Patents

Literature

98 results about "RTV silicone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

RTV Silicone (Room-Temperature-Vulcanizing silicone) is a type of silicone rubber made from a two-component system (base plus curative; A+B) available in a hardness range of very soft to medium--usually from 15 to 40 Shore A. RTV silicones can be cured with a catalyst consisting of either platinum or a tin compound such as dibutyltin dilaurate. Applications include low-temperature over-molding, making molds for reproducing, and lens applications for some optically clear grades.

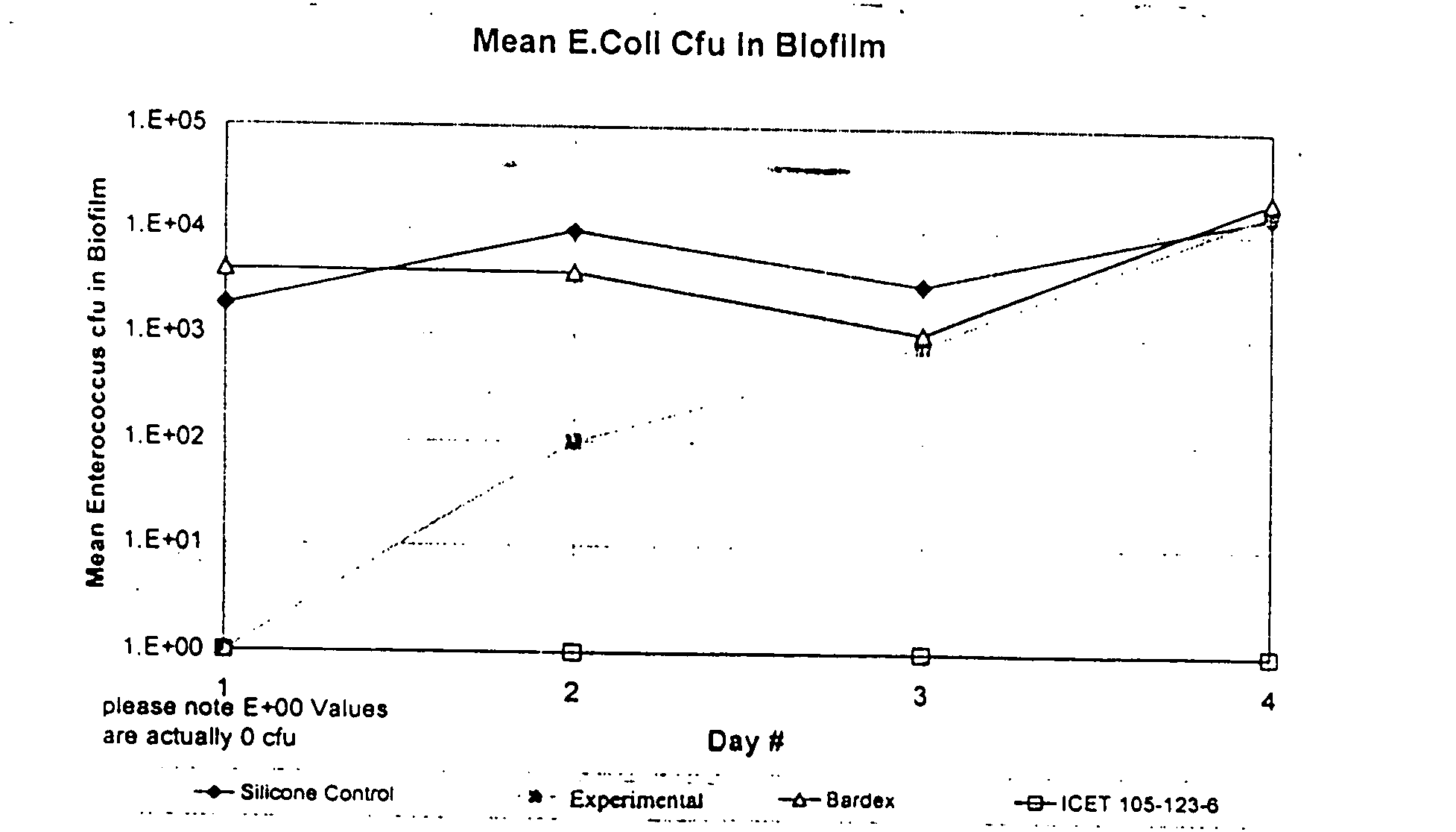

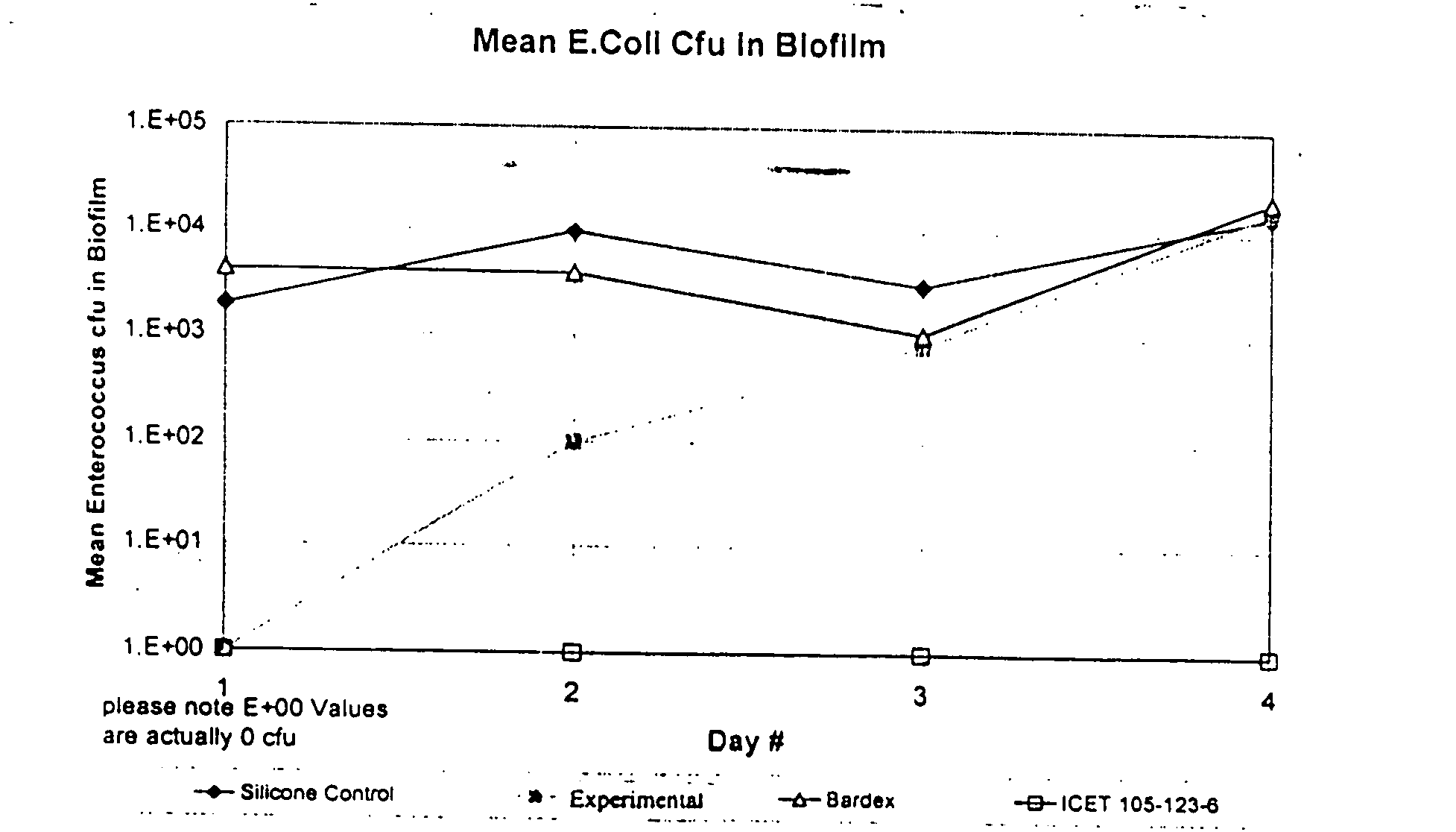

Antimicrobial composition for medical articles

InactiveUS20050048124A1Inhibition formationImprove the lubrication effectPowder deliveryBiocideSolventCalcium Chelator

An antimicrobial composition is formed from about 5 to about 25 wt % of an antimicrobial formulation and about 75 to about 95 wt % of a silicone resin. The antimicrobial formulation is formed from about 60 to about 95 wt % of an antimicrobial material, about 1 to about 30 wt % calcium chelator, about 0.001 to about 0.25 wt % pigment, and about 0.5 to about 3.5 wt % lubricant. The silicone resin may be a dispersion of about 40 to about 60 w / v % of an RTV silicone resin in a solvent, a liquid silicone resin, or a solid silicone resin. An antimicrobial coating may be formed on the surface of an article by applying an antimicrobial composition to the article and permitting the solvent to evaporate. It may also be formed by making a mixture of about 5 to about 12 wt % of an antimicrobial formulation and about 88 to about 95 wt % of a liquid or solid silicone resin and molding, overmolding, or extruding the article from the compounded mixture.

Owner:ICET

RTV silicone composition offering rapid bond strength

InactiveUS20050192387A1High strengthDevelop green strengthOther chemical processesSpecial tyresRoom temperatureUltimate tensile strength

The present invention provides for a room temperature vulcanizable silicone sealant composition that rapidly achieves a usable green strength shortly after application. Such a composition that develops a usable green strength is useful in the manufacture of architectural elements employing glazing such as windows and doors and when such a composition is used in a manufacturing process, the manufacturing process can be accelerated relative to a process that uses a silicone sealant that does not rapidly achieve a usable green strength.

Owner:GENERAL ELECTRIC CO

Heat-mediated conditioning from leave-on hair care compositions containing silicone

In brief, the present invention is directed to a method for conditioning hair which comprises: (a) applying to hair a leave-on composition comprising: (1) a nonvolatile, silicone conditioning agent; (2) a resin; and (3) a carrier; (b) applying heat via a heating appliance to the composition treated hair to dry or style the hair and wherein a reduction in the bending modulus caused by the silicone conditioning agent is at least 1.00%, even when offset by an increase in bending modulus caused by the presence of a resin, and wherein the method of the invention results in the deposition on the hair of at least 30 ug silicone / 1 g of hair.

Owner:HELENE CURTIS INDS

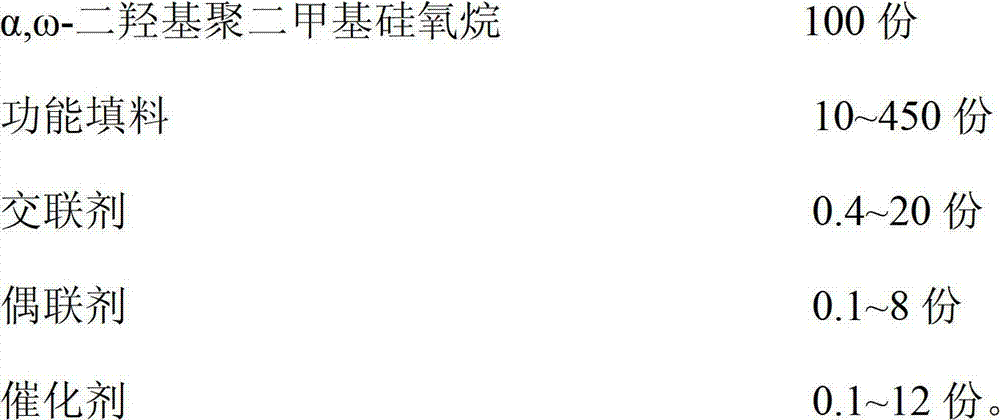

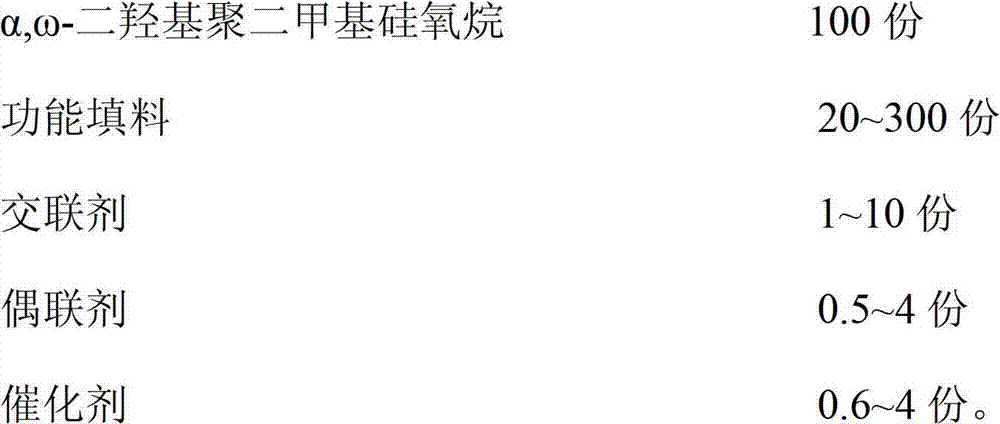

Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

InactiveCN102757647ANo viscosity peaksSimple processNon-macromolecular adhesive additivesOther chemical processesPolymer scienceRoom temperature

