Patents

Literature

88results about How to "Fast sputtering rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

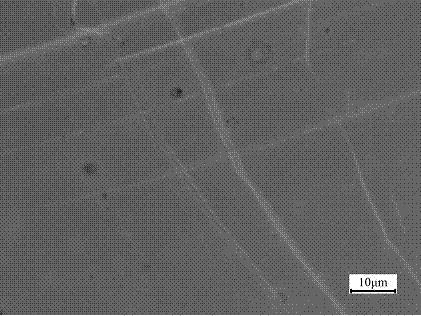

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

ActiveCN103060765AFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

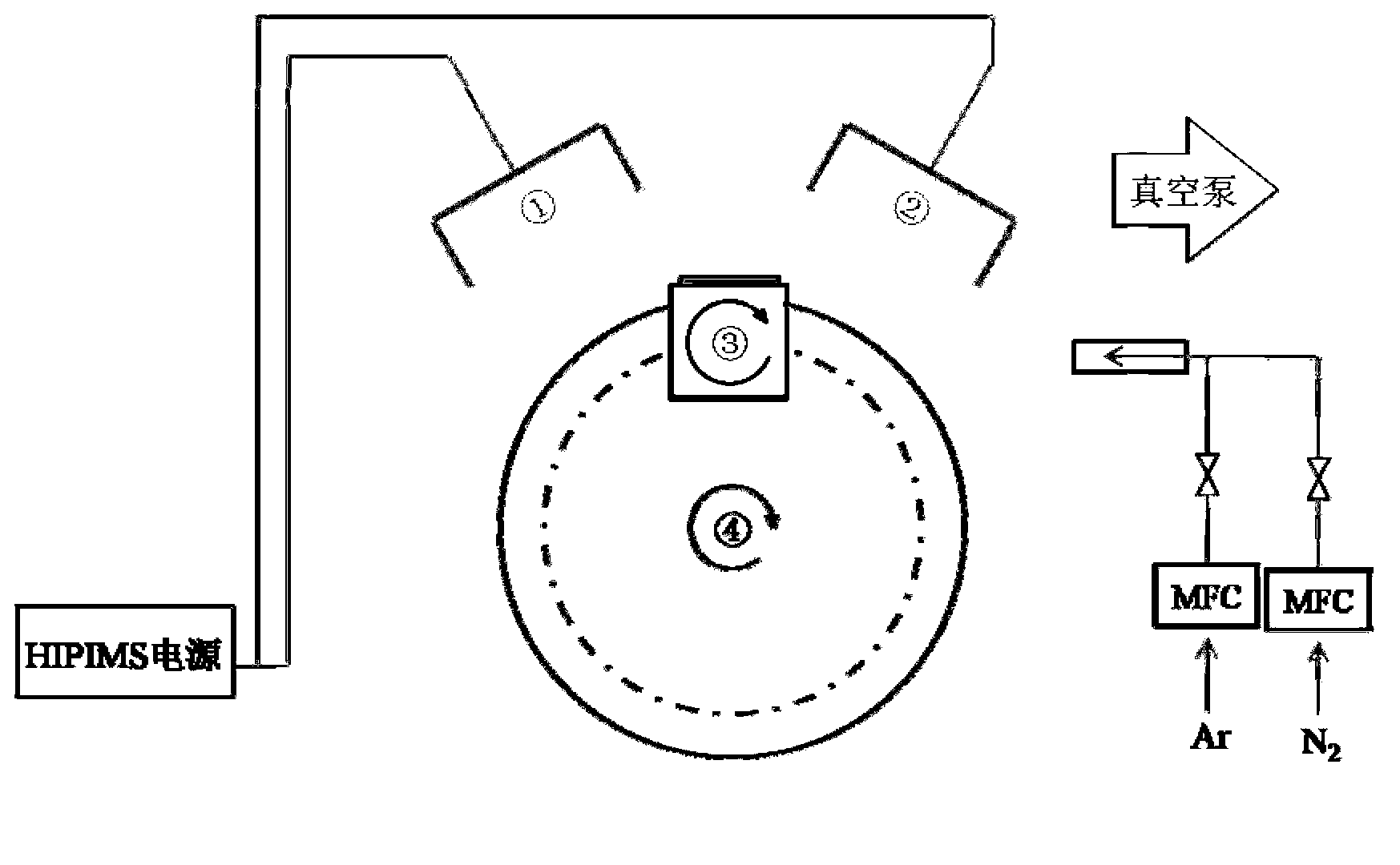

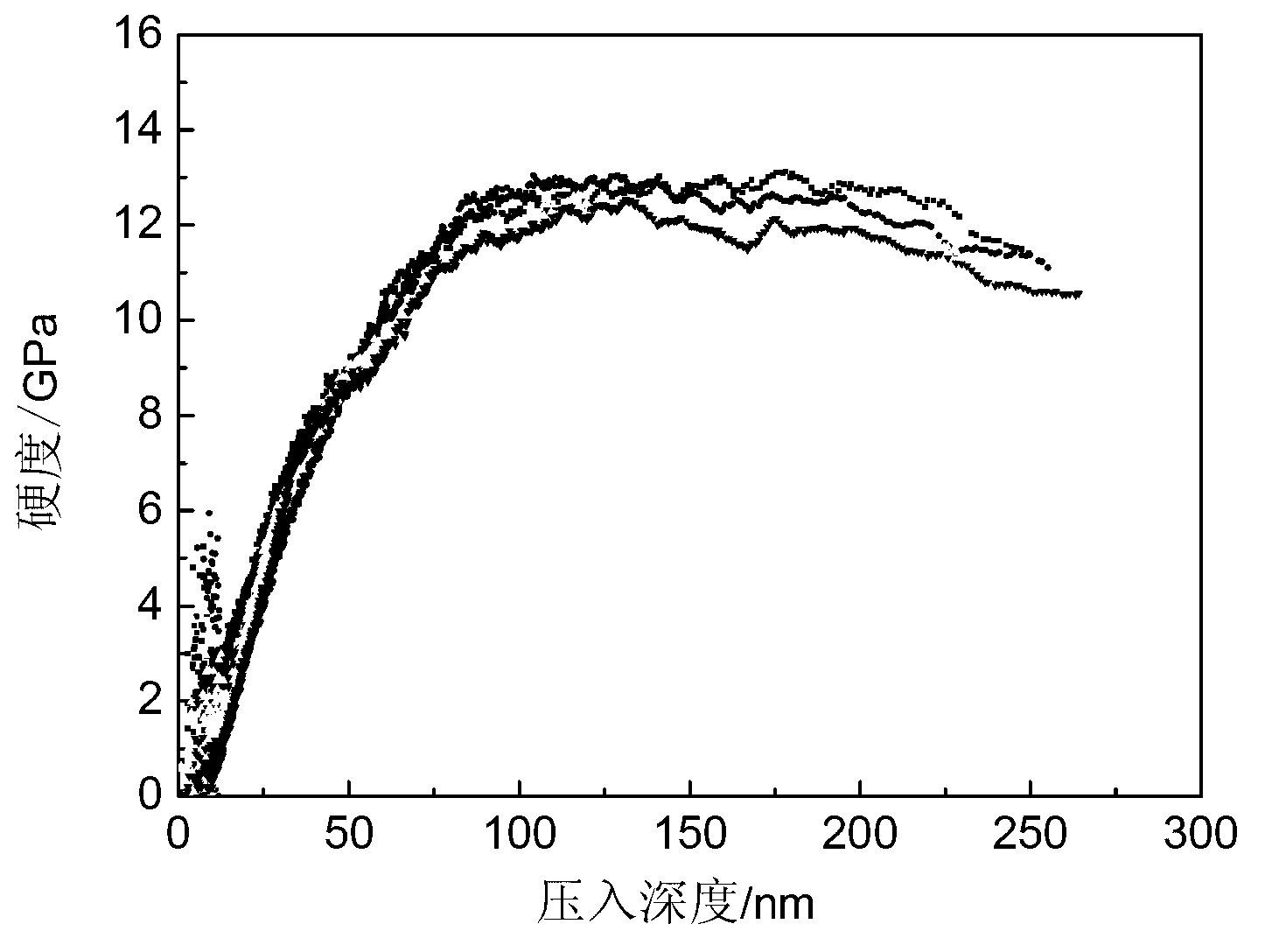

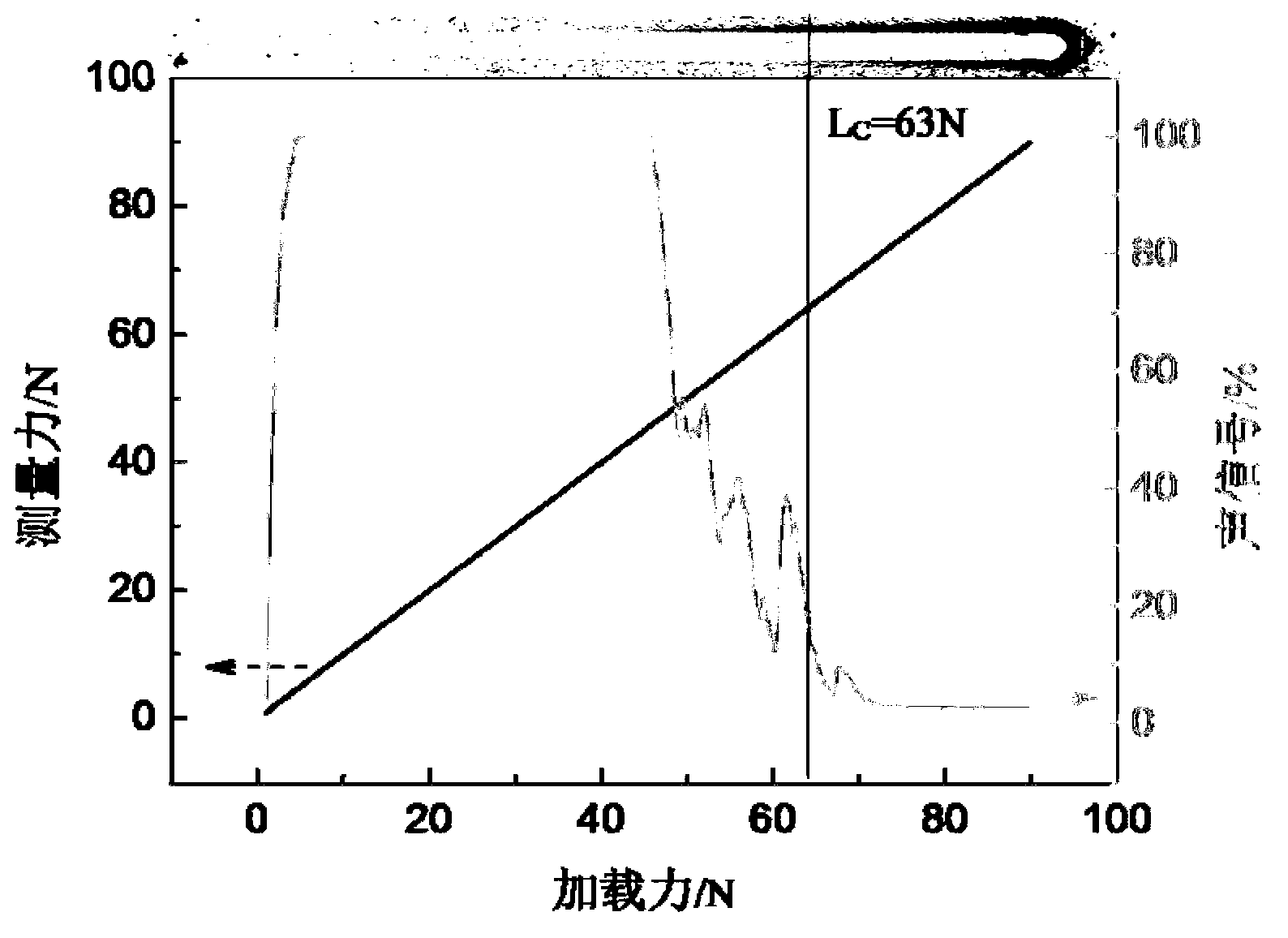

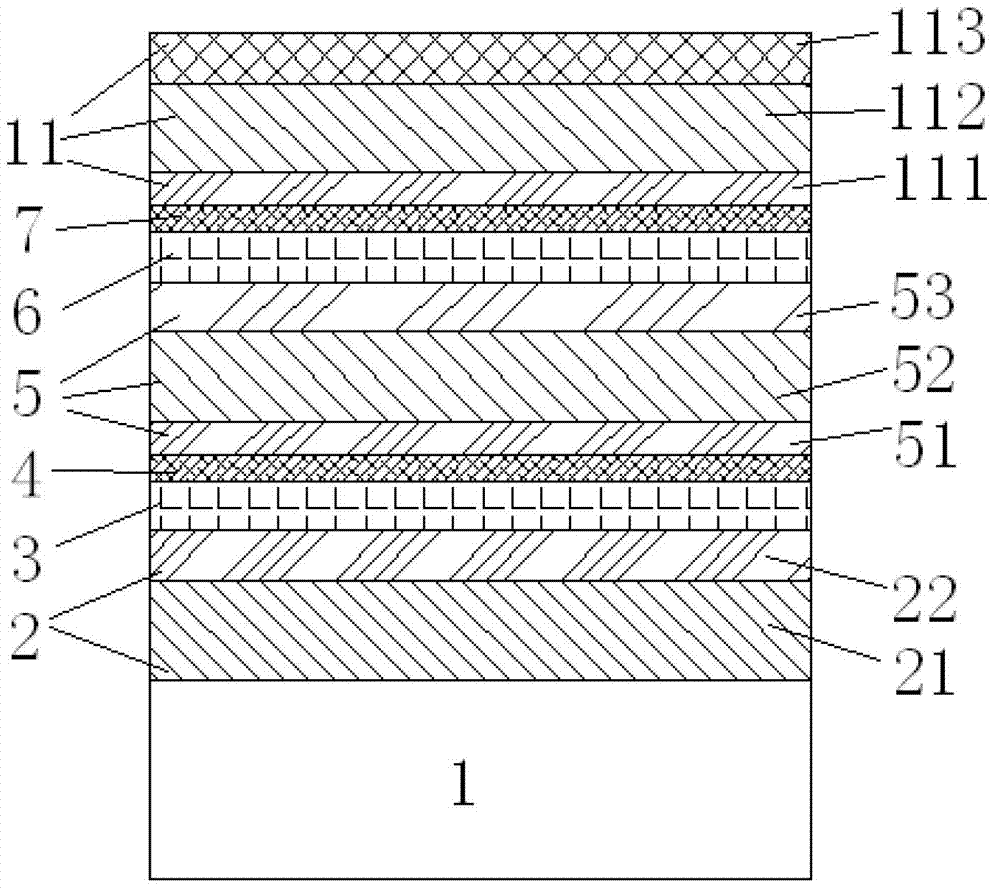

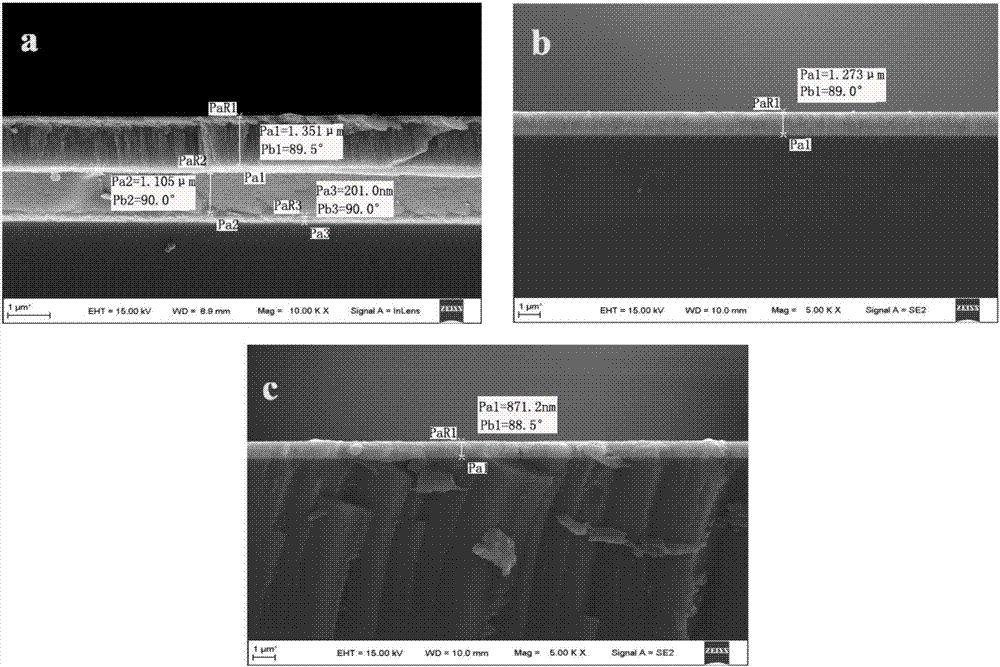

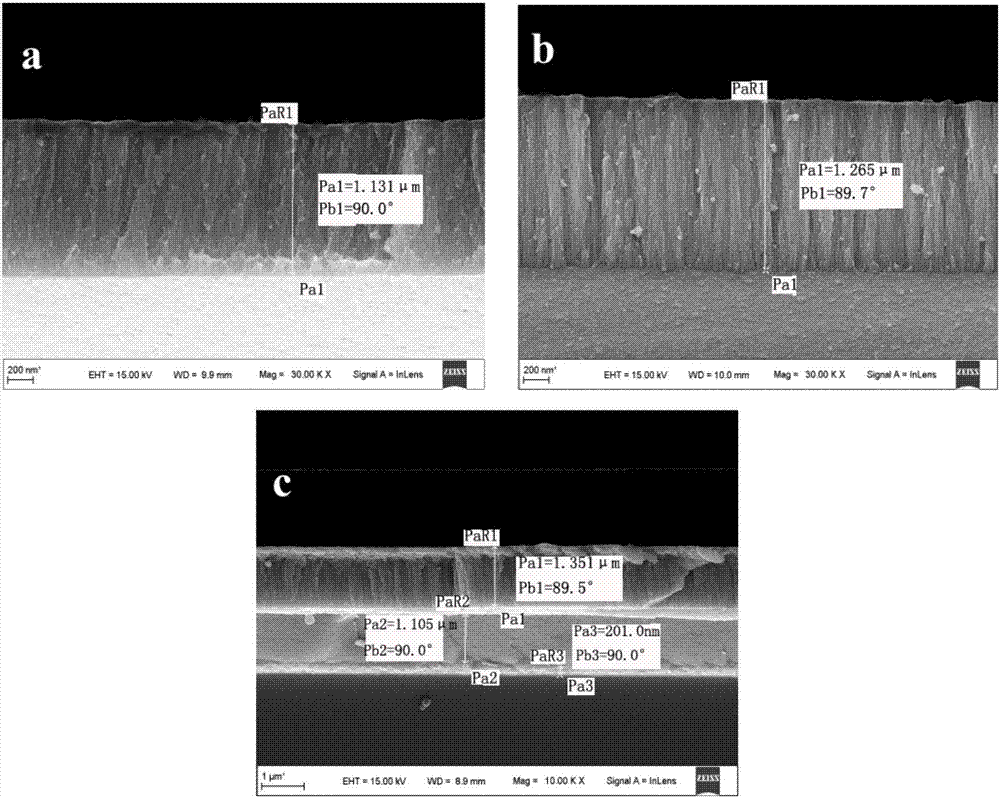

The invention discloses a preparation method of a MoS2 composite thin film with high hardness and loss abrasion on a surface of a substrate. The method comprises the following step: sequentially depositing a metal Ti priming coat, a TiN transitional layer and a Ti / MoS2 composite thin film on the surface of the substrate by using a high power pulse magnetron sputtering technology combined with optimized process conditions to obtain the MoS2 composite thin film which is strong in film binding force and high hardness and has low frictional coefficient and wear rate in various frictional environments. The nano hardness of the composite thin film is over 11GPa, the critical load value is over 60N, and the frictional coefficients in room-temperature air with relative humidity of 30%, 50% and 70%, an N2 atmosphere and a hydraulic oil environment are below 0.055. Therefore, the substrate is effectively protected in frictional reduction, and the composite thin film has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

