Preparing technology for high-aluminum-content ultra-dense Al-Cr-Si-N coating

A preparation process, al-cr-si technology, applied in the field of preparation of ultra-dense Al-Cr-Si-N nanocomposite coatings with high aluminum content, can solve the problems of low wear and low wear rate, and achieve a wide range of applications , dense structure, high hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

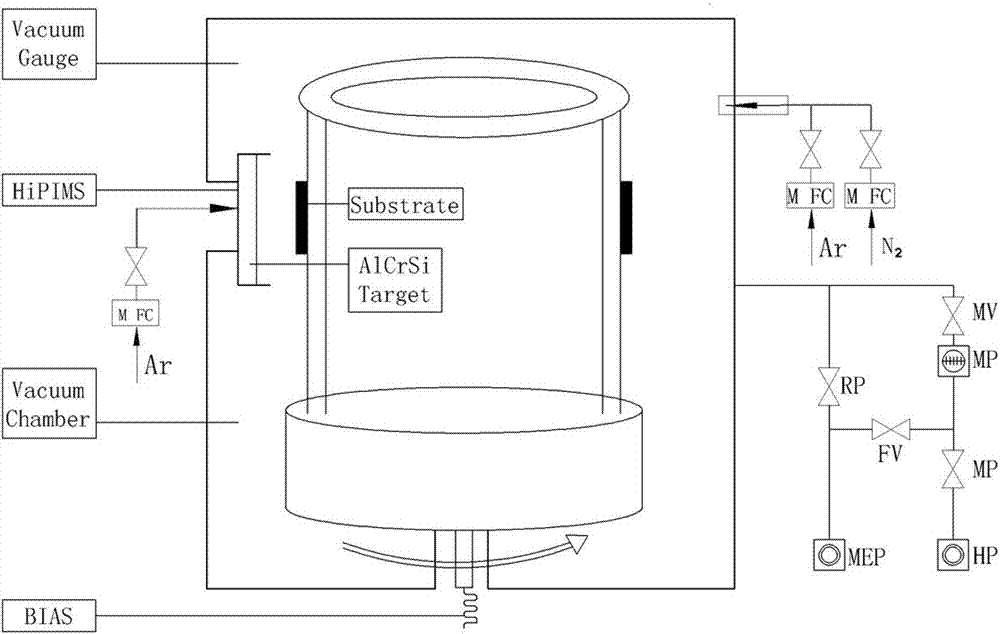

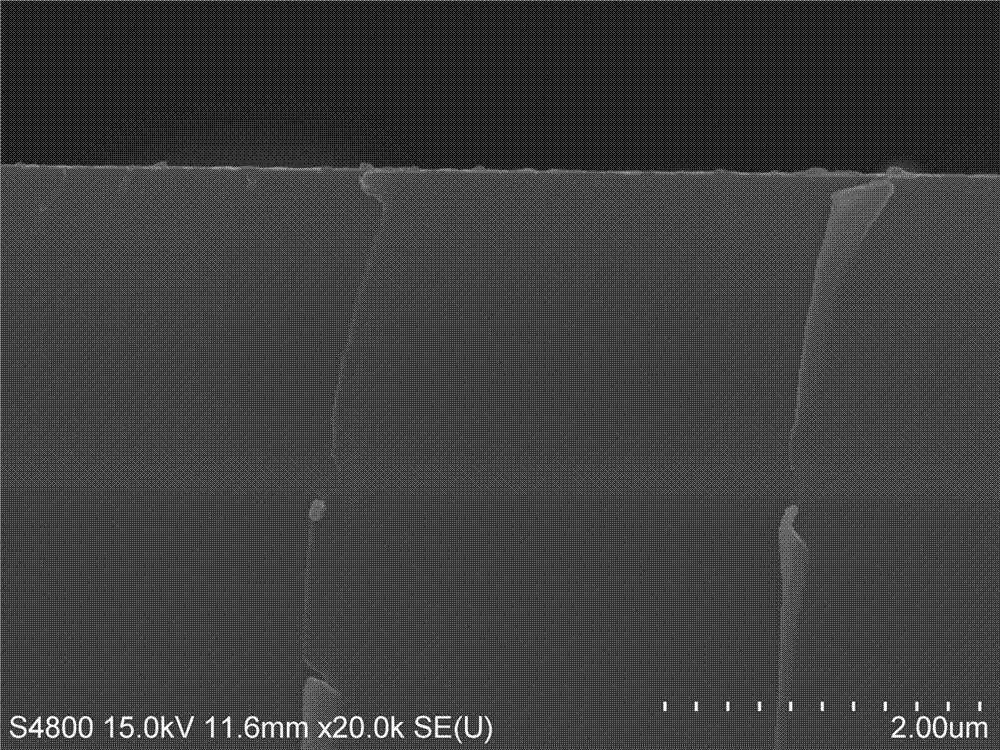

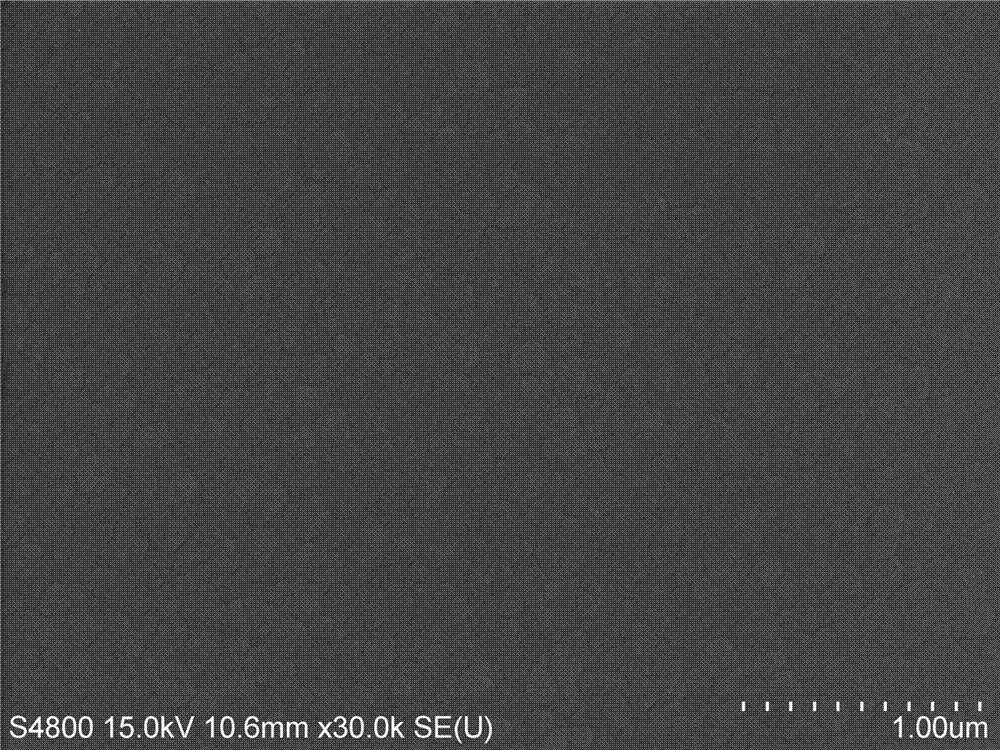

[0026] In this example, a high aluminum content Al-Cr-Si-N coating was deposited on a mirror-polished single crystal Si wafer ((100) orientation), and the sample size was 40×30×0.67 mm. The substrate was ultrasonically cleaned in degreasing agent and alcohol solution for 20 minutes respectively, then dried with high-purity nitrogen, and then placed on the sample holder in the vacuum chamber facing the target. The coating process is carried out on V-TECH HIPIMS 610 / 610 high-power pulse magnetron sputtering coating machine, and the cathode high-power target is Al-Cr-Si alloy target (atomic ratio Al:Cr:Si=6:3:1, The purity is 99.8 wt.