Patents

Literature

78results about How to "High rehydration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse cereal food and preparation method thereof

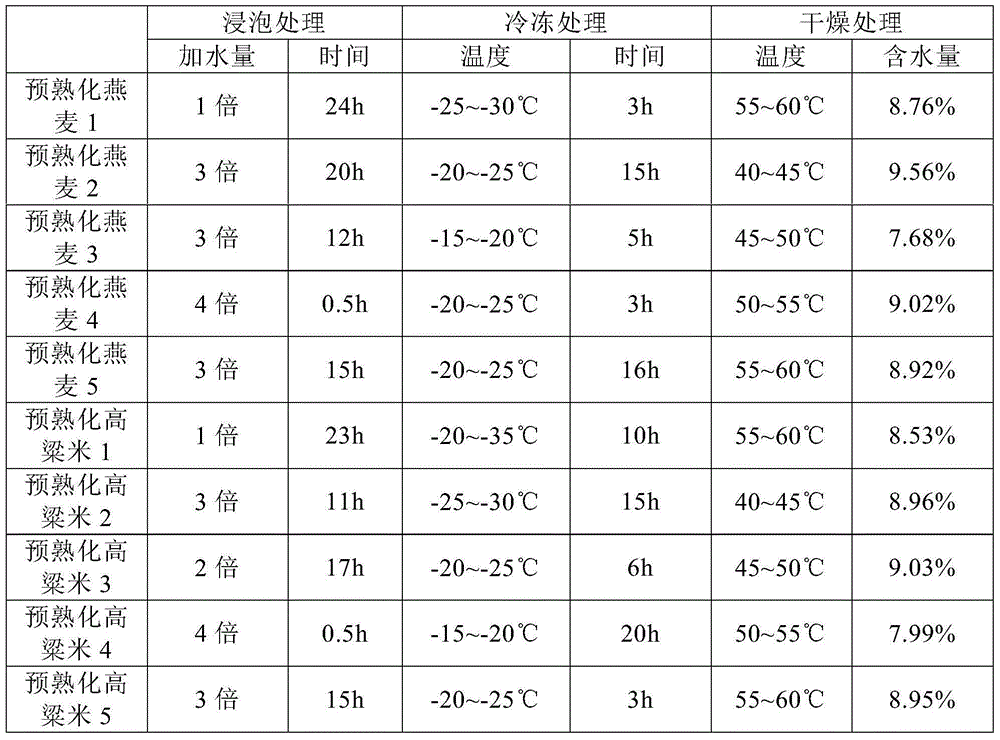

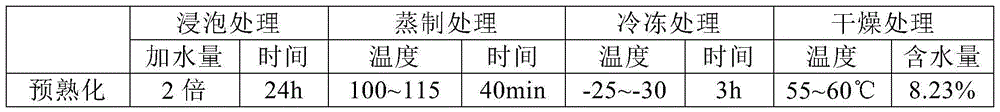

The present invention discloses a formula coarse cereal food. The formula coarse cereal food mainly comprises the following coarse cereals in parts by weight: 30 to 45 parts of oat, highland barley and / or barley, 20 to 40 parts of green bean and / or red bean, 1 to 10 parts of black beans, chickpea, garden pea, cowpea, rice bean and / or soybean; 15 to 20 parts of black rice; 5 to 15 parts of sorghum rice, red rice, brown rice and / or pearl barley; 10 to 20 parts of buckwheat, millet, and / or sticky millet. And the mixed beans cereal, the oat and the sorghum rice are subject to a pre-aging treatment, and then mixed with the rest of cereal in a proportion to obtain the formula coarse cereal food. According to the present invention, the formula coarse cereal food has more complete shape retention and has better market prospects as commodity for sale. The formula cereal food has a short aging time when cooking with rice; the cooked cereal porridge has characteristics of rich flavor, soft mouthfeel, good viscosity and uniform dispersion. The formula cereal food can provide a human body with necessary dietary fiber, vitamins and minerals.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

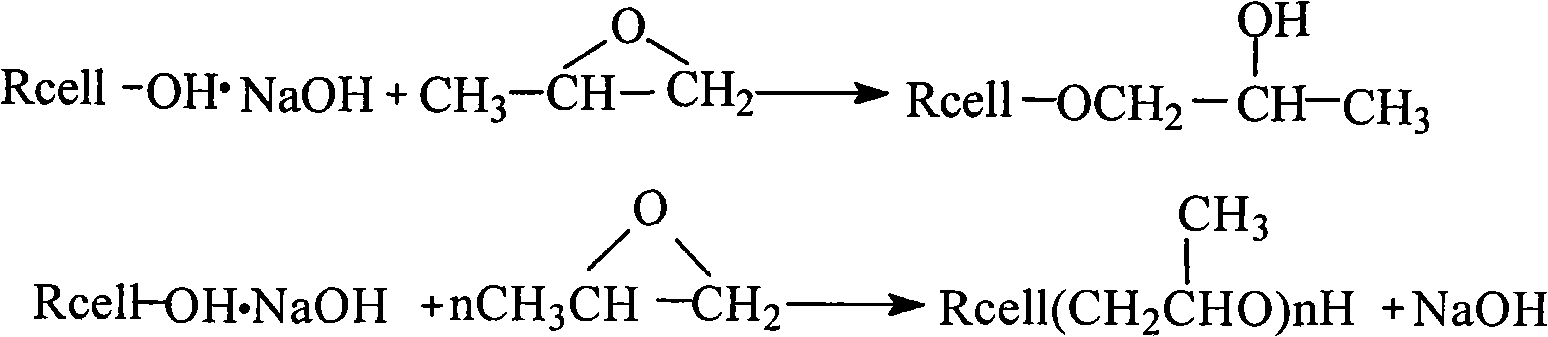

Method for preparing bacterial cellulose membrane with high rehydration

The invention relates to a method for preparing a bacterial cellulose membrane with high rehydration, which comprises the following steps: (1) performing alkaline treatment on bacterial cellulose hydrogel membrane of which bacteria and culture medium are removed; (2) performing etherification treatment on the processed membrane; (3) performing neutralization reaction on the etherified membrane to obtain a bacterial cellulose membrane subjected to hydroxypropylation; and (4) drying the bacterial cellulose membrane subjected to hydroxypropylation to obtain the bacterial cellulose membrane with high rehydration. The method aims at the defect of low rehydration performance of the prior bacterial cellulose membrane, uses a method of hydroxypropylation modification of the bacterial cellulose surface to destroy a part of hydrogen bonds in cellulose; a rehydration rate test finds that the dried bacterial cellulose membrane subjected to hydroxypropylation has high rehydration and reswelling capability; and the bacterial cellulose membrane subjected to hydroxypropylation can be used for preparing biologic composite materials, and has importance significance on biomedical materials and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Method for uniformly drying lettuce by normal pressure and negative pressure combined microwave spouted bed

InactiveCN102405958AReduce lossesHigh retention rateFruits/vegetable preservation by dehydrationMicrowaveMagnesium acetate

The invention relates to a method for uniformly drying lettuce by a normal pressure and negative pressure combined microwave spouted bed, and belongs to the technical field of fruit and vegetable food processing. The main processes of the method comprises: removing leaves and peels from fresh lettuce, cleaning, cutting into cubes (cutting into sheets), adding a EDTA-Na solution to carry out colorprotection, blanching, adding a magnesium acetate solution and a zinc acetate solution to carry out color protection, and carrying out treatments of microwave spouted drying, packaging and storage. With the present invention, the microwave drying technology is adopted so as to shorten the drying time, reduce the drying energy consumption, and reduce the loss of the chlorophyll in the lettuce during the processing process; the normal pressure spouted bed drying technology and the negative pressure spouted bed drying technology are combined to dry the lettuce, and the material has the circular motion, such that the disadvantage of the nonuniformity of the microwave drying is overcome; the product dried by the microwave spouted drying method has characteristics of good water reabsorbing capacity, high water reabsorbing rate, good crisp taste after water reabsorbing, unique lettuce aroma, high chlorophyll content, good and uniform color.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

