresponding multi-layer ceramic capacitor can be formed by co-sintering for one time.

Owner:IRICO

Pasty dental alginate impression material composition

InactiveUS20060213396A1Fluidity of can not be changedRegulate fluidityOther chemical processesProtein adhesivesCarrageenanPullulan

A pasty dental alginate impression material composition having features that fluidity of a mixture is changeable by changing mixing ratio of both pastes, sufficient working time can be kept, and liquid separation in abase material paste does not occur during storage, comprises the base material paste composed mainly of 1-20 wt. % alginate and water, and a setting material paste composed mainly of 10-60 wt. % calcium sulfate and a liquid component unreactive with the calcium sulfate, wherein the base material paste does not contain a filler substantially, but contains 0.01-5 wt. % carbonate of sodium or potassium as a retarder and 0.01-15 wt. % one or more polysaccharides such as carrageenan, pullulan, curdlan, xanthan gum, pectin, konjak glucomannan, and locust bean gum, and the setting material paste contain 0.01-10 wt. % phosphate of sodium or potassium as a retarder, and 0.5-30 wt. % polybutene.

Owner:GC CORP

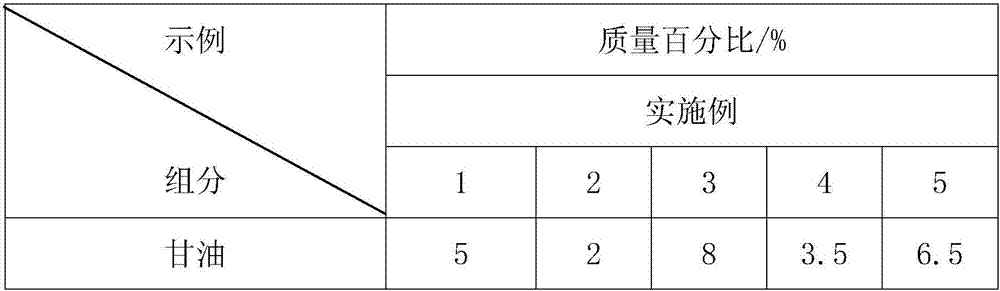

Anti-aging repair mask

InactiveCN107308039ADelay cellular agingRepair and prevent cellular damageCosmetic preparationsOrganic active ingredientsInflammatory cellDiterpene

The invention discloses an anti-aging repair facial mask, which comprises components such as diterpene from basil, flavone from Budisma flavonoids, flavonoids from kapok, glycerin, butanediol, betaine, trehalose, nicotinamide and the like. Adding natural diterpenoids, flavonoids and flavonoids active ingredients in the facial mask can effectively interrupt the peroxidation chain reaction, remove free radicals, chelate metal ions, and regulate inflammatory cells to achieve Delays cell aging, repairs and prevents cell damage; in addition, the flavonoids of Budisma can activate its repair genes, promote the repair of damaged parts, and prevent inflammation from expanding or lasting too long. The secretion and transfer of semaphorin indirectly regulates the occurrence of repair and inflammation, and regulates the fluidity of the biofilm, thereby strengthening the elastic fibers of the dermis, stabilizing the cell structure, and achieving a significant repair effect; the facial mask of the present invention can also moisturize, replenish water and Whitening effect.

Owner:FOSHAN HUIFEN COSMETICS TECH CO LTD

Special weather-resistant stain-resistant paint for pop-top can

InactiveCN105385254AImprove the defect of poor acid resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses special weather-resistant stain-resistant paint for a pop-top can. Raw materials of the special weather-resistant stain-resistant paint comprise the following components in parts by weight: 100 parts of fluorocarbon emulsion, 5 to 15 parts of acrylic emulsion, 5 to 15 parts of modified water-based epoxy resin, 2 to 10 parts of polyester resin, 5 to 10 parts of polycarbonate, 5 to 20 parts of polyurethane, 8 to 15 parts of hexafluoropropene trimer, 3 to 15 parts of rutile titanium dioxide, 2 to 5 parts of nano zinc oxide, 0.5 to 1 part of nano silver, 5 to 10 parts of nano calcium carbonate, 3 to 10 parts of mesoporous silicon dioxide, 2 to 10 parts of sea-foam stone powder, 2 to 8 parts of Kaolin, 0.1 to 1 part of organic silicon defoaming agent, 2 to 5 parts of starch, 5 to 10 parts of ethylene glycol, 2 to 8 parts of triethylene glycol monobutyl ether, 2.5 to 5.5 parts of triethylene glycol monoethyl ether, 2 to 6 parts of silane coupling agent and 50 to 80 parts of water. The special weather-resistant stain-resistant paint for the pop-top can is good in weather resistance, water resistance and stain resistance.

