Patents

Literature

69 results about "Sputter cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sputter cleaning is the cleaning of a solid surface in a vacuum by using physical sputtering of the surface. Sputter cleaning is often used in vacuum deposition and ion plating. In 1955 Farnsworth, Schlier, George, and Burger reported using sputter cleaning in an ultra-high-vacuum system to prepare ultra-clean surfaces for low-energy electron-diffraction (LEED) studies. Sputter cleaning became an integral part of the ion plating process. Sputter cleaning has some potential problems such as overheating, gas incorporation in the surface region, bombardment (radiation) damage in the surface region, and the roughening of the surface, particularly if over done. It is important to have a clean plasma in order to not continually recontaminate the surface during sputter cleaning. Redeposition of sputtered material on the substrate can also give problems, especially at high sputtering pressures.

Plasma treatment for copper oxide reduction

InactiveUS6946401B2Semiconductor/solid-state device detailsSolid-state devicesSputter cleaningHydrogen

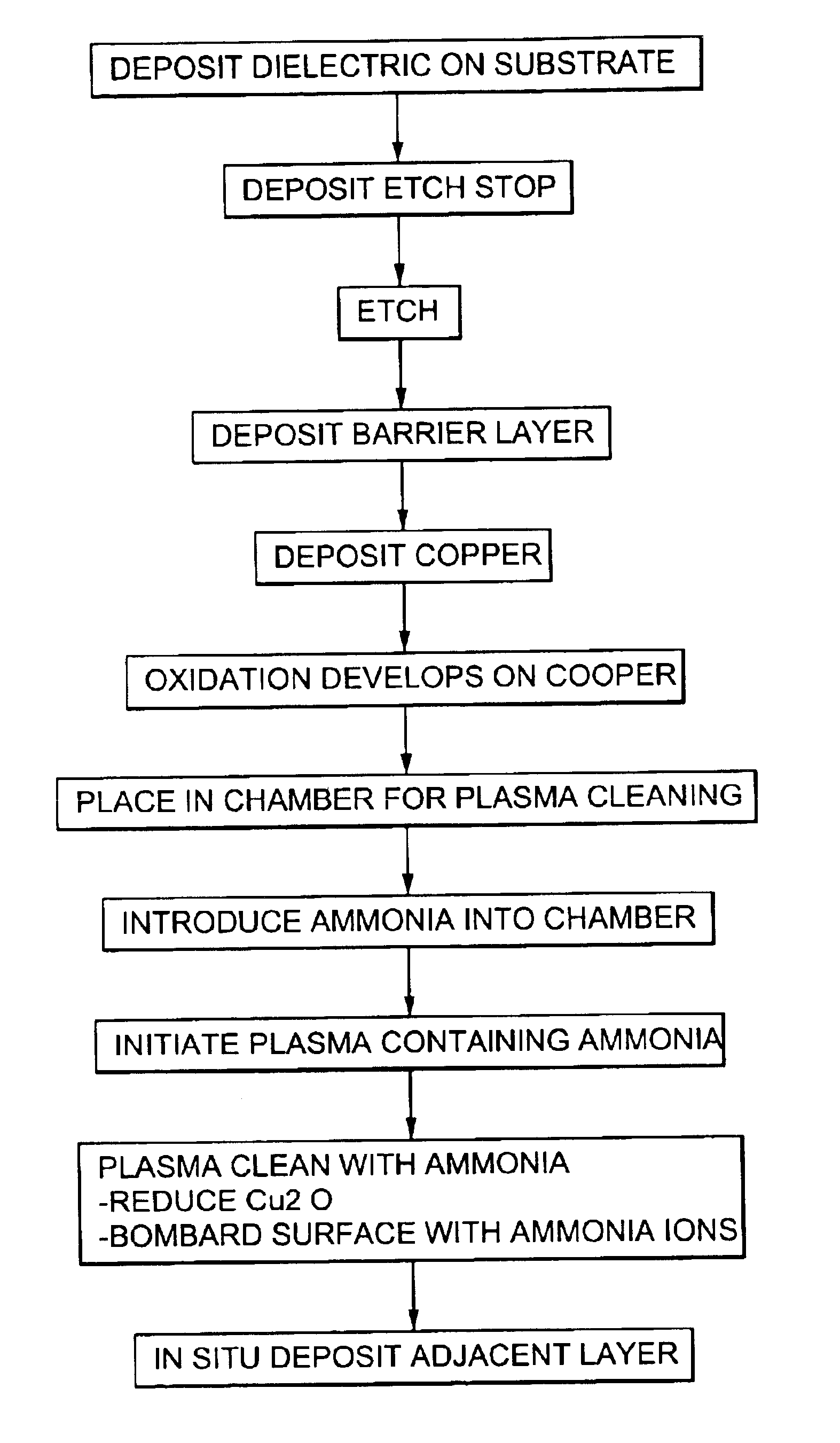

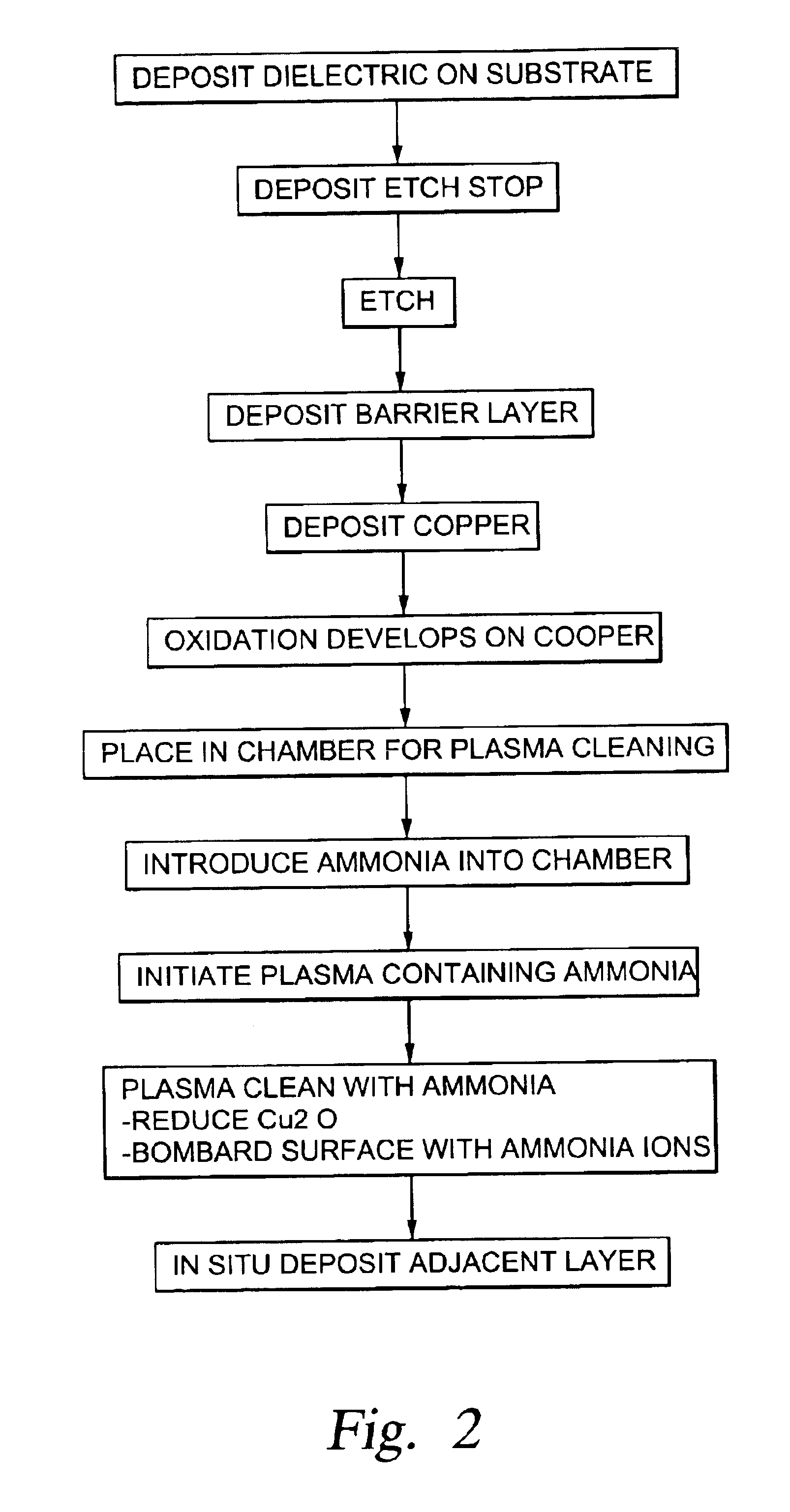

The present invention provides an in situ plasma reducing process to reduce oxides or other contaminants, using a compound of nitrogen and hydrogen, typically ammonia, at relatively low temperatures prior to depositing a subsequent layer thereon. The adhesion characteristics of the layers are improved and oxygen presence is reduced compared to the typical physical sputter cleaning process of an oxide layer. This process may be particularly useful for the complex requirements of a dual damascene structure, especially with copper applications.

Owner:APPLIED MATERIALS INC

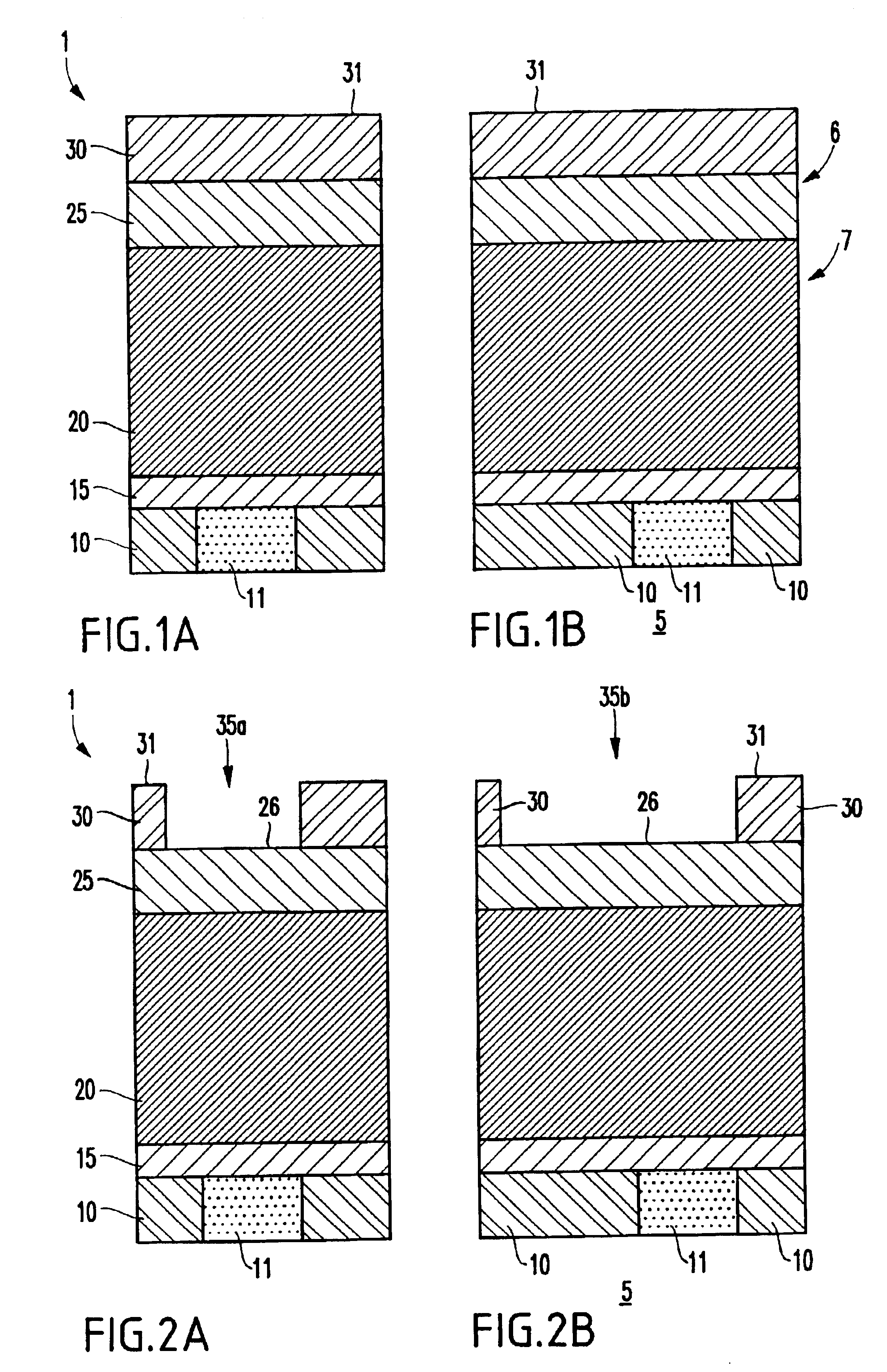

Sacrificial metal spacer damascene process

InactiveUS6846741B2Overcome limitationsEliminate the problemSemiconductor/solid-state device manufacturingSputter cleaningEngineering