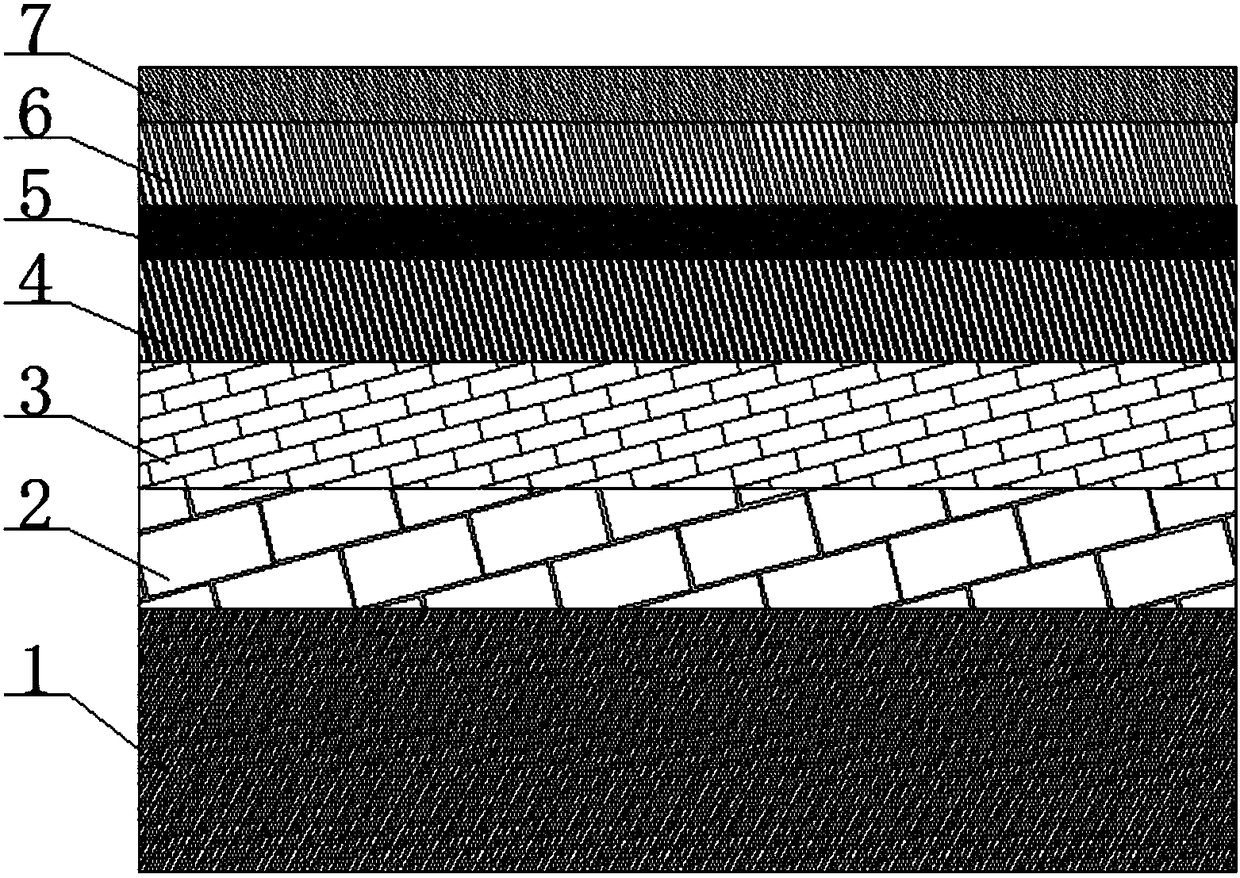

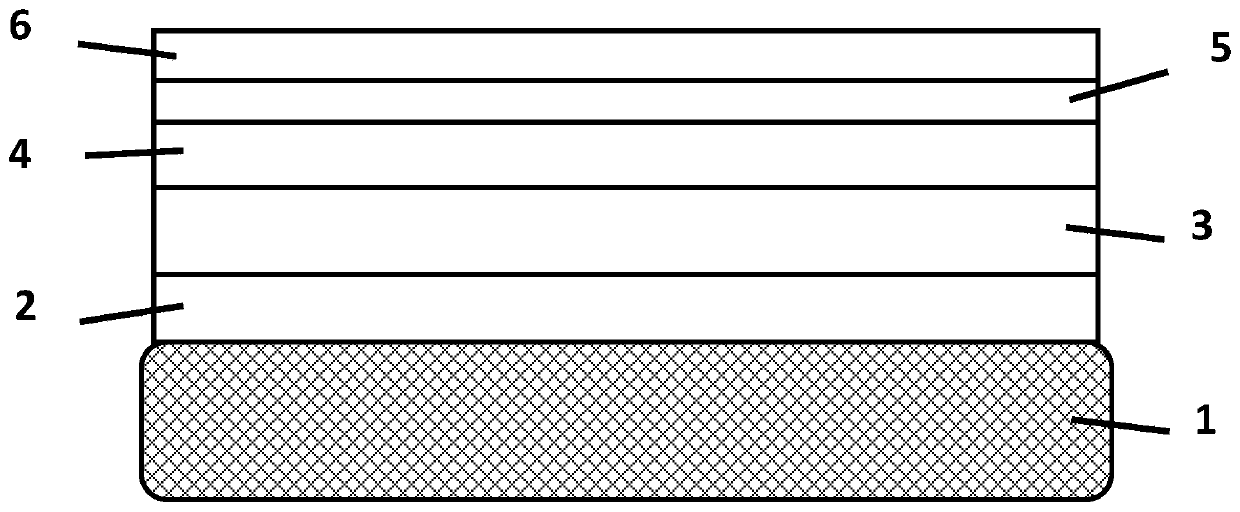

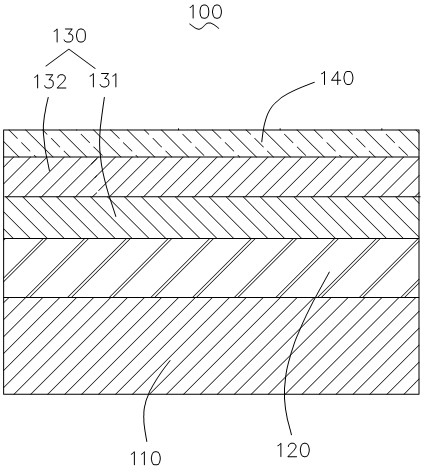

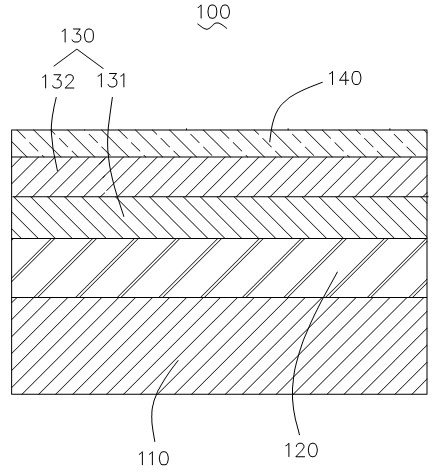

Low-emissivity film-coated glass high in infrared reflection and sandwich glass product thereof

ActiveCN102807330AOptical quality qualified improvementIncreased durabilityLow emissivityFilm coating

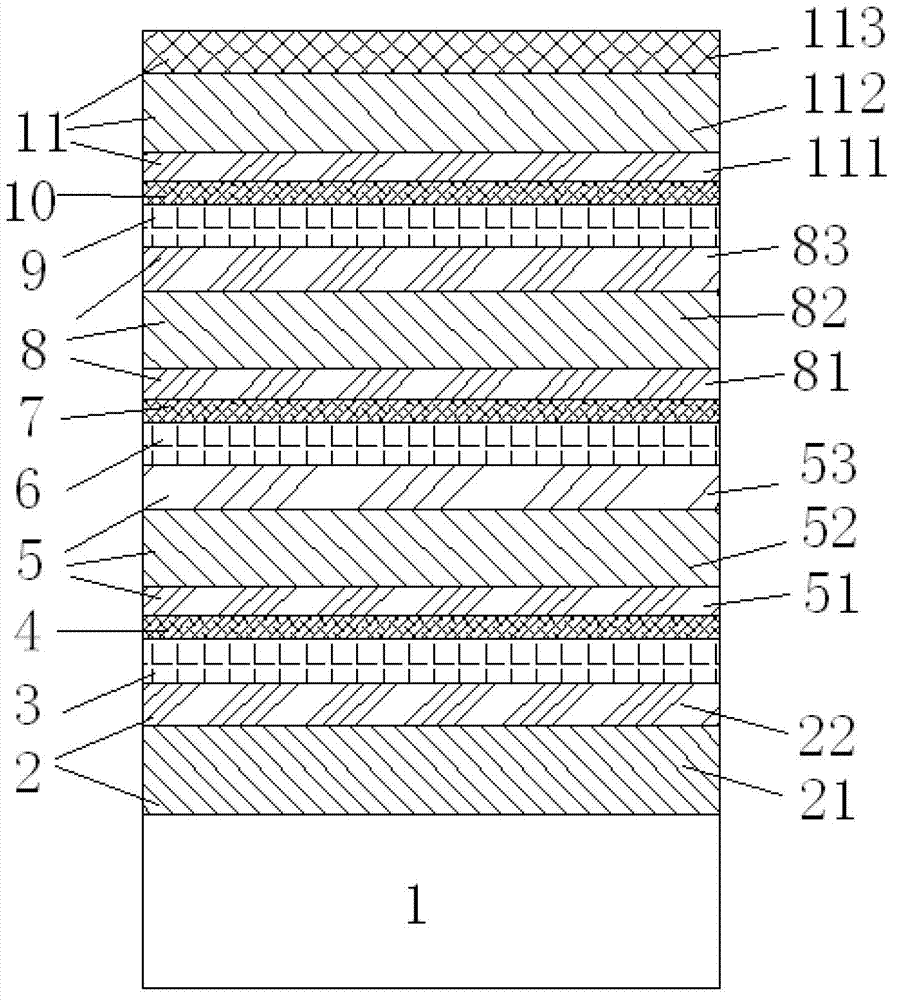

The invention relates to the field of the film coating of glass, in particular to low-emissivity film-coated glass which is high in visible light transmittance, high in infrared reflection and available in heat treatment, and a sandwich glass product thereof. A film layer structure comprises medium layers and infrared reflecting layers, which are upwards superposed alternately from a glass substrate; a sequence of superposing the medium layers and the infrared reflecting layers alternately is that the medium layers are followed by the infrared reflecting layers; and the low-emissivity film-coated glass is characterized in that an upper medium layer positioned at an uppermost layer comprises a second medium film which is selected from at least one of ZrO2 and ZrOxNy, and a third medium film which is deposited on the second medium film and is selected from at least one of oxides of Ti, Al, Si, Ta, Hf, Nb, Cr, Ni, Fe, Mo, W and Y or is selected from at least one of nitrides and nitrogen oxides of the Ti, the Al, the Ta, the Nb, the Fe, the Hf, the Ni and the Cr. The low-emissivity film-coated glass and the sandwich glass product thereof have the advantages that the film-coated glass and the sandwich glass product thereof are high in the visible light transmittance and good in mechanical stability and high-temperature heat treatment stability.

Owner:FUYAO GLASS IND GROUP CO LTD

AZO sputtering target for high-stability transparent conductive film and manufacturing method

InactiveCN101851739ARich reservesFast sputtering rateVacuum evaporation coatingSputtering coatingTransmittanceElectrically conductive

The invention discloses an AZO sputtering target for a high-stability transparent conductive film and a manufacturing method. The raw material powder used by an IZGO sputtering target comprises 2 to 3wt% of Al2O3, 0.1 to 3wt% of B2O3 and the balance of ZnO powder; the average grain diameter of the powder is 0.05 to 50 microns, and the purity of the raw material powder is larger than or equal to 4N. The material of the invention is easier to control when used in the production process of the transparent conductive film through magnetron sputtering, a serious poisoning phenomenon similar to an ITO does not exist, and the sputtering process does not need heating, which has more advantages in the production of flexible conductive films such as plastics, and the stability and the weatherability of the film are much superior to that of the ITO and traditional zinc aluminum oxide conductive films. The resistivity of the produced transparent conductive film is smaller than 5*10 to 4Omega.cm, the visible light transmittance of 400 to 700nm is larger than 85%, and the requirements of various transparent conductive films can be satisfied.

Owner:YIXING BAILUN OPTO ELECTRONICS MATERIAL

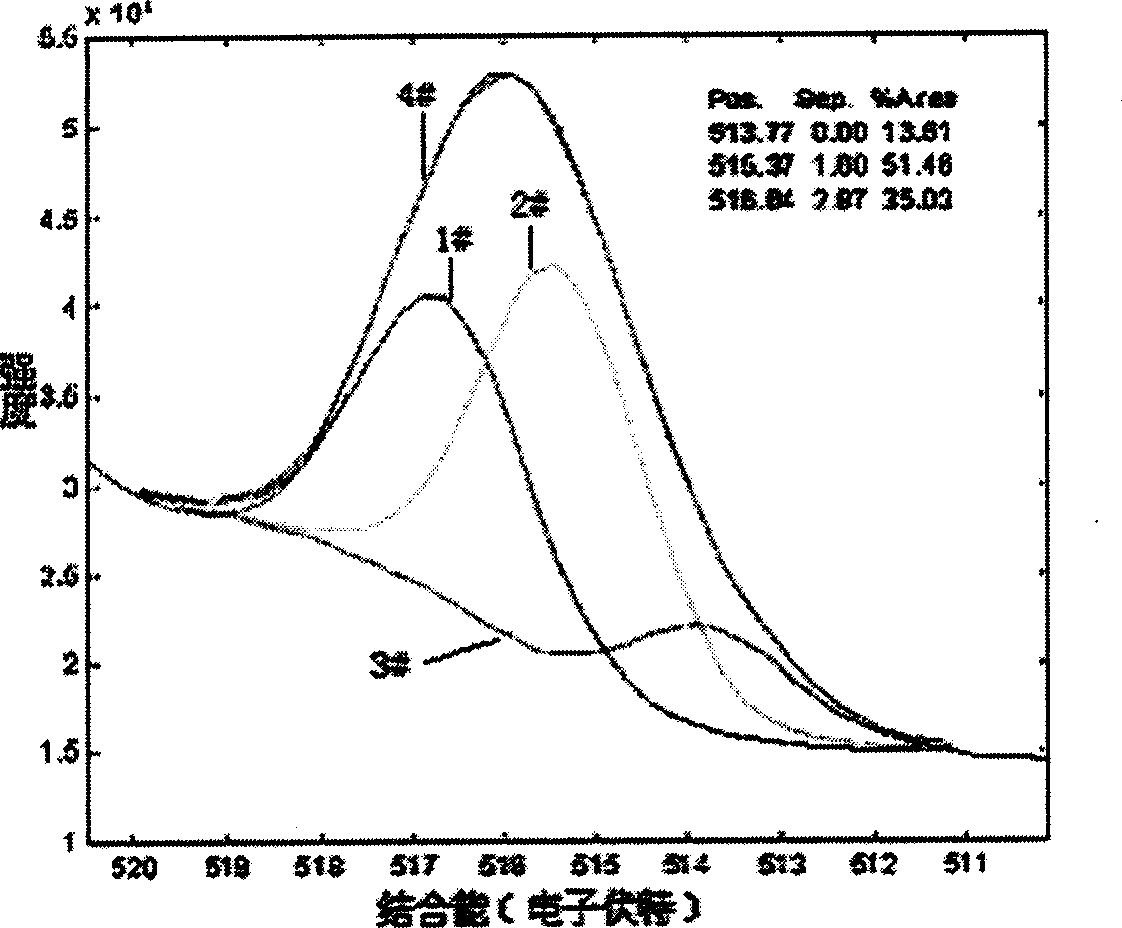

Opposite target reaction magnetocontrol sputtering method for preparing vanadium oxide film

InactiveCN1752270AIncrease profitFast sputtering rateVacuum evaporation coatingSputtering coatingThermal treatmentSilicon oxide

Owner:TIANJIN UNIV

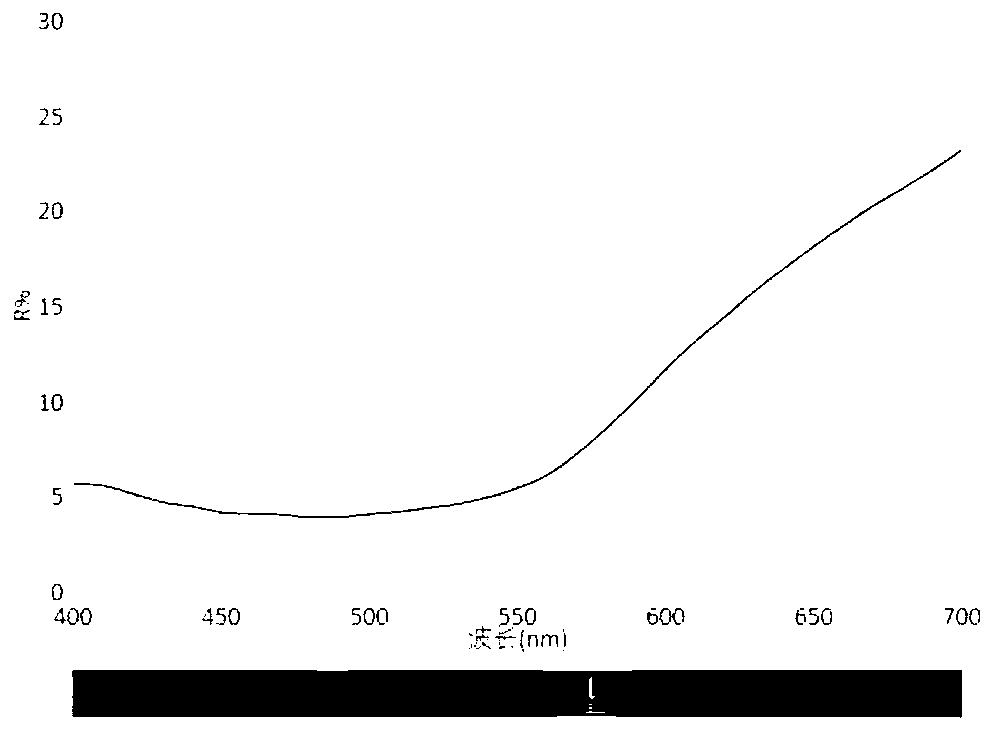

Medium-and-high-temperature solar selective absorption coating and preparation method thereof

ActiveCN102501459AImprove high temperature stabilityPromote absorptionVacuum evaporation coatingSputtering coatingSputteringMedium frequency

The invention discloses a preparation method for a medium-and-high-temperature solar selective absorption coating. The coating consists of an infrared reflection layer, an absorption layer and a reflection reduction layer from a base body to a surface; the infrared reflection layer consists of a Mo film, and the thickness of the infrared reflection layer is 50 to 200mm; the absorption layer comprises a first sub layer and a second sub layer; the first sub layer and the second sub layer consist of a Mo+AlN film respectively, and the thickness of the first sub layer and the second sub layer is 30 to 150mm; the reflection reduction layer consists of a AlN film, and the thickness of the reflection reduction layer is 30 to 100mm; according to the method, the infrared reflection layer is deposited on the base body by a Mo target direct current magnetron sputtering method; the absorption layer is deposited on the infrared reflection layer by Mo target direct current magnetron sputtering and Al target medium-frequency magnetron sputtering; the reflection reduction layer is deposited on the absorption layer by Al target medium-frequency magnetron sputtering; and the preparation method is simple, convenient to operate, easy to control, and high in sputtering velocity and can shorten a production cycle.