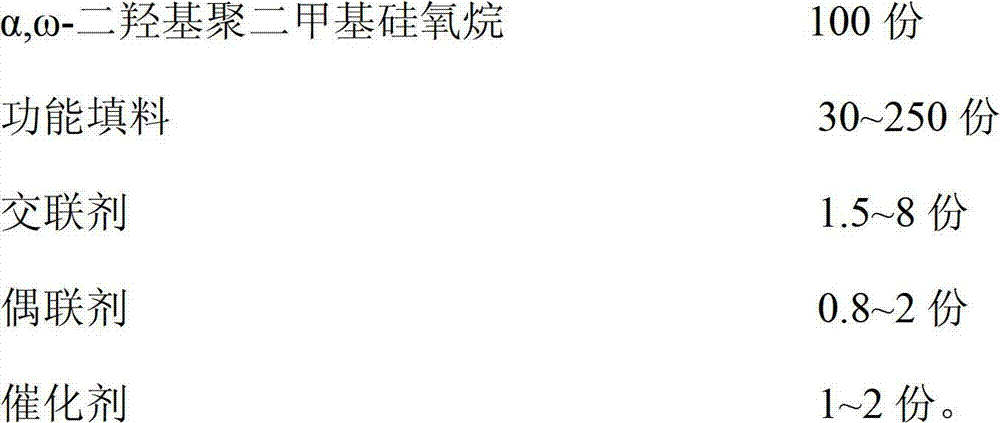

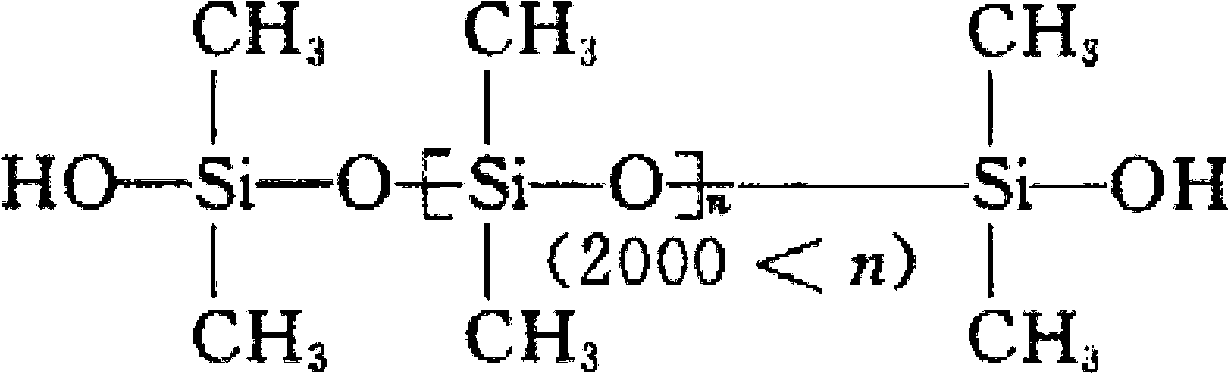

The invention relates to a single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber which comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 10-450 parts of function filler, 0.4-20 parts of crosslinking agent, 0.1-8 parts of coupling agent and 0.1-12 parts of catalyst. The invention also relates to a preparation method of the single-component catalytic dealcoholized RTV silicone rubber, and the method comprises the following steps of: preparing a ground mass, namely dewatering and blending the alpha, omega-dihydroxyl polydimethylsiloxane and the function filler to obtain the ground mass; stirring the taken ground mass in a vacuum state, adding the crosslinking agent, and stirring the materials in a vacuum state; adding the coupling agent, and stirring the materials; and adding the catalyst, vacuumizing, introducing inert gas, stirring, vacuumizing, and stirring to obtain the single-component catalytic dealcoholized RTV silicone rubber. The method provided by the invention has the advantages of no generation of viscosity peak, simple process and cost saving; and the single-component catalytic dealcoholized RTV silicone rubber has excellent comprehensive properties.

Owner:兆舜科技(广东)有限公司

RTV silicone rubber composition for electric and electronic part protection, circuit boards, silver electrodes, and silver chip resistors

InactiveUS7553901B2Prevent and retard partPrevent short-circuitingLayered productsSemiconductor/solid-state device detailsSulfur containingElectron

RTV silicone rubber compositions are provided comprising (A) an organopolysiloxane, (B) an organosilicon compound or partial hydrolytic condensate thereof, and (C) a non-aromatic amino-bearing compound. The compositions, when electric and electronic parts having a copper, silver or other metal portion on their surface are encapsulated or sealed therewith, can prevent or retard the parts from corrosion with sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

Adhesion primer for use with RTV silicones

A low VOC primer composition suitable for use with room temperature vulcanizable silicones, comprising a polyorganosiloxane resin, an acrylic resin, an organotitanate, a silane or partial hydrolyzate thereof and an organic liquid in amount effective to dissolve the other components of the primer composition that provides improved adhesion to diverse substrates.

Owner:GENERAL ELECTRIC CO

Antimicrobial composition for medical articles

InactiveUS7381751B2Inhibition formationImprove the lubrication effectBiocidePowder deliverySolventCalcium Chelator

An antimicrobial composition is formed from about 5 to about 25 wt % of an antimicrobial formulation and about 75 to about 95 wt % of a silicone resin. The antimicrobial formulation is formed from about 60 to about 95 wt % of an antimicrobial material, about 1 to about 30 wt % calcium chelator, about 0.001 to about 0.25 wt % pigment, and about 0.5 to about 3.5 wt % lubricant. The silicone resin may be a dispersion of about 40 to about 60 w / v % of an RTV silicone resin in a solvent, a liquid silicone resin, or a solid silicone resin. An antimicrobial coating may be formed on the surface of an article by applying an antimicrobial composition to the article and permitting the solvent to evaporate. It may also be formed by making a mixture of about 5 to about 12 wt % of an antimicrobial formulation and about 88 to about 95 wt % of a liquid or solid silicone resin and molding, overmolding, or extruding the article from the compounded mixture.

Owner:ICET

Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

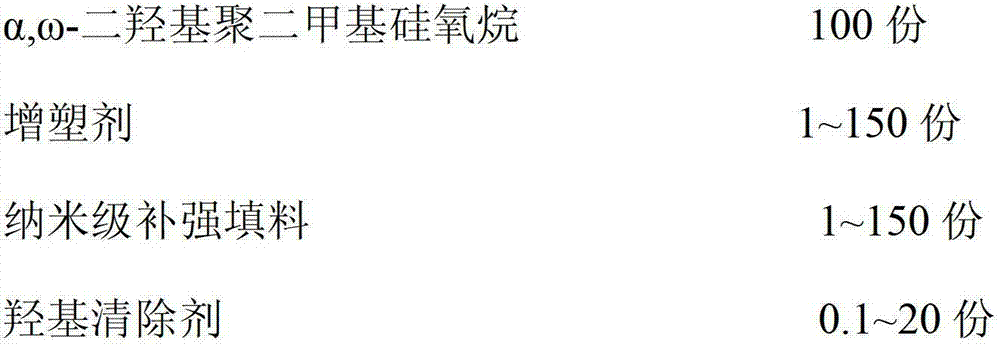

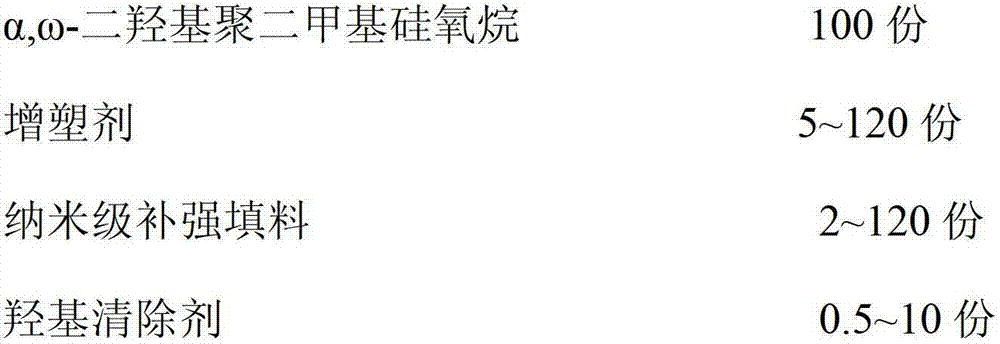

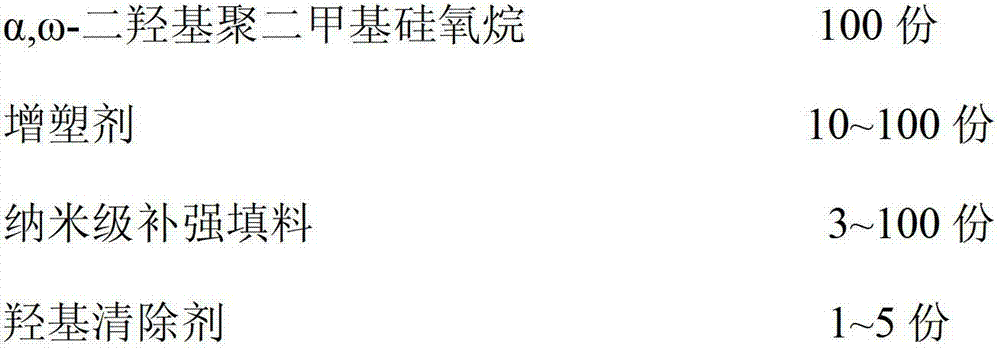

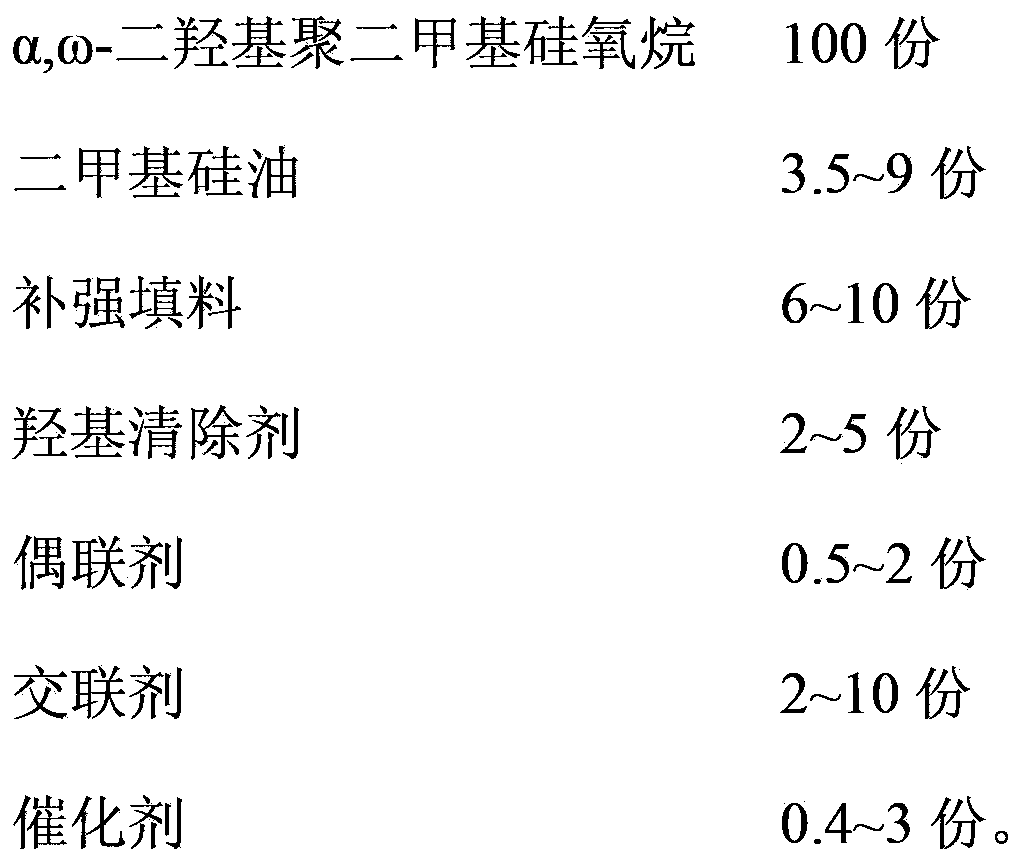

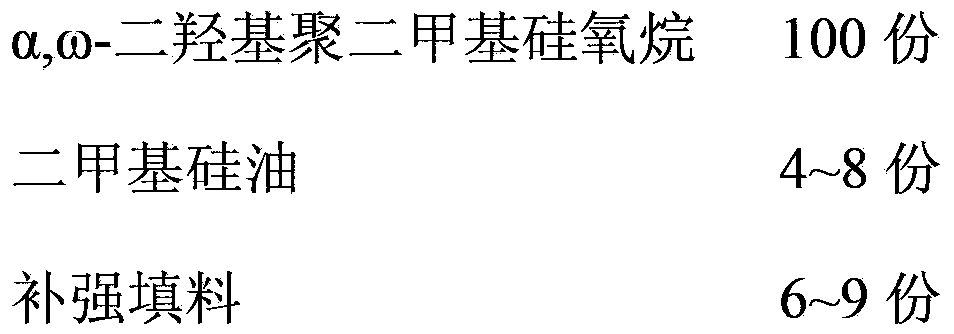

InactiveCN102757759AGood physical propertiesLong storage periodNon-macromolecular adhesive additivesOther chemical processesSealantDimethyl siloxane

The invention relates to a single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber. A ground mass comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 1-150 parts of plasticizer, 1-150 parts of nano level reinforced filler and 0.1-20 parts of hydroxyl clearing agent; and the single-component catalytic dealcoholized RTV silicone rubber comprises the following components in parts by weight: 100 parts of ground mass, 0.1-30 parts of crosslinking agent and 0.1-8 parts of coupling agent. The invention also relates to a preparation method of the single-component catalytic dealcoholized RTV silicone rubber, and the method comprises the following steps of: dewatering and blending the alpha, omega-dyhydroxyl polydimethylsiloxane, the plasticizer, the nano level reinforced filler and the hydroxyl clearing agent to obtain the ground mass; taking the ground mass, vacuumizing, stirring, adding the crosslinking agent, vacuumizing and stirring; and adding the coupling agent, vacuumizing and stirring to obtain the single-component catalytic dealcoholized RTV silicone rubber. The method provided by the invention has the advantages that a nano material is adopted as the filler, the plasticizer is added, so that the single-component catalytic dealcoholized RTV silicone rubber has better physical properties; and the nano filler is treated by adopting the silane, thus the storage life of a sealant is prolonged.

