Patents

Literature

33results about How to "Narrow size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

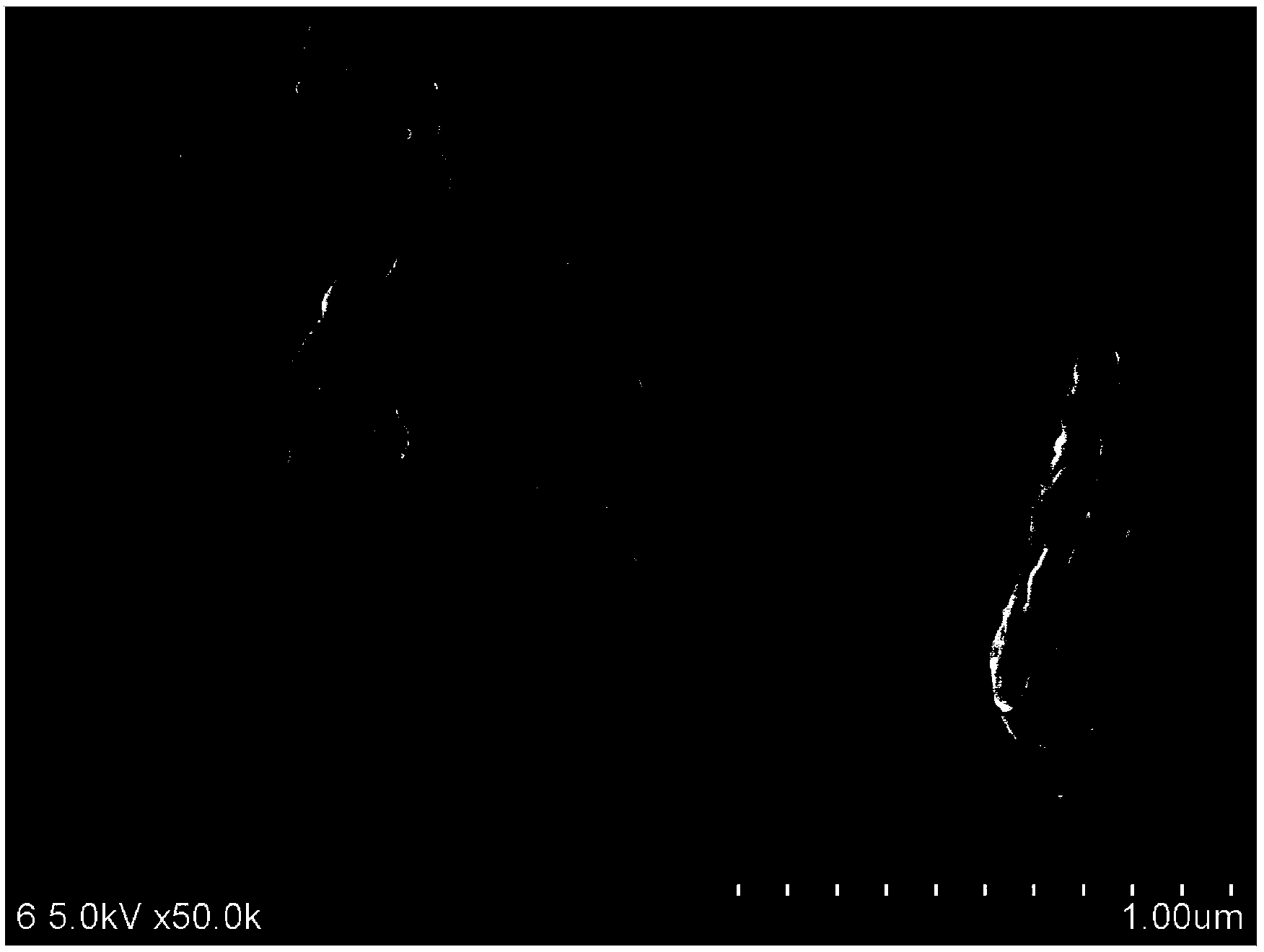

Preparation method for nano-sliver/cellulose nanocrystalline composite particle

InactiveCN102775643AIncrease loadDoes not destroy the glycosidic ring structureNanotechnologyCelluloseFree cooling

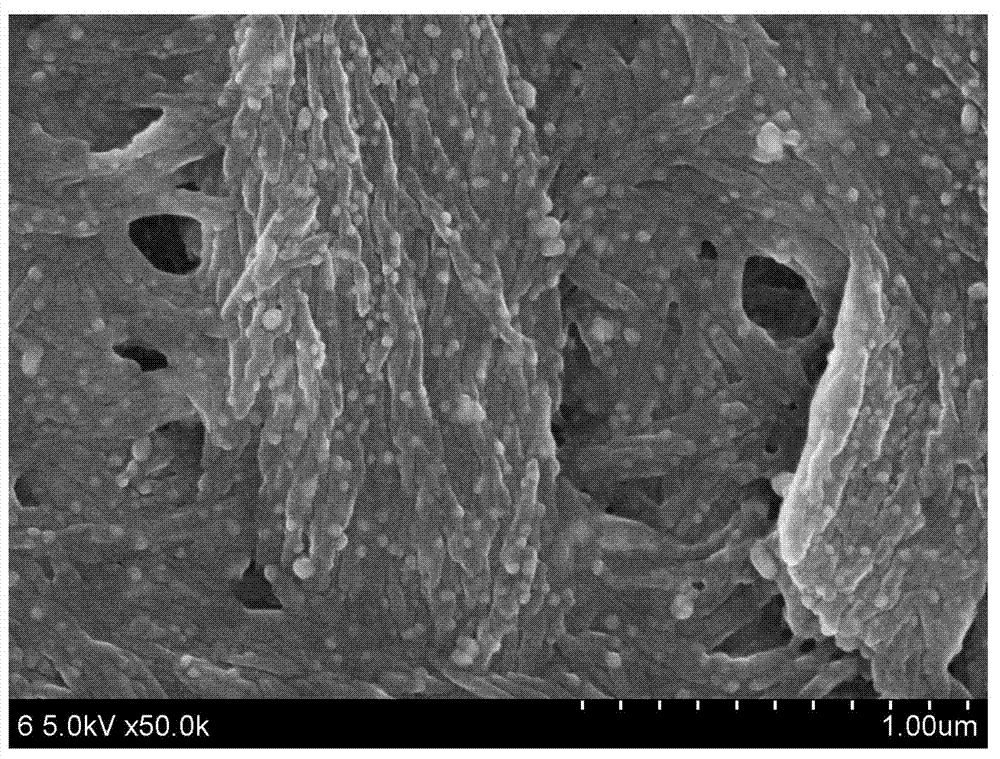

The invention relates to a preparation method for a nano-sliver / cellulose nanocrystalline composite particle. The preparation method comprises the following steps of: (1) adding a cellulose raw material into an acid-mixed solution and reacting at the temperature of 50-90DEG C for 1-20 hours; after the reaction is ended, washing a reaction product with deionized water to neutral and obtaining aldehyde cellulose nanocrystalline; and (2) adding the aldehyde cellulose nanocrystalline into a silver nitrate solution; reacting at the temperature of 60-105DEG C for 10-60 minutes; and after naturally cooling, diluting a reaction product with the deionized water, centrifuging and then carrying out free drying or vacuum drying to obtain a nano-silver / CNC (Cellulose Nanocrystalline) composite material. The preparation method disclosed by the invention is simple and convenient in process, easy in operation and environment friendly and can be used for shortening the preparation period; the prepared CNC / nano-silver has the advantages of small size, easy adjustment, large specific area, firmness in combination of the CNC and the nano-silver, durable antibacterial effect, antibacterial and enhancing functions and broad application prospect.

Owner:DONGHUA UNIV

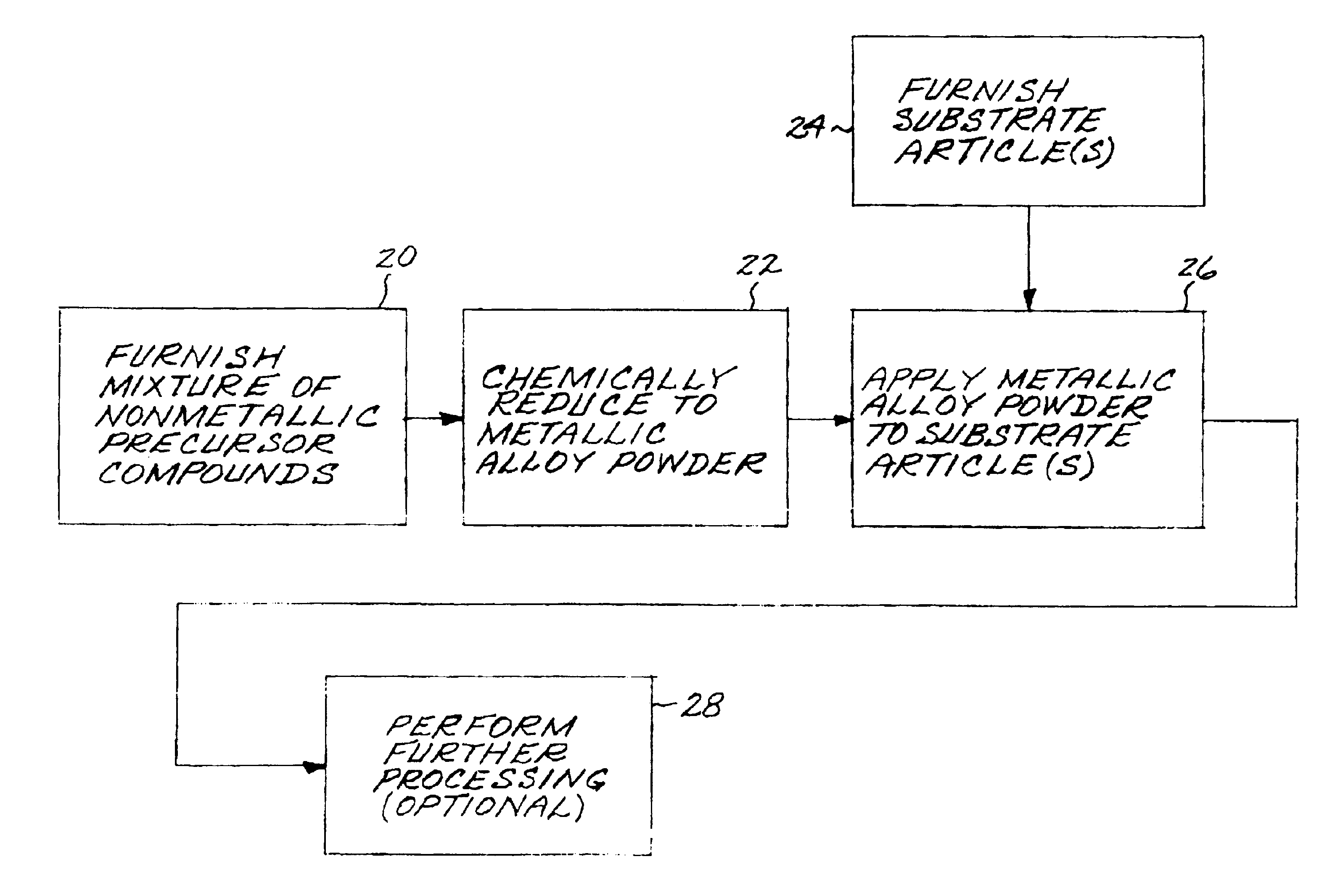

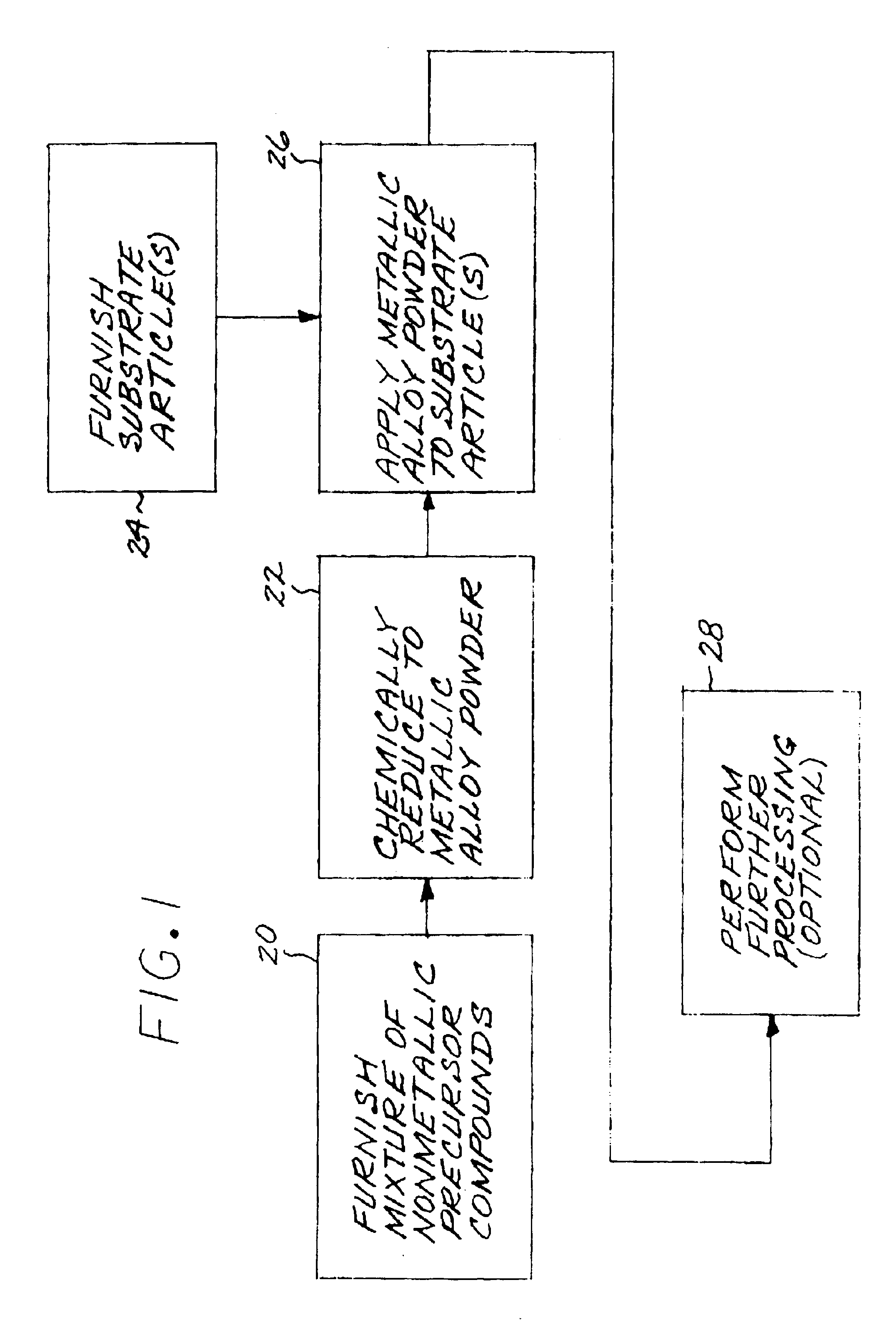

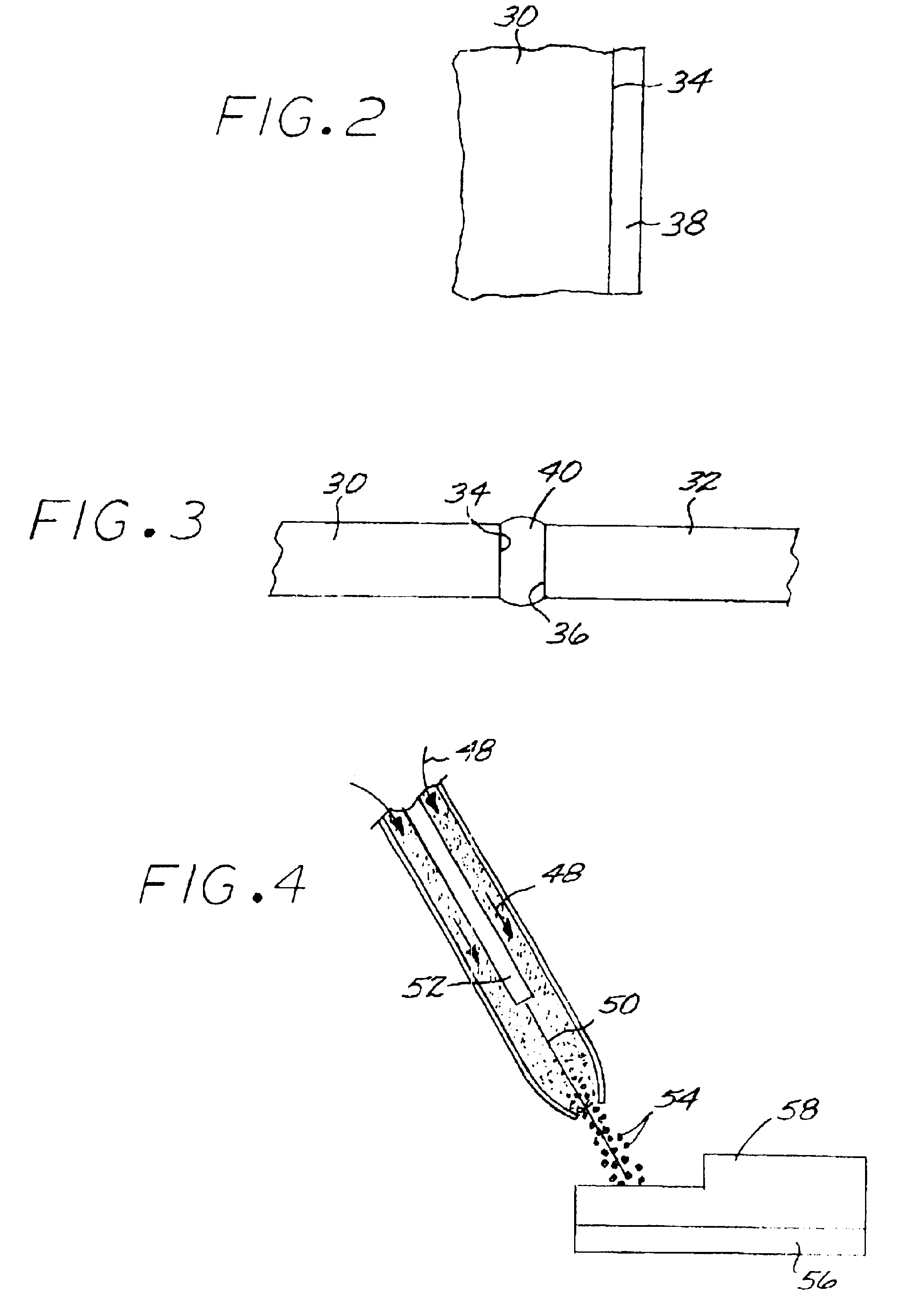

Fabrication and utilization of metallic powder prepared without melting

InactiveUS6968990B2Narrow size distributionImprove overall utilizationTurbinesMolten spray coatingMetal powderMetallic alloy

A metallic alloy made of metallic constituent elements is fabricated and utilized by first furnishing a mixture of nonmetallic precursor compounds of the metallic constituent elements, and thereafter chemically reducing the mixture of nonmetallic precursor compounds to produce a metallic alloy as a metallic alloy powder, without melting the metallic alloy. The metallic alloy powder is applied to a surface of a substrate article, preferably in a coating, joining, or deposition application.

Owner:GENERAL ELECTRIC CO

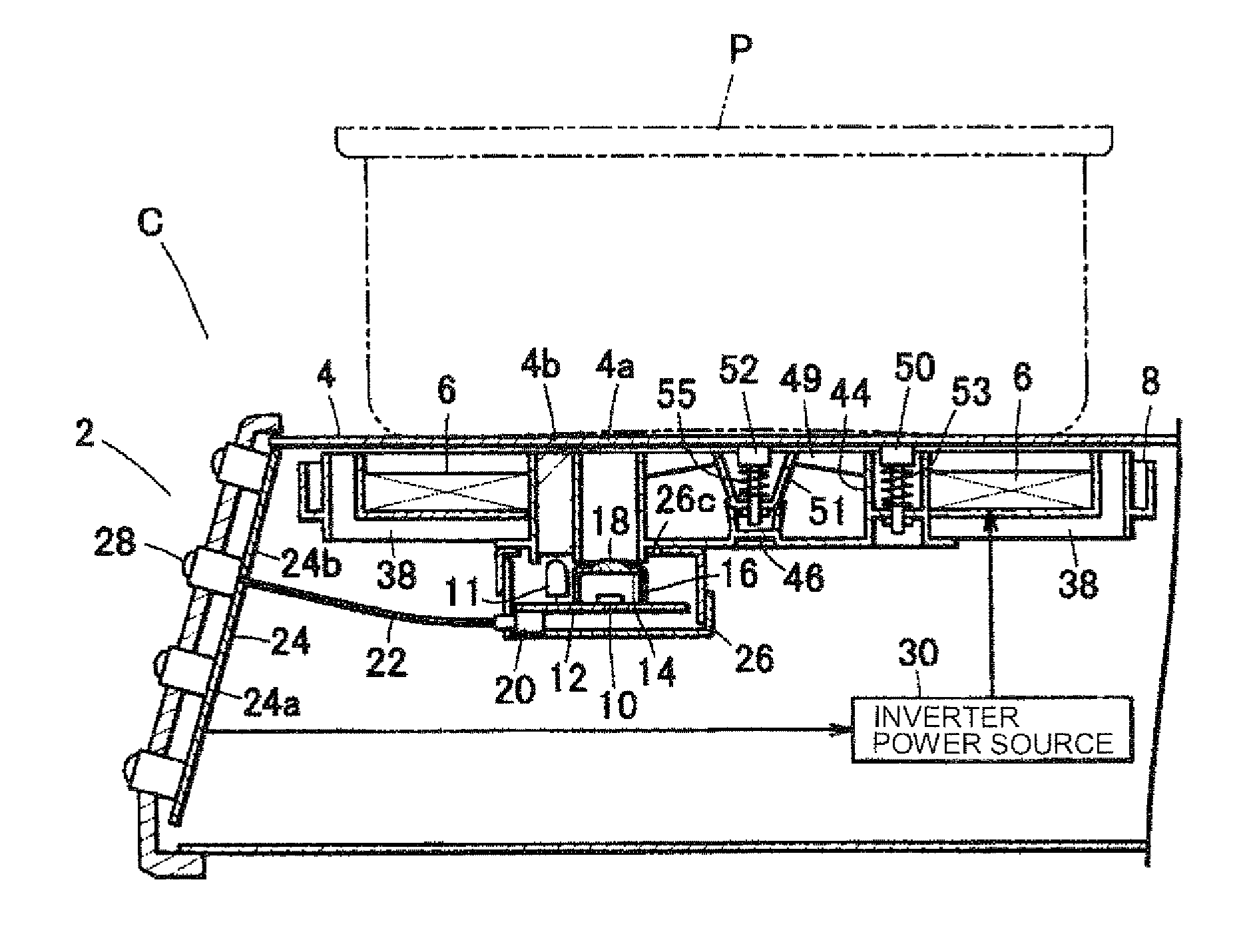

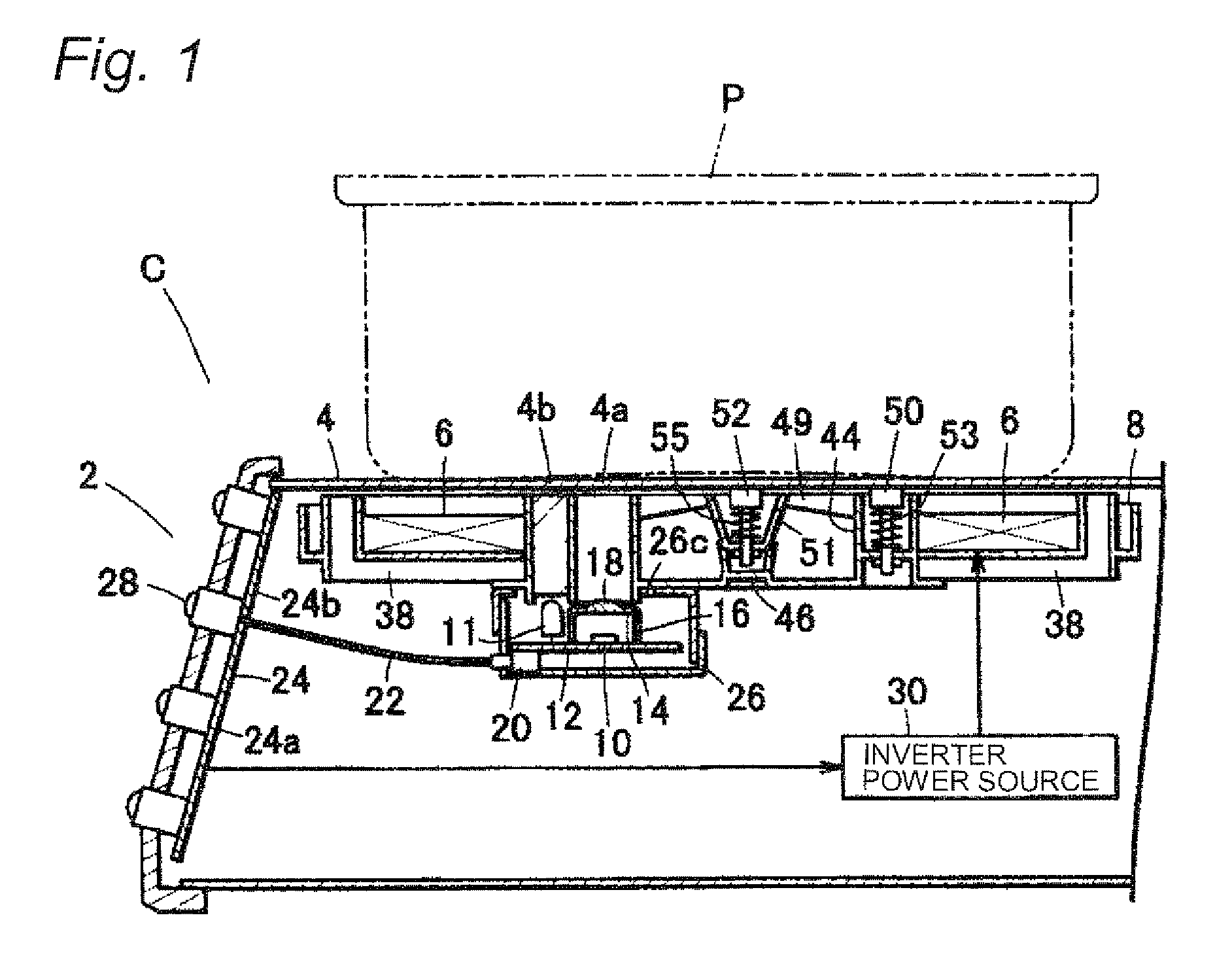

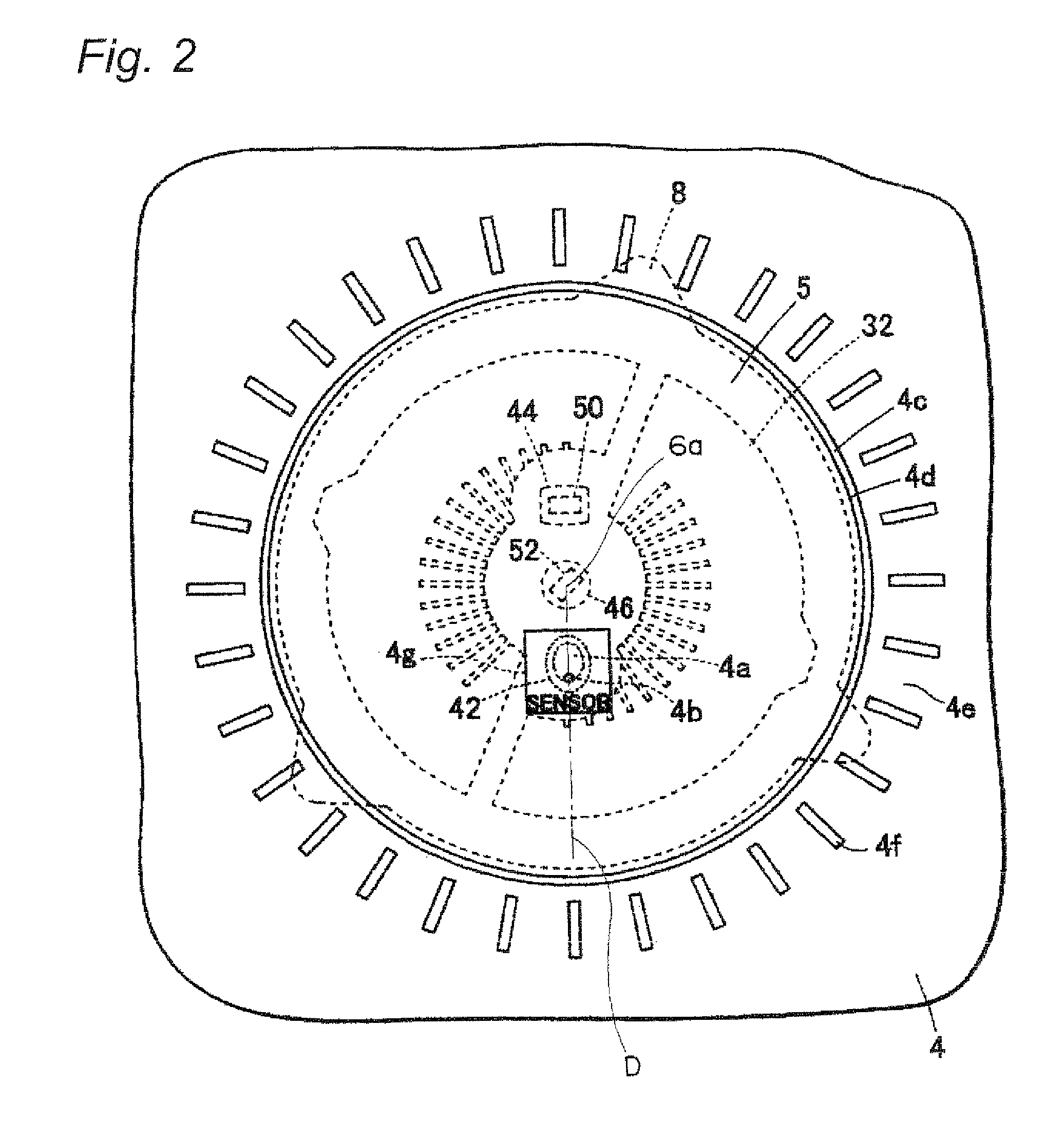

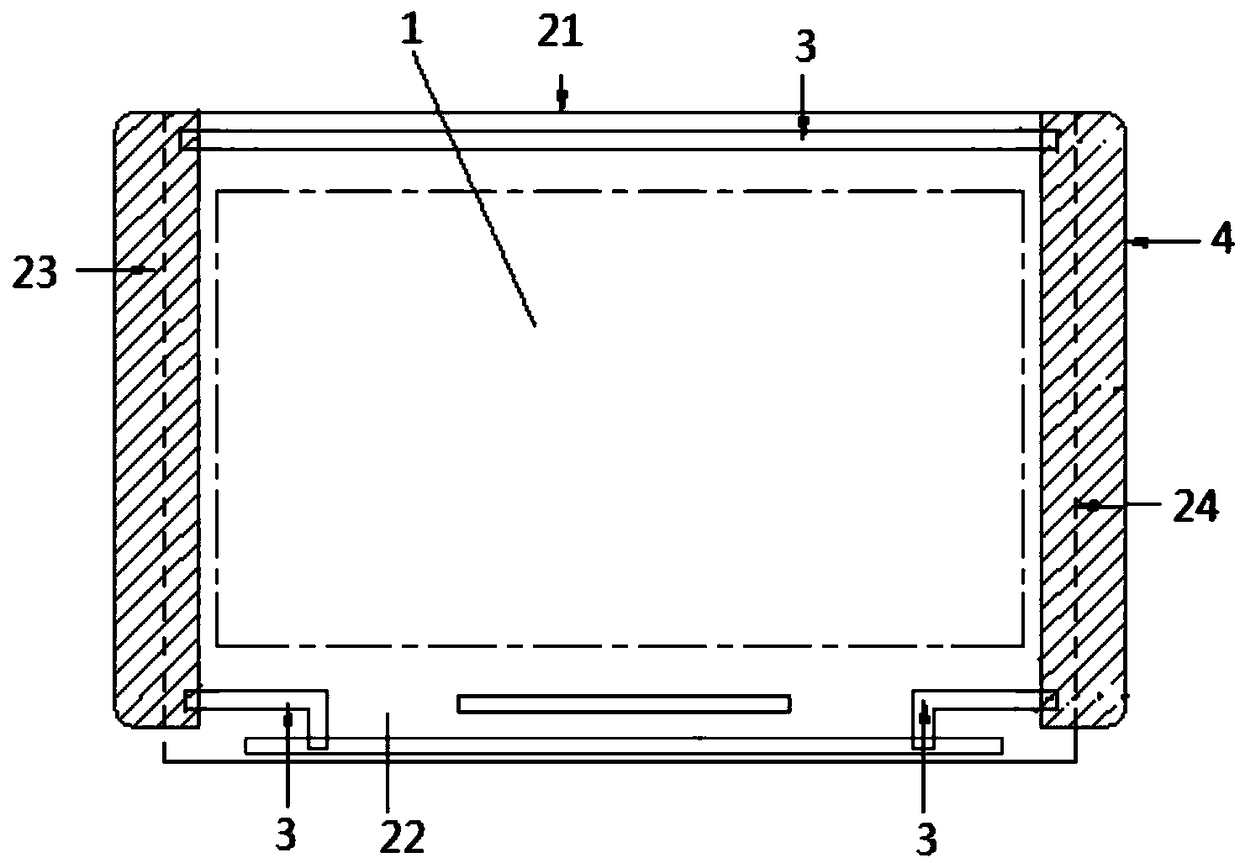

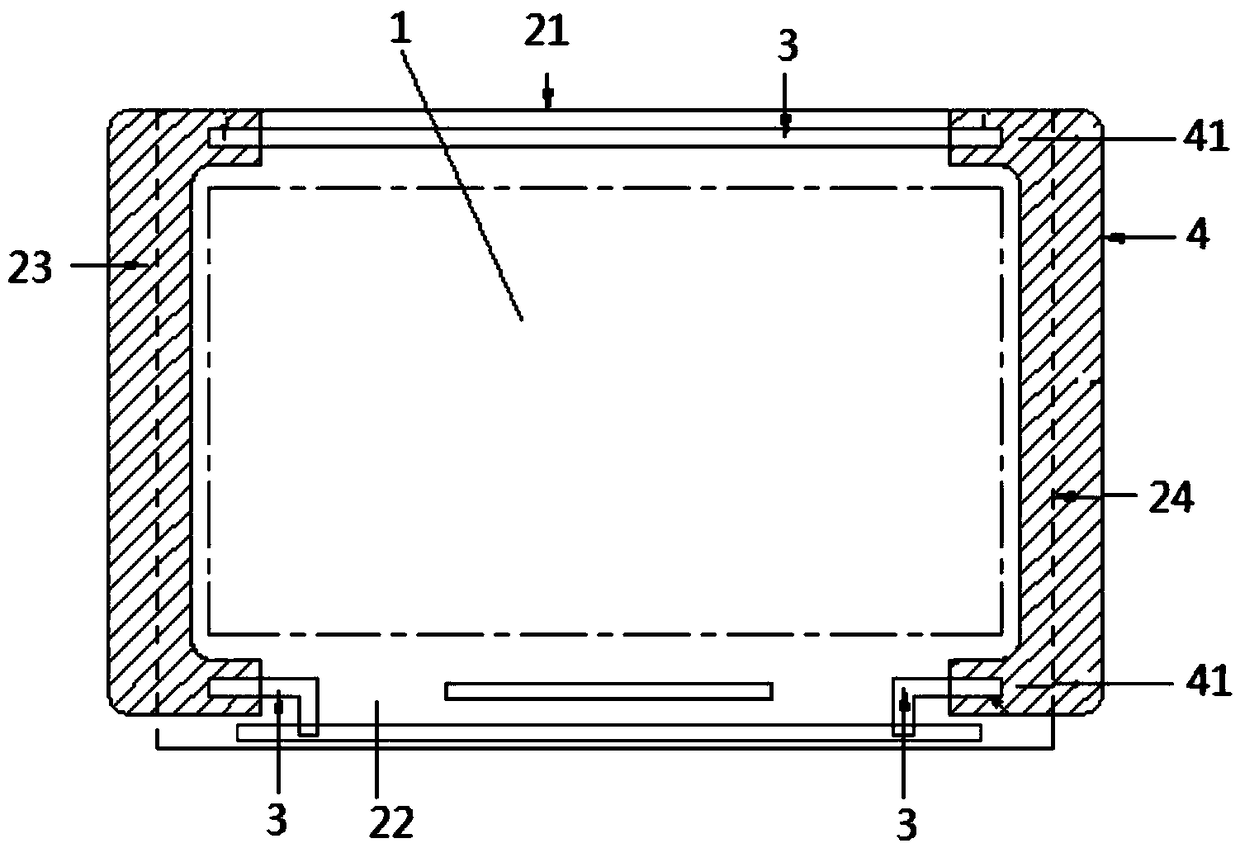

Induction heating appliance for cooking

InactiveUS8203106B2Improve usabilityNarrow sizeInduction heating apparatusOptoelectronicsInduction heating