%, the size is 300×100×5 mm), the working gas and reaction gas are Ar and N 2 (both purity 99.999%), figure 1 A schematic diagram of a high-power pulsed magnetron sputtering system. When nitrogen gas is fed to participate in the reaction, the nitrogen gas goes through the gas mixing tank on the right side, and only the argon gas enters the vacuum c...

Embodiment 2

[0030] In this embodiment, Al-Cr-Si is deposited on a mirror-polished AISI 304 stainless steel substrate (Cr-18.5, Ni-9.4, Mn-0.8, Si-0.4, P-0.1, Fe balance, all by weight percentage). -N coating, the sample size is 30 × 25 × 1 mm. The substrate was first ground and polished by metallographic sandpaper, then ultrasonically cleaned with acetone and alcohol solutions respectively, dried and placed on the sample holder facing the target in the vacuum chamber. The deposition parameters are the same as in Example 1.

[0031] The hardness of the Al-Cr-Si-N coating deposited on the stainless steel substrate was tested by nanoindentation technique, and the measured result was ~30 GPa. Figure 4 It is the X-ray diffraction pattern of the Al-Cr-Si-N coating. When the diffraction angle 2θ=44°, the (200) diffraction peaks of aluminum nitride and chromium nitride in the coating overlap, because the Al atoms are dissolved in NaCl In the CrN lattice of the structure, the lattice distortion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com