Method for producing pseudo-white-marble scenery guardrail serial craft

A technology of imitating white marble and landscape, applied in the direction of manufacturing tools, hollow objects, molds, etc., can solve the problems of uncoordinated urban development, simple and rough production process, beautification, poor decorative effect, etc., to achieve noble and elegant quality, simple installation and construction. Fast, clear and smooth patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

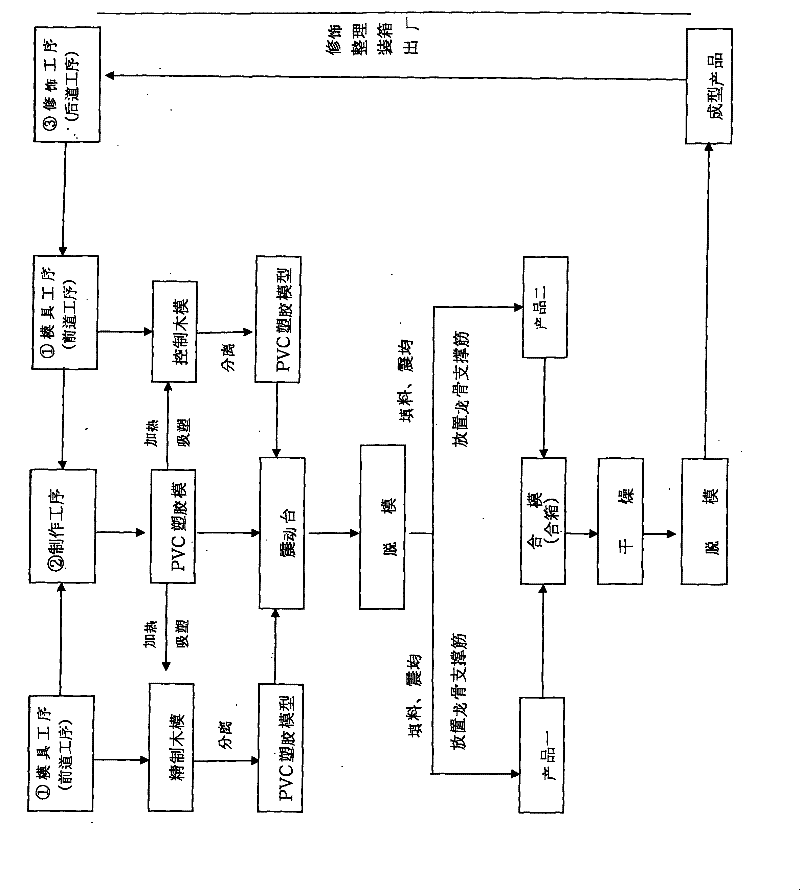

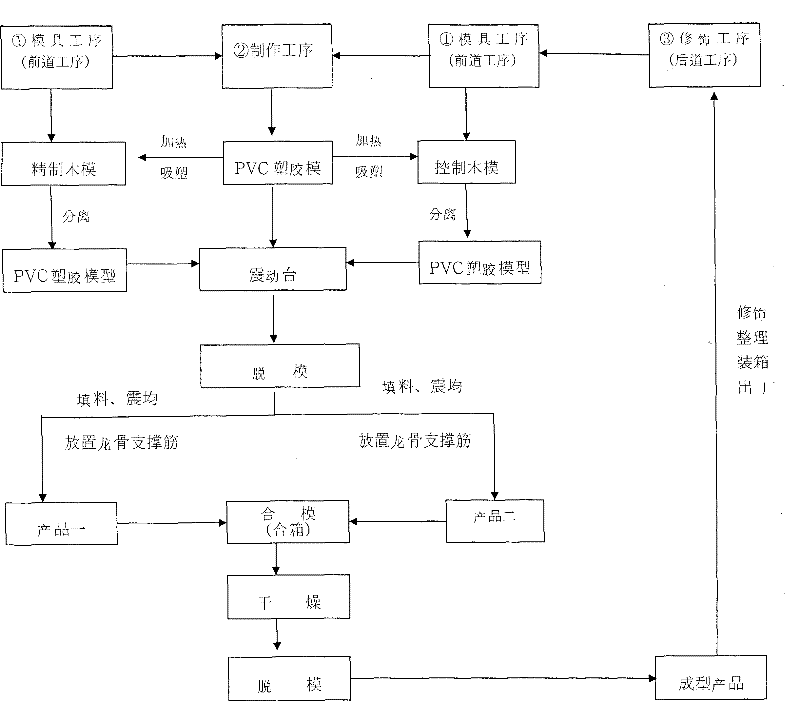

[0023] The production method of imitation white marble landscape guardrail handicraft products includes the following steps:

[0024] (1), vibrating workbench is set, and master mold is installed on the vibrating workbench, and the mold cavity of mother mold matches the shape of the product to be formed, and there are ventilation holes on the cavity side wall of said master mold and the outer wall of the master mold , the workbench is provided with an air passage, connected to a vacuum system, and the air passage communicates with the ventilation hole;

[0025] (2) Put the heated and softened PVC plastic film on the mold cavity of the mother mold, seal the periphery of the PVC plastic film with the vibration table and the periphery of the mother mold, start the vacuum system, and extract the PVC plastic film and the mold cavity of the mother mold The gas inside makes the PVC plastic film be firmly stuck in the cavity of the mother mold, and after cooling, the PVC plastic film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com