Patents

Literature

561 results about "Post curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Post curing is the process of exposing a part or mold to elevated temperatures to speed up the curing process and to maximize some of the material’s physical properties. This is usually done after the material has cured at room temperature for at least 12 hours.

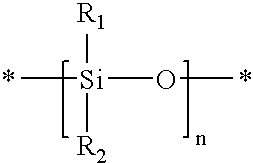

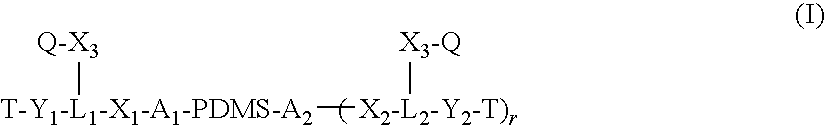

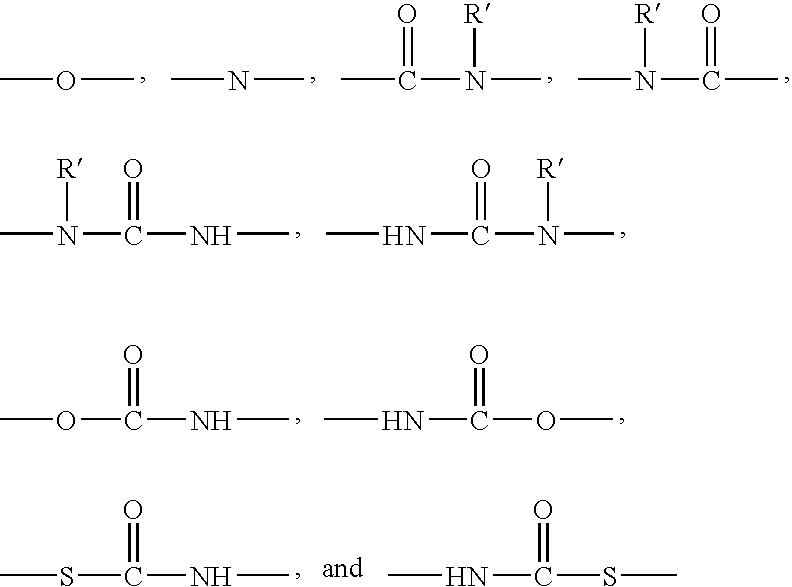

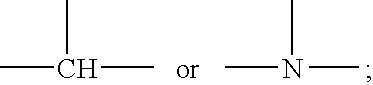

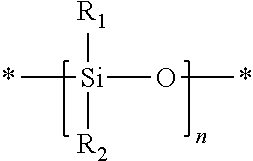

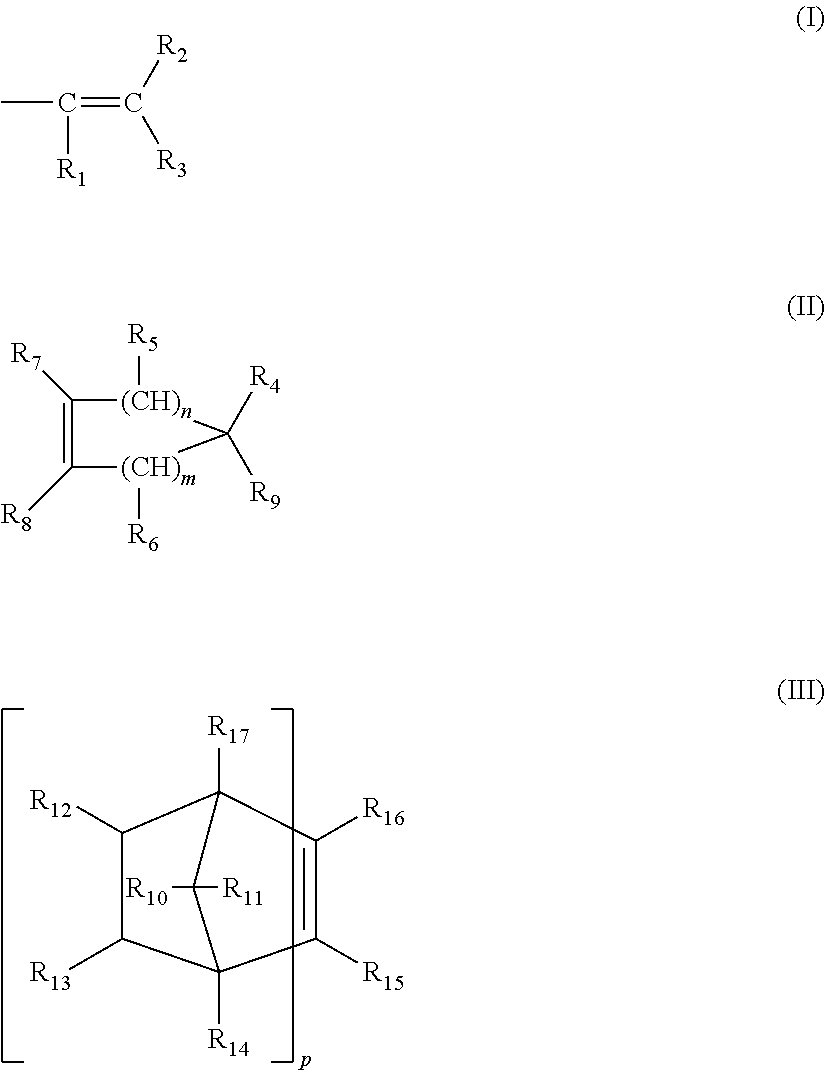

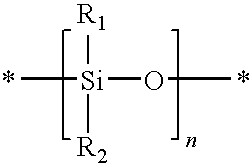

Silicone-containing prepolymers with dangling hydrophilic polymer chains

ActiveUS20080234457A1Reduce molecular weightHigh molecular weightOptical articlesProsthesisPolymer scienceHydrophilic polymers

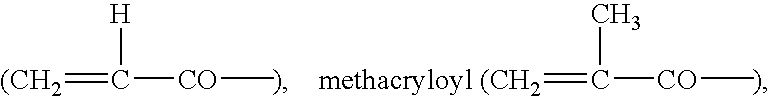

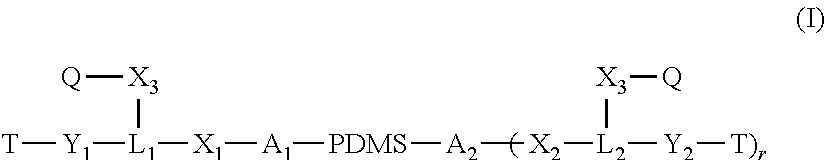

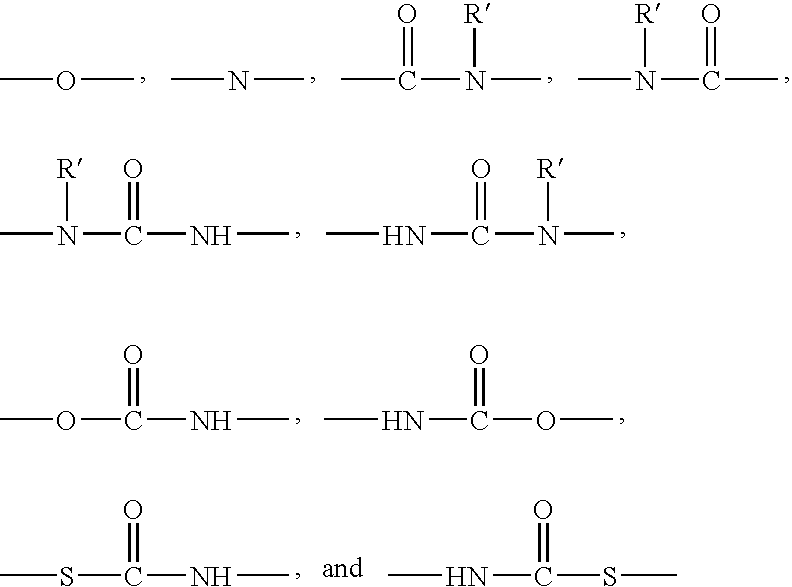

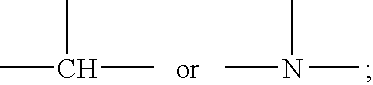

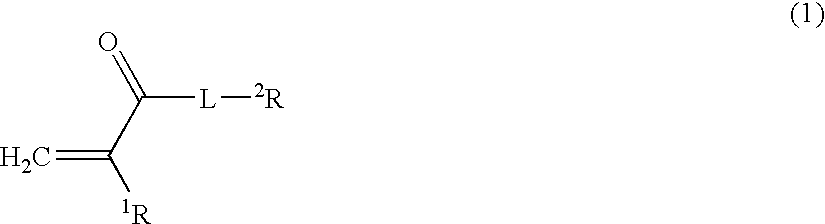

The invention provide a new class of silicone-containing prepolymers containing dangling hydrophilic polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a hydrophilic surface without post curing surface treatment. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

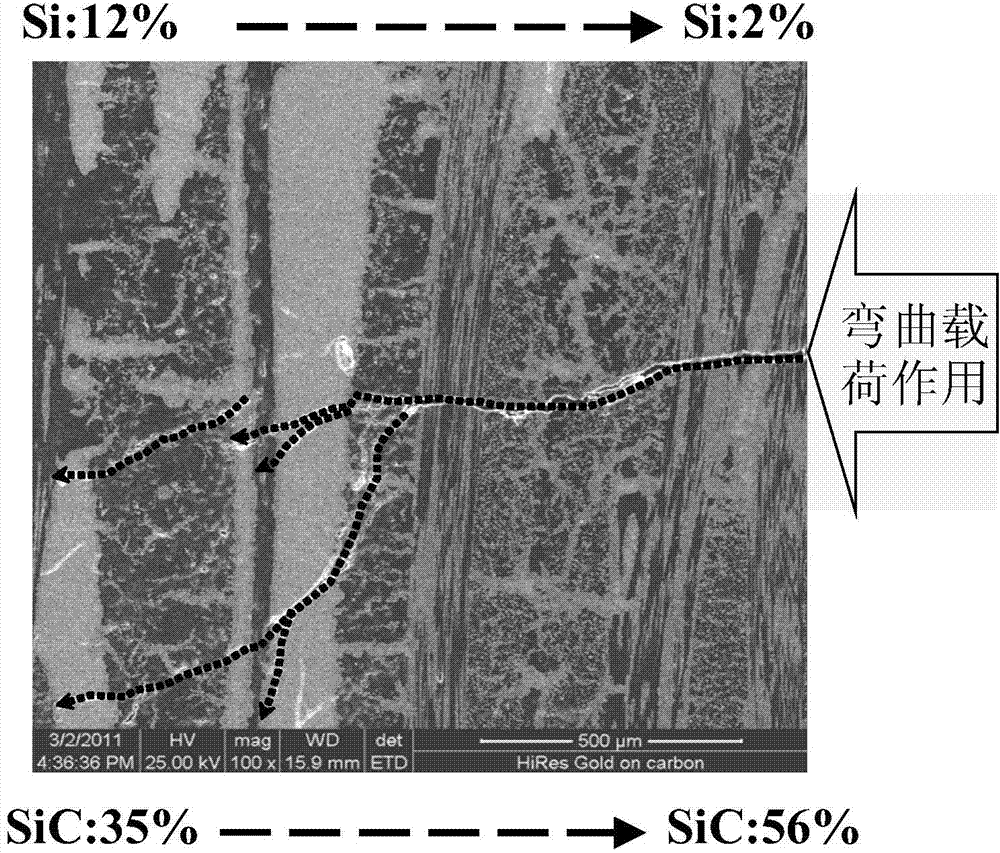

Preparation method for fiber reinforced carbon-silicon carbide-zirconium carbide-based composite material

The invention discloses a preparation method for a fiber reinforced carbon-silicon carbide-zirconium carbide-based (C / C-SiC-ZrC) composite material. The preparation method comprises the following steps of: (a) evenly dispersing ZrC nanopowder in absolute ethyl alcohol; (b) mixing phenolic resin and ZrC dispersion liquid to form slurry; (c) immersing a two-dimensional carbon fiber sheet into the slurry for dipping and drying, then carrying out continuous superposition paving on the two-dimensional carbon fiber sheet, and carrying out curing and post-curing treatment to prepare a fiber-reinforced sintered body; (d) cracking the fiber-reinforced sintered body to obtain a porous C / C prefabricate; (e) placing silicon powder into a graphite crucible, burying the porous C / C prefabricate into the silicon powder, heating to 1,500-1,650 DEG C, and preserving heat for preset time so as to carry out liquid silicon permeation. The method can be used for improving the high-temperature oxidizing property and ablation property of the carbon fiber reinforced ceramic (C / C-SiC) composite material.

Owner:DALIAN UNIV OF TECH

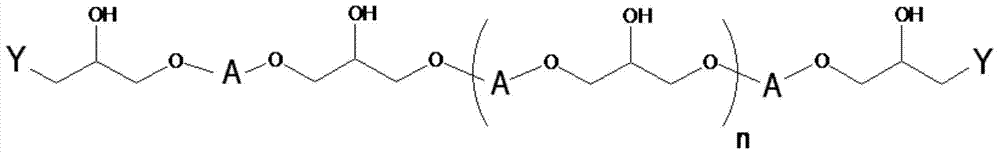

Polysiloxane copolymers with terminal hydrophilic polymer chains

The invention provides an actinically-crosslinkable linear polysiloxane copolymer. The actinically-crosslinkable polysiloxane copolymer can be used to prepare a silicone hydrogel contact lens having a hydrophilic surface without post-curing surface treatment. The invention is also related to a silicone hydrogel contact lens obtained from a lens-forming material including an actinically-crosslinkable polysiloxane copolymer of the invention and to a method for making an actinically-crosslinkable polysiloxane copolymer of the invention. In addition, the invention provides a non-crosslinkable linear polysiloxane copolymer capable of being used as a internal wetting agent which can render the surface of a silicone hydrogel contact lens hydrophilic.