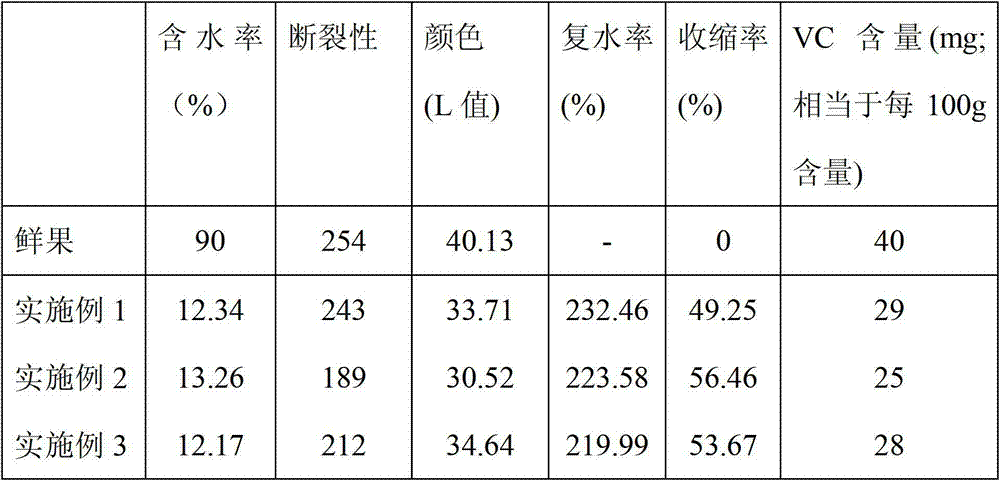

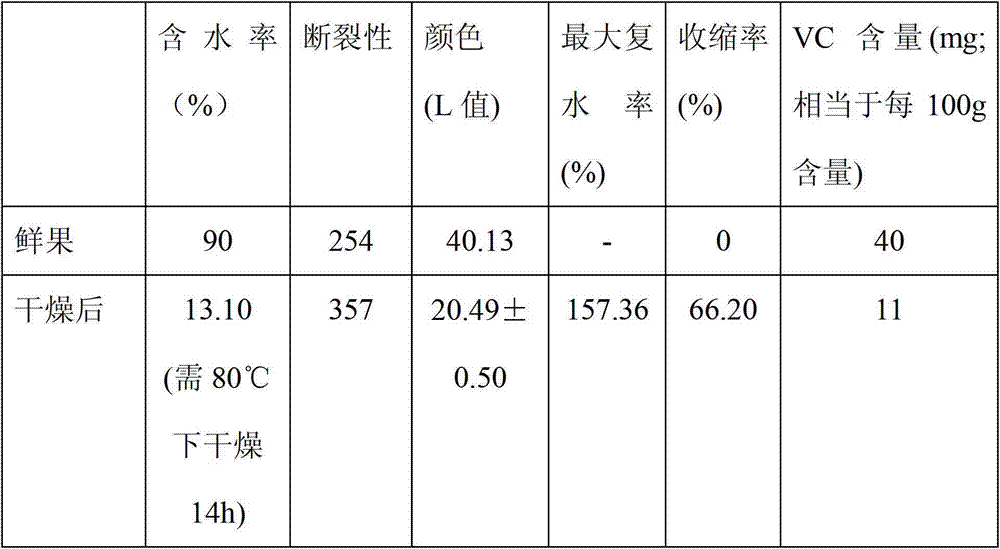

Vacuum microwave combined processing method for okra

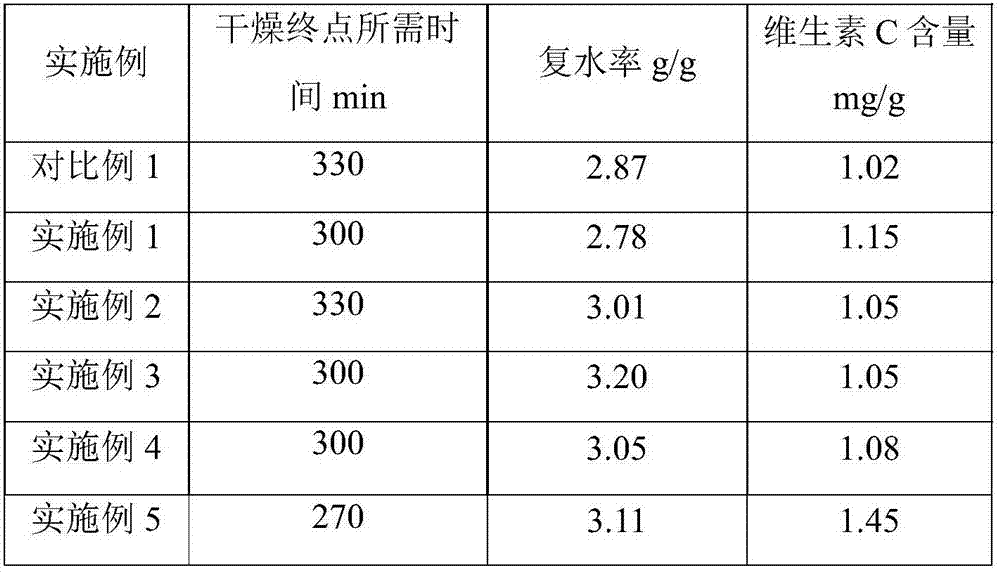

InactiveCN103081982AHigh nutritional valueShorten drying timeFruits/vegetable preservation by dehydrationMicrowaveVitamin C

The invention discloses a vacuum microwave combined processing method for okra. The vacuum microwave combined processing method specifically comprises the following steps: step 1, selecting fresh okra fruits which are fresh, free of diseases and insect pests and uniform in color as raw materials; step 2, cleaning, namely, removing the root parts of the proper okra fresh fruits and the impurities on the surfaces of the okra fresh fruits; step 3, draining, namely, horizontally paving the cleaned fresh okra fruits on a bamboo sieve for draining; and step 4, carrying out vacuum microwave-drying, namely, putting the okra fresh fruits in a vacuum microwave drying chamber for drying to obtain the okra. According to the vacuum microwave combined processing method, after the vacuum microwave-drying, the color of the okra is maintained well, bigger in rehydration ratio, smaller in shrinking percentage, big in vitamin C content retention rate, good in product quality and high in drying efficiency.

Owner:HAINAN UNIVERSITY

Method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves

ActiveCN104304426AImprove uniformity of vacuum microwave dryingUniform colorFruits/vegetable preservation by dehydrationDielectricAgaricus

The invention relates to a method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves, and belongs to the field of deep processing of agricultural products. The method comprises the following steps: cleaning agaricus bisporus and cutting into 5-8mm thick slices, protecting color by using a mixed solution of vitamin C, citric acid and calcium chloride, and carrying out variable-frequency staged ultrasound impregnation treatment on the color-protected agaricus bisporus slices: a first stage: putting the agaricus bisporus slices in clear water according to a ratio of agaricus bisporus slice to water of 1:5, and setting the water temperature to 45-50 DEG C, the ultrasonic frequency to 45KHz, the ultrasonic power to 120-150W, and the treatment time to 30-40min; a second stage: taking out the agaricus bisporus slices and putting into a mixed solution of 50-60% by mass fraction of sucrose and 5% by mass fraction of salt according to a ratio of agaricus bisporus slice to mixed solution of 1:10, and setting the water temperature to 35-40 DEG C, the ultrasonic frequency to 100KHz, the ultrasonic power to 210-240W and the treatment time to 40-50min; finally, carrying out vacuum microwave drying, and setting the microwave transmitting power to 15-20W / g, the degree of vacuum to 70-80kPa and the drying time to 15-25min. The agaricus bisporus slices subjected to variable-frequency ultrasound-assisted impregnation treatment has uniformly distributed dielectrics; when the vacuum microwave drying is carried out, a material is uniformly heated in a microwave field, and moisture is rapidly evaporated, so that the dried agaricus bisporus slice is uniformly distributed in color and luster, and is uniform in shape and better in rehydration.

Owner:JIANGSU ACAD OF AGRI SCI

A kind of preparation method of dried abalone

The invention provides a preparation method of dried abalone, and the method comprises the following steps: cleaning raw materials, removing offal, rubbing with salt to remove a black film, salting for softening, performing hot ironing, baking with charcoal, dehydrating, steaming and drying, wherein the step of salting for softening is implemented by adding table salt into abalone meat and putting in a refrigerator at 18+ / -2 DEG C for 10-12 hours. In the invention, as a special salting process is adopted, the protease in the abalone meat tissue can slightly decompose the muscular tissue to generate partial amino acid, the rehydration time before the dried abalone is taken can be shortened, the rehydration rate is improved, and the flavor of the dried abalone becomes fresh; and the charcoal baking pretreatment is utilized to enhance the flavor of the dried abalone. The method can be used for expanding the consumer market of the dried abalone to a certain degree.

Owner:FUJIAN AGRI & FORESTRY UNIV

Pleurotus eryngii slice drying processing method and application thereof

The invention belongs to the technical field of fungus processing, and discloses a pleurotus eryngii slice drying processing method and an application thereof. The pleurotus eryngii slice drying processing method comprises the following steps of: slicing pleurotus eryngii, immersing pleurotus eryngii slices in a steeping liquor, drying the immersed pleurotus eryngii slices at a high temperature, and then drying the pleurotus eryngii slices at a low temperature to obtain the dry pleurotus eryngii slices. Due to the adoption of the method, the original nutrients of the pleurotus eryngii can be well protected, the loss of the nutrients can be avoided in the drying process, a good color protection effect can be realized, the obtained dry pleurotus eryngii slices are good in color, the rehydrate rate is high, and the comprehensive quality is good. The method is economical and simple, the requirement on production equipment is low, the maintenance cost is low, and for the method, the industrialization and the mass production are easy to implement.

