Patents

Literature

1447results about How to "Avoid heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

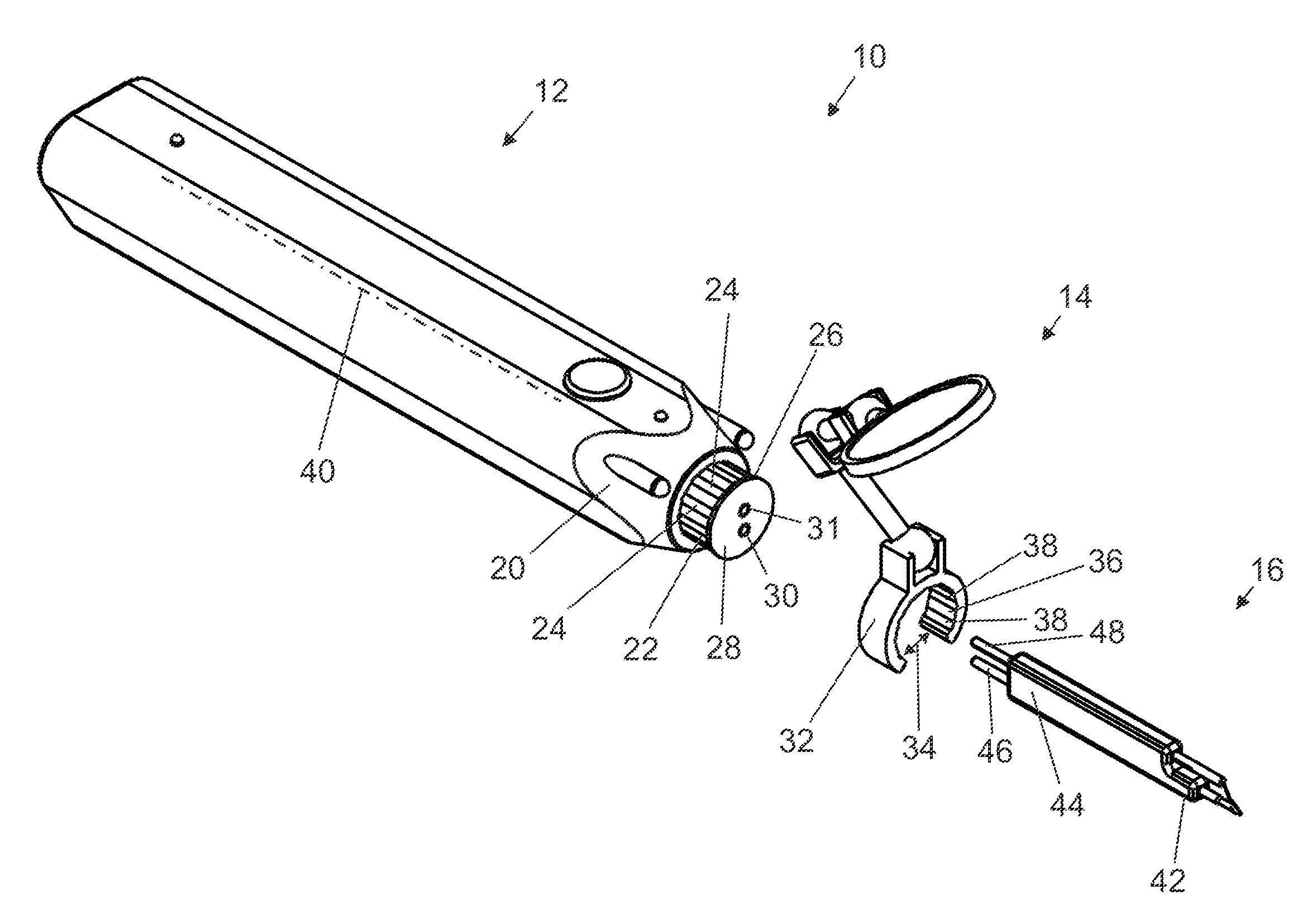

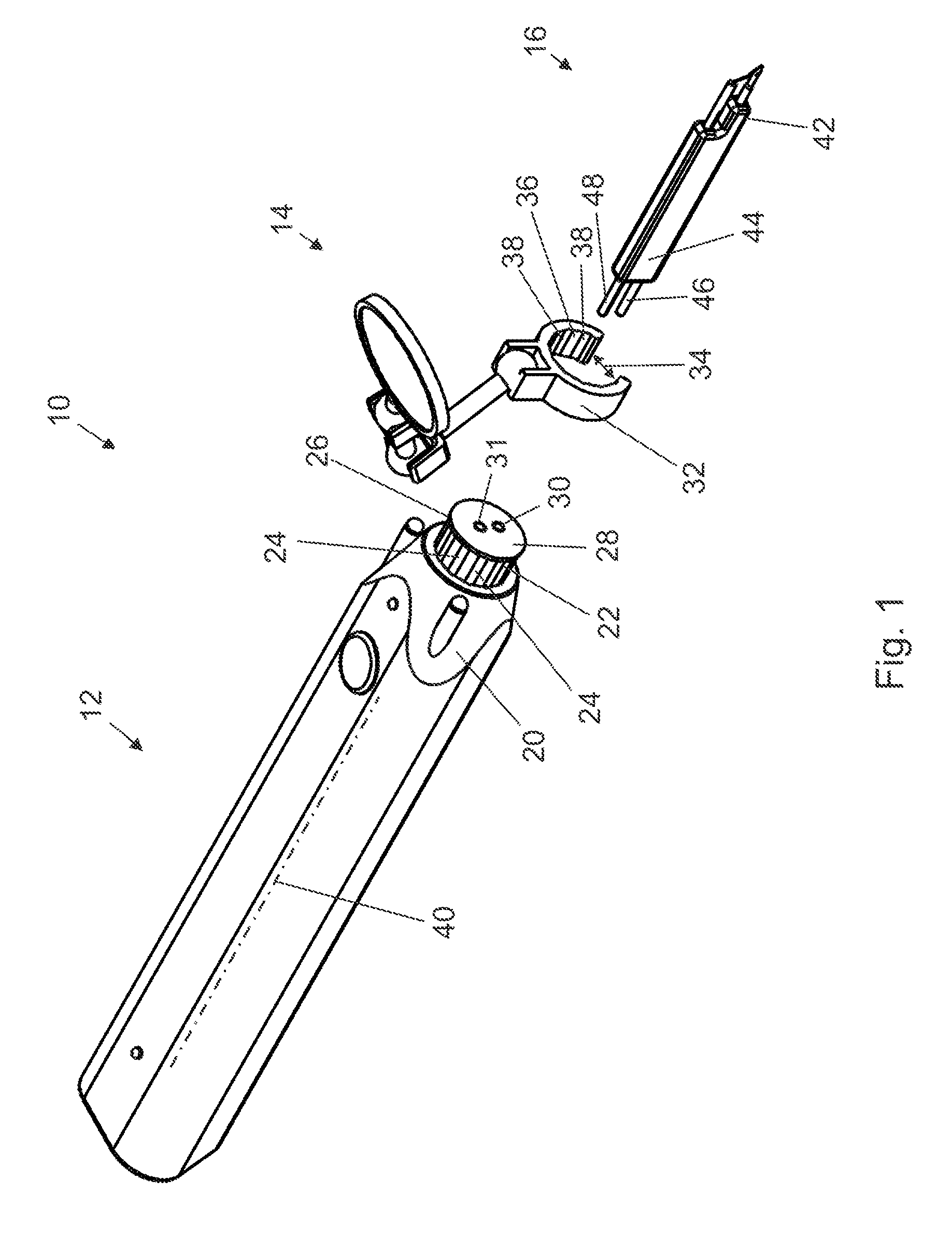

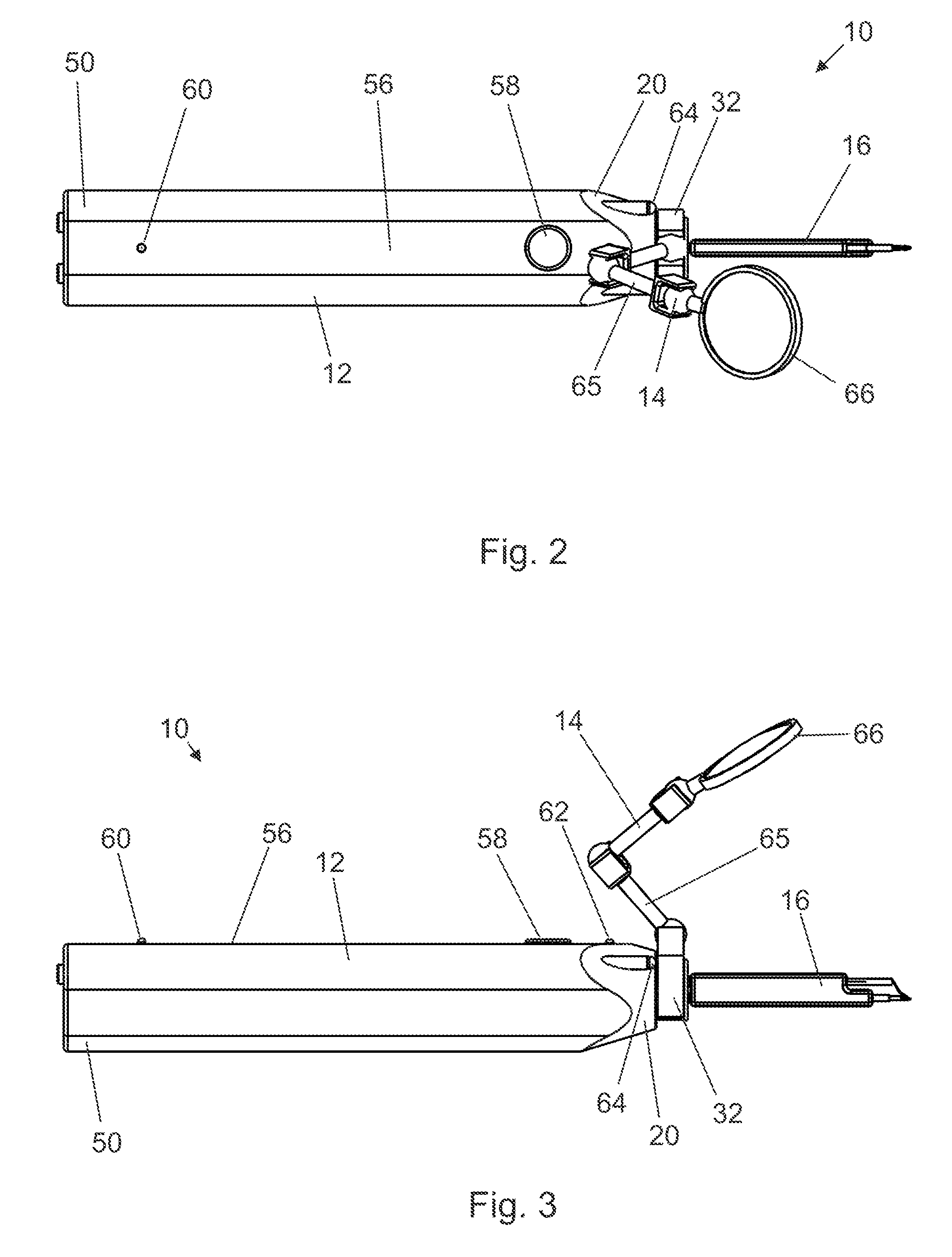

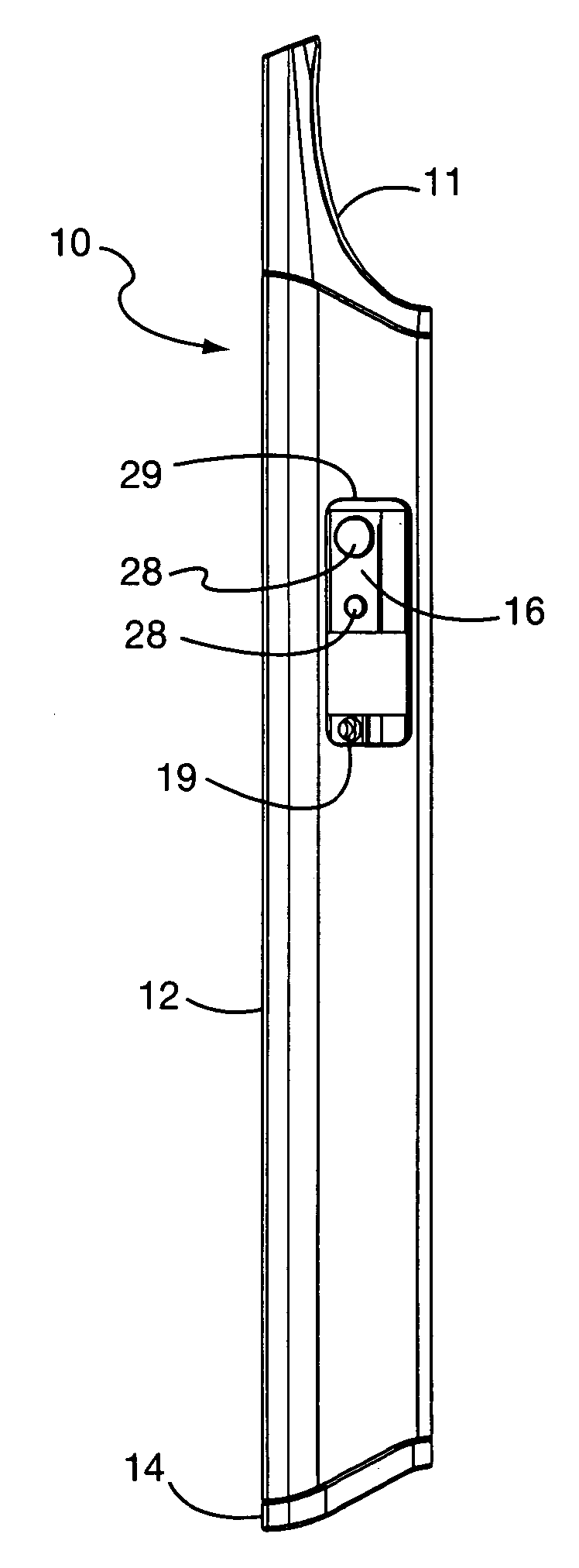

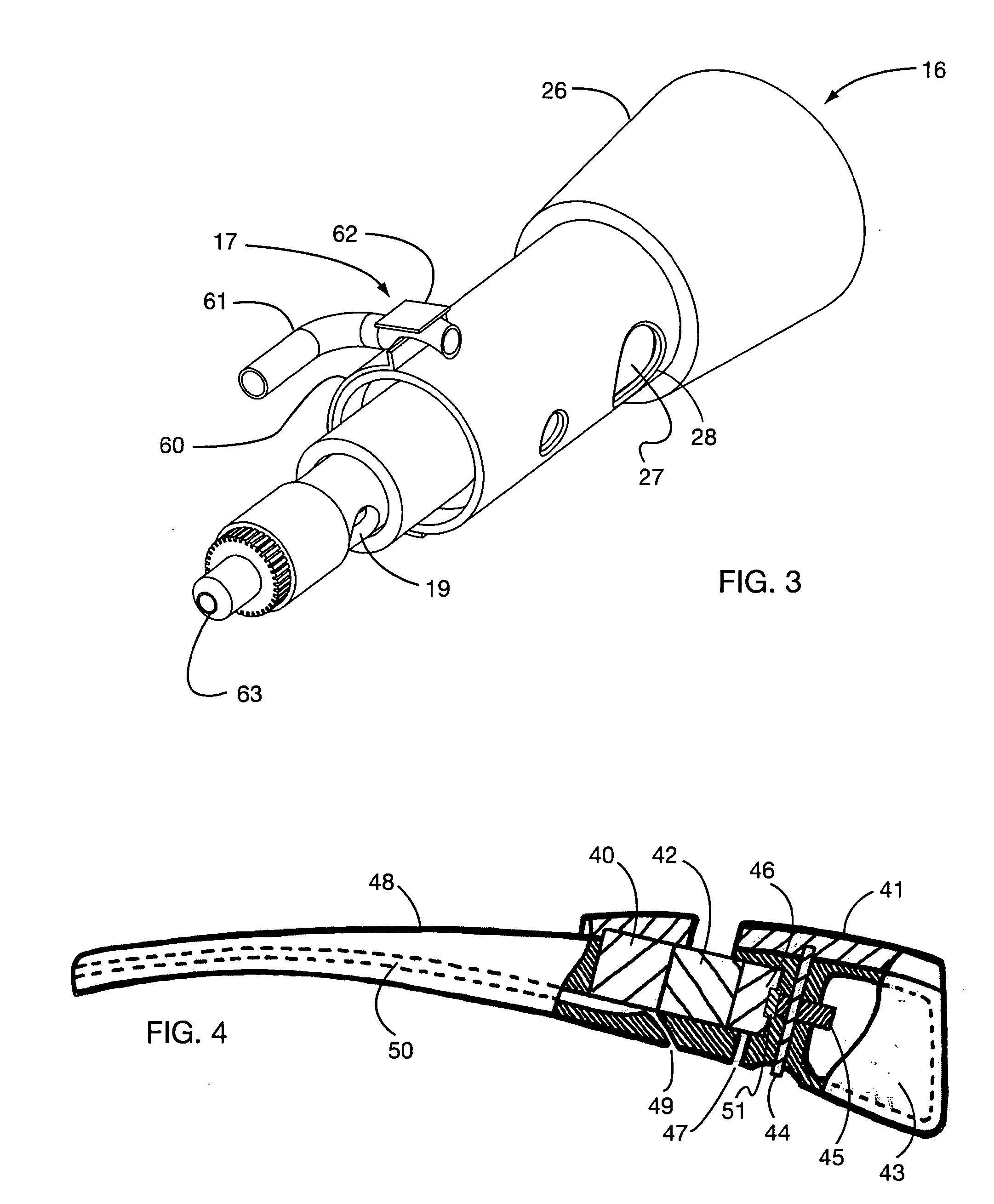

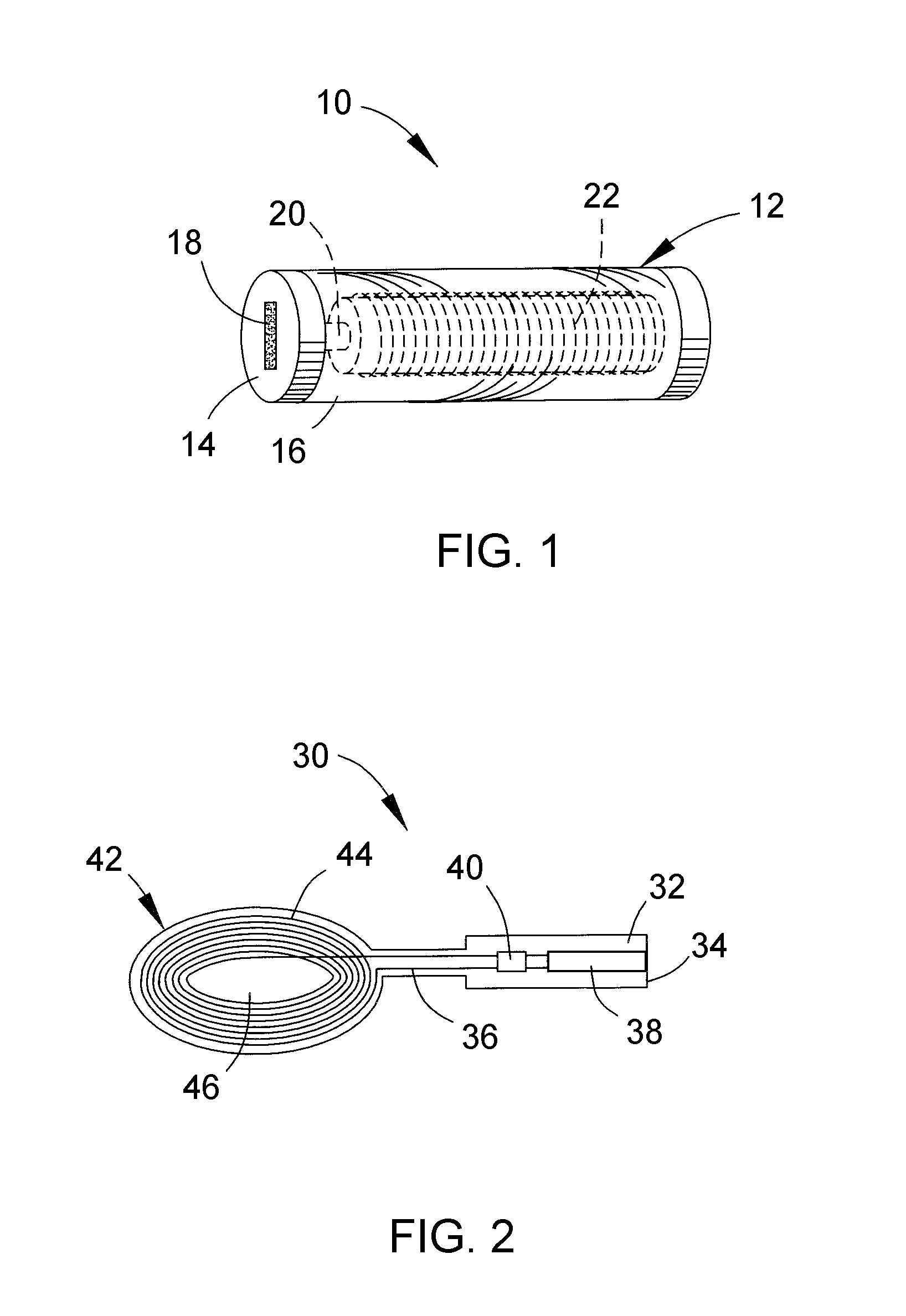

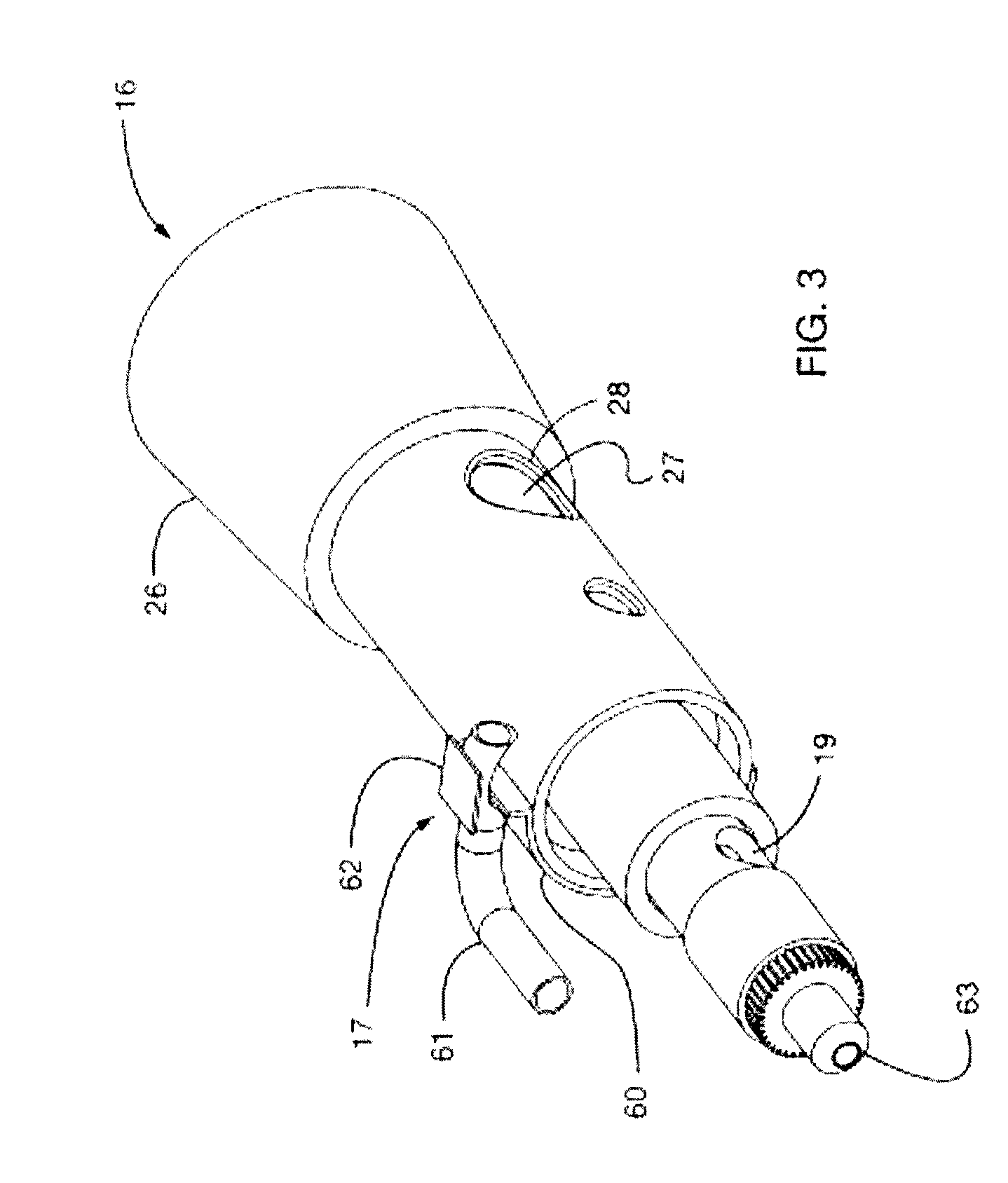

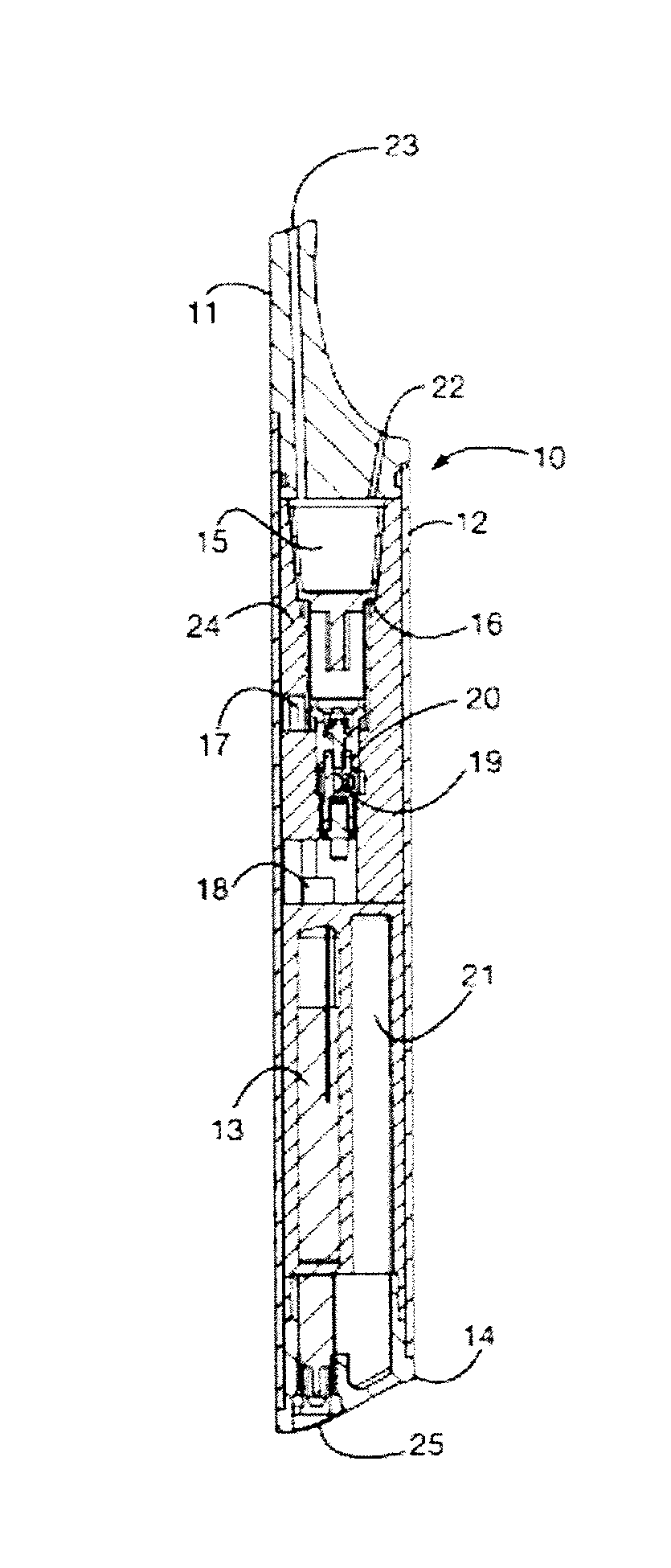

Method, apparatus, and kit for thermal suture cutting

InactiveUS7699856B2Reduce tensionMinimize disruptionSuture equipmentsDiagnosticsForcepsRemoval techniques

A novel suture removal instrument, kit and technique are described herein. The invention utilizes a newly designed thermal filament to allow the tip of the suture removal instrument to be slipped under the stitch in order to heat and cut the stitch. Current suture removal techniques utilize scissors, forceps, and / or scalpels. These techniques, which are well known in the art, are problematic because they exert tension on the stitch and are associated with patient discomfort. Small stitches add to the difficulty of suture removal because they have less suture laxity for scissor insertion. The present invention therefore allows for more rapid suture removal with less patient discomfort and at a competitive or lower cost.

Owner:BOVIE MEDICAL CORP

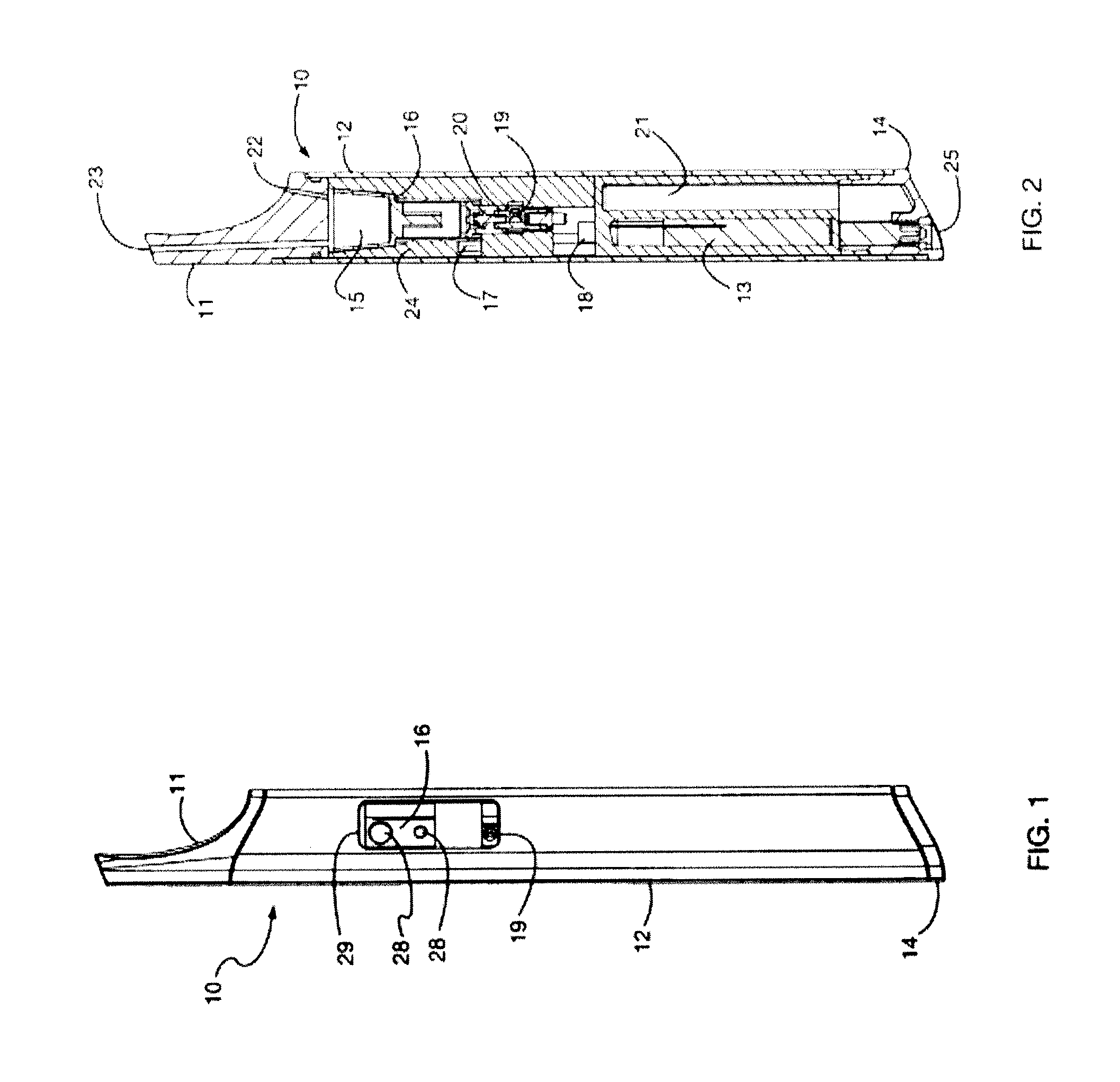

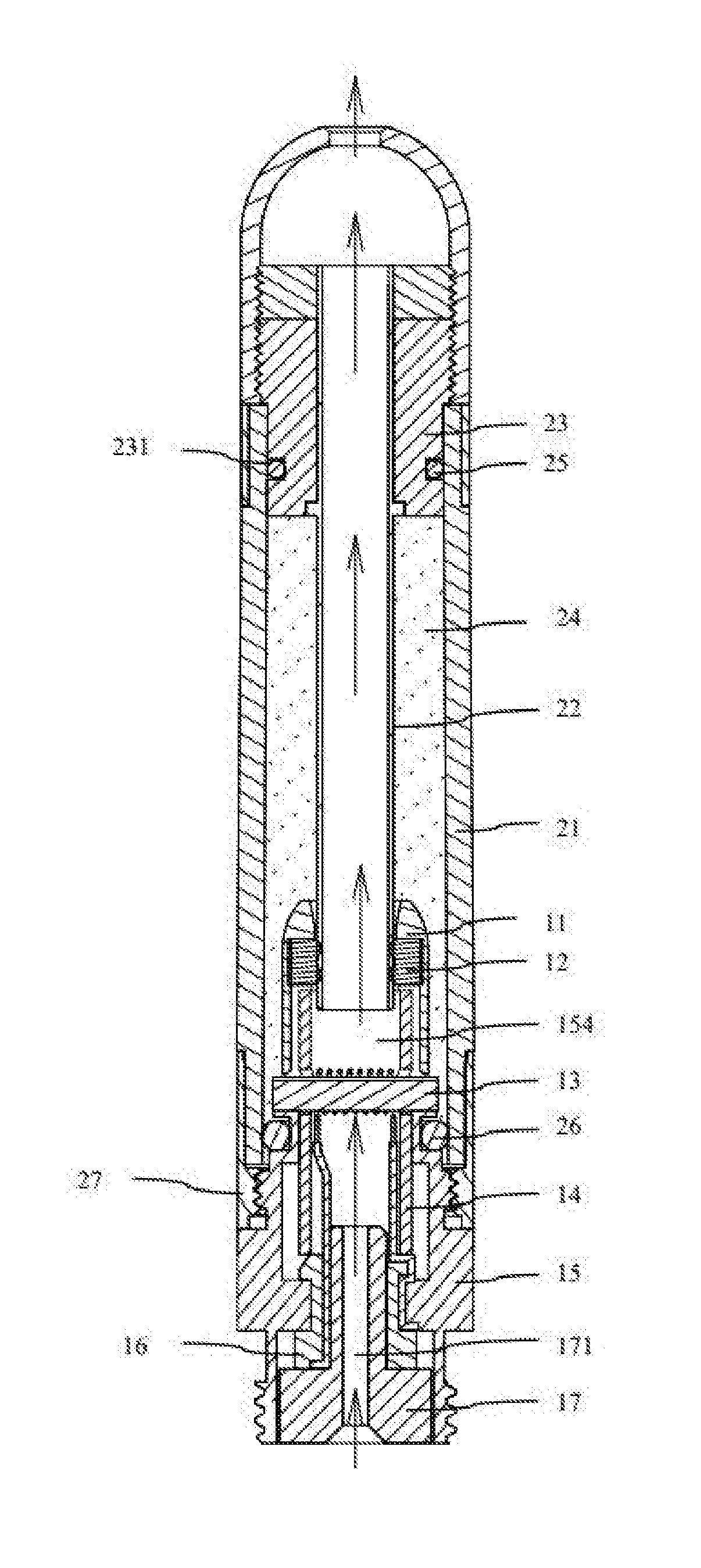

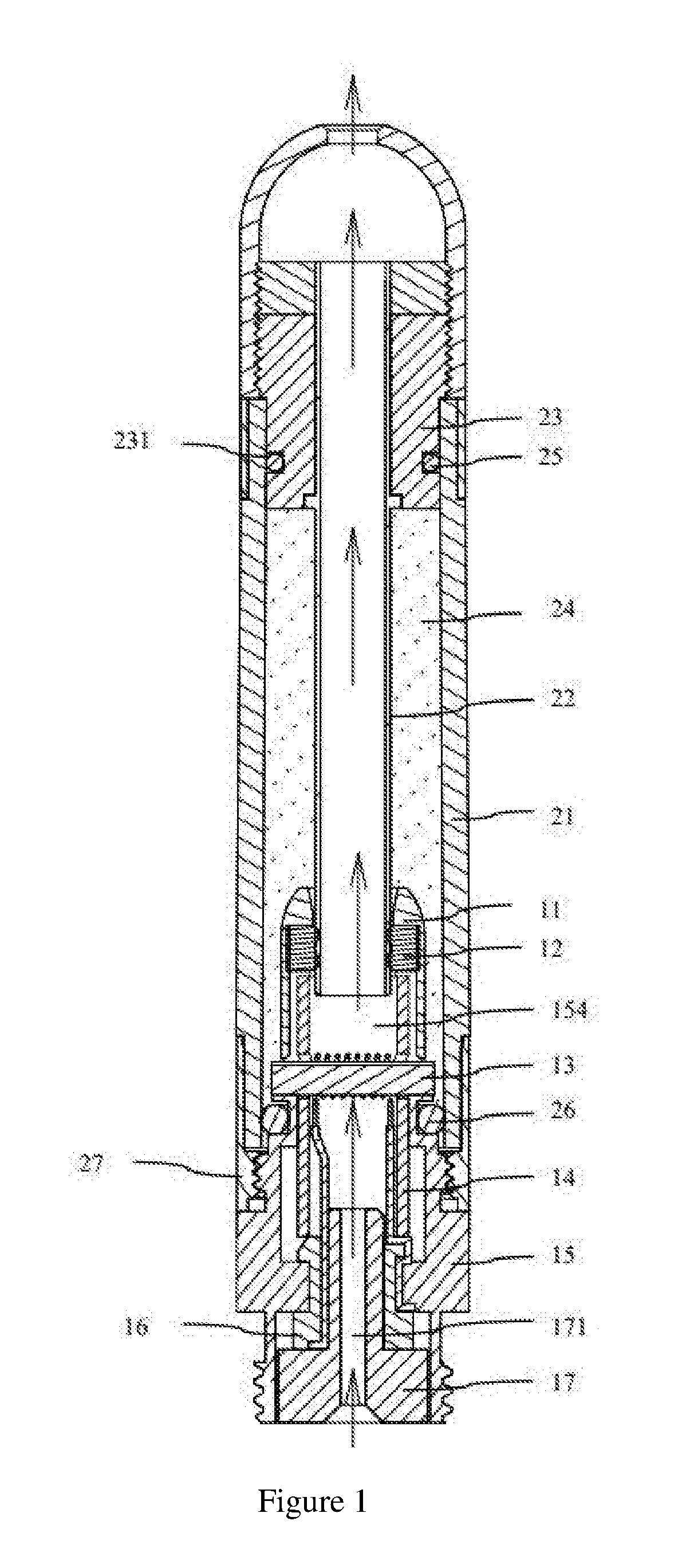

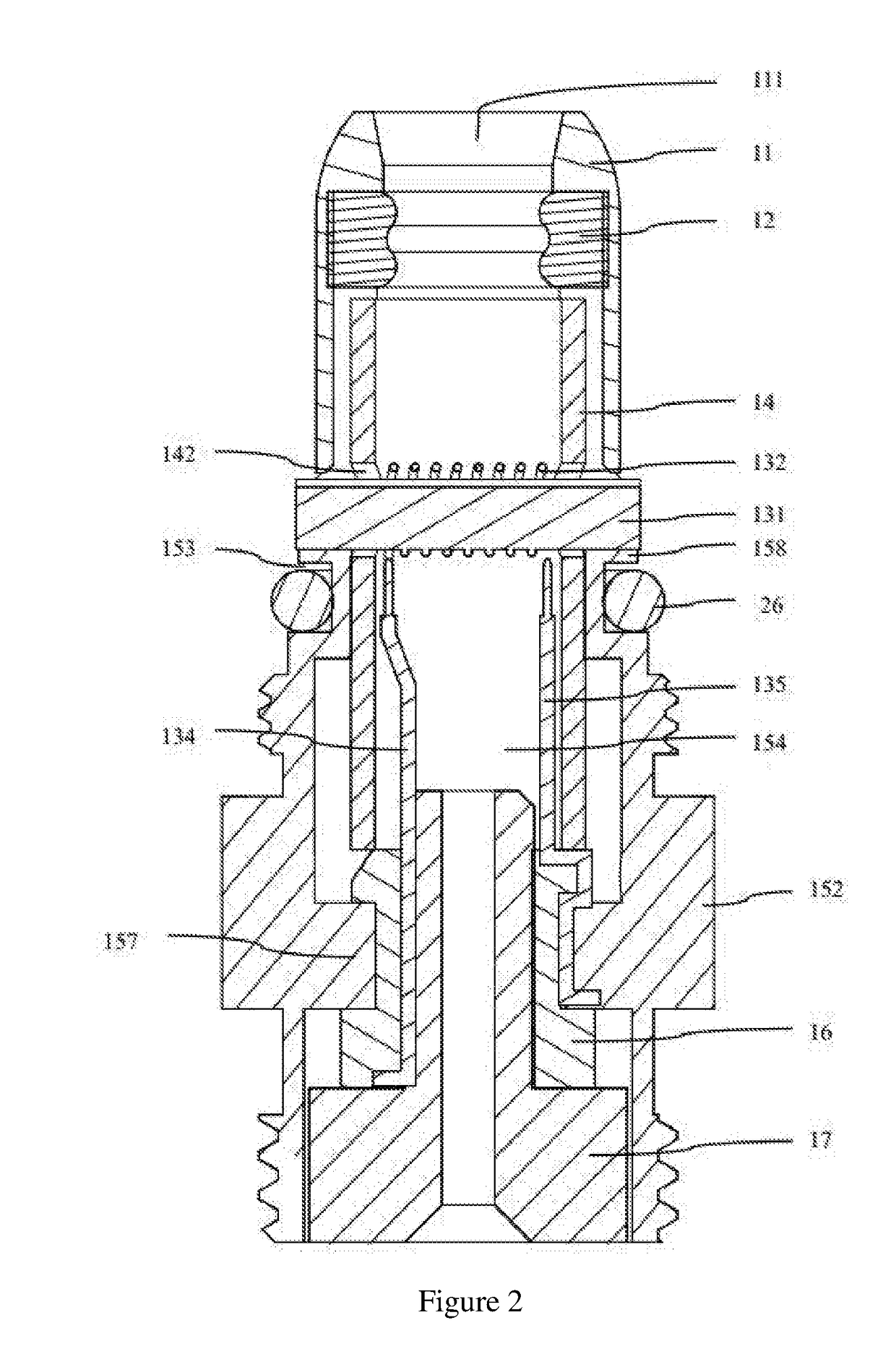

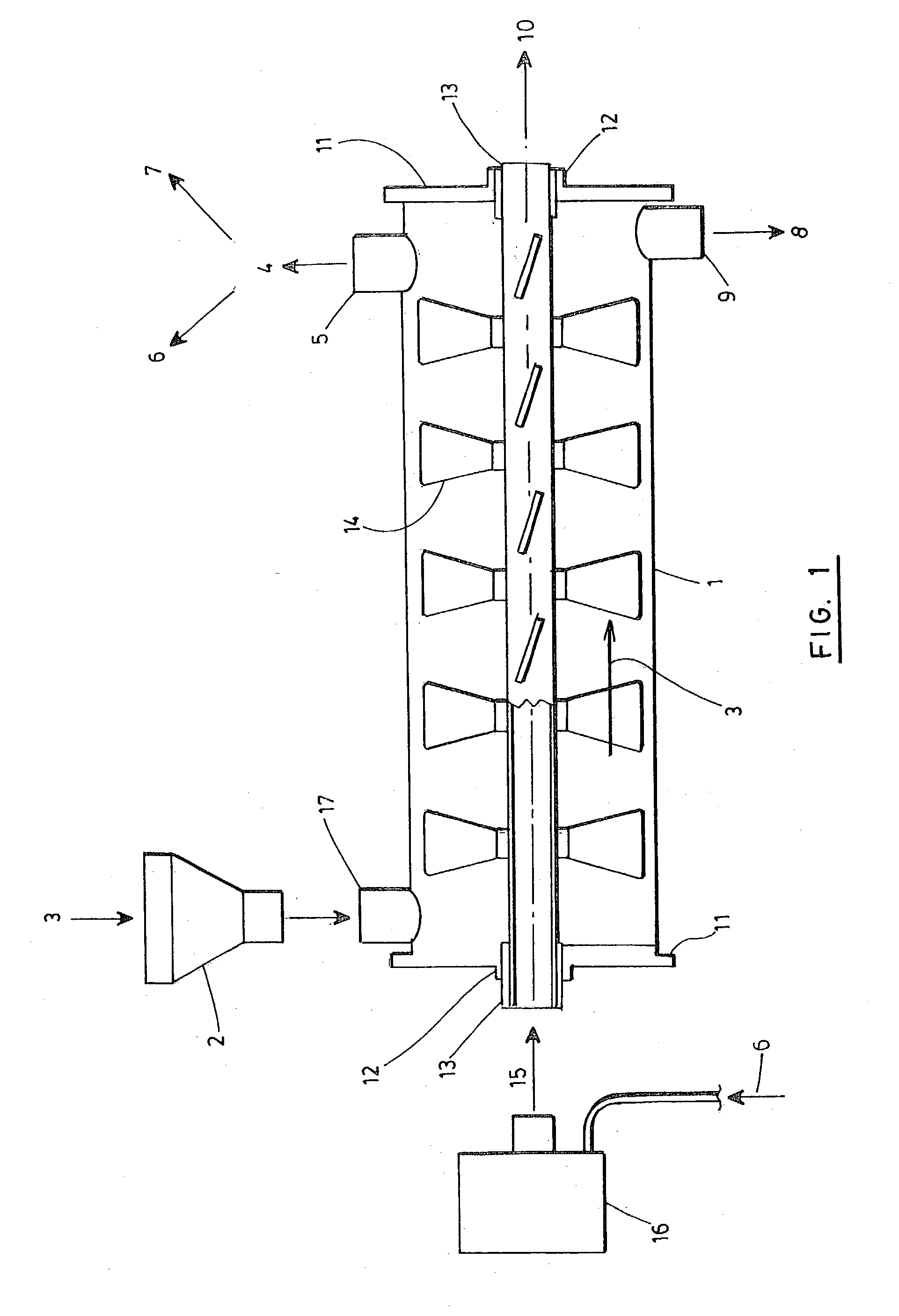

Method and system for vaporization of a substance

ActiveUS20090260641A1Avoid heatingEasy to insertCigar manufactureFuel lightersVaporizationEngineering

A smoking device for generating and releasing smoking vapor free from contamination into the mouth of a user comprising a mouthpiece for providing vapor for inhalation to a user including a tubular casing containing a heater for heating a smoking substance at a substantially constant low temperature by regulating the flow of fuel by a thermal regulator and further having means for visual indication of the operation of the device.

