Patents

Literature

40results about How to "Beautiful and elegant appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

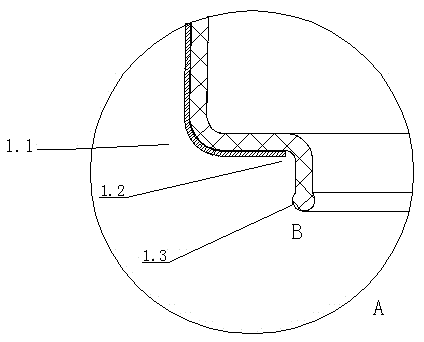

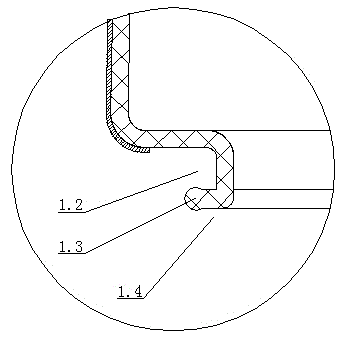

Glass body of glass and method thereof

The invention relates to a glass body of a glass. The upper and lower parts of the glass body of the glass are open. The glass body of the glass is characterized in that the openings of the glass body of the glass are provided with smooth rounded closed edges; the rounded closed edges are higher than the inner or outer wall of the glass body of the glass; and the rounded closed edges cannot scratch silica gel sealing rings or fingers of a production worker. The glass body of the glass has the characteristics of simple and reasonable structure, a small number of processing and manufacturing processes, convenience and rapidness for assembly, high production efficiency, good sealing effect, prolonged service life, safety, reliability and attractive and elegant appearance.