Owner:ALCON INC

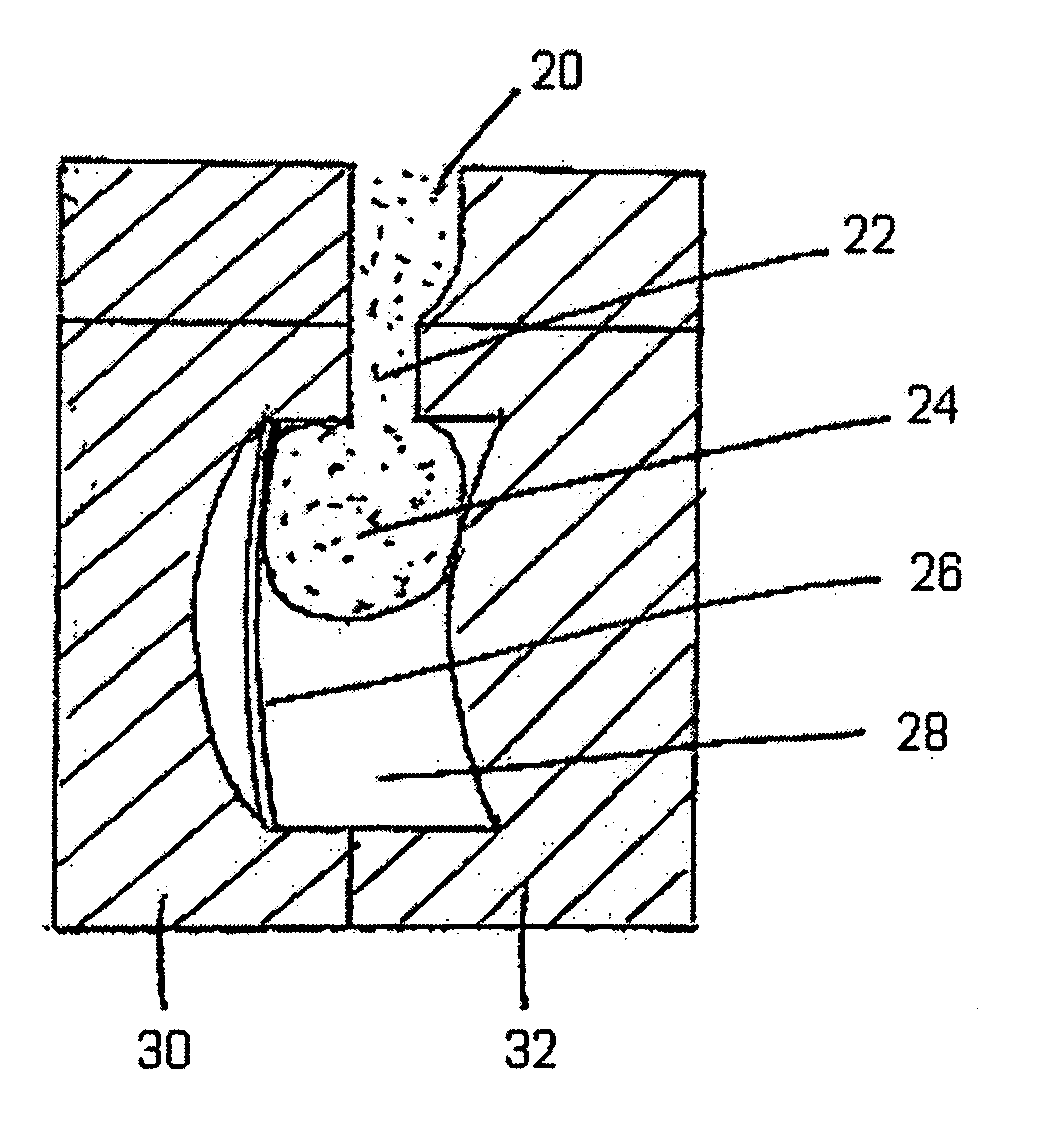

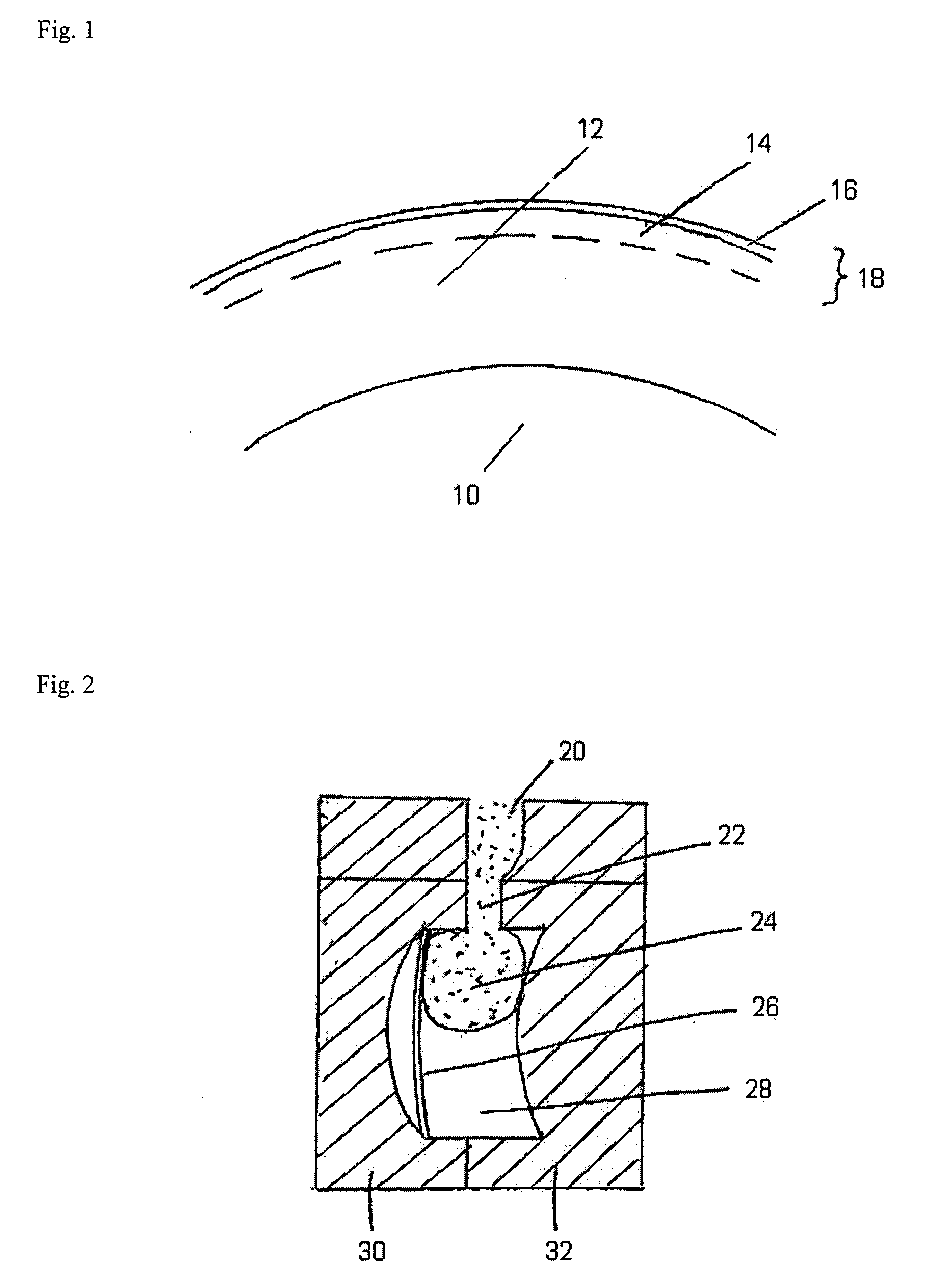

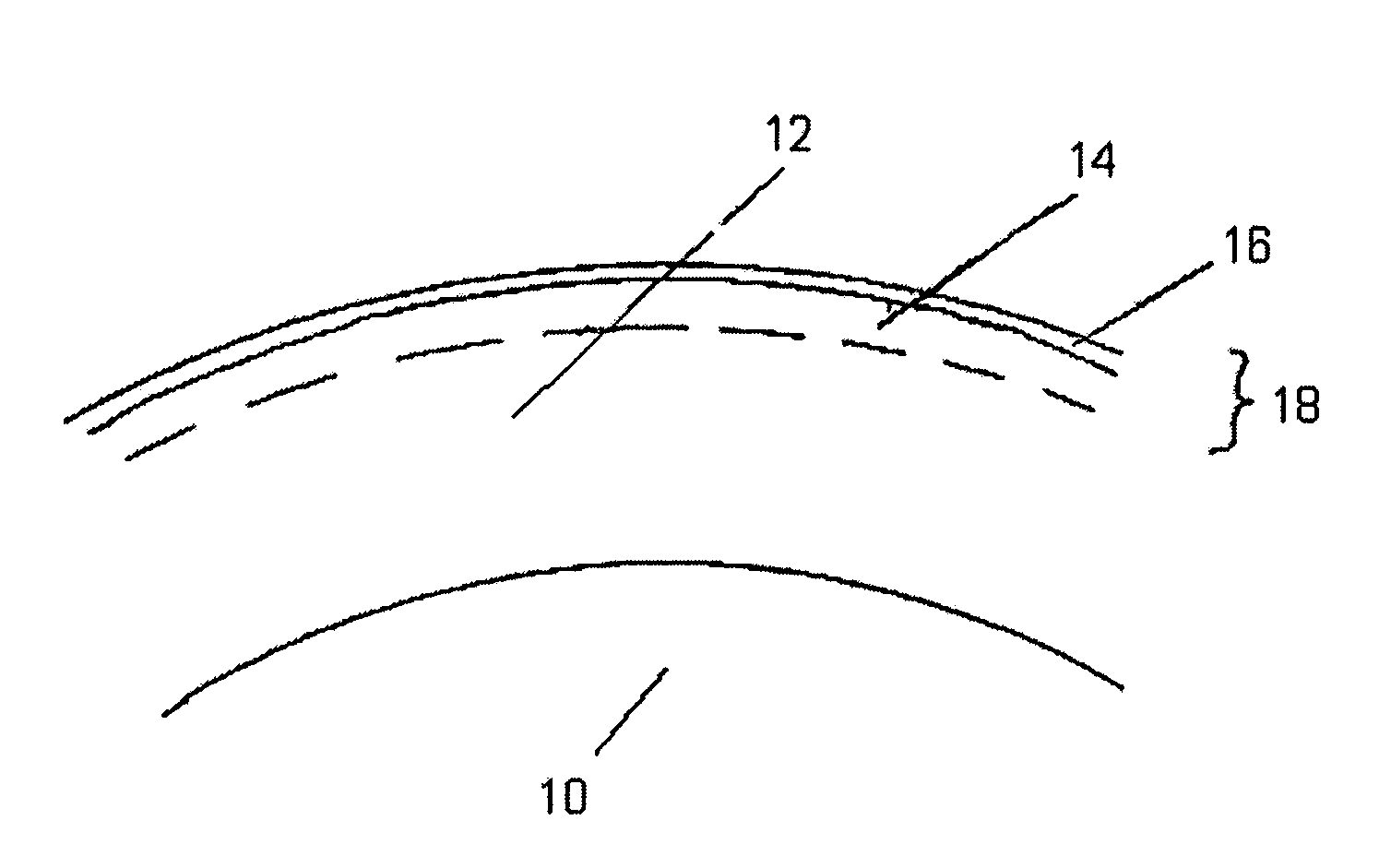

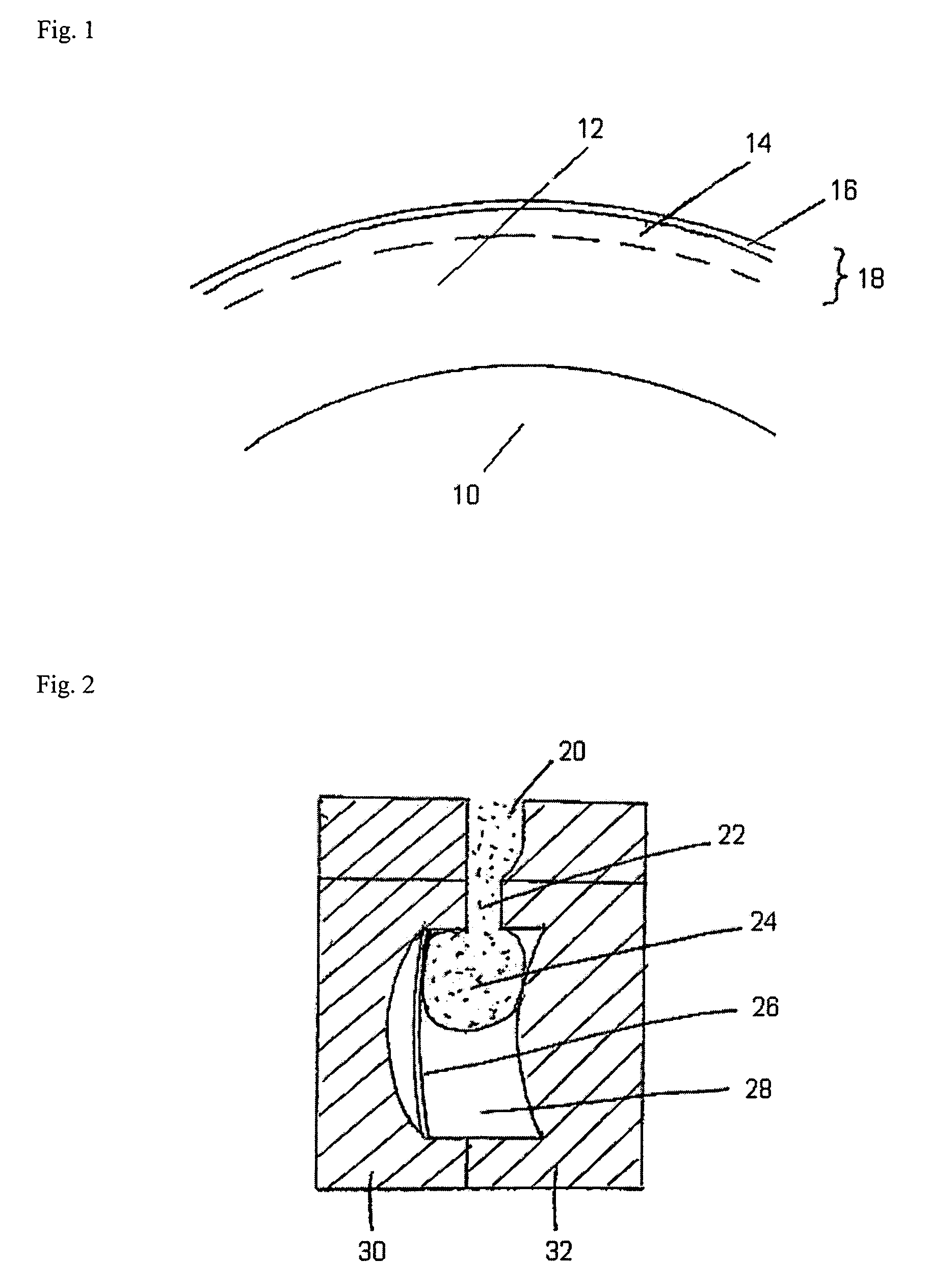

Process to mold a plastic optical article with integrated hard coating

Disclosed is a process for molding plastic optical articles with a hard coated film, comprising steps of coating one side of an optical film with a hard coating, pre-curing the hard coating to a tack free state while still maintaining the coating flexibility, making an insert from the coated film for the desired optical article, molding the plastic resin onto the insert through insert injection molding, and post-curing the molded article. The utilization of the pre-curing and post-curing steps have been found to eliminate hard coating cracks during the insert making and the molding step, while providing a hard coating with desired properties. Such an optical article possesses a hard coating integrated on its surface, thus, eliminating the need to further coat the optical article.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Silicone-containing prepolymers with dangling hydrophilic polymer chains

ActiveUS8071703B2Easy to understandIncreased staining spotsOptical articlesProsthesisPolymer scienceHydrophilic polymers

The invention provide a new class of silicone-containing prepolymers containing dangling hydrophilic polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a hydrophilic surface without post curing surface treatment. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

Resin-bonded grinding tool for processing sapphire crystals and preparation method for resin-bonded grinding tool

The invention discloses a resin-bonded grinding tool for processing sapphire crystals and a preparation method for the resin-bonded grinding tool. The resin-bonded grinding tool for processing the sapphire crystals is obtained by mixing, hot-pressing, post-curing and post-trimming forming materials and a matrix, wherein the forming materials include diamond abrasives, thermosetting resin powder, filling agents, silicon carbide whiskers and wetting agents. The silicon carbide whiskers with the Mohs hardness of 9.5 grades are added into the resin-bonded grinding tool, so that the grinding tool for grinding the sapphire crystals is high in efficiency and long in service life, and the surface smoothness of the sapphire crystals can be improved by means of the polishing function of the silicon carbide whiskers.