Owner:DONGGUAN CAMDA GENERATOR WORK

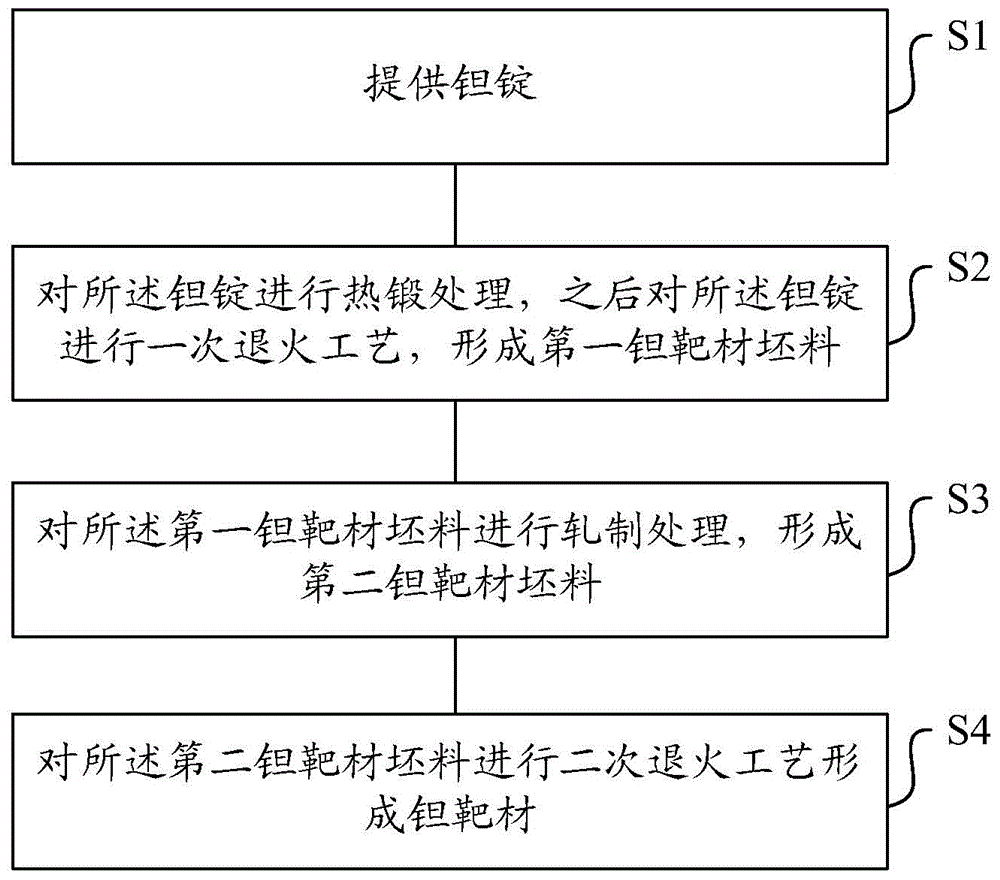

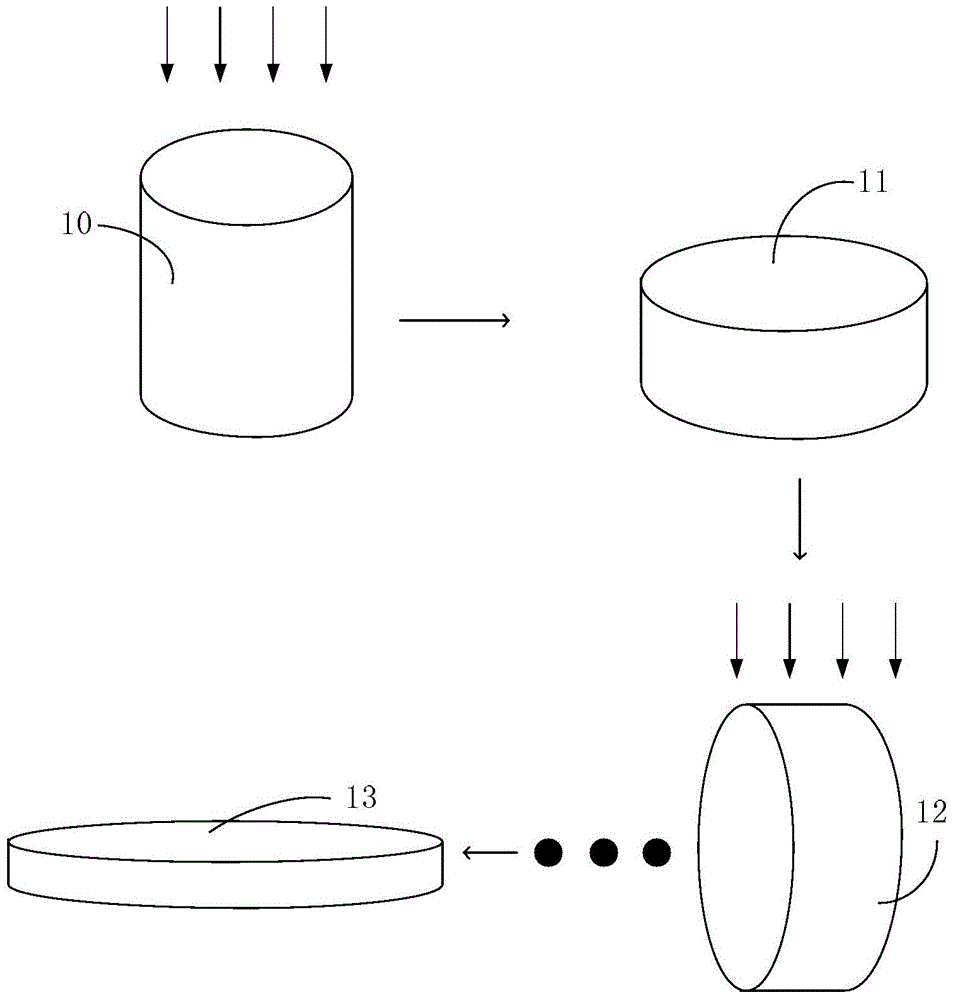

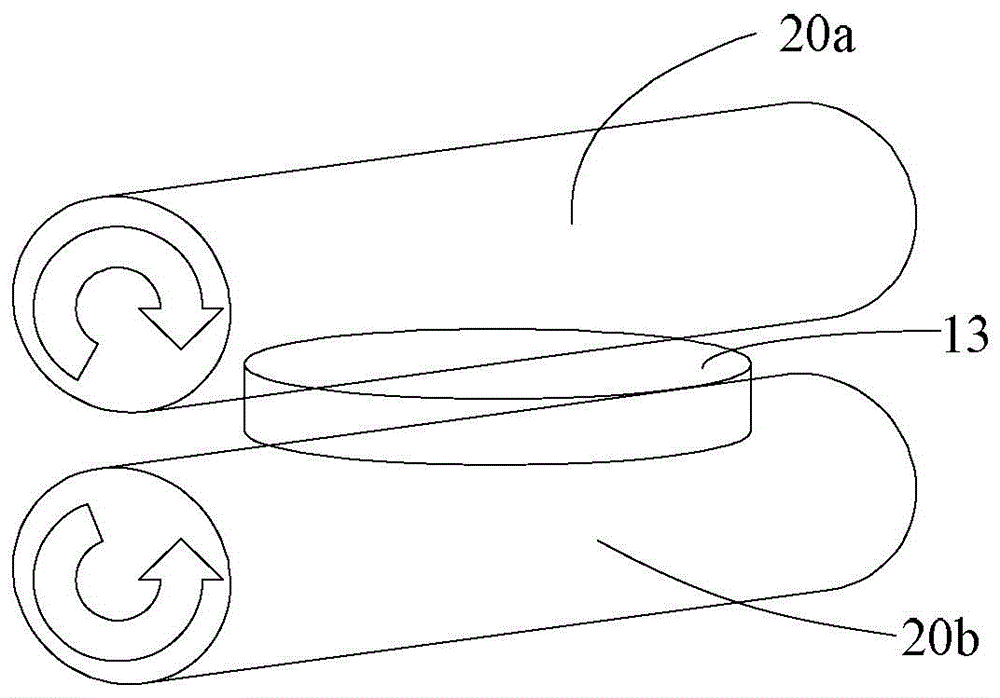

Method for manufacturing tantalum target material

ActiveCN104419901ASimple internal structureStress reliefVacuum evaporation coatingSputtering coatingIngotTantalum

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Welding method adaptable to high-temperature sputtering target material

InactiveCN103264231AIncreased sputtering powerGood electrical and thermal conductivityWelding apparatusEpoxyActivated carbon

The invention discloses a welding method adaptable to high-temperature sputtering target material. The welding method includes (1) cleaning weld faces of the target material and a back plate; (2) adding silver powder with mass percentage of 60% to 70% or activated carbon particles with mass percentage of 70%-80% to epoxy resin adhesive, and evenly coating on the weld faces of the target material and a back plate and two faces of a copper net; (3) placing and positioning the copper net and the target material on the back plate in sequence; (4) placing pressing blocks with certain weight on the target material; (5) solidifying in normal-temperature and normal-pressure environment; and (6) cleaning excess adhesive on the edge of the target material after cooling. When film is produced, the target material produced by the welding method can bear the temperature ranging from 200 DEG C to 250 DEG C, target material sputtering power can increase to almost three in one, sputtering power is increased obviously; and during the process of target material rapidly sputtering, target missing is omitted, high-speed continuous sputtering can be realized, and production efficiency is improved significantly.

Owner:LIDA OPTICAL & ELECTRONICS

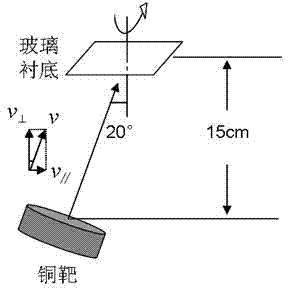

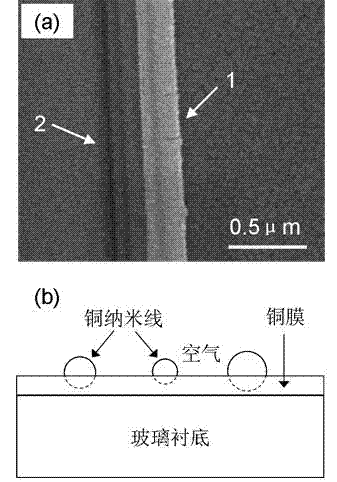

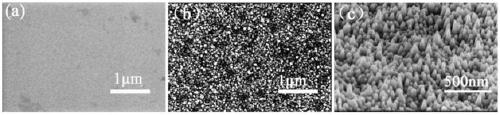

Copper nanowire / copper film composite structure and preparation method thereof

ActiveCN102345096AAvoid destructionAvoid pollutionVacuum evaporation coatingSputtering coatingSurface plasmonSubstrate bias voltage

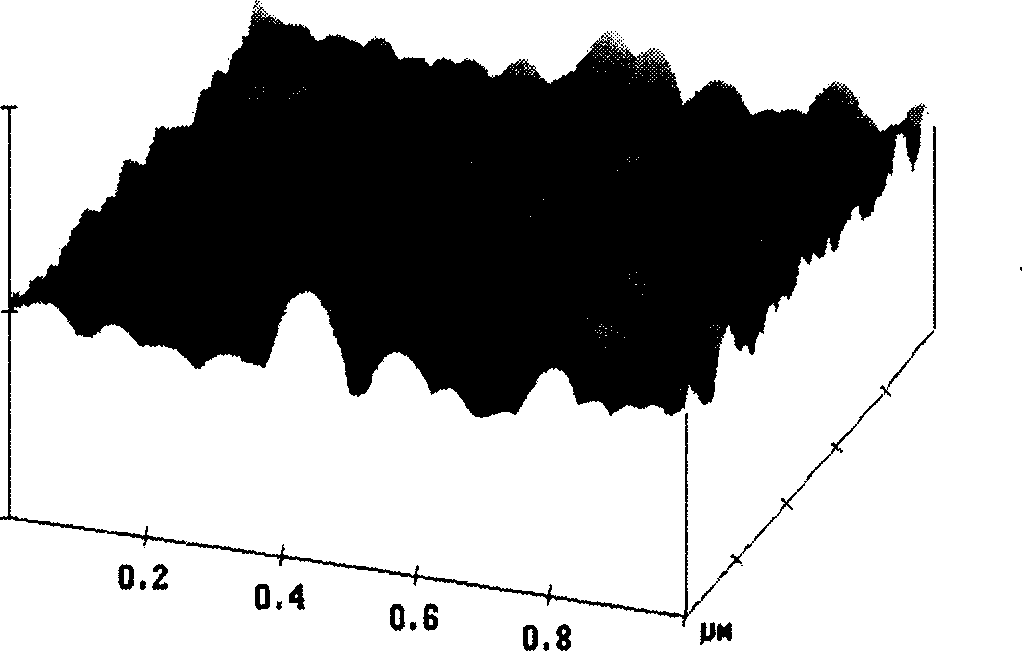

The invention provides a copper nanowire / copper film composite structure and a preparation method thereof, and aims to provide a copper nanowire / copper film composite structure and a magnetron sputtering preparation method thereof. The invention employs a small deposition angle direct current magnetron sputtering deposition technology and prepares a copper nanowire / copper film composite structure on a glass substrate by proper adjusting of film thickness, substrate temperature and substrate bias voltage. The copper nanowire / copper film composite structure provided by the invention has smooth copper nanowire surface, uniform radial thickness, a length of 0.1-5mm, a diameter of 100-500nm and a copper film thickness of 50-100nm. The copper nanowire is parallel to the copper film surface and embedded in the copper film with a thickness less than that of the copper nanowire. According to the invention, metal copper film surface is embedded with sub-wavelength copper nanowire, which has potential application prospect infields related to surface plasma.

Owner:溧阳常大技术转移中心有限公司

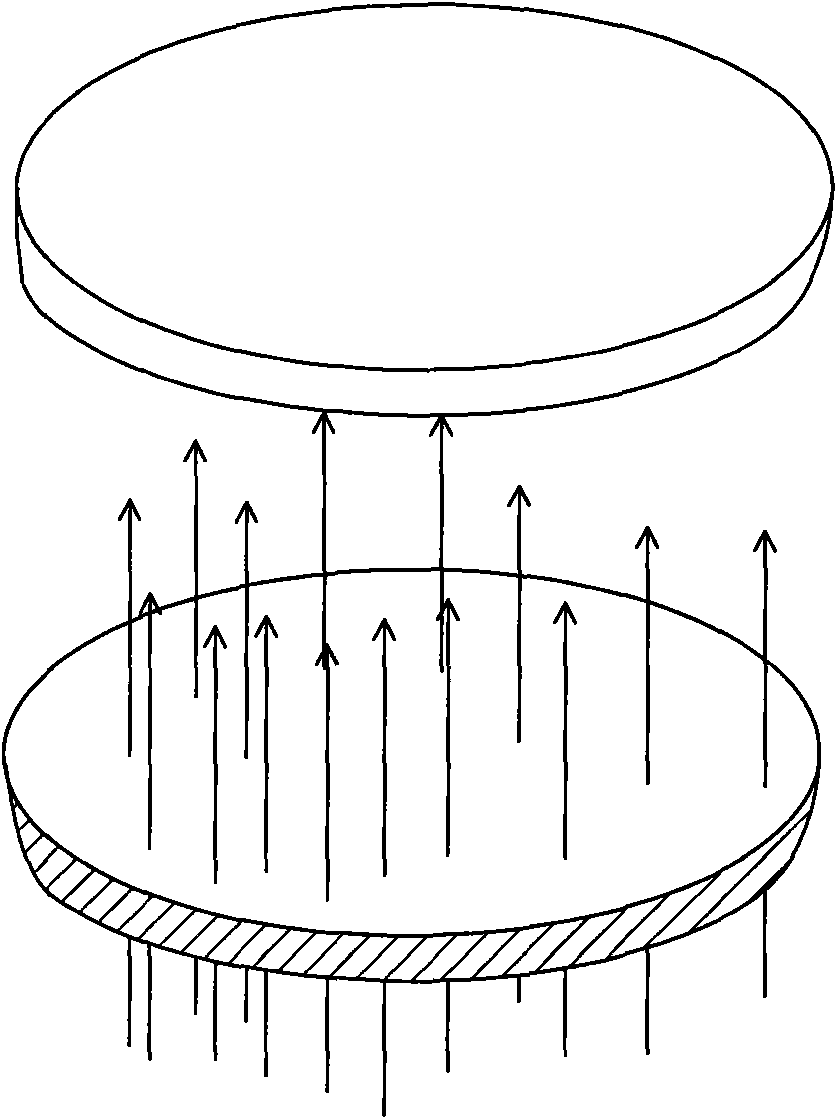

Sputter coating method

InactiveCN101565818AIncrease speedImprove crystal qualityVacuum evaporation coatingSputtering coatingNon magneticElectric field

The invention discloses a sputter coating method, which adopts a magnetic field-assisted sputtering mode for coating, wherein a target and a substrate are arranged in parallel inside an electric field between two electrodes; the target is positioned on the surface of a cathode; the substrate is positioned on an anode; a plasma is formed between the target and the substrate; the target is bombarded by ions to generate sputtering; and sputtered target composition particles are deposited on the substrate to form a membrane. The sputter coating method is characterized in that: the target is positioned inside a magnetic field generated by a permanent magnet or an electromagnet or an electromagnetic coil, and the direction of the magnetic field is perpendicular to the surface of the target. The method can greatly improve the speed of sputter coating and the crystallization quality of the coating, integrally and uniformly etch the target, improve the utilization rate of the target to between 85 and 90 percent, and obtain higher sputtering speed and the same sputtering effect for both magnetic targets and nonmagnetic targets.

Owner:SUZHOU UNIV

Preparation method of silicon-aluminum sputtering target material

InactiveCN106498350AImprove and enhance key quality indicatorsImprove key quality indicatorsMolten spray coatingVacuum evaporation coatingSputteringSand blasting

The invention discloses a preparation method of a silicon-aluminum sputtering target material high in density, low in oxygen content and not prone to embrittlement. The preparation method comprises the following steps of target material base tube preparing, wherein a stainless steel base tube of the required type is selected and checked; base tube surface pretreatment, wherein the base tube is made to enter base tube pretreatment equipment to be subjected to sand-blasting roughening, a nickel-aluminum alloy wire is utilized, a bottoming combination layer is sprayed through an arc spray method, and a target material base tube to be sprayed is obtained; raw material preparing, wherein 50 kg of silicon powder with the content ranging from 99.9% to 99.95%, the oxygen content being smaller than or equal to 1,000 ppm and the particle size ranging from 45 micrometers to 150 micrometers and 6.6 kg of high-purity spherical aluminum powder with the content ranging from 99.9% to 99.95%, the oxygen content being smaller than or equal to 1,500 ppm and the particle size ranging from 45 micrometers to 100 micrometers are weighed; powder mixing, wherein two obtained raw materials are put into a V-shaped powder mixer to be mixed for 5 hours to 6 hours; and drying, wherein an evenly-mixed silicon-aluminum powder raw material is put in a drying furnace to be dried for 2 hours to 3 hours, and the temperature is 60 DEG C.

Owner:FAKETE TECH JIANGSU

Extrusion treatment method for high-purity aluminium target for liquid-crystal flat-panel display coating film

InactiveCN105220092ASimple processUniform tissueVacuum evaporation coatingSputtering coatingClosed loopIngot

The invention discloses an extrusion treatment method for a high-purity aluminium target for a liquid-crystal flat-panel display coating film. The extrusion treatment method comprises the following steps: selecting a high-purity solid aluminium ingot and heating the aluminium ingot to a semi-melted state, conveying the aluminium ingot into an extrusion machine through a transport rail, and slowly extruding the aluminium ingot from an outlet of the extrusion machine under the co-action of the extrusion machine and a die; obtaining a total deformation amount of 81.14% through measurement and calculation; carrying out annealing treatment on a cooled aluminium tube, refining grains, and improving a structure; and finally carrying out machining which comprises surface treatment, cutting and the like on the aluminium tube according to a drawing to obtain the finished product. The preparation method for the high-purity aluminium target is simple in process, and convenient and fast, thus increasing the efficiency; the prepared high-purity aluminium target has a fine-grain structure and has grain sizes of not greater than 200 [mu]m, and the structure is uniform and has a cubic texture, so that the sputtering speed of the high-purity aluminium target can be effectively increased; and an extrusion temperature, an extrusion speed and an extrusion pressure during an extrusion process form a closed-loop system, so as to further increase the extrusion speed and the production efficiency, and ensure the most excellent performance.

