Patents

Literature

184 results about "High-power impulse magnetron sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

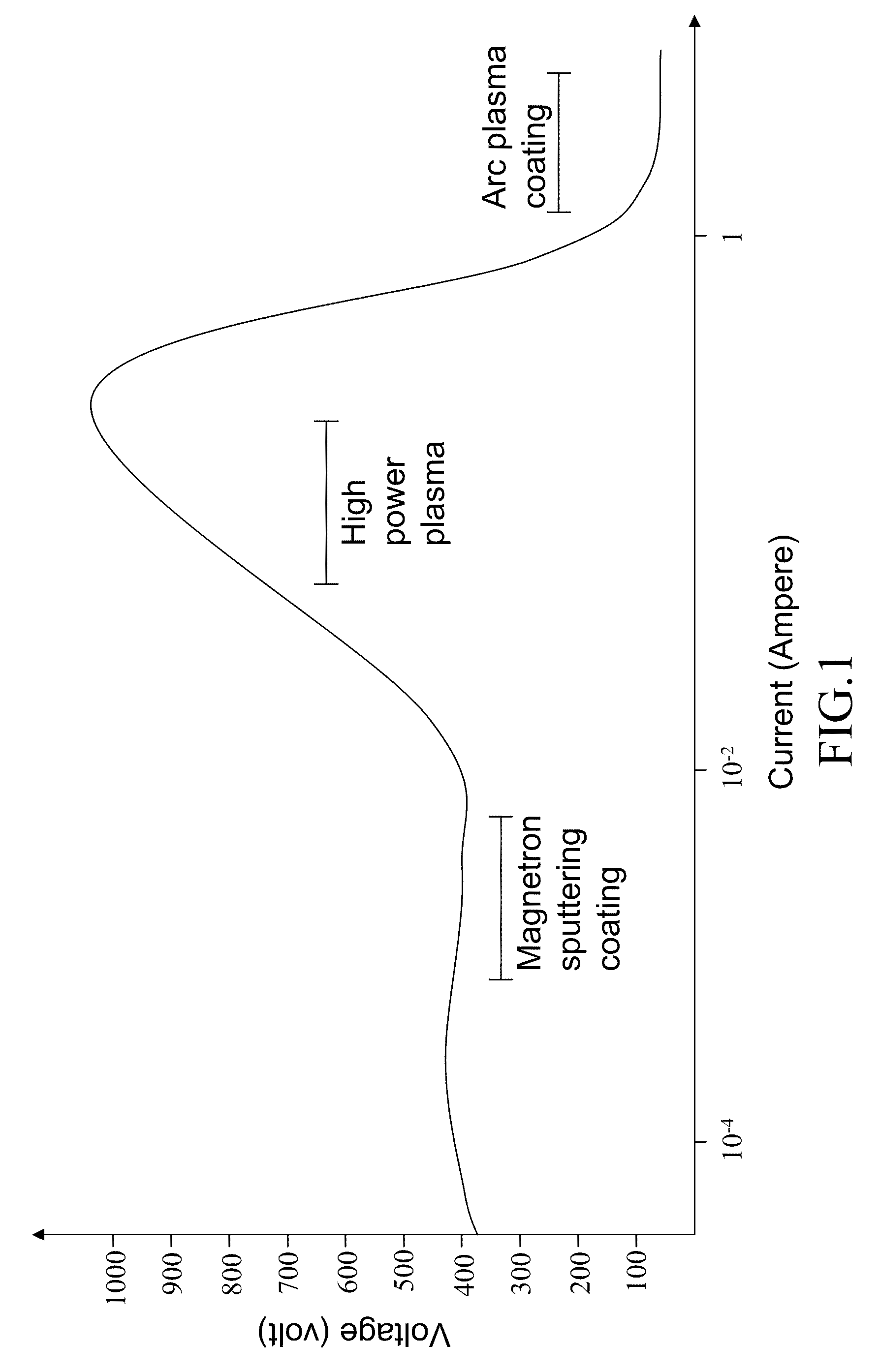

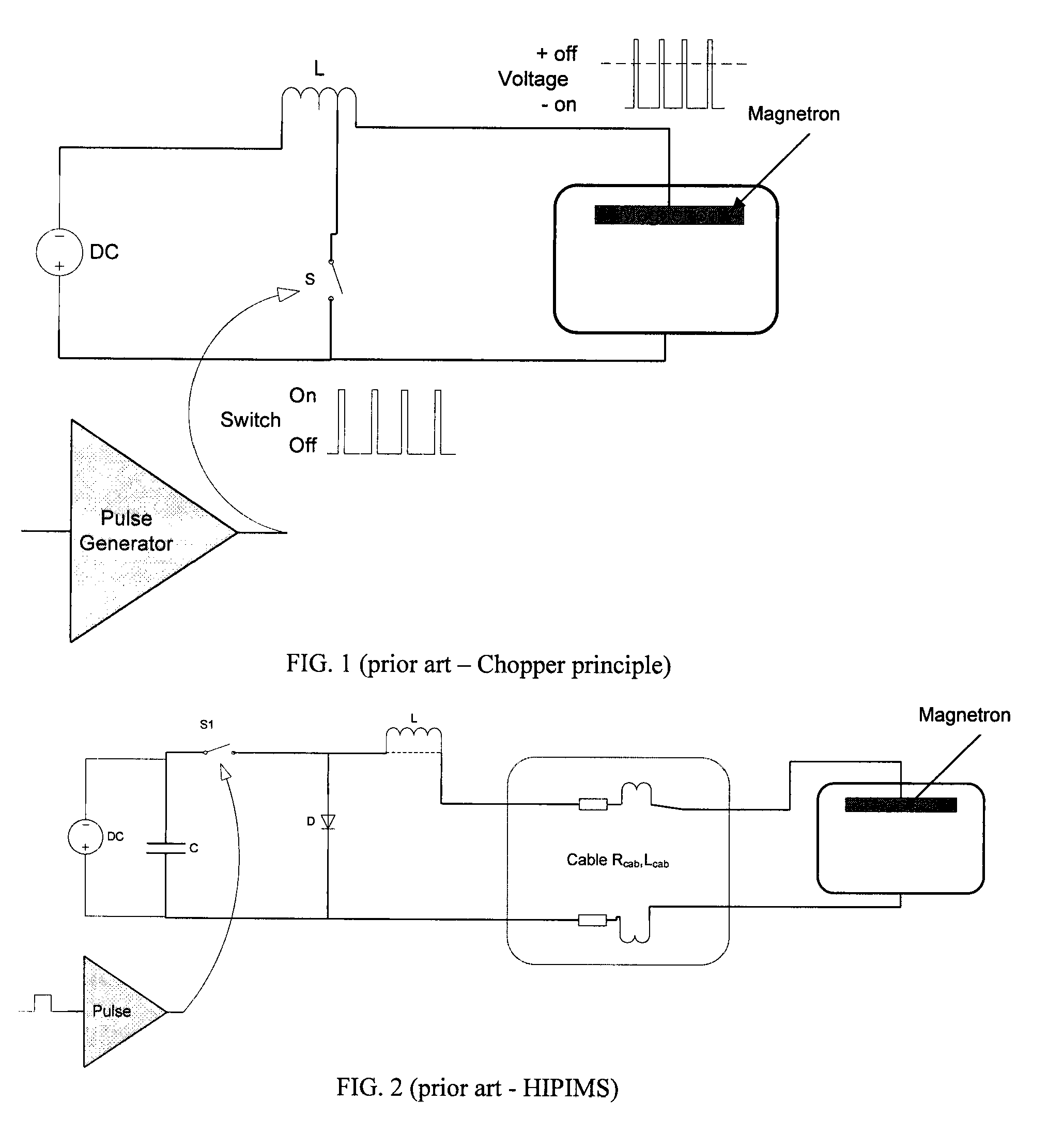

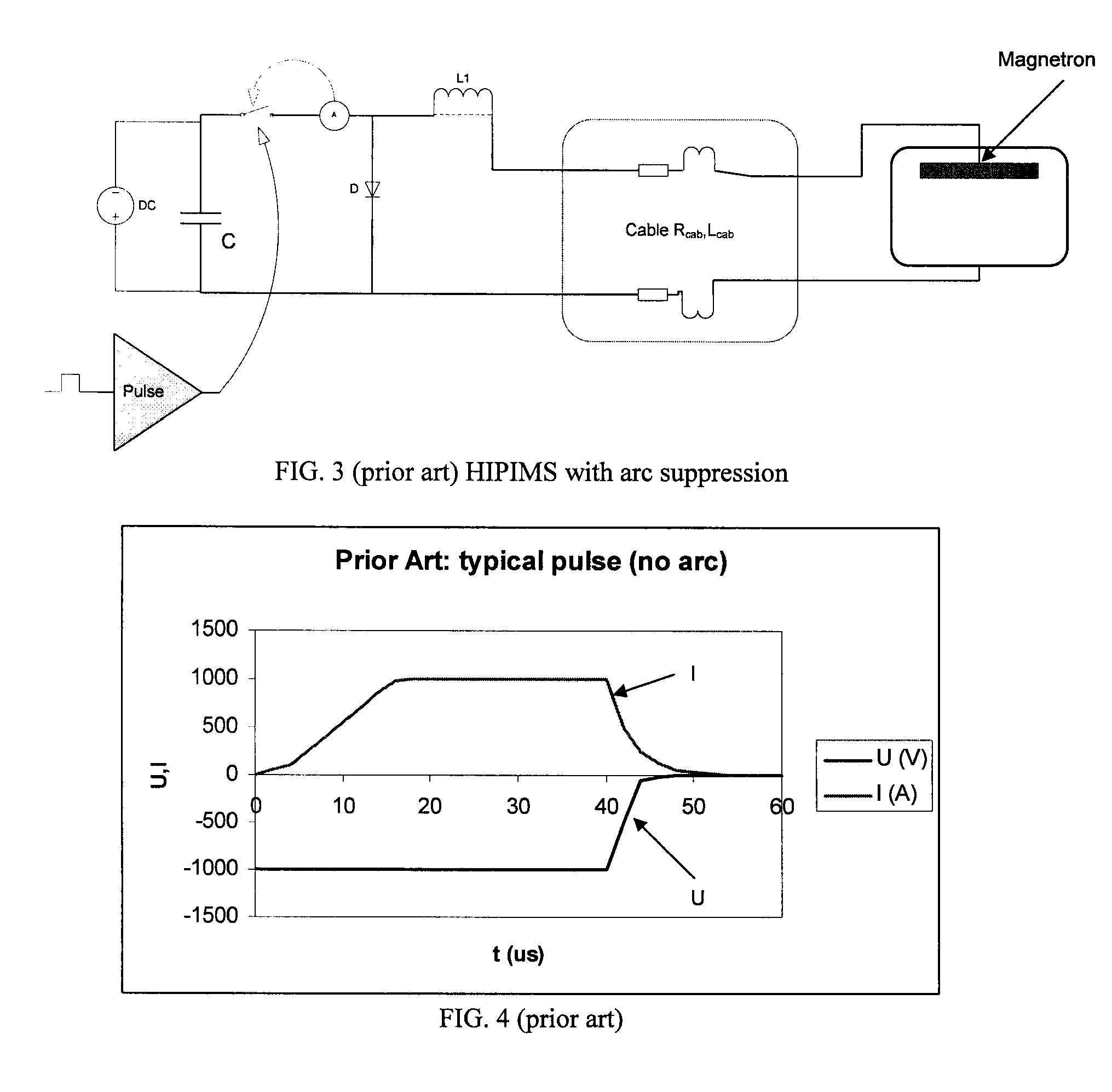

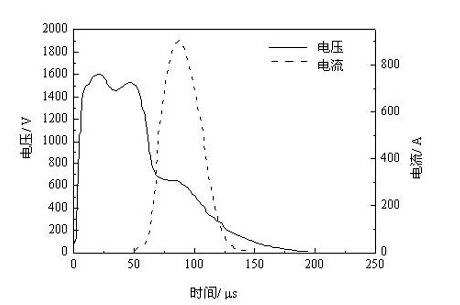

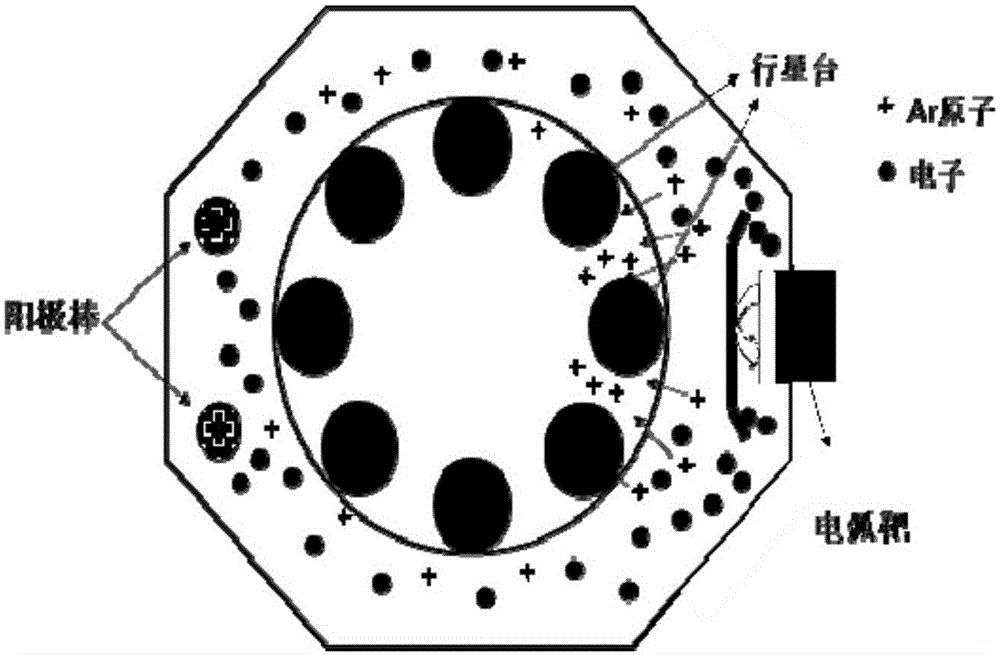

High-power impulse magnetron sputtering (HIPIMS or HiPIMS, also known as high-power pulsed magnetron sputtering, HPPMS) is a method for physical vapor deposition of thin films which is based on magnetron sputter deposition. HIPIMS utilises extremely high power densities of the order of kW⋅cm⁻² in short pulses (impulses) of tens of microseconds at low duty cycle (on/off time ratio) of < 10%. Distinguishing features of HIPIMS are a high degree of ionisation of the sputtered metal and a high rate of molecular gas dissociation which result in high density of deposited films. The ionization and dissociation degree increase according to the peak cathode power. The limit is determined by the transition of the discharge from glow to arc phase. The peak power and the duty cycle are selected so as to maintain an average cathode power similar to conventional sputtering (1–10 W⋅cm⁻²).

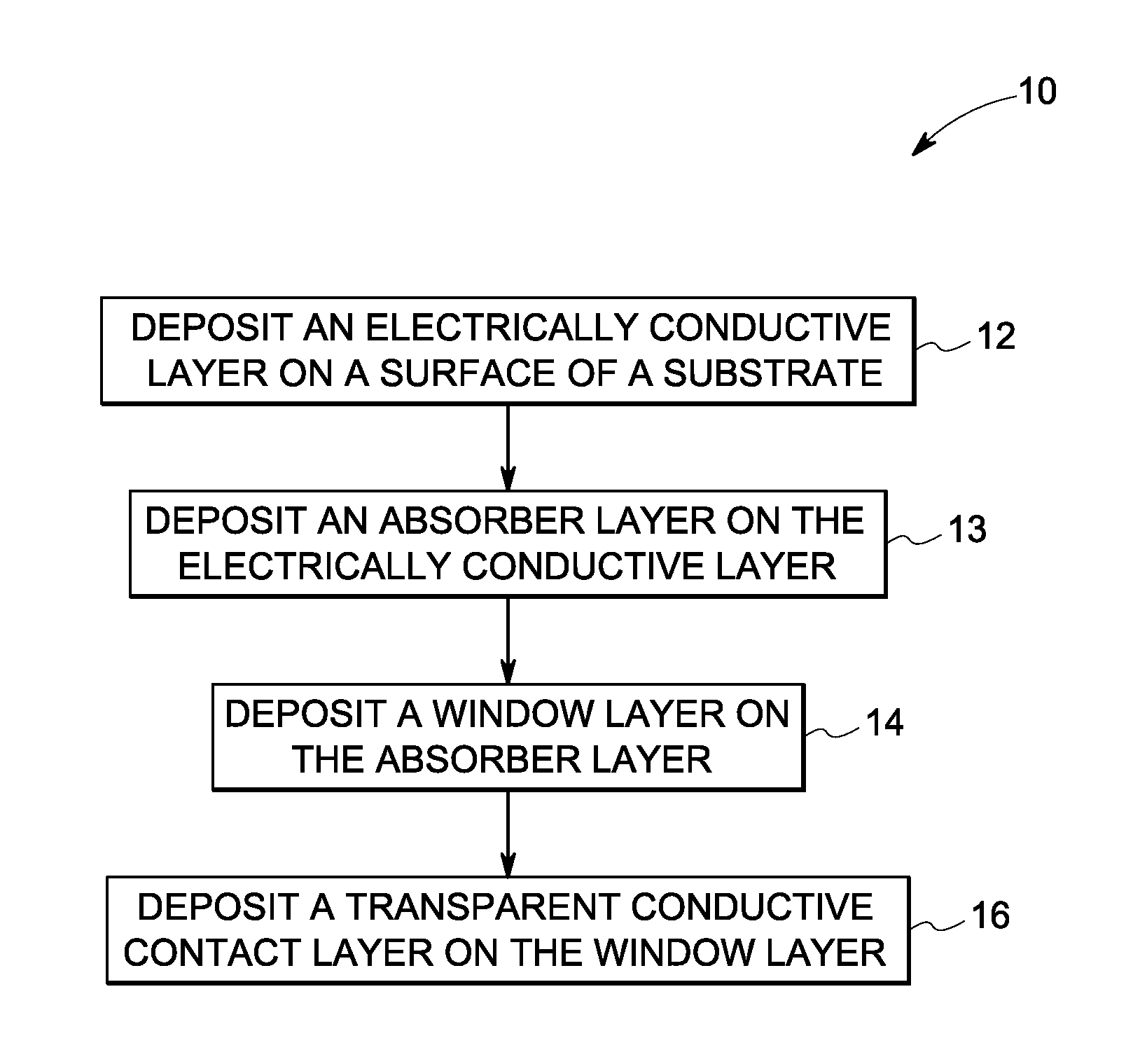

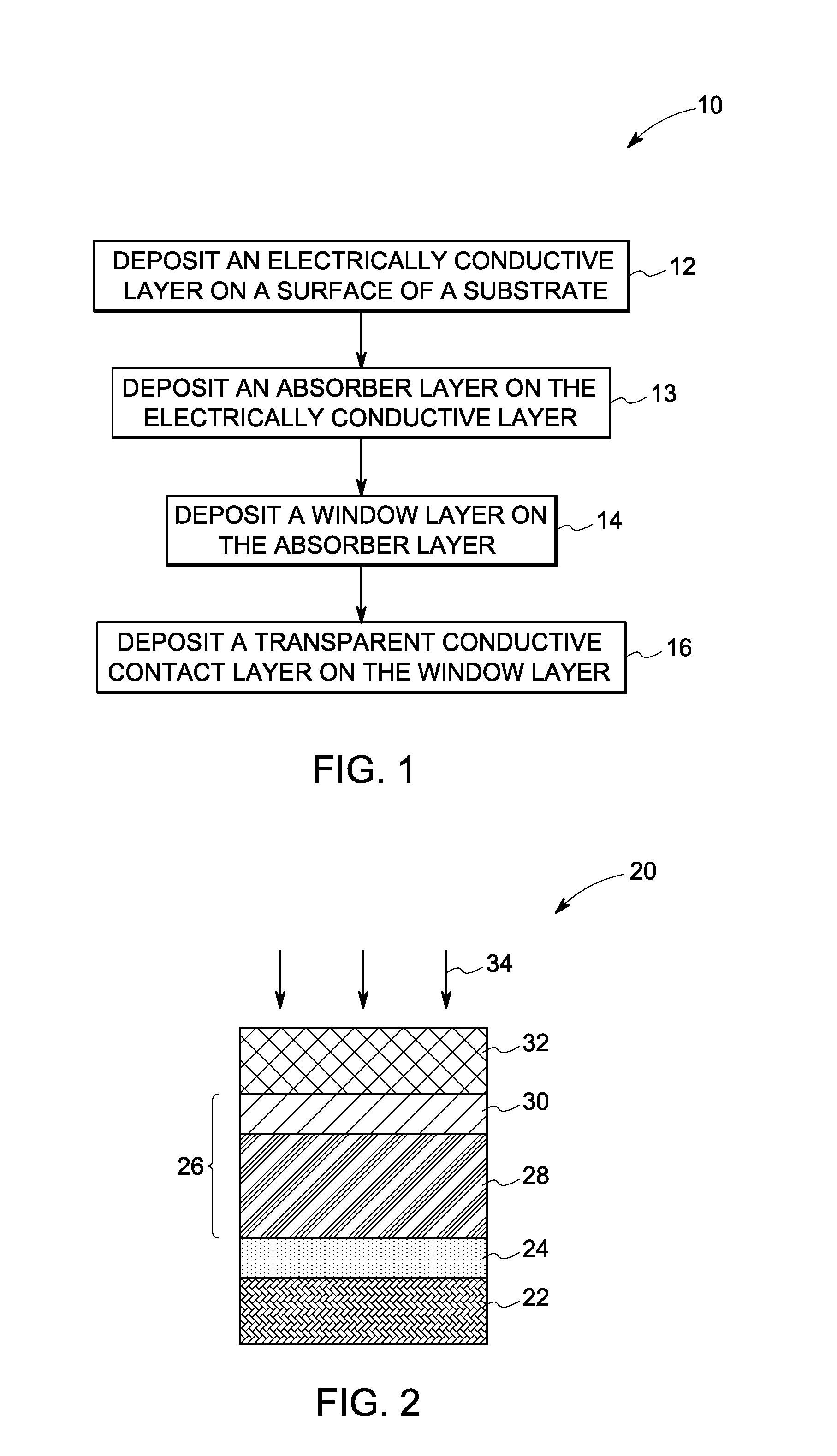

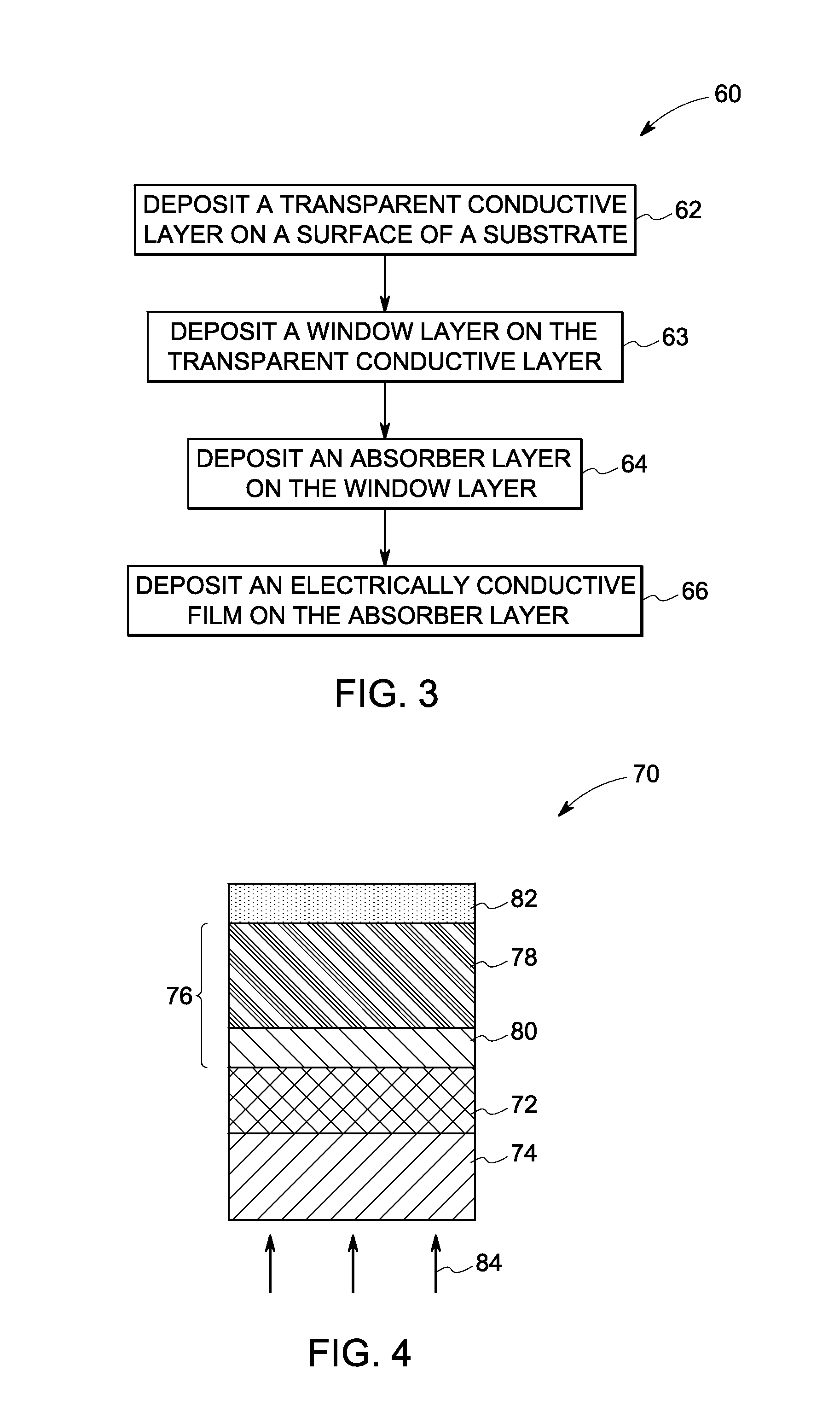

Methods of Fabrication of Solar Cells Using High Power Pulsed Magnetron Sputtering

A method of fabricating a solar cell is provided. The method includes depositing a transparent conductive contact layer on a surface of a substrate, where the transparent conductive contact layer is configured to act as a front electrode for the solar cell, depositing a window layer over the transparent conductive contact layer, depositing an absorber layer on the window layer, wherein the absorber layer and the window layer are oppositely doped and form a semiconductor junction, and where at least one of the window layer or the absorber layer is deposited by employing high power pulsed magnetron sputtering, and depositing an electrically conductive film on the semiconductor junction, wherein the electrically conductive film is configured to act as a back electrode layer for the solar cell.

