Preparation method of polymer porous membrane for removing water pollutants

A technology of water pollutants and polymer membranes, applied in the field of separation membranes, can solve the problems of complex operation process, cyclodextrin and its derivative components are easy to lose and cannot be removed, and achieve simple preparation process and large-scale continuous Separation and automatic operation, the effect of fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] 3) Preparation of polymer porous membrane: prepare a polymer porous membrane with the casting solution prepared in step 2, and the polymer porous membrane is a polymer flat membrane or a polymer hollow fiber membrane.

[0046] On the basis of the above scheme, the polymer membrane material described in step 1) is polysulfone, polyethersulfone, polyvinylidene fluoride, naphthalene polyether sulfone ketone, polyacrylonitrile, polyvinyl alcohol, polyether ether A combination of any one or two or more of ketone, polyetherimide or polyvinyl chloride in any ratio, preferably polysulfone, polyethersulfone, polyvinylidene fluoride or naphthalene polyethersulfone ketone Any one or two or more of the composition in any ratio.

[0047] On the basis of the above scheme, the porogen in step 1) is any one or two or more of water-soluble polymer polyvinylpyrrolidone, polyethylene glycol, formic acid, acetic acid, nano-silica or titanium dioxide Proportioning composition.

[0048] On the ba...

Embodiment 1

[0068] The dried polymer membrane material polysulfone 8g, 0.1g porogen nano titanium dioxide, dissolved in 86.9g N,N-dimethylacetamide organic solvent, heated to increase the temperature, fully stirred at 50 ℃ until the polymer The membrane material is completely dissolved, continue to heat up under stirring conditions, when the temperature rises to 80°C, add 5g of α-cyclodextrin to the above solution, continue to stir to make it fully swell and dissolve, and prepare a mixed solution;

[0069] Maintain the temperature of the mixed solution at 80°C, add 5g of the cross-linking agent epichlorohydrin to the mixed solution, cross-link at 80°C for 5 hours, stand still, filter, and vacuum to defoam to obtain a casting solution;

[0070] First take the weight per unit area as 71.5g / m 2 , The polyester non-woven fabric base film with the pore size range of 23.31μm is installed on the film scraper, and then the prepared casting liquid is poured into the hopper of the film scraper, and the c...

