Preparation method and product of graphene-modified carbon fiber sizing agent

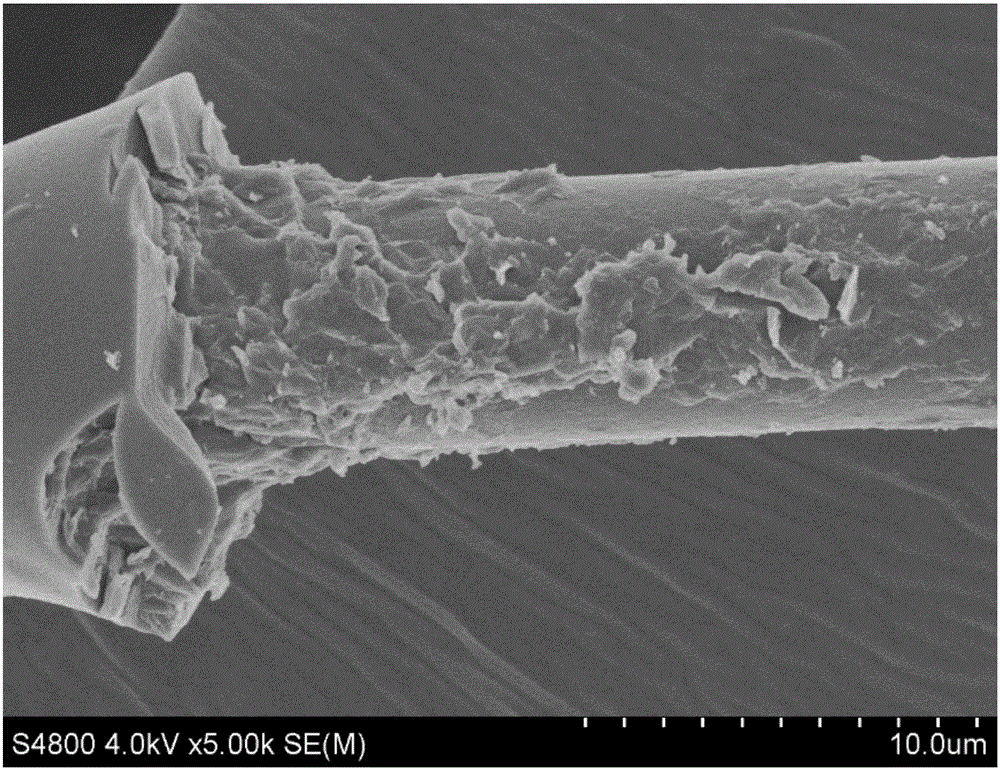

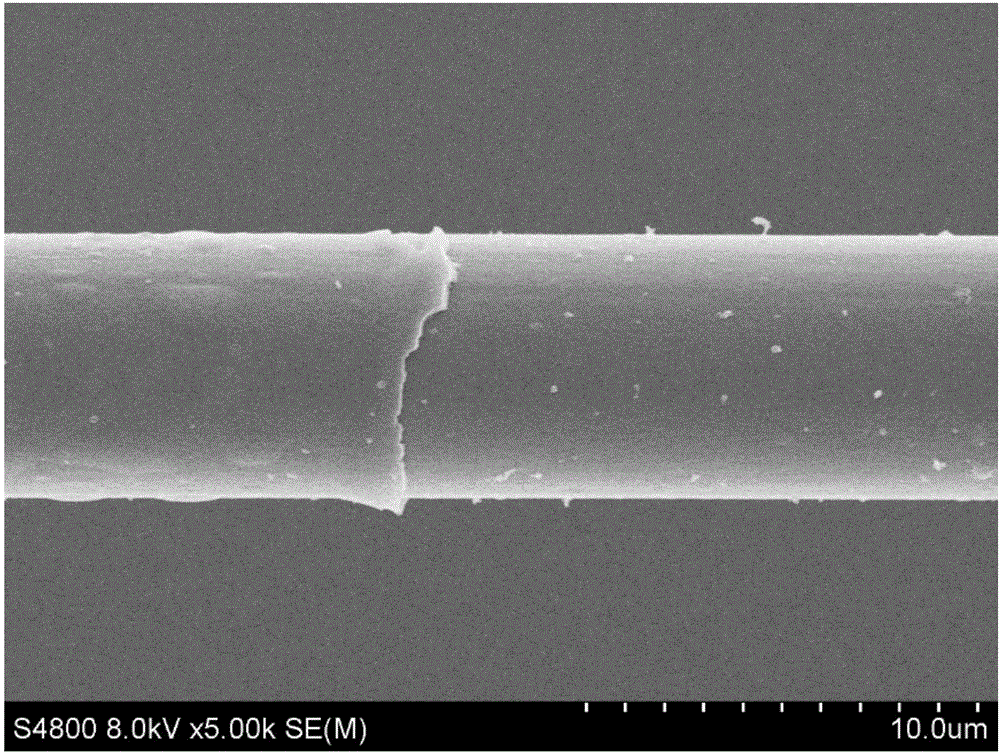

A technology of graphene modification and carbon fiber, which is applied in the direction of carbon fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of uneven dispersion and poor stability of graphene, and achieve improved anchoring effect, good stability and wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of modified graphene solution:

