Patents

Literature

77results about How to "Improve battery stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

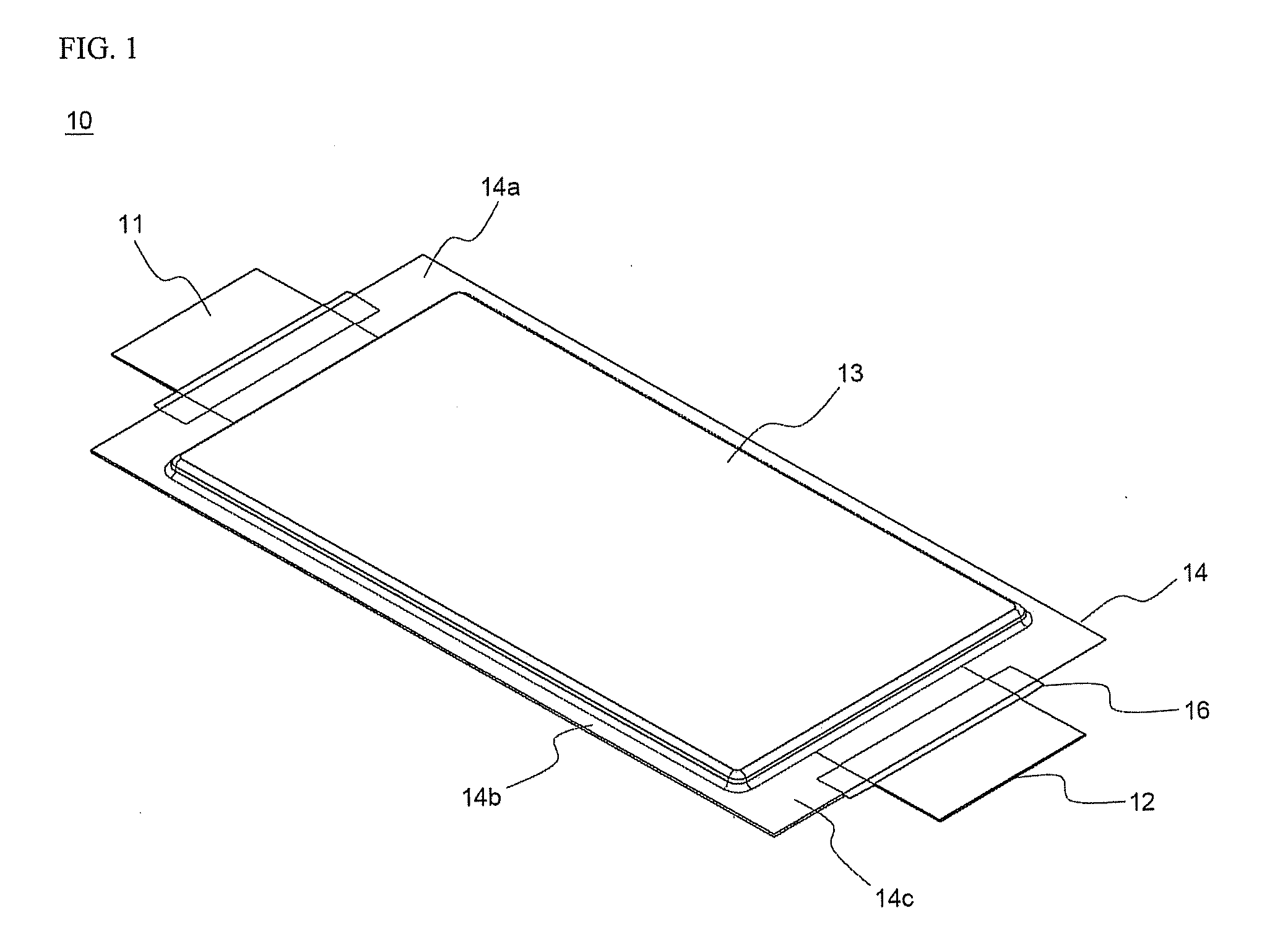

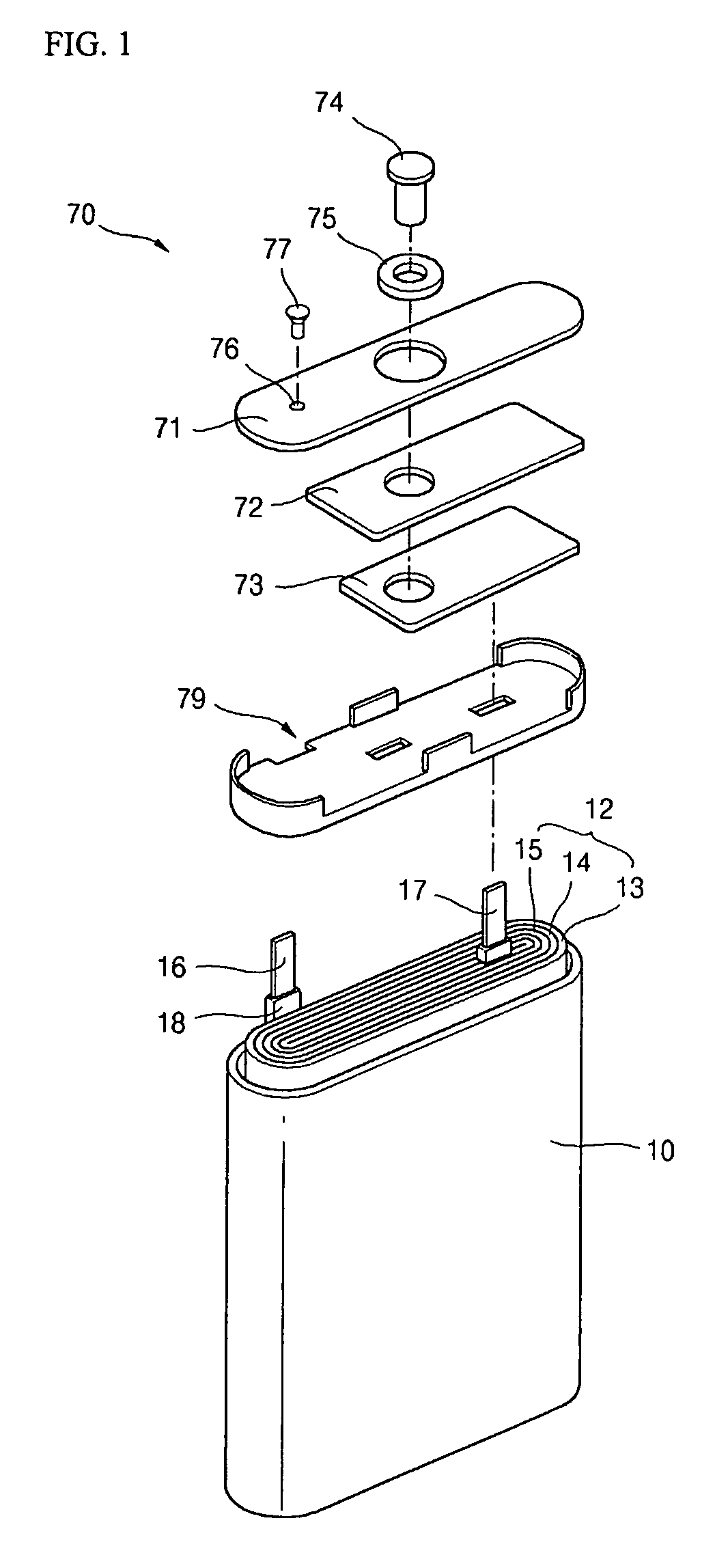

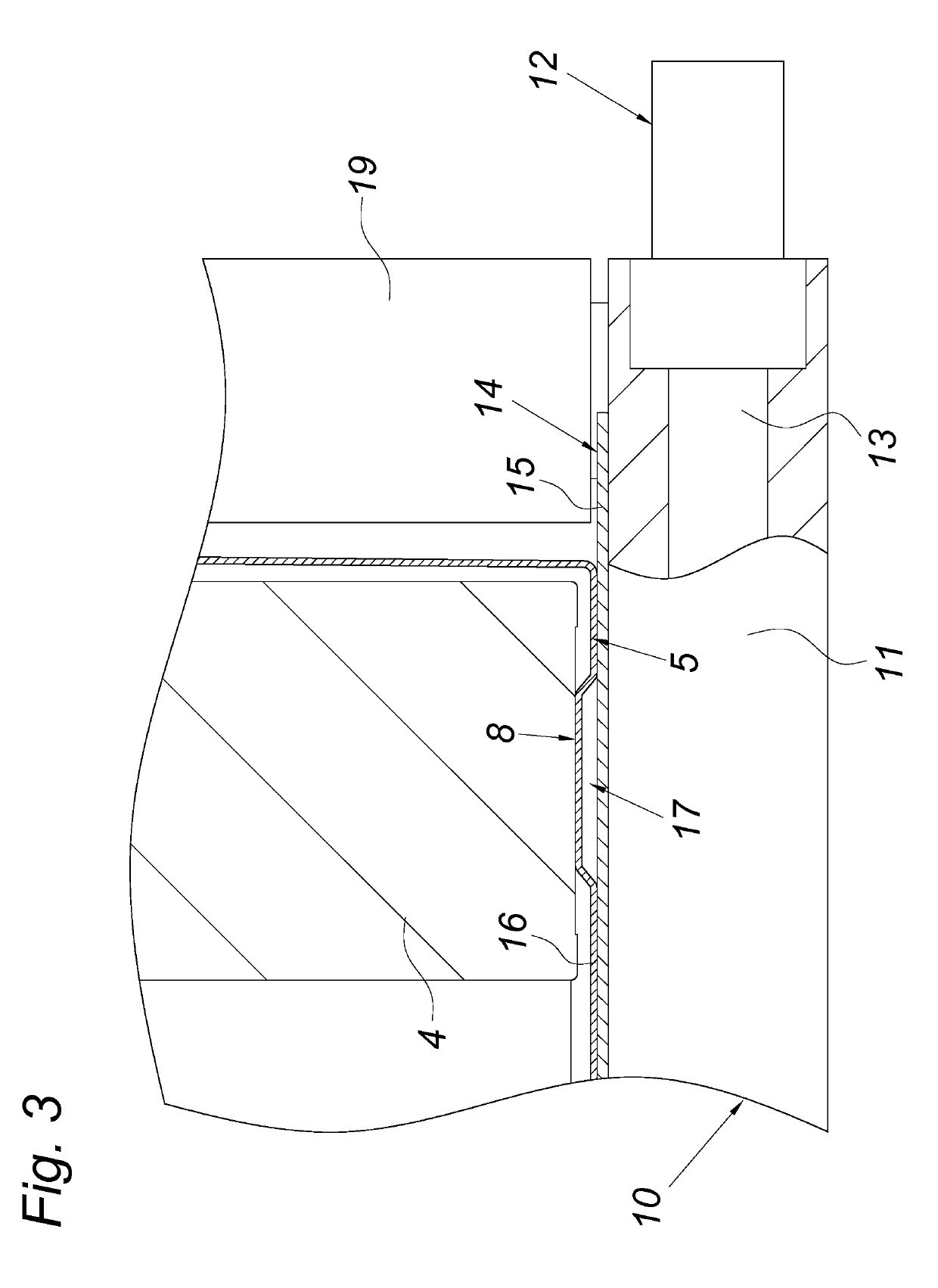

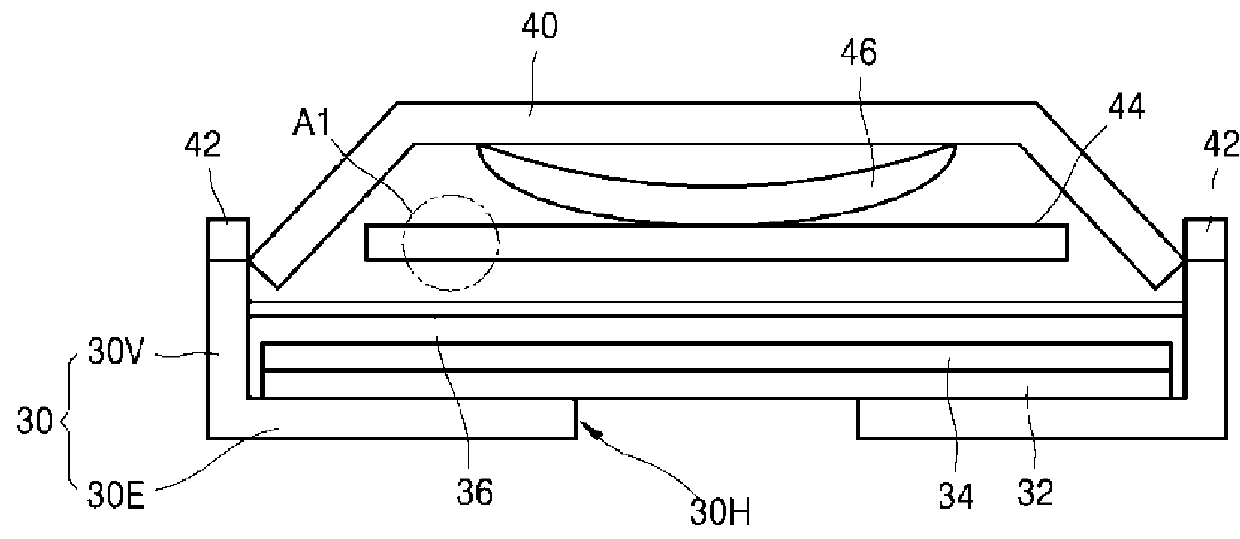

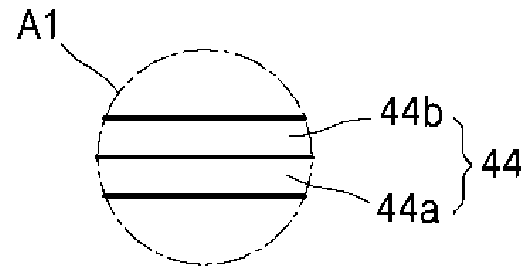

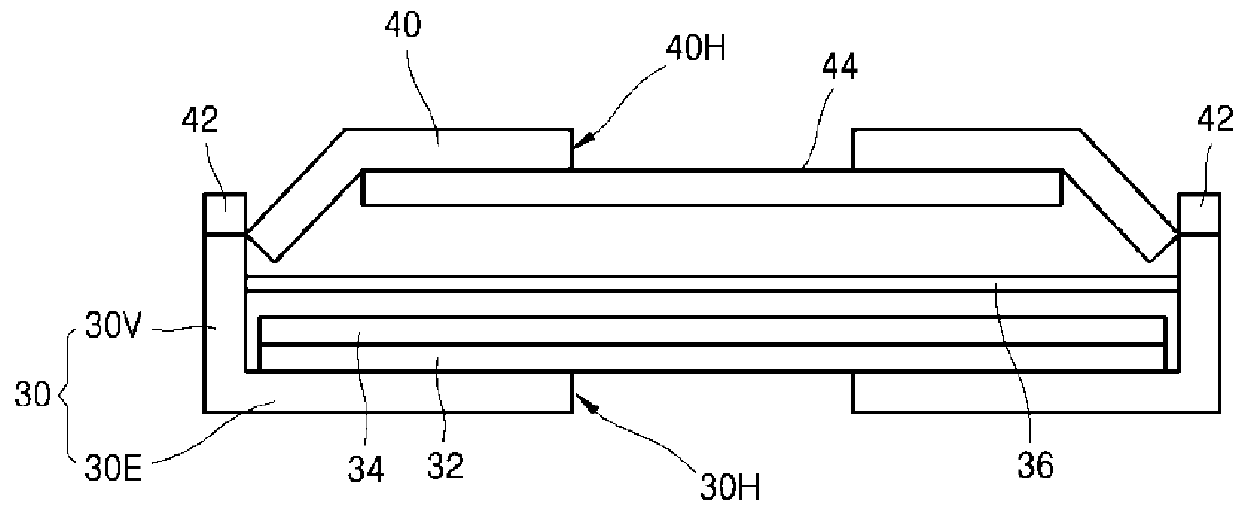

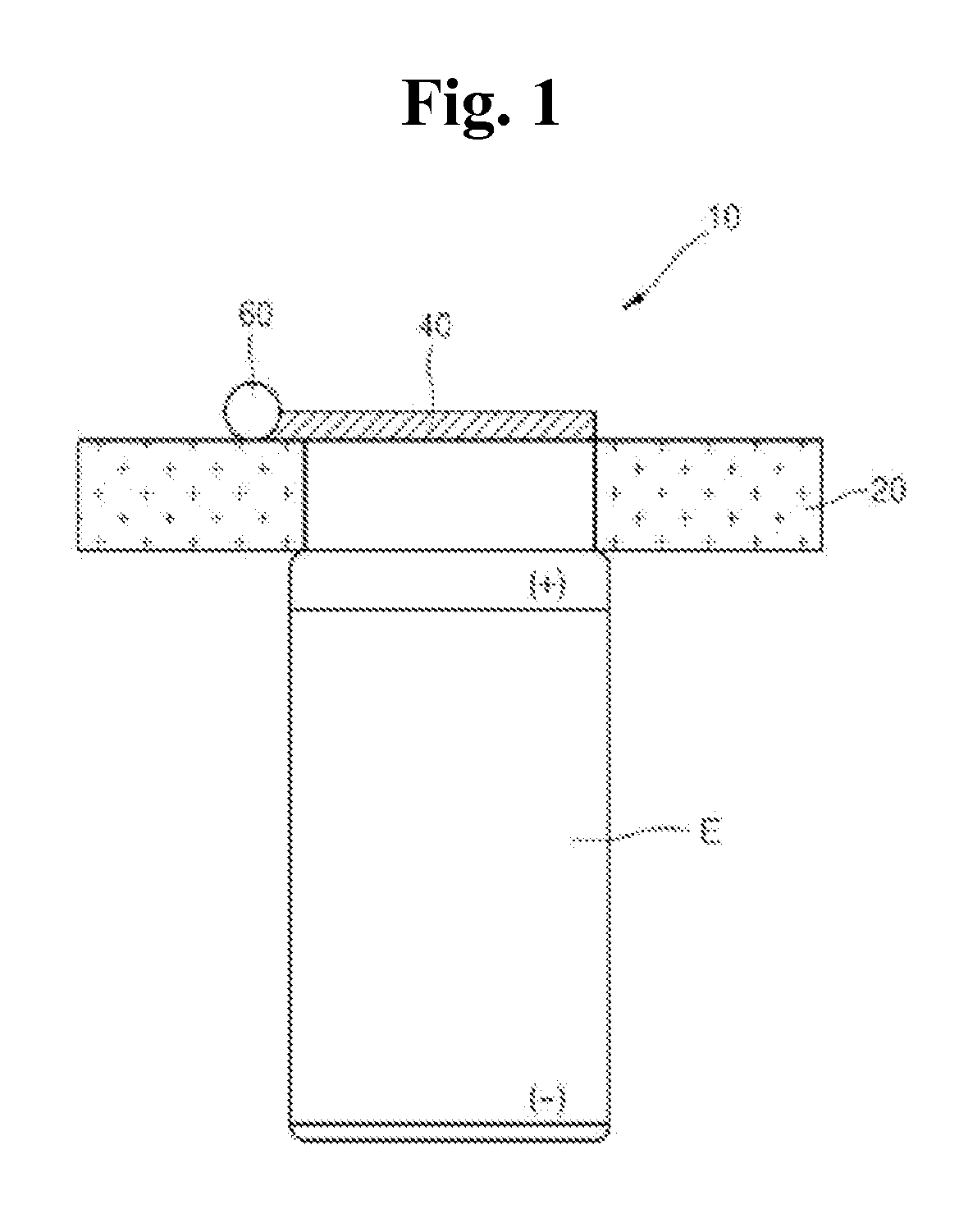

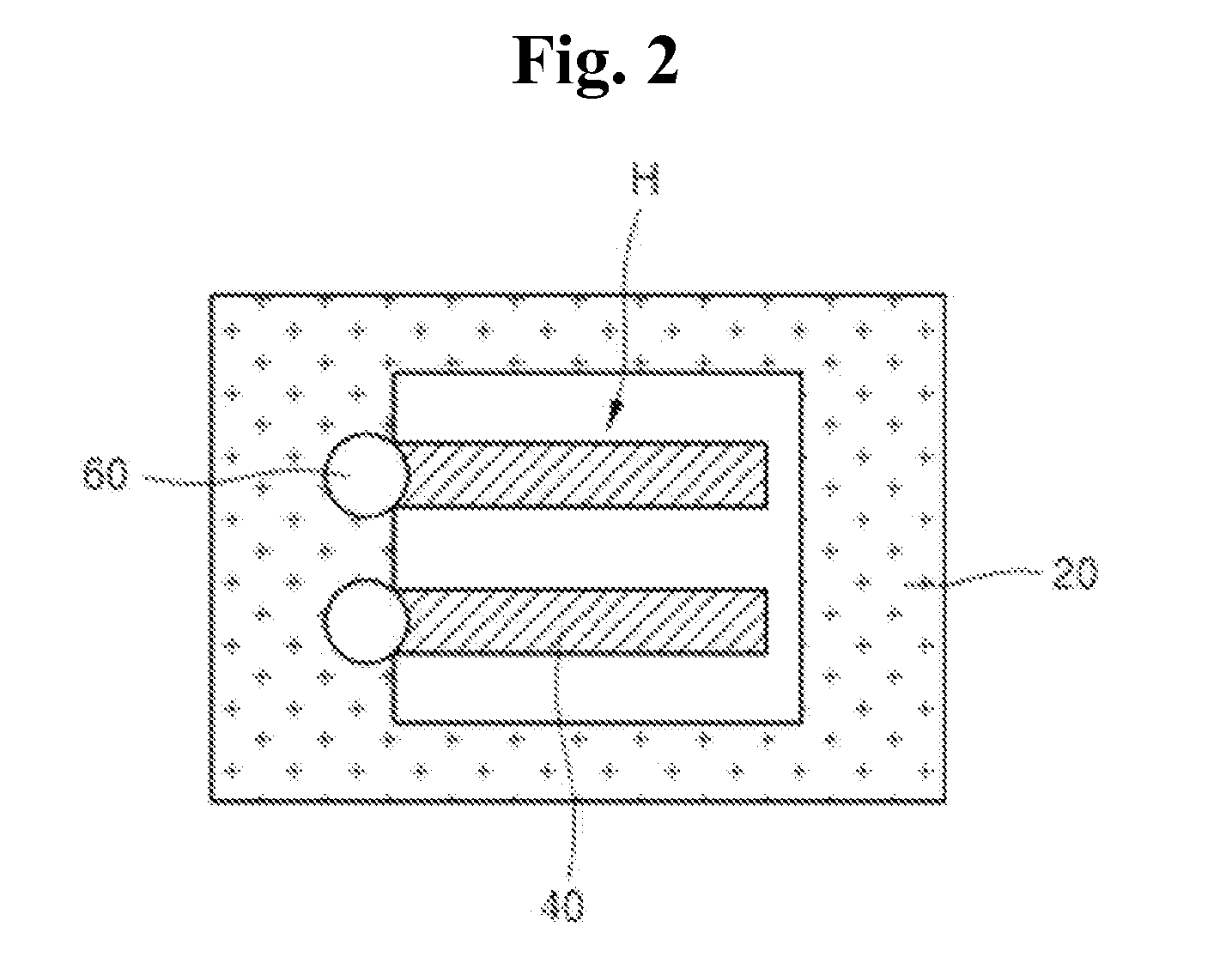

Pouch type secondary battery with safety vent

InactiveUS20040038126A1Avoid explosionAvoid fireFinal product manufactureSmall-sized cells cases/jacketsInternal pressureEngineering

A pouch type secondary battery has a safety vent which prevents explosion and fire by removing a sealing mechanism of a pouch casing when the internal temperature increases due to overcharging, overdischarging or over-heating, and which exhausts internal gas before explosion and fire of the battery when the internal gas pressure excessively increases due to overcharging, overdischarging or internal short-circuit. The pouch type secondary battery includes an electrode assembly having positive and negative electrode plates with a separator interposed therebetween, and positive and negative electrode terminals extending from the positive and negative electrode plates, respectively, a pouch casing having a space in which the electrode assembly is housed to be sealed, a seal portion provided at the periphery of the space, and at least one of the positive and negative electrode terminals exposed to the seal portion, and at least one opening member disposed at the seal portion and made of a resin material having a lower melting point than a melting point of the seal portion of the pouch casing.

Owner:SAMSUNG SDI CO LTD

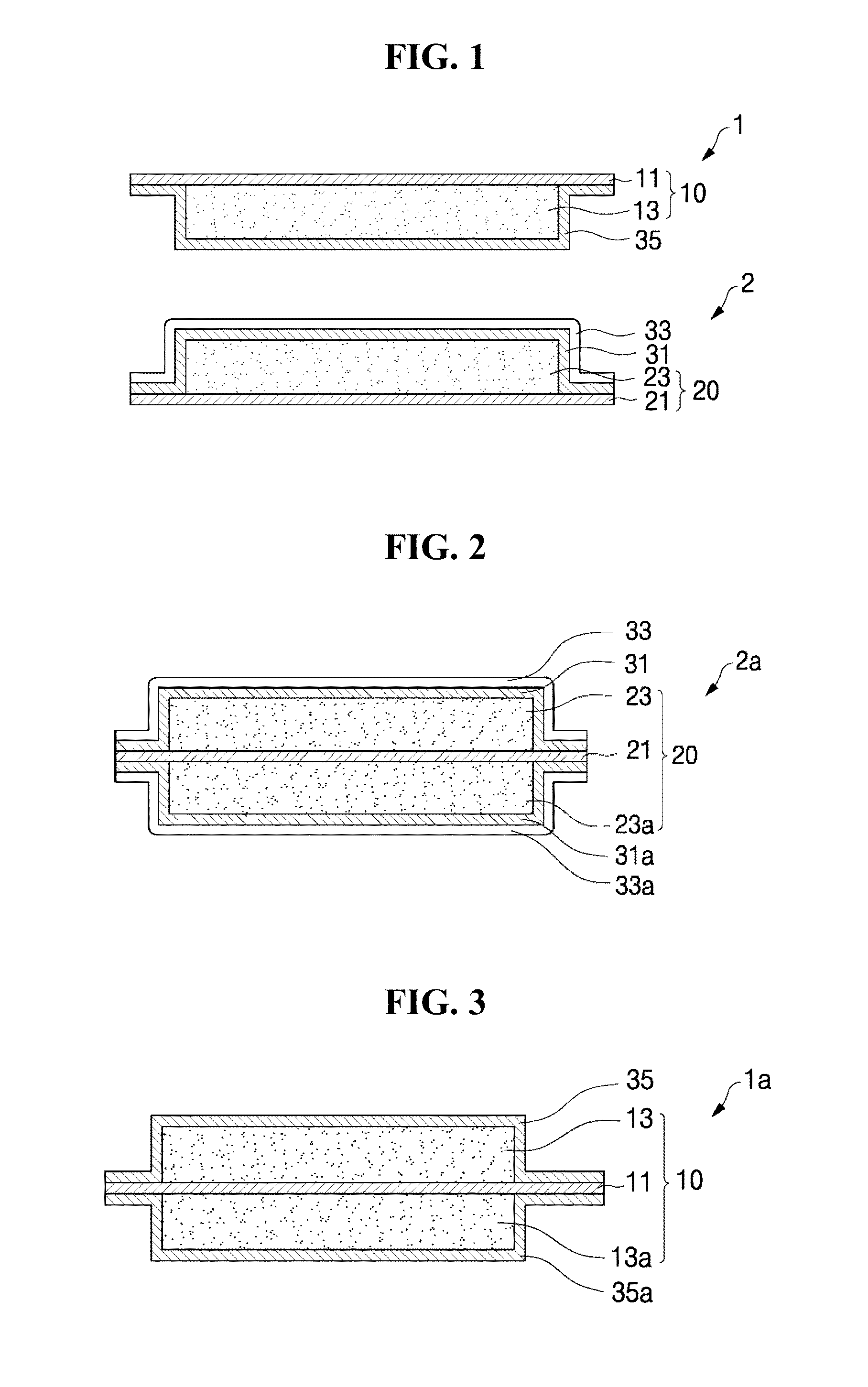

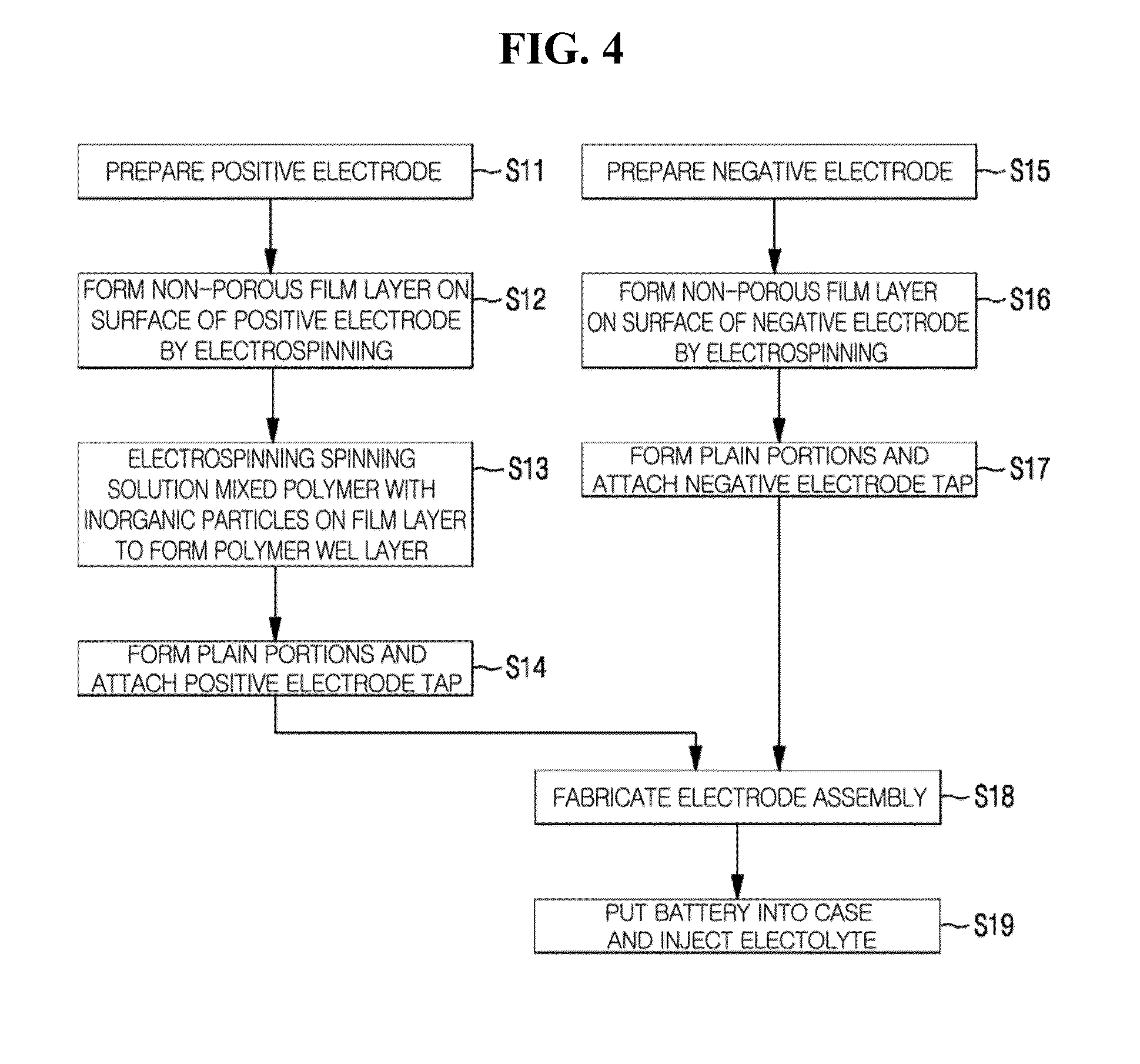

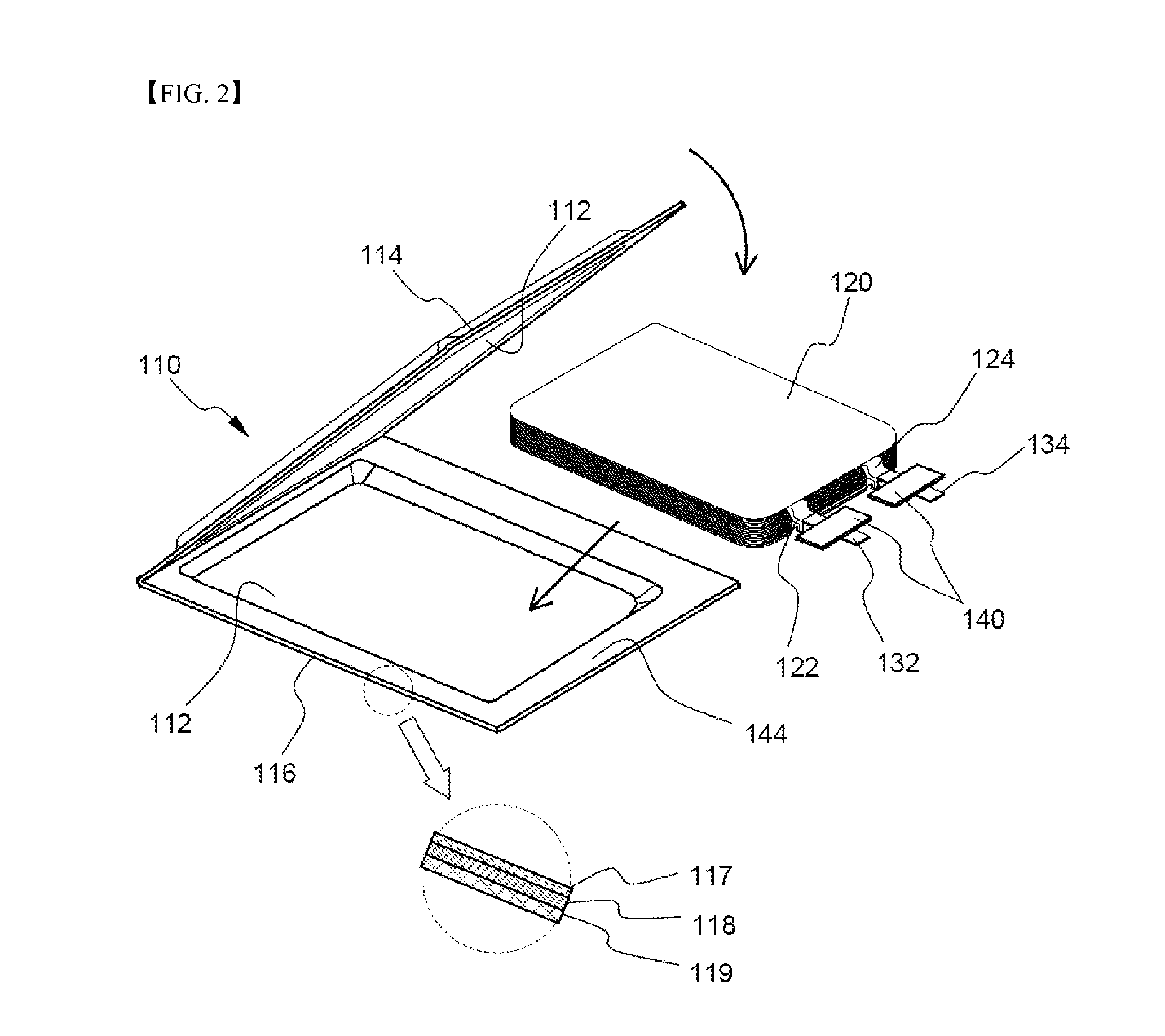

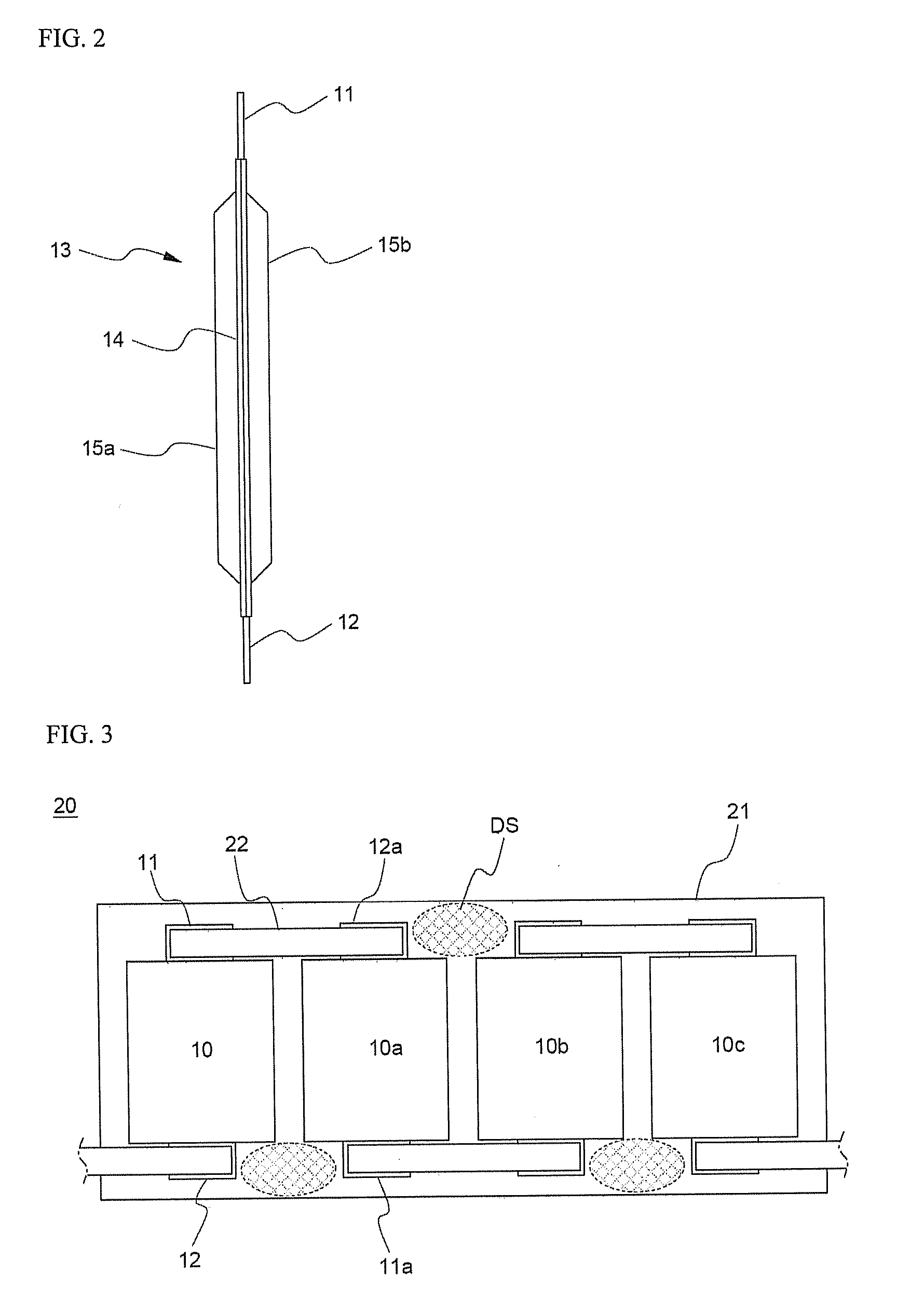

Heat-resistant separator, electrode assembly and secondary battery using the same, and method for manufacturing secondary battery

InactiveUS20130236766A1Improve stabilityAvoid dendrite formationElectric shock equipmentsCell seperators/membranes/diaphragms/spacersFiberInorganic particle

A porous polymer web layer of ultrafine fibers, and a non-porous film layer made of a material that is swellable and allows conduction of electrolyte ions in an electrolyte solution, are integrally provided on one surface or both surfaces of a positive electrode or a negative electrode, and a short circuit between the positive electrode and the negative electrode by the inorganic particles contained in polymer web is prevented although a battery is overheated. The electrode assembly includes: a positive electrode; a negative electrode; and a separator that separates the positive electrode and the negative electrode. The separator comprises: a first non-porous polymer film layer; and a porous polymer web layer that is formed on the first non-porous polymer film layer and is made of ultrafine fibers of a mixture of a heat-resistant polymer and inorganic particles or a mixture of a heat-resistant polymer, a swellable polymer, and inorganic particles.