Owner:合肥市易远新材料有限公司

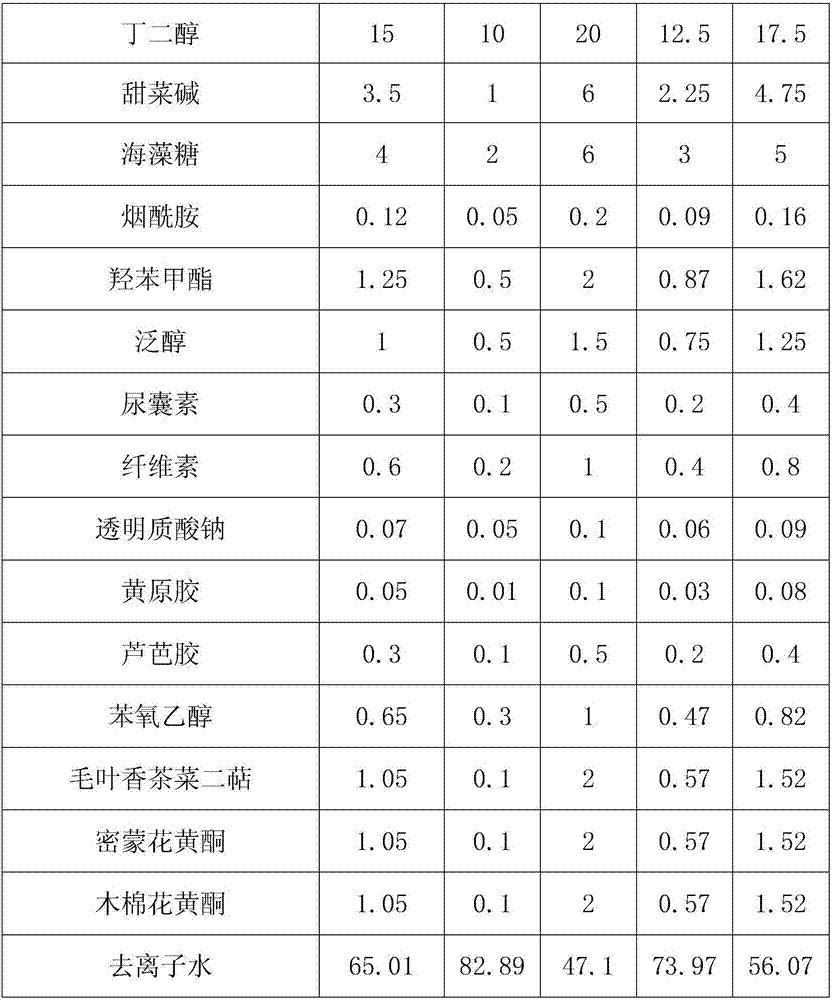

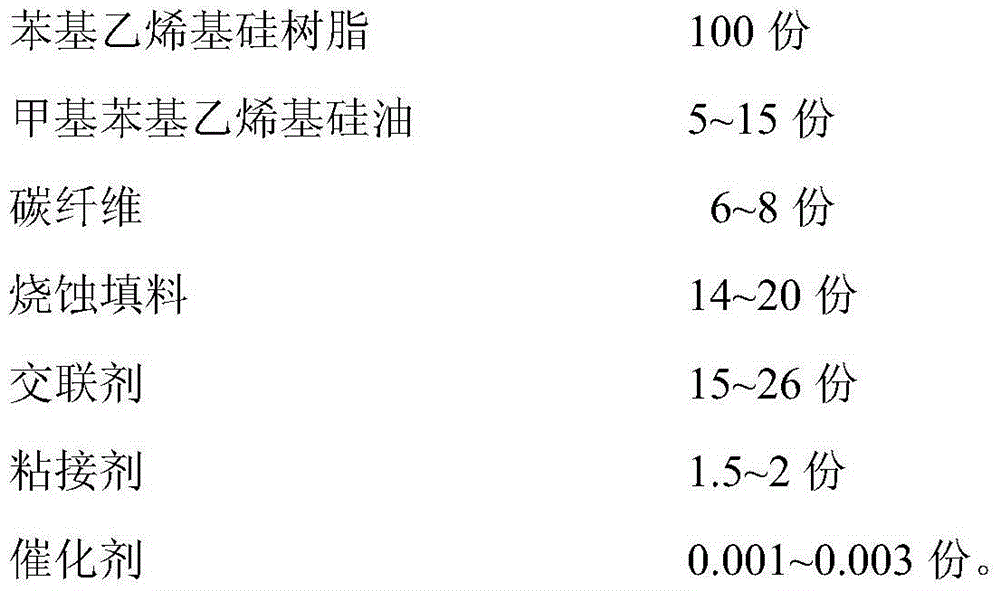

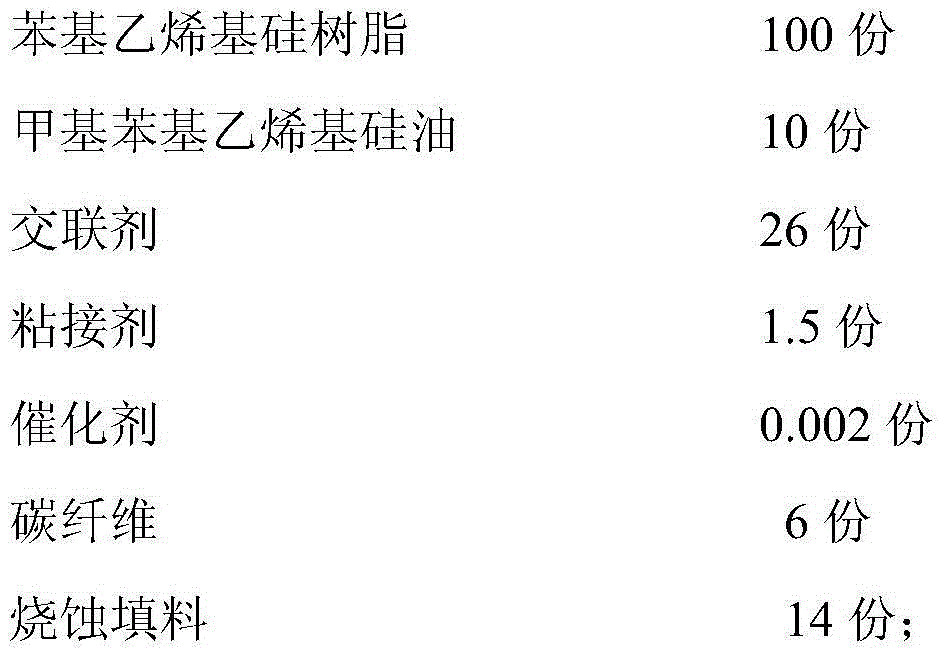

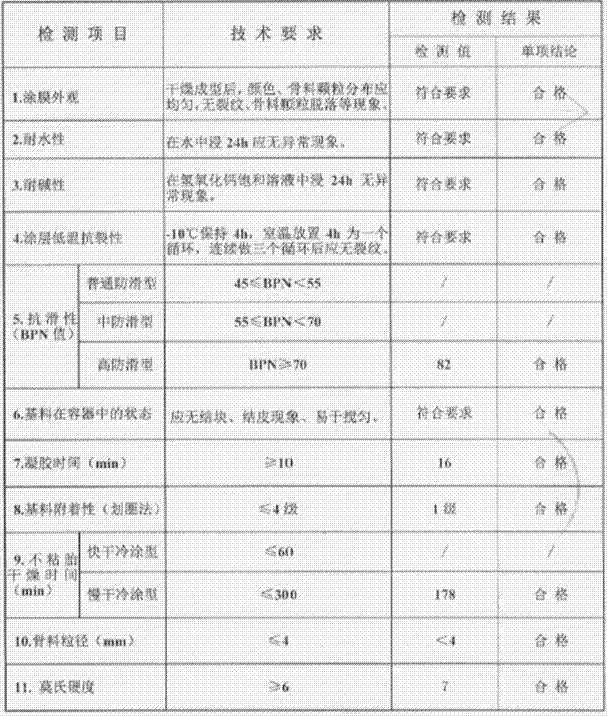

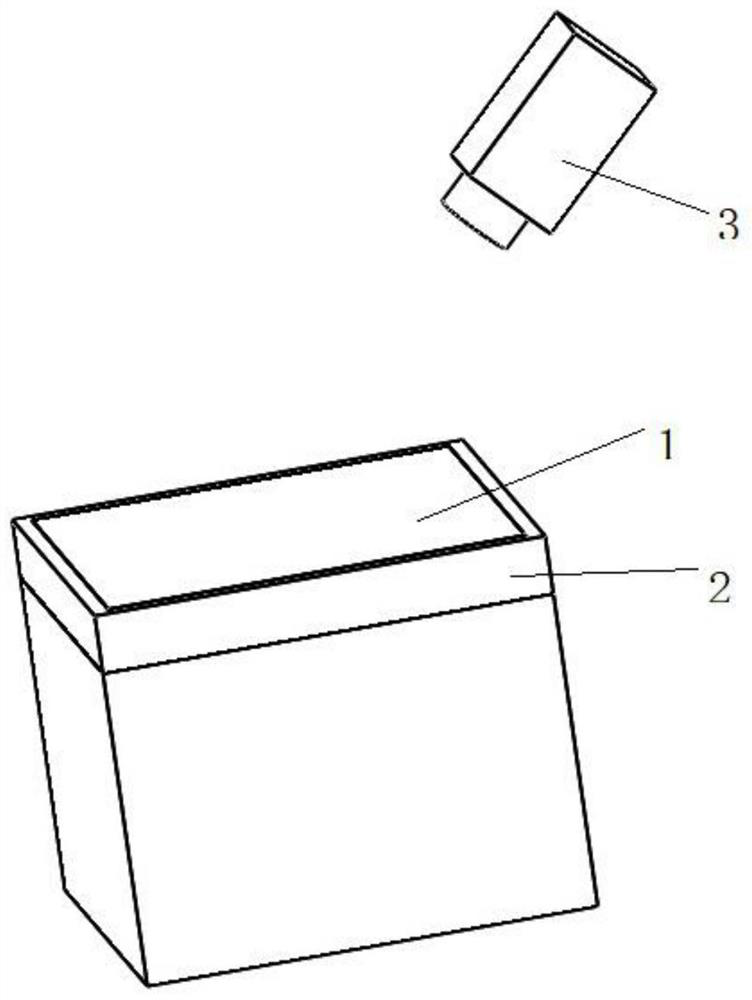

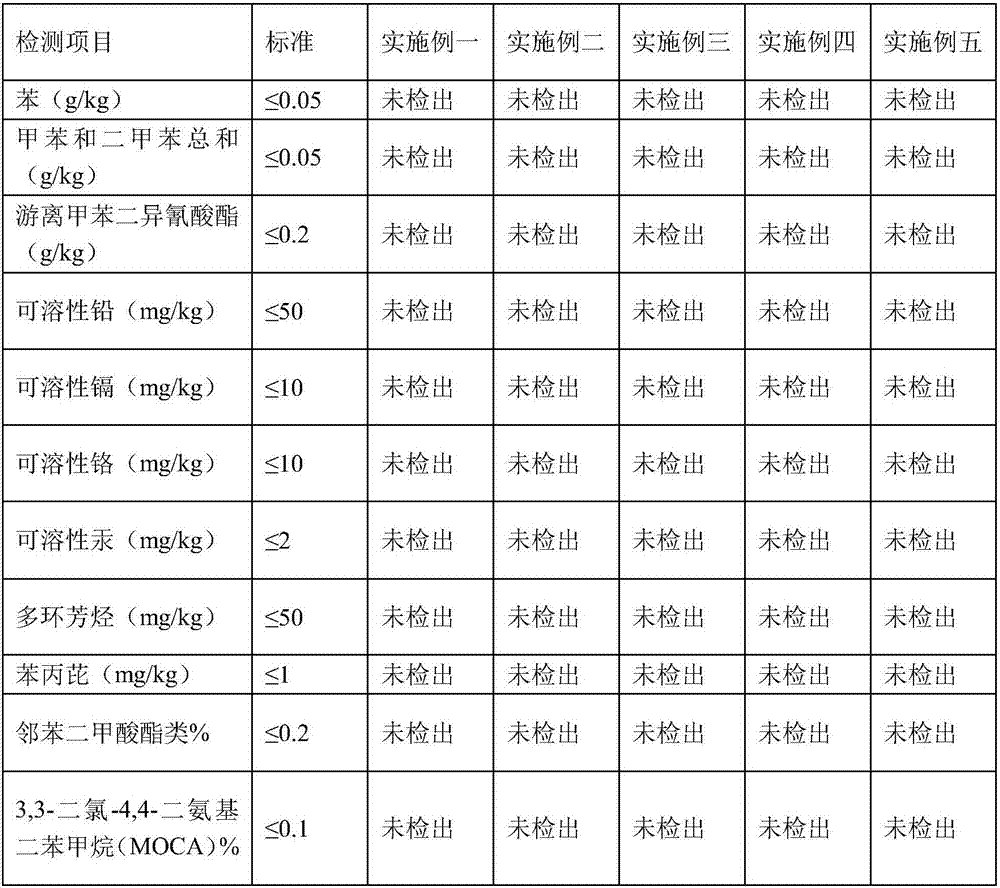

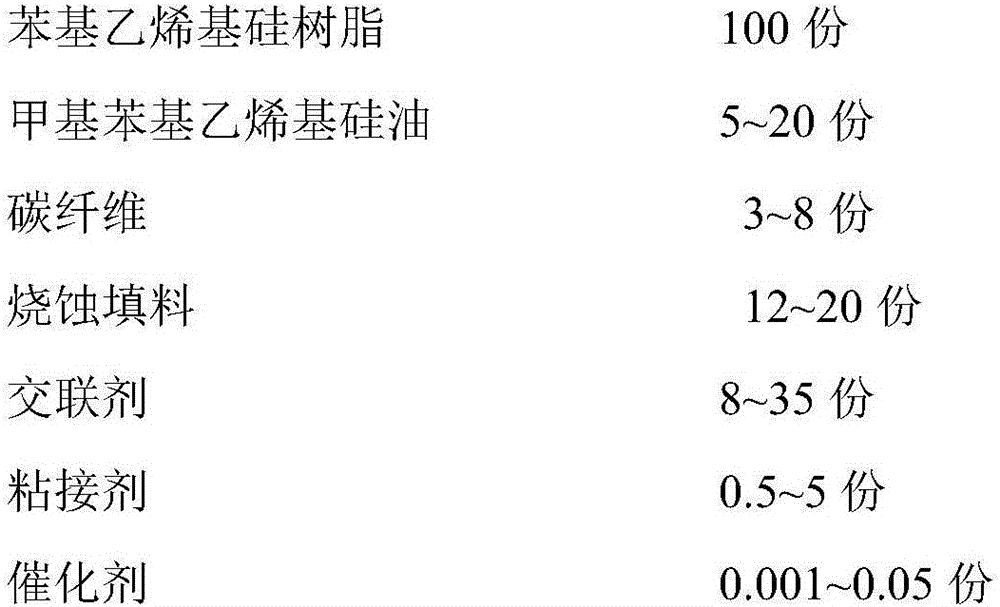

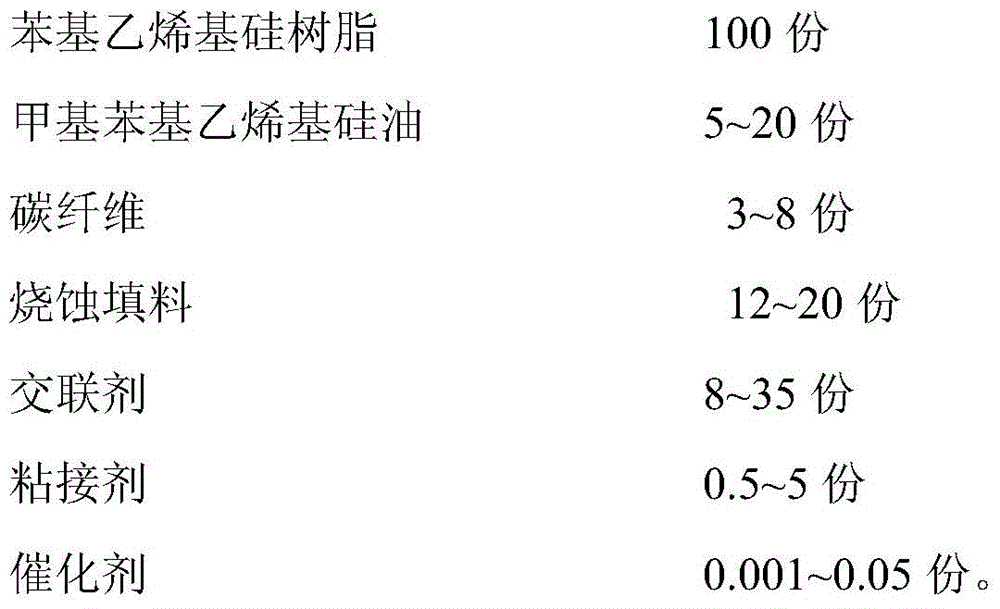

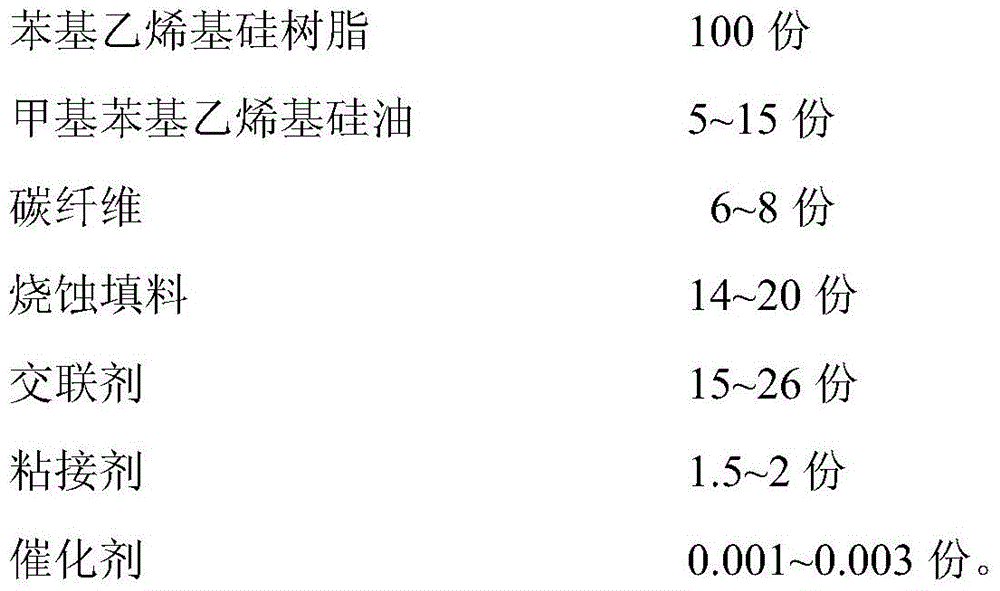

Silicon resin coating layer material as well as preparation method and use method thereof

The invention relates to a silicon resin coating layer material as well as a preparation method and a use method thereof. The silicon resin coating layer material is prepared by mixing the following raw materials in parts by weight: 100 parts of phenyl vinyl silicon resin, 5-20 parts of methyl phenyl vinyl silicone oil, 3-8 parts of carbon fibers, 12-20 parts of ablative fillers, 8-35 parts of a cross-linking agent, 0.5-5 parts of an adhesive and 0.001-0.05 parts of a catalyst. The coating layer material prepared from the silicon resin as a base material does not need to be reinforced with white carbon black and is excellent in mechanical property and ablation resistance; in addition, the compatibility of the adhesive and a sizing material is good; the coating layer material can be stored for a long term after being prepared, does not need priming during use and is an ideal propellant coating material.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Eye mask for moisturizing and removing beverage and wrinkles and preparation method of eye mask

