Symmetric magnetron sputtering process and application of diamond-like carbon coating thereof

A diamond coating and magnetron sputtering technology, which is applied in coating, sputtering coating, metal material coating process, etc., can solve the problem of affecting the stability of the discharge process, the continuity of production, and the particle source of multi-arc ion plating carbon application, the inability to obtain diamond-like coatings, etc., to achieve the effect of improving target utilization, simple structure, and increasing plasma concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

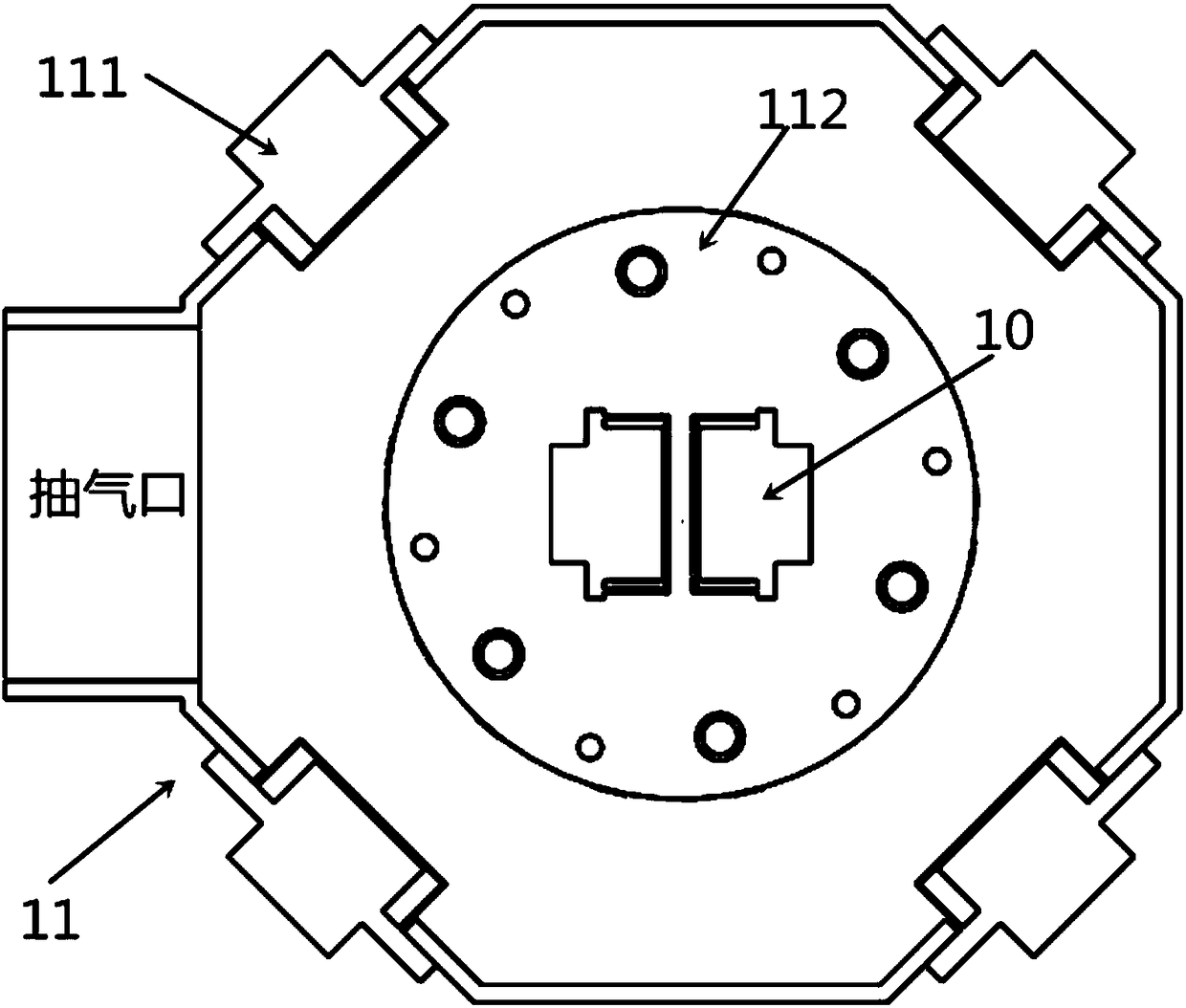

[0050] see image 3 , shown: the unbalanced magnetron coating machine 11 for preparing the diamond-like coating of the present invention, the unbalanced magnetron coating machine 11 is a conventional mature equipment in the field, can be purchased directly from the market, and is equipped with four groups of unbalanced magnetrons A sputtering metal target 111, a turret 112, and a symmetrical magnetron sputtering cathode 10 are installed in the center of the chamber. The diamond-like coating metal base layer and the gradient composite layer are prepared using the magnetron sputtering cathode. When the gradient composite is prepared , turn off the reaction gas, feed argon gas, turn on the symmetrical magnetron sputtering cathode 10 and the magnetron sputtering metal target 111, by adjusting the target power of the magnetron sputtering metal target 111, utilize the symmetrical magnetron sputtering cathode 10 discharge process The high-energy ionized sputtering effect of electron ...

Embodiment 2

[0062] see Figure 5 As shown: the unbalanced magnetron coating machine 12 for preparing the doped diamond-like coating of the present invention is equipped with two groups of unbalanced magnetron sputtering metal targets 121 and a turntable 122, and the chamber corresponds to two groups of unbalanced magnetrons. A symmetrical slit magnetron sputtering cathode 10 is installed on one side of the central axis of the sputtering metal target 121, and an anode water cooling column or an anode gas distribution pipe 13 is installed at the corresponding cavity of the symmetrical slit magnetron sputtering cathode 10. By using the water-cooled anode to accelerate the overflow of carbon particles, or through the action of air flow to facilitate the overflow of carbon particles, the diamond-like coating metal base layer and the gradient composite layer are prepared by magnetron sputtering cathode, and the reaction is closed when the gradient composite is prepared. The gas is fed with argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com