Patents

Literature

199 results about "Removal techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

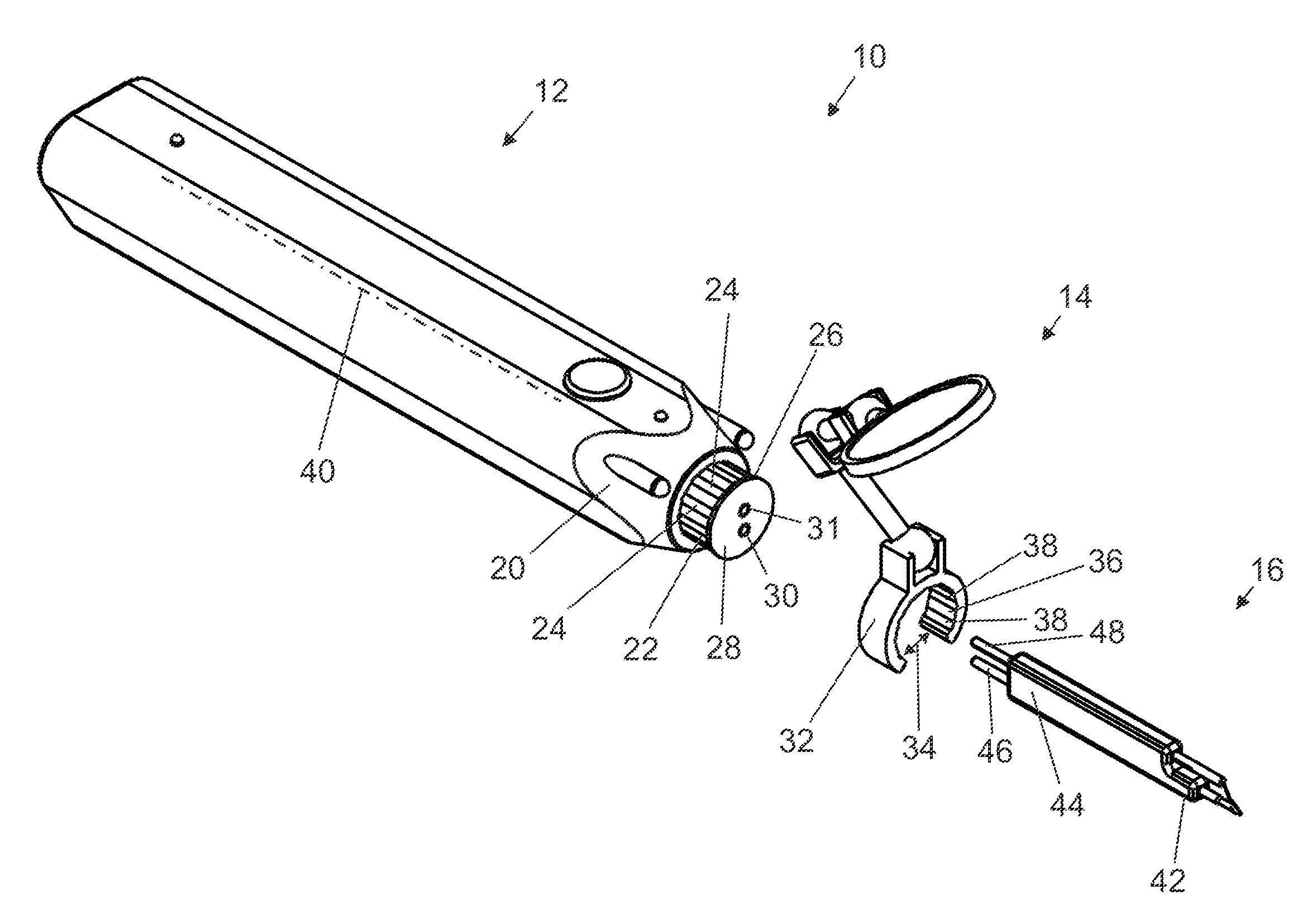

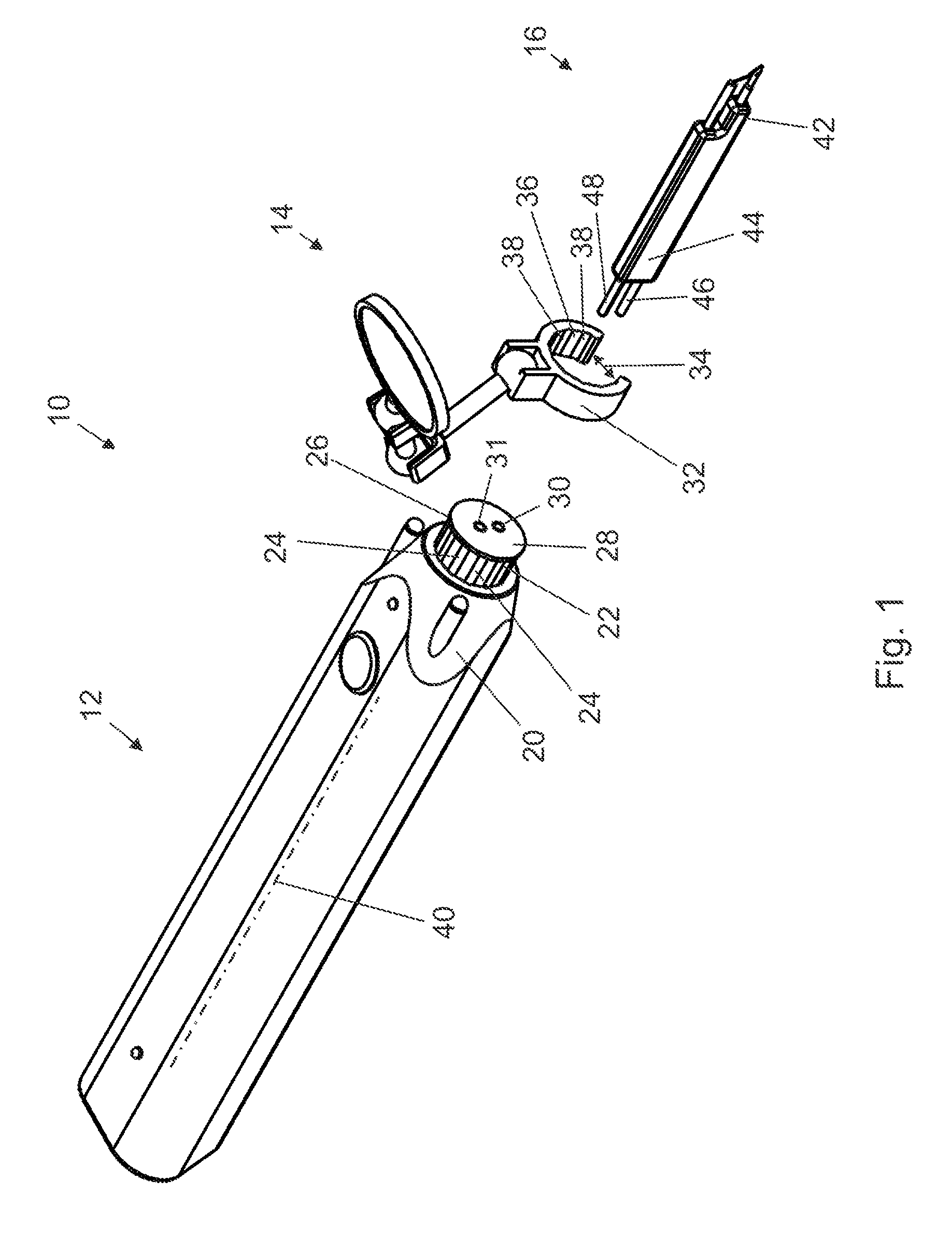

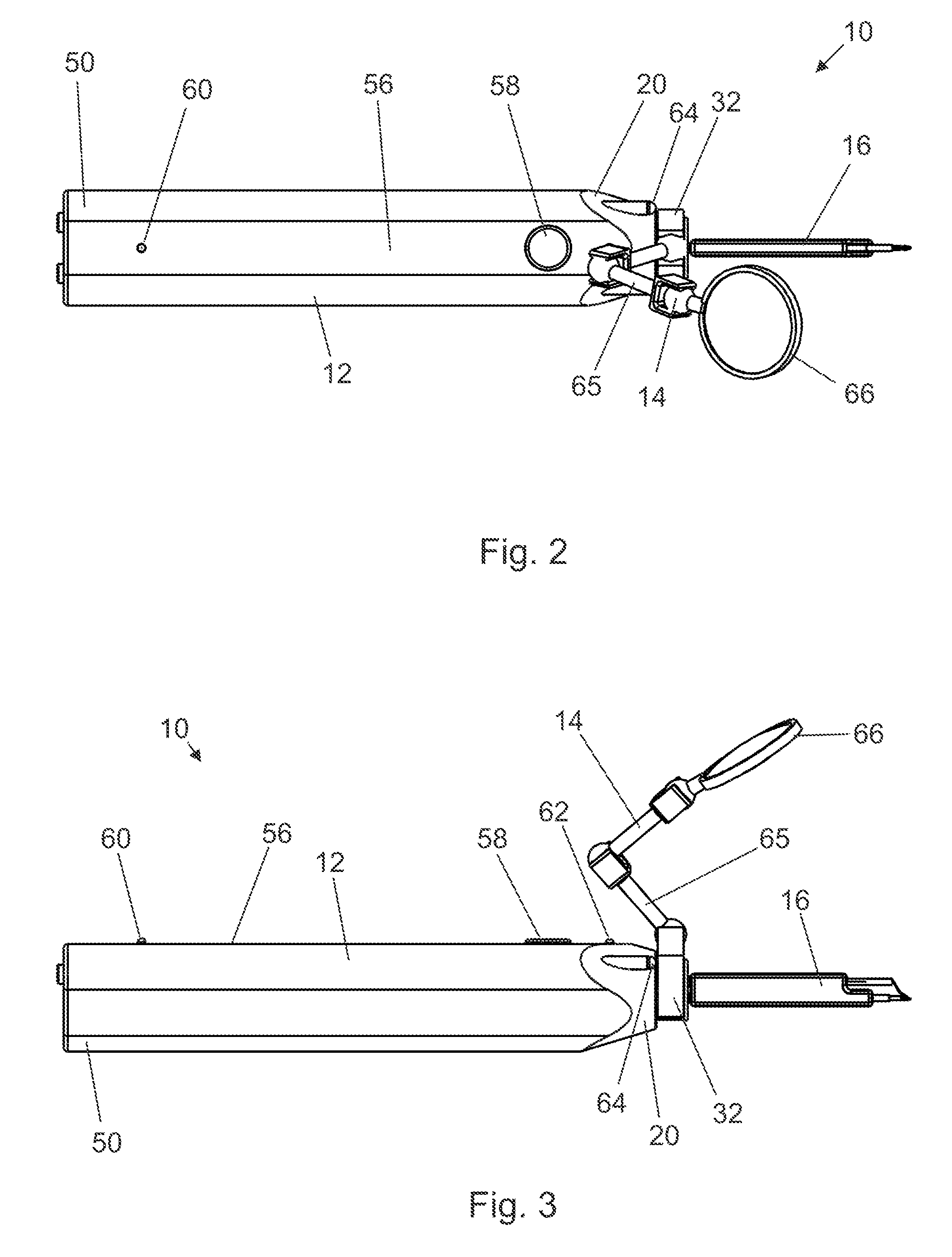

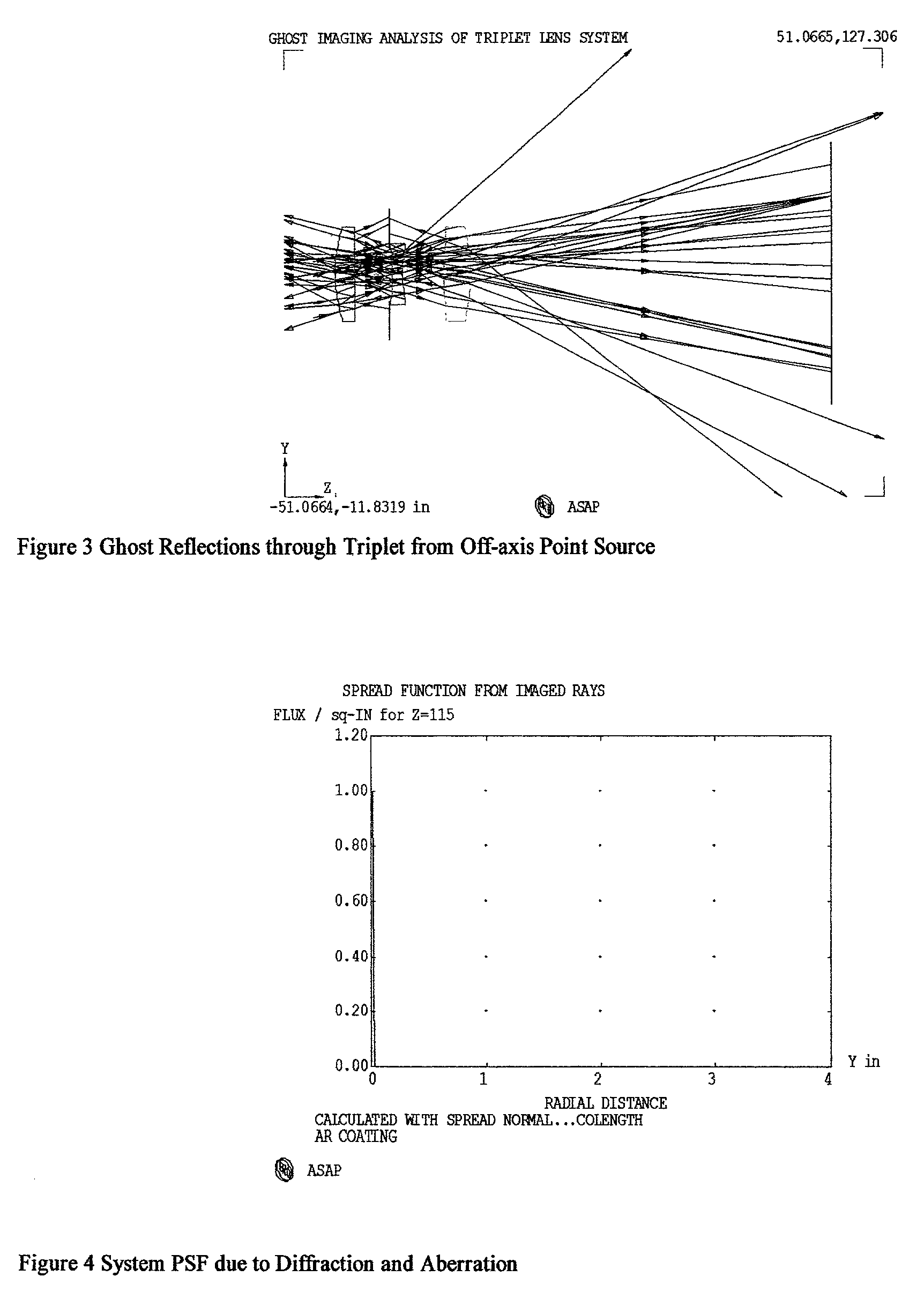

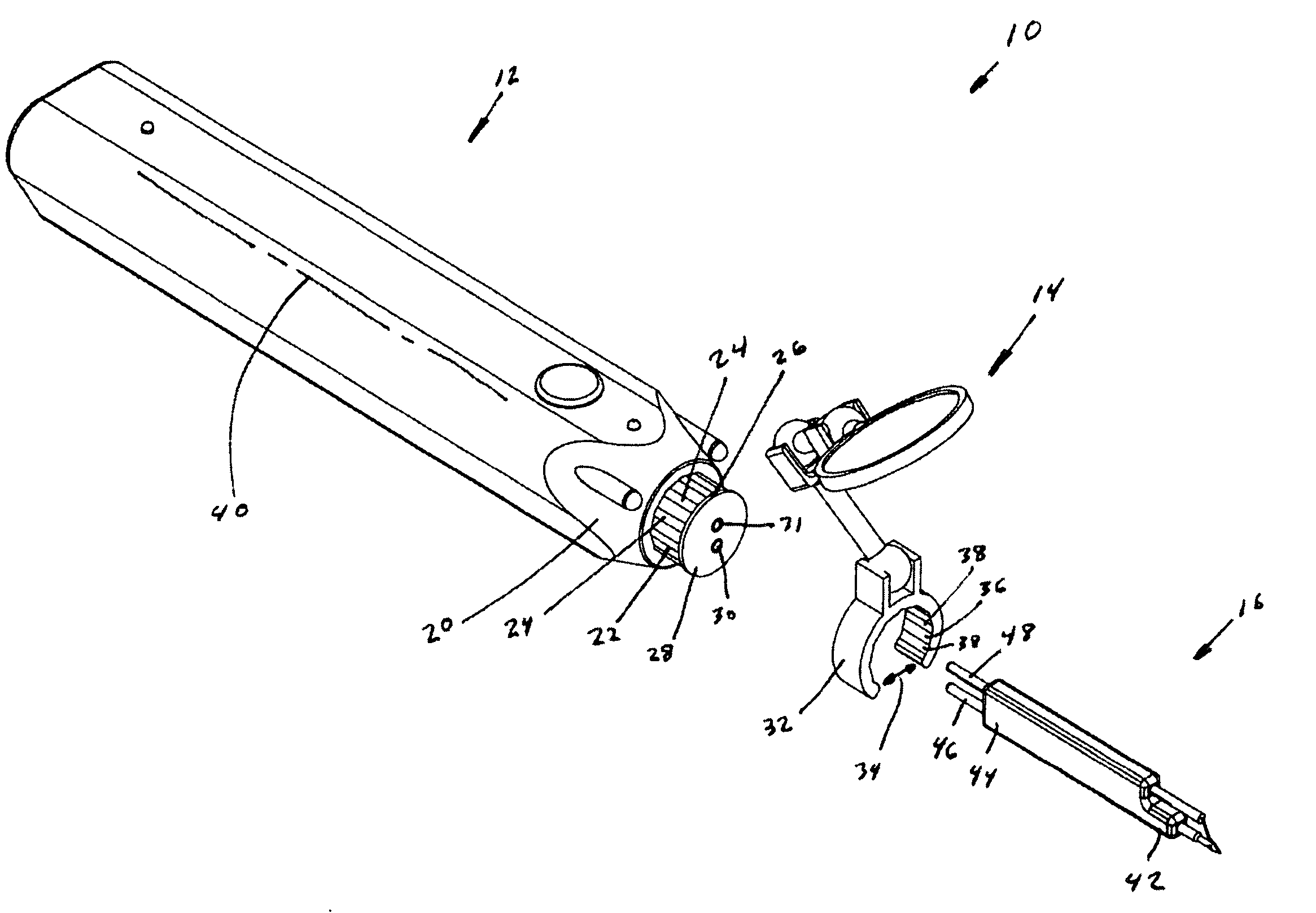

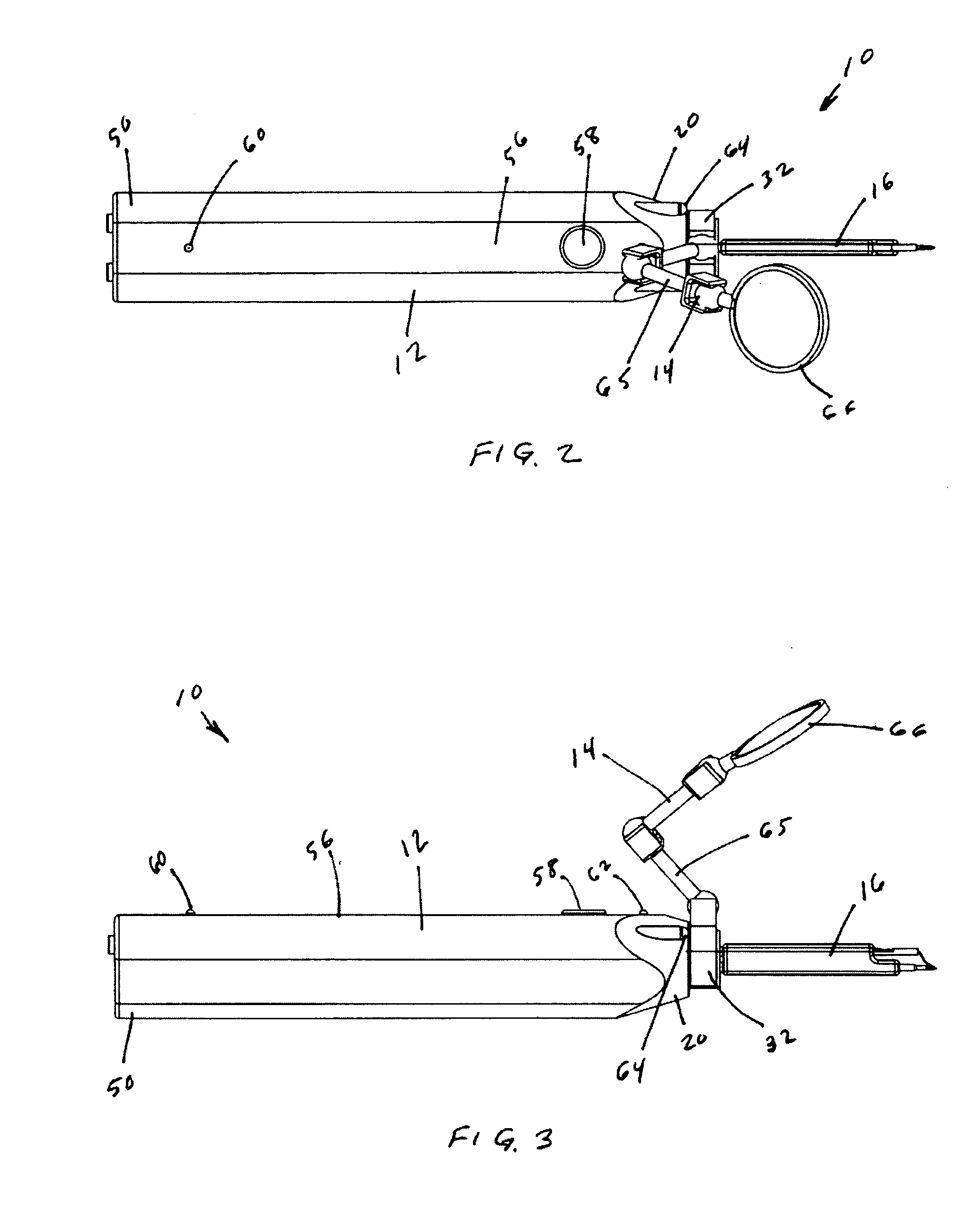

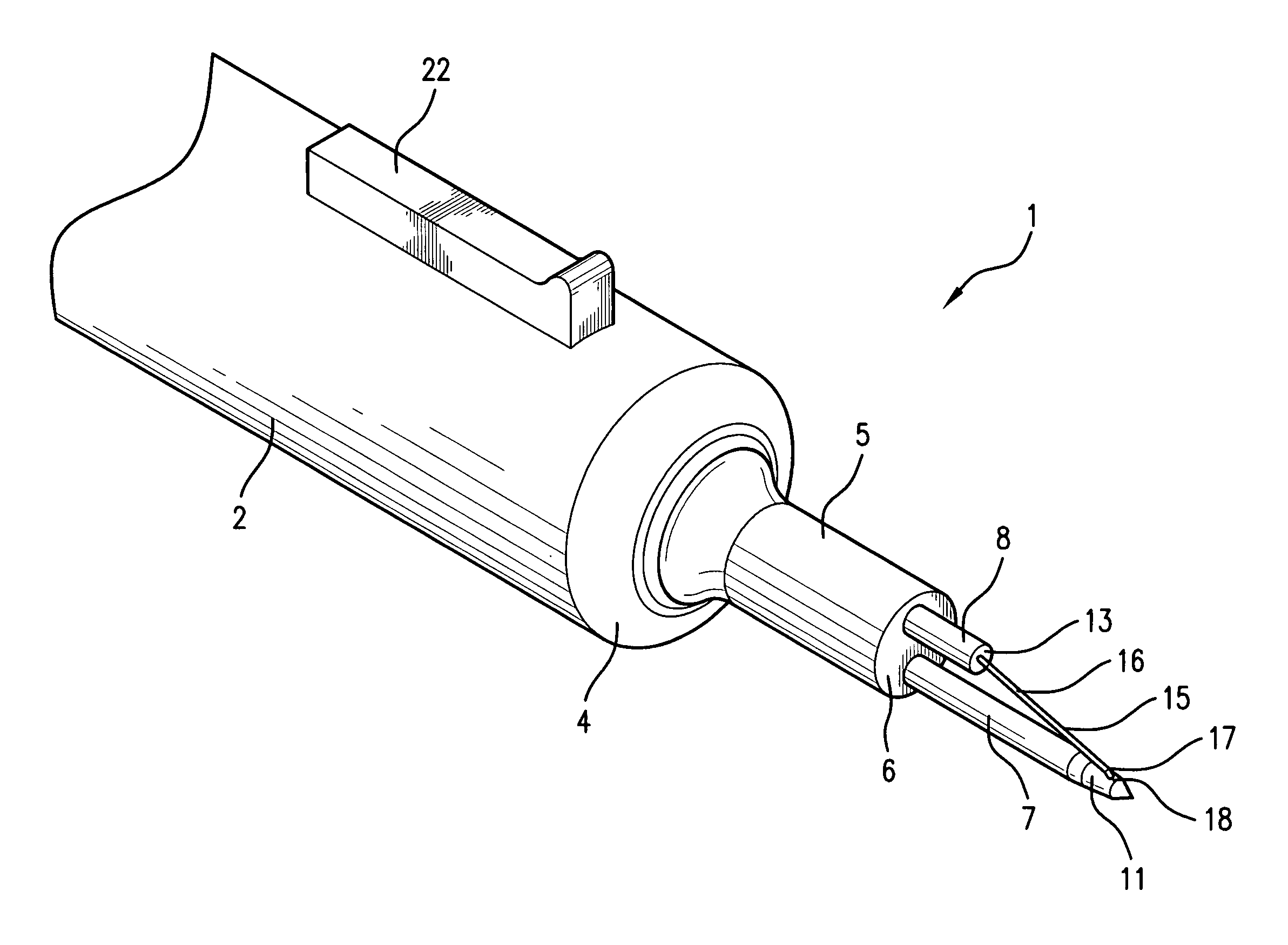

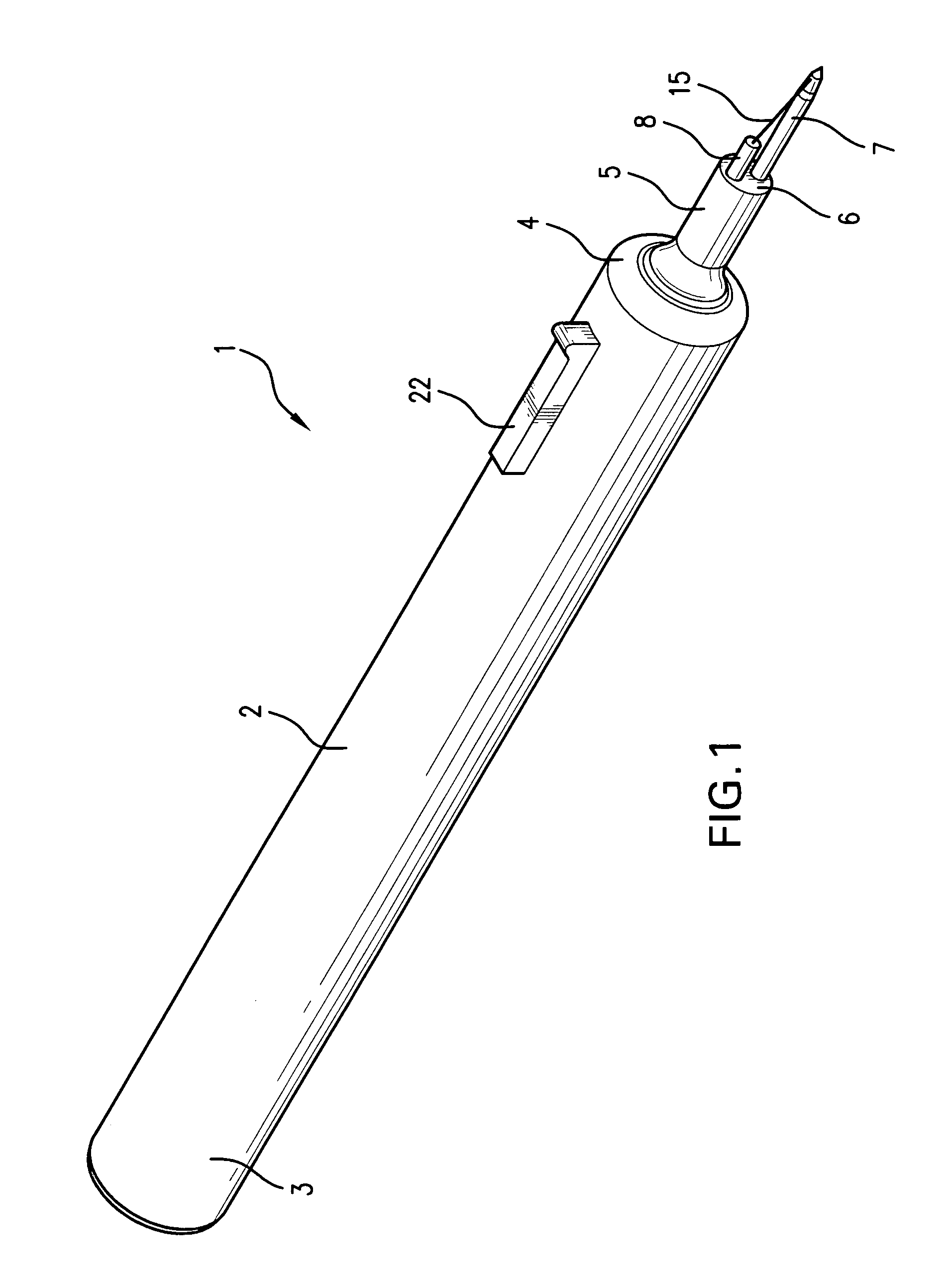

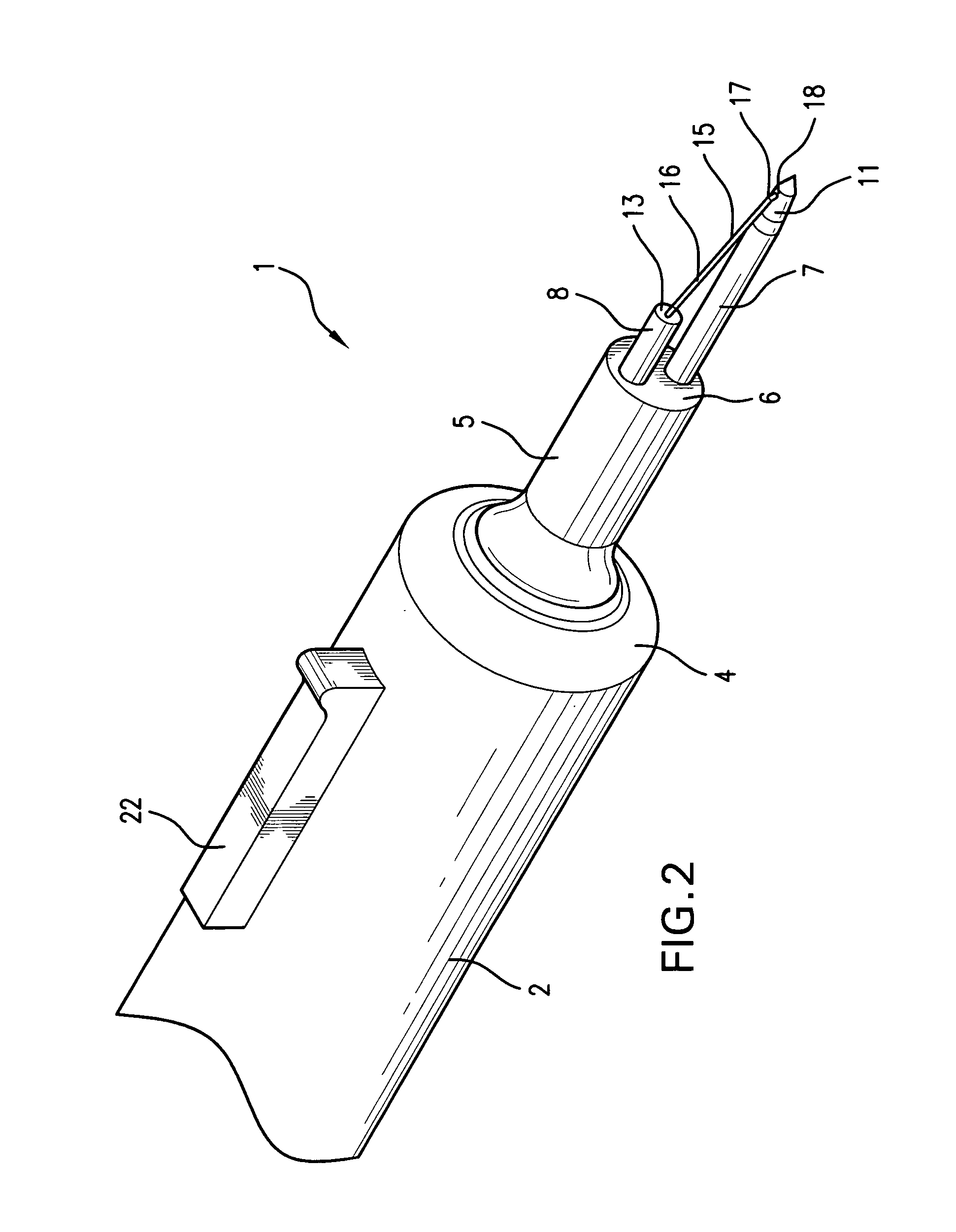

Method, apparatus, and kit for thermal suture cutting

InactiveUS7699856B2Reduce tensionMinimize disruptionSuture equipmentsDiagnosticsForcepsRemoval techniques

A novel suture removal instrument, kit and technique are described herein. The invention utilizes a newly designed thermal filament to allow the tip of the suture removal instrument to be slipped under the stitch in order to heat and cut the stitch. Current suture removal techniques utilize scissors, forceps, and / or scalpels. These techniques, which are well known in the art, are problematic because they exert tension on the stitch and are associated with patient discomfort. Small stitches add to the difficulty of suture removal because they have less suture laxity for scissor insertion. The present invention therefore allows for more rapid suture removal with less patient discomfort and at a competitive or lower cost.