Owner:GENERAL ELECTRIC CO

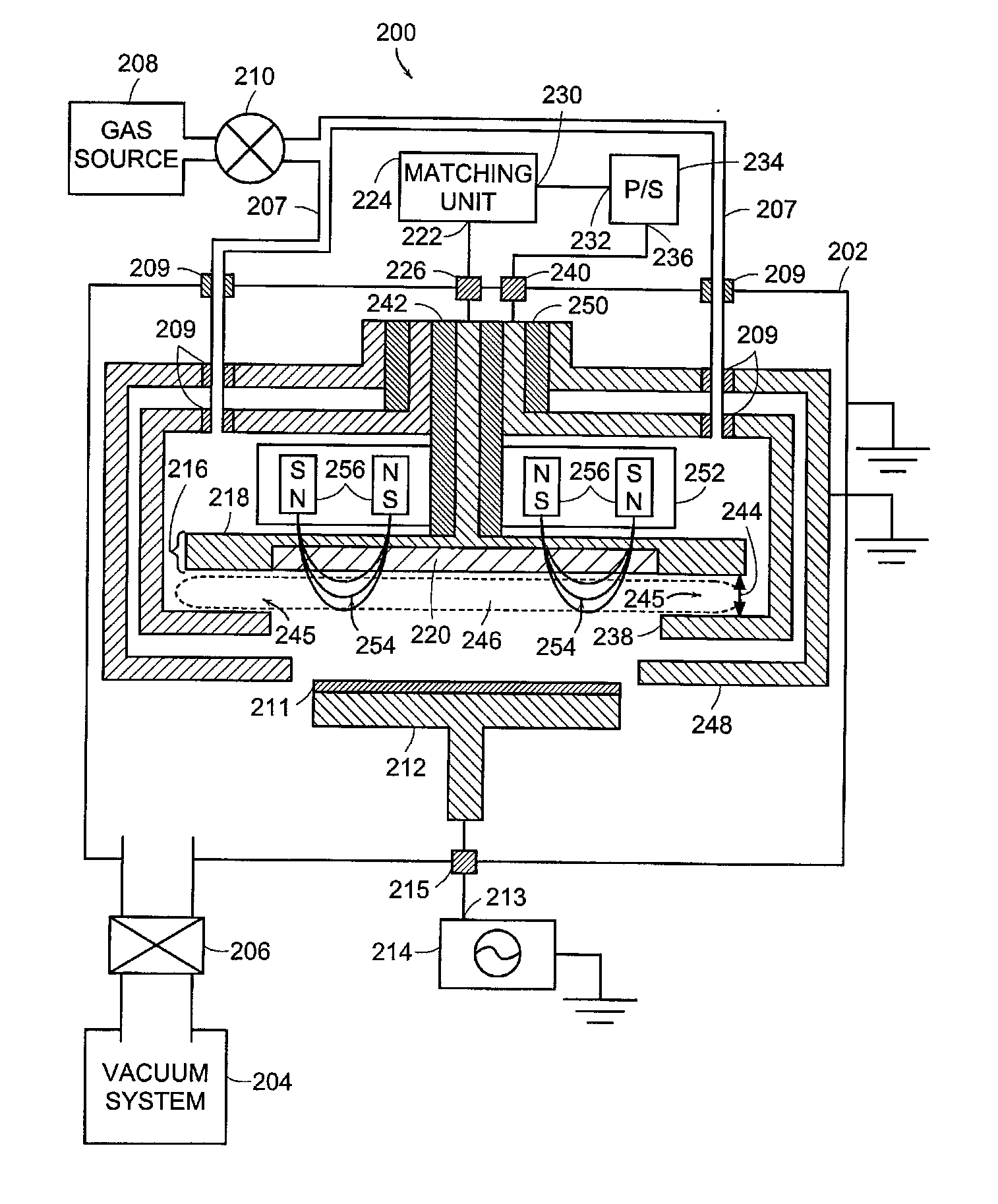

High-power pulsed magnetron sputtering

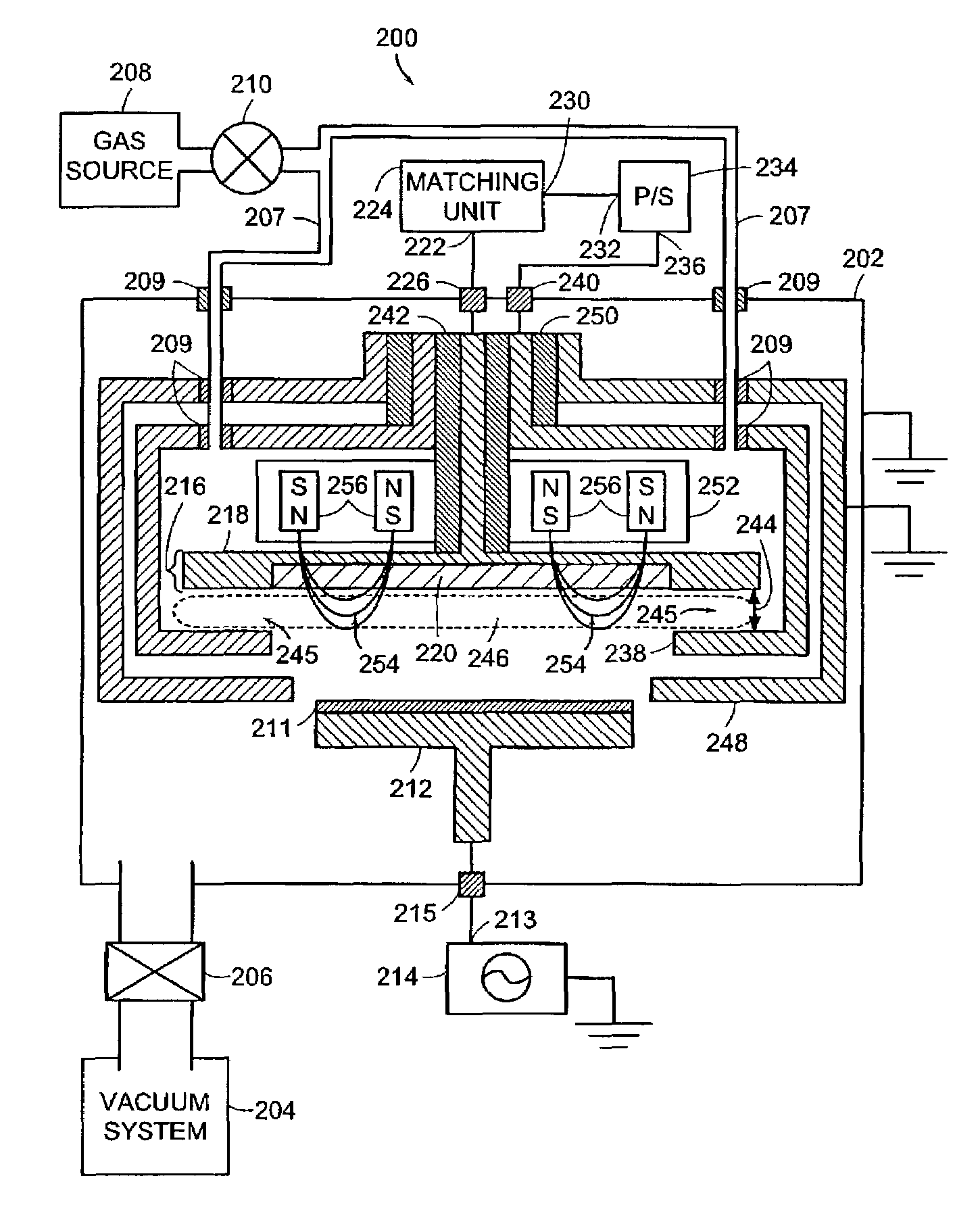

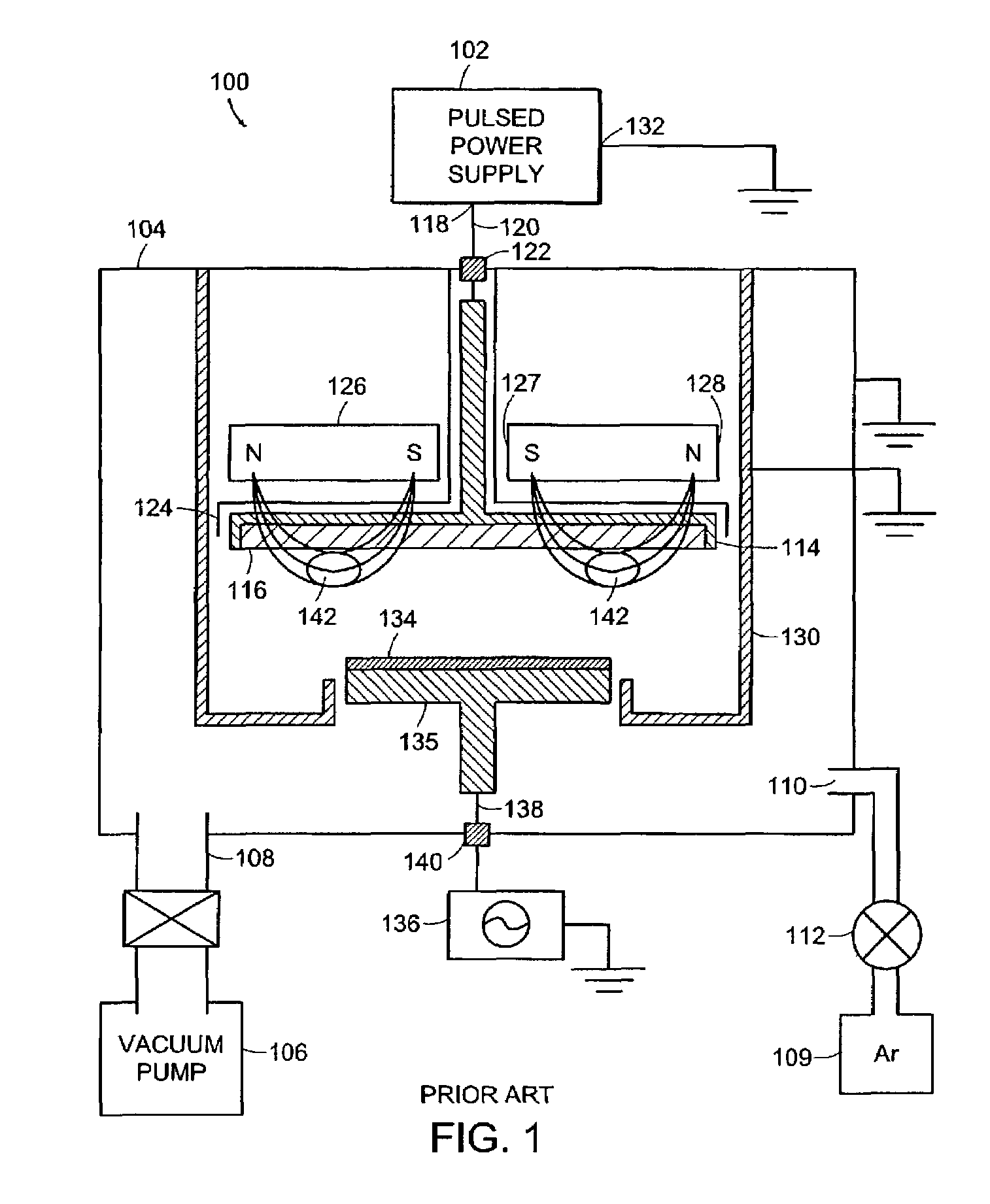

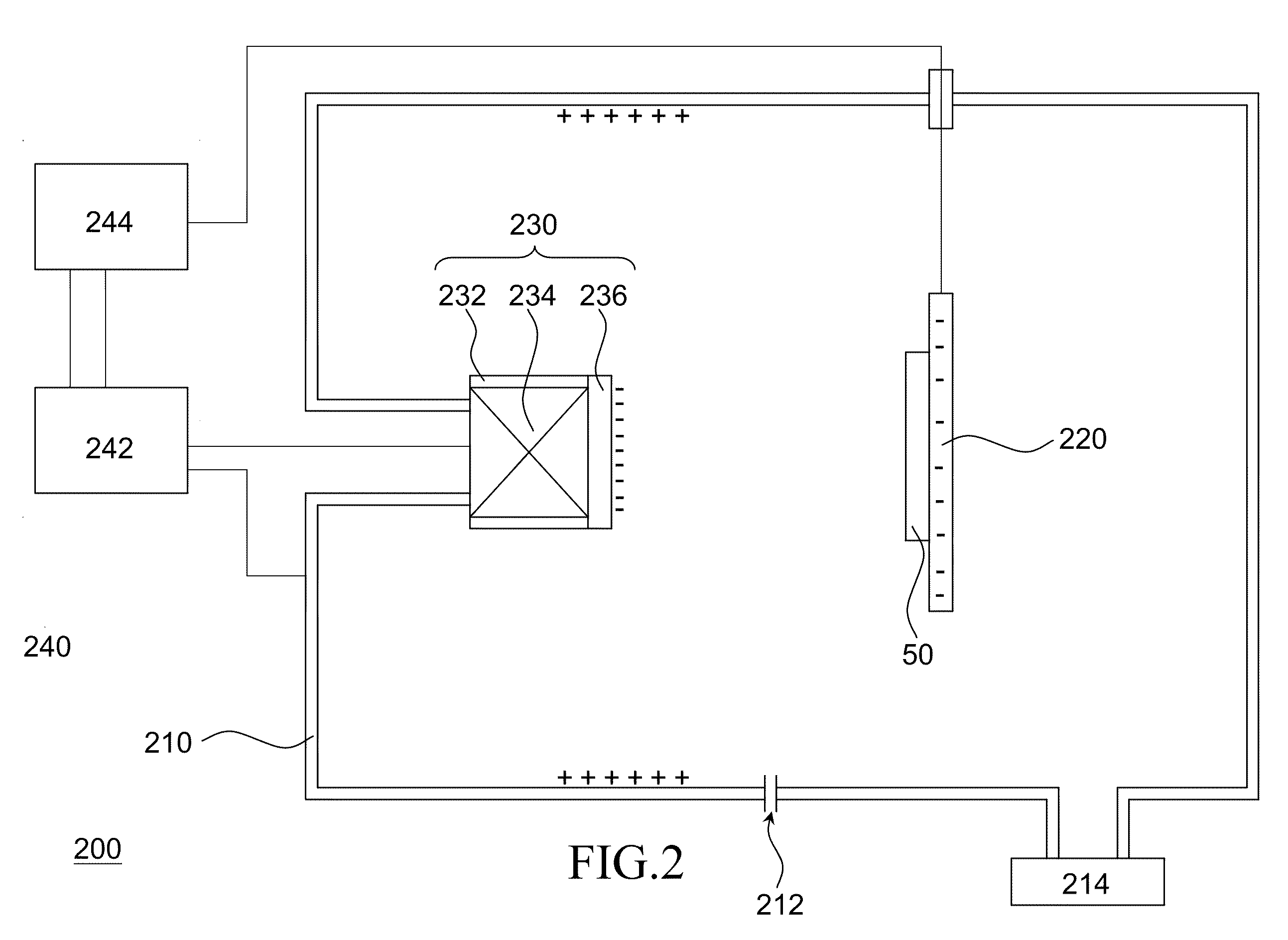

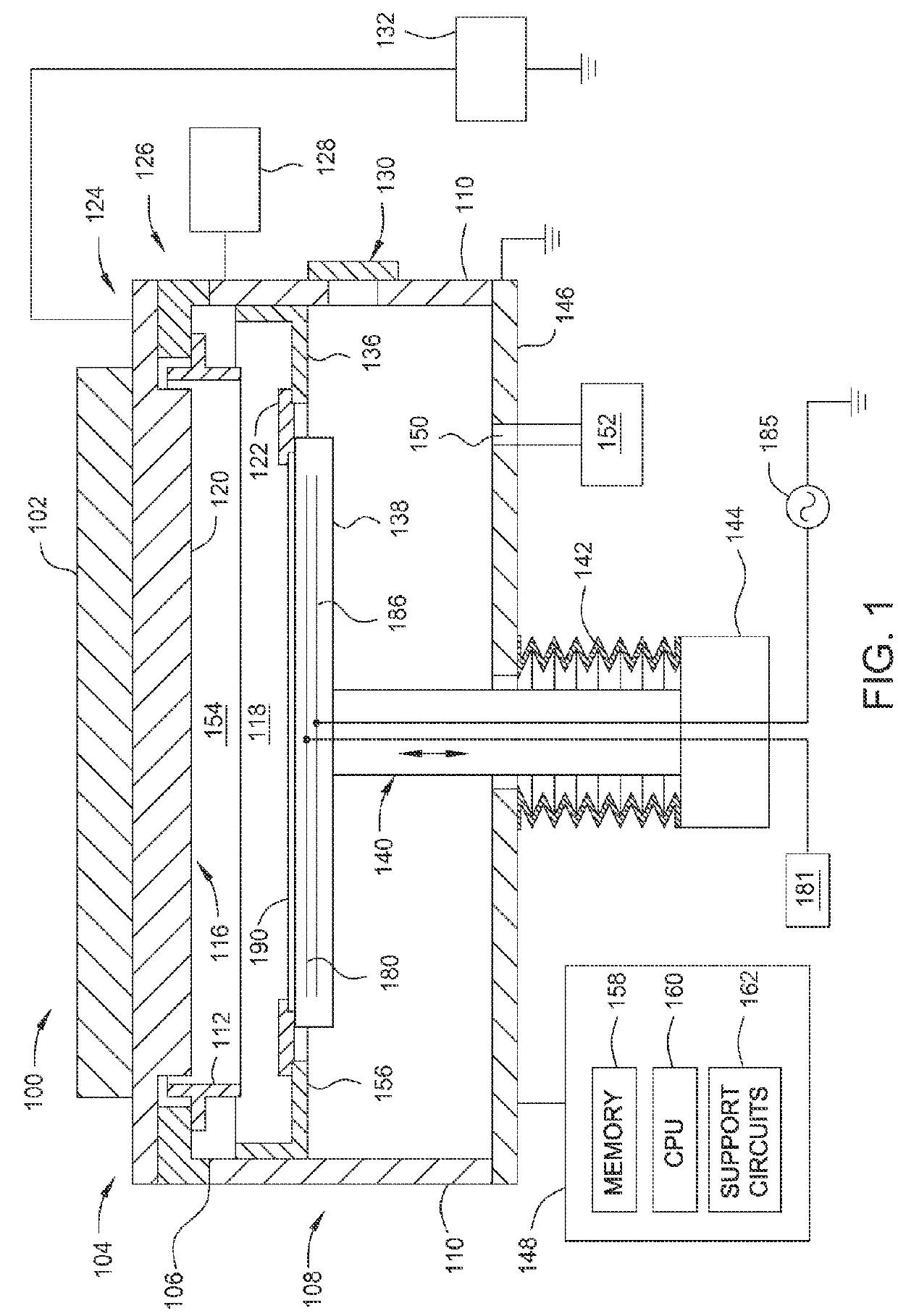

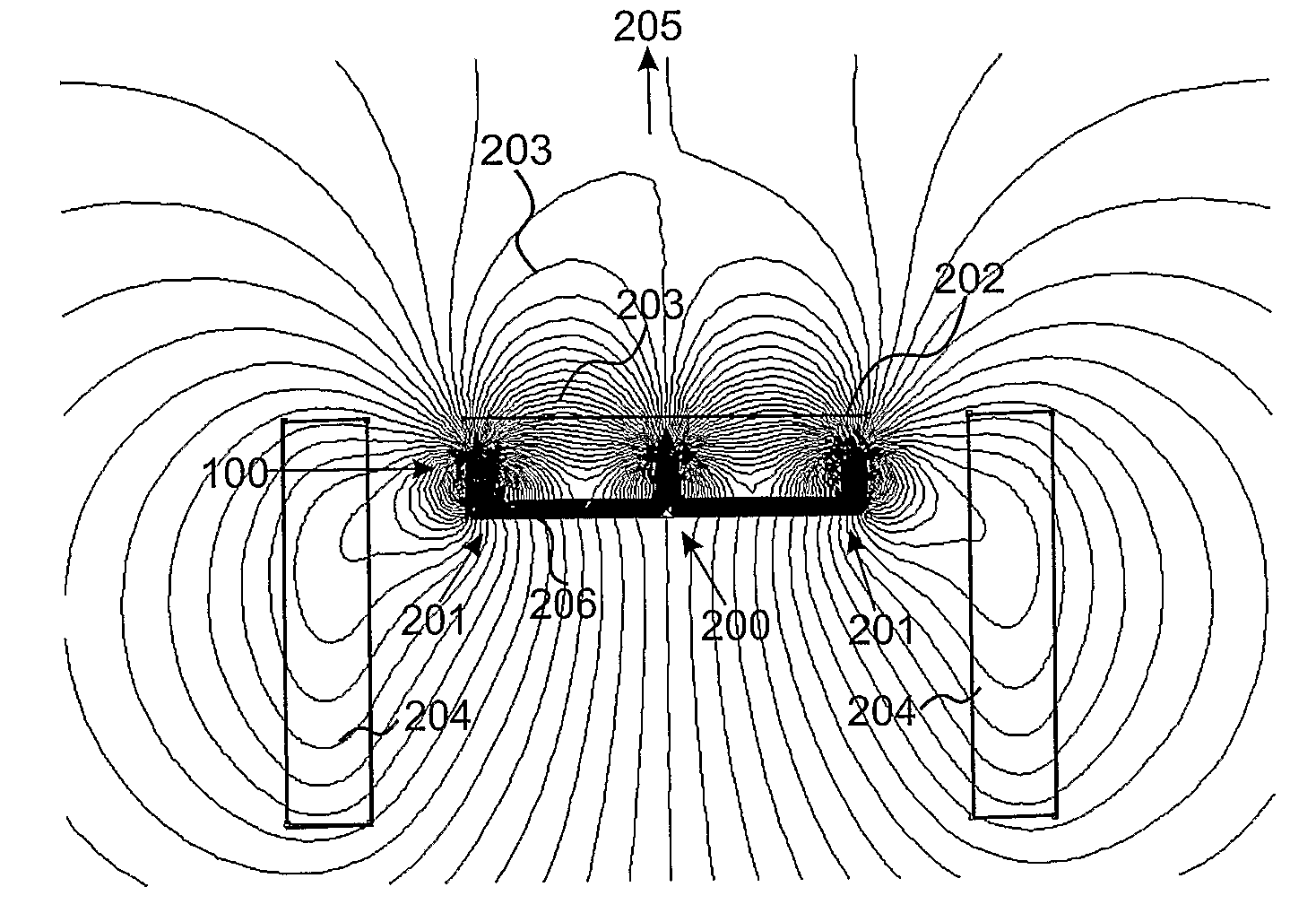

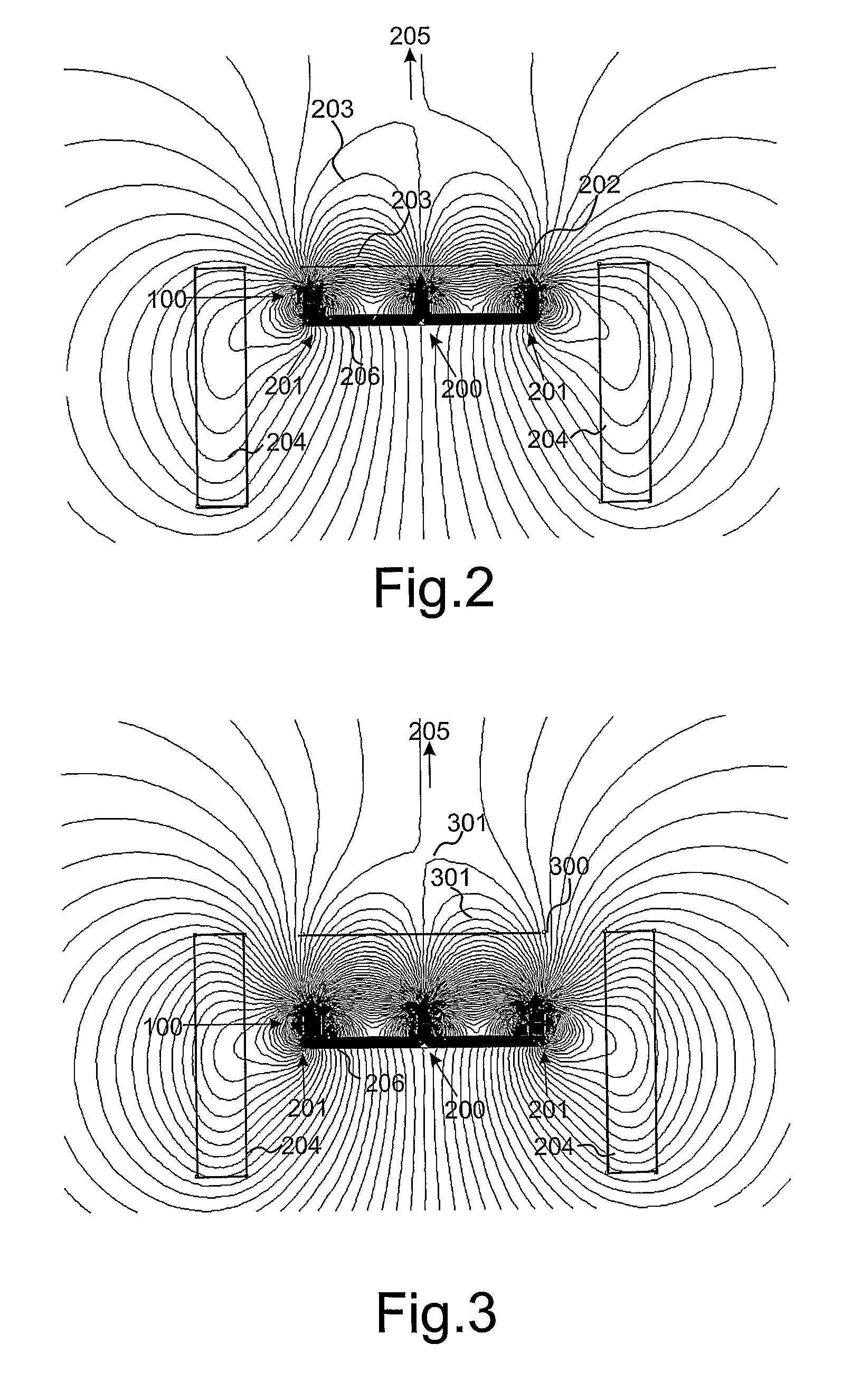

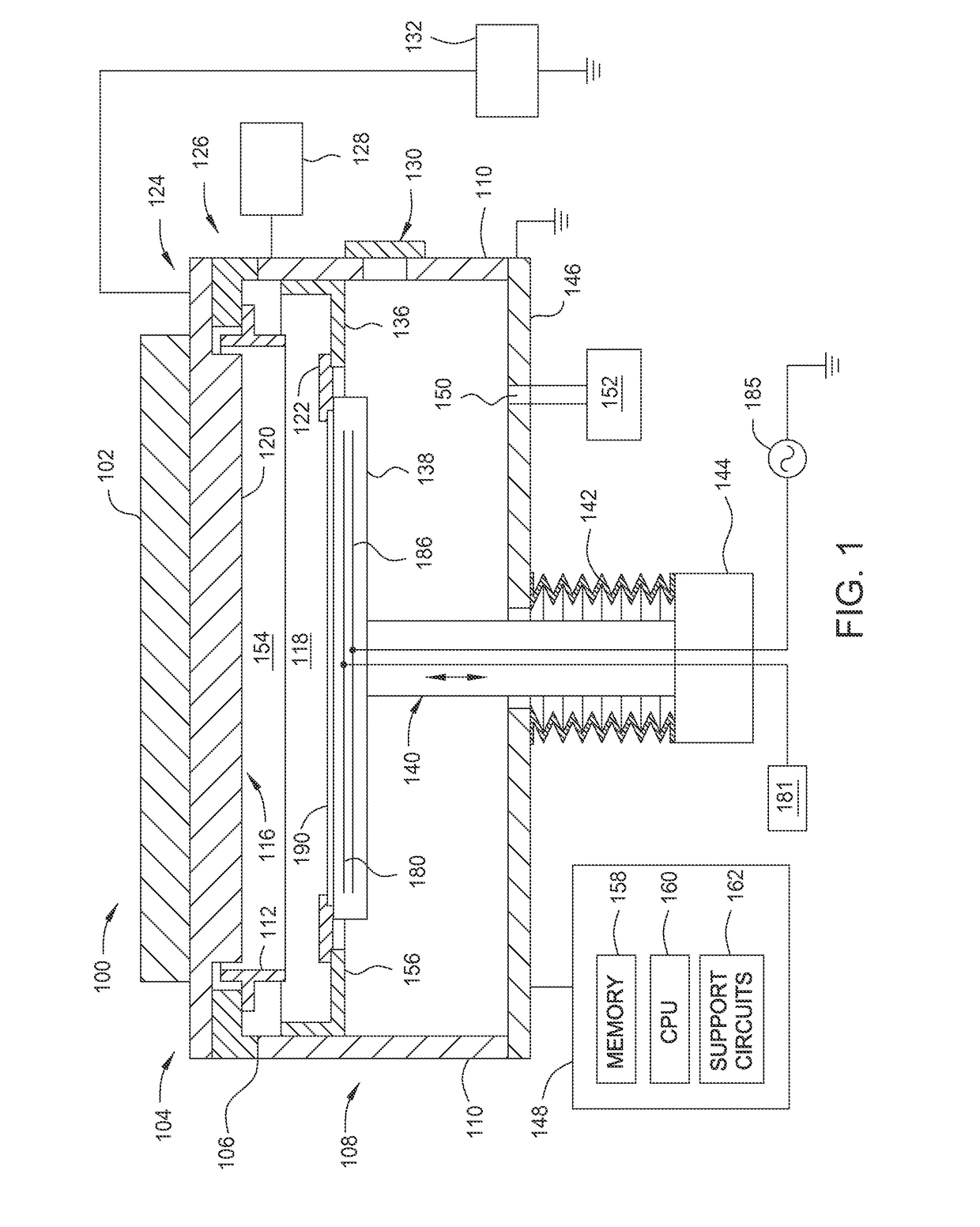

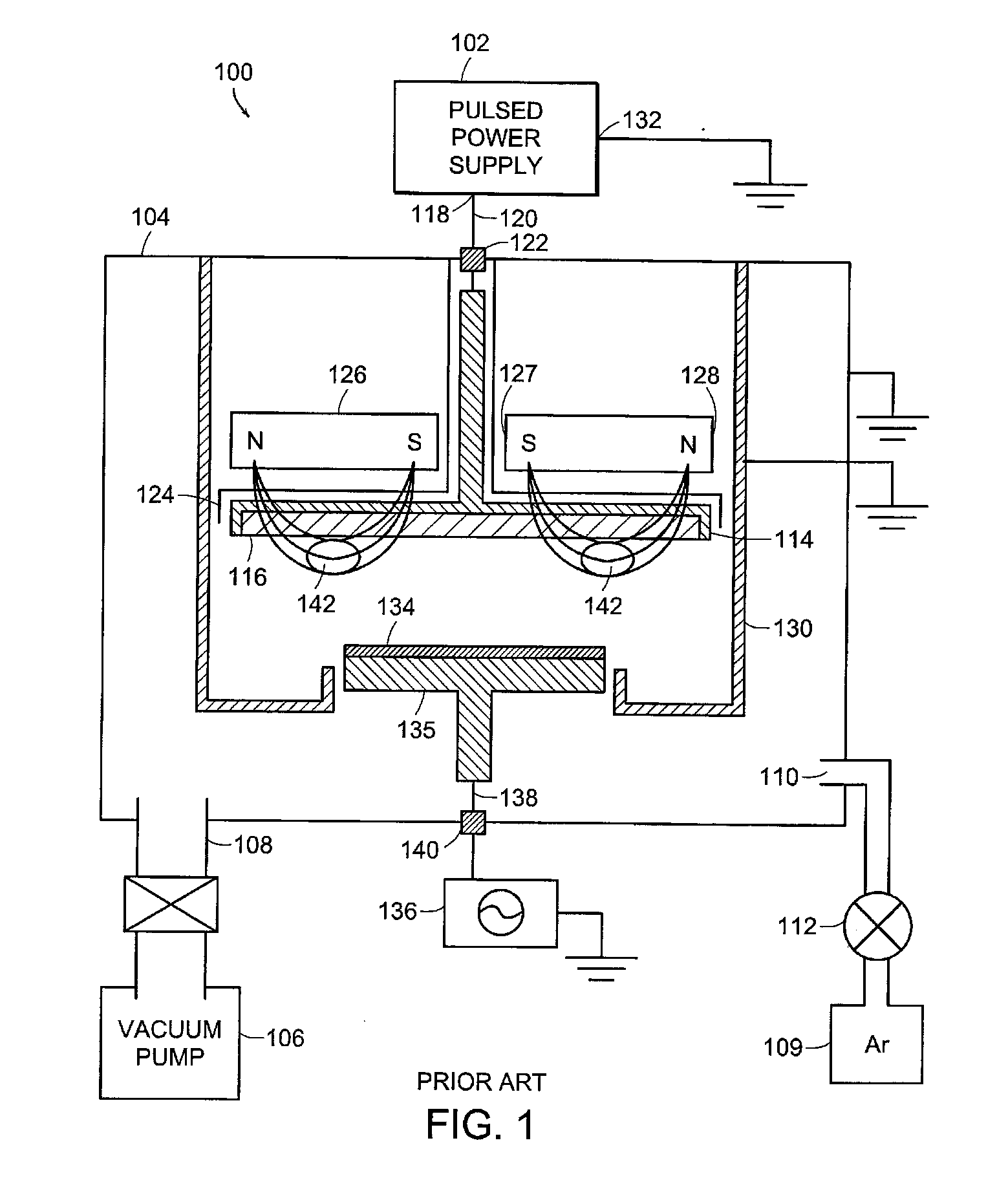

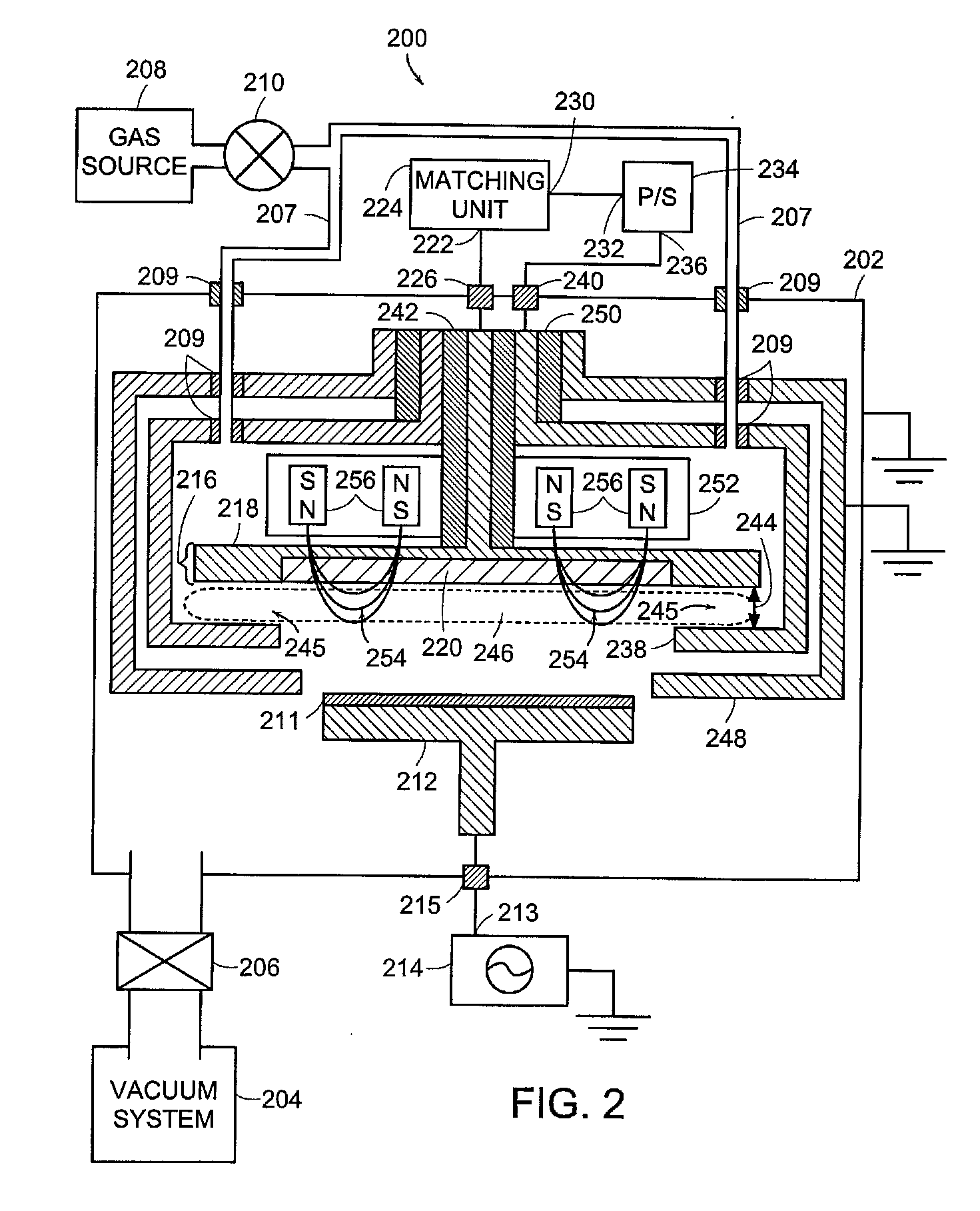

Magnetically enhanced sputtering methods and apparatus are described. A magnetically enhanced sputtering source according to the present invention includes an anode and a cathode assembly having a target that is positioned adjacent to the anode. An ionization source generates a weakly-ionized plasma proximate to the anode and the cathode assembly. A magnet is positioned to generate a magnetic field proximate to the weakly-ionized plasma. The magnetic field substantially traps electrons in the weakly-ionized plasma proximate to the sputtering target. A power supply produces an electric field in a gap between the anode and the cathode assembly. The electric field generates excited atoms in the weakly ionized plasma and generates secondary electrons from the sputtering target. The secondary electrons ionize the excited atoms, thereby creating a strongly-ionized plasma having ions that impact a surface of the sputtering target to generate sputtering flux.

