Method for preparing slow-release type skeleton-type TiN/Cu-Zu metal layer antibacterial film

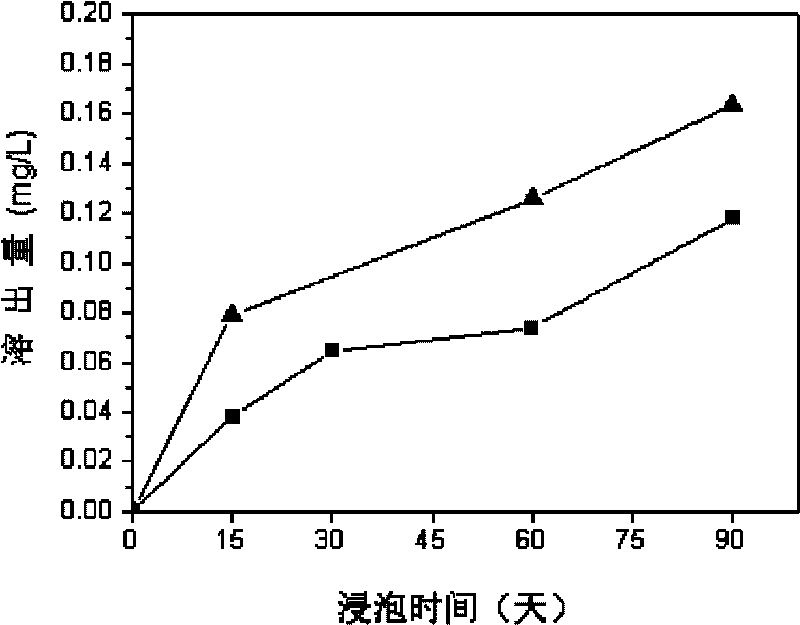

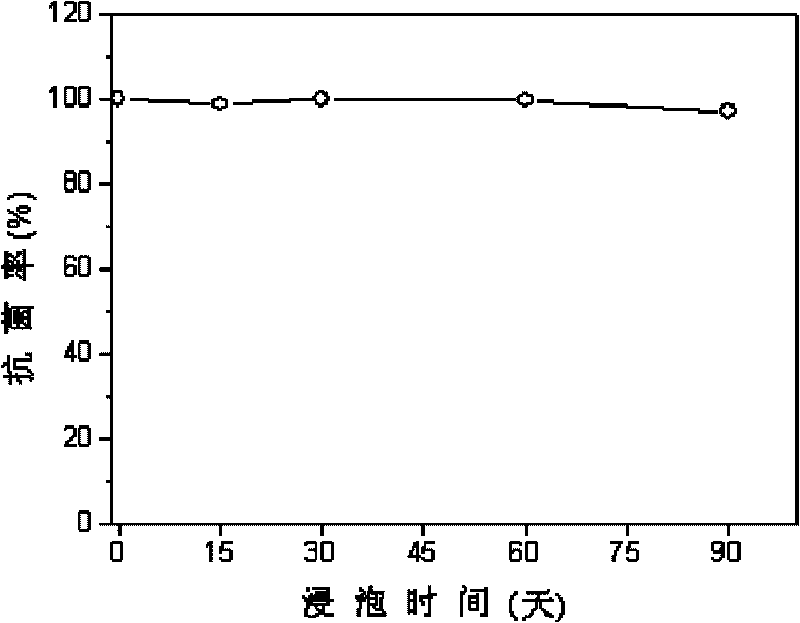

A skeleton-type, slow-release technology, applied in botany equipment and methods, metal material coating technology, coating, etc., can solve the problem of poor antibacterial effect persistence of antibacterial film, achieve long-lasting ion dissolution effect, and stable dissolution rate , long-term antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

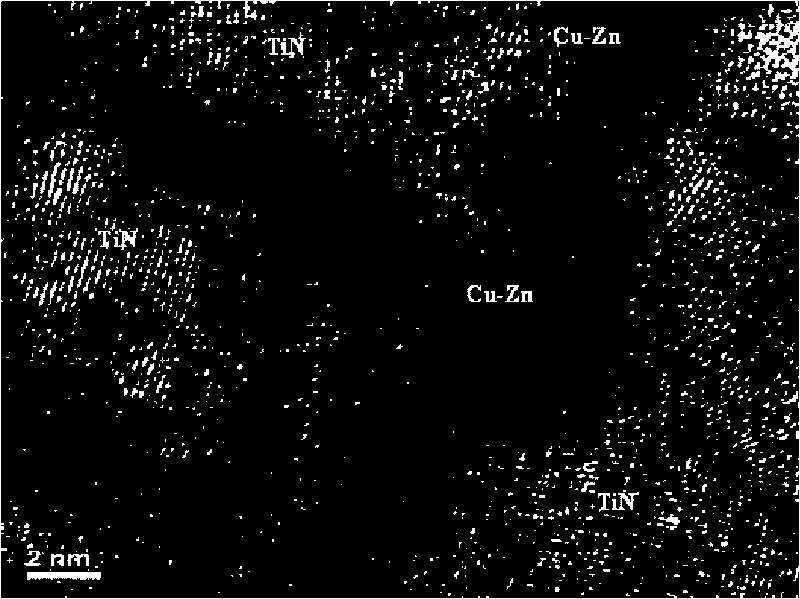

[0009] Specific embodiment one: the preparation method of the slow-release skeleton type TiN / Cu-Zn metal layer antibacterial film in the present embodiment is as follows: one, the substrate is put into the vacuum chamber target platform, and the vacuum degree in the vacuum chamber is 2 * 10 -3 The substrate was heated to 200°C under the condition of Pa, and then the surface of the substrate was sputtered under the conditions of argon flow rate of 10sccm-20sccm, RF power of 300W, substrate negative bias voltage of 800V, pulse frequency of 10kHz, and pulse width of 30μs. 2. Rotate the target stage of the vacuum chamber under the condition that the argon gas flow rate is 6 sccm, the nitrogen gas flow rate is 2 sccm, the deposition pressure is 0.56 Pa, and the substrate deposition bias voltage is compound bias voltage, and alternately deposit TiN layers and Cu-Zn metal layer, the total thickness of the film layer is 0.1 μm to 10 μm, wherein the first layer and the outermost layer o...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment is different from Embodiment 1 in that the substrate in step 1 is metal, ceramic or plastic. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the metal is stainless steel, aluminum alloy, titanium alloy, copper alloy or low carbon steel. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com