Owner:BOVIE MEDICAL CORP

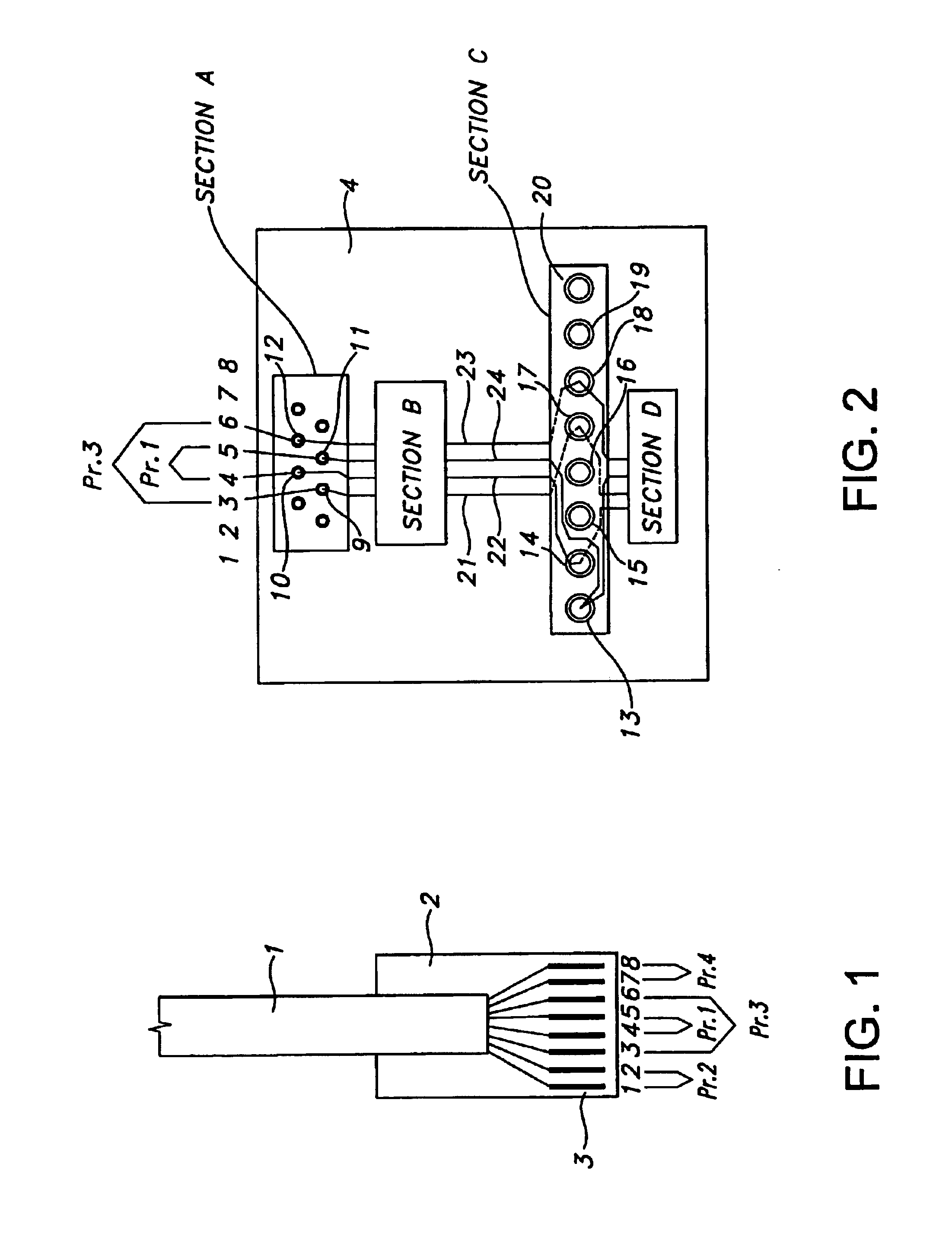

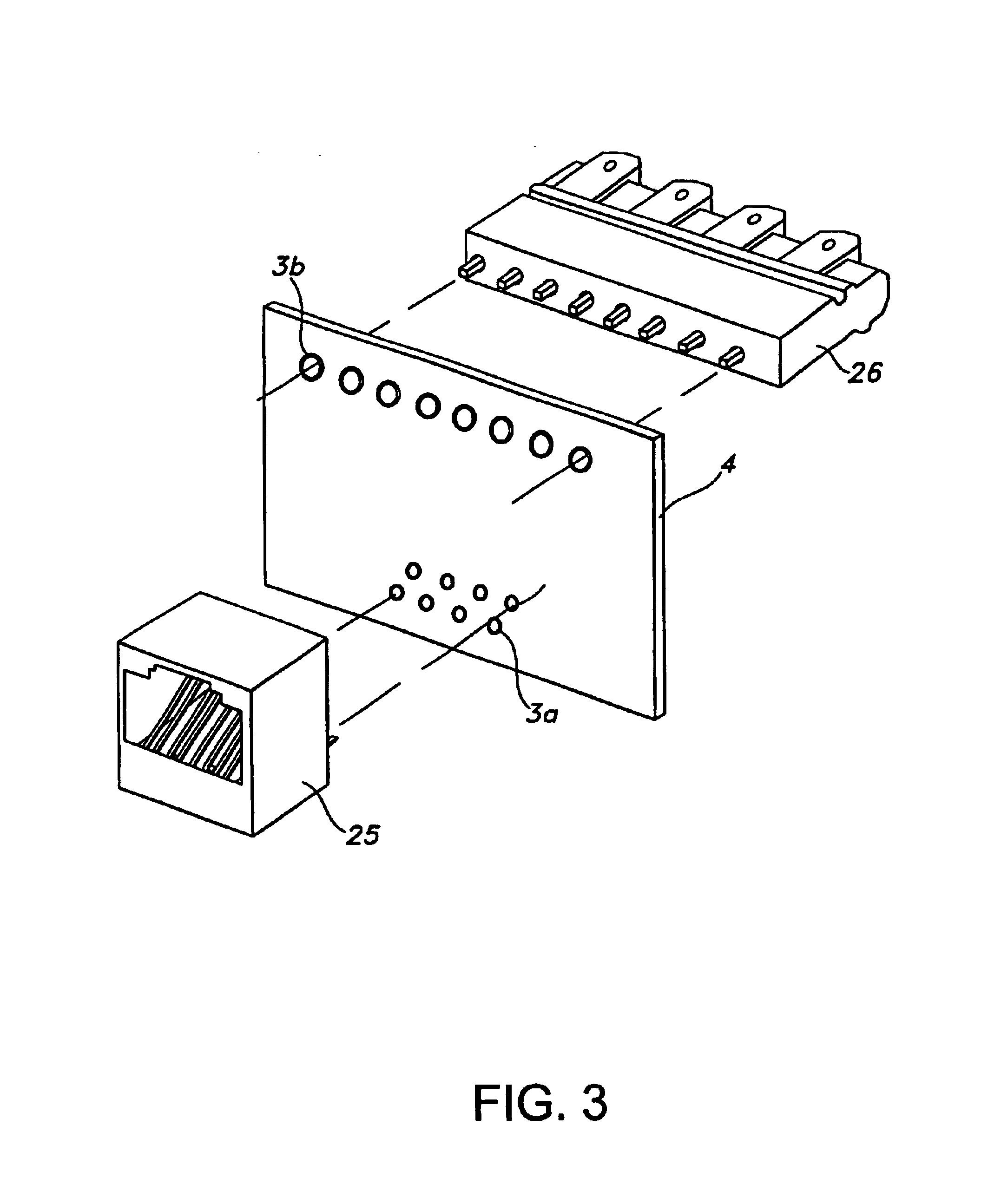

Bi-directional balance low noise communication interface

InactiveUS6840816B2Reduce crosstalkSimple and inexpensive to manufacturePrinted circuit detailsCoupling device detailsLow noiseCommunication interface

The present invention relates to RJ45 modular inserts that are connected to a printed circuit board used to transfer high speed signals for telecommunication interface media connections. The printed circuit board is configured to reduce near-end cross-talk (“NEXT”) without compromising impedance. NEXT is substantially reduced by utilizing a low reactance dielectric insert with a two-stage combination positive and negative compensation removal technique. By utilizing this method, the pair-to-pair NEXT is substantially reduced and differential pair impedance are controlled in a simple and cost effective manner.

Owner:ORTRONICS INC

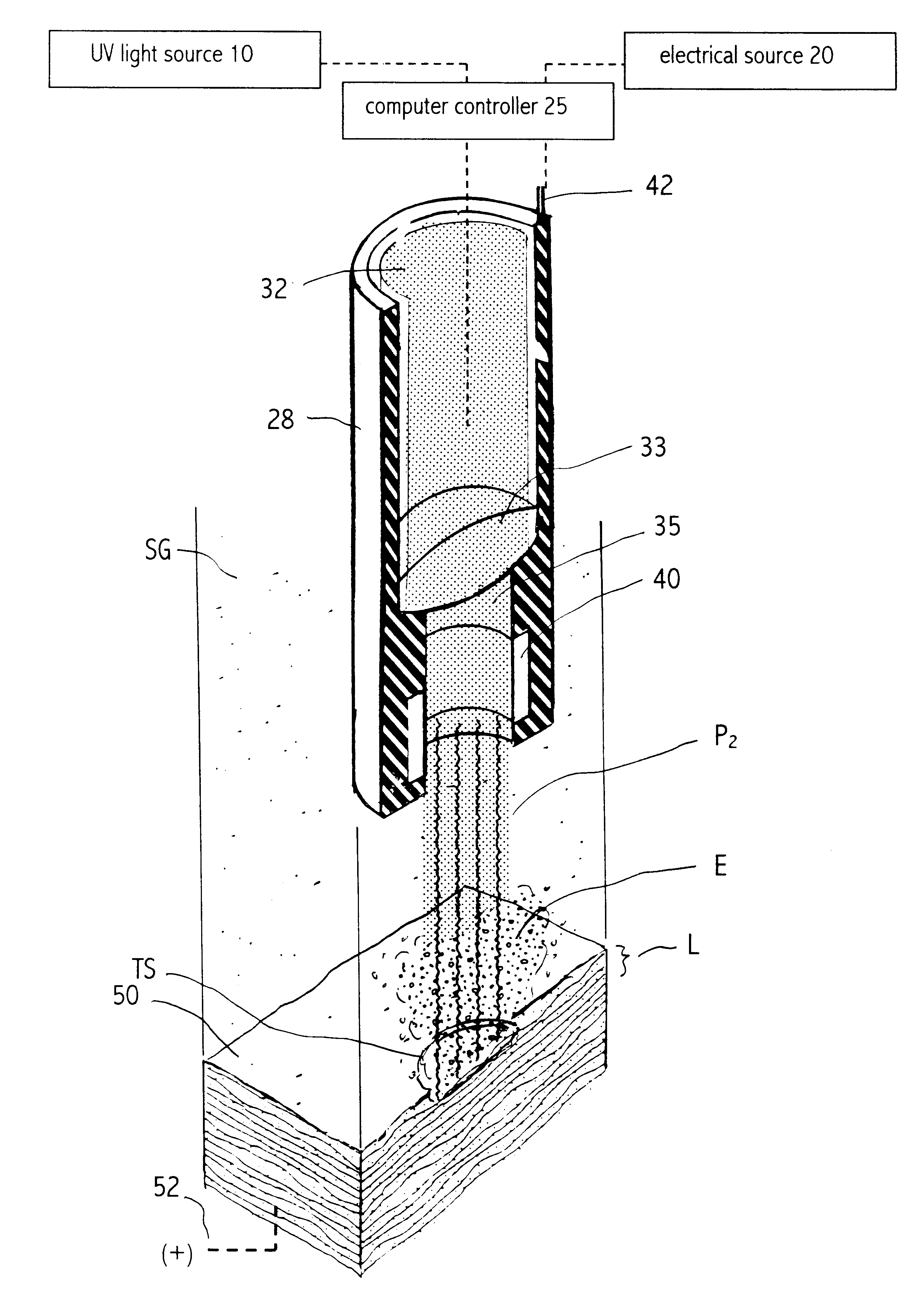

Photoionization enabled electrochemical material removal techniques for use in biomedical fields

InactiveUS6387088B1Accurate volume controlDepth accurateDiagnosticsSurgical instrument detailsThermal energyControl manner

A method for controlled removal of surface tissue layer portions with a non-contact energy delivery modality that applies electrical energy to the targeted tissue surface to cause electrochemical ablation. The system provides (i) a UV energy source for irradiating a beam path through a selected neutral gas environment overlying the targeted tissue thereby creating an ionized gas volume (i.e., a conductive non-equilibrium plasma), and (ii) an electrical source for creating an intense electrical field in the ionized gas volume to thereby apply energy to the targeted surface layer to cause volatilization and removal of the surface layer in a plasma-mediated ablation. The ultrafast plasma creation events are repeated at a high repetition rate to ablate surface layer portions in a controlled manner. Each ultrafast plasma creation event is of such a high intensity and such a brief duration that thermal energy is not transferred to the tissue thus preventing collateral thermal damage to regions adjacent to the targeted site.

