Porous carbon fiber electrode for flow battery and preparation method thereof

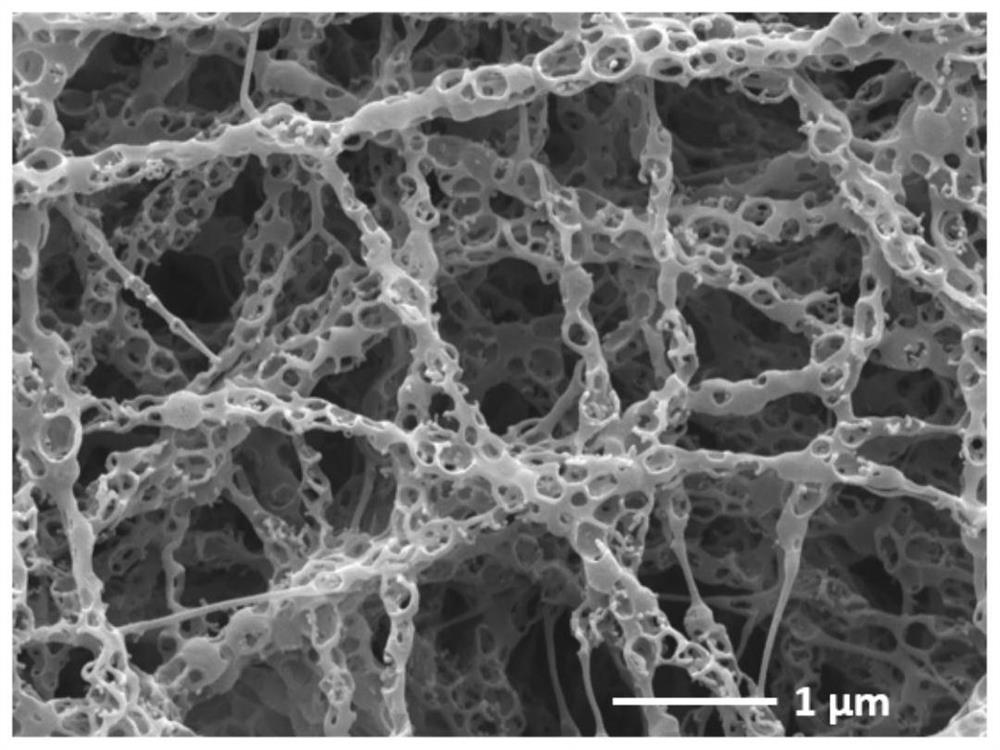

A porous carbon fiber, flow battery technology, applied in battery electrodes, fiber processing, fiber chemical characteristics, etc., can solve the problems of porous fiber filaments that are difficult to obtain a uniformly distributed pore structure and cannot contribute specific surface area, etc., to achieve good transmission performance, The effect of reducing activation loss and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

