A kind of multi-diameter size electrode and its preparation method and application

A technology with multiple diameters and sizes, applied in battery electrodes, spinning solution preparation, circuits, etc., can solve problems such as reduced permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

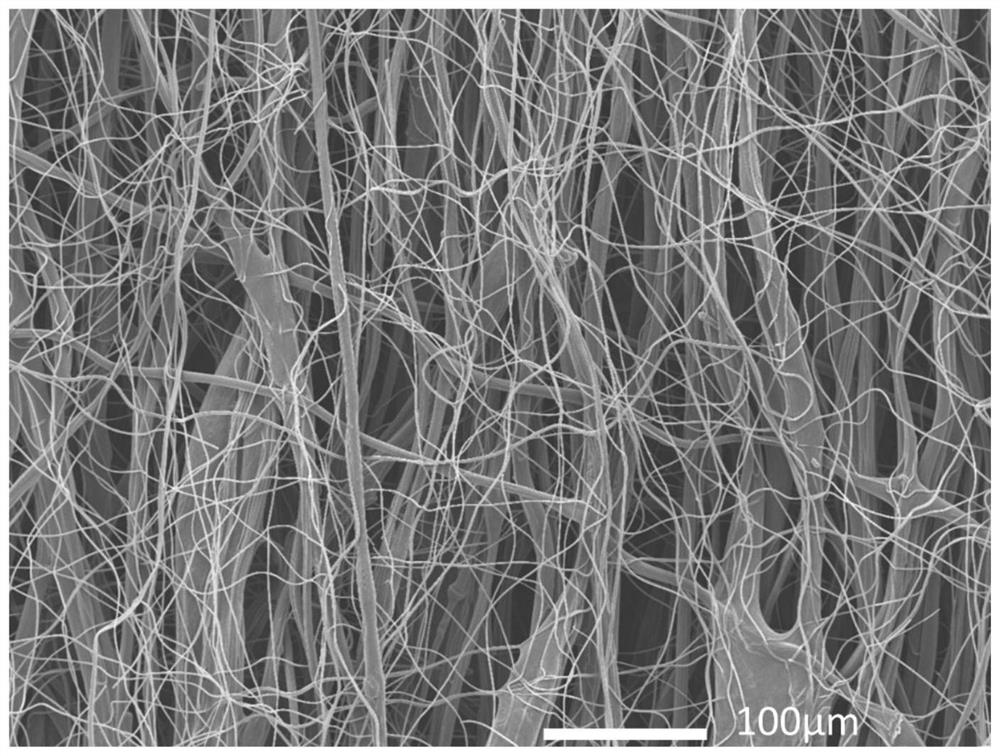

[0045] A double-diameter electrode prepared by the following method:

[0046] S1. Weigh 2.4g of polyacrylonitrile and 17.6g of N,N-dimethylformamide, mix them, and heat them in a water bath at 70°C for 12h to prepare a 12wt% spinning precursor solution (i.e. spinning solution); another 3g is weighed Polyacrylonitrile and 17g N,N-dimethylformamide were mixed, heated and dissolved in a water bath at 70°C, and prepared into a 15wt% spinning precursor solution;

[0047] S2, take 10mL 12wt% spinning precursor solution in the syringe, and connect a 17G needle (inner diameter 1.07mm), set the advancing speed of the solution to 1mL h -1 ; In addition, take 15mL 15wt% spinning precursor solution, connect a 15G needle (inner diameter 1.40mm), and set the advancing speed of the solution to 1.5mL h -1 . The electrospinning voltage was set to 17kV, the distance from the needle to the receiving end was 20cm, and the rotating speed of the receiving wheel was 200rpm. The ambient temperatur...

Embodiment 2

[0054] A kind of double-diameter electrode, its preparation method is basically the same as embodiment 1, difference is:

[0055] The concentrations of the two electrospinning precursor solutions are 10wt% and 15wt%, respectively, and the corresponding needles during electrospinning are 20G (inner diameter 0.60mm) and 15G (inner diameter 1.40mm) needles, respectively. The advancing speed of the needle corresponds to 1.0mL h -1 , and 1.5mL h -1 . After the same pre-oxidation and carbonization process as in Example 1, an electrode with double diameters can be obtained.