Owner:周林斌

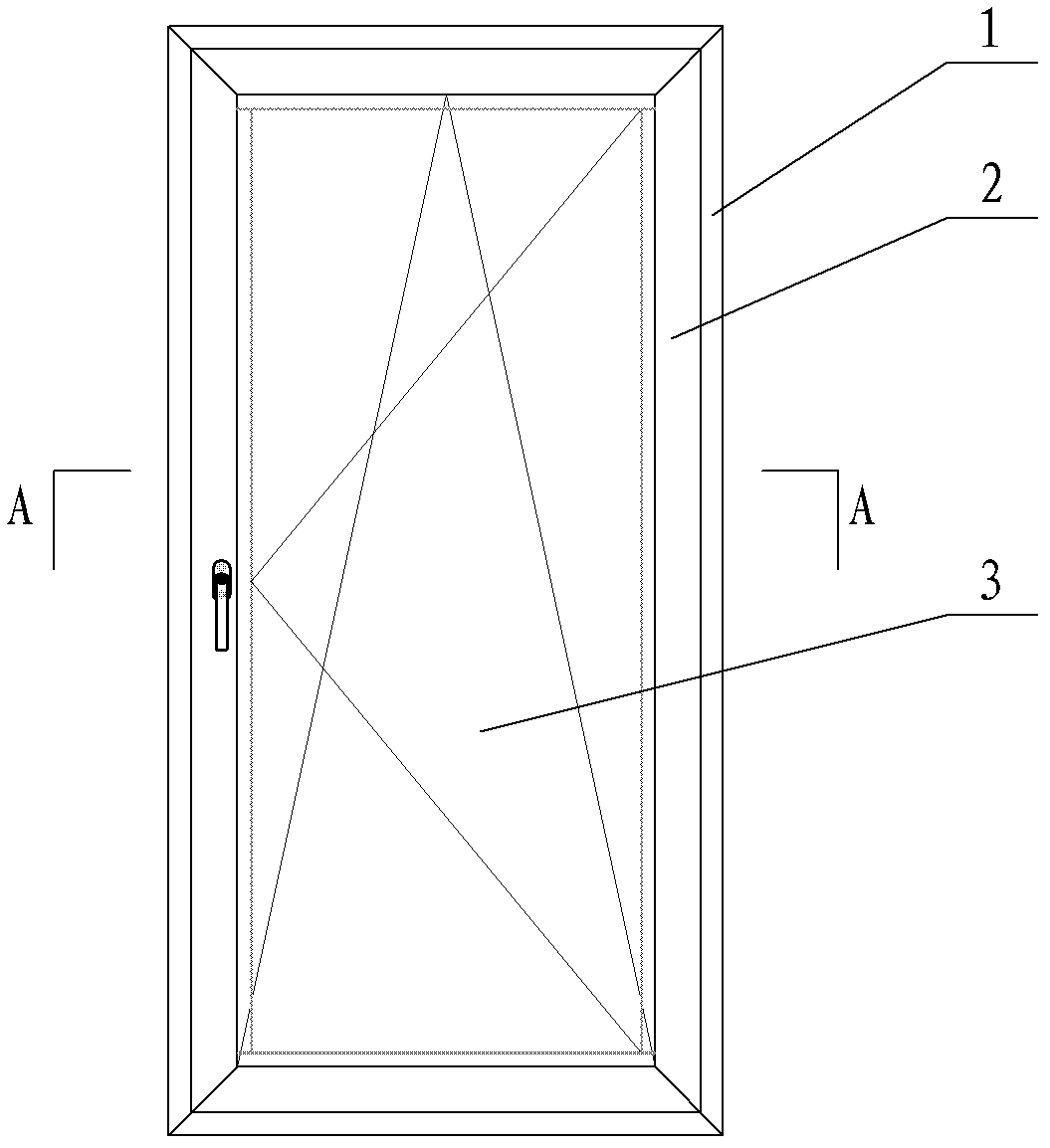

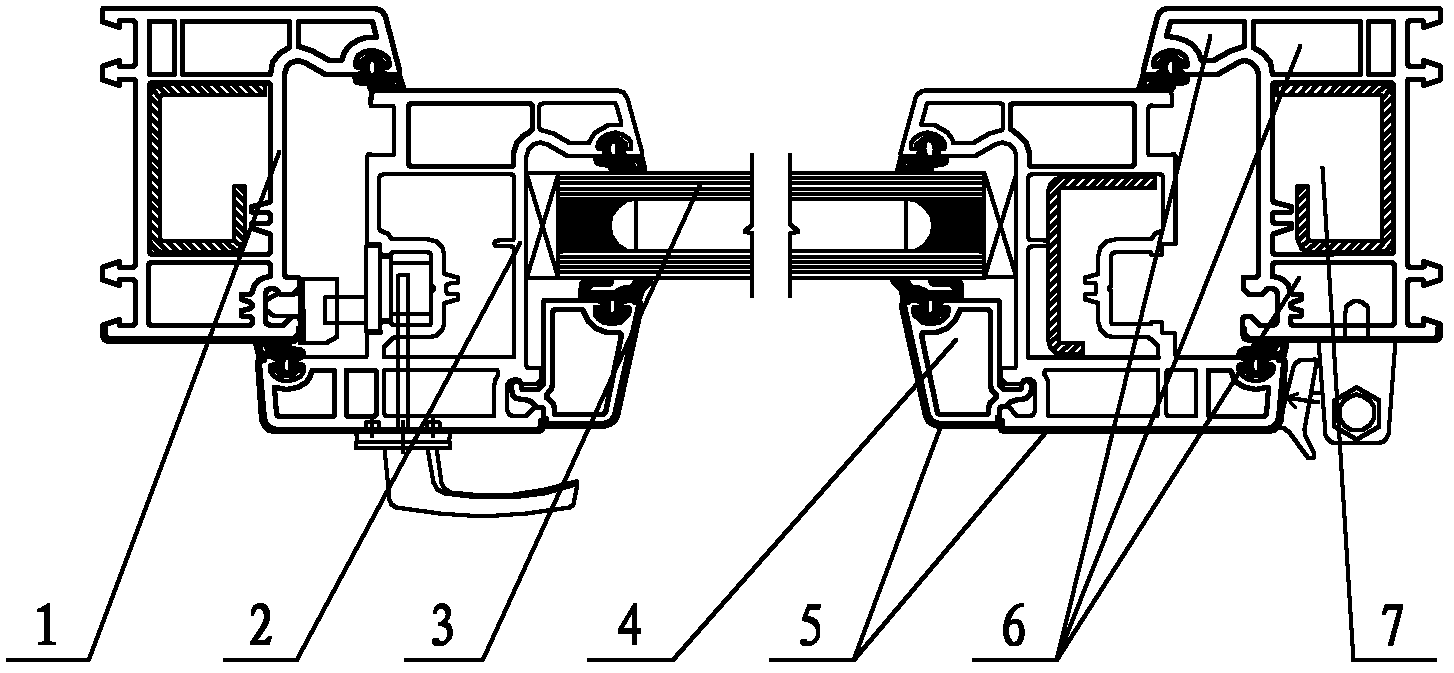

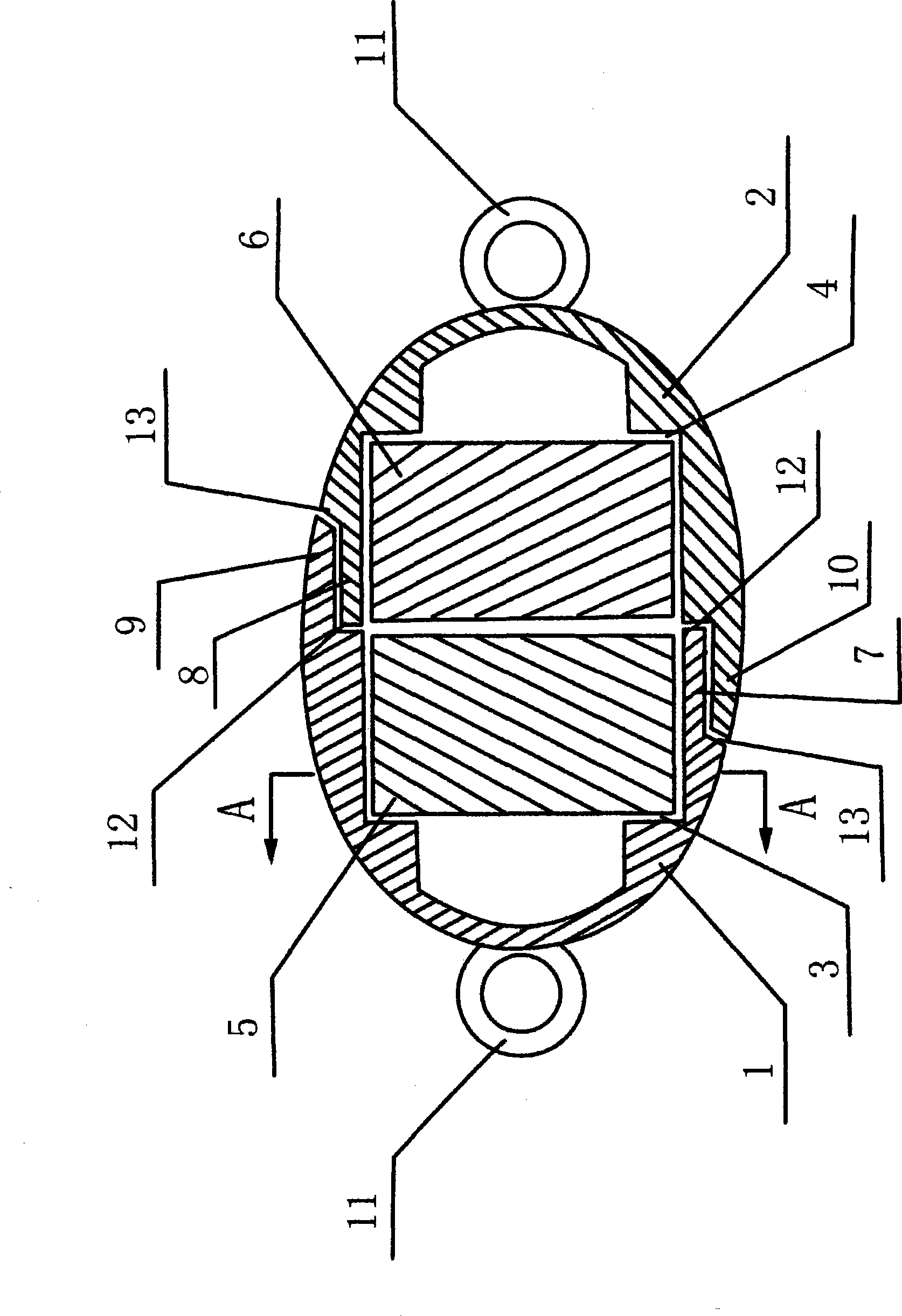

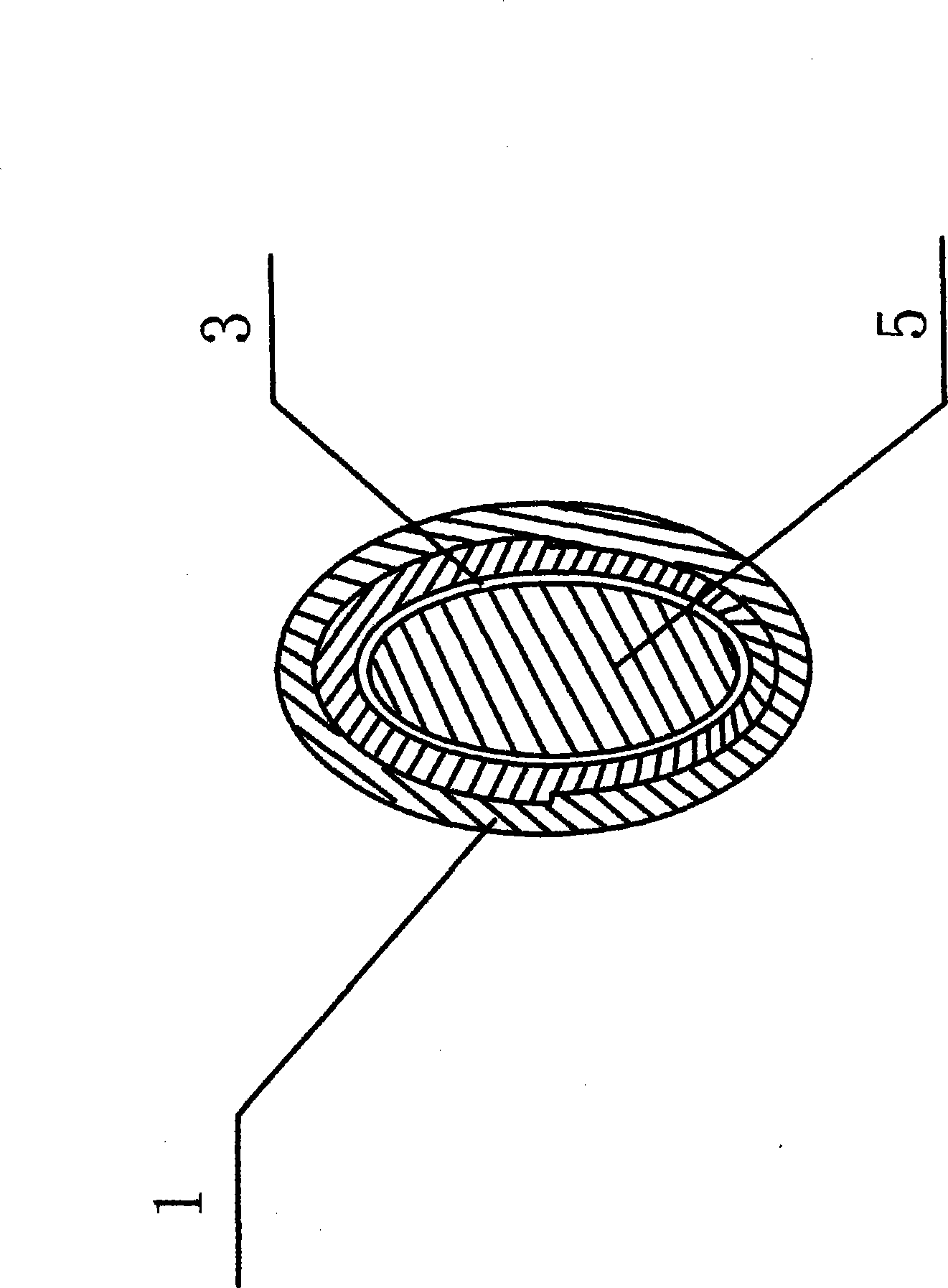

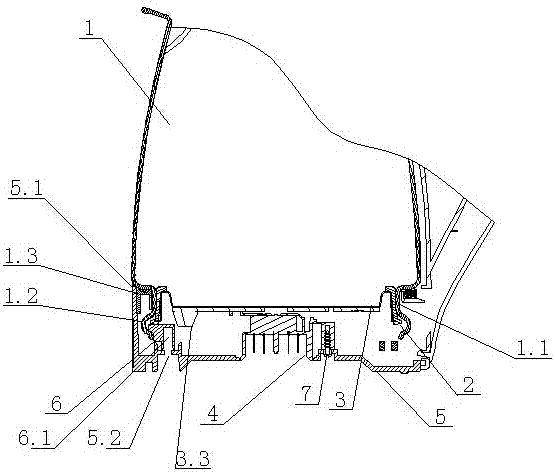

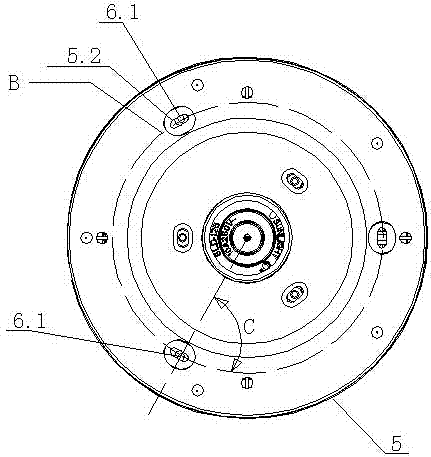

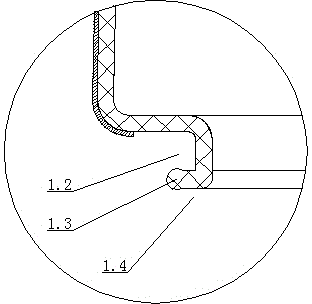

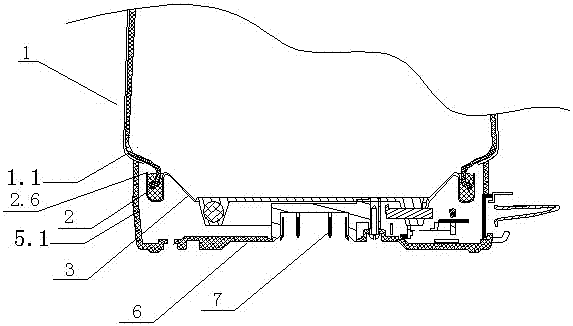

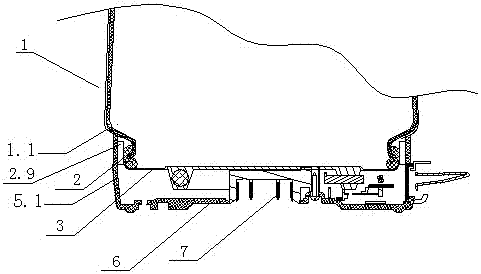

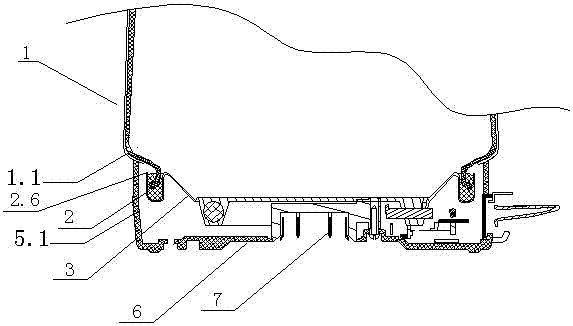

Natural veneer composite heat-insulating plastic steel doors and windows

InactiveCN102536048ABeautiful and elegant appearanceImprove insulation performanceWing framesEngineeringSteel frame

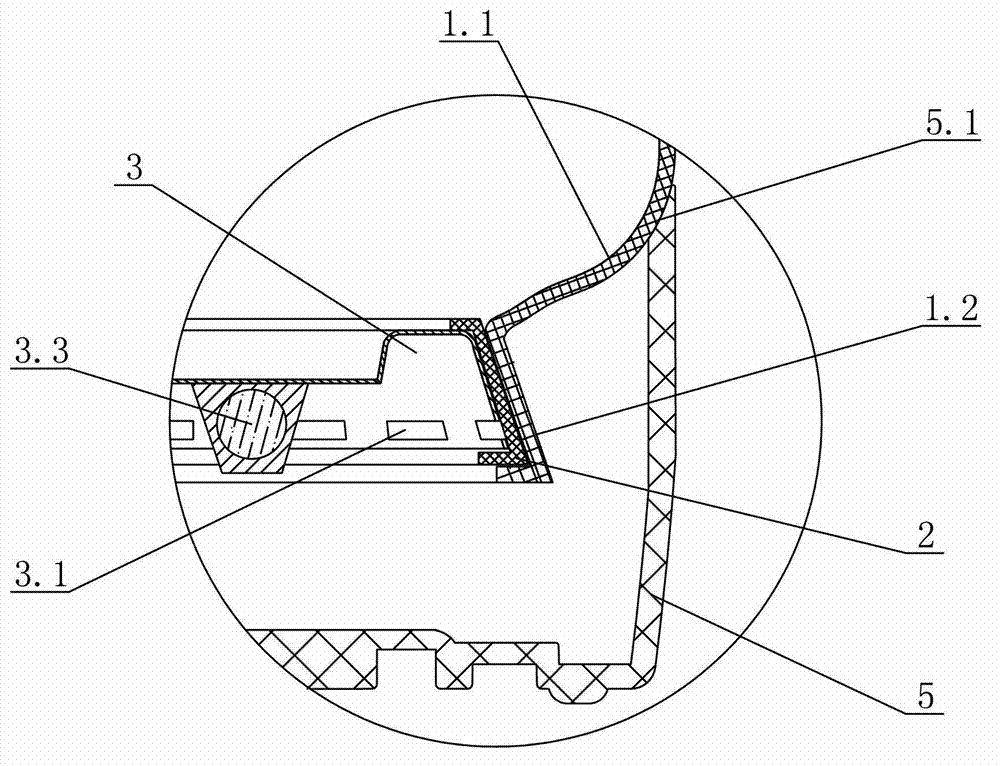

The invention relates to a doors and windows of buildings, in particular to natural veneer composite heat-insulating plastic steel doors and windows, which comprise plastic steel fan sections (2), wherein the plastic steel fan sections (2) are arranged in plastic steel frame sections (1) in a rotational mode; glass (3) is arranged in the plastic steel fan sections (2); natural veneers (5) are pasted on surfaces of indoor sides and / or outdoor sides of the plastic steel frame sections (1) and the plastic steel fan sections (2). According to the natural veneer composite heat-insulating plastic steel doors and windows, the natural veneers are pasted on surfaces of indoor sides and / or outdoor sides of the sections of the plastic steel doors and windows, so that the heat-insulating performance of the original plastic steel doors and windows is enhanced, the natural veneers have the natural textures of wood, and the natural veneer composite heat-insulating plastic steel doors and windows are attractive in appearance.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

