Fuel battery unit with electric field-membrane electrode combined structure and a reversible regenerable oxyhydrogen electrolysis unit thereof

A fuel cell and combined structure technology, which is applied in the field of fuel cell devices and reversible regenerative hydrogen-oxygen electrolysis devices, can solve the problems of poor power density stability, decreased power generation efficiency, and shortened working life, so as to improve electrolysis efficiency and reduce The effect of decomposing voltage and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

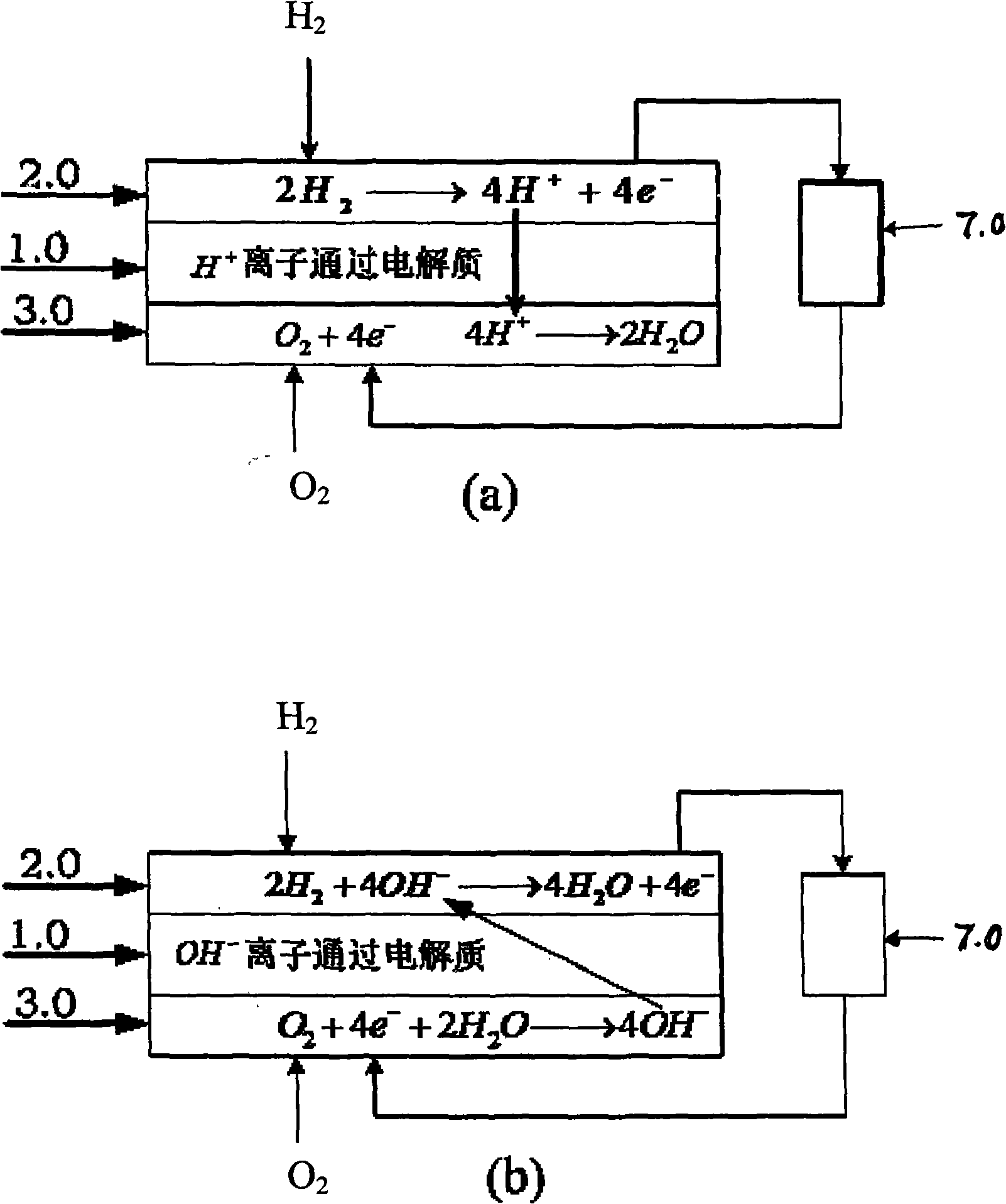

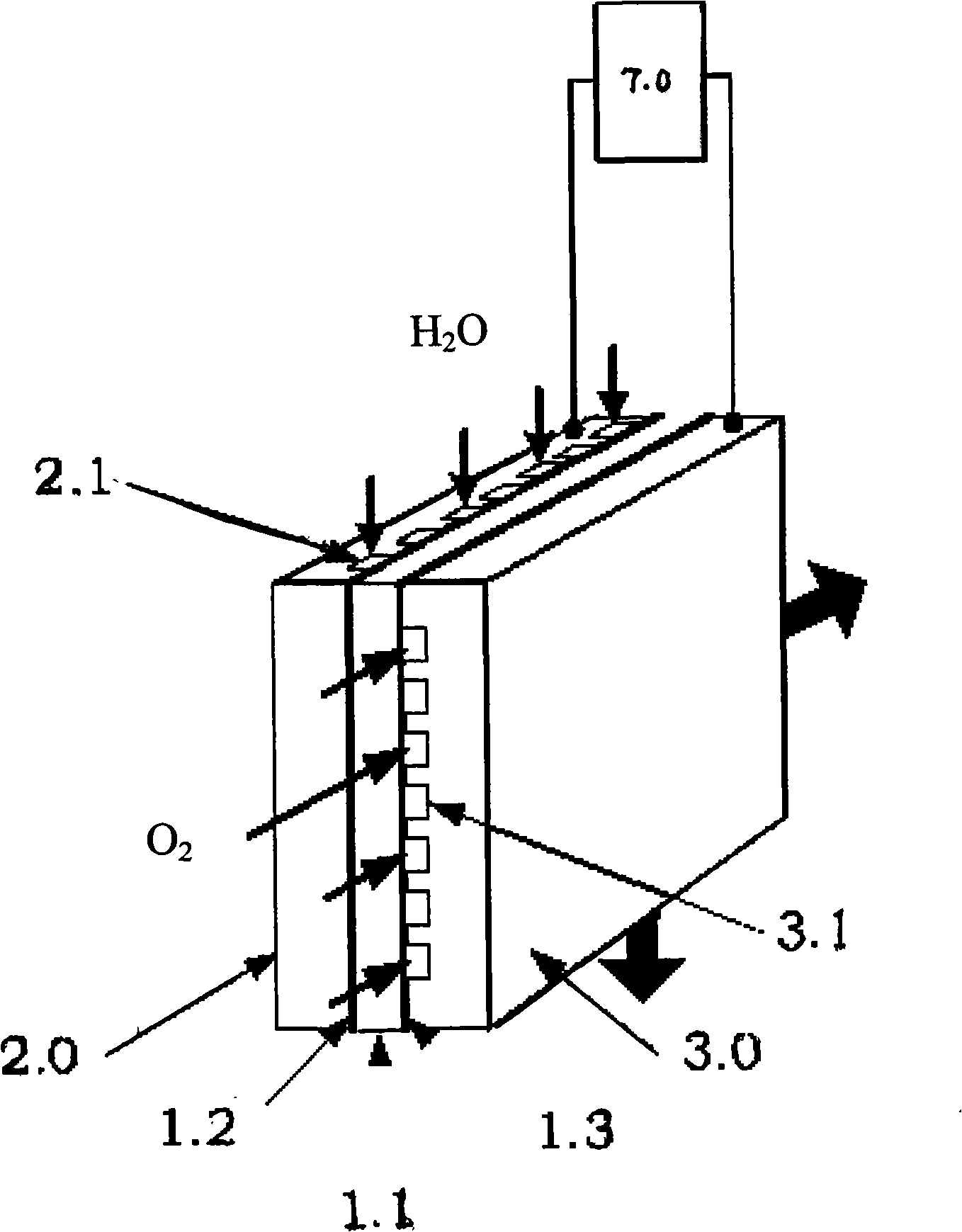

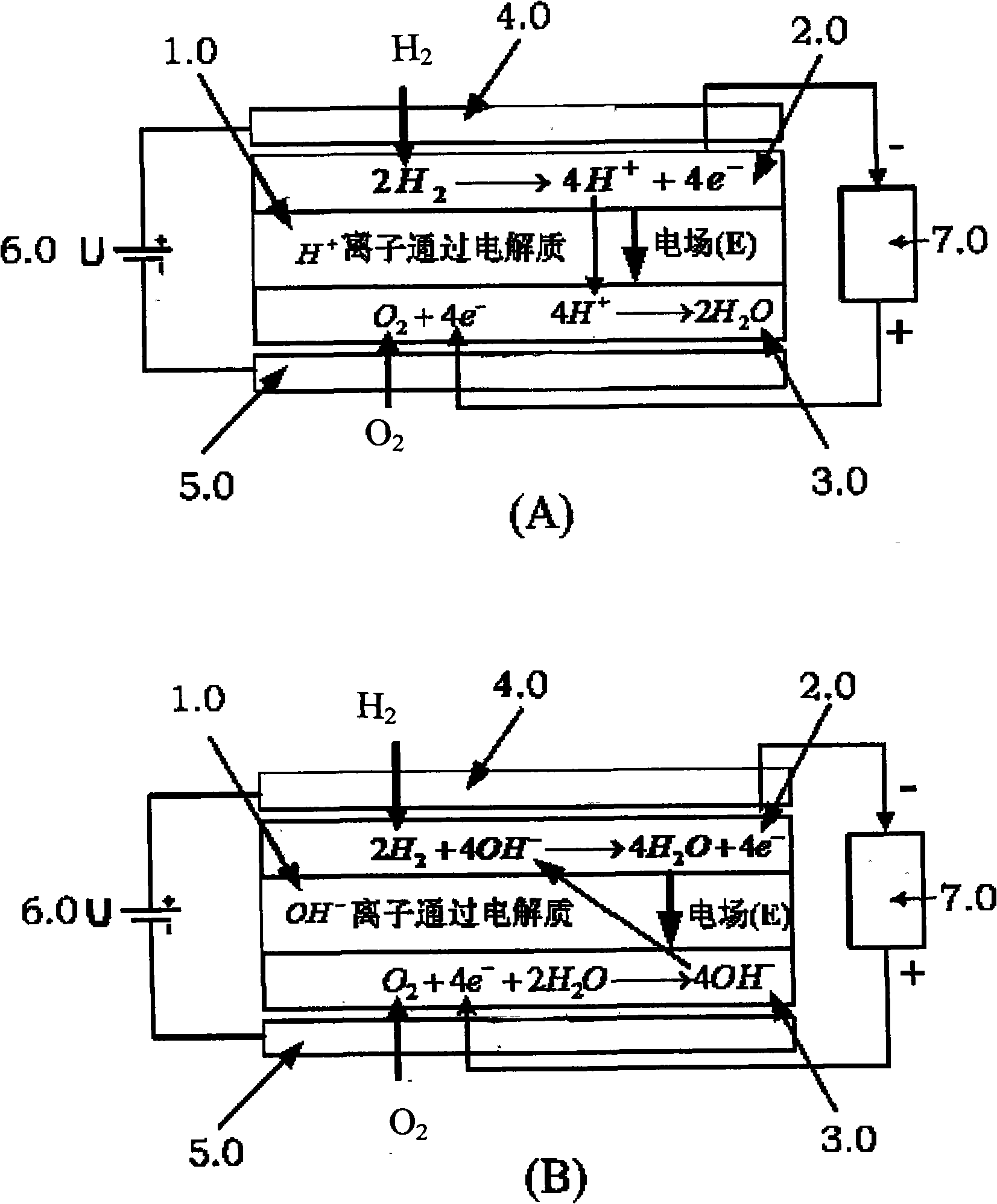

[0038] refer to image 3 As shown, a fuel cell device with an electric field-membrane electrode (E-field MEA) combined structure is composed of electrolyte 1.0, anode 2.0, cathode 3.0, electric field positive electrode 