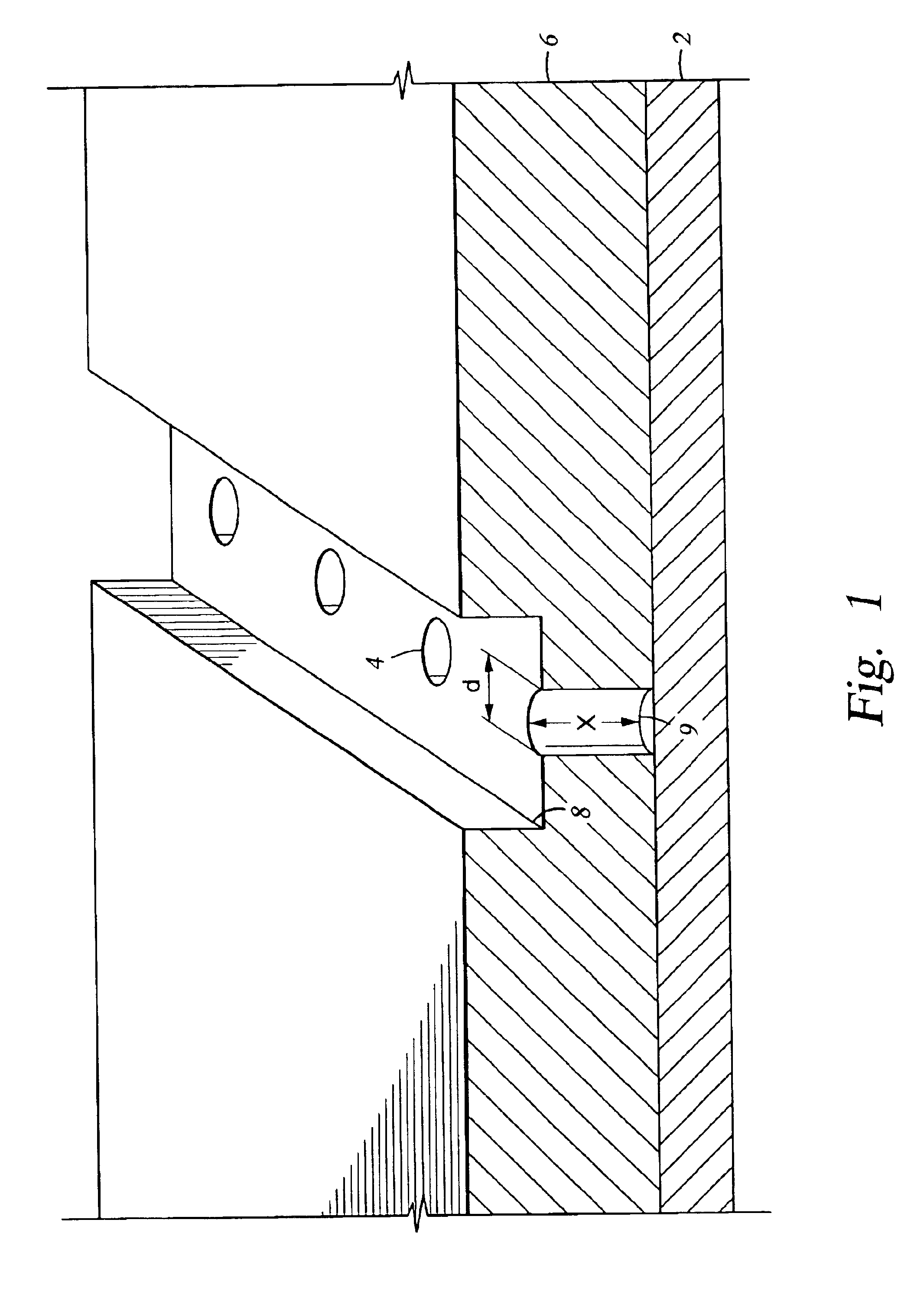

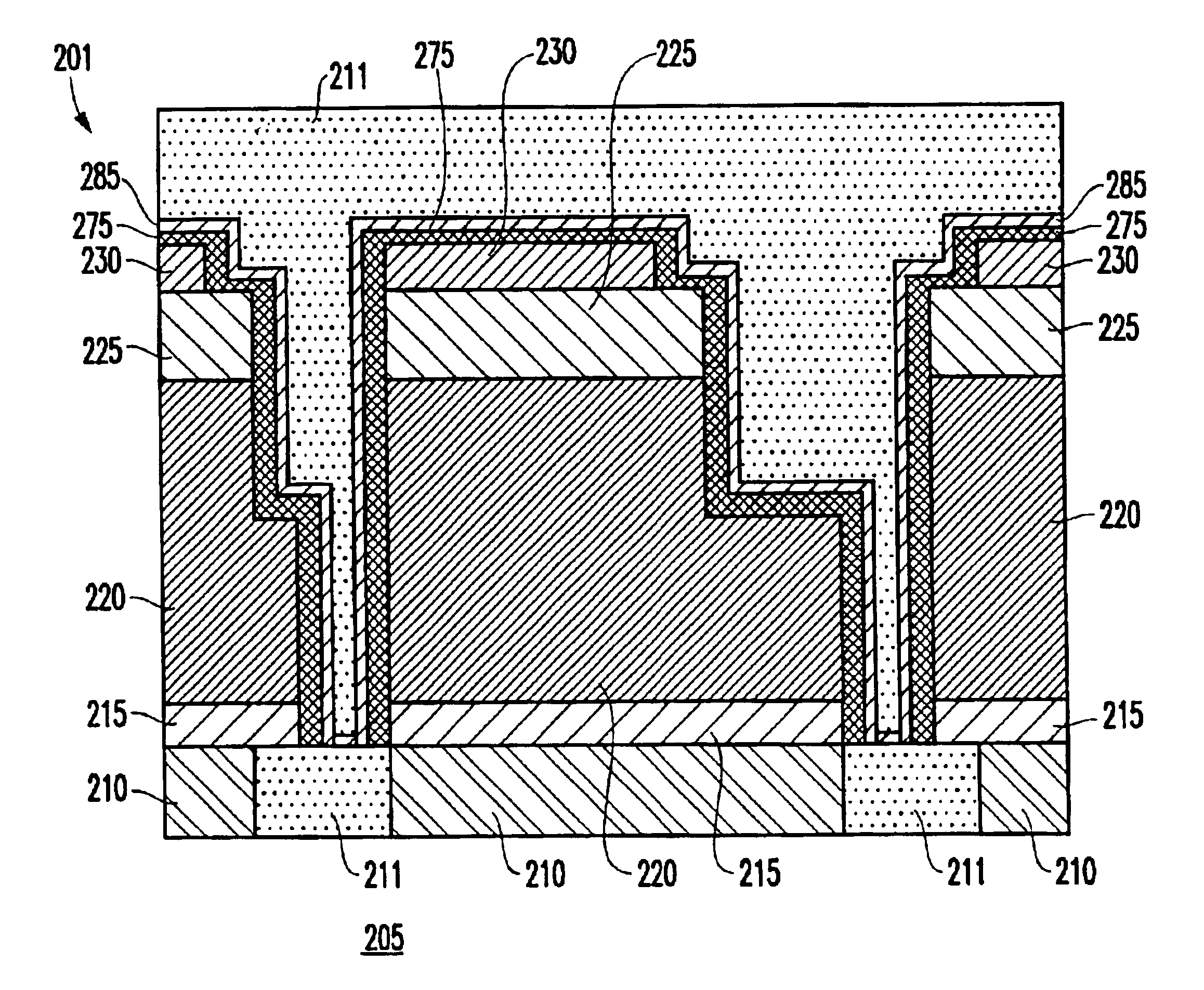

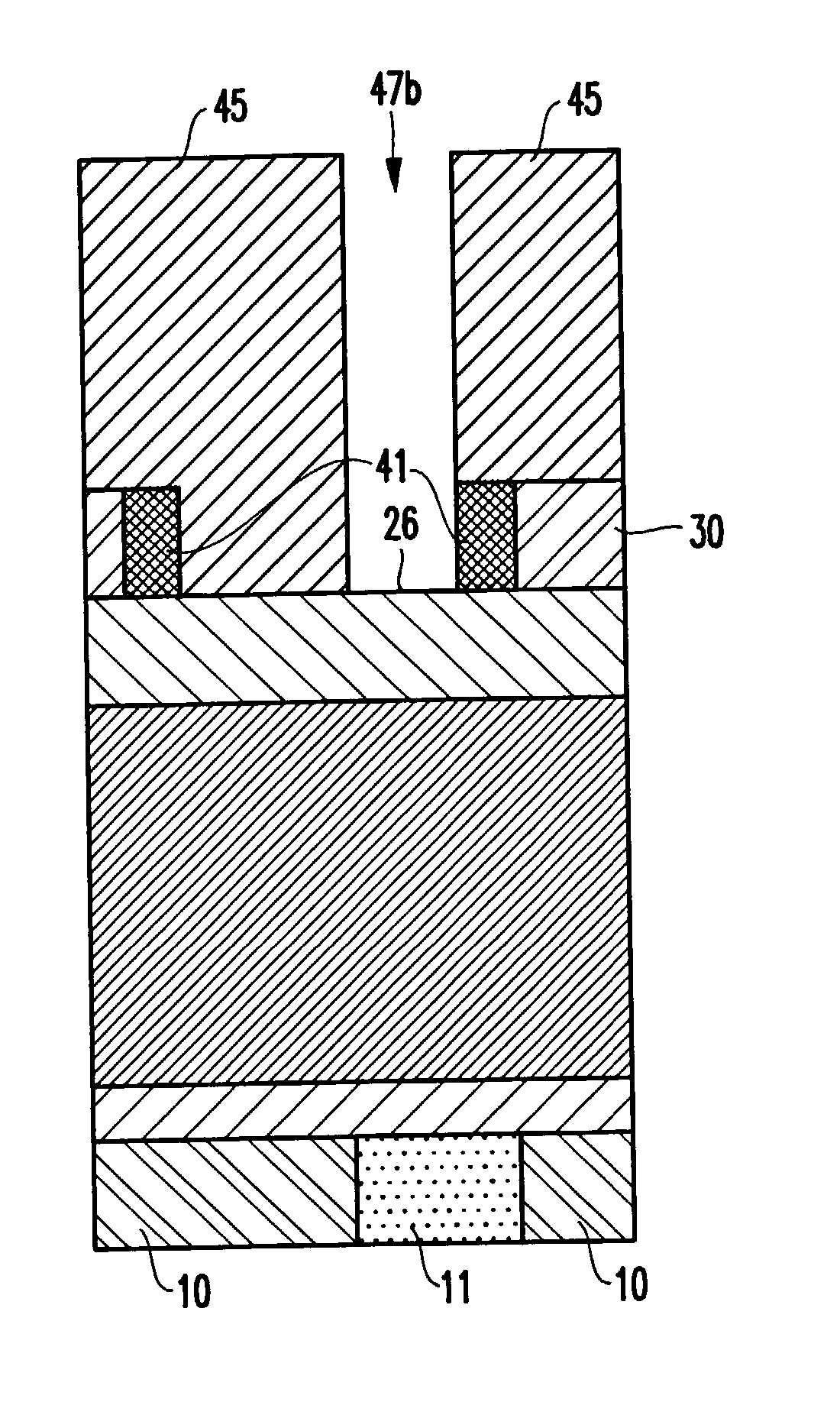

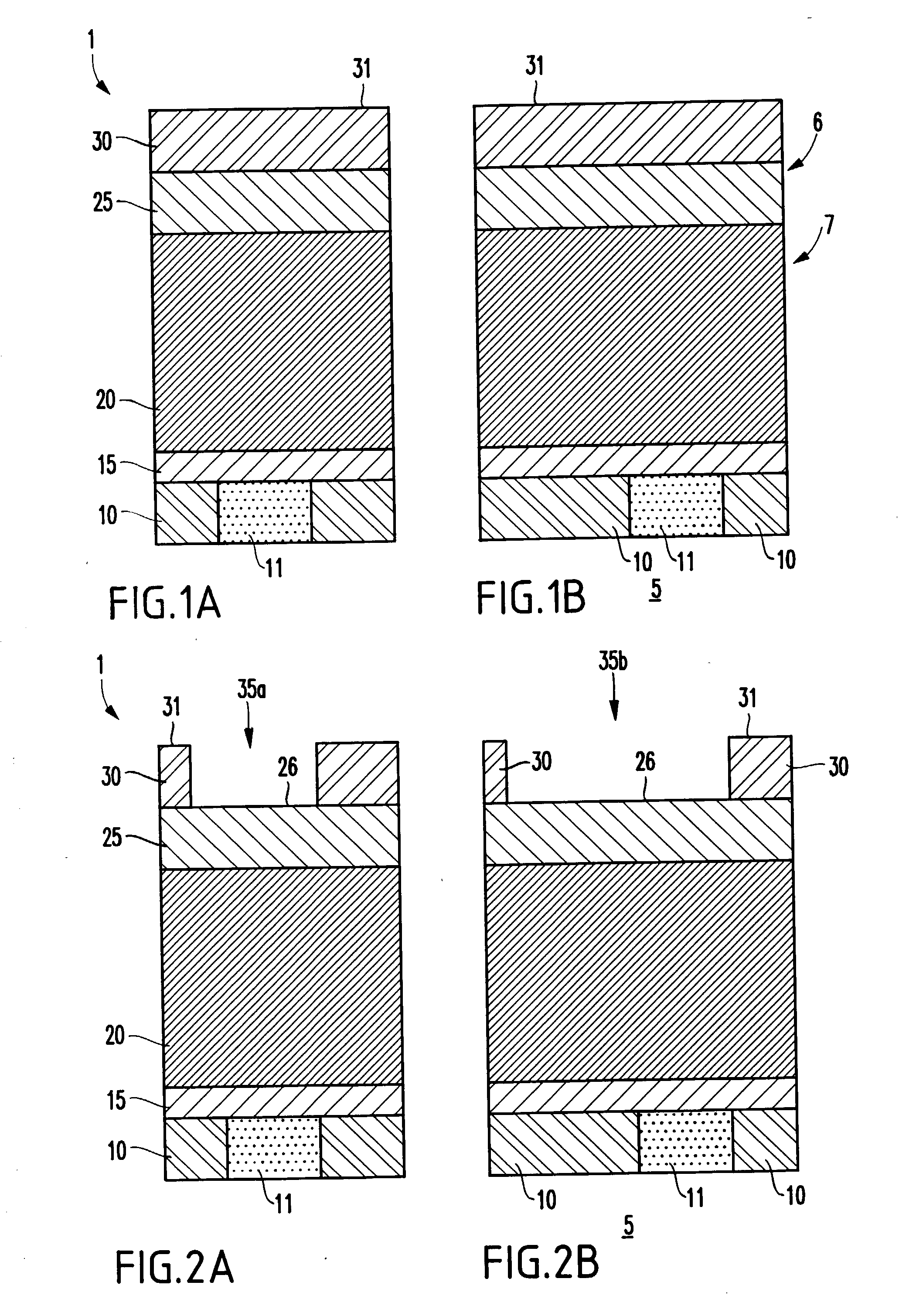

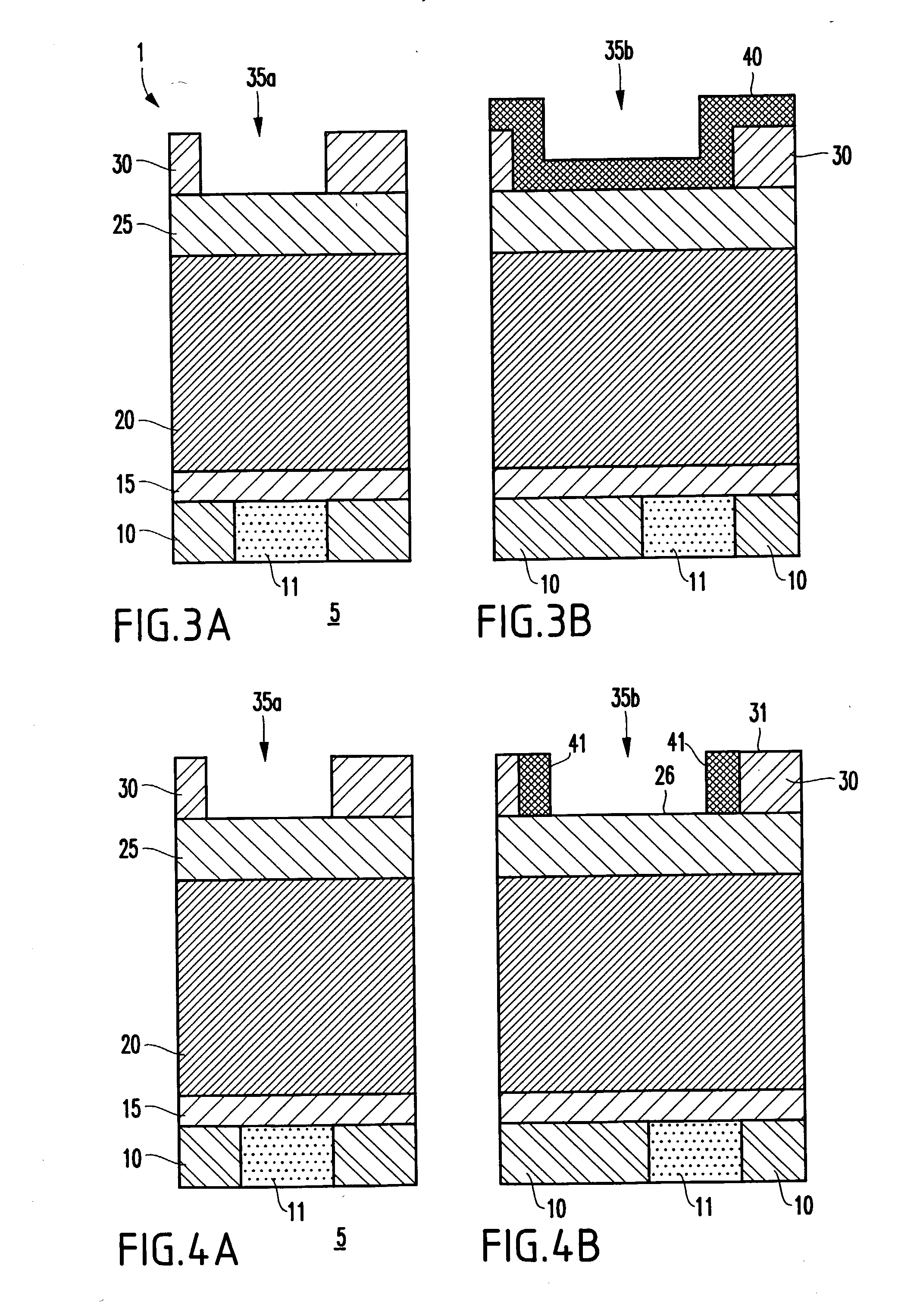

A method and structure for a dual damascene interconnect structure comprises forming wiring lines in a metallization layer over a substrate, shaping a laminated insulator stack above the metallization layer, patterning a hardmask over the laminated insulator stack, forming troughs in the hardmask, creating sacrificial tungsten sidewall spacers in the troughs, patterning the laminated insulator stack, removing the sacrificial sidewall spacers, forming vias in the patterned laminated insulator stack, and depositing a metal liner and conductive material into the vias and troughs, wherein the laminated insulator stack comprises a dielectric layer further comprising oxide and polyarylene. The step of depositing prevents the laminated insulator stack from sputtering into the vias. Moreover, the step of depositing comprises cleaning the vias and troughs, optionally performing a reactive ion etching or argon sputter cleaning, depositing a plurality of metal layers over the vias and troughs, and depositing copper in the vias and troughs.

Owner:GLOBALFOUNDRIES INC

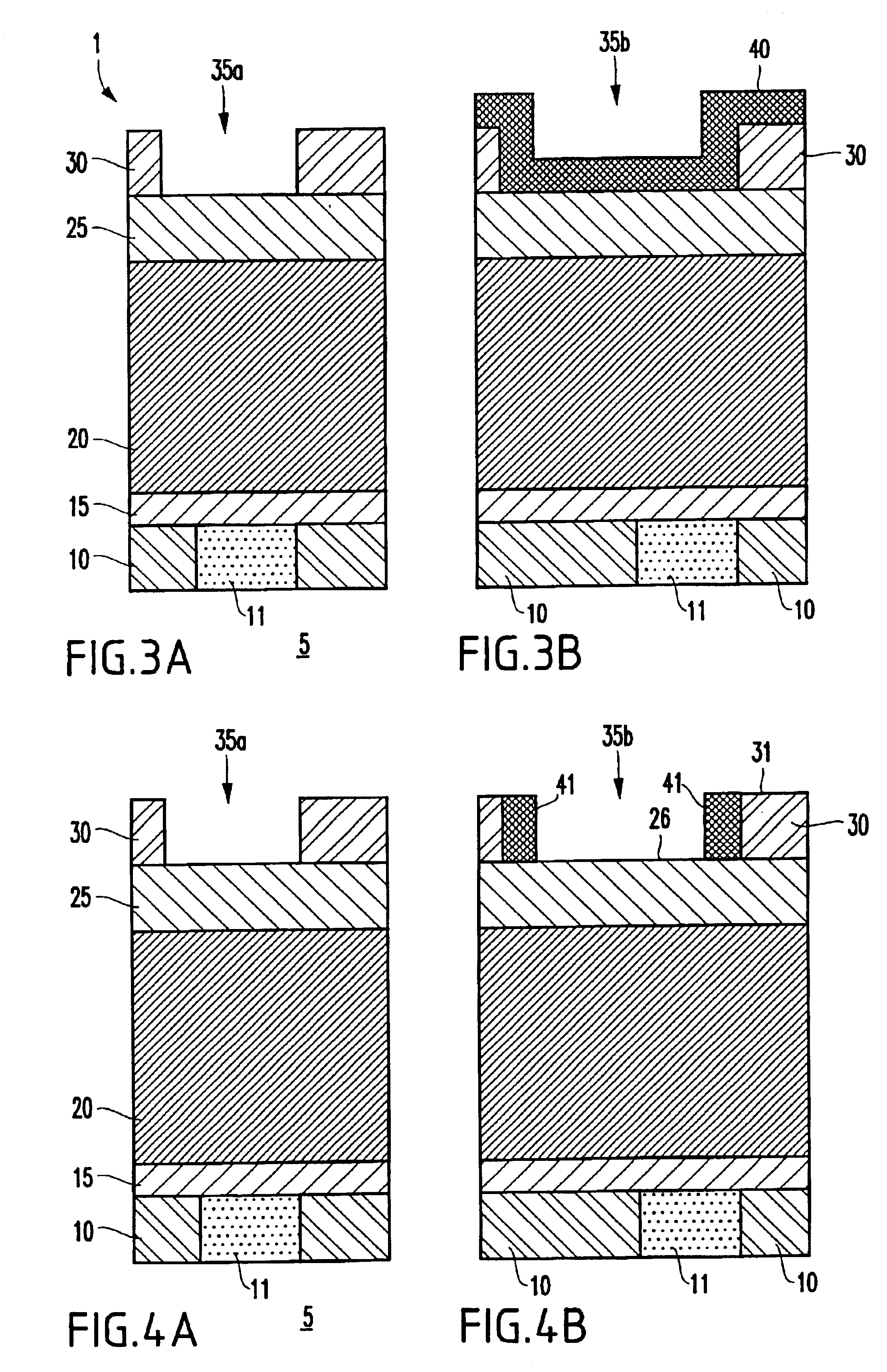

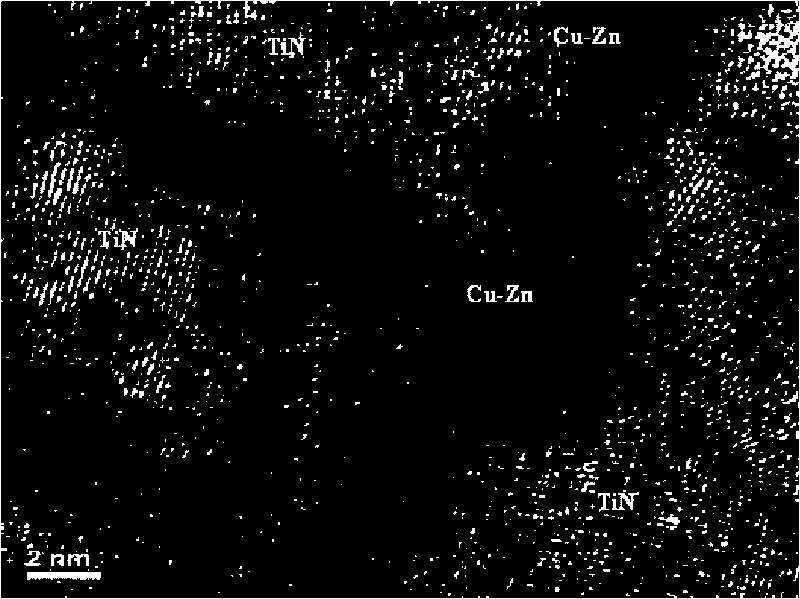

Method for preparing slow-release type skeleton-type TiN/Cu-Zu metal layer antibacterial film

InactiveCN101705468AGood dissolution effectDissolution rate is stableBiocideVacuum evaporation coatingSputter cleaningNitrogen gas

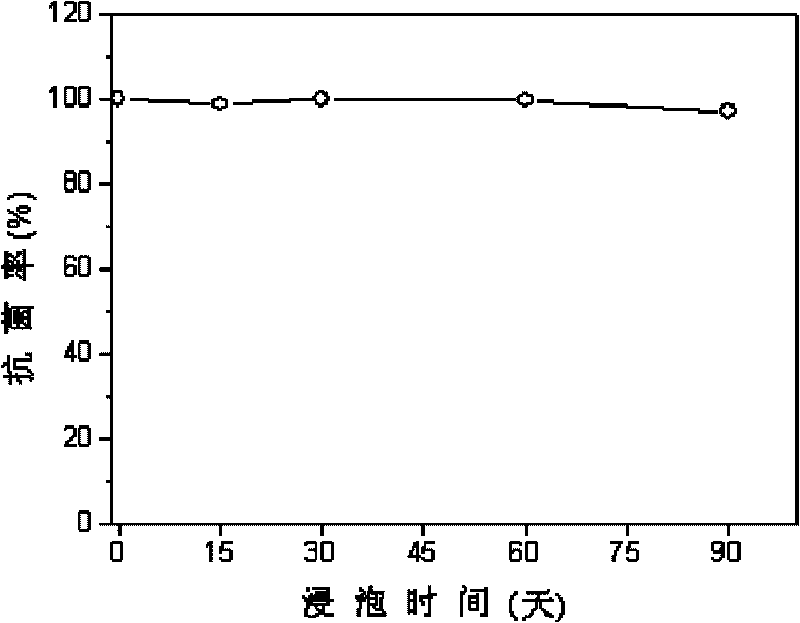

The invention discloses a method for preparing a slow-release type skeleton-type TiN / Cu-Zu metal layer antibacterial film and relates to a preparation method of an antibacterial film, which solves the problem that an antibacterial film prepared by the conventional method has poor durability of antibacterial effect. The method has the following steps of: 1. putting a matrix on a target platform of a vacuum room; and then heating to 200 DEG C and sputter cleaning for 20 min; 2. rotating the target platform of the vacuum room under the condition that argon flow is 6sccm, nitrogen flow is 2sccm, deposition pressure is 0.56Pa, and the deposition bias of the matrix is compound bias; and alternately depositing TiN layers and metal layers on the surface of the matrix till the total thickness of film layers is 0.1 micrometer-10 micrometers to obtain the slow-release type skeleton-type TiN / Cu-Zu metal layer antibacterial film. After the slow-release type skeleton-type TiN / Cu-Zu metal layer antibacterial film is soaked for three months, the ion dissolving speed is not reduced, and the antibiosis rate against colibacillus can still reach above 97%.

Owner:HARBIN INST OF TECH

Sacrificial metal spacer damascene process

InactiveUS20040018714A1Overcome limitationsEliminate the problemSemiconductor/solid-state device manufacturingSputter cleaningEngineering

A method and structure for a dual damascene interconnect structure comprises forming wiring lines in a metallization layer over a substrate, shaping a laminated insulator stack above the metallization layer, patterning a hardmask over the laminated insulator stack, forming troughs in the hardmask, creating sacrificial tungsten sidewall spacers in the troughs, patterning the laminated insulator stack, removing the sacrificial sidewall spacers, forming vias in the patterned laminated insulator stack, and depositing a metal liner and conductive material into the vias and troughs, wherein the laminated insulator stack comprises a dielectric layer further comprising oxide and polyarylene. The step of depositing prevents the laminated insulator stack from sputtering into the vias. Moreover, the step of depositing comprises cleaning the vias and troughs, optionally performing a reactive ion etching or argon sputter cleaning, depositing a plurality of metal layers over the vias and troughs, and depositing copper in the vias and troughs.

Owner:GLOBALFOUNDRIES INC

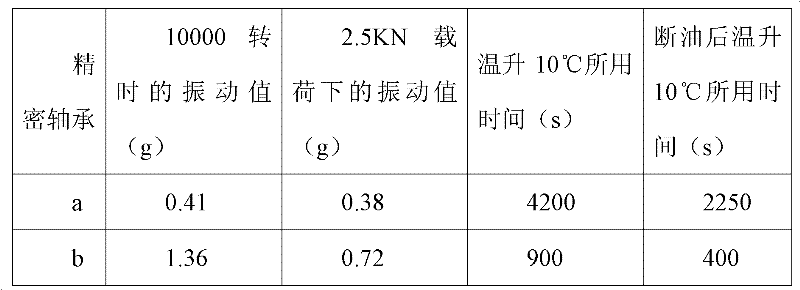

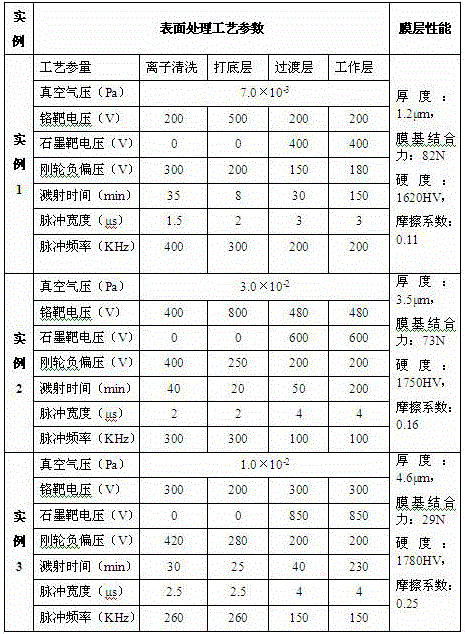

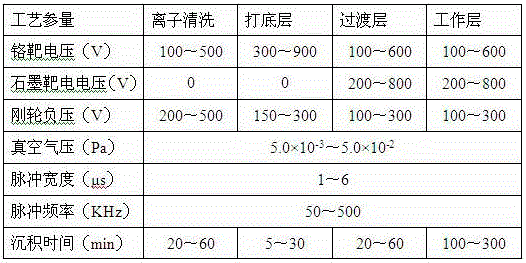

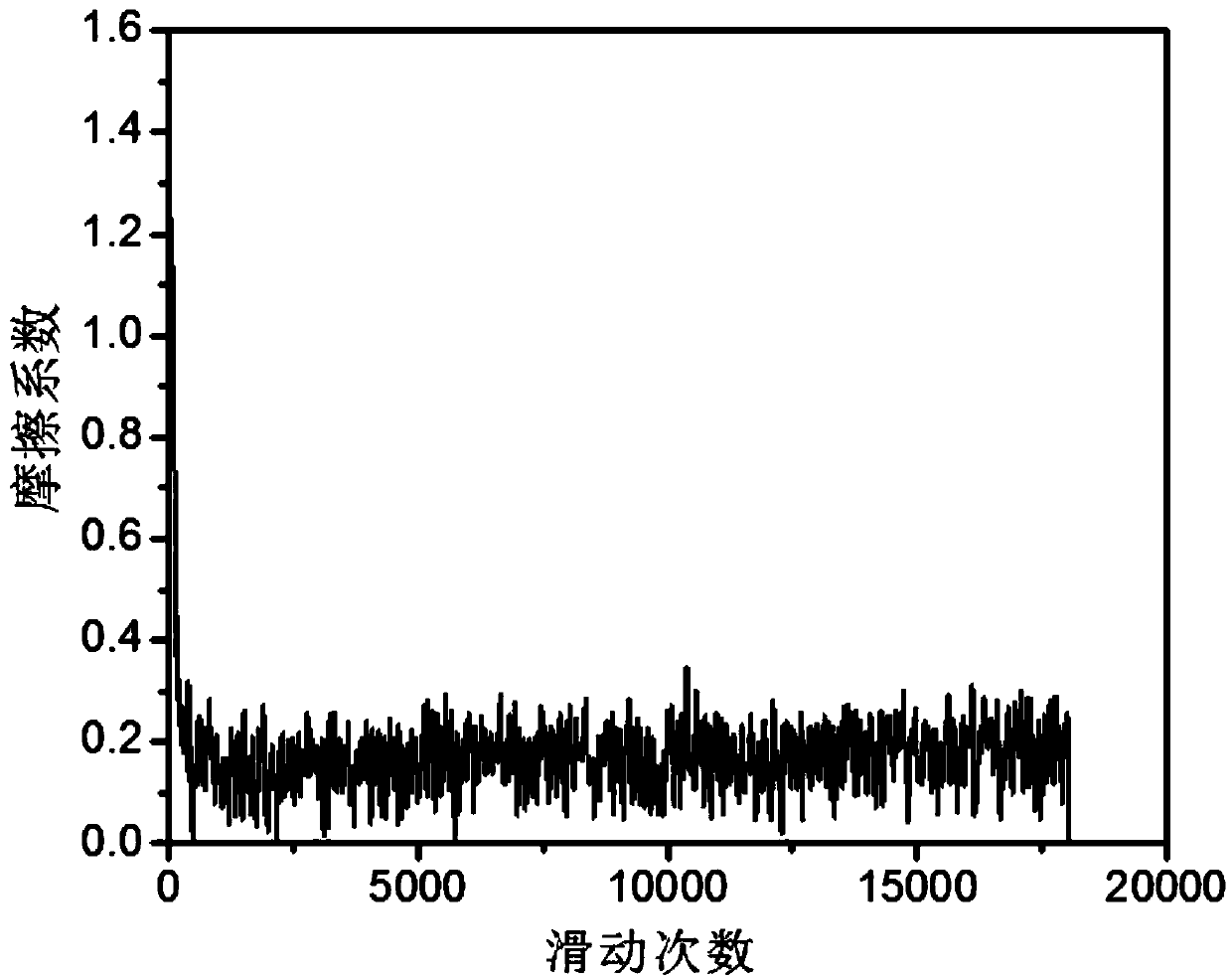

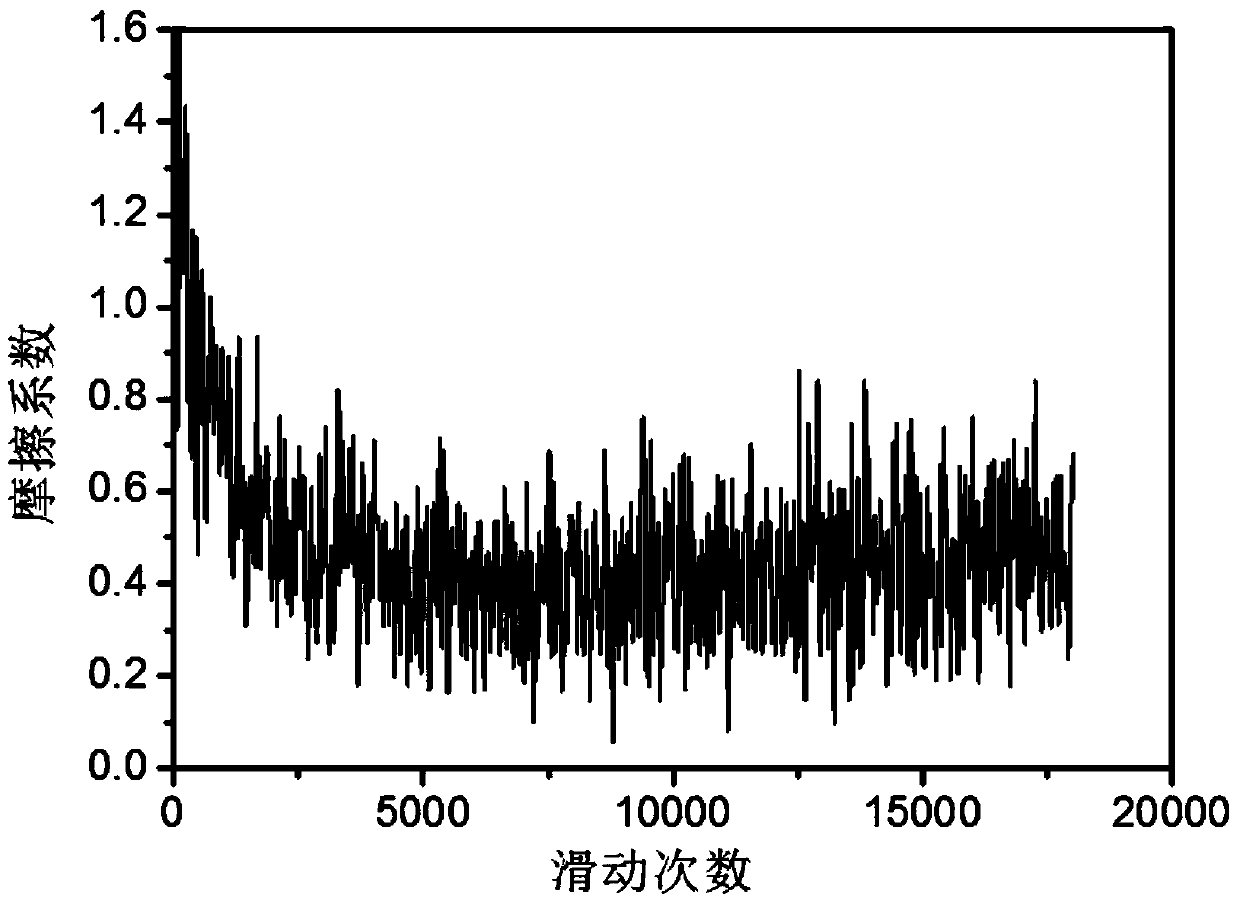

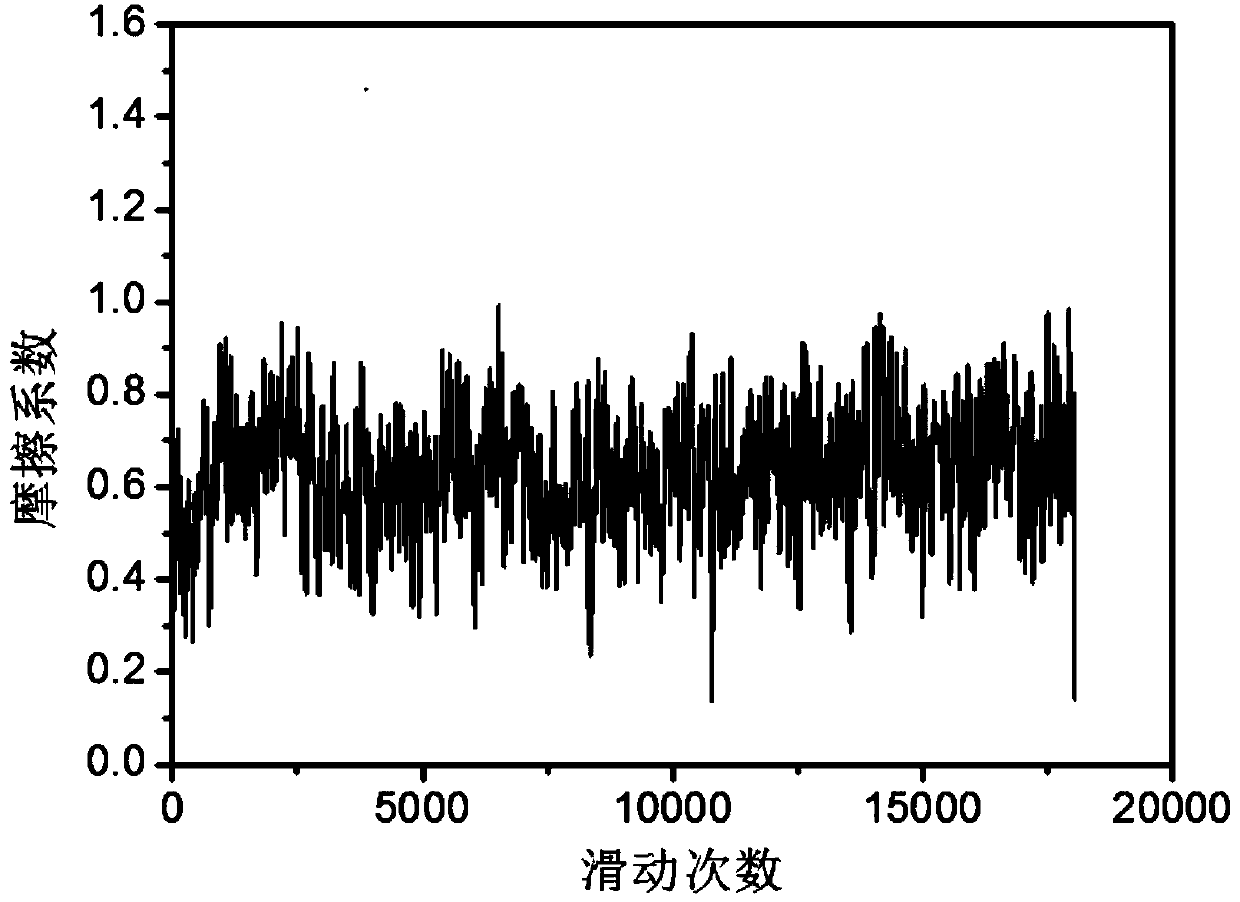

Method for self-lubricating steel balls for precision bearing by ion-plating GLC (graphite-like carbon) coating

InactiveCN102230153AIncrease rotation speedVibration increases slowlyVacuum evaporation coatingSputtering coatingVibration amplitudeCold air

The invention provides a method for self-lubricating steel balls for a precision bearing by ion-plating a GLC (graphite-like carbon) coating. The method comprises the following steps: ultrasonically cleaning the steel balls to be treated, then washing with deionized water and drying with cold air; placing the dried steel balls in a workpiece disk in a vacuum chamber of magnetron sputtering ion-plating equipment for sputter cleaning; depositing a pure chromium base layer; depositing a transition layer; and depositing a graphitelike working layer. The steel balls treated by the method has the characteristics of strong bearing capacity, high revolving speed, small vibration amplitude and low friction coefficient, thus being applicable to the fields such as aerospace and the like.