Owner:SOUTH CHINA AGRI UNIV

Rapid reconstitutable snail rice noodle dry noodle preparation technology

PendingCN109259064AGeneration of controlPrevent direct dryingFood thermal treatmentFood ingredientsWell controlWater content

The invention discloses a rapid reconstitutable snail rice noodle dry noodle preparation technology, and relates to the field of preparation technologies of snail rice noodle dry noodle. Compared withtraditional curing, curing can be conducted slowly and the reconsitutable rate can be well controlled through secondary curing. In the curing process, the 40-50 degrees temperature region is utilizedso that generation of bacterial groups and mould can be well controlled, meanwhile, curing is conducted, the humidity changes from low to high, and then from high to low, accordingly the noodle is effectively prevented from being directly dried, and the water content of the rice noodle is effectively maintained. In the drying stage, the temperature changes from high to low, and then from low to high, the humidity is lower and lower gradually, the wind speed changes from low to high and then from high to low, therefore the rice noodle is not hardened immediately while being dried, the interiorof the noodle is loose by controlling the temperature and the wind speed, thus the rehydration rate of the noodle can be well improved, and the rice noodle can be rapidly boiled when being eaten.

Owner:广西螺霸王食品有限公司

Method for quickly preparing dried day-lily flowers

InactiveCN106720208AReduce processing timeIncrease productivityFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingDaylilyYield ratio

The invention relates to a method for quickly preparing dried day-lily flowers, and belongs to the technical field of agricultural product processing. The method comprises the steps of firstly paving day-lily flowers on a fixation container uniformly at a thickness of 3-5cm, feeding the fixation container into a fixation chamber and carrying out fixation at 66-69 DEG C for 42-52s; obtaining fixed day-lily flowers; cooling to 20-40 DEG C; baking the cooled day-lily flowers in baking equipment in a multi-section baking manner to obtain the baked day-lily flowers; controlling the temperature to be 88-92 DEG C and the total baking time to be 40-60 minutes during baking; and dampening to obtain a finished product after baking. The obtained product is high in nutrient value, high in rehydration rate, high in color and luster recovery rate after being immersed into water, crisp and tasty in taste after being cooked and high in yield of the excellent product. The method is simple in process and high in efficiency; the yield ratio of a first-rate product is high; and massive flow line production and application are facilitated.

Owner:湖南新发食品有限公司

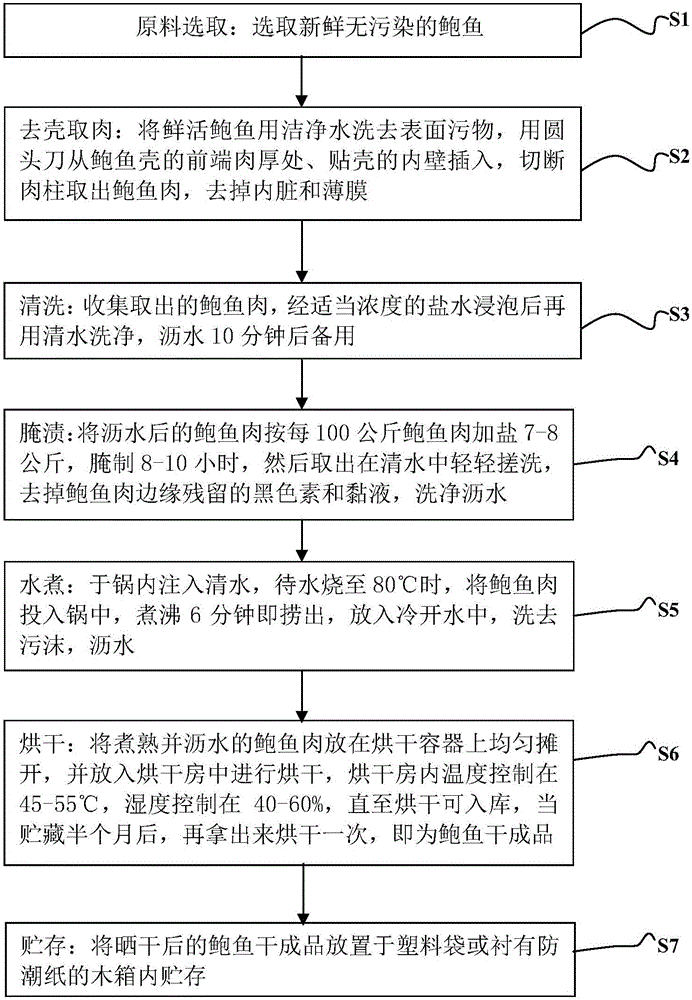

Preparation method for dry abalone

InactiveCN106262034ARetain nutrientsSimple processFood dryingFood ultrasonic treatmentSolar heatHeat pump

The invention discloses a preparation method for dry abalone, relating to the technical field of drying processing of marine products. The method comprises the following steps: selecting raw materials; removing shells to take meat; cleaning; pickling; cooking with water; drying; and storing, thereby acquiring the end product. According to the preparation method for dry abalone, the operation is simple; the special fresh fragrance of the abalone is maintained and the abalone drying efficiency and the abalone drying quality are improved. According to the preparation method, the ultrasonic and solar-heat pump combined drying modes are combined, the respective functions and advantages are utilized in sections and the method has a great significance in increasing the abalone drying efficiency and abalone drying quality and saving cost.

