Patents

Literature

485 results about "Cellulose nanocrystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

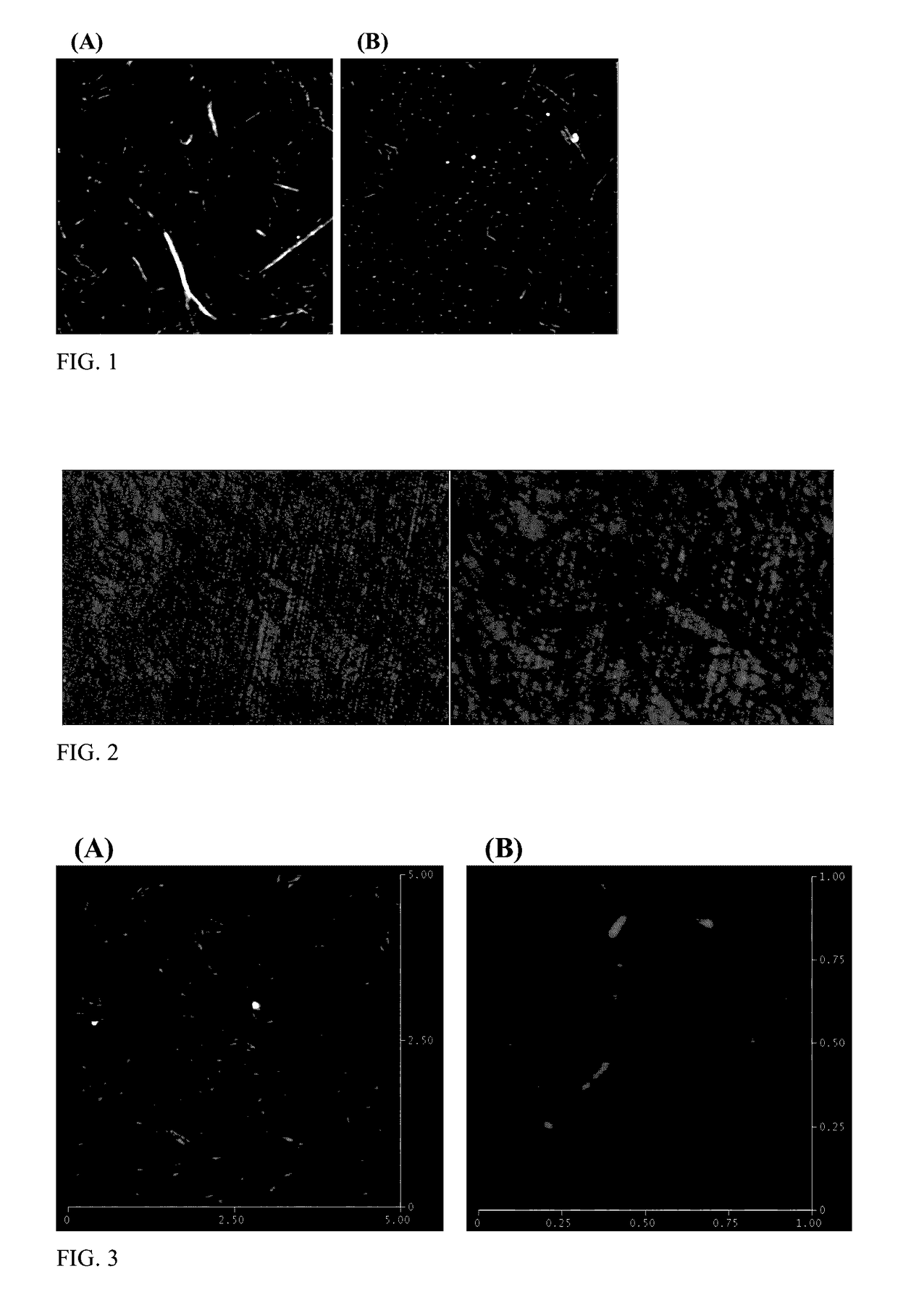

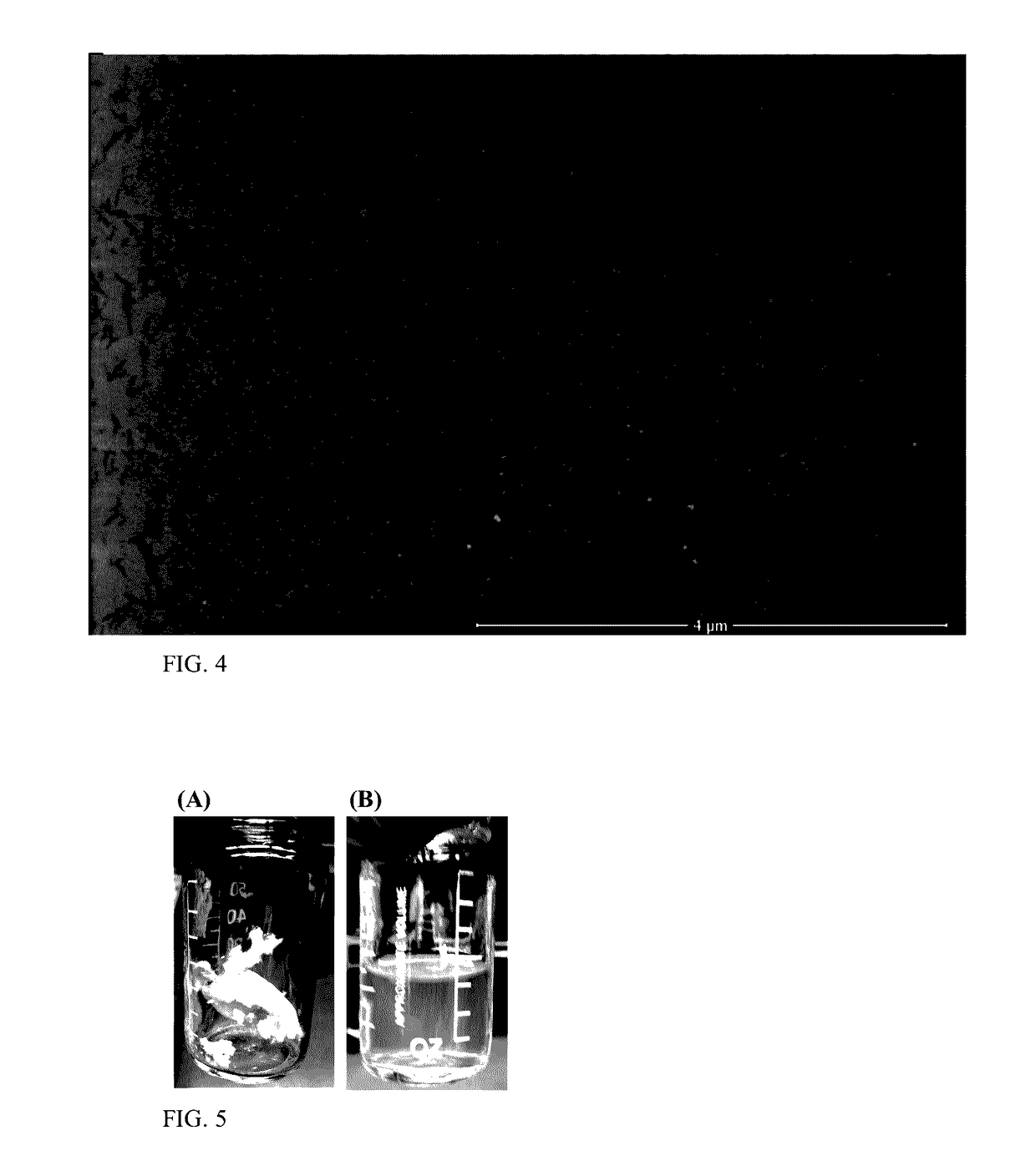

Method for preparing fibrilia carboxylation cellulose nanowhiskers

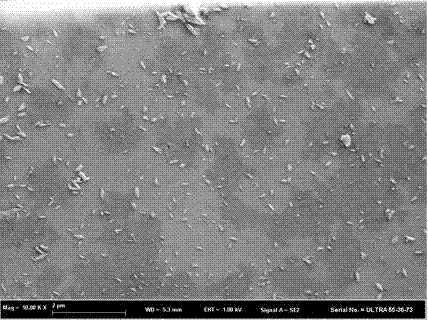

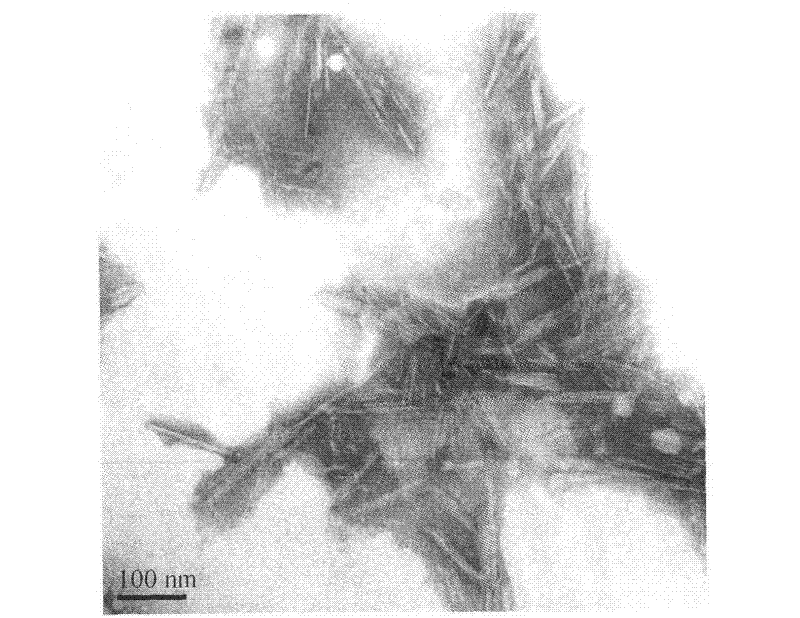

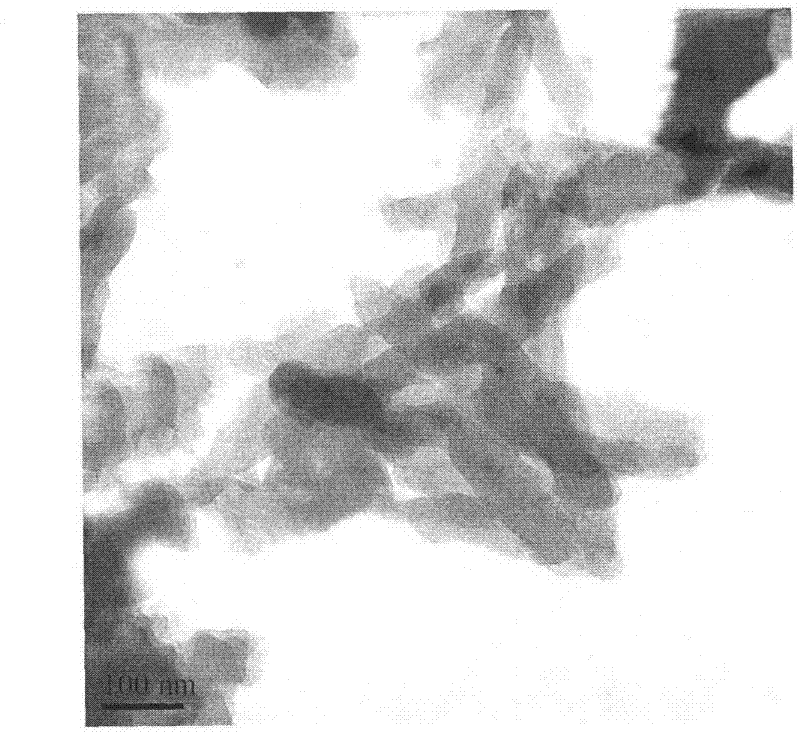

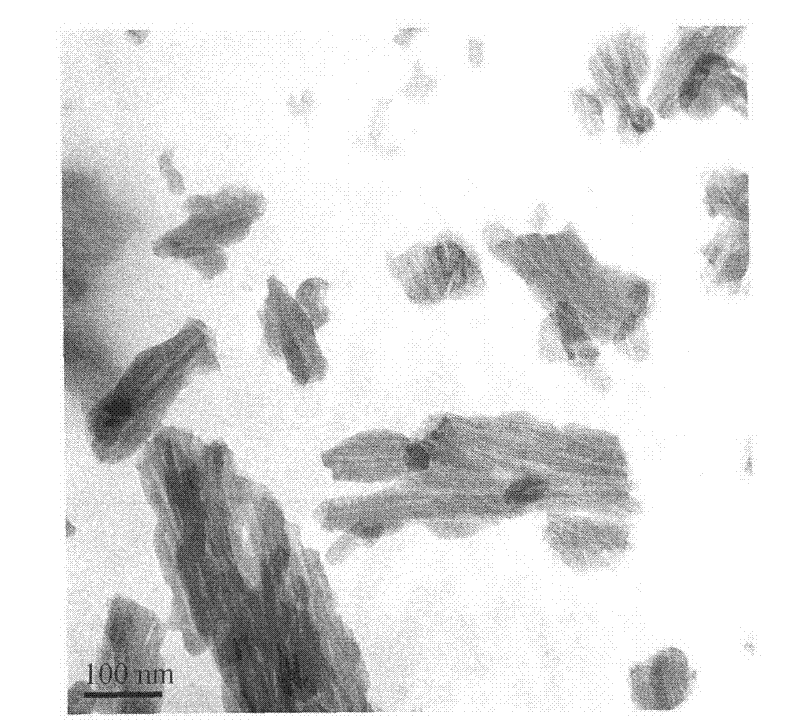

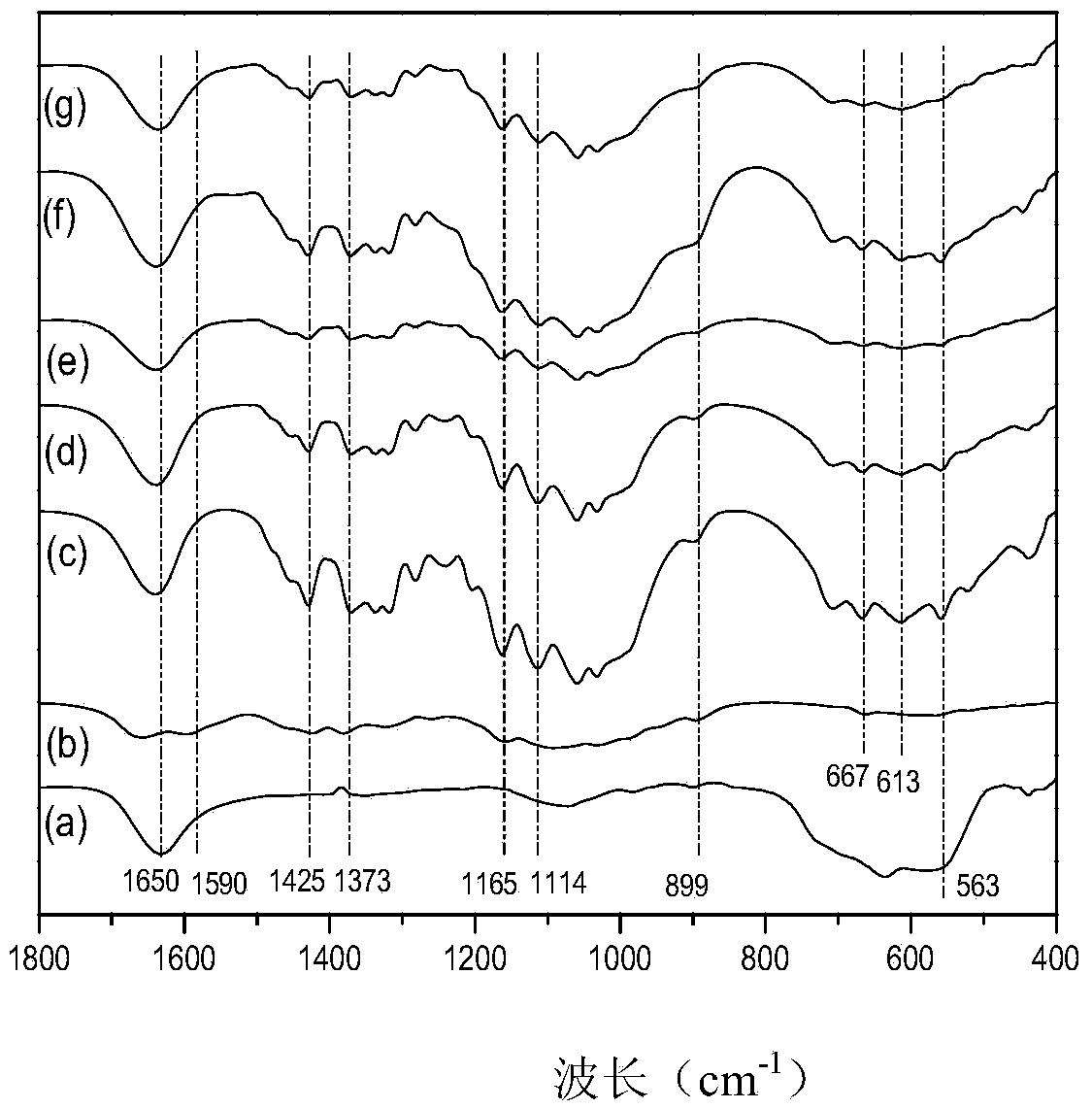

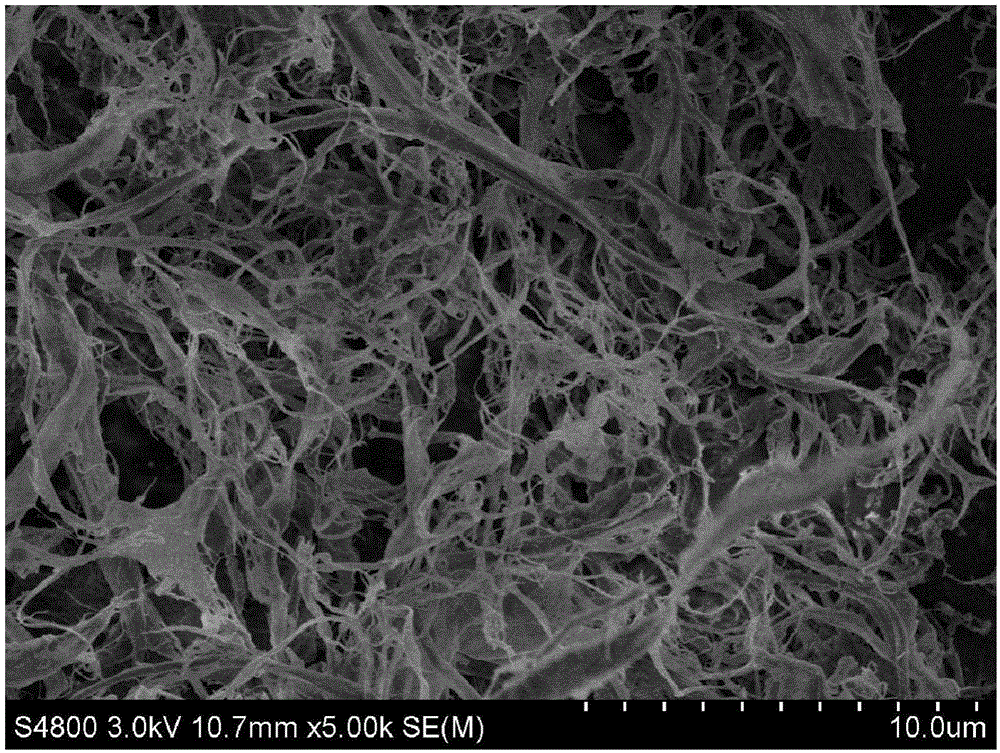

The invention provides a method for preparing fibrilia carboxylation cellulose nanowhiskers, which is characterized by comprising the following steps: soaking fibrilia powder in sodium hydroxide for processing, then processing the fibrilia powder by a former treating agent and taking out the fibrilia powder to be dried in a vacuum oven to obtain preprocessed fibrilia powder; and placing the preprocessed fibrilia powder in a TEMPO oxidation system for catalytic oxidation to obtain a stable cellulose nanowhiskers suspending liquid after mechanical processing and freeze drying the suspending liquid to obtain the fibrilia carboxylation cellulose nanowhiskers having grain diameters of 3-10 nm. According to the invention, fibrilia carboxylation and nano fibrillation are realized and surfaces of prepared nanocrystalline celluloses have carboxyl functional groups, thus the surfaces generate negative charges, electrostatic repulsion among the negative charges can avoid the reunion of nanoparticles, so that the nanocrystalline celluloses can be well dispersed in water and the obtained nanocrystalline celluloses have excellent uniformity of grain sizes.

Owner:DONGHUA UNIV

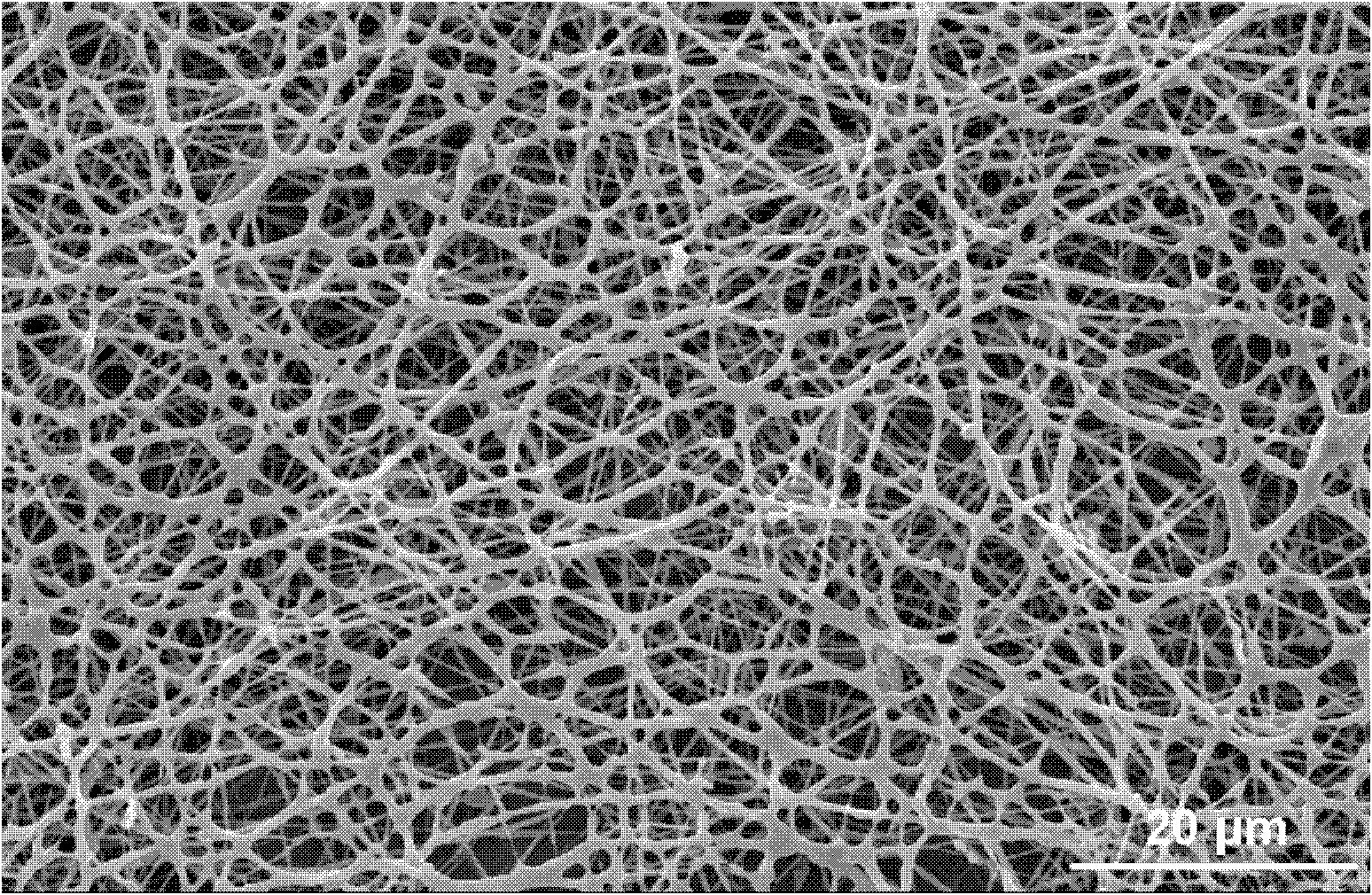

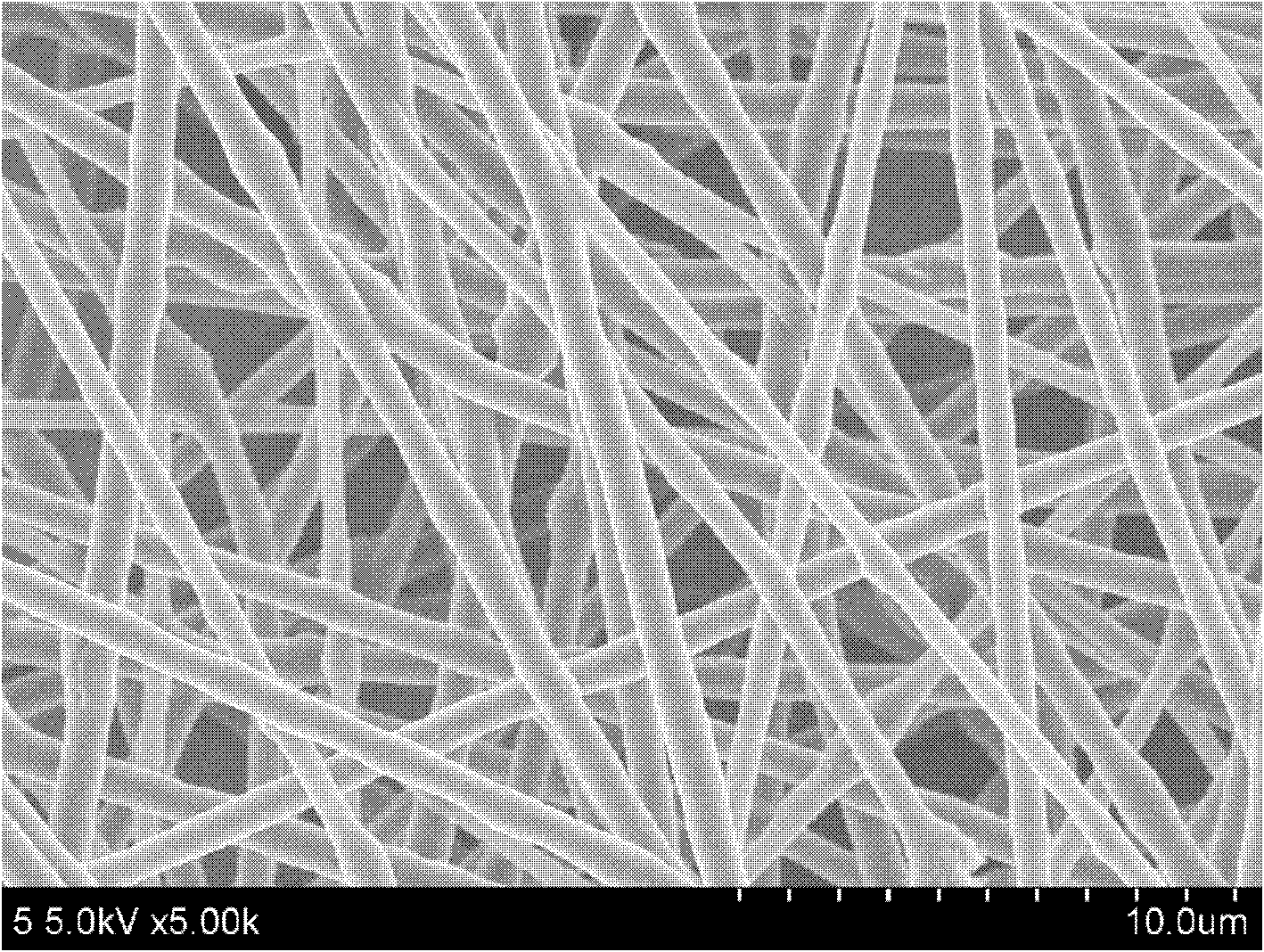

Method for preparing cellulose nanocrystal/electrostatic spinning nanofiber filter film

