Patents

Literature

347 results about "Fiber size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

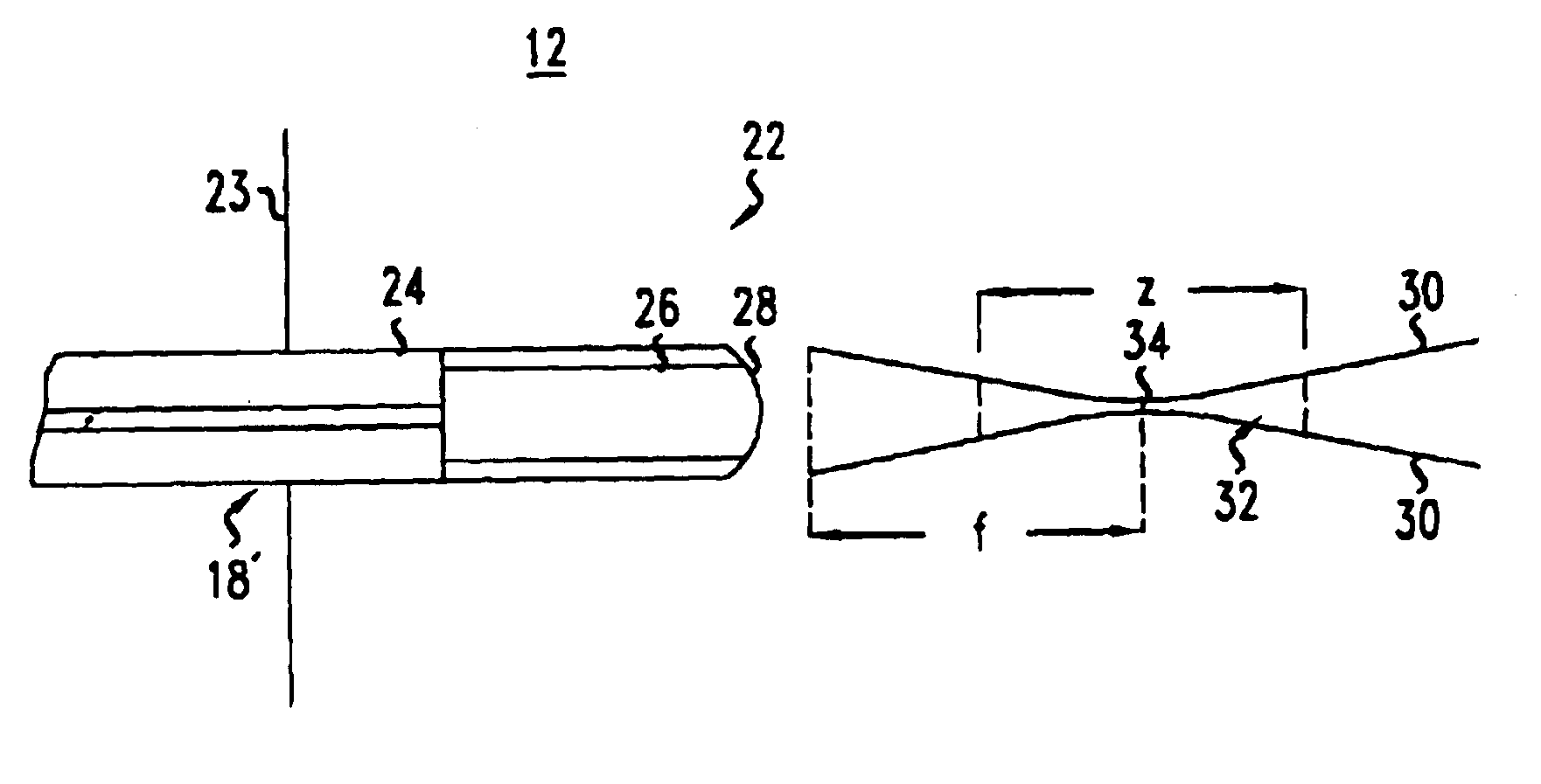

The two types of optical fibers are Multimode and Singlemode. The outside diameter of both fibers core plus cladding is 125 micron. The size of a micron is one-millionth of a meter; therefore the size of a fiber’s core plus cladding is 0.0005 inches.

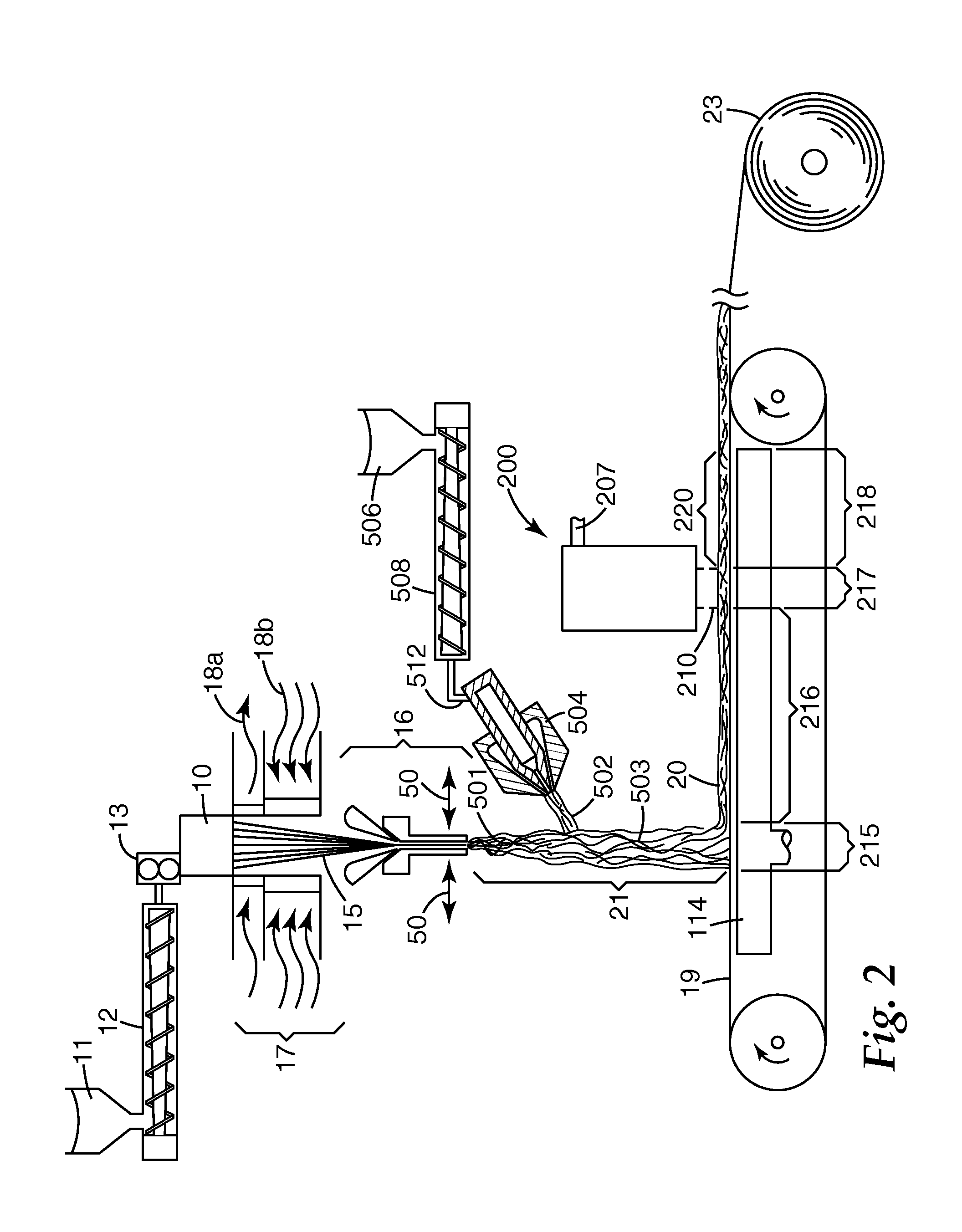

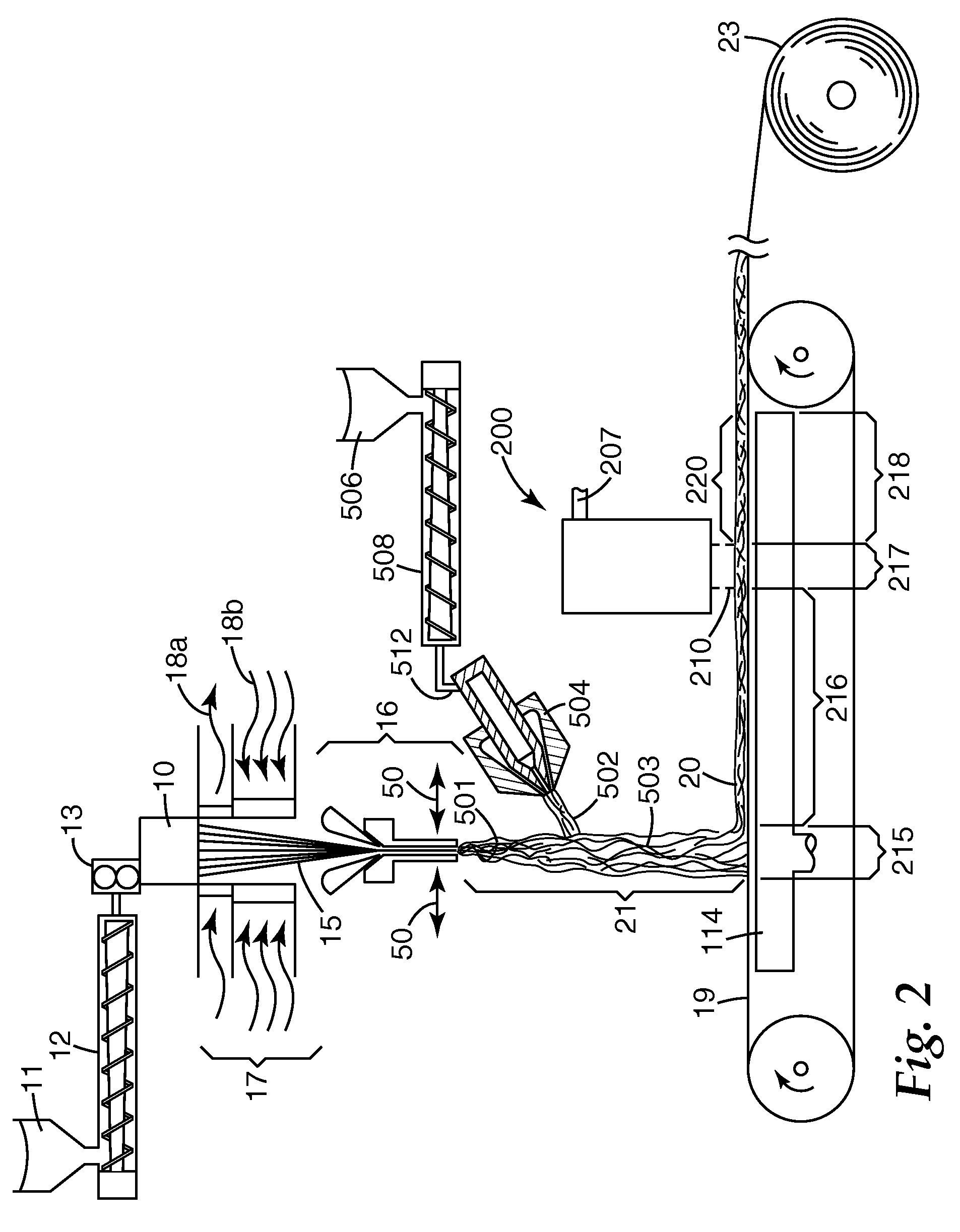

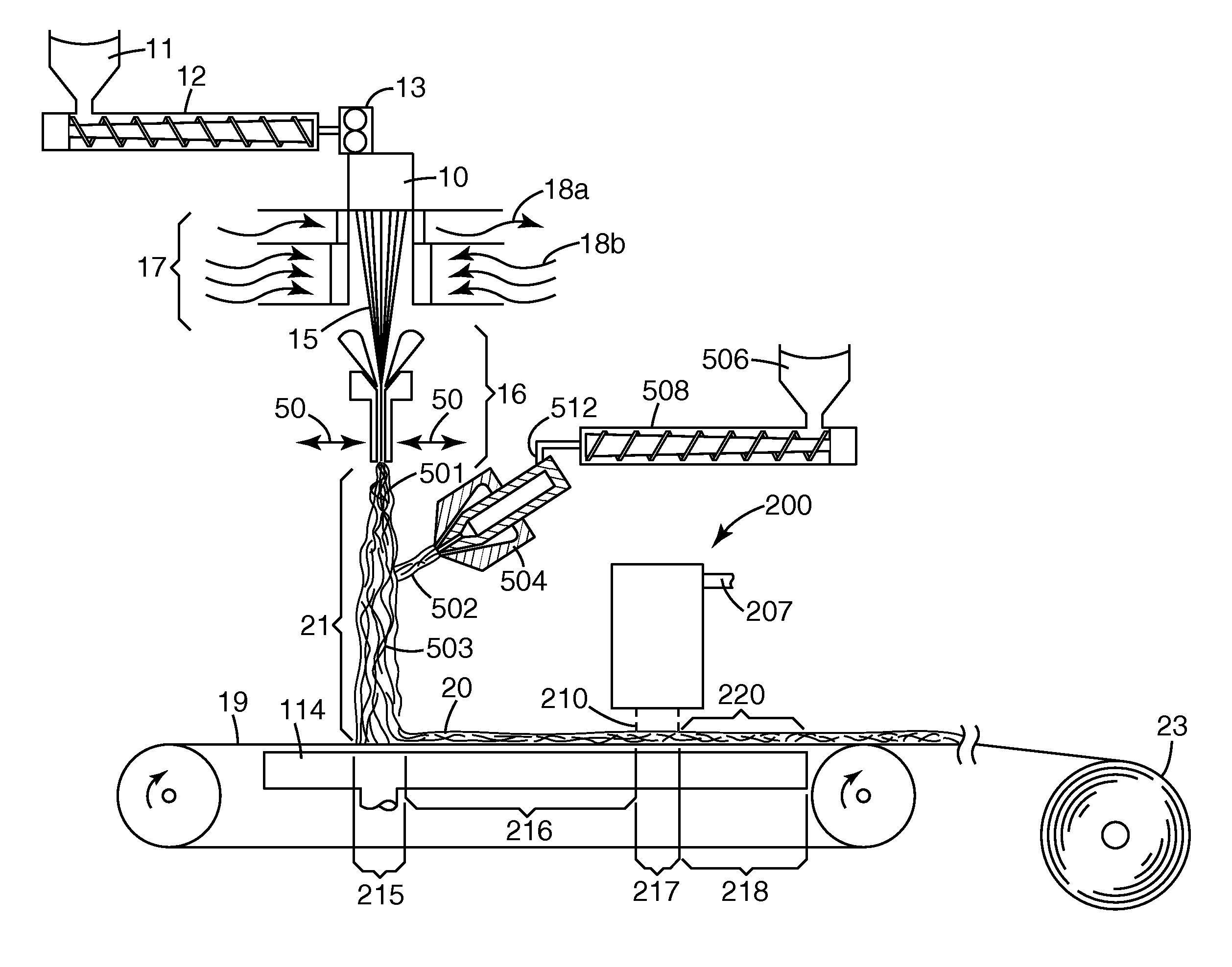

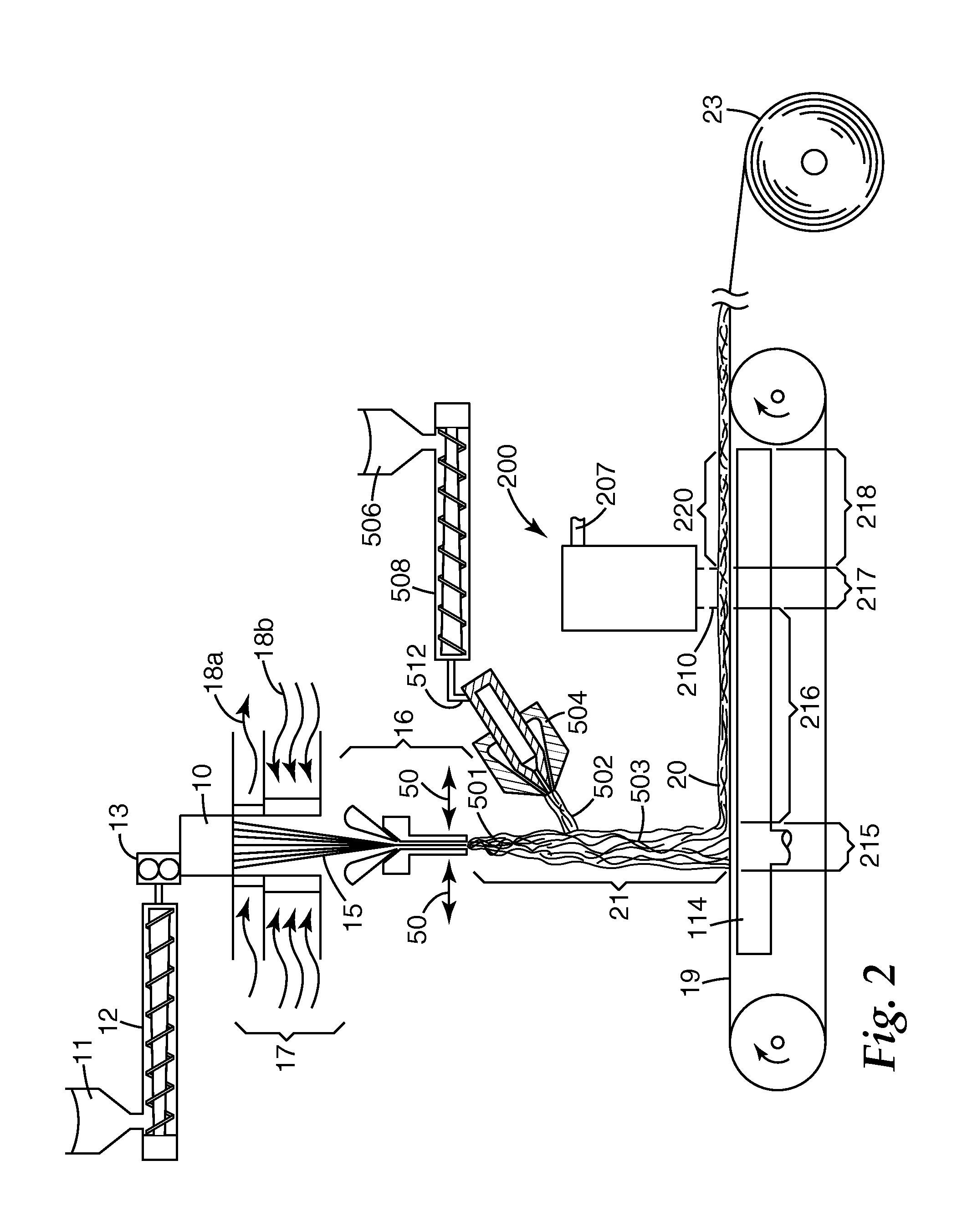

Monocomponent Monolayer Meltblown Web And Meltblowing Apparatus

ActiveUS20080026659A1Good molding effectIncrease fiber surface areaDispersed particle filtrationMagnetic materials for record carriersPolymer scienceRespirator