Owner:AMOGREENTECH CO LTD

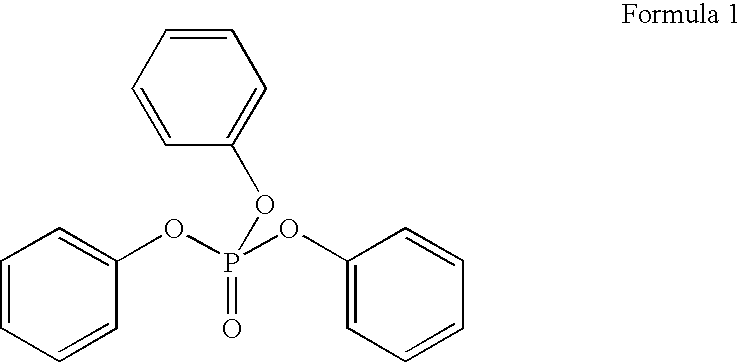

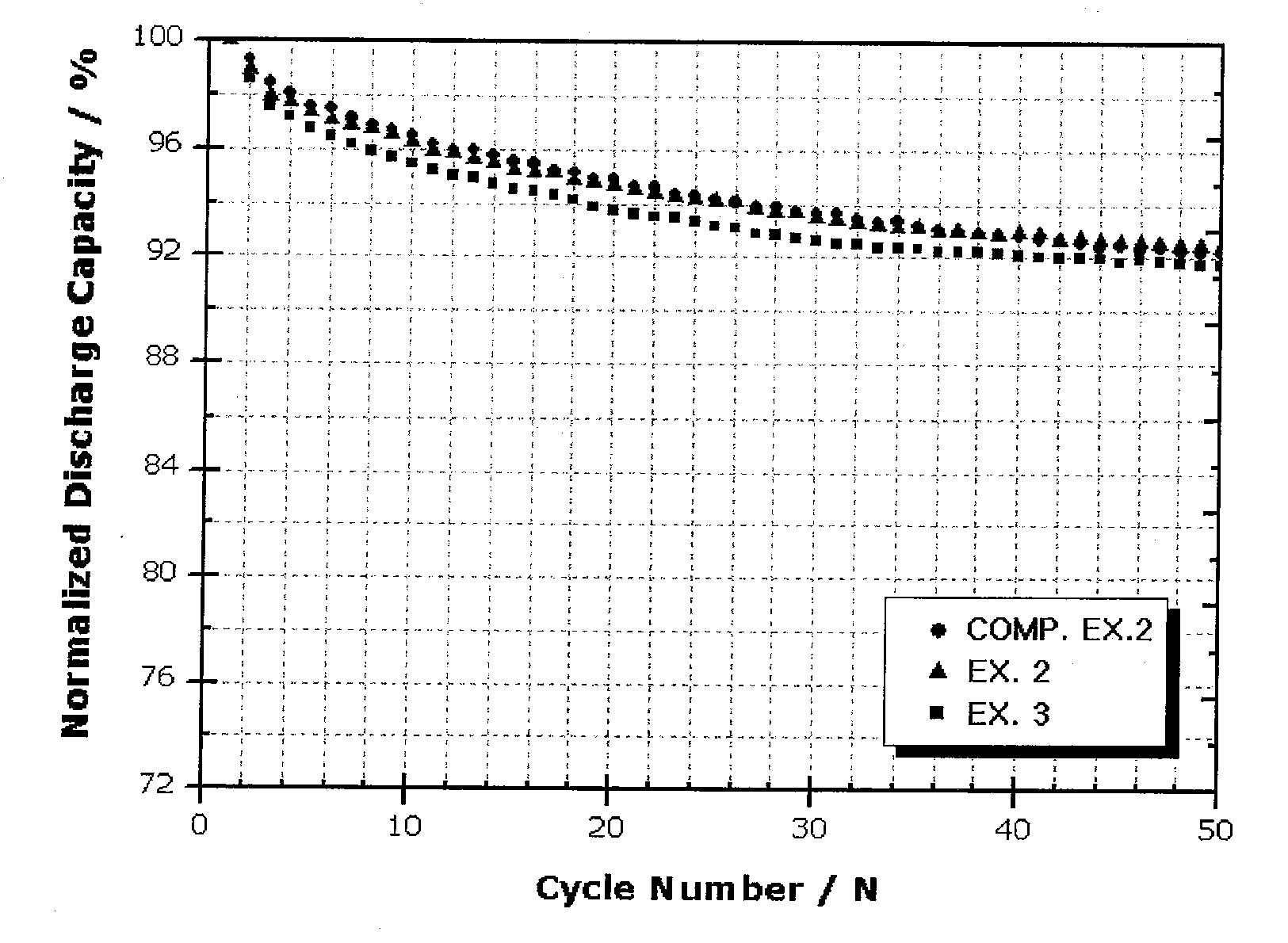

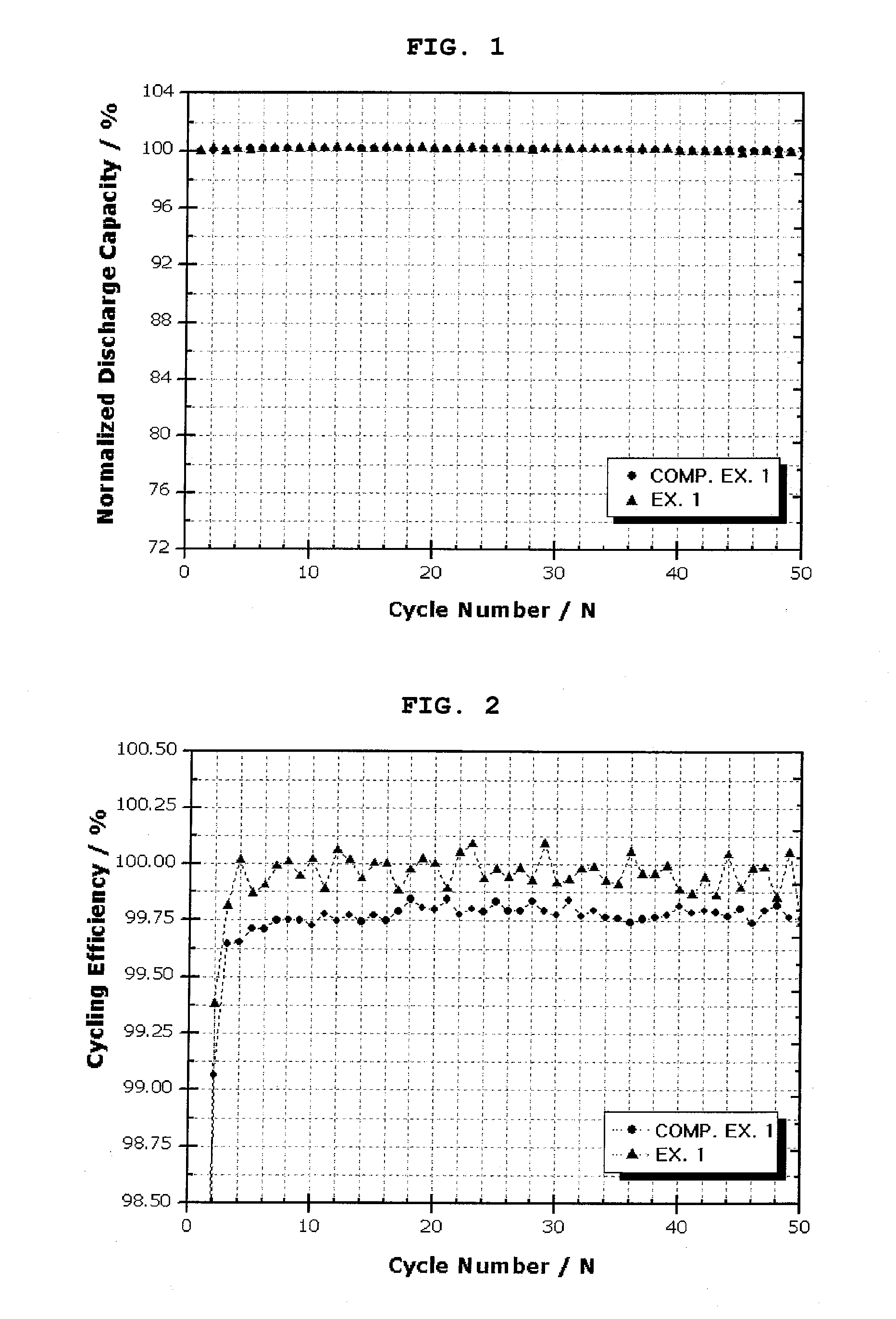

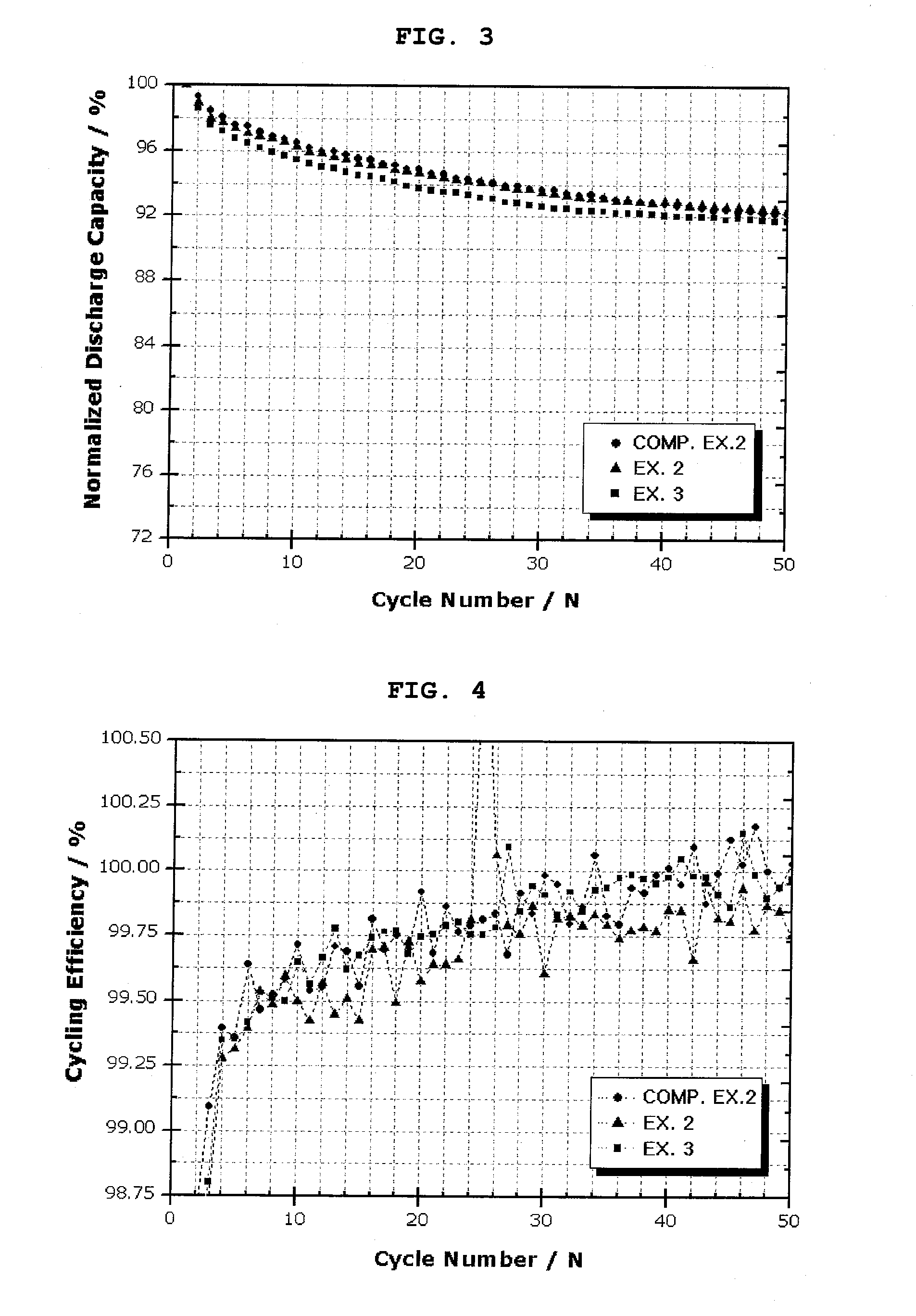

Electrolyte for lithium ion rechargeable battery and lithium ion rechargeable battery comprising the same

ActiveUS20050277027A1Improve battery stabilityPrevents and improves swellingOrganic electrolyte cellsLi-accumulatorsLithiumHigh temperature storage

The present invention relates to an electrolyte for a lithium ion rechargeable battery and a lithium ion rechargeable battery including the same. The electrolyte includes a non-aqueous organic solvent, a lithium salt, and triphenyl phosphate. A lithium ion rechargeable battery including the electrolyte has improved overcharge stability and shows excellent chemical properties including reducing swelling, high-temperature storage stability, and cycle life characteristics.

Owner:SAMSUNG SDI CO LTD

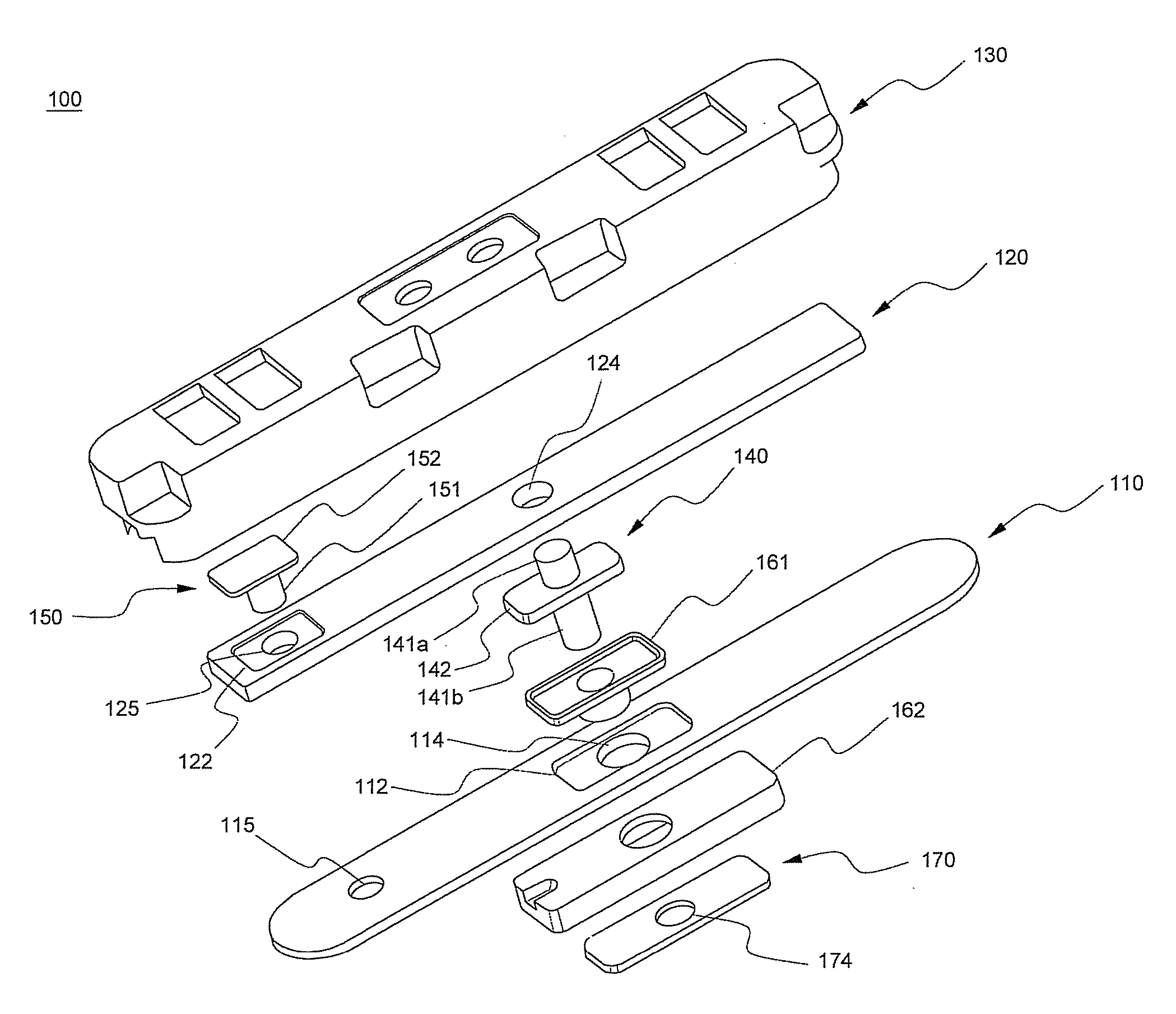

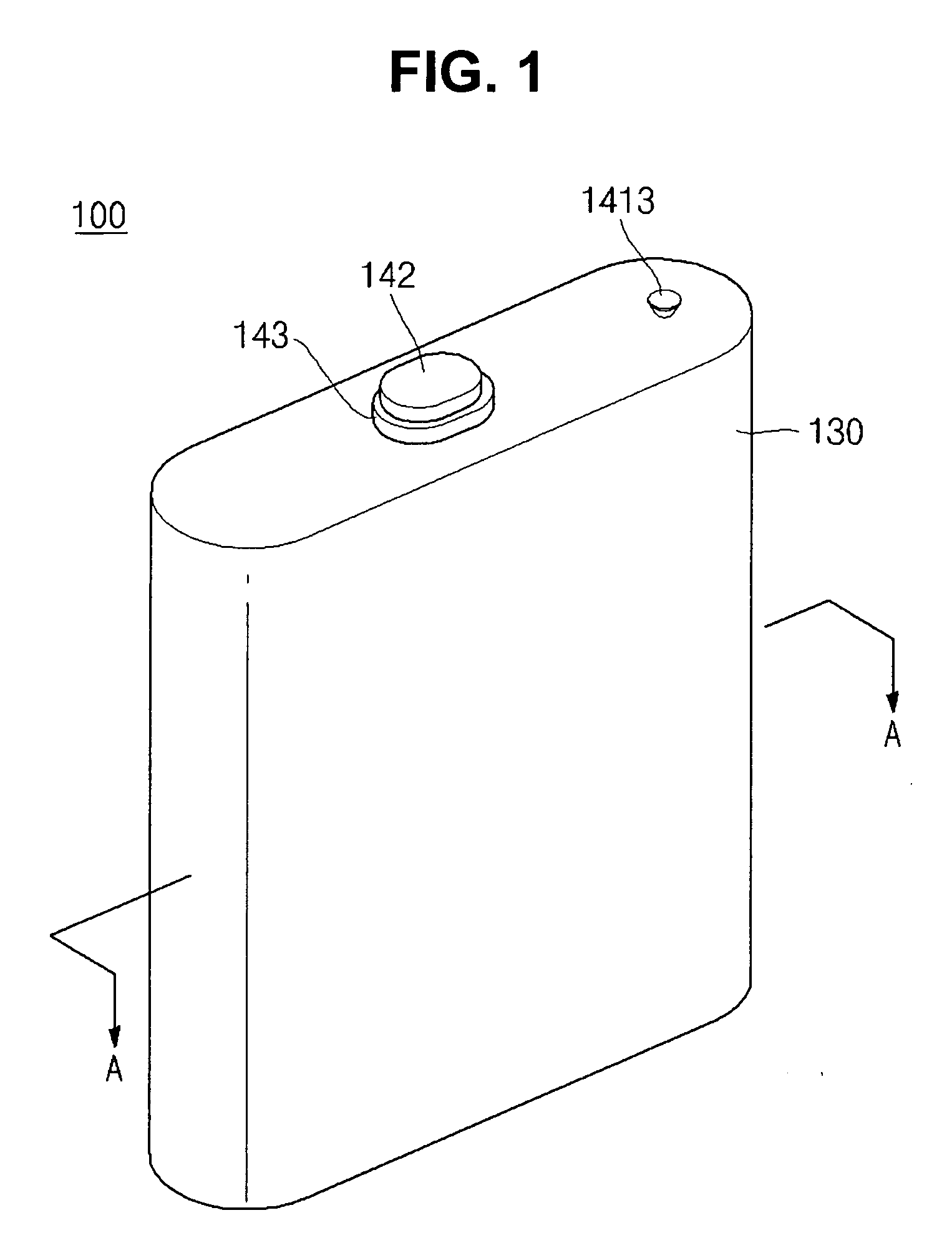

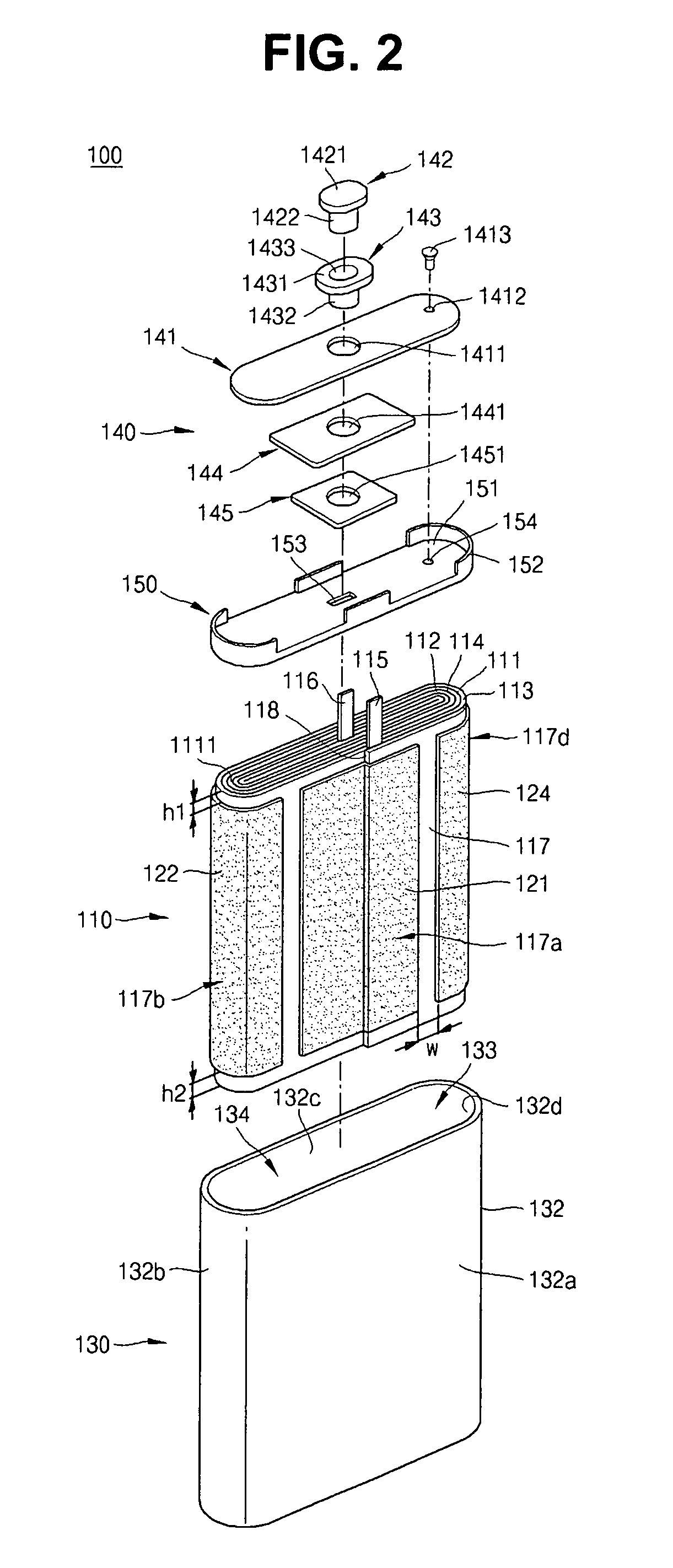

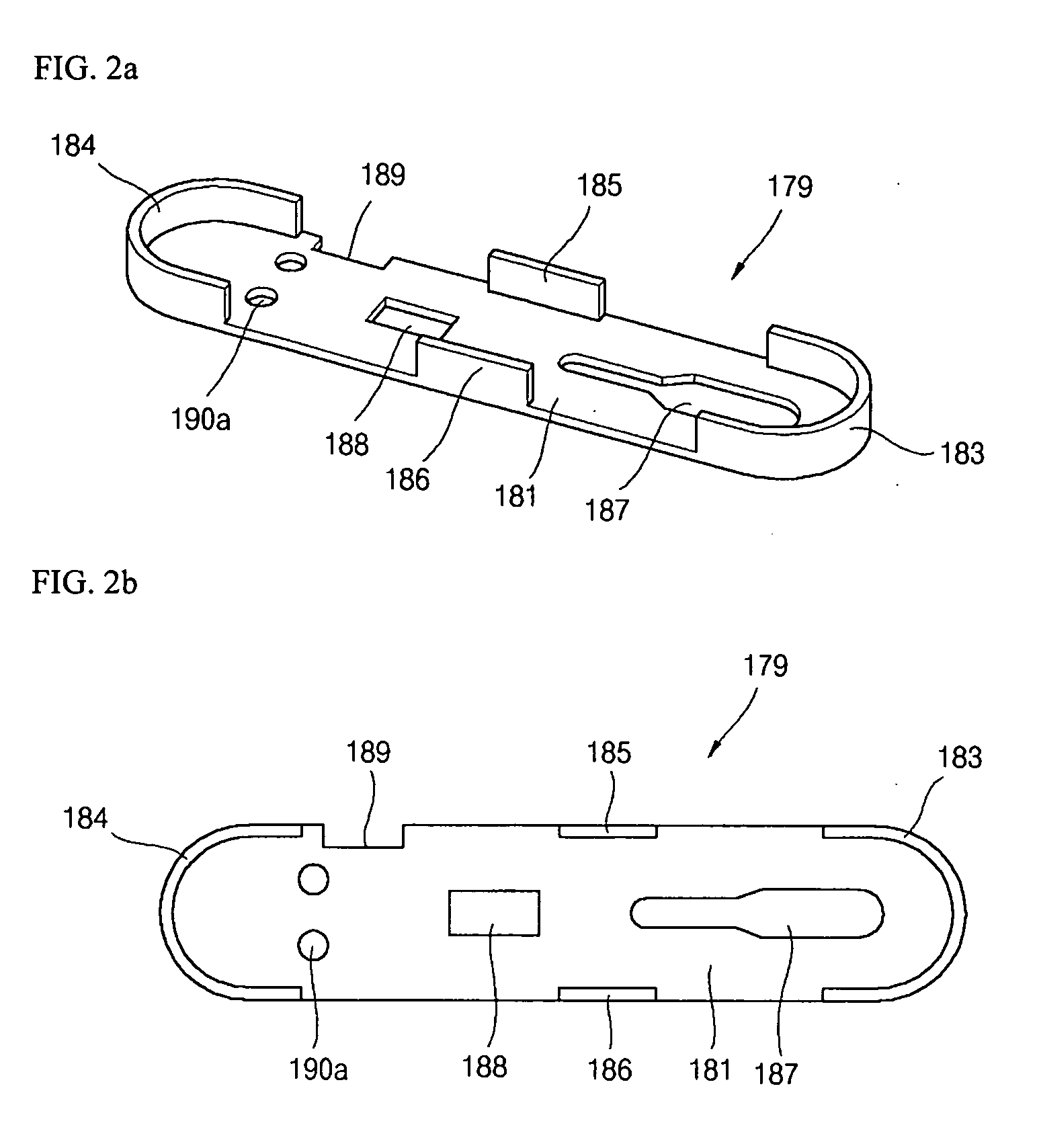

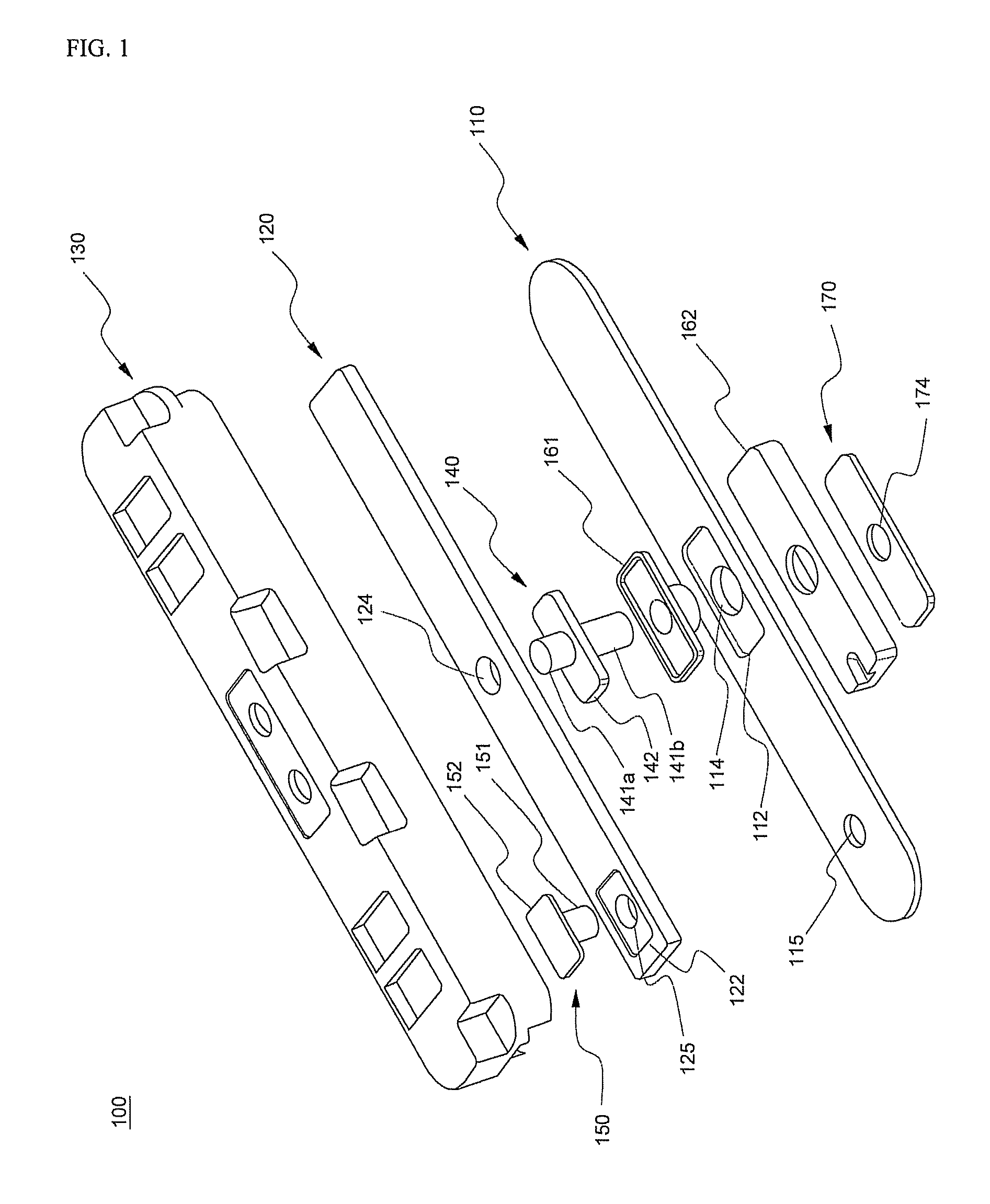

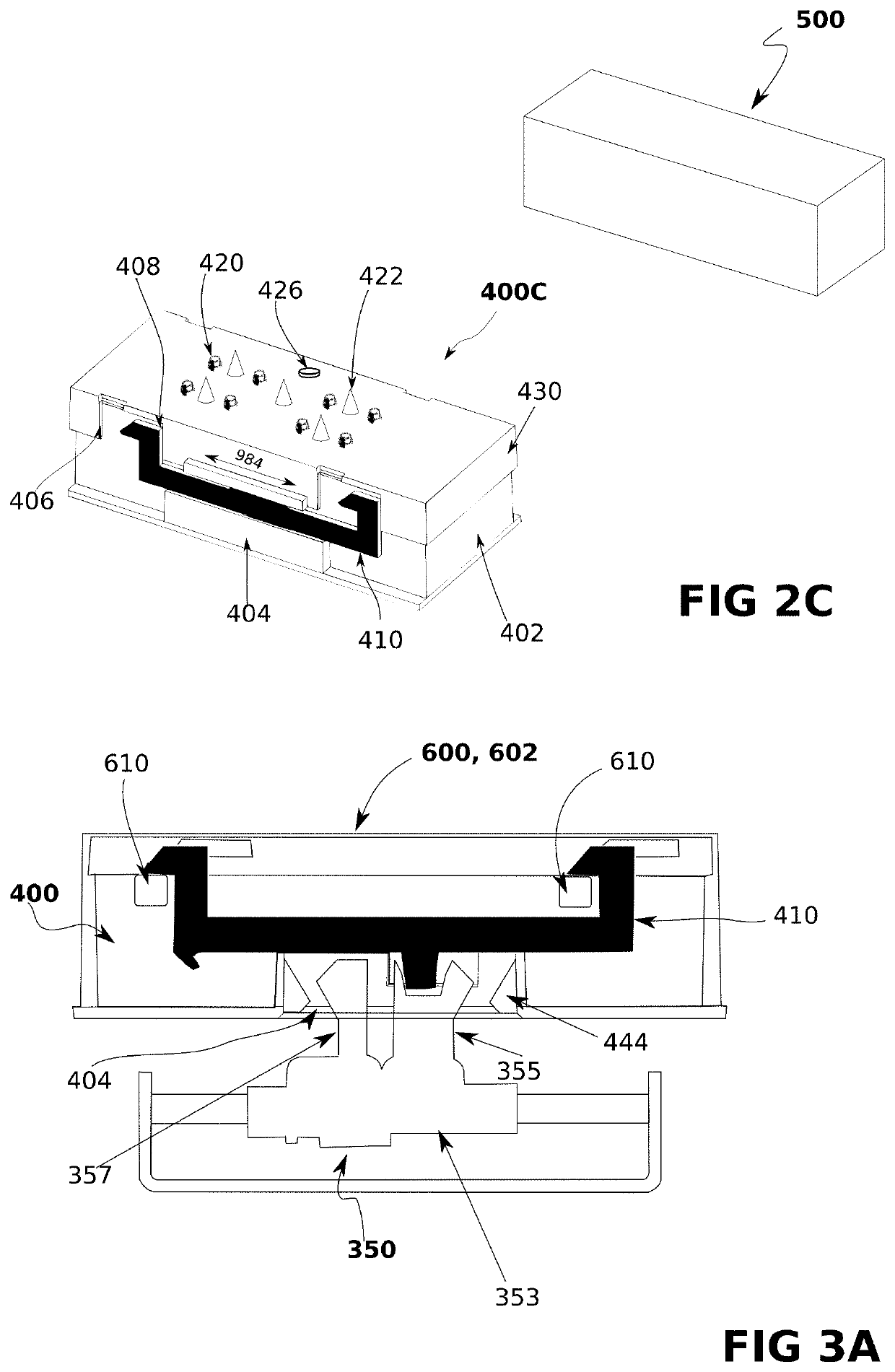

No-welding type battery pack using forced-inserting type rivet

ActiveUS20070160878A1Simplify the assembly processShorten production timeFinal product manufactureCell lids/coversElectricityCoupling

Disclosed herein is a no-welding type battery pack using one or more forced-inserting type rivets. A cap assembly includes a base plate mounted to an open upper end of a battery case, a protection circuit module (PCM) mounted on the base plate, and a top cap coupled to the upper end of the battery case while the top cap covers the PCM. The top cap is made of an insulative material. The electrical connection and the mechanical coupling between the PCM and the base plate are accomplished by one or more forced-inserting type rivets. The cap assembly is included the battery pack. The no-welding type battery pack using the one or more forced-inserting type rivets is manufactured without welding or soldering requiring an excessive amount of time and skilled technique during the electrical connection between the battery cell and the PCM. As a result, the assembly process of the battery pack is simplified, and therefore, the manufacturing time of the battery pack is reduced. Consequently, the manufacturing costs of the battery pack are decreased, the automation of the assembly process is accomplished, and the structural stability of the battery pack is improved.