InactiveCN104083296ARepairs and strengthens natural barrier functionRepair and enhance mobilityCosmetic preparationsToilet preparationsWrinkle skinAntioxidant

The invention discloses an eye mask for moisturizing and removing beverage and wrinkles and a preparation method of the eye mask. The eye mask comprises a coating layer, an active layer, a pervious bed and an isolated layer, wherein the active layer is prepared from kiwifruit seed oil, peony seed oil, tea oil, almond oil, antioxidant, glycerinum, isopropyl myristate and essence. The preparation method of the eye mask comprises the following steps: (1) weighing the kiwifruit seed oil, the peony seed oil, the tea oil, the almond oil, the antioxidant, the glycerinum, the isopropyl myristate and the essence according to the ratio, then respectively feeding the materials to an agitating pan, heating to 50-70 DEG C, and stirring for 5-10 minutes at the speed of 30-60r / min, so as to obtain an active substance; (2) evenly coating the active substance on the coating layer, forming an active layer on the coating layer, then sequentially attaching the pervious bed on the active layer, attaching the isolated layer on the pervious bed, and then carrying out ultraviolet sterilization, so as to obtain the product disclosed by the invention. The product disclosed by the invention is mild in process and condition, and can prevent the activity of an oily ingredient from being damaged, and the final product is convenient to use, and has a plurality of effects of moisturizing, removing beverage and wrinkles, and the like.