InactiveCN102806021AImprove adsorption capacityPurify waterSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberPolymer science

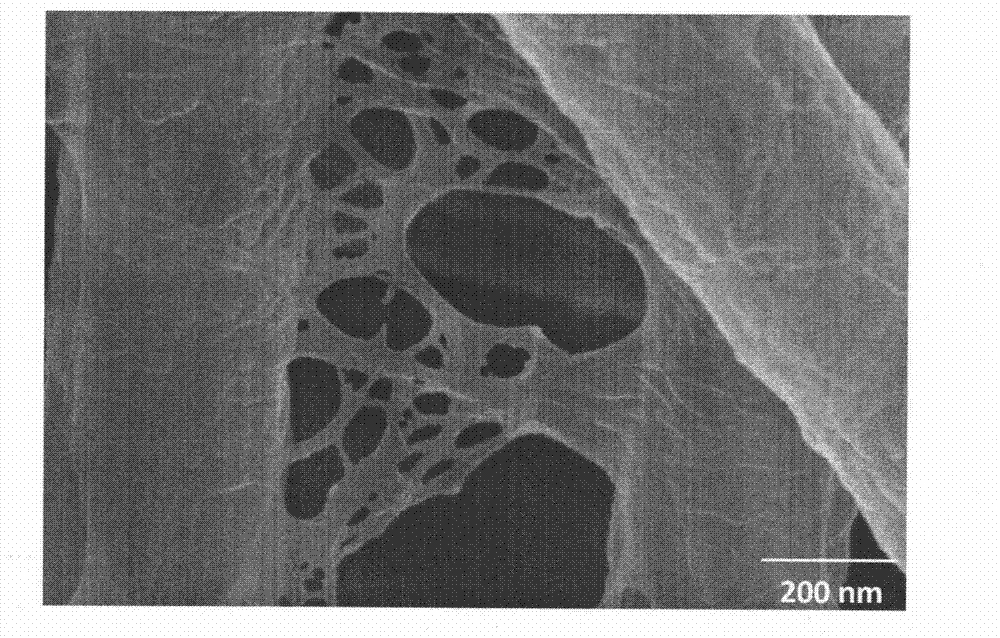

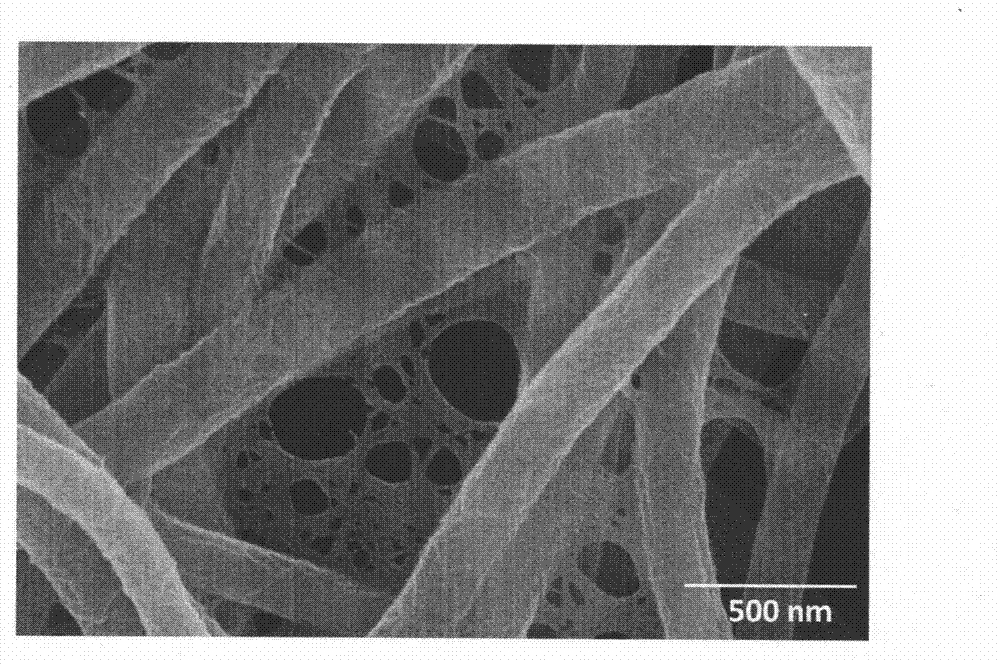

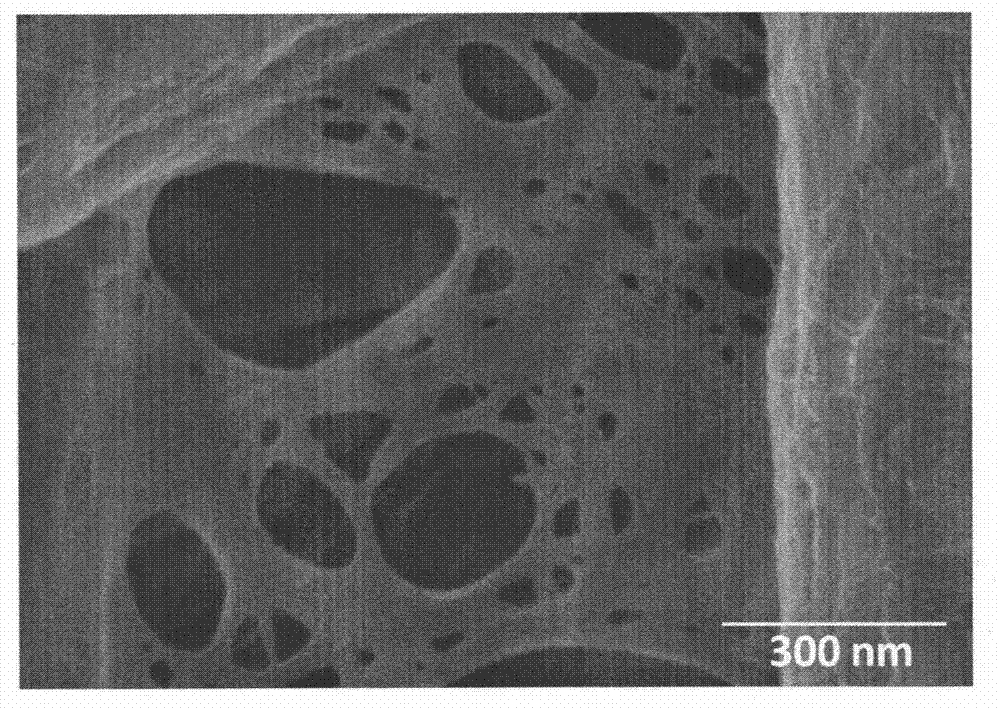

The invention provides a method for preparing a cellulose nanocrystal / electrostatic spinning nanofiber filter film. The method is characterized in that the prepared cellulose nanocrystals of which the diameter is 3 to 10nm are coated on the surface of an electrostatic spinning nanofiber film to form a network structure so as to filter out impurities in raw water, intercept suspended solids, colloid, bacteria and the like in the water and effectively adsorb residual chlorine and heavy metal in the water; and therefore, the aim of purifying water quality can be fulfilled. Moreover, due to the adoption of a multi-layer compounded mode, the mechanical strength of the nano fiber film can be improved by the cellulose nanocrystals, so that the filter film has the advantages of simple structure, high mechanical strength, good filtering effect, low cost and the like, and has wide application prospect in the fields of drinking water purification, textile dyeing wastewater treatment, polyvinyl acetate (PVA) slurry recycling and the like.

Owner:DONGHUA UNIV

Preparation method of nanometer zinc oxide-bamboo charcoal composite particle with antibacterial and adsorption functions

ActiveCN103535376ANo pollution in the processSimple preparation processMaterial nanotechnologyBiocideFreeze-dryingZno nanoparticles

The invention relates to a preparation method of nanometer zinc oxide-bamboo charcoal composite particle with antibacterial and adsorption functions. The preparation method comprises the following steps: (1) adding a bamboo raw material into a mixed acid solution, reacting at 50-90 DEG C for 1-20 hours, adding alkali liquor to neutralize the solution after the reaction to obtain a carboxylated bamboo cellulose nanocrystals; (2) adding the carboxylated bamboo cellulose nanocrystals into a solution of 0.005-5 mol / L zinc ions, adding alkali liquor to neutralize, diluting the reaction product through deionized water, centrifuging and freeze drying or vacuum drying the reaction product, and then, vacuum calcining the reaction product at 200-600 DEG C for 1-8 hours to obtain the nanometer zinc oxide-bamboo charcoal composite particle. The process disclosed by the invention is simple, convenient, easy to operate and free of environmental pollution, and the preparation period of the composite particle is shortened; the prepared nanometer zinc oxide-bamboo charcoal composite particle is small in size, easy to regulate and control and large in specific surface area, the bamboo charcoal is very firmly combined with the nanometer zinc oxide, so that the antibacterial effect is durable, and the nanometer zinc oxide-bamboo charcoal composite particle has good adsorption capacity on toxic substance, thereby having a wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV +1

Nanocellulose compositions and processes to produce same

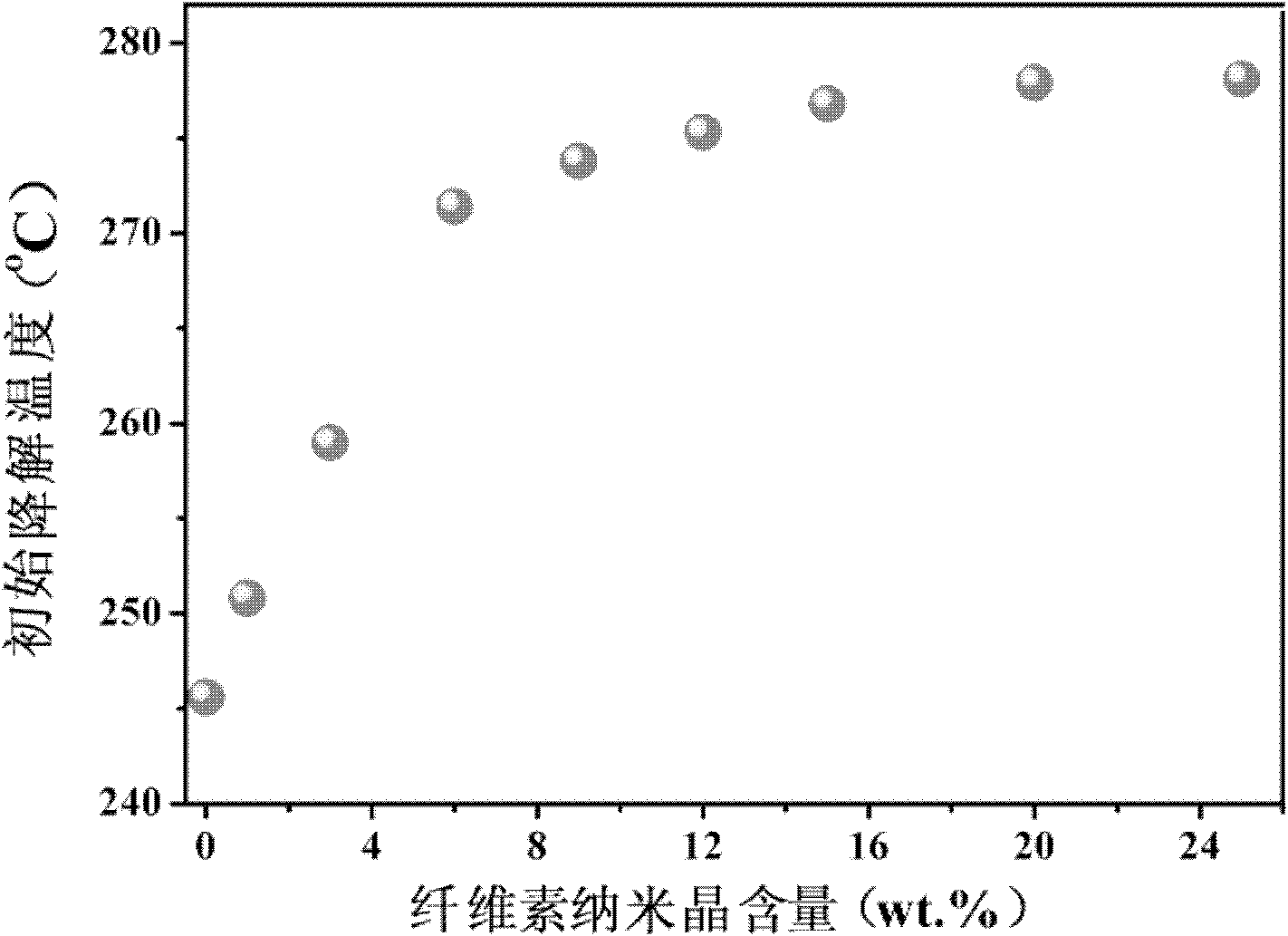

A composition comprising nanocellulose is disclosed, wherein the nanocellulose contains very low or essentially no sulfur content. The nanocellulose may be in the form of cellulose nanocrystals, cellulose nanofibrils, or both. The nanocellulose is characterized by a crystallinity of at least 80%, an onset of thermal decomposition of 300° F. or higher, and a low light transmittance over the range 400-700 nm. Other variations provide a composition comprising lignin-coated hydrophobic nanocellulose, wherein the nanocellulose contains very low or essentially no sulfur content. Some variations provide a composition comprising nanocellulose, wherein the nanocellulose contains about 0.1 wt % equivalent sulfur content, or less, as SO4 groups chemically or physically bound to the nanocellulose. In some embodiments, the nanocellulose contains essentially no hydrogen atoms (apart from hydrogen structurally contained in nanocellulose itself) bound to the nanocellulose. Various compositions, materials, and products may incorporate the nanocellulose compositions disclosed herein.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Recyclable Organic Solar Cells On Substrates Comprising Cellulose Nanocrystals (CNC)