Owner:LG ENERGY SOLUTION LTD

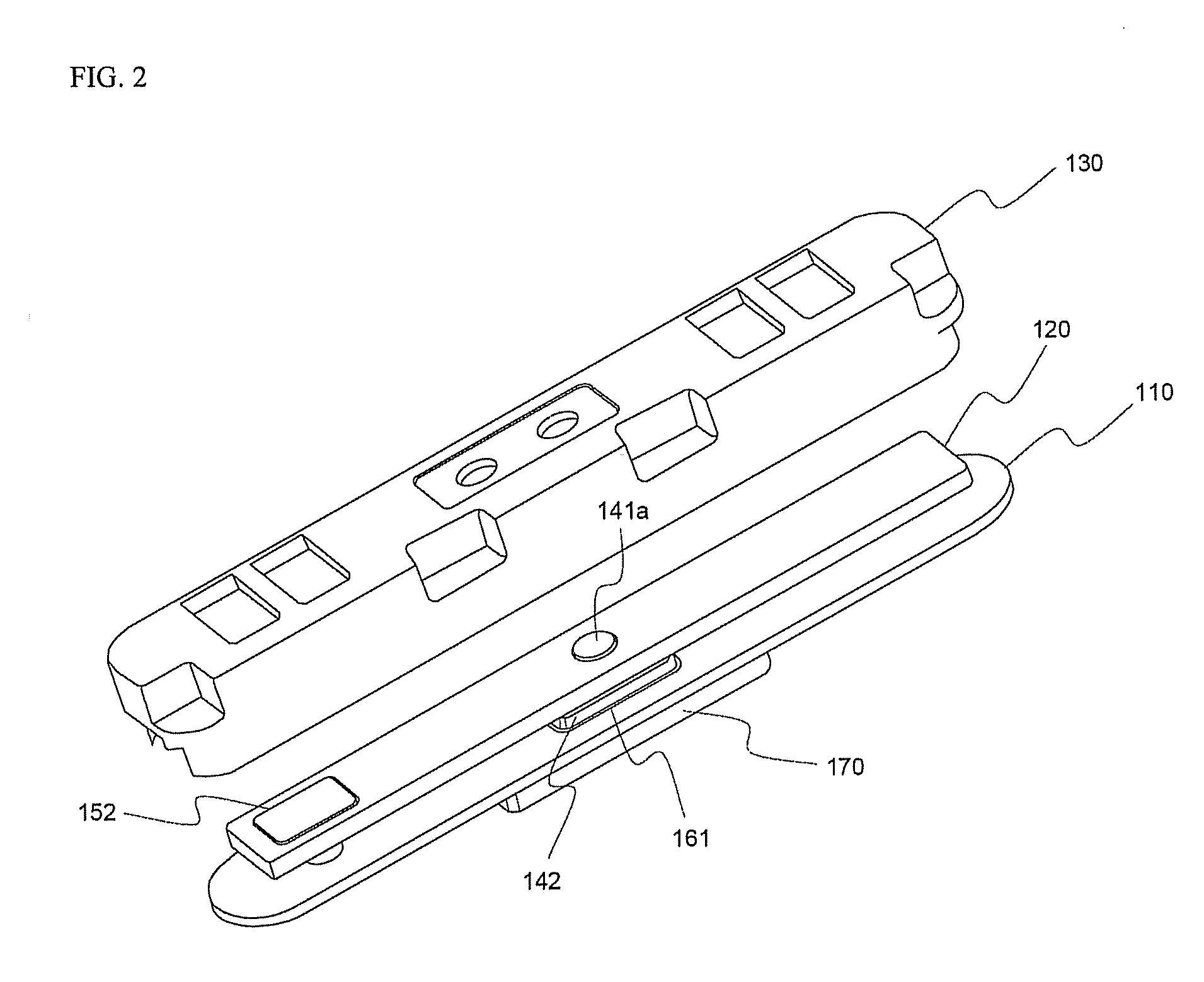

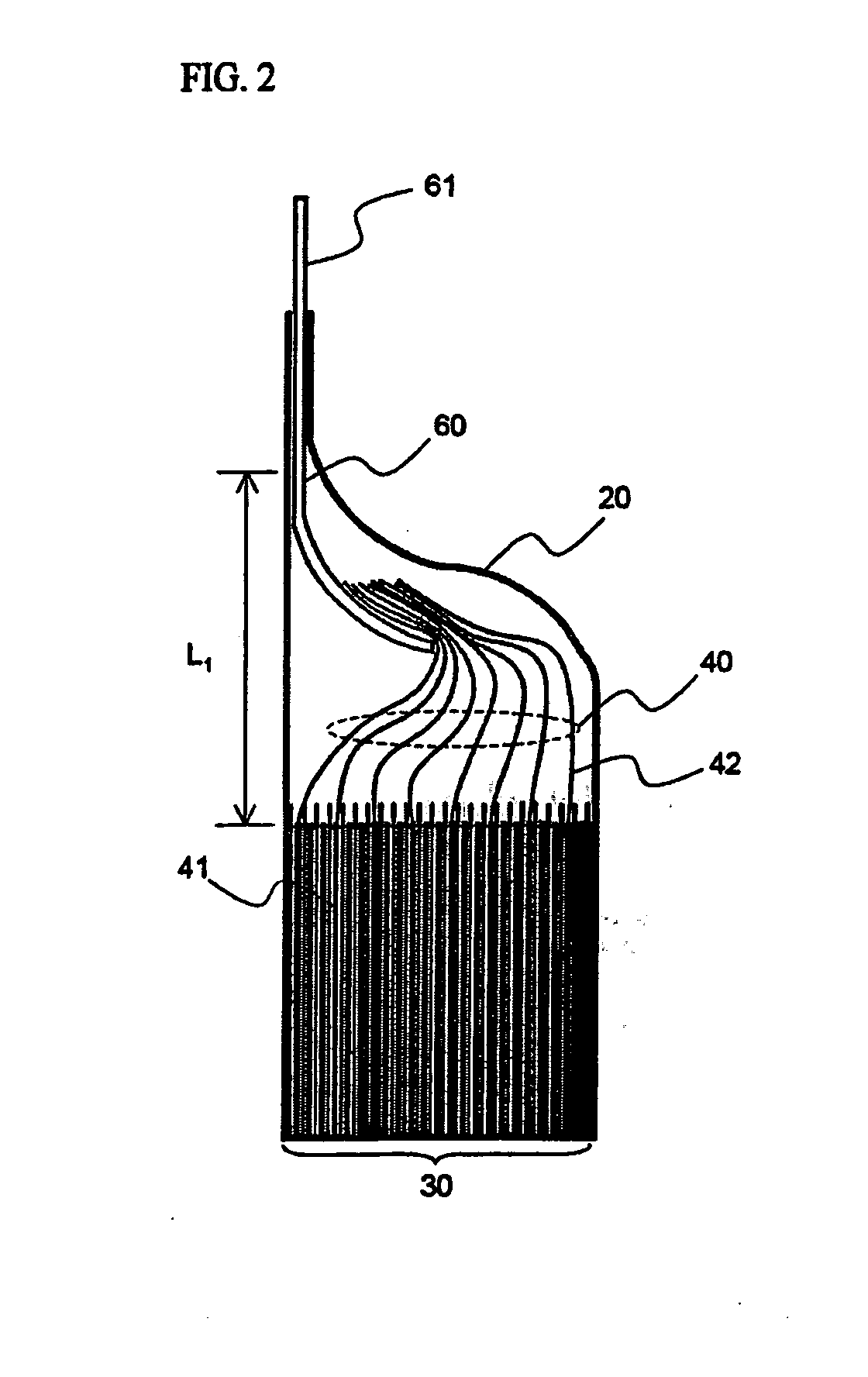

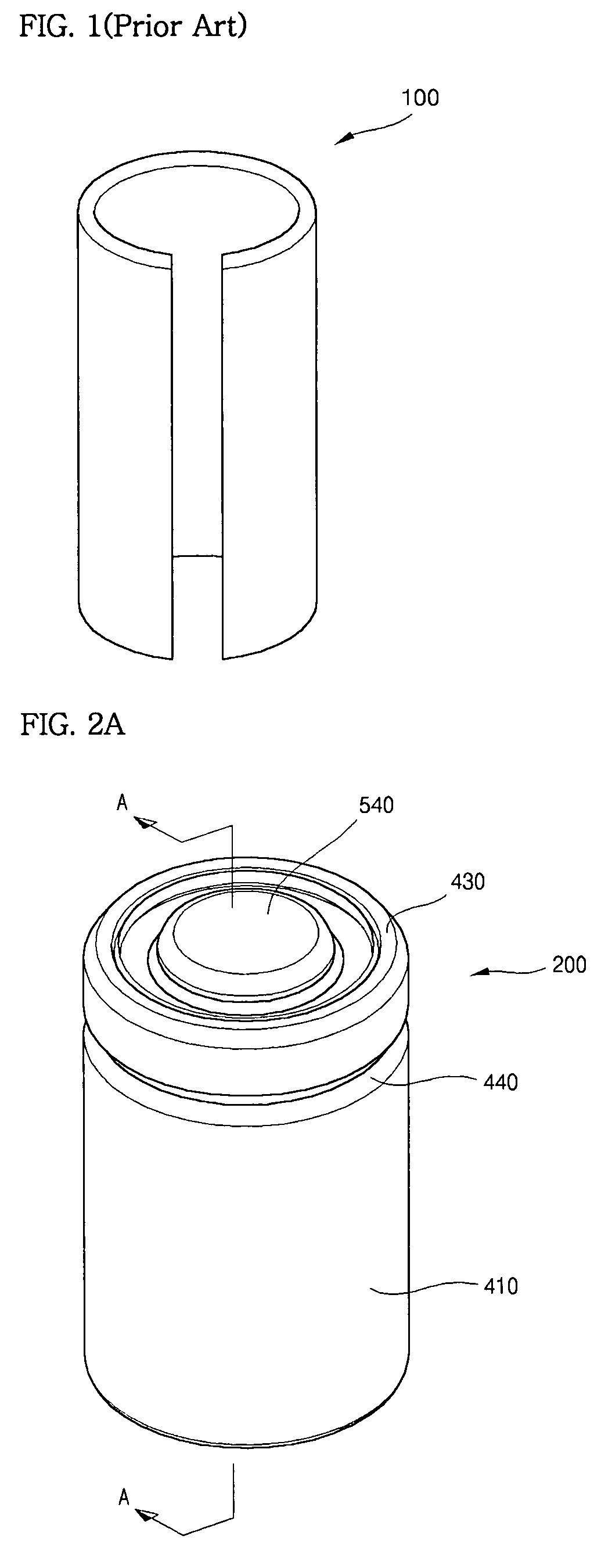

Secondary battery

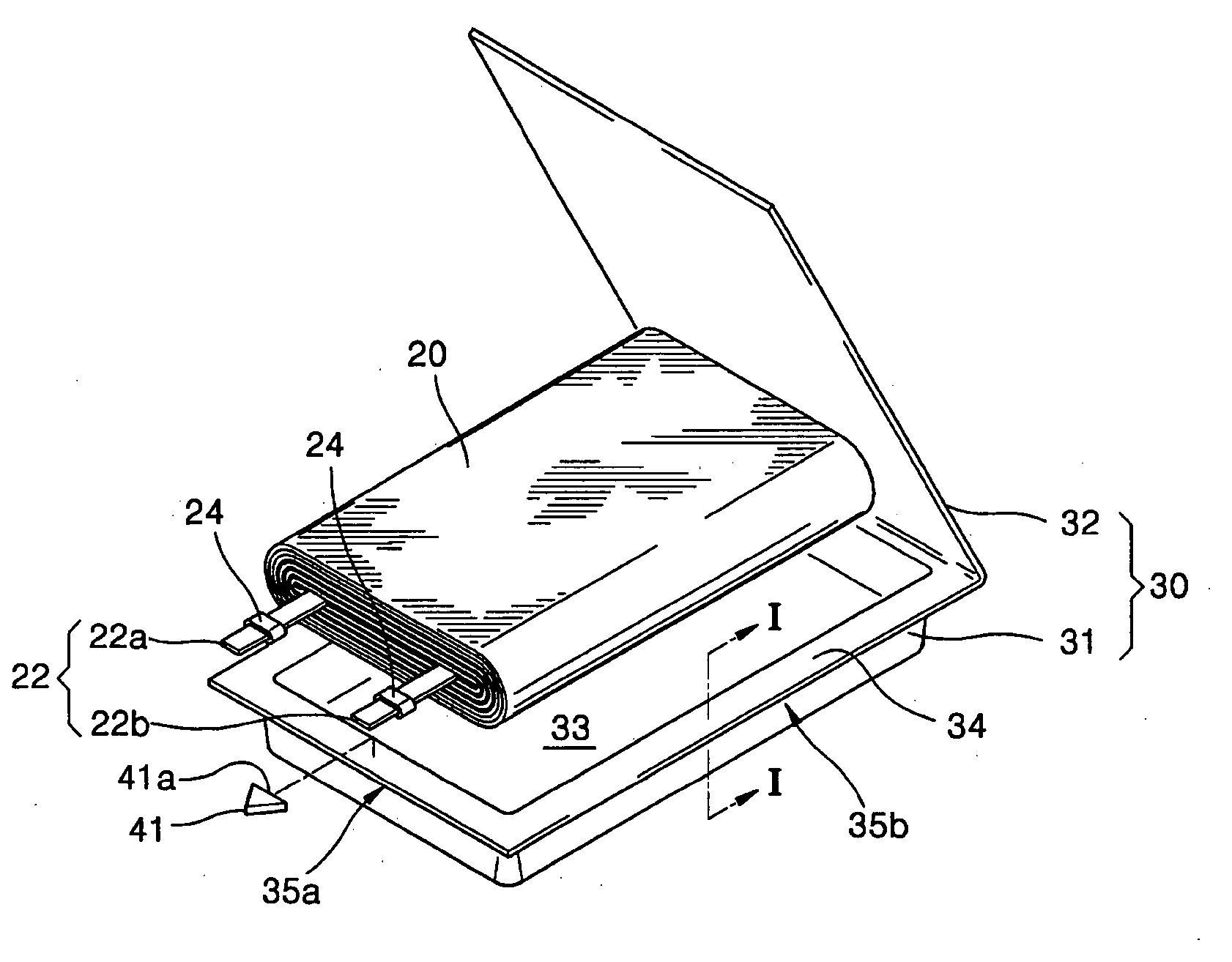

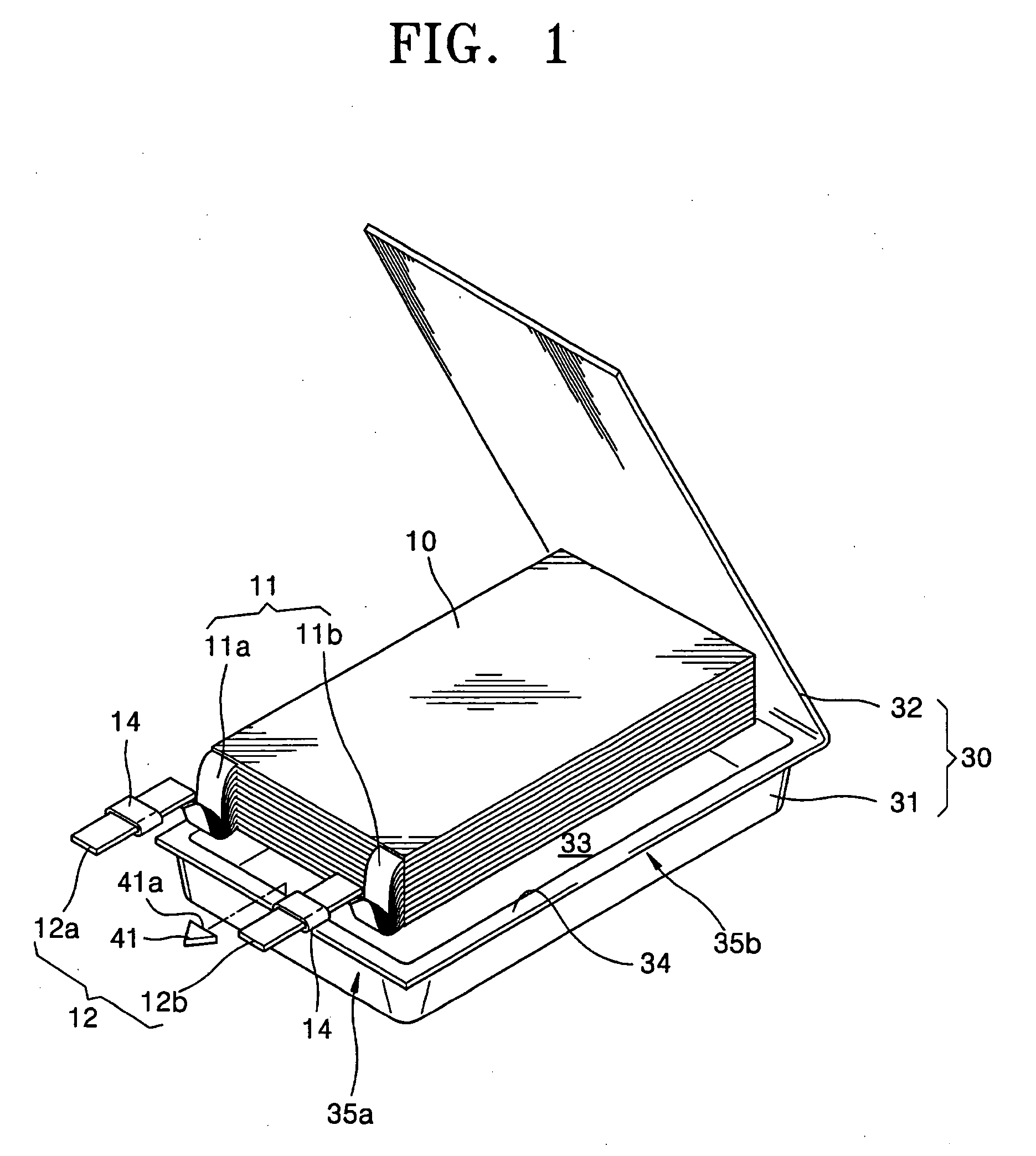

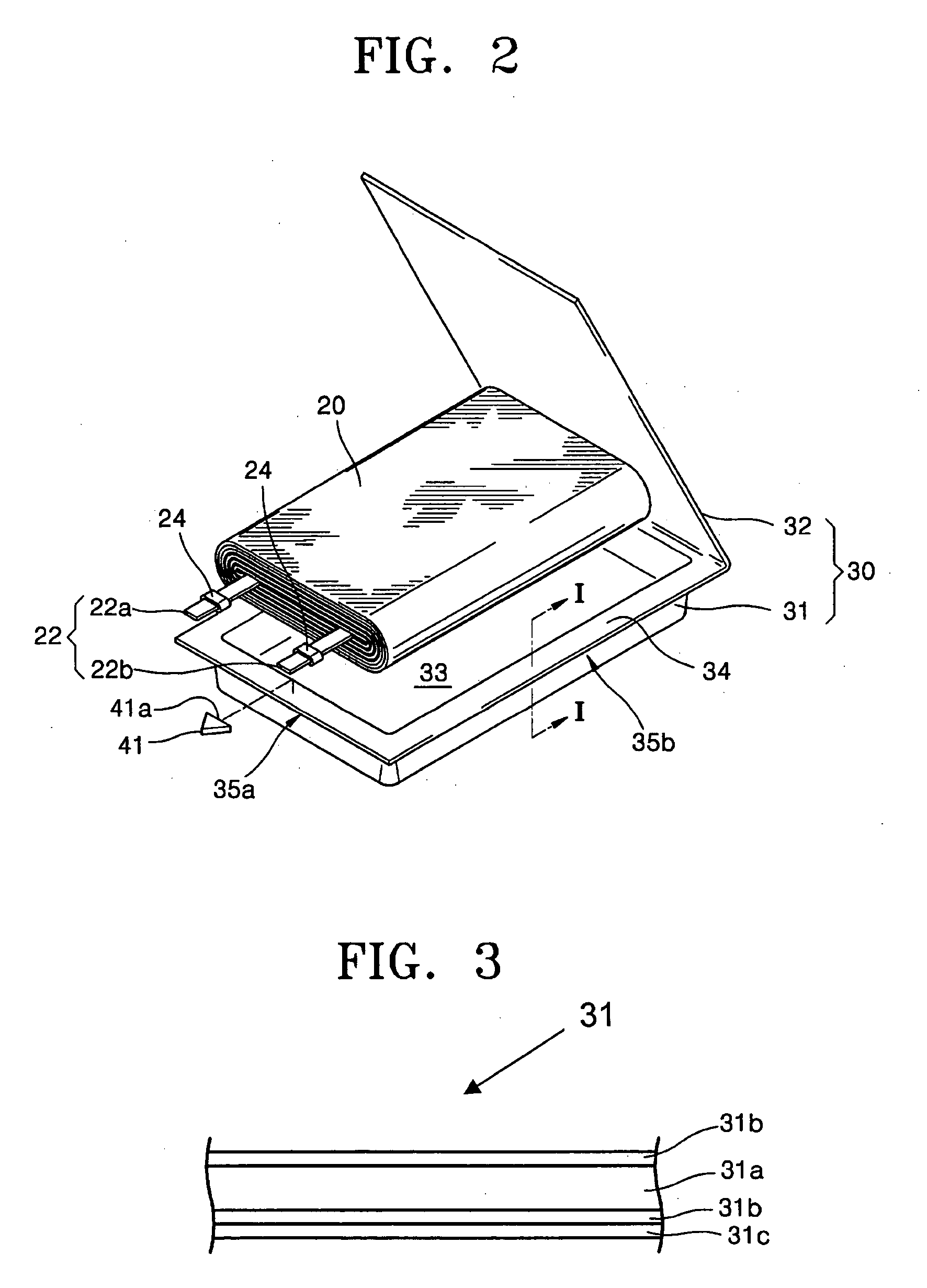

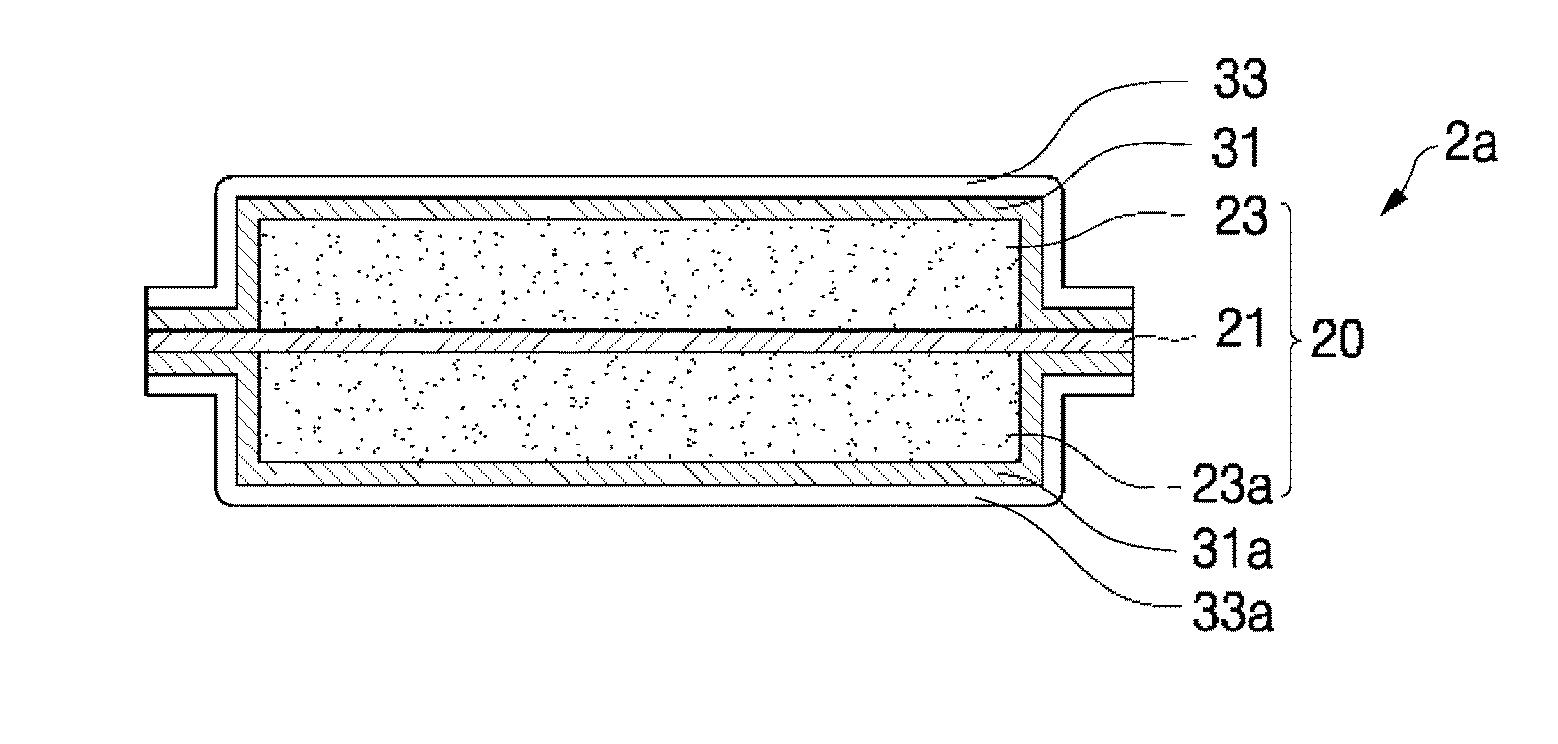

InactiveUS20100035132A1Shape can not be easilyIncrease heat radiationFinal product manufactureCell electrodesBiomedical engineeringElectrode

A secondary battery includes an electrode assembly in which a first electrode plate, a separator, and a second electrode assembly are sequentially stacked forming a stack and is wound about one edge of the stack, and a plurality of finishing tapes attached to the outer surface of the electrode assembly and spaced apart from each other along the winding direction of the electrode assembly.

Owner:SAMSUNG SDI CO LTD

Battery module with cooling structure of high efficiency

ActiveUS20140099527A1Improve cool efficiencyReduce battery sizeLarge-sized flat cells/batteriesFinal product manufactureElectrical batteryStructural stability

Owner:LG ENERGY SOLUTION LTD

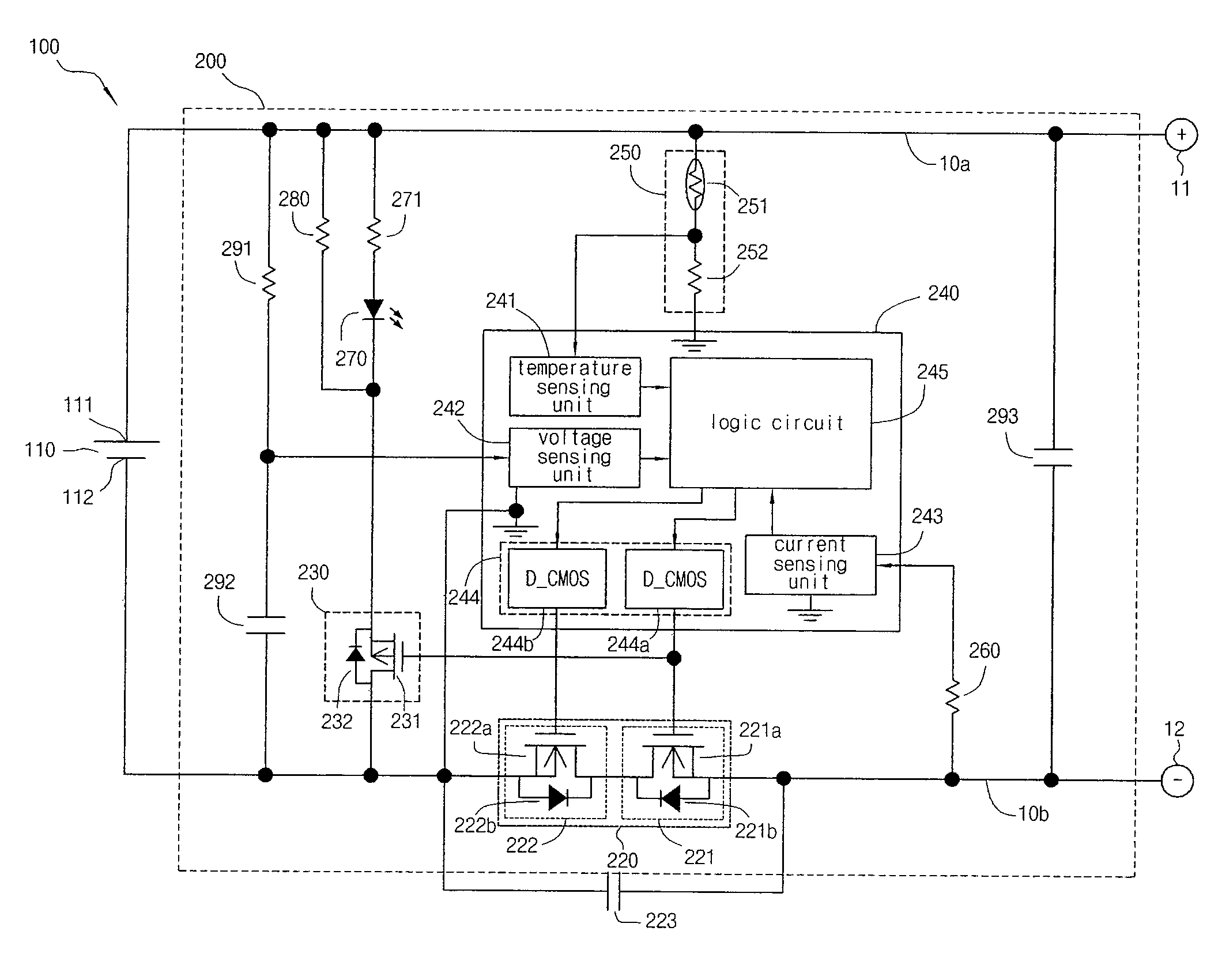

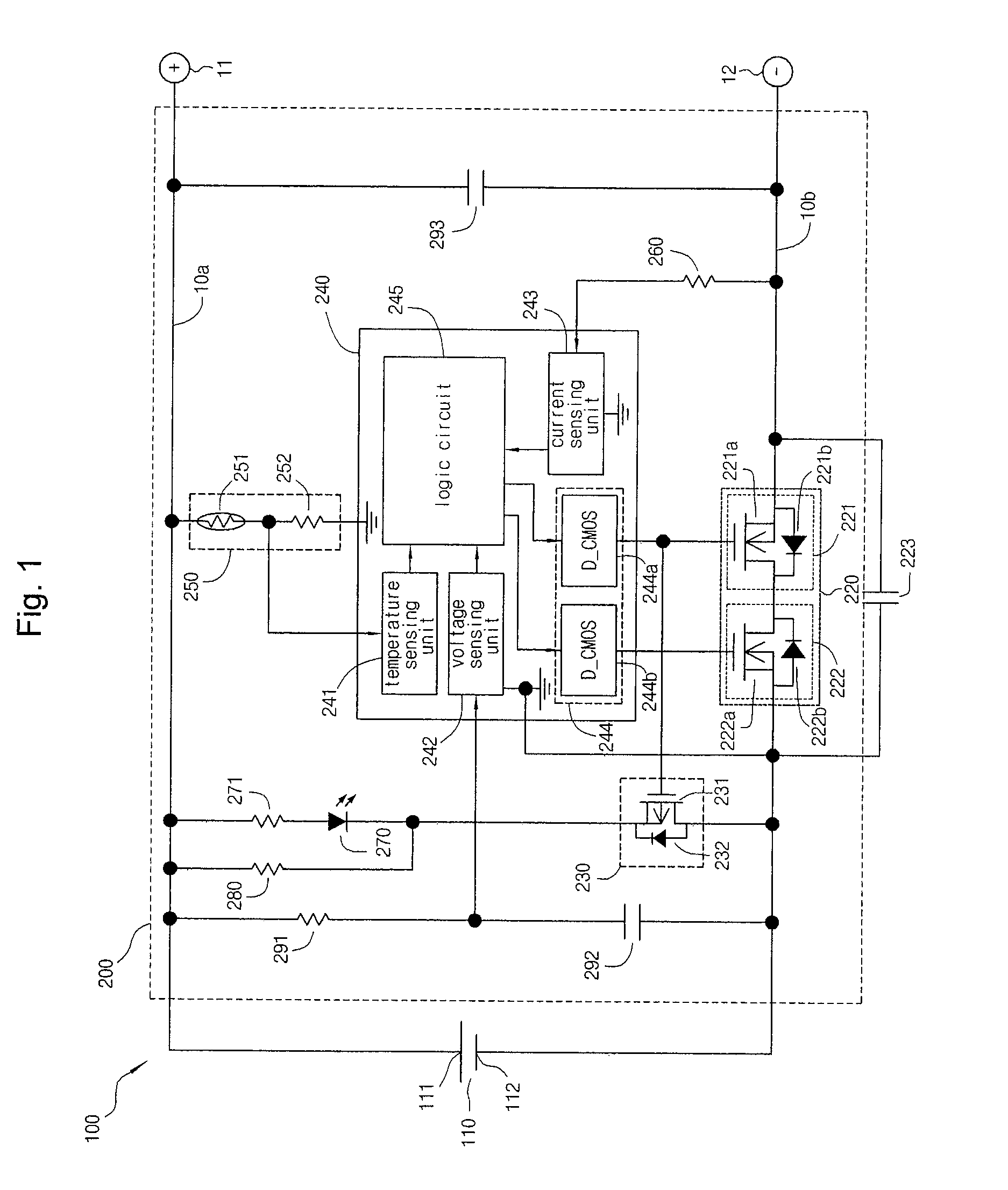

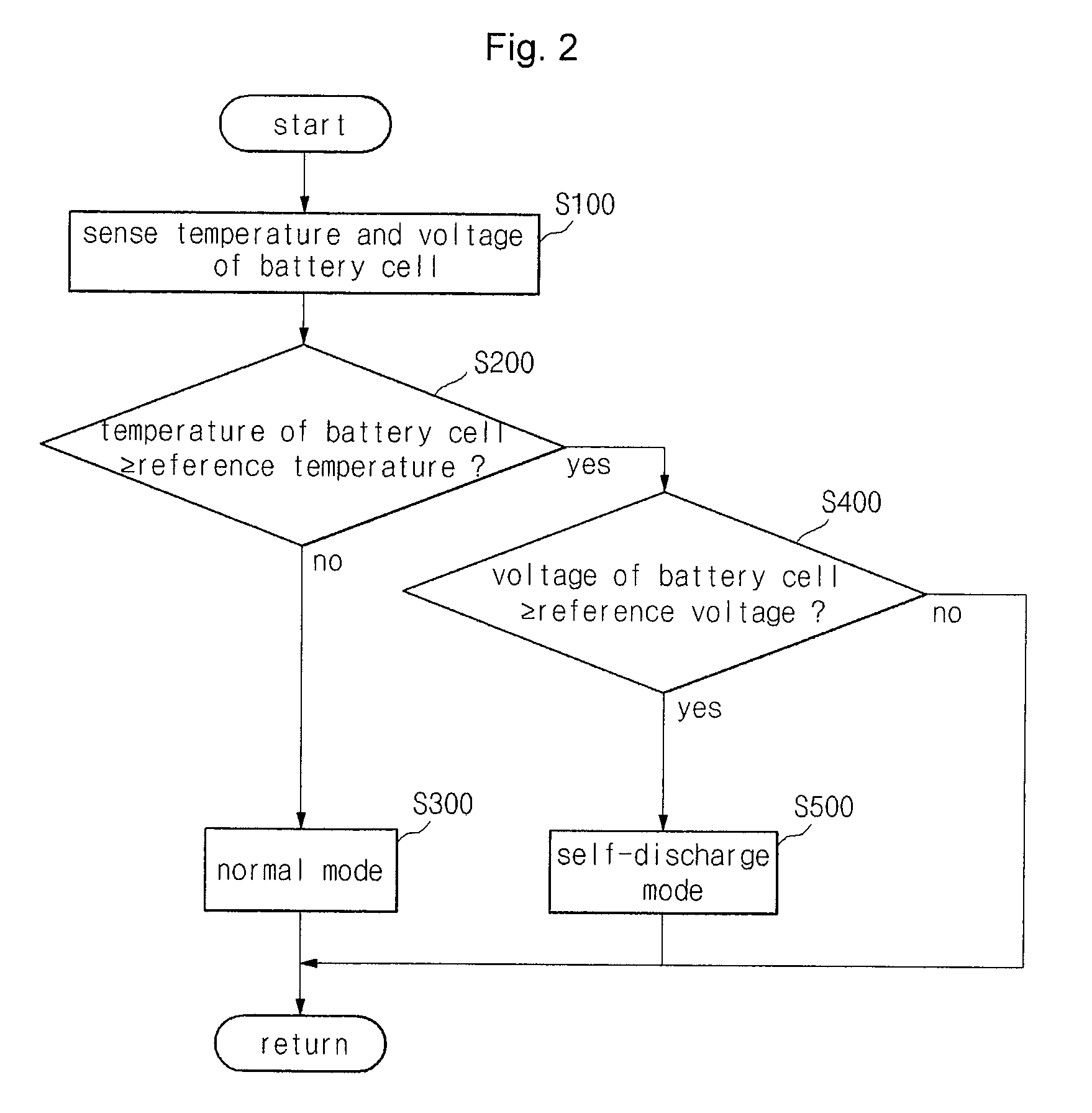

Protection circuit for battery pack and battery pack including the same

ActiveUS20100194346A1Inhibit swellingImprove battery stabilityElectric powerBattery overcharge protectionElectrical and Electronics engineeringSelf-discharge

A protection circuit for a battery pack including a rechargeable battery cell having a positive electrode and a negative electrode is disclosed. The protection circuit includes a self-discharge switching device electrically connected to the positive electrode and the negative electrode of the battery cell, and a control unit electrically connected to the battery cell and the self-discharge switching device to turn-on or turn-off the self-discharge switching device according to a temperature of the battery cell.