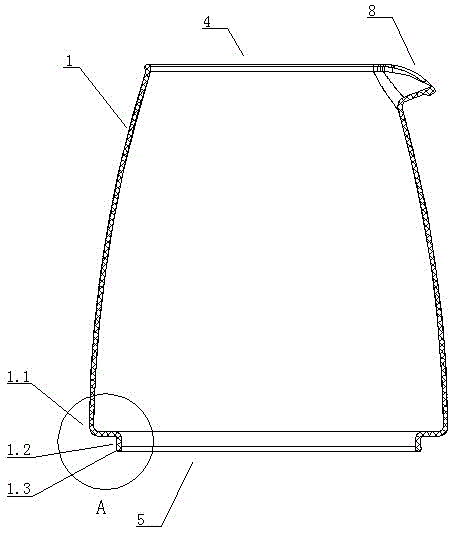

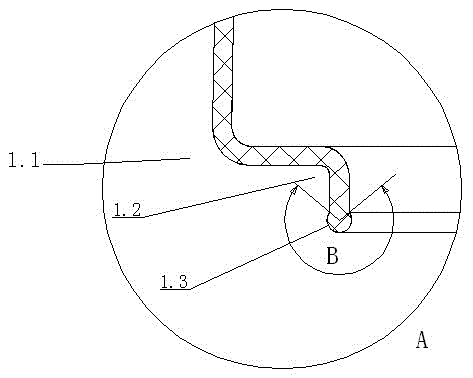

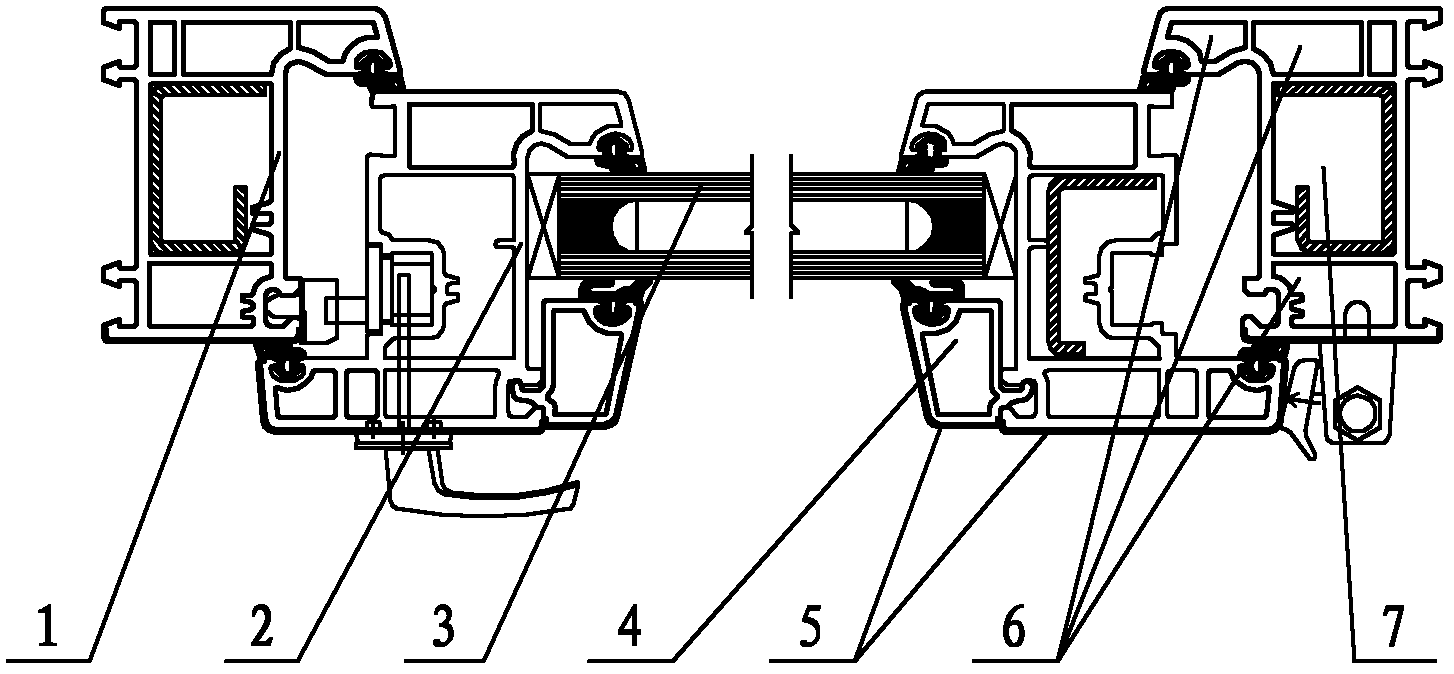

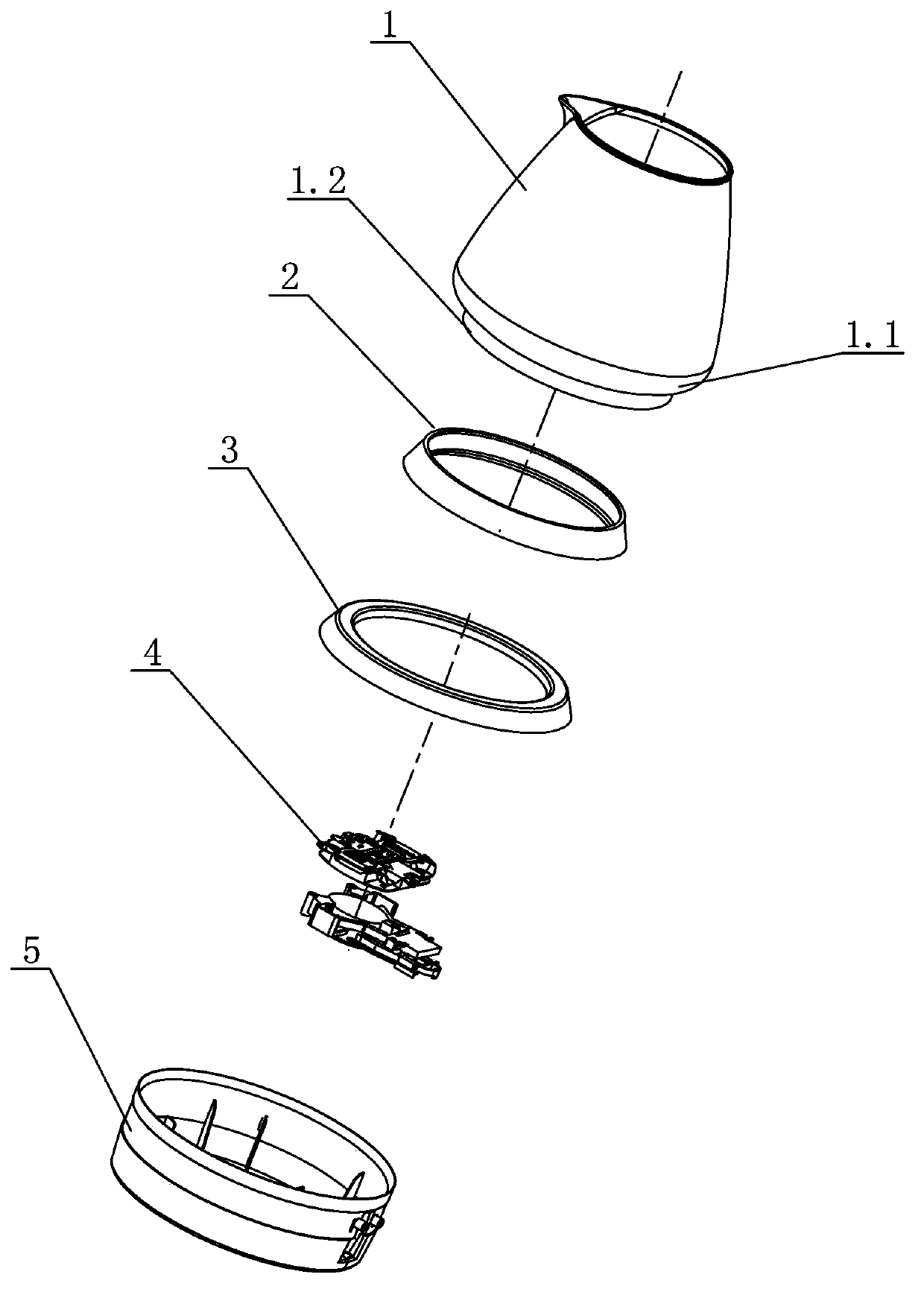

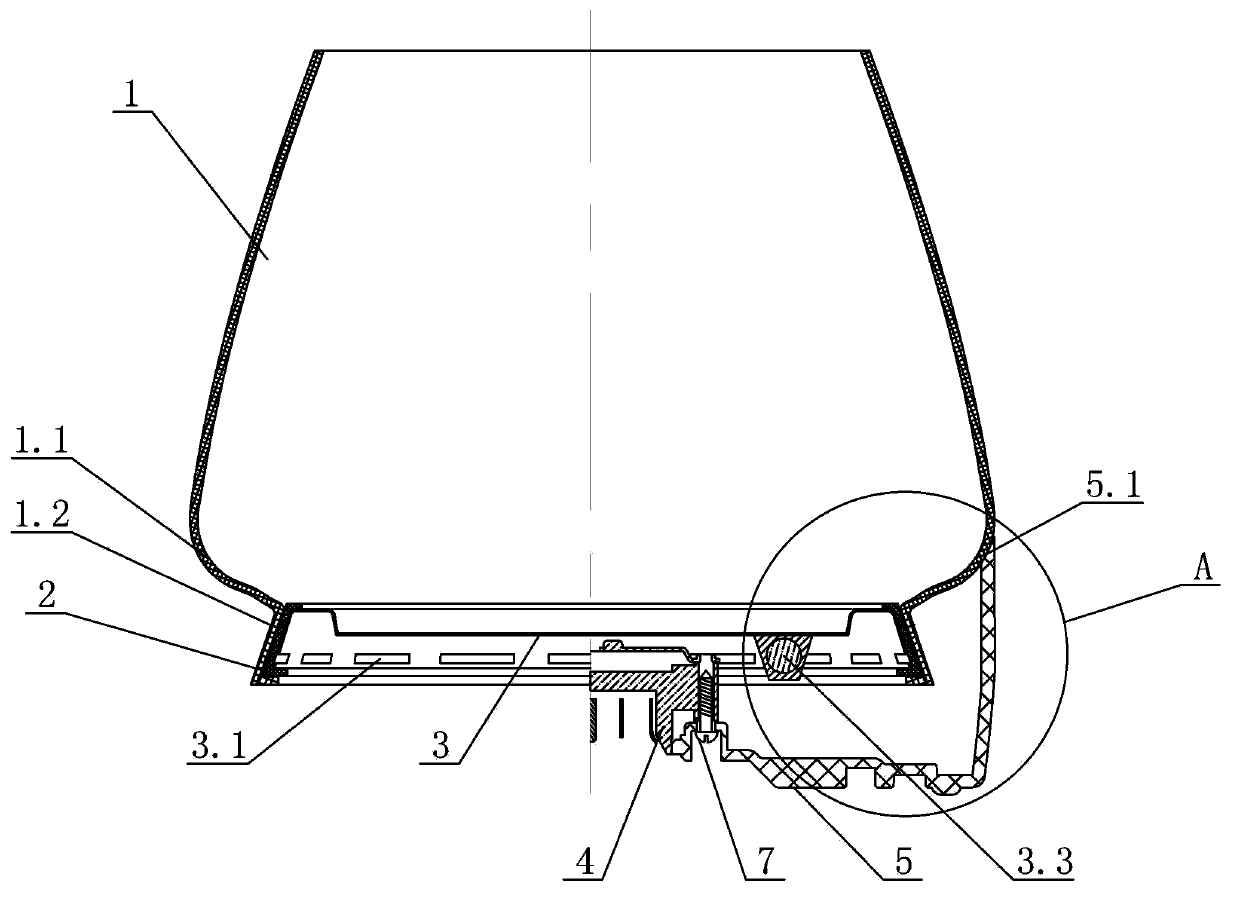

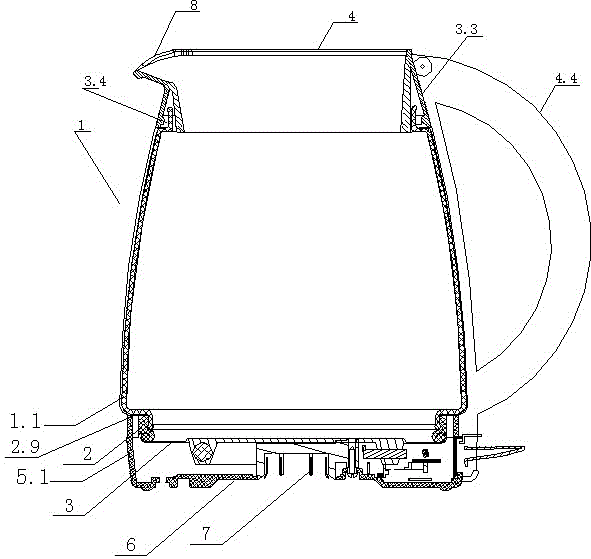

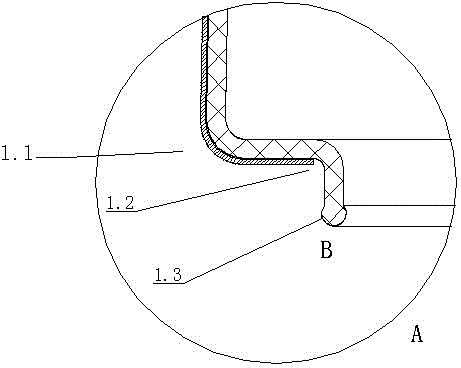

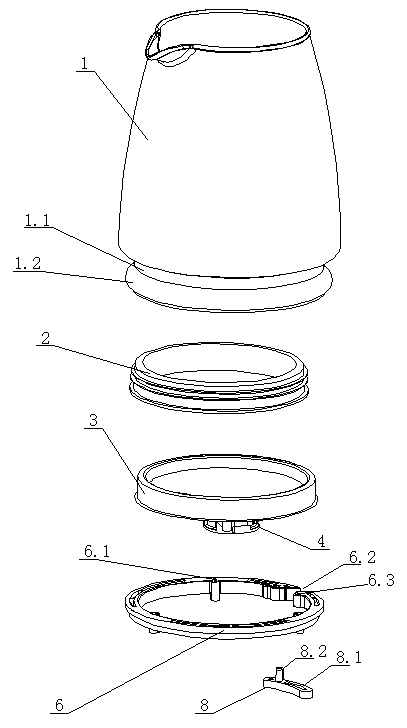

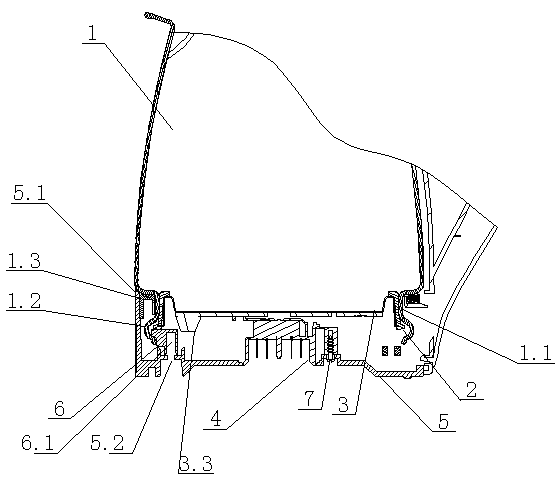

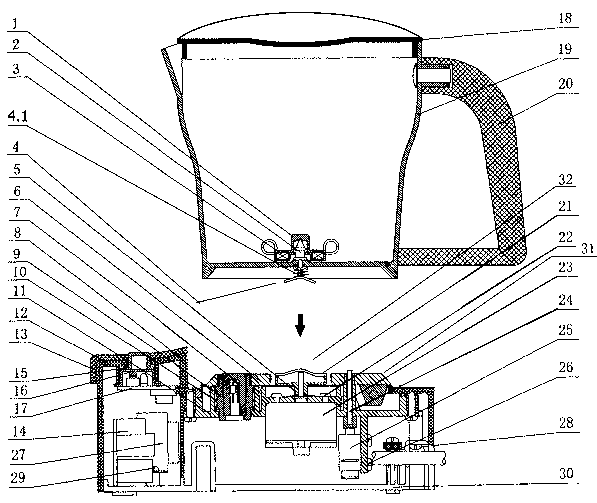

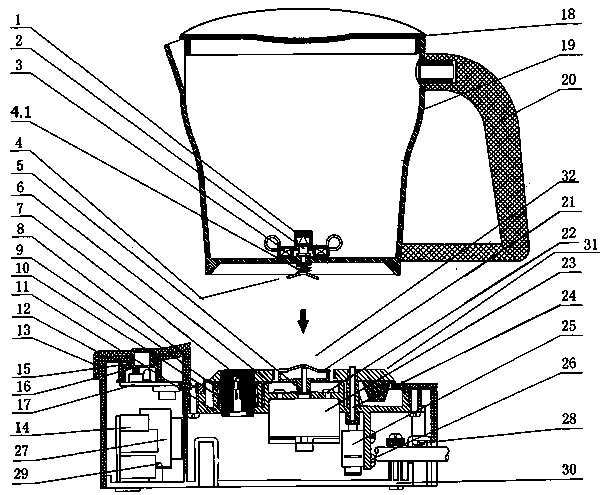

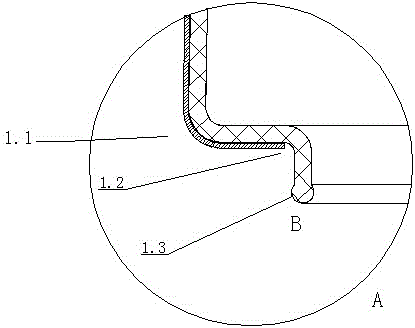

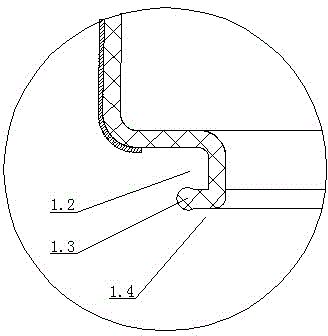

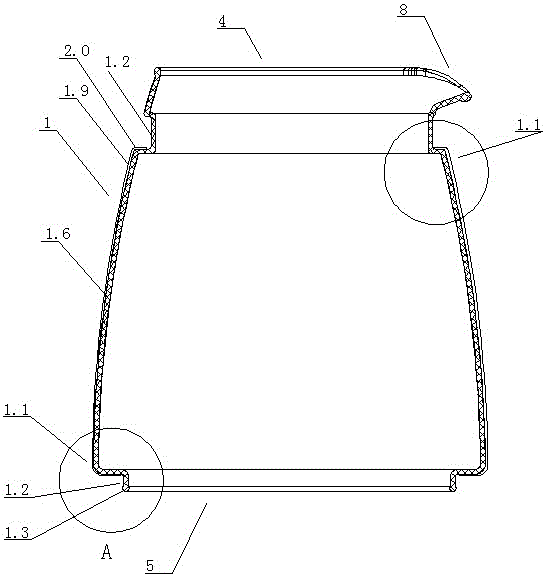

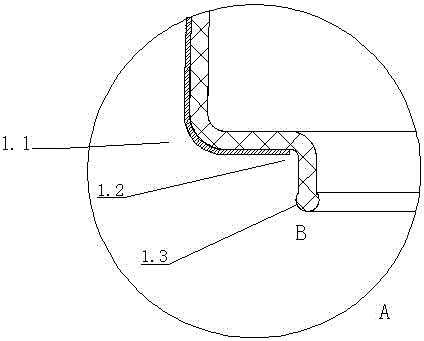

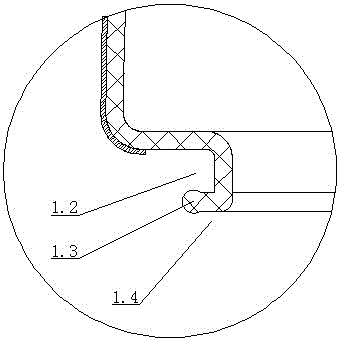

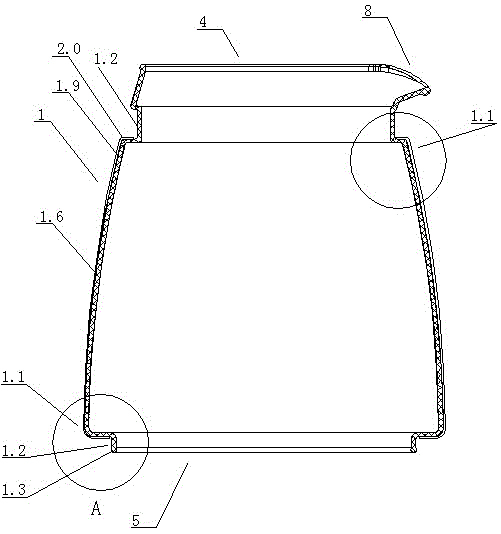

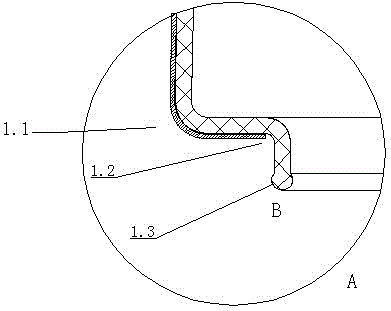

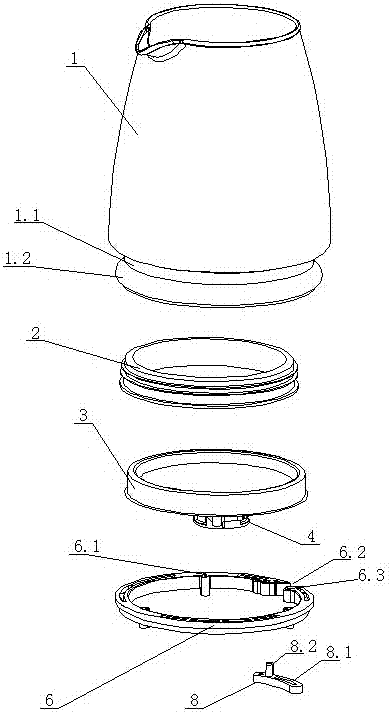

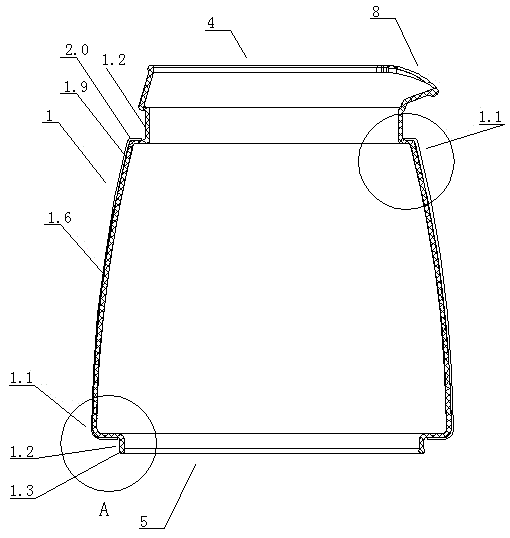

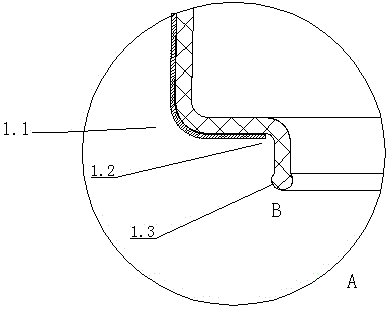

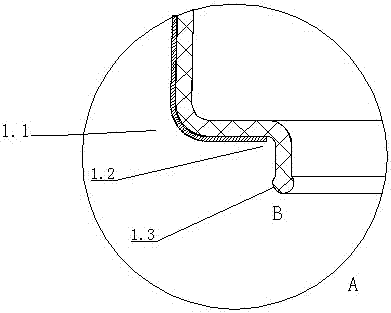

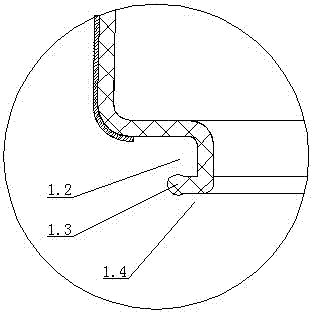

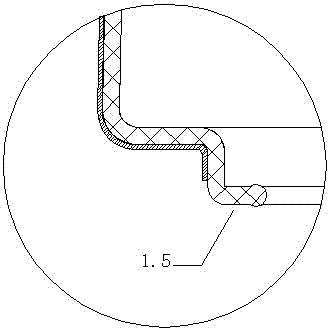

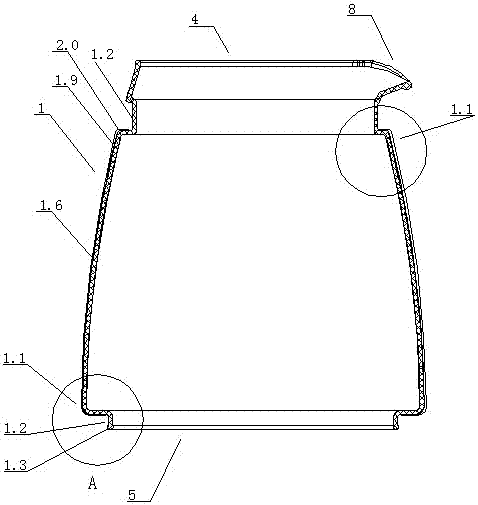

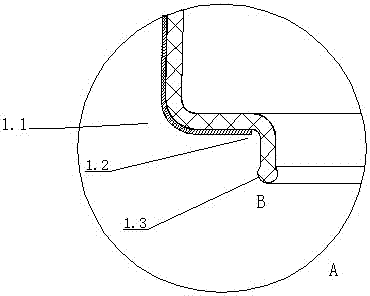

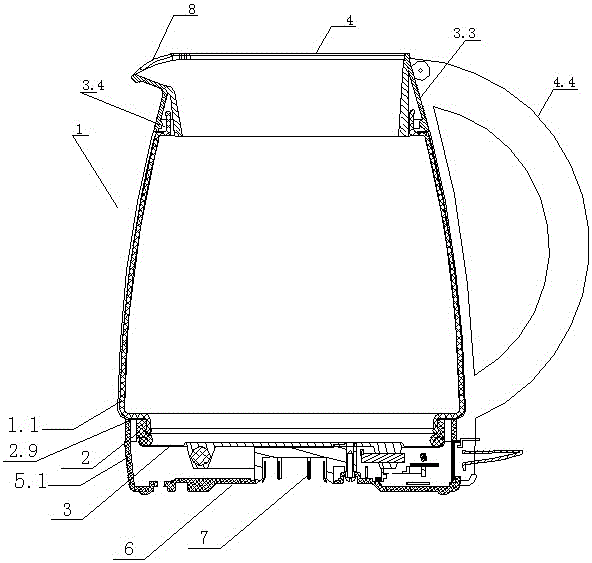

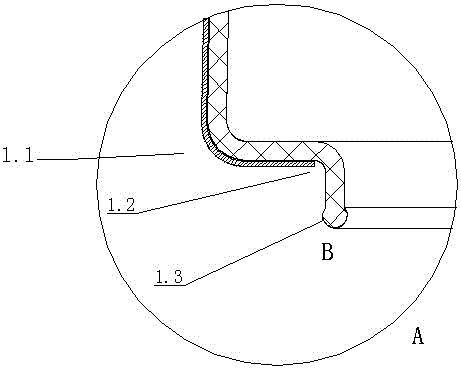

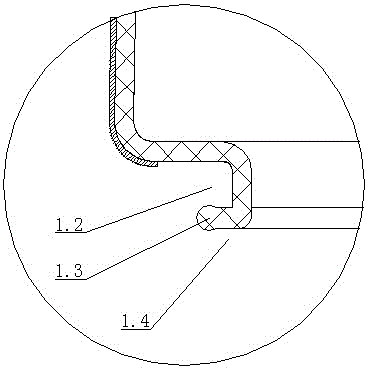

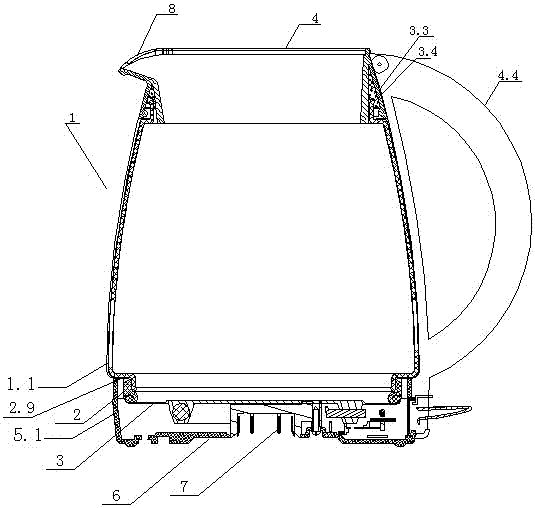

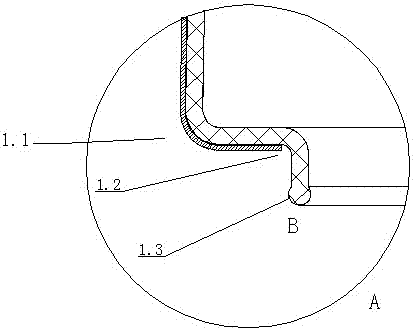

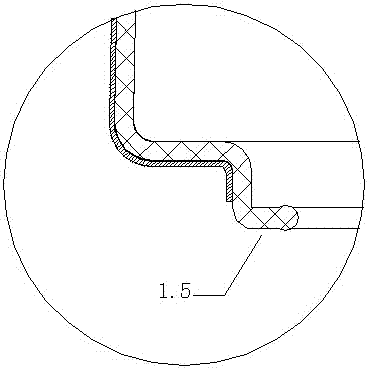

Electric heating glass kettle and assembling method thereof

InactiveCN102949087ASimple structureReduce the amount of processingCooking-vessel materialsWater-boiling vesselsTemperature controlEngineering

The invention relates to an electric heating glass kettle and an assembling method thereof. The electric heating glass kettle structurally comprises a glass kettle body, a heating plate which is arranged at the bottom of the glass kettle body, and a base, wherein a sealing ring is arranged at a position wherein the heating plate and the glass kettle body are connected with each other. The electric heating glass kettle is characterized in that the lower part of the glass kettle body is provided with an inwards bent step part and an inwards folded edge which is arranged below the step part, the heating plate is assembled in the inwards folded edge, and the base and the heating plate are fixedly assembled together and are arranged on the external side of the step part in a bagged way. The assembling method of the electric heating glass kettle comprises the following steps of: 1) forcibly pressing the heating plate to place the heating plate in the sealing ring; 2) slightly bending the component and placing the component in the inwards folded edge of the glass kettle body; 3) assembling a temperature control connector at the bottom of the heating plate; and 4) correspondingly sheathing the supporting part of the base on the external side of the step part of the glass kettle body, and fixing the base and the heating plate by using screws. The electric heating glass kettle and the assembling method thereof have the advantages of simple and reasonable structure, fewer manufacturing process, convenience and rapidness in assembling, high production efficiency, good sealing effect, prolonged service life, high safety and hygienic performance, and attractive and elegant appearance.