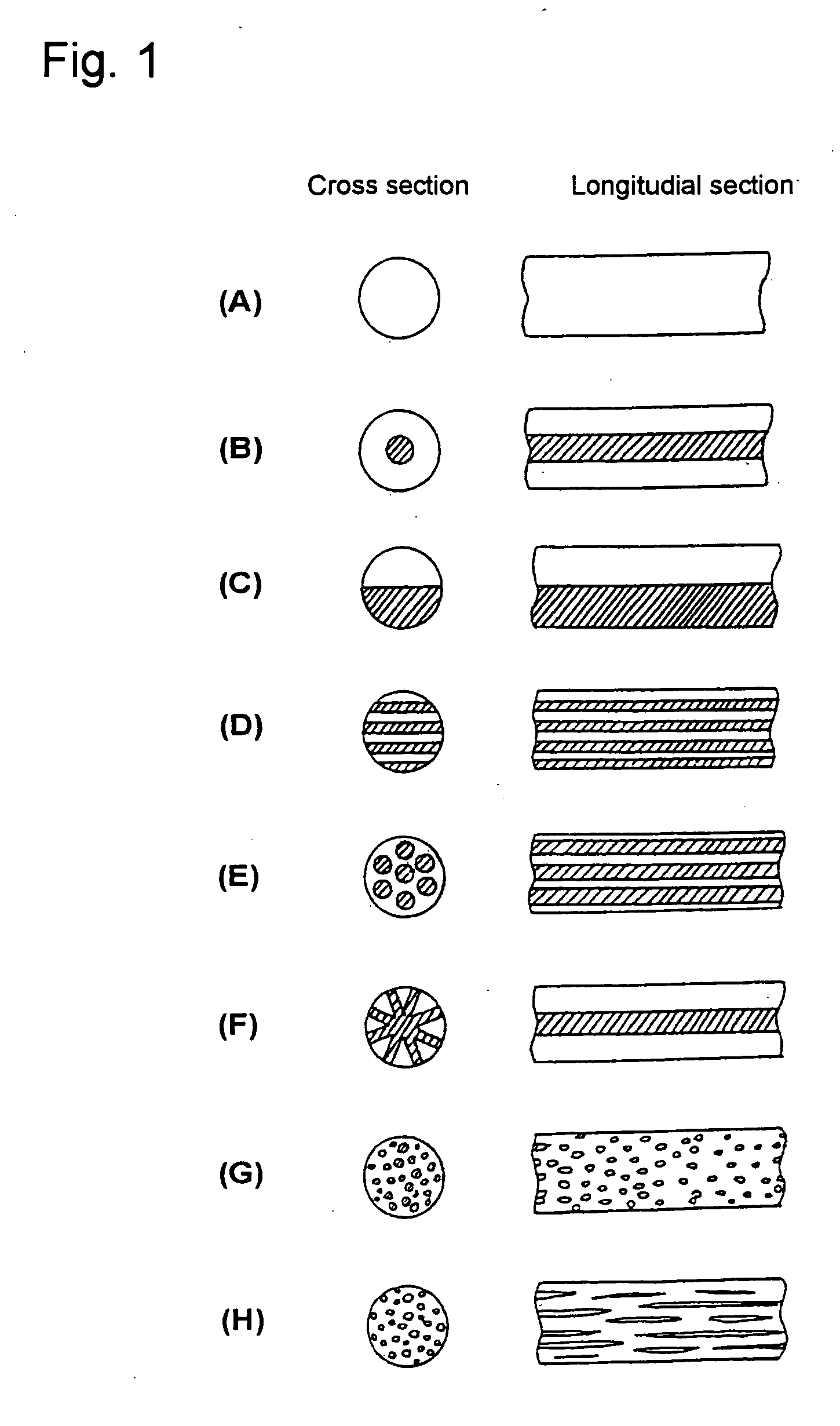

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

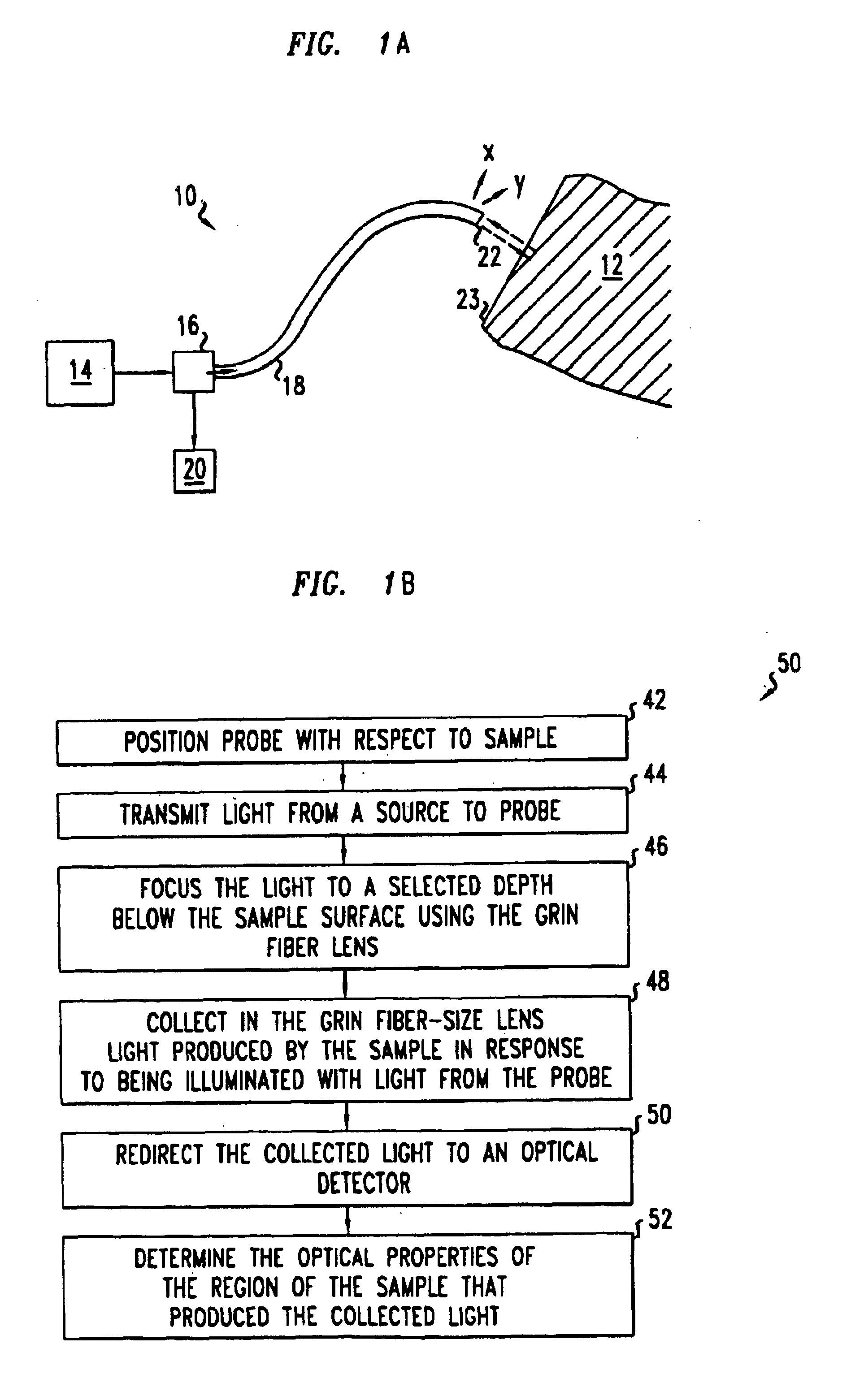

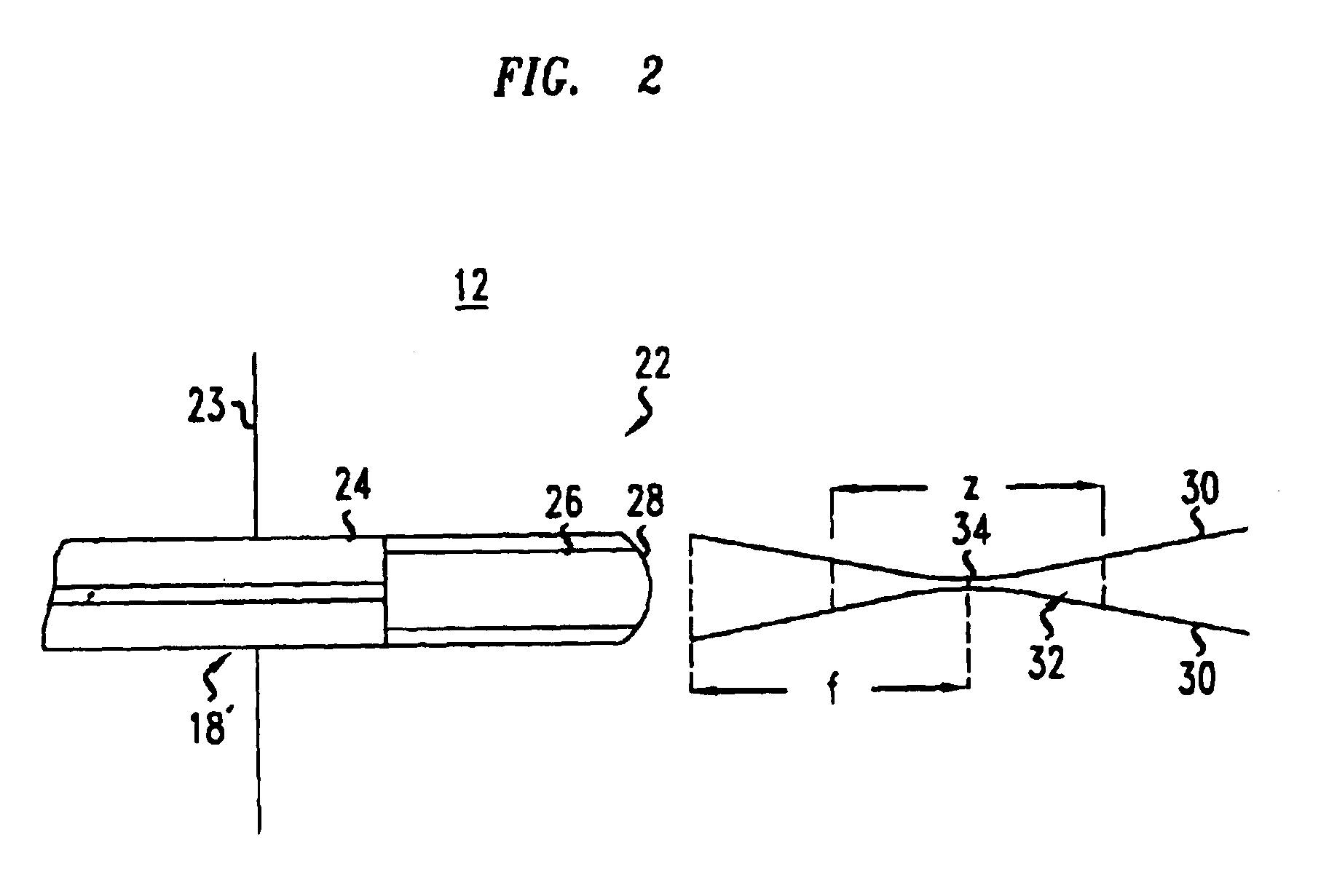

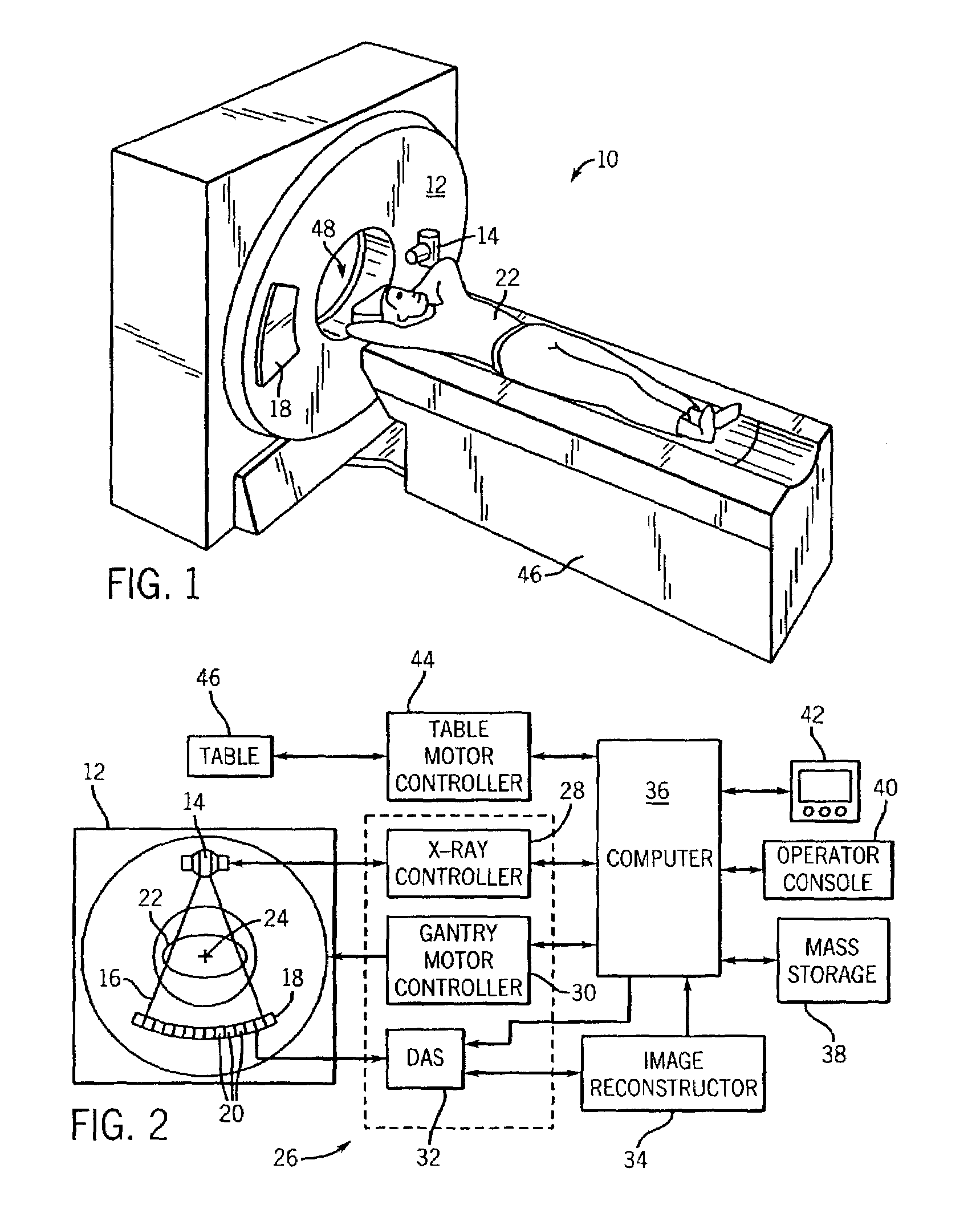

Grin-fiber lens based optical endoscopes

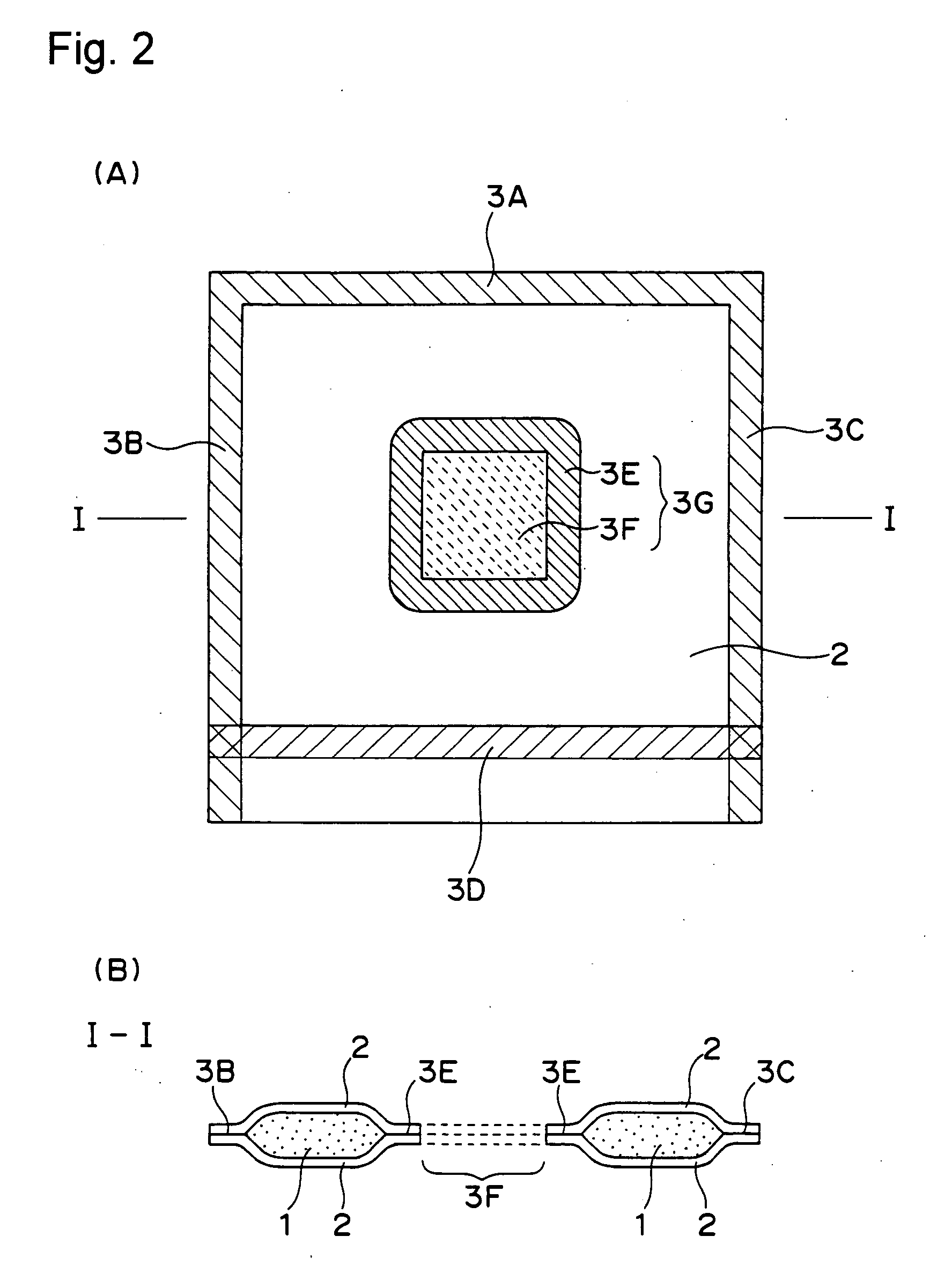

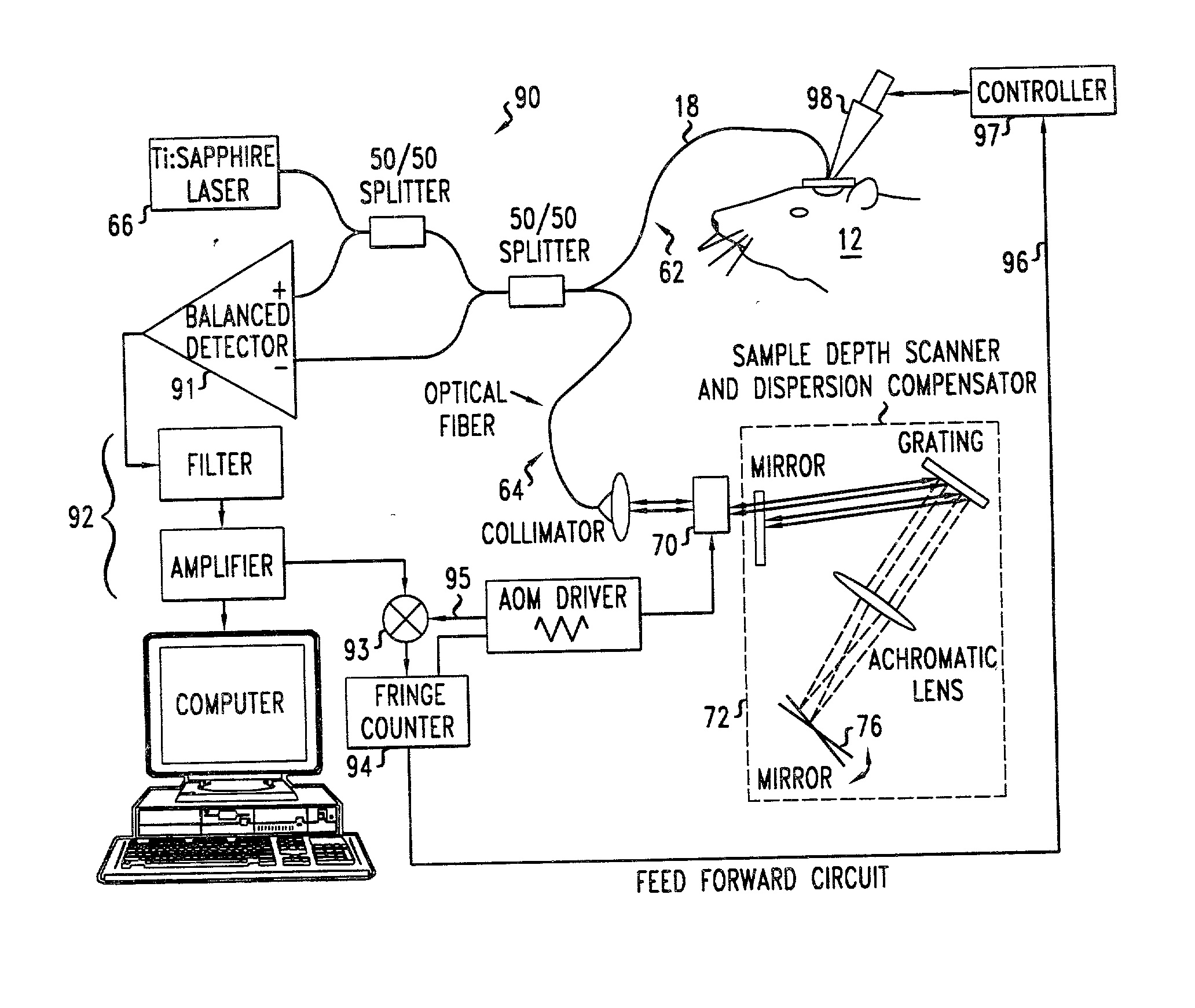

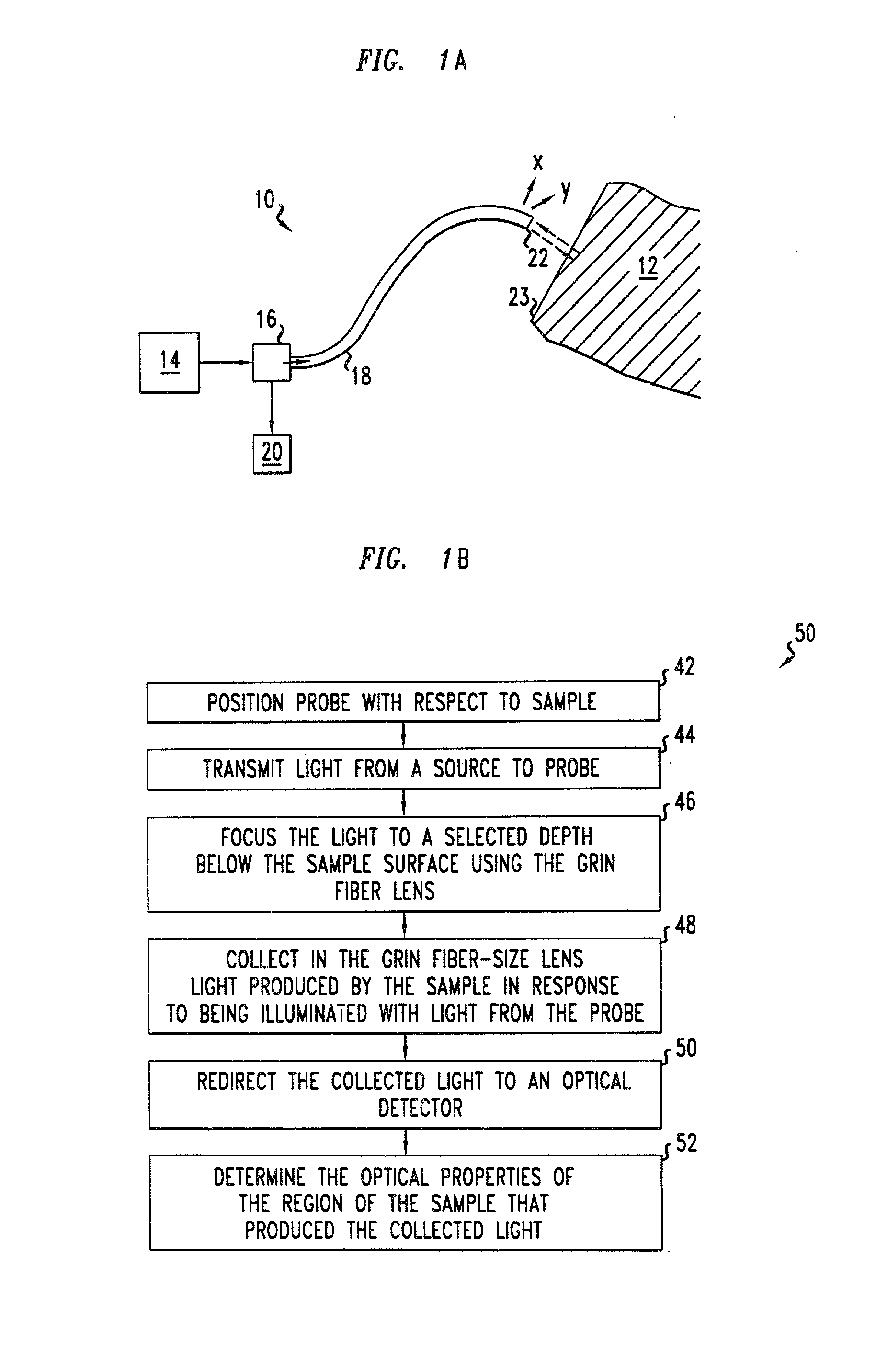

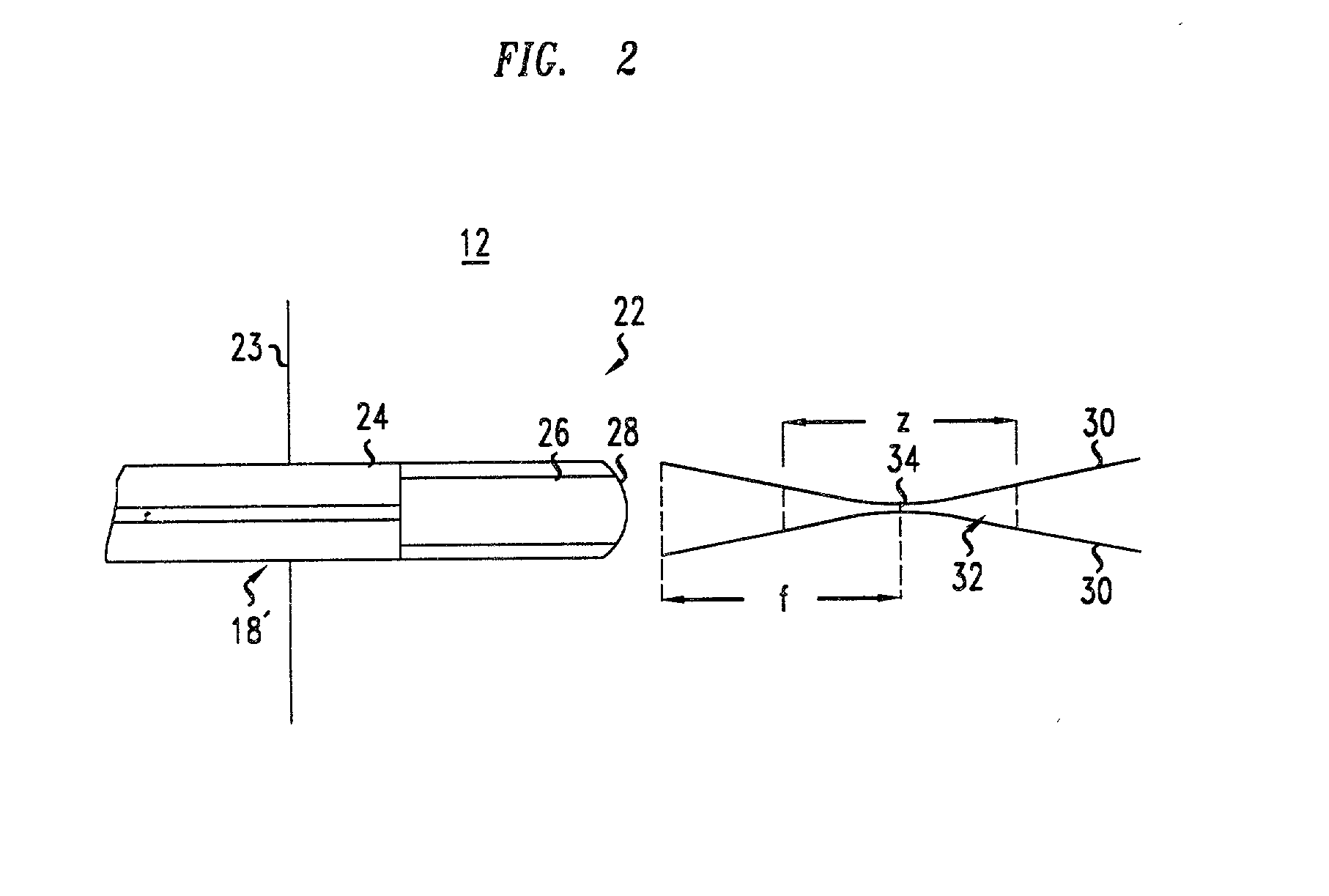

An optical system for monitoring or imaging a sample includes a probe, an optical splitter or circulator, and an optical detector. The probe includes an optical fiber and a GRIN fiber-size lens fused to one end of the fiber. The optical splitter or circulator receives light from a source and directs a portion of the received light to the fiber. The optical detector is coupled to receive a portion of light collected from the sample by the GRIN fiber-size lens and is configured determine a characteristic of the sample from the received light.