Owner:SAMSUNG SDI CO LTD

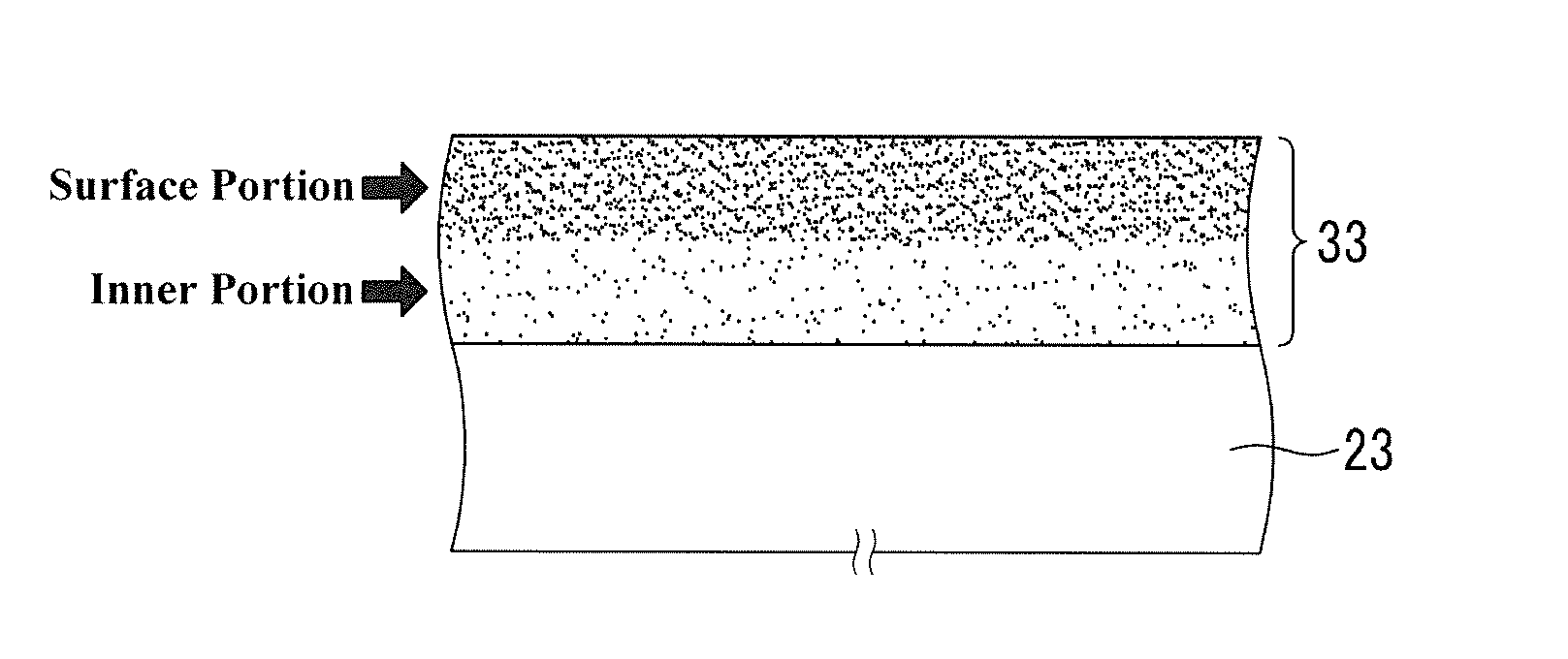

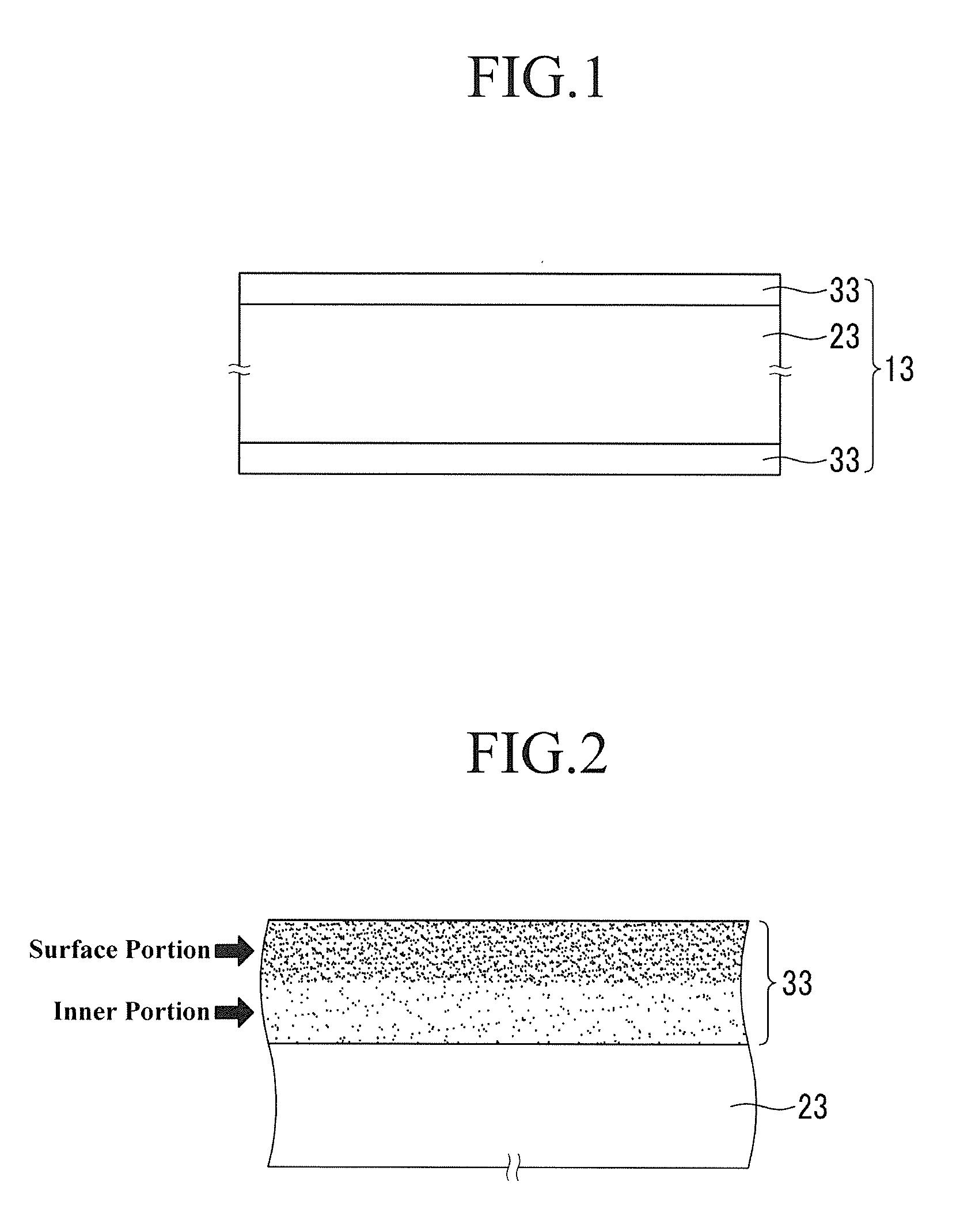

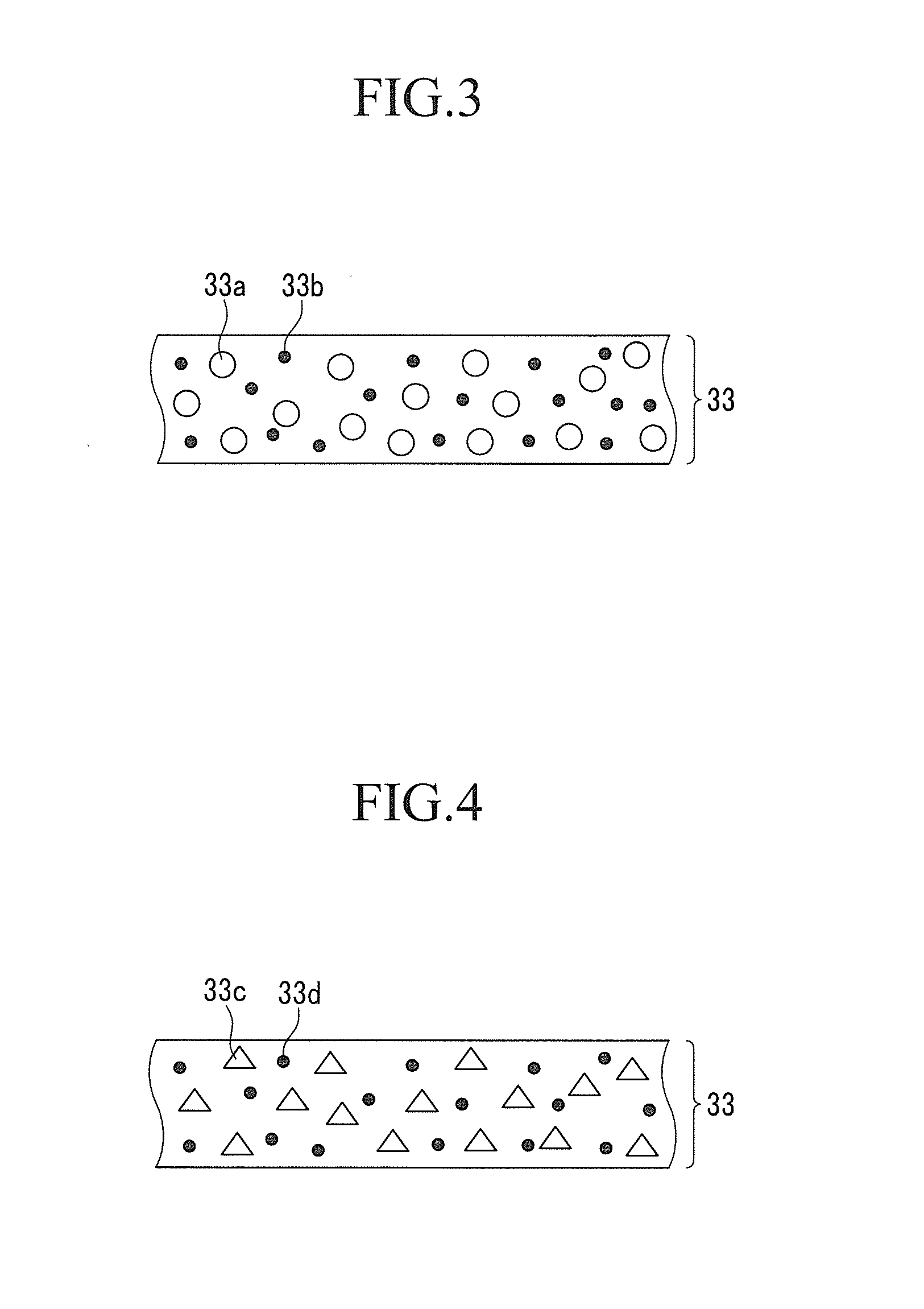

Separator and method of manufacturing the same and rechargeable lithium battery including the same

ActiveUS20130302661A1Good adhesionImprove battery stabilityFinal product manufactureLi-accumulatorsPolymerPorous substrate

A separator for a lithium battery includes a porous substrate and a coating layer on at least one side of the porous substrate, the coating layer having a first side adjacent to the porous substrate, and a second side opposite the first side. The coating layer may include an inorganic compound and a polymer binder, and an amount of the polymer binder at the second side is greater than an amount of the polymer binder at the first side. A rechargeable lithium battery includes the separator.

Owner:SAMSUNG SDI CO LTD

Electrode active material having core-shell structure

ActiveUS20110129729A1Maximize capacityInhibition of capacity fadingActive material electrodesNon-conductive material with dispersed conductive materialOligomerElectric capacity

Disclosed is an electrode active material having a core-shell structure, which includes: (a) a core capable of intercalating and deintercalating lithium ions; and (b) a shell including a polymer or an oligomer having a glass transition temperature of 25° C. or less when impregnated with an electrolyte, wherein a surface of the core is coated with the shell. Also, an electrode manufactured by using the electrode active material and a secondary battery including the electrode are disclosed. The shell (b) suppresses the formation of an SEI layer during initial charge of a battery, and prevents initial capacity reduction. Accordingly, it is possible to achieve a high capacity battery. The electrode active material having a core-shell structure, specially a metal (loid) based electrode active material having a core-shell structure can have a slightly higher electric capacity, compared to a conventional electrode active material, specially a conventional metal (loid) based electrode active material, and can minimize gas generation during charge / discharge.

Owner:LG ENERGY SOLUTION LTD

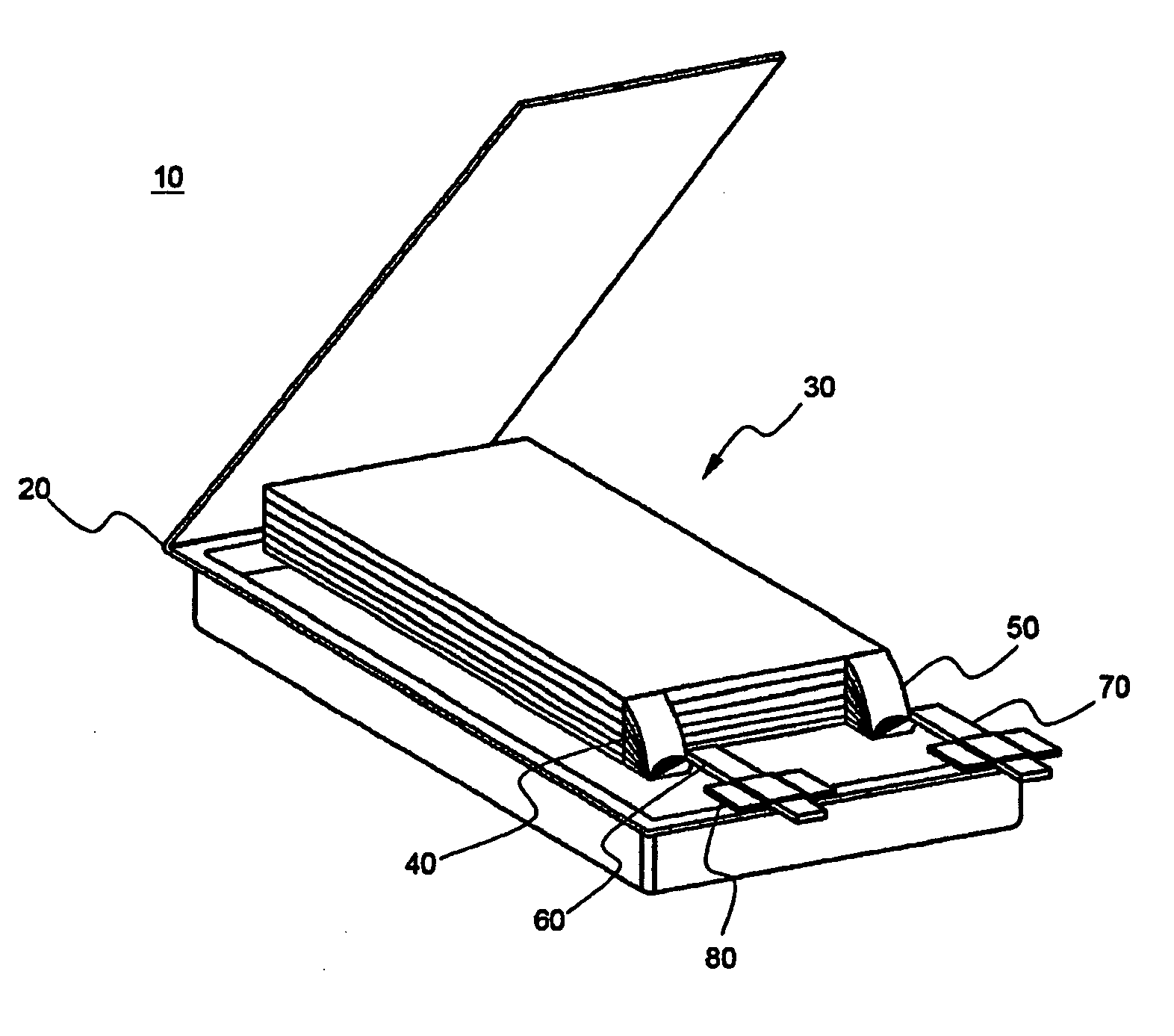

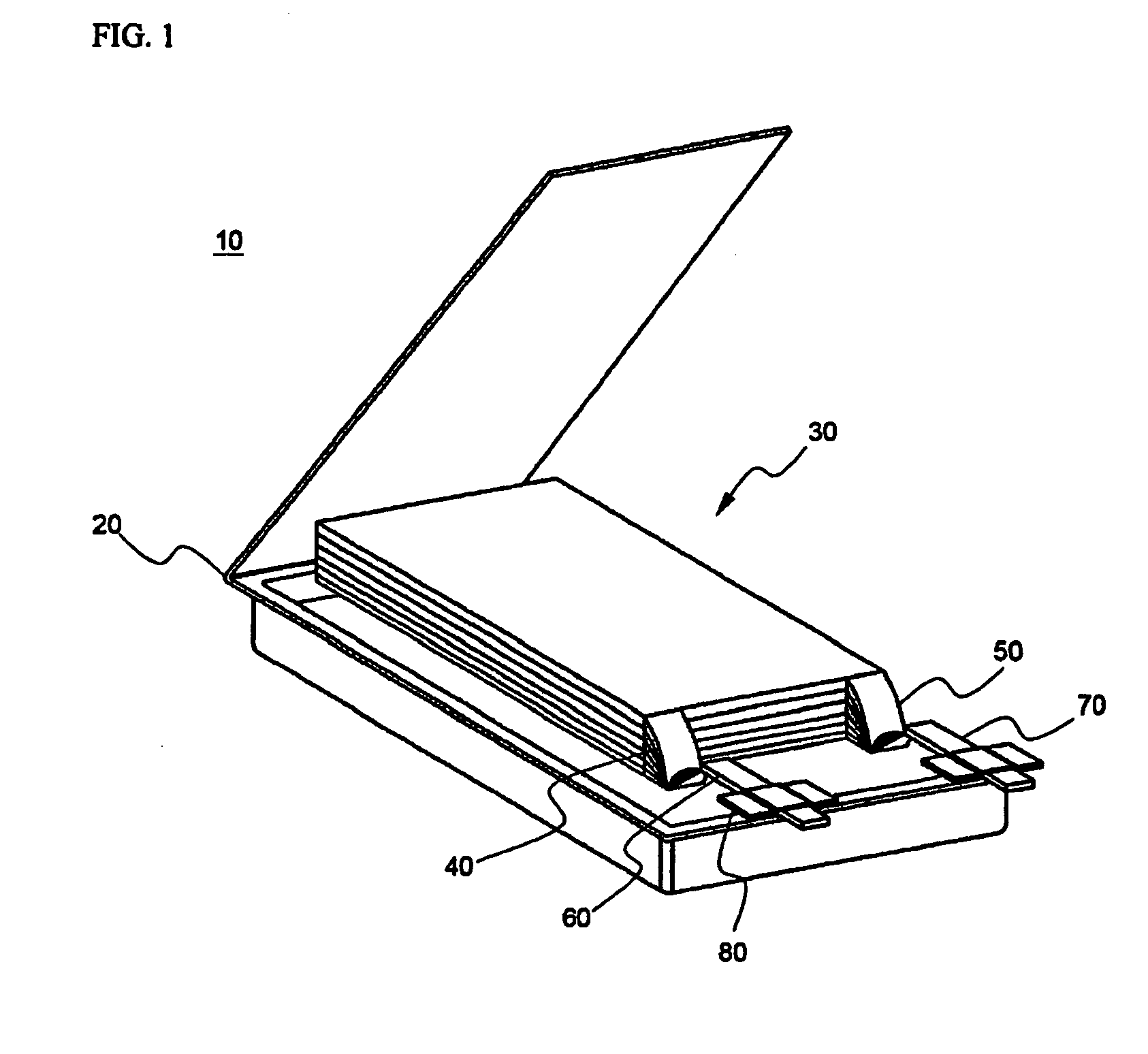

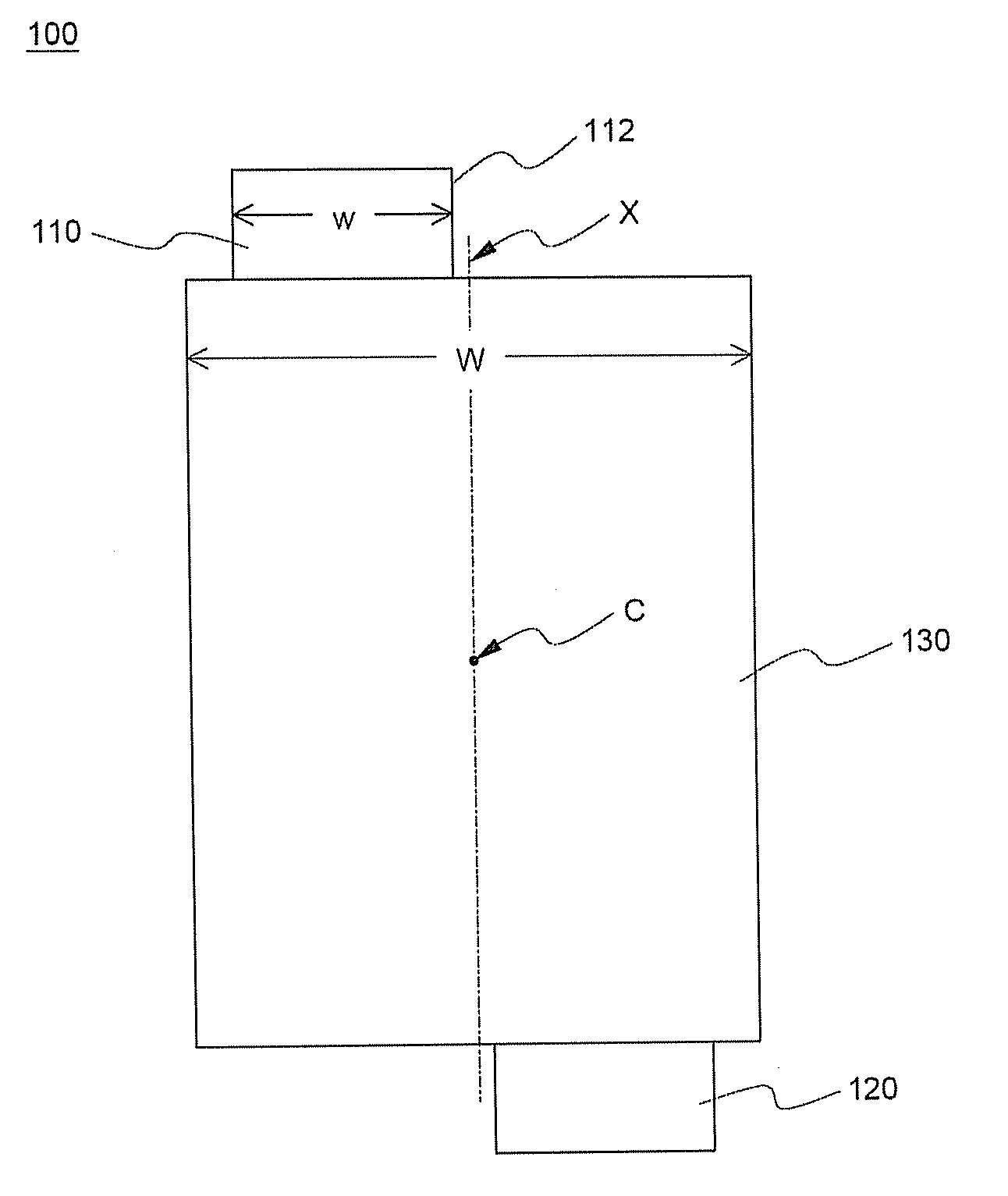

Linthium secondary battery improved safety and capacity

ActiveUS20100055558A1Improve safety of batteryLarge capacityFinal product manufactureSmall-sized cells cases/jacketsElectrical and Electronics engineeringContact region

Disclosed herein is a secondary battery having an electrode assembly constructed in a structure in which a plurality of electrodes are stacked, while separators are disposed respectively between the electrodes, and electrode taps of the electrodes are connected with each other, the electrode assembly being mounted in a battery case, wherein regions where the electrode taps are coupled to electrode leads (electrode tap-electrode lead coupling regions) are located at an upper-end contact region of the battery case, and the contact region is bent in the thickness direction of the battery, whereby the electrode assembly is separated from an inner space of the battery case.

