Patents

Literature

181 results about "Cellulose compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose Compounds. Excipient (pharmacologically inactive substance) What is it? Cellulose is one of many polymers found in nature. Microcrystalline cellulose (C6H10O5)n is refined wood pulp. It is a white, free-flowing powder. Chemically, it is an inert substance, is not degraded during digestion and has no appreciable absorption.

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259AImprove toughnessGood film formingOther chemical processesWater/sewage treatment by sorptionFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

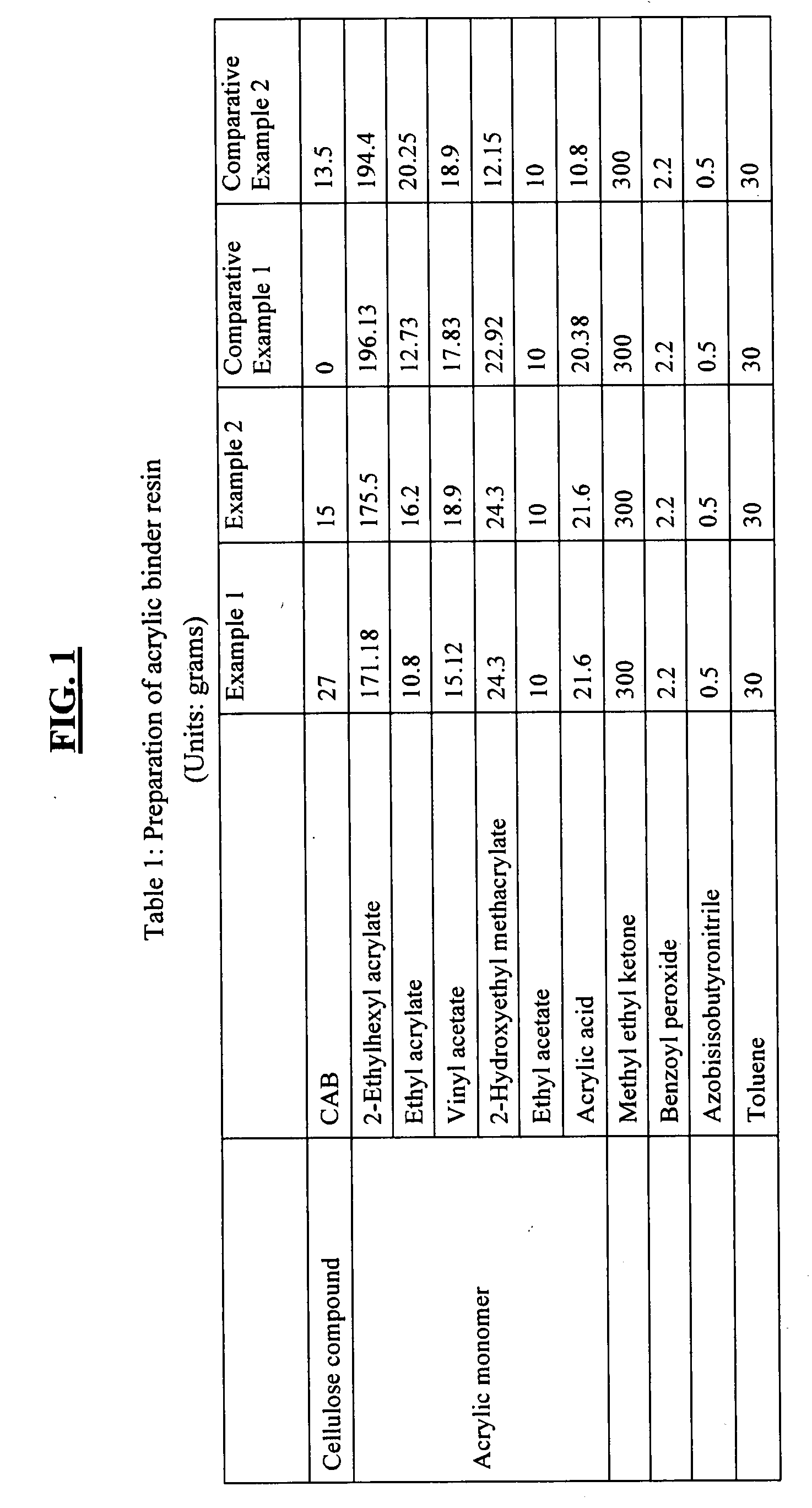

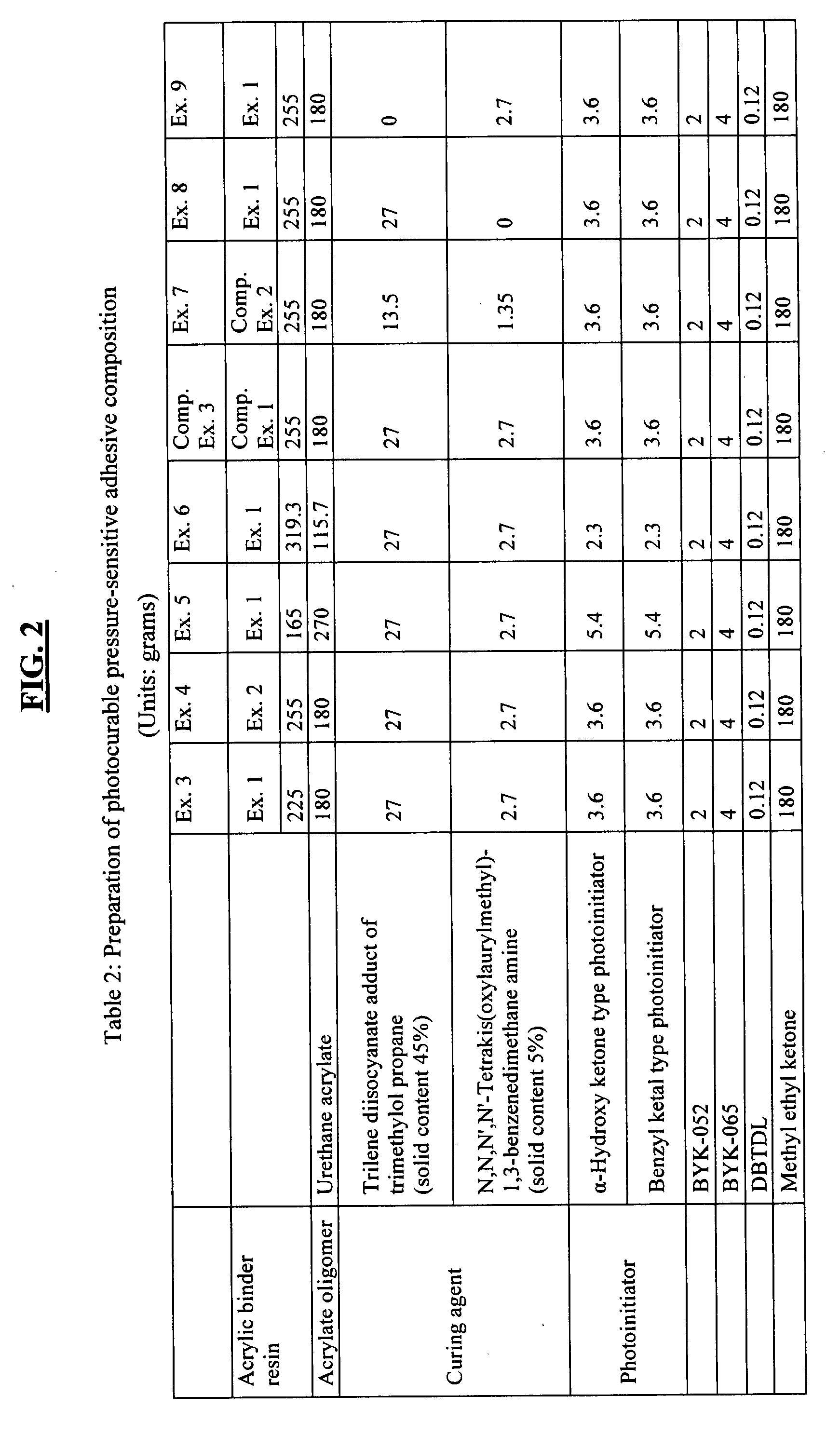

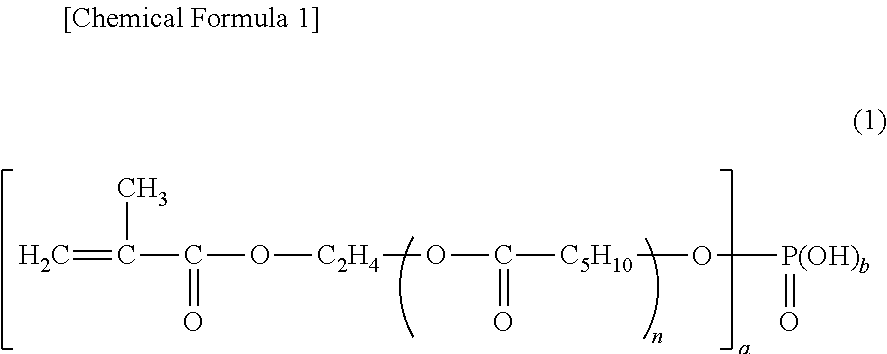

Photocurable pressure-sensitive adhesive composition including acrylic binder resin, adhesive tape using the same, and associated methods

InactiveUS20080108721A1Excellent initial adhesionExcellent photocurabilityFibre treatmentAcid polymer adhesivesOligomerCellulose compounds

Owner:CHEIL IND INC

Encased food products with contrasting components

A food product that includes a casing of a gelatin-free, water-based, set hydrocolloid gel that forms an enclosure, and at least one solid, liquid, soft or particulate center enclosed by the casing. The casing is made of a carageenan, alginate, agarose, gellan gum, pectin or cellulose compound, and the food product can withstand changes in temperature. Also, a process for the production of such a food product, wherein a liquid hydrocolloid mass is partially set and a hard, liquid, soft or particulate center is injected therein with the final completing or the setting of the hydrocolloid mass providing the encapsulation of the center.

Owner:NESTEC SA

Method for preparing bacteria cellulose compound film and application thereof as face pack material

InactiveCN101386877AIncrease productionIncrease moisture contentCosmetic preparationsToilet preparationsDry weightCellulose compounds

The invention discloses a preparation method for a bacterial cellulose composite membrane and application of the bacterial cellulose composite membrane as a facial mask material. The preparation method comprises the following steps: (1) selecting a strain; (2) preparing a seed containing a polyglutamic acid (PGA) and a liquid culture medium; (3) culturing seed cells; (4) producing bacterial cellulose by static liquid fermentation; and (5) purifying a bacterial cellulose membrane. The bacterial cellulose composite membrane can be used as a facial mask carrier or is directly used as a wet facial mask. The preparation method improves the yield of the bacterial cellulose by adding the polyglutamic acid (PGA) into the culture medium, improves the water content and the mechanical strength of a wet membrane, and has simple process and low cost; and the experiments prove that the method can ensure that the dry weight of the bacterial cellulose is improved to between 14 and 16g / L from the prior dry weight of between 8 and 10g / L, and the water content is increased to 99 percent from 98 percent.

Owner:SHANGHAI INST OF TECH

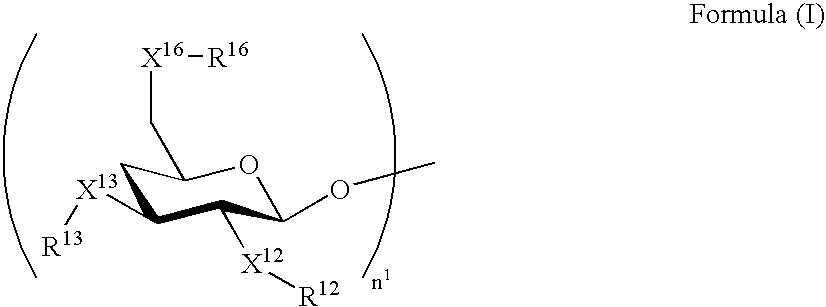

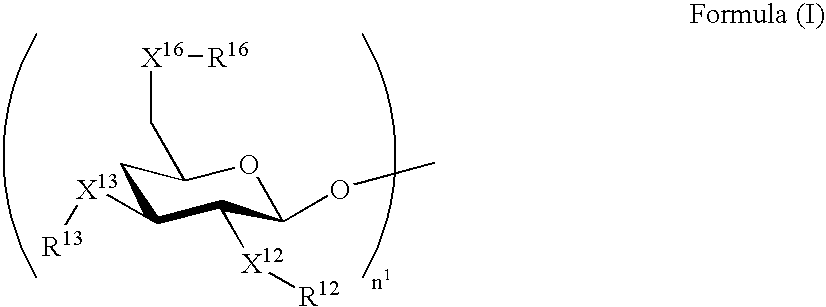

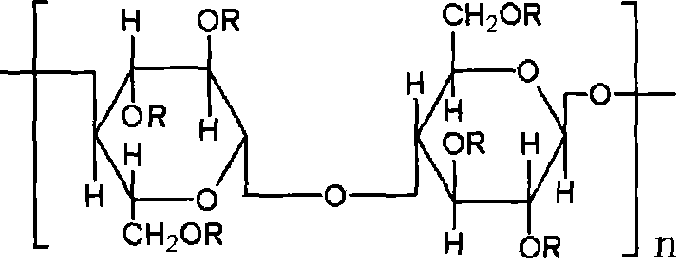

Cellulose compound, cellulose film, optical compensation sheet, polarizing plate, and liquid crystal display device

InactiveUS20080107829A1Hardly detectable coloringGood opticsLiquid crystal compositionsCellulosic plastic layered productsLiquid-crystal displayHydrogen atom

A cellulose film, containing a cellulose compound of formula (I), wherein, R16, R13, and R12 represent a hydrogen atom, or a group containing an aliphatic or aromatic group; —X16—, —X13—, and —X12— represent *1—O—, *1—OOC—, or *1—OOCNH—; n1 represents an average polymerization degree of 10 to 1,500, and the following relationships are satisfied; DS16long<(DS13long+DS12long) Expression (I) 2.5≧(DS13long+DS12long+DS16long)>0.01 Expression (II) wherein DS16long, DS13long, and DS12long represent a substitution degree at the 6-, 3- or 2-position of the substituent having absorption at the longest wavelength, among the 3n1 substituents on the 6-, 3- or 2-position; and said substituent has an absorption maximum wavelength at the longest wavelength in the range of 270 to 450 nm and a molar extinction coefficient of 2,000 to 1,000,000 for a solution of CH3—X16—R16, CH3—X13—R13 or CH3—X12—R12 corresponding to —X16—R16, —X13—R13 or —X12—R12, respectively.