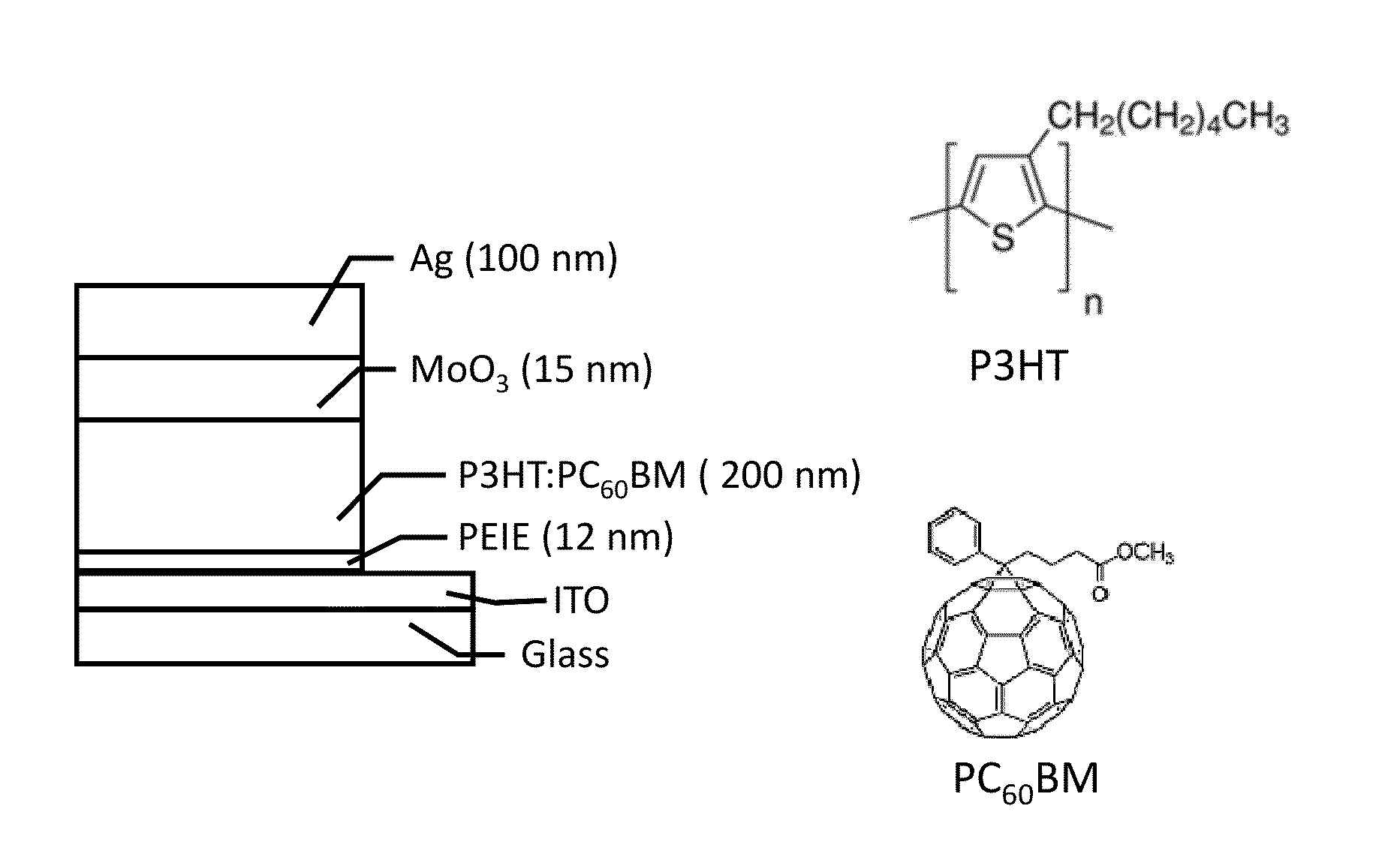

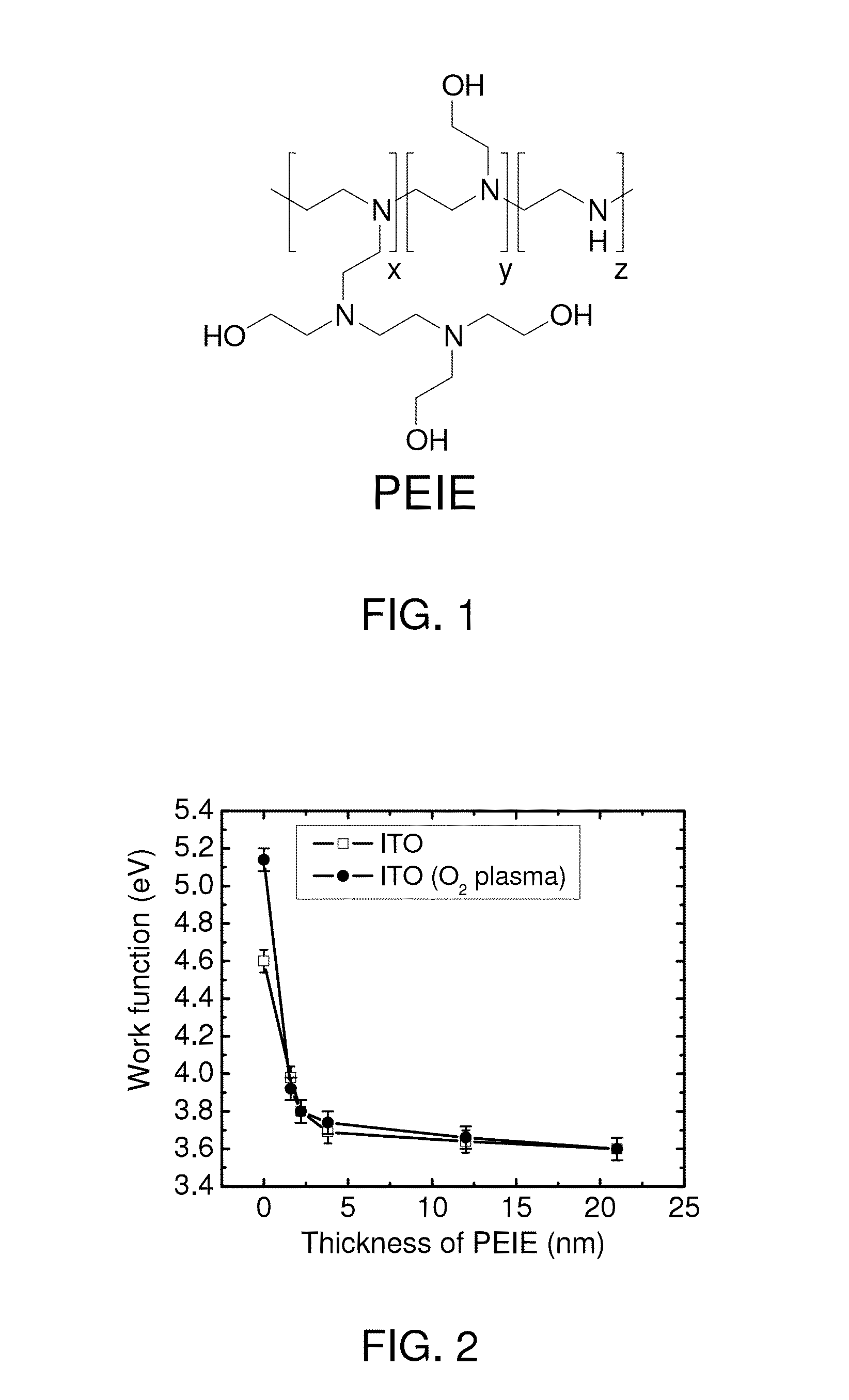

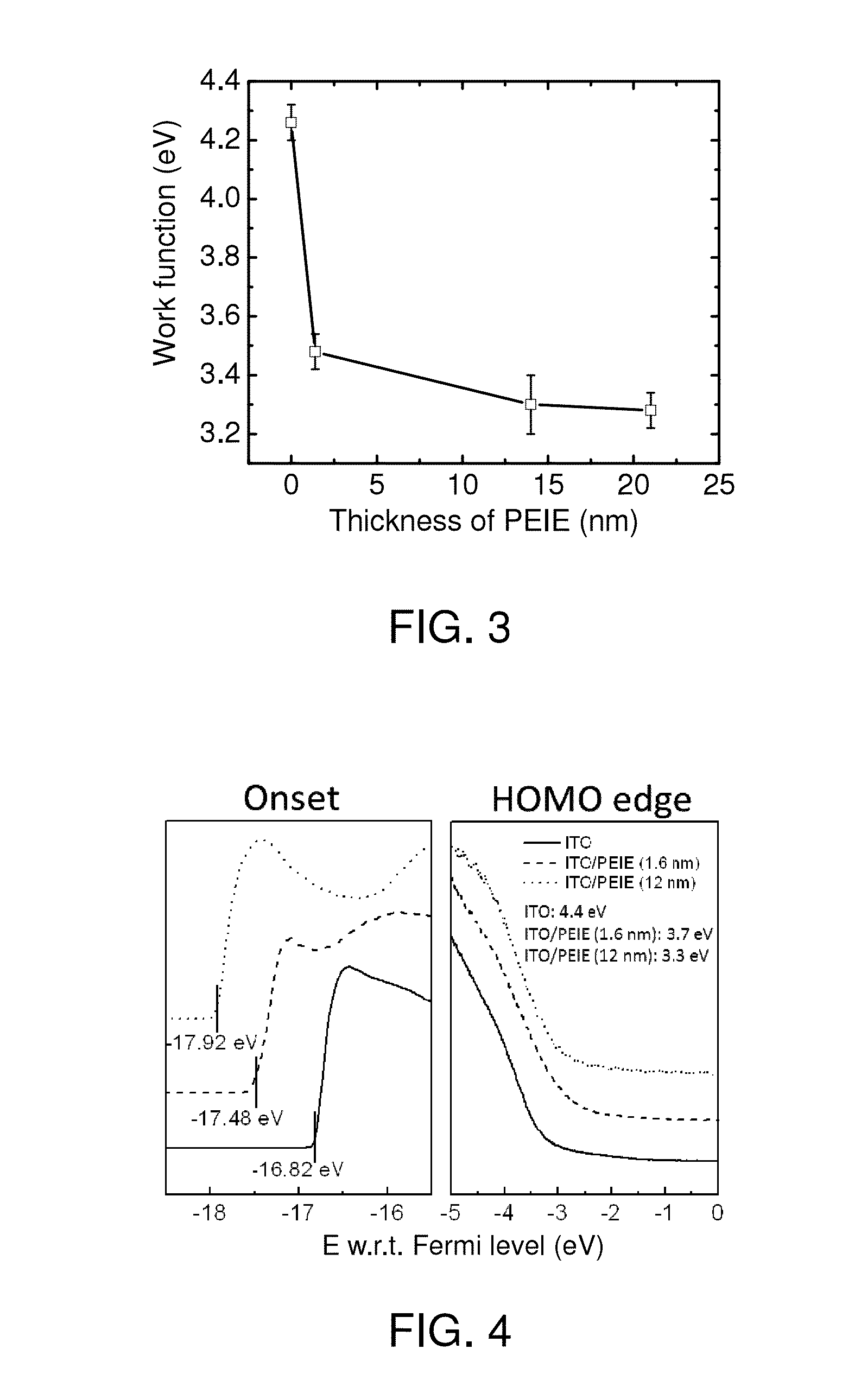

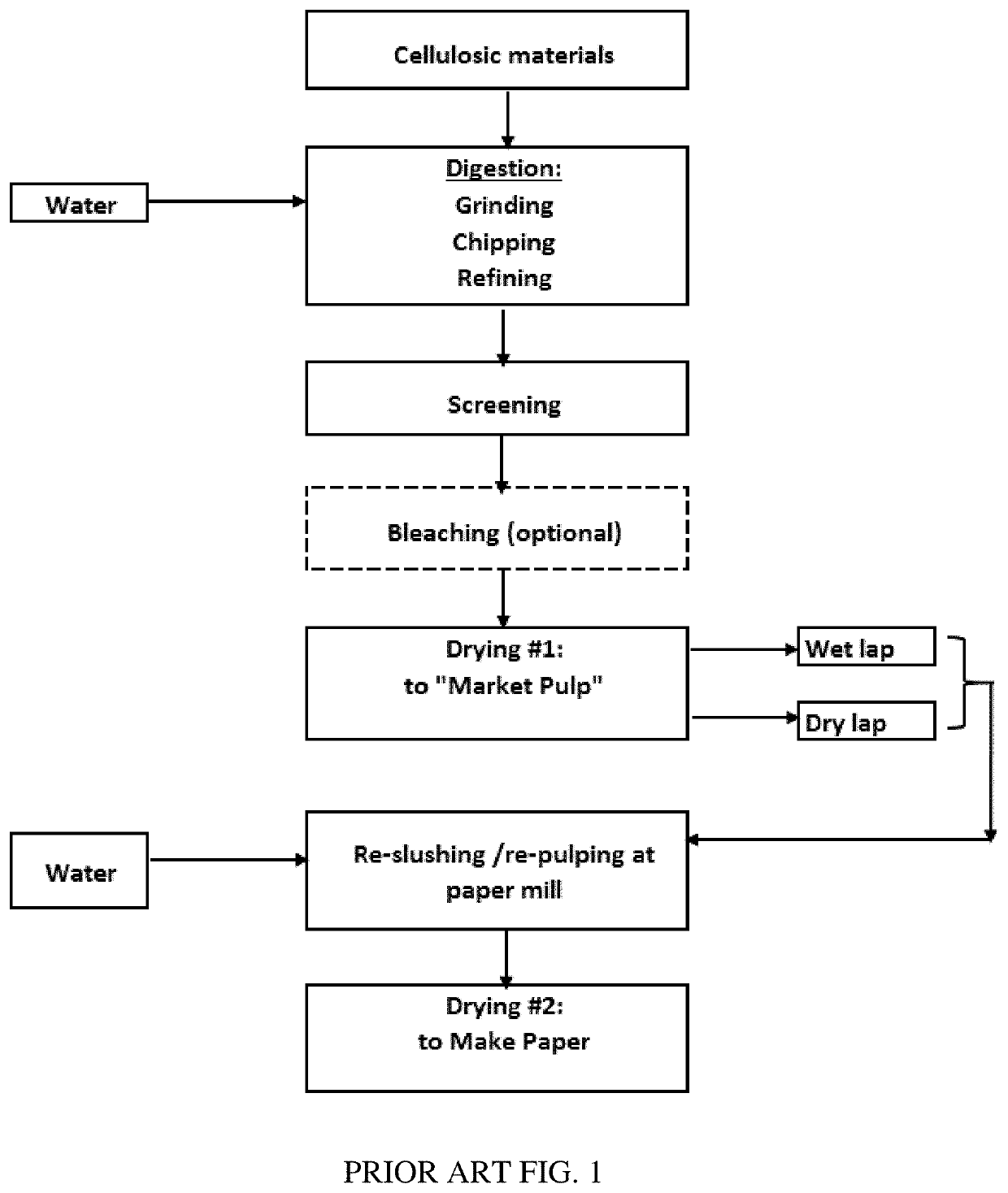

Recyclable organic solar cells are disclosed herein. Systems and methods are further disclosed for producing, improving performance, and for recycling the solar cells. In certain example embodiments, the recyclable organic solar cells disclosed herein include: a first electrode; a second electrode; a photoactive layer disposed between the first electrode and the second electrode; an interlayer comprising a Lewis basic oligomer or polymer disposed between the photoactive layer and at least a portion of the first electrode or the second electrode; and a substrate disposed adjacent to the first electrode or the second electrode. The interlayer reduces the work function associated with the first or second electrode. In certain example embodiments, the substrate comprises cellulose nanocrystals that can be recycled. In certain example embodiments, one or more of the first electrode, the photoactive layer, and the second electrode may be applied by a film transfer lamination method.

Owner:PURDUE RES FOUND INC +2

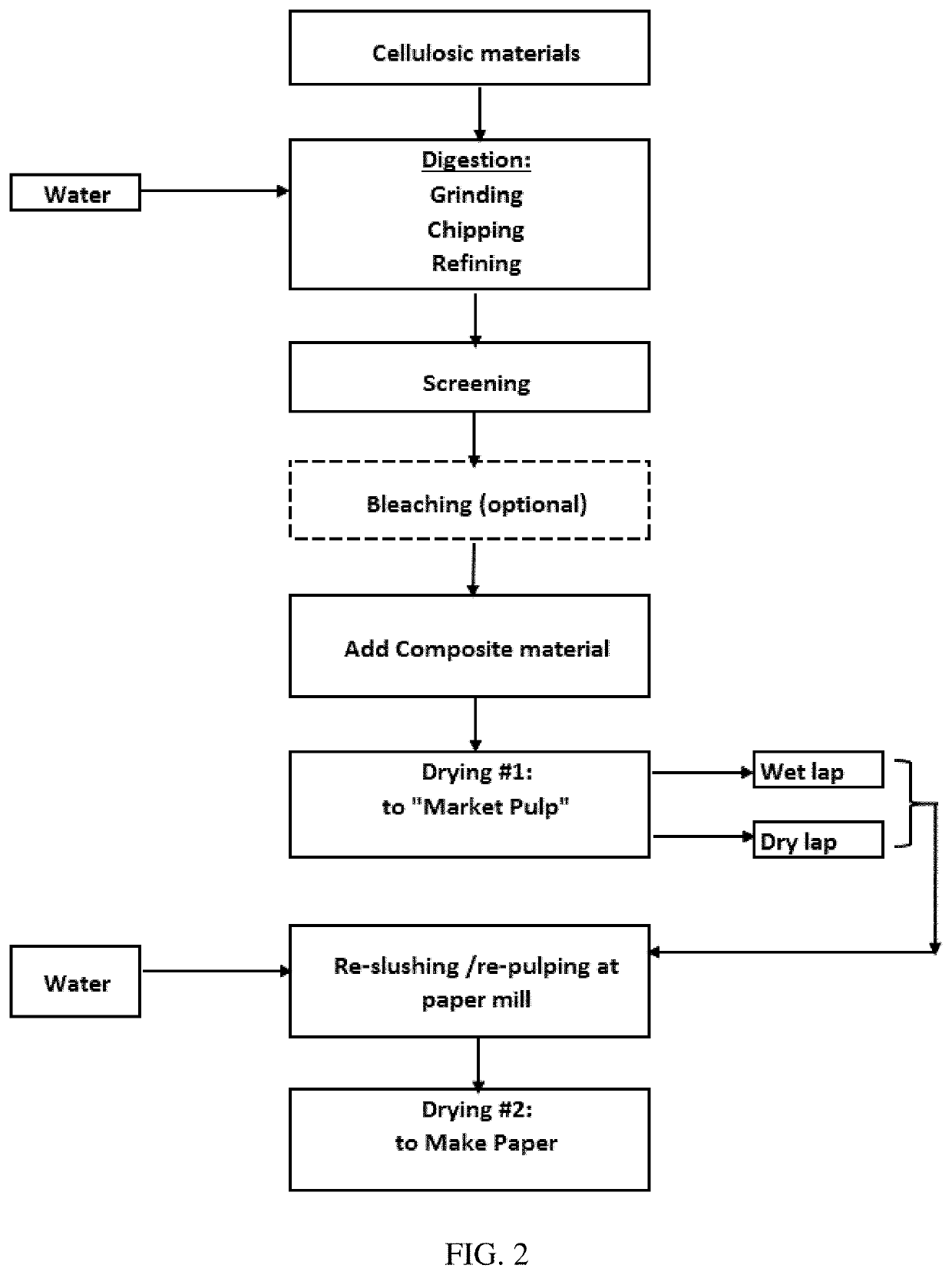

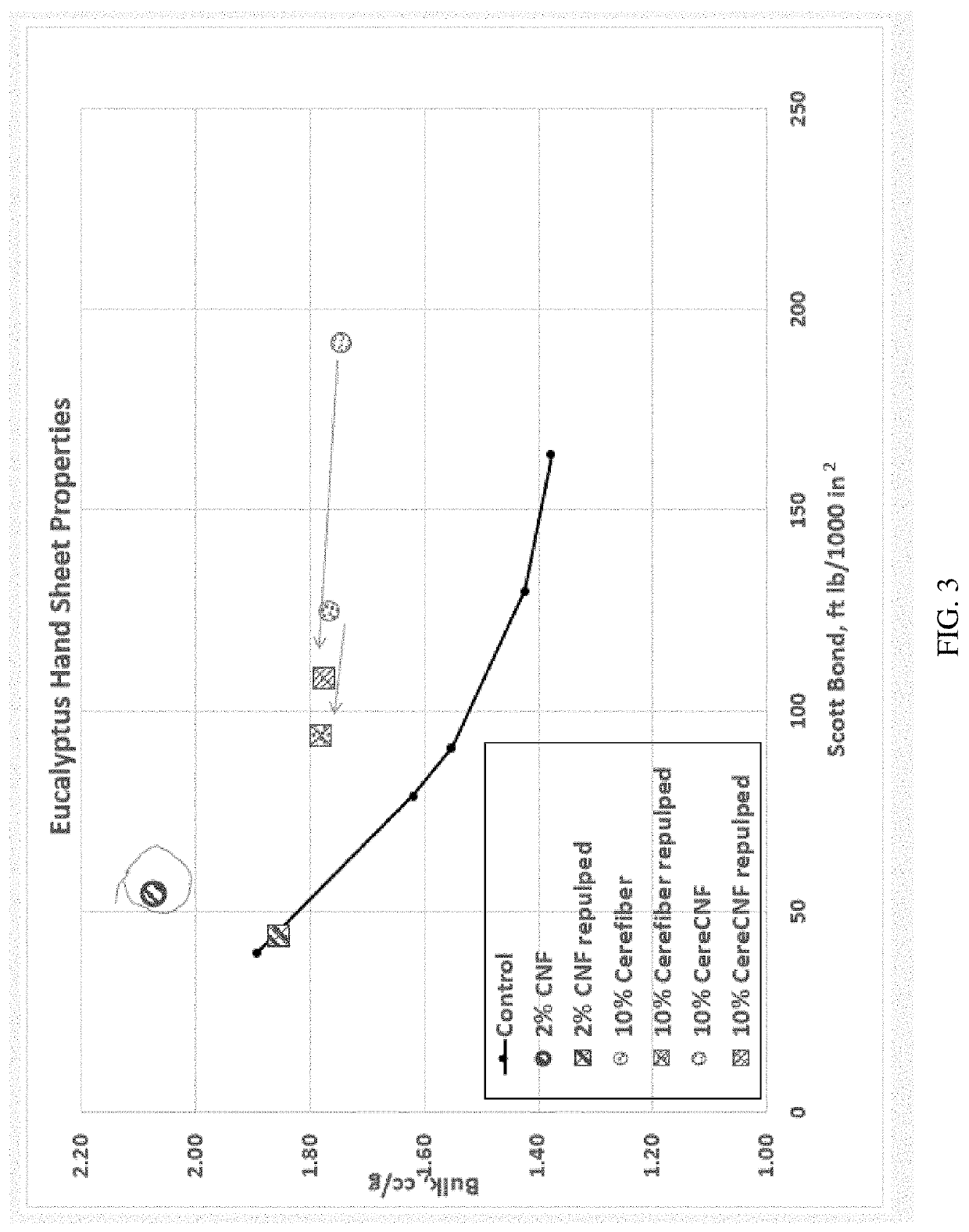

Method to Produce Composite-Enhanced Market Pulp and Paper

ActiveUS20200347549A1Enhanced market pulpHigh freenessPulp properties modificationNon-macromolecular organic additionFiberPolymer science

An improved market pulp and process for making the same by adding a composite material are described. The composite material includes cellulose nanocrystals, cellulose nanofibers, or another high aspect ratio, high surface area cellulose material (or a starch, or both) and a crosslinking compound that crosslinks a portion of the surface hydroxyl groups to form a 3-D matrix. Adding the composite material to market pulp has been shown to improve the strength of twice-dried paper products, made from such an enhanced market pulp. By crosslinking a portion of the surface hydroxyl groups in the market pulp to form a 3-D matrix, a first drying step may be accomplished without loss of benefits afforded when the market pulp is later re-pulped to make a paper product.

Owner:UNIVERSITY OF MAINE

Medicine sustained release nanofiber membrane for treating periodontitis and preparation method for medicine sustained release nanofiber membrane

The invention relates to a medicine sustained release nanofiber membrane for treating periodontitis and a preparation method for the medicine sustained release nanofiber membrane. The nanofiber membrane comprises biodegradable polymer, cellulose nanocrystals and an active medicine, wherein the mass ratio of the biodegradable polymer to the cellulose nanocrystals is (4-99):1; and the actual loading capacity of the active medicine of the nanofiber membrane is 10 to 500mu g / mg. The preparation method for the medicine sustained release nanofiber membrane comprises the following steps of: (1) adding the cellulose nanocrystals which are dispersed in an organic solvent A into an organic solution B of the biodegradable polymer with stirring to obtain mixed liquid; (2) adding the active medicine into the mixed liquid to obtain an electrostatic spinning stock solution; and (3) performing electrostatic spinning on the electrostatic spinning stock solution, drying a product, and thus obtaining the nanofiber membrane. The preparation process is simple, quick, cheap and efficient, and is suitable for industrialized batch production; and the obtained nanofiber membrane has high biocompatibility, high medicine loading capacity, appropriate hydrophillic performance and a broad application prospect, and the sustained release of the active medicine is slow.

Owner:DONGHUA UNIV

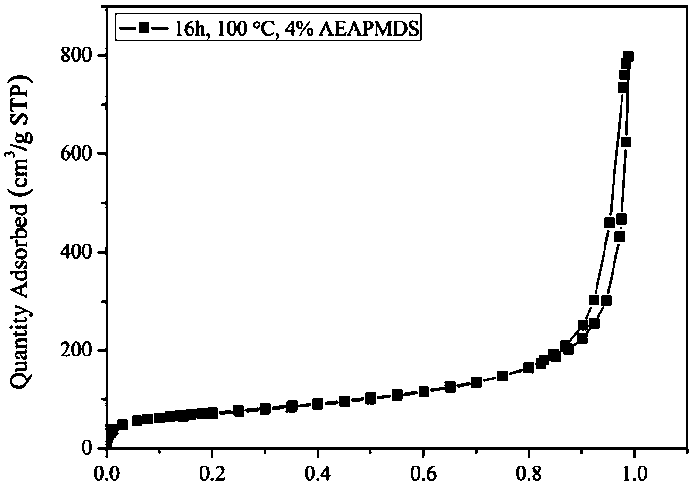

Method for preparing nanometer hollow bar-shaped silicon dioxide materials

The invention relates to a method for preparing nanometer hollow bar-shaped silicon dioxide materials by using nanometer crystal cellulose as templates. According to the method, the cellulose and the tetraethoxysilane are adopted as raw materials. Firstly, the cellulose raw materials are hydrolyzed by sulfuric acid with the weight concentration being 64 percent to obtain nanometer crystal cellulose with negative charges on the surface, then, cetyl trimethyl ammonium bromide is used so that the charges on the surface of the cellulose nanometer crystals are changed into positive charges, then, sol obtained through tetraethoxysilane hydrolysis is absorbed onto the surface of the cellulose nanometer crystals under the alkaline condition, and finally, silicon dioxide gel is formed through condensation polymerization, so the nanometer crystal cellulose compounds covered by the silicon dioxide is obtained through the preparation. After the compounds are subjected to freezing drying, powder is obtained, the powder is roasted in a Muffle furnace to remove the cellulose nucleus, and the nanometer hollow bar-shaped silicon dioxide materials are obtained. The cellulose nanometer crystals adopted by the method are used as the templates, raw materials are rich, the preparation is simple, in addition, the dimension and the shape of the templates can be regulated and controlled through the hydrolysis time and the intensity, the hollow bar-shaped silicon dioxide materials with the inner diameter being dozens of nanometers can be prepared, in addition, the whole experiment process is safe, and the obtained products are uniform.

Owner:NANJING FORESTRY UNIV

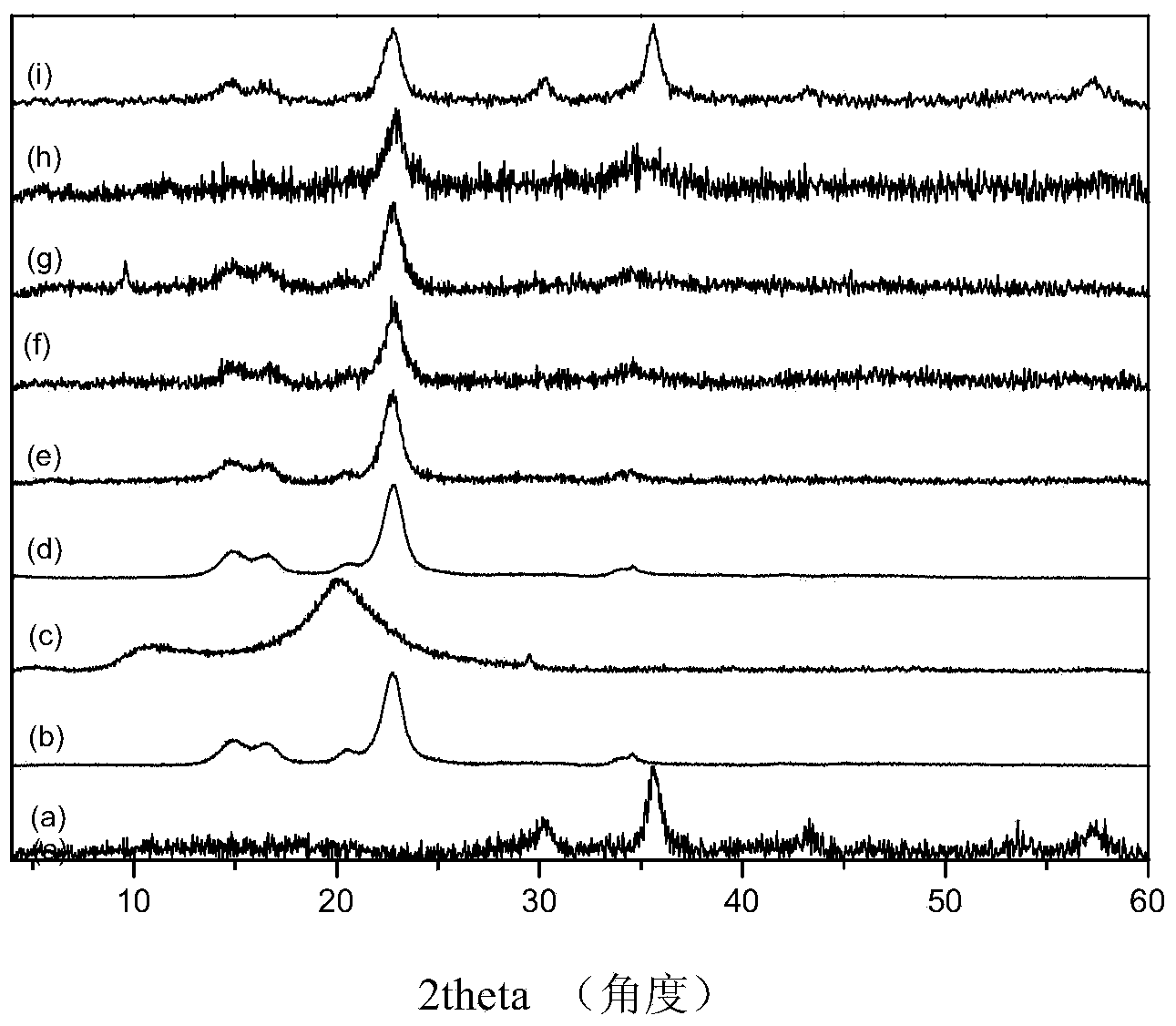

Preparation of super-hydrophobic coating with nanocrystalline cellulose/silicon dioxide composite template process

The invention discloses a method for preparing a super-hydrophobic coating with a nanocrystalline cellulose / silicon dioxide (NCC / SiO2) composite template process. The method comprises the following steps: (1) treating microcrystalline cellulose (MCC) with 56% sulfuric acid; (2) performing centrifugal washing; (3) replacing water in an NCC suspension solution with ethanol; (4) grinding for later use; and (5) freezing a sample to subzero 30 DEG C and performing vacuum freeze-drying. The method has the advantages that stearic acid is taken as a modifier and can produce a dehydration reaction with surface -OH of SiO2 / NCC, and stearic acid further introduces hydrophobic -CH3 groups, so that the surface energy of SiO2 / NCC is reduced; and an NCC and SiO2 compound has not only the properties of a biopolymer material but also the properties of an inorganic material such as weather resistance, hardness and the like, can be used for modifying indoor and outdoor coatings, and can play a role in aspects of building floor cleaning, furniture pollution prevention and the like.

Owner:广东新红阳科技有限公司

Preparation method of magnetic cellulose nanocrystal

ActiveCN103709422AEvenly distributedCompact distributionOn/in organic carrierOn/in inorganic carrierMetalSodium triphosphate

The invention discloses a preparation method of a magnetic cellulose nanocrystal. The method comprises the steps: adding cellulose raw materials into an acid solution, stirring at the temperature of 30-105 DEG C for 0.5-24h to react, and washing to obtain a cellulose nanocrystal; adding the cellulose nanocrystal into a 0.00005-1mol / L ferric salt solution, stirring for 0.1-3h, adding a chitosan solution, and stirring to obtain a cellulose nanocrystal and metal ion complex mixed solution; adding a sodium tripolyphosphate solution, stirring for 1-60min, adding an alkaline solution to adjust the pH value to 8-13, and reacting at the temperature of 20-90 DEG C for 0.1-3h; and after the reaction is ended, washing by using deionized water, and drying to obtain a magnetic cellulose material. Chitosan is added in the step of mixing the cellulose nanocrystal and the ferric salt solution, so that ferric ions are complexed with the chitosan, and furthermore, ferroferric oxide is more uniformly and tightly distributed on the surface of the cellulose nanocrystal material.

