Preparation method of dimer acid modified epoxy resin toughened carbon fiber prepreg

A technology of carbon fiber prepreg and epoxy resin, which is applied in the field of composite materials, can solve the problems of poor wettability of carbon fibers, etc., and achieve the effects of improving toughness, good toughening effect, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

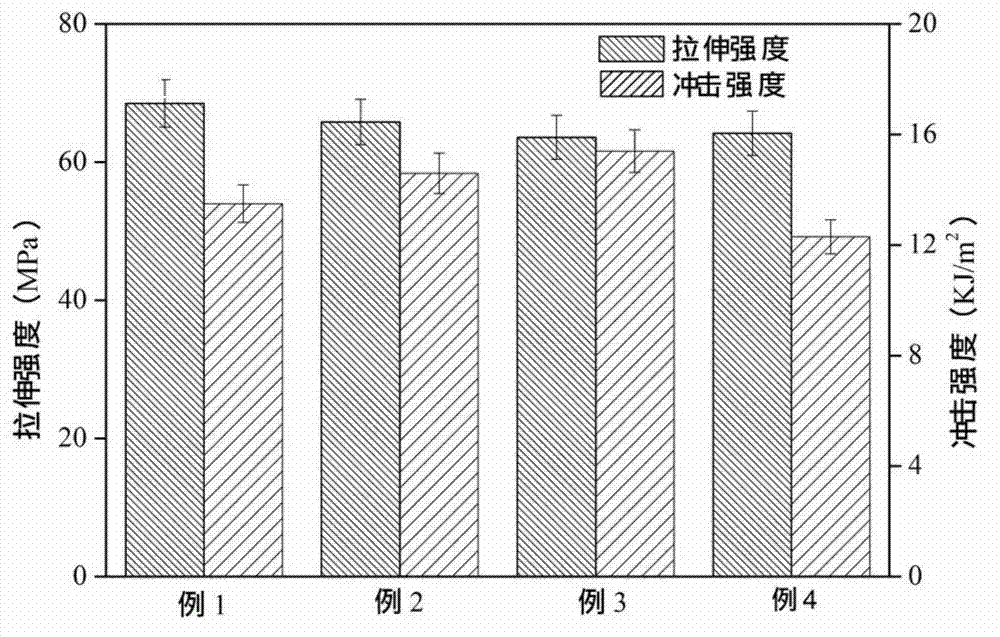

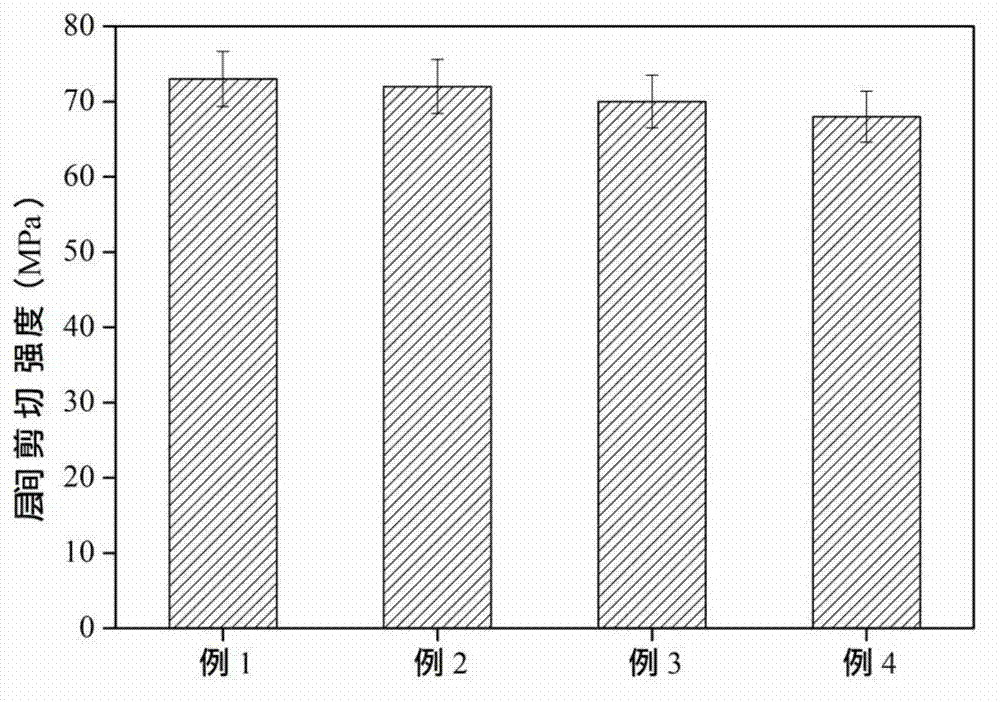

Embodiment 1

[0021] Weigh 400g of dimer acid (viscosity of 5000cps), 600g of liquid bisphenol A glycidyl ether and 1g of catalyst triphenylphosphine into a reaction kettle, react at 120°C for 6h under the protection of nitrogen, and cool the product to obtain di Polyacid modified epoxy resin. Take 130g (mass fraction is 5%) of the above-mentioned dimer acid modified epoxy resin, add 1560g of liquid bisphenol A epoxy resin, 1040g of solid bisphenol A epoxy resin, 208g of curing agent urea derivatives, stir vigorously Finally, the air bubbles are removed by vacuum to obtain an epoxy resin system for prepregs. The epoxy resin system was poured into the spline mold and cured at 100°C for 2 hours to prepare the cast body spline. The above resin system is prepared with a film machine to prepare a film, and then compounded with a carbon fiber fabric through a compound machine to prepare a carbon fiber prepreg. The prepreg was cut into layers, cured on a flat vulcanizer at 100°C for 2 hours to p...

Embodiment 2

[0023] Weigh 500g of dimer acid (viscosity is 6500cps), 500g of liquid bisphenol AD glycidyl ether and 3g of catalyst tetrabutylphosphorus chloride and place them in a reaction kettle, react at 140°C for 4h under the protection of nitrogen, and cool the product to prepare Obtain