Preparation and application of cellulose nanocrystals (CNCs)-reinforced collagen compound substrate

A nano-microcrystalline and composite matrix technology, which is applied in skin care preparations, cosmetic preparations, dressing preparations, etc., can solve problems such as poor mechanical properties, difficulty in shaping, and inability to support tissue reconstruction, and achieve high production efficiency , The preparation process is simple, the effect of excellent liquid absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

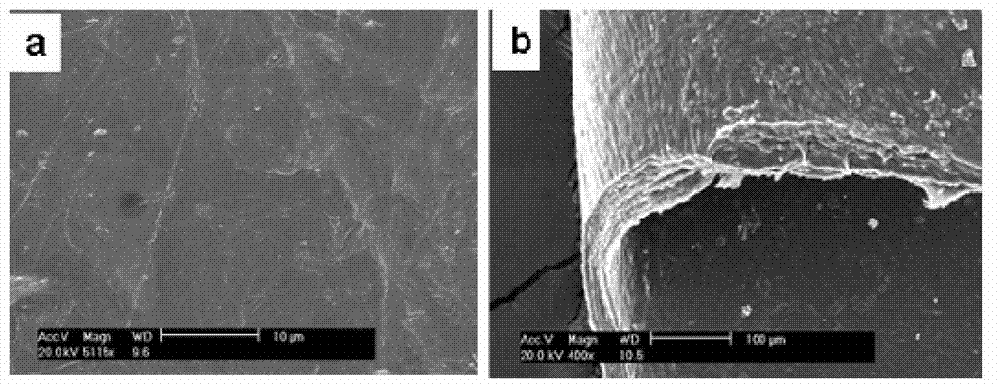

[0039]Add 15g of cotton cellulose to 150mL of 64%w / w concentrated sulfuric acid, in a constant temperature water bath at 45°C, mechanically stir the reaction for 6 hours, add 800mL of deionized water to terminate the reaction, after cooling, ultrasonically (35kHz) disperse for 30min, remove After dialysis with ionized water for 3 days, freeze overnight at -20°C, and then freeze-dry in a lyophilizer for 12 hours to prepare nanocrystalline cellulose (cellulose nanocrystals, CNCs). Use the 0.3% acetic acid solution as the solvent to prepare the CNCs solution and the collagen solution with a mass concentration of 1%; get 0.5 g of the above CNCs solution and drop it into the 9.5 g of the above collagen solution, and mechanically stir for 2 hours to obtain the CNCs solution with a content of 5% w / w CNCs / collagen mixed solution, then pour the mixed solution into a polytetrafluoroethylene mold, put it in an oven at 35°C, and make a 5wt% CNCs-reinforced collagen composite film after the...

Embodiment 2

[0041] Rinse the commercially available bacterial cellulose with clean water several times to remove the culture medium and impurities on the surface of the membrane, then soak the membrane in 0.5mol / L NaOH solution, cook at 90°C for 20min or more, cool, place in deionized water and soak repeatedly until Neutral, bacterial cellulose solid was obtained after freeze-drying. Take 5g of dried bacterial cellulose, add it to 100mL of sulfuric acid with a mass percentage of 35%, react in a constant temperature water bath at 50°C for 4 hours, add 800mL of deionized water to terminate the reaction, and after cooling, disperse with ultrasonic (35kHz) for 30min, and dialyze with deionized water for 3 days After drying, nanocrystalline cellulose (cellulose nanocrystals, CNCs) is obtained. Use acetic acid solution with a mass concentration of 1% as a solvent to prepare CNCs solution and collagen solution with a mass concentration of 3%; take 1g of the above CNCs solution and drop it into 9...

Embodiment 3

[0043] The method of degrading cotton cellulose with sulfuric acid in Example 1 was used to prepare nanocrystalline cellulose (cellulose nanocrystals, CNCs). Use acetic acid solution with a mass concentration of 0.5% as a solvent to prepare CNCs solution and collagen solution with a mass concentration of 2%; respectively take different volumes of the above CNCs solution and drop them into the above collagen solution, and mechanically stir for 2 hours to obtain the CNCs solution. 1wt%, 3wt%, 5wt%, 7wt% and 10wt% CNCs / collagen mixed solution, then pour the mixed solution into a polytetrafluoroethylene mold, put it in an oven at 40°C, and evaporate the solvent to make 1wt %, 3wt%, 5wt%, 7wt% and 10wt% CNCs reinforced collagen composite membranes. The swelling rate of the composite membrane was measured by weighing method, and the results were as follows: Figure 5 shown. Using a mechanical strength testing machine (Instron5543), each group of 5 parallel samples was used to meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com