Preparation method for compound super absorbent resin containing kieselguhr and cellulose

A technology of superabsorbent resin and diatomite, which is applied in the preparation of composite superabsorbent resin and the field of composite resin preparation, can solve the cumbersome process, low thermal stability of cellulose graft polymerization products, and weak thermal stability of cellulose and other problems, to achieve the effects of wide sources, enhanced adsorption and chemical activity, and improved liquid absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

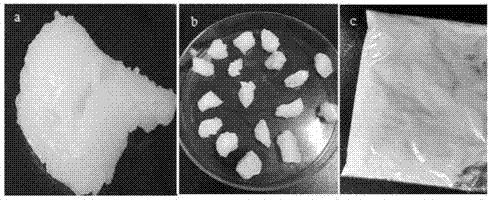

Image

Examples

Embodiment 1

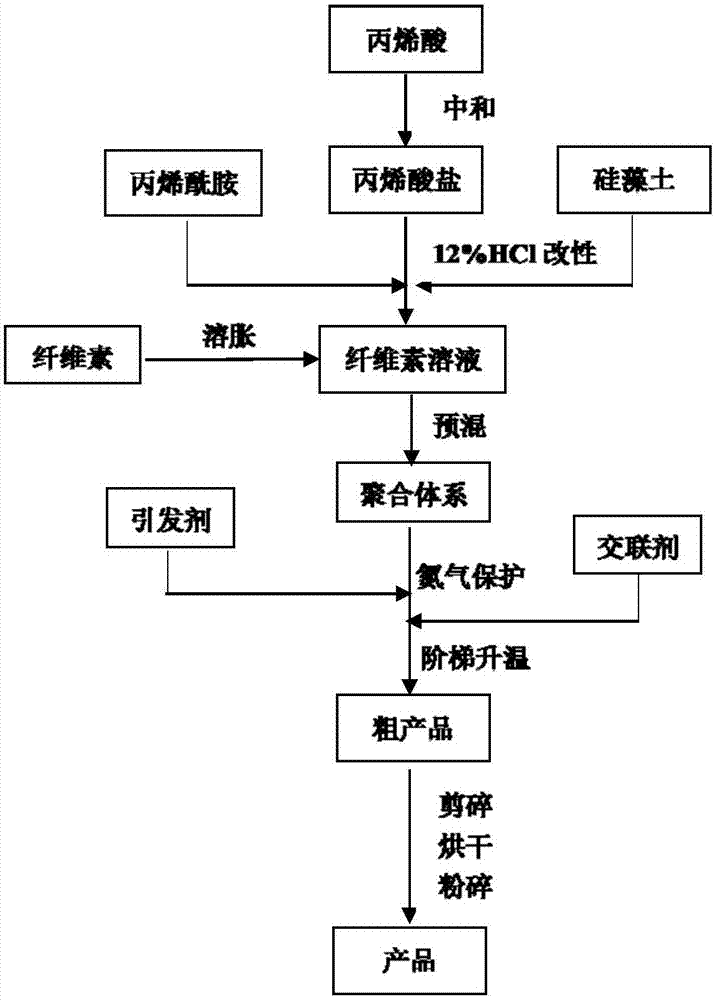

[0032] A preparation method of a composite superabsorbent resin comprising diatomite and cellulose, comprising the following process steps:

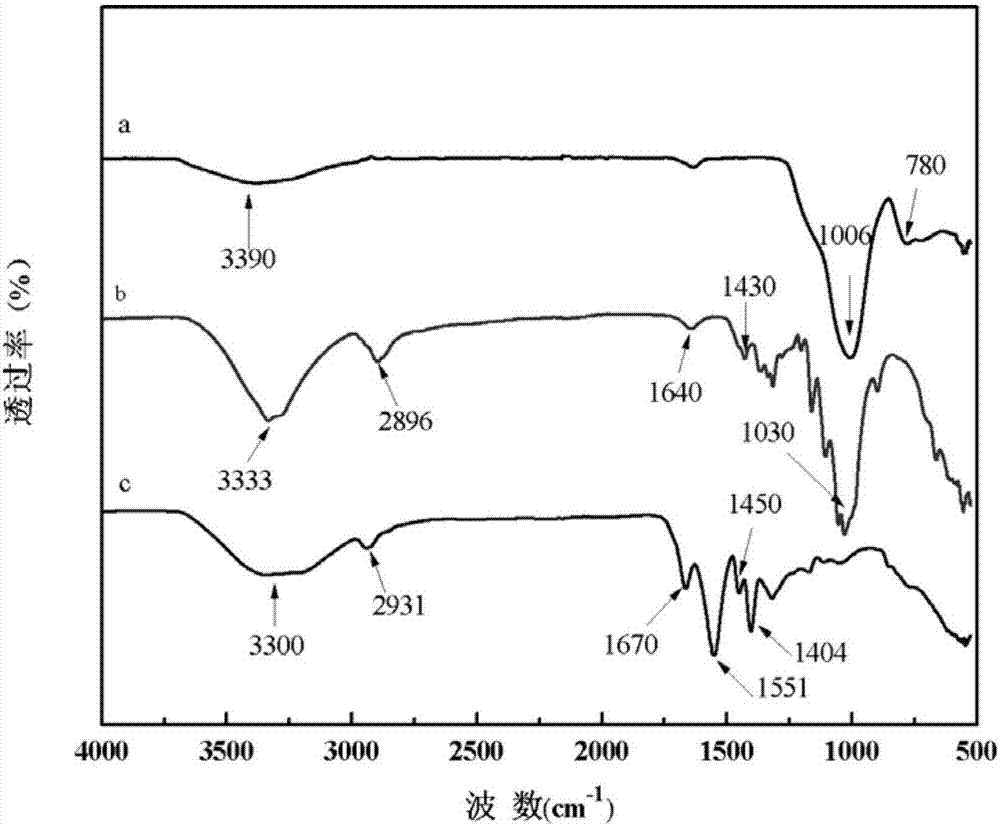

[0033] Step 1, adding diatomite to 12% hydrochloric acid solution for modification, the solid-to-liquid ratio of diatomite and hydrochloric acid is 1:5, heating and stirring in a water bath at a temperature of 80°C for 4 hours, washing with distilled water, and suction filtration, drying in an oven to constant weight to obtain modified diatomite;

[0034] Step 2: In an ice-water bath, the molar ratio of sodium hydroxide to acrylic acid is 0.8, and the sodium hydroxide solution is slowly added dropwise to the acrylic acid while stirring to partially neutralize it. After cooling to room temperature, press the acrylamide The mass is 30% of the monomeric acrylic acid, and the mass of the modified diatomite is 4% of the monomeric acrylic acid, adding acrylamide and modified diatomite, ultrasonication, and cooling for later use;

[0035] Step...

Embodiment 2

[0038]This embodiment is basically the same as Embodiment 1, the only difference is that the mass of acrylamide is 20% of the monomeric acrylic acid.

Embodiment 3

[0040] This embodiment is basically the same as Embodiment 1, the only difference is that the mass of acrylamide is 35% of the monomeric acrylic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com