dimer acid modified epoxy resin. Take 260g (mass fraction is 10%) of the above-mentioned dimer acid modified epoxy resin, add 1380g of liquid bisphenol F epoxy resin, 1220g of solid bisphenol A epoxy resin, 130g of curing agent modified dicyandiamide, strong After stirring, air bubbles are removed by vacuum to obtain an epoxy resin system for prepregs. The epoxy resin system was poured into the spline mold and cured at 120°C for 2 hours to prepare the cast body spline. The above resin system is prepared with a film machine to prepare a film, and then compounded with carbon fiber through a compound machine to prepare a unidirectional carbon fiber prepreg. The prepreg was cut into layers, cured on a ...

Embodiment 3

[0025] Weigh 600g of dimer acid (viscosity 8000cps), 400g of liquid bisphenol F glycidyl ether and 5g of catalyst benzyltriphenylphosphine bromide and place them in a reaction kettle, react at 160°C for 2h under the protection of nitrogen, and cool the product , to prepare dimer acid modified epoxy resin. Take 390g (mass fraction is 15%) of the above-mentioned dimer acid modified epoxy resin, add 1760g of liquid novolac epoxy resin, 840g of solid bisphenol A epoxy resin, 247g of curing agent dicyandiamide and 13g of imidazole derivatives. After stirring, air bubbles are removed by vacuum to obtain an epoxy resin system for prepregs. The epoxy resin system was poured into the spline mold and cured at 140°C for 2 hours to prepare the cast body spline. The above resin system is prepared with a film machine to prepare a film, and then compounded with carbon fiber through a compound machine to prepare a unidirectional carbon fiber prepreg. The prepreg was cut and laid up, cured o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com