Owner:PUTIAN HUILONG SEAFOOD

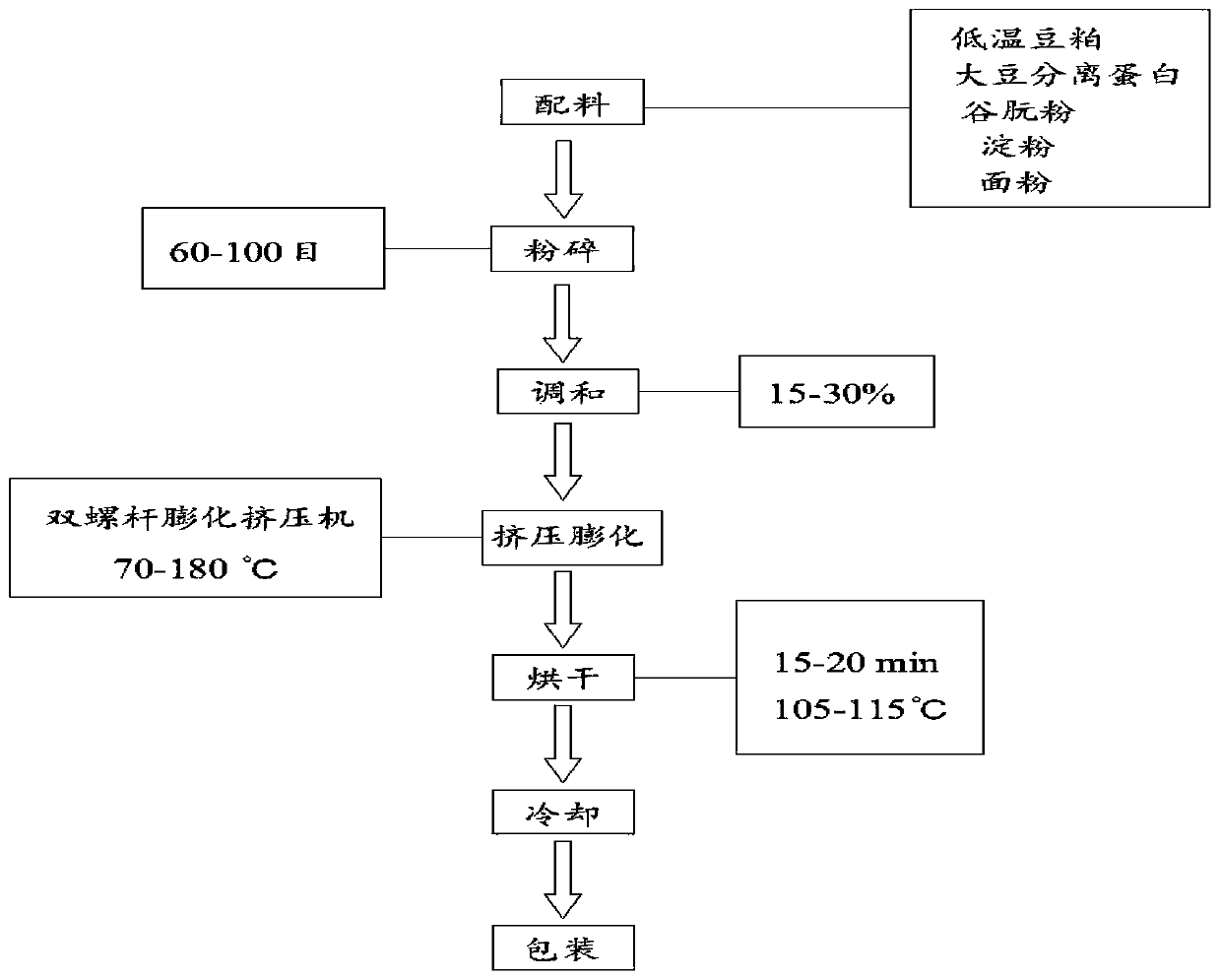

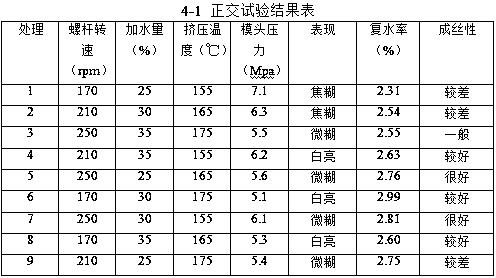

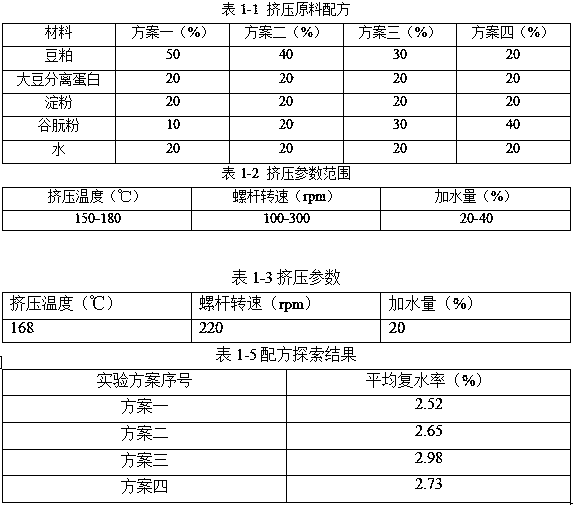

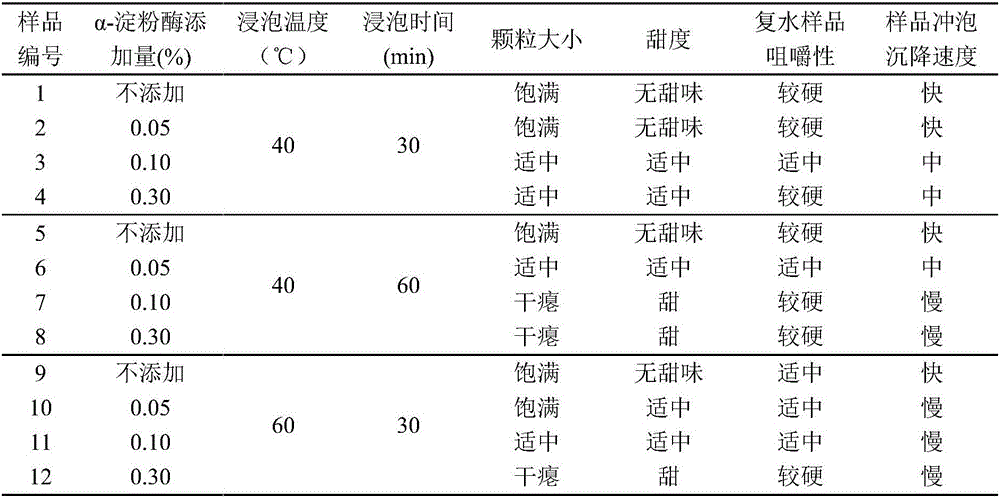

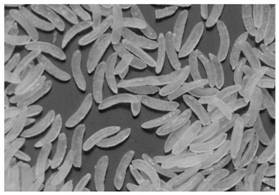

Tissue protein with high rehydration rate and preparation method thereof

InactiveCN110915981AHigh rehydration rateHigh yieldProteins working-up by texturisingVegetable proteins working-upBiotechnologyTissue protein

The invention discloses a tissue protein with high rehydration rate and a preparation method thereof. The method includes the following steps: step 10, uniformly stirring and mixing crushed low temperature soybean meal with vital wheat gluten, soy protein isolates and starch to form a vegetable protein mixed raw material; step 20, performing mixing and smashing on the vegetable protein mixed raw material obtained by the step 10; step 30, adding a proper amount of water into the smashed vegetable protein mixed raw material obtained by the step 20 to performing blending; step 40, performing extruding and expanding on the blended vegetable protein mixed raw material obtained by the step 30; and step 50, performing cutting, drying and cooling on the extruded and expanded product in the step 40, and finally obtaining the texturized vegetable protein with high rehydration rate. Through the tissue protein with high rehydration rate obtained by the preparation method, the rehydration rate of the tissue protein can be significantly enhanced, the yield of the tissue protein used by food production can be increased, and using costs can be reduced.

Owner:JIANGSU QUANYING BIOLOGICAL TECH CO LTD

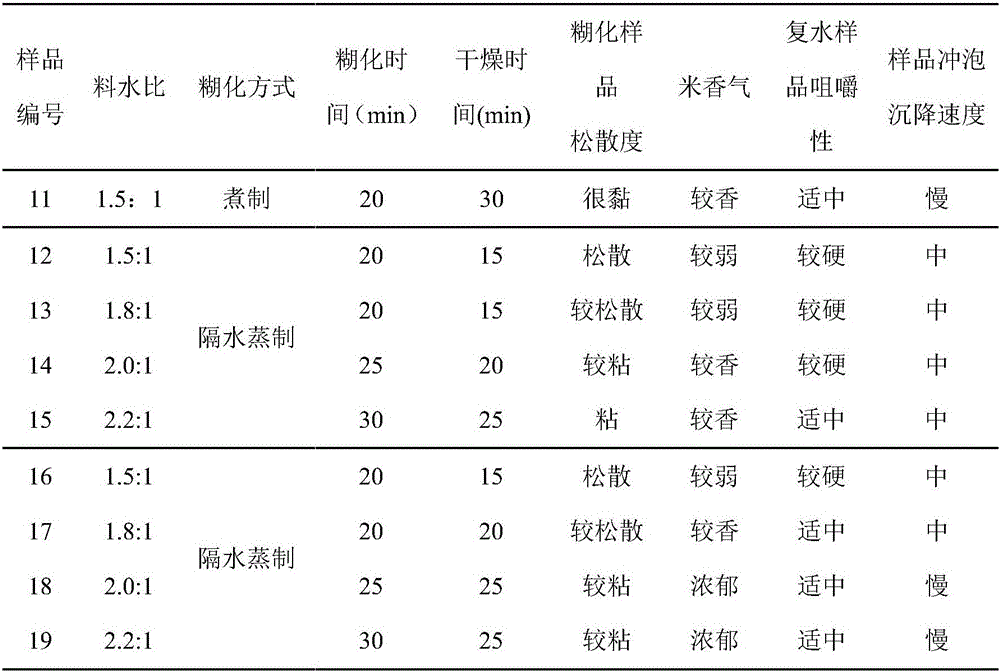

Instant millet porridge and preparation method thereof

InactiveCN106578950ANatural tasteStrong rice fragranceLipidic food ingredientsFood dryingPre treatmentFood processing

The invention belongs to the technical field of food processing, and in particular relates to instant millet porridge and a preparation method thereof. Millet is pretreated by an enzymic method technology, gelatinization is conducted by a water-insulating steaming process, dry millet is obtained after strong hot air dehydration, and then the instant millet porridge is obtained through blending. The prepared instant millet porridge maintains the shape of the traditional boiled millet porridge, and has natural taste, strong millet fragrance, short rehydration time and high rehydration rate. The instant millet porridge and the preparation method thereof are simple and practical in processing method, low in cost, high in product quality and convenient to eat.

Owner:CHINA AGRI UNIV

Instant-brewed self-heated rice, preparation method therefor and application of instant-brewed self-heated rice

The invention provides instant-brewed self-heated rice and a preparation method therefor. The self-heated rice is prepared through pulverizing raw material rice and / or whole grains such as millet, then, stirring and mixing the powder with food additives, and carrying out extruded aging, cutting granulating, re-aging, and drying and sterilizing. The self-heated rice comprises the ingredients in parts by weight: 80-100 parts of raw material rice meal, 0-20 parts of whole-grains powder, 20-30 parts of water and 5-20 parts of food additives. According to the instant-brewed self-heated rice and the preparation method therefor, through mixing the food additives of a specific ratio with the water and the rice meal, the rapid rehydration of the rice subjected to grinding, extruded aging and cutting shaping during brewing is improved, the rice rapidly imbibes to swell in case of heating, and rehydrated rice grains are full, are uniform and glossy in color, moderate in softness and complete in grain and are not half-cooked. During production of instant-brewed rice or porridge, the instant-brewed self-heated rice can be rapidly heated with a heating bag and can also be rapidly brewed with hot water. According to the method provided by the invention, powder ground from the rice is mixed with a proper amount of food additives and a proper volume of water, and thus, nutrients and mouth feel of the rice are reserved excellently.