Owner:兆舜科技(广东)有限公司

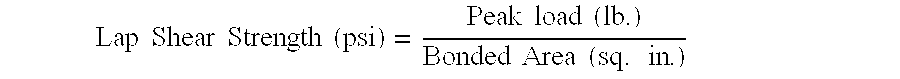

Low shear adhesion RTV silicone

An RTV seal forming silicone composition has a silicone base material that includes a lipophilic secondary phase insoluble in the silicone base material upon cure thereof. The resulting silicone has a shear adhesion strength as measured by transverse displacement of less than 50 pounds per square inch allowing for polymerized silicone removal without damage to an oil pan assembly.

Owner:PERMATEX

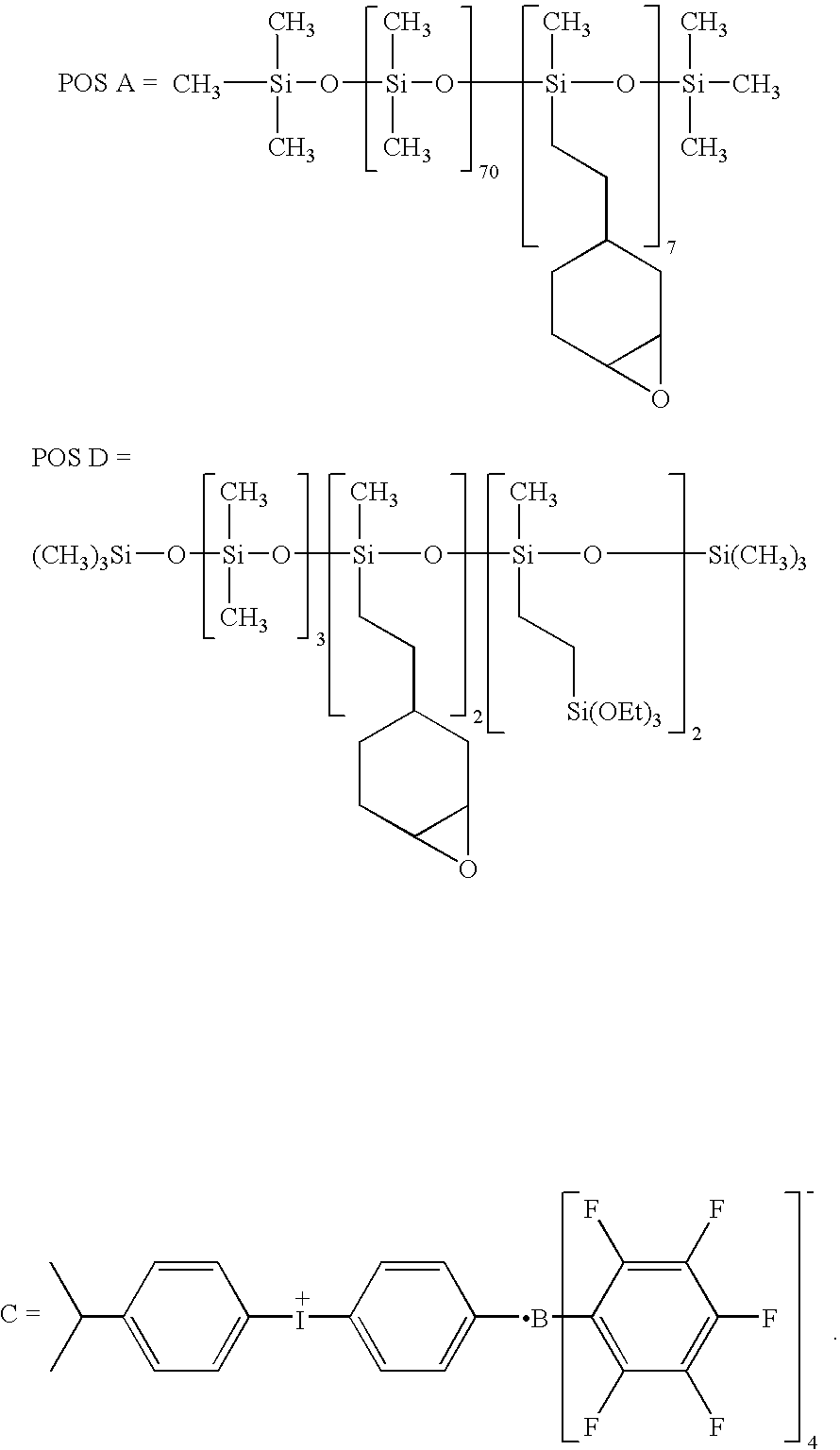

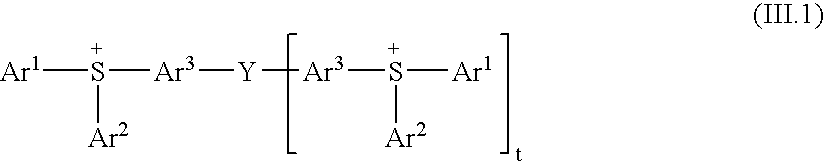

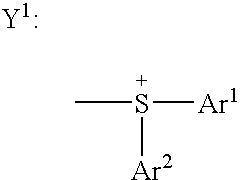

Silicone composition used in the production of antifriction varnishes, method for the application of said varnishes to a support and support thus treated

InactiveUS6902816B1Efficient use ofEconomical and easy to usePhotomechanical apparatusCoatingsEpoxyPolymer science

The invention relates to silicone compositions that are used in the production of varnishes that can be applied to supports in order to reduce the friction coefficient. The inventive composition comprises at least one polyorganosiloxane A (POS) which can be cationically and radically cross-linked by functional cross-linking groups (GFR) and a primer C chosen from onium borates, characterized in that the inventive composition also comprises molecules (POS D) which are substituted by secondary functional groups (GFS) carried by silicon atoms and selected from those that include at least one alkoxy and / or epoxy and / or carboxy motif and optionally a charge (e.g. silica). The invention can be used with anti-friction varnishes for RTV silicone coatings for material used in air bags, thermal transfer ribbons or packing films.

Owner:RHODIA CHEM SA

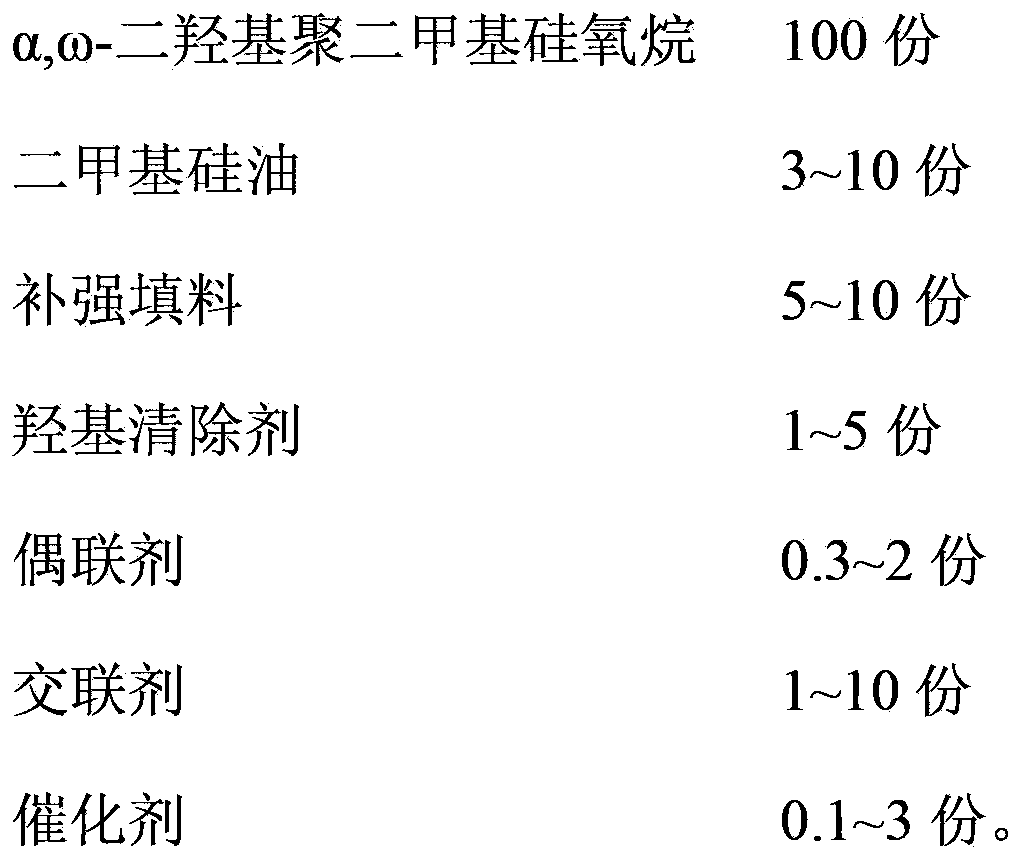

Transparent dealcoholized single-component RTV silicone rubber sealant and preparation method thereof

InactiveCN103361023AImprove anti-yellowing effectFast curingNon-macromolecular adhesive additivesOther chemical processesScavengerOmega

The invention relates to a transparent dealcoholized single-component RTV silicone rubber sealant and a preparation method thereof. The preparation method comprises the following steps: stirring 100 parts by mass of alpha, omega-dihydroxyl polydimethylsiloxane, 3 to 10 parts by mass of dimethicone, 5 to 10 parts by mass of a reinforcing filling material and 1 to 5 parts by mass of a hydroxyl radical scavenger under vacuum in a power mixer; then adding 0.3 to 2 parts of a coupling agent and carrying out stirring under vacuum; and adding 1 to 10 parts of a cross-linking agent and 0.1 to 3 parts of a catalyst and carrying out stirring under vacuum and packaging so as to obtain a finished product. The sealant provided by the invention has the advantages of yellowing resistance, a fast curing speed, no toxicity, environment friendliness, etc.

Owner:兆舜科技(广东)有限公司

Method of restoring damaged foul release coating area on a metallic surface, and surface obtained thereby

InactiveUS6165620ARestoring foul release coating effectivenessLaminationPretreated surfacesEpoxySilanes

A method is provided for applying a two-part RTV silicone tie coat directly onto damaged foul release coating area on a metallic substrate to enable restoration procedures. The direct application onto aged epoxy or silicone surface of an effective amount of an aminoalkyltrialkoxysilane, such as gamma -aminopropyltrimethoxy-silane, in a two-part RTV silicone tie coat, has been found to provide cohesive failure results with directly applied two-part RTV silicone top coat. A treated metallic substrate is obtained thereby.