Owner:FUJIFILM CORP

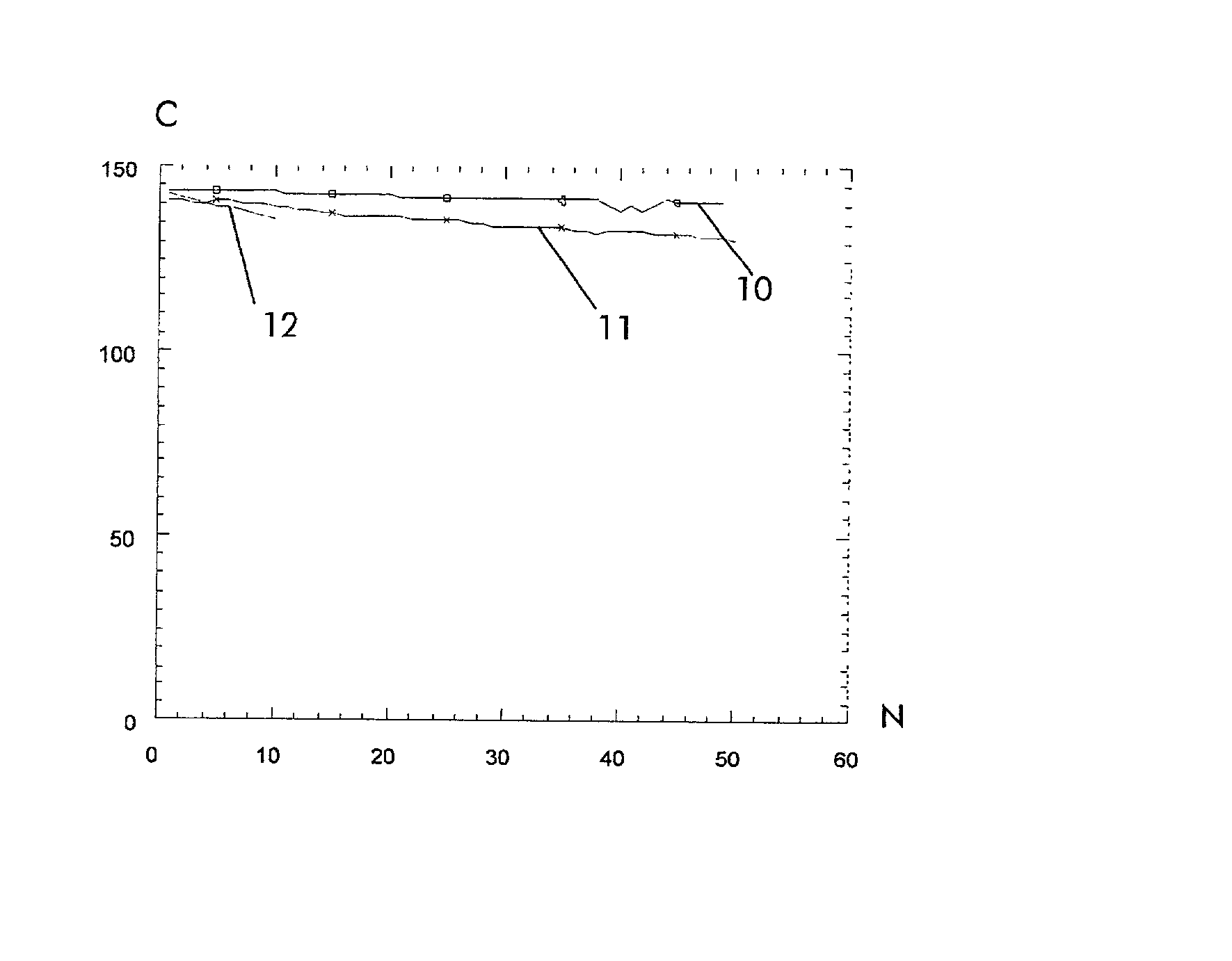

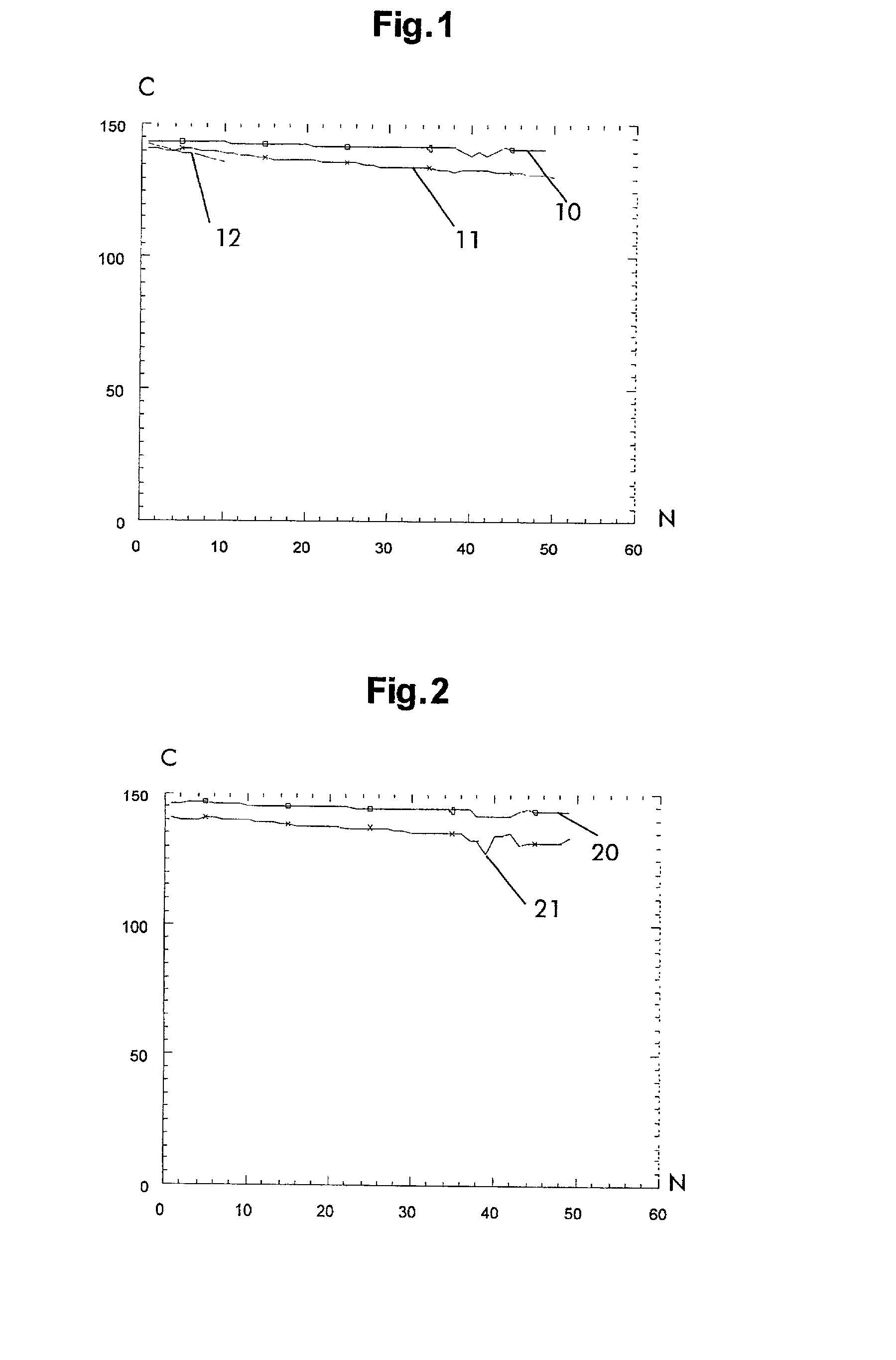

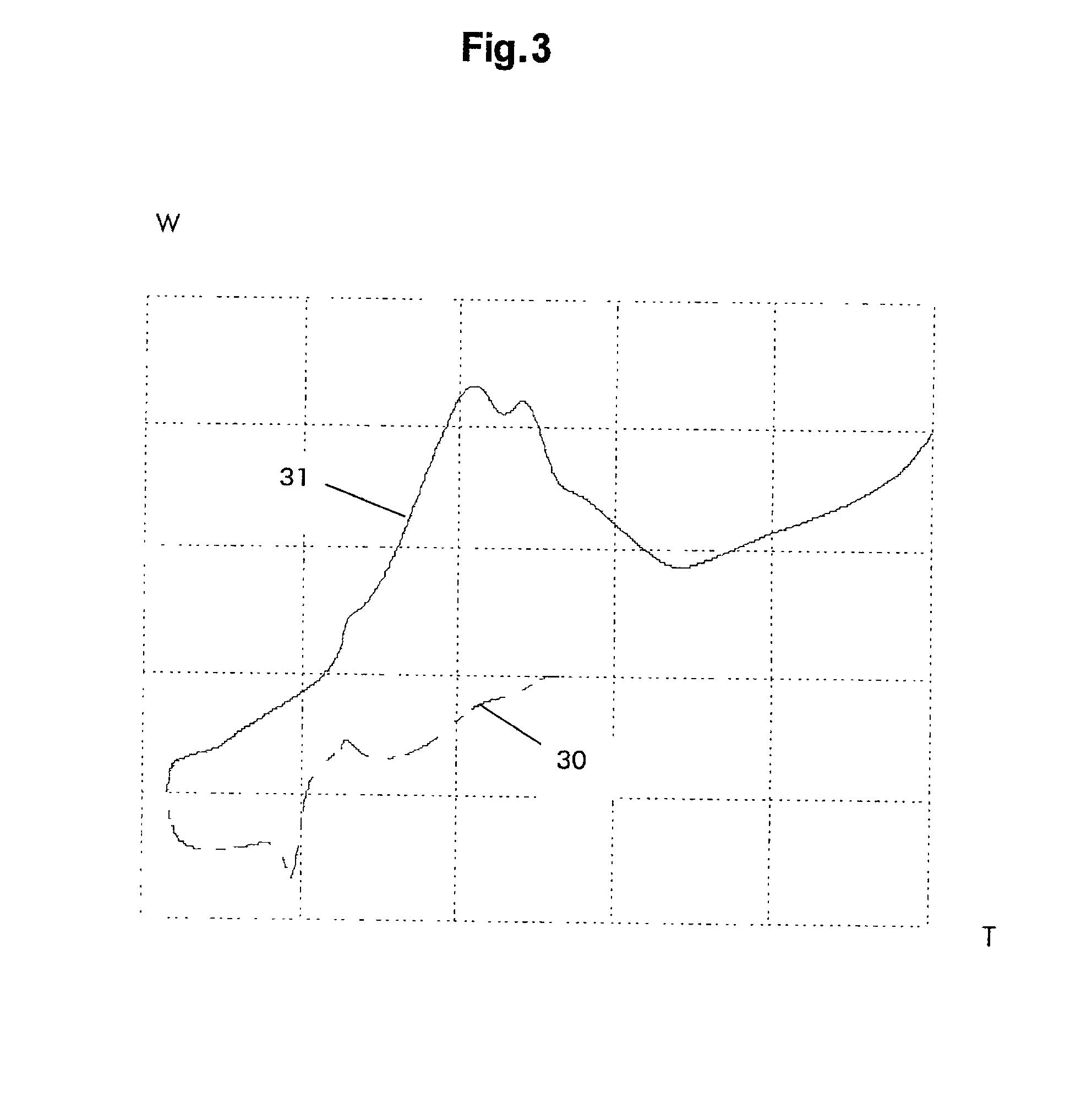

Controlled release pharmaceutical composition with resistance against the influence of ethanol employing a coating comprising neutral vinyl polymers and excipients

The invention relates to a controlled release pharmaceutical composition, comprising a core, comprising a pharmaceutical active ingredient, whereby the core is coated by an ethanol resistance conferring coating layer which has the effect of conferring the release profile of the pharmaceutical active ingredient to be resistant against the influence of ethanol, whereby the ethanol resistance conferring coating layer comprises at least 70% by weight of a mixture of a polymeric portion a) and an excipients portion b), with the polymeric portion a) is consisting of a water insoluble essentially neutral vinyl polymer or vinyl copolymer and the excipients portion b) is consisting of the excipients b1) 100 to 250% by weight of a non-porous inert lubricant, b2) 1 to 35% by weight of a cellulosic compound, b3) 0.1 to 25% by weight of an emulsifier and additionally or alternatively to b3), b4) 0.1 to 30% by weight of a plasticizer whereby the excipients of the excipients portion b) are each calculated on the dry weight of the polymer portion a).