Owner:SOUTH CHINA UNIV OF TECH

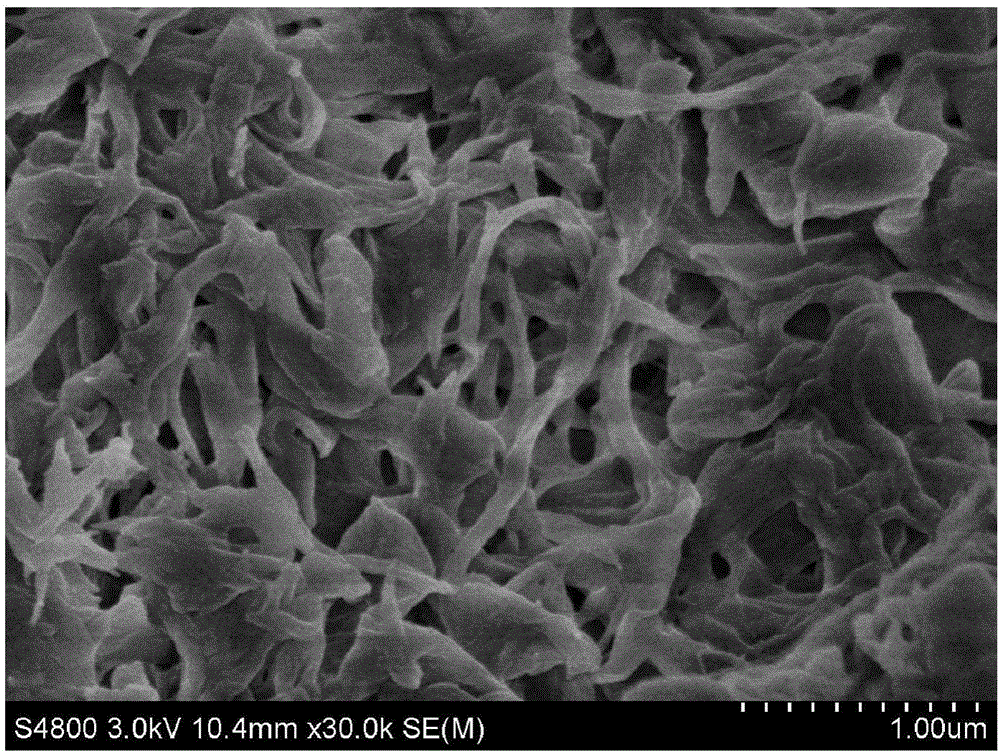

Method for sustainably preparing nanometer cellulose

The invention discloses a method for sustainably preparing nanometer cellulose in an environment-friendly and economic mode. The preparing method includes the following steps that 1, cellulose raw materials and organic acid are hydrolyzed and esterified; 2, the treated cellulose is prewashed in a centrifugal sedimentation mode, the organic acid is separated to be continuously recycled, washed cellulose suspension liquid is dialyzed, and then reacted acid and accessory substances are removed; 3, the dialyzed suspension liquid is separated to obtain small-particle cellulose nanometer crystals; 4, cellulose solid precipitated on a lower layer of the suspension liquid is treated through a high-pressure homogenizer or an ultrasonication physical machine to obtain colloidal cellulose nanometer fibrils. According to the method, in the preparing process, the modified cellulose raw materials are synchronously hydrolyzed and esterified through relative-safety and environment-friendly food-grade organic acid; compared with inorganic strong acid, the used organic acid is low in corrosion performance, high in boiling point, small in reaction pressure and easy to control and operate, and the cellulose nanometer crystals with the stable quality and the cellulose nanometer fibril products with the stable quality can be obtained at the same time.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

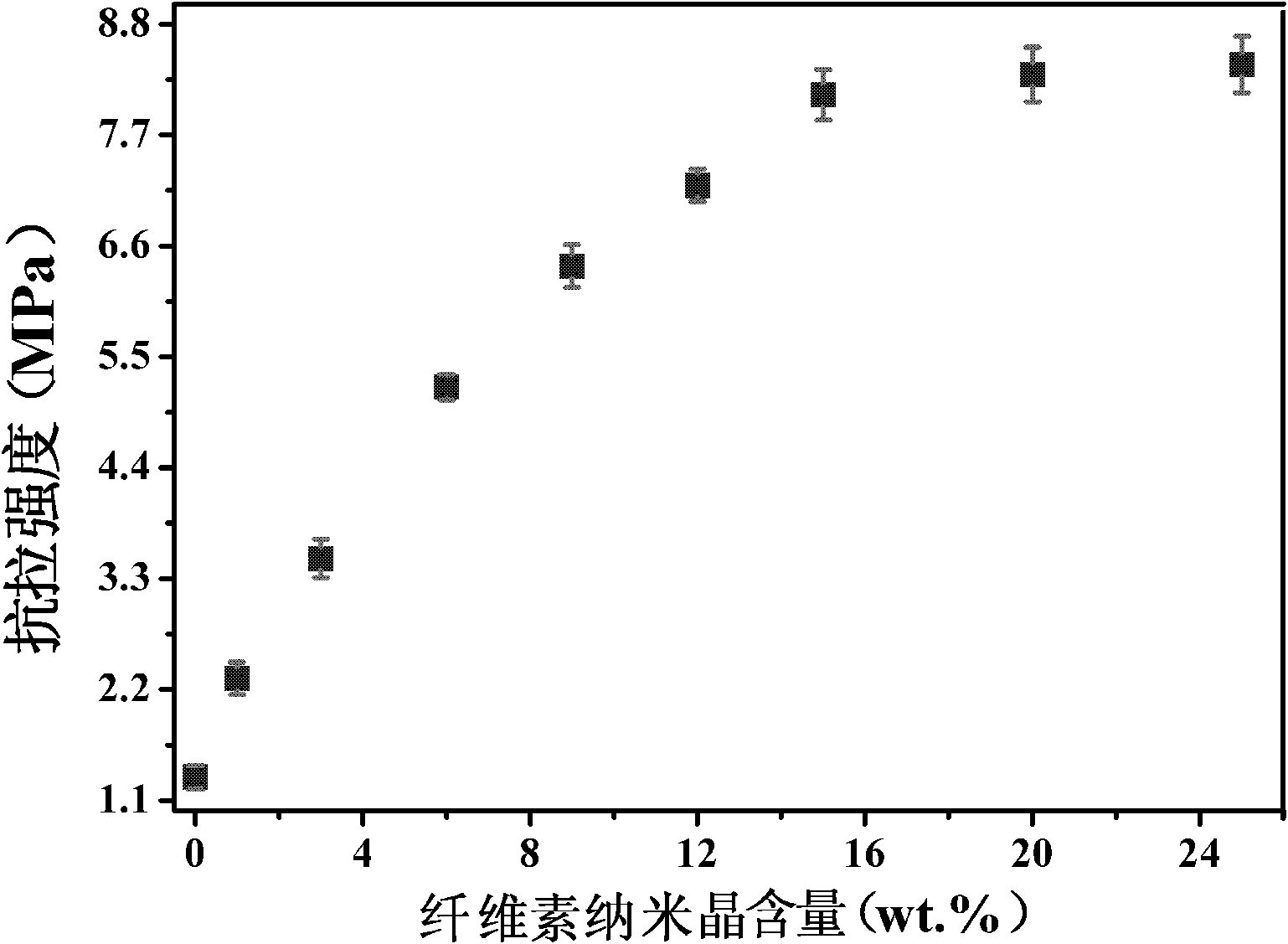

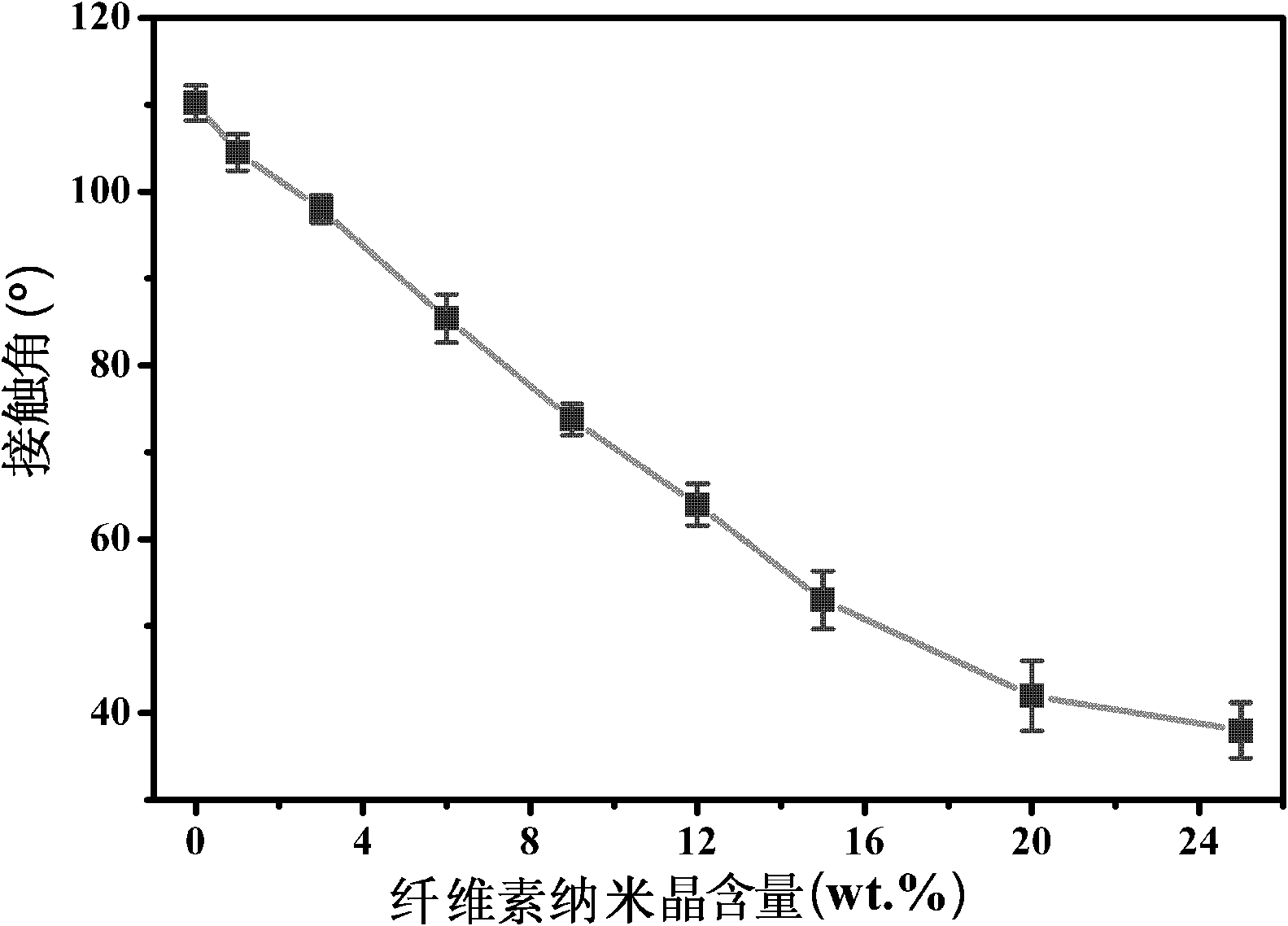

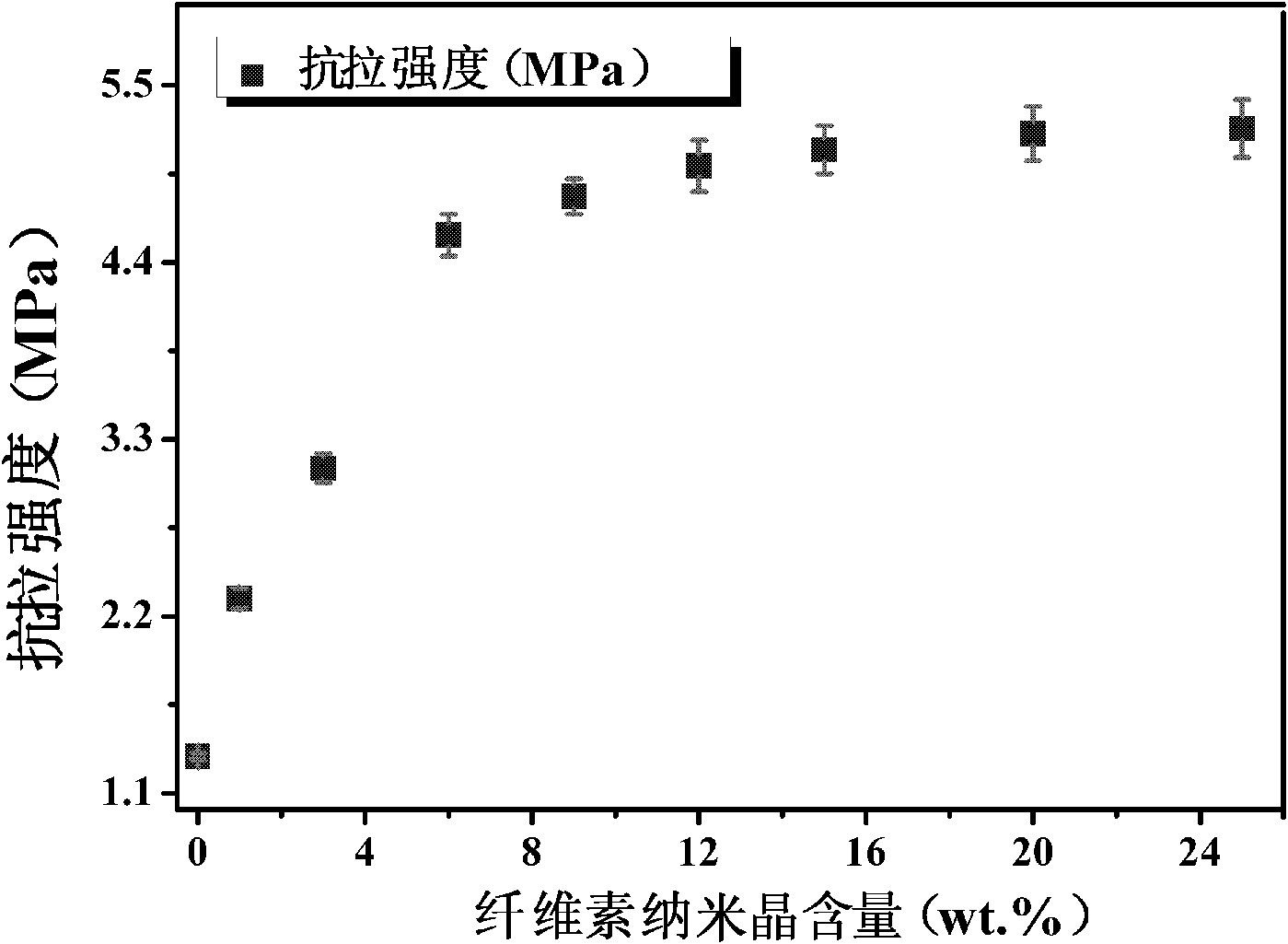

Preparation and application of cellulose nanocrystals (CNCs)-reinforced collagen compound substrate

ActiveCN102886063AHigh mechanical strengthImprove adhesionCosmetic preparationsToilet preparationsWound dressingRepeatability

The invention discloses a preparation method and an application of a cellulose nanocrystals (CNCs)-reinforced collagen compound substrate, which belong to the field of tissue engineering. The preparation method comprises the following steps of: preparing CNCs by adopting a method for degrading cellulose with sulfuric acid; preparing a CNCs solution and a collagen solution, and mixing the CNCs solution and the collagen solution physically; and pouring the mixed solution into a mold, and molding to obtain the CNCs-reinforced collagen compound substrate. According to the CNCs-reinforced collagen compound substrate prepared with the method, the problems of poor mechanical strength and poor hydrophilicity of the conventional collagen material are solved; and the CNCs-reinforced collagen compound substrate can be applied in the fields of wound dressings, tissue inducing regeneration membranes, soft tissue patches, tissue engineering skin, facial masks and the like. A preparation process technic provided by the invention is easy and practicable, has high repeatability, and is suitable for industrial production of CNCs-reinforced collagen compound substrates of different requirements.

Owner:JINAN UNIVERSITY

Drilling fluid additives and fracturing fluid additives containing cellulose nanofibers and/or nanocrystals

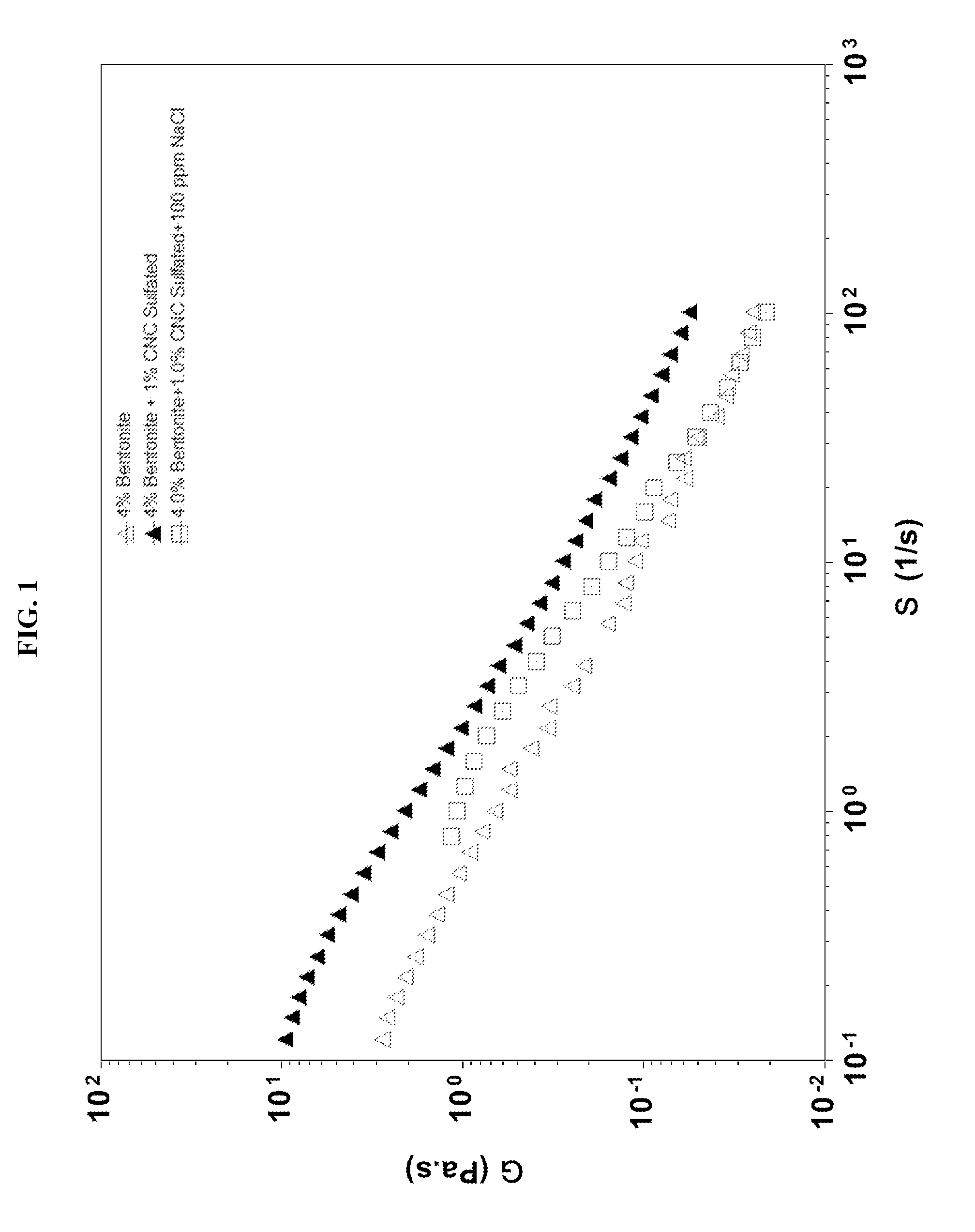

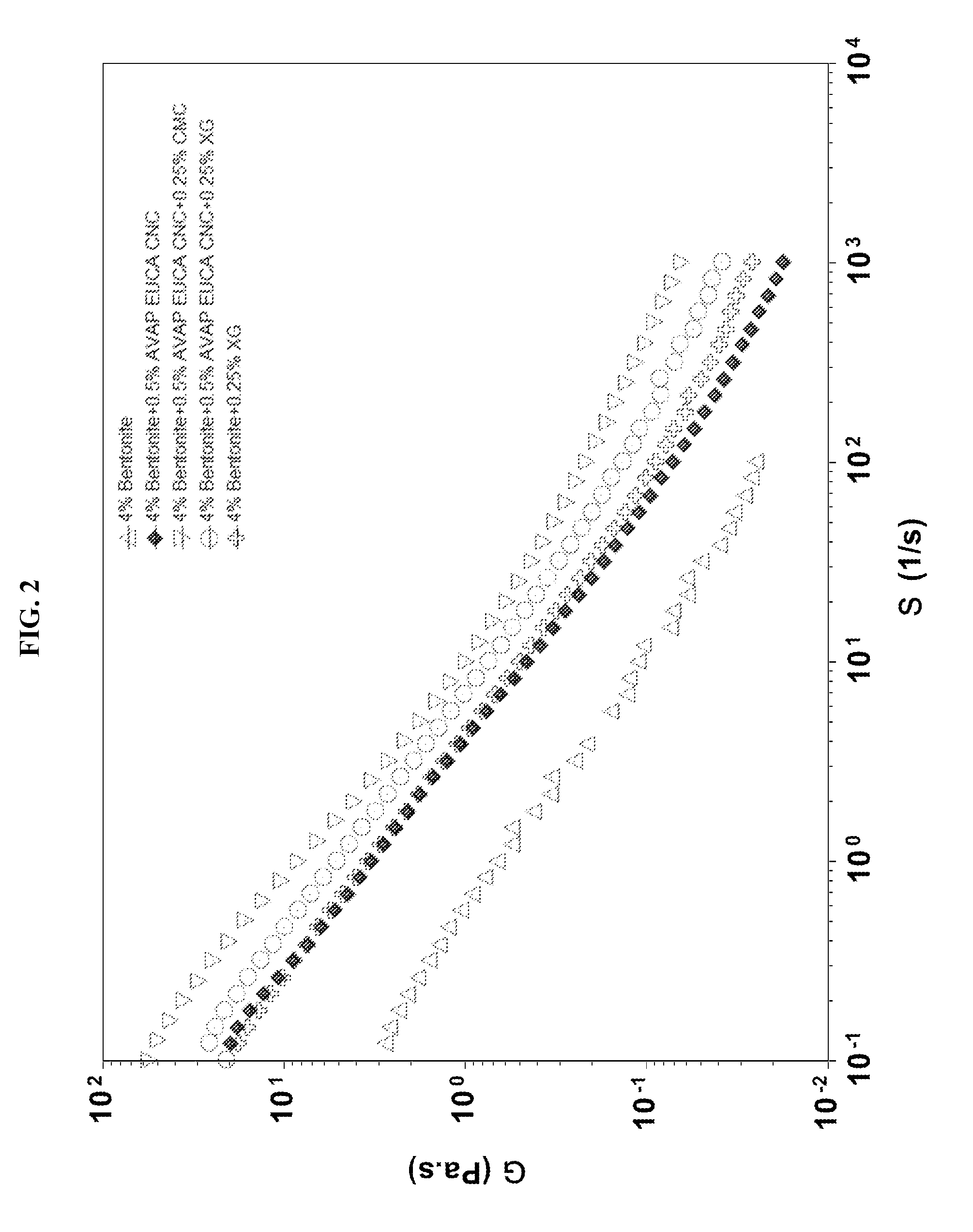

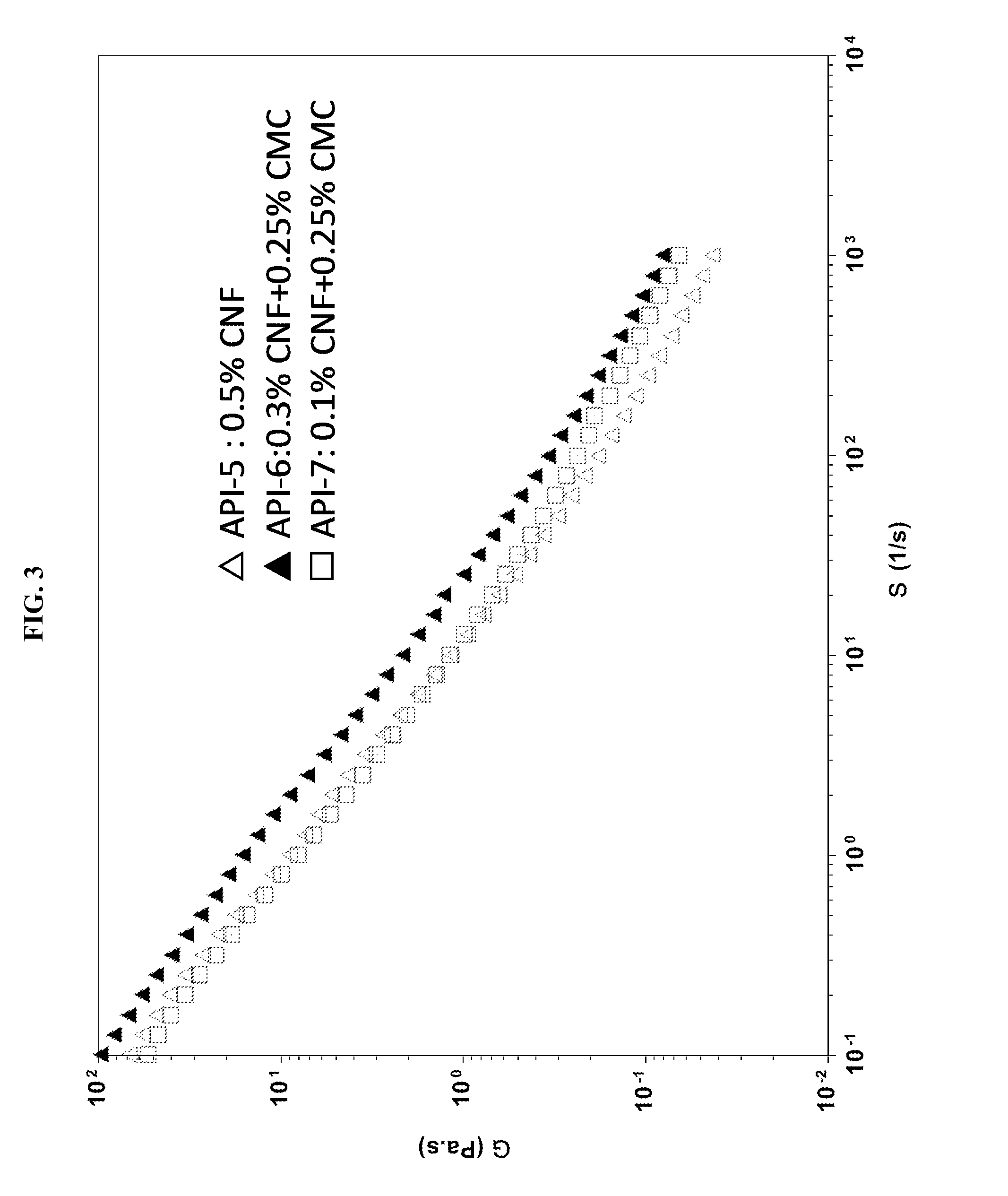

This disclosure provides drilling fluids and additives as well as fracturing fluids and additives that contain cellulose nanofibers and / or cellulose nanocrystals. In some embodiments, hydrophobic nanocellulose is provided which can be incorporated into oil-based fluids and additives. These water-based or oil-based fluids and additives may further include lignosulfonates and other biomass-derived components. Also, these water-based or oil-based fluids and additives may further include enzymes. The drilling and fracturing fluids and additives described herein may be produced using the AVAP® process technology to produce a nanocellulose precursor, followed by low-energy refining to produce nanocellulose for incorporation into a variety of drilling and fracturing fluids and additives.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