Owner:XIAN UNIV OF TECH

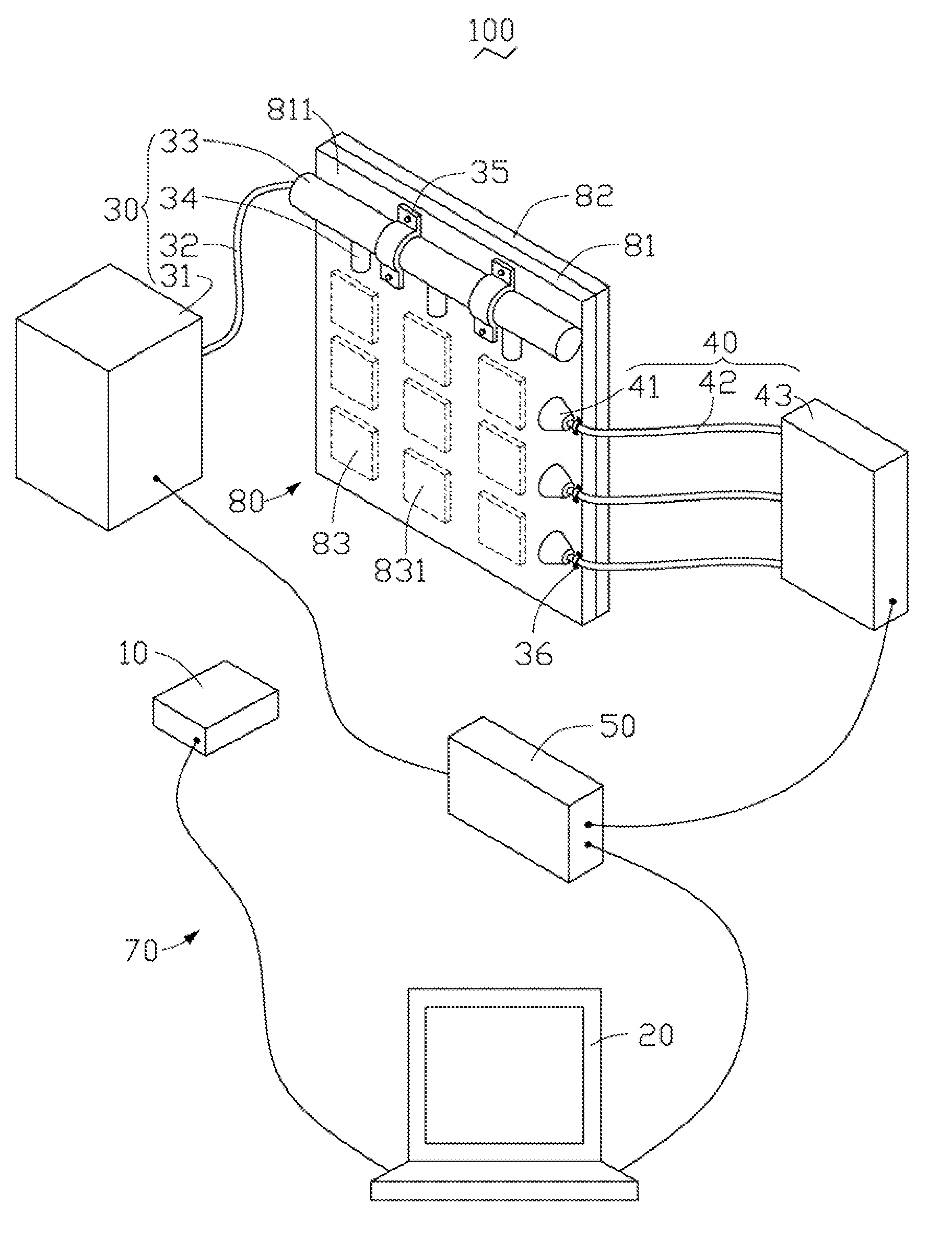

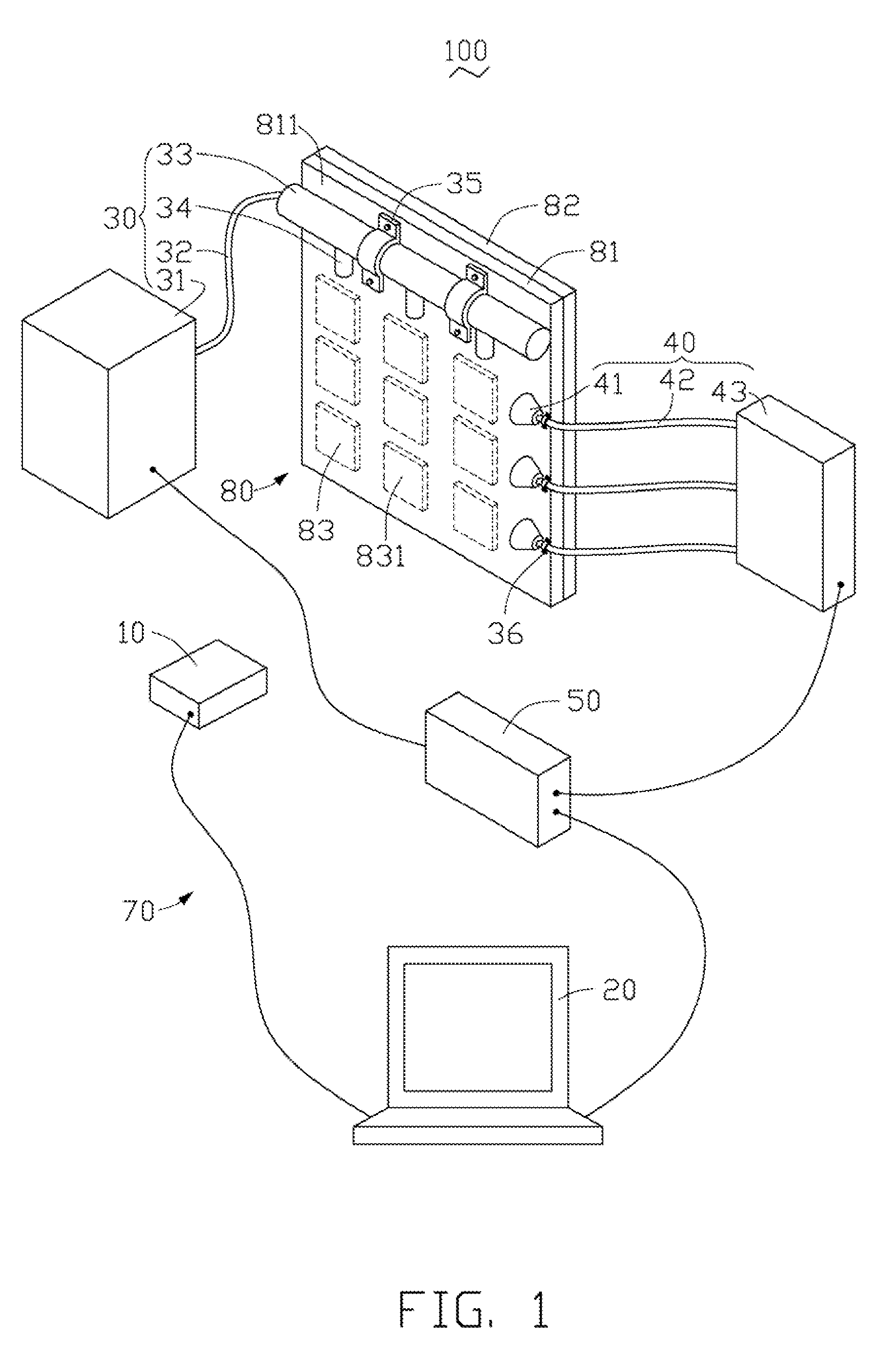

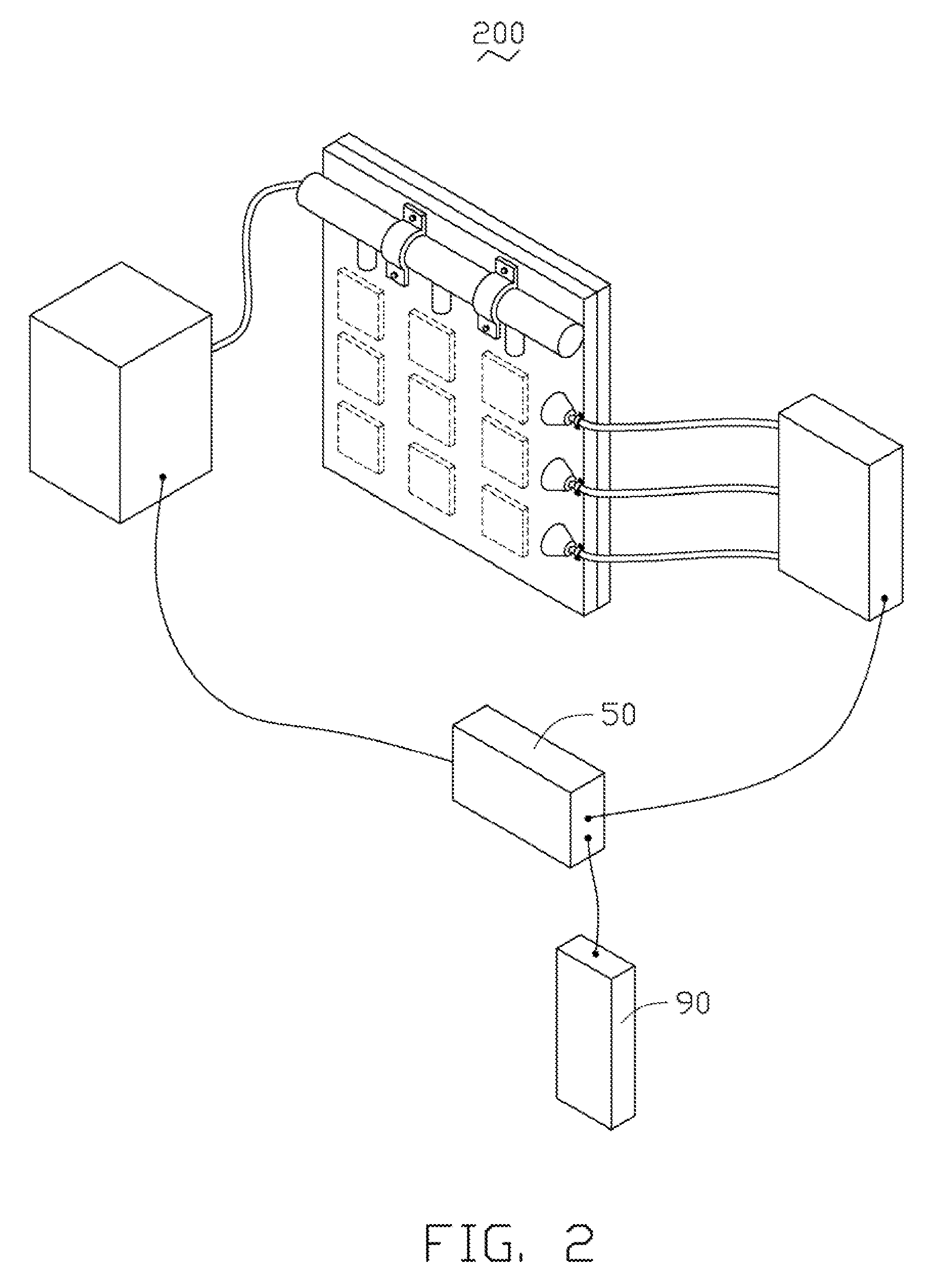

Solar cell device

A solar cell device includes a solar cell panel having an outer surface and a cleaning system. The cleaning system includes a cleaning component configured for sputtering a cleaning fluid to clean the outer surface, and a controller. The controller is electrically connected to the cleaning component and is configured for controlling the cleaning component.

Owner:HON HAI PRECISION IND CO LTD

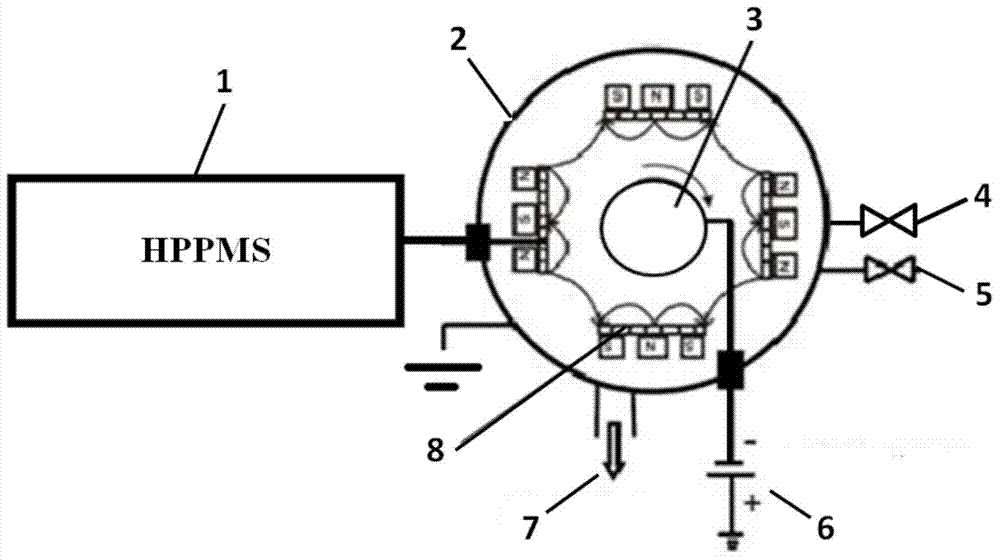

Metal support surface modification method

InactiveCN103924202AIncrease ionization rateHigh densityStentsSurgeryVoltage amplitudeSputter cleaning

The invention relates to a metal support surface modification method and belongs to the technical field of metal surface modification. The method is used for depositing a titanium / titanium oxide film on the surface of a metal support by effectively utilizing high power pulse magnetron sputtering technology. The method includes the following steps: firstly, putting the metal support in a vacuum chamber of high power pulse magnetron sputtering equipment, and vacuumizing the vacuum chamber to 0.5*10<-3> Pa to 2*10<-3>Pa; filling argon into the vacuum chamber, and sputter cleaning the metal support and a target; introducing argon into the vacuum chamber, and preparing a titanium transition layer with high binding force on the surface of the metal support by utilizing the high power pulse magnetron sputtering technology, by means of regulating such parameters as sputtering voltage amplitude, frequency, pulse width, sputtering voltage and matrix bias voltage; finally, introducing argon and oxygen into the vacuum chamber, and preparing a firmly combined titanium oxide film on the surface of the metal support by regulating such parameters as sputtering voltage amplitude, frequency, pulse width, sputtering voltage and matrix bias voltage. The method is mainly applied to surface modification of the metal support.

Owner:SOUTHWEST JIAOTONG UNIV

Method for preparing high-purity corrosion-resistant aluminum coating on titanium alloy component

ActiveCN101892459AHigh purityImprove bindingVacuum evaporation coatingSputtering coatingSputter cleaningIntermediate frequency

The invention discloses a method for preparing a high-purity corrosion-resistant aluminum coating on a titanium alloy component. The method comprises the following steps by adopting high-power intermediate frequency magnetron sputtering equipment: removing oil strain from the surface of a component; performing argon plasma sputter cleaning on the component; and depositing an aluminum coating, wherein the component is the titanium alloy component. Comprehensive properties such as coating thickness, density, binding force, coating temperature and the like are adjusted by adjusting different process parameters; and a layer of aluminum coating with high comprehensive properties is deposited on the surface of the titanium alloy component so that aluminum coatings formed on the two sides of the titanium alloy component have the comprehensive properties.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