Owner:云南光电辅料有限公司

Polysiloxane copolymers with terminal hydrophilic polymer chains

The invention provides an actinically-crosslinkable linear polysiloxane copolymer. The actinically-crosslinkable polysiloxane copolymer can be used to prepare a silicone hydrogel contact lens having a hydrophilic surface without post-curing surface treatment. The invention is also related to a silicone hydrogel contact lens obtained from a lens-forming material including an actinically-crosslinkable polysiloxane copolymer of the invention and to a method for making an actinically-crosslinkable polysiloxane copolymer of the invention. In addition, the invention provides a non-crosslinkable linear polysiloxane copolymer capable of being used as a internal wetting agent which can render the surface of a silicone hydrogel contact lens hydrophilic.

Owner:ALCON INC

Process to mold a plastic optical article with integrated hard coating

InactiveUS7025458B2Excellent surface optical qualityDesired abrasion and scratching resistanceOptical articlesEye diagnosticsShell moldingFree state

Disclosed is a process for molding plastic optical articles with a hard coated film, comprising steps of coating one side of an optical film with a hard coating, pre-curing the hard coating to a tack free state while still maintaining the coating flexibility, making an insert from the coated film for the desired optical article, molding the plastic resin onto the insert through insert injection molding, and post-curing the molded article. The utilization of the pre-curing and post-curing steps have been found to eliminate hard coating cracks during the insert making and the molding step, while providing a hard coating with desired properties. Such an optical article possesses a hard coating integrated on its surface, thus, eliminating the need to further coat the optical article.

Owner:HOYA OPTICAL LABS OF AMERICA INC

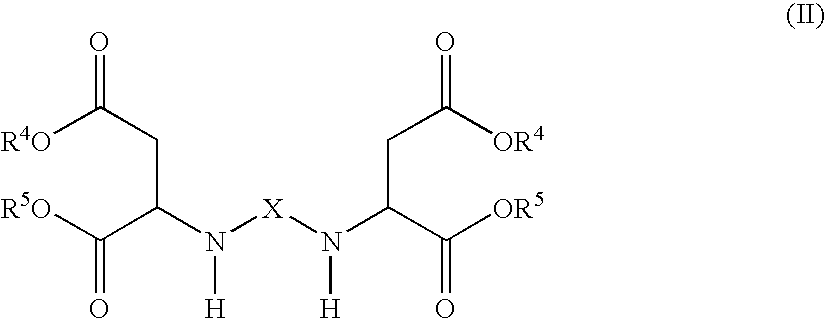

Polyurethane-urea elastomers

The present invention is directed to polyurethane-urea materials and to a process for their production. These polyurethane-ureas are preferably optically clear and comprise the reaction product of a (cyclo)aliphatic polyisocyanate or prepolymer thereof, with an isocyanate-reactive component that comprises one or more aromatic diamines which contains two primary amine groups, and one or more compounds containing two secondary amine groups which may be linked to aliphatic and / or aromatic moieties. This isocyanate-reactive component may additionally comprise one or more hydroxyl-functional compounds. The present invention offers a relatively fast “Green-Cure Time” of solid polyurethane-ureas which enables these to be demolded in a relatively short time period, followed by subsequent post-curing outside the mold.

Owner:COVESTRO LLC

Method for manufacturing bamboo macrofiber composite material

InactiveCN101642923AImprove permeabilityMovement does not affectReed/straw treatmentFlat articlesAdhesiveVolumetric Mass Density

The invention relates to a method for manufacturing a bamboo macrofiber composite material. Bunchy bamboo fibers of which the green and yellow are removed are taken as raw materials and dipped with awater soluble phenol formaldehyde adhesive, and the production steps comprise material preparation (comprising the preparation of bamboo macrofiber reinforcement and a water soluble phenol formaldehyde resin matrix), adhesive dipping, extraction, warm-pressing, curing and post curing. The method has the advantages that: (1) the method has reasonable process, strong production continuity, high efficiency, low energy consumption, and no environmental pollution; (2) the manufactured bamboo macrofiber composite material has no mold and no crack, and has the density between 0.9 and 1.3g / cm<3>, thehardness between 60 and 150MPa, the static bending strength between 140 and 160MPa, the water-absorbing expansion rate between 0.3 and 2 percent, the surface wear resistance between 0.04 and 0.09g / 100r, and the formaldehyde emission between 0.1 and 0.4mg / L; and (3) the invention provides a more positive production technique for reasonably utilizing the bamboo resources, so that the reconstituted bamboo timber application prospect is better.

Owner:仇峰 +1

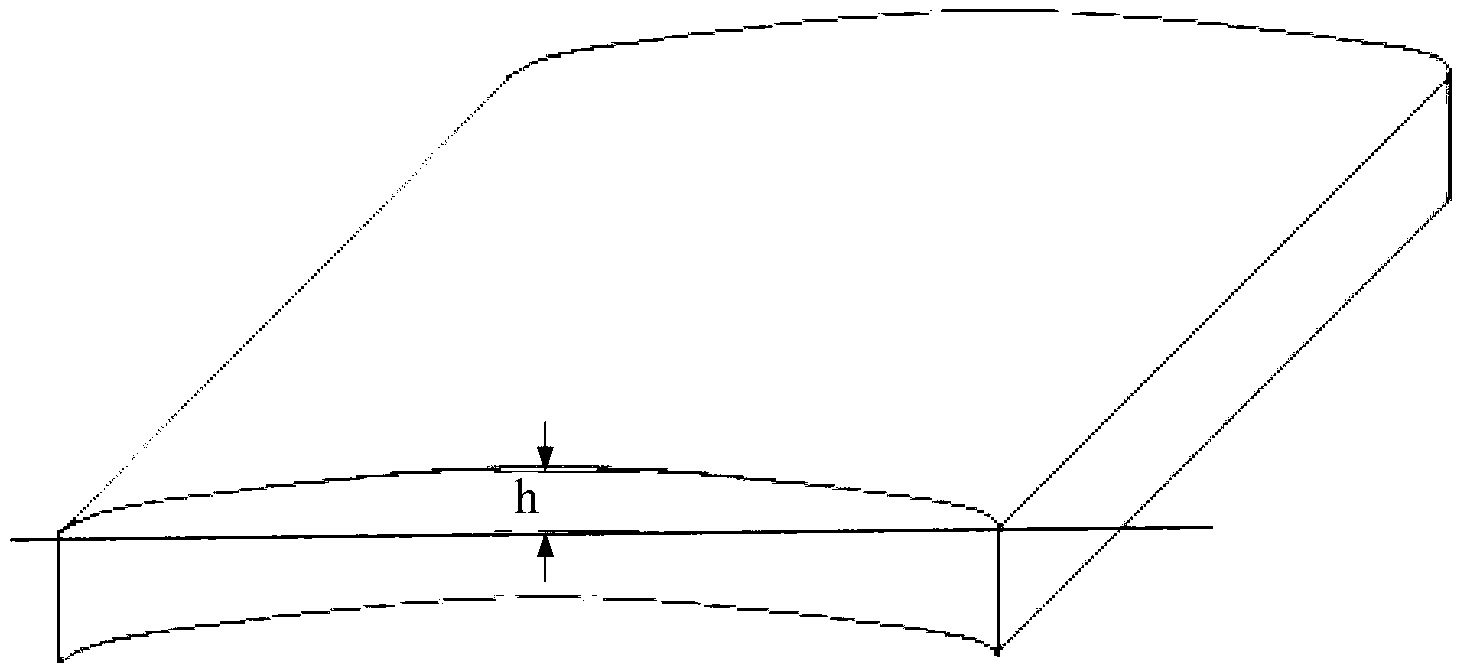

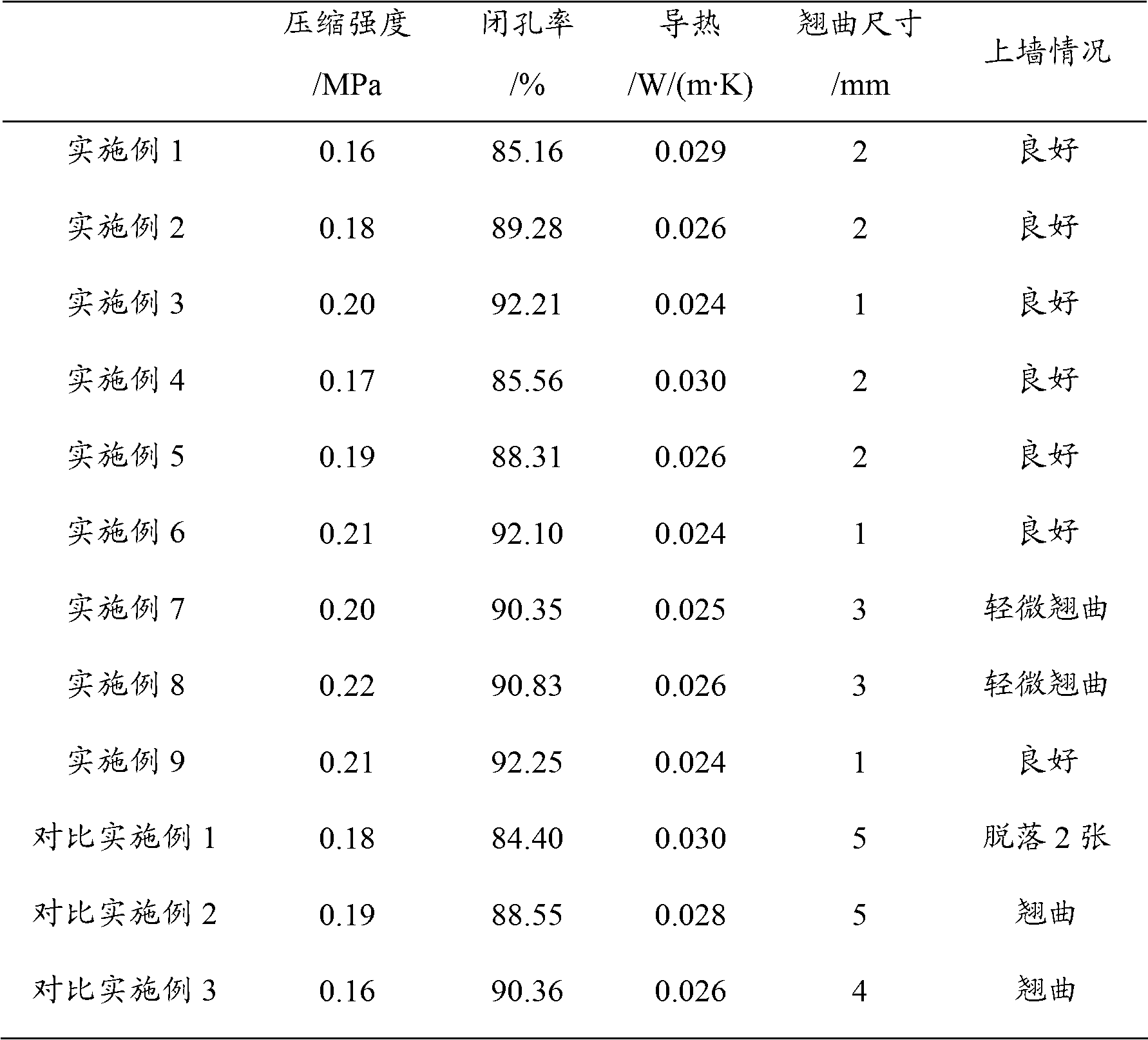

Preparation method of phenolic foam boards

The invention provides a preparation method of phenolic foam boards. The method comprises the steps as follows: mixing 90 to 120 parts by weight of alkaline phenolic resin, 4 to 15 parts by weight of foaming agents, 2 to 6 parts by weight of emulsifiers, 2 to 8 parts by weight of flexibilizers and 10 to 30 parts by weight of curing agents so as to prepare a foaming system of the phenolic foam boards; heating for foaming; solidifying for shaping; and then post-solidifying so as to prepare the phenolic foam boards. The post-solidifying treatment is performed on the conditions that temperature is 30 to 80 DEG C, the humidity is 40 to 90%, and the time is 24 to 72 hours. The preparation method provided by the invention is realized by post-solidifying boards, and adding an inorganic fire retardant and a high-activity modifier to the foaming system of the phenolic foam boards so as to prepare phenolic foam boards with the warping dimension being equal to or less than 4 mm, the wall-mounting condition is good or the boards are warped slightly, and no dropping phenomenon occurs; therefore, the boards accord with the requirements for good boards in the markets, and the method solves the warping problem of the phenolic foam boards.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Method for preparing solvent-free multicomponent polyurethane synthetic leather based on steam injection coating

InactiveCN103031736ASolve environmental pollutionQuality improvementLaminationLamination apparatusAlcoholFoaming agent

The invention discloses a method for preparing solvent-free multicomponent polyurethane synthetic leather based on steam injection coating. The method comprises the following steps: firstly, adding polyhydric alcohol, isocyanate, chain extender, vulcanizing agent, catalyst, coupling agent, foaming agent, foam stabilizer, colorant, component absorbing carbon dioxide and water and filler into a plurality of stock tanks of a polyurethane casting machine; secondly, conveying the raw materials to a mixing head of the casting machine for mixing by regulating a metering pump on the raw material tank to obtain mixed size; coating the mixed size on release paper by a steam injection spreader, fitting base cloth on the mixed size layer of the release paper and then drying the base cloth; and finally, continuously reacting the mixed size by post curing till complete curing, and peeling the release paper after cooling to obtain the solvent-free multicomponent polyurethane synthetic leather. No solvent is used in the production process, so that the environmental pollution problem of DMF, TOL, MEK, THF and other solvents generated by the existing solvent polyurethane synthetic leather can be solved.

Owner:SHAANXI UNIV OF SCI & TECH

Silicone-Containing Polymeric Materials with Hydrolyzable Groups

The invention provides a silicone hydrogel contact lens including a hydrolyzable units. The hydrolyzable units can be converted by hydrolysis into a hydrophilic units which is capable of imparting the silicone hydrogel contact lens a hydrophilic surface without post-curing surface treatment. The invention also provides an actinically crosslinkable prepolymer including hydrolyzable units and use of the prepolymer of the invention. In addition, the invention provides a method for making wettable silicone hydrogel contact lens without posterior surface treatments other than hydrolysis.