Owner:GENERAL ELECTRIC CO

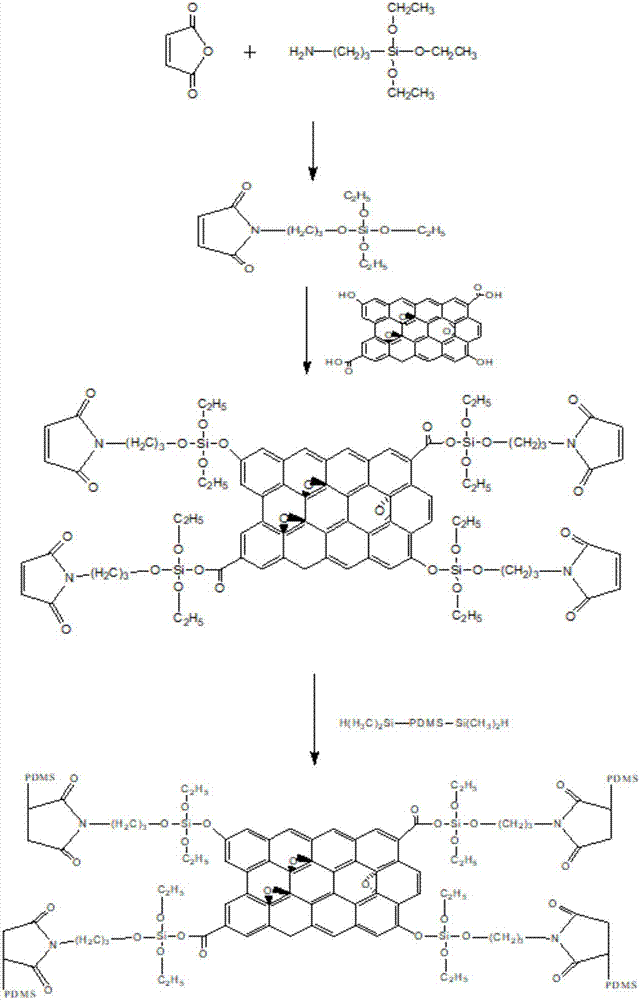

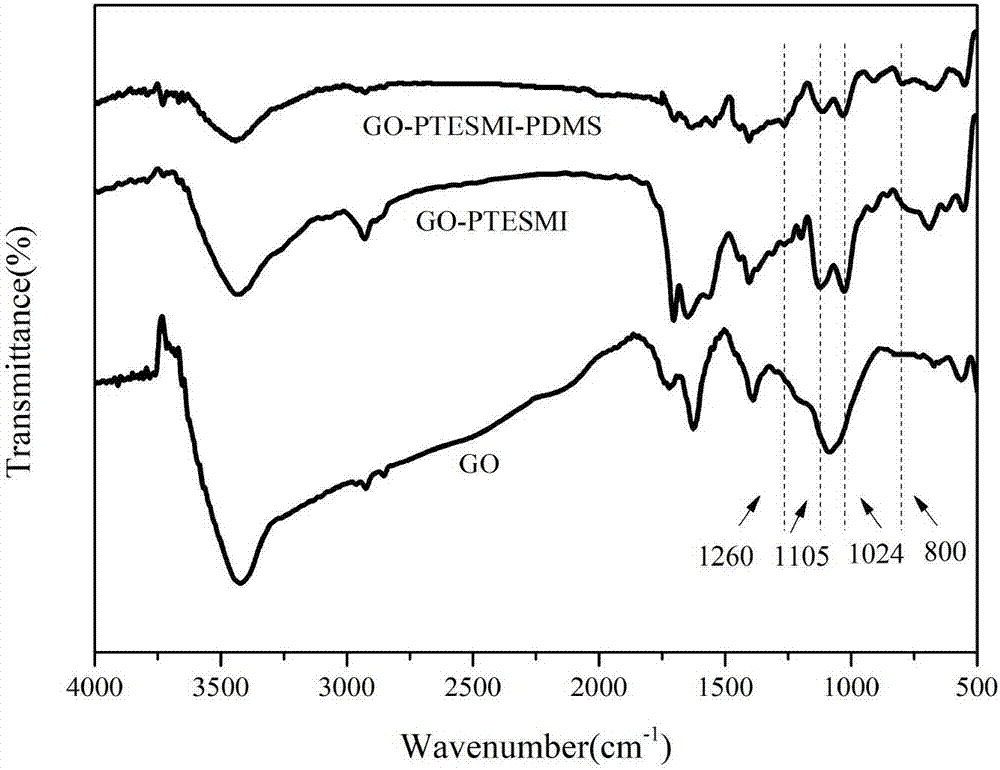

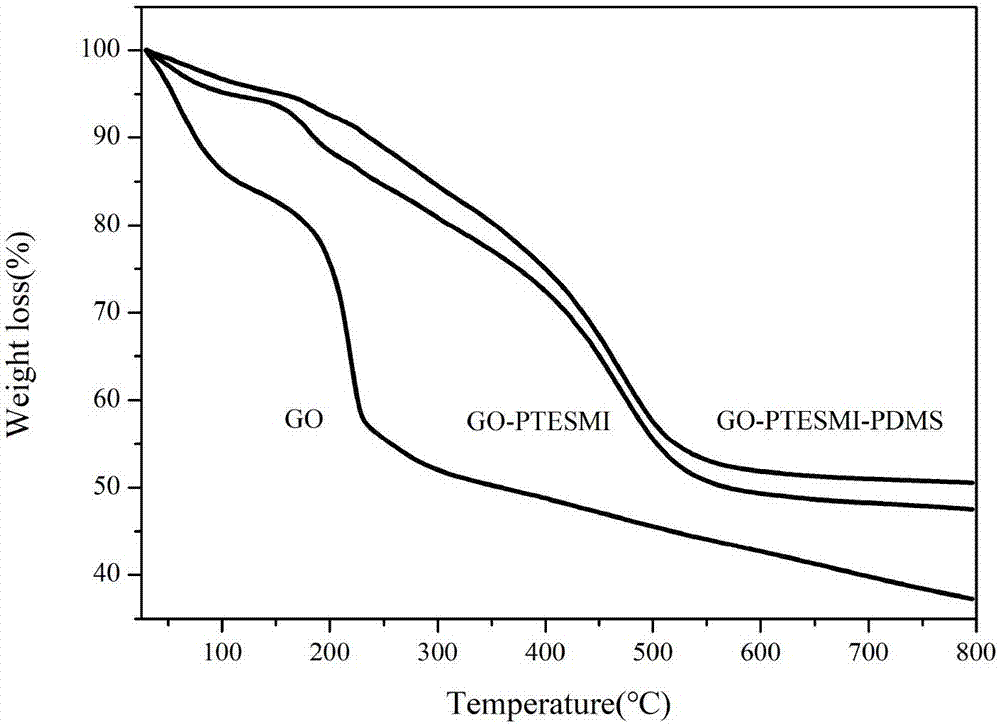

Functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and preparation method thereof

The invention discloses a functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and a preparation method thereof. The method comprises steps as follows: firstly, the surface of GO is grafted with maleimide siloxane, GO-PTESMI is obtained, then double bonds of maleimide on grafting chains in GO-PTESMI are subjected to a hydrosilation reaction with Si-H group terminated PDMS (polydimethylsiloxane) in a solution, and GO (functionalized GO) with surface linked with PDMS grafting chains containing imide groups is prepared; then the functionalized GO is dispersed in a dispersing agent uniformly, and the silicone rubber nanocomposite with different content of functionalized GO is prepared through solution blending. According to the invention, imide bonds and polysiloxane long chains are introduced to the surface of GO, so that interface interaction force and mechanical properties of the nanocompoiste can be improved simultaneously, and the RTV silicone rubber material with capacity of playing excellent performance of GO better is prepared.

Owner:FUJIAN NORMAL UNIV

Oil resistant rtv silicone

InactiveUS20100225069A1Good oil resistanceEngine sealsSealing arrangements for enginesSilica gelRTV silicone

The compositions and methods of the invention are related to RTV silicones having enhanced oil resistance. The compositions of the invention are useful for forming seals having oil resistance and desired tensile strengths after exposure to oil, including gear oil. The compositions are also useful for manufacturing articles sealed with the cured oil resistant RTV silicones.

Owner:ILLINOIS TOOL WORKS INC

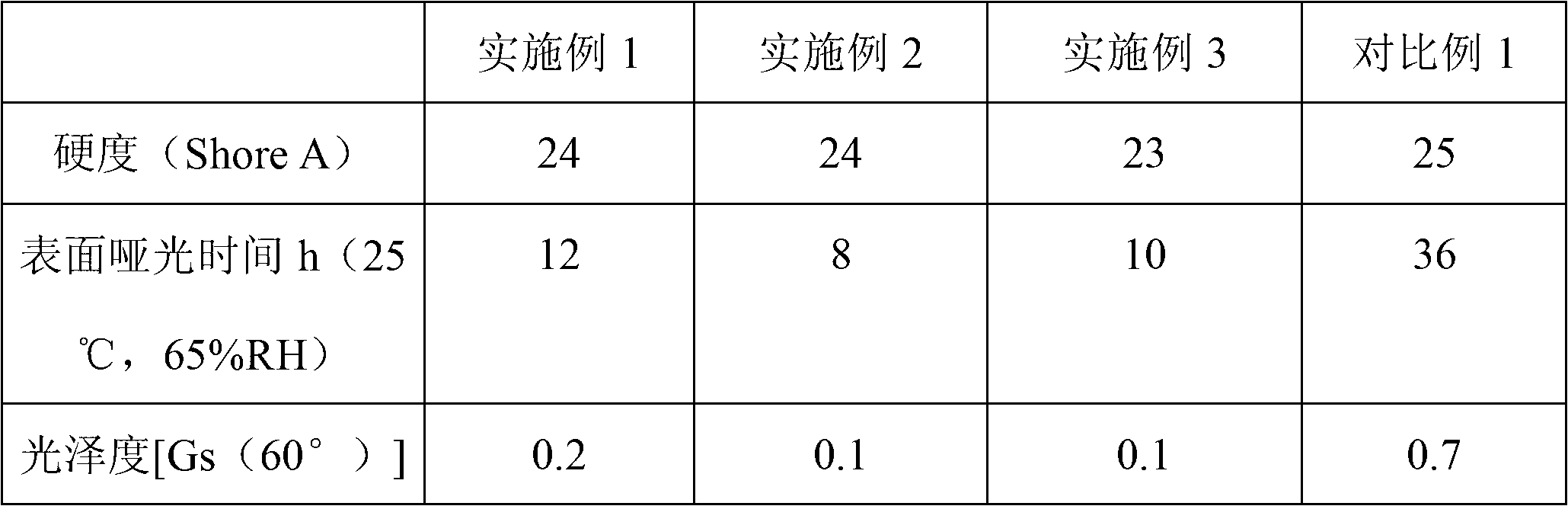

Condensation type RTV silicone rubber composition with matte surface, its preparation method and application

ActiveCN102796381AGood storage stabilityGood matteSemiconductor devicesPlasticizerInorganic pigments

The invention relates to a condensation type RTV silicone rubber composition with a matte surface. The composition is composed of three components: A, B and C. Specifically, component A comprises, by weight part: 80-120 of 107 silicone rubber, 20-110 of a filling material, 5-80 of a plasticizer, 1-10 of hydroxy silicone oil, and 1-10 of an inorganic pigment; component B comprises, by weight part: 2-15 of a crosslinking agent, 1-8 of a silane coupling agent, 5-35 of the plasticizer, and 0.05-0.6 of a catalyst; and component C comprises, by weight part: 0.5-5 of a matt agent. The silicone rubber provided in the invention has good storage stability and excellent matte effect, can be widely applied in maskless LED display screen module potting, and effectively reduces the production cost. After using the silicone rubber, the glossiness can be reduced to less than 0.5Gs (60DEG C), and the matte effect is very excellent.

Owner:兆舜科技(广东)有限公司

Silicone composition used in the production of antifriction varnishes, method for the application of said varnishes to a support and support thus treated

InactiveUS20050037210A1Easily and industrially crosslinkedBroaden applicationLayered productsFibre treatmentCross-linkEpoxy

The invention relates to silicone compositions that are used in the production of varnishes that can be applied to supports in order to reduce the friction coefficient. The inventive composition comprises at least one polyorganosiloxane A (POS) which can be cationically and radically cross-linked by functional cross-linking groups (GFR) and a primer C chosen from onium borates, charcterised in that the inventive composition also comprises molecules (POS D) which are substituted by secondary functional groups (GFS) carried by silicon atoms and selected from those that include at least one alkoxy and / or epoxy and / or carboxy motif and optionally a charge (e.g. silica). The invention can be used with anti-friction varnishes for RTV silicone coatings for material used in air bags, thermal transfer ribbons or packing films.