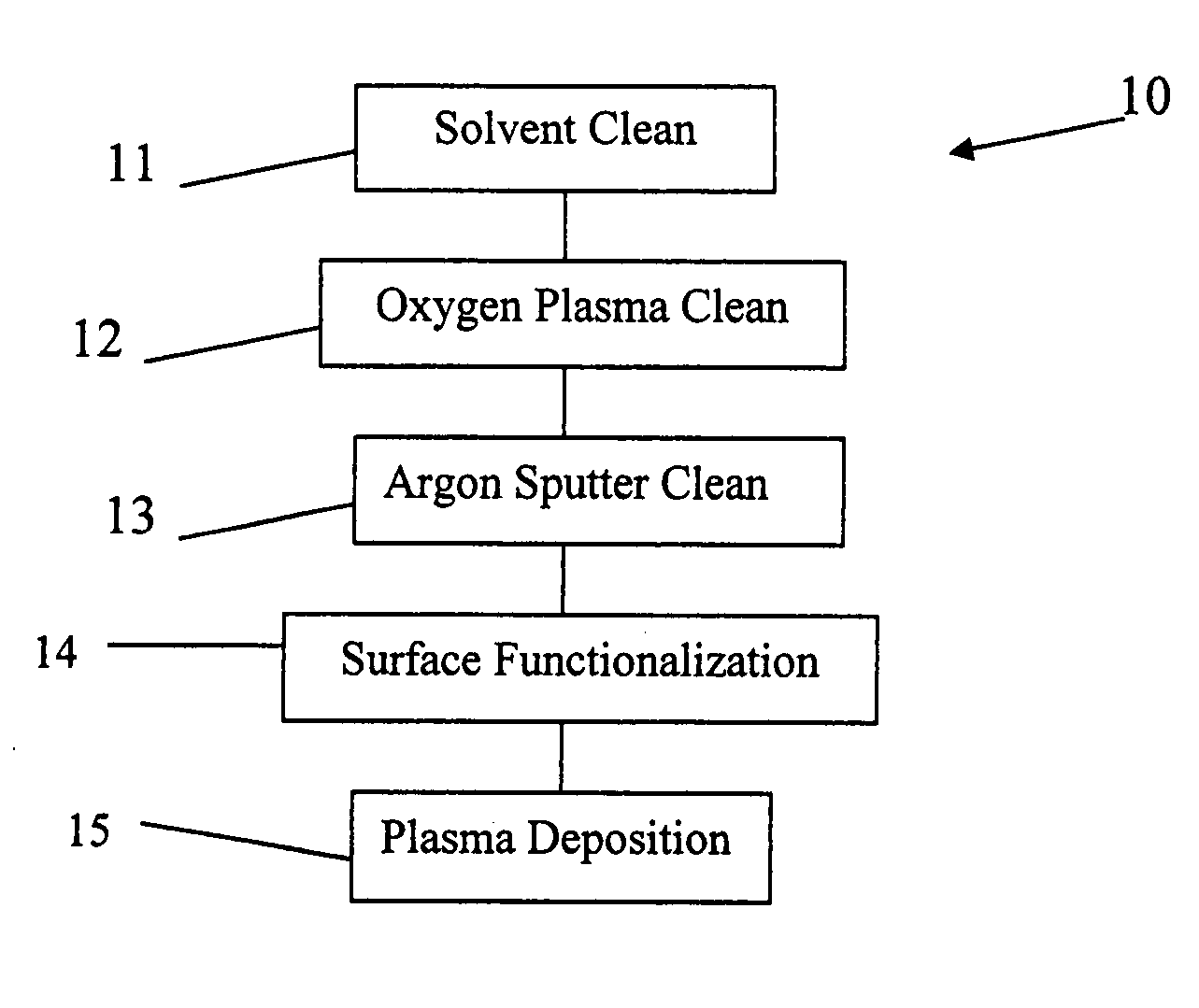

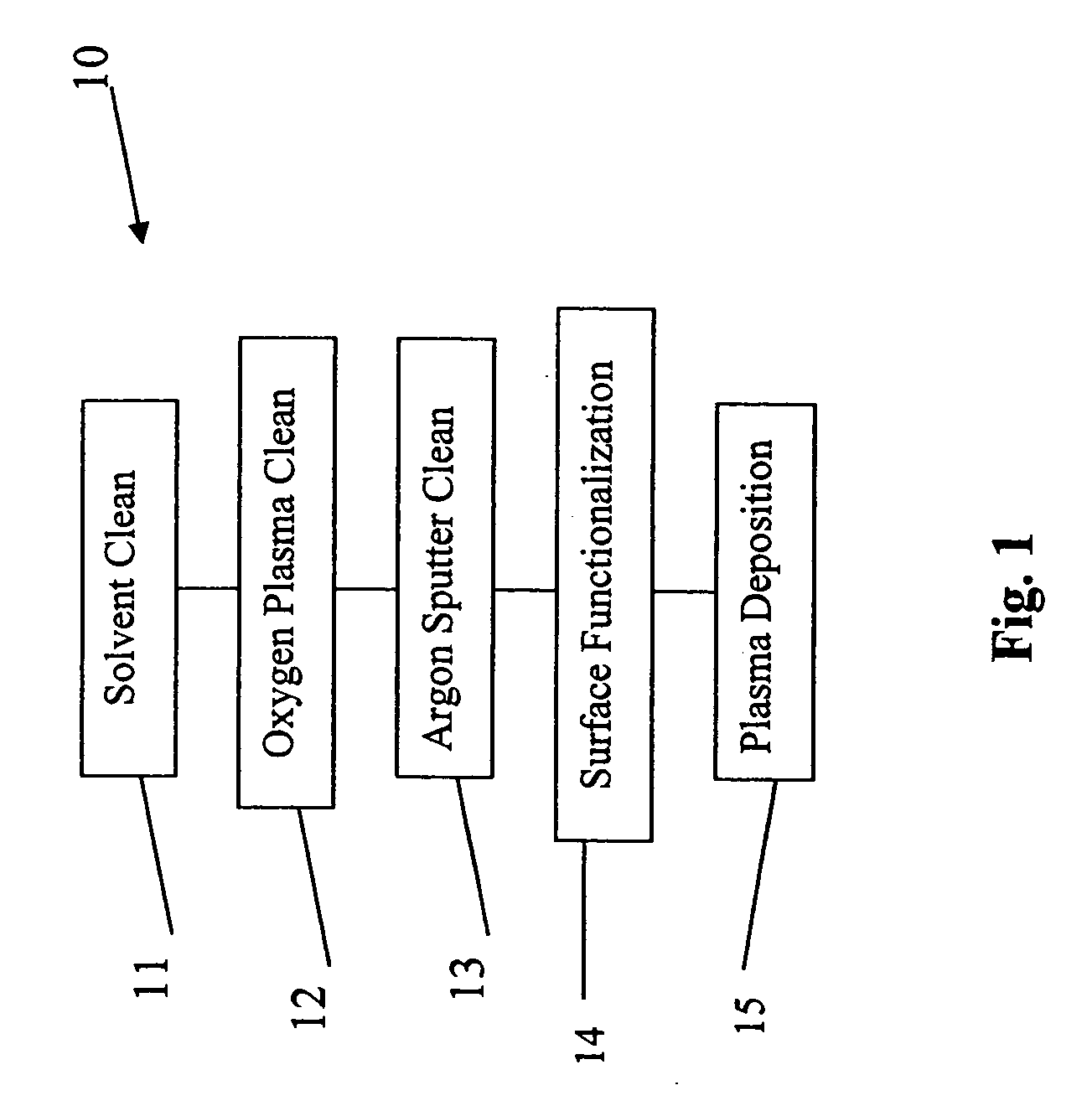

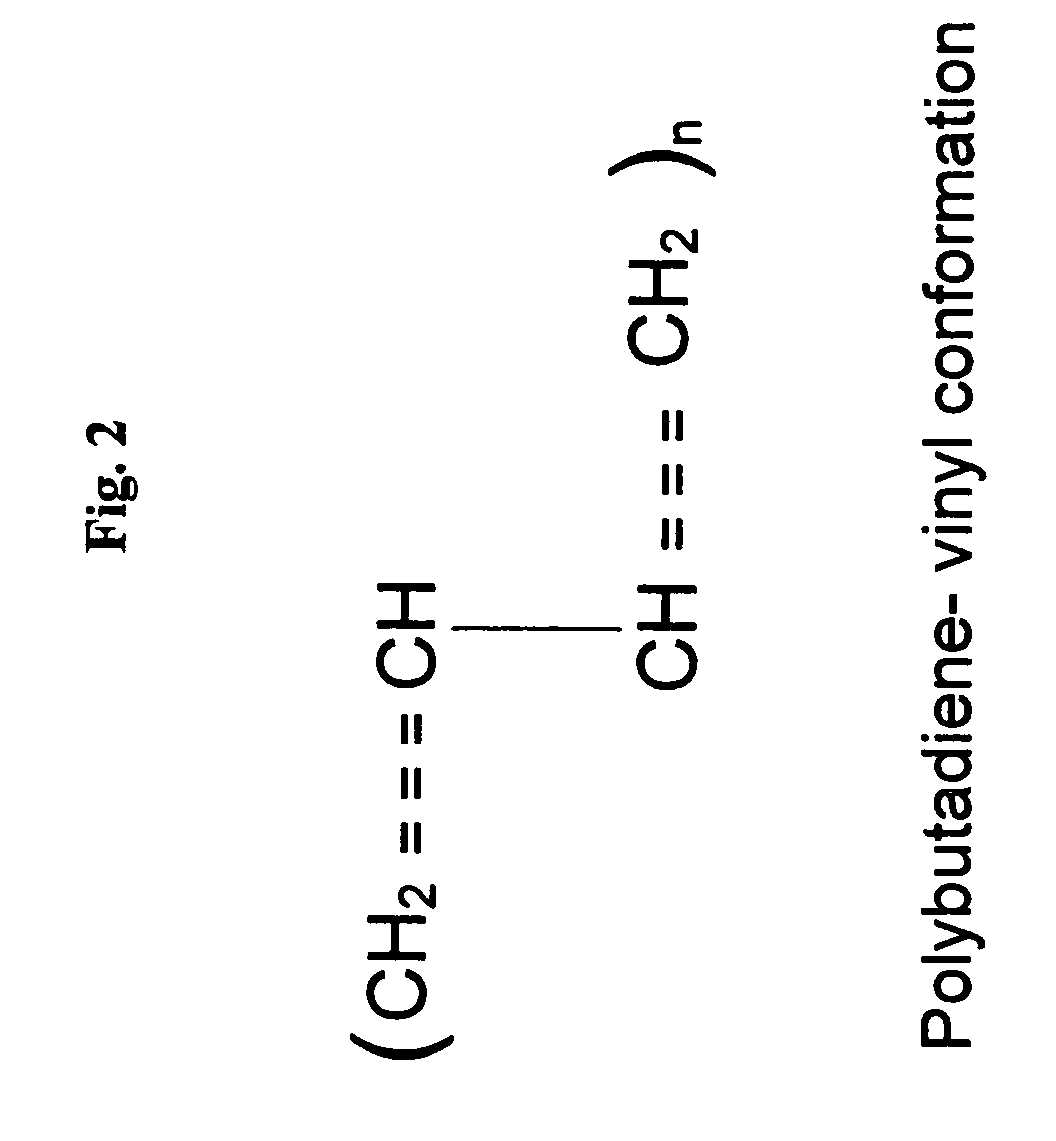

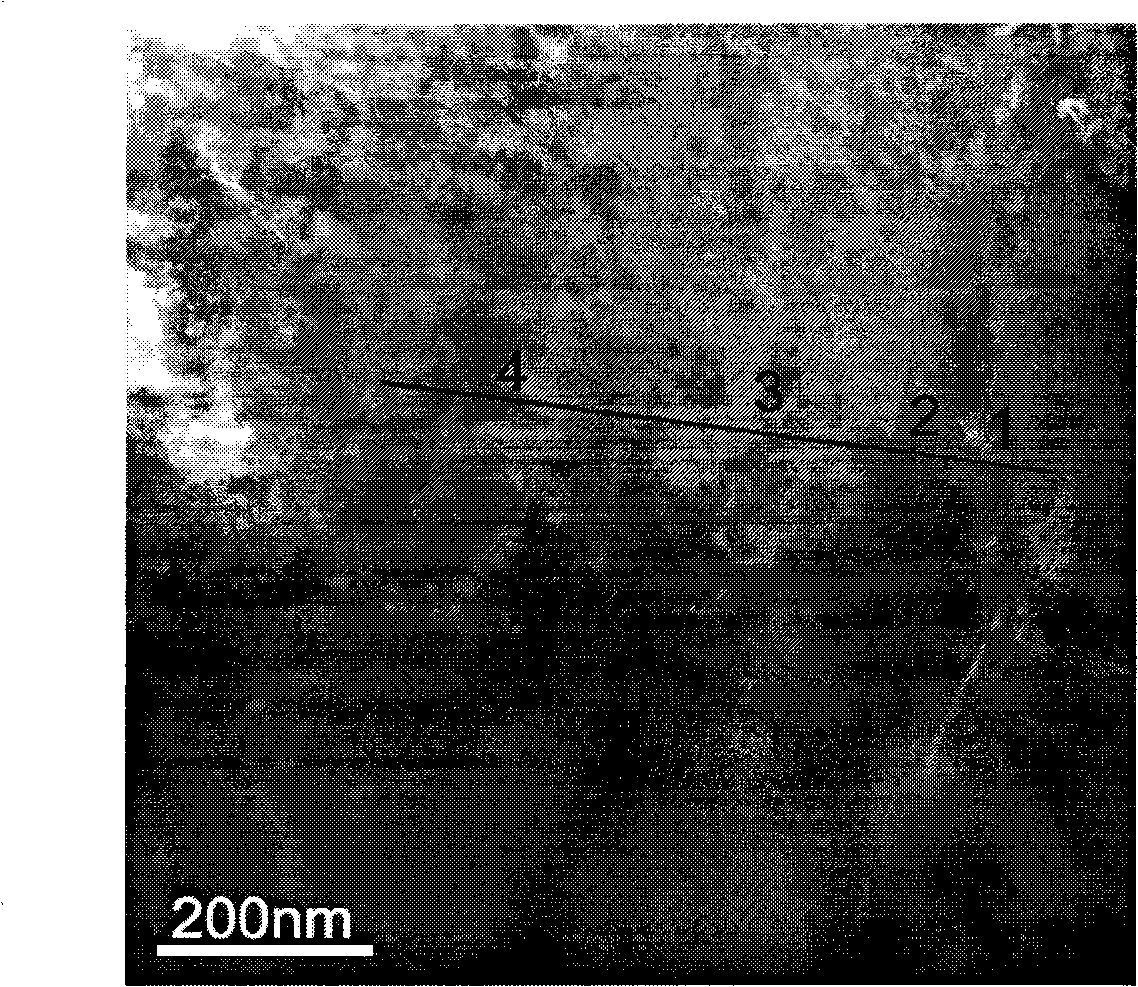

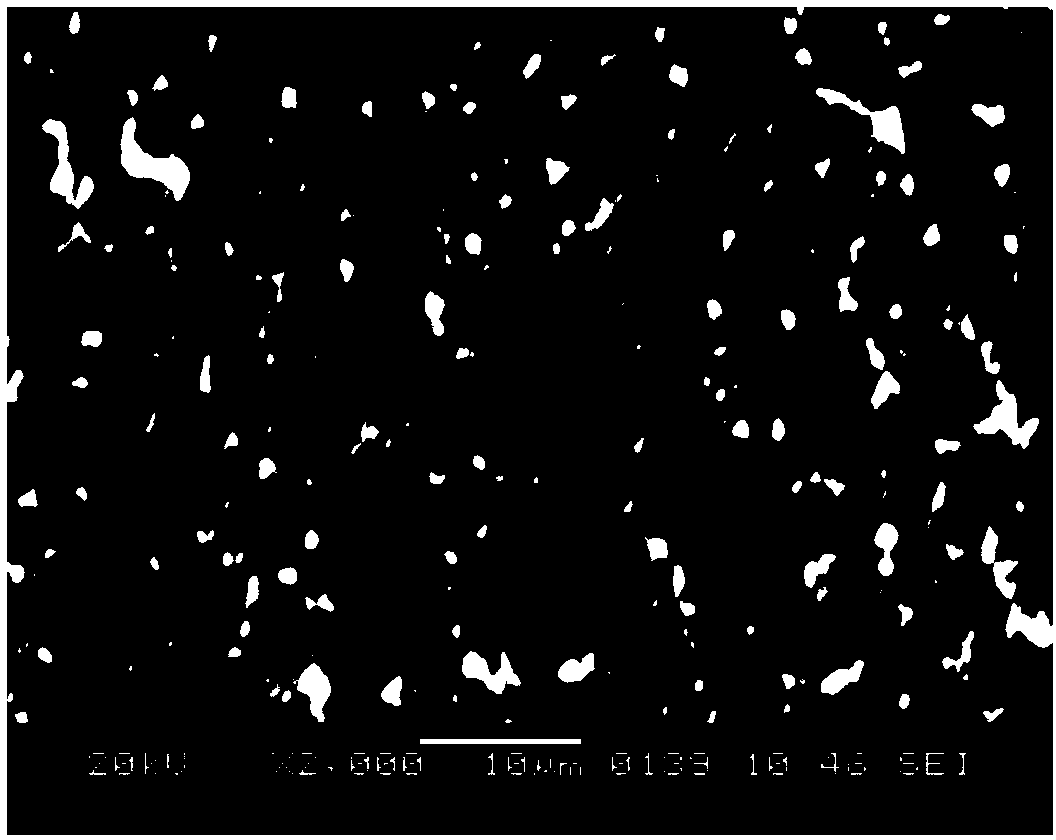

Method of forming a polymer layer on a metal surface

InactiveUS20040234703A1High mechanical strengthReduce generationPretreated surfacesCoatingsSputter cleaningSolvent

A method of forming a polymer tie layer on a metal surface by cleaning the metal surface with solvent; cleaning the metal surface with oxygen plasma; sputter cleaning the metal surface with argon using a lower chuck bias plasma generating unit; functionalizing the metal surface; and depositing the tie layer on the metal surface by radio frequency plasma deposition under pulsed conditions of a duty cycle, where the duty cycle is reduced over time. This method produces a tie layer chemically bound to the metal surface. The tie layer, thus, has high bonding strength to the metal and high elasticity, making it very resistant to cracks, scratches, delamination, and wicking. The tie layer can have functional groups on its surface for the chemical attachment of a second coating, or can act on its own by providing lubricity or blood compatibility, or both to the underlying metal.

Owner:WESTERN LIFE SCI

Preparation method for Ti-Si-N nano-coating

InactiveCN101403116AImproved resistance to shock loadsImprove antioxidant capacityVacuum evaporation coatingSputtering coatingSputter cleaningCritical load

The invention relates to a method for preparing a Ti-Si-N nano-coating and belongs to a method for preparing coatings for tool and mould. The method solves the problem of easy shedding of the coating in working conditions prepared by the existing method of reactive magnetron sputtering, and realizes metallurgical binding between a transition layer and the coating, thus improving the mechanical property of the coating. The method comprises the following steps of: (1) preheating; (2) sputter cleaning; (3) ion nitriding; (4) preparing the transition layer; and (5) preparing a surface layer. The method has the advantages of high production efficiency and low cost, the critical load Lc of the prepared coating and the substrate of a metal ceramic cutting tool is more than or equal to 65N, and the surface micro hardness HV is more than or equal to 3400. The method is suitable for manufacturing coating tools for low machinability materials, high speed dry-type milling stainless steel, iron-base super-alloy, high strength construction steel, wear-resistance cast steel, glass sealing alloy, and the like, and has good popularization and application prospect in manufacturing industries, such as automobile, aviation, space flight, resource equipment, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

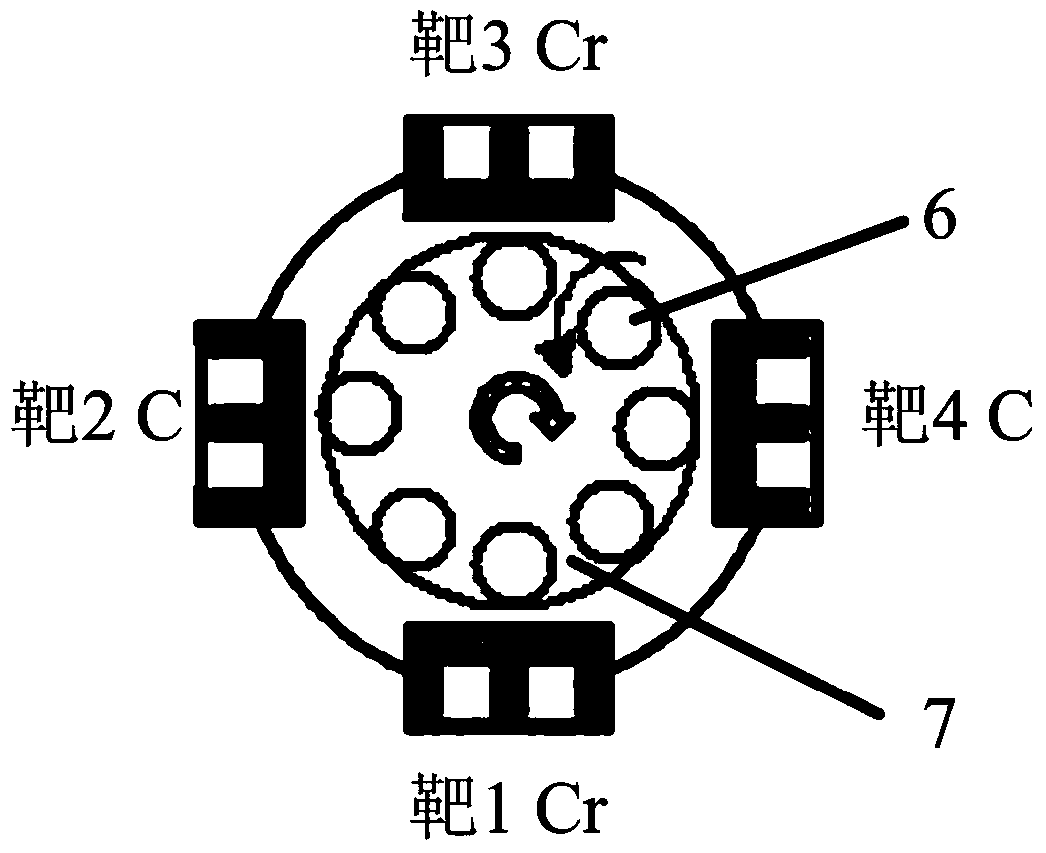

Method for preparing Cr/CrN/Cu-TiN film on surface of stainless steel operation instrument

InactiveCN104195508ALow costIncrease anti-adhesive and antibacterial propertiesVacuum evaporation coatingSputtering coatingEtchingSputter cleaning

The invention discloses a method for preparing a Cr / CrN / Cu-TiN film on the surface of a stainless steel operation instrument, and relates to a method for preparing a film on the surface of a stainless steel instrument, aiming at solving the problem that patients suffer from cross infection in operation as body fluid, such as blood largely adhered to a conventional operation instrument, so that the operation instrument cannot be completely cleaned, sterilized and disinfected. The method comprises the following steps: I, performing ultrasonic washing; II, performing chemical etching; III, performing Ar ion sputter cleaning; IV, performing Cr ion sputter cleaning; V, depositing a Cr layer; VI, depositing a CrN layer; VII, depositing a Cu-TiN layer, that is, the preparation for the Cr / CrN / Cu-TiN film is completed on the surface of the stainless steel operation instrument. The method has the advantages that the thickness of the Cr / CrN / Cu-TiN film is greatly smaller than that of a conventional Cr or Ni film, so that the cost is saved, and the anti-adhesion and antibacterial properties are improved. The method is mainly used for preparing Cr / CrN / Cu-TiN films on the surfaces of the stainless steel operation instruments.

Owner:JIAMUSI UNIVERSITY

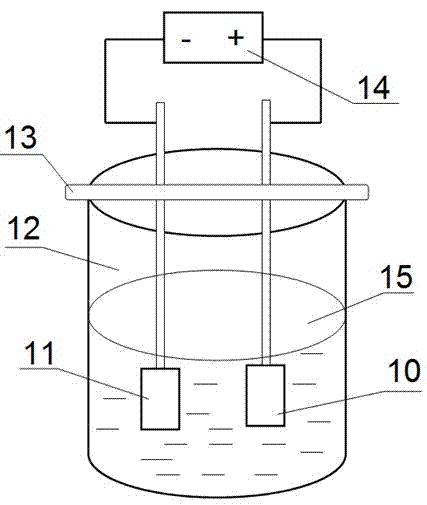

Method for preparing Ag-Ti-O antibacterial nanotube film on surface of titanium alloy

InactiveCN103046056AStrong and long-lasting antibacterial abilityLow cytotoxicityVacuum evaporation coatingSurface reaction electrolytic coatingSputter cleaningBiocompatibility Testing

The invention provides a method for preparing an Ag-Ti-O antibacterial nanotube film on the surface of a titanium alloy, and belongs to the technical field of nanotube film preparation. The method is characterized by including placing a preprocessed test piece on a sample stage of pulse DC magneto-controlled sputter coating equipment, and placing a plane TiAg alloy target opposite to the sample; feeding argon into a vacuum chamber, and sputter-cleaning the vacuum chamber and the preprocessed test piece; coating a TiAg alloy film layer on the surface of the test piece after the cleaning; and then performing anodic oxidation treatment on the alloy film layer to prepare the Ag-Ti-O nanotube film. The film prepared through the method is good in film-substrate cohesion, and has a long-acting antibacterial property and excellent biocompatibility.

Owner:TAIYUAN UNIV OF TECH

Method for preparing carbon-doped titanium oxide thin film with photocatalytic activity

InactiveCN102489286ASolve the immobilization problemProcess stabilityPhysical/chemical process catalystsSputter cleaningTitanium thin film

Owner:HAINAN UNIVERSITY

Method for preparing a coating of the surface of medical devices made of nickel-titanium alloy

ActiveUS20120094143A1Lower resistanceFewer penetrable holesSurgeryVacuum evaporation coatingSputter cleaningBiocompatible coating

Provided is a method for plating a biocompatible coating with nano structure on the surface of a nickel-titanium shape memory alloy, particularly a method suitable for plating a coating on the surface of medical devices made of nickel-titanium alloy. The method includes the following steps: heat treating, surface pretreating, ion sputter cleaning, depositing a pseudodiffusion layer, plating a sub-layer film, plating a pure TiN layer, and so on. The coating has the following advantages: 1) it could deform in response to the deformation of substrate without delaminating and cracking; 2) it has less resistance to the deformation of substrate; 3) it has less penetrable holes so as to reduce the dissolution of nickel into bio-body through these holes; 4) the coating has better biocompatibility compared to the substrate material.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

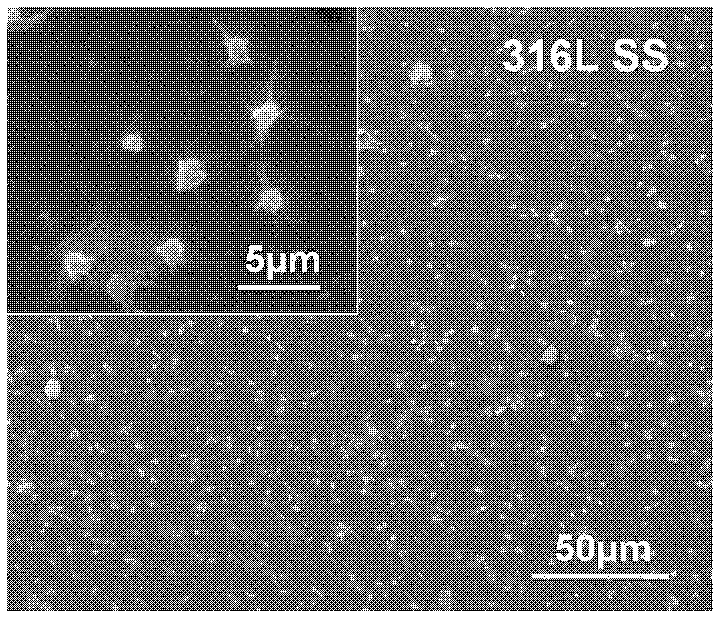

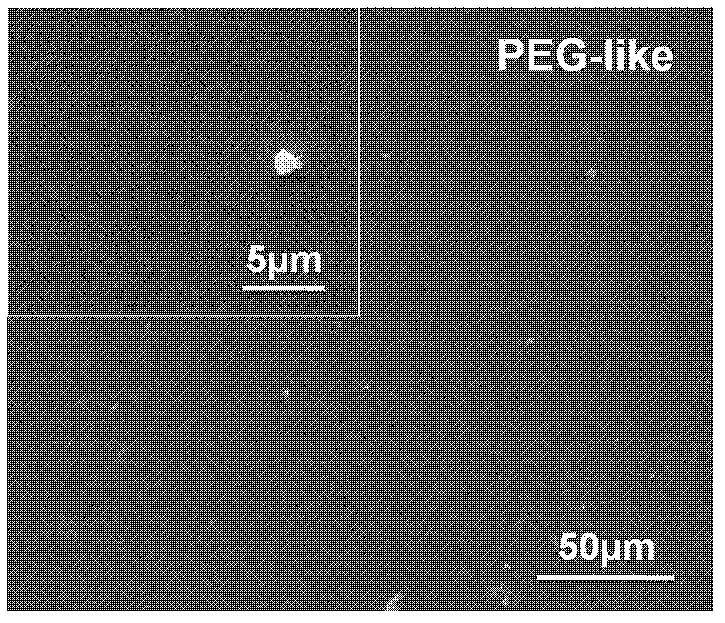

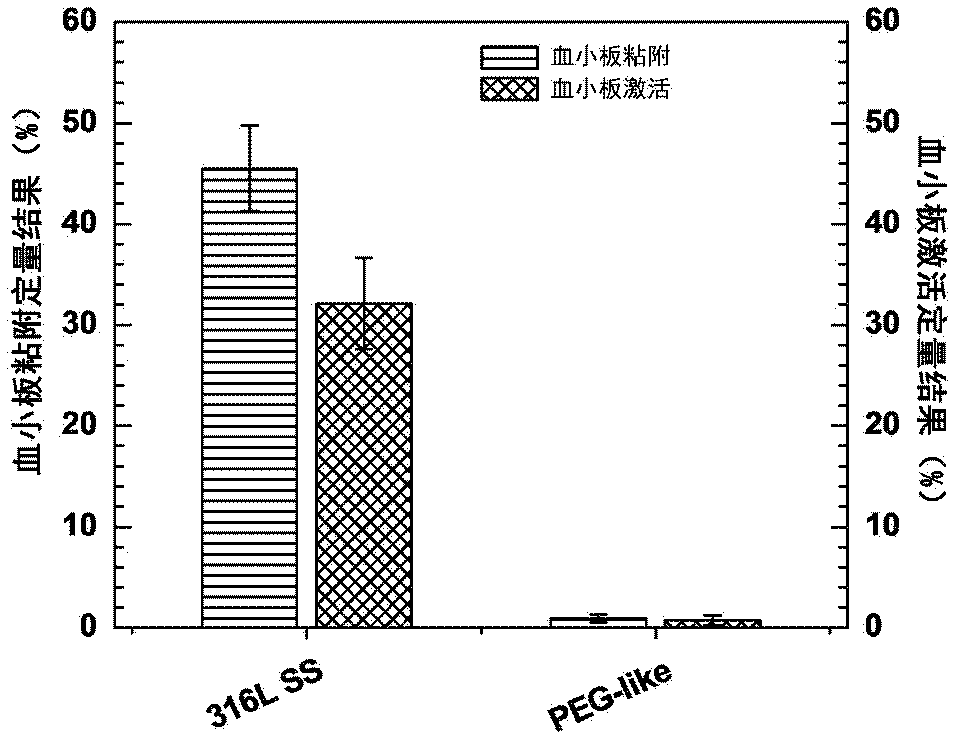

Preparation method of recyclable surface film of inferior vena cava filter based on (PEG) polyethylene glycol-like