Owner:EVONIK OPERATIONS GMBH

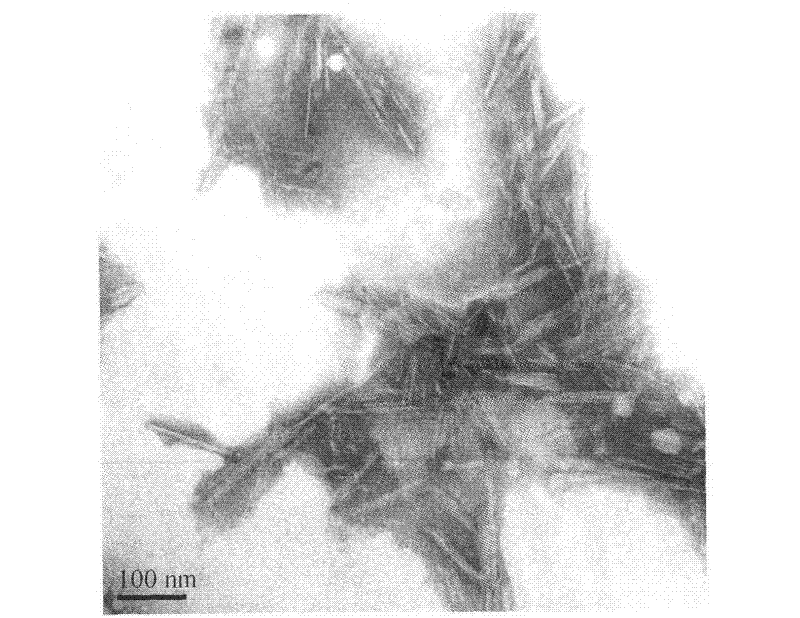

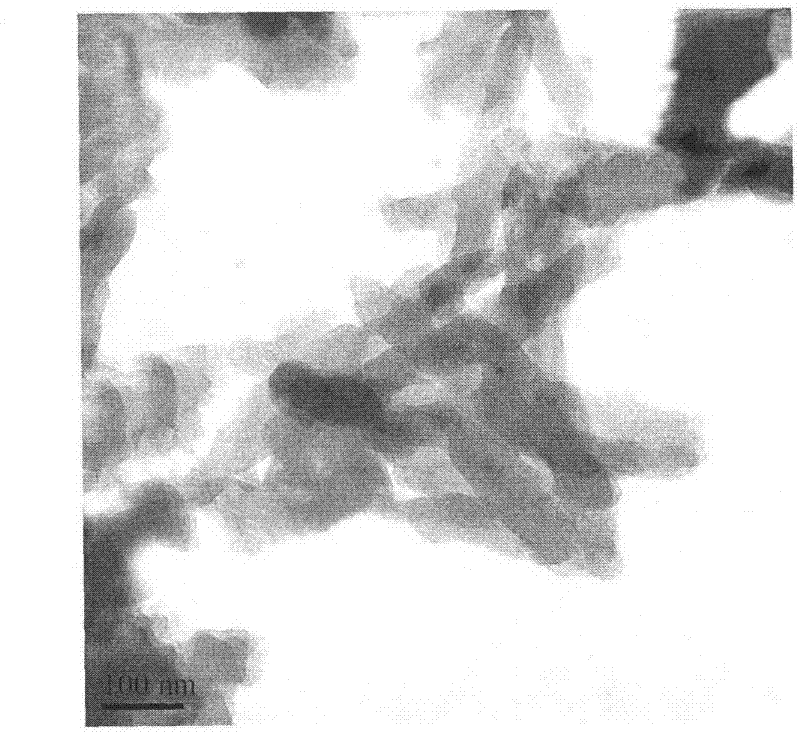

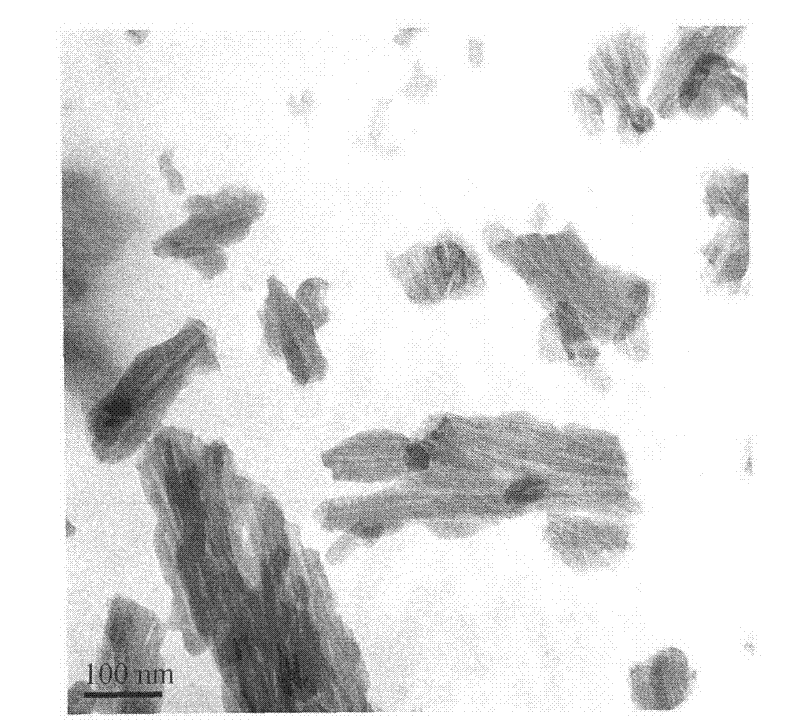

Method for preparing nanometer hollow bar-shaped silicon dioxide materials

The invention relates to a method for preparing nanometer hollow bar-shaped silicon dioxide materials by using nanometer crystal cellulose as templates. According to the method, the cellulose and the tetraethoxysilane are adopted as raw materials. Firstly, the cellulose raw materials are hydrolyzed by sulfuric acid with the weight concentration being 64 percent to obtain nanometer crystal cellulose with negative charges on the surface, then, cetyl trimethyl ammonium bromide is used so that the charges on the surface of the cellulose nanometer crystals are changed into positive charges, then, sol obtained through tetraethoxysilane hydrolysis is absorbed onto the surface of the cellulose nanometer crystals under the alkaline condition, and finally, silicon dioxide gel is formed through condensation polymerization, so the nanometer crystal cellulose compounds covered by the silicon dioxide is obtained through the preparation. After the compounds are subjected to freezing drying, powder is obtained, the powder is roasted in a Muffle furnace to remove the cellulose nucleus, and the nanometer hollow bar-shaped silicon dioxide materials are obtained. The cellulose nanometer crystals adopted by the method are used as the templates, raw materials are rich, the preparation is simple, in addition, the dimension and the shape of the templates can be regulated and controlled through the hydrolysis time and the intensity, the hollow bar-shaped silicon dioxide materials with the inner diameter being dozens of nanometers can be prepared, in addition, the whole experiment process is safe, and the obtained products are uniform.

Owner:NANJING FORESTRY UNIV

Rechargeable lithium storage cell

A rechargeable lithium storage cell includes a positive electrode, whose electrochemically active material includes one or more oxides of a transition metal, and a negative electrode, consisting of a conductive support and an active layer containing a binder and an electrochemically active material. The binder is a polymer containing no fluorine. The electrochemically active material is a mixed oxide of lithium and titanium with the general formula Li.sub.xTi.sub.yO.sub.4 in which 0.8.ltoreq.x.ltoreq.1.4 and 1.6.ltoreq.y.ltoreq.2.2. The non-fluorinated polymer is preferably soluble in water or capable of forming a stable emulsion in suspension in water. The binder preferably contains an elastomer, especially an acrylonitrile / butadiene copolymer and / or a cellulose compound such as carboxymethylcellulose.

Owner:SAFT FINANCE S AR L

Bacteria cellulose compound film, preparation and uses thereof

InactiveCN101509026AIncrease productionIncrease moisture contentMicroorganism based processesAbsorbent padsDry weightLiquid medium

The invention relates to a bacterial cellulose composite membrane, a preparation method and application thereof; the preparation steps include the selection of a strain, the preparation of a seed and liquid medium, the culture of a seed cell, the production of a bacterial cellulose composite membrane by liquid fermentation and separation as well as purification and the like, finally the bacterial cellulose composite membrane is prepared. The bacterial cellulose composite membrane which is obtained by the invention has simple preparation process and low cost, significantly increases the conversion rate of raw materials and the output and water content of bacterial cellulose, can cause the dry weight of bacterial cellulose to be improved from the traditional 8-10g / L to 14-16g / L, and leads the water content to be raised from 98 to 99%. The bacterial cellulose composite membrane which is obtained by the invention can be used as a wound dressing.

Owner:SHANGHAI INST OF TECH +1

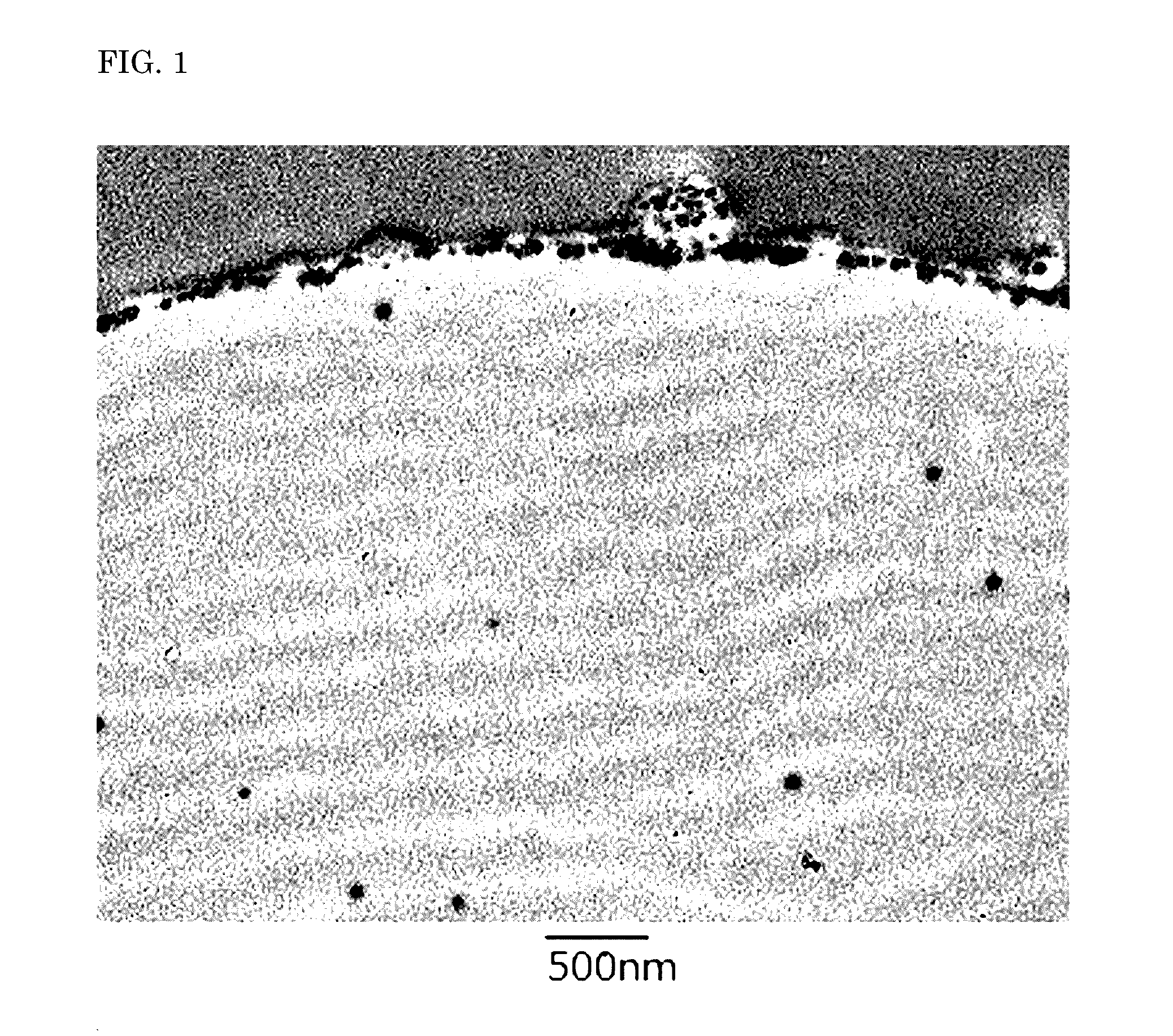

Composite particles, method for producing composite particles, and use thereof

ActiveUS20170058116A1Improve dispersion stabilitySimple stepsPolyurea/polyurethane coatingsOptical elementsPolymer scienceCellulose compounds

There are provided a method for producing particles by suspension polymerization which ensures an excellent dispersion stability of the monomer and a simpler washing step, composite particles obtainable by this production method, and use of the composite particles. The method for producing composite particles includes a polymerization step of subjecting a monomer mixture which contains a polymerizable vinyl monomer to aqueous suspension polymerization in a presence of small polymer particles having a volume-average particle size of 20 to 500 nm, with a water-soluble cellulose compound adsorbing on surfaces of the small polymer particles, and thereby obtaining composite particles which contain the small polymer particles and large polymer particles greater than the small polymer particles.

