Patents

Literature

1077results about How to "Avoid fever" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

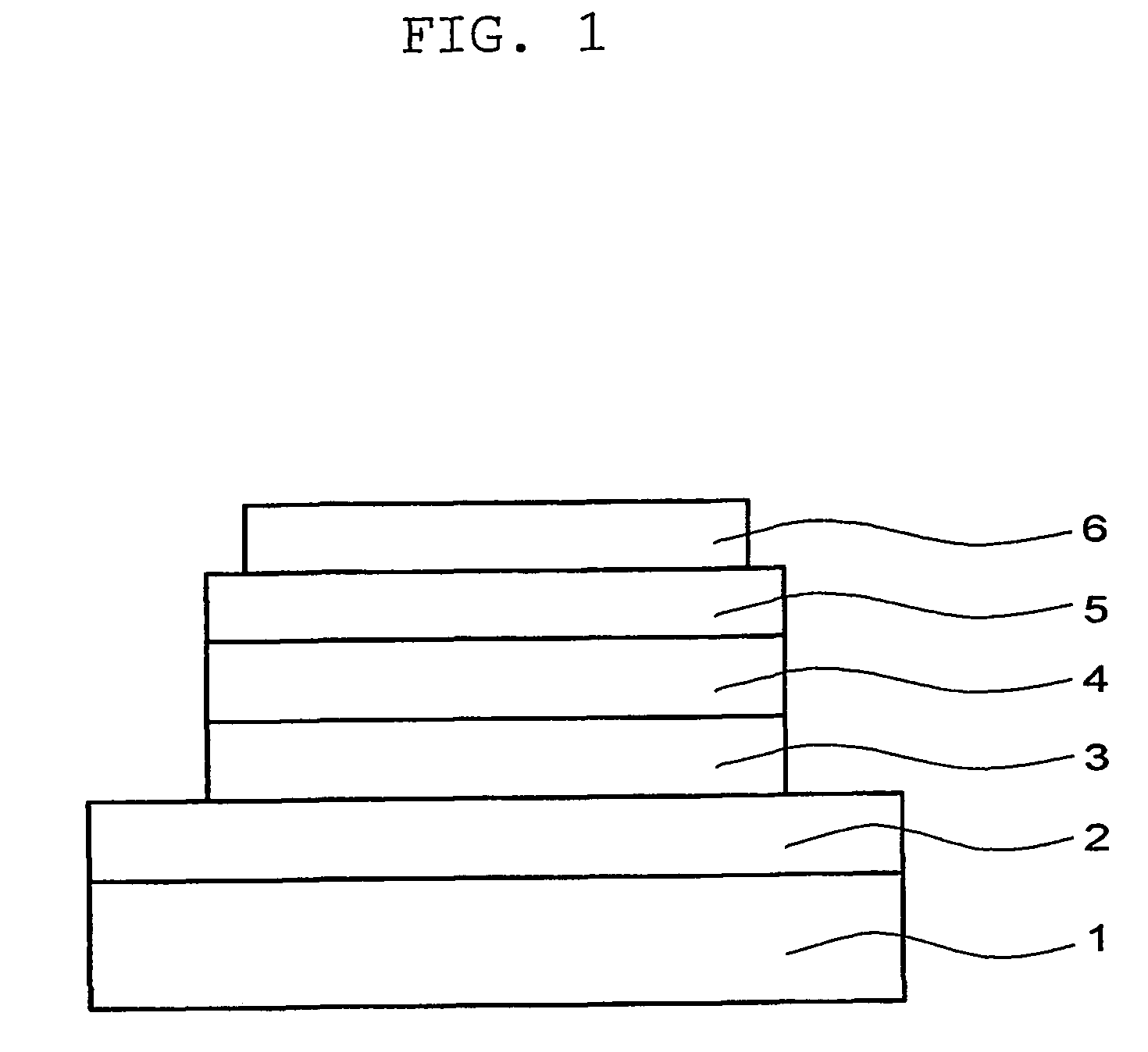

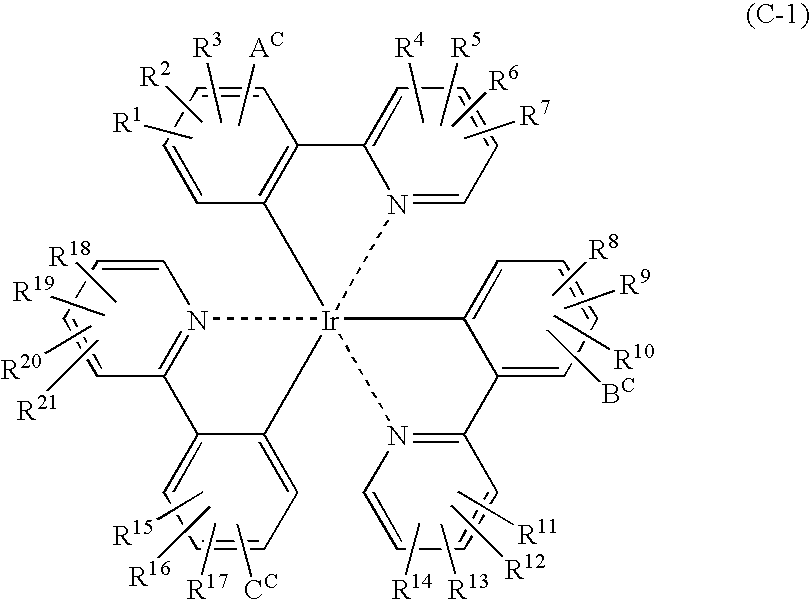

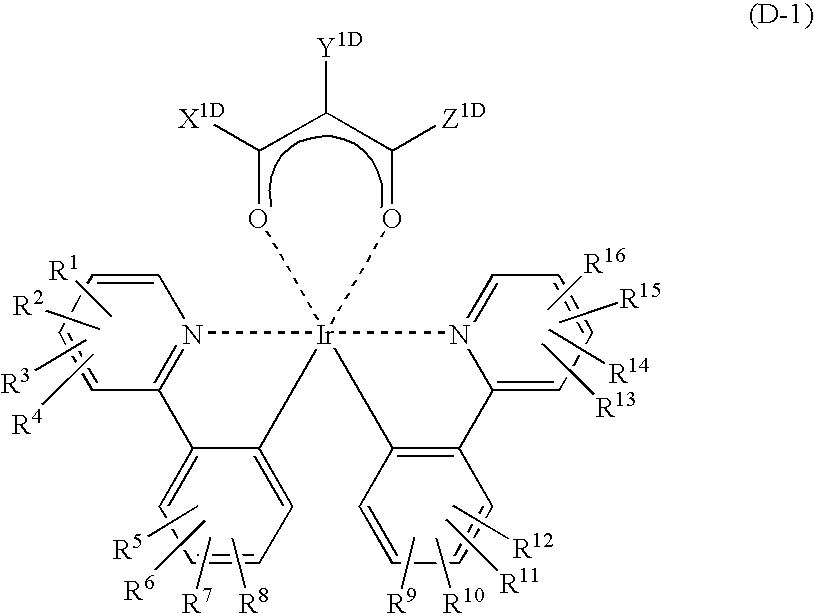

Light emitting material and organic light-emitting device

InactiveUS7396598B2High efficiency of light emissionKeep energy smallDischarge tube luminescnet screensGroup 8/9/10/18 element organic compoundsFluorescenceTriplet state

Owner:SAMSUNG ELECTRONICS CO LTD

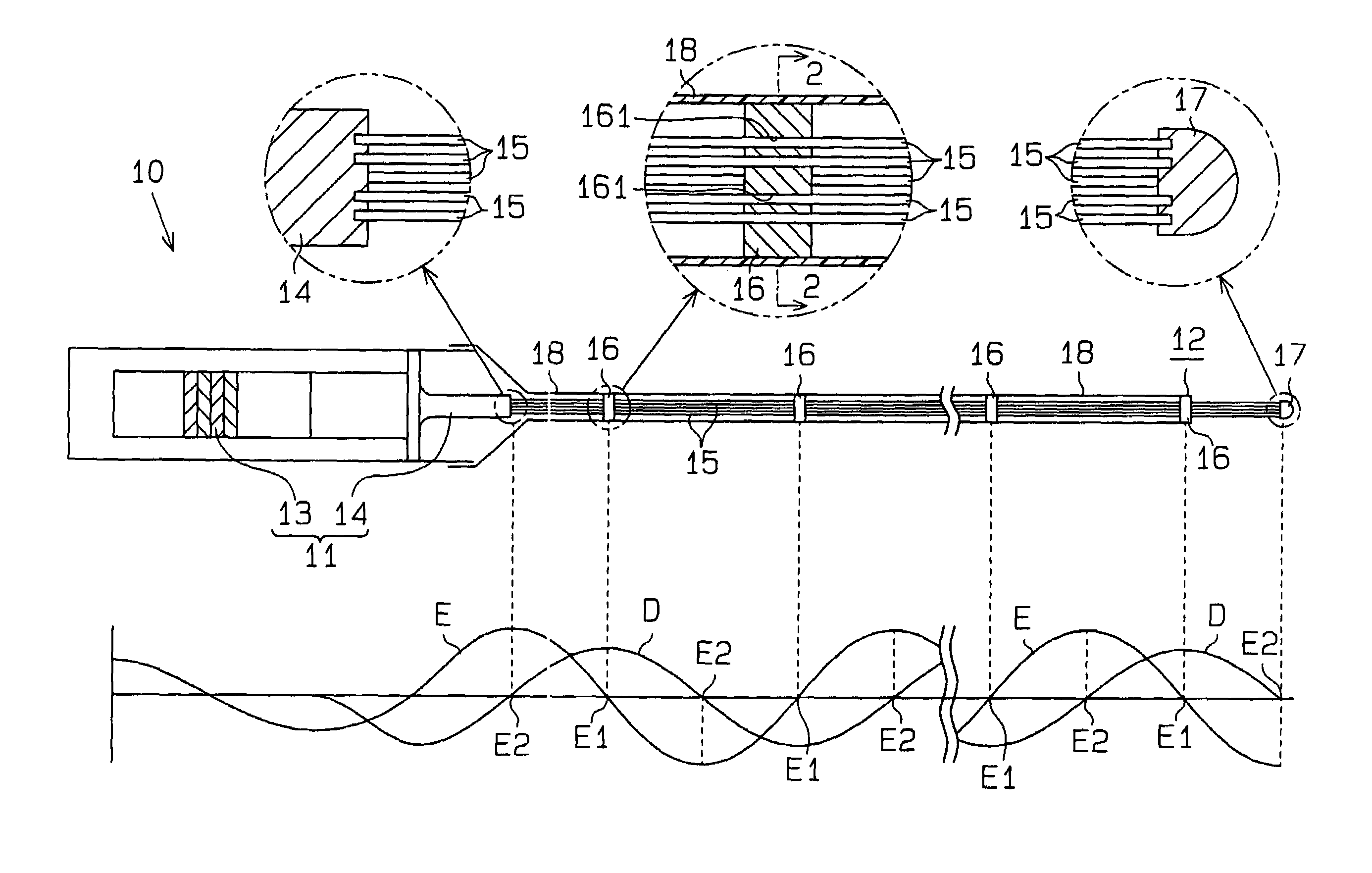

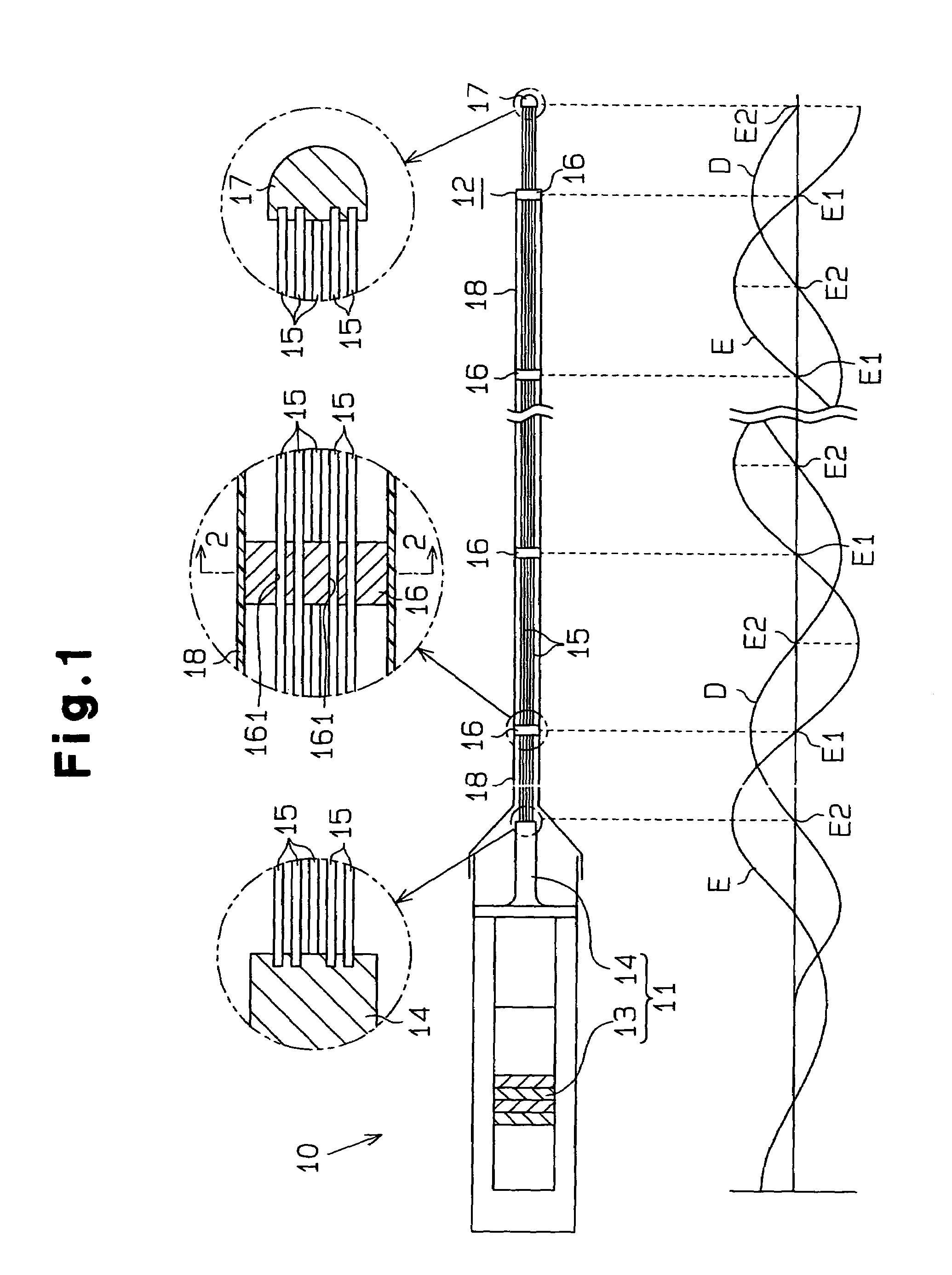

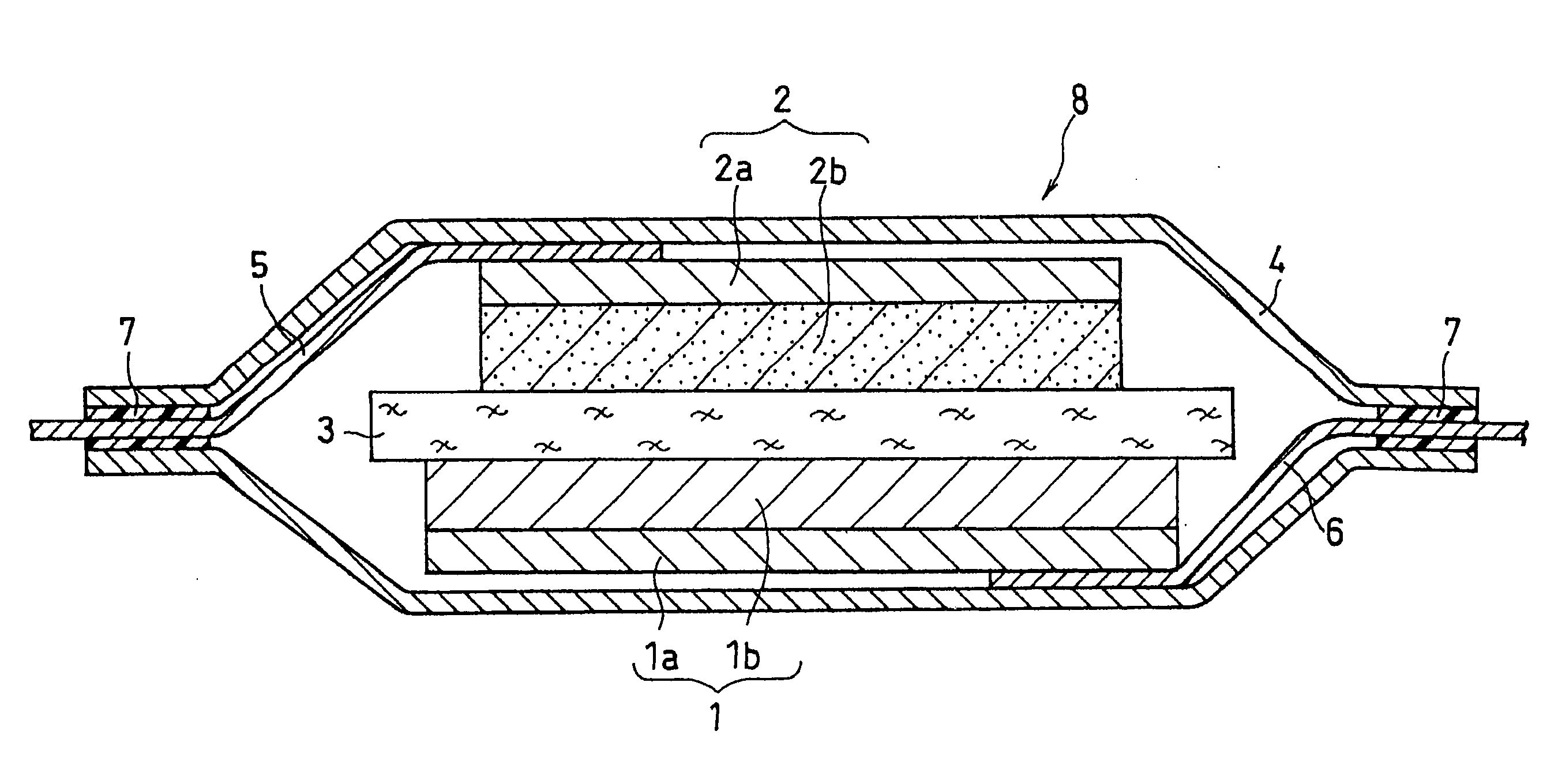

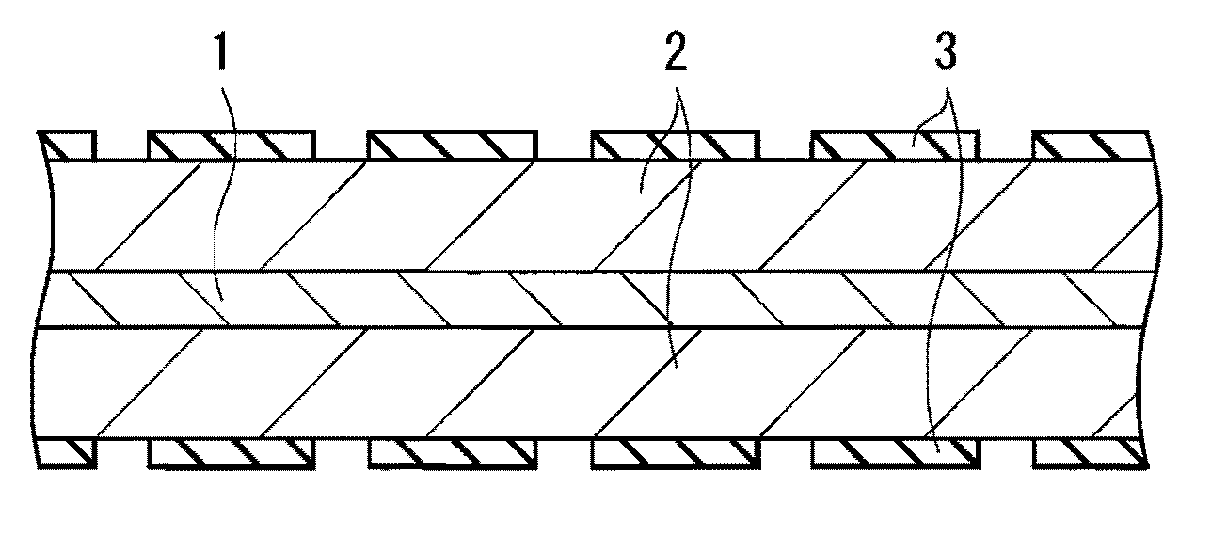

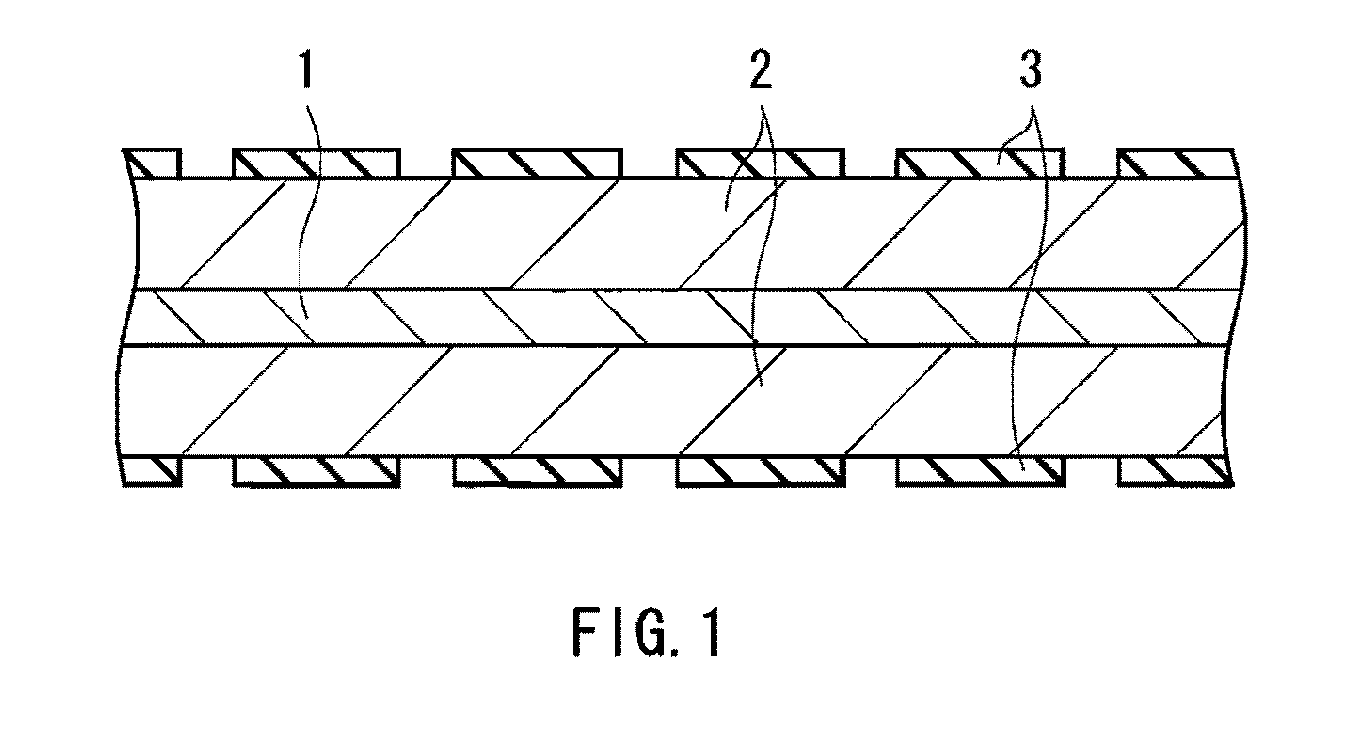

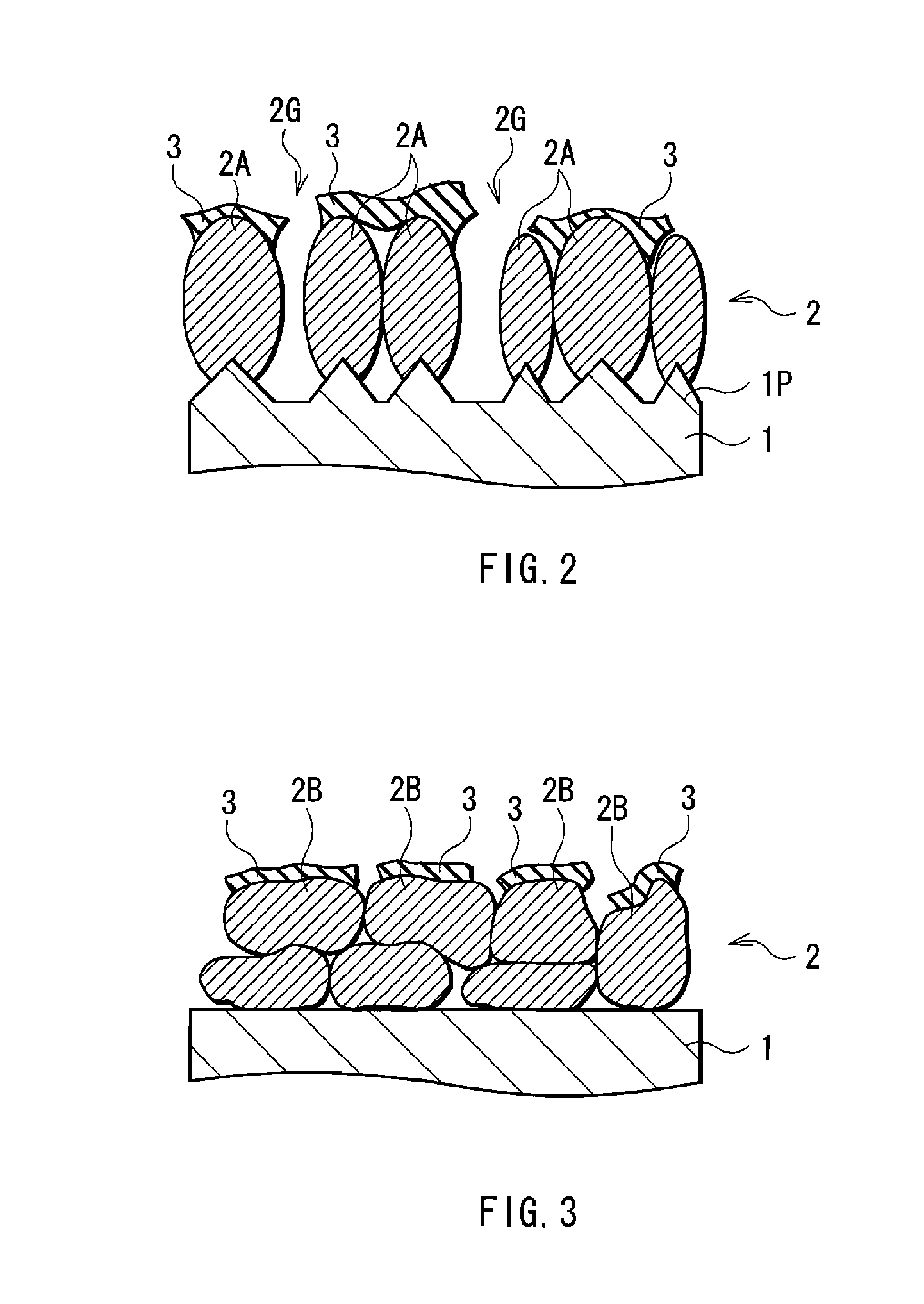

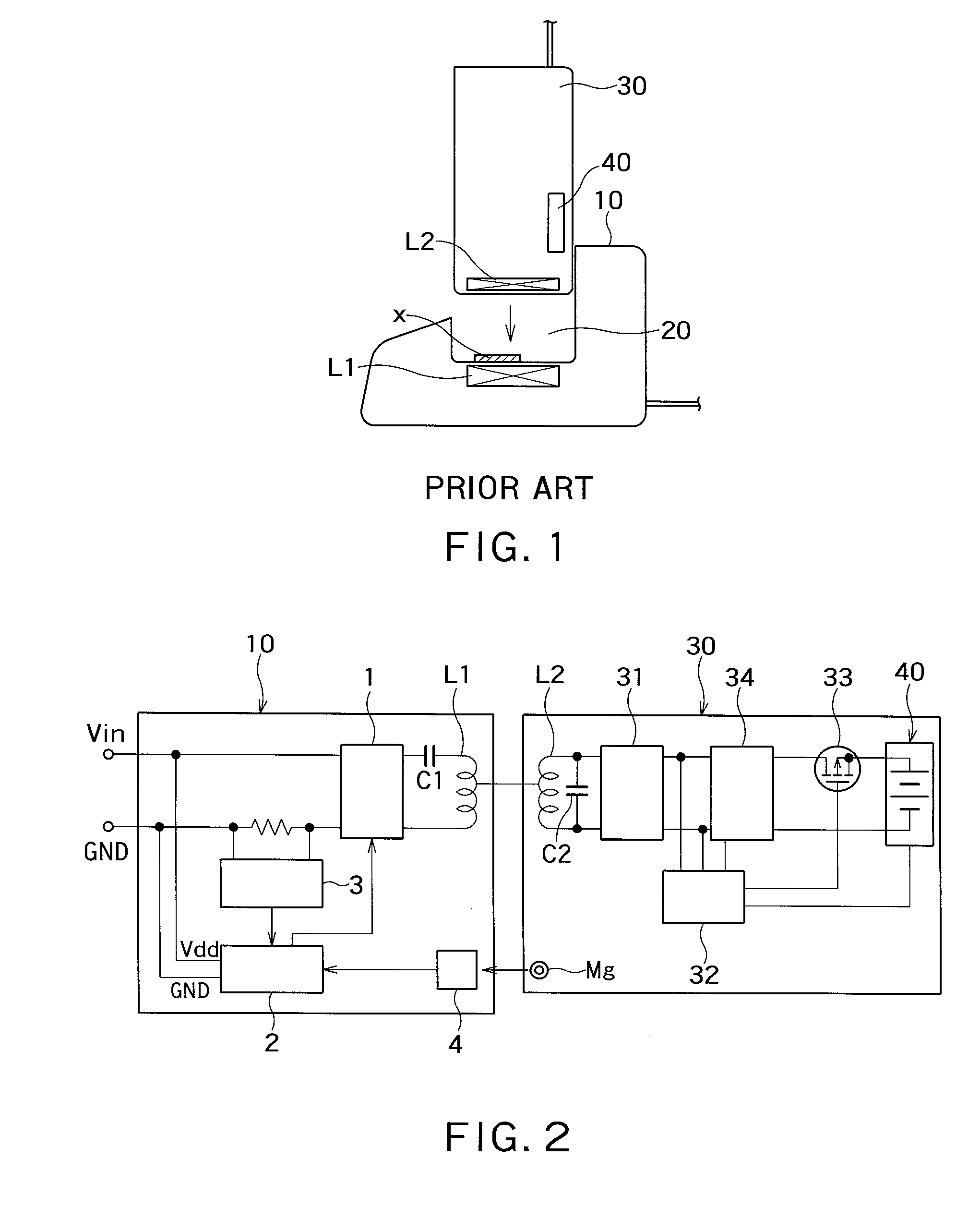

Ultrasonic wave generating/transmitting apparatus

InactiveUS7001335B2Avoid feverAvoid contactUltrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsEngineeringUltrasonic vibration

Disclosed is an ultrasonic generating and transmitting apparatus equipped with a transmission section for transmitting ultrasonic vibration from a vibration section. A plurality of linear members for transmitting ultrasonic vibration and binding plates which bind the linear members in such a state as to be apart from one another are provided. The transmission section is comprised of the linear members and the binding plates.