Owner:周林斌

Medical stone and purple sand mixed mud pottery and preparation method thereof

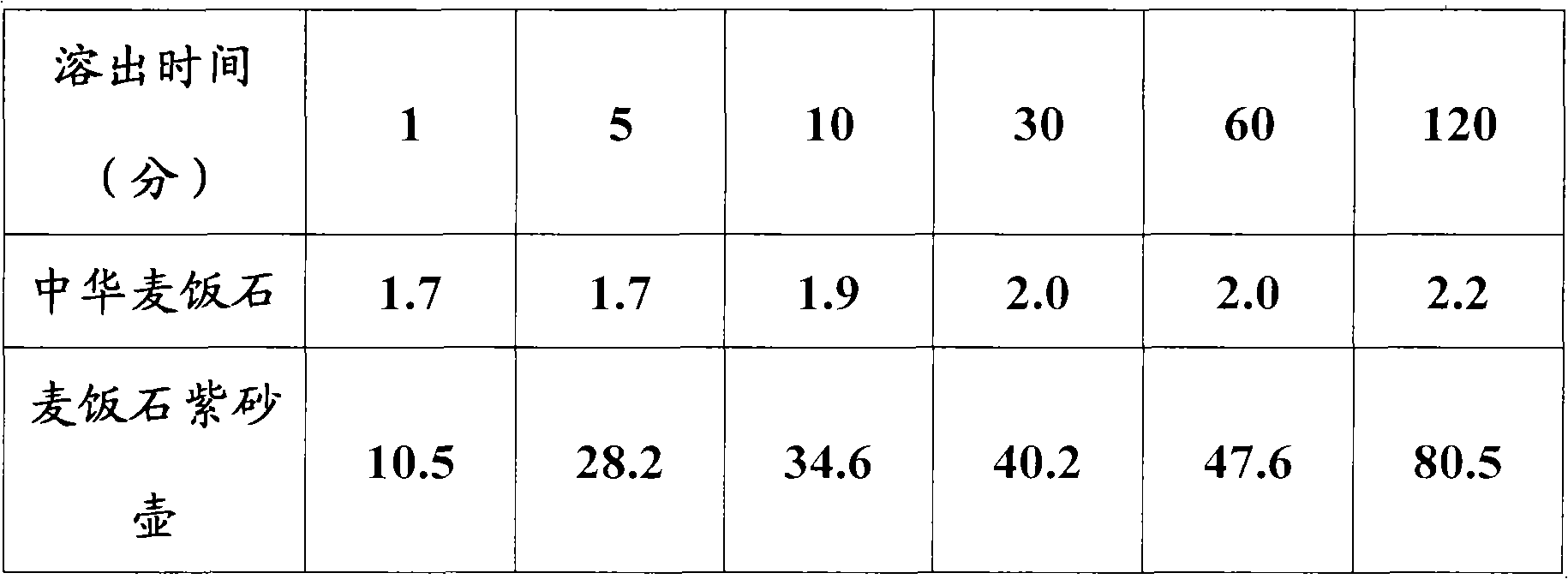

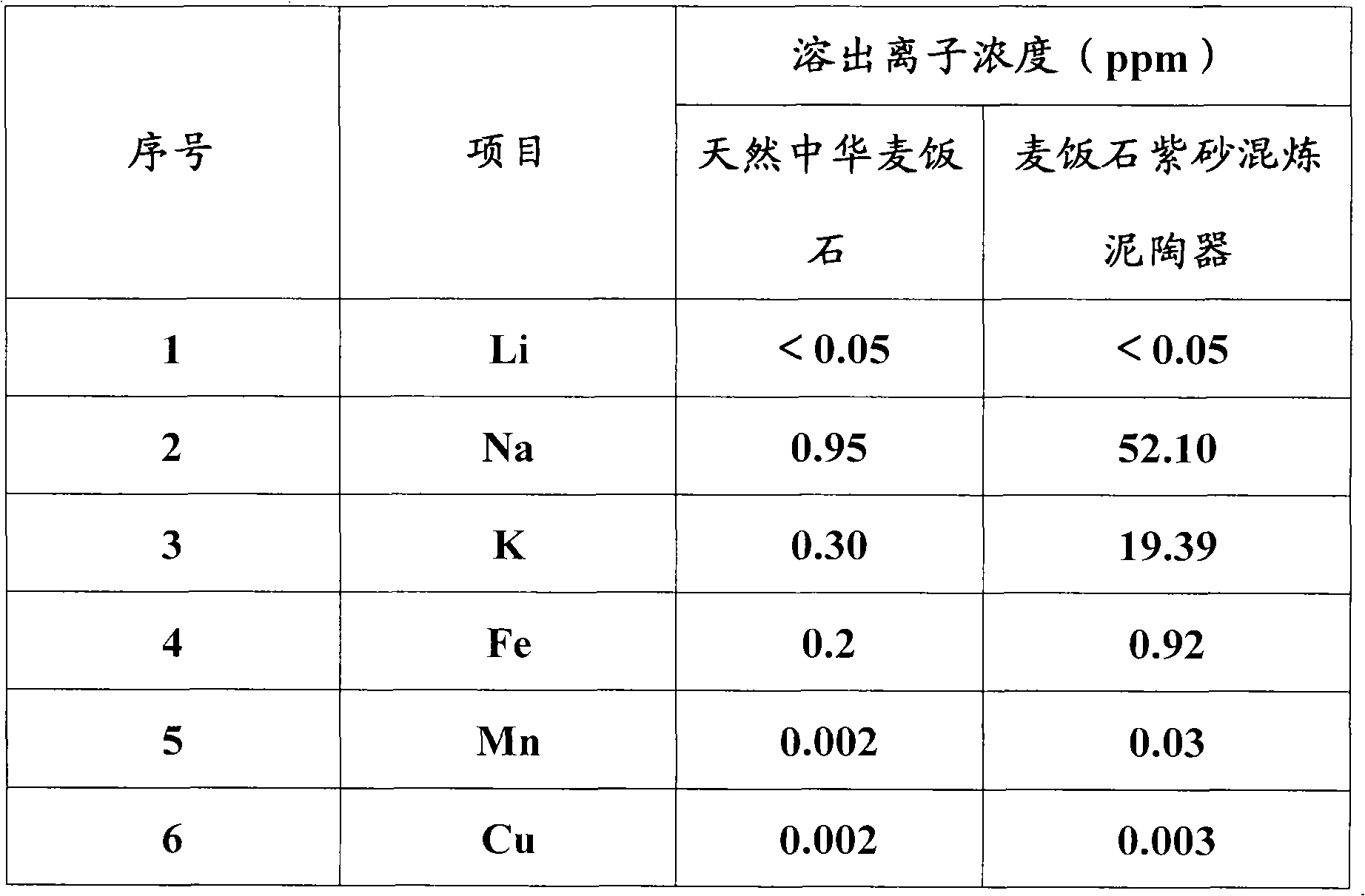

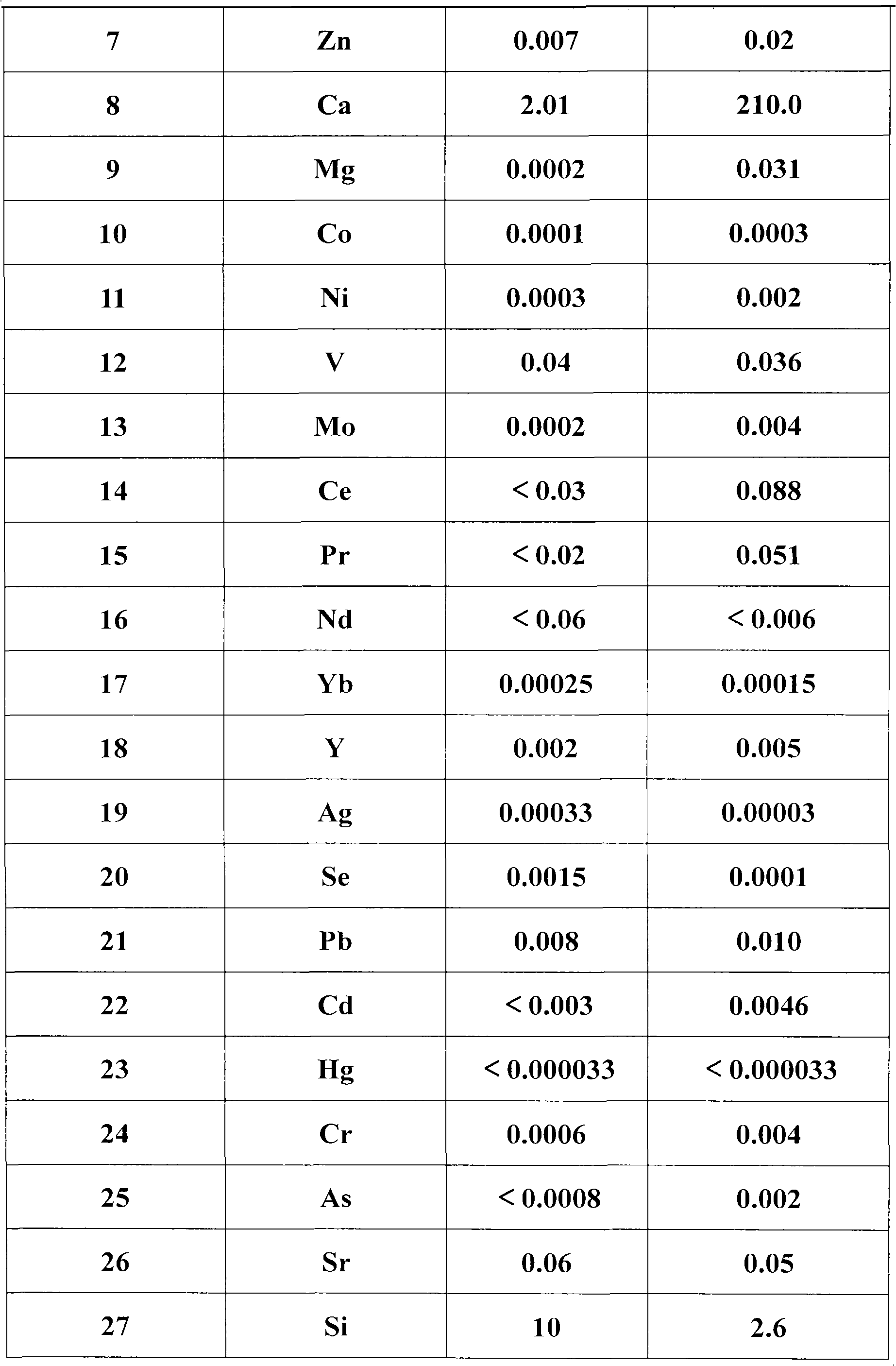

The invention discloses a medical stone and purple sand mixed mud pottery and a preparation method thereof. The medical stone and purple sand mixed mud pottery is prepared from mixed mud containing 50-80 percent by weight of natural medical stone and 20-50 percent by weight of purple sand without adding any chemical adhesive or adding easily vitreous minerals such as kaolin for obstructing ion dissolution passages and ion adsorption surface micropores during firing. The raw materials are crushed, ground, extracted and refined to prepare medical stone and purple sand mixed mud; and the medical stone and purple sand mixed mud is treated by processes such as blanking, drying, roasting and the like to prepare the medical stone and purple sand mixed mud pottery.

Owner:刘中秀

Electric glass kettle and assembly method thereof

InactiveCN103385653ASimple structureReduce the amount of processingWater-boiling vesselsWarming devicesTemperature controlEngineering

The invention relates to an electric heating glass kettle and an assembling method thereof. The electric heating glass kettle structurally comprises a glass kettle body, a heating plate which is arranged at the bottom of the glass kettle body, and a base, wherein a sealing ring is arranged at a position wherein the heating plate and the glass kettle body are connected with each other. The electric heating glass kettle is characterized in that the lower part of the glass kettle body is provided with an inwards bent step part and an inwards folded edge which is arranged below the step part, the heating plate is assembled in the inwards folded edge, and the base and the heating plate are fixedly assembled together and are arranged on the external side of the step part in a bagged way. The assembling method of the electric heating glass kettle comprises the following steps of: 1) forcibly pressing the heating plate to place the heating plate in the sealing ring; 2) slightly bending the component and placing the component in the inwards folded edge of the glass kettle body; 3) assembling a temperature control connector at the bottom of the heating plate; and 4) correspondingly sheathing the supporting part of the base on the external side of the step part of the glass kettle body, and fixing the base and the heating plate by using screws. The electric heating glass kettle and the assembling method thereof have the advantages of simple and reasonable structure, fewer manufacturing process, convenience and rapidness in assembling, high production efficiency, good sealing effect, prolonged service life, high safety and hygienic performance, and attractive and elegant appearance.