Owner:SEKISUI PLASTICS CO LTD

Cellulose Compound Film, Optical Compensation Sheet, Polarizing Plate, and Liquid Crystal Display Device

InactiveUS20070259134A1Liquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

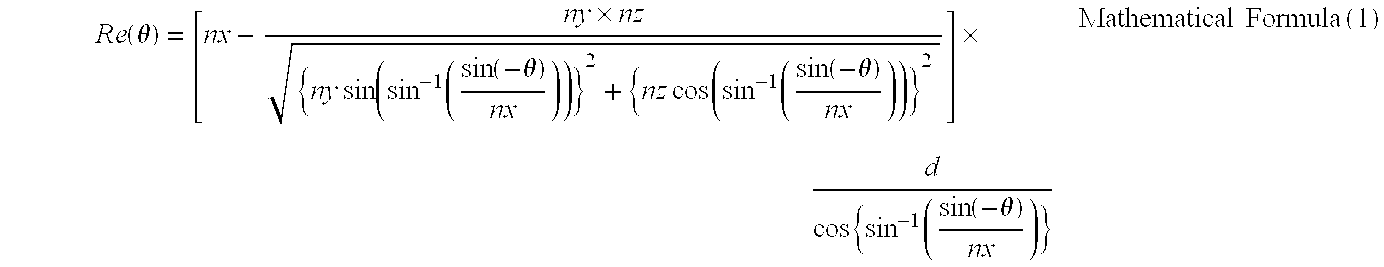

A cellulose compound film containing a cellulose compound having two or more substituents whose polarizability anisotropies Δα calculated by mathematical formula (1) are different from each other, wherein substitution degrees of the following substituents A and B in the cellulose compound satisfy relationship as defined by mathematical formula (A1), in which the substituent A has the lowest Δα and the substituent B has the highest Δα: Δ α=α x-α y+α z2Mathematical formula (1)wherein, in characteristic values obtained after diagonalization of polarizability tensor, αx is the largest component, αy is the second largest component, and αz is the smallest component; DSB2+DSB3−DSB6≧−0.1 Mathematical formula (A1) wherein DSB2, DSB3, and DSB6 represent a substitution degree of the substituent B at the 2-, 3-, or 6-position of a β-glucose ring constituting unit of cellulose, respectively; and an optical compensation film, a polarizing plate, and a liquid crystal display device, using the cellulose compound film.

Owner:FUJIFILM CORP

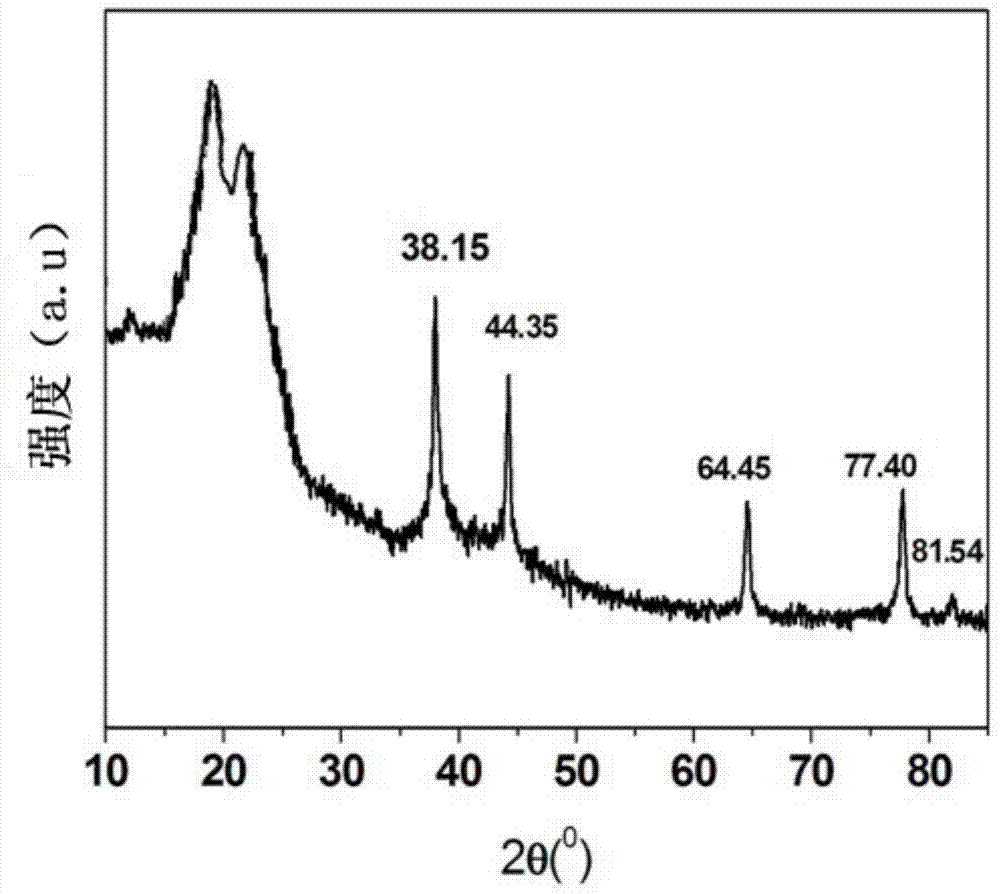

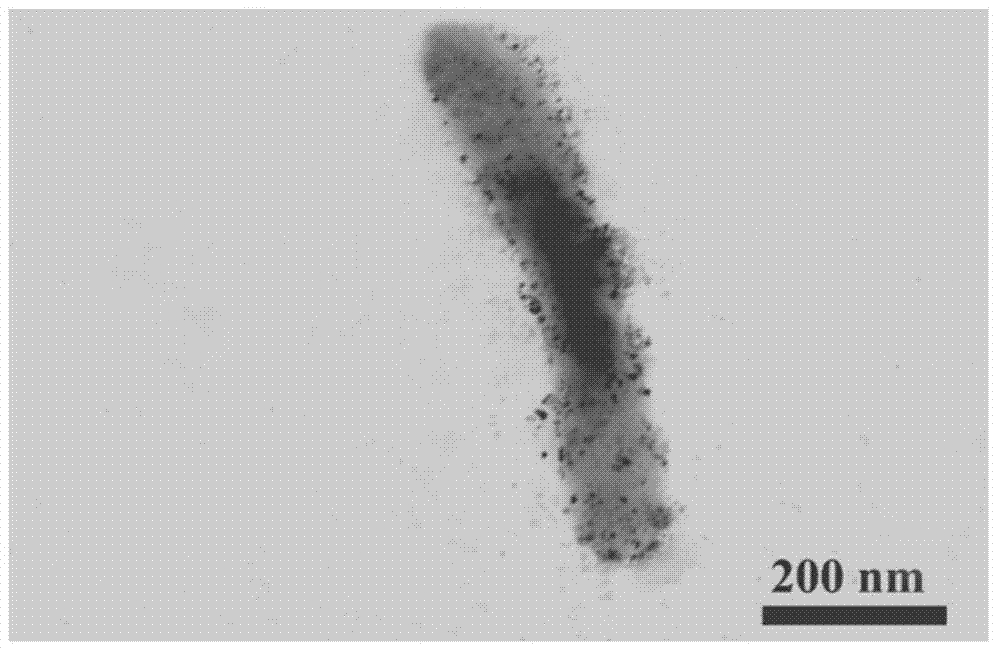

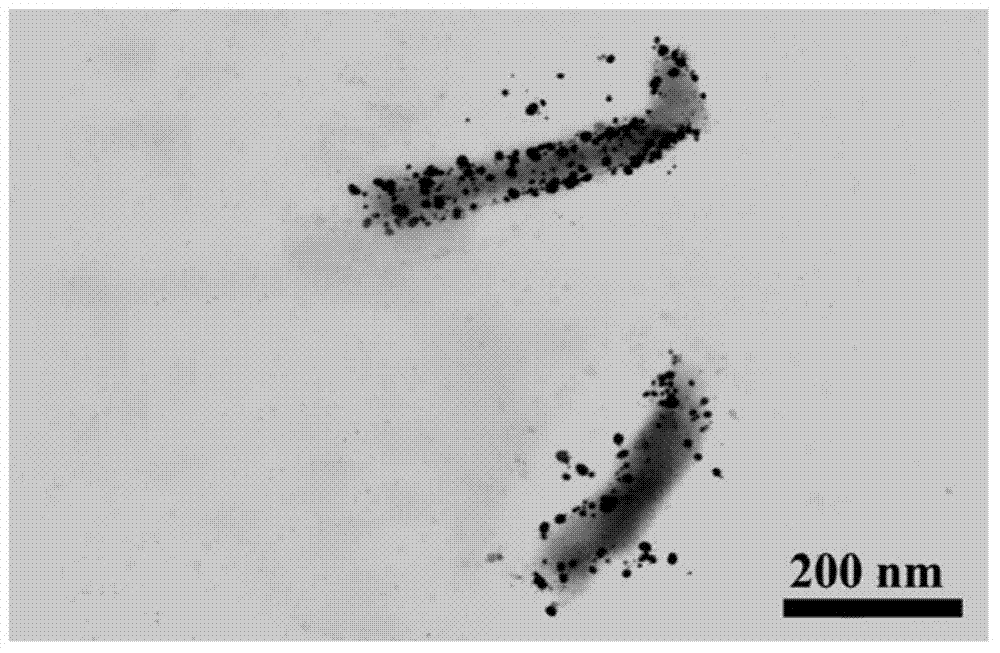

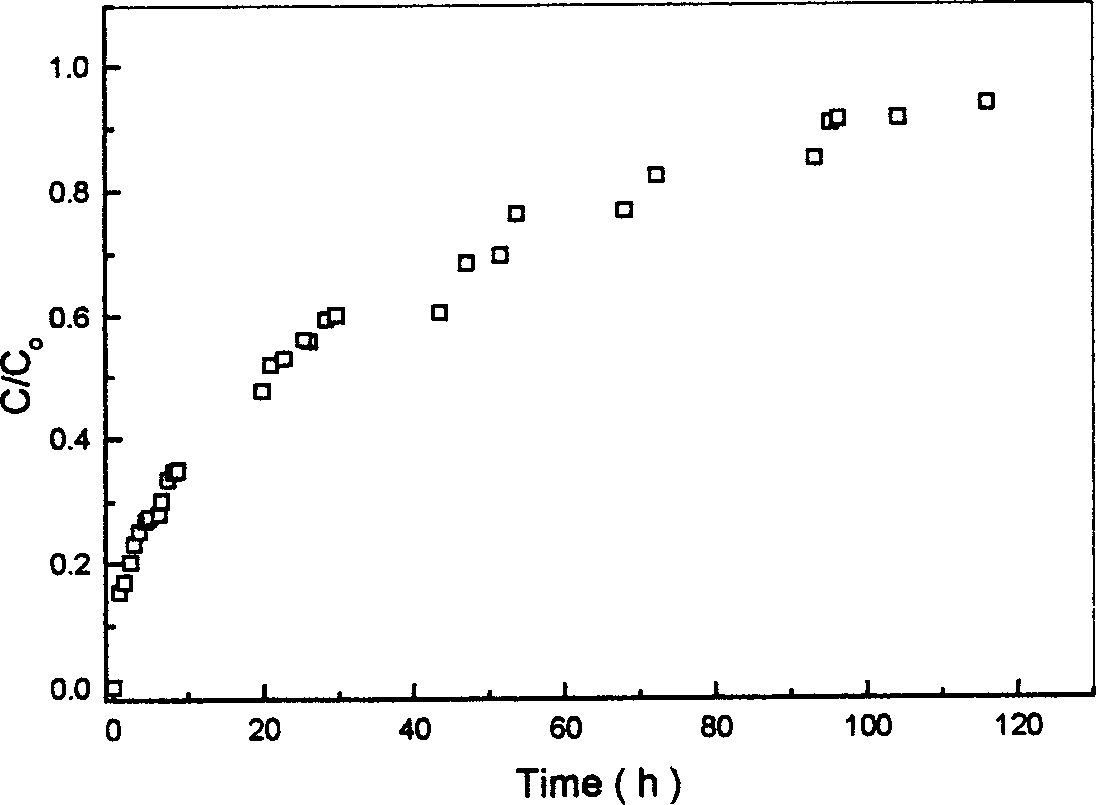

Nanometer silver-nanocrystalline cellulose compound, preparation method of nanometer silver-nanocrystalline cellulose compound, and application of nanometer silver-nanocrystalline cellulose compound

The invention belongs to the technical field of nanometer materials, and discloses a preparation method of the nanometer silver-nanocrystalline cellulose compound. The preparation method includes the following steps of adding a nanometer silver-nanocrystalline cellulose aqueous solution to a silver salt aqueous solution under the stirring condition, conducting stirring to obtain mixed liquor, stirring the mixed liquor in an ultrasonic container, conducting an ultrasonic reaction, conducting centrifugal separation on the reaction liquor after the reaction is completed, and taking and washing sediments to obtain the nanometer silver-nanocrystalline cellulose compound. The nanometer silver-nanocrystalline cellulose compound obtained through the method can serve as an antibacterial material to be applied to the field of articles of daily use, the medical treatment and public health field, the building material coating field and the electronic product field. The sizes of nanometer silver particles in the nanometer silver-nanocrystalline cellulose compound are the same. Dispersity of the nanometer silver particles in the nanometer silver-nanocrystalline cellulose compound is good. Nanometer silver is evenly loaded on the nanometer silver-nanocrystalline cellulose and not prone to agglomeration. The nanometer silver-nanocrystalline cellulose compound has good solubility in water.