Owner:RHODIA CHEM SA

Rtv silicone rubber composition for electric and electronic part protection, circuit boards, silver electrodes, and silver chip resistors

InactiveUS20060257672A1Prevent and retard partPrevent short-circuitingSemiconductor/solid-state device detailsPrinted circuit aspectsSilver electrodeCopper

RTV silicone rubber compositions are provided comprising (A) an organopolysiloxane, (B) an organosilicon compound or partial hydrolytic condensate thereof, and (C) a non-aromatic amino-bearing compound. The compositions, when electric and electronic parts having a copper, silver or other metal portion on their surface are encapsulated or sealed therewith, can prevent or retard the parts from corrosion with sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

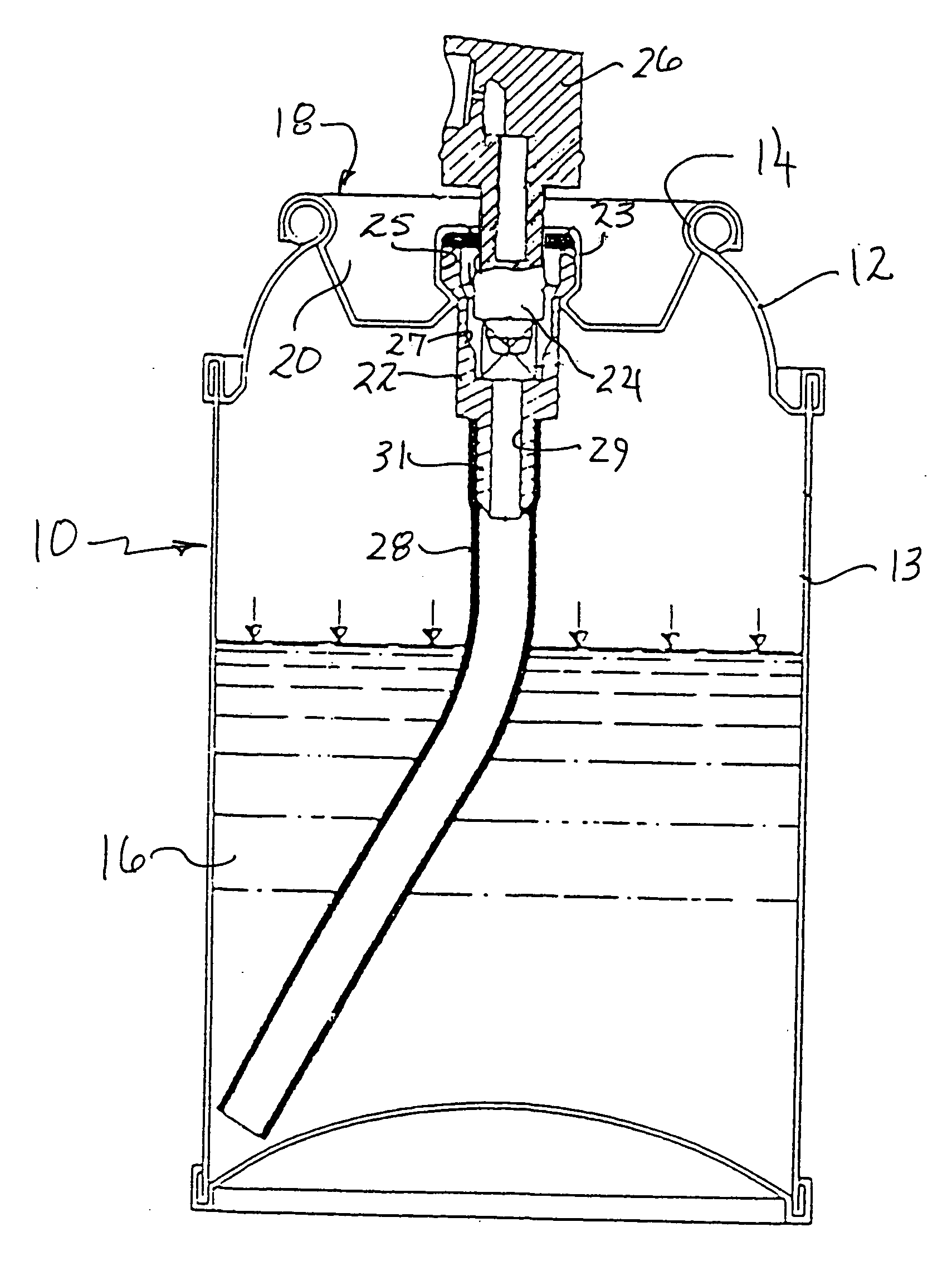

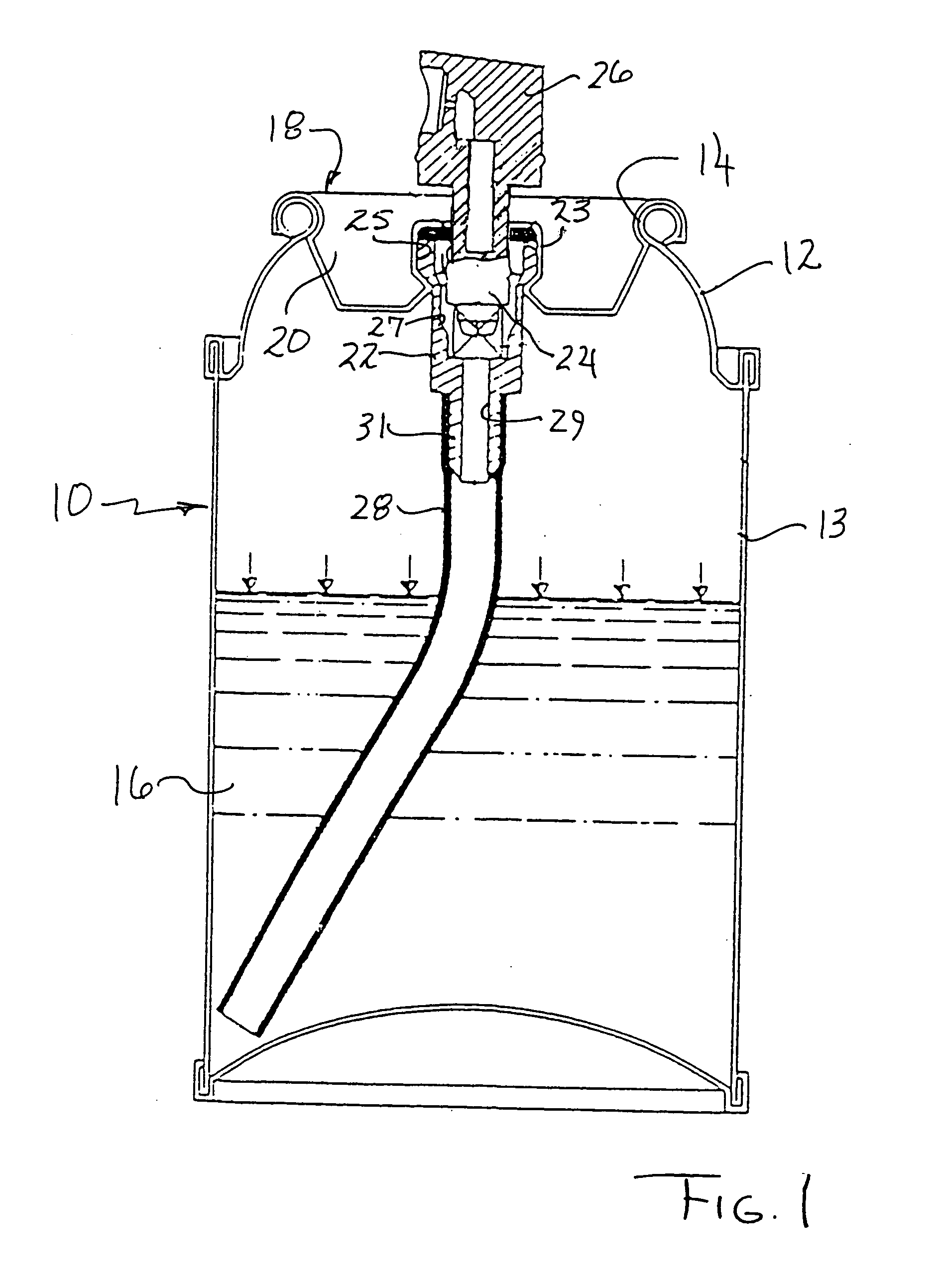

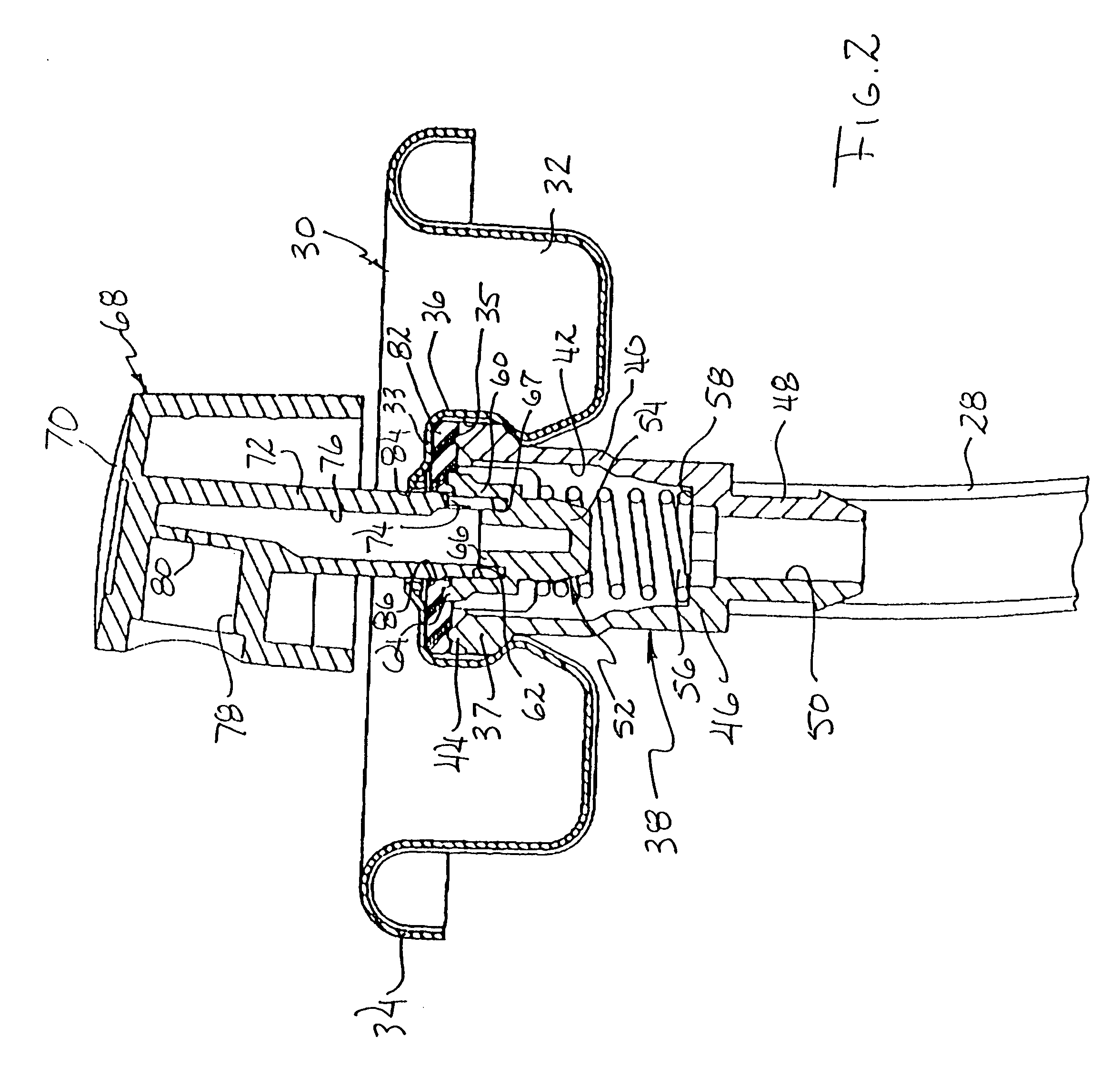

RTV silicone spray system

InactiveUS20060102661A1Obstruct passageControl flowPowdered material dispensingLiquid dispensingAerosol spraySynthetic resin

Owner:ULSTREETCAROTIVE

Coating for use with medical devices and method of making same

InactiveUS20050064210A1Facilitate drug deliveryAdherence to flexibleLayered productsSurgeryUrinary catheterBody area

Owner:COVIDIEN AG

Low shear adhesion RTV silicone

An RTV seal forming silicone composition has a silicone base material that includes a lipophilic secondary phase insoluble in the silicone base material upon cure thereof. The resulting silicone has a shear adhesion strength as measured by transverse displacement of less than 50 pounds per square inch allowing for polymerized silicone removal without damage to an oil pan assembly.