Owner:GEMCH MATERIAL TECH SUZHOU

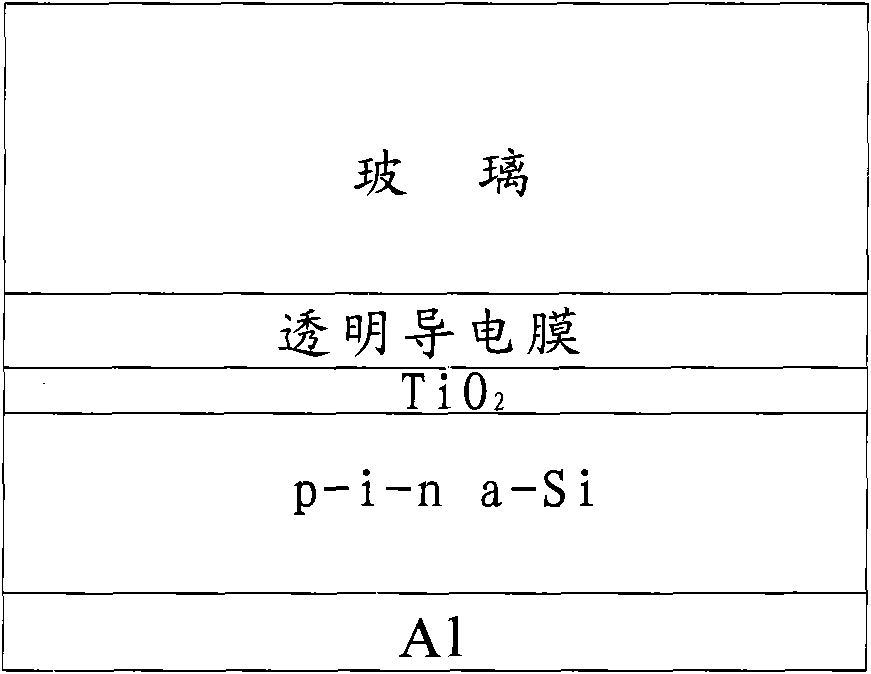

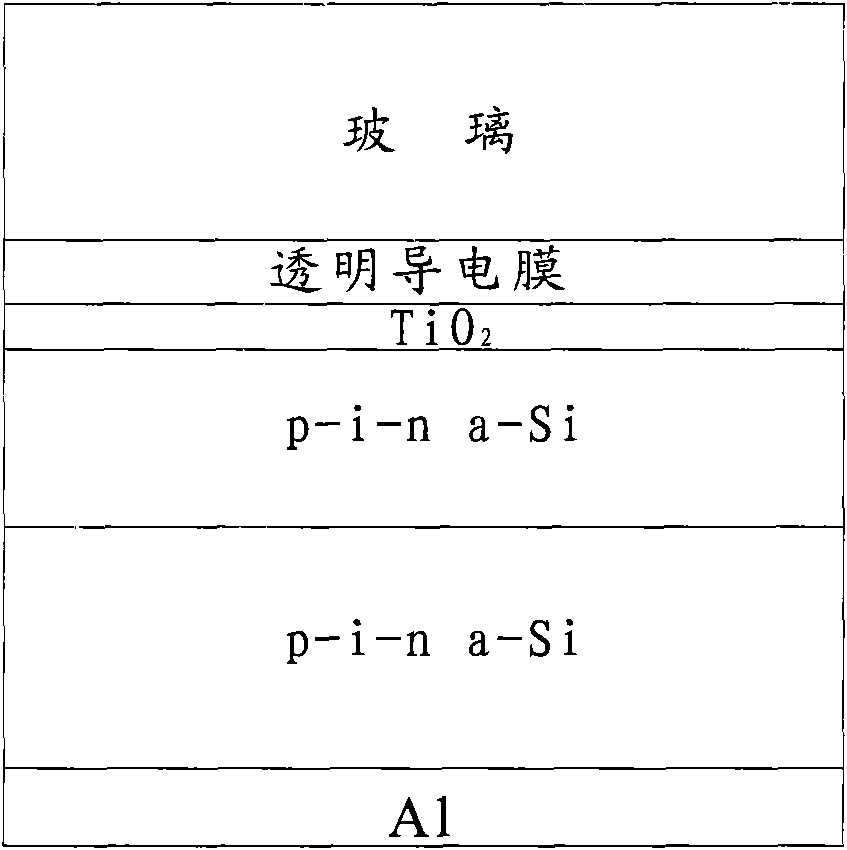

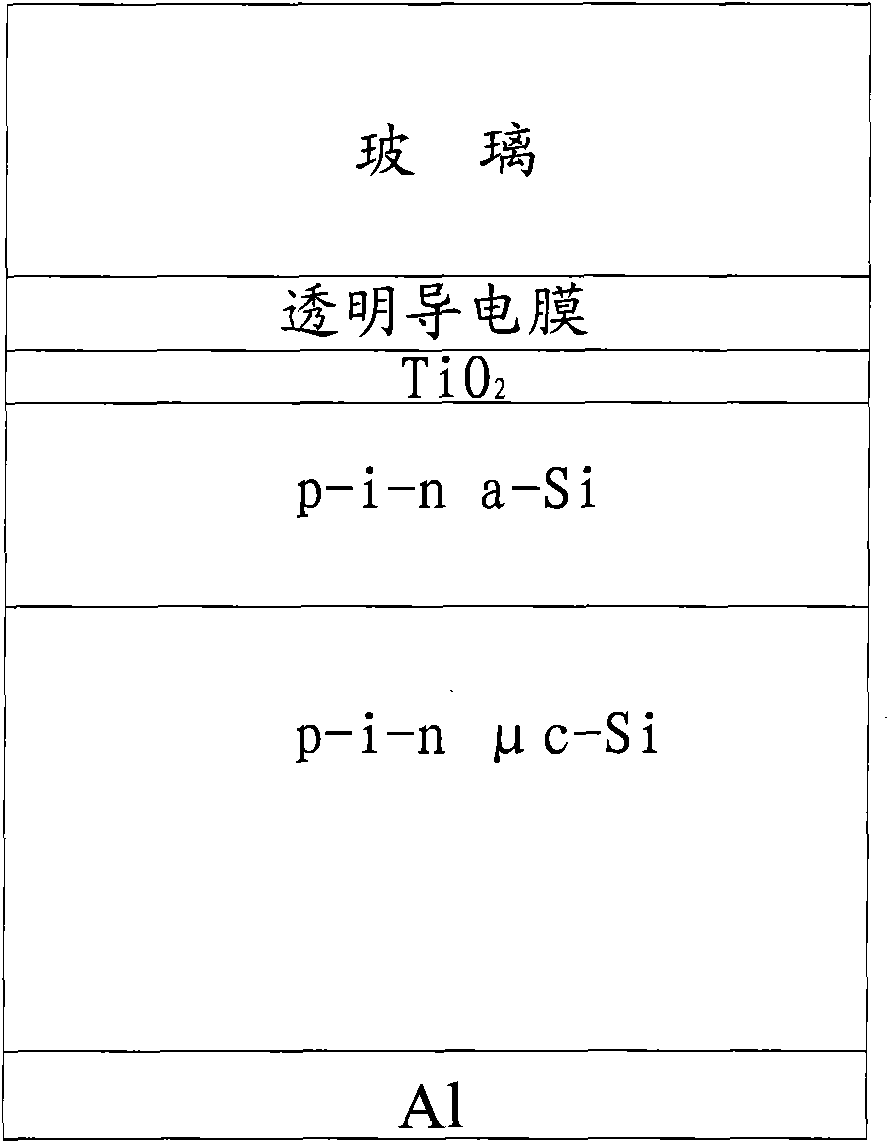

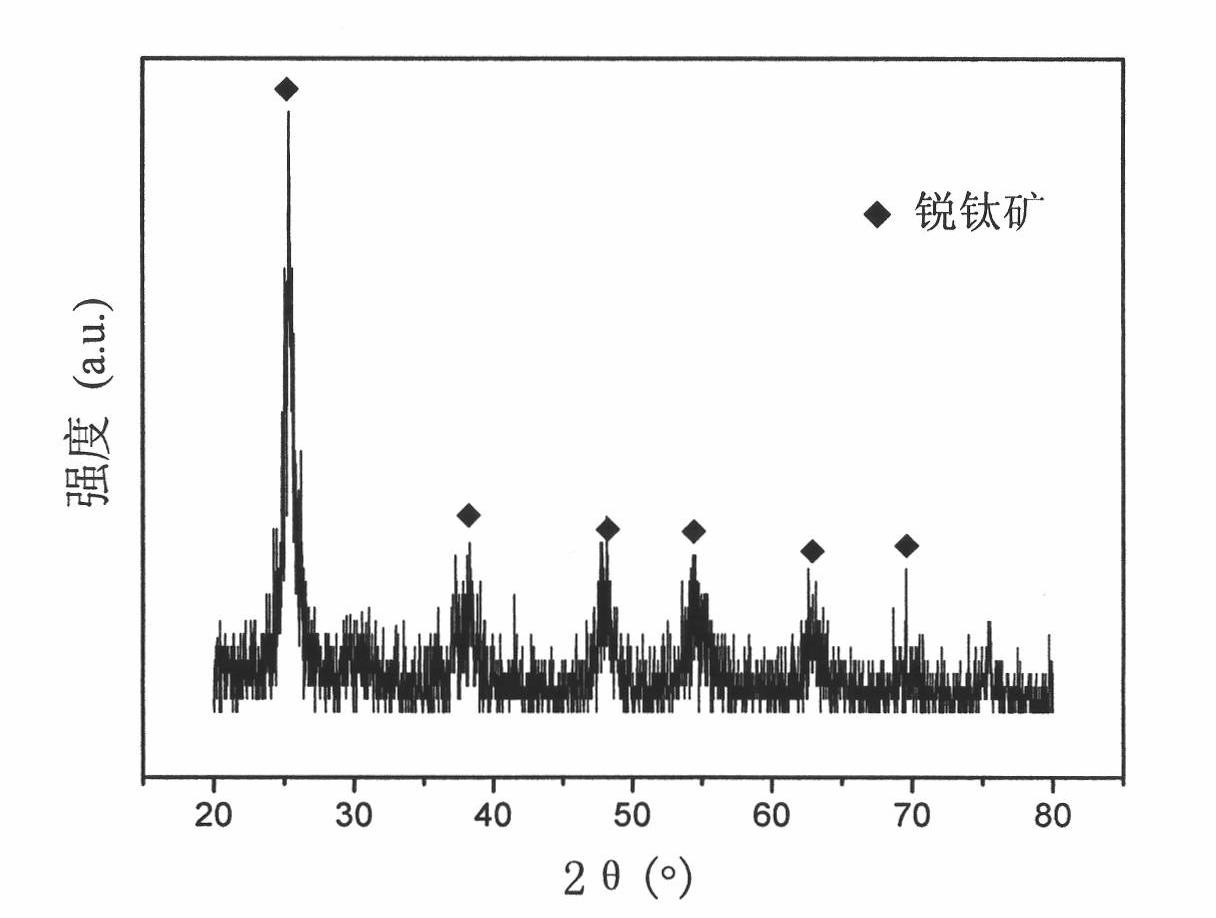

Method for preparing titania film by using gas flow reaction sputtering under middle gas pressure and method for preparing solar cell

InactiveCN101838794AImprove thermal stabilityIncreased chance of collisionVacuum evaporation coatingSputtering coatingSuperoxideHigh energy

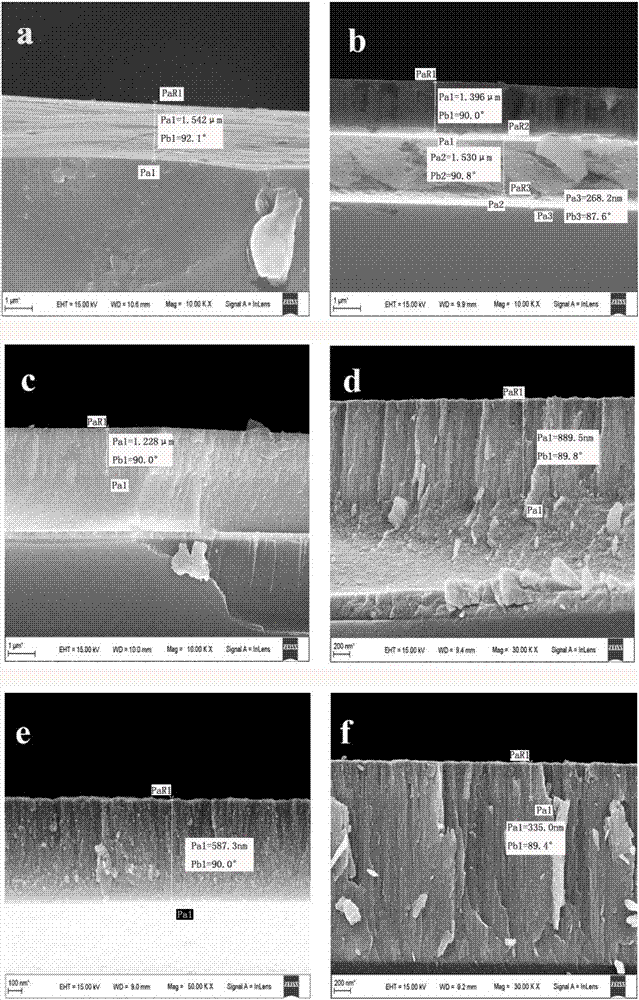

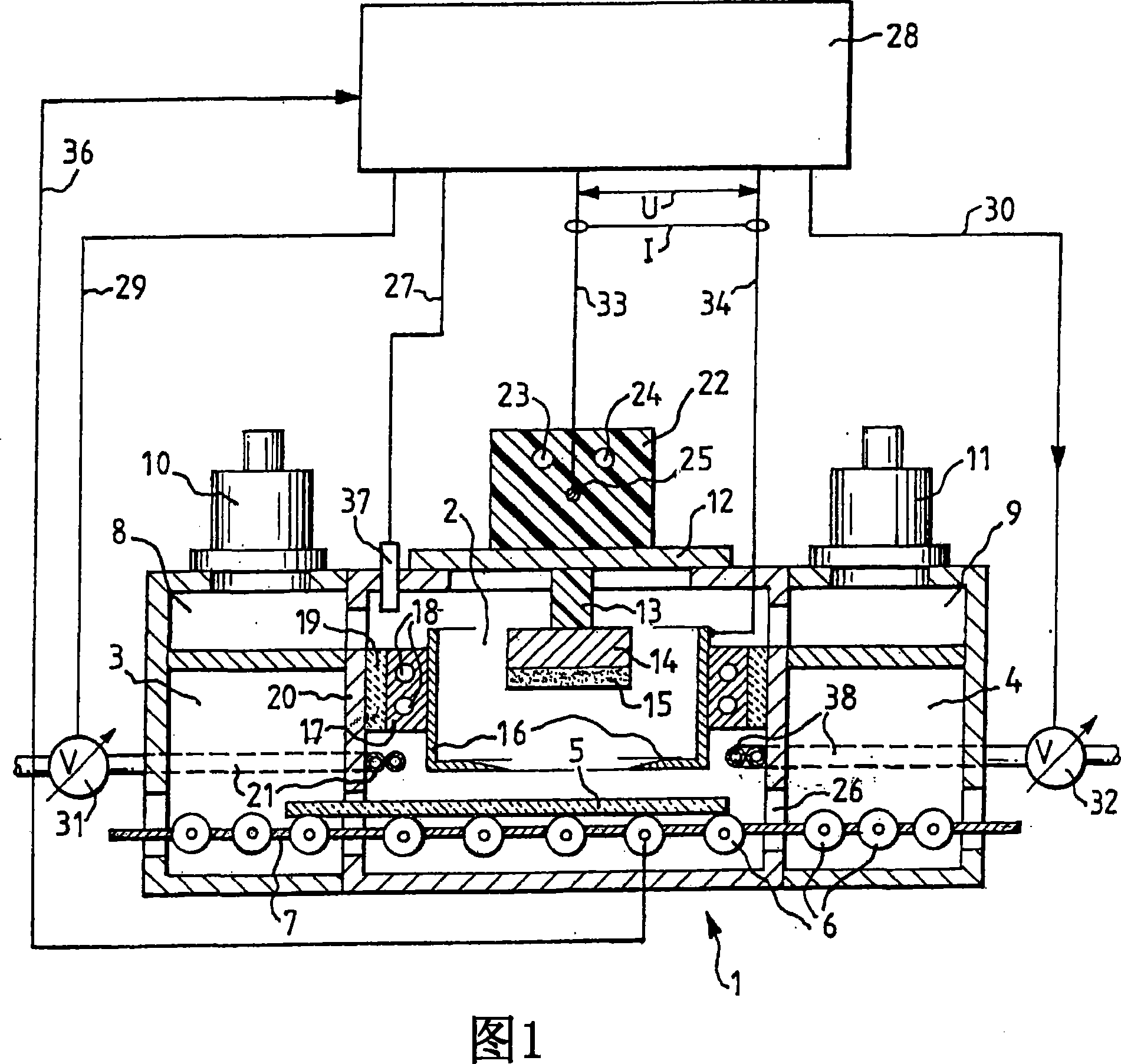

The invention discloses a method for preparing a titania film by using gas flow reaction sputtering under a middle gas pressure and a method for preparing a solar cell. The preparation method for the titania film comprises the following steps of: A), placing a glass substrate plated with a transparent conducting film into a reaction chamber of vacuum sputtering coating equipment and vacuumizing the reaction chamber; and B), introducing a working gas into a target chamber between a pair of titanium targets which is oppositely arranged in a cathode device of the vacuum sputtering coating equipment, and introducing oxygen outside the target chamber, wherein the sputtering gas pressure of the working gas is 10 to 100 Pa, and a TIO2 film is formed on the transparent conducting film by sputtering deposition. The method improves the sputtering gas pressure, and prevents high-energy superoxide anions O- and neutral argon particles from bombarding the substrate so as to reduce crystal defects and improve the electrical conductivity and the thermal stability of the TIO2 film.

Owner:苏州羿日新能源有限公司

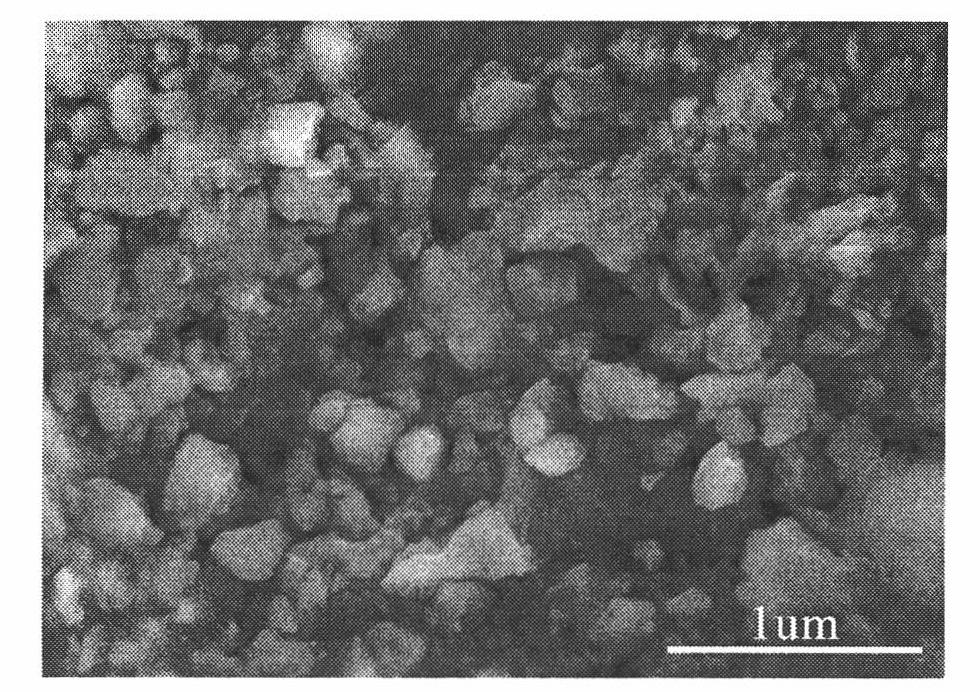

Method for preparing metal ion-doped titanium dioxide target material and target material thereby

The invention relates to a method for preparing a metal ion-doped titanium dioxide target material and a target material thereby. The target material is prepared by adopting the steps of preparing metal ion-doped titanium dioxide powder through a solution reaction and compressing and sintering. The preparation process is simple and is easy to realize uniform doping of one or more metal ions; the doping amount of the ions can be precisely controlled, and the metal ions can enter a titanium dioxide crystal lattice in the preparation process to generate chemical bonding; the average crystal granularity of titanium dioxide in the prepared target material is below 200 nano, and the target material has high density; and the target material can be used for preparing a metal ion-doped titanium dioxide nano film by adopting a magnetron sputtering method.