Owner:SOUTH CHINA UNIV OF TECH

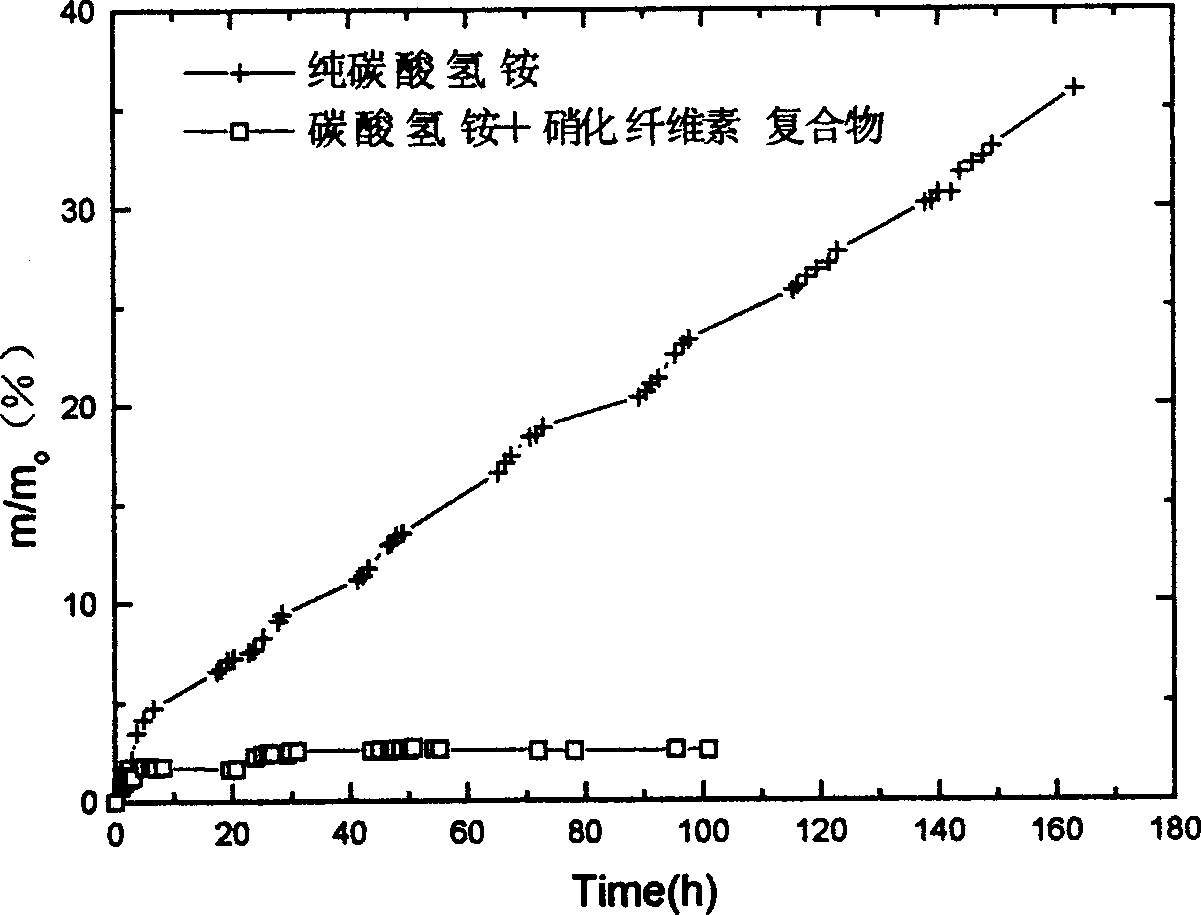

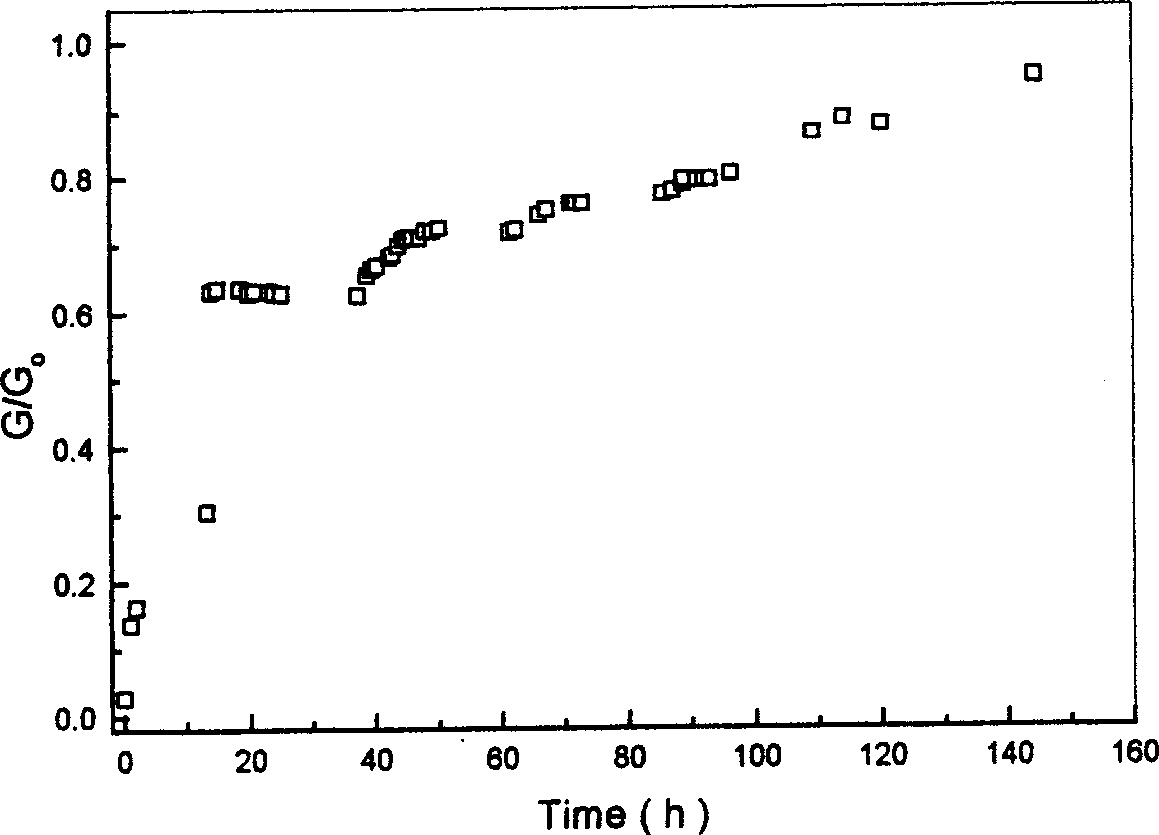

Film-coated slow-released fertilizer and preparation process thereof

InactiveCN1465552ABiodegrades quicklyMeet the needs of sustainable developmentFertilizer mixturesAlcoholNitrocellulose

The present invention relates to a coated granular slowly-releasing fertilizer and its preparation method. It is characterized by that the surface of the nitrogen granular fertilizer is covered witha layer of coated film, and said coated film is formed from nitro-cotton and tung oil as dry oil additive, and the coated film is 5%-30% of total weight and added quantity of tung oil is 0-20% of coated film weight. Its preparation method includes the following steps: dissolving the cellulose compound and its derivative for example nitro-cotton in solvent to obtain covering solution, said solventis ethyl alcohol and ethyl ether mixed solution, then coating surface of granular fertilizer with said covering solution, finally recovering solvent so as to obtain the invented coated granjlar slowly-releasing fertilizer.

Owner:NANJING UNIV +1

Process for highly efficient catalytic conversion of cellulose raw material to diol

ActiveUS20150057469A1Rapid and high methodIncreased space-time yieldPreparation by OH group eliminationPreparation by oxygen reductionIridiumHydrogen pressure

This invention provides a method for highly efficient catalytic conversion of cellulosic raw materials to glycols. In the process, cellulosic compounds such as crop stalk, wood powder and etc., as feedstock are subjected to one-step catalytic conversion with a ternary composite catalyst composed of organic acid or inorganic acid which does not contain tungsten, a transition metal from Groups 8, 9 or 10 such as iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, or a mixture thereof, and a tungsten oxide, a tungsten sulfide, a tungsten chloride, a tungsten hydroxide, tungsten bronze, tungstic acid, a tungstate, a metatungstate acid, a metatungstate, a paratungstate acid, a paratungstate, a peroxotungstic acid, pertungstate and heteropoly tungstate, or a mixture thereof. The reaction is carried out under hydrothermal conditions at a temperature between 120-300° C. with hydrogen pressure between 1-13 MPa.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

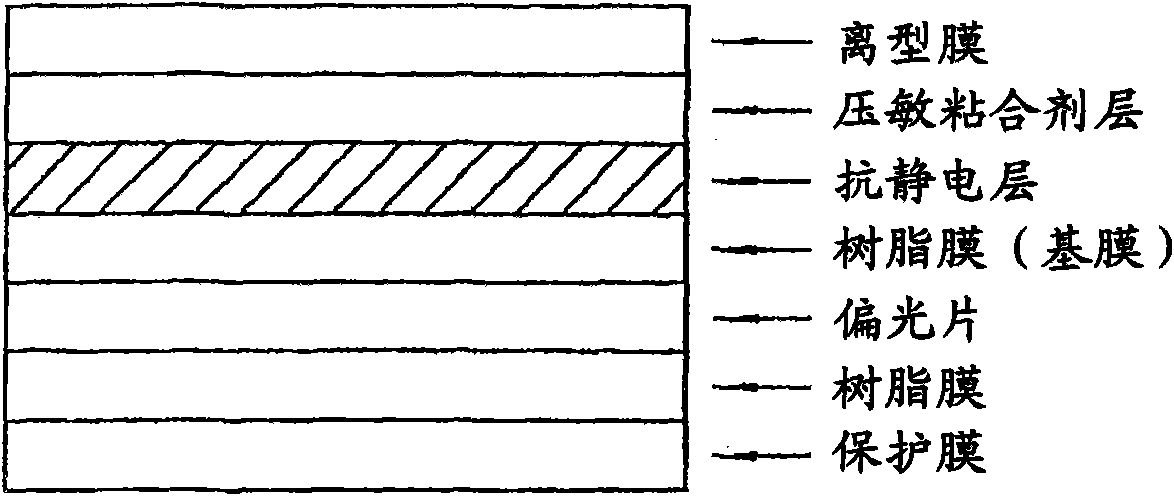

Polarizing film comprising antistatic coating layer

ActiveCN101868510AImprove adhesionFavorable light transmittanceLayered productsElectrical equipmentLiquid-crystal displayCellulose compounds

A polarizing film comprising an antistatic coating layer is provided. The coating layer contains polyethylene dioxythiophene (PEDOT) doped with polystyrenesulfonate (PSS), a curable resin, a hydroxyacrylate compound, a cellulose compound and a photopolymerization initiator. The coating layer has good adhesion to a triacetyl cellulose film and a pressure-sensitive adhesive (PSA) layer. The polarizing film is advantageous in terms of transparency, surface resistance and moisture resistance. The use of the polarizing film prevents malfunction of a liquid crystal display (LCD) associated with static electricity.

Owner:CHEIL IND INC

Preparation method of cellulose compound aerogel

The invention aims at providing a preparation method of cellulose compound aerogel. The preparation method includes the steps that with durian shells as the raw material, carboxylated nanocellulose is prepared through oxidative degradation with ammonium sulfate; then, the prepared carboxylated nanocellulose is compounded with cellulose dissolving liquid, and the cellulose compound aerogel is prepared under certain technological conditions. According to the preparation method, the production process is environmentally friendly, and the prepared cellulose aerogel has high strength and a large specific surface area.