Owner:HITACHI LTD

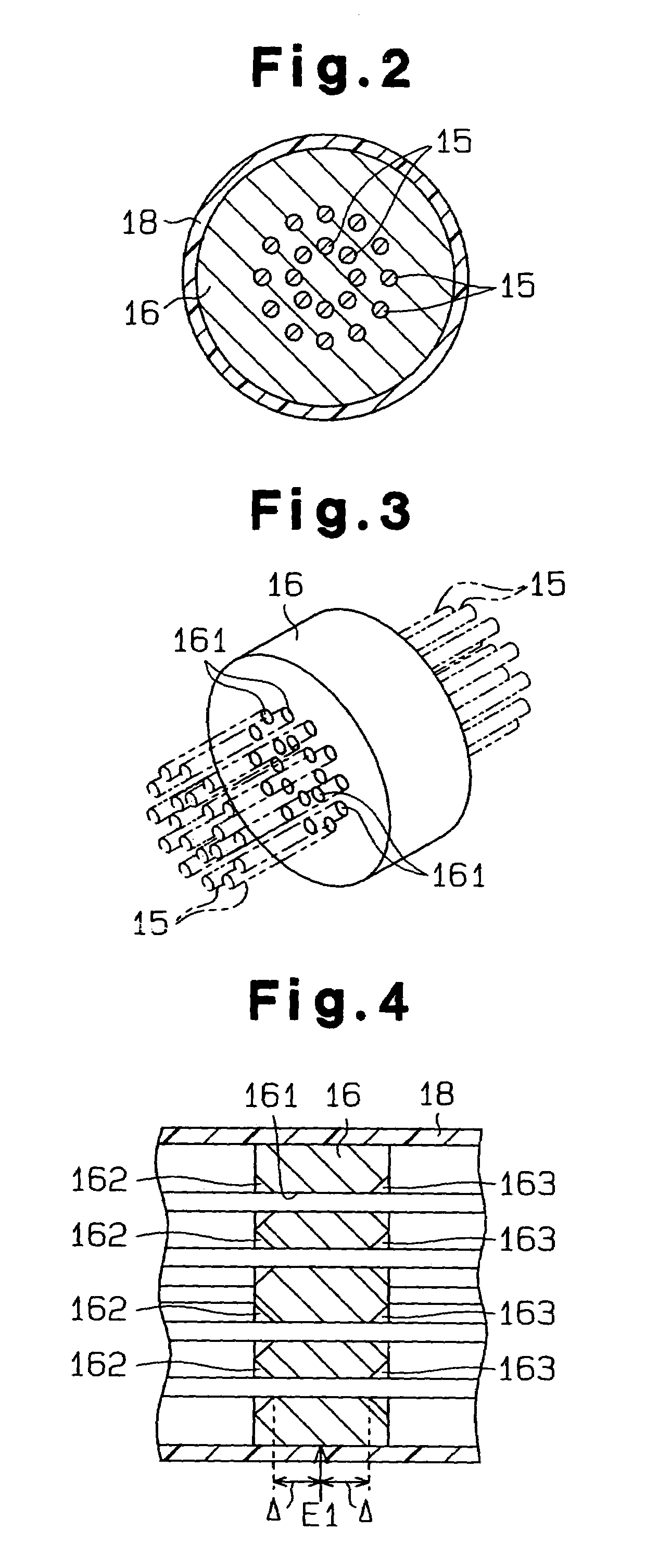

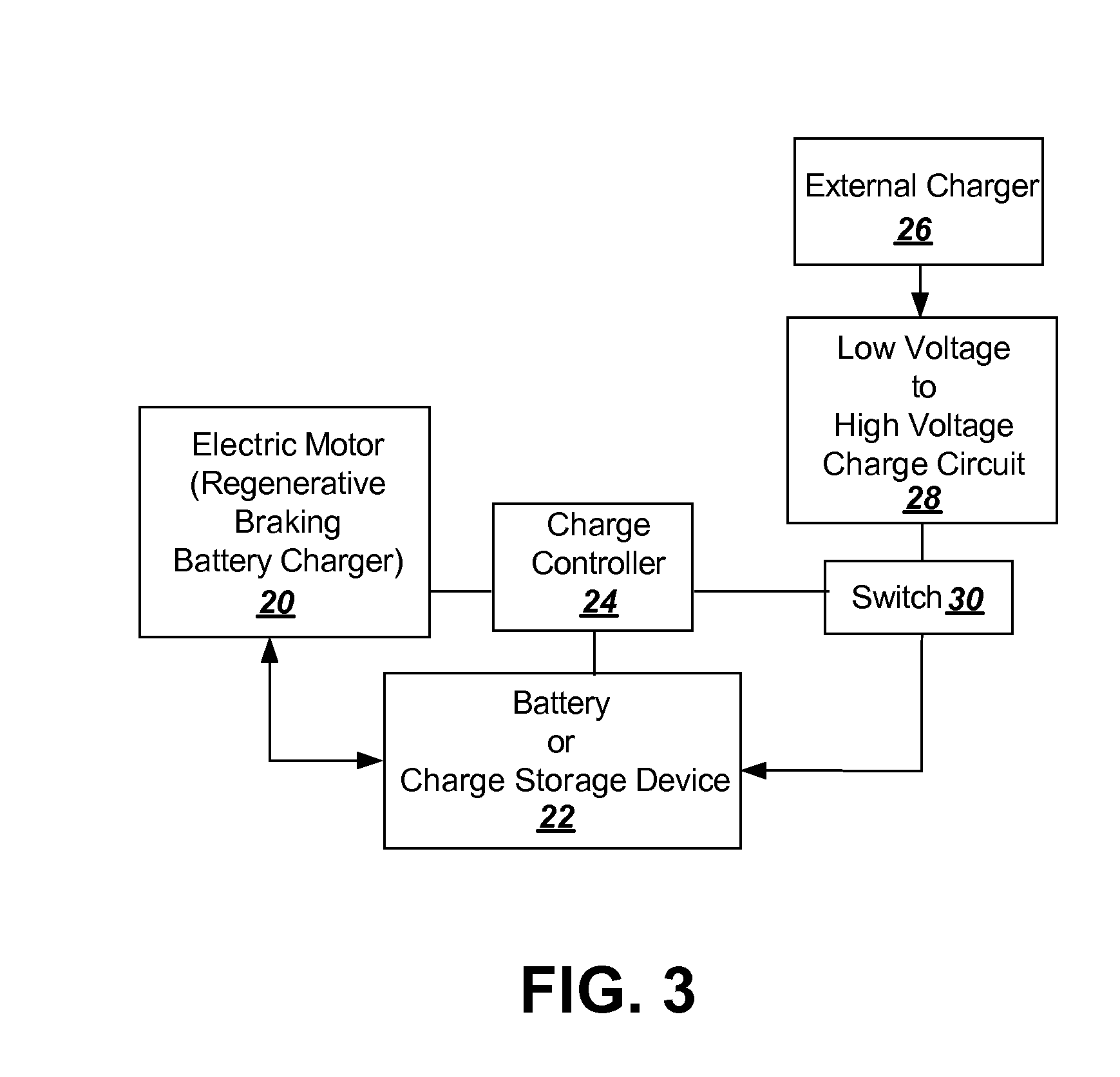

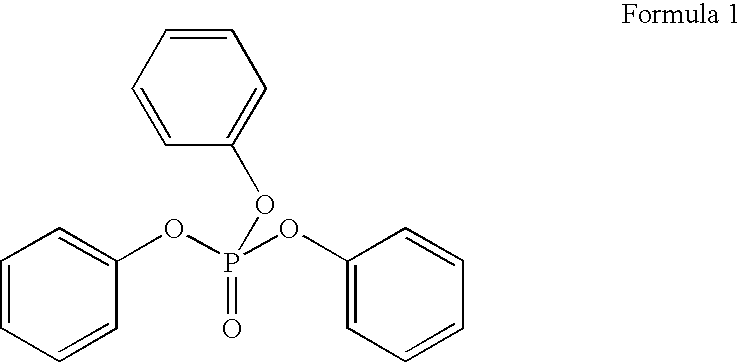

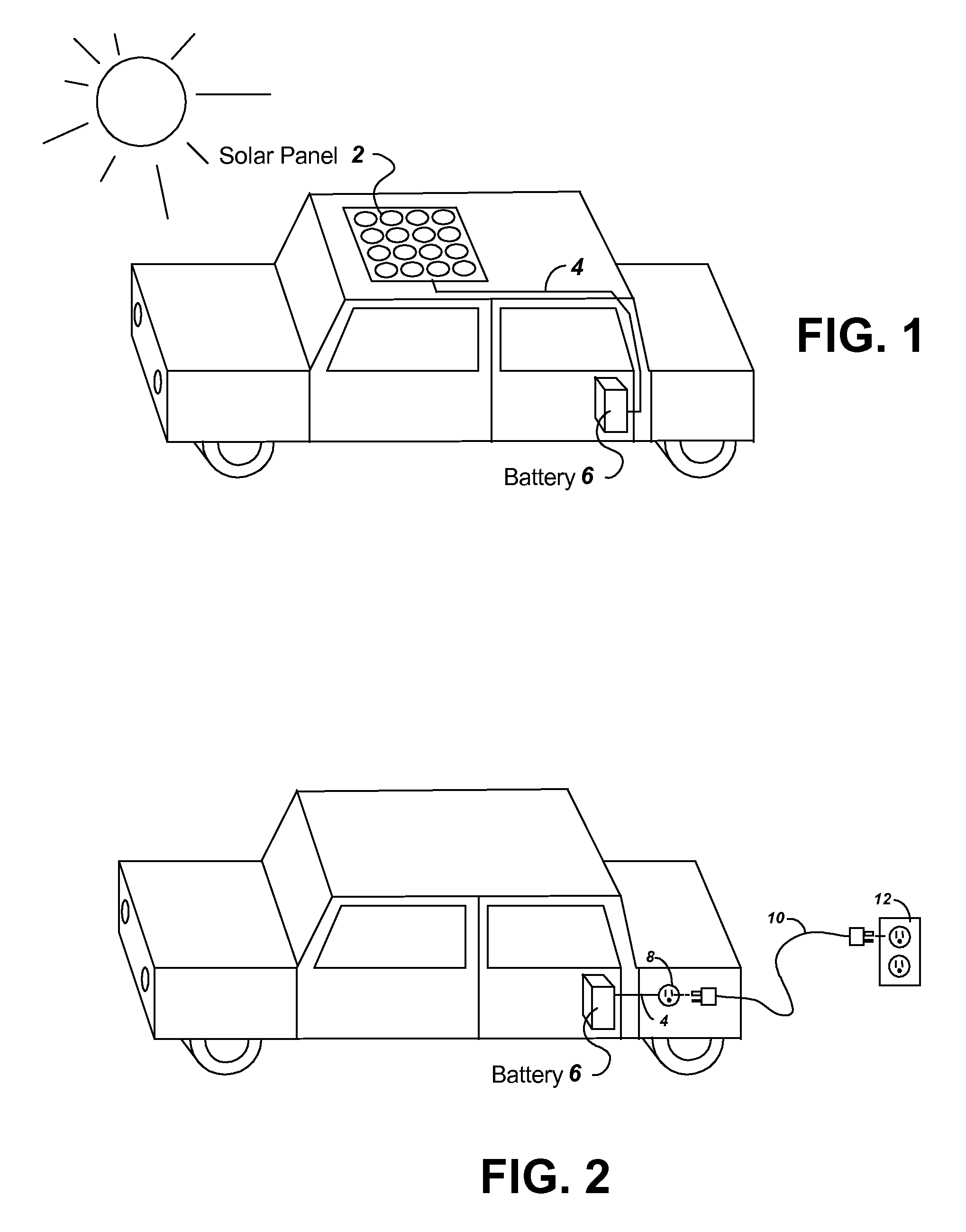

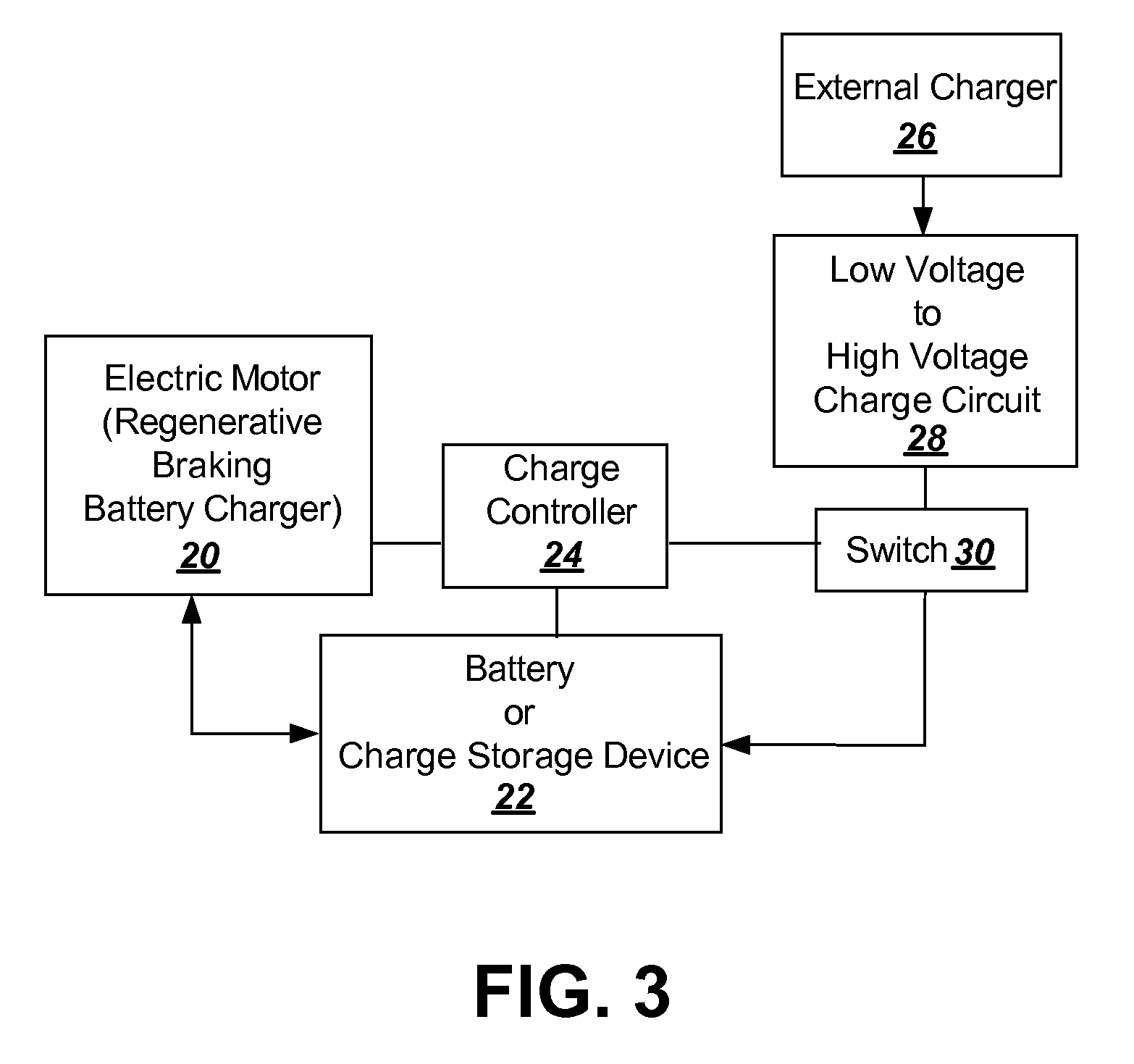

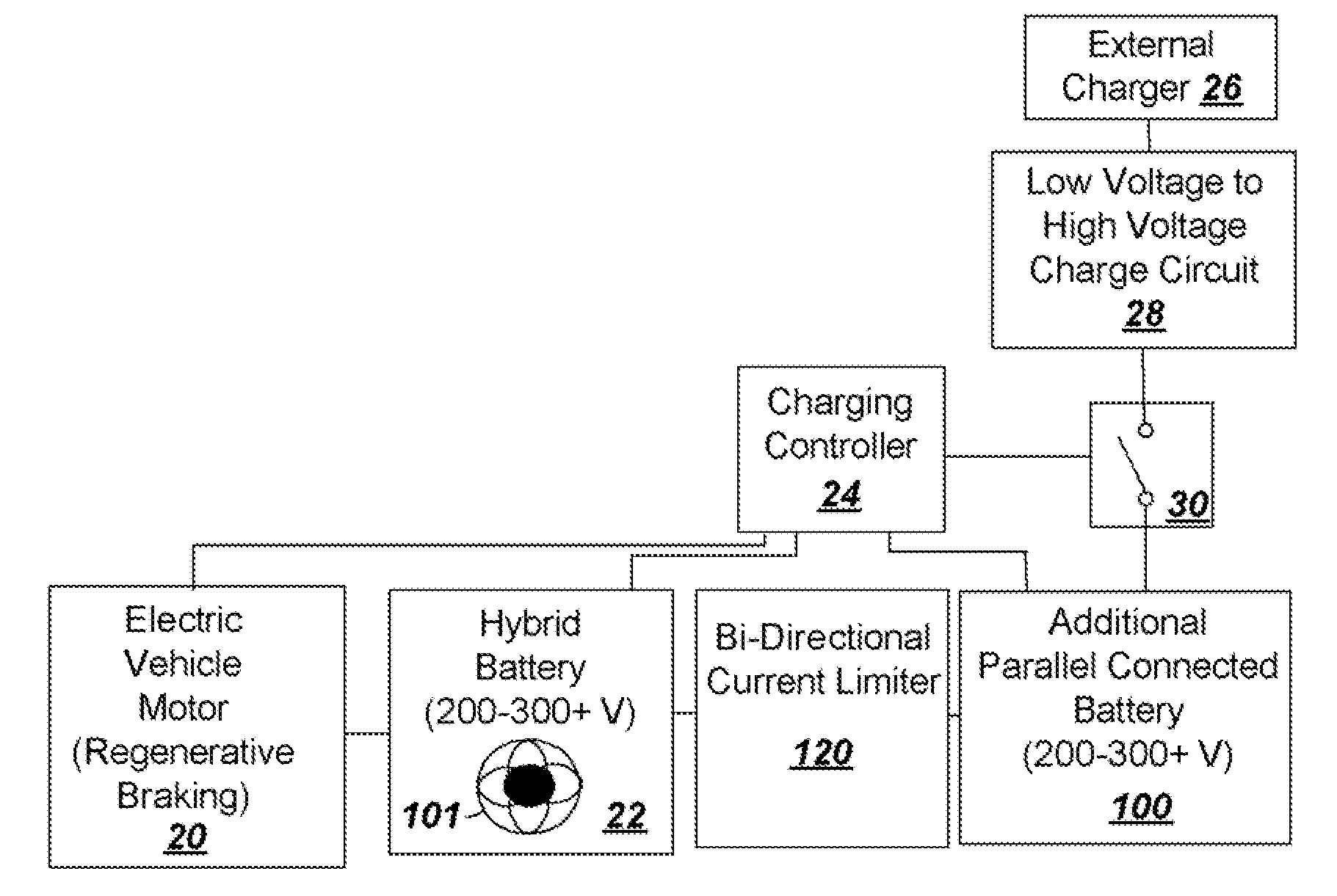

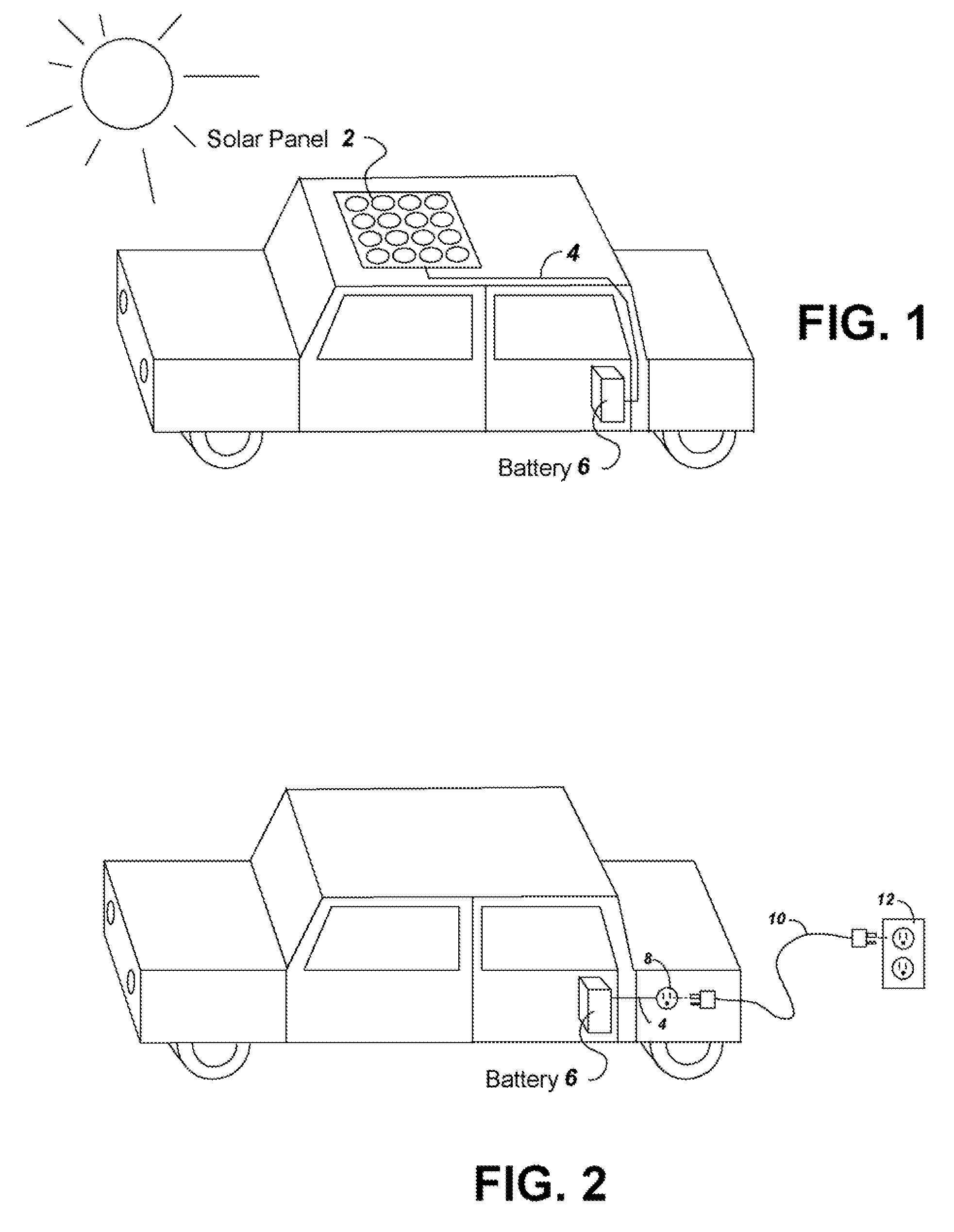

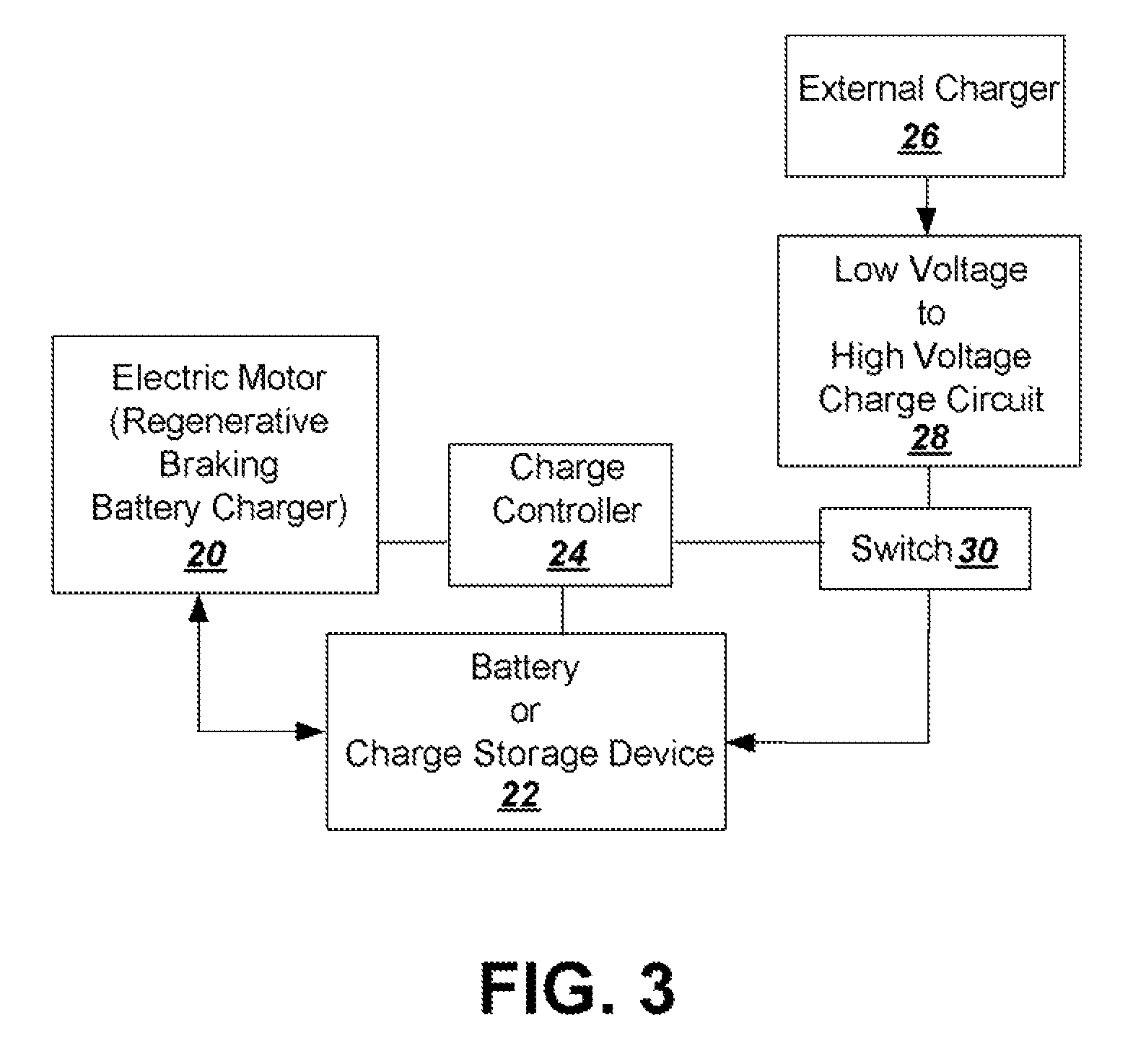

Current limiting parallel battery charging system to enable plug-in or solar power to supplement regenerative braking in hybrid or electric vehicle

InactiveUS20080203966A1Simple processBattery system is simplifiedHybrid vehiclesBatteries circuit arrangementsEngineeringSolar power

To provide additional charge storage for an electric vehicle, an additional battery (100) is connected in parallel with a regenerative braking direct charged battery (22) through a current limiting circuit (104 or 120). The additional battery (100) is charged by an external charger such as a plug-in charger or a solar panel that supply minimal current to prevent generation of battery heat. Current flows from the additional battery (100) to the regenerative braking charged batteries (22) so that both batteries can be charged. However, when excessive charge is drawn to drive the vehicle electric motor (20), the current limiter circuit (104 or 120) serves to prevent the discharge of additional battery (100) from creating excessive heat in the additional battery (100). Further, when regenerative braking is applied the current limiter circuit (120), or a diode buffer (102) in combination with current limiter (104), serves to prevent charging from creating excessive heat in the additional battery (100) and eliminates the need for a cooling structure in the additional battery (100).