An infrared permeable window 4a, which is surrounded by a light shielding layer 7b and is narrower than an infrared sensor display window 4g, is formed inwardly of the infrared sensor display window 4g, and an infrared incident area 43a for detecting infrared rays of light and a light emitting unit 56a are provided below the infrared permeable window 4a. Also, a light emitting surface 4b is provided inwardly of the infrared permeable window 4a, so that the user can assuredly place a cooking container P on the infrared permeable window 4a.

Owner:PANASONIC CORP

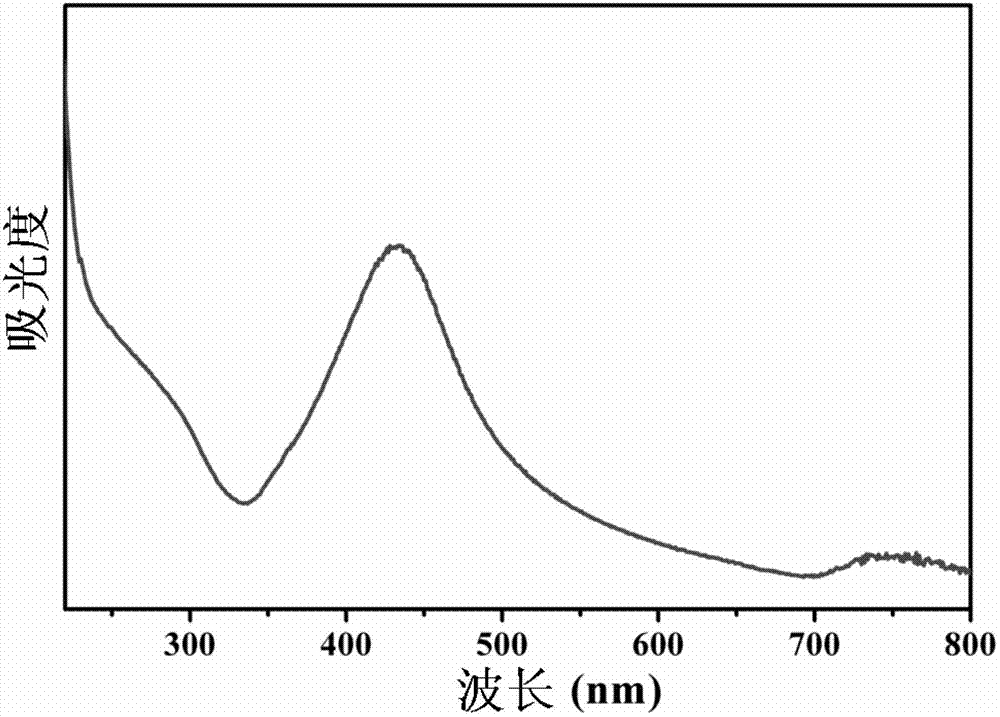

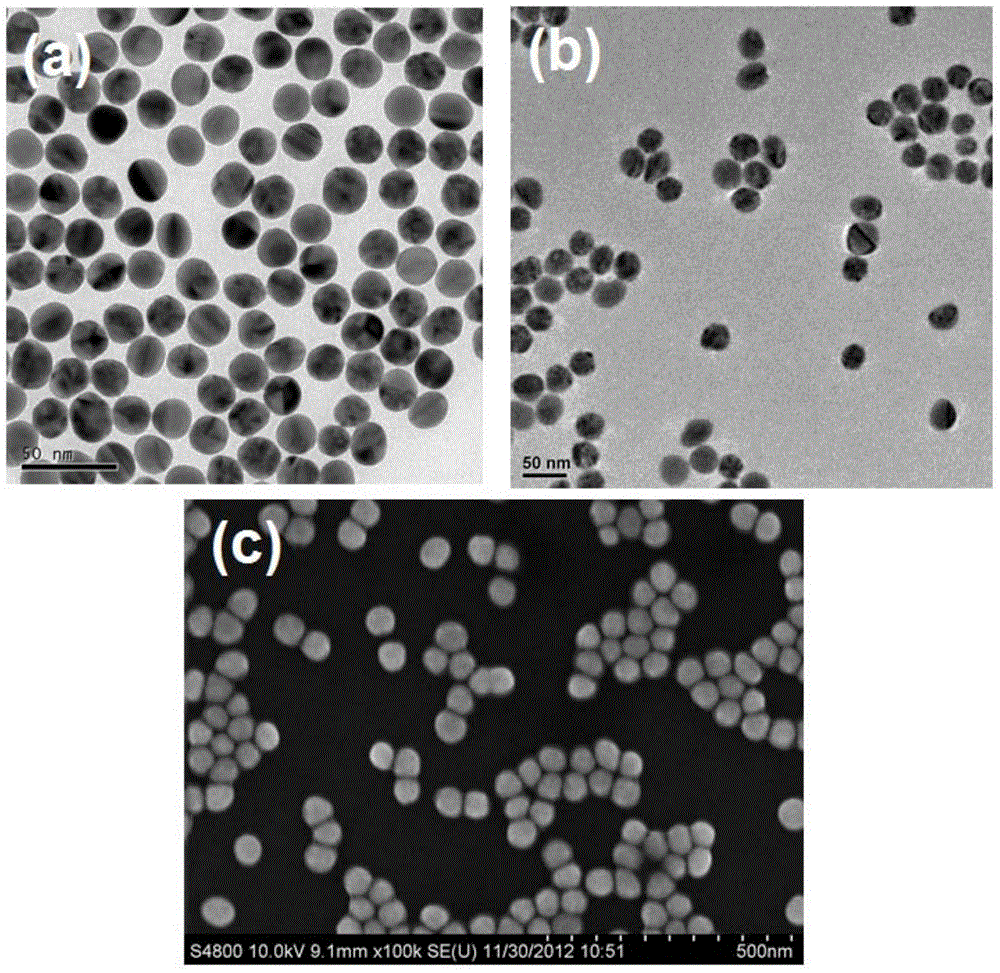

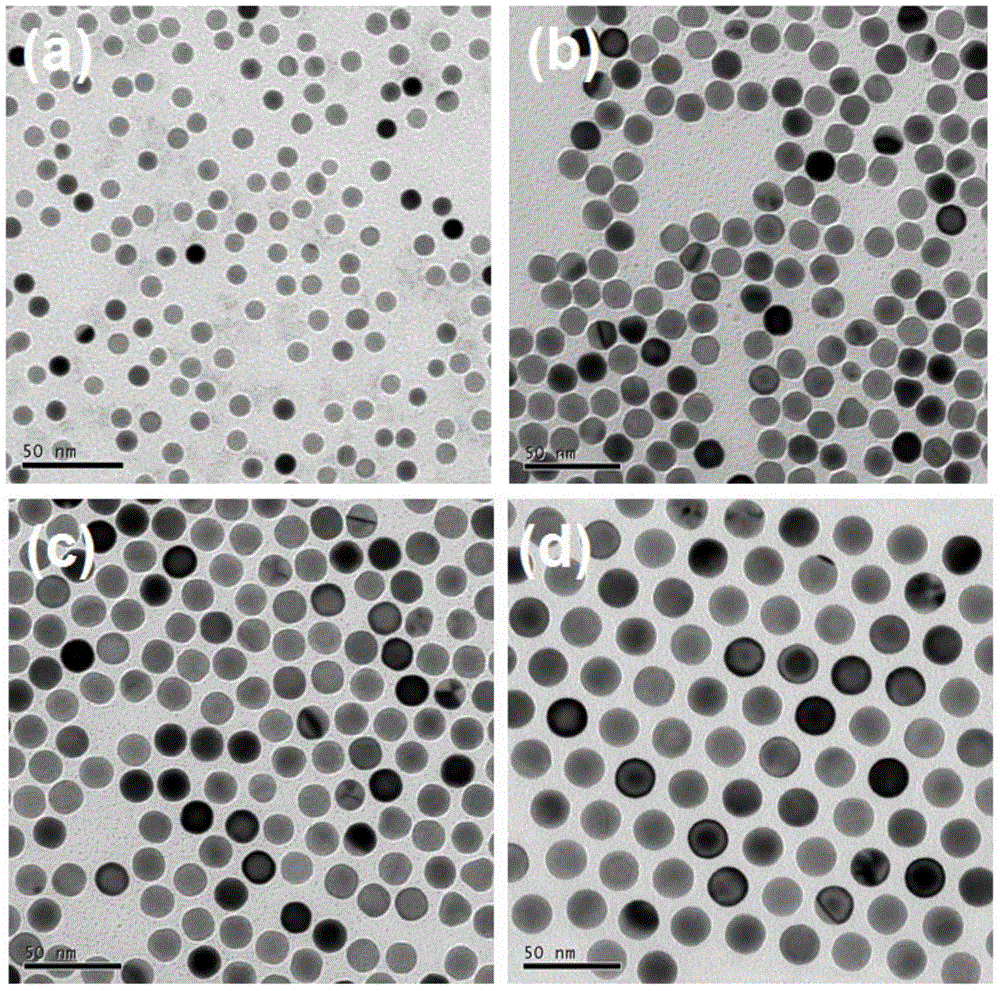

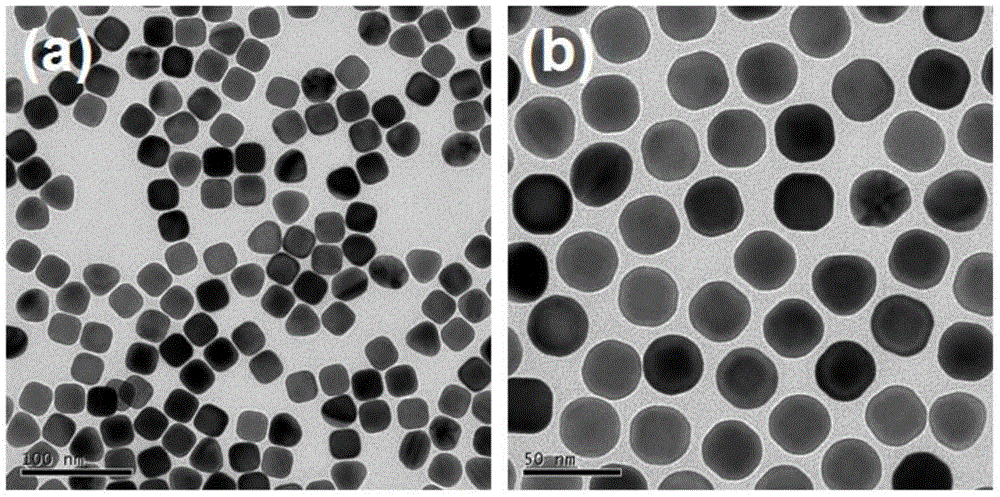

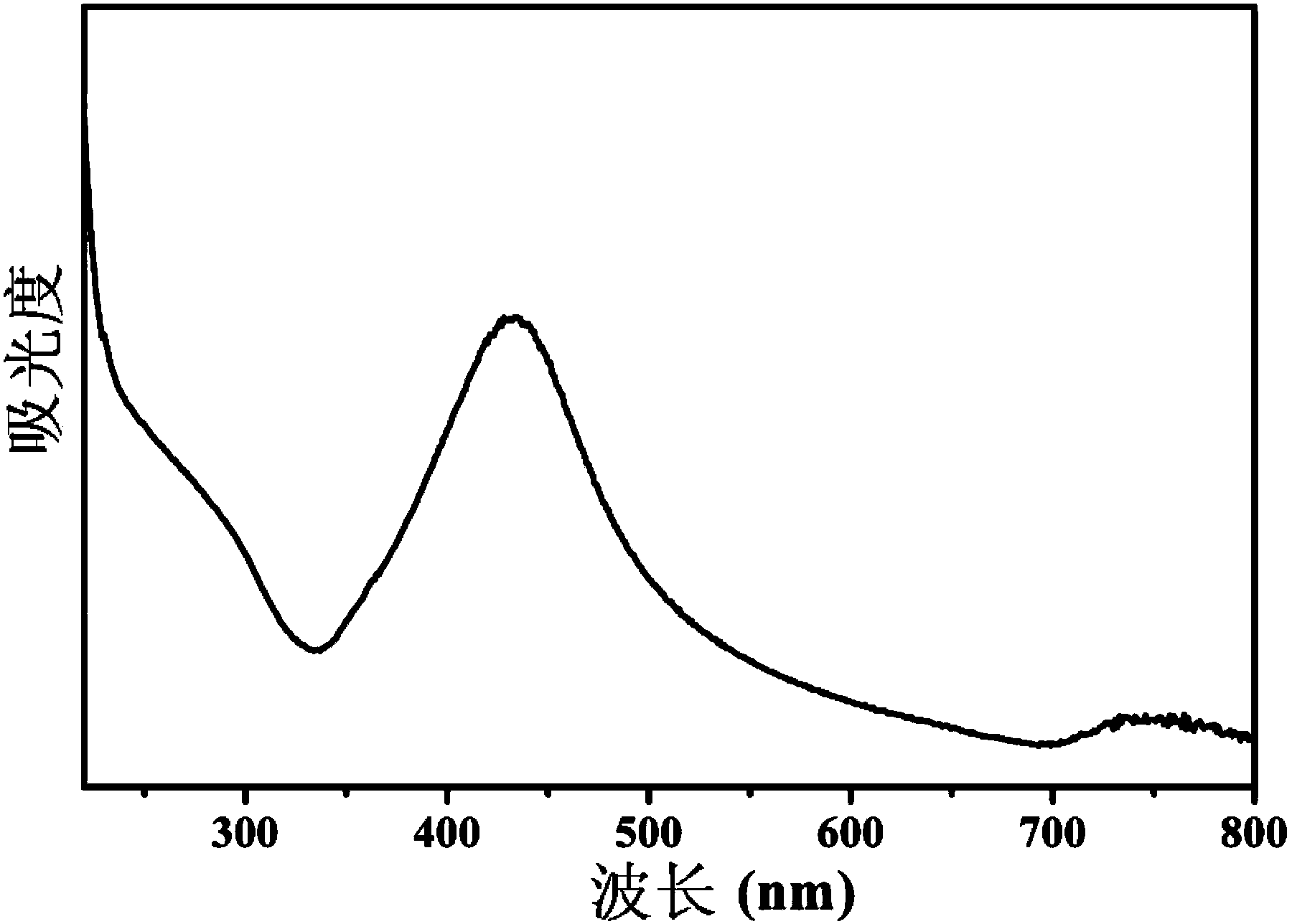

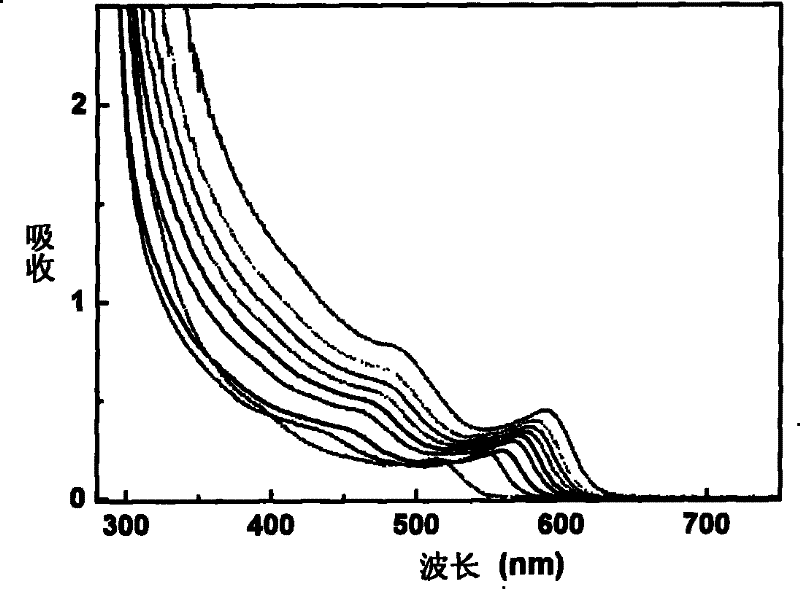

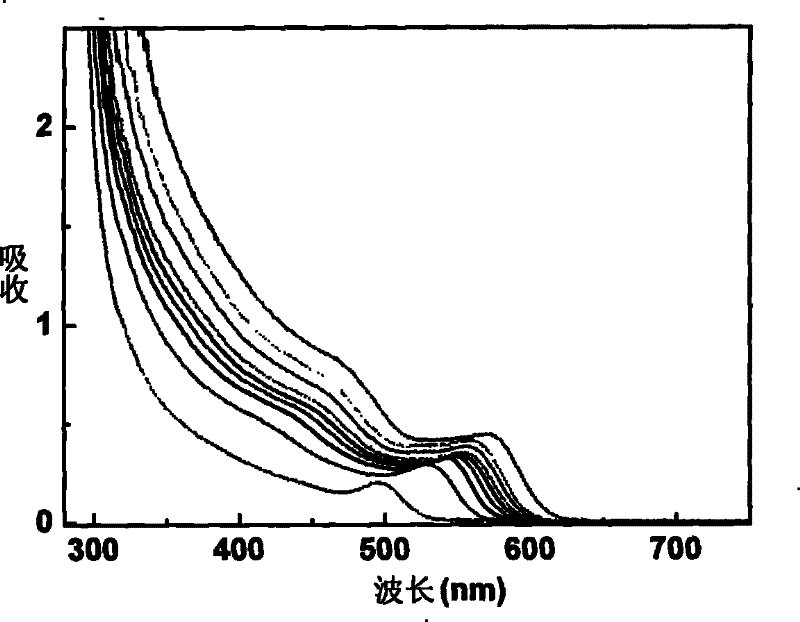

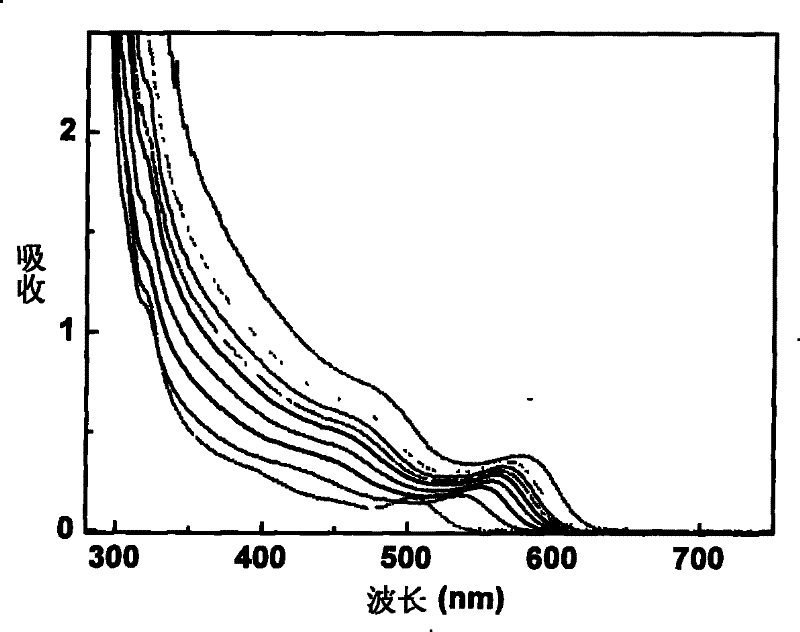

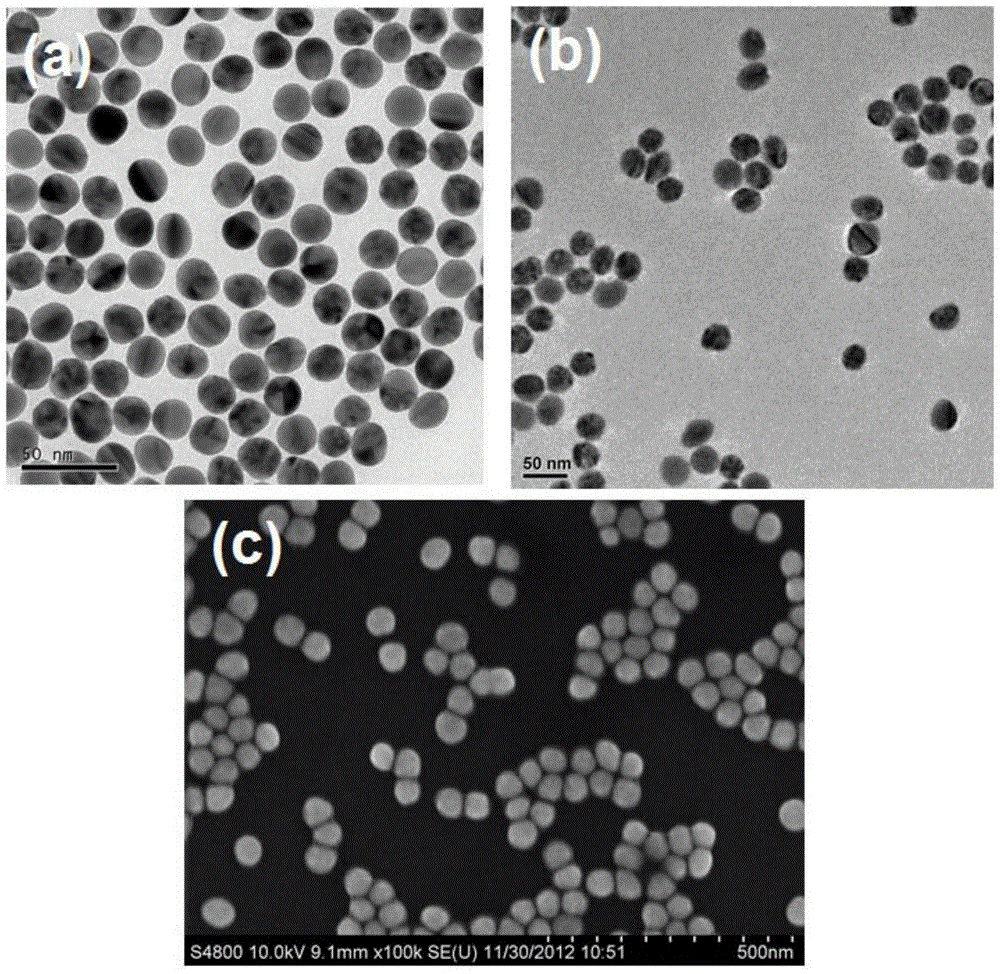

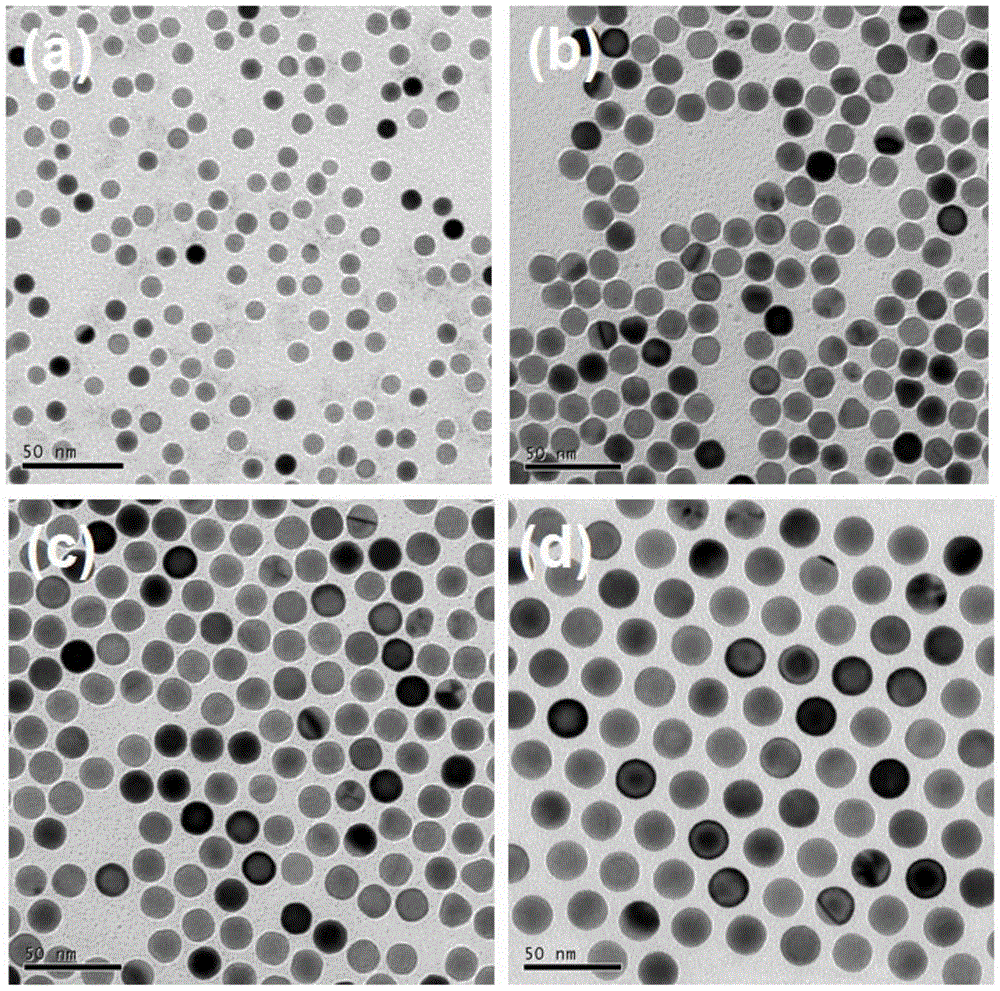

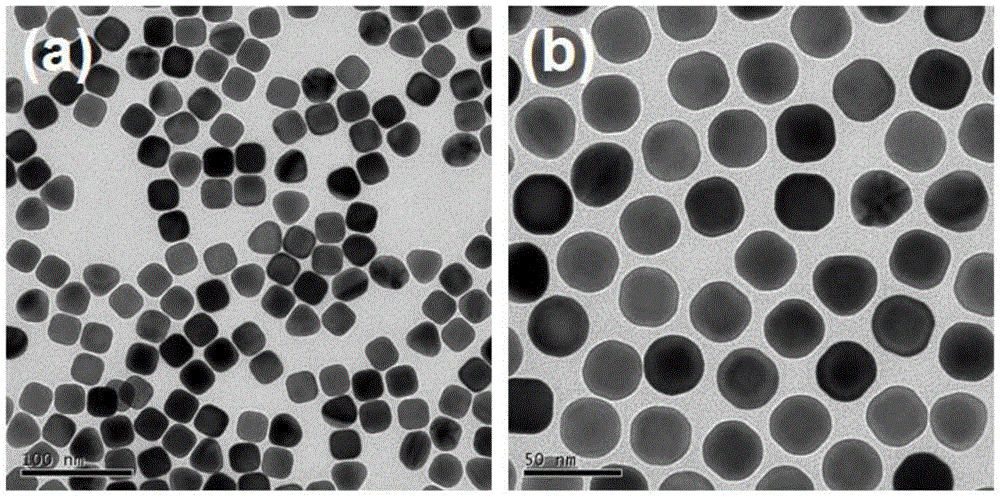

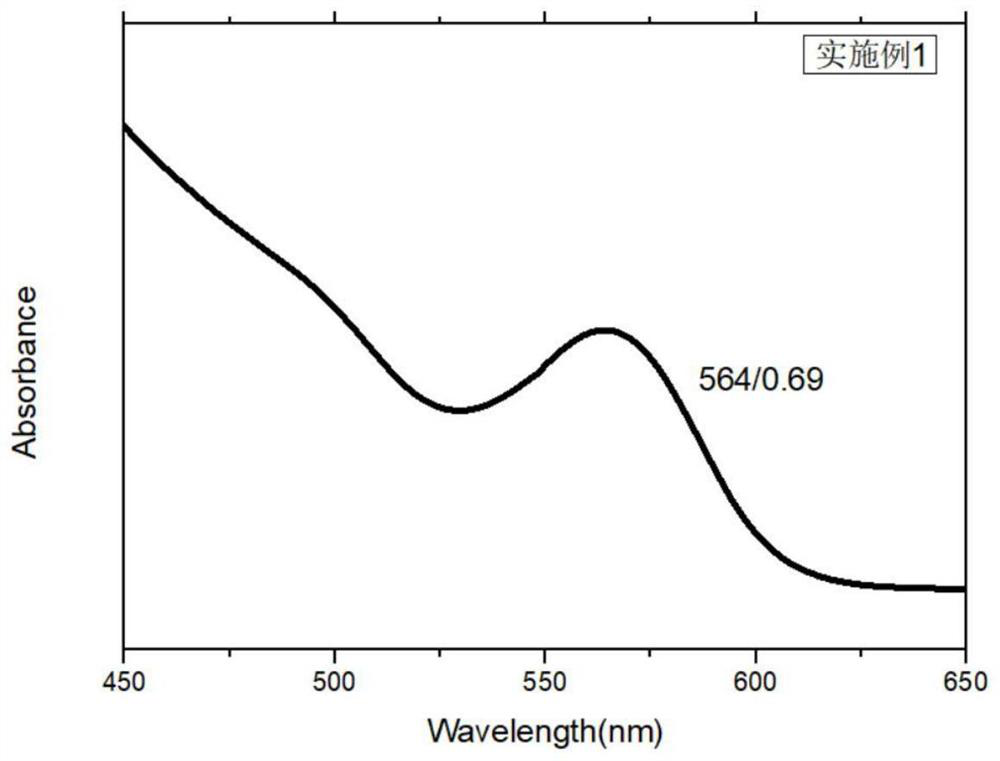

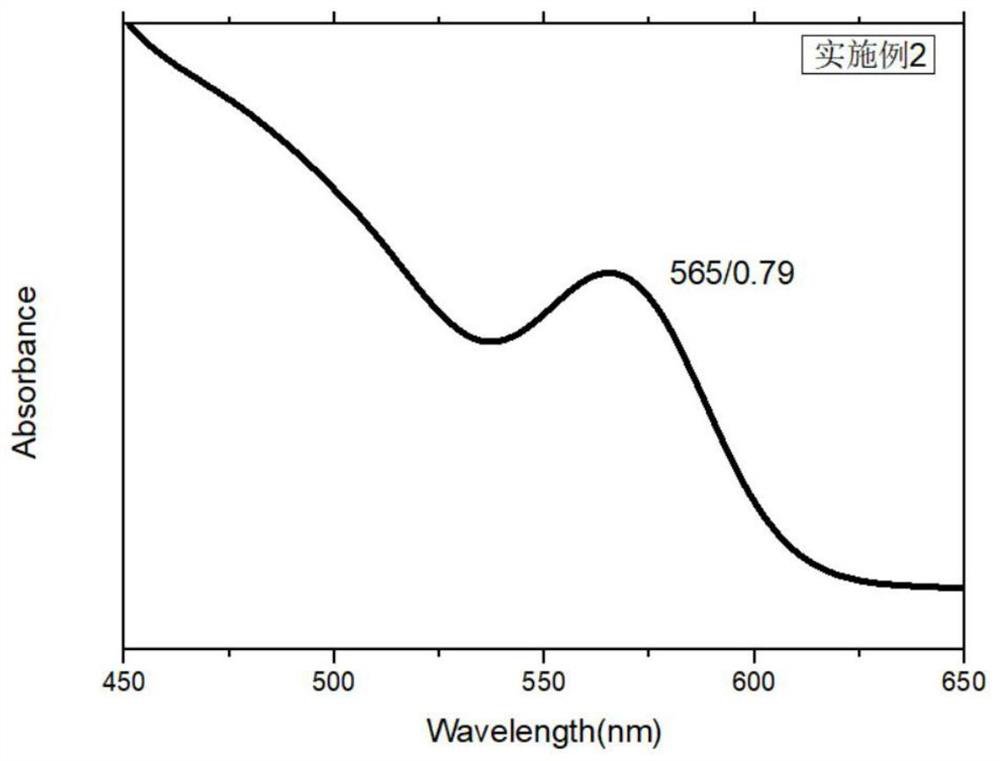

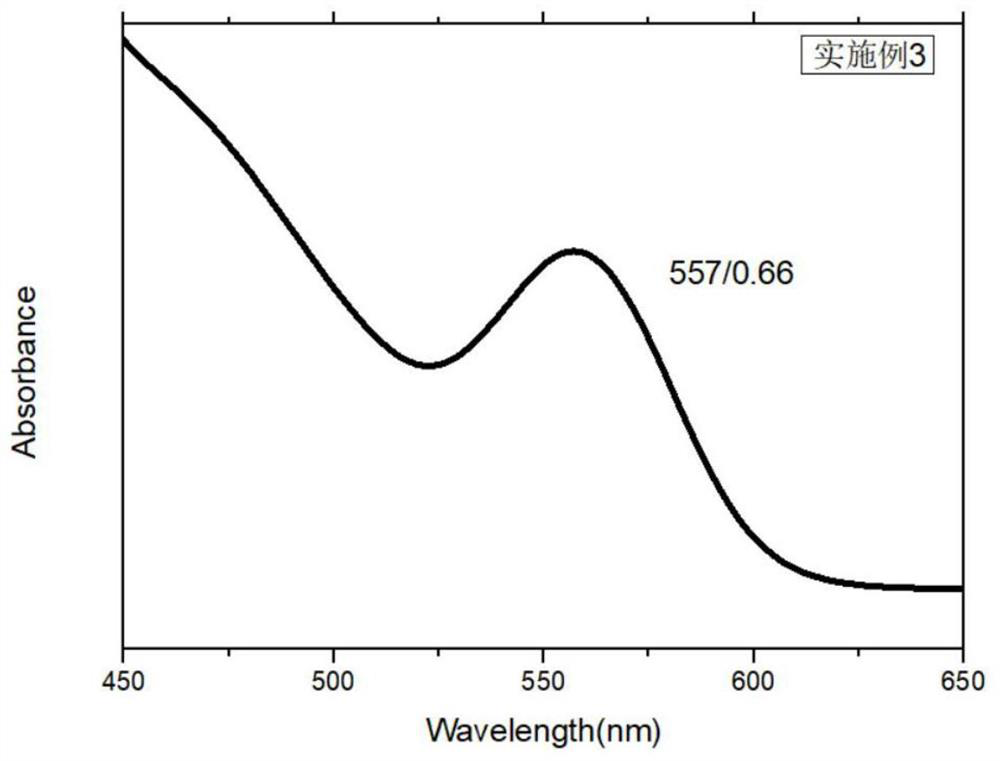

Spheroidal gold particle and step-by-step rapid synthesis method thereof

The invention relates to a spheroidal gold particle and a step-by-step rapid synthesis method thereof. The method includes the following steps: soluble gold salt, surfactant and reducer are prepared into mixed solution, and gold particle seeds are added in the process of rapid agitation, and thereby react to grow into spheroidal gold particles, the grain size of which is 5nm to 100nm; the surfactant is the mixed surfactant of cetyltrimethylammonium bromide or cetyltrimethylammonium chloride and cetyltrimethylammonium bromide, the reducer is ascorbic acid, and the gold particle seeds are spheroidal gold particles, the grain size of which is 2nm to 60nm. The gold particle seeds can be monocrystalline or polycrystalline, and the synthesized spheroidal gold particles have the same crystal form as the gold particle seeds. Since the invention adopts the surfactant and the reducer and the gold particle seeds are added in the process of rapid agitation, reaction is rapid enough, consequently, the gold salt can rapidly and uniformly grow on the surfaces of the gold particle seeds, and the obtained spheroidal gold particles is narrow in grain size and has a good degree of sphericity.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