Owner:林向阳

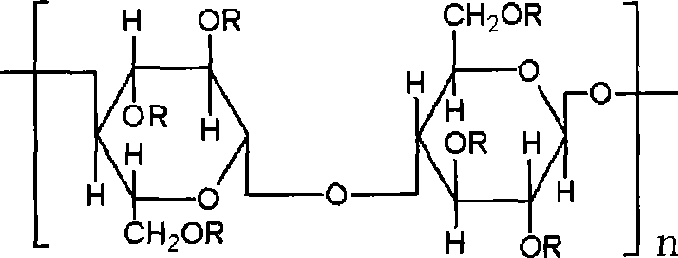

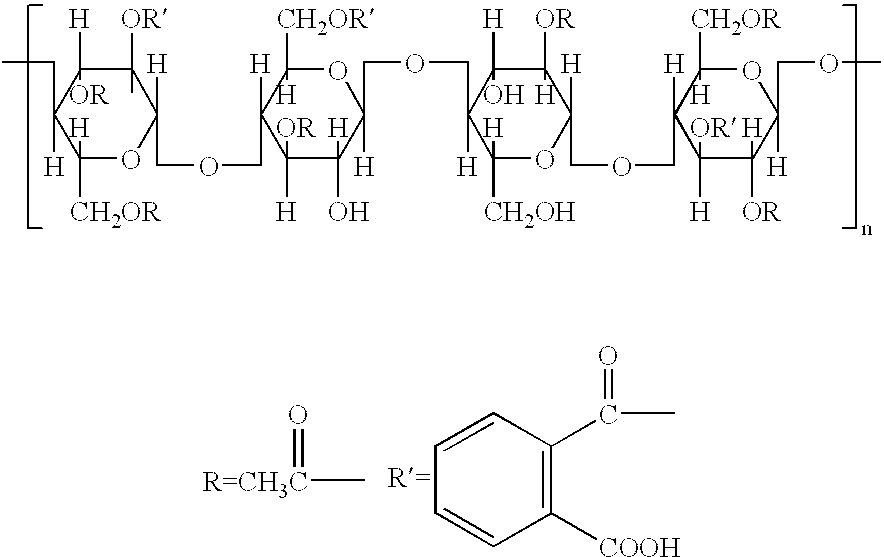

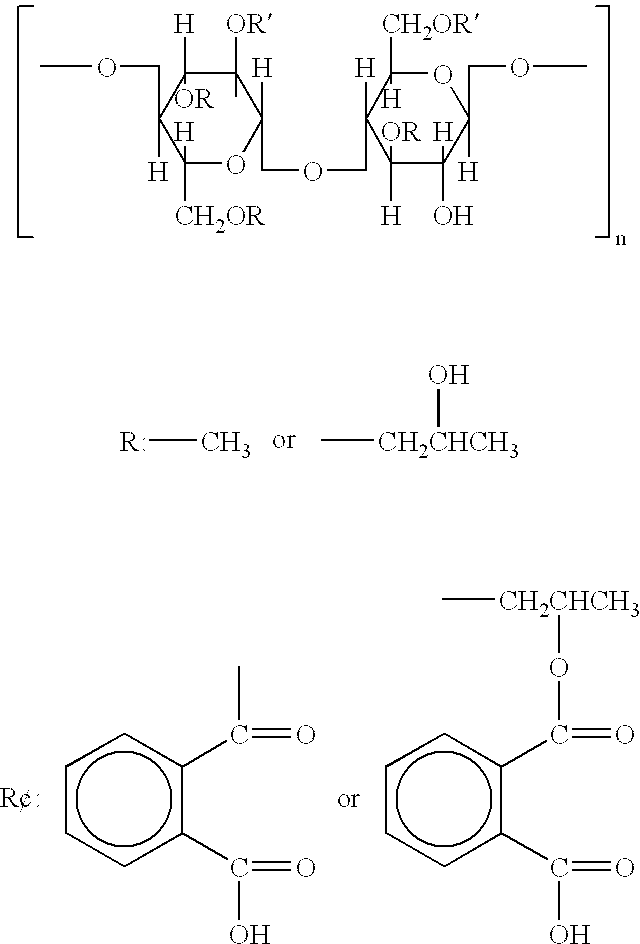

Polysubstituted radical cellulose composite ether and its preparing method

Owner:HUZHOU ZHANWANG PHARMA

Method for preparing bio-ethanol by taking seaweed processing waste as raw material

InactiveCN101701225AImprove enzymatic hydrolysis efficiencyOpportunity for facilitationMicroorganism based processesFermentationFiberCellulose compounds

The invention relates to a method for preparing bio-ethanol by taking seaweed processing waste as raw material, which is characterized by comprising the steps: selecting the seaweed processing waste, and pretreating the raw material by sulfuric acid or hydrogen peroxide; then, adding cellulase or cellobiase for cellulose compound enzymolysis, and filtering enzymolysis liquid to remove insoluble components; and finally, supplementing inorganic salt, inoculating saccharomyces cerevisiae strain, and carrying out alcoholic fermentation under the anaerobic condition. The original structure of algae cellulose is changed by the pretreatment process, and the action probability between the cellulose and degrading enzyme can be promoted, so that the enzymolysis efficiency of the cellulose is improved; furthermore, after the cellulose is treated by the compound enzymolysis of the cellulase and the cellobiase, the feedback inhibition of the cellobiose for the cellulose can be effectively eliminated, the content of glycolysis sugar of yeast can be improved, and the yield of alcoholic fermentation is further improved.

Owner:OCEAN UNIV OF CHINA

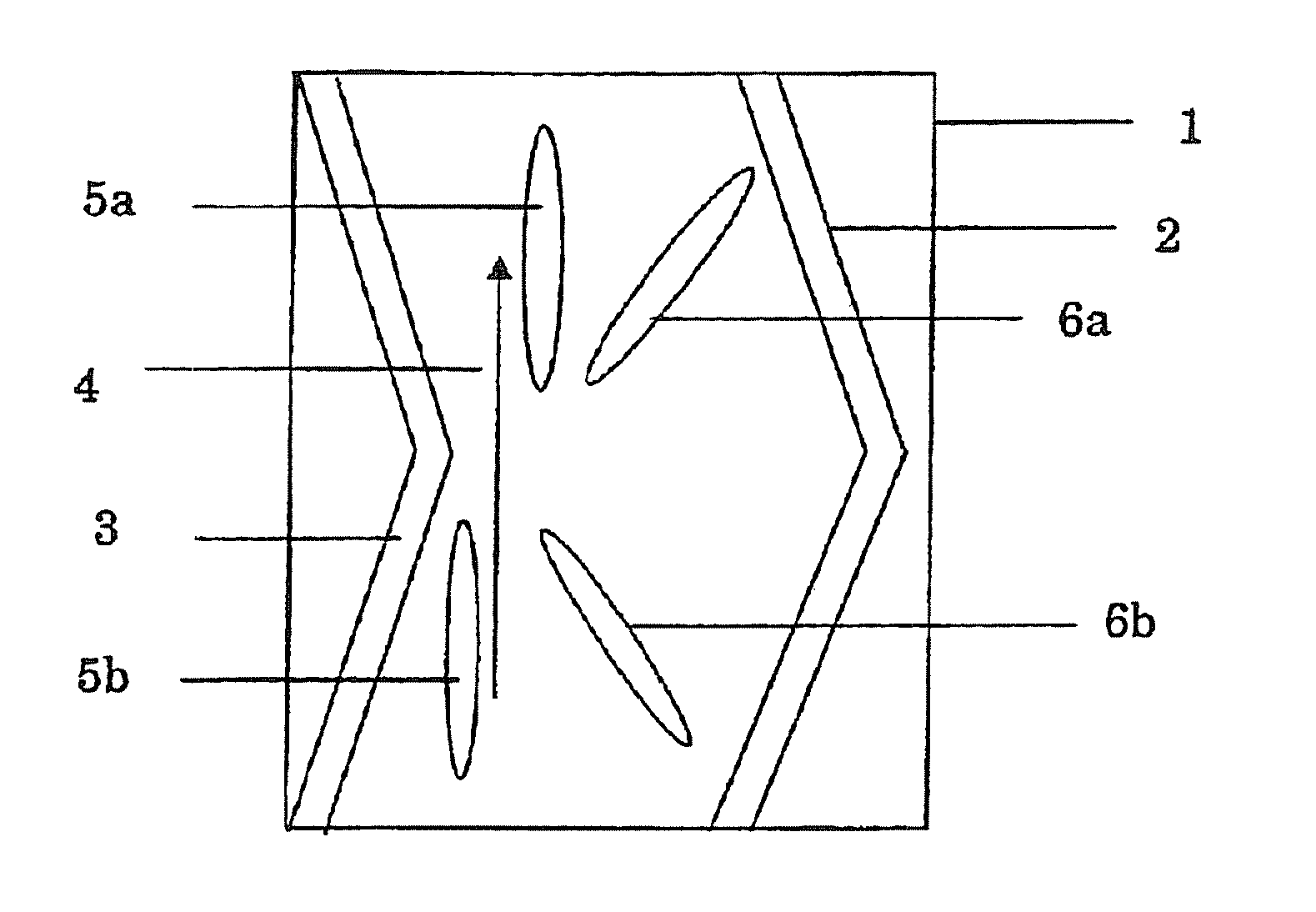

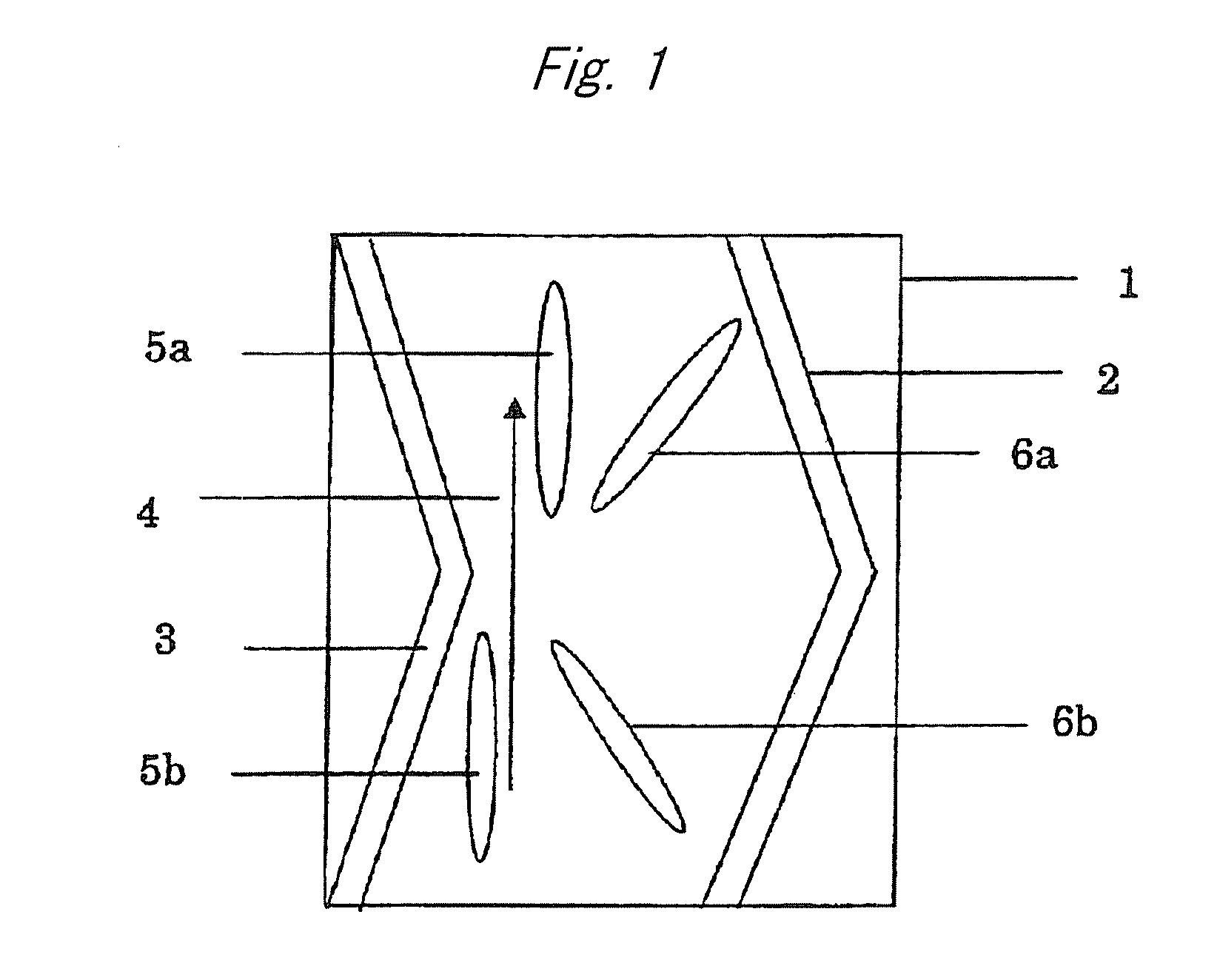

Multilayered photosensitive material for flexographic printing plate

InactiveUS6897006B2Efficient processIncreased durabilityPhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundCellulose compounds

The invention discloses a multilayered photosensitive material for processing into a flexographic printing plate by direct patterning with an infrared laser beam. The multilayered material comprises: (A) a substrate; (B) a photosensitive resinous layer having sensitivity to light excepting infrared light and comprising (b1) an elastomeric binder resin, (b2) a polymerizable monomeric compound and (b3) a polymerization initiator formed on the substrate (A); (C) a barrier layer of a composition comprising a resin such as a polyvinyl pyrrolidone and alkali-soluble cellulose compounds, which transmits light other than infrared light and is removable in the development treatment, formed on the photosensitive resinous layer (B); and (D) a masking layer of a composition comprising (d1) a film-forming binder resin, (d2) an infrared absorbing compound and (d3) a compound having no transmissivity to lights other than infrared light and removable by irradiation with an infrared laser beam, formed on the barrier layer (C).

Owner:TOKYO OHKA KOGYO CO LTD

Biodegradable microbicidal vaginal barrier device

An intravaginal bio-erodible microbicidal barrier device. The device comprises (a) at least one micronized compound selected from the group consisting of cellulose acetate phthalate and hydroxypropylmethylcellulos- e phthalate, and (b) at least one water soluble or water dispersible cellulose compound selected from the group consisting of hydroxypropylmethylcellulose, methylcellulose, hydroxyethylcellulose, hydroxypropylcellulose, hydroxyethylmethylcellulose, hydroxyethylethylcellulose and hydroxypropylethylcellulose; or a pectin, such as an apple pectin. The device is prepared by a combination of foaming, freezing and freeze-drying processes.