Owner:WARD THOMAS A

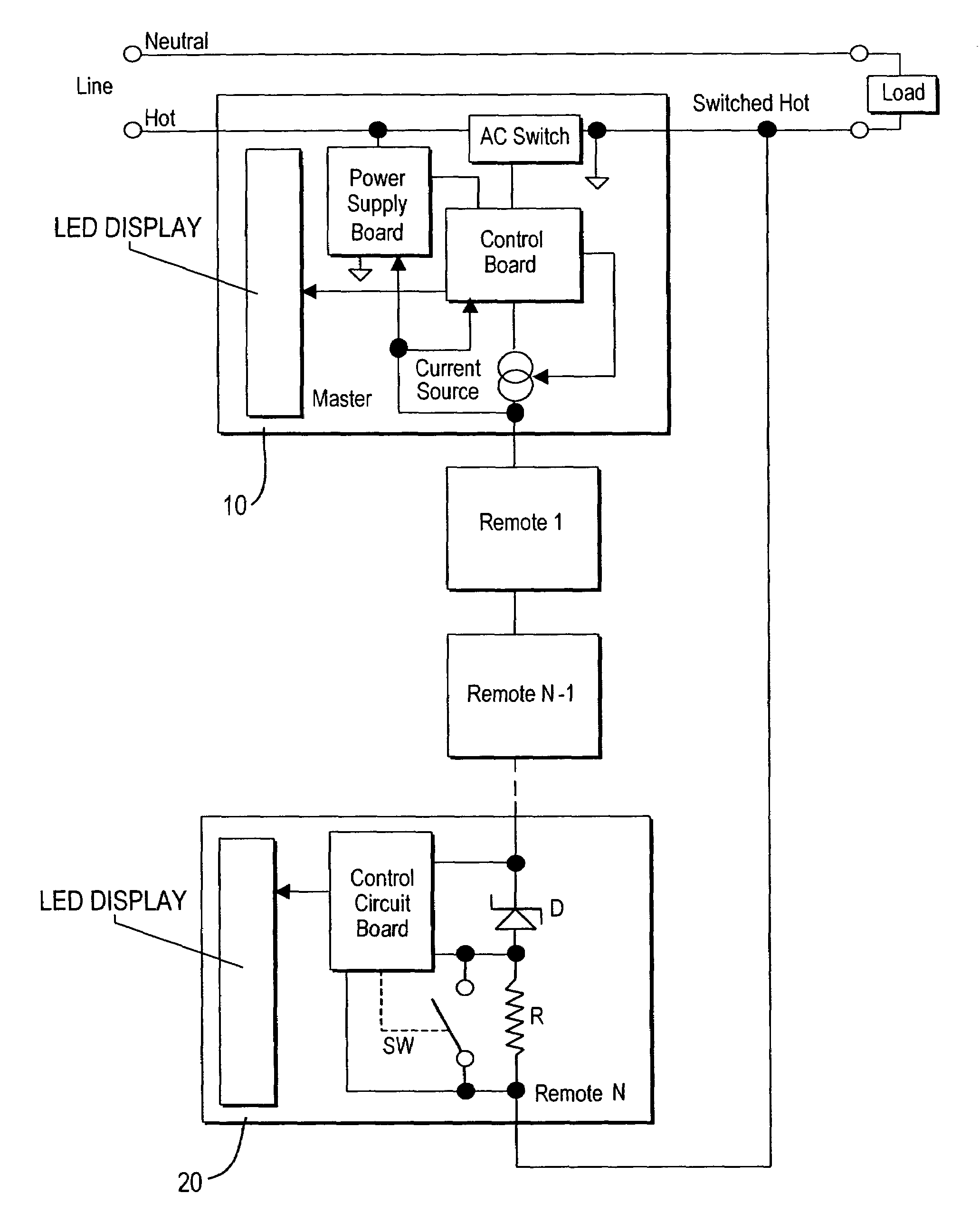

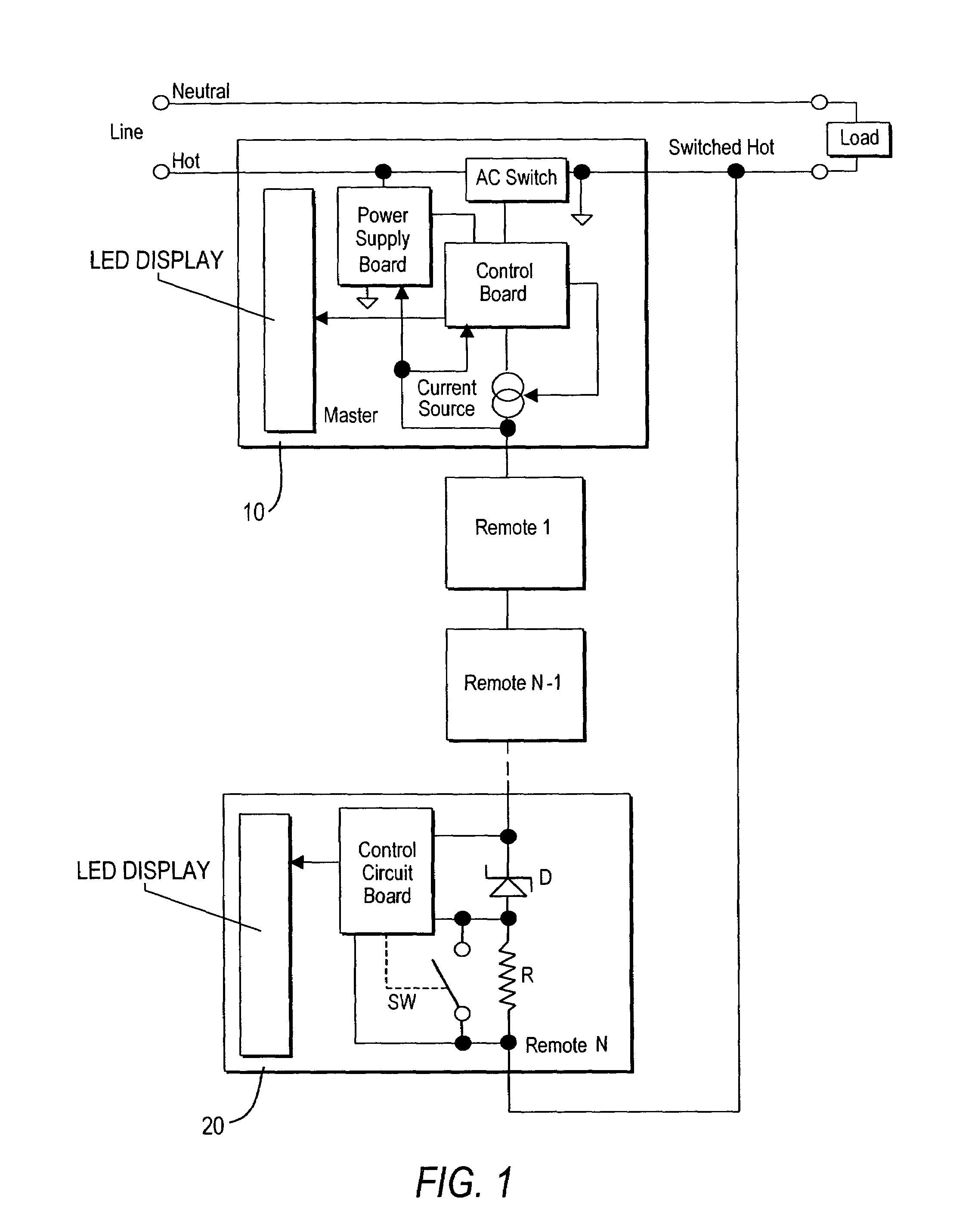

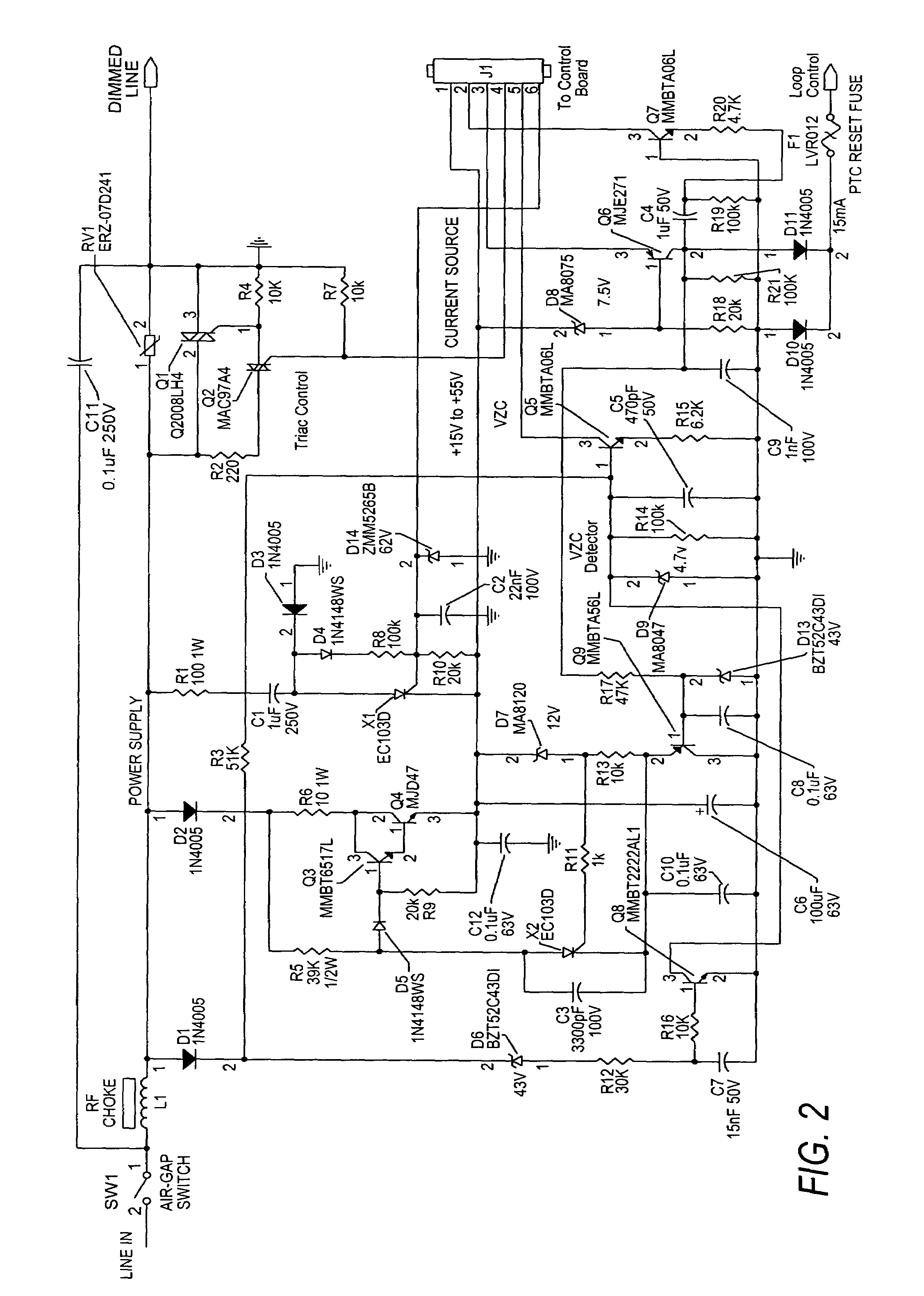

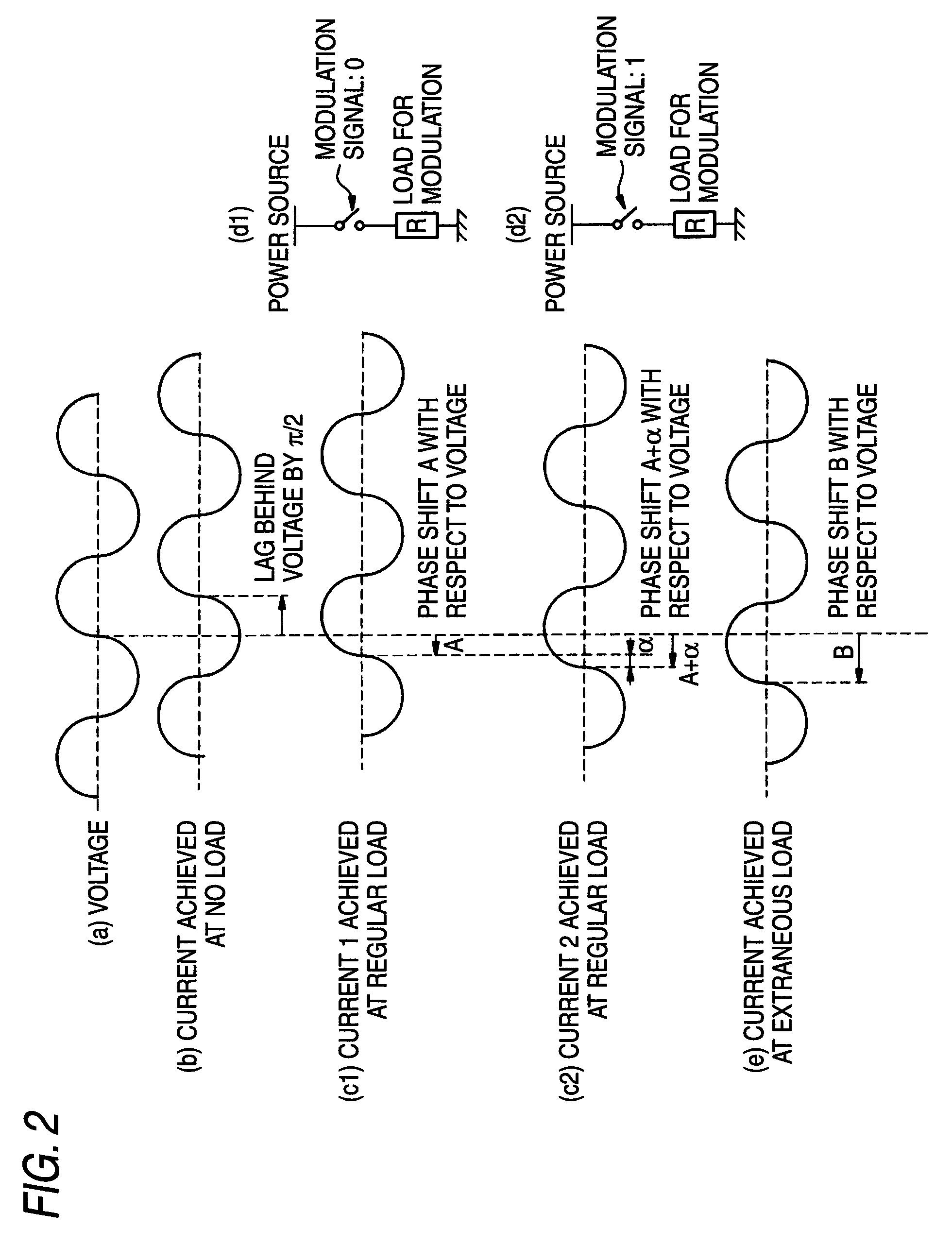

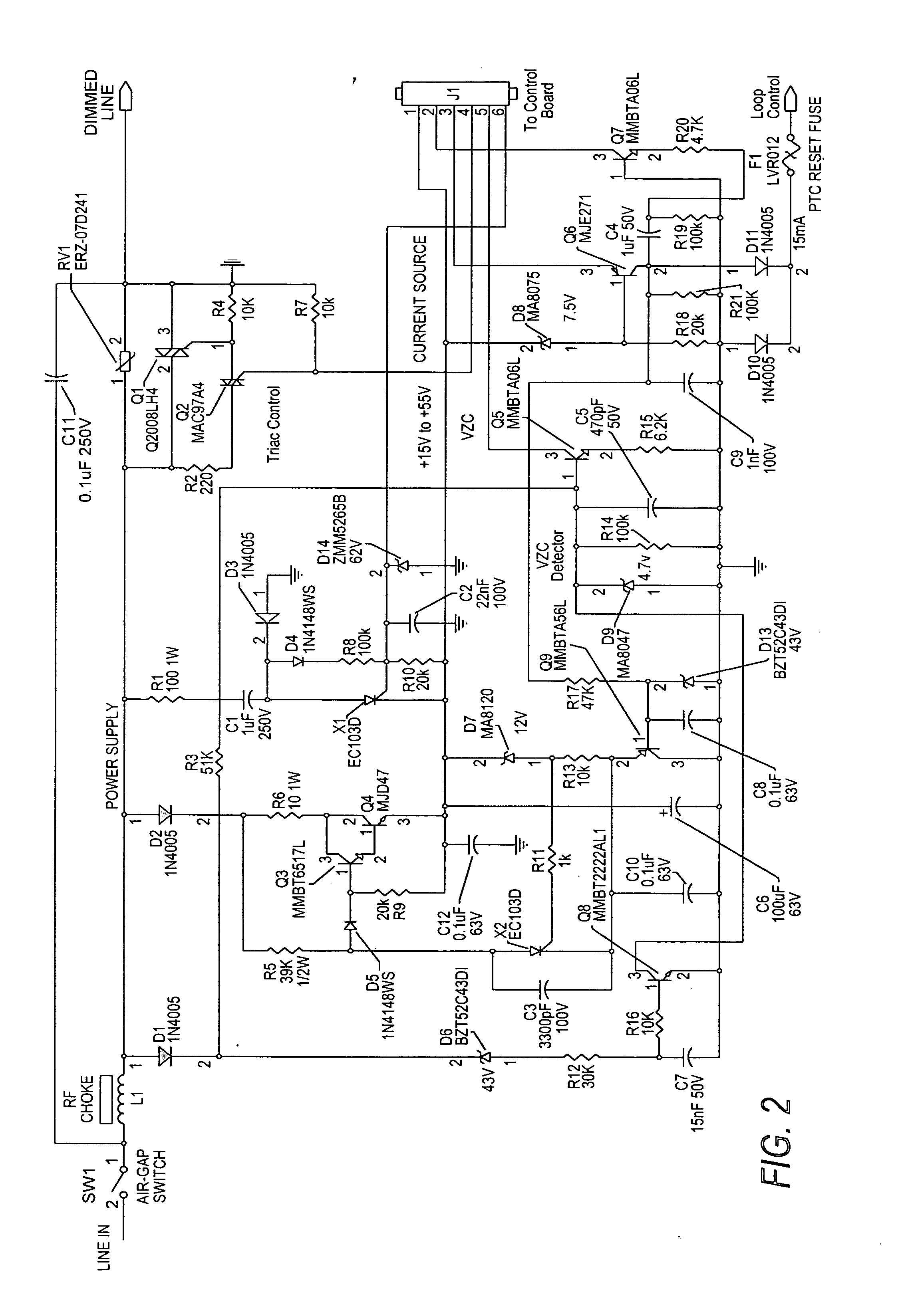

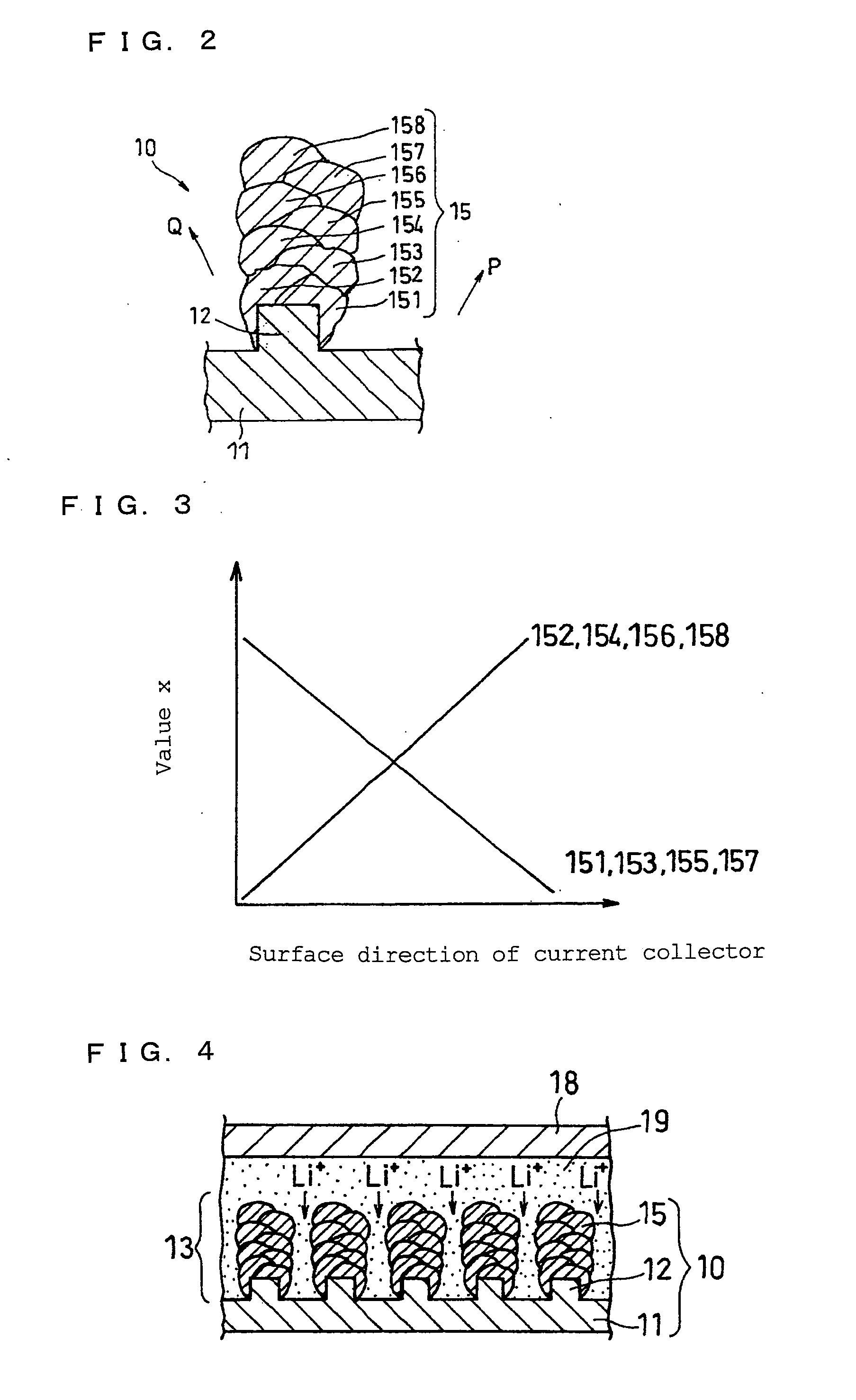

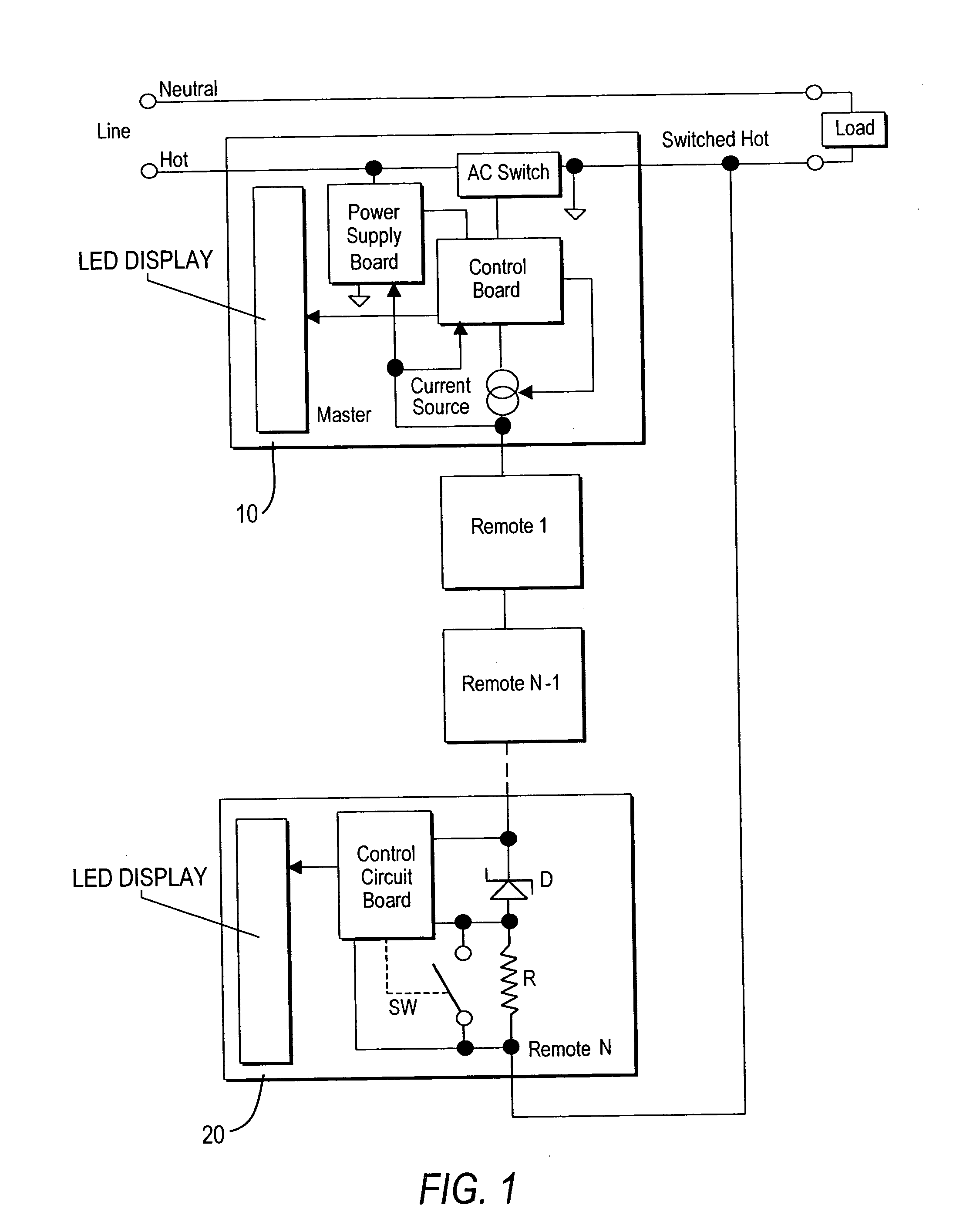

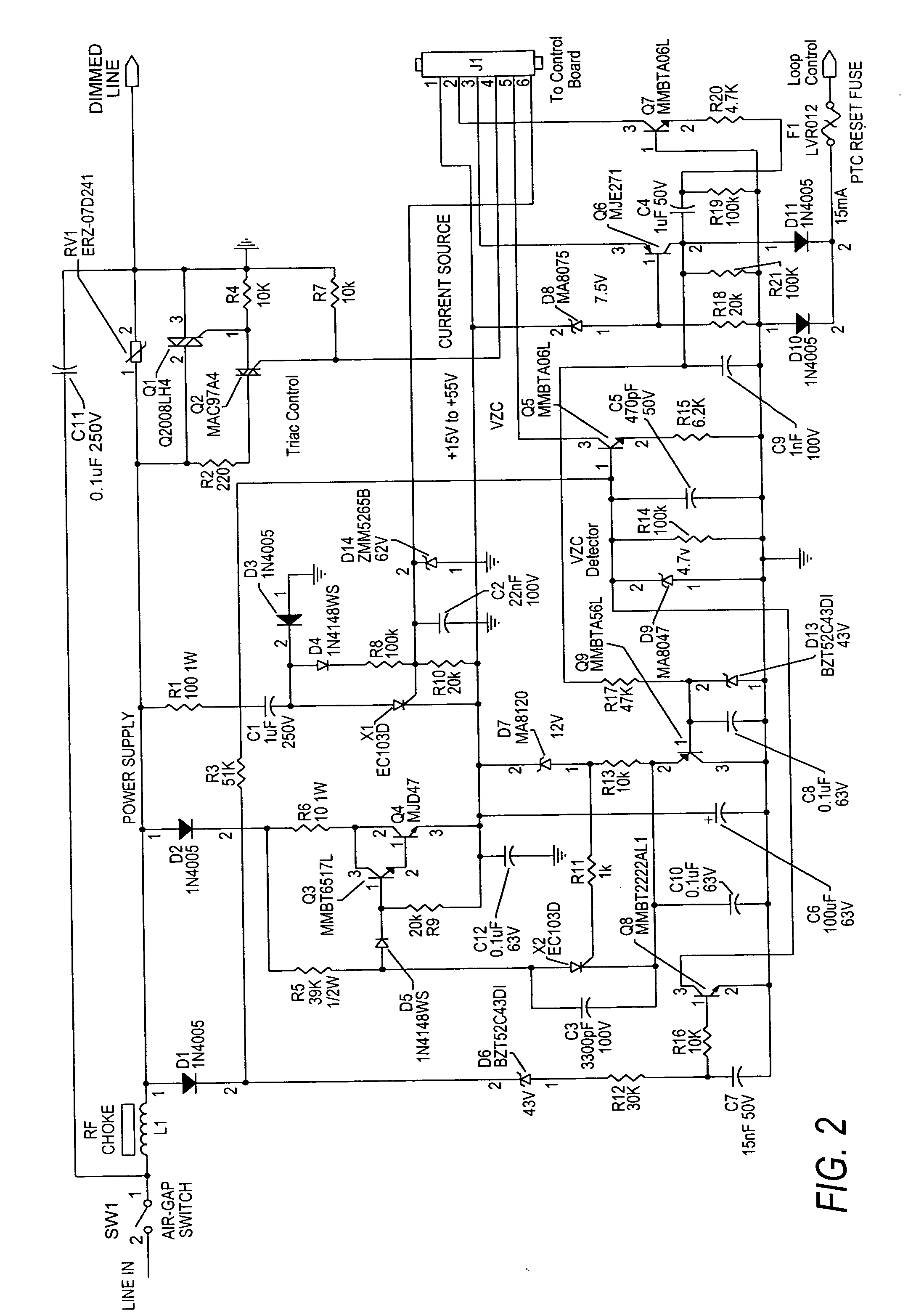

Dimmer control system with two-way master-remote communication

ActiveUS7012518B2Avoid noise problemsAvoid feverFrequency-division multiplex detailsPower distribution line transmissionCapacitanceNormal load

A dimmer control system has a communication control loop that connects a master unit in series with a plurality of remote units, and it is superimposed in series on the dimmer load line so as to allow two-way communication between the master unit and remote units without affecting the operation of the load. Communications from the master to the remote units are encoded in loop current fluctuations, whereas communications from any remote to the master unit are encoded in loop voltage fluctuations. The master unit has a switched power supply, for use during normal LOAD ON operation, in tandem with a capacitive power supply, for use during LOAD OFF operation of the control units so as to minimize hum. The master unit power supply circuit provides an output rail voltage comprised of a reference voltage for the load superimposed with a control loop voltage for the voltage drop across the series-connected remote units. The master unit has a POWER OFF detection circuit and a non-volatile memory for storing system status information, so that when power is restored, the system can be restored to its former power level. The switch units are formed with a cover frame mounting a switch plate on a hinge axis allowing ON / OFF movement of an opposing side thereof. An array of LED light pipes is mounted in the switch plate aligned with the hinge axis, in order to minimize displacement of the light pipes during actuator movement.

Owner:EATON INTELLIGENT POWER LTD

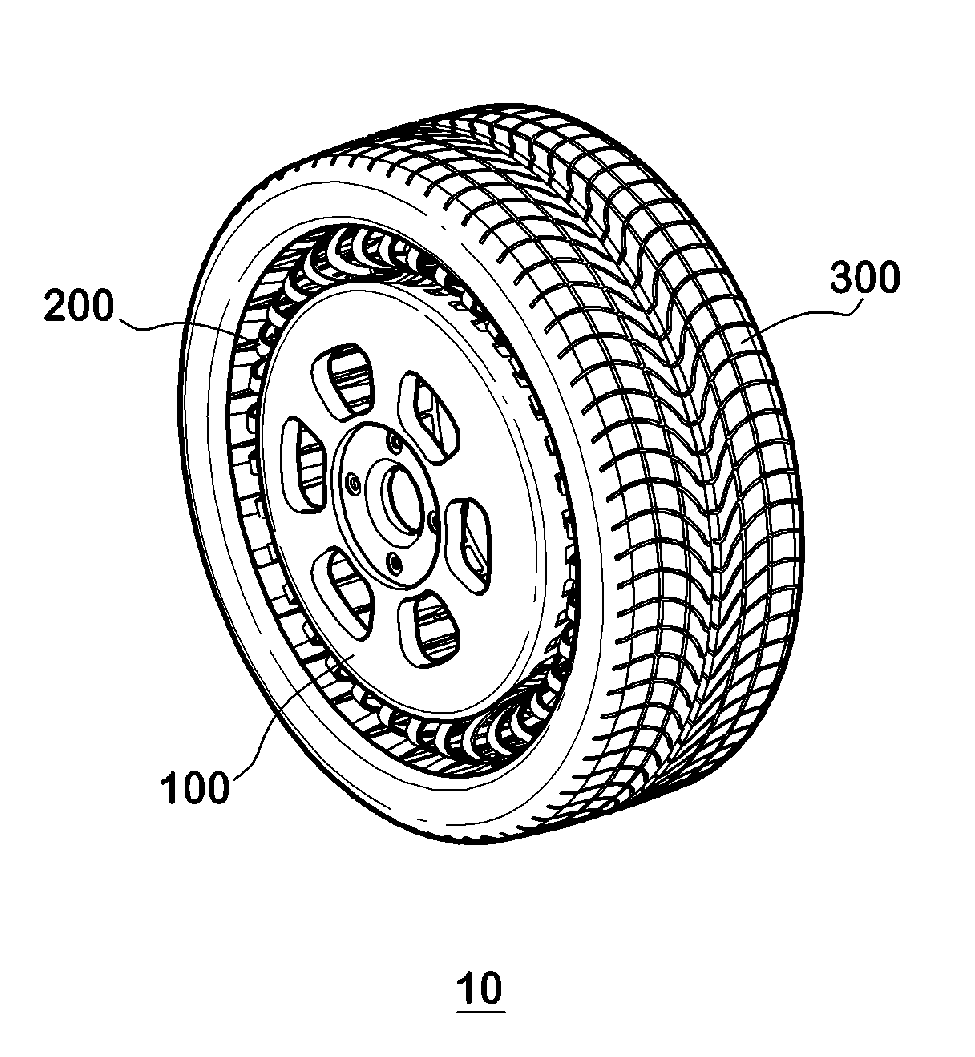

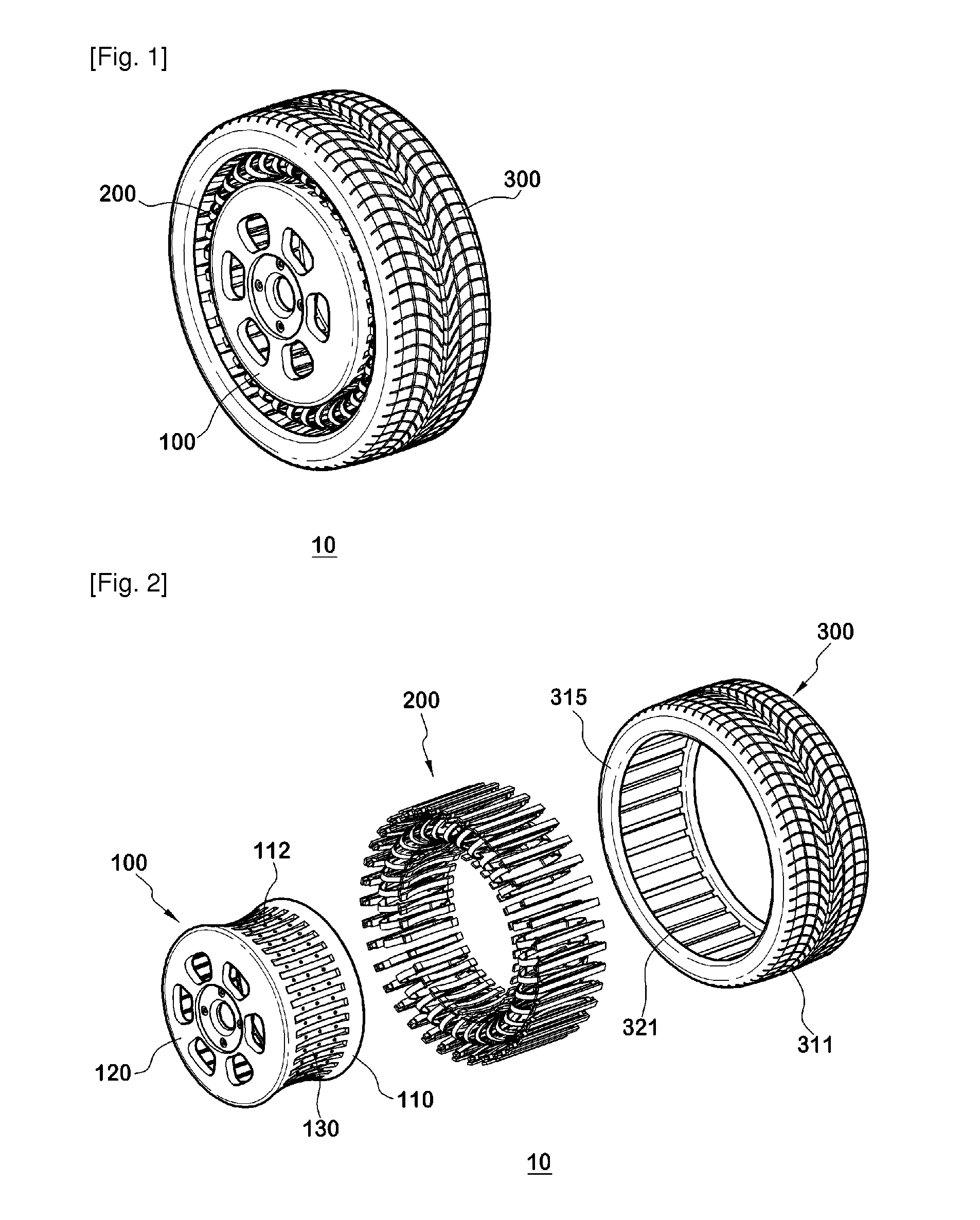

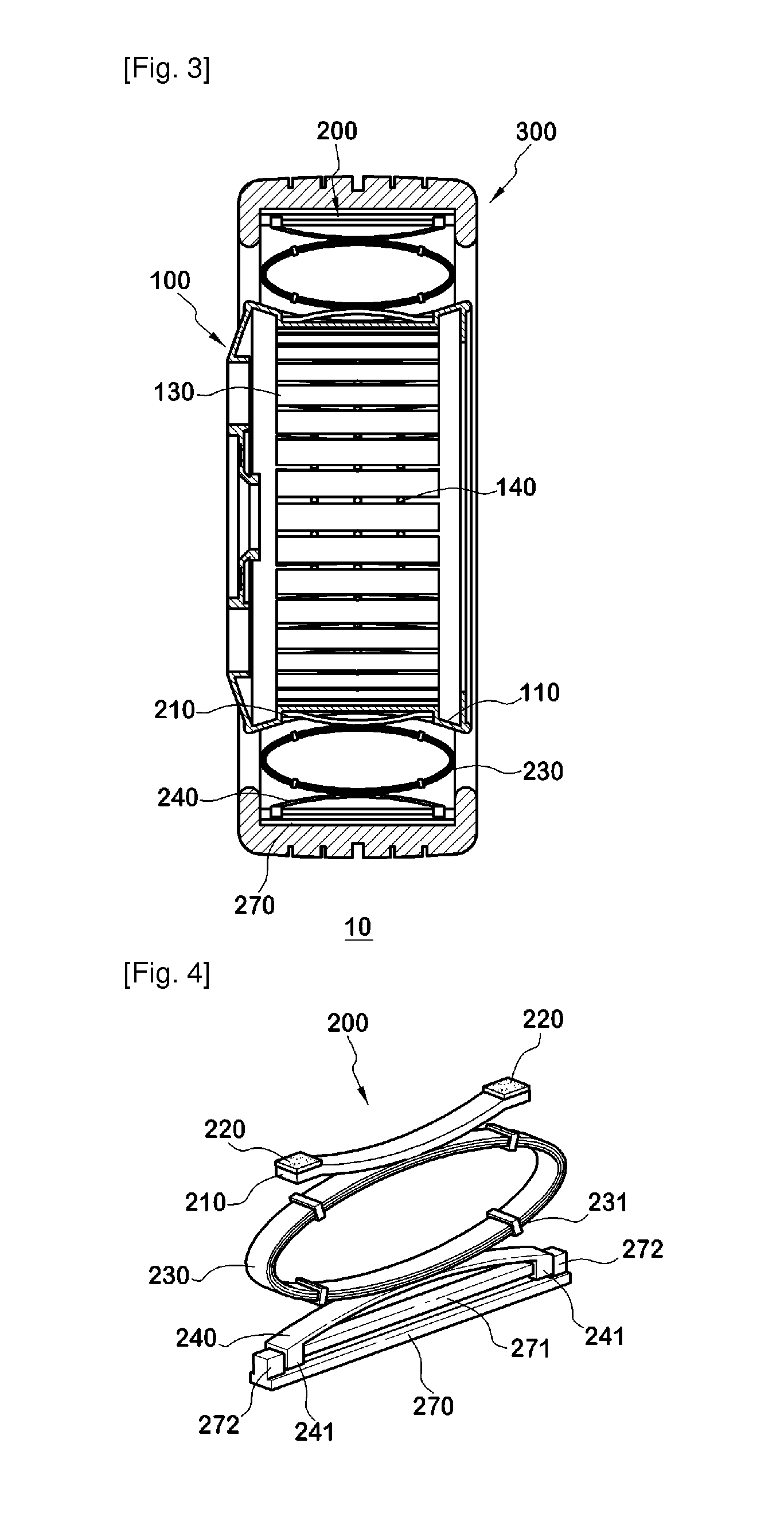

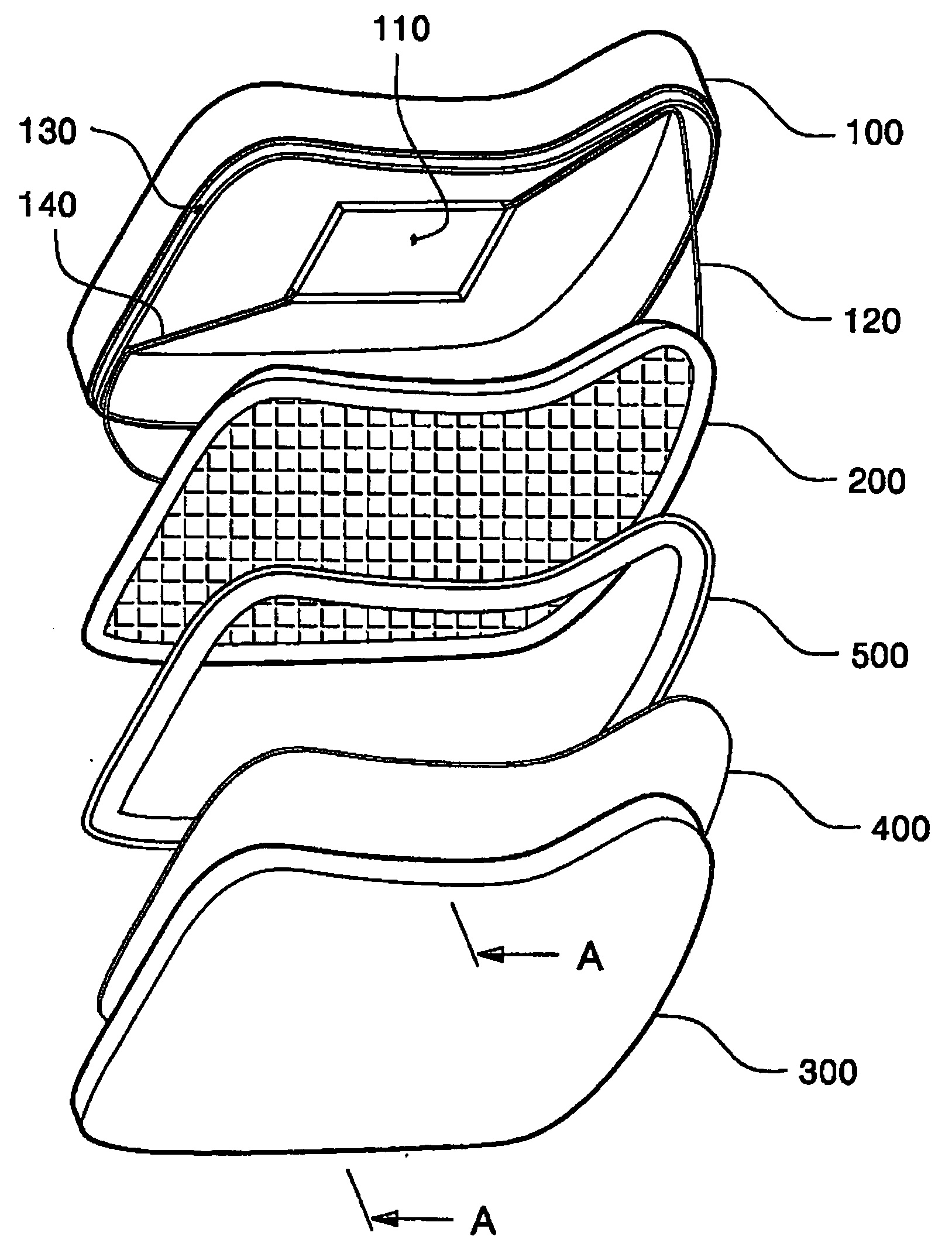

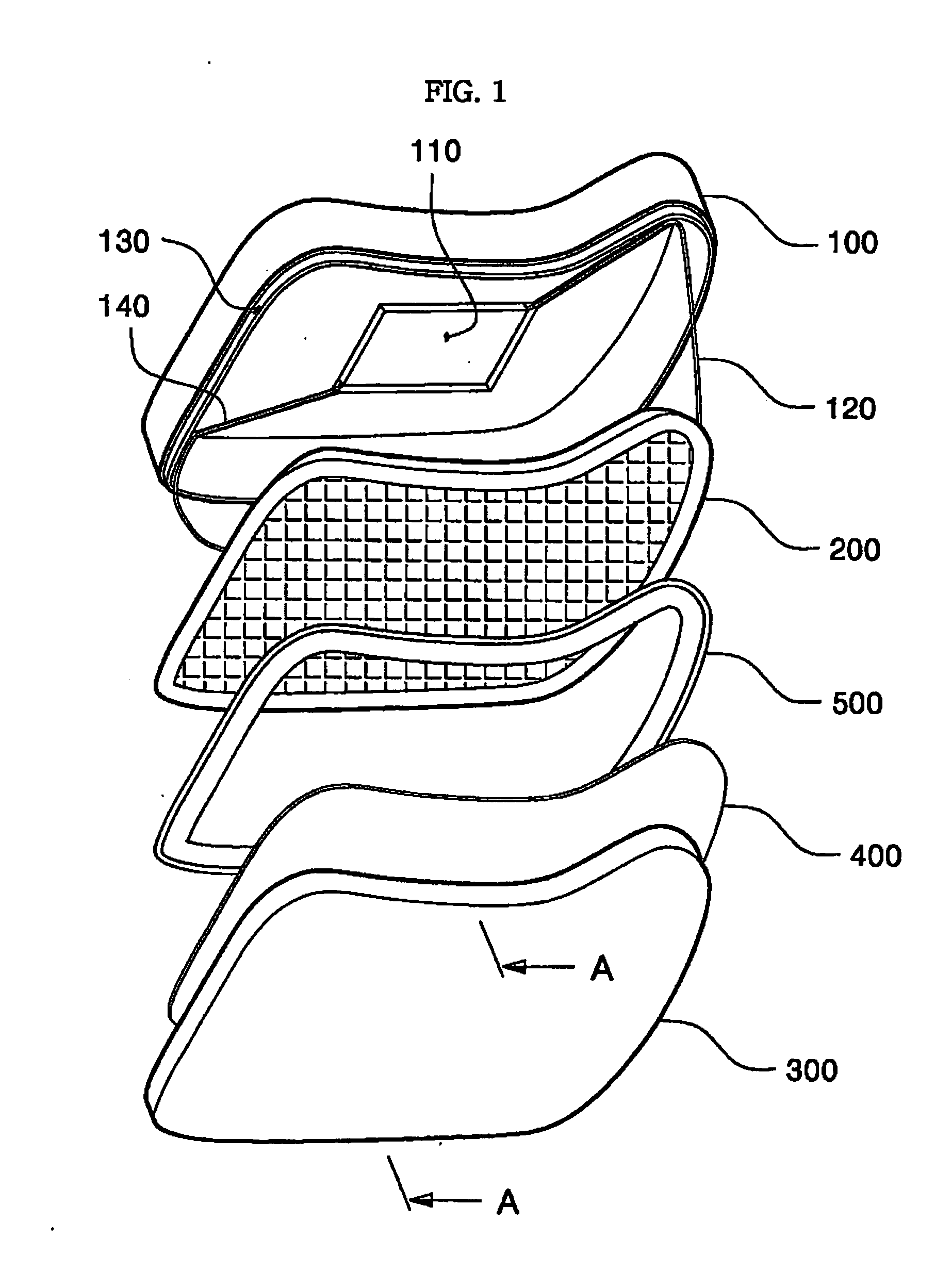

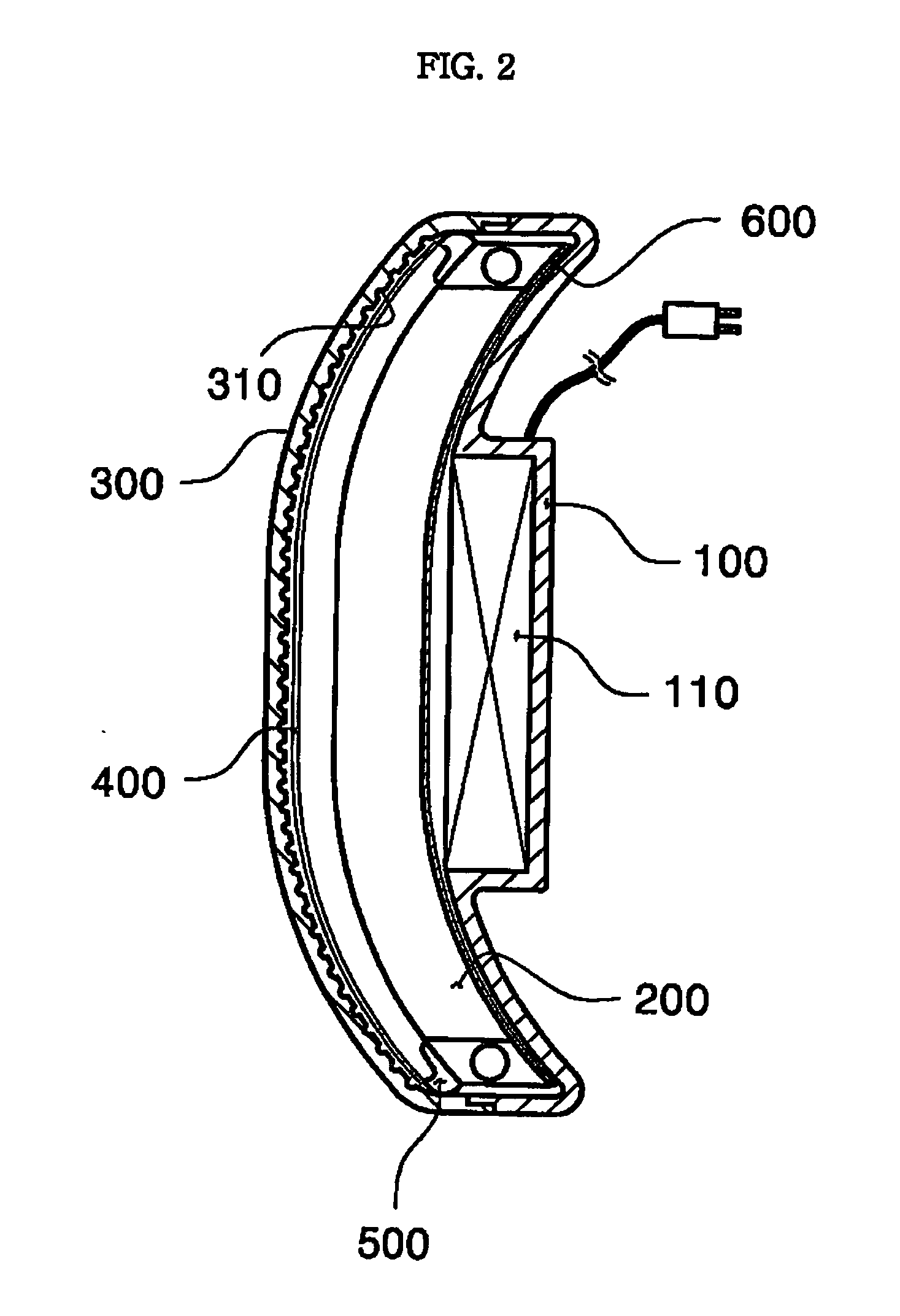

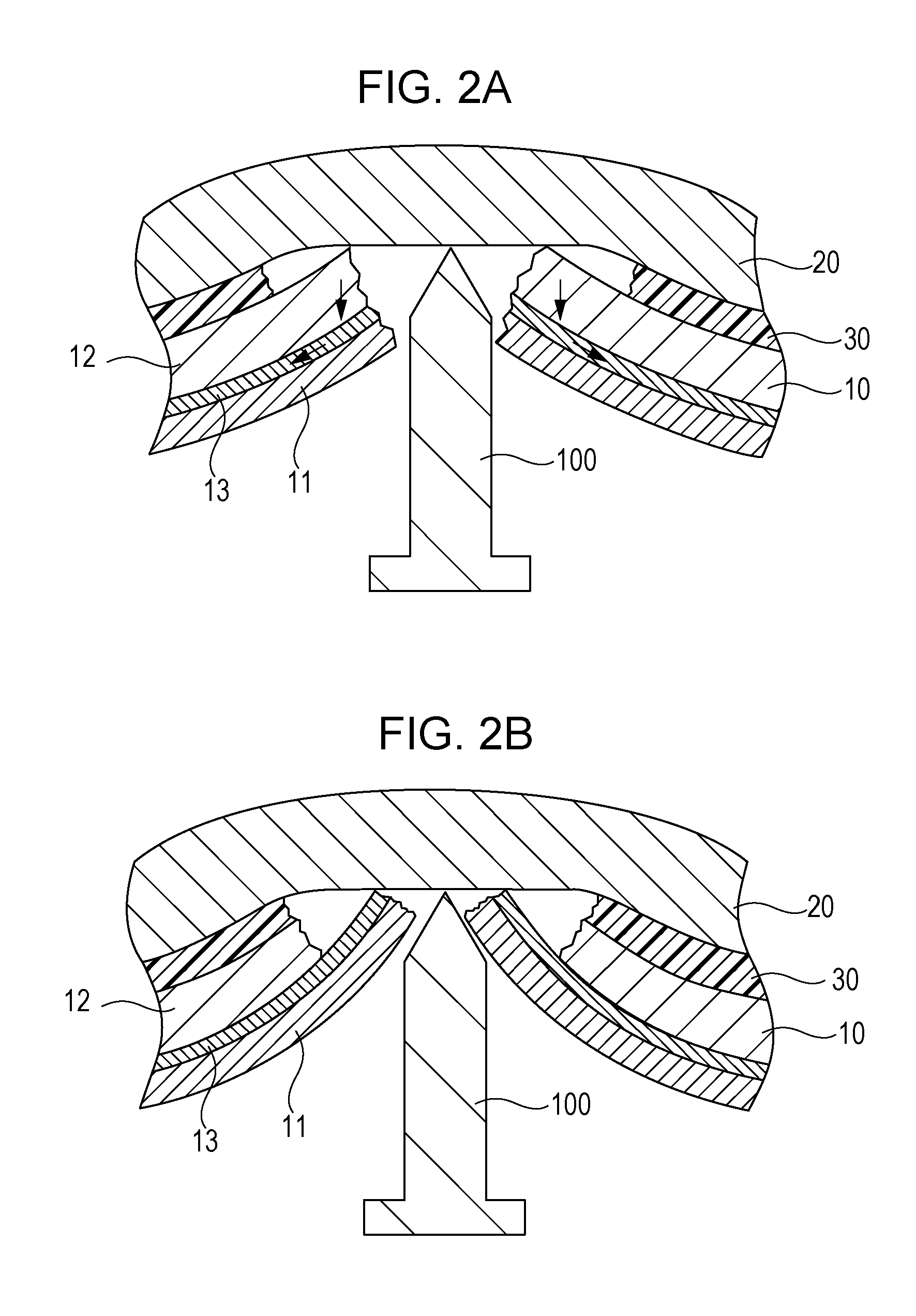

Non-pneumatic wheel and wheel, suspension and tire used therein

InactiveUS20110248554A1Prevent tire blowoutReduce vehicle accidentRimsLeaf springsCornering forceBrake fade

Provided is a non-pneumatic wheel (100) for a vehicle, and a wheel (100), suspension (200; 200-1), and tire (300) used therein that are capable of ensuring driving stability because there is no air chamber between a wheel (100) and a tire (300) to blowout. They are also capable of ensuring good road holding, preventing standing waves, reducing brake fade and cornering force, providing good handling and ride comfort, staying quiet when rolling, and are economical and environmentally friendly. The non-pneumatic wheel (100) includes a wheel (100), a shock absorbing member (220; 220-1) coupled to an outer periphery of the wheel (100) and absorbing or attenuating noise and vibration due to external shock, a plurality of resilient members (230; 230-1; 230-2) arranged around and coupled to an outer periphery of the shock absorbing member (220; 220-1) in a radial direction and having a plurality of resilient rings (230-1a) that are resiliently deformed in response to an external force, resilient links (240) respectively coupled to the resilient rings (230-1a) to evenly transmit external shock to the resilient rings (230-1a), rail plates (270) to which sliders (261) formed at both ends of the resilient links (240) are slidably coupled, and a tire (300) having a plurality of coupling grooves (321) formed along an inner periphery such that the rail plates (270) are inserted into the coupling grooves (321).