Embodiment 2

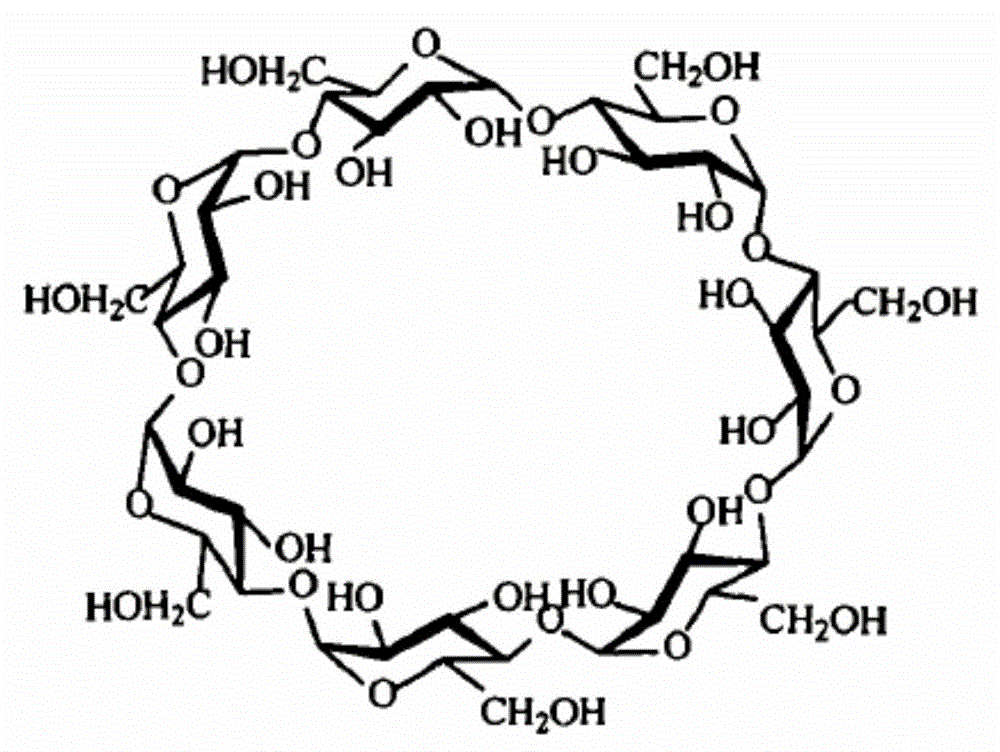

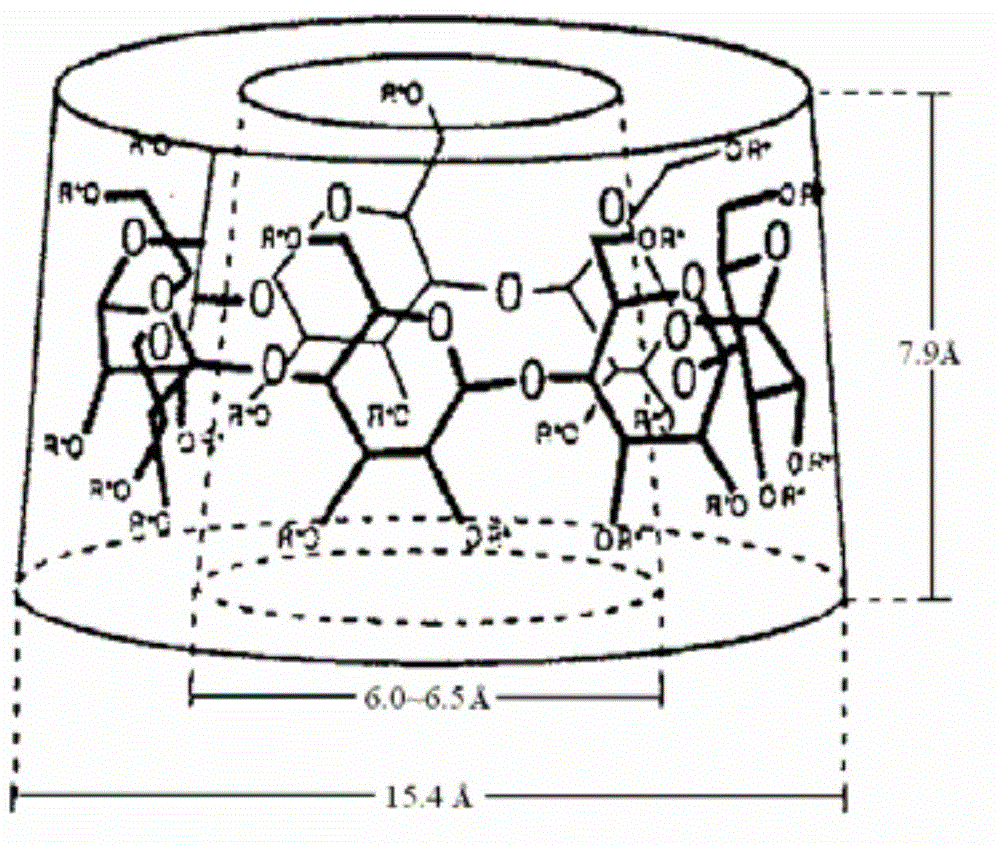

[0072] Take the dried polymer membrane material 14g polyethersulfone and 2g polysulfone, a porogen consisting of 7g polyethylene glycol and 3g acetic acid, dissolve it in 66g N-methylpyrrolidone organic solvent, heat it up, and keep it at 40℃. Fully stir until the polymer film material is completely dissolved, continue to heat up under stirring conditions, when the temperature rises to 50 ℃, add 8g β-cyclodextrin (such as figure 1 , 2 Shown), continue to stir to fully swell and dissolve, and prepare a mixed solution;

[0073] Maintain the temperature of the mixed solution at 50°C, add 25g of the crosslinking agent 1,2-ethylene glycol diglycidyl ether to the mixed solution, crosslink the reaction at 50°C for 12 hours, stand, filter, vacuum defoaming Get the casting liquid;

[0074] First take the weight per unit area as 36.9g / m 2 , The polyester non-woven fabric base film with the pore size range of 23.21μm is installed on the film scraper, and then the prepared casting liquid is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com