Thermosetting non-photocureable 3D printing material and printing method thereof

A 3D printing and thermosetting technology, applied in the field of 3D printing, can solve the problems of low precision and poor product strength, and achieve the effect of smooth surface, improved comprehensive performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

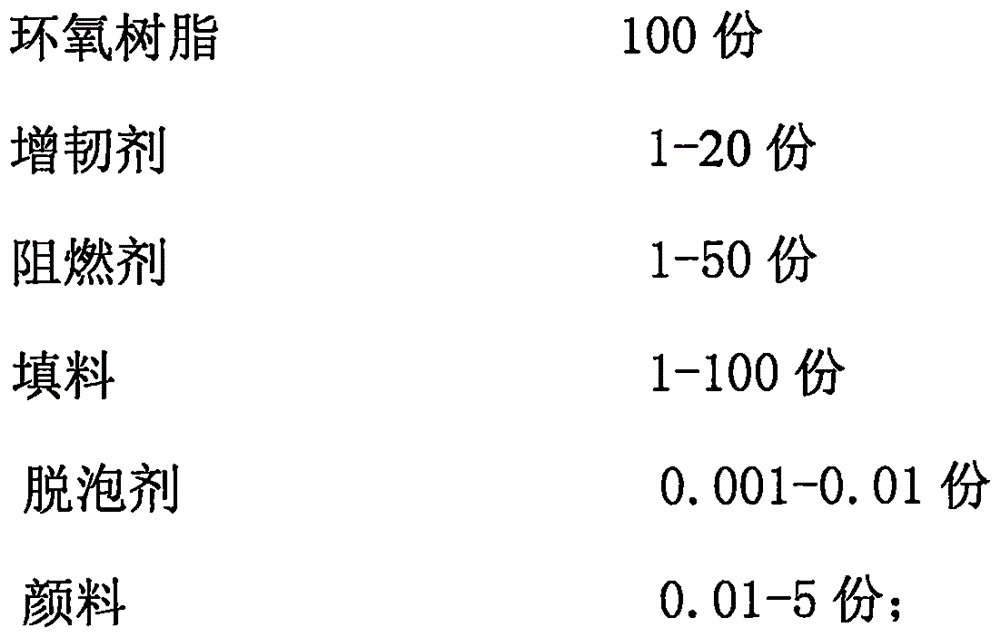

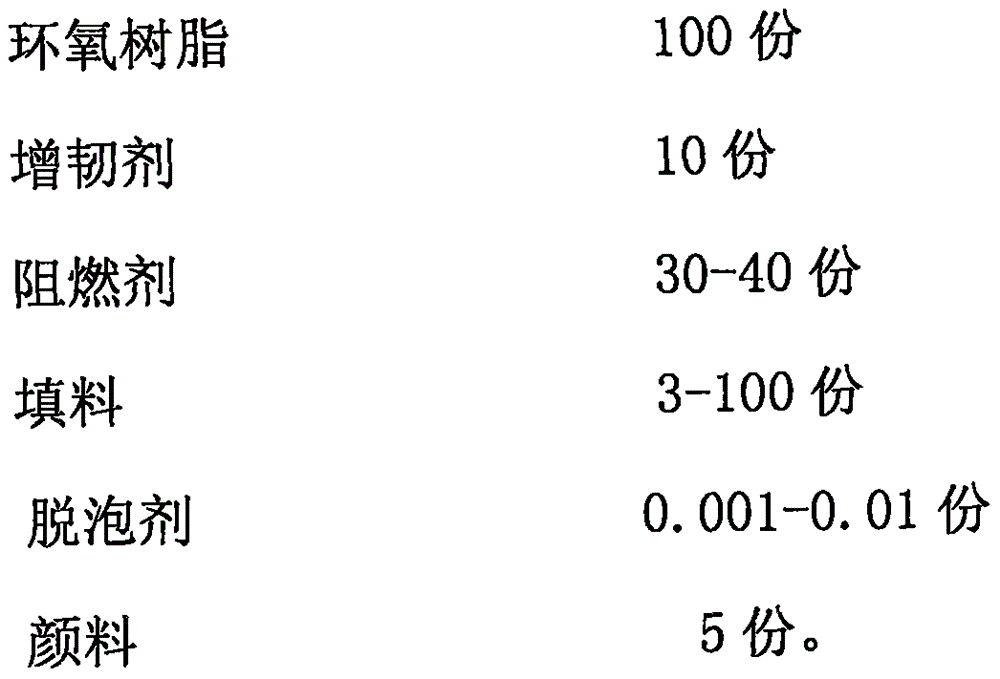

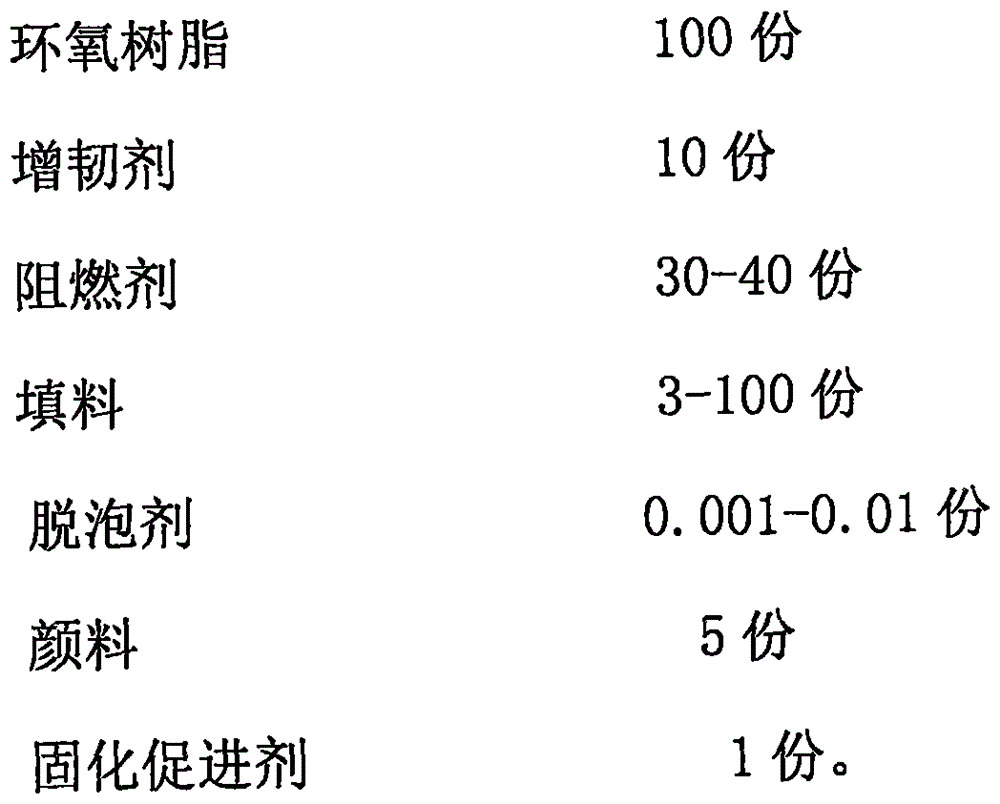

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of component A: Take 100g of epoxy resin E51, 10g of toughening agent carboxyl liquid nitrile rubber, 30g of flame retardant aluminum hydroxide, 100g of filler fumed silica, 100g of defoaming agent SAG470.001g and inorganic pigment titanium dioxide 5g, stir evenly, and then put it into a desiccator to vacuumize and defoam; after defoaming, component A is obtained;

[0039] (2) Preparation of component B: Take 7g of curing agent ethylenediamine, 0.001g of defoaming agent SAG47 and 0.001g of curing accelerator DMP-301g, stir evenly, and then put it in a desiccator to vacuumize and defoam; Get component B;

[0040] (3) Printing: first print component A in a thin layer, and then spray component B onto the surface of component A for fast curing; repeat thin layer printing of component A, and then spray component B onto the surface of component A , print in a loop until the model is completely printed;

[0041] (4) Post-curing: After the model is completely ...

Embodiment 2

[0043] (1) Preparation of component A: Take 100g of epoxy resin E44, 10g of toughening agent carboxyl liquid nitrile rubber, 30g of flame retardant aluminum hydroxide, 100g of filler fumed silica, 0.01g of defoaming agent SAG47 and inorganic pigment titanium dioxide 5g, stir evenly, and then put it into a desiccator to vacuumize and defoam; after defoaming, component A is obtained;