Owner:日照尚健食品有限公司

Production process of low-mildew dry rice noodles of Liuzhou river snails rice noodles

PendingCN109259065AGeneration of controlReduce exposureFood thermal treatmentFood ingredientsSnow moldSteam cooking

The invention discloses a production process of low-mildew dry rice noodles of Liuzhou river snails rice noodles and relates to the field of the production process of rice noodles. Secondary high-temperature steam cooking is adopted in a cooking process so that mildew and bacterial colonies can be effectively controlled; and in the process of aging, fluffing and drying, treatment is carried out ina closed high-temperature environment so that generation of the mildew or the bacterial colonies can be well controlled. During fluffing, the rice noodles are fluffed in a novel principle same as combing hair with a comb; in a traditional method, the rice noodles is in contact with water through a roller in a normal temperature environment, so that the mildew, the bacterial colonies and the likeare liable to generate again, and meanwhile subsequent drying becomes difficult; through the principle same as combing the hair with the comb, the contact between the rice noodles and the water and manual contact of the rice noodles can be reduced, and therefore generation of the mildew is effectively controlled.

Owner:广西螺霸王食品有限公司

Coated Chinese chestnut kernels with figs and effects of invigorating stomachs and benefiting lungs and method for preparing coated Chinese chestnut kernels

The invention discloses coated Chinese chestnut kernels with figs and effects of invigorating stomachs and benefiting lungs. The coated Chinese chestnut kernels are made of, by weight, 300-310 parts of Chinese chestnuts, 20-23 parts of ginger shoots, 19-22 parts of whole-egg powder, 50-56 parts of the figs, 4-5 parts of poria flowers, 6-7 parts of honey, a small quantity of catechol, an appropriate quantity of film coating solution and an appropriate quantity of water. The coated Chinese chestnut kernels have the advantages that the coated Chinese chestnut kernels are made of abundant processing raw materials, main materials and diversified auxiliary materials such as the ginger shoots, the figs and the poria flowers are reasonably matched with one another and are processed to obtain the coated Chinese chestnut kernels which are finished products, the finished products contain abundant nutrition, effects of invigorating the stomachs, benefiting the lungs, clearing intestines, diminishing swelling and removing toxicity can be realized if people eat the coated Chinese chestnut kernels for a long term, and the coated Chinese chestnut kernels are suitable for extensive people and is particularly suitable for people with poor appetite and indigestion; color protecting and film coating operation is carried out on Chinese chestnut kernels in processing procedures, accordingly, browning and aging of the Chinese chestnut kernels can be prevented, and colors, aroma and taste of the products can be excellently kept.

Owner:望江县玉田种植专业合作社

Humidity controlling and drying method of banana slices using multi-mode ultrasound pretreatment

InactiveCN107509803AAvoid surface crustingImprove drying rateFruits/vegetable preservation by irradiation/electric treatmentFood processingProcess engineeringDrying time

The present invention discloses a humidity controlling and drying method of banana slices using a multi-mode ultrasound pretreatment, and belongs to the technical field of agricultural product processing. The provided humidity controlling and drying method of the banana slices using the multi-mode ultrasound pretreatment comprises the following steps: uniform-sized banana selecting, peeling, pith removing, slicing, multi-mode ultrasonic pretreating, humidity controlling and drying device adjusting to be constant in humidity and temperature, and drying. Aiming at disadvantages that during a single hot air drying process, the banana slices are liable to be blackened, a drying time is long, an energy consumption is large, etc., the new humidity controllable drying technology is used. Besides, the multi-mode ultrasound pretreatment technology conducts the pretreatment of the bananas, promotes a heat transfer and mass transfer efficiency during the drying process, and improves drying efficiency, rehydration rate, color and luster and other dry product quality of the banana slice humidity controlling drying compared with non-ultrasonic pretreatment.