Owner:ZOND CORP +1

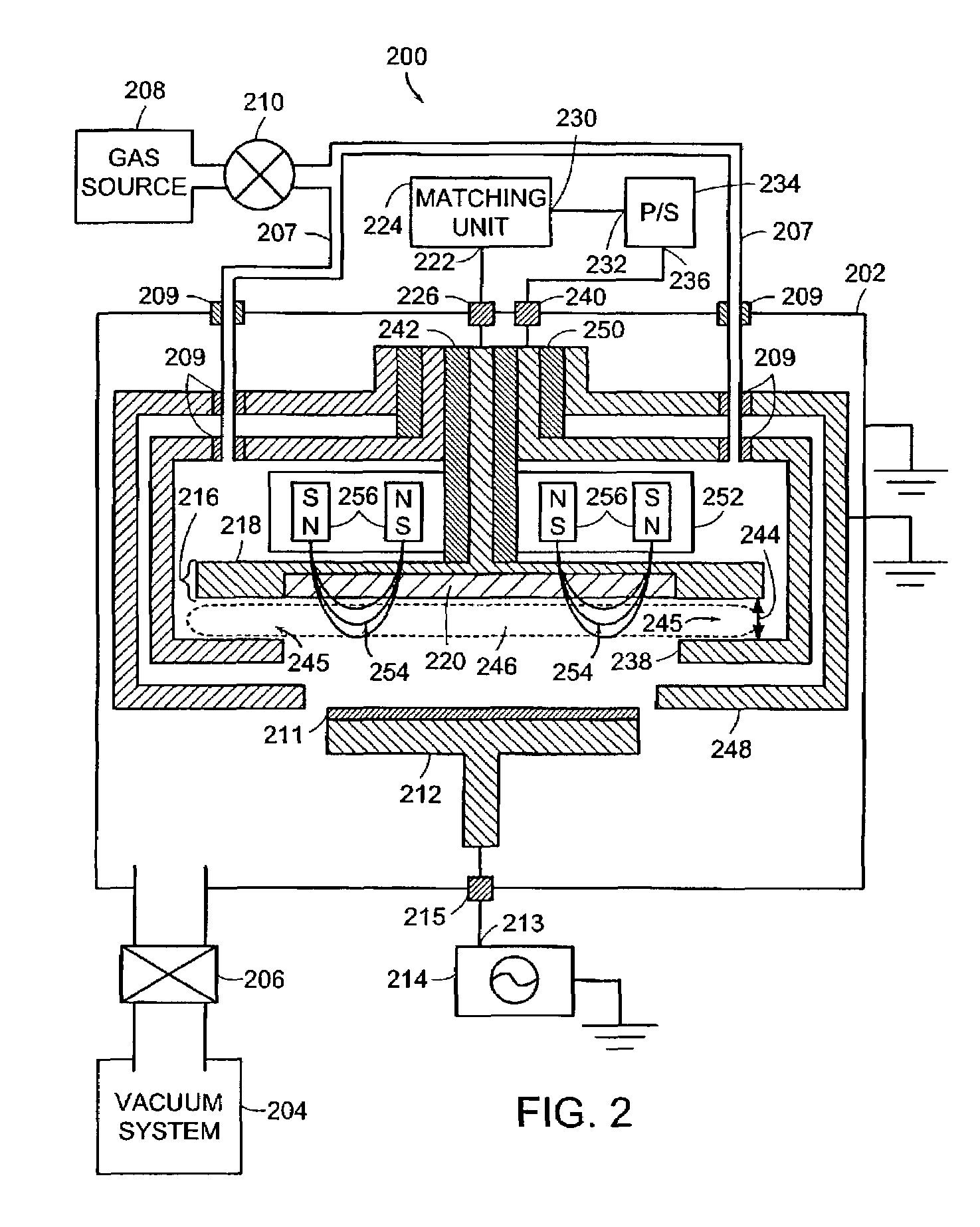

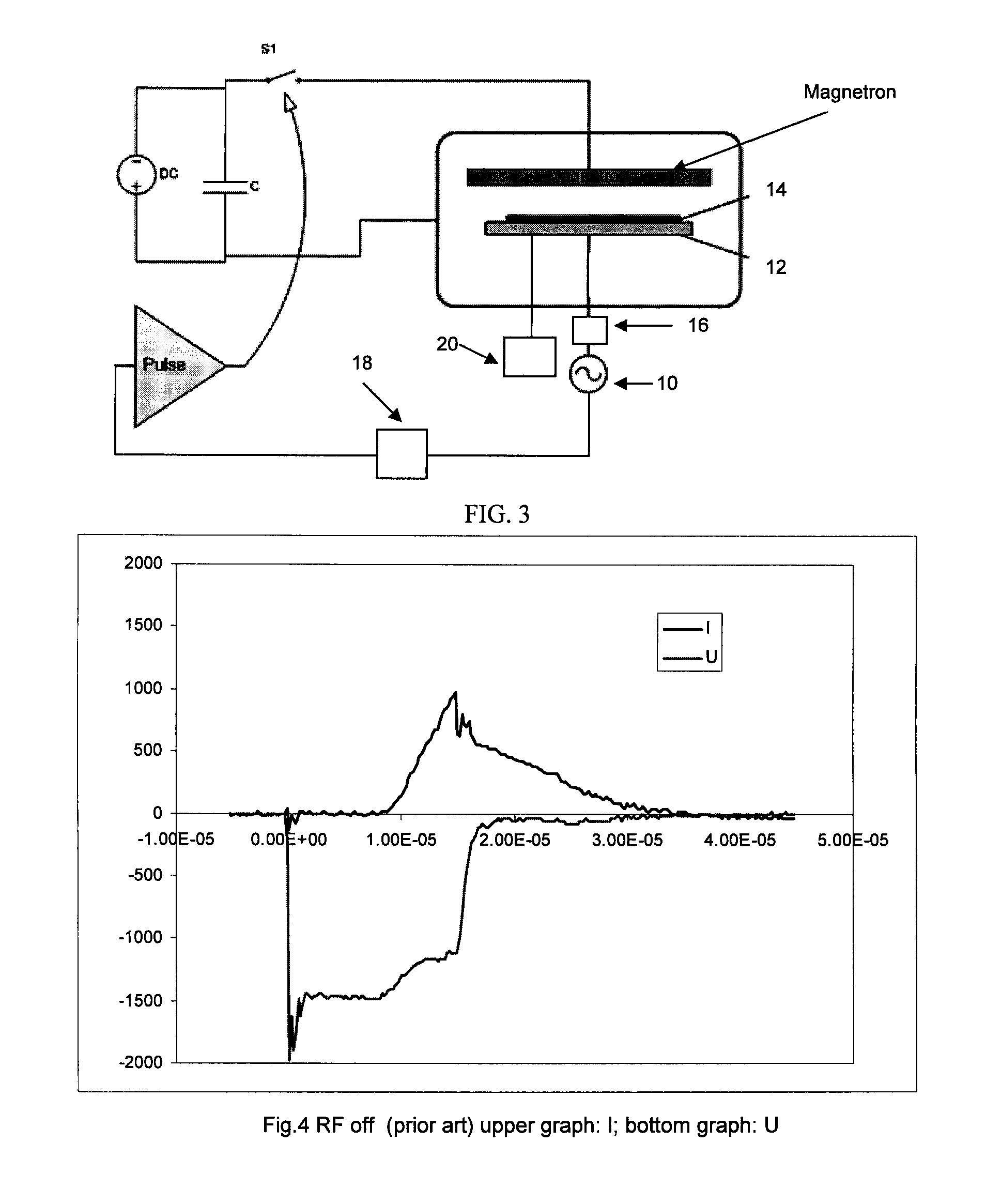

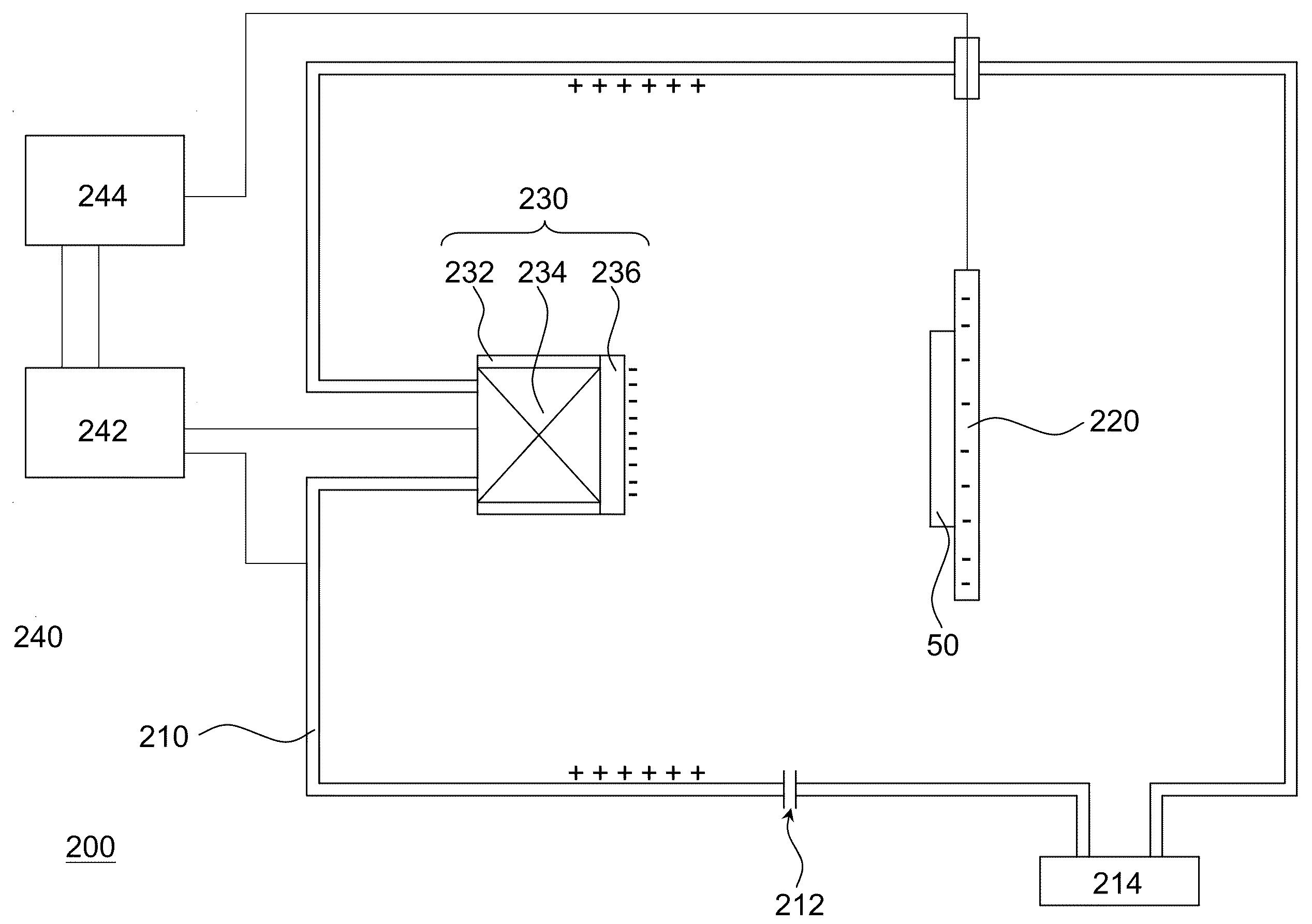

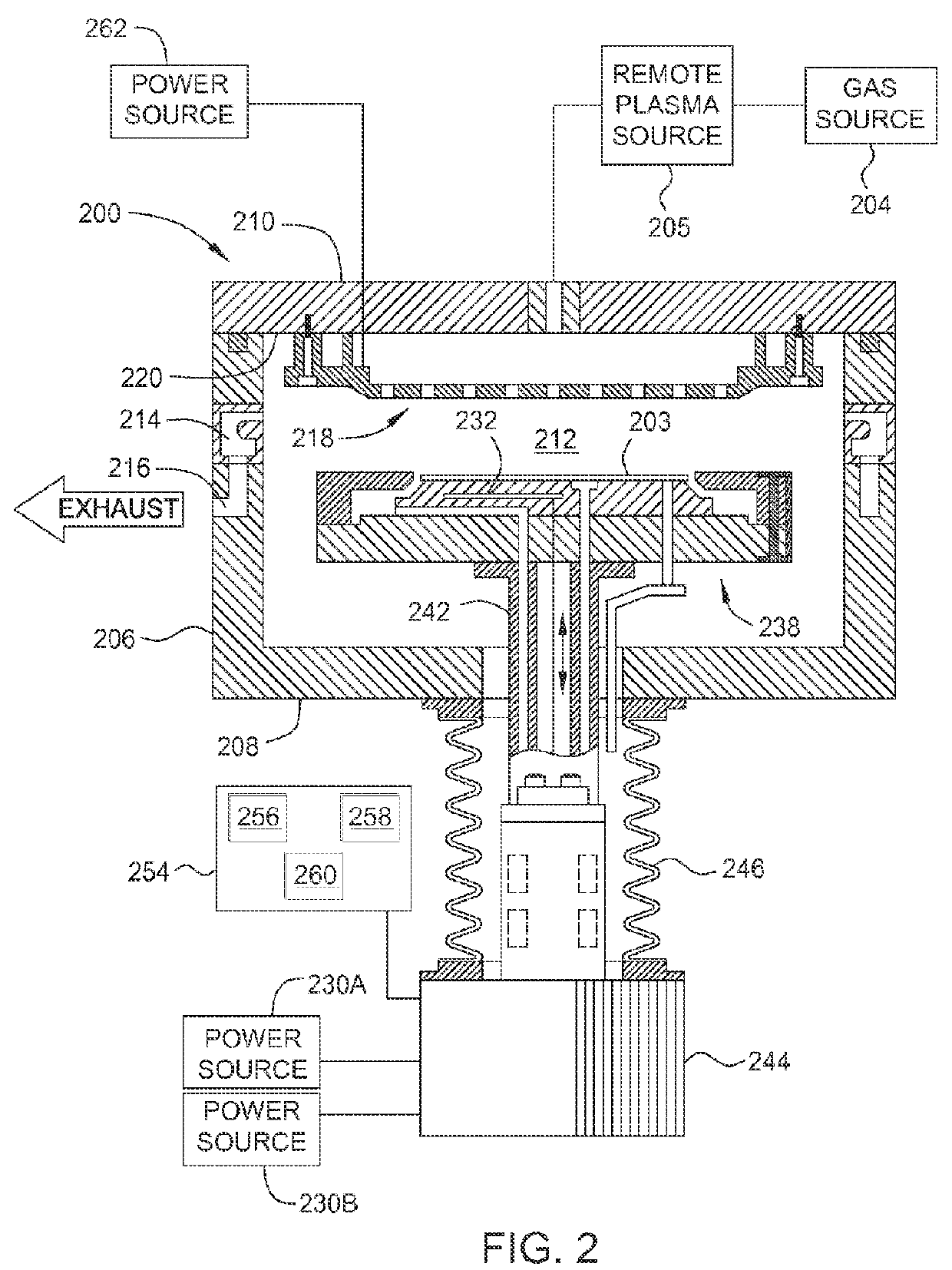

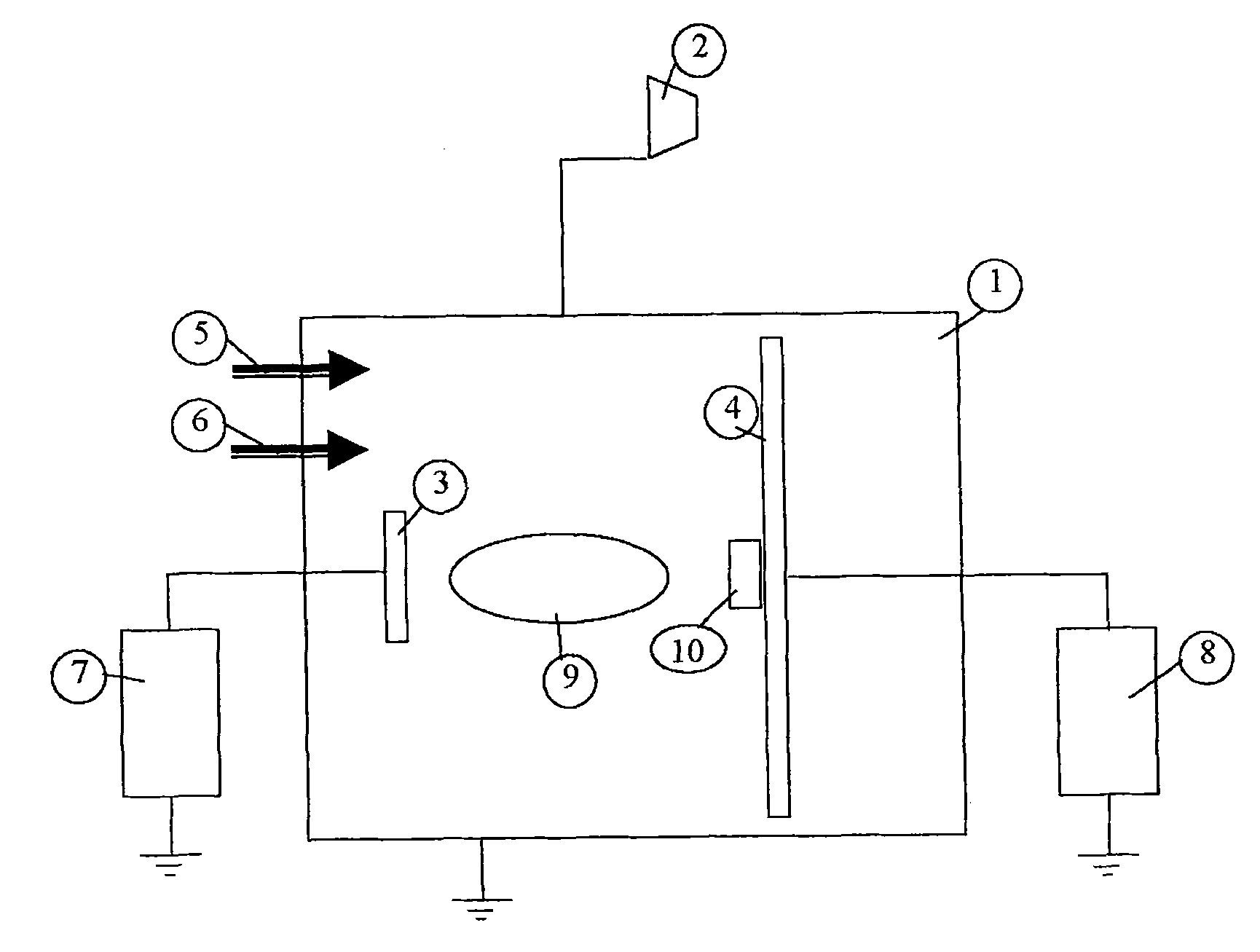

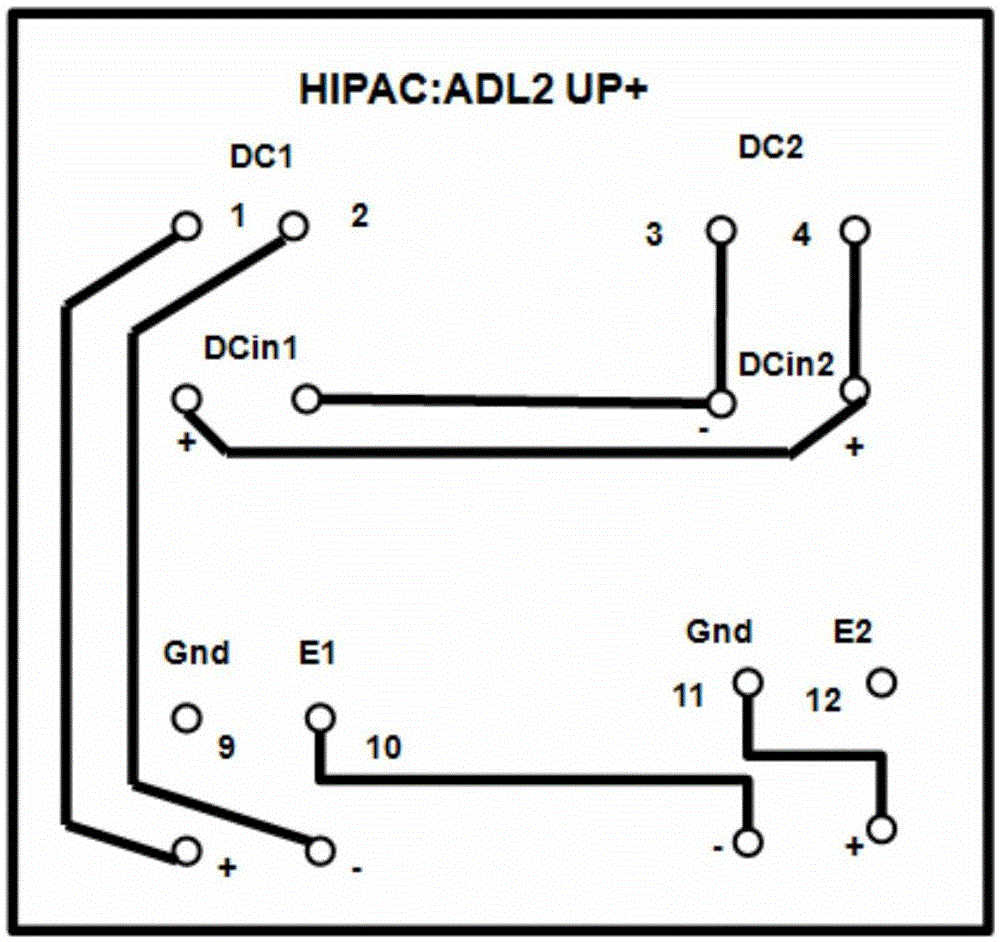

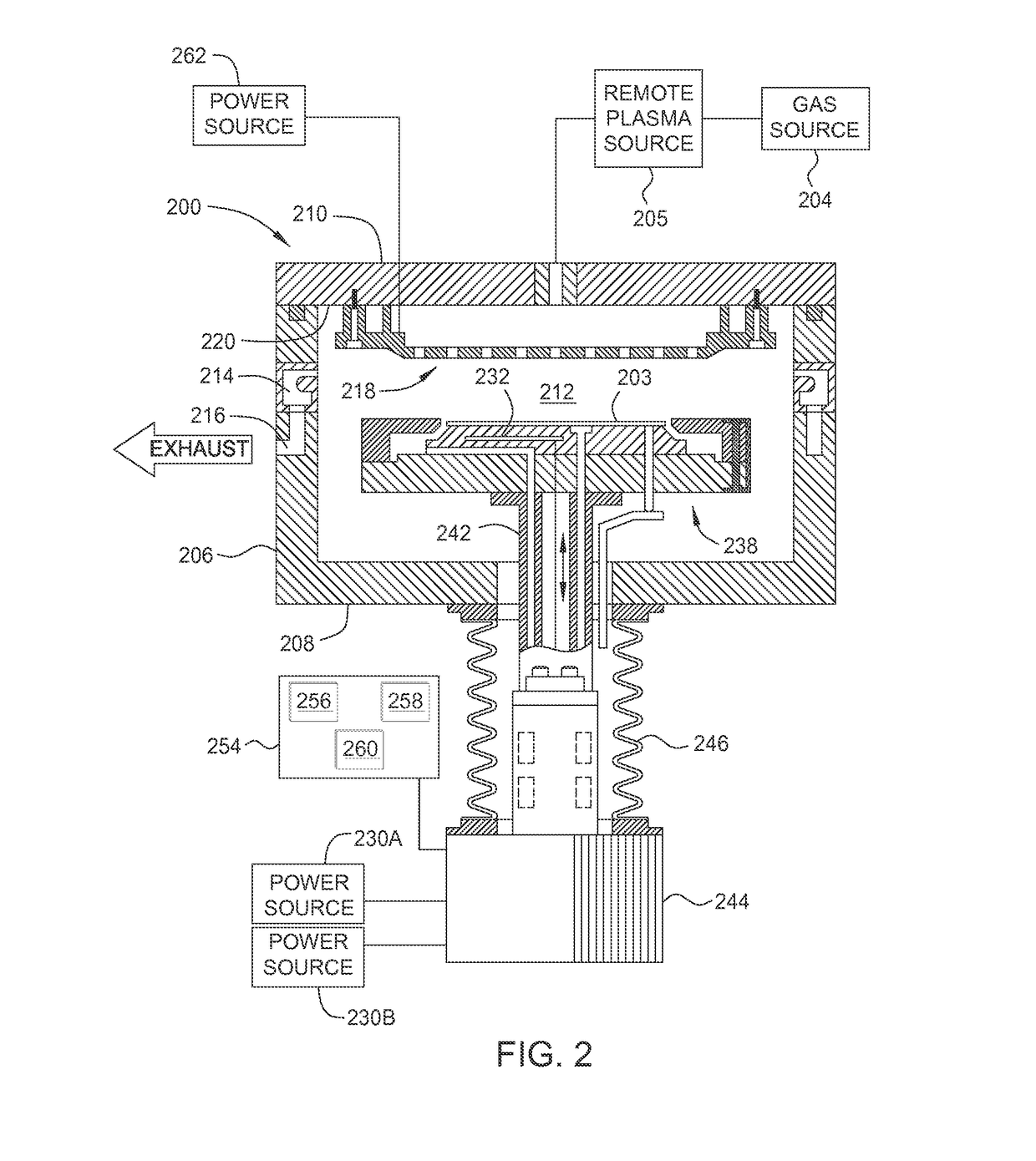

RF substrate bias with high power impulse magnetron sputtering (hipims)

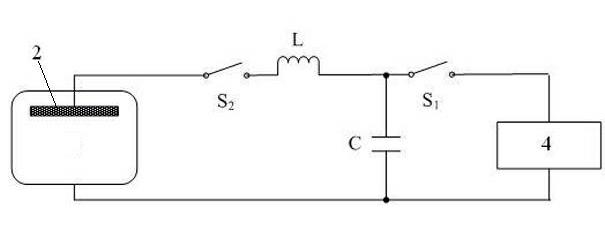

An apparatus for generating sputtering of a target to produce a coating on a substrate with a current density on a cathode of a magnetron between 0.1 and 10 A / cm2 is provided. The apparatus comprises a power supply that is operably connected to the magnetron and at least one capacitor is operably connected to the power supply. A first switch is also provided. The first switch operably connects the power supply to the magnetron to charge the magnetron and the first switch is configured to charge the magnetron according to a first pulse. An electrical bias device is operably connected to the substrate and configured to apply a substrate bias.