Owner:INNER MONGOLIA UNIV OF TECH

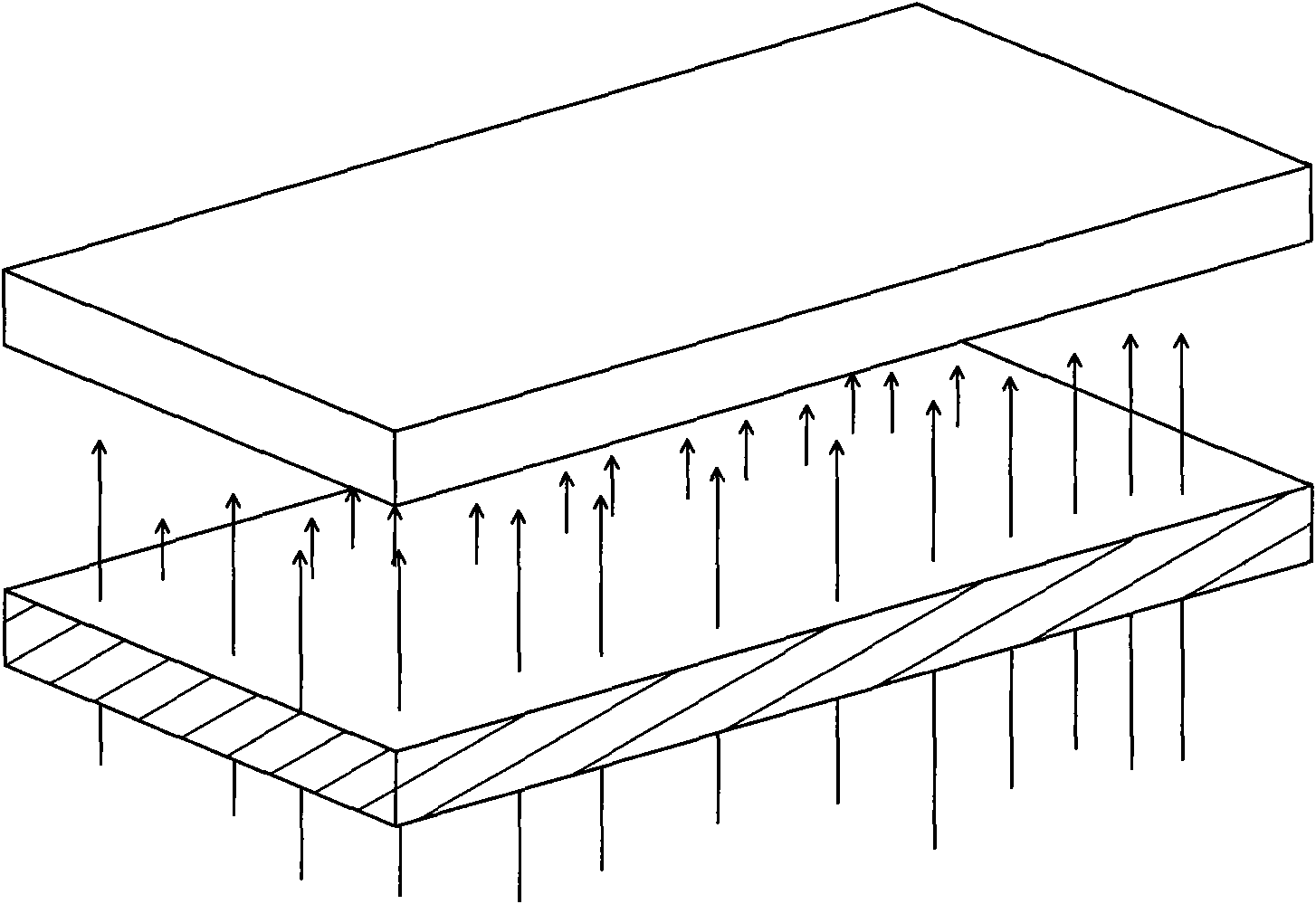

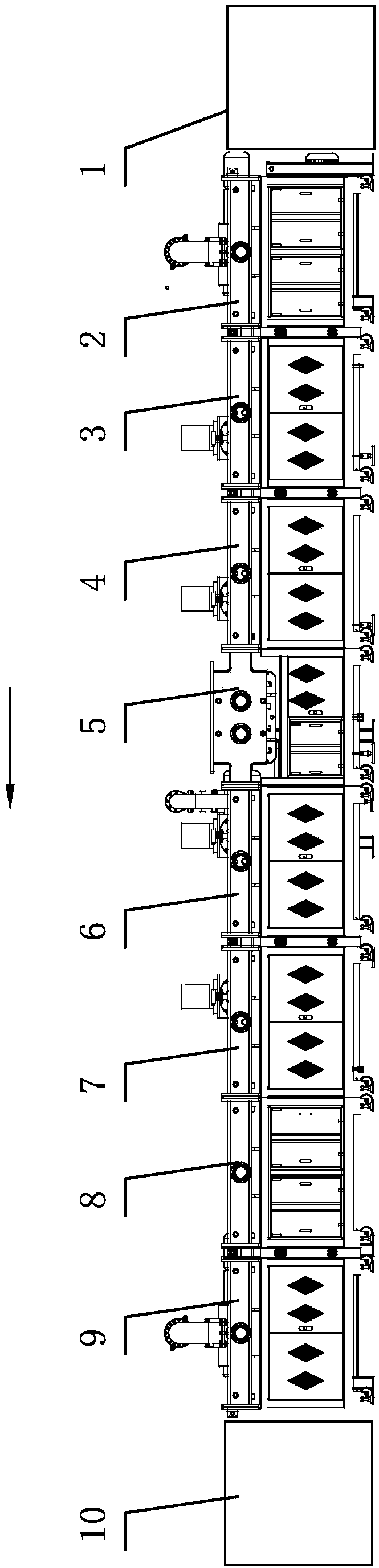

Multi-cavity horizontal magnetron sputtering film-coating production line and film-coating method thereof

InactiveCN108570651AAvoid pollutionMeet coating requirementsVacuum evaporation coatingSputtering coatingSputteringProduction line

The invention belongs to the technical field of film-coating devices, and particularly discloses a multi-cavity horizontal magnetron sputtering film-coating production line. The multi-cavity horizontal magnetron sputtering film-coating production line, in a forward direction of a substrate, successively comprises a feeding platform, a substrate feeding chamber, a heating chamber, a front bufferingchamber, at least two mutually independent magnetron sputtering vacuum film-coating chambers, a rear buffering chamber, a cooling chamber and a discharging platform, and further comprises a transmitting mechanism for transmitting the substrate. The magnetron sputtering film-coating production line is good in film forming effect of magnetron sputtering, high in production efficiency, and high in utilization ratio of a target material, and capable of satisfying the continuous film-coating requirements of a multi-layer functional film, and reducing the using cost of the target material.

Owner:GUANGDONG ZHENHUA TECH CO LTD

Symmetric magnetron sputtering process and application of diamond-like carbon coating thereof

InactiveCN108330459AIncrease ionization rateIncrease profitVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention discloses a symmetric magnetron sputtering process and application of a diamond-like carbon coating thereof. Due to the electron gathering effect in the discharging process of symmetricmagnetron sputtering cathodes opposite in direction, the ionization rate of sputtered carbon particles is increased, the high-energy carbon particles overflow from a gap between the symmetric cathodesand is subjected to doping of metal atoms of a magnetron sputtering metal target so that the diamond-like carbon coating can be formed, and due to the symmetric magnetron sputtering process, the target material utilizing rate can be increased, and the ionization rate of sputtered particles is also greatly increased; and the diamond-like carbon coating is composed of a metal base layer, a gradientcomposite layer and a metal-doped diamond-like carbon coating, and in the deposition process of the diamond-like carbon coating, the diamond-like carbon coating in certain gradient and with stable doping proportion can be obtained by adjusting the power of the magnetron sputtering metal target. Due to the process, high energy ionized carbon ions can be obtained, and the compact and fine diamond-like carbon coating can be formed easily.

Owner:WENZHOU POLYTECHNIC

Preparation method of TZO semiconductor material for high-transmittance energy-saving glass

InactiveCN105272210AImprove transmittanceFast sputtering rateVacuum evaporation coatingSputtering coatingSputteringZinc tin oxide

The invention discloses a preparation method of a TZO semiconductor material for high-transmittance energy-saving glass and a preparation method thereof. ZnO and SnO2 powder is used as main materials; even mixing is carried out, a biscuit is manufactured, and drying, sintering and machining are carried out to obtain a zinc / tin oxide semiconductor material with the relative density larger than 95%; volume resistivity is smaller than or equal to 6*10<-2> omega.cm, the material is used as the magnetron sputtering target material for manufacturing Low-E glass with the transmittance larger than or equal to 85% and replaces zinc-tin alloy coating materials which are greatly used at present, the process of producing a zinc / tin oxide film through magnetron sputtering is more stable, the production technology is simpler, the sputtering speed is high, the production efficiency is improved by more than 5%, the large-area coating film layer has uniform ingredients and fine structure, the requirement of manufacturing double-silver three-silver Low-E glass for sputtering equipment is lowered, and the TZO semiconductor material has the advantages for preparing large-size high-transmittance glass.

Owner:NANJING TEMCH OPTOELECTRONICS MATERIAL CO LTD

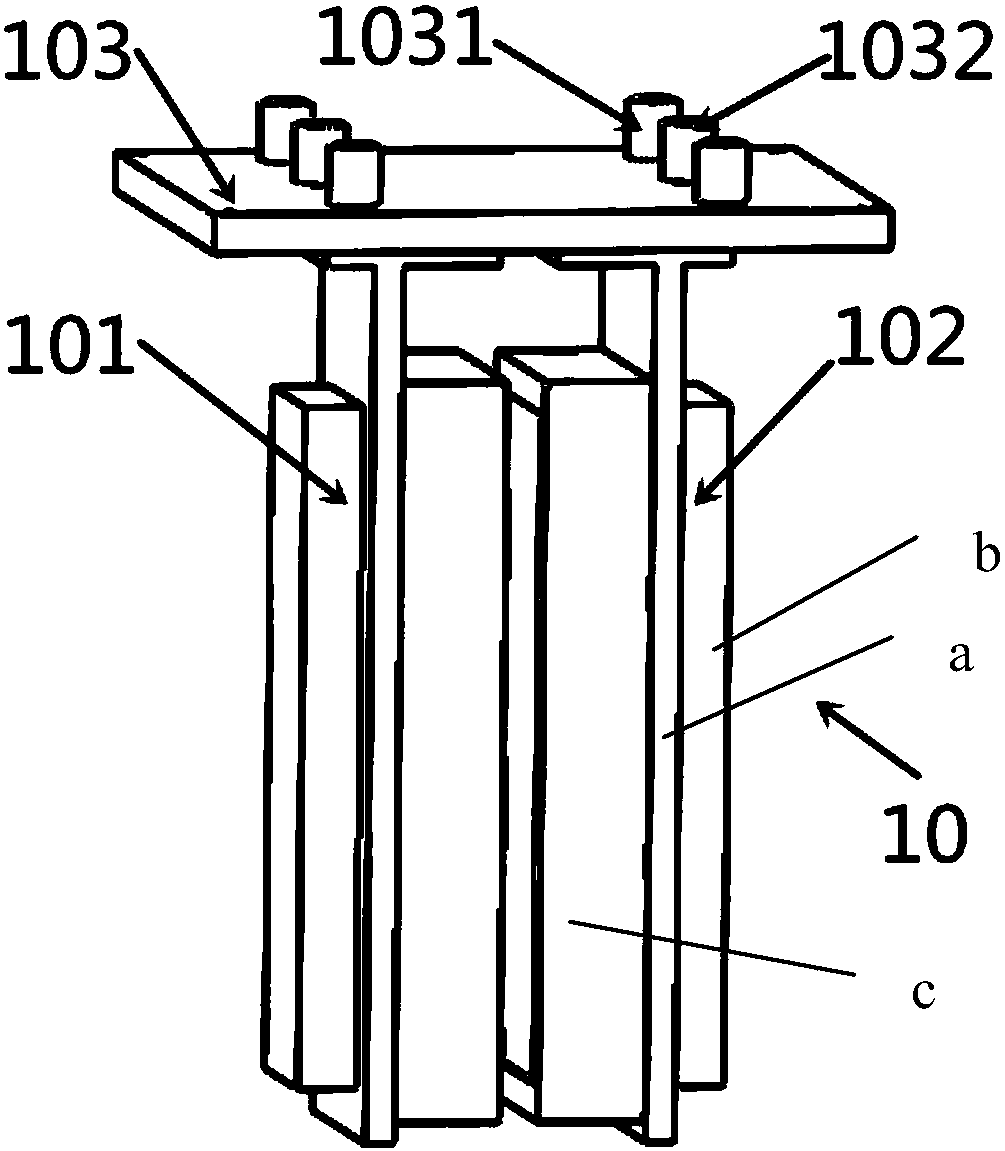

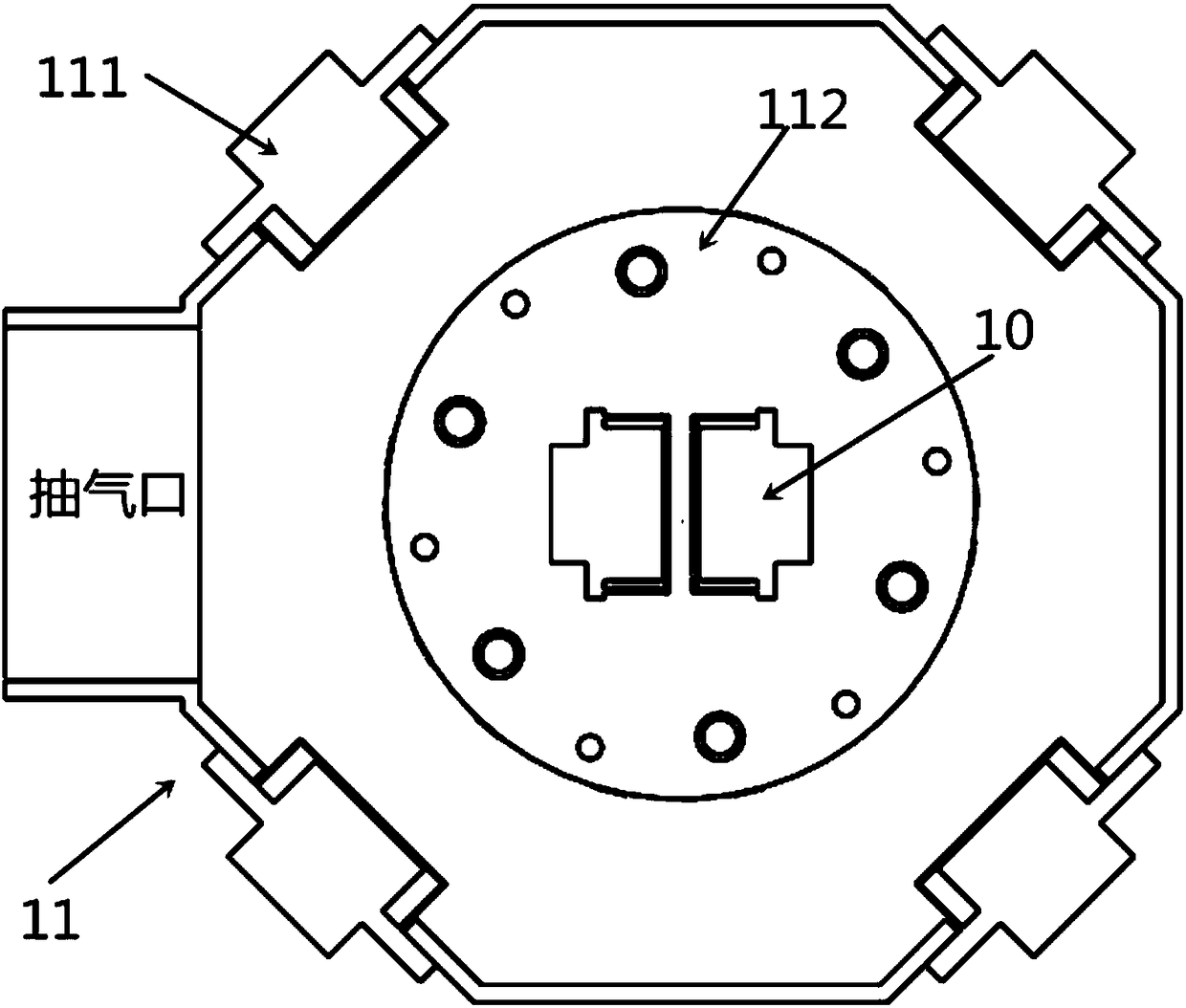

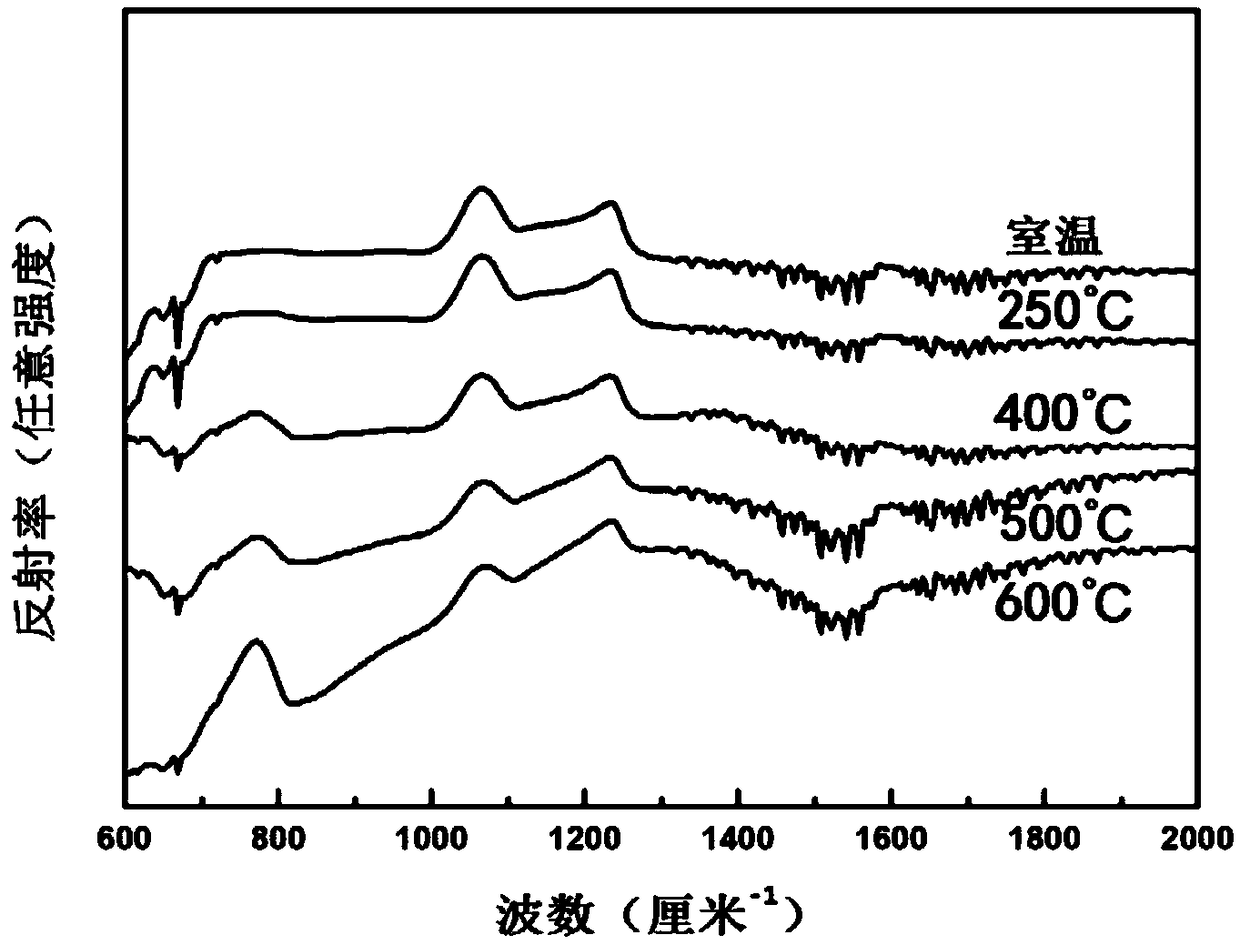

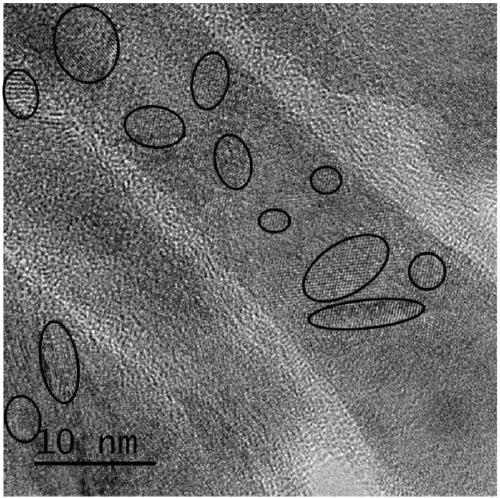

Boron-carbon-nitrogen film encapsulating highly-oriented boron nitride nanocrystal and preparation method of boron-carbon-nitrogen film

ActiveCN109161844AOrderly and controllable growth orientationFully regulated growthVacuum evaporation coatingSputtering coatingBoron carbonitrideRadio frequency magnetron sputtering

The invention relates to a boron-carbon-nitrogen film encapsulating highly-oriented boron nitride nanocrystal and a preparation method of the boron-carbon-nitrogen film, and belongs to the technical field of film materials and preparation thereof. The boron-carbon-nitride film is of an amorphous structure containing boron nitride nanocrystals and growing on a silicon substrate. According to the preparation method, boron nitride containing carbon is used as a target material, and the boron-carbon-nitrogen film is prepared in a deposition chamber of a radio frequency magnetron sputtering device,wherein the substrate temperature ranges from room temperature to 600 DEG C, working gases comprise an argon gas and a nitrogen gas, flow rates are 50 sccm and 0-50 sccm respectively, and the workingpressure is 1 to 3 Pa. Ordered and controllable growth of the orientation of boron nitride nanocrystals in a film can be realized by adjusting technological parameters, and the obtained boron-carbon-nitride film has an optical band gap of about 2.7 to 4.5 eV, and has good and adjustable optical properties. The preparation method provided by the invention has the advantages of simple and safe process, mature technology, high sputtering rate, uniform deposition film, controllable size and the like, and is suitable for industrial mass production and promotion.