Owner:JIANGSU UNIV

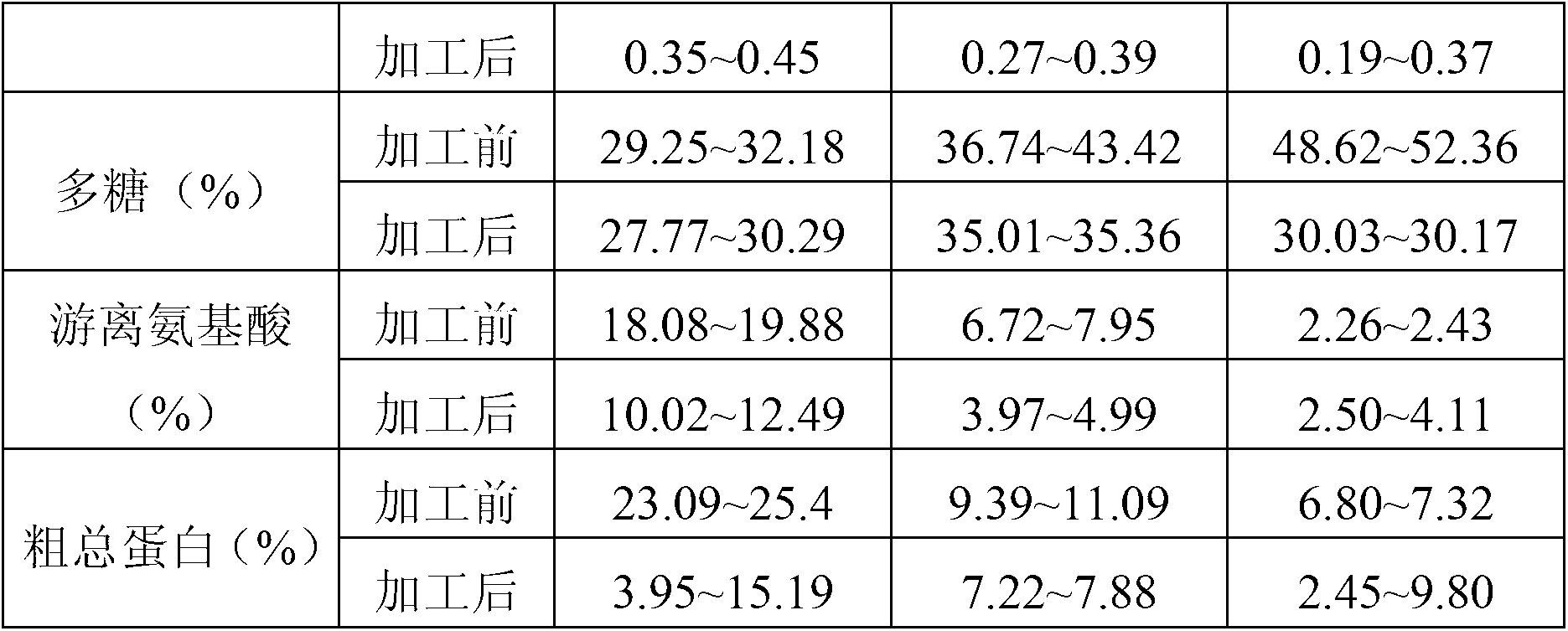

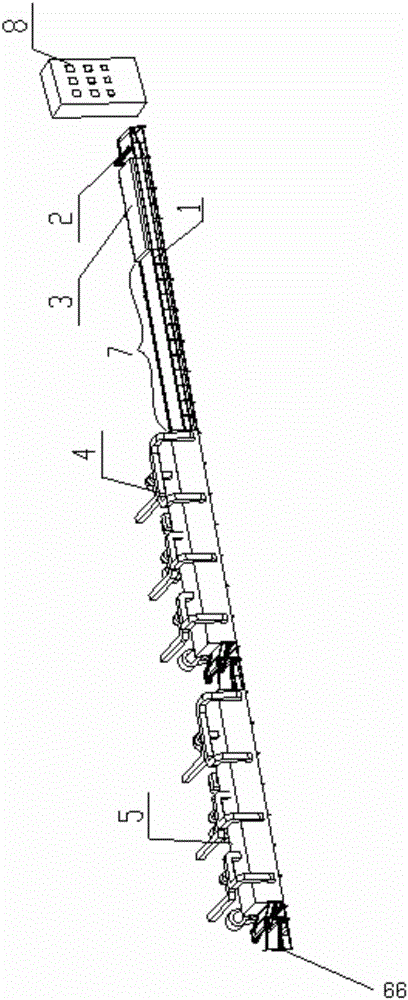

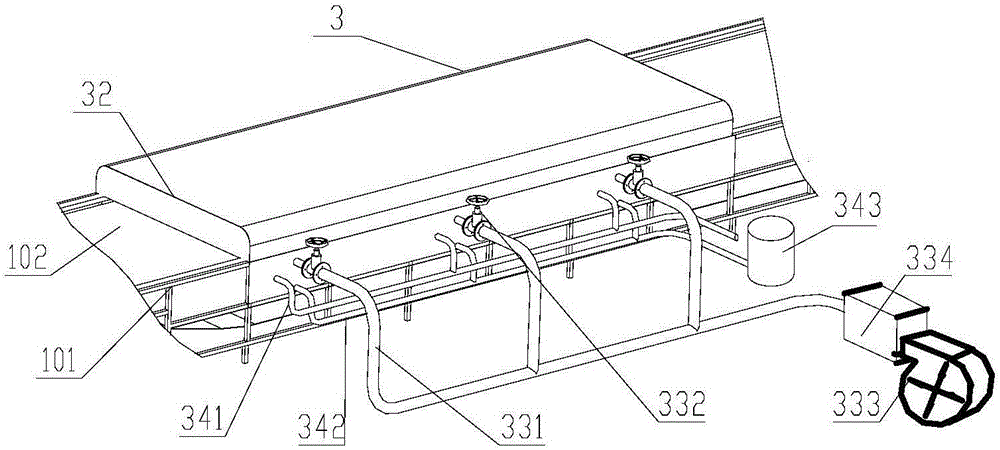

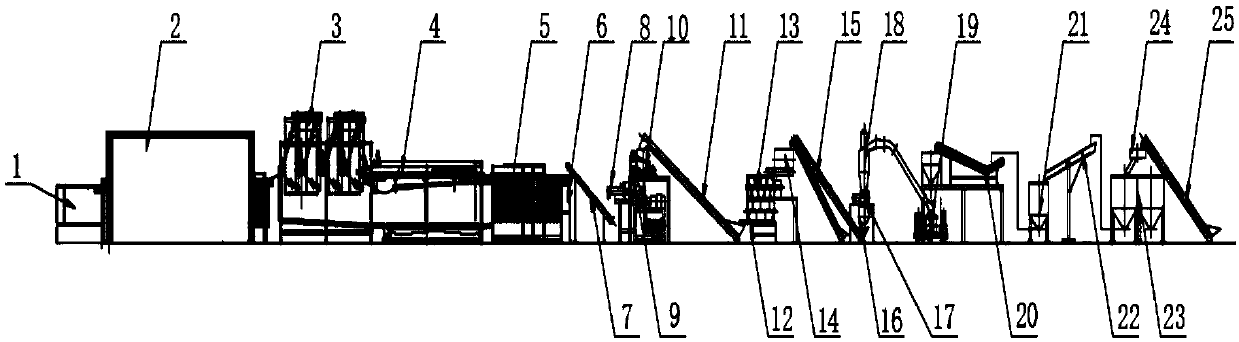

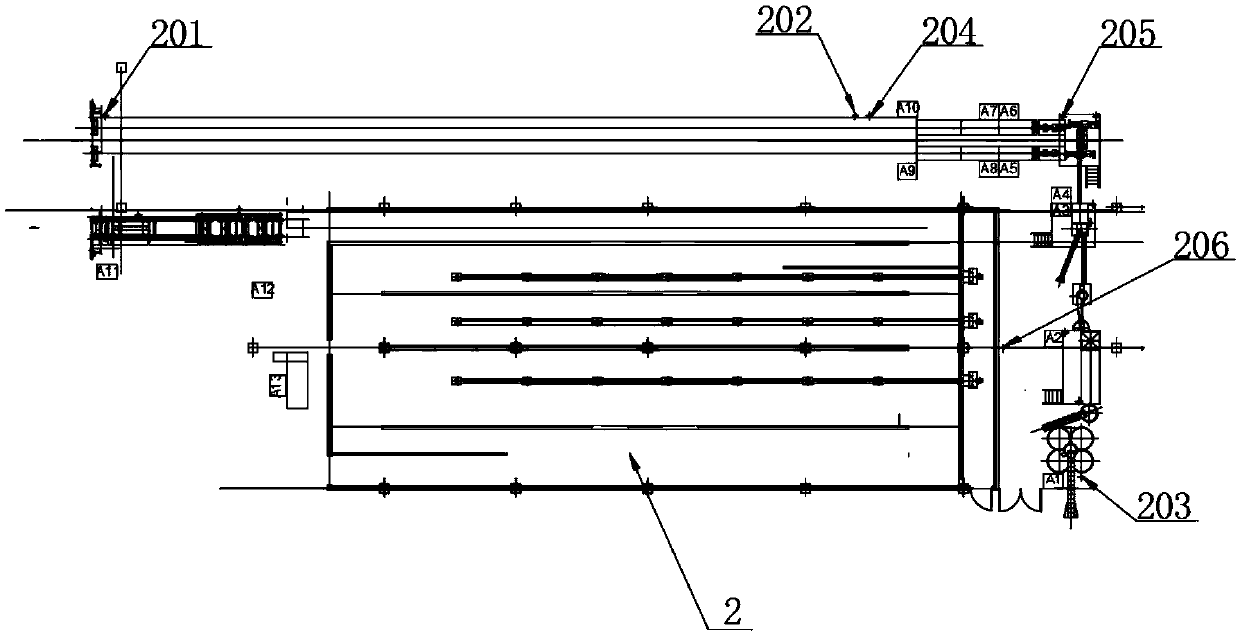

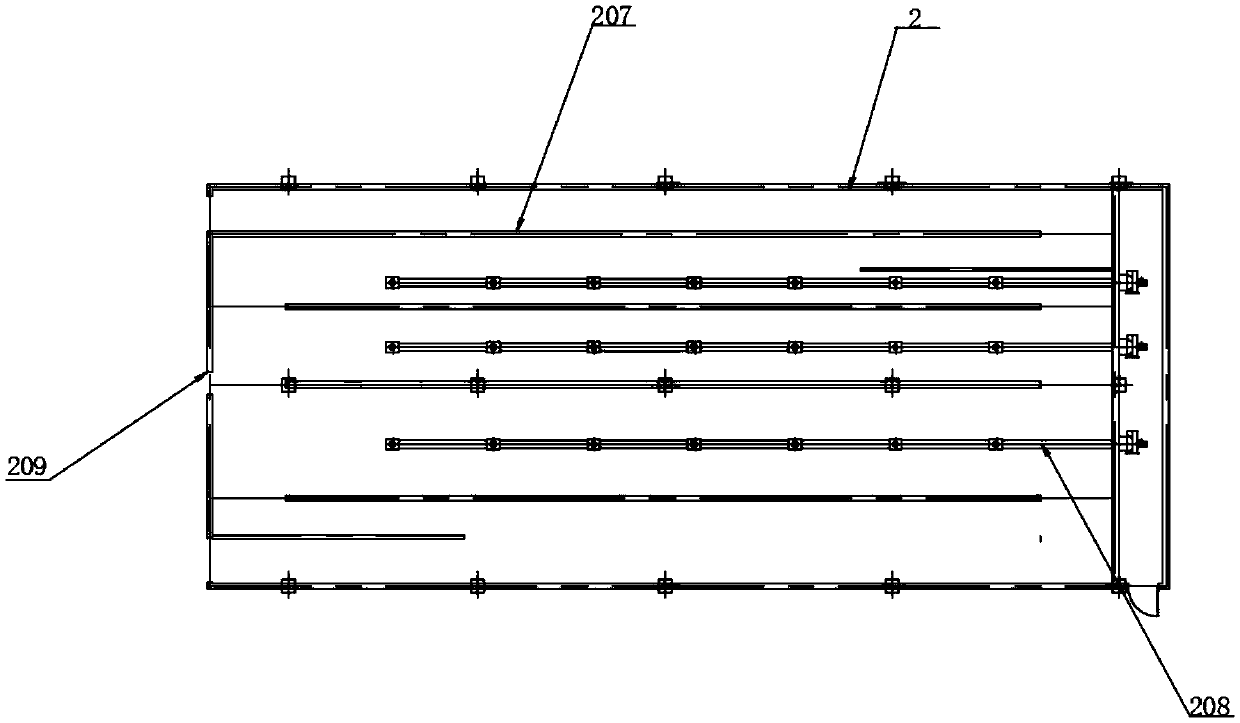

Production line and production technology for preparing river snail rice noodles

InactiveCN111406890ADry fastPrevent direct dryingFood scienceProduction lineAgricultural engineering

The invention discloses a production line and production technology for preparing a river snail rice noodles. The production line comprises an automatic falling rod cut-off machine, wherein a dryer ishorizontally arranged at one side of the automatic falling rod cut-off machine; a fluffing machine is arranged at one side of the dryer; a water pouring conveyor is arranged at one side of the fluffing machine; one end of the water pouring conveyor is fixedly connected with an aging machine; a suspended cut-off machine is fixedly arranged at one side of the aging machine; a mesh belt conveyor isarranged at one side of the suspended cut-off machine; a noodle extruder is arranged at one side of the mesh belt conveyor; and one end of the noodle extruder is fixedly connected with a self-cookingextruder. The production line is reasonable in structural design and high in work efficiency. A gas and a liquid generated by the river snail rice noodles are separately conveyed to carry out drying treatment on the river snail rice noodles, so that the river snail rice noodles can be quickly dried. Through the arrangement of a moisture removal fan, the drying treatment on the river snail rice noodles is strengthened, and meanwhile, the inside of the dryer can be prevented from being humid to affect the working effect.