Owner:LUCENT TECH INC

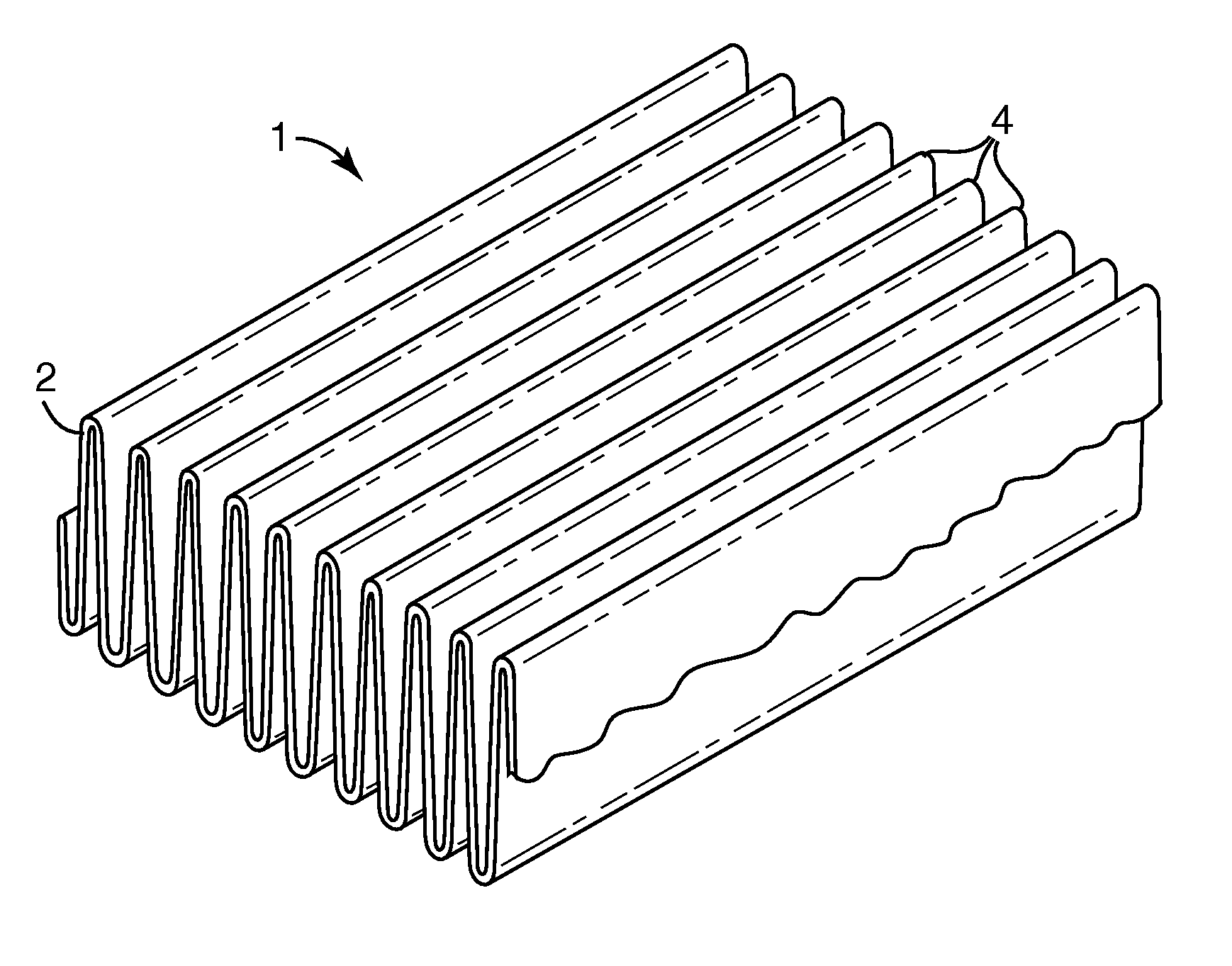

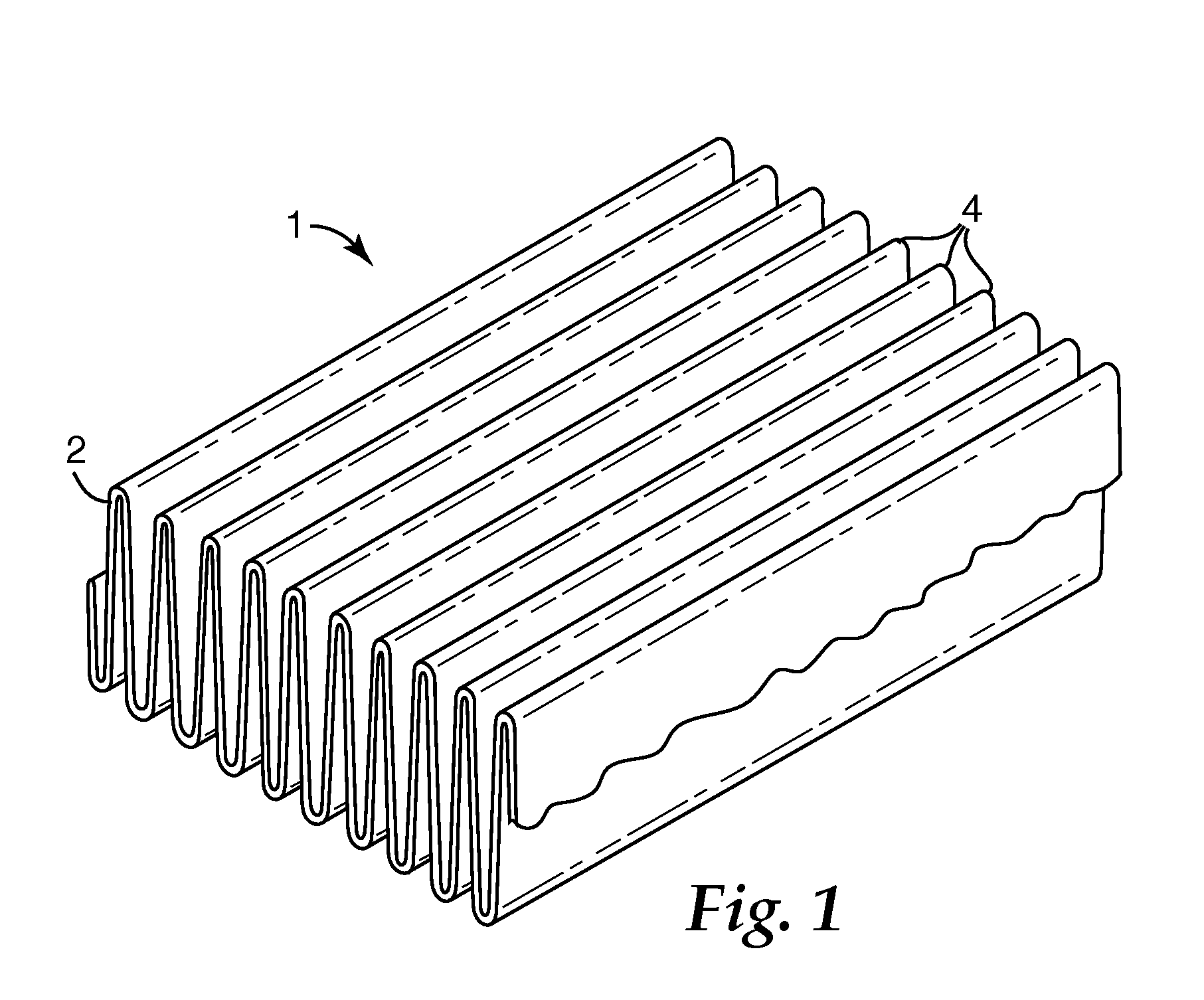

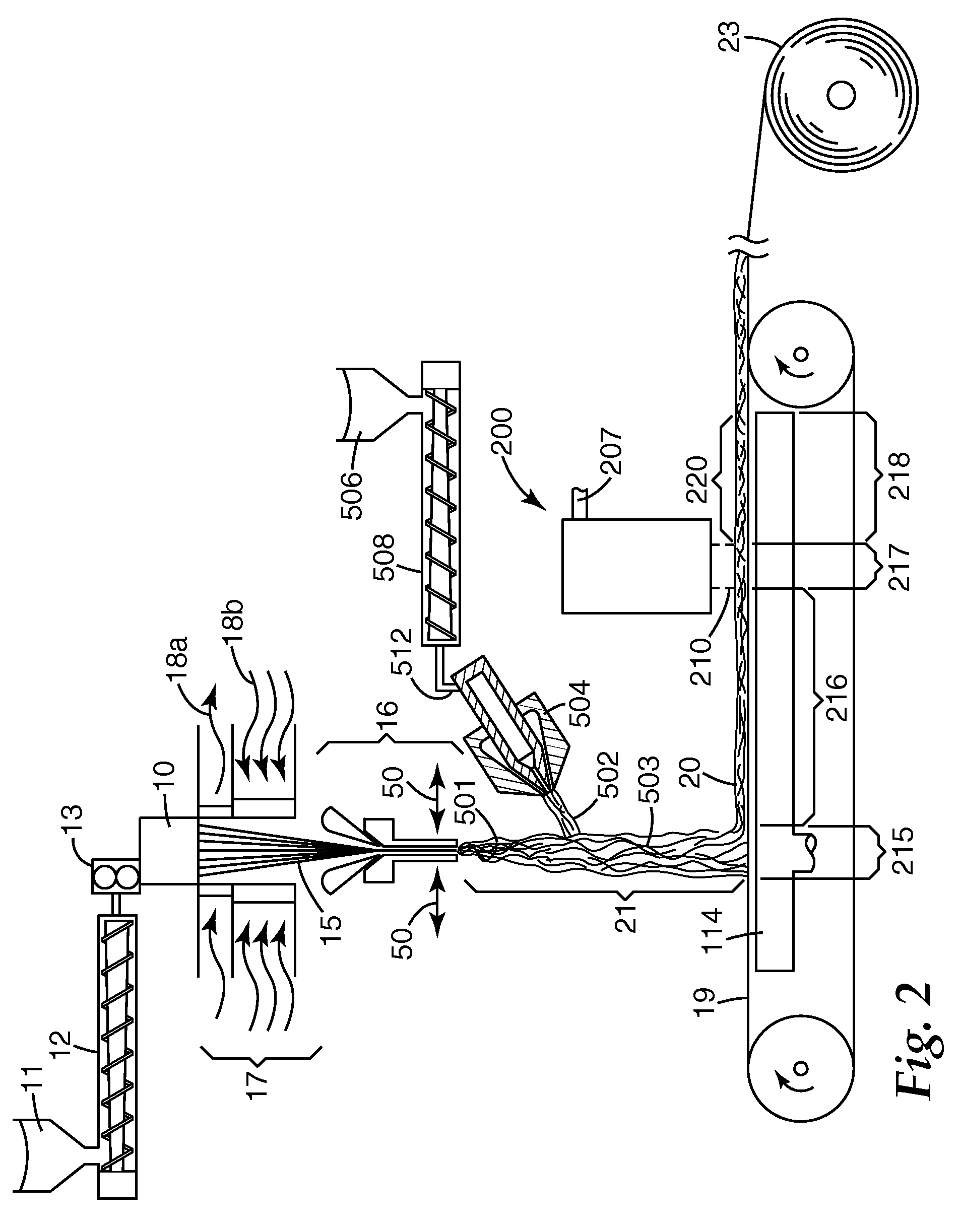

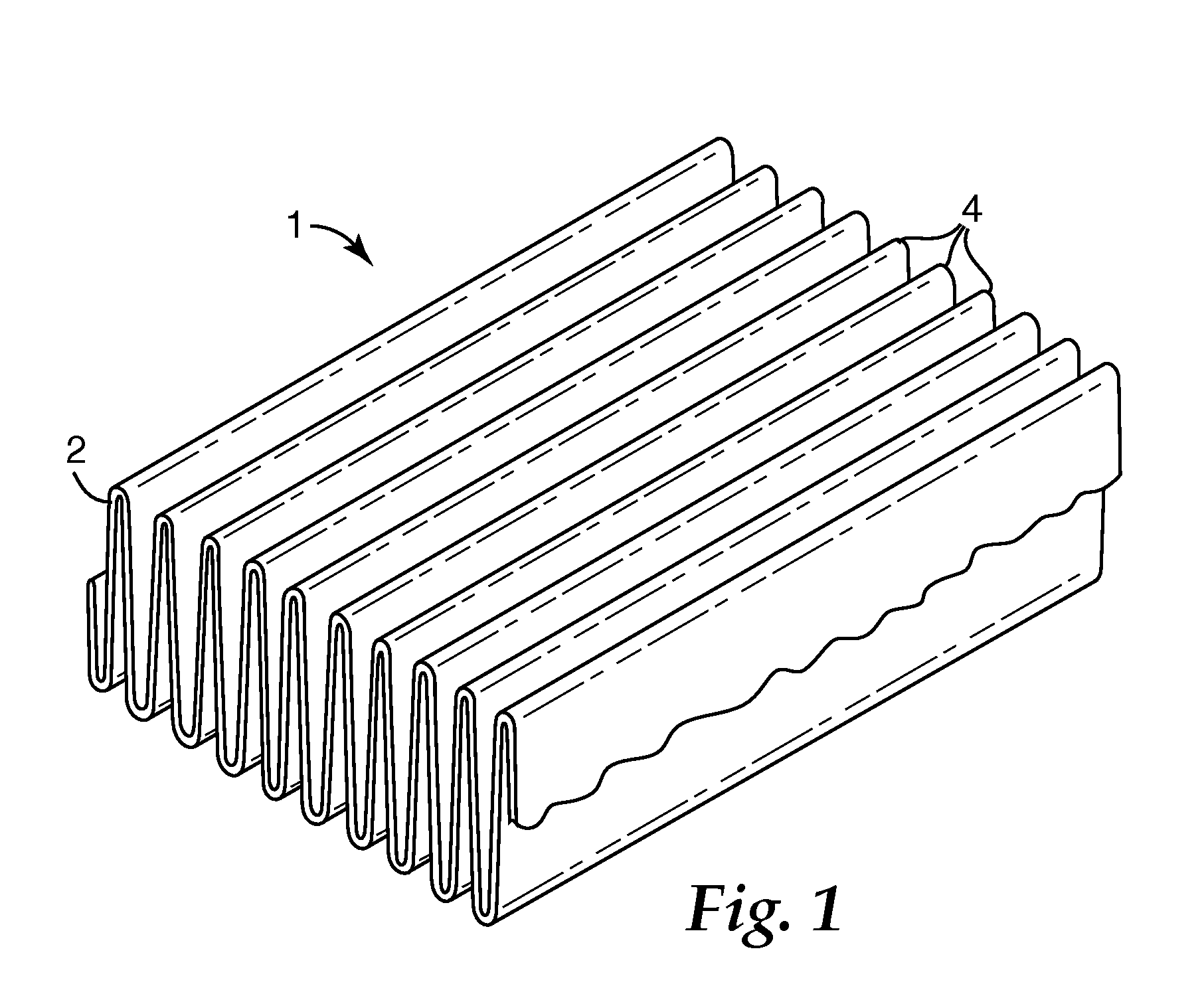

Pleated filter with bimodal monolayer monocomponent media

InactiveUS20080022643A1Improve filtering effectIncrease fiber surface areaDispersed particle filtrationLoose filtering material filtersPolymer scienceFilter media

A pleated filter is made from a monocomponent monolayer nonwoven web containing a bimodal mass fraction / fiber size mixture of intermingled larger size and smaller size continuous monocomponent polymeric fibers of the same polymeric composition. Rows of pleats are formed in the nonwoven web, and the pleated web is cut to a desired size and shape to provide a filter element containing a self-supporting porous monocomponent monolayer matrix of fibers bonded to one another at at least some points of fiber intersection and having an average initial submicron efficiency of at least 15% at a 1.52 meters / sec face velocity. The filter element is deformation resistant without requiring stiffening layers, bicomponent fibers or other reinforcing measures in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

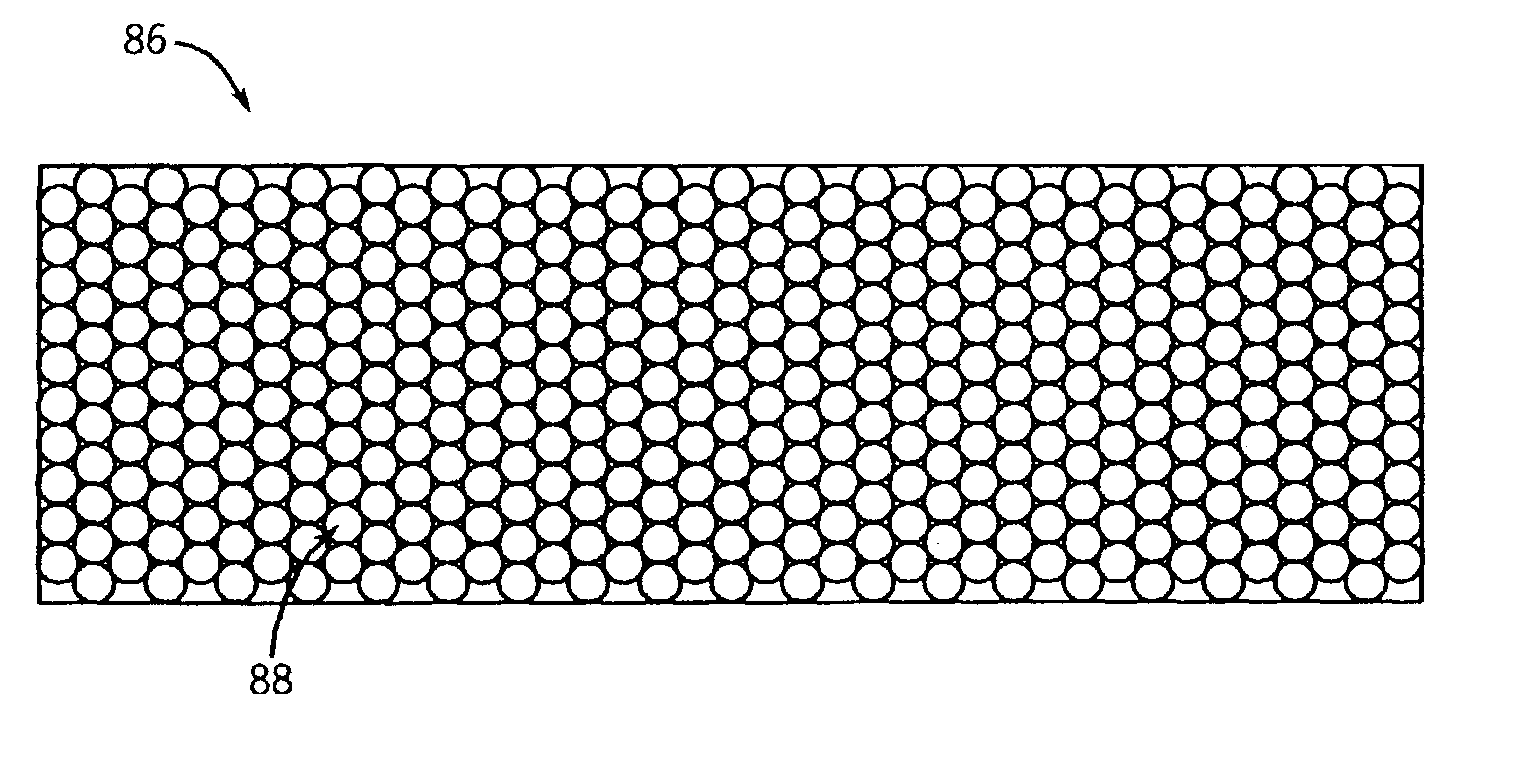

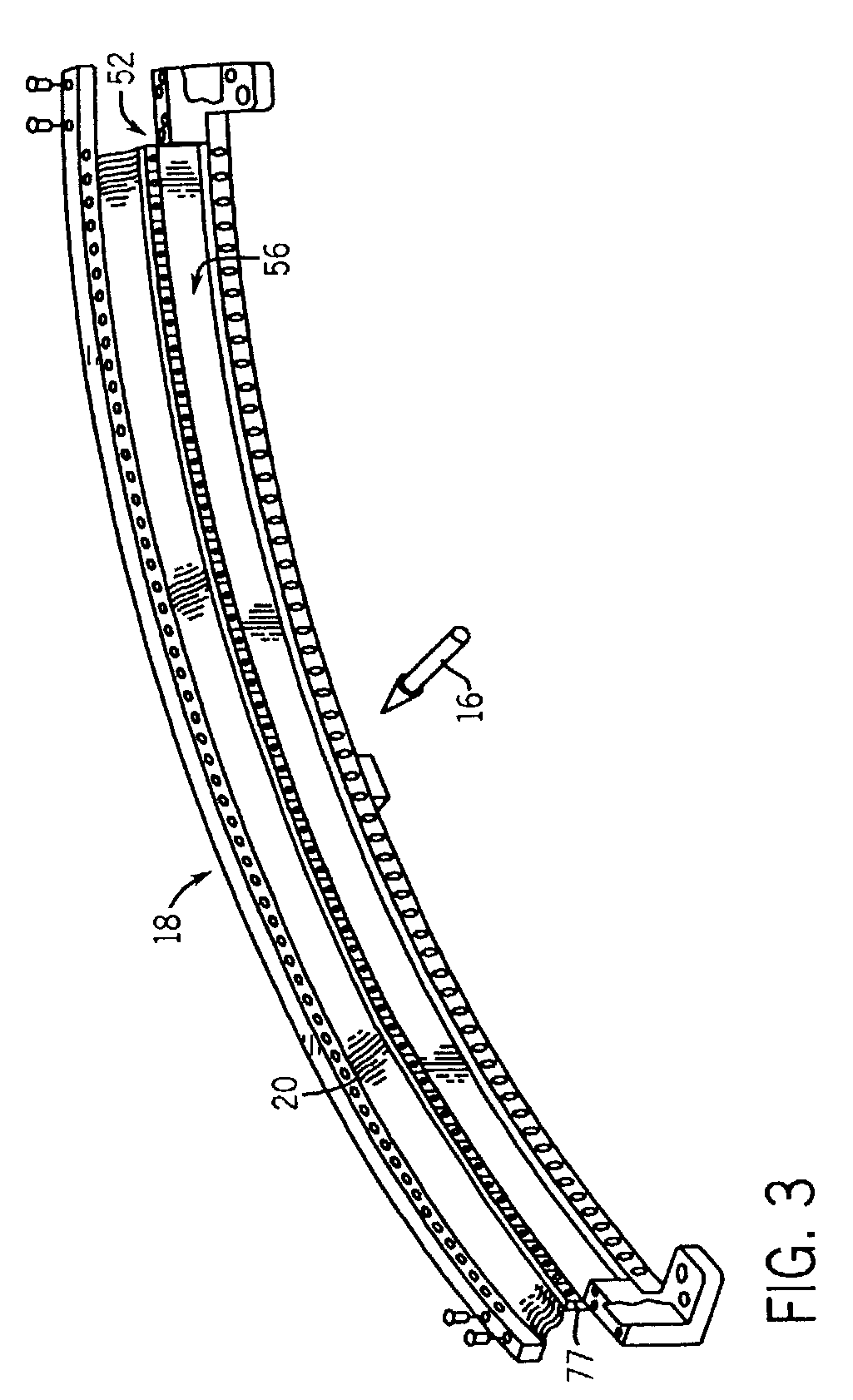

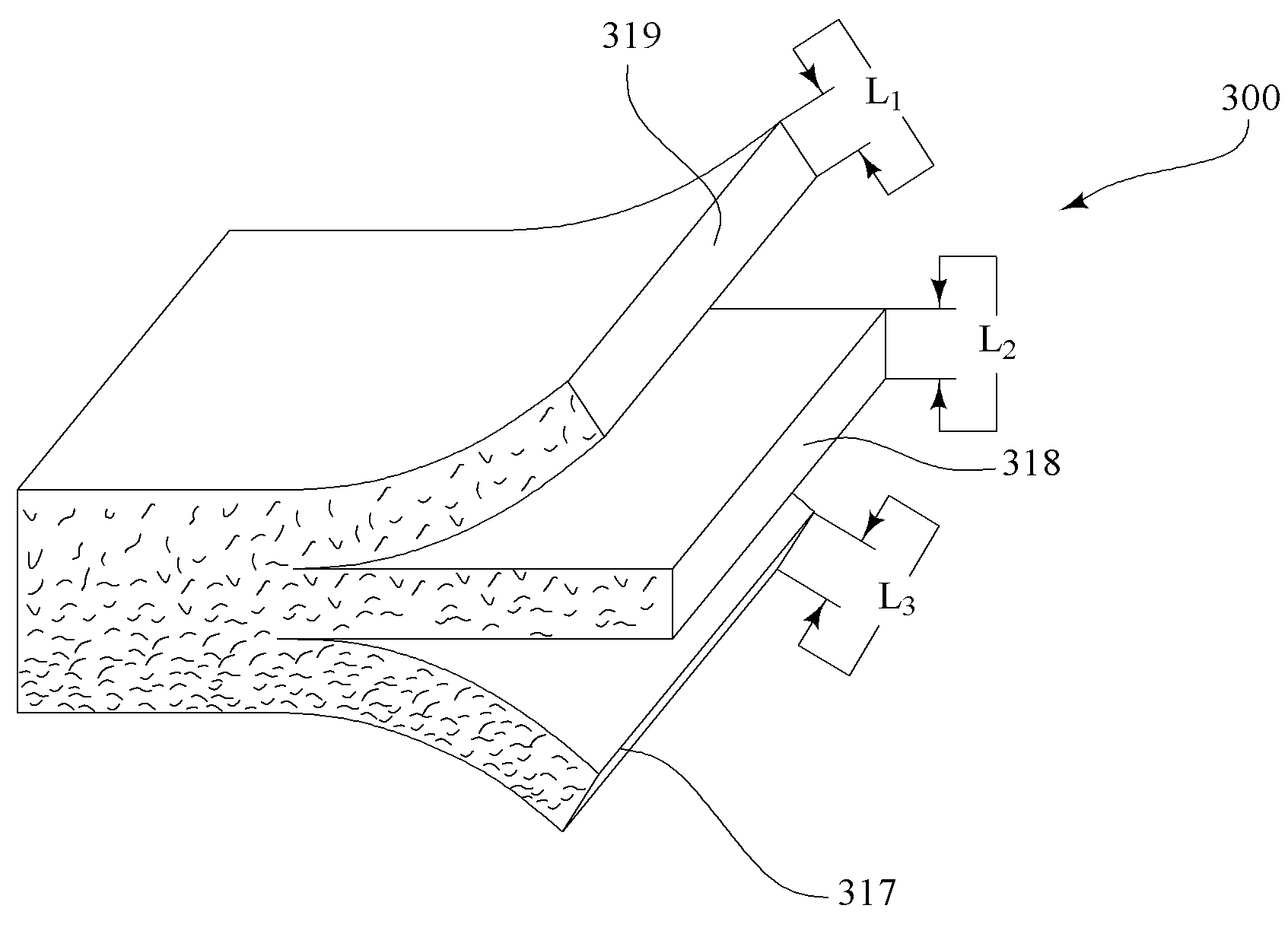

CT detector array having non pixelated scintillator array

InactiveUS7054408B2Improve efficiencyImprove light outputSolid-state devicesHandling using diaphragms/collimetersImage resolutionScattering loss