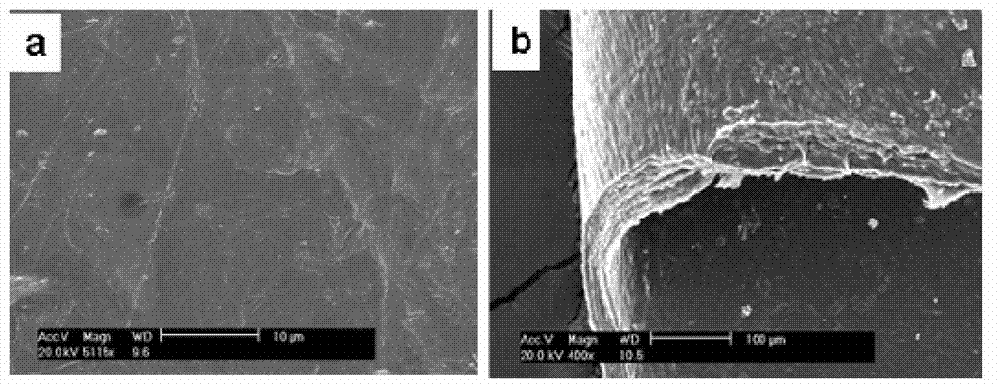

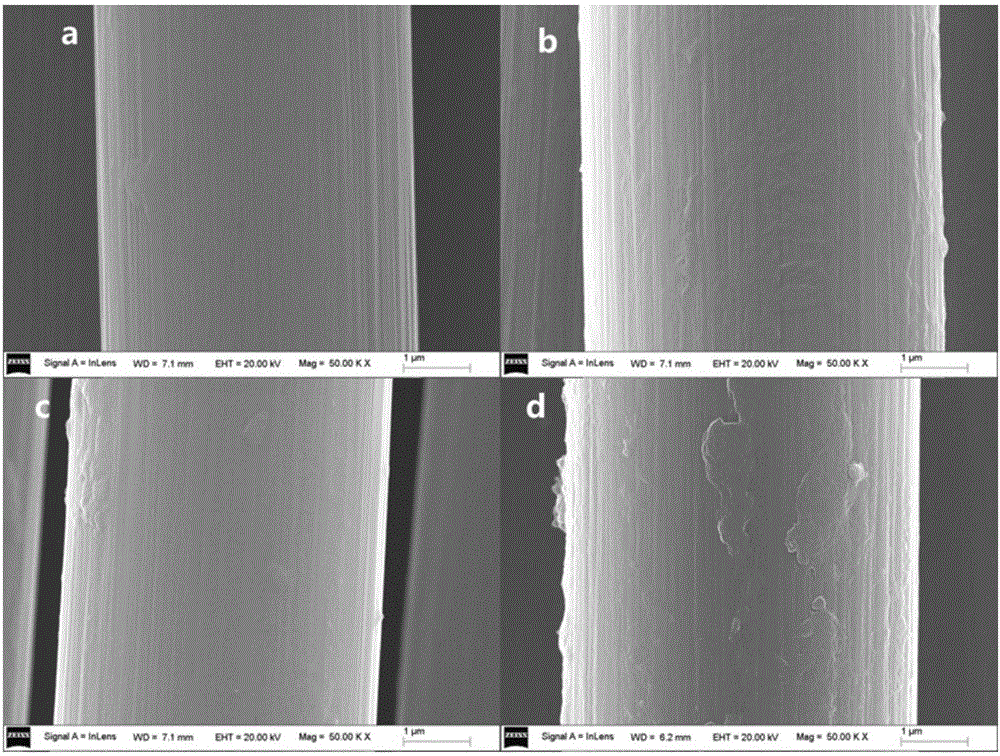

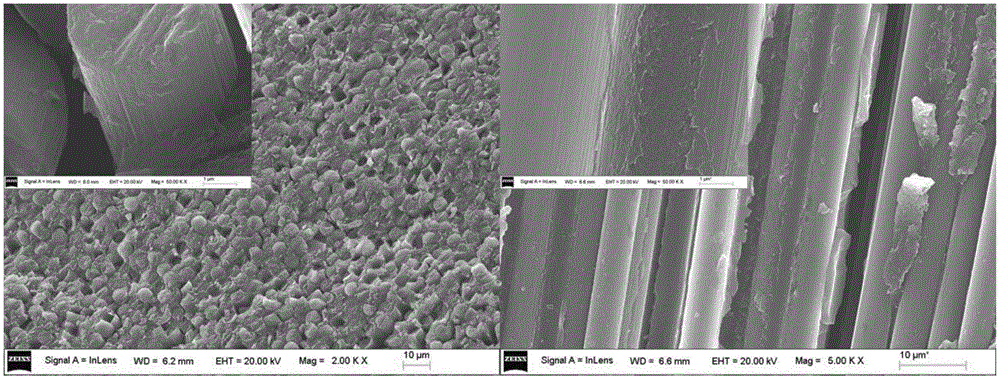

Preparation method of composite material with fiber surface coated with cellulose nano crystals and used for multi-scale enhancement

ActiveCN105131529ALow priceRealize interface modificationFibre treatmentFiber-reinforced compositeFibrous composites

The invention relates to a preparation method of a composite material with the fiber surface coated with cellulose nanocrystals and used for multi-scale enhancement. By adoption of the preparation method, the technical problems of poor macro-mechanical properties, low preparation efficiency and high cost of an existing fiber composite material are solved. The preparation method comprises the following steps: (1) putting the cellulose nanocrystals and deionized water in a device for mechanical stirring, carrying out ultrasonic dispersion and obtaining a sizing solution; (2) fixing unsized continuous fiber on a traction machine, and removing water by an impregnating vessel filled with the sizing solution and then winding for standby application; (3) preparing the obtained continuous fiber with the surface coated with the cellulose nanocrystals into a composite material strip sample, and curing according to the curing procedures of a selected resin system and obtaining the fiber-enhanced composite material coated with the cellulose nanocrystals. The preparation method can be widely used in the field of preparation of the composite material.

Owner:BEIJING UNIV OF CHEM TECH

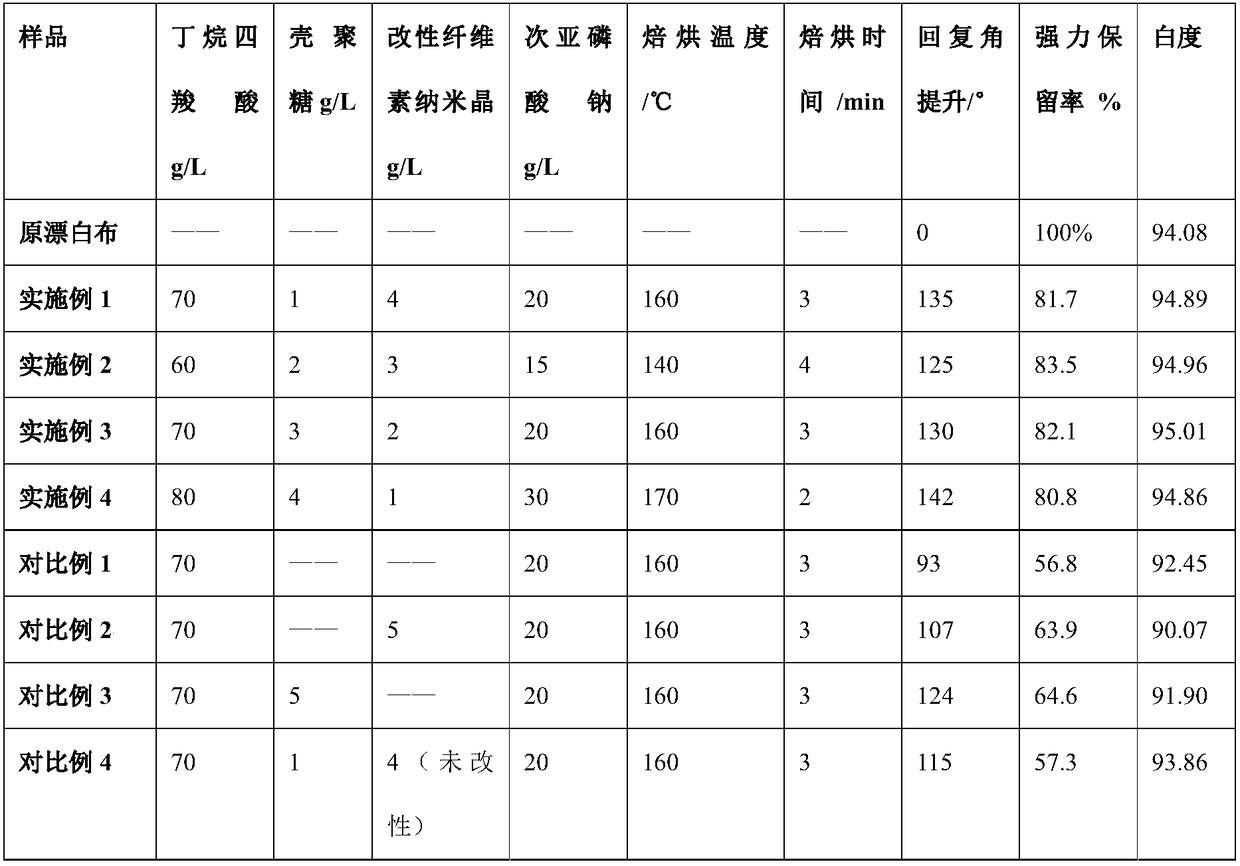

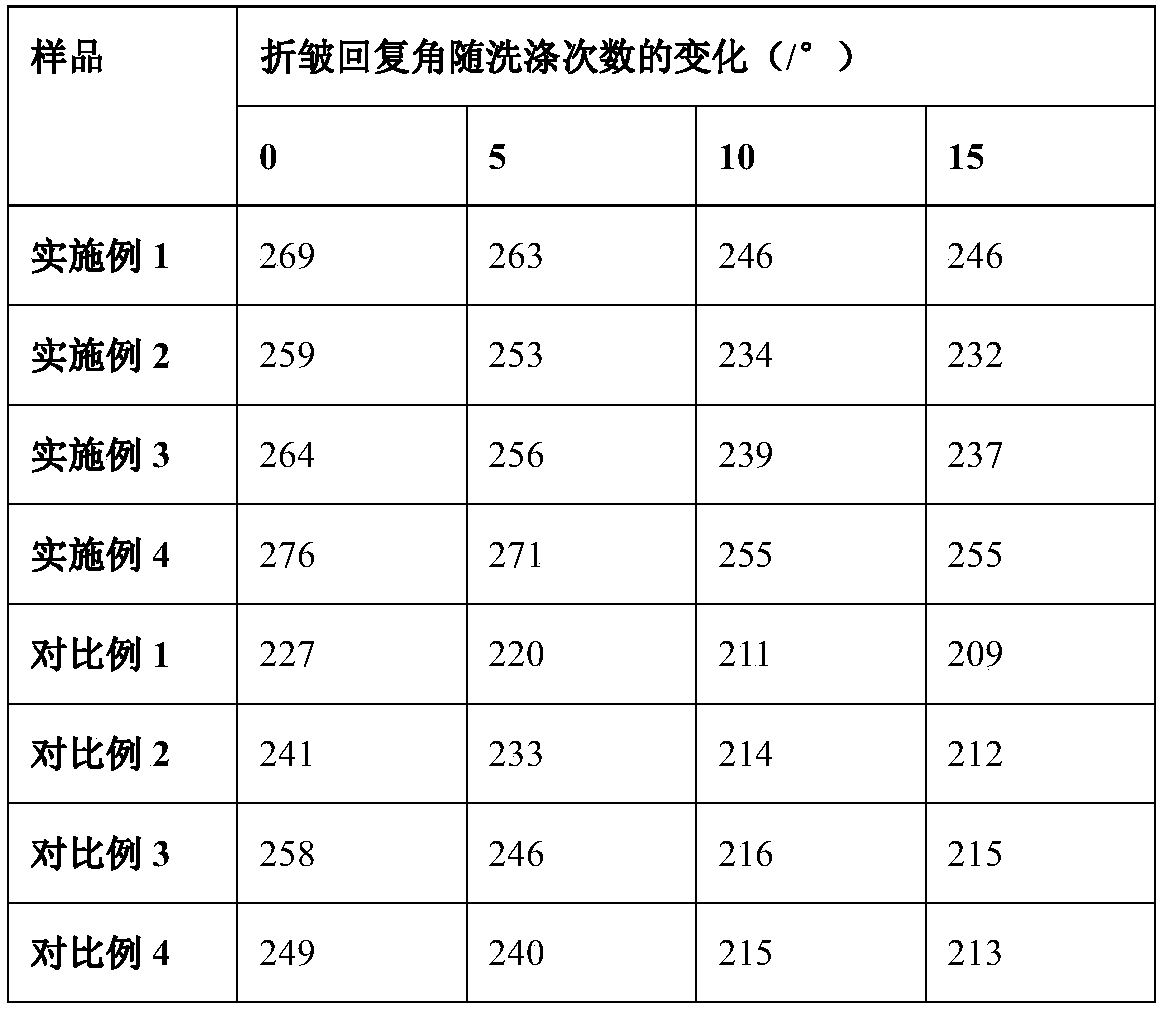

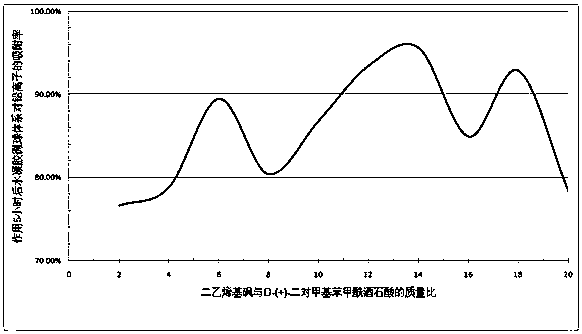

Crease-resistant finishing liquid for cotton fabric and application of crease-resistant finishing liquid

ActiveCN109137499AHigh strengthImprove stabilityWrinkle resistant fibresVegetal fibresFiberCarboxylic acid

The invention discloses crease-resistant finishing liquid for cotton fabric and application of the crease-resistant finishing liquid and belongs to textile finishing. The crease-resistant finishing liquid is characterized in that a laccase / TEMPO system is used to oxidize cellulose nanocrystals into aldehyde groups, the aldehyde groups and Girard's reagent T have Schiff base reaction to prepare positive ion modified cellulose nanocrystals, and the modified cellulose nanocrystals, 1,2,3,4-butanetetracarboxylic acid and chitosan are compounded to apply to the crease-resistant finishing of the cotton fabric. The crease-resistant finishing liquid has the advantages that the chitosan and the cellulose nanocrystals used by the finishing liquid are natural biomass materials and can copolymerize with BTCA on cotton fibers under high temperature to generate a long branched chain structure, and accordingly the cotton fabric after finishing has good crease resistance; in addition, by introducing the cellulose nanocrystals and the chitosan, the break strength retention and dyeing performance of the fabric after the crease-resistant finishing are improved, and the fabric is good in washing resistance stability and meets environment protection standards.