Owner:PERMATEX

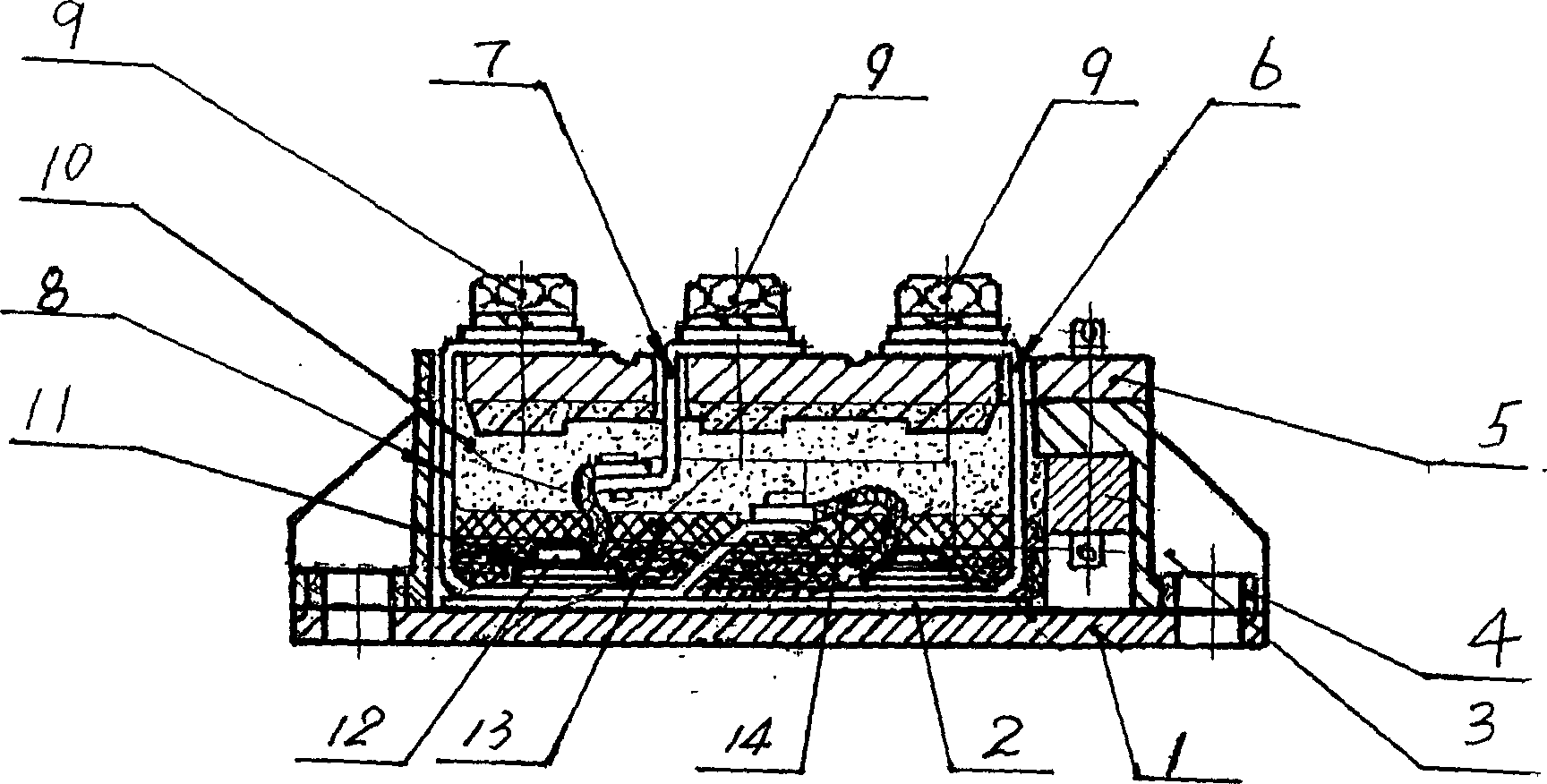

Ultrafast recovery diode module

ActiveCN1828889AOptimize the installation positionWith super softSemiconductor/solid-state device detailsSolid-state devicesEpoxyUltra fast

The present invention discloses a ultra-fast restorer diode module. It contains red copper base plate, aluminium nitride ceramics coller clad plate, plastic casing, three main electrodes, epoxy protective layer, double compositions elastic silicon gel protective layer, RTV silicone rubber protective layer, ultra-fast restorer diode chip in connection wire, said red copper processed by pre-bending. Said invention has high frequency, ultra-fast recovering, ultra-soft and super - durable property.

Owner:CHANGZHOU RUIHUA POWER ELECTRONICS DEVICES

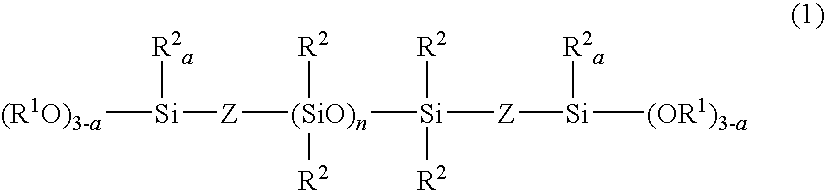

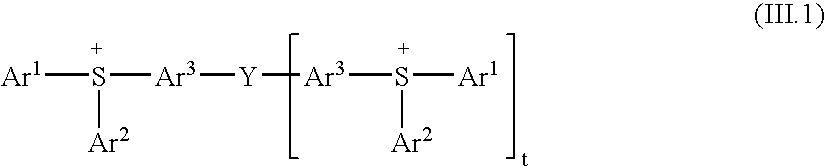

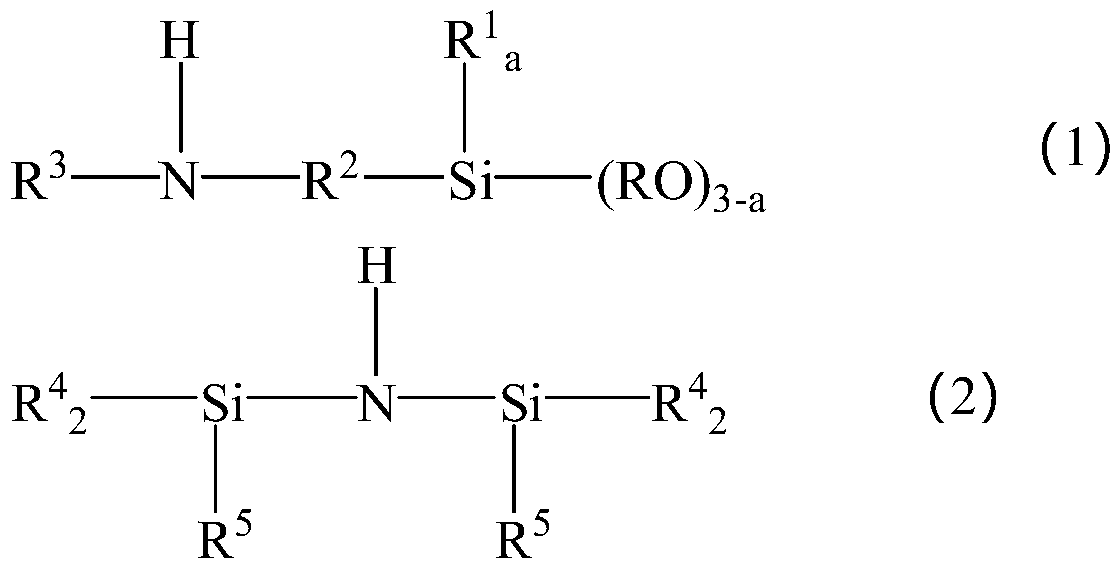

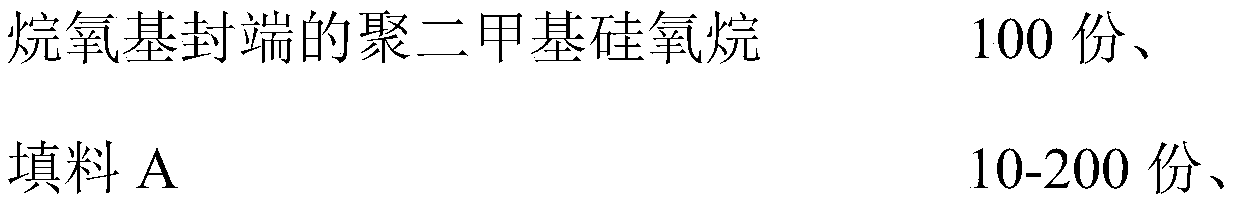

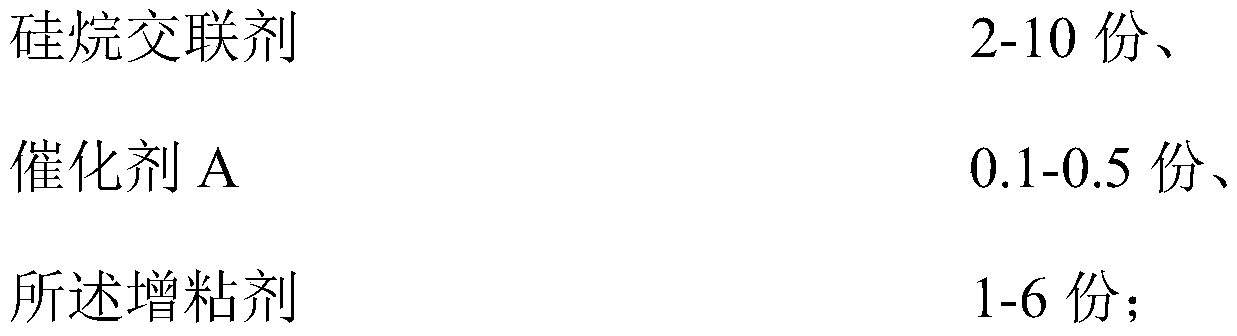

Tackifier, dealcoholized RTV silicone rubber and preparation method thereof

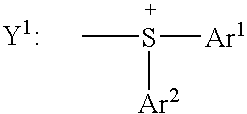

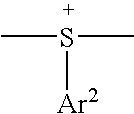

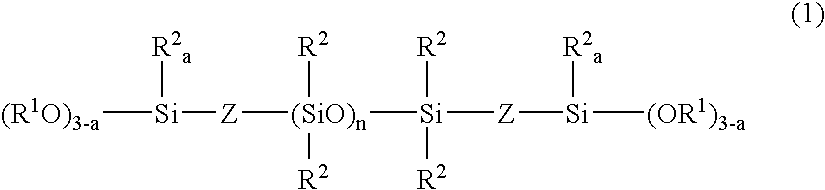

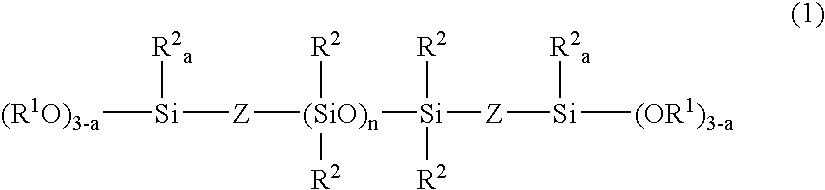

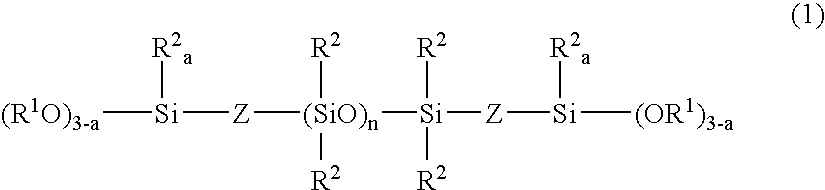

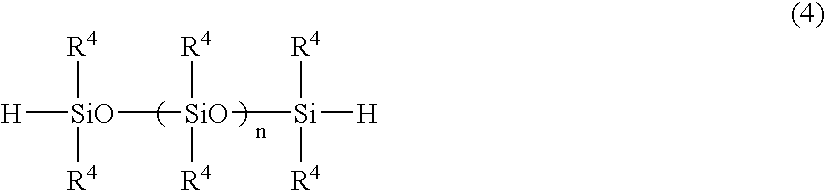

The invention relates to a tackifier, dealcoholized RTV silicone rubber and a preparation method thereof. The tackifier is composed of a mixture obtained through reaction of a compound shown in the formula (1) and a compound shown in the formula (2), wherein R is selected from C1-C6 alkyl; R1 is selected from C1-C10 alkyl; R2 is selected from C1-C10 alkylene; R3 is selected from -H, C1-C10 alkyl group, or amino-substituted C1-C6 alkyl group; a is selected from 0 or 1; R4 is selected from C1-C6 alkyl; and R5 is selected from C1-C6 alkenyl. The tackifier can be used for preparing the dealcoholized RTV silicone rubber, and can improve the adhesion property of the dealcoholized RTV silicone rubber to a base material.

Owner:GUANGZHOU BAIYUN CHEM IND

Silicone-containing composition and personal care products containing same

InactiveUS20160228349A1Reduce decreaseHigh glossCosmetic preparationsHair cosmeticsSilorane ResinsSilicone oil

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Intumescent flame-retardant fireproof and heatproof material

The invention discloses an intumescent flame-retardant fireproof and heatproof material. The intumescent flame-retardant fireproof and heatproof material is prepared from, by weight, 60-80 parts of methyl RTV silicone rubber, 20-35 parts of alkali free glass fiber cotton, 5-20 parts of silicate fiber, 3-10 parts of mullite fiber, 1-3 parts of benzoyl peroxide, 0.5-2 parts of dibutyltin dilaurate, 1-5 parts of diphenyl silanediol, 1-3 parts of henylethynyl polysiloxane,5-10 parts of nanometer TiO2, 3-10 parts of nano-MMT, 2-10 parts of silicon carbide, 2-8 parts of boron nitride, 2-5 parts of cerium oxide, 3-10 parts of ferric oxide, 5-10 parts of flame retardant and 5-20 parts of aerogel. The intumescent flame-retardant fireproof and heatproof material has the advantages of excellent fireproof and good heatproof performance, and long service life.