Owner:HUNAN AMAZING GRACE BIOTECH

Micro-foaming PA/ASA (polyamide/acrylonitrile styrene acrylate) material and preparation method thereof

The invention discloses a micro-foaming PA / ASA (polyamide / acrylonitrile styrene acrylate) material and a preparation method thereof. The micro-foaming PA / ASA material is prepared from PA resin, ASA resin, a toughening agent, a lubricating agent, a compatilizer, an antioxidant and a foaming agent in parts by weight by virtue of two-step method fusion and extrusion as well as injection molding. The toughness of the material is improved, and the material has excellent mechanical properties of both PA and ASA, and is stable in size, good in fluidity and excellent in weathering resistance; and meanwhile, the problems of poor fluidity and shrinkage marks during injection molding of a PA / ASA product are solved, so that the micro-foaming PA / ASA material can be widely applied to the fields of automobiles, electronic appliances, electric tools and the like.

Owner:ORINKO NEW MATERIAL CO LTD

Pavement abrasion-resistant layer based on epoxy resin and method for preparing same

InactiveCN102775947AHigh strengthImprove toughnessIn situ pavingsNon-macromolecular adhesive additivesPolymer scienceFirming agent

The invention relates to the technical field of using epoxy resin thin layer materials for paving pavements directly, in particular to a pavement abrasion-resistant layer based on the epoxy resin. The pavement abrasion-resistant layer is composed of materials of, by weight, 65 parts to 85 parts of epoxy resin, 10 parts to 27 parts of modified epoxy resin, 4 parts to 12 parts of dioctyl phthalate, 14 parts to 28 parts of amino-terminated polyether (for short, ATPE), 15 parts to 35 parts of alicyclic amine hardeners, 10 parts to 25 parts of modified amine hardeners and 30 parts to 50 parts of curing accelerators. The invention relates to a method for preparing the pavement abrasion-resistant layer based on the epoxy resin simultaneously. The method has the advantages of being high in strength, good in toughness, high in shock-resistant strength, good in chemical corrosion resistant, abrasion-resistant, water-proof and anti-freeze performances, and capable of being widely used in construction industries of bridges, roads, buildings and the like, and having broad development prospect.

Owner:HUBEI QIANGHUA ROAD & BRIDGE SURFACE NEW MATERIALS PAVING ENG

Laser melting forming method and device for pure copper part

InactiveCN111940731APrevent oxidationSimple processAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningUltrasonic vibration

The invention discloses a laser melting forming method and device for a pure copper part. The forming method comprises the steps that a substrate is arranged on a heating plate, and the substrate is preheated; a forming bin is vacuumized and then filled with inert gas; pure copper powder is stacked on the substrate layer by layer, laser scanning melting is carried out layer by layer according to apreset scanning path, and finally the pure copper part is formed; the forming method further comprises the steps that monitoring is carried out on the temperature of a molten pool in the laser scanning melting process; and when the temperature of the molten pool is lower than the preset temperature, the substrate is controlled to vibrate until the temperature of the molten pool is recovered to apreset temperature range value. According to the laser melting forming method and device for the pure copper part, the problem of pure copper oxidation can be avoided, the technological process is simple, convenient and stable, and the pure copper part can be formed at a time; and meanwhile, the liquidity of molten metal in a molten pool is improved, bubbles overflow quickly, the solidification state of the molten pool is improved under the action of ultrasonic vibration, sufficient feeding is achieved, and the phenomena of incomplete fusion in layers and poor interlayer bonding in the pure copper solidification process are reduced.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding

ActiveCN112404795AFast solidificationEasily ionizedWelding/cutting media/materialsSoldering mediaSilica fumeNitriding

The invention relates to a seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding. According to the technical scheme, the seamless self-protection flux-coredwire is composed of 70 wt%-80 wt% of a stainless steel strip and 20 wt%-30 wt% of flux-cored powder, and the stainless steel strip is filled with the flux-cored powder. The stainless steel strip comprises the following chemical components of, in percentage by weight, 0.03-0.08 wt% of C, less than or equal to 1wt% of Si, less than or equal to 2 wt% of Mn, 18-20 wt% of Cr, 8-11 wt% of Ni, less thanor equal to 0.03 wt% of S, less than or equal to 0.03 wt% of P and the balance Fe and inevitable impurities. The flux-cored powder comprises the following chemical components of, in percentage by weight, 40-43 wt% of barium fluoride, 5-8 wt% of marble, 8-10 wt% of aluminum powder, 2-4 wt% of silicon powder, 7-10 wt% of manganese powder, 2-5 wt% of manganese nitride, 10-13 wt% of nickel powder, 5-7 wt% of chromium powder and the balance iron powder. According to the seamless self-protection flux-cored wire, weld metal formed by welding the low-nitrogen non-magnetic naval vessel steel is high in strength, good in ductility and toughness, non-magnetic and excellent in seawater corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

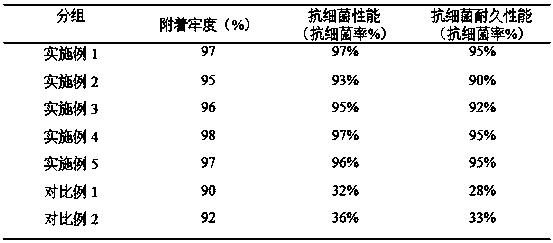

Water-based ink with antibacterial properties and preparation method thereof

The invention discloses a water-based ink with antibacterial properties and a preparation method thereof. The water-based ink is prepared from the following components in parts by weight: 20~30 partsof water-based acrylic resin, 6~10 parts of pigment, 15~20 parts offilling, 3~5 parts ofan additive, 3~5 parts ofan antibacterial agentand 35~45 parts ofa solvent. The solvent is prepared fromethyl alcohol,propanediol, ammonium hydroxide, ethanolamine and deionized water. Theweight ratio of the ethyl alcohol to the propanediol to the ammonium hydroxide to the ethanolamine tothe deionized waterare4~6:0.5~1.5:1~3:0.5~1.5:30~35, and the mass concentration of the ammonium hydroxide is 23%~28%.The water-based antibacterial ink mainly uses water as solvents,volatilization of organic volatiles can be effectively reduced,green environmental protection can be realized, and the ink obtained has a good dispersing, adhesion and antibacterial properties.