Owner:NEW YORK BLOOD CENT

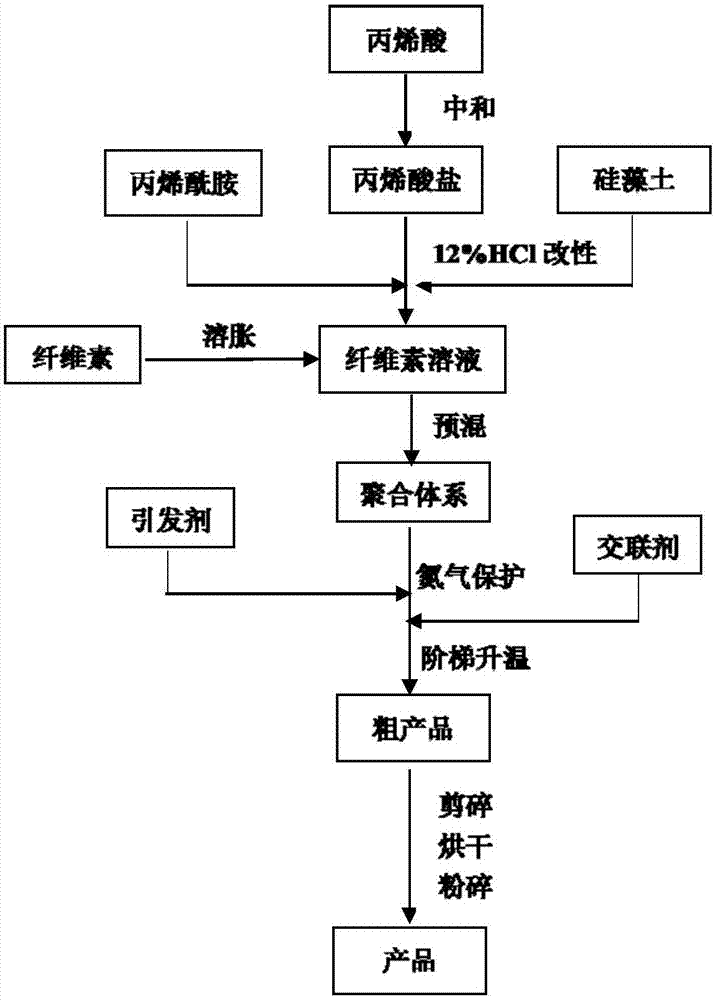

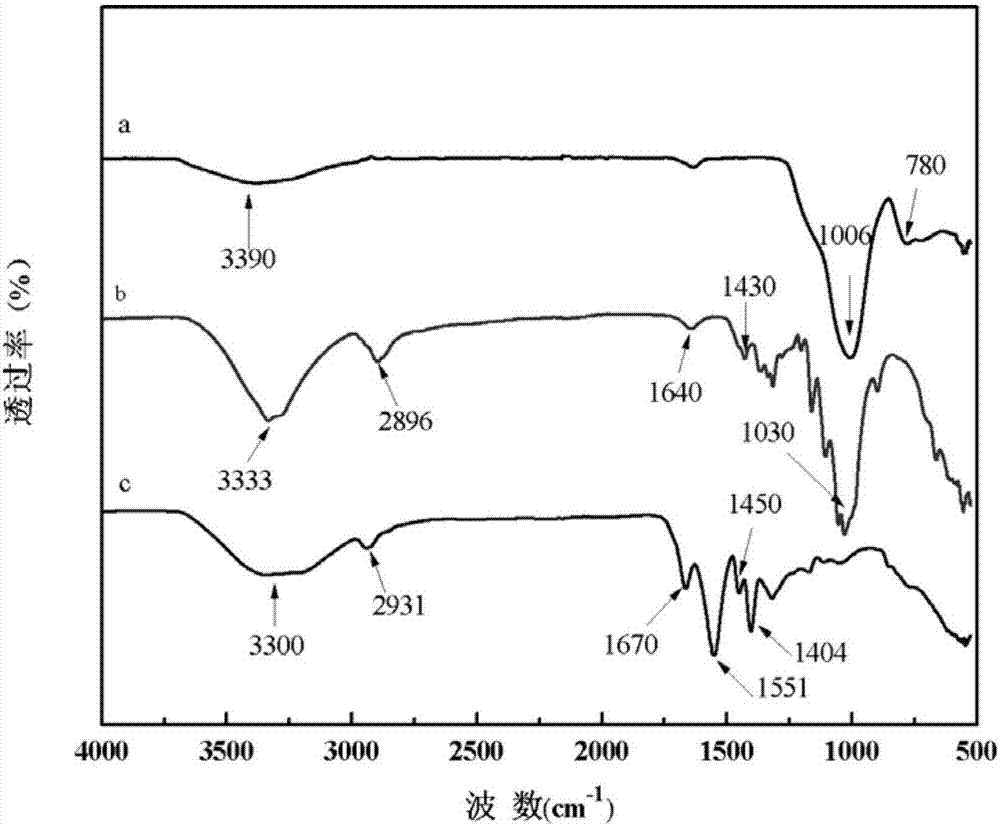

Preparation method for compound super absorbent resin containing kieselguhr and cellulose

The invention discloses a preparation method for a compound super absorbent resin containing kieselguhr and cellulose. The method comprises the following steps: firstly modifying the kieselguhr by using hydrochloric acid solution, adding acrylate, acrylamide and the modified kieselguhr which are processed by ultrasound to the swelling cellulose and premixing, and adding a potassium persulfate initiator to induce to generate a free radical, finally adding an N,N'-methylene bisacrylamide cross-linking agent, generating a gel-like compound by copolymerization, drying, and smashing to obtain the sodium polyacrylate / polyacrylamide / kieselguhr / cellulose compound super absorbent resin. The water absorption rate of the compound resin under the room temperature is up to 660.98 g / g, and the absorption rate of 0.9% of normal saline is up to 90.56 g / g. In addition, the heat stability of the compound super absorbent resin is higher, the compound super absorbent resin has the excellent comprehensive performances of good water-absorbing property, salt resistance, heat resistance, high water-retaining property and biocompatibility, and is particularly suitable for the fields, such as agriculture and forestry, environmental protection, and park.

Owner:NANJING UNIV OF SCI & TECH

Process for improving the energy density of feedstocks using formate salts

ActiveUS20120203043A1Hydrocarbon purification/separationLiquid hydrocarbon mixture productionLevulinic acidFormate

Methods of forming liquid hydrocarbons through thermal deoxygenation of cellulosic compounds are disclosed. Aspects cover methods including the steps of mixing a levulinic acid salt-containing feedstock with a formic acid salt, exposing the mixture to a high temperature condition to form hydrocarbon vapor, and condensing the hydrocarbon vapor to form liquid hydrocarbons, where both the formic acid salt and the levulinic acid salt-containing feedstock decompose at the high temperature condition and wherein one or more of the mixing, exposing, and condensing steps is carried out a pressure between about vacuum and about 10 bar. Other methods and parameters for generating energy dense liquid hydrocarbons are also disclosed and claimed.

Owner:UNIVERSITY OF MAINE

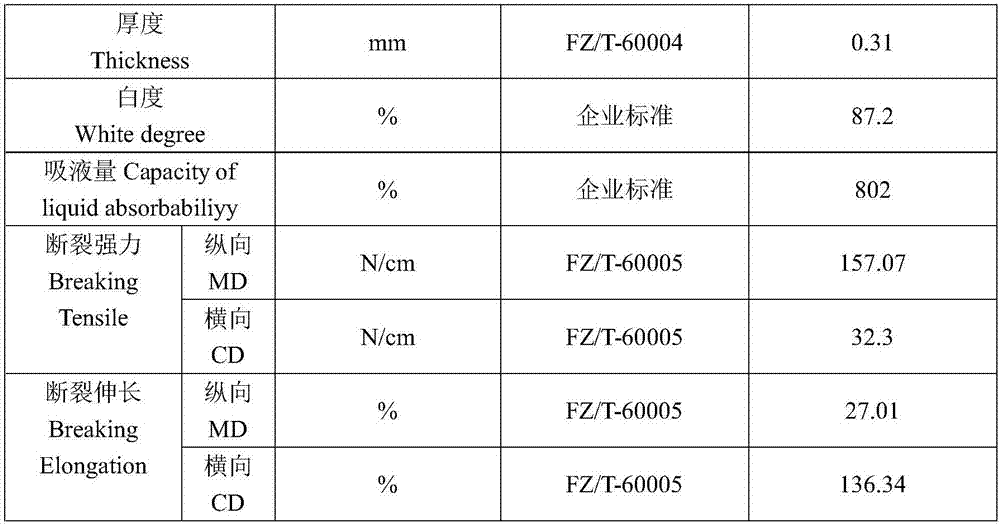

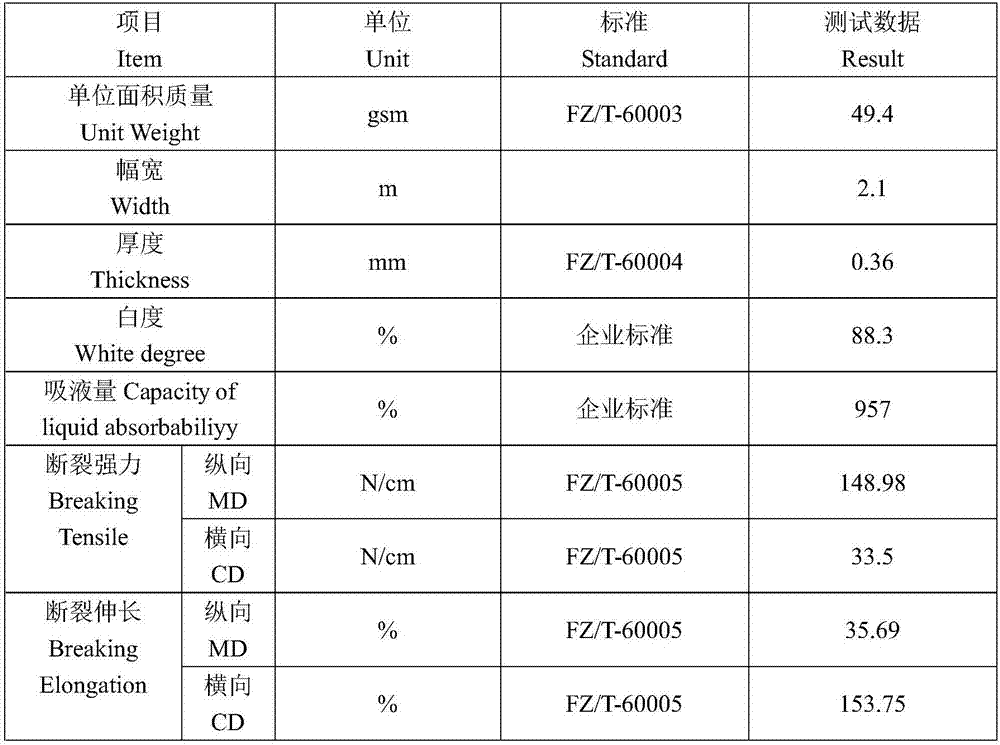

Different-shape polyester fiber and wood pulp cellulose compound spunlacing wet tissue cloth and preparation method for same

The invention relates to the technical field of wood pulp wet tissue manufacturing and concretely relates to a different-shape polyester fiber and wood pulp cellulose compound spunlacing wet tissue cloth and a preparation method for the same. The different-shape polyester fiber and wood pulp cellulose compound spunlacing wet tissue cloth is prepared by 25wt% of polyester fibers, 25wt% of hollow polyester fibers and 50wt% of wood pulp fibers via a spunlacing way, or prepared by 50wt% of hollow polyester fibers and 50wt% of wood pulp fibers via a spunlacing way. Compared with the prior art, a wet papermaking technology and carded web-forming spunlacing technology are integrated to one production line and the products are mainly composite cloth; the product prepared by the method is mainly characterized by great water absorbing property, static resistance, even net formation, binder avoidance, bacteria shielding, softness and ventilation; the wood pulp layer and the polyester fiber layer can be formed online; and the proportion of the hollow polyester fibers, the polyester fibers and the wood pulp fibers can be flexibly adjusted, so the thickness of the product can be flexibly adjusted.

Owner:上海缔荣纺织科技有限公司

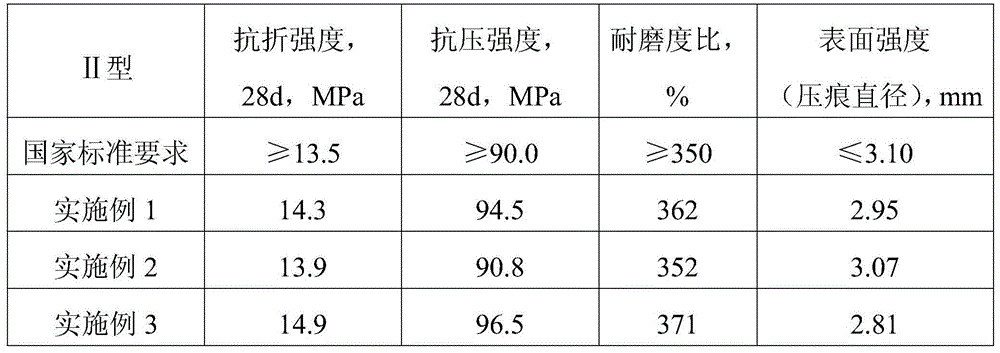

Cement-based abrasion-resistant material for II type concrete floor

InactiveCN104478351AStir wellRaw materials are easy to getSolid waste managementSlagCellulose compounds

The invention relates to a cement-based abrasion-resistant material for a concrete floor, and particularly relates to a cement-based abrasion-resistant material for an II type concrete floor. The cement-based abrasion-resistant material is prepared from the following substances in parts by weight: 35-50 parts of ordinary portland cement, 20-40 parts of silicon carbide, 5-20 parts of steel slag, 0.5-3 parts of redispersible latex powder, 0.15-0.35 part of water reducing agents, 1-15 parts of silicon ash, 0.05-0.15 part of cellulose compounds and 5-15 parts of fly ash. The cement-based abrasion-resistant material disclosed by the invention is compounded from common building raw materials, chemical raw materials and industrial waste residues, has the advantages of easiness for obtaining raw materials, sufficiency in supply, low toxicity, no volatilization, simplicity for processing and preparation and low cost. Various indexes of the cement-based abrasion-resistant material all meet the requirements of the cement-based abrasion-resistant material for the II type concrete floor in a JCT 906-2002 'a cement-based abrasion-resistant material for a concrete floor' standard. The cement-based abrasion-resistant material disclosed by the invention can be used for well solving the problem of surface weak layer of the traditional concrete floor and has the advantages of high strength and high abrasion-resistant property.