Owner:GENERAL ELECTRIC CO

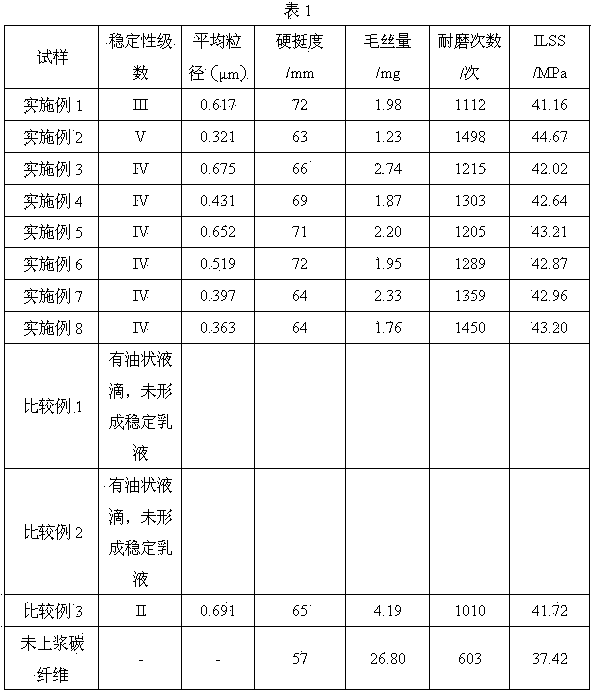

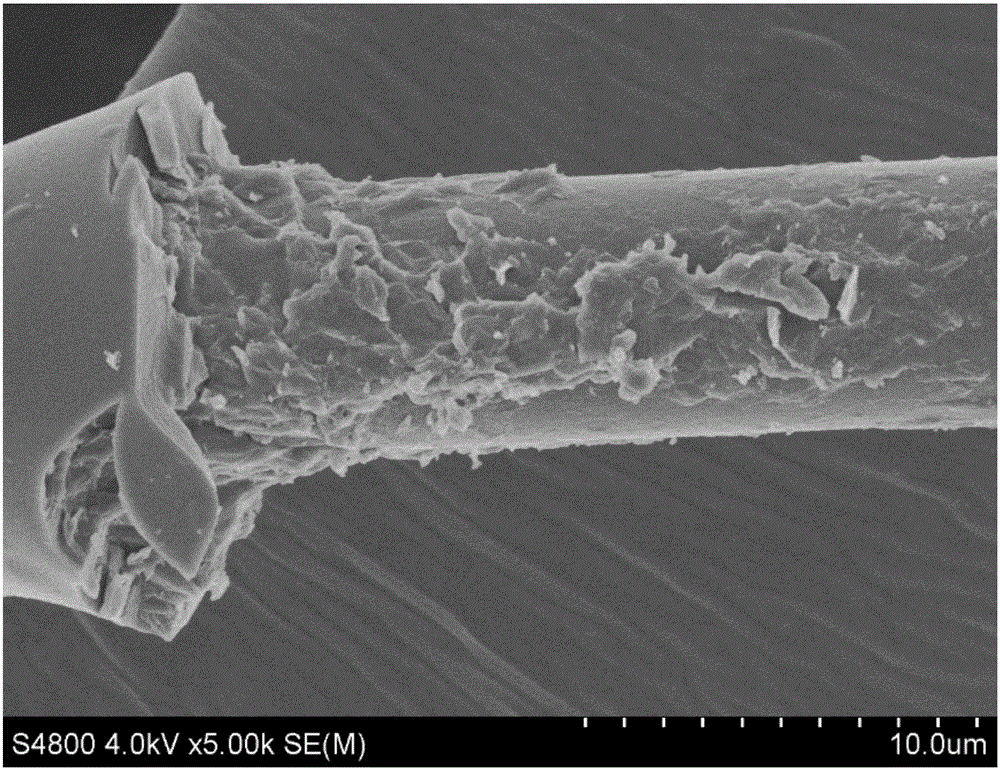

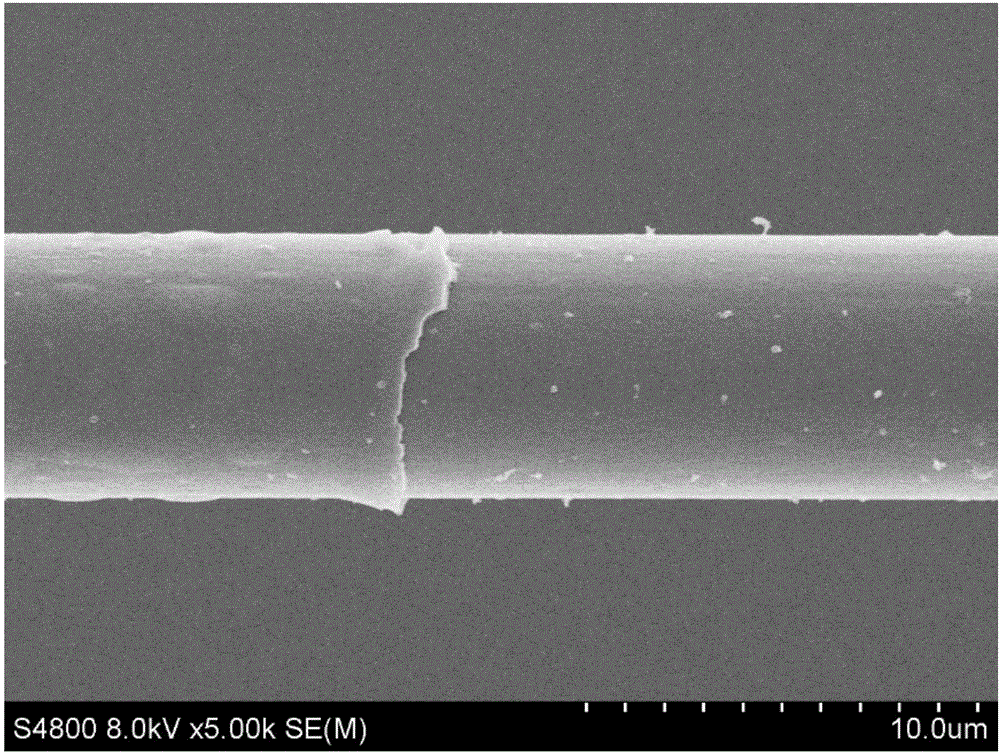

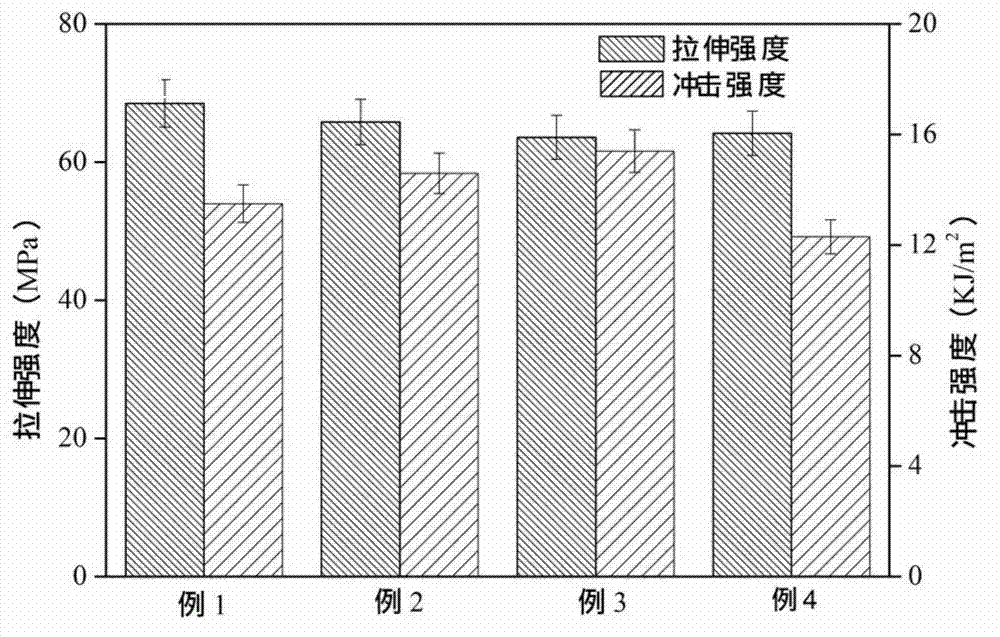

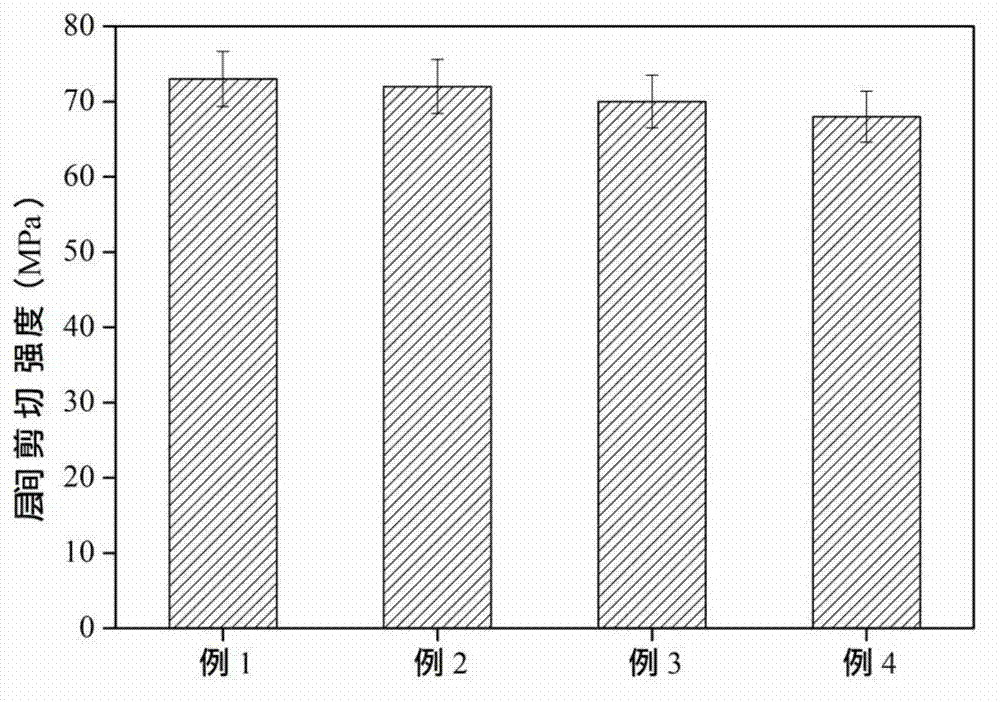

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

Product and Method of Forming a Gradient Density Fibrous Filter

InactiveUS20070227359A1Improve filtering effectImprove filtration efficiencyCombination devicesIsotope separationPolymer scienceFilter media

A filter media product and method of making the same wherein at least two filter media thicknesses of differing average coarse and fine fiber sizes are held in intertangled relationship forming a gradient density fibrous filter media with the fiber sizes having an overall average in successive thicknesses being either greater or less than the average fiber size of the intertangled fiber thickness(es).

Owner:AAF MCQUAY INC

Carbon fiber emulsion sizing agent improved by carbon nano tube and preparation method of carbon fiber emulsion sizing agent

InactiveCN102212967APlay the role of stress transmissionIncreased interlaminar shear strengthCarbon fibresEmulsionCarbon fibers

The invention relates to a carbon fiber emulsion sizing agent improved by a carbon nano tube and a preparation method of the carbon fiber emulsion sizing agent. The carbon fiber emulsion sizing agent comprises a carbon fiber sizing agent, the carbon nano tube, a dispersing agent and a solvent. The preparation method comprises the following steps of: 1, preparing the carbon fiber sizing agent; and 2, adding the carbon fiber sizing agent into the solvent to prepare a sizing working solution, mixing the carbon nano tube and the sizing working solution, performing ultrasonic treatment for 1 to 4 hours at the power of 300 to 600w, adding the dispersing agent, and performing ultrasonic dispersion for 2 to 4 hours to obtain the carbon fiber emulsion sizing agent improved by the carbon nano tube. The carbon fiber emulsion sizing agent has favorable stability, the post processability of carbon fiber can be improved after being processed by the emulsion sizing agent, the interfacial bond strength between the carbon fiber and substrate resin can be enhanced, the shear strength among layers is enhanced, and the performance of a composite material is improved to a certain extent. Moreover, the preparation method is simple, low in cost and environment-friendly.

Owner:DONGHUA UNIV

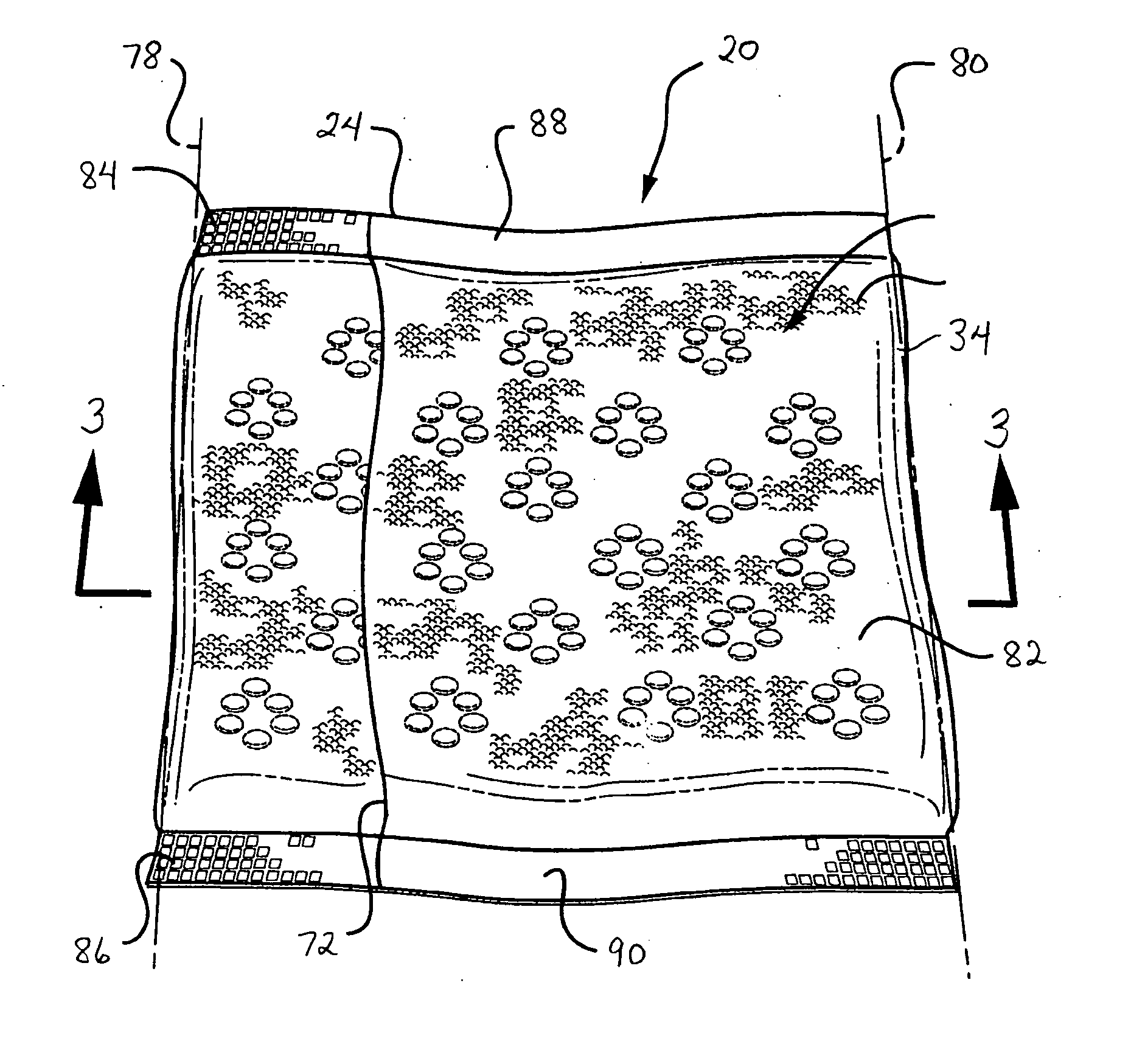

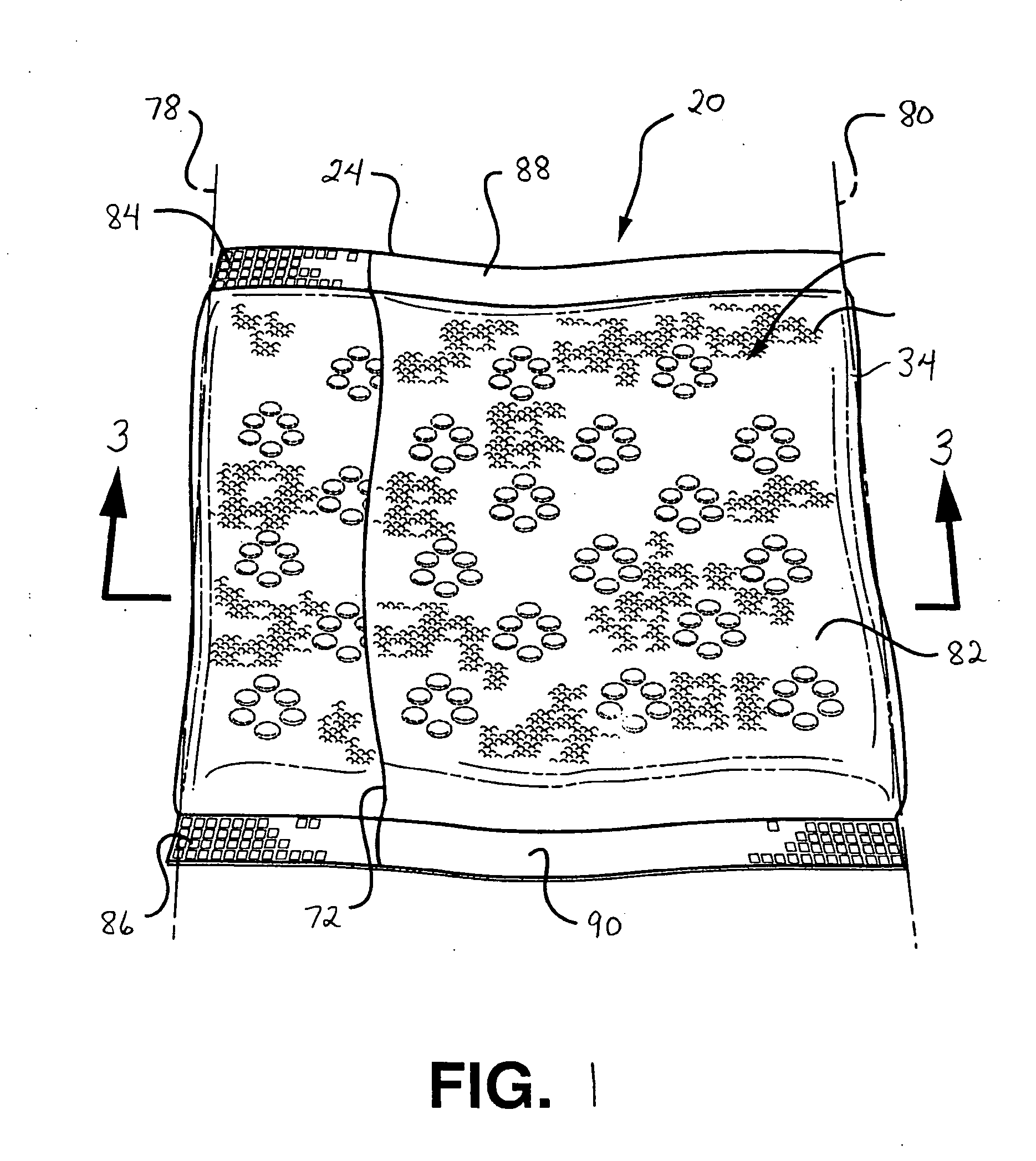

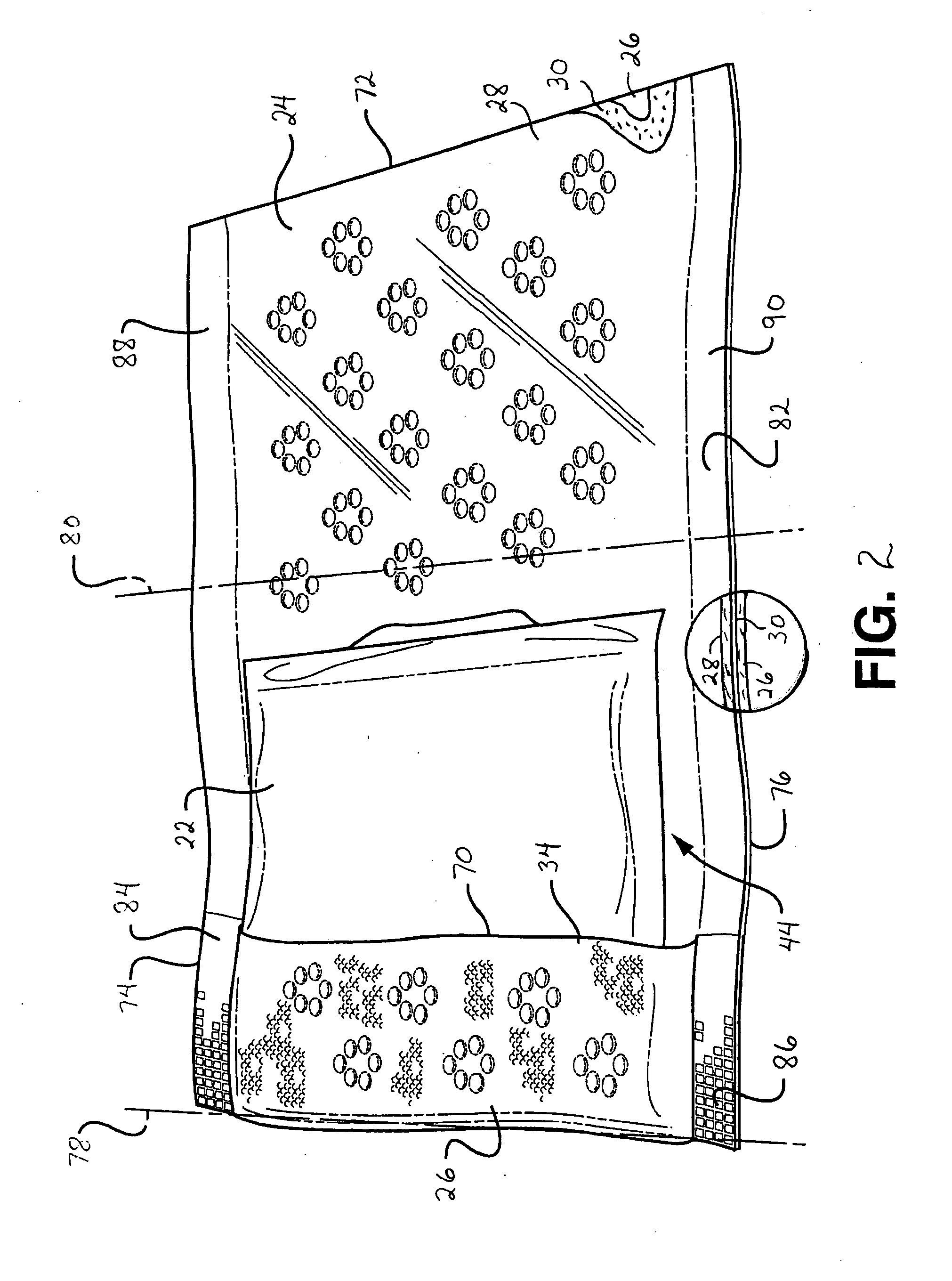

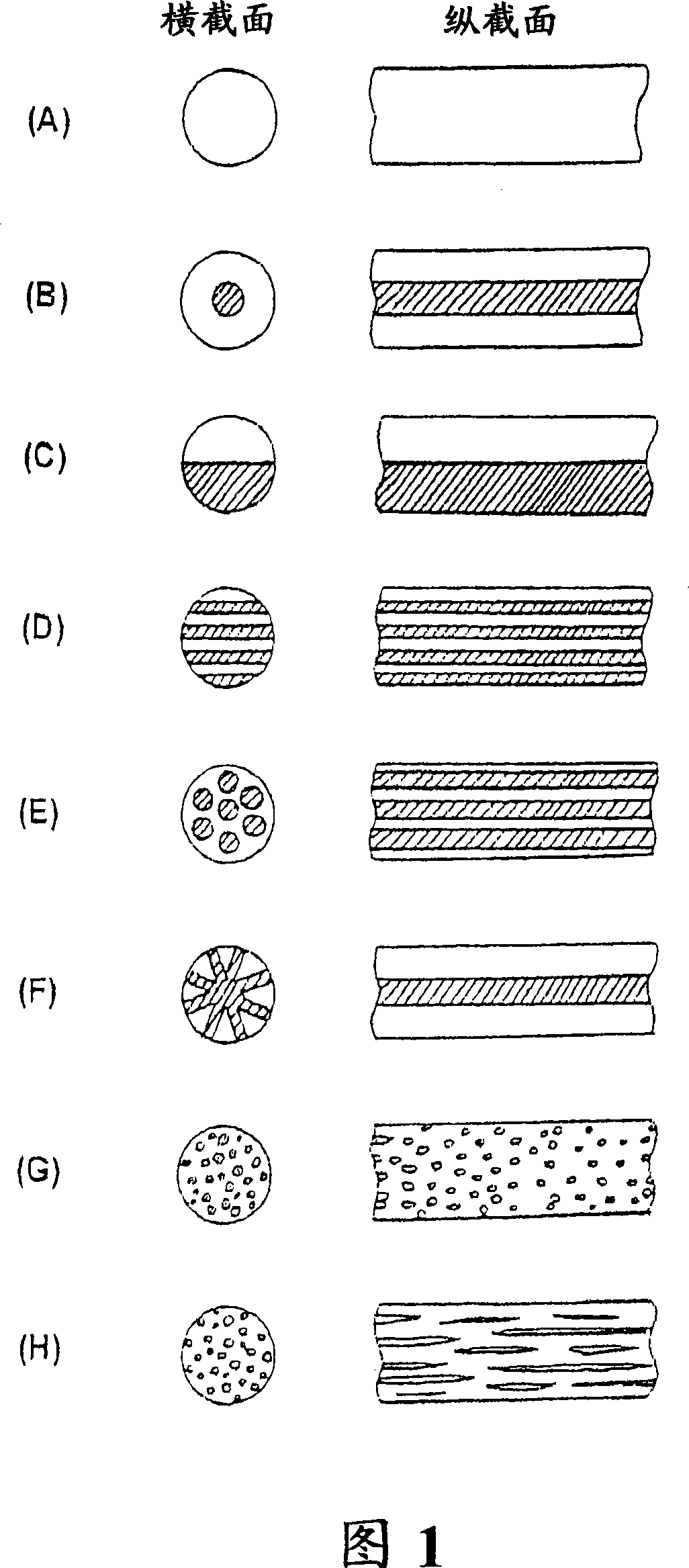

Absorbent personal care article with a wrap member having distinct component layers

InactiveUS20070073255A1Effective controlEasy to processBaby linensTamponsPersonal careBiomedical engineering

A wrapped article (20) includes a personal care absorbent personal care article (22), and a separately provided wrap member (24) which operatively encloses the absorbent personal care article (22). At least a major portion of the wrap member (24) includes an outer layer (26), an inner layer (28) and an intermediate layer (30) that is sandwiched between the inner and outer layers, and includes an operative amount of an odor control agent (32). In particular aspects, the intermediate layer (30) can include a nonwoven fibrous web, and the fibrous web can have selected fiber sizes. In another aspect, the intermediate layer (30) of the wrap member (24) can include a meltblown nonwoven web. In further aspects, the outer layer (26) can include a nonwoven fibrous web having particular fiber sizes, and the inner layer (28) can include another nonwoven fibrous web having the same or different fiber sizes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Fiber size, sized reinforcements, and articles reinforced with such reinforcements

InactiveUS20050163998A1Improve the immunityExcellent characteristicsFibre treatmentSpecial tyresPolyolefinCoupling

A fiber-size composition contains a modified polyolefin, a hydrophilic coupling agent, and an enhancer with at least one of the following: a fluorine-containing compound, a hydrophobic coupling agent, a cyclic fatty acid, or at least two saturated fatty acids with at least one of said fatty acids having at least two acid groups. When reinforcing fiber materials sized with the composition are used to form composite articles, the articles show improved properties such as strength and color.