Owner:ALCON INC

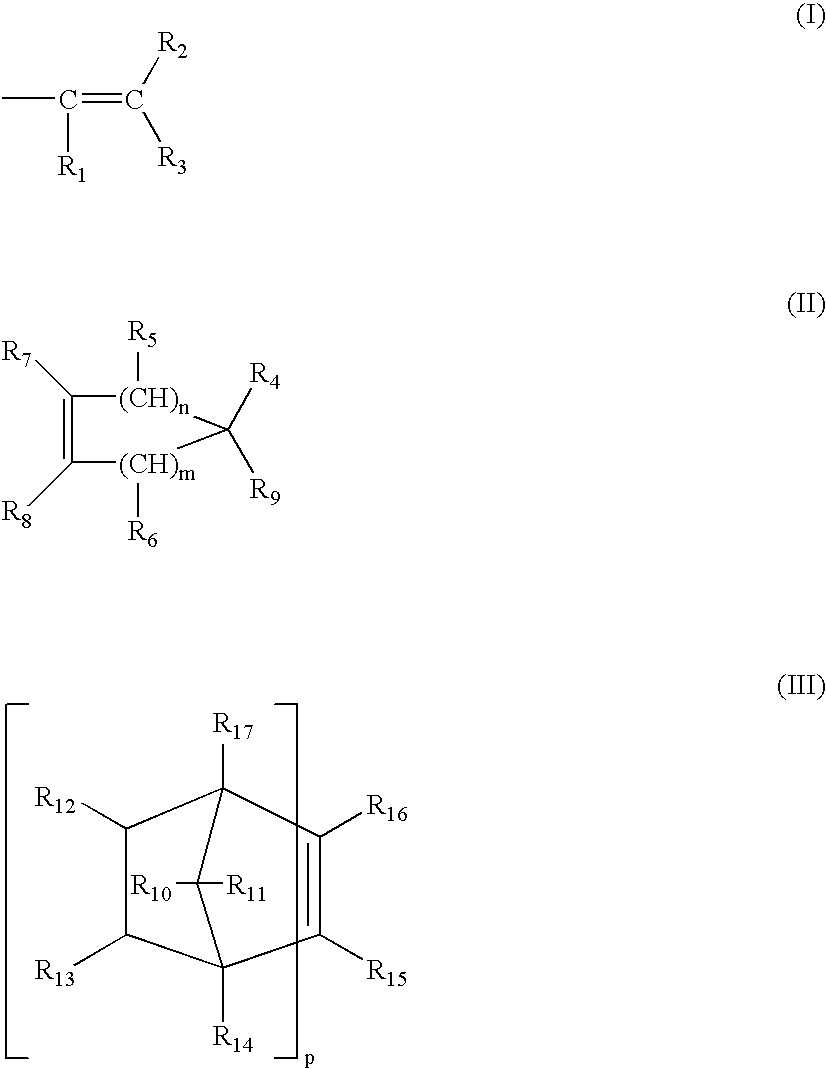

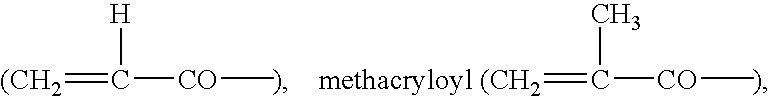

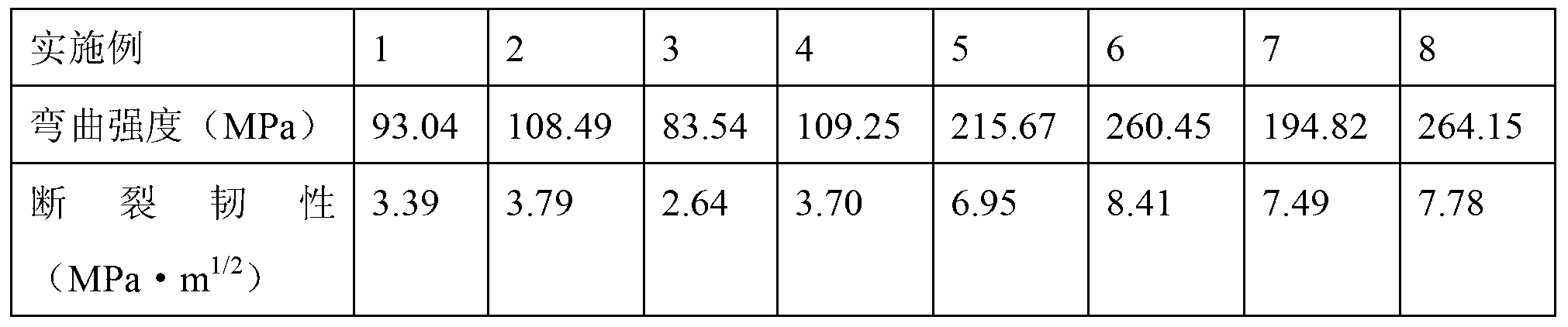

Thermo-curable 3D printing photosensitive resin and preparation method thereof

ActiveCN106947034AIncrease activation energyHigh tensile strengthAdditive manufacturing apparatus3D object support structuresDecompositionHalf-life

The invention discloses a thermo-curable 3D printing photosensitive resin and a preparation method and an application thereof. The photosensitive resin includes, by weight, 50-70 parts of a prepolymer, 30-50 parts of a diluent, 1-5 parts of a photo-initiator and 0.5-5 parts of a thermal-initiator, wherein the decomposition temperature of the thermal-initiator is higher than or equal to 100 DEG C when the half-life period thereof is 1 h. After photo-curing 3D printing shaping, the 3D printing photosensitive resin can be subjected to curing by heating as a post-curing method with a stable constant temperature heating device, such as a drying box and the like, so that the 3D printing photosensitive resin develops application in a non-transparent sample, a sample having complex shape, an ultra-thick sample, a colored sample and the like, and enables the samples to have better mechanical performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

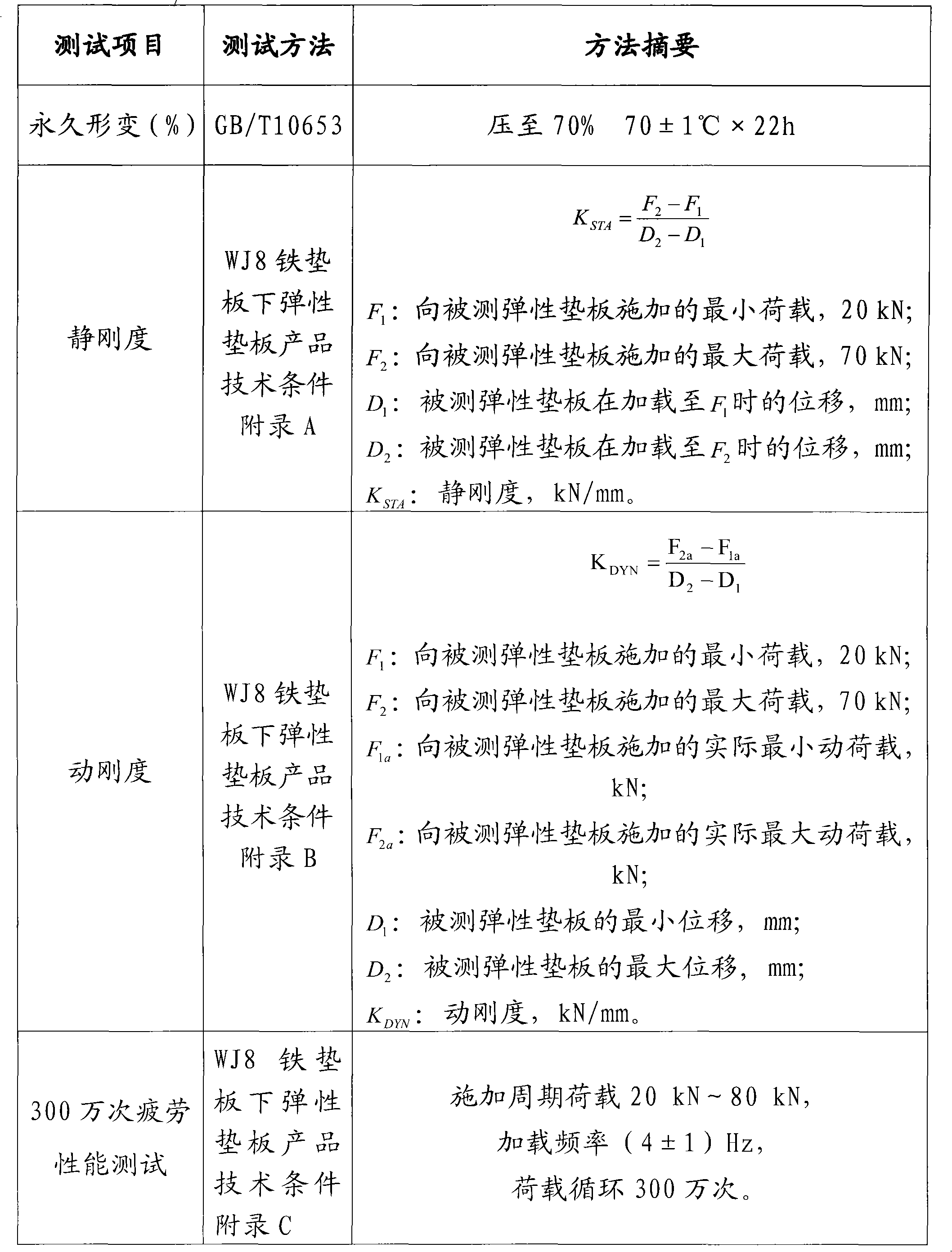

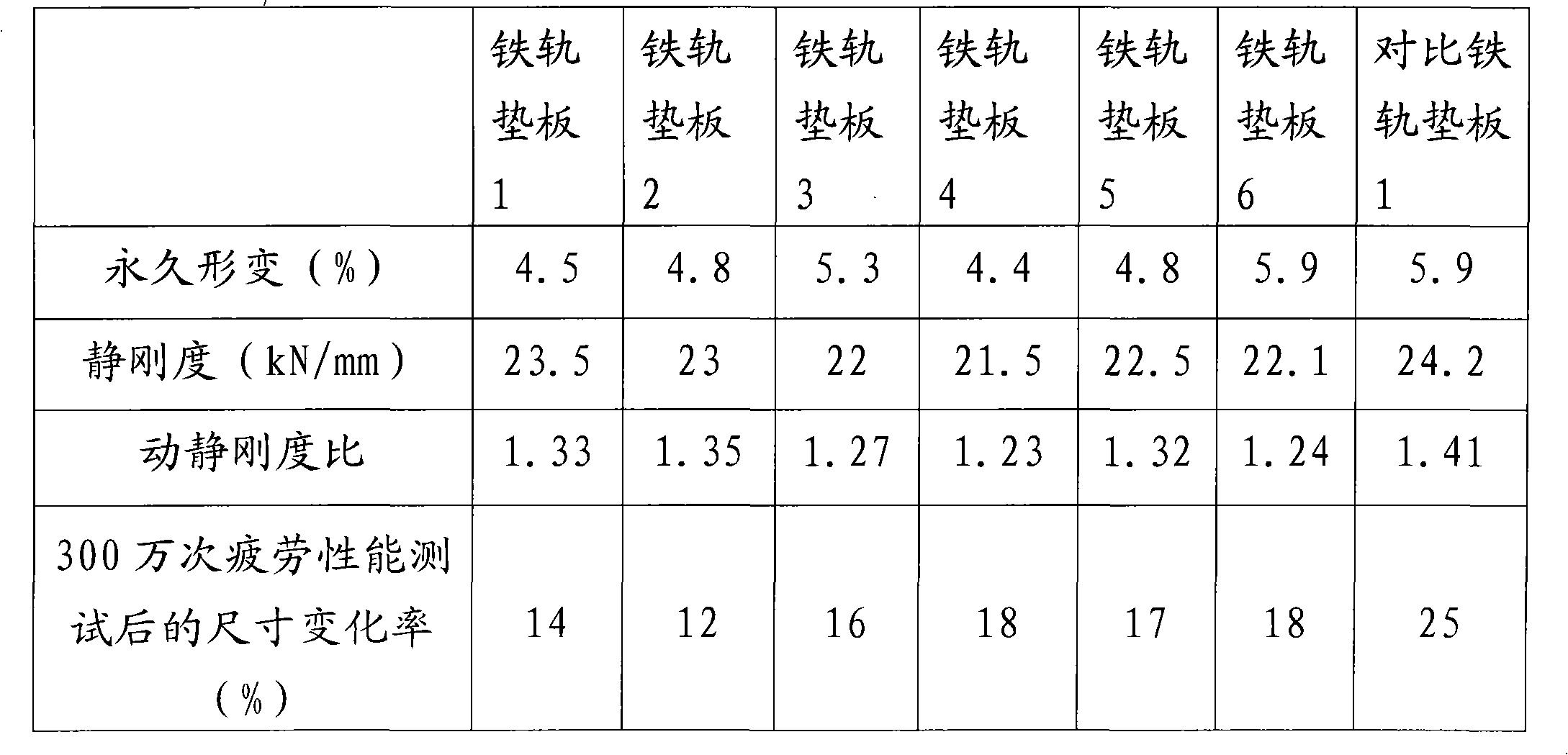

Rail tie plate and preparation method thereof

ActiveCN101942786AFlexible and adjustable static stiffnessAdapt to requirementsRail fastenersCushioningPolyurethane elastomer

The invention provides a polyurethane rail tie plate which is a microporous polyurethane elastomer made from raw materials of a polyalcohol composition, an NCO-blocking modified isocyanate curing agent and a foaming agent. The invention further provides a preparation method of the polyurethane tie plate, comprising the following steps: adding the foaming agent to the polyalcohol composition; adding the modified isocyanate curing agent to a mixture of the polyalcohol composition and the foaming agent according to a certain proportion at the temperature of 25-60 DEG C; and stirring and evenly mixing the obtained mixture, casting for molding, curing, taking out and then post-curing to obtain the polyurethane tie plate. The dynamic-static stiffness ratio of the tie plate is not more than 1.5; fatigue tests for 3 million times show no damage to appearance of the tie plate and low dimensional change rate of not more than 30%, thus achieving good damping and cushioning effects and enhancing comfortableness when a train runs; and meanwhile the rail tie plate has good durability.

Owner:WANHUA CHEM BEIJING +1

Vegetable oleic acid modified epoxy resin and preparation method thereof, polymer containing vegetable oleic acid modified epoxy resin, and preparation method and application of polymer

ActiveCN104710598AGood flexibilityImprove the level ofOrganic chemistryAnti-corrosive paintsPliabilityDouble bond

The invention discloses a vegetable oleic acid modified epoxy resin. The invention also discloses a preparation method for the vegetable oleic acid modified epoxy resin, a polymer containing the vegetable oleic acid modified epoxy resin, and a preparation method and application of the polymer. According to the invention, since vegetable oleic acid with an unsaturated double bond is introduced into the epoxy resin, post-curing of the unsaturated double bond improves comprehensive properties of a paint film. The polymer of the invention is applied in a cathodic electrophoretic coating material, and a formed coating has the characteristics of good flexibility, good leveling property, high gloss, low curing temperature, good corrosion resistance, etc., can be cured at 140 to 160 DEG C and is low in cost; and products using the coating has good storage stability.