Owner:OERLIKON ADVANCED TECH +1

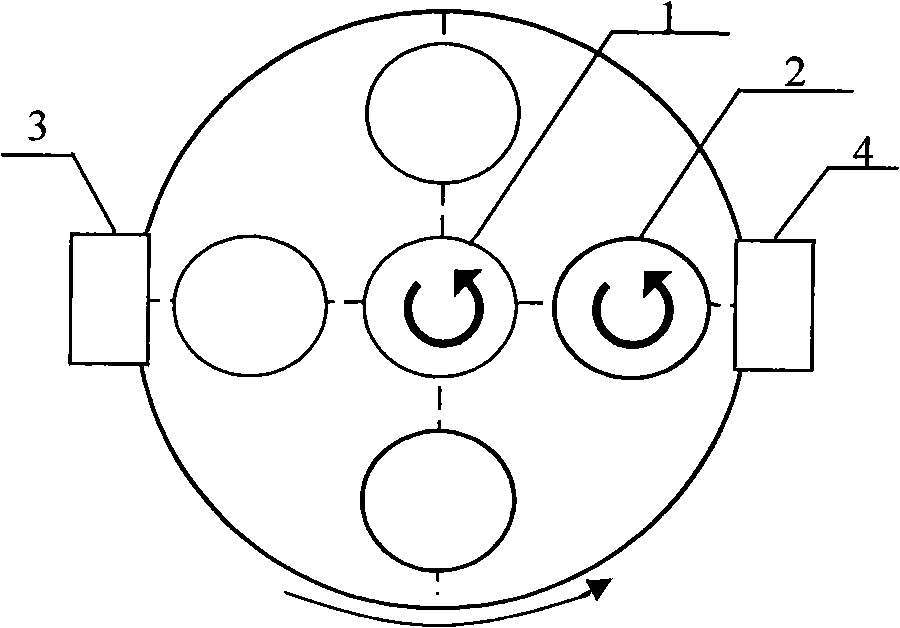

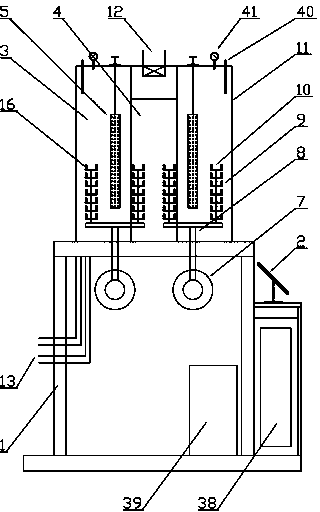

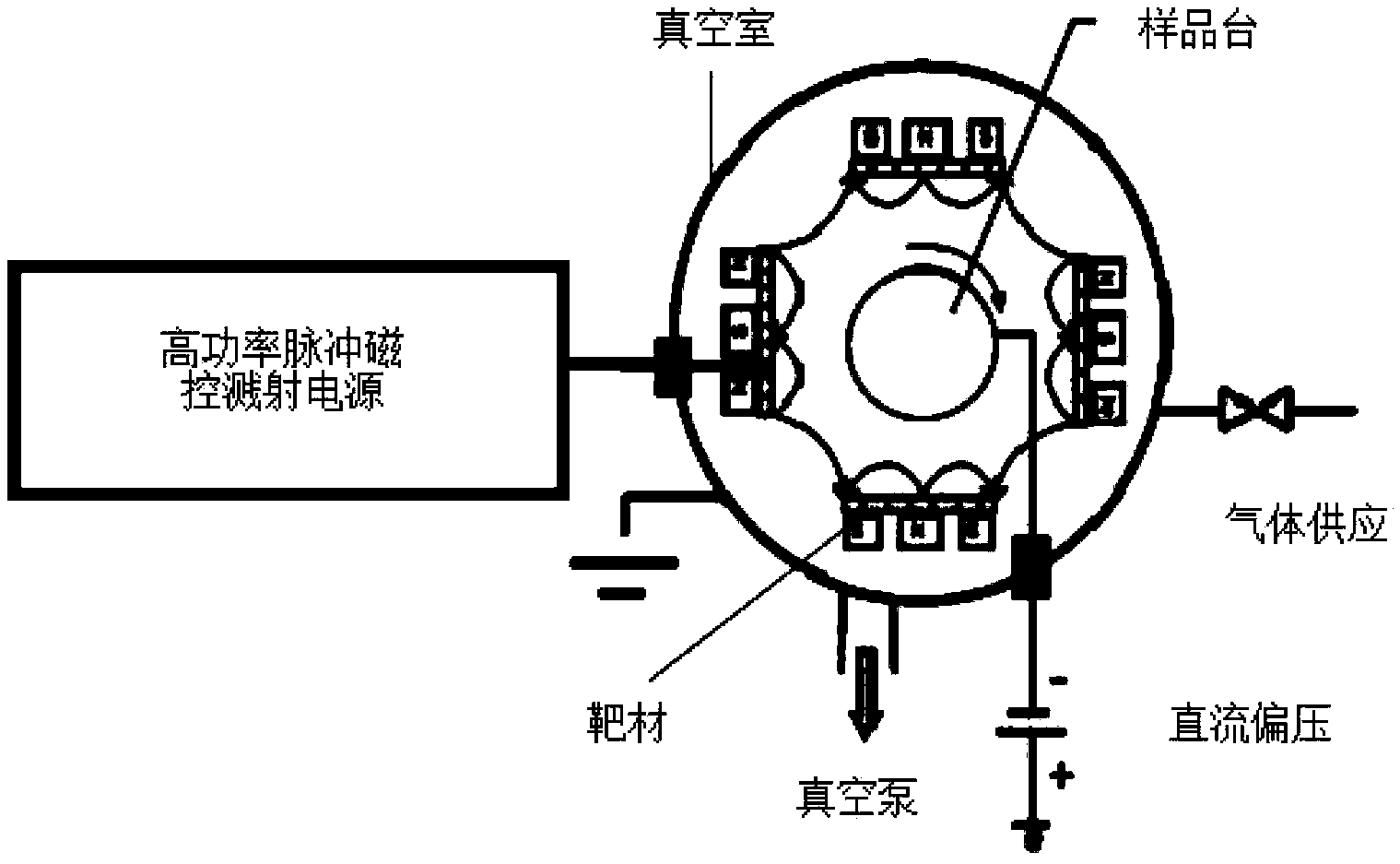

High-power pulse magnetron sputtering apparatus and surface treatment apparatus using the same

InactiveUS20110011737A1High coatingImprove adhesionCellsElectric discharge tubesSputteringReactive gas

A magnetron sputtering apparatus suitable for coating on a workpiece is provided. The magnetron sputtering apparatus includes a vacuum chamber, a holder, a magnetron plasma source and a high-power pulse power supply set, wherein the magnetron plasma source includes a base, a magnetron controller and a target. A reactive gas is inputted into the vacuum chamber, and the holder supporting the workpiece is disposed inside the vacuum chamber. The magnetron plasma source is disposed opposite to the workpiece, wherein the magnetron controller is disposed in the base, and the target is disposed on the base. The high-power pulse power supply set is coupled to the vacuum chamber, the magnetron plasma source and the holder, and a high voltage pulse power is inputted to the magnetron plasma source to generate plasma to coat a film on the surface of the workpiece.

Owner:INST NUCLEAR ENERGY RES ROCAEC

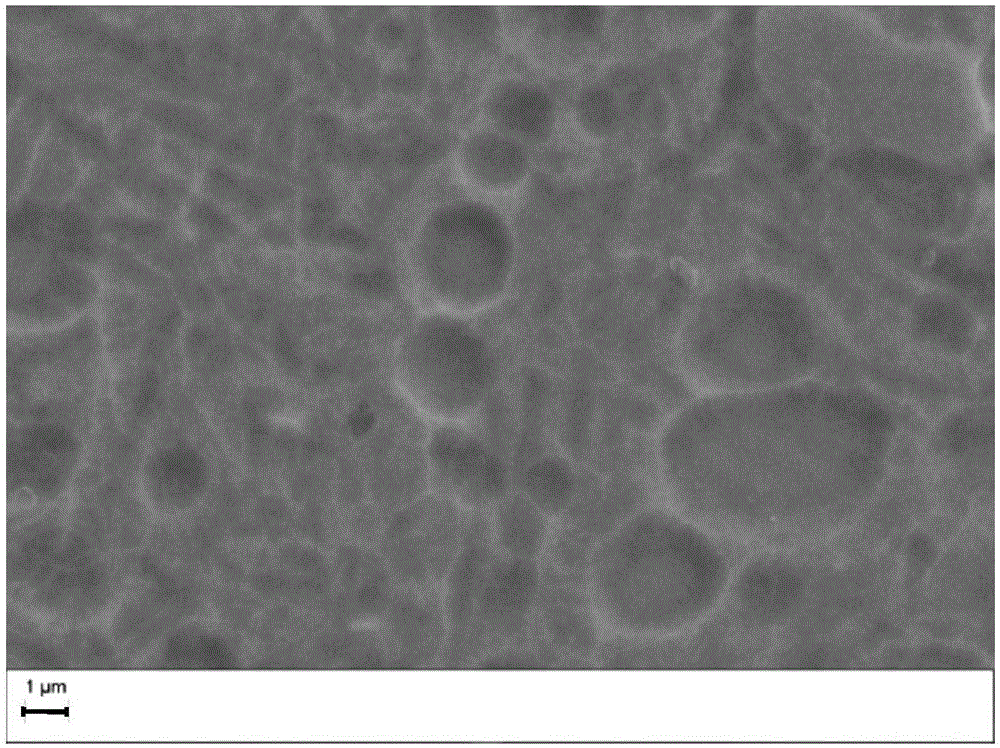

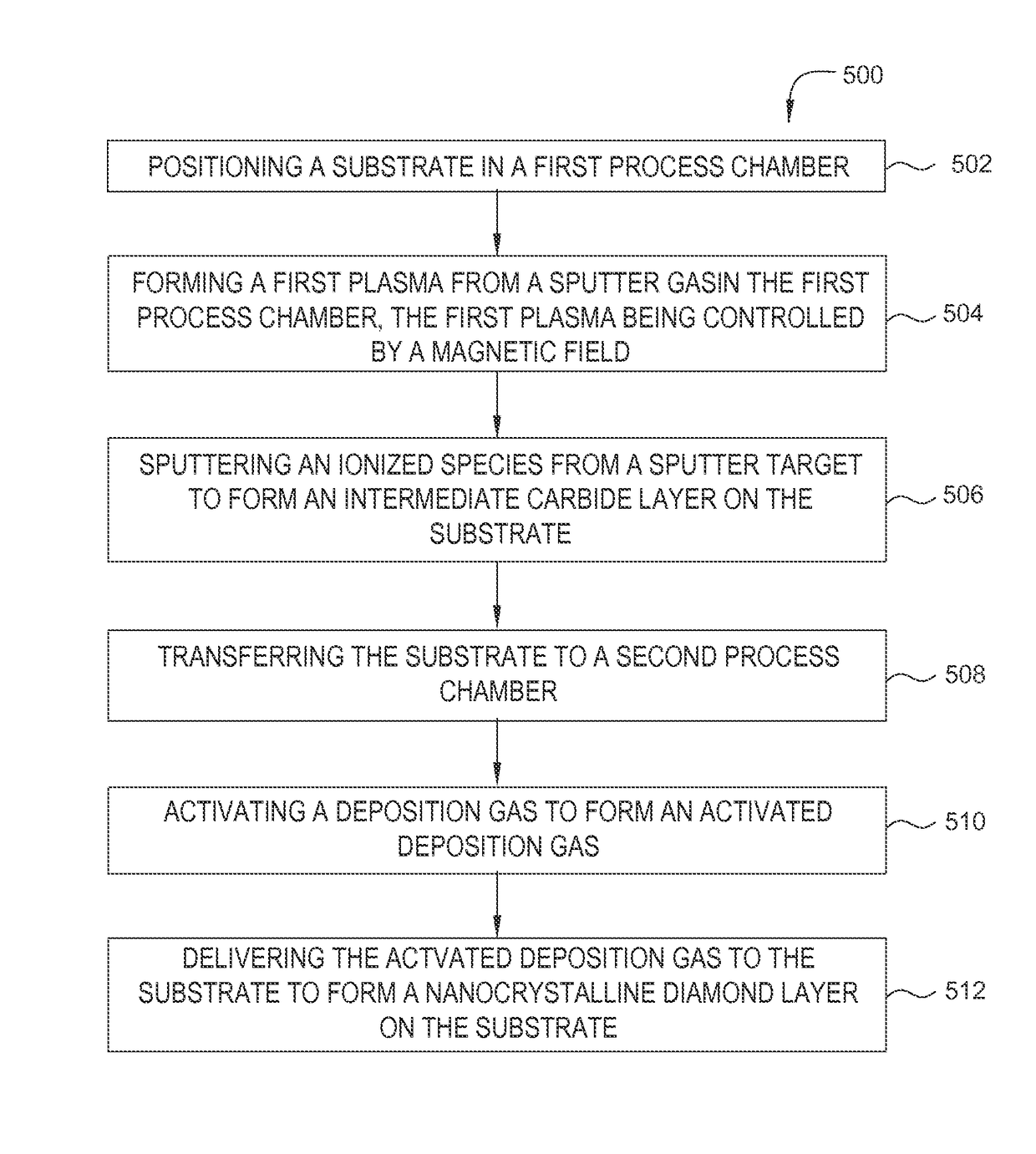

High power impulse magnetron sputtering process to achieve a high density high sp3 containing layer

ActiveUS20160053366A1Reduce the temperatureVacuum evaporation coatingSputtering coatingSputteringHigh density

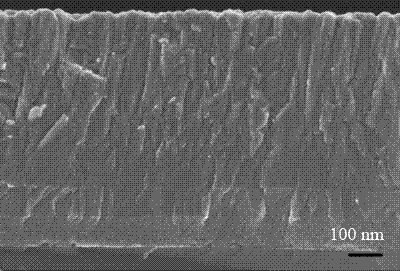

Methods for depositing a nanocrystalline diamond layer are disclosed herein. The method can include delivering a sputter gas to a substrate positioned in a processing region of a first process chamber, the first process chamber having a carbon-containing sputter target, delivering an energy pulse to the sputter gas to create a sputtering plasma, the sputtering plasma having a sputtering duration, the energy pulse having an average power between 1 W / cm2 and 10 W / cm2 and a pulse width which is less than 100 μs and greater than 30 μs, the sputtering plasma being controlled by a magnetic field, the magnetic field being less than 300. Gauss, and delivering the sputtering plasma to the sputter target to form an ionized species, the ionized species forming a crystalline carbon-containing layer on the substrate.

Owner:APPLIED MATERIALS INC

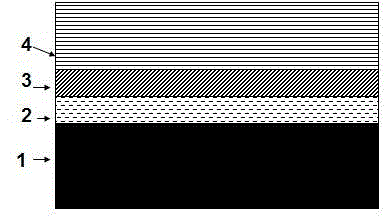

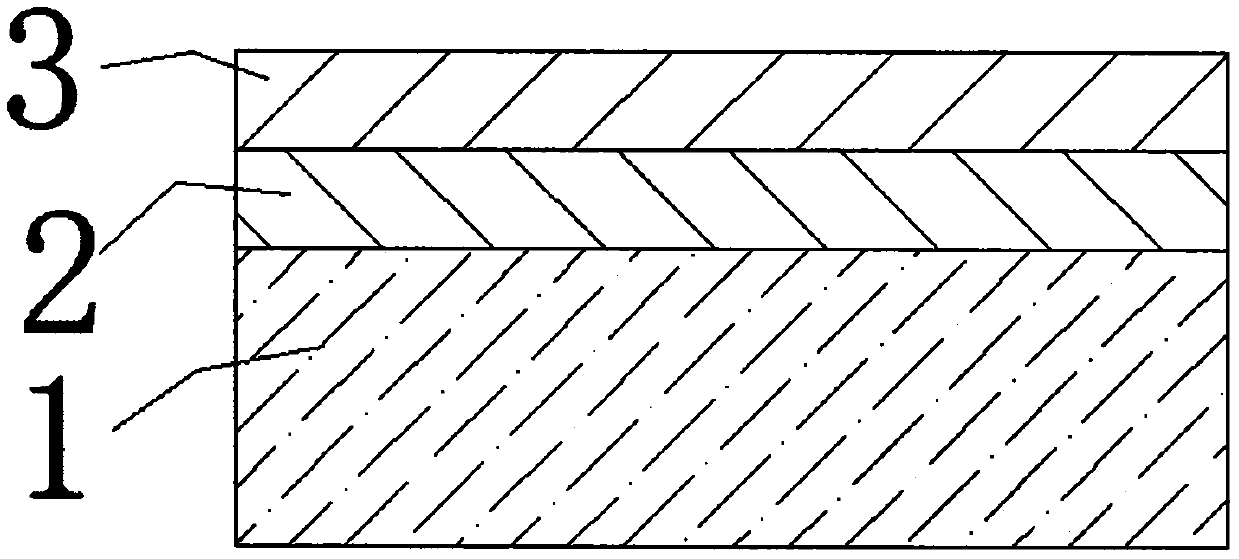

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

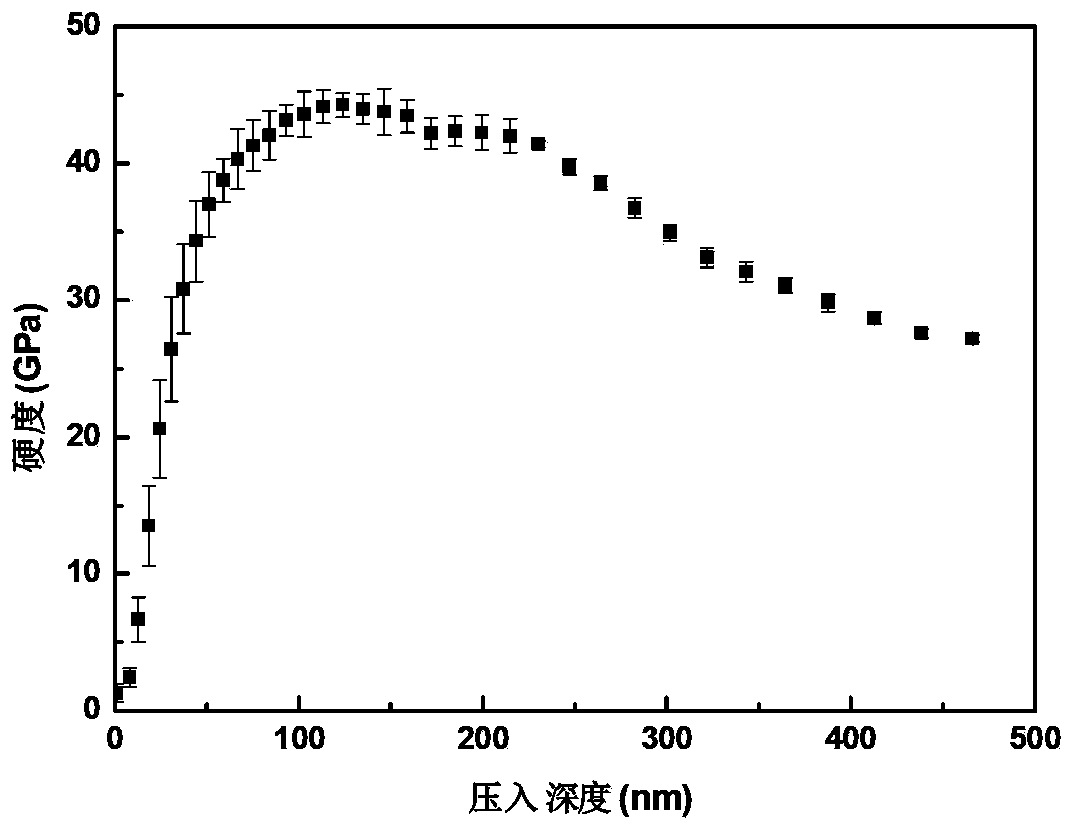

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Cutting tool comprising a multiple-ply pvd coating

The invention relates to a tool comprising a substrate that consists of hard metal, cermet, ceramic, steel or high speed steel, and a multiple-ply coating that is applied using the PVD method and has a total thickness of 1 (mu)m to 20 (mu)m, said multiple-ply coating comprising a connecting layer and a wear-resistant layer deposited directly onto said connecting layer, characterised in that the connecting layer has a multiple-ply design and is deposited by means of cathodic vacuum arc vapour deposition (arc PVD), plies of said connecting layer which lie one immediately over the other having different compositions, and each of the multiple plies of said connecting layer being formed from carbides, nitrides, oxides, carbonitrides, oxycarbides, carboxy nitrides of at least two different metals selected from Ti, V, Cr, Zr, Nb, Mo, Ru, Hf, Ta, W, Al, Si, Y, Li and B, and solid solutions thereof; and said wear-resistant layer having a single or multiple-ply design and being deposited by means of high-power impulse magnetron sputtering (HIPIMS), each of said one or more plies of the wear-resistant layer being formed from carbides, nitrides, oxides, carbonitrides, oxycarbides, carboxy nitrides of at least two different metals selected from Ti, V, Cr, Zr, Nb, Mo, Ru, Hf, Ta, W, Al, Si, Y, Li and B and solid solutions thereof.