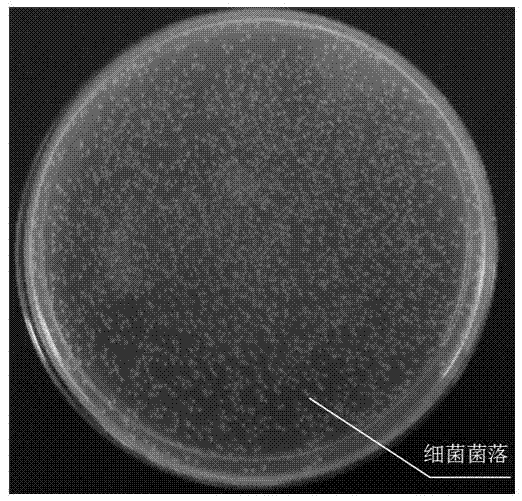

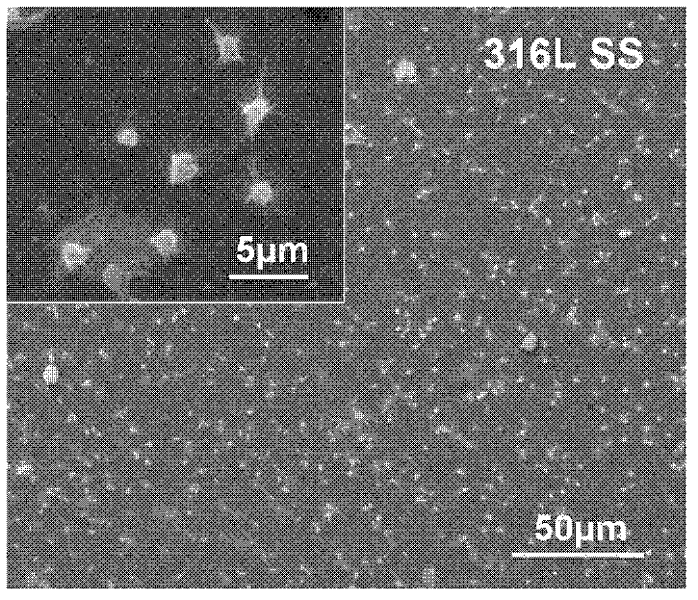

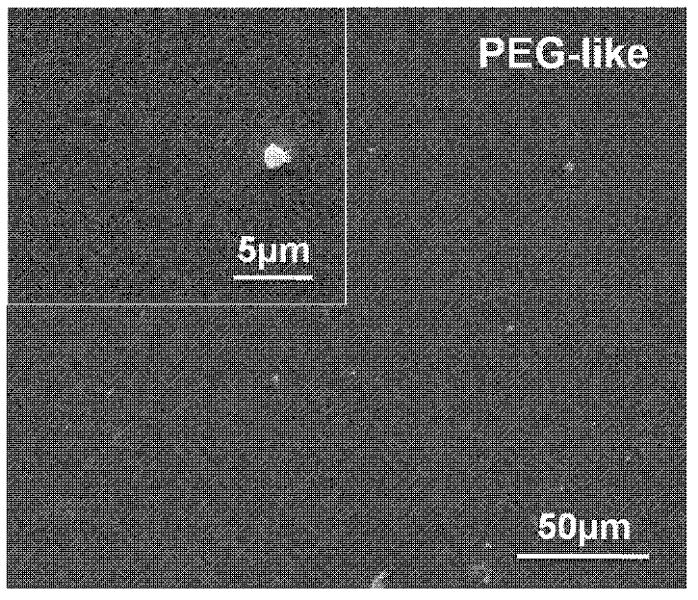

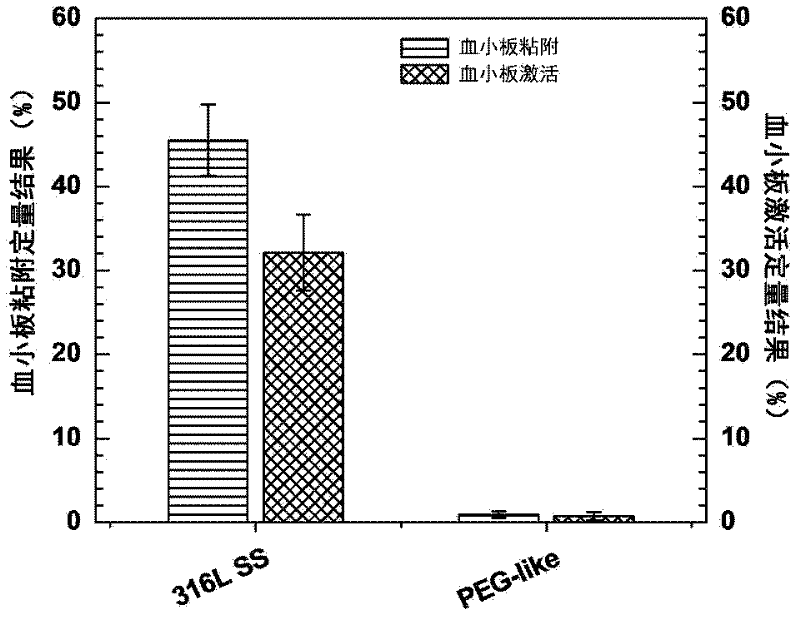

InactiveCN102330059AImprove bioremediation performanceHigh unit contentVacuum evaporation coatingSputtering coatingTetraglycolCell adhesion

The invention discloses a preparation method of a recyclable surface film of an inferior vena cava filter based on (PEG) polyethylene glycol-like, which comprises the following steps of: feeding the inferior vena cava filter in a plasma polymerization vacuum chamber; when the vacuum degree reaches 0.5Pa, introducing argon gas with the flow of 2.5sccm and carrying out sputter cleaning for 15 minutes under the conditions that the radio-frequency power is 100W and the negative bias voltage is 80V; after the sputter cleaning is finished, vacuumizing the vacuum chamber to be 0.5Pa again; and introducing a reacting gas of tetraglycol dimethyl ether and depositing a plasma polymer thin film for 30-120 minutes under the conditions that the work pressure is 2-5Pa, the radio-frequency power is 5-30W, the negative bias voltage is 80V and the pulse duty factor is 10-100 percent. The inferior vena cava filter prepared by the method disclosed by the invention has strong binding force between the surface-like PEG thin film layer and the inferior vena cava filter and excellent bioremediation performance for resisting protein and cell from adhering.

Owner:CHENGDU SOUTHWEST JIAOTONG UNIV SCI & TECH GARDEN MANAGEMENT +1

Preparation method of 6LiF conversion film used for 4H-SiC-based semiconductor neutron detector

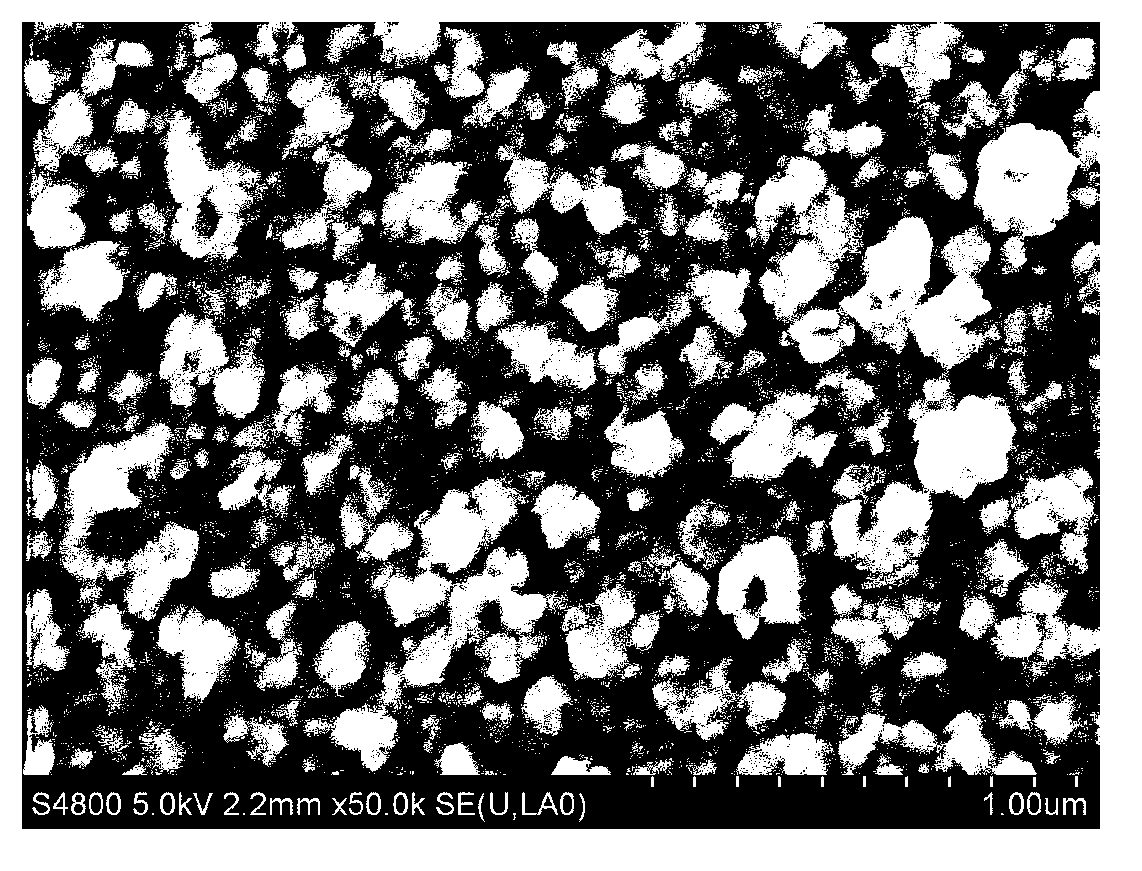

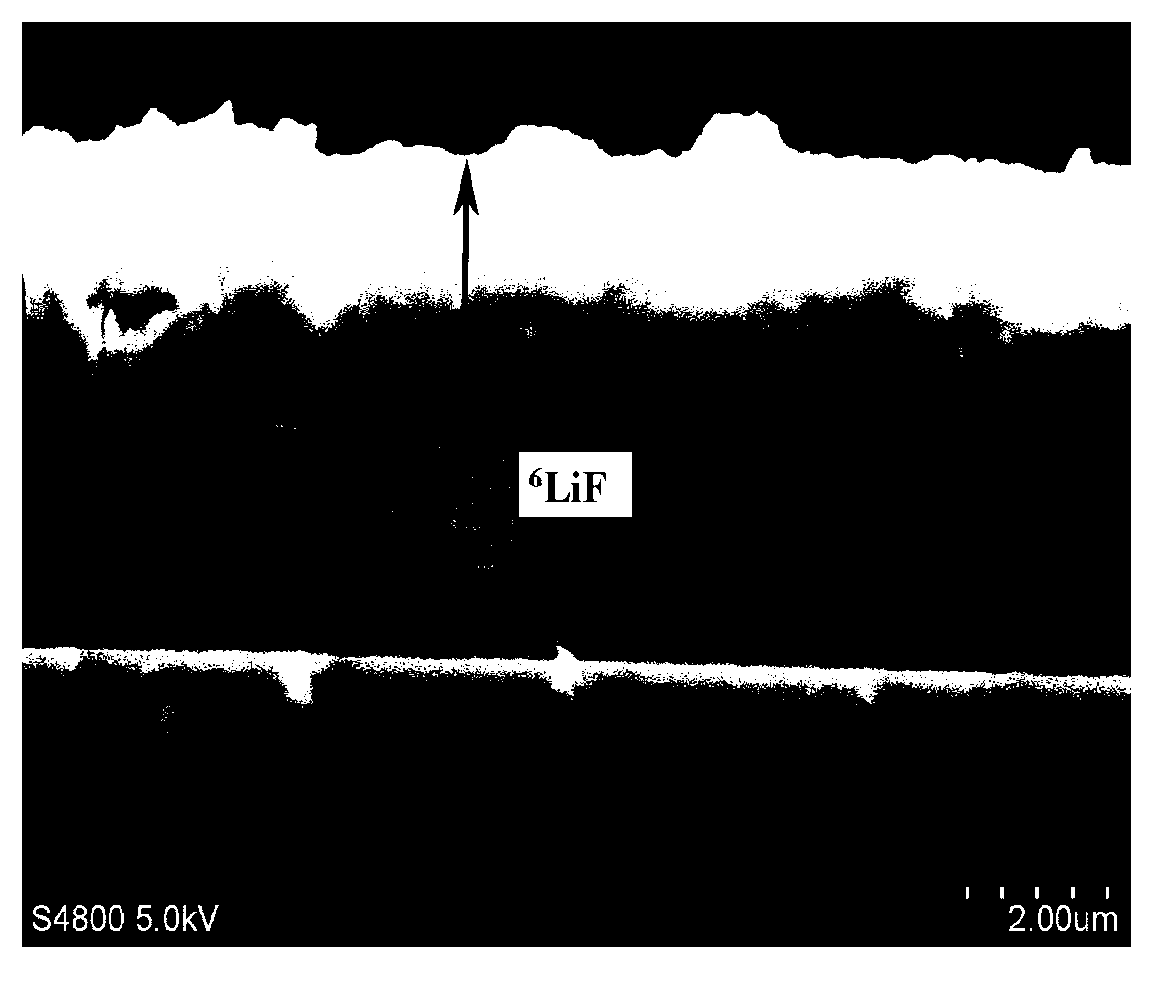

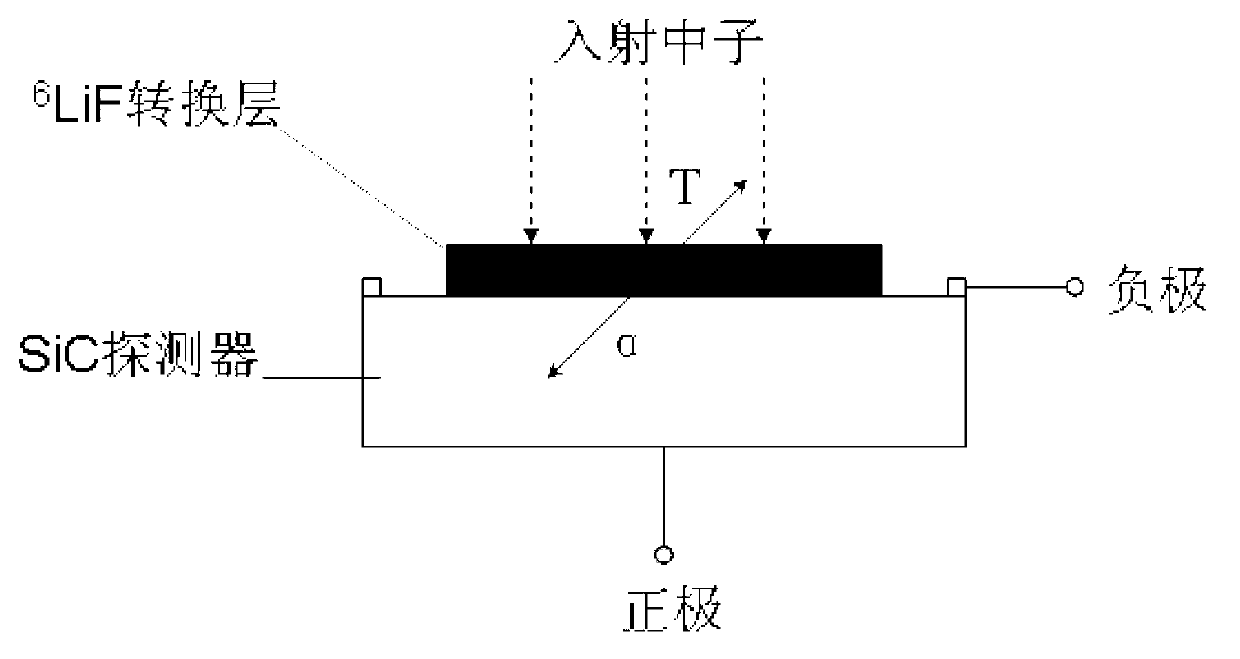

InactiveCN103132037AWide bandgapLarge crystal atomic off-site energyMeasurement with semiconductor devicesVacuum evaporation coatingSputter cleaningSingle crystal

The invention discloses a preparation method of a 6LiF conversion film used for a 4H-SiC-based semiconductor neutron detector. The preparation method mainly includes the following steps: a single-crystal 4H-SiC matrix is respectively immersed in acetone and absolute ethyl alcohol for ultrasonic cleaning; impurities in the single-crystal 4H-SiC matrix are removed by using of the method of unsymmetrical pressure anti-sputter-cleaning, and impurities of 6LiF target material are removed by using of the method of pre-sputter-cleaning; the 6LiF target material is used as a magnetic-control target, and a 6LiF coating is deposited on the single-crystal 4H-SiC matrix in a sputtered mode; argon is used as luminance build-up gas for the sputtering cleaning and the sputtering deposition; and the sputtering deposition is controlled by magnetism so that the thickness of the 6LiF coating can reach a designed thickness, the vacuum degree in a reaction magnetron sputtering coated vacuum furnace is adjusted to not less than 10<-3>Pa, the 6LiF coating is discharged from the furnace after natural cooling, and then the 6LiF coating conversion film deposited on the 4H-SiC matrix is obtained. The obtained 4H-SiC / 6LiF conversion film has the advantages of being small in size, high in detection efficiency, irradiation-damage-resisting, heat-resisting, strong in n / gamma screening capacity and the like, preparation technology is simple in operation, and the thickness of the 6LiF conversion film can be controlled.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF +1

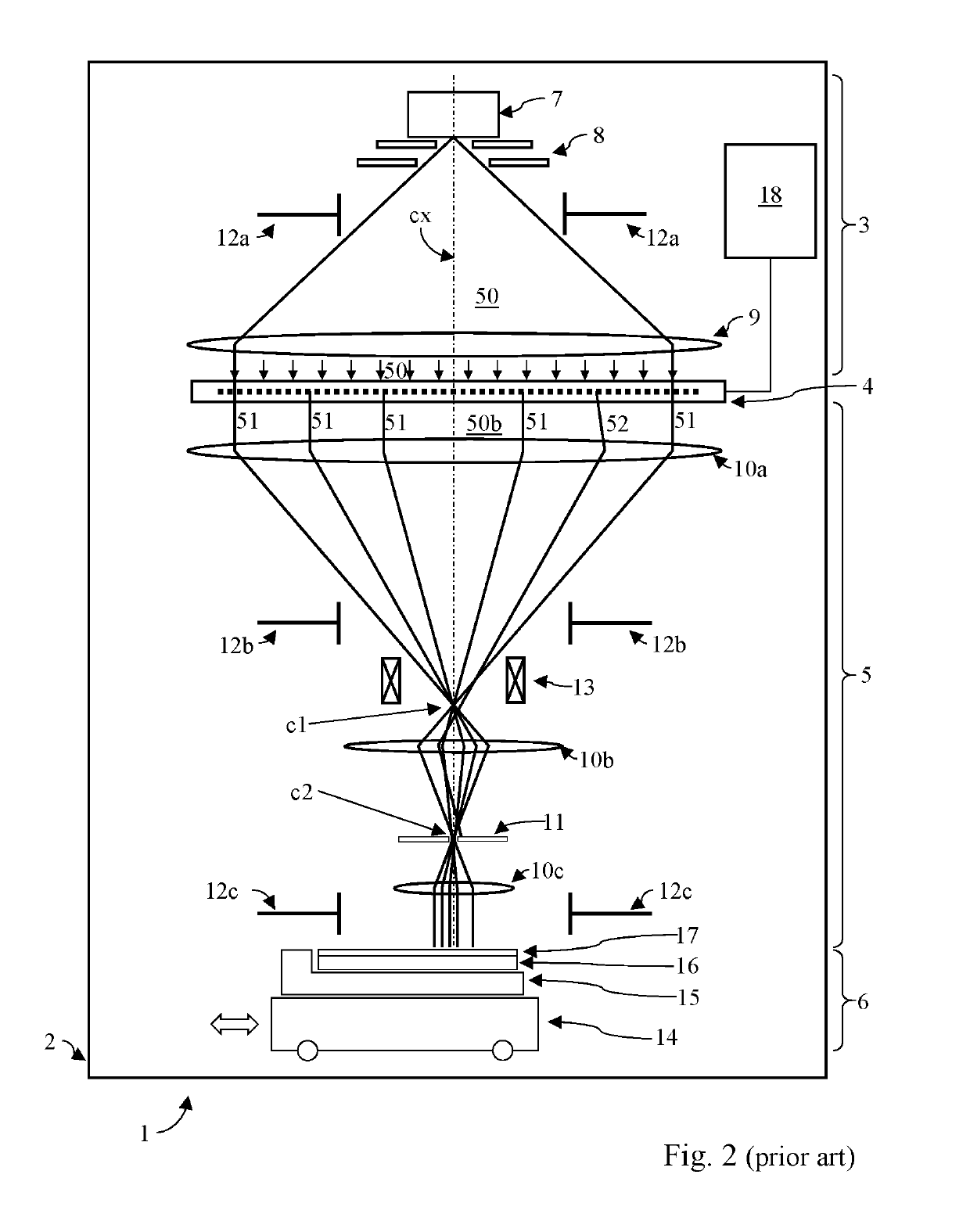

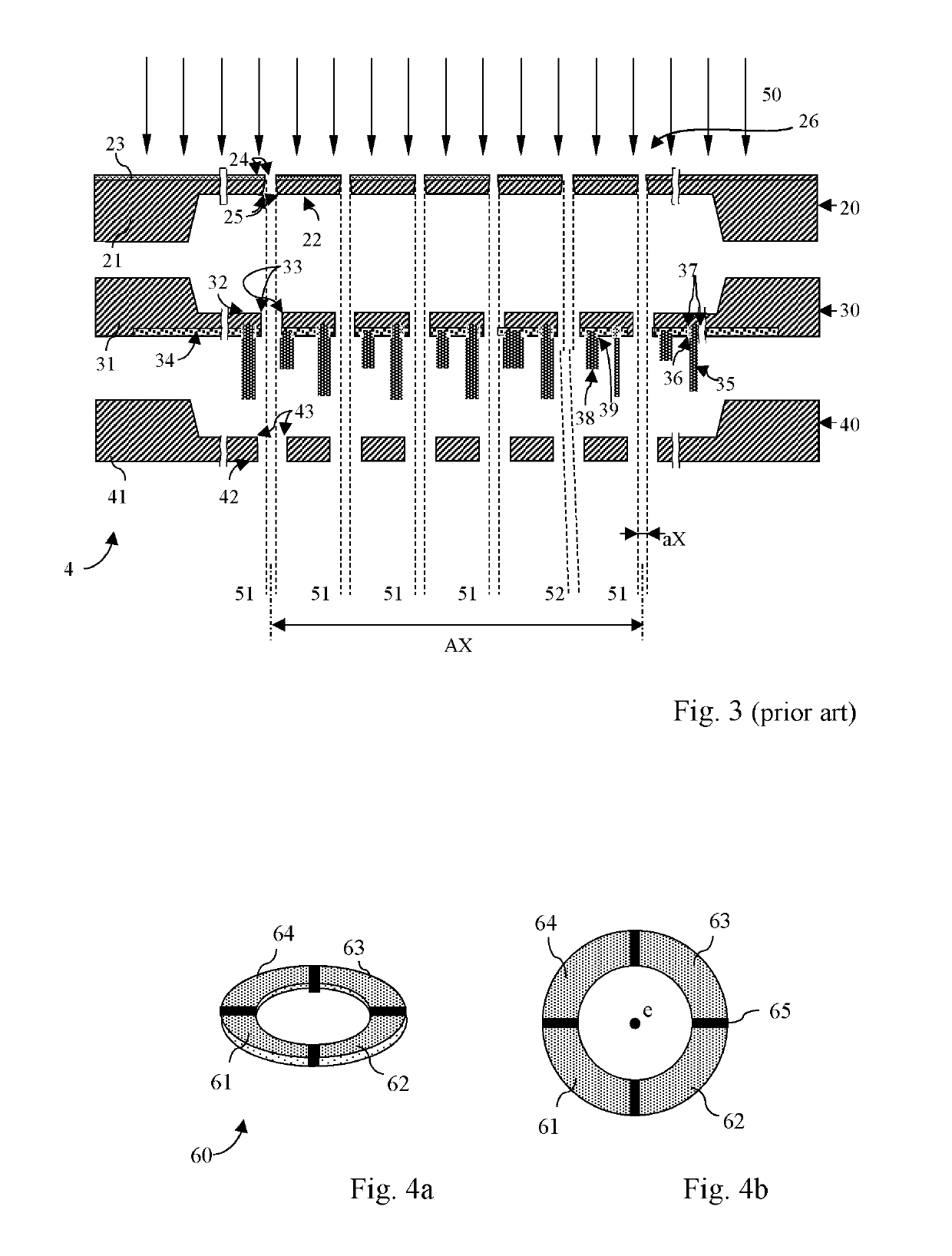

Charged-Particle Source and Method for Cleaning a Charged-Particle Source Using Back-Sputtering

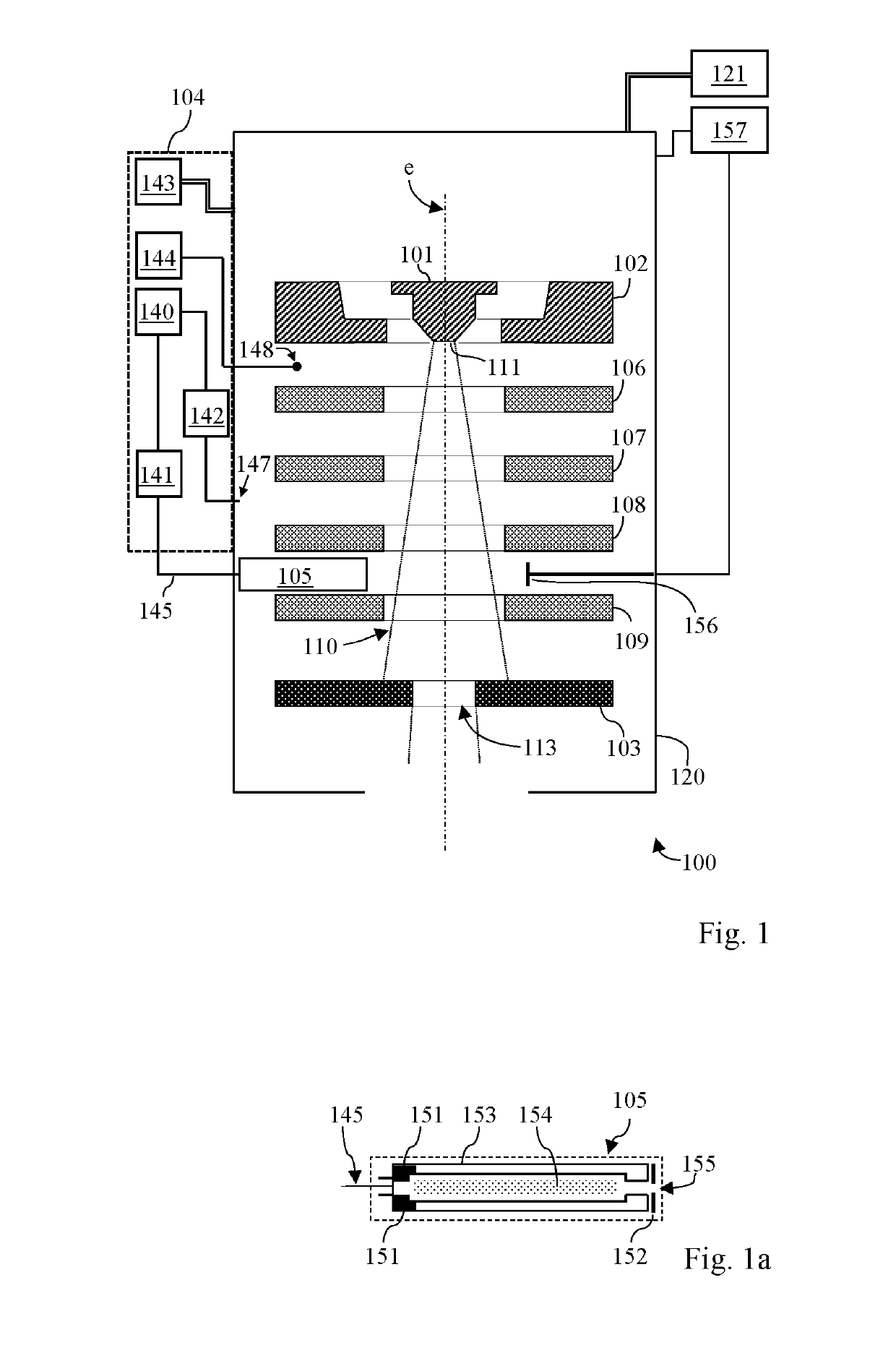

ActiveUS20190237288A1Increased ionizationEfficient implementationElectric discharge tubesSputter cleaningSecondary electrons

A charged-particle source for emission of electrons or other electrically charged particles comprises, located between the emitter electrode having an emitter surface and a counter electrode, at least two adjustment electrodes; a pressure regulator device is configured to control the gas pressure in the source space at a pre-defined pressure value. In a first cleaning mode of the particle source, applying a voltage between the emitter and counter electrodes directs gas particles towards the counter electrode, generating secondary electrons which ionize particles of the gas in the source space, and electrostatic potentials are applied to at least some of the adjustment electrodes, generating an electric field directing the ionized gas particles onto the emitter surface.