Owner:SHENYANG JIANZHU UNIVERSITY

Soybean separation protein/cellulose mixed solution, and preparation method and use thereof

InactiveCN101168603AReduce churnNo pollution in the processConjugated cellulose/protein artificial filamentsWet spinning methodsProtein solutionCellulose compounds

The invention relates to soybean separation protein / cellulose mixed solution. Soybean separation protein is dispersed in the combination water solution of NaOH and carbamide, the combination water solution is agitated to be even to obtain 0.5 to 5 wt percent of soybean separation protein solution, then the prepared soybean separation protein solution is precooled to -12 to -13 DEG C, cellulose is added into the prepared soybean separation protein solution and then is agitated to be even to obtain the transparent soybean separation protein / cellulose mixed solution; the weight ratio of the soybean separation protein and the cellulose is 0.5:9.5 to 5:5, and the soybean separation protein and the cellulose occupy 4 to 8 wt percent of the mixed solution. Or the mixed water solution which is precooled to -12 to -13 DEG C and composed of the NaOH, the carbamide and the soybean separation protein is utilized to directly dissolve the cellulose to obtain the soybean separation protein / cellulose mixed solution. The obtained mixed solution can prepare soybean separation protein / cellulose film, soybean separation protein / cellulose fiber or other soybean separation protein / cellulose compound materials through a tape-casting way, etc.

Owner:WUHAN UNIV

Paint formulations comprising cellulose ether/network building polymer fluid gel thickeners

InactiveUS20080227892A1Promote atomizationLow gel levelCoatings with pigmentsThixotropic paintsGellan gumCarrageenan

Paint formulations that exhibit improved performance characteristics due to the presence of a combination of a cellulose ether (carboxymethylcellulose and / or hydroxyethylcellulose) and a network building polymer (gellan gum, carrageenan, etc., as examples) as a thickening system therein are provided. Such a combination permits long-term shelf stability of the paint formulation while simultaneously according effective flow, leveling, and other important properties to the final paint formulation. The combination of the cellulose ether and a network building polymer allows for a lower viscosity cellulosic compound to impart the desired rheological behavior therein while also permitting the other desirable characteristics noted above. Such paint compositions also exhibit improved atomization for spray applications with such a thickening system.

Owner:CP KELCO U S INC

Method for improving boiling property and palatability of germinated brown rice

InactiveCN103719703AGood cooking effectImprove palatabilityFood ultrasonic treatmentFood preparationPectinaseWax

The invention relates to a method for improving boiling property and palatability of germinated brown rice, which belongs to the technical field of food machining. The method specifically comprises treating brown rice by using ultrasonic auxiliary external cellulose compound pectinase, and through the synergistic effect of endogenous enzyme activated when the brown rice sprouts, the brown rice cortex is subjected to partial hydrolysis, so as to make the germinated brown rice cortex loose and porous. The germinated brown rice produced by using the method is good in boiling property, light in bran wax taste and good in palatability, and the hardness of the germinated brown rice after being boiled is reduced by 10-30% when being compared with the hardness of the untreated germinated brown rice.

Owner:南京丰禾生物科技股份有限公司

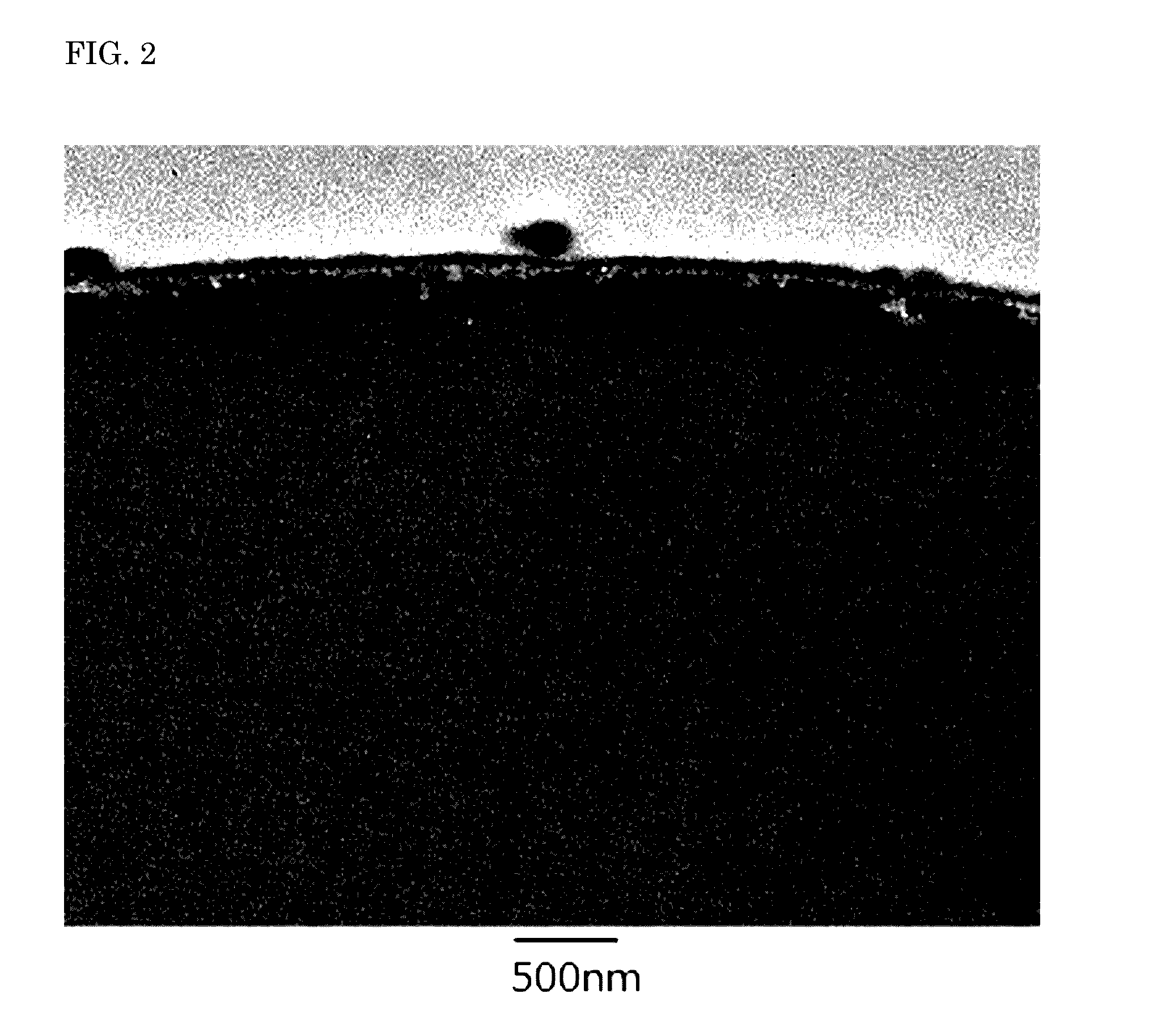

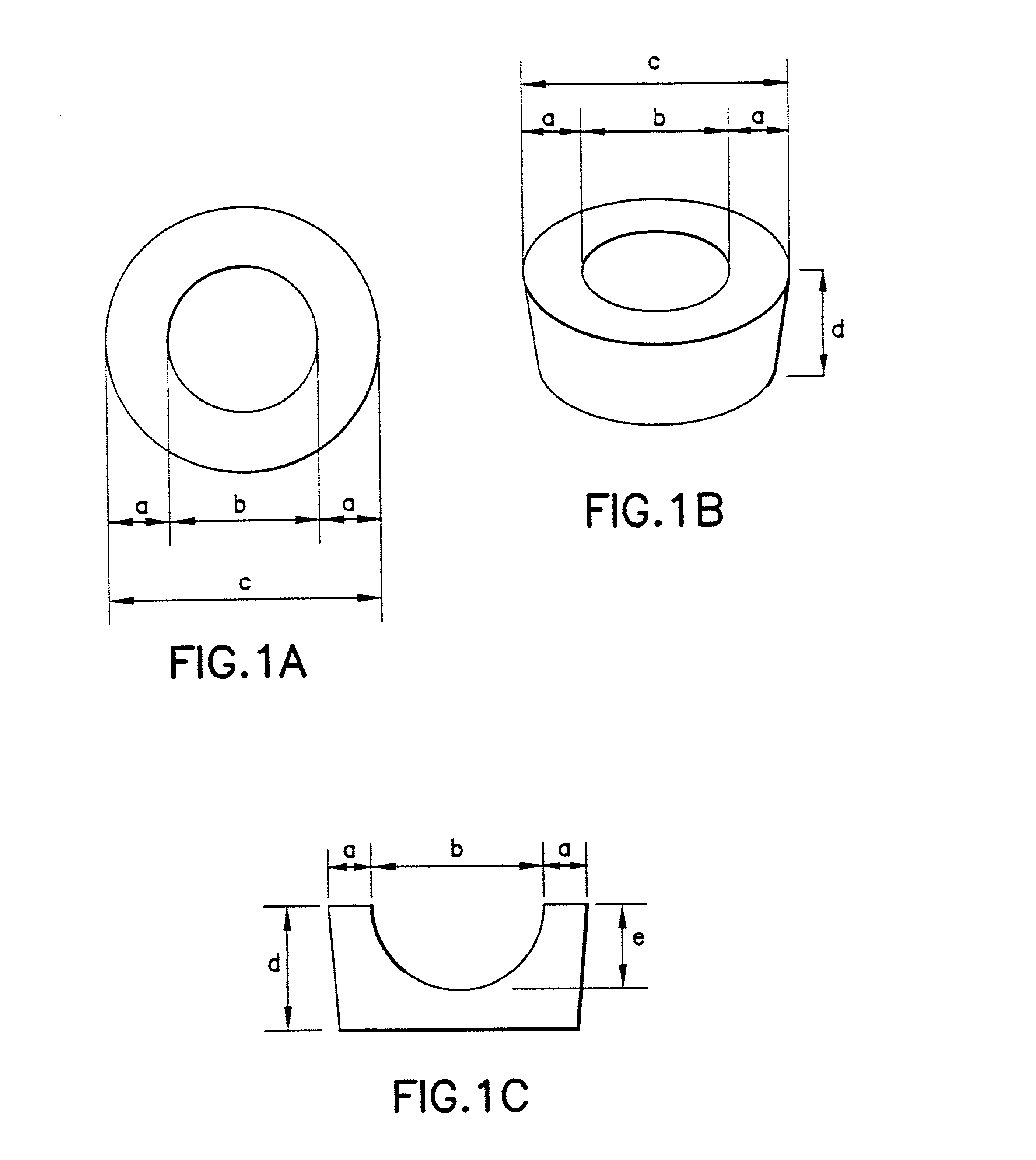

Cellulose compound hollow fiber membrane

InactiveUS6632366B1Improve balanceGood water permeabilitySemi-permeable membranesMembranesAcetic acidHollow fibre membrane

The present invention relates to a cellulose compound hollow fiber membrane having high mechanical strength and is hardly degraded by microorganisms, wherein a cellulose compound is comprised as a membrane material, the thickness of the membrane is 50 to 500 mum, a dense membrane surface having an average pore diameter of 0.001 to 0.05 mum exists on the internal and / or external surface thereof, the inside of the membrane is composed of a three-dimensional network-like porous structure having voids with an average pore diameter of 0.05 to 2 mum, and 70% by weight or more of the membrane material is cellulose acetate propionate or cellulose acetate butyrate.< / PTEXT>

Owner:DAICEL CHEM IND LTD

Cellulose compound composition, cellulose compound film, optically compensatory sheet, polarizing plate and liquid crystal display device

InactiveUS20080241430A1Liquid crystal compositionsPolarising elementsCarbon numberLiquid-crystal display

A cellulose compound composition includes a cellulose compound that includes (A) an aliphatic acyl group having a carbon number of 5 to 30 and (B) an acyl group containing an aromatic group.

Owner:FUJIFILM CORP

Composite type soil water retention agent and preparation

InactiveCN101463247ASimple structureIncrease the granular structureOther chemical processesCellulose compoundsUrease Inhibitors

The invention relates to a soil water retaining agent, in particular to a starch and a cellulose compound water retaining agent and preparation thereof, comprising the ingredients, based on parts by weight of: 100-200 parts of organic substances, 0.2-3 parts of active covering agent, 150-200 parts of acrylamide, 50-100 parts of starch, 20-50 parts of attapulgite, 20-40 parts of perlite, 2-4 parts of initiators and 0.5-1 part of crosslinking agent. The compound soil water retaining agent of the invention simultaneously retains the advantages of starch and cellulose water retaining agents, and can play a role of improving the soil structure owing to the addition of equivalent organic materials therein; the addition of humic acid is capable of serving as a urease inhibitor to a certain extent, which enhances the utilization ratio of a fertilizer N that is applied along with the water retaining agent.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com