Owner:WALTER AG

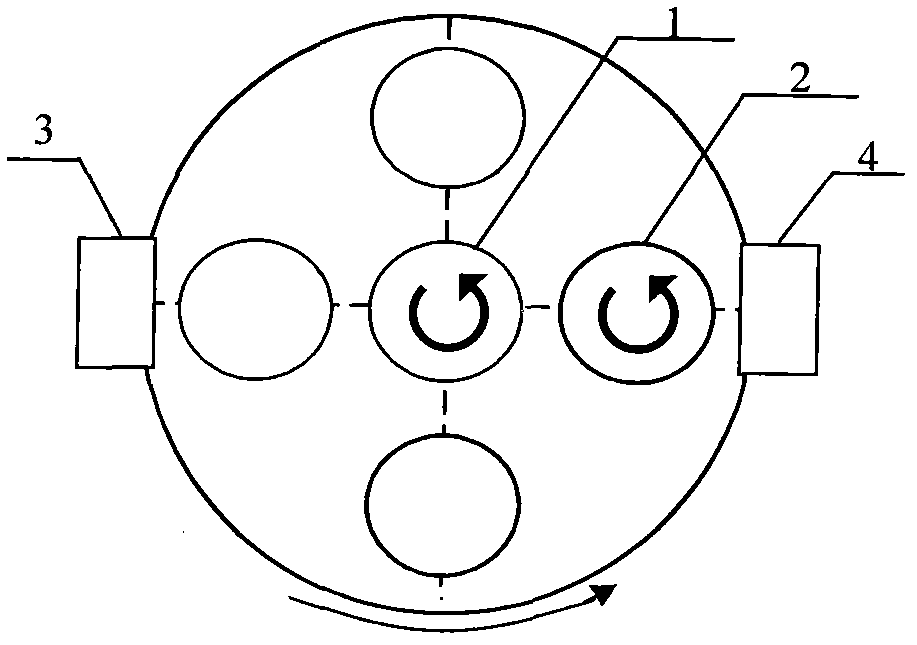

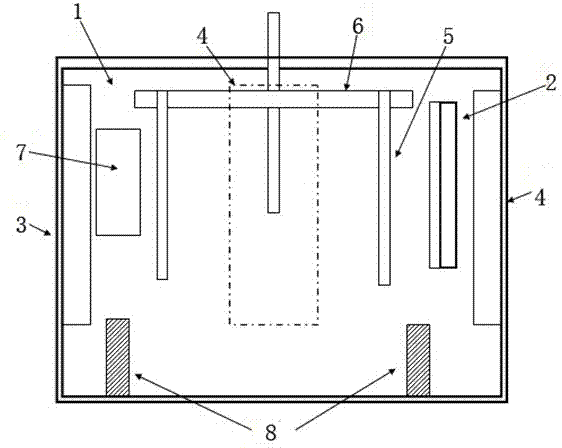

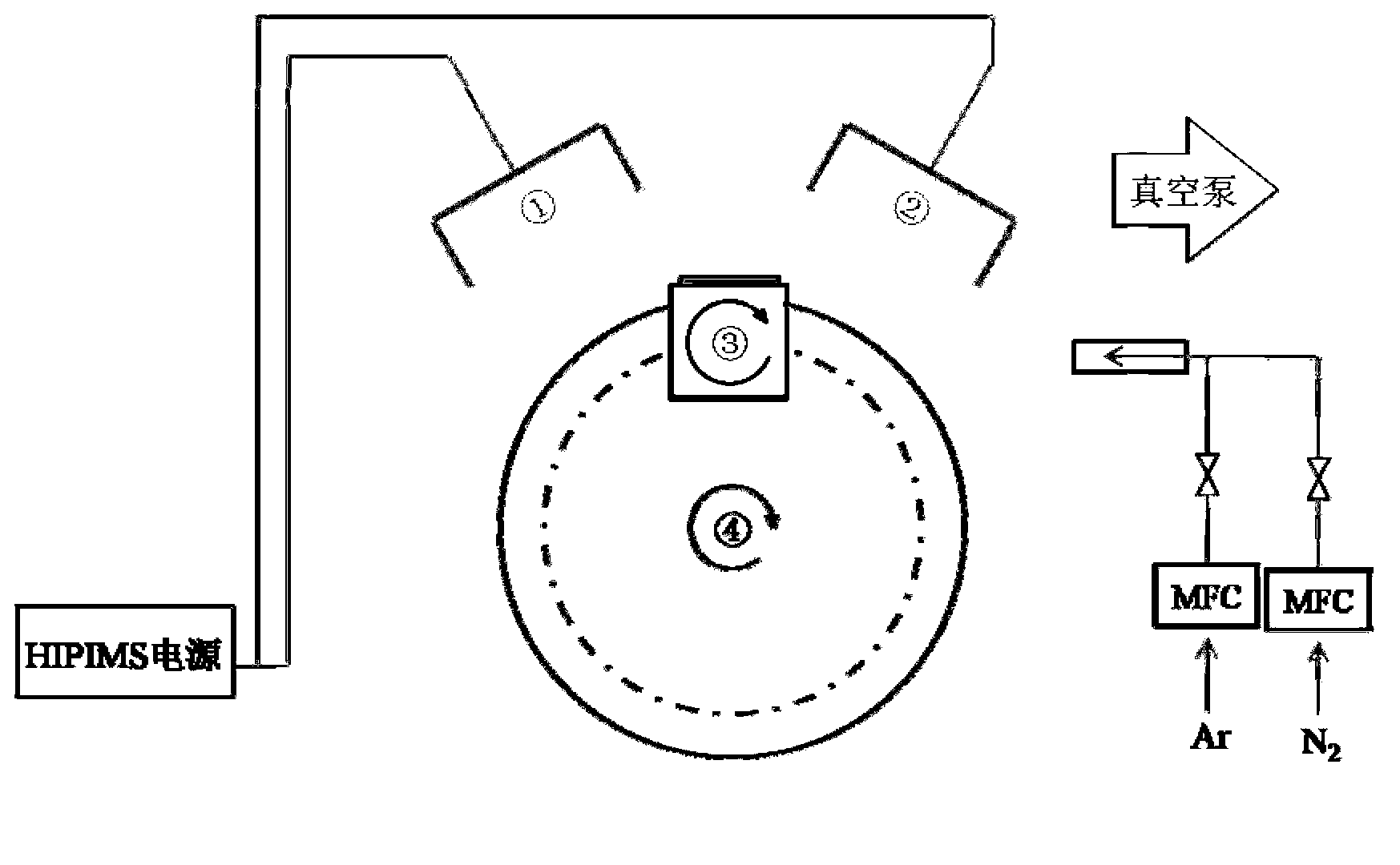

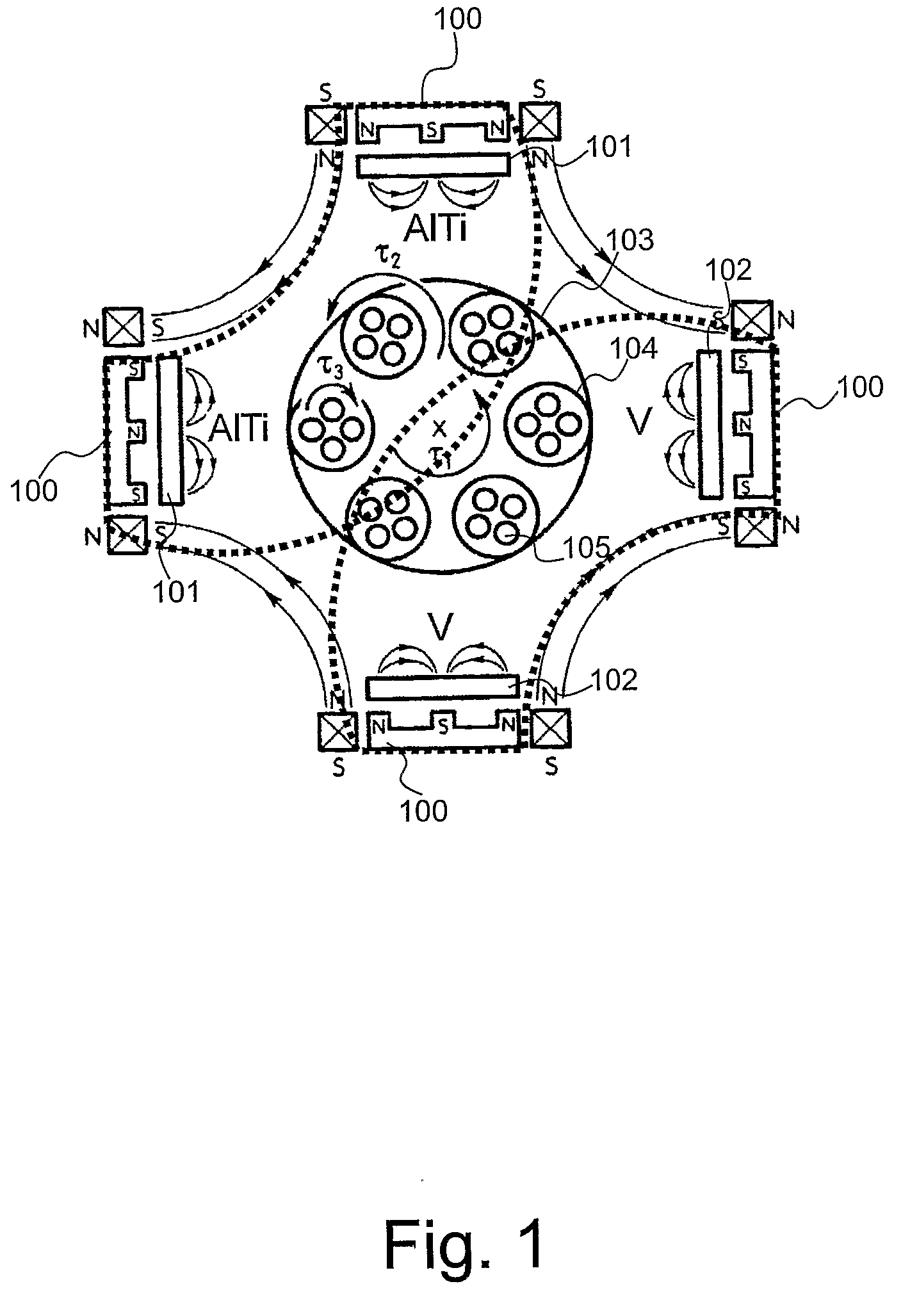

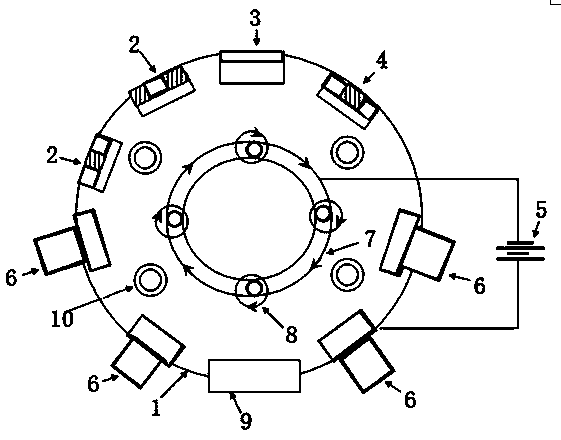

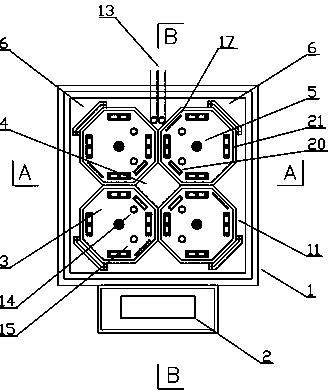

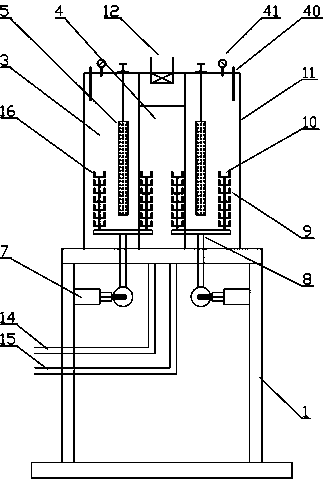

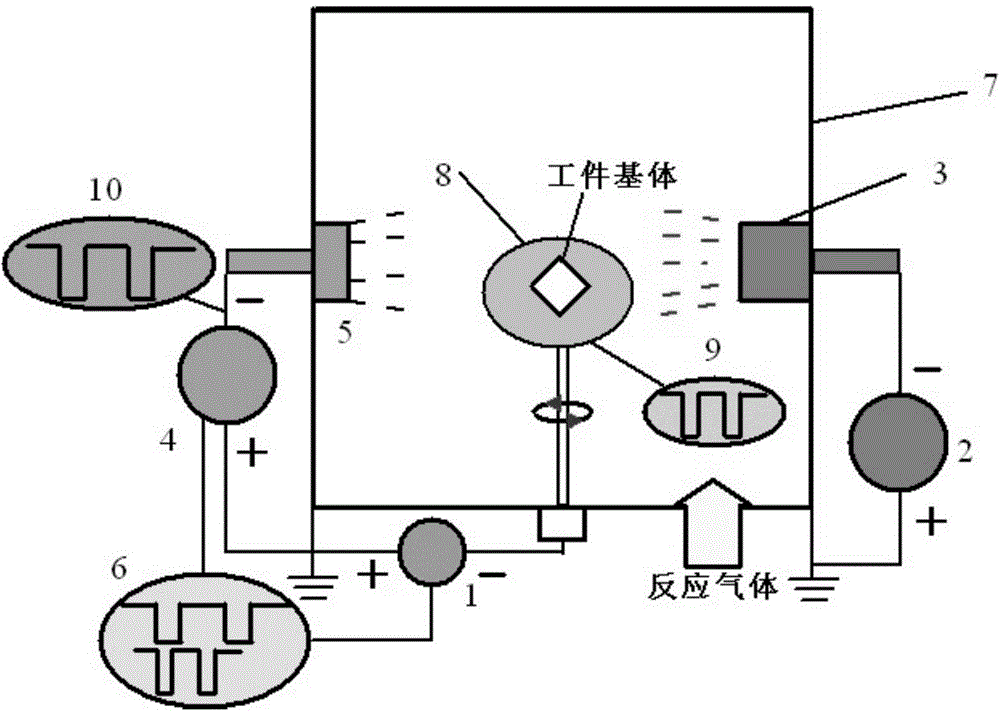

High-power pulse plasma reinforced composite magnetron sputtering deposition device and application method thereof

ActiveCN103668095AFast preparationImprove uniformityVacuum evaporation coatingSputtering coatingChemical compositionVacuum chamber

The invention relates to the technical field of thin-film materials and particularly relates to a high-power pulse plasma reinforced composite magnetron sputtering deposition device. The device comprises a vacuum chamber, magnetic control targets, a work rest and a rotary support, wherein the magnetic control targets comprise a high-power pulse magnetron sputtering target and pulse direct-current magnetic control targets, fixed in the vacuum chamber, and are arranged in opposite direction in a right angle, the magnetic field arrangement manners of all magnetic control targets are opposite, and a closed field is formed; the magnetic fields of all magnetic control targets are unbalanced magnetic fields; through the implementation of the structure, the better magnetic field distribution and ion plating effects are achieved, high-quality coating with good coating binding force, compact coating, good mechanical performance, accurate and controllable chemical components can be deposited conveniently and the device is applied to high-speed cutting tools.

Owner:GUANGDONG UNIV OF TECH

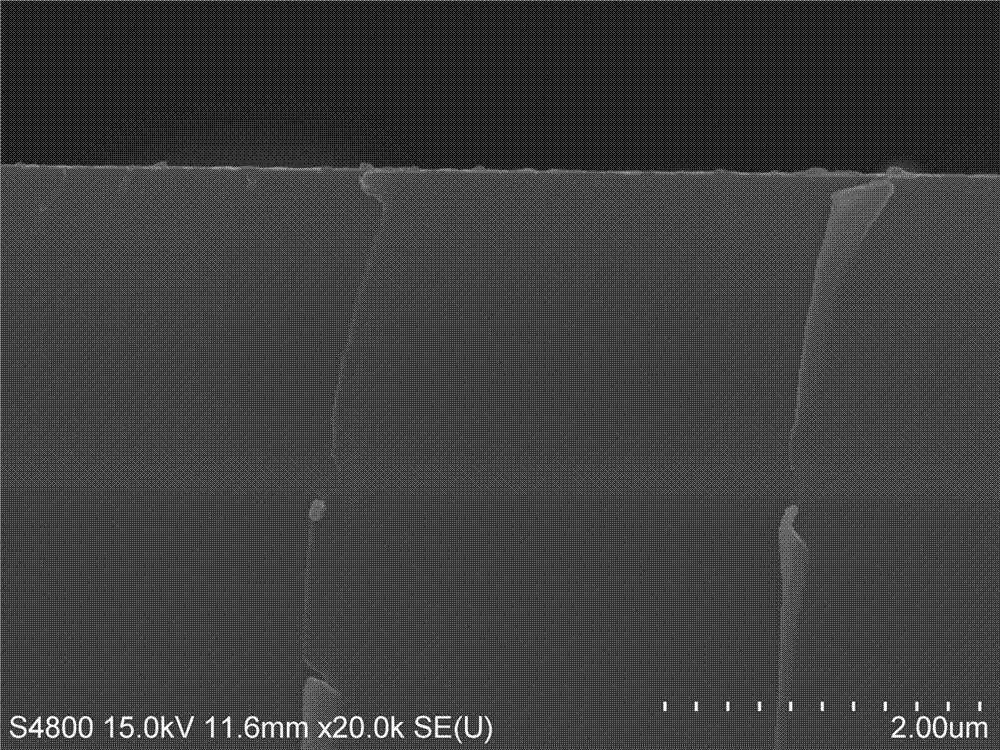

AlCrSiN-based multilayer nanometer composite cutter coating layer and preparation method thereof

InactiveCN104928638AExtend your lifeImprove mechanical propertiesVacuum evaporation coatingSputtering coatingWear resistantChromium

The invention relates to an AlCrSiN-based multilayer nanometer composite cutter coating layer and a preparation method thereof, and belongs to the technical field of preparation of cutter coating layers. A cutter basal body of the AlCrSiN-based multilayer nanometer composite cutter coating layer adopts a WC-Co hard allot or high-speed steel; the coating layer structure comprises a Ti metal bonding layer, an AlTiN transition layer and an AlCrSiN main wear resistant layer, wherein the AlTiN transition layer consists of 29-35 at.% of aluminum, 15-20 at.% of titanium, and 47-51 at.% of nitrogen; and the AlCrSiN main wear resistant layer consists of 25-30 at.% of aluminum, 20-25 at.% of chromium, 1-10 at.% of silicon, and 45-50 at.% of nitrogen. The transition layer AlTiN coating layer is prepared by a high-power pulse magnetron sputtering technology; and the AlCrSiN coating layer is prepared by an arc ion plating technology. The AlCrSiN-based multilayer nanometer composite cutter coating layer has the advantages of high hardness, low friction coefficient, low internal stress, high bonding strength and good high-temperature stability; a deposition coating cutter is suitable for cutting a high-hardness steel material under the condition of high speed; and the service life of the cutter can be largely prolonged.

Owner:GUANGDONG UNIV OF TECH

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

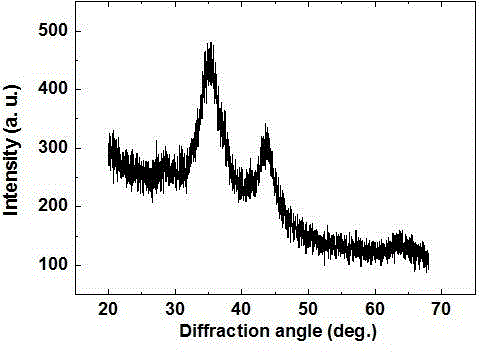

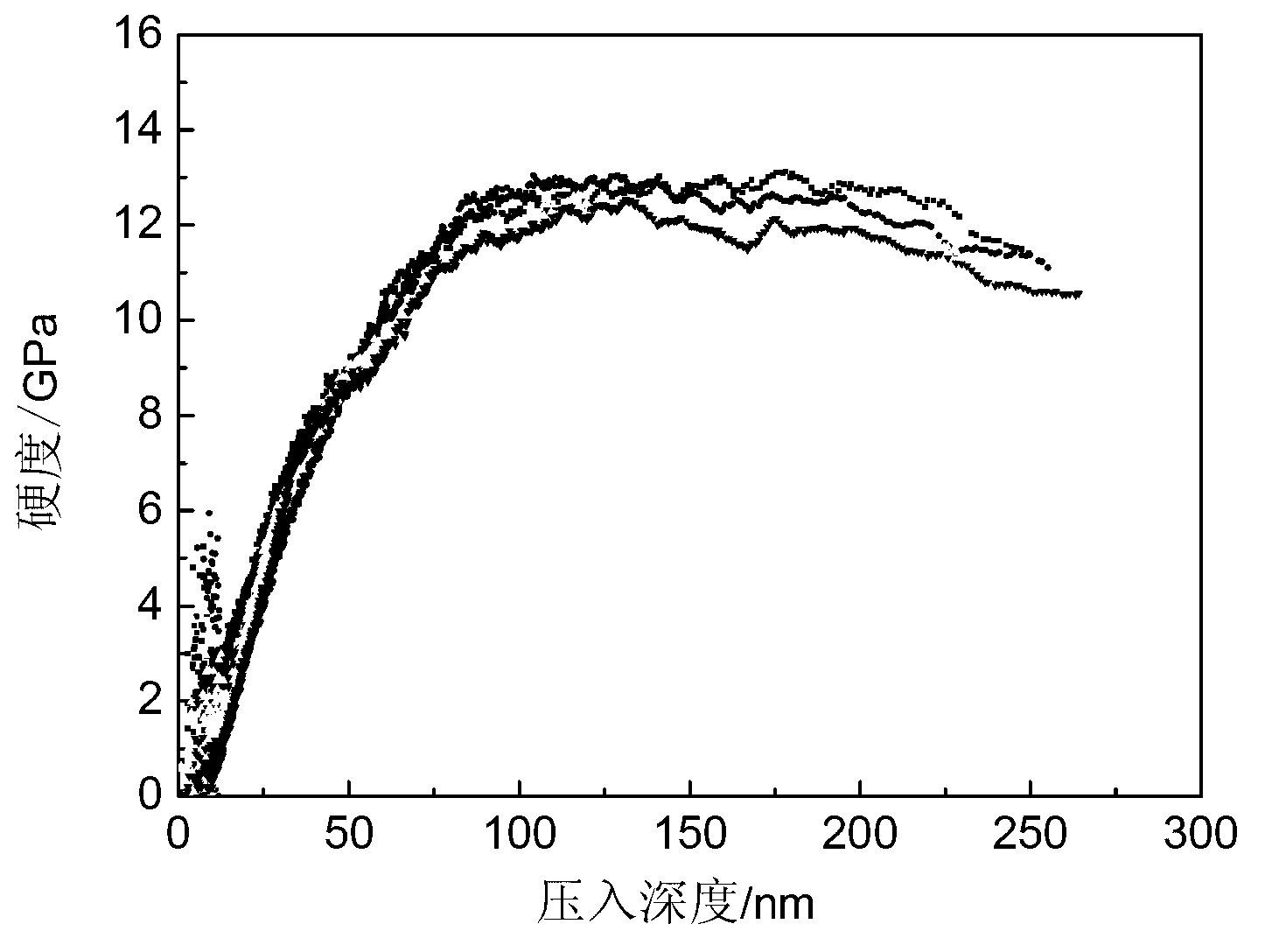

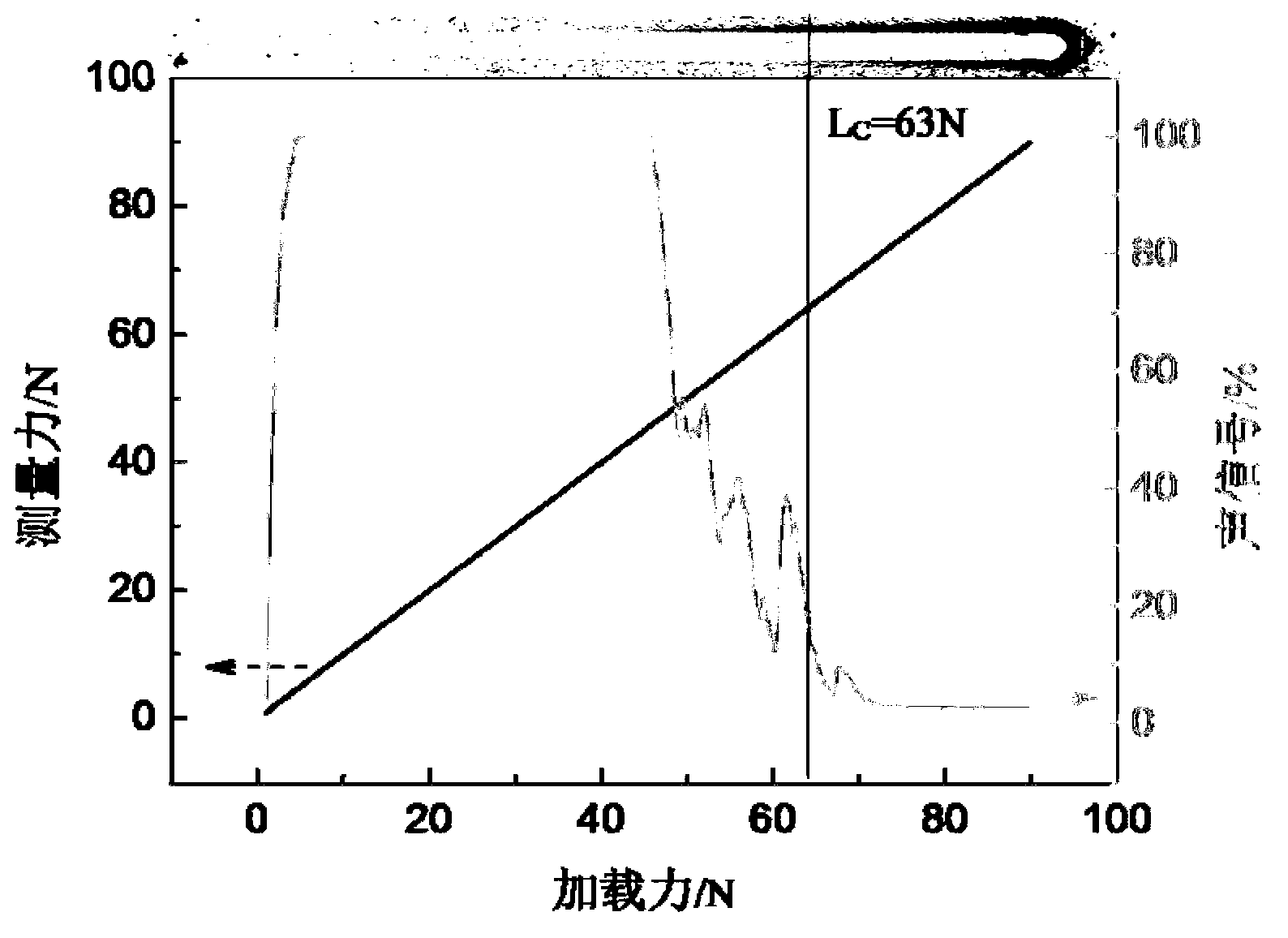

ActiveCN103060765AFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

The invention discloses a preparation method of a MoS2 composite thin film with high hardness and loss abrasion on a surface of a substrate. The method comprises the following step: sequentially depositing a metal Ti priming coat, a TiN transitional layer and a Ti / MoS2 composite thin film on the surface of the substrate by using a high power pulse magnetron sputtering technology combined with optimized process conditions to obtain the MoS2 composite thin film which is strong in film binding force and high hardness and has low frictional coefficient and wear rate in various frictional environments. The nano hardness of the composite thin film is over 11GPa, the critical load value is over 60N, and the frictional coefficients in room-temperature air with relative humidity of 30%, 50% and 70%, an N2 atmosphere and a hydraulic oil environment are below 0.055. Therefore, the substrate is effectively protected in frictional reduction, and the composite thin film has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

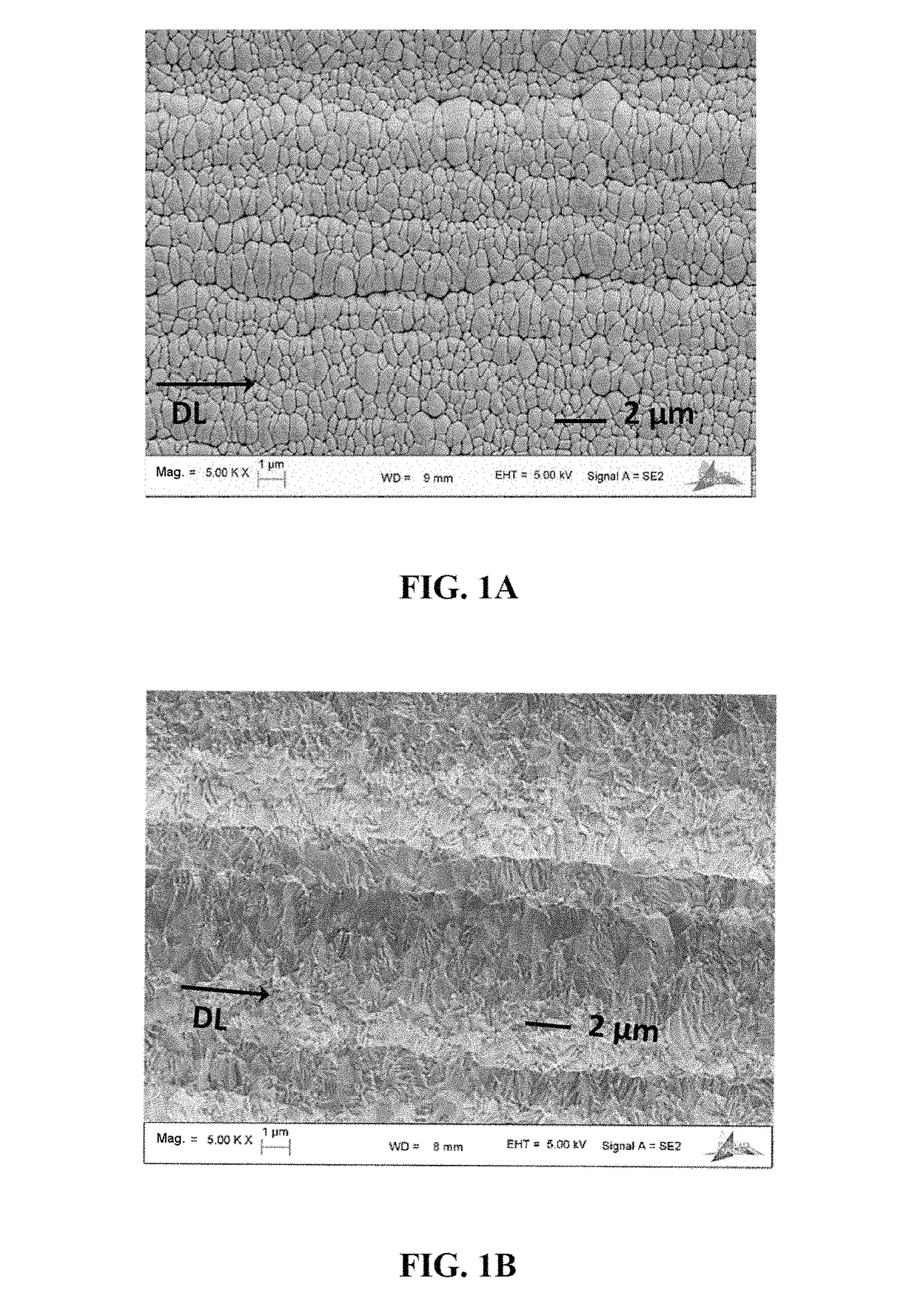

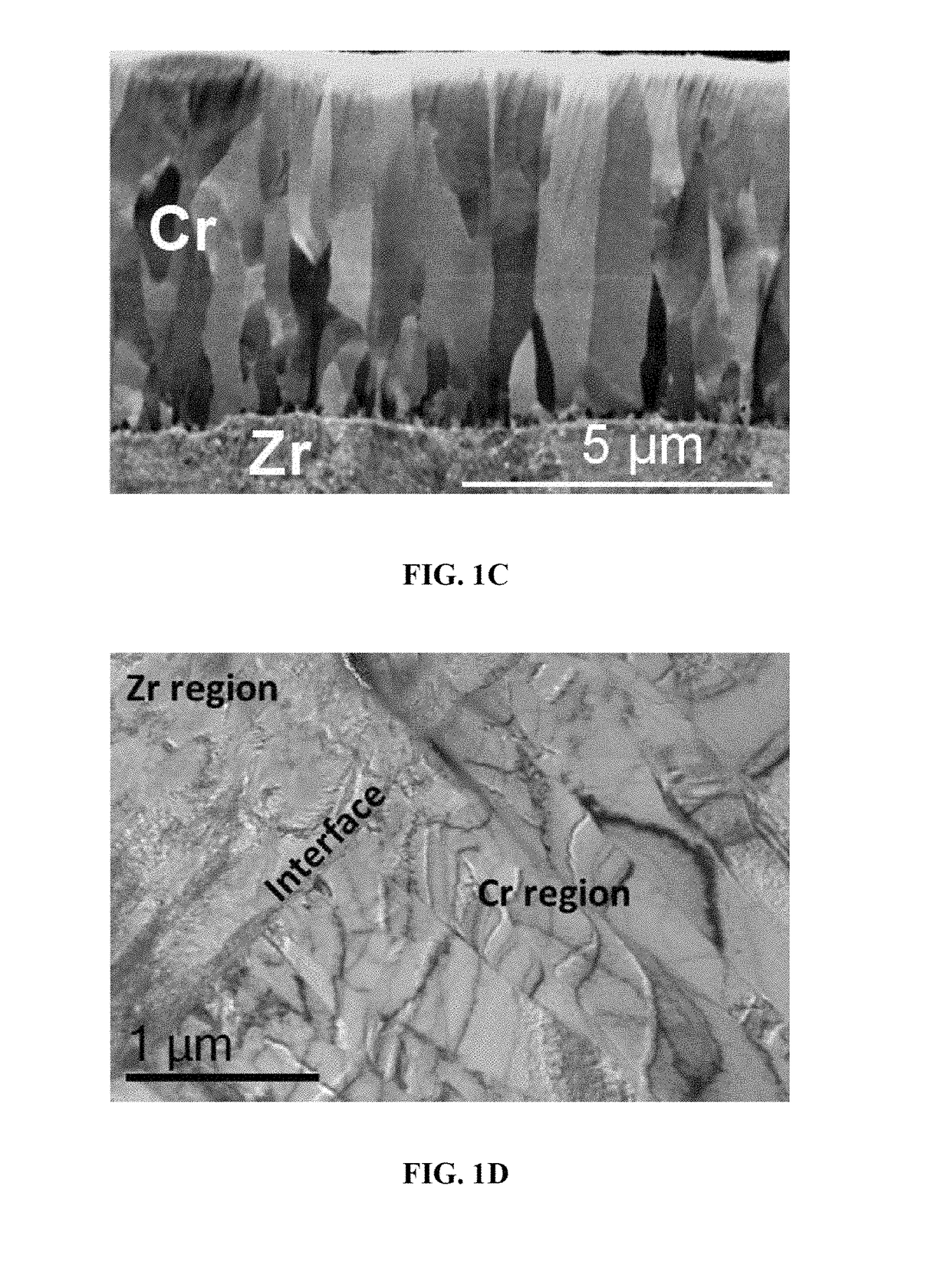

Nuclear fuel claddings, production method thereof and uses of same against oxidation/hydriding

