Silicon resin coating layer material as well as preparation method and use method thereof

A coating layer, silicone resin technology, applied in mechanical equipment, jet propulsion devices, rocket engine devices, etc., can solve problems such as inconvenience in construction, and achieve the effects of convenient construction operation, good compatibility, and excellent ablation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

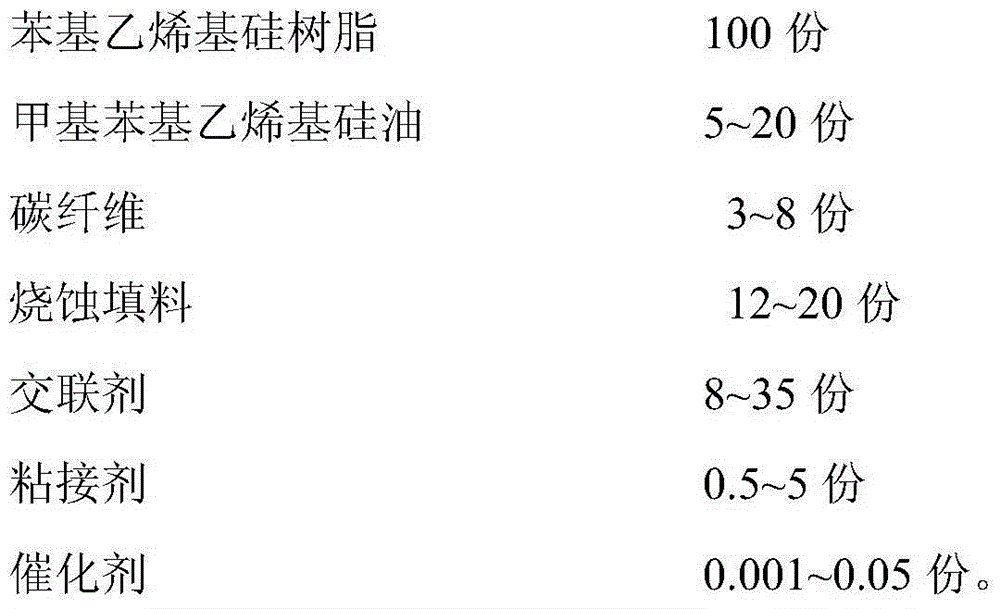

[0024] Silicone resin covering layer material is made of the following raw materials in parts by weight:

[0025]

[0026] Among them, phenyl vinyl silicone resin, Vi content 3.62wt.%, R / Si=1.48, Ph / R=50.77%; methyl phenyl vinyl silicone oil, Vi content 0.2wt.%, Ph / R 30% , viscosity (25°C) 1000mpa s; the crosslinking agent is phenyl hydrogen-containing silicone oil, the hydrogen content is 0.6wt.%, and the phenyl content is 58%; the adhesive is silanol-terminated methylphenyl vinyl silicone Alkane oligomer and KH560 condensation reaction product; catalyst is tetramethyldivinyl disiloxane complex with platinum content of 2%; ablation filler is made of silicon carbide, aluminum oxide, zinc oxide according to the mass ratio of 7:7 : 4 compositions.

[0027] The preparation method is as follows:

[0028] Using a three-roll mill, add phenyl vinyl silicone resin, methyl phenyl vinyl silicone oil, carbon fiber, ablation filler, crosslinking agent, and adhesive in sequence, and m...

Embodiment 2

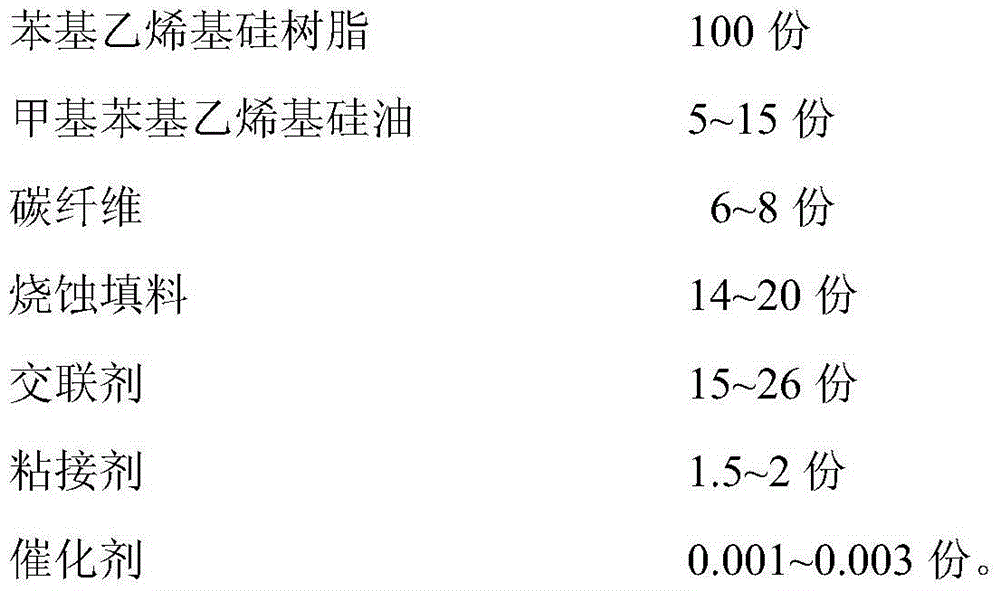

[0030] Silicone resin covering layer material is made of the following raw materials in parts by weight:

[0031]

[0032] Among them, phenyl vinyl silicone resin, Vi content 5.86wt.%, R / Si=1.48, Ph / R=50.77%; methyl phenyl vinyl silicone oil, Vi content 0.2wt.%, Ph / R 30% , viscosity 1000mpa s; crosslinking agent hydrogen content 1.5wt.%, phenyl content 30%; adhesive agent is the condensation reaction product of silanol-terminated methylphenyl vinyl siloxane oligomer and KH560; catalyst It is a tetramethyldivinyldisiloxane complex with a platinum content of 2%. The ablation filler is composed of silicon carbide, aluminum oxide, and zinc oxide in a mass ratio of 7:7:4.

[0033] The preparation method is as follows:

[0034] Using a three-roll mill, add phenyl vinyl silicone resin, methyl phenyl vinyl silicone oil, crosslinking agent, adhesive, carbon fiber, and ablation filler in sequence, and mix the materials to obtain a glue with uniform dispersion and stable performance....

Embodiment 3

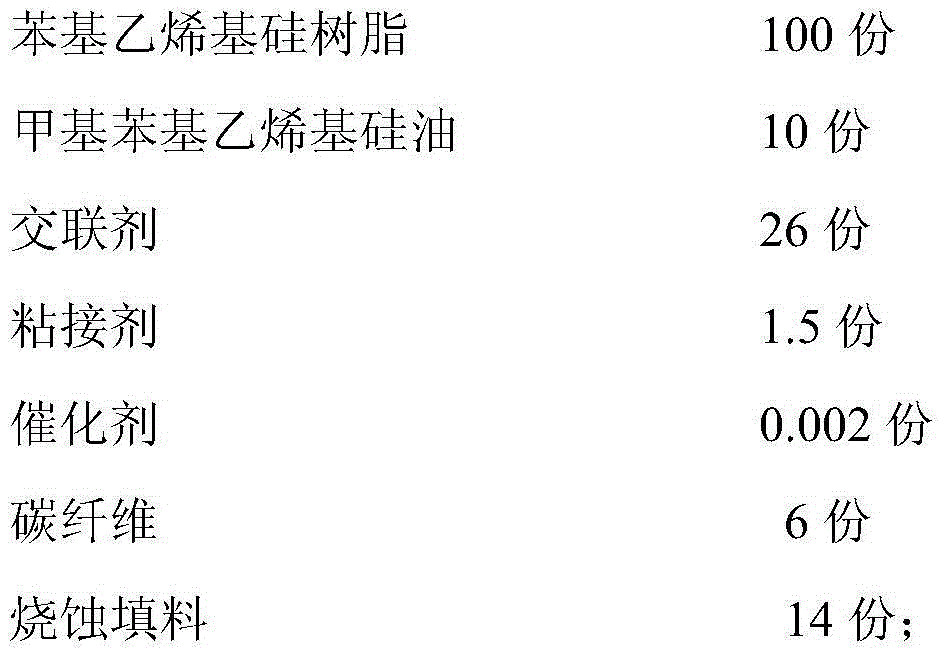

[0036] Silicone resin covering layer material is made of the following raw materials in parts by weight:

[0037]

[0038] Among them, phenyl vinyl silicone resin, Vi content 5.86wt.%, R / Si=1.48, Ph / R=50.77%; methyl phenyl vinyl silicone oil, Vi content 0.2wt.%, Ph / R 30% , viscosity 1000mpa s; crosslinking agent hydrogen content 1.5wt.%, phenyl content 30%; adhesive agent is the condensation reaction product of silanol-terminated methylphenyl vinyl siloxane oligomer and KH560; catalyst It is a tetramethyldivinyldisiloxane complex with a platinum content of 2%. The ablation filler is composed of silicon carbide, aluminum oxide, and zinc oxide in a mass ratio of 7:7:4.

[0039] The preparation method is as follows:

[0040] Using a three-roll mill, add phenyl vinyl silicone resin, crosslinking agent, adhesive, carbon fiber, and ablation filler in sequence, and mix the materials to obtain a rubber compound with uniform dispersion and stable performance. Before use, add the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com