Owner:LG ENERGY SOLUTION LTD

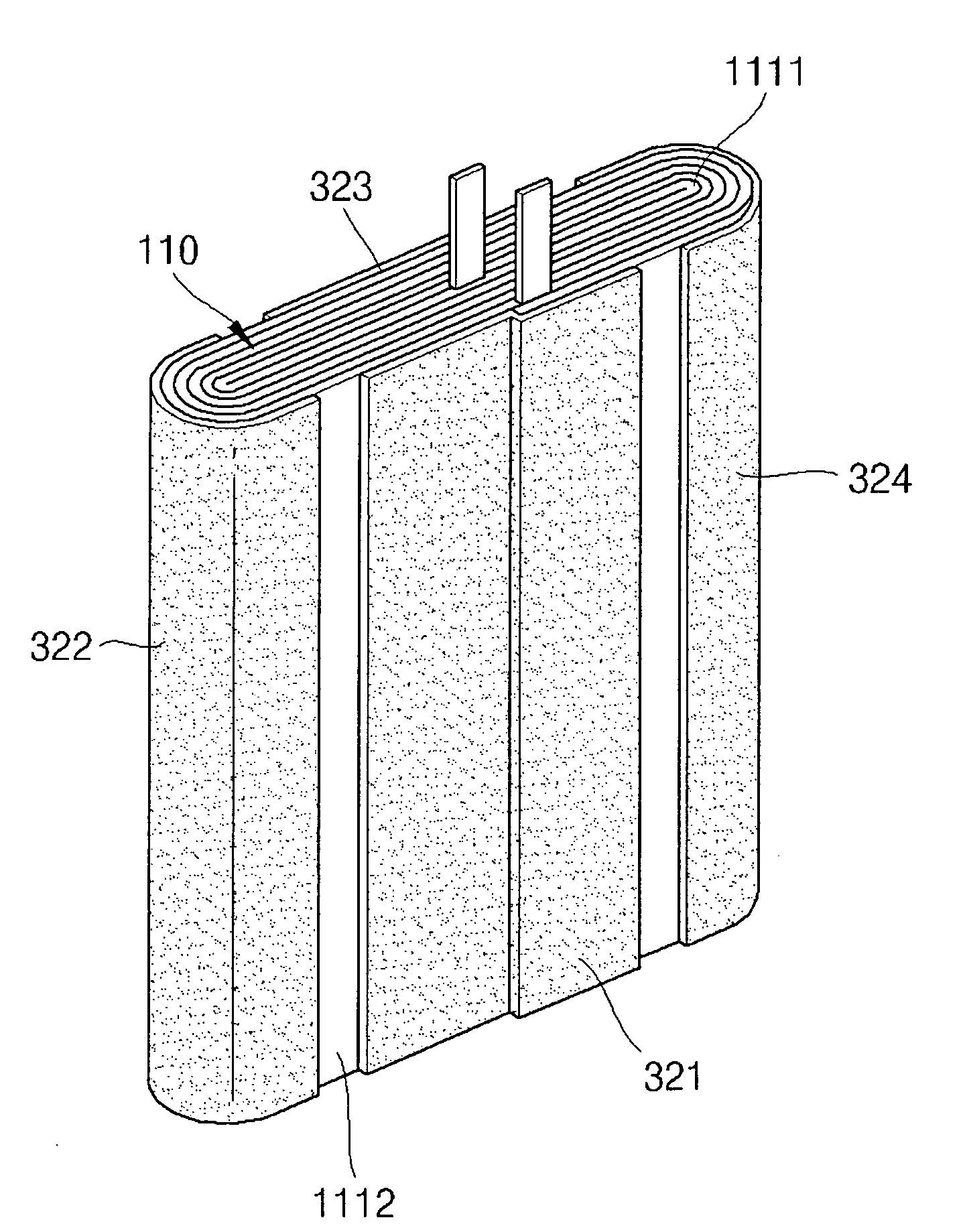

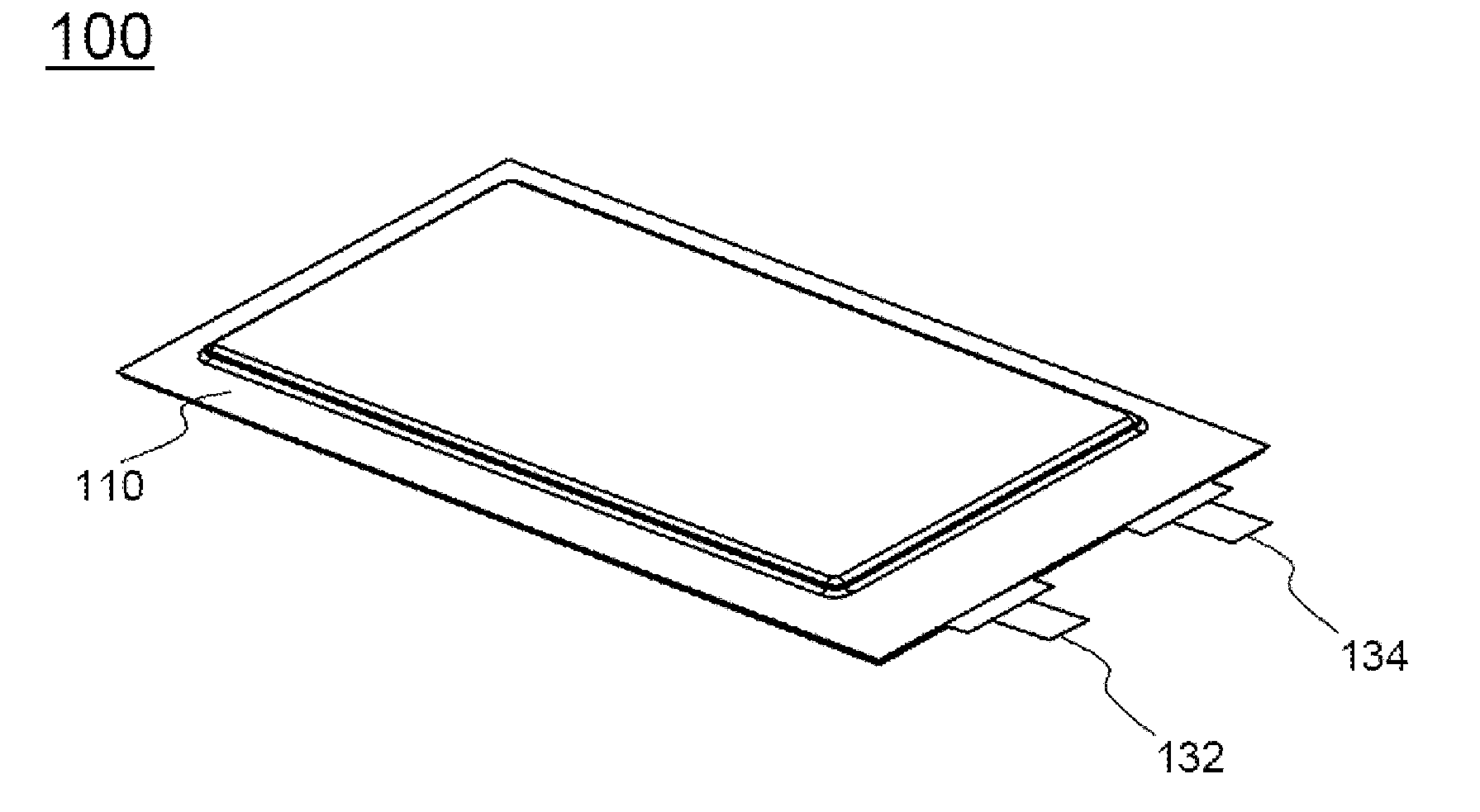

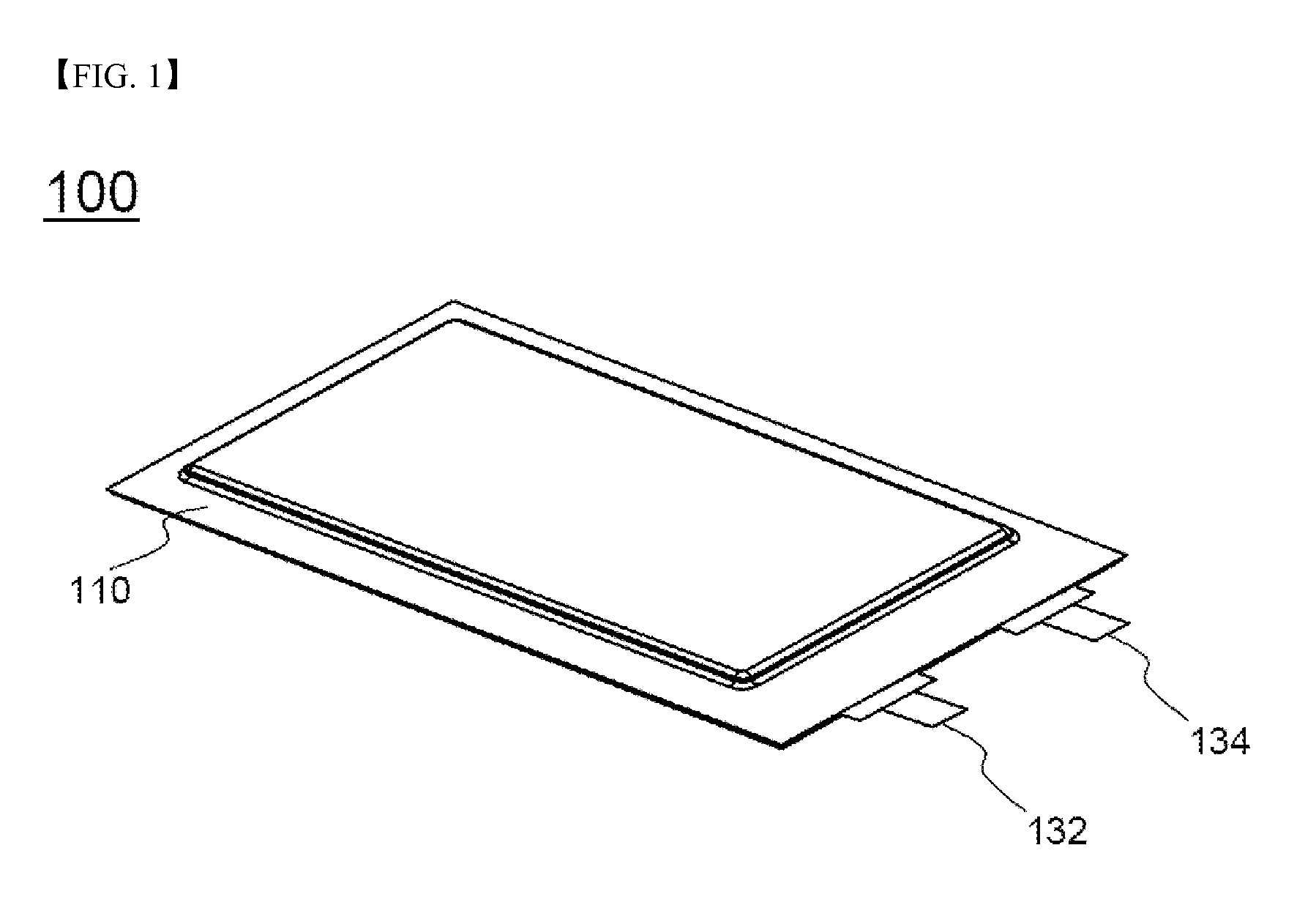

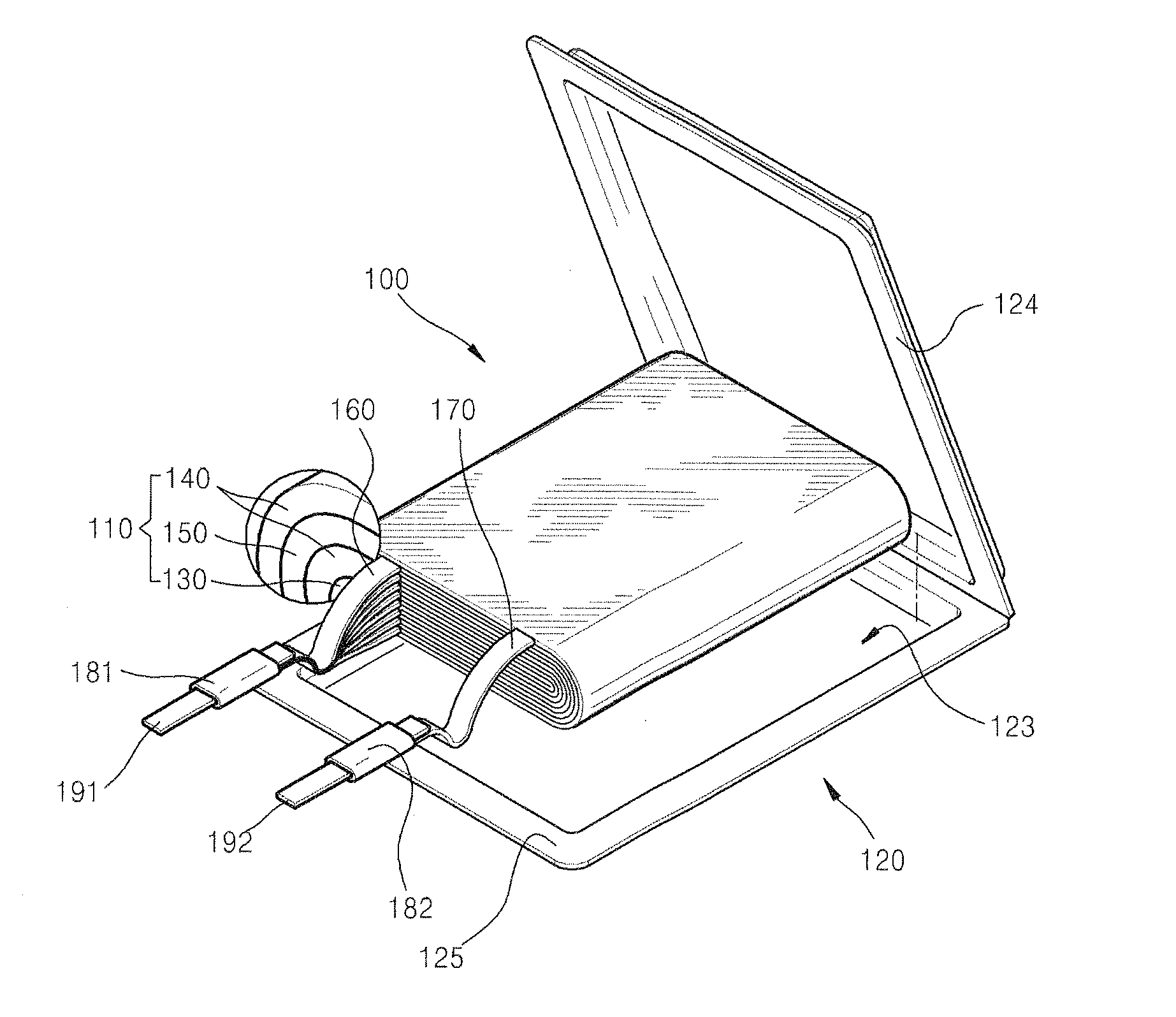

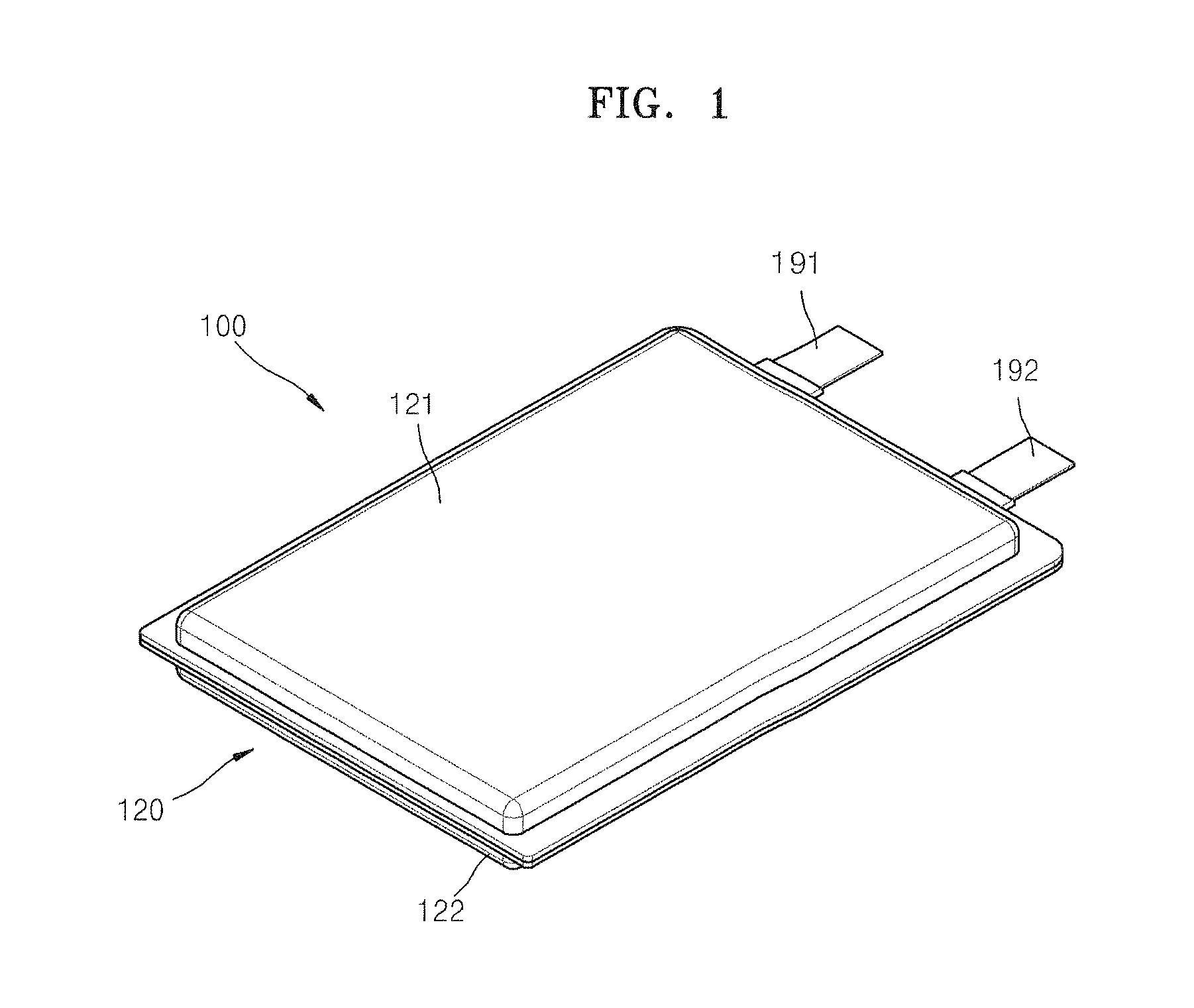

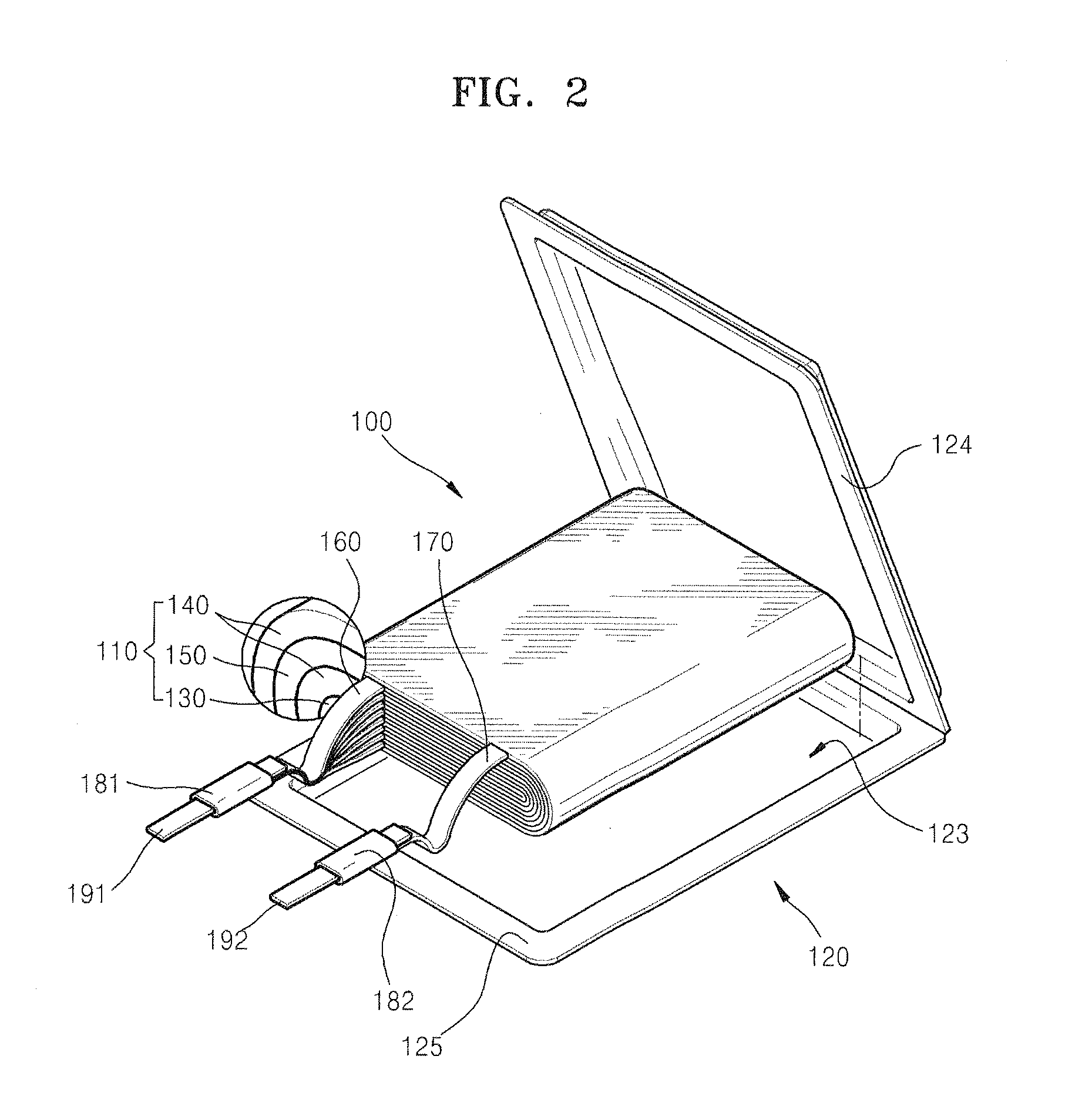

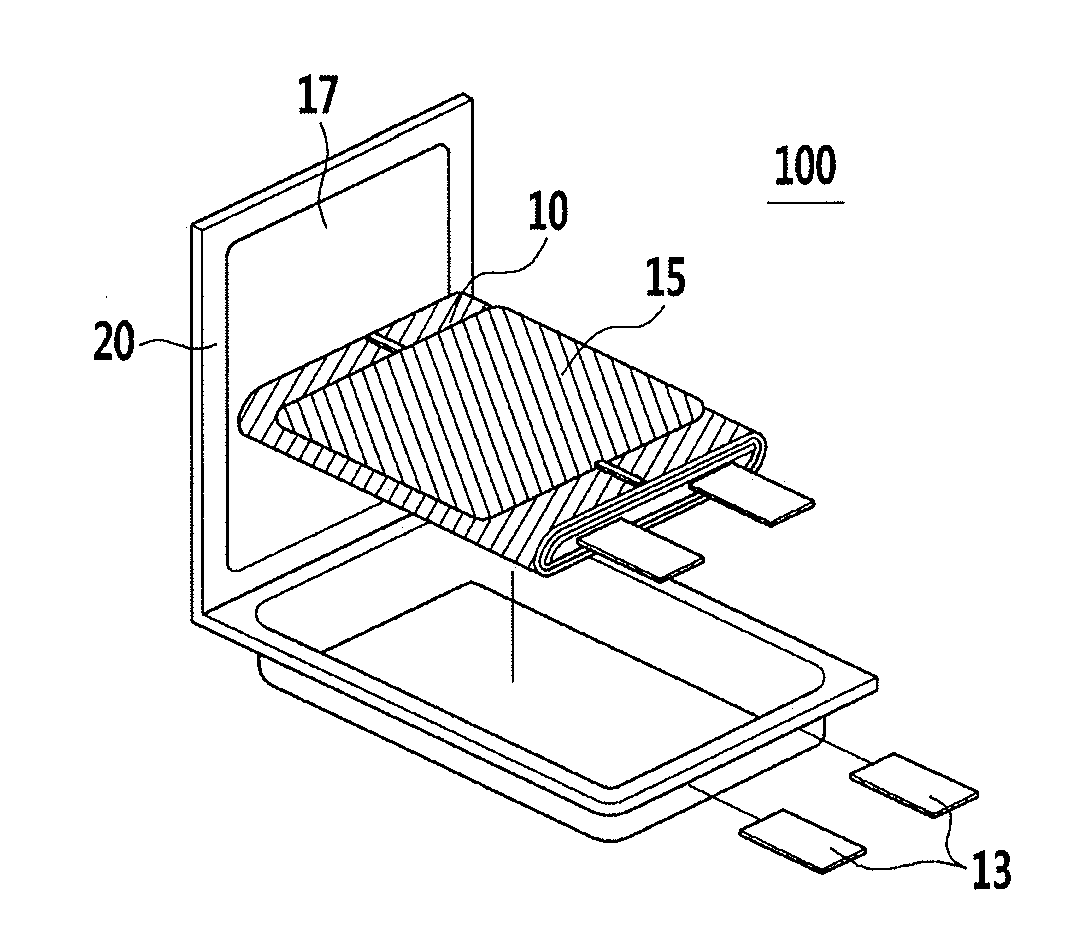

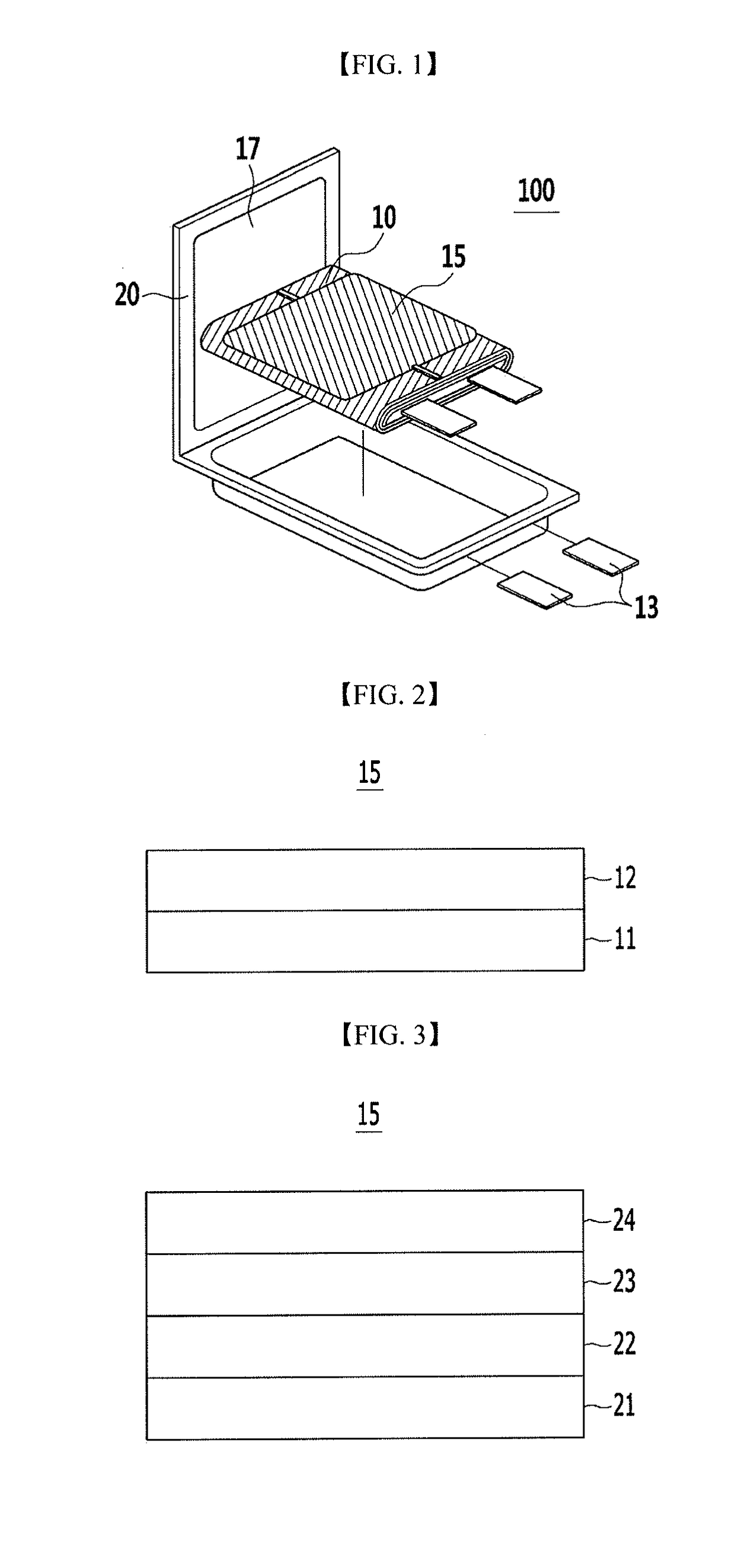

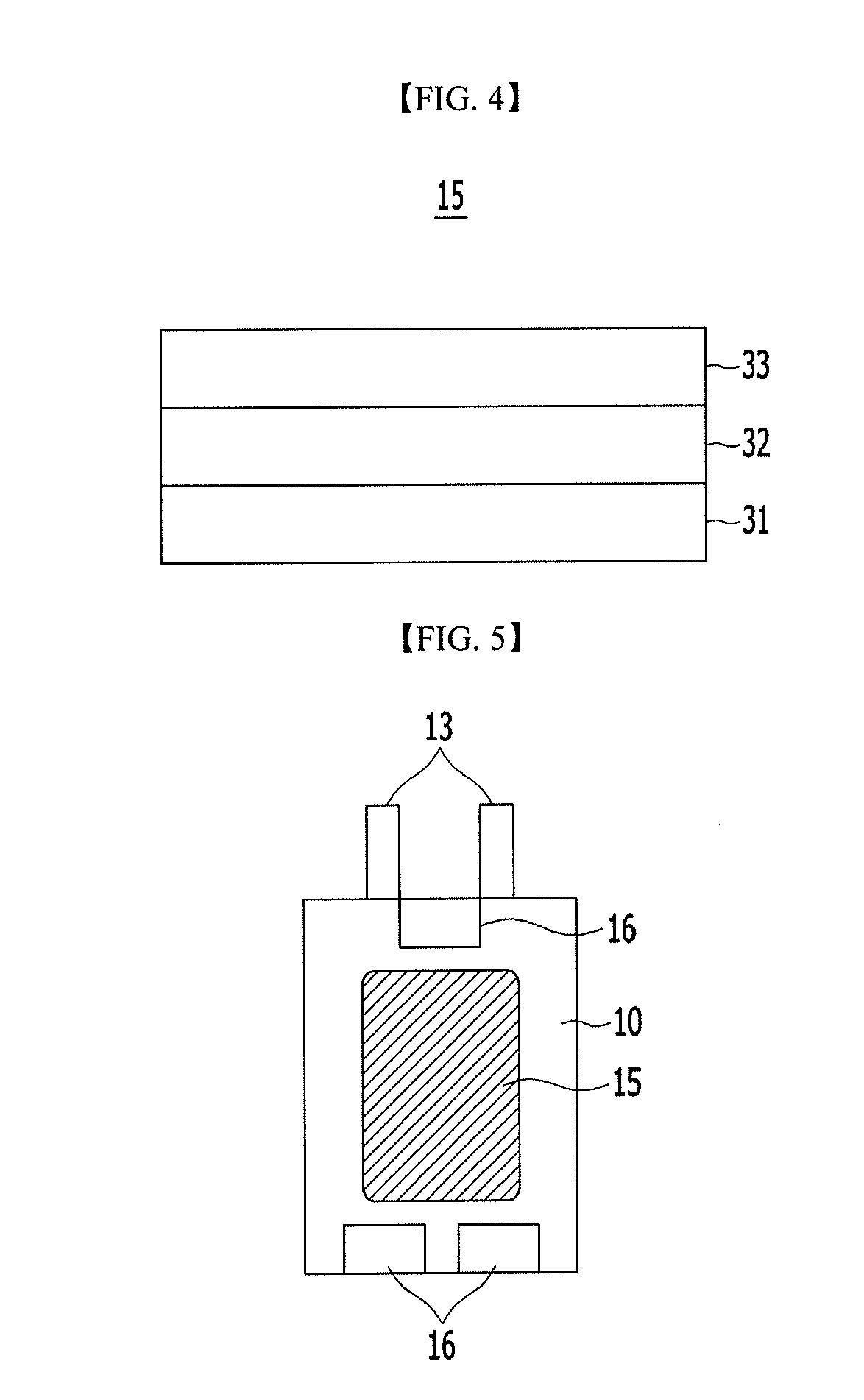

Lithium polymer battery

InactiveUS20130059183A1Improve battery stabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureLithium polymer cellCurrent collector

A lithium polymer battery including: an electrode assembly including: a first electrode plate including a first electrode current collector electrically connected to a first electrode tab and a first electrode active material layer formed on at least one surface of the first electrode current collector, a second electrode plate including a second electrode current collector that is electrically connected to a second electrode tab and a second active material layer formed on at least one surface of the second electrode current collector, and a separator interposed between the first electrode plate and the second electrode plate; and a case for housing the electrode assembly, wherein the separator is attached to a portion of a first electrode uncoated area of a first electrode uncoated area of the first electrode current collector to prevent a short between the first electrode plate and the second electrode plate.

Owner:SAMSUNG SDI CO LTD

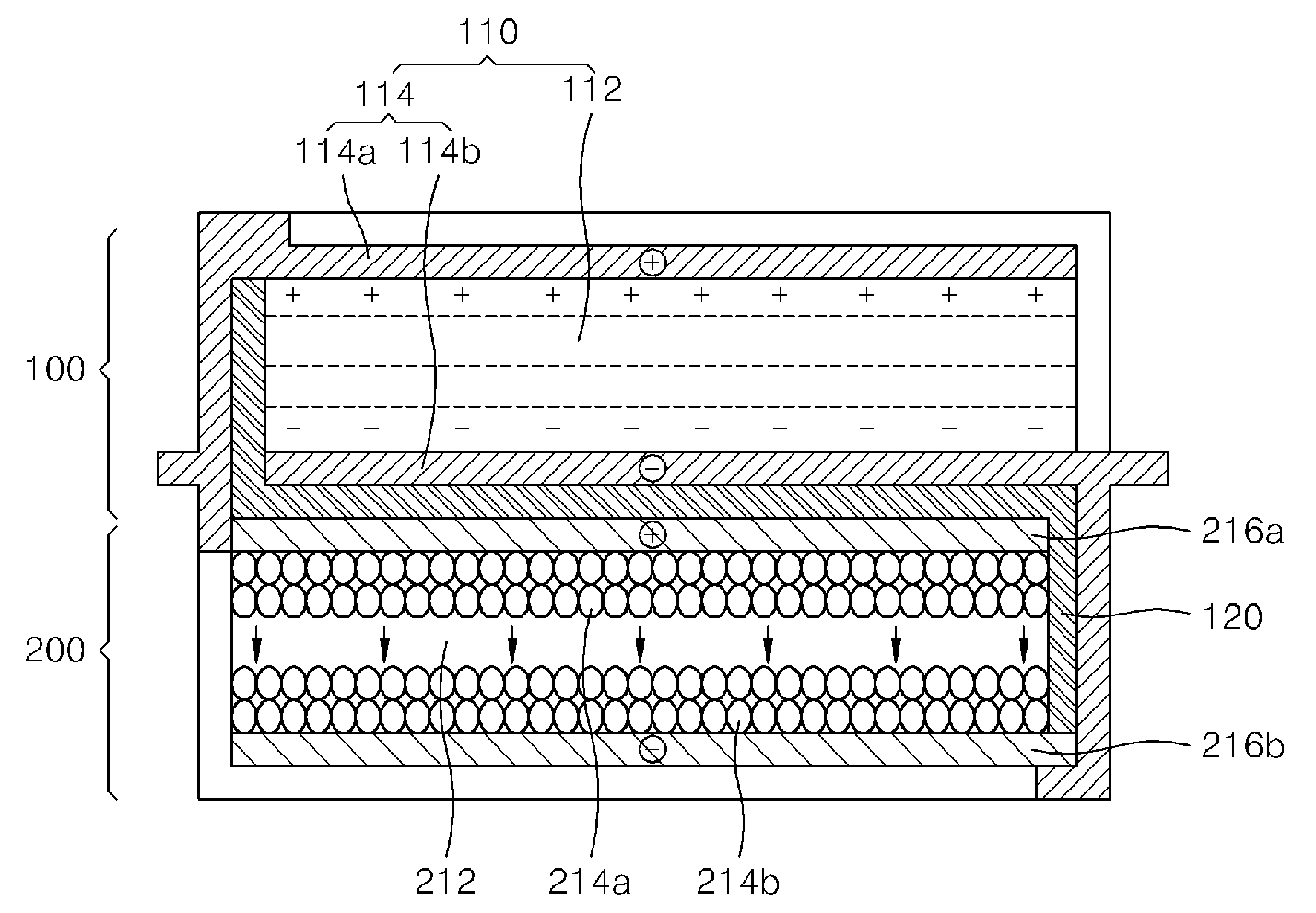

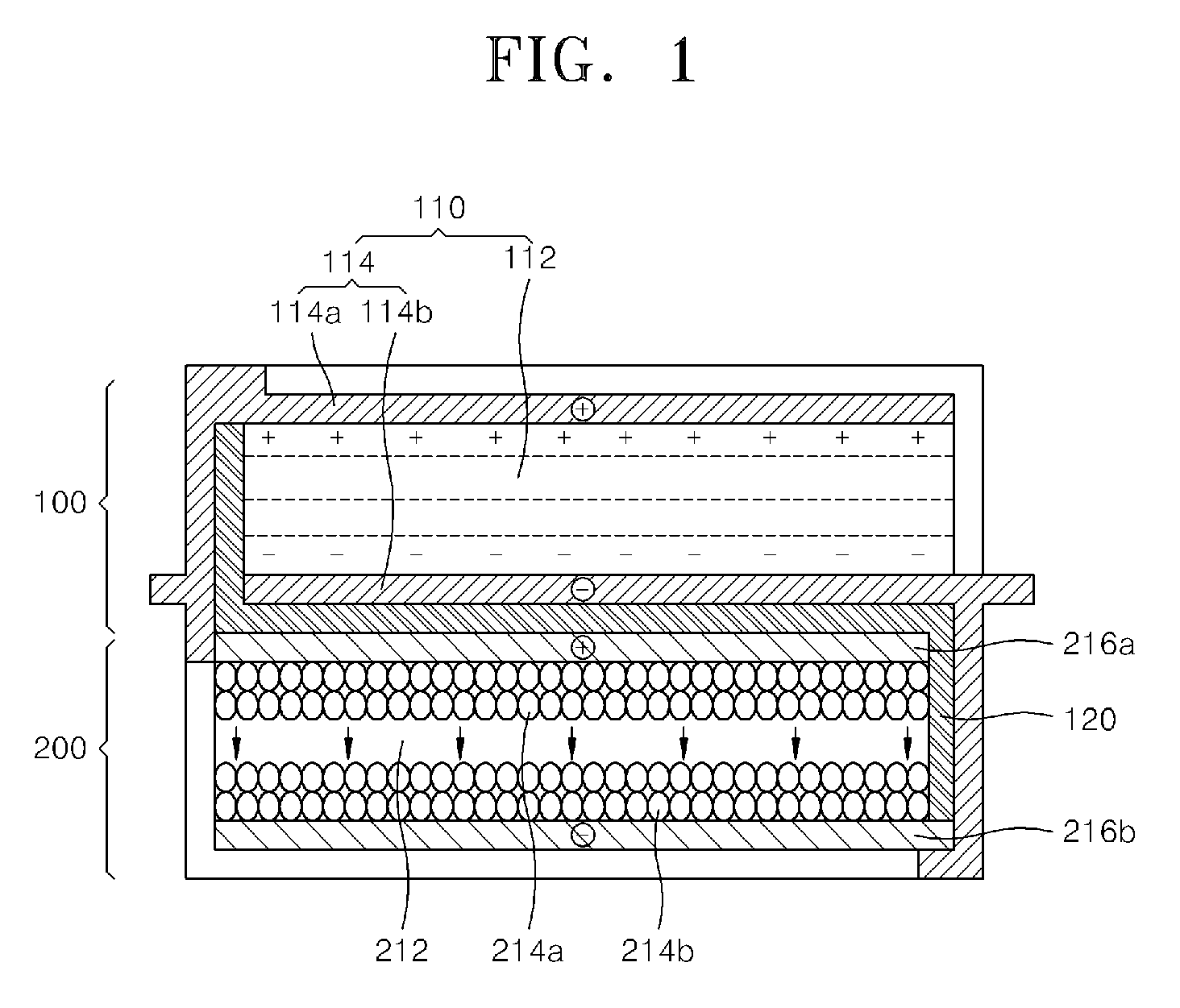

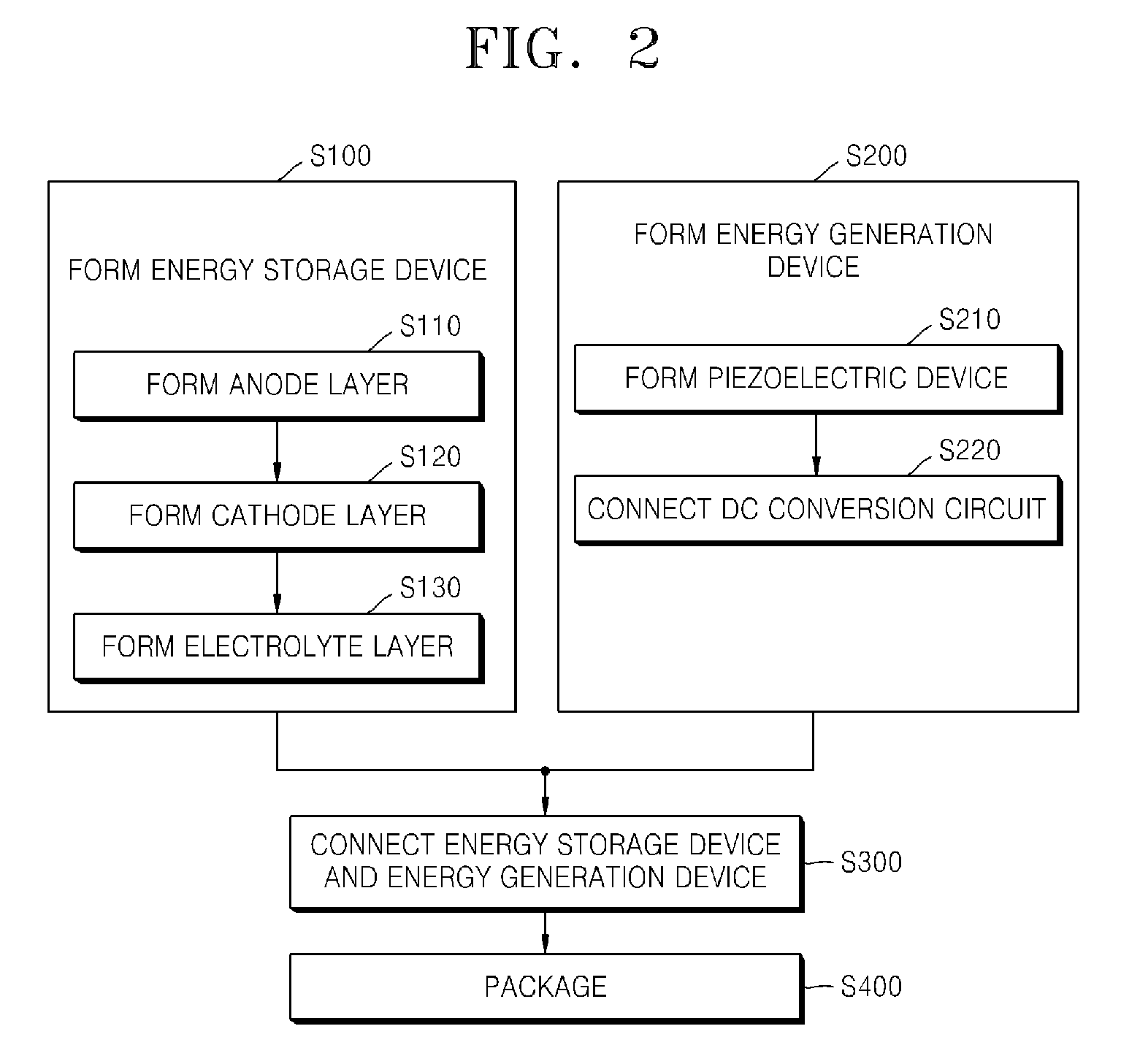

Thin film type integrated energy harvest-storage device

InactiveUS20090121585A1Improve conversion efficiencyImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesCell electrodesElectricityEngineering

Provided is thin film type energy generation-storage device in which an energy generation device generating energy using a piezoelectric material and an energy storage device storing the generated energy are formed in a thin film type one unit.