Owner:JT INT SA

Method and system for vaporization of a substance

ActiveUS20090260642A1Avoid heatingEasy to insertCigar manufactureFuel lightersEngineeringVaporization

A smoking device for generating and releasing smoking vapor free from contamination into the mouth of a user comprising a mouthpiece for providing vapor for inhalation to a user including a tubular casing containing a heater for heating a smoking substance at a substantially constant low temperature by regulating the flow of fuel by a thermal regulator and further having means for visual indication of the operation of the device.

Owner:JT INT SA

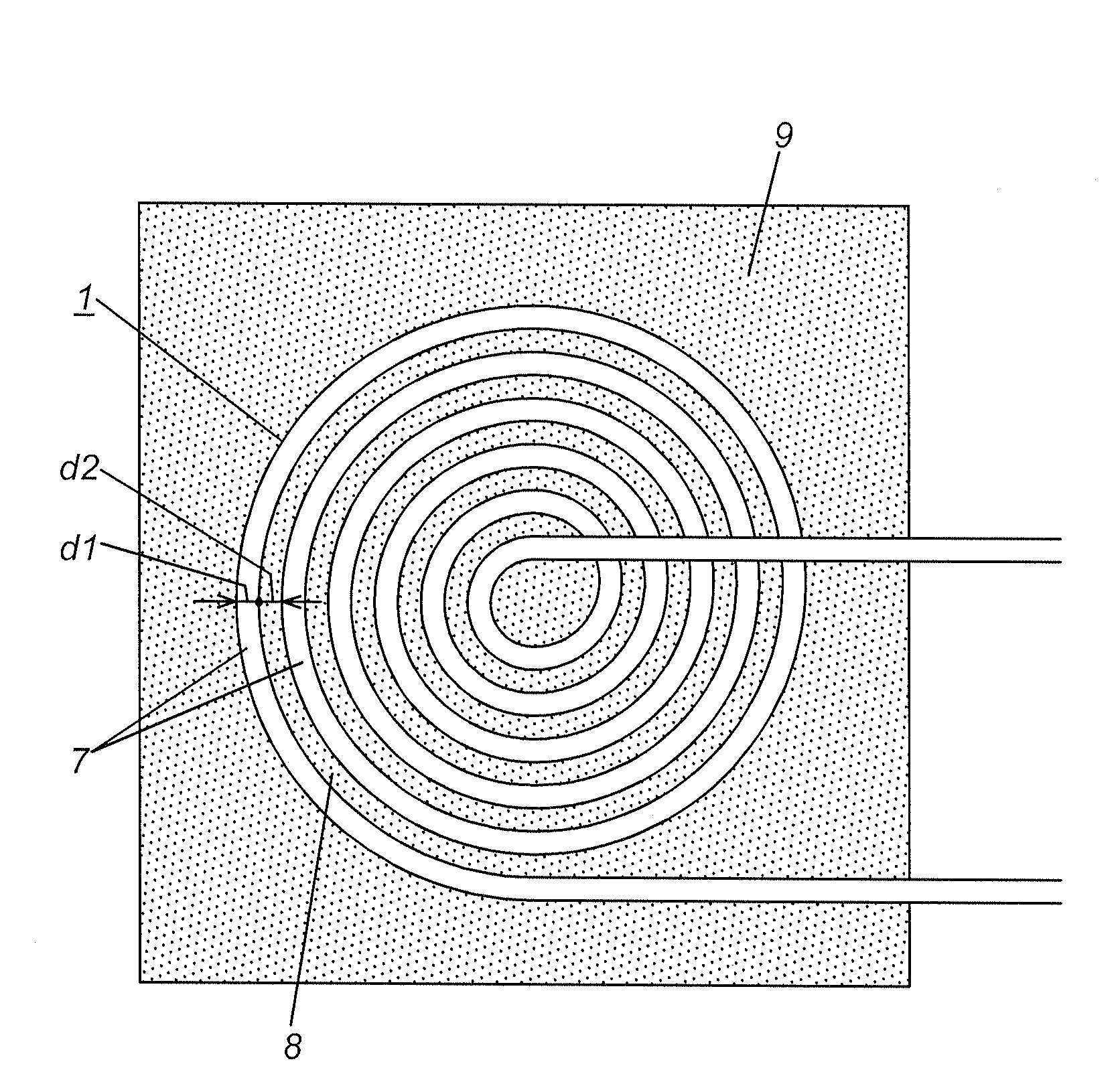

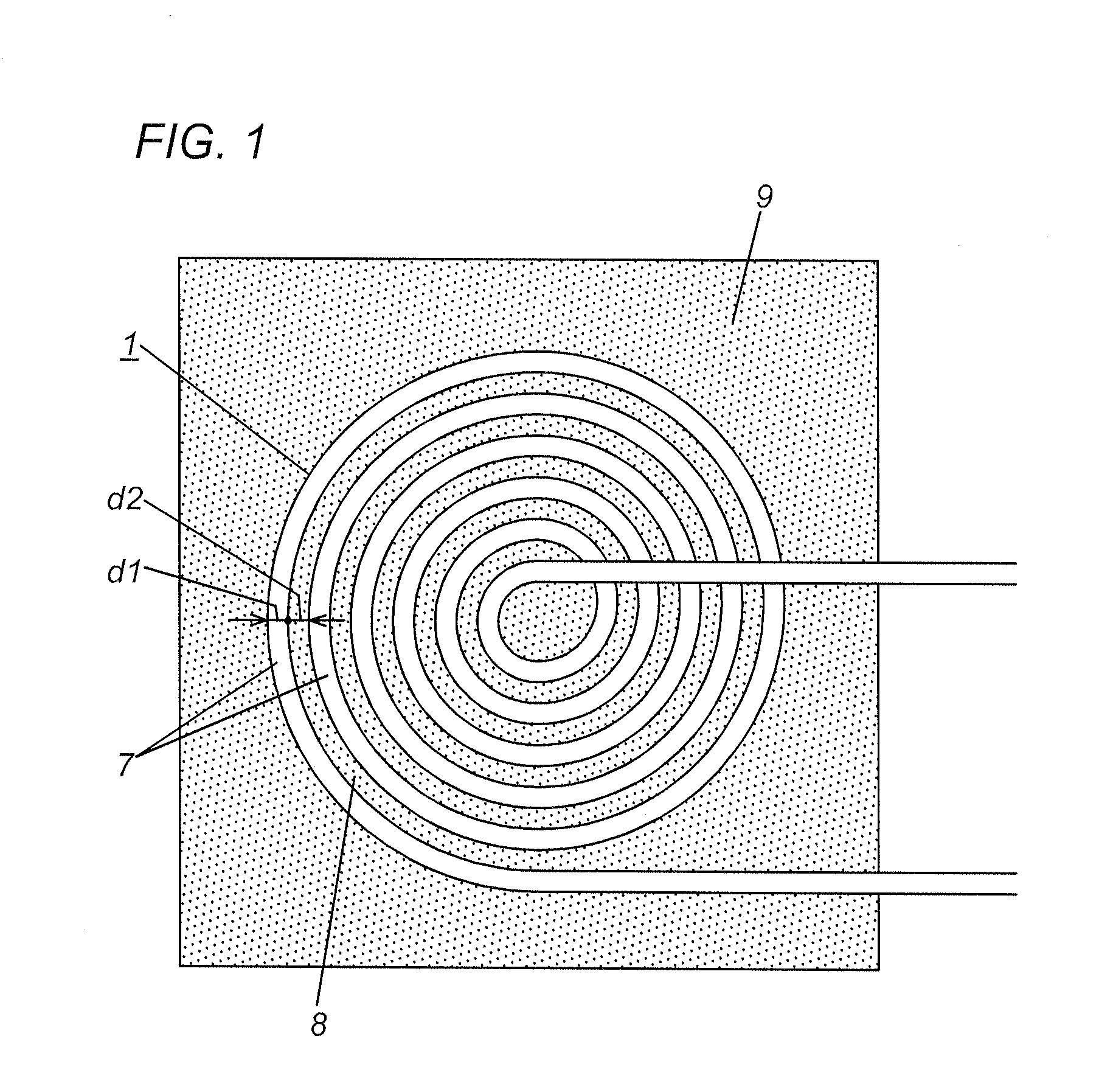

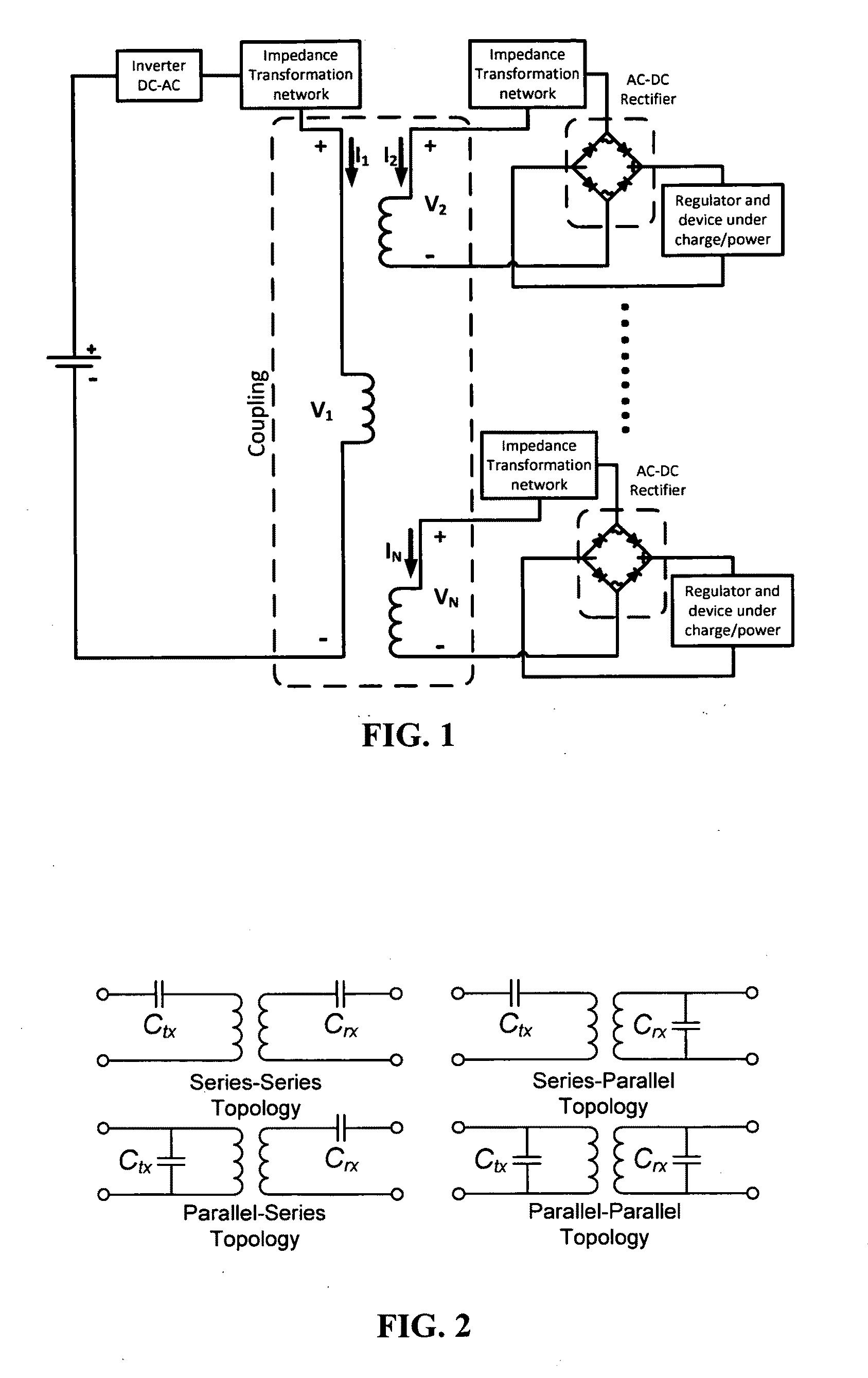

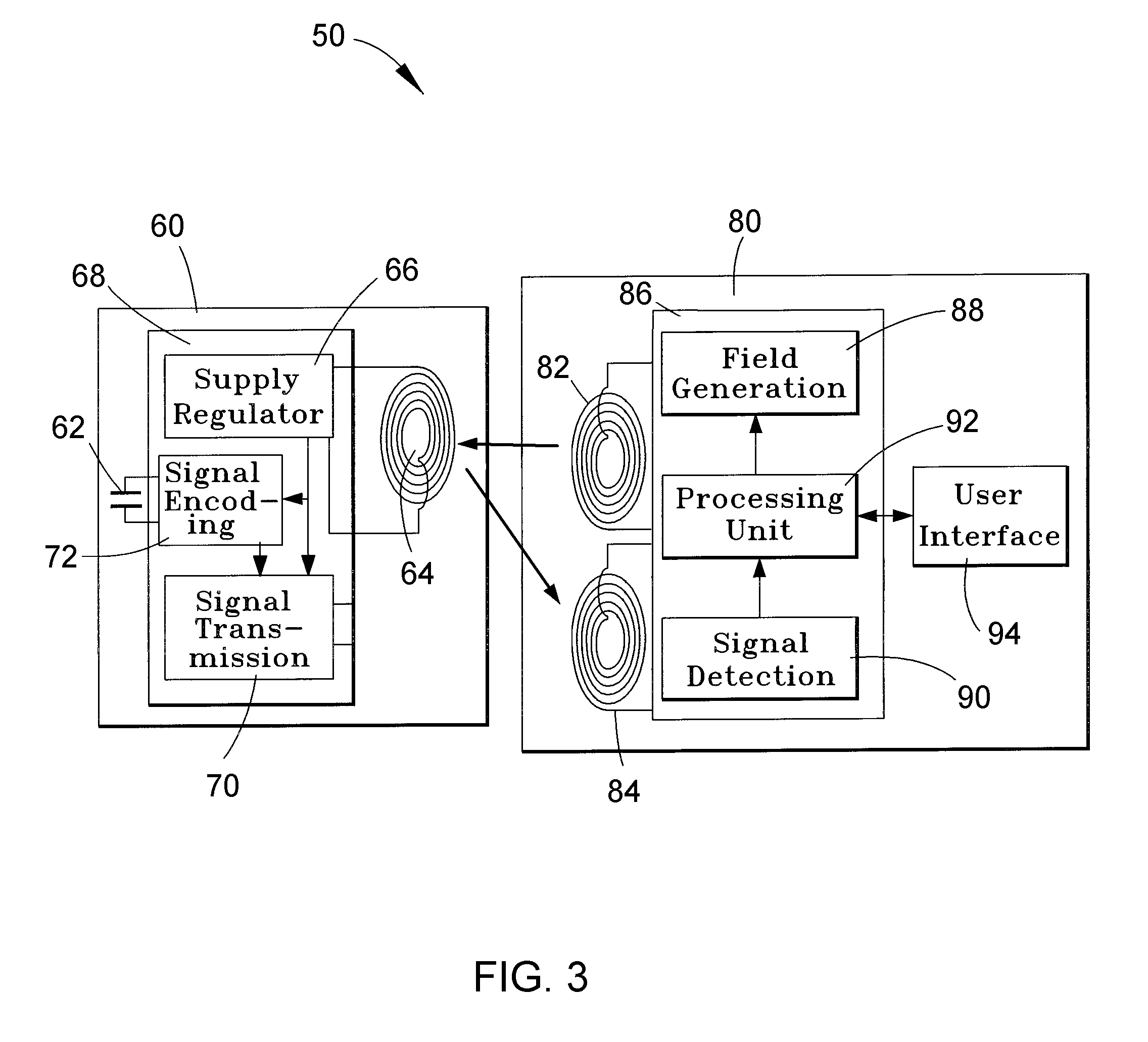

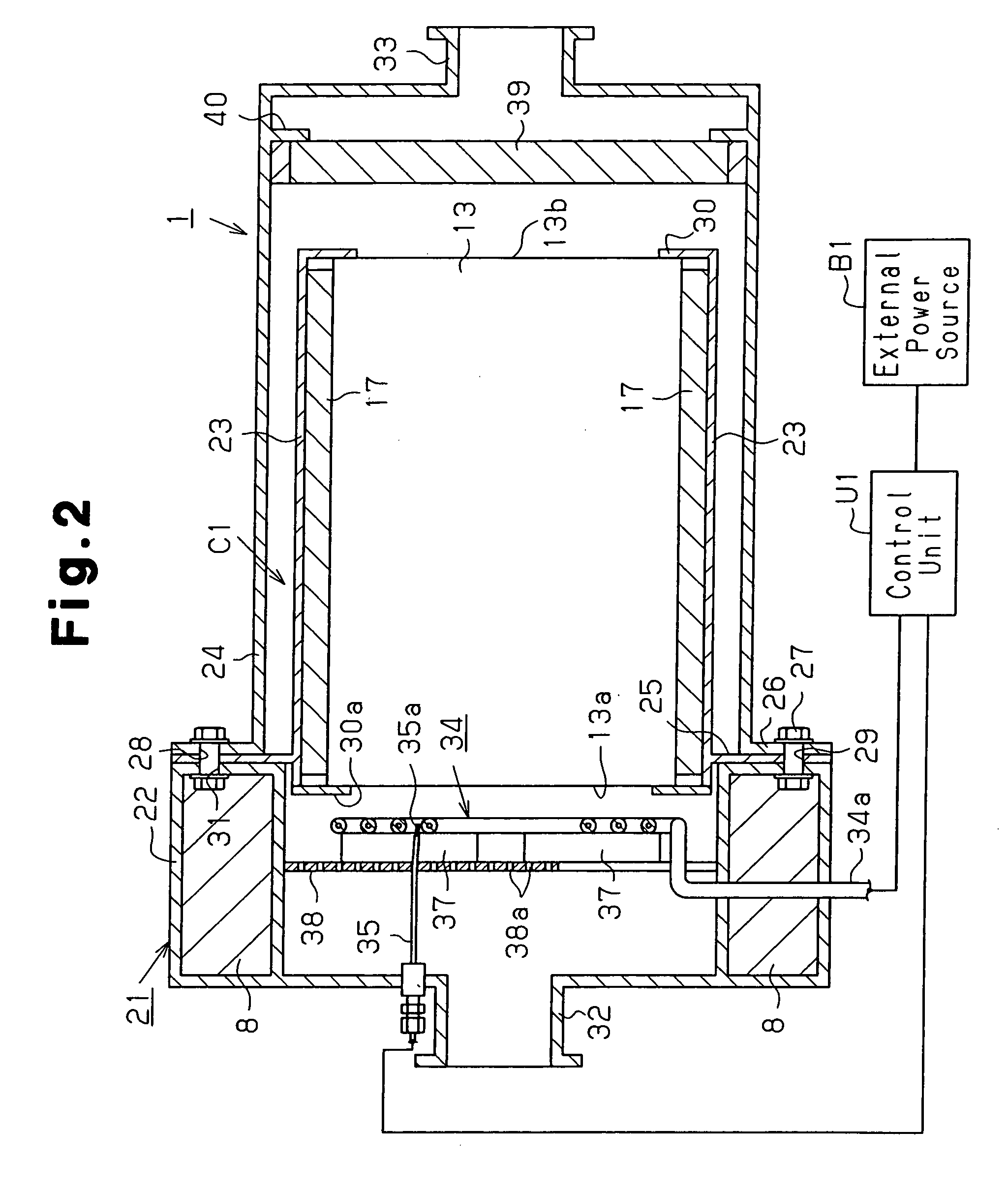

Planar coil and contactless electric power transmission device using the same

InactiveUS20100277004A1Avoid it happening againImprove productivityBatteries circuit arrangementsElectromagnetic wave systemElectric power transmissionEddy current

This invention has an object to a planar coil, a contactless electric power transmission device using the same. This planar coil is configured to suppress an eddy current developed between adjacent turns of wire for minimizing adverse effects on ambient electrical appliances resulting from heat generation. The planar coil 1 in the present invention is formed of spiral shaped wire 7 coated with thinned insulative film, in which adjacent turns of the wire 7 are spaced in radial direction at such a predetermined interval to suppress an eddy current. This planar coil 1 is preferably employed as a power transmission coil or power receiving coil.

Owner:PANASONIC CORP

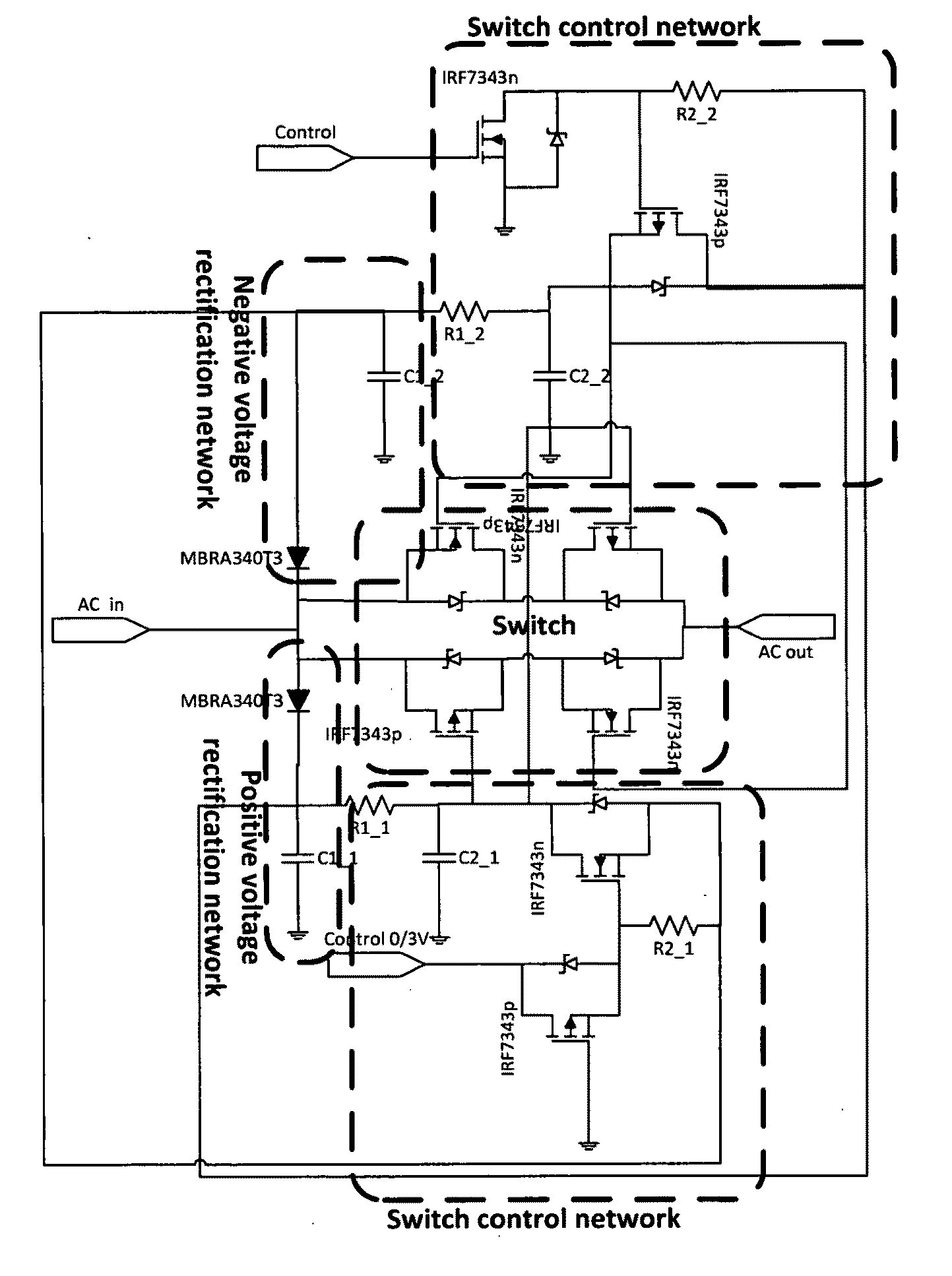

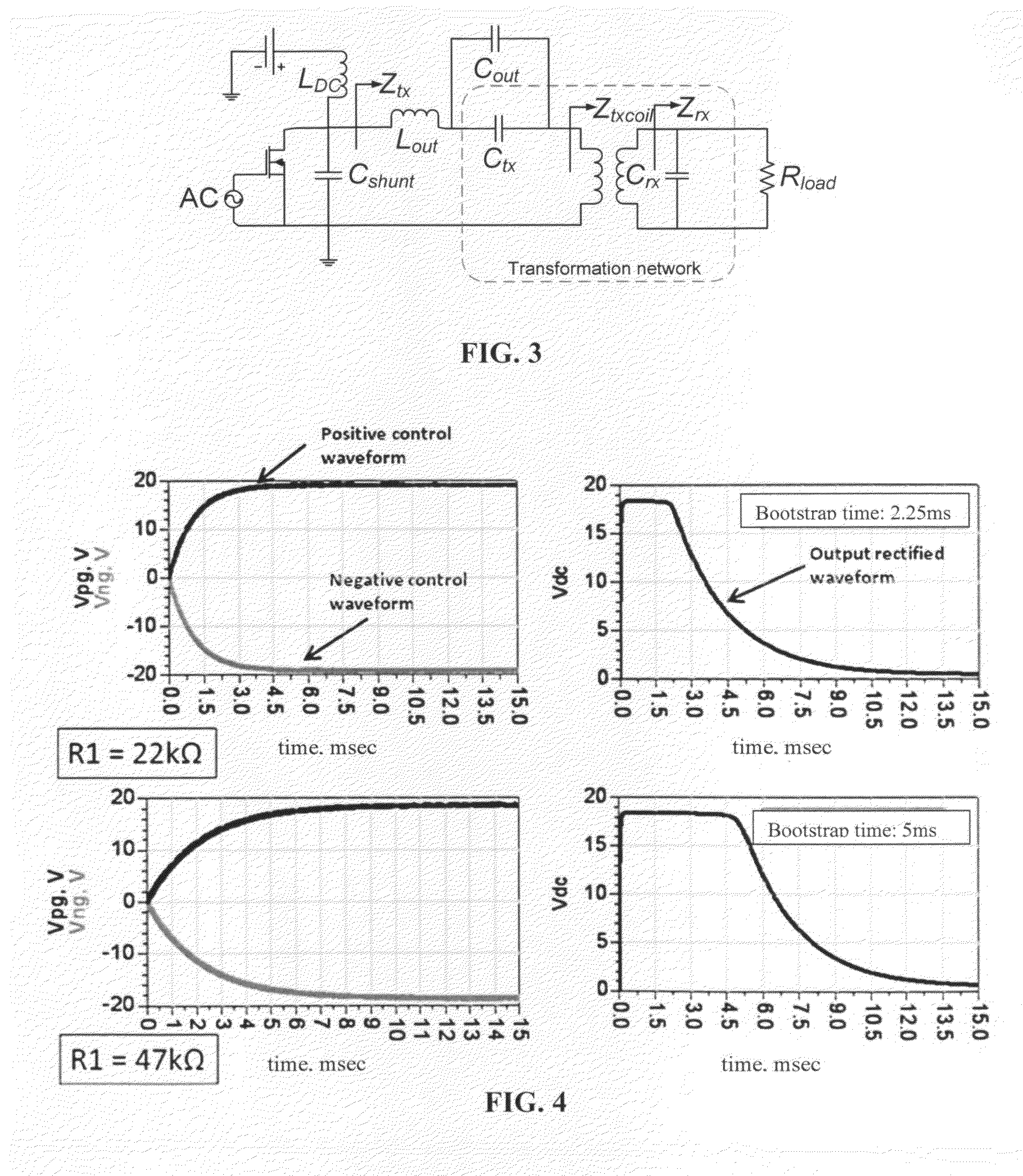

Miniature high voltage/current ac switch using low voltage single supply control

InactiveUS20100110741A1Improve efficiencyAvoid heatingAc-dc conversionSafety/protection circuitsElectric power transmissionHigh voltage igbt

Embodiments of the invention pertain to a method and apparatus for planar wireless power transfer where the receiver switches off and / or performs a duty cycle. In an embodiment, the switch can be used in a system that having a high voltage / current solid state switch, without having a high voltage control signal. An embodiment provides a switch that is capable of breaking, or greatly reducing, the connection of the receiver coil and the receiver circuitry in order to enable the receiver to decouple from the power transfer system. This embodiment can allow the transmitter to put out more power to other devices without providing power to the switched device. When the switch is used for a fully charged device, the switching can prevent or reduce damage to the fully charged device.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Wireless dynamic power control of an implantable sensing device and methods therefor

InactiveUS20100161004A1Improve functionalityEnhanced data rate transferElectrotherapyDiseaseCommunications system

Communication systems and methods for dynamically controlling the power wirelessly delivered by a remote reader unit to separate sensing device, such as a device adapted to monitor a physiological parameter within a living body, including but not limited to intraocular pressure, intracranial pressure (ICP), and cardiovascular pressures that can be measured to assist in diagnosing and monitoring various diseases. The communication method entails electromagnetically delivering power from at least one telemetry antenna within the reader unit to at least one telemetry antenna within the sensing device, and controlling the power supplied to the sensing device within a predetermined operating power level range of the sensing device.