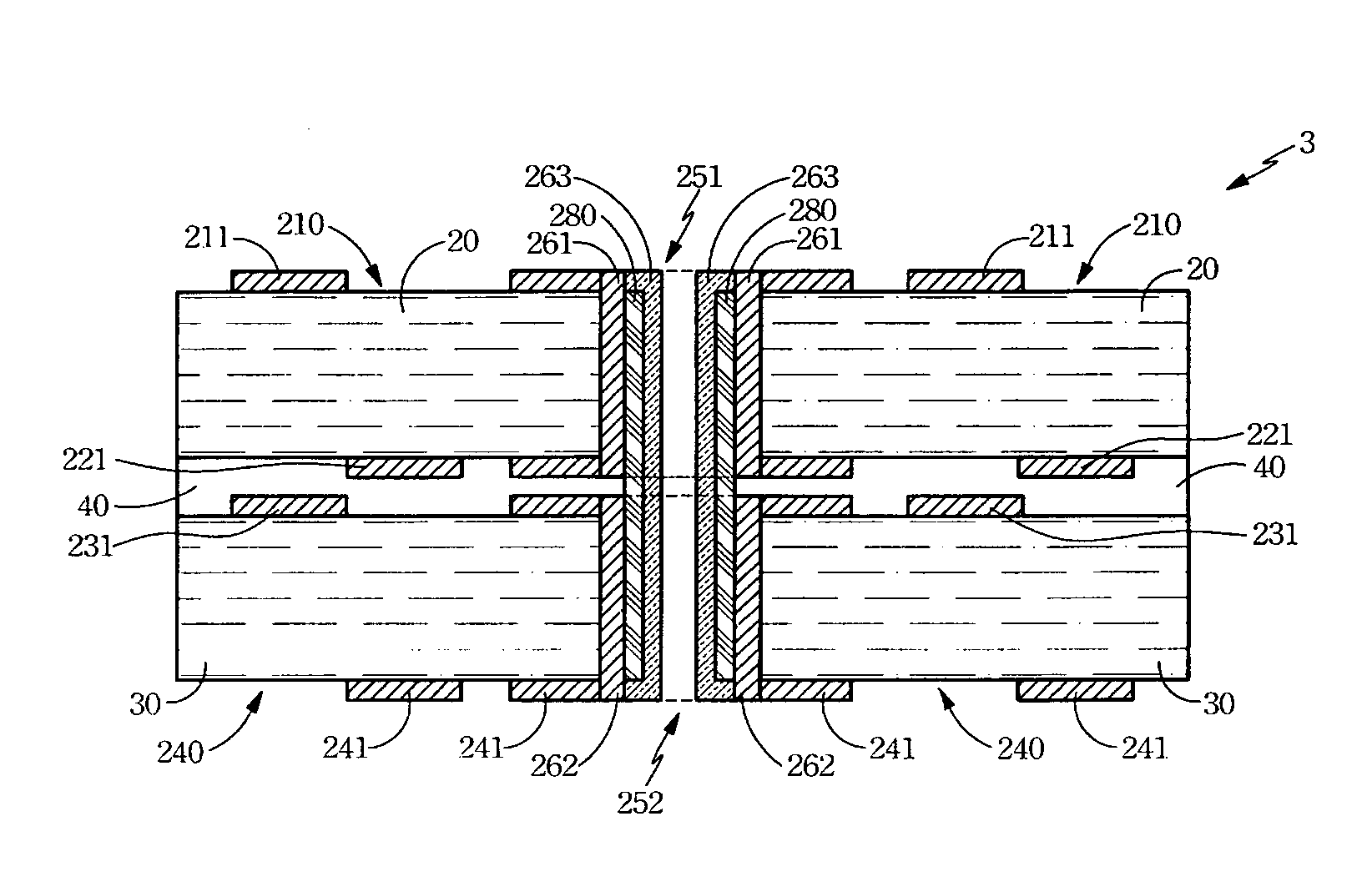

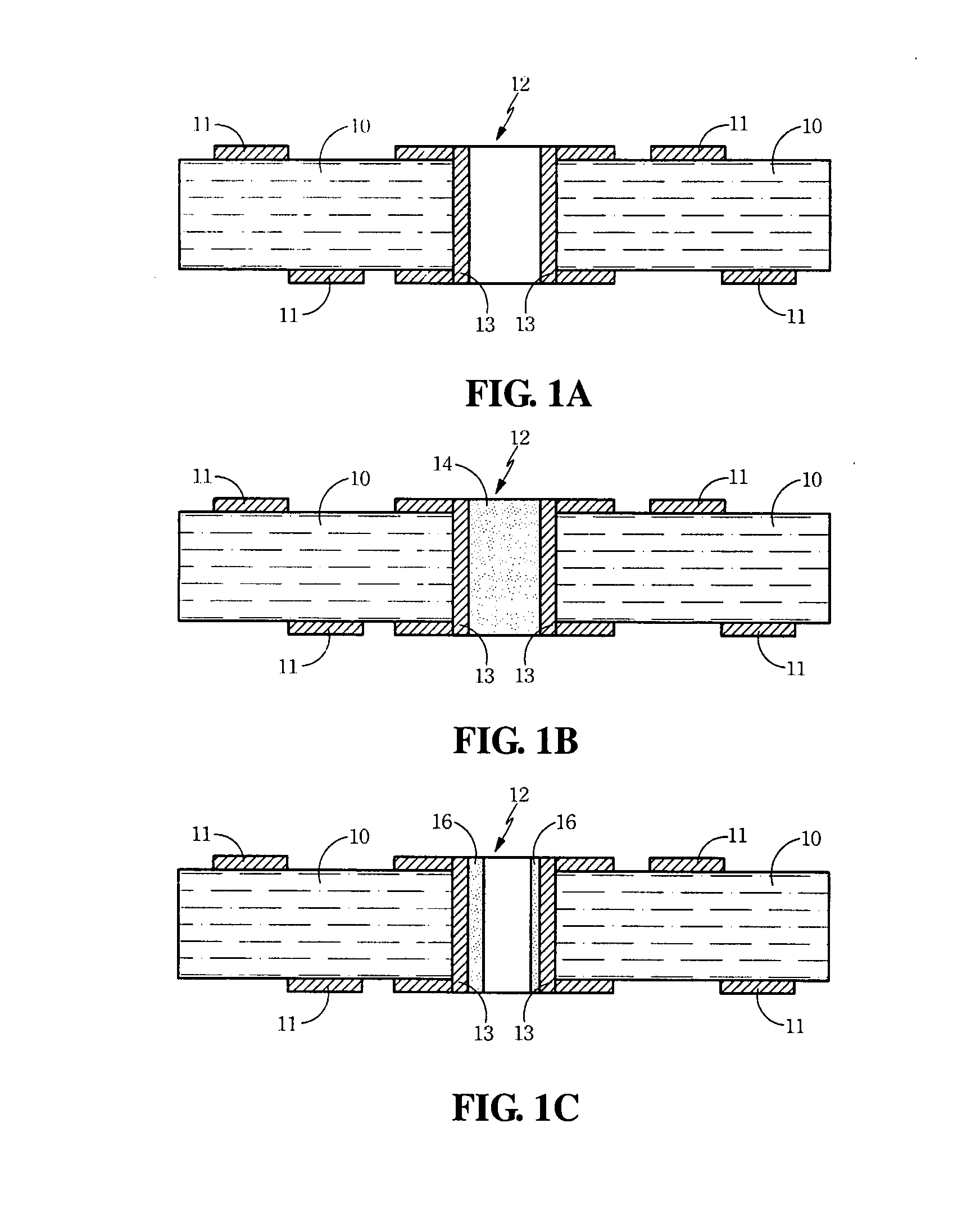

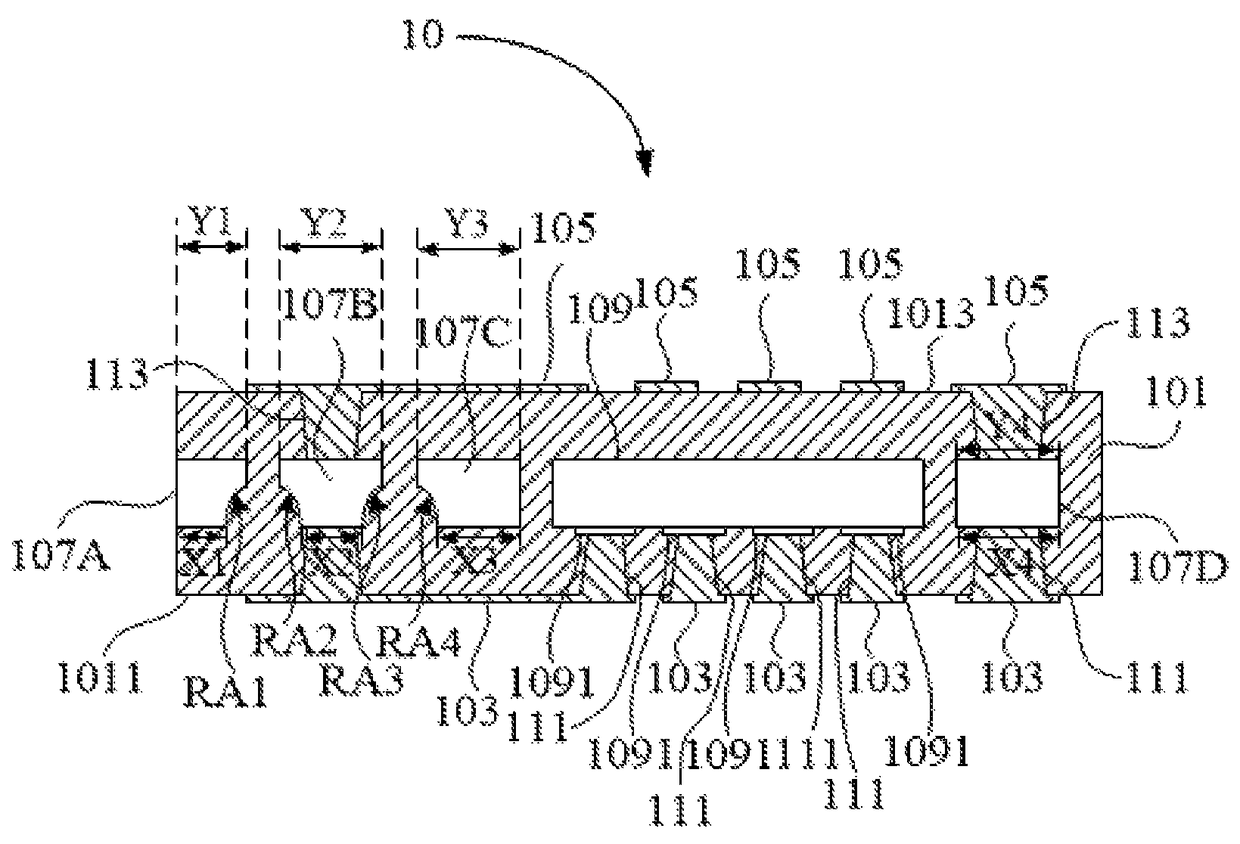

Method for making a circuit board and multi-layer substrate with plated through holes

InactiveUS20080271915A1Decrease in numberNarrow sizePrinted circuit assemblingCross-talk/noise/interference reductionElectrophoretic depositionEngineering

A method for making a circuit board includes the following steps. At least two substrates are provided, wherein each substrate includes two surfaces, two circuit layers respective formed on the two surfaces and at least a via passing through the two surfaces. A metal layer is formed on the side wall of the via, wherein the metal layer electrically connects two circuit layers on the two surfaces of each substrate to each other. An insulating film is at least formed on the surface of the metal layer by an electrophoretic deposition process. Vias of two substrates are aligned with each other and two substrates are laminated to each other, so as to form a multi-layer substrate. Another metal layer is formed on the insulating film, wherein each metal layer is an independent electrical channel.

Owner:ADVANCED SEMICON ENG INC

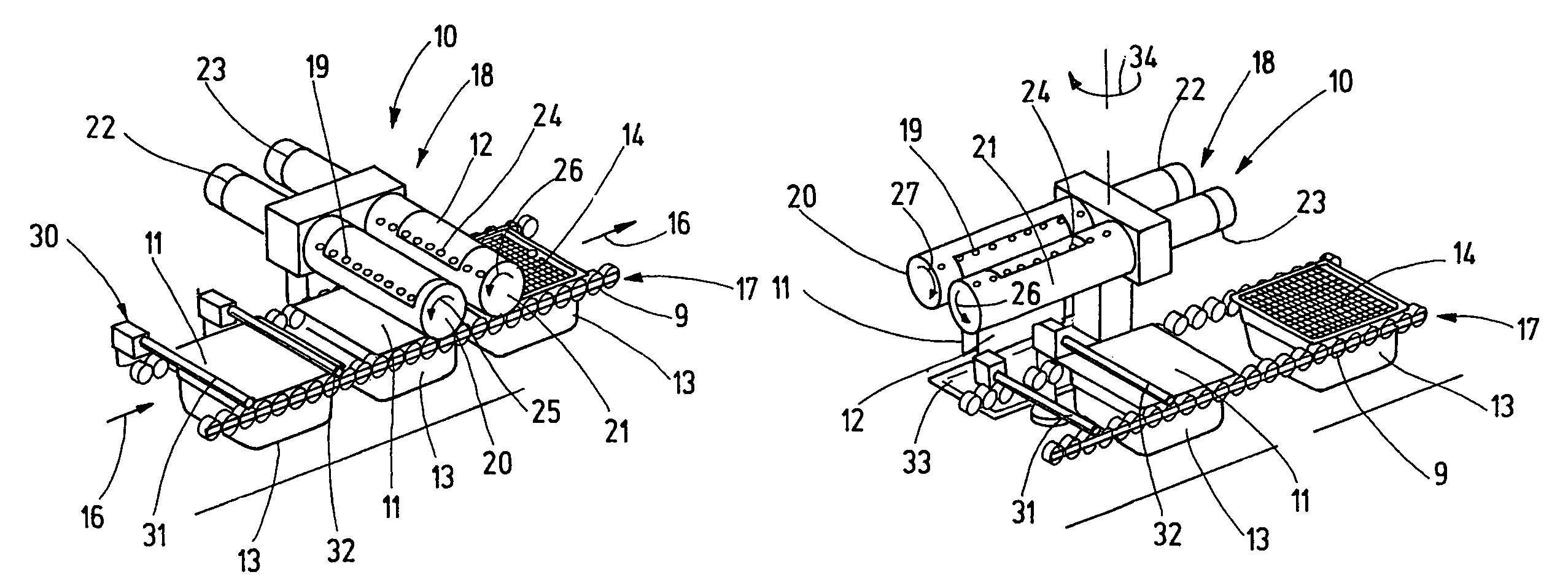

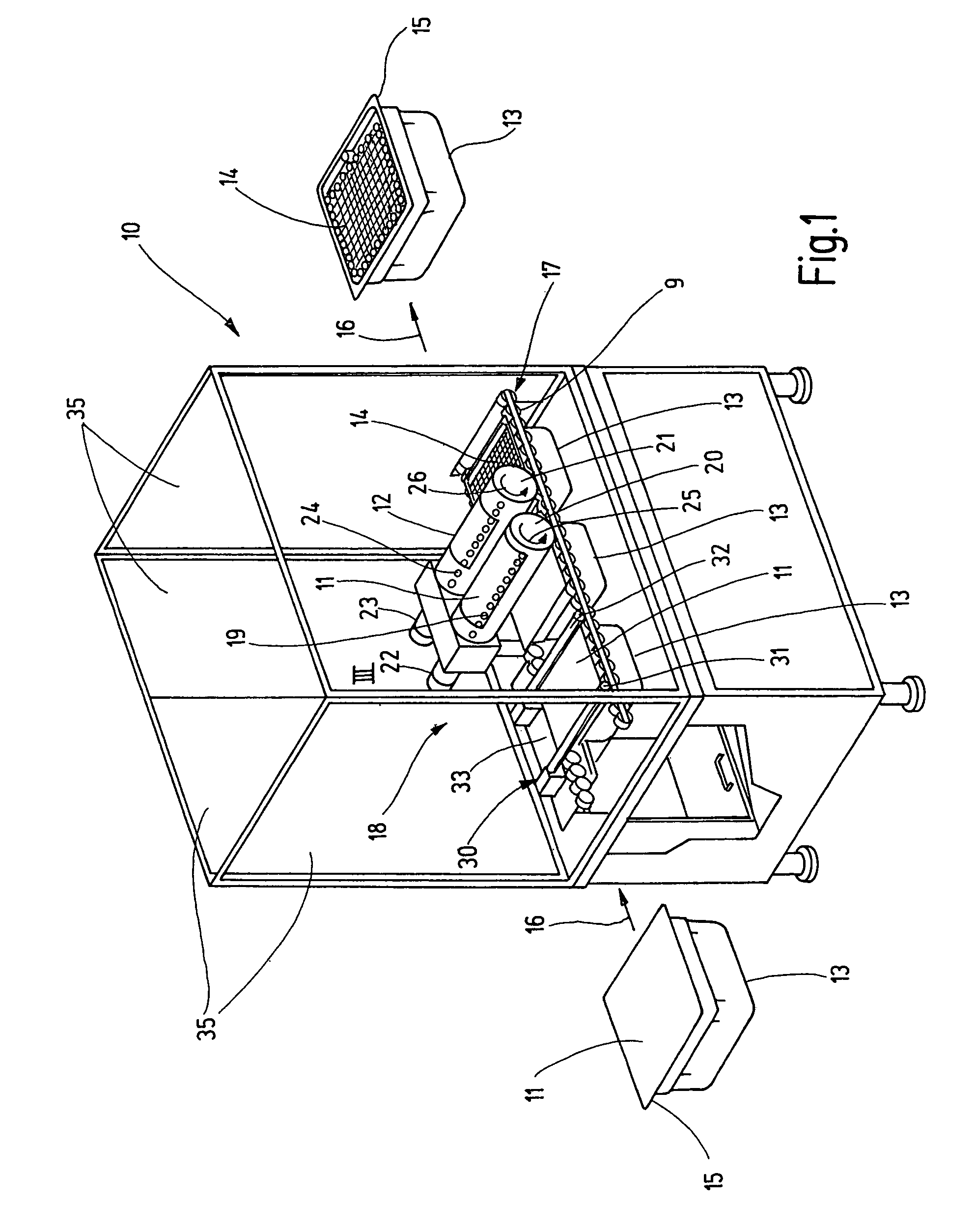

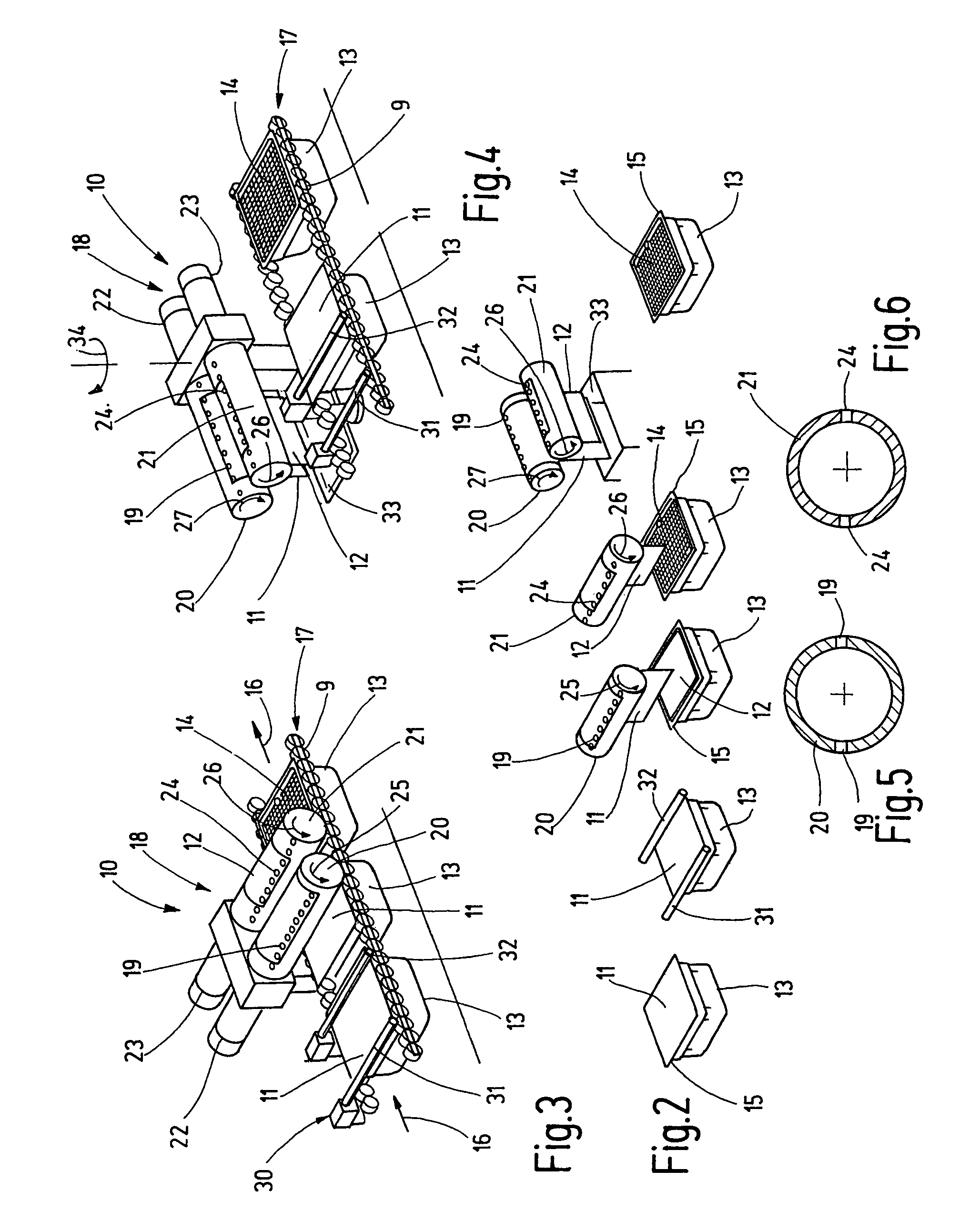

Method and device for removing a cover from a storage box

InactiveUS7565786B2Reliable removalLeast amount of resistance to separationWrapping material feeding apparatusBinding material removalEngineering

The present invention relates to a method and a device for removing a cover from a storage box that is closed using a lid-like cover attached thereto at the edges. For removal, the adhesive strength of the cover is reduced in the region of a few of the sealed edges and the cover is then removed by peeling it off the storage box, whereby the cover is peeled off by rolling it onto a roller.