Owner:广西螺霸王农业科技有限公司

Coated chestnut kernels which are capable of relieving dyspepsia and contain hawthorn fruit, and method for preparing coated chestnut kernels

InactiveCN105995858AReduce concentrationAdd flavorFood coatingFood ingredient functionsFlavorAdditive ingredient

The invention discloses coated chestnut kernels which are capable of relieving dyspepsia and contain hawthorn fruit. The coated chestnut kernels are prepared from, by weight, 300-310 parts of chestnut, 18-23 parts of radish leaf, 12-15 parts of banlangen granule, 34-38 parts of hawthorn fruit, 26-30 parts of black tea juice, 6-7 parts of honey, a small amount of catechol, a proper amount of coating liquid and a proper amount of water. Multiple auxiliary materials including radish leaf, hawthorn fruit and black tea juice are added during processing, and due to the fact that the auxiliary materials contain rich nutrients, the coated chestnut kernels can reduce blood fat and blood pressure, strengthen heart, tonify spleen and invigorate stomach, and relieve dyspepsia; besides, chestnut kernels are subjected to color protection and coating during processing, so that browning and aging of chestnut kernels are avoided, and the obtained product has good color and flavor.

Owner:ANHUI TRUELOVE FOODS

Processing technique for dewatering and drying fruits and vegetables

InactiveCN106901267AReduce in quantityFast rehydrationFood freezingFruit and vegetables preservationSucroseAdditive ingredient

The invention discloses a processing technique for dewatering and drying fruits and vegetables and belongs to the technical field of food processing. The processing technique comprises the following steps: firstly, selecting raw materials; secondly, cleaning and sorting the raw materials; thirdly, segmenting; fourthly, blanching and carrying out color protection; fifthly, treating antifreeze protein solution and cooling leachate; sixthly, prefreezing; seventhly, carrying out vacuum freeze drying; eighthly, packaging. According to the processing technique disclosed by the invention, saline water or sucrose water is adopted for blanching and then the antifreeze protein solution is adopted for treating; a vacuum freeze drying technology is adopted; a product obtained by dewatering and drying in the method can retain tissue shapes, color flavor taste and nutritional ingredients of the dried fruits and vegetables to the maximum extent; the product has the characteristics of high rehydration capability, high rehydration rate, good mouthfeel, small quantities of surface microorganisms, long storage period, convenience in transporting, carrying and eating and the like, and is easy for industrial production; a processed product can be widely used as health-care food, leisure food, ready meal products or fast food as well as various seasonings for dishes or main agents.

Owner:XUZHOU UNIV OF TECH

Infrared temperature-control drying method adopting multi-mode ultrasonic pretreatment and used for carrots

InactiveCN107509804AImprove qualityImprove drying efficiencyFood processingFruits/vegetable preservation by dehydrationVitamin CDrying time

The invention belongs to the technical field of agricultural product processing and provides an infrared temperature-control drying method adopting multi-mode ultrasonic pretreatment and used for carrots. The method comprises the steps as follows: fresh carrots in the same size are selected, the selected carrots are cleaned and the cleaned carrots are sliced, and multi-mode ultrasonic pretreatment and infrared temperature-control drying are conducted. The invention aims to overcome the defects that the drying time is long, energy consumption is high, the material heating temperature is unstable, the quality is low and the like in the hot-air drying or infrared drying process. The novel infrared temperature-control drying technology is adopted, material microstructures such as cell rapture, micro-channel formation and cell swelling are changed through multi-mode ultrasonic pretreatment, compared with a method without ultrasonic pretreatment, the method has the advantages that the infrared temperature-control drying efficiency of carrots, the rehydration rate, vitamin C and other quality of dried products are improved, and energy consumption is reduced. The final moisture content of dried carrot slices prepared with the method is controlled at 13% or below, the moisture activity is lower, growth and reproduction of microorganisms are not facilitated, and the dried carrot slices can be preserved for a long term.

Owner:JIANGSU UNIV

Nutritional and health-care coated Chinese chestnut kernels containing grape wine and preparation method thereof

InactiveCN106072310AGood effectPrevent browningAlcoholic food ingredientsFood dryingPhysical healthAdditive ingredient

The invention discloses nutritional and health-care coated Chinese chestnut kernels containing grape wine. The nutritional and health-care coated Chinese chestnut kernels containing grape wine is characterized by being prepared from the following raw materials in parts by weight: 300-310 parts of Chinese chestnuts, 30-35 parts of grape wine, 18-22 parts of fruits of russianolive, 18-21 parts of shortening powder, 20-24 parts of cherry juice, 6-7 parts of honey, a small amount of catechol, a proper amount of a film-coating solution and a proper amount of water. In the processing process of the coated Chinese chestnut kernels, multiple auxiliary materials, such as the grape wine, shortening powder, cherry juice and the like, are added, and thus coated Chinese chestnut kernels are rich in nutritional ingredients, have the fragrance of the grape wine when being taken, and are beneficial to body health, and have life-maintaining and health-protecting effects after being taken for a long term. Furthermore, color-protecting and coating operations are conducted on the Chinese chestnut kernels in the processing process to prevent occurrence of browning and aging of the Chinese chestnut kernels, so that the color, smell and taste of the coated Chinese chestnut kernels are kept excellent.

Owner:ANHUI TRUELOVE FOODS

Method for processing collybia albuminosa by vacuum low-temperature freeze drying technology

InactiveCN111838652AComprehensive nutrition retentionNo breakage lossFood freezingFruit and vegetables preservationFreeze-dryingCollybia

The invention discloses a method for processing collybia albuminosa by a vacuum low-temperature freeze drying technology, and belongs to the technical field of food processing. Fresh termitomyces albuminosus is subjected to primary treatment, then the vacuum low-temperature freeze-drying technology is adopted to prepare a dried product with the water content being 5% or below, and then grading selection (or sealed pre-packaging and temporary storage can be conducted firstly), inspection, sealed packaging, inspection, warehousing and the like are conducted. According to the termitomyces albuminosus dehydrated product processed by the method, all nutritional ingredients can be well retained, the original quality is maintained, the product is resistant to storage and convenient to transport,the product can obtain a very high rehydration rate, and the unique fresh taste and flavor of the product are reproduced.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

Bottle gourd heat clearing and thirst stopping film applied castanea mollissina kernels and preparation method thereof

InactiveCN106072317ARich in nutrientsGreat tasteClimate change adaptationFood preservationThirstAdditive ingredient

The present invention discloses bottle gourd heat clearing and thirst stopping film applied castanea mollissina kernels. The castanea mollissina kernels are prepared from the following raw materials in parts by weight: 300-310 parts of castanea mollissina, 25-28 parts of bottle gourds, 7-9 parts of refined rhizoma polygonati powder, 25-28 parts of carassius auratus pulp, 23-26 parts of yellow river irrigated muskmelons, 6-7 parts of honey, a small amount of catechol, an appropriate amount of film applying liquid, and an appropriate amount of water. The various accessory materials are added in the processing process of the film applied castanea mollissina kernels, such as the bottle gourds, refined rhizoma polygonati powder, carassius auratus pulp, etc., so that the castanea mollissina kernels are rich in nutritious ingredients and good in tastes, and have functions of clearing heat and stopping thirst. In addition, during the processing processes, the castanea mollissina kernels are subjected to color protecting and film applying operations, which prevent the occurrences of browning and aging, and enable the products to maintain good in color, smell and taste.