Owner:SHATTUCK JOHN H +1

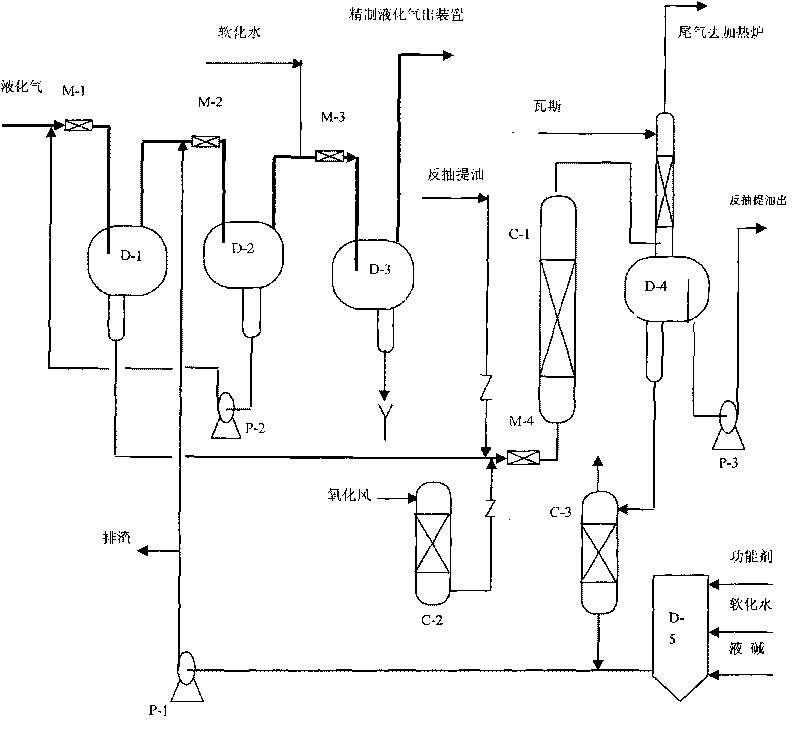

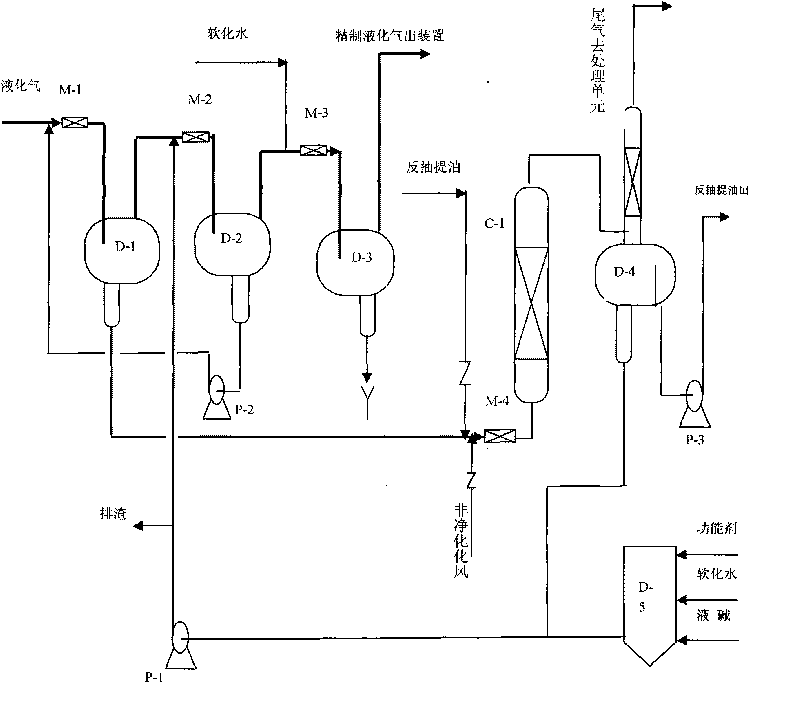

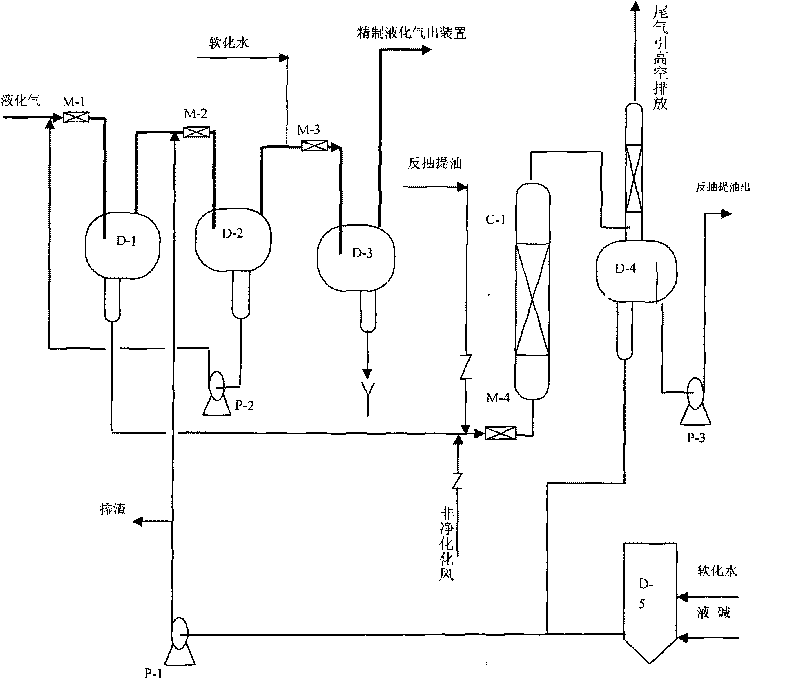

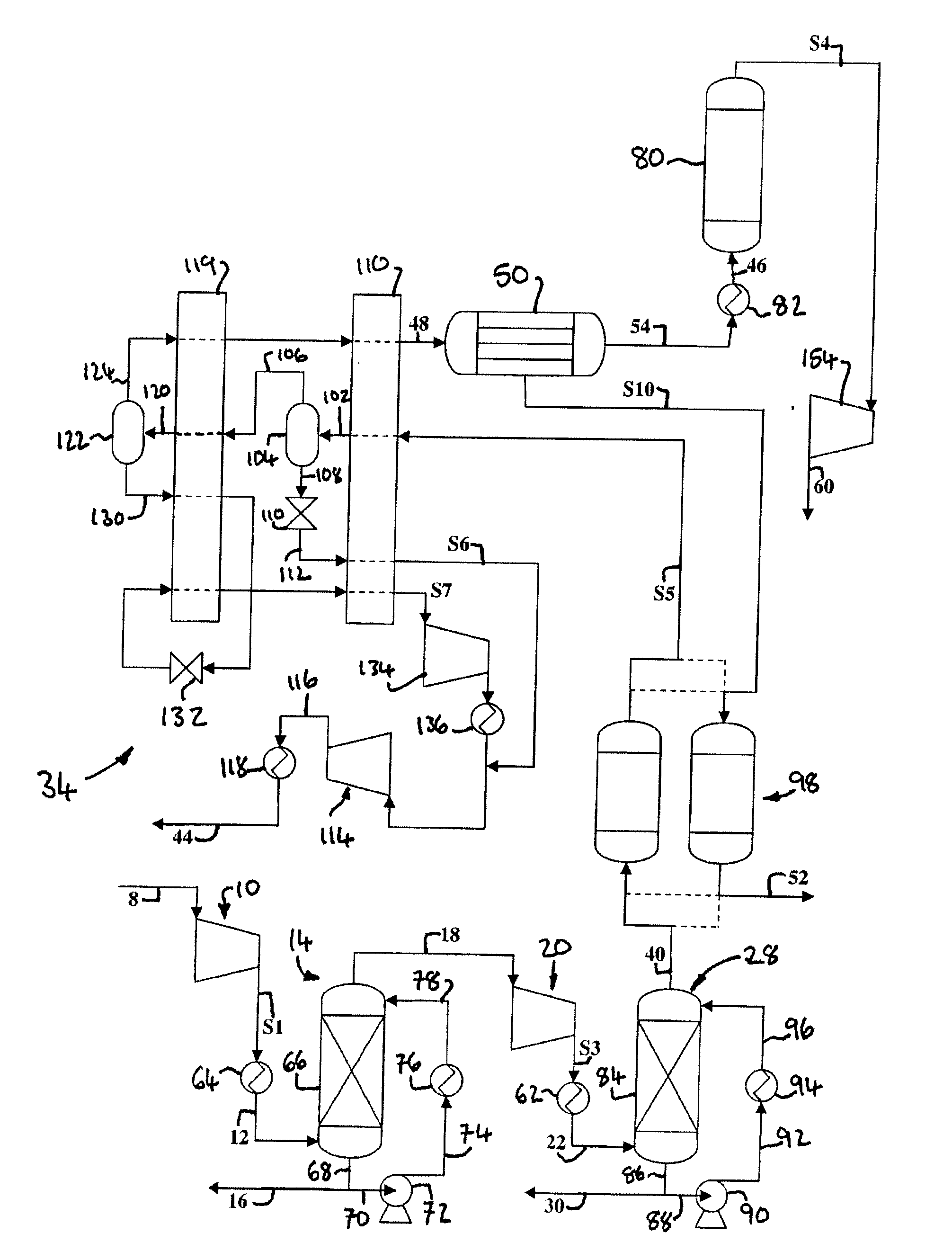

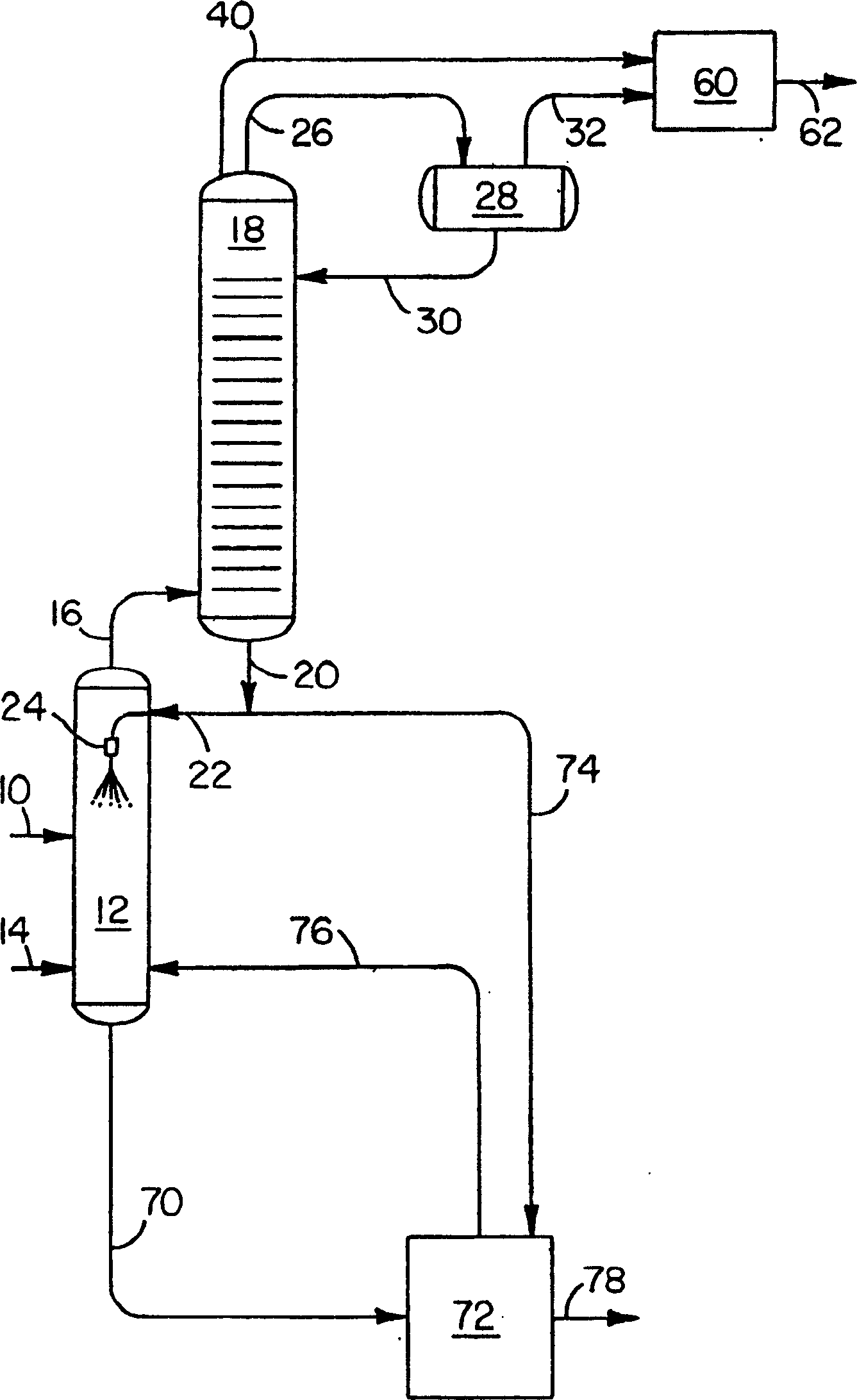

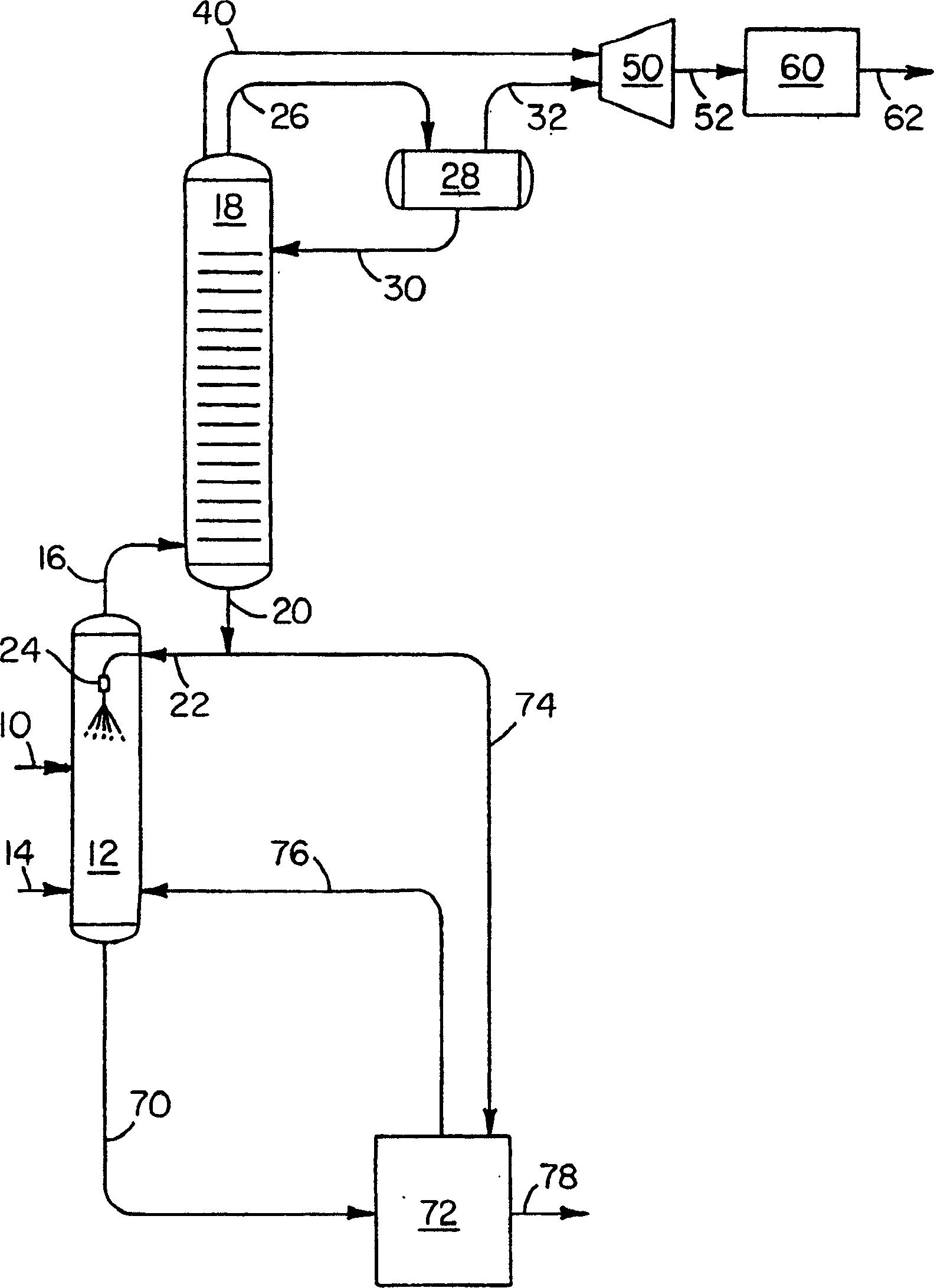

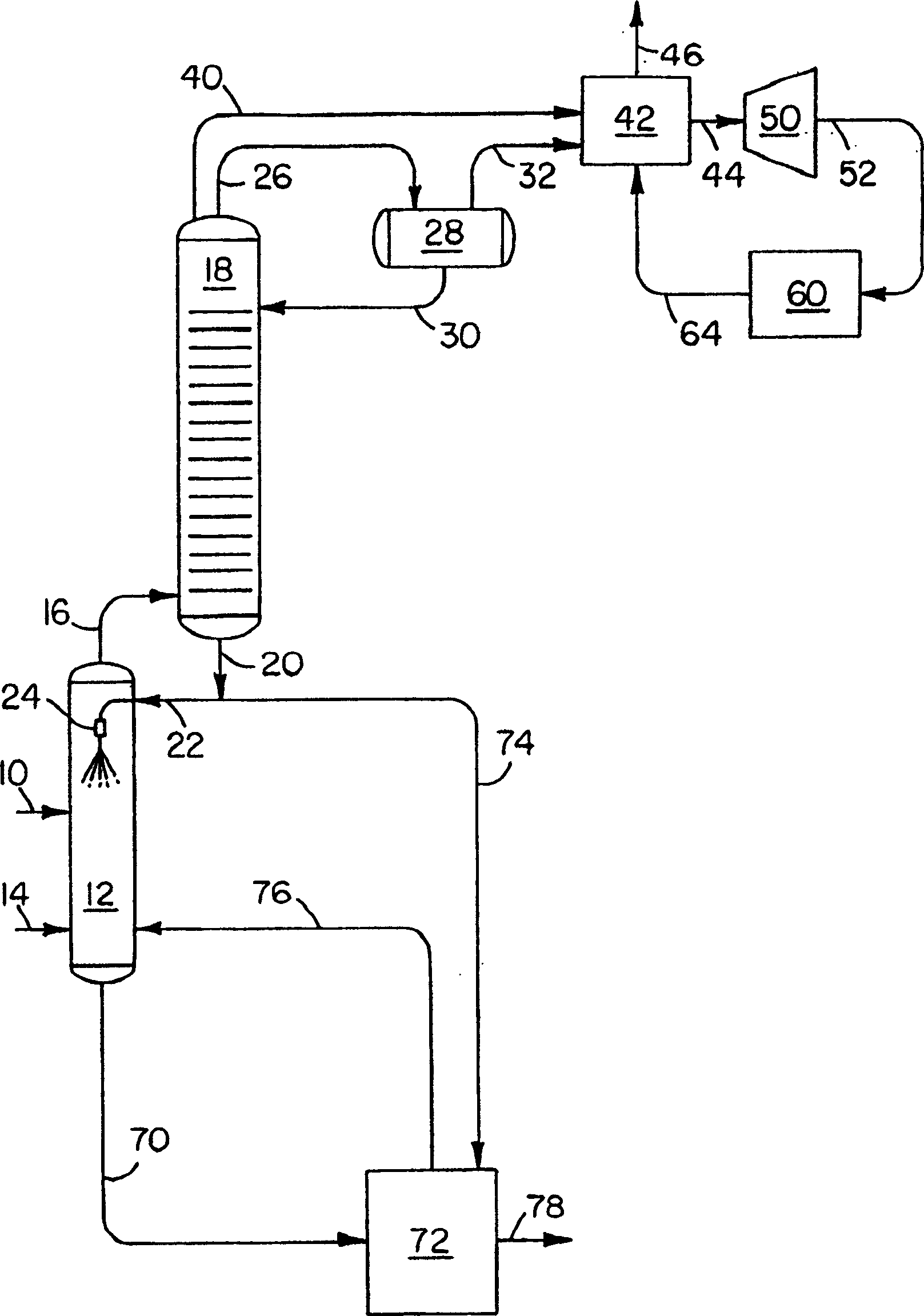

Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

ActiveCN101705108AImprove abilitiesHigh activityGaseous fuelsRefining with aqueous alkaline solutionsSlagCarbonyl sulfide

The invention relates to a liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur, in particular to a sweetening technique for liquefied gas in an oil refinery. The oil refining liquid hydrocarbon refers to components of liquefied gas and light gasoline, wherein the liquefied gas is a raw material for producing MTBE, and the light gasoline is a component for producing high-cleanness gasoline. In order to solve the problem of high total sulfur in the oil refining MTBE and the light gasoline, according to the shape and the distribution rule of sulfocompounds in the liquid hydrocarbon, processes such as functional reinforcement of a recycle solvent, three-phase mixed reinforced regeneration, regenerated catalyst and extractant separation and recycle solvent deoxidization and the like are adopted in the conventional process of liquid hydrocarbon extraction, oxidization and mercaptan removal, so the technical effects of reinforcing the mercaptan removal depth, improving carbonyl sulfide removal rate, and avoiding forming disulphide in the extracting, saving energy and reducing emission and the like are achieved. Thus, the liquid hydrocarbon can be deeply desulfurated, the problem of high total sulfur in the oil refining MTBE and the light gasoline is solved and the slag discharging quantity in the conventional process is greatly reduced.

Owner:HEBEI REFINING TECH CO LTD

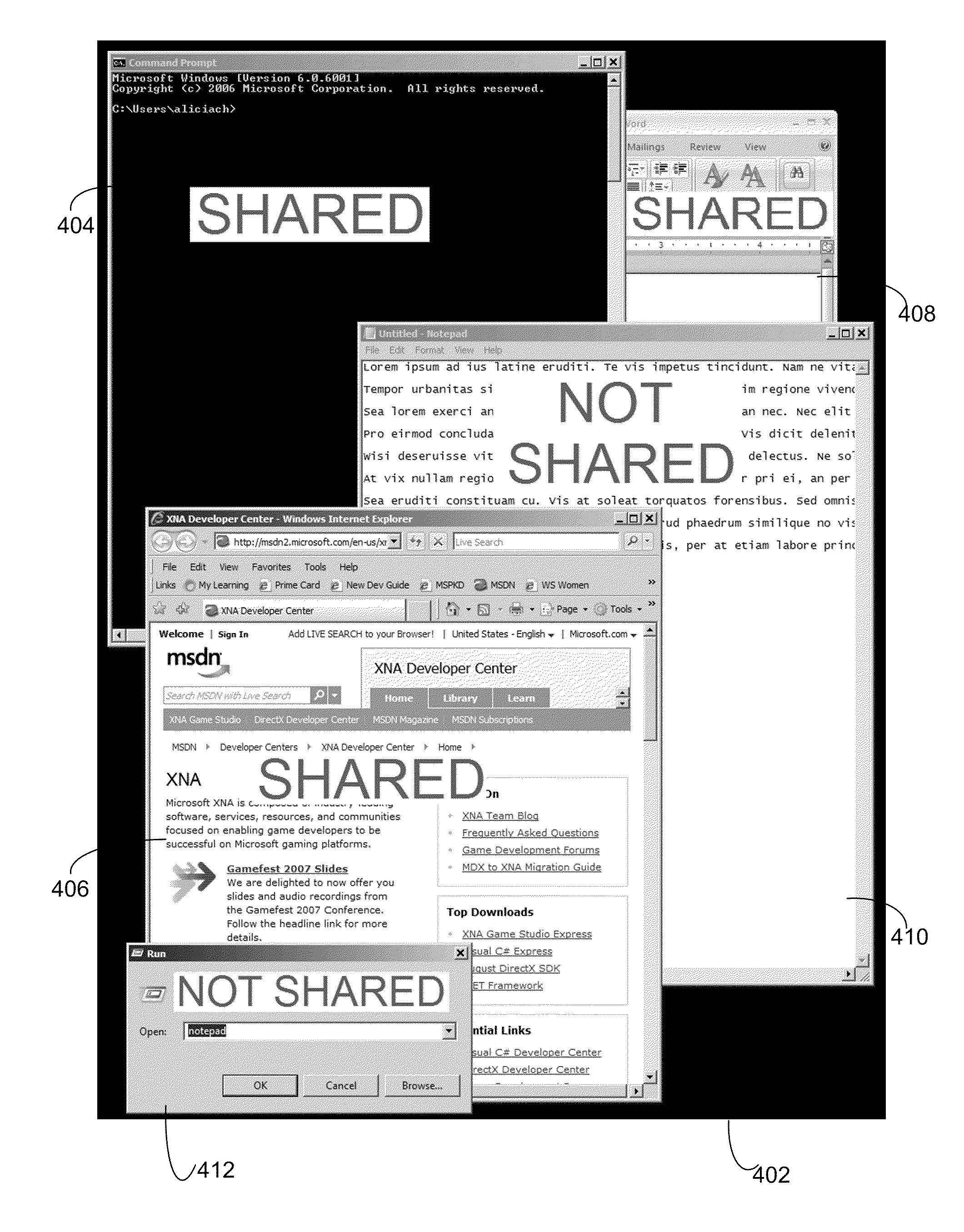

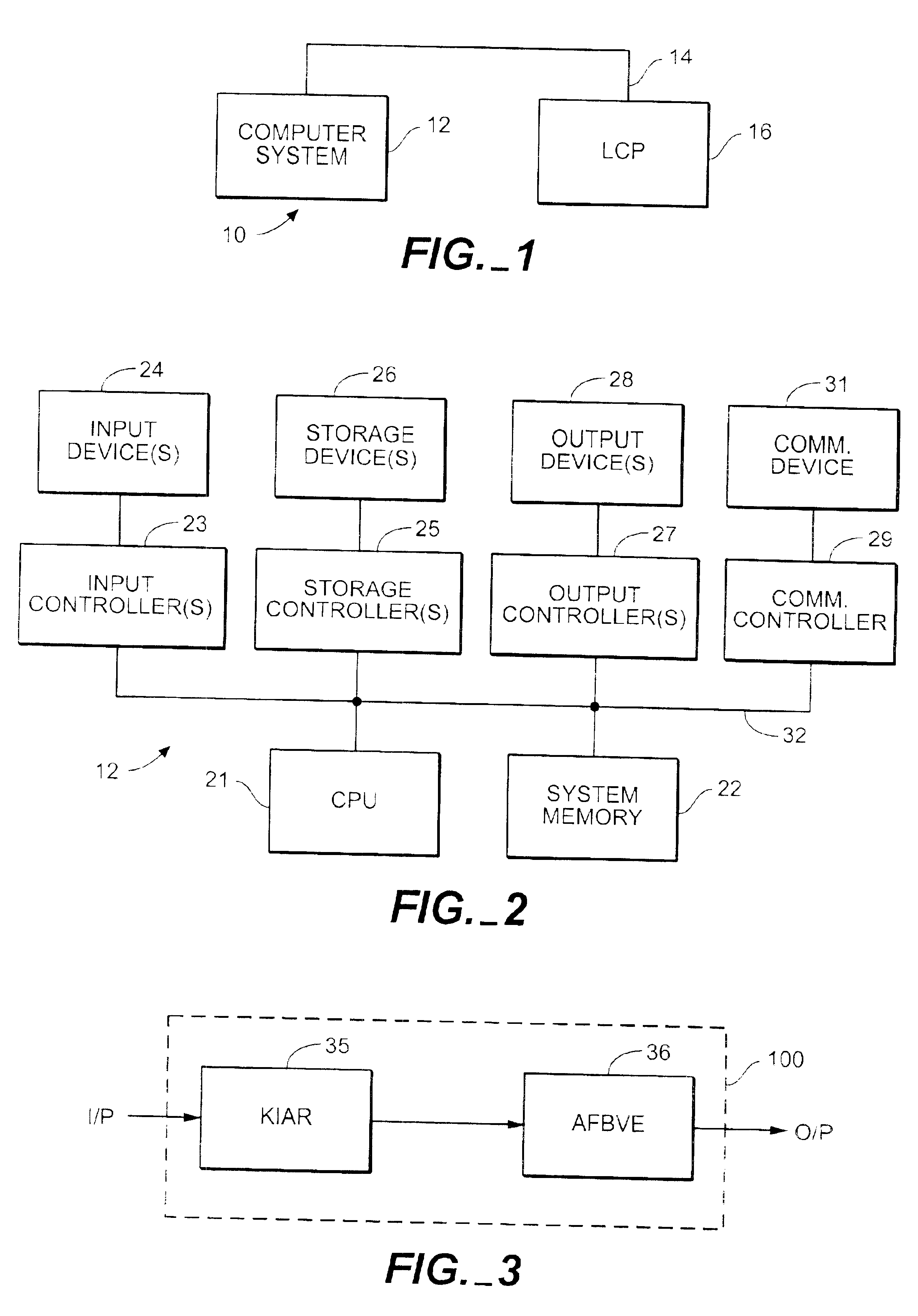

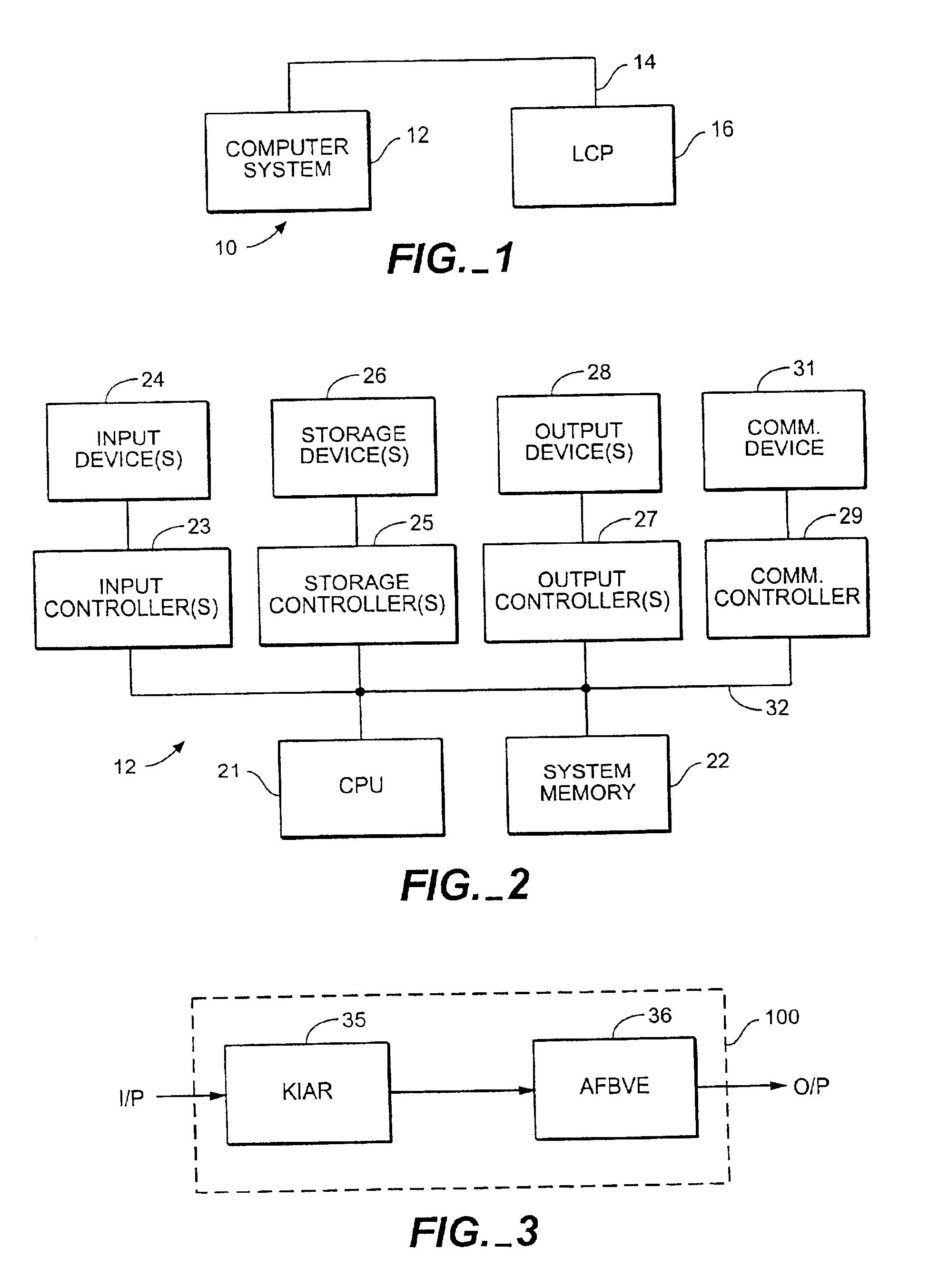

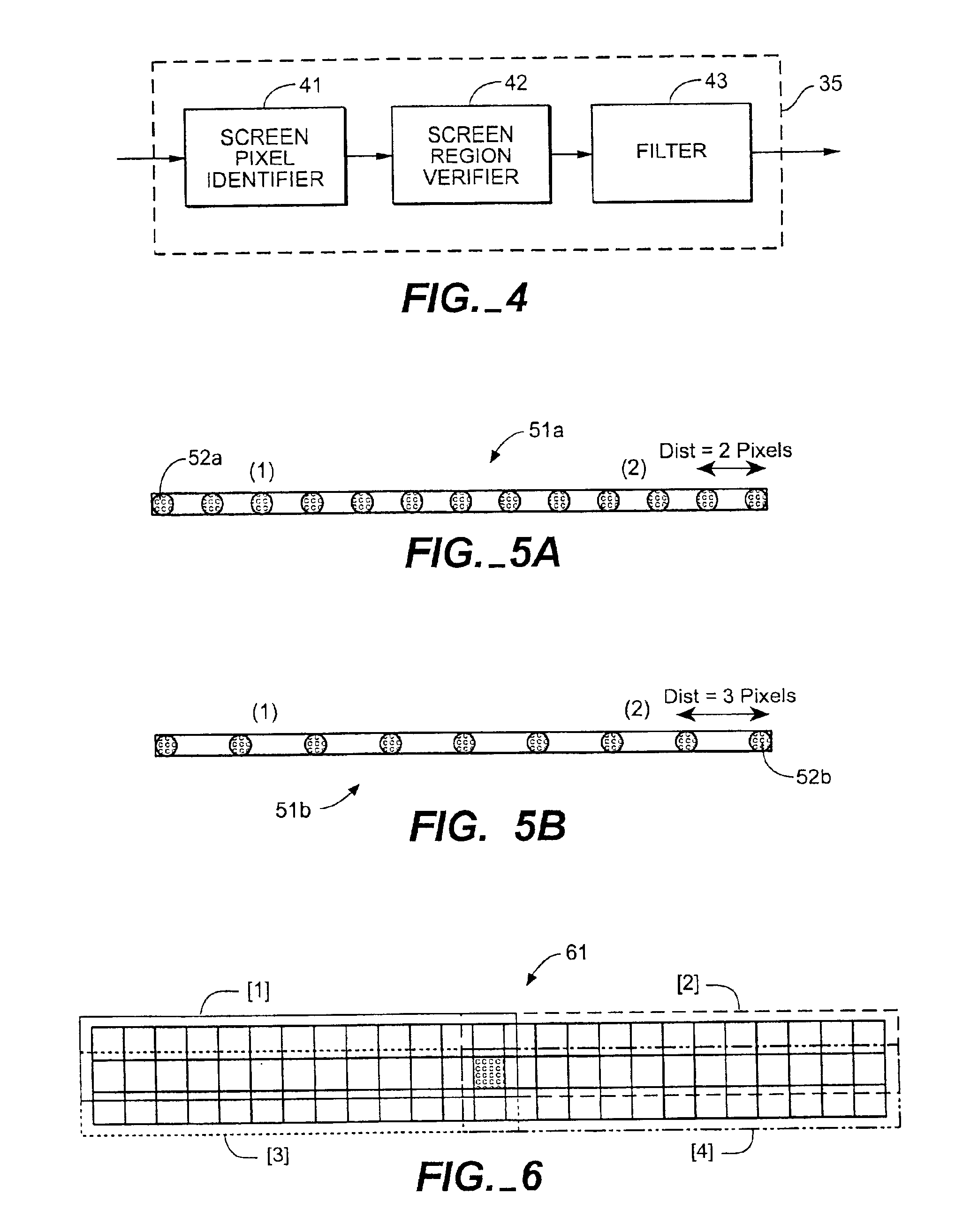

Application sharing with occlusion removal

Techniques are disclosed for window sharing with occlusion removal. In an embodiment, the techniques begin with a blank composition image, to which shared windows are added. For each window of a desktop from which at least one window is shared, traversing the windows from greatest z-depth to least z-depth, the window is processed based on whether it is shared and is occluded. Shared windows are copied to the composition image. Where a part of a shared window is occluded and cannot be retrieved, an indication of this occlusion is added to the composition image. When the windows have been processed, the composition image is encoded and sent to a client computer where it is displayed to produce the window sharing between computers.

Owner:MICROSOFT TECH LICENSING LLC

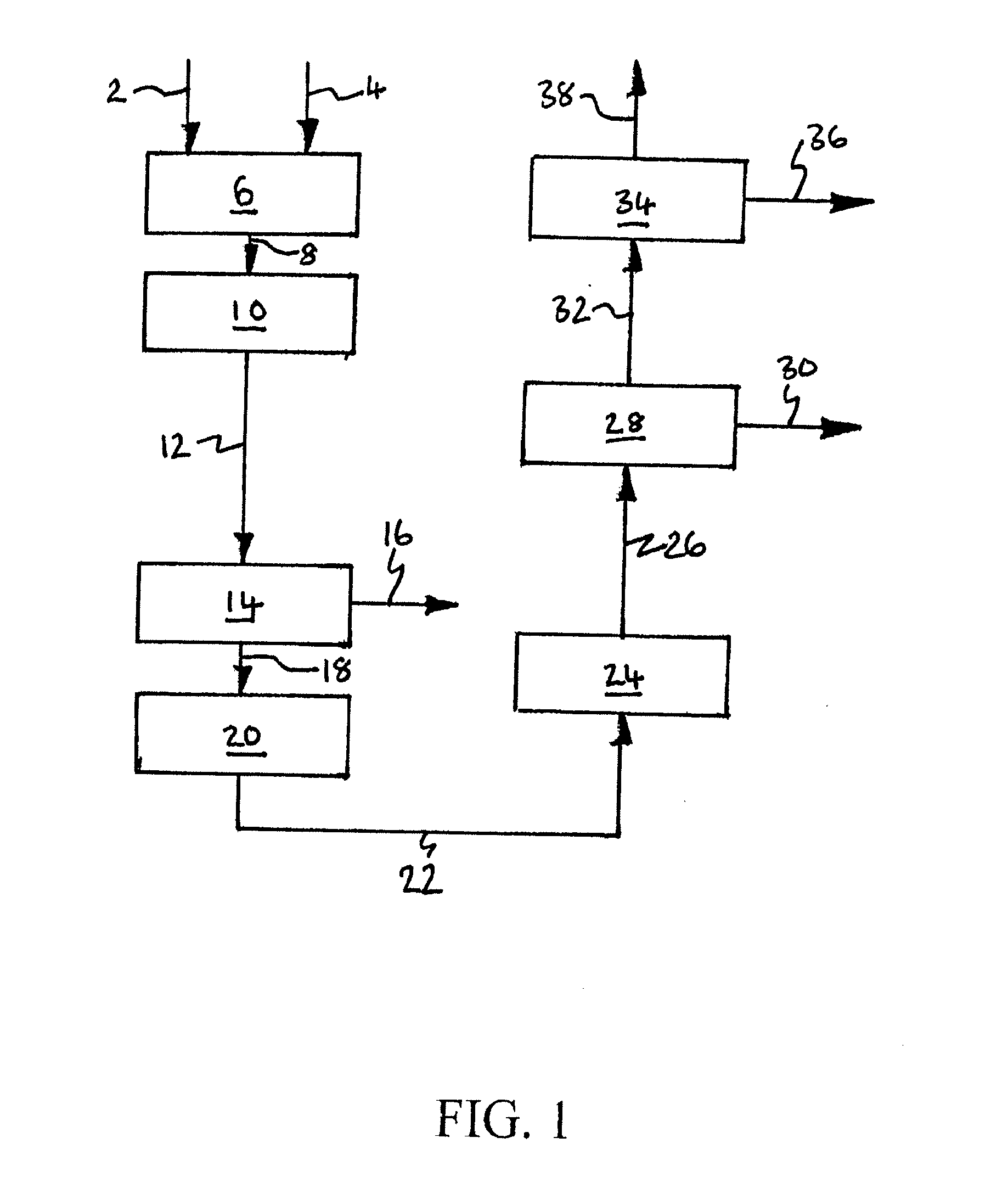

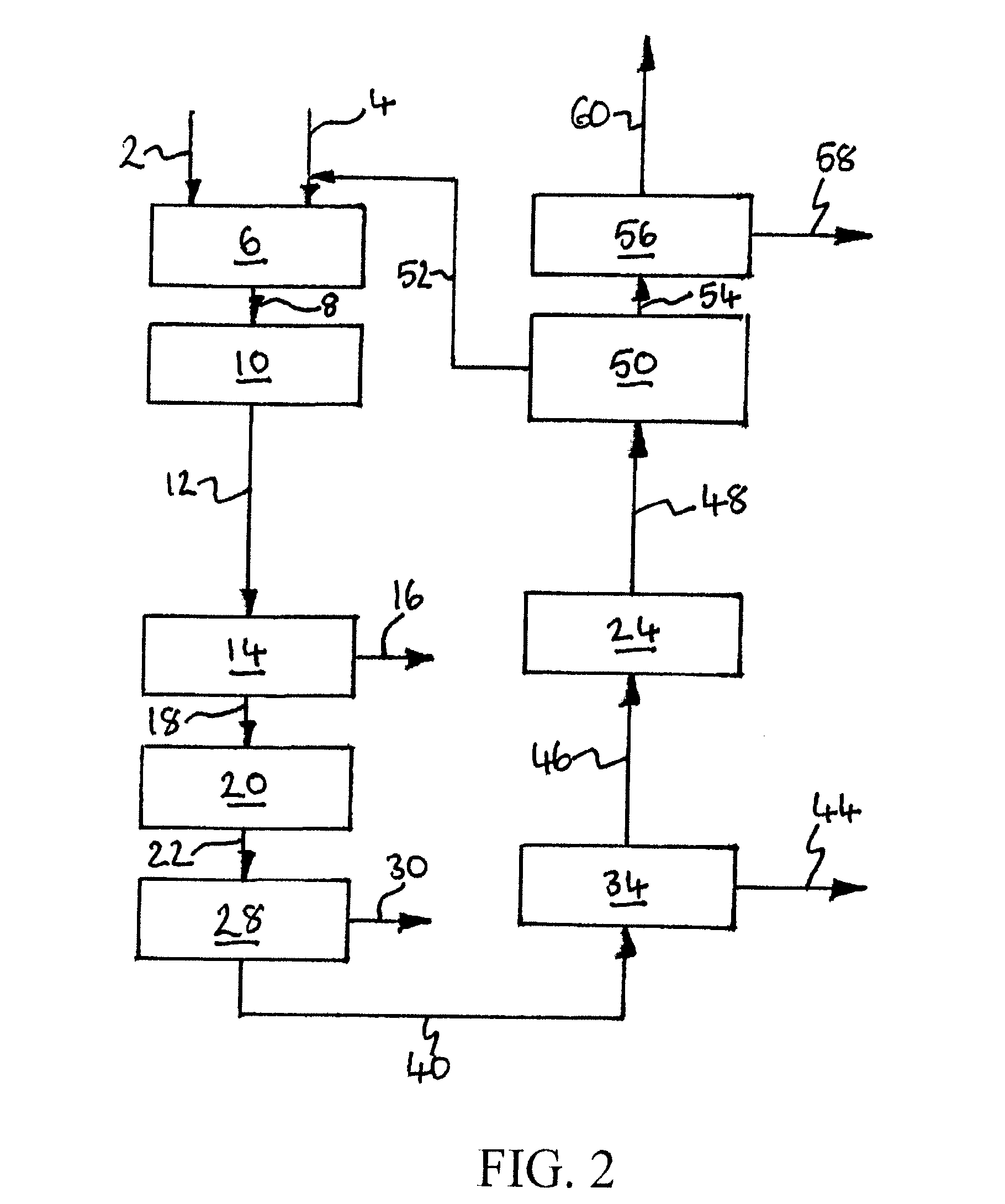

Treatment of Flue Gas From an Oxyfuel Combustion Process

Carbon monoxide (CO) may be removed from flue gas generated by oxyfuel combustion of a hydrocarbon or carbonaceous fuel, by contacting the flue gas, or a CO-containing gas derived therefrom, at a first elevated temperature, e.g. at least 80° C., and at a first elevated pressure, e.g. at least 2 bar (0.2 MPa), with at least one catalyst bed comprising a CO-oxidation catalyst in the presence of oxygen (O2) to convert CO to carbon dioxide and produce carbon dioxide-enriched gas. The carbon dioxide produced from the CO may be recovered from the carbon dioxide-enriched gas using conventional carbon dioxide recovery techniques. NO in the flue gas may also be oxidized to nitrogen dioxide (NO2) and removed using conventional NO2 removal techniques, or may be reduced in the presence of a reducing gas to nitrogen (N2) which does not have to be removed from the gas.