Owner:佛山市咪旗电器有限公司

Method for assembling heating explosion proof kettle

The invention discloses a method for assembling a heating explosion proof kettle. The method is characterized by comprising the steps that the blast-production technology is adopted for a glass body of the glass, the glass body of the glass is sleeved with a protective film, the protective film is attached to the outer wall of the glass body to the greatest extent, and the exterior of a main body of the glass is wrapped totally; a silica gel sealing ring is expanded and placed at an opening closing-up edge of an upper opening of the glass body of the glass in a sleeving mode, then an opening of a fixing ring is enlarged, the fixing ring is placed in the upper opening of the glass body of the glass or at the periphery of the silica gel sealing ring in a groove at the periphery of the opening, the opening of the fixing ring is tightened by screwing, then an opening of a water pouring opening part is placed in the periphery of the fixing ring from top to bottom in a sleeving mode and fixed, a handle is arranged at the other end, symmetrical with a water pouring opening, of the water pouring opening part of the glass body of the glass, and the upper end and the lower end of the handle are fixedly connected with the water pouring opening part and a bearing portion respectively, so that the outer wall of one side of the middle of the handle shields longitudinal welding marks of the protective film. The method has the advantages of being simple and reasonable in structure, good in explosion proof performance, long in service life, safe, reliable and aesthetic and elegant in appearance.

Owner:凤阳县新越玻璃制品有限公司

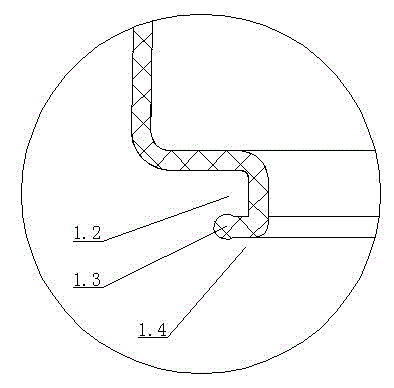

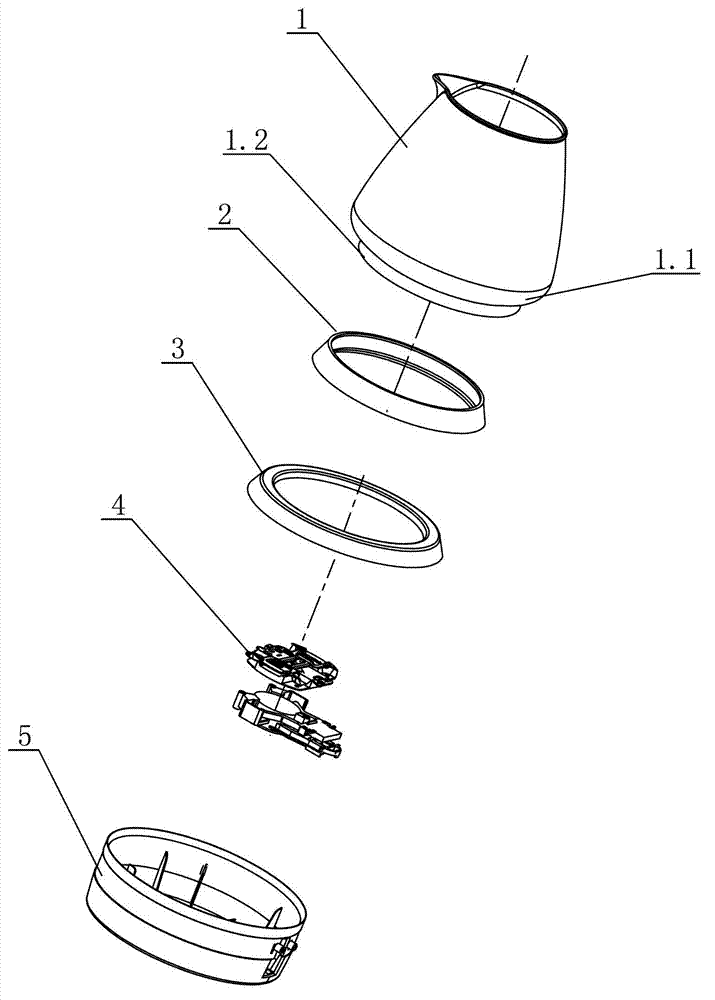

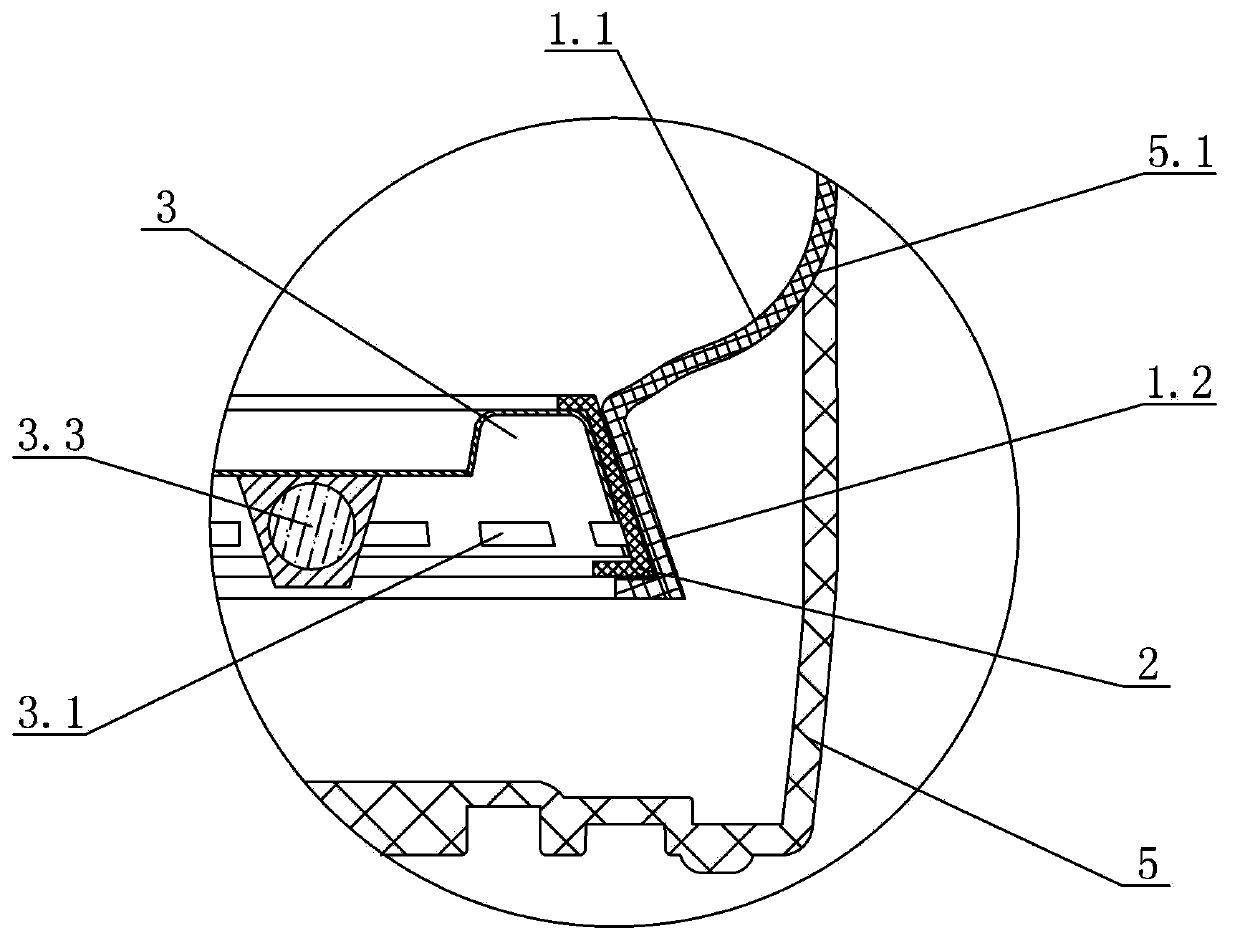

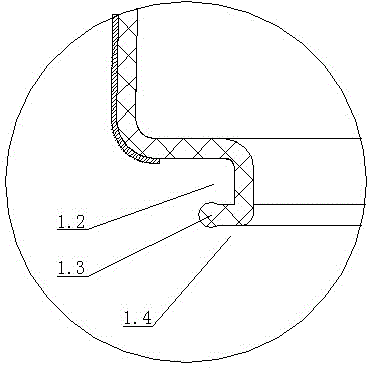

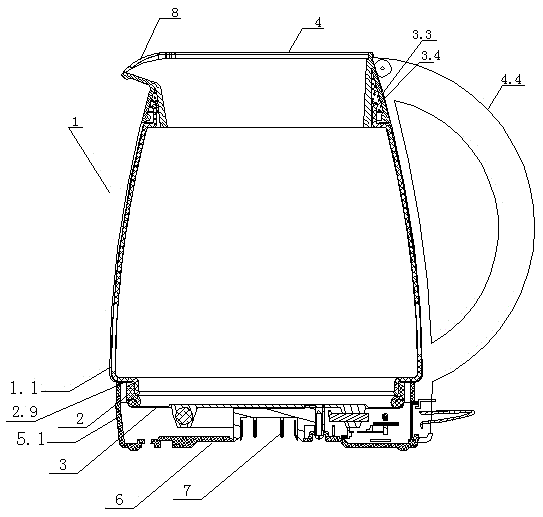

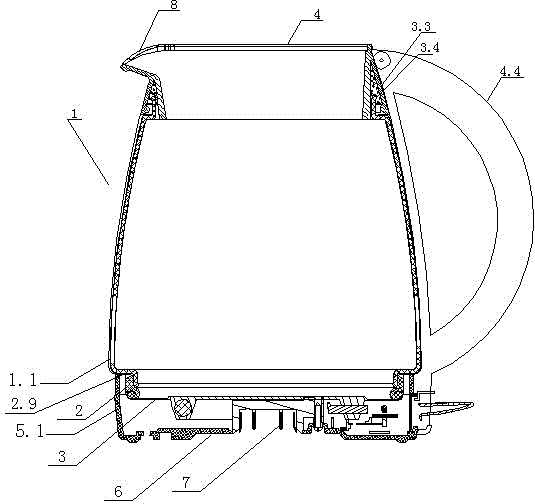

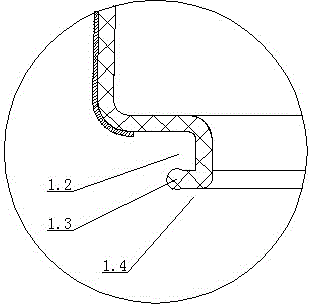

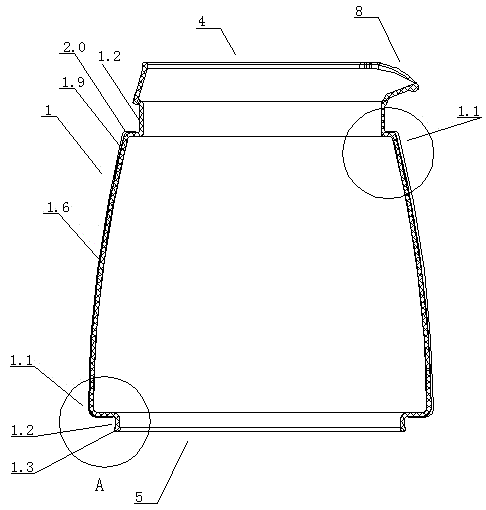

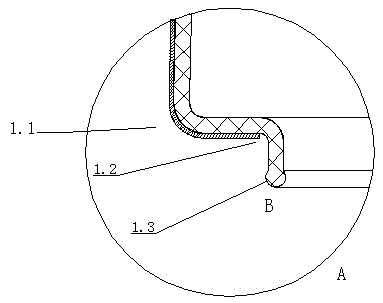

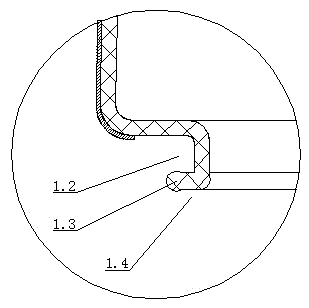

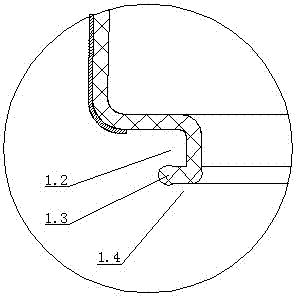

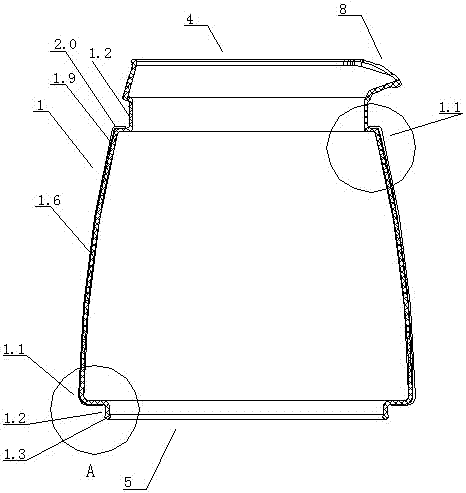

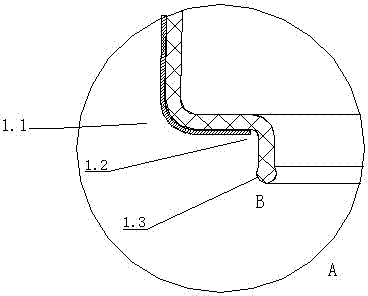

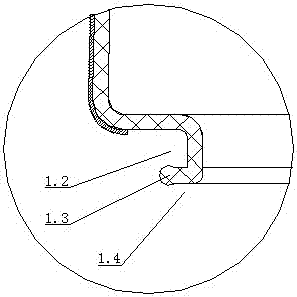

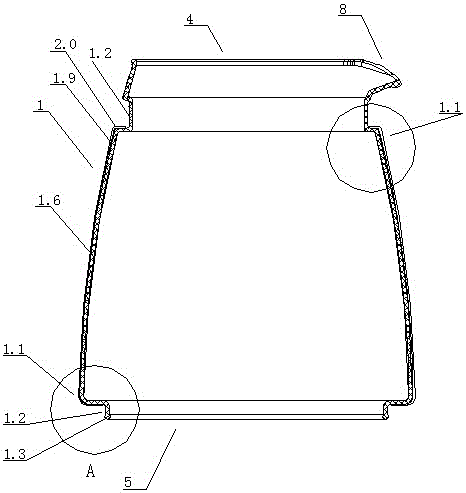

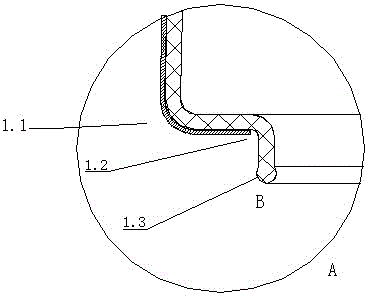

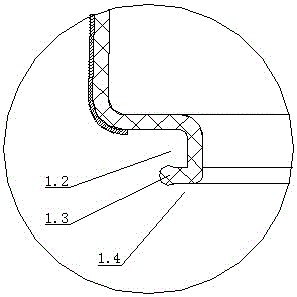

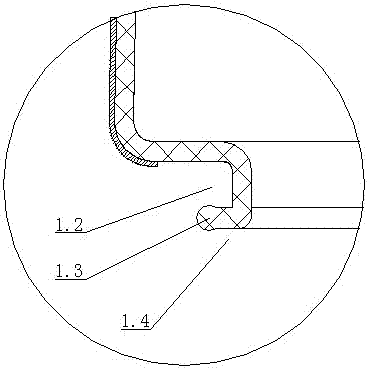

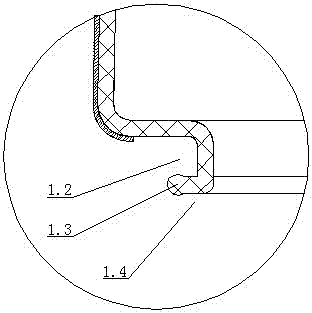

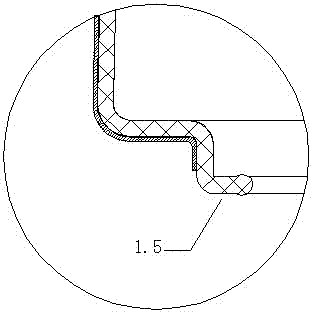

Glass kettle sealing and fixing structure and assembling method thereof

ActiveCN104223942ASimple structureLess processingWater-boiling vesselsWarming devicesEngineeringWater bottle

The invention relates to a glass kettle sealing and fixing structure. The glass kettle sealing and fixing structure comprises a glass kettle body, and a heating plate and a base which are arranged at the bottom of the glass kettle body, wherein an annular sealing ring is arranged at the connecting position of the outer wall of the heating plate and the inner wall of the opening of the bottom of the glass kettle body, and an inwards curved stepped part is arranged at the lower part of the glass kettle body. The glass kettle sealing and fixing structure is characterized in that an annular outwards convex inner groove is formed below the stepped part, the heating plate and the sealing ring are assembled in the stepped part, an opening fixing supporting ring is arranged at the lower part of the heating plate and in the annular outwards convex inner groove, the diameter of the opening fixing supporting ring is larger than the inner wall of the opening of the bottom of the glass kettle body, the perimeter of the opening fixing supporting ring is smaller than the perimeter of the inner wall of the opening of the bottom of the glass kettle body, and the base and the heating plate are fixedly assembled and wrapped on the outer side of the stepped part. The glass kettle sealing and fixing structure has the advantages that the structure is reasonable, the manufacturing processes are fewer, the structure is convenient and quick to assemble, the production efficiency is high, the sealing effect is good, the service life is prolonged, the structure is safe and sanitary and the appearance is attractive and elegant.