Owner:ELECTRONICS & TELECOMM RES INST

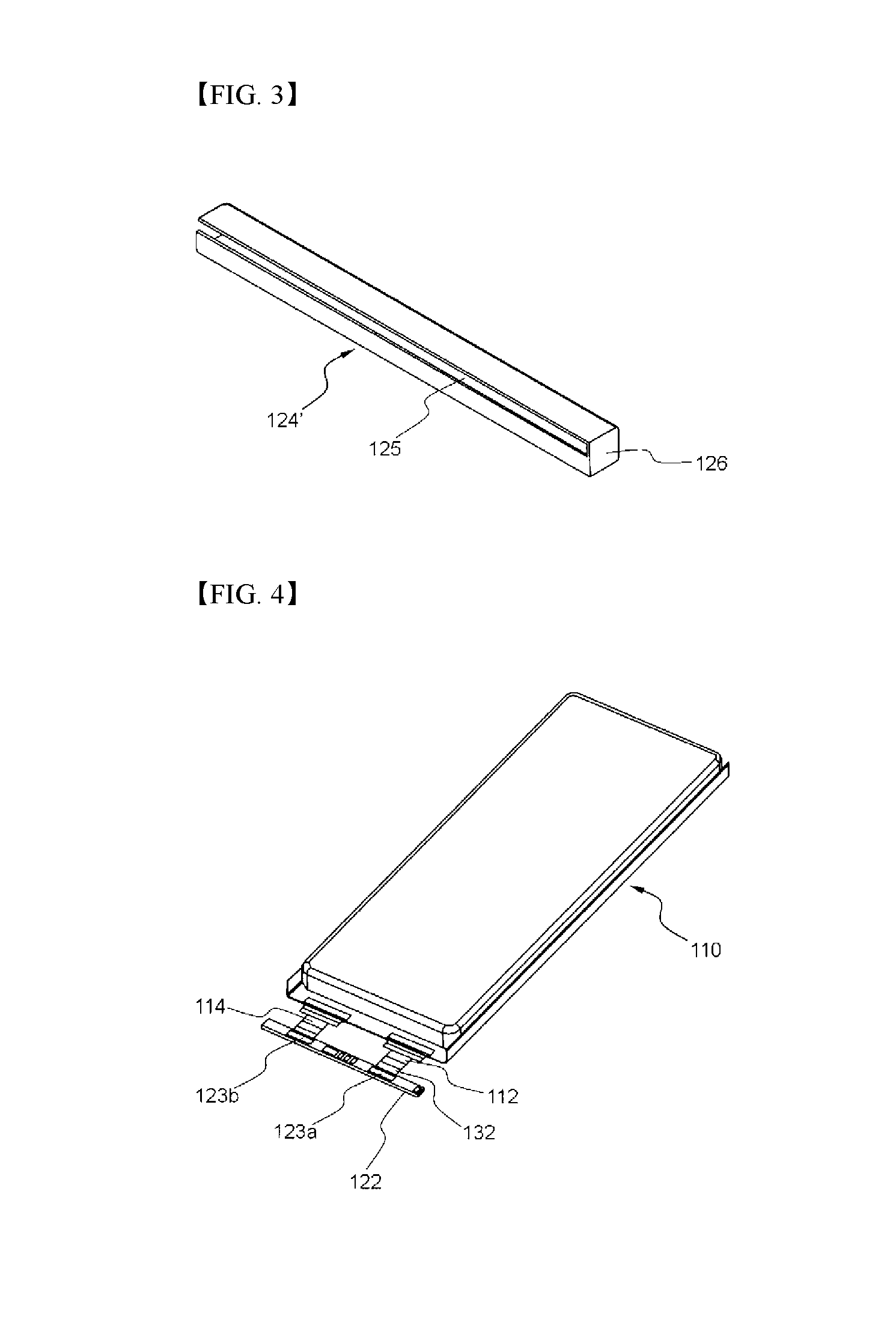

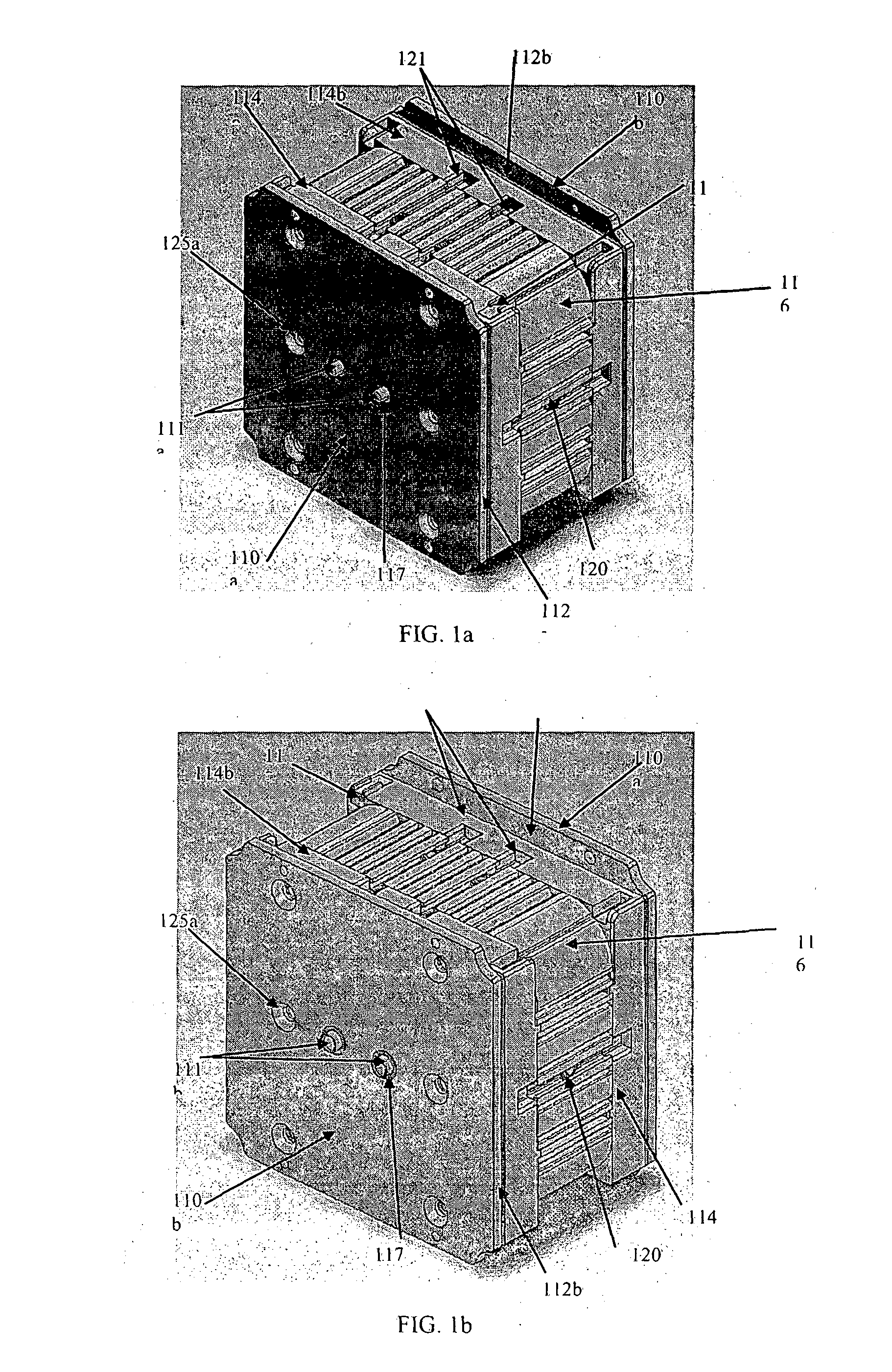

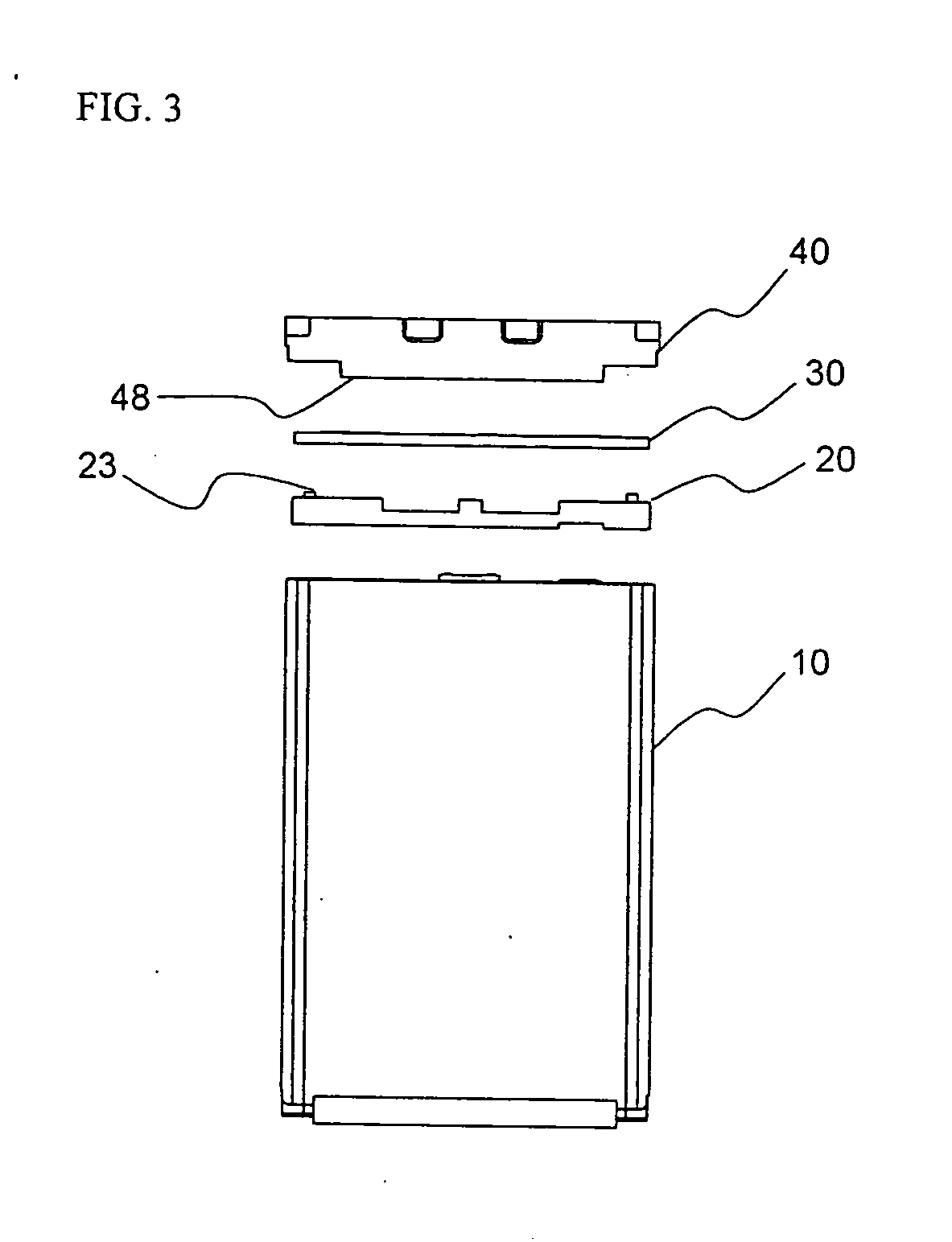

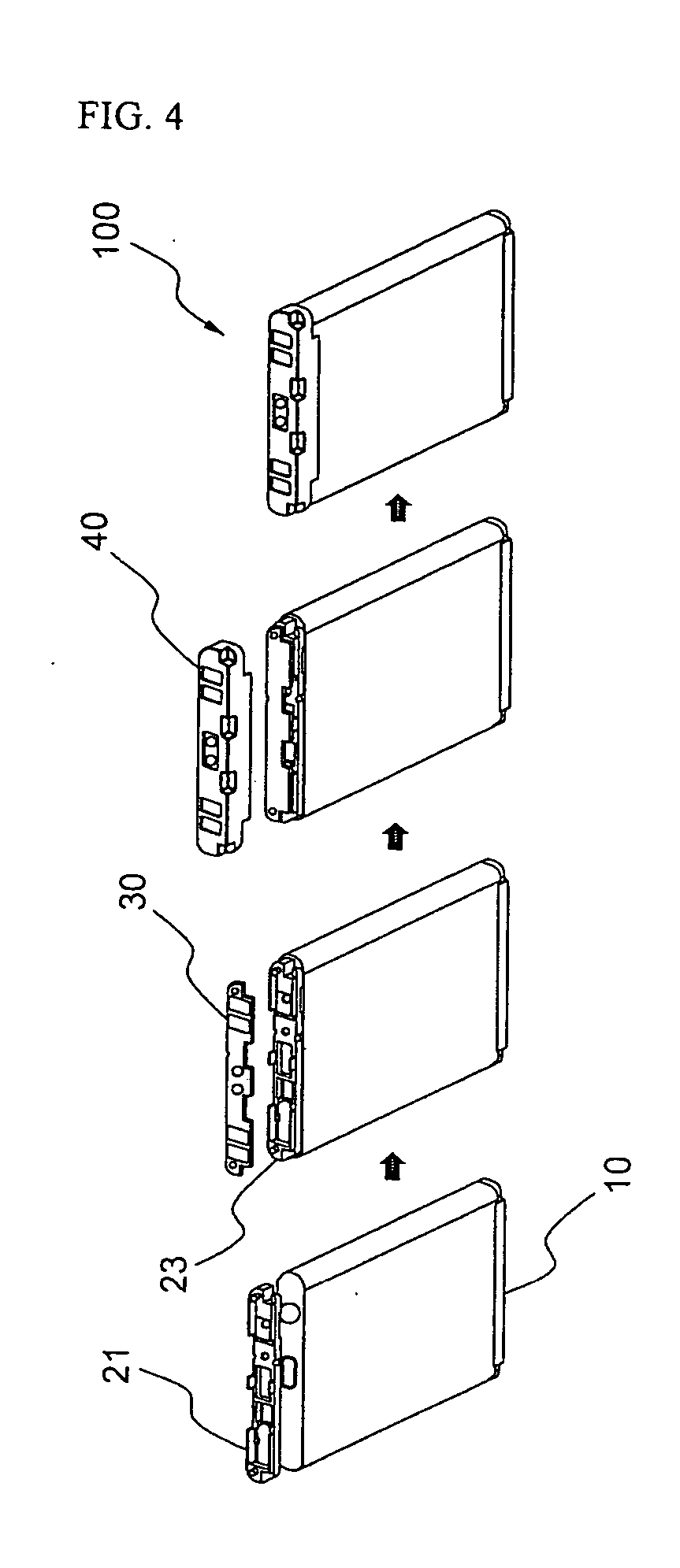

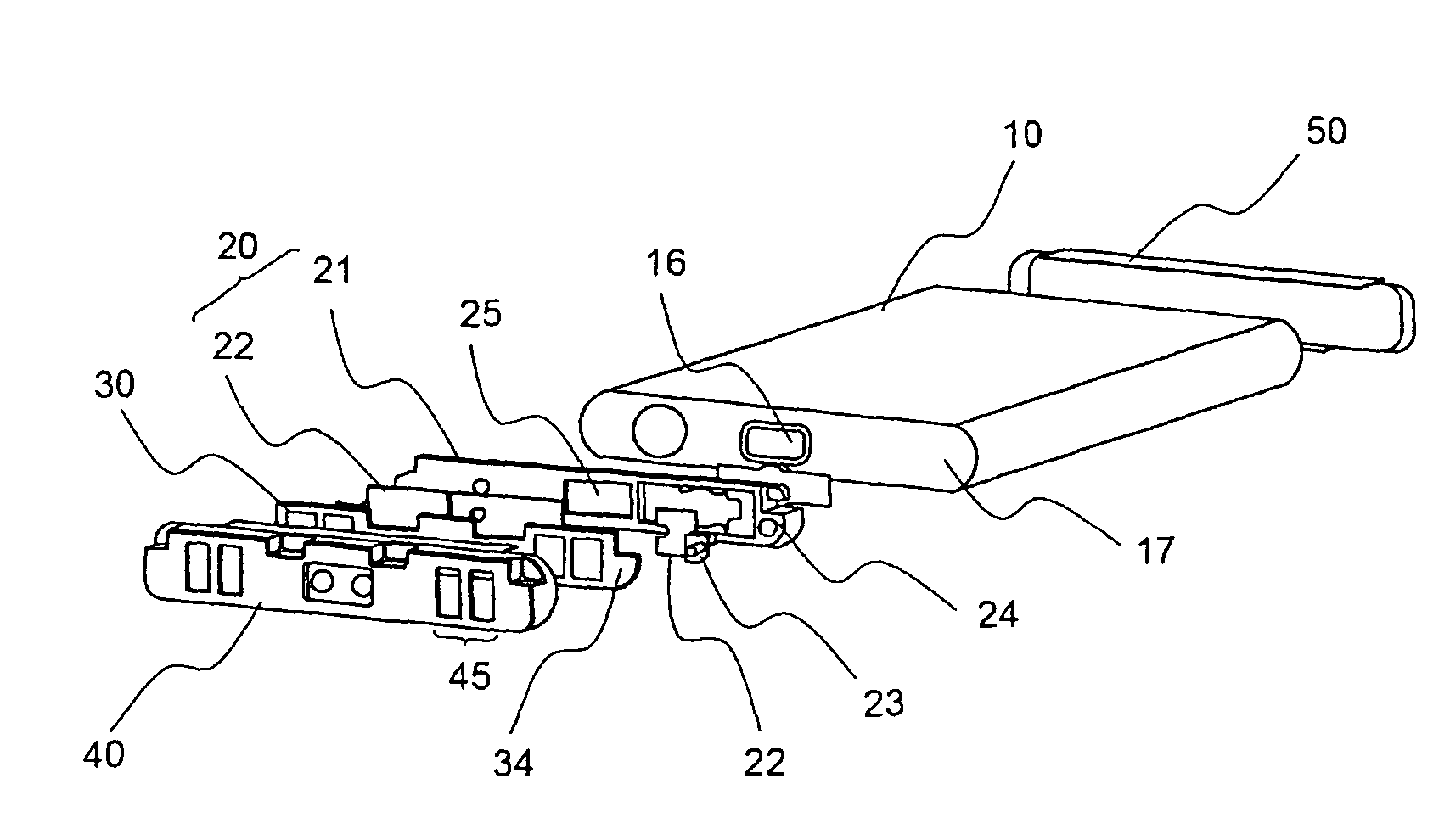

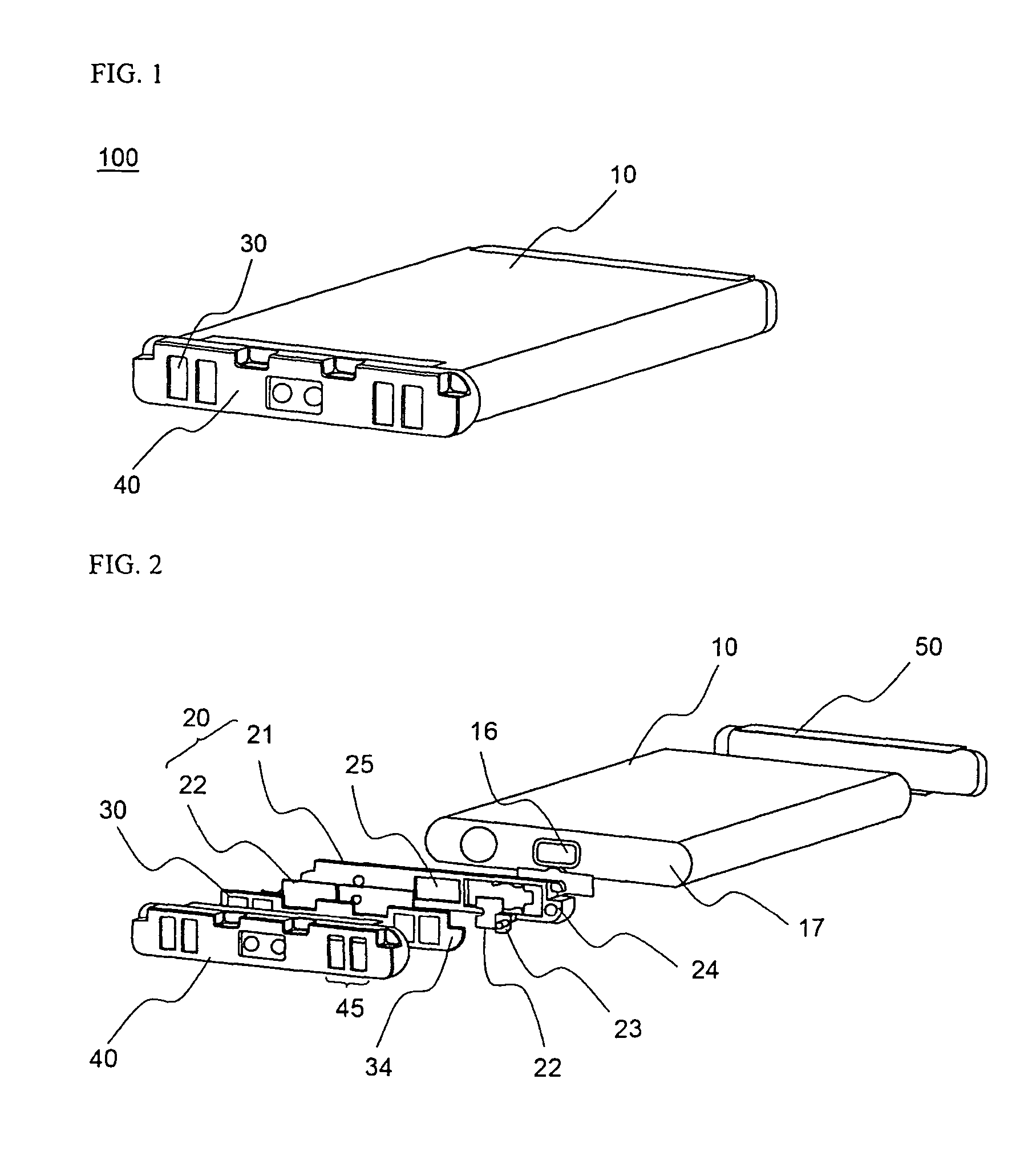

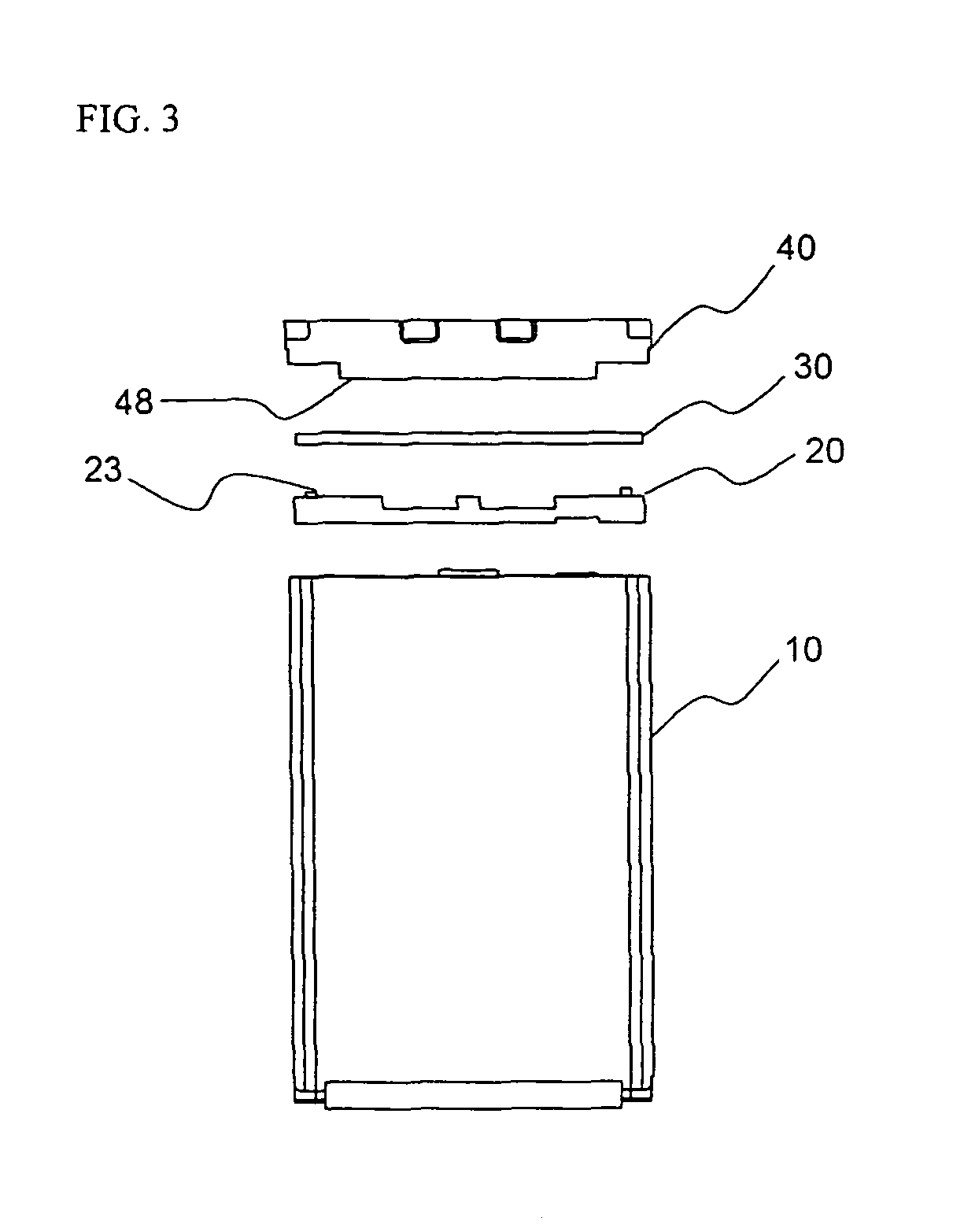

Secondary battery pack having PCM

ActiveUS20160233479A1Simplify the assembly processImprove battery stabilityBatteries circuit arrangementsLi-accumulatorsAnodeBattery pack

Owner:LG ENERGY SOLUTION LTD

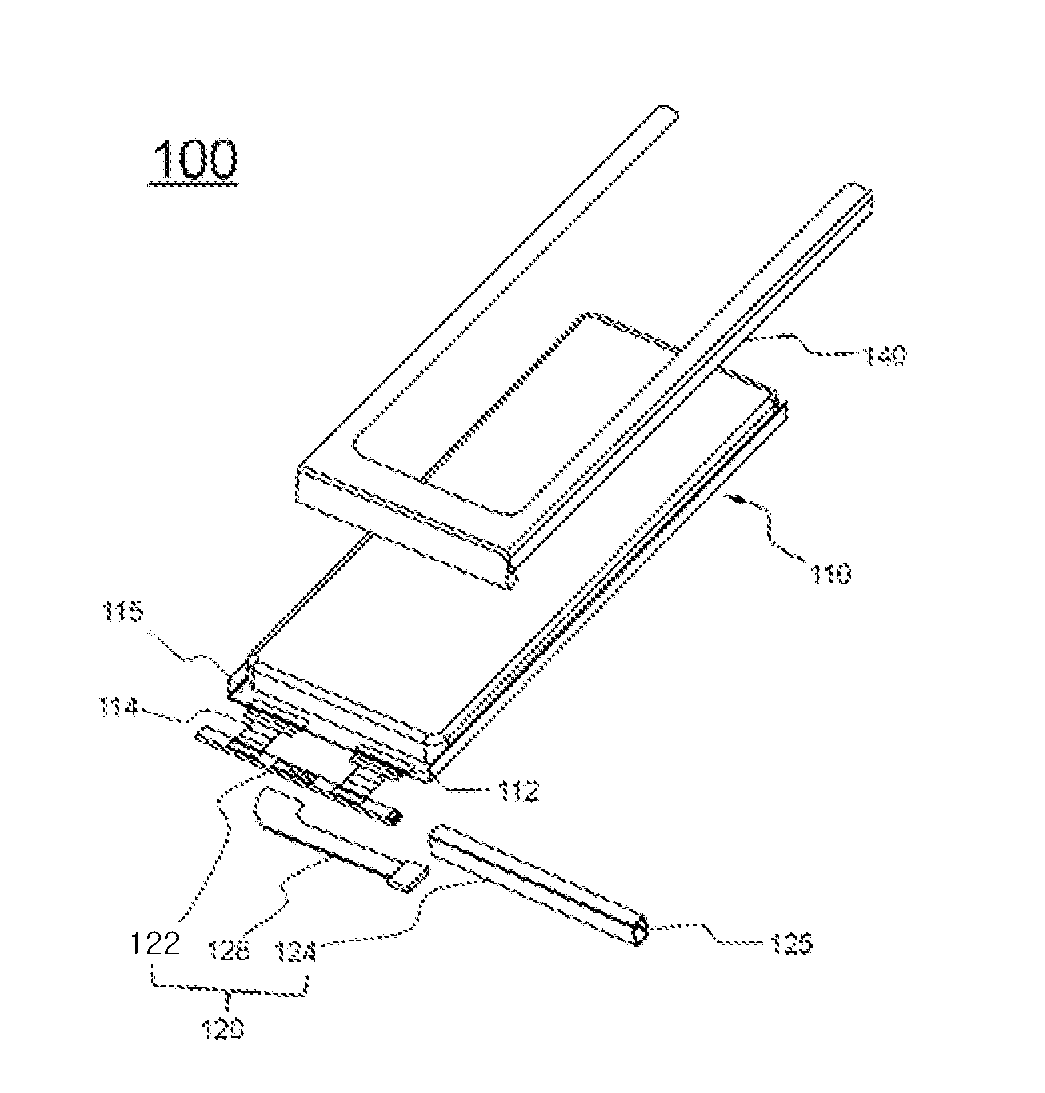

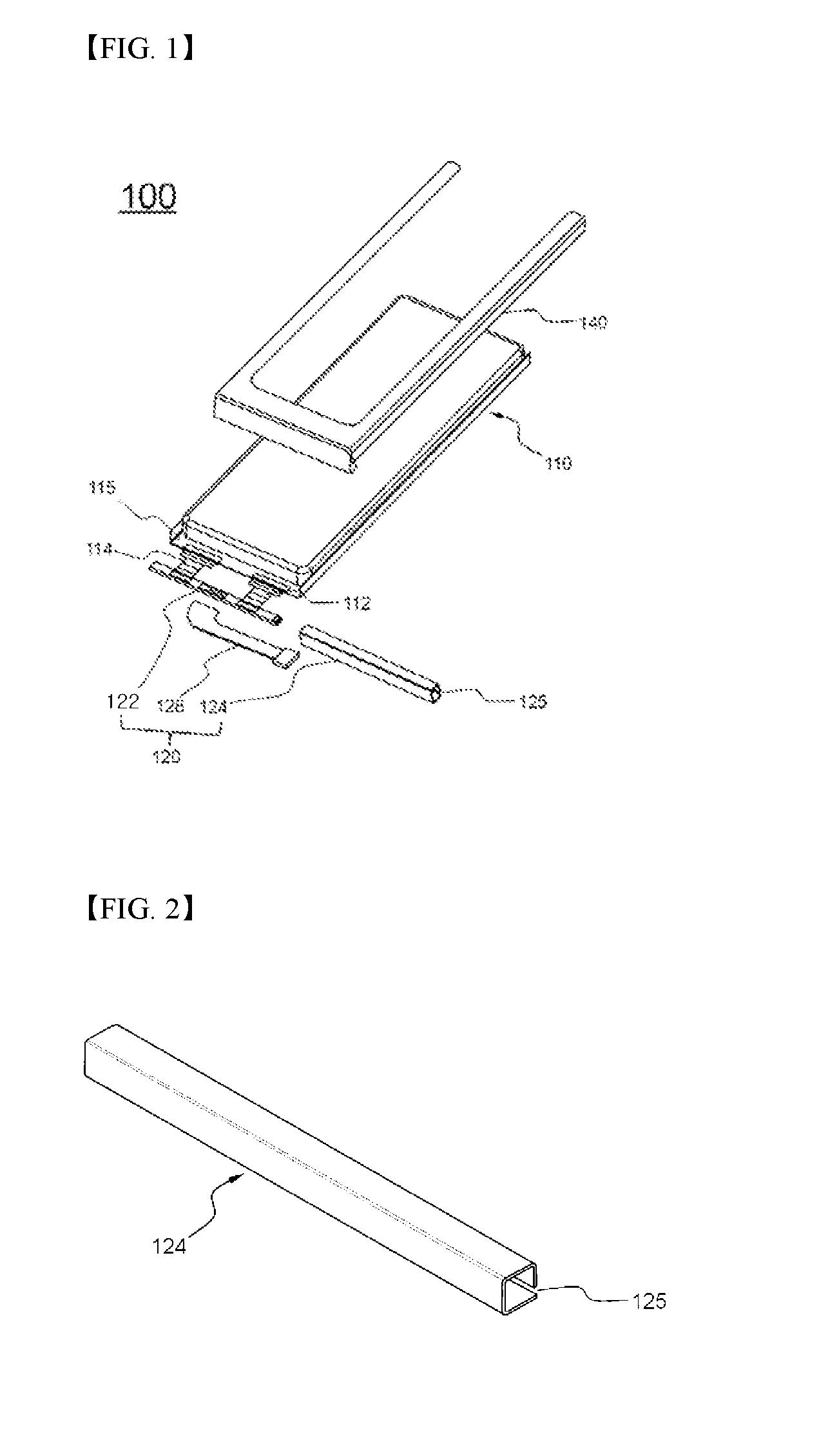

Battery suitable for preparation of battery module

ActiveUS20070059593A1Increase in sizeShorten connection lengthLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery cell

Disclosed herein are a battery having an electrode assembly which can be charged and discharged, mounted in a plate-shaped battery case, and cathode and anode terminals protruding from opposite ends of the battery case, wherein the electrode terminals are deviated from each other about the vertical central axis on the plane of the battery cell while the electrode terminals are arranged in a symmetrical fashion, the battery case includes an upper case and a lower case, only one of which is provided with a location part for receiving the electrode assembly, and the electrode terminals are deviated toward the upper or lower case which has no location part on the vertical section of the battery cell, and a battery module including the same.

Owner:LG ENERGY SOLUTION LTD

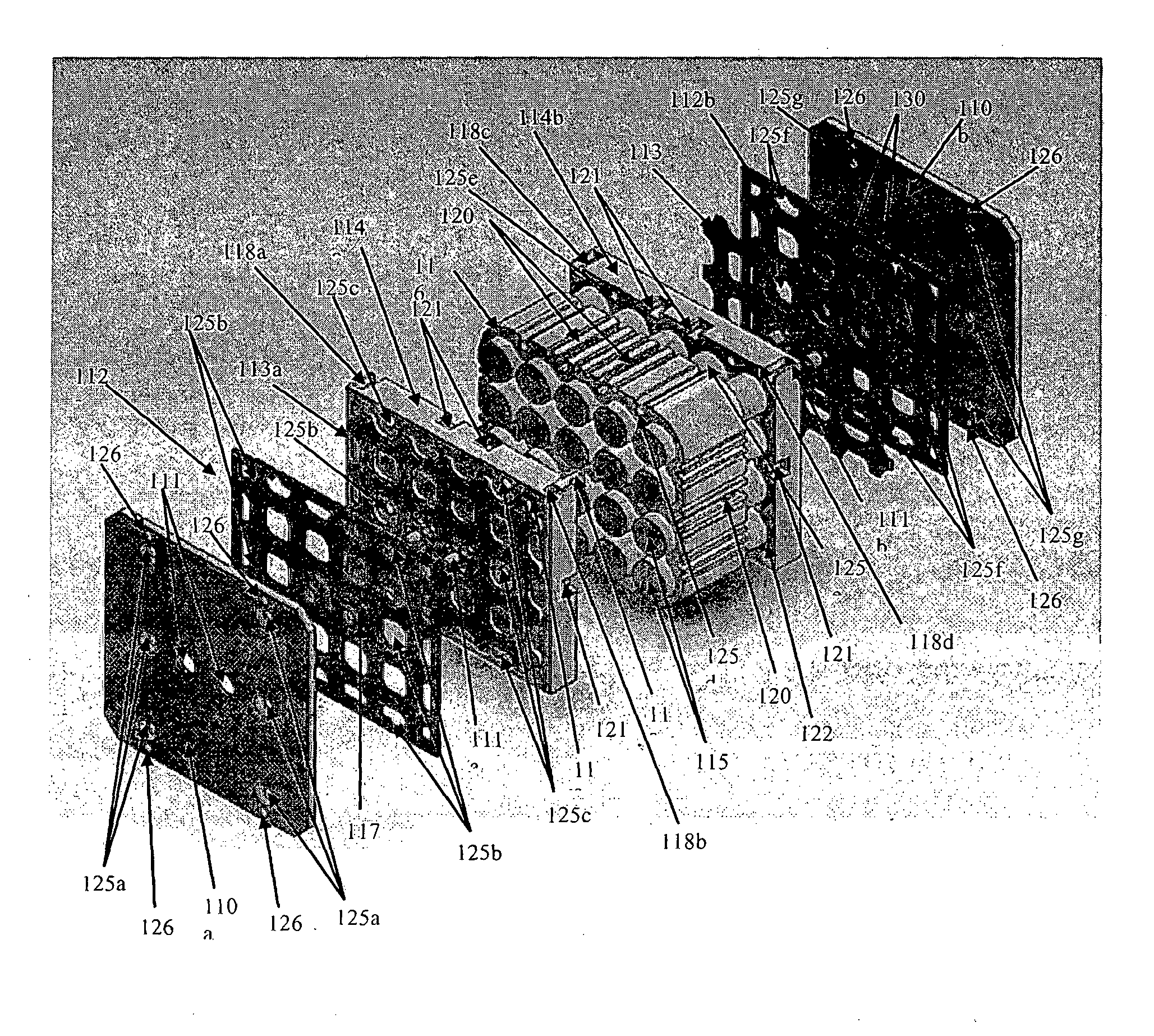

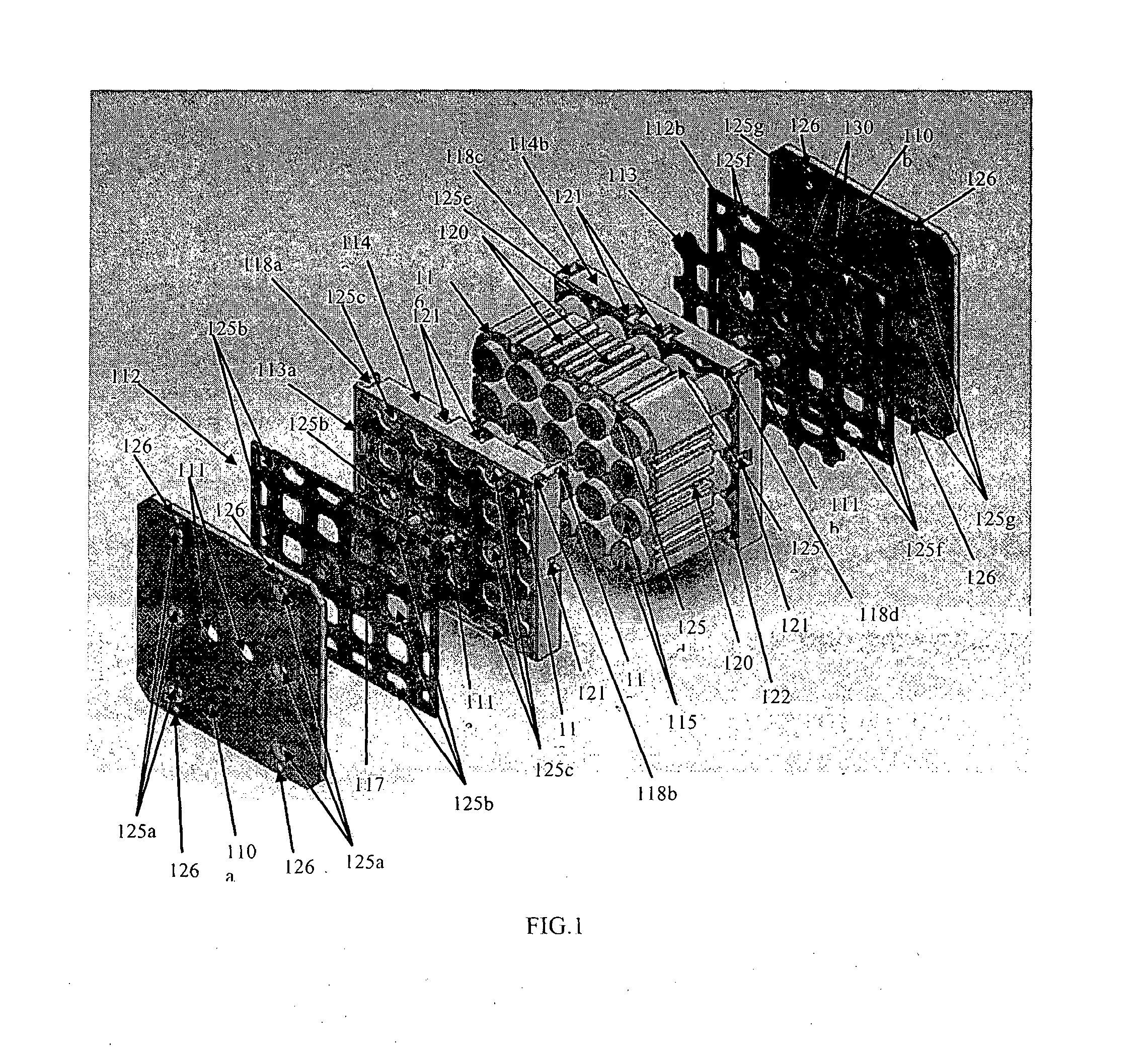

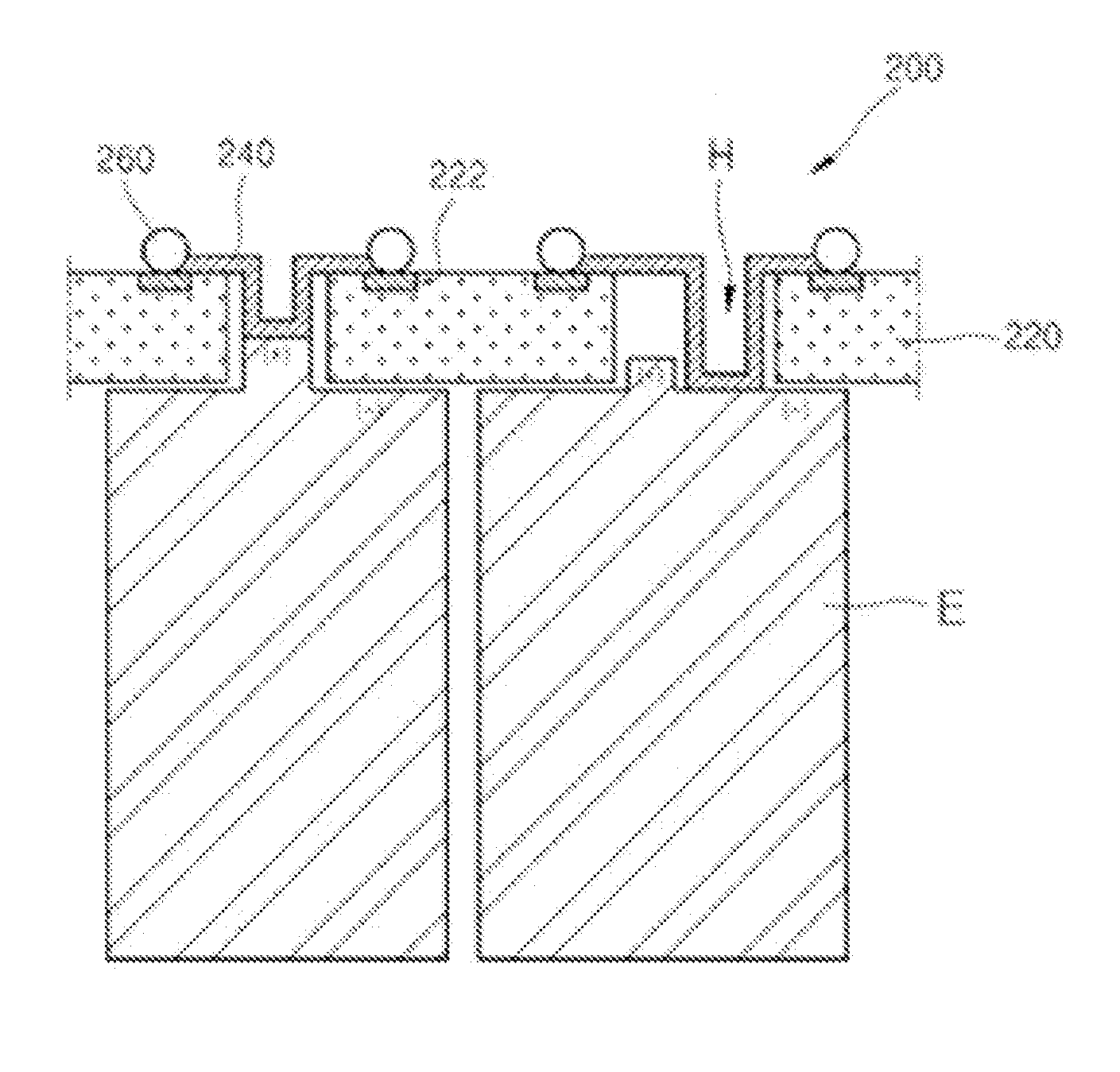

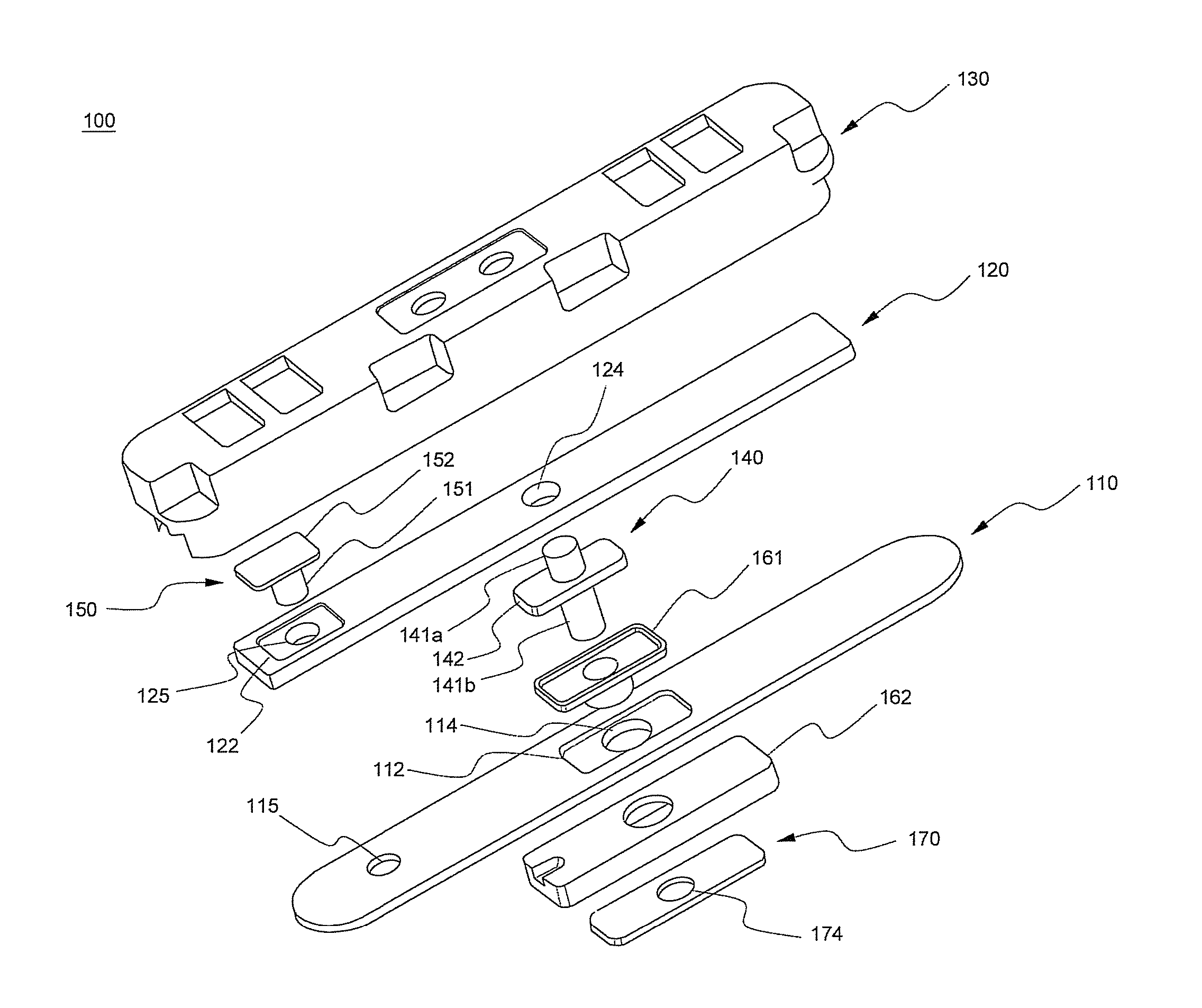

Non-welded battery module

InactiveUS20150086823A1Improve battery stabilityImprove structural stabilityFinal product manufactureWaste accumulators reclaimingNickelElectrical connection

This invention relates to an improvement in battery packs. The present invention resides in a combination of an electric battery pack and a apparatus for making an electrical connection to the battery without involving the spot welding process. The present assembly method enables terminal blocks containing multiple battery packs joint in series having a “U-turn” configuration without external electrical connection. Any two battery packs are firmly locked together through the pressure plates (200) without being electrically connected together. The present embodiment uses two separate nickel or other conductive material plated copper sheets (113a or 113b) that are embedded between the battery cell holder (114a, 114b) and the silicone rubber pressure sheet (112a, 112b). The first end portion block of battery packs supported by an end pressure plate (300) can be connected together to the second end portion of the block battery packs by using a modified nickel or other conductive material plated copper sheet (113) that enable the two battery packs to be connected internally, thus, making the “U-turn” configuration possible. This method is one of the most cost efficient ways to connect internally, to avoid using any external wires or circuits, which eventually maintain the internal resistance of each of the battery packs.