Owner:杭州杭氧化医工程有限公司

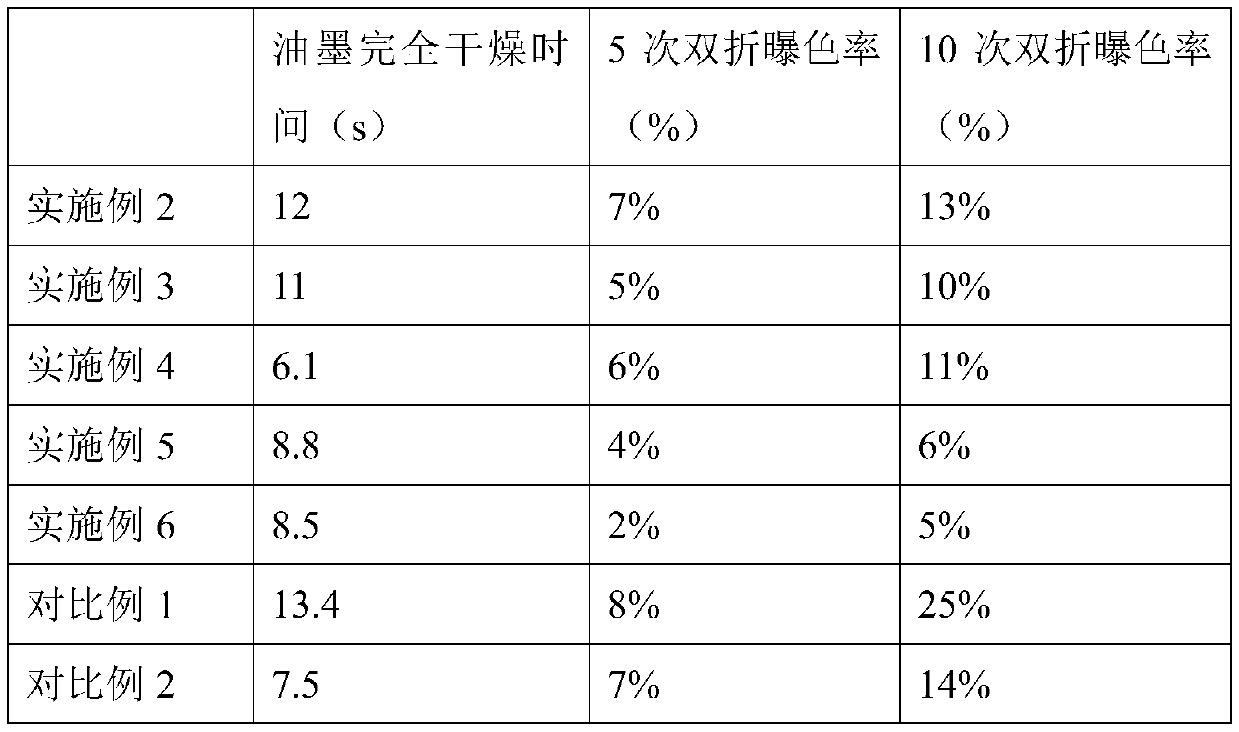

Laser paper printing ink and preparation method thereof

The invention relates to laser paper printing ink and a preparation method thereof. The laser paper printing ink comprises the following ingredients (by weight): 15-20 parts of waterborne acrylic resin, 10-20 parts of waterborne polyurethane resin, 10-18 parts of dipropylene glycol diacrylate, 15-20 parts of a pigment, 6-10 parts of nanometer titanium dioxide, 2-4 parts of nano-zinc oxide, 8-10 parts of a filler, 14-20 parts of a reactive diluent, 3-5 parts of a photoinitiator, 1-3 parts of a photosensitizer, and 0.1-0.2 part of an auxiliary agent. The invention is beneficial for the ink to adhere to the surface of a printed material by the surface tension at the initial stage of drying; and in the drying process of the printing ink which is thoroughly adhered to the surface of the printedmaterial by solvent volatilization and penetration into the printed material, the formed net structure can make the solvent to be volatilized at a proper drying rate. In addition, due to high viscosity, cohesiveness of the printing ink penetrating through the printed material can be improved, and the color exposure problem is reduced.

Owner:宜昌金兴新材料有限公司

Heat-preservation and heat-insulation putty powder and preparation method thereof

The invention discloses heat-preservation and heat-insulation putty powder and a preparation method thereof. The heat-preservation and heat-insulation putty powder is prepared from the following raw materials in parts by weight: 600 to 700 parts of calcium triple superphosphate powder, 50 parts of indianite nanotubes, 50 parts of kaolin, 50 parts of glass fibers, 150 to 250 parts of white cement,30 parts of redispersible latex powder, 3 to 5 parts of carboxymethyl cellulose and 3 to 5 parts of modified starch ether. The preparation method of the heat-preservation and heat-insulation putty powder comprises the following steps: crushing inorganic components and organic components respectively and mixing. The putty powder disclosed by the invention has the advantages of environment-friendlymaterials, simple preparation technology, easiness for construction and polishing and high bonding strength; especially, the putty powder has heat-preservation and heat-insulation effects, belongs toa functional putty powder product and has a very good market prospect.

Owner:衢州顺天钙业有限公司 +1

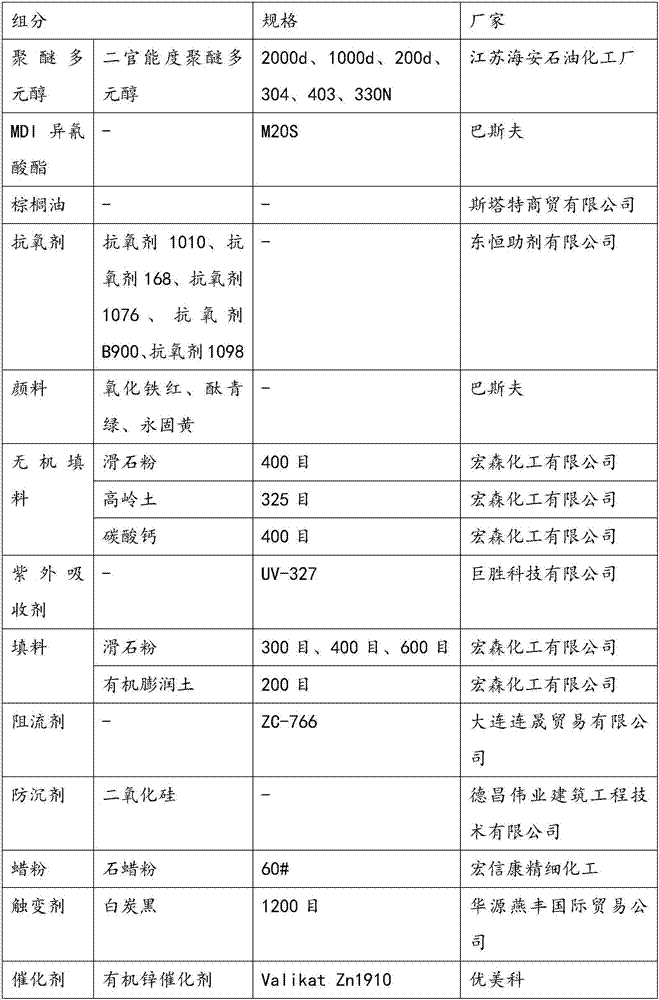

All-plastic water-ripple self-setting runway and preparation method thereof

ActiveCN107245296AIncrease elasticityRegulate fluidityGround pavingsPolyurea/polyurethane coatingsWaxPolyol

The invention relates to an all-plastic water-ripple self-setting runway and a preparation method thereof. The all-plastic water-ripple self-setting runway comprises a bottom base layer, a prime coat, a flexible elastic layer and a water ripple surface layer which are sequentially arranged from bottom to top, wherein the flexible elastic layer is prepared by mixing a component A and a component B in a mass ratio of 1:(5.3-7.2) with 0.3-0.5 wt% of a catalyst and performing spreading and leveling; the water ripple surface layer is prepared by spraying and mixing a component C and a component D in a mass ratio of 1:(1.8-2.3); the component A is prepared by mixing polyether polyols, MDI and palm oil; the component B is prepared by mixing polyether polyols, an antioxidant, a pigment, an inorganic filler, an ultraviolet absorbent and palm oil; the component C is prepared by mixing MDI and polyether polyols; and the component D is prepared by mixing polyether polyols, an antioxidant, a pigment, a filler, an ultraviolet absorbent, a stop-off agent, an anti-settling agent, wax powder and a thixotropic agent. The all-plastic water-ripple self-setting runway has the advantages of impact resistance and no granule shedding.

Owner:陈两

Low-shrinkage and high-adhesion black concrete as well as preparation method and application thereof

ActiveCN109133795AHigh blacknessIncreased durabilityCeramic shaping apparatusBridge structural detailsIron BlackLow shrinkage

The invention discloses low-shrinkage and high-adhesion black concrete. By compounding carbon black and iron black and adding other components, size of capillary pores of a concrete matrix is reduced,microstructure of the matrix is enabled to be matched with diameter of water-soluble carbon black particles, so that the carbon black particles and iron oxide black powder are fixed better, slurry flowability is adjusted, the concrete is endowed with higher blackness and durability by coupling mechanical fixing and static fixing, and an asphalt bridge surface can keep color consistency for a longtime. Meanwhile, by introducing a water reducing agent and a water retention component, the problem of poor concrete workability caused by high doping amount of carbon black is solved, and slurry viscosity and workability are improved under the condition that strength of the matrix is guaranteed.