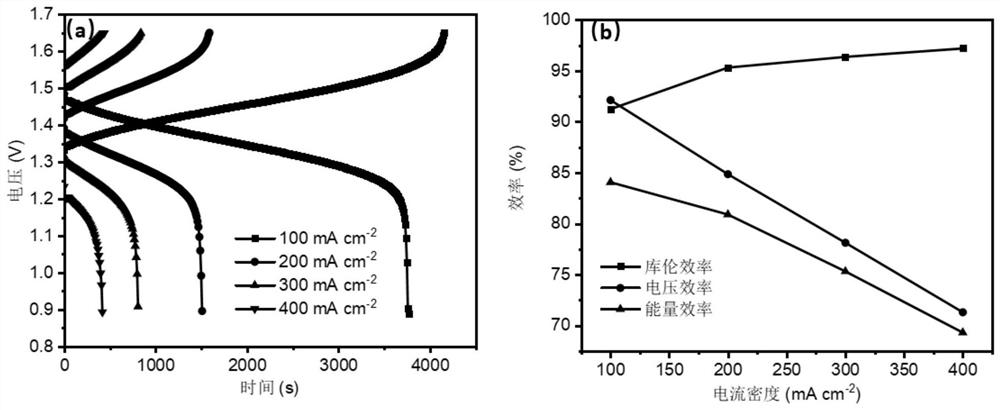

Examples

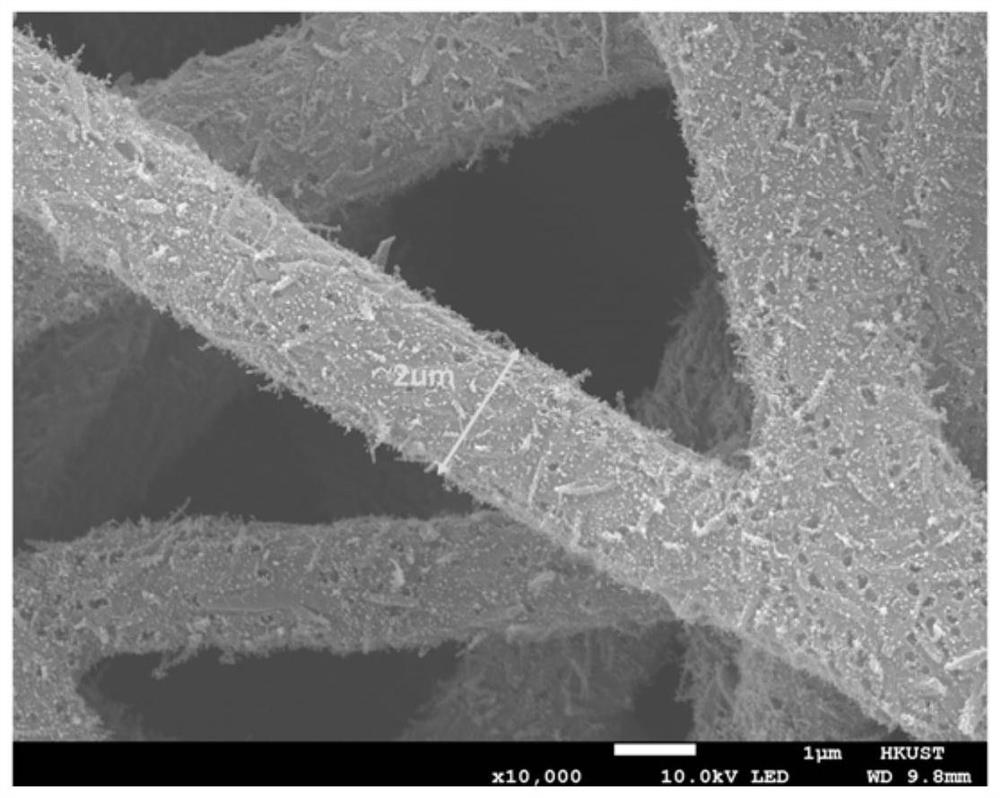

Embodiment 1

[0046] A porous carbon fiber electrode is prepared by the following method:

[0047] (1) Weigh 3g of polyvinyl alcohol and 17g of deionized water, mix, heat and dissolve in a water bath at 70 °C; add 10 μL of 5wt% boric acid, stir in a water bath at 70 °C for 2 hours; Stir at room temperature for 6h;

[0048] (2) Take 15mL of the precursor solution of step (1), connect a 20G (inner diameter 0.60mm) needle, and set the advancing speed of the solution to 1.0mL h -1 , the electrospinning voltage is 17kV, the distance from the needle to the receiving end is 20cm, the receiving rotor speed is 200rpm, the ambient temperature is 25°C, the relative humidity is 40%, and the composite fiber membrane is removed after spinning for 10h;

[0049] (3) Put the composite fiber membrane of step (2) in a muffle furnace, pre-oxidize at 280°C for 1h, and the heating rate is 2°C min -1 ;Place the pre-oxidized composite fiber membrane in a nitrogen protective atmosphere, carbonize it at 1300 °C fo...

Embodiment 2

[0055] A porous carbon fiber electrode is prepared by the following method:

[0056] (1) Weigh 2g of polyvinyl alcohol and 18g of deionized water, mix, heat and dissolve in a 70°C water bath, add 2.5g of lignin, continue to heat and stir for 10h; add 13.5g of 60% PTFE water emulsion, at room temperature under stirring for 6h;

[0057] (2) Take 15mL of the precursor solution of step (1), connect a 20G (inner diameter 0.60mm) needle, and set the advancing speed of the solution to 1.0mL h -1 , the electrospinning voltage is 17kV, the distance from the needle to the receiving end is 20cm, the receiving rotor speed is 200rpm, the ambient temperature is 25°C, the relative humidity is 40%, and the composite fiber membrane is removed after spinning for 10h;

[0058] (3) The composite fiber membrane of step (2) is placed in a muffle furnace, pre-oxidized at 280°C for 1 h, and the heating rate is 2°C min -1 ; Put the pre-oxidized composite fiber membrane in a nitrogen protective atmos...

Embodiment 3

[0062] A porous carbon fiber electrode is prepared by the following method:

[0063] (1) Weigh 2g of polyvinyl alcohol and 18g of deionized water, mix, heat and dissolve in a 70°C water bath, add 2.5g of lignin, continue to heat and stir for 10h; add 5g of 60% PTFE water emulsion, at room temperature Stir for 6h;

[0064] (2) Take 15mL of the precursor solution of step (1), connect a 20G (inner diameter 0.60mm) needle, and set the advancing speed of the solution to 1.0mL h -1 , the electrospinning voltage is 17kV, the distance from the needle to the receiving end is 20cm, the receiving rotor speed is 200rpm, the ambient temperature is 25°C, the relative humidity is 40%, and the composite fiber membrane is removed after spinning for 10h;

[0065] (3) The composite fiber membrane of step (2) is placed in a muffle furnace, pre-oxidized at 280°C for 1 h, and the heating rate is 2°C min -1 ; Put the pre-oxidized composite fiber membrane in a nitrogen protective atmosphere, carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com