Thin film and switch material for phase change memory chip, and preparation method of switch material

A phase-change memory and switching material technology, applied in electrical components and other directions, can solve the problems of difficult commercial production, increased complexity of PCM chip device processing and preparation processes, and low yield, and achieve improved productivity, yield, and electrical conductivity. The effect of improving, increasing productivity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of the switch material for the phase change memory chip. The preparation method comprises: powder-making, hot-pressing sintering and cooling of the mixture under vacuum conditions, and the mixture contains mixed chalcogen compounds and carbon nanotubes.

[0045] Further, as an optional solution, in the mixture, the chalcogen compound and the carbon nanotubes are mixed in the form of powder. Preferably, the powdered elemental sulfur compound is obtained by grinding in a protective gas (such as nitrogen+hydrogen) environment.

[0046] As an optional implementation, the method for preparing the mixture may be: ball milling the chalcogen compound in a closed environment of protective gas (non-oxidizing atmosphere, such as nitrogen + hydrogen) to prepare the first powder. Then, fill it with argon to normal pressure, add carbon nanotubes and continue ball milling. The size of the crushed chalcogen compound doped with ...

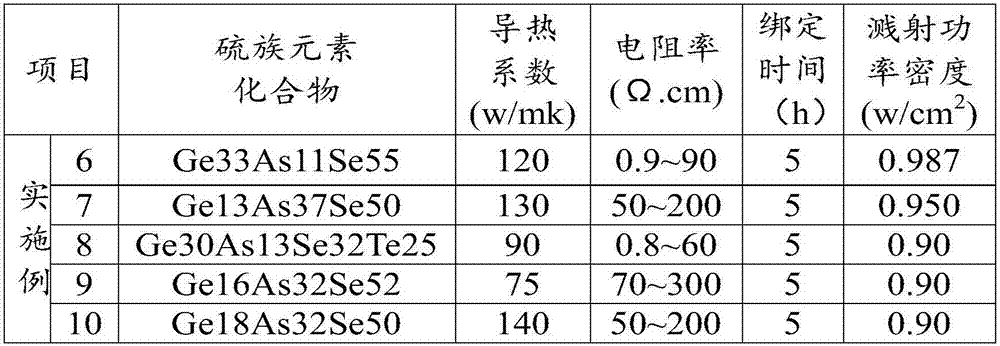

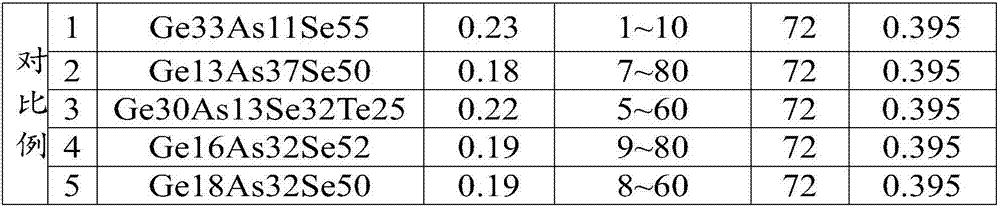

Embodiment 1

[0062] A switch material for phase-change memory chips. It is formed by doping 5 at % carbon nanotubes in a ternary chalcogen compound of Ge, As, Se. Among them, the ternary chalcogen compound is Ge33As12Se55, its thermal conductivity is 0.23W / mk, and its resistivity is 10 3 ~10 4 (Ω.cm). The switching material after carbon nanotube doping is Ge31.4As11.4Se52.2CNT5. CNT is a single-walled carbon nanotube with an inner diameter of 5nm and a length of about 2000nm, and its type is an electrical conductor. Its preparation method is as follows: the ternary chalcogen compound and carbon nanotubes are ball-milled into powder in a closed environment of protective gas atmosphere, and the powder is put into a graphite mold, and then in the graphite mold, 1.0×10 -3 Under the vacuum degree of Pa, sinter at 280°C and 400 tons of pressure for 120 minutes, and cool to room temperature. The thermal conductivity of the switch material provided in this embodiment is 120W / mk, and the resis...

Embodiment 2

[0064] A switch material for phase-change memory chips. It is formed by doping 8 at % carbon nanotubes in a ternary chalcogen compound of Ge, As, Se. Among them, the ternary chalcogen compound is Ge13As37Se50, its thermal conductivity is 0.18W / mk, and its resistivity is 7×10 3 ~8×10 4 (Ω.cm). The switching material after carbon nanotube doping is Ge12As34Se46CNT8. CNT is a single-walled carbon nanotube with an inner diameter of 6nm and a length of about 2000nm, and its type is an electrical conductor. Its preparation method is as follows: the ternary chalcogen compound and carbon nanotubes are ball-milled into powder in a closed environment of protective gas atmosphere, the powder is put into a graphite mold, and then in the graphite mold, 1.5×10 -3 Under the vacuum degree of Pa, sinter at 300°C and 500 tons of pressure for 140 minutes, and cool to room temperature. The thermal conductivity of the switch material provided in this embodiment is 130W / mk, and the resistivity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com