4.0, and electric field negative electrode 5.0. Among them, the DC power supply 6.0 is the power supply for the positive pole of the electric field 4.0 and the negative pole of the electric field 5.0. Its main function is to provide a stable or regulated internal electric field E for the three-in-one component composed of the membrane electrode MEA. Load 7.0 is an external load powered by a fuel cell. Among them, (A) and (B) respectively represent acidic and alkaline electrolyte fuel cells.

[0039] refer to image 3 As shown, the operating principle of a fuel cell device with an electric field-membrane electrode (E-field MEA) combined structure in this embodiment is:

[0040] Anode-cathode reactions and electron flow in acidic electrolyte (PEM) fuel cells: A...

Embodiment 2

[0046] This embodiment 2 "a water electrolysis cell device with an electric field-membrane electrode (E-field MEA) combined structure" is composed of electrolyte 1.0, anode 2.0, cathode 3.0, electric field positive electrode 4.0, and electric field negative electrode 5.0. Among them, the DC power supply 6.0 is the power supply for the positive pole of the electric field 4.0 and the negative pole of the electric field 5.0. Its main function is to provide a stable or regulated internal electric field E for the three-in-one component composed of the membrane electrode MEA. The power supply 7.0 is the electrolysis power supply of the water electrolysis cell.

[0047] The working principle of this embodiment 2 "a water electrolysis cell device with an electric field-membrane electrode (E-field MEA) combined structure" is: at the positive electrode, water is oxidized to release electrons 2H 2 O→O 2 +4H + +4e - The reaction produces oxygen. In the negative electrode H + Removed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com