Owner:NIPPON PAINT GUANGZHOU

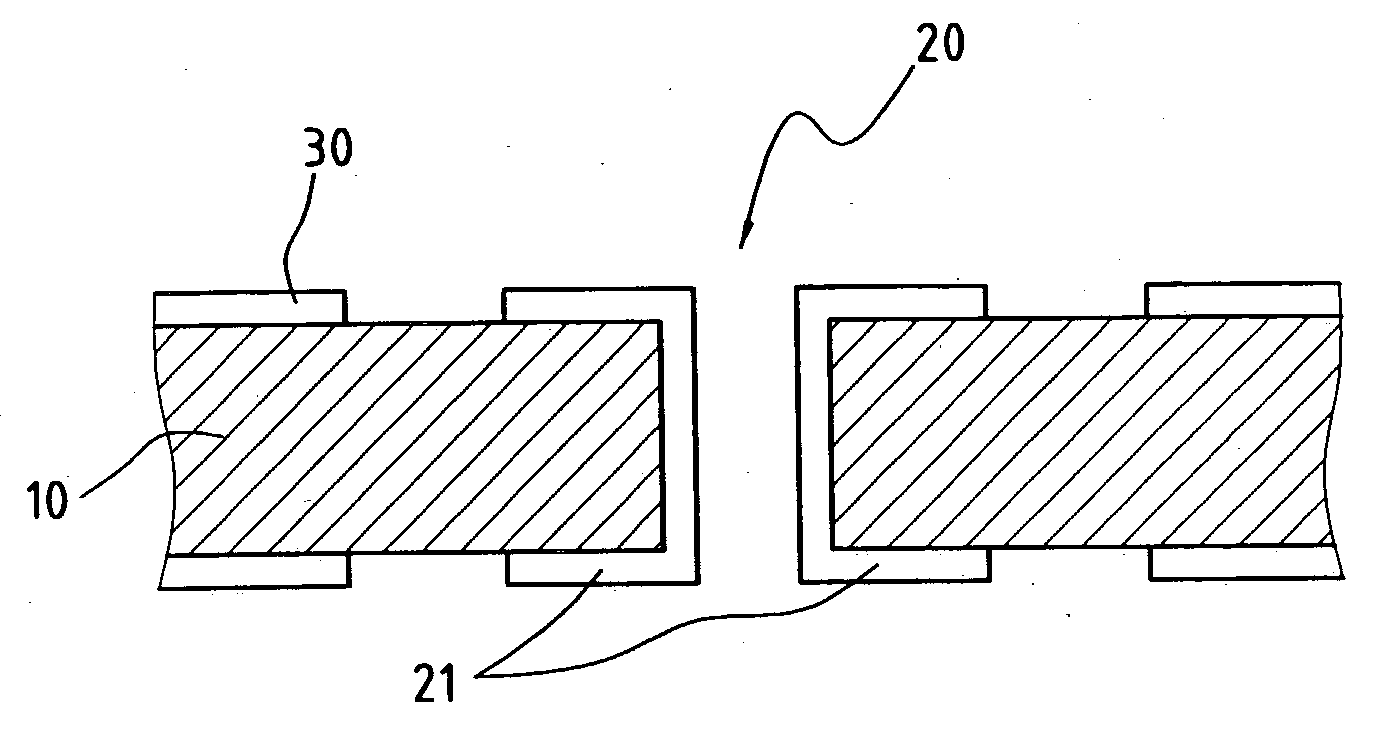

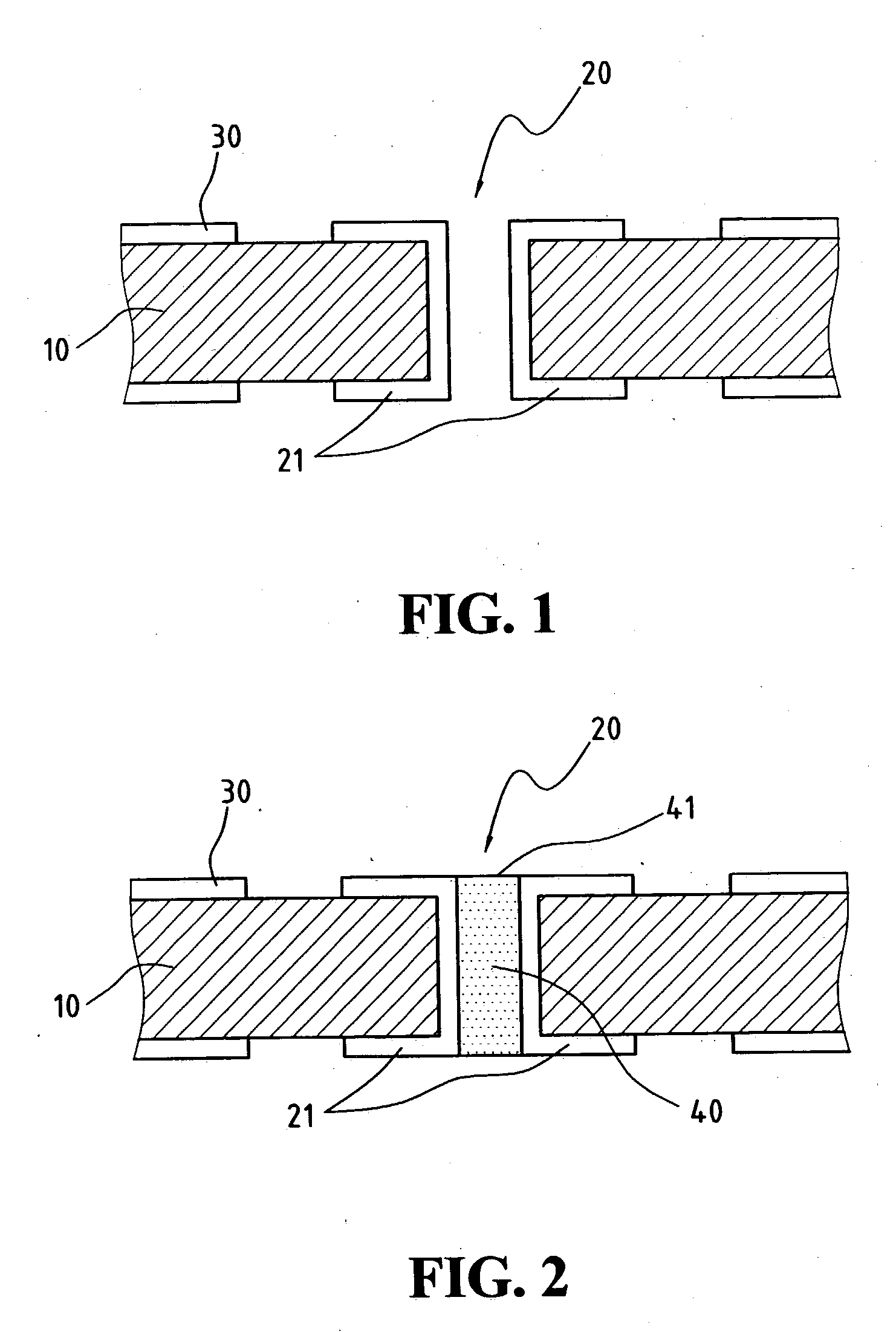

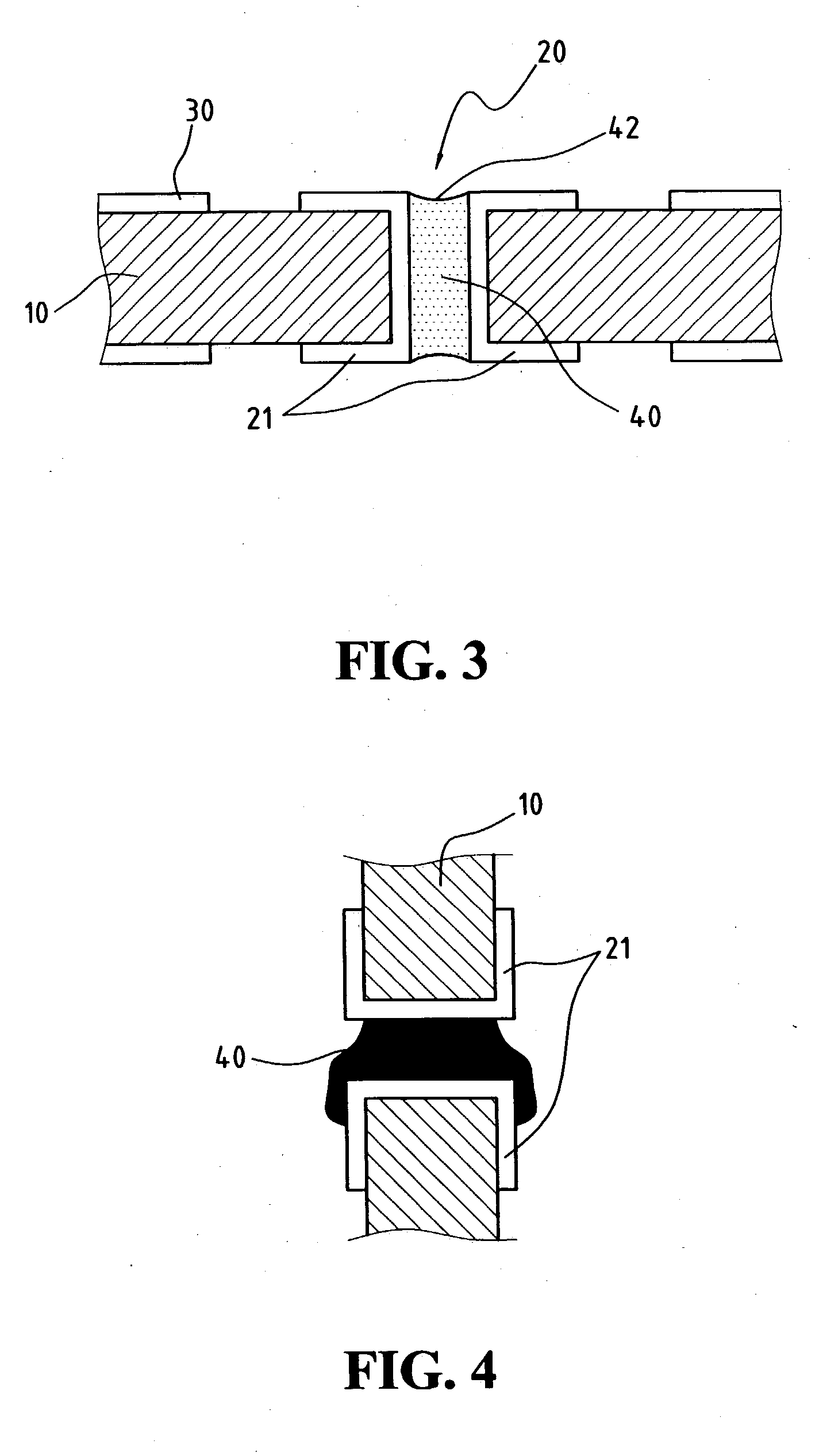

Resin Paste For Die Bonding And Its Use

InactiveUS20070290369A1Broaden applicationIncrease supplySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEthylene Homopolymers

Disclosed is a resin paste for die bonding comprising a butadiene homopolymer or copolymer (A) having a carboxylic acid terminal group, a thermosetting resin (B), a filler (C), and a printing solvent (D), wherein the elastic modulus of the resin paste following drying and curing is within a range from 1 to 300 MPa (25° C.). The solid fraction is preferably from 40 to 90% by weight, the thixotropic index is preferably from 1.5 to 8.0, and the viscosity (25° C.) is preferably from 5 to 1,000 Pa·s. Using this resin paste, a semiconductor device is produced by a method comprising (1) applying a predetermined quantity of the resin paste to a substrate, (2) drying the resin paste to effect B-staging of the resin, (3) mounting a semiconductor chip on the B-staged resin, and (4) conducting post-curing of the resin.

Owner:HITACHI CHEM CO LTD

High comprehensive performance composite grinding piece and manufacturing method thereof

ActiveCN105500225AImprove polishing efficiencyReduce internal stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWeather resistanceCerium

The invention discloses a high comprehensive performance composite grinding piece which comprises a base material, grinding particles and an adhesion agent, wherein the surface of the base material is divided into a plurality of areas; the grinding particles attached to the identical areas have identical sizes; the grinding particles attached to the different areas have different sizes; the sizes of the grinding particles attached to the various areas of the base material increase gradually from the center of the base material to the edge of the base material; the grinding particles are composite grinding particles formed by compositing nano cerium dioxide particles and silicon dioxide particles; and the adhesion agent consists of a component A and a component B. The invention also provides a manufacturing method of the high comprehensive performance composite grinding piece. The manufacturing method comprises the following steps of a gluing procedure, a sand planting procedure, a post curing procedure, a flexing water carrying procedure, a laser cutting procedure, a base material deformation prevention treatment procedure and a storage procedure. The manufacturing method is simple and convenient, and is low in manufacturing cost, and the manufactured composite grinding piece has weather resistance, fatigue resistance, high temperature resistance and abrasion resistance, and is long in service life and high in polishing efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

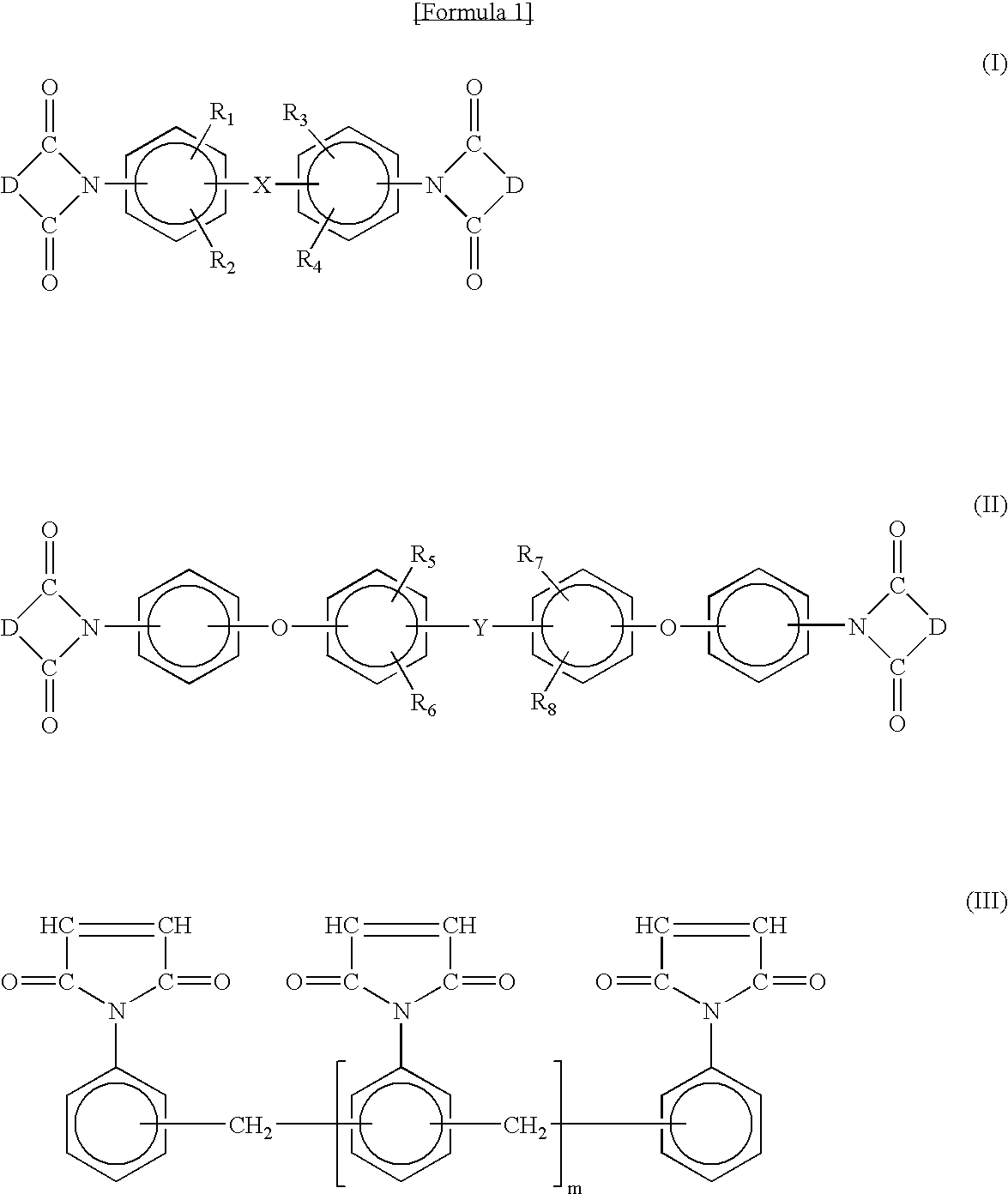

Preparation method of carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material

The invention discloses a preparation method of a carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material. The preparation method is characterized by comprising the following steps: (a), carrying out thermal treatment onto the fibers by adopting different temperatures; (b), dipping the fibers which are not subjected to thermal treatment and the thermally-treated fibers obtained in the step (a) in resin glue liquor, drying, continuously superposing and laying up, applying a certain pressure after laying up, and carrying out curing and post-curing treatment in sequence to prepare a composite material biscuit body with fiber / base body interface adhesive strength in gradient change; (c), carrying out high-temperature pyrolysis onto the composite material biscuit body obtained in the step (b) to obtain a carbon / carbon porous body with porosity in gradient change; (d), carrying out liquid silicon permeation onto the carbon / carbon porous body obtained in the step (c) under a high temperature to obtain the C / C-SiC composite material with SiC ceramic base body content in gradient change. The preparation method disclosed by the invention is simple in process, short in preparation period, low in cost and capable of preparing a large workpiece with a complex shape.