Owner:JIANGSU SOBUTE NEW MATERIALS

PVC composition for inspection wells and preparation method thereof

The invention discloses a PVC composition for inspection wells and a preparation method thereof, and belongs to the PVC processing technical field. The composition is composed of the following components by the weight percentage: 50-70% of a PVC compound, 20-30% of an acrylonitrile-styrene-butadiene copolymer resin, and 10-20% of a composite rigid particle modifier. The PVC compound is composed of the following components in parts by weight: 100 parts of PVC resin, 5-8 parts of a calcium zinc stabilizer, 1.5-3.5 parts of a lubricant, 0.8-1.5 parts of a weather resistance modifier, and 1-2 parts of a colorant. The composite rigid particle modifier is a compound obtained by compounding AS resin and nano calcium carbonate according to the weight ratio of 1 to (4-6). The composition adopts rigid particles for toughening, so that the ring stiffness and the tensile strength of the composition are greatly improved under the condition without reduction of the impact strength of the composition; and the cost is low, and the production method is simple, convenient and controllable.

Owner:CHINA PETROLEUM & CHEM CORP

Prepn of high flowability polypropylene

The present invention relates to the preparation process of high flowability polypropylene and solves the technological problem of providing high energy ray preparation process of high melt flowability polypropylene. The present invention features that polypropylene grains are set inside high energy ray irradiation chamber and irradiated in the irradiation dosage over 100 Mrad at normal temperature for over 10 hr to obtain high flowability polypropylene with melt rate of flow MRF as high as 50-100 g / 10 min. The present invention adopts high energy gamma ray with powerful penetration capacity and homogeneous degradation from inside grain to outside and can regulate the flowability of the polypropylene product easily via regulating irradiation dosage. The process of the present invention needs no mechanical stirring, low power consumption and low cost.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

A kind of silicone resin covering layer material and its preparation and use method

ActiveCN104610753BImproves ablation resistanceGood self-adhesiveRocket engine plantsFiberPolymer science

The invention relates to a silicon resin coating layer material as well as a preparation method and a use method thereof. The silicon resin coating layer material is prepared by mixing the following raw materials in parts by weight: 100 parts of phenyl vinyl silicon resin, 5-20 parts of methyl phenyl vinyl silicone oil, 3-8 parts of carbon fibers, 12-20 parts of ablative fillers, 8-35 parts of a cross-linking agent, 0.5-5 parts of an adhesive and 0.001-0.05 parts of a catalyst. The coating layer material prepared from the silicon resin as a base material does not need to be reinforced with white carbon black and is excellent in mechanical property and ablation resistance; in addition, the compatibility of the adhesive and a sizing material is good; the coating layer material can be stored for a long term after being prepared, does not need priming during use and is an ideal propellant coating material.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Method for regulating composition and structure of mesophase pitch through thermal copolymerization reaction

ActiveCN109610049AShorten the formation timeShort manufacturing timeFibre chemical featuresThermal stateActive component

The invention relates to a method for regulating the composition and structure of mesophase pitch through a thermal copolymerization reaction. The method comprises the following steps: firstly, addingan aromatic active component containing a branched chain into high-aromaticity fused ring pitch, so as to ensure that a pitch material is uniformly mixed at a thermal state; secondly, ensuring that the uniformly mixed pitch material is subjected to self pressure boost in a closed container, so as to be subjected to thermal copolymerization reaction; thirdly, performing melt spinning treatment, oxidation resistance non-melting treatment and high-temperature carbonization treatment on mesophase pitch obtained through thermal copolymerization reaction, so as to obtain mesophase pitch based carbon fiber. Through the regulation of the composition and the structure of the mesophase pitch material, the purpose of reducing of the splitting degree of the mesophase pitch based carbon fiber is realized, so that the structure and the performance of the carbon fiber are improved.

Owner:WUHAN UNIV OF SCI & TECH

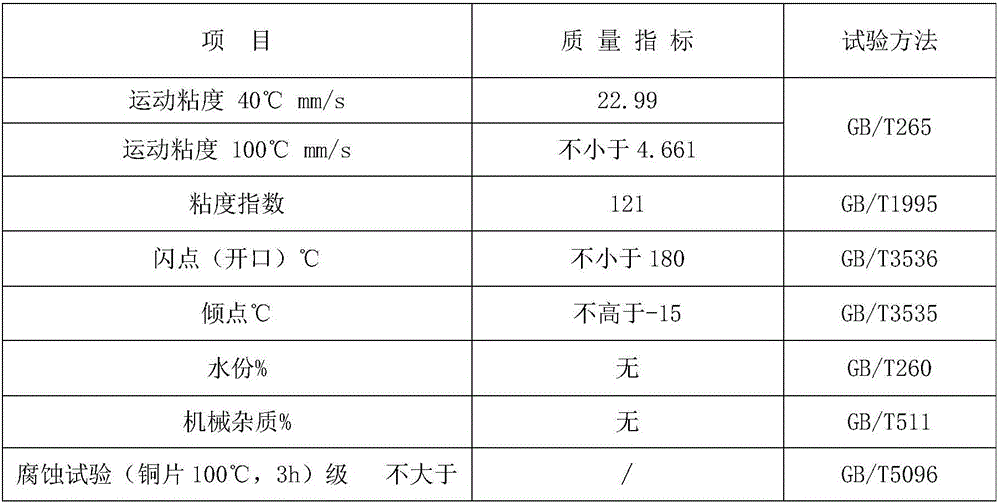

Isostatic press oil for sinter molding of rare earth magnet steel, and preparation method of isostatic press oil

InactiveCN106010750ALow viscosityImprove liquidityLubricant compositionDispersityTriethanolamine oleate

The invention discloses isostatic press oil for sinter molding of rare earth magnet steel. The isostatic press oil is colorless and odorless transparent liquid and has the characteristics of being low in viscosity, good in fluidity, high in viscosity index and the like; the isostatic press oil is capable of evenly passing pressure, and products processed by using the isostatic press oil are easy to clean; a flow promoting agent adopting triethanolamine oleate as a main material is added into the isostatic press oil, and the flow promoting agent has good dispersity and fluidity, is fine, smooth and soft in material texture and has good stability, so that the viscosity of the oil is well reduced, and the fluidity of the oil is improved. Furthermore, gel prepared by taking ethyl orthosilicate as a silicon source is added into the isostatic press oil, and the gel is capable of effectively promoting the dispersity of all raw materials and further adjusting the viscosity of the finished product oil at the same time, so that the stability of the finished product oil is improved.

Owner:浙江模德科技有限公司

Nanowhisker leveling thickener for paint and preparation method thereof

InactiveCN105985668ARegulate fluidityGood dispersionCoatingsPigment treatment with macromolecular organic compoundsSlagPerformance index

The invention discloses a nanowhisker leveling thickener for paint and a preparation method thereof. The nanowhisker leveling thickener is prepared from, by weight, 24-36 parts of attapulgite, 13-25 parts of sericite, 16-28 parts of dolomite, 20-30 parts of kyanite, 15-25 parts of phyllite, 8-16 parts of waste ardealite, 5-10 parts of carbide slag, 3-6 parts of sodium sulfate, 2-5 parts of barium fluoride, 1-3 parts of molybdenum trioxide, 6-12 parts of a modifier A and 4-8 parts of a modifier B. The nanowhisker leveling thickener is excellent in thickening and leveling performance, evident in sagging prevention effect and capable of effectively adjusting paint viscosity and preventing sagging of coatings, thick-layer paint can be achieved, and performance indexes of the prepared paint all reach national standard requirements on first-grade products.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