Owner:GRONINGER

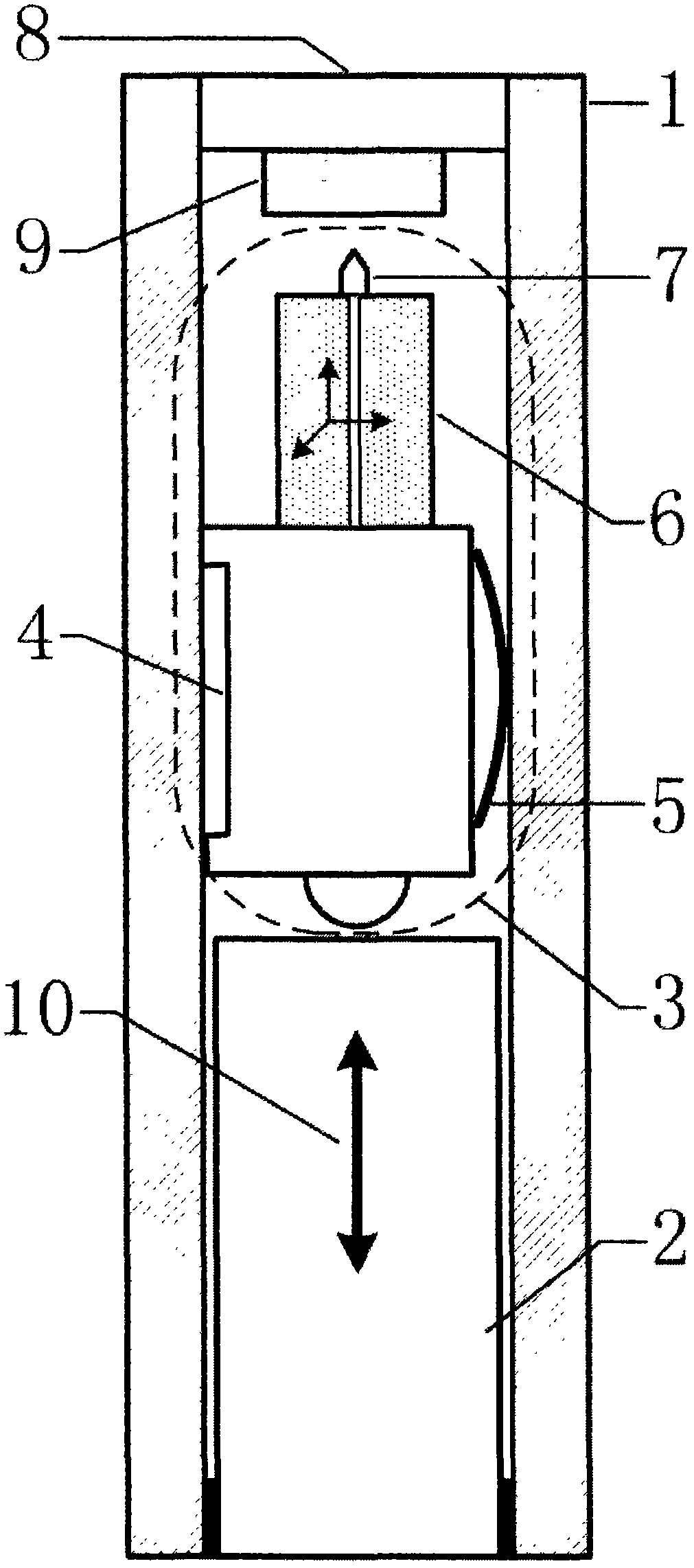

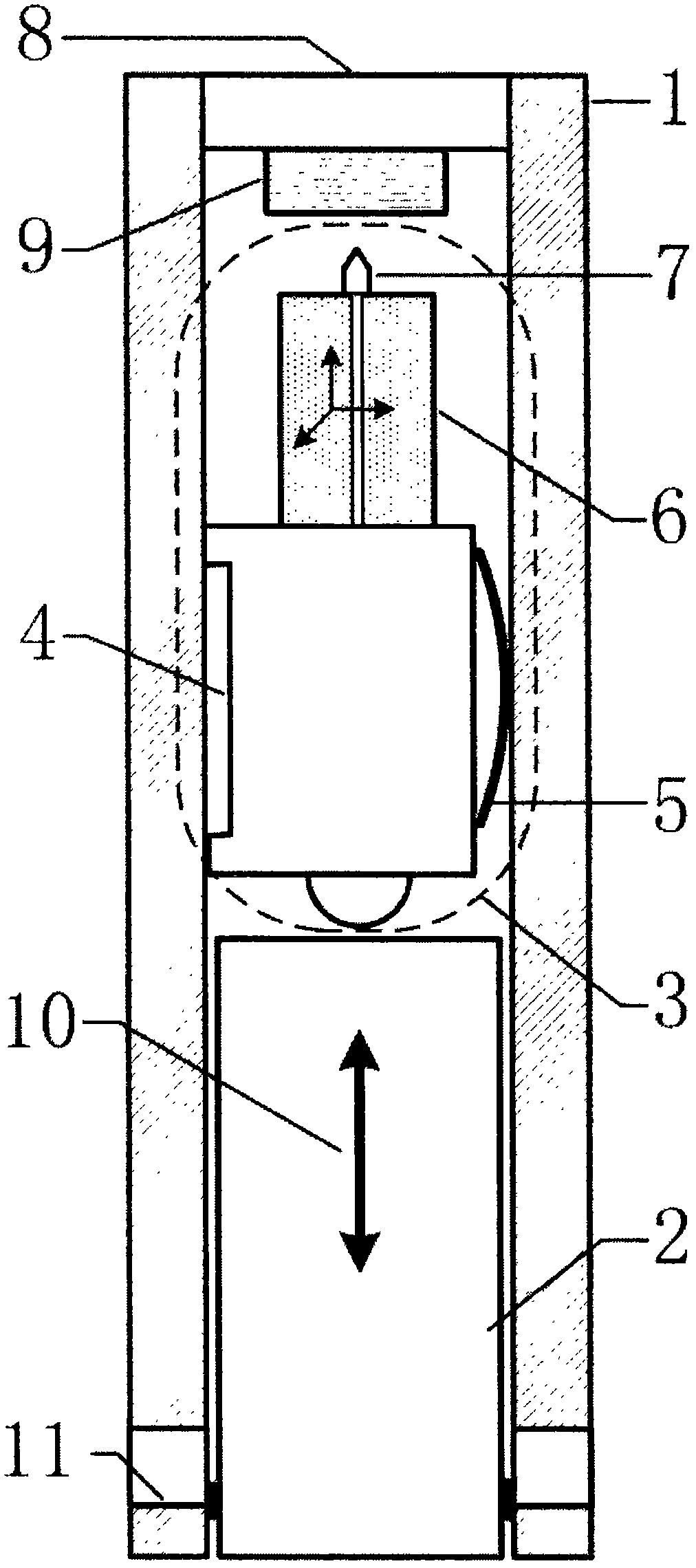

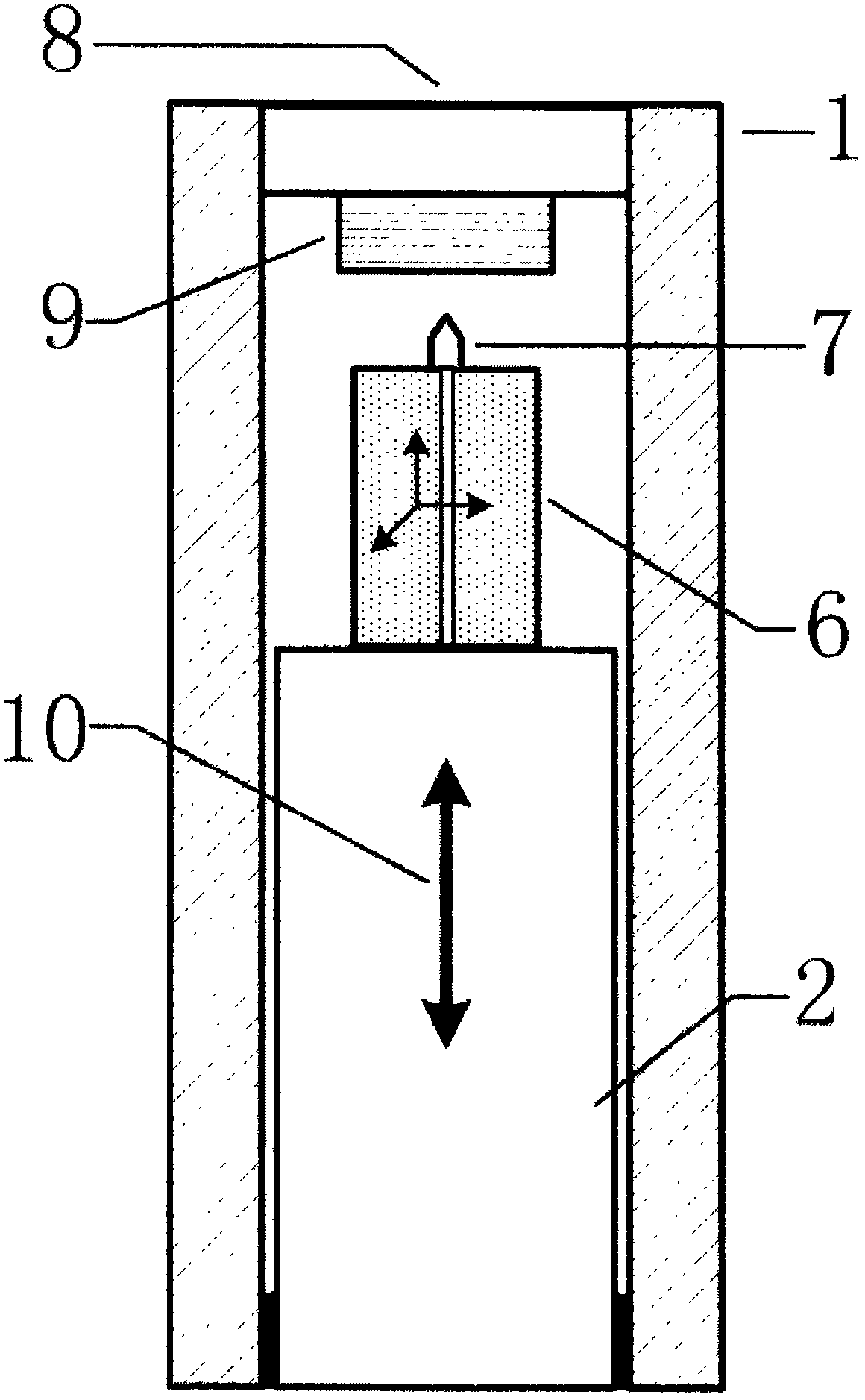

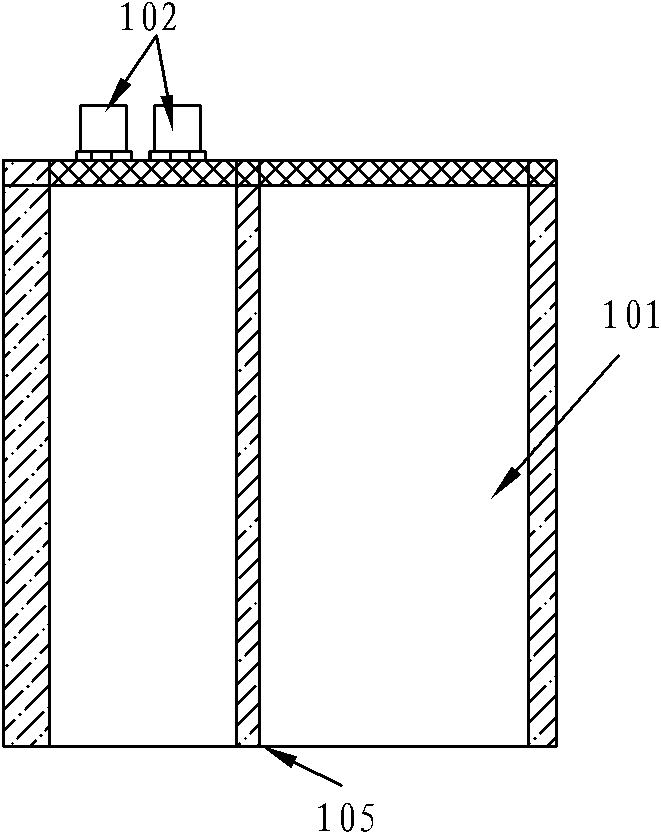

Circular-tube-shaped externally-insulated narrow-size lens body of scanning probe microscope

The invention relates to a circular-tube-shaped externally-insulated narrow-size lens body of a scanning probe microscope. The circular-tube-shaped externally-insulated narrow-size lens body comprisesa circular-tube-shaped insulated frame, a circular-tube-shaped piezoelectric motor, a circular-tube-shaped scanning unit, a probe and a sample table, the circular-tube-shaped piezoelectric motor is fixed on one internal end of the circular-tube-shaped insulated frame coaxially, a stepping direction of a free end of the circular-tube-shaped piezoelectric motor coincides with an axial direction ofthe circular-tube-shaped insulated frame, the sample table is arranged at the other end of the circular-tube-shaped insulated frame, the circular-tube-shaped scanning unit comprises a sliding block, asliding block spring piece, a circular-tube-shaped four-quadrant XYZ piezoelectric scanning tube and the probe, the sliding block spring piece elastically presses a sliding rod onto the circular-tube-shaped insulated frame, an axial direction of the sliding block coincides with that of the circular-tube-shaped insulated frame, one end of the sliding block points to the free end of the circular-tube-shaped piezoelectric motor, and the other end of the sliding block is coaxially provided with the circular-tube-shaped four-quadrant XYZ piezoelectric scanning tube. The scanning probe microscope lens body is narrow in size, free from conducting loops on a cross section, applicable to extreme physical conditions including extremely-low-temperature conditions, high-intensity magnetic fields andthe like, and particularly applicable to quick-change magnetic fields.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

