Low-fat additive-free yogurt and preparation method thereof

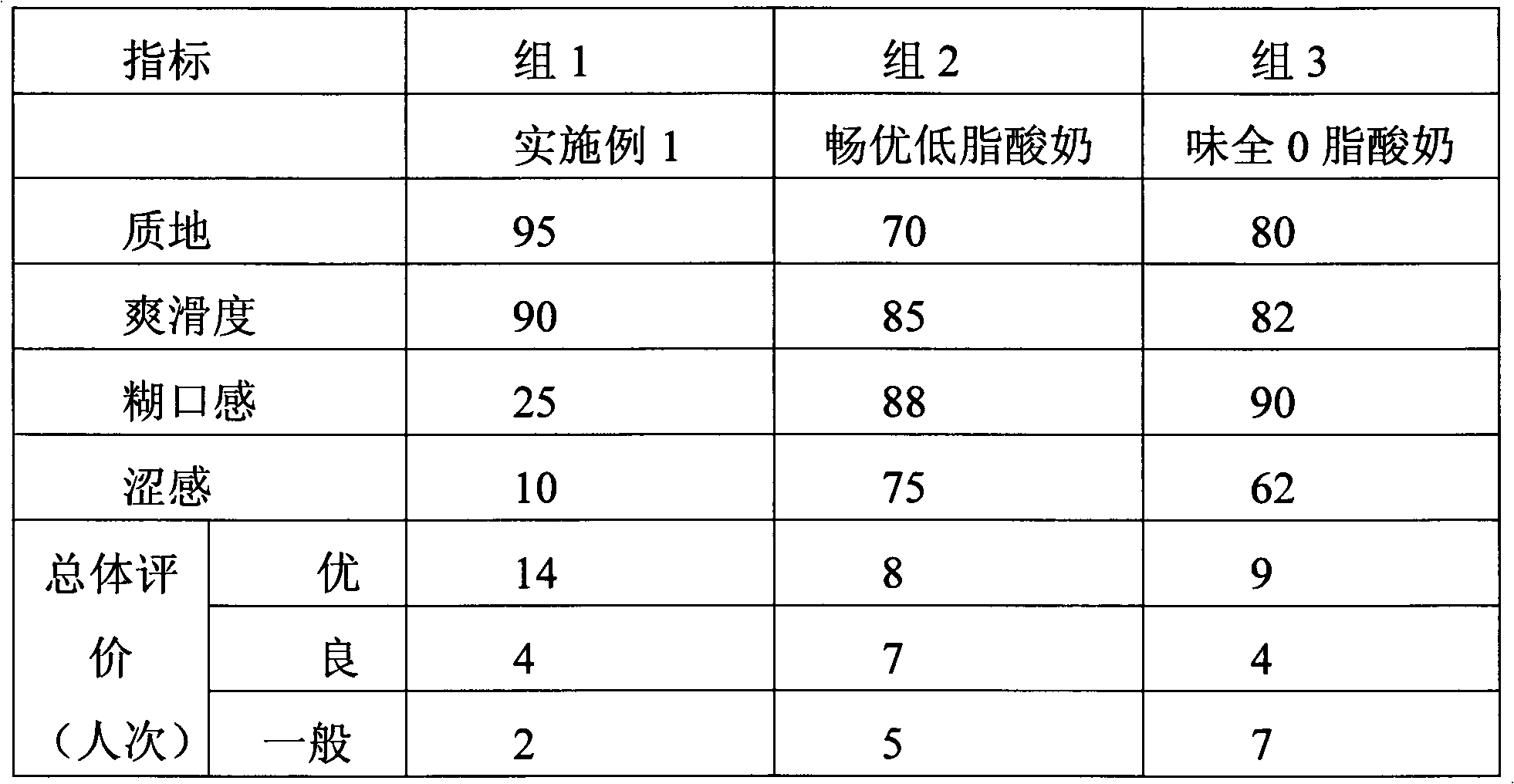

A technology without additives and yogurt, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of disgusting exogenous additives, powdery taste of low-fat milk, and insufficient smoothness, so as to reduce fat intake And chemical synthetic additives, fine texture, smooth taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