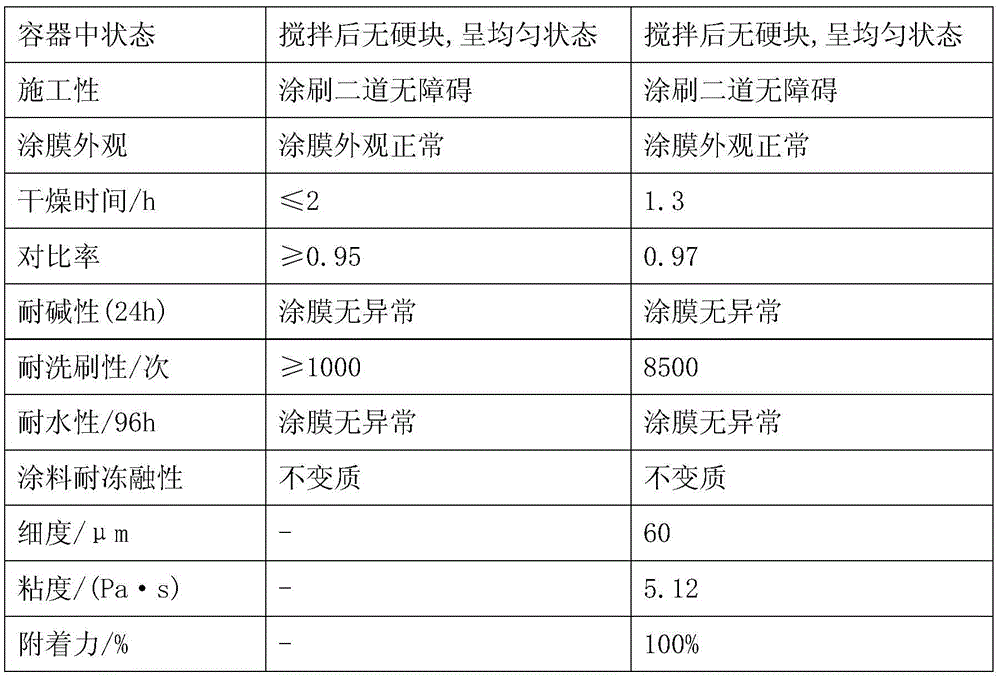

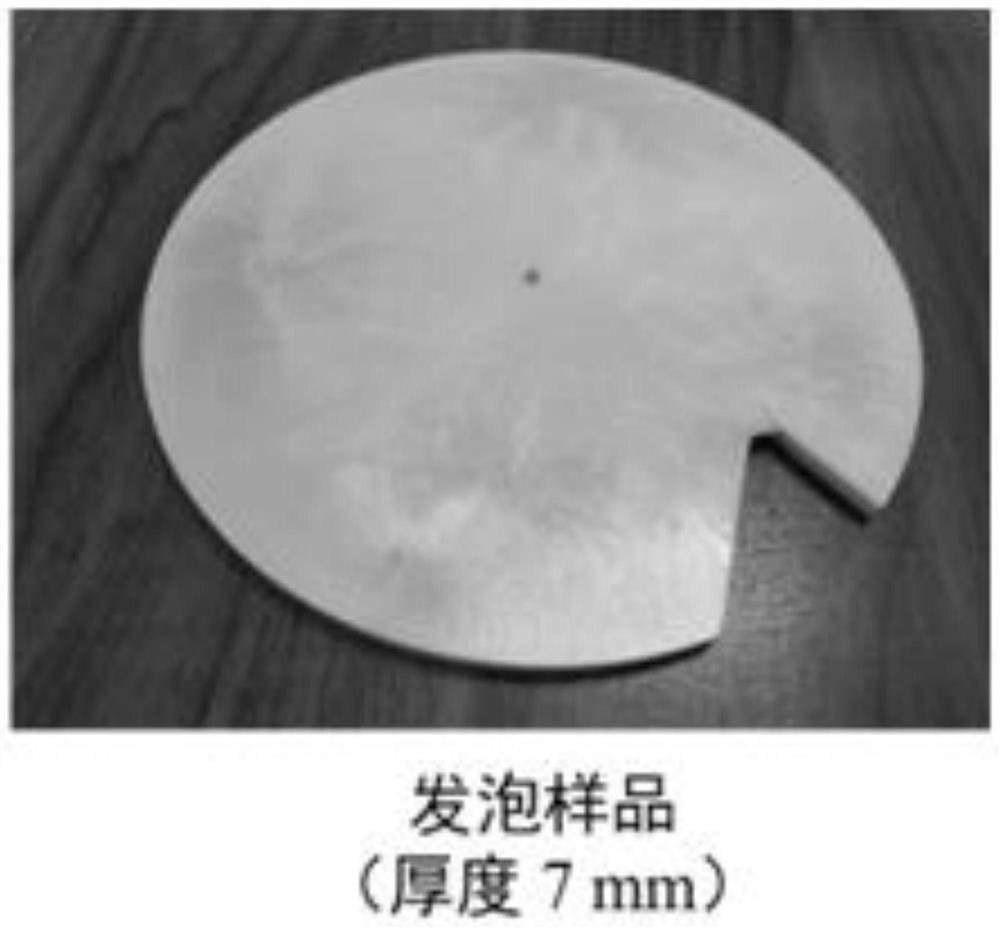

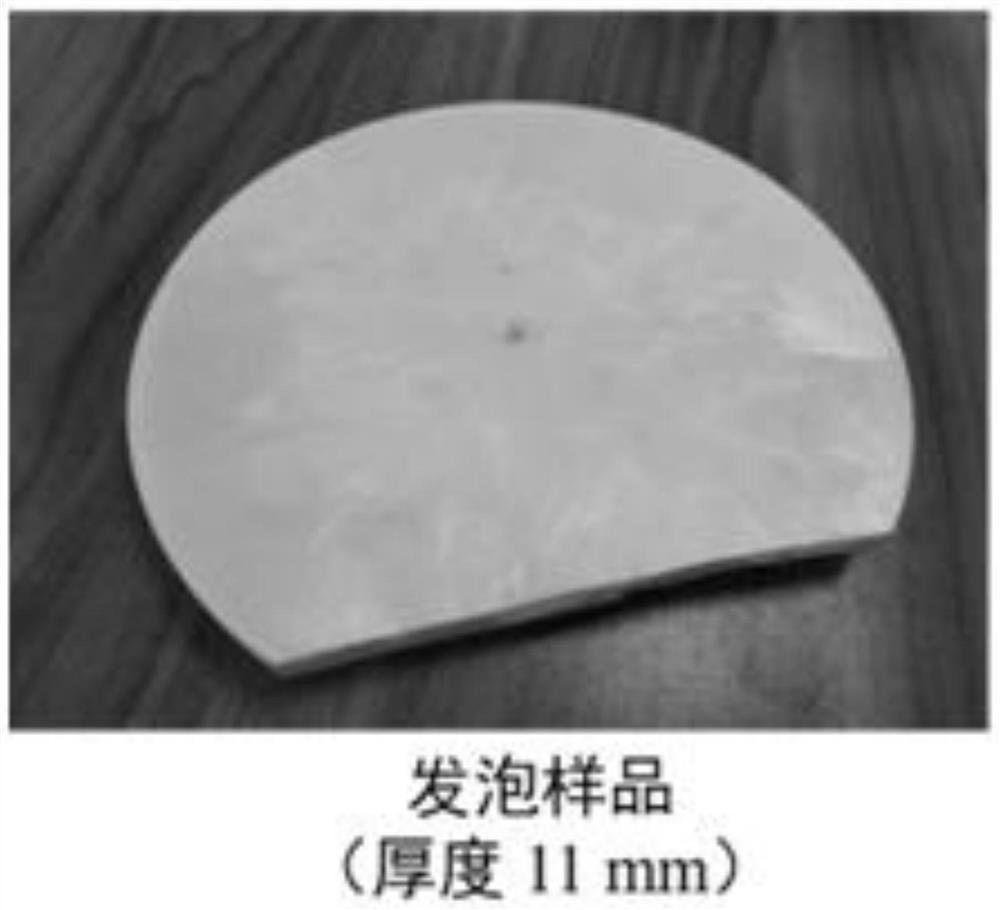

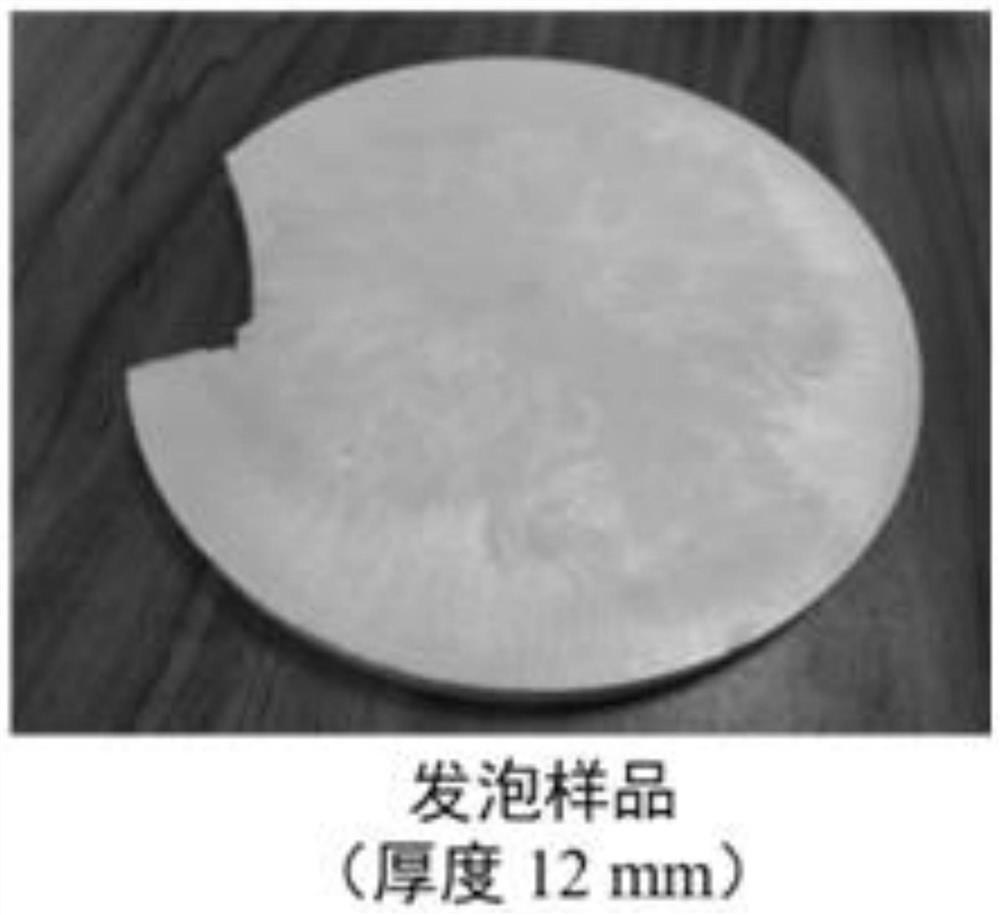

Foamed light diffusion material and preparation method thereof

ActiveCN113352536AReduce residual contentReduce the possibility of precipitation sticking moldBulk chemical productionPolymer scienceInjection molding process

The invention relates to the field of light diffusion materials, and particularly discloses a foamed light diffusion material and a preparation method thereof. The foamed light diffusion material is prepared from the components in parts by weight: 93-105 parts of PC, 0.1-0.5 part of antioxidant and 0.3-0.8 part of a release agent. The preparation method comprises the following steps that granules are prepared, and 93-105 parts by weight of PC, 0.1-0.5 part by weight of antioxidant and 0.3-0.8 part by weight of the release agent are uniformly mixed and extruded to obtain the granules; and injection molding foaming and monomer removal are carried out, supercritical carbon dioxide is injected in the injection molding process to carry out foaming and steam stripping monomer removal to obtain the foamed light diffusion material. The temperatures of different areas of a screw rod are 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 230 to 380 DEG C and 60 to 80 DEG C in sequence; and the pressure maintaining pressure is 60 to 100 MPa. The foamed light diffusion material can be used for processing an LED lamp housing, and has the advantages of high haze and low residual monomer content; and in addition, the preparation method has the advantage of reducing the possibility of mold sticking of a product in the processing process.