[0041] Graphene oxide aqueous solution (1wt%): 100g;

[0042] Gallic acid: 20g;

[0043] Add a mass fraction of 40% sodium hydroxide solution to the graphene oxide aqueous solution, adjust the pH value to 10, sonicate for 10 minutes in an ultrasonic instrument with a power of 400W and a frequency of 20kHz, and add gallons 20 times the mass of graphene oxide acid, then react at 40°C for 12h, then use a 0.2μm microporous membrane to filter the filtrate, and then use a 0.025μm microporous membrane to filter the previous filtrate, and use distilled water to wash the black modified graphene obtained by filtration. Then the modified graphene obtained by filtration is dissolved in a small amount of distilled water and stored in the form of modified graphene aqueous solution to avoid agglomeration of graphite after drying, that is, to obtain a modified graphene solution of suitable size.

[0044] Prepare carbon fiber sizing:

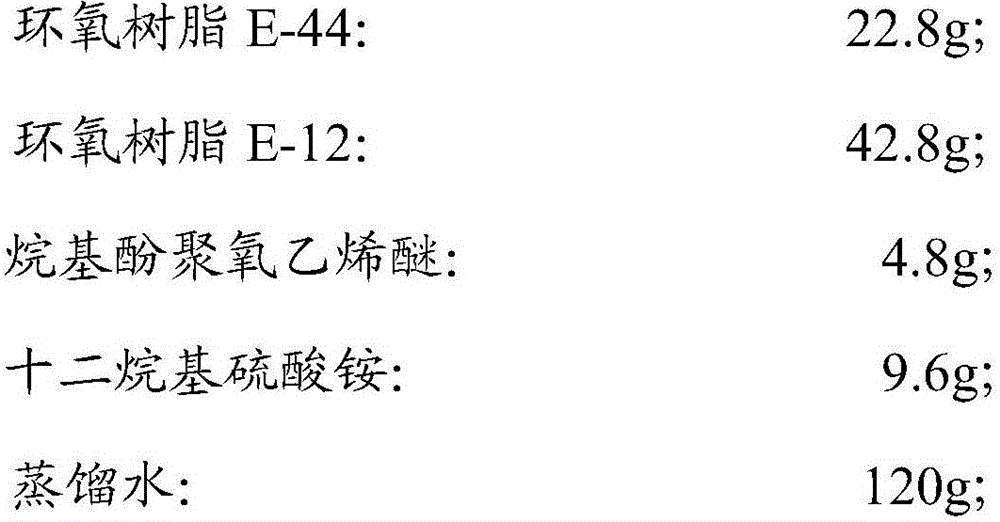

[00...

Embodiment 2

[0048] Preparation of modified graphene solution:

[0049] Graphene oxide aqueous solution (0.1wt%): 100g;

[0050] Hydrazine hydrate: 10g;

[0051] Add dropwise a calcium hydroxide solution with a mass fraction of 40% in the graphene oxide aqueous solution, adjust the pH value to 9, and perform ultrasonic treatment for 20 minutes in an ultrasonic instrument with a power of 500W and a frequency of 100kHz, and add hydration water with a mass fraction of 100 times the graphene oxide quality. Hydrazine, then react at 20°C for 24h, then use 0.2μm microporous membrane to filter the filtrate, then use 0.025μm microporous membrane to filter the previous filtrate, and use distilled water to wash the black modified graphene obtained by filtration. Then the modified graphene obtained by filtration is dissolved in a small amount of distilled water and stored in the form of modified graphene aqueous solution to avoid agglomeration of graphite after drying, that is, to obtain a modified g...

Embodiment 3

[0056] Preparation of modified graphene solution:

[0057] Graphene oxide aqueous solution (0.1wt%): 100g;

[0058] Rutin: 2g;

[0059] In the graphene oxide aqueous solution, it is 40% ammonia water that the mass fraction is added dropwise, and the pH value is adjusted to 13, and the power is 600W, and the frequency is 120kHz ultrasonic treatment for 20min, adding rutin with 20 times the quality of graphene oxide, and then React at 25°C for 24 hours, then use a 0.2 μm microporous membrane to filter the filtrate, then use a 0.025 μm microporous membrane to filter the previous filtrate, and use distilled water to wash the black modified graphene obtained by filtration to reach neutrality, then The modified graphene obtained by filtration is dissolved in a small amount of distilled water, and stored in the form of a modified graphene aqueous solution, so as to avoid agglomeration of graphite after drying, and obtain a modified graphene solution with a suitable size.

[0060] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com