Owner:AIR PROD & CHEM INC

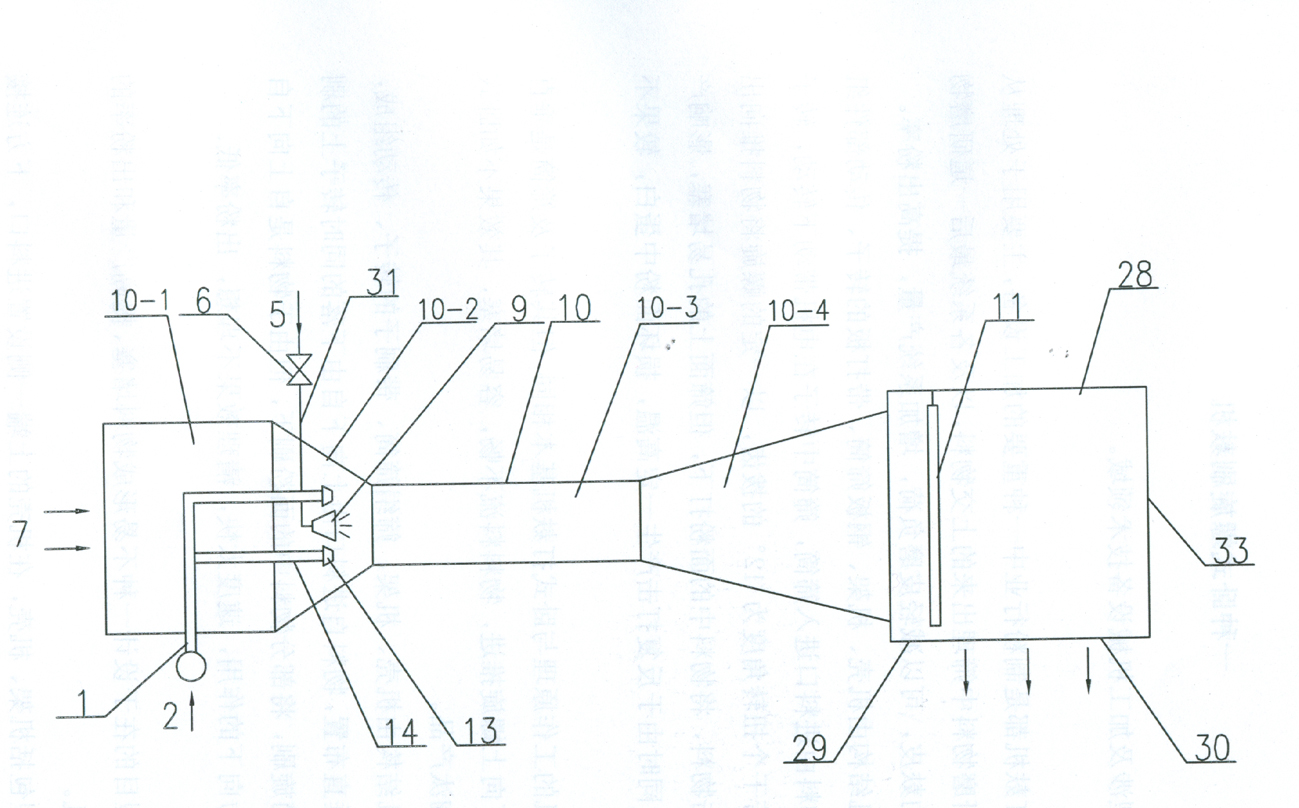

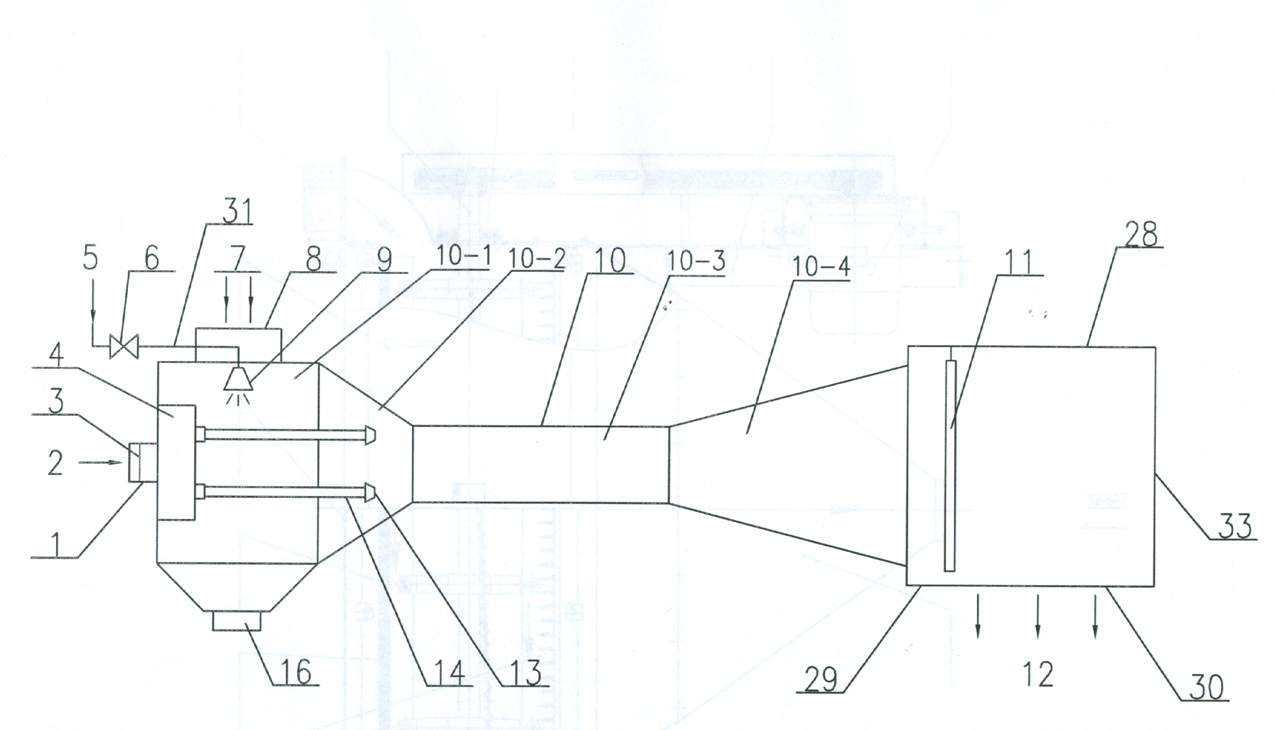

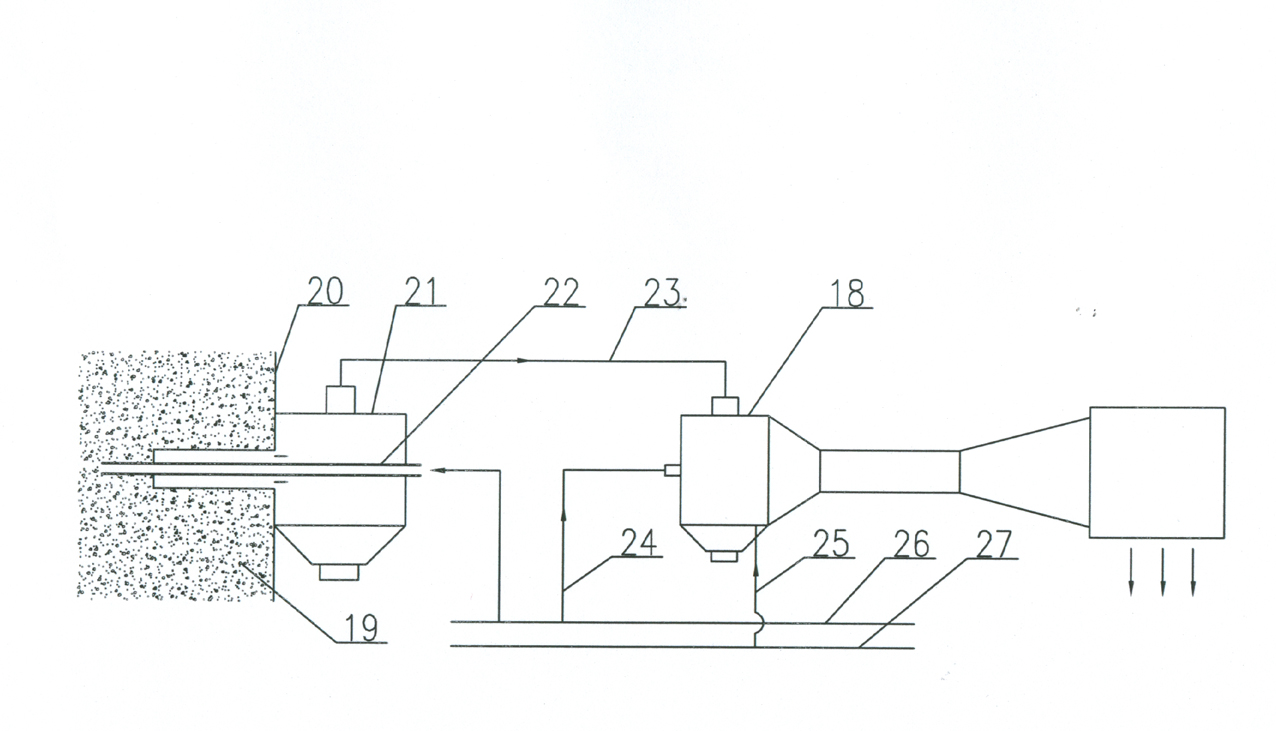

Compressing-deslagging-drilling dust remover for coal pits

ActiveCN101943021ANot limited by gas concentrationSimple structureDust removalFire preventionStraight tubeEngineering

The invention discloses a compressing-deslagging-drilling dust remover for coal pits, which relates to a device for ventilation and dust removal in a coal pit. The dust remover comprises a Venturi tube mixer, wherein the Venturi tube mixer comprises a gas inlet chamber, a constricted tube section, a straight tube section and a conical divergent section; a high pressure gas inlet tube is arranged in the gas inlet chamber; the outer end of the high pressure gas inlet tube is arranged outside the gas inlet chamber; the inner end of the high pressure gas inlet tube is connected with at least one straight tube which is parallel to the central axis of the Venturi tube mixer; the other end of the straight tube is provided with a high pressure gas injection head; the outlet of the high pressure gas injection head is arranged in the Venturi tube mixer; the Venturi tube mixer is also provided with a water inlet tube; the water inlet tube is provided with a valve; the inner end of the water inlet tube is connected with a water atomization injection head; and the water atomization injection head is arranged in the Venturi tube mixer. By using the high pressure gas injection principle and the wet dust removal technique, the dust remover has the advantages of simple structure, small size, light weight, convenient transportation and high dust removal efficiency.

Owner:YANGZHOU YINJIANG MINING EQUIP

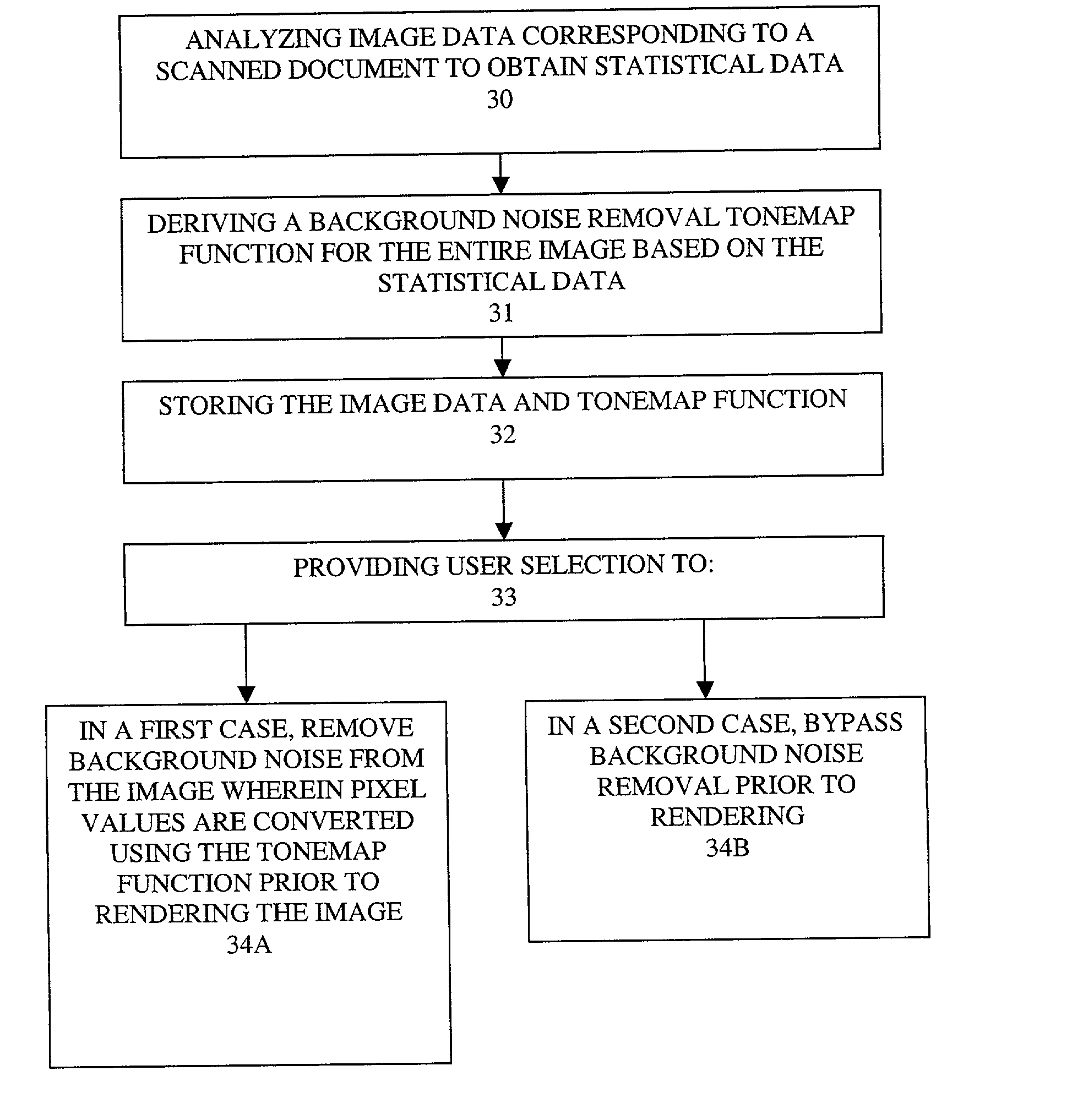

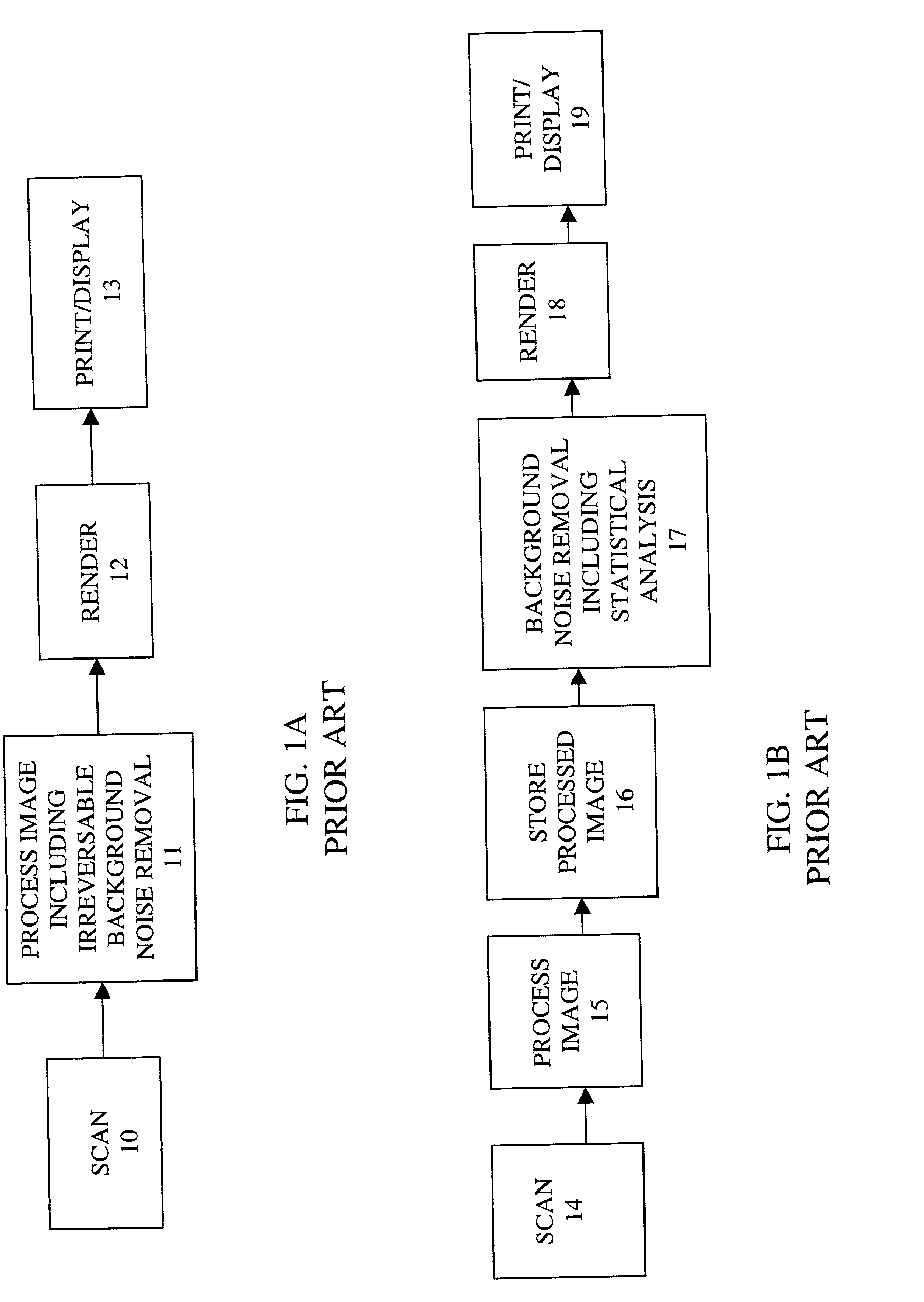

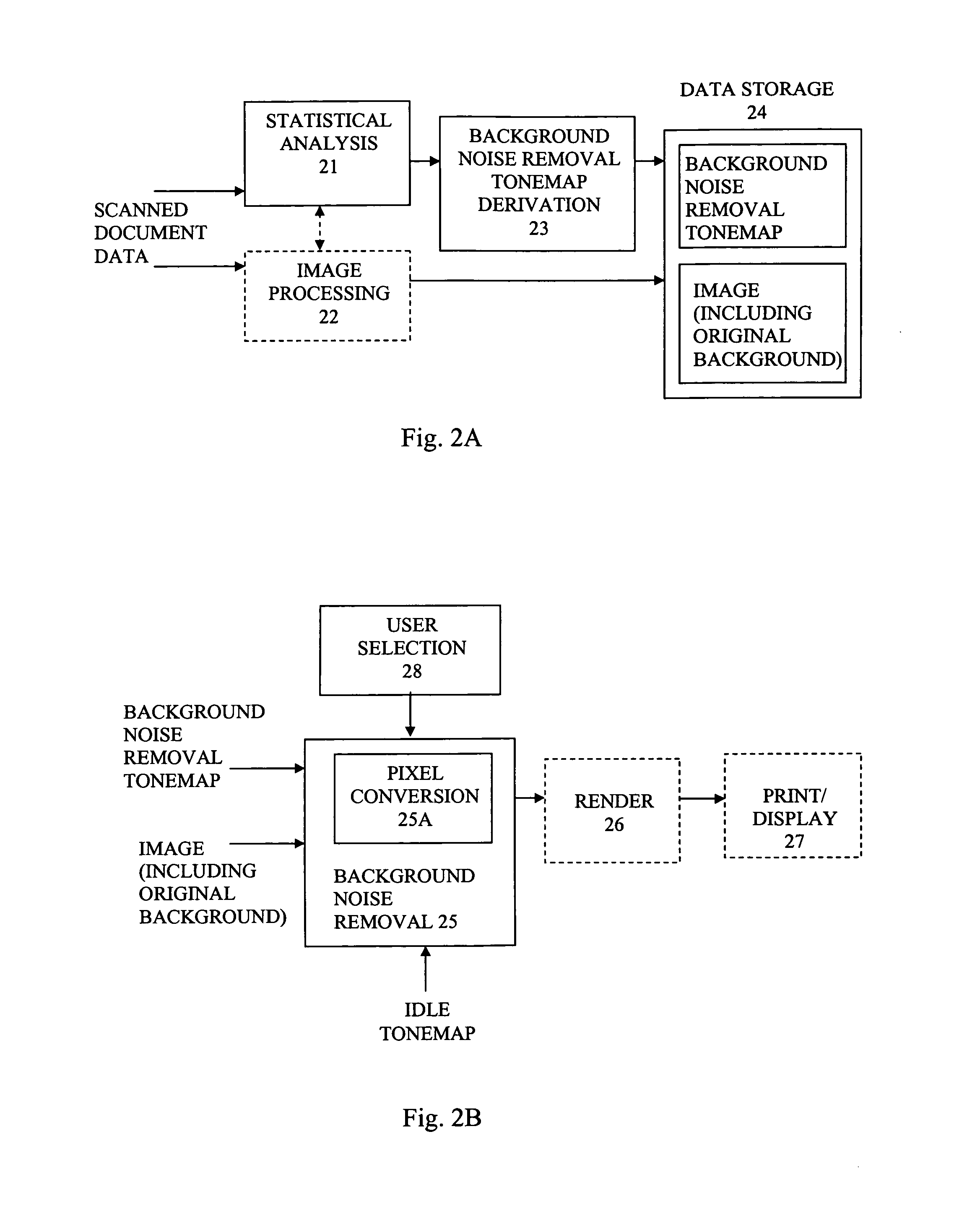

User selected background noise removal for scanned document images

InactiveUS7050650B2Improve methodImprove system efficiencyImage enhancementCharacter and pattern recognitionPattern recognitionPaper document

A system and method of removing background noise from a digital image of a scanned document is described. The system and method is a reversible background noise removal technique that allows a user to select whether background noise is removed or not. In addition, since the present invention divides the background noise removal operations into a two phase process, the overall efficiency of the system and method are significantly improved.

Owner:HEWLETT PACKARD DEV CO LP

Developable bottom antireflective coating compositions especially suitable for ion implant applications

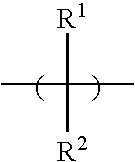

InactiveUS20100196825A1Good reflectivity controlImprove adhesionPhotosensitive materialsSemiconductor/solid-state device manufacturingLithography processAromatic moiety

Compositions characterized by the presence of an aqueous base-soluble polymer having aromatic moieties and aliphatic alcohol moieties have been found which are especially useful as developable bottom antireflective coatings in 193 nm lithographic processes. The compositions enable improved lithographic processes which are especially useful in the context of subsequent ion implantation or other similar processes where avoidance of aggressive antireflective coating removal techniques is desired.

Owner:IBM CORP

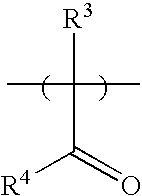

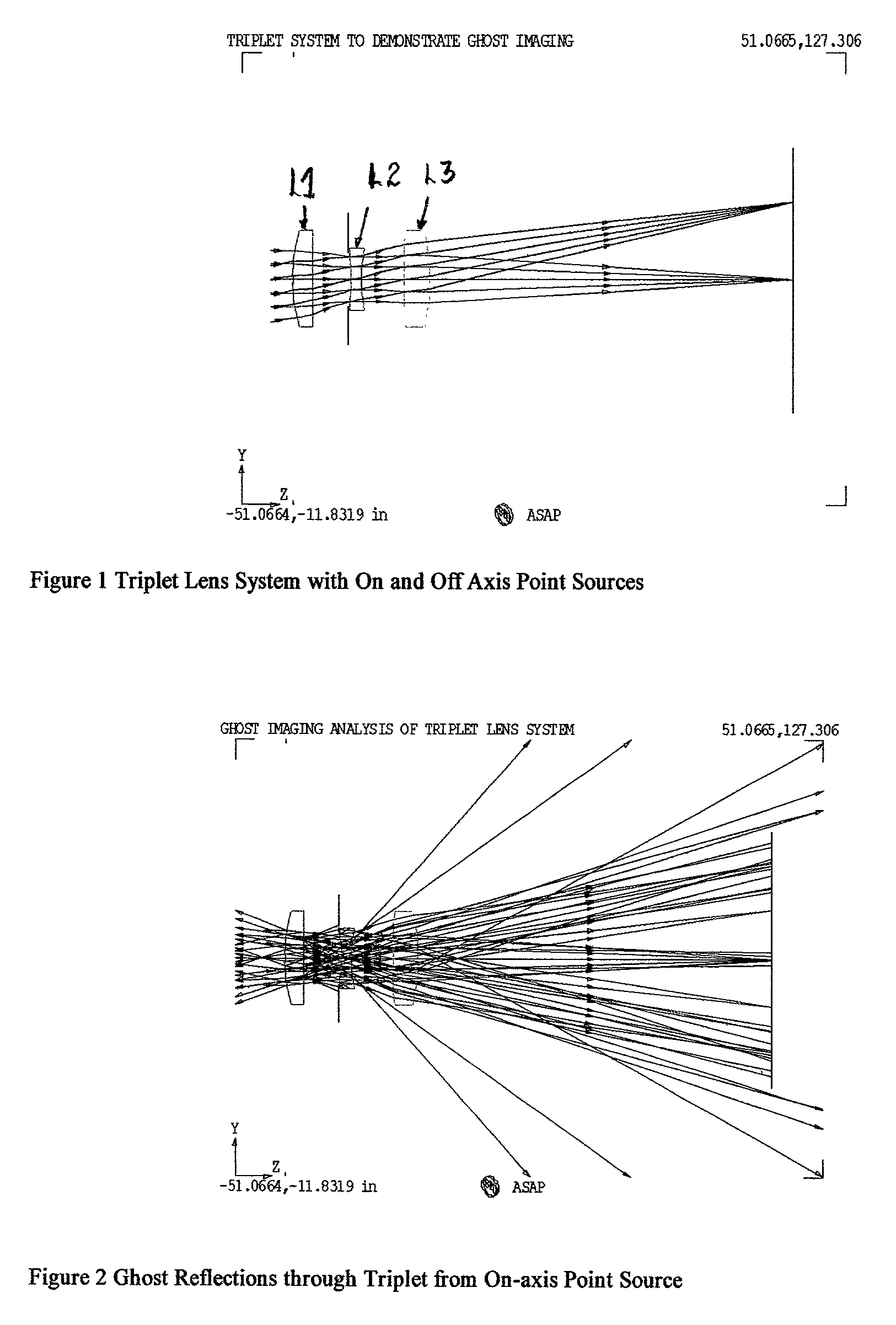

Ghost image correction system and method

A new and useful method and system for correcting for ghost images in a telecentric optical system is provided. Ghost images generated from planar optical surfaces in the image space after the major elements of a telecentric optical system are shift invariant. In other words the ghost images produced by these optical elements do not change their shape with different field angles or points. The ghost image's invariance with field position will allow the ghost image to be subtracted or removed from the image of an object recorded on a digital detector such as CCD or CMOS detector when its optical system is telecentric in image space. This subtraction may be accomplished, for example, with a removal technique using a measured ghost function germane and invariant to that particular optical system. The combination of the ghost image and scatter functions is linearly shift invariant and therefore, both noise contributions could be removed from the resulting digital image using similar removal techniques.

Owner:LIGHTSHARP

Method, apparatus, and kit for thermal suture cutting

InactiveUS20050203546A1Reduce tensionMinimize disruptionSuture equipmentsDiagnosticsForcepsRemoval techniques

A novel suture removal instrument, kit and technique are described herein. The invention utilizes a newly designed thermal filament to allow the tip of the suture removal instrument to be slipped under the stitch in order to heat and cut the stitch. Current suture removal techniques utilize scissors, forceps, and / or scalpels. These techniques, which are well known in the art, are problematic because they exert tension on the stitch and are associated with patient discomfort. Small stitches add to the difficulty of suture removal because they have less suture laxity for scissor insertion. The present invention therefore allows for more rapid suture removal with less patient discomfort and at a competitive or lower cost.