Owner:LIEW CHUNG PENG

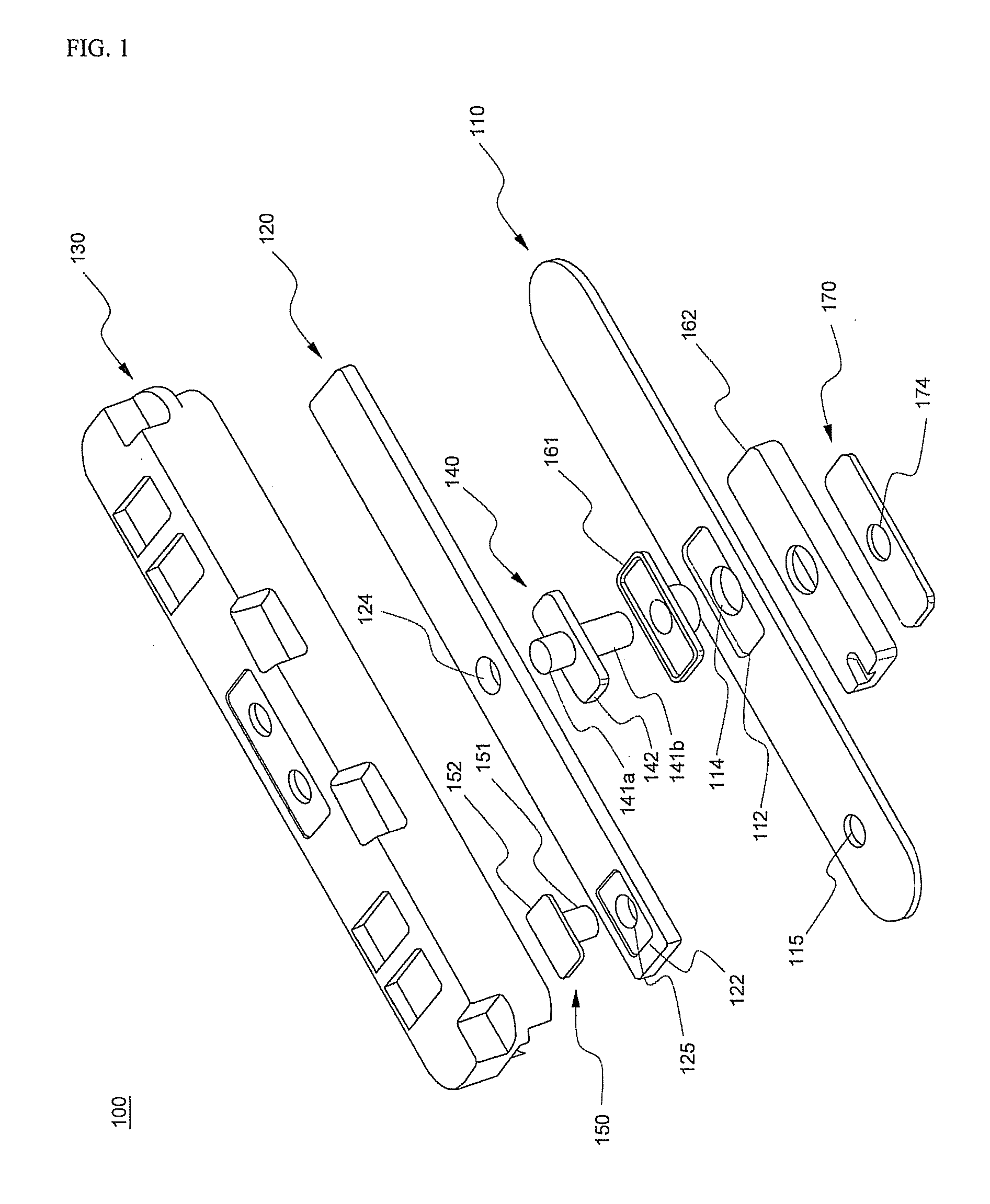

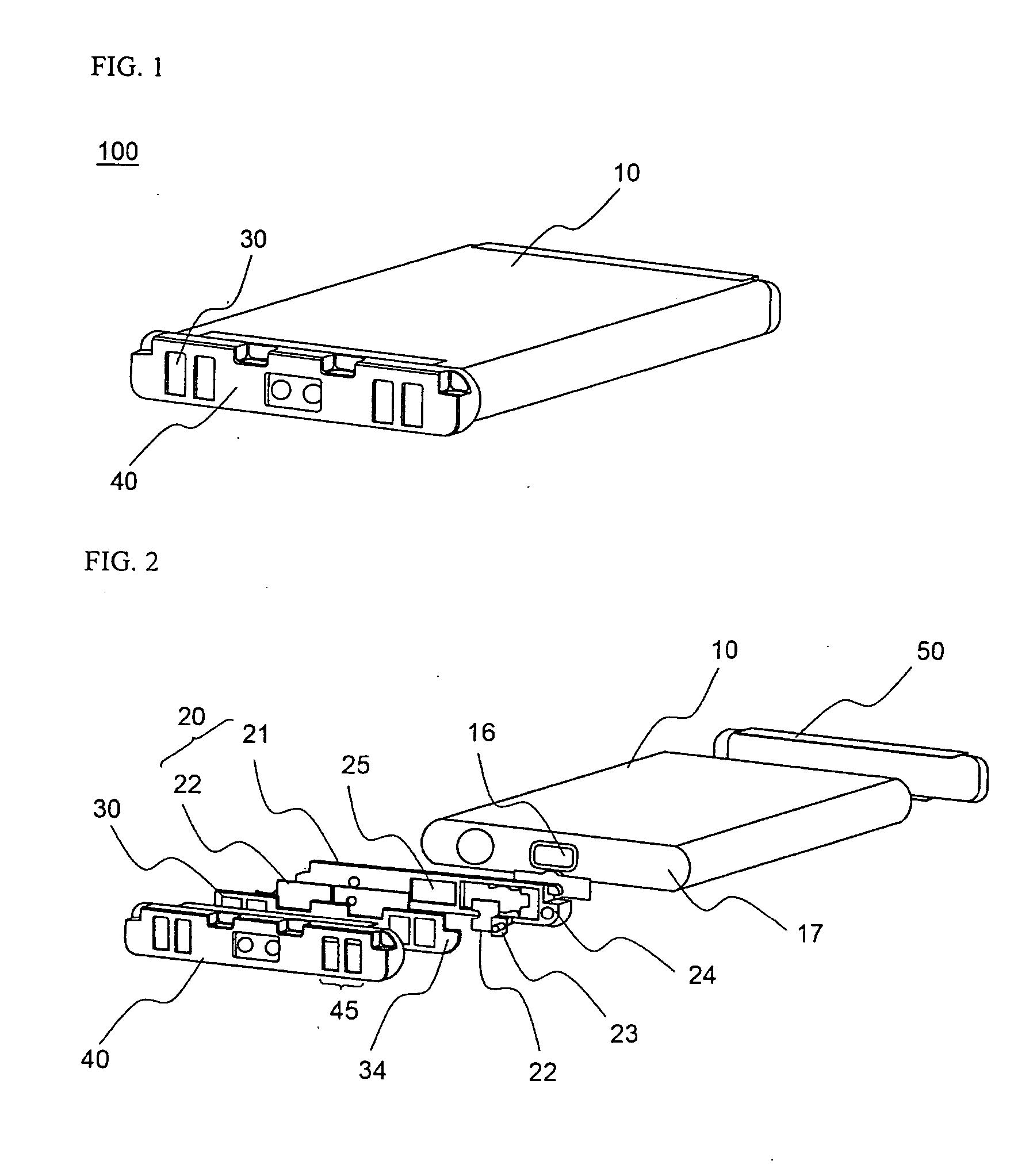

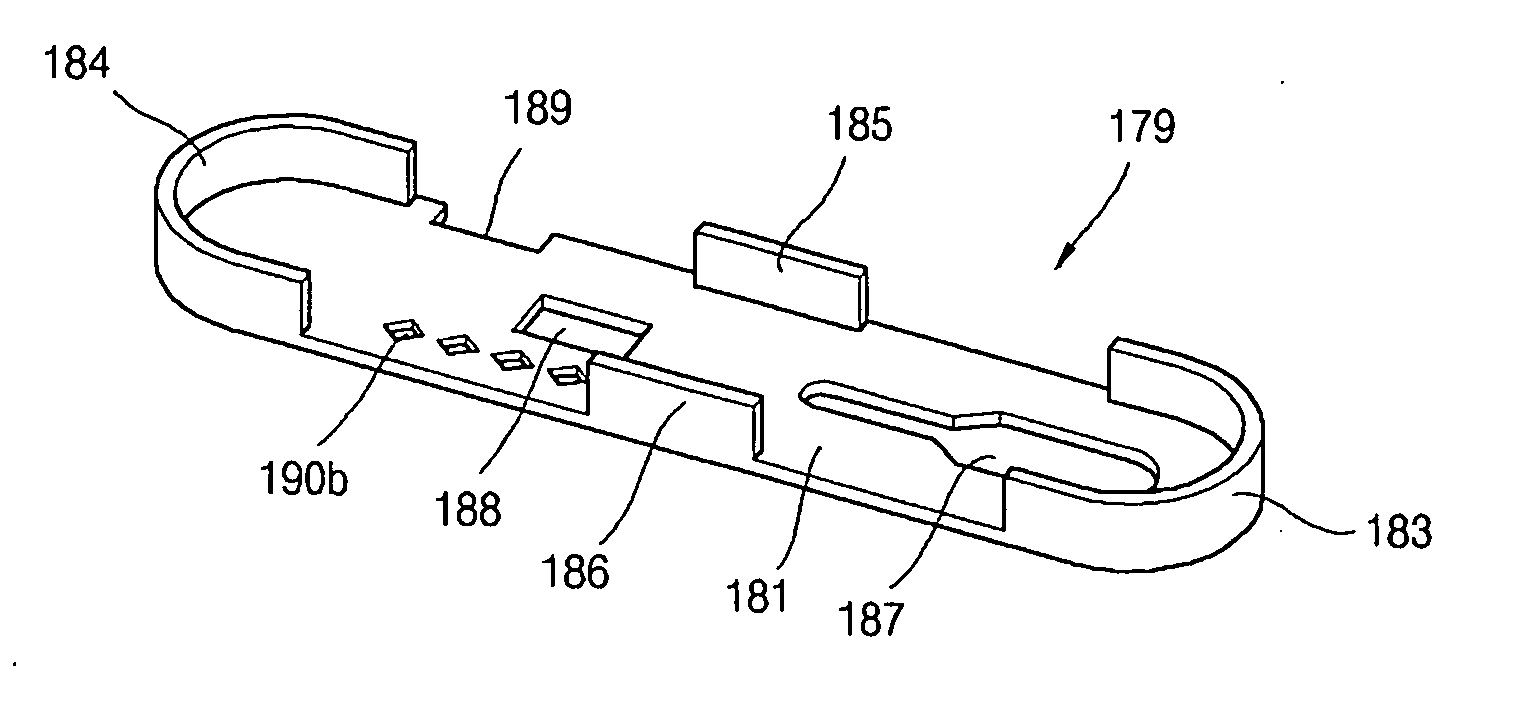

No-welding type battery pack

ActiveUS20070188132A1Simplify the assembly processIncrease battery capacityBatteries circuit arrangementsCells structural combinationInternal resistanceEngineering

Disclosed herein is a battery pack, which comprises a connecting member including an insulation frame mounted to the upper end of a battery cell and a pair of connection protrusions formed at the upper end surface of the frame, the connection protrusions being in contact with electrode terminals of the battery cell, a protection circuit module (PCM) mounted to the connecting member, the PCM including connection grooves, into which the connection protrusions are inserted such that the PCM can be coupled to the connecting member, and which are connected to a protection circuit, and a cap housing coupled to the connecting member or the battery cell while the PCM is surrounded by the cap housing. The no-welding type battery pack according to the present invention has effects in that the assembly process of the battery pack is simplified, which enables the automatic manufacture of the battery pack, defectiveness and changes of internal resistance of the battery pack due to external impacts are minimized, the capacity of the battery is increased, and the stability of the battery pack is improved.

Owner:LG ENERGY SOLUTION LTD

Lithium rechargeable battery

ActiveUS20060115726A1Improve battery stabilityCell electrodesFinal product manufactureLithiumEngineering

Owner:SAMSUNG SDI CO LTD

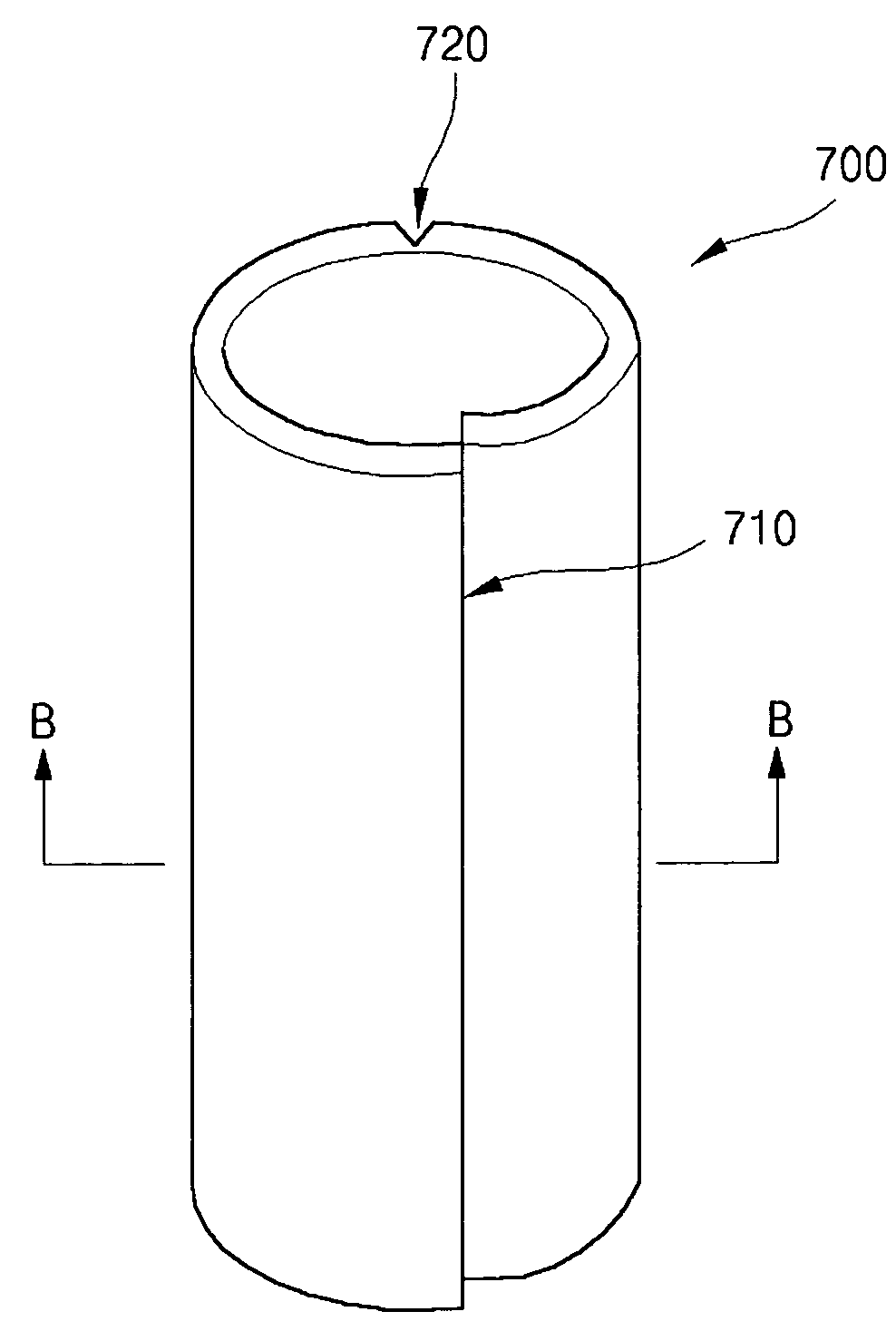

Cylindrical lithium secondary battery

InactiveUS7691530B2Improve battery stabilityFinal product manufactureSmall-sized cells cases/jacketsLithiumMechanical engineering

A cylindrical lithium secondary battery includes a wound electrode assembly having a first electrode plate, a second electrode plate, and a separator interposed between the first electrode plate and the second electrode plate. A core member is substantially in a shape of a pipe and has a cut formed along a longitudinal direction thereof, the cut forming two edges. The core member is inserted into a central space of the electrode assembly and has a predetermined deformation direction when subjected to external pressure. The battery also includes a case with a space for accommodating the electrode assembly and an open upper portion, and a cap assembly fixed to the upper portion of the case to hermetically seal the upper portion of the case.

Owner:SAMSUNG SDI CO LTD

Rechargeable lithium battery

ActiveUS20180083311A1Strong toughnessShrinkage of the electrode assemblyFinal product manufactureSmall-sized cells cases/jacketsElectrical and Electronics engineeringLithium battery

Owner:SAMSUNG SDI CO LTD

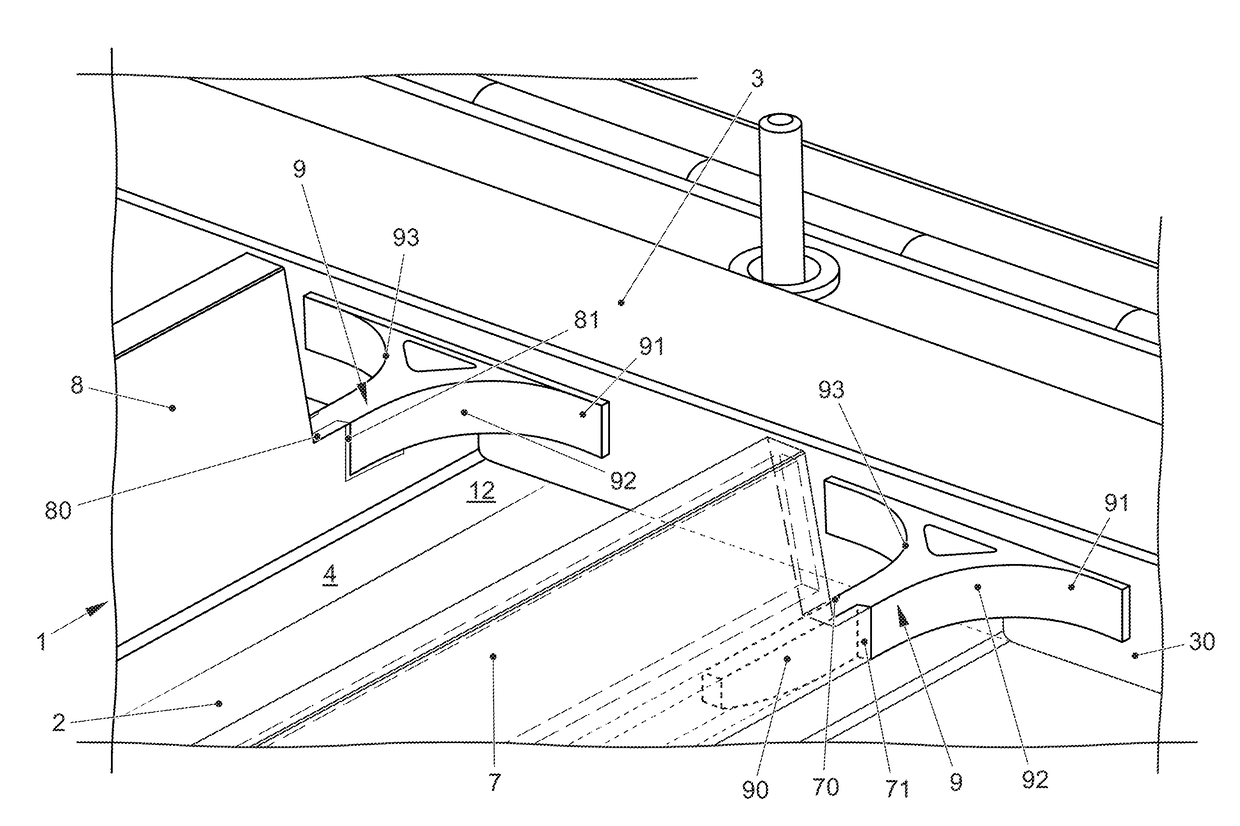

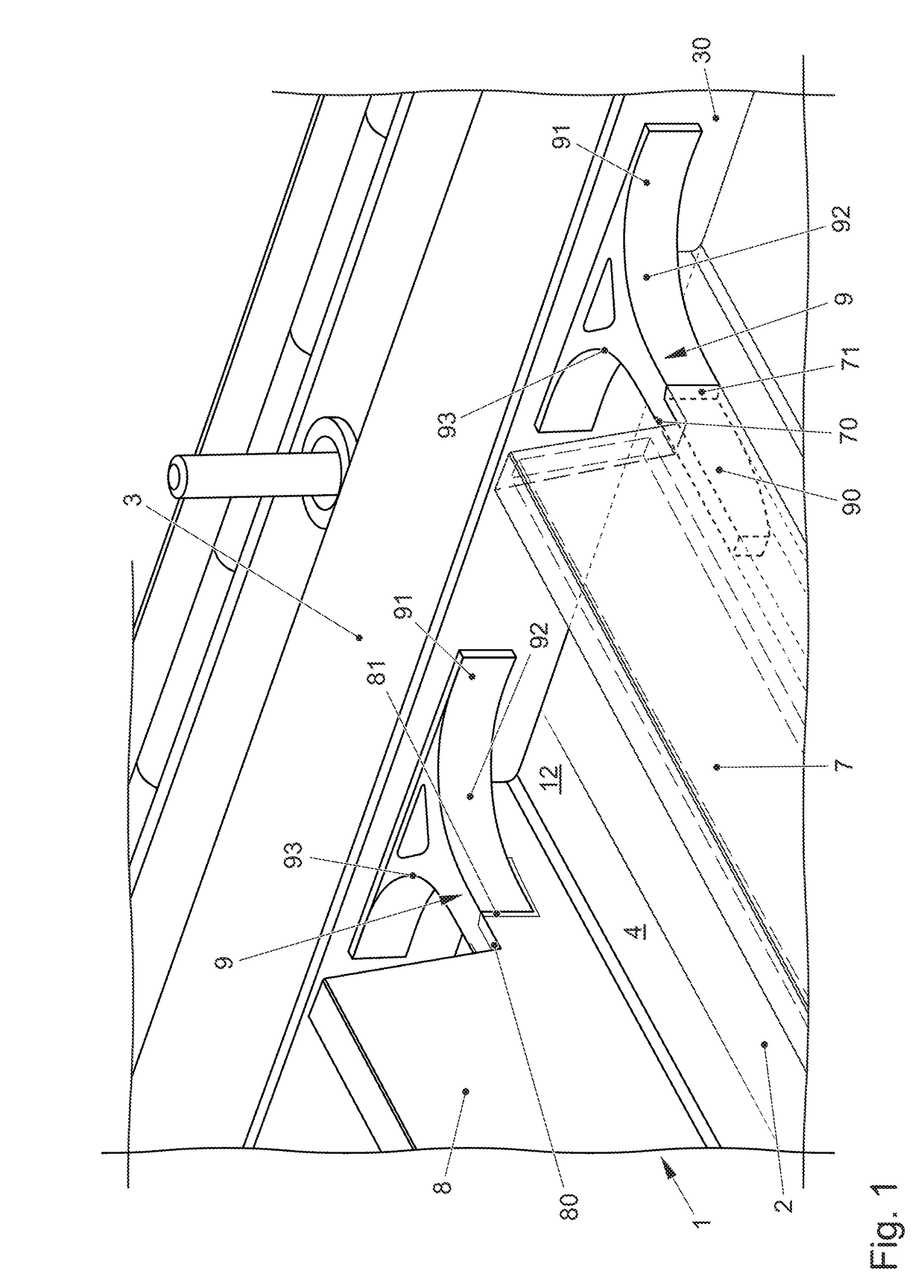

Battery housing of a traction battery of a motor vehicle

ActiveUS20170355255A1Effective protectionReduce risk of damageElectric propulsion mountingBattery isolationMotorized vehicleMechanical engineering

Owner:DR ING H C F PORSCHE AG

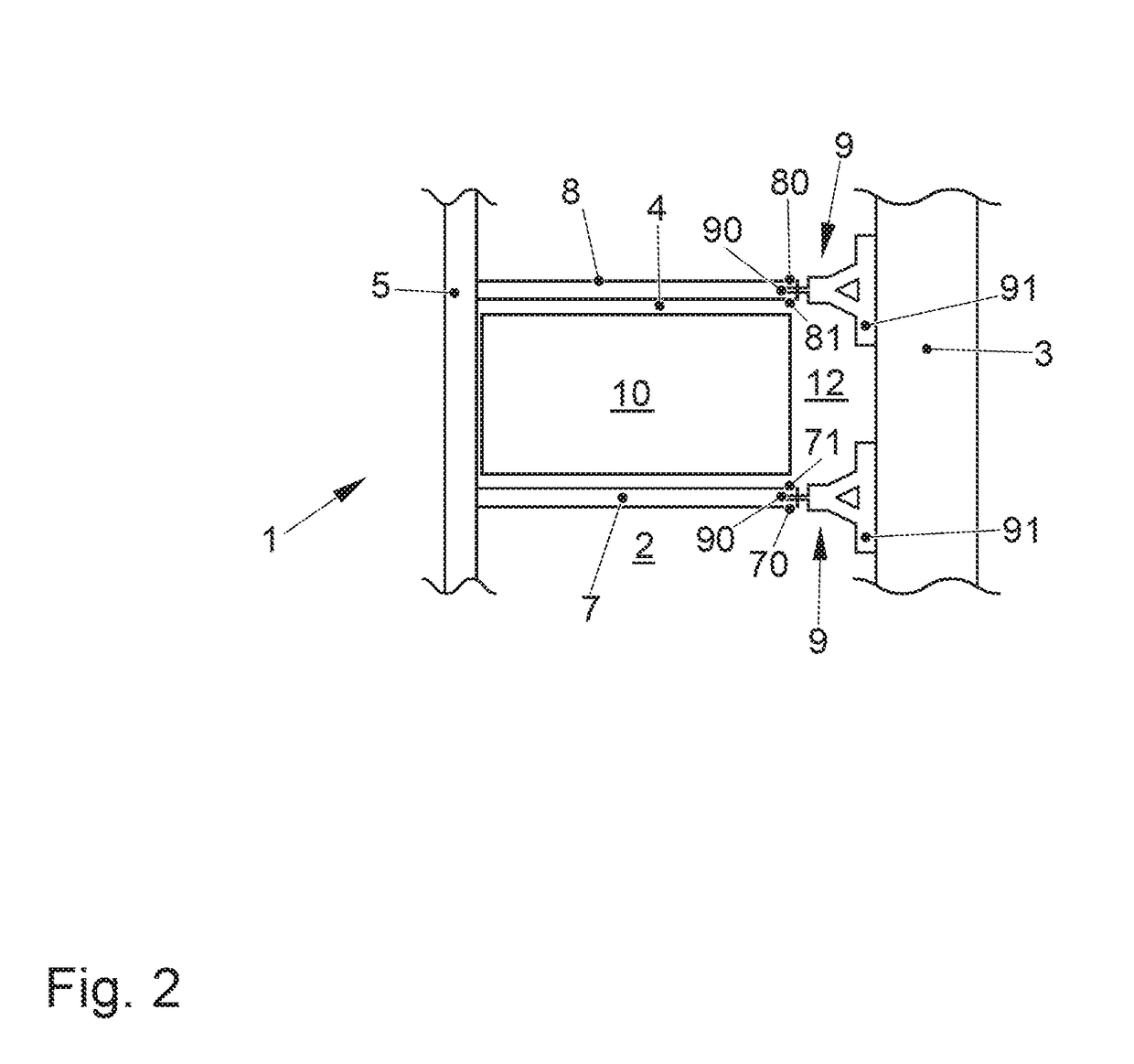

Battery

ActiveUS20190334134A1Improve battery stabilityImprove power densitySecondary cellsCell component detailsHeat conductingBusbar

A battery is provided that includes a plurality of electrically coupled battery modules. Each battery module includes a plurality of combined battery cells having positive and negative poles arranged at opposing end faces of the battery module. Each battery module also includes a busbars electrically connecting said positive poles and a busbar connecting said negative poles. The battery includes an electrical insulation and a heat conducting plate arranged at one end face of the battery modules for cooling and / or heating the battery cells thereof. The heat conducting plate is provided at an end face of the battery modules that includes poles of the battery cells. The electrical insulation, which is formed as a thermal contact element, is located between the busbars of the battery modules and the heat conducting plate. The positive and negative poles of the battery cells are located on opposing end faces of each battery module.