ActiveUS20170287578A1Improve the immunityHigh strengthFuel elementsNuclear energy generationEtchingNiobium

The invention relates to a nuclear fuel cladding comprising: i) a substrate containing a zirconium-based inner layer, optionally coated with at least one intermediate layer formed by at least one intermediate material selected from among tantalum, molybdenum, tungsten, niobium, vanadium, hafnium or the alloys thereof; and ii) at least one protective outer layer placed on the substrate and formed by a protective material selected from either chromium or an alloy of chromium. The nuclear fuel cladding produced using the method of the invention has improved resistance to oxidation / hydriding. The invention also relates to the method for the production of the nuclear fuel cladding by ion etching of the surface of the substrate and deposition of the outer layer on the substrate with a high power impulse magnetron sputtering method (HiPIMS), as well as to the use thereof to protect against oxidation and / or hydriding.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

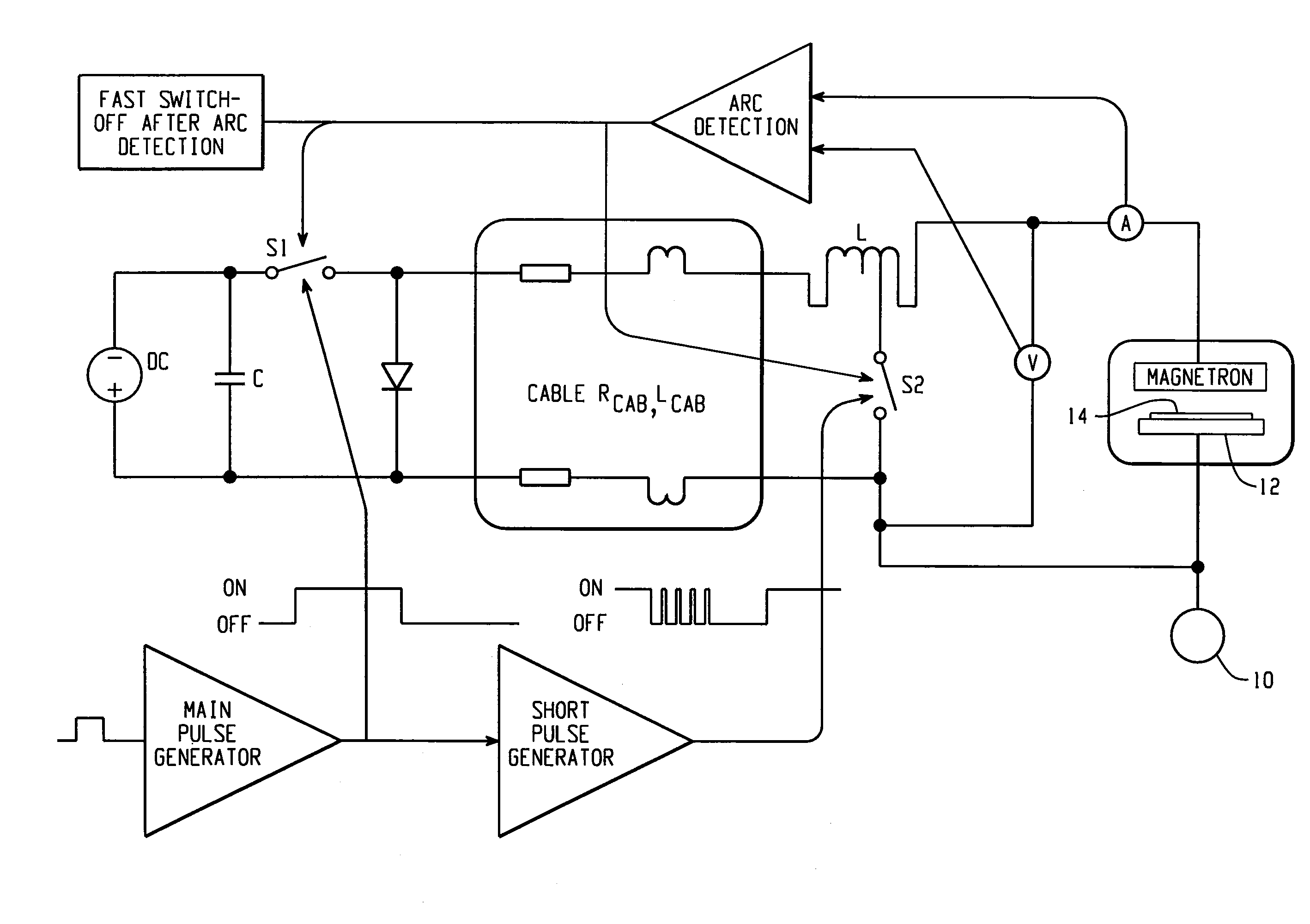

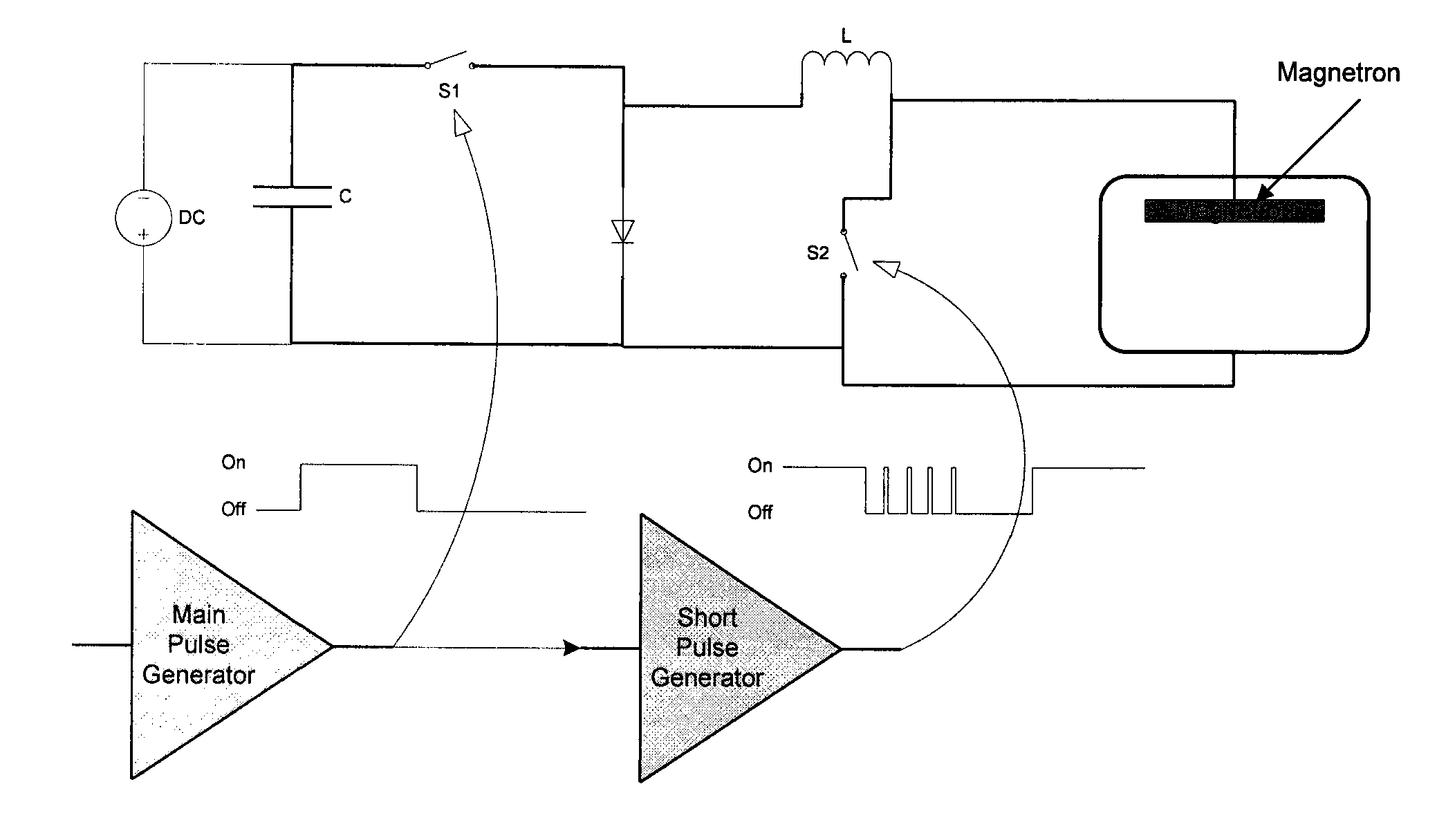

Arc suppression and pulsing in high power impulse magnetron sputtering (hipims)

An apparatus for generating sputtering of a target to produce a coating on a substrate is provided. The apparatus comprises a magnetron including a cathode and an anode. A power supply is operably connected to the magnetron and at least one capacitor is operably connected to the power supply. The apparatus also includes an inductance operably connected to the at least one capacitor. A first switch and a second switch are also provided. The first switch operably connects the power supply to the magnetron to charge the magnetron and the first switch is configured to charge the magnetron according to a first pulse. The second switch is operably connected to discharge the magnetron. The second switch is configured to discharge the magnetron according to a second pulse.

Owner:EVATEC

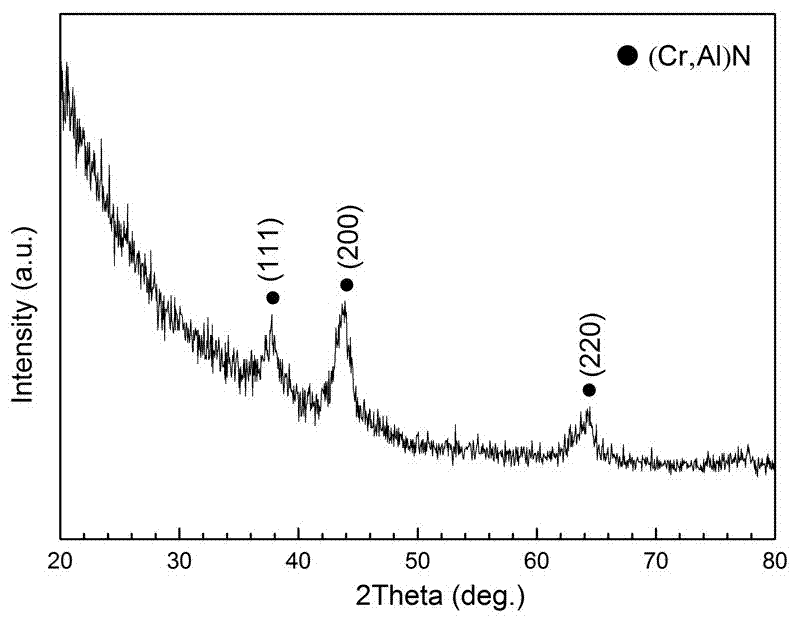

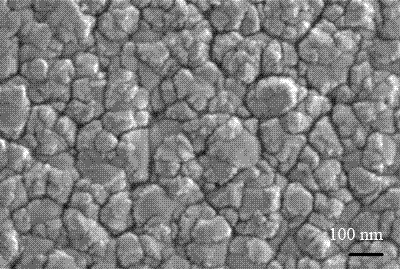

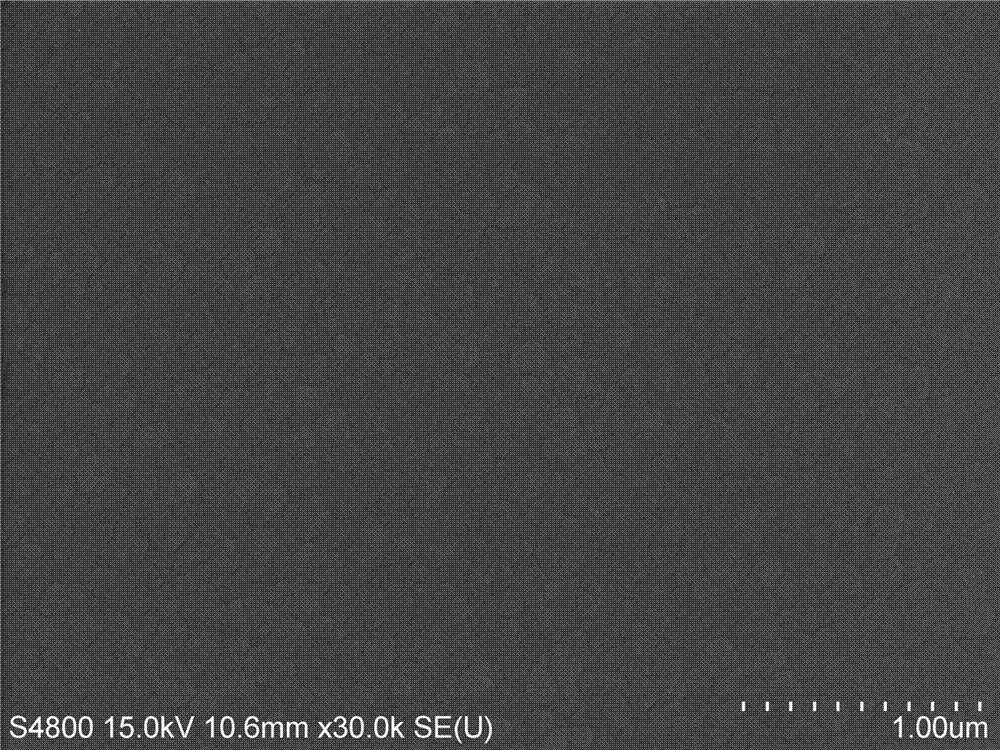

High-power pulsed magnetron sputtering CrAlSiN nano-composite coating and preparation method thereof

ActiveCN107130222AFine grainCompact structureVacuum evaporation coatingSputtering coatingSputteringAlloy

The invention relates to a nano-composite coating and a preparation technology thereof, and specifically relates to a preparation technology of a CrAlSiN nano-composite coating. The CrAlSiN nano-composite coating is prepared on metal or a hard alloy matrix by adopting a co-sputtering technology of high-power pulse and direct current pulse. Pure metals of Cr, Al and Si (the purities are all 99.99% by weight) are selected to be target materials, wherein a Cr target is selected by the high-power pulse, and an Al target and a Si target are selected by a direct current pulse sputtering. Ar gas is piped in before a film is coated, -800 V bias voltage is adopted, and a substrate is washed by glow for 10-30 min. Then the three target materials are opened, bombard washing is conducted on the surfaces of the substrate and the target materials, and the bias voltage is gradually reduced to -30-100 V. The Al target and the Si target are closed, and a pure Cr transition layer is deposited for 10-40 min. Reactant gas N2 is piped in, the Al target and the Si target are opened, and a CrAlSiN coating is deposited for 120-360 min. According to the high-power pulsed magnetron sputtering CrAlSiN nano-composite coating and the preparation method thereof, the CrAlSiN nano-composite coating is good in overall performance, simple in preparation technology, controllable in component and good in repeatability; and industrialized production is easy.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

High power impulse magnetron sputtering vapour deposition

InactiveUS20090200158A1Shorten the timeAdjustable distanceCellsElectric discharge tubesTarget surfacePhysical vapor deposition

Method and apparatus for physical vapour deposition (PVD) and in particular high power impulse magnetron sputtering (HIPIMS) deposition is described. The present apparatus and process provide for the creation of a weaker magnetic field in the region of the cathode which reduces the confinement of a significant part of the plasma near the target surface. By weakening the magnetic field in the region of the target, the deposition rate of materials at a substrate has been found to increase by a factor of 9 relative to that of conventional HIPIMS processes employing typical magnetic field strengths.

Owner:SHEFFIELD HALLAM UNIVERSITY

Preparation method of matrix surface nano compound Me-Si-N superhard coating

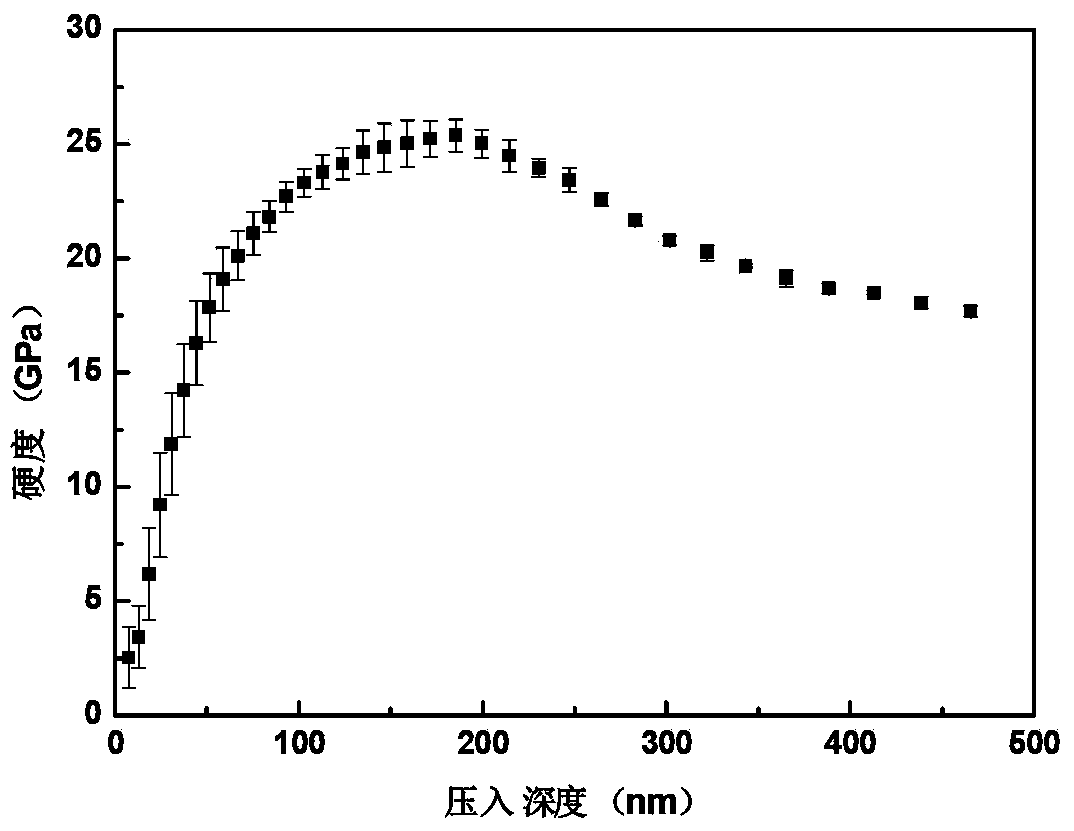

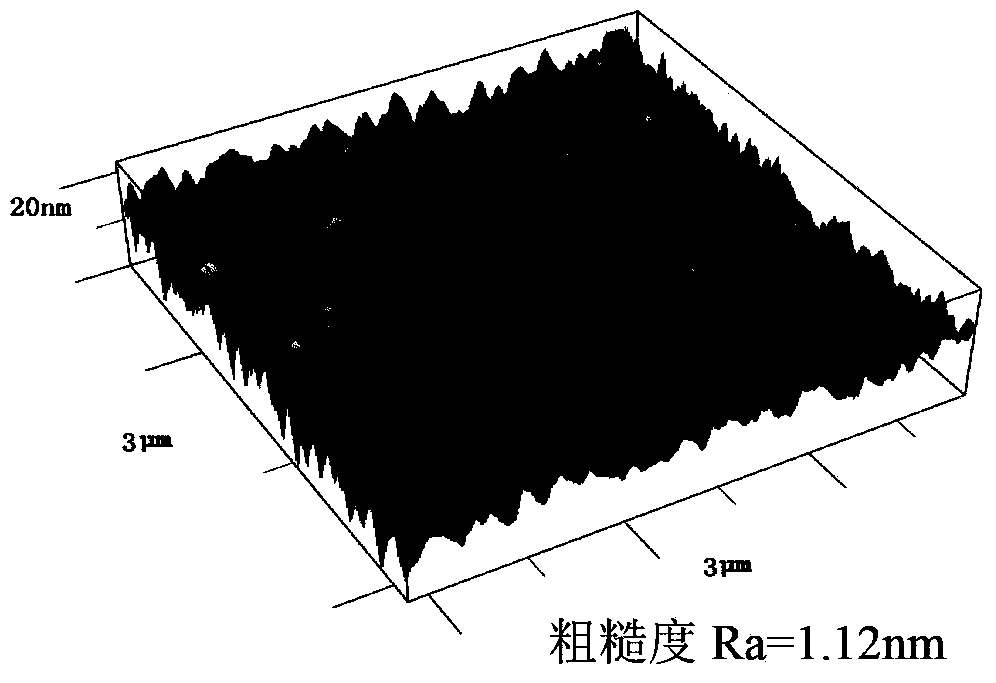

ActiveCN103382548AReduce roughnessReduce roughness Ra valueVacuum evaporation coatingSputtering coatingSputteringSurface roughness

The invention provides a preparation method of matrix surface nano compound Me-Si-N (Me=Ti, Cr, Zr, W or the like) superhard coating. The preparation method utilizes the high-power pulse magnetron sputtering (HIPIMS) technology, through optimizing technology parameters, to prepare the Me-Si-N nano compound superhard coating by magnetron sputtering reactions. Compared to the prior art, the technology can obtain a superhard Me-Si-N nano compound coating with low surface roughness, and the preparation method is a preparation technology with a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

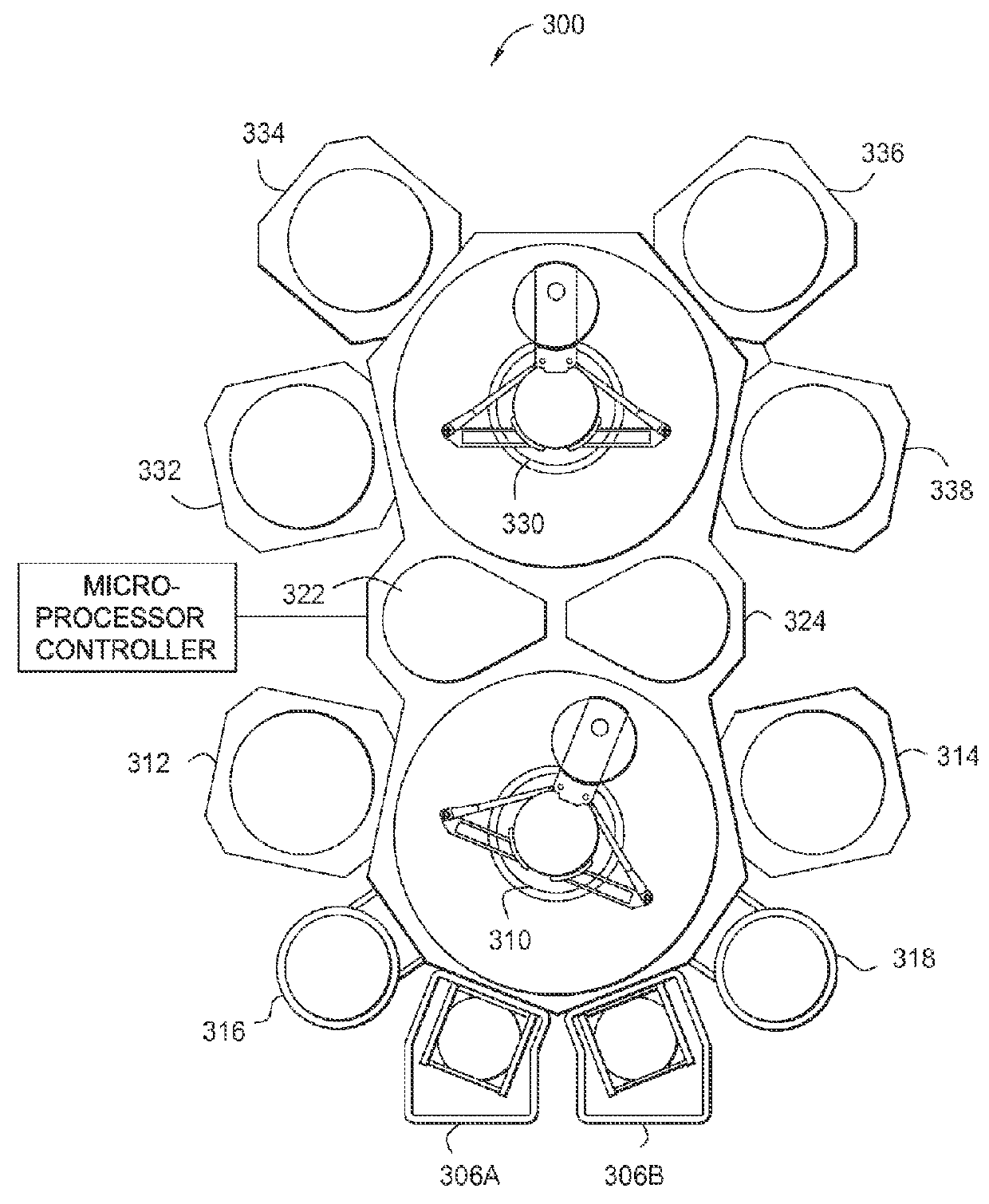

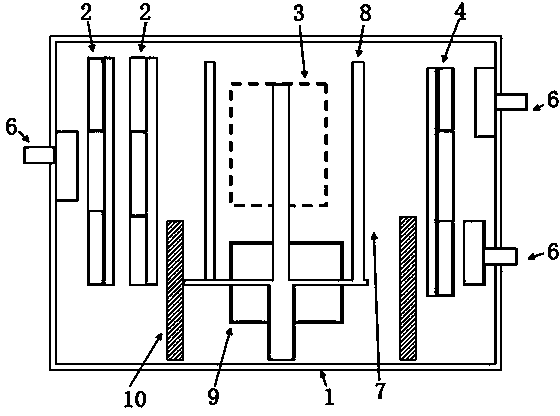

Multifunctional fully-automatic ion-plating machine for deposition of cutting tool coating and using method of multifunctional fully-automatic ion-plating machine

ActiveCN103695858AIncrease profitIncrease gas ionization rateVacuum evaporation coatingSputtering coatingAlloyOxygen

The invention relates to the technical field of thin film materials, in particular to a multifunctional fully-automatic ion-plating machine for the deposition of a cutting tool coating. The machine comprises a vacuum chamber, bipolar pulse magnetron sputtering targets, a rectangular anode layer gas ion source, a high-power pulse magnetron sputtering source, a bias power supply, cathode arc sources, a workpiece rack and a support, wherein the bipolar pulse magnetron sputtering targets, the anode layer gas ion source, the high-power pulse magnetron sputtering source, the bias power supply and the cathode arc sources are controlled through five groups of independent switches respectively. Due to the adoption of the structure, pure metal, alloy and reaction film layers can be prepared, and multi-element and multilayer nanometer composite coatings and oxygen-containing coatings can also be prepared to meet the requirements of metal cutting tools with different shapes and sizes on high-speed machining.