Owner:DALIAN UNIV OF TECH

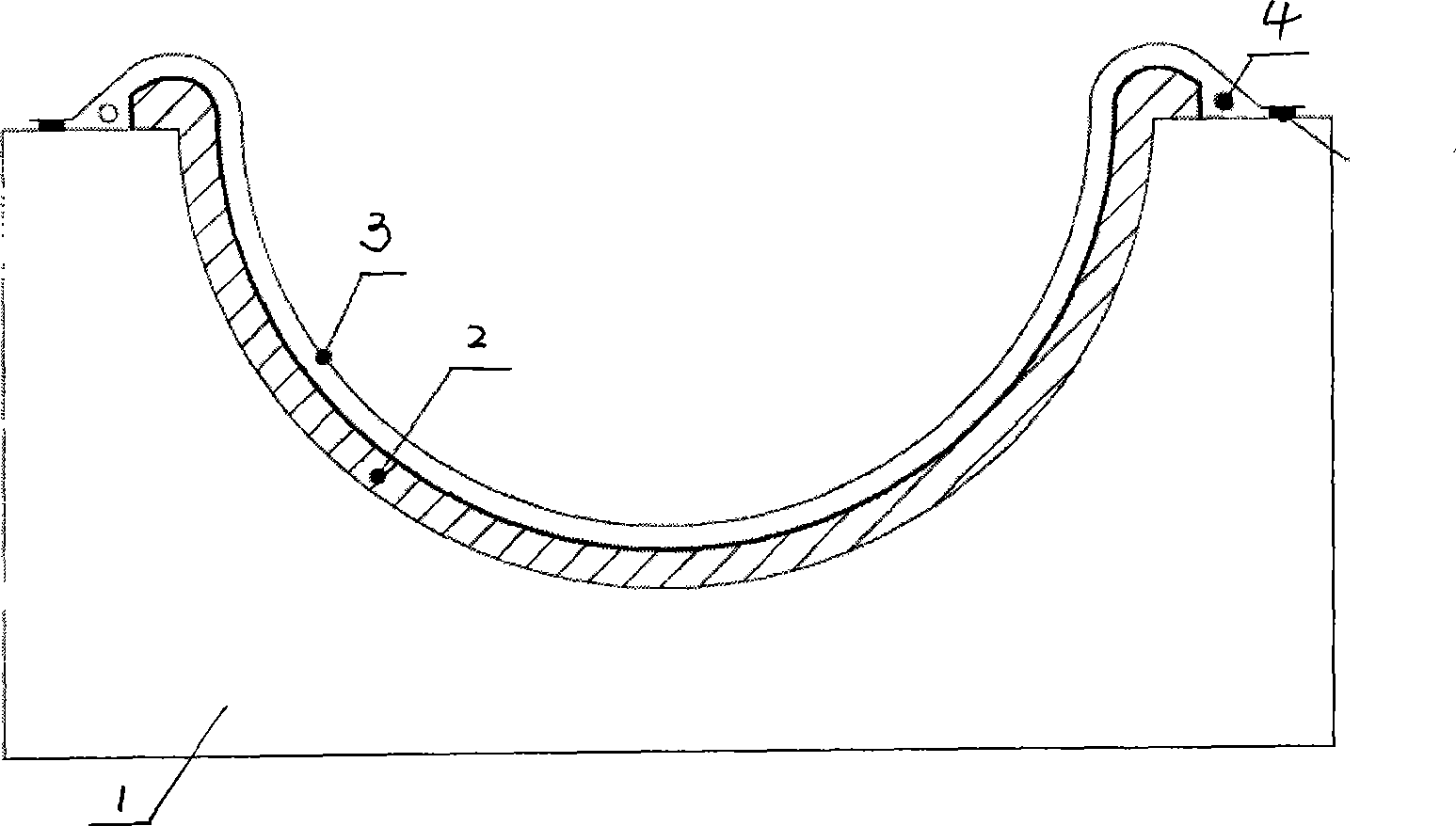

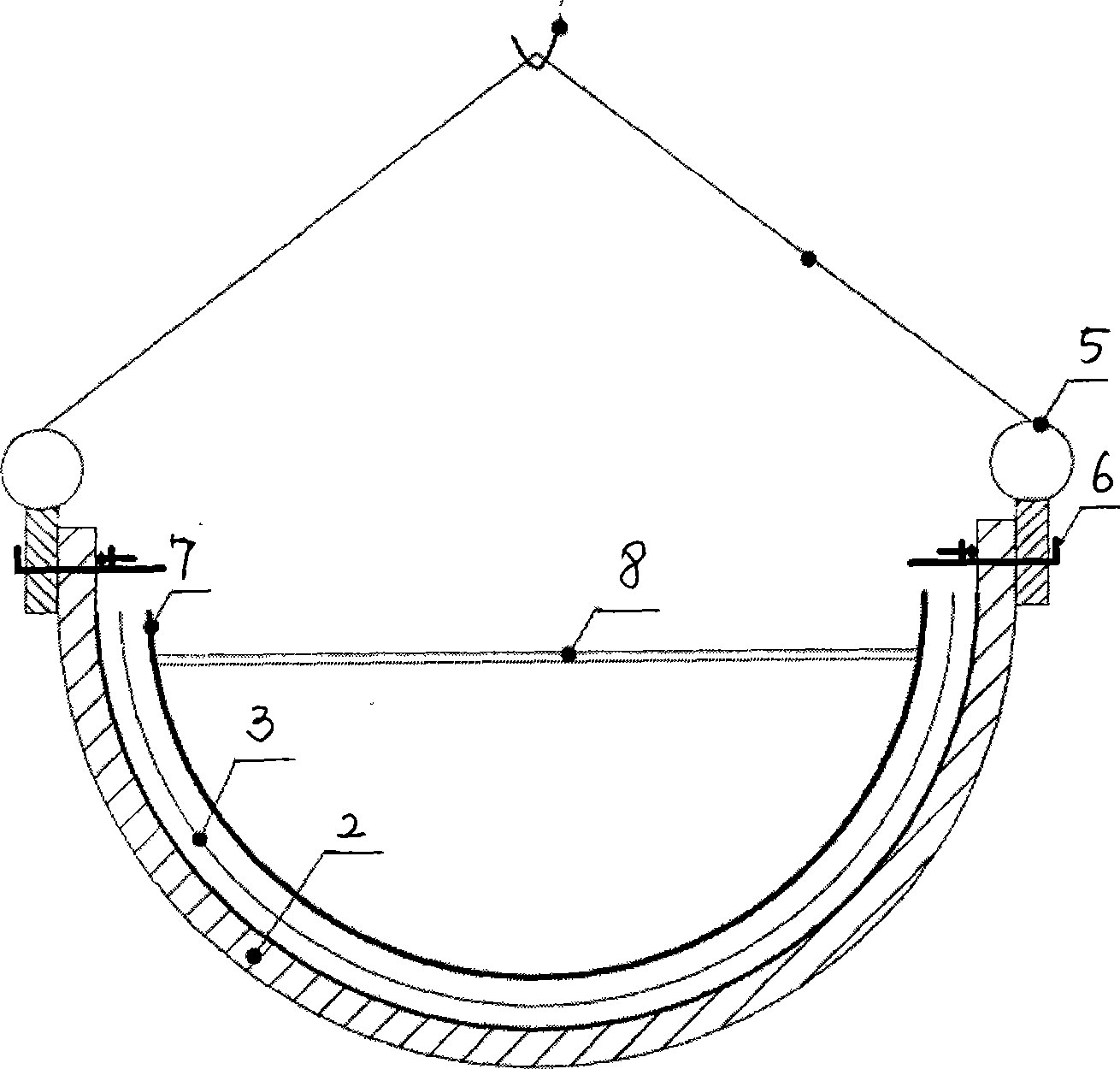

Method for manufacturing megawatt wind power generator blade root

The invention relates to a method for making a blade root of a megawatts level aerogenerator, which comprises the following steps: firstly, making a single insert female die, and laying a glass cloth required to be prefabricated according to blade design paper in the female die; secondly, laying a vacuum bag on the outermost layer, sealing the periphery, vacuumizing, compacting all the laid layers, placing a glass reinforced plastics cambered supporting plate on the vacuum bag, supporting two sides of the cambered supporting plate with transverse supporting rods, and stopping vacuumizing; and thirdly, laying a plurality layers of glass fiber cloth in a blade root mould in advance, lifting up an insert and placing the insert into the blade root mould, sealing the peripheries of the vacuum bag and the blade root mould, vacuumizing again, injecting glue, and finally curing and moulding the product. The method overcomes the collapse and the corrugation of the glass cloth on two sides of the blade mould, has the advantages of simple and convenient production, high efficiency, and easily manufactured insert, does not generate a gap because of the good matching of the shapes of the glass cloth laid in the insert and the blade mould, and avoids the easy generation of a dried region in the glass cloth under a cured insert.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Preparation method of1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer

The invention discloses a preparation method of a 1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer. The preparation method comprises the following steps of: 1, dewatering polymer polyhydric alcohol by stirring under a vacuum condition at 80 to 150 DEG C; 2, under the protection of nitrogen, reacting excessive 1,5-naphthalene diisocyanate-based polyurethane with the polymer polyhydric alcohol at 100 to 150 DEG C so as to generate a prepolymer containing redundant -NCO groups; 3, performing chain extension by adopting a full pre-polymerization method, mixing a prepolymer component with a chain extender component according to a proportion, and stirring at a high speed, injecting the mixture solution into a mould of which the temperature is between 80 and 110 DEG C, and demoulding after precuring for 10 to 60 minutes, wherein the chain extender component does not contain the polymer polyhydric alcohol; and 4, post-curing the product subjected to demoulding, for 13 to 18 hours at 100 to 120 DEG C. The 1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer prepared by using the method disclosed by the invention is used as a high-strength damping material for bearing dynamic fatigue, such as buffering damping components of an elevator motor and other equipment which can easily generate acting force with a certain frequency.

Owner:POLYMERCHEM

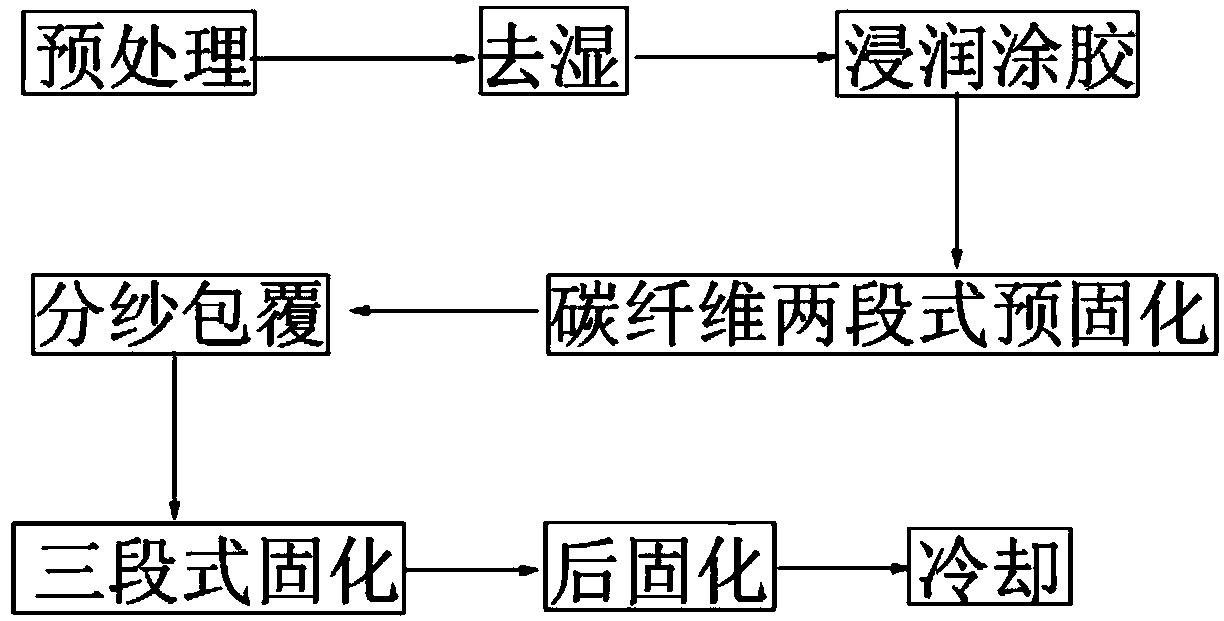

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

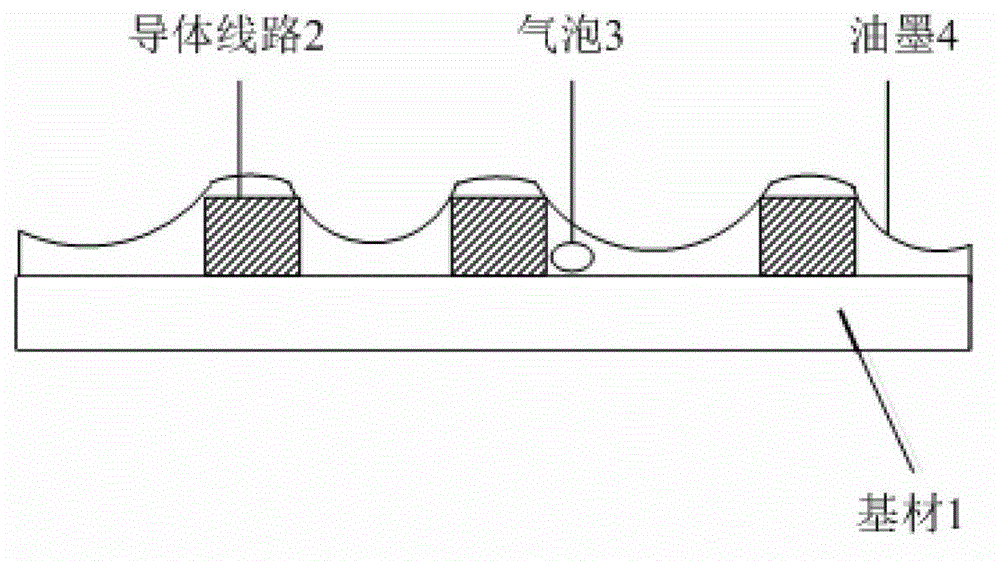

Solventless thermosetting photosensitive via-filling material

A via-filling material improves a via-filling process in manufacturing multi-layered printed circuit boards. The via-filling material is capable of undergoing UV pre-cure and thermal post-cure step. Exposed to ultraviolet light, the via-filling material filled up the two ends of the via form solid barrier films so that the inside via-filling material will not flow out during a thermal post curing process due to an lower viscosity of said material. The dual-cure treatment resolves the problems of polishing, sagging and bubbling in the via-filling process and ensures the integrity of the filling material. As a result, the via-filling material with smooth surface and a solid inside without void or hole therein formed.