Owner:JILIN UNIV

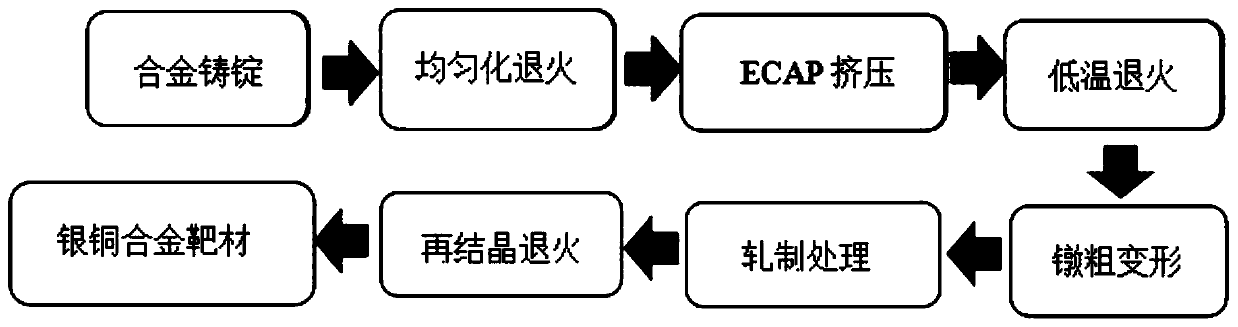

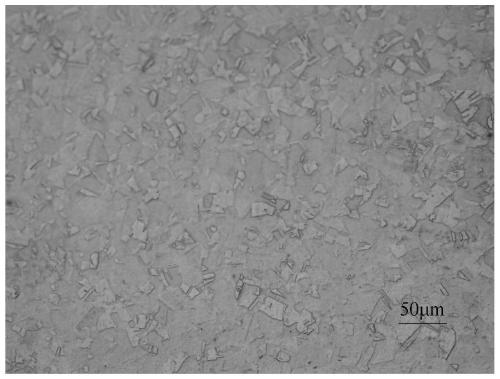

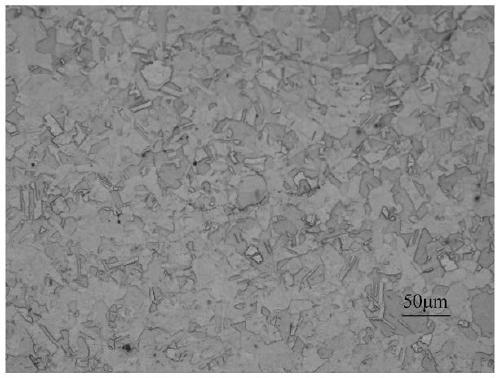

Silver-copper alloy target material and preparation method thereof

ActiveCN110318024AUniform thicknessFast sputtering rateVacuum evaporation coatingSputtering coatingAdditive ingredientIngot

The invention provides a silver-copper alloy target material and a preparation method thereof and belongs to the technical field of sputtering target materials. The preparation method of the silver-copper alloy target material, provided by the invention, comprises the following steps of conducting smelting on copper and silver under a protective atmosphere to obtain a liquid alloy; conducting spraying deposition treatment on the liquid alloy to obtain a silver-copper alloy cast ingot; conducting homogeneous annealing, ECAP extrusion, low-temperature annealing, upsetting deformation and rollingtreatment on the silver-copper alloy cast ingot in sequence to obtain a silver-copper alloy raw ingot; and conducting recrystallization annealing treatment on the silver-copper alloy raw ingot to obtain the silver-copper alloy target material. The silver-copper alloy target material prepared through the method has the characteristics of being small in grain size, uniform in crystal grain distribution, uniform in ingredient and high in compactness.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Color fiber fabric and production method thereof

InactiveCN110396670AEasy to oxidizeImprove anti-oxidation and anti-corrosion performanceVacuum evaporation coatingSputtering coatingFiberComposite film

The invention provides a production method of color fiber fabric. The production method comprises the following steps that at least one composite film is deposited on at least one surface of the fiberfabric through a vacuum deposition method, wherein the composite film sequentially comprises a cushioning layer, a reflective layer, a first protective layer, a color producing layer and a second protective layer from bottom to top; the color producing layer comprises at least one of ZnO, Fe2O3, TIO2 and CuO; and when the layers of the composite film are deposited, working gas needs to be continuously introduced, and the working gas comprises argon and / or nitrogen and / or oxygen. According to the production method, the color adjustment control of the fiber fabric is simple and practicable, theproblem that the metal film is easily oxidized is solved, and the oxidation resistance of a surface film of the fiber fabric is enhanced, so that colored film coated on the surface of the fiber fabric is more durable; and the method is suitable for industrial production. The invention further provides the color fiber fabric. The color fiber fabric is rich in color and good in color fastness and can be prepared through an industrial method.

Owner:北京斐摩科技有限公司

Preparation method of high-selectivity absorbing coating of solar vacuum tube

The invention provides a preparation method of a high-selectivity absorbing coating of a solar vacuum tube, which adopts a magnetron reactive sputtering method, wherein the sputtering gas is argon, the reactant gas is highly pure nitrogen and carbon tetrafluoride gas, and the used equipment is a three-target magnetron sputtering film coating machine. The preparation method comprises the following steps: firstly, depositing a titanium nitride TiN infrared reflecting film by magnetron reactive sputtering on the outer wall of the inner tube of a glass tube; then depositing an aluminum nitride-stainless steel (AlN-SS) composite absorbing film; finally depositing an aluminum-carbon-fluorine (Al-C-F) composite protecting film to form a Glass / TiN / AlN-SS / AL-C-F selective absorbing coating.

Owner:SHANDONG SHUAIKE NEW ENERGY

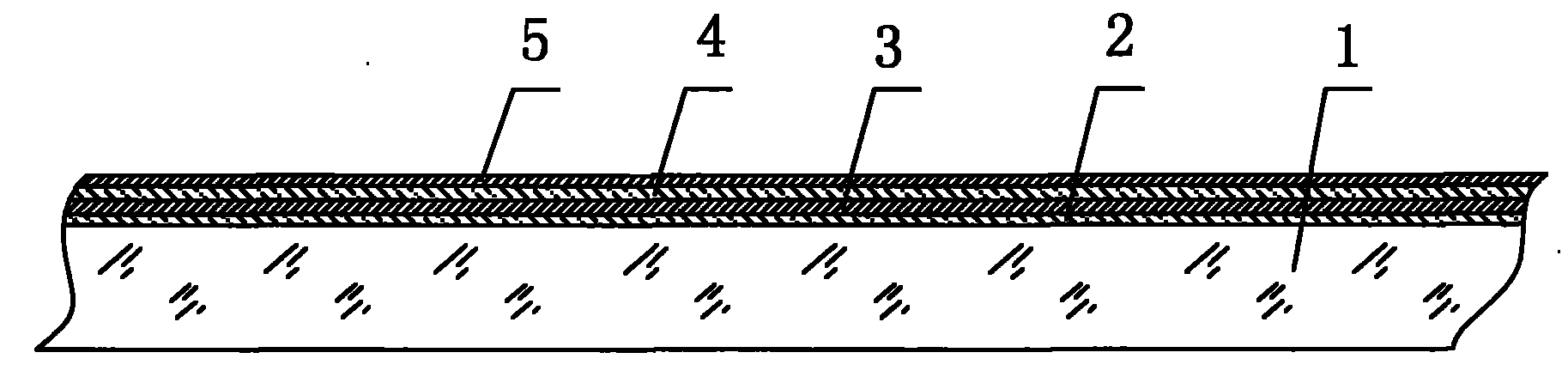

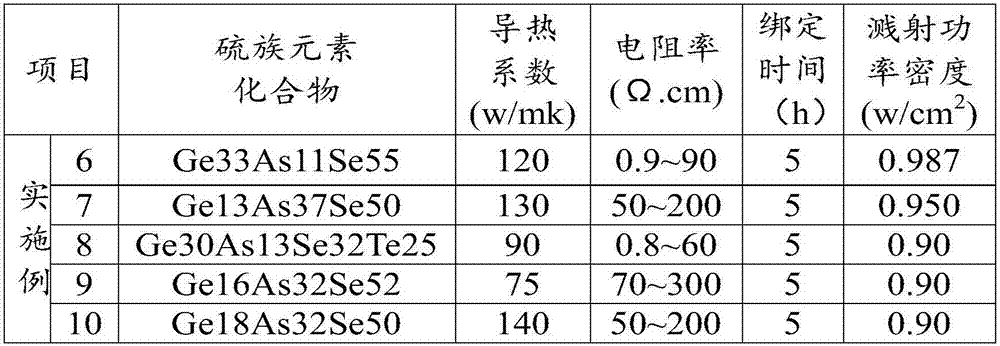

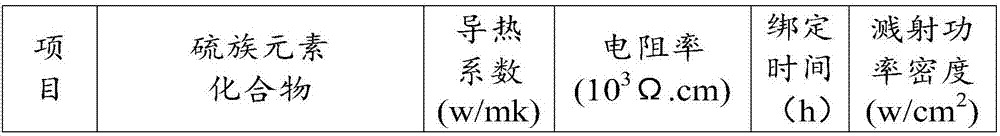

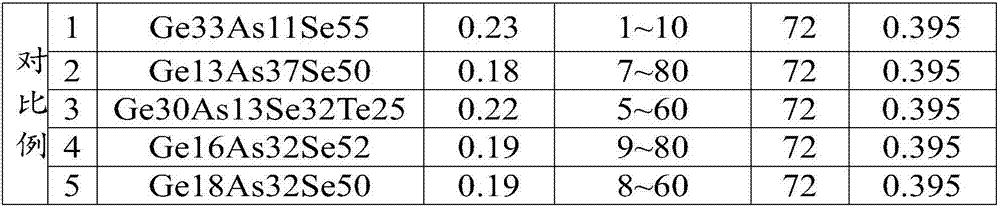

Thin film and switch material for phase change memory chip, and preparation method of switch material

ActiveCN107302053AImprove conductivityImprove thermal conductivityElectrical apparatusProduction rateMemory chip

The invention relates to a thin film and a switch material for a phase change memory chip, and a preparation method of the switch material, belonging to the field of materials. The switch material comprises a chalcogenide doped with a carbon nano tube. Due to introduction of the carbon nano tube, the thermal conductivity and electric conductivity of the material are improved substantially, but the I-V curve characteristic of the material as the switch material is not changed, so that the machinability, yield rate and production rate of a target material made of the mixed material are improved substantially in the post-processing process, meanwhile, the thin film sputtered by the target material maintains the performance of the nano-second switch material, so as to be used for preparing the phase change material-based memory chip.

Owner:PIONEER MATERIALS INC CHENGDU

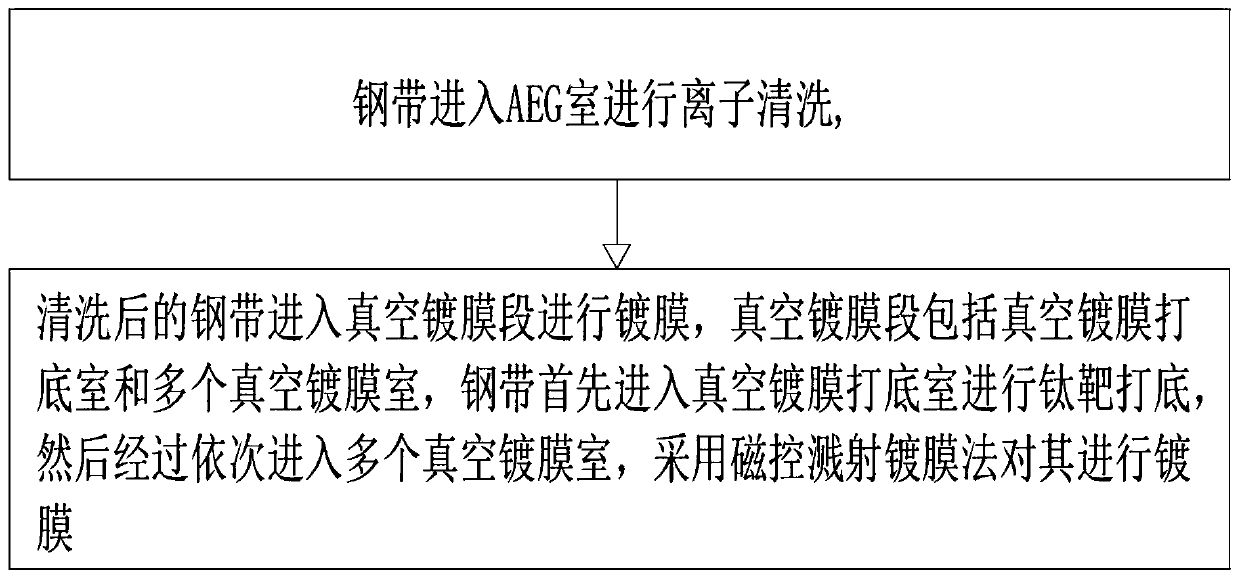

Steel strip ion coating coloring process

InactiveCN110453192AUniform colorPrevent the film from falling offVacuum evaporation coatingSputtering coatingMetallurgyVacuum coating

The invention provides a steel strip ion coating coloring process. The process comprises the following steps that S1, a steel strip enters an AEG chamber for ion cleaning, an anode rod and a cleaningtarget material are mounted in the AEG chamber, and the anode rod is located above the cleaning target material; and argon is introduced into the AEG chamber in a high vacuum environment, high-energyargon ions are generated through glow discharge of the argon, and bombards the steel strip at a high speed under the action of a magnetic field and an anode bar. The cleaned steel strip enters a vacuum coating section for coating, and the vacuum coating section comprises a vacuum coating bottoming chamber and a plurality of vacuum coating chambers; and the steel strip enters a vacuum coating bottoming chamber to be subjected to target bottoming, and then enters the plurality of vacuum coating chambers in sequence, and is subjected to coating through a magnetron sputtering coating method. The steel strip ion coating coloring process has the advantages that the sputtering speed is high, the coating effect is good after sputtering, the color is uniform, the color difference is small, and theconsumption of the target material is small.

Owner:ZHAOQING HONGWANG METAL IND

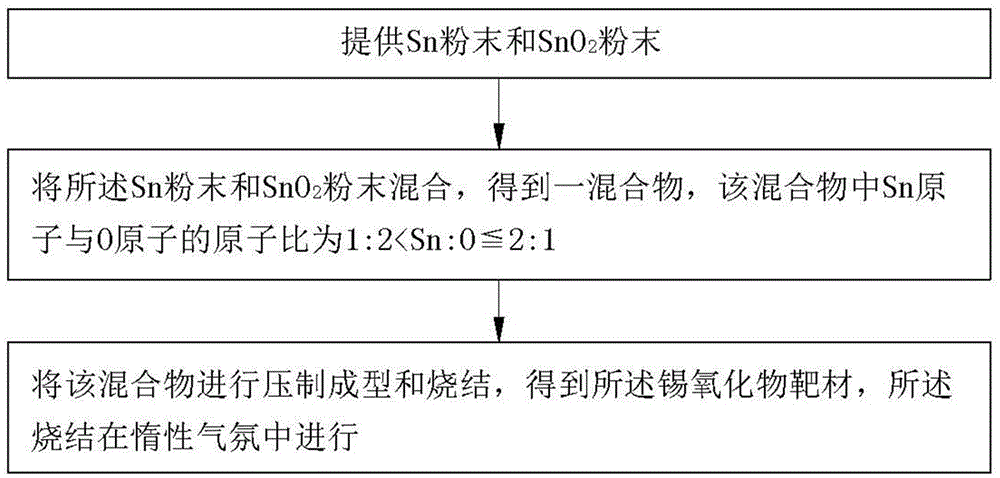

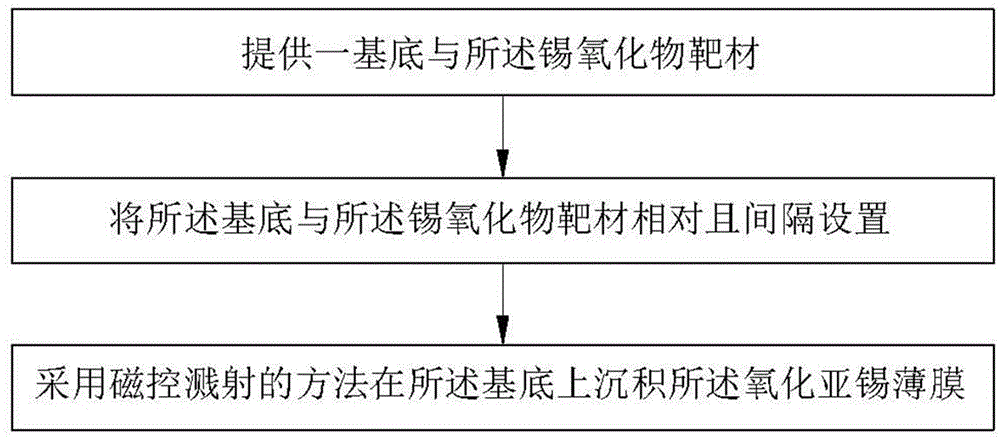

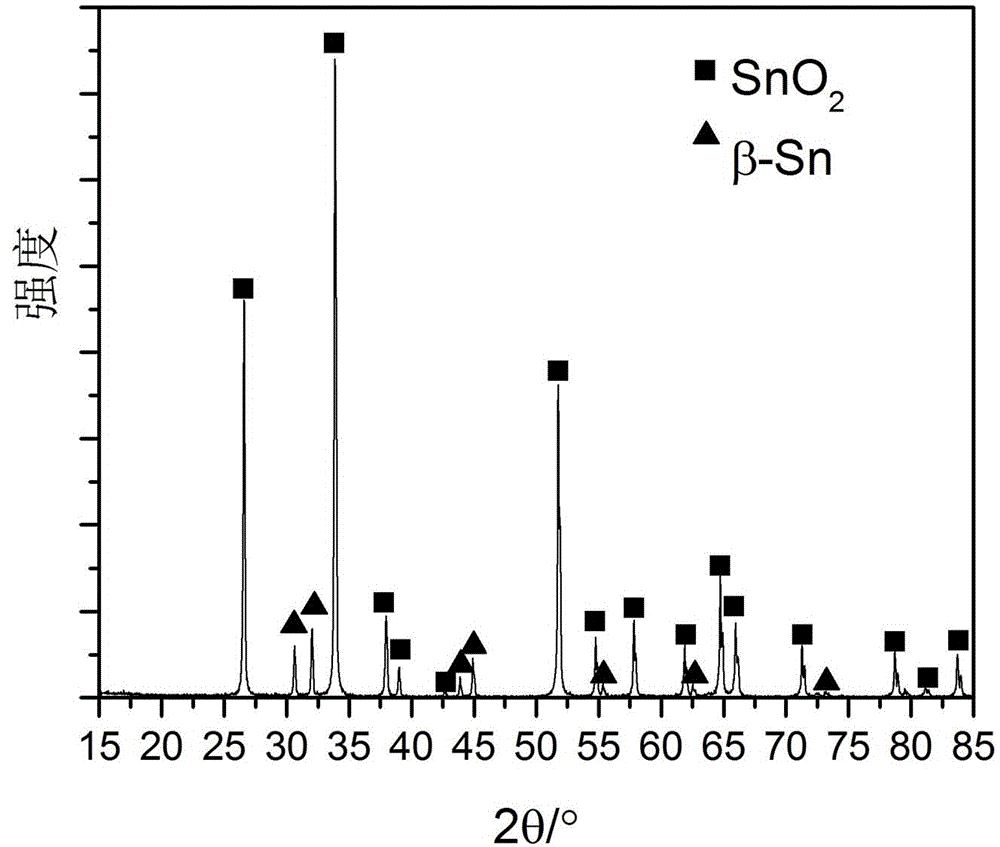

Tin oxide target and preparation method thereof

InactiveCN106191774AHigh melting pointFast sputtering rateVacuum evaporation coatingSputtering coatingSTANNOUS OXIDEMaterials science

The invention provides a tin oxide target. The tin oxide target is used for preparing stannous oxide films and comprises elemental Sn and SnO2 which are mixed evenly. The atomic ratio of Sn atoms to O atoms in the tin oxide target is greater than 1:2 but smaller than or equal to 2:1. The invention further provides a preparation method of the tin oxide target.

Owner:TSINGHUA UNIV +1

Method for preparing tantalum oxide film by direct current magnetron sputtering method

InactiveCN106958008AGood ion transmission abilityReduce conductivityVacuum evaporation coatingSputtering coatingSputteringDirect current magnetron sputtering

The invention discloses a method for preparing a tantalum oxide film by a direct current magnetron sputtering method. The method comprises the following steps: taking a preprocessed base material and placing in a reaction chamber of a magnetron sputtering instrument, after vacuumizing the reaction chamber, charging Ar with a purity of 99.95% as working gas and O2 with a purity being 99.95% as reactive gas, adjusting a sputtering working gas pressure, setting sputtering power, sputtering a Ta target material, and obtaining the tantalum oxide film on the base material. According to the method for preparing a tantalum oxide film by a direct current magnetron sputtering method, an obtained TaOx film has excellent ion transmission performance, low conductivity and higher transmittance. The tantalum oxide film layer is better in compactness.