Owner:NINGBO ZHETIE DAPHOON CHEM

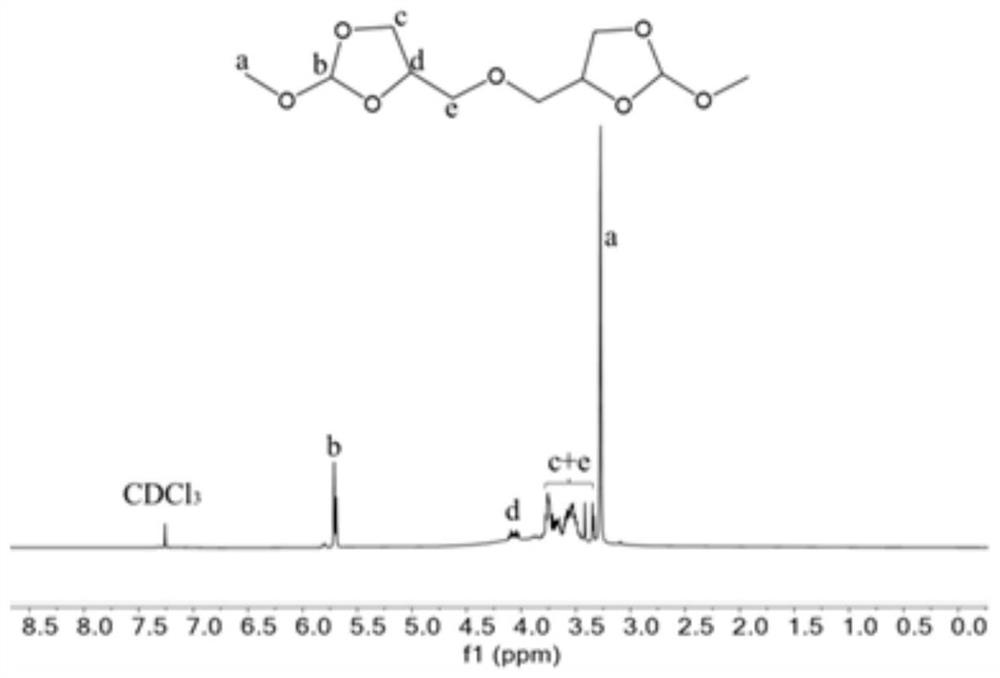

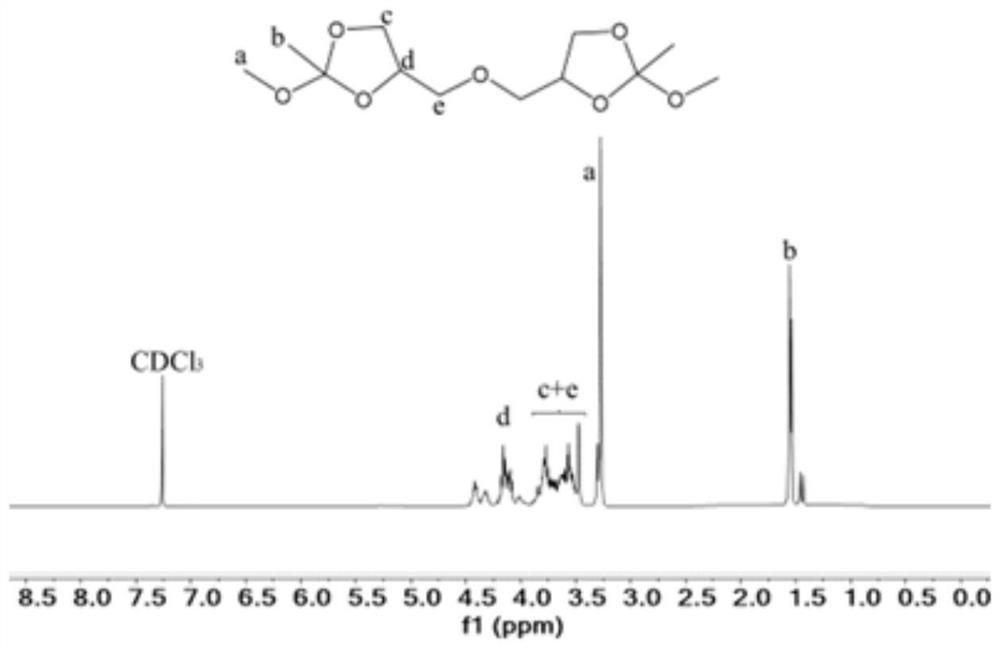

Orthoester miscible substance pharmaceutic adjuvant, preparation method and local sustained-release drug delivery preparation containing orthoester miscible substance pharmaceutic adjuvant

PendingCN114366711AEasy to prepareWon't breakOrganic chemistryAerosol deliveryDrug release rateEthyl group

The invention discloses an orthoester miscible pharmaceutical adjuvant, which relates to the field of pharmaceutical adjuvants and is mainly obtained by mixing and dissolving different orthoester compounds according to different proportions or mixing and dissolving orthoester compounds and biocompatible medical polymer materials according to different proportions. The chemical formula I of the orthoester compound is shown in the specification, wherein R represents hydrogen, methyl, ethyl, propyl, isopropyl, butyl or phenyl. The invention also provides a preparation method of the pharmaceutic adjuvant and a local sustained-release drug delivery preparation containing the adjuvant. The invention has the following beneficial effects: the fluidity of the orthoester miscible pharmaceutical adjuvant is adjustable; the degradation rate is adjustable, and the drug release rate is adjustable; a good solvent, which can dissolve small molecule and protein drugs; local injections, cream and ointment can be prepared; the biological compatibility is good, the metabolism is clear, and the clinical conversion use is easy.

Owner:ANHUI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com