Owner:GUANGDONG UNIV OF TECH

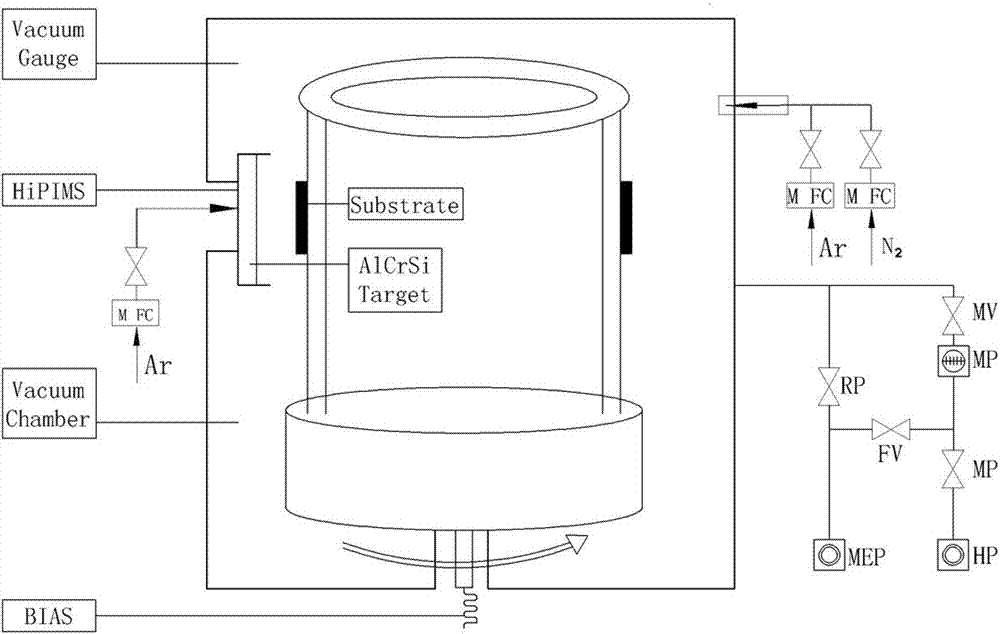

Preparing technology for high-aluminum-content ultra-dense Al-Cr-Si-N coating

ActiveCN106987816AImprove antioxidant capacityInhibited DiffusionVacuum evaporation coatingSputtering coatingAlloyMaterials science

The invention relates to a nano composite coating and a preparing technology thereof, in particular to a preparing technology for a high-aluminum-content ultra-dense Al-Cr-Si-N nano composite coating. An Al-Cr-Si-N nano composite coating is deposited on a metal or alloy base body through the high-power pulse magnetron sputtering technology. An Al-Cr-Si alloy target is selected as a target material, wherein the atomic ratio of Al to Cr to Si is 6:3:1, purity is 99.8 wt.%, and the size is 300 x 100 x 5 mm; before film coating, inflation of Ar is conducted firstly, striking is conducted at the bias voltage of -800 V, high-power pulse magnetron sputtering of the Al-Cr-Si target is conducted, and bombardment cleaning is conducted on the surface of the base body. Then, the bias voltage is reduced to -30 V, an Al-Cr-Si transition layer is deposited, then inflation of the reaction gas N2 is conducted finally, and deposition of the Al-Cr-Si-N coating is started. The related preparing technology for the high-aluminum-content ultra-dense Al-Cr-Si-N nano composite coating is simple, repeatability is good, and industrial production is easy. The prepared Al-Cr-Si-N coating is high in hardness, good in tenacity, low in internal stress and excellent in abrasion resisting performance; and the coating organization structure is extremely dense and is firmly combined with the base body, and the high-temperature oxidation resisting capability is high.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

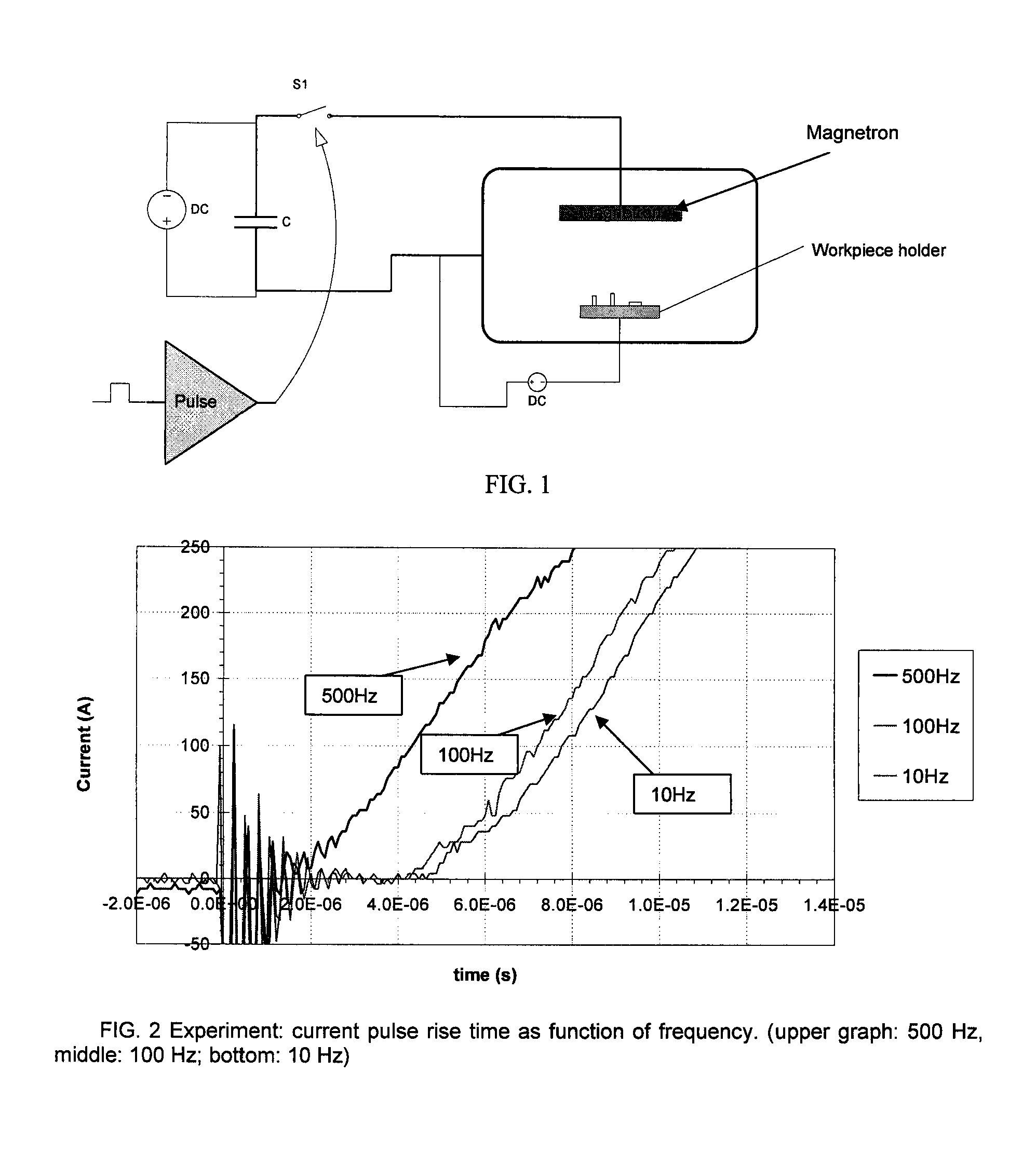

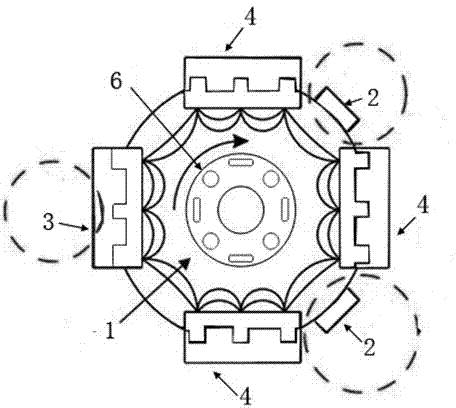

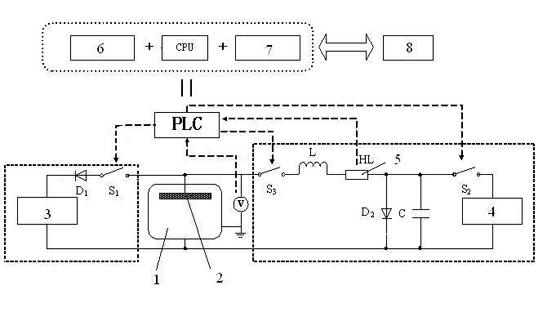

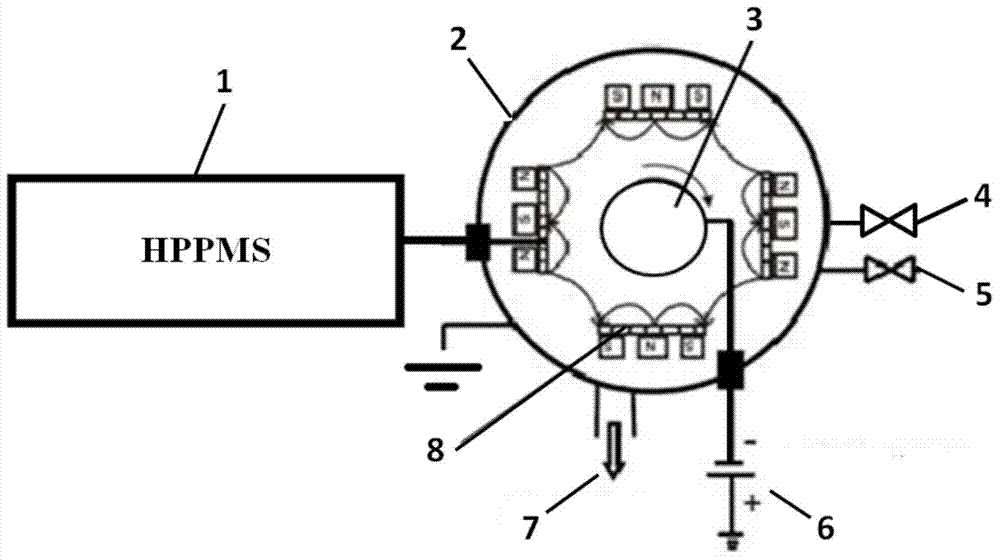

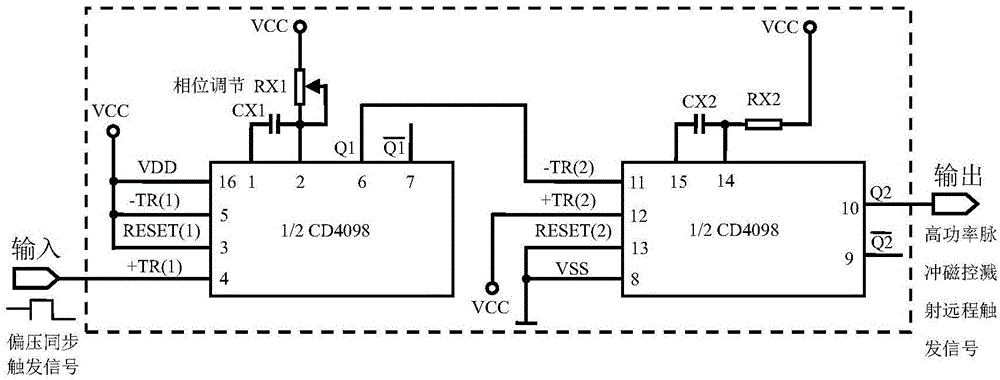

Ionization-rate-controllable coating device based on high-power impulse magnetron sputtering

InactiveCN102108492AReduce lag timeGuaranteed deposition rateElectric discharge tubesVacuum evaporation coatingLow voltageEngineering

The invention relates to an ionization-rate-controllable coating device based on high-power impulse magnetron sputtering, which comprises a vacuum sputtering system, a low-voltage direct-current power system, a high-voltage impulse power system, a PLC (Programmable Logic Controller) central control system and a computer, wherein the low-voltage direct-current power system provides a low-voltage current for the vacuum system, and the high-voltage impulse power system provides a high-voltage impulse current for the vacuum system; the PLC central control system is used for controlling the vacuum system, low-voltage direct-current power system and high-voltage impulse power system; and the PLC and computer are used for transmitting and controlling data. The invention effectively shortens the delay time of the impulse current due to the preset direct-current voltage, effectively ensures the film deposition rate by coupling the direct-current magnetron sputtering, and establishes a plasma ionization-rate-adjustable HIPIMS (high-power impulse magnetron sputtering) technique, thereby providing technical support for research in related science.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

