Method for preparing nanometer hollow bar-shaped silicon dioxide materials

A silica and hollow technology is applied in the field of preparing nanometer hollow rod-shaped silica materials to achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

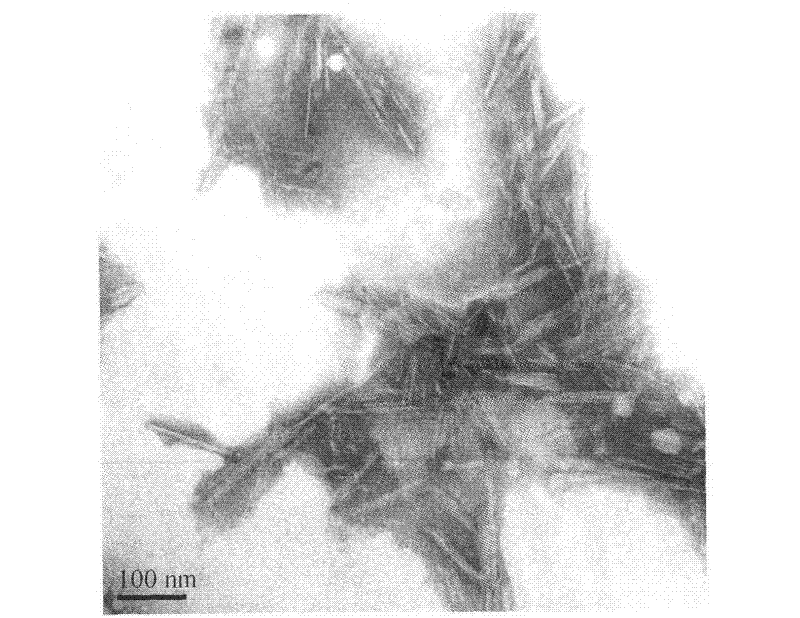

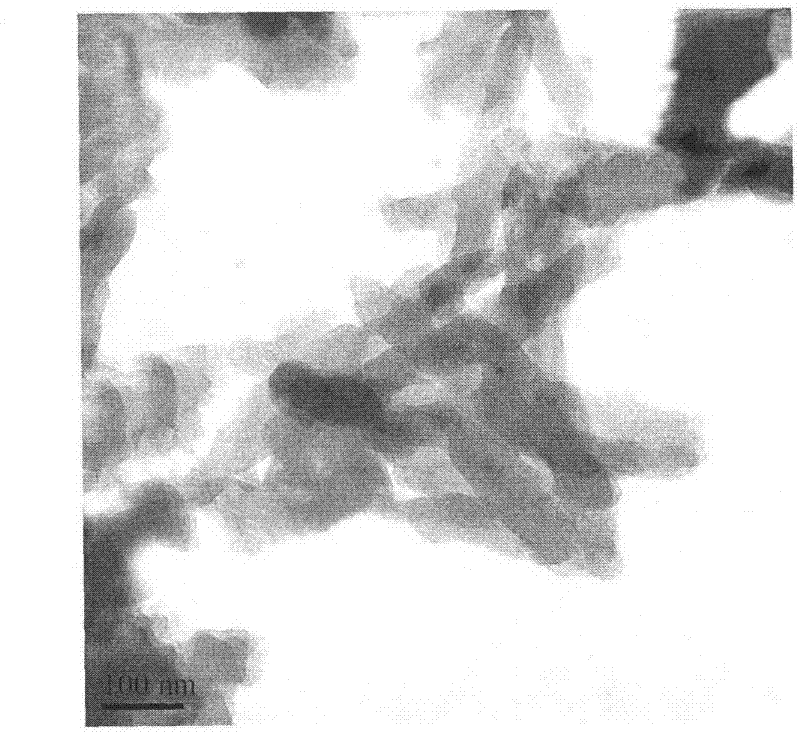

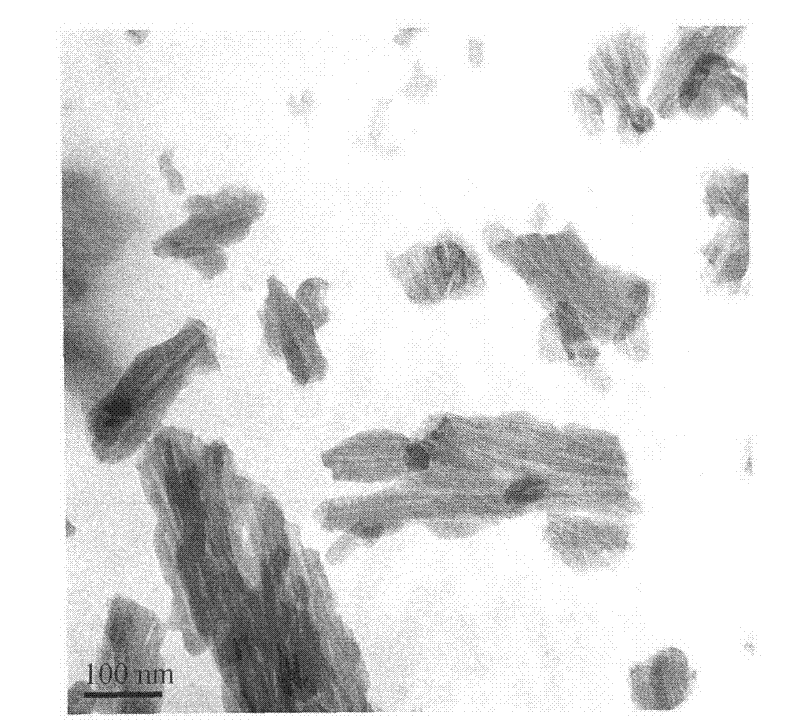

[0015] Using microcrystalline cellulose as raw material, combine 5g microcrystalline cellulose and 250mL H with a weight concentration of 64% 2 SO 4 Pour into a 500mL three-necked flask equipped with a stirrer. The mixture was hydrolyzed at 45°C for 30 minutes. After the reaction, the reactants were immediately poured into 10 times the volume of distilled water to terminate the reaction. Then centrifuge at 12000 rpm for 20 minutes to discard the upper layer of acid; then add distilled water to resuspend, and centrifuge again to ensure that the excess acid is removed. Finally, the separated and precipitated nanocrystalline cellulose is transferred to a dialysis bag (molecular weight cutoff MwCO=14000) to further remove acid. This process takes several days until the pH of the dialysate stabilizes. The prepared cellulose nanocrystal has a uniform particle size, a length of about 100-150 nm, and a width of about 10 nm. See attached for the transmission electron microscope figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com