Owner:INTEGRATED SENSING SYST INC

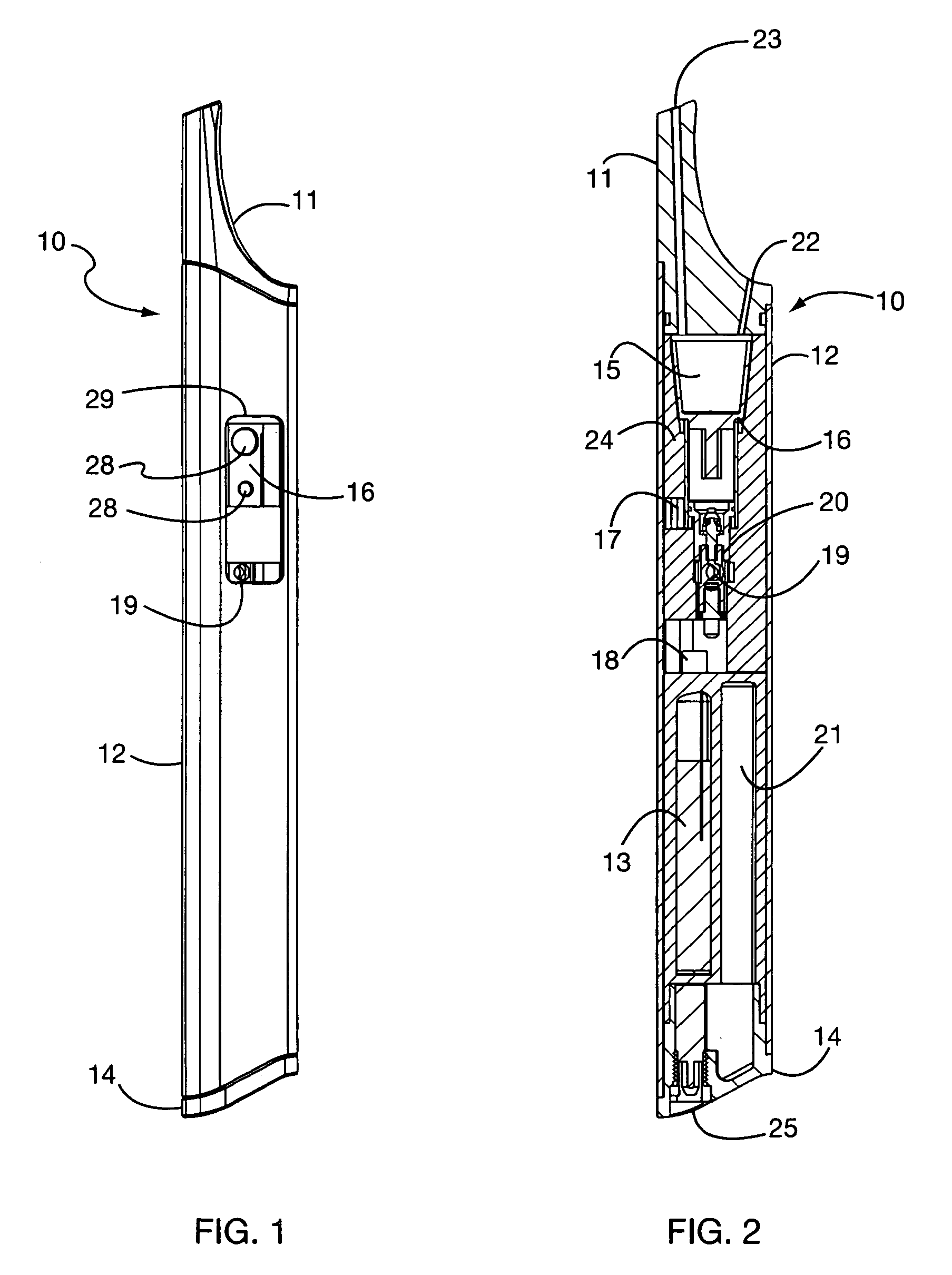

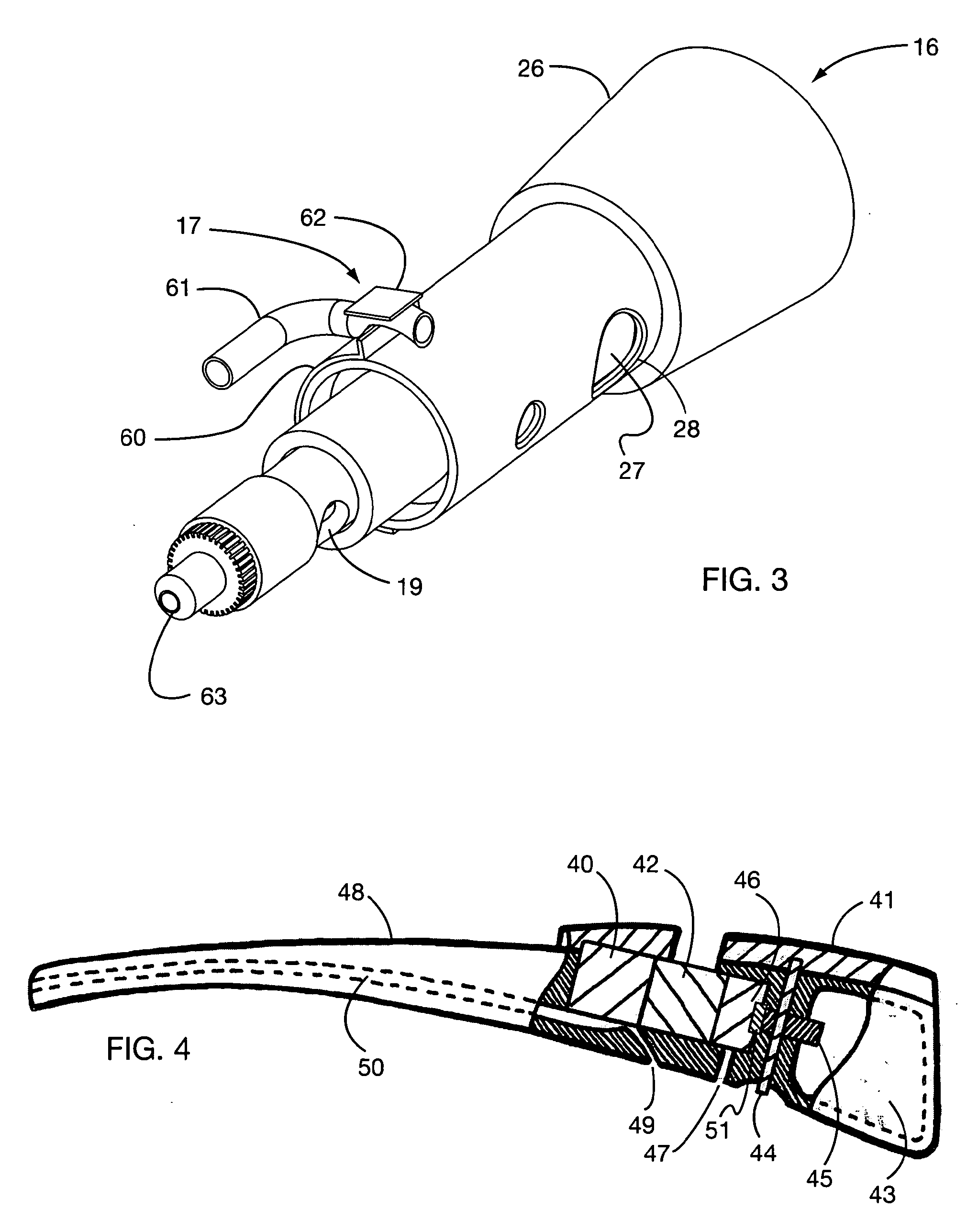

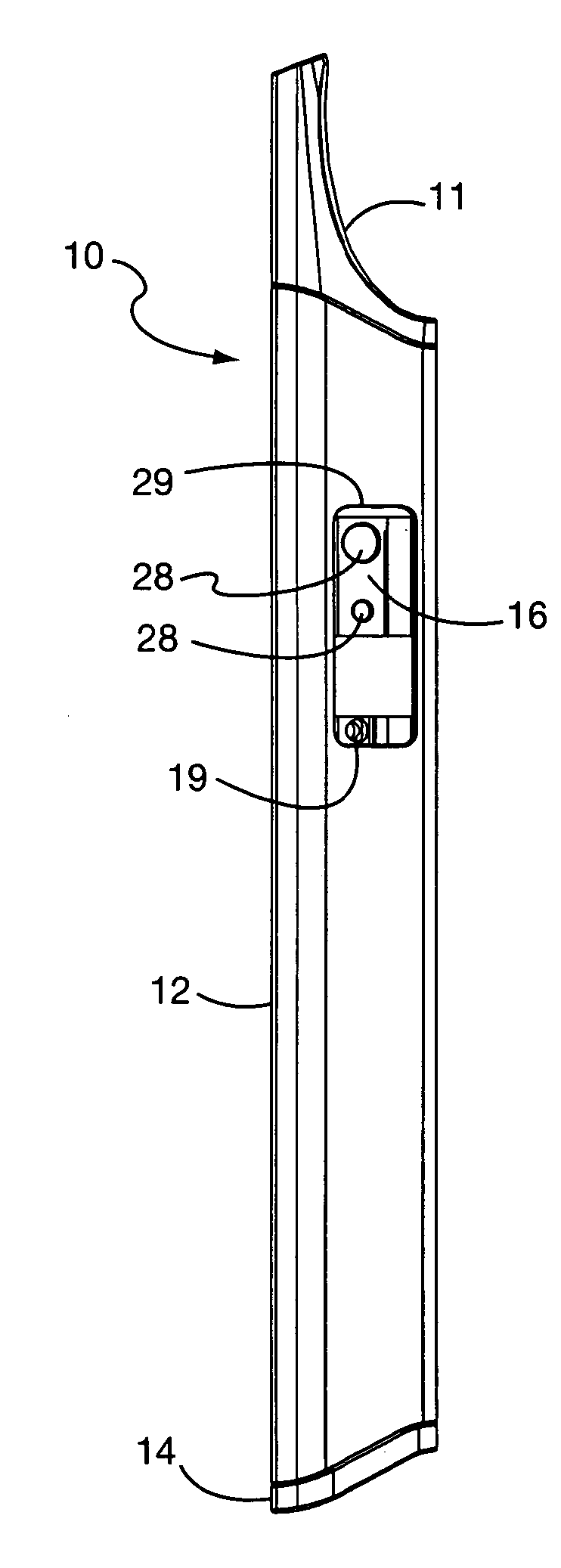

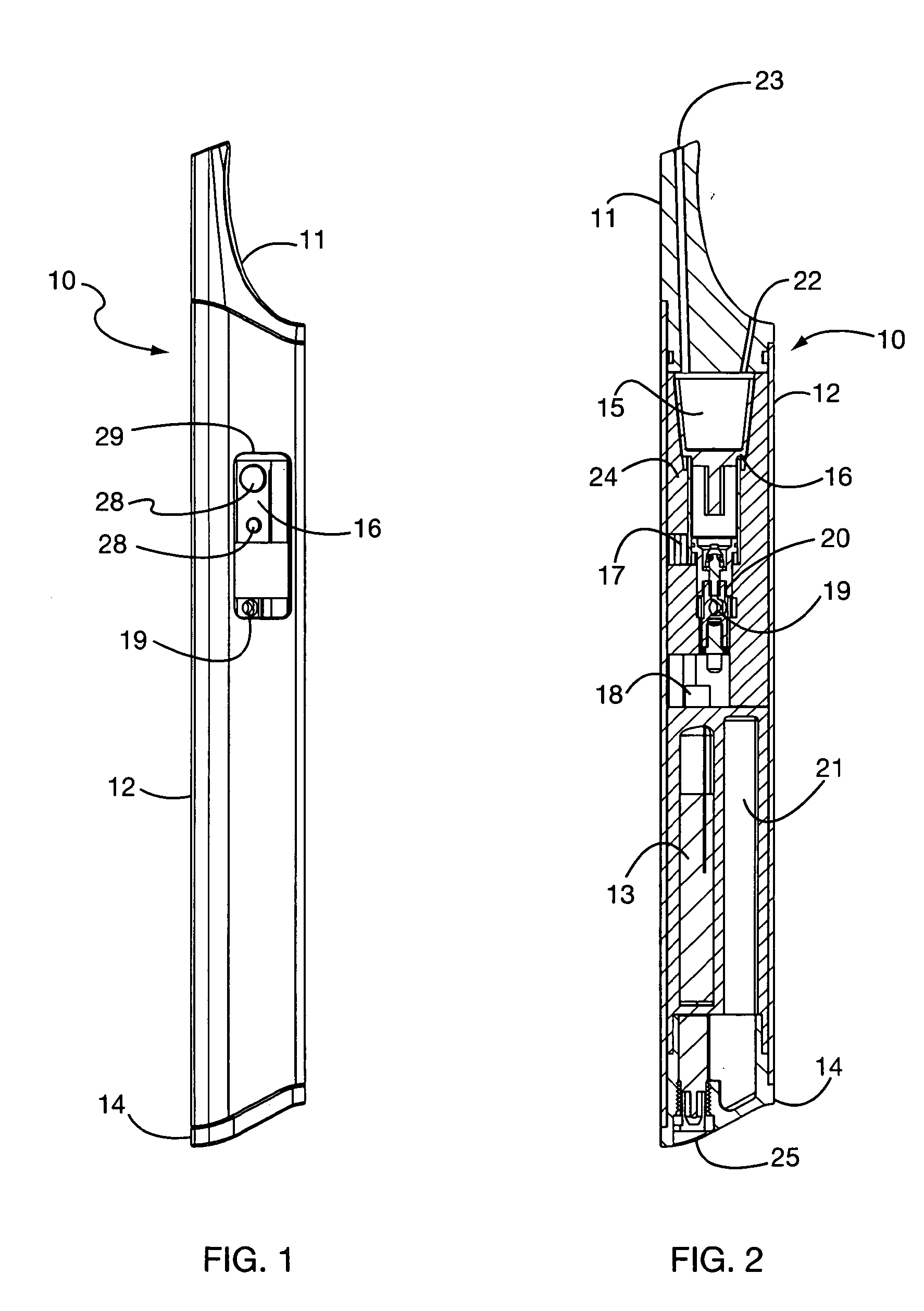

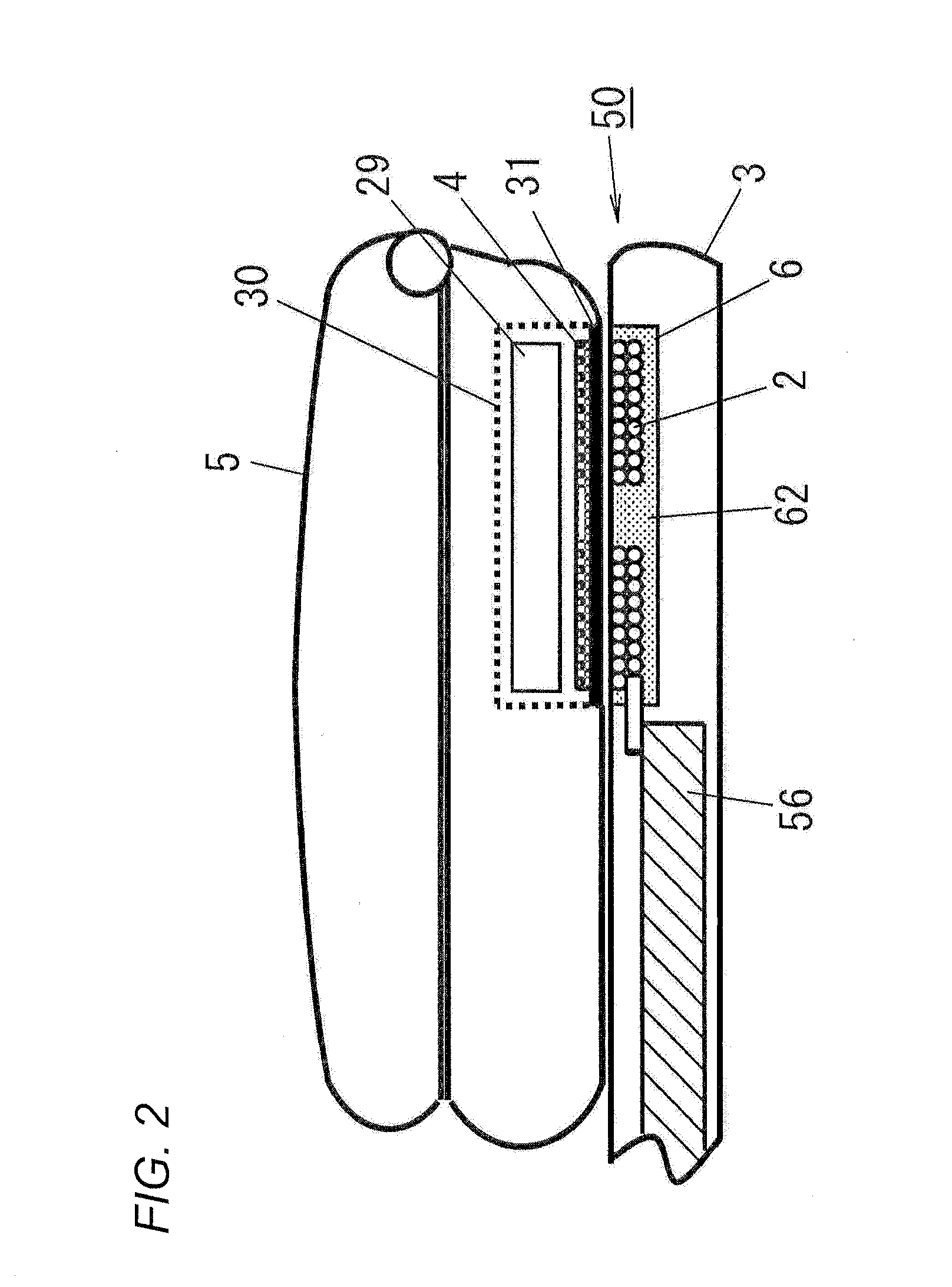

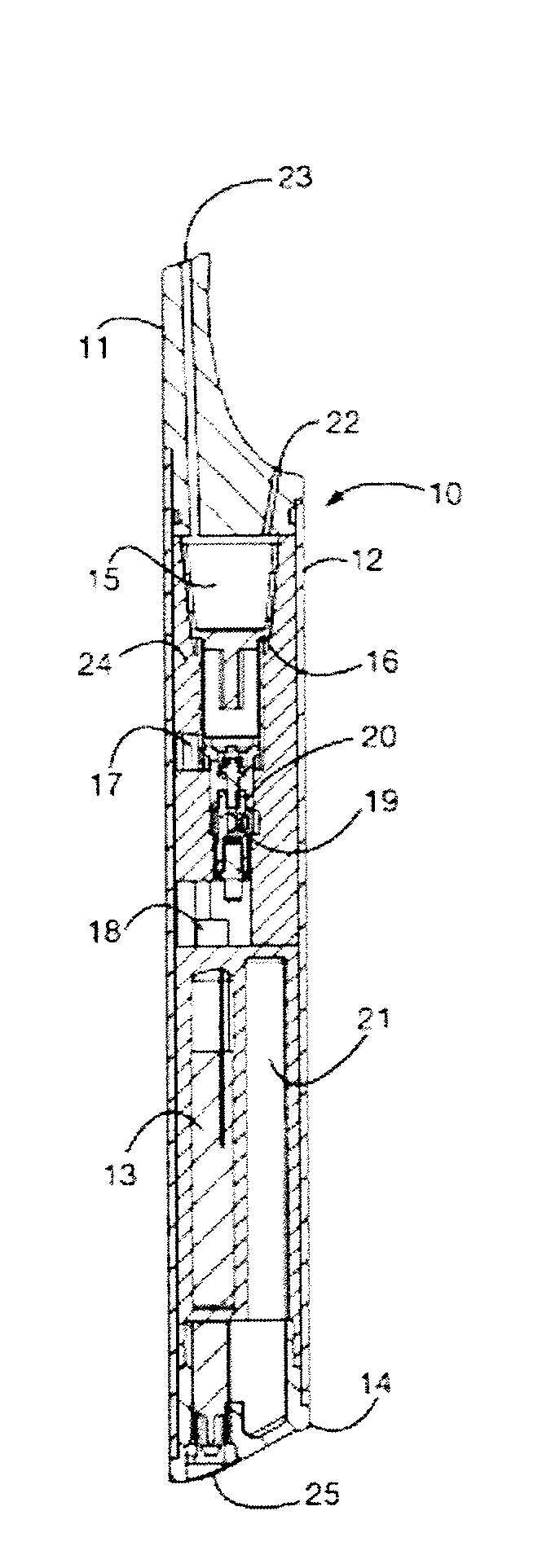

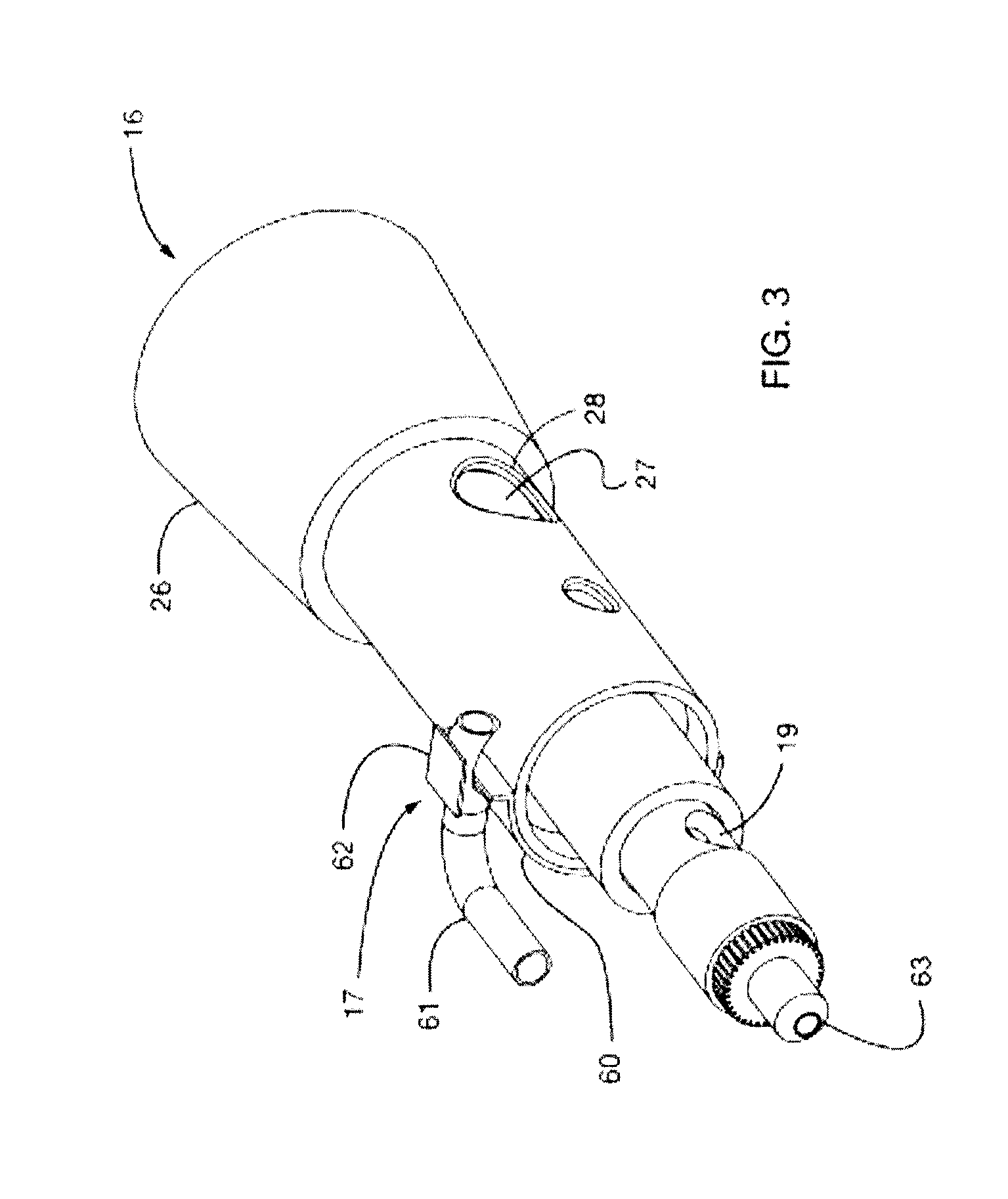

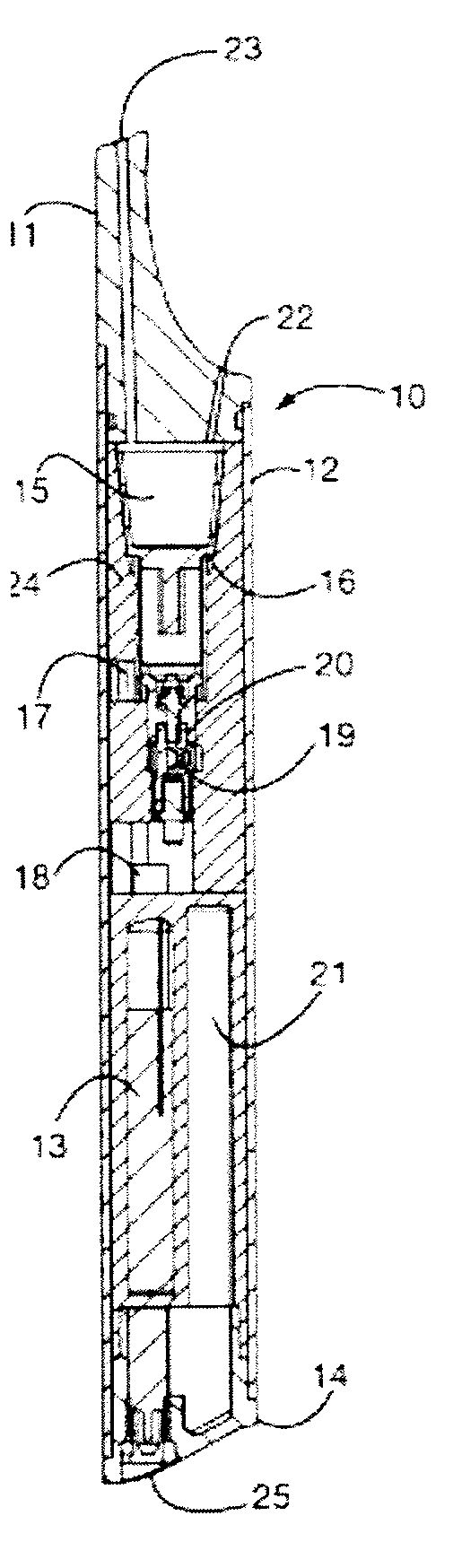

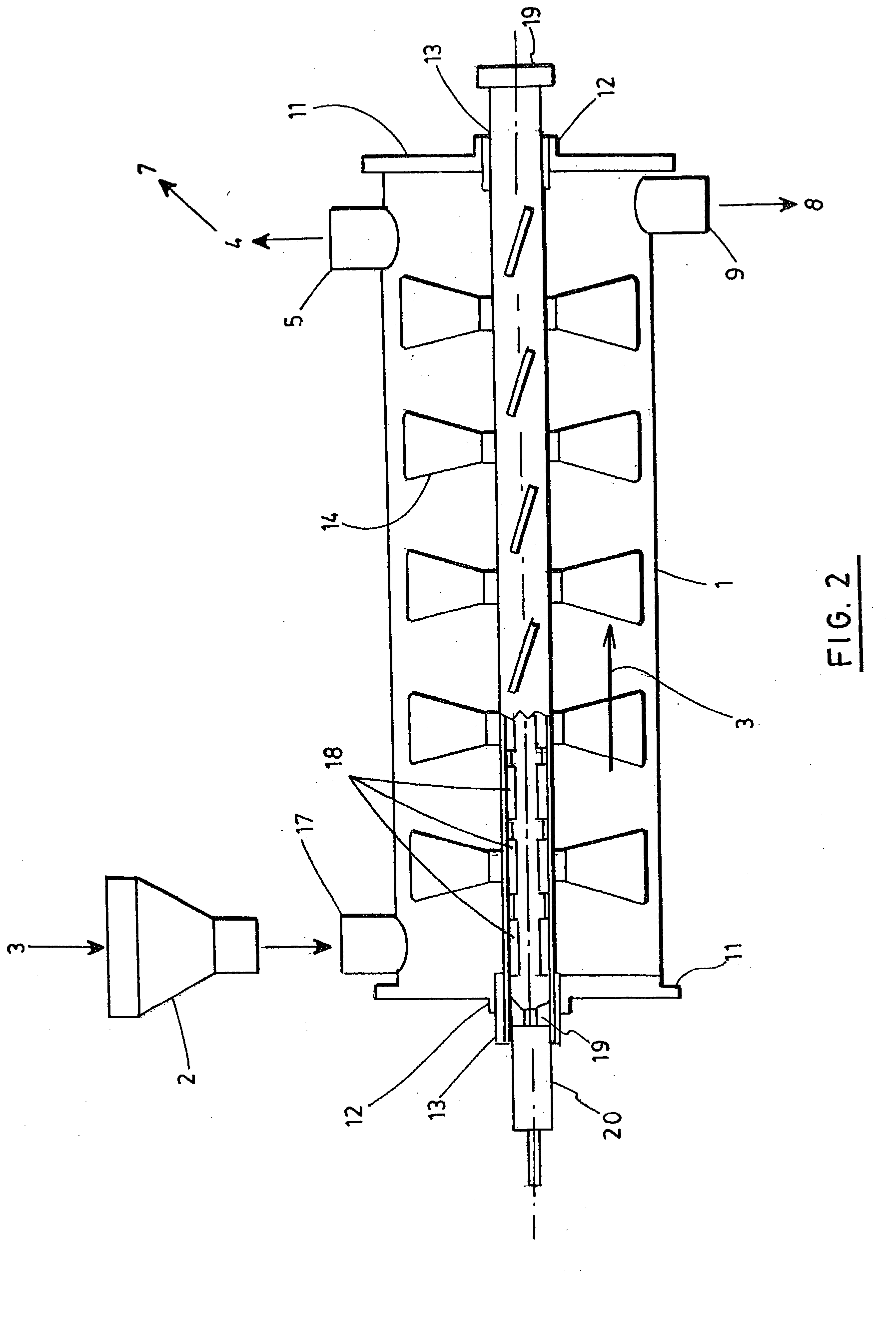

Devices for vaporization of a substance

ActiveUS20160338412A1Avoid heatingEasy to insertInput/output for user-computer interactionTemperature control using digital meansMicrocontrollerDisplay device

Devices for generating and releasing vapor. In particular, described herein are portable devices for generating a low-temperature inhalable vapor having an elongated tubular body containing a vaporization chamber and a battery-powered heater, a removable mouthpiece covering the vaporization chamber, a display configured to indicate the temperature of the vaporization chamber; a microcontroller configured to regulate the temperature of the vaporization chamber, and a control to select from among a variety of temperature settings.

Owner:JLI NAT SETTLEMENT TRUST

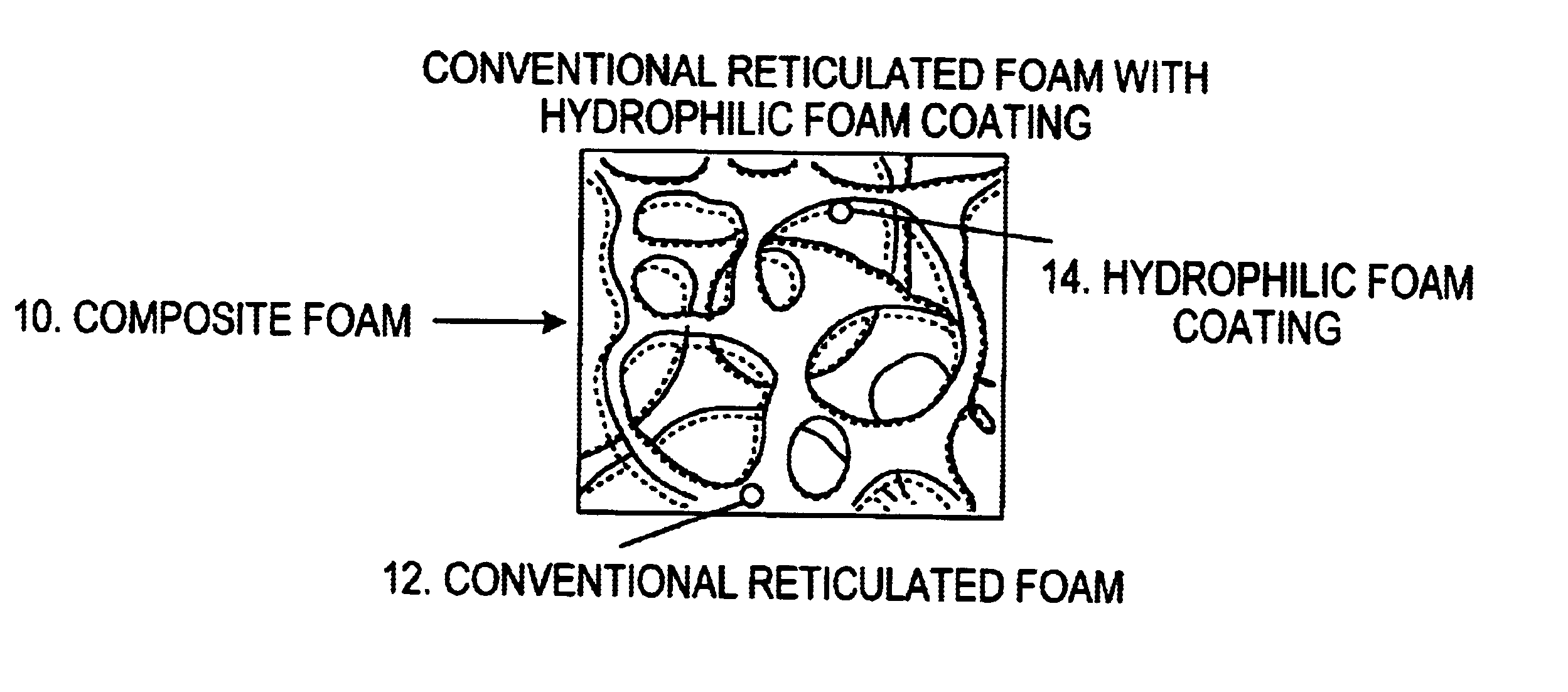

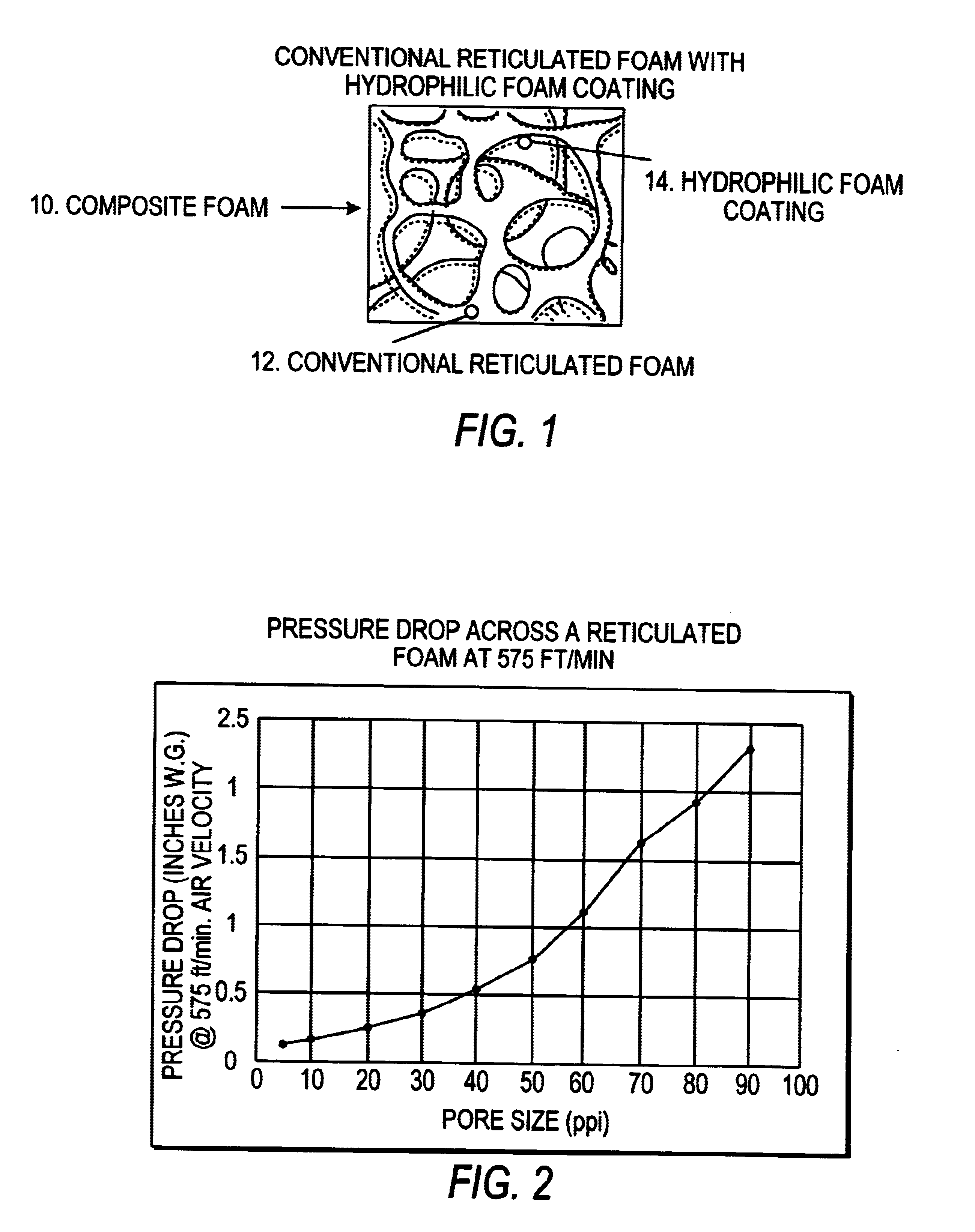

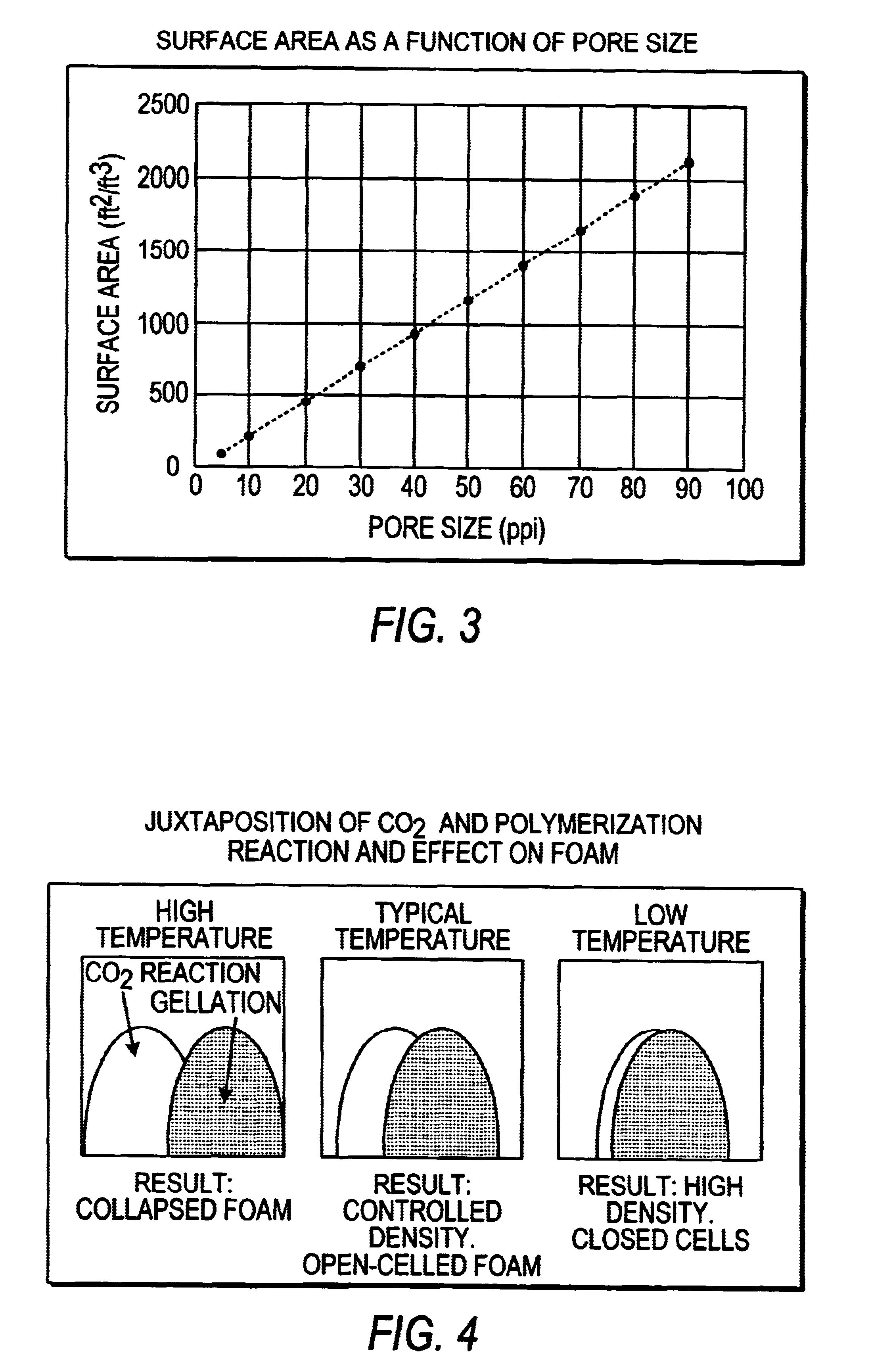

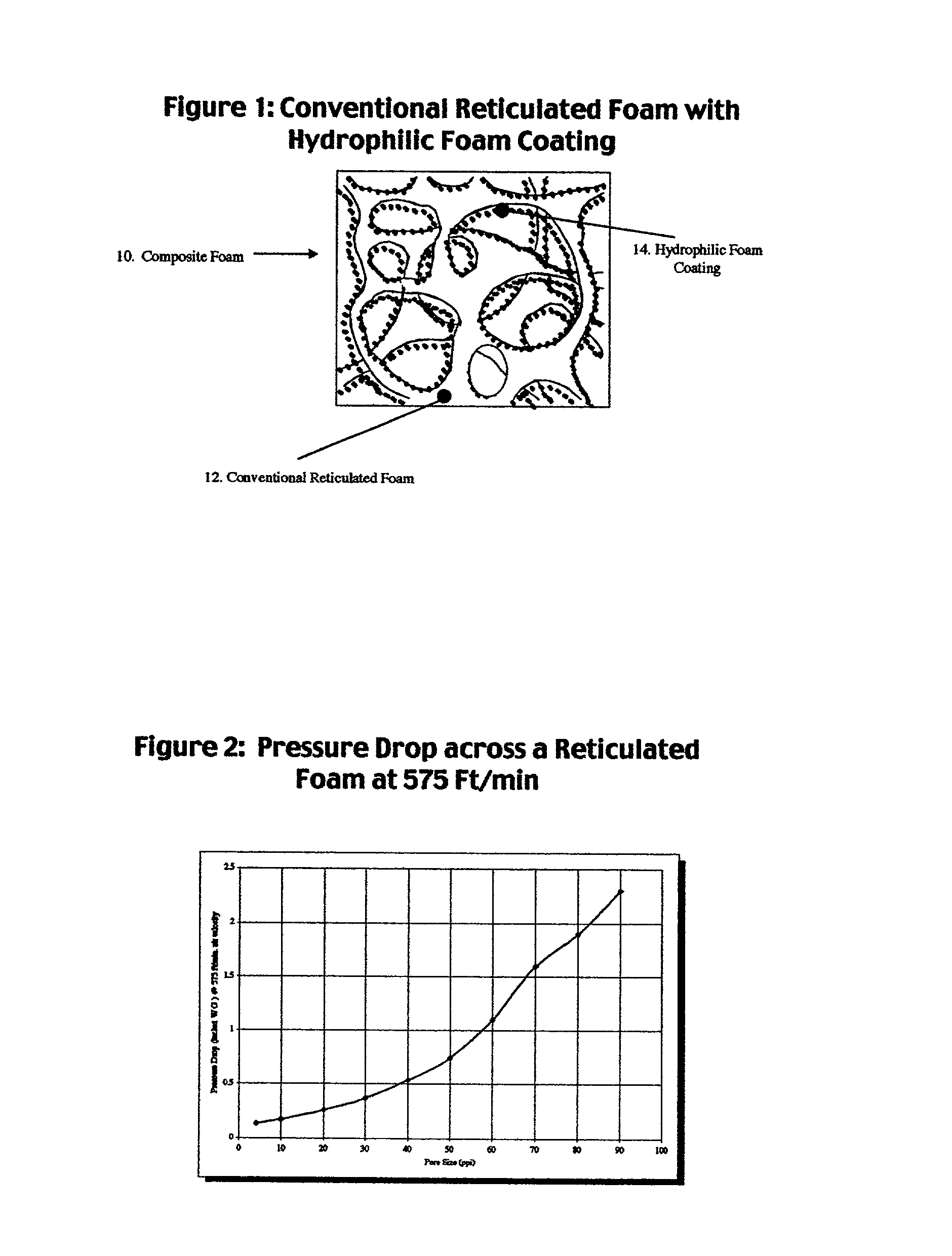

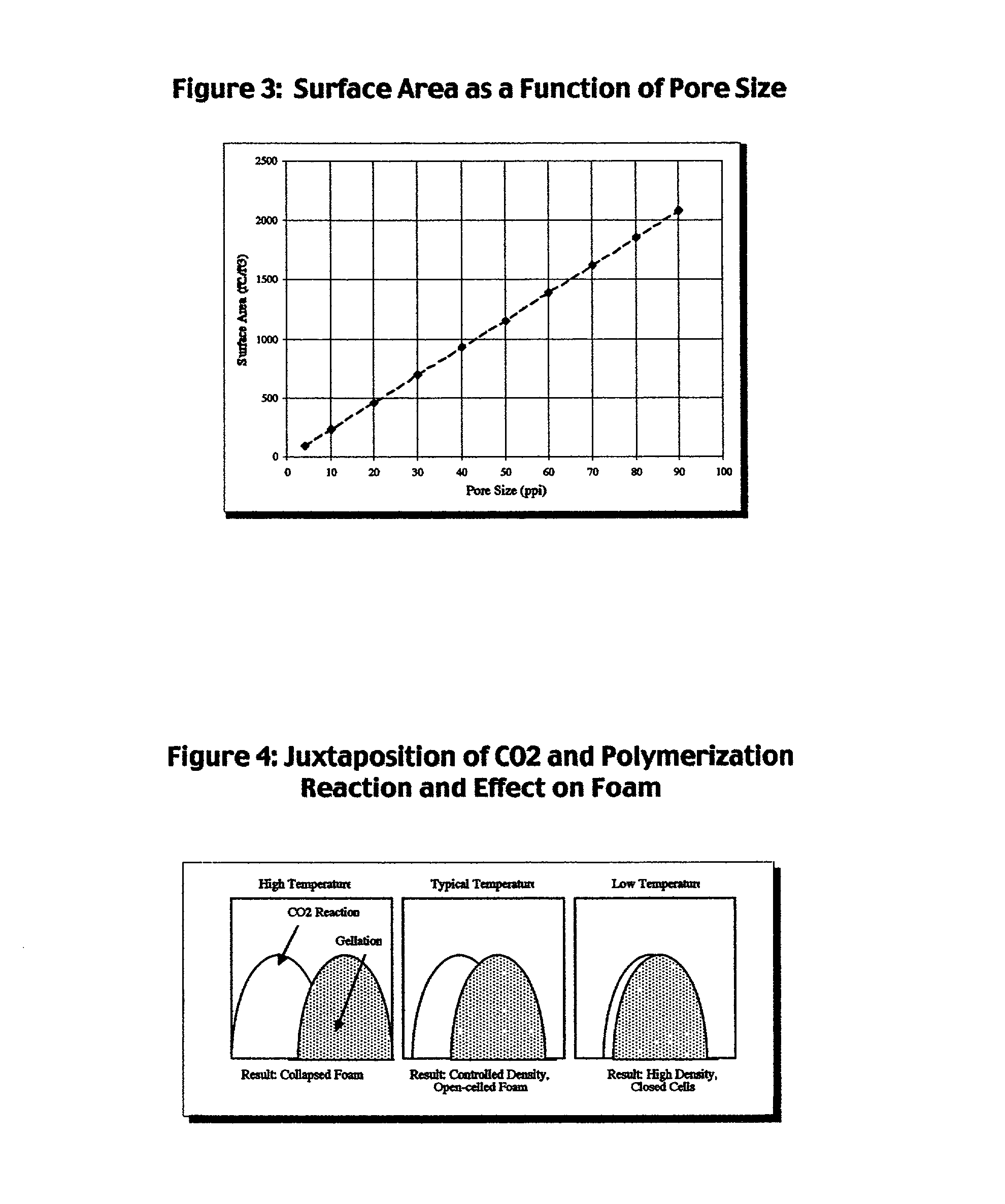

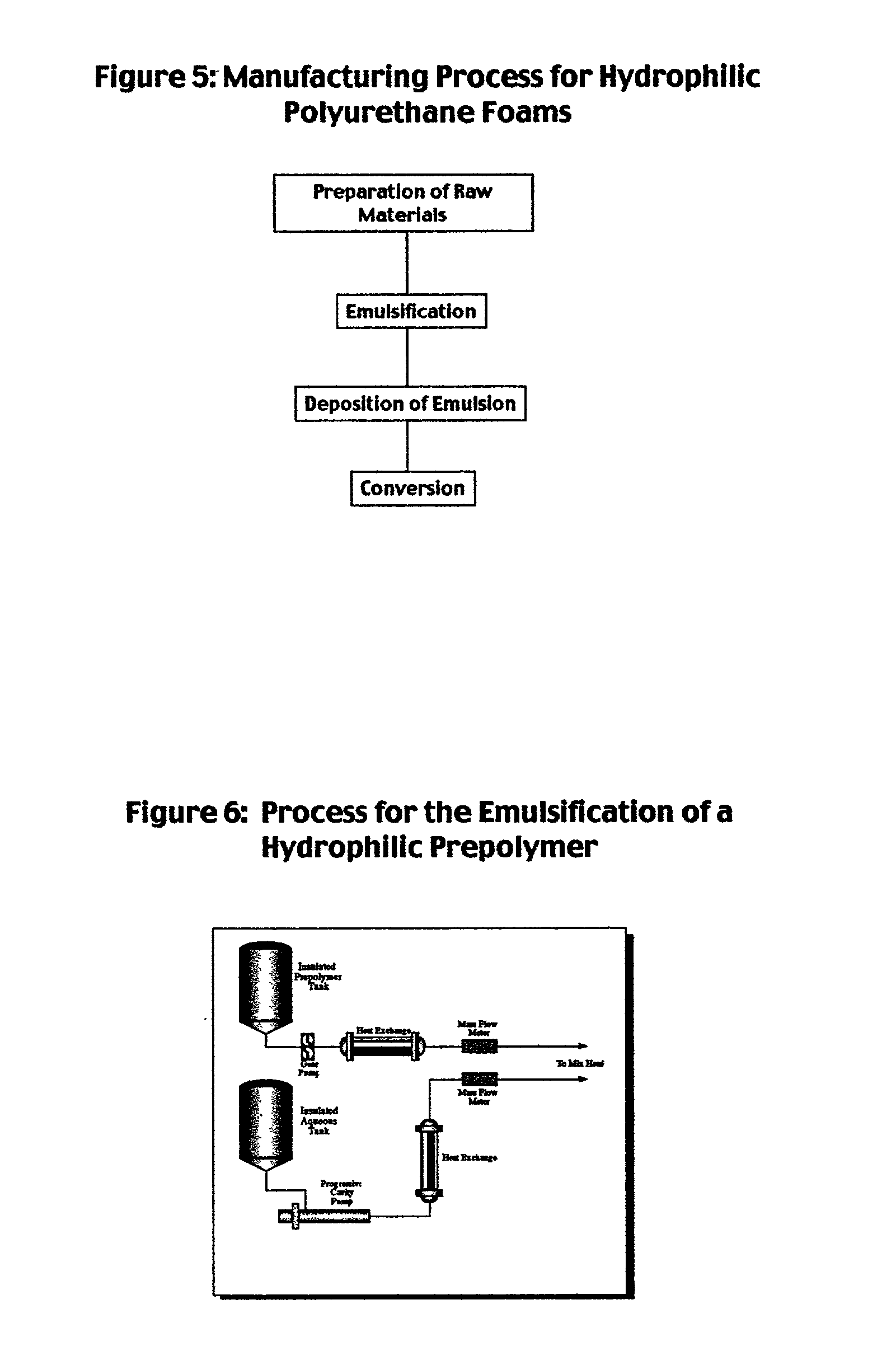

Foam composite

InactiveUS6617014B1Low viscosityIncrease temperatureSynthetic resin layered productsCoatingsPolymer chemistryMaterials science

A foam composite made up of a scaffold of a substantially hydrophobic foam material having plurality of surfaces defining a plurality of pores, and a coating of a substantially hydrophilic foam material disposed upon the surfaces of the hydrophobic foam. The resulting foam composite exhibits structural characteristics of the hydrophobic foam and absorbency characteristics of the hydrophilic foam.

