Emulsion type carbon fiber sizing agent and preparation method and application thereof

An emulsion-type carbon fiber and sizing agent technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve problems such as improving the stability of sizing agent, and achieve the effect of overcoming excessive emulsifier dosage, overcoming poor stability and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

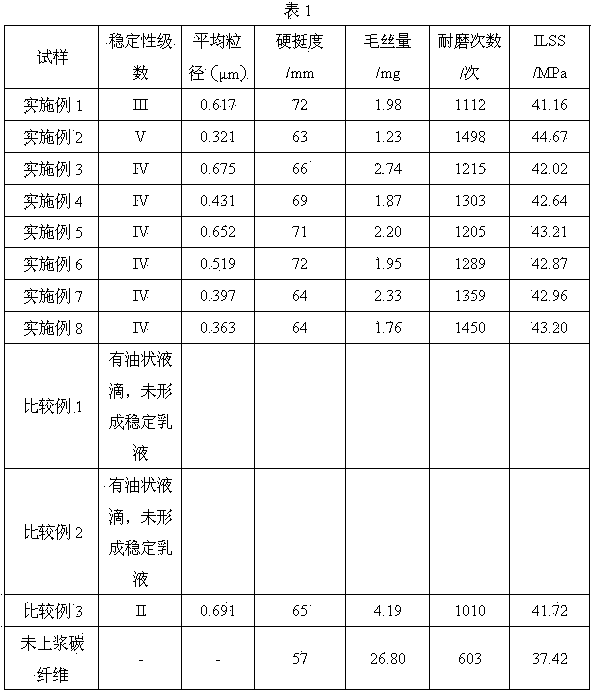

Examples

Embodiment 1

[0050] The composition of the sizing agent is: 100 parts of epoxy resin (AG80) as the main slurry, 0.1 part of graphene oxide, 6 parts of emulsifier, 15 parts of diluent neopentyl glycol diglycidyl ether, and 400 parts of water. Wherein the emulsifier is octylphenol polyoxyethylene ether (OP-10), sorbitan monooleate (Span-80) and sodium dodecylbenzenesulfonate with a mass ratio of 10:65:25 (SDBS) mixture.

[0051] The preparation method of the sizing agent is as follows: first, add the main slurry AG80 epoxy resin into the beaker, add neopentyl glycol diglycidyl ether and emulsifier, stir and mix the mixture evenly in a water bath at 30 ℃ to make the viscosity lower; then The mixture was taken out and stirred at 2000 rpm for 20 min with a high-shear dispersing emulsifier. Next, take graphene oxide, dissolve it in water, adjust the pH value of the graphene oxide aqueous solution to 6 with ammonia water, and ultrasonicate for 20 min, put the solution in a constant pressure drop...

Embodiment 2

[0053] The composition of the sizing agent is: 100 parts of epoxy resin (E-51) as the main slurry, 0.3 parts of graphene oxide, 5 parts of emulsifier, 10 parts of diluent neopentyl glycol diglycidyl ether, and 400 parts of water. Wherein the emulsifier is octylphenol polyoxyethylene ether (OP-10), sorbitan monooleate (Span-80) and sodium dodecylbenzenesulfonate with a mass ratio of 10:65:25 (SDBS) mixture.

[0054] The preparation method of the sizing agent is as follows: First, add the main slurry epoxy resin (E-51) into a beaker, add neopentyl glycol diglycidyl ether and emulsifier, and stir the mixture evenly in a water bath at 30 °C to make the viscosity Then the mixture was taken out and stirred at a speed of 2000 rpm for 20 min with a high-shear dispersing emulsifier. Next, take graphene oxide and dissolve it in water; adjust the pH value of the graphene oxide aqueous solution to 6 with ammonia water, sonicate for 20 min, put it in a constant pressure dropper, add it dr...

Embodiment 3

[0056] The composition of the sizing agent is: 100 parts of the main slurry epoxy resin (E-55), 2 parts of graphene oxide, 0.5 parts of emulsifier, 50 parts of diluent acetone, and 400 parts of water. Wherein the emulsifier is octylphenol polyoxyethylene ether (OP-10), sorbitan monooleate (Span-80) and sodium dodecylbenzenesulfonate with a mass ratio of 10:65:25 (SDBS) mixture.

[0057] The preparation method of the sizing agent is as follows: first, add the main slurry epoxy resin (E-55) into the beaker, add acetone, stir the mixture evenly in a water bath at 30 ℃ to make the viscosity lower; then, take the mixture out and use A high-shear dispersing and emulsifying machine stirred at a speed of 2000 rpm for 20 min. Next, take graphene oxide and dissolve it in water; adjust the pH value of the graphene oxide aqueous solution to 6 with ammonia water, sonicate for 20 min, put it in a constant pressure dropper, add it dropwise to the mixture at a rate of 0.1 mL / min, and adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com