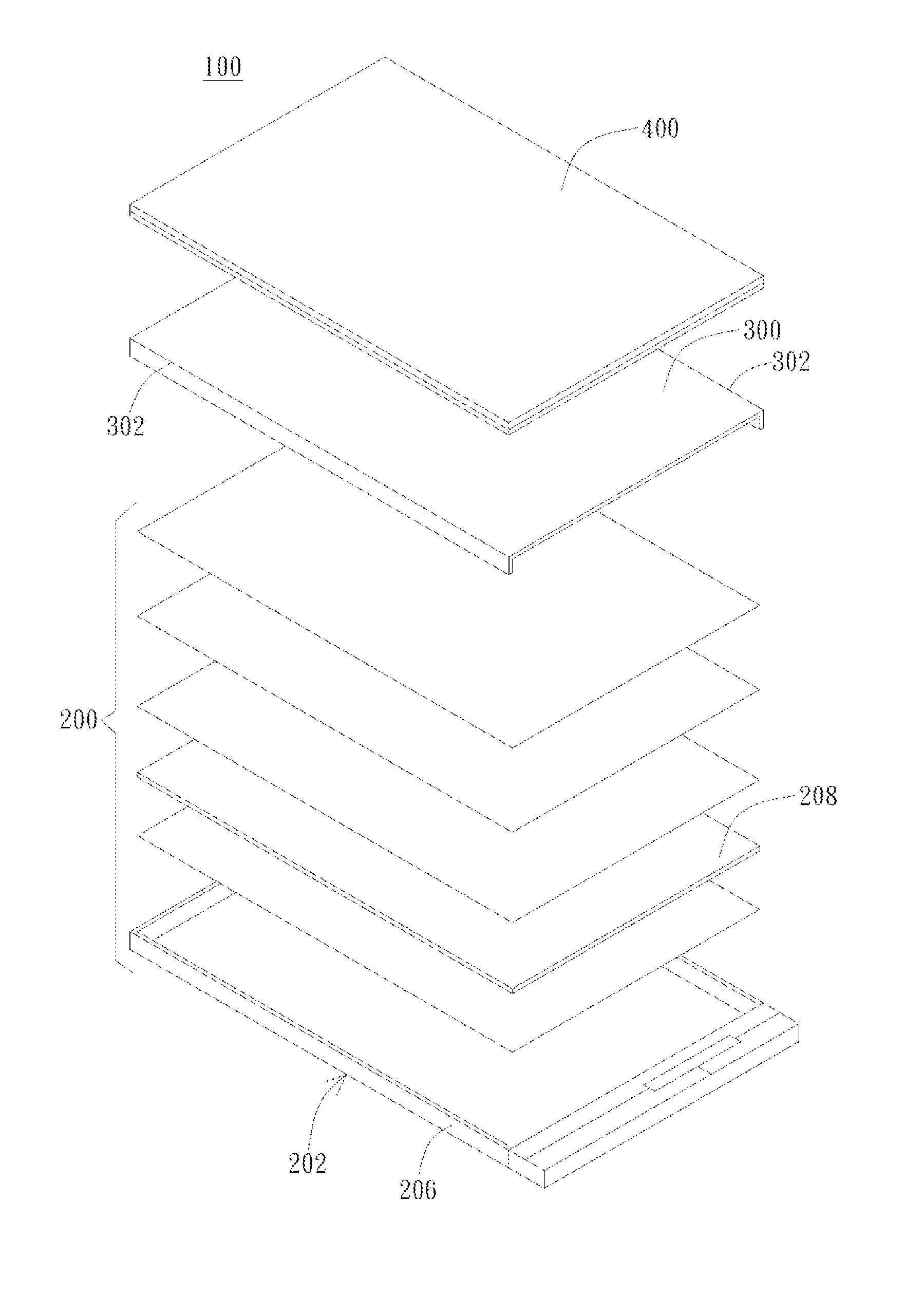

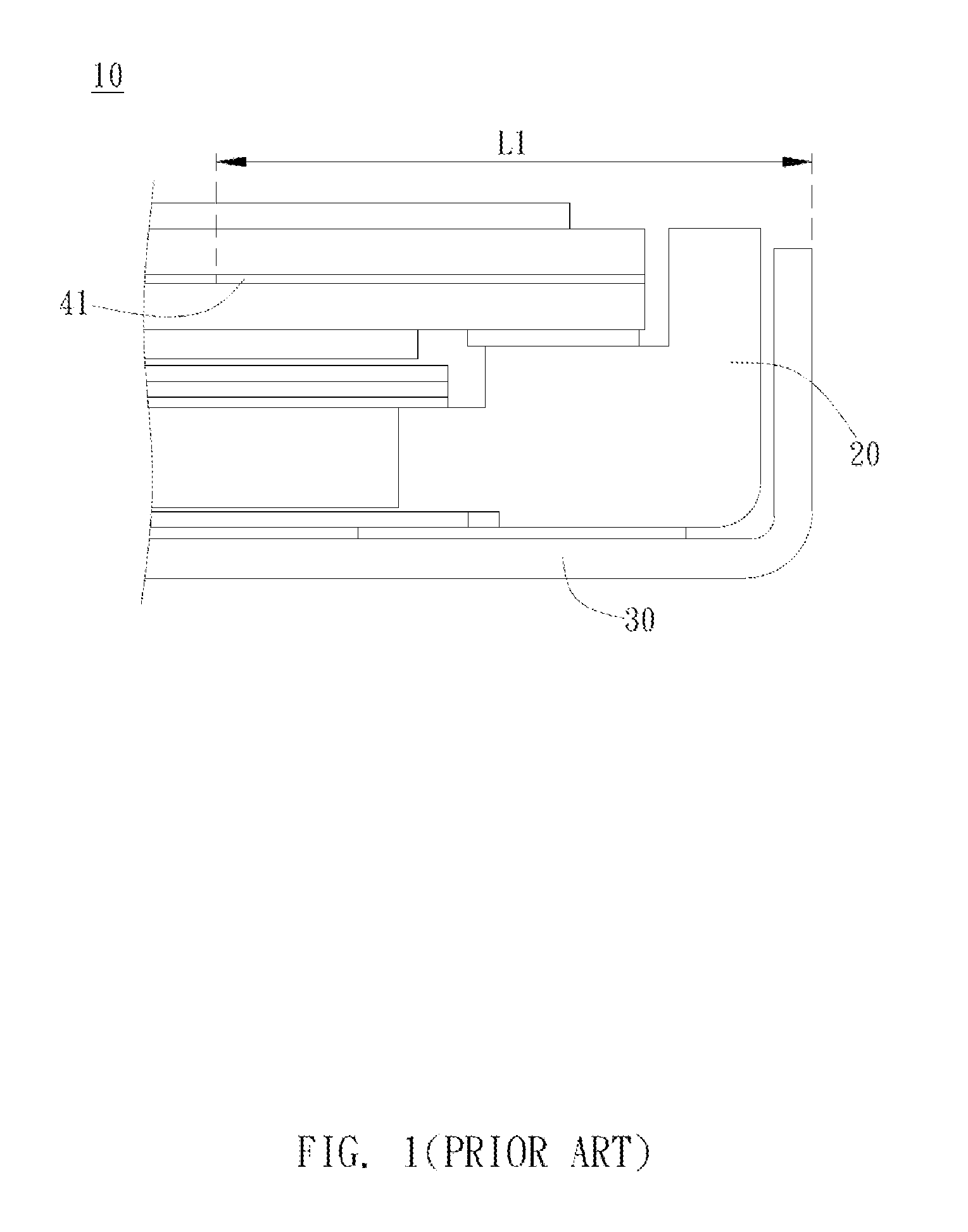

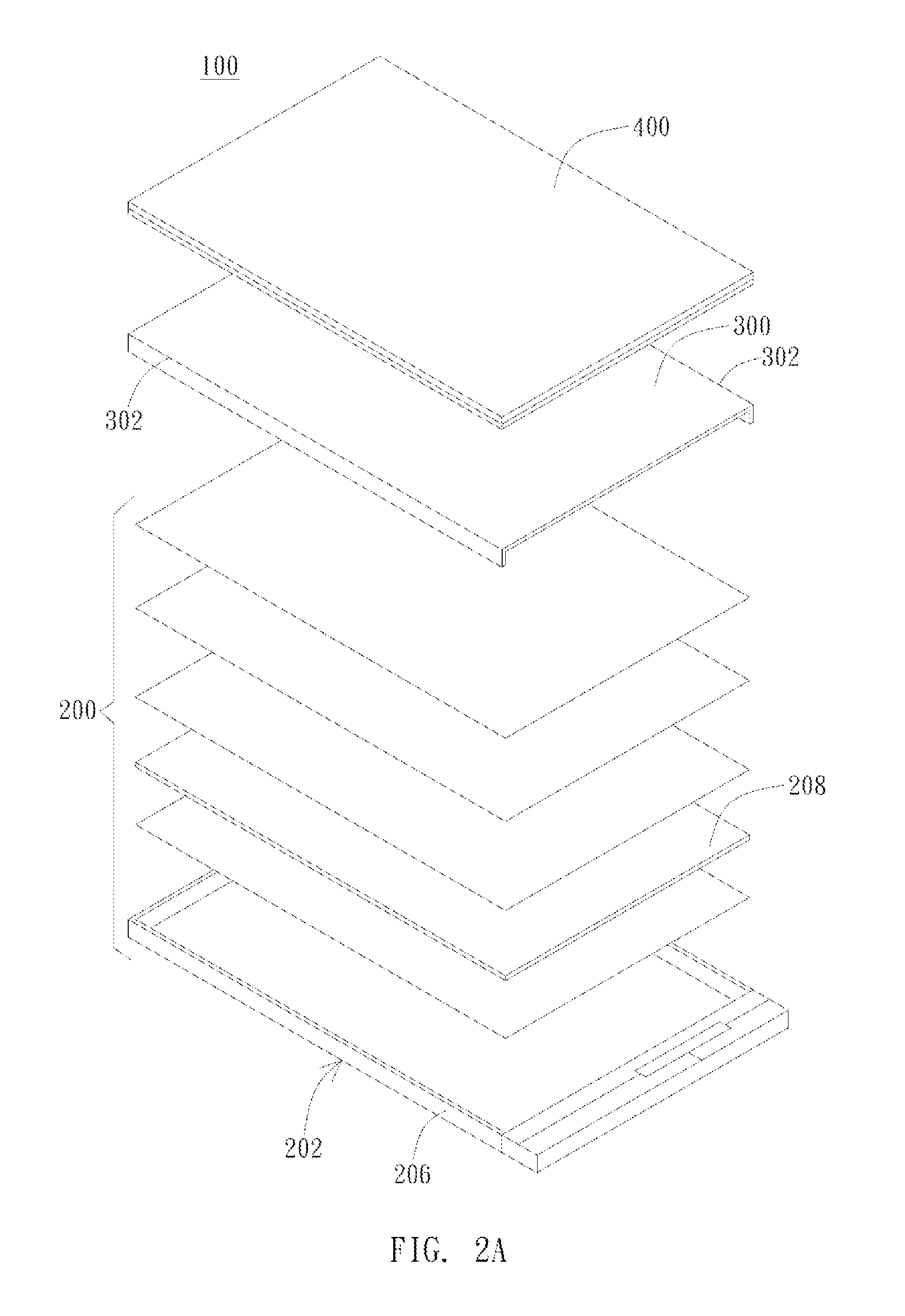

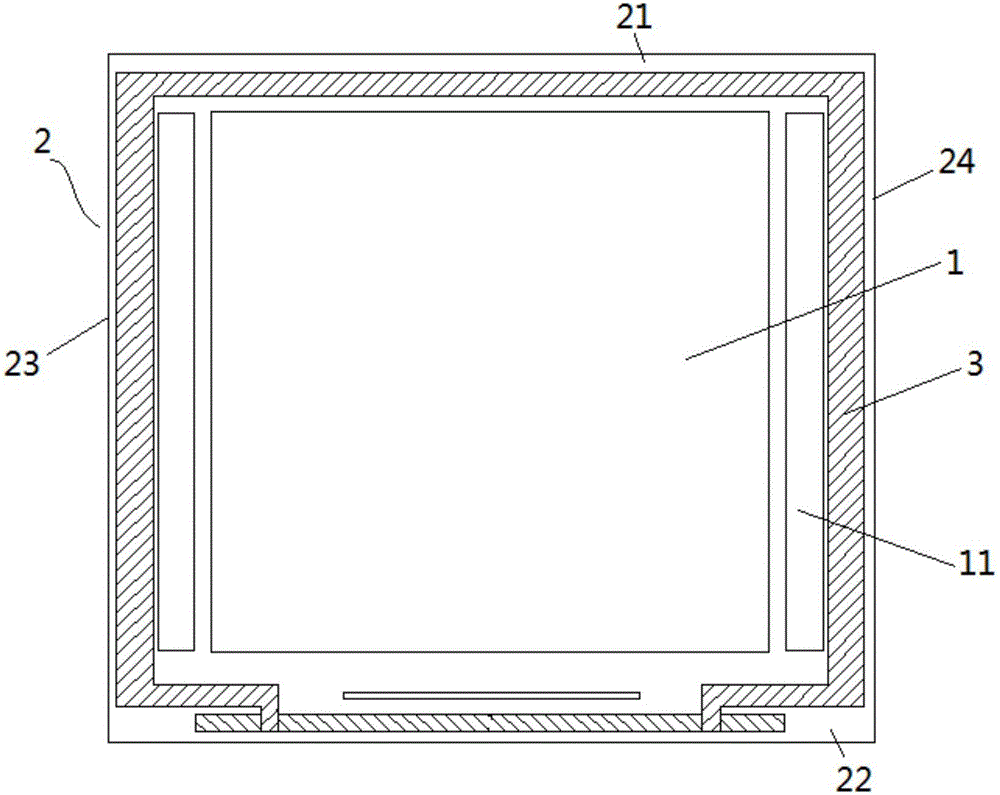

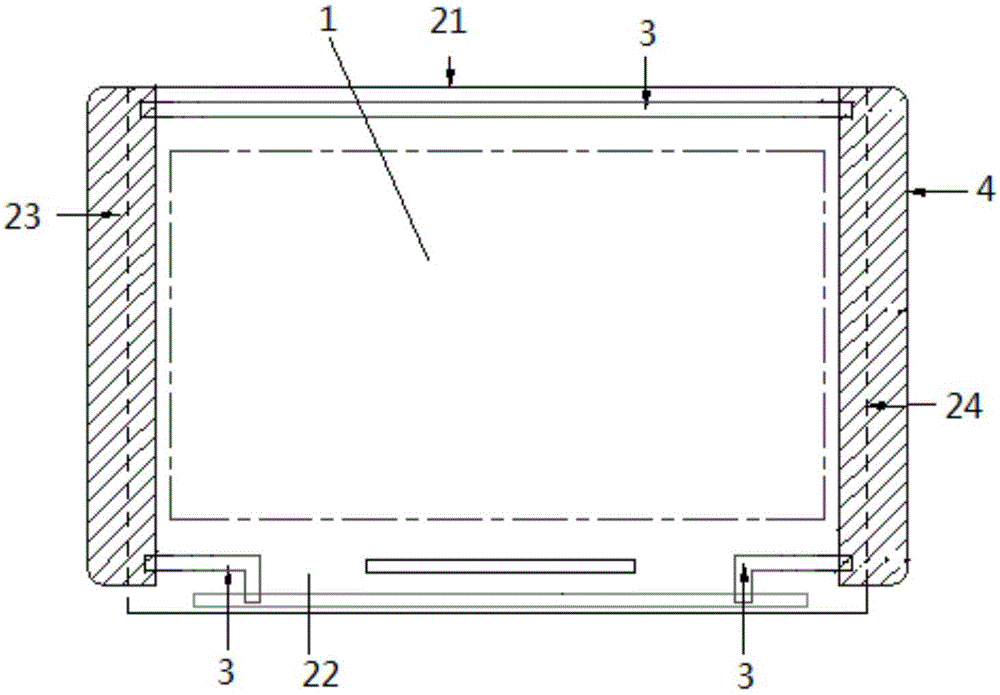

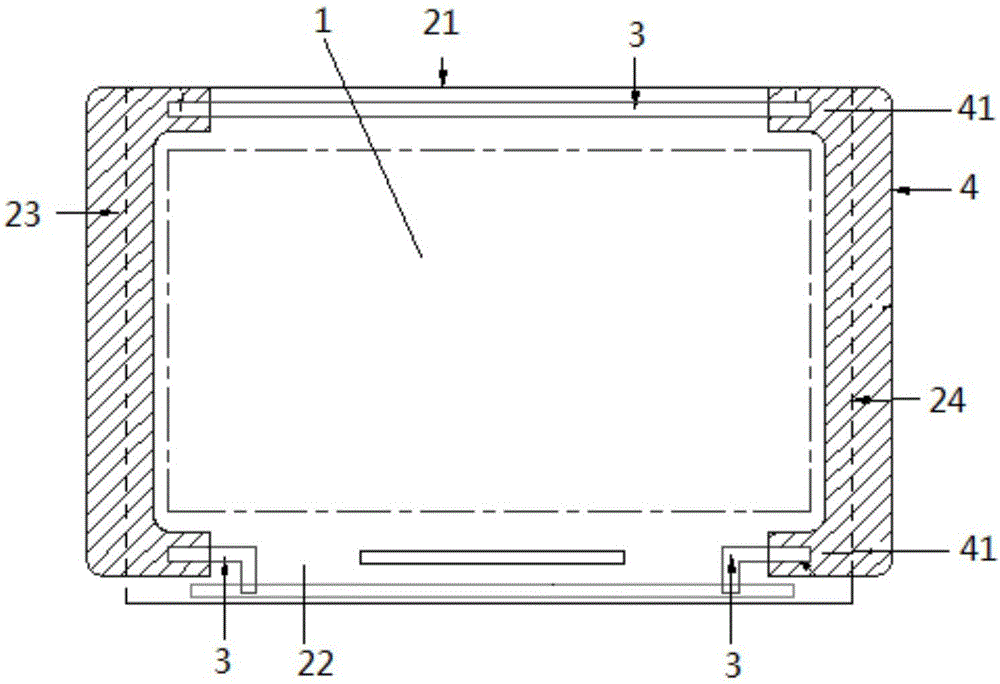

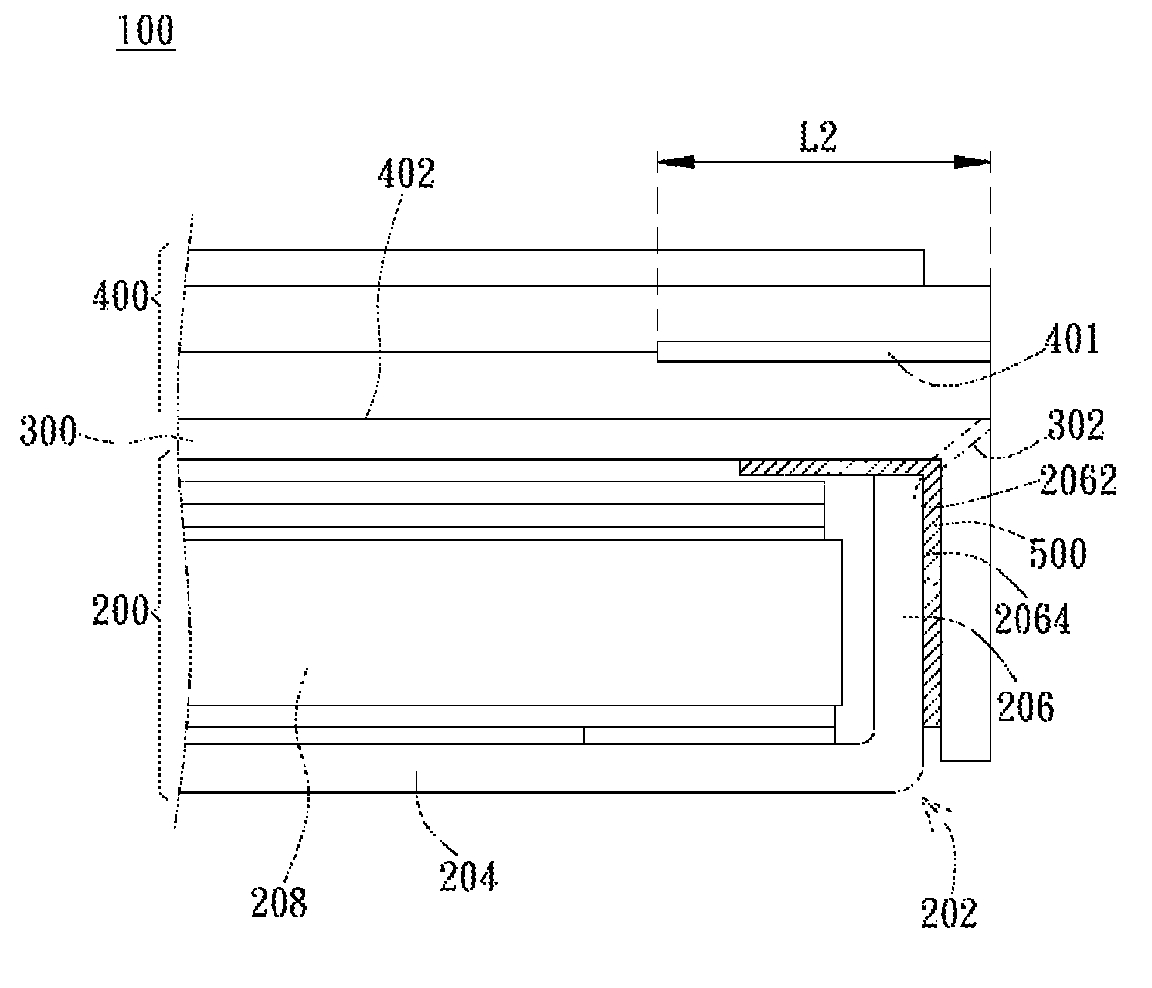

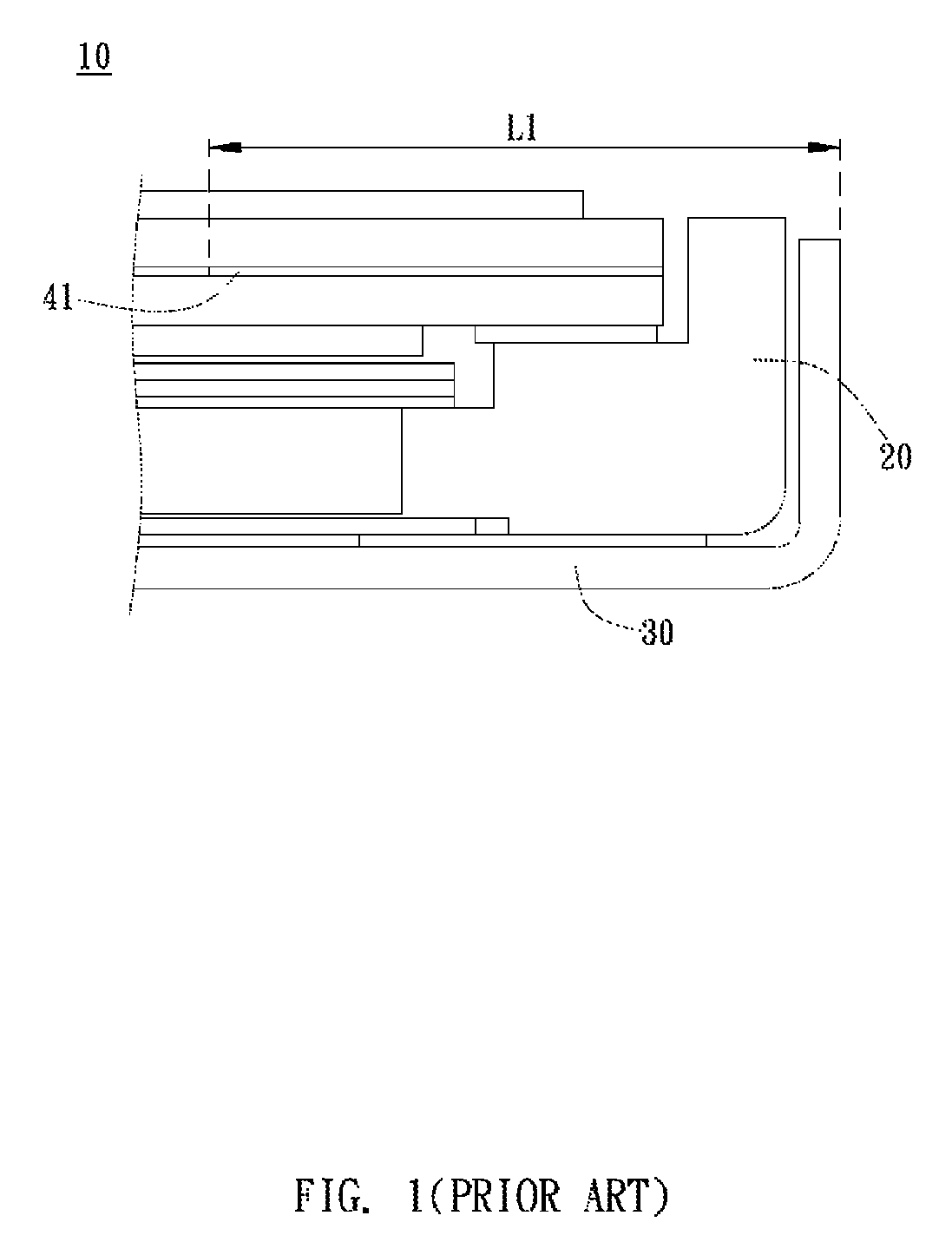

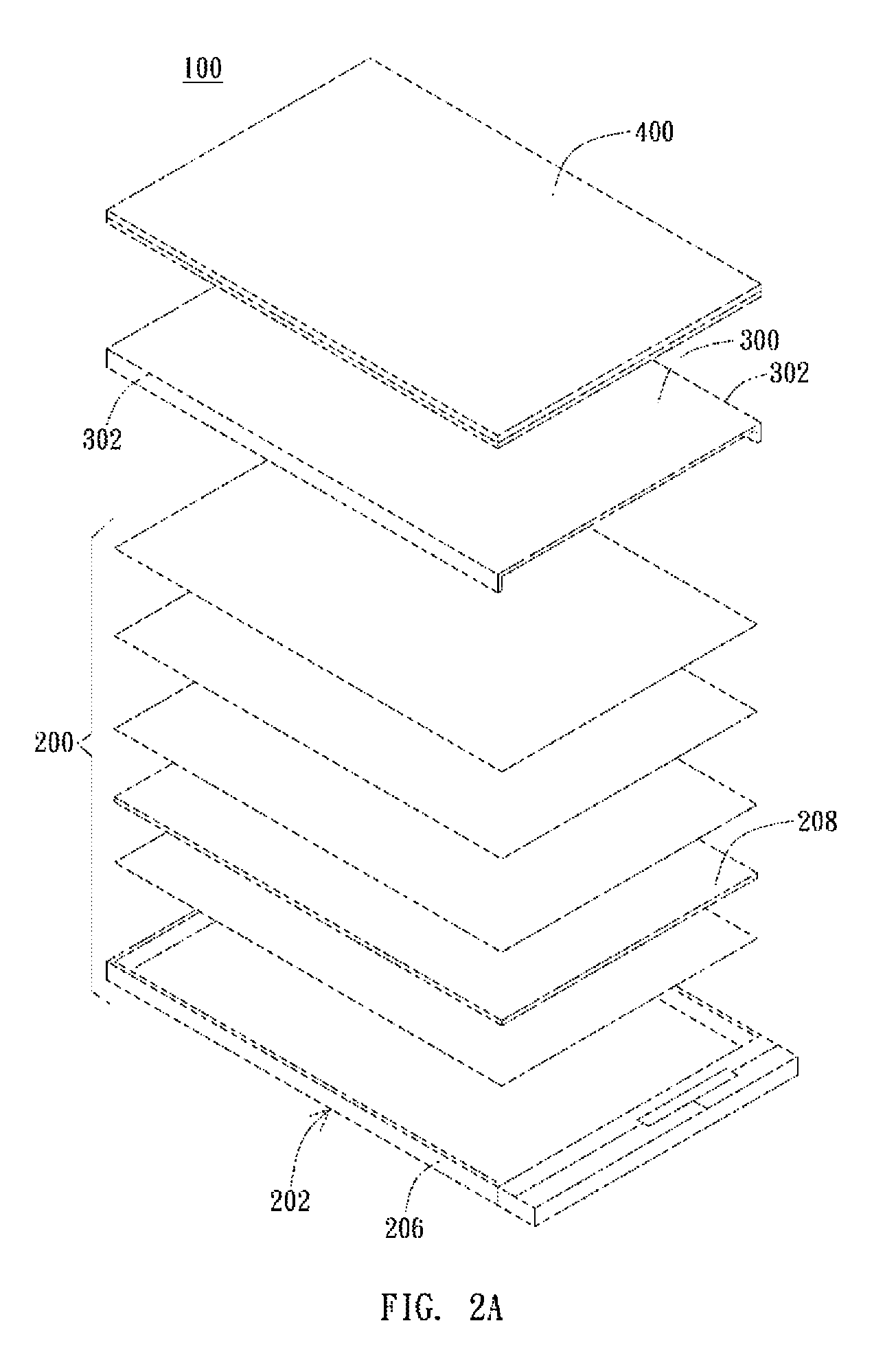

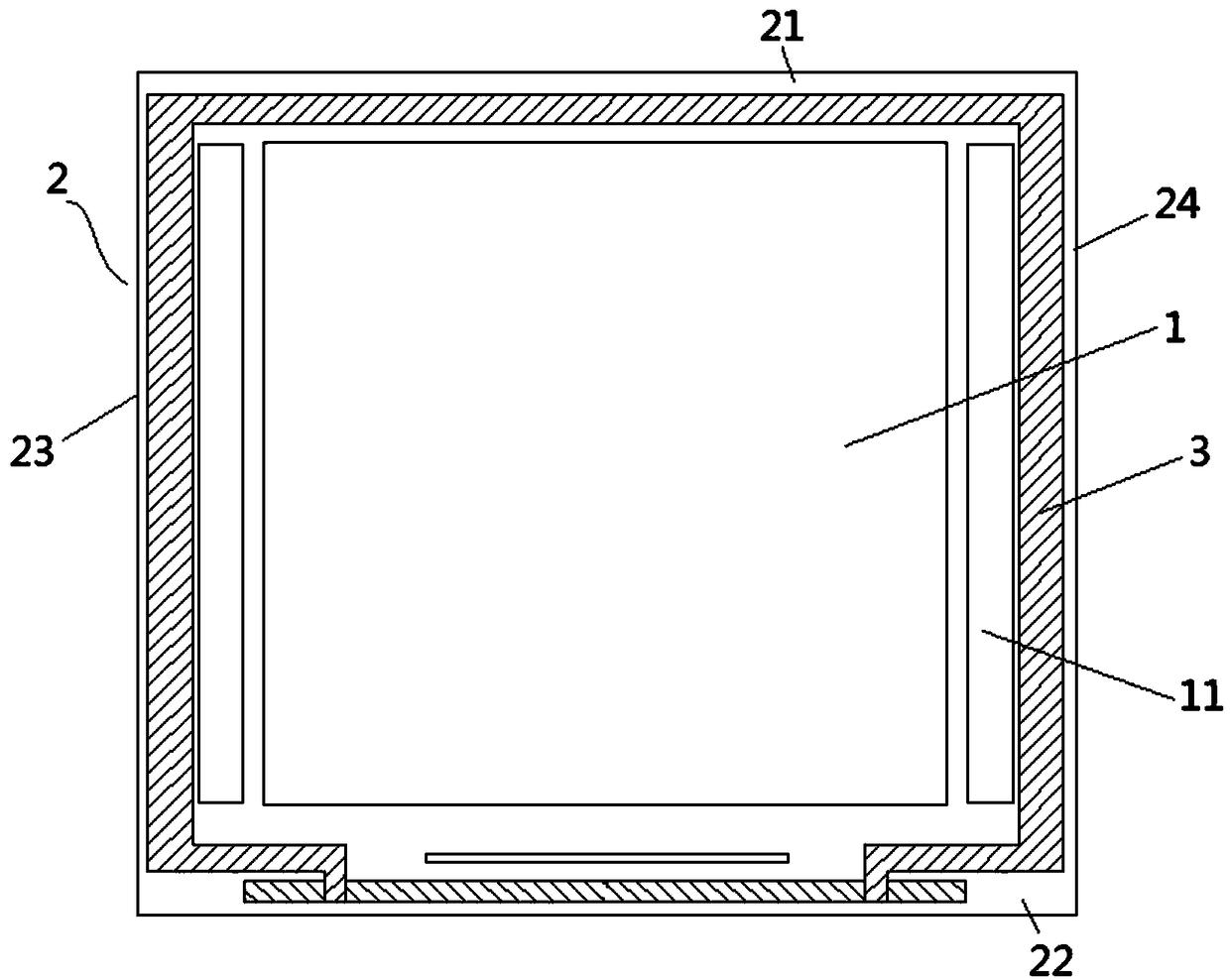

Display Device with Narrowed Frame Border and Manufacturing Method Thereof

ActiveUS20130265739A1Simple structureSize of display can be narrowedLayered productsAdhesivesDisplay deviceEngineering

A display device with narrowed frame border and a manufacturing method thereof are provided. The display device includes a backlight module, an optical film, and a display panel. The backlight module includes an outer frame and a light source module. The outer frame has a bottom plate and a sidewall connected to the bottom plate, and the light source module is disposed in the outer frame near the sidewall. The optical film is disposed on the backlight module and covers the light source module. One side of the optical film protrudes outside from the sidewall and is bent to attach a portion of the sidewall. The display panel is disposed on the optical film opposite to the backlight module.

Owner:AU OPTRONICS CORP

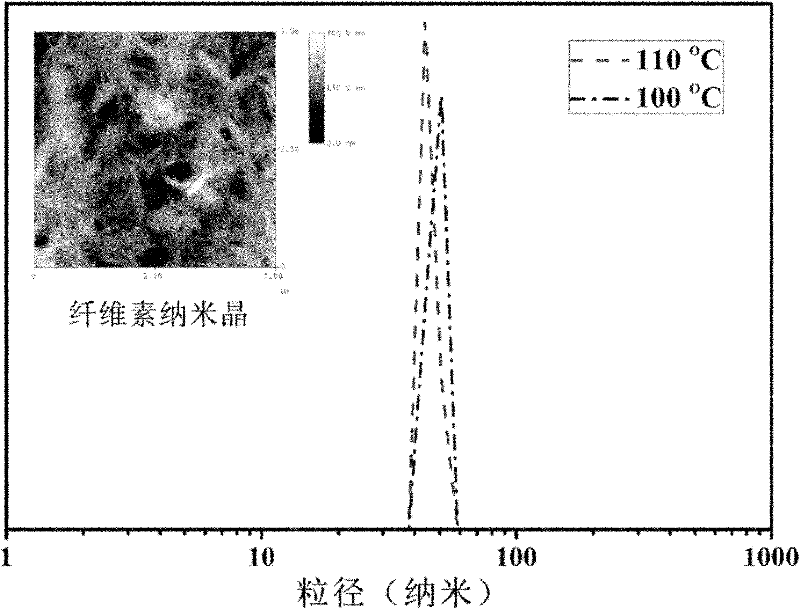

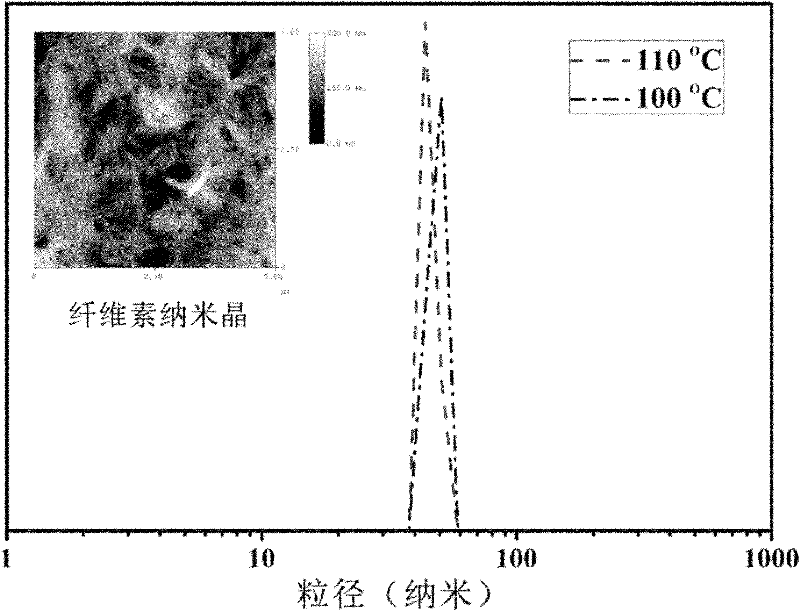

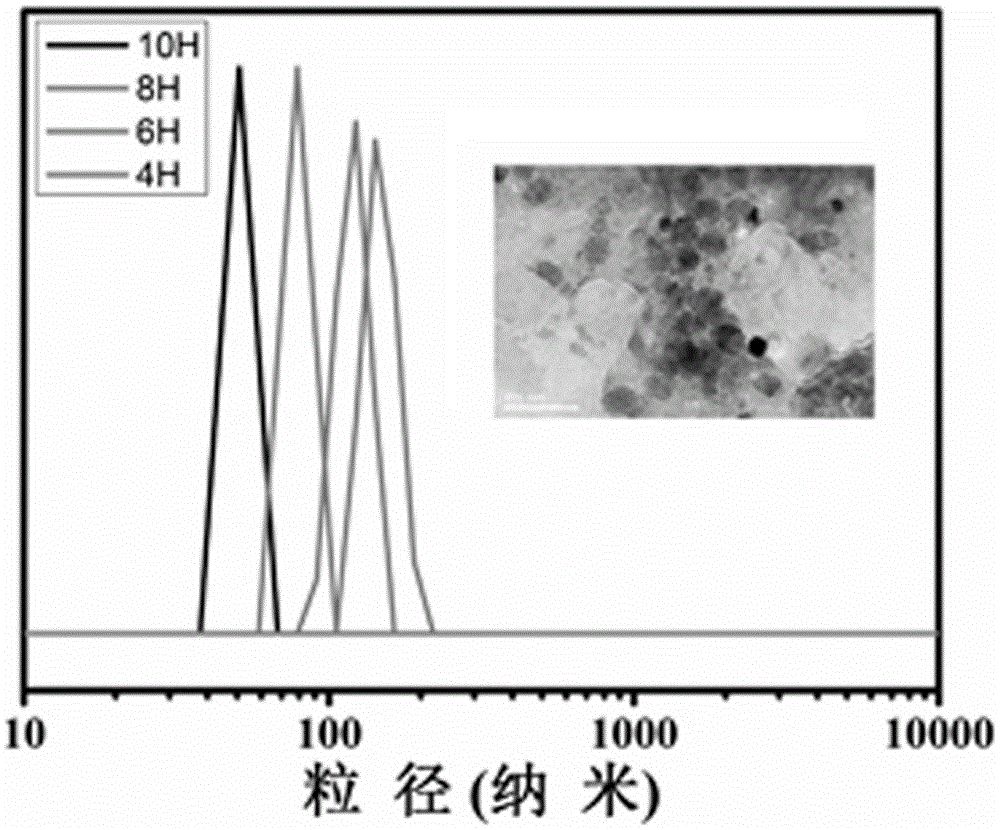

Preparation method of narrow-distribution cellulose nanocrystalline

InactiveCN102040663BNo pollution in the processSimple preparation processNanotechnologyIndustrial scaleMicrocrystalline cellulose

The invention relates to a preparation method of narrow-distribution cellulose nanocrystalline, comprising the following steps of: (1) placing microcrystalline cellulose into volatile acid liquor, transferring to a hydrothermal kettle and reacting for 1-5h at 100-120 DEG C; (2) after naturally cooling the hydrothermal kettle, diluting a reaction product by using deionized water, removing supernatant liquor after standing for layering, adding a volatile alkali solution, regulating the pH value of the solution to 7, and then heating to obtain cellulose nanocrystalline dispersion liquor; and drying the dispersion liquor to obtain the cellulose nanocrystalline. The preparation method has the advantages of simple process, easiness for operation and no environmental pollution in the whole preparation process and is suitable for industrial scale production; and the prepared cellulose nanocrystalline has the advantages of small size, narrow distribution, easiness for controlling the size, large specific surface area and high reactivity and effectively avoids the problems of wide distribution, nonuniformity and the like of the particles of the cellulose nanocrystalline, thereby having wideapplication prospect.

Owner:DONGHUA UNIV

OLED display panel with narrow frame structure

ActiveCN106450033ANarrow sizeSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveMetal

The invention discloses an OLED display panel with a narrow frame structure. The OLED display panel with the narrow frame structure comprises a display area and a frame area positioned at the periphery of the display area, wherein a metal wire is arranged on one of opposite frames in the frame area; a cathode in the display area is connected with the metal wire through an anode; a conductive adhesive tape is arranged on the back side of the display area; and the two ends of the conductive adhesive tape are electrically connected with the two ends of the metal wire in the two opposite frames after being bent. The conductive adhesive tape is adhered to the back side of the OLED display panel, the conductive adhesive tape is bent by the left side and the right side of the display panel onto one of the opposite frames, the conductive adhesive tape is electrically connected with the two ends of the metal wire on the other one of opposite frames separately, and the conductive adhesive replaces the metal wire on one of the opposite frames, so that the size of the frame area is narrowed and the size of the display area is increased.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Preparation method for nano-sliver/cellulose nanocrystalline composite particle

InactiveCN102775643BNo pollution in the processSimple preparation processNanotechnologyCelluloseFree cooling

The invention relates to a preparation method for a nano-sliver / cellulose nanocrystalline composite particle. The preparation method comprises the following steps of: (1) adding a cellulose raw material into an acid-mixed solution and reacting at the temperature of 50-90DEG C for 1-20 hours; after the reaction is ended, washing a reaction product with deionized water to neutral and obtaining aldehyde cellulose nanocrystalline; and (2) adding the aldehyde cellulose nanocrystalline into a silver nitrate solution; reacting at the temperature of 60-105DEG C for 10-60 minutes; and after naturally cooling, diluting a reaction product with the deionized water, centrifuging and then carrying out free drying or vacuum drying to obtain a nano-silver / CNC (Cellulose Nanocrystalline) composite material. The preparation method disclosed by the invention is simple and convenient in process, easy in operation and environment friendly and can be used for shortening the preparation period; the prepared CNC / nano-silver has the advantages of small size, easy adjustment, large specific area, firmness in combination of the CNC and the nano-silver, durable antibacterial effect, antibacterial and enhancing functions and broad application prospect.

Owner:DONGHUA UNIV

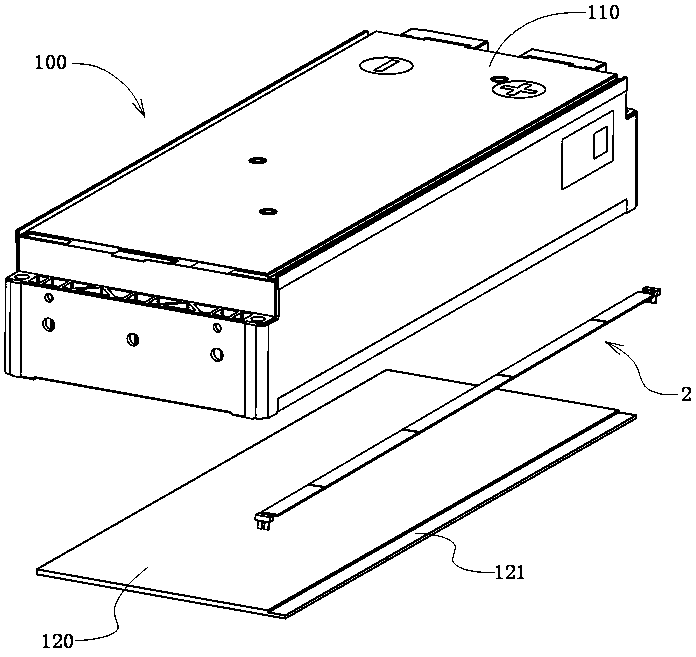

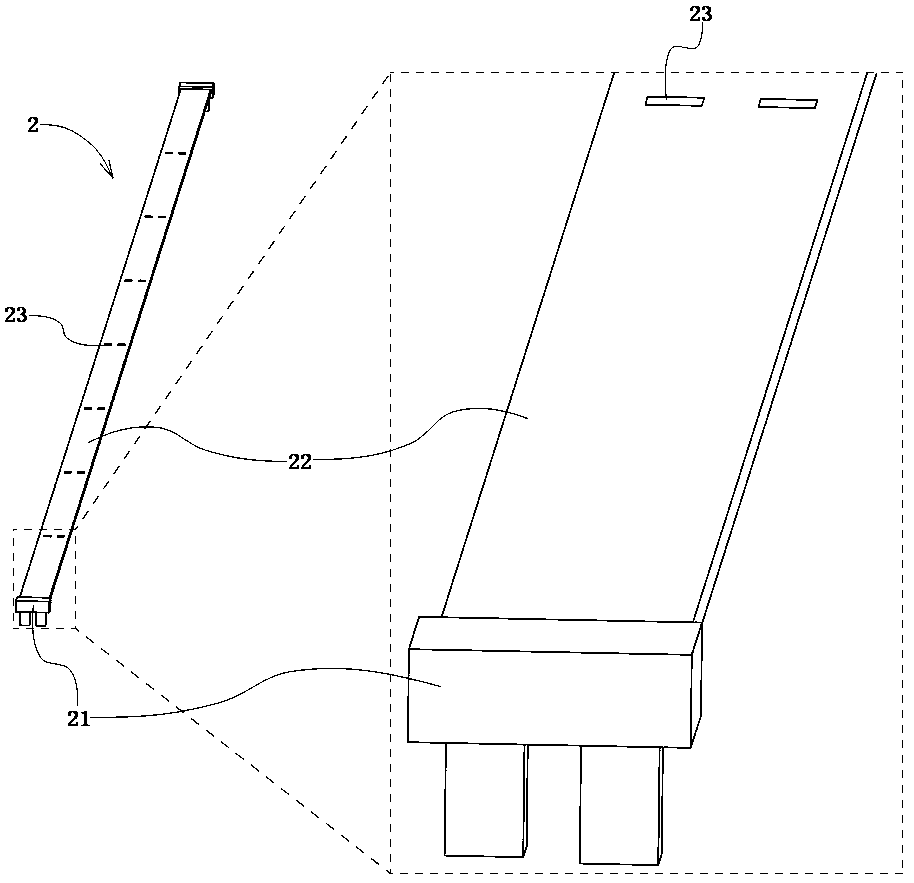

Liquid leakage detection device and battery module and battery pack thereof

PendingCN111337201ANarrow sizeThin structureDetection of fluid at leakage pointCell/batteries leak testingEngineeringCapillary Tubing

The invention discloses a liquid leakage detection device and a battery module and a battery pack thereof. The liquid leakage detection device comprises a strip-shaped body and a wiring part arrangedat the end part of the strip-shaped body. Along the long-strip direction of the strip-shaped body, the strip-shaped body is internally provided with two wires which are parallel to each other and areburied in an insulator, and the two wires are connected with a wiring part. A plurality of wire windows are arranged on the upper surface of the strip-shaped body along the wire arrangement direction.The wire windows are opened on the insulator, so that the wires are exposed. A liquid leakage detection device is arranged on a bottom plate of the battery module in the battery pack. Capillary holesor capillary tubes are formed between the wire windows and the batteries above the wire windows, so that the wire windows can adsorb battery leakage in the battery module through a capillary effect,the battery leakage enables the two wires to be short-circuited, and whether the batteries have a leakage problem or not can be judged by detecting the resistance between the two wires.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Display device with narrowed frame border and manufacturing method thereof

ActiveUS8905563B2Small volumeMaintain structural strengthMechanical apparatusLayered productsDisplay deviceComputer module

Owner:AU OPTRONICS CORP

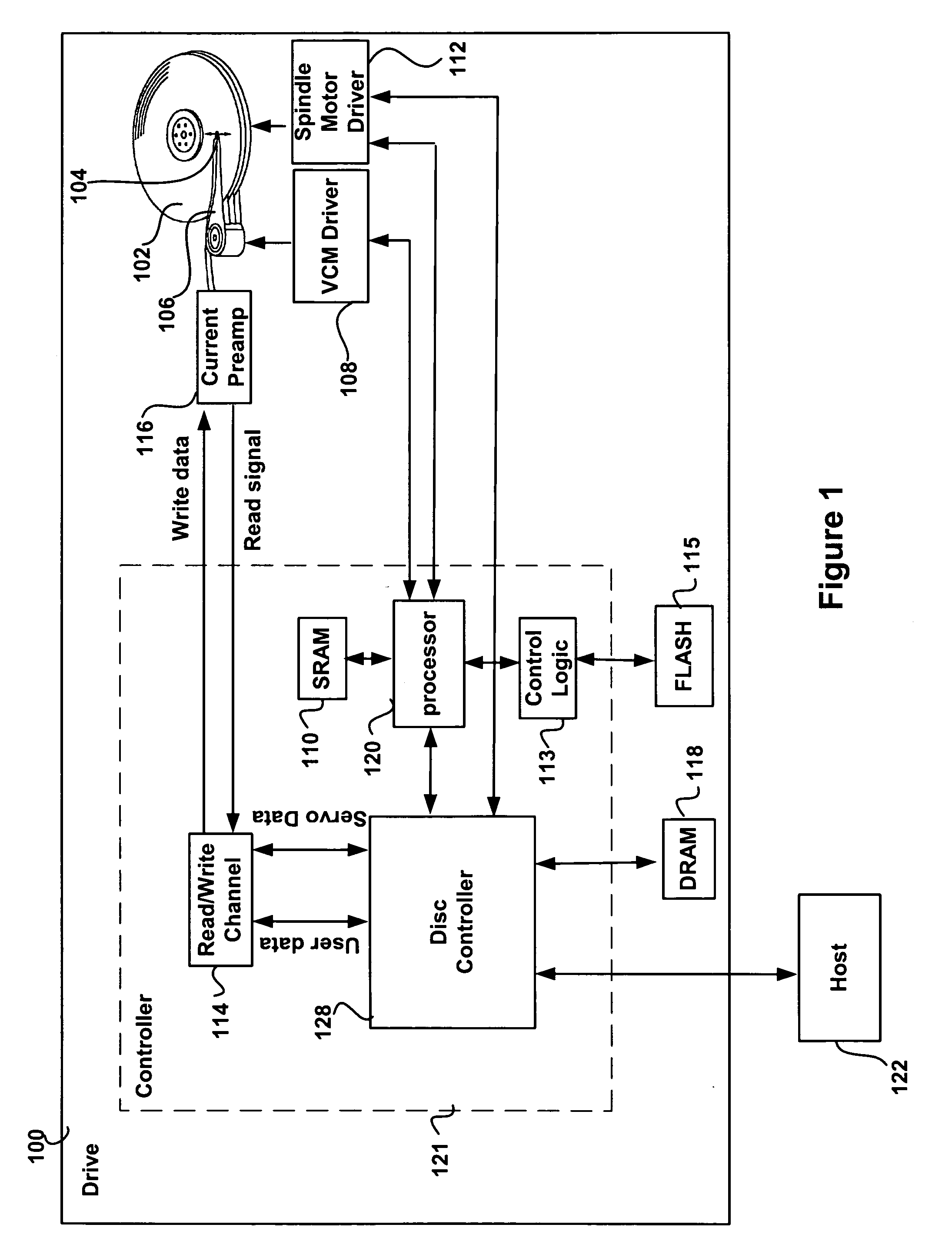

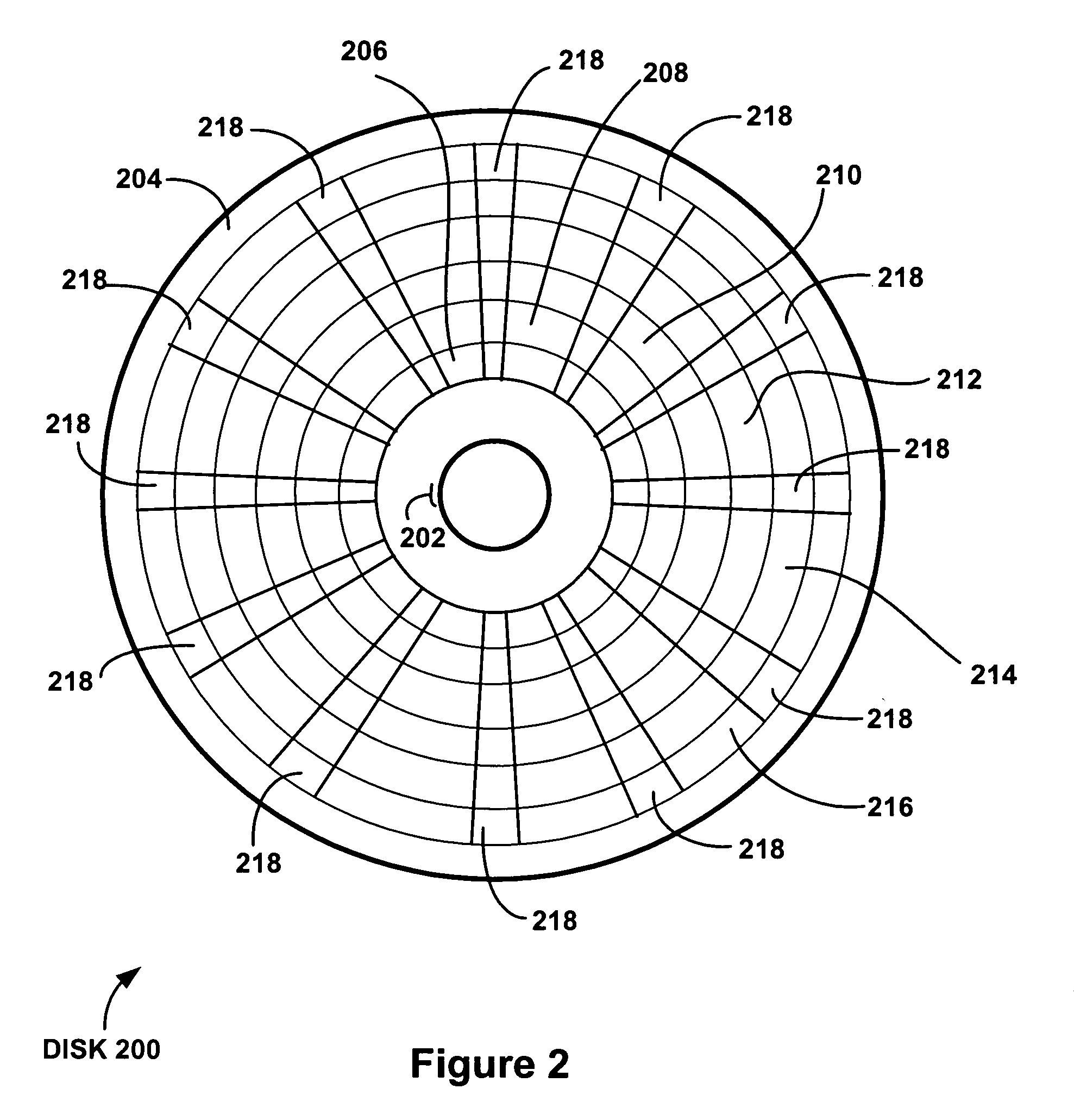

System and method for disk formatting

InactiveUS20050141134A1Increase the skew angleNarrow sizeRecord information storageAlignment for track following on disksComputer scienceDisk formatting

The gap of a write head on an arm of a rotating media storage device is positioned at an angle off perpendicular from an arm chord, which is a line defined from the center of the gap to the center of the pivot of the arm. This increases the skew for a written field on a disk. This increased skew can narrow the tracks and / or allow the use of a wider, less expensive write head.