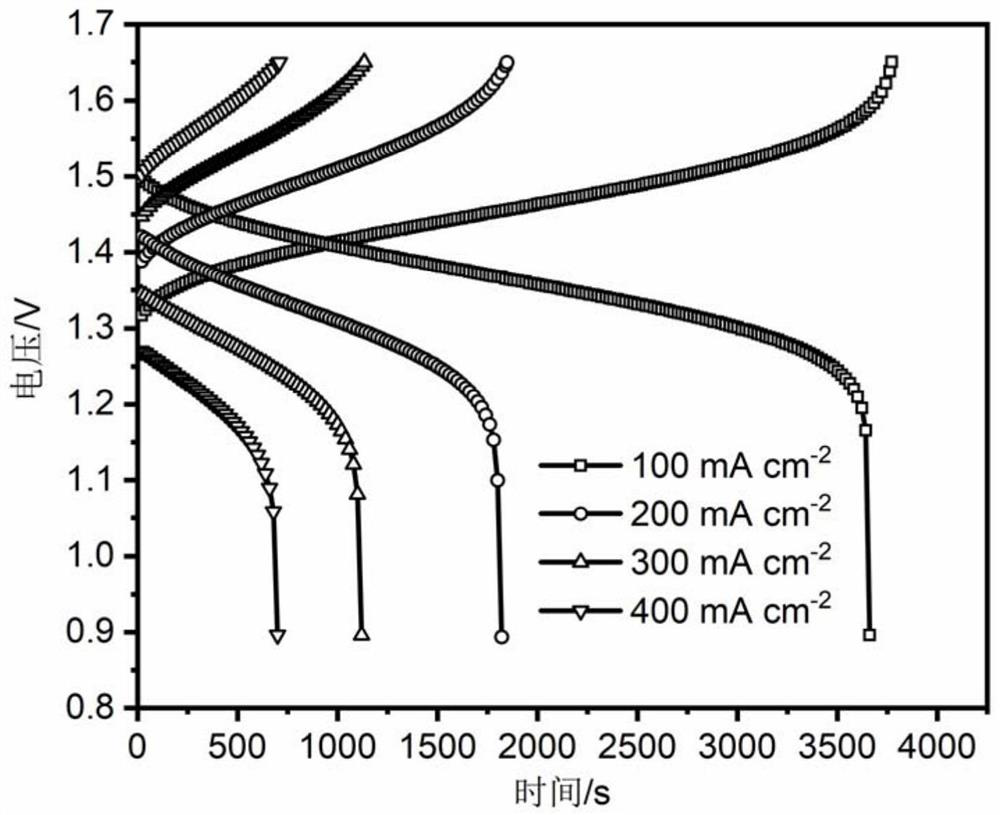

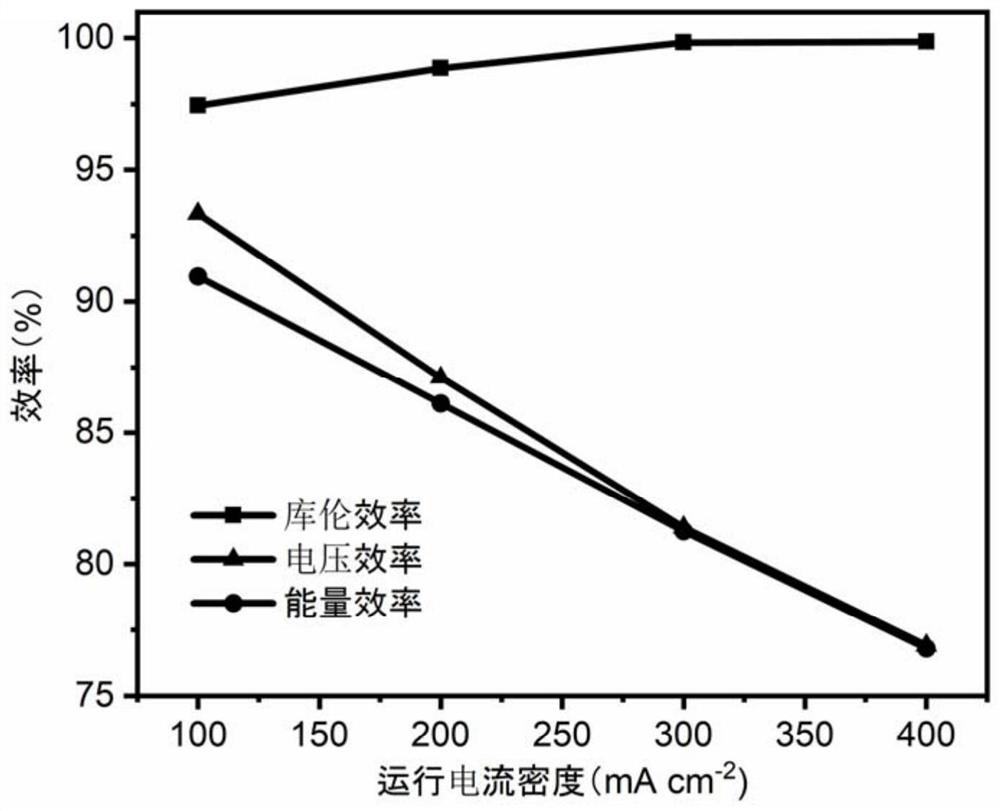

[0056] The fiber filament diameters of the fiber filament groups of the dual-diameter electrode obtained in this example were 500 nm and 10 μm, respectively. After battery test, at 300mA cm -2 Under the current density, the voltage efficiency of the battery is 79.25%, and the energy efficiency is 78.67%.

Embodiment 3

[0058] A kind of three-diameter electrode, its preparation method is basically the same as embodiment 1, difference is:

[0059] With three different concentrations of electrospinning precursor solutions, the concentrations are 5wt%, 10wt% and 15wt%, respectively, and the corresponding needles during electrospinning are 22G (inner diameter 0.40mm), 20G (inner diameter 0.60mm) and 15G (inner diameter 1.40mm). mm) needle. The advancing speed of the needle corresponds to 0.5mL h -1 , 1.0 mL h -1 , and 1.5mL h -1 . Electrodes with three diameters can be obtained through the same pre-oxidation and carbonization as in Example 1.

[0060] The fiber diameters of the fiber groups of the three-diameter electrode obtained in this example were 200 nm, 500 nm and 10 μm, respectively. After battery test, at 300mA cm -2 Under the current density, the voltage efficiency of the battery is 75.48%, and the energy efficiency is 74.82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com