Owner:湛江市创志电器有限公司

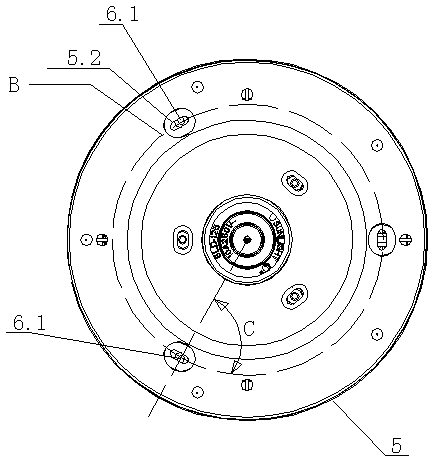

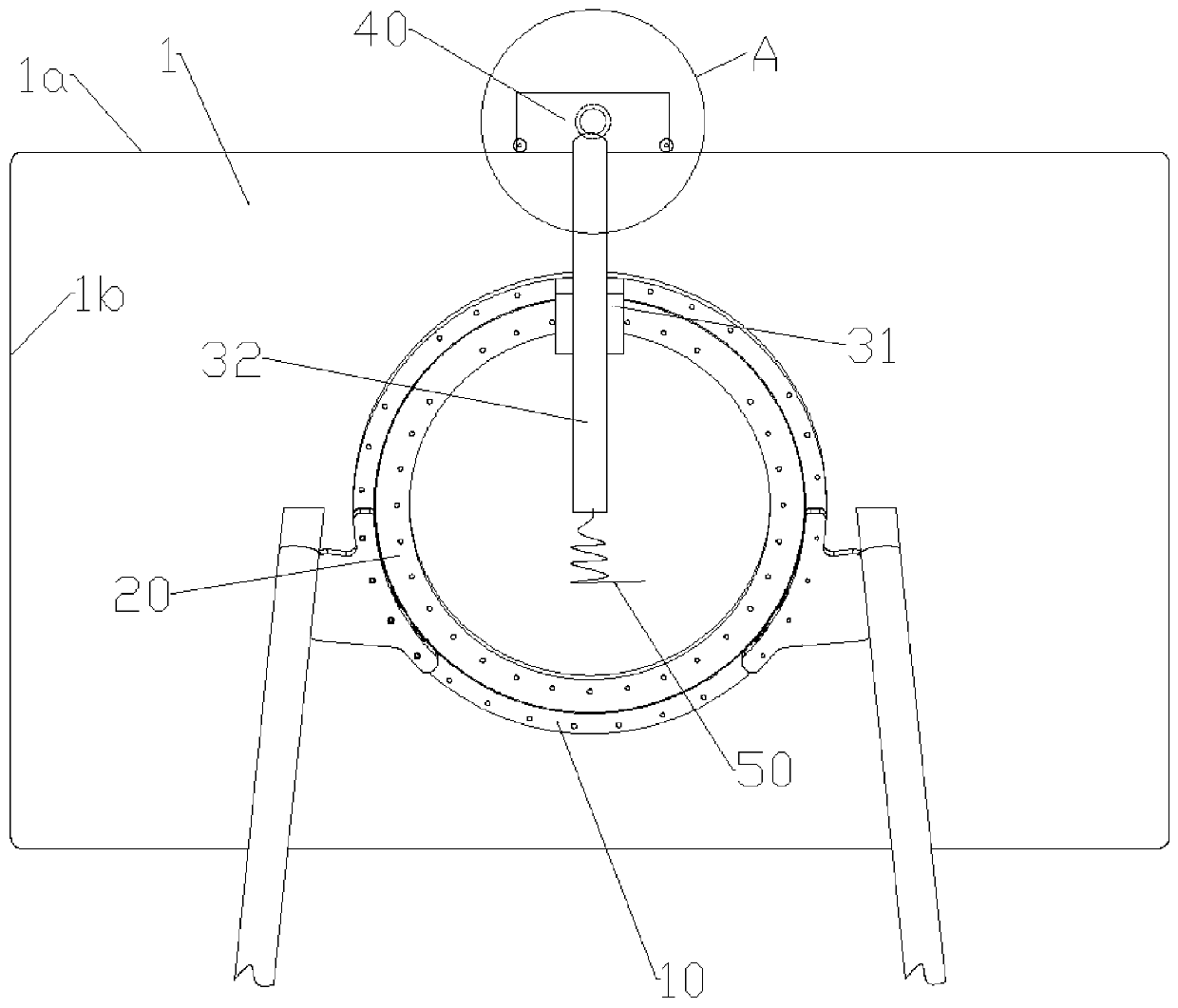

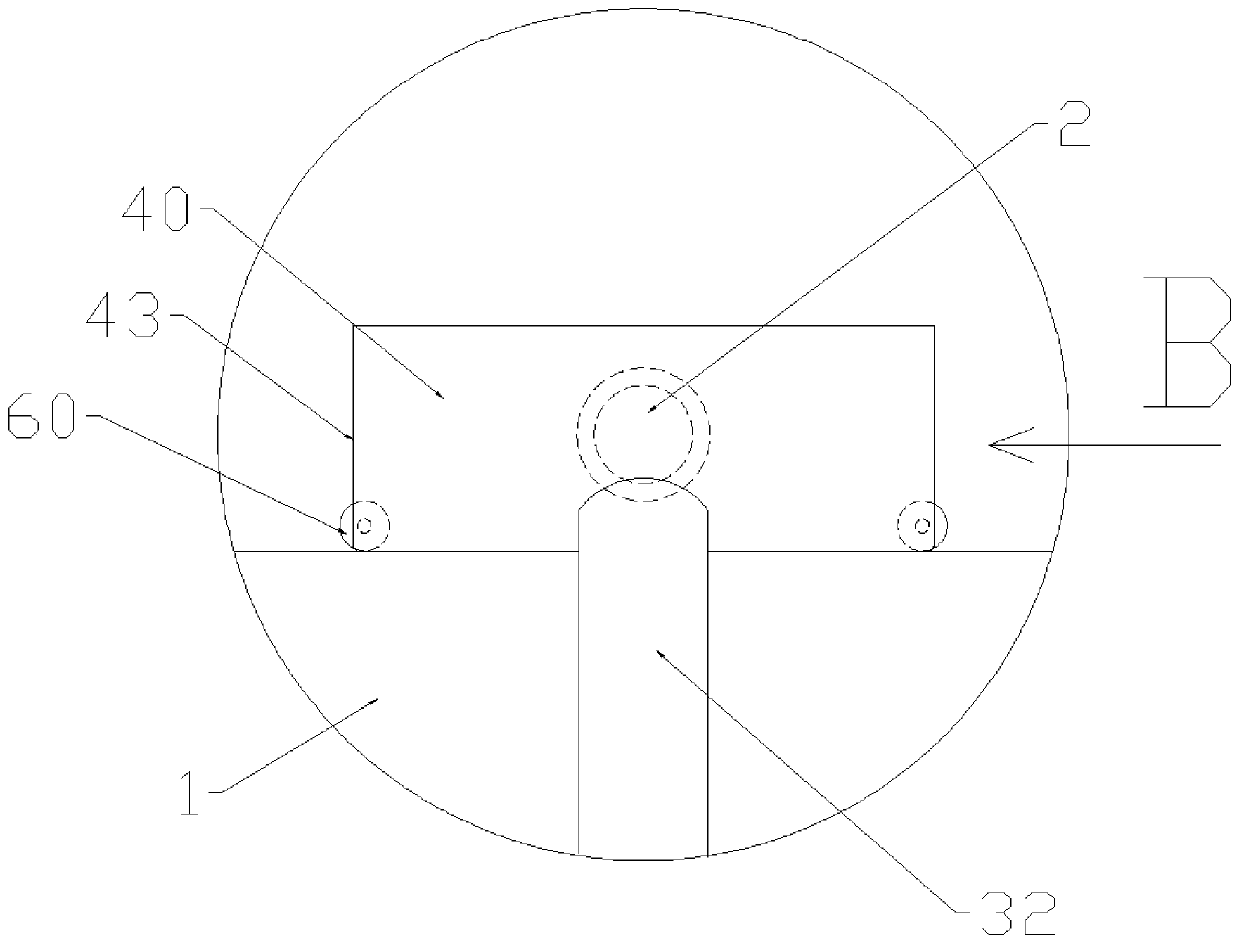

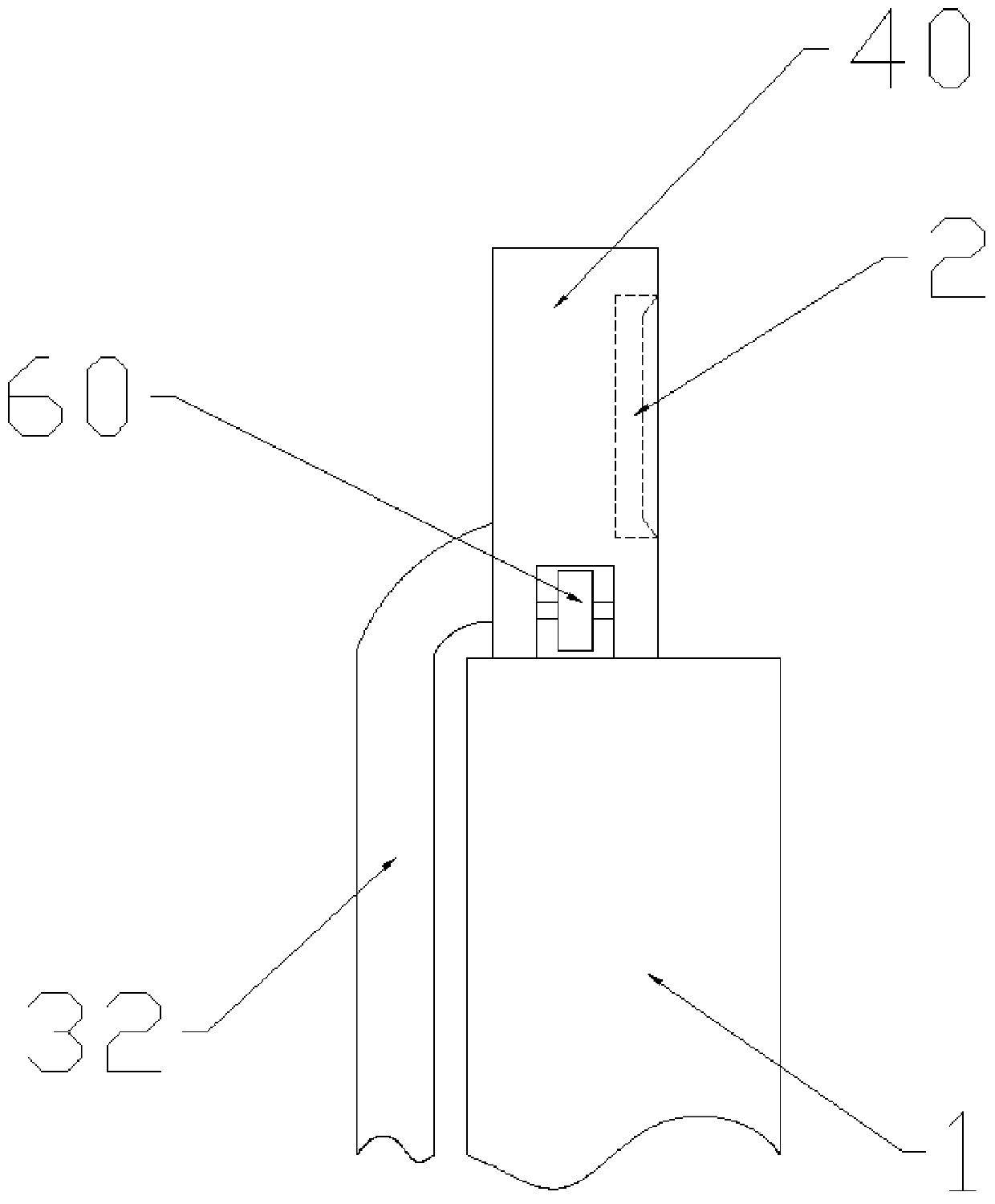

Lifting linkage structure of rotation screen camera

PendingCN110594545ASimple structureBeautiful and elegant appearanceStands/trestlesCamera body detailsDisplay deviceEngineering

Owner:TAIZHOU STRONKIN ELECTRONICS

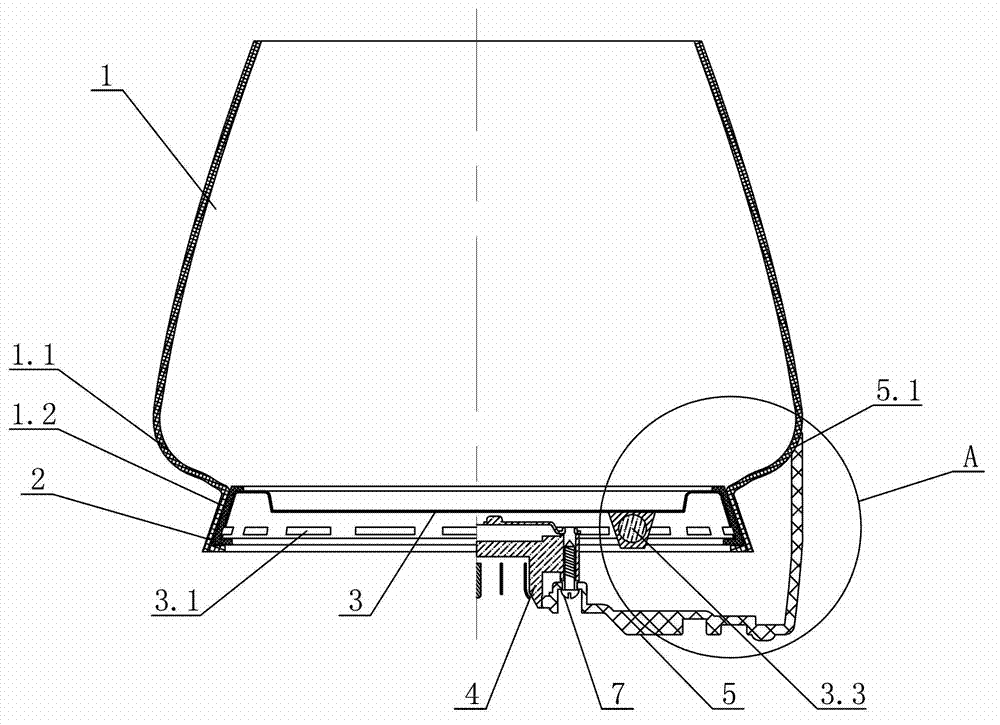

Milk foam kettle and method thereof

Disclosed is a milk foam kettle. The milk foam kettle comprises a container, a heater, a transmission assembly, a stirrer, a motor and a body, and is characterized in that the container is arranged in a separated mode and the friction transmission assembly or the resistance transmission assembly is arranged between the container and the body. The milk foam kettle has the advantages of being simple and reasonable in structure, few in processing and manufacturing procedure, convenient and fast to assemble, high in production efficiency, good in sealing effect, long in service life, safe and reliable, and attractive and elegant in appearance.