Owner:JIANGNAN UNIV

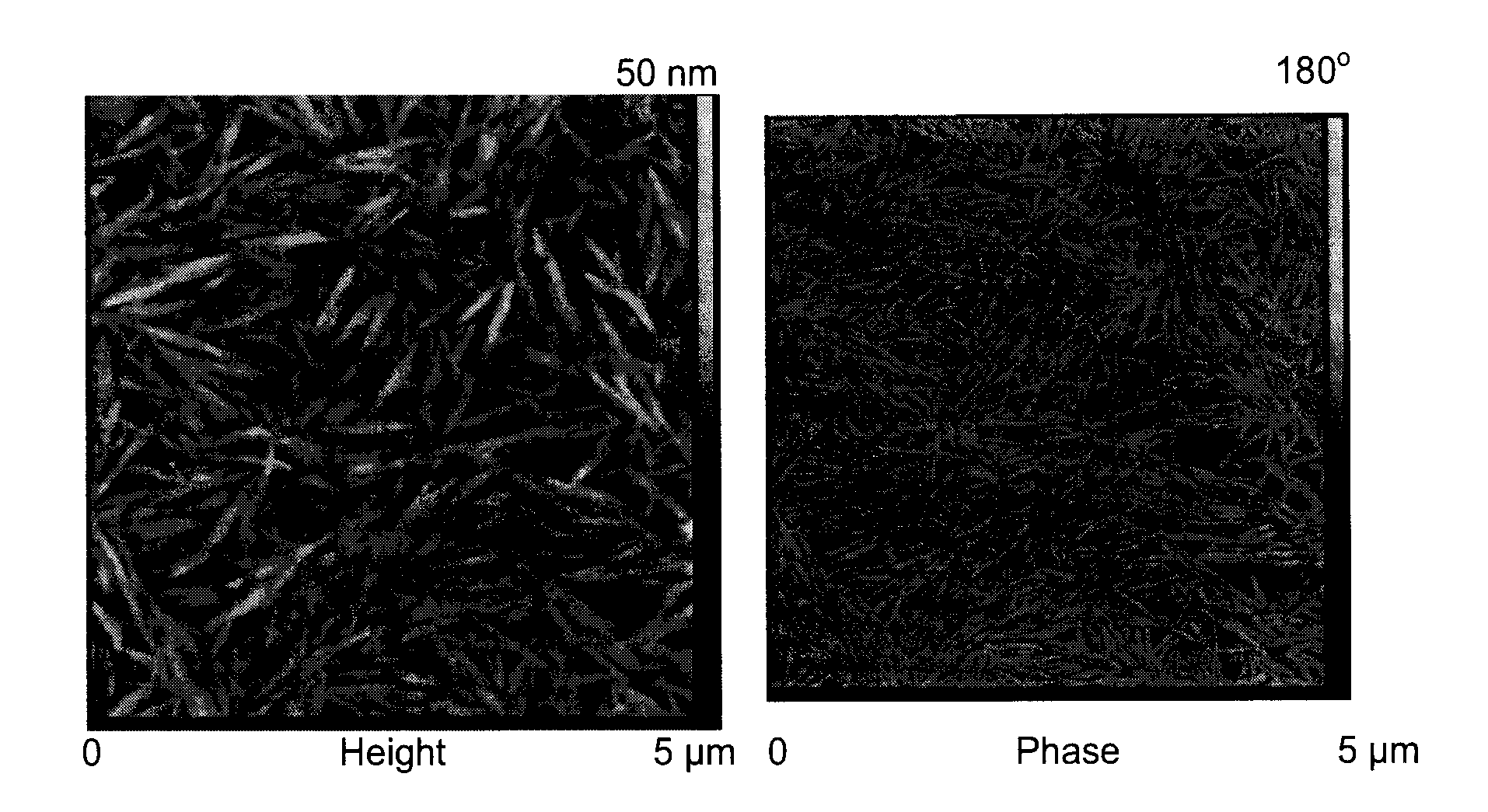

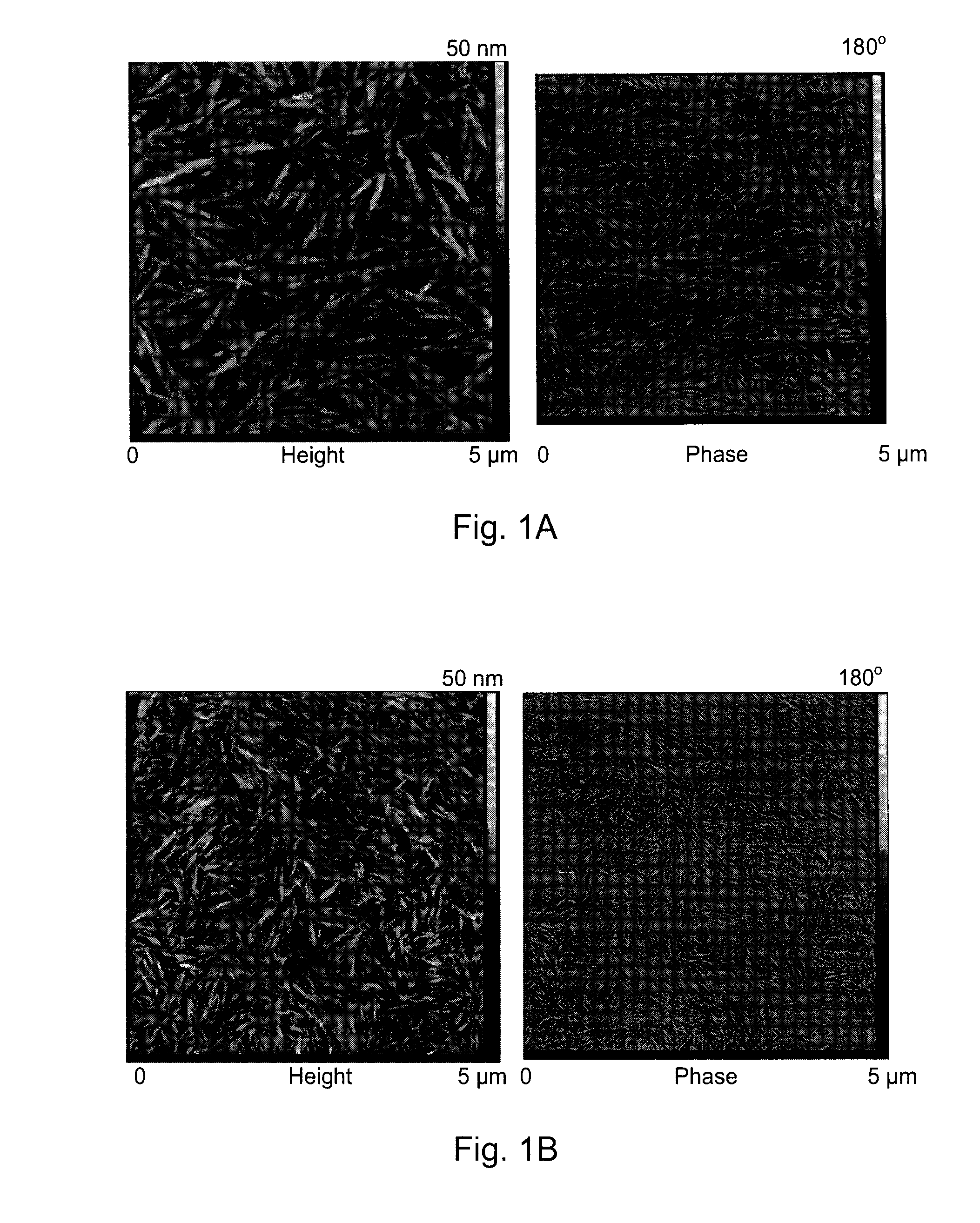

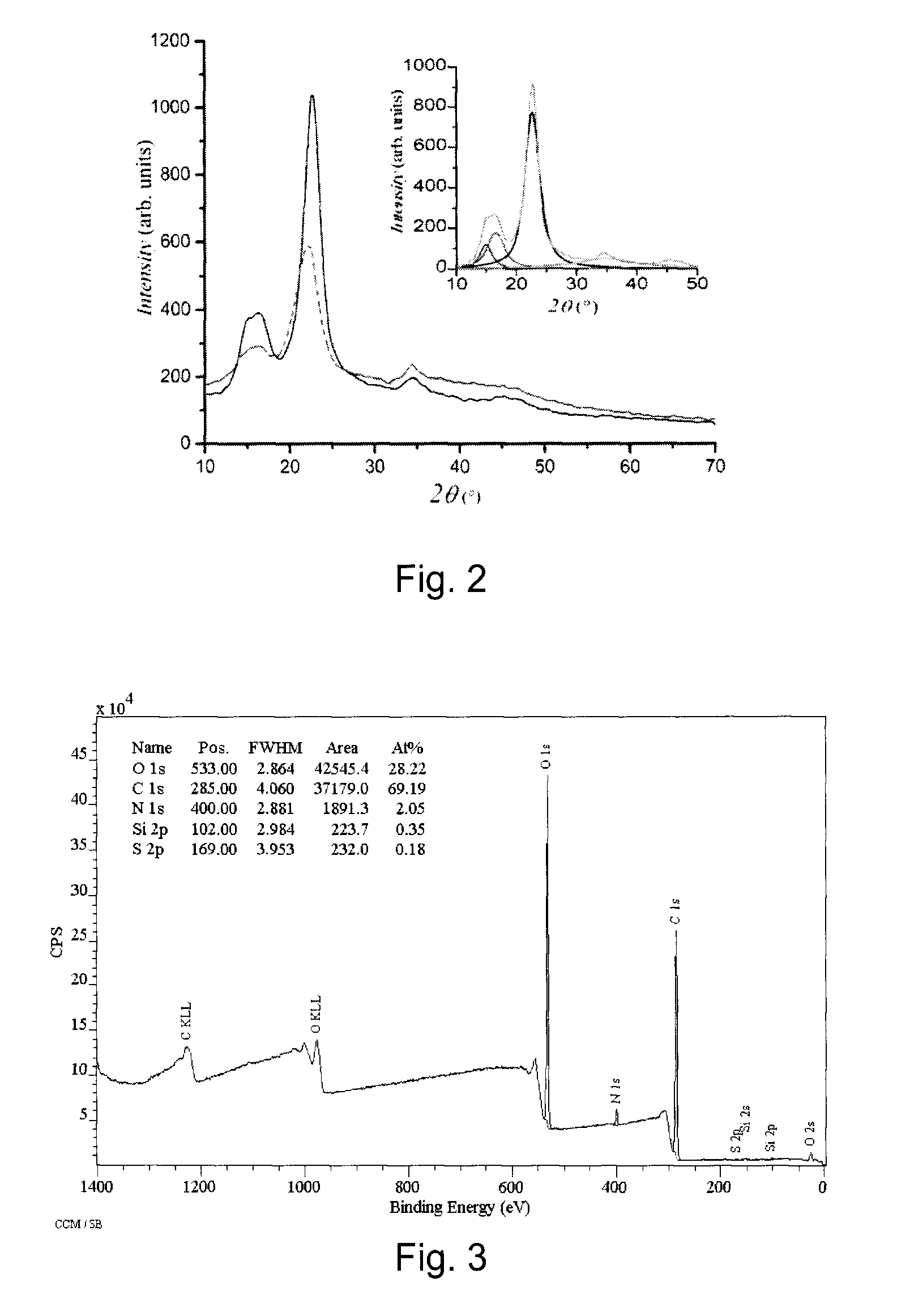

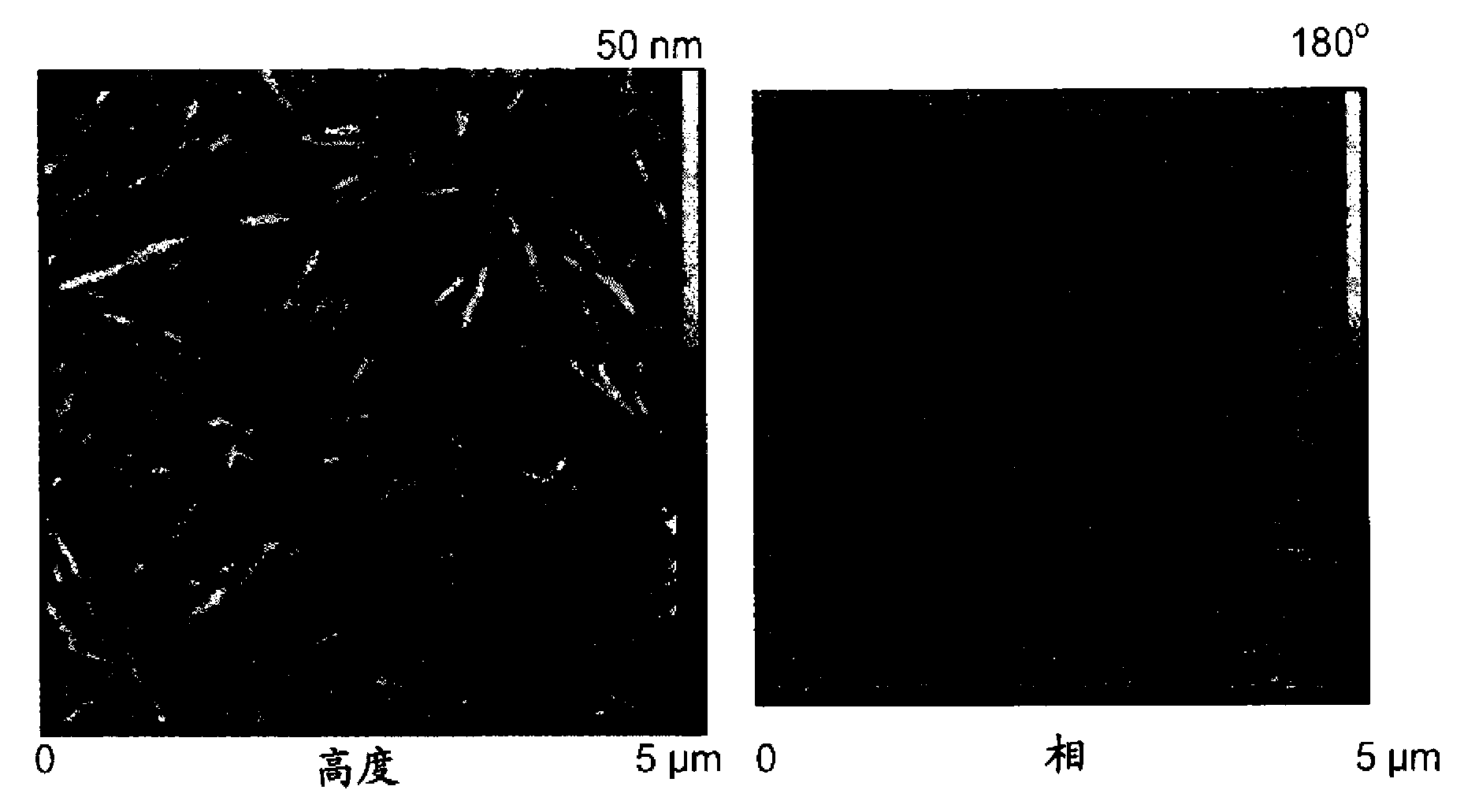

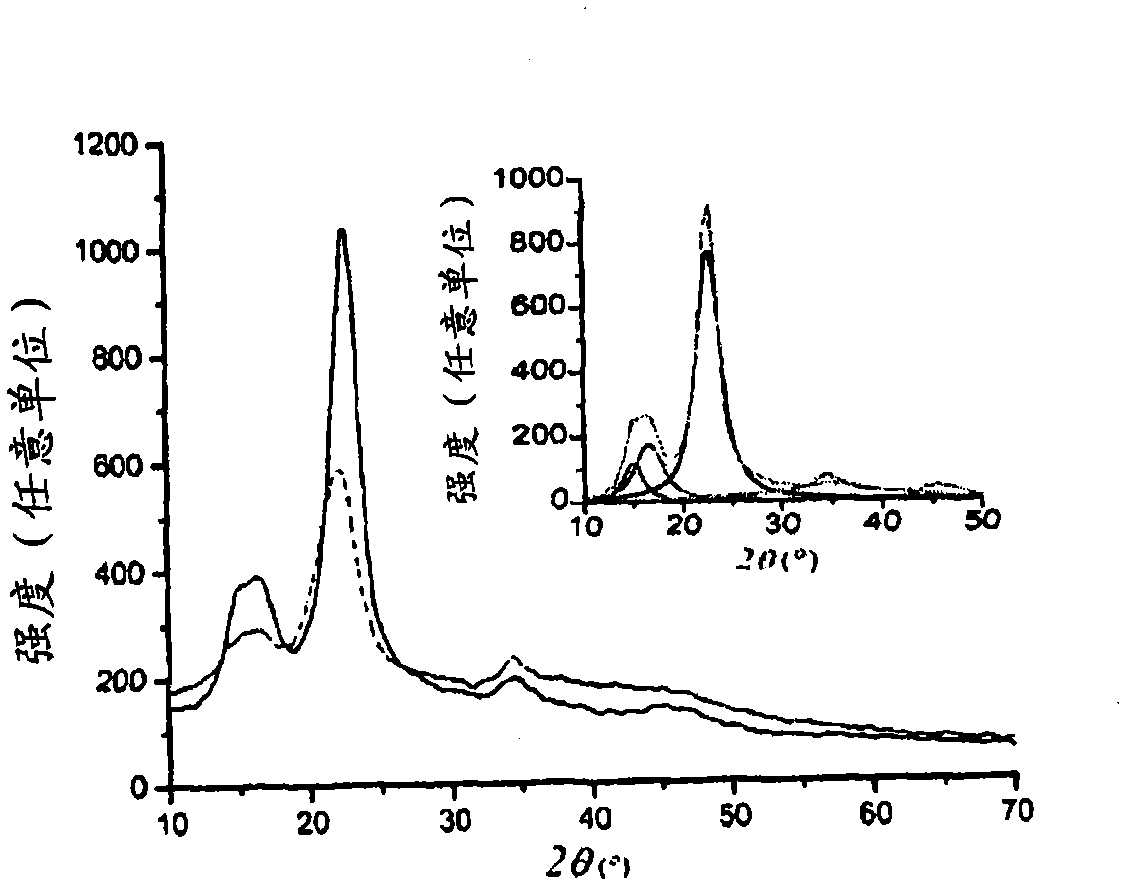

Cellulose nanocrystals from renewable biomass

InactiveUS20120244357A1Quality improvementSignificant comprehensive benefitsIndividual molecule manipulationSynthetic resin layered productsPersulfateRenewable biomass

A process for producing cellulose nanocrystals (CNCs) involves providing a cellulosic material, contacting the cellulosic material with an inorganic persulfate at an elevated temperature to produce CNCs, and recovering the CNCs. The process permits one-step production of CNCs from vegetative biomasses such as flax and hemp. Cellulose nanocrystals produced by the process with carboxylic groups are more uniform and have higher aspect ratios than CNCs produced by prior art processes.

Owner:NAT RES COUNCIL OF CANADA

Cellulose nanocrystals from renewable biomass

A process for producing cellulose nanocrystals (CNCs) involves providing a cellulosic material, contacting the cellulosic material with an inorganic persulfate at an elevated temperature to produce CNCs, and recovering the CNCs. The process permits one-step production of CNCs from vegetative biomasses such as flax and hemp. Cellulose nanocrystals produced by the process with carboxylic groups are more uniform and have higher aspect ratios than CNCs produced by prior art processes.

Owner:NAT RES COUNCIL OF CANADA

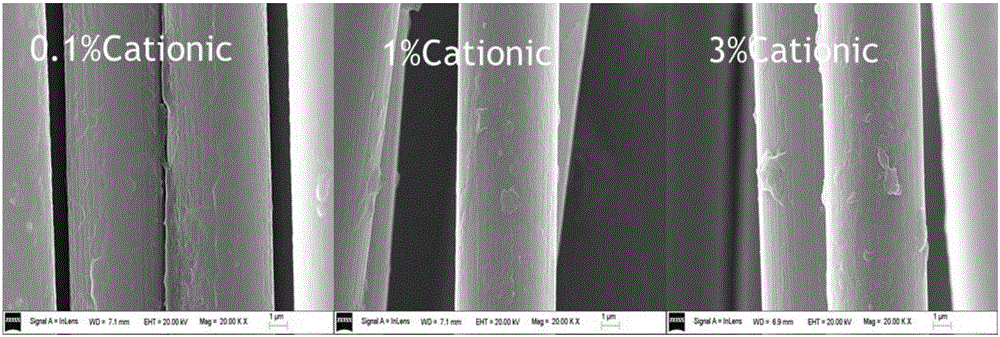

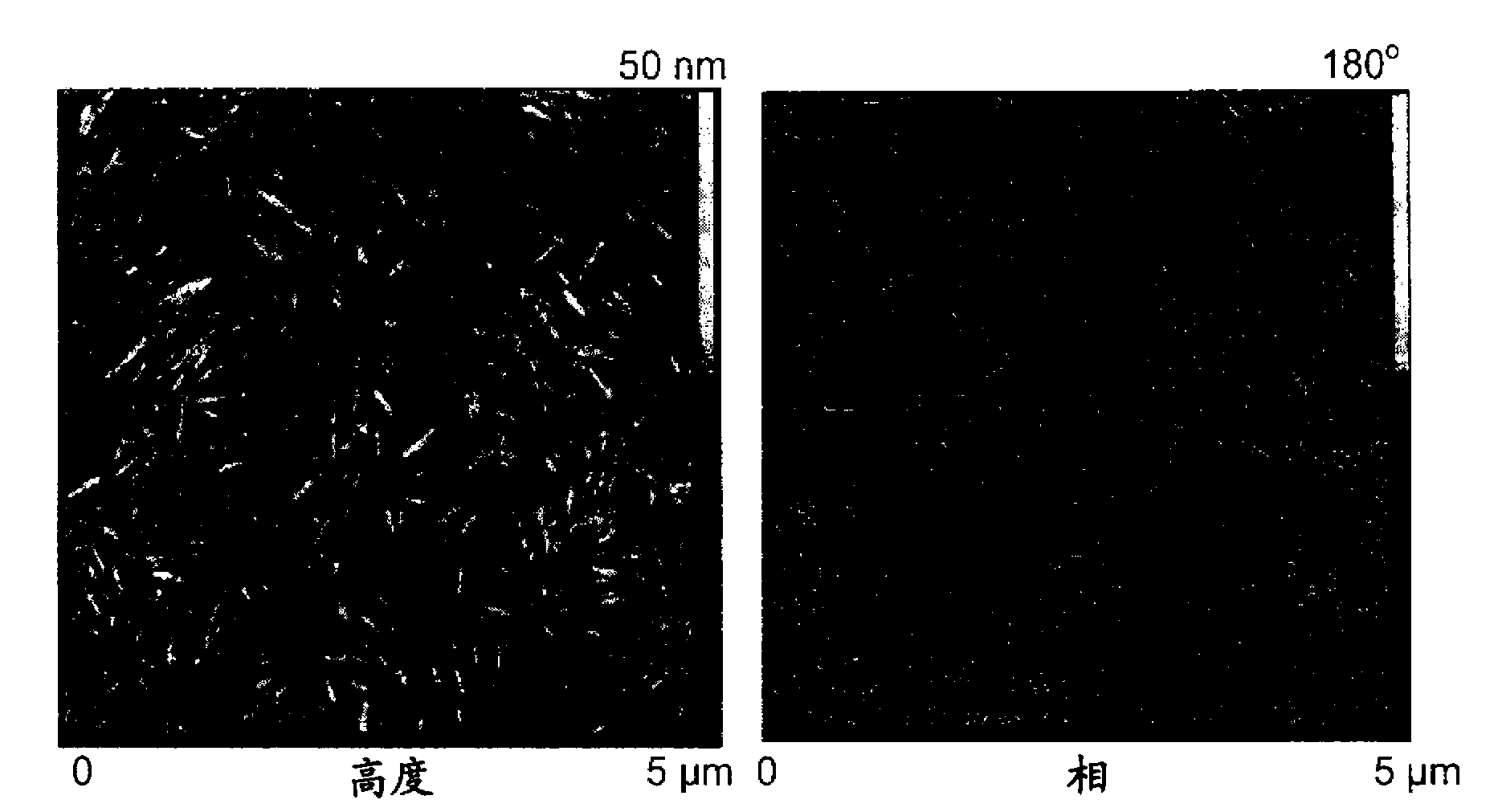

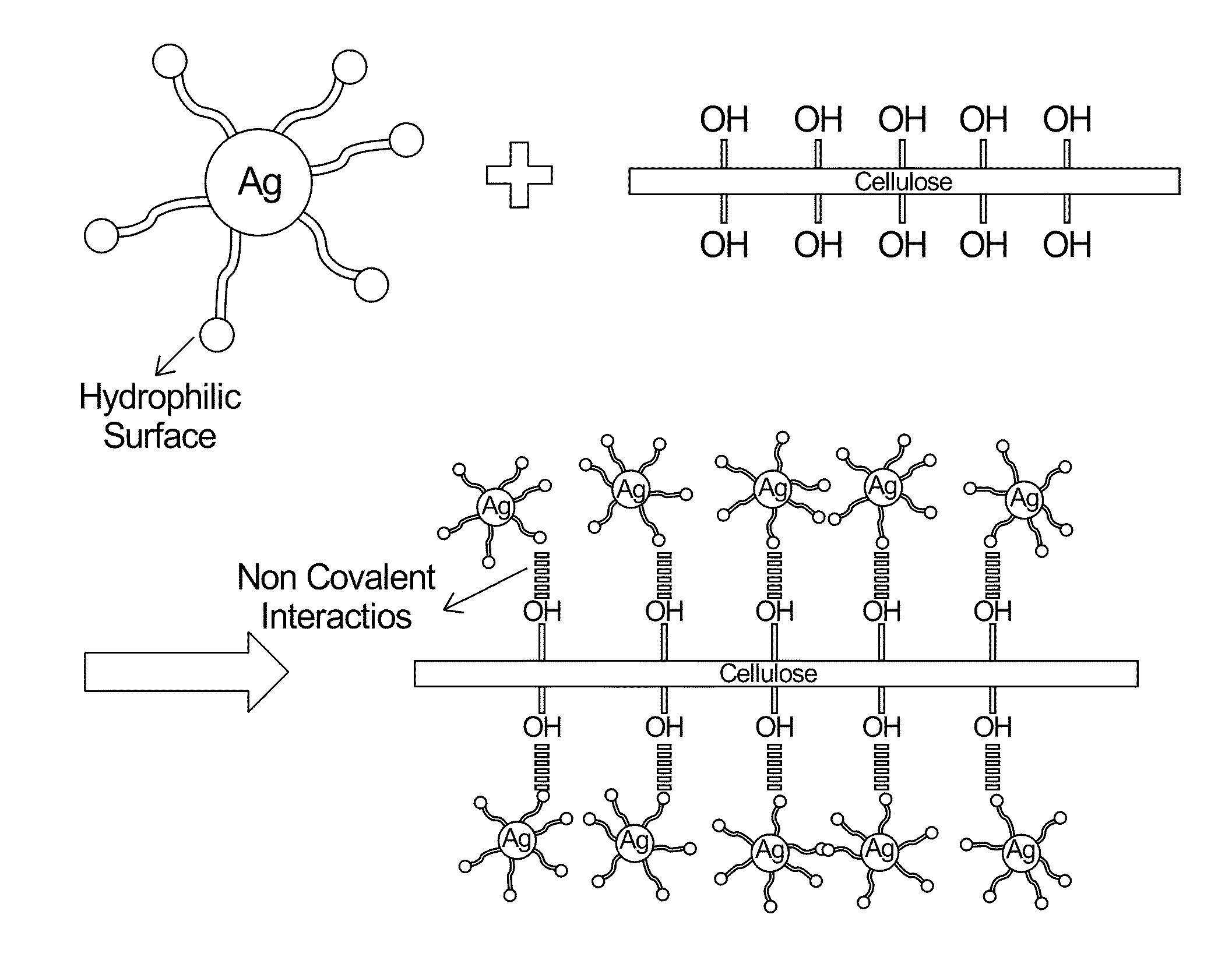

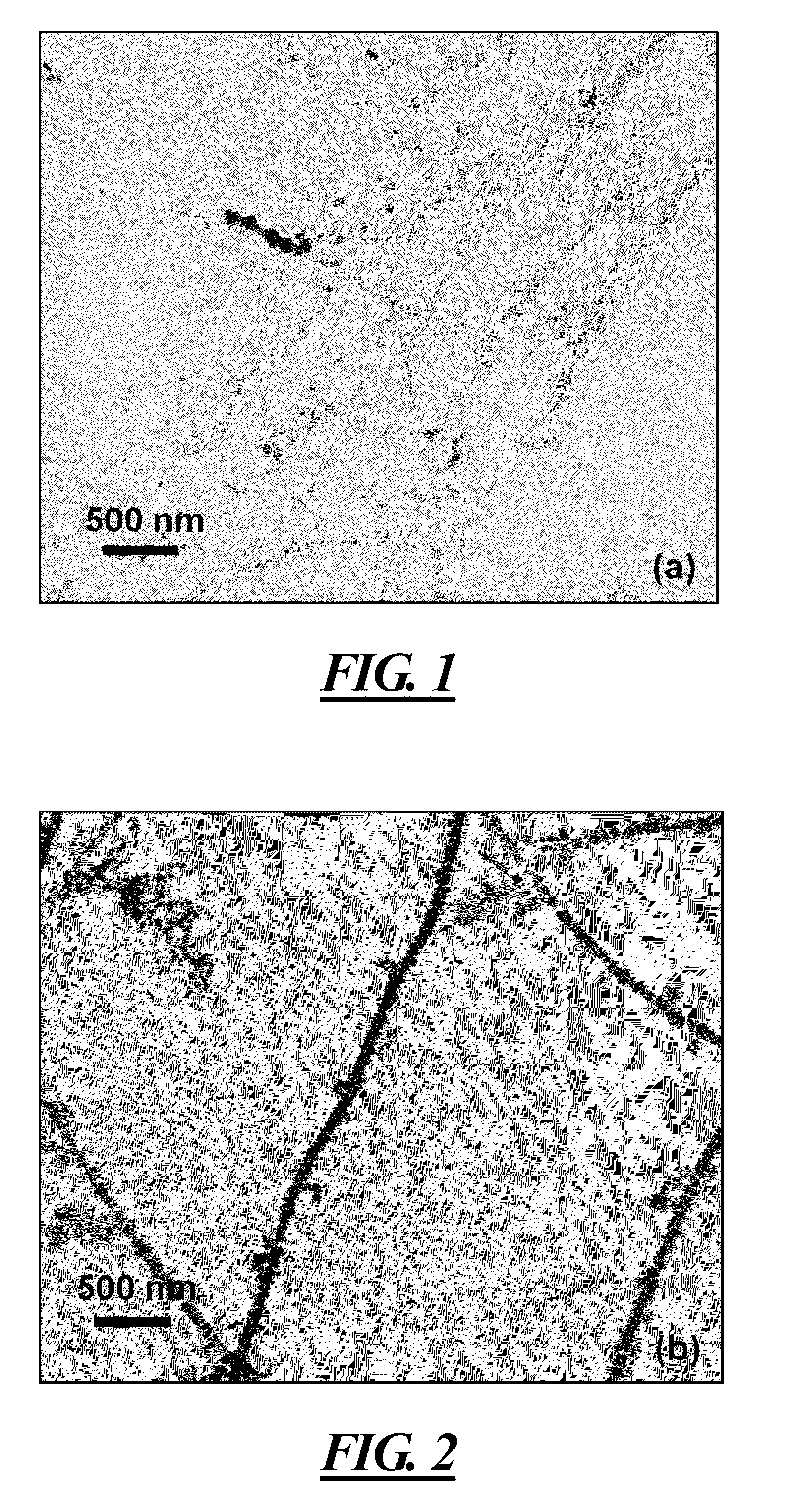

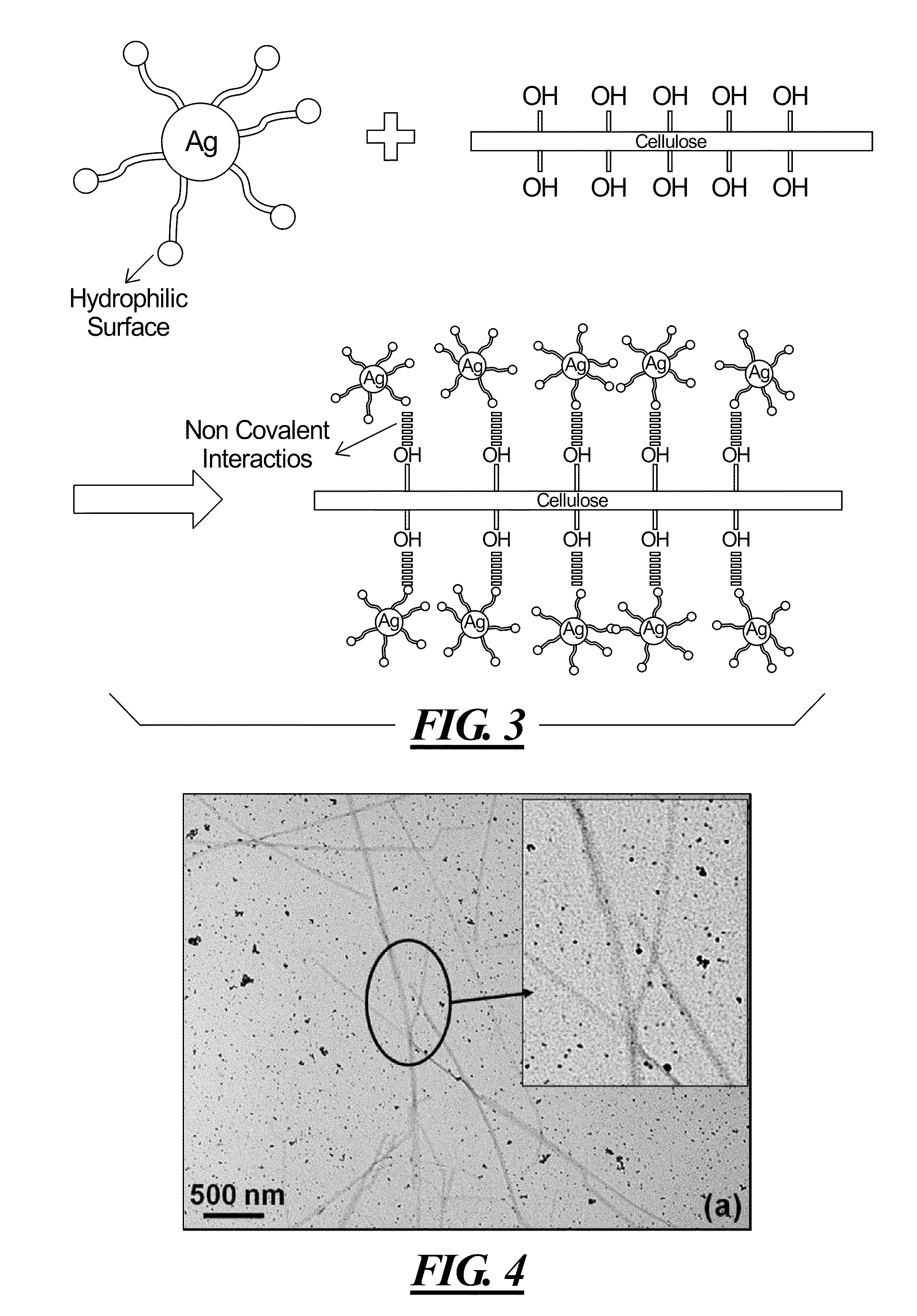

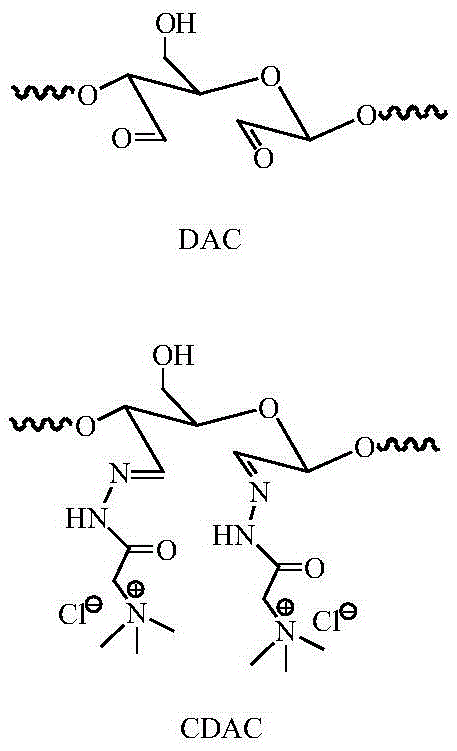

Surfactant-Assisted Inorganic Nanoparticle Deposition on a Cellulose Nanocrystals

Natural biopolymers in the form of cellulose nanocrystals (CNC) are shown to have the required characteristics to serve as chemically reactive biotemplates for metallic and semiconductor nanomaterial synthesis. Silver (Ag), gold (Au), copper (Cu) and platinum (Pt), cadmium sulfide (CdS), zinc sulfide (ZnS) and lead sulfide (PbS) nanoparticles, nanoparticle chains and nanowires may be synthesized on CNCs by exposing metallic precursor salts to a cationic surfactant, cetyltrimethylammonium bromide (CTAB), and a reducing agent. The nanoparticle density and particle size may be controlled by varying the concentration of CTAB, pH of the salt solution, as well as the reduction time or reaction time between the reducing agent and the metal precursor.