Owner:IMS NANOFABTION

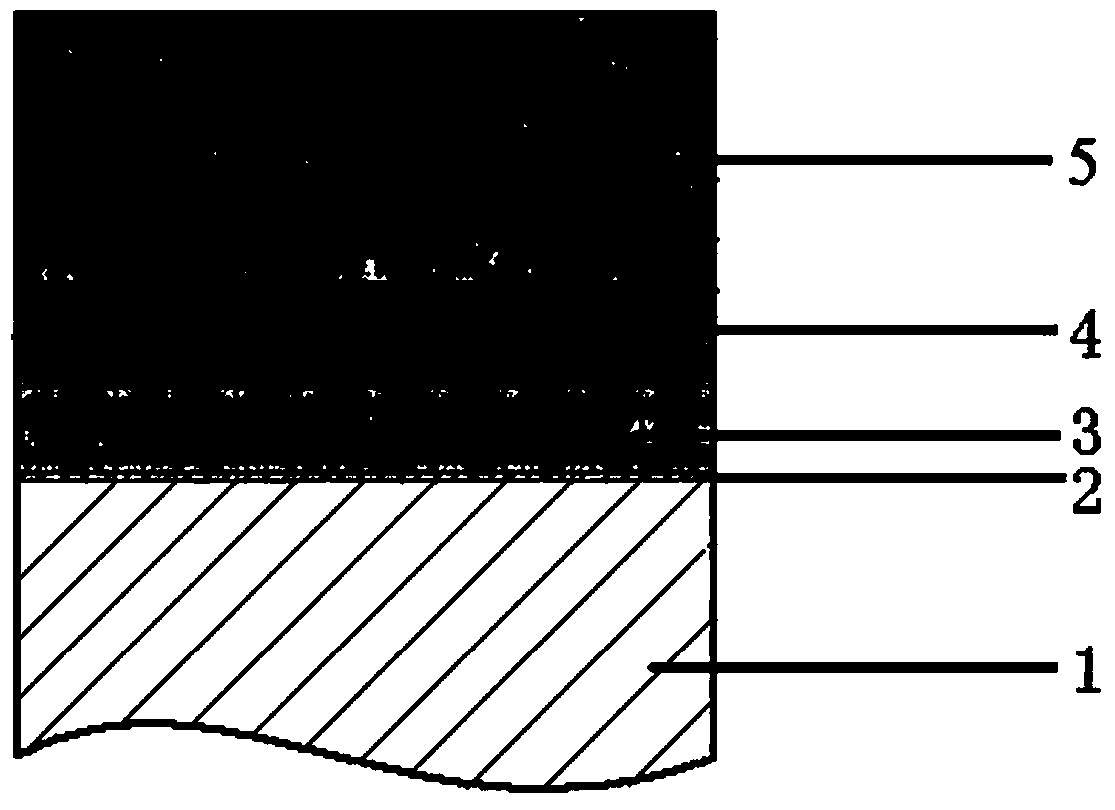

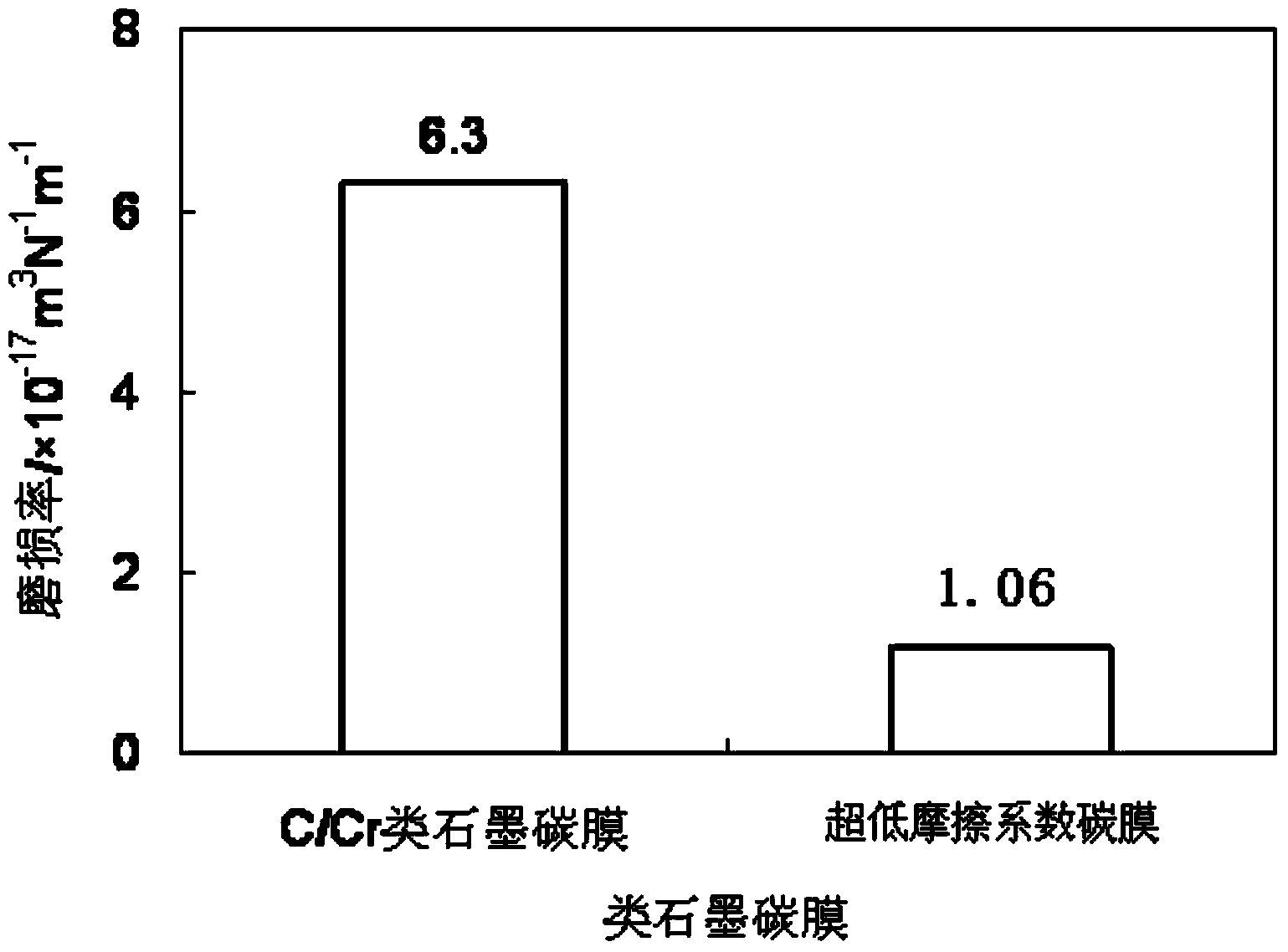

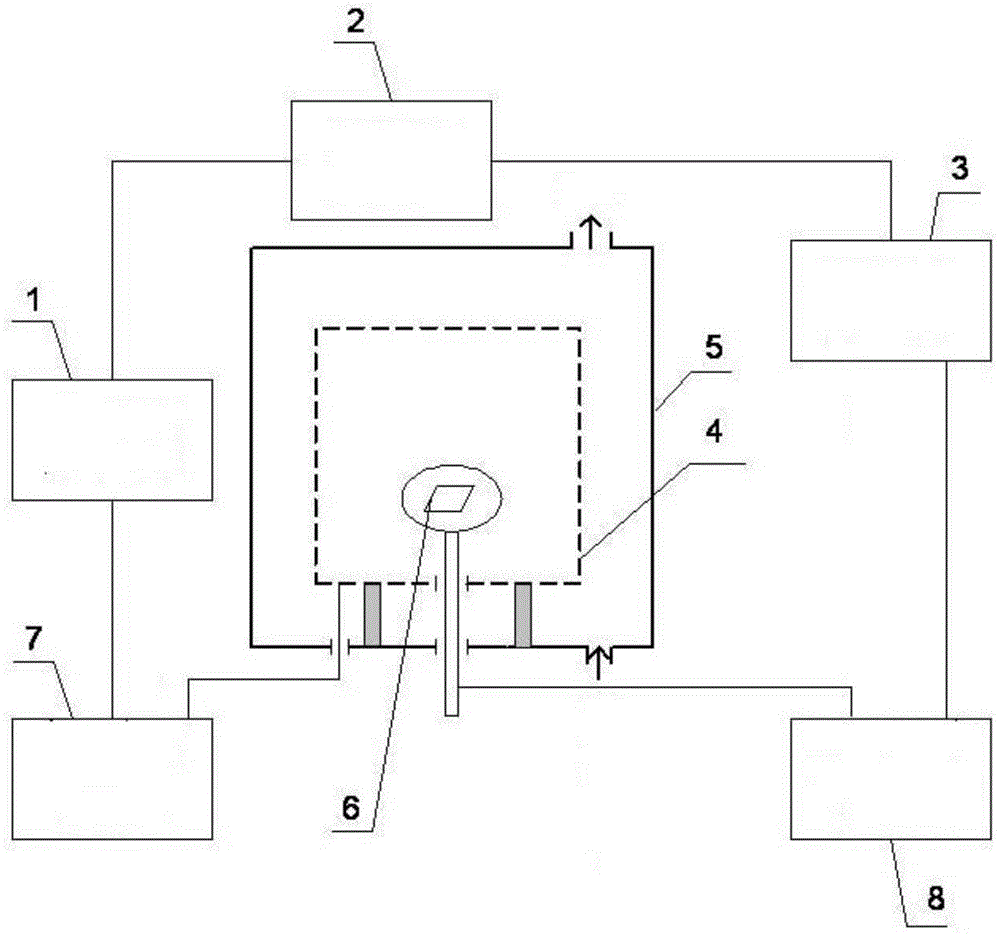

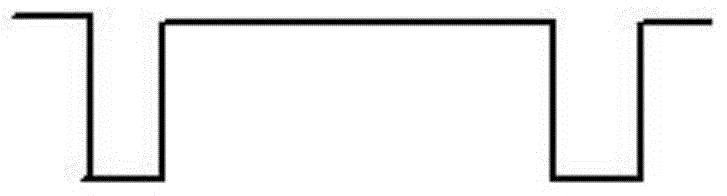

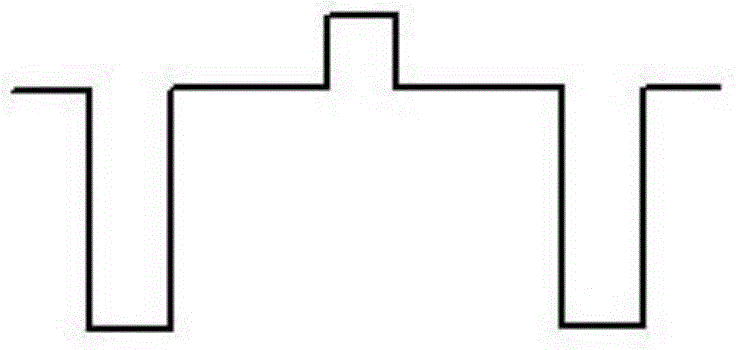

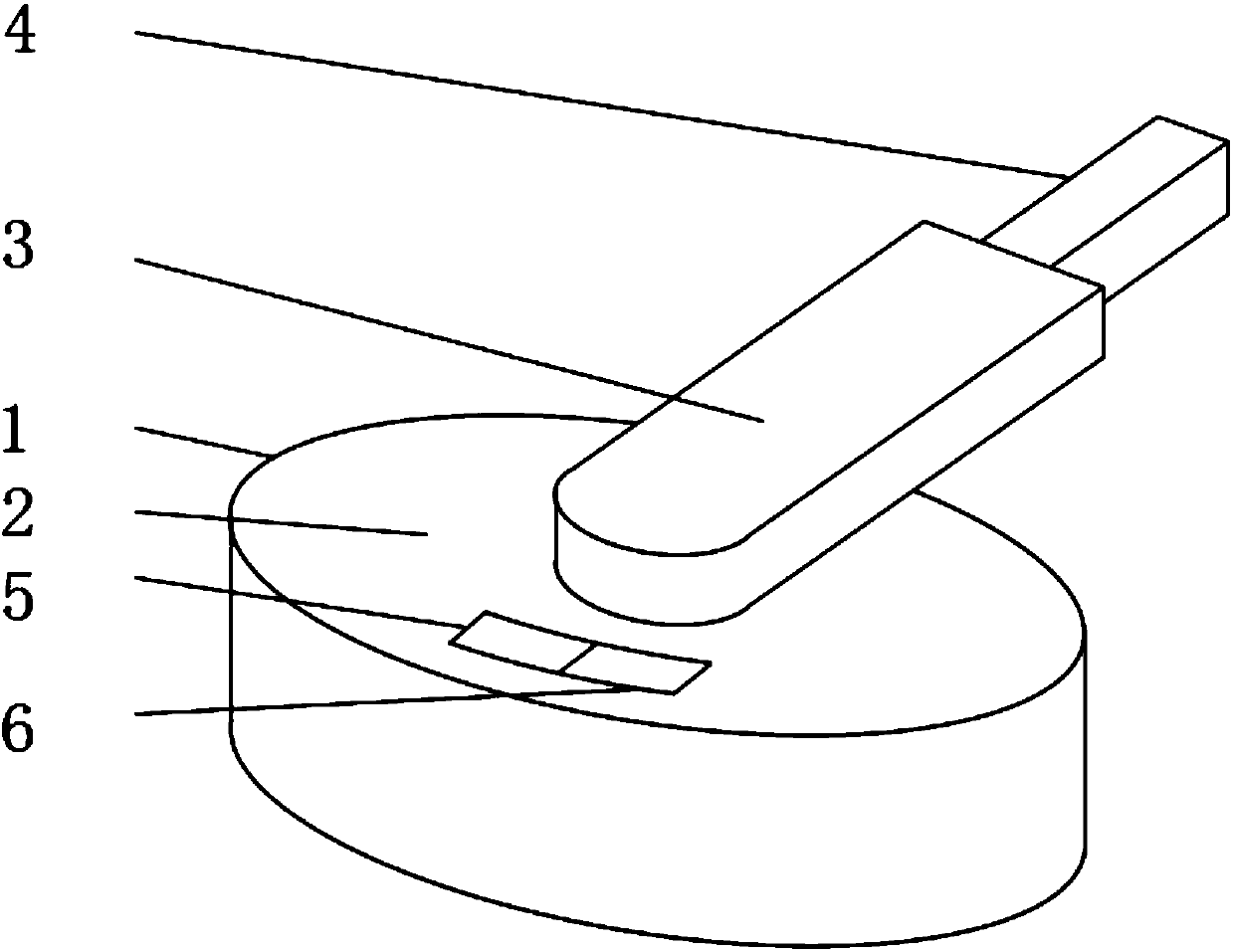

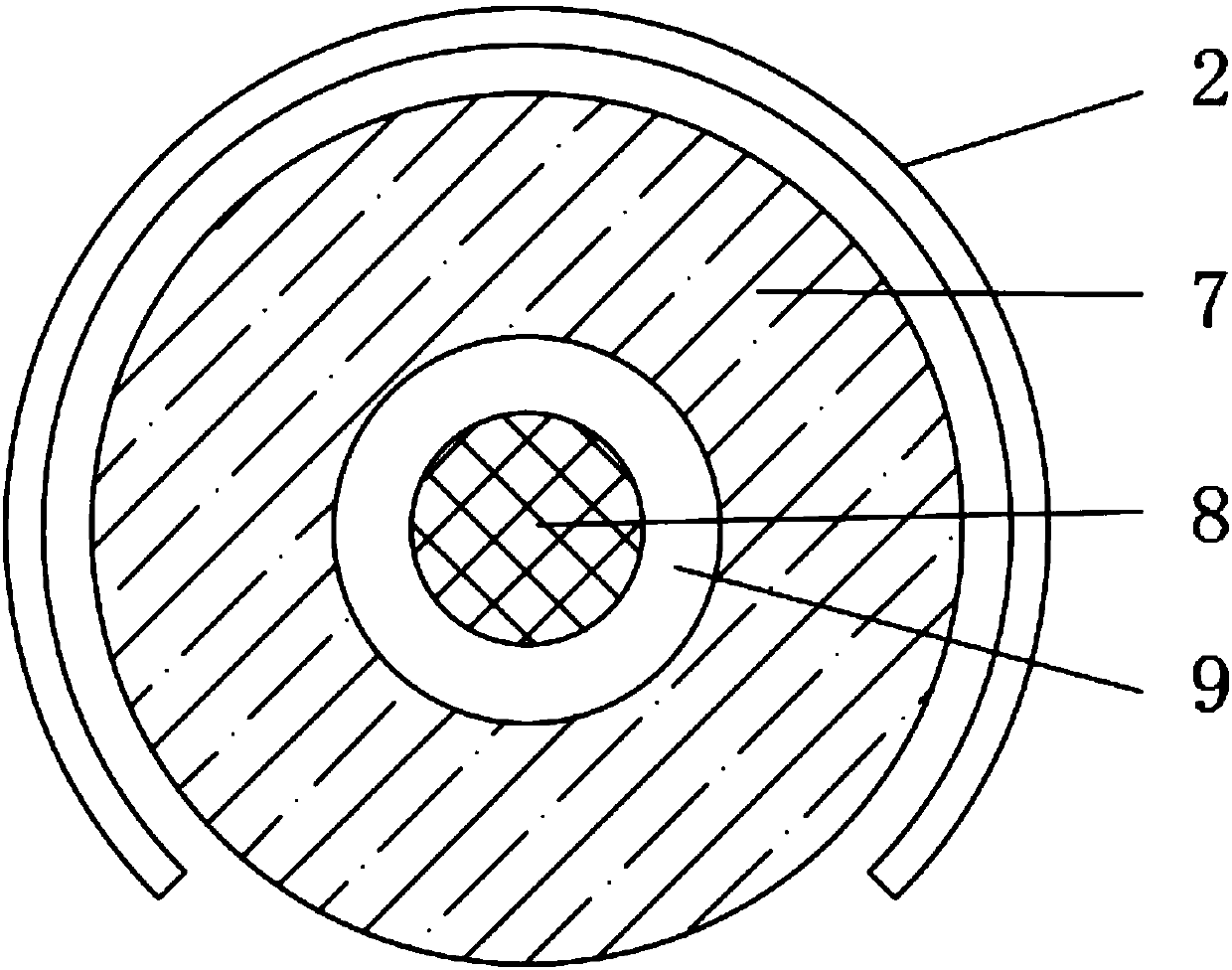

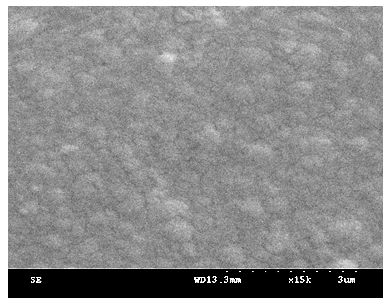

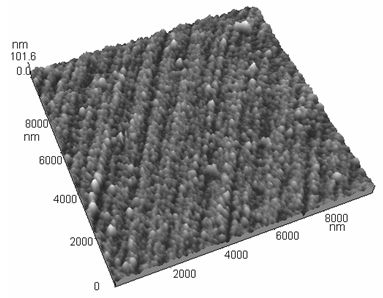

Super-lubricated surface strengthening method of graphite-like carbon film for high-speed gear

ActiveCN103469217AImprove friction and wear performanceImprove transmission efficiencySurface finishCarbon film

The invention relates to a super-lubricated surface strengthening method of a graphite-like carbon film for a high-speed gear. The method comprises the following steps: firstly, sequentially carrying out shot blasting, micro-jetting and fluid polishing pre-treatment on the surface of the gear to enable the surface smoothness of the gear to be less than 0.2 micron; then, by adopting an unbalanced magnetron sputtering composite target technology, introducing elements such as Y and Ta into a graphite-like carbon film preparation technology to prepare a graphite-like carbon film with ultralow friction coefficient on the surface of the gear, namely carrying out sputter cleaning on the surface of a base metal 1; and sequentially preparing a Cr transitional layer 3, a Cr / C gradient layer 4 and a graphite-like composite work layer 5 with ultralow friction coefficient on a fluid polishing surface layer 2. The method provided by the invention solves the problem that a solid lubricating film of the high-speed gear is short in service life, and the vibrating noise of the high-speed gear is effectively reduced. The vibrating noise of a transmission gear by adopting the technology is reduced by 10-15%, so that the method provides a novel technical path for reducing the vibrating noise of the gear.

Owner:CSIC NO 12 RES INST

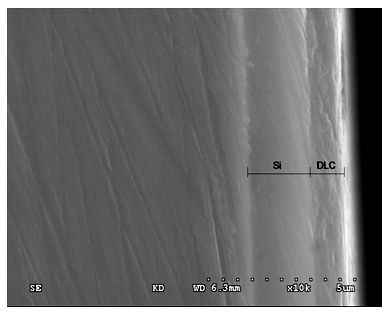

Bias voltage regulation and control aperture plate plasma immersion ionic deposition DLC method

ActiveCN105112883ARealize the structureAchieve stressChemical vapor deposition coatingSputter cleaningVoltage regulation

The invention discloses a bias voltage regulation and control aperture plate plasma immersion ionic deposition DLC method, and relates to a plasma immersion ionic deposition DLC method. The method aims at solving the problems that when an existing MPIID method is used for depositing a DLC film, the bonding force is poor, the performance of the film is not prone to being regulated and controlled, and the DLC film deposited on large or complex parts is uneven. The method includes the steps that (1) an aperture plate and a workpiece are arranged in a vacuum chamber, the workpiece is placed on a sample support in the aperture plate, the aperture plate and the workpiece are insulated, the aperture plate is connected with a aperture plate high-voltage pulse power source, and the workpiece is connected with a workpiece high-voltage pulse power source; (2) workpiece sputter cleaning is carried out; (3) plasma nitrogen treatment is carried out; (4) sputtering etching treatment is carried out; (5) a SiC transition layer is manufactured; and (6) a bias voltage regulation and control thin film is manufactured. The method is used for manufacturing the bias voltage regulation and control aperture plate plasma immersion ionic deposition DLC film.

