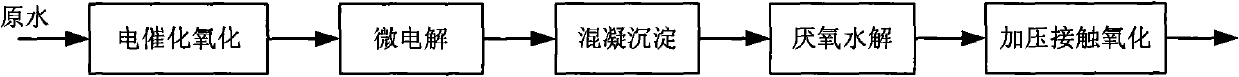

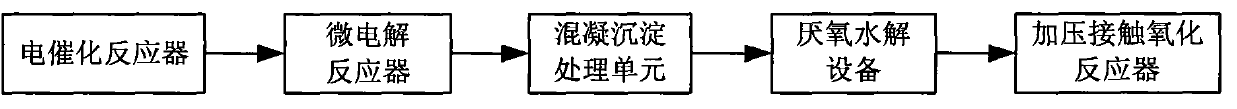

Process and equipment for treating high-concentration pyridine waste water

A wastewater treatment and pyridine technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc. The effect of high stability, short process flow, and low consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the high-concentration pyridine wastewater of a pesticide company, the main pollutants were pyridine derivatives m-dichloropyridine and o-dichloropyridine. Using this process for treatment, the pH of the raw water is adjusted to 3.0, and the working current density of the multi-dimensional electrocatalytic oxidation section is controlled at 15mA / cm 2 , the residence time is 1 hour; then enter the micro-electrolysis reactor for treatment, maintain acidity (pH=about 4) and aeration and oxygenation, the reaction residence time is 1.5 hours; add Ca(OH) to the effluent 2 Adjust the pH of wastewater to 9.0, and add PAM for coagulation and precipitation reaction. The detection of the effluent after precipitation shows that the removal rate of m-dichloropyridine is 99.82%, the removal rate of ortho-dichloropyridine is 99.93%, and the removal rate of COD is 76%. Experiments have shown that the ring structure of pyridine in the physical and chemical treatment section has been...

Embodiment 2

[0037] The chlorpyrifos pesticide production workshop of a pesticide company contained high-concentration process wastewater of pyridines. The wastewater was reddish brown and had a strong pungent smell. Its main water quality indicators: pH 5-6, COD 36705mg / L, TOC 6312mg / L, TP 1835mg / L, salt content 16%. Adopt the process of the present invention to process. Pyridine wastewater is added with acid to adjust the pH to about 3, then enters the electrocatalytic oxidation reactor, and the current density is controlled at 14mA / cm 2 The residence time of wastewater is 60 minutes, and the effluent flows into the micro-electrolyzer; the micro-electrolyzer is filled with cast iron chips and coke, the iron-carbon volume ratio is 1:1, and an appropriate amount of acid is added to control the pH of the wastewater between 3-5, and the residence time of the wastewater 60min; the effluent directly enters the coagulation sedimentation tank, with Ca(OH) 2 Adjust the pH to about 8, and add co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com