Owner:周林斌

Assembling method for heating anti-explosion glass cup kettle

ActiveCN104957984ASimple structureLess processingWater-boiling vesselsTectorial membraneWater bottle

Disclosed is an assembling method for a heating anti-explosion glass cup kettle. The assembling method is characterized by comprising the following steps that a glass cup body adopts the blowing technology, the glass cup body is sleeved with a protection film, the protection film is attached to the outer wall of the cup body as closely as possible, and the glass cup body is totally wrapped; a downward annular opening arranged on the periphery of a water pouring opening piece is arranged upwards, glue is applied into the annular opening, and the plane of the glue capacity is lower than the upper peripheral end of the annular opening to be in adhesive and sealed connection with the inner wall and outer wall of the upper opening of the glass cup body and a rolling closing opening. The upper end and the lower end of a handle are fixedly connected with a water pouring opening piece and a bearing portion. The outer wall of one side of the middle of the handle shields a longitudinal welding mark of the protection film. The heating anti-explosion glass cup kettle has the advantages of being simple and reasonable in structure, good in explosion prevention, long the service life, safe, reliable, and attractive and beautiful in appearance.

Owner:安徽凤阳美居玻璃制品有限公司

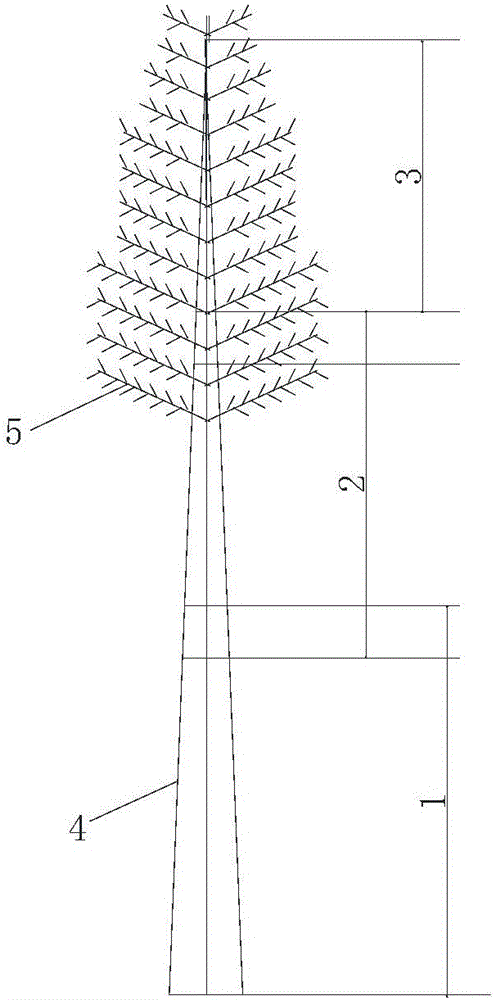

Disguised tree signal tower

InactiveCN104989153AExquisite and lifelike structureBeautiful and elegant appearanceArtificial flowers and garlandsTowersEconomic benefitsSmall footprint

The invention discloses a disguised tree signal tower, which comprises a tower body and a tower base, wherein the lower end of the tower body is fixed on the tower base; the tower body comprises a rod section A, a rod section B and a rod section C which are connected together in a sleeving way; tree barks cover the outside of the tower body; the upper part of the tower body is provided with a branch structure; tree leaves are arranged on the tree branches; the tree branch structure comprises 12 layers; three tree branches are arranged in each layer; through being counted from top to bottom, the first layer forms a first region, the second to third layers form a second region, the fourth to fifth layers form a third region, the sixth to eighth layer form a fourth region, and the ninth to twelfth layers form a fifth region; and the lengths of the tree branches in the first region, the second region, the third region, the fourth region and the fifth region are sequentially increased. The disguised tree signal tower has the advantages that 1, the structure is exquisite and vivid, and the appearance is attractive and elegant; 2, the structure stability is high, and the technicality is high; 3, the occupied area is small, and the economic benefits are obvious; and 4, the service life is long, and the appearance effect is permanent.

Owner:TIANJIN FANGHUA COMM ENG

Milk foam making kettle and method

ActiveCN103381056ASimple structureReduce the amount of processingBeverage vesselsElectric machineryProcess engineering

A milk foam making kettle comprises a container, a heater, a transmission assembly, a stirring device, a motor and a main body. The milk foam making kettle is characterized in that the container is arranged in a split mode, and a friction transmission assembly or a resistance transmission assembly is arranged between the container and the main body. The milk foam making kettle has the advantages of being simple and reasonable in structure, having fewer machining and manufacturing procedures and being convenient and fast to assemble, high in production efficiency, good in sealing effect, long in service life, safe and reliable and attractive and elegant in appearance.

Owner:临沂高新区人才职业培训学校有限公司

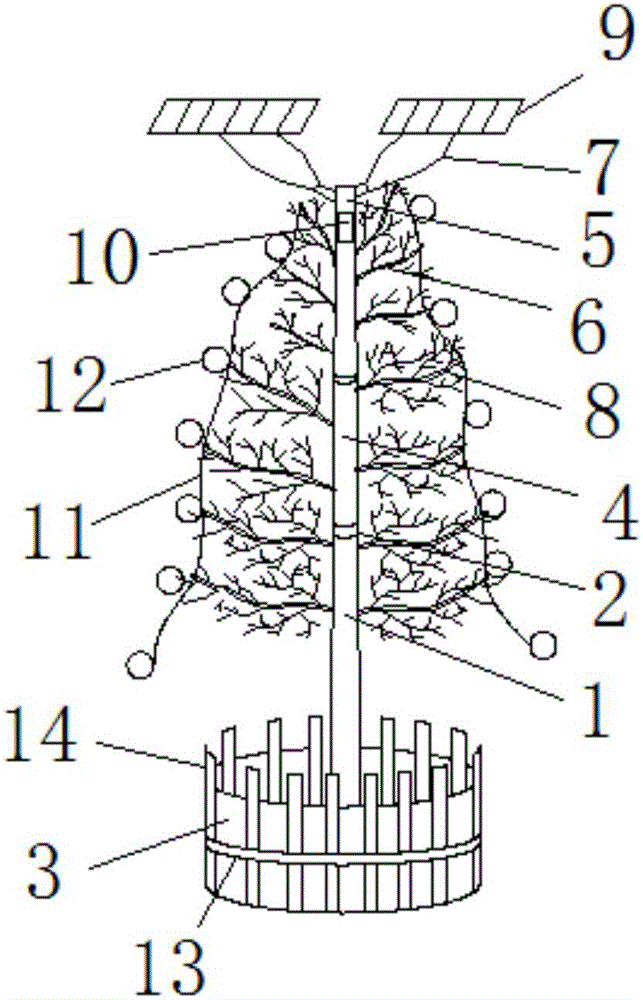

Garden landscape tree

InactiveCN106042757AExquisite and lifelike structureImprove stabilitySpecial ornamental structuresTree trunkEngineering

The invention discloses a garden landscape tree. The garden landscape tree comprises a first-stage tree trunk, hoops, a tree protection pool, a second-stage tree trunk, a third-stage tree trunk, tree branches, solar panel supports, leaves, solar panels, a power collection box, power transmission lines, light-emitting diodes, a protective belt and baffles. The first-stage tree trunk is connected with the corresponding hoop, and the tree protection pool is arranged below the first-stage tree trunk. The first-stage tree trunk is connected with the second-stage tree trunk through the corresponding hoop. The second-stage tree trunk is connected with the third-stage tree trunk through the corresponding hoop. The third-stage tree trunk is connected with the tree branches, and the third-stage tree trunk and the solar panel supports are cast integrally. The tree branches are connected with the leaves. The solar panel supports are connected with the solar panels. The third-stage tree trunk is connected with the power collection box. The power collection box is connected with the power transmission lines. The light-emitting diodes are hung on the upper sides of the power transmission lines. The tree protection pool is fixed through the protective belt and defined by the baffles. The garden landscape tree has the advantages of being novel in design and resistant to corrosion, aging and high temperature.

Owner:章勤正

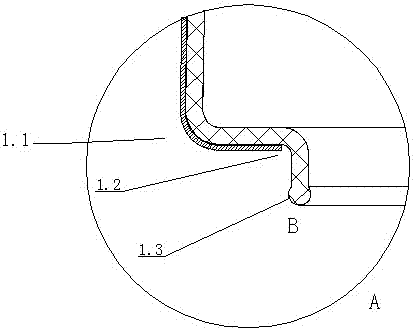

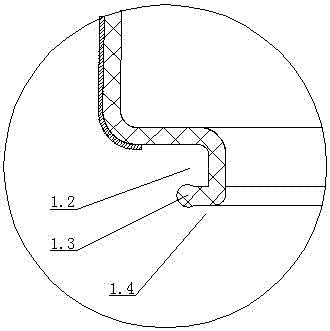

Heating explosion prevention glass water kettle

Disclosed is a heating explosion prevention glass water kettle. A main body, an upper opening, a lower opening, a protection film, glue, a water pouring opening piece, a handle and a bearing portion are arranged on a cup body. The heating explosion prevention glass water kettle is characterized in that steps are arranged at the opening of the glass cup body, the steps are in smooth connection with the exterior of the main body, the protection film is arranged at the bent portions of the steps and the main body and the exterior of the main body, the protection film is higher than the outer wall of the glass cup body, and clamped and positioned by the outer wall of the glass cup body and the water pouring opening piece, the handle is arranged at the other end symmetric with the water pouring opening of the water pouring opening piece of the glass cup body, and the outer wall of one side of the handle is shielded by a longitudinal welding mark of the protection film; the upper end of the handle is fixedly connected with the upper opening of the glass cup body, and the lower end of the handle is fixedly connected with the bottom cover or a bottom ring of the bearing portion. The heating explosion prevention glass water kettle has the advantages of being simple and reasonable in structure, good in explosion prevention, long in the service life, safe, reliable, and attractive and beautiful in appearance.

Owner:安徽凤阳美居玻璃制品有限公司

Heated explosion-proof glass spout

ActiveCN104957986BSimple structureReduce the amount of processingWater-boiling vesselsEngineeringNozzle

Disclosed is a heating explosion prevention glass cup kettle nozzle. A main body, an upper opening, a lower opening, a protection film, glue and a water pouring opening piece are arranged on a cup body. The heating explosion prevention glass cup kettle nozzle is characterized in that steps are arranged at the opening of the glass cup body, the steps are in smooth connection with the exterior of the main body, the protection film is arranged at the bent portions of the steps and the main body and the exterior of the main body, the protection film is clamped and positioned by the outer wall of the glass cup body and the water pouring opening piece, the glue and the water pouring opening piece are arranged on an opening of the glass cup body, the glue wraps the rolling closing edge of the upper opening of the glass cup body to be connected and sealed with the inner wall of the water pouring opening piece, a downward annular opening is formed in the periphery of the water pouring opening piece, and the glue is applied into the annular opening to be in adhesive and sealed connection with the rolling closing opening of the inner wall and the outer wall of the upper opening of the glass cup body. The heating explosion prevention glass cup kettle nozzle has the advantages of being simple and reasonable in structure, good in explosion prevention, long the service life, safe, reliable, and attractive and beautiful in appearance.

Owner:凤阳县新越玻璃制品有限公司

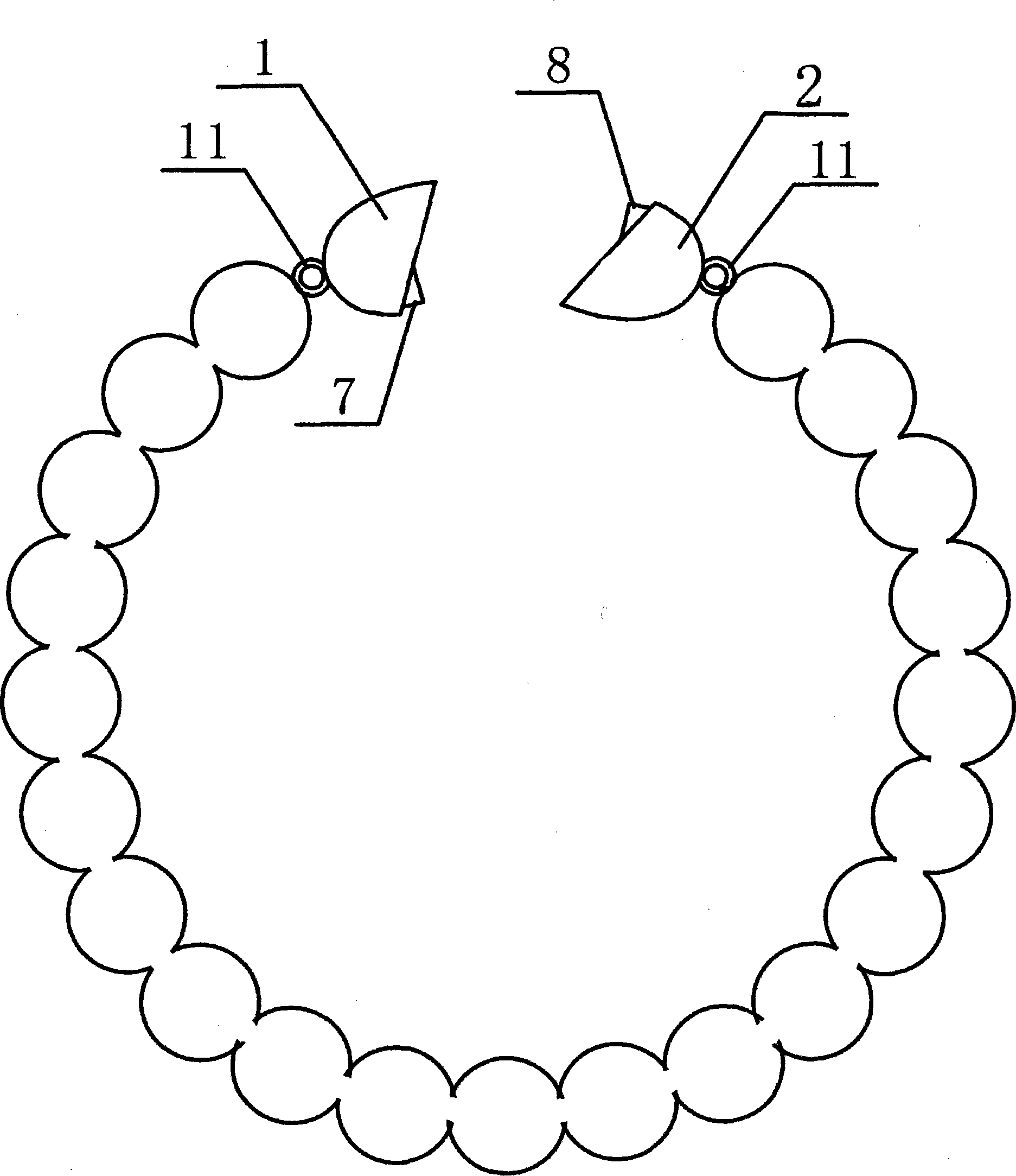

Magnetic inclining unlocking-type pearl necklace and jewelery lock catch

Owner:沈阳月光珠宝制造有限公司

Spout of heating explosion proof glass

ActiveCN104957988ASimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneEngineering

The invention discloses a spout of a heating explosion proof glass. A glass body is provided with a main body, an upper opening, a lower opening, a protective film and a silica gel sealing ring, and the spout is characterized in that steps are arranged at the openings of the glass body of the glass, the steps are in smooth connection with the exterior of the main body, the protective film is arranged at bending positions of the steps and the main body and the exterior of the main body, the protective film is higher than the outer wall of the glass body of the glass, and the protective film is clamped and located by the outer wall of the glass body of the glass and an external contracting part or a water pouring opening part or a bearing portion; the silica gel sealing ring and a heating disc are arranged at the lower opening of the glass body of the glass, and the silica gel sealing ring wraps, connects and seals a rolling circle opening closing edge on the lower portion of the glass body of the glass and the heating disc. The spout has the advantages of being simple and reasonable in structure, good in explosion proof performance, long in service life, safe, reliable and aesthetic and elegant in appearance.

Owner:凤阳县新越玻璃制品有限公司

Sealed and fixed structure of glass kettle and its assembly method

ActiveCN104223942BSimple structureReduce the amount of processingWater-boiling vesselsWarming devicesMechanical engineeringEngineering

The invention relates to a glass kettle sealing and fixing structure. The glass kettle sealing and fixing structure comprises a glass kettle body, and a heating plate and a base which are arranged at the bottom of the glass kettle body, wherein an annular sealing ring is arranged at the connecting position of the outer wall of the heating plate and the inner wall of the opening of the bottom of the glass kettle body, and an inwards curved stepped part is arranged at the lower part of the glass kettle body. The glass kettle sealing and fixing structure is characterized in that an annular outwards convex inner groove is formed below the stepped part, the heating plate and the sealing ring are assembled in the stepped part, an opening fixing supporting ring is arranged at the lower part of the heating plate and in the annular outwards convex inner groove, the diameter of the opening fixing supporting ring is larger than the inner wall of the opening of the bottom of the glass kettle body, the perimeter of the opening fixing supporting ring is smaller than the perimeter of the inner wall of the opening of the bottom of the glass kettle body, and the base and the heating plate are fixedly assembled and wrapped on the outer side of the stepped part. The glass kettle sealing and fixing structure has the advantages that the structure is reasonable, the manufacturing processes are fewer, the structure is convenient and quick to assemble, the production efficiency is high, the sealing effect is good, the service life is prolonged, the structure is safe and sanitary and the appearance is attractive and elegant.