Owner:YEH TODD

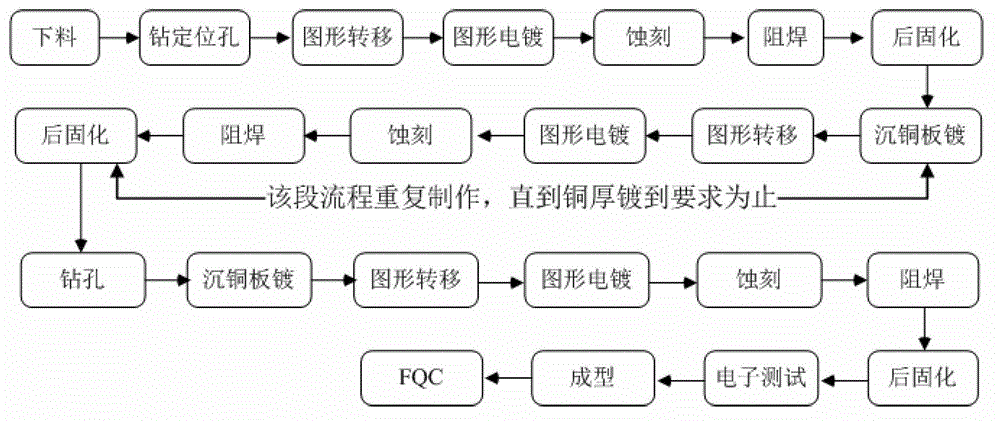

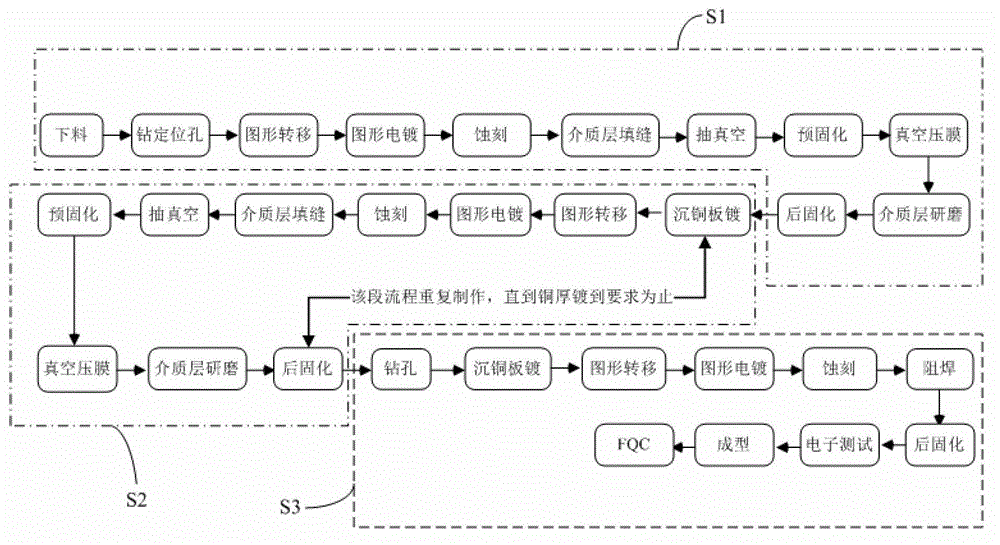

Method for manufacturing copper PCB (Printed Circuit Board) circuit

ActiveCN102917542AReduce dropImprove consistencyConductive material chemical/electrolytical removalElectrical conductorEngineering

The invention provides a method for manufacturing a thick copper PCB (Printed Circuit Board) circuit. The method comprises the steps of: a positioning hole drilling step for drilling a positioning hole in a printed board substrate; a pattern transfer step for bonding a dry film on the printed board substrate and forming patterns on the dry film; a pattern electroplating step for electroplating copper on the patterns unprotected by the dry film; a film removing step to remove the dry film; an etching step for etching the copper unprotected by lead and tin and removing the lead and tin to obtain a conductor circuit pattern of a current layer; a dielectric layer joint filling step for arranging a dielectric layer oil ink layer on all the substrate area of a circuit board; a dielectric layer grinding step for removing oil ink on a copper face; a post-curing step for curing the structure; a copper deposition electroplating step for depositing a copper deposited metal layer on a circuit copper layer and the surface filled with the dielectric layer oil ink; and a full-board electroplating step for electroplating copper on the entire circuit board. When the final thickness of copper does not reach the preset thickness of the copper, the steps from pattern transfer to full-board electroplating are executed repeatedly.

Owner:JIANGNAN INST OF COMPUTING TECH

Method for preparing melt spun chlorine-resistance high resilient polyurethane fiber

InactiveCN102011211AIncrease elasticityGuaranteed physical propertiesFilament/thread formingArtificial filament heat treatmentFiberCross-link

The invention discloses a method for preparing melt spun chlorine-resistance high resilient polyurethane fiber, comprising the following steps: 1) a thermoplastic polyurethane slice is prepared by a one-step method; 2) the slice is uniformly mixed with chlorine-resistance cross-linking agent; 3) melt extrusion is carried out; 4) spinning moulding is carried out; and 5) post curing is carried out. By utilizing the invention, the requirement on higher chlorine resistance and resilience in special fields is met, combination of the chlorine-resistance cross-linking agent and polyurethane fiber is good, and the physical performance of fiber can be effectively maintained when being used in a chlorine-containing environment; and besides, diamine is adopted as chain extension agent, the hard section of the formed polyurethane urea has higher cohesive energy, three-dimensional hydrogen bonds can be formed, and the microphase separation degree is improved, thus improving the resilience of fiber.

Owner:奥斯汀新材料(张家港)有限公司

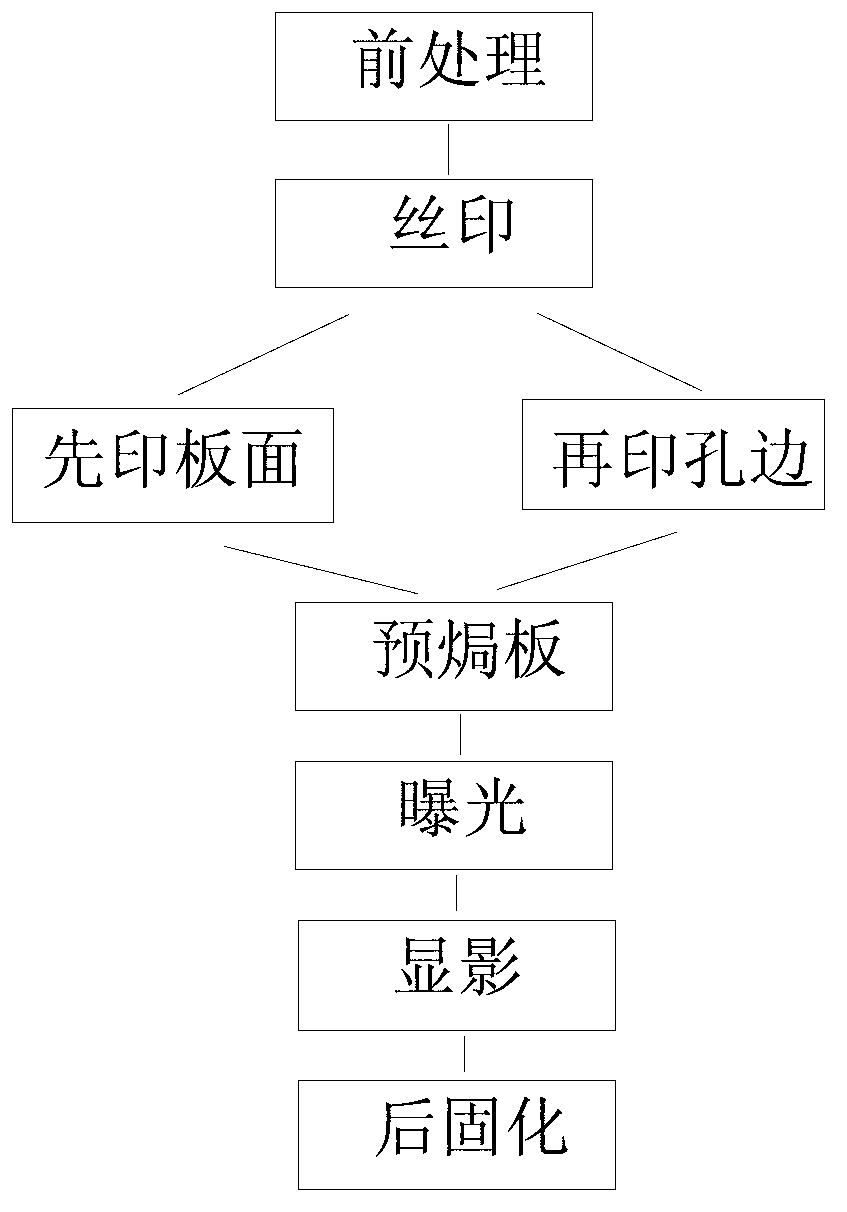

Green oil silk-printing method for printed circuit board

ActiveCN102795006AImprove electrical performanceGood lookingOther printing apparatusEngineeringPrinted circuit board