Owner:HYDROPHILIX +1

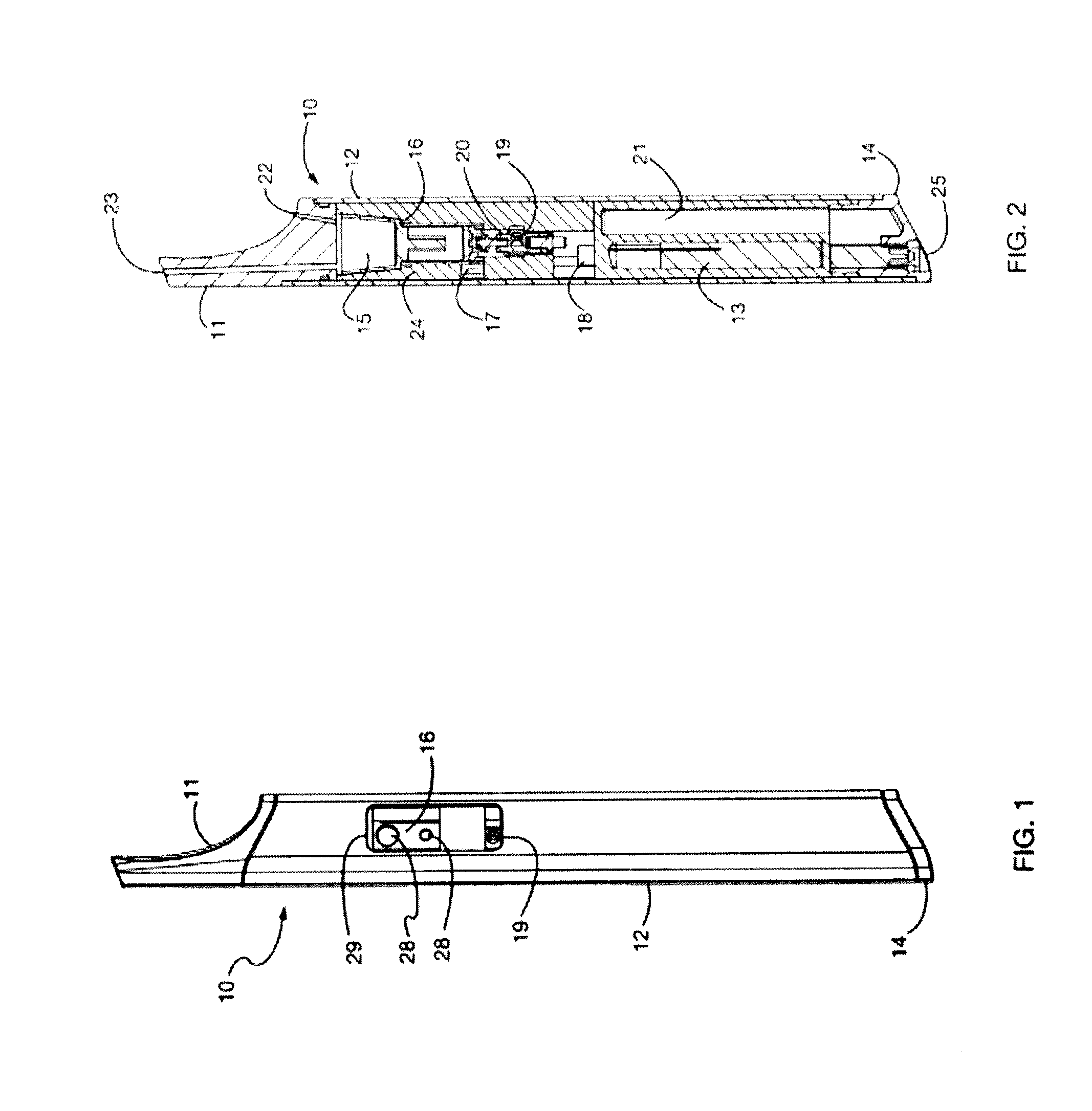

Electronic vaporization device

InactiveUS20160262459A1Avoid heatingEasy to insertRespiratorsBatteries circuit arrangementsVaporizationEngineering

Portable devices for generating an inhalable vapor that include an elongate cylindrical body that may have an oval cross-section, an oven configured to fit within the body and to hold a vaporizable material, a detachable mouthpiece covering the oven, a single-button interface comprising a single button that is configured to be pressed to begin heating, select a heating temperature, and turn off heating and one or more light emitting diode (LED) indicator configured to show information about the status of the device, including a user-selectable temperature setting.

Owner:JUUL LABS INC

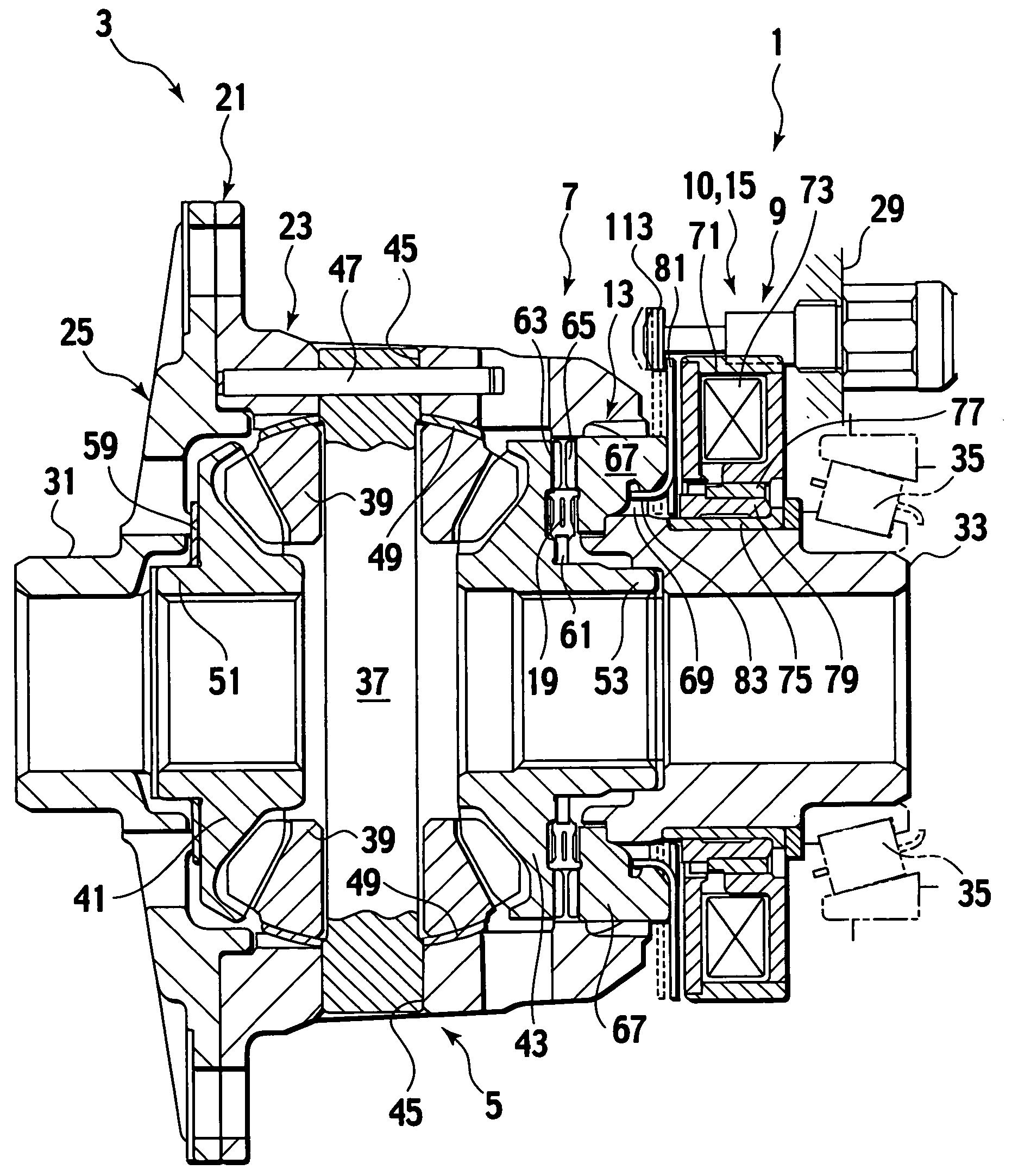

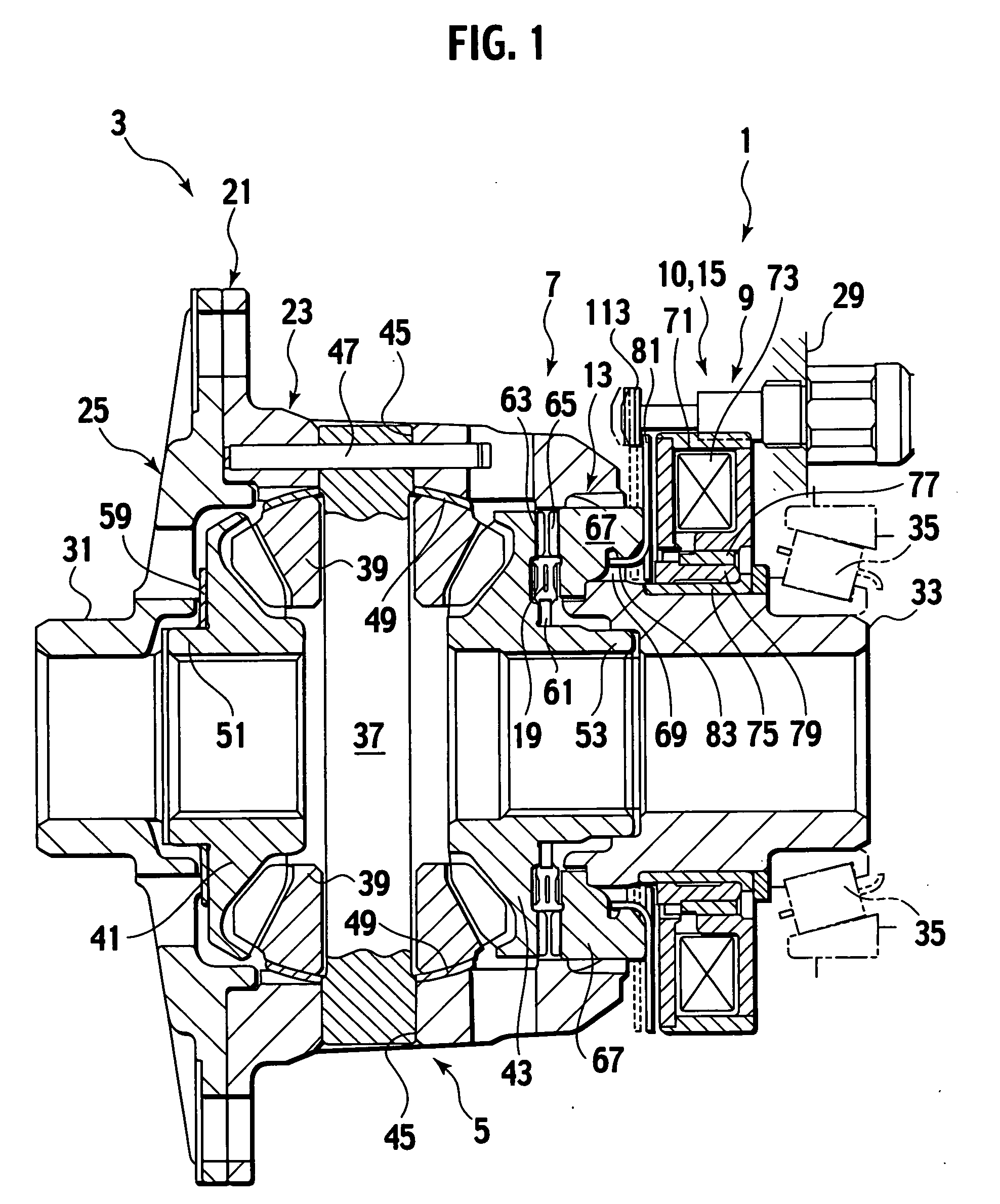

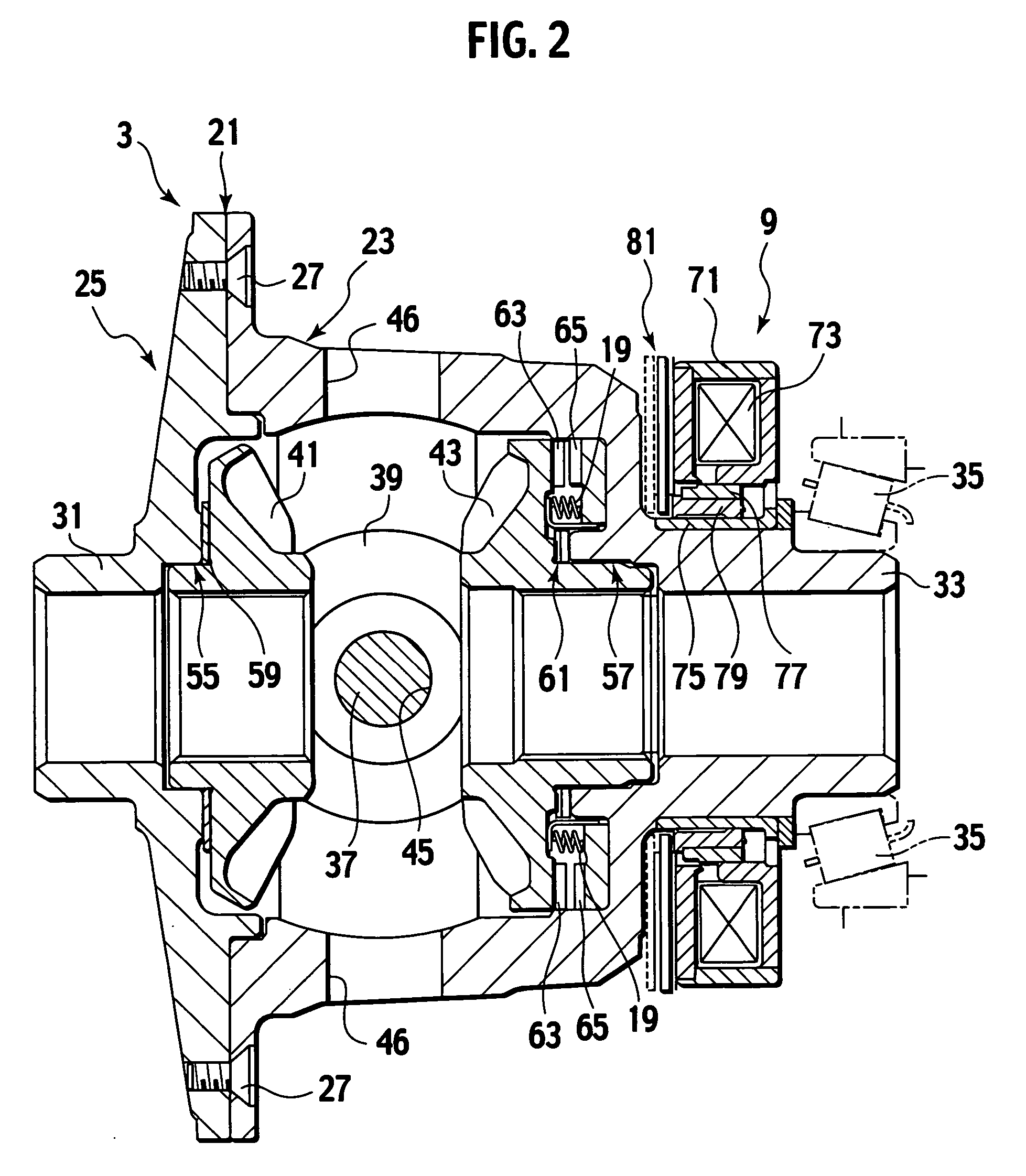

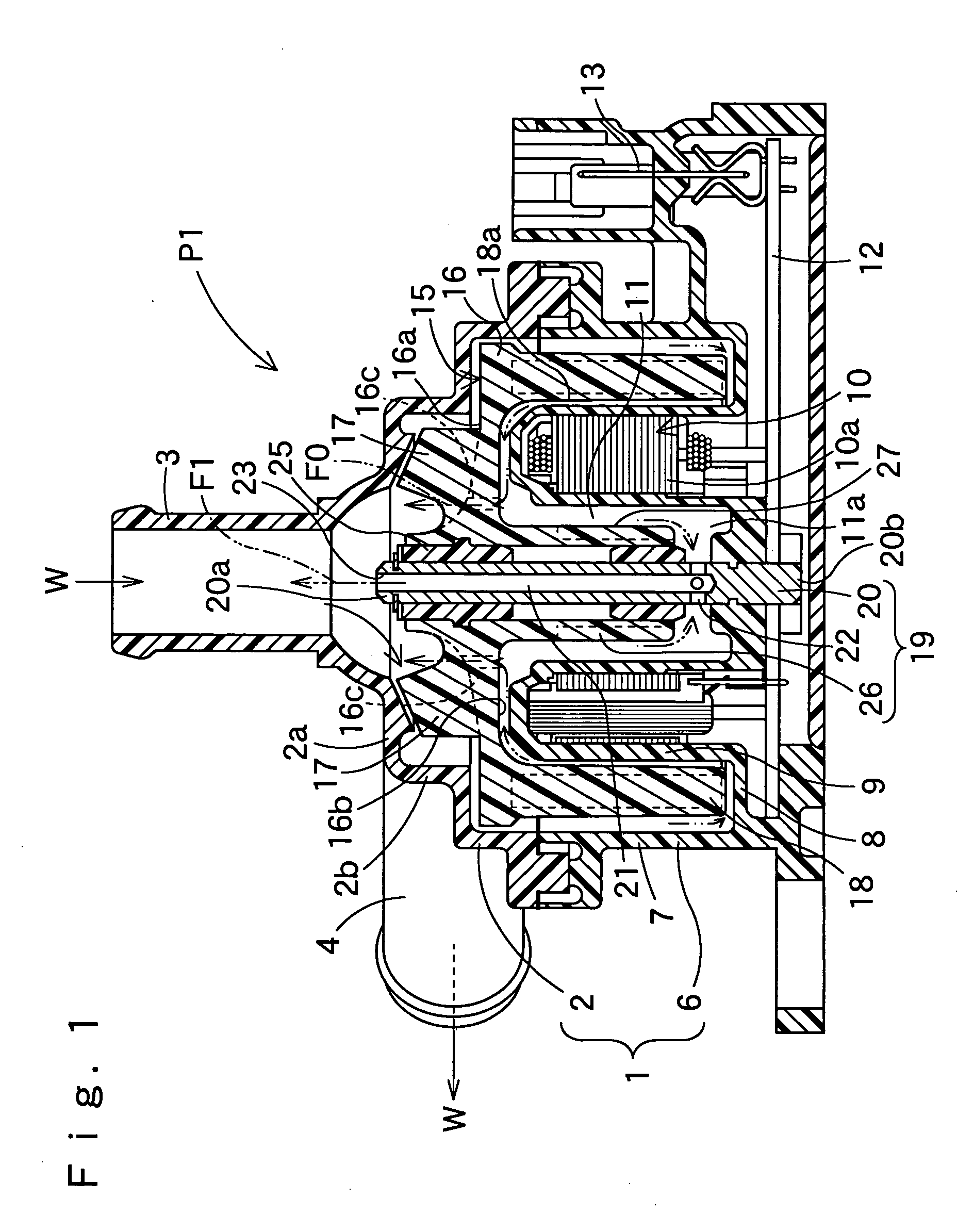

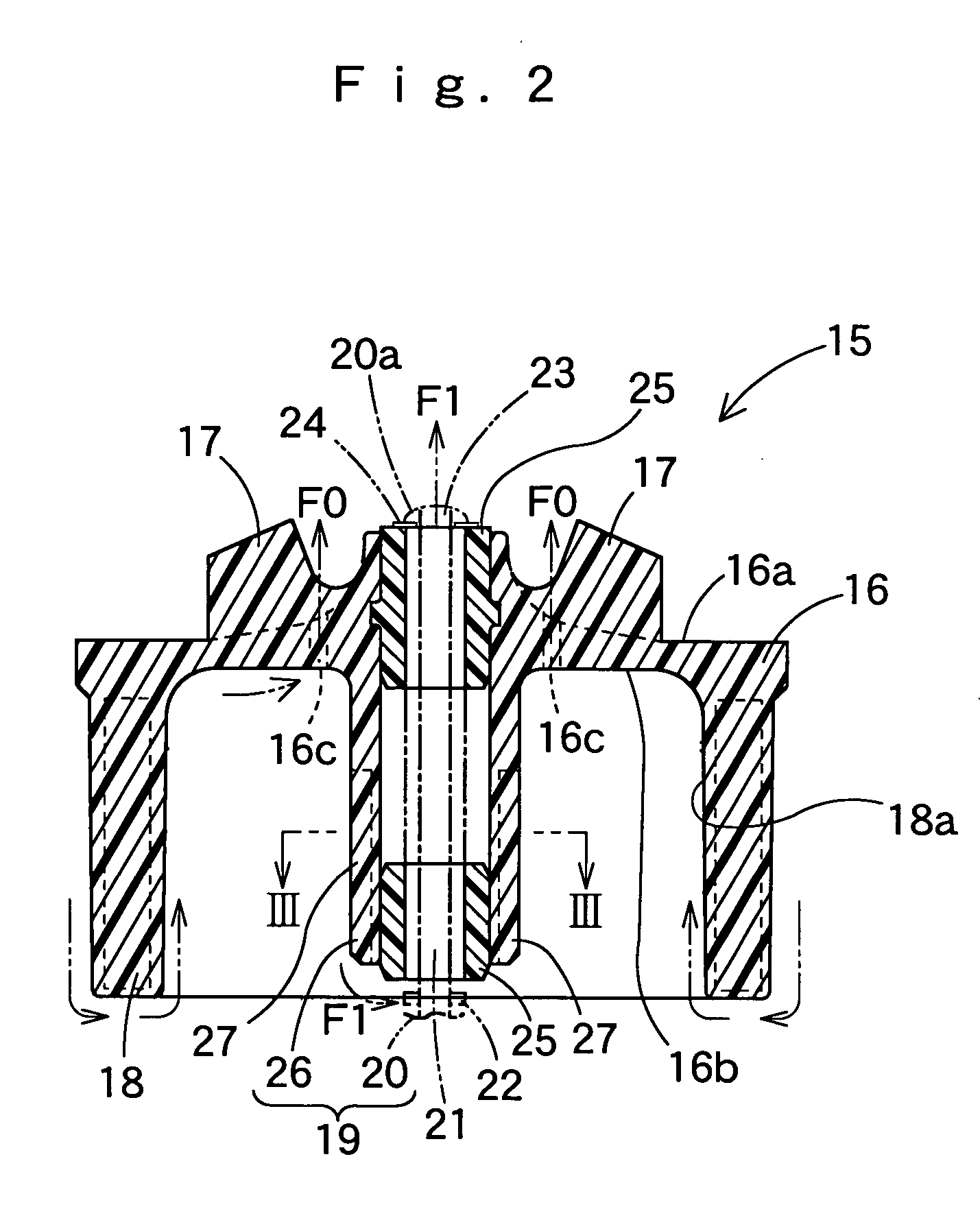

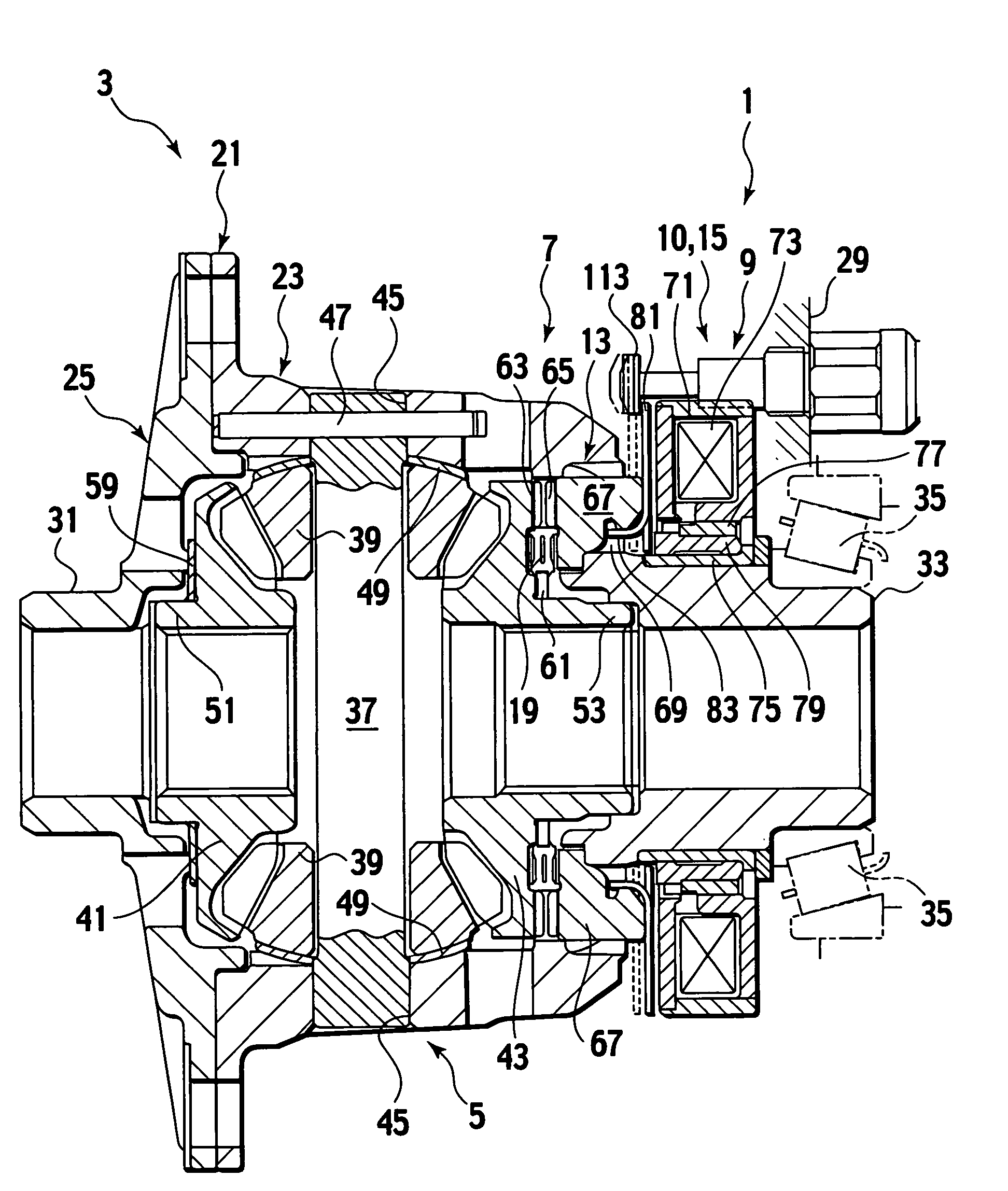

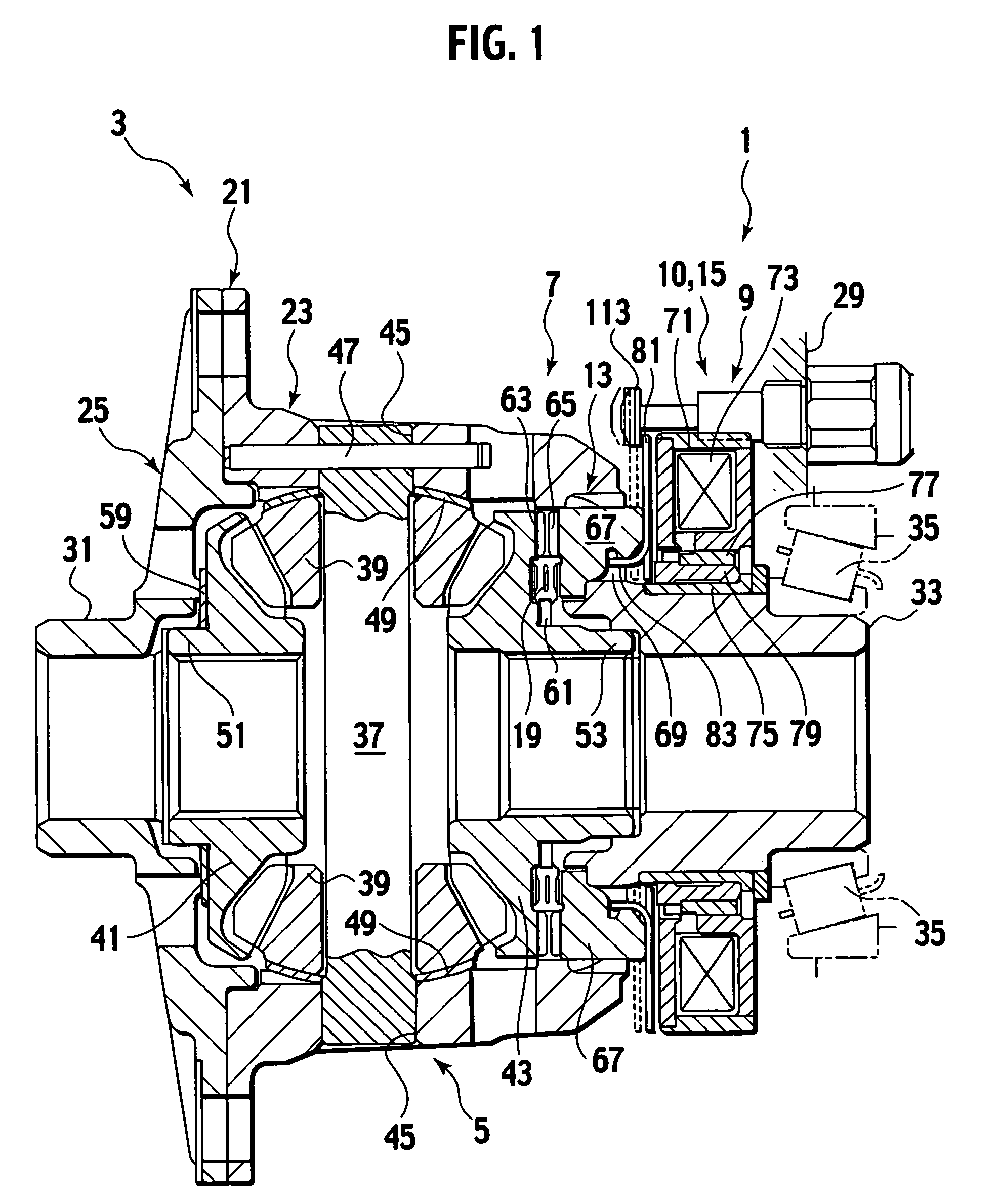

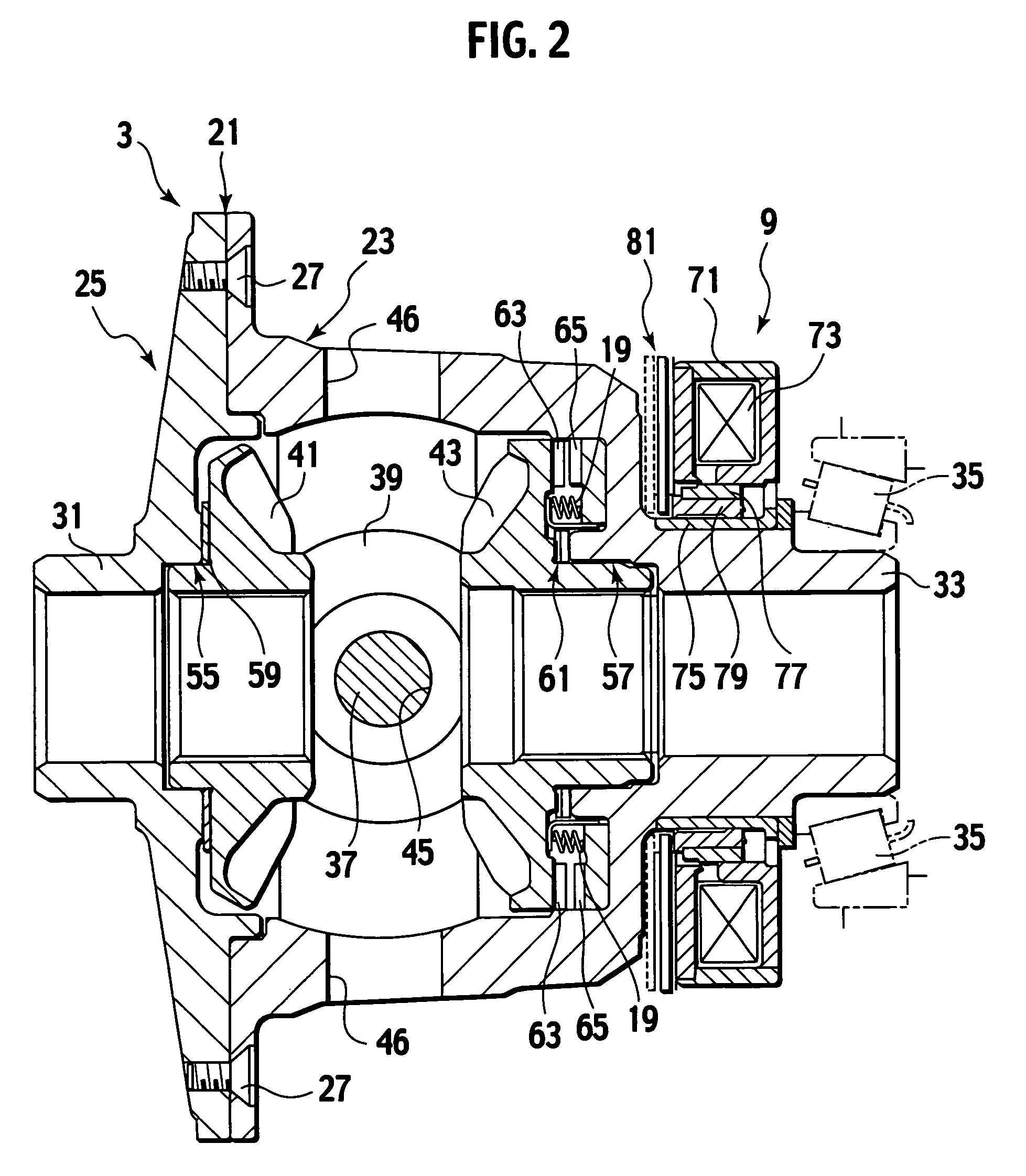

Electromagnetic actuator, and electromagnetic clutch and differential using the same

ActiveUS20050279607A1Inhibit heat generationSuppress power consumptionMechanical actuated clutchesFluid actuated clutchesElectromagnetic clutchEngineering

The electromagnetic actuator includes an electromagnetic coil configured to provide actuation force in accordance with a solenoid current to be supplied, to a clutch and configured to actuate the clutch to control relative rotation between first and second members. The electromagnetic actuator includes a detector configured to detect the clutch actuated to produce a detection signal. The electromagnetic actuator includes a controller configured to respond to the detection signal from the detector to control the solenoid current.