Owner:CHON YOUNG ILL +4

Lamp for vehicle

InactiveUS20060044825A1Easy to modifyReduced space required for installationVehicle headlampsPoint-like light sourceExit planeLight guide

The present invention relates to a lamp for a vehicle, wherein light is caused to be incident into a light guide panel from a side surface of the plate-shaped light guide panel, the light is propagated within the light guide panel by means of total reflection and scattered by a scattering pattern formed on a rear surface of the light guide panel so that the light can be radiated to a front surface of the light guide panel, and the light radiated to the front surface is then radiated forward with a predetermined pattern by means of a cover member provided with a lens pattern. A lamp for a vehicle according to the present invention comprises a housing having an opening through which light radiates; a light-transmitting cover member which has a light incidence plane and a light exit plane, and is fixedly installed on the housing to hermetically cover the opening of the housing and provided with a lens pattern formed on the light incidence plane and / or the light exit plane; a plate-shaped light guide panel which has a light incidence plane defined at a side surface thereof to receive light and a light exit plane defined at a front surface thereof to face the cover member and is provided with a scattering pattern for scattering light incident on the light incidence plane thereof toward the light exit plane thereof; a light source installed at a portion adjacent to the light incidence plane of the light guide panel to emit the light to the light incidence plane; and a reflection plate installed on a rear surface of the light guide panel to reflect the light toward a front surface of the light guide panel.

Owner:TECHSIGN

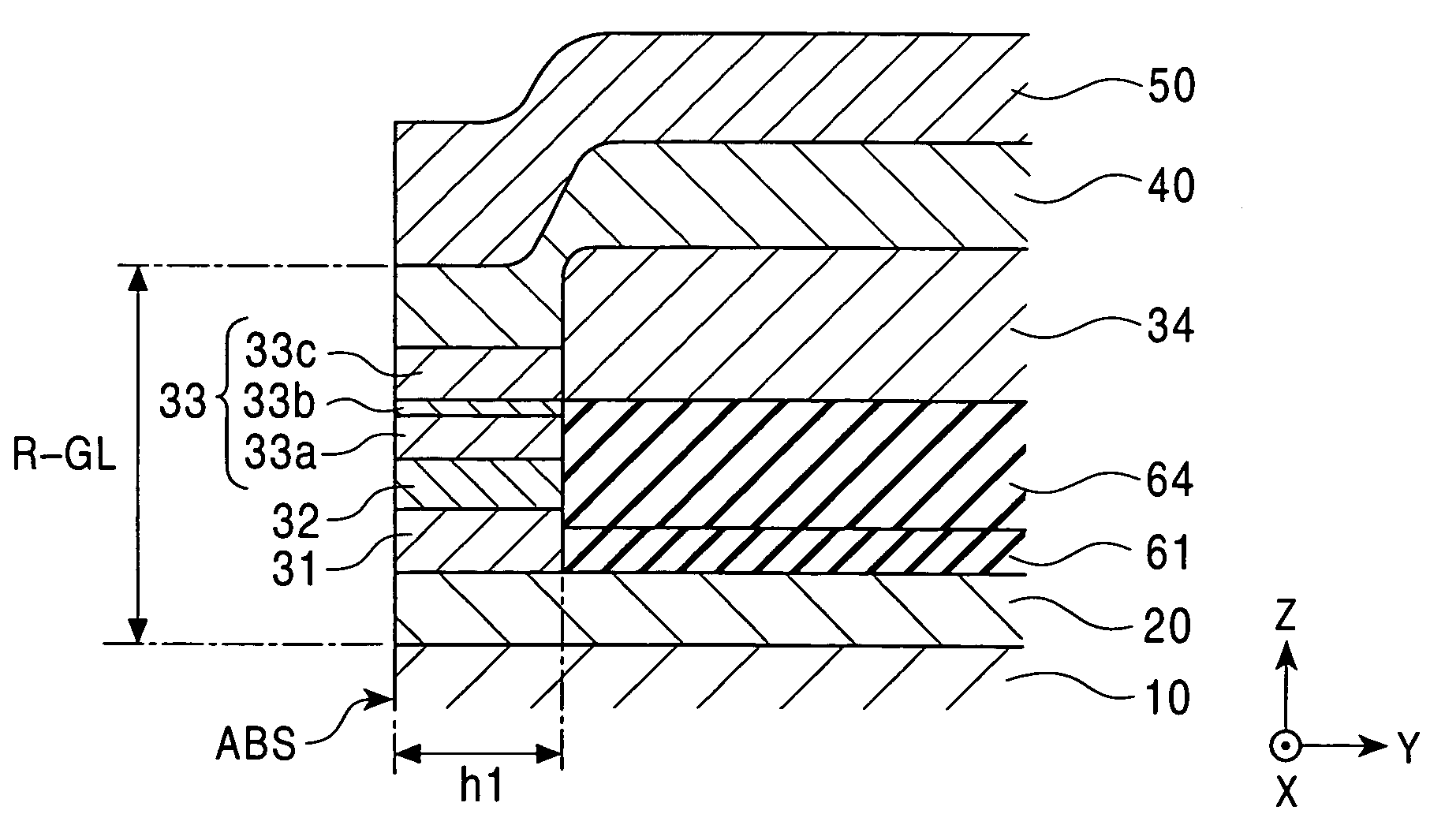

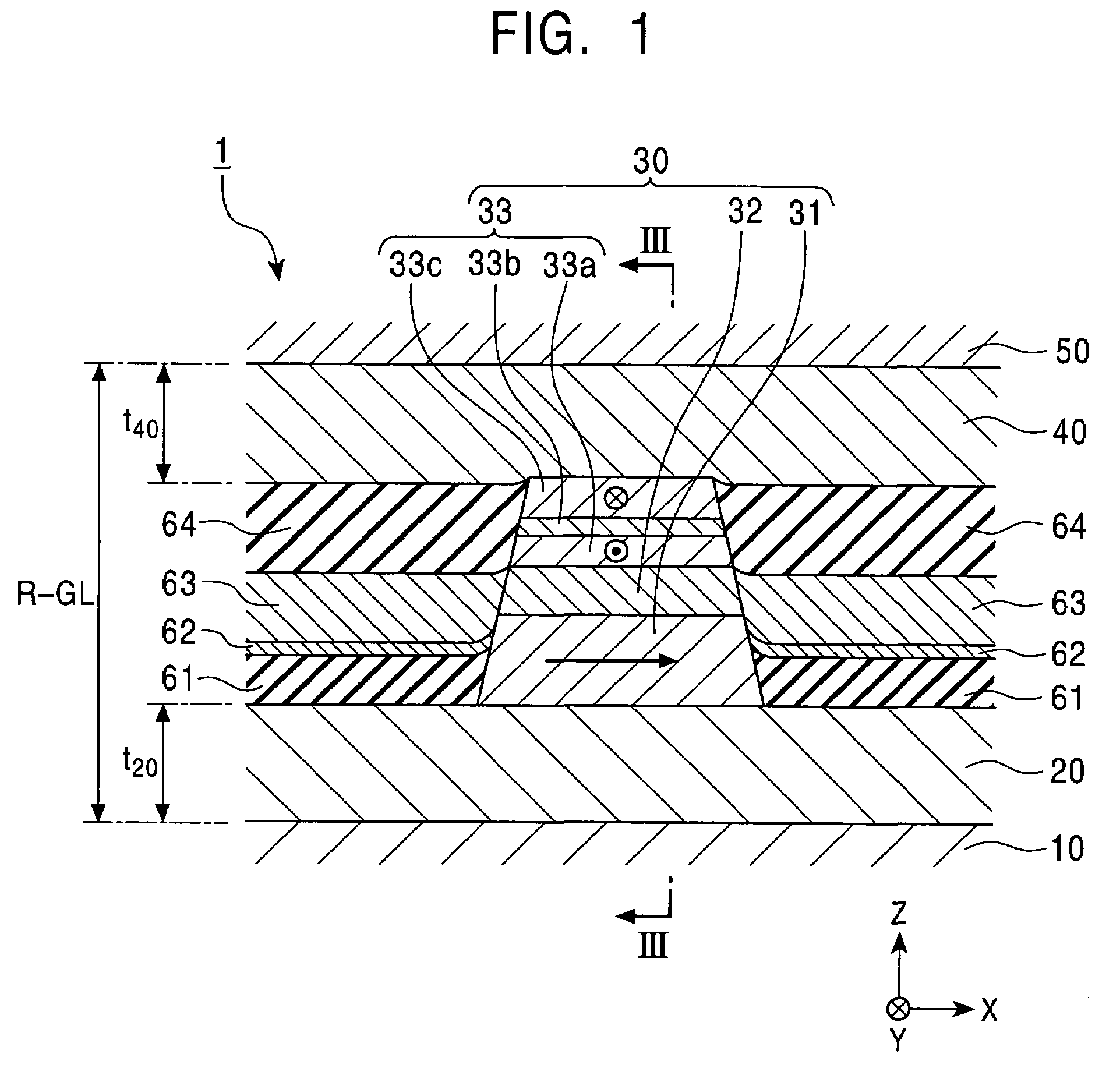

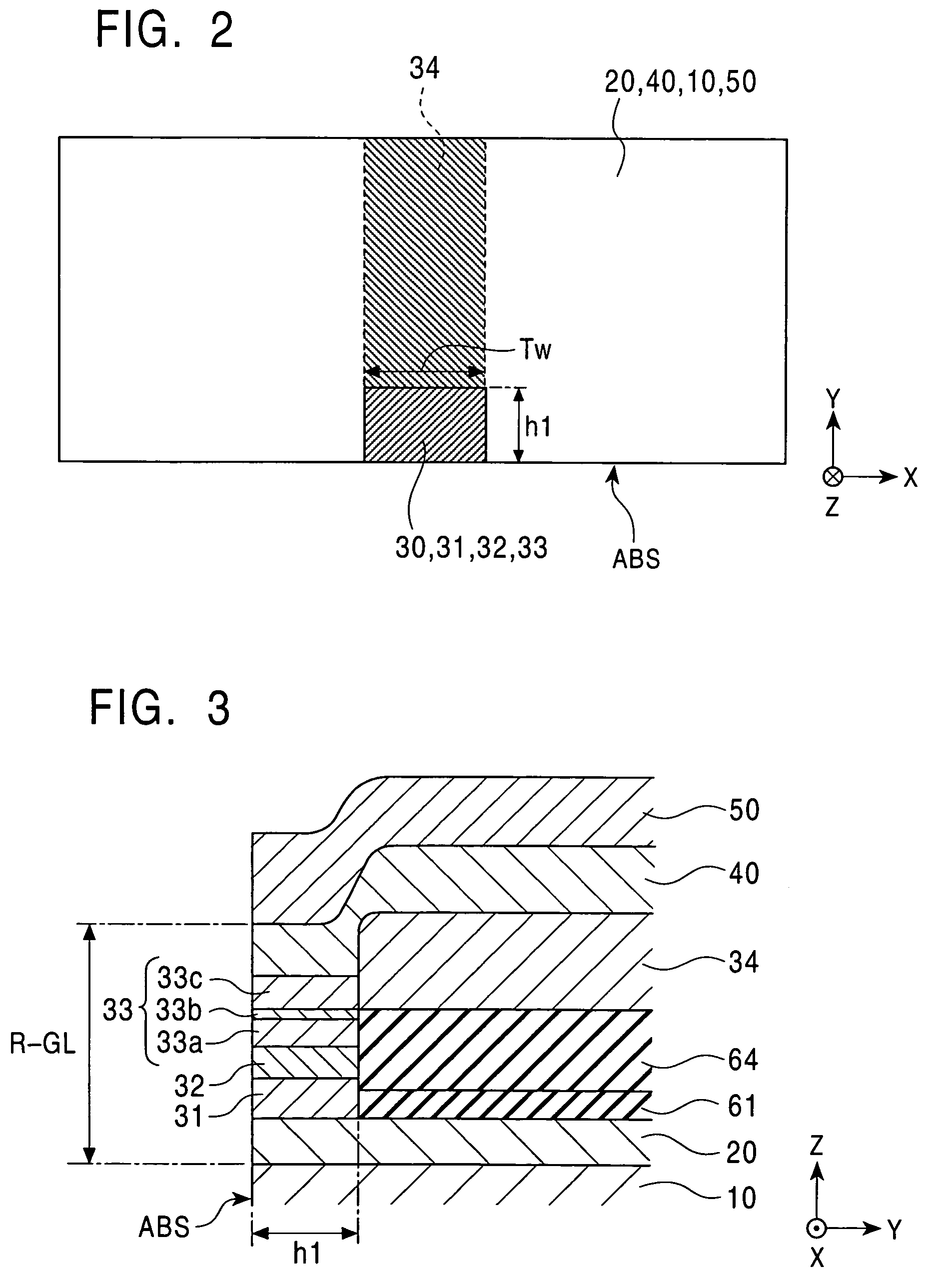

CPP giant magnetoresistive head having antiferromagnetic film disposed in rear of element

ActiveUS7220499B2Avoid feverSuppresses component temperature riseNanomagnetismMagnetic measurementsFilm planeMagnetization

A CPP giant magnetoresistive head includes lower and upper shield layers with a predetermined distance therebetween, and a giant magnetoresistive element (GMR) including pinned and free magnetic layers disposed between the upper and lower shield layers with a nonmagnetic layer interposed between the pinned and free magnetic layers. A current flows perpendicularly to the film plane of the GMR. The magnetoresistive head further includes an antiferromagnetic layer (an insulating AF of Ni—O or α-Fe2O3) provided in the rear of the GMR in a height direction to make contact with the upper or lower surface of a rear portion of the pinned magnetic layer which extends in the height direction, and an exchange coupling magnetic field is produced at the interface with the upper or lower surface, so that the magnetization direction of the pinned magnetic layer is pinned by the exchange coupling magnetic field in the height direction.

Owner:TDK CORPARATION

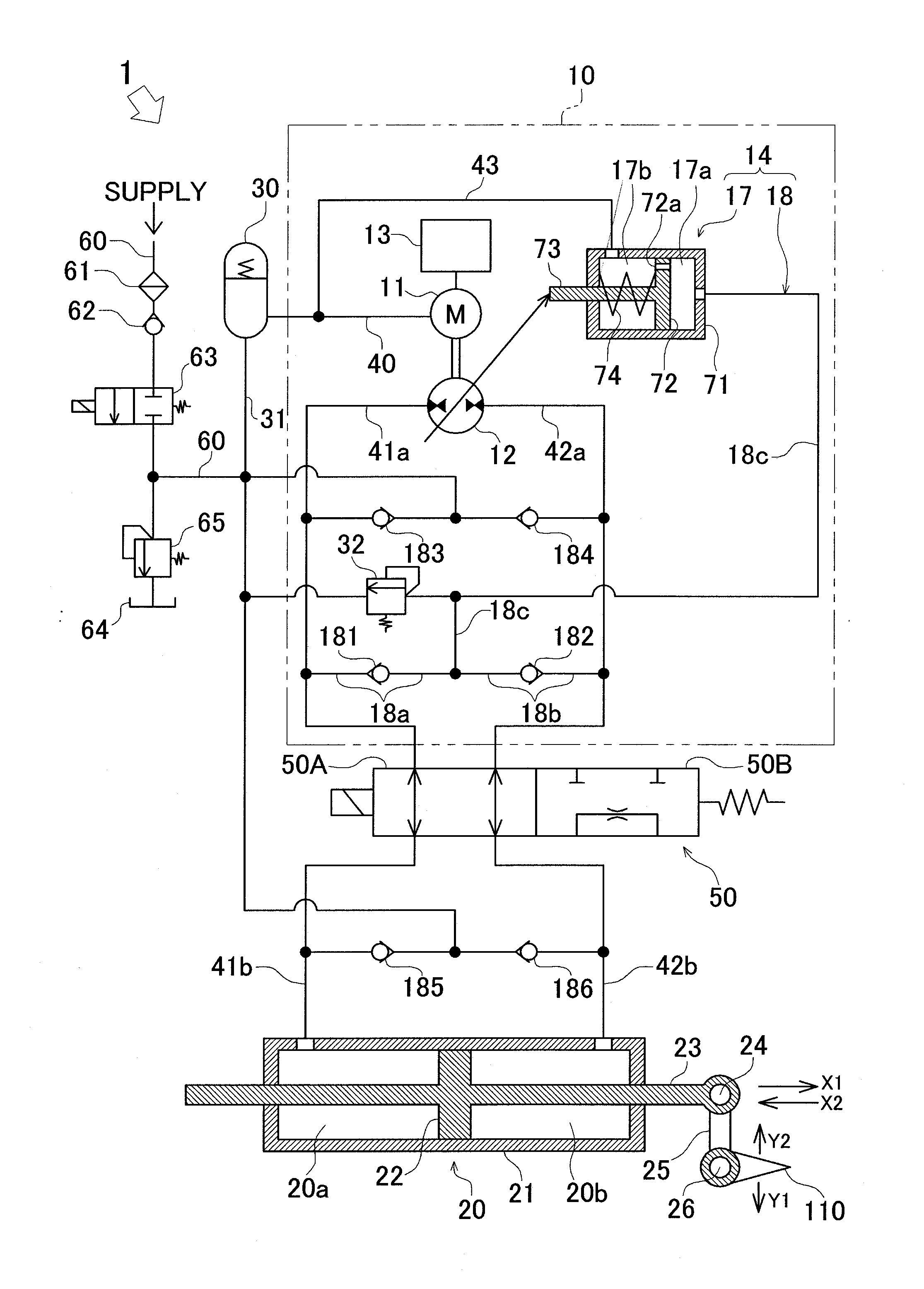

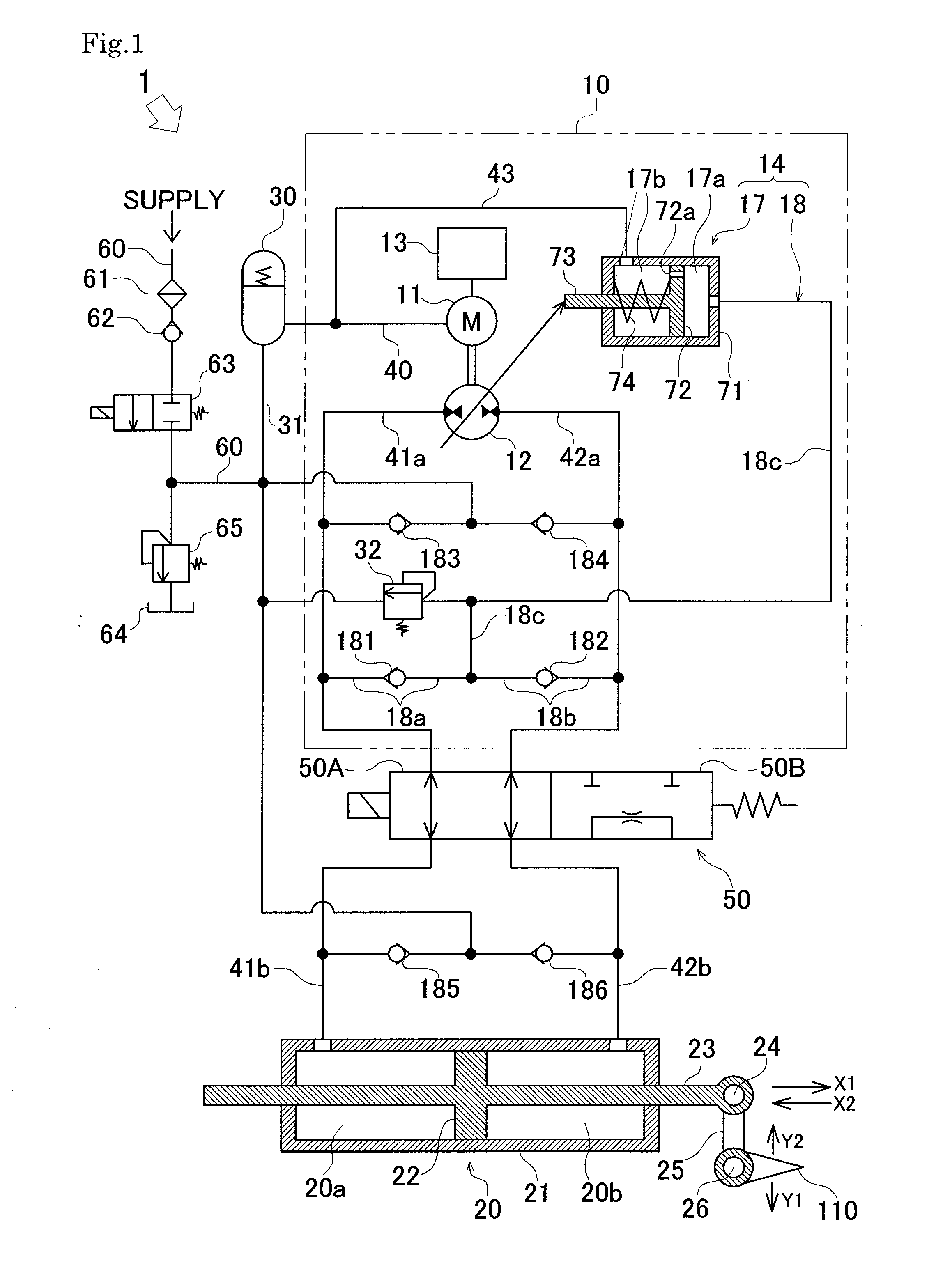

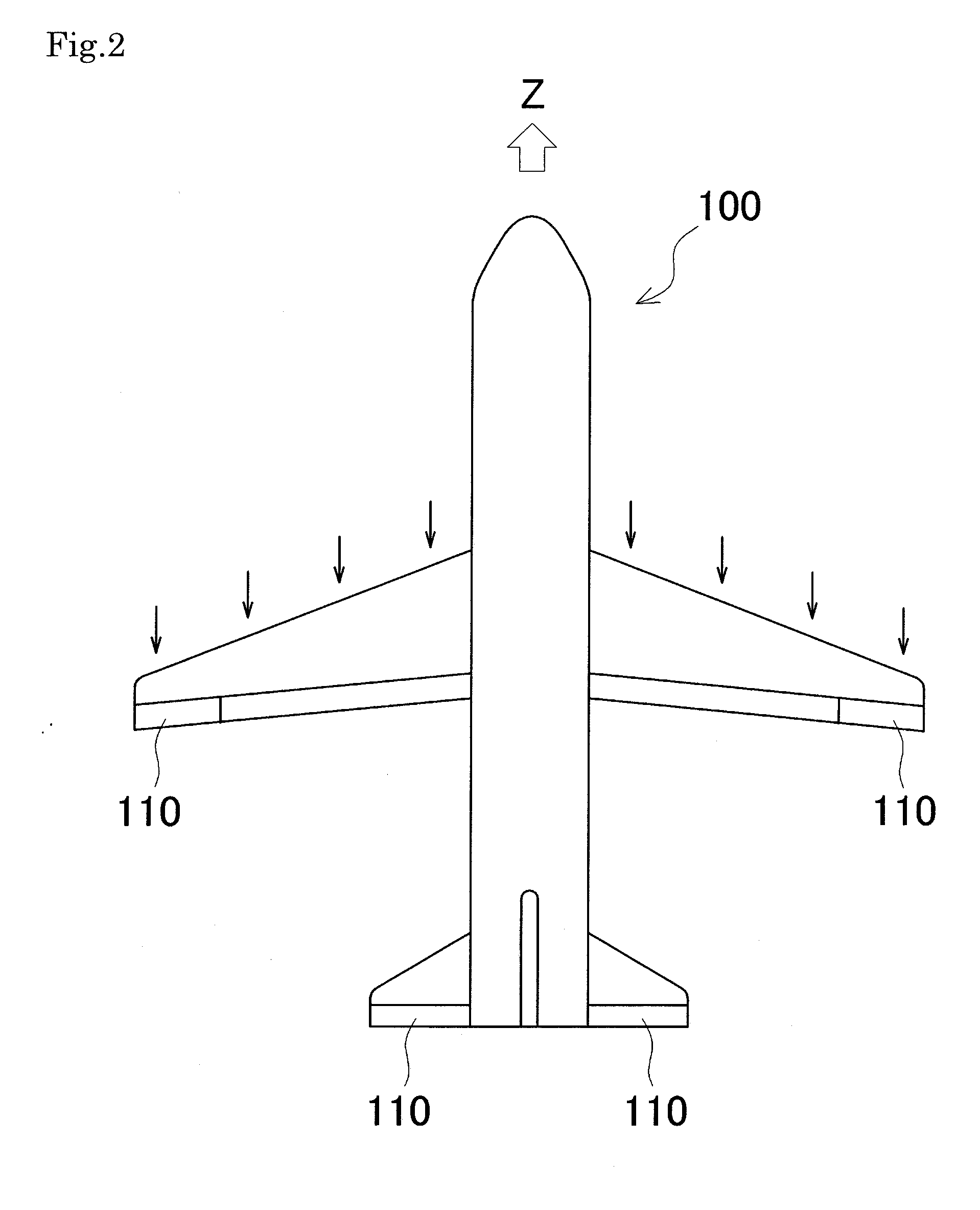

Hydraulic fluid supply device and electric actuator

ActiveUS20090266934A1Reduce power consumptionAvoid feverFluid couplingsAircraft stabilisationEngineeringHydraulic fluid

An electric actuator of the present invention includes a hydraulic fluid supply device and an actuator actuated in response to an input of hydraulic fluid from a variable-volume pump. The hydraulic fluid supply device includes an adjustable-speed motor, the variable-volume pump which is driven by the adjustable-speed motor and ejects hydraulic fluid, an electric motor control unit which controls the adjustable-speed motor so as to achieve an intended rotation speed, and a pump control unit which controls the variable-volume pump so that the ejection volume of the variable-volume pump decreases with an increase in the ejection pressure of the variable-volume pump.

Owner:NABLESCO CORP

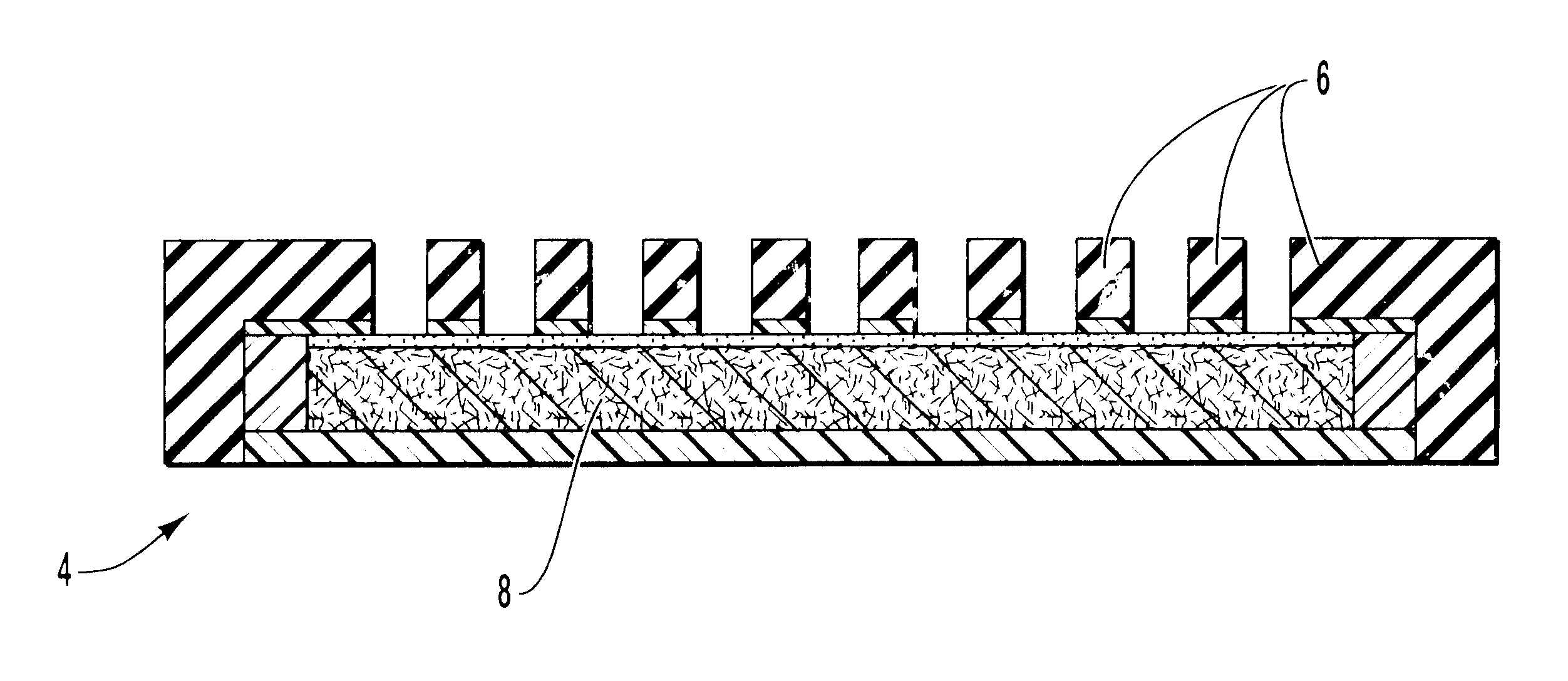

Method for manufacturing a heat generating apparatus

InactiveUS6453648B1Even heat distributionPrevent oxidationSolid materialLiquid materialActivated carbonEngineering

Owner:NUVO RES

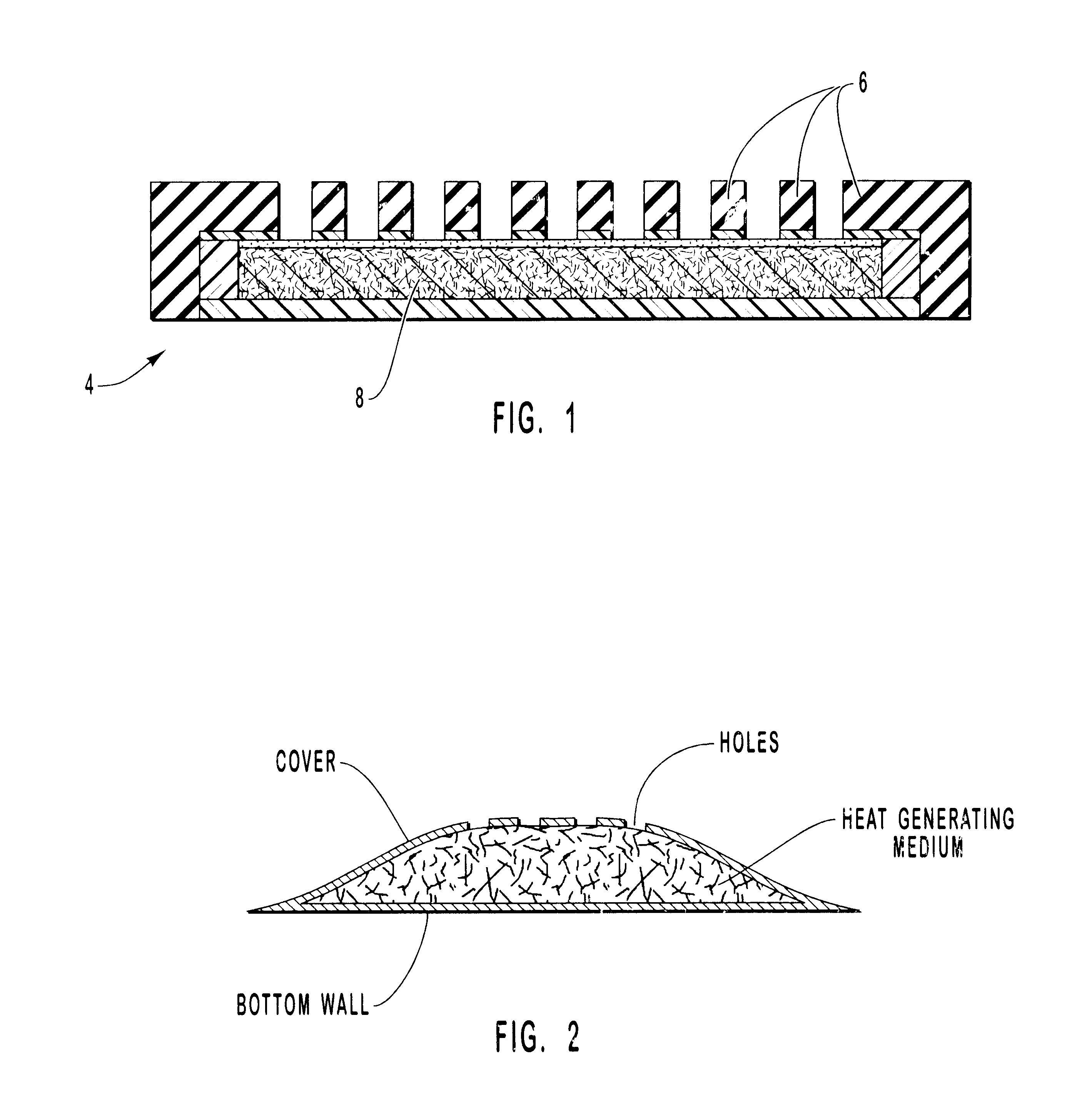

Electrolyte for lithium ion rechargeable battery and lithium ion rechargeable battery comprising the same

ActiveUS20050277027A1Improve battery stabilityPrevents and improves swellingOrganic electrolyte cellsLi-accumulatorsLithiumHigh temperature storage

The present invention relates to an electrolyte for a lithium ion rechargeable battery and a lithium ion rechargeable battery including the same. The electrolyte includes a non-aqueous organic solvent, a lithium salt, and triphenyl phosphate. A lithium ion rechargeable battery including the electrolyte has improved overcharge stability and shows excellent chemical properties including reducing swelling, high-temperature storage stability, and cycle life characteristics.

