Mechanical and electric mixed electric controlling stepless variable speed driving system

A continuously variable speed, drive system technology, applied in mechanical equipment, transmission, gear transmission, etc., can solve the limitations of wide applicability, portability and optimizability, reduce reliability and power transmission smoothness, transmission Efficiency can not be guaranteed and other problems, to achieve the effect of improving fuel economy, easy design, and less matching parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

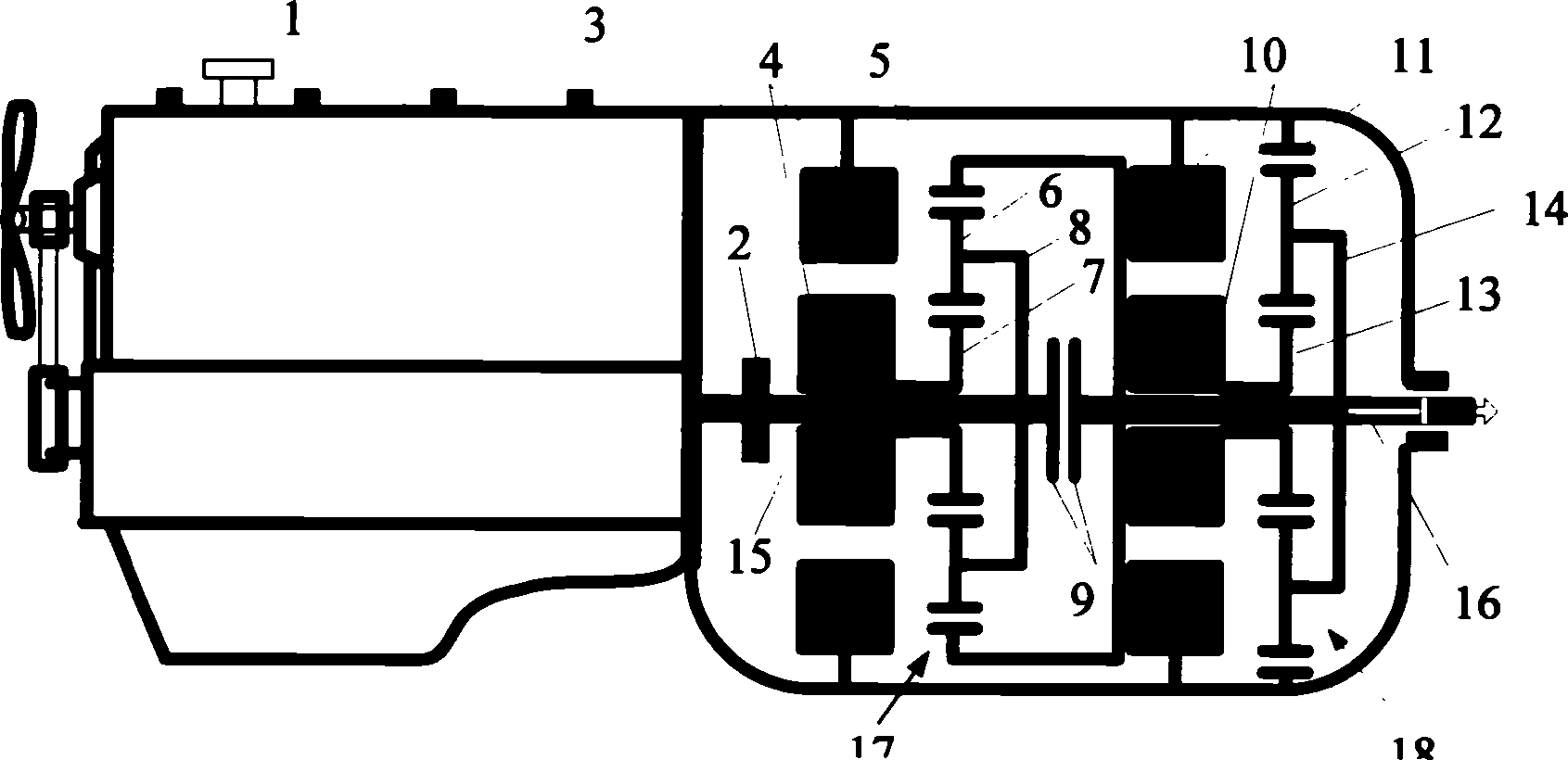

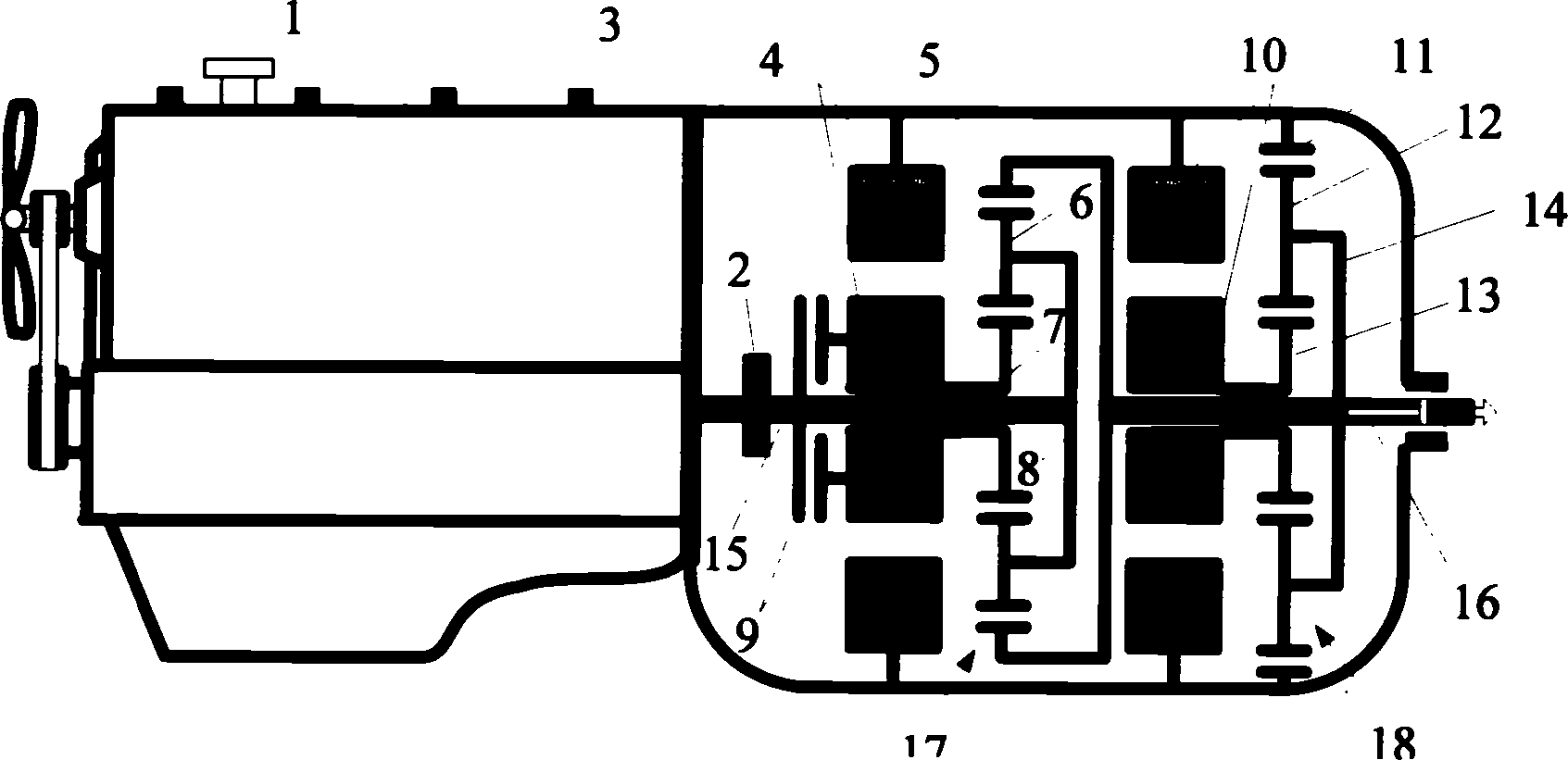

[0026] Depending on the arrangement of the clutch, different embodiments are possible. figure 1 with figure 2 It is two kinds of specific implementation examples of the present invention. figure 1 with figure 2 The same elements are denoted by the same reference numerals and characters.

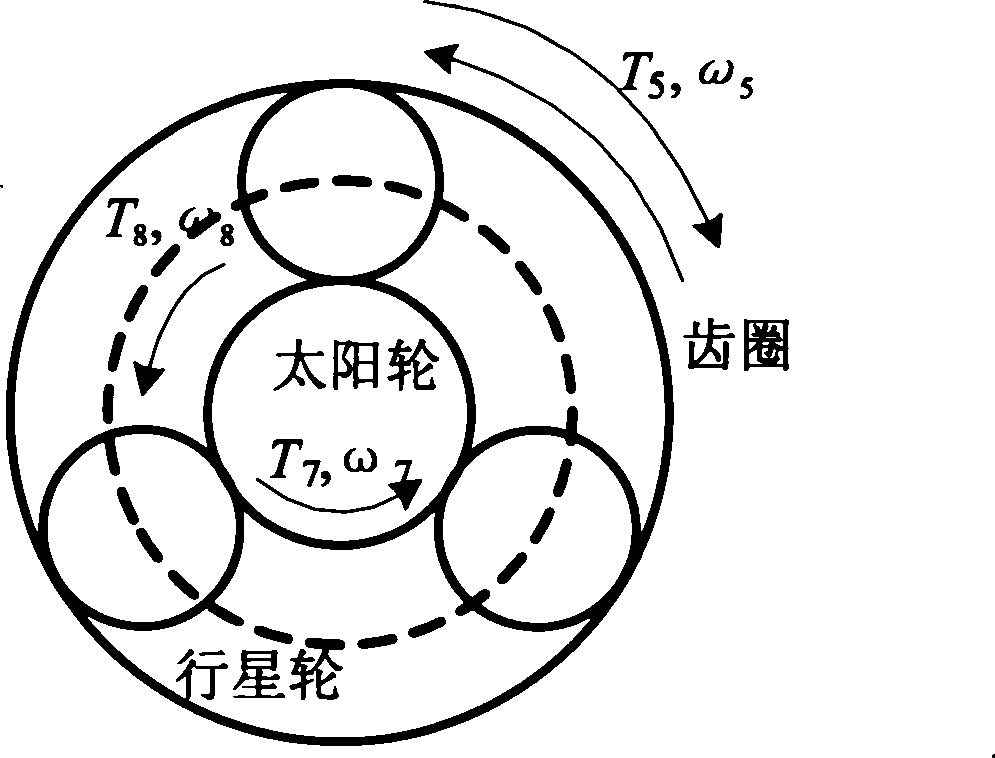

[0027] exist figure 1 In the first embodiment shown, the electromechanical hybrid electronically controlled continuously variable speed drive system consists of an internal combustion engine 1, a torsional shock absorber 2, a housing 3, a first motor 4, a second motor 10, and a first drive shaft 15, the second transmission shaft 16, the first planetary gear train 17, the clutch 9, and the second planetary gear train 18 form. Among them, the first planetary gear system 17 is composed of a coaxial sun gear 7, a planet carrier 8, an inner ring gear 5 and several planetary gears 6 connecting the sun gear and the inner ring gear, and the second planetary gear system 18 is composed of a coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com