Owner:MIBA BATTERY SYST GMBH

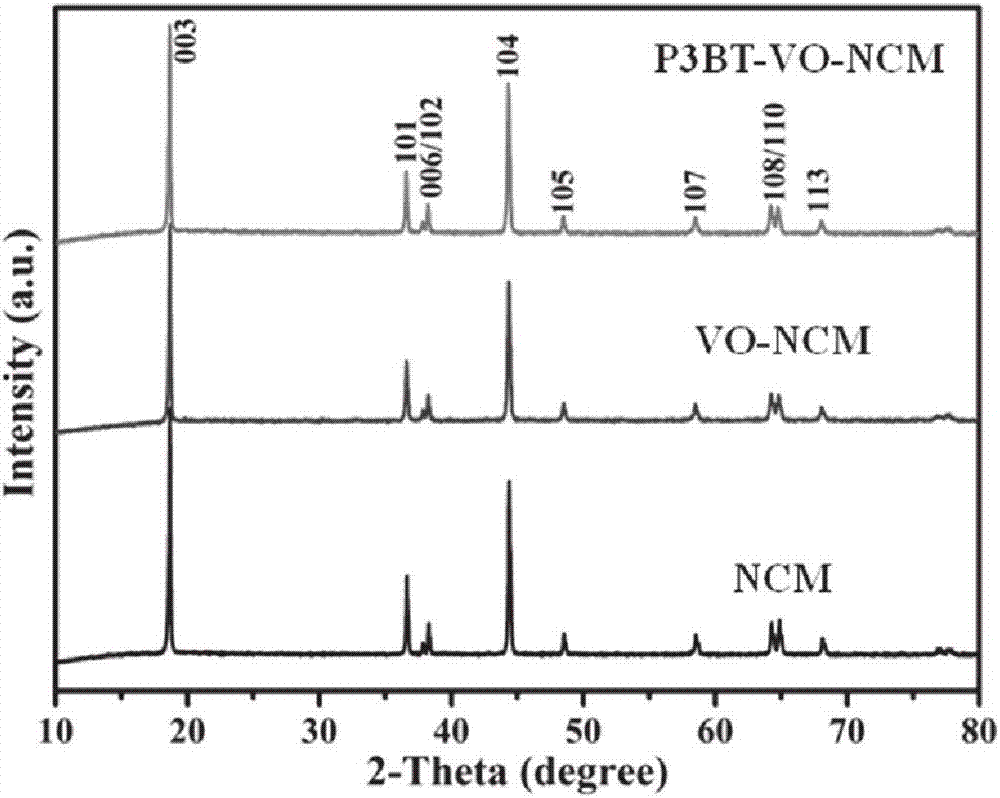

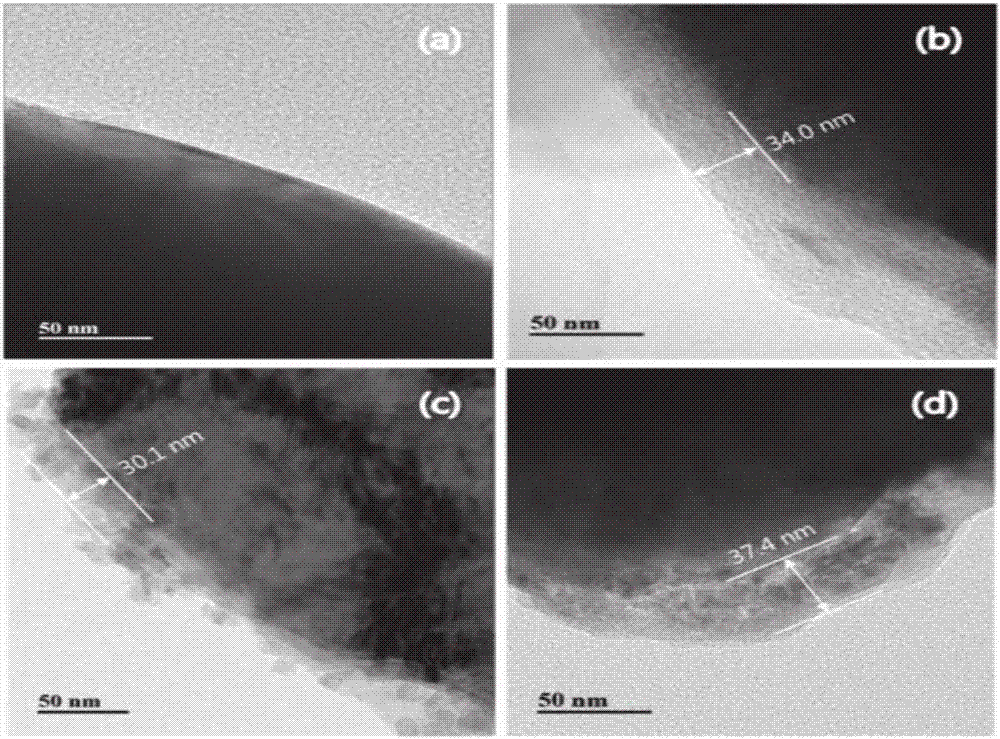

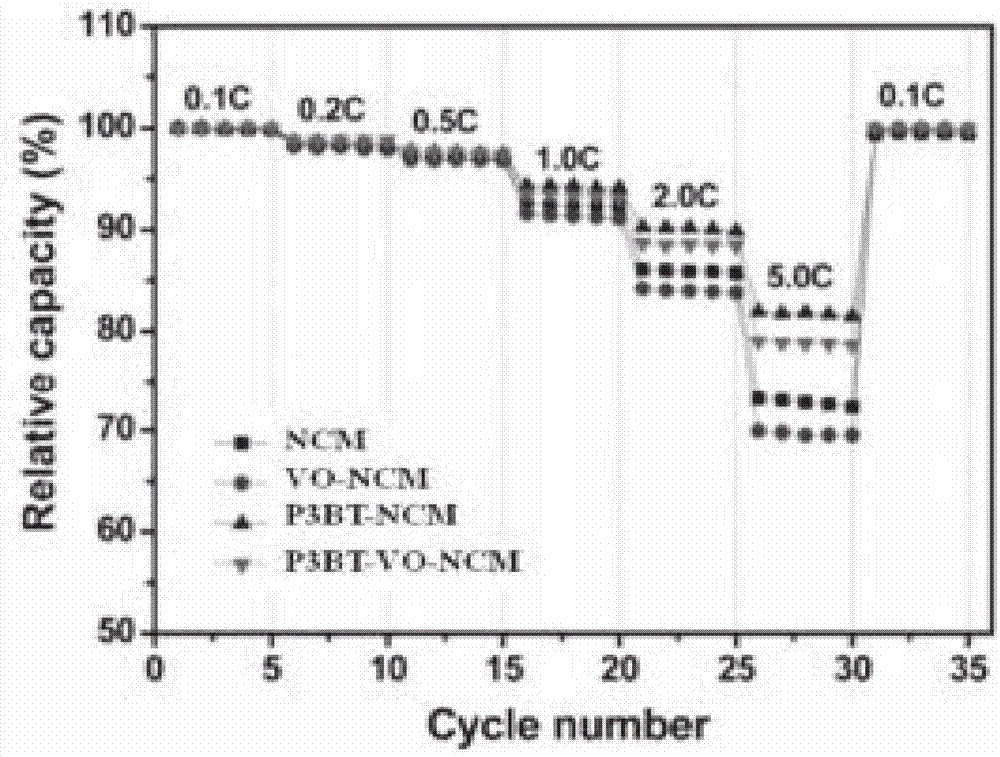

High-security double-coated Ni-Co lithium manganite anode material and preparation method thereof

InactiveCN107394166AAvoid churnImprove battery stabilityCell electrodesSecondary cellsManganitePolymer

The invention discloses a high-security double-coated Ni-Co lithium manganite anode material and a preparation method thereof. In the anode material, a core is made of Ni-Co lithium manganite; and the anode material also comprises an inner layer coating material (V2O5) and an outer layer coating material (a conductive high-molecular polymer). The two coating layers with uniform thickness can be formed on the surfaces of particulate matters of the anode active material, the inner layer is made of V2O5, and the outer layer is made of the conductive high-molecular polymer. Relative to other inorganic matters, V2O5 has higher ionic conductivity and reacts with LiOH and Li2CO3 on the surface of an NCM (Ni-Co-Mn) material in a preparation process to form LiVO3 at the same time, so that the reaction of the anode material and HF (hydrogen fluoride) in electrolyte is avoided. Through adoption of the conductive high-molecular polymer of the outer layer, on one hand, the characteristic of electronic conductivity of the anode material can be improved, and on the other hand, the loss of a V element in a long-term circulation process of a battery can be avoided; and therefore, the stability of the battery is improved.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

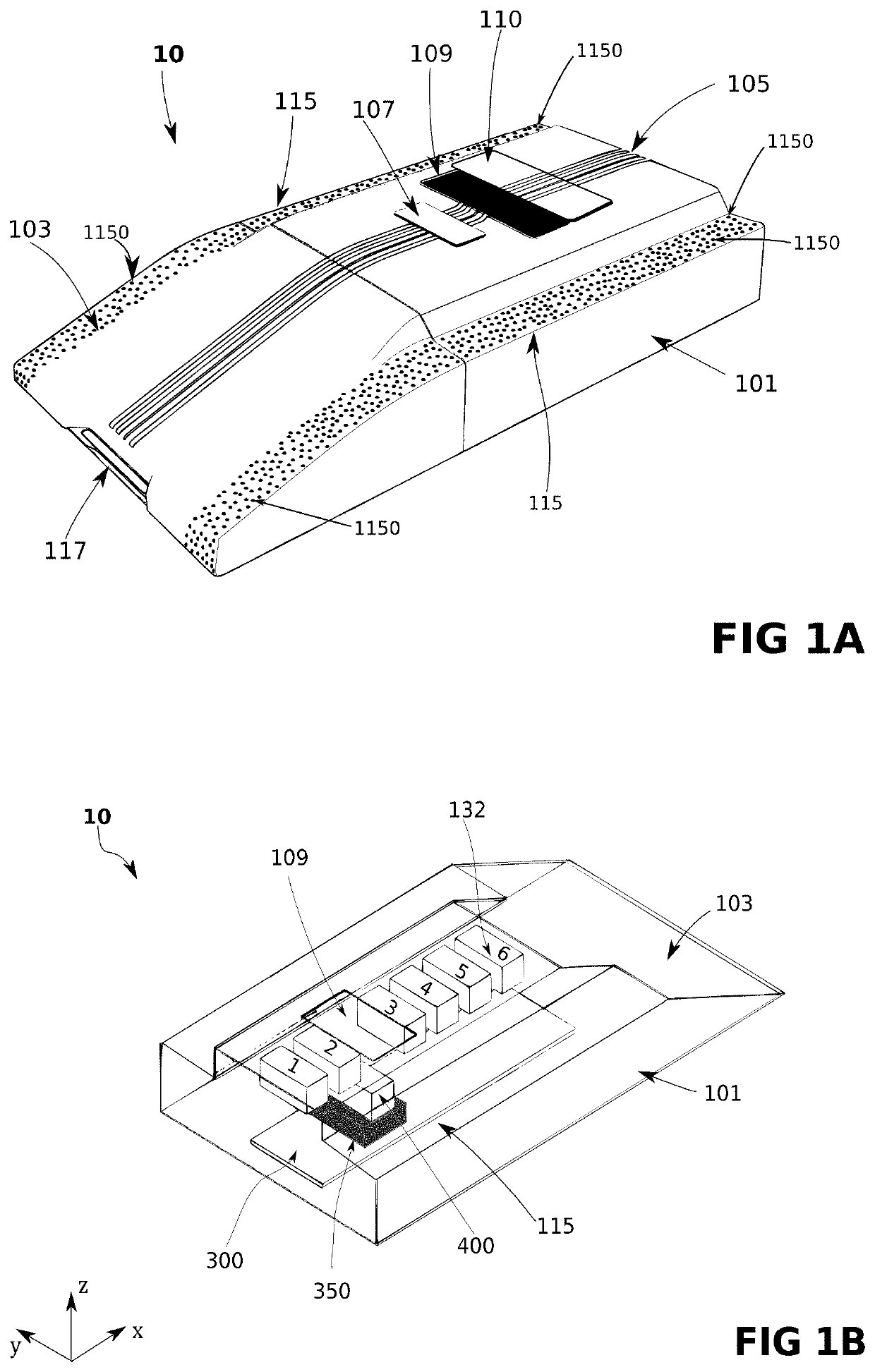

Coin cell battery analyzed with in-situ x-ray analysis, method of manufacturing the same, and method of analyzing the same using x-ray

ActiveUS20160036011A1Large capacityImprove battery stabilityFinal product manufactureElectrode carriers/collectorsX-rayX ray analysis

An in-situ X-ray analyzed coin cell battery includes a case, a cap combined with the case, and an energy storage member provided between the case and the cap. A hole through which an X-ray is irradiated is defined in at least one of the case and the cap.

Owner:SAMSUNG ELECTRONICS CO LTD

Battery assembly using printed circuit board substrate including bus bar

InactiveUS20170025660A1Improve battery stabilityWorkability of soldering can be improvedCells structural combinationCell component detailsElectrical bondingPrinted circuit board

Disclosed is a battery assembly with a PCB substrate, comprising a bus bar stepped and end processed for enhanced assembly performance and electrical bonding reliability, and a PCB substrate having an assembling groove with an end of the bus bar and an insulating film for an improved stability.

Owner:VITZROCELL

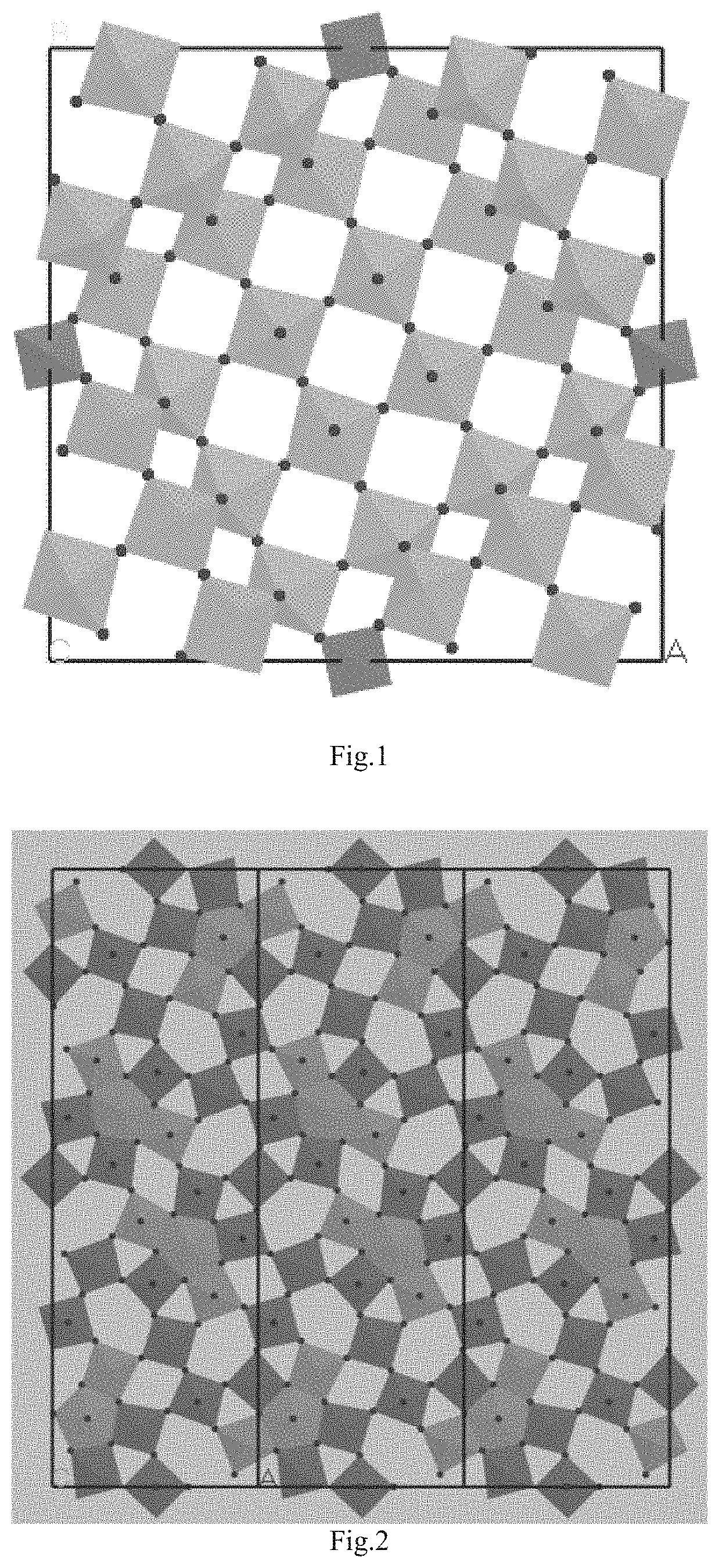

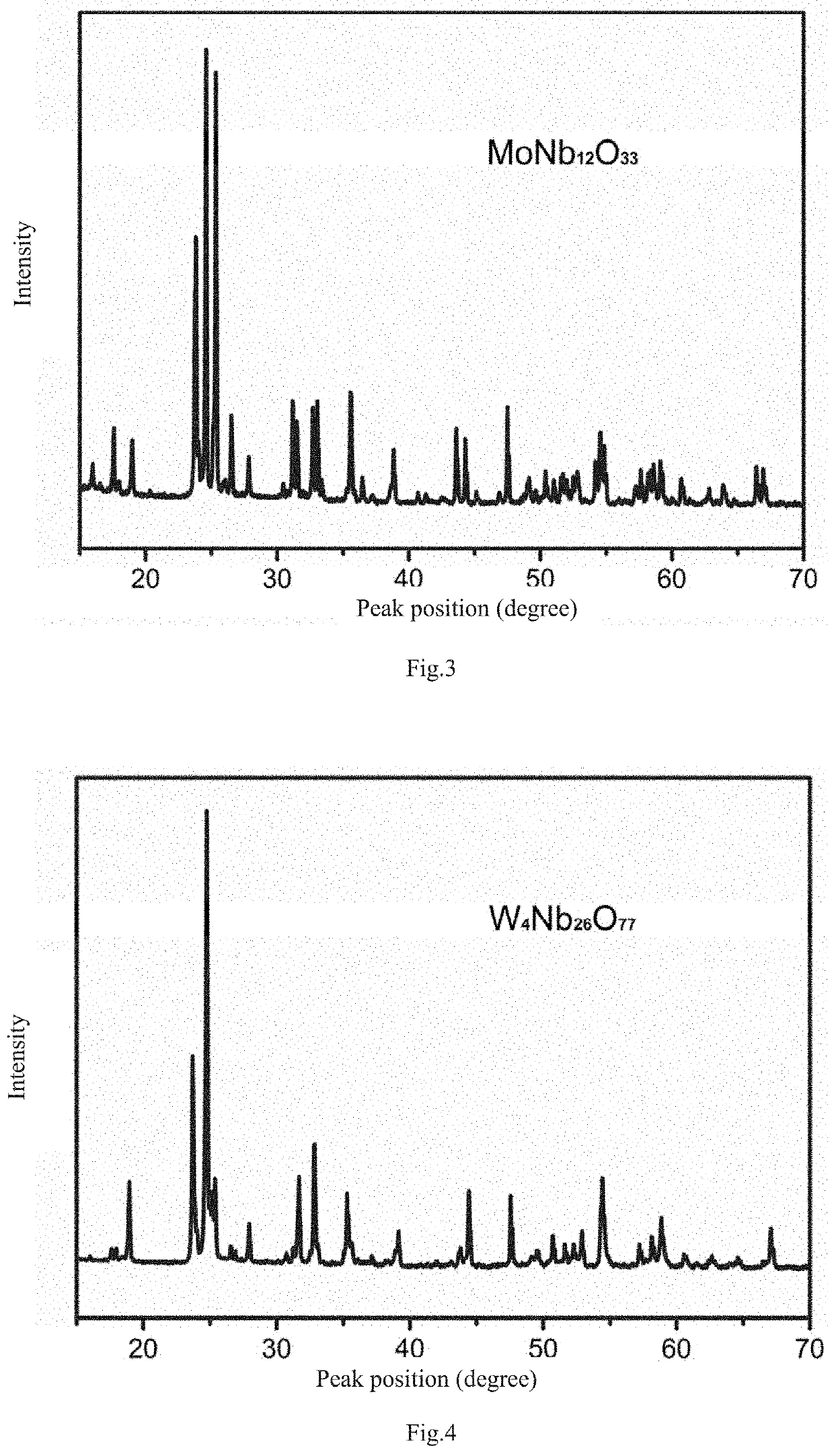

Anode Material of Lithium Ion Battery And Non-aqueous Electrolyte Battery

InactiveUS20200152963A1Improve charge rate performanceImprove performanceNegative electrodesElectrode collector coatingPhysical chemistryAqueous electrolyte

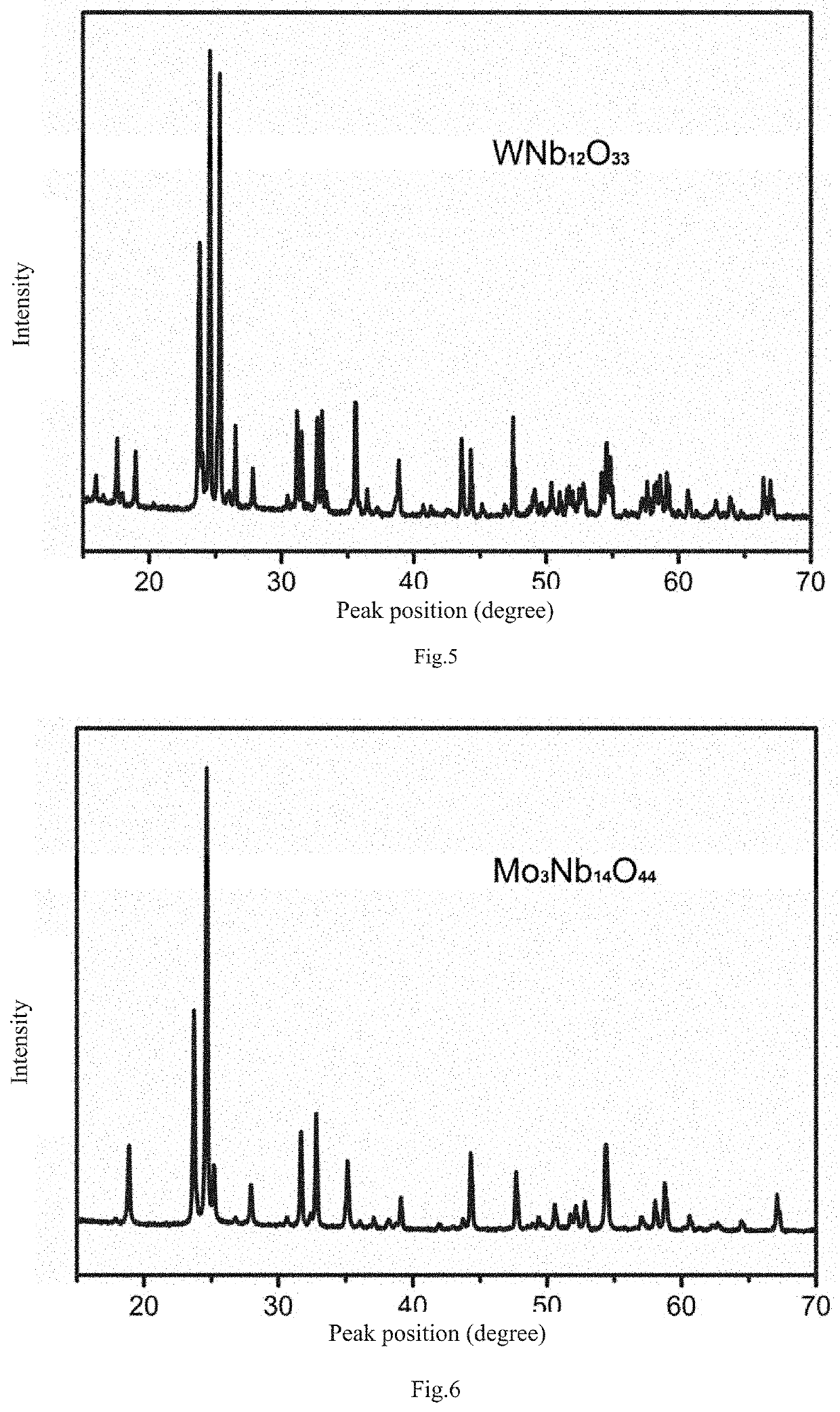

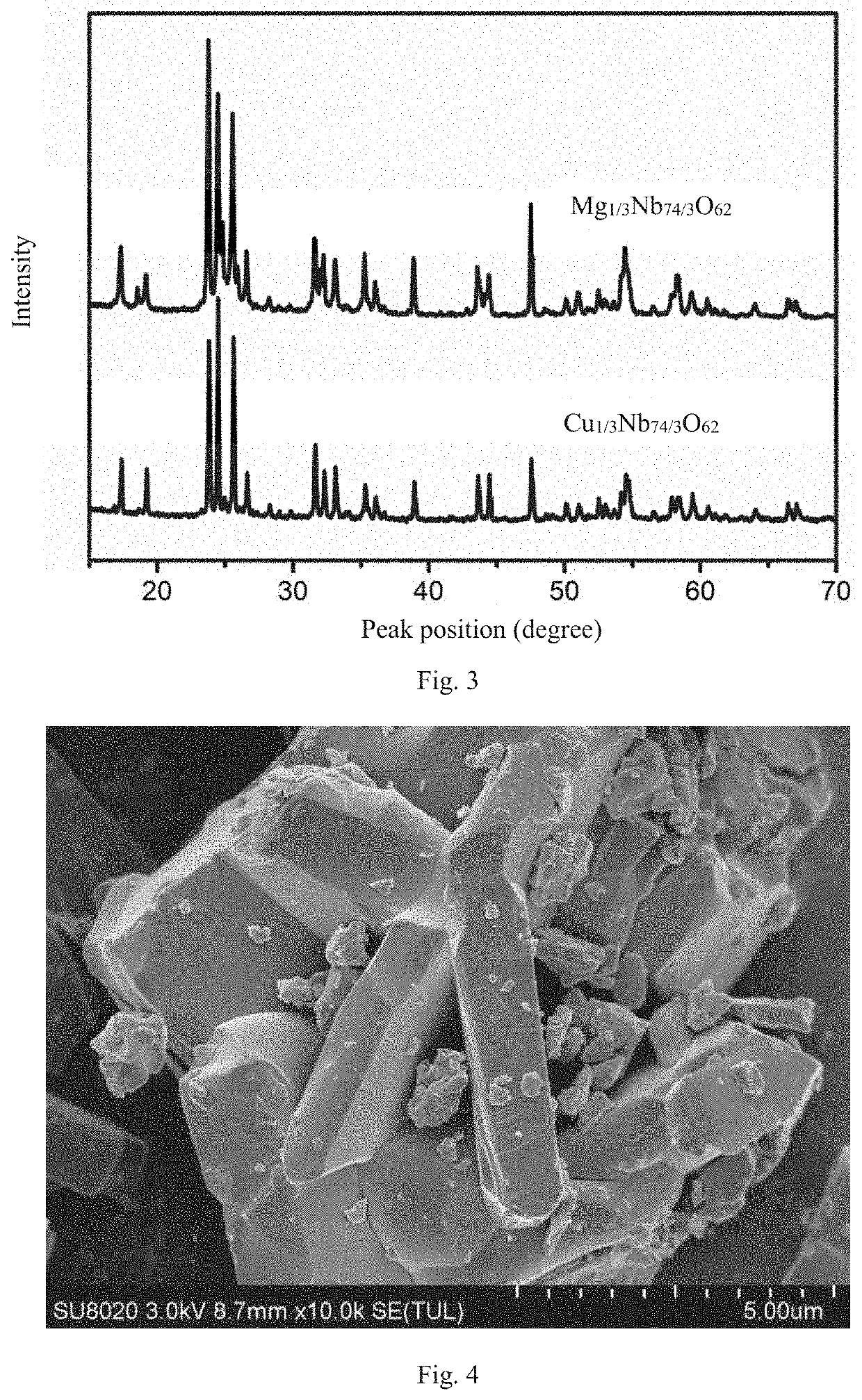

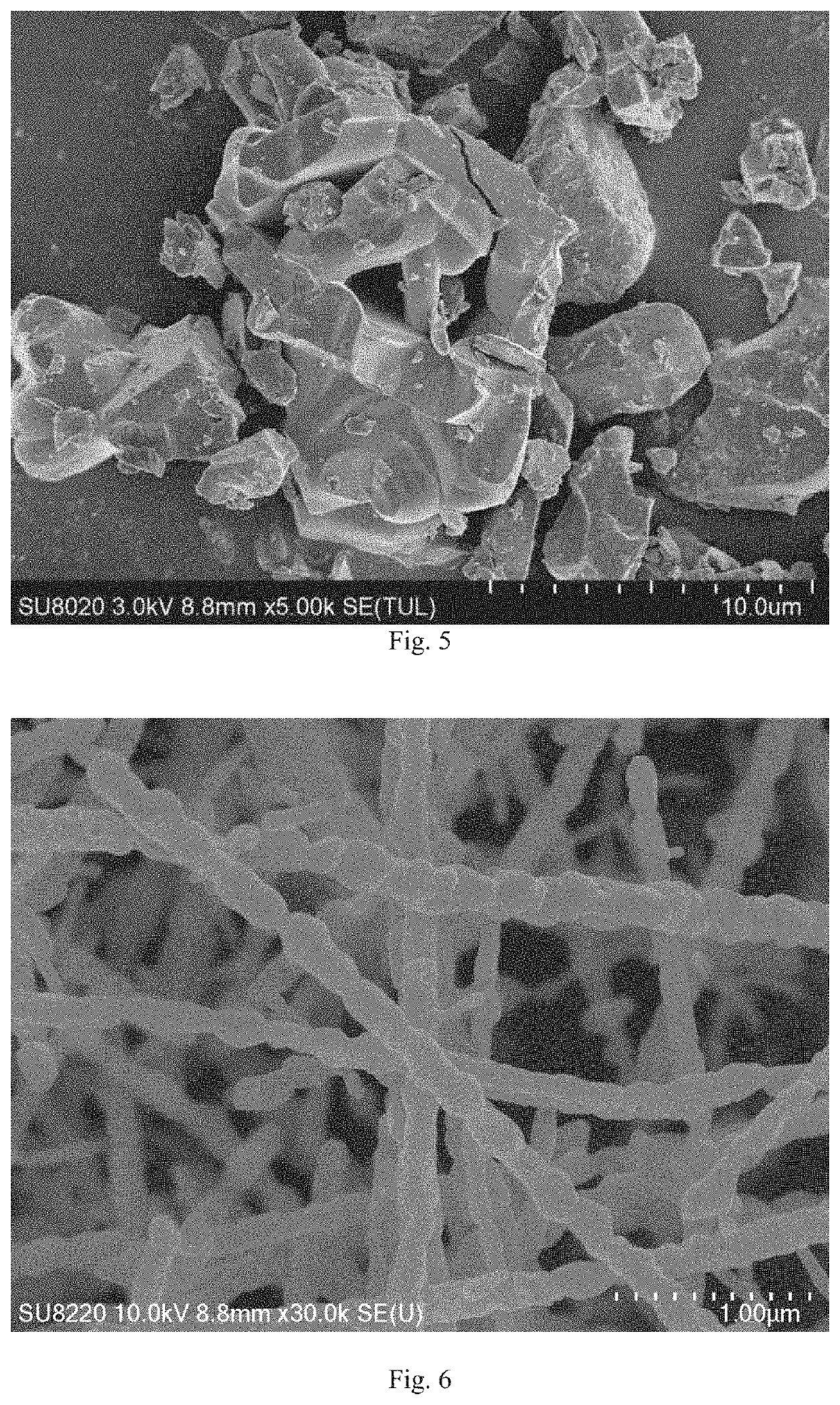

An anode material of a lithium-ion battery according to the present invention is disclosed. A chemical formula of the anode material of the lithium-ion battery is MxNbyOz, wherein, M is a pentavalent non-niobium metal ion or a hexavalent non-niobium metal ion, and x, y, z satisfy the following conditions: 1<x≤16, 2≤y≤28, and 13≤z≤94.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Anode Material of Lithium Ion Battery And Non-aqueous Electrolyte Battery

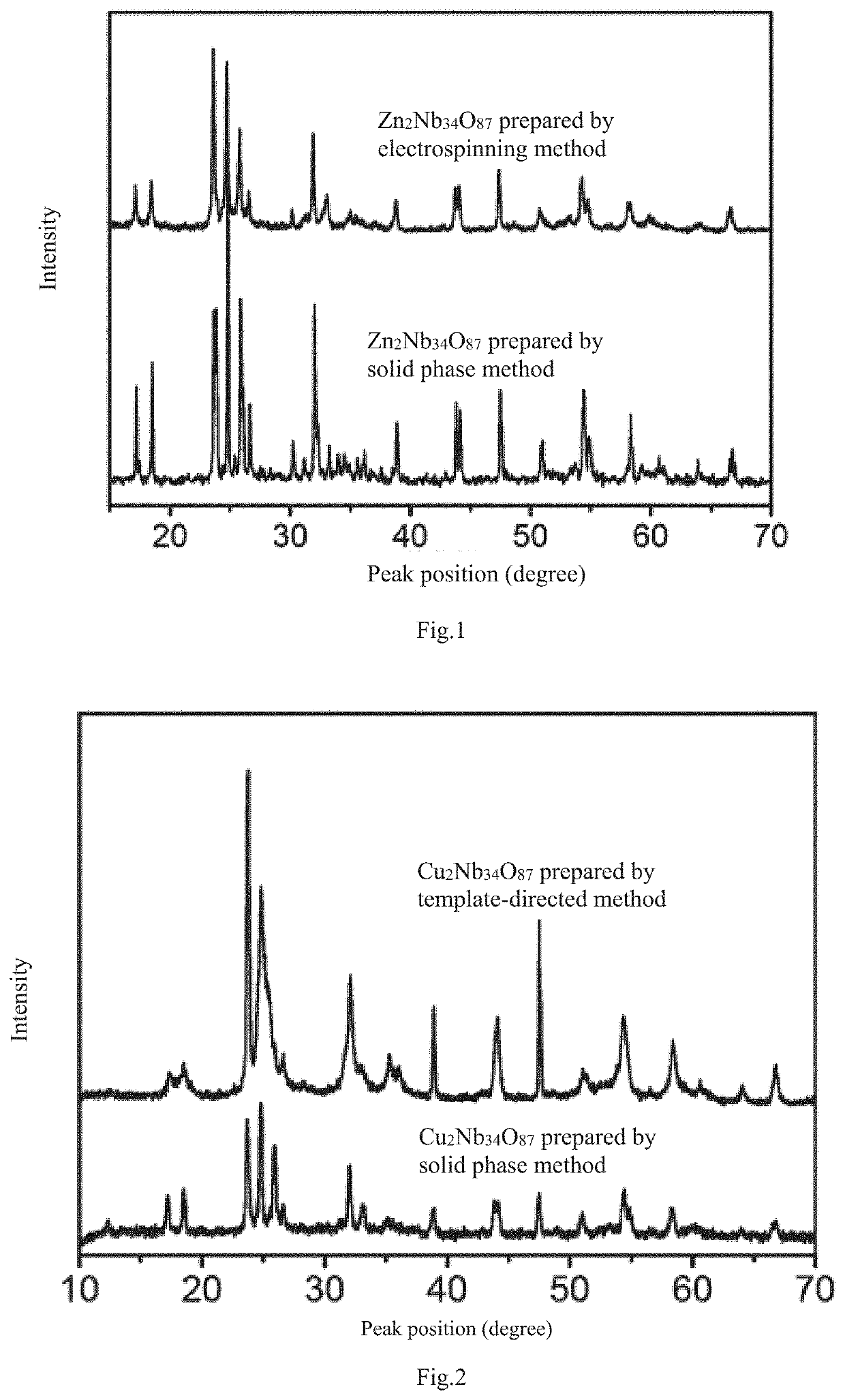

ActiveUS20200112018A1Improve charge rate performanceImprove performanceSolid electrolytesSecondary cellsPhysical chemistryAqueous electrolyte

An anode material of a lithium-ion battery and a non-aqueous electrolyte lithium-ion battery are disclosed in the present invention. The anode material of a lithium-ion battery, wherein, a chemical formula of the anode material of the lithium-ion battery is MxNbyOz, wherein, M is a bivalent non-niobium metal ion, and x,y,z satisfy the following conditions: 0<x≤3, 1≤y≤34, and 3≤z≤87.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

No-welding type battery pack

ActiveUS7939189B2Simplify the assembly processIncrease battery capacityBatteries circuit arrangementsCells structural combinationBattery cellBattery pack

Disclosed herein is a battery pack, which comprises a connecting member including an insulation frame mounted to the upper end of a battery cell and a pair of connection protrusions formed at the upper end surface of the frame, the connection protrusions being in contact with electrode terminals of the battery cell, a protection circuit module (PCM) mounted to the connecting member, the PCM including connection grooves, into which the connection protrusions are inserted such that the PCM can be coupled to the connecting member, and which are connected to a protection circuit, and a cap housing coupled to the connecting member or the battery cell while the PCM is surrounded by the cap housing.

Owner:LG ENERGY SOLUTION LTD

No-welding type battery pack using forced-inserting type rivet

ActiveUS7976969B2Simplify the assembly processShorten the timeFinal product manufactureCell lids/coversElectrical connectionSoldering

Disclosed herein is a no-welding type battery pack using one or more forced-inserting type rivets. A cap assembly includes a base plate mounted to an open upper end of a battery case, a protection circuit module (PCM) mounted on the base plate, and a top cap coupled to the upper end of the battery case while the top cap covers the PCM. The top cap is made of an insulative material. The electrical connection and the mechanical coupling between the PCM and the base plate are accomplished by one or more forced-inserting type rivets. The cap assembly is included the battery pack. The no-welding type battery pack using the one or more forced-inserting type rivets is manufactured without welding or soldering requiring an excessive amount of time and skilled technique during the electrical connection between the battery cell and the PCM. As a result, the assembly process of the battery pack is simplified, and therefore, the manufacturing time of the battery pack is reduced. Consequently, the manufacturing costs of the battery pack are decreased, the automation of the assembly process is accomplished, and the structural stability of the battery pack is improved.

Owner:LG ENERGY SOLUTION LTD

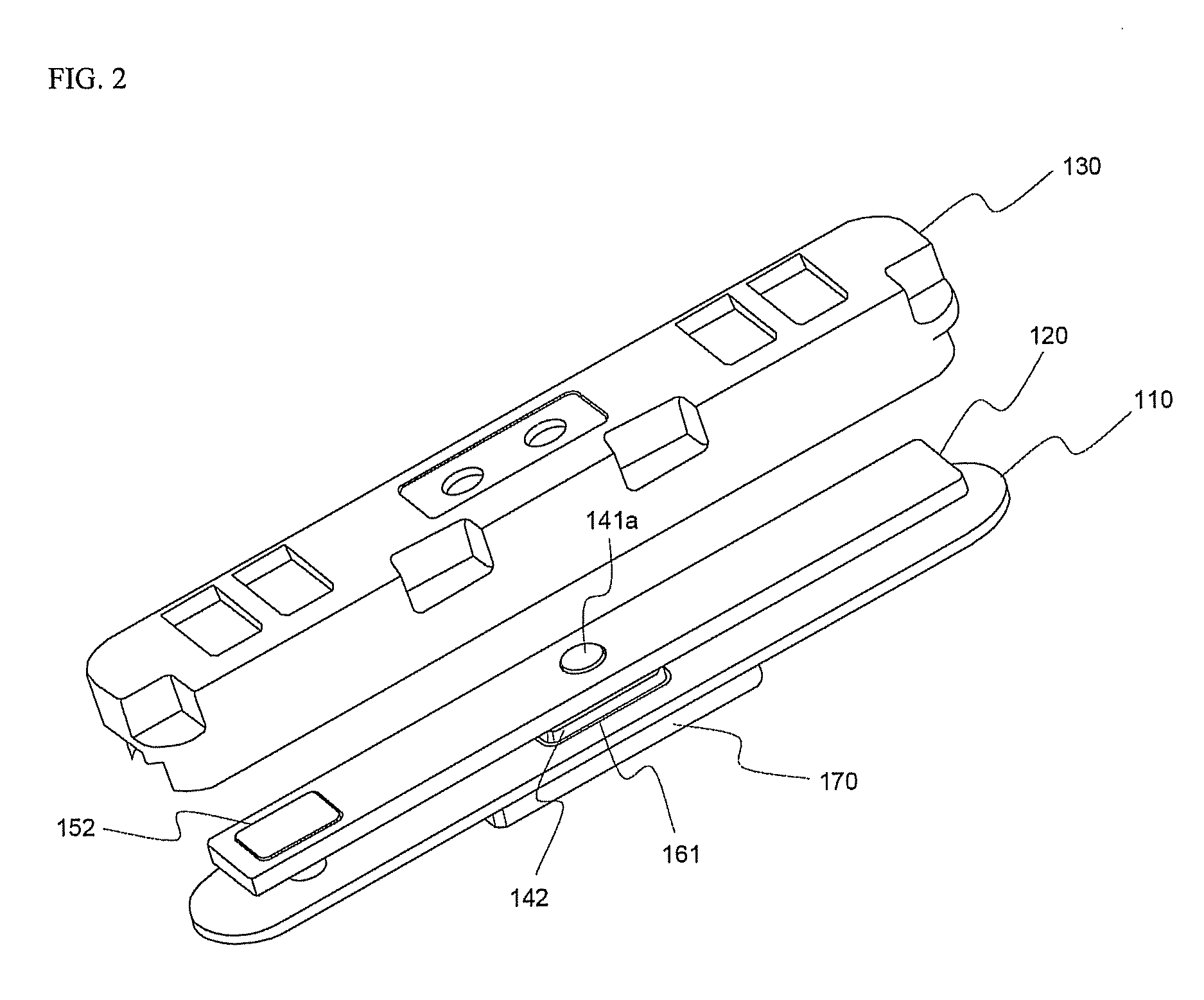

Battery and a system for swapping and/or charging a battery of a mobile robot

ActiveUS20200091565A1Promote exchangeEasy battery replacementCharging stationsCells structural combinationComputer hardwareElectrical connector

A battery configured to be attached to a battery holder for use by a mobile robot comprising: a battery body encapsulating the battery; at least two electrical connectors protruding from the battery body; at least one fixing unit located on the battery body said fixing unit configured to fix the battery to the battery holder; at least two damping pins protruding from the battery body; and at least one battery communication component configured to transmit battery status data. A battery holder configured to hold the battery and at least one of storing, swapping and charging a battery.

Owner:STARSHIP TECH OU

Secondary battery with improved storage characteristics and method for manufacturing the same

ActiveUS20120321933A1Improve stabilityImprove wettabilityFinal product manufactureSecondary cellsInorganic particleElectrical battery

Provided is a secondary battery comprising a separator having an inorganic layer wherein active sites of inorganic particles in the inorganic layer are modified into non-reactive sites. Use of the separator leads to improvements in wettability of an electrolyte and thermoelectric stability and storage characteristics of the secondary battery. Provided is also a method of manufacturing the same secondary battery.

Owner:LG ENERGY SOLUTION LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com