Owner:SAMSUNG SDI CO LTD

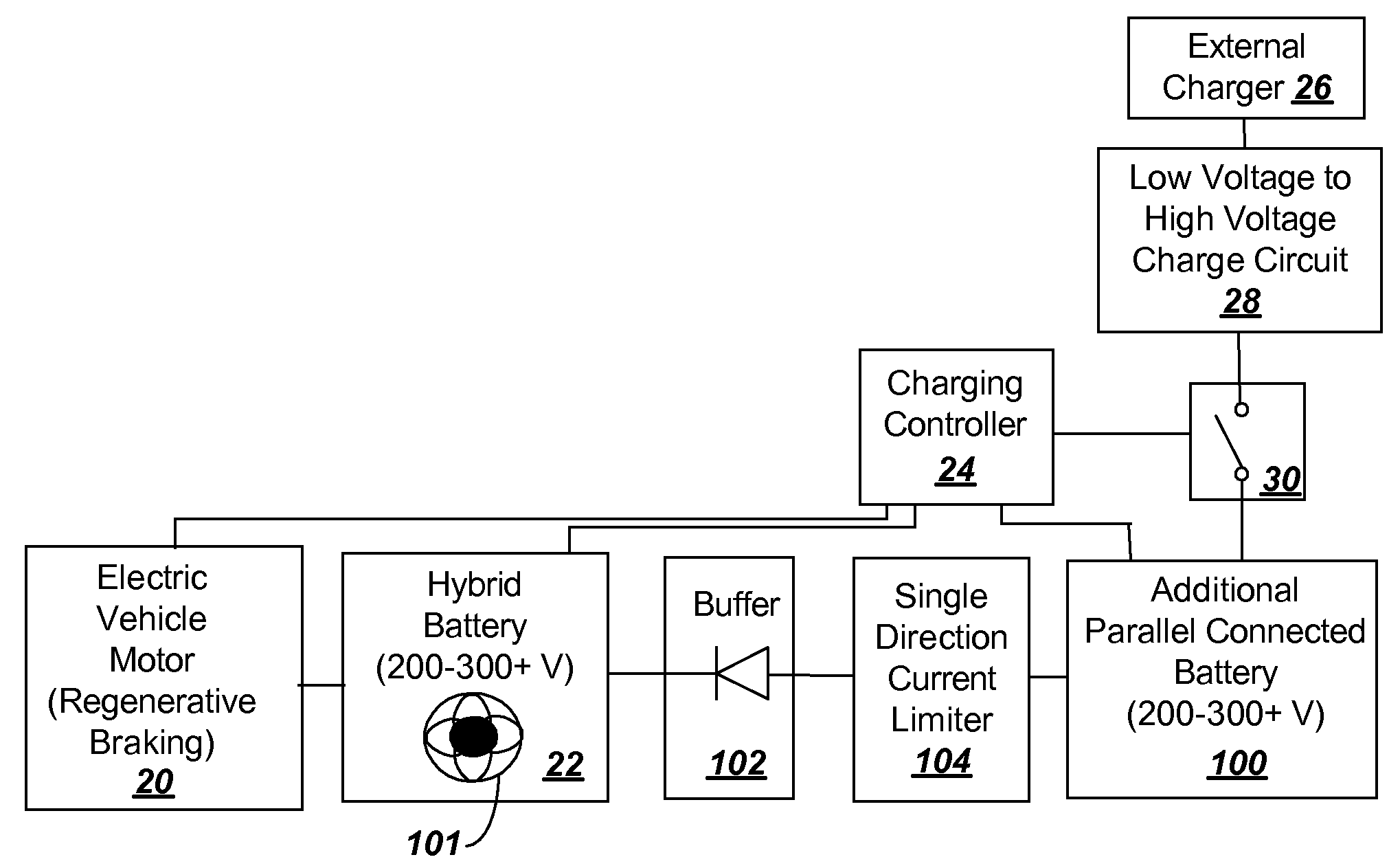

Current limiting parallel battery charging system to enable plug-in or solar power to supplement regenerative braking in hybrid or electric vehicle

InactiveUS7872443B2Battery system is simplifiedAvoid excessive currentHybrid vehiclesBatteries circuit arrangementsSolar powerElectric vehicle

To provide additional charge storage for an electric vehicle, an additional battery (100) is connected in parallel with a regenerative braking direct charged battery (22) through a current limiting circuit (104 or 120). The additional battery (100) is charged by an external charger such as a plug-in charger or a solar panel that supply minimal current to prevent generation of battery heat. Current flows from the additional battery (100) to the regenerative braking charged batteries (22) so that both batteries can be charged. However, when excessive charge is drawn to drive the vehicle electric motor (20), the current limiter circuit (104 or 120) serves to prevent the discharge of additional battery (100) from creating excessive heat in the additional battery (100). Further, when regenerative braking is applied the current limiter circuit (120), or a diode buffer (102) in combination with current limiter (104), serves to prevent charging from creating excessive heat in the additional battery (100) and eliminates the need for a cooling structure in the additional battery (100).

Owner:WARD THOMAS A

Current clamping parallel battery charging system to supplement regenerative braking in electric vehicle

InactiveUS20110089904A1Simple processBattery system is simplifiedCircuit monitoring/indicationCharging stationsElectrical batteryEngineering

To provide additional charge storage for an electric vehicle, an additional battery (100) is connected in parallel with a regenerative braking direct charged battery (22) through a current limiting or clamping circuit (104 or 120). The additional battery (100) is charged by an external charger such as a plug-in charger or a solar panel that supply minimal current to prevent generation of battery heat. Current flows from the additional battery (100) to the regenerative braking charged batteries (22) so that both batteries can be charged. However, when excessive charge is drawn to drive the vehicle electric motor (20), the current limiting or clamping circuit (104 or 120) serves to prevent the discharge of additional battery (100) from creating excessive heat in the additional battery (100). Further, when regenerative braking is applied the current clamping circuit (120), or a diode buffer (102) in combination with current limiter (104), serves to prevent charging from creating excessive heat in the additional battery (100) and eliminates the need for a cooling structure in the additional battery (100).

Owner:WARD THOMAS ALLAN

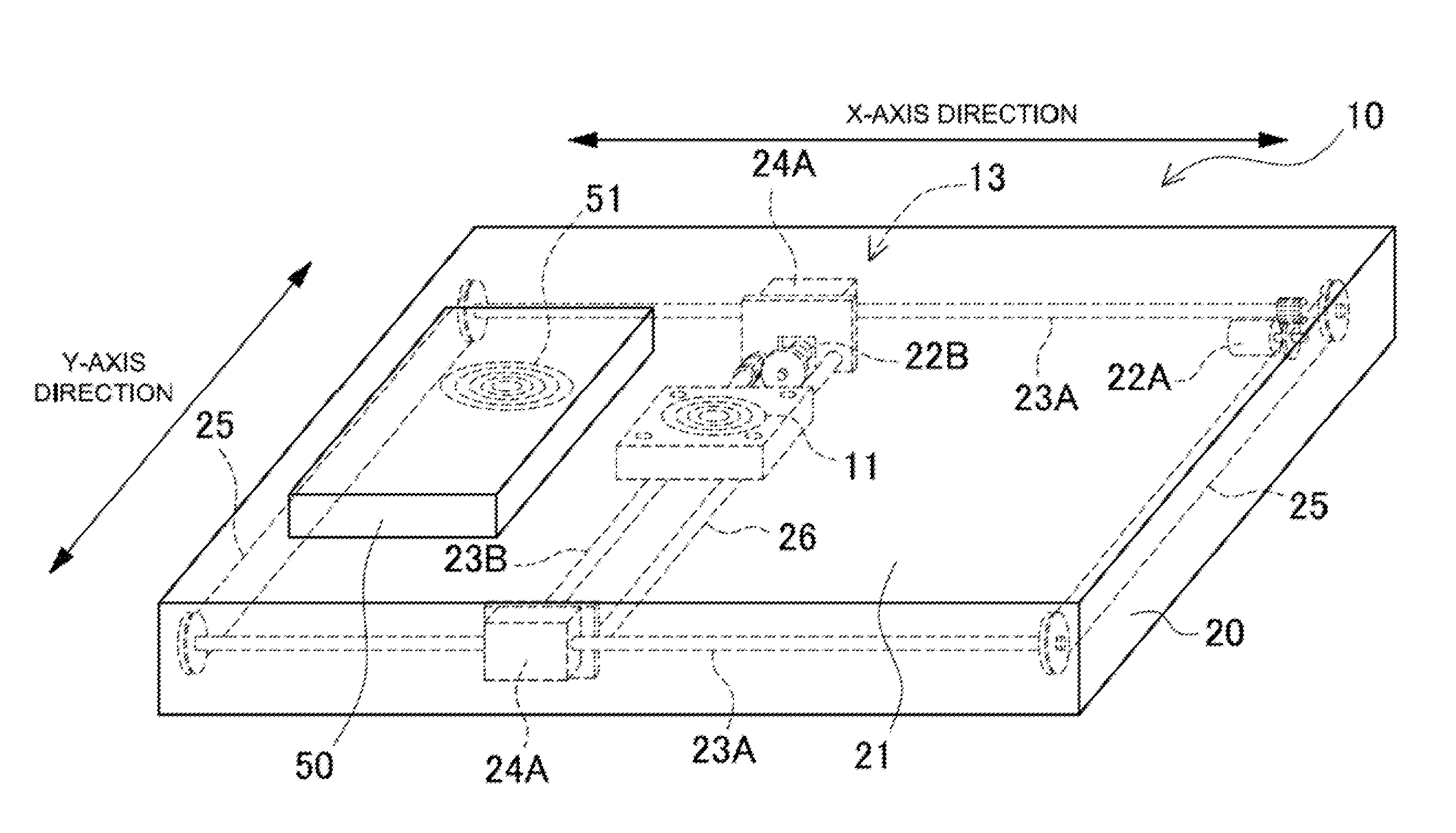

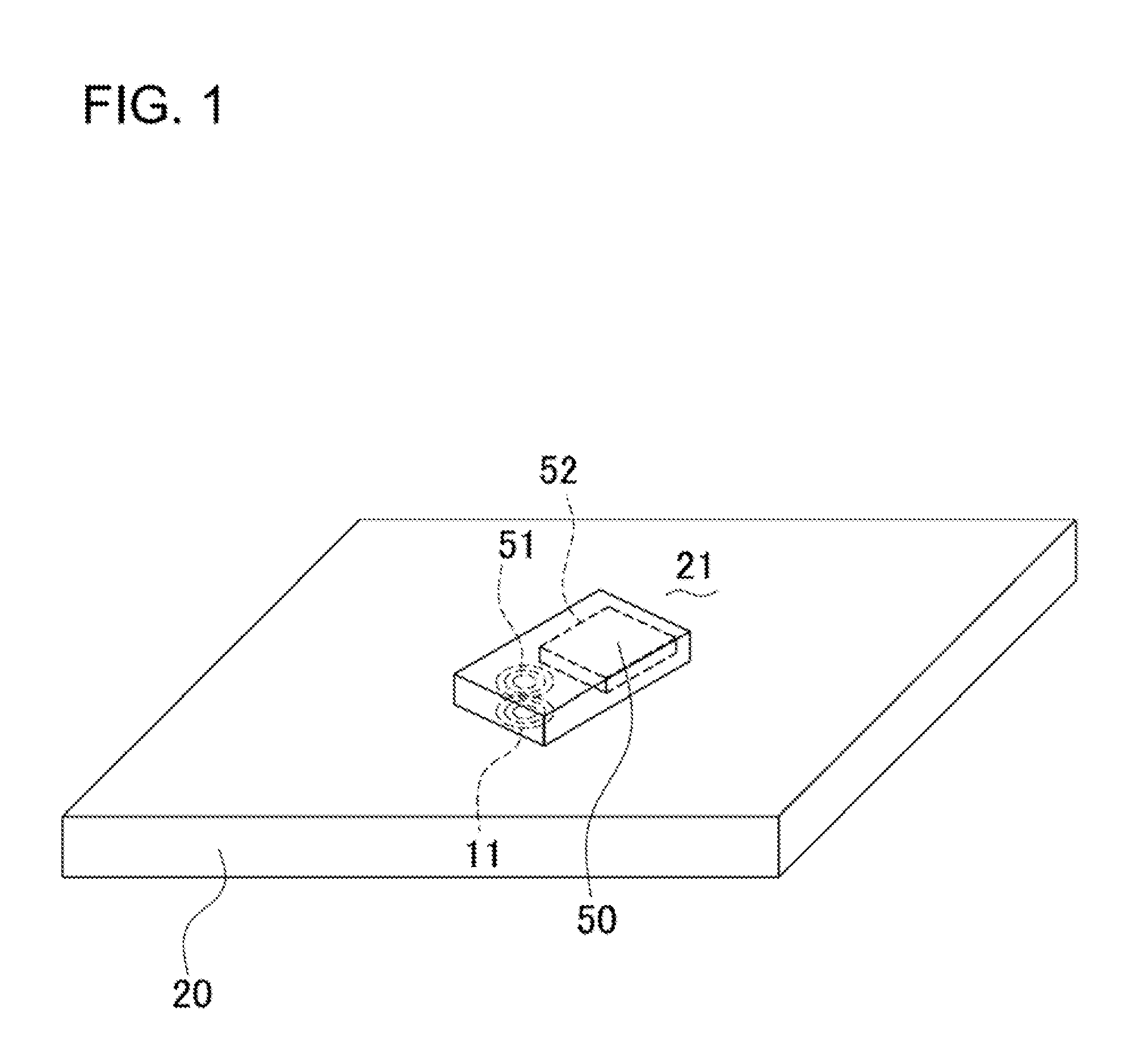

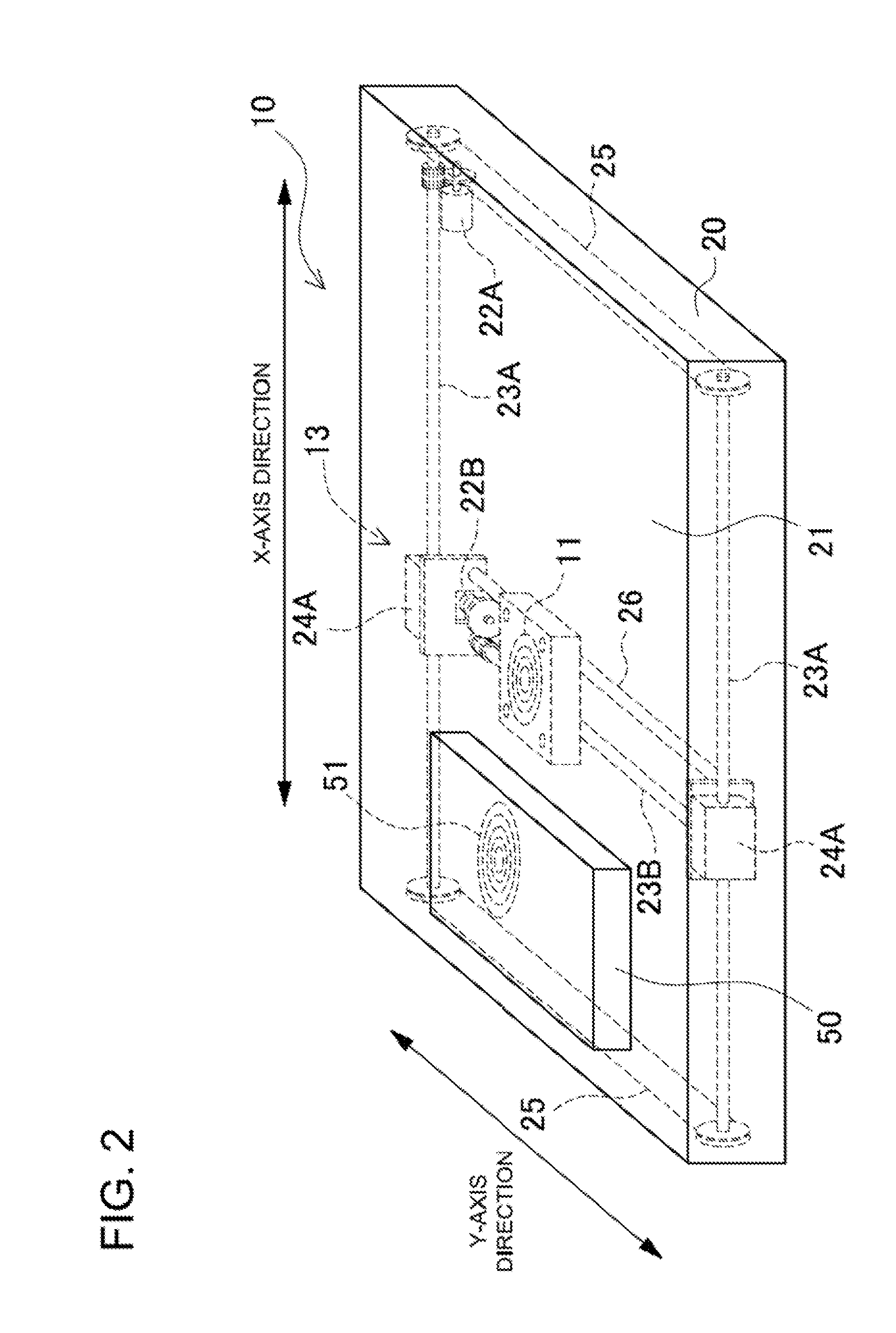

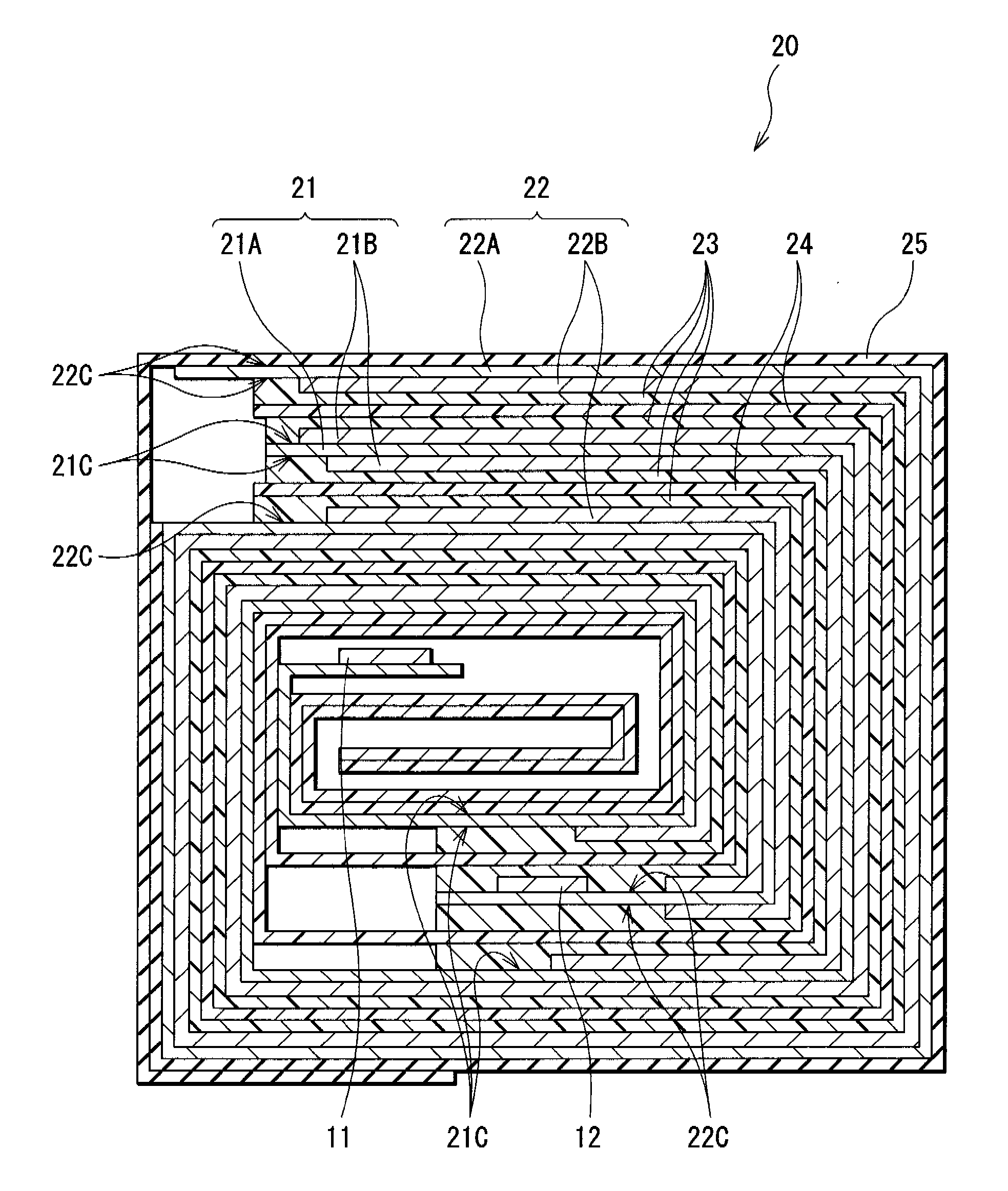

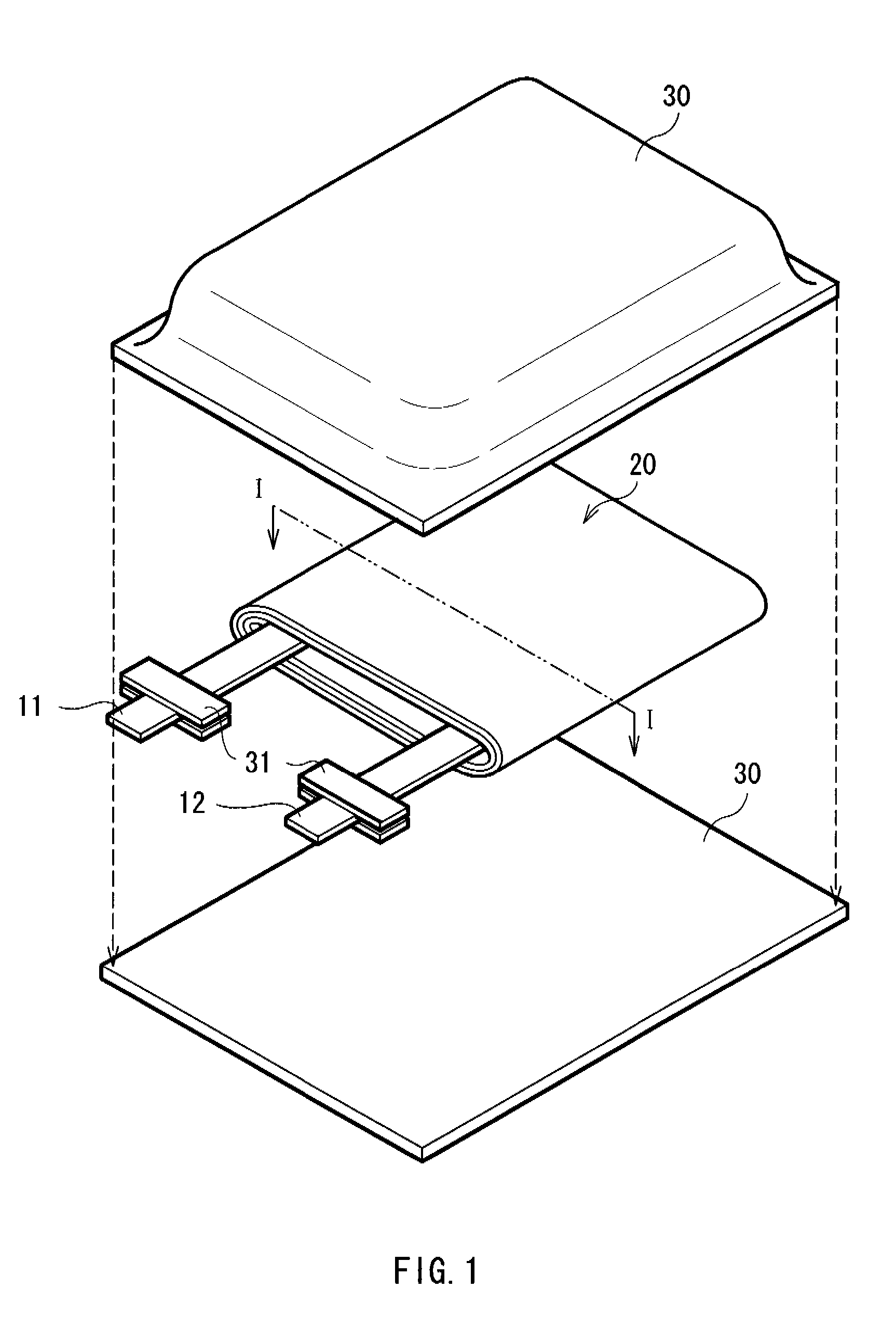

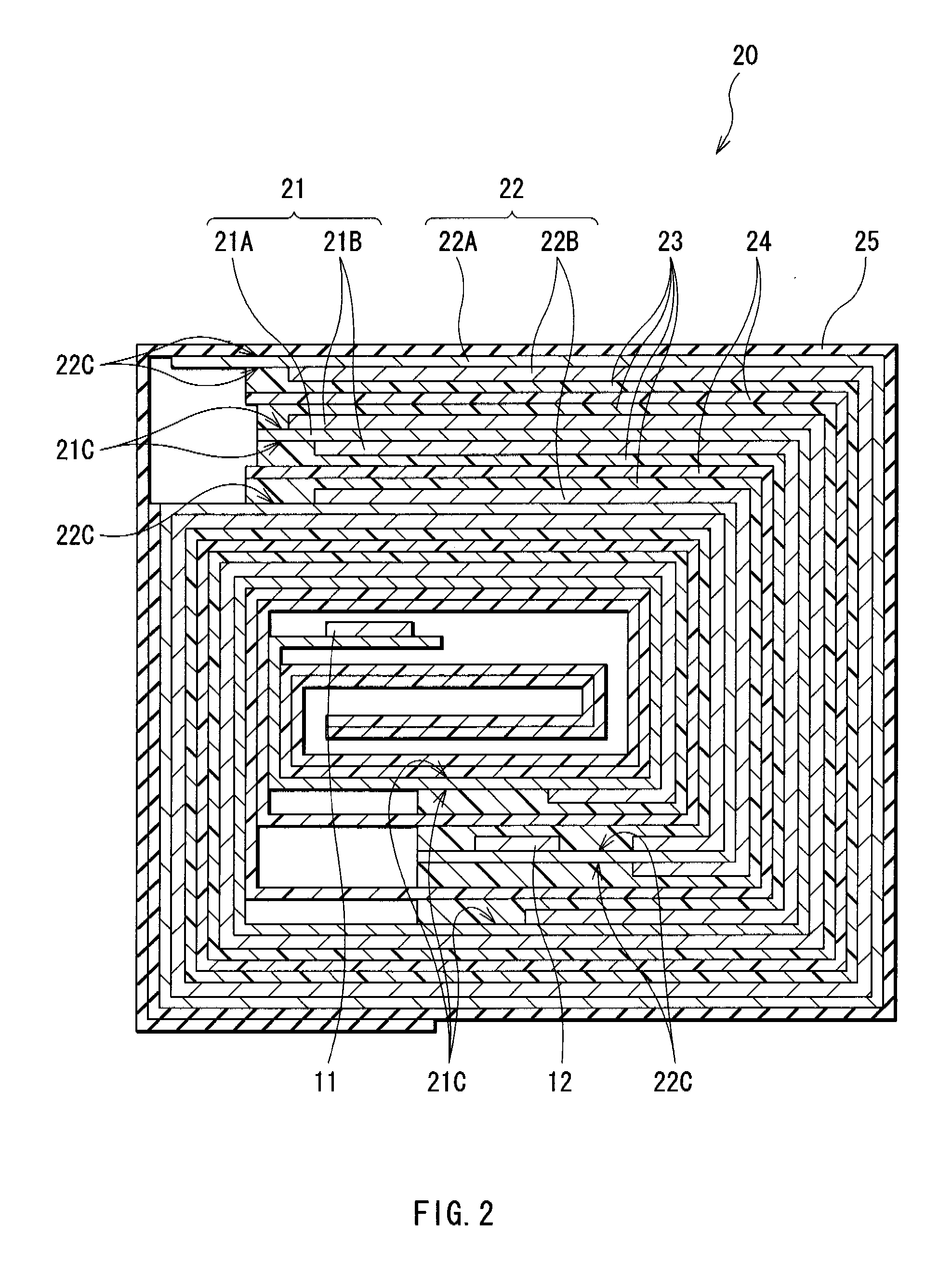

Device housing a battery and charging pad

InactiveUS20110128714A1Reduces rectifying circuit element ON-resistanceReduce voltage dropElectric powerBattery overcharge protectionElectric power transmissionControl circuit

A charging pad 10 is provided with a power supply coil 11, and a device housing a battery 50 containing an induction coil 51. A device housing a battery 50 is provided with a rectifying circuit 53 that rectifies AC power induced in the induction coil 51, a charging circuit 54 that charges the internal battery 52 with output from the rectifying circuit 53, a shorting circuit 56 that short circuits the terminals of the induction coil 51, and a control circuit 57 that controls the shorting circuit 56 ON when a charging abnormality is detected. If the control circuit 57 detects a charging abnormality during power transmission from the charging pad 10 power supply coil 11 to the device housing a battery 50 induction coil 51, it controls the shorting circuit 56 ON to cut-off the supply of power from the induction coil 51 to the rectifying circuit 53.

Owner:SANYO ELECTRIC CO LTD

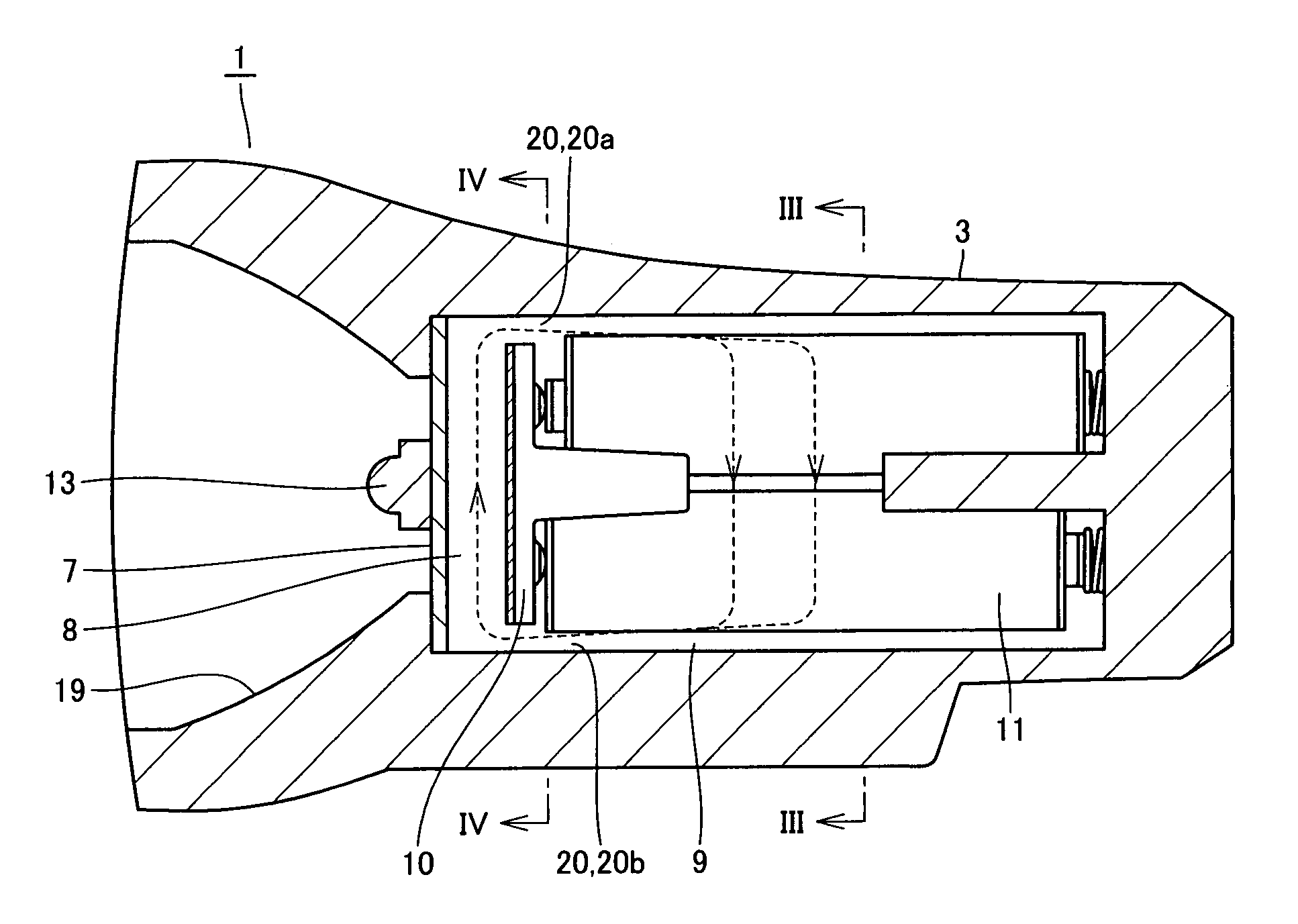

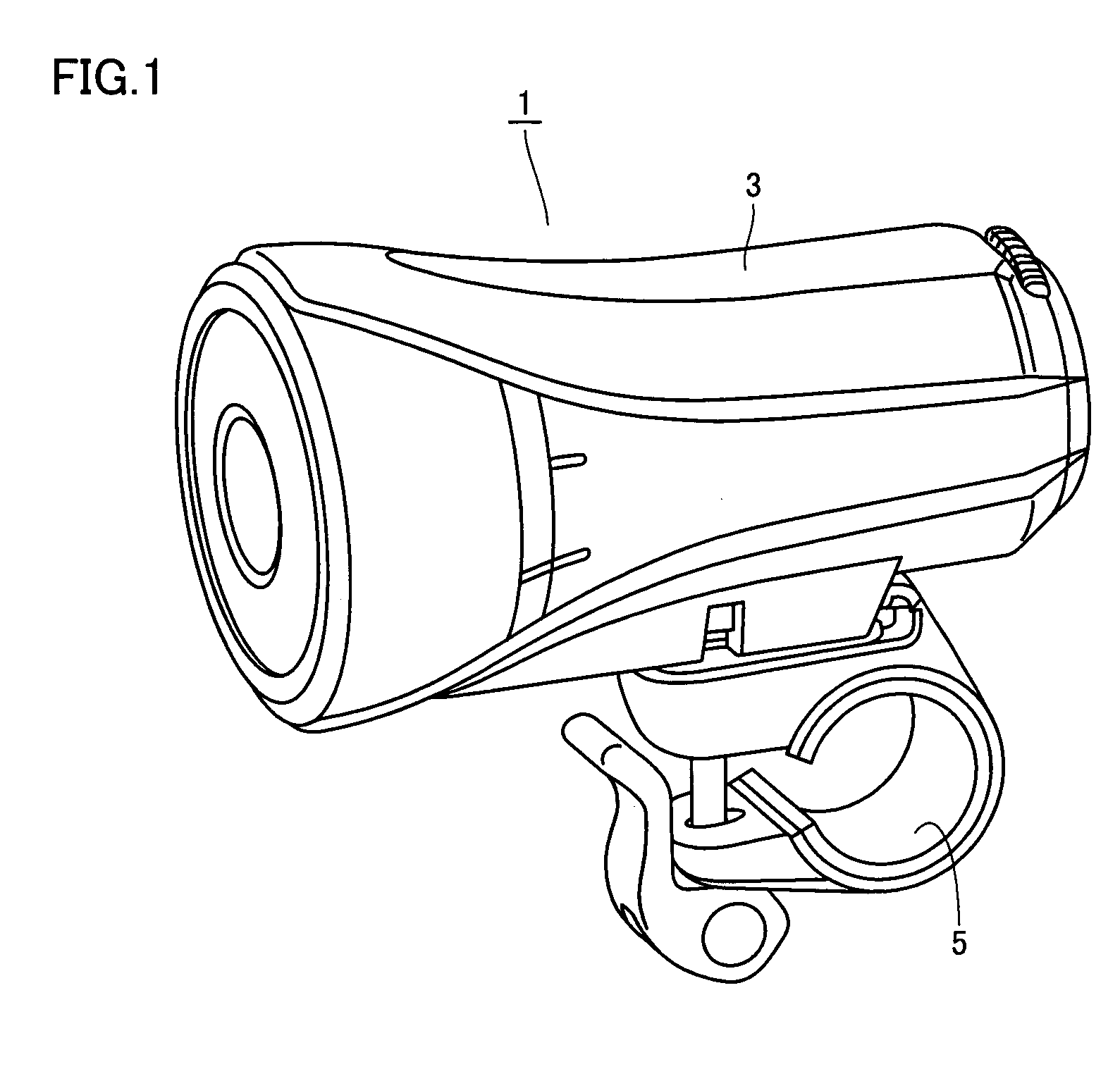

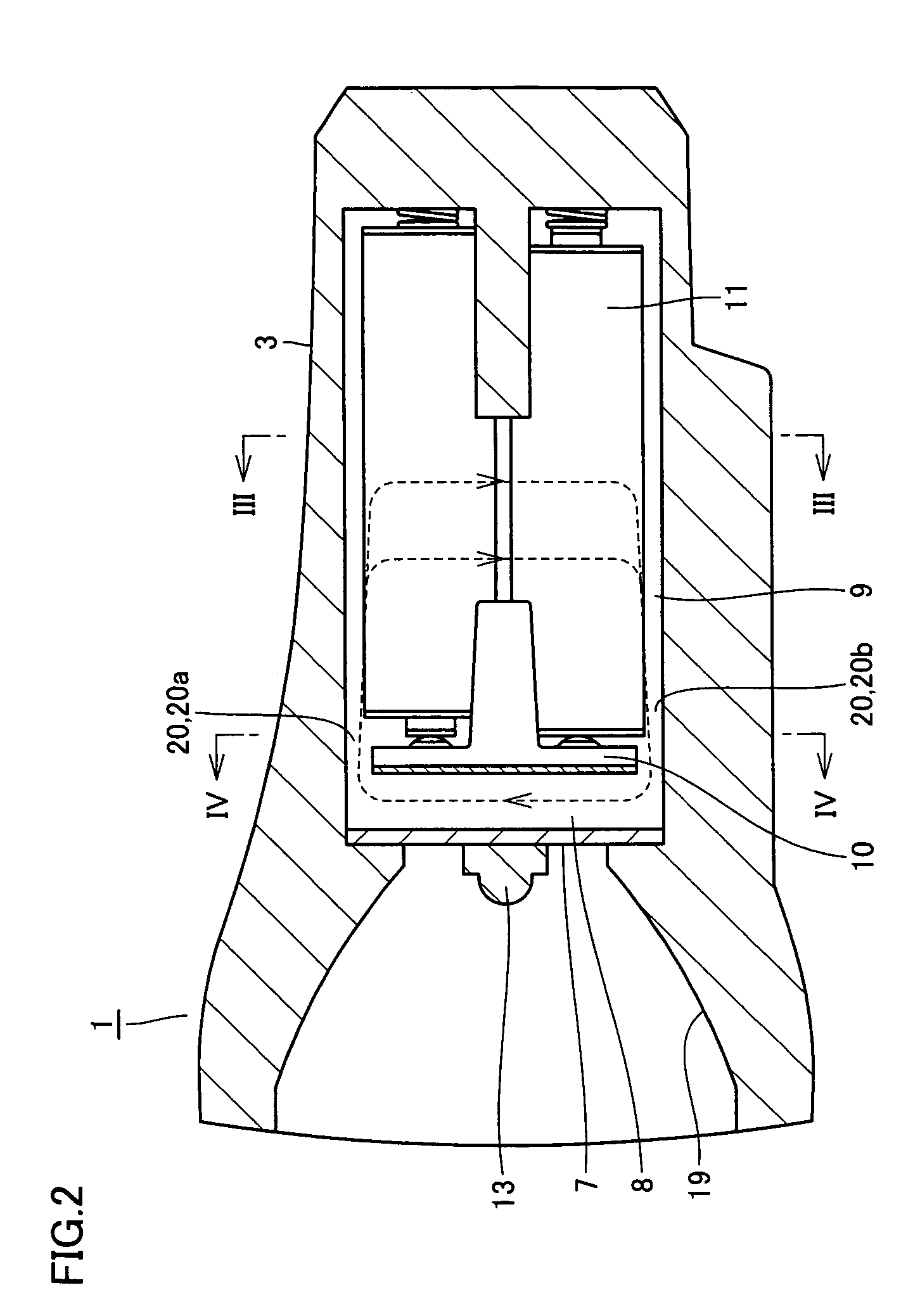

Headlamp

InactiveUS7258475B2Avoid feverEffective coolingPoint-like light sourceLighting elementsEngineeringLight-emitting diode

In a casing of a headlamp, a substrate portion to which a light-emitting diode as a light source is mounted, and a battery case accommodating a battery for providing necessary power to the light-emitting diode are provided. The substrate portion is spaced apart from a partition disposed on the front side of the battery case, with spacing provided therebetween. The partition is provided with a vent hole, having an upper vent hole and a lower vent hole, for establishing communication of the spacing between the substrate portion and the partition with the space within the battery case, for circulation of the air. Thus, a headlamp capable of suppressing adverse effects of the heat generated from the light-emitting diode or the like on the elements mounted on the substrate is provided.

