Method for processing industrial wastes of edible vinegar through anaerobic digestion coupling pyrolysis technology

A technology for industrial waste and anaerobic digestion, which is applied in the field of vinegar industrial waste treatment by using anaerobic digestion coupled pyrolysis technology, can solve the problem of high efficiency, environmental protection, high cost of grid-connected power generation, and air pollution that have not been seen in vinegar residue. To achieve the effect of improving the overall gas production rate, solving the problem of low processing load and increasing the concentration of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

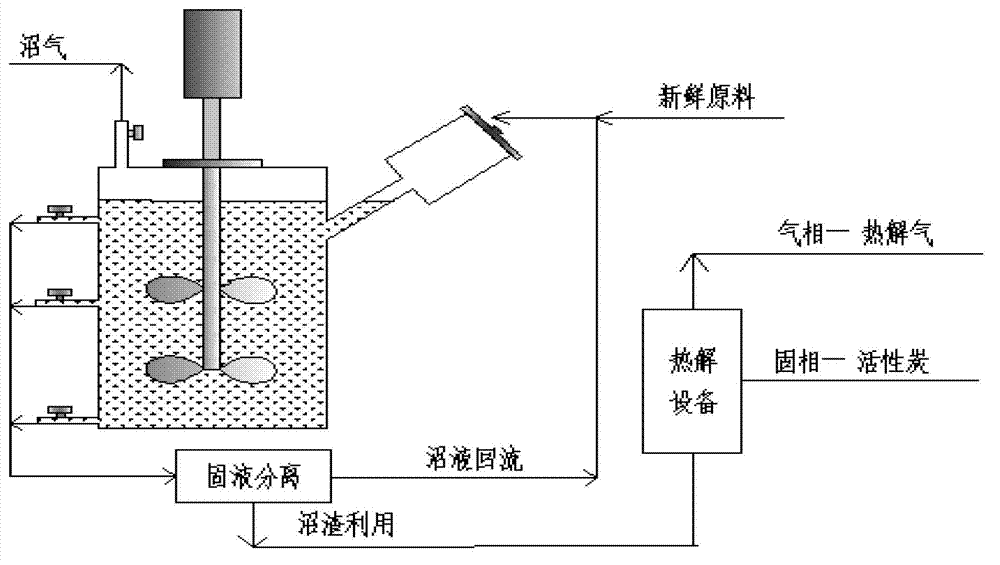

[0028] 1. Anaerobic digestion of vinegar residue: Mix 20g of vinegar residue with water until the solid content is 10wt%, and then add the sewage treatment plant sludge with a total solid concentration of 3wt% into the CSTR anaerobic digestion reactor. The sludge and vinegar residue The total solid concentration ratio is 1:1, stirred and mixed, anaerobic digestion is performed at 37°C to generate biogas for 30 days, and then all materials are discharged;

[0029] 2. Biogas slurry reflux: After the solid-liquid separation of the anaerobic digestion reaction output, the biogas residue undergoes pyrolysis reaction, and the biogas slurry and new vinegar residue are mixed at a total solid concentration ratio of 1:1 and then enter the CSTR reactor. The anaerobic digestion biogas reaction was carried out for 30 days, and then all the materials were discharged;

[0030] 3. Repeat step 2 to form a continuous and stable cycle process of anaerobic digestion coupled with pyrolysis technol...

Embodiment 2

[0033] 1. Anaerobic digestion of vinegar residue: Mix 20g of vinegar residue with water until the solid content is 15wt%, and then add the sewage treatment plant sludge with a total solid concentration of 5wt% into the CSTR anaerobic digestion reactor. The sludge and vinegar residue The total solid concentration ratio is 1:2, stirred and mixed, anaerobic digestion is performed at 37°C to generate biogas for 30 days, and then all materials are discharged;

[0034] 2. Biogas slurry reflux: After the solid-liquid separation of the anaerobic digestion reaction output, the biogas residue undergoes pyrolysis reaction, and the biogas slurry and new vinegar residue are mixed and constant at a total solid concentration ratio of 1:2 before entering the CSTR reactor The anaerobic digestion biogas reaction was carried out for 30 days, and then all the materials were discharged;

[0035]3. Repeat step 2 to form a continuous and stable cycle process of anaerobic digestion coupled with pyrol...

Embodiment 3

[0038] The system includes an anaerobic digestion stirring system, a 11L CSTR anaerobic digestion reactor (working volume 9L), a constant temperature circulating water bath device, and a single-stage pyrolysis tube furnace.

[0039] 1. Add 9L of sludge from a sewage treatment plant with a total solid concentration of 5wt% and 20g of vinegar residue into the CSTR anaerobic digestion reactor, stir and mix, and perform anaerobic digestion at 37°C to produce biogas. Part of the material is discharged after 1 day. The volume is 200mL;

[0040] 2. After the solid-liquid separation of the output of anaerobic digestion reaction, the biogas residue is dried and then enters a single-stage tubular pyrolysis furnace for pyrolysis reaction at 800°C. About 150mL of biogas slurry is recovered and mixed with new vinegar residue. Add the volume to 200mL into the CSTR anaerobic digestion reactor for anaerobic digestion;

[0041] 3. After that, the CSTR anaerobic digestion reactor has a daily i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com