Owner:BOVIE MEDICAL CORPORATION

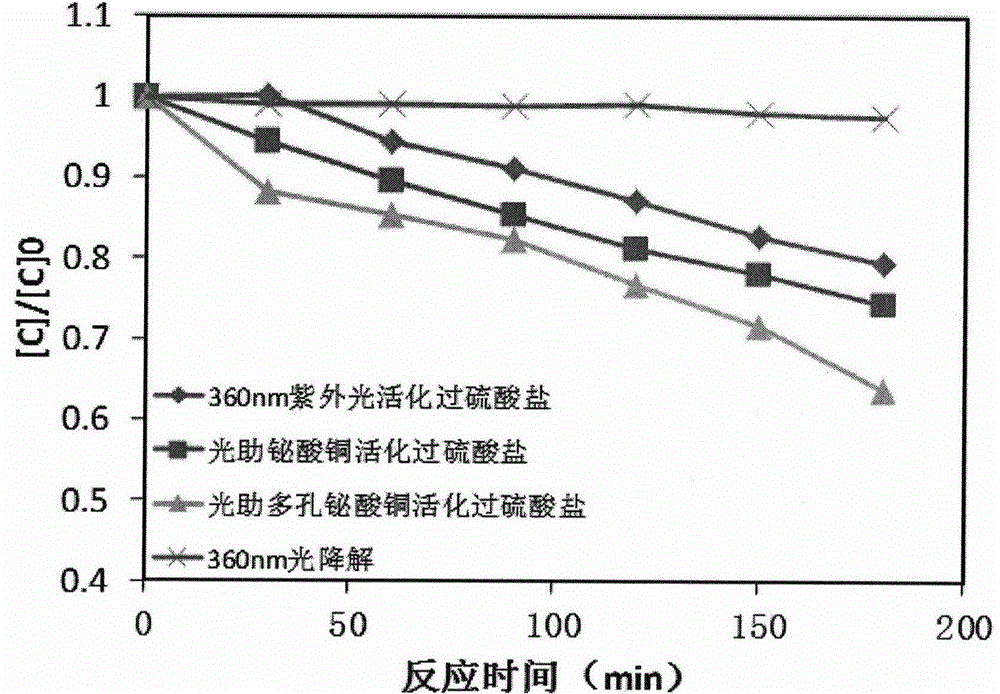

Construction and application method of photoassisted porous copper bismuthate activated persulfate water treatment high-grade oxidation technology

ActiveCN104909427AAchieve enhanced removalImprove efficiencyWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsCoumarin degradationWater quality

The invention provides a construction and application method of a photoassisted porous copper bismuthate activated persulfate water treatment high-grade oxidation technology, and belongs to the field of water treatment technologies and environmental functional materials. The shape of porous copper bismuthate can be powder or particles, and a porous copper bismuthate material with a high specific surface area is prepared by using bismuth nitrate, copper nitrate and polyvinylpyrrolidone as main materials, so the coumarin degradation ability of free radicals generated in the activation process of persulfate under photoassisted conditions is improved. The novel porous copper bismuthate is provided as a catalyst to solve the problem of poor coumarin removal effect of present routine sewage treatment, realizes successful application in a persulfate system, provides theoretic reference for coumarin compound removal technologies, and provides scientific basis and technical support for water safety and water environment improvement.

Owner:BEIJING FORESTRY UNIVERSITY

Technique for removing ginkgolic acid in folium ginkgo extract

ActiveCN101194918AEfficient removalSimple processIon-exchange process apparatusIon-exchanger regenerationPolyamideGinkgolide

The invention discloses a removal technique of ginkgolic acid in a ginkgo leaf extract, which utilizes ginkgo leaf extract which passes through a macroreticular resinous to be raw material, and the process comprises firstly utilizing polyamide which is pre-processed to be a removing agent of the ginkgolic acid, and then changing superpositions of resin pillar with pre-processing strong alkalinity macroporous ion to remove ginkgolic acid. The process has simple technique, stability and low cost, which can effectively remove ginkgolic acid in ginkgo leaf extract, and can not affect yield rates of ginkgo biloba flavonoids and ginkgolide.

Owner:石药银湖制药有限公司

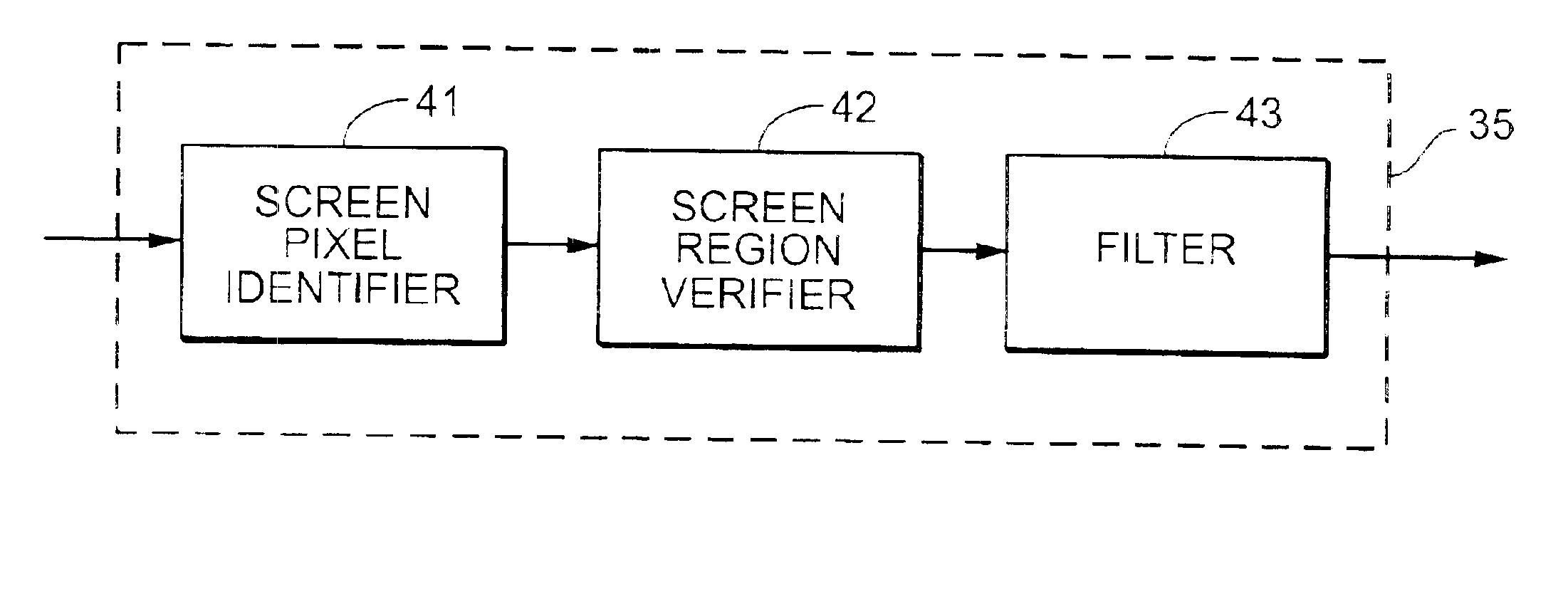

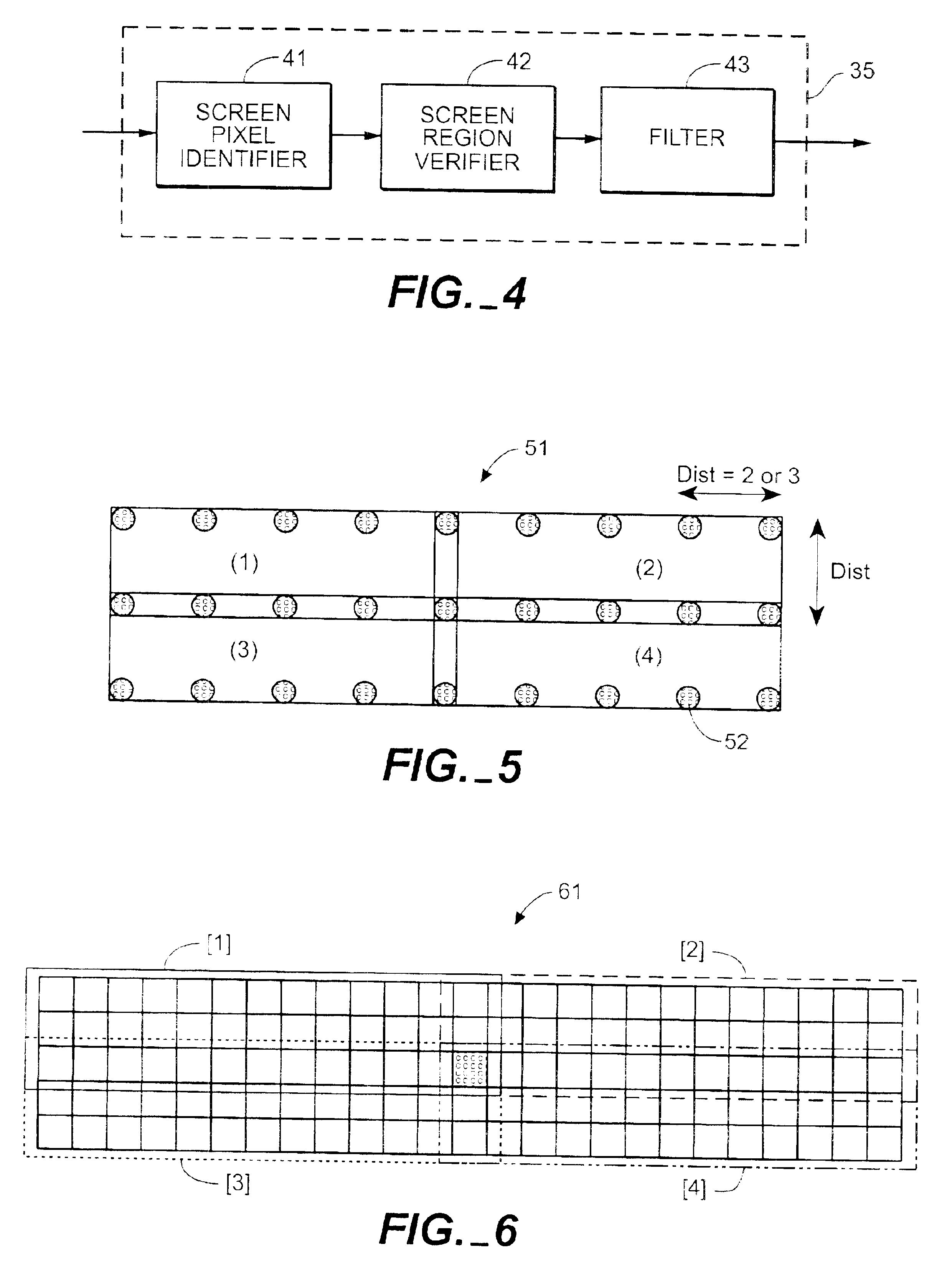

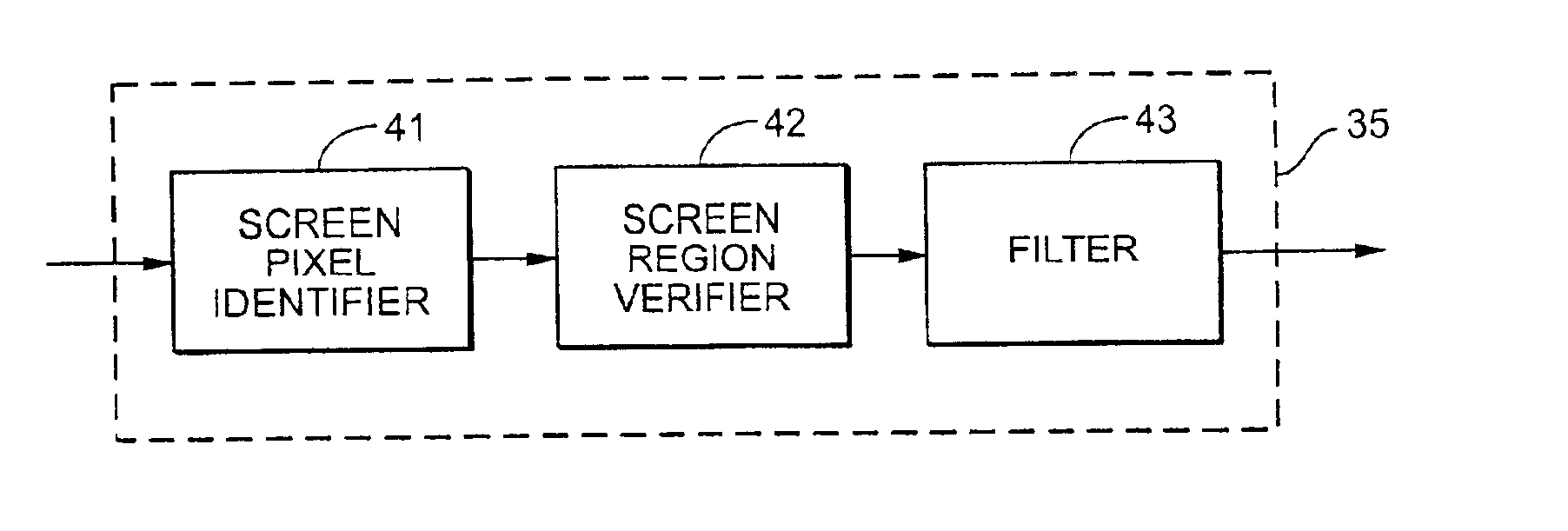

Image artifact removal technique for LCP

A technique is provided that identifies screen and non-screen regions of a projected or displayed image to smooth and selectively remove moiré from the screen regions while maintaining sharpness in the non-screen regions. Each pixel in the image is classified as a screen or non-screen pixel and then pixels in a predetermined surrounding area of each pixel are examined to check the classification of that pixel. A low pass filter is applied to pixels in the image, such that, when the low pass filter is applied, a center of the low pass filter is selectively shifted relative to a current pixel based on the examination.

Owner:SEIKO EPSON CORP

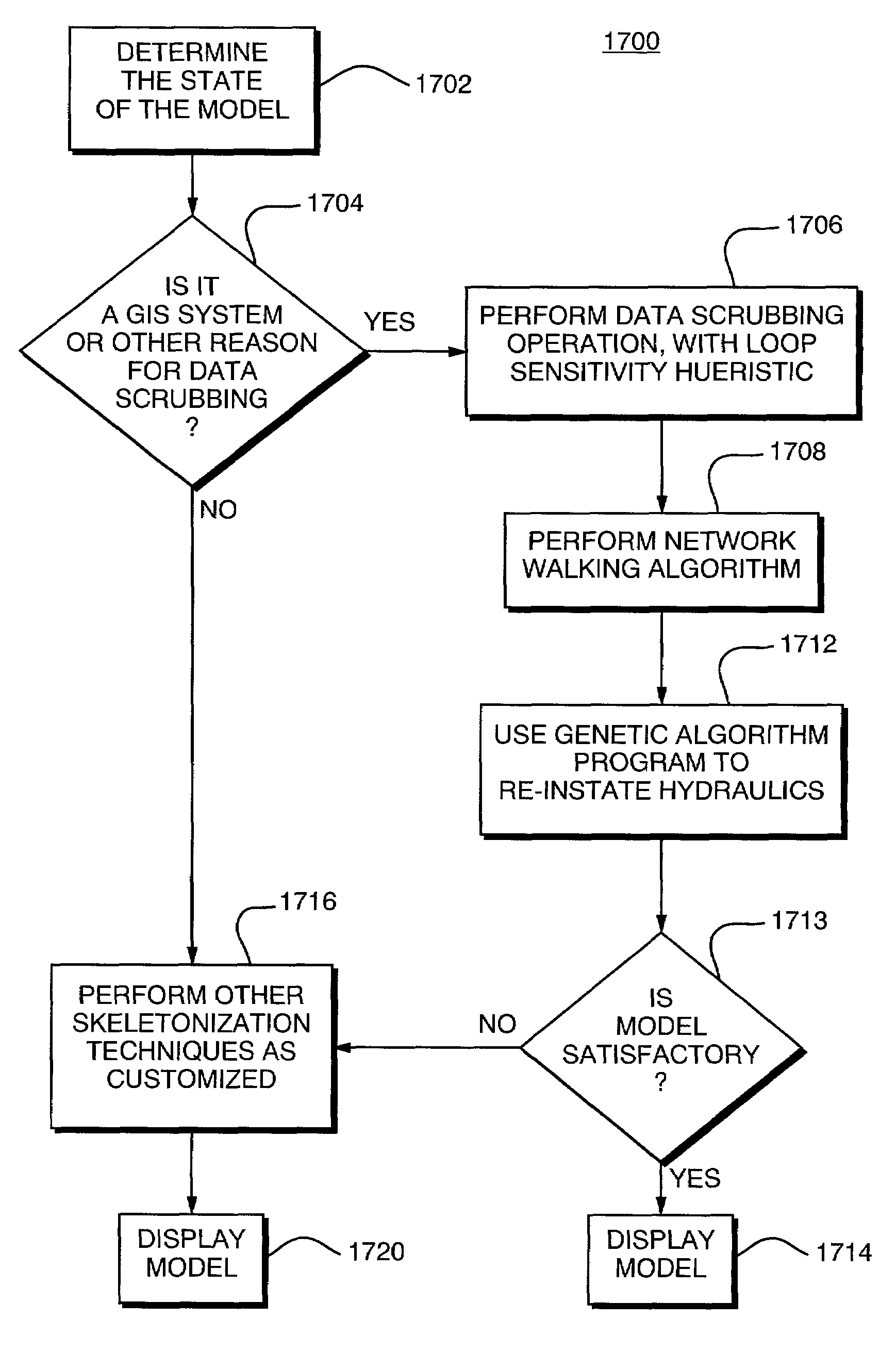

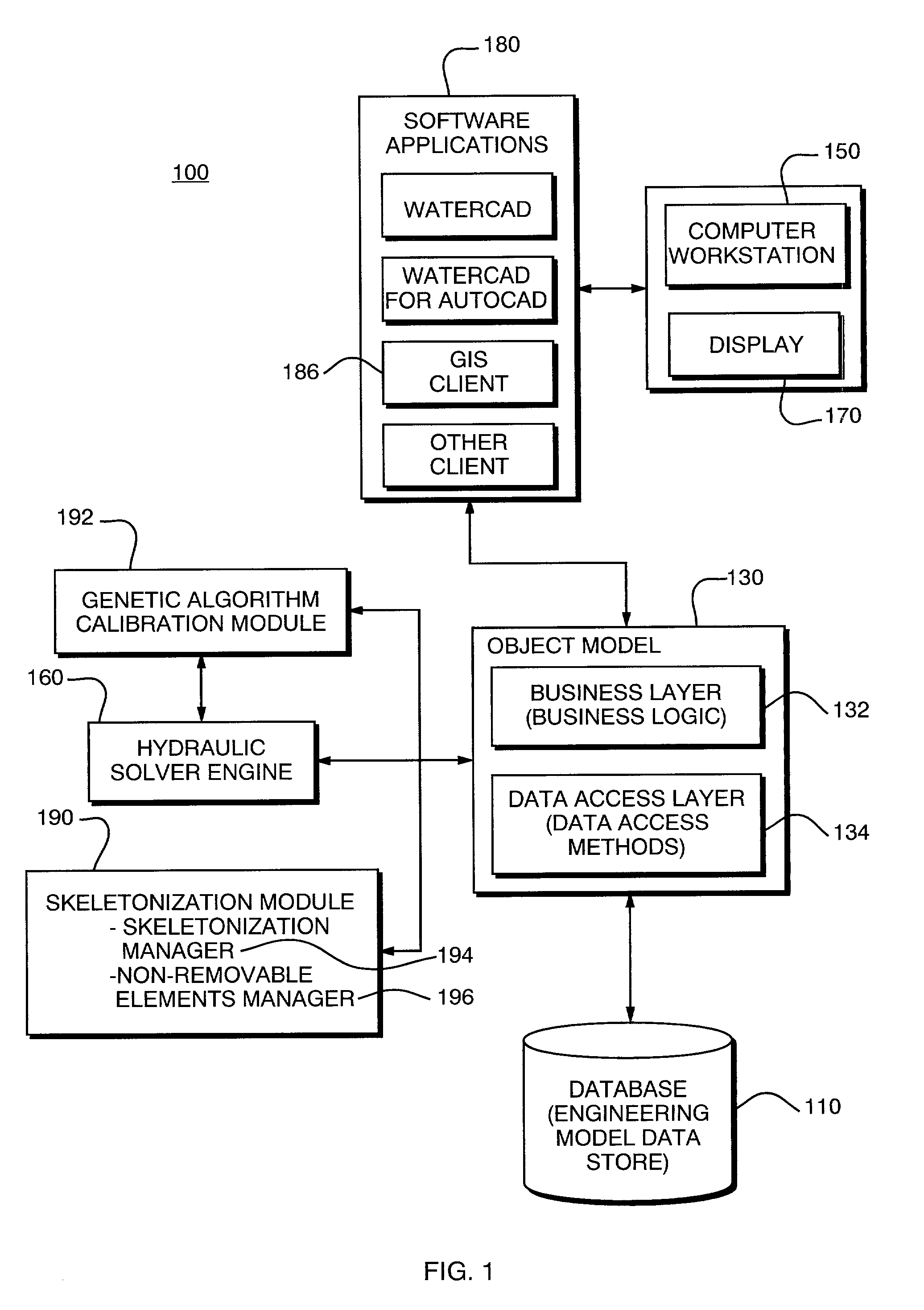

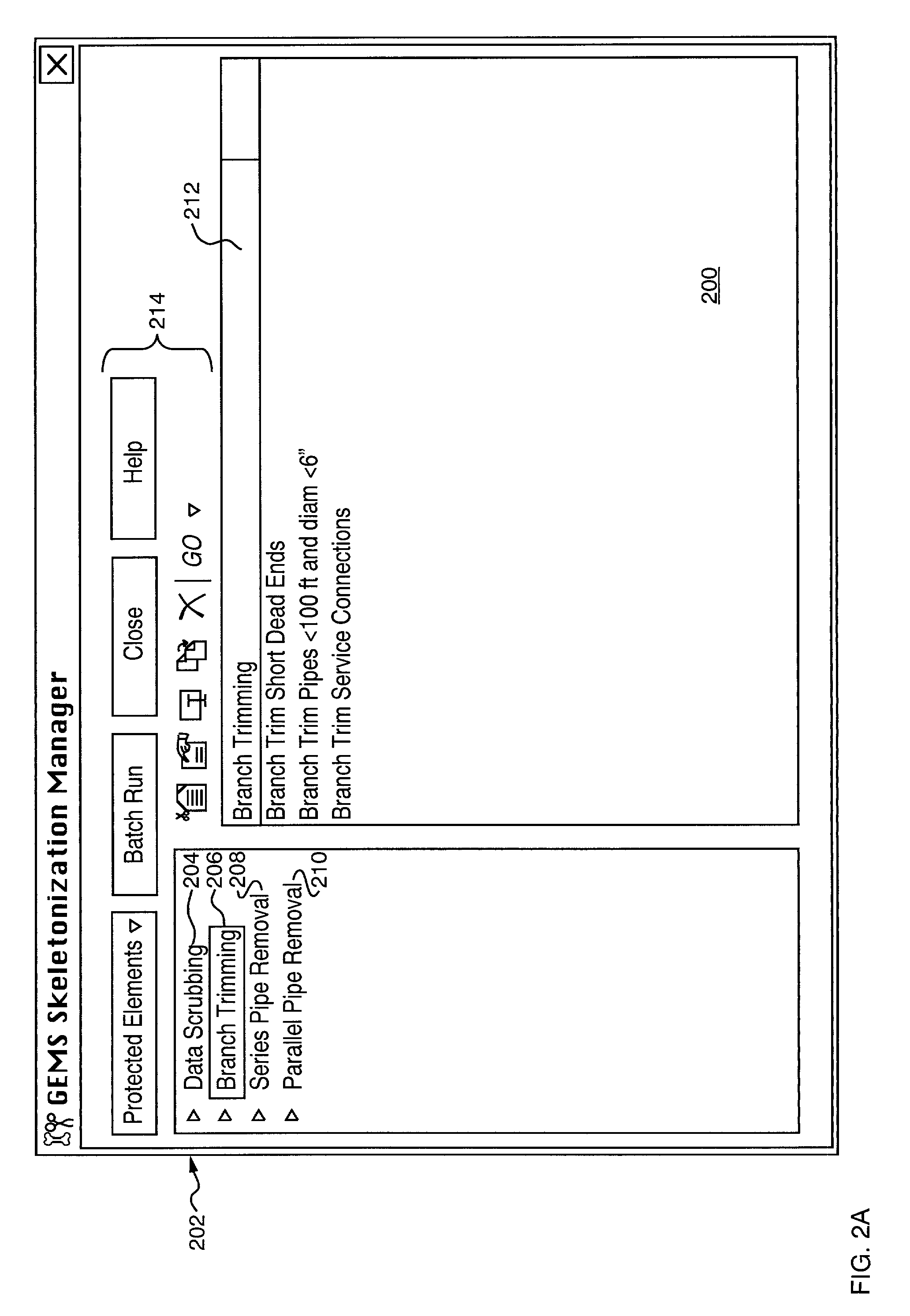

Method and system for reduction of a network topology-based system having automated optimization features

ActiveUS7054799B1Reduce in quantityData scrubbingComputation using non-denominational number representationDesign optimisation/simulationHydraulic circuitParallel computing

A method and system for reduction of a network topology-based system having automated optimization features is provided. The method allows for skeletonization to be performed by one or more desired processes including Data Scrubbing, Parallel and Series Pipe Removal techniques, and Branch Trimming techniques. The Data Scrubbing technique includes a loop retaining sensitivity setting that allows the user to determine how large the hydraulic loops are that remain in the system. The data scrubbing technique also includes a network-walking feature in which the software will check each element, when desired, and determine whether it is safe to remove that element without affecting the topological and hydraulic connectivity of the engineering model being reduced. The feature also includes a genetic algorithm-based feature that allows for hydraulics or system behavior to be reintroduced into the model, which may have been eliminated when the elements that gave rise to those effects were removed using the data scrubbing skeletonization technique.