Owner:CATEYE

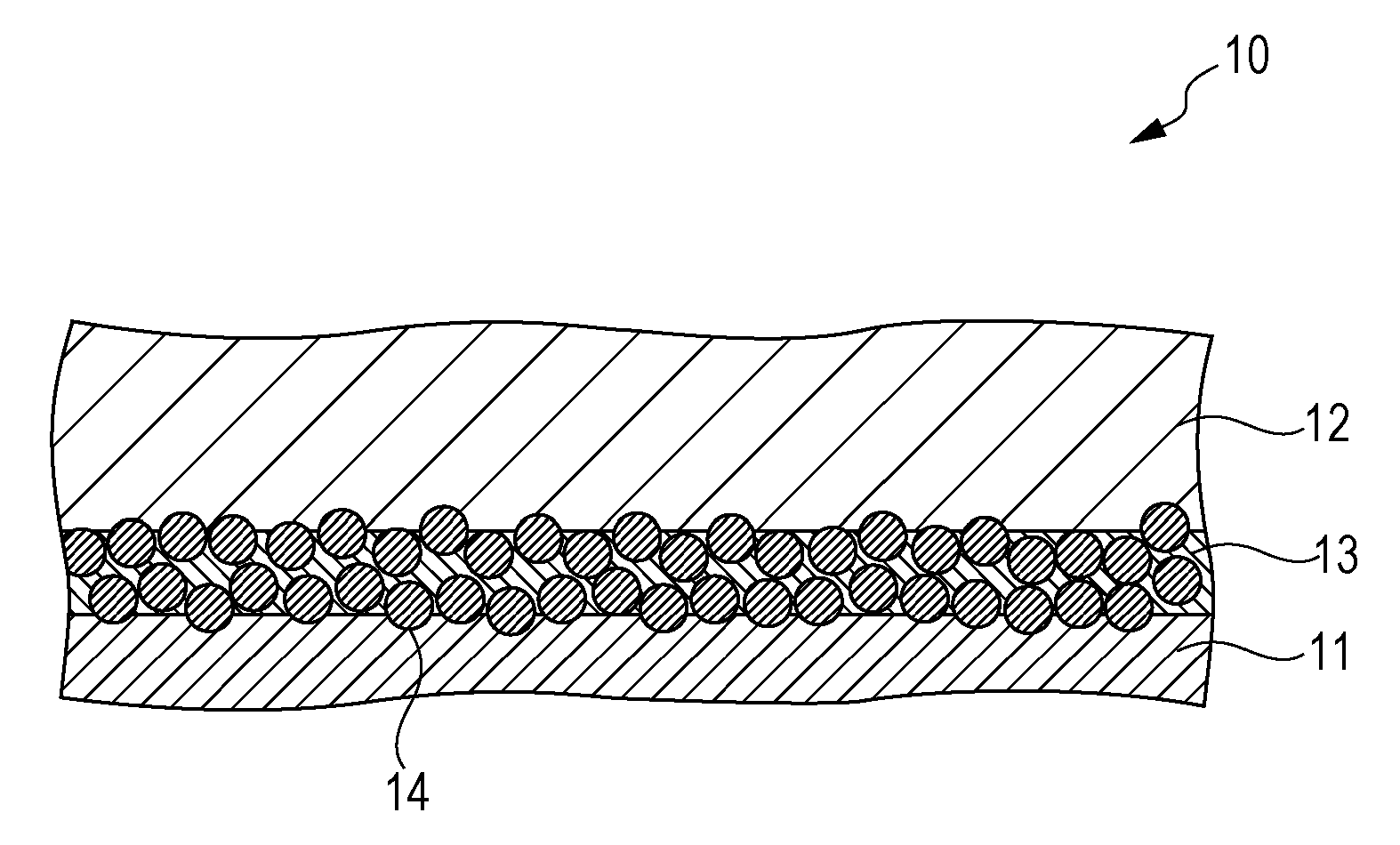

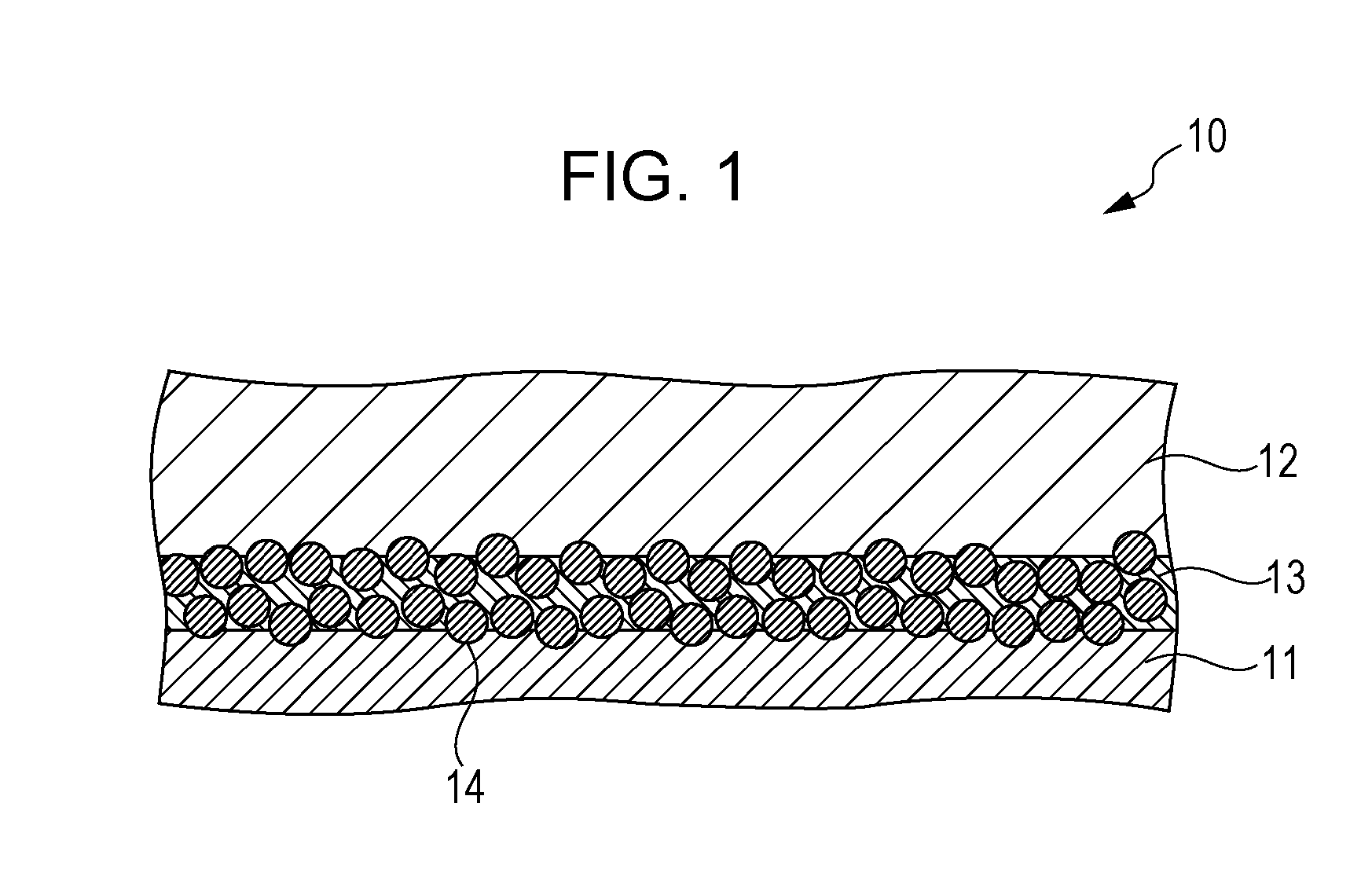

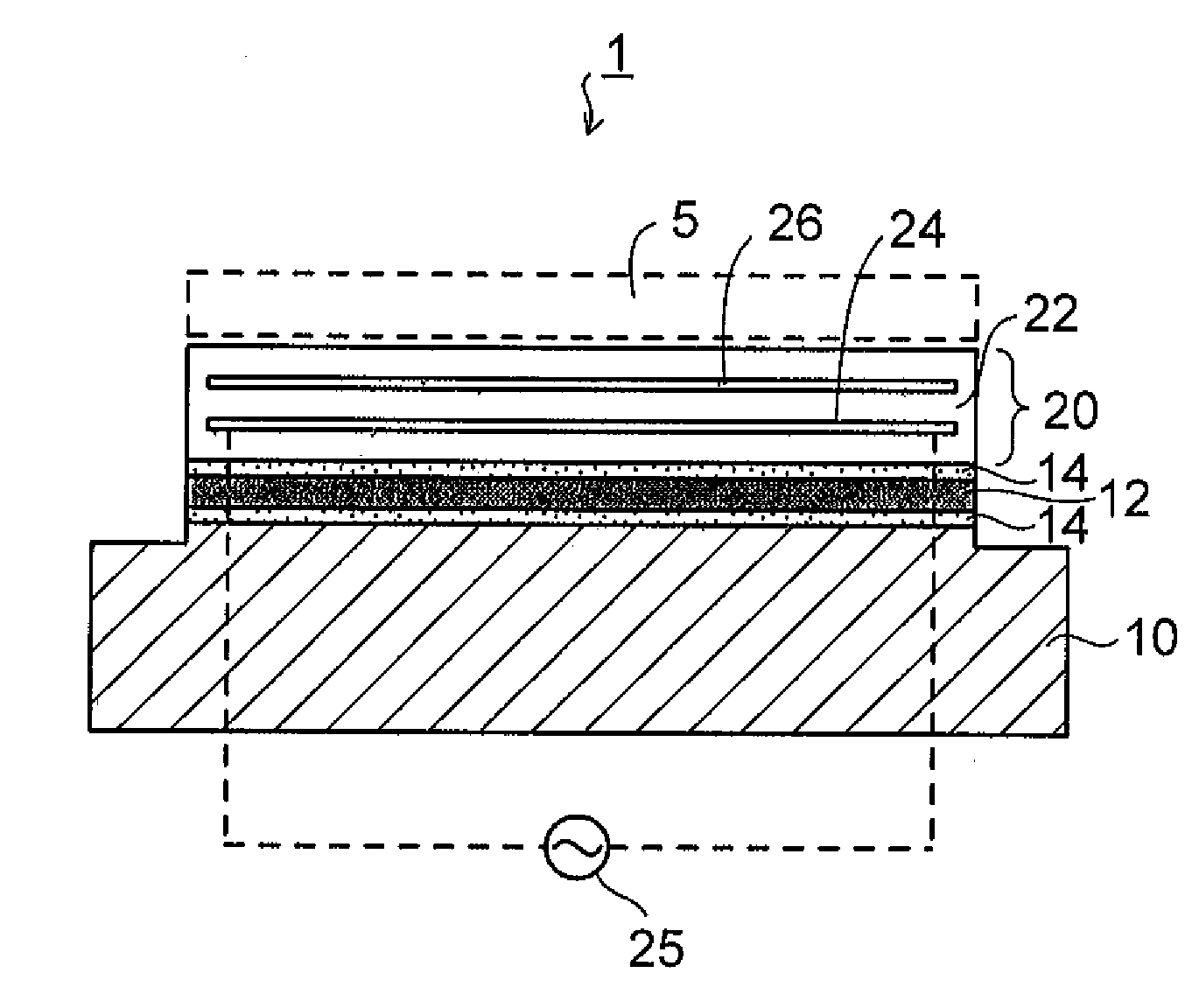

Positive electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20160093922A1Avoid feverImprove securityElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsHardnessMaterials science

A positive electrode according to an embodiment includes a positive electrode current collector, a positive electrode mixture layer disposed on the current collector, and an intermediate layer disposed between the positive electrode current collector and the positive electrode mixture layer. The intermediate layer includes particles, the particles are mainly composed of a material having a thermal conductivity of 100 W / m·K or more and a specific resistance of 103 Ω·m or more, and the particles have a Vickers hardness of 5 GPa or more.

Owner:PANASONIC CORP

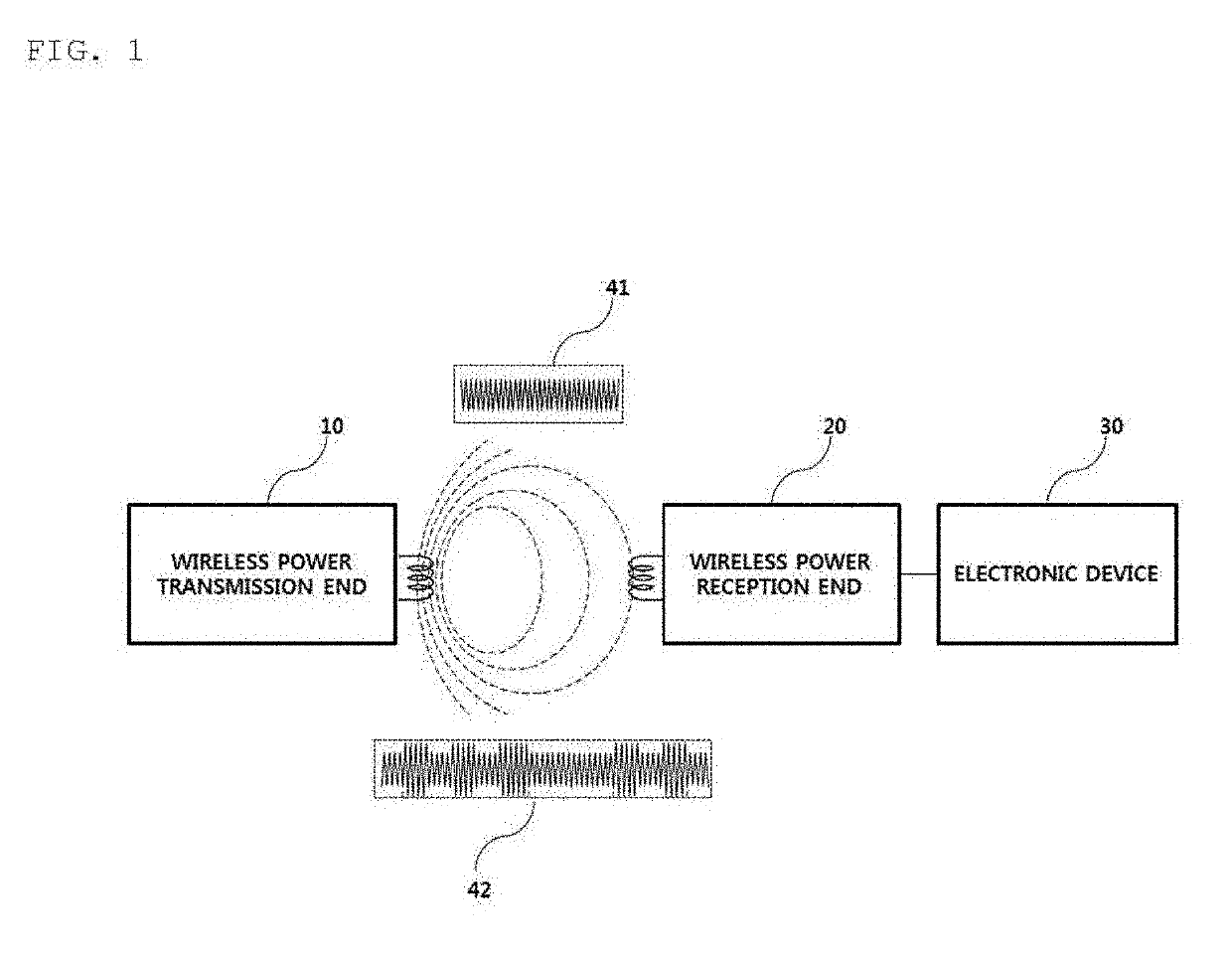

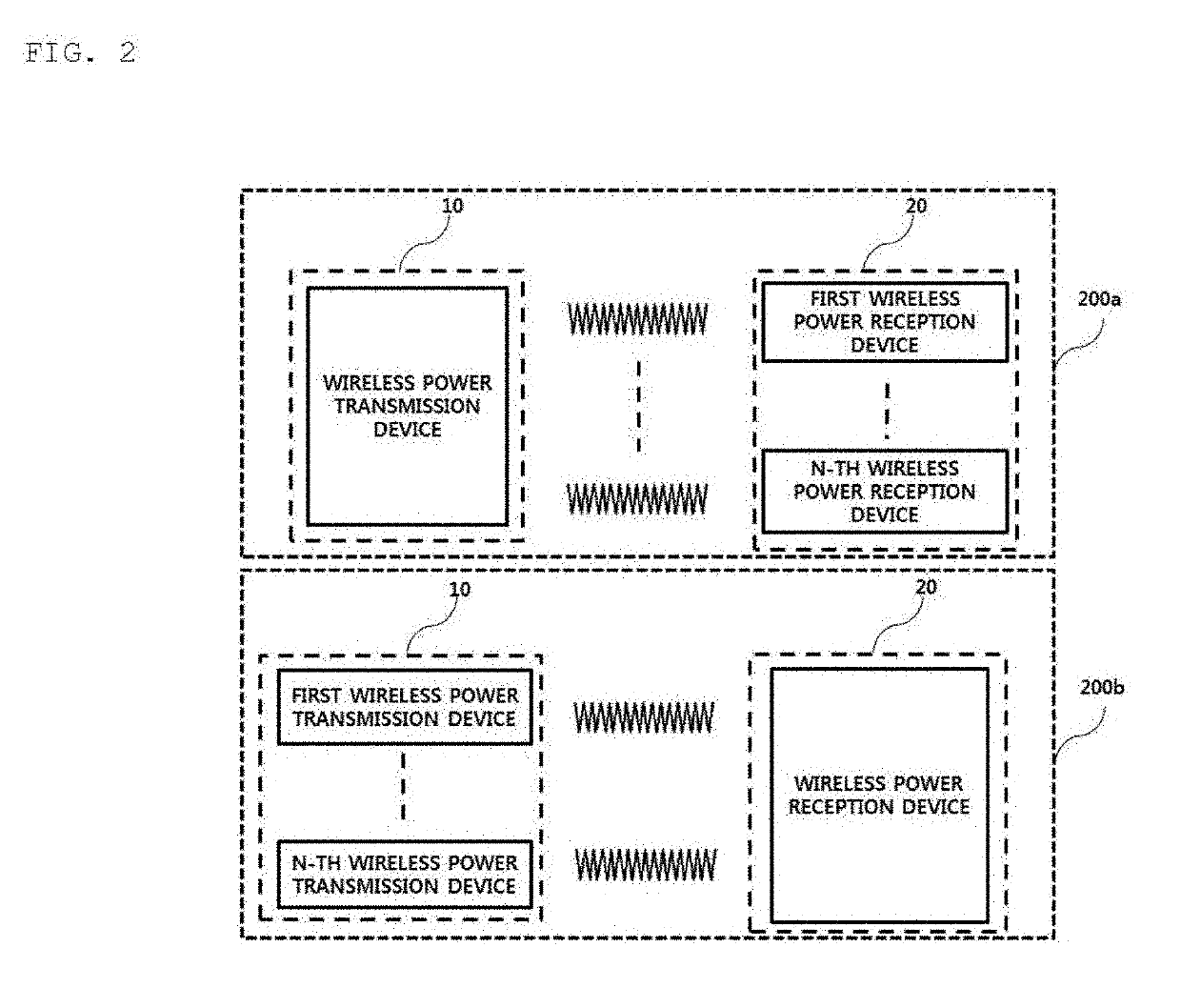

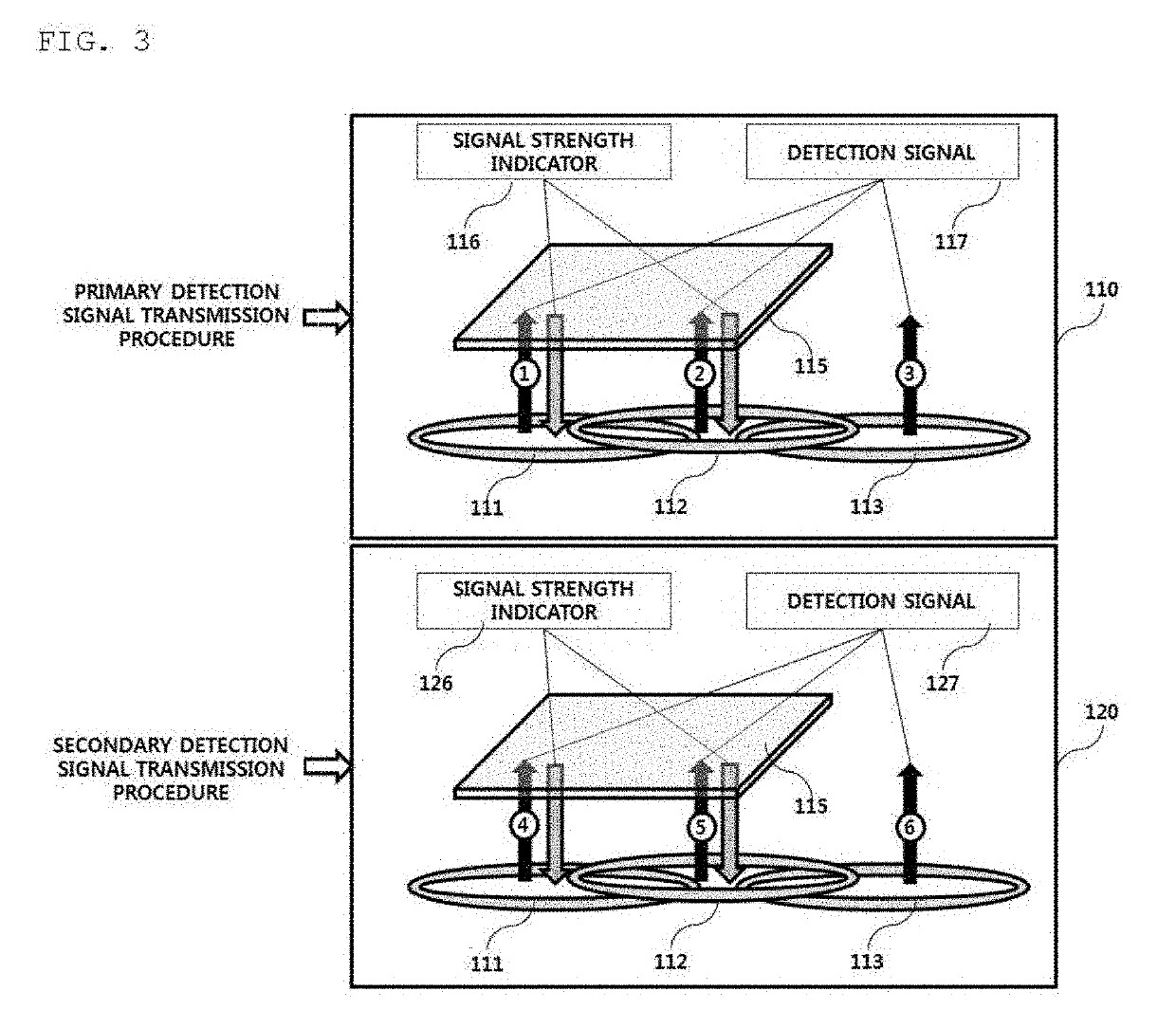

Wireless power control method and device for wireless charging

ActiveUS20190214852A1Avoid feverHeat generation is minimizedBatteries circuit arrangementsTransformersPower inverterEngineering

The present invention relates to a wireless power control method and device for wireless charging, and the wireless power control method of a wireless power transmitter according to an embodiment of the present invention may comprise: a step of receiving, from a wireless power receiver, a first feedback signal requesting power control; a step of determining the intensity of a first transmission power on the basis of the first feedback signal; a step of determining an inverter type and a power control method which correspond to the determined intensity of the first transmission power; a step of activating an inverter corresponding to the determined inverter type; and a step of controlling the intensity of alternating current power outputted from the inverter, by using the determined power control method.

Owner:LG INNOTEK CO LTD

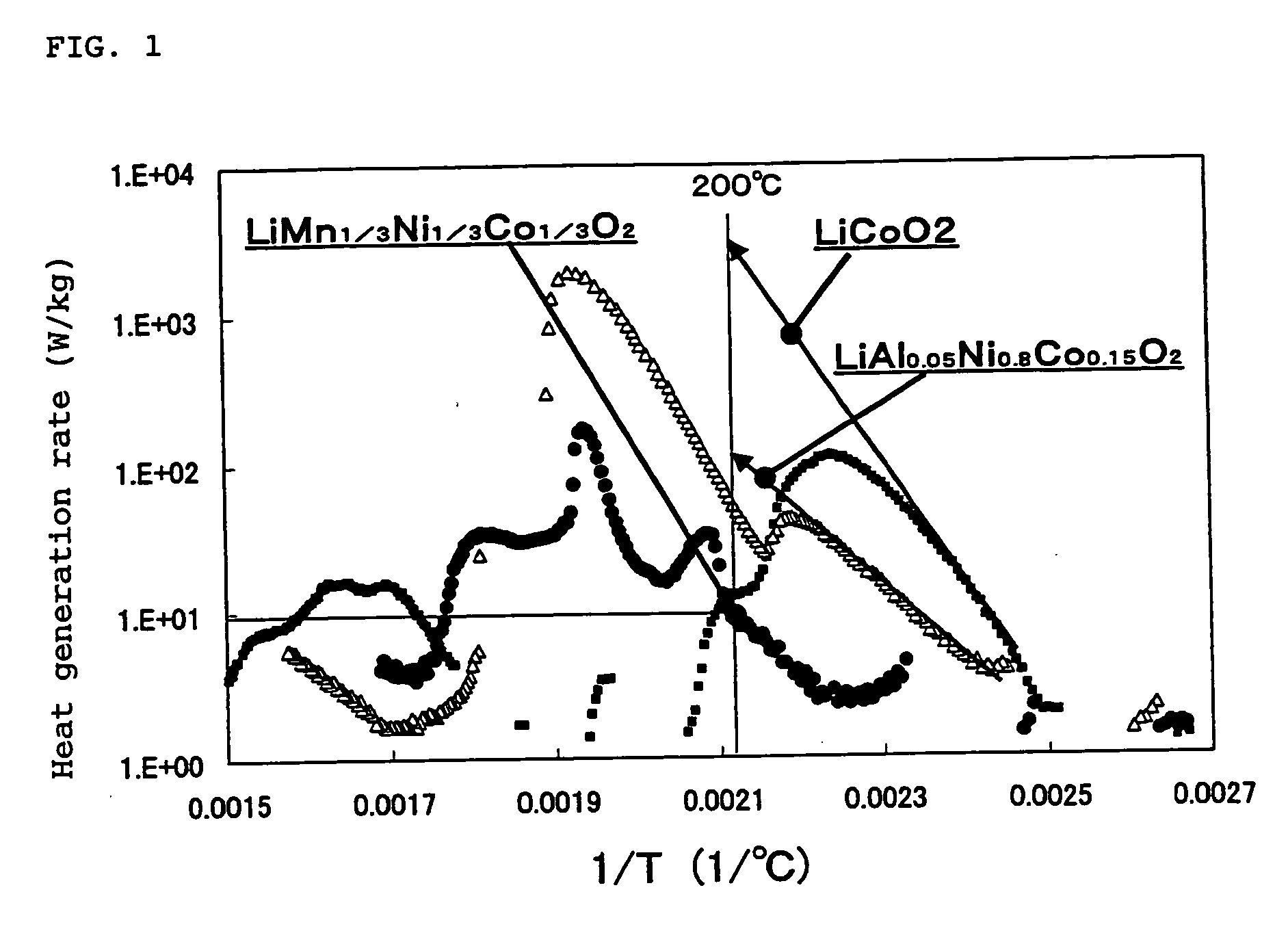

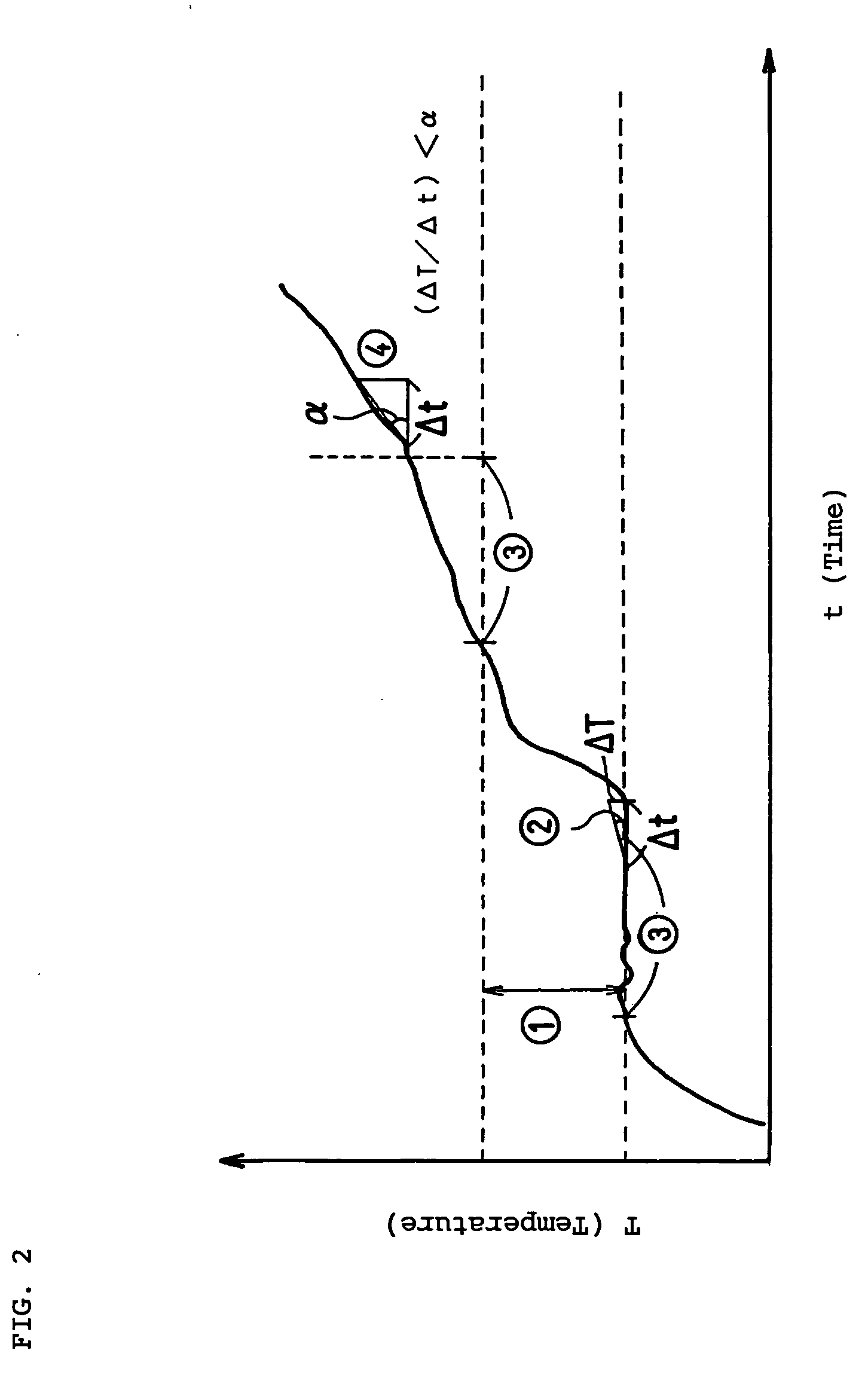

Non-aqueous electrolyte secondary battery

ActiveUS20060141341A1Improve security levelIncrease energy densityCell temperature controlNon-aqueous electrolyte accumulator electrodesLithium oxidePolyolefin

A non-aqueous electrolyte secondary battery including: a positive electrode having a positive electrode material mixture containing a composite lithium oxide; a negative electrode; a polyolefin separator; a non-aqueous electrolyte; and a heat-resistant insulating layer interposed between the positive and negative electrodes. The positive electrode active material mixture has an estimated heat generation rate at 200° C. of not greater than 50 W / kg. The estimated heat generation rate is determined by obtaining a relation between absolute temperature T and heat generation rate V of the positive electrode material mixture using an accelerating rate calorimeter; plotting a relation between the inverse of absolute temperature T and the logarithm of heat generation rate V according to the Arrhenius law; obtaining a straight line fitted to the plotted points in a heat generation temperature range of T<200° C.; and extrapolating the straight line to the temperature of 200° C.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