Owner:HARBIN INST OF TECH

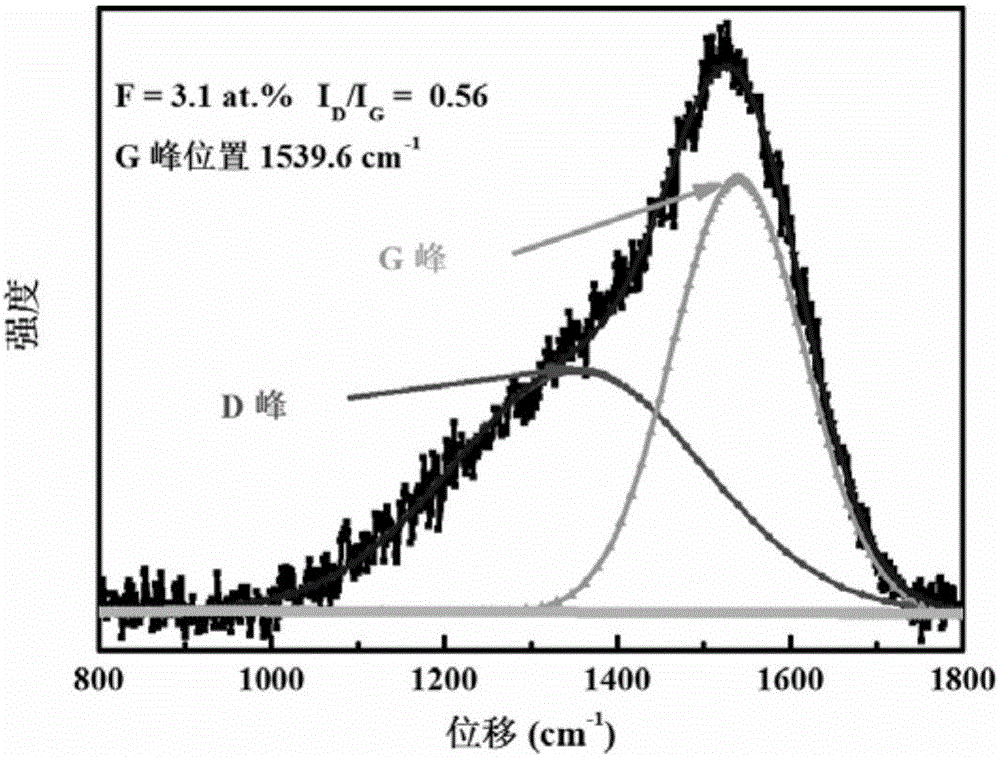

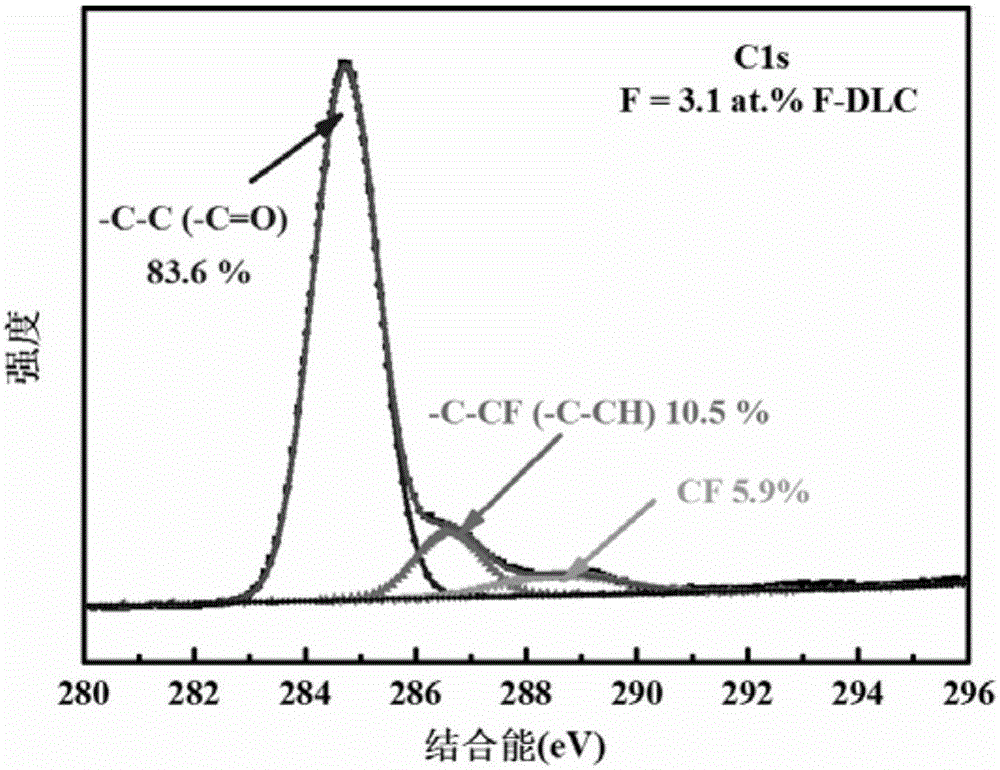

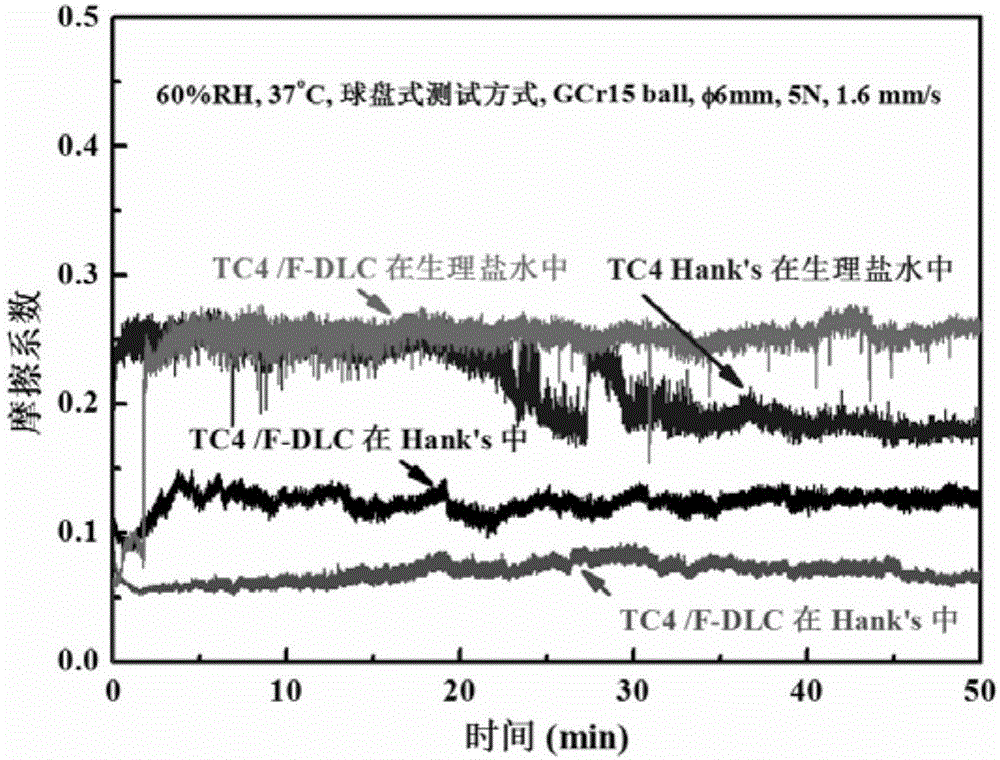

Method for preparing antifriction wear-resistant F-DLC film on titanium alloy surface

InactiveCN106498362AHigh hardnessImprove wear resistanceChemical vapor deposition coatingSputter cleaningWear resistant

The invention discloses a method for preparing an antifriction wear-resistant F-DLC film on a titanium alloy surface. A plate hollow cathode HP-PECVD method is adopted. According to the plate hollow cathode HP-PECVD method, on the basis of a traditional PECVD method, a sample disk for carrying samples in an existing deposition system reaction chamber is changed into two parallel plates; a base body is placed between the two plates; negative bias voltage is applied to the space between the two plates to form a hollow cathode effect. The method specifically comprises the following steps of (1) pretreatment; (2) sputter cleaning; (3) deposition of a Si transition layer; and (4) deposition of the F-DLC film. The F-DLC film deposited on the titanium alloy surface through the method has the antifriction wear-resistant function, the tribology performance of titanium alloy in the vivo environment can be improved, and the problem that aseptic loosening complications caused by frictional wear of titanium alloy artificial joints is solved.

Owner:CHONGQING UNIV OF TECH

Low temperature preparation method for space silicon carbide reflector module modified layer

InactiveCN105970169AShorten the processing cycleReduce consumptionVacuum evaporation coatingSputtering coatingSputter cleaningOptoelectronics

The invention discloses a low temperature preparation method for a space silicon carbide reflector module modified layer. The low temperature preparation method for the space silicon carbide reflector module modified layer comprises the following steps of (1) SiC substrate cleaning: cleaning an SiC substrate by using ultra-phonic for 10-15 minutes and then drying the SiC substrate; (2) modified layer sputtering preparation: putting the cleaned SiC substrate onto a substrate frame of a film coating chamber of PVD film mulching equipment, and then vacuumizing the film coating chamber, and opening a baking device and baking at the temperature of 80-100 DEG C; (3) when the vacuum degree reaches 5x10-4P, opening an air inflating system to inflate methane as the reactant gas, and then cleaning the substrate in a re-sputter manner, and sputtering the substrate for 5-6 hours under the conditions that the bias voltage of the substrate is -50v[-]-200v and the sputtering power is 2000-3000W after the re-sputter cleaning, and finally obtaining a modified layer. According to the method, the modified layer is prepared in a magnetron sputtering manner by using methane as the reactant gas and reacting at 80-100 DEG C, so that the sputtering rate is high, the machining cycle of the modified layer of an SiC base is shortened and the energy source consumption is reduced.

Owner:NANJING SIMITE OPTICAL INSTR

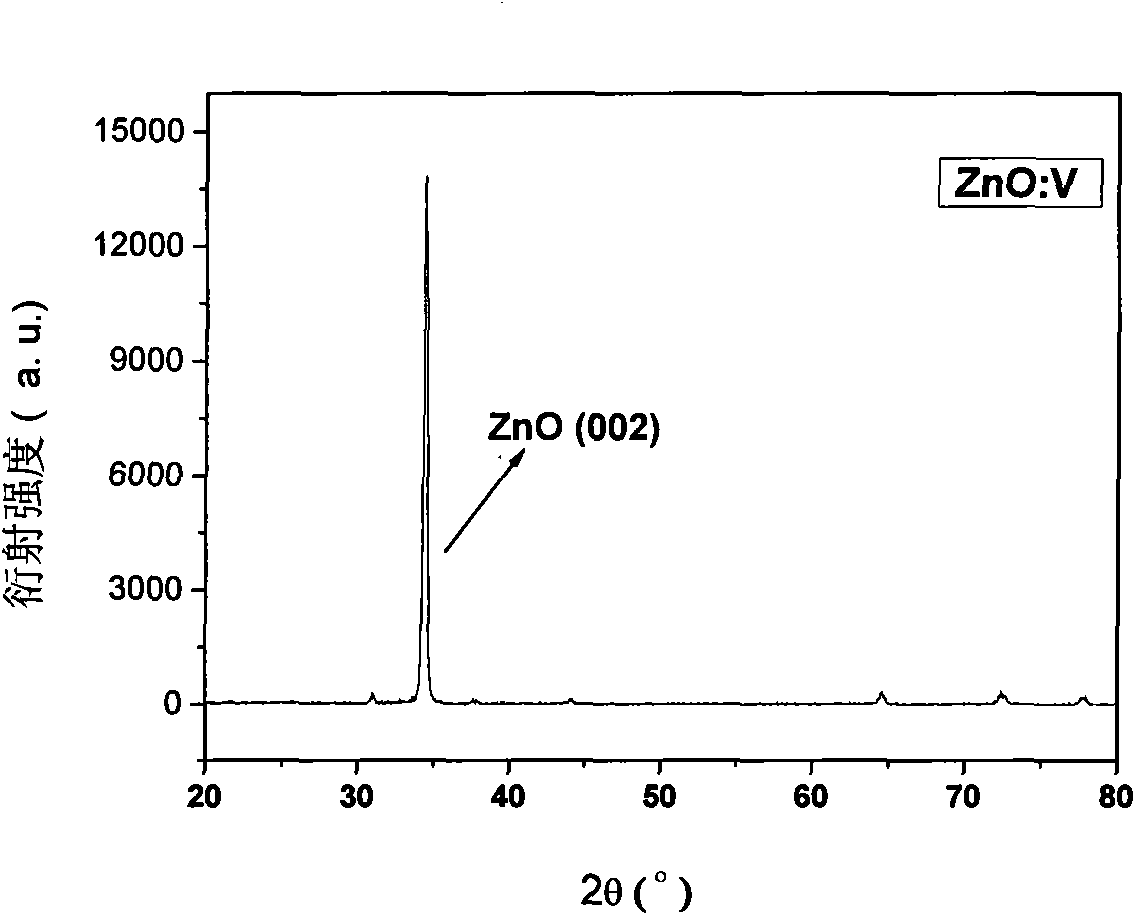

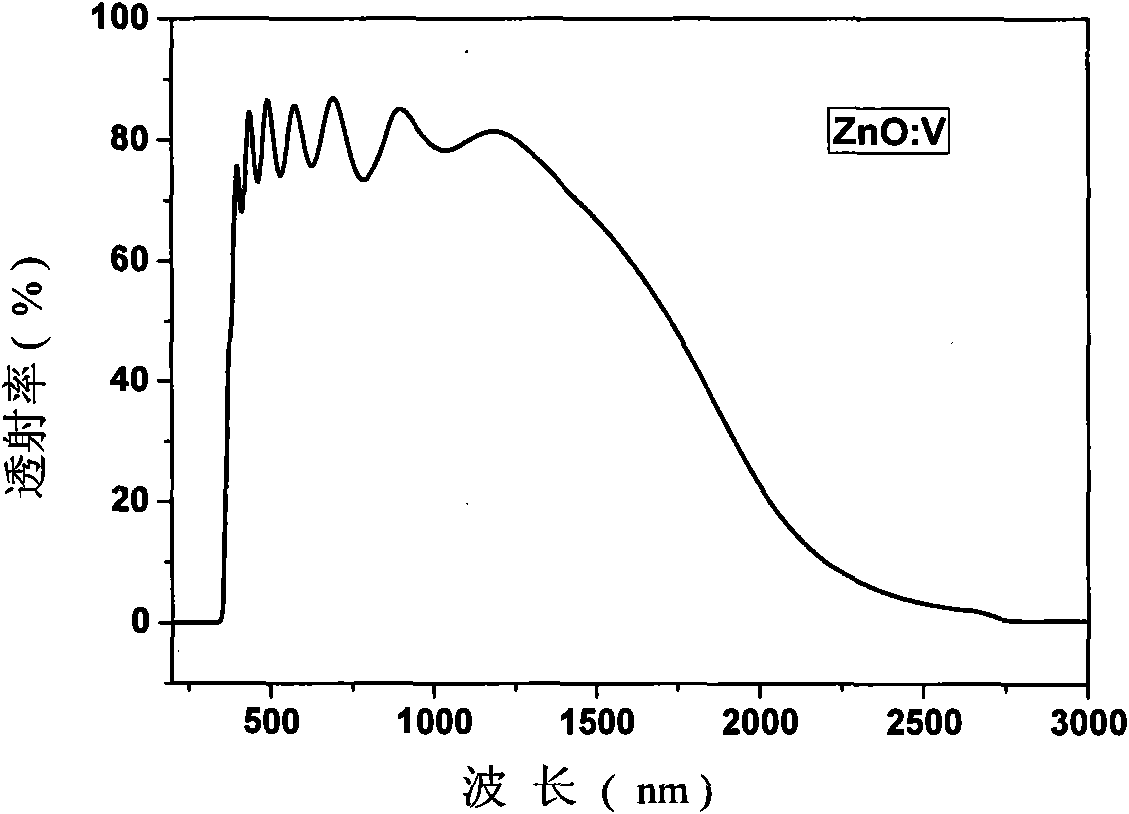

Low-temperature manufacturing method and special target of ZnO transparent conductive film

InactiveCN102080212AImprove performanceImprove mobilityVacuum evaporation coatingSputtering coatingSputter cleaningElectron mobility

The invention discloses a low-temperature manufacturing method and a special target of a ZnO transparent conductive film. The method comprises the following steps of: preparing a ceramic target by using V2O5 as a doping material of ZnO; carrying out plasma anti-sputter cleaning on a substrate with high-purity Ar; and then growing a V2O5-doped ZnO-based transparent conductive film at low temperature. The invention has the advantages that Zn<2+> is replaced with V<5+>, the valence state difference of the V<5+> and the Zn<2+> is 3, three conduction electrons can be provided, and then enough free carriers can be provided under the condition of low doping dose, the ionized impurity scattering is effectively lowered, the electron mobility is increased, and the combination property of the transparent conductive film is improved. Meanwhile, low-temperature growth realizes growth on flexible substrate materials such as organic polymers and the like and provides broader space for the application to flexible photoelectric devices. Treating the surface of the substrate in the way of plasma anti-sputter is beneficial to growing of high-quality films under the condition of low temperature.

Owner:上海太阳能电池研究与发展中心

Preparation method of recyclable surface film of inferior vena cava filter based on (PEG) polyethylene glycol-like

InactiveCN102330059BDeposition does not occur easilyNot easy to disengageVacuum evaporation coatingSputtering coatingTetraglycolSputter cleaning

The invention discloses a preparation method of a recyclable surface film of an inferior vena cava filter based on (PEG) polyethylene glycol-like, which comprises the following steps of: feeding the inferior vena cava filter in a plasma polymerization vacuum chamber; when the vacuum degree reaches 0.5Pa, introducing argon gas with the flow of 2.5sccm and carrying out sputter cleaning for 15 minutes under the conditions that the radio-frequency power is 100W and the negative bias voltage is 80V; after the sputter cleaning is finished, vacuumizing the vacuum chamber to be 0.5Pa again; and introducing a reacting gas of tetraglycol dimethyl ether and depositing a plasma polymer thin film for 30-120 minutes under the conditions that the work pressure is 2-5Pa, the radio-frequency power is 5-30W, the negative bias voltage is 80V and the pulse duty factor is 10-100 percent. The inferior vena cava filter prepared by the method disclosed by the invention has strong binding force between the surface-like PEG thin film layer and the inferior vena cava filter and excellent bioremediation performance for resisting protein and cell from adhering.

Owner:CHENGDU SOUTHWEST JIAOTONG UNIV SCI & TECH GARDEN MANAGEMENT +1

Preparation method of wear-resistant coating

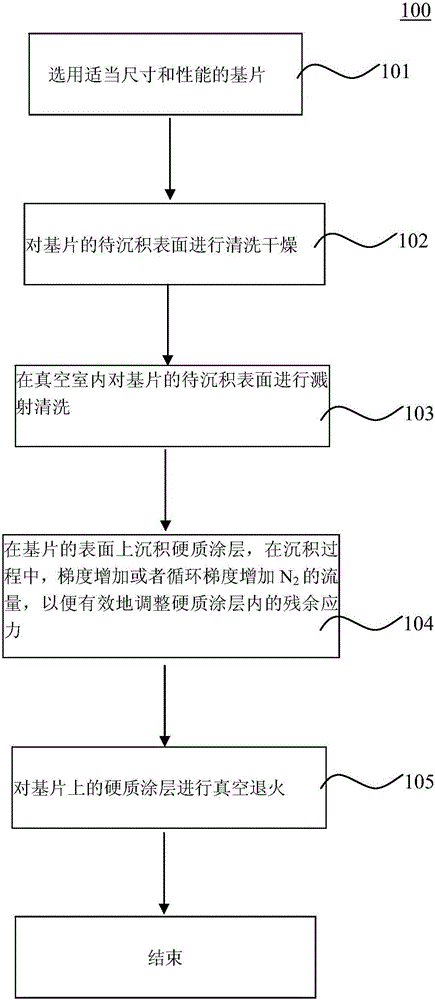

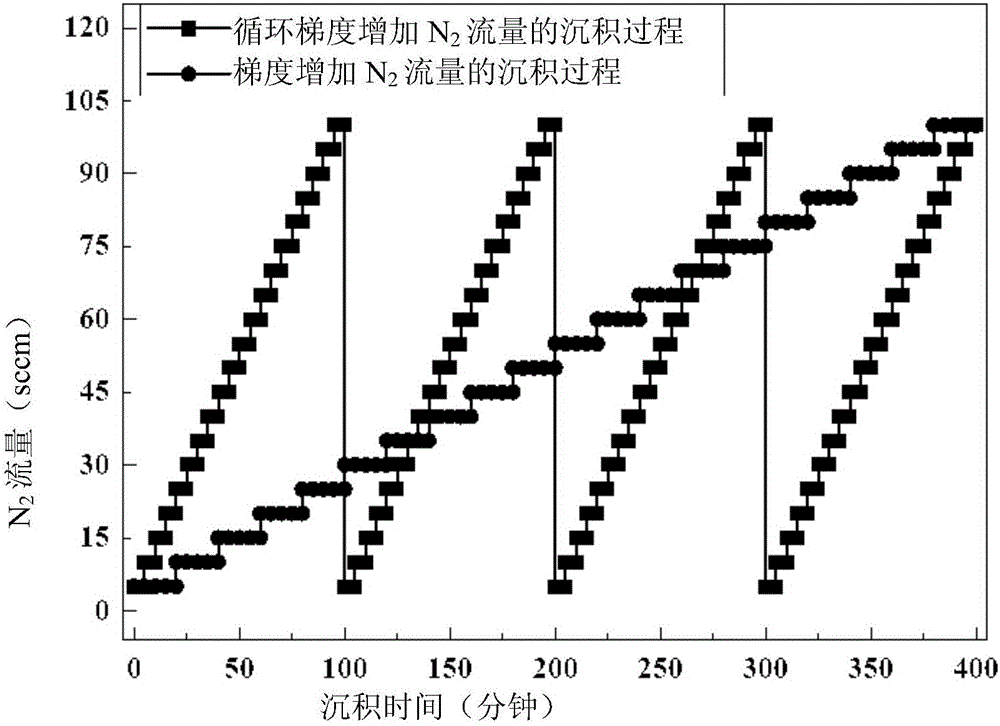

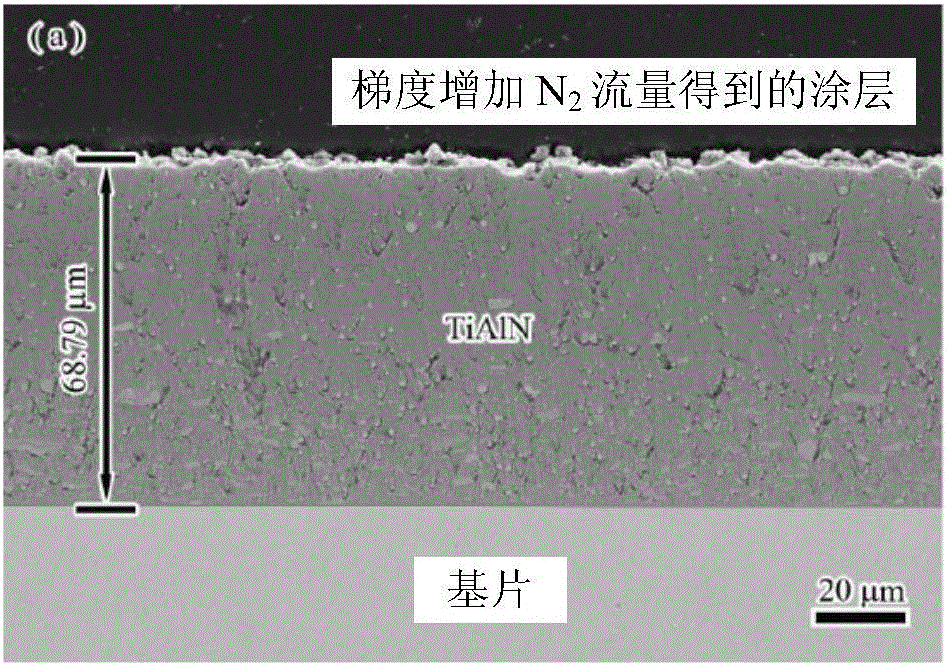

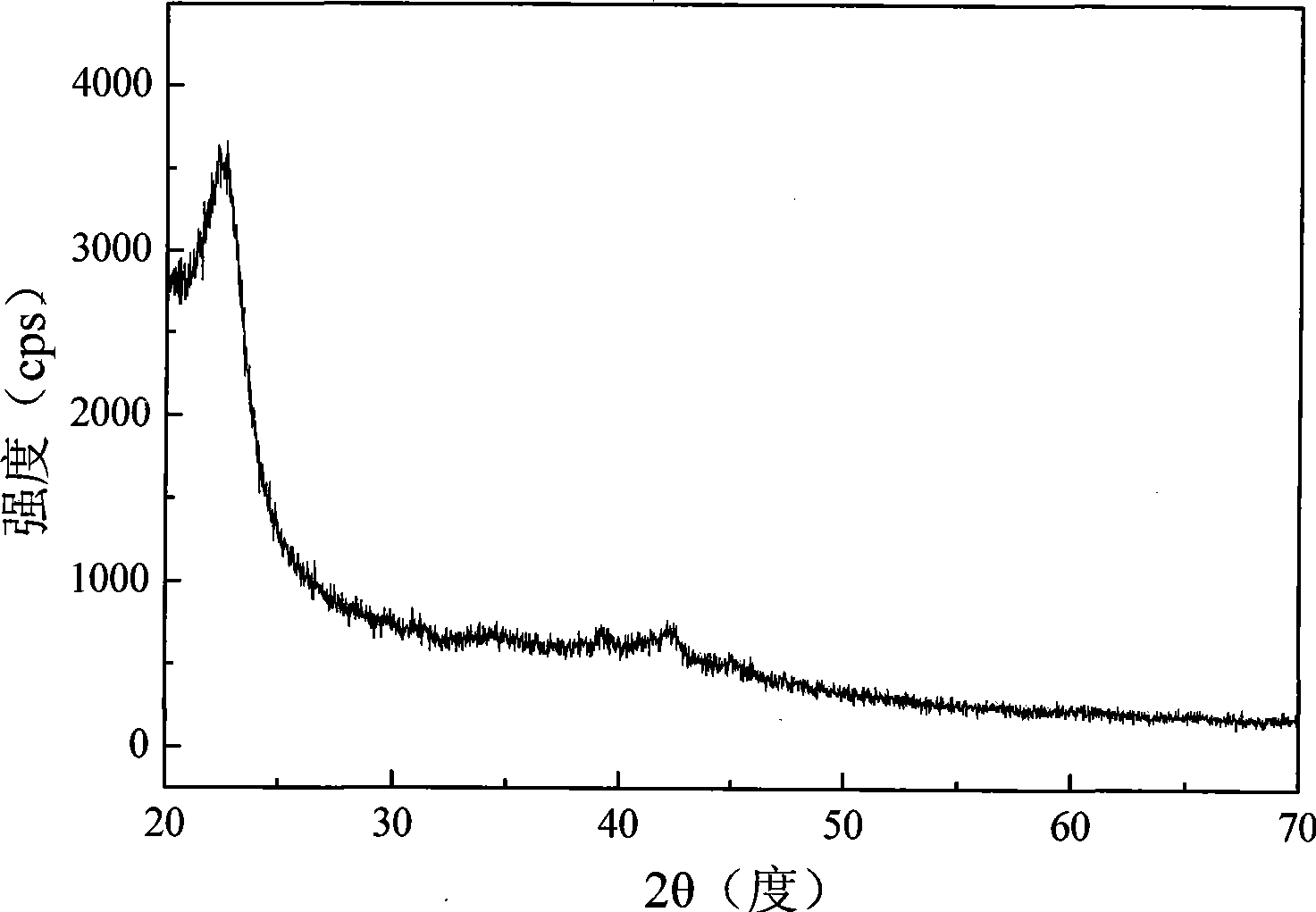

InactiveCN106191790AReduce residual stressImprove scratch resistanceVacuum evaporation coatingSputtering coatingSputter cleaningWear resistant

The invention relates to a preparation method of a wear-resistant coating. The preparation method is used for preparing a hard coating on the surface of a substrate and comprises the following steps: selecting the substrate with predetermined size and performance; cleaning and drying a to-be-deposited surface of the substrate; performing sputter cleaning on the to-be-deposited surface of the substrate in a vacuum room of arc ion plating equipment; injecting inert gases and N2 into the vacuum room; depositing a nitride hard coating on the surface of the substrate by adoption of the arc ion plating technology, and in the deposition process, enabling gradient increase or circular gradient increase of the flowrate of N2 to facilitate adjusting the residual stress in the hard coating; and performing vacuum annealing on the hard coating on the substrate to finally obtain the wear-resistant coating with large thickness. Through gradient increase or circular gradient increase of the flowrate of N2, the residual stress of the coating with large thickness is effectively reduced, and the coating has better scratch resistance and fracture toughness.