Owner:TOCHIGI FUJI IND CO LTD

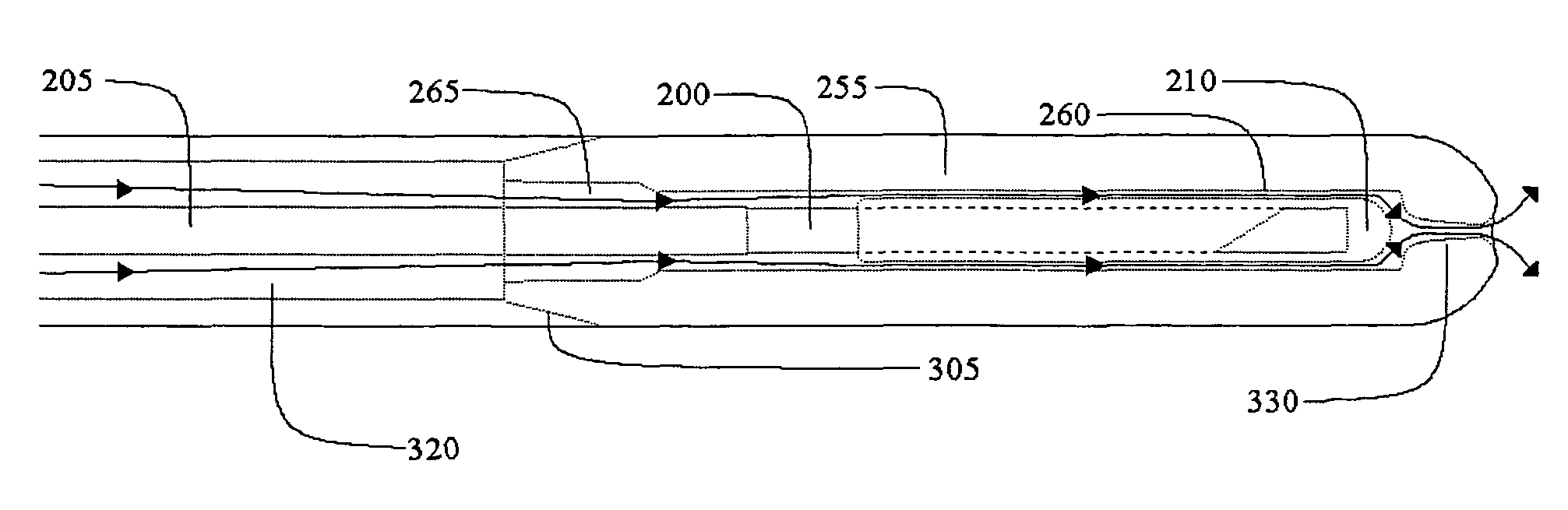

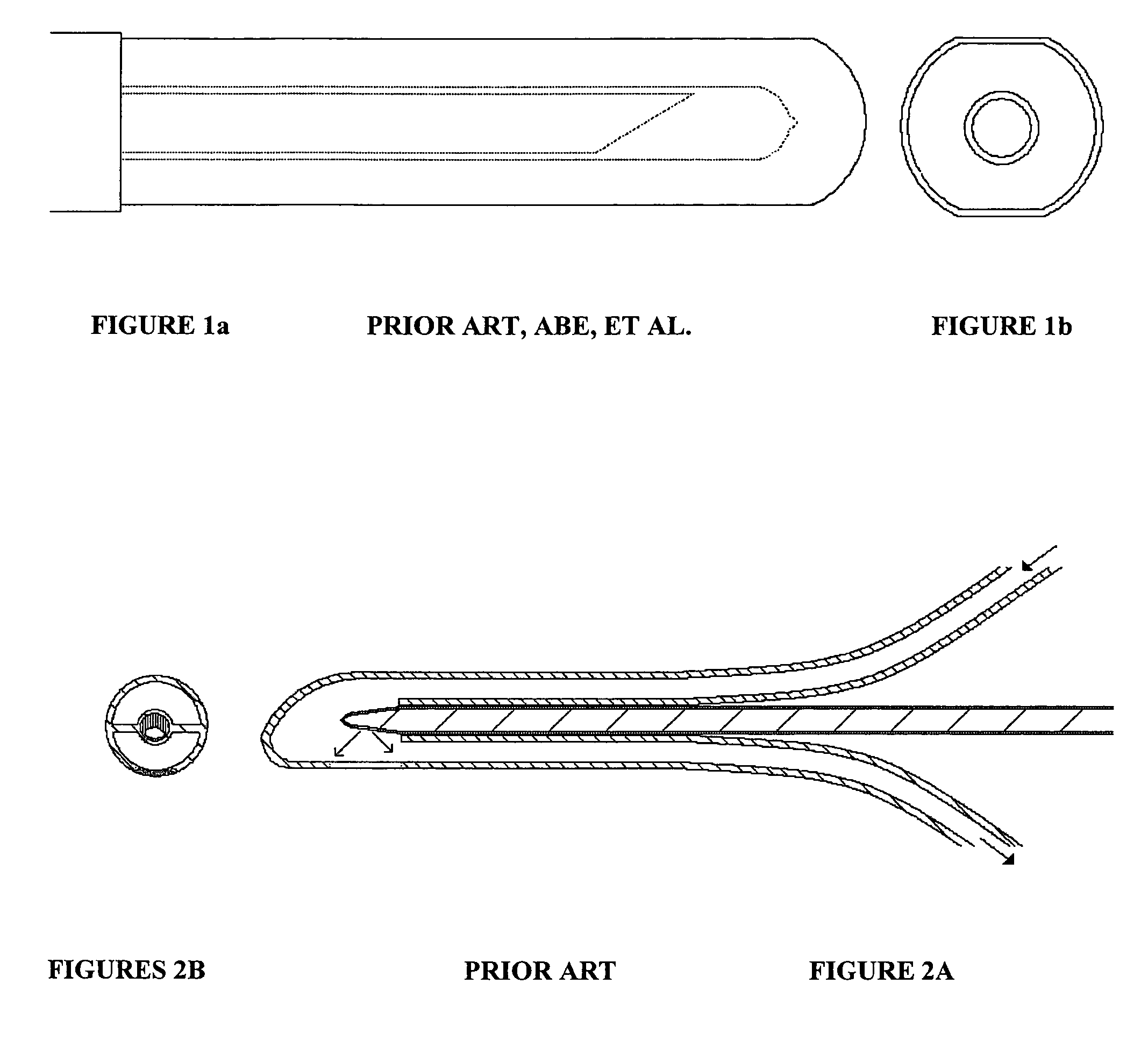

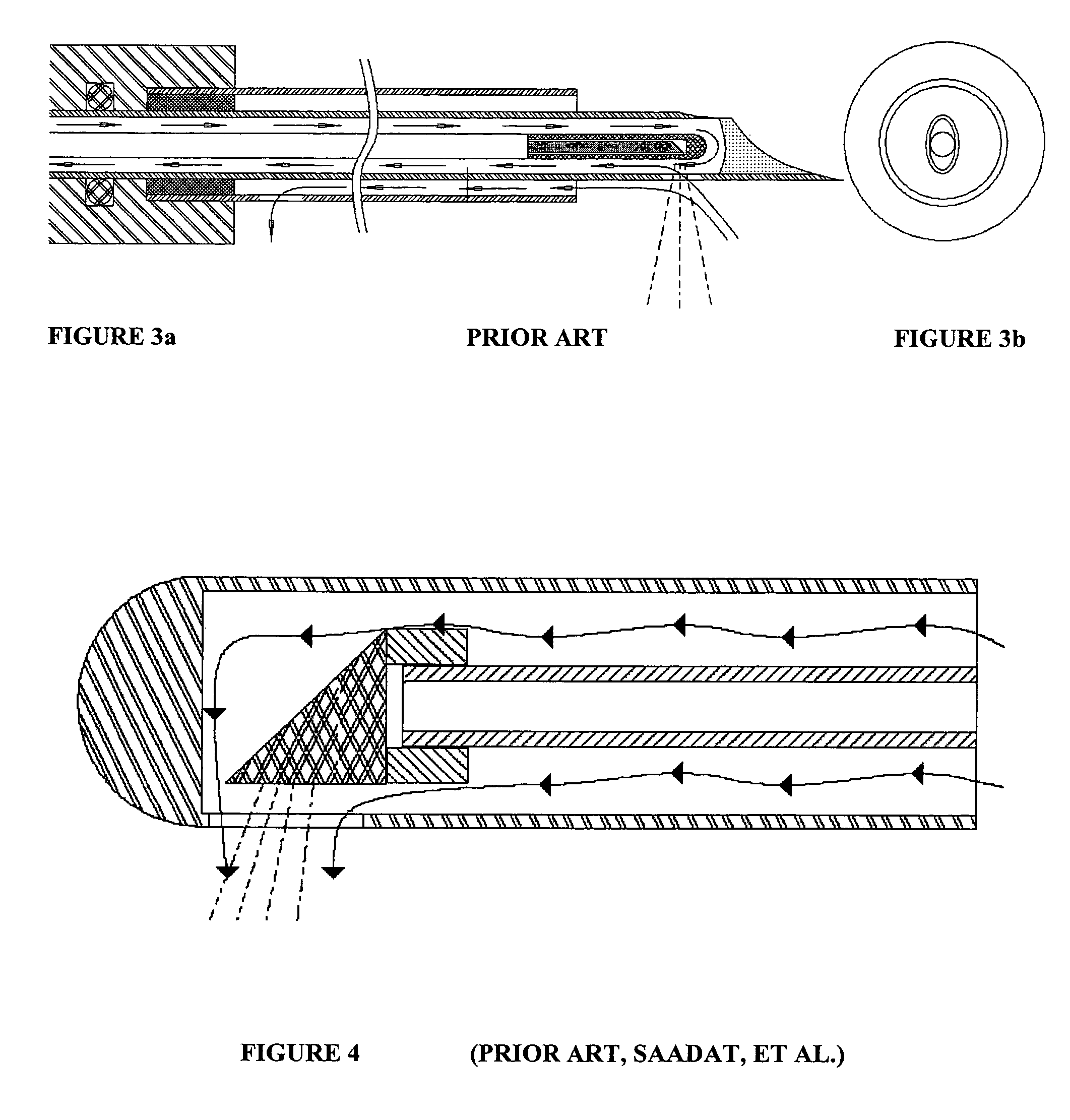

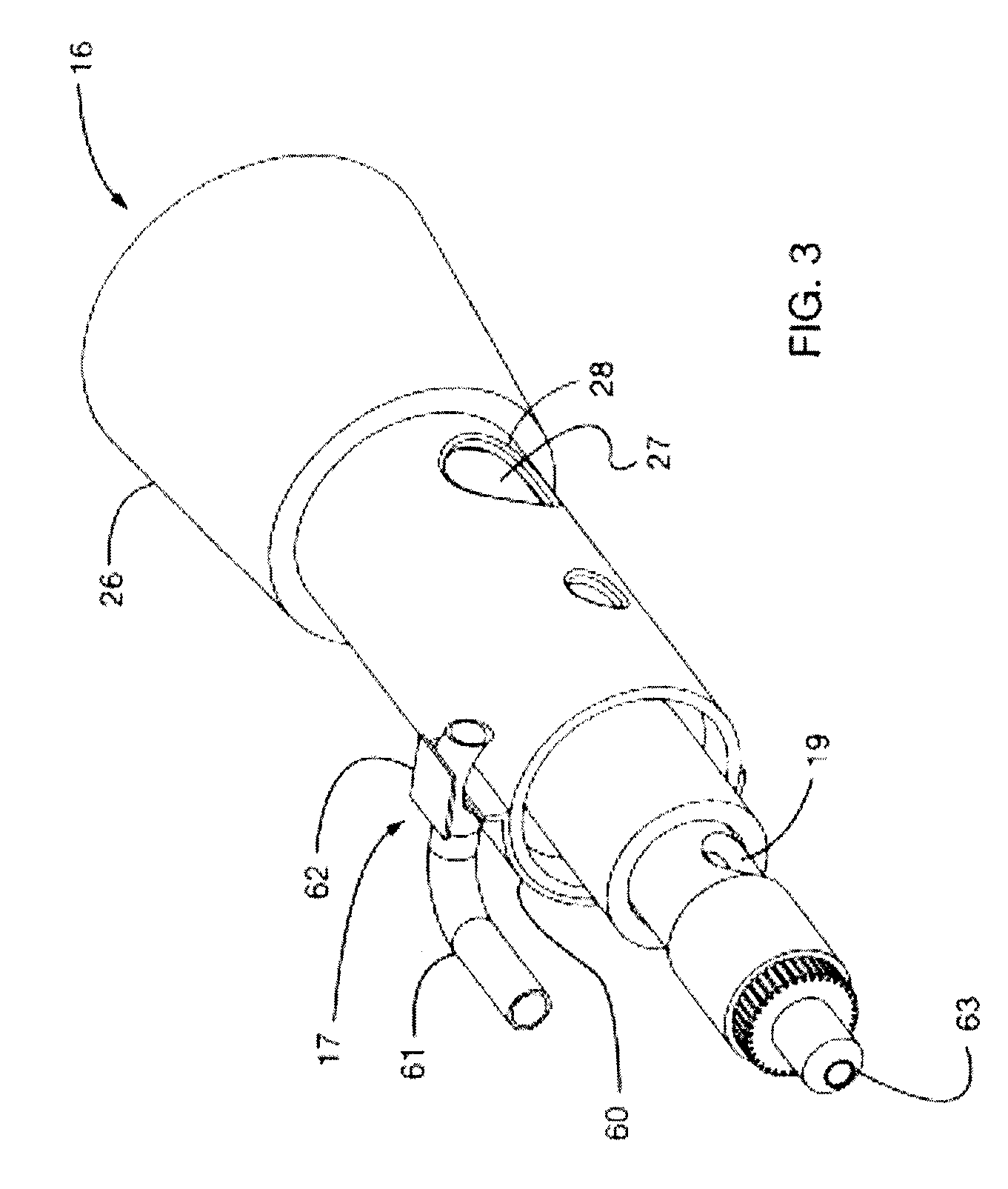

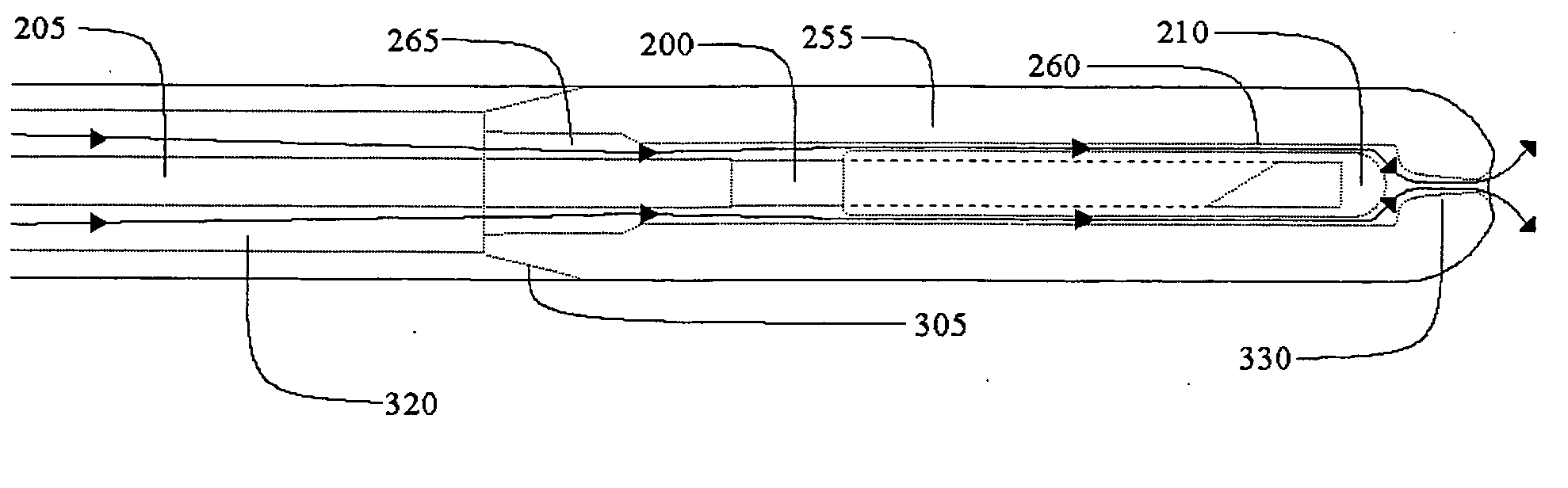

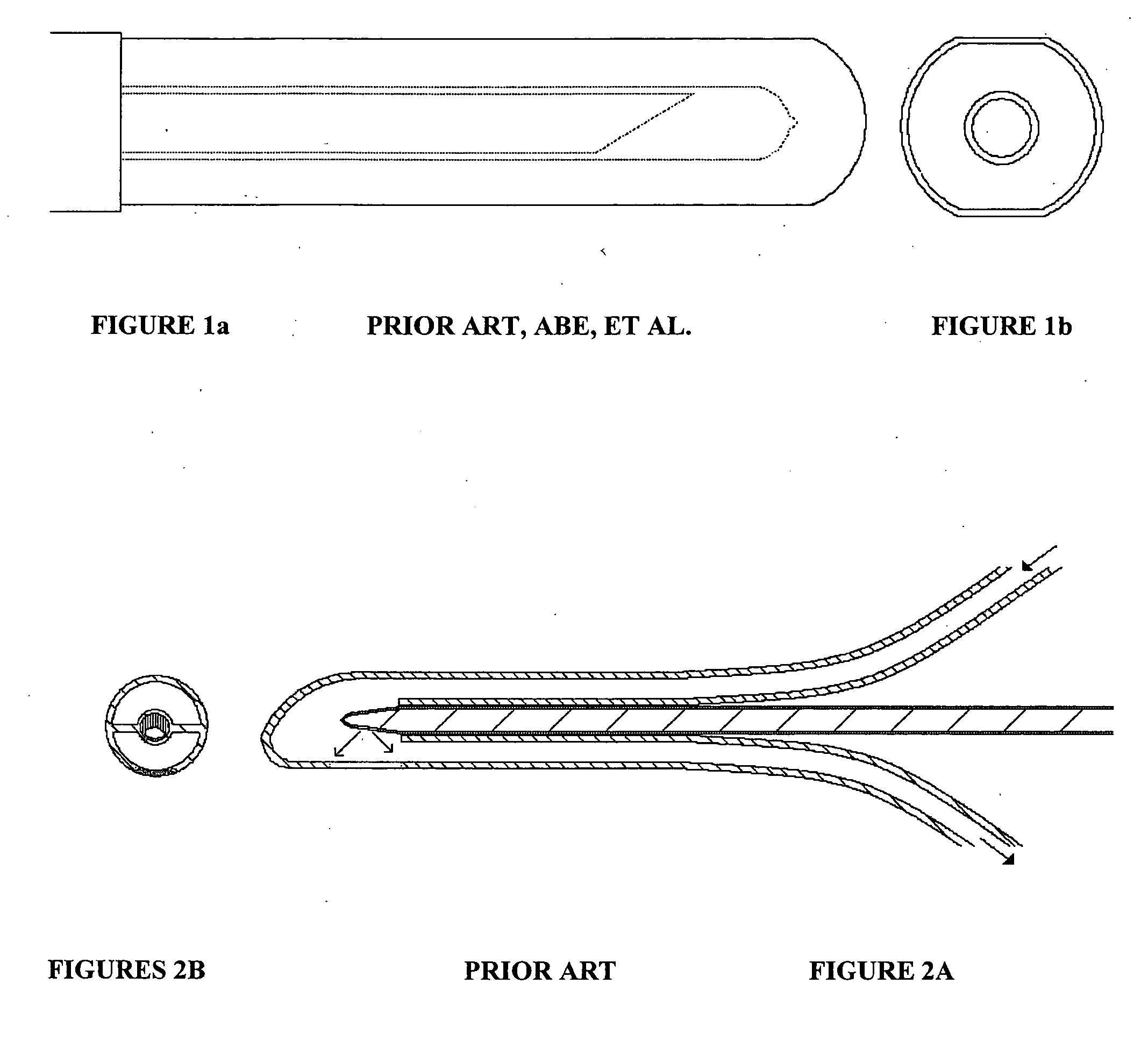

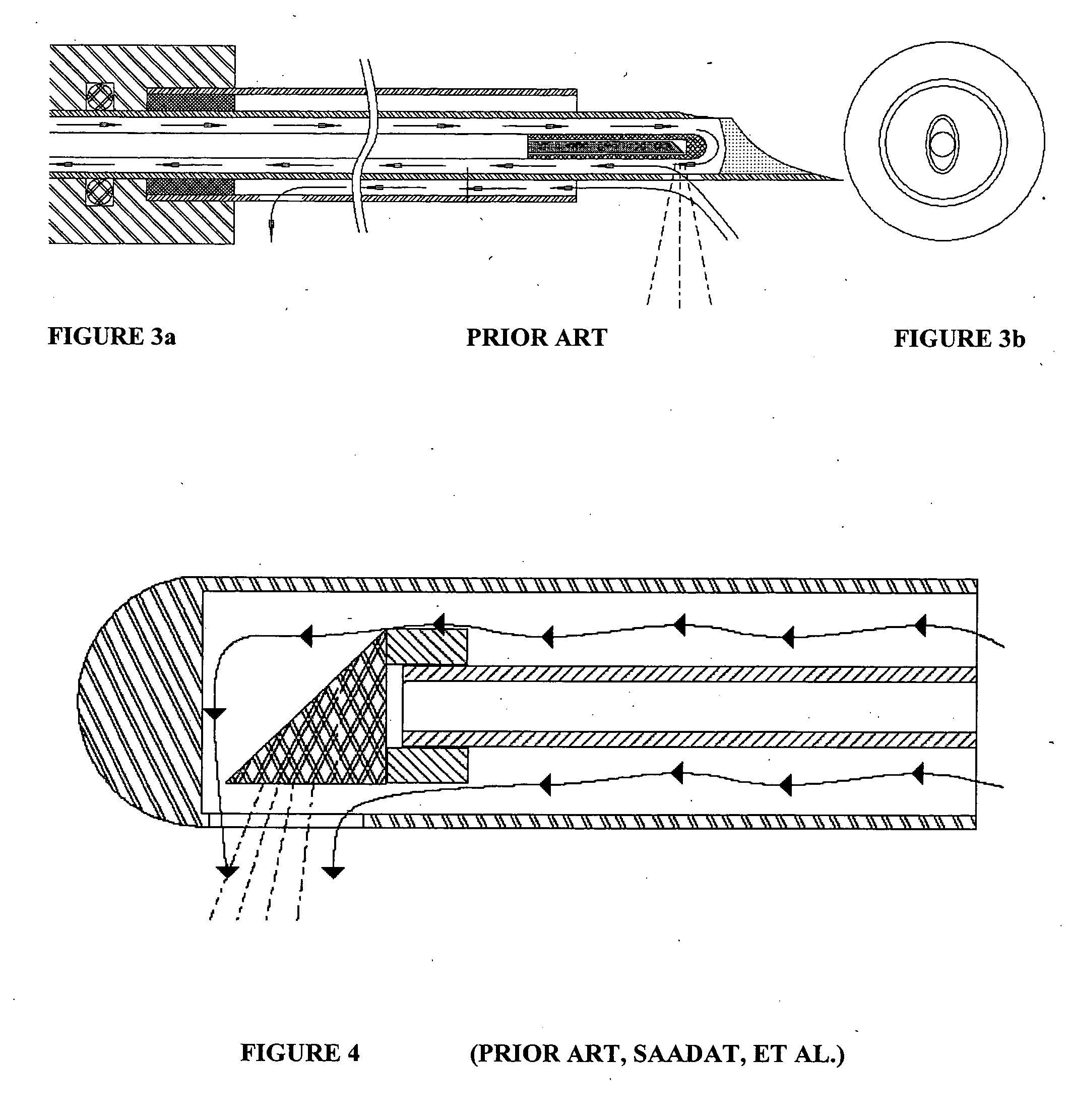

Lateral laser fiber for high average power and peak pulse energy

ActiveUS7909817B2Minimize reflectionAvoid seizuresSurgical instrument detailsFree rotationRefractive index

An improved optical fiber comprising a waveguide with an input for coupling focused laser energy into the waveguide and communicating electromagnetic radiation in a propagation direction to an internally reflective tip of the waveguide, a tissue contacting surface wherein the light path from the reflecting surface to the transmitting surface in substantially homogenous in refractive index and cooled by fluid flow. In minimizing the variations in refractive index within the lateral light path, while providing active cooling directly below the tissue contact surface, the invention prevents internal reflections and beam distortion and greatly improves the efficiency and durability of the laterally directing probe. Free rotation of the tissue contact surface, about the lateral tip, may be provided and tissue vaporization efficiency may be improved by providing a morcellating tool on the tissue contact surface.

Owner:BOSTON SCI SCIMED INC

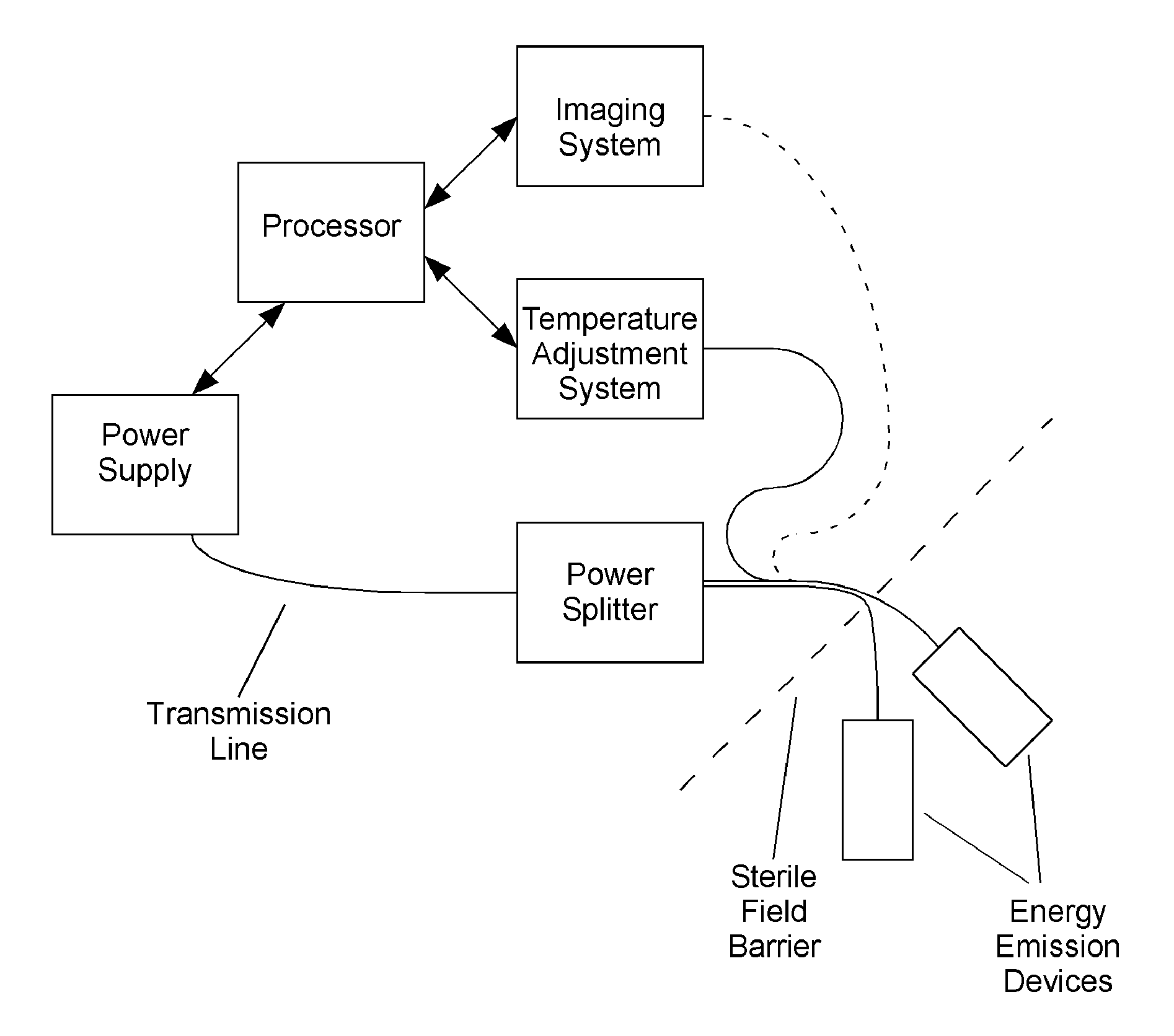

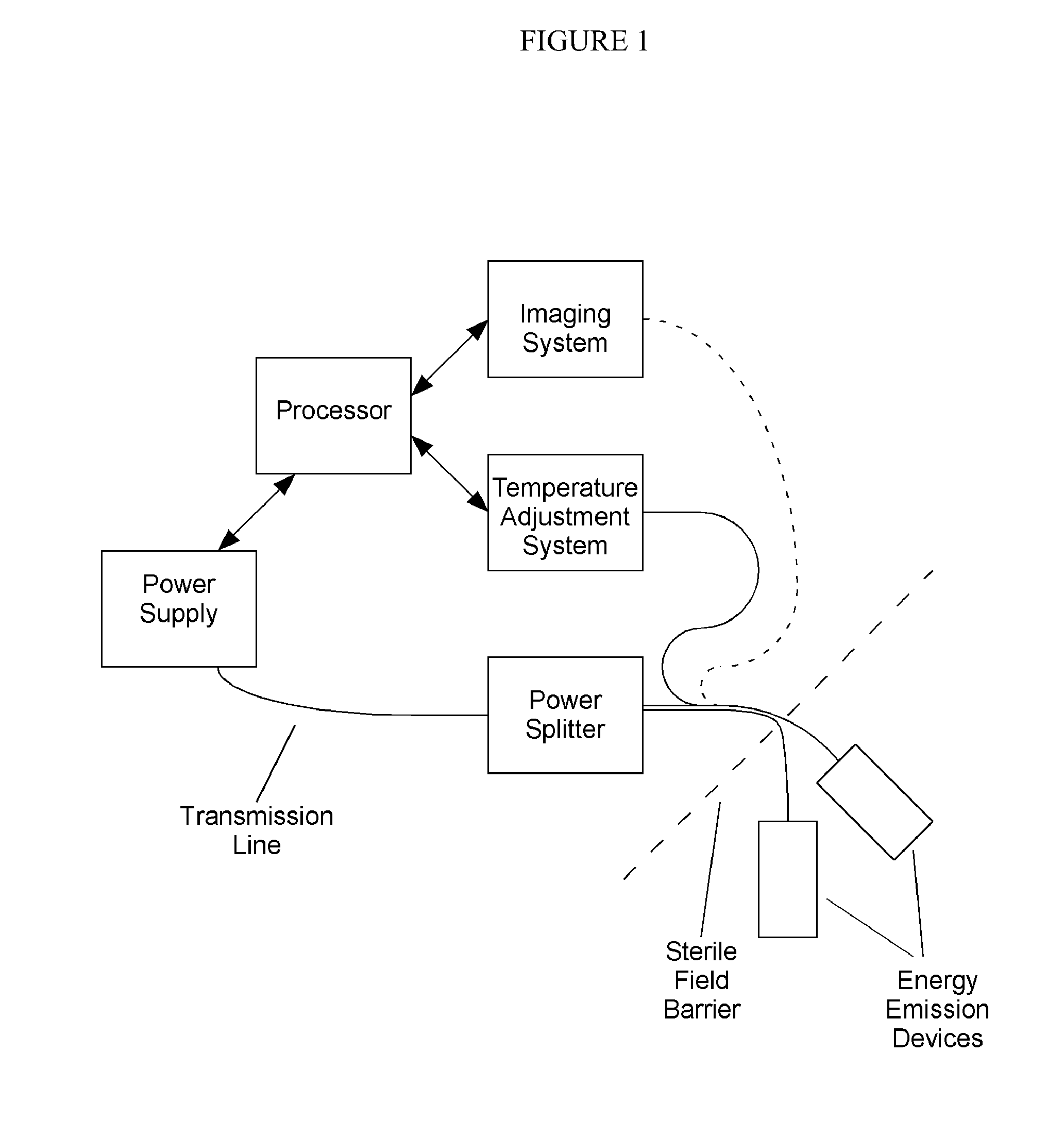

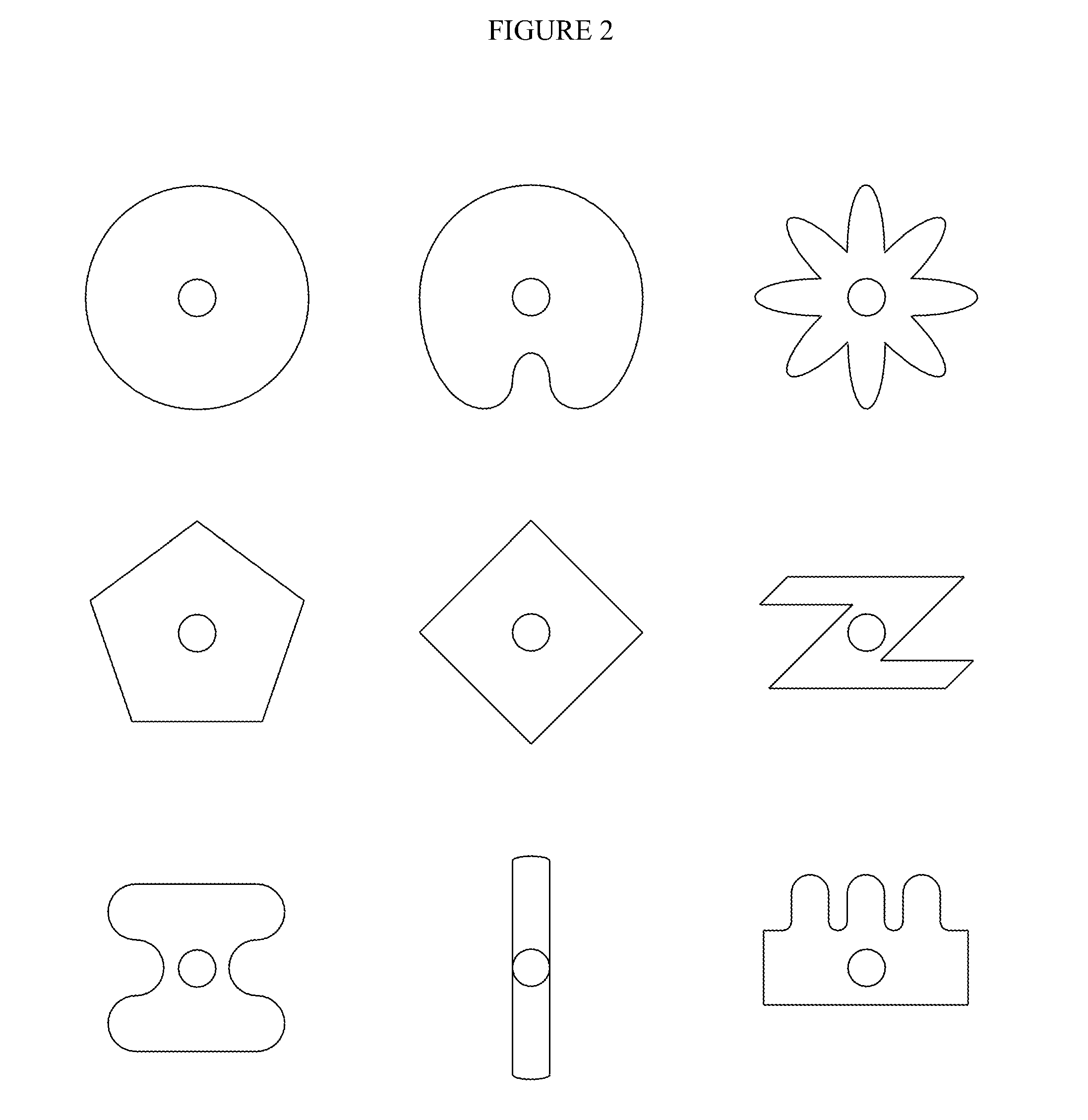

Energy delivery systems and uses thereof

ActiveUS20130116679A1Reduced flexibilityAvoiding undesiredGuide needlesSurgical instruments for heatingThrombusDelivery system

The present invention relates to comprehensive systems, devices and methods for delivering energy to tissue for a wide variety of applications, including medical procedures (e.g., tissue ablation, resection, cautery, vascular thrombosis, treatment of cardiac arrhythmias and dysrhythmias, electrosurgery, tissue harvest, etc.). In certain embodiments, systems, devices, and methods are provided for delivering energy to difficult to access tissue regions (e.g. peripheral lung tissues), and / or reducing the amount of undesired heat given off during energy delivery.