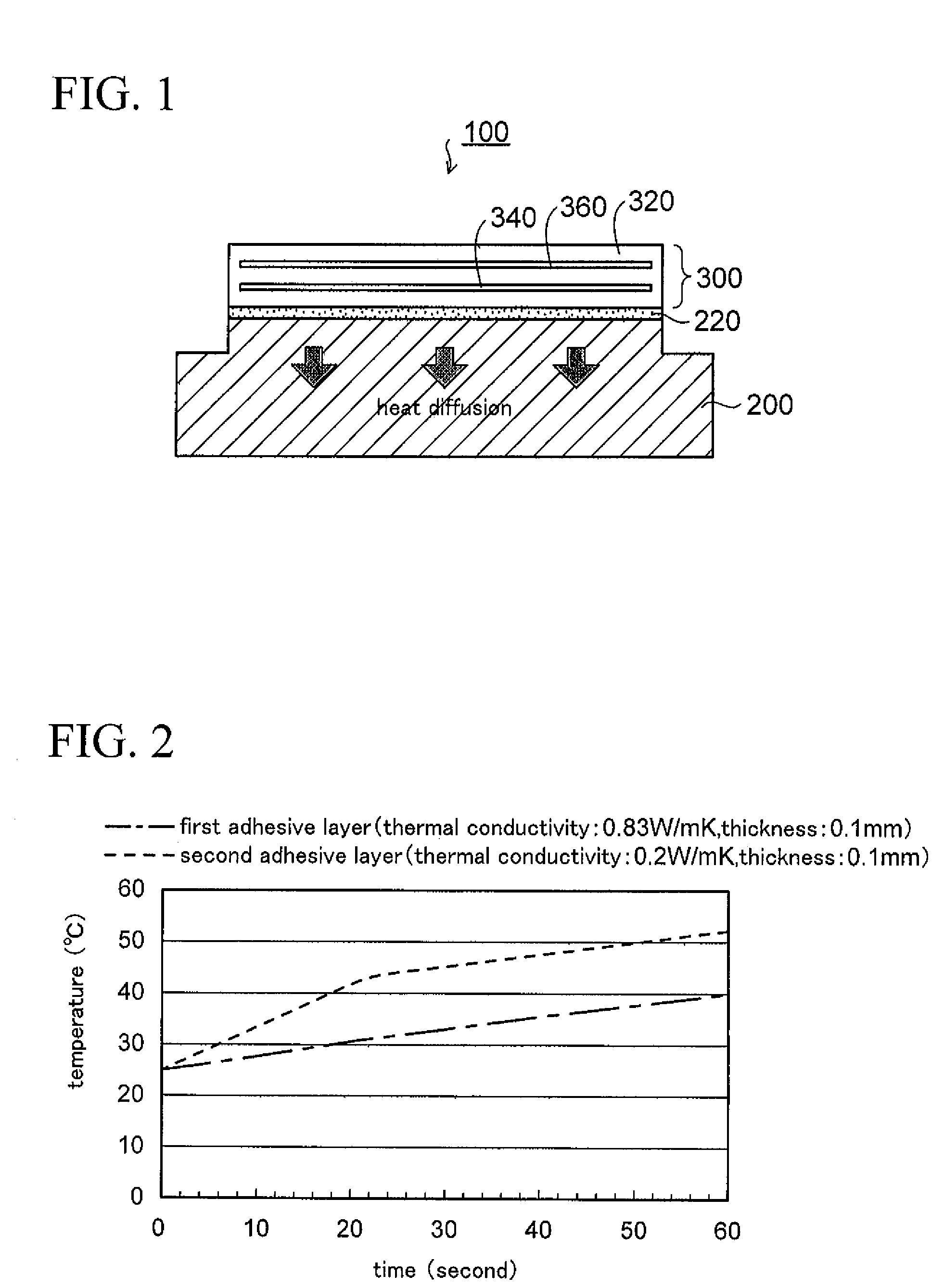

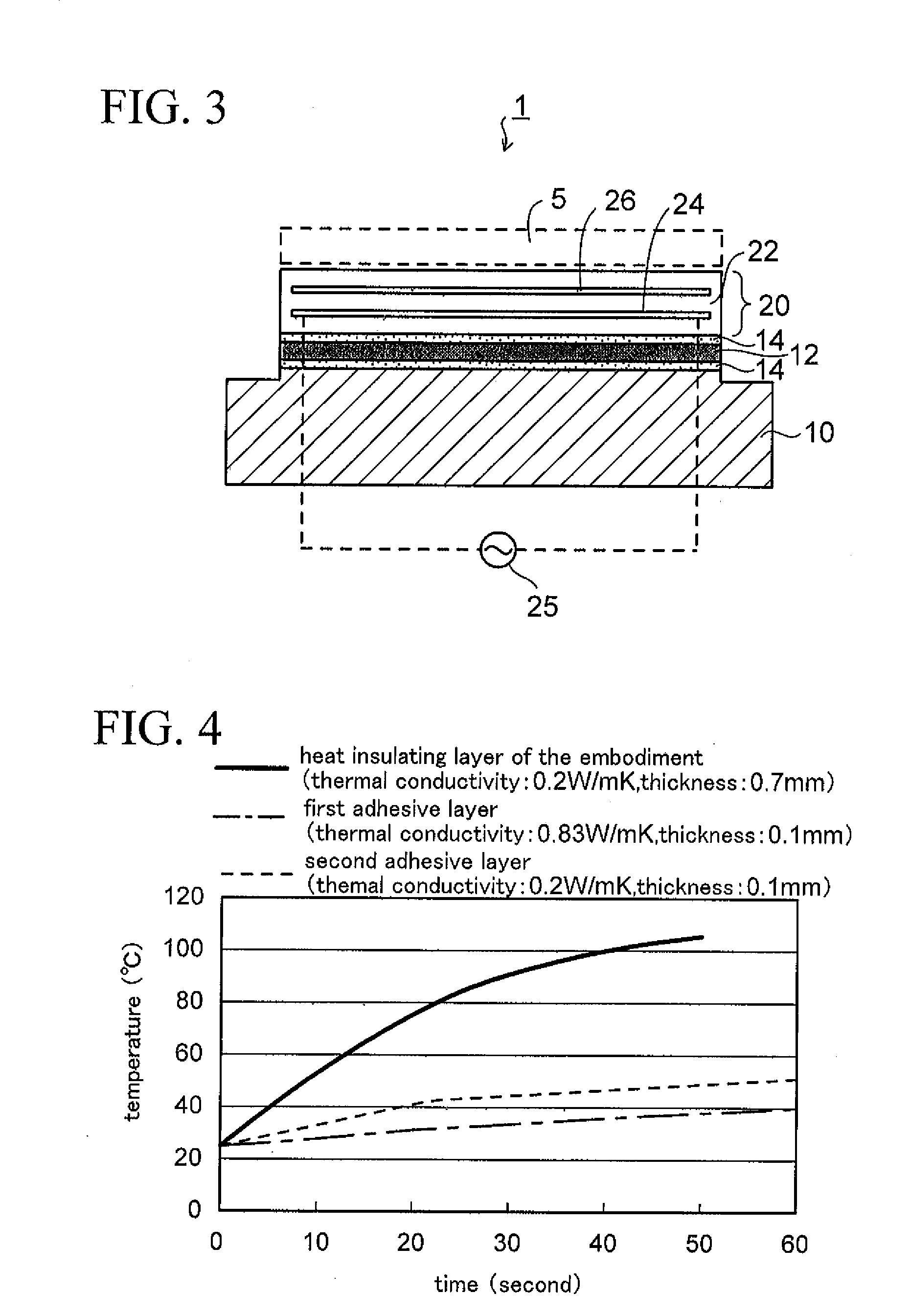

Electrostatic chuck

InactiveUS20090059461A1Adhesive strengthHigh adhesive strengthSemiconductor/solid-state device manufacturingElectrostatic holding devicesEngineeringElectrical and Electronics engineering

An electrostatic chuck of the invention includes a base portion; a heat insulating layer bonded onto the base portion; and a chuck function portion bonded on the heat insulating layer and composed by providing a heater electrode and an electrostatic chuck (ESC) electrode in a ceramic substrate portion. Adhesive layers are respectively provided on the both surface sides of the heat insulating layer. In the case where the base portion and the chuck function portion are bonded together with high adhesion strength, openings are formed in the heat insulating layer and are filled with the adhesive layers.

Owner:SHINKO ELECTRIC IND CO LTD

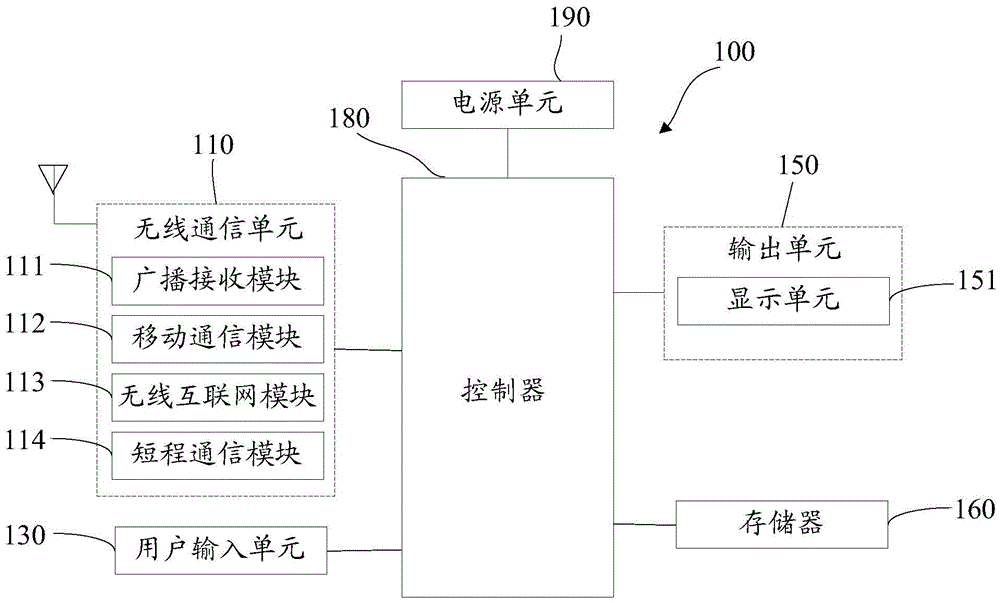

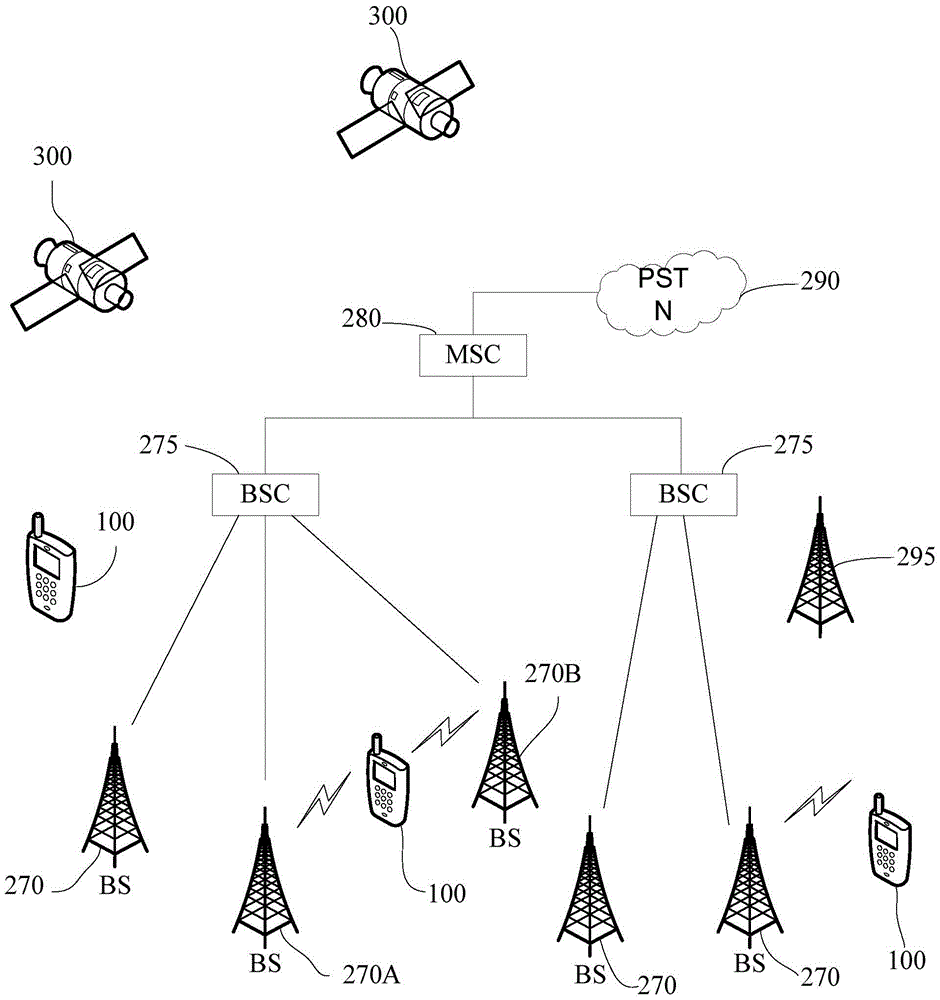

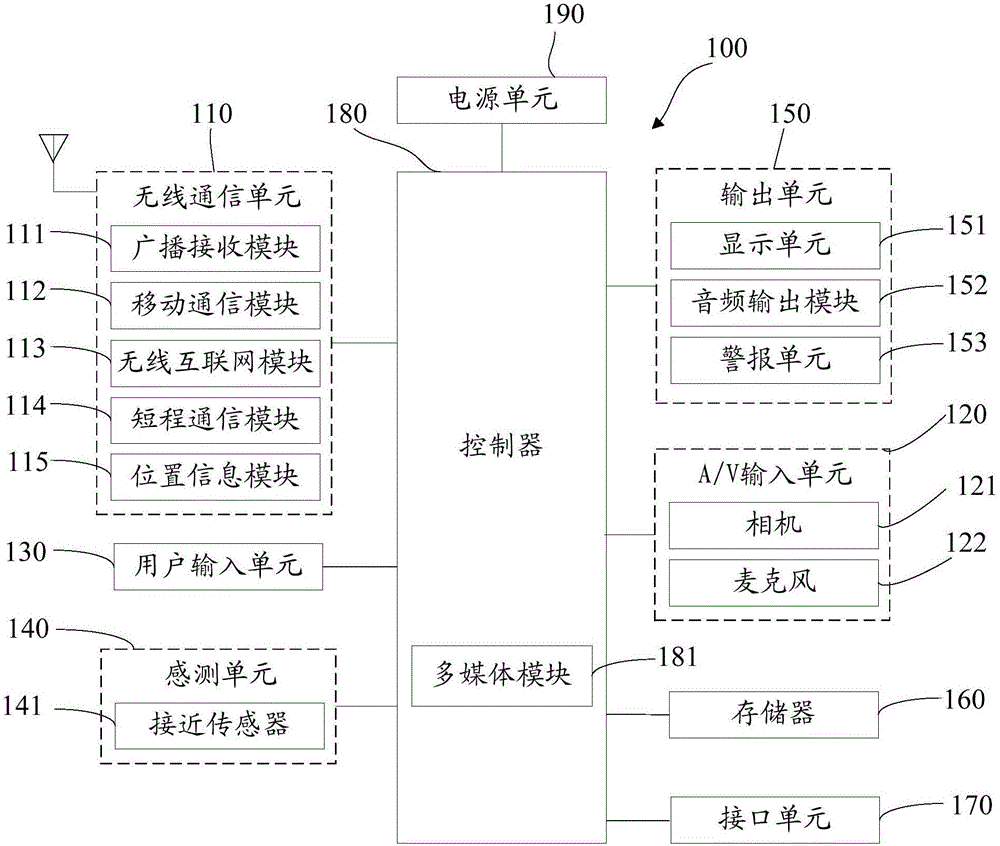

Sub-screen display method and terminal

InactiveCN105487796AAvoid feverImprove experiencePower supply for data processingInput/output processes for data processingComputer terminalOn-screen display

Owner:NUBIA TECHNOLOGY CO LTD

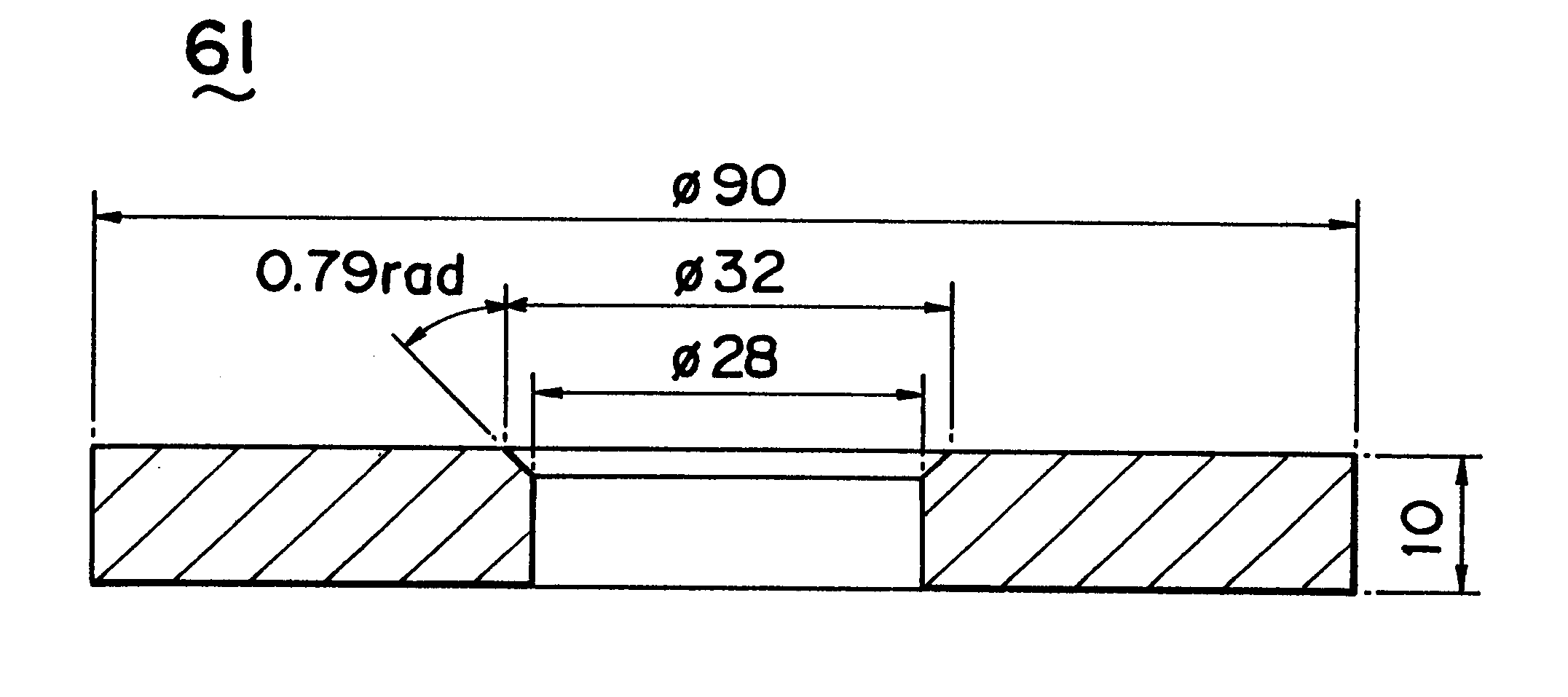

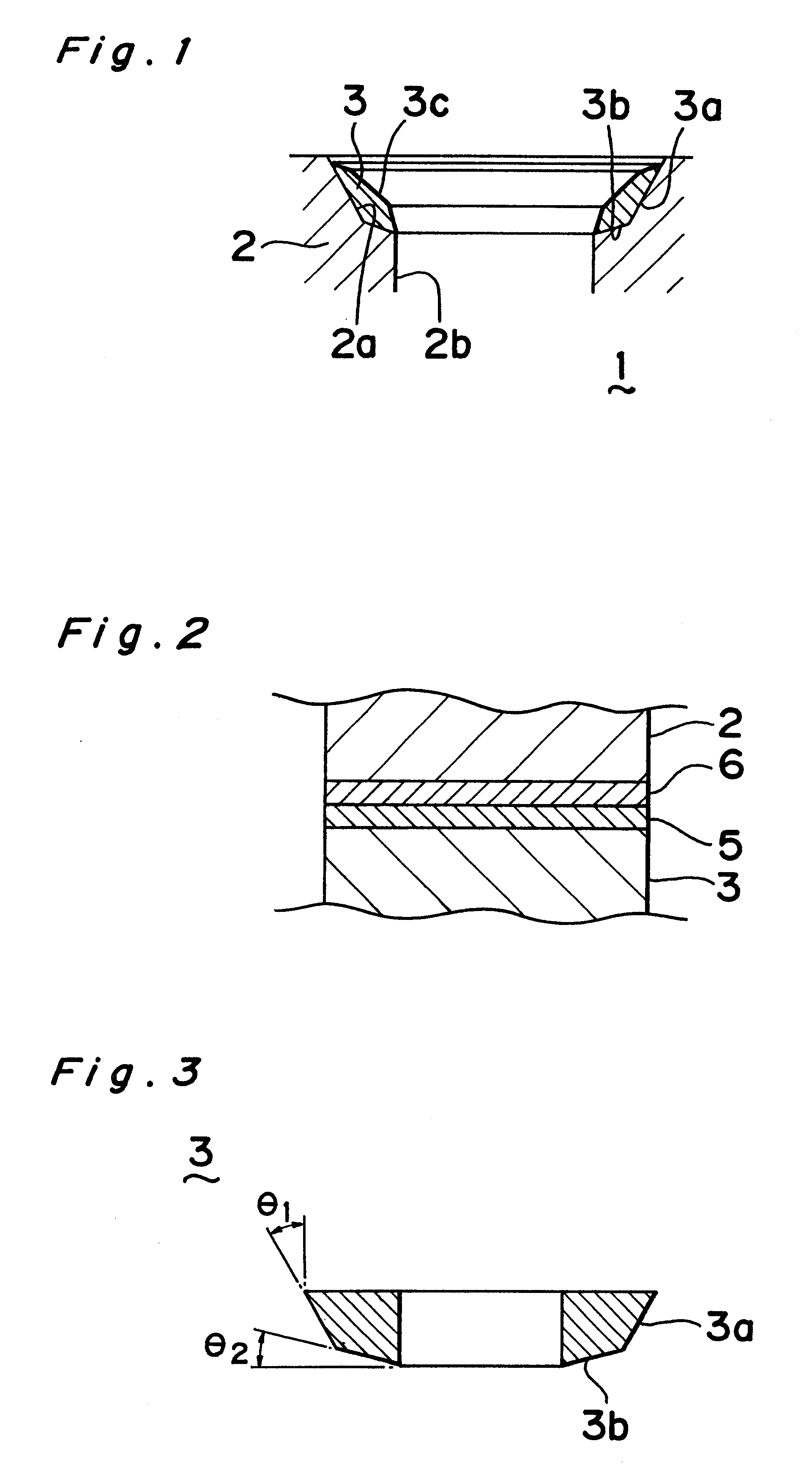

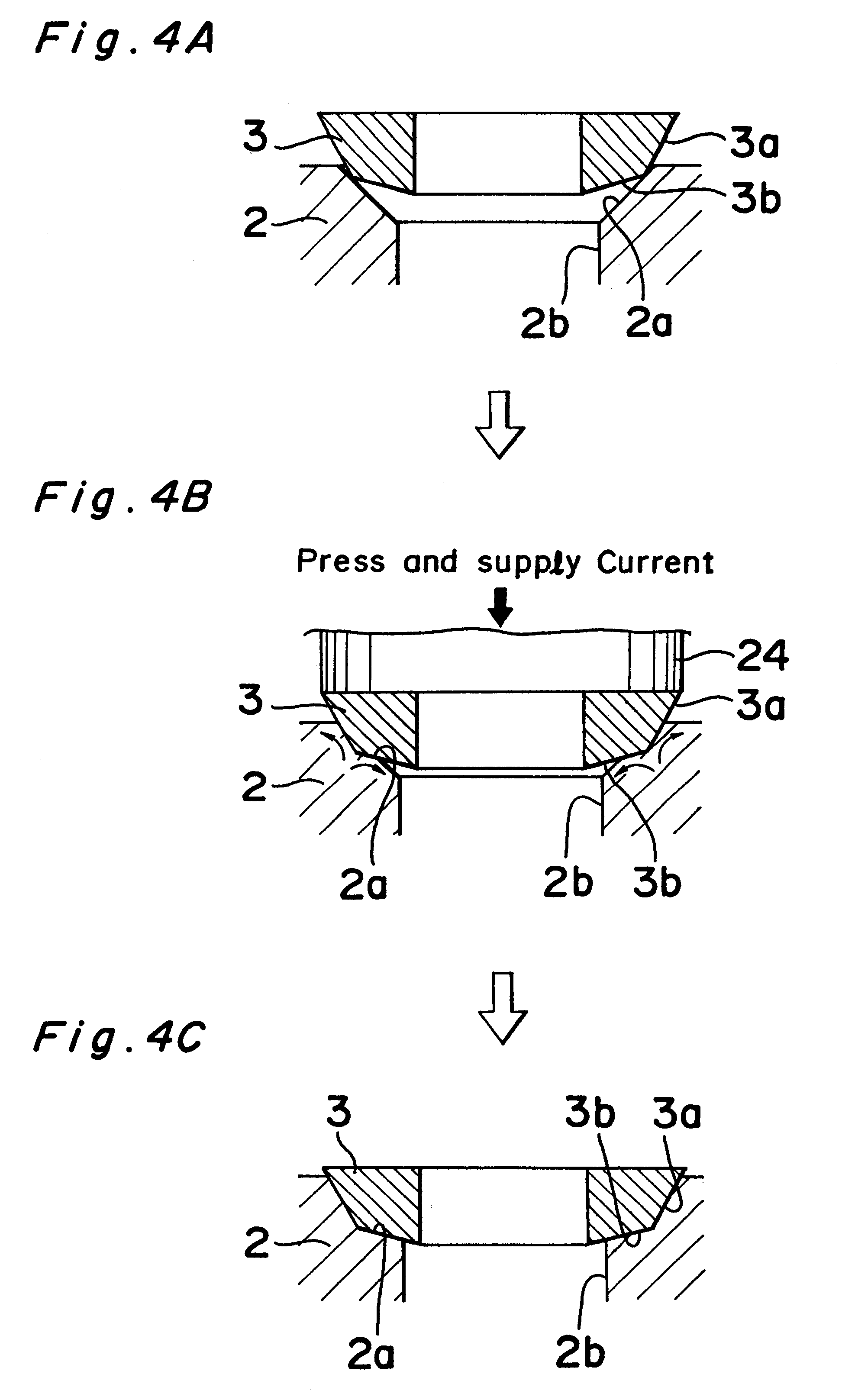

Joined metal member and method of joining said member

InactiveUS6323458B1Improve conductivityAvoid feverElectric heatingCylinder headsThermal conductivityEngineering

In order to provide a method of joining a cylinder head 2 and a valve seat 3 by press and heat generated on passing an electrical current through both members 2, 3, to achieve satisfactory joining with minimized heat generated inside when the current is supplied, while eliminating the need for an infiltration step and reduce the production cost, inhibiting an increase in thermal conductivity of the valve seat 3 and improving the wear resistance thereof. The valve seat 3 is made of a sintered material made from a powdery material with a high electrical conductivity element such as Cu dispersed therein. The current and the pressure are applied with a first joining surface 3a of the valve seat 3 and a joining surface 2a of the cylinder head body 2 being put into surface contact with each other in advance.

Owner:MAZDA MOTOR CORP

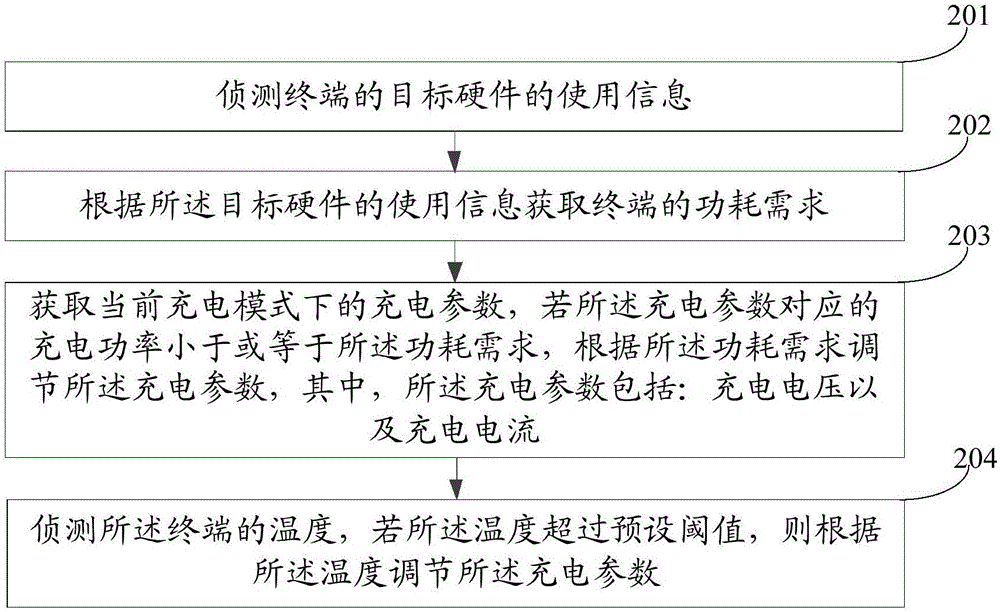

Charging method and terminal

InactiveCN106230038AAvoid situations where the power consumption is greater than the charging capacityAvoid feverCircuit monitoring/indicationDifferent batteries chargingCharge currentEngineering

Embodiments of the invention disclose a charging method and a terminal. The charging mode of the terminal can be adjusted according to the power consumption demands of the terminal in different scenarios, and thus, the user experience is improved. The method comprises the steps as follows: detecting use information of target hardware of a terminal; acquiring the power consumption demand of the terminal according to the use information of the target hardware; acquiring the charging parameters under a current charging mode, and adjusting the charging parameters according to the power consumption demand if the charging power corresponding to the charging parameters is lower than or equal to the power consumption demand, wherein the charging parameters include charging voltage and charging current; and detecting the temperature of the terminal, and adjusting the charging parameters according to the temperature if the temperature exceeds a preset threshold.

Owner:NUBIA TECHNOLOGY CO LTD

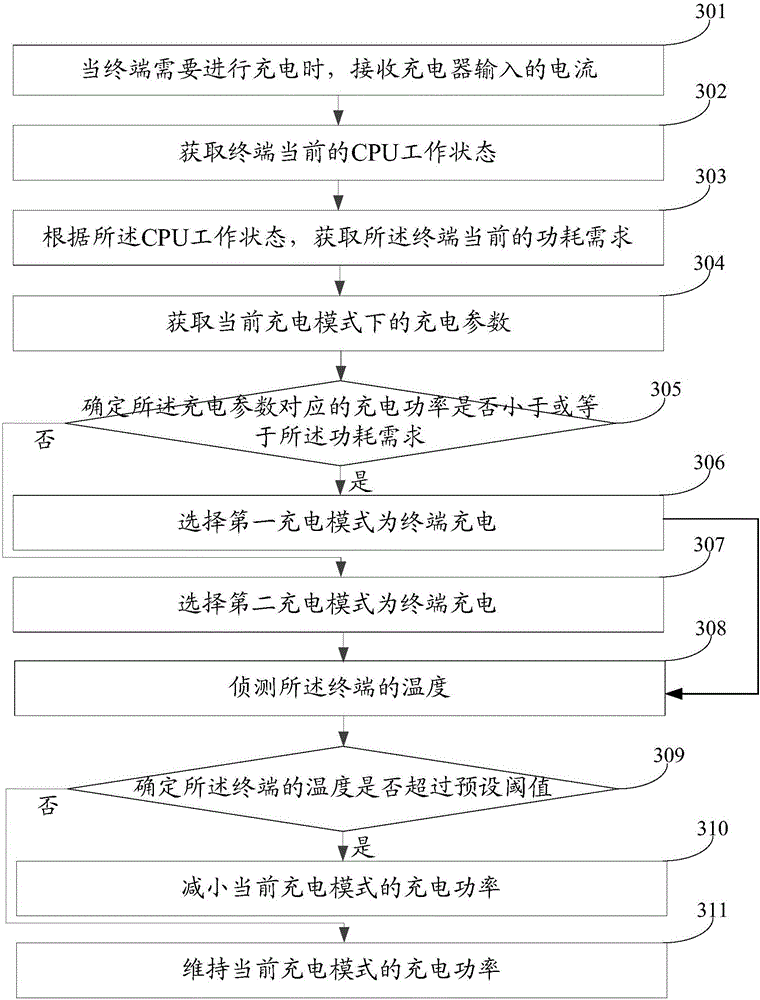

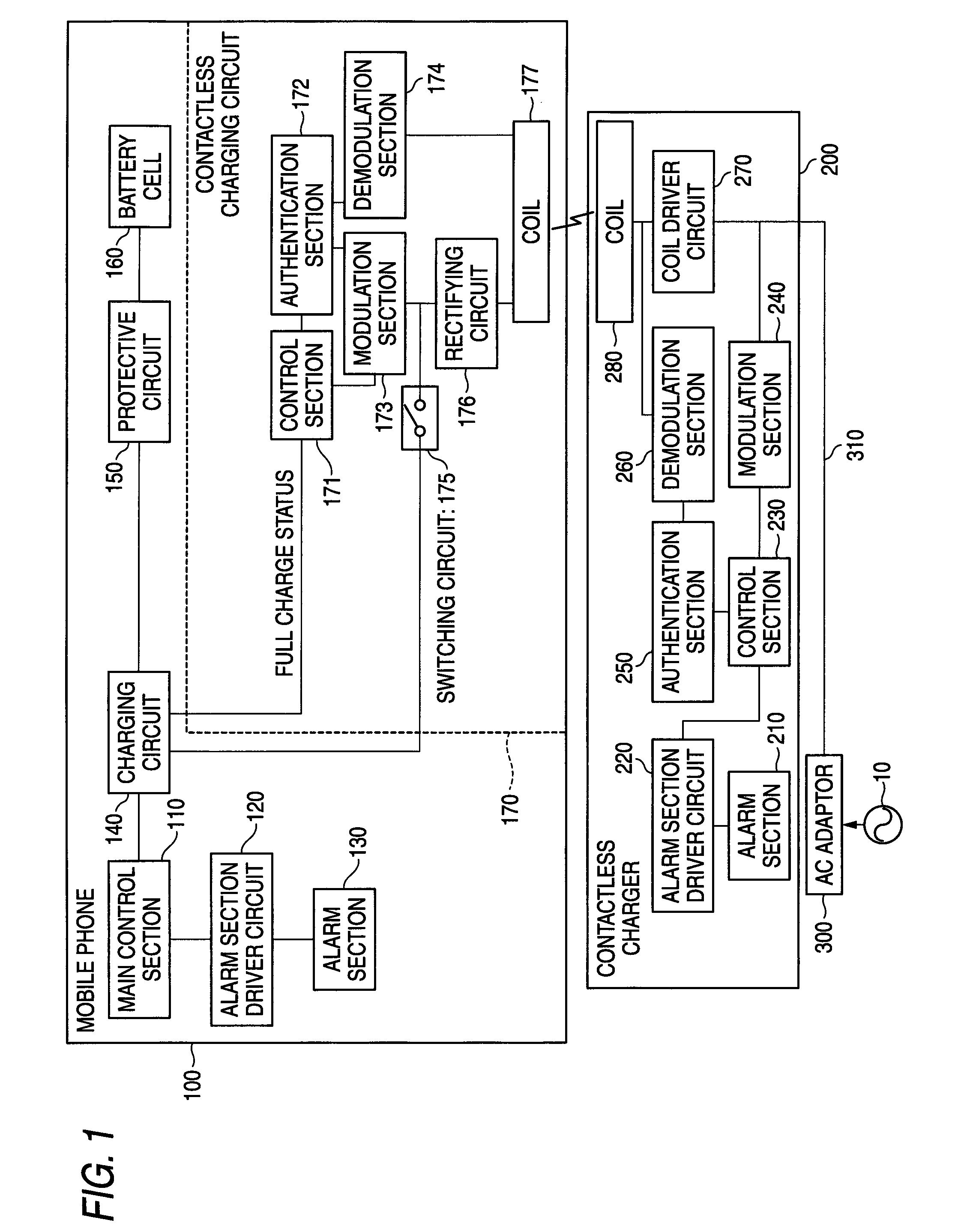

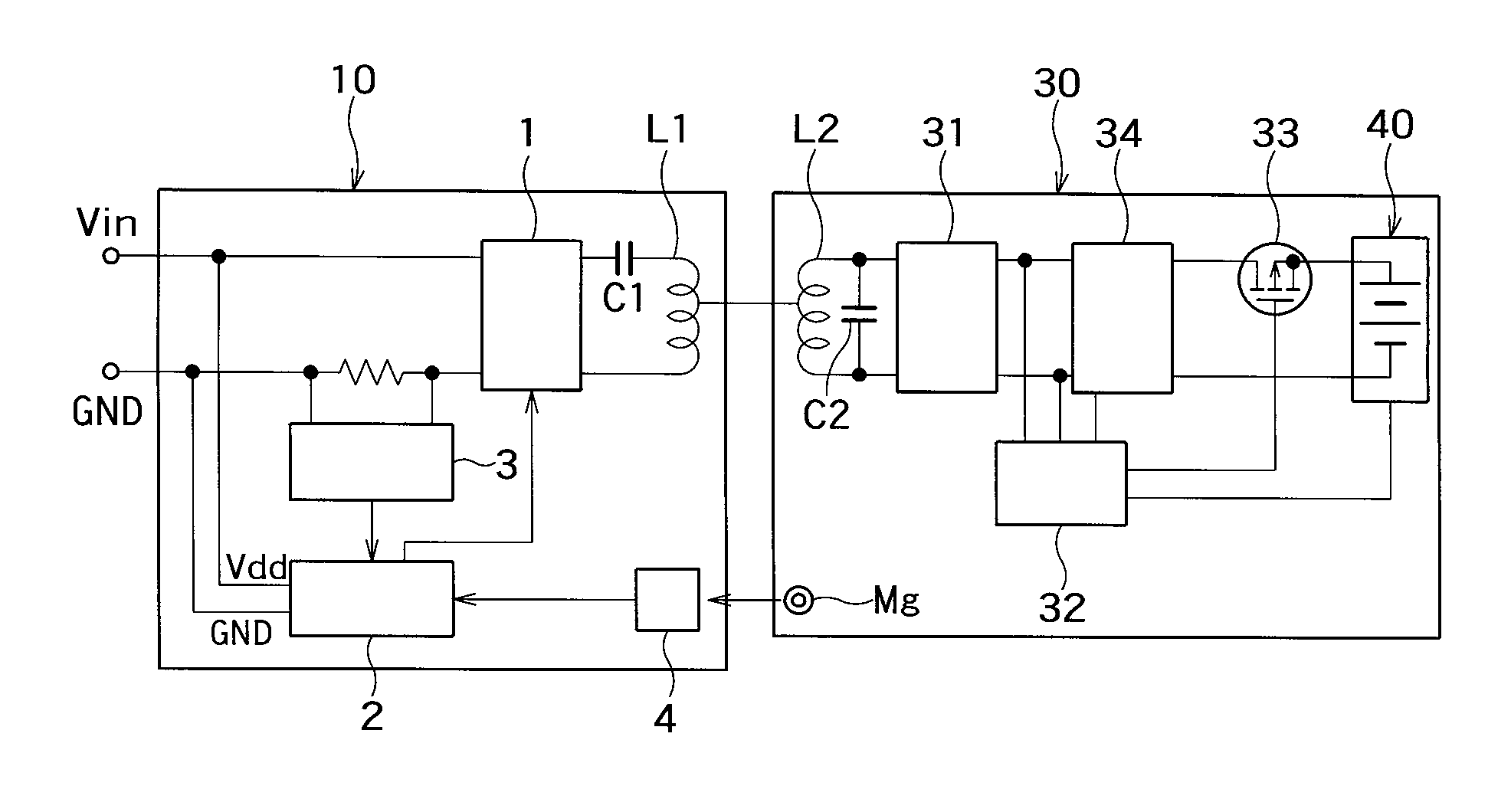

Contactless battery charger, electronic device, battery pack, and contactless charging system