Owner:OWENS CORNING COMPOSITES +1

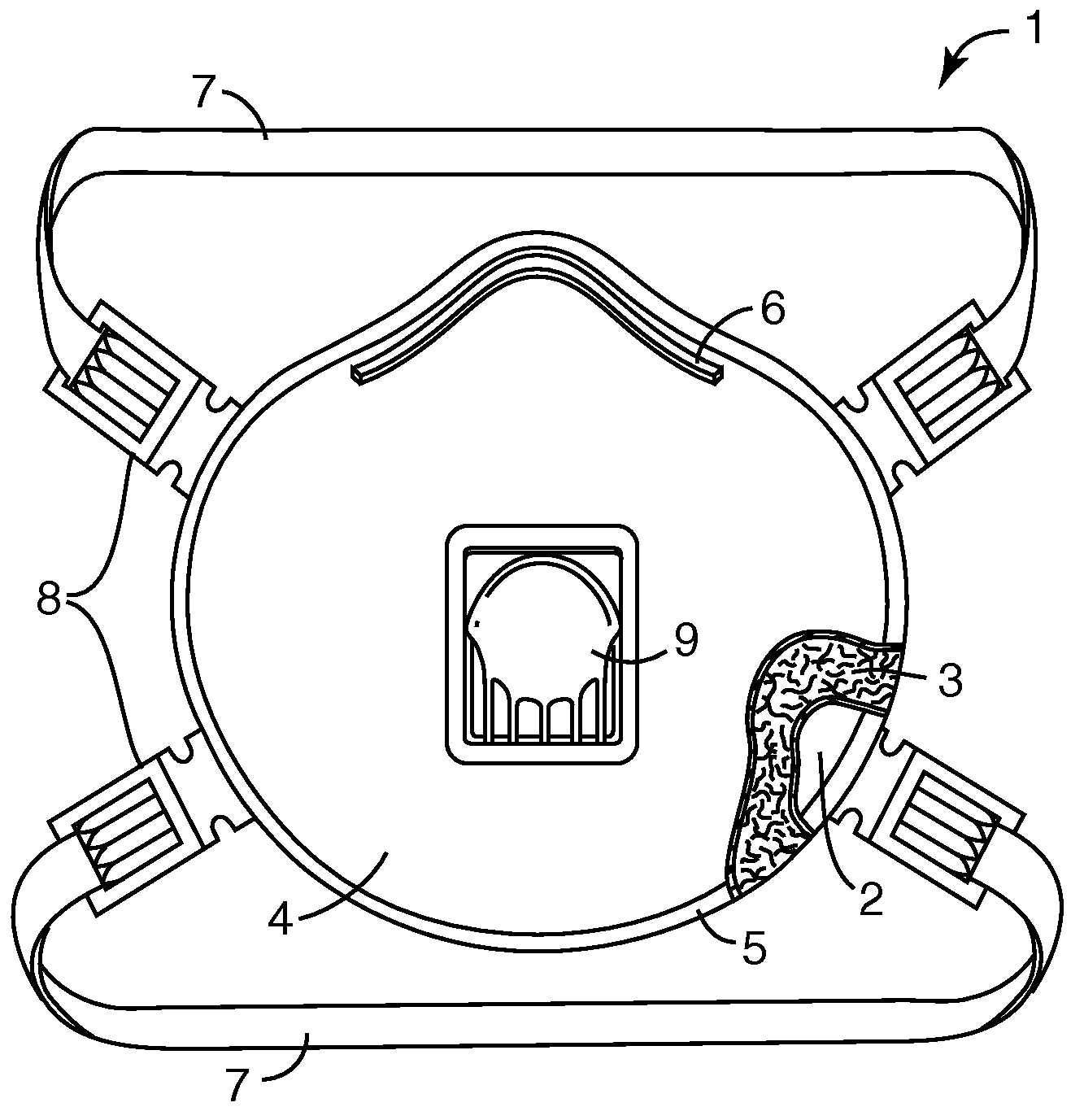

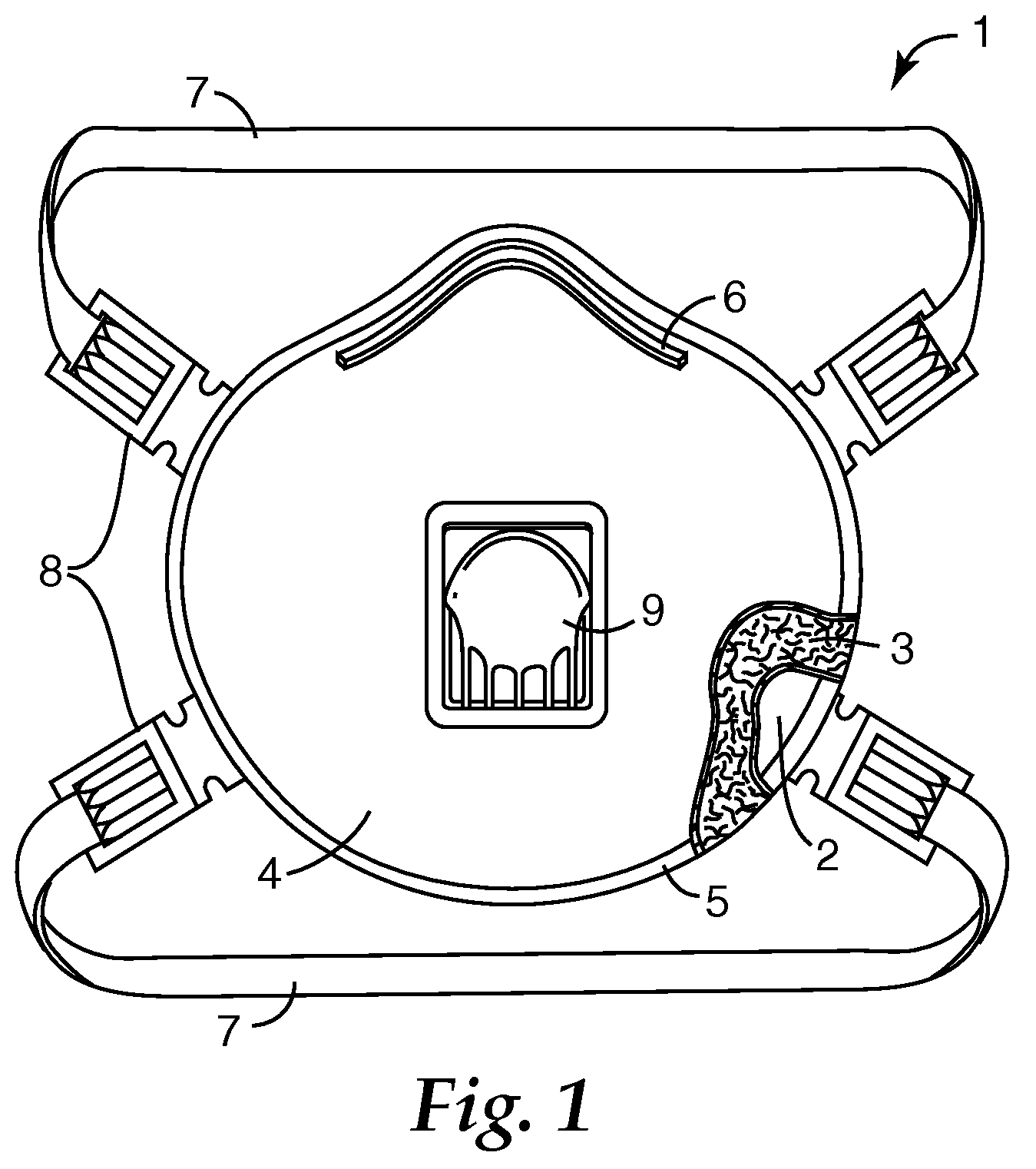

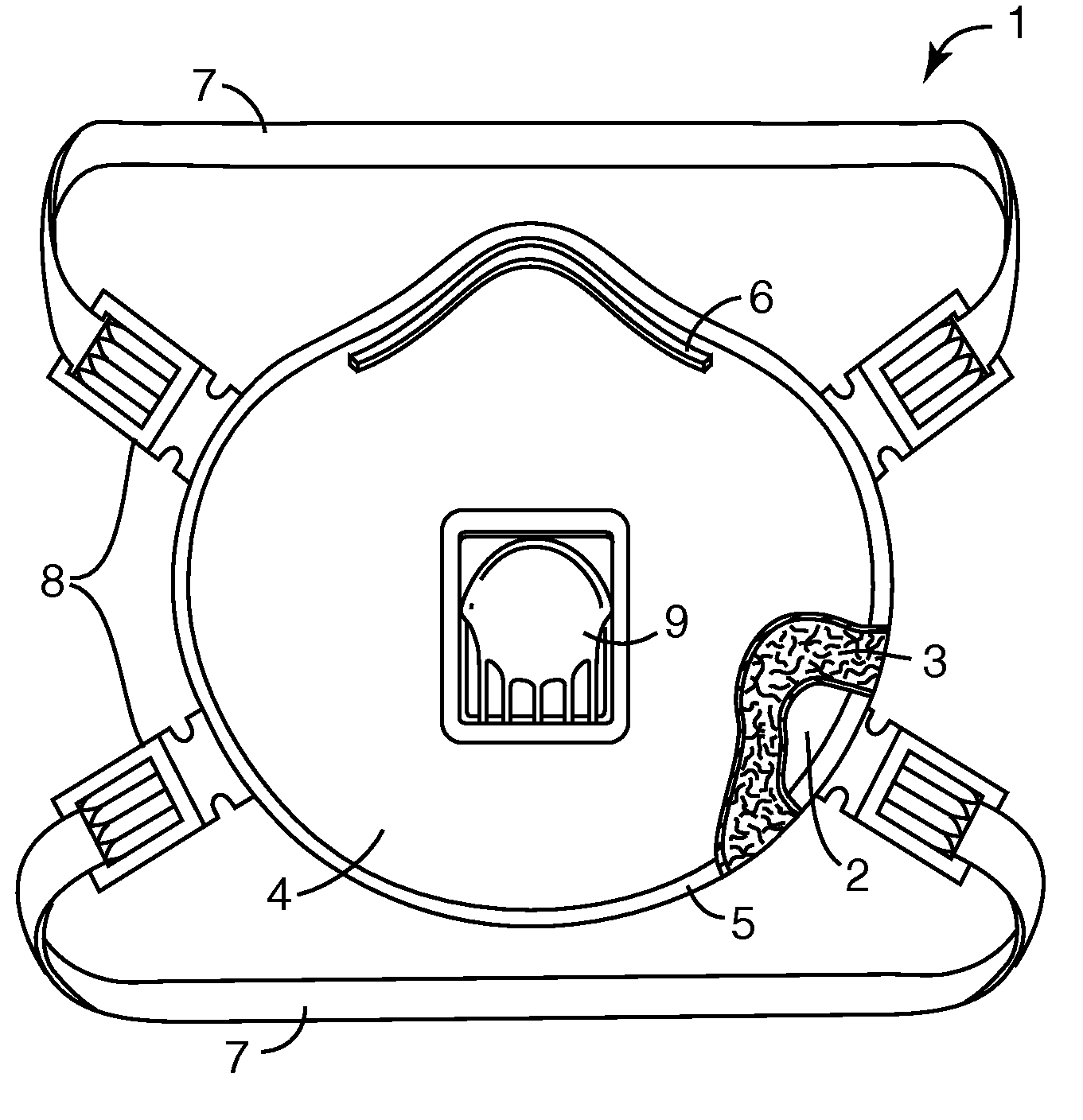

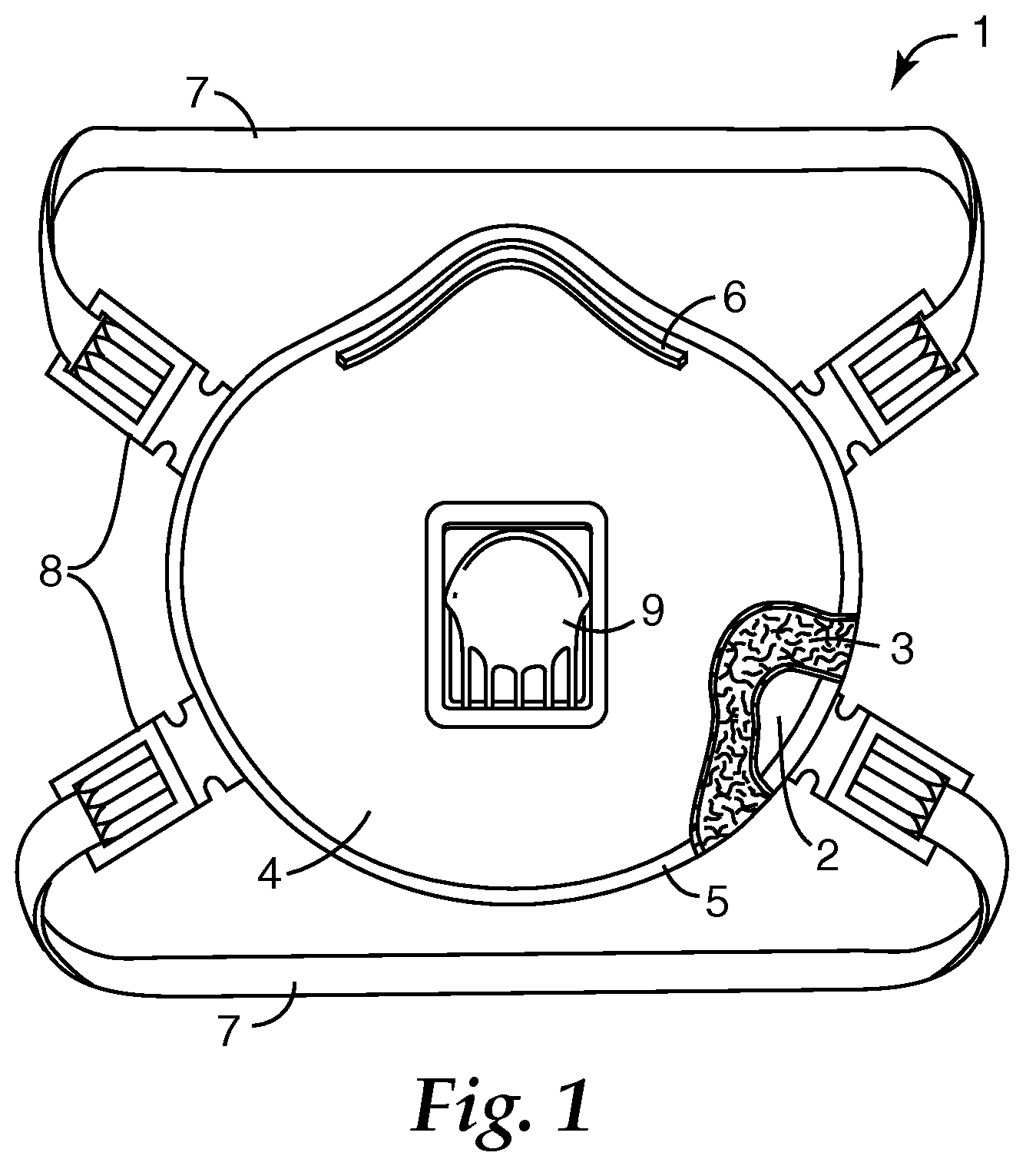

Molded Monocomponent Monolayer Respirator With Bimodal Monolayer Monocomponent Media

InactiveUS20080026173A1Good molding effectIncrease fiber surface areaBreathing filtersLayered productsPolymer scienceRespirator

A molded respirator is made from a monocomponent monolayer nonwoven web containing a bimodal mass fraction / fiber size mixture of intermingled continuous monocomponent polymeric microfibers and larger size fibers of the same polymeric composition. The respirator is a cup-shaped porous monocomponent monolayer matrix whose matrix fibers are bonded to one another at at least some points of fiber intersection. The matrix has a King Stiffness greater than 1 N. The respirator may be formed without requiring stiffening layers, bicomponent fibers, or other reinforcement in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

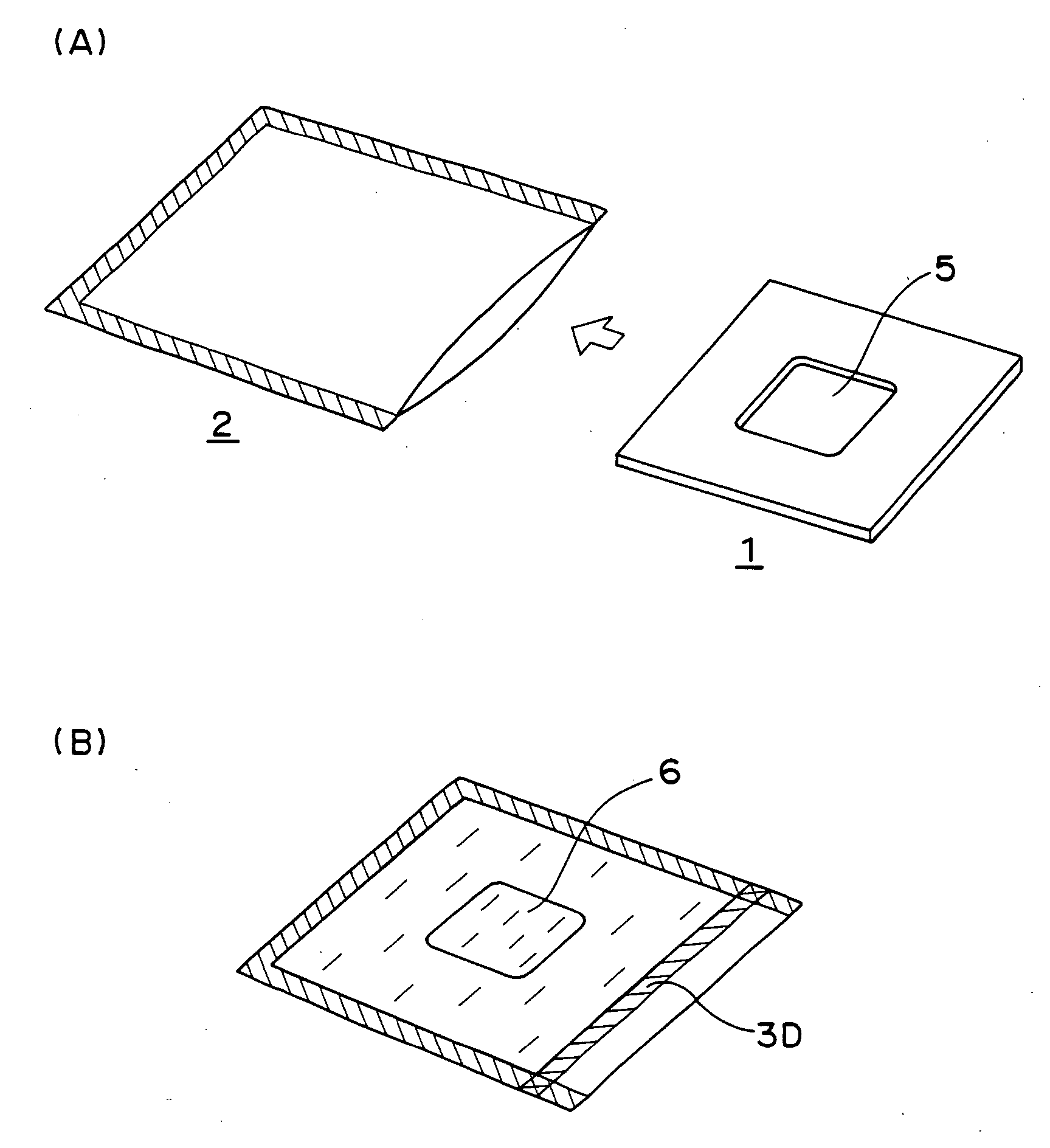

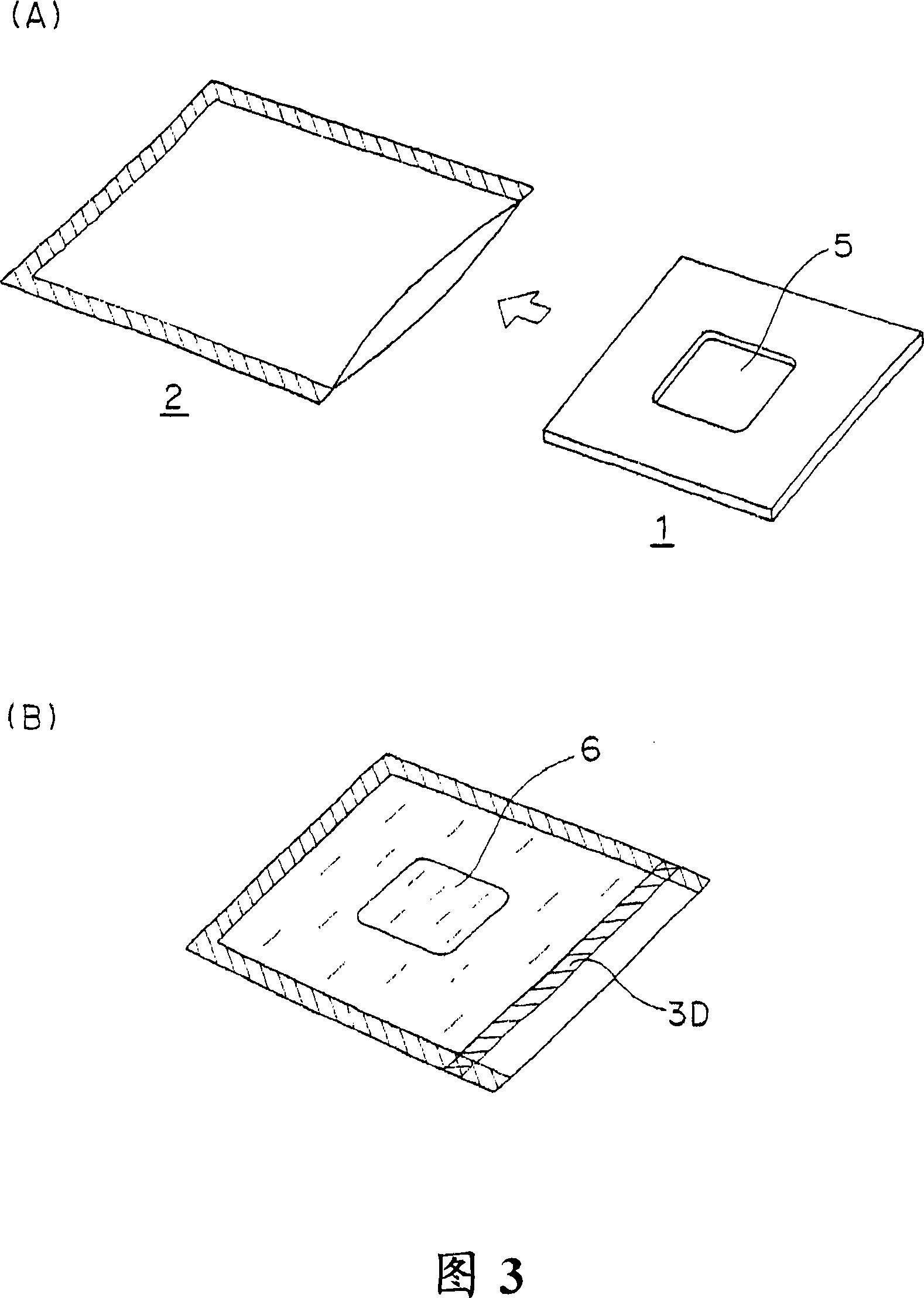

Vacuum Heat Insulator

InactiveUS20080095970A1Low environmental loadImprove recycling efficiencyEnvelopes/bags making machineryThermal insulationPolyesterMaterials science

The present invention provides a heat insulator that is extremely low in environmental load during production and recycling, is superior in handleability and workability, and shows favorable heat-insulating properties over an extended period of time. The present invention relates to vacuum heat insulator, comprising at least a core member and an external packaging member that stores the core member and can keep inside under reduced pressure, wherein the core member is a sheet-shaped fiber aggregate containing a polyester fiber having fiber size of 1 to 6 deniers in an amount of 50 wt % or more.

Owner:SAMSUNG R&D INSTITUTE JAPAN CO LTD

Grin-fiber lens based optical endoscopes

An optical system for monitoring or imaging a sample includes a probe, an optical splitter or circulator, and an optical detector. The probe includes an optical fiber and a GRIN fiber-size lens fused to one end of the fiber. The optical splitter or circulator receives light from a source and directs a portion of the received light to the fiber. The optical detector is coupled to receive a portion of light collected from the sample by the GRIN fiber-size lens and is configured determine a characteristic of the sample from the received light.