Owner:东北大学秦皇岛分校

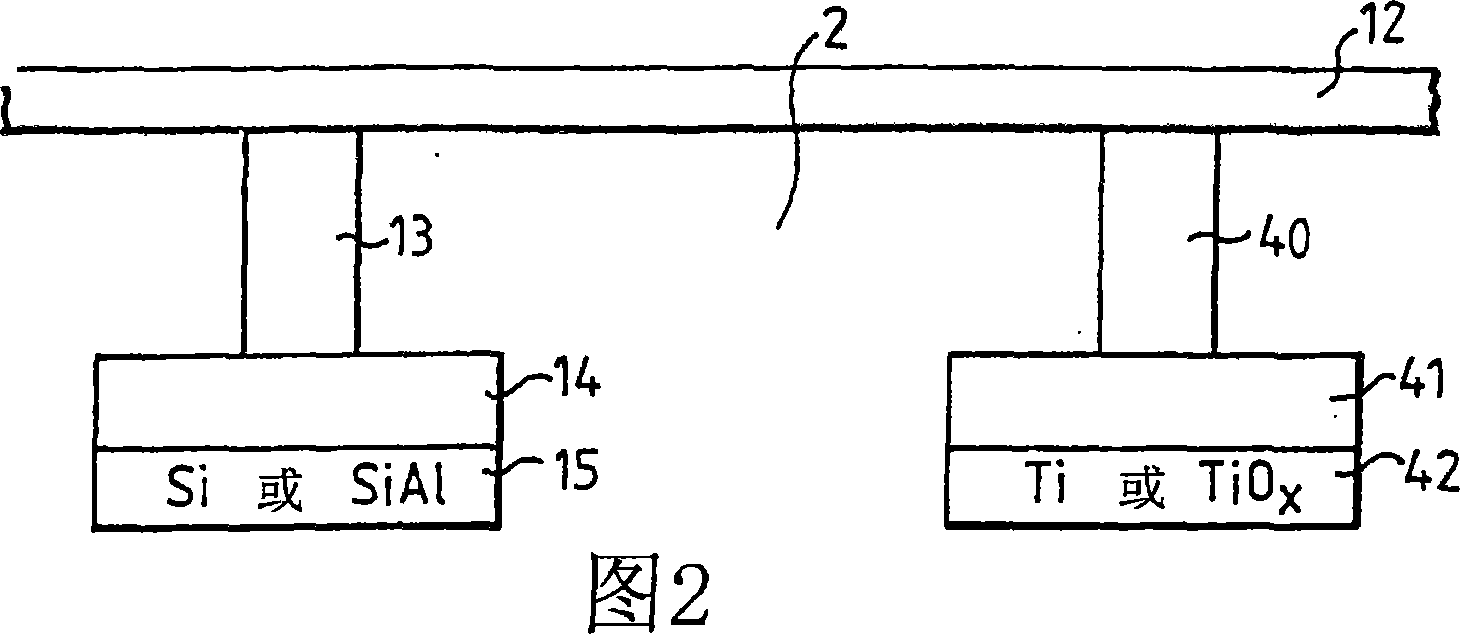

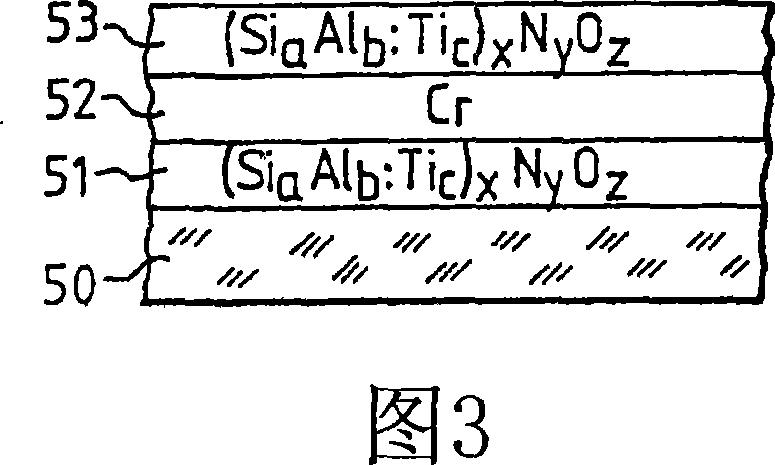

Target material and its use in a sputter process

InactiveCN1961094ADifferent reflective colorsEasy to set upVacuum evaporation coatingSputtering coatingSputteringTitanium

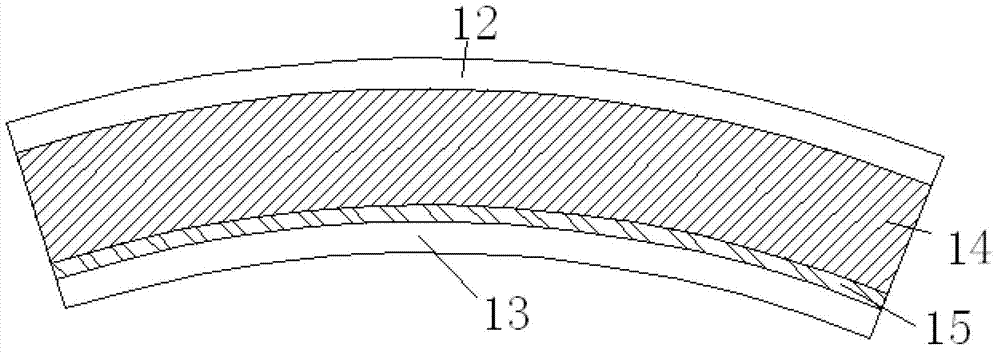

The invention relates to a target material for the production of a protective layer for a solar control and absorption layer by means of sputtering. This target material is comprised of silicon doped with titanium. The protective layer, which can be produced with the target material, is heatable without significant changes of its properties. It is therefore also suitable for coating lass, which is heated and subsequently bent.

Owner:APPLIED MATERIALS INC

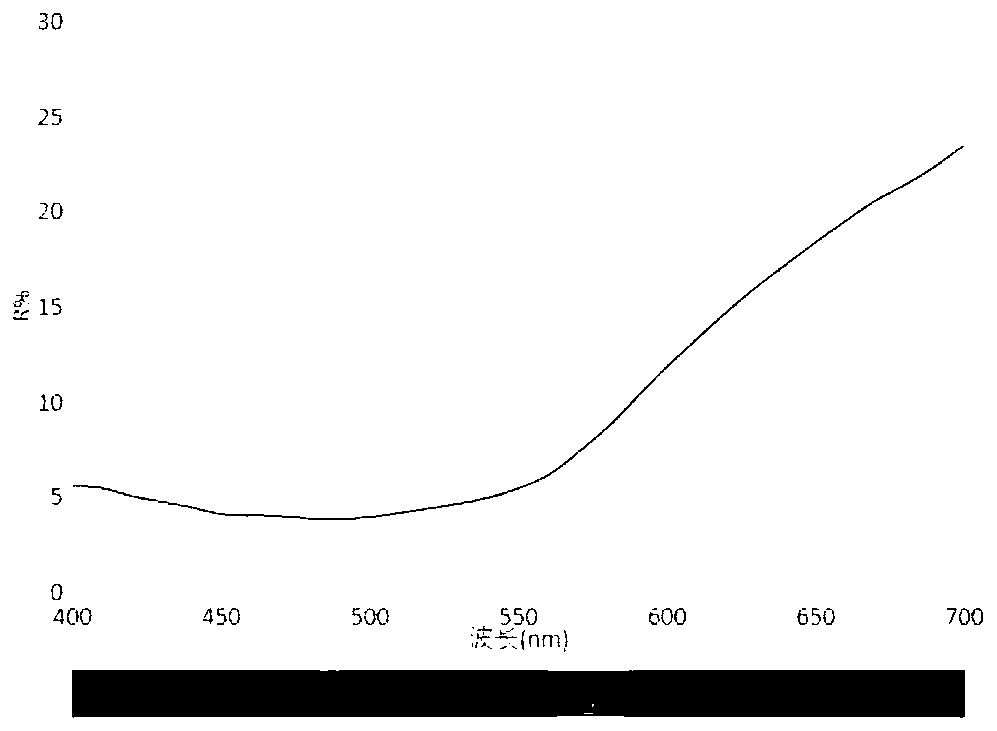

Vanadium-based high-temperature solar selective absorption coating and preparation method thereof

InactiveCN102618837AThe preparation process is stablePromote absorptionVacuum evaporation coatingSputtering coatingHigh absorptionSilicon dioxide

The invention relates to a vanadium high-temperature solar selective absorption coating and a preparation method thereof. The selective absorption coating consists of three layers of film and comprises a bottom infrared reflection layer, an intermediate absorption layer and a surface anti-reflection layer, wherein the bottom infrared reflection layer is deposited on the surface of a substrate, the intermediate absorption layer is deposited on the bottom infrared reflection layer, and the surface anti-reflection layer is deposited on the intermediate absorption layer; and the bottom infrared reflection layer consists of a metal vanadium (V) film, the intermediate absorption layer comprises a first sub-layer and a second sub-layer, both the first and the second sub-layers respectively consist of a V + silicon dioxide (SiO2) film or a V + aluminum oxide (Al2O3) film, and the surface anti-reflection layer consists of a SiO2 film or an Al2O3 layer. The vanadium-based high-temperature solarselective absorption coating is stable in high temperature and has high absorption rate to the solar spectrum and low transmission rate. The preparation technique is simple and convenient to operate and easy to control, the sputtering speed is fast, the production period can be shortened, the process is stable, and the equipment cost and production cost can be greatly reduced.

Owner:DONGGUAN CAMDA GENERATOR WORK

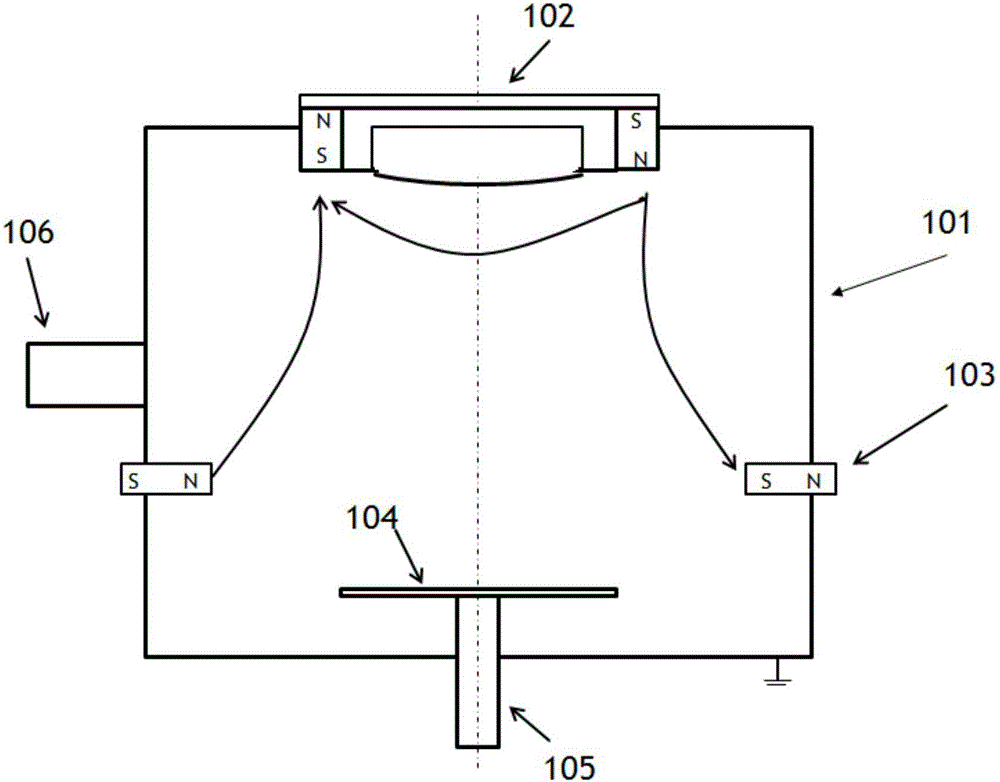

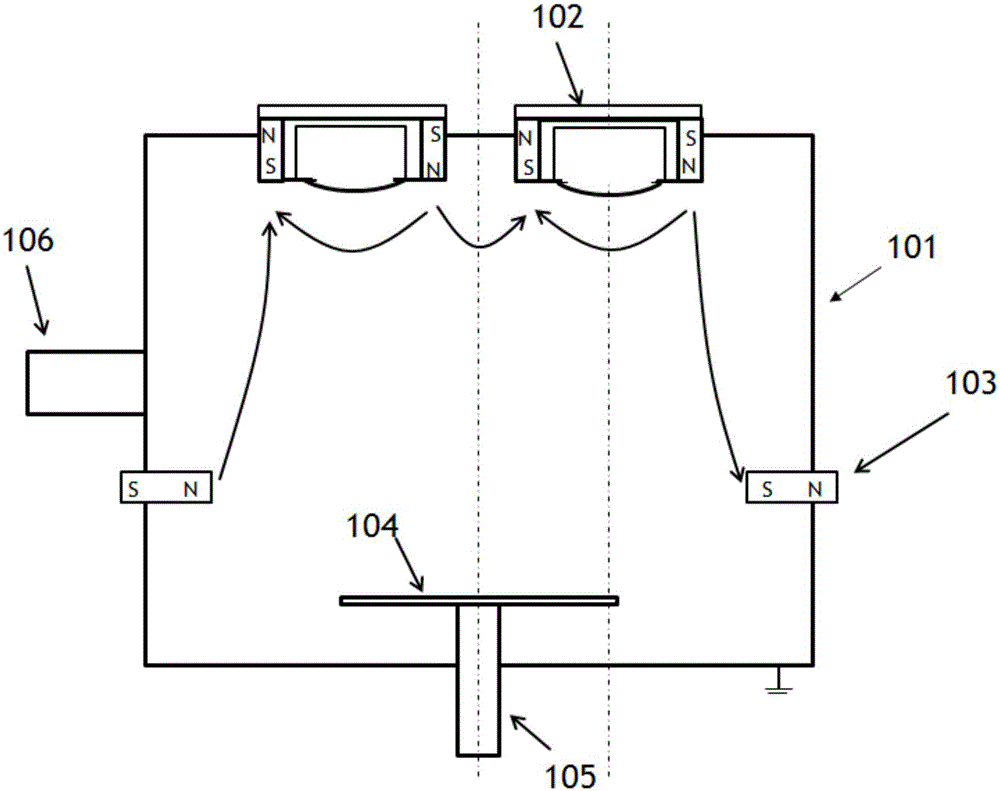

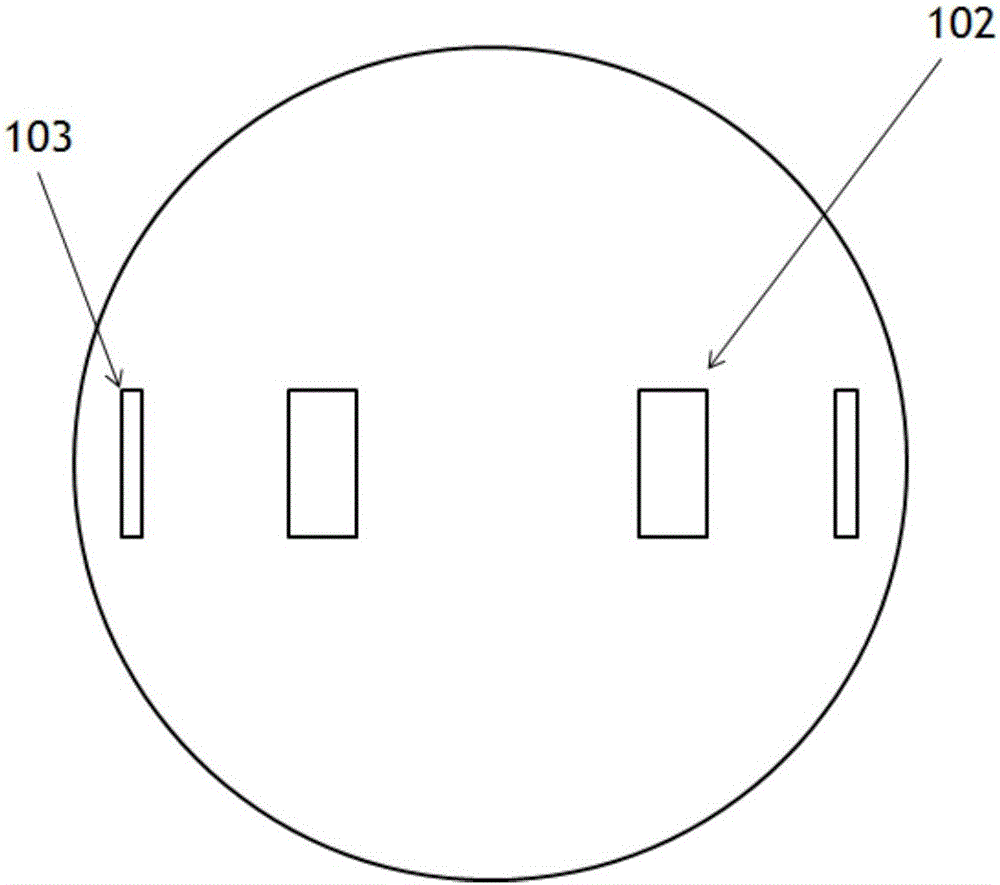

Magnetic-pole-assisted unbalanced magnetic control sputtering device

ActiveCN106637109AImprove uniformityUniform thicknessElectric discharge tubesVacuum evaporation coatingMicrostructureElectrical and Electronics engineering

Owner:重庆花喜鹊科技有限公司

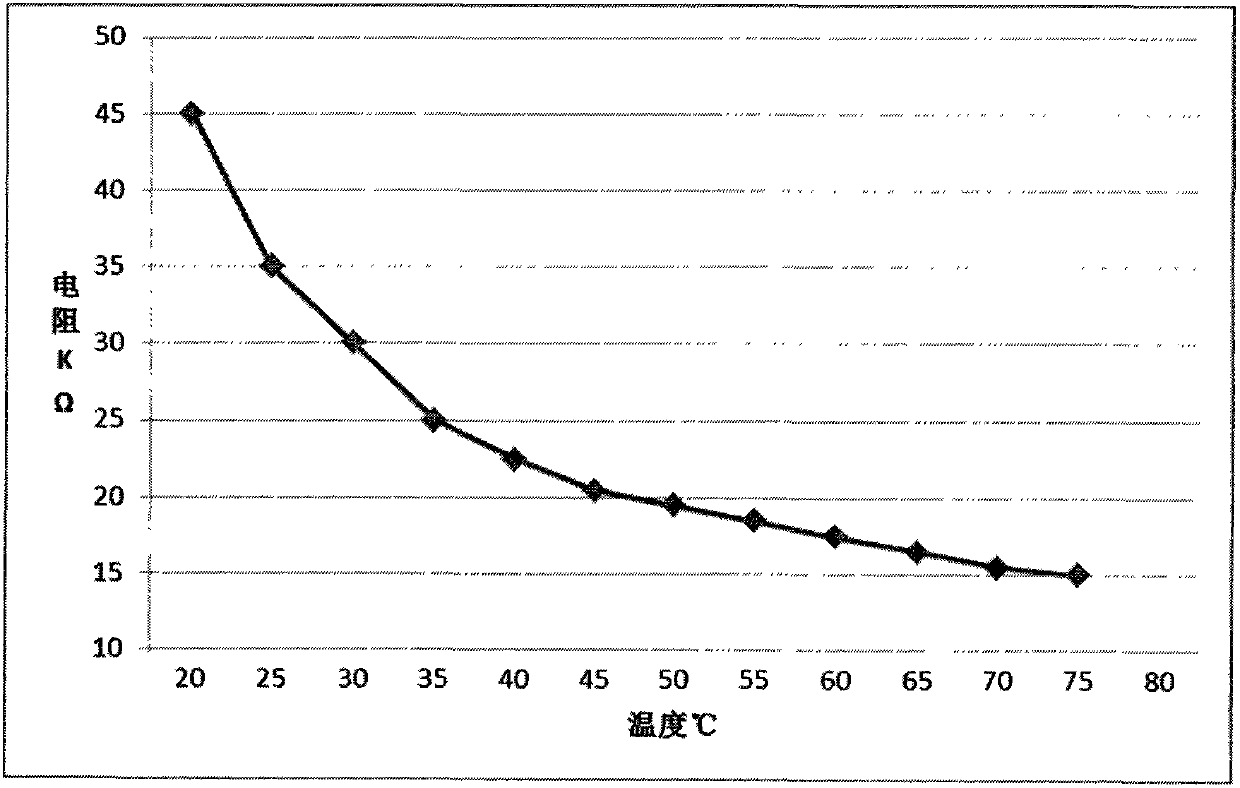

Magnetron sputtering preparation method of vanadium oxide

InactiveCN104213087AImprove target utilizationFast sputtering rateVacuum evaporation coatingSputtering coatingTemperature coefficientSilicon oxide

The invention relates to a magnetron sputtering preparation method of vanadium oxide, and belongs to the technical field of film preparation. The preparation method comprises the following steps: step one, washing the surface of a silicon chip; step two, depositing a layer of silicon oxide film on the surface of the silicon chip; step three, utilizing target materials having the advantages of high utilization rate and uniform sputtering on film to carry out magnetron sputtering to deposit a vanadium film; wherein the technology conditions are as follows: the bottom vacuum is 3*10<-4> Pa, the argon / oxygen ratio is 100:1 to 140:1, the sputtering power is 150 W to 240 W, and the substrate temperature is 25 to 200 DEG C. The preparation method has the advantage that a vanadium oxide film having a high resistance temperature coefficient and a low room temperature resistance can be prepared just through changing the sputtering technological conditions without carrying out a high temperature hot treatment, and thus the film plating technology is simplified.