Owner:US SEC AGRI +1

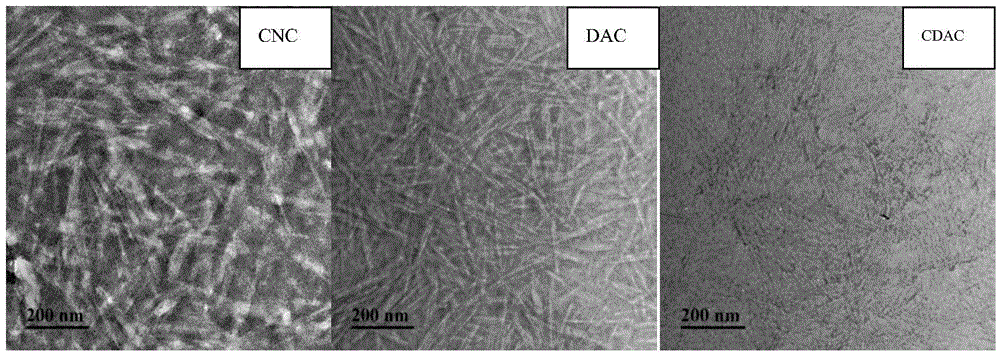

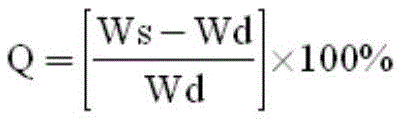

Preparation method of cellulose nanocrystal and chitosan composite membrane

The invention discloses a preparation method of a cellulose nanocrystal and chitosan composite membrane, and belongs to the field of modification of natural polymers. The method comprises the steps that cellulose nanocrystal (CNC) sol is prepared by conducting concentrated sulfuric acid hydrolysis on microcrystalline cellulose; the cellulose nanocrystal (CNC) sol is reacted with sodium periodate to prepare dialdehyde cellulose nanocrystal (DAC) sol and the cellulose nanocrystal (CNC) sol is reacted with a Girard's reagent T to prepare cationic cellulose nanocrystal (CDAC) sol. The CDAC sol is directly mixed with a chitosan-acetic acid solution, vacuum defoamation tape casting is conducted in a polytetrafluoroethylene mold, drying at room temperature is conducted, and the membrane is obtained. Compared with a pure chitosan membrane, the mechanical property of the prepared cellulose nanocrystal and chitosan composite membrane can be obviously improved, and the swelling degree in water is obviously reduced.

Owner:JIANGNAN UNIV

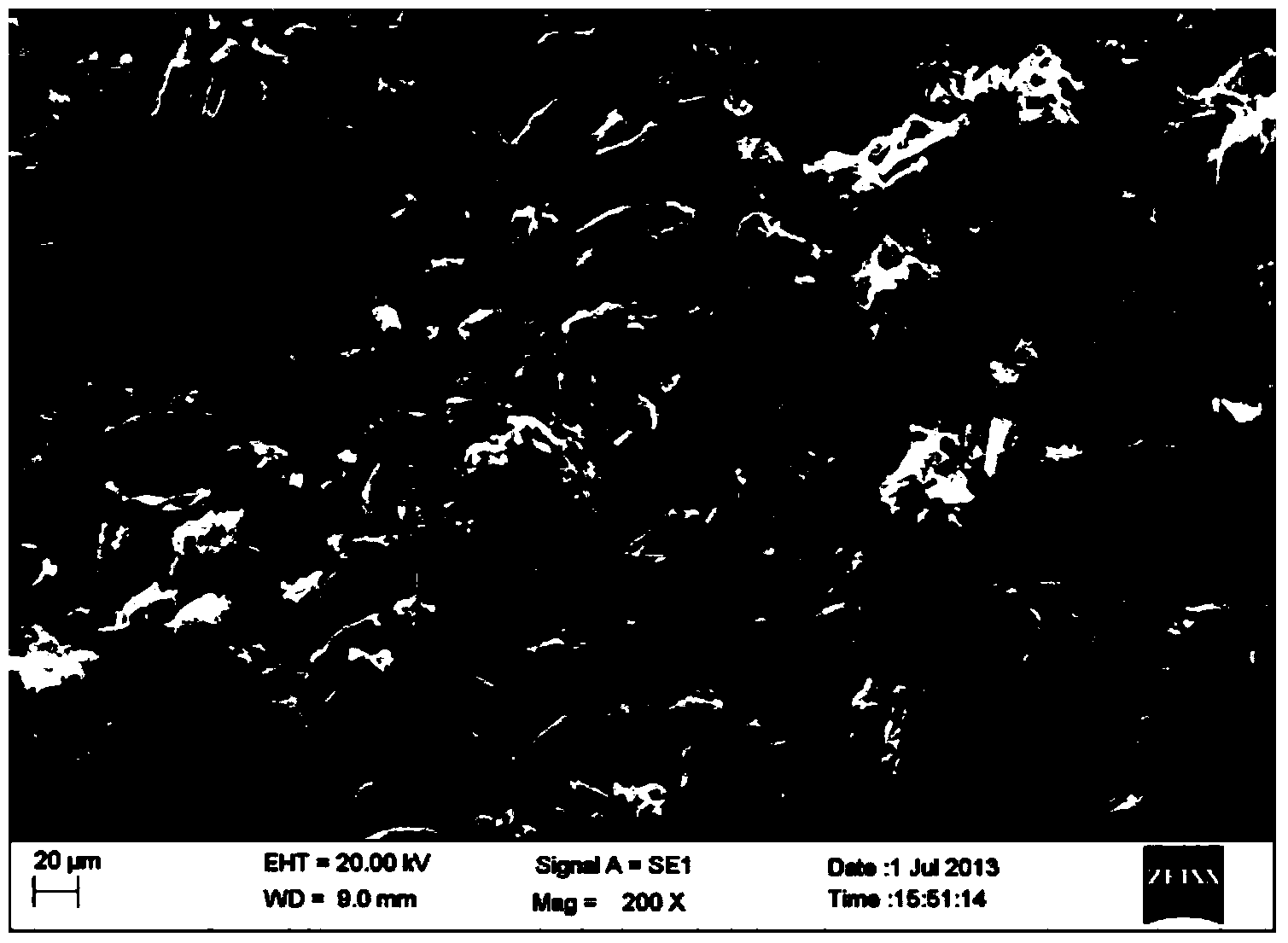

Preparation method of cellulose nanocrystal/graphene/polyvinyl alcohol aerogel

InactiveCN108579626ALarge specific surface areaSmall apertureOther chemical processesAerogel preparationResource utilizationFreeze-drying

The invention relates to a preparation method of cellulose nanocrystal / graphene / polyvinyl alcohol ternary composite enhanced aerogel. The preparation method comprises 1) preparation of cellulose nanocrystals, 2) preparation of a cellulose nanocrystal / graphene mixed solution, 3) preparation of a cellulose nanocrystal / graphene / polyvinyl alcohol ternary composite solution, 4) inorganic salt induction, 5) alcohol solution replacement, and 6) freeze drying. Through reasonable adjustment of the ratio of cellulose nanocrystals, graphene to polyvinyl alcohol, the aerogel with better performances is prepared. The aerogel has a large specific surface area, a small pore size, low density and good adsorptivity. The graphene oxide sheet improves the mechanical properties of the aerogel. The polyvinyl alcohol improves the biocompatibility and degradability of the product. The spherical aerogel has a large effective adsorption area and high adsorption efficiency. The resource utilization of gas and solid wastes and the water environment control and treatment are effectively combined so that the circular economy is promoted.

Owner:NANJING FORESTRY UNIV +1

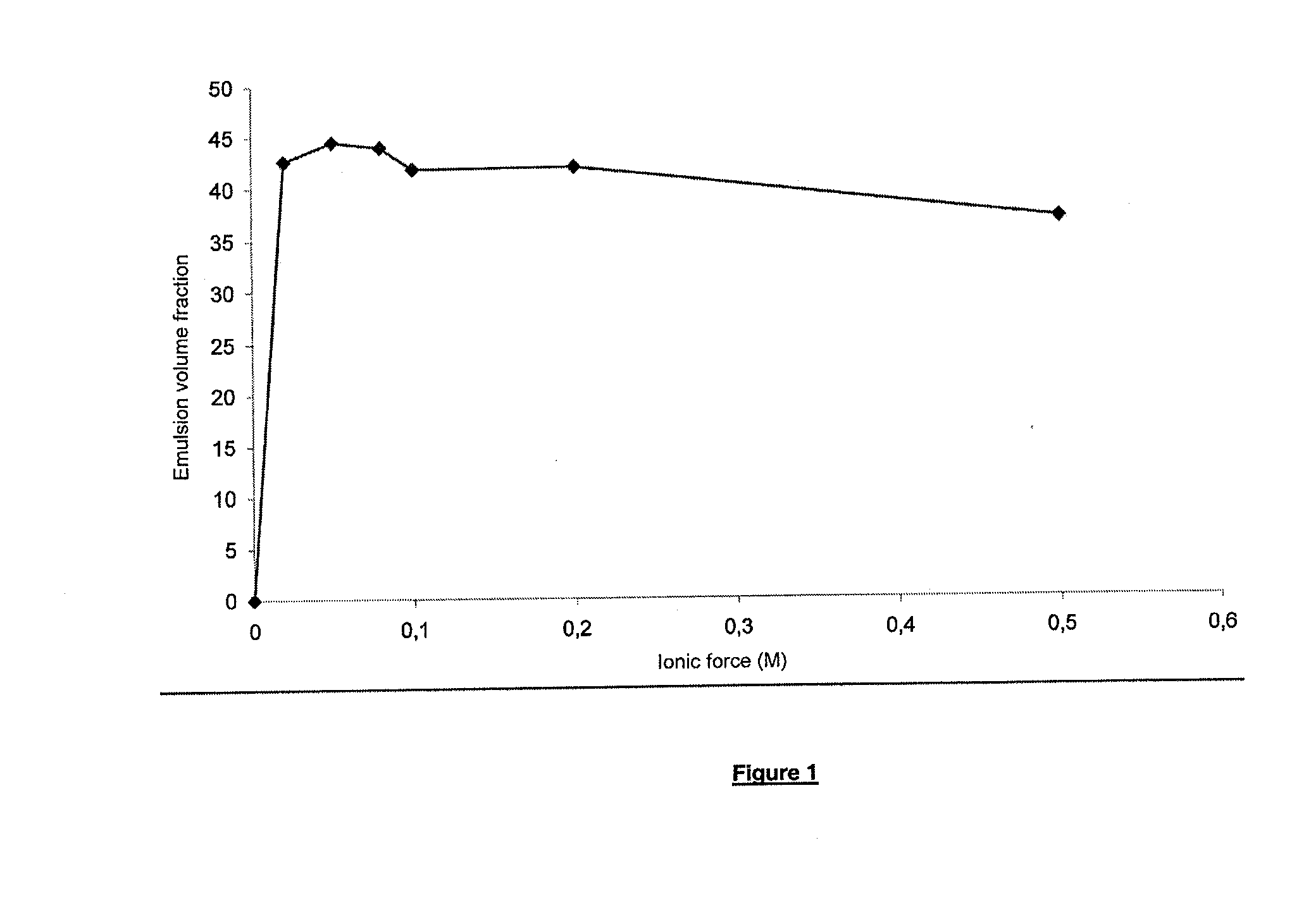

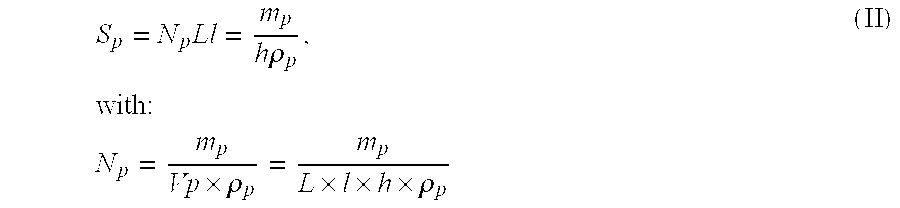

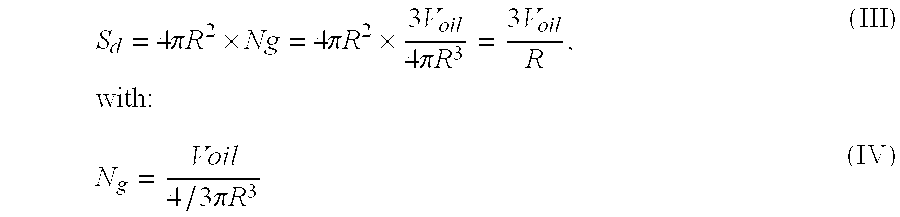

Composition in the Form of an Emulsion, Comprising a Hydrophobic Phase Dispersed in an Aqueous Phase

ActiveUS20130122071A1Way stableChange stabilityCosmetic preparationsMaterial nanotechnologyPickering emulsionPolymer chemistry

The present invention relates to a composition in the form of an emulsion, advantageously a Pickering emulsion, comprising a hydrophobic phase dispersed in an aqueous phase, which composition contains emulsifying particles capable of stabilizing said emulsion, at least some of said particles consisting of cellulose nanocrystals having an elongated shape, which have the following features: a length between 25 nm to 1 μm, and a width between 5 to 30 nm.

Owner:INST NAT DE RECH POUR LAGRICULTURE LALIMENTATION & LENVIRONNEMENT

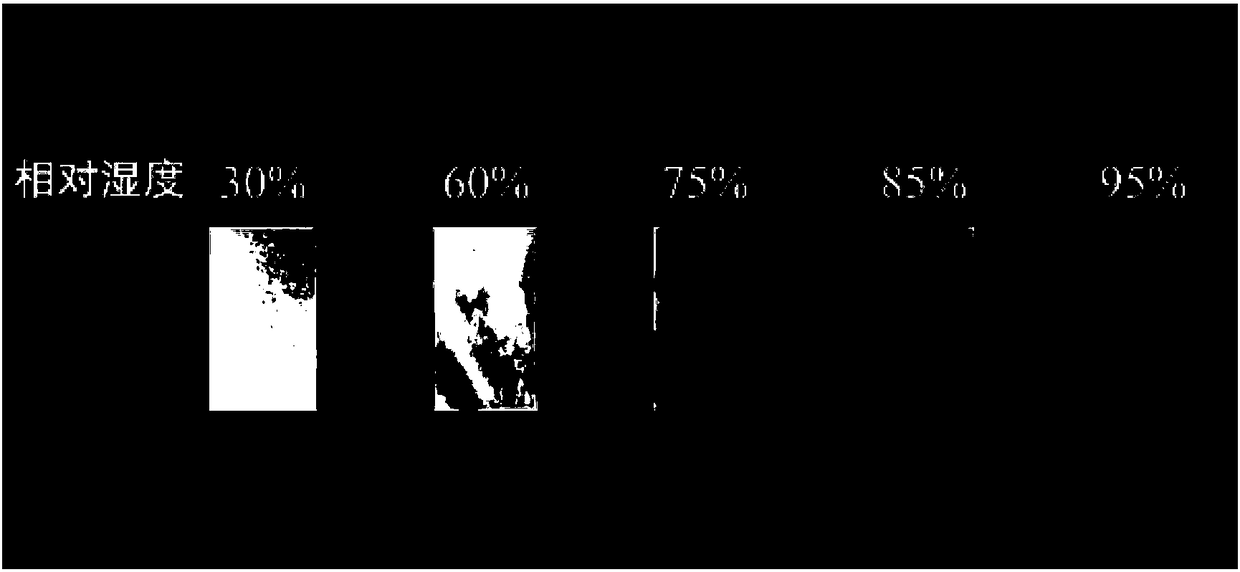

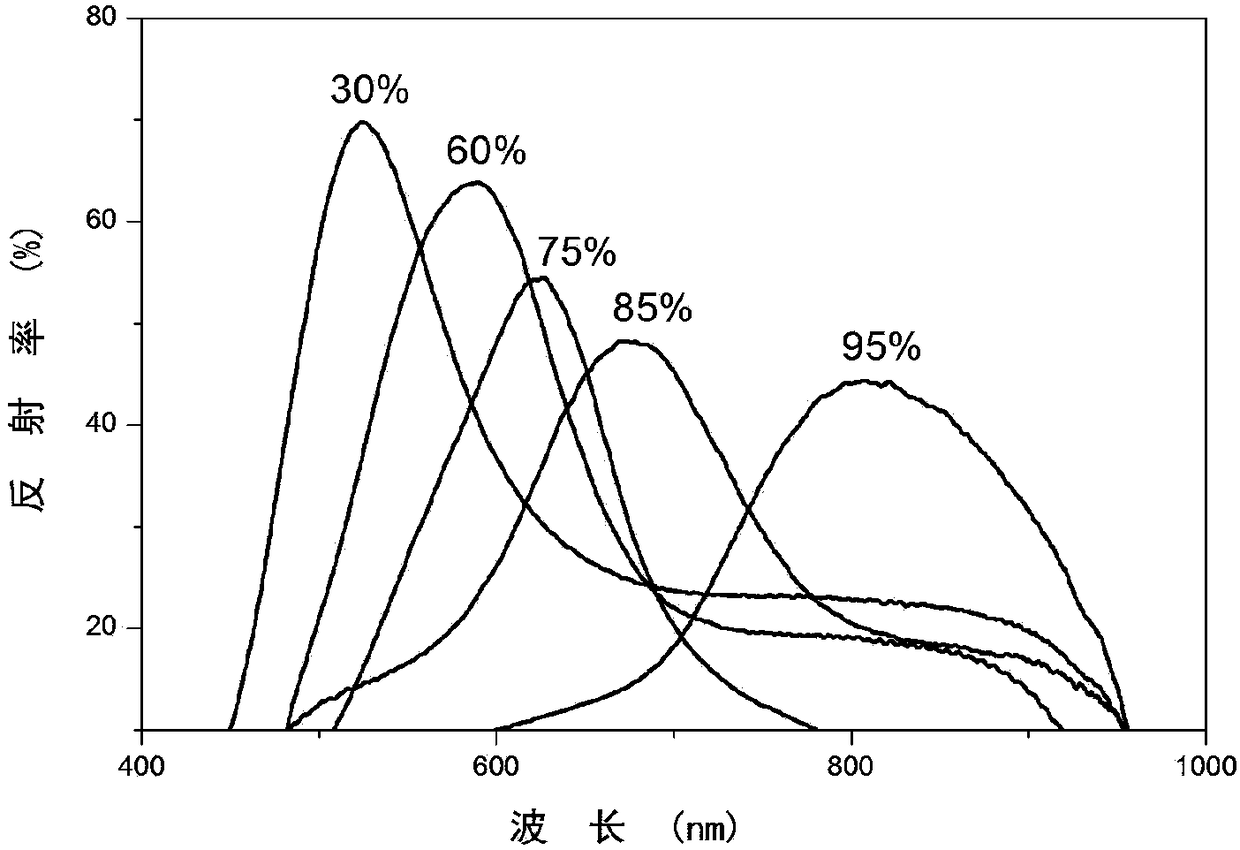

Chiral nematic cellulose nanocrystal-glycerol composite film and preparation method and application thereof

ActiveCN108314803AExcellent optical propertiesGood humidity detectionMaterial analysis by observing effect on chemical indicatorFiberComposite film

The invention provides a chiral nematic cellulose nanocrystal-glycerol composite film preparation method which comprises the steps: mixing fiber with sulfuric acid to perform hydrolysis reaction to obtain cellulose nanocrystal suspension liquid; sequentially washing and concentrating the cellulose nanocrystal suspension liquid to obtain chiral nematic cellulose nanocrystal suspension liquid with amass concentration of 1.5 to 5.5%; mixing the chiral nematic cellulose nanocrystal suspension liquid with a glycerol aqueous solution to form a film to obtain a chiral nematic cellulose nanocrystal-glycerol composite film. The chiral nematic cellulose nanocrystal-glycerol composite film prepared by the preparation method disclosed by the invention not only has the excellent optical characteristicof cellulose nanocrystal, but also has the humidity sensitive characteristic of the glycerol; the chiral nematic cellulose nanocrystal-glycerol composite film has a very good humidity detecting effect when being used as a humidity sensitive indication material; furthermore, raw materials are easy to obtain, and simpleness in operation is achieved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method of preparing polymer by emulsion polymerization by controllable free radical Pickering emulsion

The invention discloses a method of preparing a polymer by emulsion polymerization by a controllable free radical Pickering emulsion. The method is mainly applied to polymerization systems such as an RAFT method, an ATRP method and a NMP method. The method is characterized by comprising the following steps: forming an aqueous phase by cellulose nanocrystals, deionized water and a water soluble component; then forming an oil phase from an oil soluble monomer and an oil soluble component; stirring and emulsifying the mixture to obtain a Pickering emulsion which is excellent in stability; and storing the Pickering emulsion for more than 30 days at room temperature. Cooling, ultrasonic treatment, centrifugalization, dialysis and freezing and drying are performed on the product to obtain a molecular weight controlled polymer. The invention provides the preparation method of the controllable polymerized Pickering emulsion, wherein the preparation method is simple in process, green and environment-friendly and low in cost.