Owner:湛江市创志电器有限公司

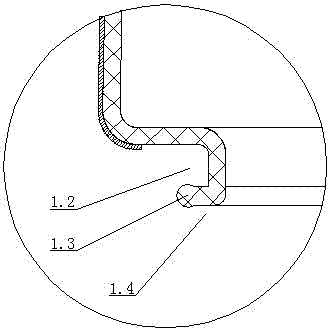

Method for assembling spout of heating explosion proof glass

The invention discloses a method for assembling a spout of a heating explosion proof glass. The method is characterized by comprising the steps that the blast-production technology is adopted for a glass body of the glass, the glass body of the glass is sleeved with a protective film, the protective film is attached to the outer wall of the glass body to the greatest extent, and the exterior of a main body of the glass is wrapped totally; a silica gel sealing ring is expanded and placed at an opening closing-up edge of an upper opening of the glass body of the glass in a sleeving mode, then an opening of a fixing ring is enlarged, the fixing ring is placed in the upper opening of the glass body of the glass or at the periphery of the silica gel sealing ring in a groove at the periphery of the opening, the opening of the fixing ring is tightened by screwing, then an opening of a water pouring opening part is placed in the periphery of the fixing ring from top to bottom in a sleeving mode and fixed, and the inner wall of the water pouring opening clamps the periphery of the opening of the glass body of the explosion proof glass, the positions of closed openings of the protective film and the fixing ring. The method has the advantages of being simple and reasonable in structure, good in explosion proof performance, long in service life, safe, reliable and aesthetic and elegant in appearance.

Owner:凤阳祈菲乐玻璃制品有限公司

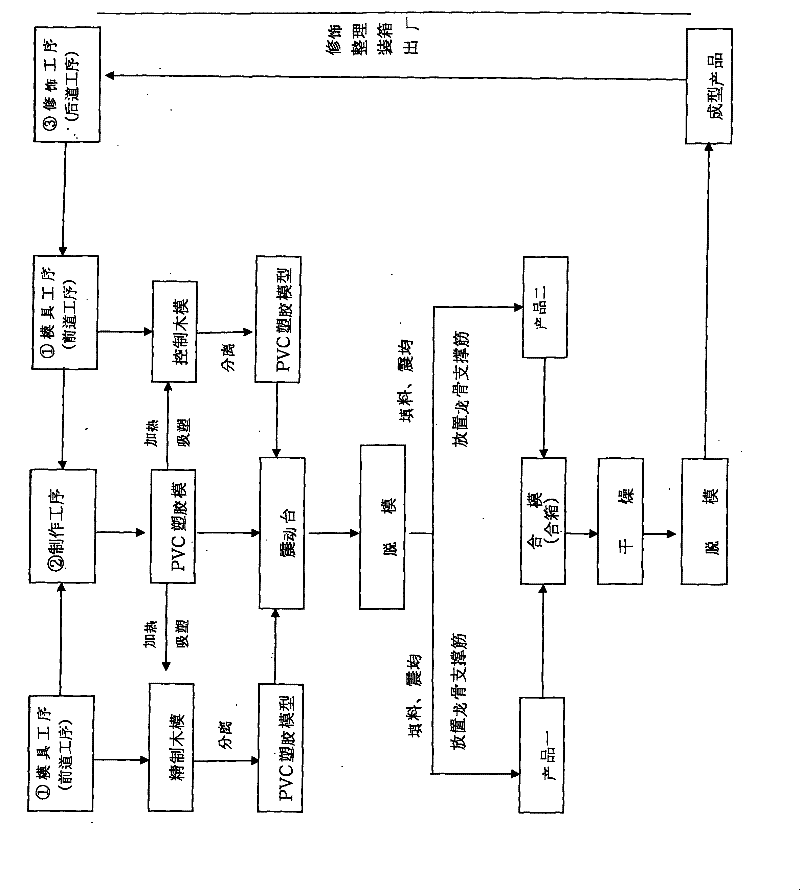

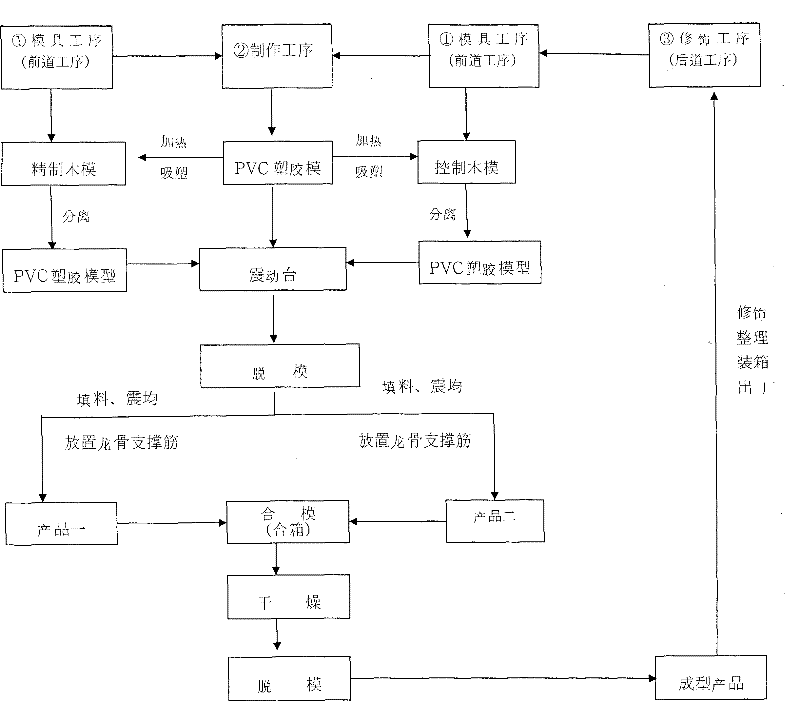

Method for producing pseudo-white-marble scenery guardrail serial craft

InactiveCN101905479BDifferent colorsLong lasting colorMouldsHollow articlesVacuum pumpingPolyvinyl chloride

The invention discloses a method for producing a pseudo-white-marble scenery guardrail serial craft, which comprises the following steps of: firstly, mounting an oscillation working platform and installing a female die on the oscillation working platform; adhering a PVC (polyvinyl chloride) plastic film which is heated and baked to be soft onto a die cavity of the female die and firmly adhering and sucking the PVC plastic film in the die cavity of the female die by a vacuum-pumping method; after cooling, separating the PVC plastic film to form a PVC plastic model; placing the PVC plastic model into a support die and fixing the support die on the oscillation working platform; filling moulding slurry into a PVC plastic model die cavity; filling a support object which can bear pressure; starting the oscillation working platform, naturally drying and demoulding after 3 days to 5 days to obtain the upper half part of the product; and preparing the lower half part of the product by the samemethod, precisely combining with the upper half part of the obtained product before drying, fusing into a whole without an air hole on the combining surface, drying and demoulding to obtain the product. The method of the invention is simple and has convenient operation, and the manufactured product has high quality and reasonable cost.

Owner:翁兆华

Explosion-proof heating glass cup body manufacturing method

ActiveCN104957980BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneAdhesive disc

The manufacturing method of the explosion-proof heated glass cup body is characterized in that it includes the following steps: the glass cup body adopts a blowing process, the outside of the glass cup body is covered with a protective film, the protective film is as close as possible to the outer wall of the cup body, and the glass cup The outside of the main body is completely wrapped; heat the glass body and the protective film together, and the protective film shrinks and fits the outer wall of the glass cup; place the heated protective film glass body on the table, rotate it and use a knife to cut the glass Cut off the protective film on the upper and lower steps of the cup body; inject glue into the upward annular opening on the periphery of the heating plate, and then insert the lower opening of the explosion-proof glass cup into the glue on the upward annular opening on the periphery of the heating plate, so that the cup The inner wall and outer wall of the opening under the body are bonded and sealed with the glue of the upward annular opening on the periphery of the heating plate; the invention has the advantages of simple and reasonable structure, less processing and manufacturing procedures, high production efficiency, good explosion-proof, prolonged service life, safety and reliability, and beautiful appearance Elegant features.

Owner:凤阳县新越玻璃制品有限公司

Heating explosion-proof glass kettle

ActiveCN104957983BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneEngineering

Owner:安徽凤阳美居玻璃制品有限公司

Method for assembling glass body of heating explosion proof glass

The invention discloses a method for assembling a glass body of a heating explosion proof glass. The method is characterized by comprising the steps that the blast-production technology is adopted for the glass body of the glass, the glass body of the glass is sleeved with a protective film, the protective film is attached to the outer wall of the glass body to the greatest extent, and the exterior of a main body of the glass is wrapped totally; the glass body of the glass and the protective film are heated together, and the protective film shrinks to be attached to the outer wall of the glass body of the glass; the glass body of the glass provided with the protective film which is heated ready is placed on a table top, the glass body is rotated, and the parts, located on an upper step face and a lower step face of the glass body of the glass, of the protective film are cut down; patterns and water level scales can be printed on the protective film; the step face of the glass body of the glass is sleeved with a bottom cover from top to bottom, closed protective film openings serve for shielding, and the closed protective film openings are prevented from being torn. The method has the advantages of being simple and reasonable in structure, good in explosion proof performance, long in service life, safe, reliable and aesthetic and elegant in appearance.

Owner:凤阳祈菲乐玻璃制品有限公司

An assembly method for heating explosion-proof glass cup body

ActiveCN104957979BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneMaterials science

A method for assembling a heated explosion-proof glass body is characterized in that it includes the following steps: the glass body adopts a blowing process, the outside of the glass body is covered with a protective film, the protective film is as close as possible to the outer wall of the glass, and the glass body The outside of the body is completely wrapped; heat the glass body and the protective film together, and the protective film shrinks to fit the outer wall of the glass cup; place the heated protective film glass body on the table, rotate it and use a knife to cut the glass The protective film on the upper and lower steps of the cup body is cut off; patterns and water marks can be printed on the protective film; the bottom cover is placed on the outside of the step surface of the glass cup body from top to bottom, and the protective film is closed to cover , to prevent the protective film from being torn. The invention has the characteristics of simple and reasonable structure, good explosion-proof, long service life, safety and reliability, and beautiful and elegant appearance.

Owner:凤阳祈菲乐玻璃制品有限公司

An assembly method for heating an explosion-proof kettle

ActiveCN104957978BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneEngineering

The invention discloses a method for assembling a heating explosion proof kettle. The method is characterized by comprising the steps that the blast-production technology is adopted for a glass body of the glass, the glass body of the glass is sleeved with a protective film, the protective film is attached to the outer wall of the glass body to the greatest extent, and the exterior of a main body of the glass is wrapped totally; a silica gel sealing ring is expanded and placed at an opening closing-up edge of an upper opening of the glass body of the glass in a sleeving mode, then an opening of a fixing ring is enlarged, the fixing ring is placed in the upper opening of the glass body of the glass or at the periphery of the silica gel sealing ring in a groove at the periphery of the opening, the opening of the fixing ring is tightened by screwing, then an opening of a water pouring opening part is placed in the periphery of the fixing ring from top to bottom in a sleeving mode and fixed, a handle is arranged at the other end, symmetrical with a water pouring opening, of the water pouring opening part of the glass body of the glass, and the upper end and the lower end of the handle are fixedly connected with the water pouring opening part and a bearing portion respectively, so that the outer wall of one side of the middle of the handle shields longitudinal welding marks of the protective film. The method has the advantages of being simple and reasonable in structure, good in explosion proof performance, long in service life, safe, reliable and aesthetic and elegant in appearance.

Owner:凤阳县新越玻璃制品有限公司

Assembly method of heating explosion-proof glass kettle

ActiveCN104957984BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneEngineering

The method for assembling the heated explosion-proof glass jug is characterized in that it includes the following steps: the glass body is blown, the outside of the glass body is covered with a protective film, the protective film is as close as possible to the outer wall of the glass, and the outer surface of the glass main body is fully covered. Wrapping; put the circular opening with the outer periphery of the spout upwards, apply glue in the circular opening, the capacity plane of the glue is lower than the peripheral upper end of the circular opening and the inner wall, outer wall and rounded mouth of the upper opening of the glass cup. The upper and lower ends of the handle are respectively fixedly connected to the spout and the supporting part, and the outer wall on one side of the middle part of the handle covers the longitudinal welding marks of the protective film. The invention has the characteristics of simple and reasonable structure, good explosion-proof, long service life, safety and reliability, and beautiful and elegant appearance.

Owner:安徽凤阳美居玻璃制品有限公司

A kind of processing method of explosion-proof glass cup body

ActiveCN104957981BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneCuff

A method for processing an explosion-proof glass body is characterized in that it includes the following steps: the glass body adopts a blowing process, the outside of the glass body is covered with a protective film, the protective film is as close as possible to the outer wall of the glass, and the glass body is The outside is completely wrapped; heat the glass body and the protective film together, and the protective film shrinks to fit the outer wall of the glass; place the heated glass body with the protective film on the table, rotate it and use a knife to cut the glass The protective film on the upper and lower steps of the glass body is cut off; patterns and water marks can be printed on the protective film; the bottom cover is placed on the outside of the step surface of the glass cup body from top to bottom, and the protective film is closed to cover. Prevent the protective film closure from being torn. The invention has the characteristics of simple and reasonable structure, less processing steps, convenient and fast assembly, high production efficiency, good explosion-proof, prolonged service life, safety and reliability, and beautiful and elegant appearance.

Owner:安徽鑫民玻璃股份有限公司

Cup body of explosion-preventing glass cup

Provided is a cup body of an explosion-preventing glass cup. A main body, an upper opening, a lower opening and protecting films are arranged on the cup body. The cup body is characterized in that openings of the cup body of the glass cup are provided with steps; the steps are in smooth connection with the outside of the main body; bending parts among the steps and the main body and the outside of the main body are provided with the protecting films which are arranged higher than the outer wall of the cup body of the glass cup; and the protecting films are clamped for positioning by the outer wall of the cup body of the glass cup or external contracting parts or water-pouring port parts. The cup body of the explosion-preventing glass cup is characterized by being simple and reasonable in structure, few in operation for manufacture and production, convenient and quick in assembly, high in production efficiency, fine in explosion-preventing performance, long in service lifetime and attractive and elegant in external appearance and is safe and reliable.

Owner:湖北华强日用玻璃有限公司

An explosion-proof heating kettle

ActiveCN104957982BSimple structureReduce the amount of processingWater-boiling vesselsTectorial membraneWater bottle

A heating and explosion-proof kettle, the cup body is provided with a main body, an upper opening, a lower opening, a protective film, a silicone sealing ring, a pouring spout, a handle, and a supporting part, and it is characterized in that the opening of the glass cup body is provided with Steps, the steps are smoothly connected with the outside of the main body, the bending part of the steps and the main body and the outside of the main body are provided with a protective film, the protective film is higher than the outer wall of the glass cup, and the protective film is covered by the outer wall of the glass cup and the outer shrinkage part Or the pouring spout or the supporting part is clamped and positioned; the lower opening of the glass cup body is provided with a silicone seal ring and a heating plate, and the silicone seal ring wraps and seals the rounded edge of the lower part of the glass cup body and the heating plate; the handle It is arranged at the other symmetrical end of the pouring spout of the glass body, and the outer wall on one side of the handle covers the longitudinal welding mark of the protective film; the present invention has the advantages of simple and reasonable structure, good explosion-proof, prolonged service life, safety and reliability, and beautiful and elegant appearance. features.

Owner:广东安博朗科技有限公司

Explosion-proof heated glass body

ActiveCN105078225BSimple structureReduce the amount of processingWater-boiling vesselsWarming devicesTectorial membraneEngineering

Provided is an explosion-proof cup body of a heating glass body. The cup body is provided with a main body, an upper opening, a lower opening, a protection film, a heating disc and a bearing portion and is characterized in that openings of the cup body of the glass body are provided with steps; the steps are in smooth connection with the outside of the main body; the bending part between each step and the main body and the outside of the main body are provided with protection films higher than the outer wall of the cup body of the glass body; the protection films are clamped for positioning by the outer wall of the cup body of the glass body and the bearing portion outside; the heating disc is arranged below the lower opening or the tail ends of the protection films; an upward annular opening is arranged on the periphery of the heating disc; and by gluing the inside of the annular opening, the annular opening is connected with the inner wall of the lower opening and the outer wall of the cup body in a sealing mode by adhesion. The explosion-proof cup body of the heating glass body has following characteristics: the explosion-proof cup body is simple and reasonable in structure, few in procedures for manufacture and production, convenient and rapid in assembly, high in production efficiency, fine in explosion-proof performance, long in service lifetime and attractive and elegant in external appearance and is safe and reliable.

Owner:凤阳祈菲乐玻璃制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com