Owner:ANHUI TRUELOVE FOODS

Coated chestnut kernels which are capable of tonifying deficiency and lung-stomach and contain milk, and method for preparing coated chestnut kernels

InactiveCN105995859AReduce concentrationAdd flavorFood freezingFood preservationAdditive ingredientPollen

The invention discloses coated chestnut kernels which are capable of tonifying deficiency and lung-stomach and contain milk. The coated chestnut kernels are prepared from, by weight, 300-310 parts of chestnut, 65-70 parts of lowfat milk, 12-15 parts of broken masson pine pollen, 5-7 parts of herba taraxaci, 16-19 parts of pumpkin powder, 6-7 parts of honey, a small amount of catechol, a proper amount of coating liquid and a proper amount of water. Multiple auxiliary materials including lowfat milk, broken masson pine pollen and herba taraxaci are added during processing, and due to the fact that the auxiliary materials contain rich nutrients and have high nutrition value, the coated chestnut kernels are good for health and can tonify deficiency and lung-stomach, promote the secretion of saliva or body fluid and lubricate the intestines; besides, chestnut kernels are subjected to color protection and coating during processing, so that browning and aging of chestnut kernels are avoided, and the obtained product has good color and flavor.

Owner:ANHUI TRUELOVE FOODS

Summer radish overheat bulking drying method

InactiveCN103004957ANatural colorHigh rehydration rateFruits/vegetable preservation by dehydrationGlycerolEnvironmental engineering

The invention discloses a summer radish overheat bulking drying method which comprises the steps of (1) cleaning a summer radish, cutting the summer radish to be with the thickness of 5mm, and pretreating the summer radish with glycerol; (2) draining the moisture, and predrying the summer radish in an electric heating constant-temperature air-blowing drying oven; (3) flatly putting the summer radish on a steel wire tray of a bulking machine carrying room, sealing the carrying room, and bulking the summer radish through overheat steam; and (4) releasing the pressure after bulking, and opening the carrying room to obtain the dried summer radish. The summer radish obtained through overheat steam bulking drying is natural in color, high in rehydration rate and high in nutrition retention rate.

Owner:QINGDAO WINCHANCE TECH

A method of uniformly drying Agaricus bisporus slices combined with frequency conversion ultrasonic assisted dipping pretreatment and vacuum microwave

ActiveCN104304426BImprove uniformity of vacuum microwave dryingUniform colorFruits/vegetable preservation by dehydrationBiotechnologyAgaricus

Owner:JIANGSU ACAD OF AGRI SCI

Making method of dehydrated spinach

InactiveCN106879722AProtect NutrientsPromote exudationFruits/vegetable preservation by freezing/coolingFruits/vegetable preservation by dehydrationGeonoma congestaEmerald

The invention relates to the technical field of processing of vegetables, in particular to a making method of dehydrated spinach. The making method comprises the following specific steps of thoroughly cleaning collected fresh spinach, soaking the cleaned spinach in a maltol solution, performing draining, spraying a thin layer of bacillus mucilaginosus liquid to the surface of the drained spinach, then performing freezing treatment, performing vacuum primary drying on the frozen spinach, finally, placing the dried spinach under the pressure of 6-8 atmospheric pressure, controlling the initial temperature to be 10 DEG C, and gradually performing temperature rise to 40 DEG C, so as to obtain the dehydrated spinach. The finally-obtained dehydrated spinach is emerald green in color, level in leaf surfaces, and clear in veins, and has rich delicate fragrance of the spinach.

Owner:蚌埠清菲农业科技有限公司

Production method for freeze-dried meat product

InactiveCN103766576AHigh in proteinHigh fiberProteins working-up by texturisingVegetable proteins working-upTissue proteinCellulose

The invention discloses a production method for a freeze-dried meat product. The method comprises: immersing, specifically immersing tissue protein in water according to a tissue protein / water mass ratio of 1:4; seasoning, specifically adding essence and spices into tissue protein according to ratios; cutting; draining water; freezing quickly; drying in vacuum; and performing moistureproof packaging, specifically cooling dried tissue protein in drying equipment to normal temperature and bagging. The meat product prepared by employing the provided production method for the freeze-dried meat product has the advantages of high protein and high cellulose; during processing, nutritional compositions are not lost, the water recovery rate is high and complete water recovery can be finished within 3 min; and during processing, the raw materials are not influenced by temperature, the color, the appearance and the taste basically remain unchanged, the taste is not changed, and the meat product is beneficial for human body health and is capable of satisfying market demands.

Owner:李康伟

Preparation method of green-tea-flavor dried bambusa oldhami shoots

ActiveCN108094955AMaintain colorStay brittleFood freezingFood ingredient as taste affecting agentShootFreeze-drying

The invention discloses a preparation method of green-tea-flavor dried bambusa oldhami shoots, and belongs to the technical field of food processing and preparation. The preparation method of the green-tea-flavor dried bambusa oldhami shoots comprises the following steps: washing, pretreatment, cooking, washing, drying, packing and so on. During the drying process of the dried bambusa oldhami shoots according to the preparation method, a microwave technology and a vacuum freeze-drying technology are combined so that the prepared dried bambusa oldhami shoots are relatively good in the aspects of color, luster and nutrients. Moreover, the bambusa oldhami shoots are steamed by using green tea according to the preparation method so that the flavor of the green tea and the bambusa oldhami shoots are integrated, and thus, the prepared green-tea-flavor dried bambusa oldhami shoots have unique taste.

Owner:广西岩星农业有限公司

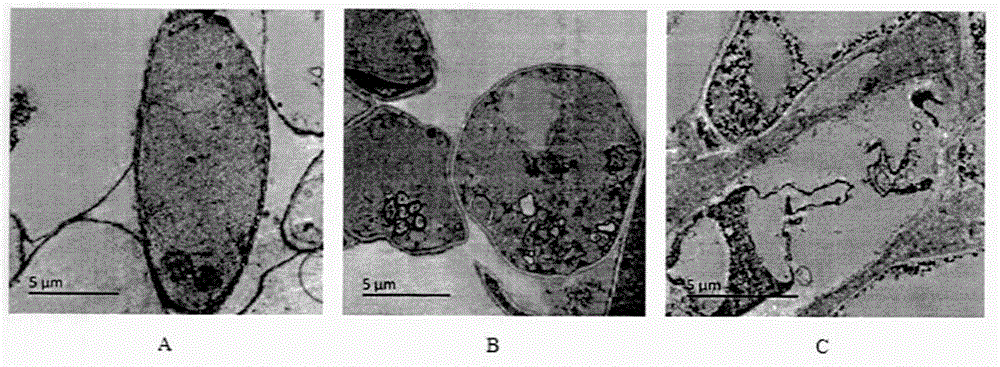

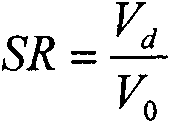

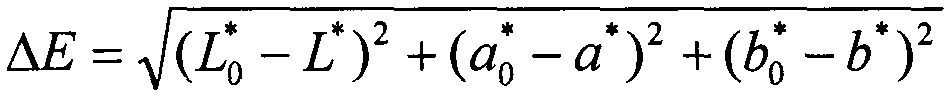

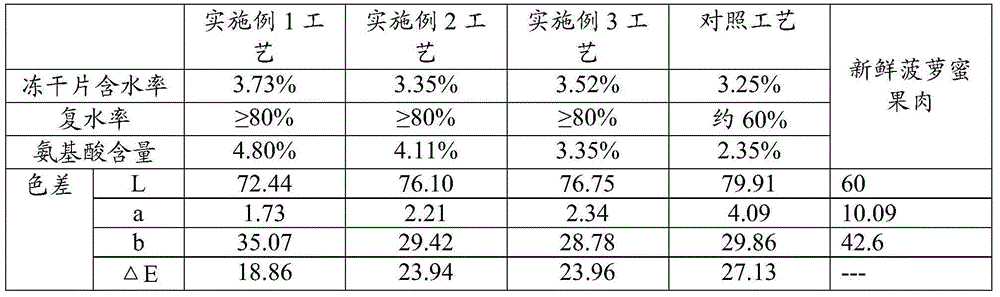

Freeze dried jackfruit pulp tablets and preparation method of tablets

InactiveCN104585299AUnique flavorAntioxidantFruit and vegetables preservationThree stageFreeze-drying

The invention relates to the field of food processing and discloses freeze dried jackfruit pulp tablets and a preparation method of the tablets. The method comprises the following steps: pre-freezing peeled, denucleated and sterilized jackfruit pulp; and after pre-freezing, putting the jackfruit pulp in vacuum freezing and drying equipment, and freezing and drying the jackfruit pulp in vacuum in three stages, namely drying for 9-11 hours at 50-100 DEG C in the first stage, drying for 2-5 hours at 40-80 DEG C in the second stage, and drying for 1-3 hours at 30-60 DEG C in the third stage to obtain the freeze dried jackfruit pulp tablets. According to the invention, jackfruits are processed by virtue of a three-stage vacuum freezing and drying method with relatively few steps by adjusting and optimizing the preparation process. Compared with an existing five-stage vacuum freezing and drying method, the method has the advantages that the rehydration rate is higher, the content of amino acids is higher, and the luster of the tablets is closer to that of fresh jackfruits. Moreover, the technical process is simplified and the energy consumption is reduced.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com