Owner:LUCENT TECH INC

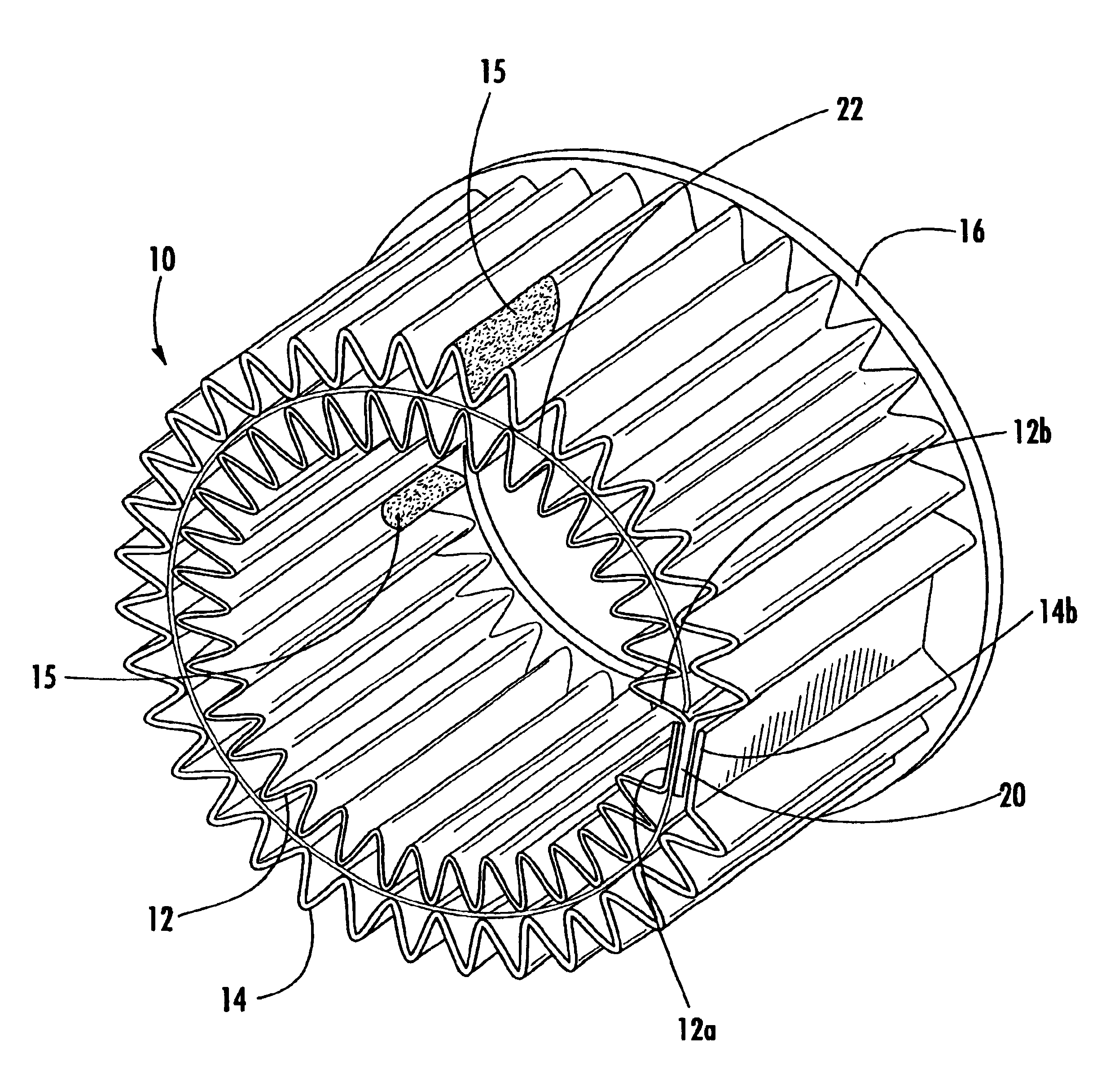

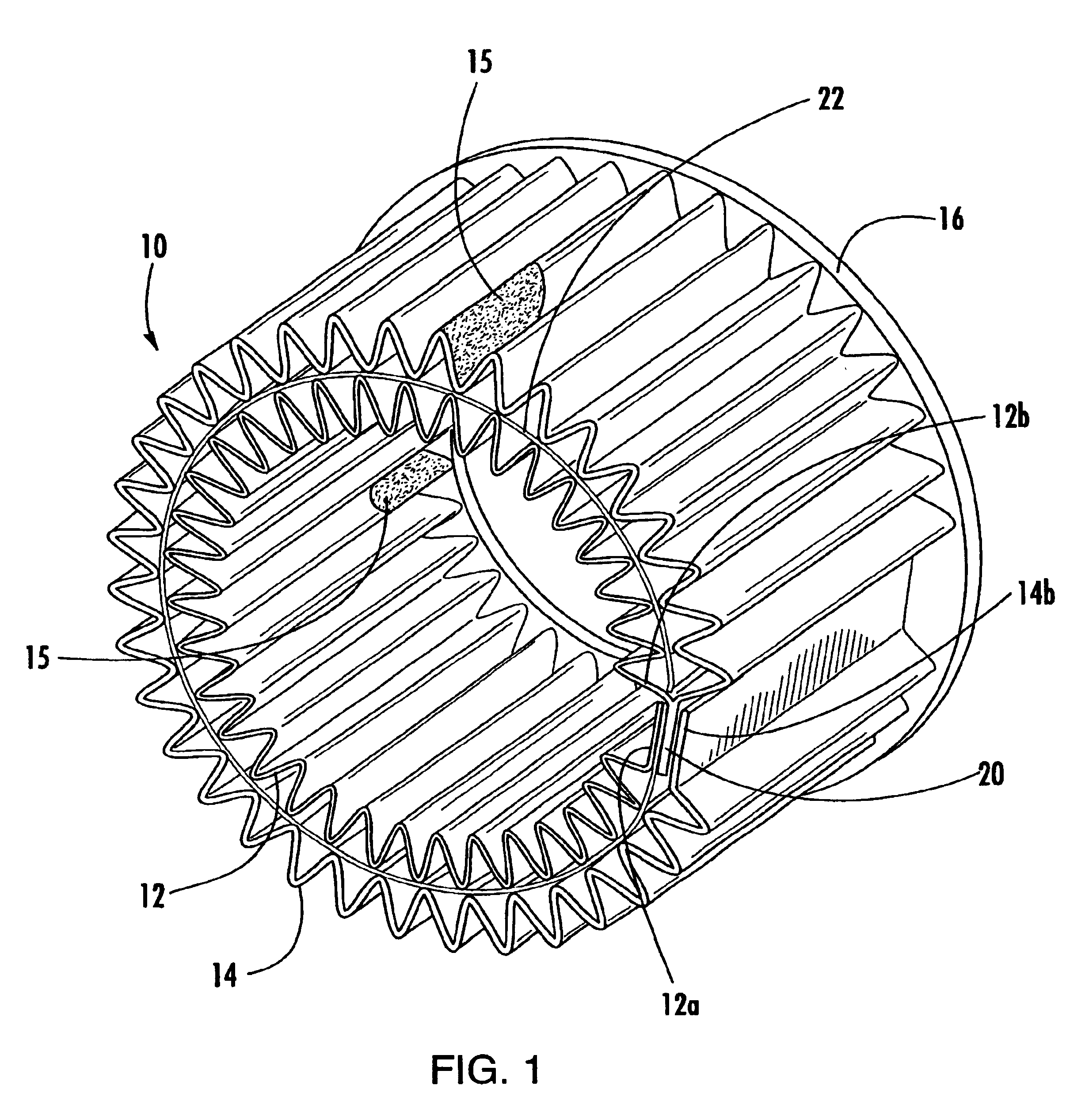

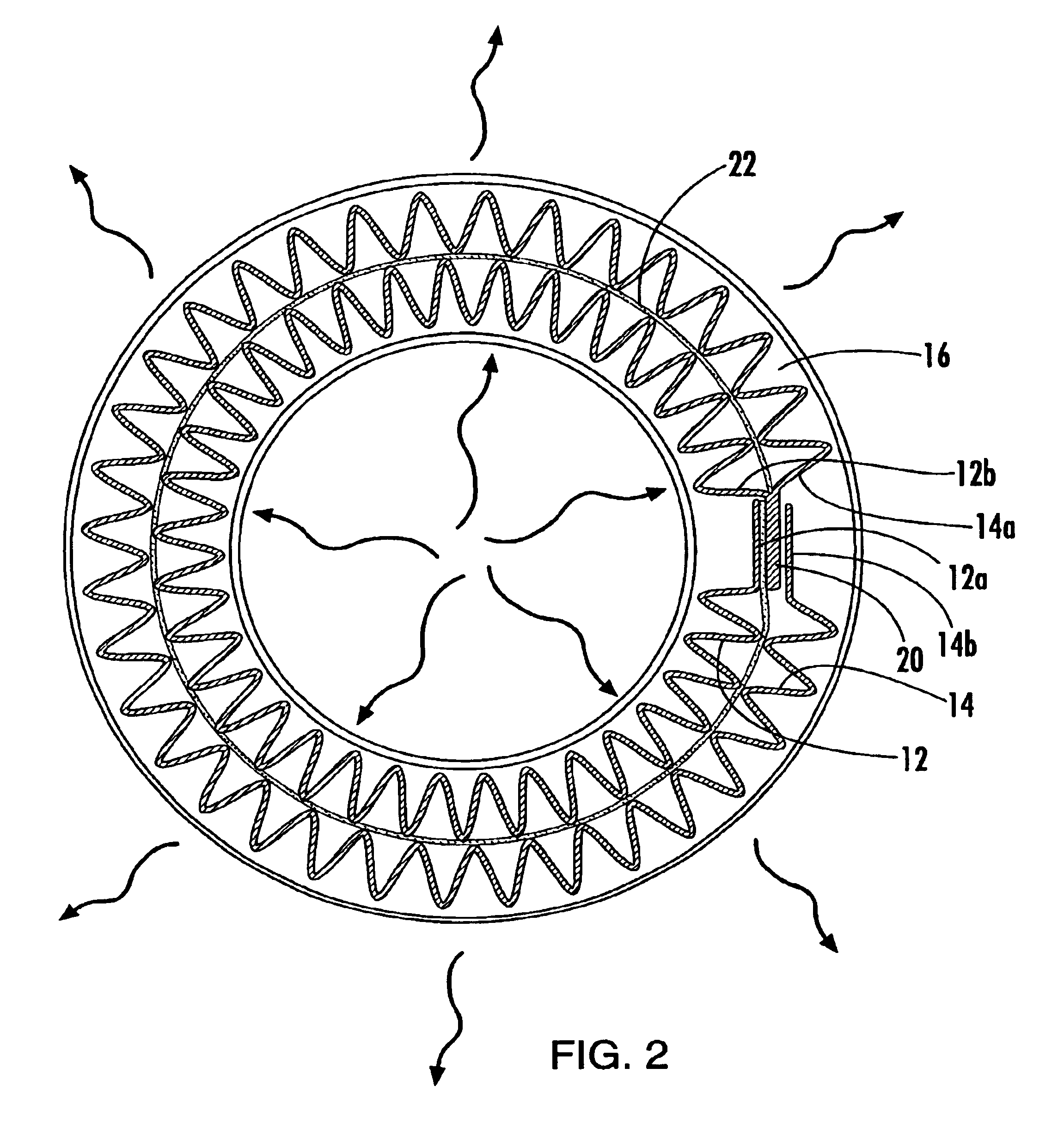

Bifilar diesel exhaust filter construction using sintered metal fibers

InactiveUS6942708B2Overcome disadvantagesCombination devicesAuxillary pretreatmentElectrical resistance and conductanceMetal fiber

A diesel particulate filter construction, for filtering particulate from a flow of exhaust, includes a first layer of electrically resistive metal filter material in line with the flow of exhaust with particulate therein and a second layer of electrically resistive filter material which is also in line with the flow of exhaust with particulate therein. The layers are pleated cylinders concentrically positioned relative to one another. Current from a power supply is routed through the first layer and the second layer, which are electrically connected in series to one another. The layers are positioned so that exhaust flows through both the layers. Sufficient heat is generated by the flow of current through the layers to generate heat to, in turn, burn off entrapped particulate. The layers may be made of made of different materials of different fiber sizes or coated with different catalysts to generate different amounts of heat from one another to improve the filtration characteristics of the particulate filter construction.

Owner:RYPOS

Fiber size, sized reinforcements, and articles reinforced with such reinforcements

InactiveUS20070082199A1Good processing characteristicsImprove adhesionFibre typesYarnHigh intensitySizing

The present invention relates to fiber-size compositions for coating glass or other reinforcing fiber materials that are used in the manufacturing of composites. The fiber-size composition contains at least about 4% by weight of a polyvinylpyrrolidone film former, at least one lubricant and a coupling agent. The sizing composition gives the fibers desirable properties such as high strength, improved flexibility, fuzz formation resistance, and fiber smoothness and softness.

Owner:OCV INTELLECTUAL CAPITAL LLC

Product and method of forming a gradient density fibrous filter

InactiveUS7896941B2Improve filtering effectImprove filtration efficiencyCombination devicesIsotope separationPolymer scienceFilter media

A filter media product and method of making the same wherein at least two filter media thicknesses of differing average coarse and fine fiber sizes are held in intertangled relationship forming a gradient density fibrous filter media with the fiber sizes having an overall average in successive thicknesses being either greater or less than the average fiber size of the intertangled fiber thickness(es).

