Preparation method of narrow-distribution cellulose nanocrystalline

A cellulose and nanocrystal technology, applied in nanotechnology and other directions, can solve the problems of wide and uneven particle distribution, and achieve the effects of simple removal, low cost and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

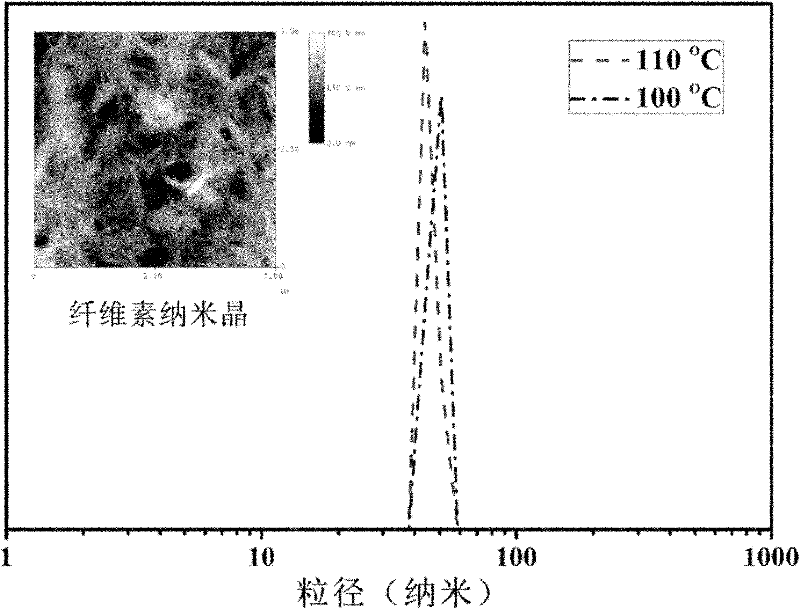

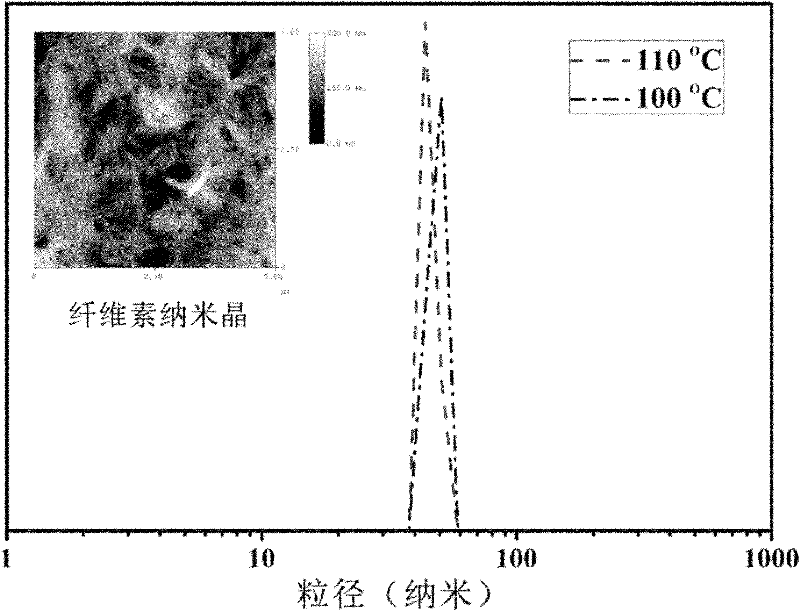

[0018] Commercially available microcrystalline cellulose was fully soaked in a hydrochloric acid solution with a concentration of 5 mol / L, and then transferred to a hydrothermal kettle lined with polytetrafluoroethylene, in which the solid content of microcrystalline cellulose was 0.008 g / mL. The reaction was carried out at 110° C. for 3 hours. After the hydrothermal kettle was naturally cooled, the reaction product was poured out and diluted with deionized water. After static layering, the supernatant was removed, and repeated several times until the dispersion formed a stable suspension. Add 2mol / L ammonia solution to adjust the pH of the solution to 7. The volatile components are removed by heating to obtain a uniformly distributed cellulose nanocrystal dispersion. The particle size distribution of rod-shaped or elliptical cellulose nanocrystals is 20-30nm as measured by the nanometer particle size and potential analyzer. By freeze-drying the cellulose nanocrystal dispers...

Embodiment 2

[0020] Commercially available microcrystalline cellulose was fully soaked in a hydrochloric acid solution with a concentration of 6 mol / L, and then transferred to a hydrothermal kettle lined with polytetrafluoroethylene, in which the solid content of microcrystalline cellulose was 0.0125 g / mL. The reaction was carried out at 100° C. for 4 hours. After the hydrothermal kettle was naturally cooled, the reaction product was poured out and diluted with deionized water. After static layering, the supernatant was removed, and repeated several times until the dispersion formed a stable suspension. Add 1 mol / L ammonia solution to adjust the pH of the solution to 7. After heating to remove volatile components, a uniformly distributed cellulose nanocrystal dispersion liquid is obtained; the diameter distribution of rod-shaped or elliptical cellulose nanocrystals is 28-42 nm as measured by a nanometer particle size and potential analyzer. By freeze-drying the cellulose nanocrystal dispe...

Embodiment 3

[0022] Commercially available microcrystalline cellulose was fully soaked in 3 mol / L acetic acid solution, and then transferred to a polytetrafluoroethylene-lined hydrothermal kettle, in which the solid content of microcrystalline cellulose was 0.006 g / mL. The reaction was carried out at 120° C. for 5 hours. After the hydrothermal kettle was naturally cooled, the reaction product was poured out and diluted with deionized water. After static layering, the supernatant was removed, and repeated several times until the dispersion formed a stable suspension. Add 1 mol / L ammonia solution to adjust the pH of the solution to 7. After heating to remove volatile components, a uniformly distributed cellulose nanocrystal dispersion liquid is obtained; the diameter distribution of rod-shaped or elliptical cellulose nanocrystals is 35-50 nm as measured by a nanometer particle size and potential analyzer. By freeze-drying the cellulose nanocrystal dispersion, cellulose nanocrystals with hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com