Owner:BENTLEY SYST INC

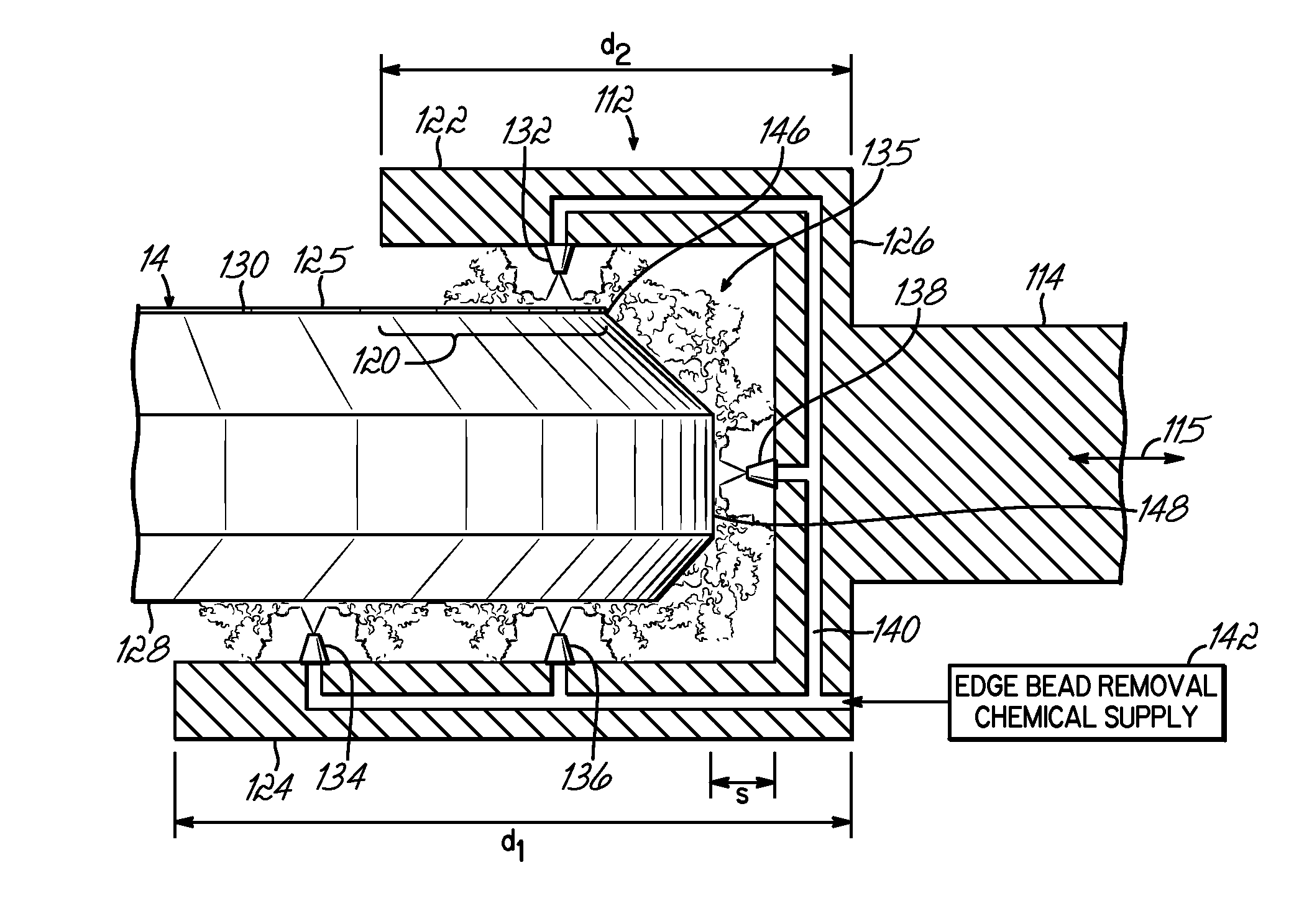

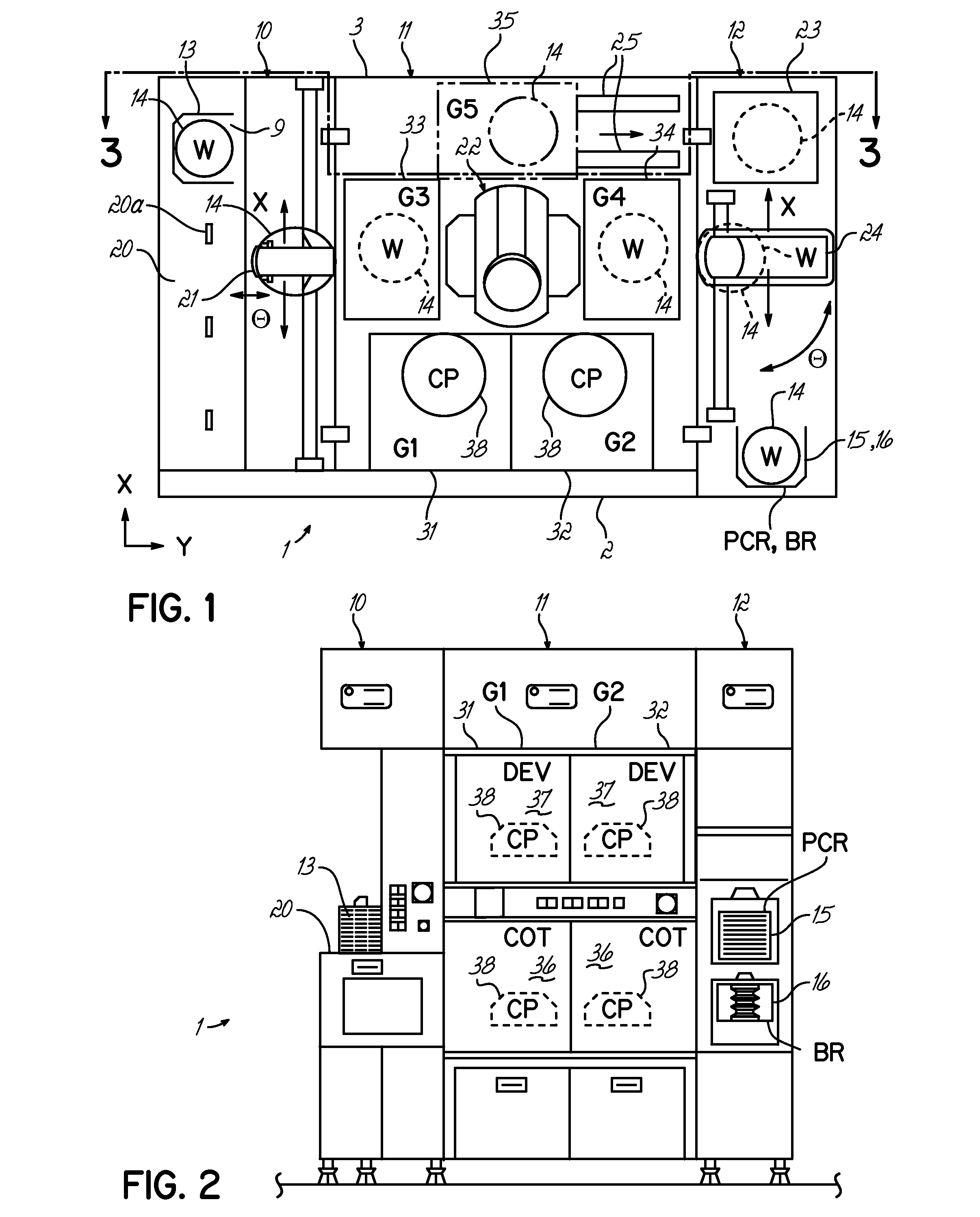

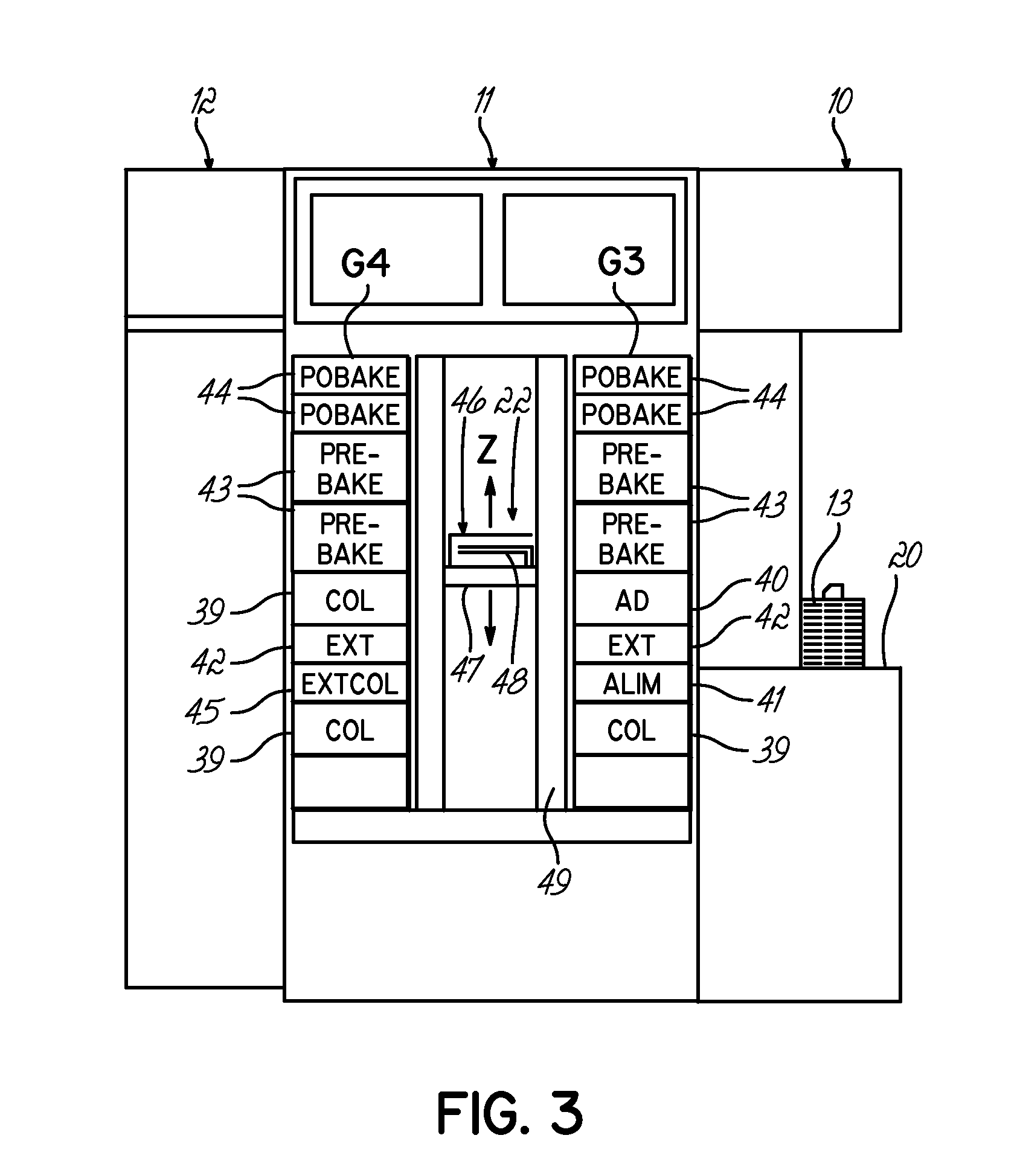

Apparatus and method for removing an edge bead of a spin-coated layer

InactiveUS20080081110A1Movable spraying apparatusSemiconductor/solid-state device manufacturingRadial positionEngineering

An edge bead removal device for a spin coater apparatus and methods of edge bead removal that overcome the deficiencies of conventional edge bead removal techniques. The edge bead removal device includes a coater cup and a head situated within the coater cup proximate to a peripheral edge of a substrate. The head is movable in a radial direction relative to an azimuthal axis of a rotatable substrate support inside the coater cup. The position of the head relative to a rim of the peripheral edge is mapped using an optical sensor. When the substrate support rotates the substrate and the head is used to dispense edge bead removal chemical, the radial position of the head is adjusted, as guided by the map, relative to the azimuthal axis to maintain a constant gap between the head and the substrate's peripheral rim.

Owner:TOKYO ELECTRON LTD

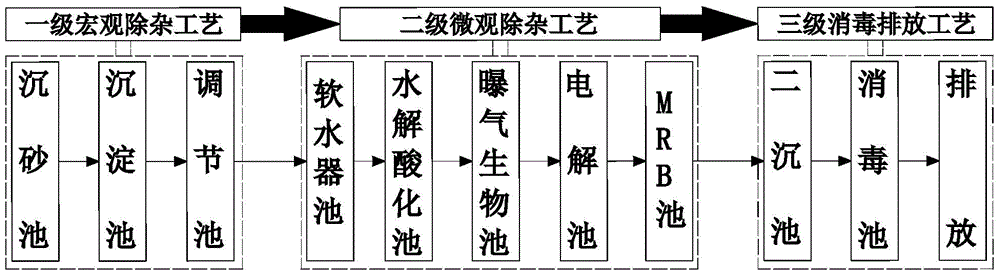

Medical wastewater three-stage treatment technique

ActiveCN104944710AWith pre-aerationReduce the impactMultistage water/sewage treatmentElectrolysisThree stage

The invention relates to the field of medical wastewater treatment, particularly a medical wastewater three-stage treatment technique which comprises the following steps: a primary macroscopic impurity removal technique is performed, wherein the primary macroscopic impurity removal technique comprises sedimentation tank treatment, precipitation tank treatment and regulating tank treatment, and is used for macroscopic impurity removal; medical wastewater after the primary macroscopic impurity removal technique enters a secondary microscopic impurity removal technique, wherein the secondary microscopic impurity removal technique comprises water softener tank treatment, hydrolysis-acidification tank treatment, aeration biological tank treatment, electrolysis cell treatment and MBR (membrane bioreactor) tank treatment, and is used for microscopic impurity removal; and medical wastewater after the secondary microscopic impurity removal technique enters a tertiary disinfection discharge technique, wherein the tertiary disinfection discharge technique comprises secondary sedimentation tank treatment, disinfection tank treatment and discharge, and is mainly used for sterilizing and disinfecting the wastewater. The technique can remove different pollutants in the medical wastewater by using different treatment processes, and can implement efficient purification on the medical wastewater.

Owner:ZONBONG LANDSCAPE

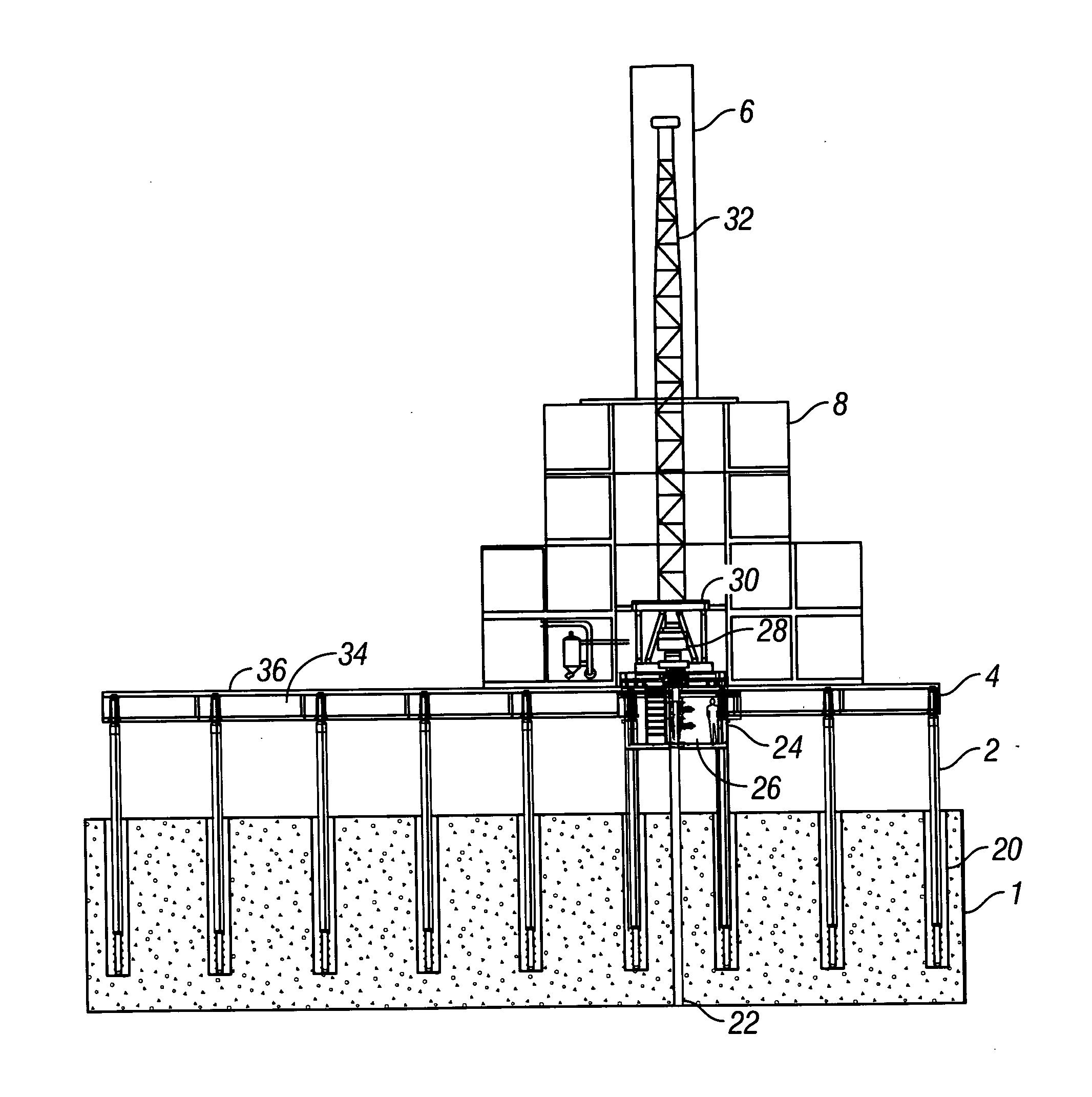

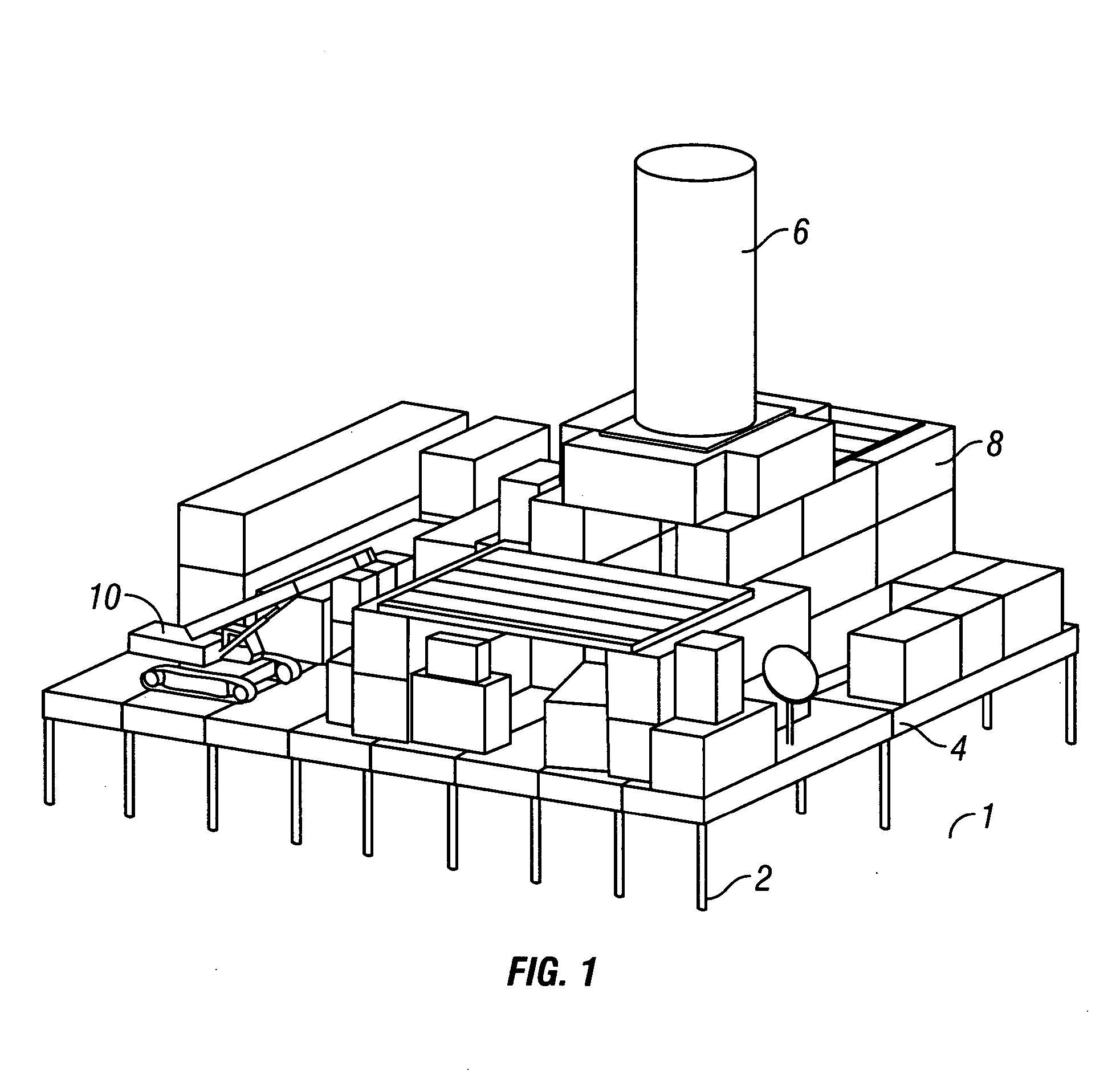

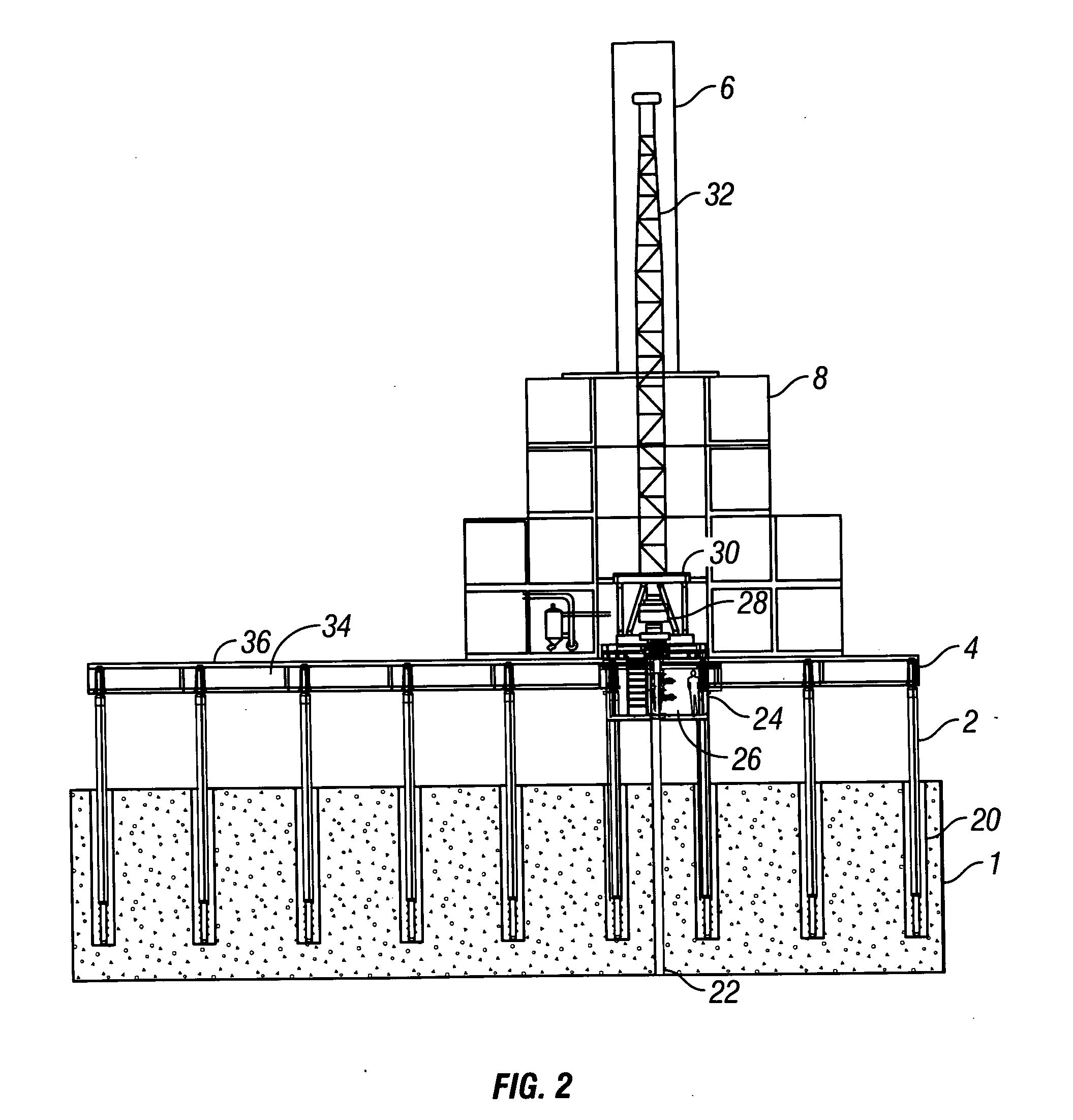

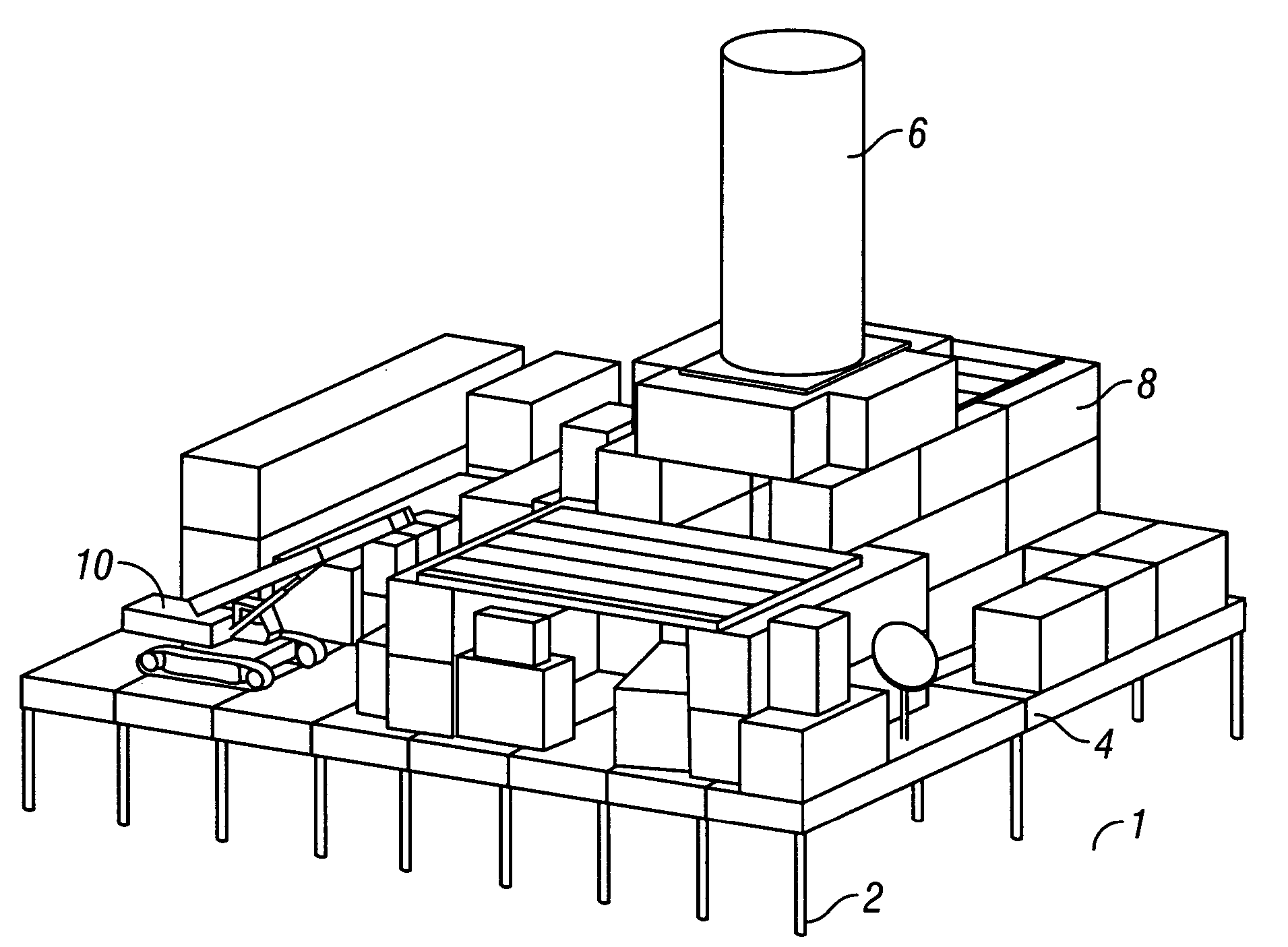

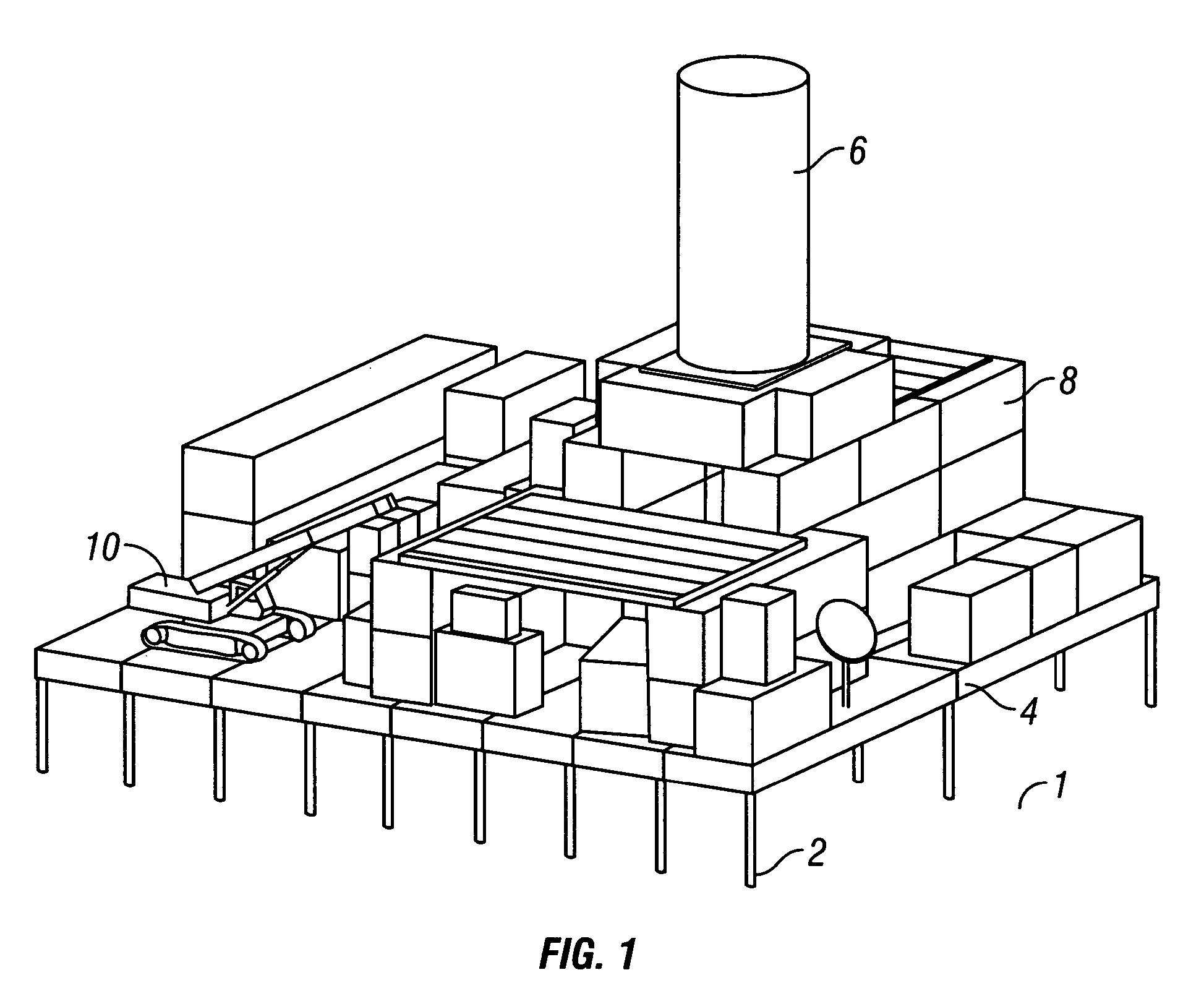

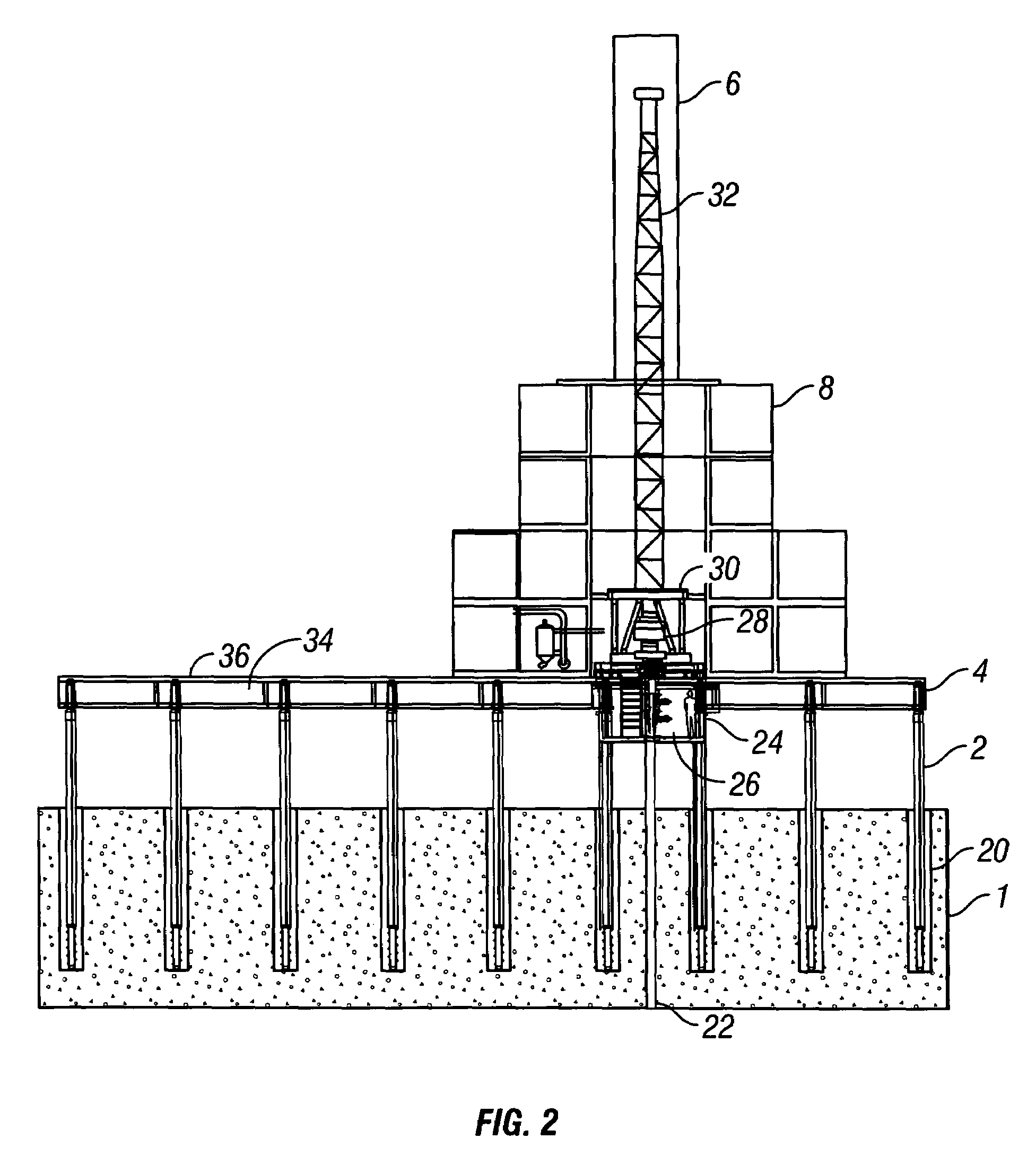

Arctic platform

The instant disclosure relates to a system and method of constructing drilling and production platforms that are particularly useful in remote, inaccessible and / or environmentally sensitive operating environments. According to one aspect of the invention, an arctic drilling platform is provided wherein various methods and means of interlocking neighboring platform modules are provided. Methods and means for sealing the intersections formed between a plurality of interlocked platform modules are also disclosed. According to further aspects of the invention, improved platform floor plans are provided, and various wellhead cellar layouts and sealing means are also described. Methods and means of enhancing the usefulness of modular storage platforms are disclosed, and a number of support post installation and removal techniques are also provided. Also taught are a variety of methods of adjusting the height and level of an assembled drilling platform, and methods and means of adding extension members useful for extending the length of a support post are also described.