Owner:PANASONIC CORP

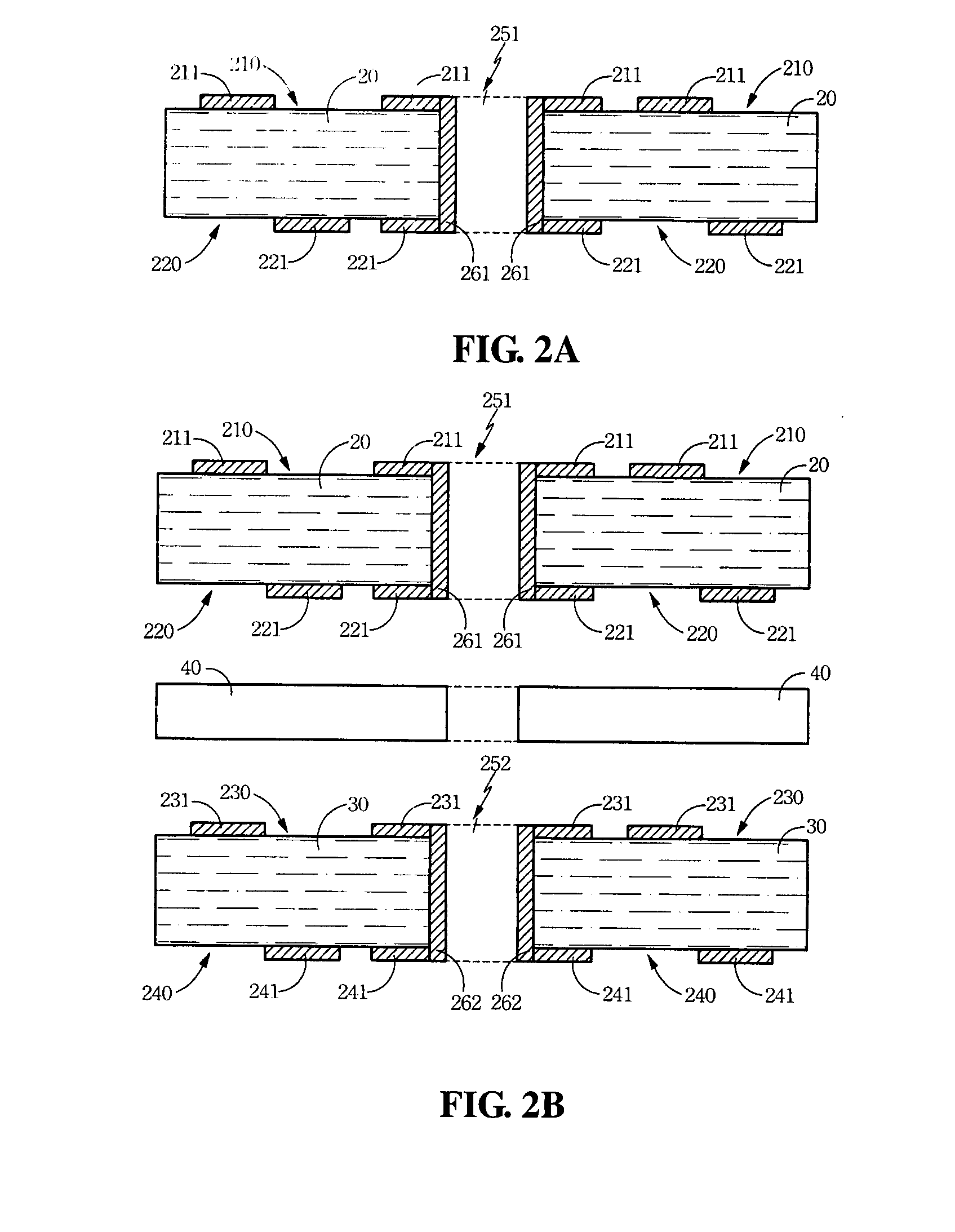

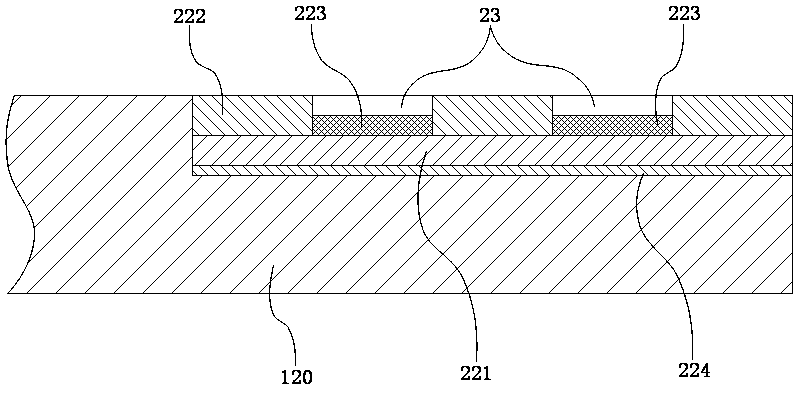

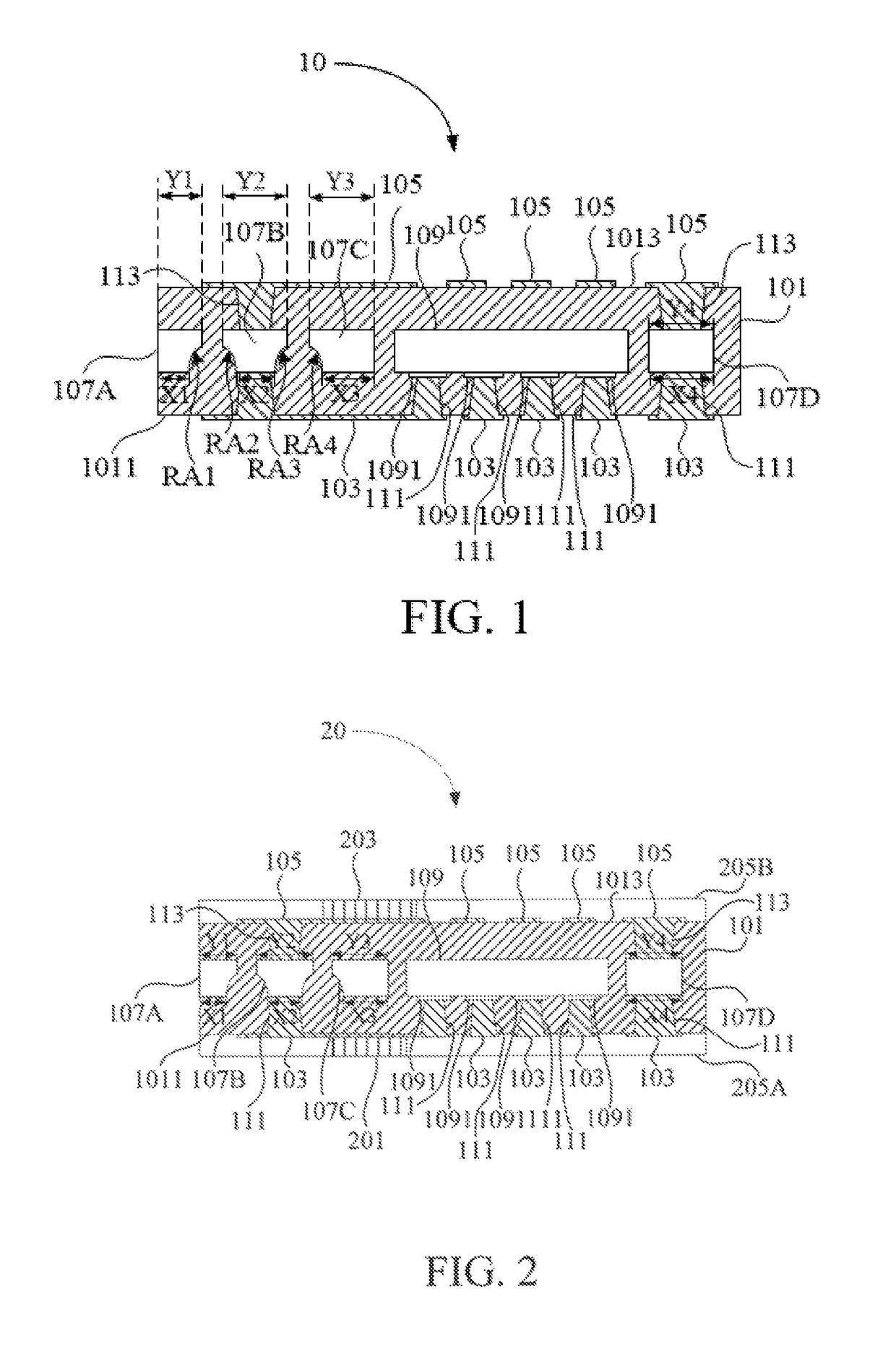

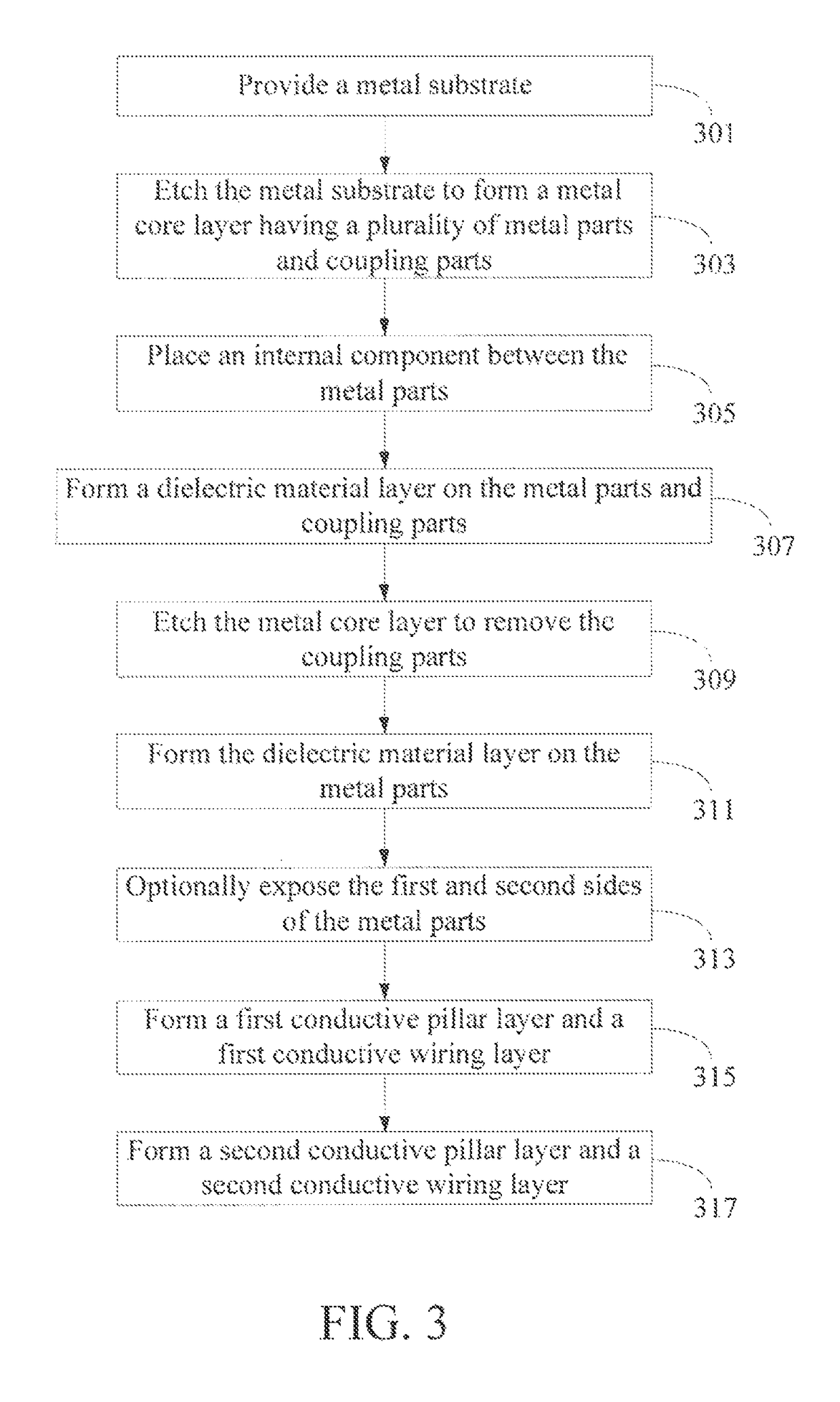

Substrate structure and manufacturing method thereof

ActiveUS9805996B2Improve propertiesEnhanced signalSemiconductor/solid-state device detailsPrinted circuit aspectsOptoelectronics

A substrate structure and a manufacturing method thereof are provided. The substrate structure comprises a dielectric material layer, a conductive wiring layer, a metal core layer, and a conductive pillar layer. The conductive wiring layer is disposed on a surface of the dielectric material layer. The metal core layer having a metal part is disposed inside the dielectric material layer. The conductive pillar layer is disposed inside the dielectric material layer and between the metal core layer and the conductive wiring layer. The metal part has a first side and a second side opposite the first side. One of the first side and the second side is electrically connected to the conductive pillar layer. A width of the first side is different from a width of the second side.

Owner:PHOENIX PIONEER TECH

Green method for synthesizing appearance and size controllable semiconductor nanocrystalline

ActiveCN101486451BHigh crystallinityHigh fluorescence quantum efficiencyBinary selenium/tellurium compoundsVegetable oilFluorescence

The invention provides a green synthesis method of a cadmium selenide nano-crystal with controllable shape and size. Natural vegetable oil is taken as a solvent and a ligand, different selenium sources and cadmium oxide are taken as precursors, the nano-crystal can be obtained by adjusting the ratio between the ligand and the precursors, with the size adjustable from 2nm to 13nm and the ratio between the length and diameter from 1 to 10; the nano-crystal has high degree of crystallinity, fluorescence quantum efficiency is 15 percent to 40 percent and fluorescence emission spectrum is 490nm to660nm. The obtained point nano-crystal can maintain stable sphalerite structure under high temperature, with narrow size distribution, wherein, fwhm equals to 27 plus or minus 1nm. The obtained rod-shaped or multibranched (two-branch, three-branch, four-branch) nano-crystal has quite narrow size distribution, and wide fluorescence half band width, wherein, fwhm equals to 23 plus or minus 1nm. Theobtained arc-shaped and random rod-shape nano-crystal has different radiuses of curvature, wurtzite, sphalerite, twin crystal and dislocation coexist in the same nano single crystal.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

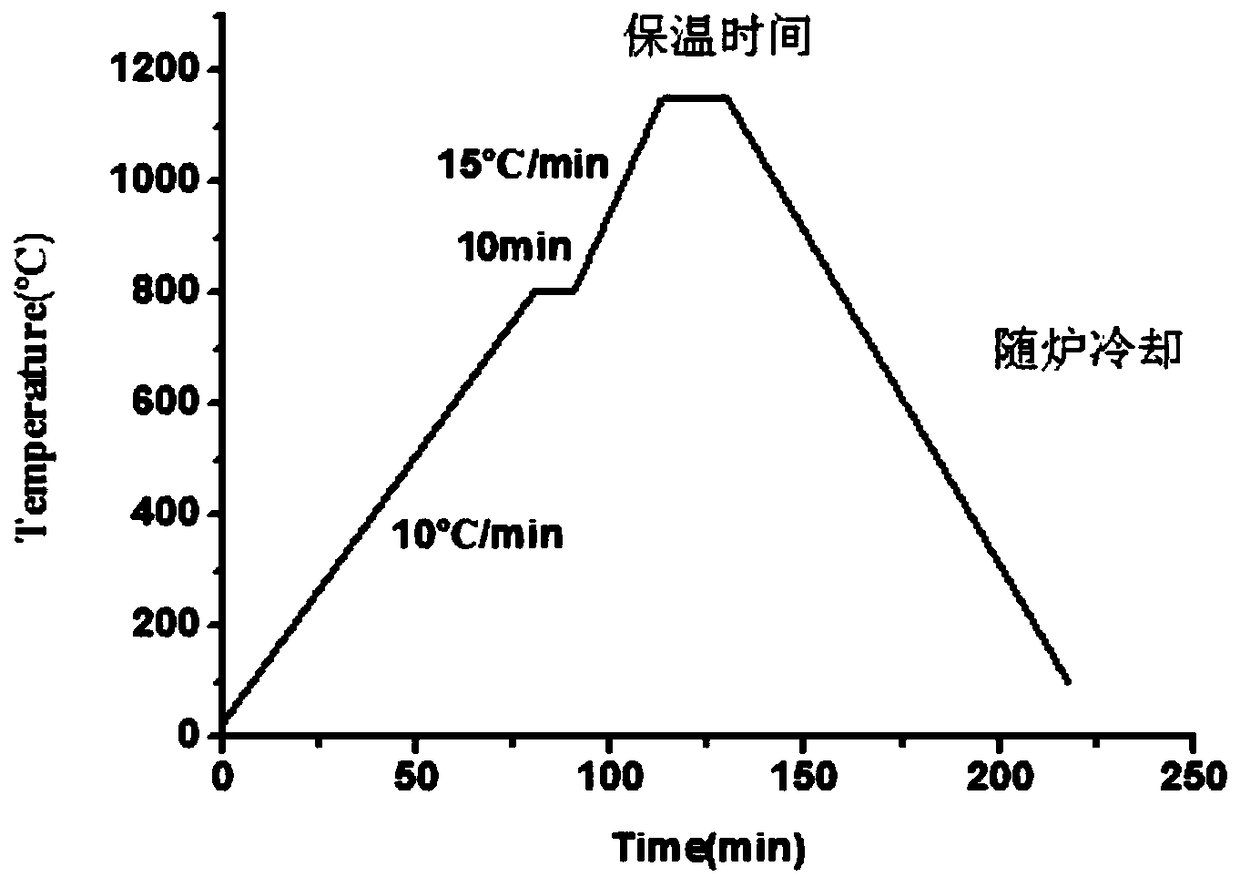

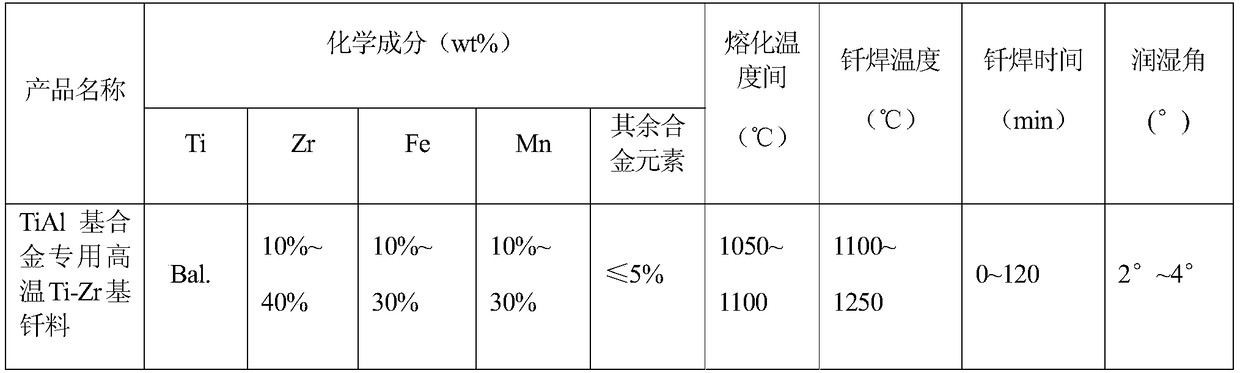

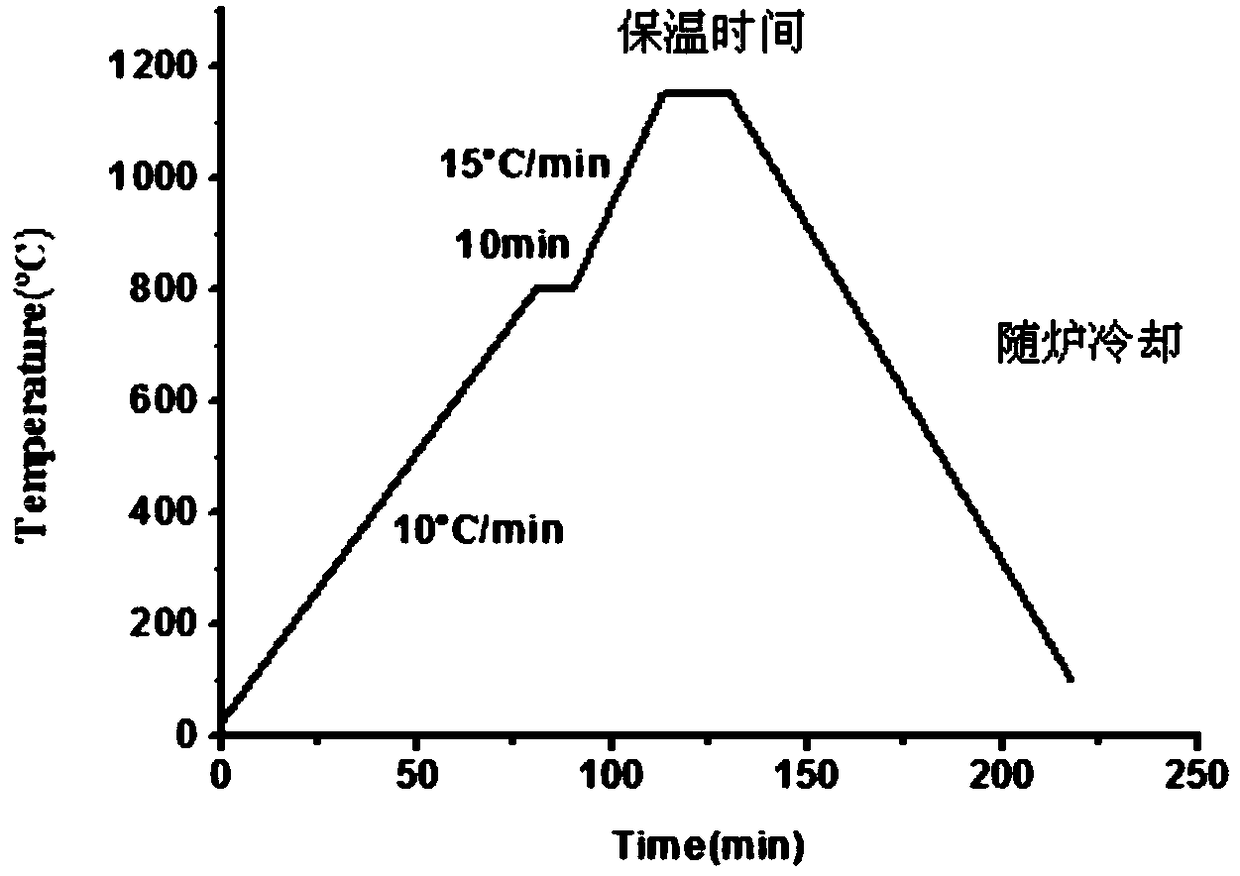

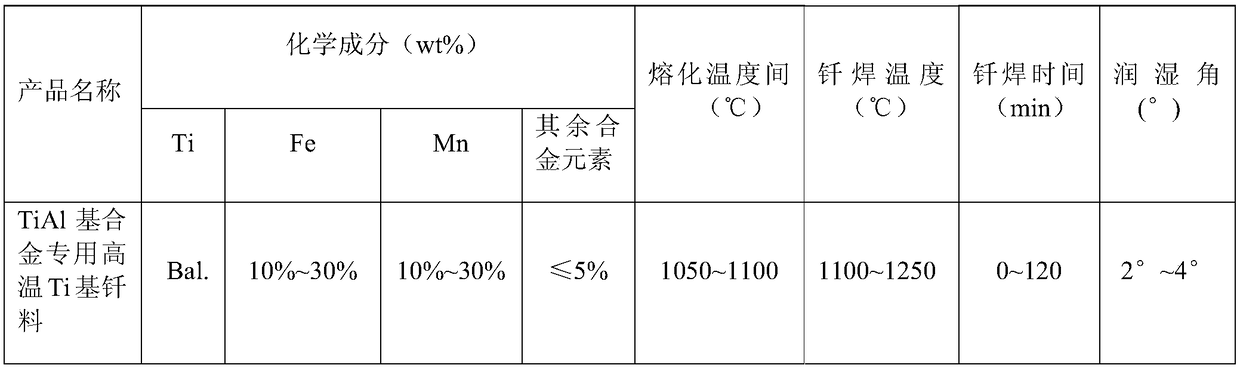

A kind of high-temperature Ti-ZR-based brazing alloy special for Tial-based alloys and its preparation method and brazing process

ActiveCN106925906BImprove wettabilityImprove liquidityWelding/cutting media/materialsSoldering mediaVacuum pumpingPumping vacuum

The invention relates to a high-temperature brazing filler as well as a preparation method and a brazing process thereof, in particular to a high-temperature Ti-Zr-based brazing filler for a TiAl-based alloy as well as a preparation method and a brazing process of the high-temperature Ti-Zr-based brazing filler, and solves the problems that after a conventional brazing filler is adopted for brazing, the joint mechanical properties and the high-temperature properties are poor, the brazing filler melting point is low, as well as the brazing filler preparation process and the brazing process are complex. The high-temperature brazing filler provided by the invention comprises the following raw materials in percentage by weight: 10.0-40.0% of Zr, 10-30% of Fe, 10-30% of Mn, 0-5% of one or more of Al, B, Co, Cr, Mg, Ag, Nb and Zn, and the balance of Ti. The preparation method comprises the following steps: 1, weighing raw materials; 2, loading melting equipment with the raw materials, carrying out vacuum pumping, injecting argon gas, carrying out melting for several times, and cooling; and 3, subjecting a mother alloy obtained after the melting to quenching and melt spinning, so as to obtain the high-temperature brazing filler. Then, a brazing filler foil obtained after the quenching is adopted for brazing according to the brazing process of which the temperature and the cycle reach 1100-1250 DEG C and 0-120 min correspondingly. Compared with the conventional brazing filler, the prepared high-temperature brazing filler has the advantages that the melting point is high, the wettability is high, the mechanical properties are excellent, as well as the brazing filler preparation process and the brazing process are simple.

