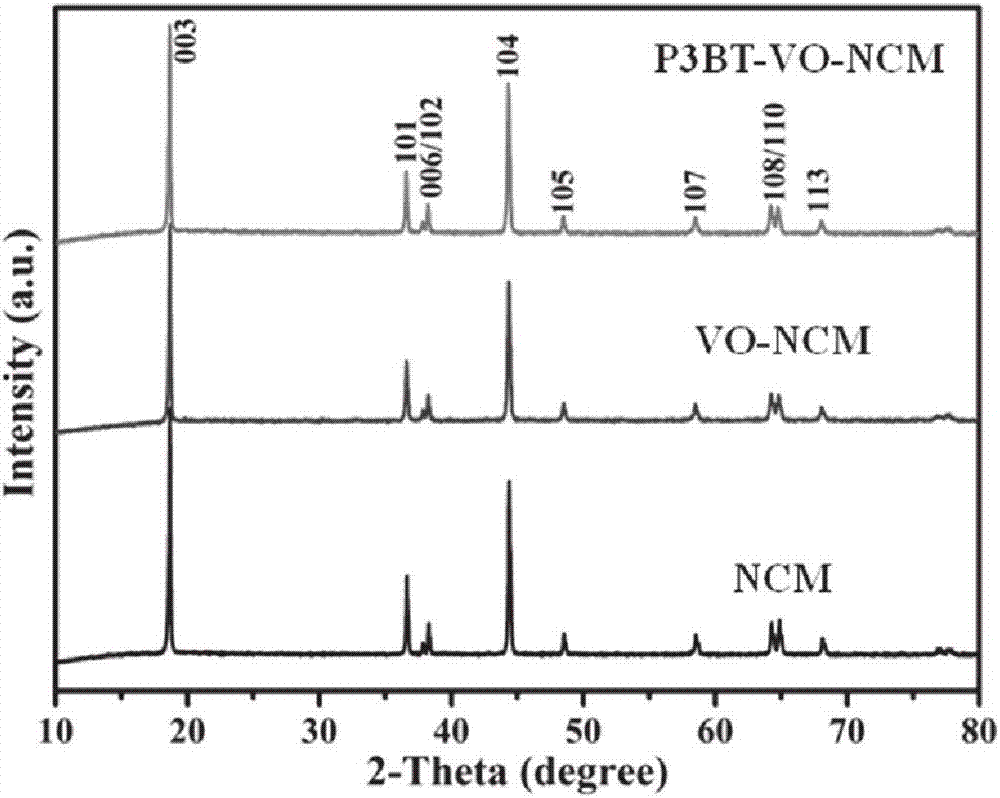

High-security double-coated Ni-Co lithium manganite anode material and preparation method thereof

A technology of nickel-cobalt lithium manganate and double-layer coating is applied in the field of high-safety double-layer-coated nickel-cobalt lithium manganate cathode material and its preparation field, which can solve the problem of increasing interface resistance, reducing battery performance, and reducing lithium ion Conductivity and other issues to avoid leakage and improve battery stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