Owner:SHENZHEN POLYTECHNIC

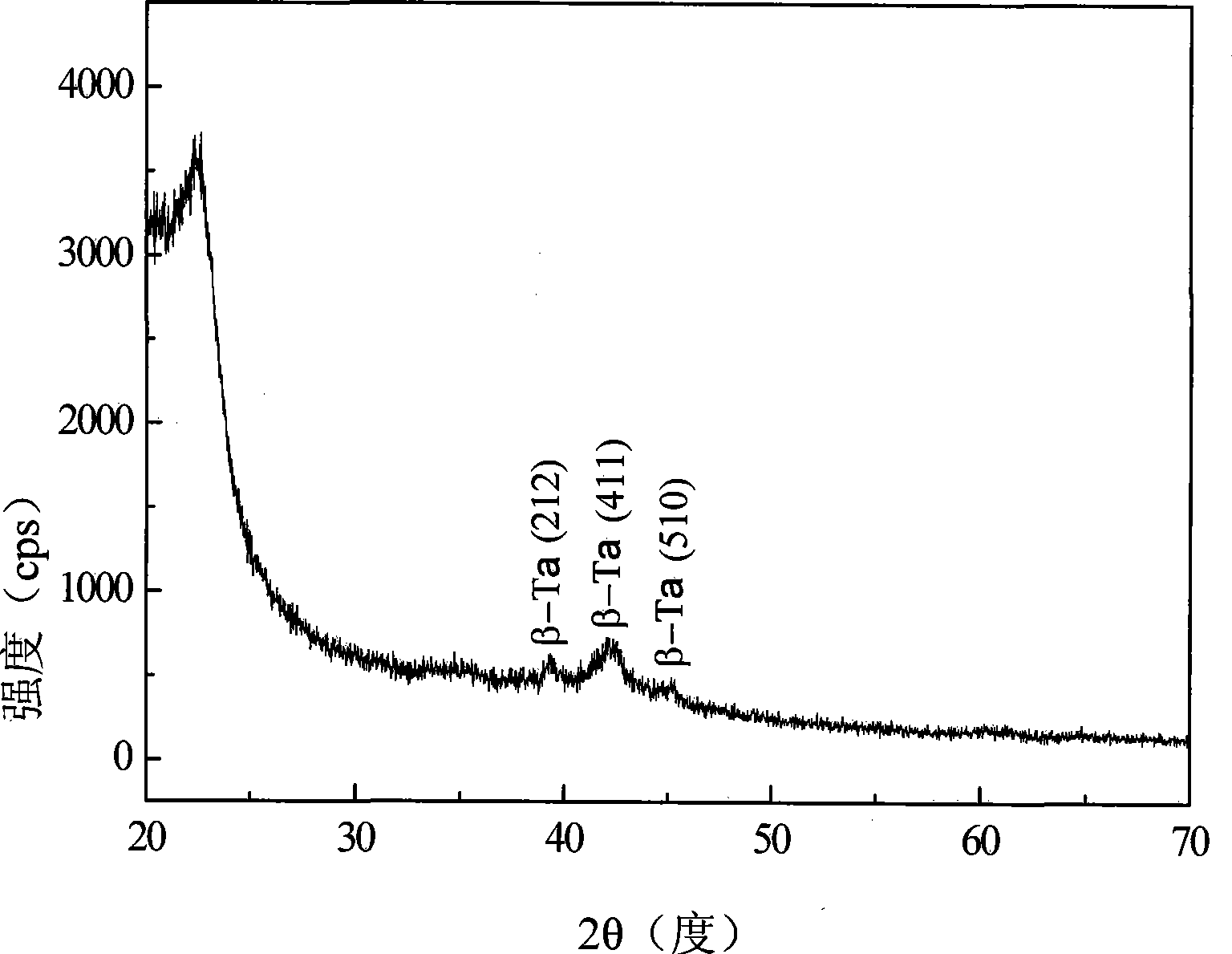

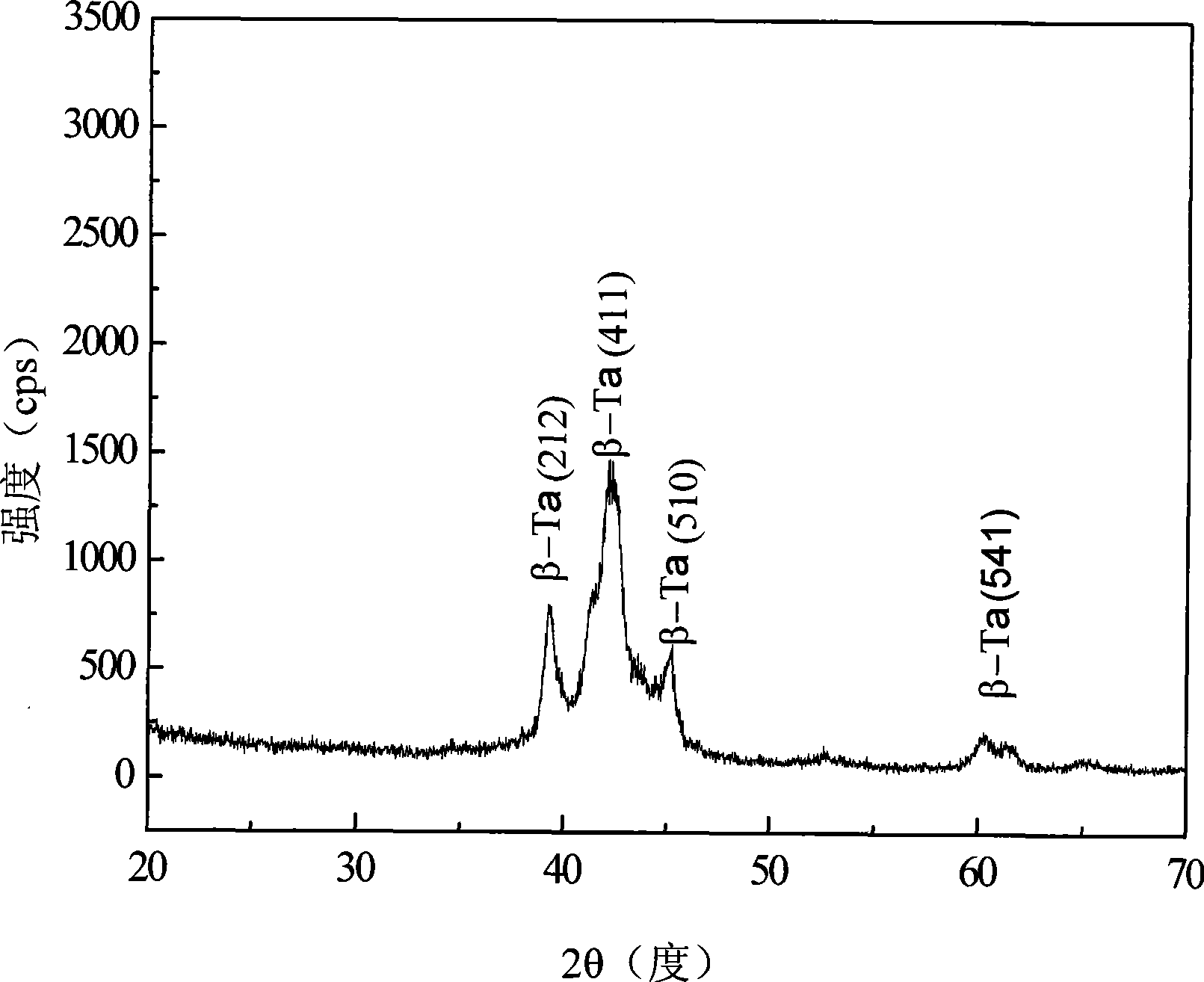

Method for plating tantalum on TiNi alloy surface

InactiveCN101497988AGood biocompatibilityReduce precipitationVacuum evaporation coatingSputtering coatingSputter cleaningBiocompatibility Testing

The invention relates to a method for plating tantalum on the surface of TiNi alloy. The method solves the problem that the corrosion resistance property is poor when the TiNi alloy is implanted into the human body for a long time. The method comprises the follow steps: firstly, the TiNi alloy is mechanically polished, ultrasonically cleaned and dried; secondly, the sputter cleaning is carried out; thirdly, tantalum ions are used for bombarding the TiNi alloy which is then deposited and cooled to room temperature; and fourthly, the tantalum-plated TiNi alloy is just obtained after vacuum annealing. The tantalum-plated TiNi alloy prepared by the method has good corrosion resistance property, restricts Ni ions from dissolving out simultaneously and improves the biocompatibility. The invention has simple production process and convenient operation.

Owner:HARBIN INST OF TECH

Portable automobile glass cleaning device

InactiveCN107933517AEfficient mixingQuick cleanCleaning apparatus for vehicle exteriorsKey pressingSputter cleaning

The invention discloses a portable automobile glass cleaning device. The portable automobile glass cleaning device comprises a cleaning device main body, wherein the cleaning device main body consistsof a splash-proof outer frame and a brake handle; a cleaning fluid inlet and a cleaning water inlet are formed in the surface of the splash-proof outer frame; the brake handle is connected with an anti-slipping grab handle through a connecting handle; a starting key is arranged on the other side of the anti-slipping grab handle; a small motor is arranged in the brake handle and is electrically connected with a rotating shaft; the rotating shaft is connected with a cleaning brush through a connecting ring; and a liquid storage box and a sprinkling chamber are formed between the splash-proof outer frame and the cleaning brush. In the portable automobile glass cleaning device, the rotating shaft is used for driving the cleaning brush to rotate, cleaning fluid and clear water are added in thedevice through an adding hole in the top of the device, the liquid storage box and the sprinkling chamber are formed in the device, liquid which is added in the device can be mixed effectively, and is uniformly splashed to the cleaning brush, then the small motor drives the rotating shaft and the cleaning brush to rotate, and thus, automobile glass can be cleaned rapidly.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

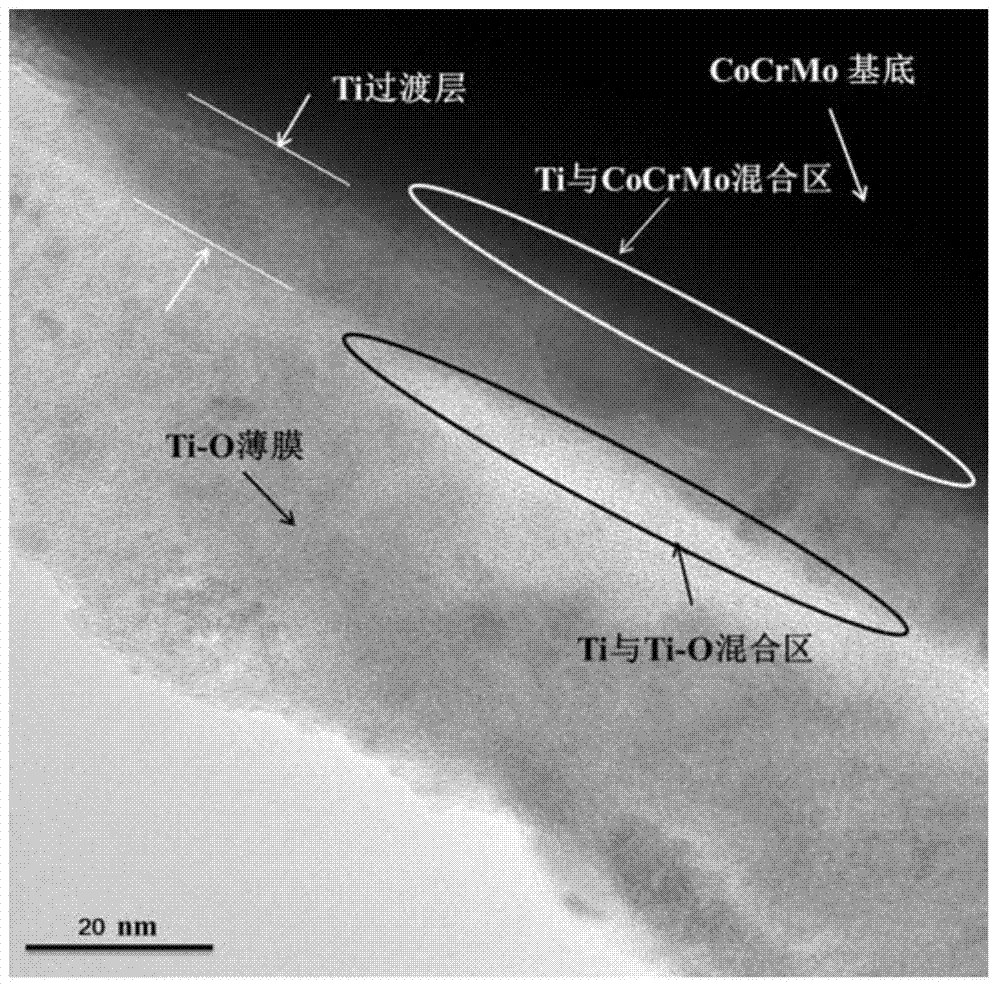

Method for preparing high-hardness diamond film on surface of medical CoCrMo alloy

InactiveCN101967626AHigh hardnessImprove stabilityChemical vapor deposition coatingSputter cleaningPolymer science

The invention discloses a method for preparing a high-hardness diamond film on the surface of medical cobalt-chrome-molybdenum (CoCrMo) alloy. The method comprises the following steps of: performing sputter-cleaning on polished and cleaned CoCrMo alloy by using hydrogen (H2) gas; depositing a silicon (Si) film transition layer on the surface of the CoCrMo alloy by taking silicane (SiH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition; and preparing a diamond like carbon (DLC) film on the Si film transition layer by taking methane (CH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition. Film bases prepared by the method are combined in a saw-toothed mode, good combination performance is represented between the film bases, and the defect of low boundary bearing capacity caused by low combination performance is overcome; meanwhile, the sp3C bond content of prepared DLC film is high, the DLC film with high hardness can be obtained and the wear resistance of the DLC film is effectively improved. In addition, the method has the advantages of simple process and low cost and has great application potential in the technical field of surface modification of a biomaterial.

Owner:CHINA UNIV OF MINING & TECH

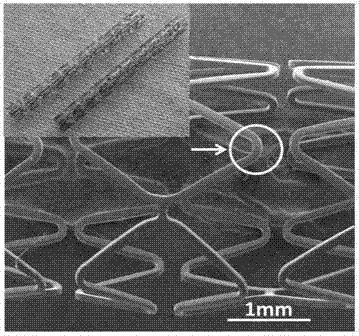

Micro arc ion plating surface treatment method for flexible gear for harmonic reducer

InactiveCN106119775AHigh hardnessImprove bindingVacuum evaporation coatingSputtering coatingSputter cleaningDevices vacuum

The invention discloses a micro arc ion plating surface treatment method for a flexible gear for a harmonic reducer. The method comprises the following implementation steps that firstly, the cleaned and dried flexible gear is placed into a four-target micro arc ion plating device vacuum chamber; and after vacuum pumping is conducted, the four-target micro arc ion plating device vacuum chamber is inflated with argon, after surface impurities are removed through ion sputter cleaning, micro arc ion plating is conducted, certain electrical parameters are applied to a chromium target, a graphite target and the flexible gear, a pure chromium bottoming layer, a transition layer and an amorphous carbon work layer are sequentially deposited, and the vacuum chamber air pressure and film plating time are controlled. By means of the method, the reducer is endowed with the properties of high speed, high load bearing, low friction, abrasion resistance and self-lubrication, and therefore the technological content of domestic reducers is improved, and the service life of the domestic reducers is prolonged.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Preparation method of polymer carbon film for anti-wear and anti-friction surface modification of fluororubber, and fluororubber obtained by using carbon film

ActiveCN109651638AReduce coefficient of frictionImprove wear resistanceVacuum evaporation coatingSputtering coatingCarbon filmChemical structure

The invention discloses a preparation method of a polymer carbon film for anti-wear and anti-friction surface modification of fluororubber, and a fluororubber prepared by using the carbon film. The method comprises the following steps: fluororubber used as a substrate, and undergoes sputter cleaning; a medium-frequency magnetron sputtering deposition technique is used to carry out bombard sputtering on a graphite target to produce mixed plasma; and a medium-frequency pulse direct-current bias power supply is turned on during sputtering of the target to accelerate the mixed plasma to the substrate and deposit on the fluororubber substrate. The polymer-like carbon film prepared by the method is uniform and compact, is closely combined with the fluororubber substrate, and can achieve a high bonding strength without depositing a transition layer. The fluororubber modified by the method has a low friction coefficient in a vacuum (being less than 10 to 3 Pa) environment and an atmospheric environment, and has good wear resistance. The surface modification method is used to make the fluororubber substrate keep the original chemical structure and properties.

Owner:JIANGXI UNIV OF SCI & TECH

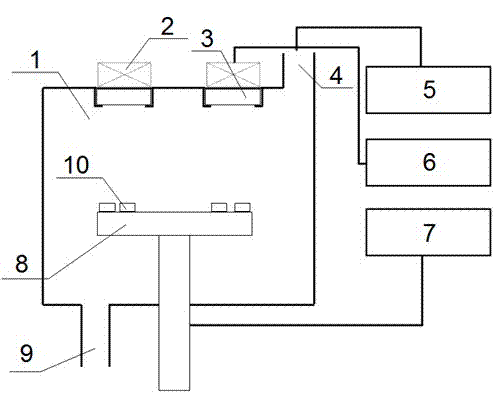

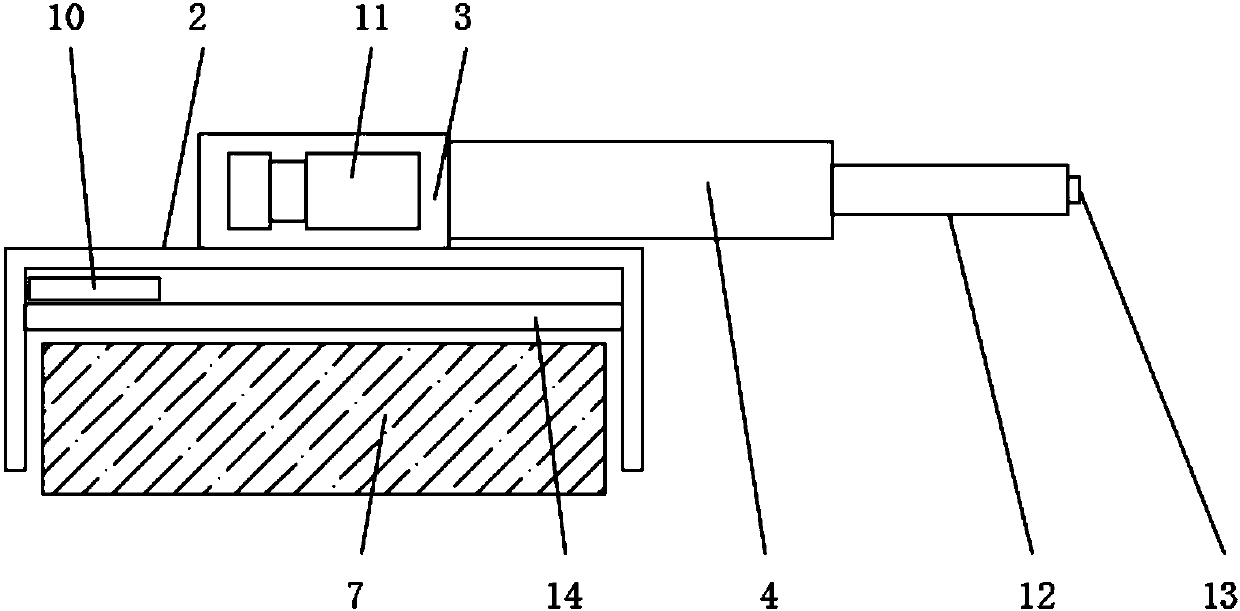

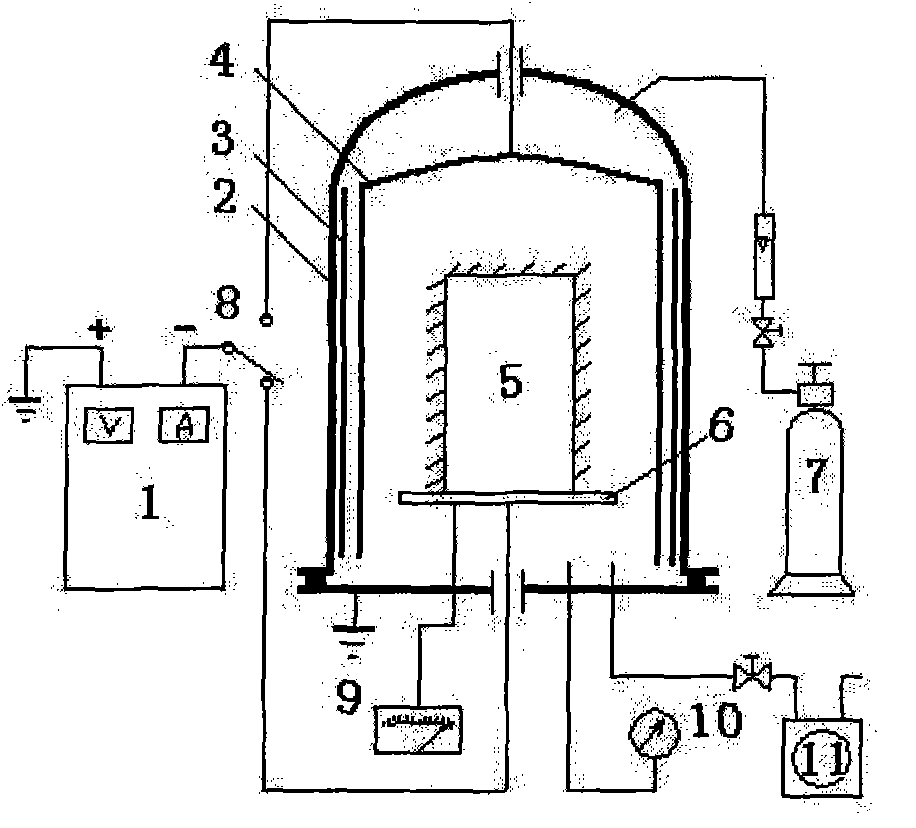

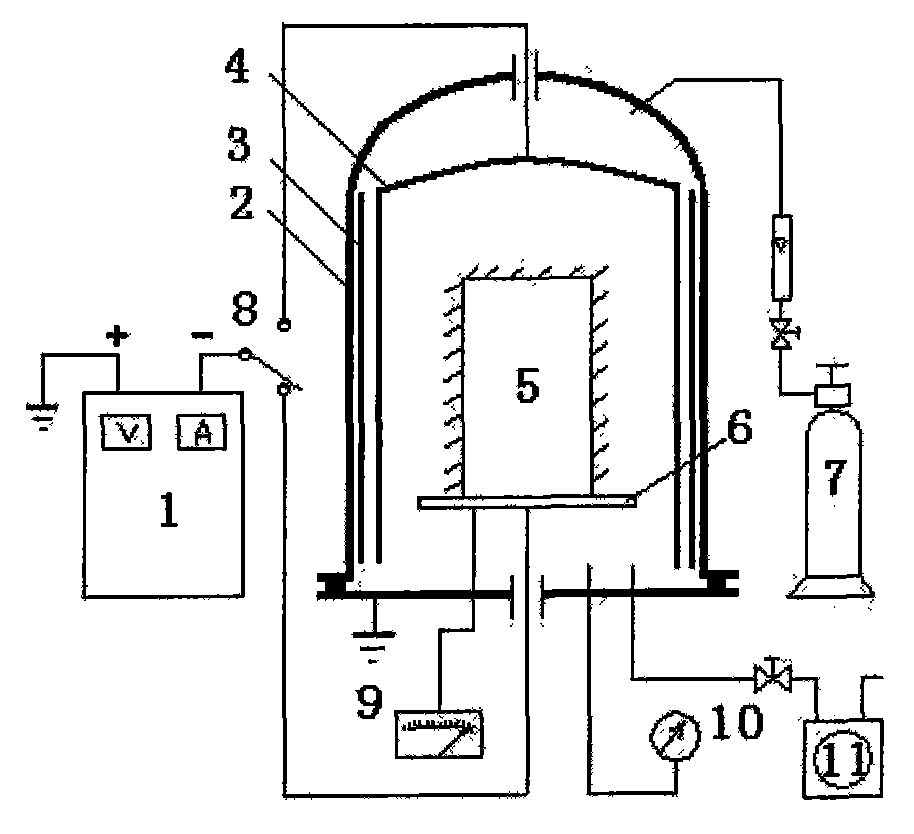

Ion chemical heat treating furnace having glow discharge-aided heating function

InactiveCN102011087AAvoid damageImprove temperature uniformitySolid state diffusion coatingSputter cleaningThermal radiation

The invention discloses an ion chemical heat treating furnace having a glow discharge-aided heating function. A steel cylinder (4) is arranged in the vacuum chamber of a furnace body (2), a workpiece (5) to be processed is arranged on a workbench (6), and the cylinder, the workbench and the furnace body are mutually insulated. Prior to an ion chemical heat treatment, the negative pole of a direct current (DC) power supply (1) of the ion chemical heat treating furnace is connected to the cylinder by a change-over switch (8), and the cylinder generates a glow discharge and is heated, so that the workpiece can be preheated by the heat radiation of the cylinder. When the workpiece reaches a preheating temperature, the negative pole of the DC power supply is switched to the workbench, and the workpiece starts glow-discharge heating and is subject to the ion chemical heat treatment, so that the sputter cleaning time of the workpiece can be shortened, thereby preventing the DC power supply from over-current damage. In the ion chemical heat treatment process, the cylinder and the workpiece can be simultaneously connected to the negative pole of the DC power supply, the temperature uniformity of the workpiece can be improved by the aided heating of the cylinder, and the problem that the temperature of the workpiece is difficult to measure is also solved.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com