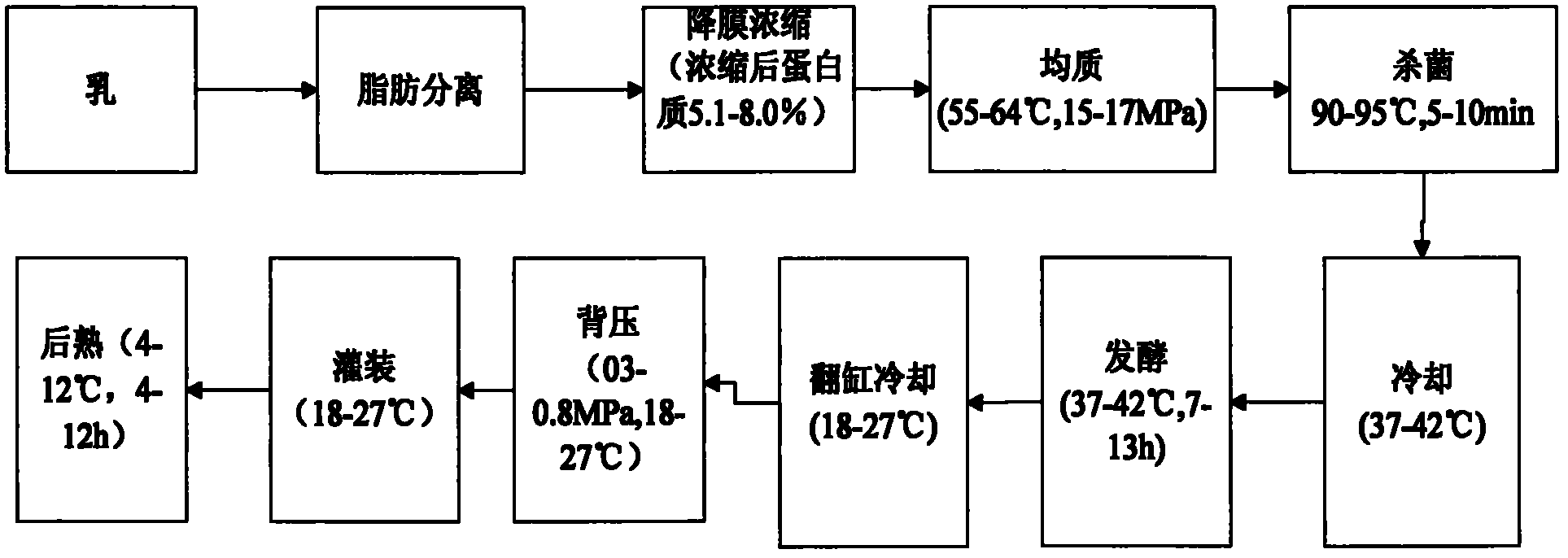

Method used

Image

Examples

Embodiment 1

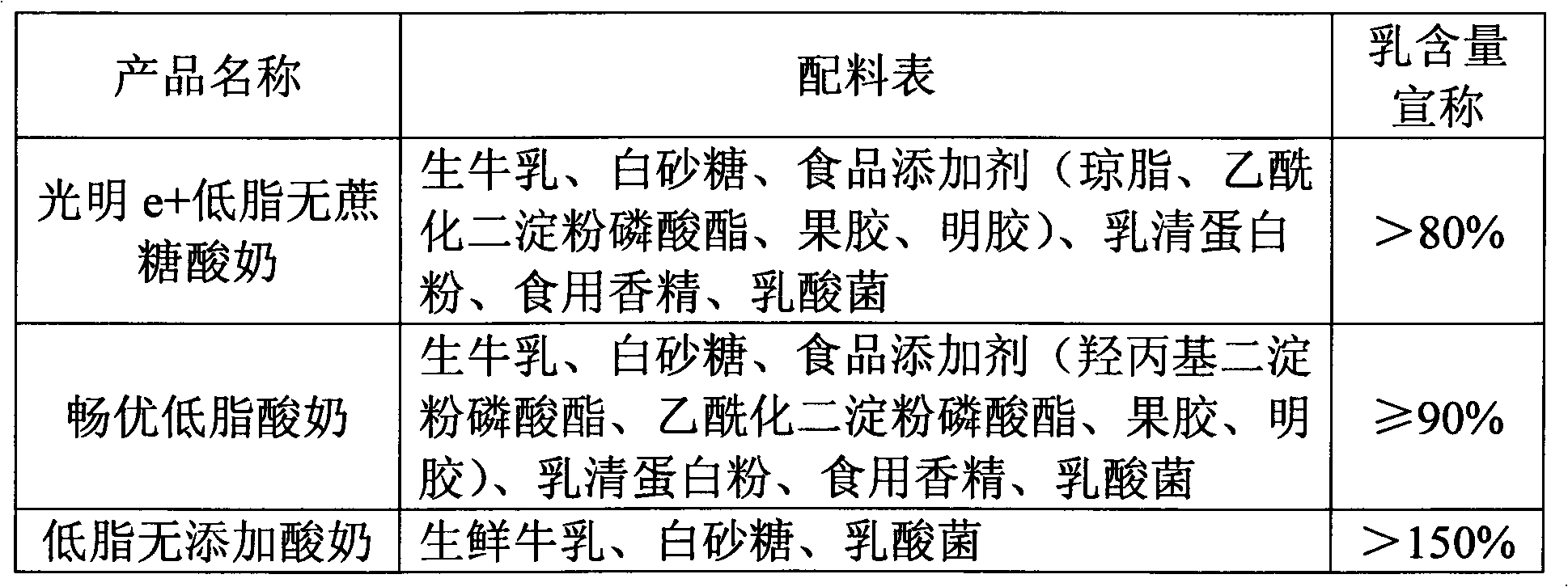

[0027] Low-fat yogurt without additives: fresh milk, fat ≥ 3.1%, protein ≥ 2.8% (Bright Dairy Co., Ltd.);

[0028]Starter, YO0925-A (Lactobacillus bulgaricus, Streptococcus thermophilus), (Danisco AG).

[0029] The preparation method of low-fat yogurt without additives: the fresh milk is processed by a fat separator to obtain milk with a milk fat content of 0.5% after fat separation, and is processed by a falling film concentration evaporation process, that is, the milk flows through a single-effect evaporator, vacuum The temperature is 7.2bar, and the evaporation boiling point is 70°C. Concentrate to obtain concentrated milk with a protein content of 5.5%; homogenization temperature is 55°C, homogenization pressure is 15MPa for the first stage, and the second stage pressure is 3MPa; sterilize at 90°C for 10 minutes, and cool to 37°C; add strains and inoculate the number of fermentation bacteria Respectively: Lactobacillus bulgaricus 5×10 5 cfu / ml, Streptococcus thermophilus...

Embodiment 2

[0031] Low-fat yogurt without additives: fresh milk, fat ≥ 3.1%, protein ≥ 2.8% (Bright Dairy Co., Ltd.);

[0032] White sugar, Guangming Dairy Co., Ltd.;

[0033] Starter: YC381 (Lactobacillus bulgaricus, Streptococcus thermophilus), Hansen Strain Co., Ltd.