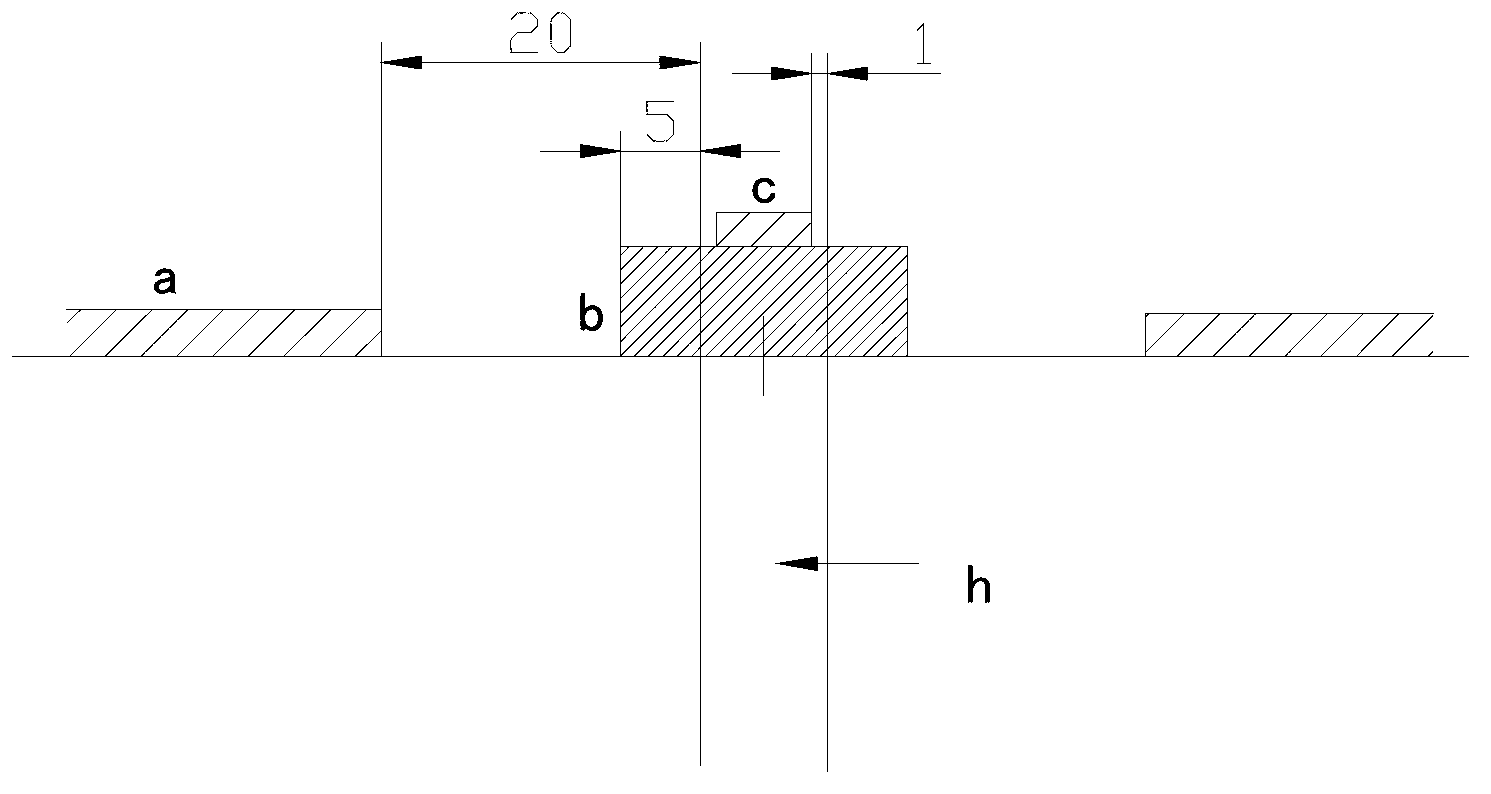

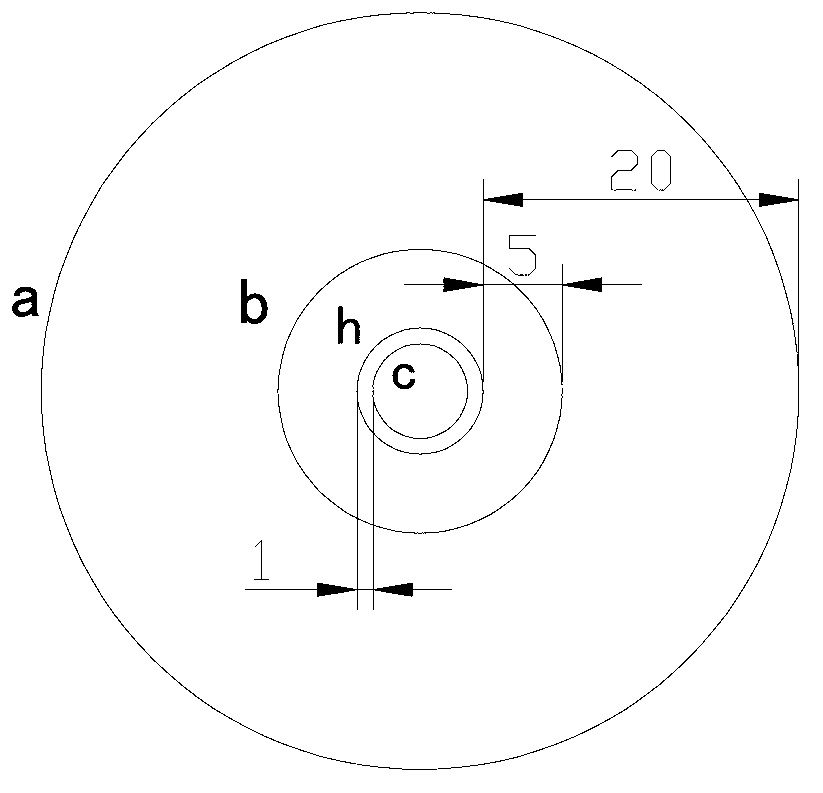

The invention discloses a green oil silk-printing method for a printed circuit board (PCB). The green oil silk-printing method comprises the following steps: preprocessing, carrying out silk-printing, pre-baking the board, exposing, developing and post-curing, wherein a flow process of carrying out silk-printing on the surface of the board, preheating, carrying out silk-printing on the hole edge of a drilled hole and preheating is adopted in the silk-printing step; in the process of carrying out silk-printing on the surface of the board and preheating, the radius of an oil blocking PAD corresponding to the drilled hole is greater than that of the drilled hole by 5 mil; in the process of carrying out silk-printing on the hole edge of a drilled hole and preheating, the radius of a printing oil window of the drilled hole is greater than that of the drilled hole by 20 mil, and a blocking point with a radius smaller than that of the drilled hole by 1 mil is arranged in the middle of the printing oil window; and the number of meshes in the silk-printed hole edge of the drilled hole is more than that of the meshes in the silk-printed board surface. According to the green oil silk-printing method for the PCB, the silk-printing requirement of not blocking a small hole by green oil can be well met, the defects of blockage of the green oil on the hole, under developing, lateral erosion in film printing and developing, a tin ring on the hole edge and a tin ball hidden in the hole after prevention of tin spraying, and the like are reduced, the PCB is good in electric property and appearance, the method is simple in process and convenient to operate, and the production efficiency is improved.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Method for preparing leather sample observed by metallurgical microscope

InactiveCN102305736AFast penetrationFully infiltratedPreparing sample for investigationFiberMicroscopic observation

The invention relates to a method for preparing a leather sample observed by a metallurgical microscope, and belongs to the technical field of leather inspection. The method comprises the following steps of: (1) adding a promoter into an unsaturated polyester resin, stirring, adding a curing agent, stirring, standing, and discharging the mixed air to obtain an immobilized resin; (2) immersing a sample into the immobilized resin, and curing to obtain a cured sample; (3) grinding both ends of the cured sample until the ends are flat, fixing in a mould, injecting the immobilized resin into the mould, curing, demoulding, and post-curing to obtain a post-cured sample block; and (4) grinding and polishing the post-cured sample block by using abrasive paper to obtain the leather sample observed by the metallurgical microscope. In the method, the unsaturated polyester resin is used as a main ingredient of the immobilized resin, and operation steps are designed according to a capillary action principle to ensure that the immobilized resin can be quickly and fully permeated into the leather sample, so the adhesion and deformation of section fiber of leather are furthest avoided.

Owner:QILU UNIV OF TECH

Cast-in-place box girder low-temperature steam maintenance operating method

InactiveCN1830644ASolve insulation problemsGuaranteed uniformityCeramic shaping apparatusEngineeringUltimate tensile strength

A low-temp steam curing method for in-situ cast box beam includes such steps as spraying insulating layer on external mould, laying down steam tubes, building steam curing shed, burying a temp strain gauge at each measuring point, parallelly connecting them via a switch to a reader, laying aside, heating, making temp constant, cooling and post curing. Its advantages are high speed, high strength and no crack.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

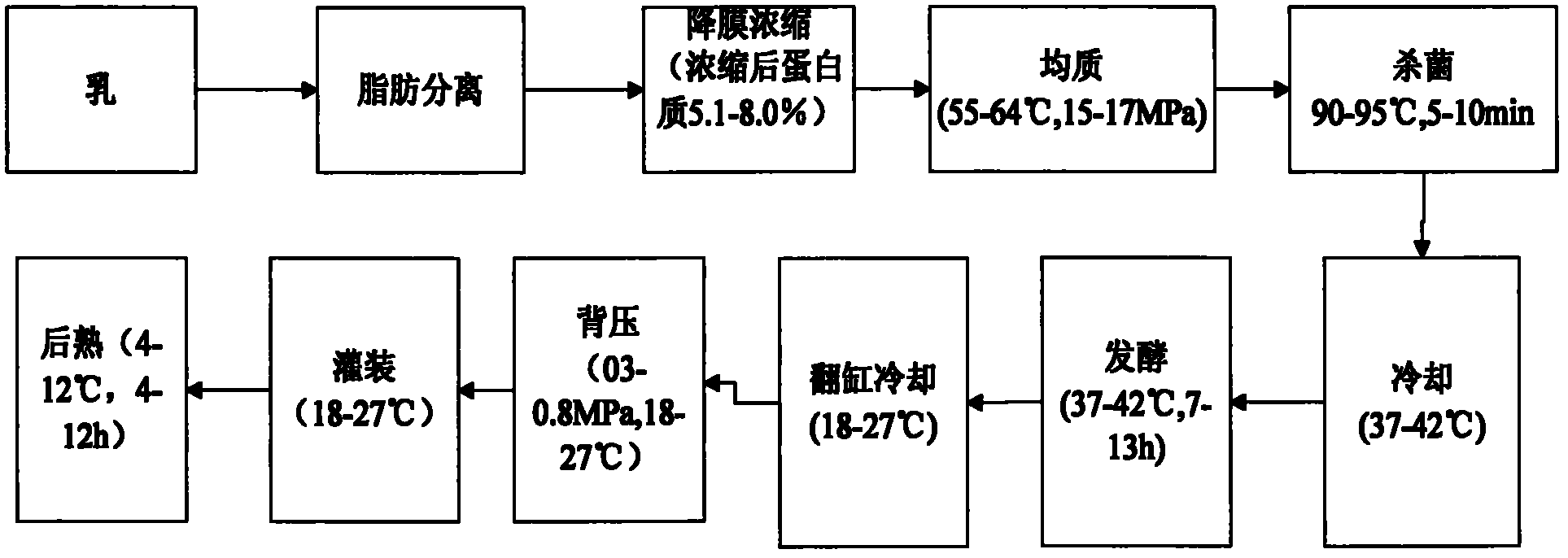

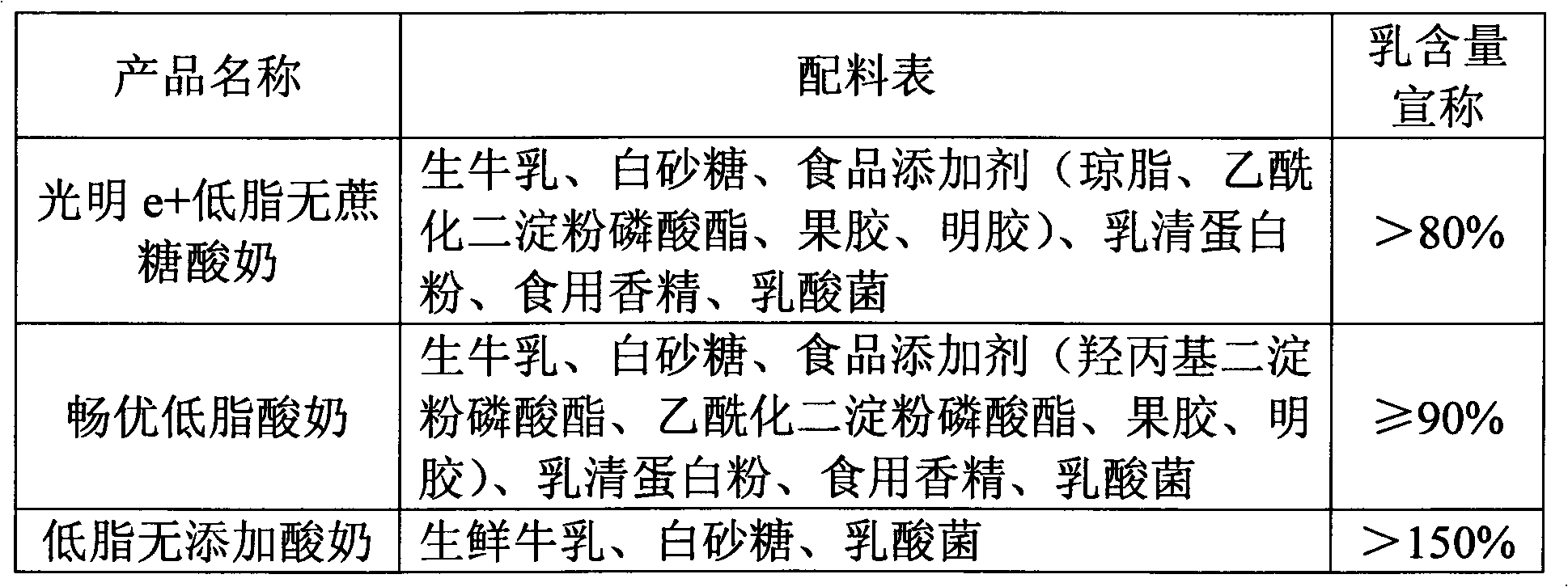

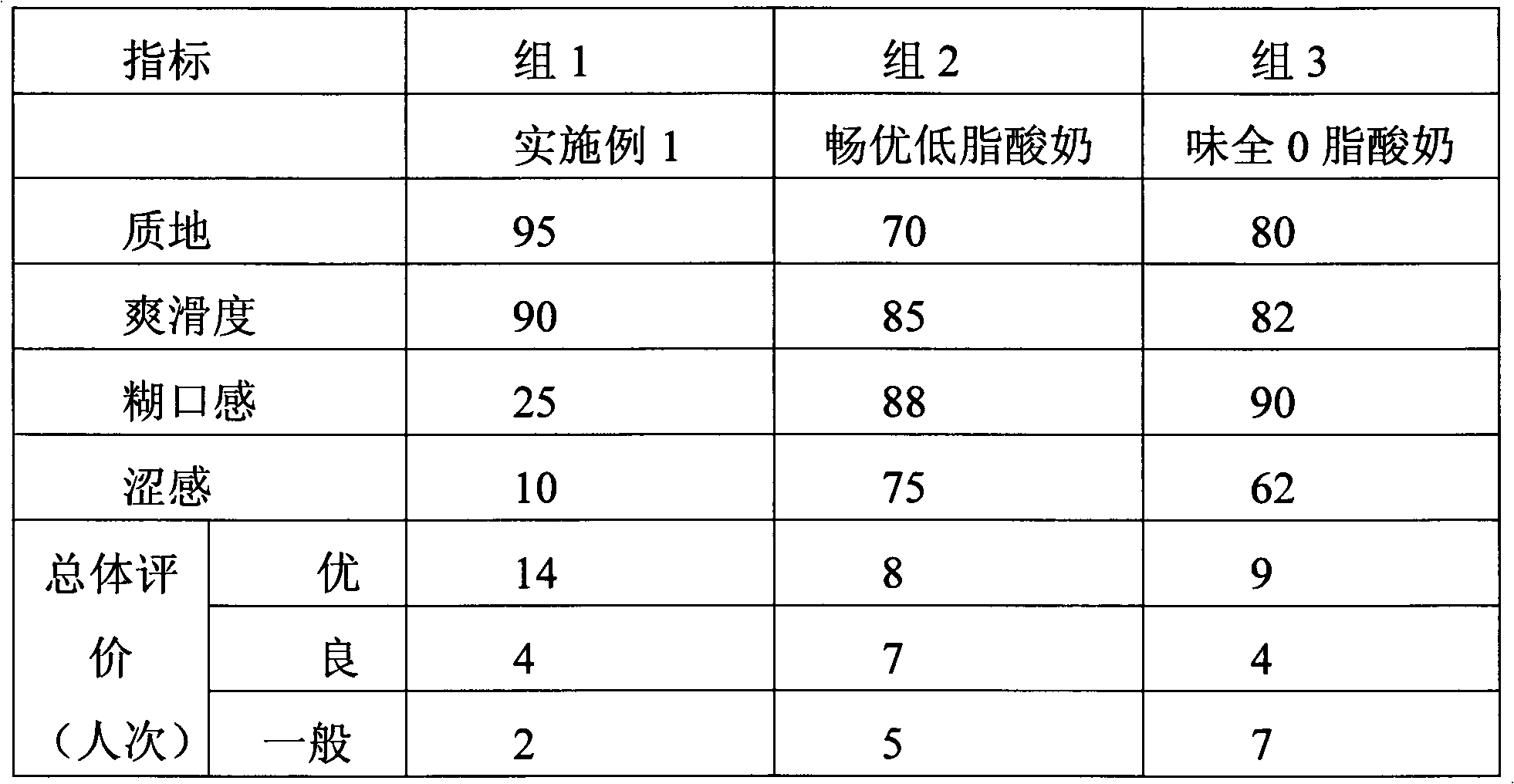

Low-fat additive-free yogurt and preparation method thereof

The invention discloses low-fat additive-free yogurt and a preparation method thereof. The low-fat additive-free yogurt includes main ingredients such as raw milk and fermenting agent, and raw milk is degreased, concentrated, fermented with fermenting culture, cooled, counterbalanced, filled and post-cured to be made into the additive-free yogurt with low content of fat. According to the low-fat additive-free yogurt and the preparation method thereof, by increasing the content of proteins inside the raw milk and prolonging the fermentation time, partial proteins are modified, a substance with the structure and taste being similar to that of the fat is generated, and a taste of smoothness and coolness is applied to the low-fat yogurt; and through the counterbalancing processing technique, protein particles in the yogurt can be eliminated, an exquisite taste is applied to the yogurt, and the viscosity of the yogurt is greatly improved by utilizing the yogurt post-curing technique. On the premise that no external fat substitute is used and no additive such as a thickening agent and essence is utilized, the low-fat additive-free yogurt with a taste being similar to that of whole fermented milk is developed only by improving the raw material and yogurt manufacturing technique conditions.

Owner:BRIGHT DAIRY & FOOD

Preparation method of glass fiber enhanced thermosetting resin matrix composite material

InactiveCN101955666ASimple preparation processSuitable for industrial productionGlass fiberResin matrix

The invention discloses a preparation method of a glass fiber enhanced thermosetting resin matrix composite material, which comprises the following steps of: one, preparing a modified thermosetting resin; two, preparing modified thermosetting resin glue solution; three, brushing the modified thermosetting resin glue solution on a glass fiber cloth; four, performing pressing and curing; and five, performing post-curing. The preparation method has a simple preparation process and is suitable for industrial production. The glass fiber enhanced thermosetting resin matrix composite material prepared by the method has excellent dielectric property, outstanding comprehensive mechanical properties, high temperature resistance and heat and humidity resistance, and can be used for high-frequency digital printed circuit boards, high-performance wave-transmitting structural materials and aero-space structural materials.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com