Owner:曾照韦

Bicomponent condensed type room temperature sulfidization silicon rubber high-efficiency curing agent

The invention discloses a double-component condensed type RTV silicone rubber curing accelerator which is obtained by mixing cross-linking agent, catalyst and catalyst promoter by a certain ratio; the invention also discloses curing agent which contains the curing accelerator and the application of the curing agent in silicon rubber preparation. The curing accelerator of the invention can effectively improve the curing speed and the silicon rubber performance after curing.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

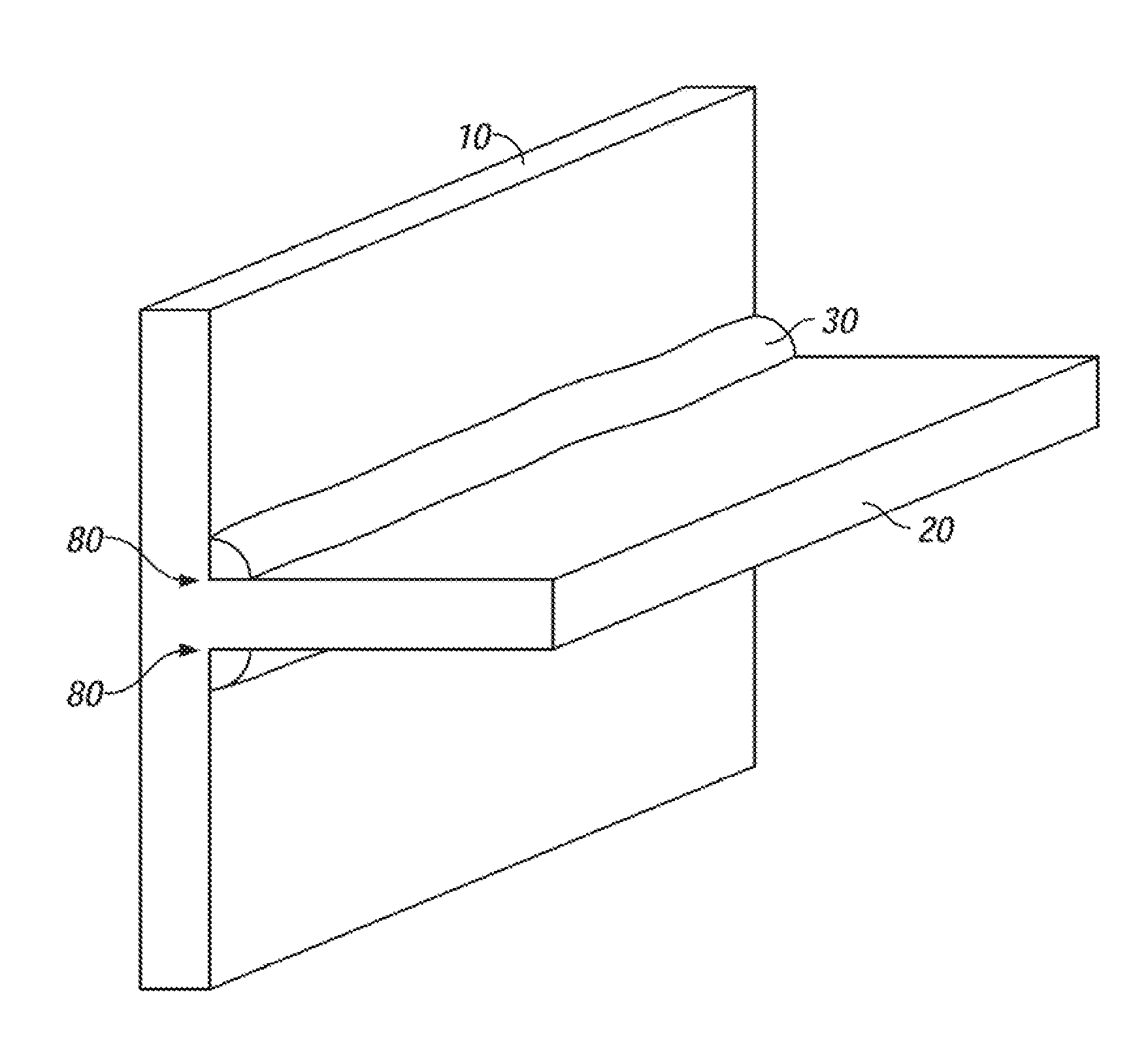

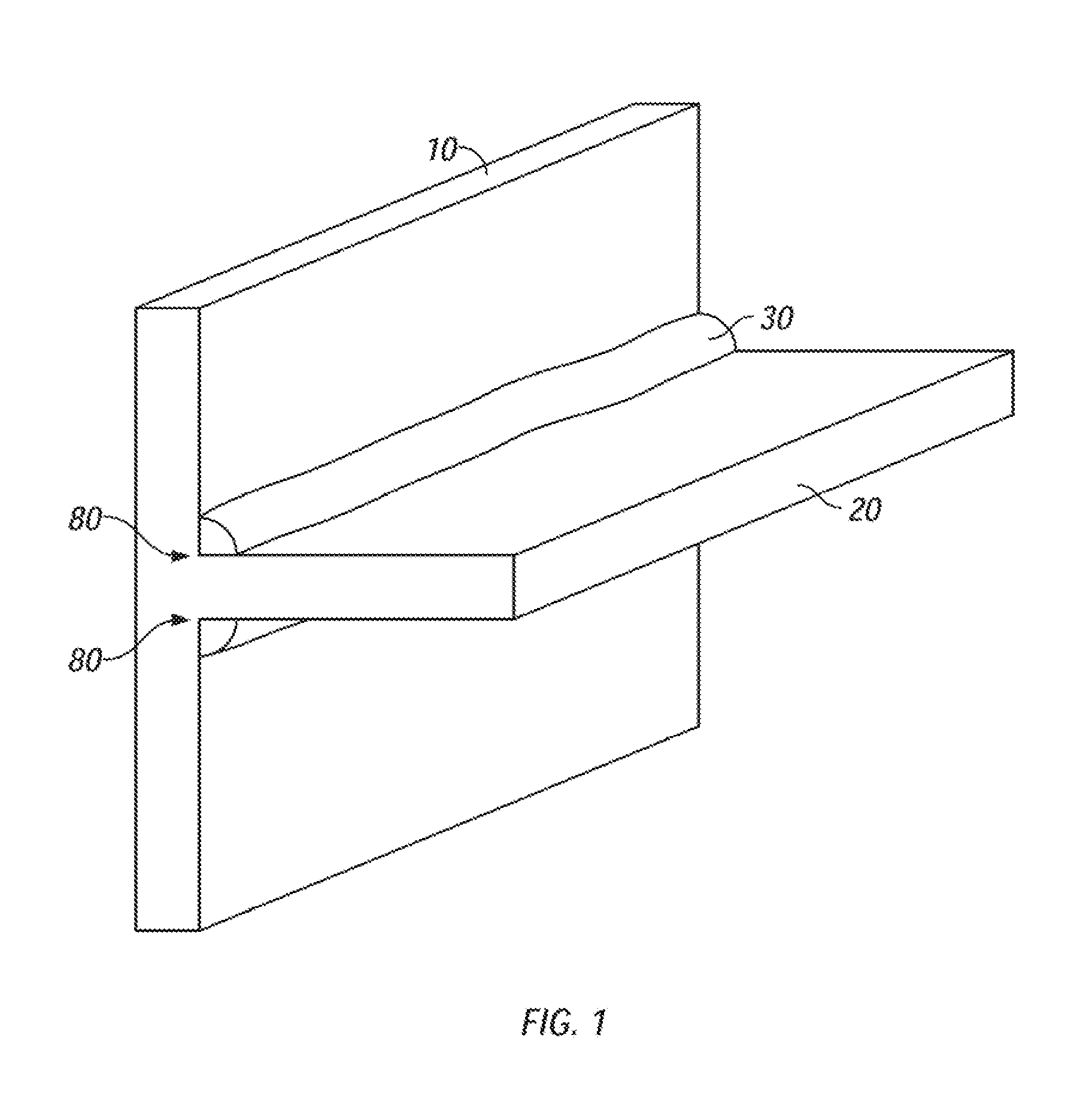

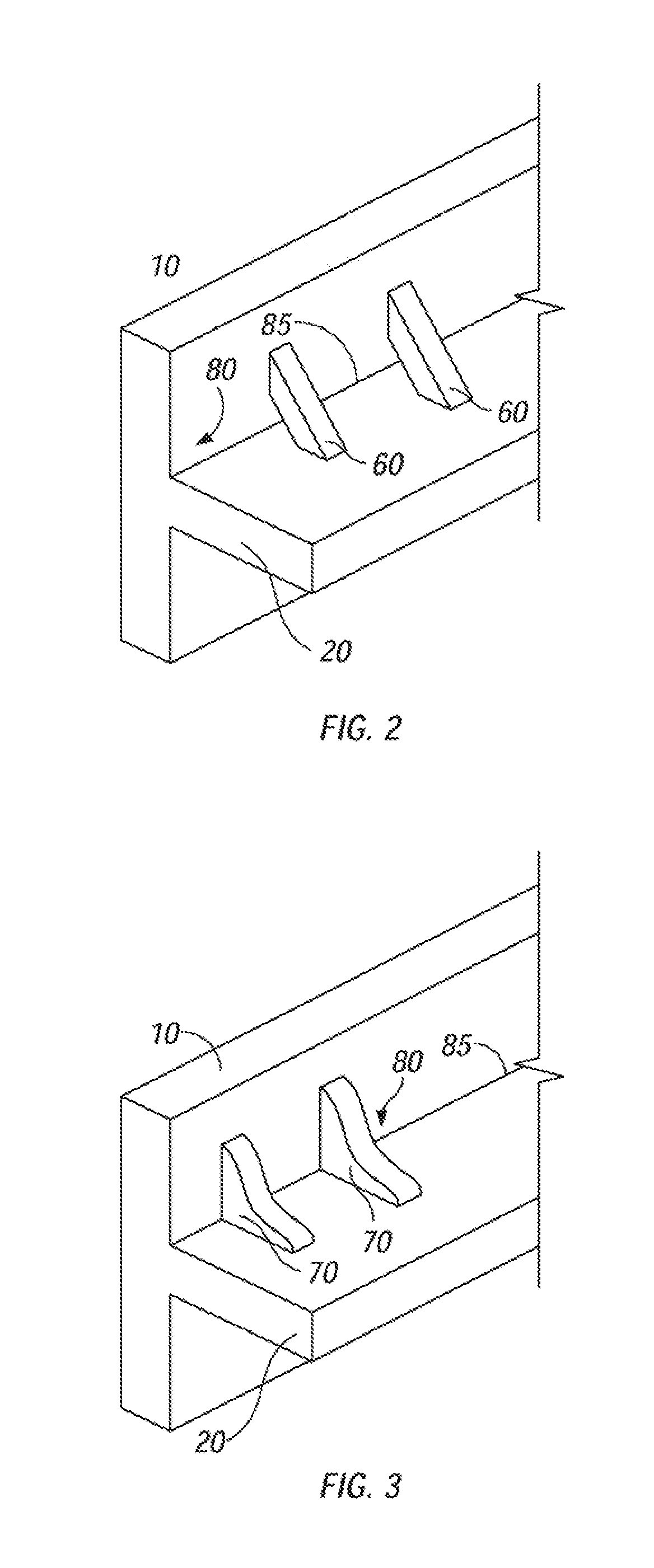

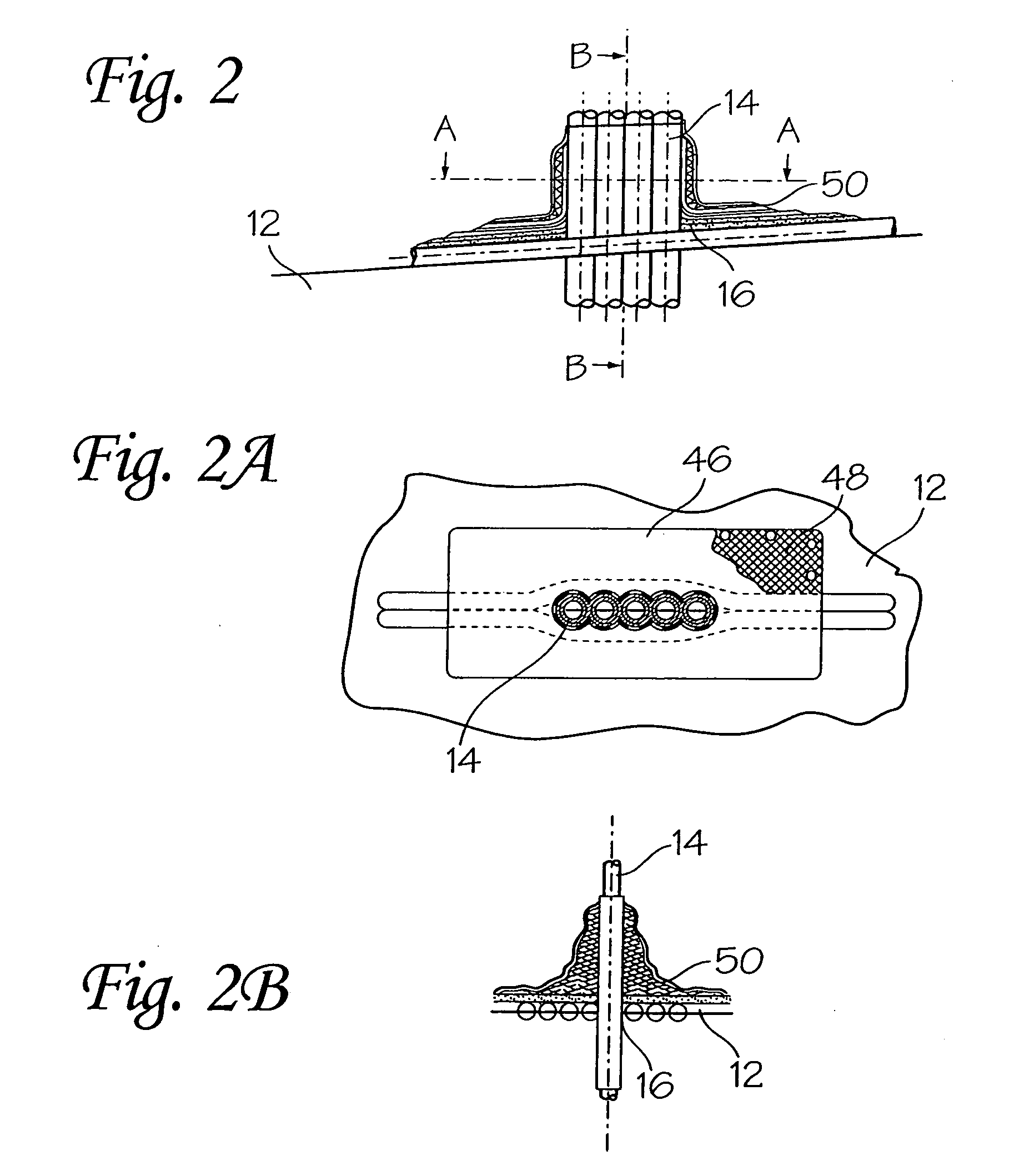

Ribbed telescope mirrors with thermal gradient control

Ribbed mirrors allowing heat to be conducted past the glass during optical polish and application of coatings and methods of fabricating same. The method comprises placing a bridge of thermally conductive material in thermal contact with the mirror plate and the supporting rib at the interior angle. The preferred thermally conductive material is RTV silicone. However, the RTV silicone can be mixed with a powdered heat conductor such as diamond dust, aluminum oxide and silicon carbide. Alternatively, the thermally conductive fillet can be made from a segment of thermally conductive rigid material, such as copper, diamond, beryllium, silver and aluminum having an exterior angle matching the interior angle and a thermally conductive plastic such as RTV silicone or thermally conductive grease, silicone or epoxy applied to surfaces of the exterior angle.