Owner:AAF MCQUAY INC

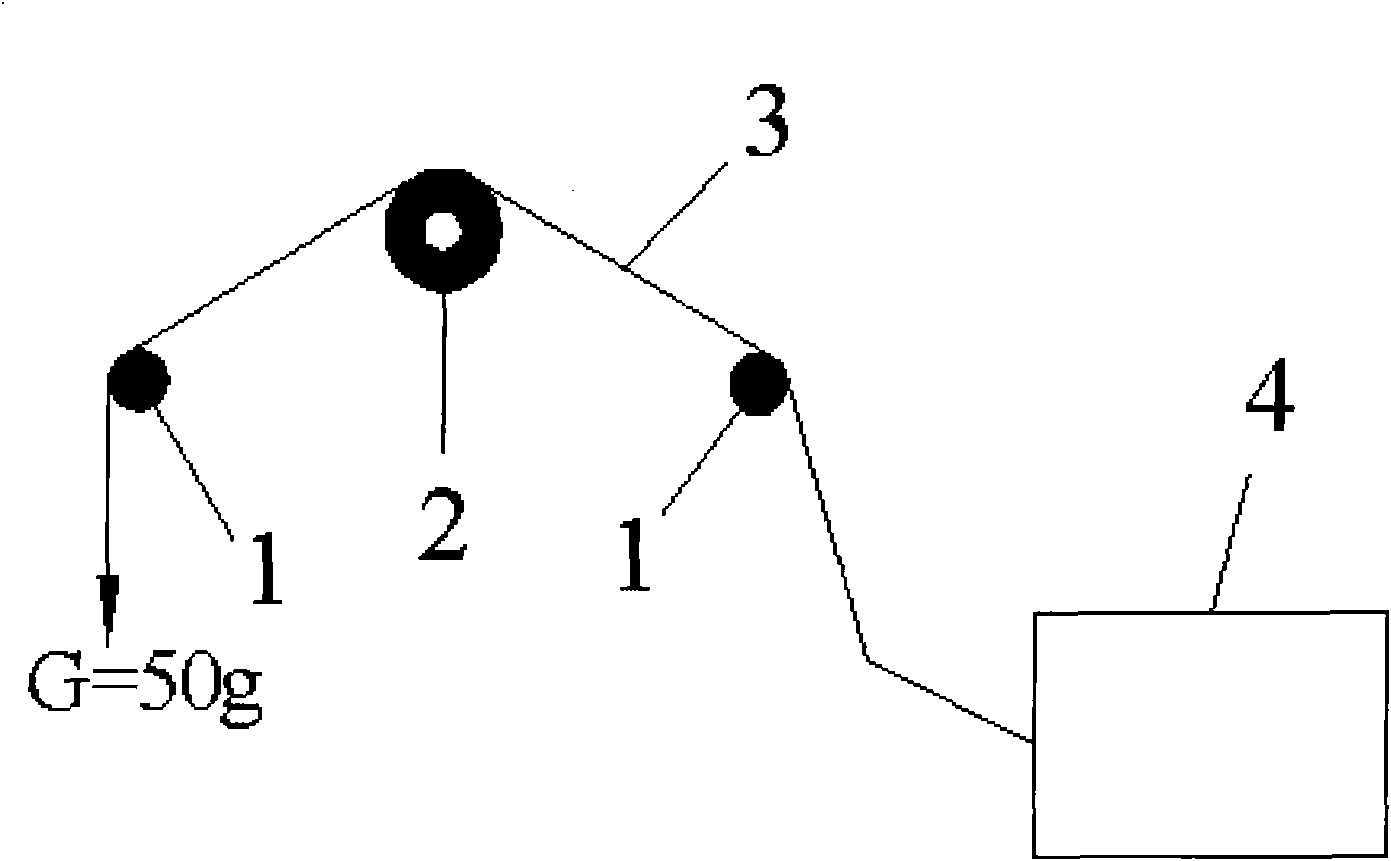

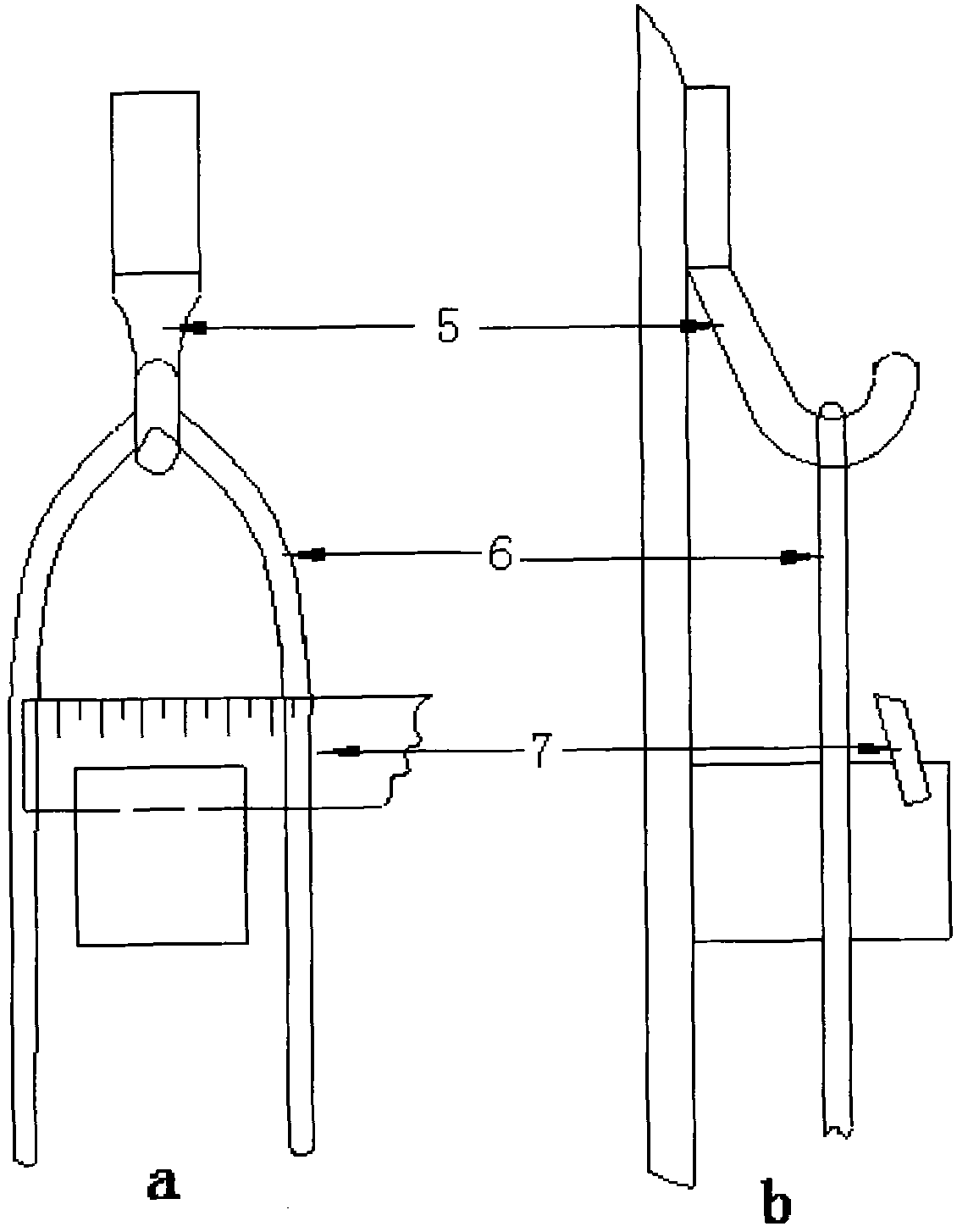

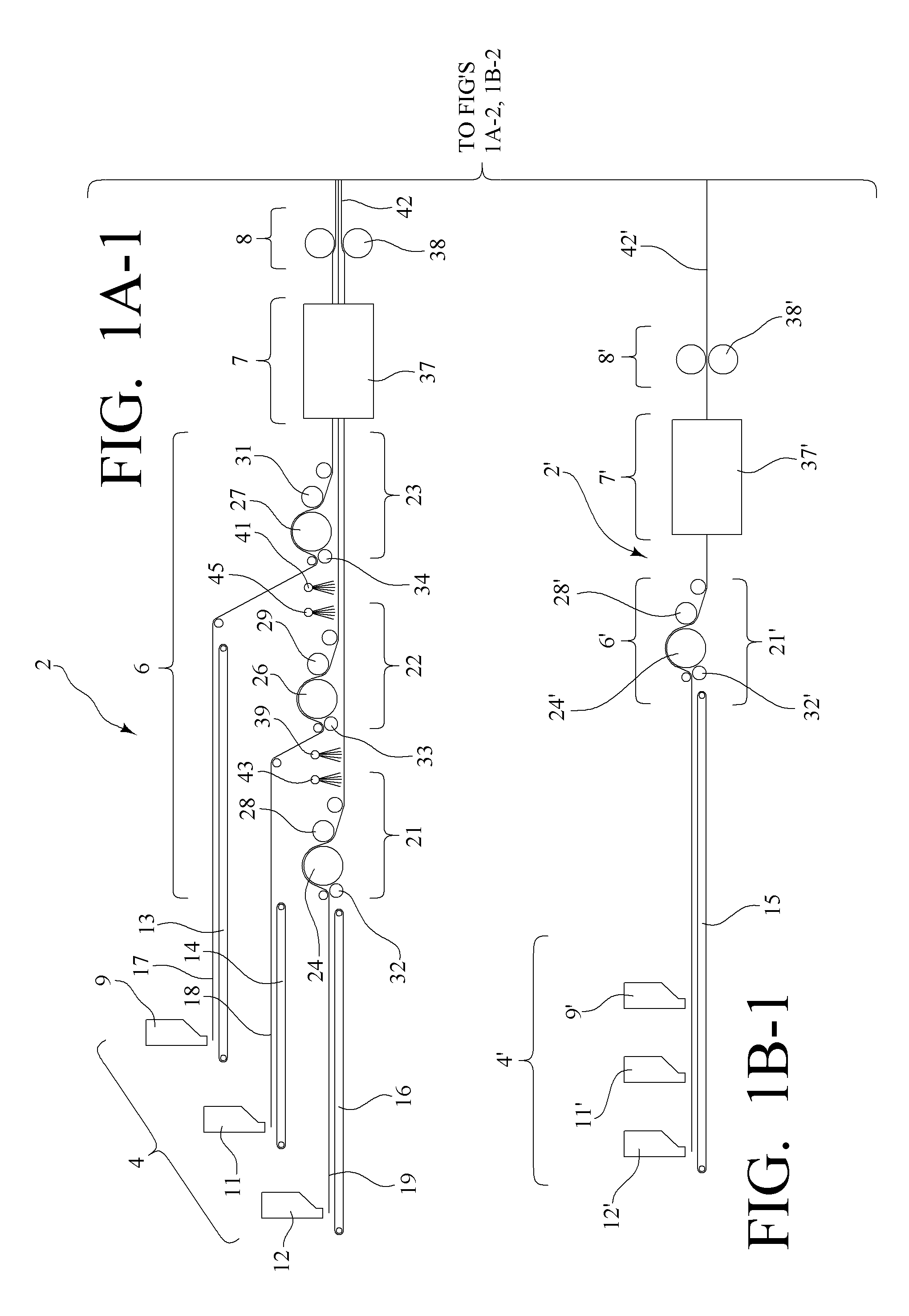

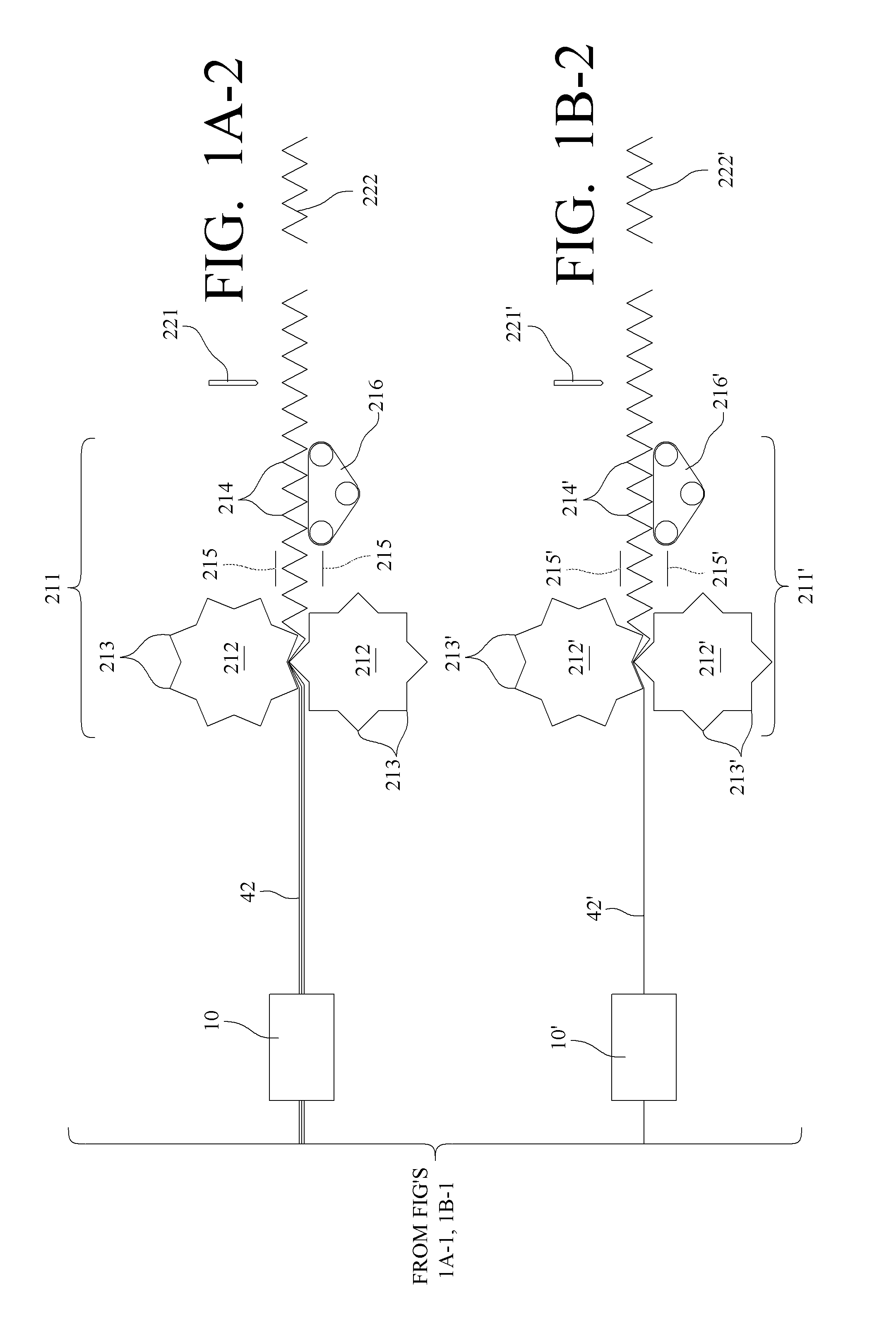

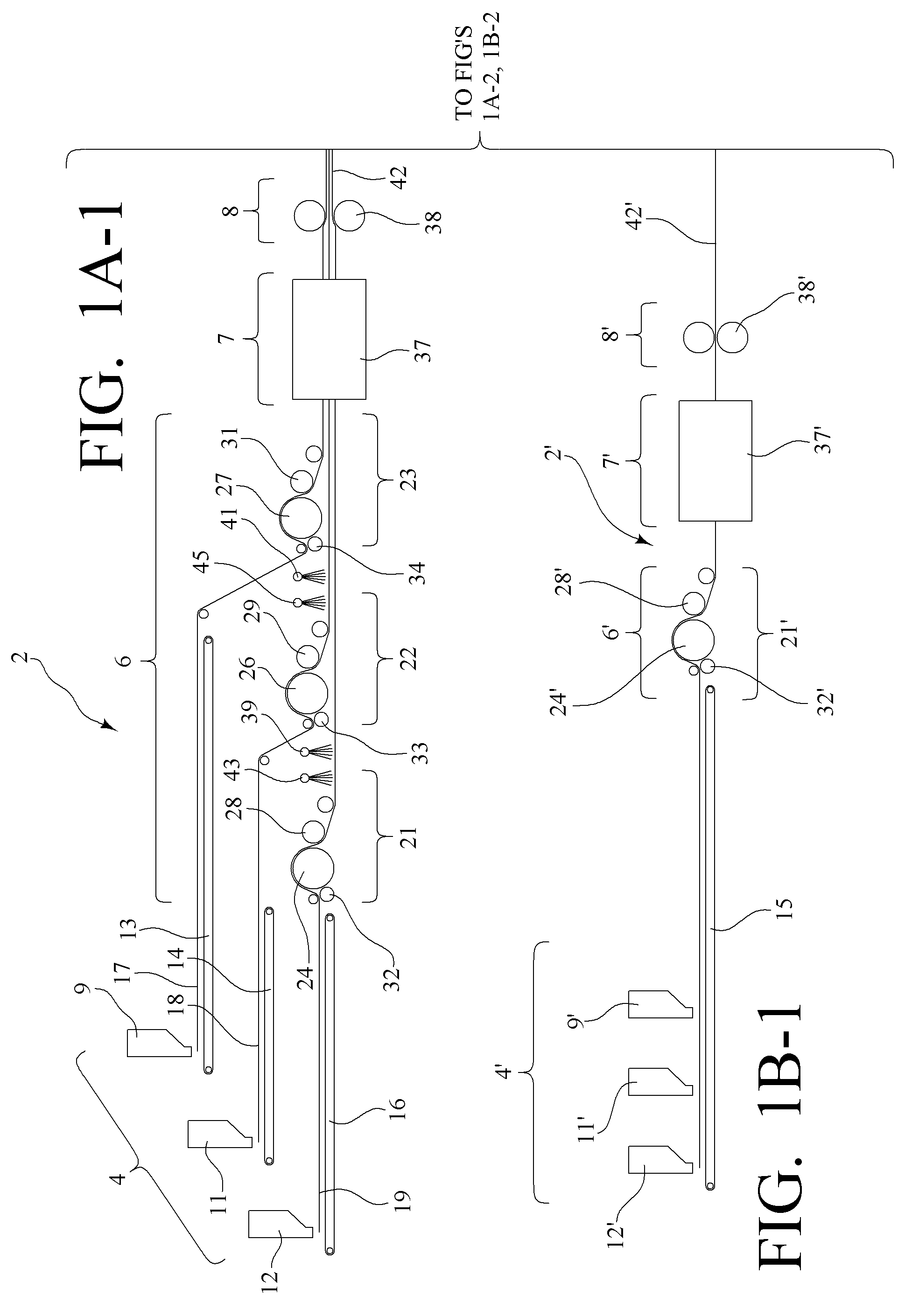

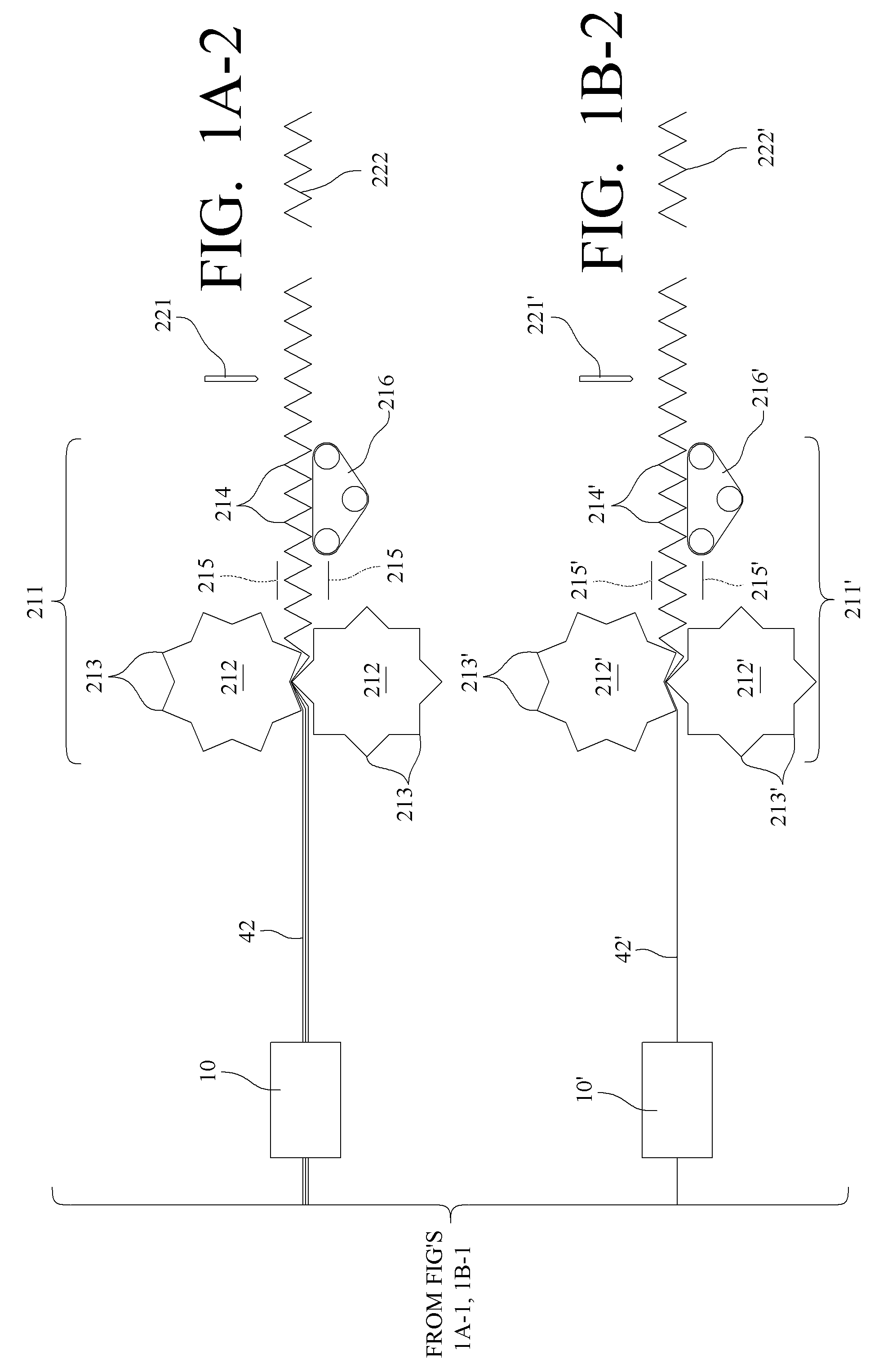

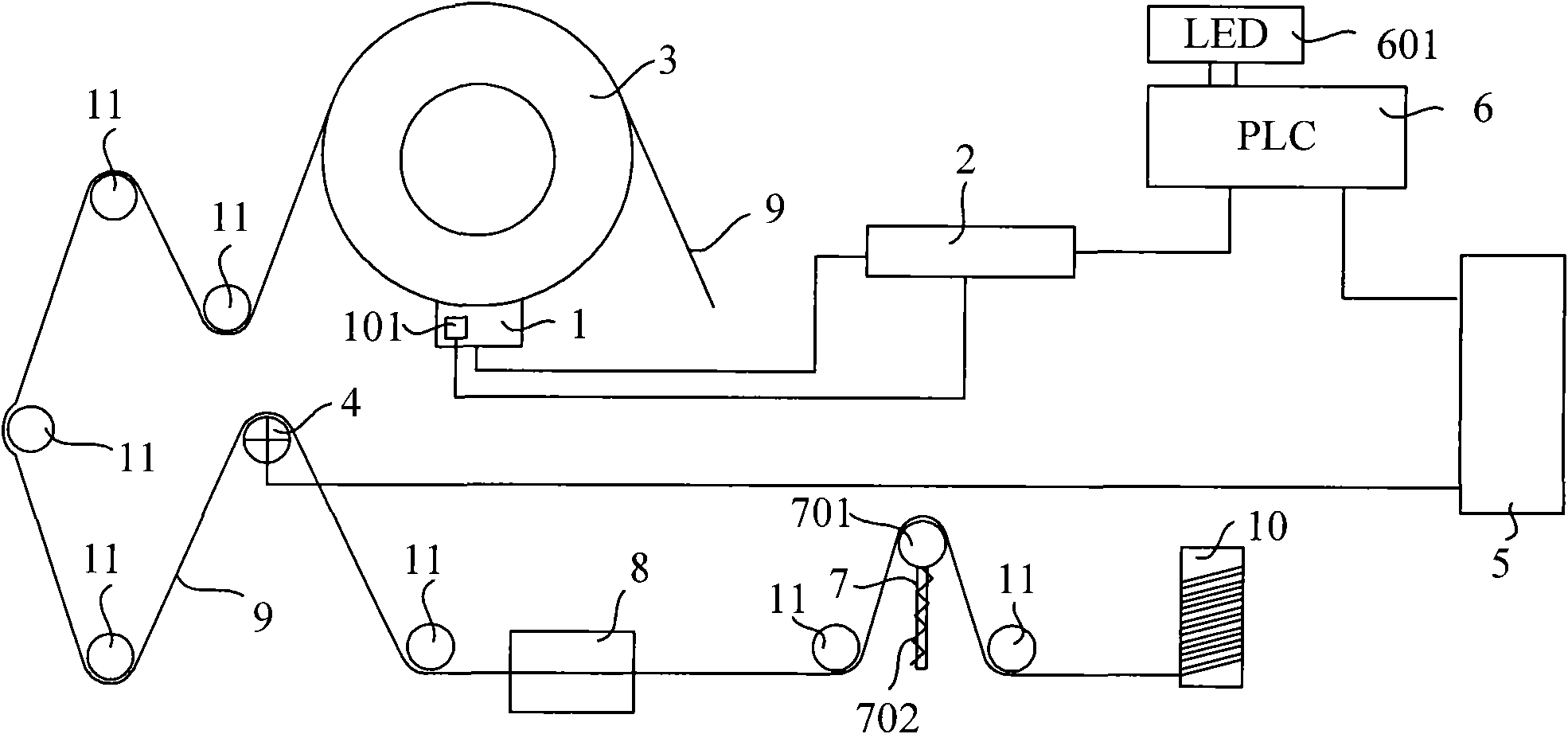

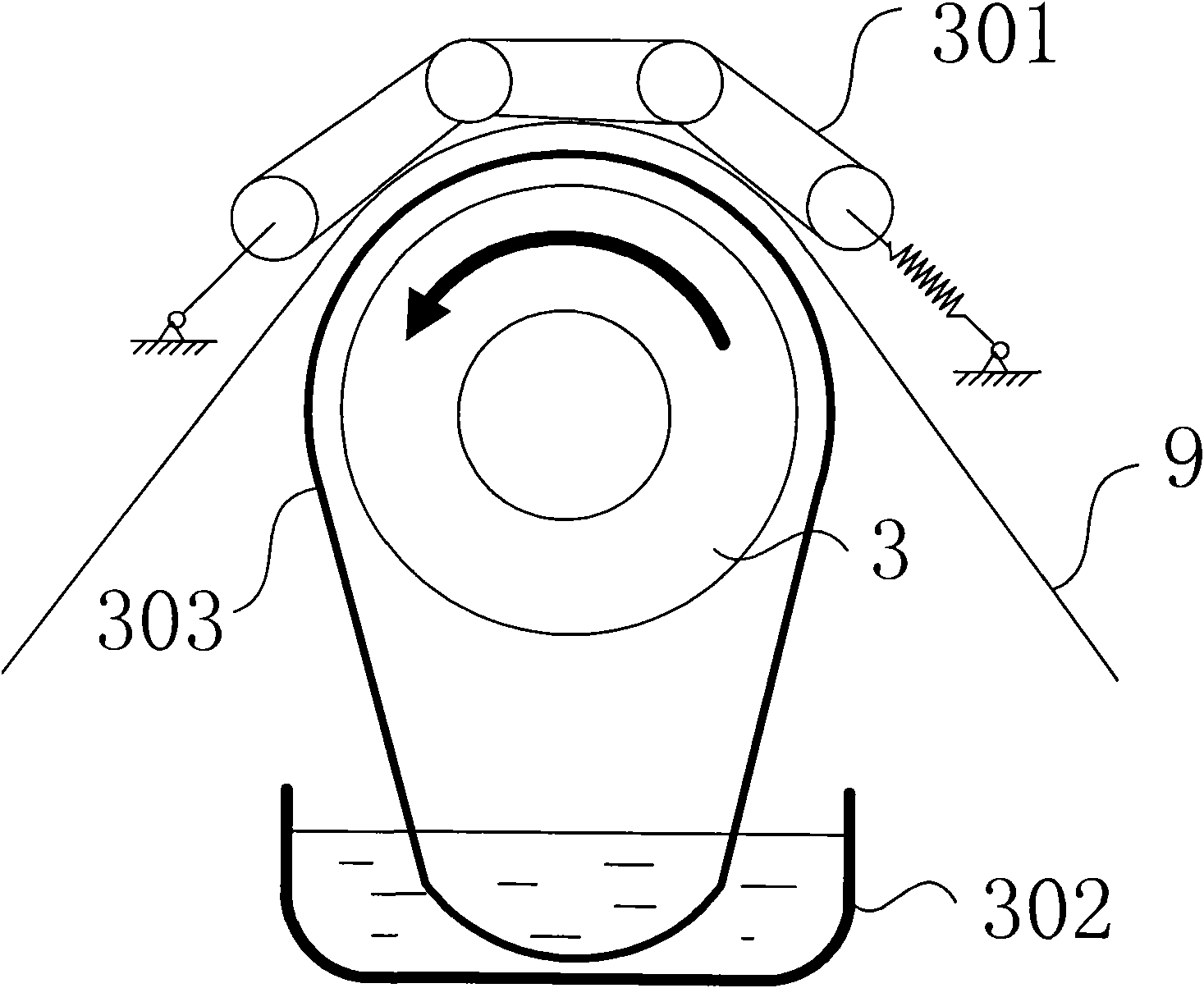

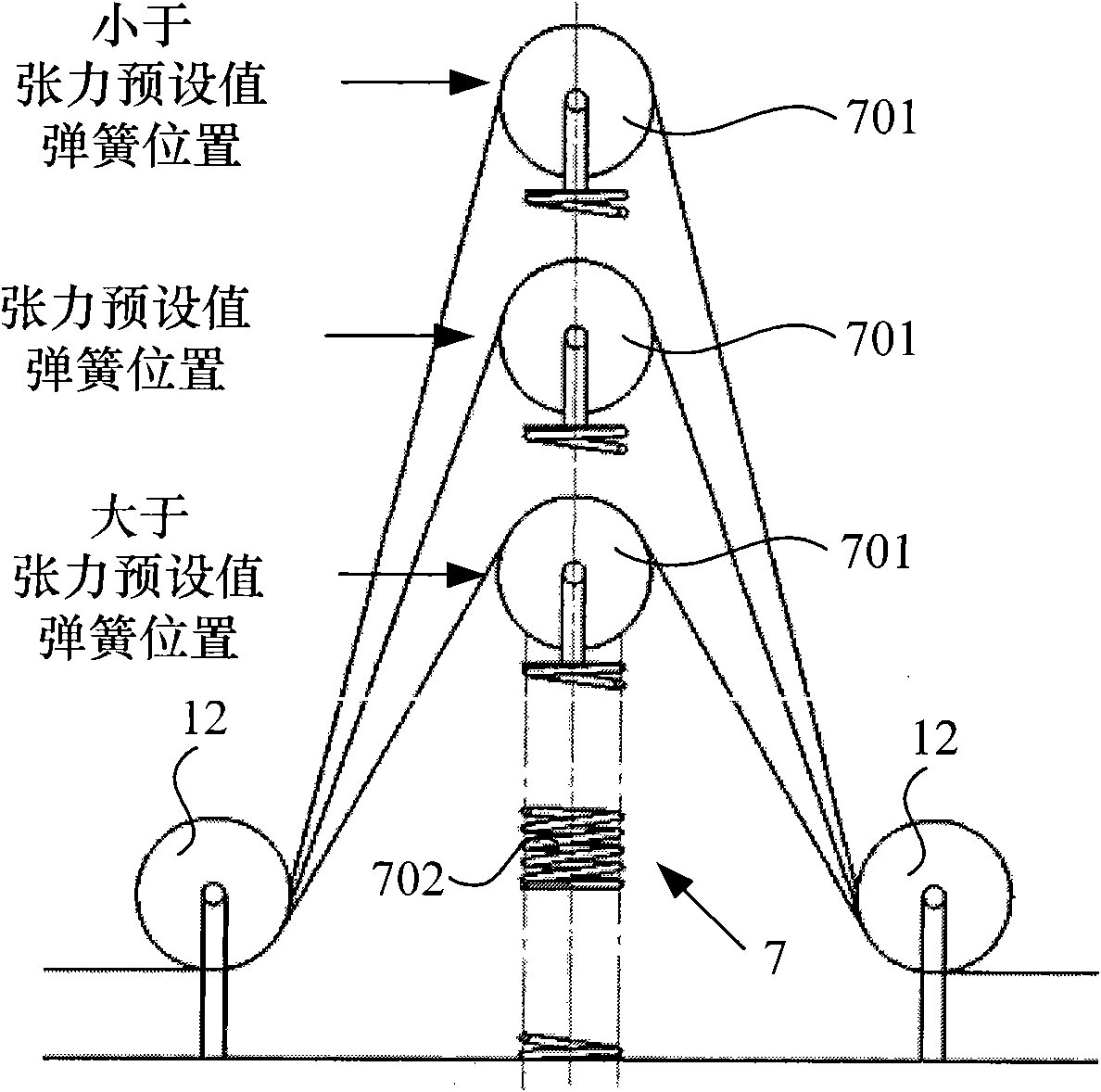

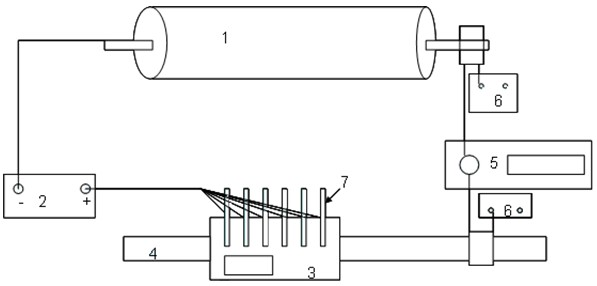

Tension control device of fiber sizing equipment of winding machine and control method thereof

InactiveCN101804928AHigh control precisionRealize real-time monitoringFilament handlingProgramme control in sequence/logic controllersWinding machineControl signal

The invention discloses a tension control device of fiber sizing equipment of a winding machine and a control method thereof. The control device comprises a servo motor, a motor driver, a glue dipping roller, a tension sensor, a tension signal amplifier, a PLC (Programmable Logic Controller), a spring guide roller, a frictioning plate and a roller wheel. The control method comprises the following steps of: firstly, initializing, pre-tightening fiber and starting the device; secondly, measuring the tension value of the fiber by the tensor sensor, and transmitting the tension value to the PLC; thirdly, transmitting a control signal to the motor driver by the PLC; fourthly, controlling the tension of the fiber and the preset value of the tension to be in an error range by the motor driver through the rotating speed of the glue dipping roller controlled by the servo motor; and fifthly, transmitting the fiber to the winding machine through the frictioning plate. The invention has high tension control precision and can monitor the tension in real time. Compared with spring measuring equipment, the tension control device of the fiber sizing equipment of the winding machine greatly improves the measuring precision and the response speed and is convenient to operate.

Owner:BEIHANG UNIV

Fiber size, sized reinforcements, and articles reinforced with sized reinforcements

InactiveUS7732047B2Satisfactory performanceImprove performanceSpecial tyresNon-woven fabricsPolyolefinAntioxidant

A fiber size composition contains a modified polyolefin, a hydrophilic coupling agent, a boron-containing, fluorine-containing compound, a blend of at least two fatty acids and a compound selected from phosphorus(V) compounds and sulfur(VI) compounds, the fiber size composition being substantially free of conventional lower oxidation state antioxidants and optical brighteners. Composite materials produced from reinforcing fiber materials sized with a fiber size composition according to the invention exhibit improved properties such as, for example, increased strength and / or improved color stability.

Owner:OCV INTELLECTUAL CAPITAL LLC

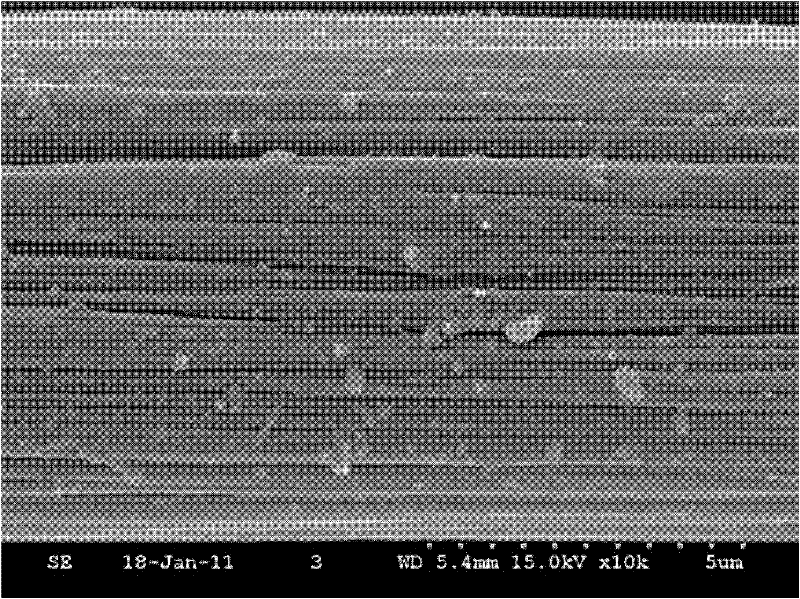

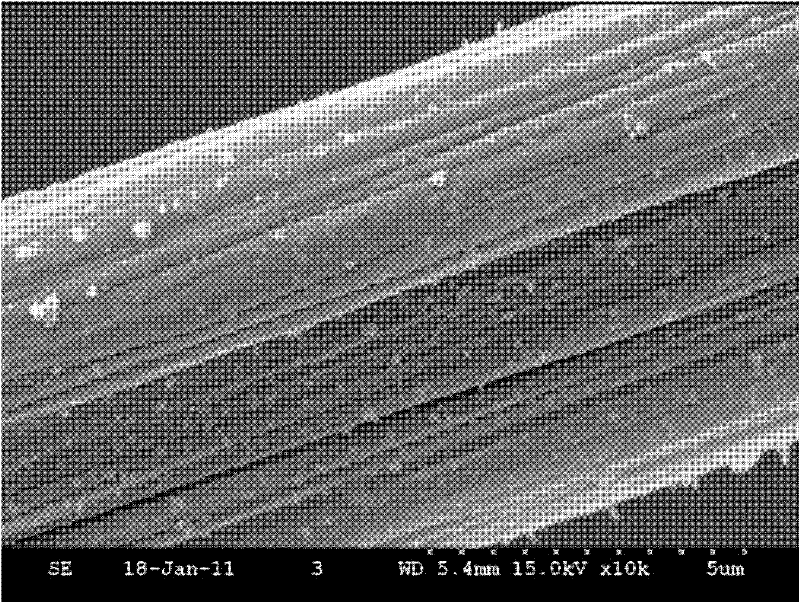

Sizing agent for carbon fiber, method for sizing carbon fiber by said sizing agent, sized carbon fiber and knitted or woven fabric using said carbon fiber

InactiveUS7135516B2Satisfactory solubility in waterImprove machinabilityCarbon fibresLayered productsSolubilityCarbon fibers

The present invention relates to a carbon fiber sizing agent comprised of water-soluble thermoplastic resin and amphoteric surfactant within a weight ratio range of 6 / 1 to 1 / 3, a carbon fiber sizing method comprising treating carbon fibers using a sizing liquid containing the aforementioned sizing agent, sized carbon fibers comprising adhering the aforementioned sizing agent to their surfaces, and a fabric that uses said carbon fibers. The carbon fiber sizing agent of the present invention has satisfactory solubility in water over a wide pH range, and is able to impart to carbon fibers adequate convergence for forming stable chopped carbon fibers, superior workability and satisfactory uniform tow dispersibility in water over a wide pH range. Since a fabric of the present invention demonstrates affinity to water over a wide pH range, it is suitable for applications such as immersing said fabric in an aqueous matrix in order to impregnate the fabric with that matrix.

Owner:MITSUBISHI CHEM CORP

Molded monocomponent monolayer respirator with bimodal monolayer monocomponent media

InactiveUS7858163B2Good molding effectIncrease fiber surface areaBreathing filtersLayered productsPolymer scienceRespirator

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967AGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

Fiber size, sized reinforcements, and articles reinforced with sized reinforcements

InactiveUS20060083922A1Desirable short-term mechanicalDesirable aging propertySpecial tyresCoatingsPolyolefinAntioxidant

A fiber size composition contains a modified polyolefin, a hydrophilic coupling agent, a boron-containing, fluorine-containing compound, a blend of at least two fatty acids and a compound selected from phosphorus(V) compounds and sulfur(VI) compounds, the fiber size composition being substantially free of conventional lower oxidation state antioxidants and optical brighteners. Composite materials produced from reinforcing fiber materials sized with a fiber size composition according to the invention exhibit improved properties such as, for example, increased strength and / or improved color stability.

Owner:OCV INTELLECTUAL CAPITAL LLC

Pleated filter with bimodal monolayer monocomponent media

InactiveUS7754041B2Lower overall pressure dropEfficient captureDispersed particle filtrationLoose filtering material filtersPolymer scienceFilter media

A pleated filter is made from a monocomponent monolayer nonwoven web containing a bimodal mass fraction / fiber size mixture of intermingled larger size and smaller size continuous monocomponent polymeric fibers of the same polymeric composition. Rows of pleats are formed in the nonwoven web, and the pleated web is cut to a desired size and shape to provide a filter element containing a self-supporting porous monocomponent monolayer matrix of fibers bonded to one another at at least some points of fiber intersection and having an average initial submicron efficiency of at least 15% at a 1.52 meters / sec face velocity. The filter element is deformation resistant without requiring stiffening layers, bicomponent fibers or other reinforcing measures in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent and a preparation method and application thereof. The sizing agent comprises main size, an emulsifier, graphene oxide, a diluent and water, wherein the amount of the emulsifier is 0.5-6 weight percent of that of the main size; and the amount of graphene oxide is 0.1-2 weight percent of that of the main size. The preparation method comprises the following steps: mixing the main size, the diluent and the emulsifier, stirring and premixing; and slowly adding an aqueous solution of graphene oxide for performing phase inversion emulsification to form Pickering emulsion in which graphene oxide and the emulsifier are stable, thereby obtaining the sizing agent. The preparation method disclosed by the invention is easy to operate, the stability of the sizing agent is improved by adopting the synergistic effect of graphene oxide and the emulsifier, the amount of the emulsifier is reduced, the environmental pollution is alleviated, the defects that the sizing agent with a single stable emulsifier is low in stability and the amount of the emulsifier is extremely large are overcome, the selection range of the main size is widened, the performances of carbon fibers can be improved after sizing, an interface bonding effect of a carbon fiber composite material is enhanced, and the mechanical strength of the carbon fiber composite material is improved.