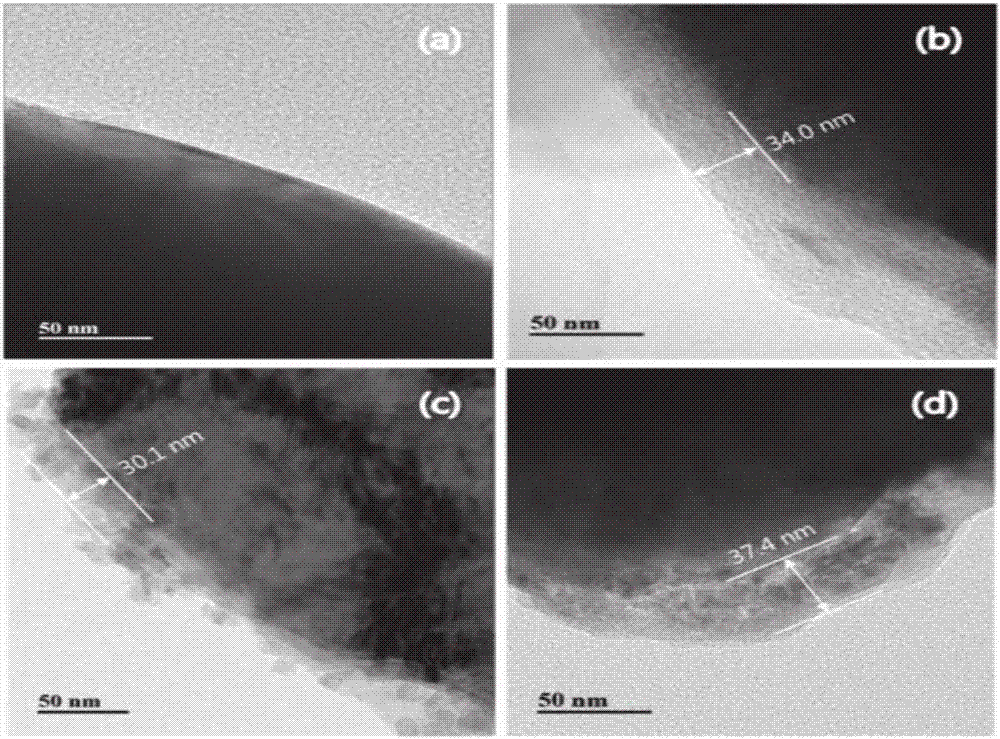

[0026] V 2 o 5 Coated NCM, butylthiophene (3BT) and sodium p-toluenesulfonate were stirred in absolute ethanol and mixed evenly, FeCl 3 As an oxidant, it was continuously dropped into the mixture, and the mixture was continuously stirred for 24 hours in an ice-water bath to carry out polymerization reaction. Afterwards, the reaction product was filtered, washed and vacuum-dried at 80° C. for 12 h to obtain P3BT-VO-NCM.

[0027] Mix P3BT-VO-NCM, acetylene black, KS-6, and PVDF evenly according to the mass ratio of 9.2︰0.3︰0.2︰0.3, add an appropriate amount of NMP, and stir to make a uniform slurry; spread the slurry evenly Put it on the aluminum foil, dry it in a blast drying oven, and then put it in a vacuum drying oven at 120°C for 12 hours in a vacuum; after natural cooling, use a punching machine to punch out a disc with a diameter of 16mm, and put the disc on the tablet press. After being compacted with a pressure of 10MPa, the positive electrode sheet is obtained. The...

Embodiment 2

[0030] The material and battery preparation process are similar to those in Example 1, and the conductive polymer monomer is pyrrole.

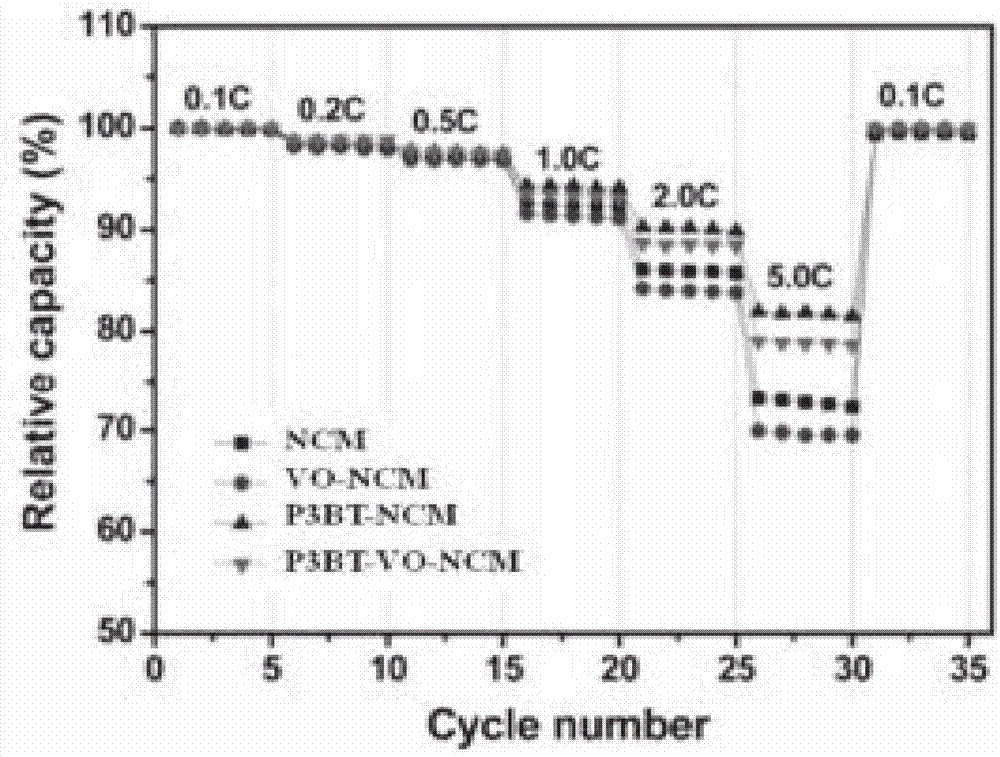

[0031] Carry out constant current charge and discharge test at room temperature. The test voltage range of rate performance is 2.6V ~ 4.3V. Cycle 5 times at 0.1C. The voltage range of the cycle performance test is also 2.6V ~ 4.3V, 100 cycles at 0.5C. The first discharge capacity of electrochemical test at 0.5C is 170.2mAh / g.

Embodiment 3

[0033]The material and battery preparation process are similar to those in Example 1, and the conductive polymer monomer is 3-hexylthiophene.

[0034] Carry out constant current charge and discharge test at room temperature. The test voltage range of rate performance is 2.6V ~ 4.3V. Cycle 5 times at 0.1C. The voltage range of the cycle performance test is also 2.6V ~ 4.3V, 100 cycles at 0.5C. The first discharge capacity of electrochemical test at 0.5C is 170.1 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com