Owner:NEUWAVE MEDICAL

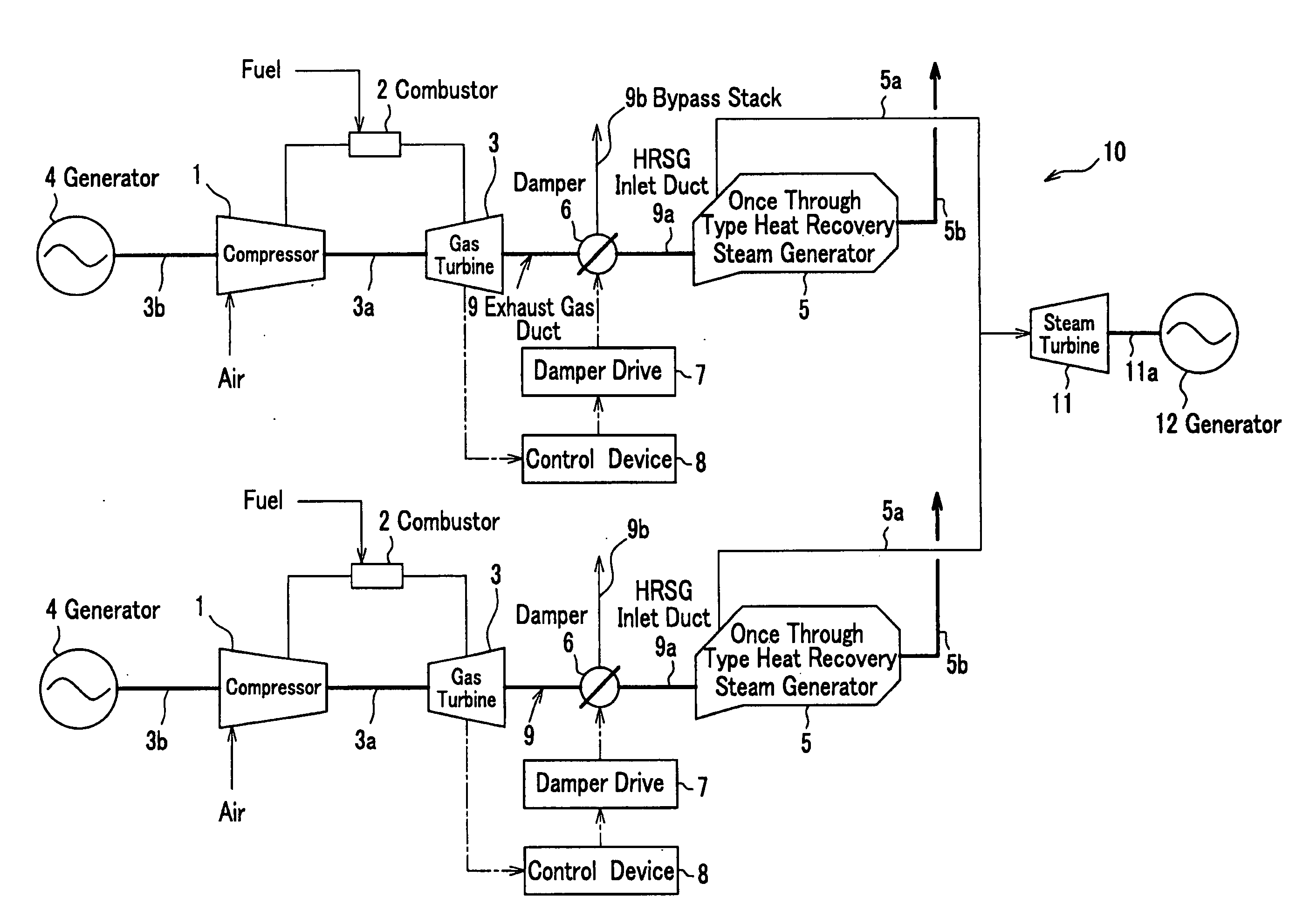

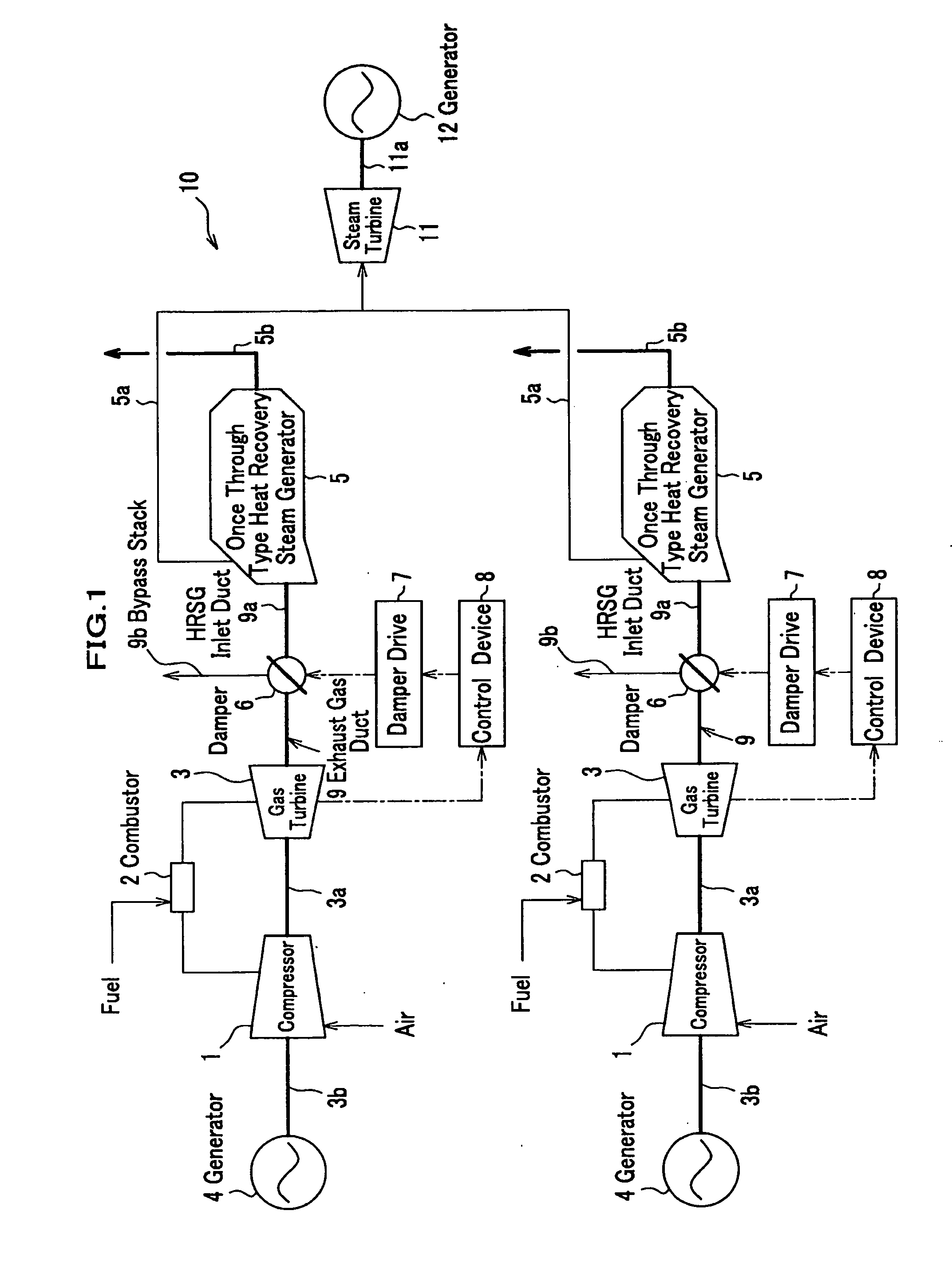

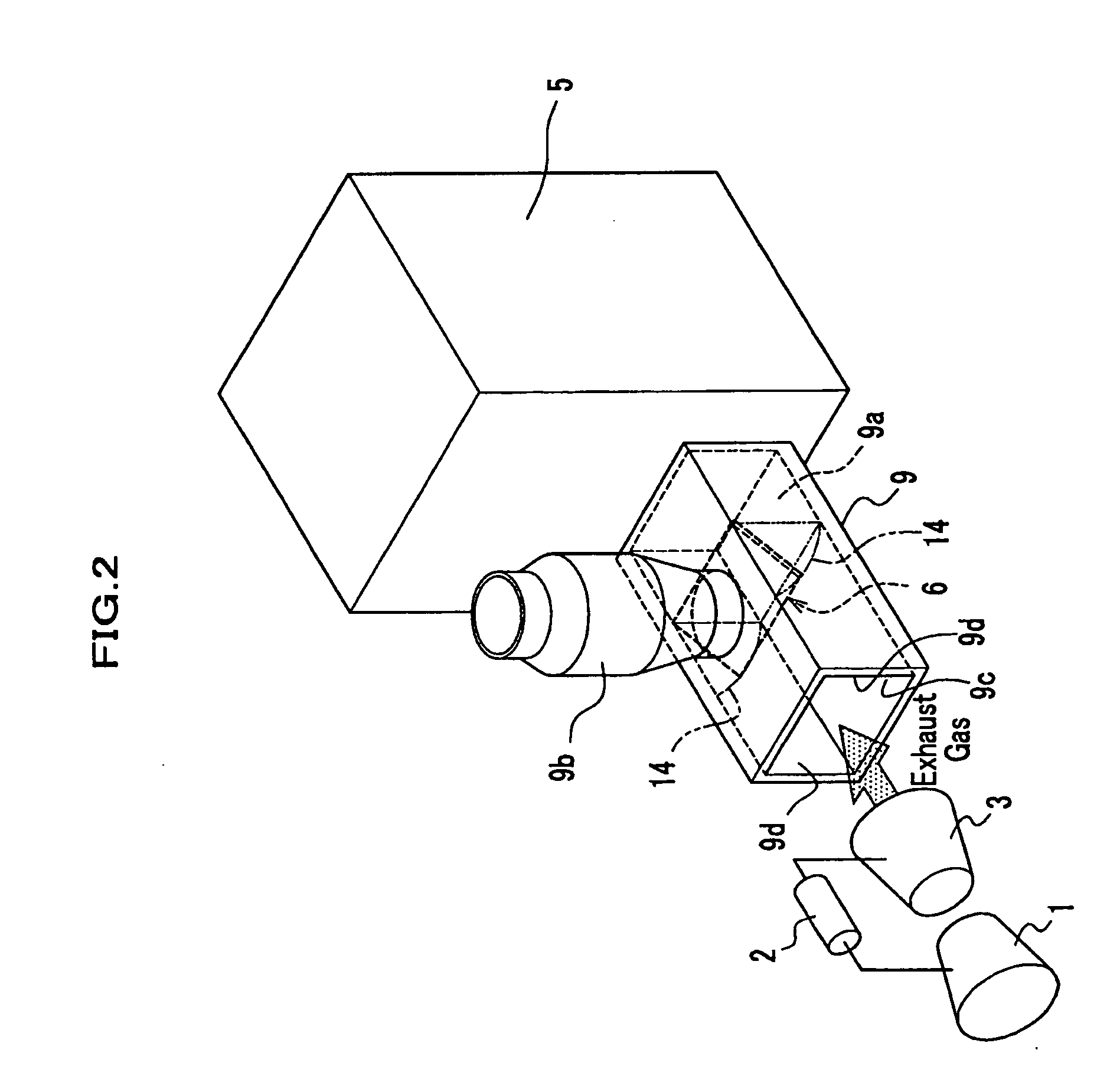

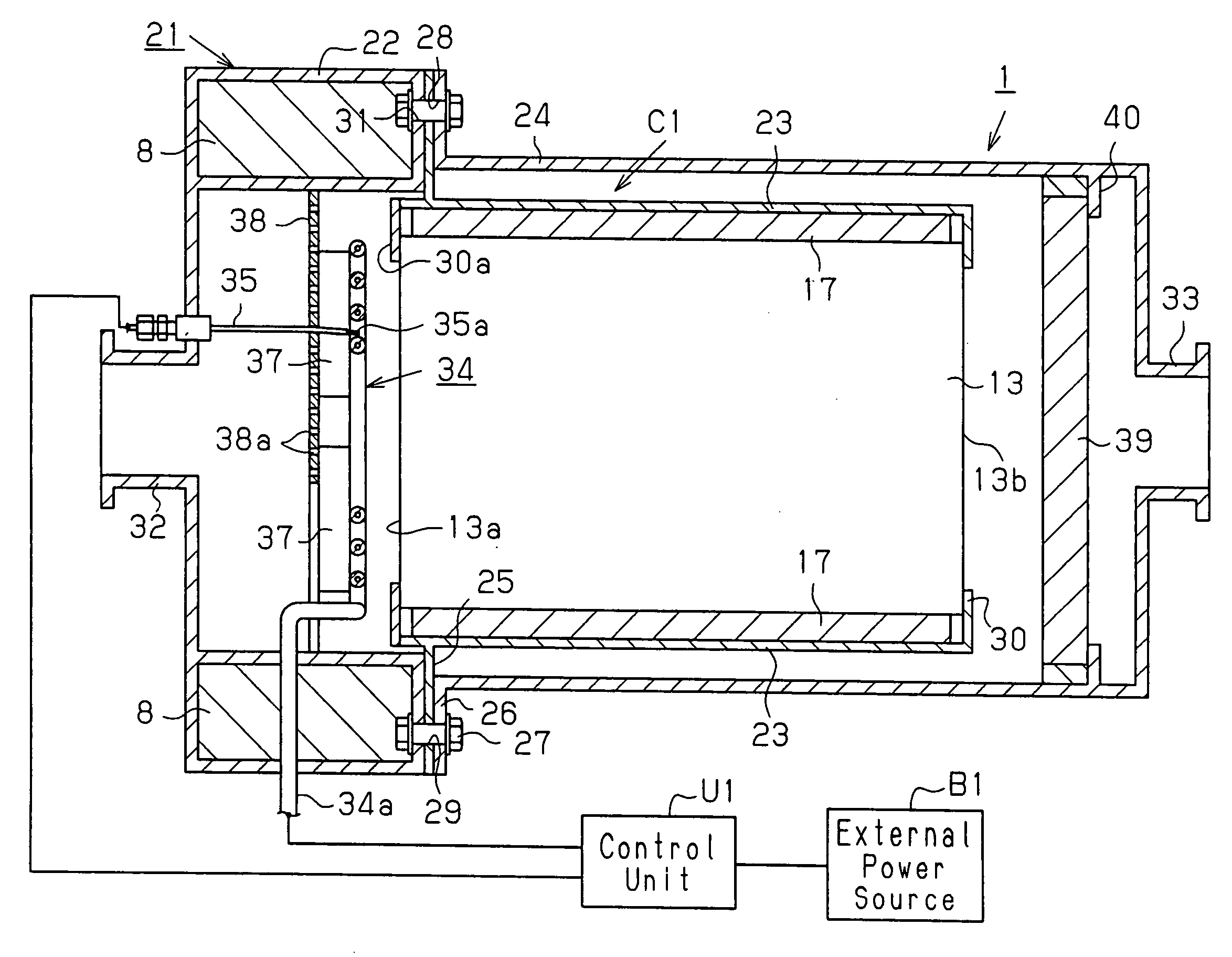

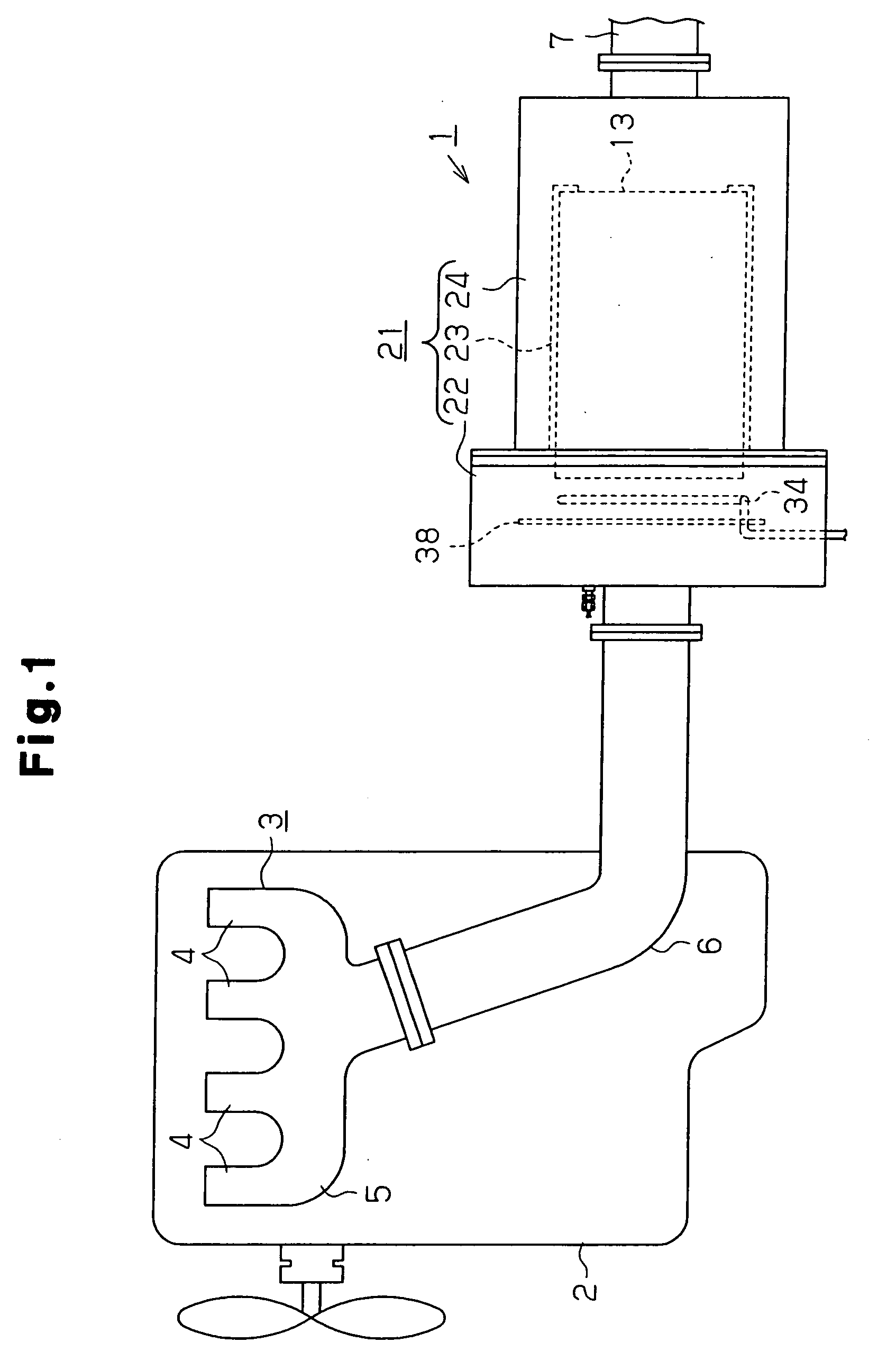

Fast start-up combined cycle power plant

InactiveUS20050268594A1Avoid vibrationReduce the amount requiredEngine fuctionsGas turbine plantsCombustorPower station

A combined cycle power plant of the present invention is configured of a compressor; a combustor for combusting compressed air compressed by the compressor together with supplied fuel; a gas turbine driven by a combustion gas exhausted from the combustor; a heat recovery steam generator for recovering high temperature exhaust heat exhausted from the gas turbine; a steam turbine driven by steam obtained from the heat recovery steam generator; and an exhaust gas duct having an HRSG inlet duct that is provided between the gas turbine and the heat recovery steam generator and introduces an exhaust passage into the heat recovery steam generator, and a bypass stack that leads the exhaust gas outside, wherein the exhaust duct is configured of a damper, a damper drive for changing any of angle and opening of the damper, and a guide mechanism for preventing a vibration of the damper.

Owner:THE TOKYO ELECTRIC POWER CO INC +1

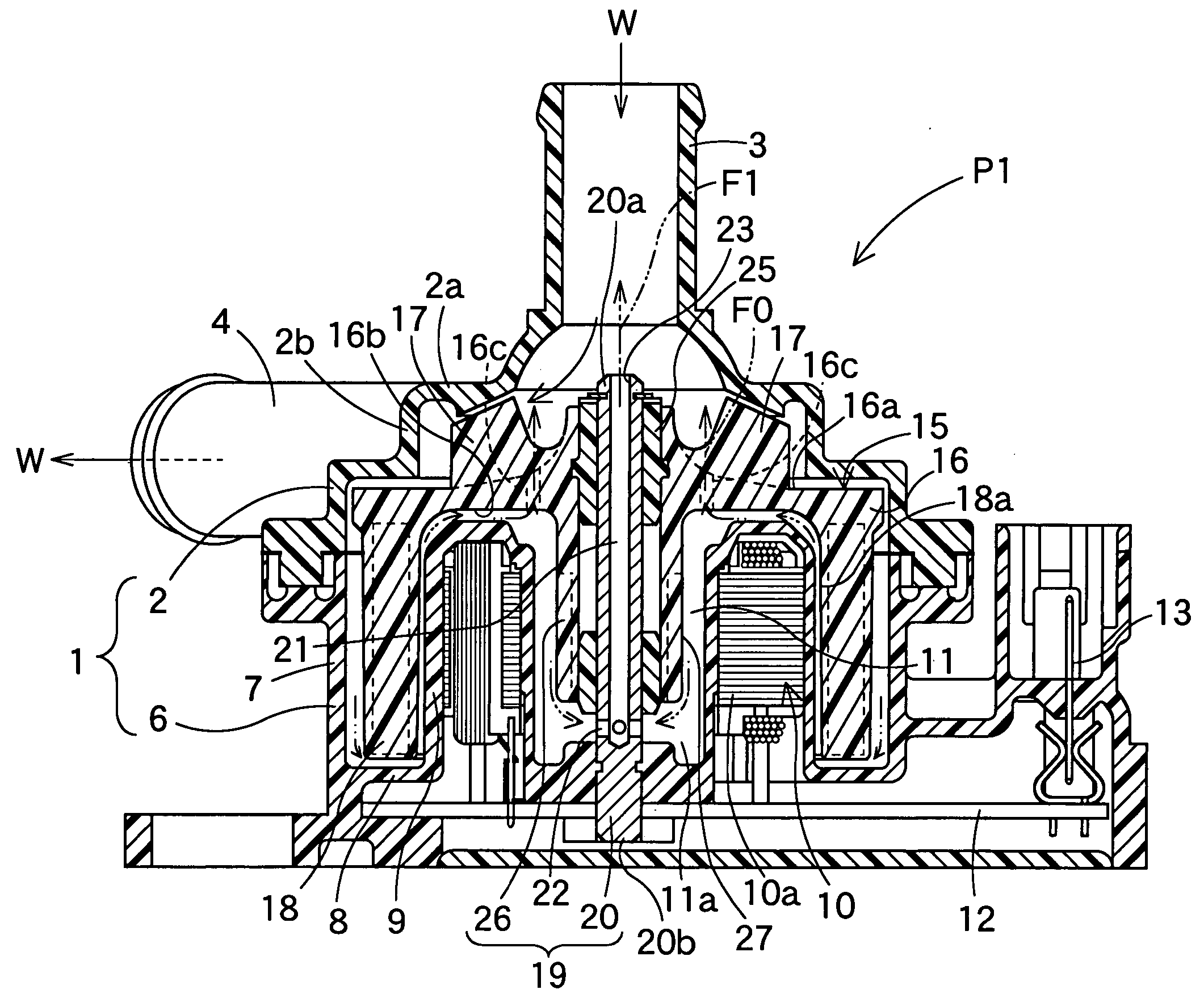

Magnetic coupling pump

InactiveUS20040234395A1Precise heatingAvoid heatingPump componentsPiston pumpsMagnetic tension forceImpeller

A magnetic coupling pump according to the present invention has a housing including a pump chamber a motor chamber. The rotor includes a plurality of impellers projected from top face of a substantially disc-shaped main body of the rotor to be located in the pump chamber, and a substantially cylindrical magnet section projected from back face of the main body to be located in the motor chamber. The rotor is located in engine coolant, and is driven by a stator located inward of the magnet section in the motor chamber for sucking coolant from an inlet port and exhausting it from an outlet port. The pump is provided along an inner circumference of the stator with a cavity communicating with passages of fluid along an inner circumference of the magnet section and the back face of the main body of the magnet section. The cavity admits the coolant. The pump according to the present invention is able to prevent heat-up in the inner circumferential part of the stator.

Owner:AISAN IND S

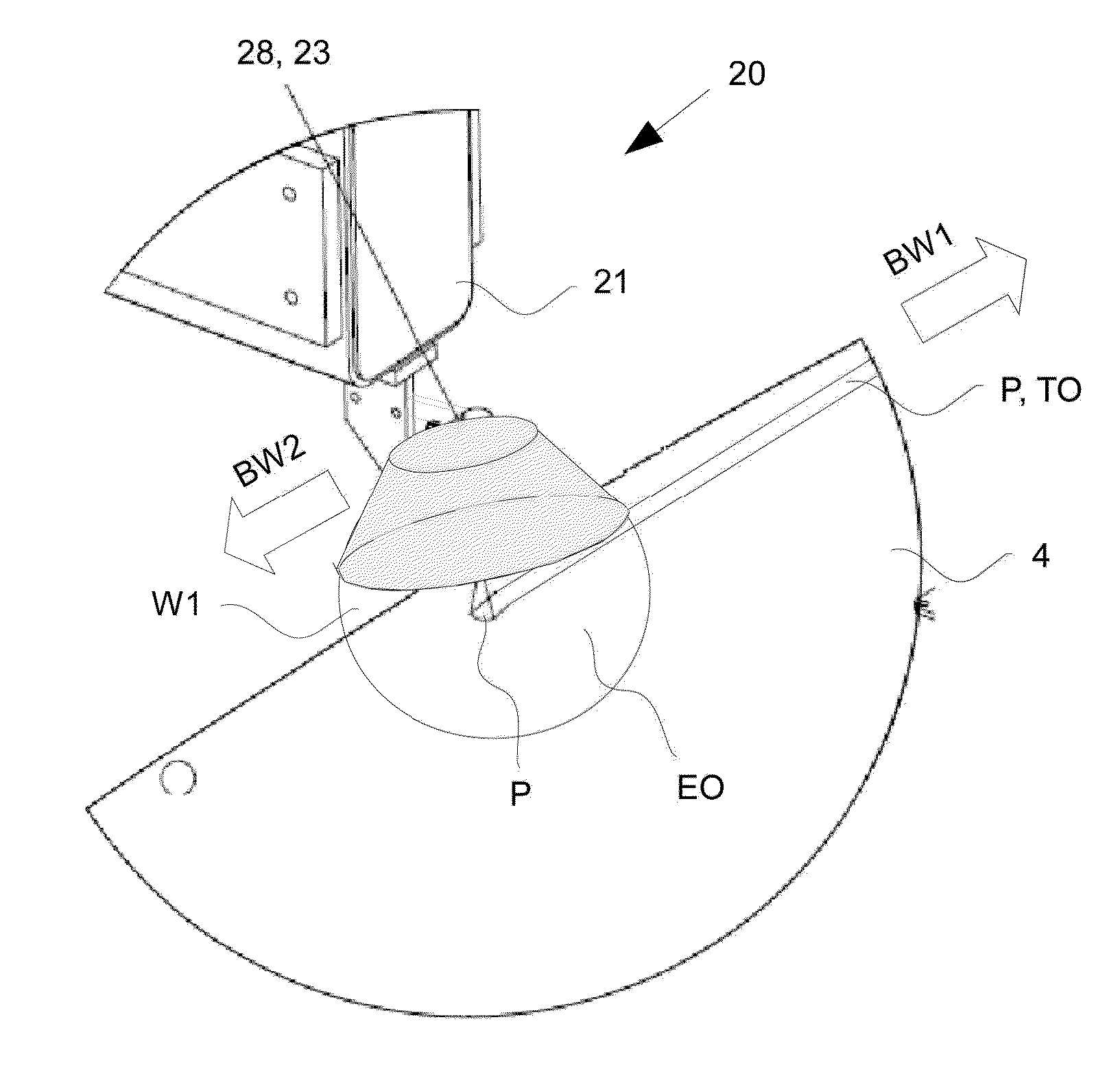

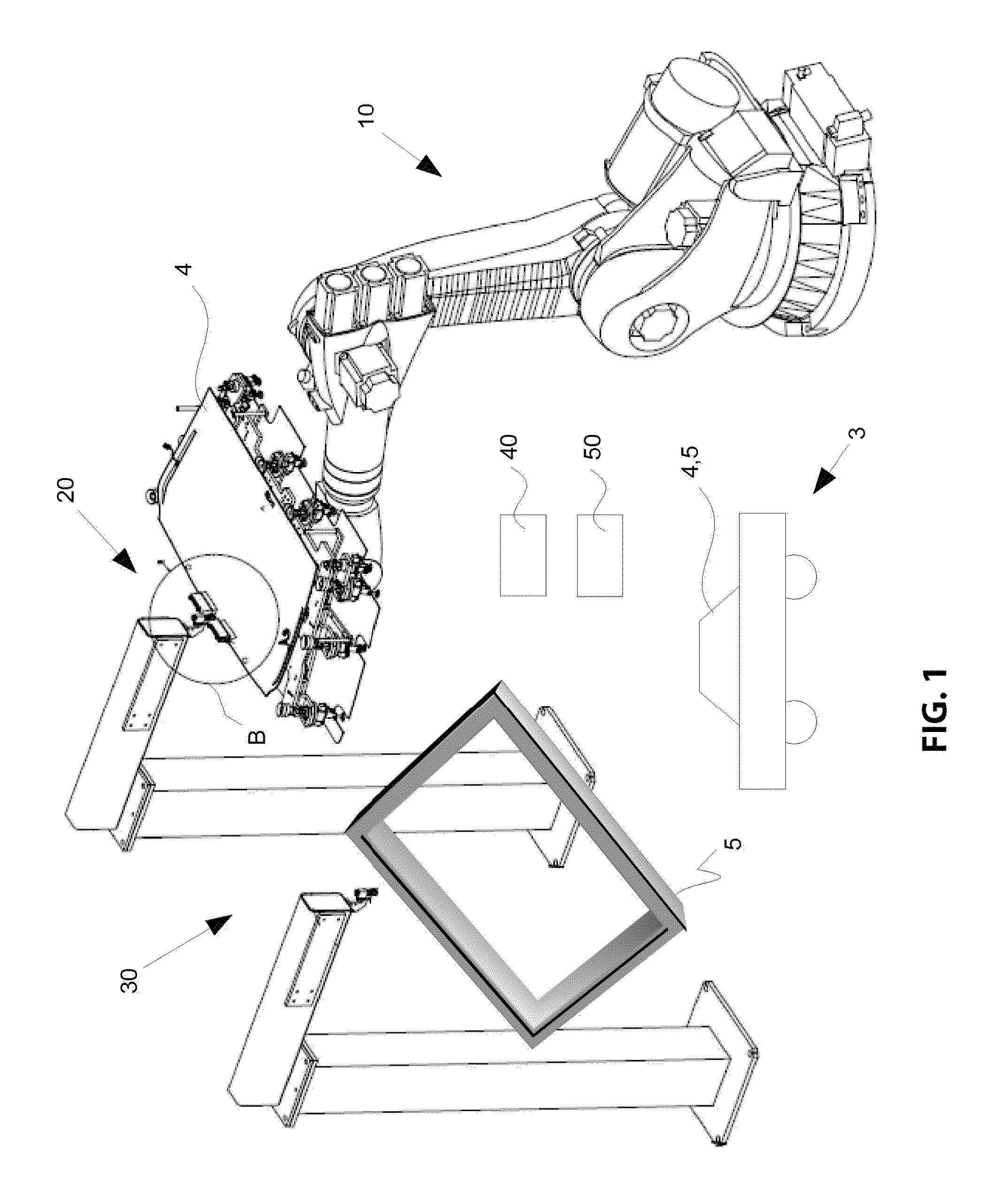

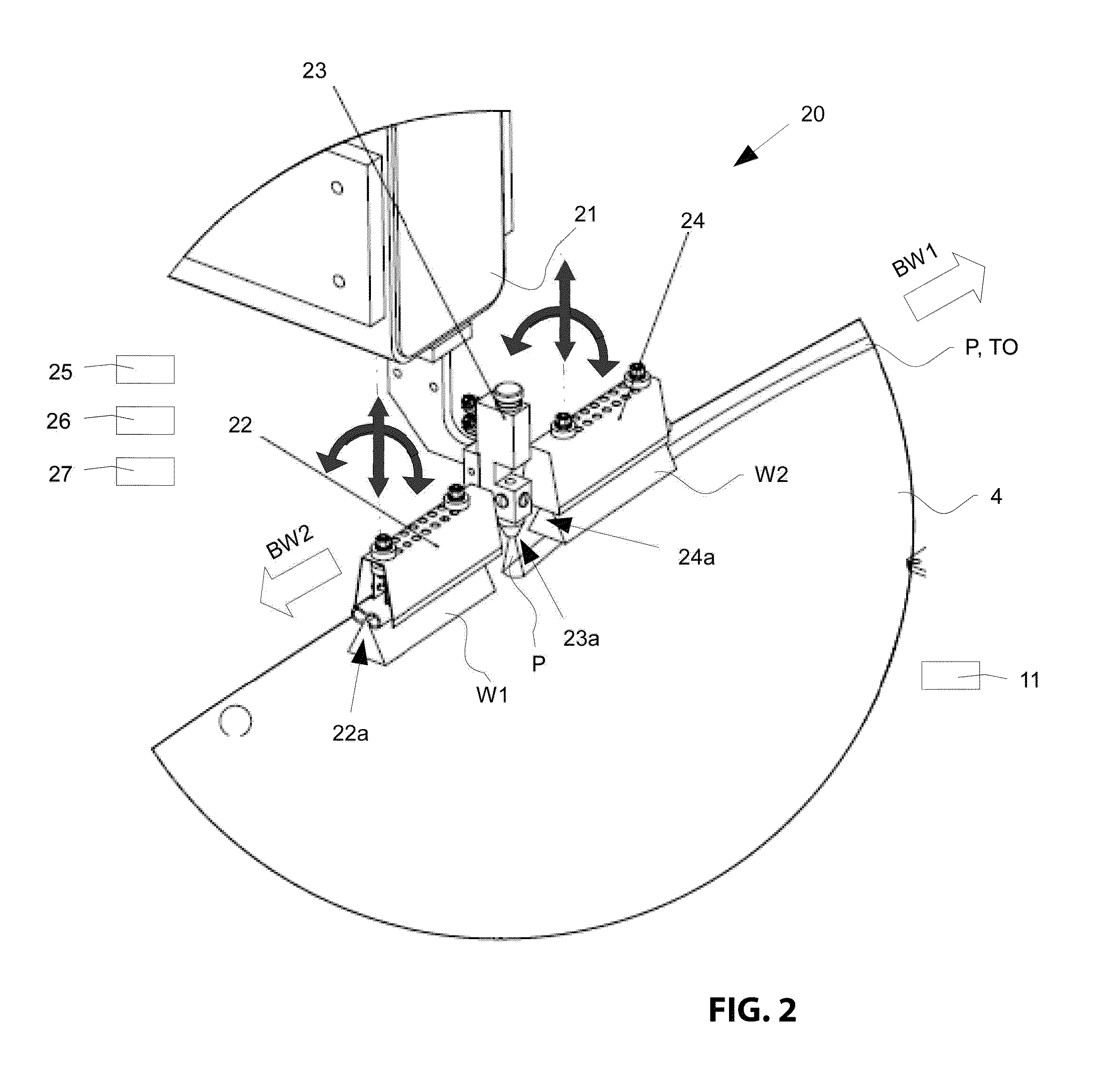

Joining surface treatment device and method

ActiveUS8678060B2Avoid heatingEnergy of of minimizedLamination ancillary operationsManual label dispensersBiomedical engineering

Owner:FFT PRODIONSSYST

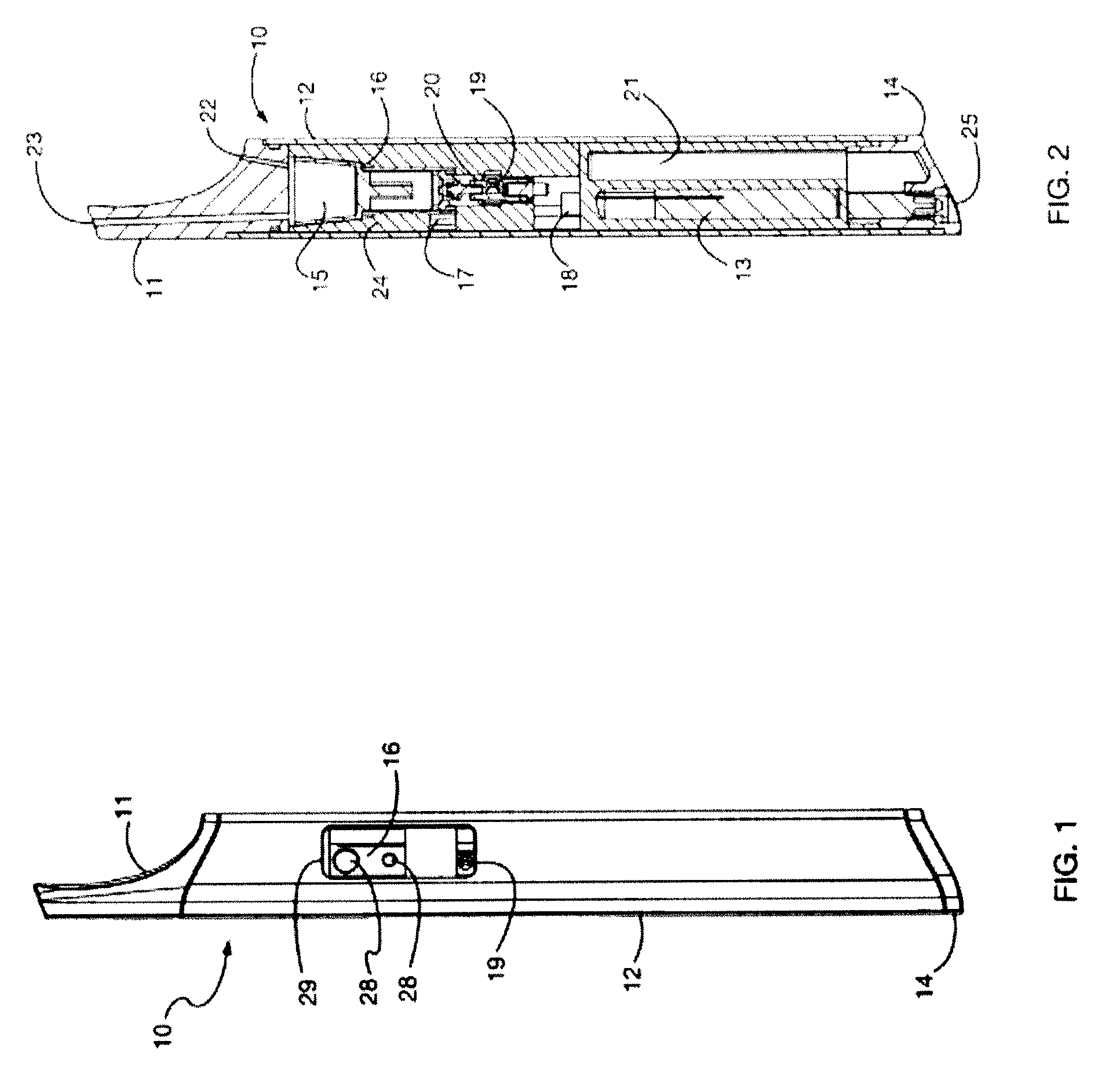

Portable devices for generating an inhalable vapor

InactiveUS20160345631A1Avoid heatingEasy to insertInput/output for user-computer interactionTemperature control using digital meansInhalationEngineering

Devices for generating and releasing vapor comprising a mouthpiece for providing vapor for inhalation to a user including a tubular casing containing a heater for heating a vaporizable substance at a substantially constant low temperature having means for visual indication of the operation of the device.

Owner:JUUL LABS INC

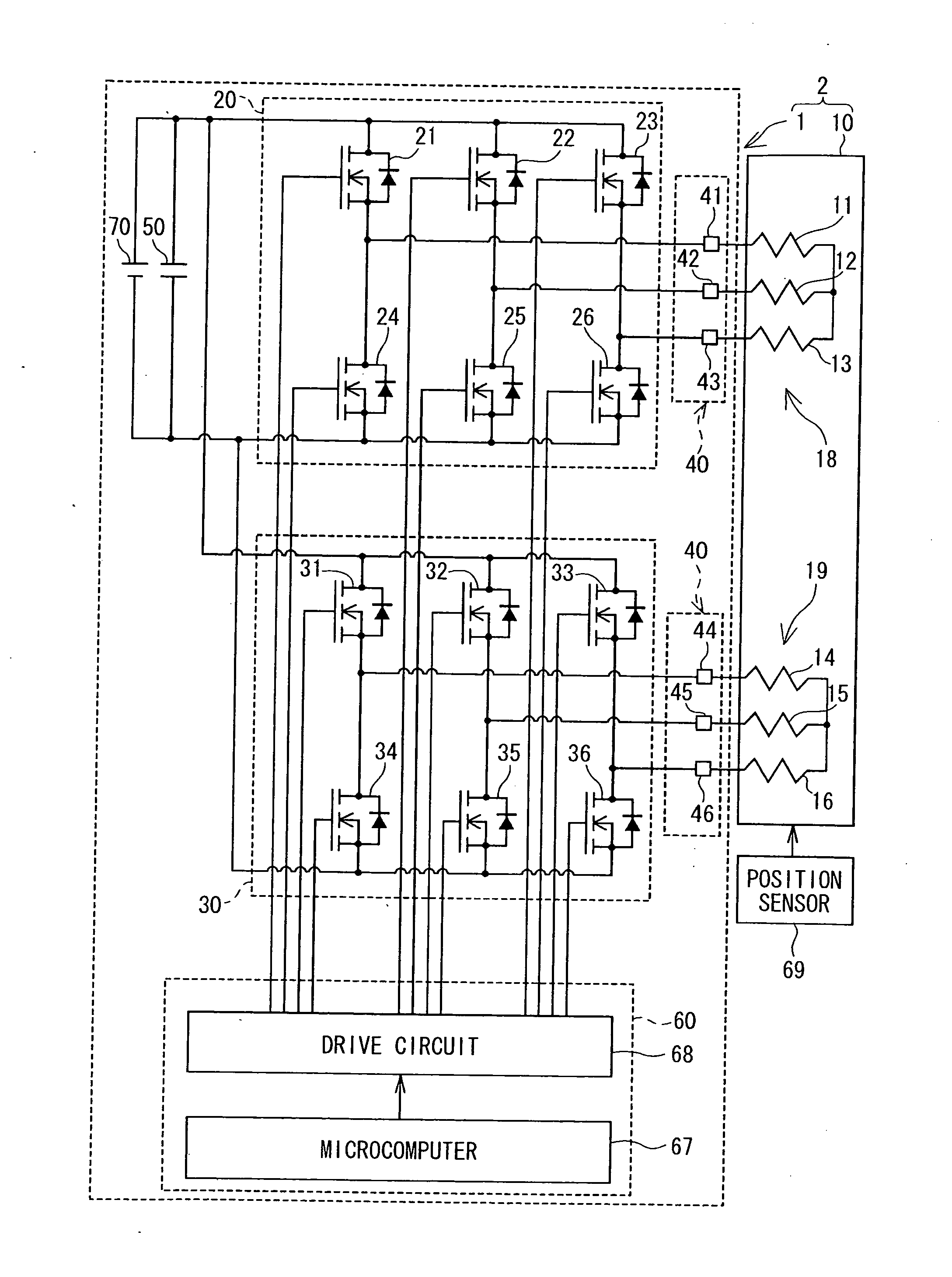

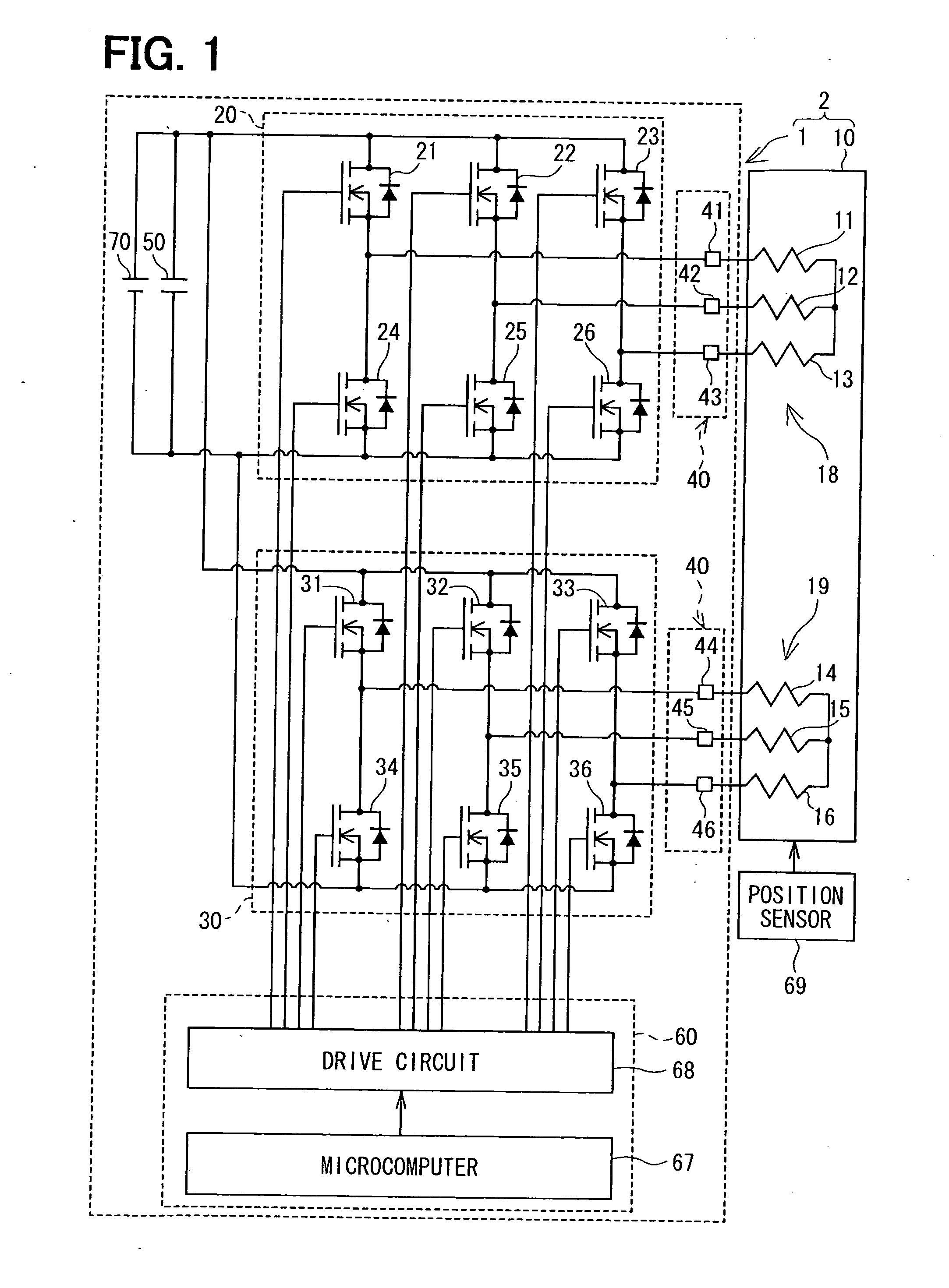

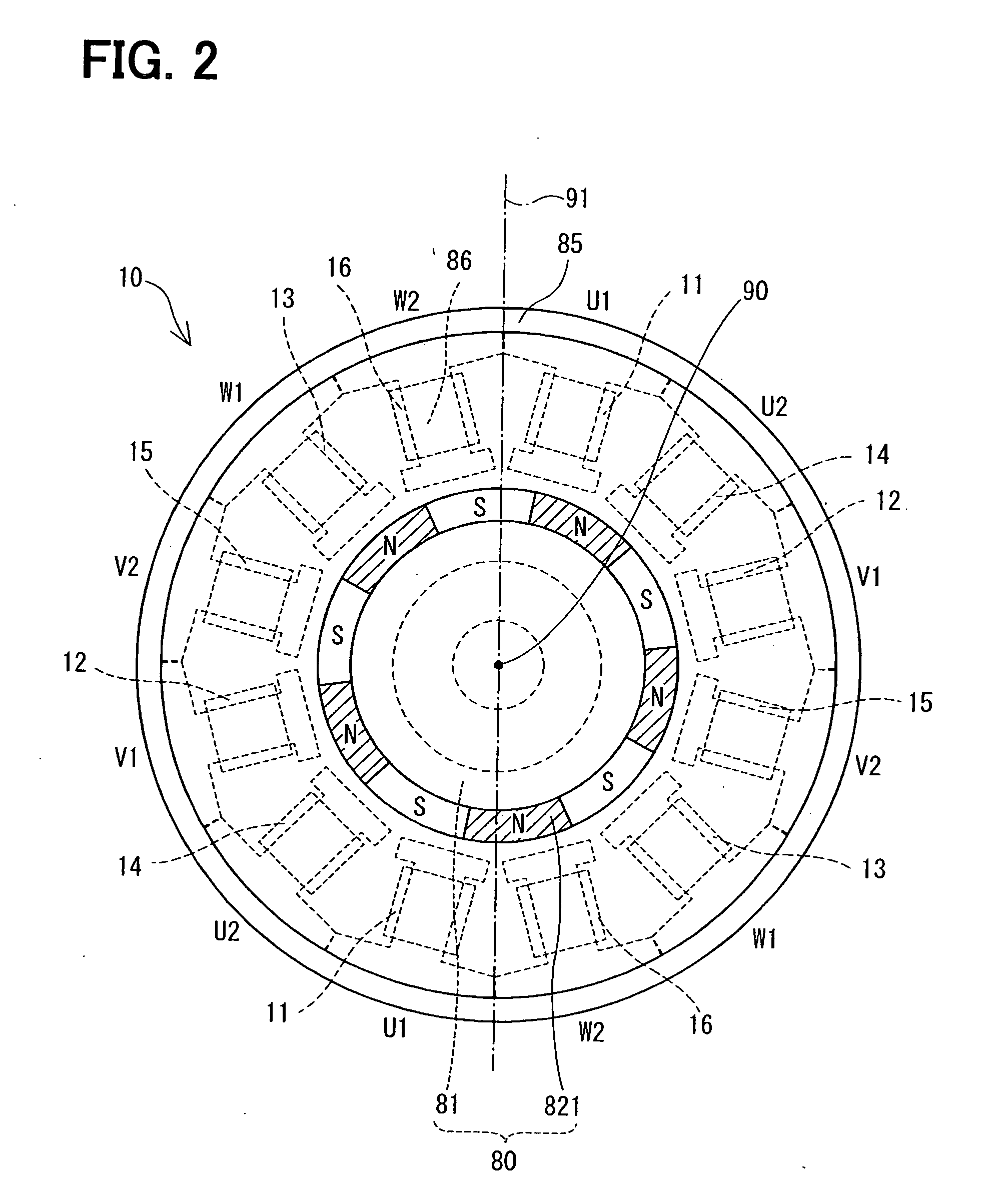

Electric power converter, driving apparatus and electric power steering apparatus

ActiveUS20120049782A1Total current dropExpand the adjustment rangeSynchronous motors startersVector control systemsElectric power steeringPhase shifted

A control unit of an electric power converter, which is used in a three-phase motor having two winding wire systems, performs for a first duty instruction signal regarding a voltage applied to a first winding wire group a flatbed two-phase modulation process, and performs for a second duty instruction signal regarding a voltage applied to a second winding wire group a flattop two-phase modulation process. By phase-shifting the second duty instruction signal by 30° from the first duty instruction signal, a timing of maximum value of the first duty instruction signal is shifted from a timing of minimum value of the second duty instruction signal. Even when the maximum value is greater than a center output value and the minimum value is smaller than the center output value, overlapping of capacitor discharge is avoided, thereby reducing a ripple electric current.