[0044] (2) Preparation of B component: The preparation of B component is consistent with the preparation method of B component in Example 1;

[0045] (3) Printing: first print component A in a thin layer, and then spray component B onto the surface of component A for fast curing; repeat thin layer printing of component A, and then spray component B onto the surface of component A , print in a loop until the model is completely printed;

[0046] (4) Post-curing: After the model is completely printed, put it in a 120°C oven for post-curing.

Embodiment 3

[0048] (1) Preparation of component A: Take 100g of epoxy resin E51, 10g of toughening agent carboxyl liquid nitrile rubber, 30g of flame retardant magnesium hydroxide, 100g of filler fumed silica, 0.01g of defoaming agent SAG47, and inorganic pigment titanium dioxide 5g and curing accelerator DMP-30 1g, stir evenly, and then put it in a desiccator to vacuumize and defoam; after defoaming, component A is obtained;

[0049] (2) Preparation of component B: Take 10g of amine curing agent T31, 0.001g of defoaming agent SAG47, and 1g of curing accelerator DMP-30, stir evenly, and then put it in a desiccator to vacuumize and defoam; , that is to get the B component;

[0050] (3) Printing: first print component A in a thin layer, and then spray component B onto the surface of component A for fast curing; repeat thin layer printing of component A, and then spray component B onto the surface of component A , print in a loop until the model is completely printed;

[0051] (4) Post-cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com