Owner:江苏华钛瑞翔科技有限公司

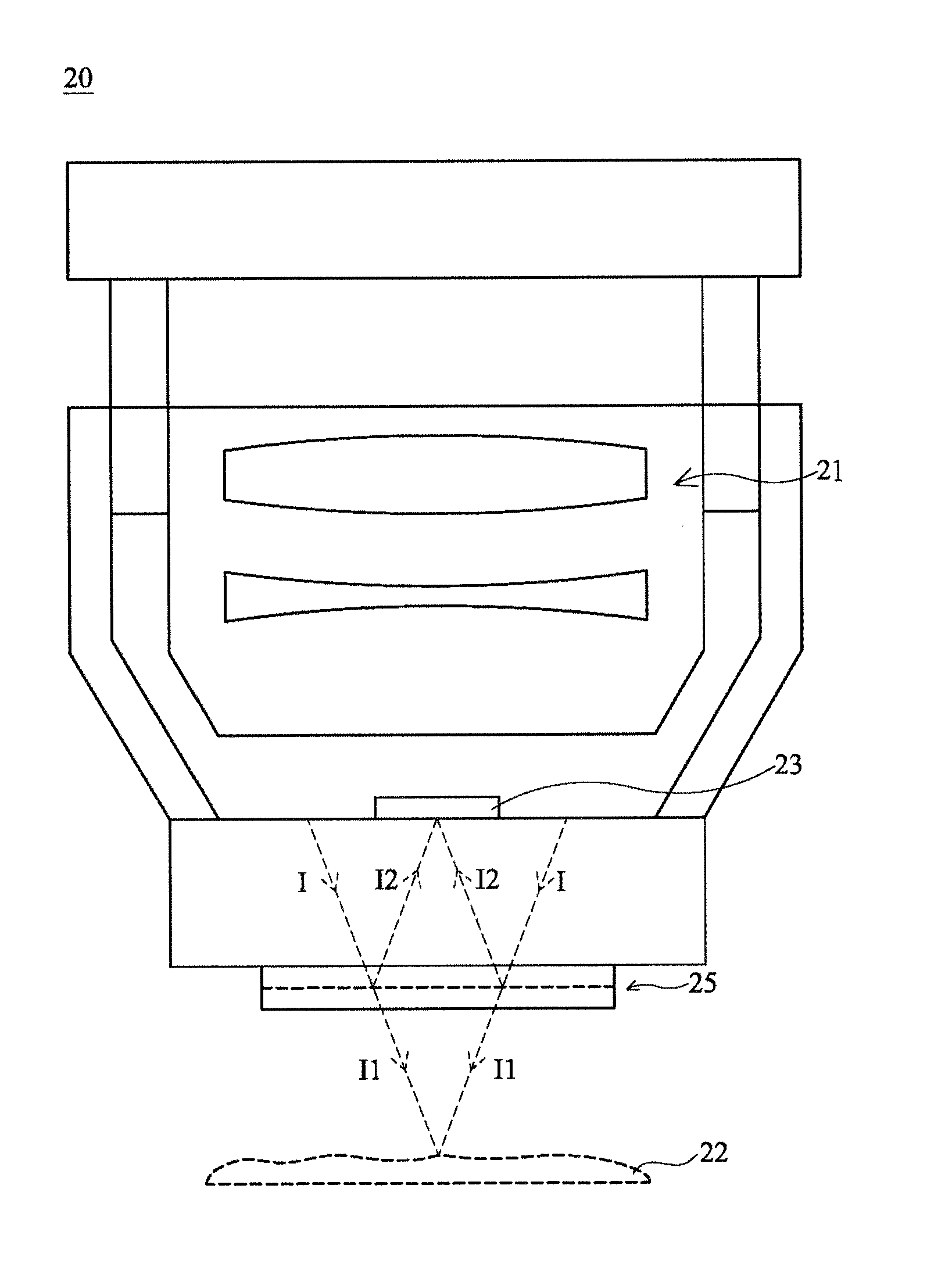

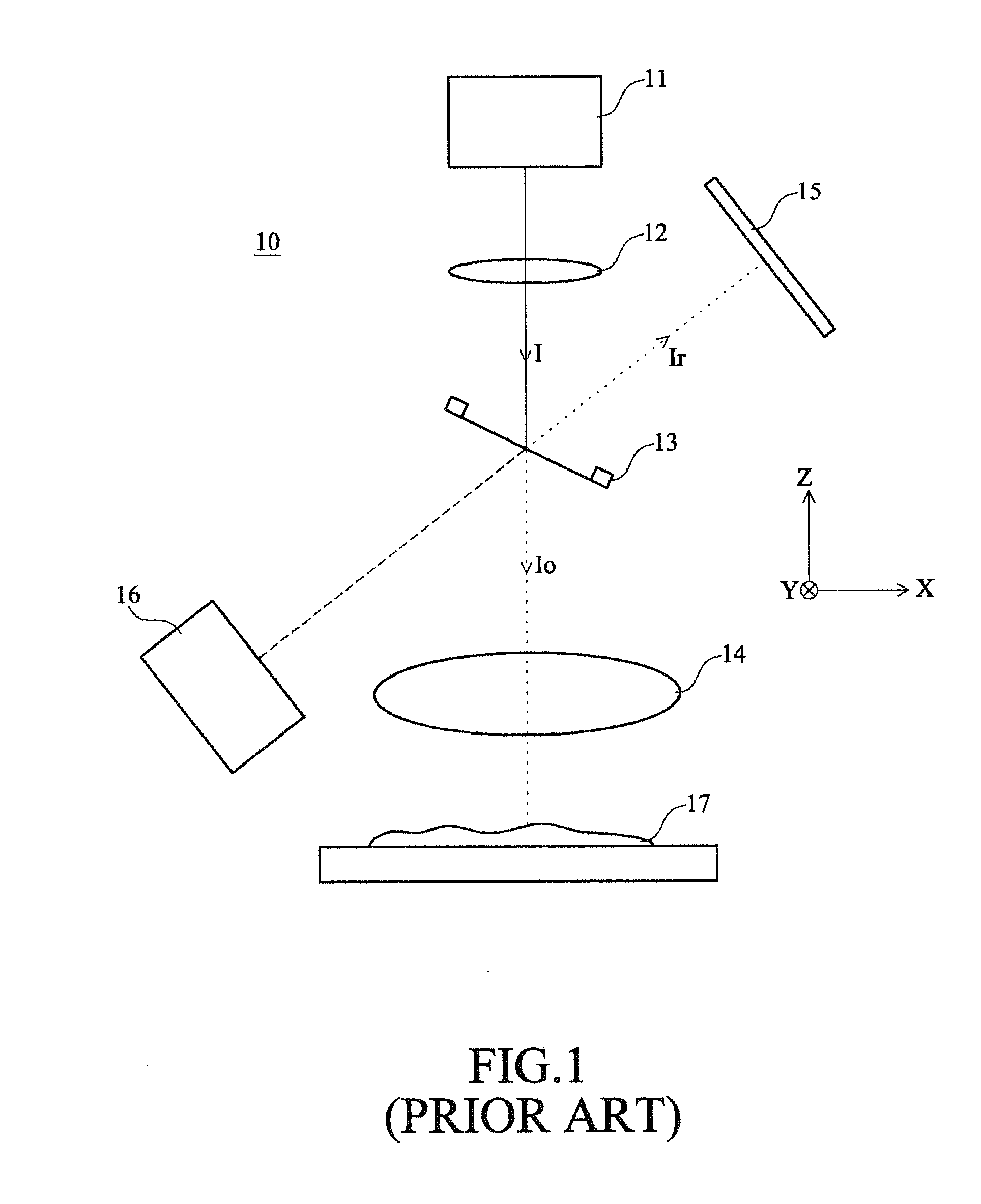

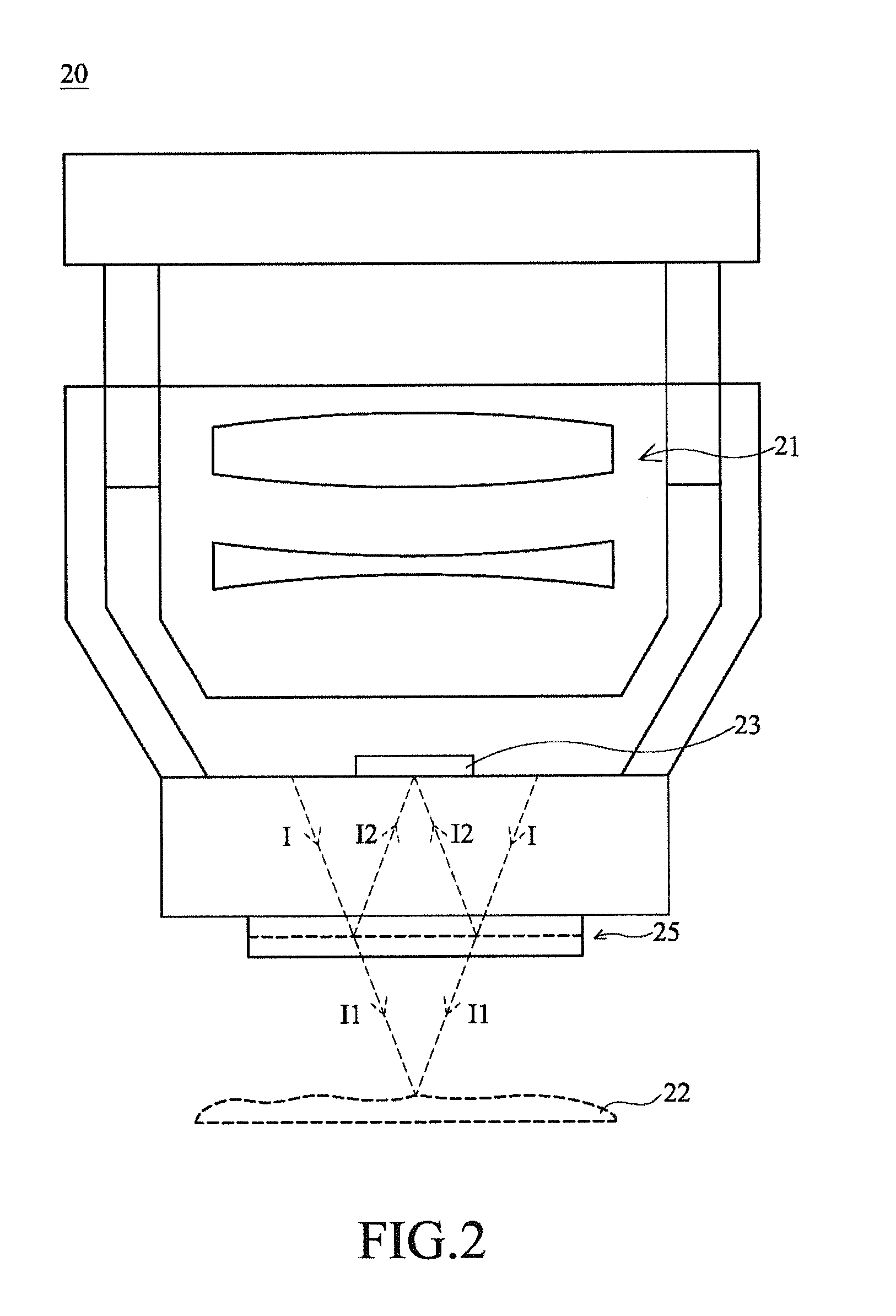

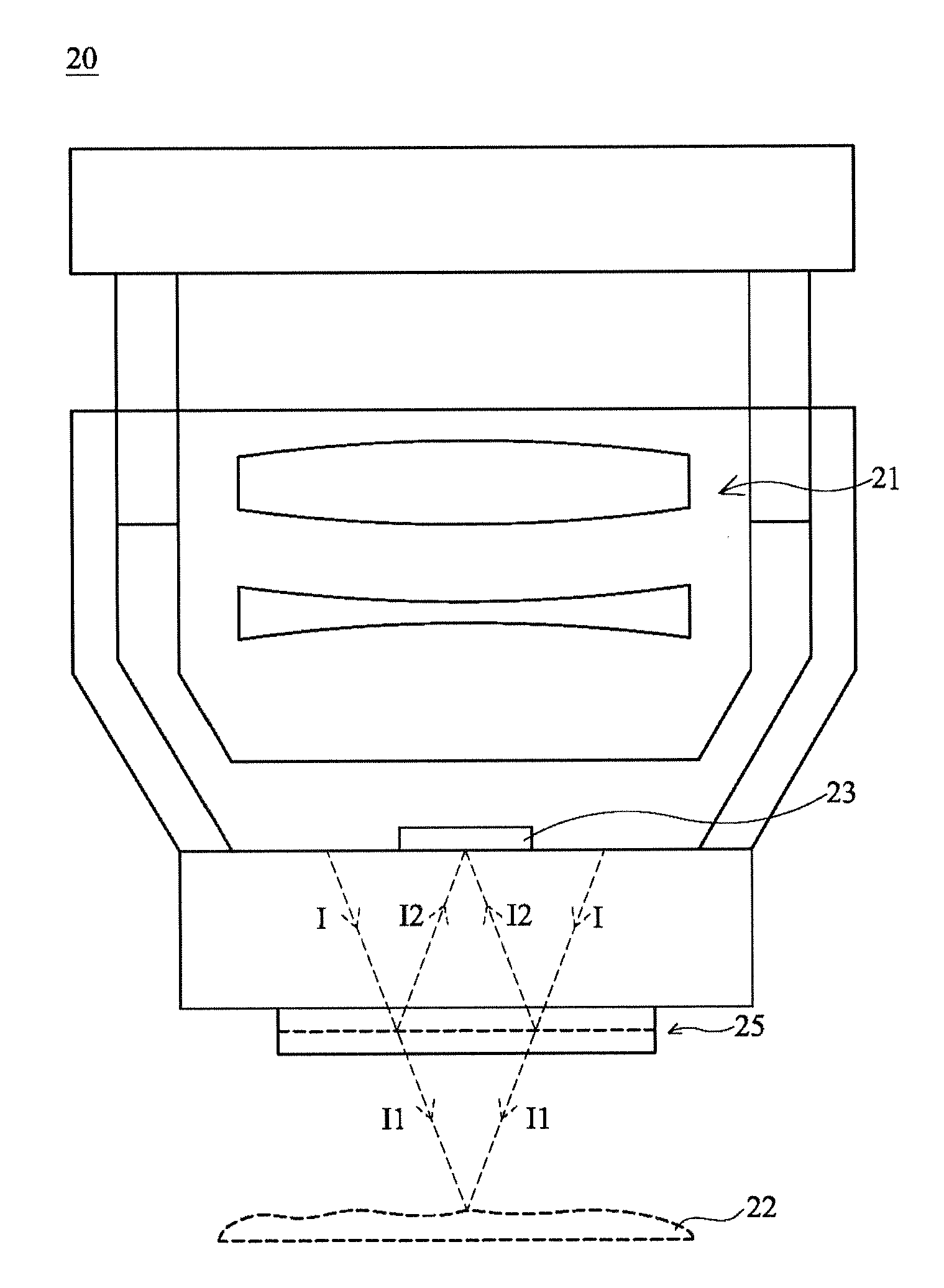

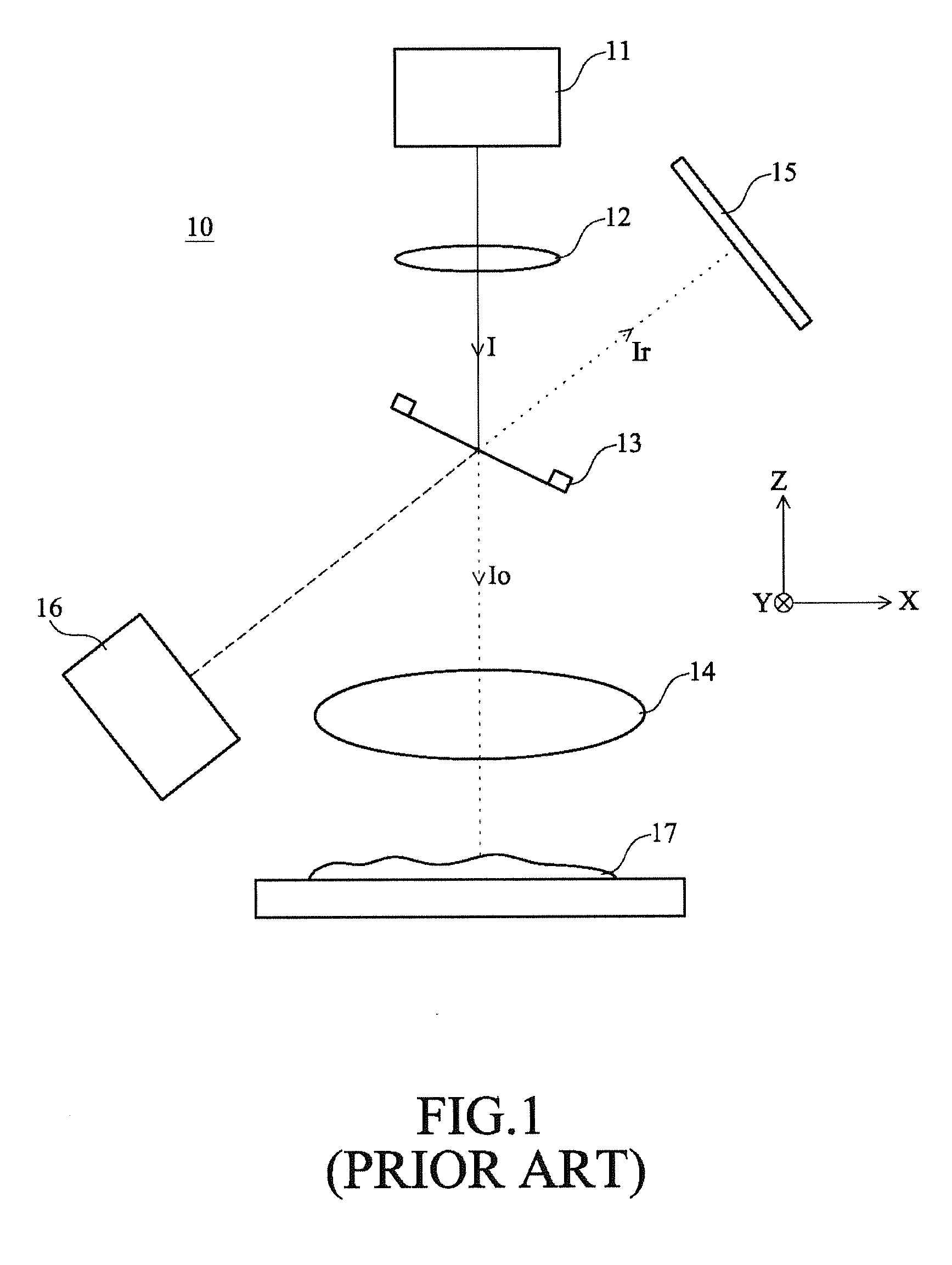

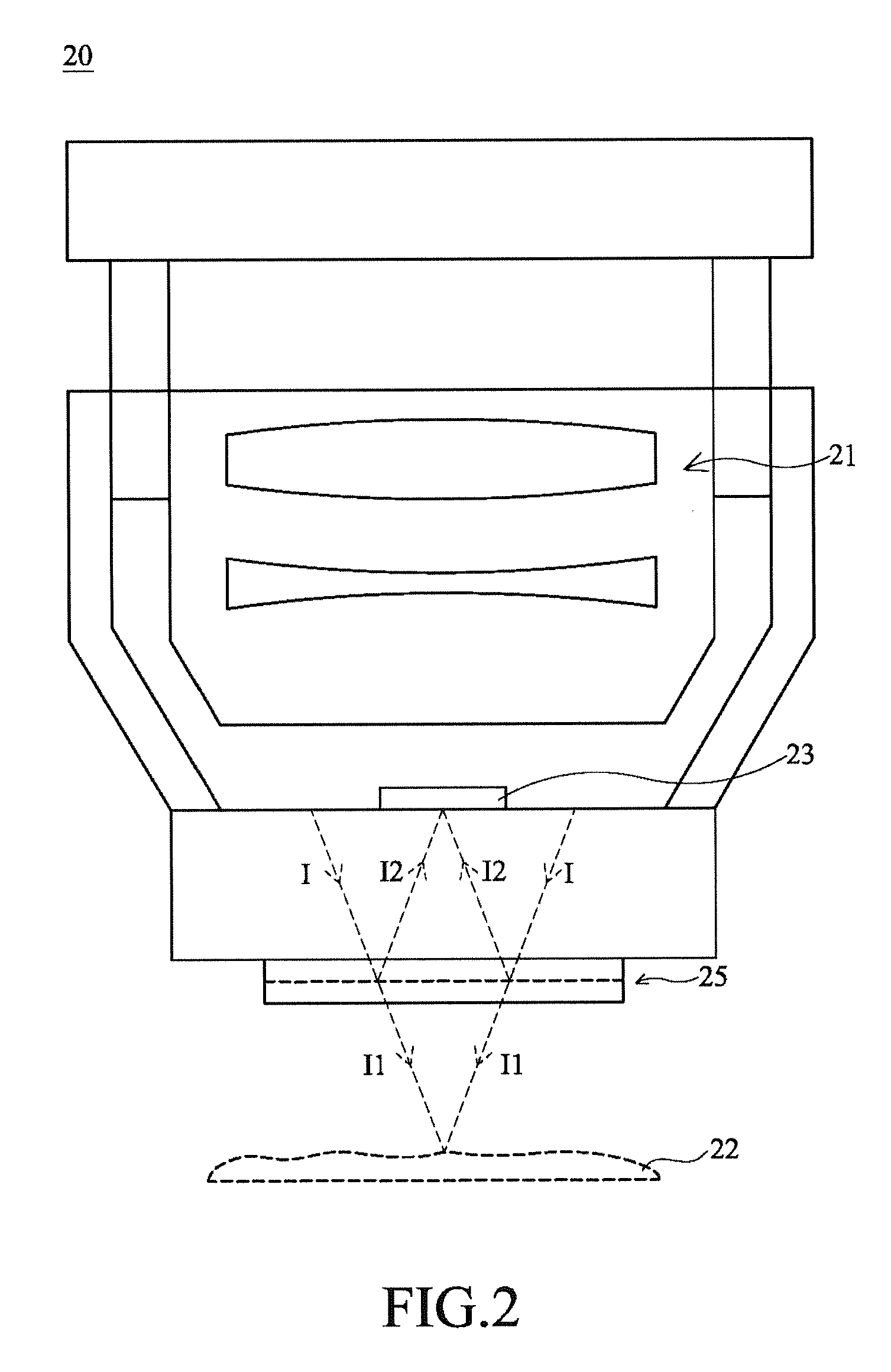

Scan lens, interferometric measuring device using same

ActiveUS20140333934A1Reduce measurementNarrow sizeMicroscopesUsing optical meansBeam splitterMeasurement testing

A scan lens and an interferometric measuring device using the scan lens are disclosed. The scan lens includes a lens set, a beam splitter, and a reflector disposed between the lens set and the beam splitter. During application the applied light beam passes through the lens set of the interferometric measuring device to fall upon the beam splitter where the light beam that passes through the beam splitter is defined as a first light beam and the light beam that is reflected by the beam splitter is defined as a second light beam. The first light beam is projected onto the test object. The second light beam is projected onto the reflector. The second light beam reflected by the reflector and the first light beam reflected or scattered by the test object will interfere with each other to form interference patterns for measuring the test object.

Owner:NAT TAIWAN UNIV

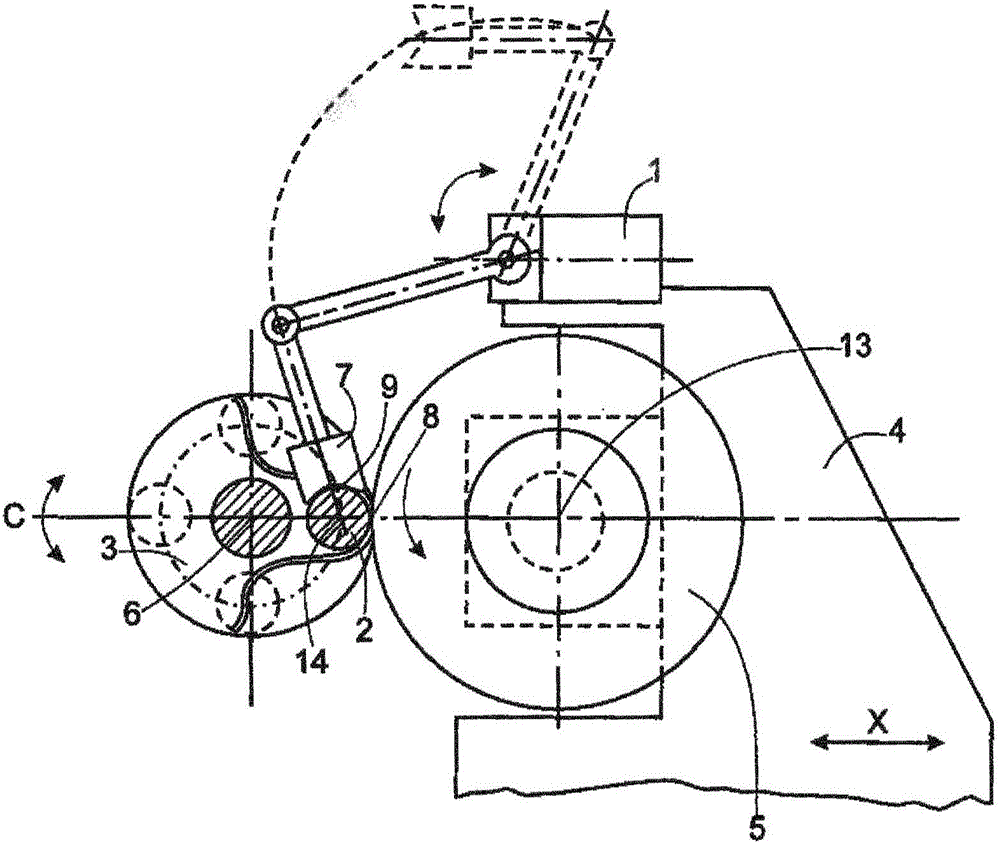

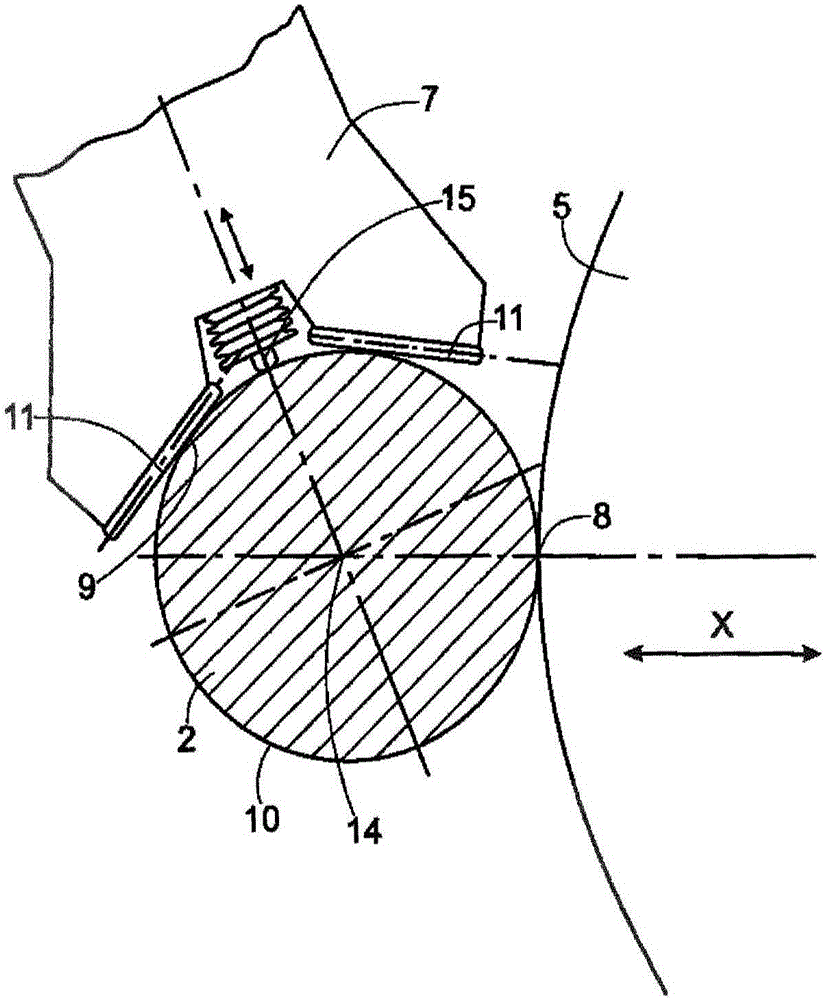

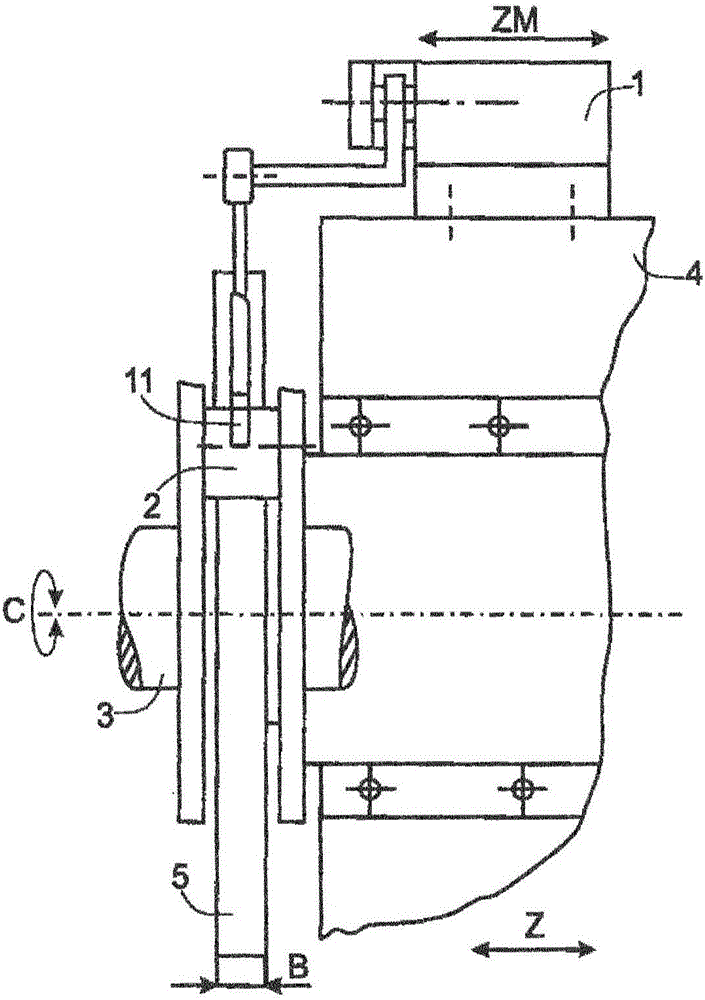

Method and grinding machine for measuring and producing a target outer contour of a workpiece by means of grinding

ActiveCN105873725AQuality improvementShape Deviation CorrectionRevolution surface grinding machinesGrinding feed controlMeasurement deviceControl system

The invention relates to a method for a measuring and producing a target outer contour (10), particularly for a pin-bearing journal (2) of a crankshaft (3), as well as a grinding machine for carrying out said method. First, using a measurement device (1), an actual contour is measured on the workpiece by acquiring measurement values for the dimensions and shape of said workpiece in at least two measurement planes that are spaced apart from one another and extend transversely to the longitudinal extension of the workpiece region in question. Said measurement planes are produced by a relative movement of the workpiece region and the measurement device in the Z axis direction, relative to the movement of the grinding disc in the direction of the Z axis thereof. These measurement values for the different measurement planes, which are spaced apart from one another, are transmitted to the CNC control system for the purpose of moving the grinding disc (5) forward, said CNC control system being controlled such that any deviations from the target contour that may be present are corrected, and the target contour of the workpiece region in question is ground adaptively based on the measurement values that were acquired for the particular measurement planes of a workpiece region.

Owner:ERWIN JUNKER GRINDING TECH

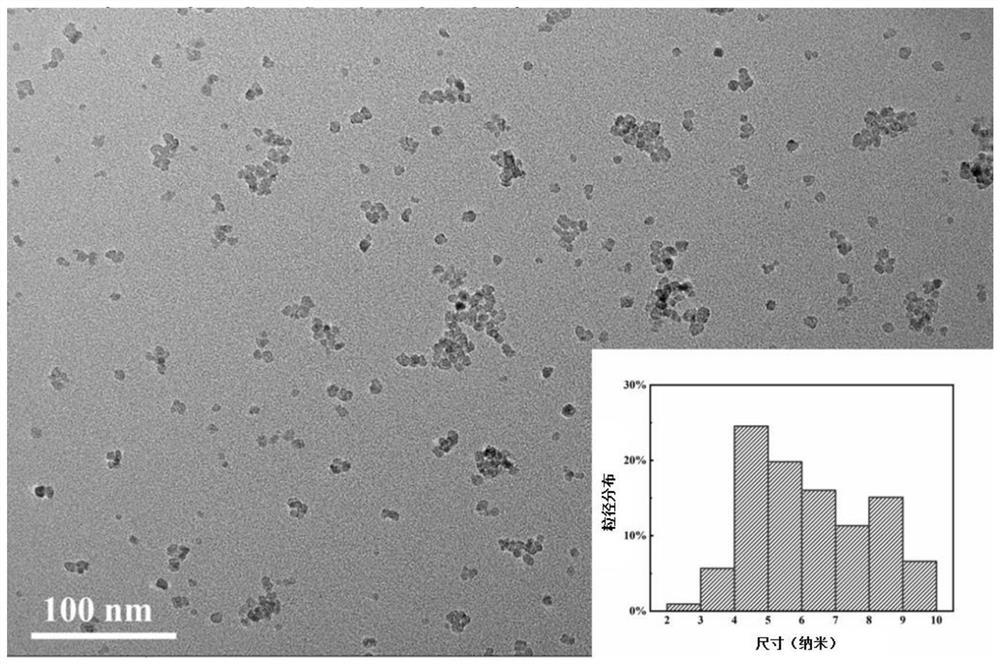

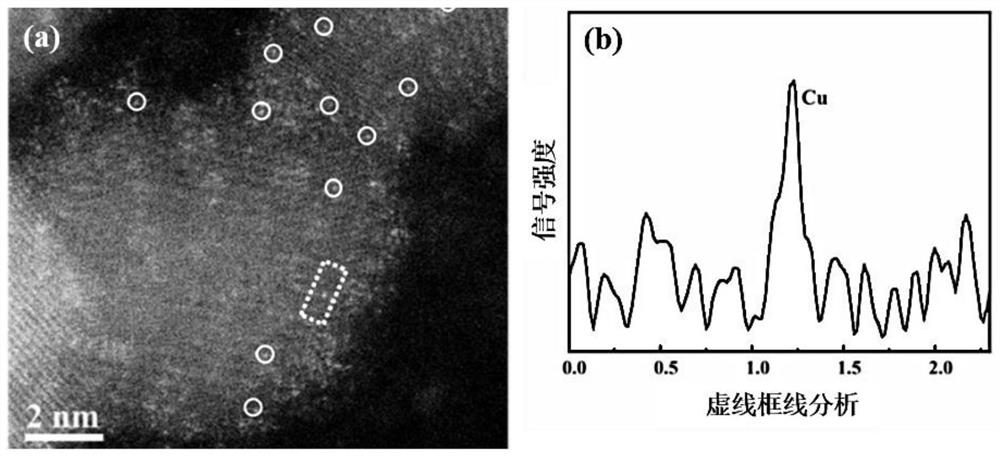

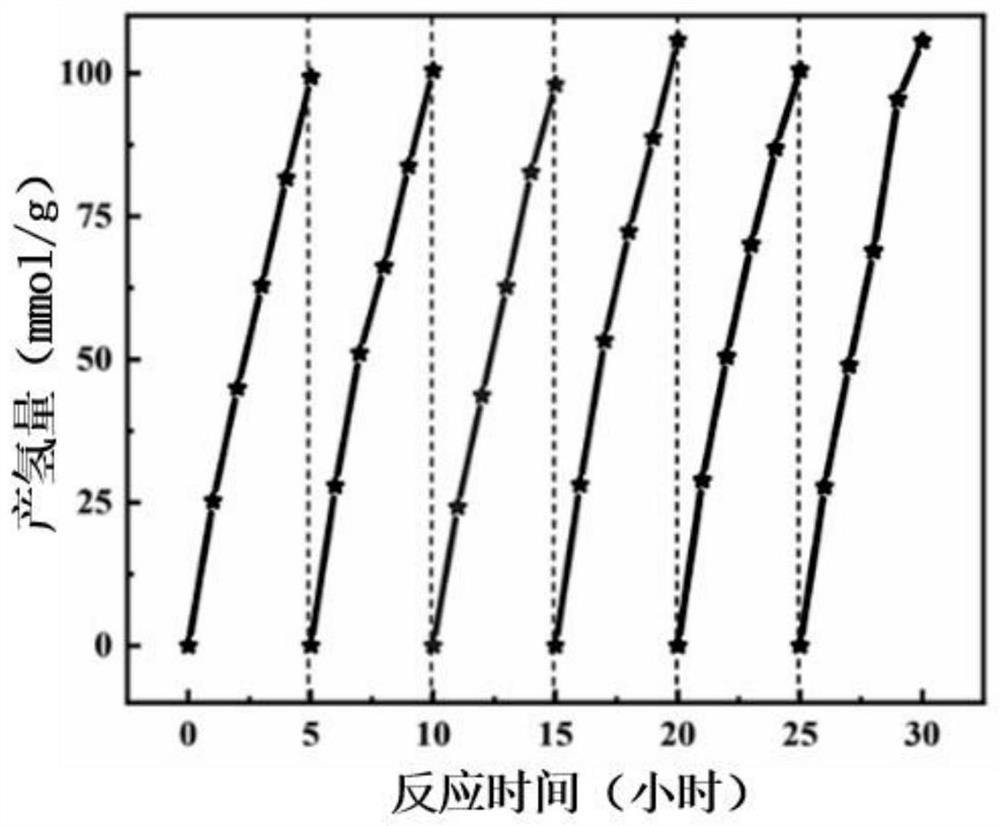

Monoatomic loaded TiO2 quantum dot photocatalyst and preparation method thereof

PendingCN114405507AEasy to prepareLow costHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsQuantum dotPhoto catalysis

The invention provides a monatomic loaded TiO2 quantum dot photocatalyst and a preparation method thereof. The metal monatomic loaded TiO2 quantum dot photocatalyst with high dispersity and large specific surface area is obtained. The preparation method is simple and low in cost, the obtained TiO2 quantum dots are good in dispersity, large in specific surface area, small in size (2-3 nm) and narrow in size distribution, the exposure rate of single atoms on the TiO2 surface is increased through the large specific surface area and the small size, and therefore the photocatalytic activity of the material is greatly improved under the condition that the single atom loading capacity is low, and the preparation cost is further reduced.