Owner:DENSO CORP

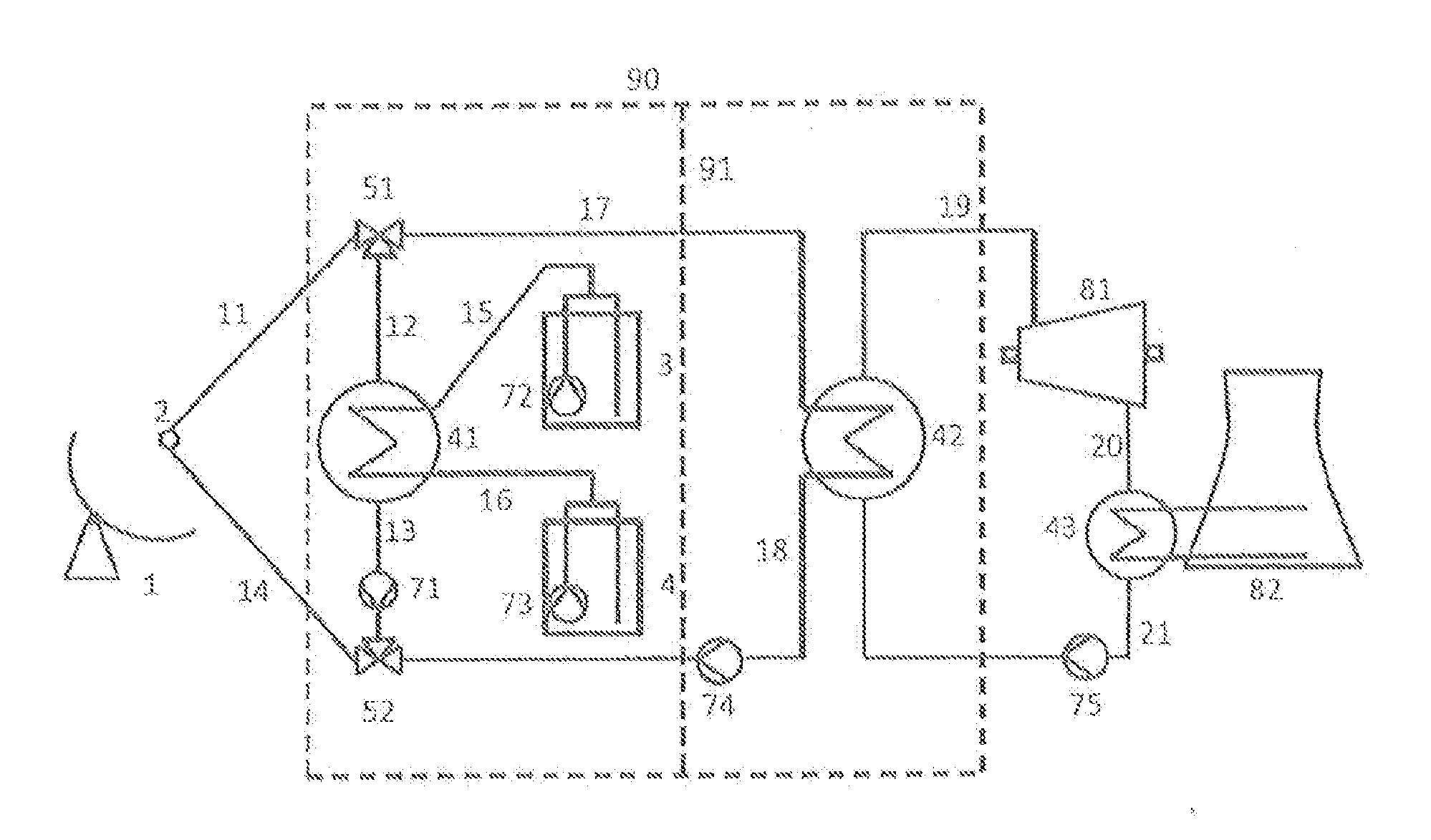

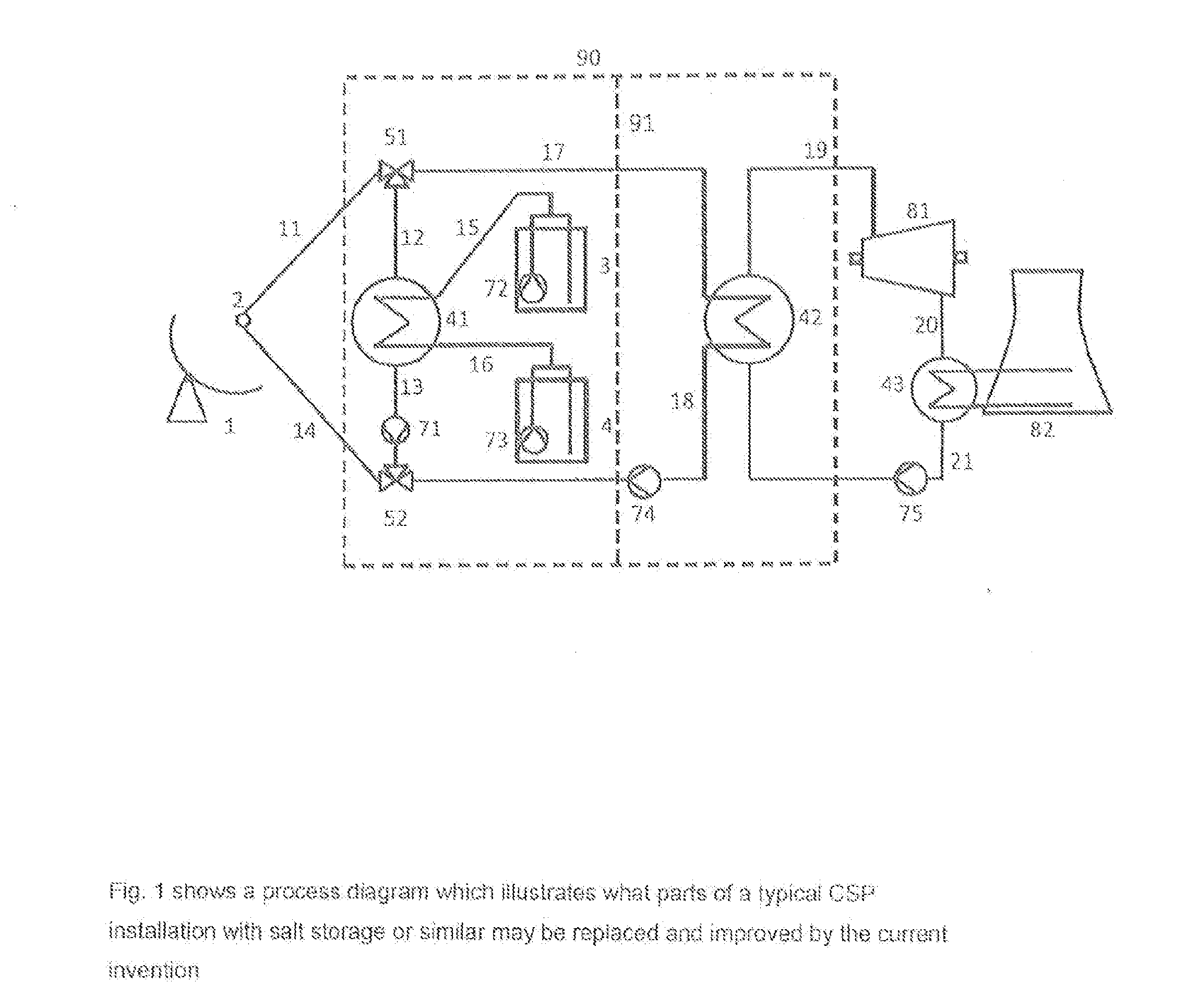

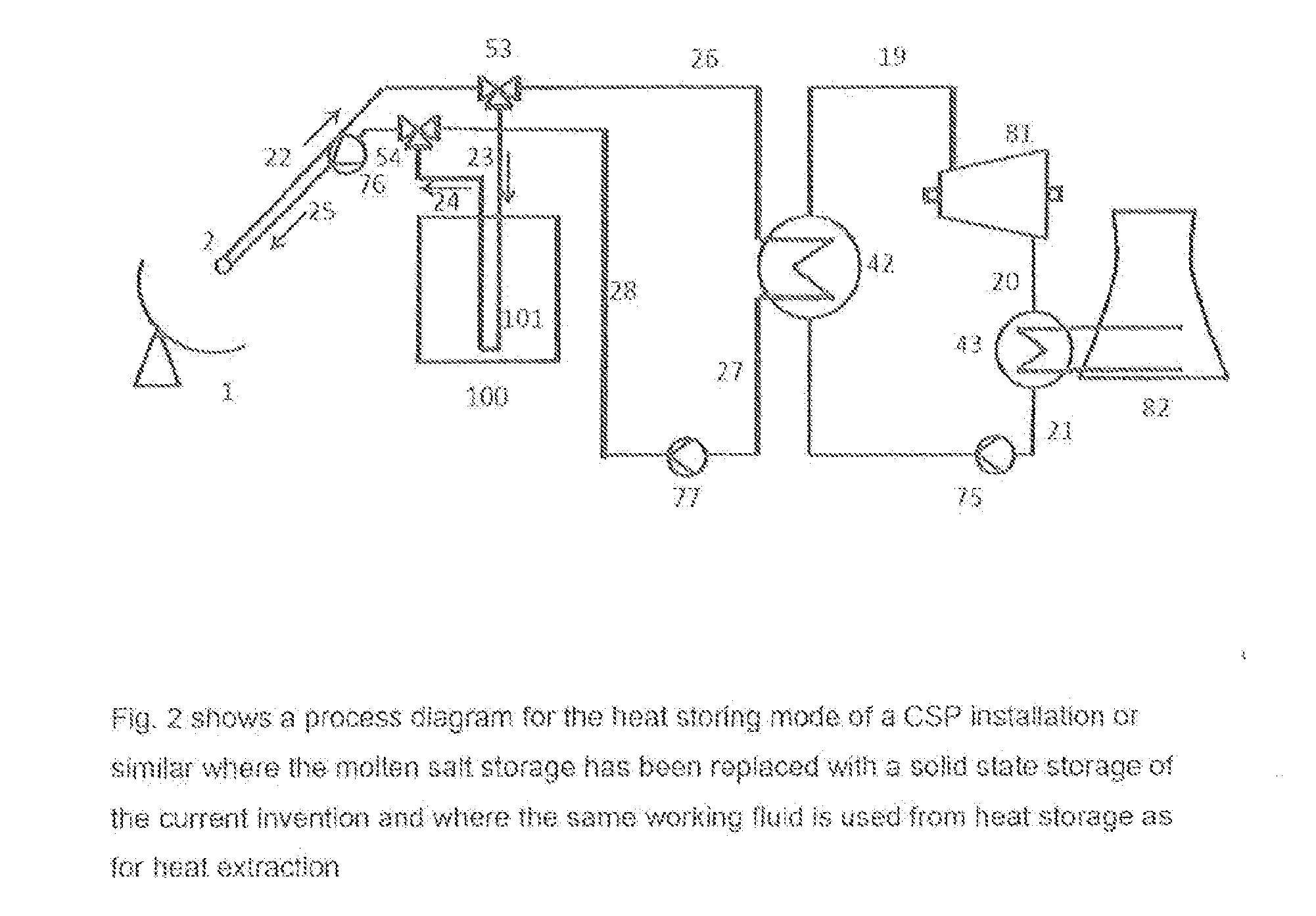

Plant for energy production

ActiveUS20150167648A1Easy to produceInhibit exchangeSolar heating energyFrom solar energyFossil fuelNuclear reactor

The invention provides a plant for production of energy, comprising any type of heat or energy source including but not limited to solar power sources, nuclear reactors, fossil fuel plants, wind power plants, tidal power plants, waste heat power plants and geothermal sources, operatively arranged at an input side of the plant, and heat delivery or energy production means such as turbine-electric generator sets, operatively arranged at a delivery side of the plant. The plant is distinctive in that it further comprises a thermal energy storage with integrated heat exchanger, comprising a solid state thermal storage material, a heat transfer fluid and means for energy input and output, wherein: the storage comprises at least one heat transfer container, solid state thermal storage material is arranged around the heat transfer container, the heat transfer container contains the heat transfer fluid and the means for energy input and output, so that all heat transferring convection and conduction by the heat transfer fluid takes place within the respective heat transfer container, the thermal energy storage with heat exchanger has been arranged inside thermal insulation, and the solid state thermal energy storage with heat exchanger, has been arranged between the input side and delivery side of the plant for storage and heat exchange of thermal energy, the storage is coupled directly or via an additional heat exchanger to the source and the storage is coupled directly or via an additional heat exchanger to the delivery side of the plant.

Owner:NEST

Foam composite

InactiveUS20020018884A1Low viscosityIncrease temperatureSynthetic resin layered productsCoatingsPolymer chemistryOpen cell

A foam composite made up of a scaffold of an open cell hydrophobic material having plurality of surfaces defining a plurality of pores, and a coating of a substantially hydrophilic foam material disposed upon the surfaces of the hydrophobic foam. The resulting foam composite exhibits structural characteristics of the hydrophobic foam and absorbency characteristics of the hydrophilic foam.

Owner:HYDROPHILIX

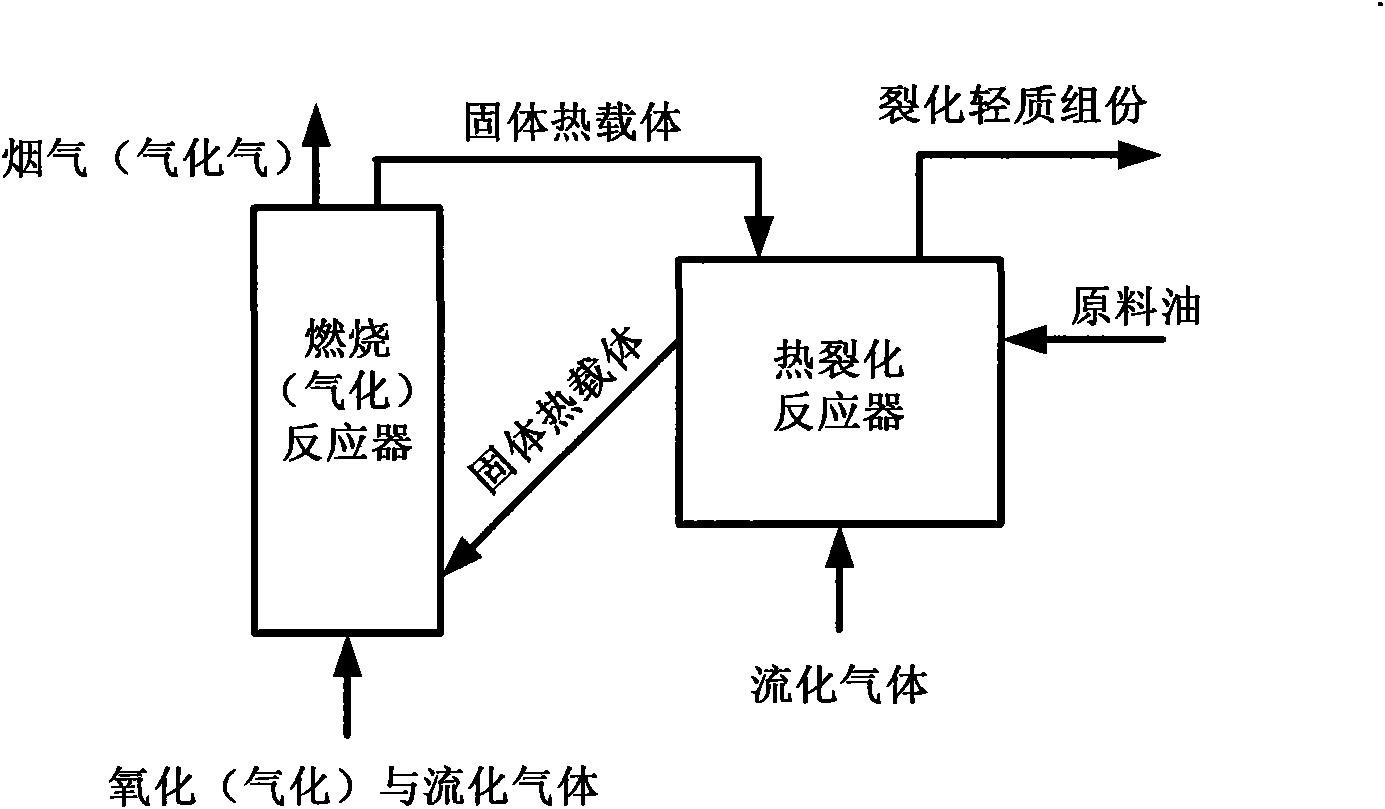

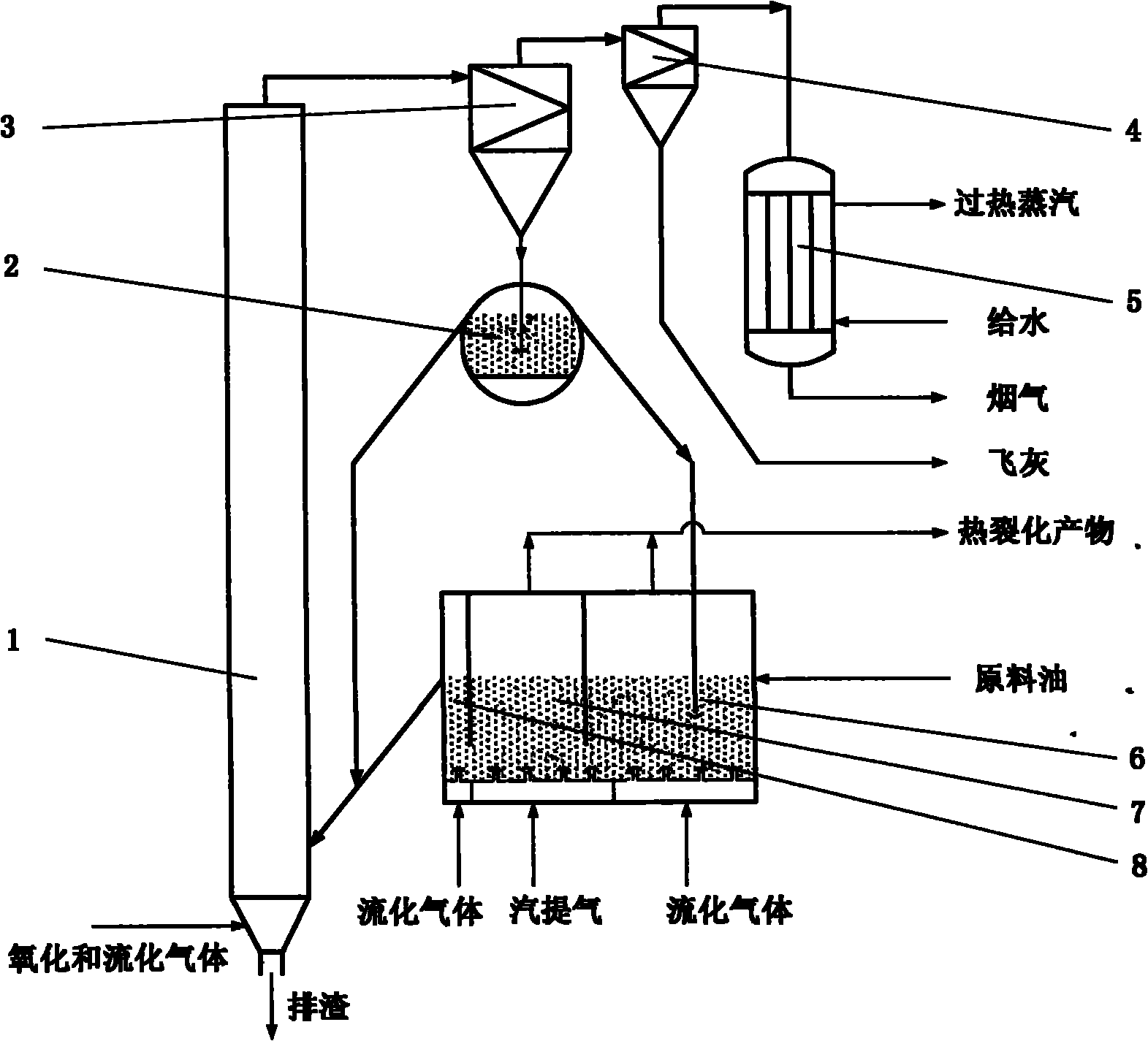

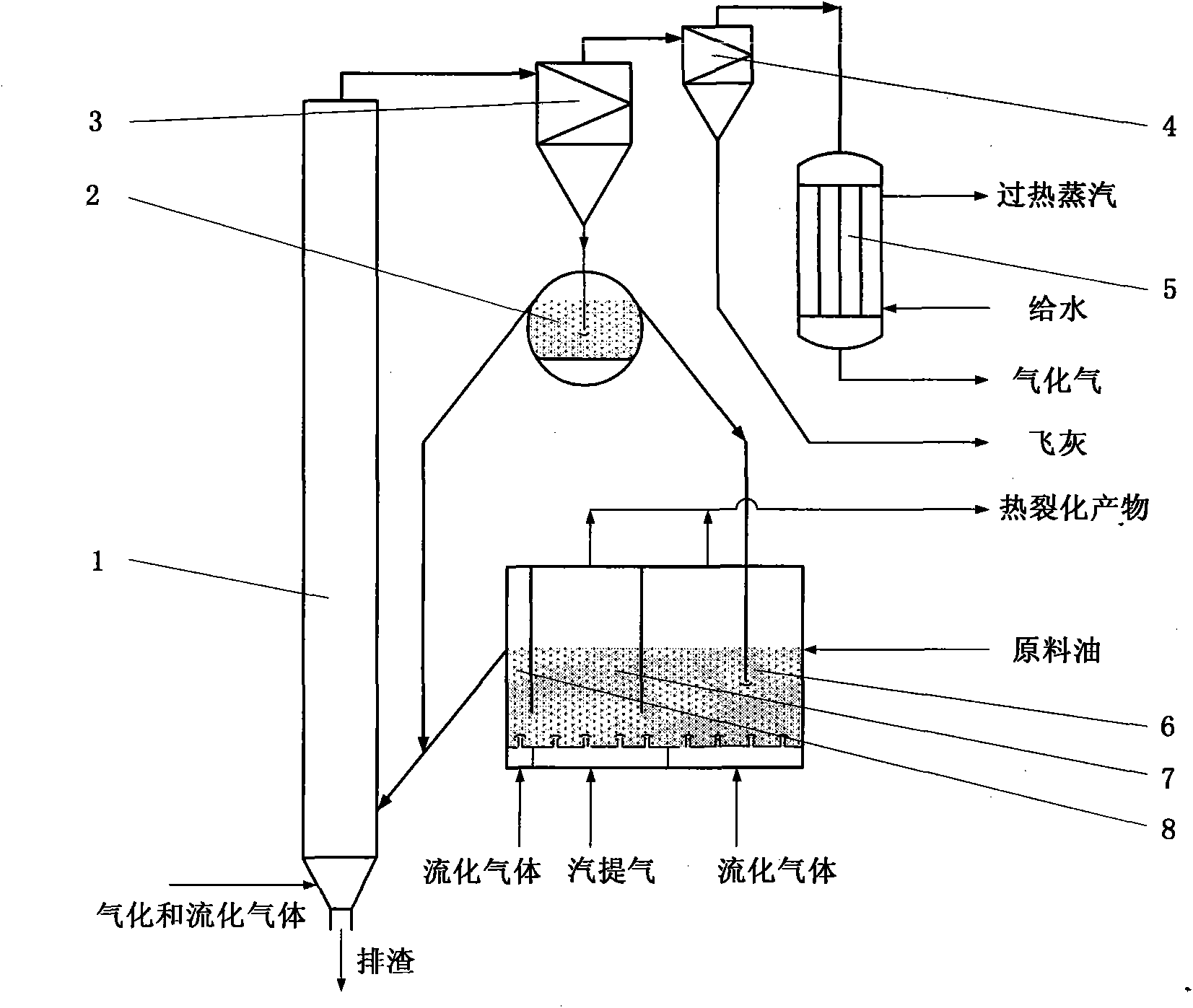

Heavy oil lightening method and device

InactiveCN102115675AAchieve conversionEfficient conversionThermal non-catalytic crackingEnergy inputHeat carrierCombustion

The invention relates to a heavy oil lightening method and technique. The method comprises steps as follows: raw oil is introduced into a thermal cracking reactor through a feed system, and mixed with a high-temperature solid heat carrier from a combustion (gasifying) reactor, so that the raw oil is subjected to fluidizing heat exchange with the solid heat carrier and carries out thermal cracking reaction on the surface of the solid heat carrier; the cracking gas generated by the thermal cracking reaction and a light component product are subjected to steam stripping by fluidizing medium gas and enter a subsequent absorption and stabilization system and a purification and separation system, heavy coke (petroleum coke) is attached to the surface of the solid heat carrier and enters the combustion (gasifying) reactor via a material returning valve, and an oxidizing (gasifying) and fluidizing gas is introduced to realize combustion (gasifying) reaction in the fluidization elevation process of the petroleum coke; and after the reaction product (fume or gasified gas) and the solid heat carrier are separated by a gas-solid separator, the fume (gasified gas) is led into a waste heat recovery system and a gas purification system, the high-temperature solid heat carrier is distributed by a distribution valve and respectively enters the thermal cracking reactor and the combustion (gasifying) reactor for cyclic use, and the collected fly ash can be used after further processing, thereby complete high-value conversion and use of the heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

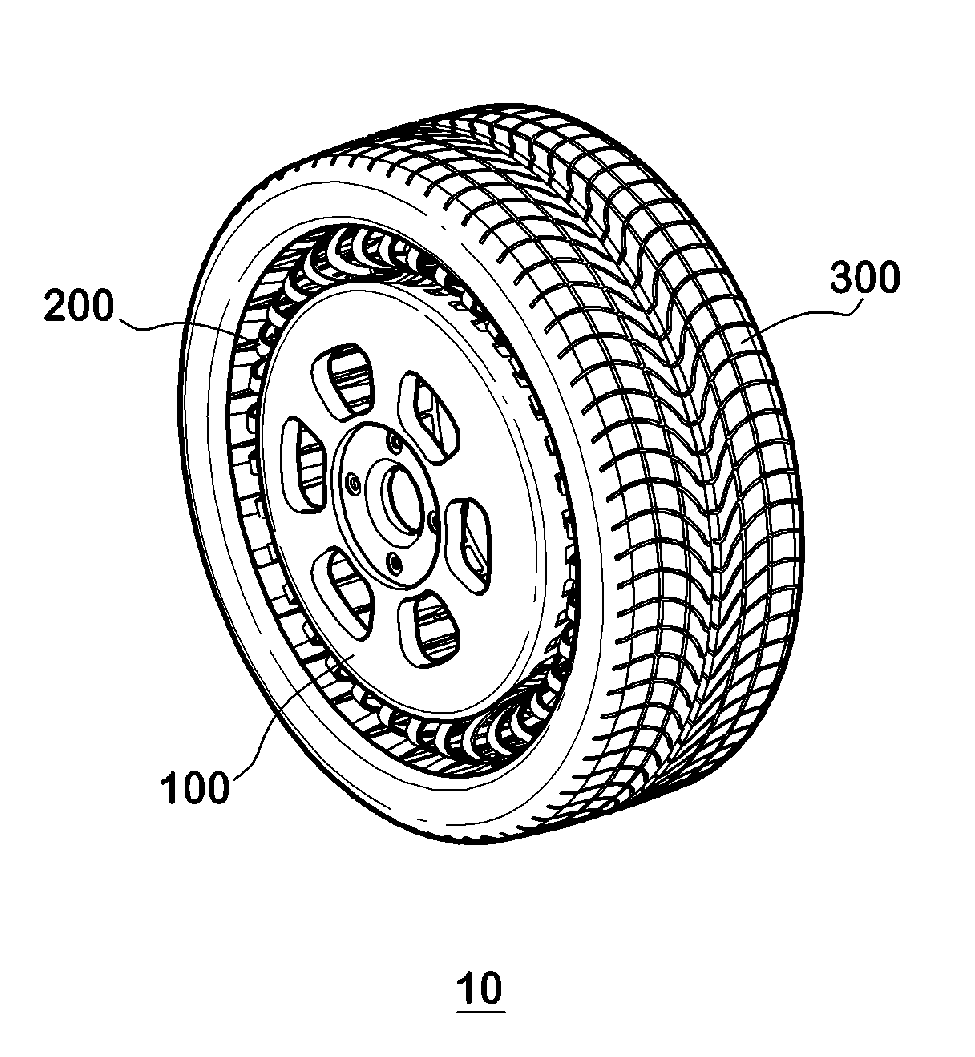

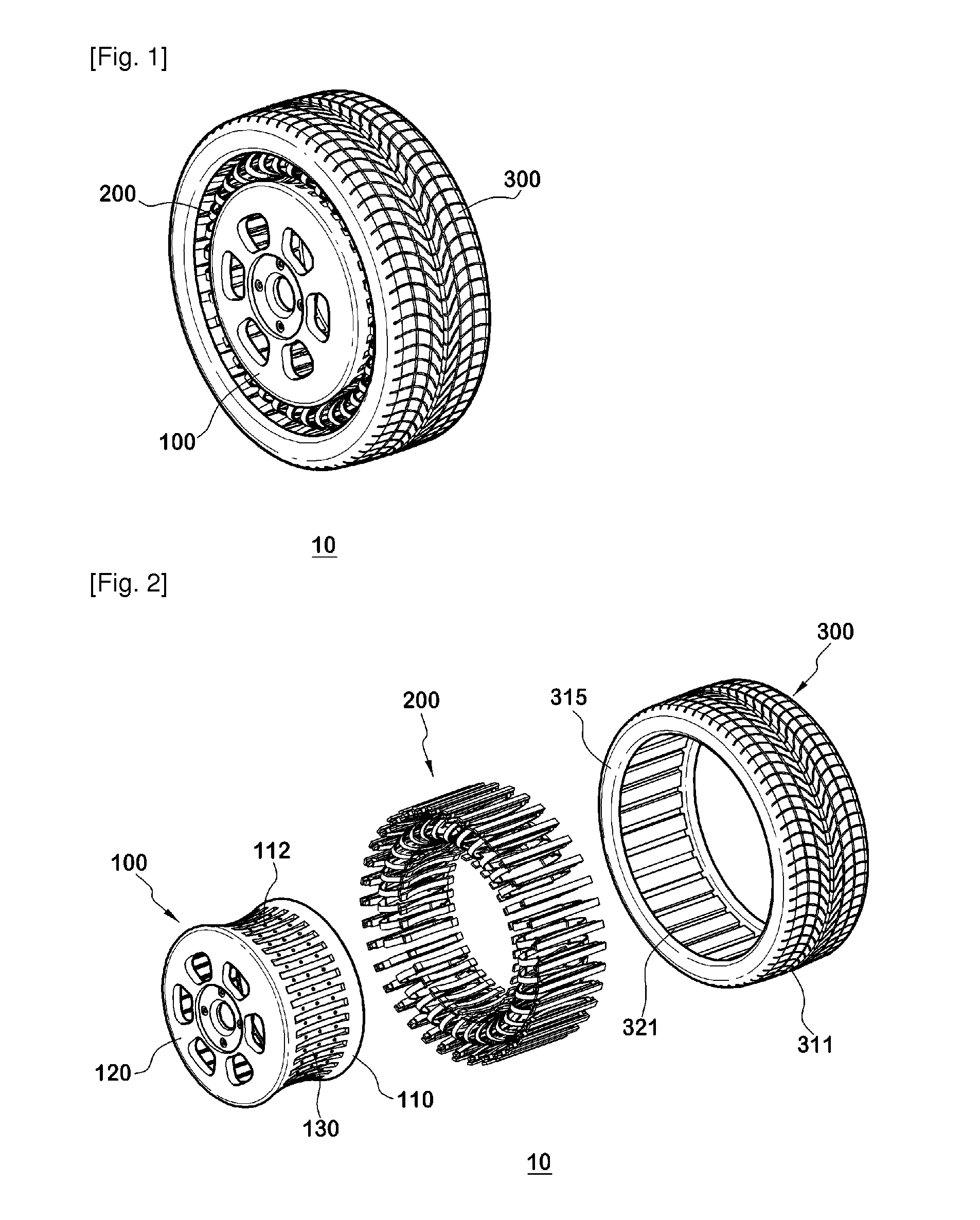

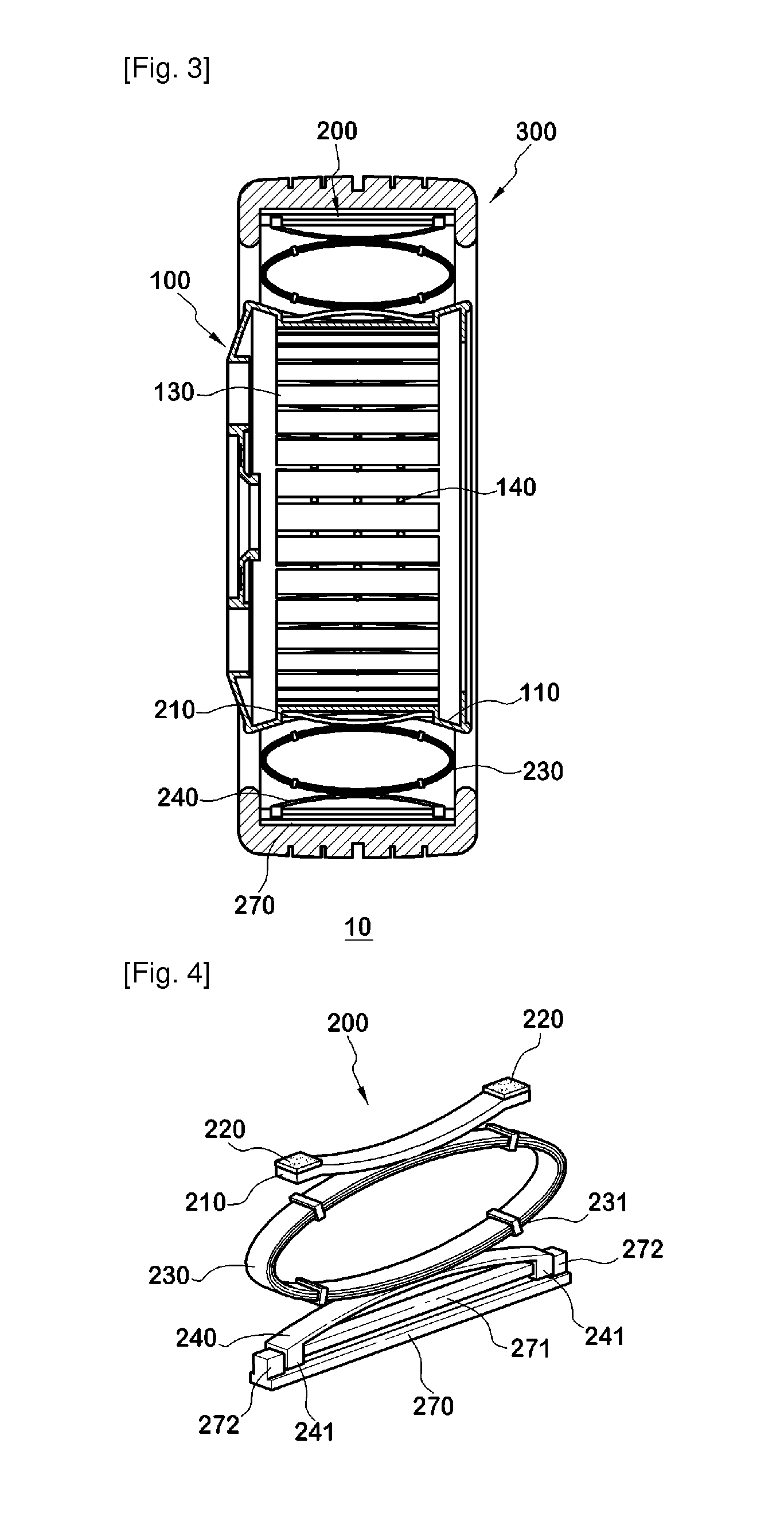

Non-pneumatic wheel and wheel, suspension and tire used therein

InactiveUS20110248554A1Prevent tire blowoutReduce vehicle accidentRimsLeaf springsCornering forceBrake fade

Provided is a non-pneumatic wheel (100) for a vehicle, and a wheel (100), suspension (200; 200-1), and tire (300) used therein that are capable of ensuring driving stability because there is no air chamber between a wheel (100) and a tire (300) to blowout. They are also capable of ensuring good road holding, preventing standing waves, reducing brake fade and cornering force, providing good handling and ride comfort, staying quiet when rolling, and are economical and environmentally friendly. The non-pneumatic wheel (100) includes a wheel (100), a shock absorbing member (220; 220-1) coupled to an outer periphery of the wheel (100) and absorbing or attenuating noise and vibration due to external shock, a plurality of resilient members (230; 230-1; 230-2) arranged around and coupled to an outer periphery of the shock absorbing member (220; 220-1) in a radial direction and having a plurality of resilient rings (230-1a) that are resiliently deformed in response to an external force, resilient links (240) respectively coupled to the resilient rings (230-1a) to evenly transmit external shock to the resilient rings (230-1a), rail plates (270) to which sliders (261) formed at both ends of the resilient links (240) are slidably coupled, and a tire (300) having a plurality of coupling grooves (321) formed along an inner periphery such that the rail plates (270) are inserted into the coupling grooves (321).

Owner:CHON YOUNG ILL +4

Vaporization assembly and electronic cigarette

InactiveUS20170295846A1Avoid heatingAvoid instabilitySteam generation heating methodsTobacco devicesEngineeringElectronic cigarette

The invention relates to a vaporization assembly and an electronic cigarette; the vaporization assembly comprises an e-liquid cup assembly and a vaporization core arranged in the e-liquid cup assembly; the e-liquid cup assembly has an e-liquid storage chamber used for accommodating e-liquid; the vaporization core comprises a vaporization base and an electric heating wire assembly; the vaporization base is internally provided with a smoke passageway used for providing passage to the smoke produced by vaporization; the electric heating wire assembly is arranged on the smoke passageway; the electric heating wire assembly comprises an electric heating wire used for heating and vaporizing the e-liquid; the vaporization core comprises an insulating tube used for isolating the vaporization base from the electric heating wire; the insulating tube is interposed in the vaporization base, and supports the electric heating wire along the length of the vaporization base.

Owner:HUIZHOU KIMREE TECH

Exhaust emission control device and casing structure of the control device

InactiveUS20050115224A1Reduce energy lossLow costInternal combustion piston enginesDispersed particle filtrationParticulatesEngineering

An exhaust gas purifying device includes a tubular casing arranged in exhaust passages of an internal combustion engine. A filter is held in the casing. The filter collects and burns particulates contained in the exhaust gas discharged by the internal combustion engine. The casing has a double structure including an inner case supporting an outer peripheral surface of the filter and an outer case arranged around the inner case. The inner and outer cases are spaced from each other with a clearance defined between the cases.

Owner:IBIDEN CO LTD

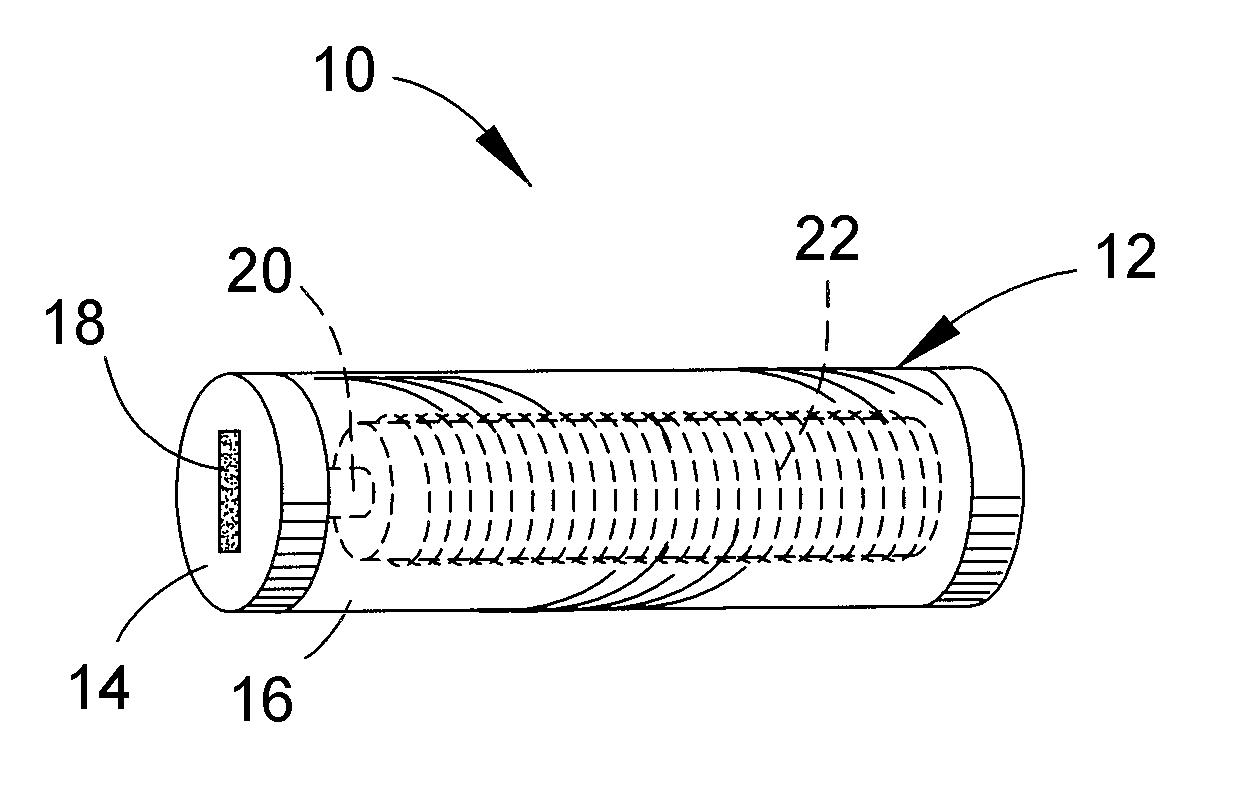

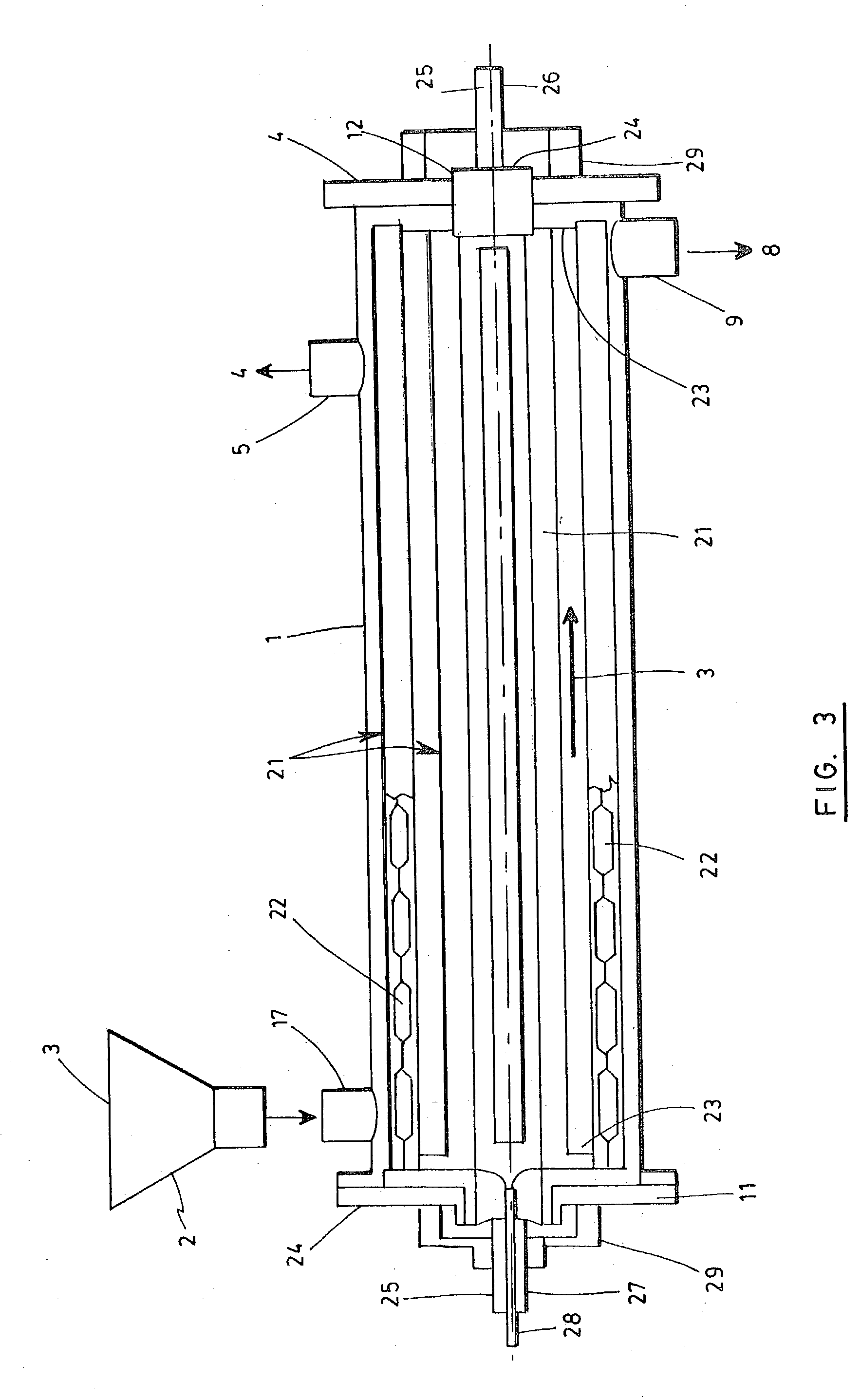

Pyrolysis system

InactiveUS20030138365A1Minimize introduction of airSecure safe and good operationMechanical conveying coke ovensRotating receptacle mixersProduct gasOxygen

A pyrolysis system includes a generally cylindrical reactor chamber having two opposite ends and a longitudinal axis. The chamber has an inlet for receiving biomass, the inlet being adapted to prevent air from entering the chamber and being located at a first opposite end; a gas outlet for recuperating biogas produced in the reactor chamber, the gas outlet being adapted to prevent air from entering the chamber and being located at a second opposite end; and a solid outlet for recuperating charcoal produced in the reactor chamber, the solid outlet being adapted to prevent air from entering the chamber and being located at the second opposite end. The biomass is then subjected to indirect heating supplied by a heated rotor that decomposes the biomass in the absence of air or oxygen into a biogas and charcoal. A controller for controlling a rate of feed of biomass, extracted carbon residue and a temperature inside the reactor chamber is also provided. In a preferred embodiment, the shaft is heated by a portion of the energy recuperated from the pyrolysis system.