Owner:SCHWARTZ RICHARD A

Organosilicon compound-curing composition and silicone-base coating composition

A curing composition comprising (A) a silane compound having formula: R12Si(OR2)2 wherein R1 is C1–C3 alkyl, C2–C3 alkenyl or phenyl, and R2 is C1–C3 alkyl, C2–C3 acyl or C3–C5 alkoxyalkyl and (B) phosphoric acid is added to an organosilicon compound to formulate a silicone-base coating composition which remains shelf stable and quickly cures at room temperature after being applied to a substrate, to form a cured coating having transparency, surface hardness, adhesion and the like. A silicone-base coating composition having the curing composition formulated therein is effective as a solventless, RTV silicone coating composition of one part type.

Owner:SHIN ETSU CHEM IND CO LTD

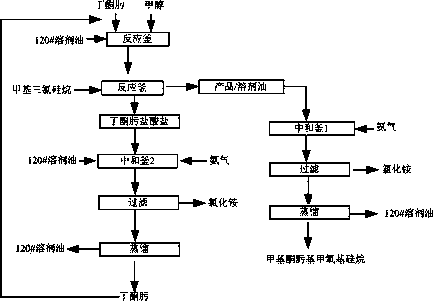

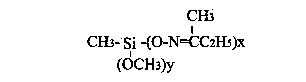

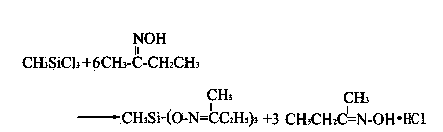

Preparation method of methyl ketone oxime methoxy silane

ActiveCN103467508ASimple methodSuitable for industrial productionGroup 4/14 element organic compoundsSilanesReaction temperature

The invention discloses a preparation method of methyl ketone oxime methoxy silane. The method comprises the following steps: (1), adding butanone oxime, methanol and miscella No. 120 into a reaction kettle with a stirring function, then dripping methyl trichlorosilane into the reaction kettle, adjusting dripping speed of the methyl trichlorosilane, and controlling the reaction temperature between 30 DEG C and 60 DEG C; (2), after the dripping is completed, performing still standing for layering, adding an upper-layer product into a first neutralization kettle, pumping ammonia gas for neutralization, then filtering, separating ammonium chloride, and distilling out miscella to obtain a product; adding a lower-layer product into a second neutralization kettle, adding the miscella, pumping ammonia gas for neutralization, then filtering, separating ammonium chloride, and distilling out the No. 120 miscella to obtain the butanone oxime. The method provided by the invention is simple, feasible, suitable for industrial production, high in product yield and low in manufacturing cost; the prepared product has excellent activation, can be used for preparing RTV silicone rubber which meets fast surface dry requirements, and has low possibility of discoloration during storage.

Owner:ZHEJIANG QUZHOU GUIBAO CHEM

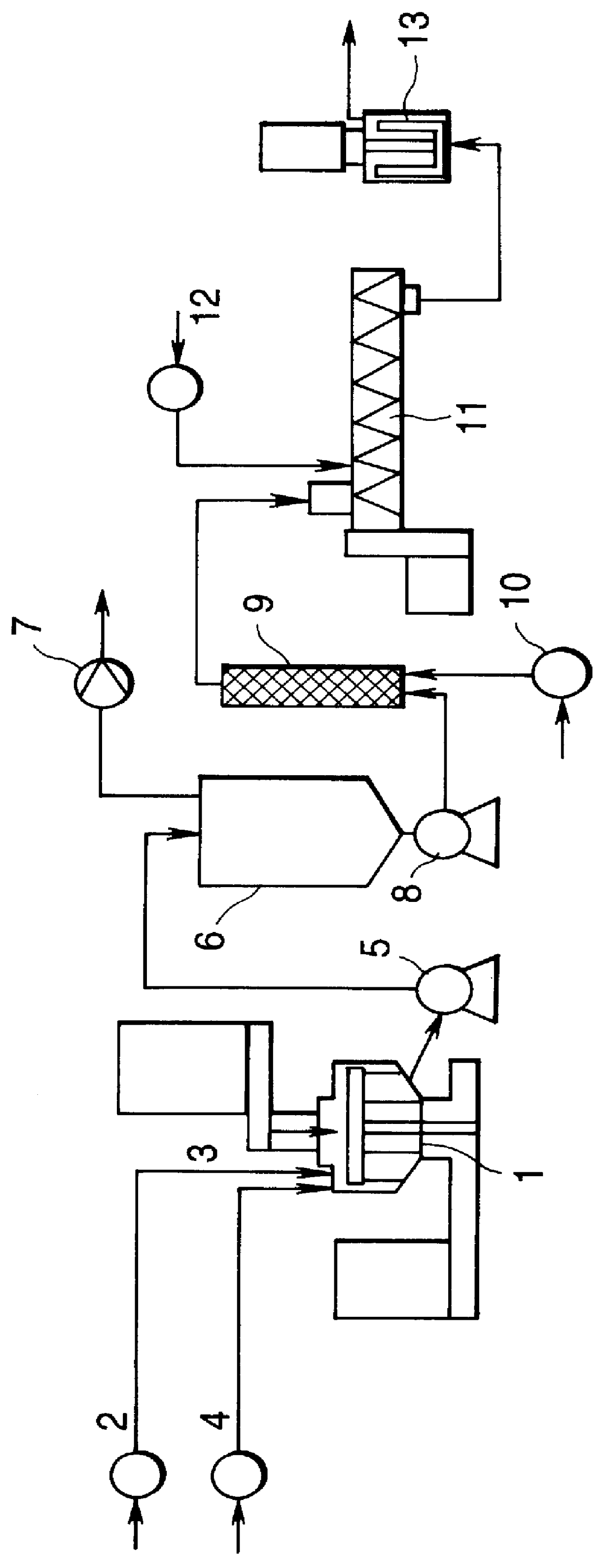

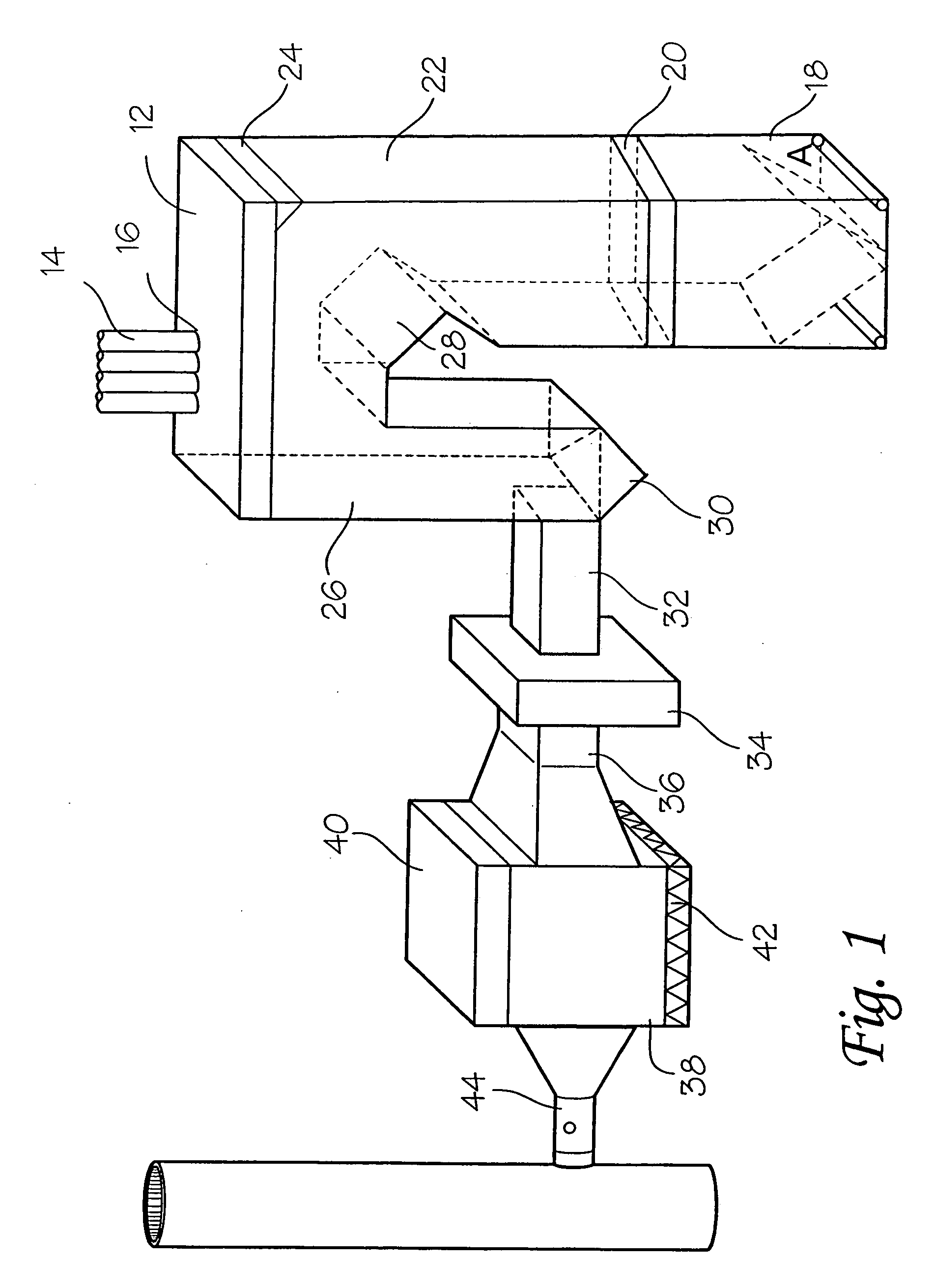

Process for the continuous production of RTV silicone rubber compositions

In a first step, a crosslinkable organopolysiloxane oil (2) is mixed with an inorganic filler (3) in a flow jet mixer (1) to form a flowing silicone rubber compound. In a second step, the silicone rubber compound is fed into a tank (6) equipped at the bottom with a vacuum discharge pump (8) and maintained in vacuum where the compound is continuously deaerated, and a thixotropy controlling agent (10) is then added and mixed with the compound in a mixer (9). In a third step, a crosslinking agent (12) is added and mixed with the silicone rubber compound in a KRC kneader (11), and the compound is degassed in a mixer (13). The process continuously produces an RTV silicone rubber composition which is anti-sagging and improved in applicability on use.

Owner:SHIN ETSU CHEM IND CO LTD

Seal and method for high temperature sealing

A seal comprising a high temperature RTV silicone adhesive sealant layer; a first non-ceramic layer mounted to the RTV silicone adhesive sealant layer; a first expanded metal layer mounted to the first non-ceramic layer; a first silicone cloth layer mounted to the first expanded metal layer; a metal reinforcement layer mounted to the first silicone cloth layer to provide structural integrity without the use of ceramic materials; a second expanded metal layer mounted to the metal reinforcement layer; a second non-ceramic layer mounted to the second expanded metal layer; a turbine mesh layer mounted to the second non-ceramic layer; a second silicone cloth layer mounted to the turbine mesh layer; a sealing castable applied over the second silicone cloth layer to provide a covering; and, a high temperature bonding adhesive disposed between each layer following the first non-ceramic layer to bind the layers together.

Owner:RUSH BRANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com