Owner:UNIV OF JINAN

Carbon fiber sizing agent

The invention discloses a carbon fiber sizing agent which is prepared from the following materials in parts by weight: 5-25 parts of phenolic resin, 1-5 parts of blend resin, 0.01-5 parts of antistatic agent and 100 parts of solvent, wherein the phenolic resin is thermoplastic phenolic resin or modified phenolic resin, and the blend resin is thermoplastic resin or thermosetting resin. The carbon fiber sizing agent is prepared through the following steps of: firstly, uniformly mixing the phenolic resin and the blend resin, adding a solvent accounting for 10-20% of the total amount of the solvent, enabling the resin to be dissolved in the solvent, and stirring the obtained mixture into a homogeneous solution at room temperature; and then, adding the antistatic agent into the homogeneous solution, stirring the obtained mixture so as to dissolve the antistatic agent, adding the rest of the solvent, and mixing the obtained product so as to obtain an integral solution, thereby obtaining the carbon fiber sizing agent. The carbon fiber sizing agent disclosed by the invention can be compatible with thermoplastic matrix resin better; the matrix resin can fully wet carbon fibers, thereby directly achieving a stress transfer effect on the fibers and the matrix; and compared with an epoxy resin sizing agent, the interlayer shear strength of a composite material of the carbon fiber sizing agent is increased by 15-20%.

Owner:ZHONGFU SHENYING CARBON FIBER

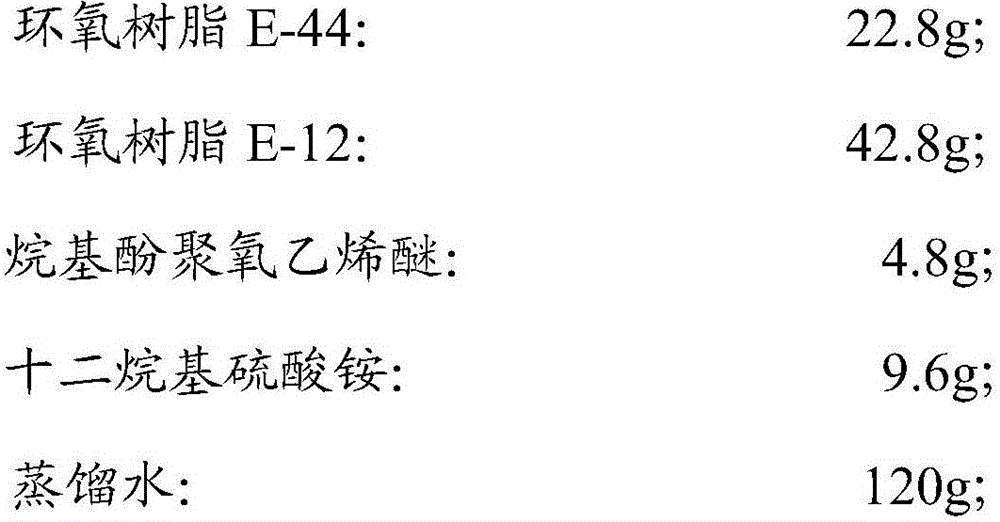

Preparation method and product of graphene-modified carbon fiber sizing agent

The invention relates to a preparation method of a graphene-modified carbon fiber sizing agent. The preparation method includes the steps of firstly, mixing solid-state epoxy resin and liquid-state epoxy resin in a fusion manner under 60-100 DEG C to obtain mixed epoxy resin; secondly, adding anionic surfactant, and stirring for emulsifying; thirdly, adding nonionic surfactant, stirring, dripping distilled water, and stirring until the system has phase reversing to obtain a sizing emulsion; fourthly, preparing a modified graphene solution; fifthly, mixing and dispersing the sizing emulsion and the modified graphene solution to obtain the graphene-modified carbon fiber sizing agent. The invention further relates to the graphene-modified carbon fiber sizing agent prepared by the method. The graphene-modified carbon fiber sizing agent prepared by the method is small and even in particle size and can well combine with the surfaces of carbon fibers. By the preparation method, the problems that the graphene is unevenly dispersed and poor in stability are solved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

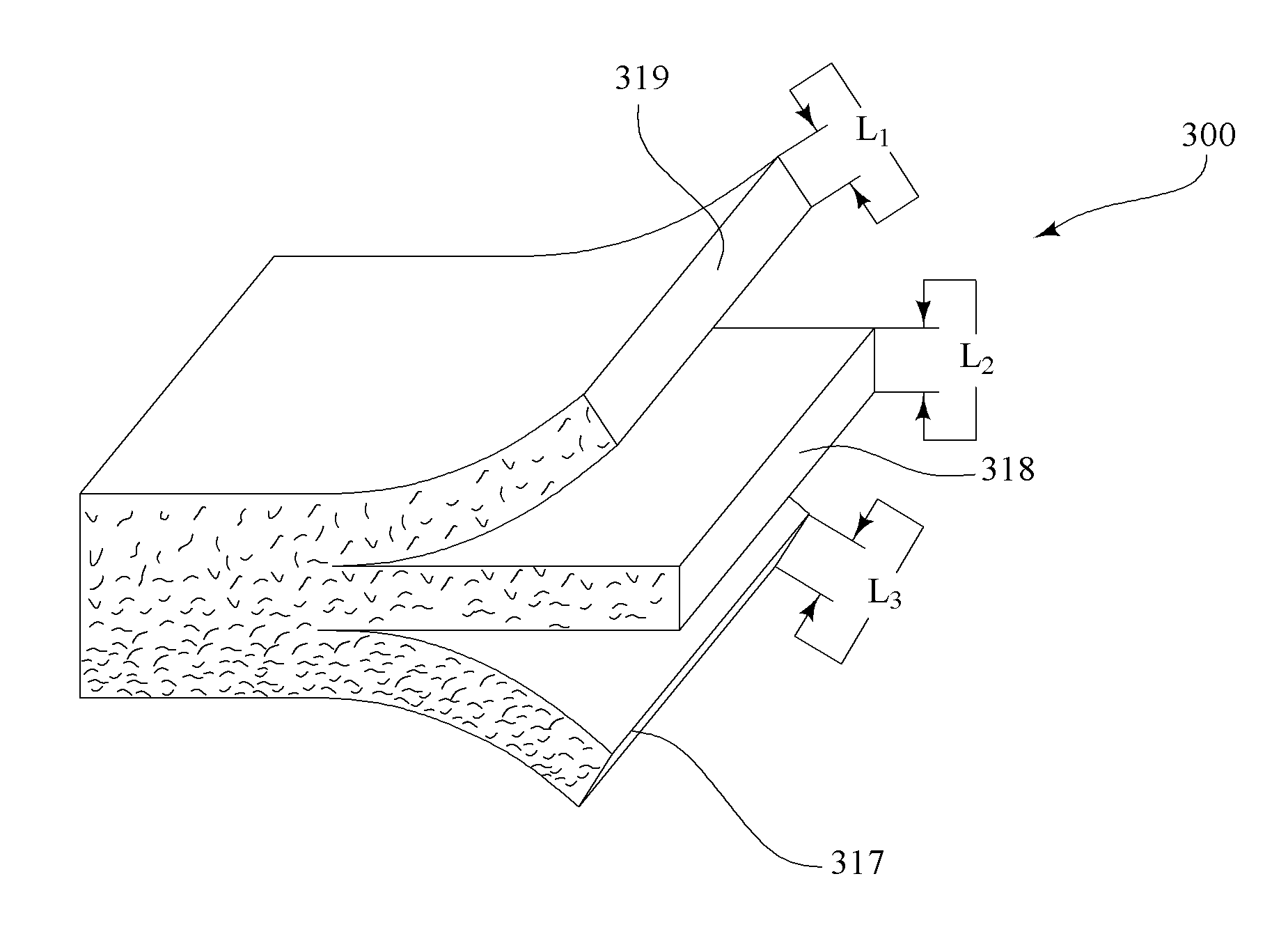

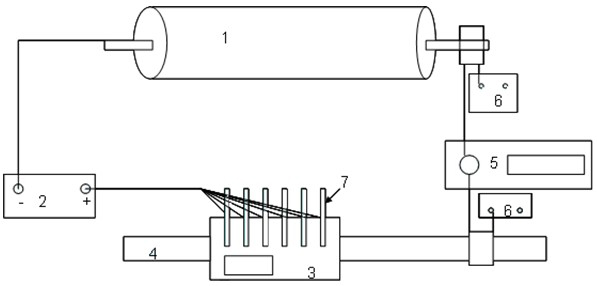

Preparation device and preparation method of cellulose-based fiber membrane with nanostructure

InactiveCN102277689ASmall fiber sizeHigh porosityFilament/thread formingNon-woven fabricsPorosityCellulose

The invention relates to a preparation device and method of a cellulose fiber film with a nanometer structure. The device includes a rotatable slide table, and the liquid supply injection pump is arranged on the slide table. When the slide table rotates, the liquid supply injection pump moves along the slide table. The liquid supply injection pump is fixedly connected to at least one spinneret, and the spinneret There is a rotary receiving device in front of the head, the spinneret and the rotary receiving device are connected to a high-voltage power supply, and the rotating shafts of the slide table and the rotary receiving device are connected to a motor and a speed controller. The method is as follows: dissolving the cellulose polymer with a solvent to obtain a polymer solution with uniform properties; inputting the polymer solution to a spinneret at a constant flow rate for electrospinning to obtain cellulose with a nanostructure fibrous membrane. The cellulose fiber membrane with nanometer structure prepared by the invention has the advantages of small fiber size, high porosity, large specific surface area, good fiber uniformity and the like.

Owner:DONGHUA UNIV

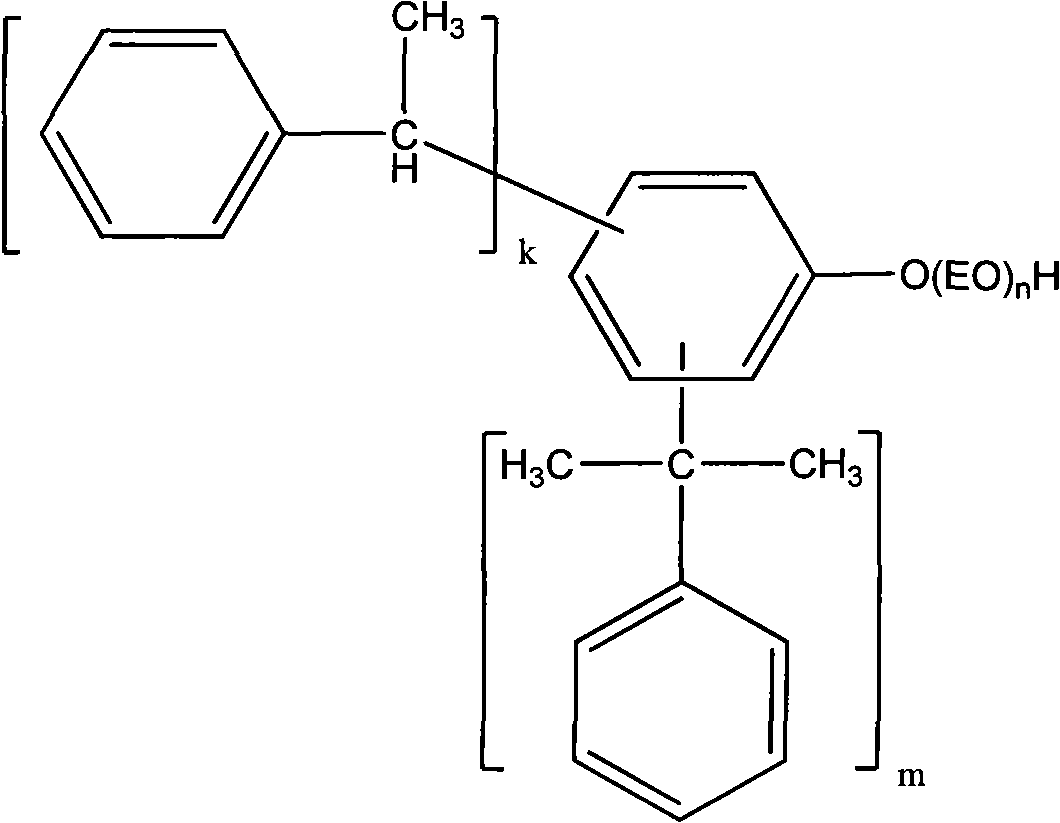

Formula and preparing method of carbon fiber sizing agent for reinforcing polypropylene

InactiveCN105176008AImprove toughnessImprove wear resistanceFibre treatmentPolypropylene compositesPolymer science

The invention discloses a formula and preparing method of a carbon fiber sizing agent for reinforcing polypropylene. Compared with traditional solvent type sizing agents, the prepared sizing agent has the advantages of being low in toxicity, low in cost, low in pollution and the like with water serving as the continuous phase. Besides, the sizing agent is suitable for a polypropylene resin matrix and solves the problem of poor cohesiveness between carbon fiber and polypropylene resin. When the sizing agent is used for sizing, the post processing capacity of carbon fiber is improved remarkably, the cohesiveness of the interface between carbon fiber and polypropylene matrix resin is high, and the macroscopical mechanical strength of a carbon fiber / polypropylene composite material is improved to a large extent.

Owner:UNIV OF JINAN

Vacuum heat insulation material

InactiveCN101023291AGood insulation performanceReduce the impactThermal insulationDomestic cooling apparatusPolyesterEnvironment effect

Disclosed is a vacuum heat insulation material which places very little burden on the environment during production and recycling processes. This vacuum heat insulation material has excellent handling properties and workability, and keeps providing good heat insulation for a long time. Specifically disclosed is a vacuum heat insulation material which is characterized by comprising at least a padding material and an envelope for holding the padding material which envelope is capable of maintaining the inside at a reduced pressure. The vacuum heat insulation material is also characterized in that the padding material is composed of a sheet-like fiber assembly containing not less than 50% by weight of polyester fibers having a fiber size of 1-6 denier.

Owner:株式会社三星日本研究所

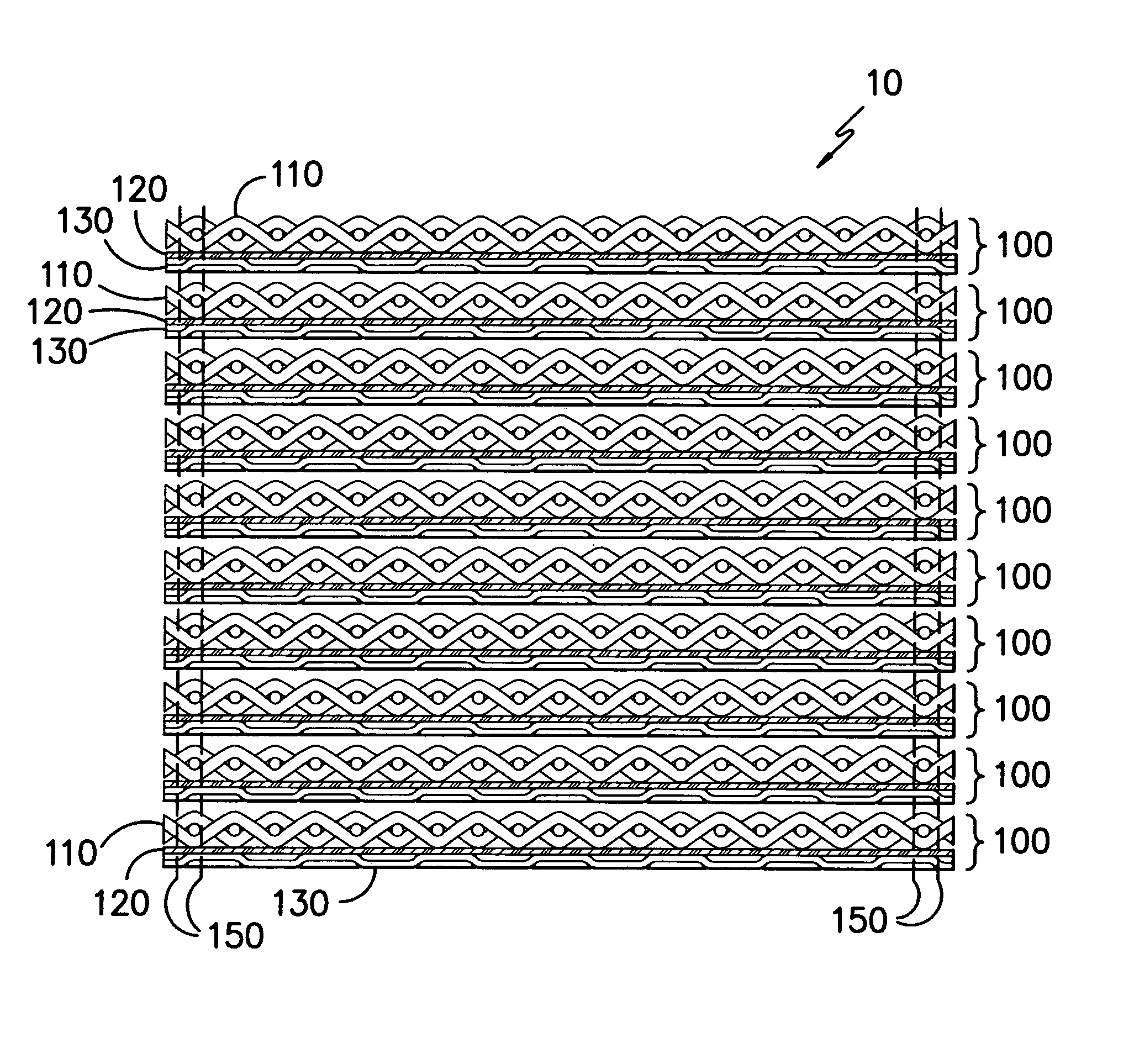

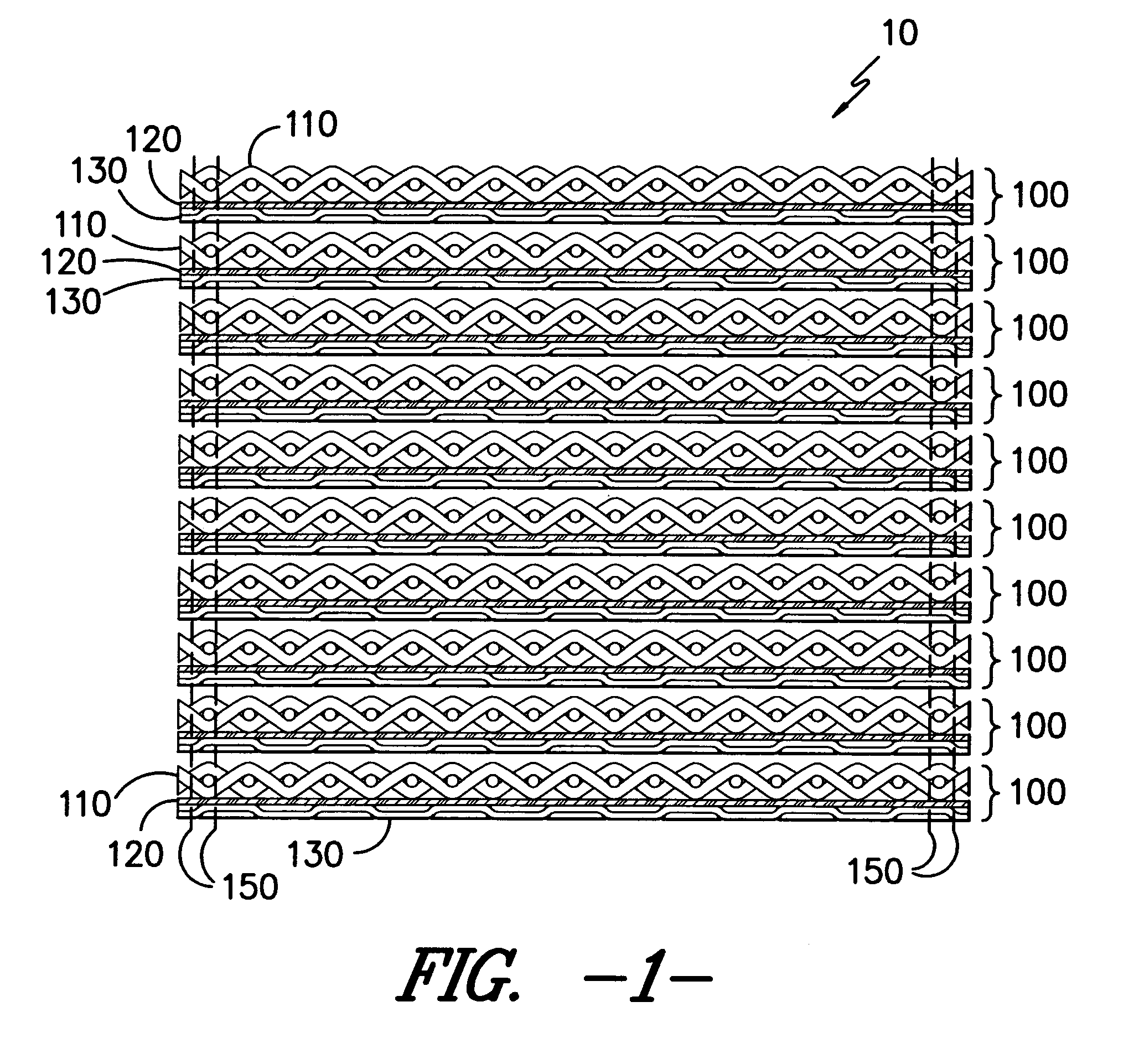

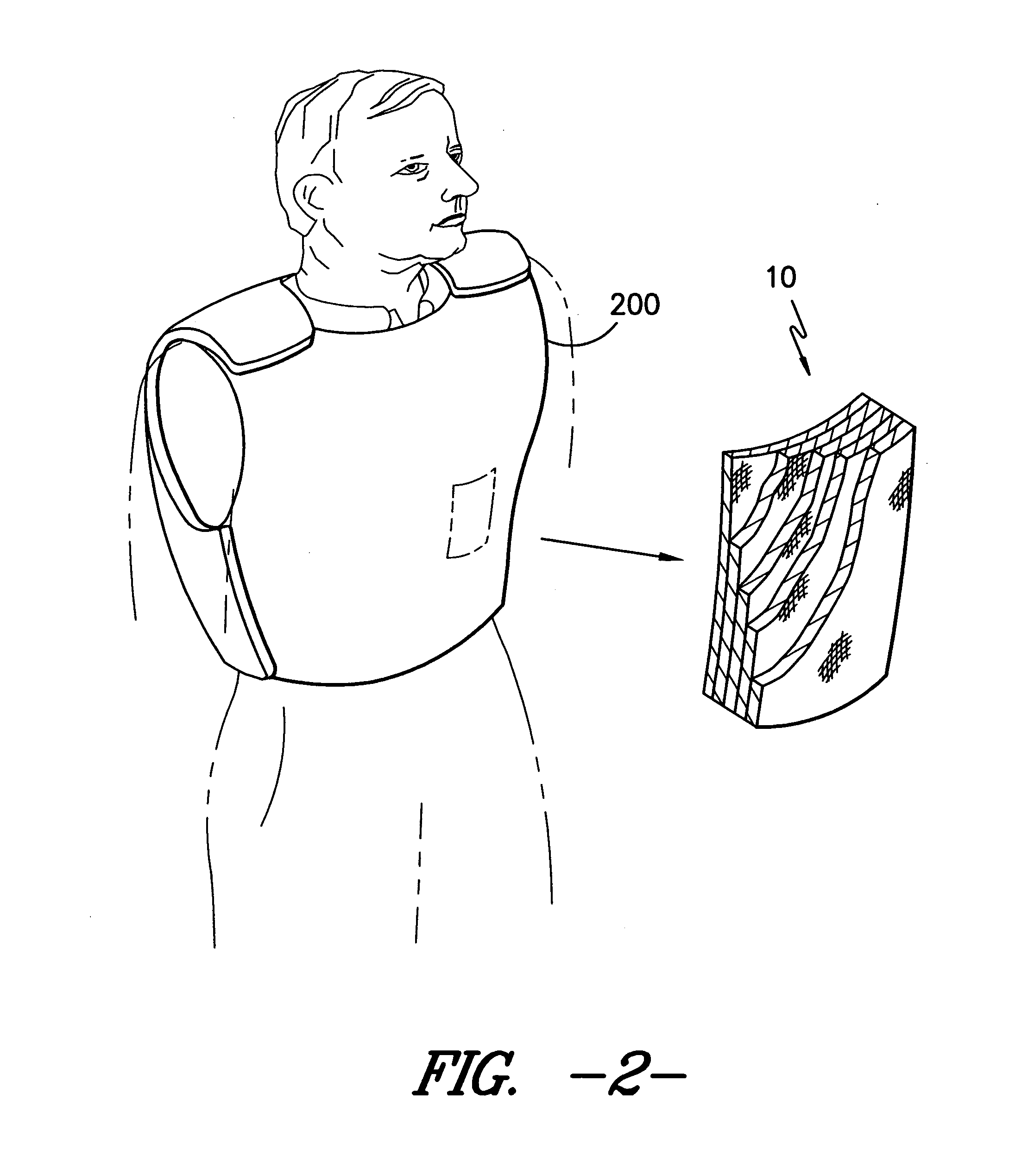

Flexible spike and knife resistant composite

A flexible spike and knife resistant composite incorporating a stack of at least ten consolidated layer groupings. Each layer grouping has a normalized stiffness of less than about 5 g / g / m2 as tested by a modified ASTM Test Method D6828-02 and contains one or two spike resistant textile layers, an adhesive layer, and one or two knife resistant textile layers. The spike resistant textile layers contain a plurality of interlocked yarns or fibers, where the yarns or fibers have a tenacity of about 8 or more grams per denier and the fiber size is less than ten denier per filament. The knife resistant textile layers contain monoaxially drawn fiber elements, where the fiber elements have an aspect ratio of greater than one and have a size greater than 100 denier per filament. The fiber elements of the knife resistant textile layer are bonded to each other or to the spike resistant layer.

Owner:MILLIKEN & CO

Preparation method of dimer acid modified epoxy resin toughened carbon fiber prepreg

The invention provides a preparation method of a dimer acid modified epoxy resin toughened carbon fiber prepreg, which comprises the following steps: by taking a component of which the molecular structure is similar to that of a carbon fiber sizing agent as toughener, preparing a dimer acid modified epoxy resin through a pre-reaction method; adding reactants into the mixed epoxy resin, adding a latent curing agent, and evenly mixing to obtain a resin system for the prepreg; and coating the resin system through a film coating machine, and then compounding with carbon fibers or a fabric made therefrom to prepare the moderate-temperature curing prepreg having fine operability and adhesivity. Compared with the traditional rubber toughened prepreg, the invention can enhance the wettability of the resin system on carbon fibers, reduce the moisture permeability of the prepreg and simultaneously improve the toughness and impact resistance of the composite material, thus being suitable for manufacturing of a prepreg for winding formation.

Owner:中威北化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com