Owner:STRUDES

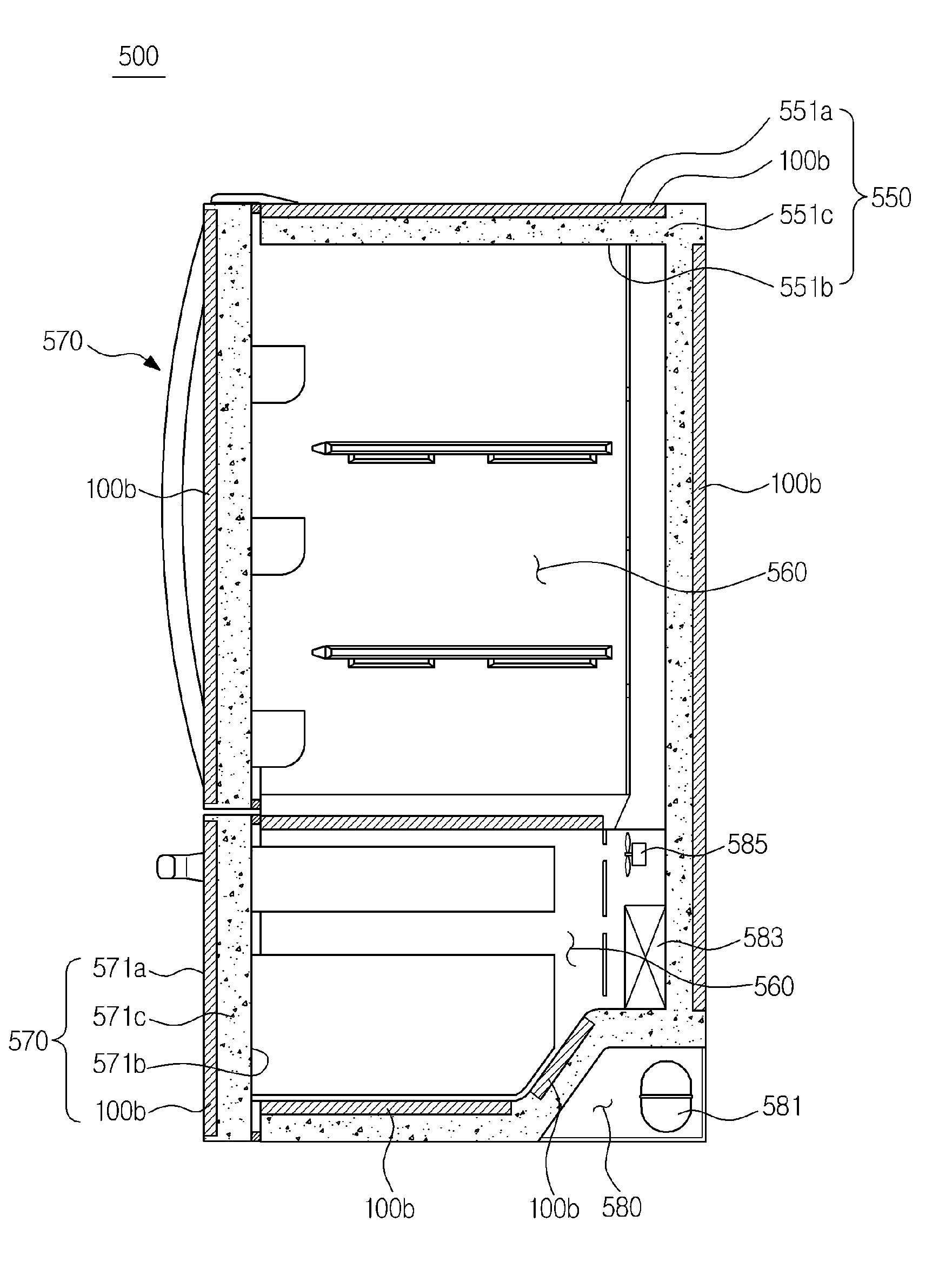

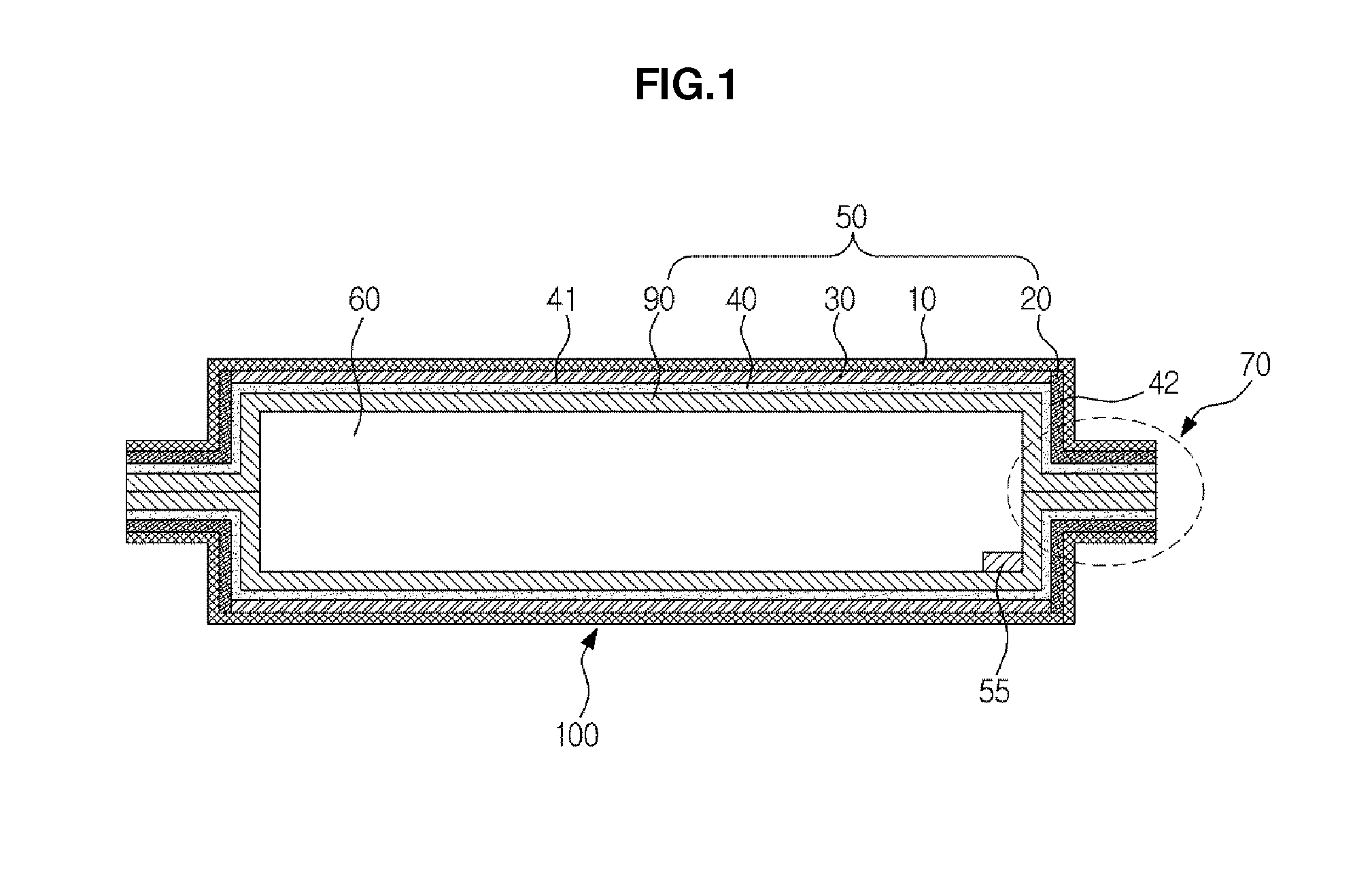

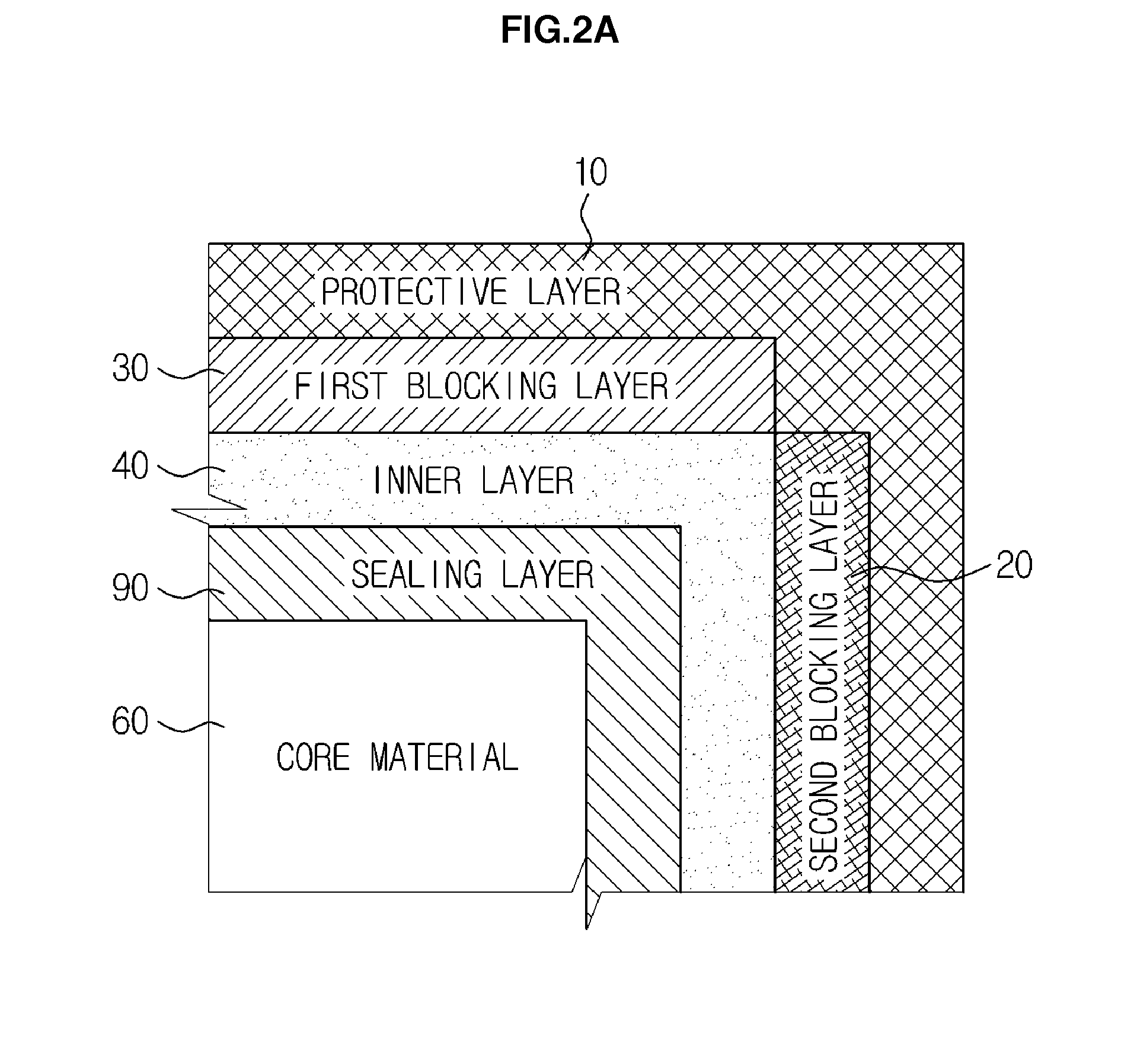

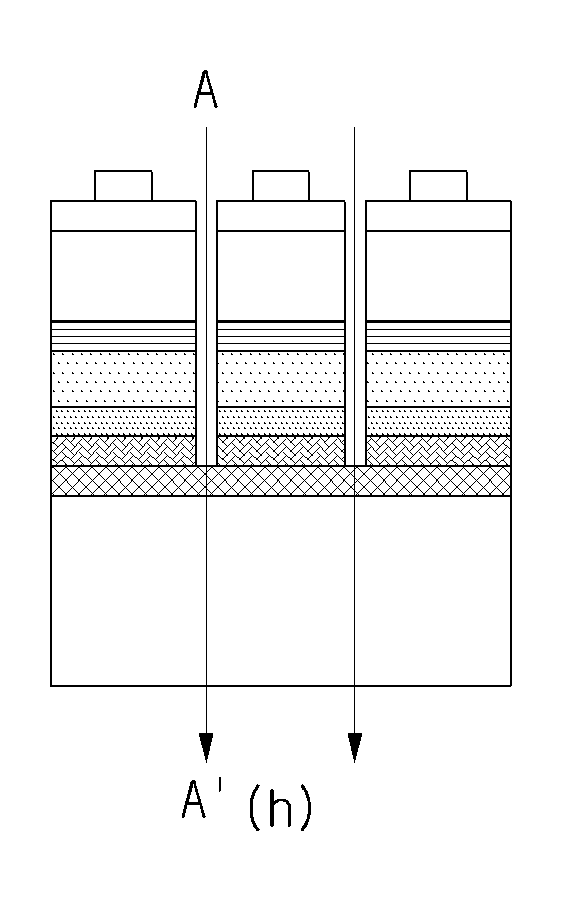

Vacuum heat insulating material and refrigerator including the same

InactiveUS20150030800A1Preventing heat bridgeReduce heat lossDomestic cooling apparatusThermal insulationEngineeringProtection layer

A vacuum heat insulating material having an improved structure to prevent the heat bridge phenomenon while improving the durability thereof, and a refrigerator having the same, the vacuum heat insulating material including a core material in a vacuum state, a sealing layer surrounding the core material, an inner layer covering the sealing layer, and having a first side and a second side connected to the first side, a protective layer located at an outside of the inner layer, a first blocking layer having at least one portion located between the first side of the inner layer and the protective layer, and a second blocking layer having at least one portion located between the second side of the inner layer and the protective layer.

Owner:SAMSUNG ELECTRONICS CO LTD

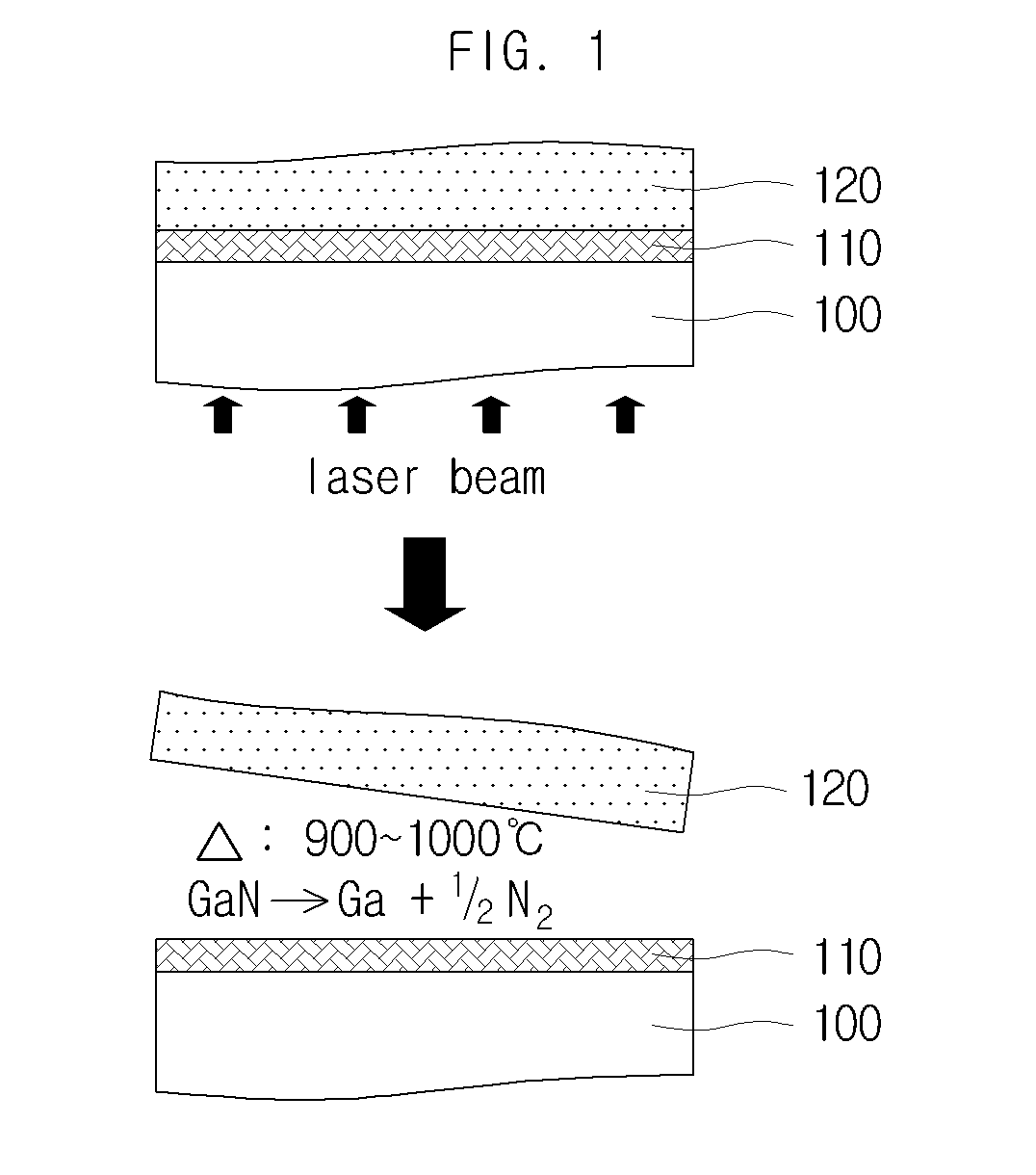

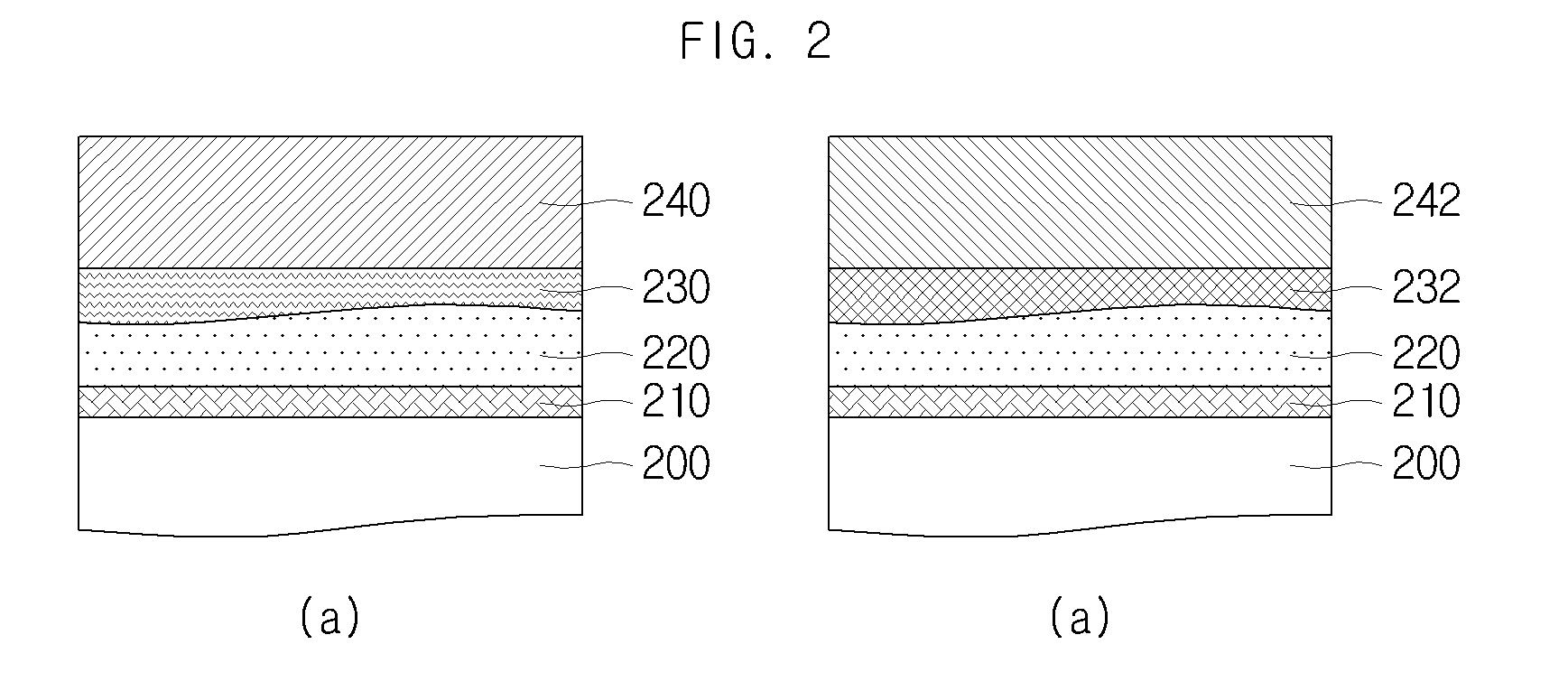

Supporting substrate for preparing semiconductor light-emitting device and semiconductor light-emitting device using supporting substrates

InactiveUS20110127567A1Improve production yieldAvoid heatingSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactEngineering

The present invention is related to a supporting substrate for preparing a semiconductor light-emitting device employing a multi-layered light-emitting structure thin-film and a method for preparing a semiconductor light-emitting device employing the supporting substrate for preparing a semiconductor light-emitting device. The supporting substrate for preparing a semiconductor light-emitting device is formed by successively laminating a sacrificial layer, a heat-sink layer and a bonding layer on a selected supporting substrate. A method for preparing a semiconductor light-emitting device employing the supporting substrate for preparing a semiconductor light-emitting device includes: preparing a first wafer in which a semiconductor multi-layered light-emitting structure is laminated / grown on an upper part of an initial substrate; preparing a second wafer which is a supporting substrate for preparing a semiconductor light-emitting device; bonding the second wafer on an upper part of the first wafer; separating the initial substrate of the first wafer from a result of the bonding; performing passivation after forming a first ohmic contact electrode on an upper part of the first wafer from which the initial substrate is separated; and preparing a single-chip by severing a result of the passivation.

Owner:LG INNOTEK CO LTD

Lateral laser fiber for high average power and peak pulse energy

ActiveUS20060282068A1Minimize reflectionAvoid seizuresSurgical instrument detailsFree rotationActive cooling

An improved optical fiber comprising a waveguide with an input for coupling focused laser energy into the waveguide and communicating electromagnetic radiation in a propagation direction to an internally reflective tip of the waveguide, a tissue contacting surface wherein the light path from the reflecting surface to the transmitting surface in substantially homogenous in refractive index and cooled by fluid flow. In minimizing the variations in refractive index within the lateral light path, while providing active cooling directly below the tissue contact surface, the invention prevents internal reflections and beam distortion and greatly improves the efficiency and durability of the laterally directing probe. Free rotation of the tissue contact surface, about the lateral tip, may be provided and tissue vaporization efficiency may be improved by providing a morcellating tool on the tissue contact surface.

Owner:BOSTON SCI SCIMED INC

Electromagnetic actuator, and electromagnetic clutch and differential using the same

ActiveUS7325664B2Preventing the system from being enlargedHeat suppressionMechanical actuated clutchesMagnetically actuated clutchesElectromagnetic clutchEngineering

The electromagnetic actuator includes an electromagnetic coil configured to provide actuation force in accordance with a solenoid current to be supplied, to a clutch and configured to actuate the clutch to control relative rotation between first and second members. The electromagnetic actuator includes a detector configured to detect the clutch actuated to produce a detection signal. The electromagnetic actuator includes a controller configured to respond to the detection signal from the detector to control the solenoid current.

Owner:TOCHIGI FUJI IND CO LTD

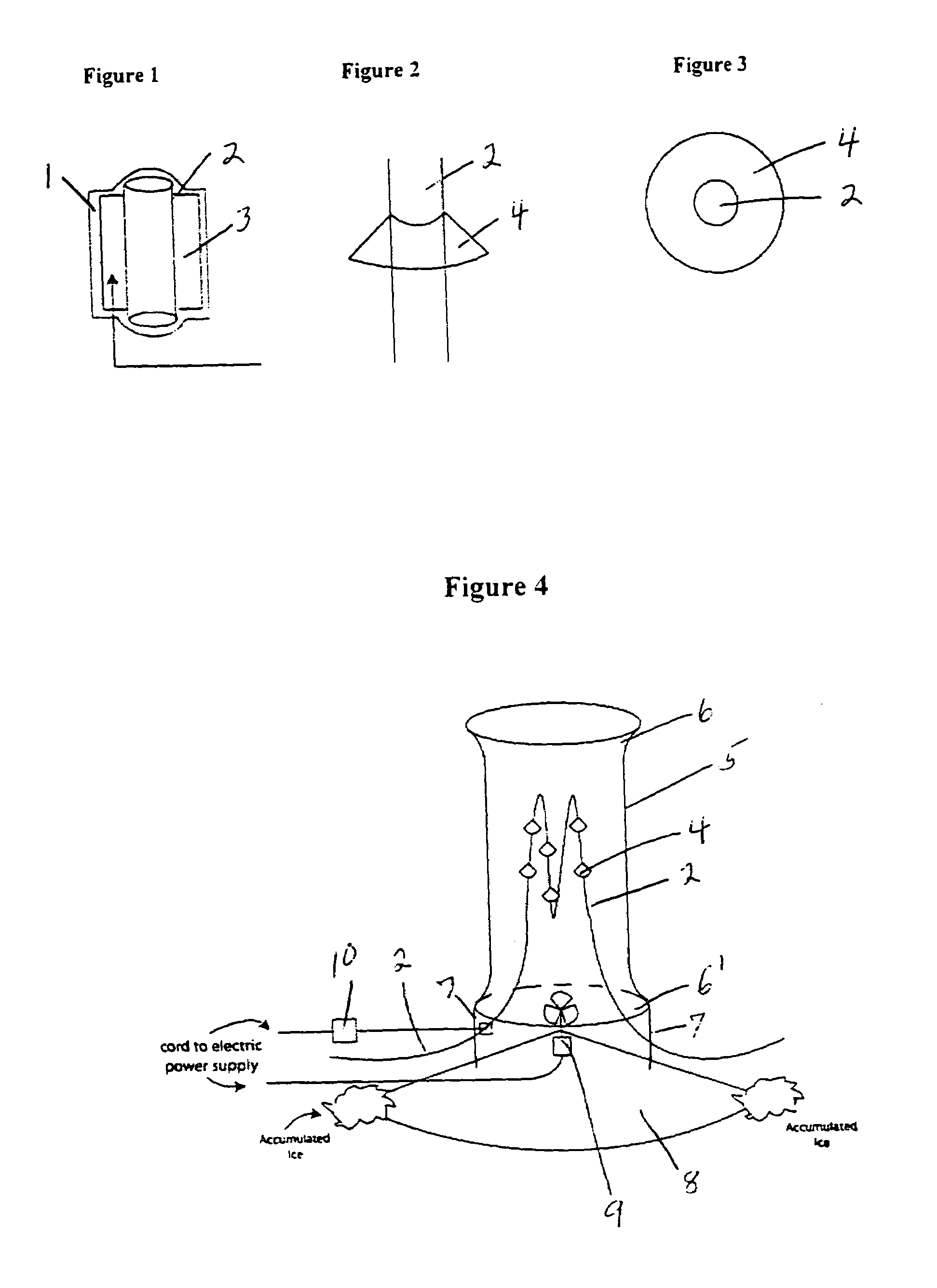

Method and apparatus for inhibiting ice accumulation in HVAC systems

InactiveUS6971248B1Degrades design efficiencyEasy to operateAir heatersCorrosion preventionHeat sinkHeating system

A non-stick coating, which inhibits frozen moisture accumulation, is applied to exterior exposed portions of heating and cooling systems where ice or other frozen moisture can accumulate and impair system design operational efficiencies; where heat exchange tubing and fins are downwardly sloped or angled; with an optional protective shell encasement which can be shaped to provide a vena contracta effect; with an optional electric fan to enhance airflow for heat exchange; with an optional electric vibrator to enhance inhibition of frozen moisture accumulation; with a downwardly sloped base to direct falling frozen moisture away from the heat exchange equipment; for use in conjunction with an air source heat pump system, an evaporative cooling system or a chiller, or as a supplement to a water-source heat pump system or to a direct expansion heat pump system; and for use with any other refrigerant-based heating system or cooling system.

Owner:WIGGS B RYLAND

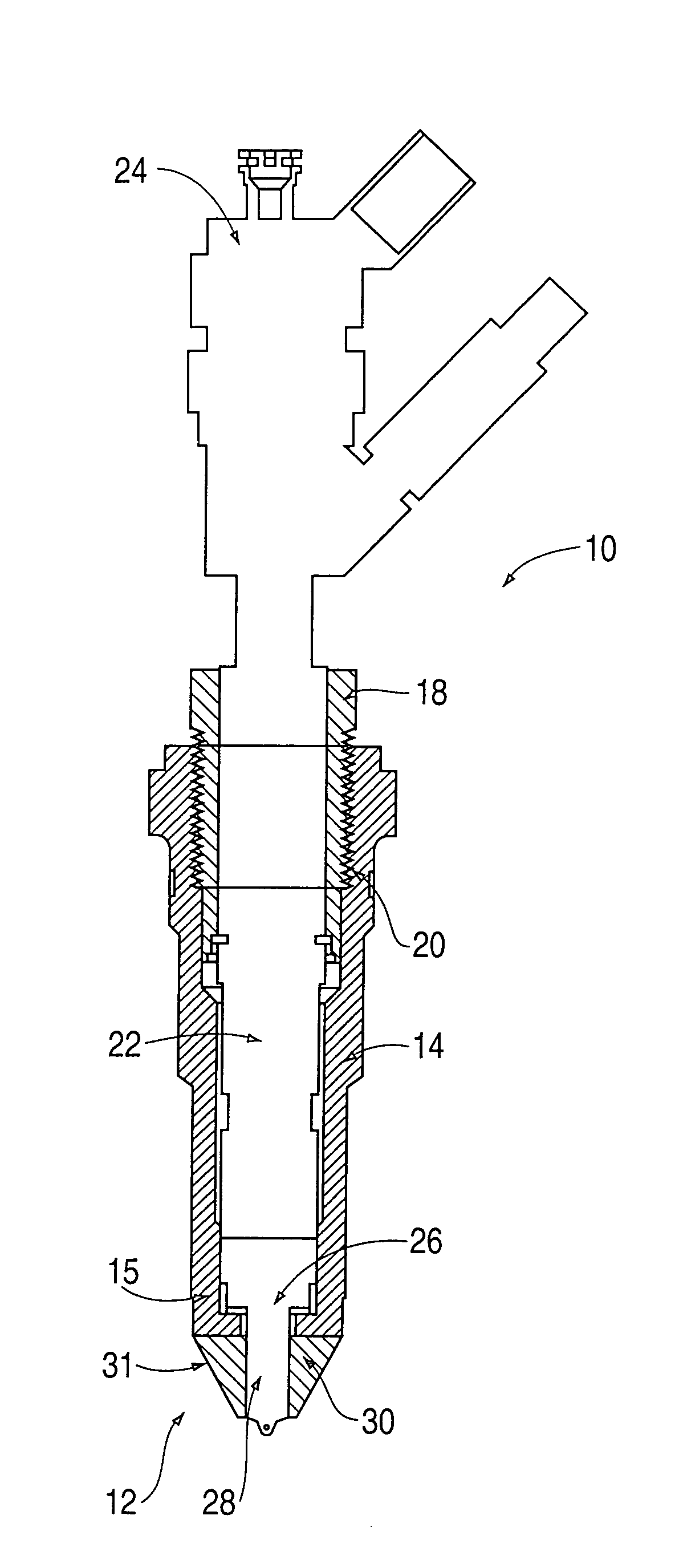

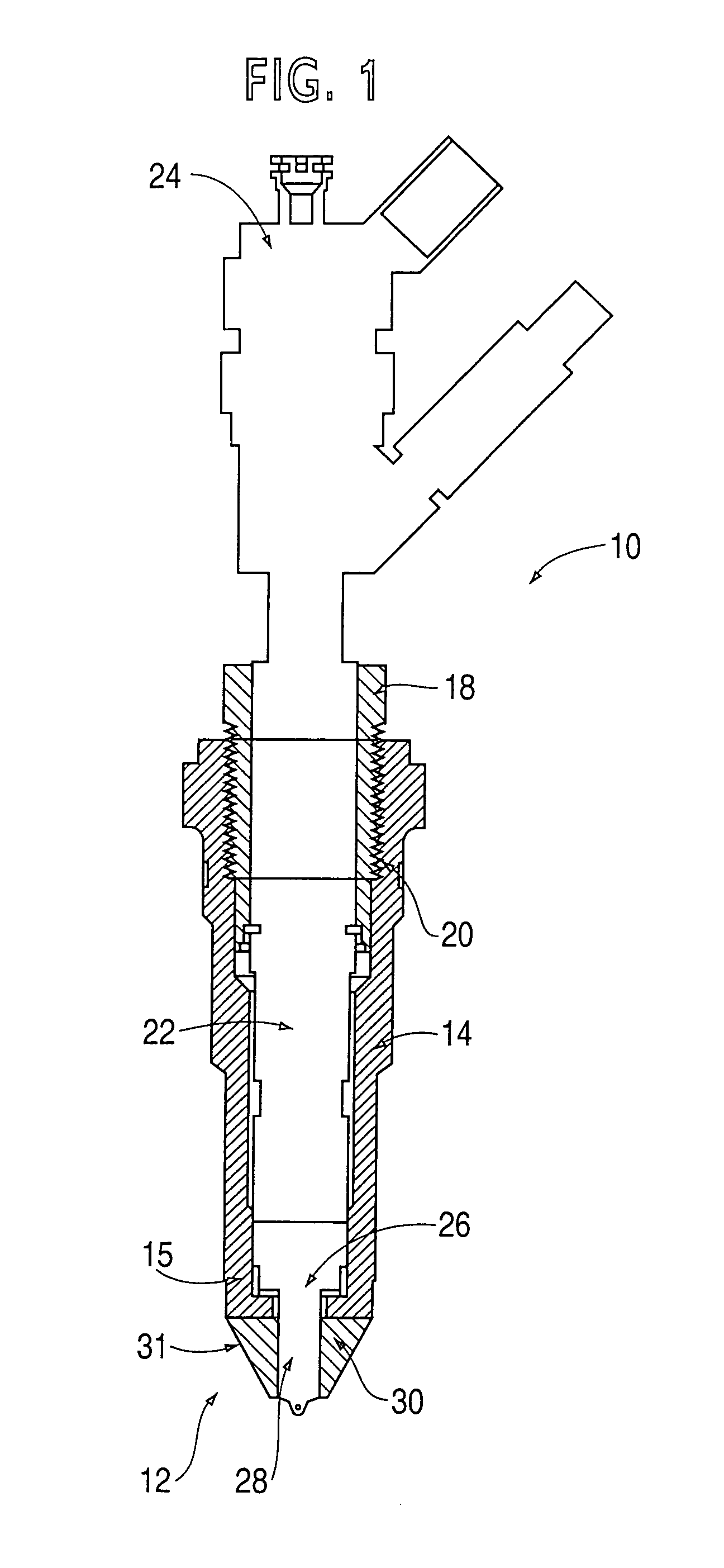

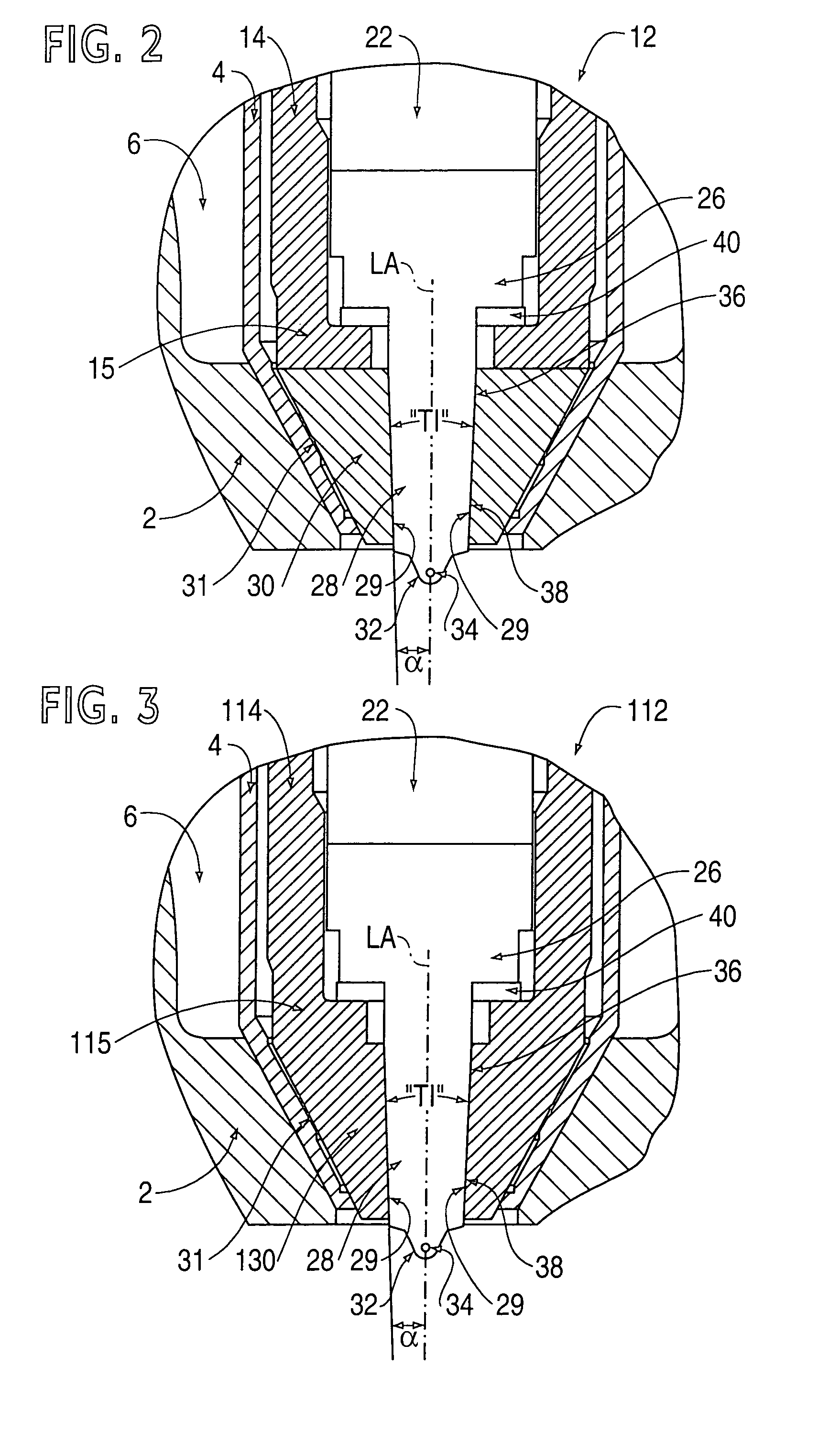

Fuel injector having a nozzle with improved cooling

InactiveUS7028918B2Improve reliabilityImprove performanceSpray nozzlesMachines/enginesInterference fitEngineering

A fuel injector having a nozzle with improved cooling including a retainer and a nozzle housing received therein. The nozzle housing includes a nozzle shank, an outer peripheral surface and at least one injection hole at a tip of the nozzle shank. The nozzle shank is positioned in a nozzle support portion of the retainer. In one embodiment, the outer peripheral surface of the nozzle shank is tapered, and the inner peripheral surface of the nozzle support portion is correspondingly tapered and sized to engage the outer peripheral surface of the nozzle shank along a tapered interface. In another embodiment, the inner peripheral surface of the nozzle support portion has a diameter smaller than a diameter of the outer peripheral surface of the nozzle shank so that an interference fit exists at a seal interface. In yet another embodiment, a nozzle seal seals an interface between the inner peripheral surface of the retainer and the outer peripheral surface of the nozzle shank to thereby prevent entry of hot gases into the interface. In another embodiment, the nozzle support portion is provided on a nozzle sleeve.

Owner:CUMMINS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com