Process for production of aromatic carboxylic acids with improved water removal technique

An aromatic, monocarboxylic acid technology, applied in the preparation of organic compounds, the preparation of carboxylate salts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

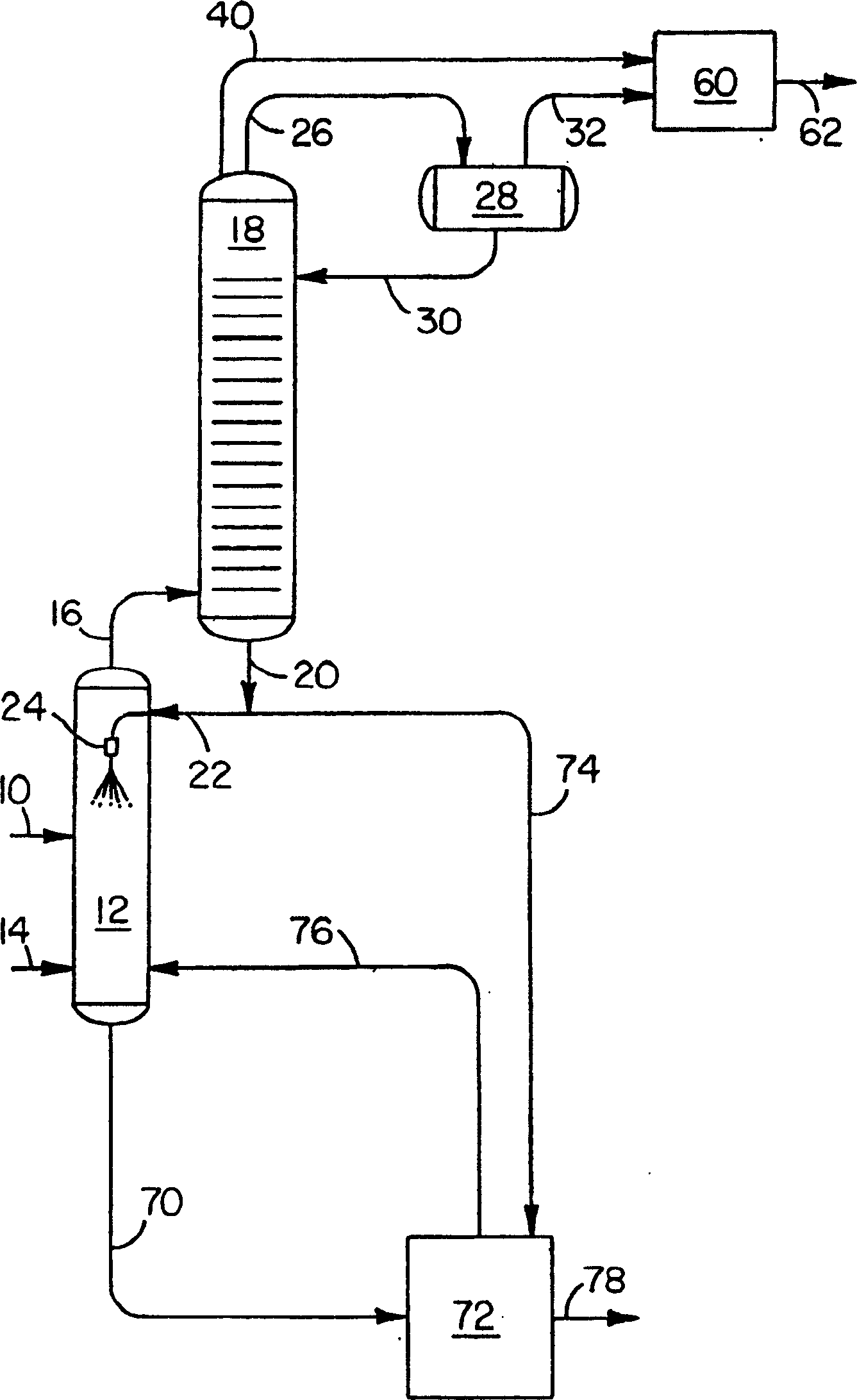

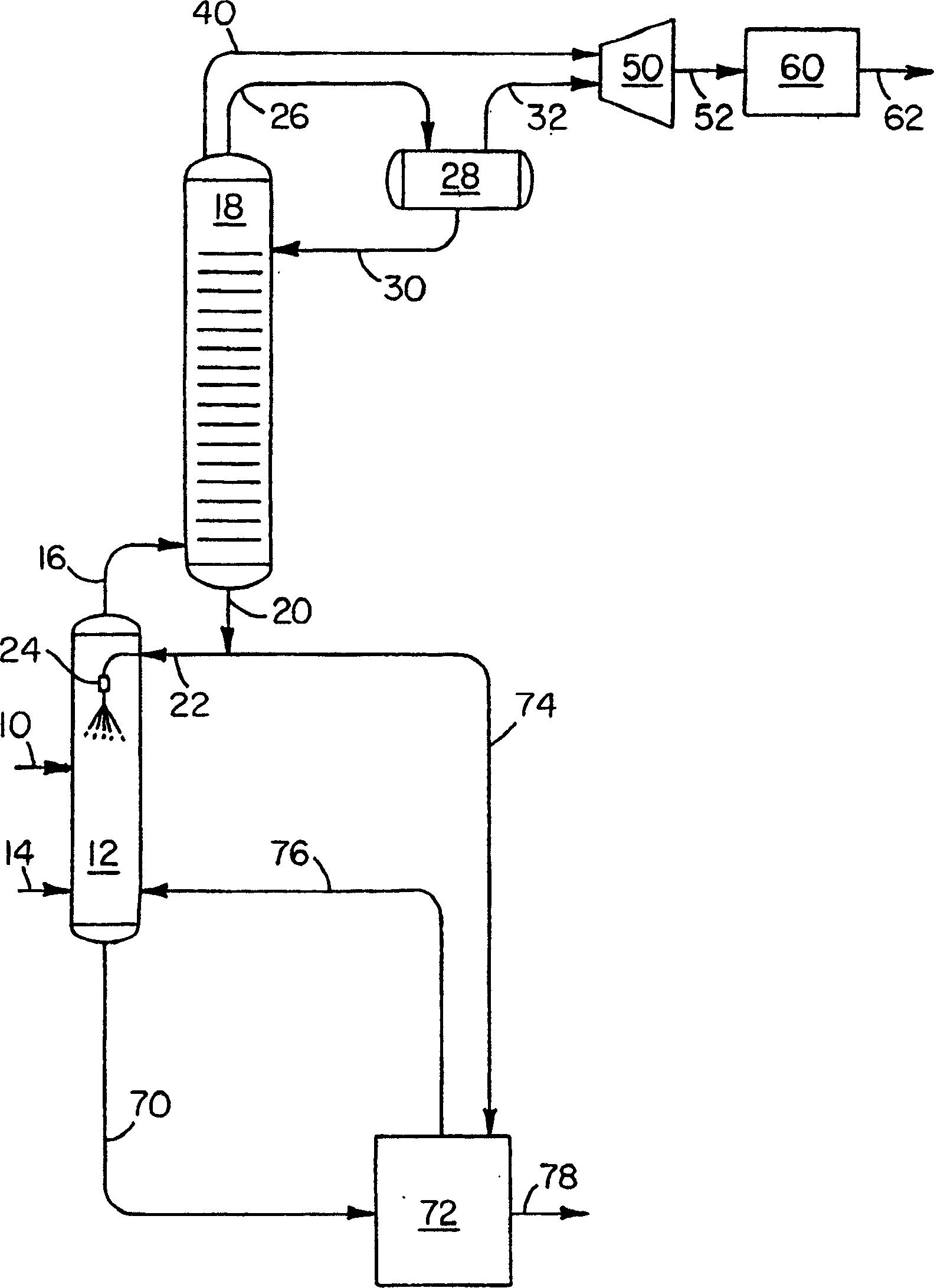

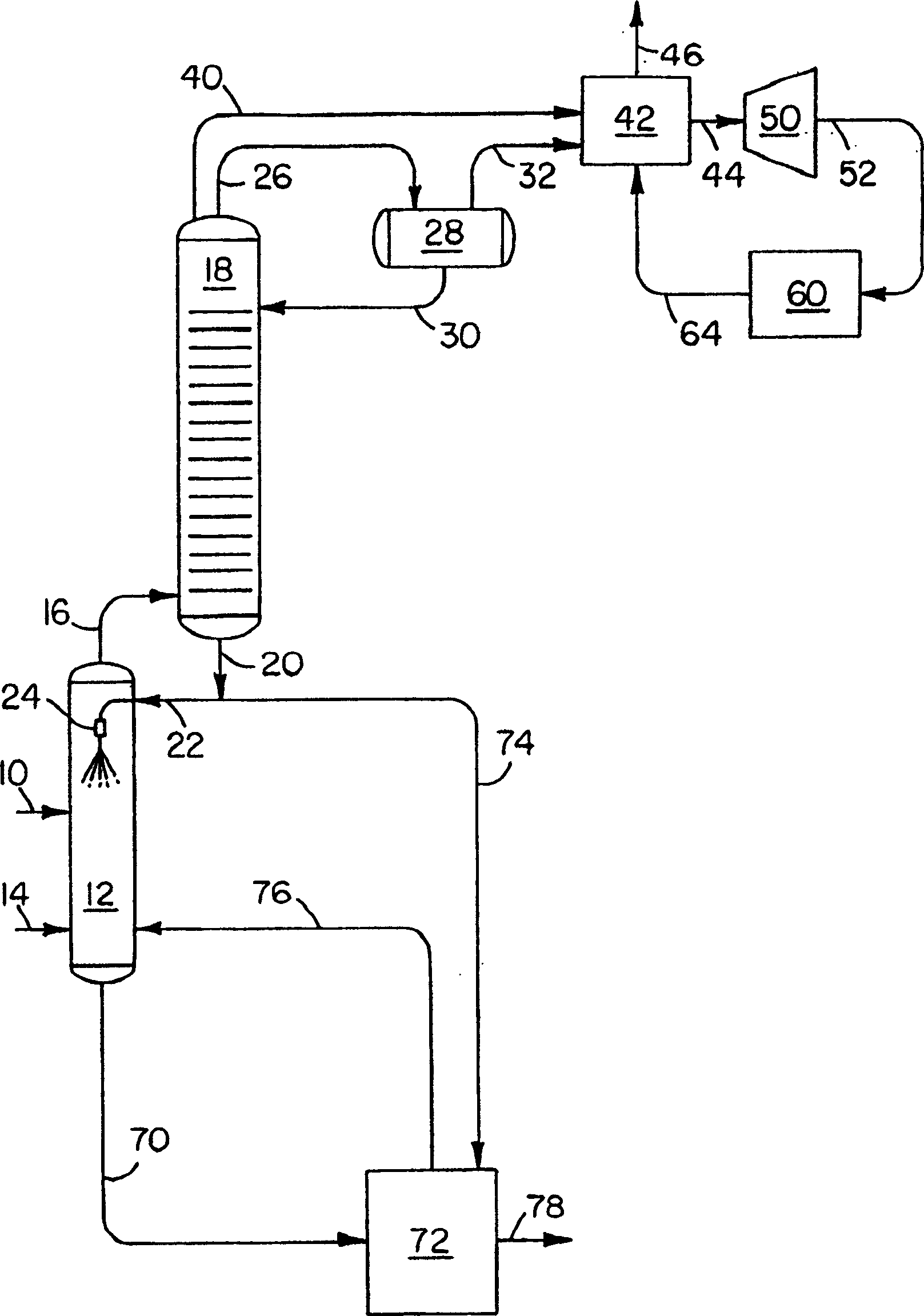

[0057] exist image 3 The method provided by the invention shown in will be further illustrated in the following examples. All parts and percentages in the examples are by weight unless otherwise specified.

[0058] Aqueous acetic acid solution containing dissolved catalyst was fed to reactor 12 through line 10 at a rate of about 30 parts / hour and p-xylene at a rate of about 1000 parts / hour. The reactor used was a vertical bubble column with a height to diameter ratio of 12:1. Air containing 0.5% water is fed through line 14 at a rate of about 4900 parts air / hour. The oxidation reaction medium is filled to approximately 85% of the reactor capacity. The temperature of the vigorously stirred reaction medium is about 140-160° C., and the pressure is controlled at about 5.9 bara (85 psia).

[0059] A reaction off-gas stream containing oxygen-depleted process gas, acetic acid and water is continuously withdrawn through an outlet located in the upper part of the reactor and sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com