[0034] The preparation method of low-fat yogurt without additives: the fresh milk is processed by a fat separator to obtain milk with a milk fat content of 0.1% after fat separation, and is processed by a falling film concentration and evaporation process, with a vacuum degree of 9.0 bar and an evaporation boiling point of 52 ° C. Concentration Obtain concentrated milk with a protein content of 8.0% and a fat content of 0.25%; heat the concentrated milk to 40°C, add 7% white sugar and stir to dissolve; homogenization temperature is 64°C, homogenization pressure is 17MPa at the first stage, and the pressure at the second stage is 5MPa; 95°C Sterilize for 5 minutes, cool to 37°C; add strains, and the number of fermented b...

Embodiment 3

[0036] Low-fat yogurt without additives raw materials: fresh milk, fat ≥ 3.1%, protein ≥ 2.8%; white sugar, Guangming Dairy Co., Ltd.;

[0037] Starter, YC381 (Lactobacillus bulgaricus, Streptococcus thermophilus), Hansen Strain Co., Ltd.

[0038] The preparation method of low-fat yogurt without additives: the milk is processed by a fat separator to obtain milk with a milk fat content of 0.15% after fat separation, and is processed by falling film concentration and evaporation process, with a vacuum degree of 9.6 bar and an evaporation boiling point of 40°C, and concentrated to obtain protein Concentrated milk with a content of 5.1% and a fat content of 0.25%; heat the concentrated milk to 40°C, add 7% white sugar and stir to dissolve; homogenization temperature is 62°C, homogenization pressure is 16MPa at the first level, and pressure at the second level is 3MPa; sterilization at 93°C 7min, cool to 41°C; add strains, and the number of fermentation bacteria inoculated with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com