Owner:常州博锐恒电子科技有限公司

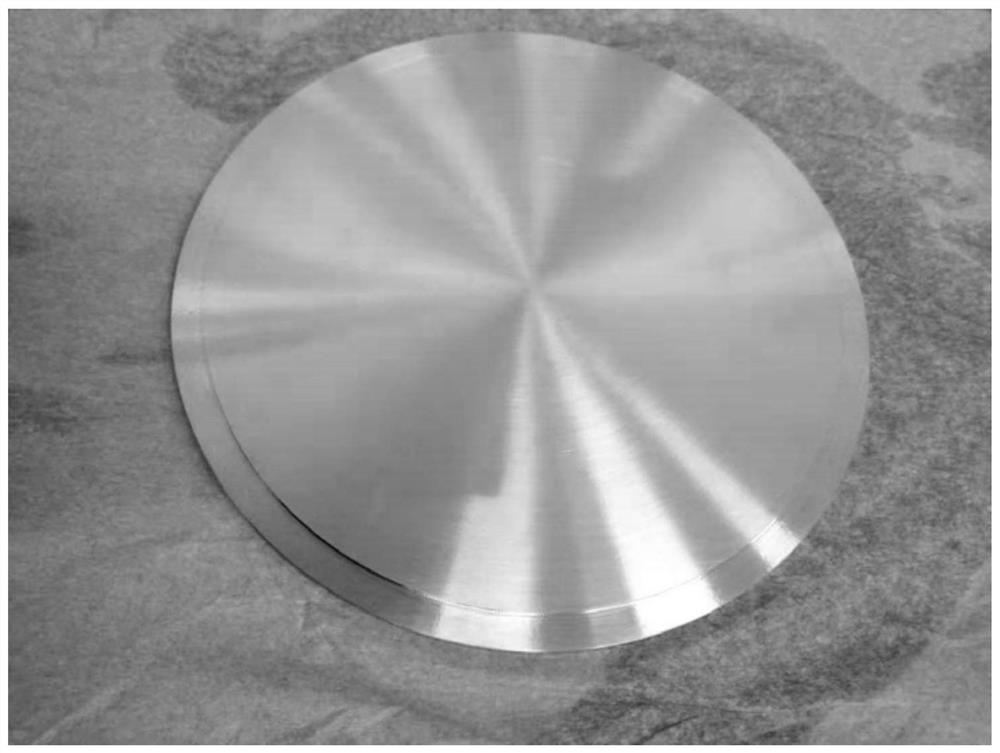

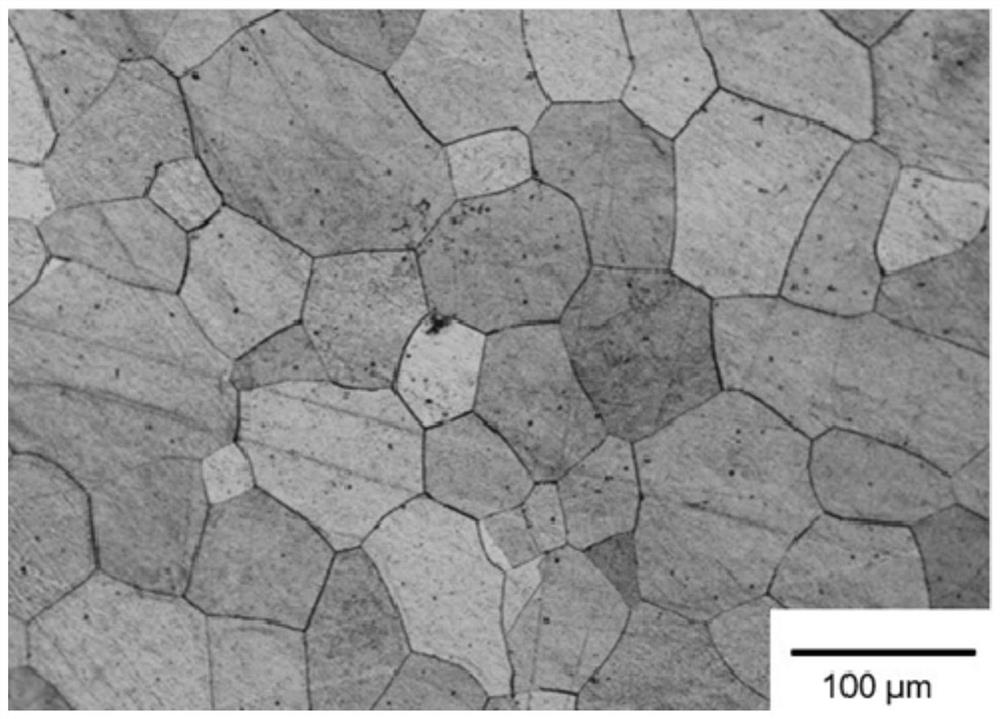

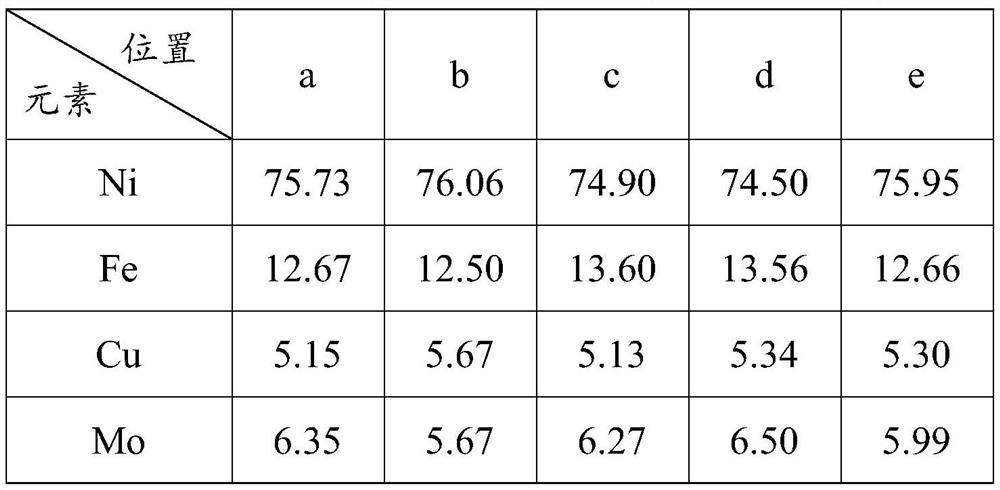

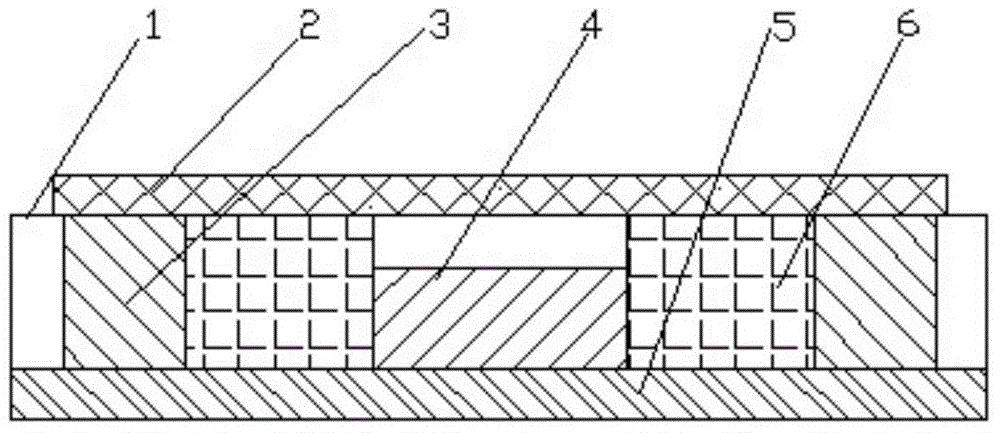

Preparation method of nickel-iron-copper-molybdenum alloy target material

ActiveCN113265627AGrain size growthSmall and uniform grain sizeVacuum evaporation coatingSputtering coatingIngotCopper

The invention discloses a preparation method of a nickel-iron-copper-molybdenum alloy target material. The preparation method of the nickel-iron-copper-molybdenum alloy target material comprises the following steps that (1) raw materials Mo and raw materials Ni are added into a smelting furnace, suspension smelting is carried out in a vacuum environment, and an alloy ingot A is obtained after cooling; (2) raw materials Fe and raw materials Cu are added into the smelting furnace containing the alloy ingot A in the step (1), smelting treatment continues to be conducted in the vacuum environment, and an alloy ingot B is obtained after cooling; (3) the alloy ingot B is refined for three times in the vacuum environment, and the melt of the alloy ingot B is cast after the third refining to obtain a cast ingot; and (4) the cast ingot obtained in the step (3) is rolled, and the nickel-iron-copper-molybdenum alloy target material is obtained. According to the preparation method, a nickel-molybdenum alloy is firstly smelted, then the raw materials Fe and Cu are added to be smelted again, and then three times of homogenizing refining are combined, so that the uniformity of components of the nickel-iron-copper-molybdenum alloy target material is guaranteed to a large extent, and the target material has the performance of high resistivity, high relative density and high magnetic permeability.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

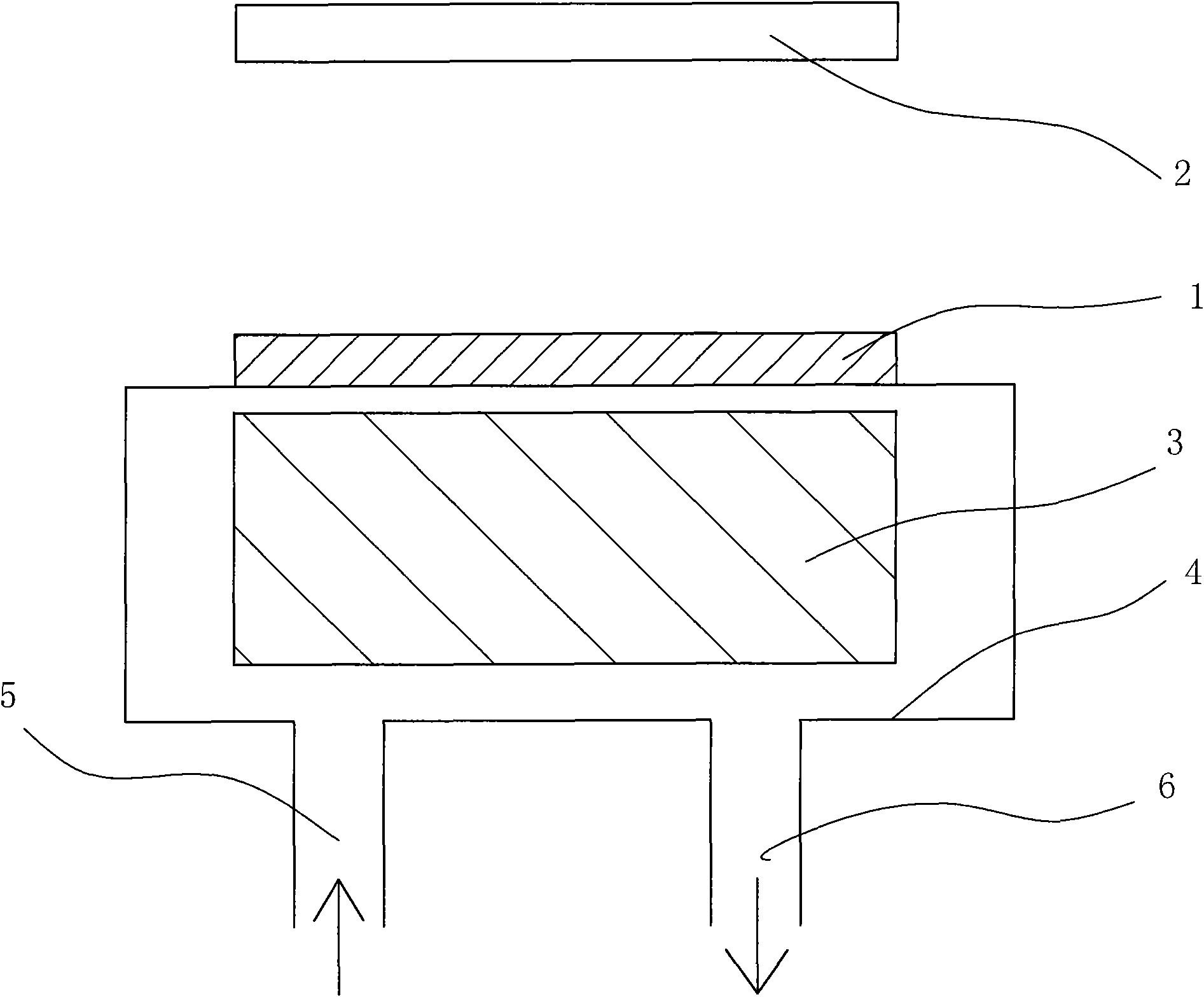

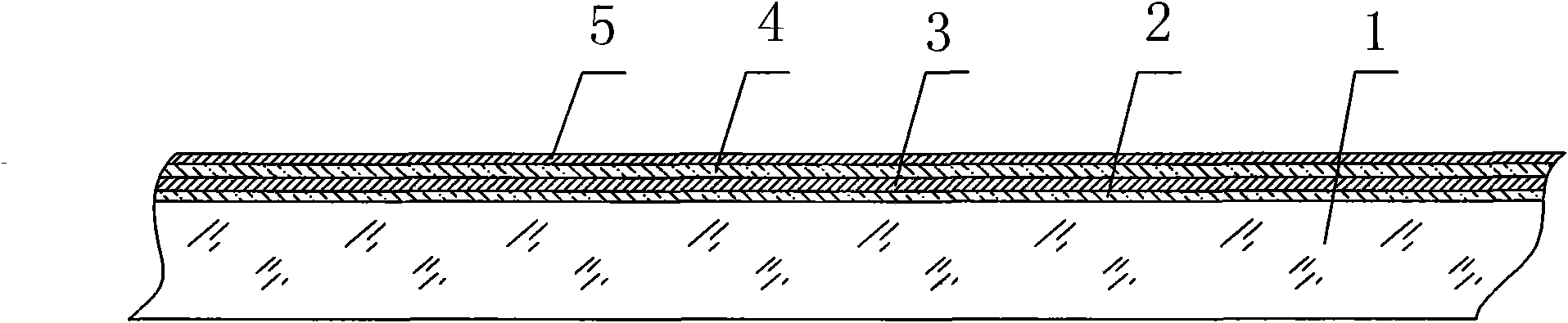

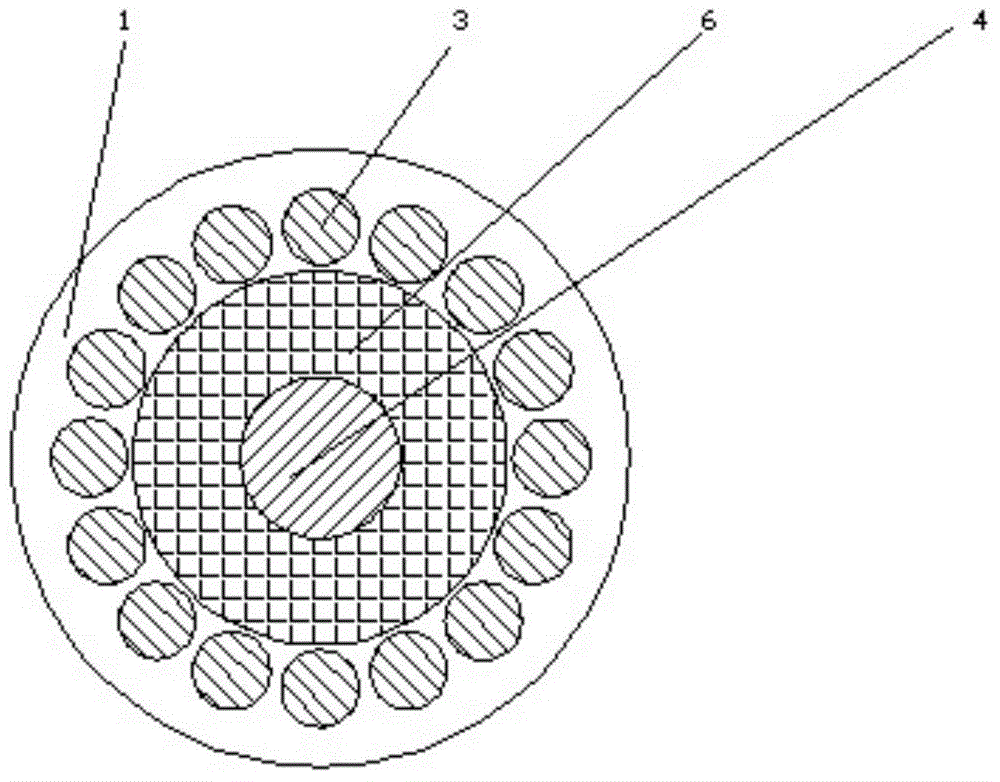

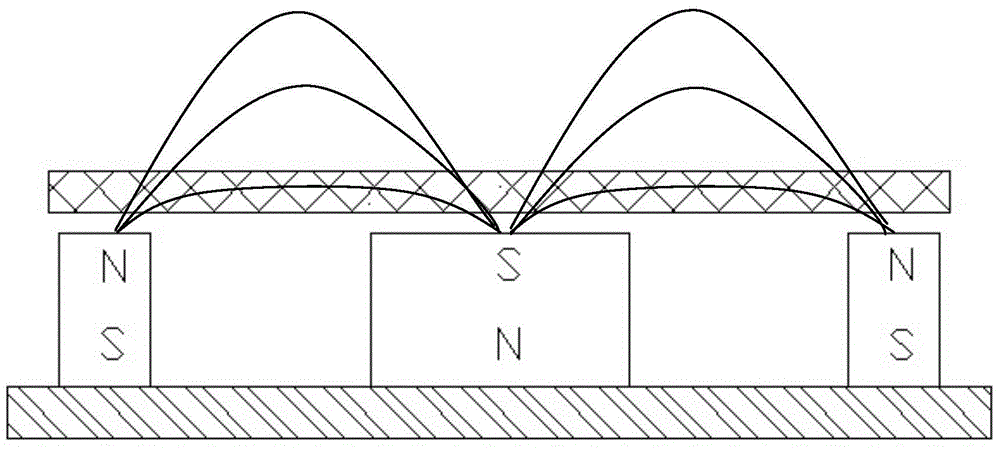

Middle and low-vacuum magnetron sputtering target cathode

ActiveCN104532202ASimple structureEasy to operateVacuum evaporation coatingSputtering coatingHeight differenceOptoelectronics

The invention belongs to the technical field of production equipment for magneto-controlled sputter coating and particularly relates to a middle and low-vacuum magnetron sputtering target cathode. The magnetron sputtering target cathode comprises a cathode shell (1), a target (2), an outer magnet (3), an inner magnet (4), a base (5) and a cooling channel (6), wherein the cathode shell (1) is in a shape of a hollow cylinder, the outer magnet (3) is embedded in the side wall of the cylinder, the inner magnet (4) is arranged in the center of the cathode shell (1), the cooling channel (6) is arranged between the inner magnet (4) and the cathode shell (1), the target (2) is arranged on the upper surface of the cathode shell (1), the base (5) is arranged on the lower surface of the cathode shell (1), and the height difference between the inner magnet (4) and the outer magnet (3) is 1-10mm. The utilization rate of the target is increased by adopting the method of optimizing the structure of the magnetron sputtering target cathode. The magnetron sputtering target cathode provided by the invention is simple in structure, is strong in operability and is reliable in performance.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com