Owner:ANADARKO PETROLEUM CORPORATION

Method for removing antibiotic contamination by adsorption of copper sulphide

InactiveCN103204562ALow costLarge adsorption capacityWater/sewage treatment by sorptionPenicillinMacrolide resistance

The invention provides a method for removing antibiotic contamination by adsorption of copper sulphide, and belongs to the field of water pollution control. The method comprises the steps of filtering waste water containing antibiotic contamination, adjusting pH to 5-9; and filtering the waste water processed in the step (1) through a bed layer containing the copper sulphide, wherein the antibiotic contamination is any one of tetracyclines, penicillins, macrolides, and sulfonamide fluoroquinolone antibiotic. Compared with the traditional removal technology of the antibiotic in a water body, the method disclosed by the invention has the beneficial effects that 1 the antibiotic contamination in the water body can be selectively complexed and removed; and the effluent concentration can be less than 1mug / L; 2, the adsorbing capacity is large; and the adsorbing capacity of copper sulphide can be up to 500mg / g; and 3, the method is fast in adsorption rate, easy to regenerate, simple and convenient to operate, low in cost and free of secondary pollution.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Arctic platform

The instant disclosure relates to a system and method of constructing drilling and production platforms that are particularly useful in remote, inaccessible and / or environmentally sensitive operating environments. According to one aspect of the invention, an arctic drilling platform is provided wherein various methods and means of interlocking neighboring platform modules are provided. Methods and means for sealing the intersections formed between a plurality of interlocked platform modules are also disclosed. According to further aspects of the invention, improved platform floor plans are provided, and various wellhead cellar layouts and sealing means are also described. Methods and means of enhancing the usefulness of modular storage platforms are disclosed, and a number of support post installation and removal techniques are also provided. Also taught are a variety of methods of adjusting the height and level of an assembled drilling platform, and methods and means of adding extension members useful for extending the length of a support post are also described.

Owner:ANADARKO PETROLEUM CORPORATION CORP

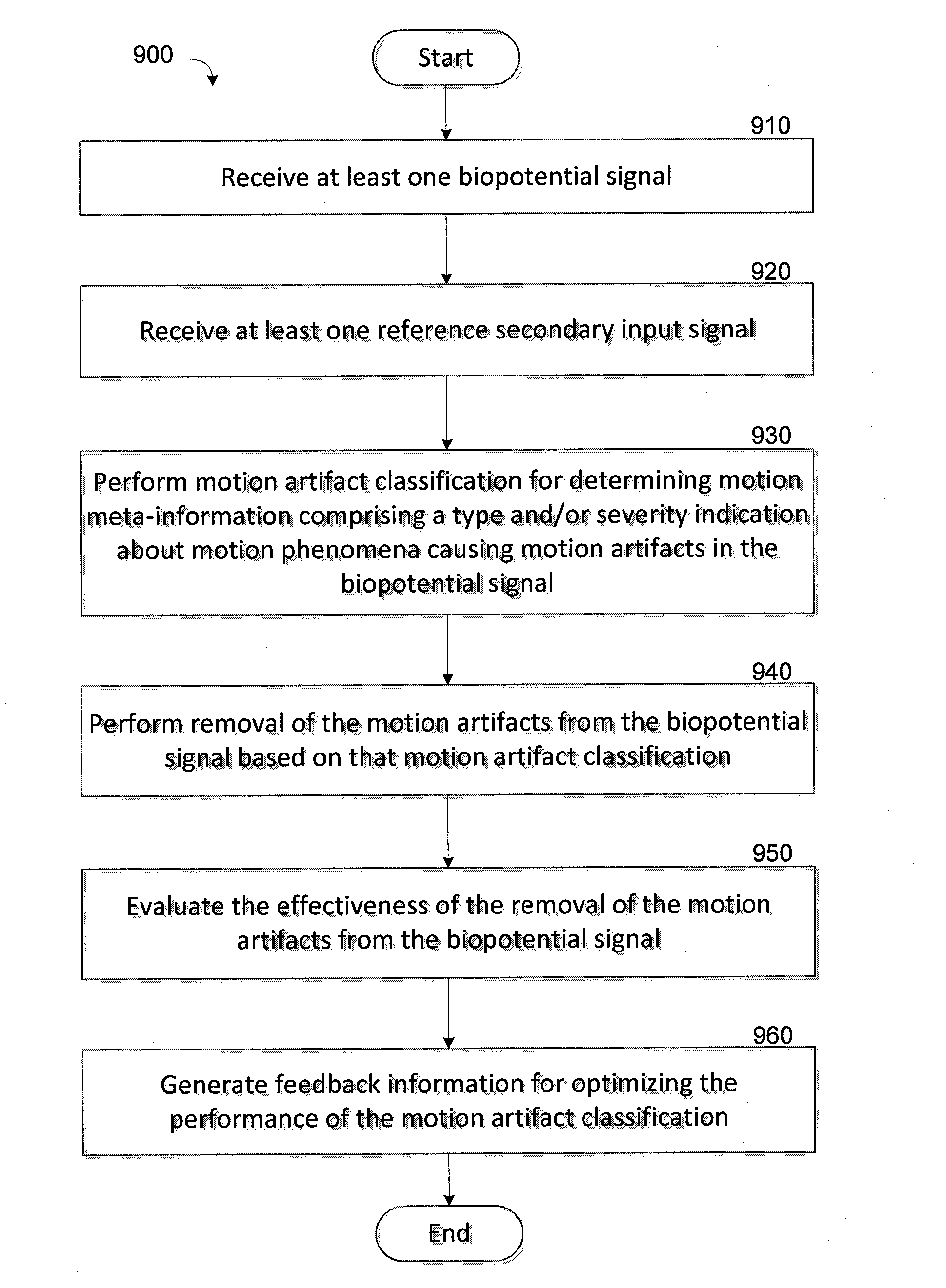

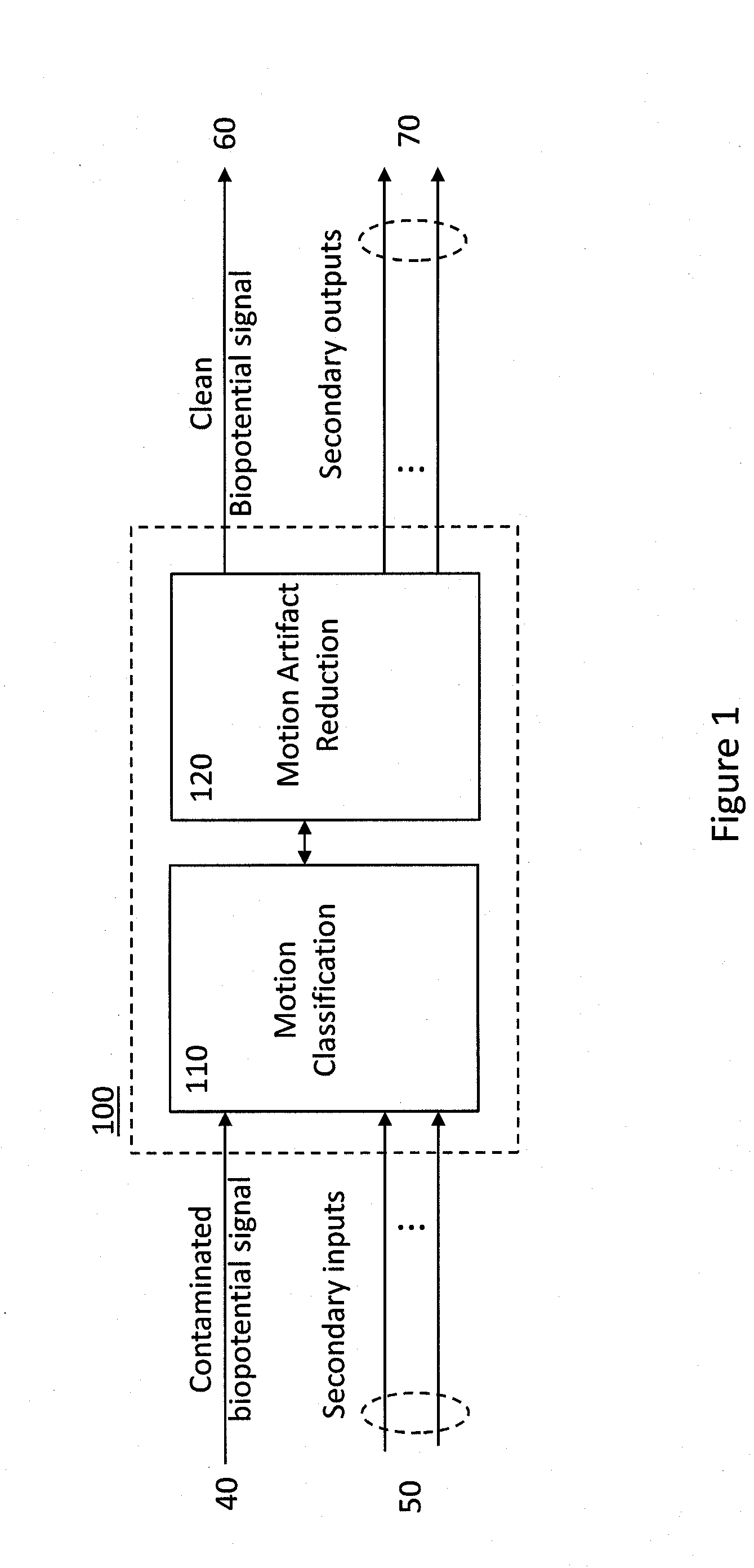

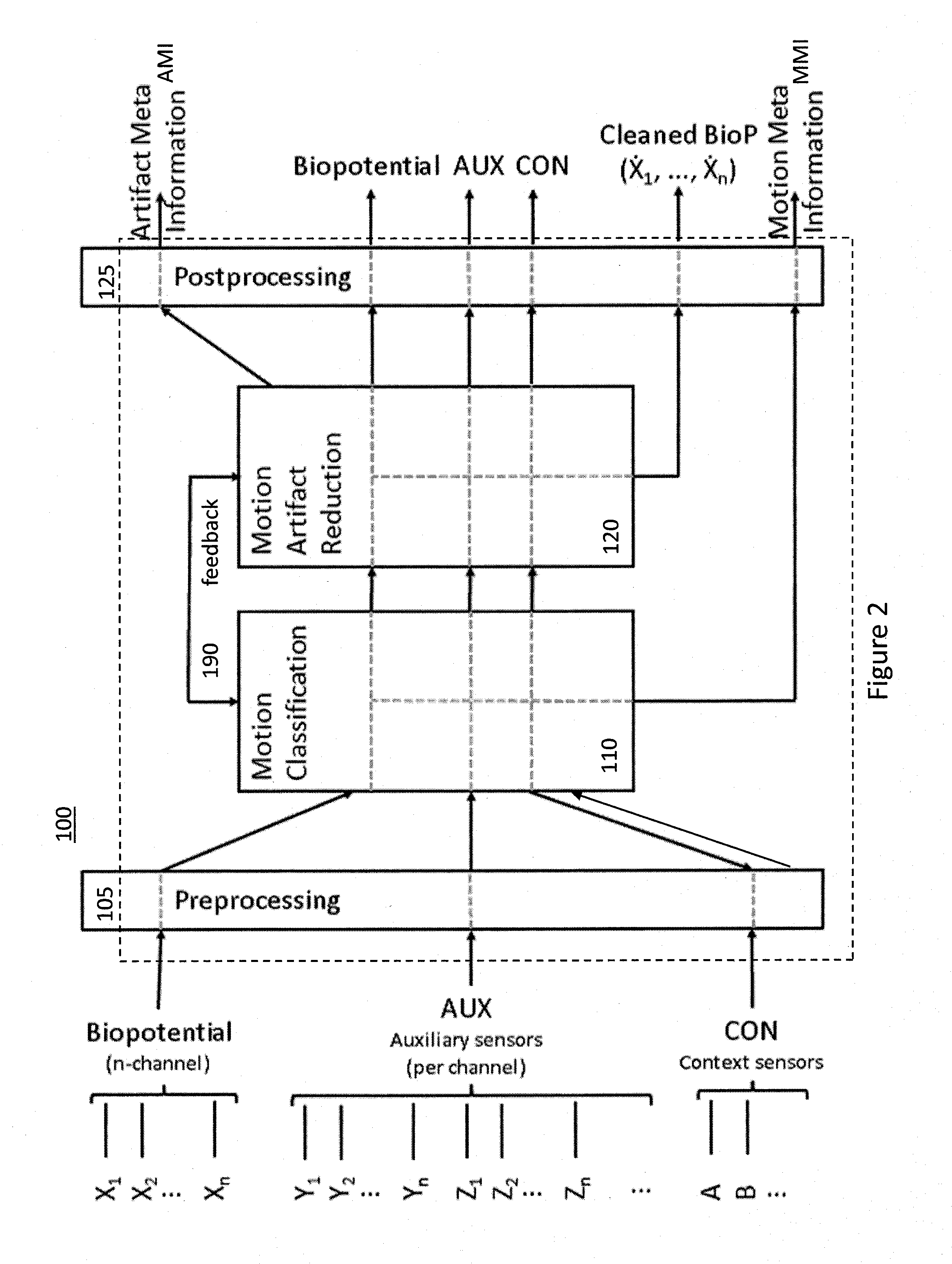

System and method for the analysis of biopotential signals using motion artifact removal techniques

ActiveUS20140309943A1Reduce artifactsImprove performanceMedical automated diagnosisDiagnostic recording/measuringRemoval techniquesMotion artifacts

A system and method for the analysis of biopotential signals using motion artifact removal techniques is disclosed. The system includes a motion classification module configured to receive at least one biopotential signal and at least one reference secondary input signal. The motion classification module performs motion artifact classification for determining motion meta-information, comprising a type and / or severity indication about motion phenomena causing artifacts in the biopotential signal. The motion classification module communicates motion meta-information to a motion artifact reduction module configured to remove motion artifacts from the biopotential signal based on the information received from the motion classification module. The system is further configured to evaluate the effectiveness of at least one algorithm used to remove motion artifacts, and generate feedback information between the motion classification module and the motion artifact reduction module to optimize motion artifact classification.

Owner:STICHTING IMEC NEDERLAND

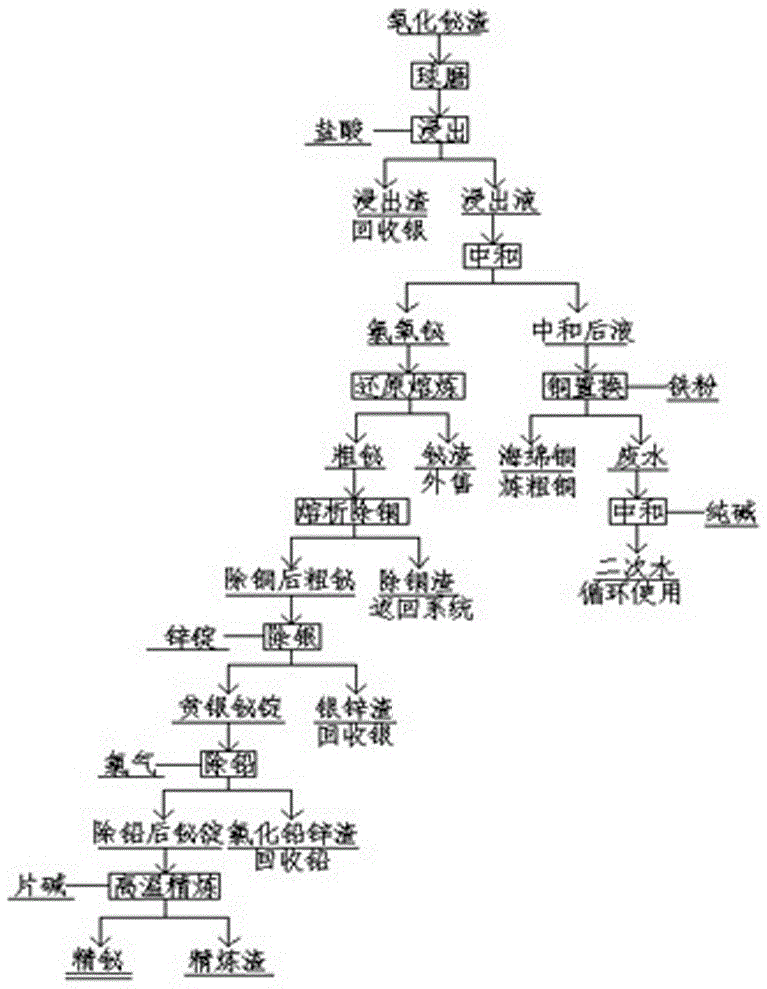

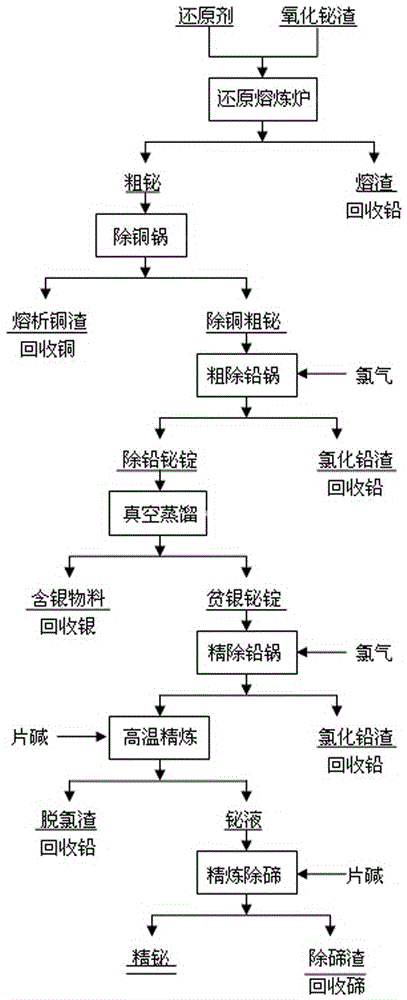

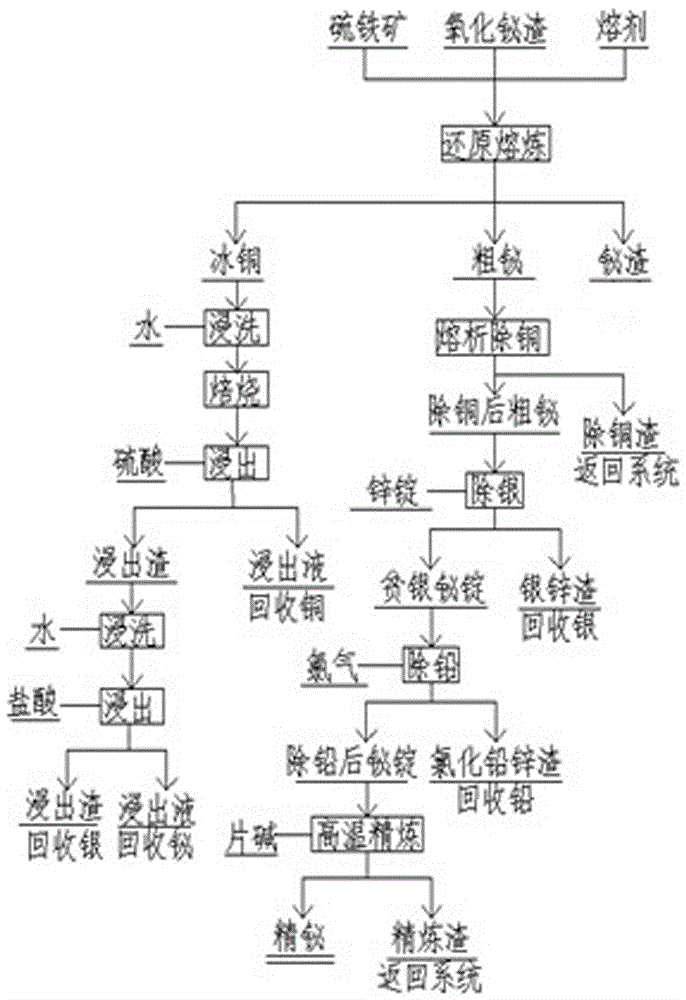

Method for refining bismuth from bismuth oxide slags

ActiveCN105803213AReduce usageAvoid it happening againProcess efficiency improvementSlagNitric oxide

The invention discloses a method for refining bismuth from bismuth oxide slags. The bismuth oxide slags and reduction agents are subjected to reduction smelting, liquation decoppering, primary lead removal through chlorine, vacuum distillation for silver removal, secondary lead removal through chlorine, high-temperature refining for dechloridation, and caustic soda flakes adding for tellurium removal, and finally refined bismuth is obtained. Alloy containing silver, copper, bismuth, lead and the like directly enters the decoppering procedure, wet pretreatment is omitted, the decoppering procedure is simplified, copper matte and silver-zinc crusts are prevented from being generated, the usage amount of nitric acid in a wet section is reduced, emission of nitric oxide in the nitric acid dissolving process is reduced, and pollution to the environment is reduced; after a zinc adding and silver removal technique is changed into the vacuum distillation for physical silver removal technique, the silver-zinc crusts which are difficult to treat are eradicated, physical separation of silver and bismuth is achieved to the maximum extent, and the recovery rate of silver is increased; and the usage amount of coal gas and auxiliary materials is reduced, the labor intensity of workers is relieved, the production period of the refined bismuth is shortened, the production cost of the refined bismuth is reduced, and the direct recovery rate and the recovery rate of the refined bismuth are increased.

Owner:河南金利金铅集团有限公司

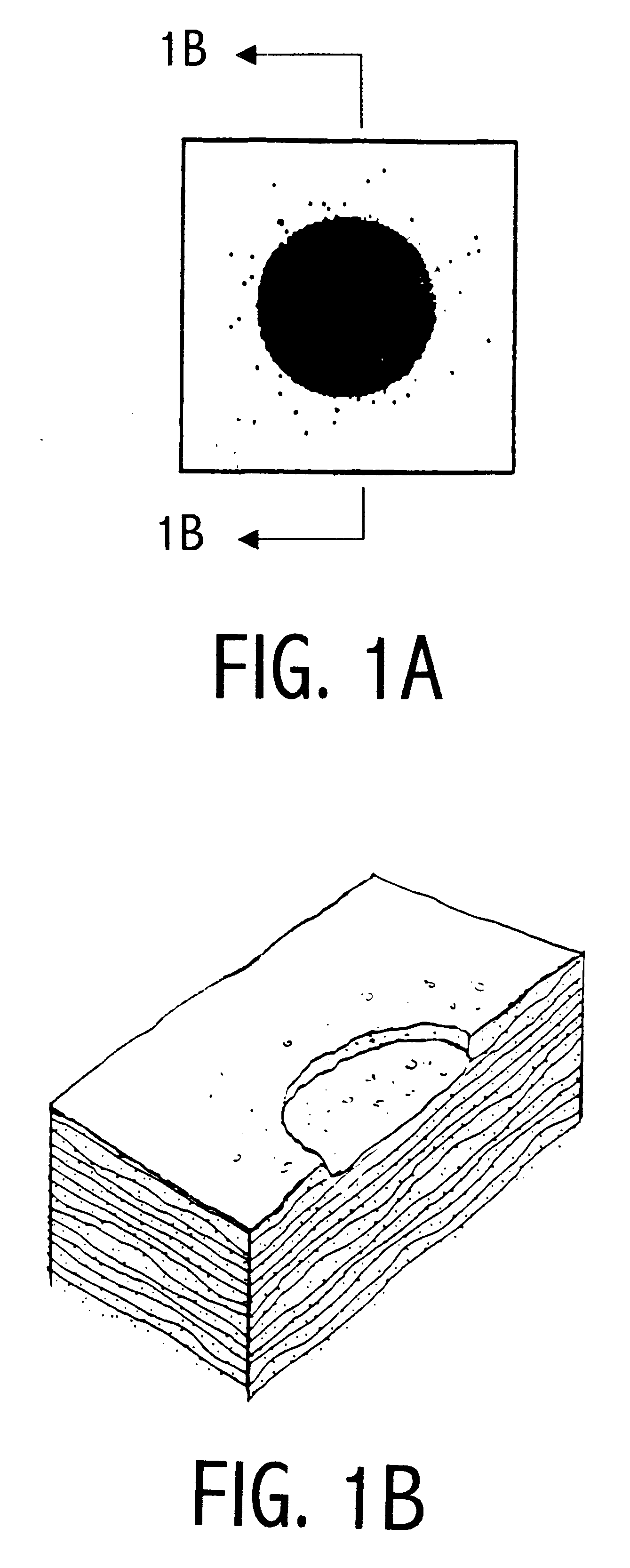

Method and instrument for thermal suture cutting

InactiveUS7048746B2Reduce tensionMinimizing patient discomfortSuture equipmentsSurgical needlesForcepsRemoval techniques

Novel suture removal instrument and technique are described herein. The invention utilizes a newly designed thermal filament to allow the tip of the suture removal instrument to be slipped under the stitch in order to heat and cut the stitch. Current suture removal techniques utilize scissors, forceps, and / or scalpels. These techniques, which are well known in the art, are problematic because they exert tension on the stitch and are associated with patient discomfort. Small stitches add to the difficulty of suture removal because they have less suture laxity for scissor insertion. The present invention therefore allows for more rapid suture removal with less patient discomfort and at a competitive or lower cost.