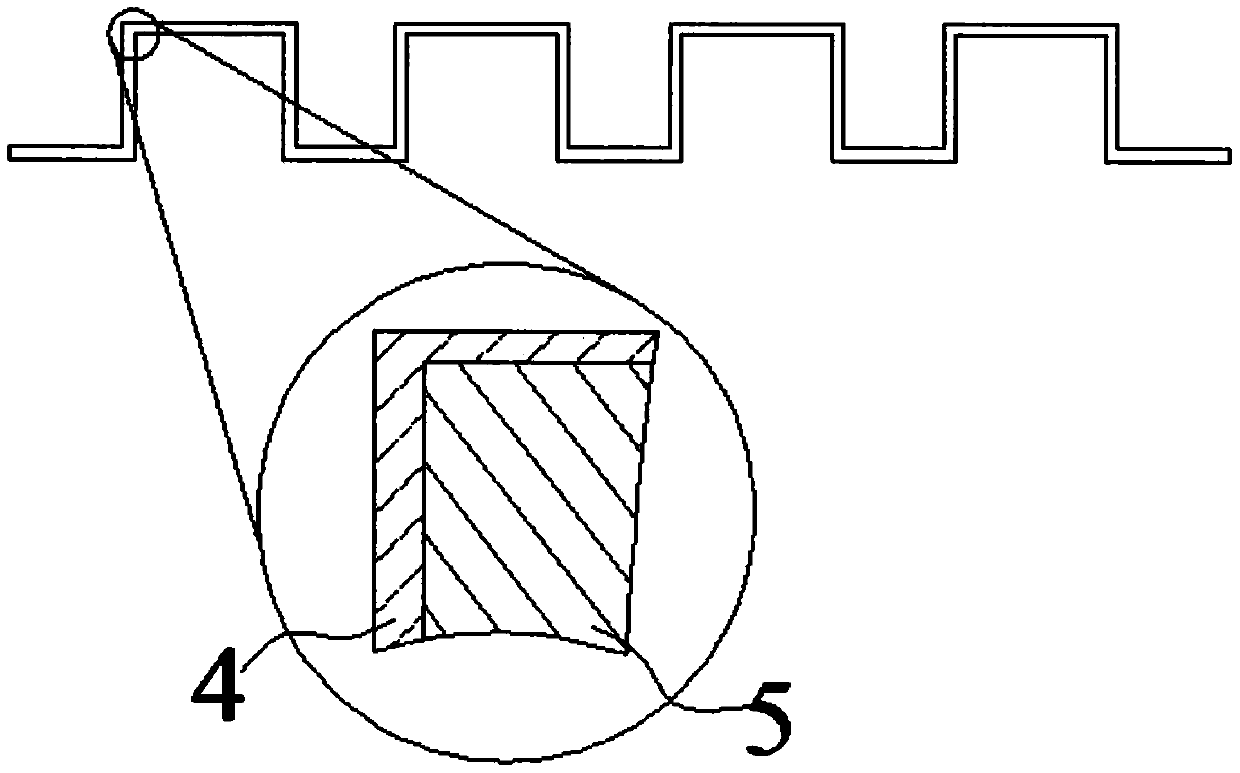

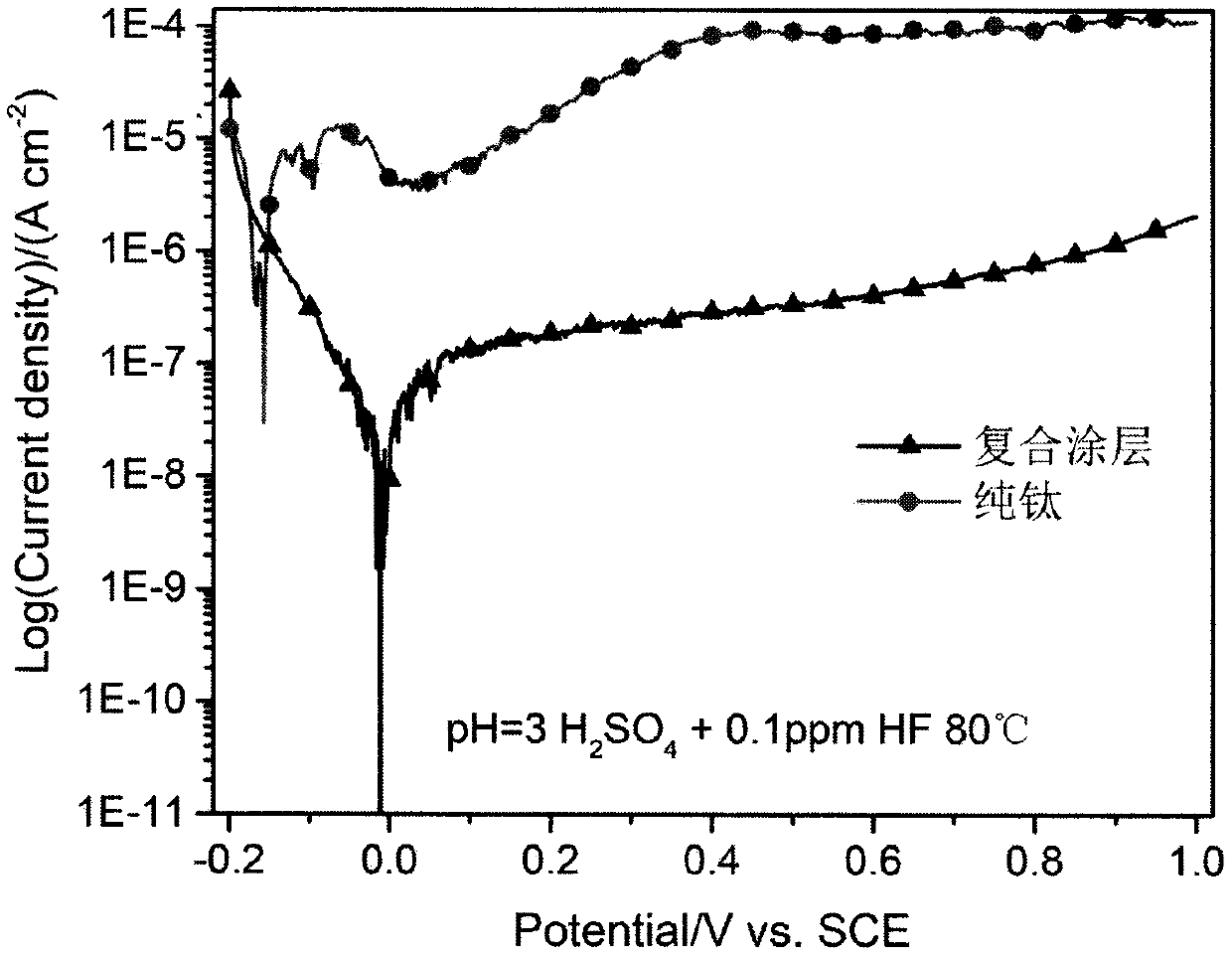

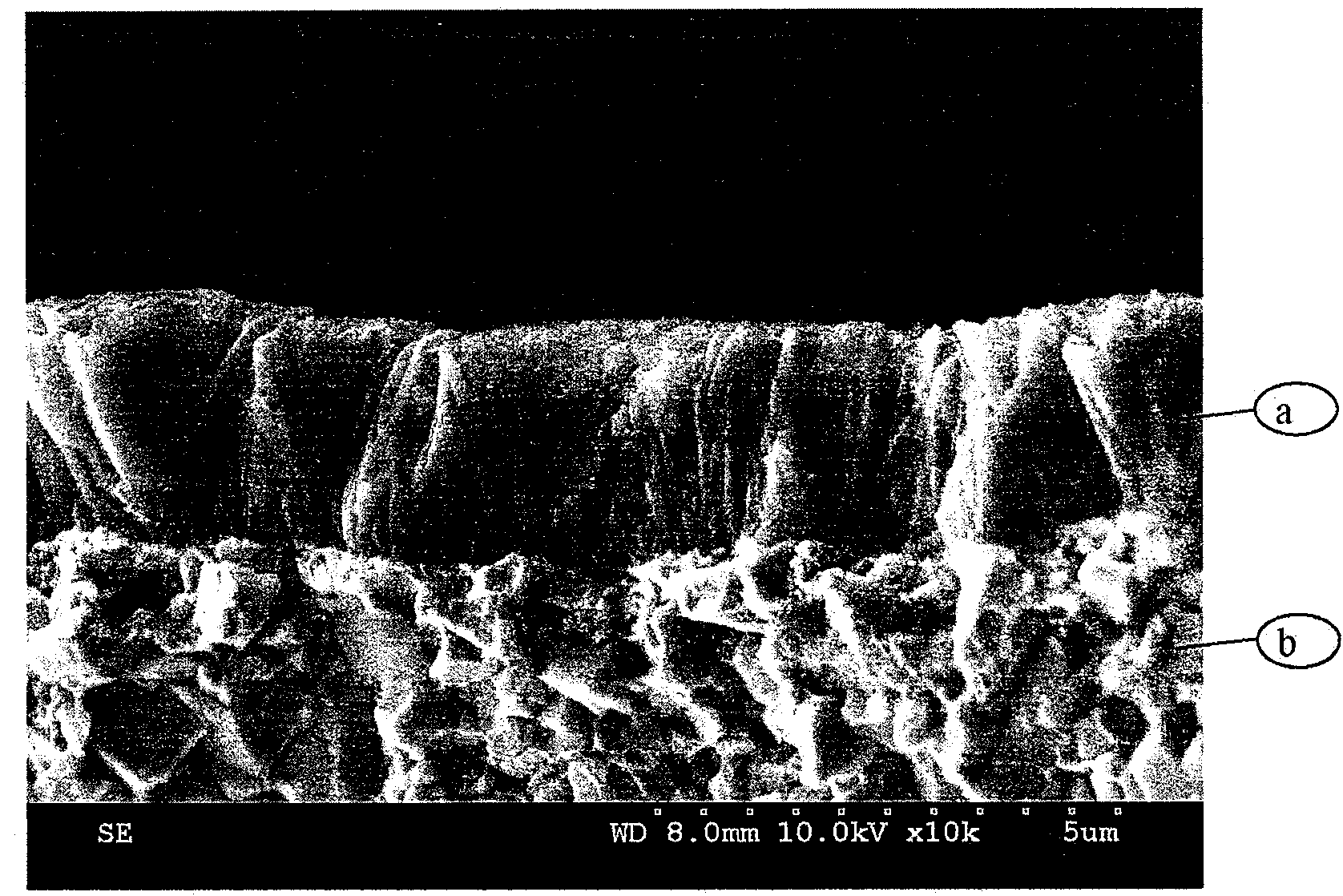

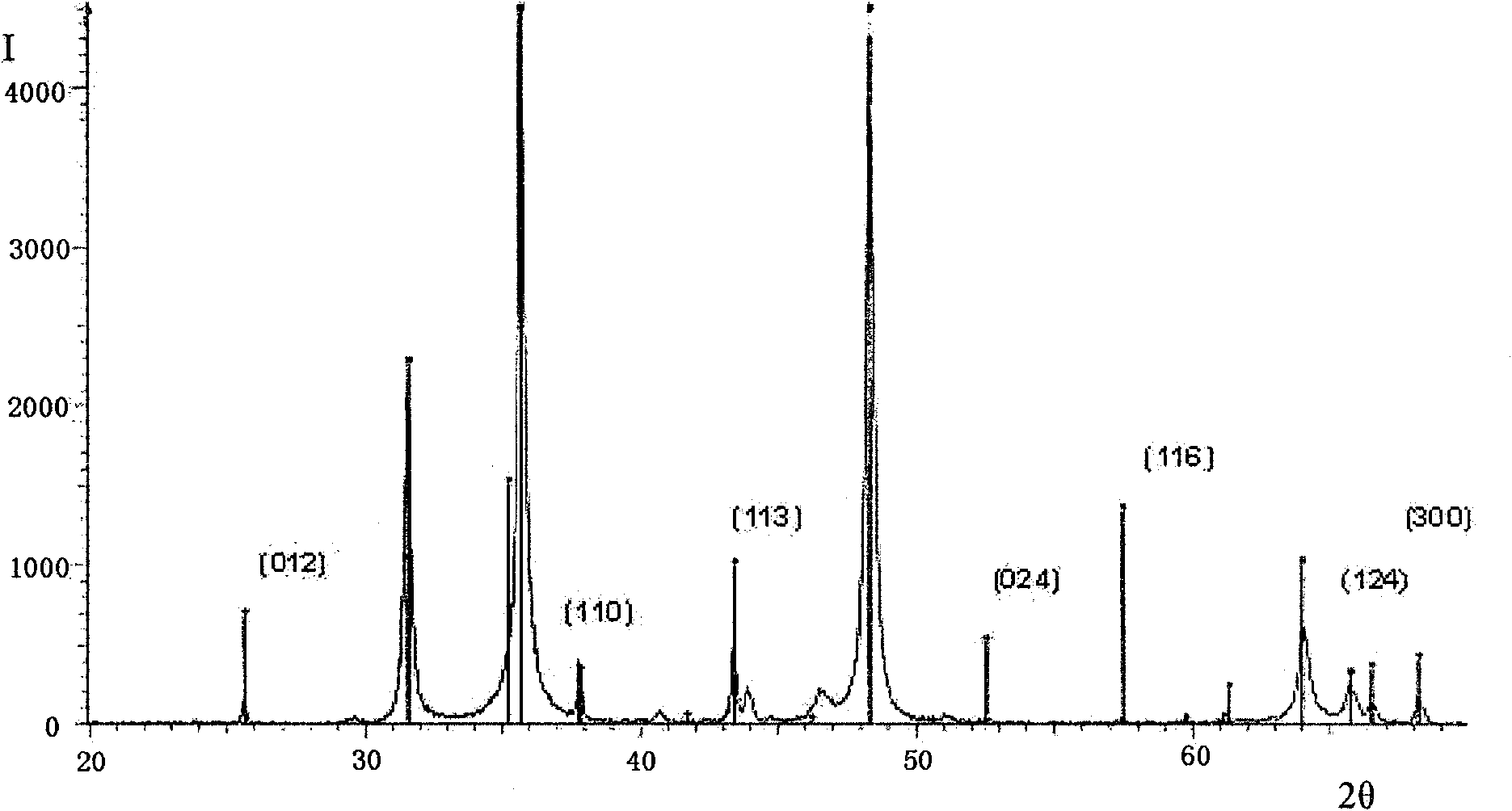

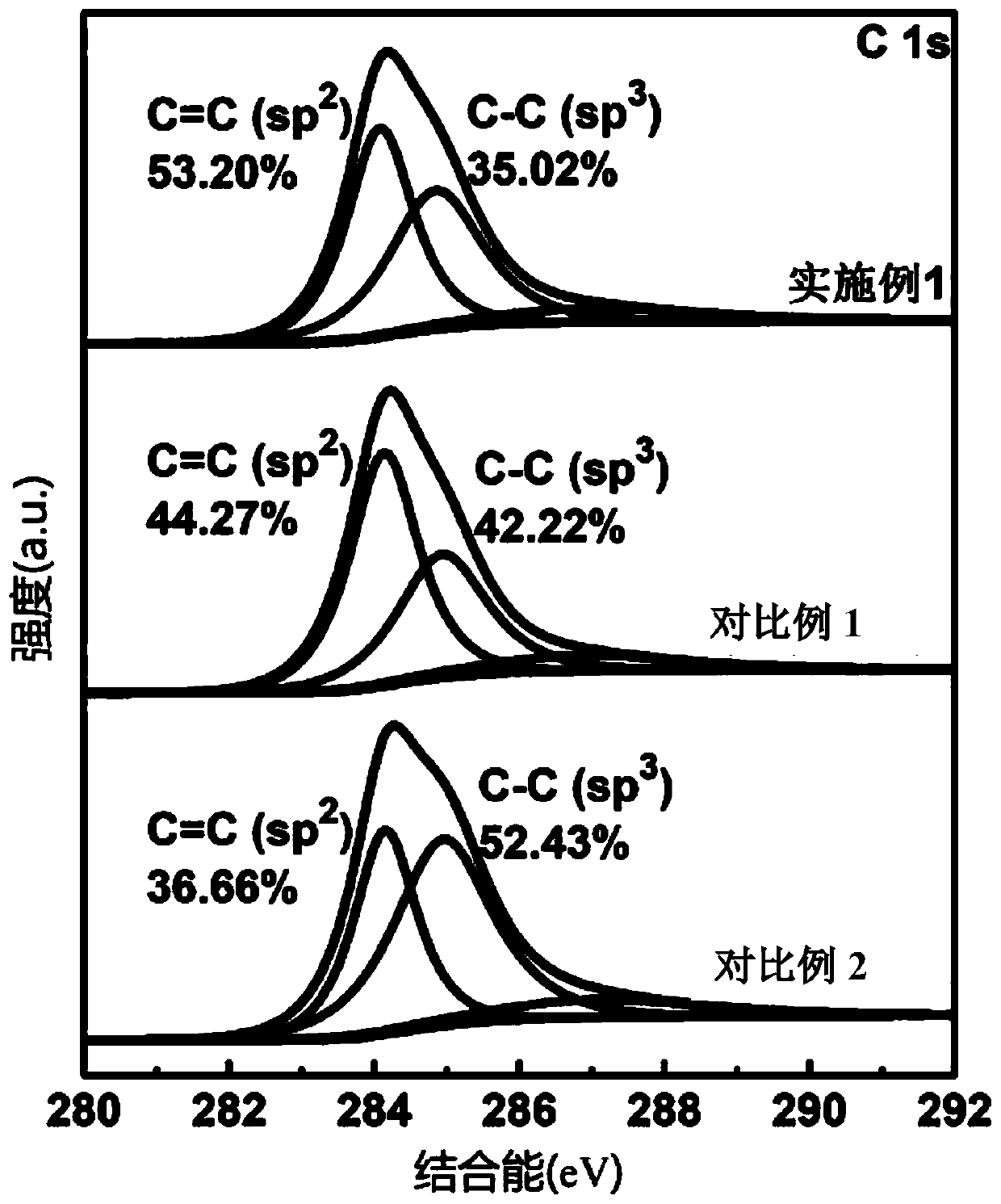

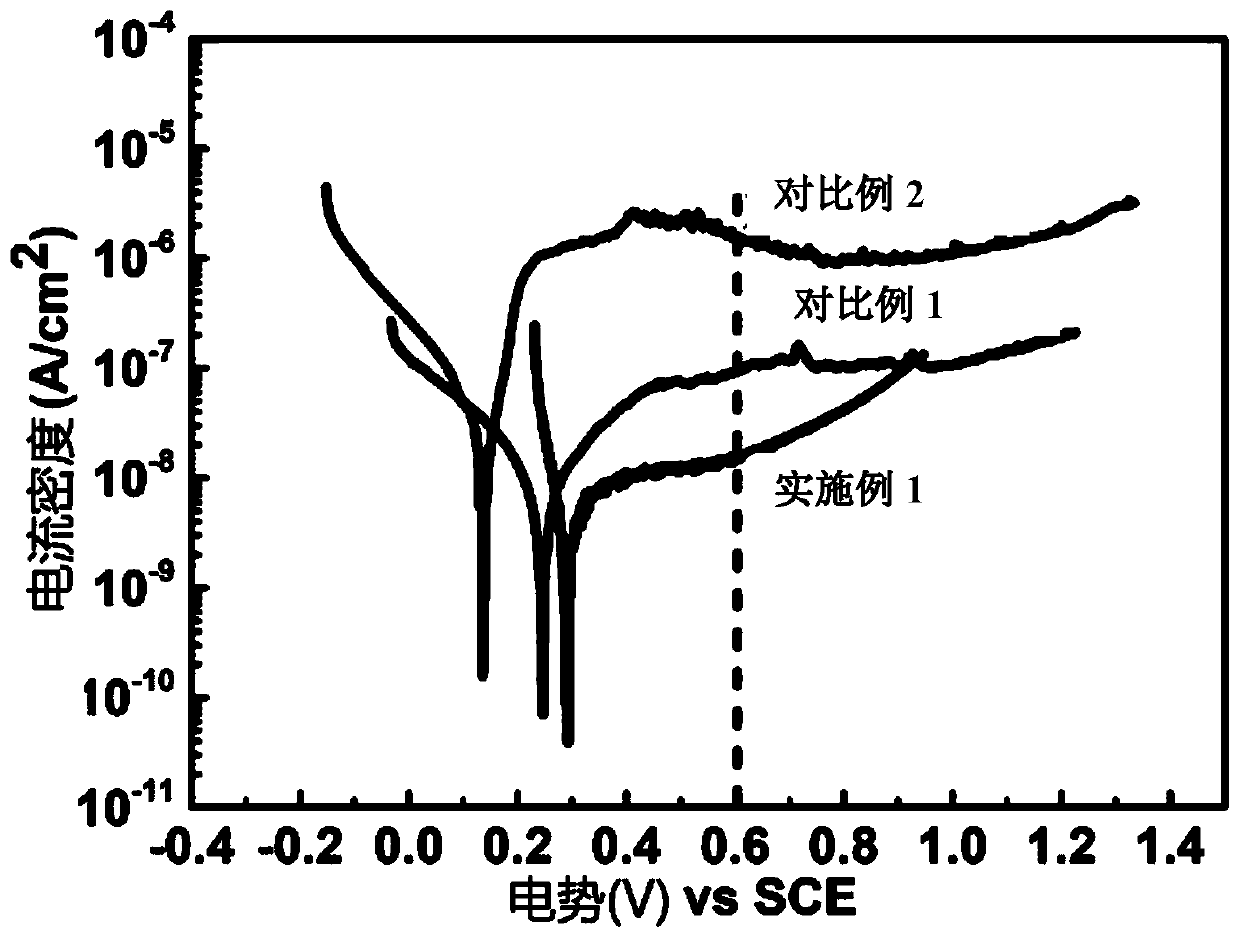

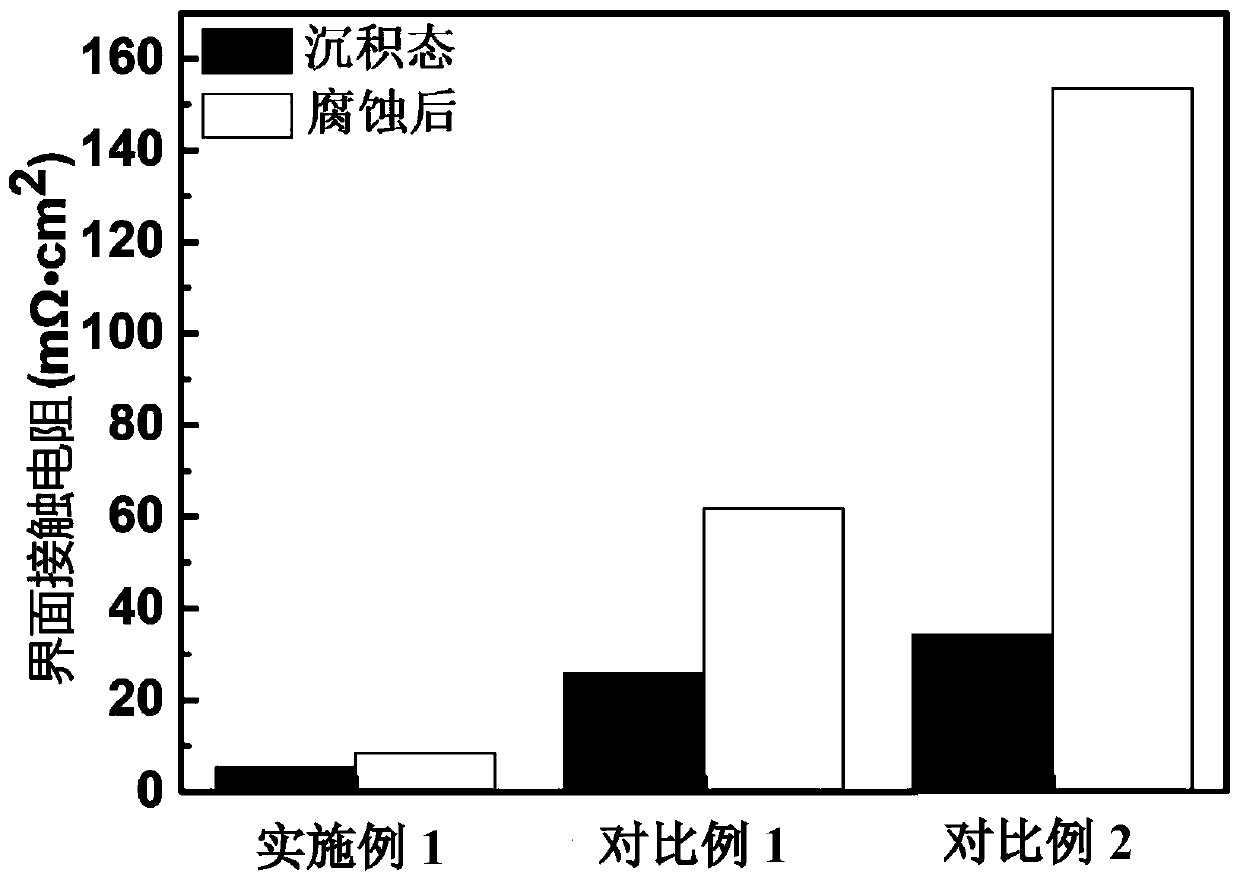

Coating for metal bipolar plates of fuel cells and preparation technology

InactiveCN110137525AImprove conductivityAccelerated corrosionFinal product manufactureFuel cellsSurface layerFuel cells

A conductive corrosion-resistant coating for metal bipolar plates of fuel cells and a preparation technology are provided. The conductive corrosion-resistant coating includes a metal substrate and a conductive corrosion-resistant coating which is deposited on the metal substrate and at least partially covers the metal substrate. A method for manufacturing a metal bipolar plate including the coating is also disclosed. The metal substrate is pure titanium, and the coating is made of a composite material composed of a composite transition layer containing Ti, C and N elements and a graphite-likecarbon (GLC) surface layer. The conductive corrosion-resistant coating is deposited by high-power impulse magnetron sputtering (HPIMS).

Owner:北京中氢绿能科技有限公司

Method for producing PVD coatings

InactiveCN101802247AEliminates the need for a voltage divider feedback systemEliminate needElectric discharge tubesVacuum evaporation coatingReactive gasCarbide

The present invention relates to a method of producing coatings of metal oxide, nitride or carbide or mixtures thereof, whereby operating a High Power Impulse Magnetron Sputtering, HIPIMS, discharged on one or more target (s) (3), in an argon and reactive gas mixture (5, 6), at peak pulse power higher than 200 Wcm-2, in which the deposition rate is improved and in the need for partial reactive gas pressure feedback systems is eliminated.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and preparation method and application thereof

ActiveCN110684946ASmooth structureSmooth internal structure Dense structureVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and a preparation method and application thereof. The preparation method of the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer comprises the following steps: with a chromium target as the target, a high-power pulse magnetron sputtering technology is adopted to deposit a chromium transition layer on the surface of a metal bipolar plate; with a graphite target as the target, a direct-current magnetron sputtering technology isadopted to deposit an amorphous carbon layer on the surface of the chromium transition layer to obtain the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer; and process conditions adopted by the direct-current magnetron sputtering technology comprises the sputtering source center magnetic field intensity of 40-60 mT, the edge magnetic field intensity of 10-20 mT and the power of 0.8-1.0 kW. The provided chromium transition layer is smooth in surface and compact in internal structure, and can effectively improve the film base bonding strength; and meanwhile, through optimization of an amorphous carbon layer preparation process, the amorphous carbon layer achieves excellent electric conductivity and corrosion resistance, and can permanently and effectively protect the metal bipolar plate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

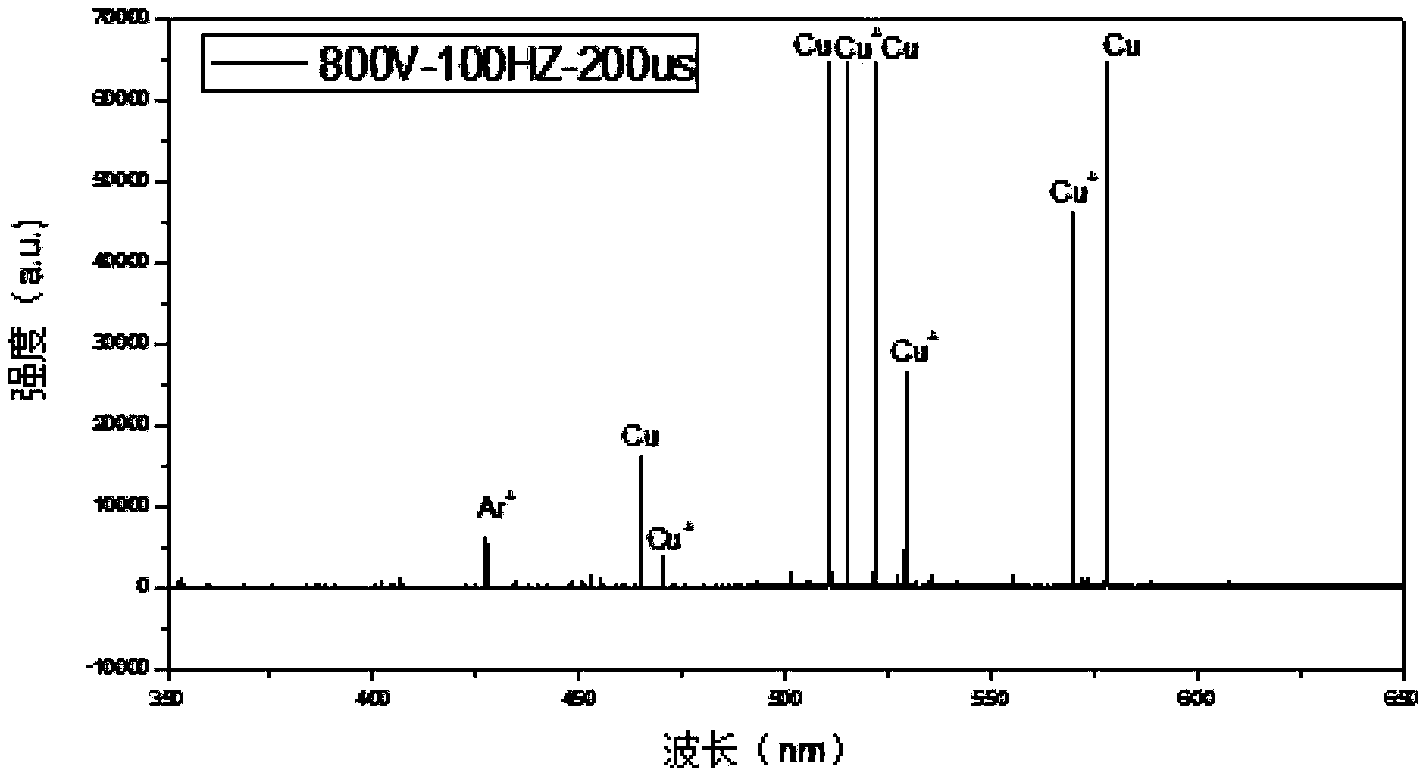

Method for depositing film through high ionization rate high power pulse magnetron sputtering

ActiveCN105154838AImprove bindingEfficient preionizationVacuum evaporation coatingSputtering coatingBack biasFilm material

The invention discloses a method for depositing a film through high ionization rate high power pulse magnetron sputtering, relates to the technical field of film materials, and mainly solves the problems that the existing target is low in ionization rate, the plasma is nonuniform and the film uniformity is poor. The method comprises the following steps: I, cleaning a chamber, and fixing a test sample on a planet platform; II, placing the planet platform in the sealed chamber, vacuumizing the chamber, and removing moisture on the test sample and absorbed air; III, applying back bias voltage on the test sample, and feeding high-purity Ar; IV, feeding Ar and N2 in the chamber, and applying impulse voltage on a sputtering target for surface coating; V, adopting a stepping motor to control the motion track of the planet platform so as to control film coating; VI, taking the test sample out when the temperature in the vacuum chamber is reduced to the room temperature. According to the invention, target magnetic field control during film preparation and target voltage applying form during film coating are changed, so that the film thickness and density are easy to control, and the binding force and the uniformity are high.

Owner:SOUTH CHINA UNIV OF TECH

High power impulse magnetron sputtering process to achieve a high density high SP3 containing layer

Methods for depositing a nanocrystalline diamond layer are disclosed herein. The method can include delivering a sputter gas to a substrate positioned in a processing region of a first process chamber, the first process chamber having a carbon-containing sputter target, delivering an energy pulse to the sputter gas to create a sputtering plasma, the sputtering plasma having a sputtering duration, the energy pulse having an average power between 1 W / cm2 and 10 W / cm2 and a pulse width which is less than 100 μs and greater than 30 μs, the sputtering plasma being controlled by a magnetic field, the magnetic field being less than 300. Gauss, and delivering the sputtering plasma to the sputter target to form an ionized species, the ionized species forming a crystalline carbon-containing layer on the substrate.

Owner:APPLIED MATERIALS INC

Method and equipment for preparing ultra-hard DLC coatings through PVD and HIPIMS

InactiveCN104213076AHigh hardnessImprove friction resistanceVacuum evaporation coatingSputtering coatingDlc coatingHigh volume manufacturing

The invention discloses a method and equipment for preparing ultra-hard DLC (Diamond-like Carbon) coatings through PVD (Physical Vapor Deposition) and HIPIMS (High Power Impulse Magnetron Sputtering). By adopting a multilayer film compositing technology and using a PVD process and an HIPIMS method, and through cathode and anode bias adjustment and acetylene gas flow control, and the design of the equipment for preparing the DLC coatings in an industrialized manner, that the ultra-hard DLC coatings are prepared by the equipment on surfaces of workpieces is achieved, and the coatings are ultra-high in hardness, high in friction resistance, high in wear resistance and high in self-lubricating performance. According to the method and equipment, provided by the invention, the coating process is simple; conditions for compositing the coatings are accurate and controllable; the film formation quality is high; the performance is stable; the product yield is high; and the cost is low. The coatings are ultra-hard and excellent in self-lubricating performance and the wear resistance. The equipment for the coatings is provided with four sets of large-scale coating units, is stable and reliable in production quality, can be applied to mass production, is convenient for lowering the manufacturing cost and achieves industrialization.

Owner:慕恩慈沃迪

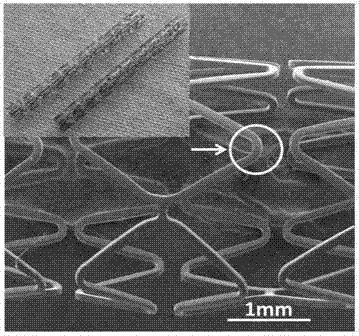

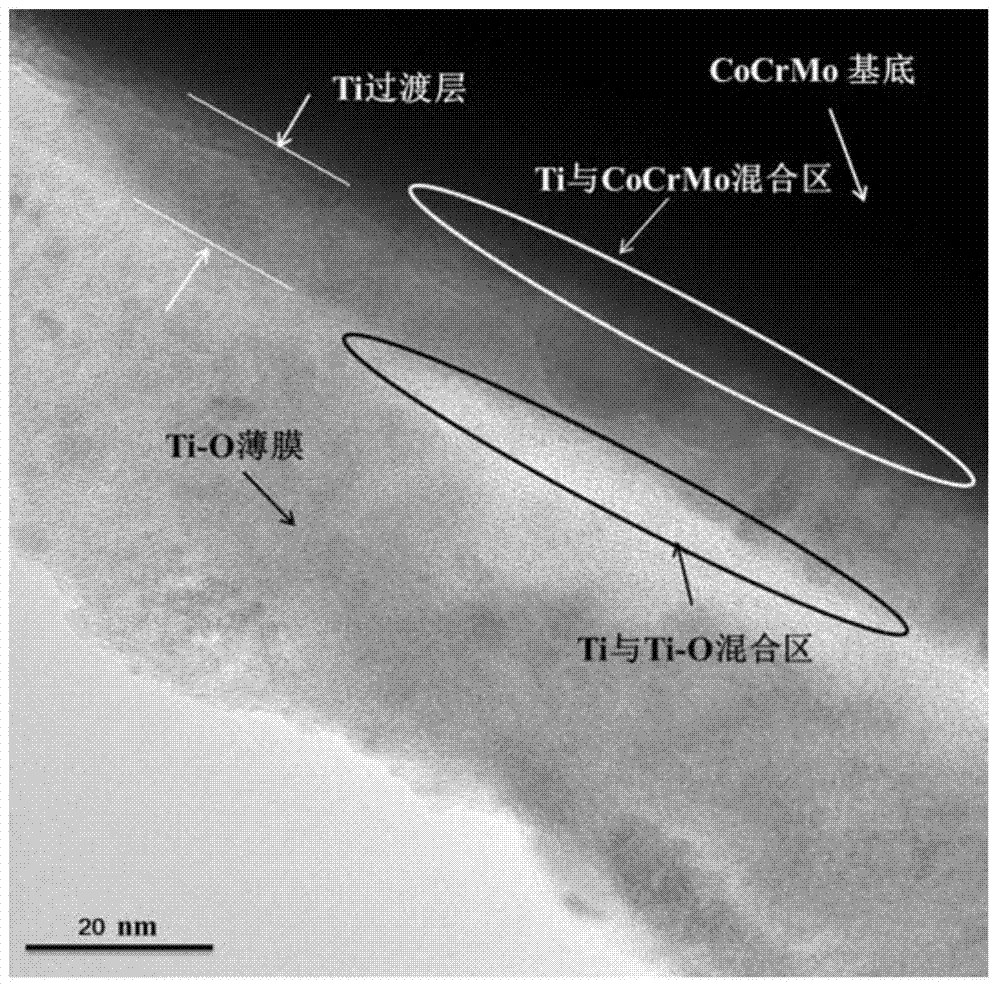

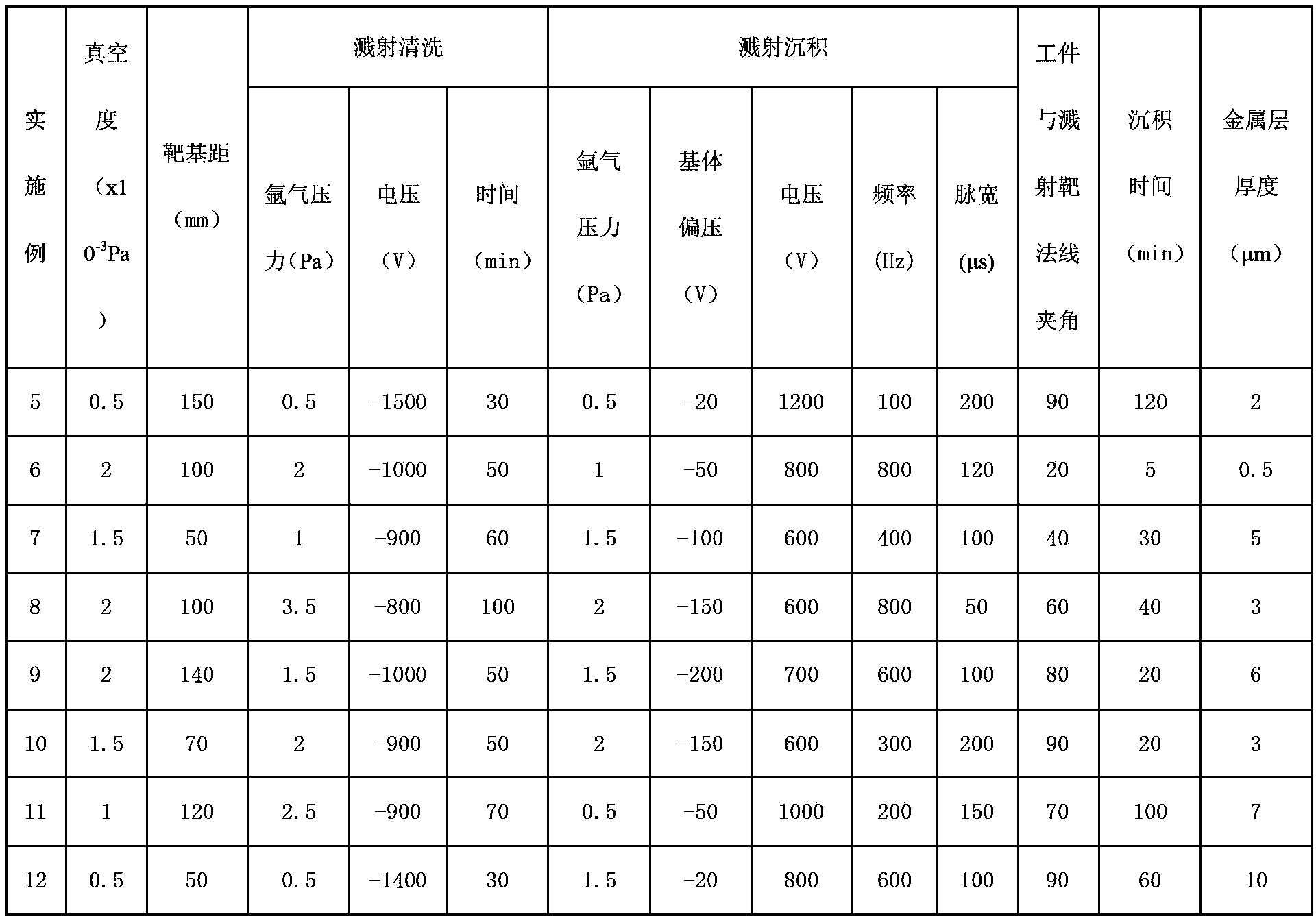

Metal support surface modification method

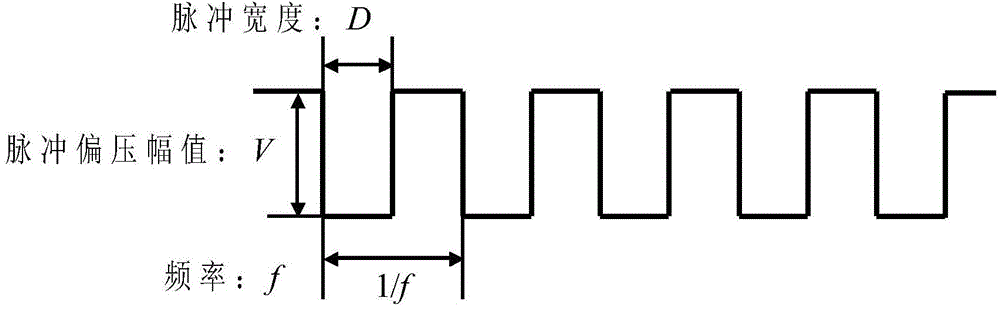

InactiveCN103924202AIncrease ionization rateHigh densityStentsSurgeryVoltage amplitudeSputter cleaning

The invention relates to a metal support surface modification method and belongs to the technical field of metal surface modification. The method is used for depositing a titanium / titanium oxide film on the surface of a metal support by effectively utilizing high power pulse magnetron sputtering technology. The method includes the following steps: firstly, putting the metal support in a vacuum chamber of high power pulse magnetron sputtering equipment, and vacuumizing the vacuum chamber to 0.5*10<-3> Pa to 2*10<-3>Pa; filling argon into the vacuum chamber, and sputter cleaning the metal support and a target; introducing argon into the vacuum chamber, and preparing a titanium transition layer with high binding force on the surface of the metal support by utilizing the high power pulse magnetron sputtering technology, by means of regulating such parameters as sputtering voltage amplitude, frequency, pulse width, sputtering voltage and matrix bias voltage; finally, introducing argon and oxygen into the vacuum chamber, and preparing a firmly combined titanium oxide film on the surface of the metal support by regulating such parameters as sputtering voltage amplitude, frequency, pulse width, sputtering voltage and matrix bias voltage. The method is mainly applied to surface modification of the metal support.

Owner:SOUTHWEST JIAOTONG UNIV

Method for improving metalized surface performance of ceramic workpiece

The invention provides a method for improving the metalized surface performance of a ceramic workpiece. A metalized layer with good combining force, high density and strong corrosion resistance of a surface prepared film base is obtained on the ceramic workpiece surface by applying a high-power pulse magnetron sputtering technology. According to the invention, the process is environment-friendly; the controllability is good and a plated film layer can meet European Union RoHS (Restriction of Hazardous Substances) standards; the metalized layers of different materials can be obtained according to requirements and the adaptability of sputtering materials is wide without limitation by high and low smelting points of the material; the high ionization rate of the sputtering materials can greatly improve the combining strength, the density and the uniformity of the film base of the metalized layer, and the electric performance and the corrosion resistance of a ceramic workpiece are improved.

Owner:SOUTHWEST JIAOTONG UNIV

High-Power Pulsed Magnetron Sputtering

Magnetically enhanced sputtering methods and apparatus are described. A magnetically enhanced sputtering source according to the present invention includes an anode and a cathode assembly having a target that is positioned adjacent to the anode. An ionization source generates a weakly-ionized plasma proximate to the anode and the cathode assembly. A magnet is positioned to generate a magnetic field proximate to the weakly-ionized plasma. The magnetic field substantially traps electrons in the weakly-ionized plasma proximate to the sputtering target. A power supply produces an electric field in a gap between the anode and the cathode assembly. The electric field generates excited atoms in the weakly ionized plasma and generates secondary electrons from the sputtering target. The secondary electrons ionize the excited atoms, thereby creating a strongly-ionized plasma having ions that impact a surface of the sputtering target to generate sputtering flux.

Owner:ZOND

Method for depositing an oxide layer on absorbers of solar cells

InactiveUS20100006426A1Improve stabilityElectric discharge tubesVacuum evaporation coatingSolar cellPhysical vapor deposition

A method for depositing at least one stable, transparent and conductive layer system on chalcopyrite solar cell absorbers. The at least one stable, transparent and conductive layer system may be formed via ionizing PVD (physical vapor deposition) technology by using either high power pulsed magnetron sputtering (HPPMS) or high power impulse magnetron sputtering (HIPIMS).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Deposition method adopting combination of arc ion plating and high power pulsed magnetron sputtering

ActiveCN104862653AAchieve pinning effectGuaranteed normal transmissionVacuum evaporation coatingSputtering coatingSemiconductor materialsAlloy

The invention provides a deposition method adopting combination of arc ion plating and high power pulsed magnetron sputtering, belongs to the technical field of material surface treatment, and aims to solve the problems of large particles caused by the fact that low-melting-point pure metal or a multi-element alloy material and a non-metal material, especially a semiconducting material and an insulating material, are taken as target materials to be applied in a traditional arc ion plating method, limitation of use extension of arc ion plating target materials, low ionization rate and low thin film deposition efficiency of a traditional magnetron sputtering technology as well as unstable discharging of conventional high power pulsed magnetron sputtering. The method comprises steps as follows: step one, a to-be-coated workpiece is placed on a sample table in a vacuum chamber, a related power supply is switched on; step two, thin film deposition is performed and comprises steps as follows: when the vacuum degree in the vacuum chamber is lower than 10<-2> Pa, working gas is introduced, gas pressure is adjusted, the related power supply is switched on, after the target surface is cleaned, a synchronous waveform matching device is adopted to adjust waveforms output by a grid bias power supply and a high power pulsed magnetron sputtering power supply, required technological parameters are set, and thin film deposition is performed.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Surface metallization method for foamed plastic by adopting high-power pulse magnetron sputtering

ActiveCN103122452ACompact structureReduce the binding forceVacuum evaporation coatingSputtering coatingLow temperature depositionSurface engineering

The invention relates to a surface metallization method for foamed plastic by adopting high-power pulse magnetron sputtering and belongs to the technical field of material surface engineering. The surface metallization method for the foamed plastic by adopting high-power pulse magnetron sputtering comprises the following steps of: firstly carrying out pre-treatment of surface sealing, cleaning, drying and distressing on the surface of foamed plastic, then loading samples, vacuumizing, and degassing; carrying out pre-sputtering to clean a foamed plastic workpiece and sputtering a target material; depositing a metal coating by adopting high-power pulse magnetron sputtering, wherein a metal coating with high ionization rate is deposited on the surface of the foamed plastic workpiece at a low temperature by controlling pulse configuration, frequency, charging voltage and sputtering / cooling time, and a metal coating with smooth surface, compact structure and high cohesion between film and substrate material is prepared; and finally cooling, taking away the foamed plastic workpiece, and inspecting properties of the metallized foamed plastic such as surface appearance, hardness and cohesion between film and substrate material. The surface metallization method for the foamed plastic by adopting high-power pulse magnetron sputtering has the advantages that the surface metallization method is applicable to various metallized coatings; the coating is smooth and compact in surface and high in cohesion between film and substrate material; the sputtering temperature and the deposition temperature are low, and a foamed plastic substrate can not deform; and the surface metallization method is safe and environment-friendly, and no chromic acid reagent which contains Cr<6+> and is related in a chemical plating process is used.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com