Owner:LUDONG UNIVERSITY

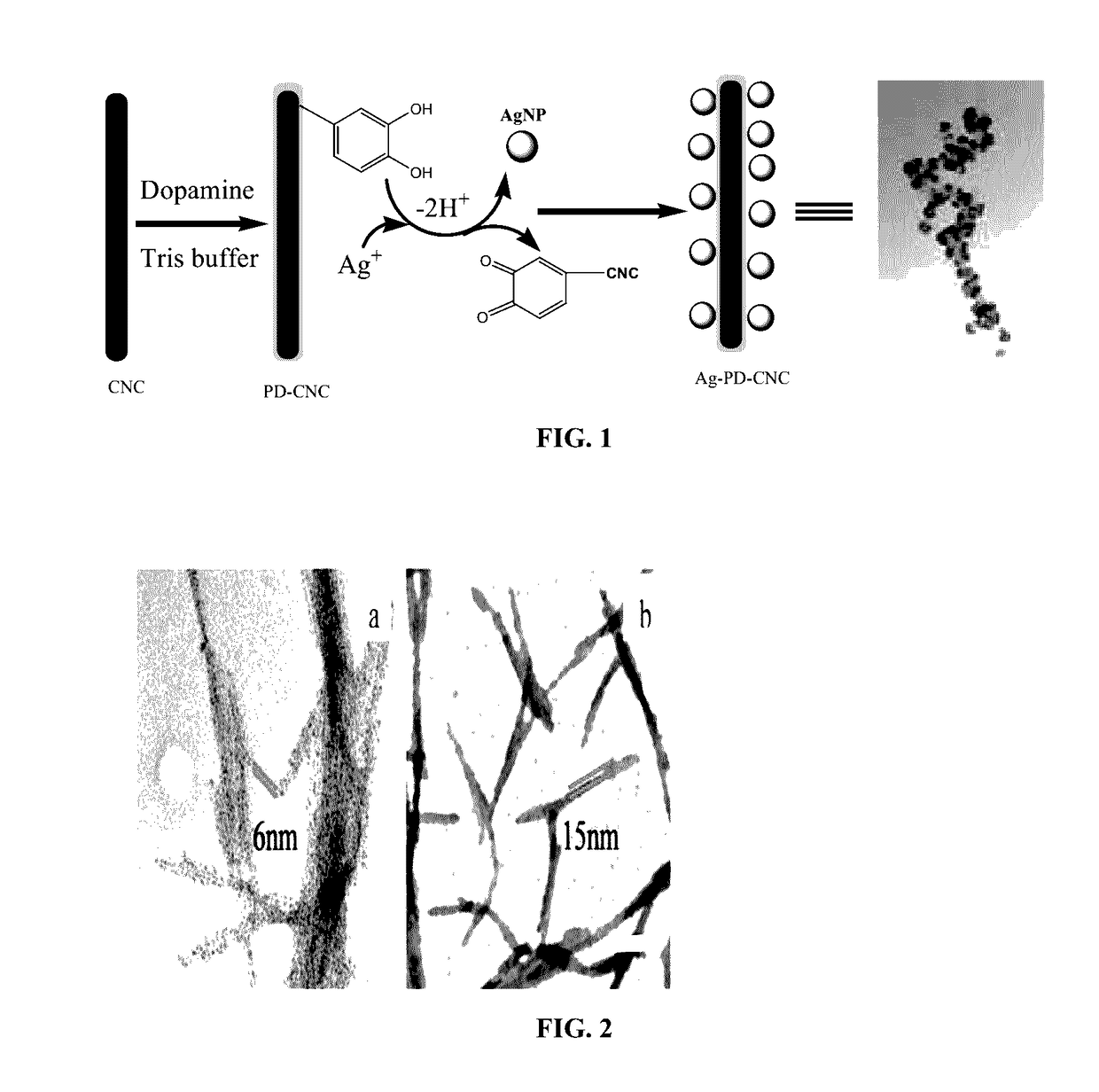

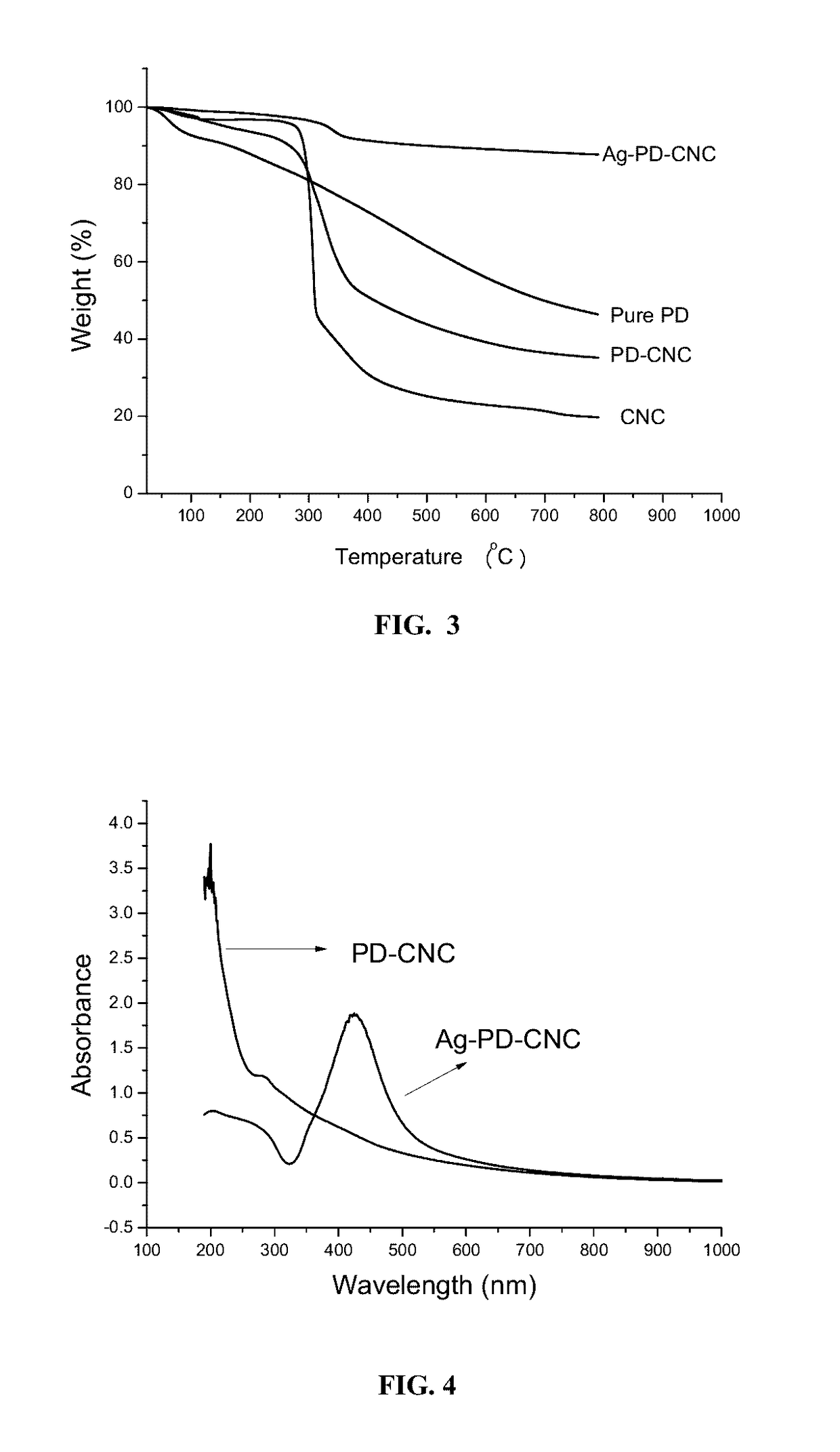

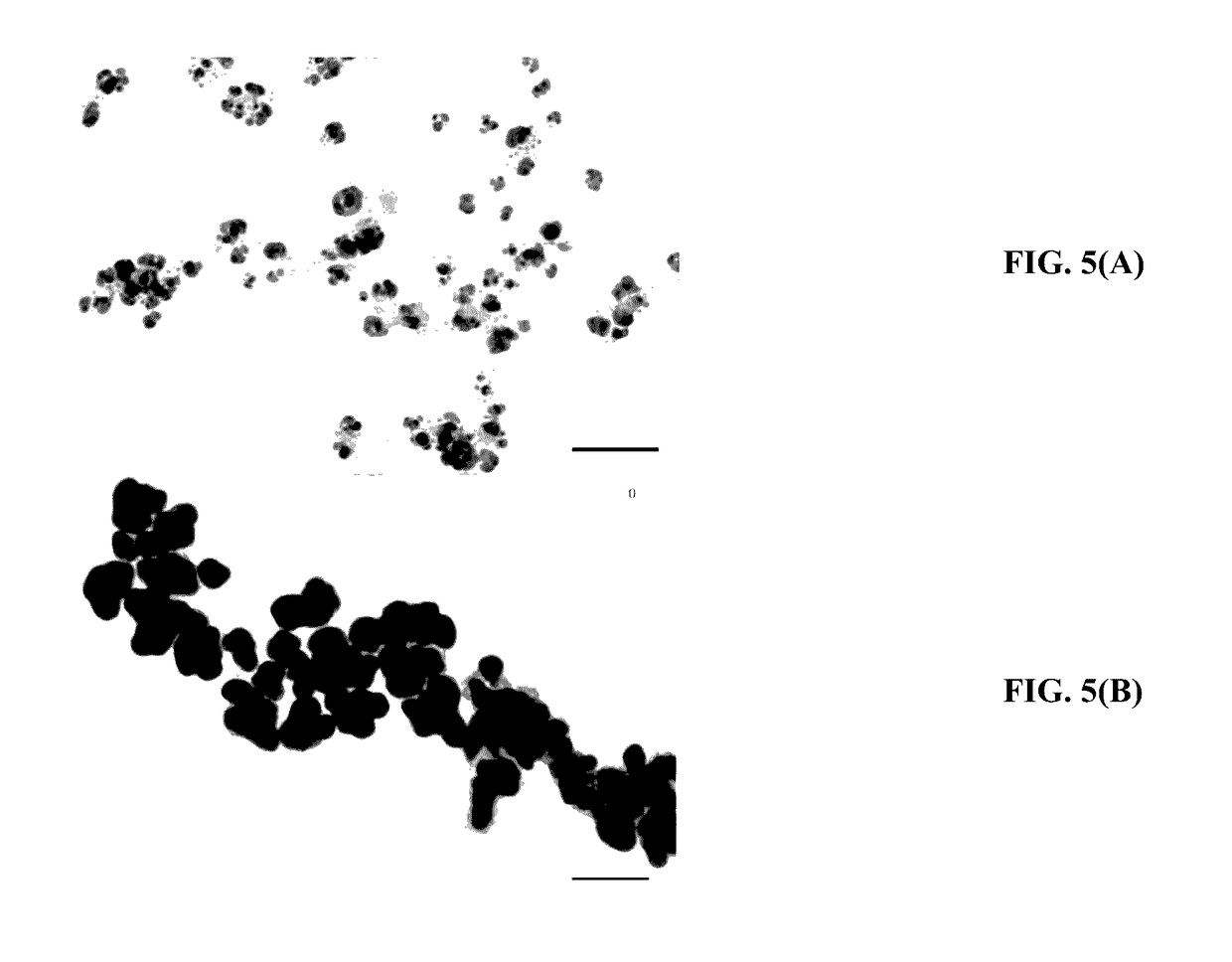

Polydopamine functionalized cellulose nanocrystals (pd-cncs) and uses thereof

InactiveUS20170142975A1High antibacterial activityBiocideOrganic-compounds/hydrides/coordination-complexes catalystsOligomerCarboxylic acid

The present disclosure relates to use of polydopamine (PD) coated cellulose nanocrystals (CNCs) as template for further conjugation of functional oligomers (amines, carboxylic acids etc.) and the immobilization of various types of CNC hybrid nanomaterial nanoparticles to improve their stability in aqueous solution, e.g. the preparation of silver nanoparticle on CNC. Surface functionalization of CNC with polydopamine can be performed by mixing dopamine and CNCs for certain time at designed temperature. The resultant PD-CNCs can be used to stabilize metallic and inorganic nanoparticles, which could be generated in-situ, and further immobilized on the surface of PD coated CNCs. Benefiting from the improved stability, the resultant nanoparticles immobilized PD-CNC system also generally possess higher catalytic activity than the nanoparticles alone.

Owner:CELLUFORCE

Method for preparing cellulose nanocrystal reinforced polyhydroxybutyrate-hydroxyvalerate (PHBV) nanofiber

InactiveCN102493021AAdjustable heightPorosity adjustableFilament/thread formingConjugated cellulose/protein artificial filamentsPorosityBiocompatibility Testing

The invention relates to a method for preparing cellulose nanocrystal reinforced polyhydroxybutyrate-hydroxyvalerate (PHBV) nanofiber. The method comprises the following steps of: (1), adding an organic solvent, namely a solution A, of cellulose nanocrystals (CNCs) into an organic solvent, namely a solution B, of a PHBV during stirring to obtain a mixed solution; (2), heating the mixed solution to 40 to 70 DEG C, fully stirring to obtain a transparent and uniform electrostatic spinning stock solution; and (3), performing electrostatic spinning on the stock solution, performing vacuum drying on the stock solution at room temperature to obtain the PHBV or CNCs. The method is simple, controllable, quick and efficient. The prepared PHBV or CNCs is or are a complete biodegradation product, has high biodegradability and biocompatibility, high porosity, adjustable aperture and tailorable shapes, and has the advantages of high mechanical property, high thermal property, appropriate hydrophilcity and the like.

Owner:DONGHUA UNIV

Method for preparation of cellulose nanocrystals and nanofibrils

A method for producing nanocellulose is described herein. The method includes contacting a cellulosic material with an oxidizing agent, and a compound selected from the group consisting of an alkali metal bromide, an alkali metal iodide, an alkali metal fluoride, an alkali metal chloride, or a combination thereof, in an aqueous solution to provide an oxidized cellulose mixture. The nanocellulose prepared according to the method is also described.

Owner:UNIV OF MASSACHUSETTS

Sodium alginate/carboxylated cellulose nanocrystal hydrogel microsphere for adsorbing lead ions

ActiveCN108014760AReduce use costImprove uniformityOther chemical processesWater contaminantsPorosityDivinyl sulfone

The invention discloses a sodium alginate / carboxylated cellulose nanocrystal hydrogel microsphere for adsorbing lead ions. The sodium alginate / carboxylated cellulose nanocrystal hydrogel microsphere comprises, by weight, 5-8 parts of sodium alginate, 6-8 parts of carboxylated cellulose nanocrystals, 0.5-0.52 parts of divinyl sulfone, 150-180 parts of distilled water and 30-40 parts of a 0.1-0.2 mol / L calcium chloride solution. The sodium alginate / carboxylated cellulose nanocrystal hydrogel microsphere has the following advantages: the sodium alginate and microcrystalline cellulose which are used as raw materials in the method are natural materials, so the microsphere is nontoxic and harmless, is friendly to the environment, and realizes appreciation and full utilization of materials as a water purifier; and the prepared hydrogel microsphere has a good homogeneity, a uniform particle size, no toxic or side effects, a large specific surface area and a large porosity, has high adsorptioncapability to lead ions and other heavy metal ions, can be used as a safe and efficient lead ion adsorbent, and has a broad industrial application prospect.

Owner:ZHEJIANG OCEAN UNIV

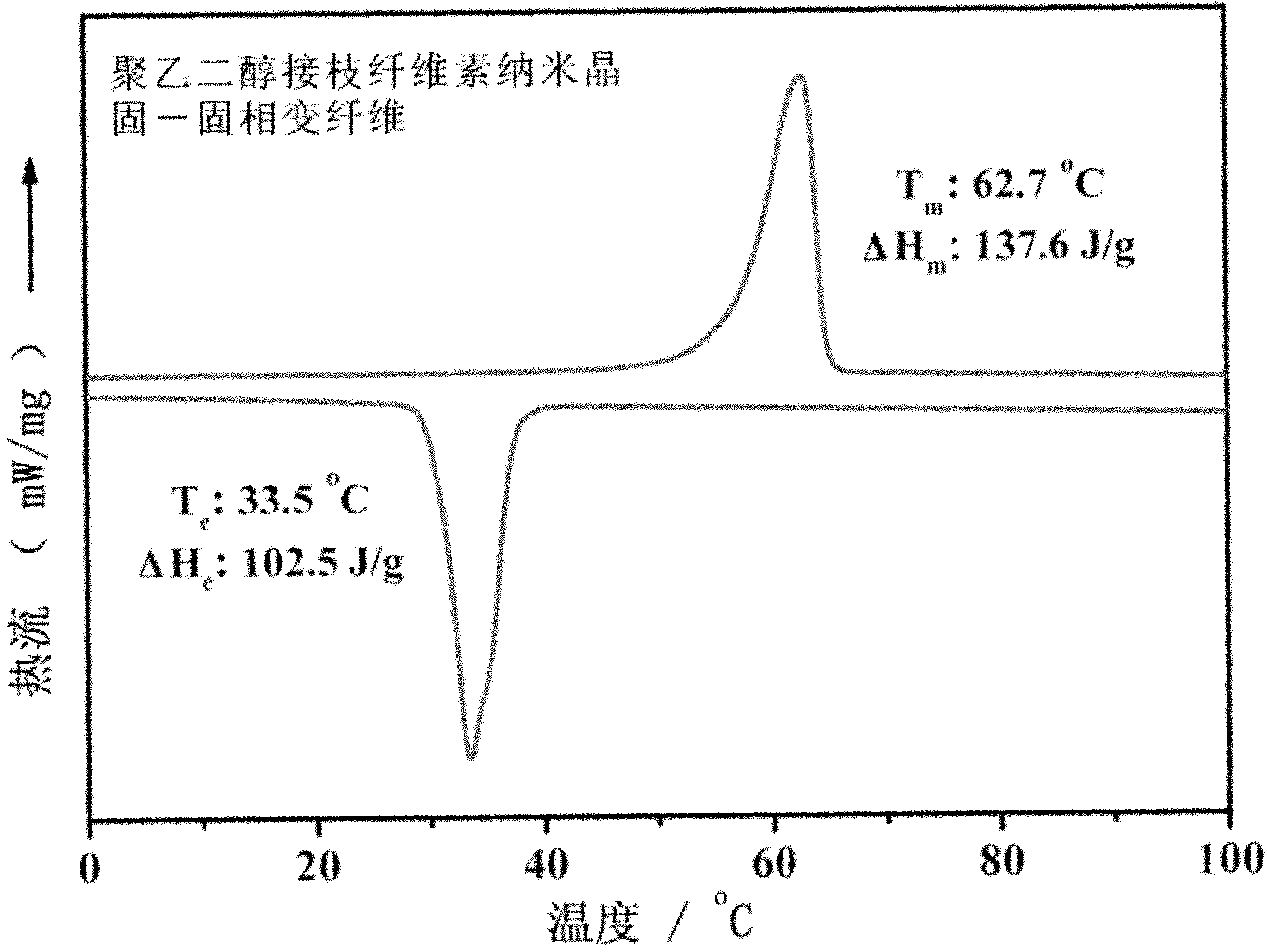

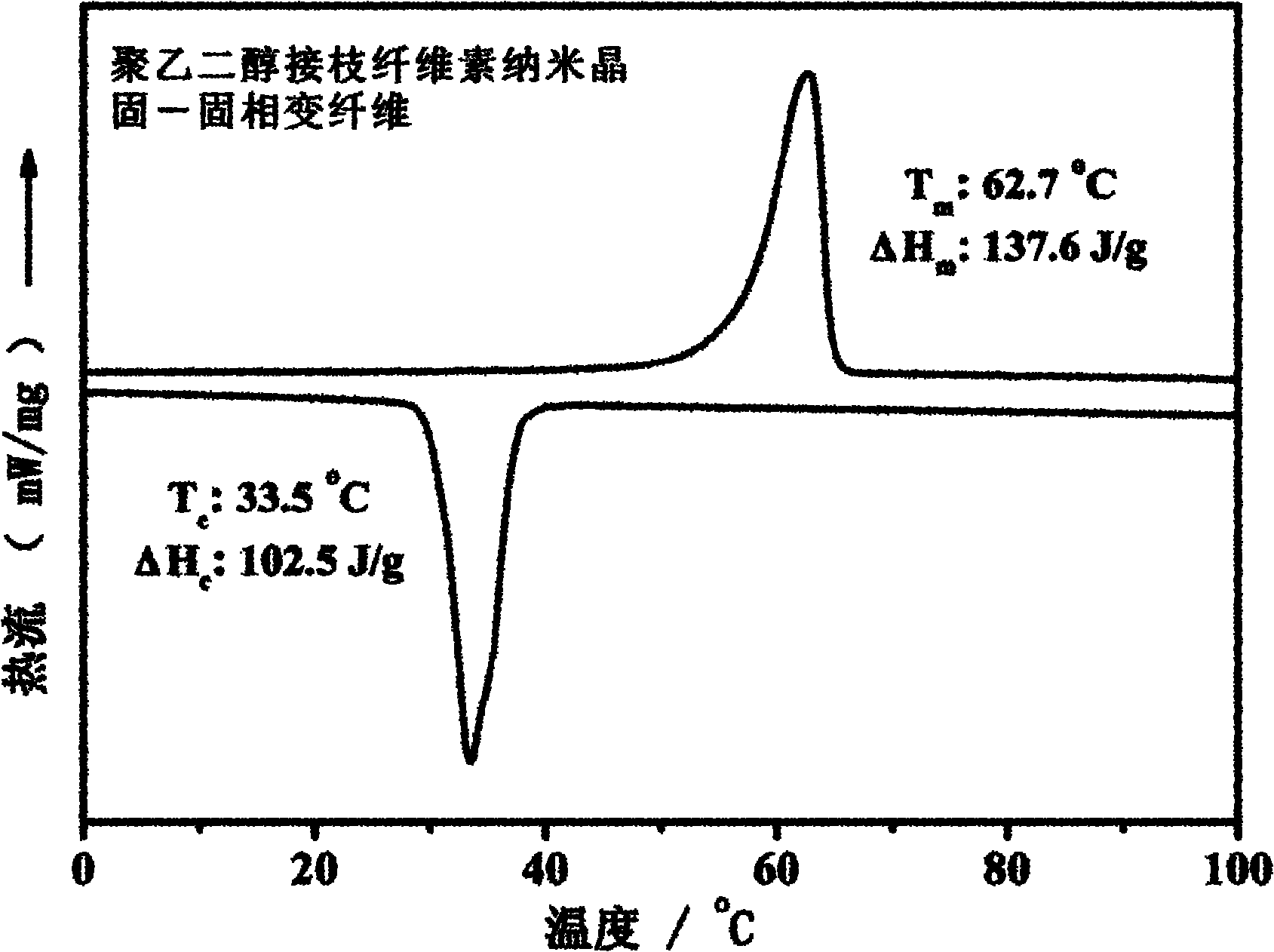

Method for preparing biodegradable solid-solid phase transition nano fibers or fiber membranes

InactiveCN101967697AThe preparation process is environmentally friendlyEnvironmental performanceFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a method for preparing biodegradable solid-solid phase transition nano fibers or fiber membranes, which comprises: (1) adding a coupling agent and a catalyst into water dispersion of cellulose nanocrystals in turn, dripping dehydrant-containing ethanol solution, stirring, reacting for 6 to 10 hours to prepare water dispersion of carboxyl cellulose nanocrystals; (2) adding PEG and a catalyst into the water dispersion of carboxyl cellulose nanocrystals in turn, dripping the dehydrant-containing ethanol solution, stirring and reacting for 10 to 12 hours to obtain polyethylene glycol grafted cellulose nanocrystal graft copolymer; and (3) preparing aqueous solution of the graft copolymer as spinning solution and spinning. In the invention, the cost is low, the whole preparation process is performed in a water system, the preparation process is simple, easy to control and suitable for industrial production; and the obtained biodegradable solid-solid phase transition nano fibers or fiber membranes have the advantages of high storage capacity and proper phase transition temperature and the like.

Owner:DONGHUA UNIV

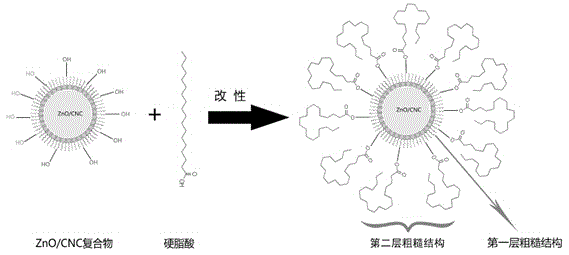

Preparation method of zinc oxide and cellulose nanocrystal composite super-hydrophobic coating

ActiveCN105670500ASimple preparation processEasy to operateAntifouling/underwater paintsPaints with biocidesZno nanoparticlesTalc / Zinc Oxide

The invention provides a preparation method of a zinc oxide and cellulose nanocrystal composite super-hydrophobic coating. The reparation method of the zinc oxide and cellulose nanocrystal composite super-hydrophobic coating is characterized by comprising the following steps that 1, nano zinc oxide with special morphology and a cellulose nanocrystal solution are mixed according to a certain proportion and added into a mixed solution of stearic acid and ethyl alcohol under the condition of magnetic stirring; 2, the mixture is taken out after a certain time and aged, dried and ground into powder, the powder is added into a mixed solution of deionized water, a catalyst ammonia water and a dispersing agent sodium dodecyl benzene sulfonate, and magnetic stirring is conducted after ultrasound is conducted till the mixture is a thick state; 3, a certain amount of polydimethylsiloxane and silane coupling agent are added for continuous magnetic stirring, and a solution is formed and coated on the base material surface to form the super-hydrophobic coating. The preparation method of the zinc oxide and cellulose nanocrystal composite super-hydrophobic coating has the advantages that the preparation technology is simple and easy to operate, the super-hydrophobic coating is suitable for being added into various coatings, and the properties of hydrophobicity, sterilization and abrasion resistance enhancing are achieved.

Owner:ZHEJIANG DAFENGFAN FURNITURE CO LTD

Processes for producing nanocellulose-lignin composite materials, and compositions obtained therefrom

InactiveUS20160168272A1Maintain good propertiesMaterial nanotechnologyPulp properties modificationCellulose fiberVortex mixer

This invention provides a process for producing a nanocellulose-lignin material, comprising: providing a starting material comprising lignin and discrete cellulose fiber fines, chemically and physically separate from the lignin; and mechanically refining the starting material to form a nanocellulose-lignin material comprising cellulose nanofibrils and / or cellulose nanocrystals chemically or physically associated with the lignin. In certain embodiments, the starting material contains about 60 wt % lignin and about 40 wt % cellulose fiber fines on a dry basis. The starting material may be obtained from an AVAP® process. The refining may utilize single disk refiners, double disk refiners, conical refiners, cylindrical refiners, beaters, grinders, homogenizers, microfluidizers, vortex mixers, rotor-stator mixers, and / or high-shear mixers, for example. A novel nanocellulose-lignin composite material is obtained.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com