Owner:WARDEN MATTHEW P +2

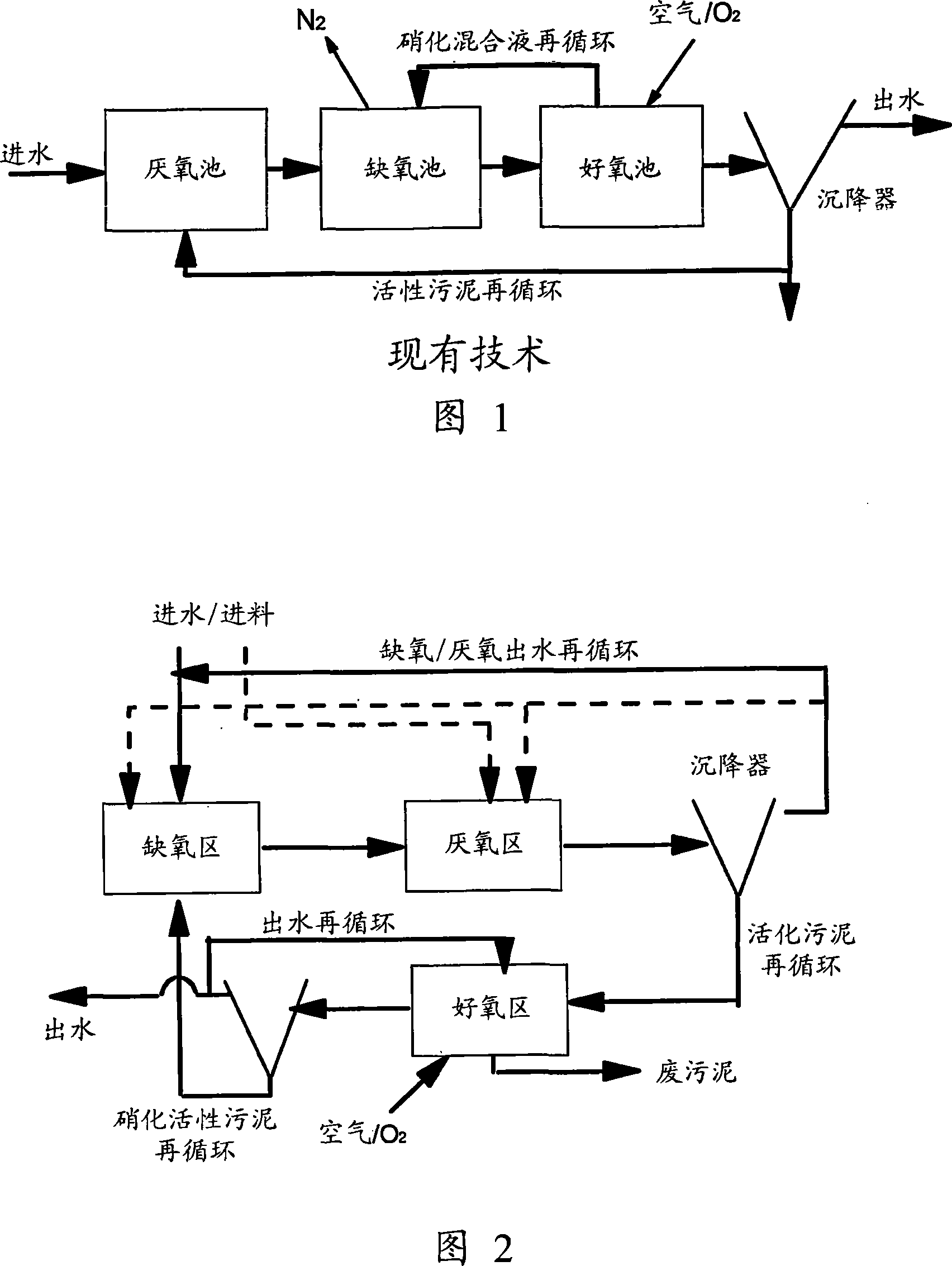

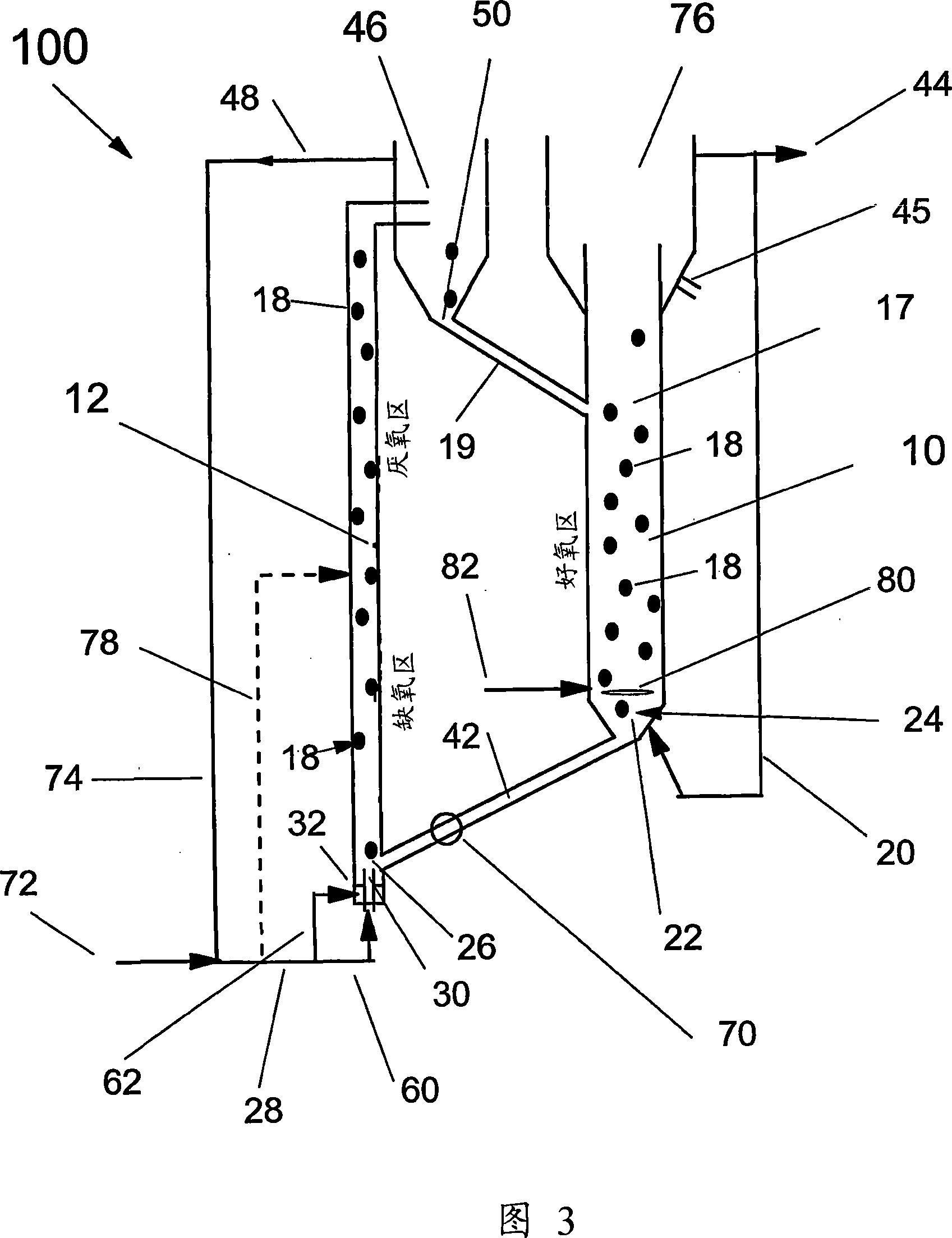

Liquid-solid circulating fluidized bed waste water treatment system for simultaneous carbon, nitrogen and phosphorus removal

InactiveCN1922111AIon-exchange process apparatusTreatment using aerobic processesActivated sludgeEngineering

Biological nutrient removal (BNR) in municipal wastewater treatment to remove carbonaceous substrates, nutrients and phosphorus, has recently become increasingly popular worldwide due to increasingly stringent regulations. Biological fluidized bed (BFB) technology, which could be potentially used for BNR processes, can provide some advantages such as high efficiency and compact structure. This present invention incorporates the fixed-film biological fluidized bed technology with the biological nutrient removal in a liquid-solid circulating fluidized bed, which has achieved the simultaneous elimination of organic carbon, nitrogen and phosphorus, in a very efficient manner and with very compact space requirements. The BNR-LSCFB has two fluidized beds, running as anoxic / anaerobic and aerobic processes to accomplish simultaneous nitrification and denitrification and to remove carbonaceous substrates, nutrients and phosphorus, with continuous liquid and solids recirculation through the anoxic / anaerobic bed and the aerobic bed. The new BNR-LSCFB system is not only an excellent alternative for conventional activated sludge type BNR technologies but is also capable of processing much higher loadings and suitable for industrial applications.

Owner:UNIV OF WESTERN ONTARIO

Descenting Systems And Methods

ActiveUS20100071633A1Reducing eliminating scentLavatory sanitoryFire rescueRemoval techniquesAirflow

Systems and methods for using a scent elimination device to conceal contraband and then training service animals to determine if an ozone-based scent-removal technique has been used to remove scent from contraband are disclosed. The systems and methods comprise providing a plurality of packages. At least one of the plurality of packages containing a predetermined amount of a contraband substance. Further, the systems and methods comprise generating a gaseous stream of descenting material from a portable device. The gaseous stream of descenting material contains ozone. Further, the systems and methods comprise dispersing the gaseous stream of descenting material over the contraband in a concentration sufficient to eliminate the scent. The descented contraband may be placed in an enclosure for transport. Further, the systems and methods comprise introducing a service animal to the plurality of packages. Finally, the systems and methods comprise rewarding the service animal for the successful detection of the at least one of the plurality of packages containing the ozone-based scent remover.

Owner:PARAH

Memory efficient image artifact removal technique for LCP

InactiveUS6879734B2Maintain clarityRipple EliminationImage enhancementTelevision system detailsLow-pass filterImage Artifact

A technique is provided that identifies screen and non-screen regions of a projected or displayed image to smooth and selectively remove moiré from the screen regions while maintaining sharpness in the non-screen regions. Each pixel in the image is classified as a screen or non-screen pixel and then pixels in a predetermined surrounding area of each pixel are examined to check the classification of that pixel. A low pass filter is applied to pixels in the image, such that, when the low pass filter is applied, one or more pixels covered by the low pass filter are respectively replaced by one or more other pixels covered by the low pass filter based on the examination.

Owner:SEIKO EPSON CORP

Process for production of aromatic carboxylic acids with improved water removal technique

InactiveCN1537092AAvoid or reduce the possibility of condensationImprove energy recoveryOrganic compound preparationCarboxylic compound preparationDistillationEnergy recovery

Disclosed is an improved process for the continuous production of aromatic carboxylic acids by the liquid-phase oxidation of an alkyl aromatic compound with an oxygen-containing gas in the presence of oxidation catalyst which results in reduced wastewater generation, reduced condensing capacity requirements, and, optionally, increased power recovery, and. The process effectively utilizes the heat of reaction in the process of removing excess water generated from the reaction and minimizes the loss of solvent used as the carrier for the reaction catalyst by removing reactor off-gas directly into a water removal column for distillation. A portion of the overhead aqueous vapors are removed from the top of the water removal column as a vapor distillate, with the remaining overhead aqueous vapors being condensed then subsequently refluxed to the fractionating zone of the water removal column. In a preferred embodiment, the combined vapor distillate and oxygen-depleted process gas are reduced to a low pressure through a power recovery device for improved process efficiency, and then fed to a pollution control device for the destruction of organic compounds before exiting the process.

Owner:GRUPO PETROTEMEX DE C V

Method for fast repairing submerged vegetation by using water quality improvement clearance

The invention provides a method for rapidly repairing settled plants by utilizing a water quality improvement clearance, particularly, by utilizing an algae removal technique of modified local earth to remove water bloom, decrease the concentration of nitrogen and phosphate in water, increase the water transparency, improve water quality of the eutrophic lake in a short term, and produce the water quality improvement. According to different extents of water quality improvement, various aquatic plant seeds or seeds treated with different methods and the products thereof are selected; the settled plants can rapidly grow in the water quality improvement, thus finally reaching a target of recovering the settled plants in the eutrophic lake. The technique can be used for ecologically recovering the settled plants in eutrophic lakes, rivers and landscape waters.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

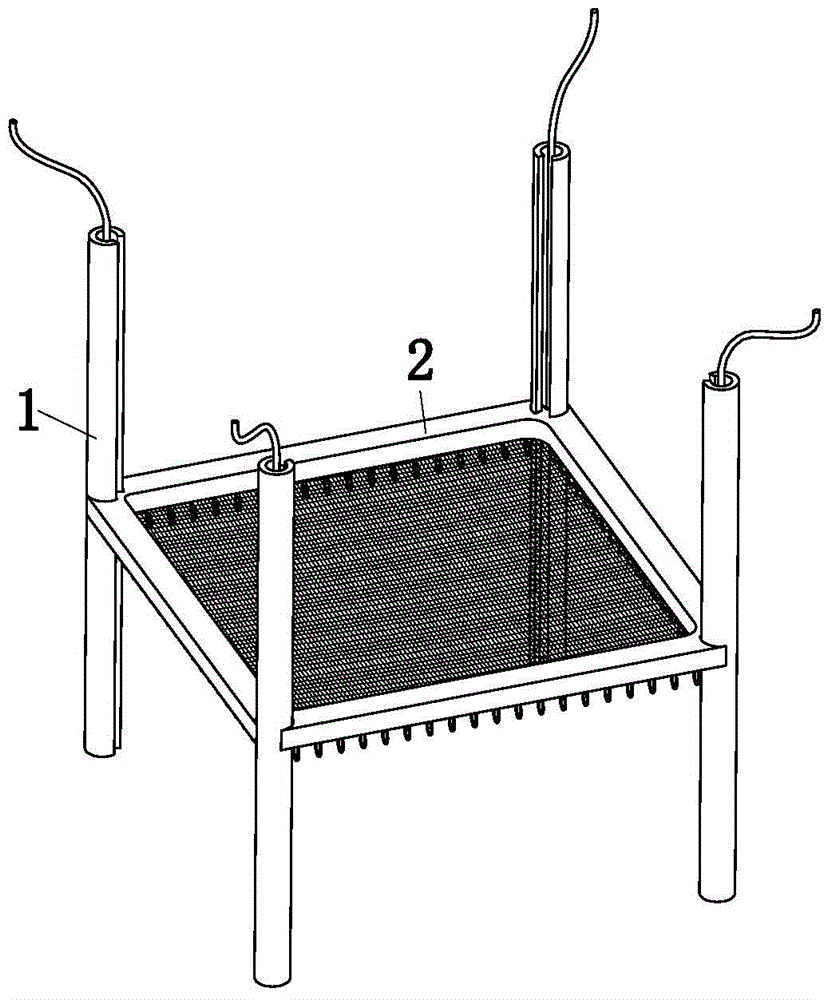

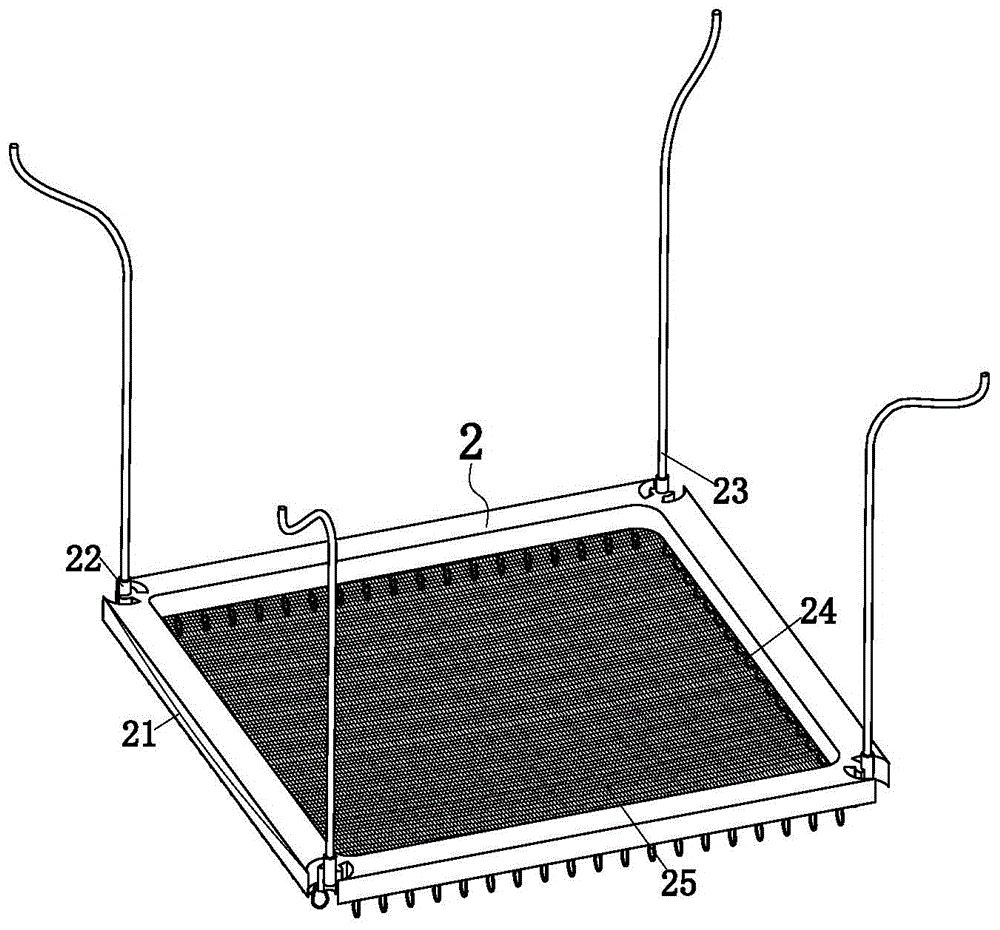

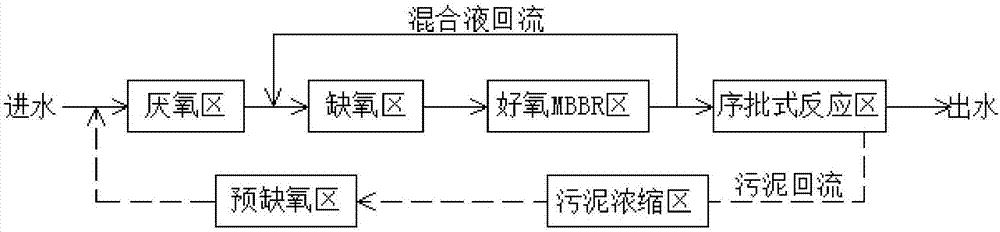

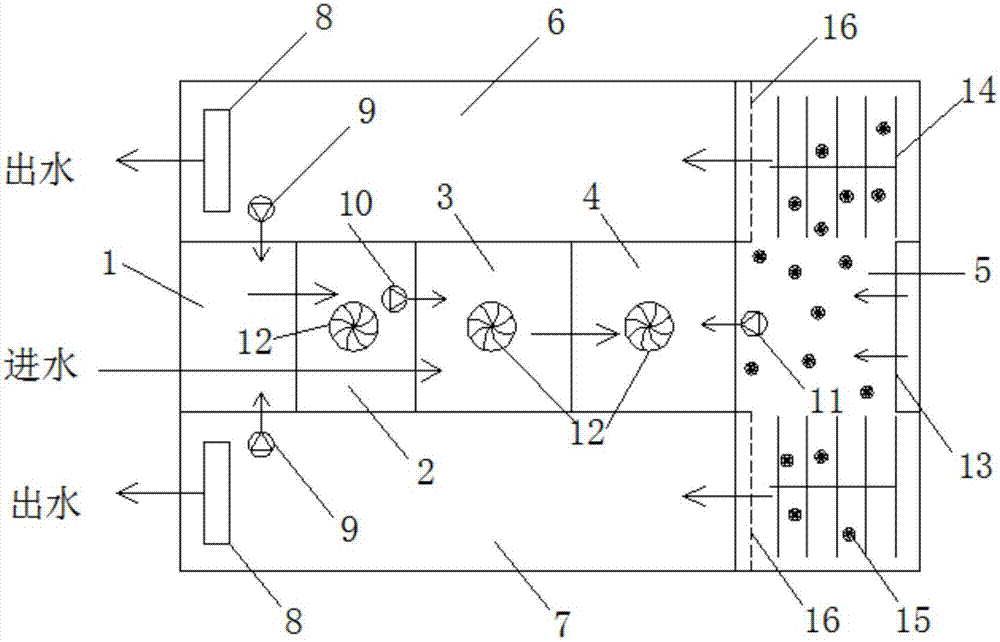

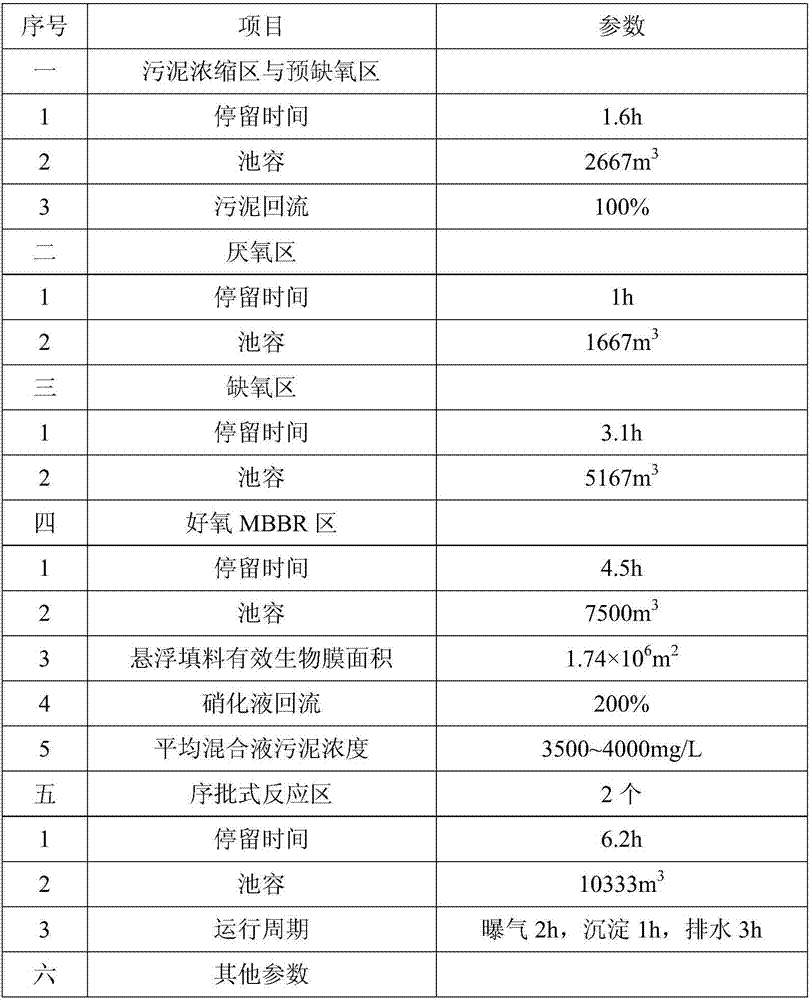

MSBR (Modified SBR) nitrogen and phosphorus removal technique based on MBBR (Moving Bed Biofilm Reactor)

InactiveCN107285463AHigh volume loadImprove adjustabilityWater contaminantsTreatment with aerobic and anaerobic processesHypoxic preconditioningMoving bed biofilm reactor

The invention discloses an MSBR (Modified SBR) nitrogen and phosphorus removal technique based on an MBBR, and belongs to the technical field of sewage treatment. The technique is based on a system consisting of seven units, including a sludge concentration area, a hypoxic preconditioning area, an anaerobic area, an anoxic zone, an aerobic MBBR area, a sequencing batch reaction I area and a sequencing batch reaction II area, wherein suspended packing is all dropped into the aerobic MBBR area, a medium hole perforating aeration system is arranged at the bottom of the aerobic MBBR area, a water distribution system is arranged at a water inlet, and an interception screening system is arranged at a water outlet. According to the MSBR nitrogen and phosphorus removal technique based on the MBBR disclosed by the invention, the advantages of an MSBR technique and the MBBR technique are combined, the technique has the advantages of high volume load and stable effluent effect, and is suitable for carrying out update or capacity increasing transformation on the original MSBR technique, so that the treatment capability of the existing technique is promoted, and meanwhile, the technique is applied to new construction items, so that the occupied area can be greatly reduced.

Owner:QINGDAO SPRING WATER TREATMENT

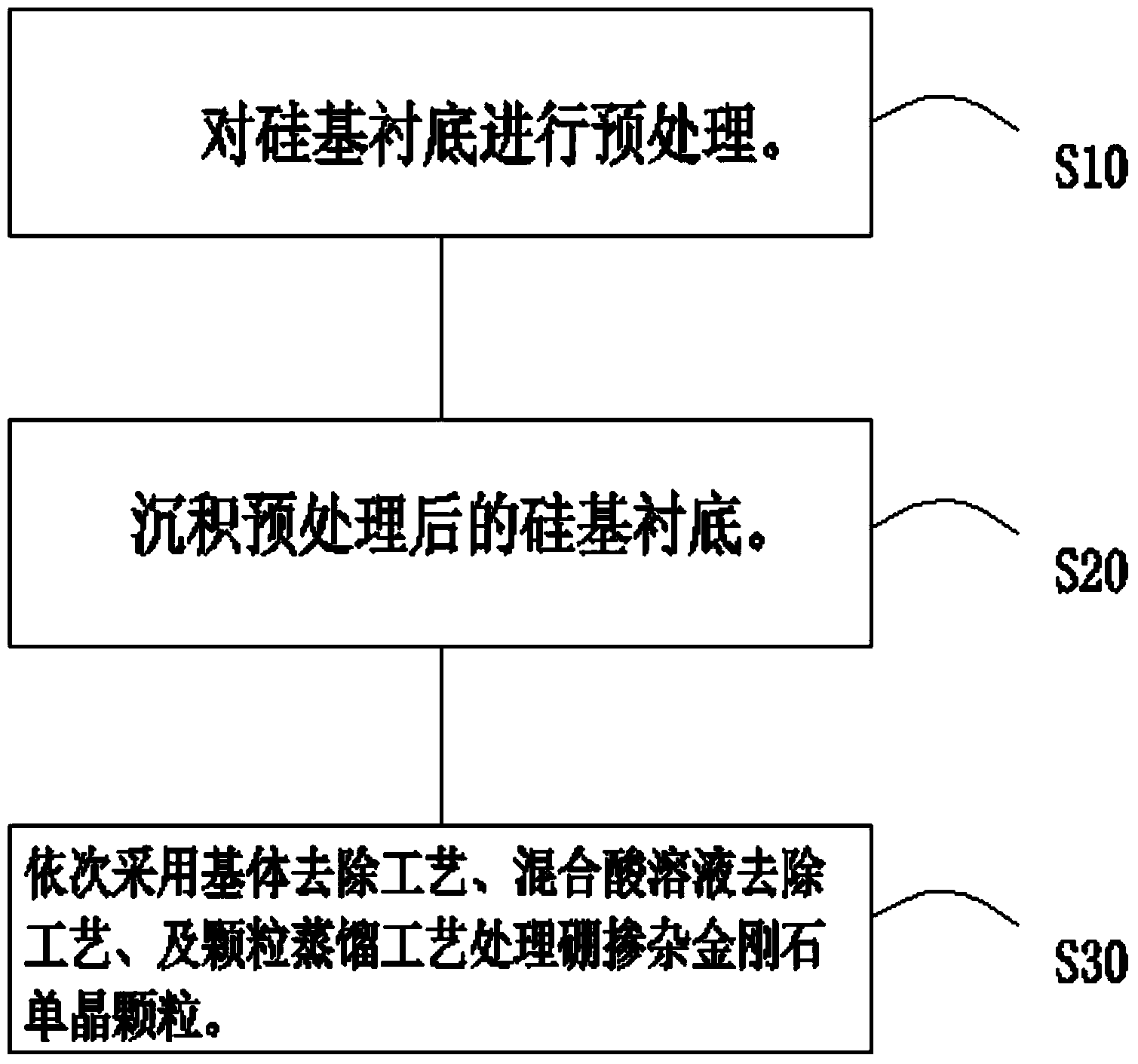

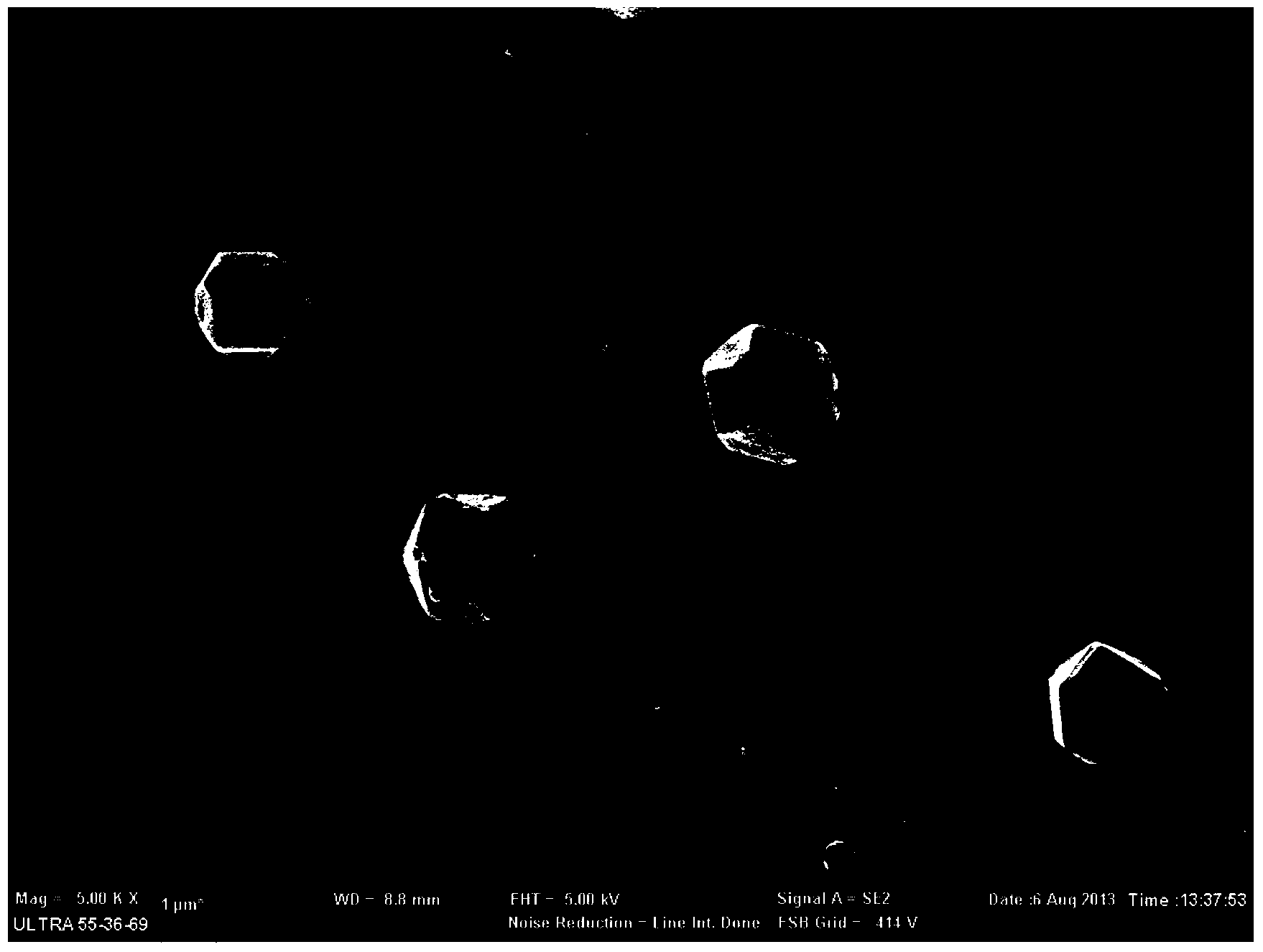

Preparation method of boron-doped ultra/fine diamond monocrystal micropowder

InactiveCN104164702AImprove impact resistanceGood crystal shapePolycrystalline material growthFrom chemically reactive gasesOctahedronDistillation

The invention discloses a preparation method of boron-doped ultra / fine diamond monocrystal micropowder, which comprises the following steps: pretreating a silicon-base substrate to be used as a substrate material for growth of monocrystal micropowder; depositing the silicon-base substrate by hot filament chemical vapor deposition to obtain uniformly dispersed boron-doped diamond monocrystal particles, wherein a boron-containing compound is added into a reaction system of hydrogen and acetone used as reactant gases, the reaction pressure is 2-4.5 kPa, and the temperature of the silicon-base substrate is 700-950 DEG C; and carrying out a substrate removal technique, a mixed acid solution removal technique and a particle distillation technique to treat the boron-doped diamond monocrystal particles, thereby obtaining the boron-doped ultra / fine diamond monocrystal micropowder. A higher proportion of hexa-octahedron or icosahedron complex crystals in the ultra / fine diamond micropowder can obviously enhance the growth rate of the ultra / fine diamond monocrystal particles and improve the crystal form and quality of the particles.

Owner:SHANGHAI JIAO TONG UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com