ActiveUS8330414B2Reduce power consumptionAvoid feverBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringBattery charger

A contactless charging system is made up of an electronic device and a contactless charger 200 that recharges the electronic device in a contactless manner. The electronic device transmits a full charge command indicating completion of charge. Upon receipt of the full charge command, the contactless charger shifts to a charge stop state in which charge of the electronic device is not performed. In the charge stop state, the contactless charger generates a load check signal for checking whether or not the electronic device is placed in the contactless charger in a rechargeable state, and transmits the signal. Further, the contactless charger also generates a charge restart check command for checking whether or not the electronic device requests recharge in a charge stop state, and transmits the command.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

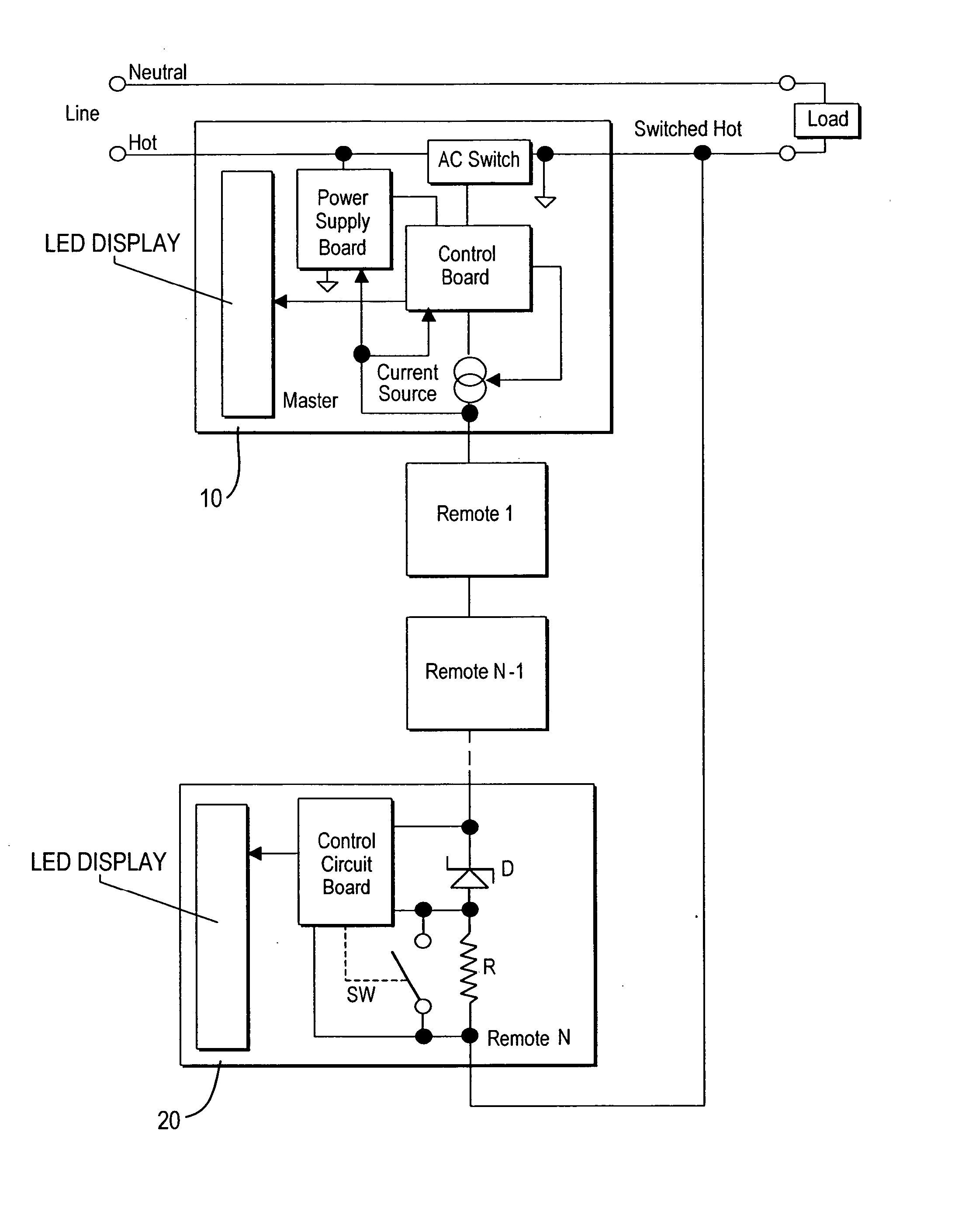

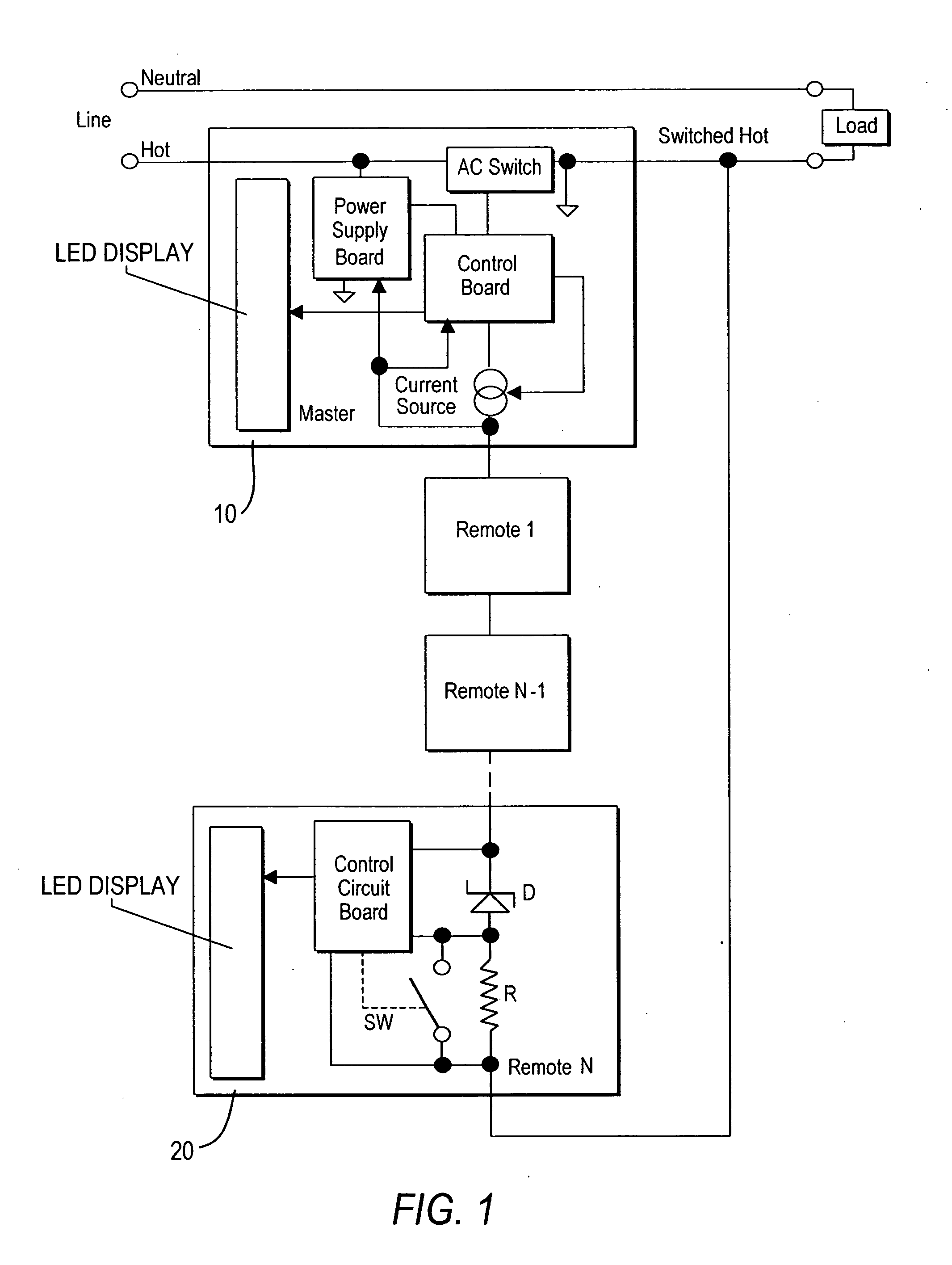

Dimmer control switch unit

ActiveUS20040206616A1Avoid large displacementAvoid noise problemsContact mechanismsElectric lighting sourcesCapacitanceNormal load

A dimmer control system has a communication control loop that connects a master unit in series with a plurality of remote units, and it is superimposed in series on the dimmer load line so as to allow two-way communication between the master unit and remote units without affecting the operation of the load. Communications from the master to the remote units are encoded in loop current fluctuations, whereas communications from any remote to the master unit are encoded in loop voltage fluctuations. The master unit has a switched power supply, for use during normal LOAD ON operation, in tandem with a capacitive power supply, for use during LOAD OFF operation of the control units so as to minimize hum. The master unit power supply circuit provides an output rail voltage comprised of a reference voltage for the load superimposed with a control loop voltage for the voltage drop across the series-connected remote units. The master unit has a POWER OFF detection circuit and a non-volatile memory for storing system status information, so that when power is restored, the system can be restored to its former power level. The switch units are formed with a cover frame mounting a switch plate on a hinge axis allowing ON / OFF movement of an opposing side thereof. An array of LED light pipes is mounted in the switch plate aligned with the hinge axis, in order to minimize displacement of the light pipes during actuator movement.

Owner:EATON INTELLIGENT POWER LIMITED

Battery

ActiveUS20070059605A1Low stiffnessForce is smallSolid electrolytesCell seperators/membranes/diaphragms/spacersPolymer electrolytesPolymer chemistry

A battery in which the relative positions of a cathode, an anode and a separator are maintained with high precision is provided. A cathode and an anode face each other with a polymer electrolyte including a polymer and a separator in between. In each of the cathode and the anode, an active material layer is disposed on a current collector. Exposed regions where the active material layers are not disposed on the current collectors and the separator are adhered to each other with the polymer electrolyte in between. Thereby, even under a high-temperature environment, the heat shrinkage of the separator can be prevented, and heat generation due to the generation of a short-circuit current can be prevented.

Owner:MURATA MFG CO LTD

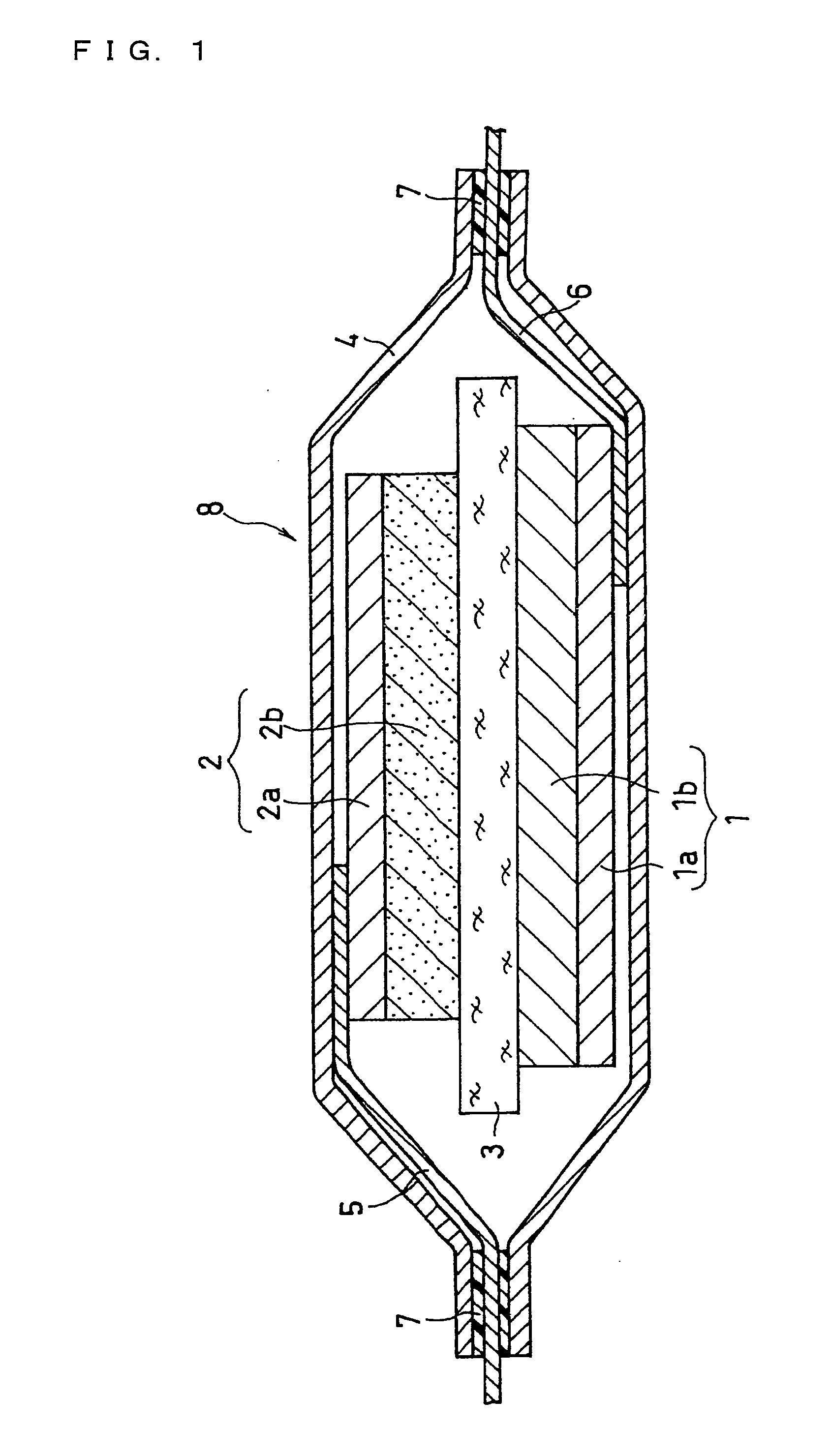

Electrode for electrochemical device and electrochemical device using the same

InactiveUS20100112442A1Large capacityImprove securityHybrid capacitor electrodesElectrode carriers/collectorsLithiumElectrochemical cell

An electrode for an electrochemical device according to the present invention includes a current collector and an active material layer formed on the current collector. The active material layer includes an active material capable of reversibly absorbing and desorbing lithium ions and having a theoretical capacity density of more than 833 mAh / cm3, and the BET specific surface area of the active material layer is 5 m2 / g or more and 80 m2 / g or less.

Owner:PANASONIC CORP

Dimmer control system with two-way master-remote communication

ActiveUS20040207342A1Avoid large displacementAvoid noise problemsFrequency-division multiplex detailsPower distribution line transmissionCapacitanceNormal load

A dimmer control system has a communication control loop that connects a master unit in series with a plurality of remote units, and it is superimposed in series on the dimmer load line so as to allow two-way communication between the master unit and remote units without affecting the operation of the load. Communications from the master to the remote units are encoded in loop current fluctuations, whereas communications from any remote to the master unit are encoded in loop voltage fluctuations. The master unit has a switched power supply, for use during normal LOAD ON operation, in tandem with a capacitive power supply, for use during LOAD OFF operation of the control units so as to minimize hum. The master unit power supply circuit provides an output rail voltage comprised of a reference voltage for the load superimposed with a control loop voltage for the voltage drop across the series-connected remote units. The master unit has a POWER OFF detection circuit and a non-volatile memory for storing system status information, so that when power is restored, the system can be restored to its former power level. The switch units are formed with a cover frame mounting a switch plate on a hinge axis allowing ON / OFF movement of an opposing side thereof. An array of LED light pipes is mounted in the switch plate aligned with the hinge axis, in order to minimize displacement of the light pipes during actuator movement.

Owner:EATON INTELLIGENT POWER LIMITED

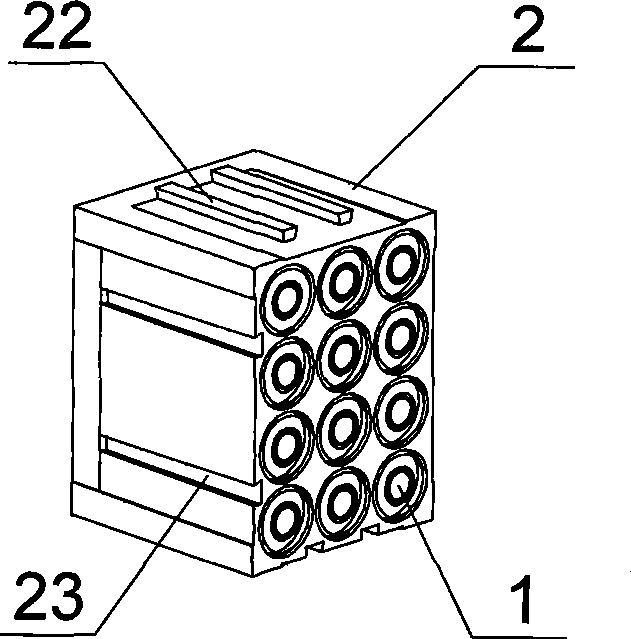

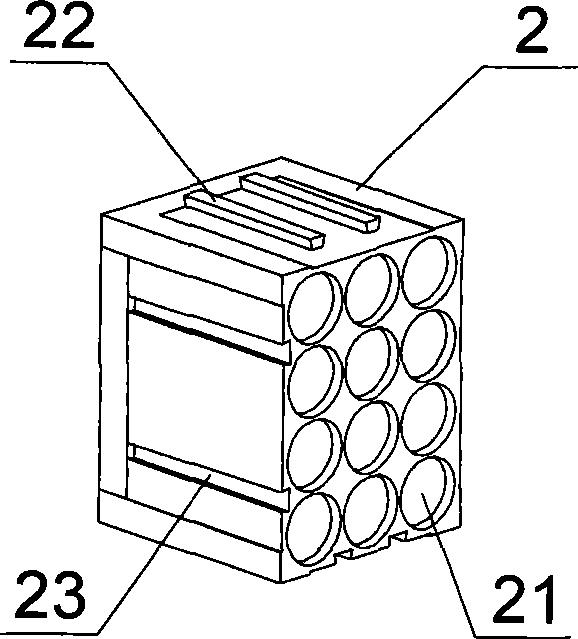

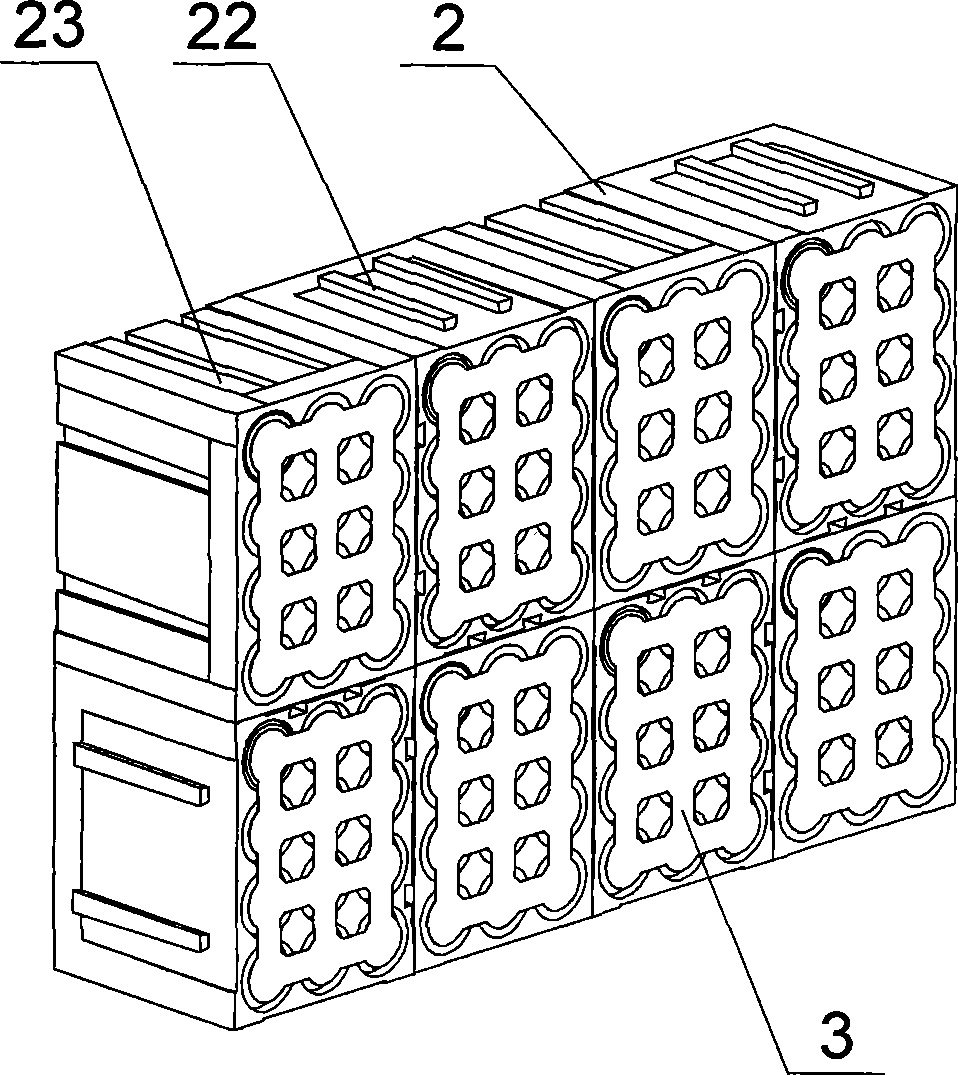

Lithium ionic cell module and cell set

ActiveCN101504973AAvoid feverAvoid fireSecondary cellsCell component detailsEngineeringLithium-ion battery

The invention discloses a lithium ion battery module with simple structure, high safety and good reliability, and a battery pack comprising the lithium ion battery module. The lithium ion battery module comprises monomer rechargeable lithium ion batteries (1) and a shell (2) made from a high-temperature resistant strong-toughness flame retardant material, wherein through holes (21) are formed between a front bottom surface and a back bottom surface of the shell (2) and are arranged in arrays, and each through hole is fixed provided with one of the monomer rechargeable lithium ion batteries (1). The lithium ion battery module and the battery pack can be widely applied to the field of power supplies.

Owner:珠海市嘉德电能科技有限公司

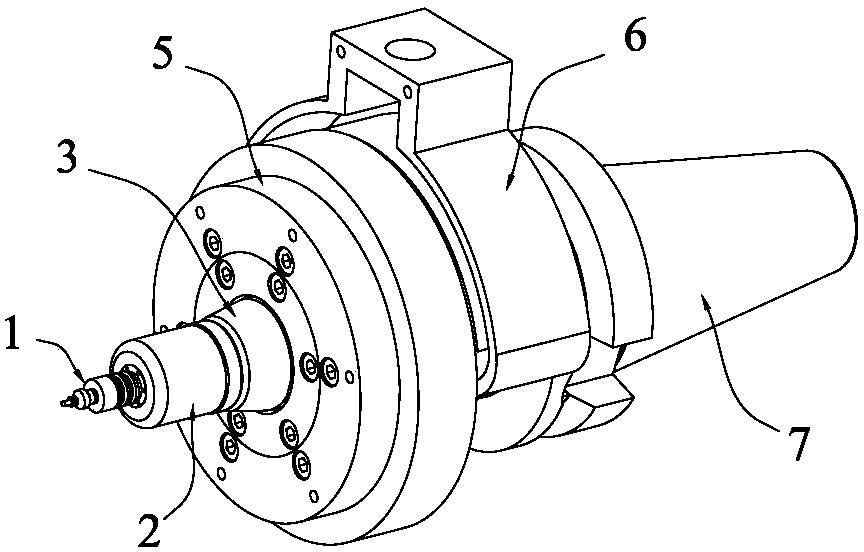

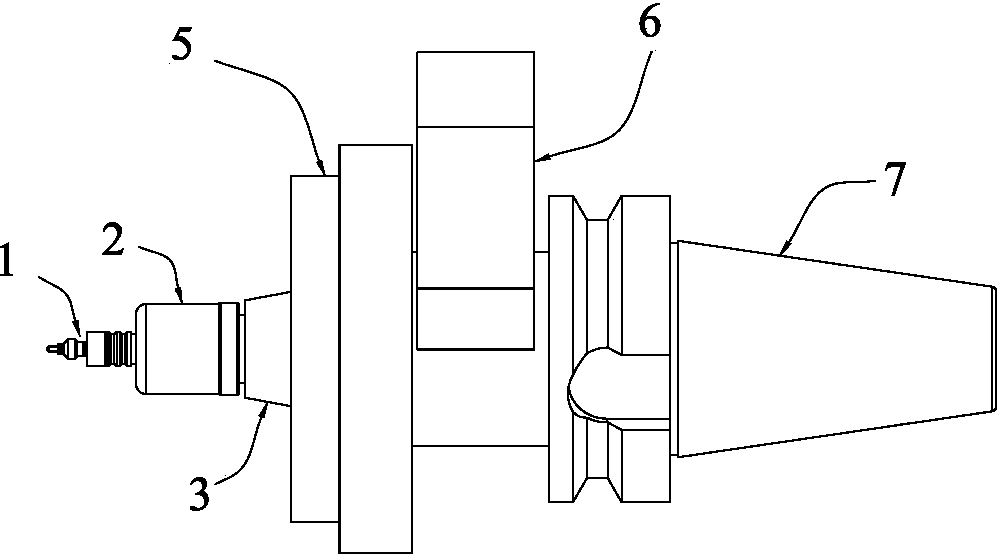

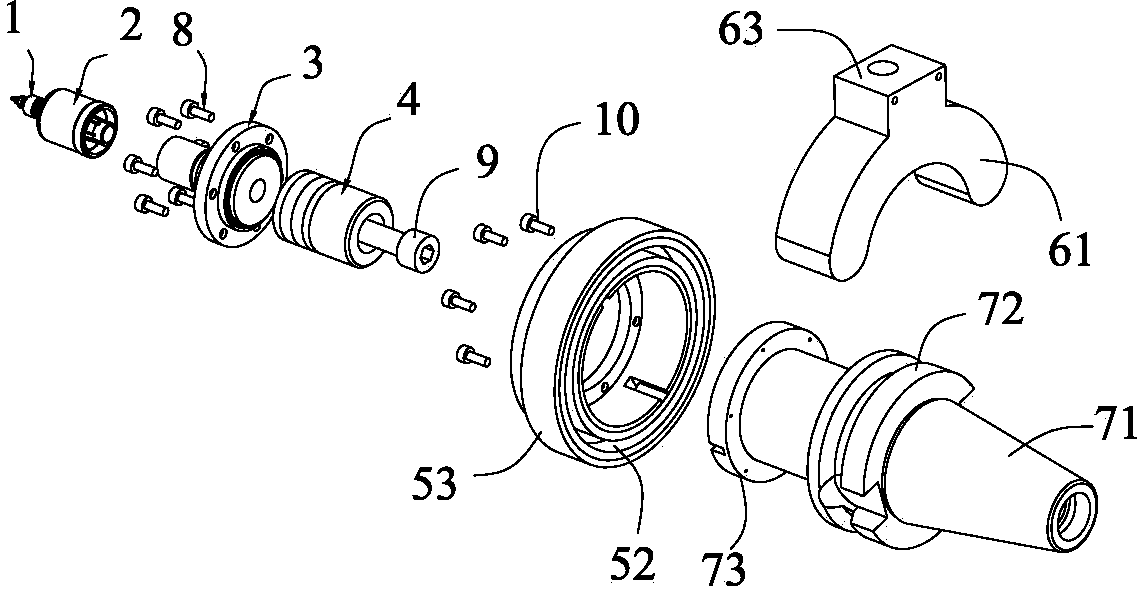

Non-contact energy transmission type ultrasonic machining device

The invention discloses a non-contact energy transmission type ultrasonic machining device. The non-contact energy transmission type ultrasonic machining device comprises a grinding head, an amplitude-change rod, a front cover plate, piezoelectric ceramic, secondary magnetic ring coil, a primary magnetic ring coil and a tool handle. The grinding head, the amplitude-change rod, the front cover plate and the tool handle are sequentially connected, the piezoelectric ceramic is arranged in a concave assembly position of the tool handle, the secondary magnetic ring coil is fixed to the front cover plate, the primary magnetic ring coil is arranged on a mechanical arm of an ultrasonic machine, and gap is formed between the secondary magnetic ring coil and the primary magnetic ring coil. The non-contact energy transmission type ultrasonic machining device is ingenious and reasonable in structural design; because of the non-contact energy transmission structure design, not only is non-contact high-efficiency transmission of electric energy achieved, but also the problem of traditional slip ring abrasion in ultrasonic machining is solved, the heat generation phenomenon caused by contact friction is avoided, the rotation speed of a spindle is increased without limitations, and meanwhile the automatic tool changing requirement of a machining center can be met; moreover, because no exposed conductors exist, electric energy transmission is not influenced by environments, and the non-contact energy transmission type ultrasonic machining device is good in working stability, safe, reliable, capable of keeping work for a long time and high in working efficiency.

Owner:张增英

Anode and battery

ActiveUS20090098458A1Excellent cycle characteristicsImprove securityOrganic electrolyte cellsNegative electrodesDecompositionMetal

A battery capable of obtaining superior cycle characteristics and safety is provided. The battery includes a cathode, an anode, and an electrolytic solution. The electrolytic solution is impregnated in a separator provided between the cathode and the anode. The anode has an insulative coat on an anode active material layer provided on an anode current collector. The coat contains an insulating material such as a meal hydroxide and a metal oxide. The coat is in a form of plate divided into a plurality of portions. The insulation property of the coat prevents internal short circuit. A plurality of portions of the coat prevent separation of the anode active material layer and decomposition of the electrolytic solution. Further, even when short circuit occurs, heat generation is prevented by heat absorption characteristics of the coat.

Owner:MURATA MFG CO LTD

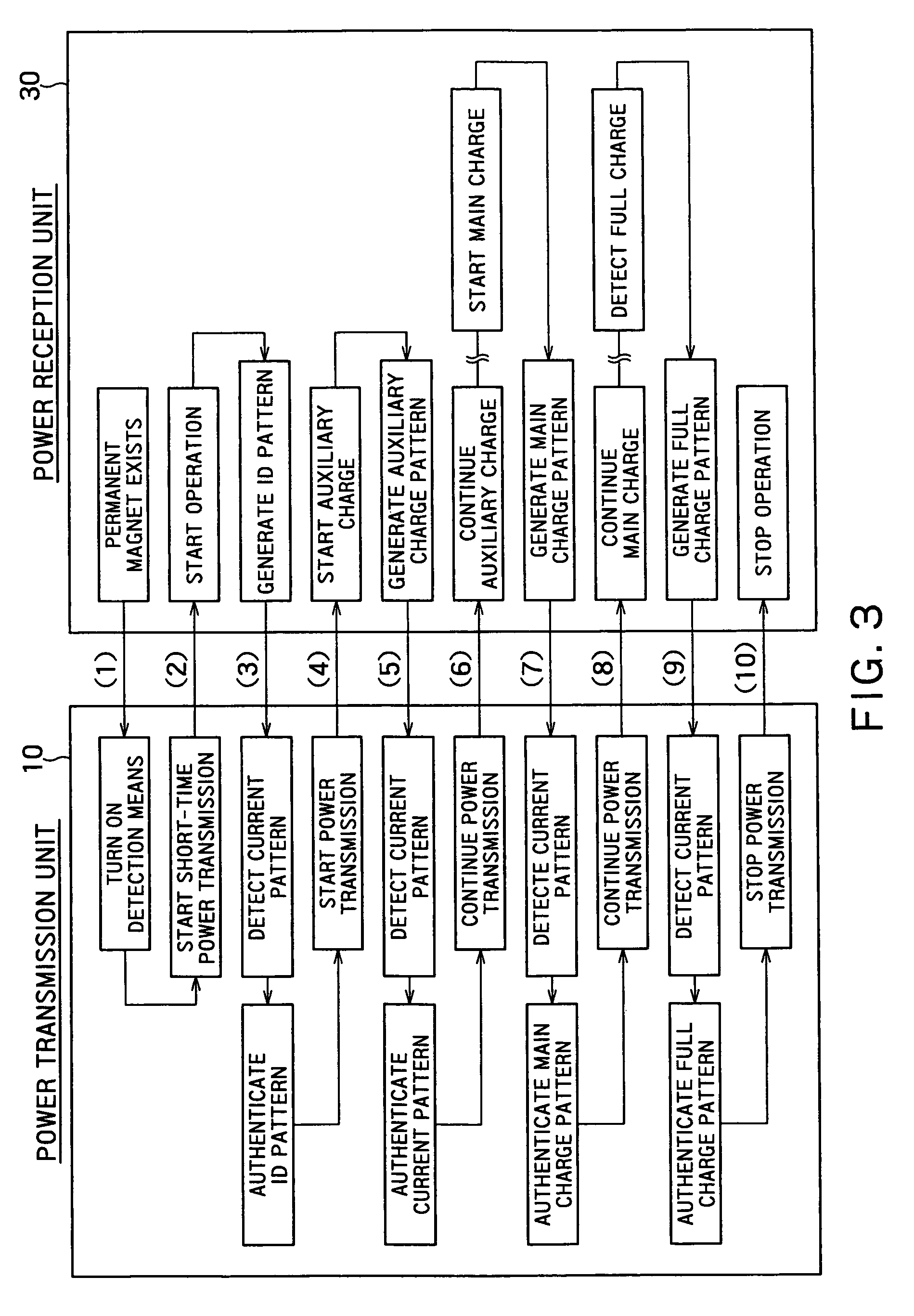

Non-contact power transfer apparatus

ActiveUS8339097B2Reduce total powerAvoid feverCircuit authenticationTransformersElectric power transmissionMicrocomputer

A non-contact power transfer apparatus includes a power transmission unit including a power transmission coil, a power transmission circuit, a current detection circuit, and a unit detection means and a first microcomputer with a control circuit for controlling each of the circuits. The non-contact power transfer apparatus also includes a power reception unit having a power reception coil, a rectification smoothing circuit, a series regulator, a charge battery unit with a rechargeable battery, a switching element for pulse-charging and a second microcomputer with a control circuit for controlling the series regulator and the switching element. As such, the power reception unit receives power via the power reception coil, while the rectification smoothing circuit and series regulator generate a set voltage. The set voltage is used to start the second microcomputer to apply an initial reset and a pulse pattern as an ID authentication pattern to the switching element.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com