Ultrafast recovery diode module

A recovery diode, ultra-fast technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of poor recovery time compatibility, large changes in reverse leakage current, and inapplicability, so as to optimize the installation position and avoid noise , the effect of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiment of the utility model is described below in conjunction with accompanying drawing:

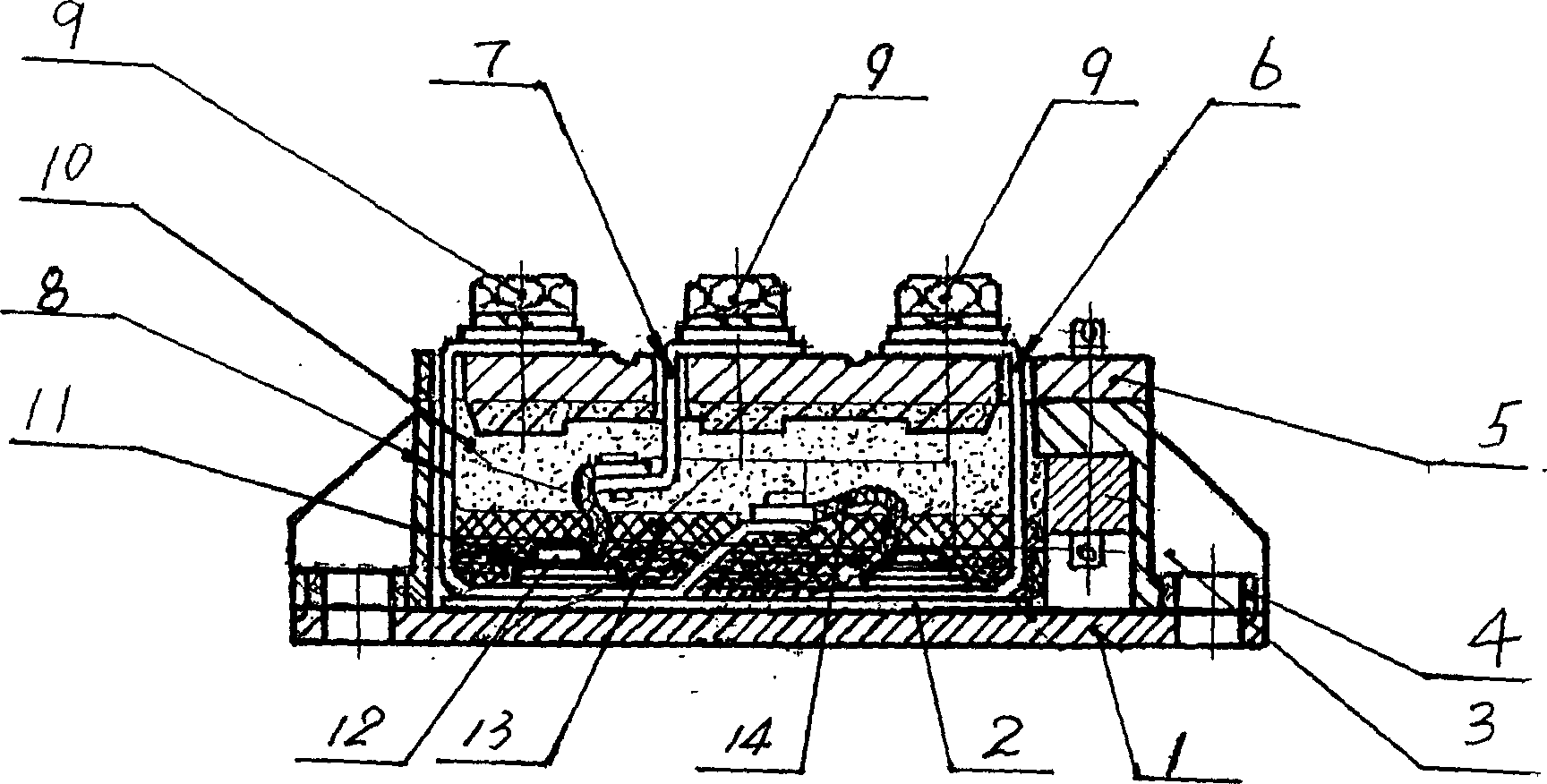

[0010] The ultra-fast recovery diode module of the present invention includes a red copper base plate 1, an aluminum nitride ceramic copper-clad plate (ie AL N DBC plate) 2, a PBS plastic shell 3, a fastening ring 4, a PBS plastic cover plate 5, and three main electrodes 6-8, three terminal screws 9, epoxy resin protection layer 10, RTV silicone rubber protection layer 11, ultra-fast recovery diode chip 12, two-component elastic silicone gel protection layer 13, internal connection wire 14, ultra-fast recovery The diode chip 12 is fixed on the main electrodes 6-8 by silver-tin welding, the three main electrodes 6-8 are fixed on the aluminum nitride ceramic copper-clad laminate 2 by silver-tin welding, and the aluminum nitride ceramic copper-clad laminate 2 is soldered by silver-tin The welding method is fixed on the red copper base plate 1, and the ultra-fast reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com