Owner:南京旭氢新材料科技有限公司

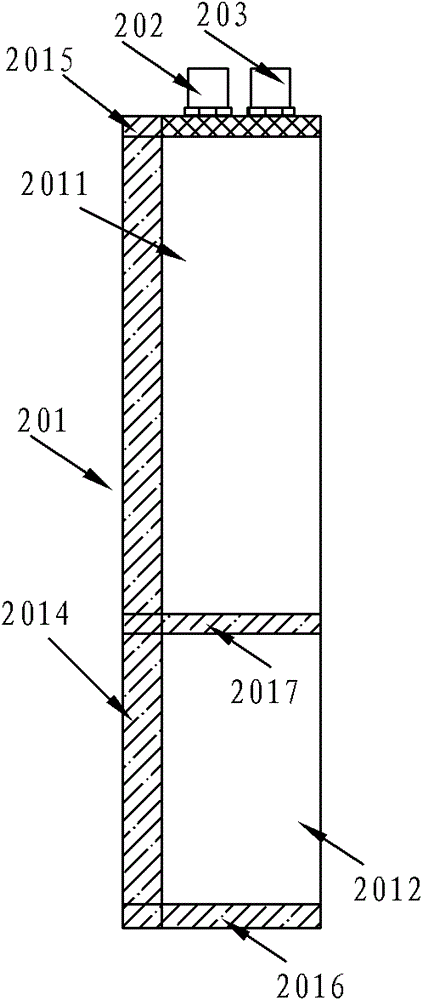

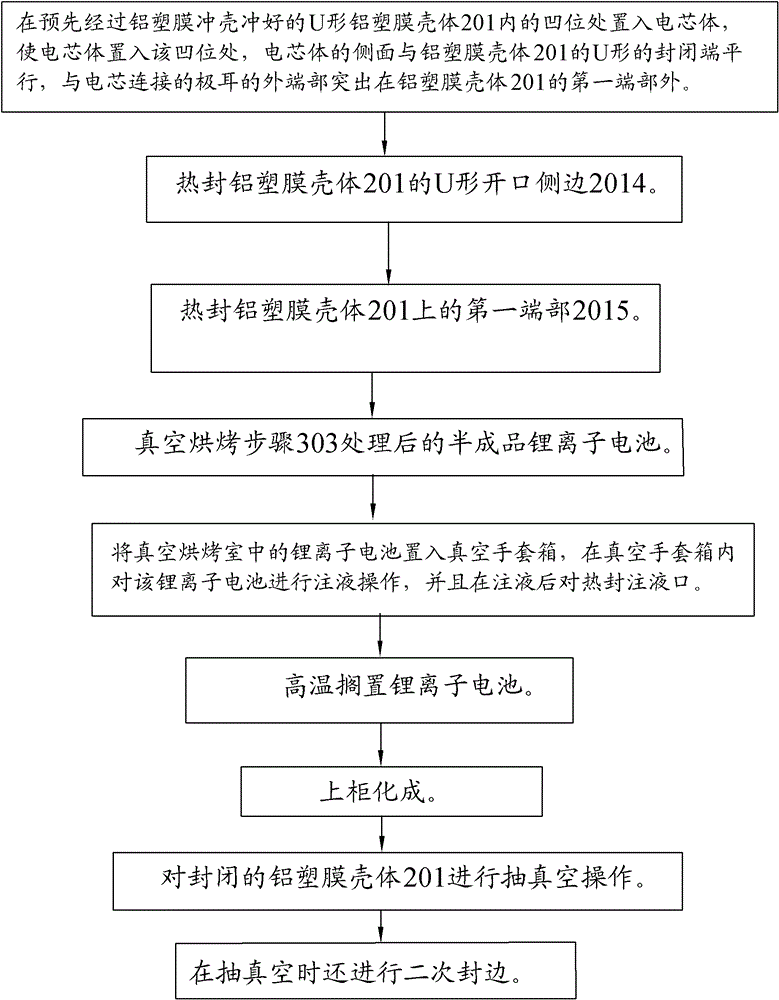

Packaging method of lithium ion battery, and lithium ion battery

InactiveCN102394316BReduce areaReduce wasteFinal product manufactureCell component detailsSurface layerEngineering

Owner:SHENZHEN GREPOW BATTERY CO LTD

A kind of high-temperature Ti-based brazing filler metal special for Tial-based alloys and its preparation method and brazing process

ActiveCN106925905BImprove wettabilityImprove liquidityWelding/cutting media/materialsWelding/soldering/cutting articlesTime rangeAlloy

The invention relates to high-temperature brazing filler metal and a preparation method and brazing technology of the high-temperature brazing filler metal, in particular to high-temperature Ti-based brazing filler metal for brazing of a TiAl-based alloy and a preparation method and brazing technology of the high-temperature Ti-based brazing filler metal. The problems that in existing brazing filler metal, postwelding connector mechanical performance and high-temperature performance are poor, the brazing filler metal melting point is low, and brazing filler metal preparation and the brazing technology are complex are solved. The brazing filler metal is prepared from, by weight percent, 10%-30% of Fe, 10%-30% of Mn, 0-5% of one or two or more kinds of Al, B, Co, Cr, Mg, Ag, Nb and Zn and the balance Ti. The preparation method comprises the steps that firstly, raw materials are weighed; secondly, the raw materials are contained in smelting equipment to be vacuumized, argon filling is carried out, then smelting is carried out many times, and cooling is carried out; and thirdly, a mother alloy obtained after smelting is subjected to quick cooling and melt-spinning, and the brazing filler metal is obtained. A quickly-cooled brazing filler metal foil band is subjected to brazing according to the brazing technology with the temperature ranging from 1,100 DEG C to 1,250 DEG C and the time ranging from 0 min to 120 min. Compared with existing brazing filler metal, the prepared brazing filler metal has the high melting point and excellent wettability and mechanical performance; and brazing filler metal preparation and the brazing technology are simple.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Scan lens, interferometric measuring device using same

A scan lens and an interferometric measuring device using the scan lens are disclosed. The scan lens includes a lens set, a beam splitter, and a reflector disposed between the lens set and the beam splitter. During application the applied light beam passes through the lens set of the interferometric measuring device to fall upon the beam splitter where the light beam that passes through the beam splitter is defined as a first light beam and the light beam that is reflected by the beam splitter is defined as a second light beam. The first light beam is projected onto the test object. The second light beam is projected onto the reflector. The second light beam reflected by the reflector and the first light beam reflected or scattered by the test object will interfere with each other to form interference patterns for measuring the test object.

Owner:NAT TAIWAN UNIV

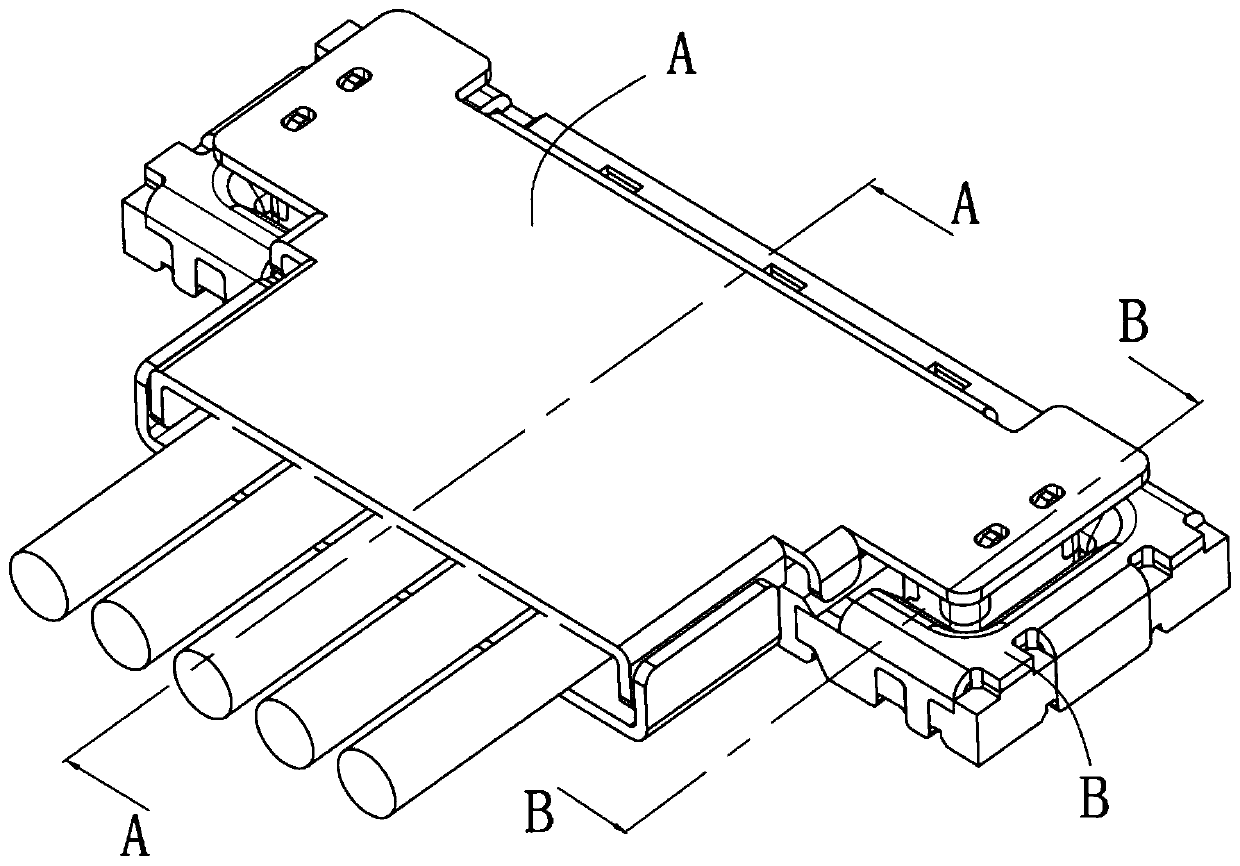

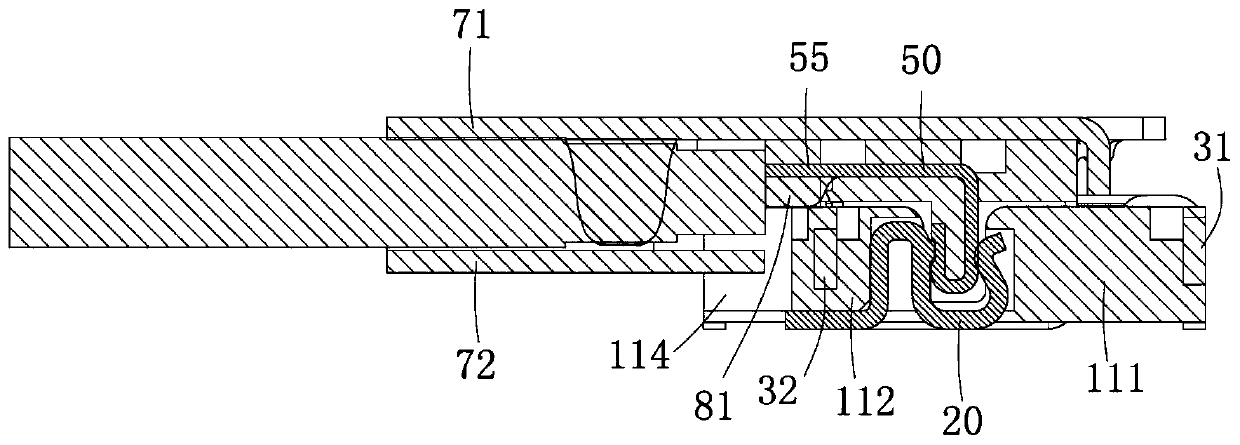

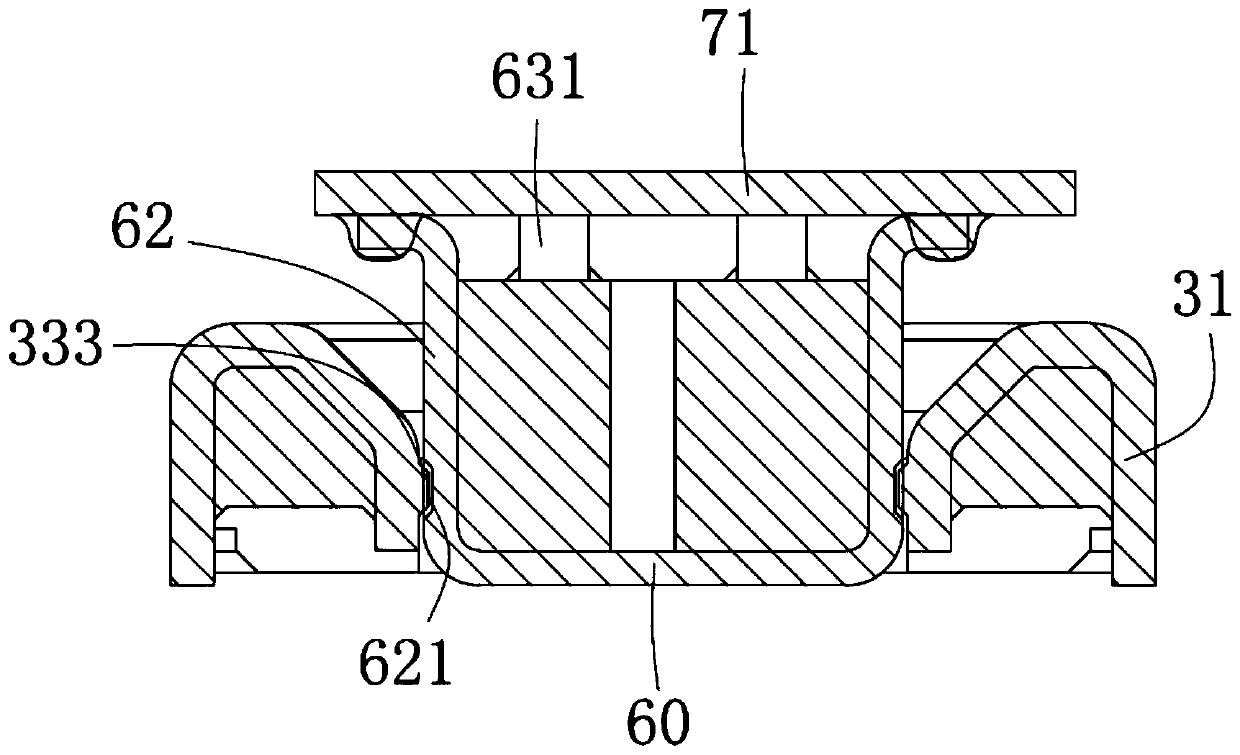

Board-to-board RF and board-to-board RF component

InactiveCN110247209ANarrow sizeSave spaceCoupling contact membersFixed connectionsEngineeringMechanical engineering

A board-to-board RF socket includes a socket body, a socket frame formed in the socket body, and a plurality of socket terminals assembled in the socket body. The socket body includes a body base portion, socket mating portions formed on both lateral sides of the body base portion, and mating holes formed in the middles of the socket mating portions. A side of the body base portion in the longitudinal direction is recessed inwardly to form a notch. The socket frame comprises a first and second frame bodies formed on both longitudinal sides of the body base portion and a lateral frame body connecting the first frame body and the second frame body, wherein the second frame body is recessed inwardly in cooperation with the notch, and the lateral frame body covers the socket mating portions. The application also provides a board-to-board RF component.

Owner:KUNSHAN KTA COMM TECH CO LTD

OLED display panel with narrow frame structure

ActiveCN106450033BNarrow sizeSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductive adhesivePhysics

The invention discloses an OLED display panel with a narrow frame structure, which includes a display area and a frame area located around the display area, one of the opposite frames in the frame area is provided with metal wiring, and the cathode in the display area is connected to the metal through the anode. Wire connection, the back of the display area is provided with a conductive tape, and the two ends of the conductive tape are respectively electrically connected to the two ends of the metal wires in the two opposite frames after being bent. In the present invention, a conductive tape is pasted on the back of the OLED display panel, and the conductive tape is bent from the left and right sides of the display panel to one of the opposite frames, and the conductive tape is respectively connected to the two ends of the metal wiring on the other opposite frame. The conductive tape replaces the metal wiring on one of the opposite frames, making the size of the frame area narrower and increasing the size of the display area.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

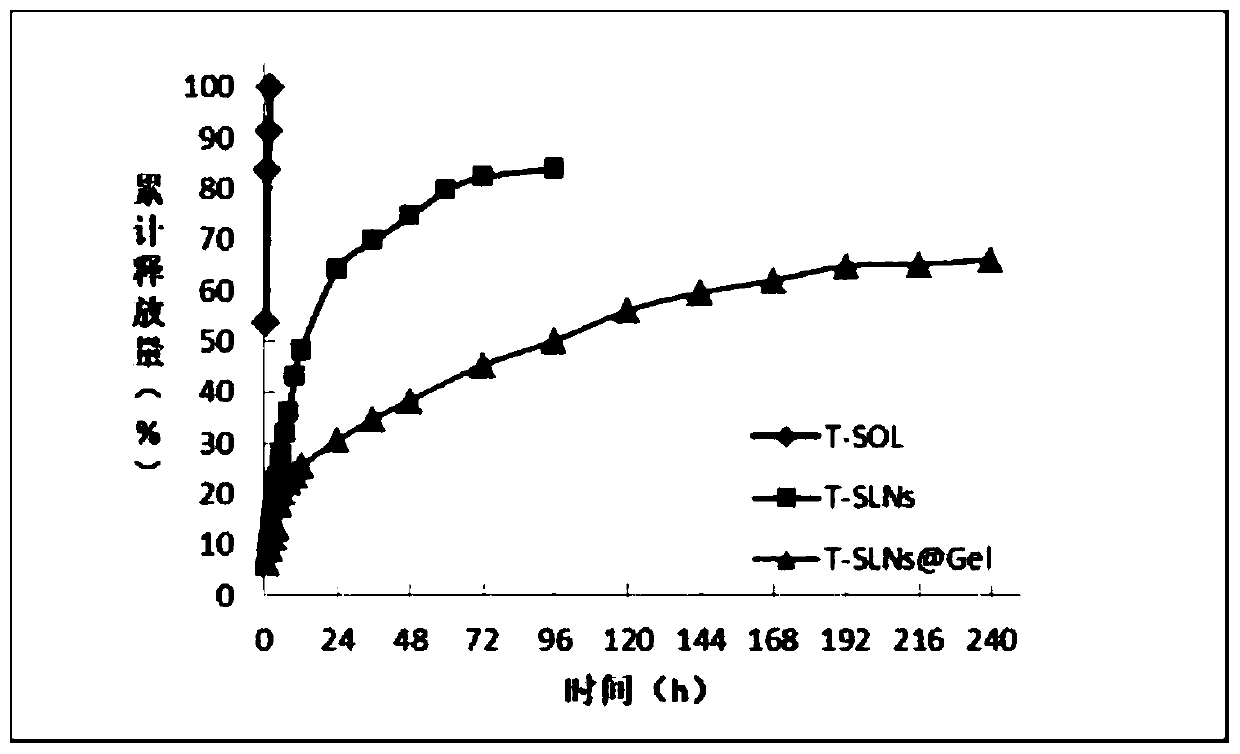

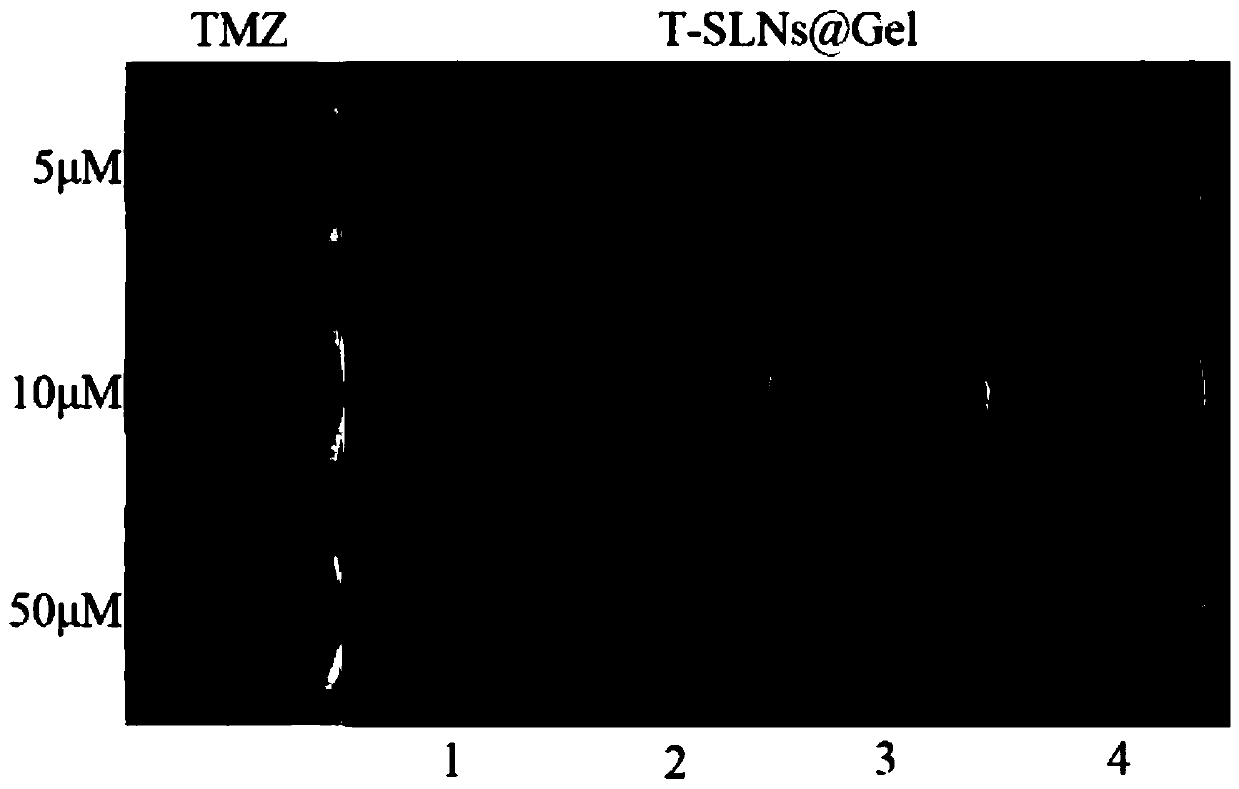

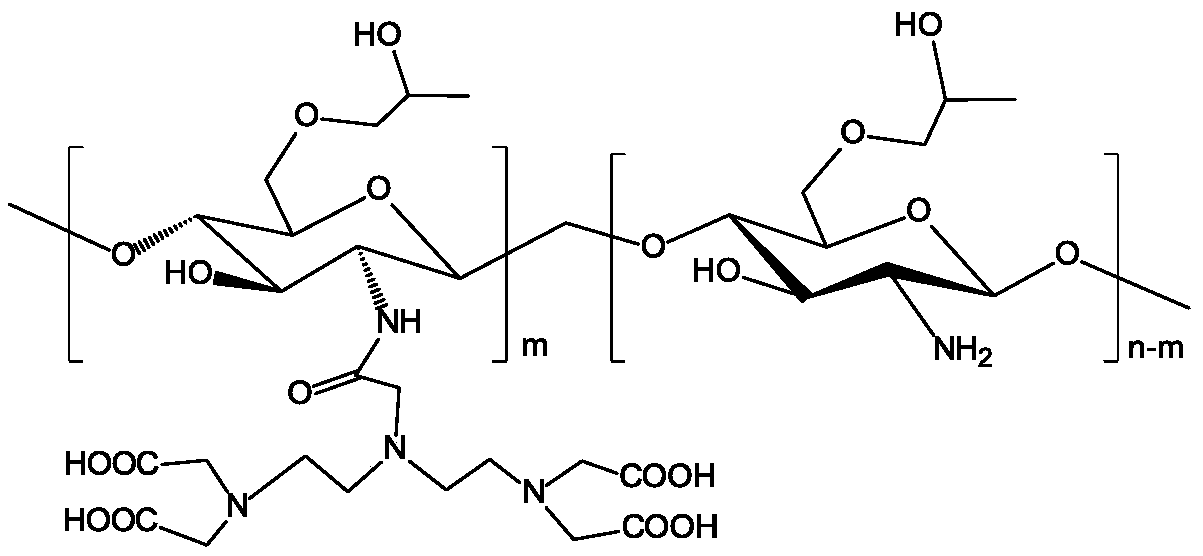

Temozolomide nuclear magnetic resonance visual injectable hydrogel as well as preparation method and application thereof

ActiveCN110585121AExtended stayIncrease concentrationOrganic active ingredientsAerosol deliveryLipid formationTopical treatment

The invention relates to temozolomide nuclear magnetic resonance visual injectable hydrogel as well as a preparation method and application thereof. According to the invention, temozolomide solid lipid nanoparticles are loaded into a nuclear magnetic resonance visual hydrogel matrix, such that temozolomide lipid nanoparticle-loaded hydrogel is prepared. A system combines the advantages of the temozolomide solid lipid nanoparticles, injectable hydrogel and modified hydroxypropyl chitosan, so that the slow release performance of the system is obviously higher than that of the temozolomide solidlipid nanoparticles and a temozolomide active compound; the hydrogel disclosed by the invention can be used for postoperative local treatment of brain glioma; residence time of drug-loaded nanoparticles at the focus part is prolonged, and local drug concentration is increased; compared with an existing oral administration dosage form, the in-situ gel containing a temozolomide composition providedby the invention can be administered immediately after surgery, and continuously releases in an operation residual cavity, so that real-time monitoring on a focus part is realized, the bioavailabilityof the drug is improved, and postoperation lifetime is favorably prolonged.

Owner:武汉布润脑医学科技有限责任公司

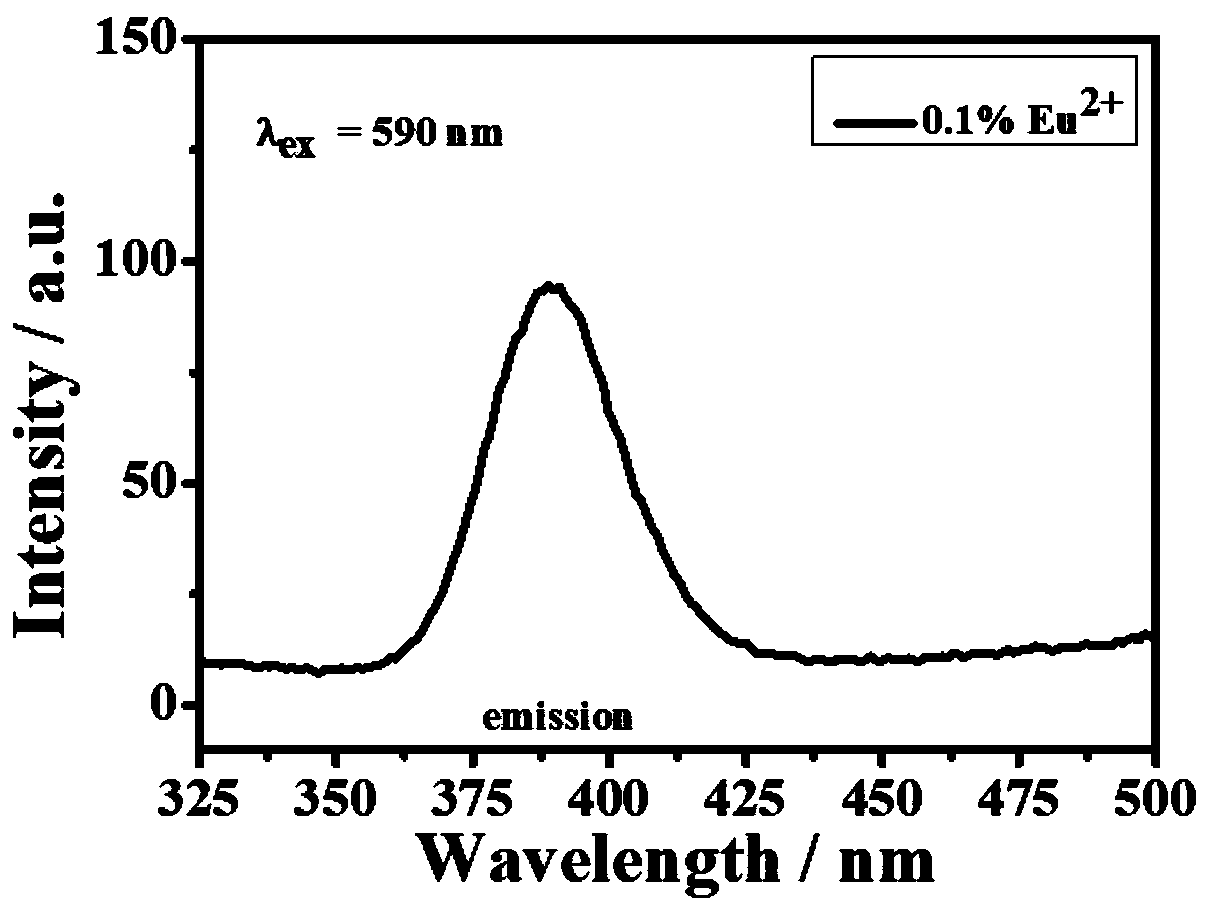

Divalent europium-doped barium fluobromide light-emitting material, preparation method and applications thereof

ActiveCN110699074AImprove luminous performanceImprove crystal defectsNanotechnologyLuminescent compositionsAqueous ethanolImage resolution

The invention discloses a divalent europium-doped barium fluobromide light-emitting material preparation method, which comprises: dissolving BaBr2 and EuBr2 in an ethanol aqueous solution to obtain asolution A; dissolving NH4F in an ethanol aqueous solution to obtain a solution B; adding the solution B into the solution A in a dropwise manner, carrying out a reaction for 5-8 h at a room temperature, washing, centrifuging, precipitating, and drying to obtain a precursor material; and carrying out annealing treatment to obtain the divalent europium-doped barium fluobromide light-emitting material. According to the invention, the light-emitting material is small in size, narrow in distribution range and regular and controllable in morphology, has excellent fluorescence and excellent opticalexcitation luminescence property, can be used for manufacturing imaging plates with high packing density to obtain imaging with high spatial resolution, and is widely applied to the fields of medicaldiagnosis, biological imaging, dosimeters and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of spherical gold particle and its step-by-step rapid synthesis method

The invention relates to a spheroidal gold particle and a step-by-step rapid synthesis method thereof. The method includes the following steps: soluble gold salt, surfactant and reducer are prepared into mixed solution, and gold particle seeds are added in the process of rapid agitation, and thereby react to grow into spheroidal gold particles, the grain size of which is 5nm to 100nm; the surfactant is the mixed surfactant of cetyltrimethylammonium bromide or cetyltrimethylammonium chloride and cetyltrimethylammonium bromide, the reducer is ascorbic acid, and the gold particle seeds are spheroidal gold particles, the grain size of which is 2nm to 60nm. The gold particle seeds can be monocrystalline or polycrystalline, and the synthesized spheroidal gold particles have the same crystal form as the gold particle seeds. Since the invention adopts the surfactant and the reducer and the gold particle seeds are added in the process of rapid agitation, reaction is rapid enough, consequently, the gold salt can rapidly and uniformly grow on the surfaces of the gold particle seeds, and the obtained spheroidal gold particles is narrow in grain size and has a good degree of sphericity.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

III-V group quantum dots and preparation method thereof

ActiveCN113861977ASmall sizeImproved size distributionNanoopticsLuminescent compositionsPhysical chemistryQuantum dot

The invention discloses III-V group quantum dots and a preparation method thereof, and belongs to the technical field of quantum dot synthesis. The preparation method of the III-V group quantum dots comprises the following steps: reacting a III group cation precursor with organic phosphine with lone pair electrons in a first solvent to obtain a first solution; and mixing the first solution with a V-group anion precursor, reacting to generate a quantum dot core, and growing. The problems that existing III-V group quantum dots are small in size and wide in size distribution can be solved.

Owner:合肥福纳科技有限公司

A kind of preparation method of surface functionalized cellulose nanospheres

The present invention relates to a method for preparing surface-functionalized cellulose nanospheres, which comprises (1) adding cellulosic fibers to the alkali liquor, swelling, filtering the solution, washing the product with water for several times until pH is 7, and drying to constant weight; (2) then adding the above product into mixed acid for fully infiltrating, reacting the above solution under stirring for 2-10 hours at 60-90 DEG C, naturally cooling the reaction products, adding an alkali solution until the pH of the solution is adjusted to 7 to obtain a dispersion liquid of cellulose nanospheres, then centrifuging the dispersion liquid, washing with water for three times, carrying out ultrasonic treatment, and then carrying out freeze drying to constant weight to obtain a cellulose nanospheres. The preparation method has advantages of low raw material cost, simple preparation process and mild preparation conditions; the surfaces of the cellulose nanospheres have functional groups, so that thermal stability and hydrophobicity are improved, self-aggregation is reduced, dispersion is easy, size is small, distribution is narrow, control is easy, specific surface area is large, reactivity is high and etc.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com